Patents

Literature

4226 results about "Carbon fiber composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090062516A1Good for healthImprove responseSugar derivativesOrganic compound preparationFiberElastomer

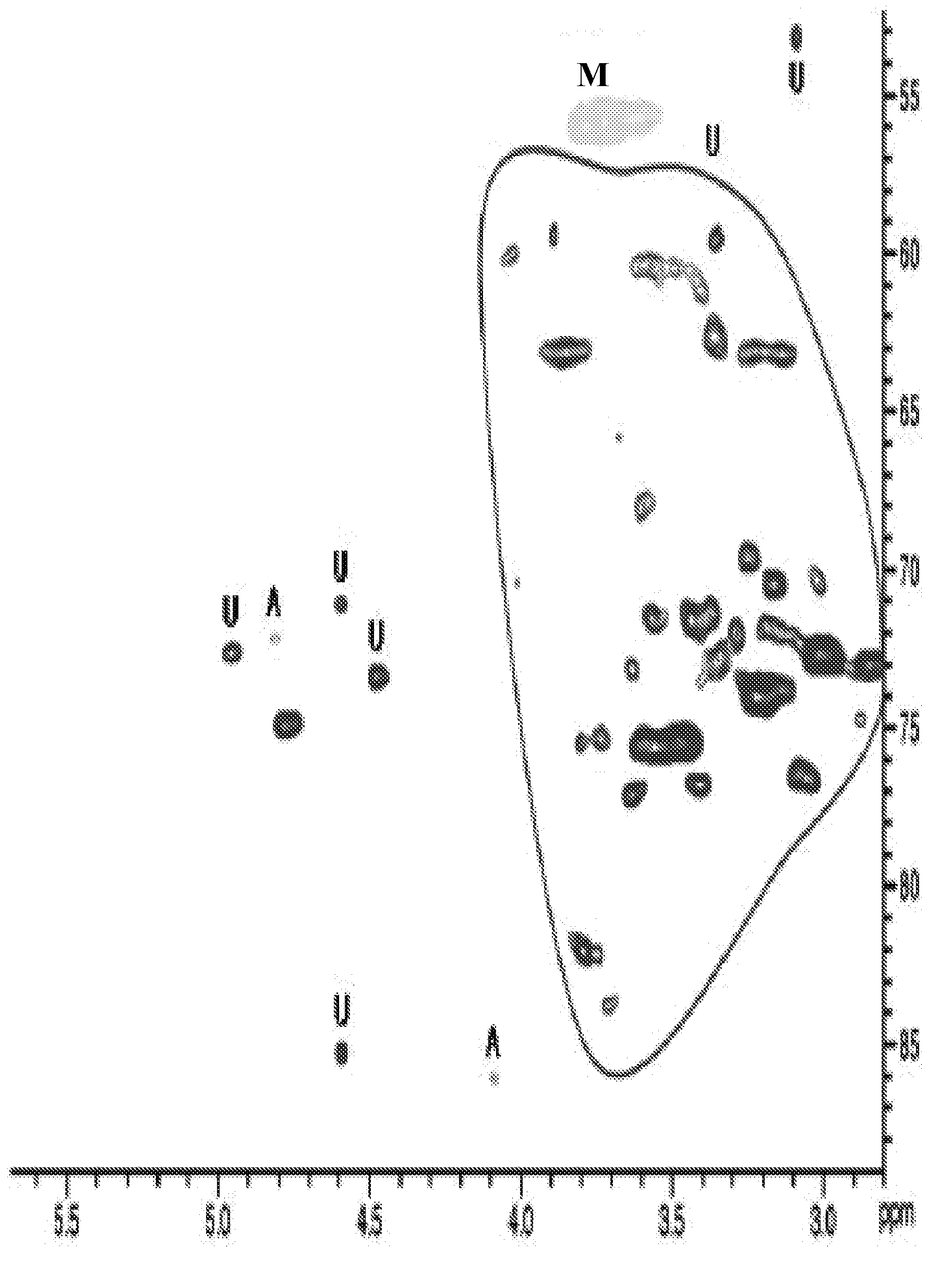

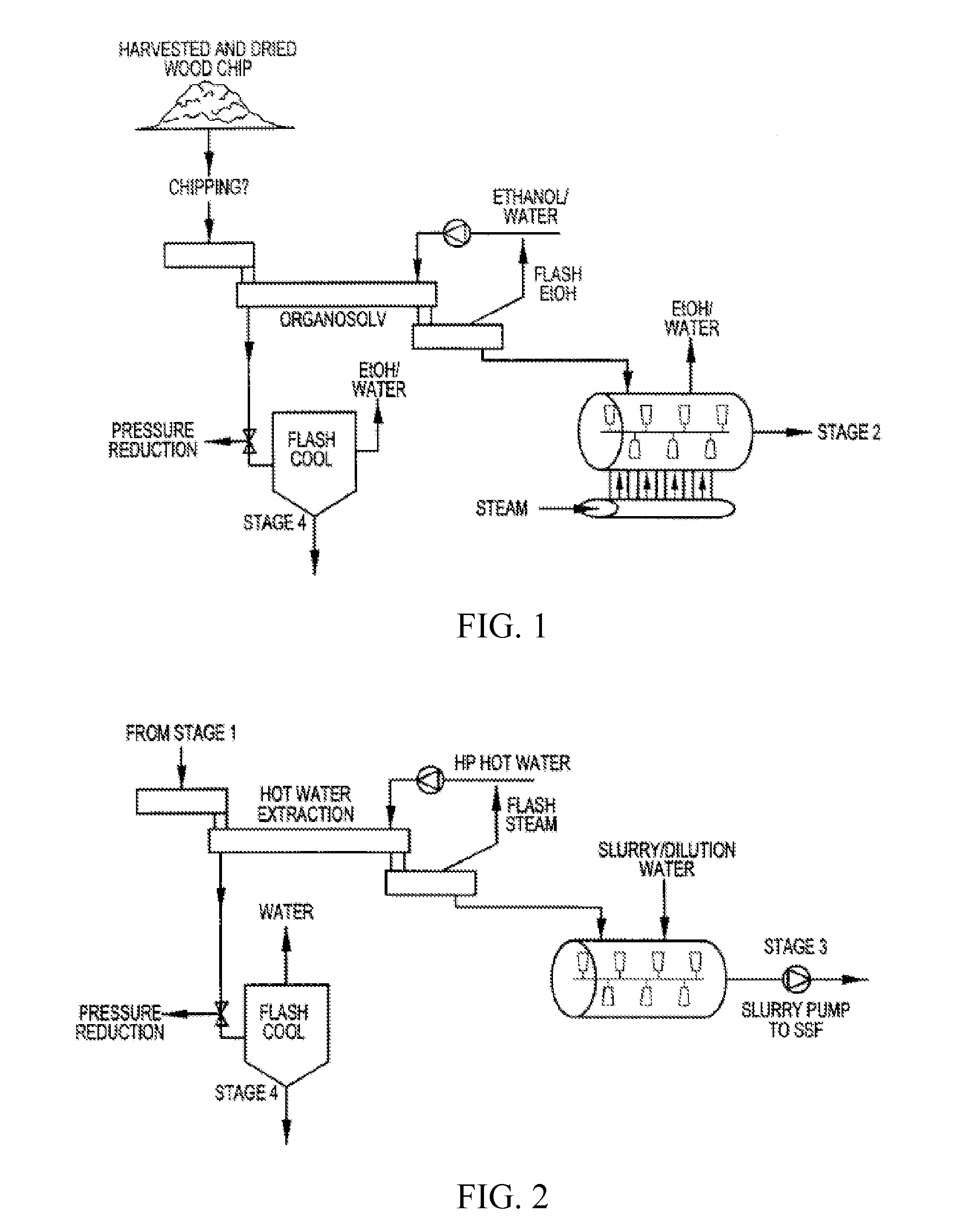

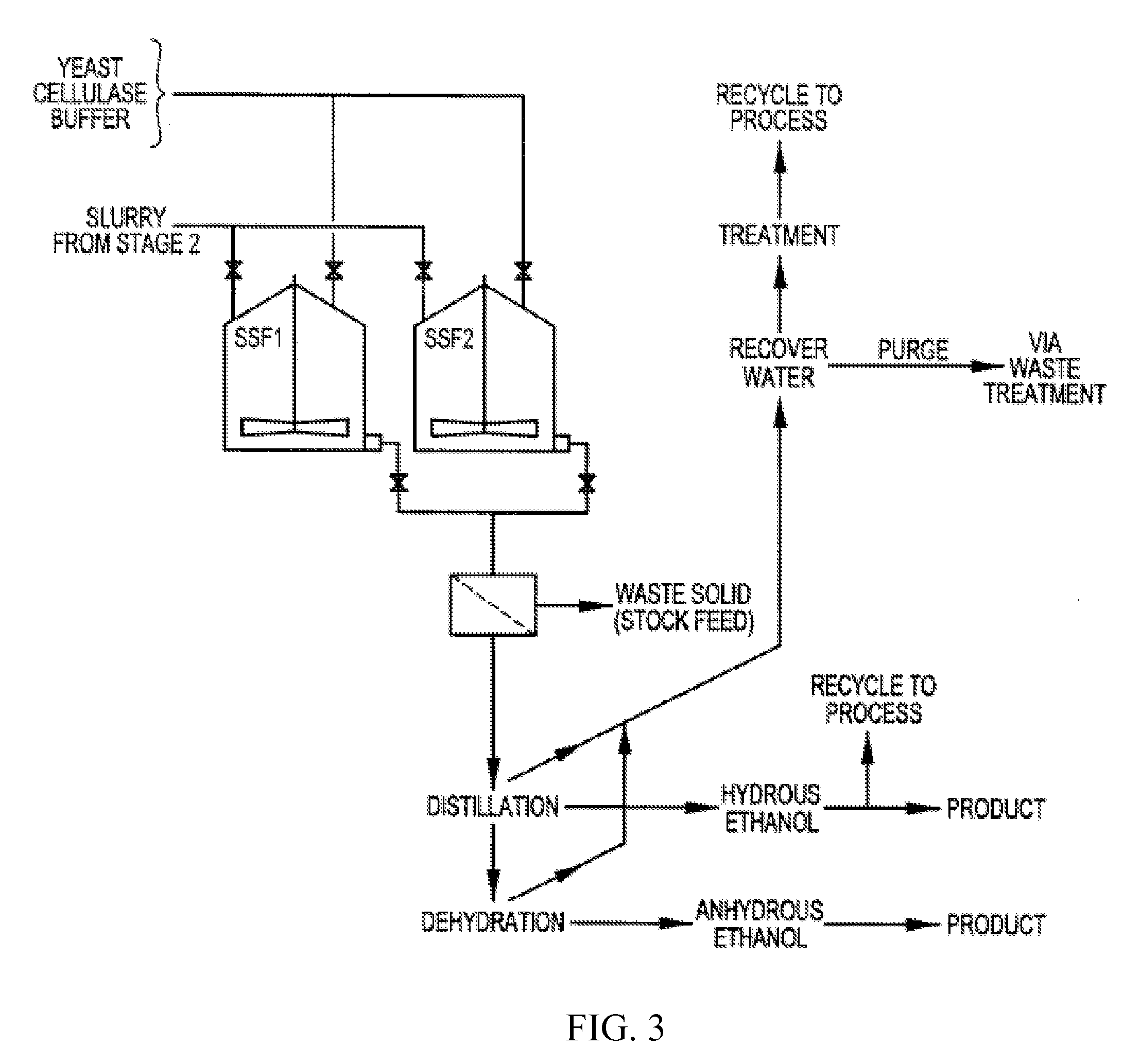

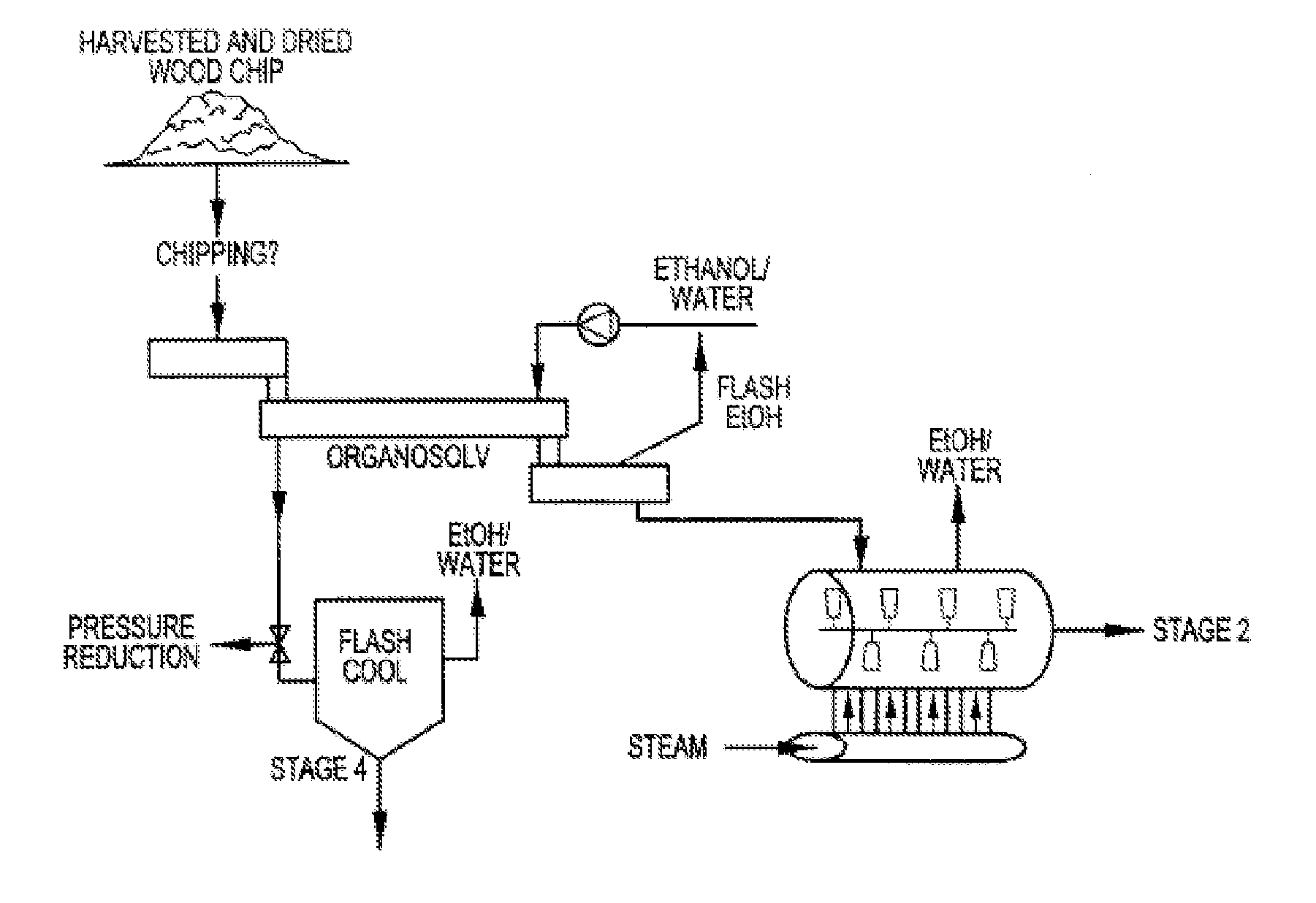

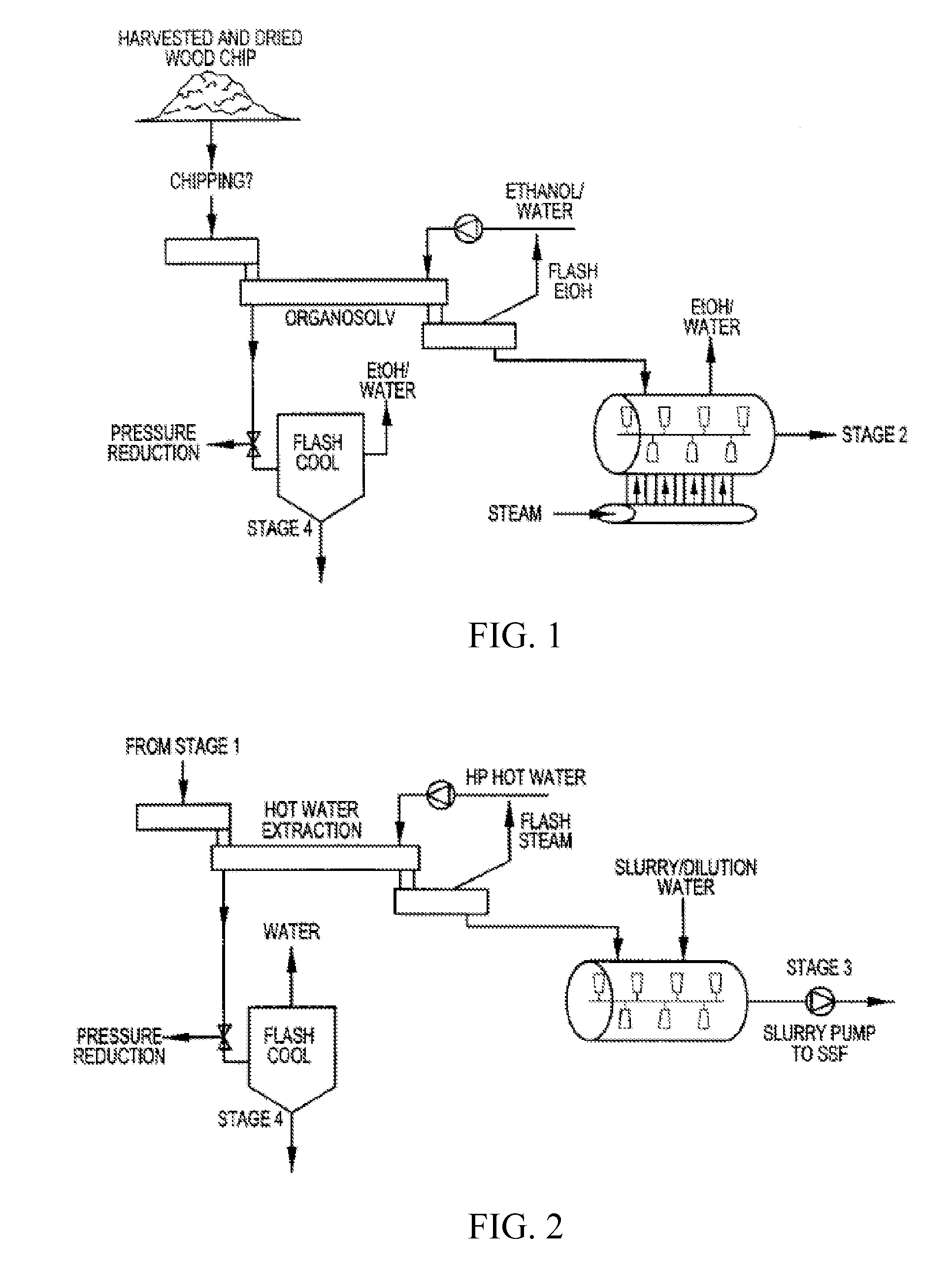

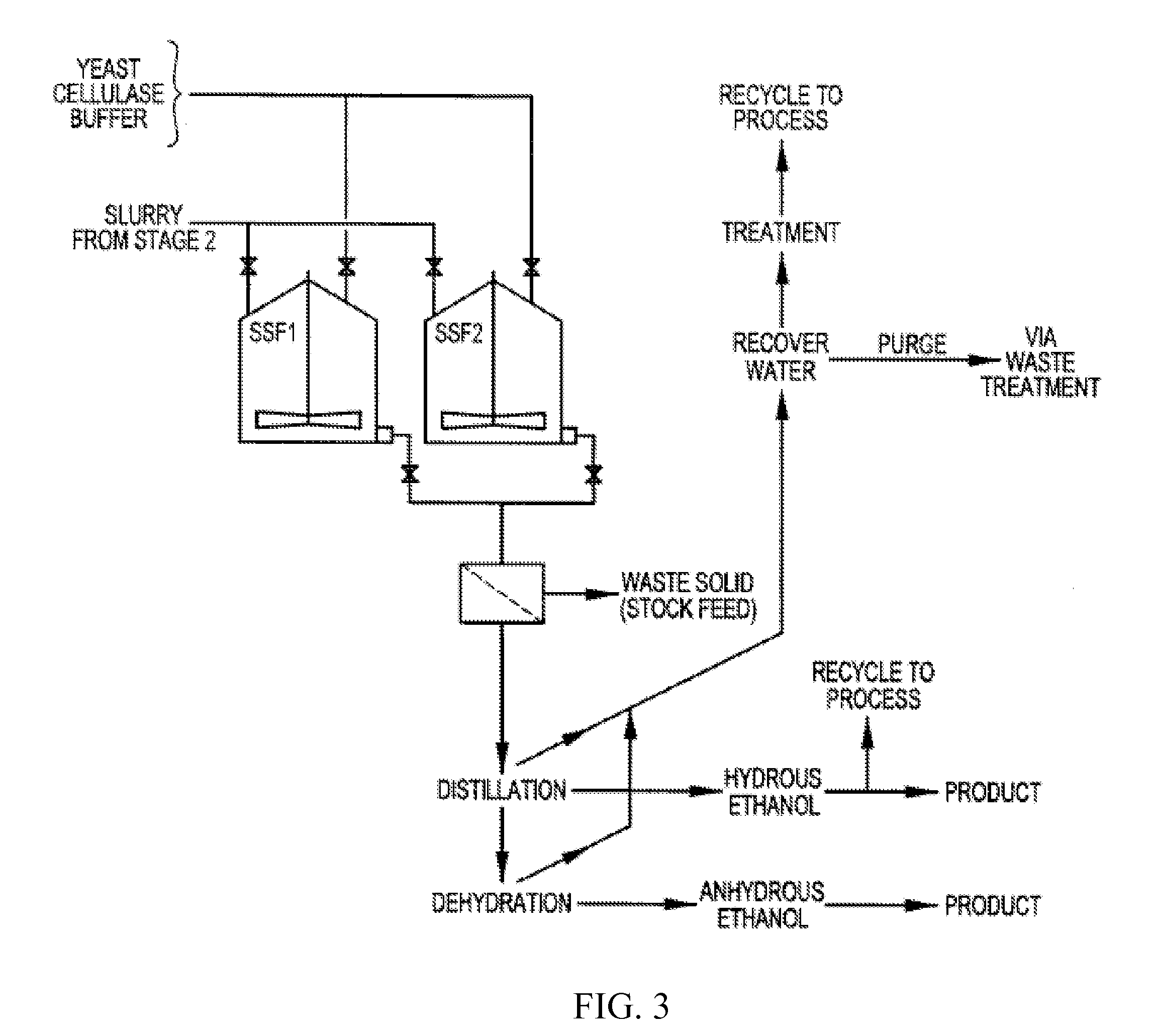

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

Graphene and carbon fiber composite material, and preparation thereof

The invention relates to a Graphene and carbon fiber-based composite material and a preparation method thereof. The composite material is prepared by taking the Graphene and the carbon fiber as raw materials, and coating a Graphene coating layer on the surface of the carbon fiber by a coating method, and the thickness of the coating layer is 1nm-5mum. The Graphene is taken as a surface coating material of the carbon fiber, and the Graphene and the carbon fiber are carbon materials and have high compatibility, thus Graphene solution coated on the surface of the carbon fiber can form the high-performance composite material and further improve the mechanical property, conductivity and heat resistance of the carbon fiber. The composite material has low cost, simple operation and strong applicability.

