Patents

Literature

706 results about "Nickel coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel boron is electroplated and delivers an even coating on every surface of parts, including recessive areas, blind holes and sharp edges. Hard chromium is electroplated and is a line-of-sight coating. This means high current-density areas get more plating than low current-density areas.

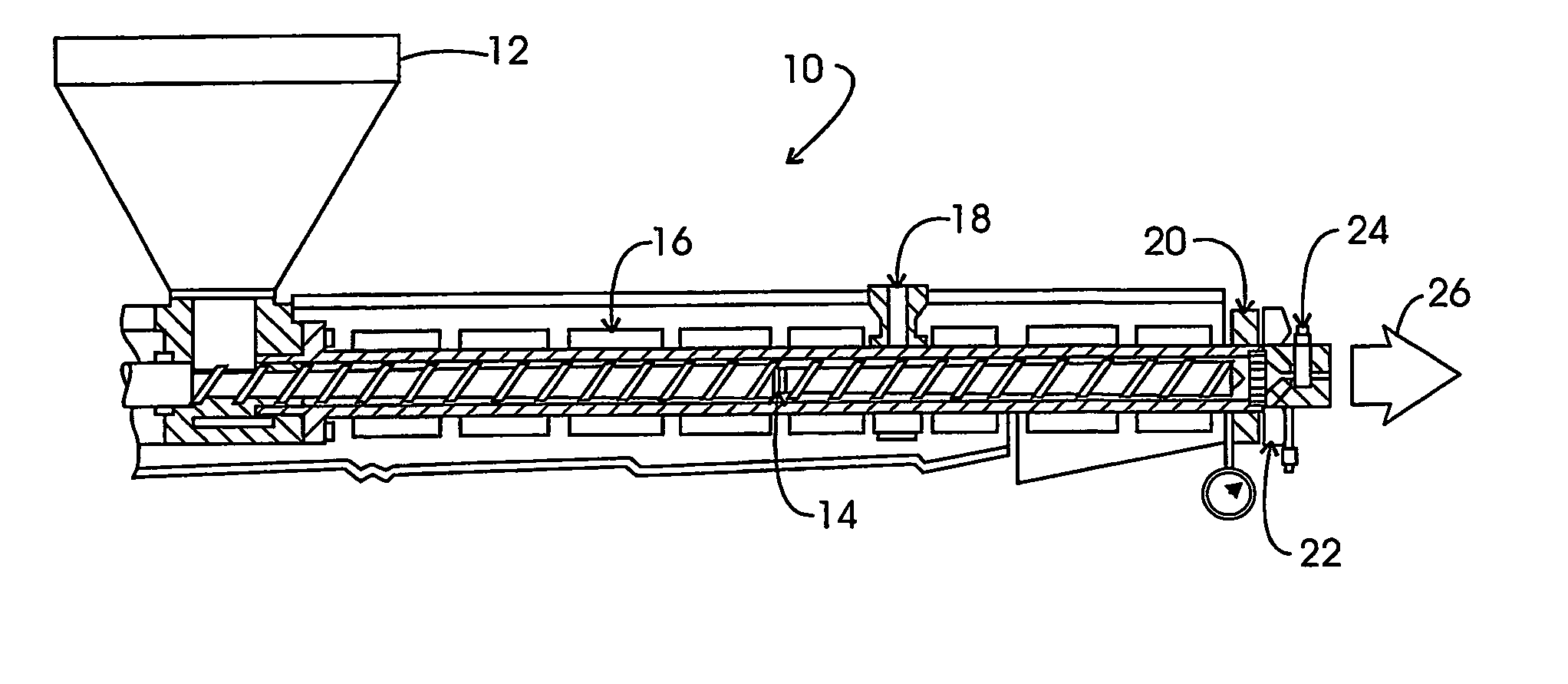

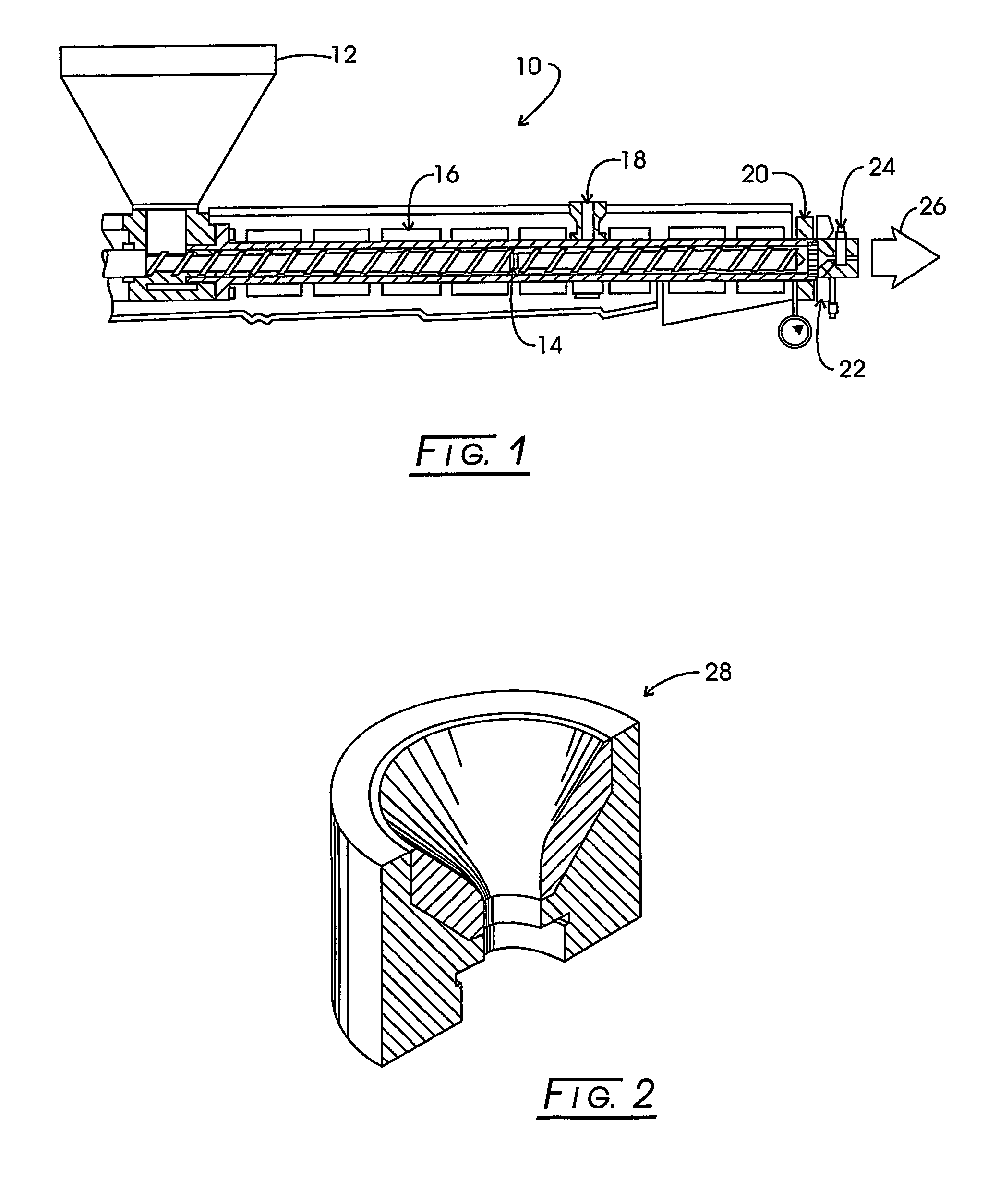

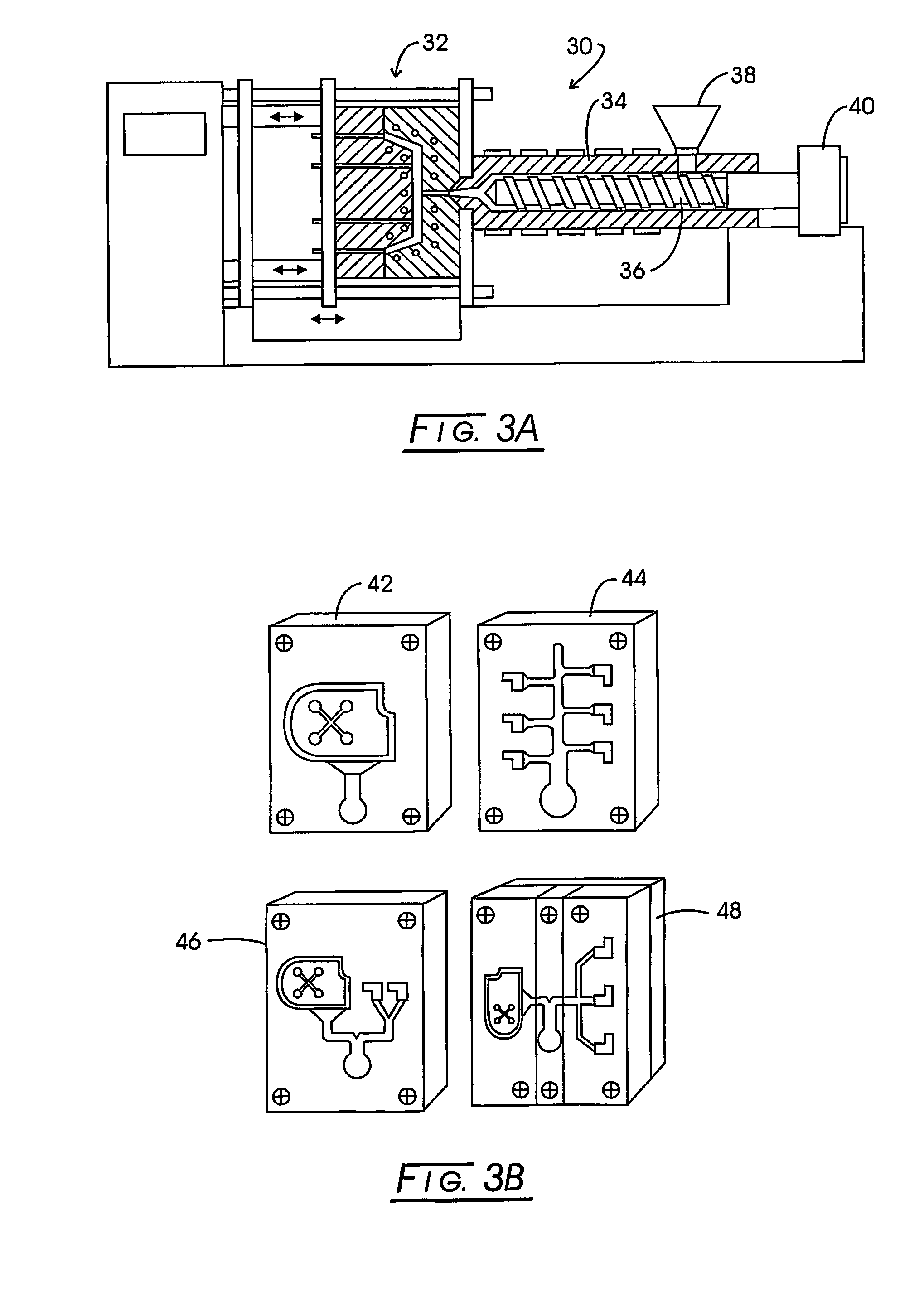

Process equipment wear surfaces of extended resistance and methods for their manufacture

A method for producing process equipment having a wear surface having extended resistance to one or more of abrasion, erosion, or corrosion, associated with fillers or solids processed by said process equipment includes applying to said process equipment wear surface a metal matrix coating filled with superabrasive particles. Diamond and cubic boron nitride superabrasive particles can fill the metal matrix, which can be a nickel coating.

Owner:DIAMOND INNOVATIONS INC

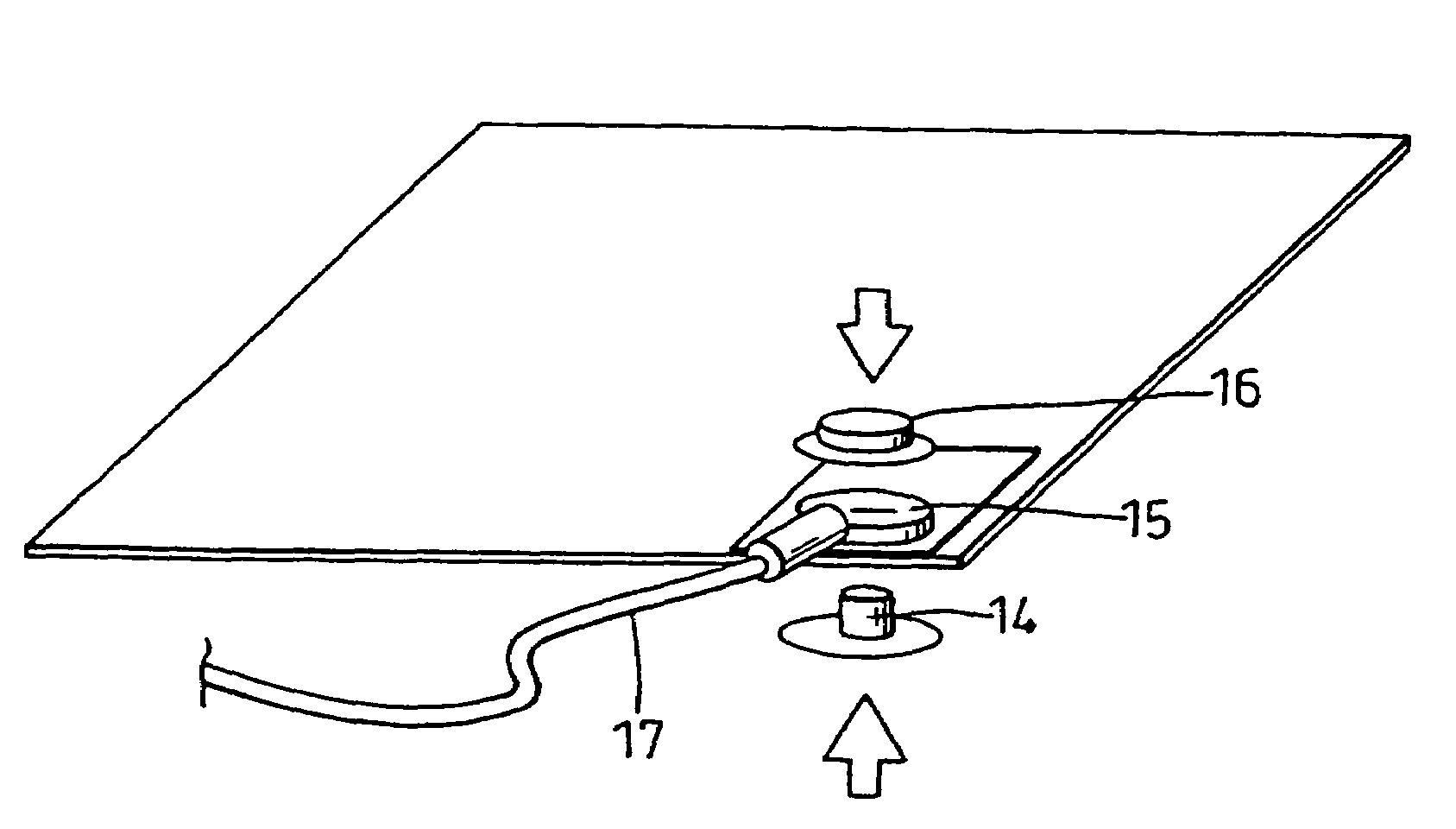

Electrical connection

InactiveUS6974935B2Low viscosityNon-metal conductorsElectrically conductive connectionsCold spotAdhesive

A device for connecting a source of electrical power to a coating or film incorporating carbon particles, an objective met by providing a coating of a nickel compound to the coating or film of carbon particles, and applying to the nickel coating a tin-copper tape coated with a silver-loaded conductive adhesive. What results is a uniform heating effect over a relatively wide area, substantially free from hot and cold spots or areas.

Owner:INSPIRATION HEALTHCARE GRP PLC

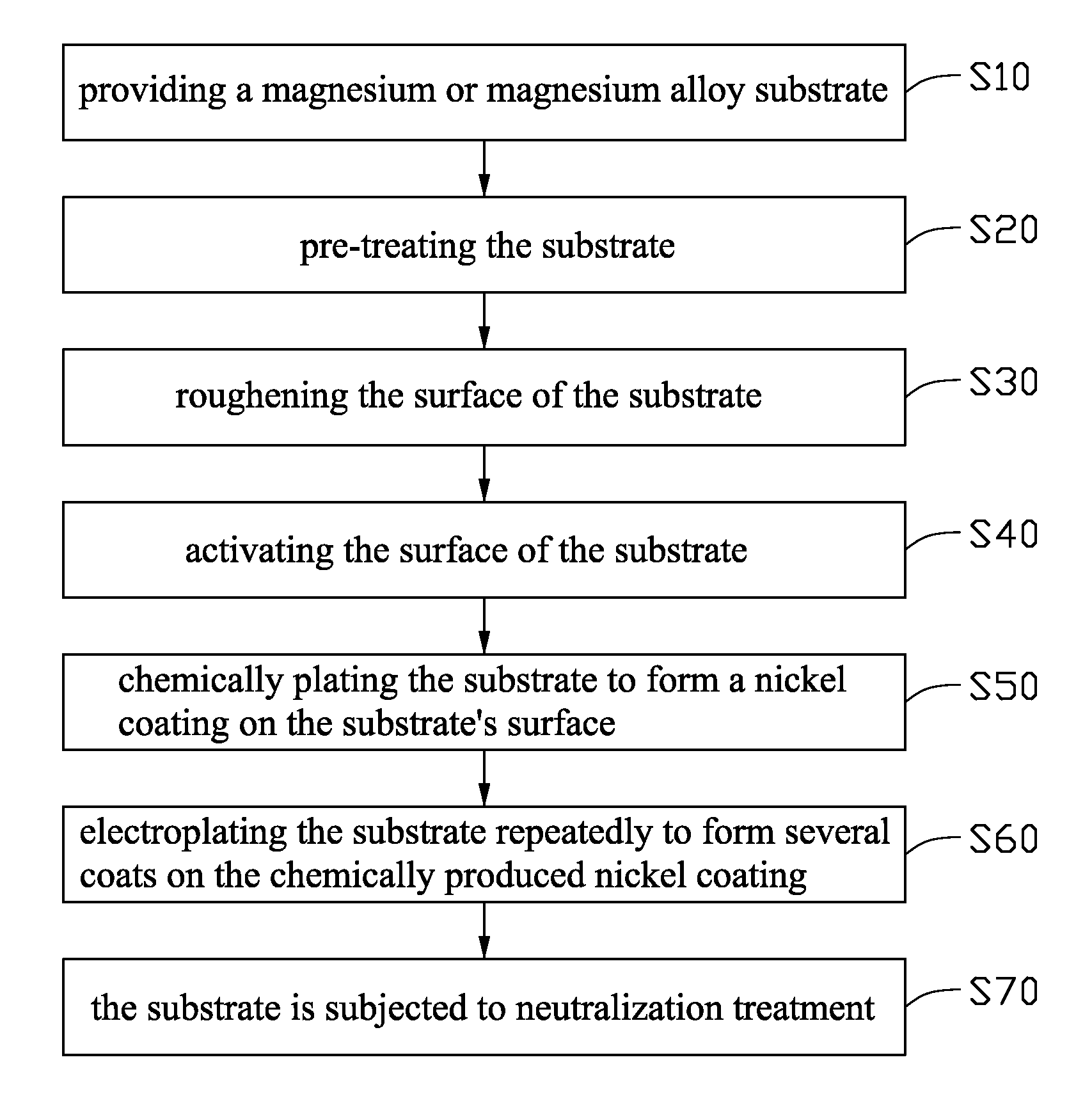

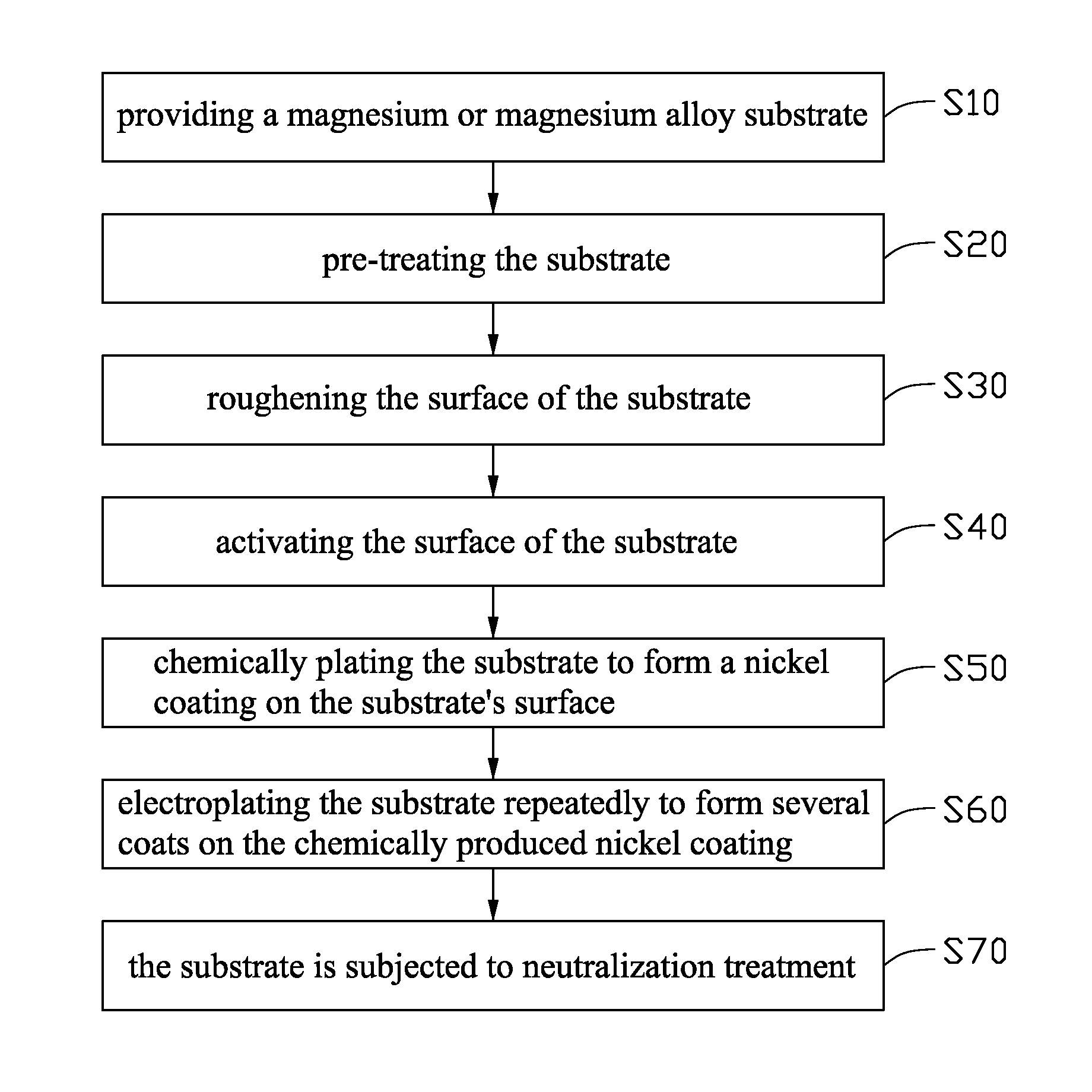

Electroplating method for magnesium and magnesium alloy

An electroplating method for magnesium and magnesium alloys, comprising: providing a magnesium or magnesium alloy substrate and pre-treating it to be cleaned; roughening the surface of the substrate; activating the surface of the substrate; chemically plating the substrate to form a nickel coating on its surface; and electroplating the substrate to form, in order, a first nickel coating, a copper coating, a second nickel coating, and a chromium coating on the chemically produced nickel coating.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Vapor-deposited porous films for energy conversion

