High-conductivity composite carbon fiber and preparation method thereof

A technology of composite carbon fiber and high conductivity, which is applied in the field of composite carbon fiber and its preparation, can solve the problems of component strength, stiffness decrease, temperature rise, carbon fiber material ablation, etc., and achieve the goal of improving lightning strike resistance, excellent electrical conductivity and thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

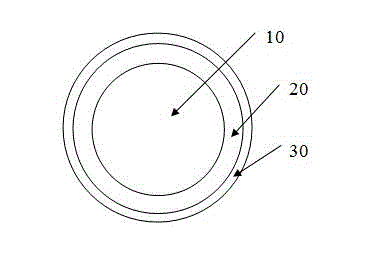

[0021] Embodiment 1: a kind of highly conductive composite carbon fiber, it is characterized in that described composite carbon fiber is made up of carbon fiber and metal coating and graphene coating attached to its surface successively.

[0022] The carbon fiber is T300 carbon fiber, the metal coating is metal nickel coating, and the thickness of the metal nickel coating is 100nm.

Embodiment 2

[0023] Embodiment 2: a kind of preparation method of highly conductive composite carbon fiber is characterized in that comprising following steps to realize:

[0024] (1) Select T300 carbon fiber for surface modification treatment;

[0025] (2) Then, a metal nickel coating is prepared on the surface of the carbon fiber by sputtering;

[0026] (3) Next, prepare a graphene coating on the above-mentioned metallic nickel coating by chemical vapor deposition;

[0027] (4) Obtain highly conductive composite carbon fibers.

[0028] Wherein the surface modification treatment parameters in the step (1) are: temperature 350 o C, air oxidation for 30min.

[0029] The parameters for preparing the metal nickel coating by sputtering in the step (2) are: the target material is nickel, the sputtering power is 300W, the flow rate of argon gas is 20sccm, the sputtering pressure is 1Pa, and the substrate temperature is 200°C. o C, sputtering time 20min.

[0030] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com