Owner:NANKAI UNIV

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090069550A1Great potentialTotal calories lowLignin derivativesPulp by-products recoveryFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

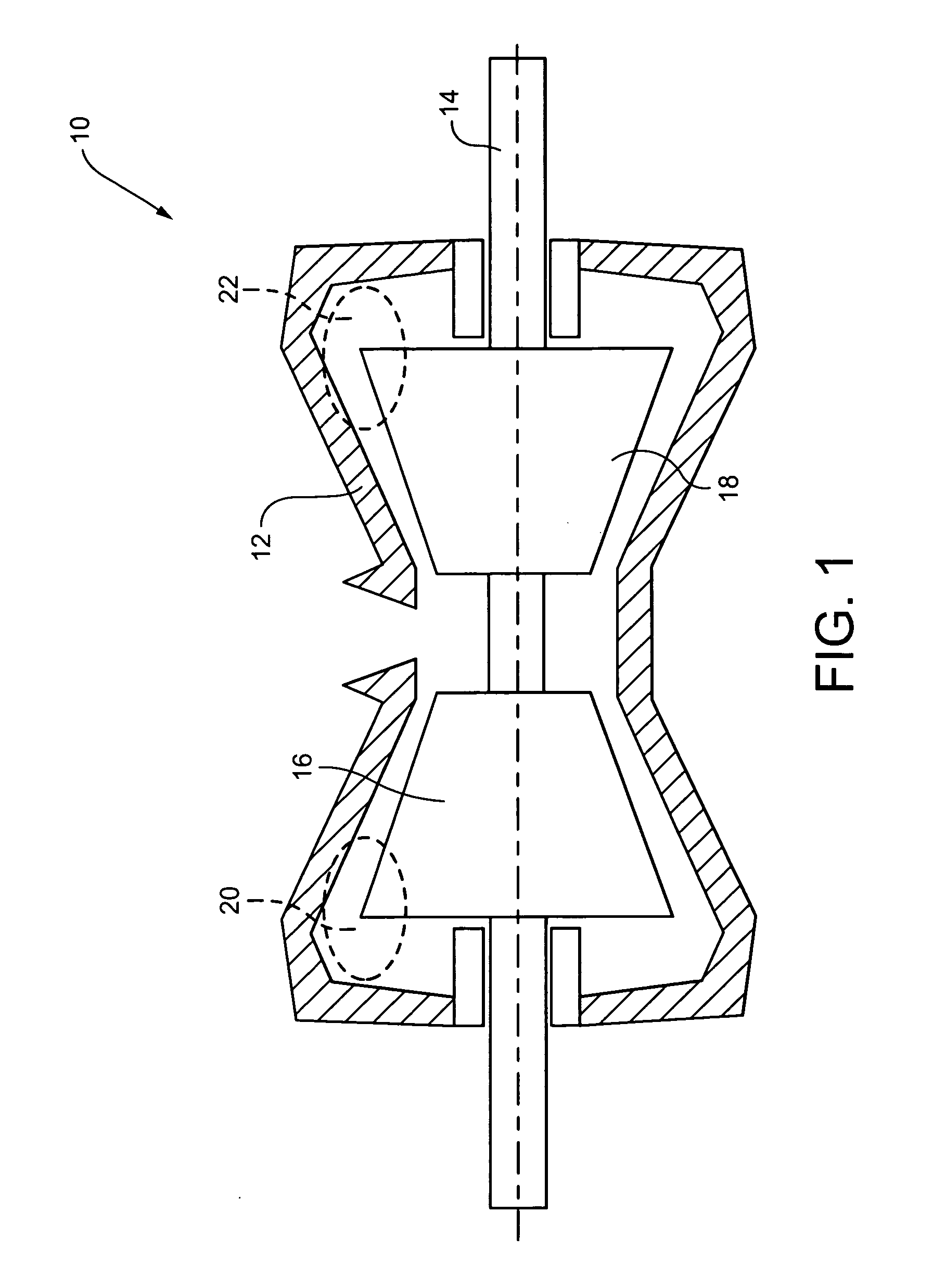

Adhesively bonded joints in carbon fibre composite structures

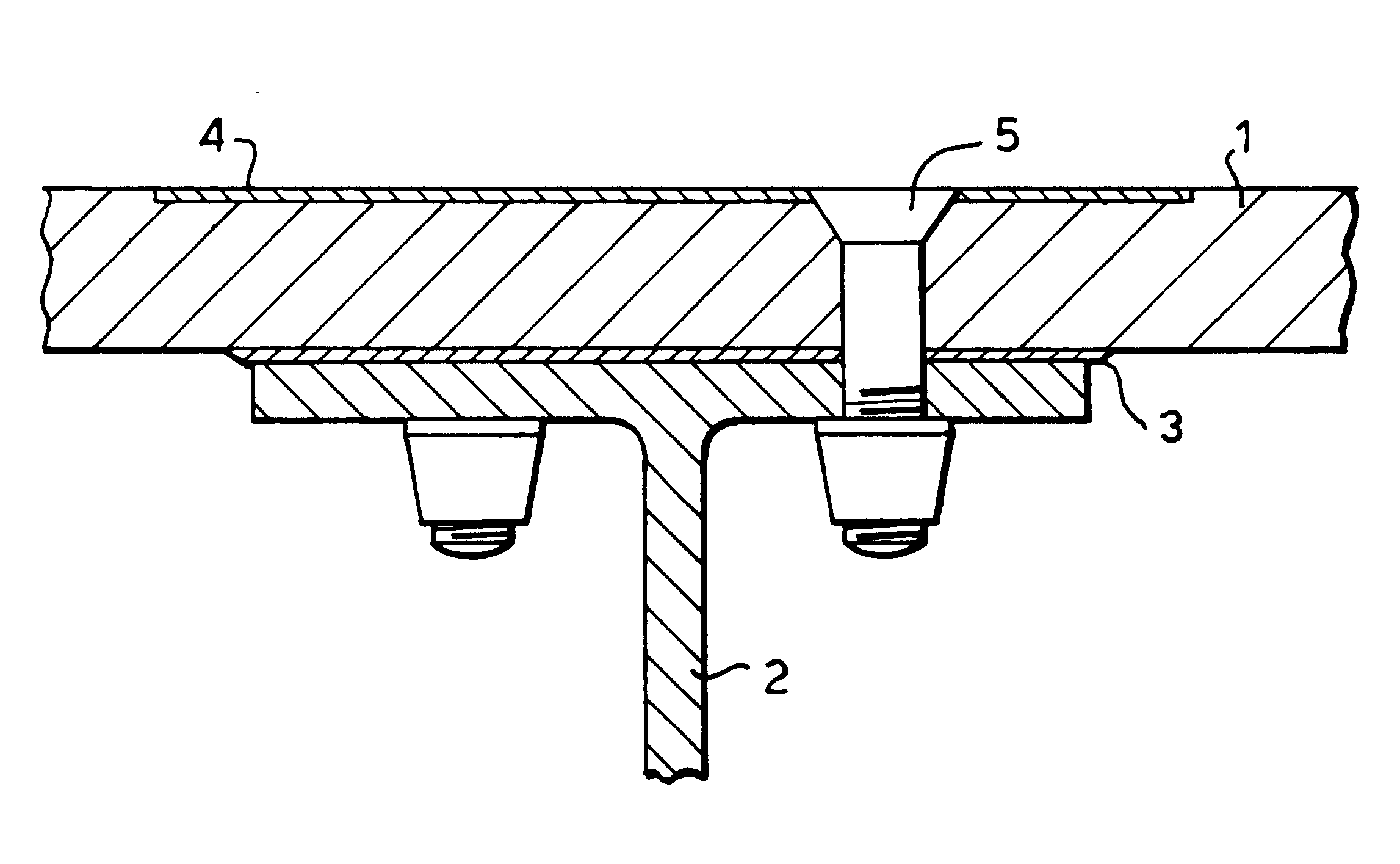

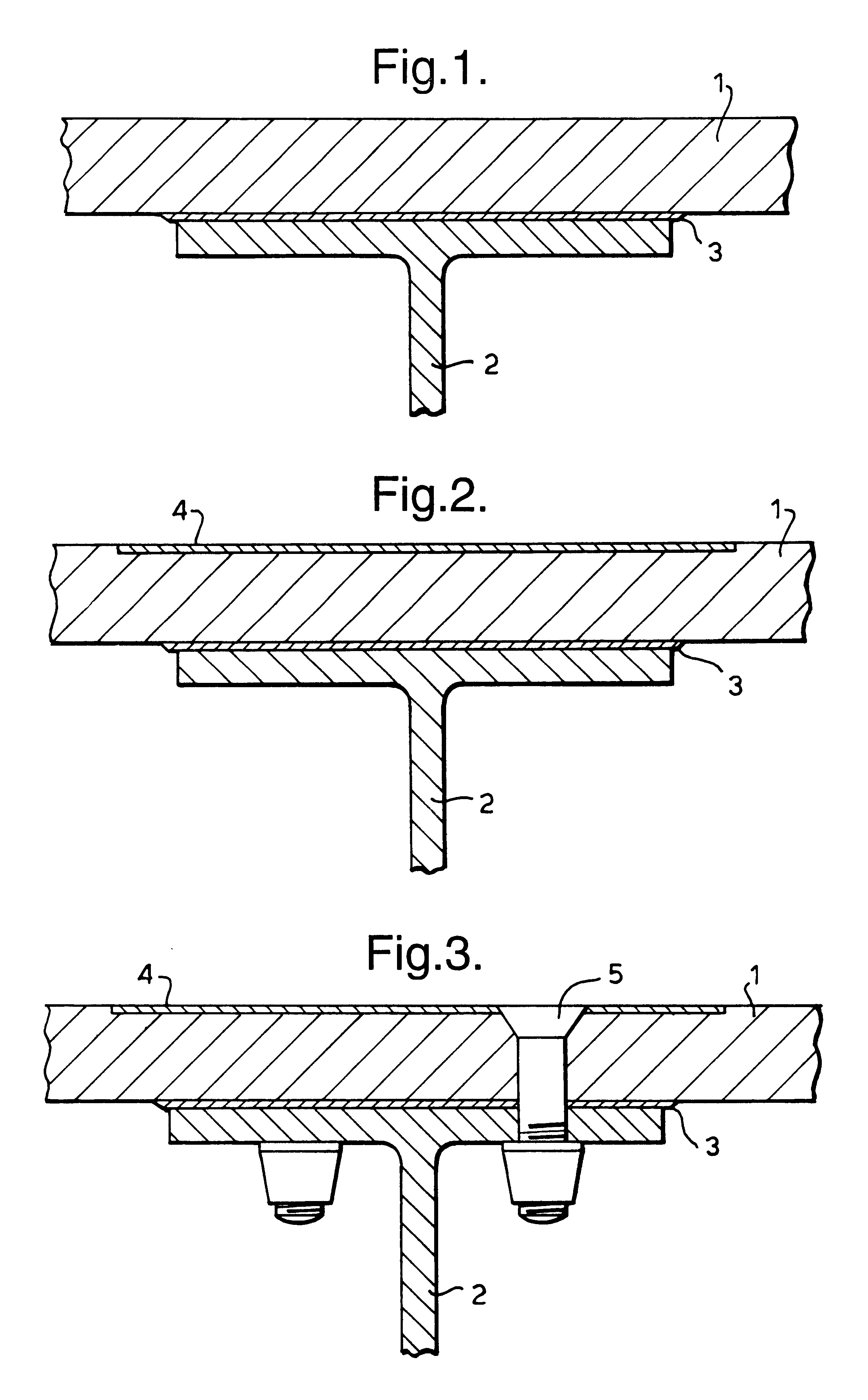

InactiveUS6320118B1Improve performanceLightning protection is goodInstallation of lighting conductorsAircraft lighting protectorsFiberPower flow

A structural joint for the transmission and control of high current flows in a carbon fiber or carbon fiber hybrid composite structure, said joint includingat least two composite structures comprising a multiplicity of resin bonded carbon fiber plies,an adhesive applied there between and capable of conducting high currentssaid adhesive comprising a conductive carrier film comprising carbon fibers,wherein the electrical conductivity of the adhesive is comparable with that of the adjacent composite structures.

Owner:BAE SYSTEMS PLC

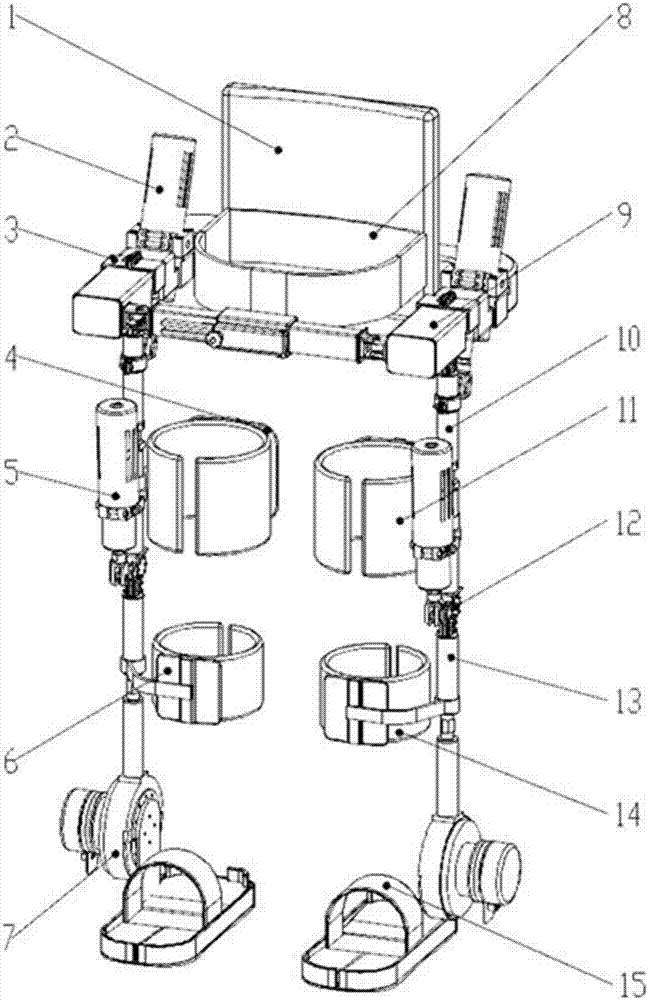

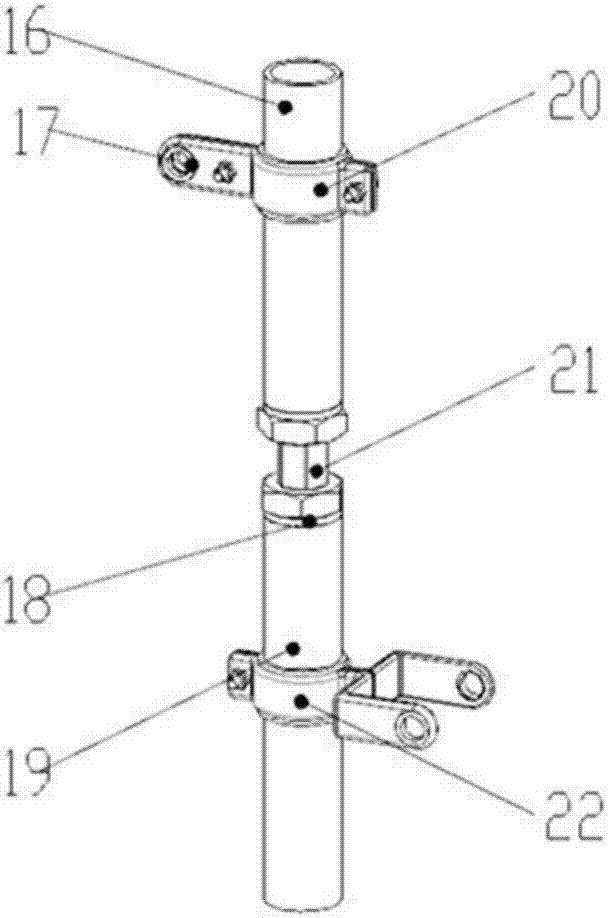

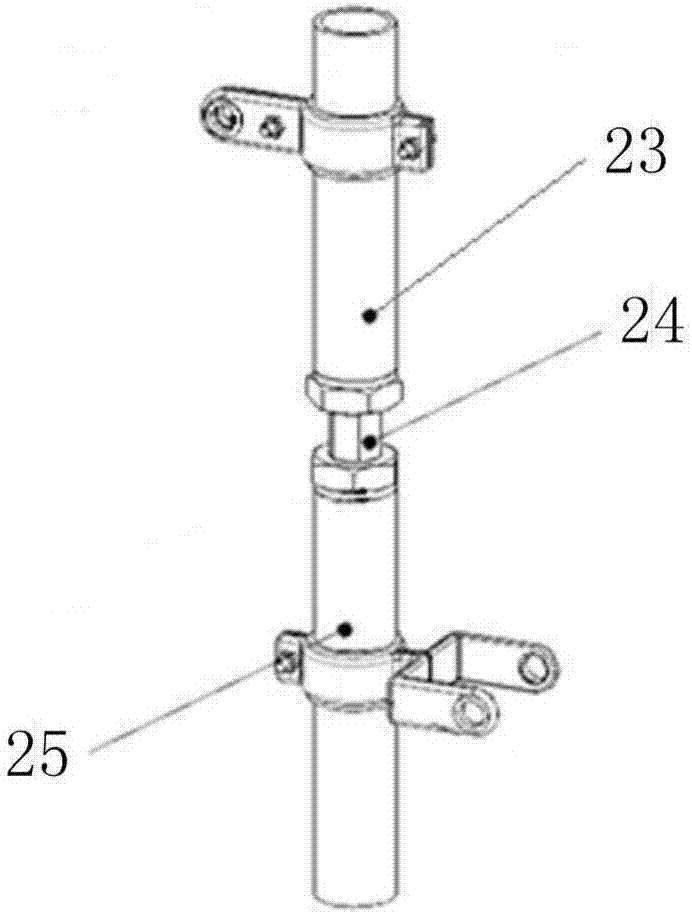

Exoskeleton rehabilitation robot for rehabilitation of lower limb walking function and control system and method thereof

ActiveCN107126344AIncrease active freedomSpeed up recoveryProgramme-controlled manipulatorChiropractic devicesKnee JointEngineering

The invention discloses an exoskeleton rehabilitation robot for rehabilitation of a lower limb walking function and a control system and method thereof. The robot comprises a backrest, a hip joint power source, a hip joint component, a waist component, a thigh bar component, a knee joint power source, a knee joint component, a shank bar component, an ankle joint component and a foot pedal. According to the lower limb exoskeleton rehabilitation robot, a driving scheme is designed by utilizing a bionics principle, so that the initiative degree of freedom of the ankle joint is increased; through initiatively pulling the heel tendon muscles of the patients, the rehabilitation speed of the ankle joint function is improved; the waist component, a connection rod mechanism and the foot pedal adopt a carbon fiber composite material, so that the structure weights and volumes are lightened while the strength is kept; and a non-polar adjustable function is set for the waist width, thigh length and shank length, and flexible bandages are equipped, so that the wearing comfort level requirement of the users is satisfied to the greatest extent. The robot disclosed by the invention not only can be used as a tool for riding instead of walk for the patients with walking disability, but also can help the stroke patients to obtain walking ability again through initiative training.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