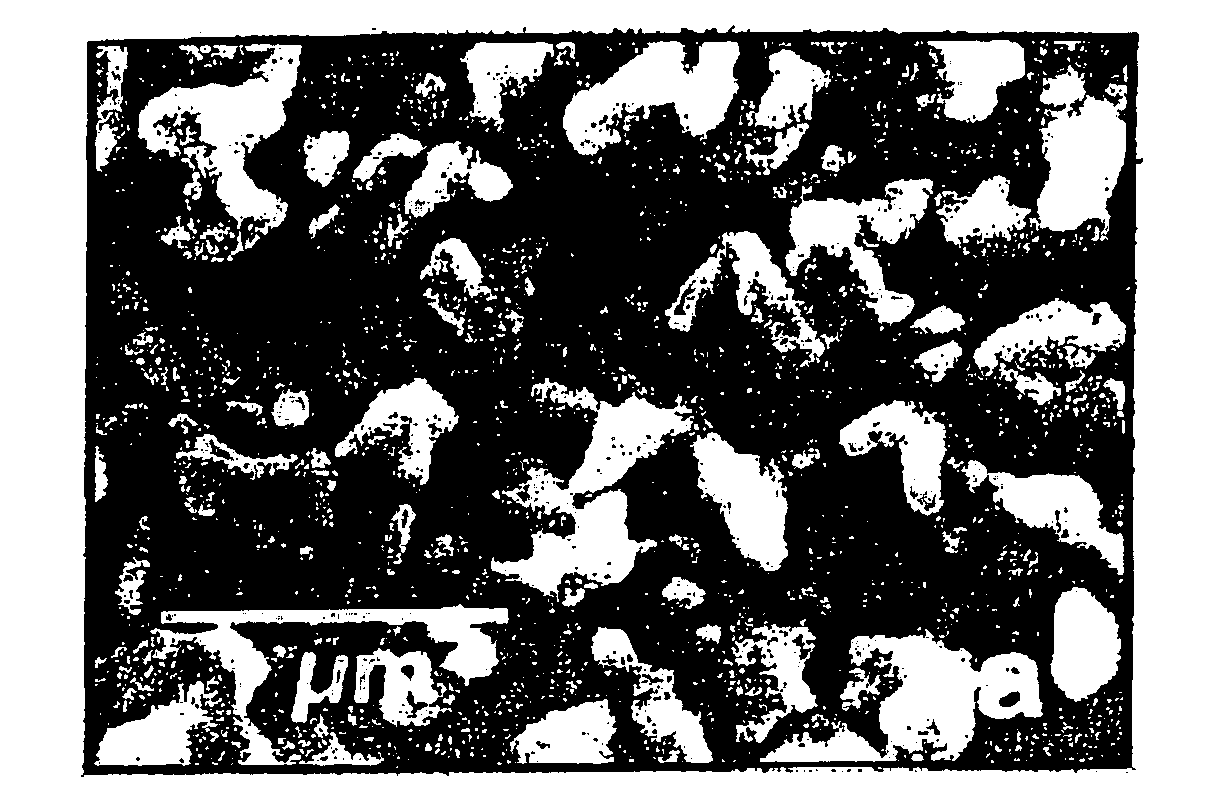

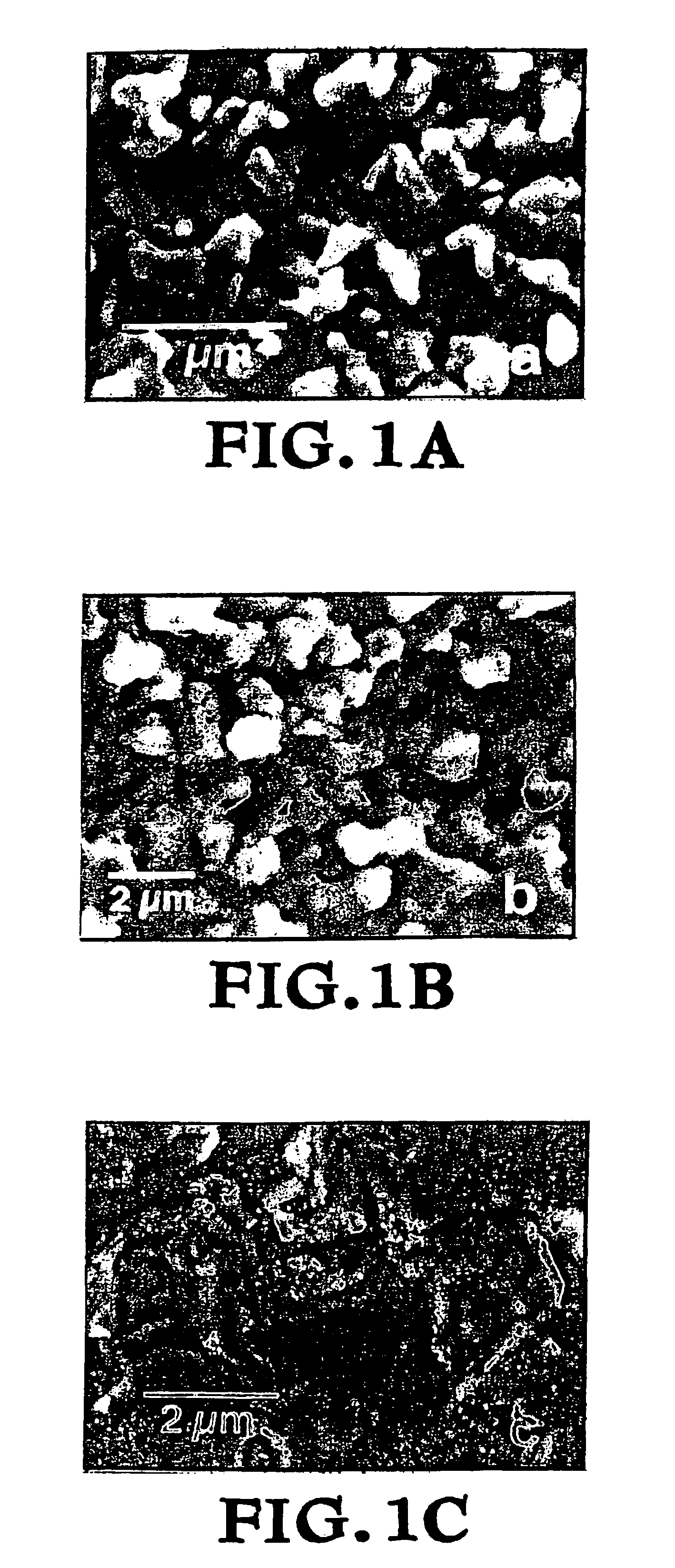

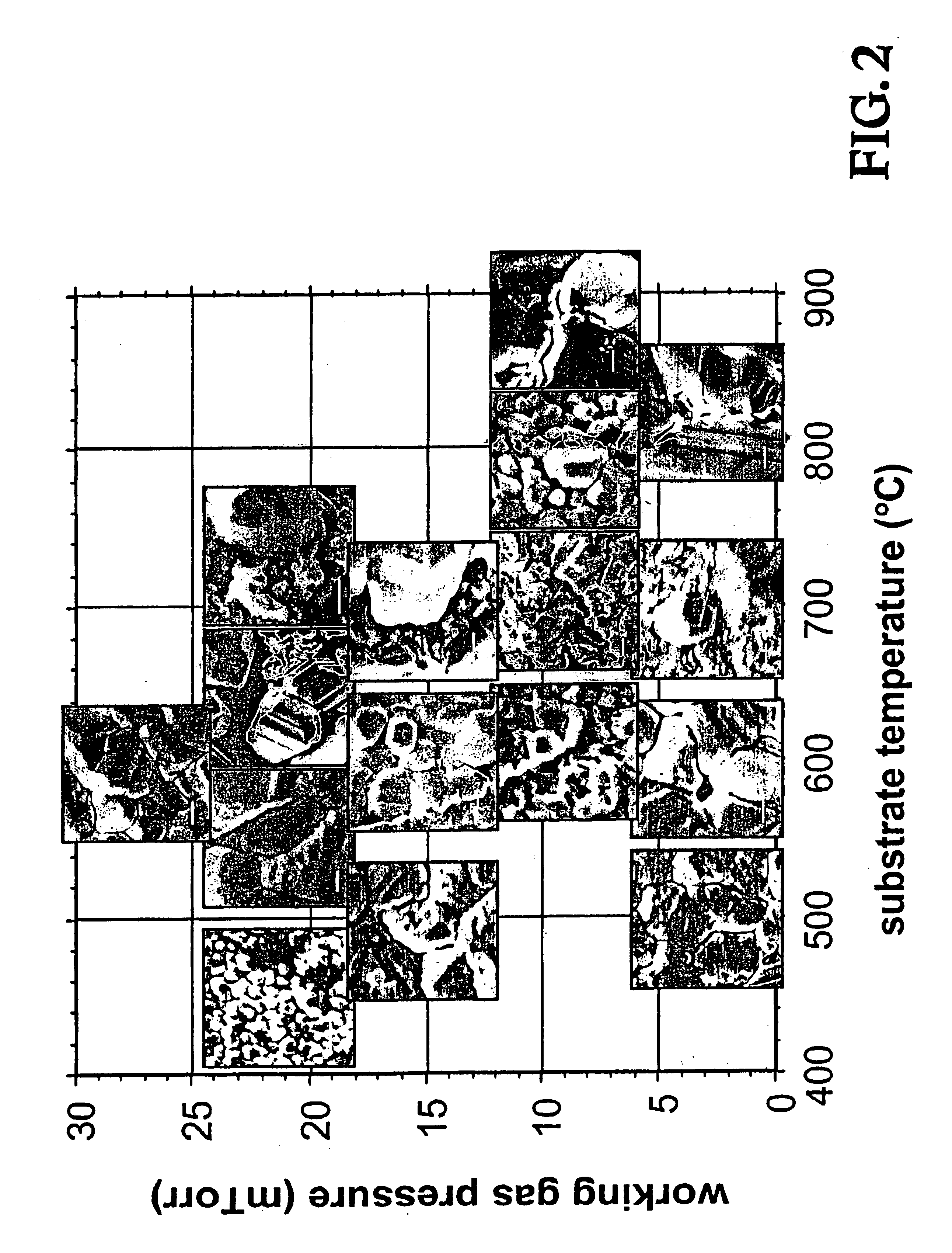

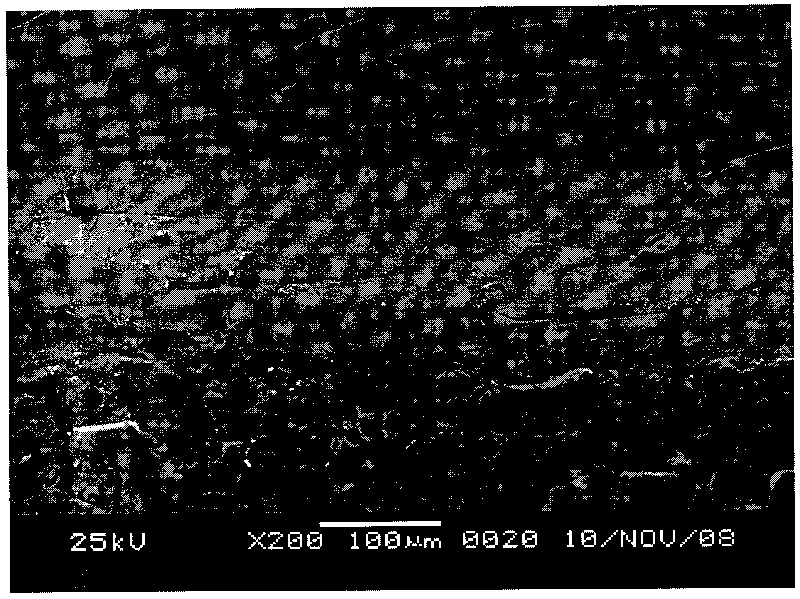

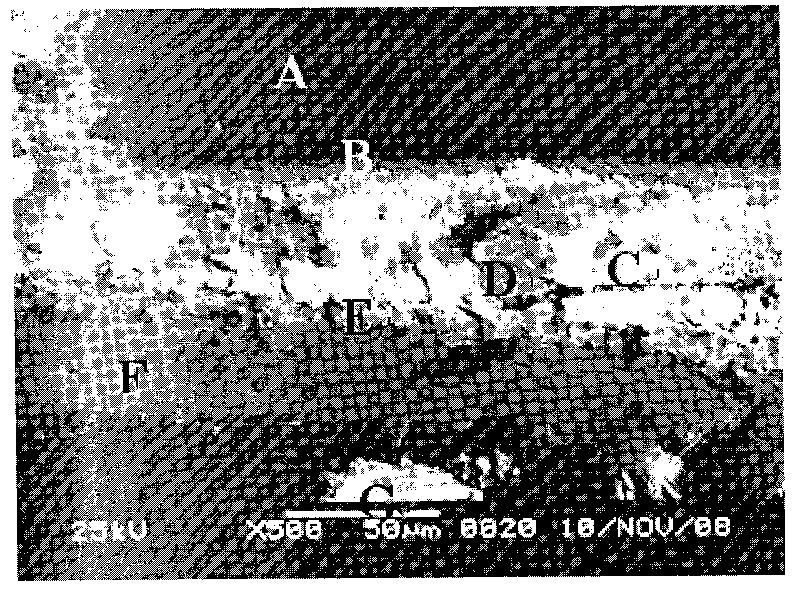

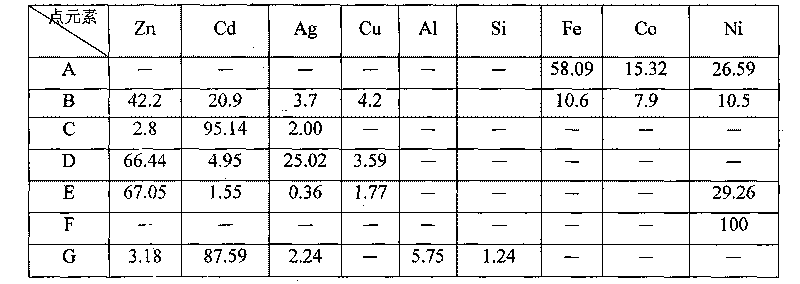

Metallic films are grown with a “spongelike” morphology in the as-deposited condition using planar magnetron sputtering. The morphology of the deposit is characterized by metallic continuity in three dimensions with continuous and open porosity on the submicron scale. The stabilization of the spongelike morphology is found over a limited range of the sputter deposition parameters, that is, of working gas pressure and substrate temperature. This spongelike morphology is an extension of the features as generally represented in the classic zone models of growth for physical vapor deposits. Nickel coatings were deposited with working gas pressures up 4 Pa and for substrate temperatures up to 1000 K. The morphology of the deposits is examined in plan and in cross section views with scanning electron microscopy (SEM). The parametric range of gas pressure and substrate temperature (relative to absolute melt point) under which the spongelike metal deposits are produced appear universal for other metals including gold, silver, and aluminum.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

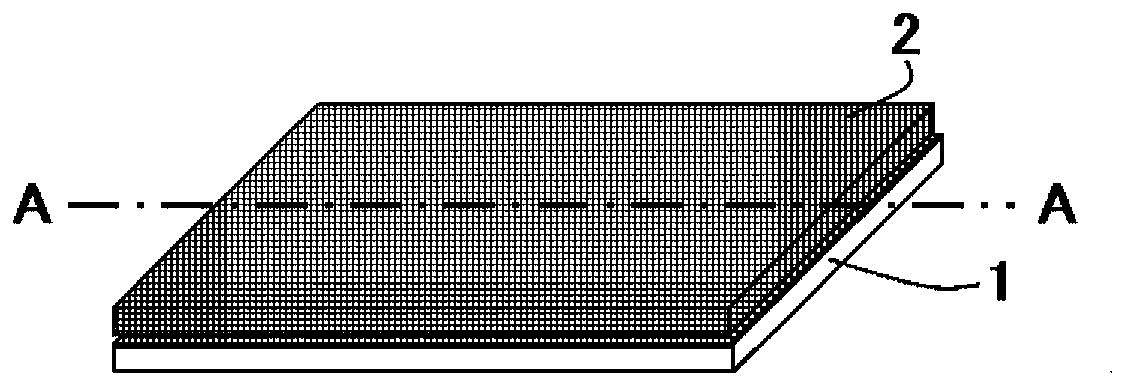

Anode ear for polymer or liquid flexible packing lithium ion electric core, and producing method thereof

ActiveCN101414673AReduce the number of bendsAvoid breakingCell component detailsPhysical chemistryMechanical engineering

The invention discloses an anode tab used in a polymer or liquid soft package lithium ion cell. The anode tab comprises an aluminum tab body on which a tab PP film is arranged. The anode tab is characterized in that a nickel coating is arranged on an end of the tab body; the nickel coating can be plated on the end of the tab body in a wrapped plating manner; the nickel coating can also be respectively plated on the front side of the tab body and the back side of the tab body; and the depth of the nickel coating at one side of the tab body can be 0.5-3.0 microns. The invention also discloses a production method of the tab used in the polymer lithium ion cell. The anode tab can be directly soldered with a protective circuit, which reduces the bending frequency of the tab, causes the tab not to be broken off easily, does not result in the problem of sealingoff (i.e., soldered joints fall off), effectively improves the product quality, prolongs the service life of the product and reduces a working procedure of changing the aluminum tabs into the nickel tabs for manufacturers of cells, and shortens the production period.

Owner:连云港海创电子科技有限公司

Chemical deplating solution and deplating method suitable for removing tin-nickel coating on surface of brass

InactiveCN101775601AImprove the status quo of low dissolution rateImprove work efficiencyWater bathsTin

The invention discloses a deplating solution and a deplating method thereof for tin-nickel coating (commonly called plated scrap) on the surface of brass. The deplating solution comprises oxidizer, accelerator, complexing agent and inhibitor, and the deplating solution is prepared by adding water to the reagents, stirring, dissolving, then putting in a water bath and slowly heating. The oxidizer adopts 65-68% nitric acid, the accelerator adopts 36-38% hydrochloric acid, the complexing agent adopts citric acid and the inhibitor adopts benzotriazole. After being deplated by the deplating solution of the invention, the surface of the brass is bright, the color of the substrate is basically unchanged, and the brass has no pinholes and small corrosion amount.

Owner:HEFEI UNIV OF TECH

Method for producing nickel coating on metal surface

A method for preparing nickel coating on metal surface relates to metal plating and provides a method for preparing nickel coating on the metal surface. The metal surface goes through oil removal and is placed in a solution tank and plated with tin coating and then placed in the solution tank; after being plated with tin, the metal surface is plated with the nickel coating; the metal plated with the nickel coating is placed in the solution tank for passivation treatment, heat preservation, hydrogen removal from the nickel coating, diffusion annealing treatment and stress relief heat treatment. High interfacial strength single-phase solid solution is obtained by rapid cooling after adopting thick nickel and tin coating, adding thin tin coating and diffusion annealing treatment. Plating bath is not added with a brightening agent while the plating coat is bright and smooth and forms a single-phase solid solution structure, thus enhancing interface combining power of the plating coat and a base plate. The method makes use of the principle predicted by a binary phase diagram that tin and nickel are mutually exclusive within a large composition range, so as to lead iron uncoated rate and copper uncoated rate to tend to be zero under the effect of a tin diffusion blocking layer, thus the plating coat can keep relatively high antiseptic property. Other machinery properties are also good; therefore, the nickel coating prepared by the method of the invention can serve as multifunctional antirust coating.

Owner:XIAMEN UNIV

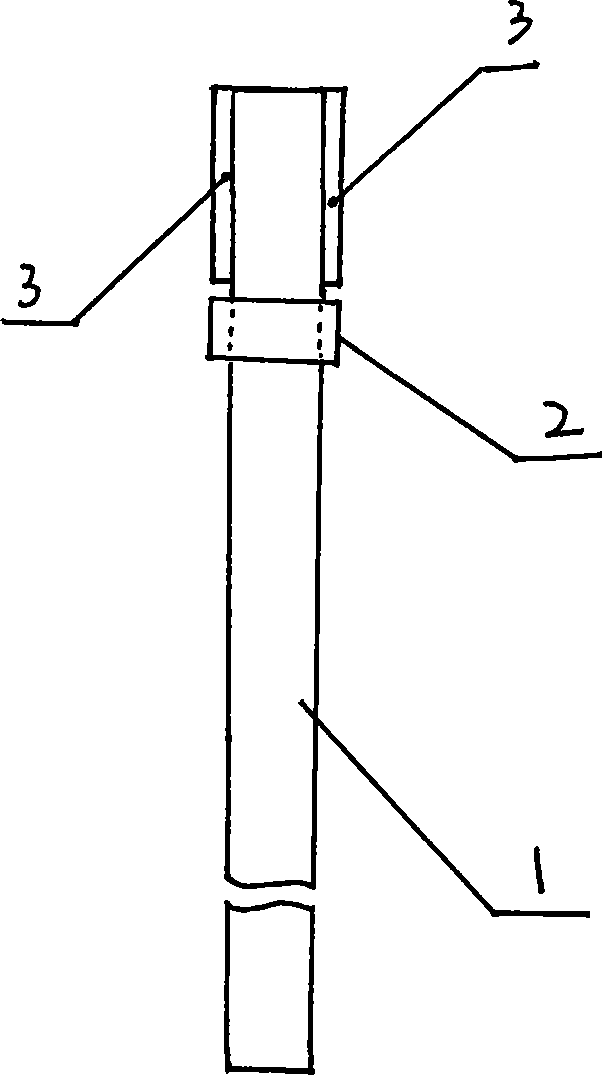

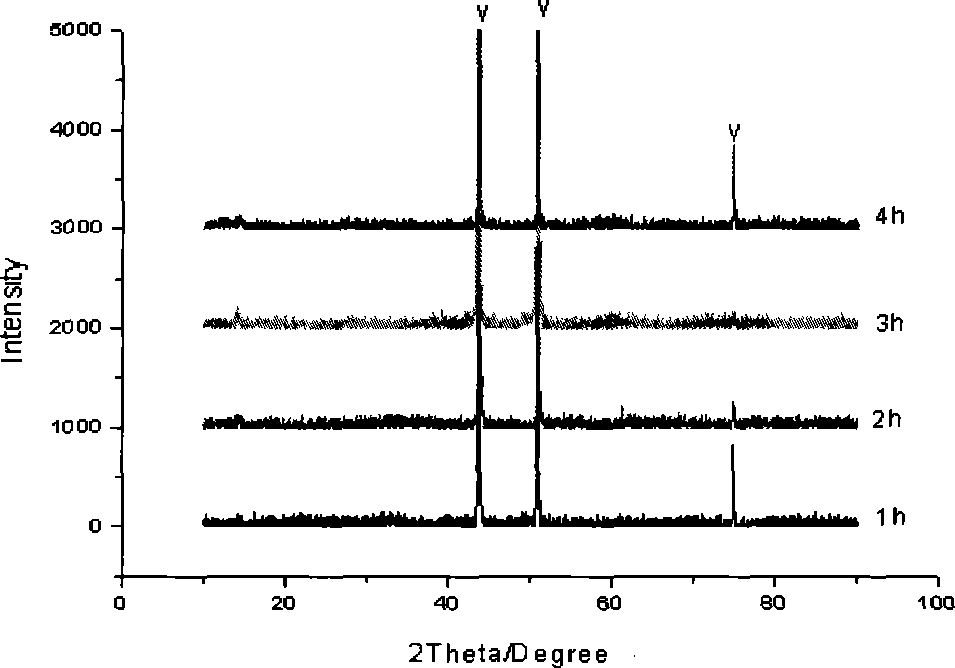

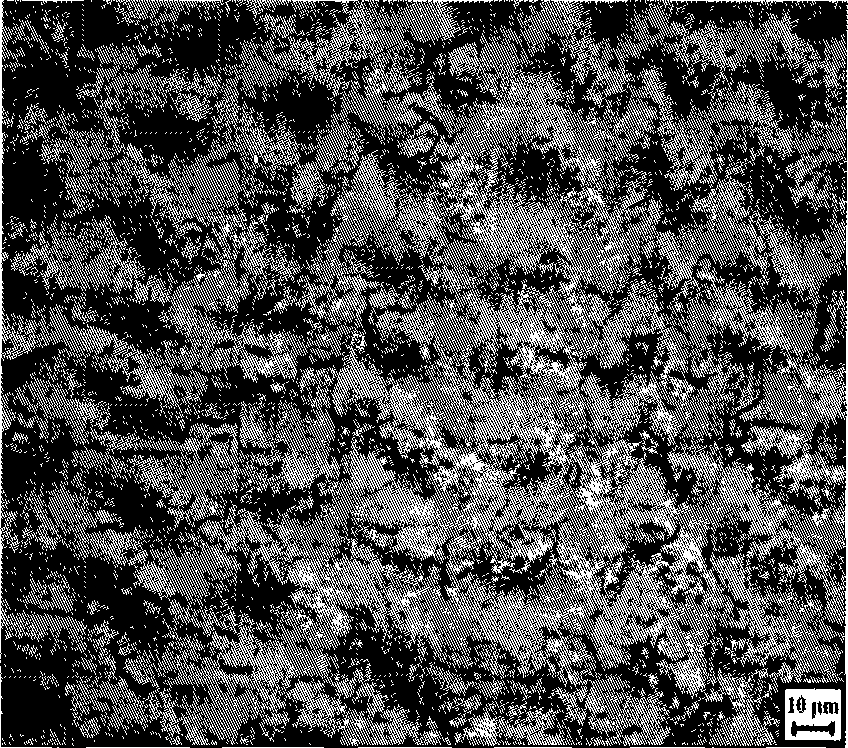

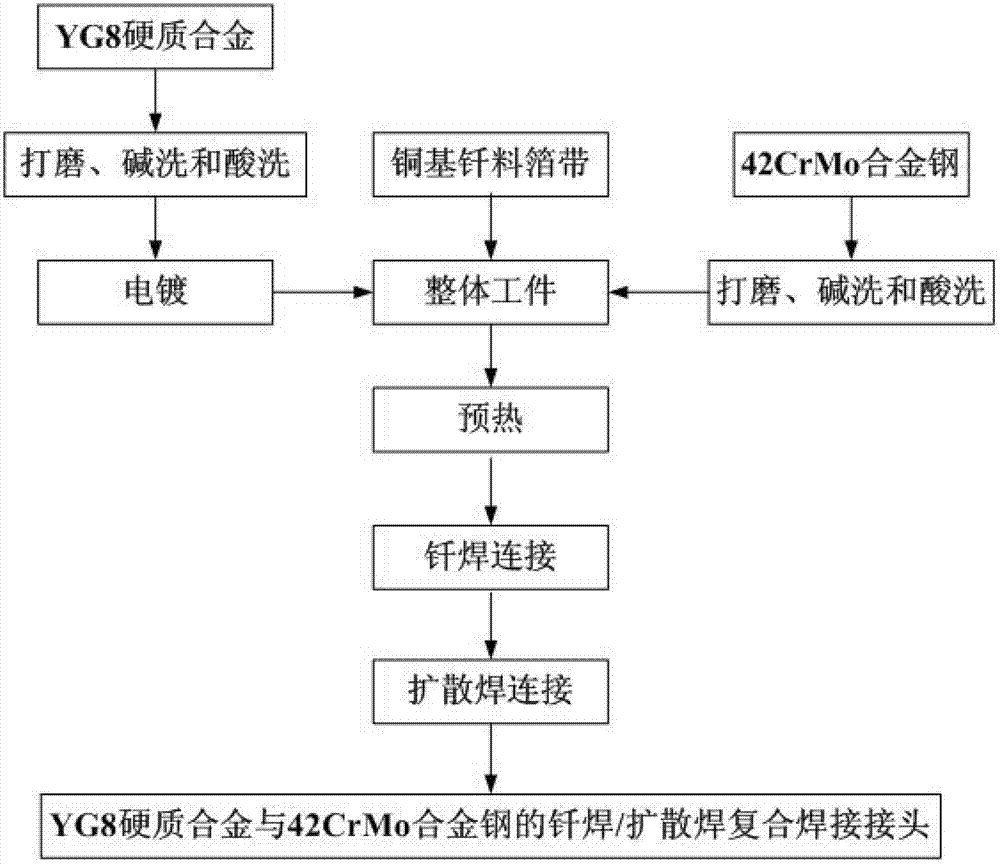

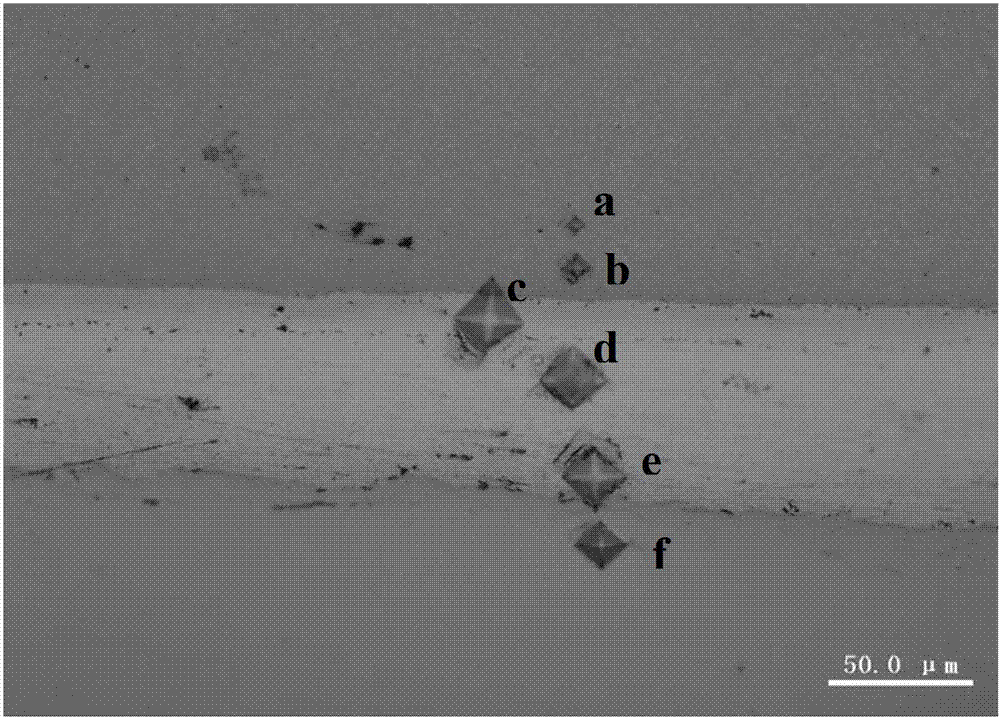

Soldering/diffusion welding hybrid welding method for cemented carbide and alloy steel

InactiveCN102922154AHigh bonding strengthGood mechanical propertiesSoldering apparatusWelding/soldering/cutting articlesAcid washingBond strength

The invention provides a soldering / diffusion welding hybrid welding method for a cemented carbide and alloy steel. The method comprises the following steps of: performing the procedures of grinding, alkali washing and acid washing on the YG8 cemented carbide and the 42CrMo alloy steel sequentially, and then, electroplating a nickel coating on the surface of the YG8 cemented carbide; lapping the YG8 cemented carbide and the 42CrMo alloy steel, and paving a copper-based solder foil strip in a lapping area, thus obtaining a whole workpiece; and performing soldering / diffusion welding hybrid welding on the whole workpiece in a vacuum soldering furnace, thus obtaining a soldering / diffusion welding hybrid welding joint of the YG8 cemented carbide and the 42CrMo alloy steel. The welding joint subjected to the soldering / diffusion welding hybrid welding is high in bonding strength and small in residual stress, has a smooth and dense surface, and is smooth and attractive; and moreover, during the welding process, the welded workpiece is not easily oxidized and is subjected to small deformation, the service life of the workpiece is obviously prolonged, and thus the method is an ideal welding technology for realizing dissimilar welding of cutting teeth and cutting tools.

Owner:XIAN UNIV OF SCI & TECH

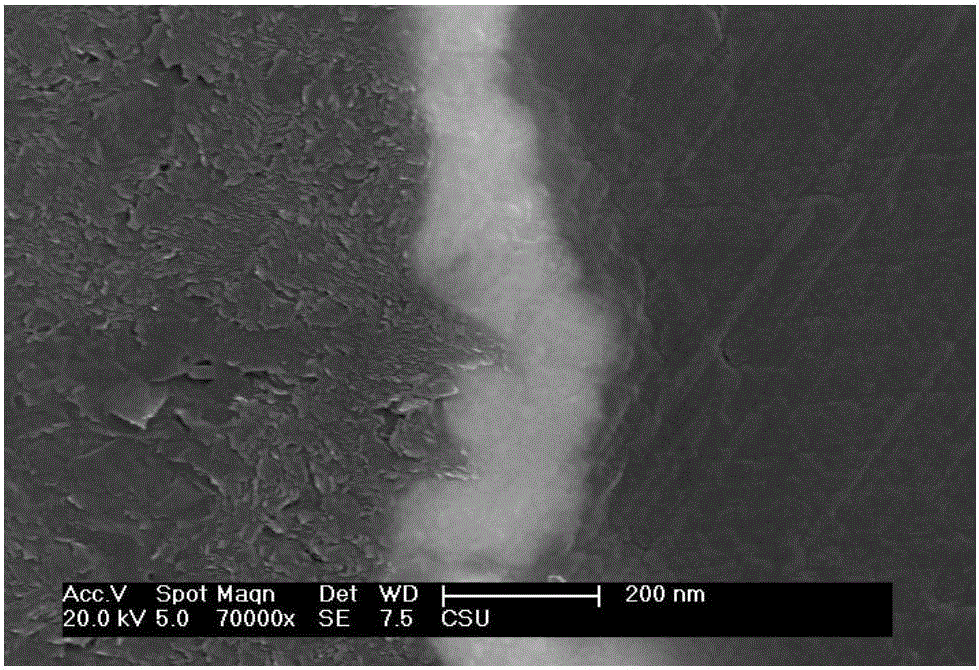

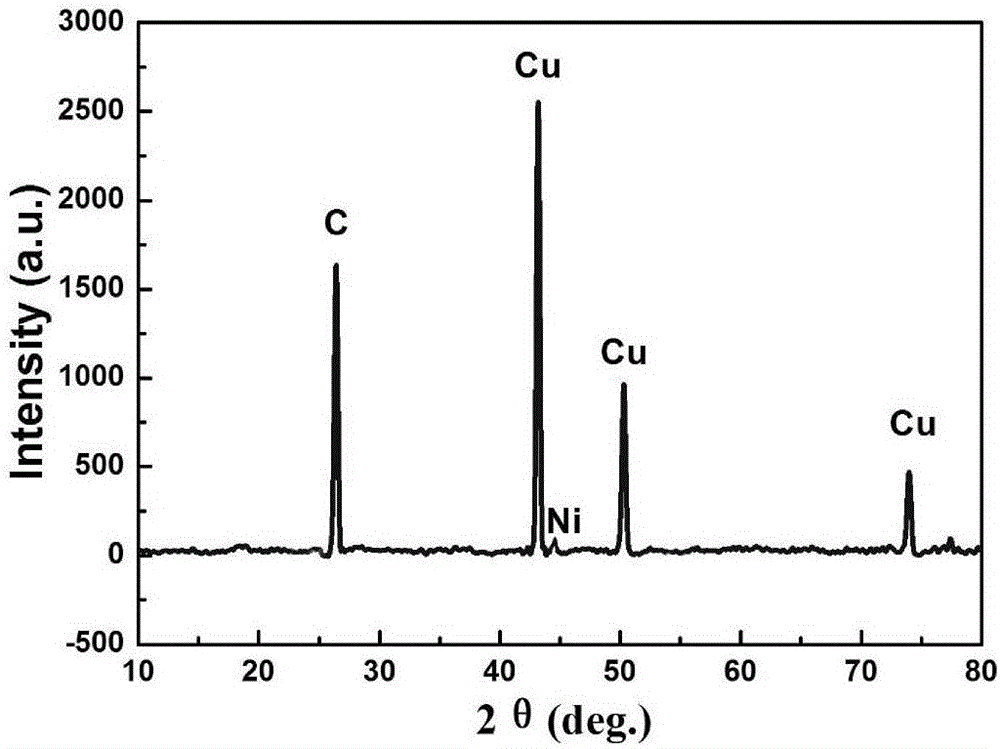

Copper-carbon composite material and preparing method thereof

ActiveCN106424713APromotes even distributionImprove performanceTransportation and packagingMetal-working apparatusFiberCarbon composites

The invention discloses a copper-carbon composite material and a preparing method thereof. Natural flake graphite, colloidal graphite, nano graphite, carbon fiber and the like can be selected as a carbon material in the copper-carbon composite material. The preparing method of the copper-carbon composite material includes the steps that firstly, a chemical nickel plating method is used for preparing a nickel plating carbon material; then a chemical copper plating method is used for plating copper on the nickel plating carbon material; and finally, vacuum semi-solid-state low-pressure sintering is conducted on the copper plating carbon material under the copper melting point temperature, and the copper-carbon composite material is prepared. The copper-carbon composite material and the preparing method thereof have the beneficial effects that a layer of even thin nickel plating layer is formed on the surface of carbon through the nickel plating method so as to reduce the wetting angle of the carbon material, the copper plating layer is formed on the surface of the nickel plating carbon material through the copper plating method so that a three-dimensional copper network can be formed by the material in the sintering process, and the bonding strength of a base body is improved through vacuum semi-solid-state low-pressure sintering. The two phases of the base body and the carbon of the copper-carbon composite material prepared through the method are distributed evenly and are well combined, and the good electricity and mechanical properties and the good frictional wear performance are achieved.