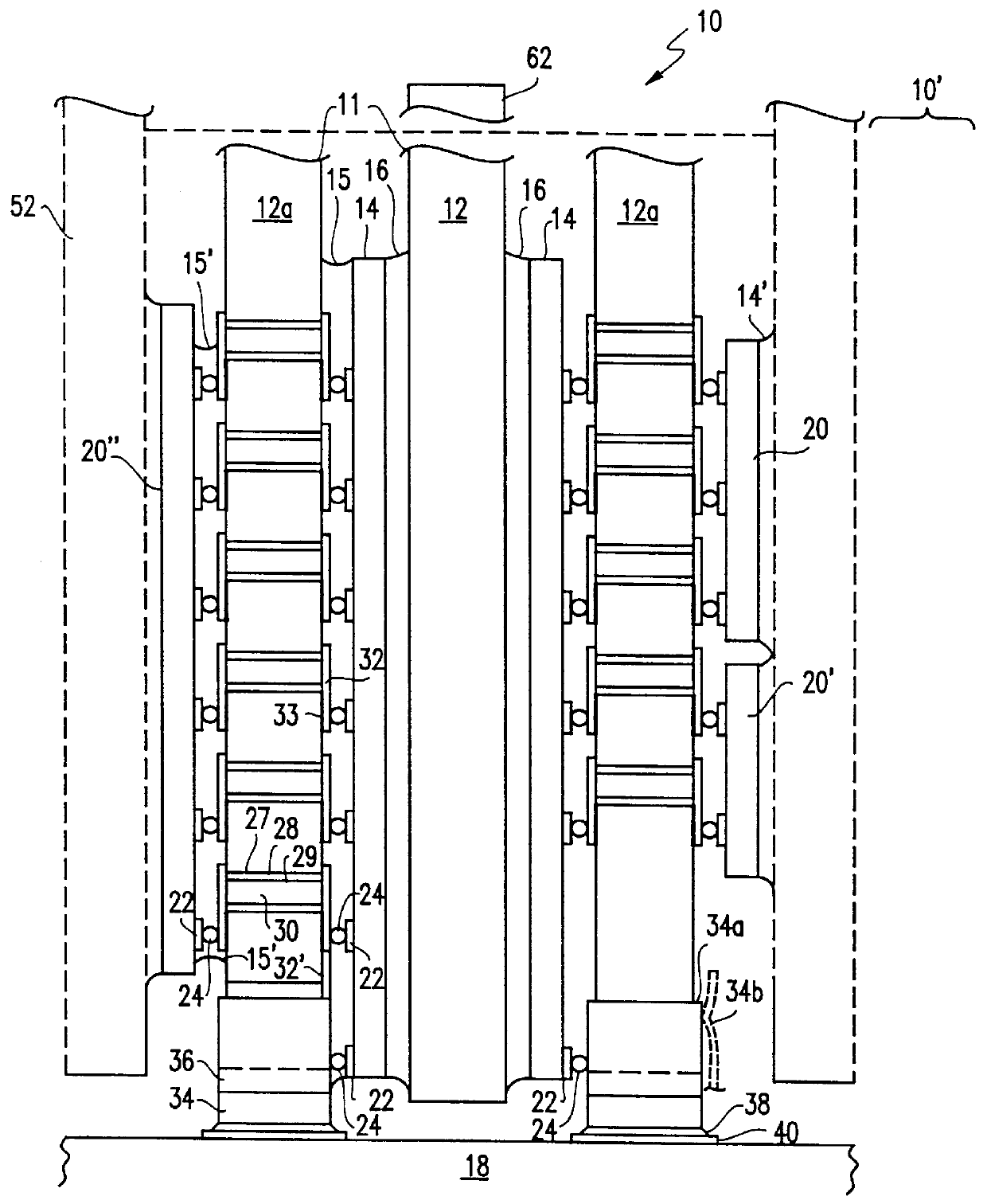

Integrated, multi-chip, thermally conductive packaging device and methodology

InactiveUS6075287AImproved compactness and shortness of connectionImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsAdhesive

Electrically conductive lamina are attached by an electrically insulating, thermally conductive adhesive and / or solder to one or more semiconductor devices such as chips and extend beyond the periphery of the chip or chips to form heat sink fins. Electrical connections may be made between such chips through holes (e.g. by a wire or plated through hole) in the electrically conductive lamina lined with an insulating material such as the electrically insulating adhesive to provide a structurally robust assembly. Surface pads and connections may overlie patterns of insulator on the lamina. A further lamina can be wrapped around lateral sides of the assembly to provide further heat sink area and mechanical protection for other heat sink fins. A graphite / carbon fiber composite matrix material is preferred for the lamina and the coefficient of thermal expansion of such materials may be matched to that of the semiconductor material attached thereto. Conductivity of the lamina also provides shielding against electrical noise to improve the noise immunity of short connections between chips made through the lamina as well as that of surface connections which may be formed on the lamina.

Owner:GOOGLE LLC

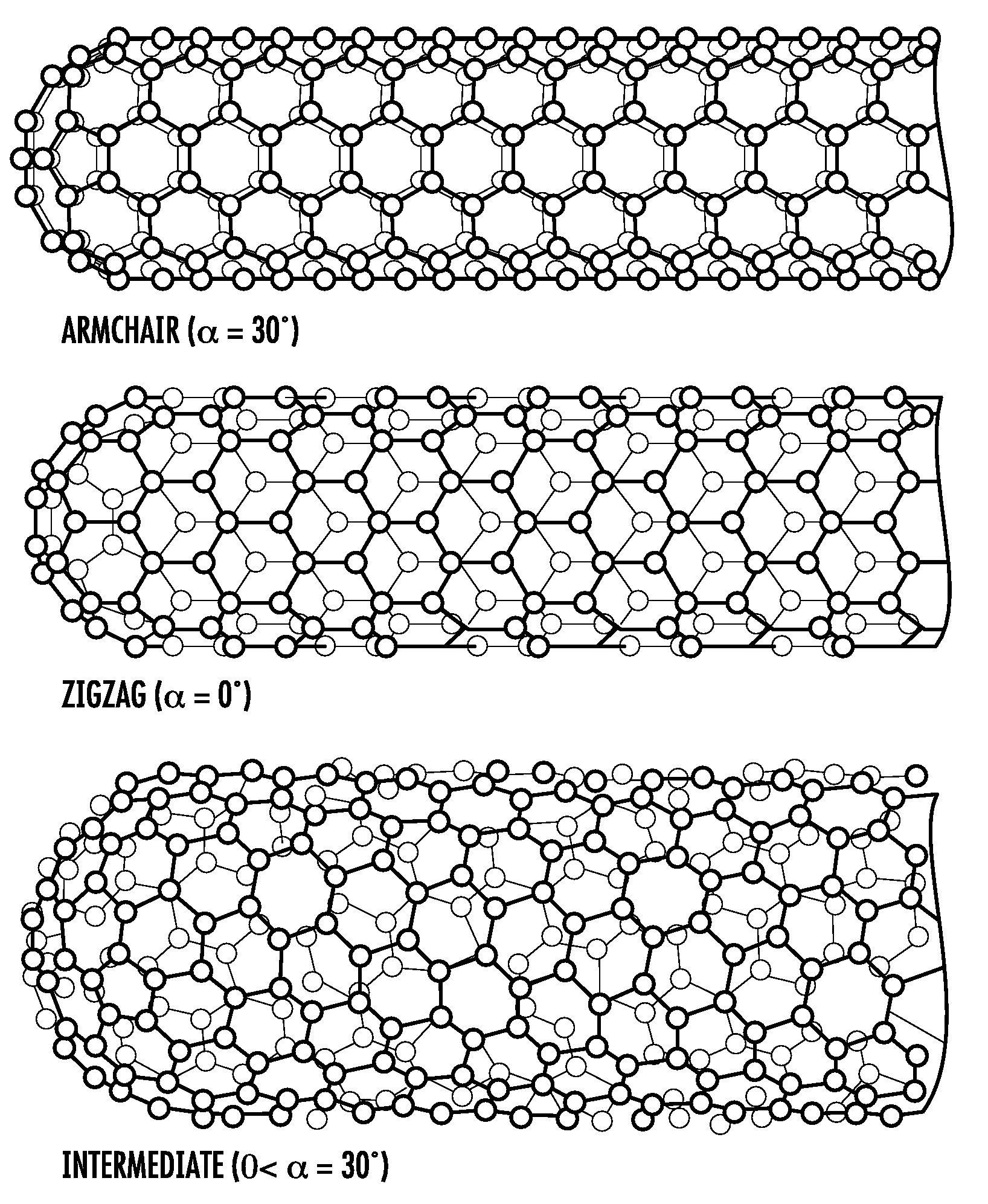

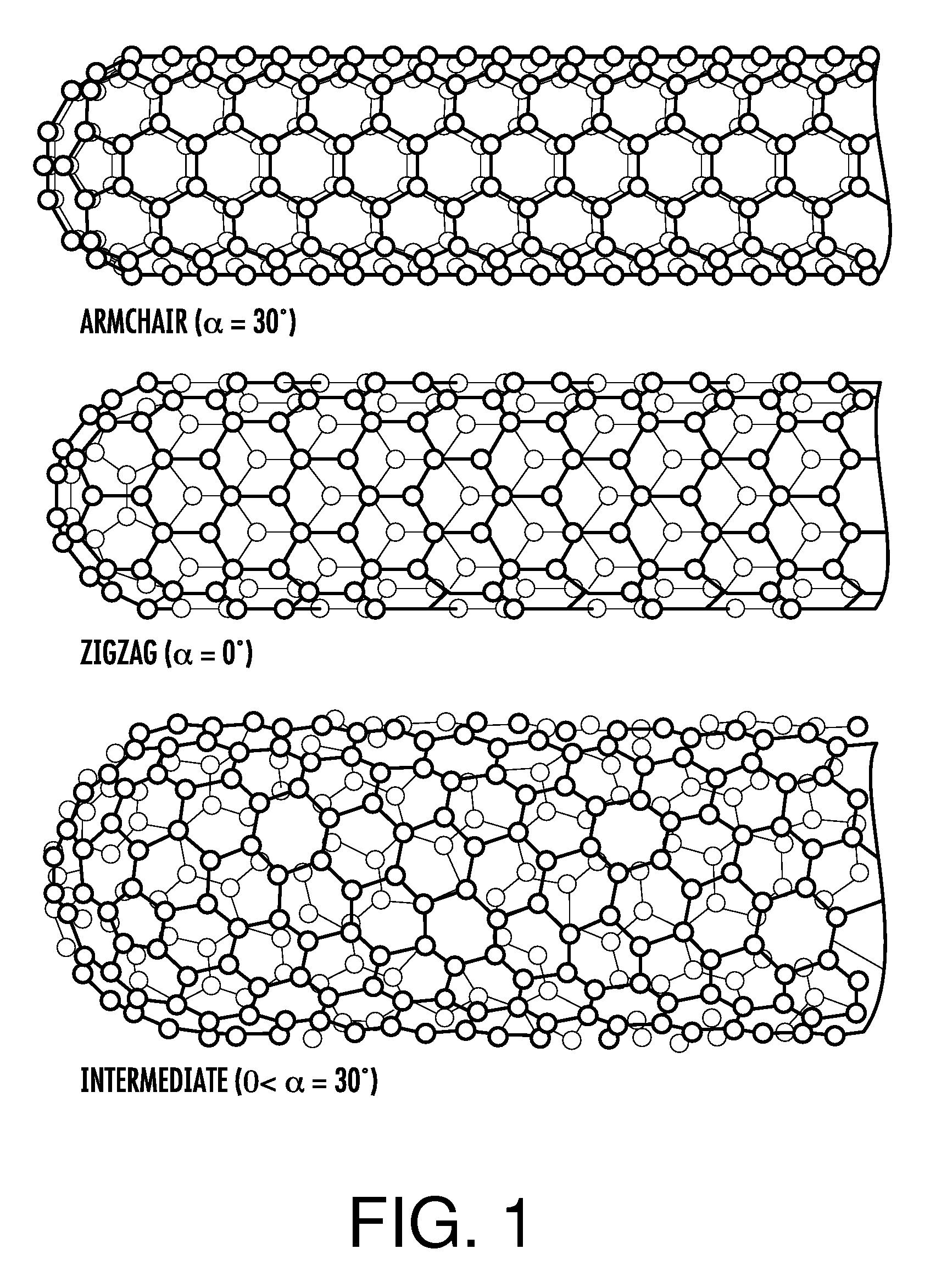

Carbon fiber composite material and method of producing the same, carbon fiber-metal composite material and method of producing the same, and carbon fiber-nonmetal composite material and method of producing the same

ActiveUS20060062986A1Evenly dispersedMaterial nanotechnologySynthetic resin layered productsCarbon nanofiberFibrous composites

Owner:HITACHI ASTEMO LTD

Carbon fiber composite material and method of producing the same, formed product of carbon fiber composite and method of producing the same, carbon fiber-metal composite material and method of producing the same, and formed product of carbon fiber-metal composite and method of producing the same

ActiveUS20050075443A1Evenly dispersedGood dispersionMaterial nanotechnologyMetal-working apparatusElastomerCarbon nanofiber

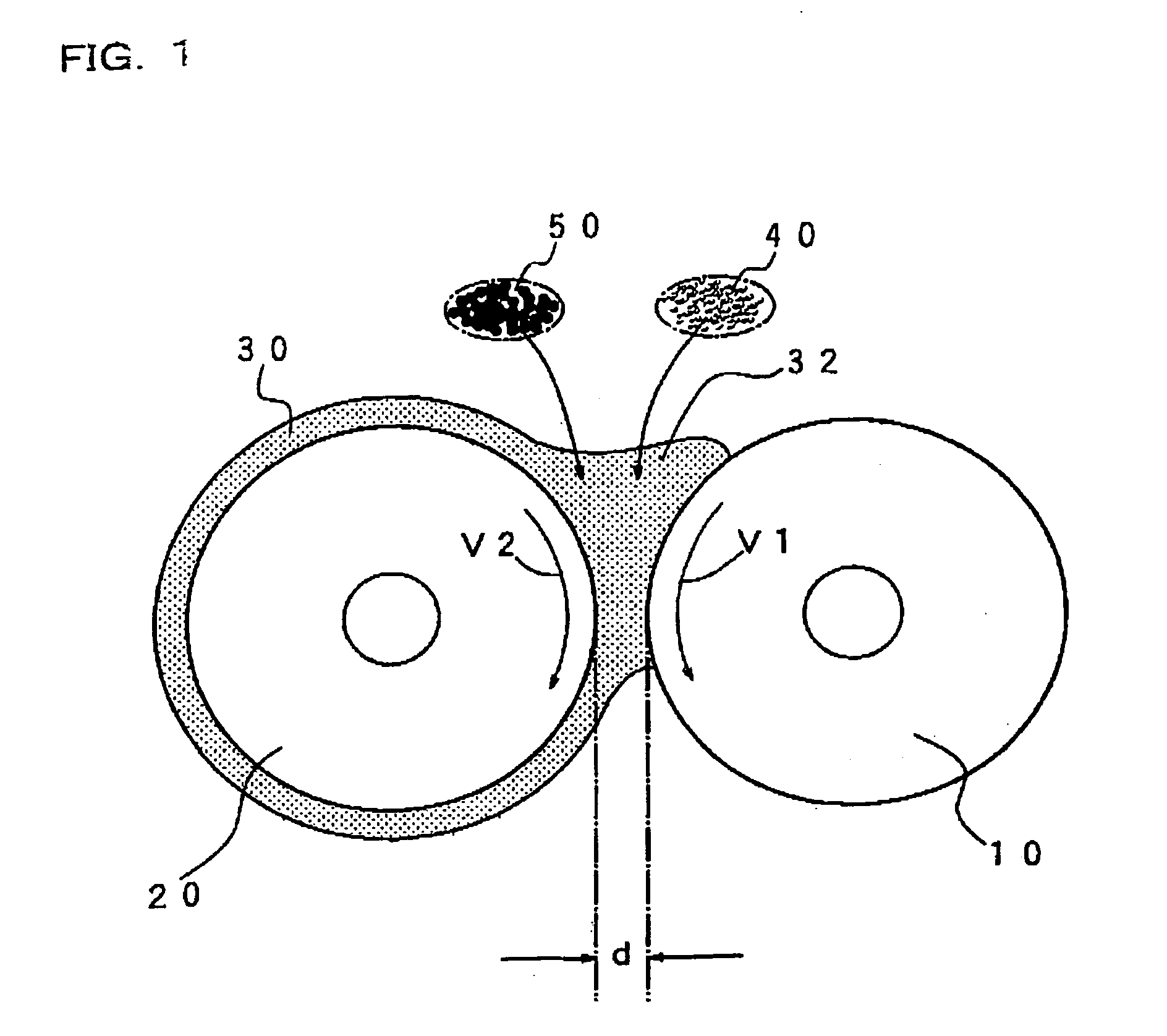

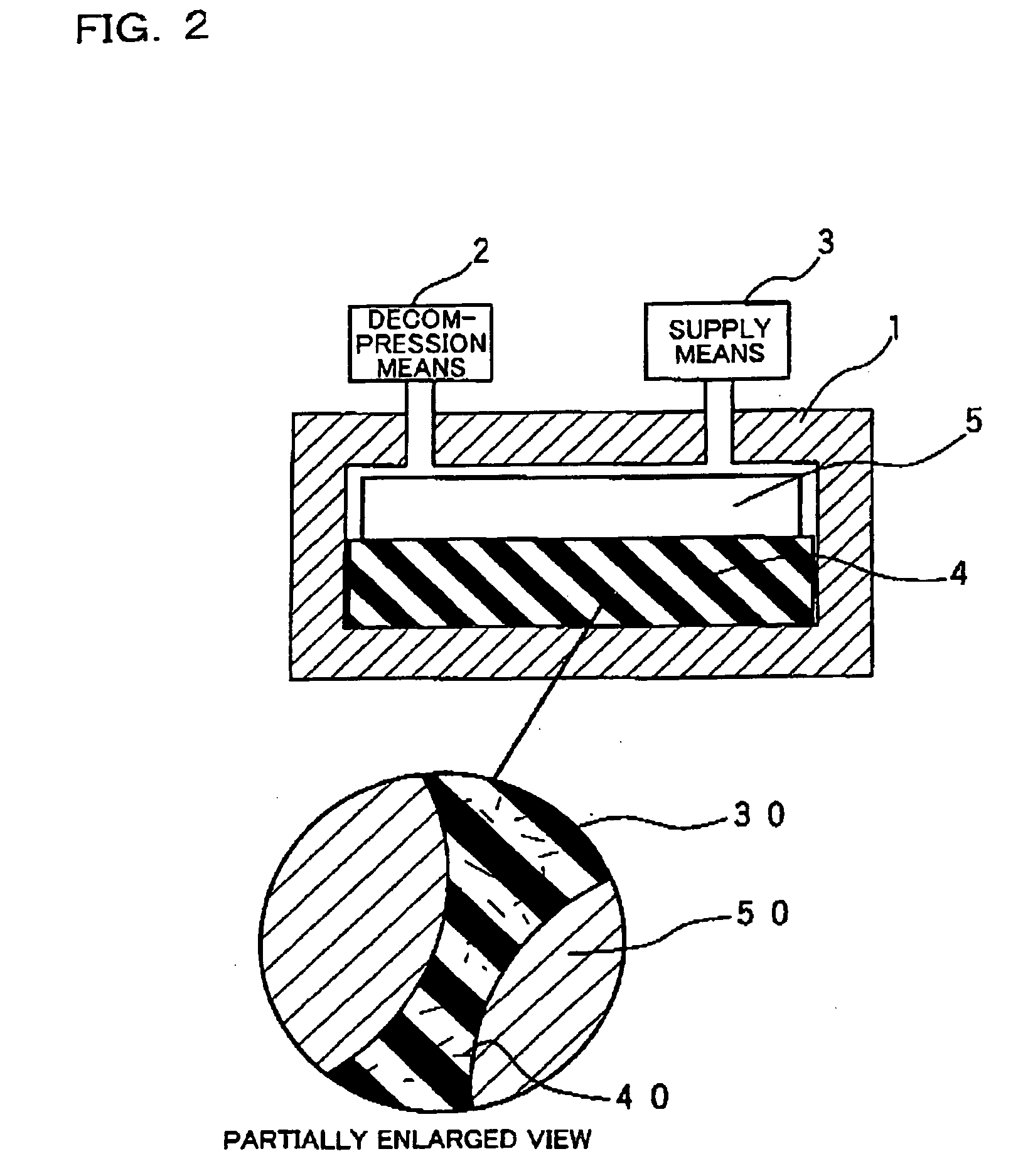

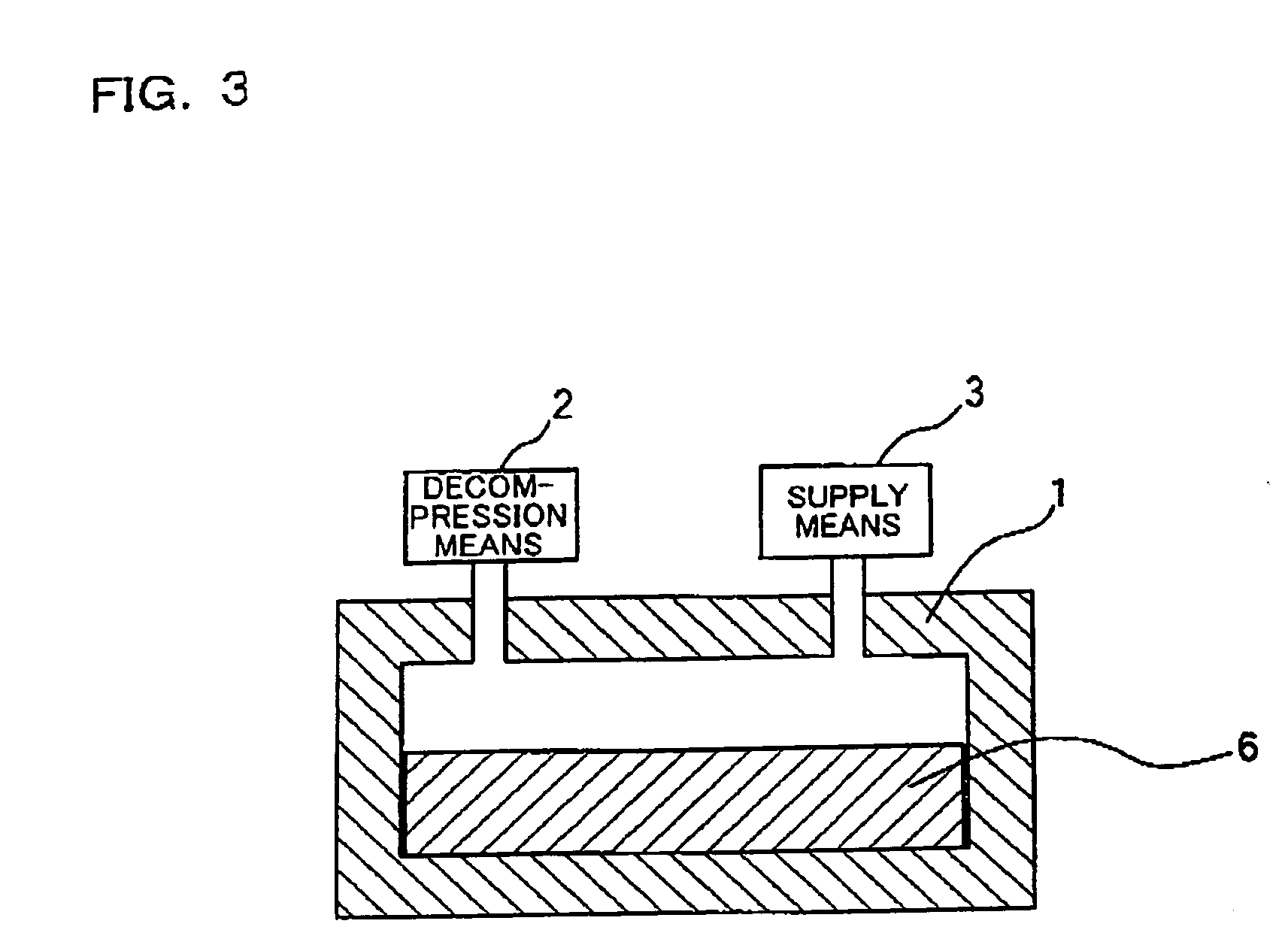

A method of producing a carbon fiber composite material including: mixing an elastomer which includes an unsaturated bond or a group having affinity to carbon nanofibers with metal particles; and dispersing the carbon nanofibers into the elastomer including the metal particles by a shear force.