Owner:CENT SOUTH UNIV

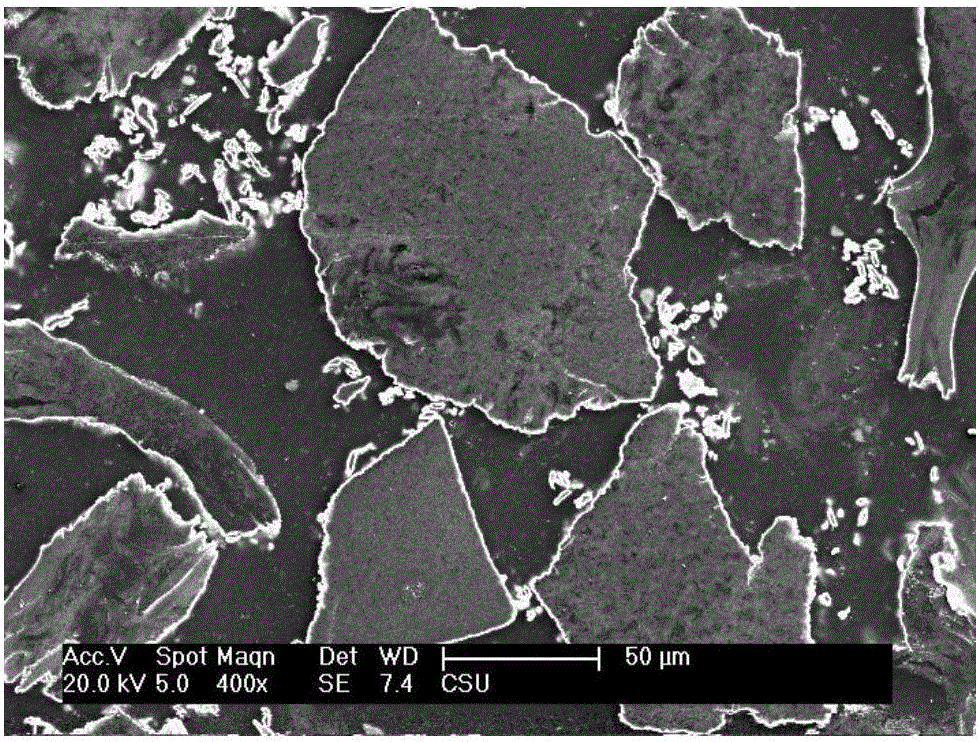

Method for preparing high-coercivity sintered Nd-Fe-B permanent magnet

ActiveCN103839670AMaximize resource efficiencyResource efficiency is stableElectrolytic coatingsInductances/transformers/magnets manufactureAlloySolid matter

The invention discloses a method for preparing a high-coercivity sintered Nd-Fe-B permanent magnet. The method includes the following steps that firstly, the vacuum rapid hardening technology is used for preparing Nd-Fe-B alloy magnetic material blank; secondly, chamfering, cleaning, washing, surface modifying and washing are sequentially performed on the blank; thirdly, a processed permanent magnet is placed to a nickel / heavy rare earth composite coating for being electroplated; fourthly, a sintered Nd-Fe-B magnetic material is placed into a vacuum heat treatment furnace to receive heat treatment. With the technology of compositing heavy rare earth on a nickel-plate, heavy rare earth solid matter can be effectively utilized, and maximum benefits of rare earth resources are achieved. Meanwhile, it is ensured that the proportion of the content of the heavy rare earth in the nickel-plate is stable, volatile matter which is prone to decomposition does not exist in the nickel-plate in subsequent heat treatment to pollute a vacuum heat treatment system, a production device with infiltration of the heavy rare earth can be stable continuously, the application range of a technology is wider, and the method can be popularized and applied in an enterprise more easily.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

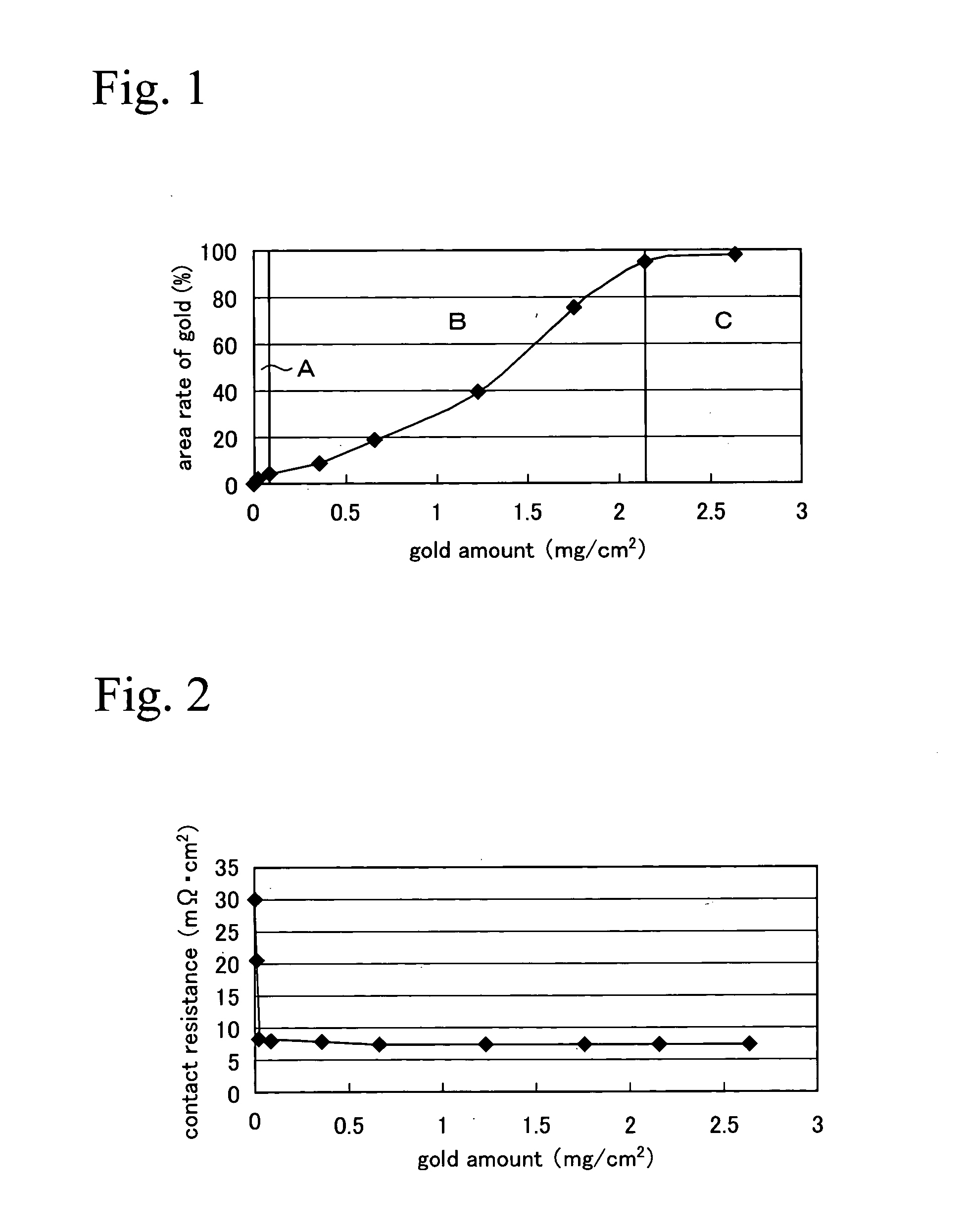

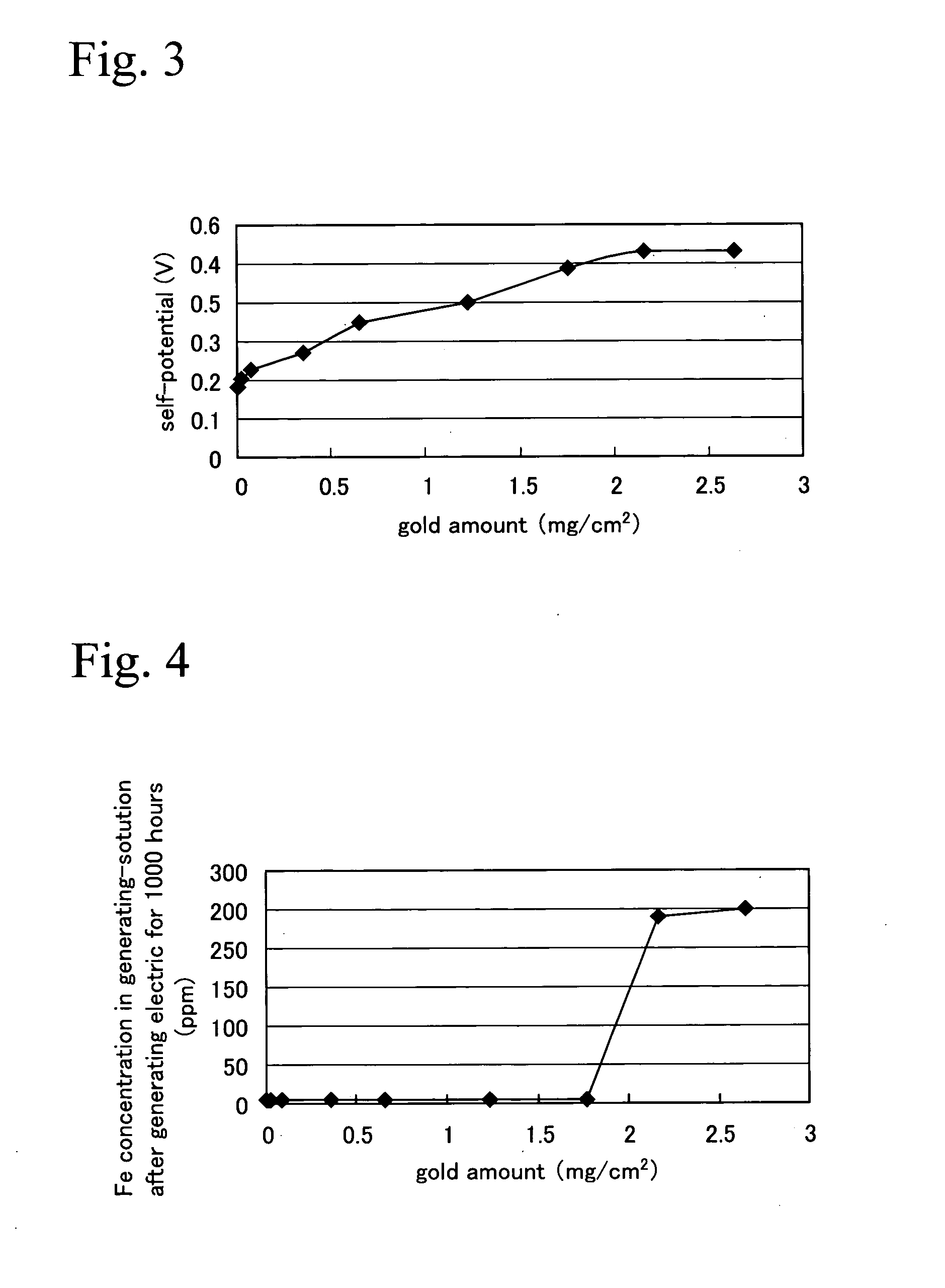

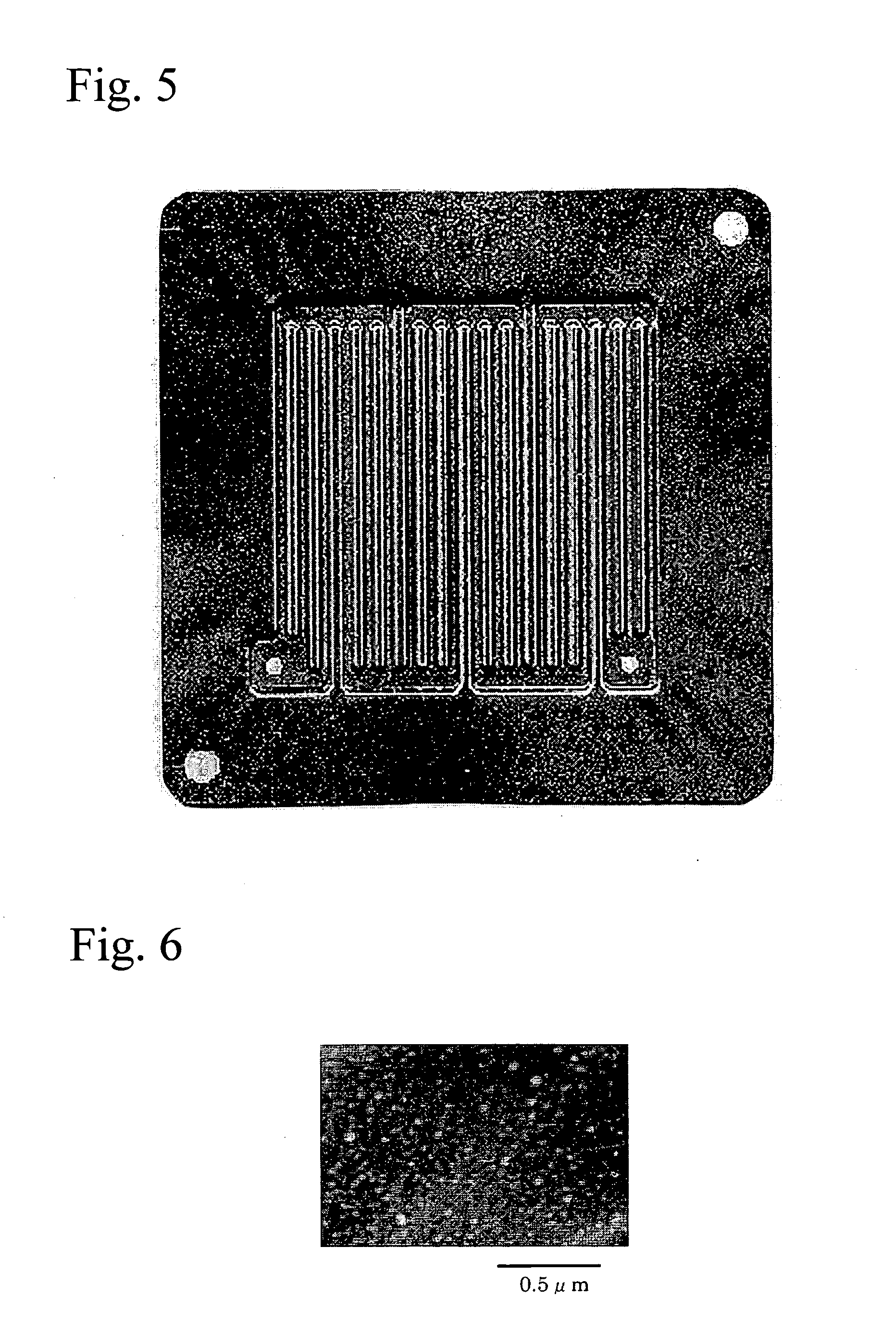

Metallic separtor for fuel cell and production method for the same

ActiveUS20040197661A1Contact resistanceDifficult to separateAnodisationFinal product manufactureFuel cellsContact resistance

A metallic separator for a fuel cell has excellent corrosion resistance and contact resistance, even when a gold coating is applied directly without a surface treatment by a nickel coating. The metallic separator for a fuel cell, comprising stainless steel having a surface, can be obtained by coating at 2.3 to 94 % of area rate on the surface without a surface treatment.

Owner:HONDA MOTOR CO LTD

Method for electroplating surface of molybdenum and copper alloy

The invention discloses a method for electroplating the surface of a molybdenum and copper alloy. The method comprises the following steps of: 1, removing oil; 2, scouring; 3, activating; 4, planting nickel; 5, carrying out vacuum heat treatment; 6, removing oil; 7, activating; and 8, carrying out subsequent electroplating. An oxide film on the surface of the molybdenum and copper alloy can be completely removed through steps of scouring and activating, a thin nickel layer is electroplated on the surface of the molybdenum and copper alloy through steps of plating nickel and carrying out vacuum heat treatment, and then the vacuum heat treatment is carried out, so that a diffusion layer with better bonding force is formed by a nickel plating layer and a base material and then is activated, and a required plating layer can be electroplated continuously. According to the method, the problem of poor bonding force of the electroplating layer of the molybdenum and copper alloy is solved, theoxide film before the molybdenum and copper alloy is electroplated is removed, process parameters of nickel pre-plating and vacuum heat treatment are determined, and an activating method of electroplating on a nickel-plated base layer is determined.

Owner:CHENGDU SIWI HIGH TECH IND GARDEN

Process of preparing nanometer antiwear composite coating on surface of metal base

InactiveCN101021013AHigh surface hardnessSimple processLiquid/solution decomposition chemical coatingNanometreNickel coating

The process of preparing nanometer antiwear composite coating on the surface of metal base includes the following steps: 1. cleaning the surface of the metal base; 2. selecting one kind of the nanometer powder or the composition as the reinforcing body; 3. surface chemical treatment of the reinforcing body with chemical reagent; 4. adding the reinforcing body treating liquid into acid chemical nickel coating liquid as the base coating liquid; 5. immersing the metal base in the composite coating liquid while stirring to complete chemical coating; 6. water washing and drying the coated metal base; and 7. surface laser heat treatment of metal base. The present invention combines nanometer technology, chemical coating technology and laser heat treatment technology organically, and is simple, efficient, feasible and suitable for use in various kinds of metal material and product.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing multilayer high corrosion resistant-wear resistant composite protective coating on magnesium alloy surface

InactiveCN102234802AImprove bindingHigh hardnessAnodisationLiquid/solution decomposition chemical coatingChemical platingWear resistant

The invention relates to a method for preparing a multilayer high corrosion resistant-wear resistant composite protective coating on a magnesium alloy surface, belonging to the technical field of metal surface treatment. The method comprises the following steps that: first, carrying out plasma anodization on a magnesium alloy to form a porous ceramic layer growing on the matrix surface, then, carrying out organic coating hole sealing treatment on the coating, carrying out chemical plating the treated coating to form an Ni-P coating, finally, carrying out electroplating to form a high corrosion resistant-wear resistant Ni-P coating. According to the invention, by the prepared composite protective coating comprising the ceramic layer, the organic coating and the nickel coating on the magnesium alloy surface, the high protection and high wear resistance of the magnesium alloy matrix are realized. According to the invention, the defect of single surface treatment technique of the magnesium alloy is overcome, and the multilayer composite coating formed on the magnesium alloy surface has characteristics of good bonding force, high rigidity, corrosion resistance and wear resistance, thusbeing an ideal protective coating for magnesium alloy, meeting the protective requirements of the magnesium alloy products in the harsh environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