Owner:HITACHI ASTEMO LTD

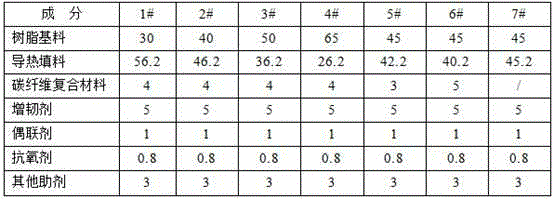

High-thermal-diffusion-coefficient high molecular material and preparation method thereof

InactiveCN104559148AImprove thermal conductivityGood radiation cooling performancePolymer scienceAntioxidant

The invention discloses a high-thermal-diffusion-coefficient high molecular material and a preparation method thereof. The high-thermal-diffusion-coefficient high molecular material is prepared from the following steps: 20-65 parts of matrix resin, 35-65 parts of high-thermal diffusion heat-conducting filler, 0.1-5 parts of carbon fiber composite, 0.1-10 parts of a flexibilizer, 0.1-2 parts of coupling agent, 0.1-2 parts of antioxidant and 0.1-15 parts of other auxiliaries. According to the high-thermal-diffusion-coefficient high molecular material, the heat conduction capability of the high molecular material is remarkably enhanced by virtue of the positive synergetic hybrid effect of a three-dimensional heat-conducting network formed by the high-thermal-diffusion-coefficient heat-conducting fillers different in shape in the processing course, and therefore the problems of poor heat conduction and thermal diffusion properties of the high molecular material for the existing LED lamp cooling housing are solved; in the preparation process, the compatibility between the surface modified high-thermal-diffusion-coefficient high molecular material and a resin matrix is improved, the viscosity of the synthetic resin melt is reduced and the dispersity of the filler is improved to enhance the processability; as a result, the product has excellent surface quality and mechanical properties; the high molecular material further has the advantages of high thermal conductivity and high tenacity.

Owner:HUIZHOU KINGBALI TECH

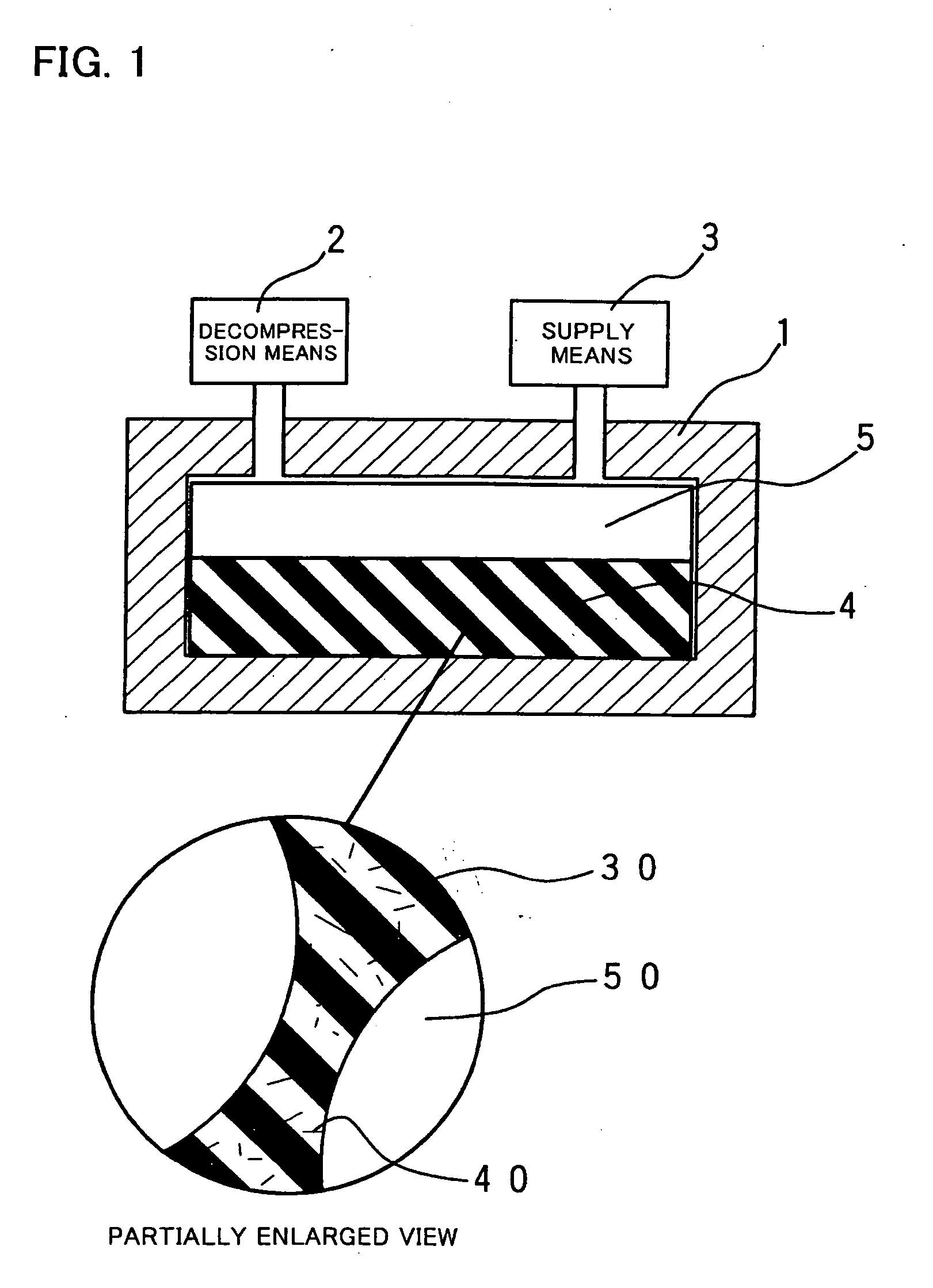

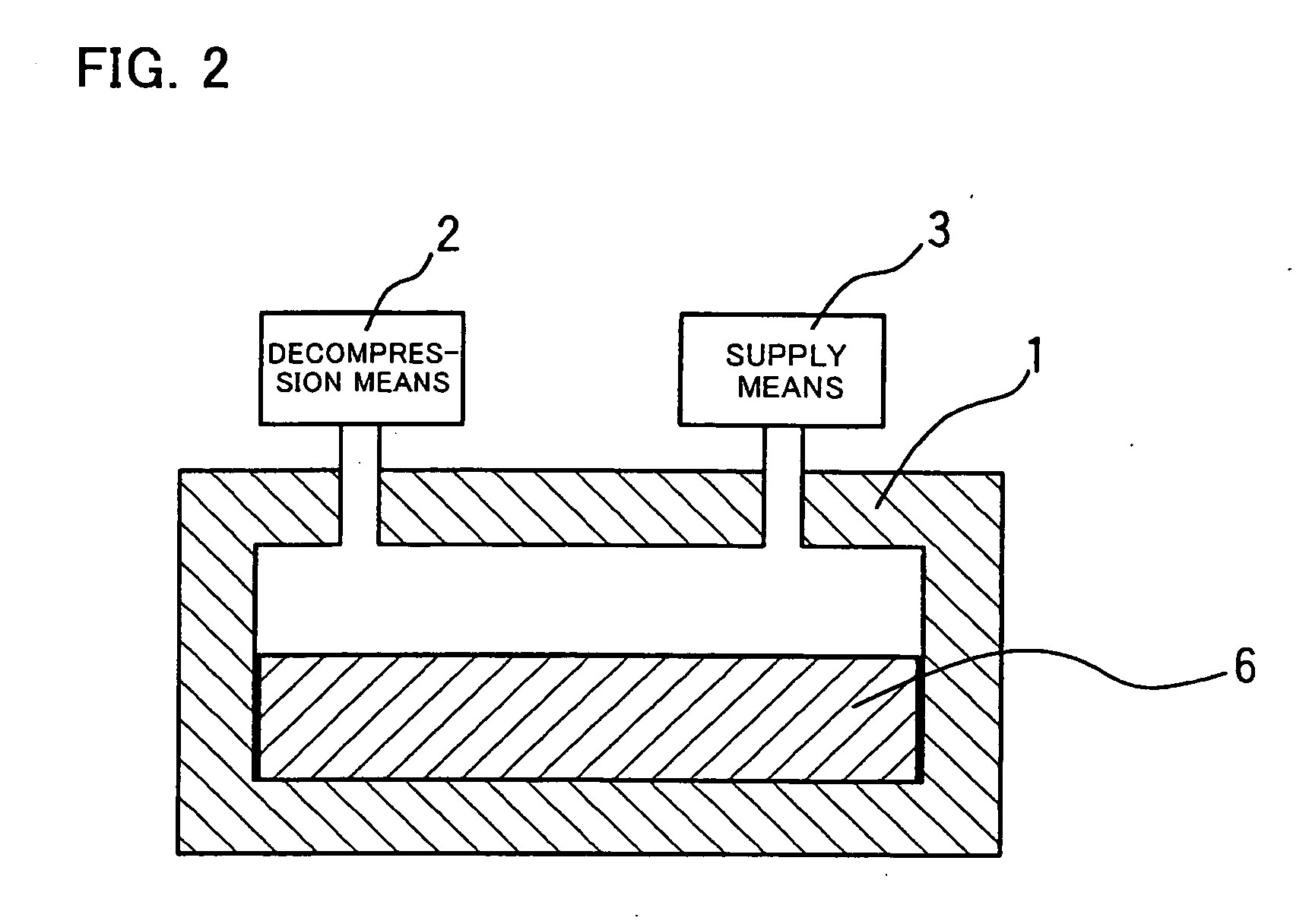

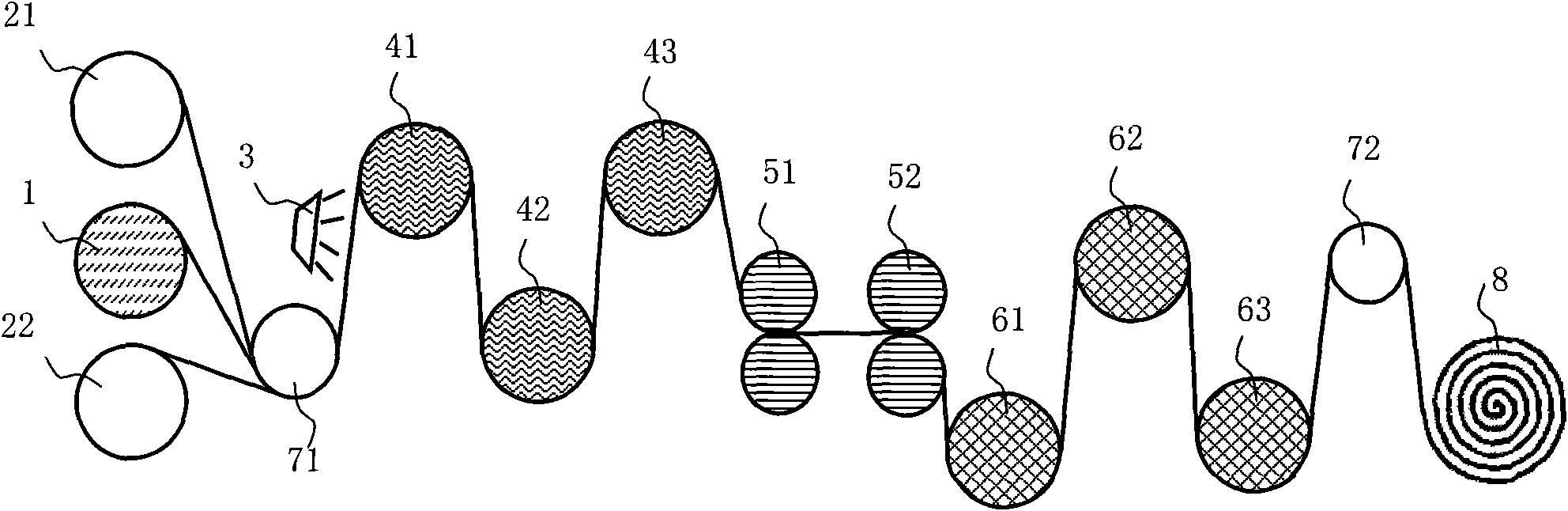

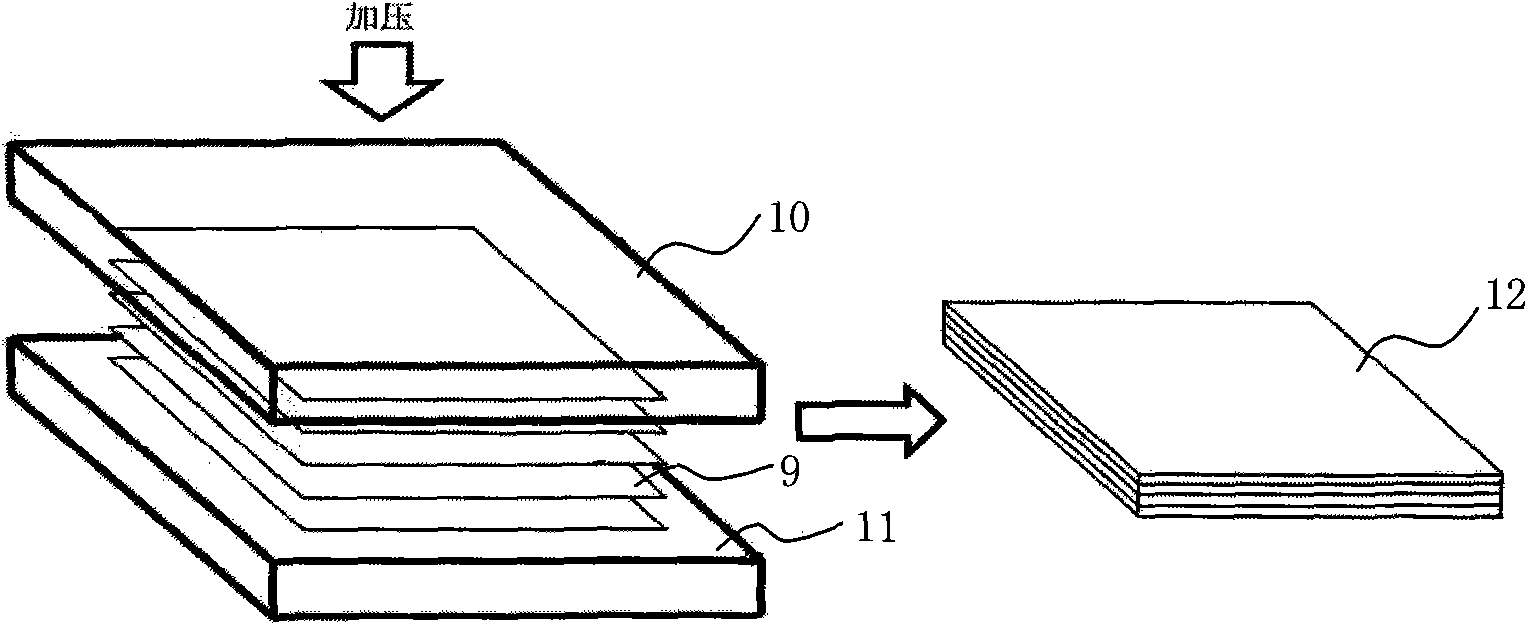

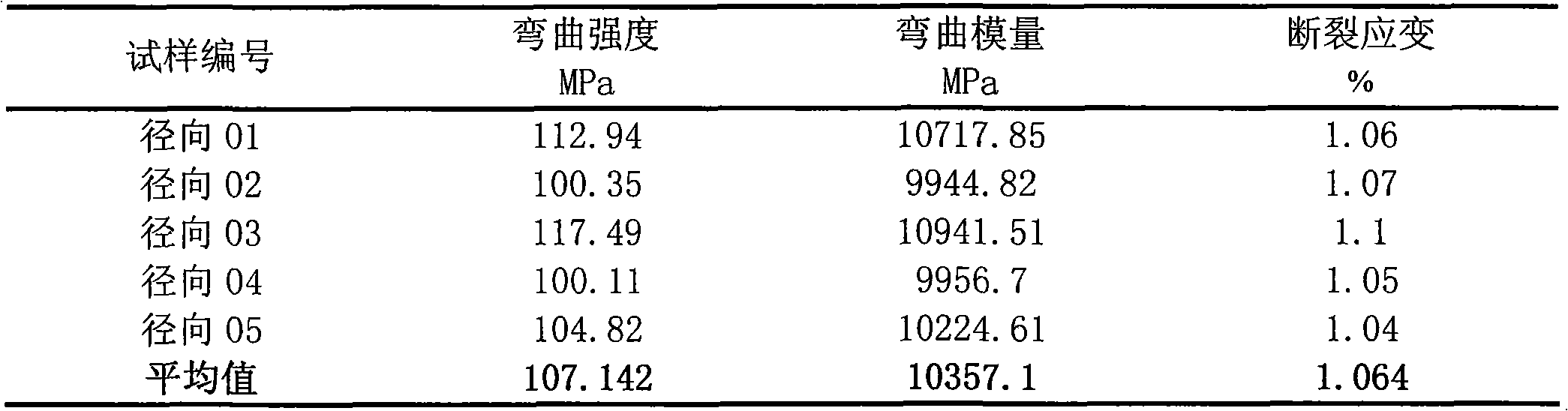

Thermoplastic resin-based carbon fiber composite and preparation method thereof

The invention discloses a thermoplastic resin-based carbon fiber composite and a preparation method thereof. The thermoplastic resin-based carbon fiber composite comprises the following components in percentage by volume: 50 to 70 percent of carbon fibers and 30 to 50 percent of thermoplastic resin. In the preparation method, according to rheological properties of the thermoplastic resin, the thermoplastic resin-based carbon fiber composite with good interface binding property is prepared by utilizing hot-roller hot-pressing continuous equipment and adjusting process conditions such as machining temperature, machining pressure, machining time and the like. Compared with the prior art, the thermoplastic resin-based carbon fiber composite has the advantages of simple structure, good interface binding property, high impact resistance and recycling property; and the preparation method can realize the uniform distribution of the carbon fibers and the thermoplastic resin and ensure the carbon fibers are immersed by the thermoplastic resin completely, so that the defect of the conventional method is overcome.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Self-emulsifying polyurethanes epoxy sizing agent for carbon fibers and preparation method thereof

The invention relates to a self-emulsifying polyurethanes epoxy sizing agent for carbon fibers and a preparation method thereof. The sizing agent comprises the following components in part by weight: 10 to 15 parts of self-emulsifying polyurethanes epoxy emulsion, 0.2 to 0.3 part of aid, and 84.7 to 89.8 parts of deionized water. The method for preparing the sizing agent comprises the following steps of: (1) preparing hydrophilic polyurethane prepolymer of the self-emulsifying polyurethanes epoxy emulsion; (2) preparing a prepolymer of which the end group is an epoxy group; (3) adding 6 to 20 parts of neutralizer into the prepolymer of which the end group is an epoxy group for neutralization, pouring the neutralized solution into water for dispersing, and removing the solvent through reduced pressure distillation to obtain the self-emulsifying polyurethanes epoxy emulsion; and (4) adding the aid and the deionized water into the polyurethanes epoxy emulsion in the ratio, and uniformly mixing to obtain the self-emulsifying polyurethanes epoxy sizing agent for the carbon fibers. The self-emulsifying polyurethanes epoxy sizing agent for the carbon fibers and the preparation method thereof have reasonable design. The sizing agent can improve the mechanical property of carbon fiber composite materials, and has excellent dilution stability.

Owner:天津碧海蓝天水性高分子材料有限公司

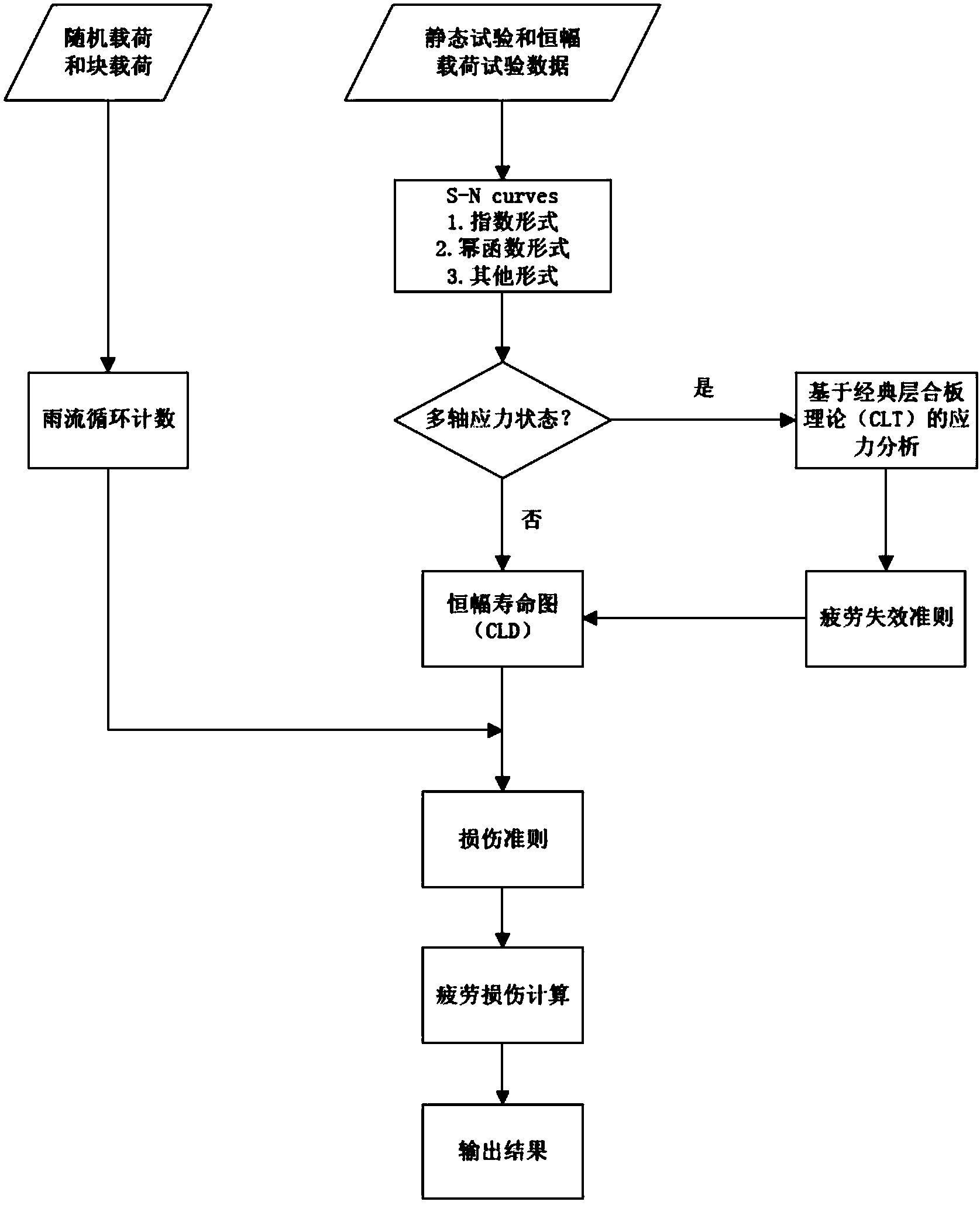

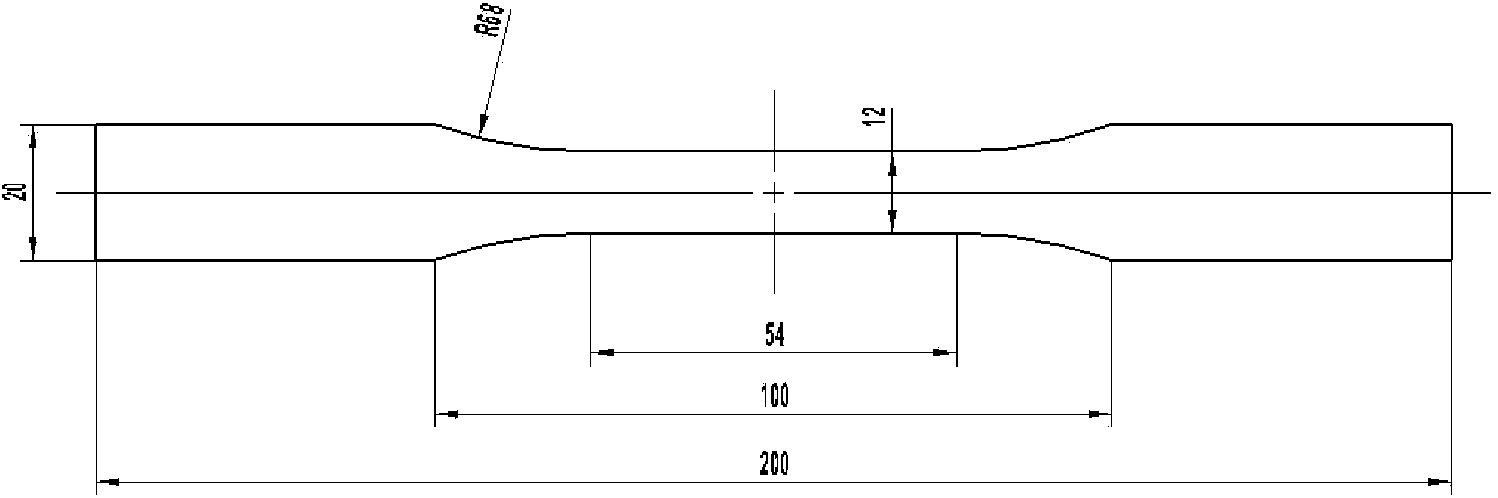

Carbon fiber composite material fatigue life estimating method based on stress ratio influences

InactiveCN103942441AAccurate lifeAccurate Damage AssessmentSpecial data processing applicationsStrength propertiesFinite element techniqueDispersity

The invention belongs to the technical field of composite materials, and discloses a carbon fiber composite material fatigue life estimating method based on stress ratio influences. Structural response calculation is carried out by means of a finite element technology. A finite element model is based on a classical laminate plate theory, and a umat subprogram taking tension and compression asymmetry into consideration is built. By carrying out constant-amplitude fatigue tests under different stress ratios, an equation of an influence mechanism of average stress on prediction of the service life of a carbon fiber composite material structure is built and is popularized to a block load and a spectrum load. A service life estimating model built through the method is based on the classical laminate plate theory and takes influences of the average stress and a variable-amplitude load into consideration, dispersity of a prediction result is little, accuracy is high, theoretical guidance is provided for reliability design of parts made of carbon fiber composite materials, and the technical problems that existing carbon fiber composite material structure fatigue life is only estimated through a test method, and accordingly cost is high and consumed time is long are solved.

Owner:SHANGHAI JIAO TONG UNIV

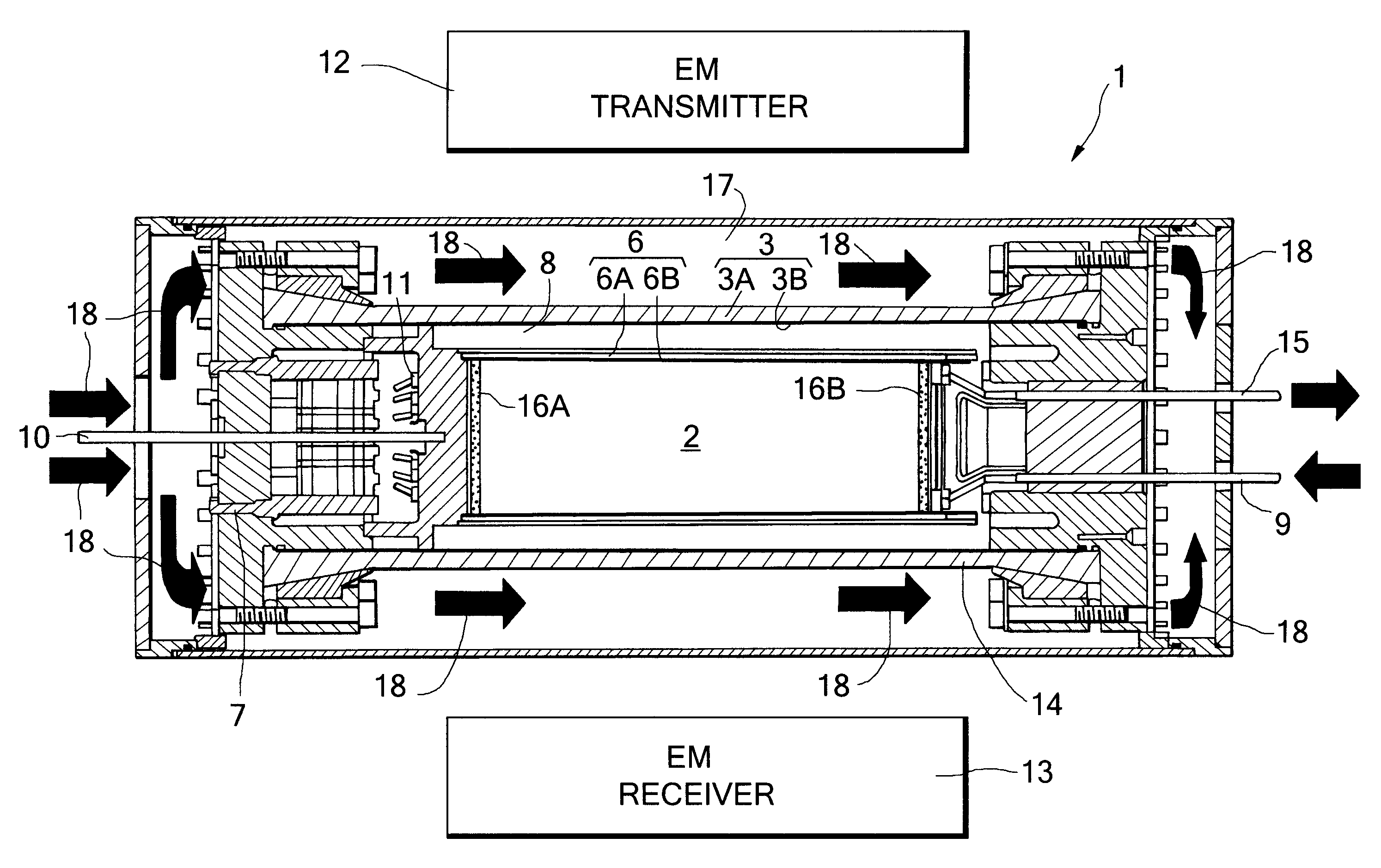

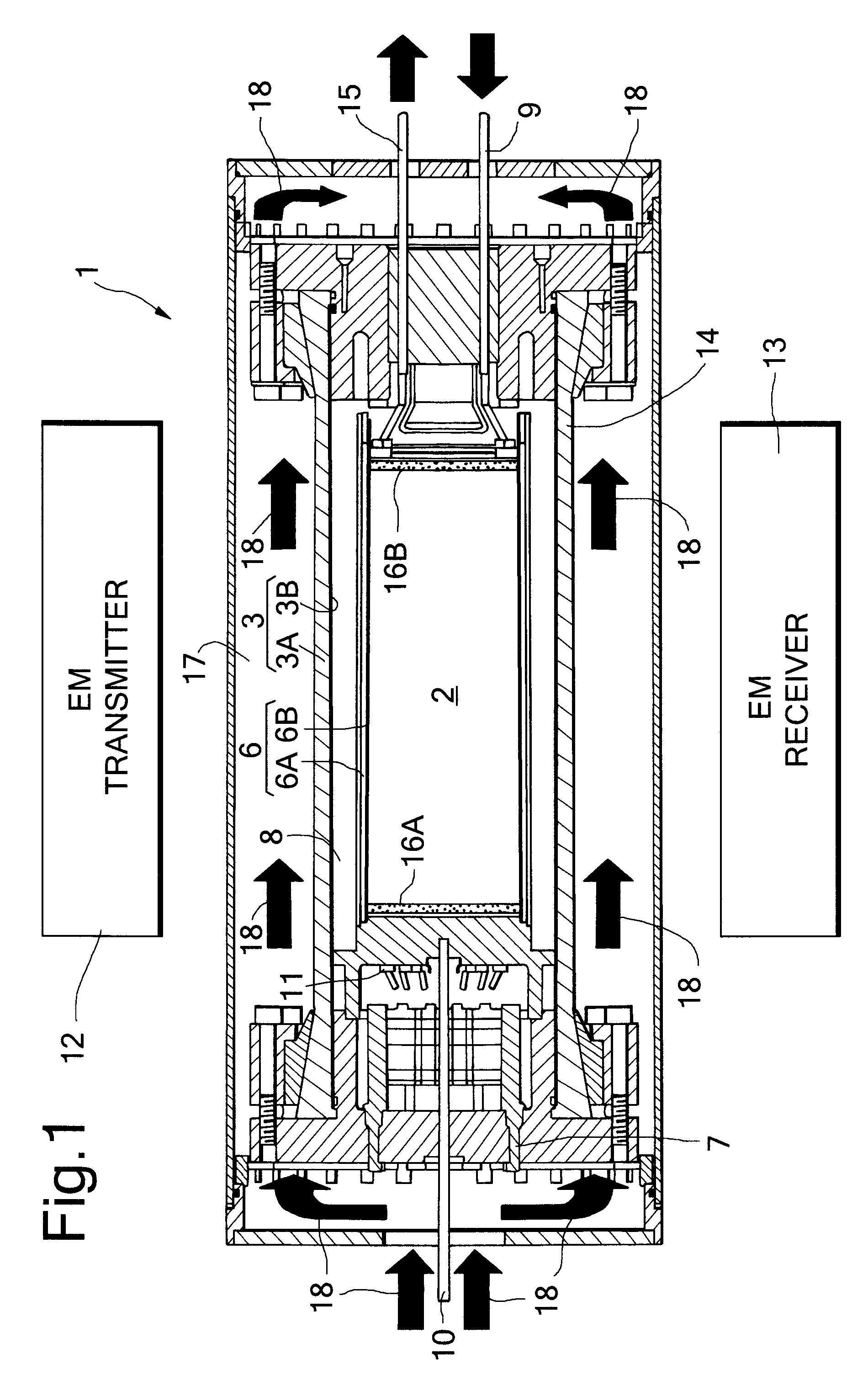

Formation core sample holder assembly and testing method

InactiveUS20100126266A1Earth material testingPermeability/surface area analysisPore fluidEngineering

A core sample holder assembly for performing laboratory core flooding experiments with a core sample:a pressure chamber provided by a tubular hull made of a carbon fiber composite material and an aluminum liner, and a pair of disk-shaped flanges;a flexible core sample holder sleeve within the pressure chamber, which sleeve comprises a tubular steel sheet with a plastic inner lining;an opening for injecting oil into an annular space between the hull and the sleeve;pressure control means for maintaining the oil at a predetermined pressure;an fluid injection port for injecting a fluid into a cylindrical core sample within the sleeve;a fluid outlet port arranged in the other flange for discharge of fluid from the core sample; andmeans for monitoring the migration of injected and / or pore fluid through the pores of the core sample.