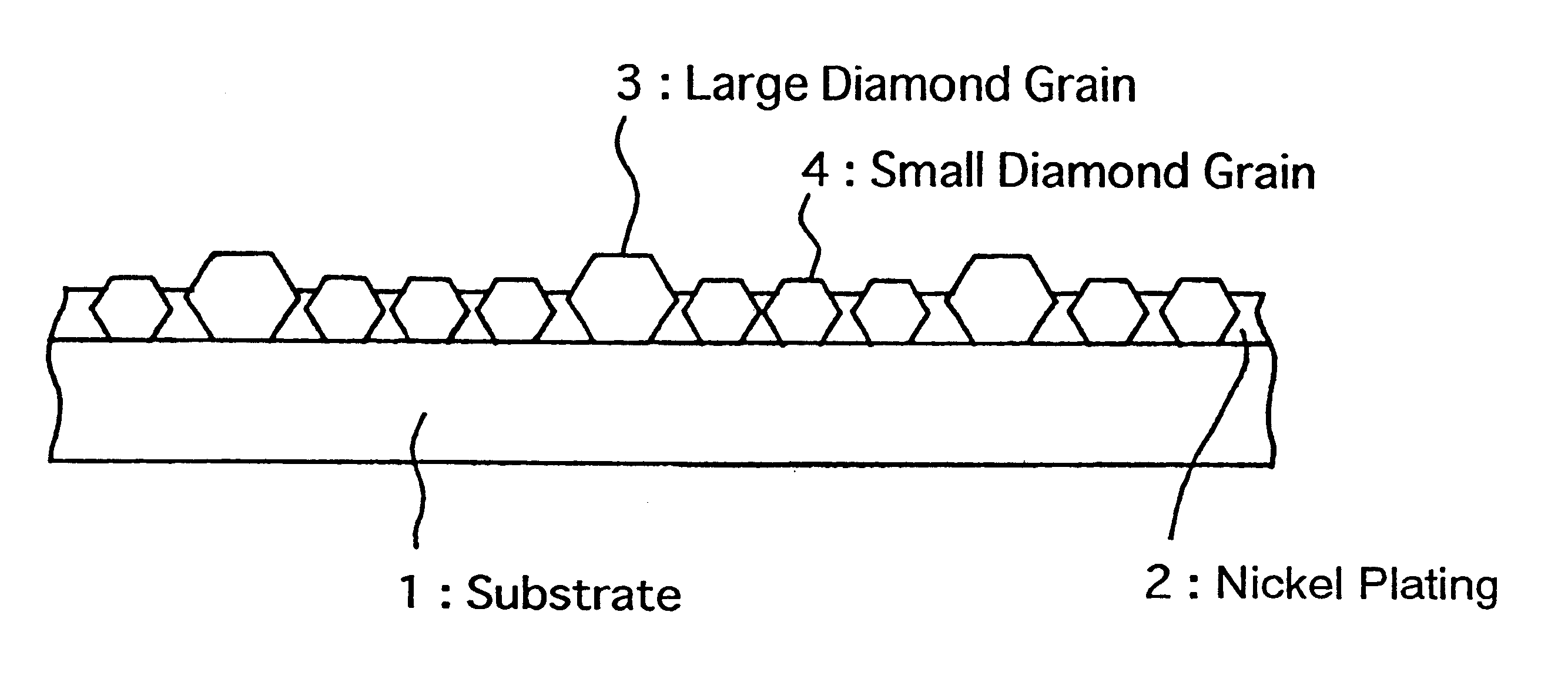

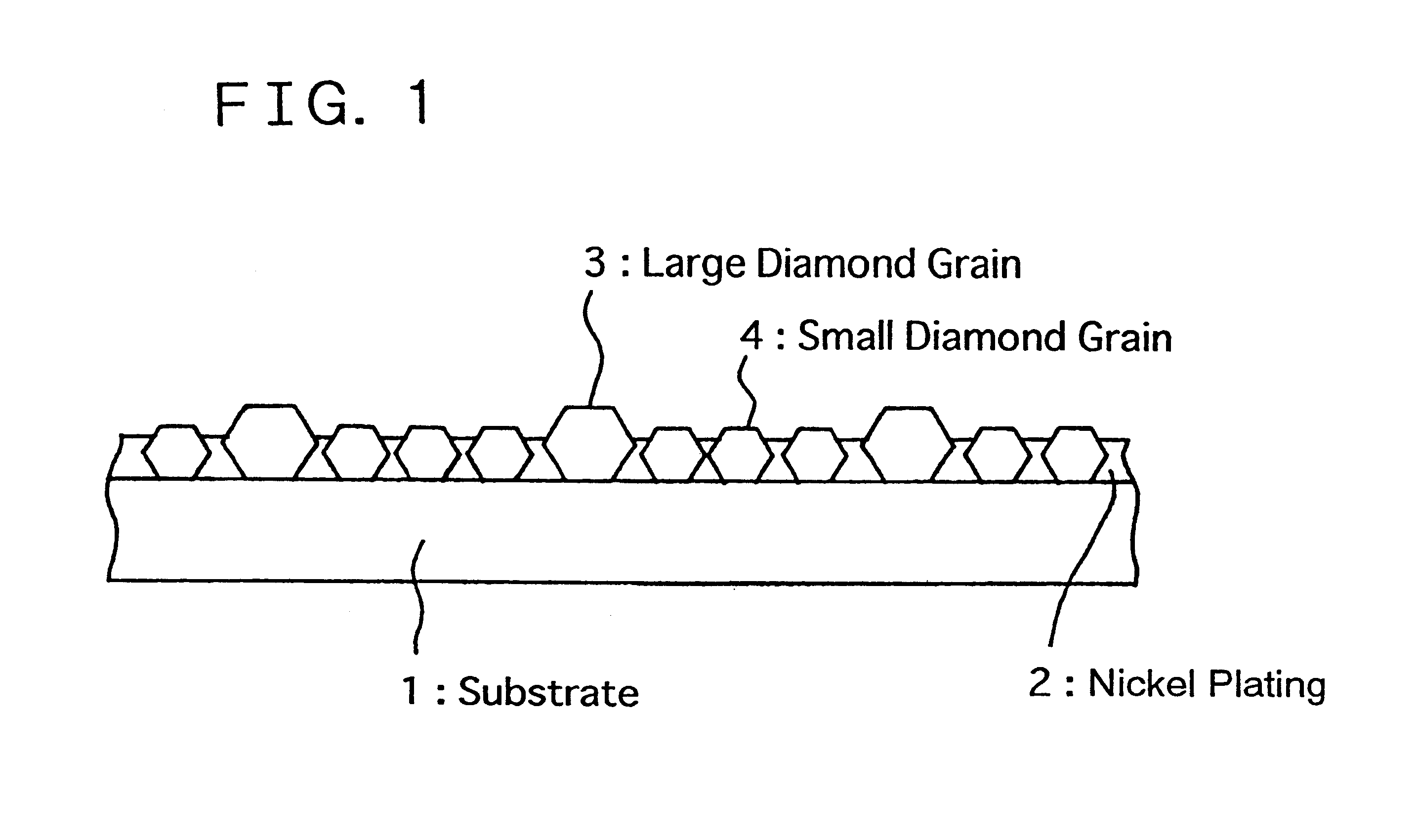

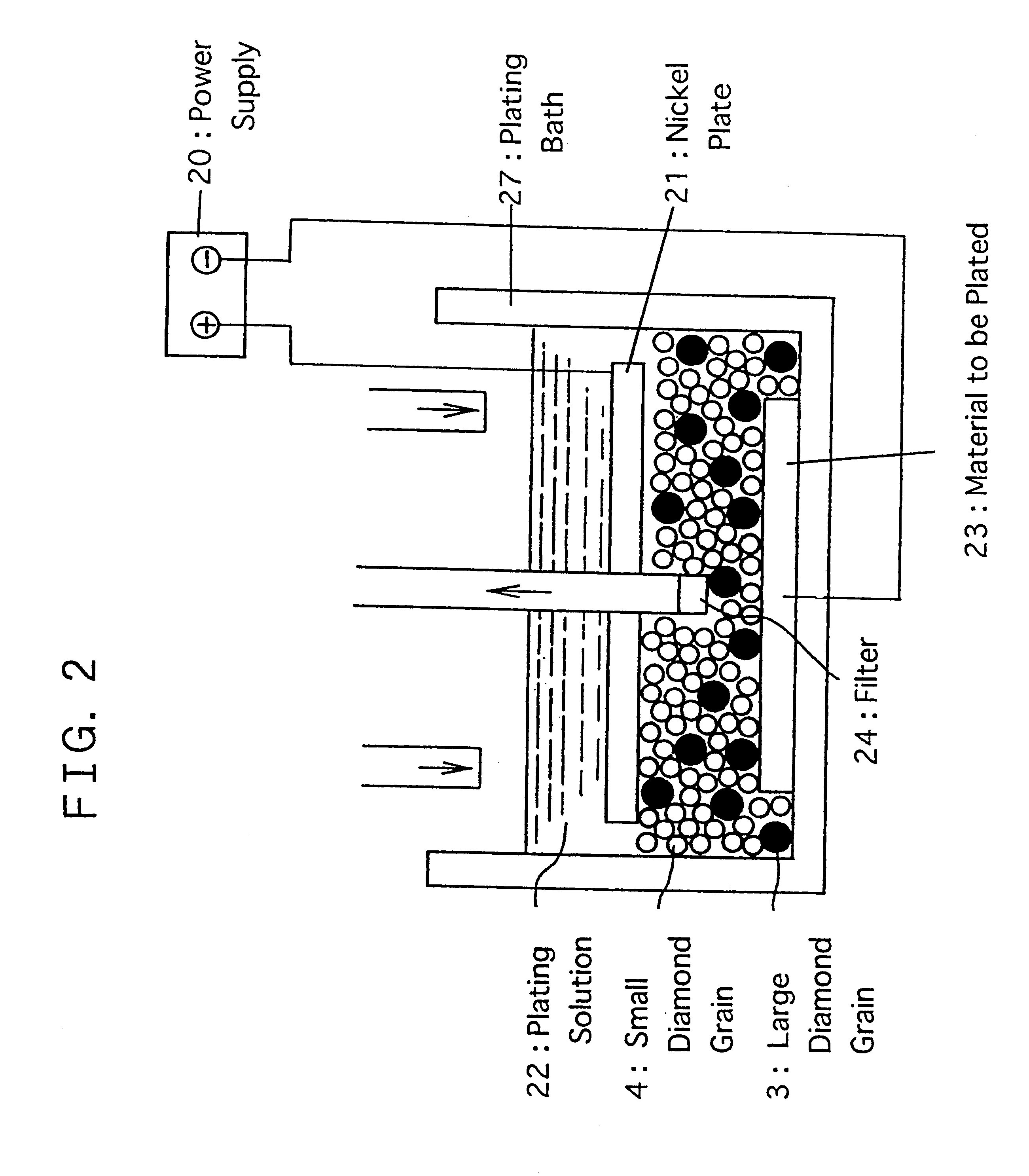

Dressing tool for the surface of an abrasive cloth and its production process

InactiveUS6306025B1Short lifeSimple processElectrolytic coatingsGrinding drivesForeign matterForeign substance

Onto the surface of a dressing tool for removing the clogging of an abrasive cloth, diamond grains of plural groups each having a different average particle diameter are subjected to be mixed and then fixed. In this state, the upper end of small diamond grains 4 is projected over nickel plating 2. Thereby foreign substances aggregated in the concave of the abrasive cloth are effectively removed and at the same time wearing the surface of the nickel plating 2 is prevented. Achieved are the stabilization of a polishing speed in polishing and the inhibition of dropping out diamond grains and wearing nickel plating in dressing.

Owner:NEC ELECTRONICS CORP

Chemical nickel-plating method on magnesium alloy surface

InactiveCN1500910AReduce pollutionUniform thicknessLiquid/solution decomposition chemical coatingFluorideAqueous solution

The present invention relates to magnesium alloy surface treating technology, and is especially chemical nickel plating process for magnesium alloy. The operation process includes the following steps: activating or finishing magnesium alloy through polishing or grinding, degreasing and acid pickling with acid fluoride bearing solution at 20-60 deg.c for 0.5-5 min; pre-treating with water solution containing fluoride bearing compound, iron bearing compound and complex at 15-45 deg.c for 5-30 min; and chemically nickel plating. The said process can make chemical nickel coating with homogeneous thickness, firm combination with substrate, high corrosion resistance and metal appearance. The process of the present invention has low cost and less environmental pollution and is suitable for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-conductivity composite carbon fiber and preparation method thereof

InactiveCN103144356ALow resistivityImprove conductivityVacuum evaporation coatingSputtering coatingMetal coatingYarn

The invention discloses a high-conductivity composite carbon fiber and a preparation method thereof, and belongs to composite carbon fibers and a preparation method thereof. The high-conductivity composite carbon fiber provided by the invention consists of carbon fibers as well as metal coatings and graphene coatings, which are sequentially adhered on the surfaces of the carbon fibers from bottom to top; the carbon fibers are carbon fiber yarns, carbon fiber bundles, carbon fiber cloth, carbon fiber paper or carbon fiber fabrics; the metal coatings are a metal copper coating, a metal nickel coating or a metal iridium coating; and the thicknesses of the metal coatings are 50-500nm. The composite carbon fiber prepared by the invention has excellent conductivity and heat conductivity, can conduct or dissipate lightning stroke energy rapidly, and improves the thunder stroke resistant capability of the carbon fiber material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

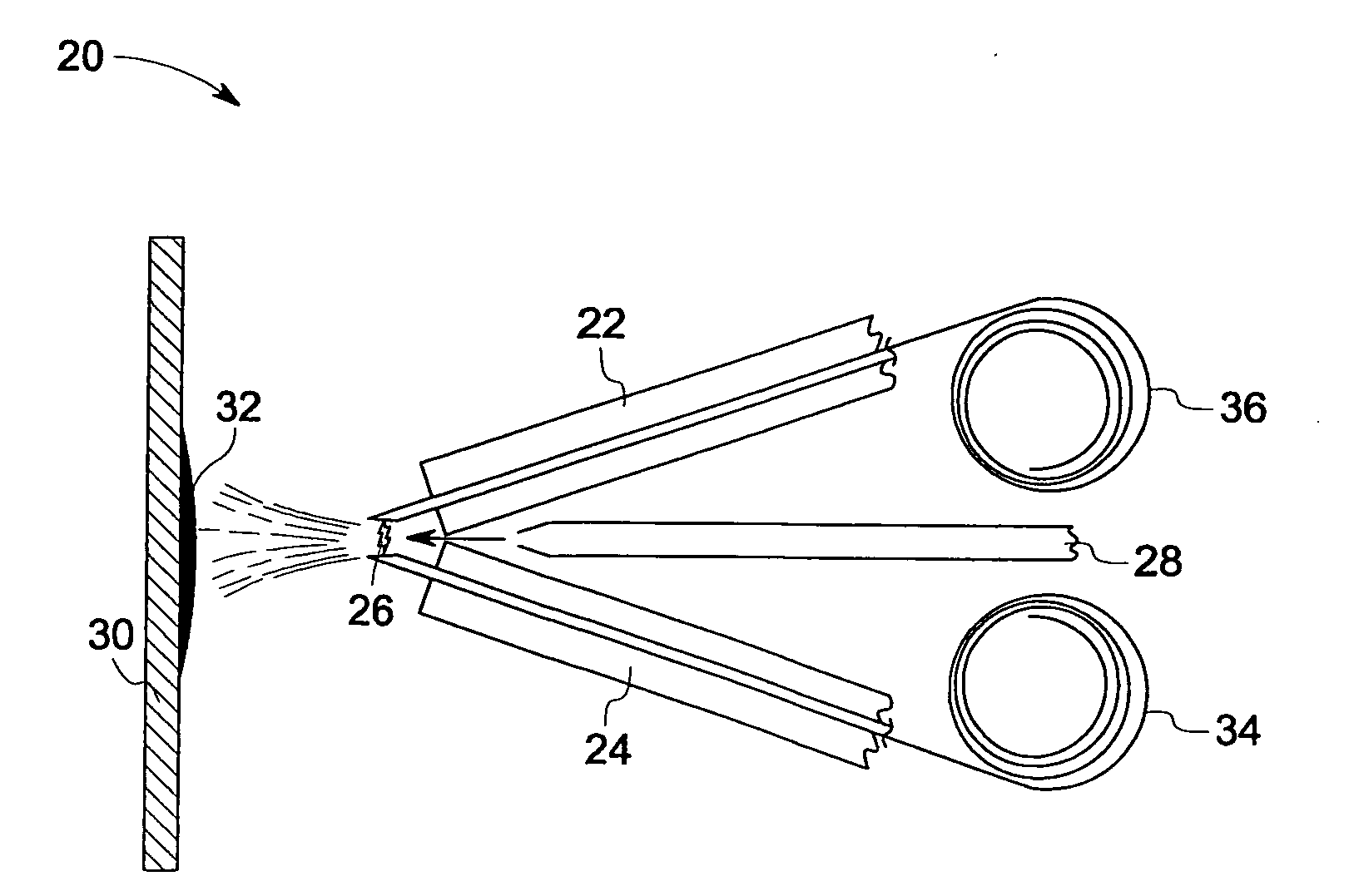

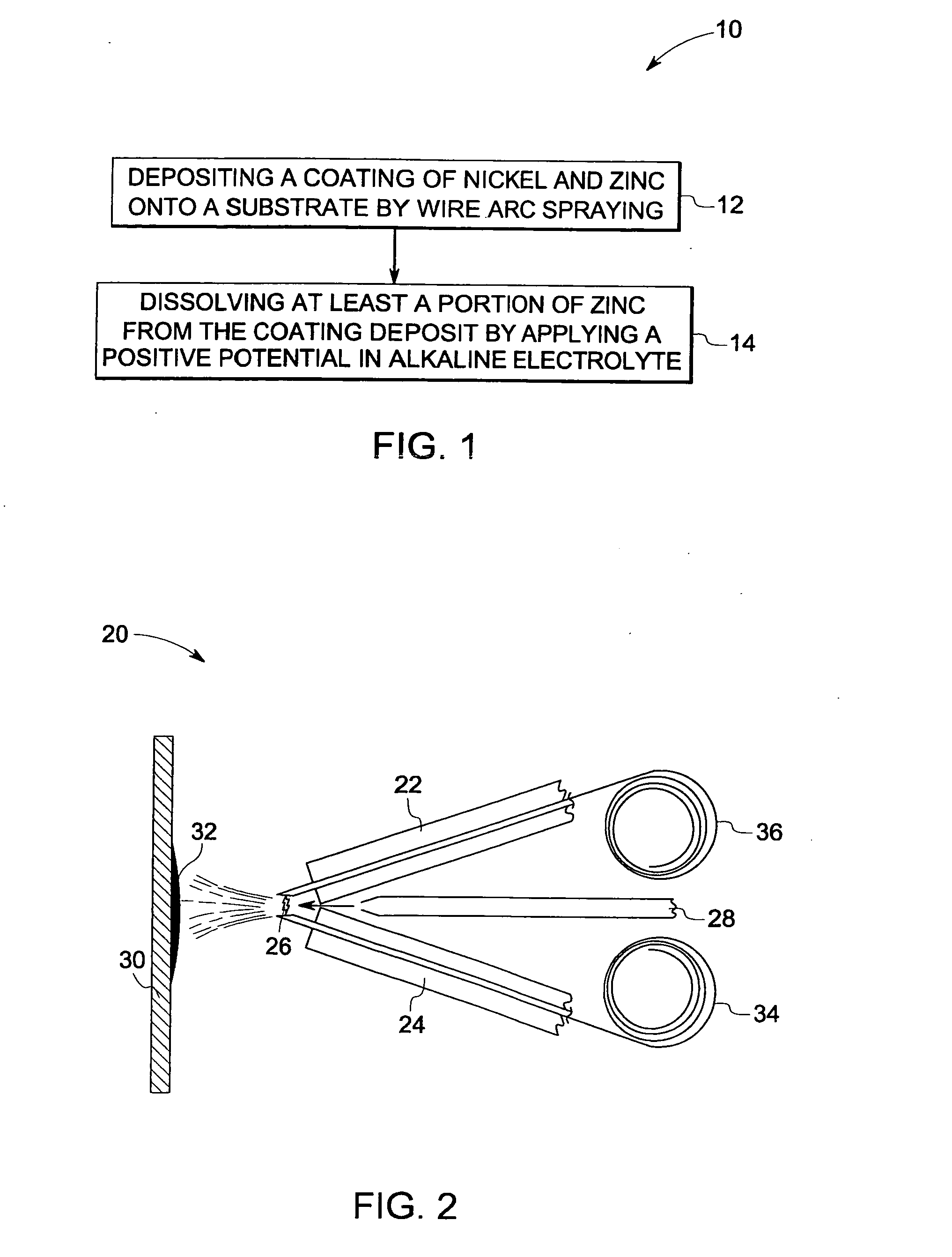

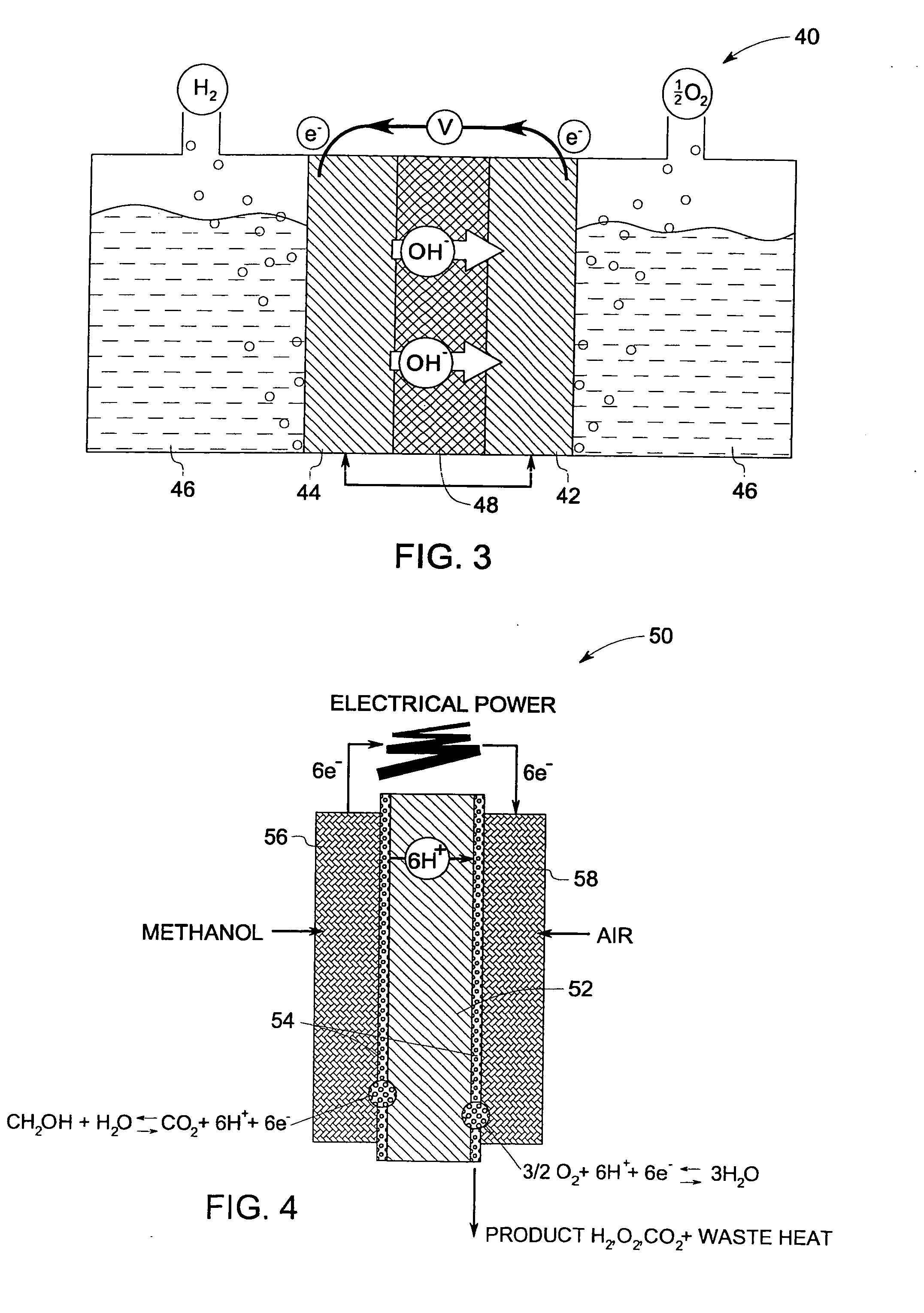

Method of forming a porous nickel coating, and related articles and compositions

InactiveUS20070278108A1Improve performanceEfficient productionPolycrystalline material growthFrom normal temperature solutionsSacrificial metalArc spray

A method of forming a porous nickel coating is provided. The method includes the steps of: depositing a coating onto a substrate by melting and atomizing two consumable electrode wires of a selected composition in a wire-arc spray device, so as to form a molten, atomized material, and directing the material to the substrate to form a coating deposit; the selected composition including nickel and a sacrificial metal; and then dissolving at least a portion of the sacrificial metal from the coating deposit by applying a positive potential in an alkaline electrolyte, so as to obtain a porous nickel coating. An electrolytic cell that includes a porous nickel coating is also described.