Owner:SHELL OIL CO

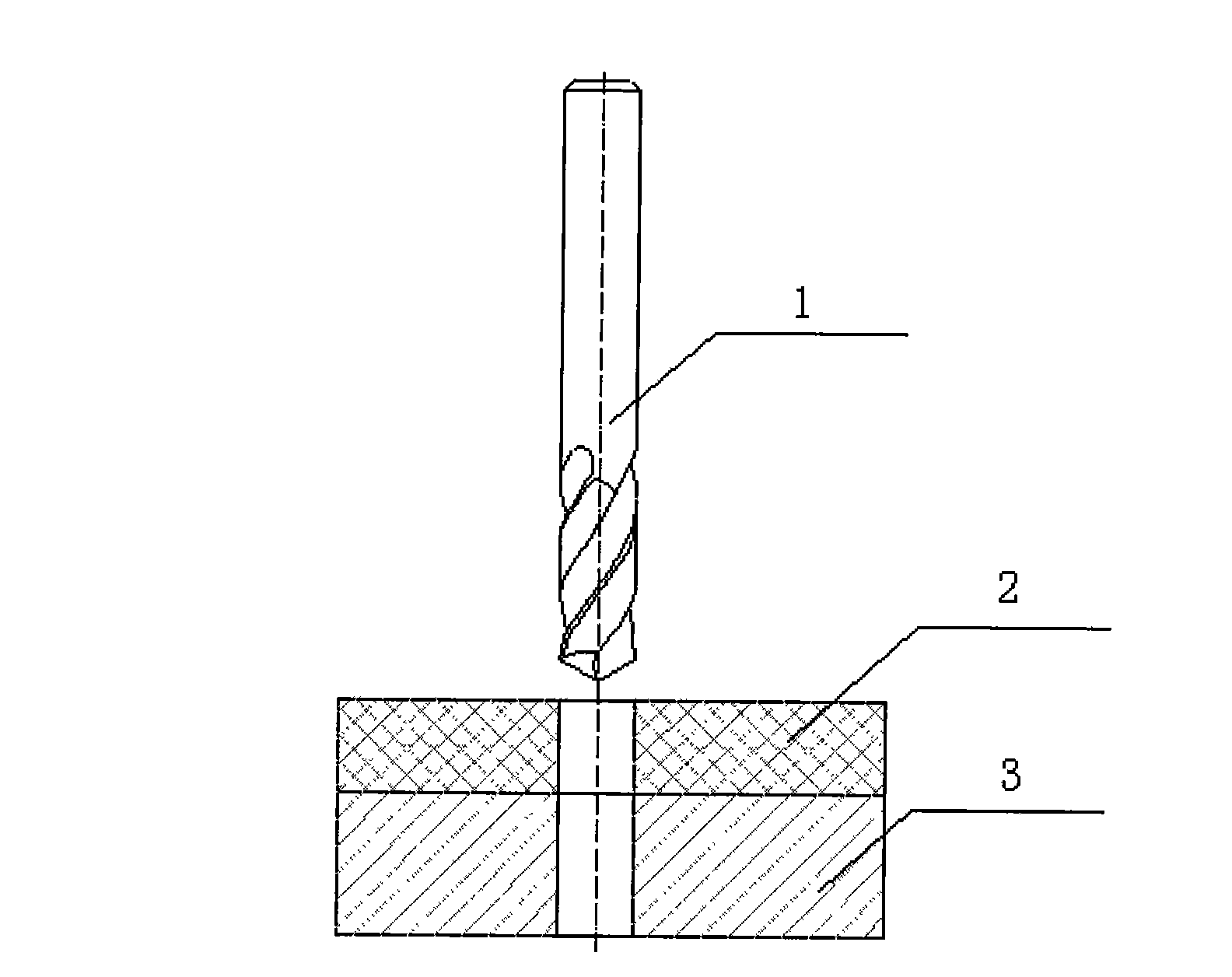

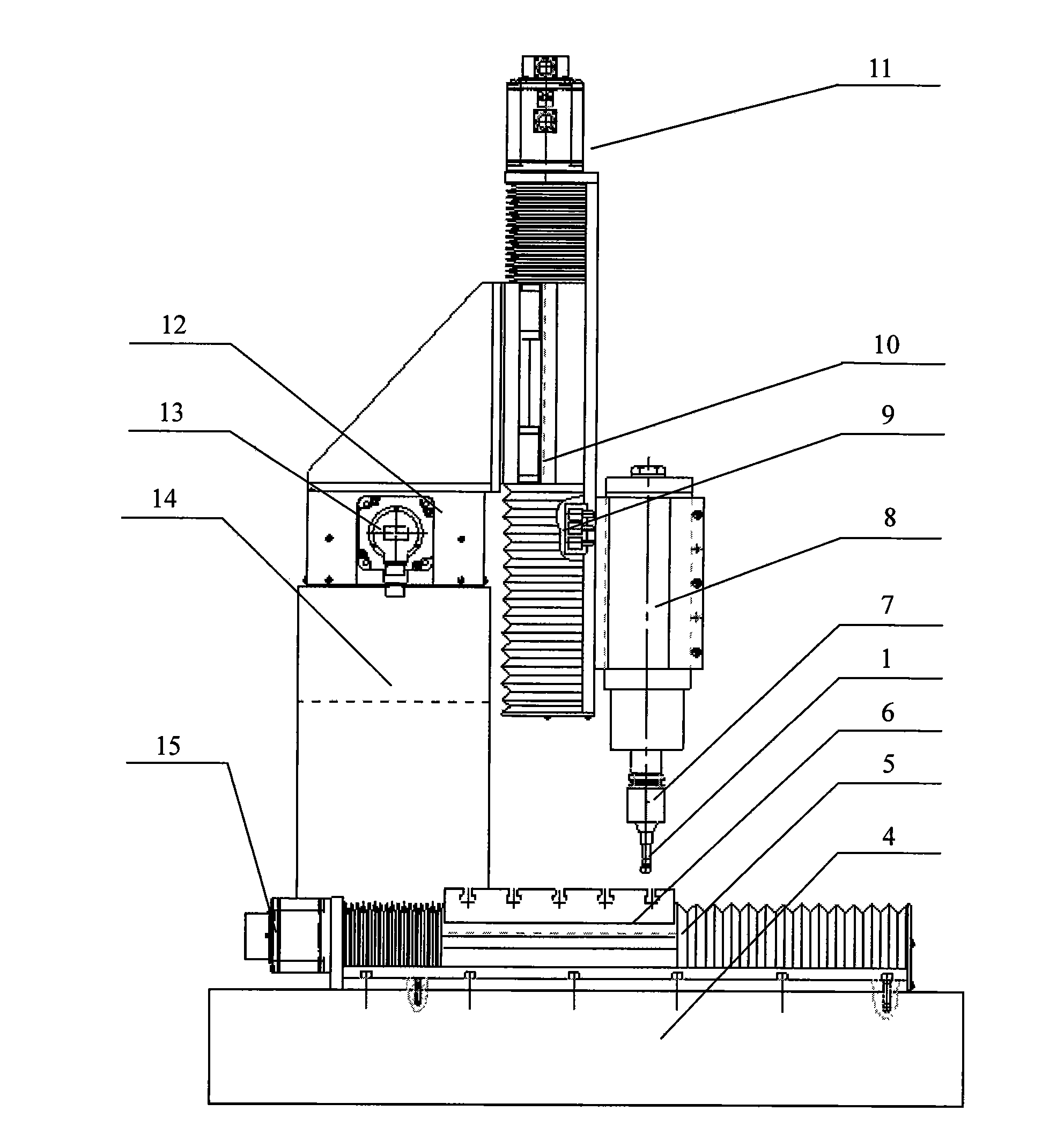

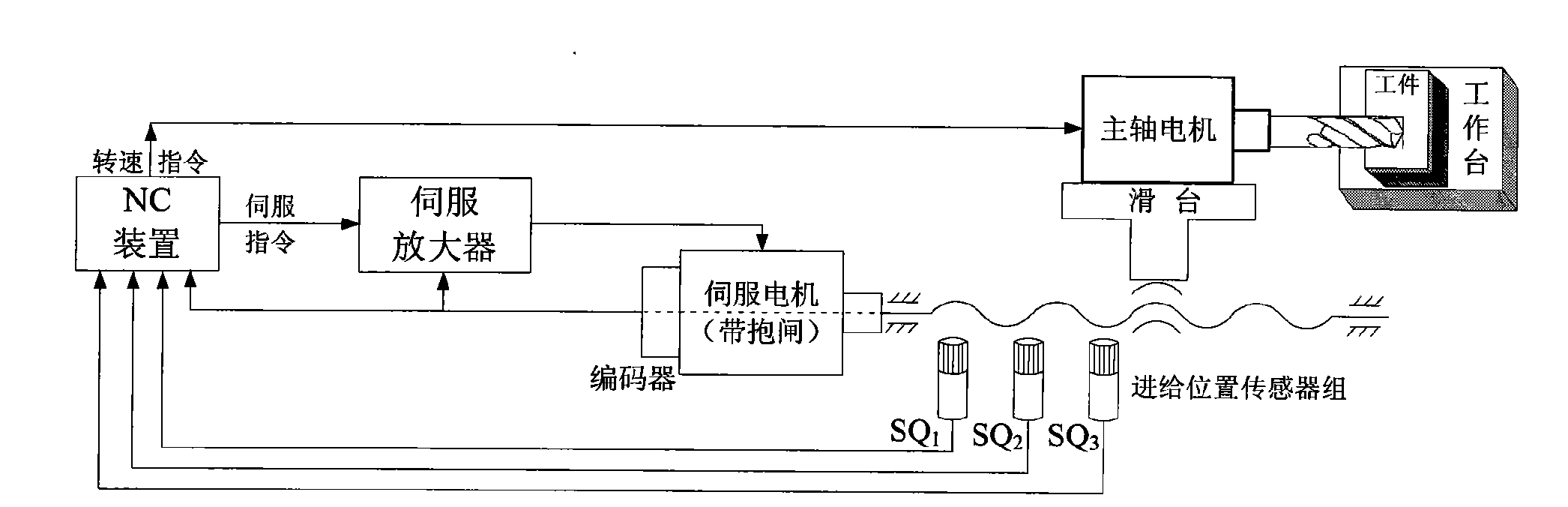

Method and device of disposing holes on carbon fiber composite material and meal material which are overlapped

InactiveCN101670448AHigh degree of automationGuaranteed stabilityAutomatic control devicesTransportation and packagingManufacturing technologyControl manner

The invention relates to a method and device of disposing high-quality holes on carbon fiber composite material and meal material which are overlapped, belonging to the field of the mechanical processing and manufacturing technology. The method of disposing high-quality holes on the carbon fiber composite material and the meal material which are overlapped is characterized in that in the process of disposing holes on the carbon fiber composite material and the meal material which are overlapped by a device of disposing holes, such as a polycrystalline diamond (PCD), a coating, a cemented carbide bit and a diamond grinding rod, the rotating speed and the feeding speed of a cutter are automatically changed according to the materials on which holes are to be disposed by the hardware triggering or software numerical-control programming control mode of a feeding position sensor set so that the cutter can be in the optical process parameter state. The device of disposing high-quality holes on the carbon fiber composite material and the meal material which are overlapped is characterized by comprising a body, the cutter the handle of the cutter, an electric main shaft, the feeding position sensor set, a vertical feeding sliding-platform, a main shaft variable-frequency speed-regulating system and a hole disposing device numerical control system. The invention realizes the adaptive continuous processing, obviously improves the quality and the processing efficiency of holes disposed integrally on different overlapped materials and lowers the production cost.

Owner:DALIAN UNIV OF TECH

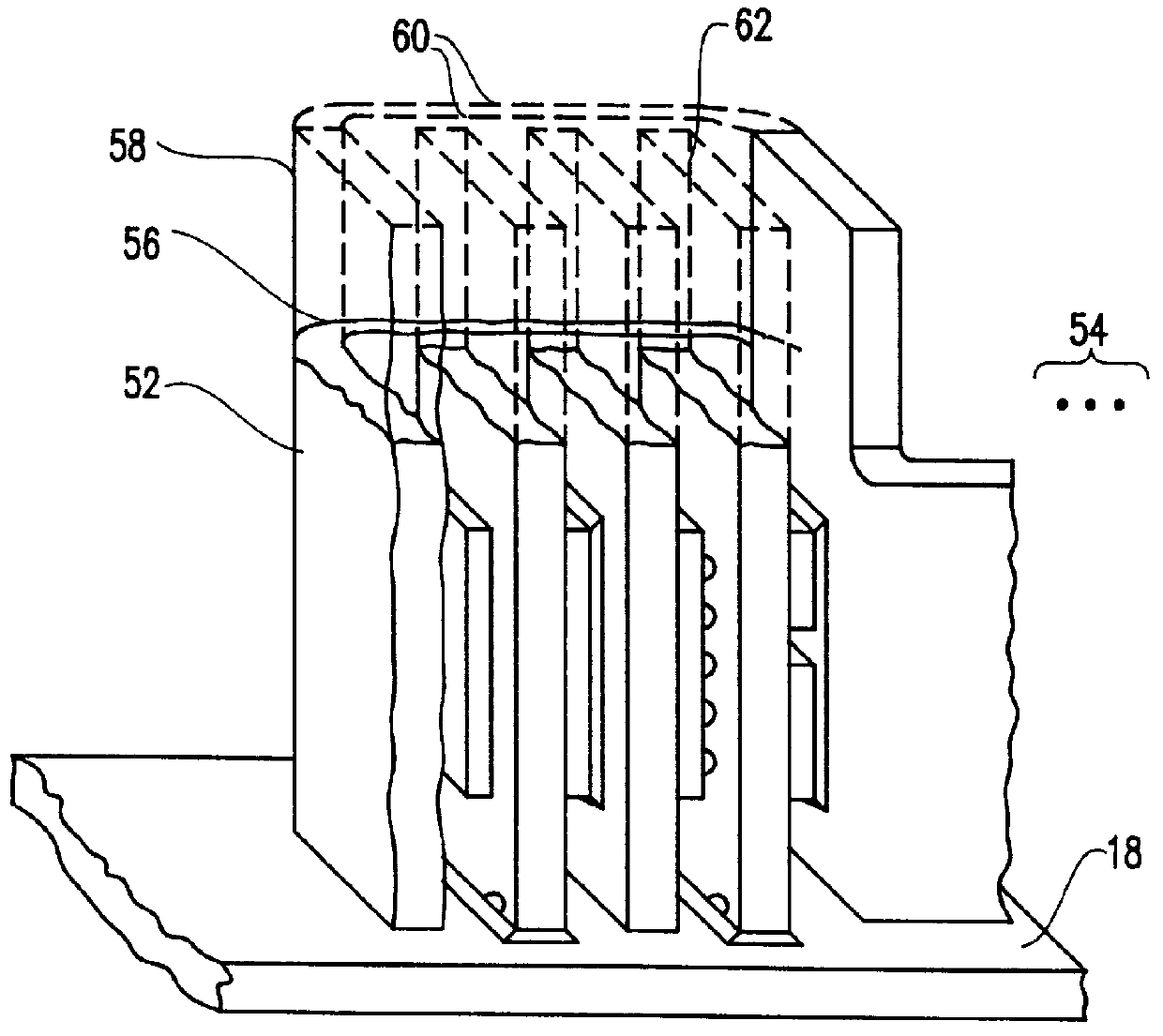

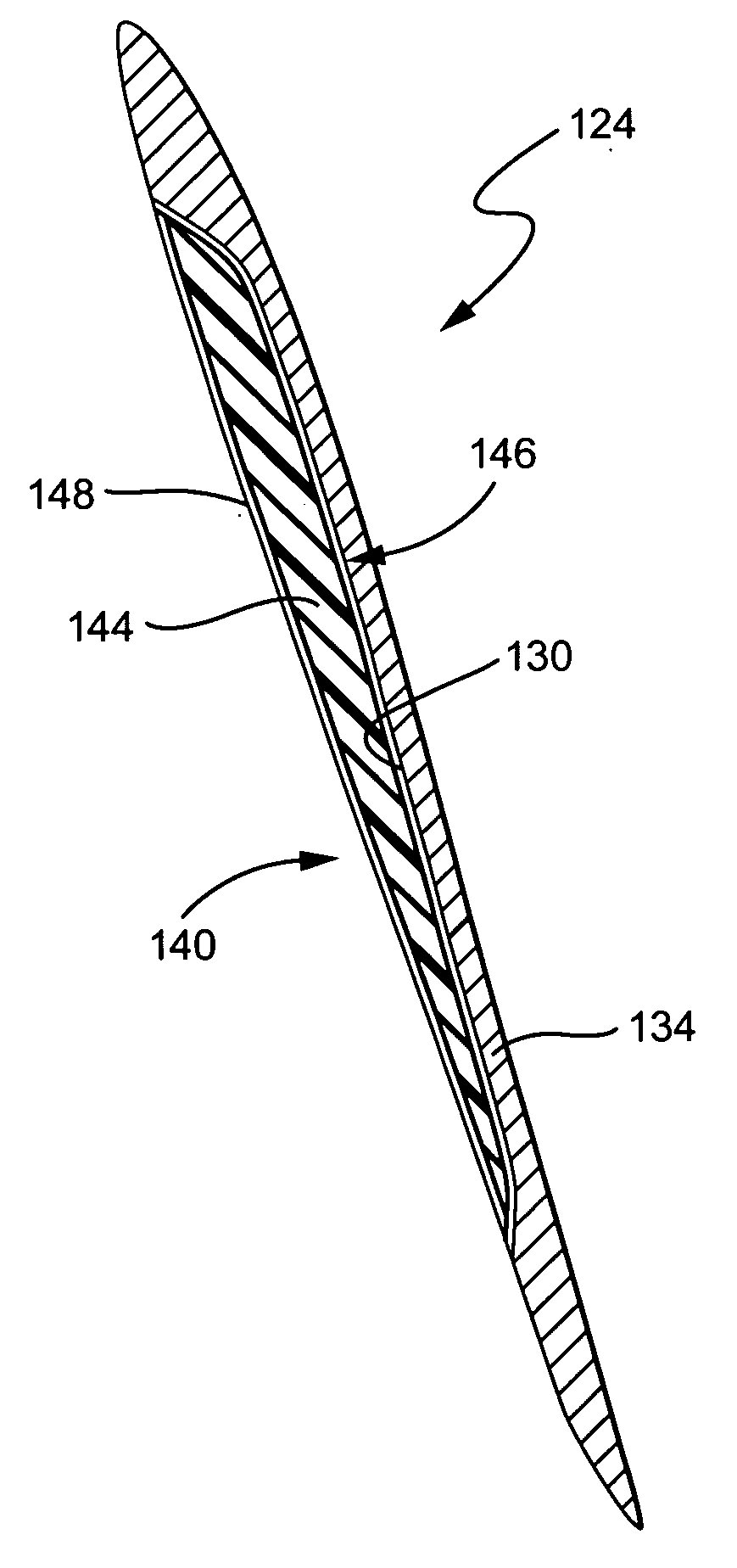

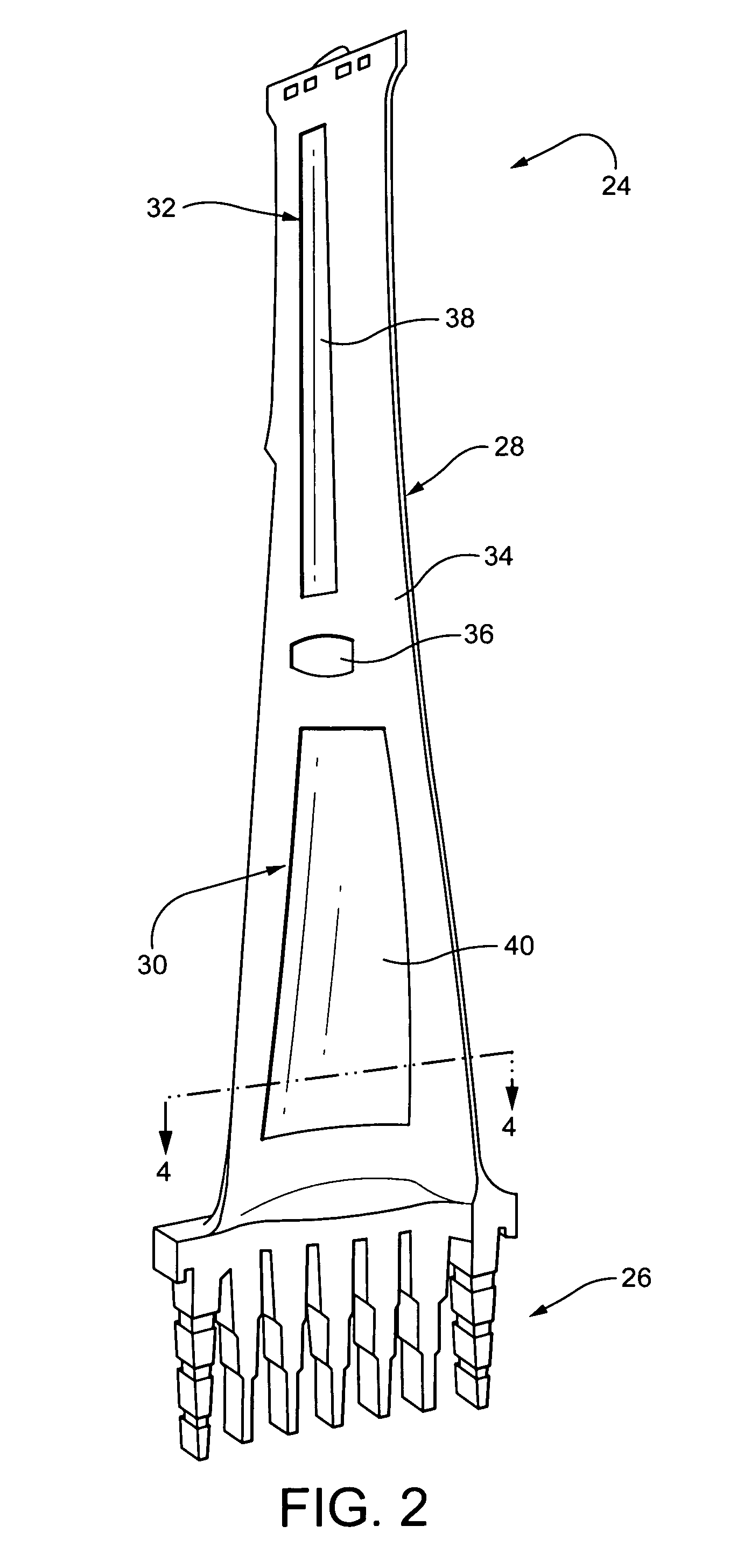

Hybrid blade for a steam turbine

To address certain deficiencies of carbon fiber material as a filler in a hybrid blade, a glass composite layer is provided as a barrier layer between a carbon fiber resin filler and the metallic main body of the blade. The glass composite layer also advantageously provides a gradient in thermal expansion between the carbon fiber composite and the body of the blade (steel) to reduce interfacial residual stress.

Owner:GENERAL ELECTRIC CO

High-toughness and high-thermal-conductivity polymer material and preparation method thereof

The invention discloses a high-toughness and high-thermal-conductivity polymer material and a preparation method thereof. The high-toughness and high-thermal-conductivity polymer material is prepared by premixing a resin-based material, a carbon fiber composite material, thermally conductive filler, a toughening agent, a coupling agent and other processing additives as raw materials, extruding, airing, pelletizing and the like in combination with a twin-screw extruder. The thermal conductivity of the obtained polymer material is improved, the polymer material has excellent mechanical properties, especially toughness, the requirements of fields of electronics, automotives and LED lamps on the processing performance of the polymer material are met and the polymer material is more conducive to being applied in the production of multiple products which have special shapes or have larger degree of deformation in the processing process and strict requirements on the toughness.

Owner:HUIZHOU KINGBALI TECH

Nacelles and nacelle components containing nanoreinforced carbon fiber composite material

Owner:THE BF GOODRICH CO +1

Method for forming carbon fiber pipe and die thereof

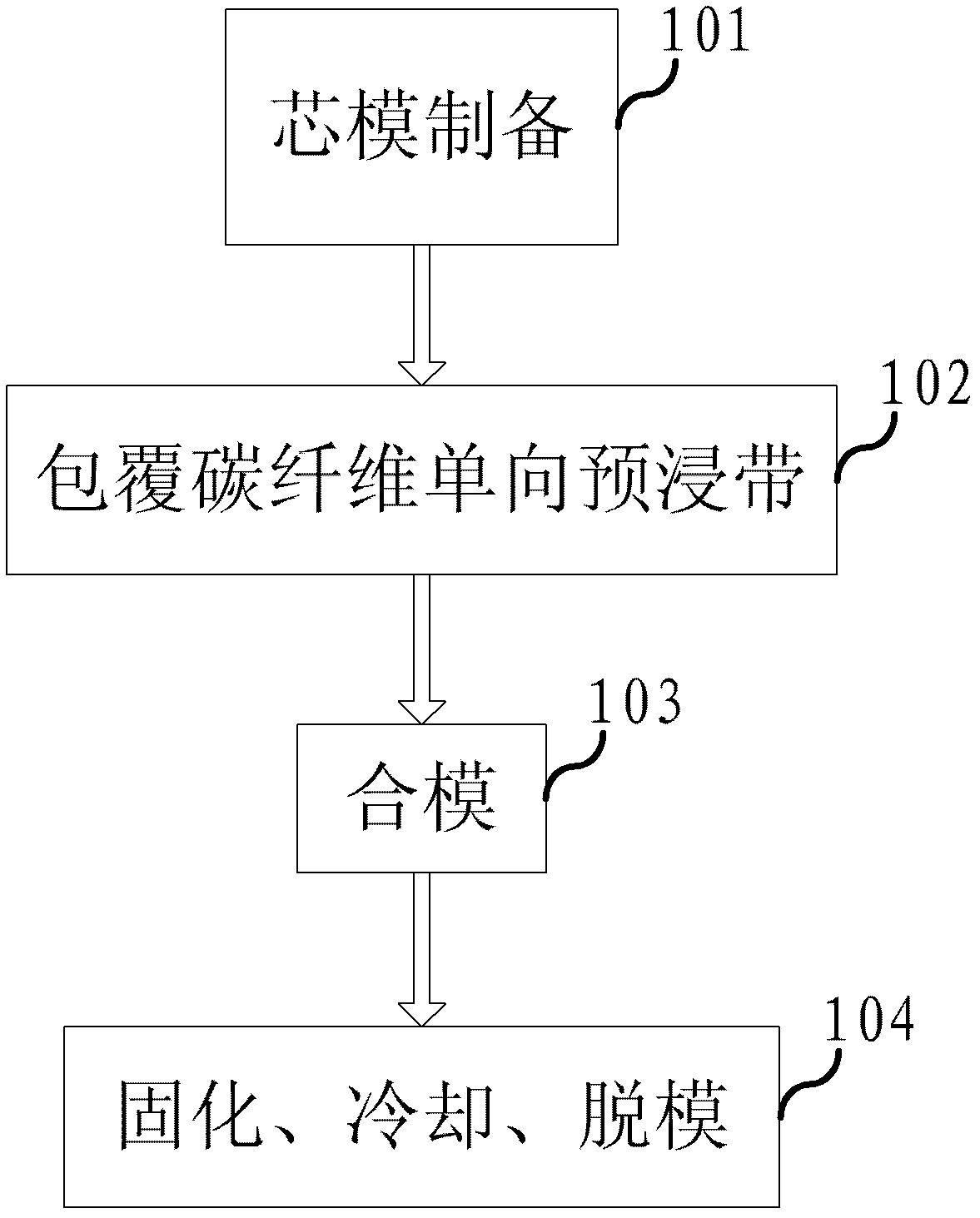

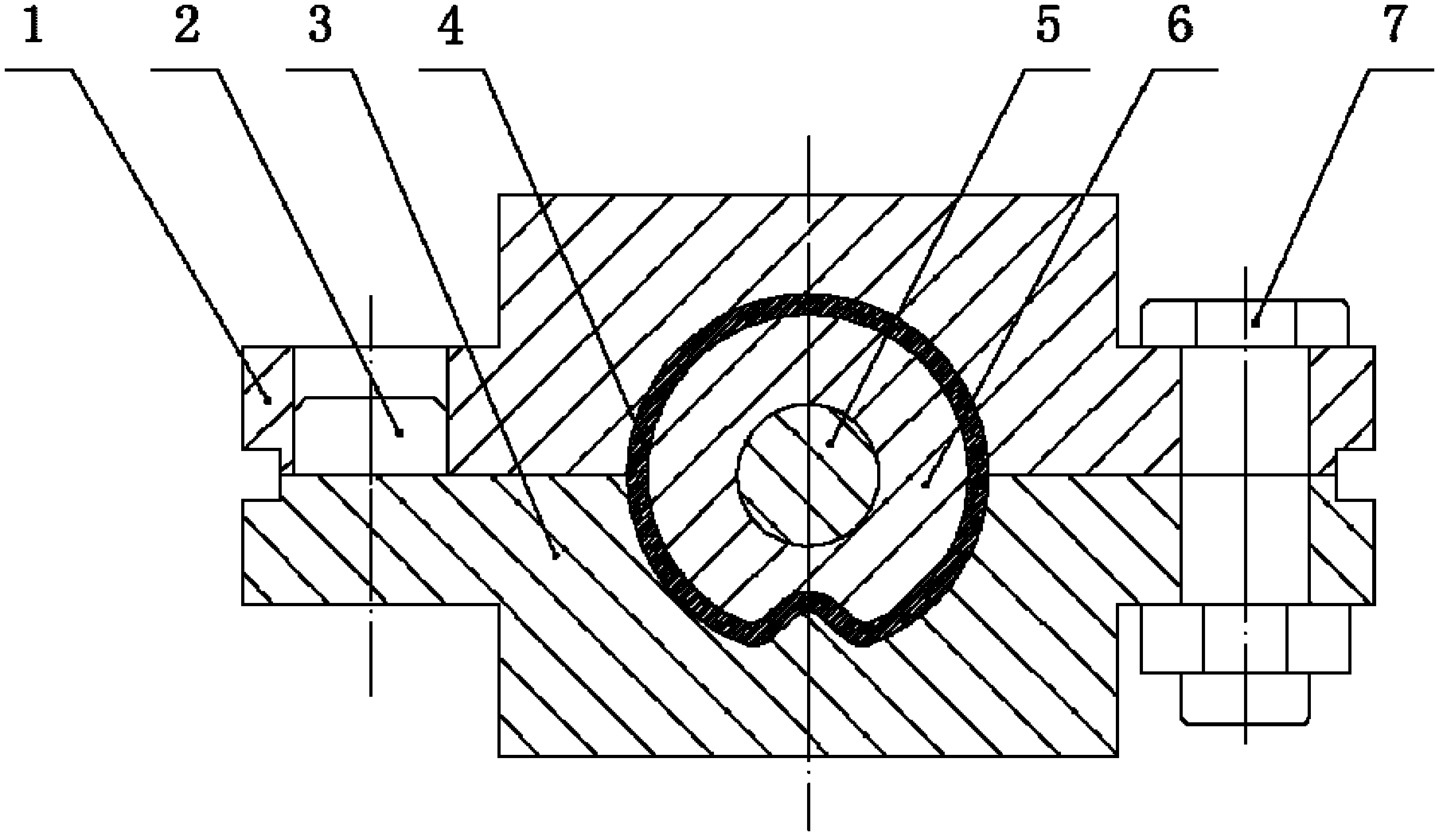

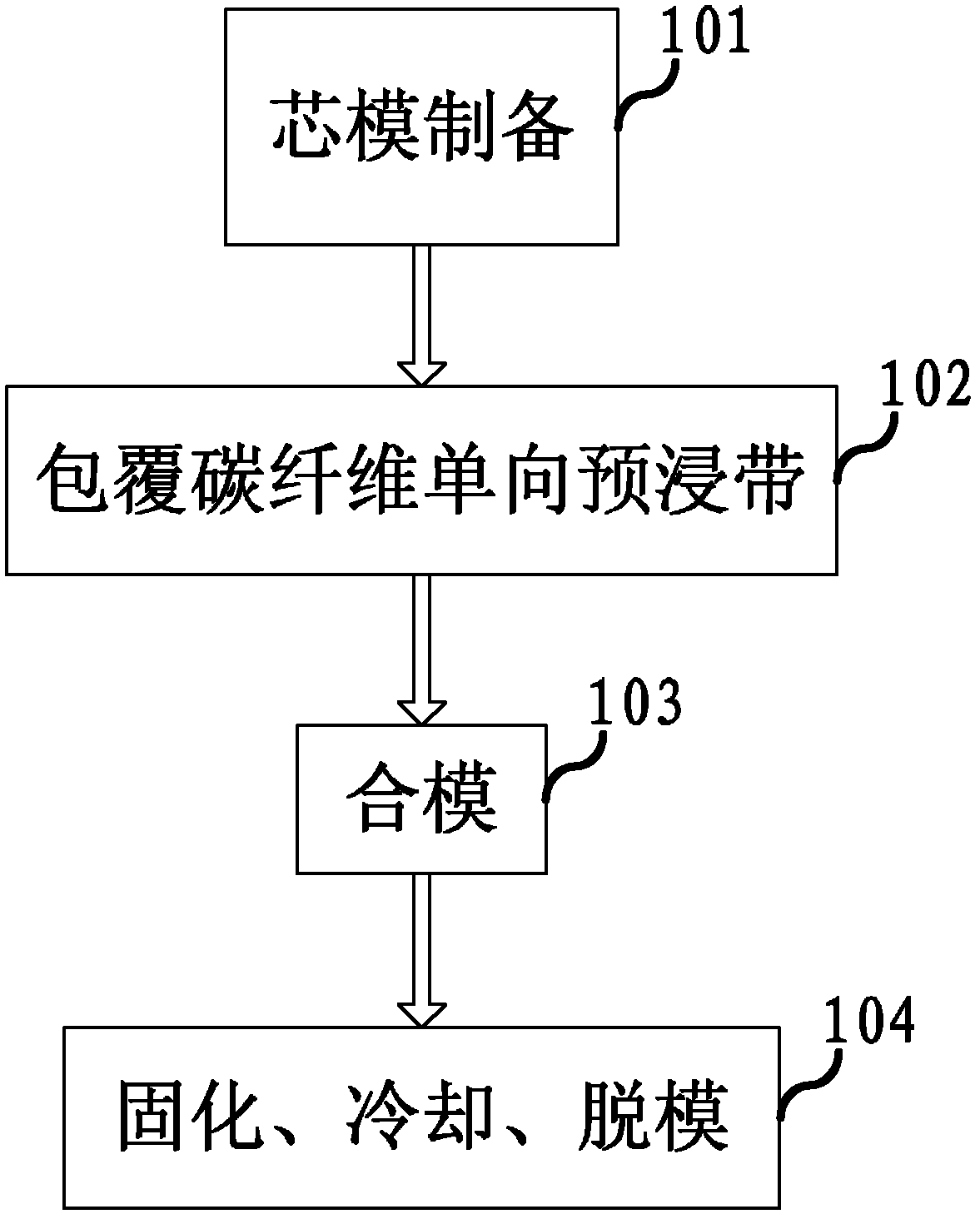

The invention discloses the technical field of carbon fiber composite materials, and discloses a method for forming a carbon fiber pipe. The method comprises the following steps of: preparing a core mould, namely preparing the core mould for wrapping carbon fiber one-way preimpregnation belts, wherein the core mould comprises a metal core rod and a rubber material wrapping the metal core rod; paving and coating the carbon fiber one-way preimpregnation belts, namely after coating a release agent on the surface of the core mould, paving and coating a plurality of layers of carbon fiber one-way preimpregnation belts according to different angles; closing the die, namely positioning the core mould in which the carbon fiber one-way preimpregnation belts are paved and coated and putting into a female die, closing the die, and fastening; and curing, cooling and demoulding, namely putting the die which is closed into a drying oven, curing, cooling with a furnace, and demoulding to form the required finished piece. The method for forming the carbon fiber pipe has the advantages of simple process, high production efficiency, low manufacturing cost, uniform wall thickness of the product, high quality and stability and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Metal-based carbon fiber composite material and producing method thereof

InactiveCN101057003AReduce weightHigh thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesFiberMolten metal