Owner:GENERAL ELECTRIC CO

Nondestructive thickness measuring method for nickel coat on Fe substrate

InactiveCN101131314ALow costEasy to carryElectrical/magnetic thickness measurementsCoated surfaceNon destructive

The invention discloses a non-destructive thickness measuring method of nickel coating on iron base metal; the method is to setting samples of known thickness of nickel coating on iron base metal, by detecting the nickel coated surface of samples through eddy current sensor installed with exciting coils and magnetic test coils, the exciting coils send out pumping signals, obtain eddy current testing data corresponding to the thickness of nickel coating on iron base metal after managing the eddy current induction signal the magnetic test coils obtained, so as to establish a thickness model of nickel coating on iron base metal, in the actual measurement, with the help of this model, the thickness of nickel coating on iron base metal can be tested using the same method. The method is nondestructive, suitable for testing the thickness of all nickel coating on iron base metal, has the advantages of low cost, easy to carry with testing equipment, simple to operate, intuitive and detect fast, can immediate get the testing results at the scene with accurate results.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD +1

Metal super-hydrophobic surface and preparation method thereof

The invention relates to a metal super-hydrophobic surface and a preparation method thereof. The preparation method comprises following two steps: firstly, electroplating method is adopted, traditional Watts electroplate liquid is taken as a base electroplate liquid, conductive metal base materials such as stainless steel, copper, aluminium alloy, and magnesium aluminum alloy, are taken as a negative electrode, and copper sheets are taken as a positive electrode so as to prepare a nickel coating layer; and secondly, an obtained electroplated surface and an ethanol solution containing fluorosilane are delivered into a heating furnace for heat treatment, and an obtained sample is subjected to washing and blow drying so as to obtain the surface with super-hydrophobicity on metal workpieces. The preparation method of the metal super-hydrophobic surface is simple; cost is low; and the preparation method is convenient for industrialized application. Contact angle of the obtained metal super-hydrophobic surface is more than 155 DEG, and rolling angel is less than 10 DEG; the metal super-hydrophobic surface possesses excellent super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance; the preparation method is suitable for obtaining the metal super-hydrophobic surfaces with super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance on the surfaces of a plurality of metal base materials with complex shapes and large area.

Owner:SOUTH CHINA UNIV OF TECH

Nickel coating carbon fiber composite material and preparation method thereof

InactiveCN103724930AImprove electromagnetic performanceImprove performanceCarbon fibresFiberChemical plating

The invention relates to a nickel coating carbon fiber composite material and a preparation method thereof. The preparation method comprises the following steps: preprocessing a carbon fiber material, depositing a nickel coating of 1 nm to 5 nm on the processed carbon fiber material by a chemical plating, CVD (chemical vapor deposition) or MOCVD (metal organic chemical vapor deposition) method, soaking the nickel-coated carbon fiber material in prepared phenolic resin, epoxy resin, cyanate ester resin or bismaleimide resin to form prepregs, properly trimming the two or more layers of prepregs, putting into a mould, and performing hot press molding in a hot press under the pressure of 30-60 MPa. The preparation method adopts a hot press molding process and is high in production efficiency, low in cost and suitable for large-scale production; the prepared nickel coating carbon fiber composite material is remarkably improved in electromagnetic performance while keeping the characteristics of high strength and light weight.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

Multi-purpose metal surface protectant and preparation method thereof

InactiveCN101514457AImprove the protective effectImprove corrosion resistanceMetallic material coating processesMoisture resistanceSolvent

The invention relates to a surface protectant mainly used for metal components of electrical appliances and a preparation method thereof. The surface protectant is prepared by 0.1-2% of organic inhibitor, 0.5-3% of film-forming substance, 0.05-0.3% of surfactant and solvent being balance through mixing and heating. The invention adopts an organic solvent as a solvent to prepare the protectant, thus having good dispersive capacity, infiltration capacity and sealing capacity; about 1mum semi-solid hydrophobic film is formed on the metal surface to block micropores on the metal surface, thus preventing harmful gases and other media from eroding the metal and improving the salt fog resistance, moisture resistance and mucedine resistance of the metal as well as the capability of the metal in resisting various severe environments; the film has good adhesive force, thus obviously improving the lubricating property and wearing resistance with no effect on the conductivity. The protectant can be widely applied to the sealing treatment of nickel coating of electronic components or printed circuit boards, aluminum alloy conduction and oxidation, gold plating, stainless steel, copper surface and zinc coating. The surface protectant is simple in production technology, convenient in use and low in cost.

Owner:西安创联华特表面处理技术有限责任公司

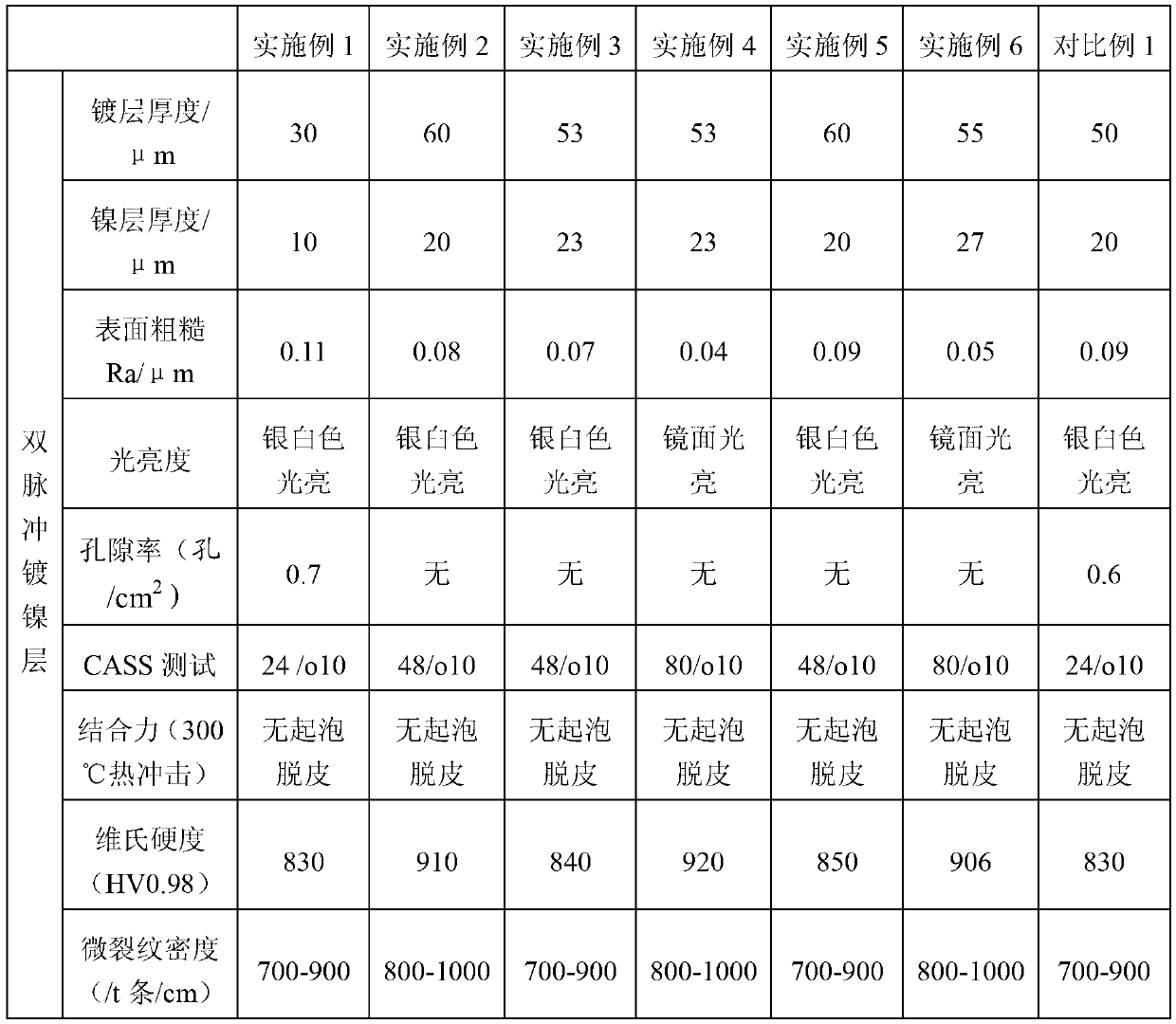

Wear-resistant worpiece and manufacturing method of wear-resistant coating thereof

The invention discloses a wear-resistant workpiece and a manufacturing method of a wear-resistant coating thereof. The preparation method of the wear-resistant coating comprises the following steps: forming a preparation piece according to the structure of a required wear-resistant workpiece; coating nickel on the surface of the preparation piece through a double-pulse method, thus forming a nickel-coated transition piece; and coating a hard chromium layer on the surface of the nickel-coated transition piece, thus forming the wear-resistant coating on the surface of the preparation piece. For the manufacturing method of the wear-resistant workpiece, a step of coating nickel on the surface of the workpiece through a double-pulse nickel coating method is added; and the double-pulse nickel coating method is characterized in that the magnitude of current or voltage is regulated by an external control means, the current is additionally controlled by controlling the pulse switch-on time, the pulse switch-off time, the pulse duty factor, the pulse current density and the like, and corresponding variables are changed to respectively achieve the effects of increasing the cathode current density, inhibiting the generation of side reaction, reducing the impurity content in the coating, improving the current distribution and the like, thus improving the quality of the coated nickel layer and prolonging the service life of the wear-resistant workpiece.

Owner:HUNAN TELI HYDRAULIC +1

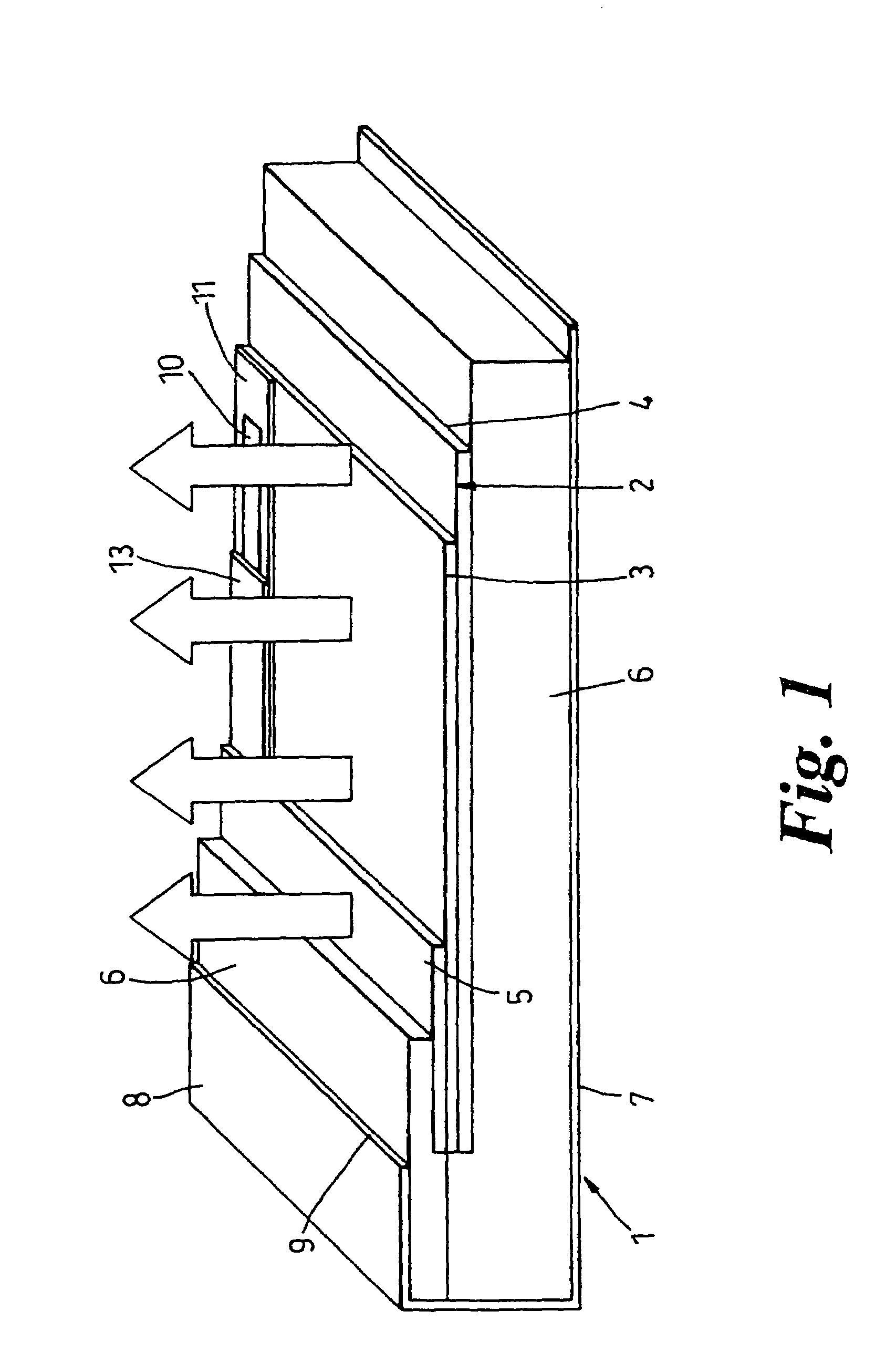

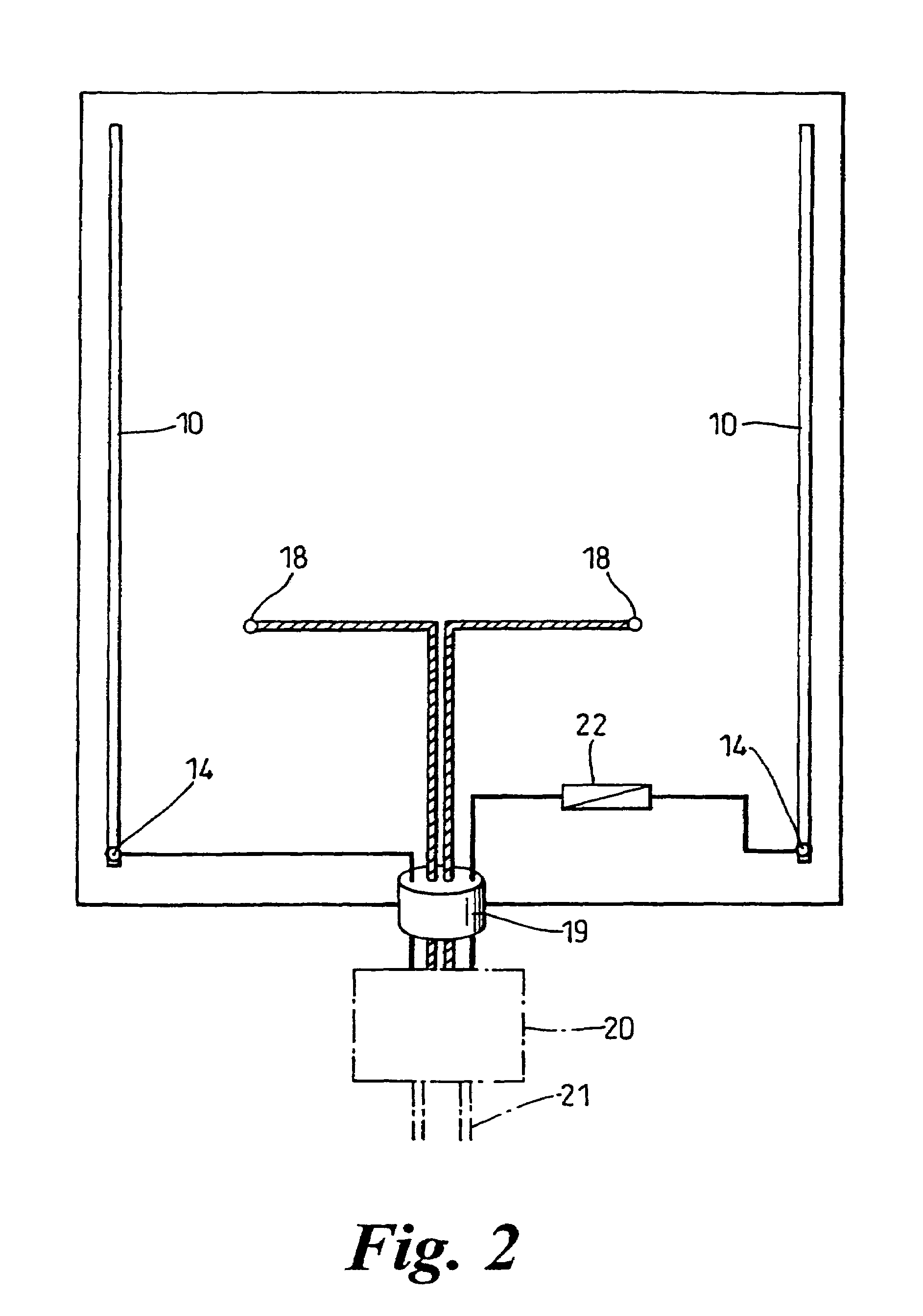

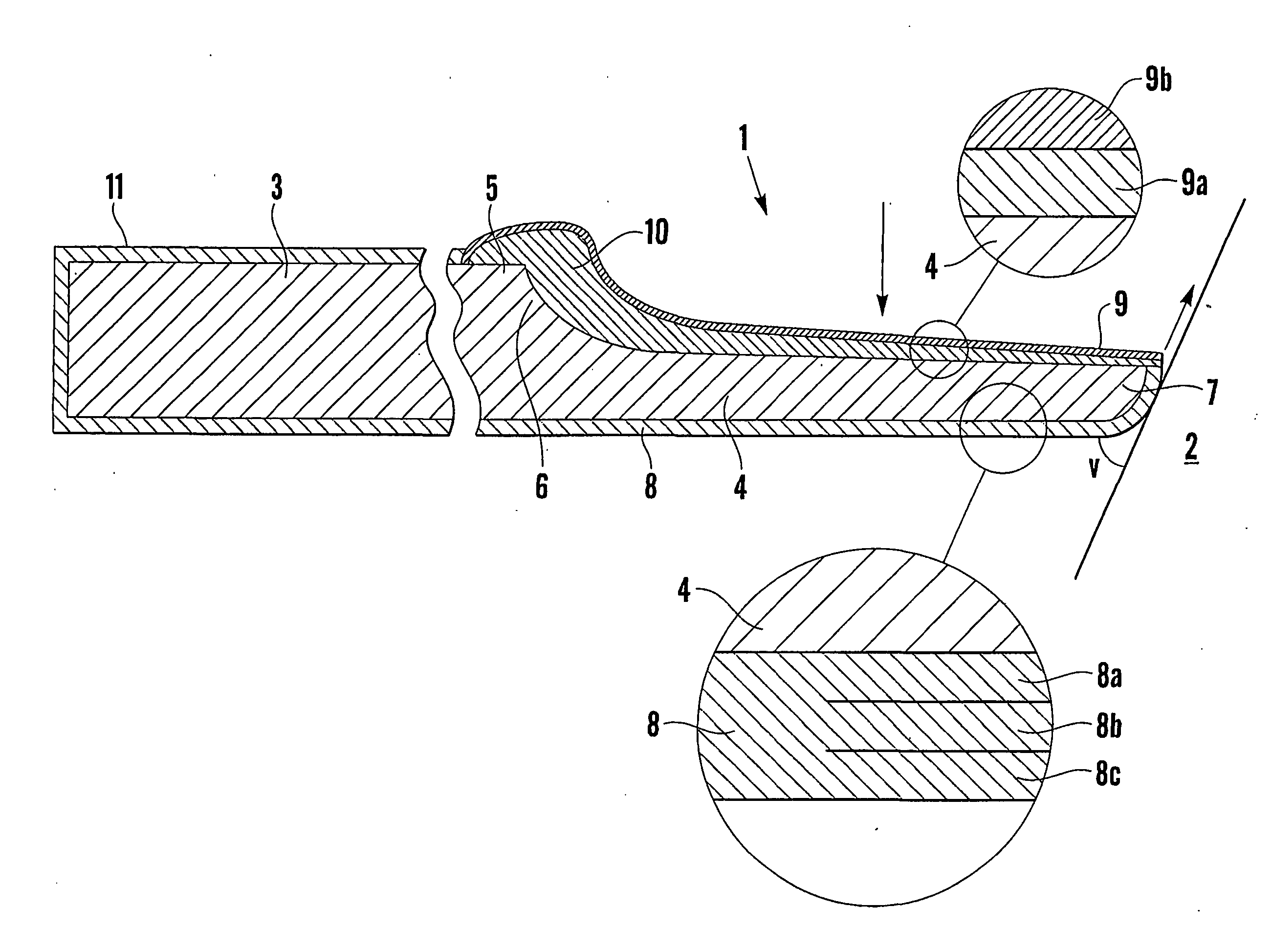

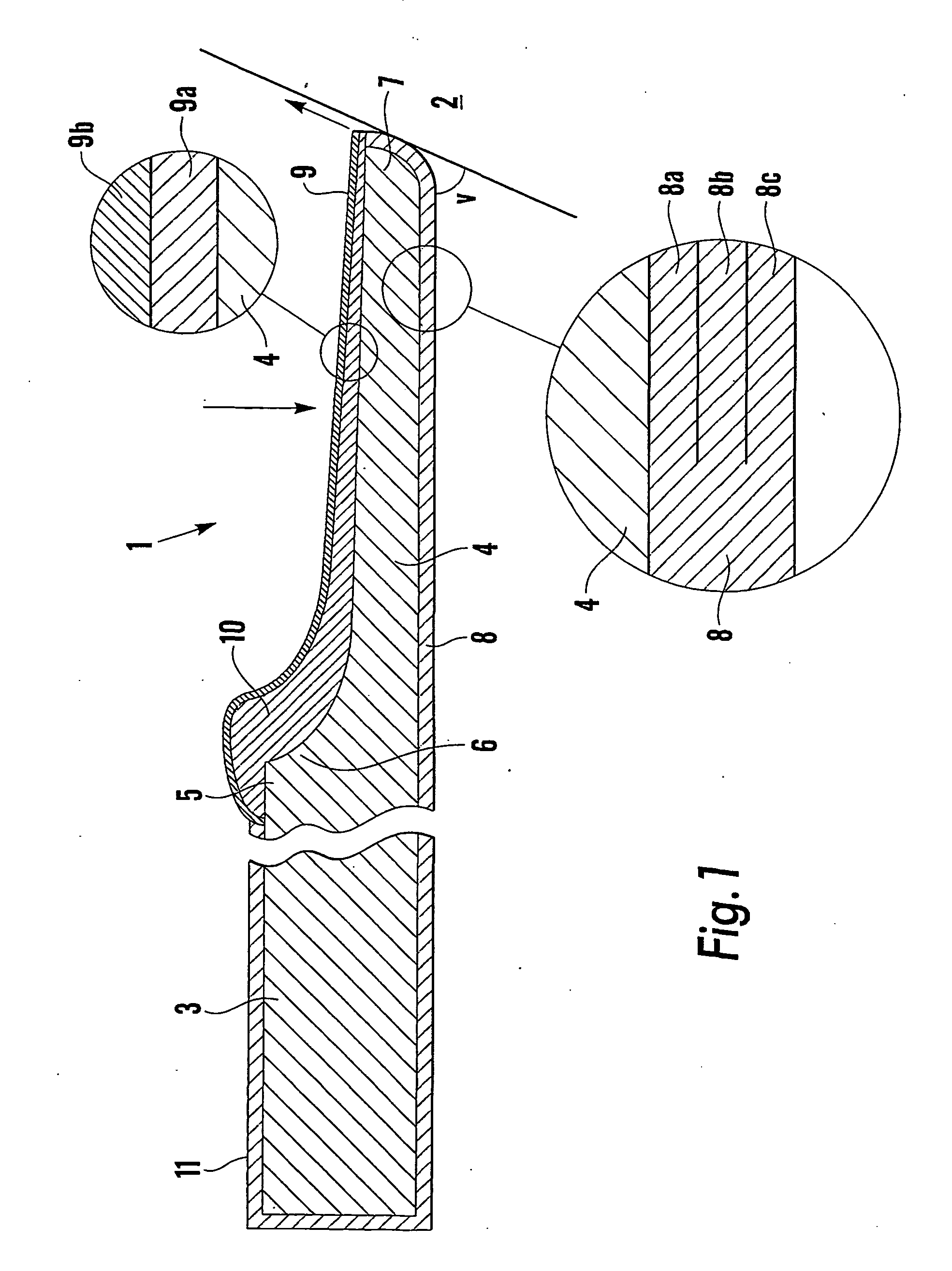

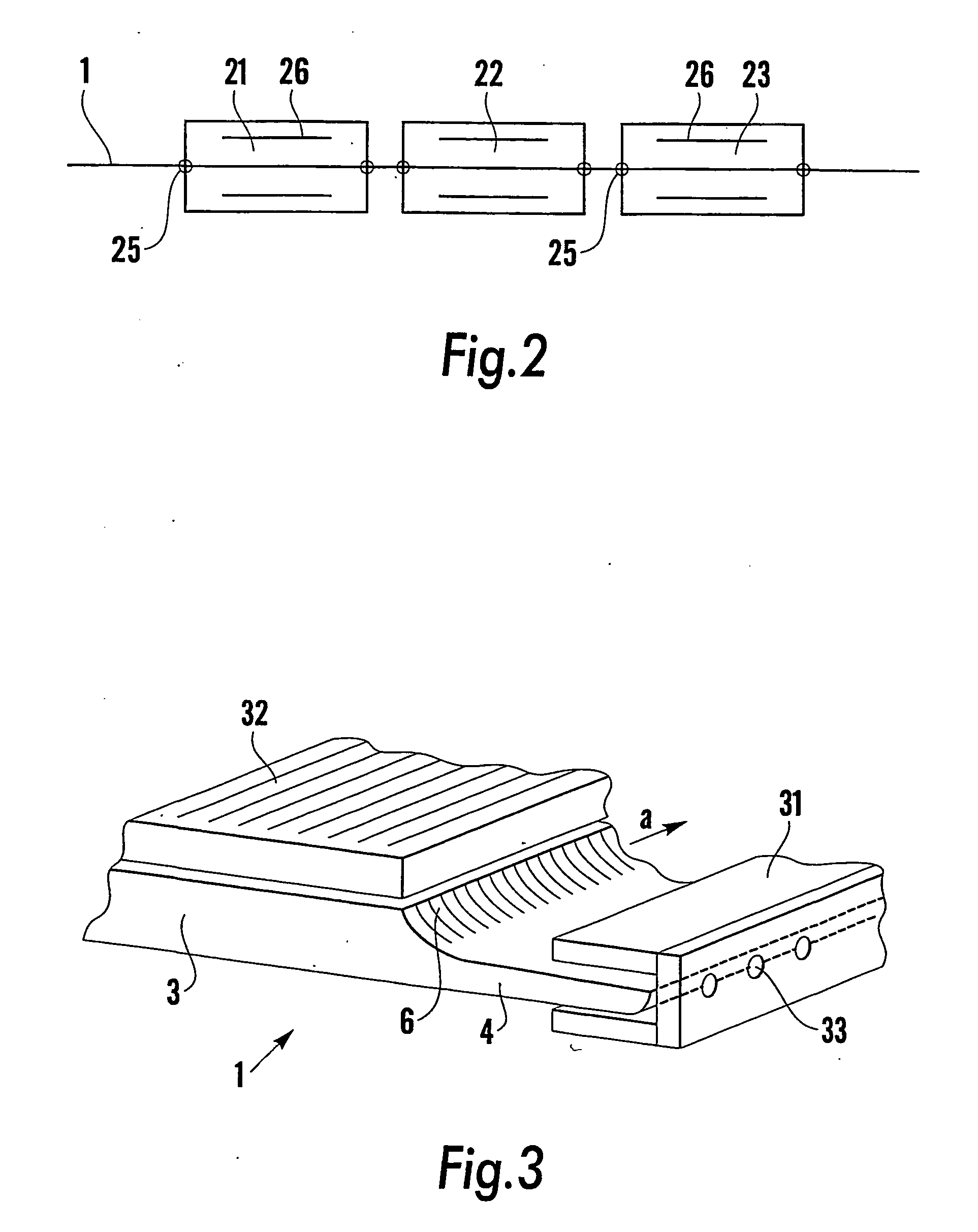

Doctor or coater blade and method in connection with its manufacturing

InactiveUS20040137261A1Improve wear resistanceEasy to wearLiquid surface applicatorsMechanical working/deformationNickel saltElectrolyte

The invention relates to a doctor or coater blade (1) of steel, having a nickel coating comprising abrasion resistant particles, said coating being constituted by an electrolytic nickel layer comprising abrasion resistant particles. The coating preferably comprises at least two electrolytic nickel layers having different composition, and may be formed differently in different sections of the blade. The invention also relates to a continuous process for electrolytic nickel coating in at least one electrolytic cell holding an electrolyte liquid comprising at least one nickel salt, and in at least one of these cells also comprising abrasion resistant particles.

Owner:SWEDEV

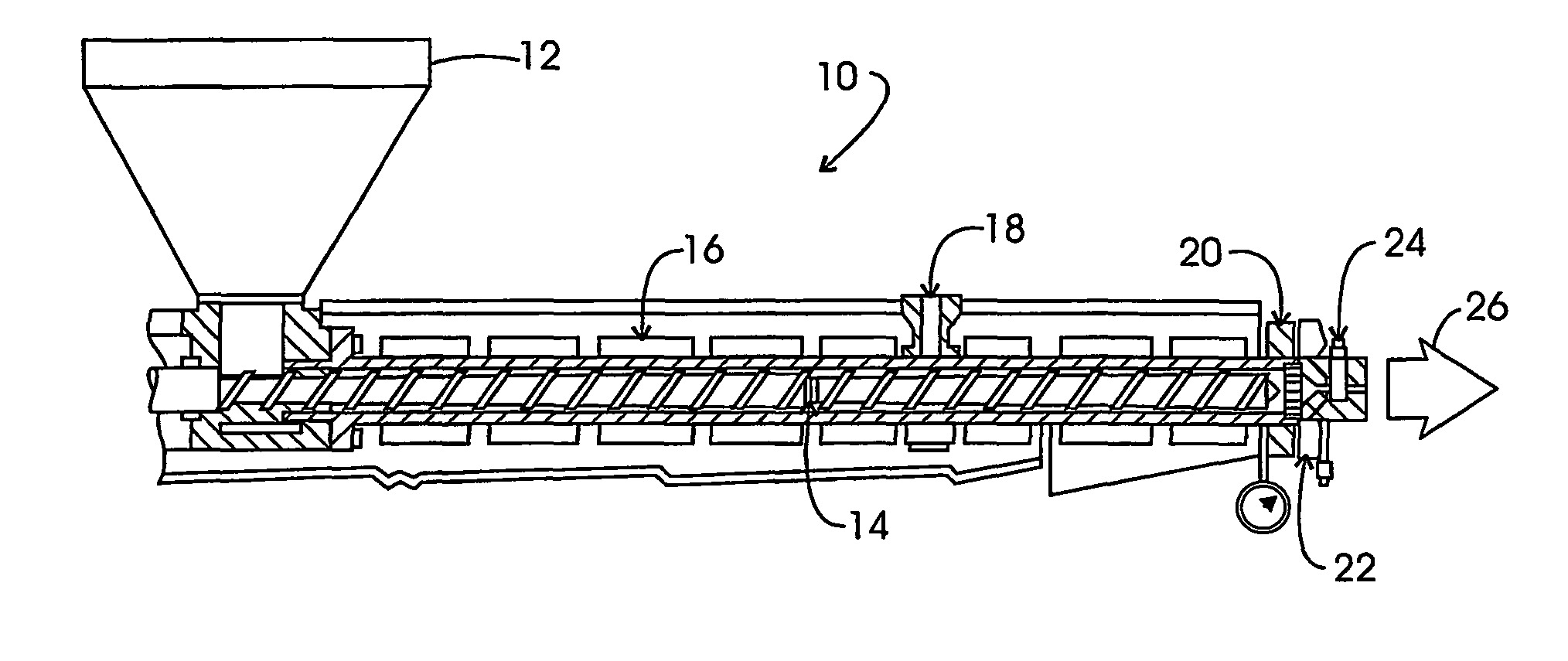

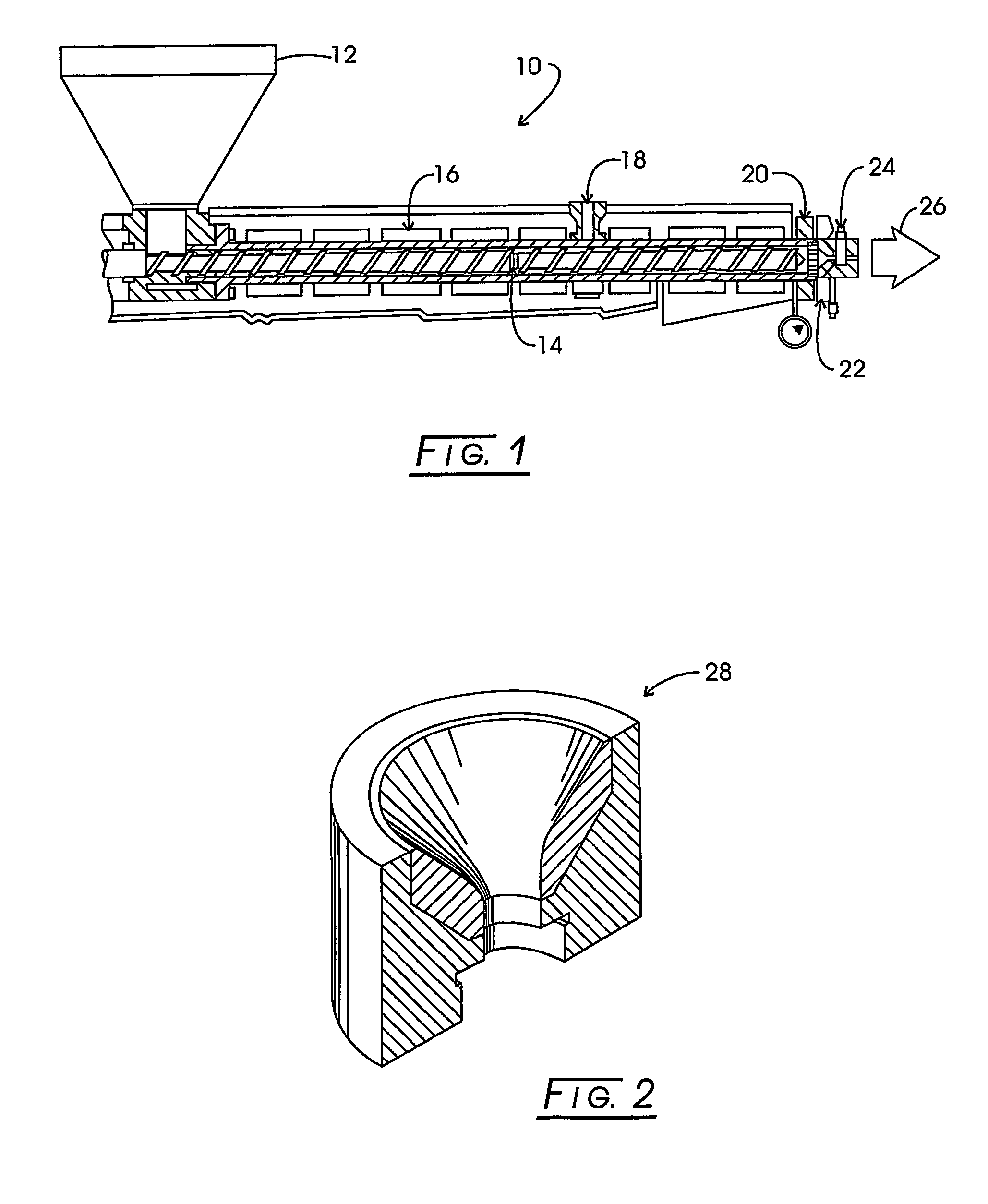

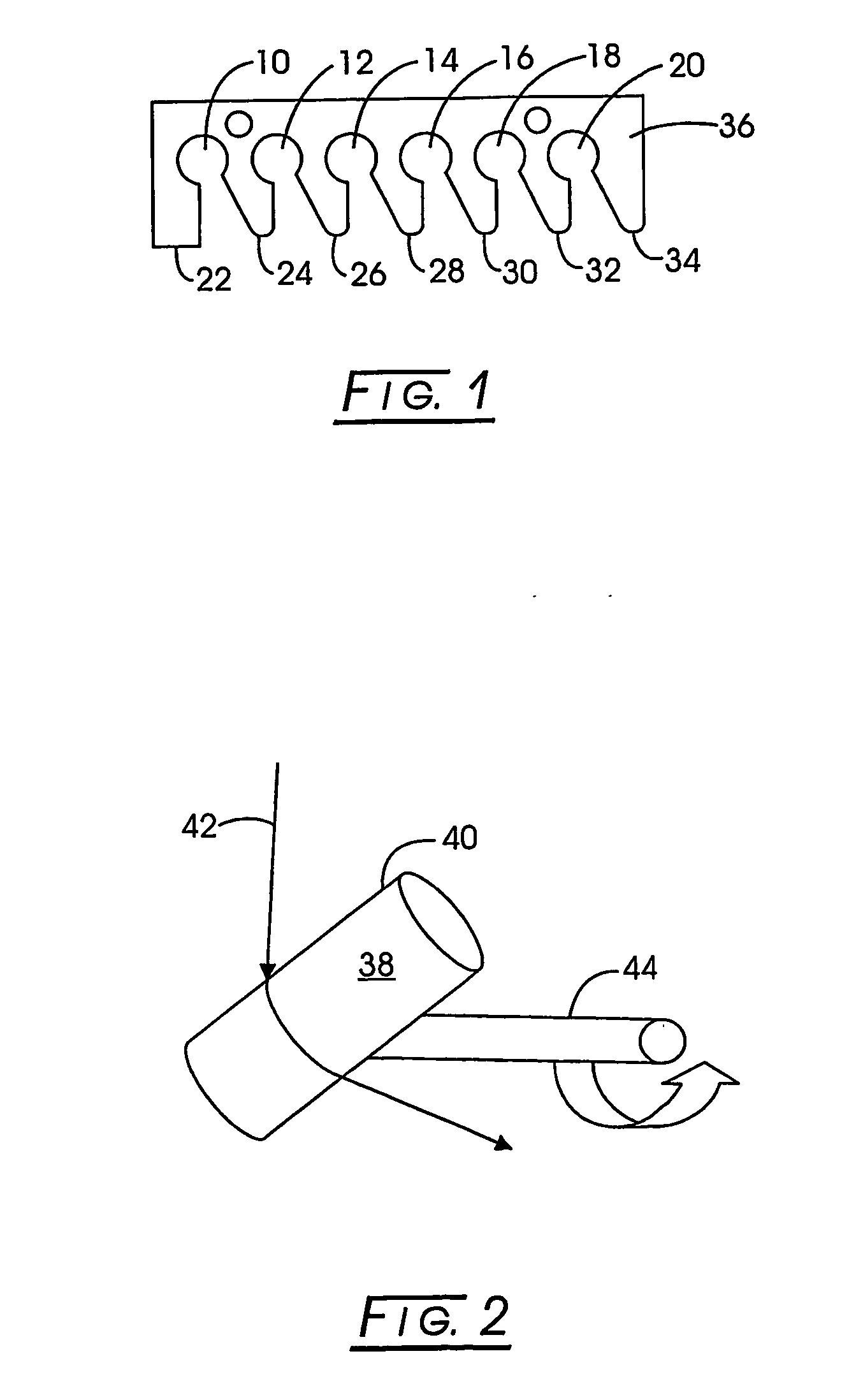

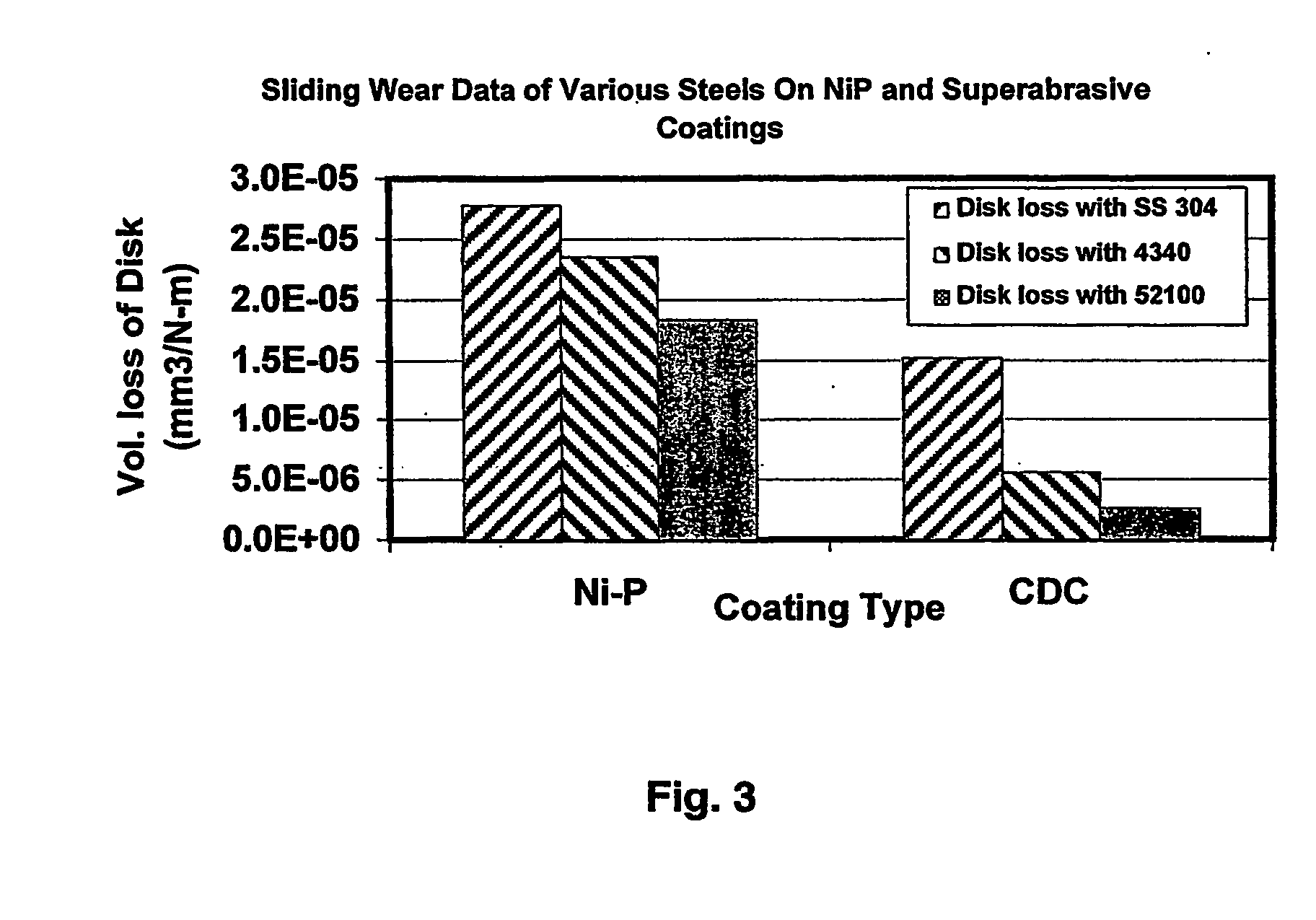

Process equipment wear surfaces of extended resistance and methods for their manufacture

A method for producing process equipment having a wear surface having extended resistance to one or more of abrasion, erosion, or corrosion, associated with fillers or solids processed by said process equipment includes applying to said process equipment wear surface a metal matrix coating filled with superabrasive particles. Diamond and cubic boron nitride superabrasive particles can fill the metal matrix, which can be a nickel coating.

Owner:DIAMOND INNOVATIONS INC

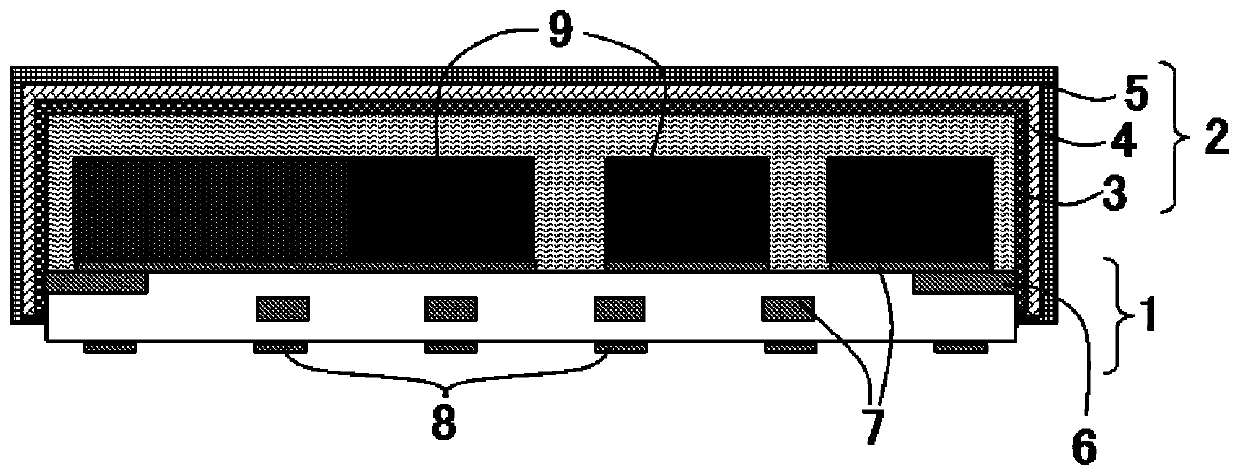

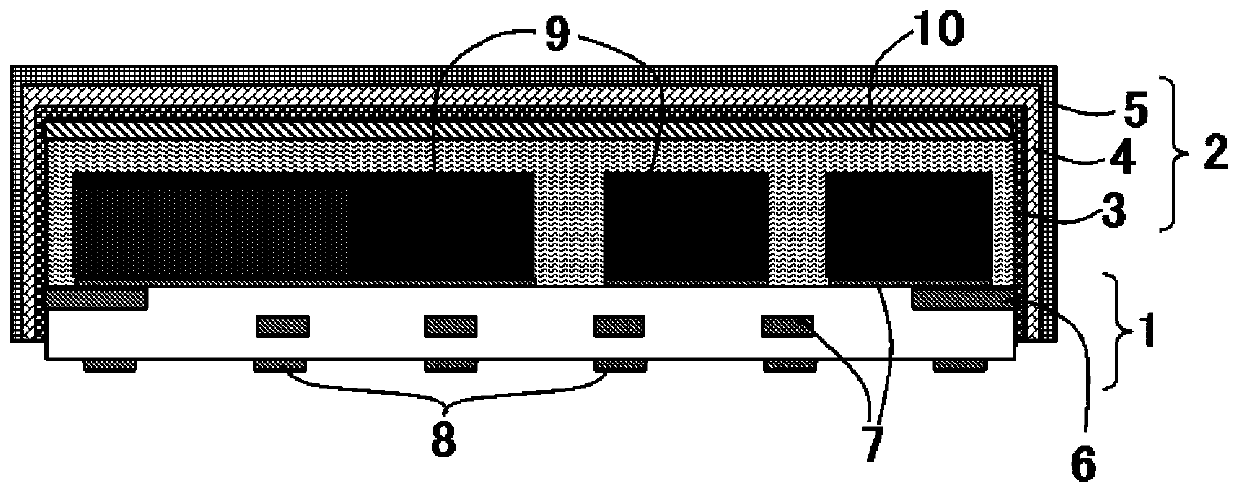

Electronic component package and method for producing same

The present invention provides an electronic component package and a method for producing the same. The electronic component package comprises: an electronic component that is mounted on a circuit substrate having a ground pattern; a sealing body that contains an epoxy resin and seals the electronic component; and a shield layer that is formed on the sealing body. This electronic component packageis characterized in that: the shield layer is obtained by sequentially stacking, from the sealing body side, a metal particle layer, a copper plating layer and a nickel plating layer; and the shieldlayer is grounded to the ground pattern. This electronic component package is excellent in terms of adhesion of the shield layer.

Owner:DIC CORP

Soldering method of high volume fraction SiC particle-reinforced Al matrix composite and kovar alloy

The invention discloses a flame soldering method of a high volume fraction SiC particle-reinforced Al matrix composite and kovar alloy, relating to a soldering method of a dissimilar material. The invention solves the problem of small possibility of welding engineering structure because the strength of the welding joint of SiCp / Al composite and kovar alloy melting is low. The method of the invention is characterized in that Ni-p is chemically plated on the surface of the high volume fraction SiC particle-reinforced Al matrix composite, and then soldering is carried out under the soldering acid and protective atmosphere after a piece to be soldered is assembled. The solder, the kovar alloy and a nickel coating of the invention mutually diffuse to form compact metallurgical bonding. In the method of the invention, the shear strength of joint connected by SiCp / Al of which the SiC particle volume fraction is 55% with kovar alloy 4J29 is 225 MPa.

Owner:ZHONGYUAN ENGINEERING COLLEGE

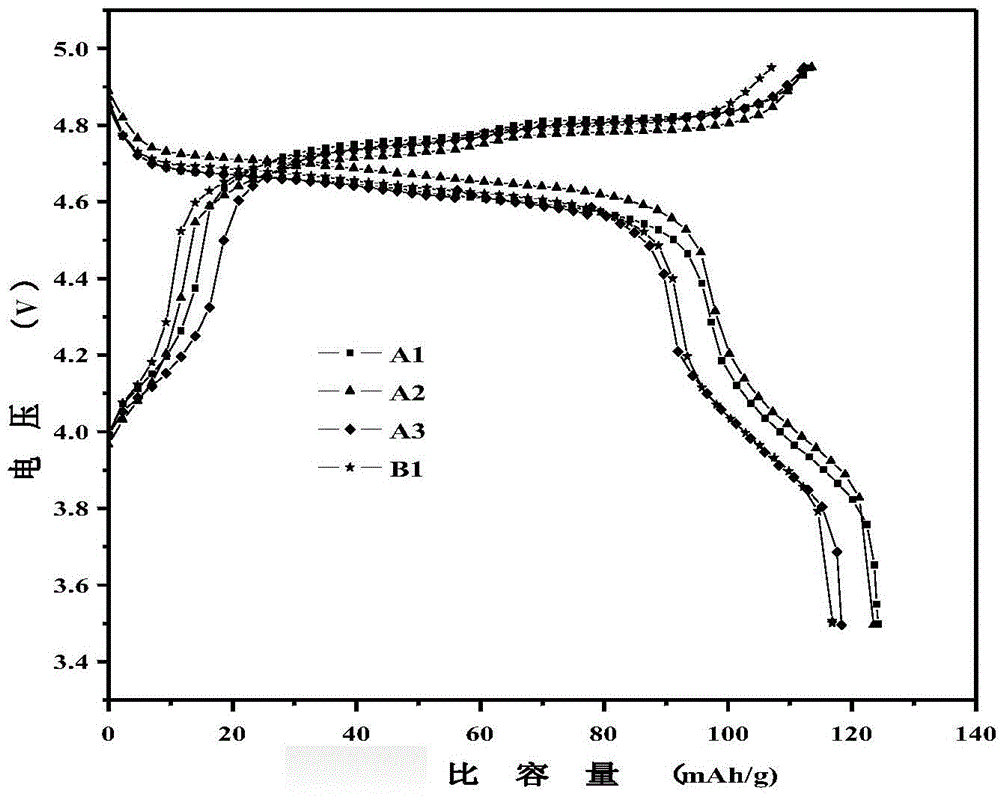

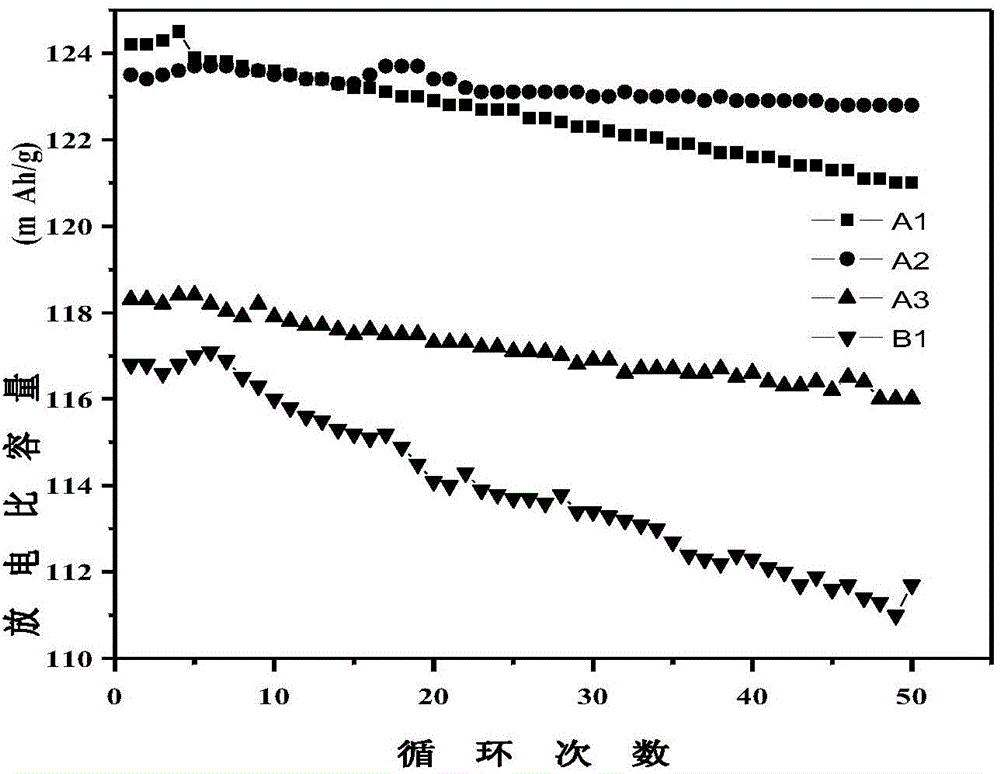

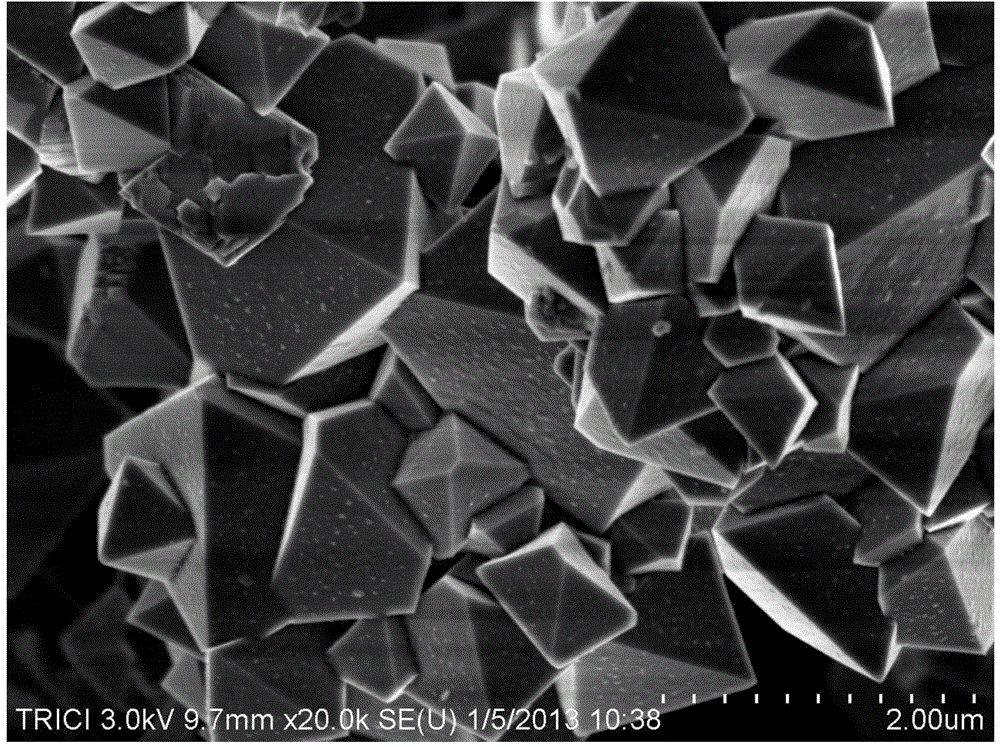

Surface modifying method for lithium nickel manganese oxide positive electrode material

ActiveCN104538604AImprove conductivityImprove cycle stabilityCell electrodesLithiumElectrical conductor

The invention discloses a surface modifying method for a lithium nickel manganese oxide positive electrode material. The surface modifying method comprises the following steps: (1) soaking lithium nickel manganese oxide powder in an activating solution for 10-60 minutes, and washing until the solution is neutral; (2) heating activated lithium nickel manganese oxide obtained in the last step in a constant-temperature electric heating tank for 20-40 minutes at a heating temperature of 300-350 DEG C, thereby obtaining a lithium nickel manganese oxide substrate with elemental nickel on surface; (3) pouring the treated lithium nickel manganese oxide substrate with elemental nickel on surface into a chemical plating solution to obtain a mixture, magnetically stirring or ultrasonically dispersing the mixture for 20-60 minutes, then performing suction filtration, washing and vacuum-drying to obtain a nickel-coated lithium nickel manganese oxide material. The surface modifying method disclosed by the invention is used for uniformly coating and modifying the surface of the lithium nickel manganese oxide material through ultrasonic chemical nickel-coating; meanwhile, the nickel coating is an excellent conductor, so that the electrical conductivity of the material can be greatly increased after coating, and the material rate performance and the material cycle performance are improved in a facilitated manner.

Owner:HEBEI UNIV OF TECH

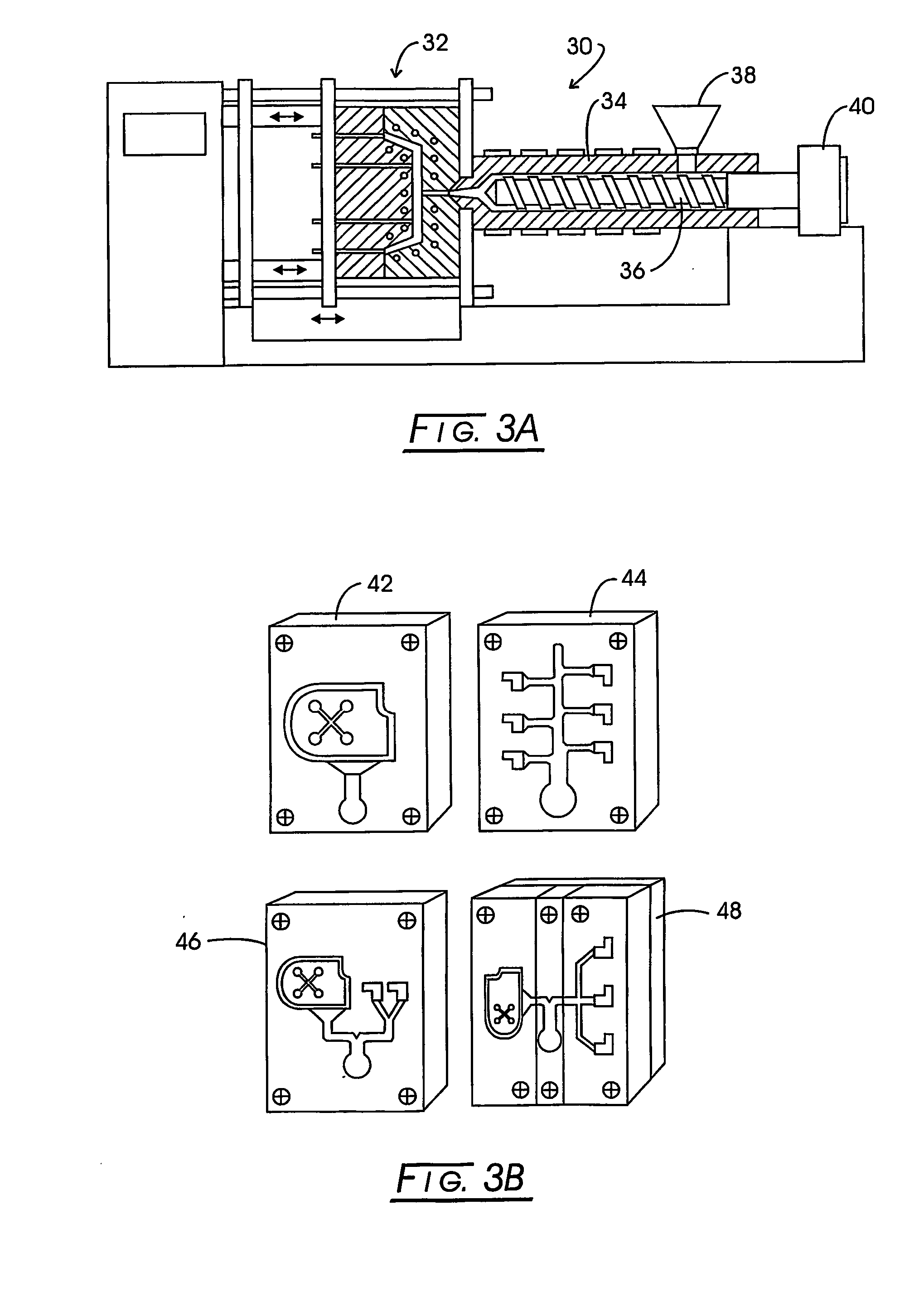

Fiber and sheet equipment wear surfaces of extended resistance and methods for their manufacture

InactiveUS20060246275A1Improve the immunityElectrolytic coatingsRecord information storageFiberProcess equipment

A method for producing process equipment having a wear surface having extended resistance to one or more of abrasion, erosion, or corrosion, associated with materials processed by said process equipment includes applying to said process. equipment wear surface a metal matrix coating filled with superabrasive particles. Diamond and cubic boron nitride superabrasive particles can fill the metal matrix, which can be a nickel coating.

Owner:DIAMOND INNOVATIONS INC

Coating method of high-density Ni layer of carbon nano tube

InactiveCN101818337AGood throwExcellent deep plating abilityLiquid/solution decomposition chemical coatingHigh densityCarbon nanotube

The invention provides a coating method of a high-density Ni layer of a carbon nano tube, which aims to improve the compactness and the uniformity of the nickel-coating layer of the carbon nano tube. The method comprises the following steps: manufacturing the carbon nano tube by an anode arc plasma method; acidulating and then washing the carbon nano tube with deionized water; standing for 4 hours, collecting supernate, and then repeatedly washing for many times until pH is 7; standing all the collected supernate for 24 hours for precipitation; filtering and drying precipitates; and finally sensitizing, activating, plating and performing heat treatment on the dried precipitates.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com