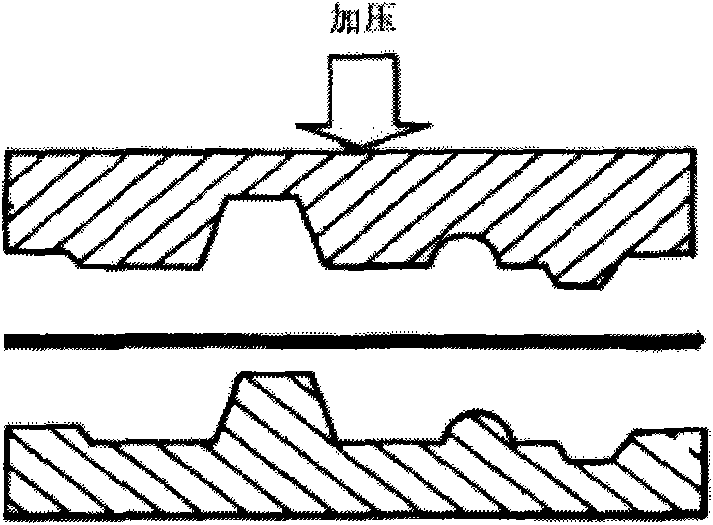

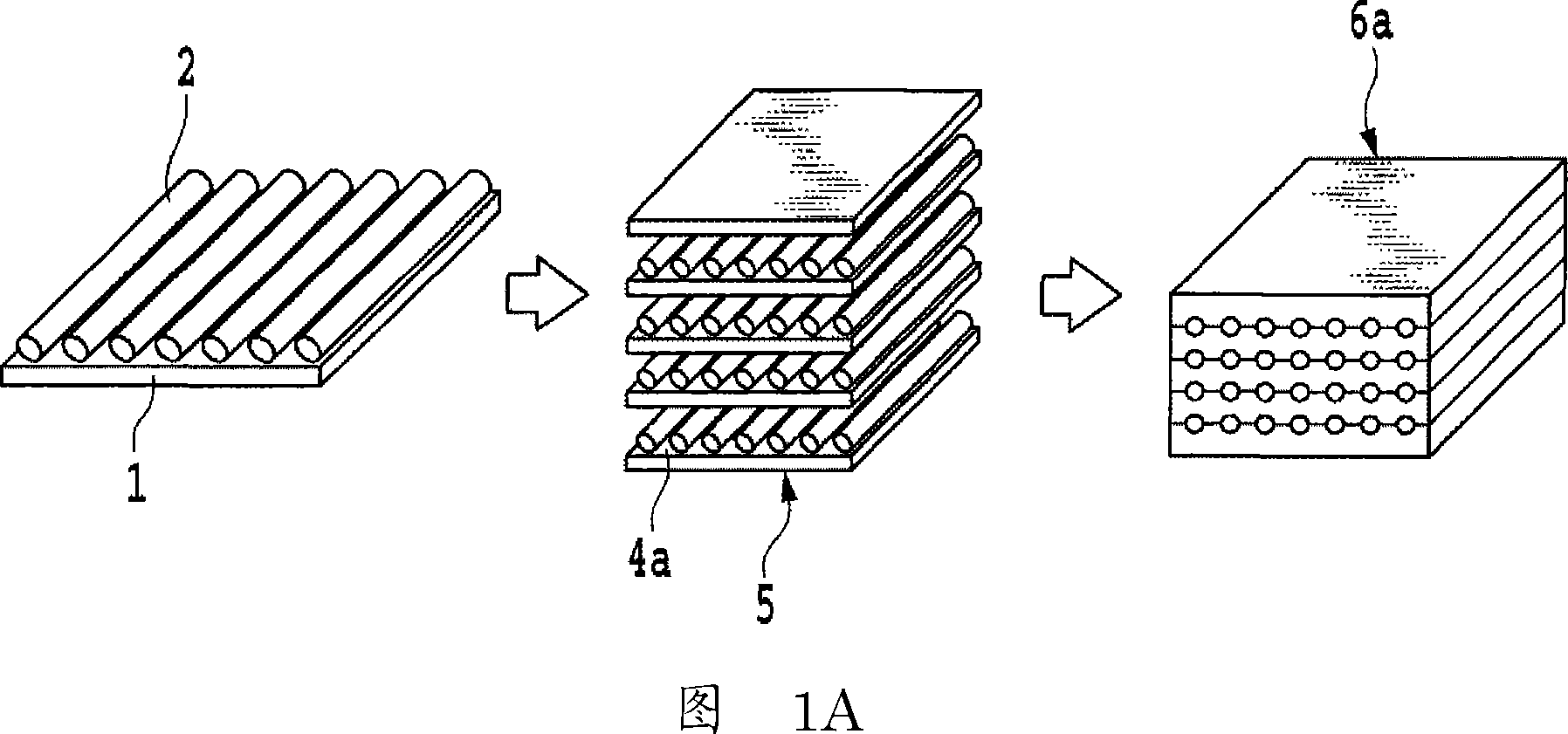

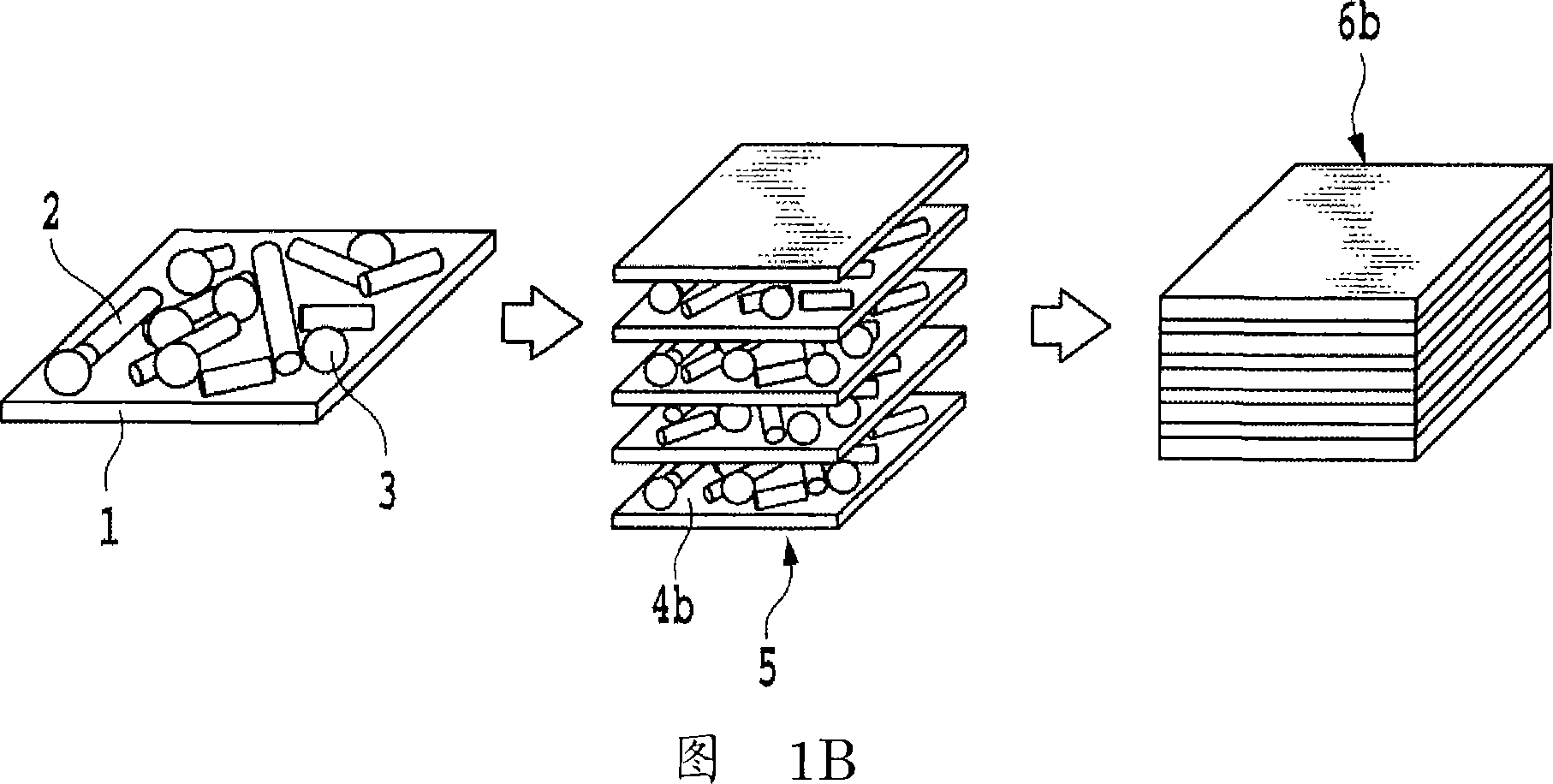

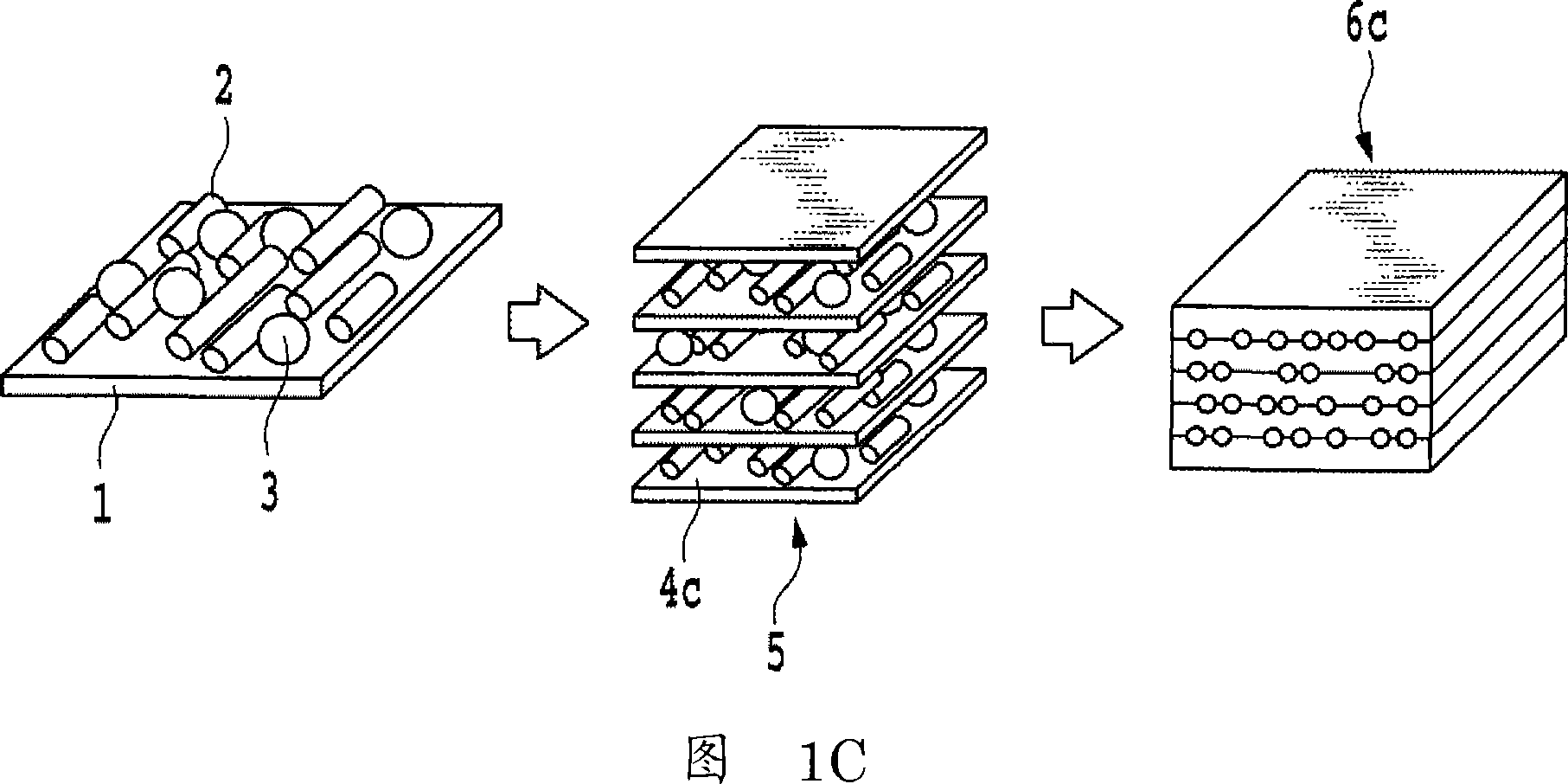

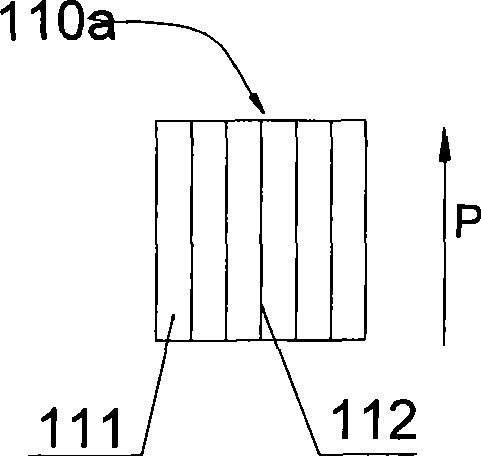

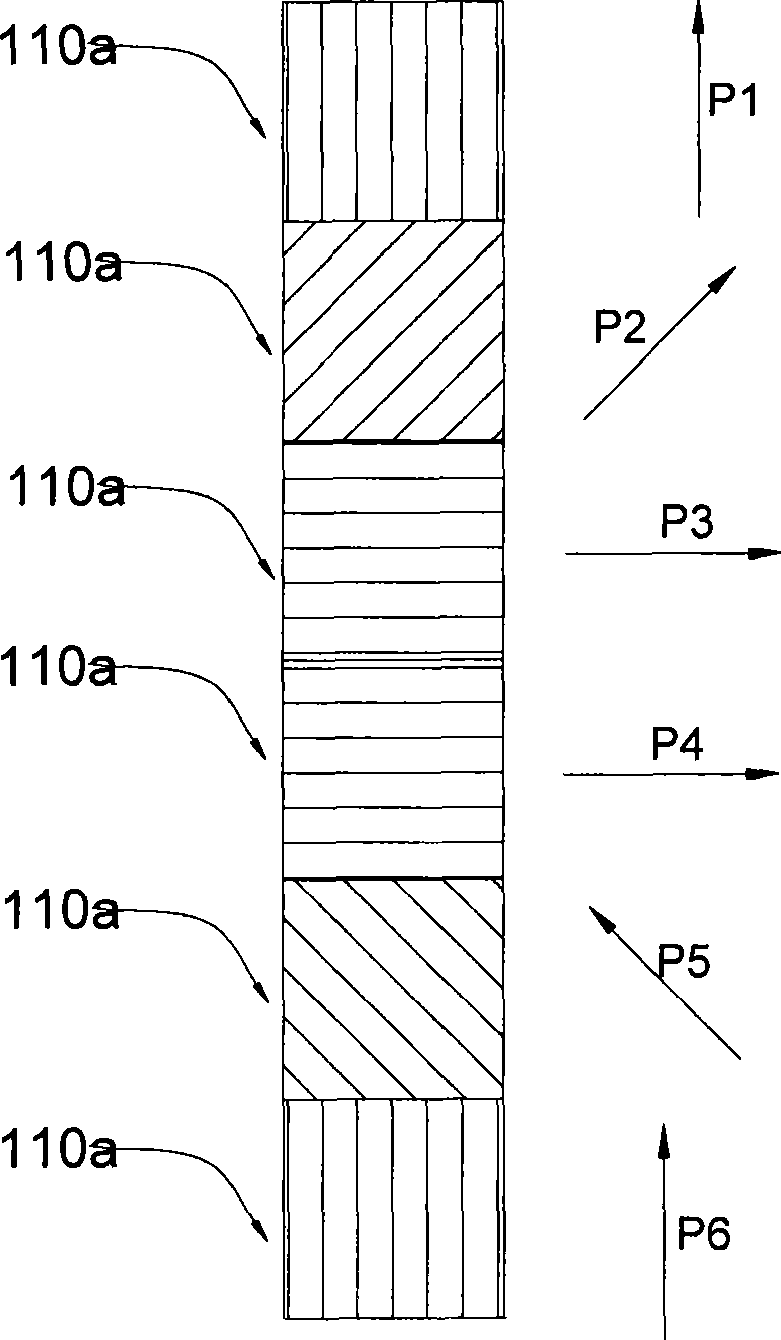

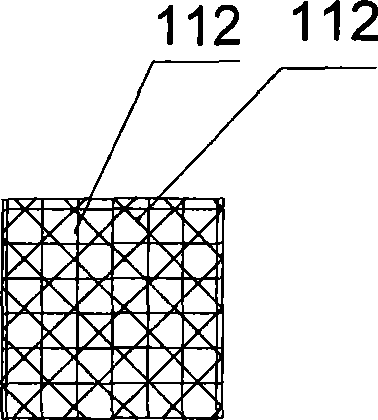

A metal base carbon fiber composite material which is produced by heating and pressing a metal and a carbon fiber, and has a structure wherein metal layers and metal layers containing a carbon fiber are laminated alternately; and a method for producing the above metal base carbon fiber composite material, which comprises a step of attaching carbon fibers onto a metal support in the form of a sheet or film to form a preform, a step of laminating a plurality of preforms to form a preform laminate, heating and pressuring the preform laminate under vacuum or in a non-oxidizing atmosphere to thereby integrate the preforms with one another. The above metal base carbon fiber composite material can be produced by the use of generally used non-expensive materials with the energy less than that used in the molten metal method, can have a wide range of dimension or shape (in particular, a large surface area), exhibits excellent thermal conductivity and also is lightweight.

Owner:岛根县

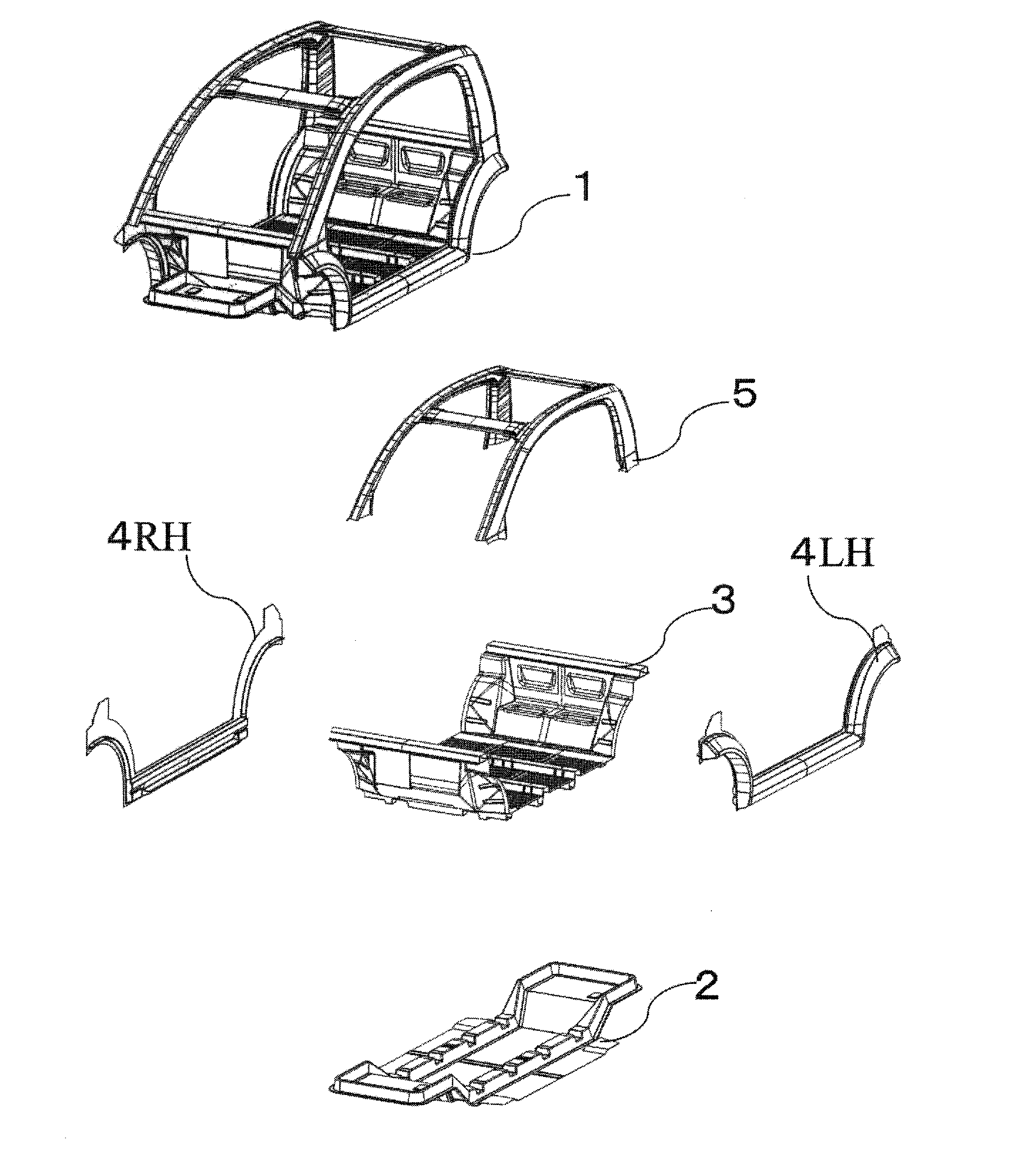

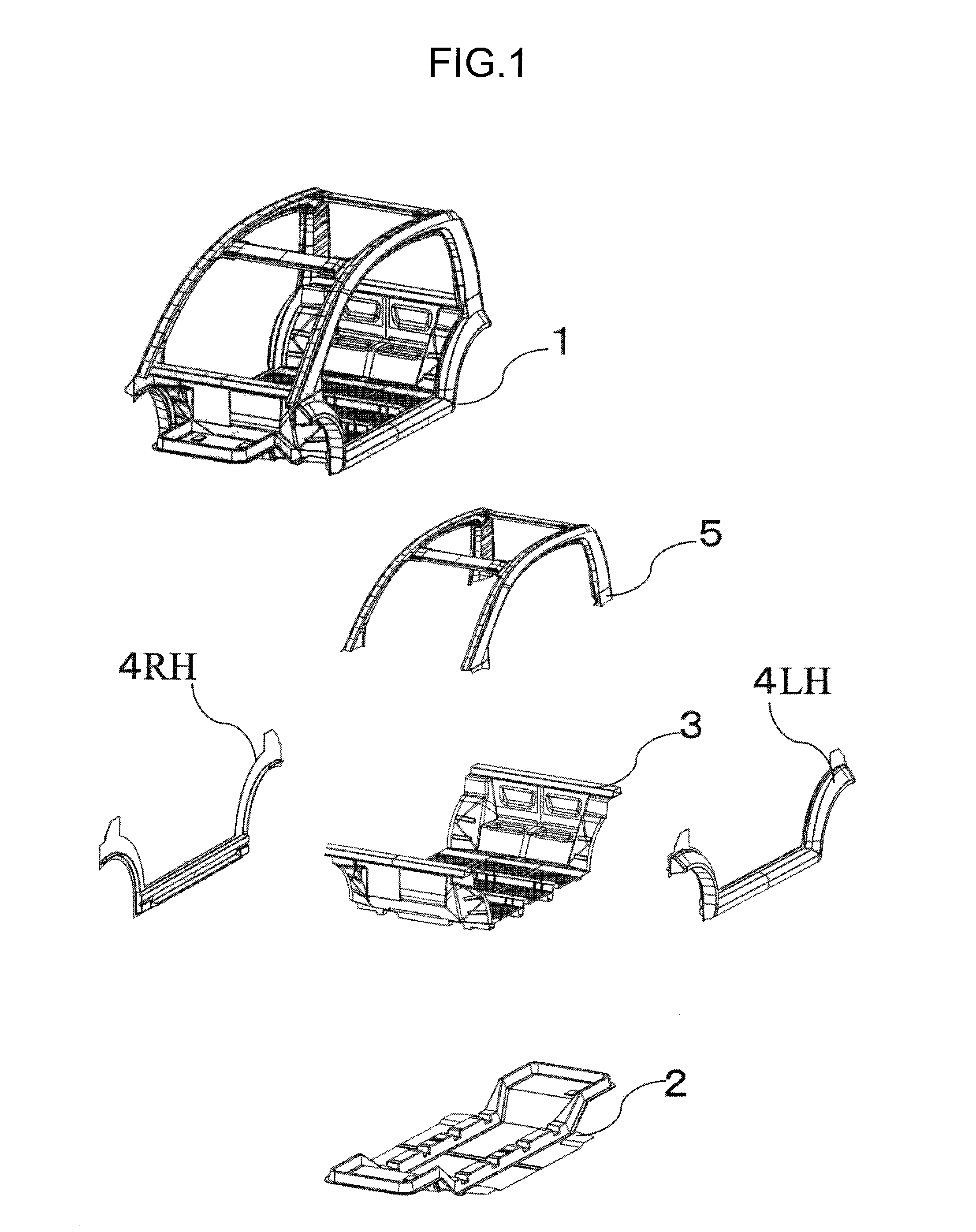

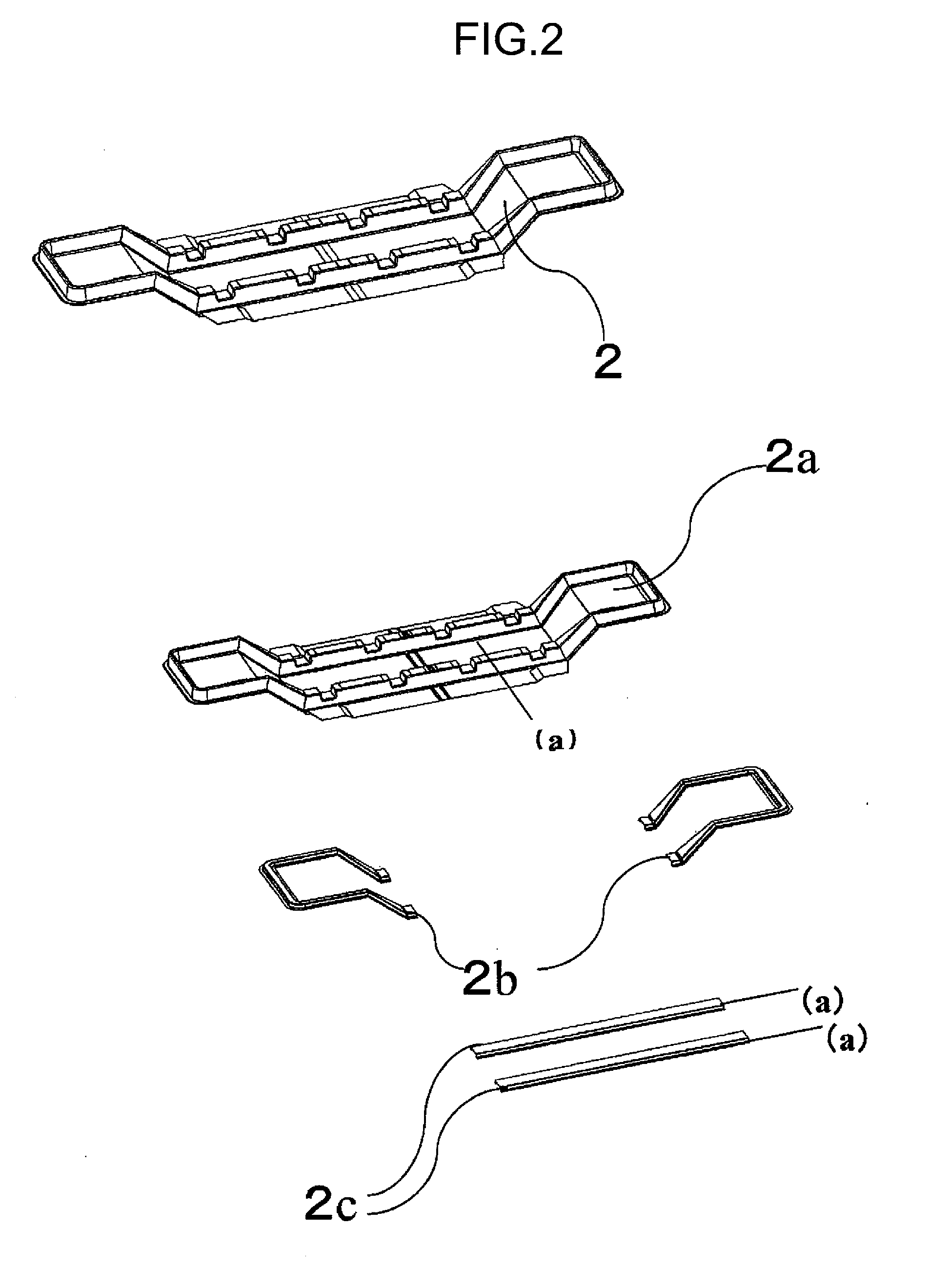

Vehicle Skeleton Member

ActiveUS20130313862A1High strengthSubstantial weight savingVehicle seatsSuperstructure subunitsFibrous compositesMechanical engineering

There is provided a vehicle skeleton member including a composite material of a thermoplastic resin and a carbon fiber, wherein the composite material is a unidirectional carbon-fiber composite material (A) that a form of the carbon fiber in the composite material is a continuous fiber aligned in one direction and / or a random carbon-fiber composite material (B) that a form of the carbon fiber in the composite material is a discontinuous fiber arranged two-dimensionally randomly.

Owner:TEIJIN LTD

Preparation method for carbon/carbon-copper composite material

InactiveCN101787504AHigh breaking strengthImprove mechanical propertiesHeating/cooling textile fabricsCross-linkCarbon composites

The invention relates to a preparation method for a carbon / carbon-copper composite material, which belongs to the technical field of special carbon fiber composite materials. The preparation method mainly comprises the following preparation processes: preparation of carbon fiber green bodies; preparation of carbon / carbon preforms; and preparation of the carbon / carbon-copper composite material. The preparation processes comprise the following steps: firstly, cross-linking fibers in a pre-oxidized fiber felt of polyacrylonitrile by using needle-punching; secondly, performing carbonization on the needle-punched pre-oxidized fiber felt to form a carbon fiber needle-punched felt; thirdly, depositing pyrolytic carbon on the surfaces of the carbon fibers by using a chemical vapor infiltration (CVI) process, or densifying the carbon fibers by using a process combining the CVI process and resin impregnation, wherein the carbon fibers are adhered together through the pyrolytic carbon or the pyrolytic carbon and resin carbon to form a porous carbon / carbon composite material preform; and fourthly, performing high-temperature treatment on the porous carbon / carbon composite material preform, and impregnating the solution of copper into the carbon / carbon composite material preform by using a gas pressure infiltration method to obtain the carbon / carbon-copper composite material finally.

Owner:SHANGHAI UNIV

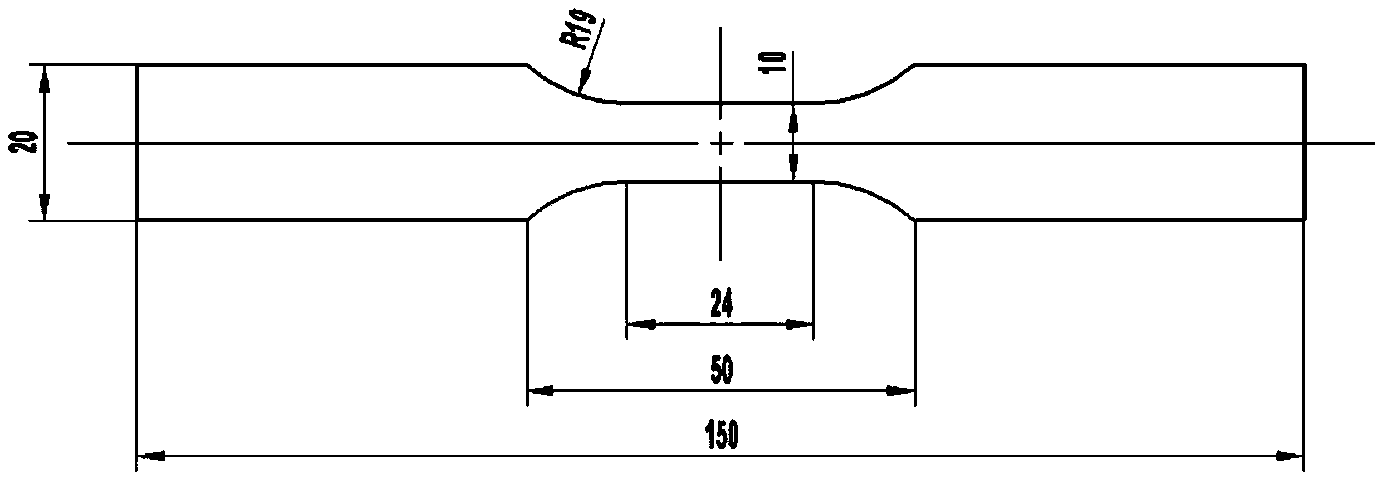

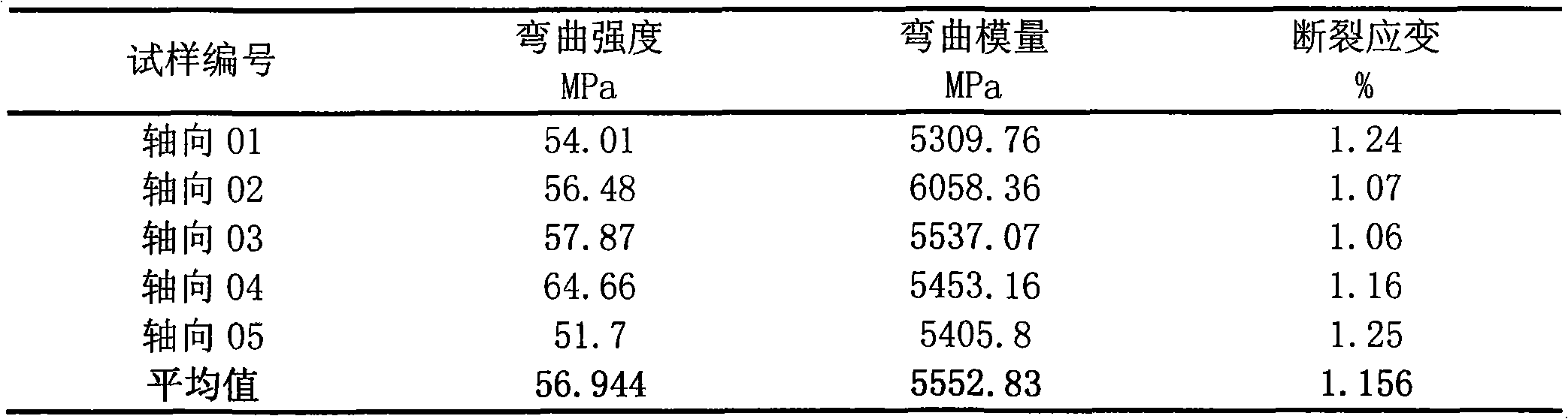

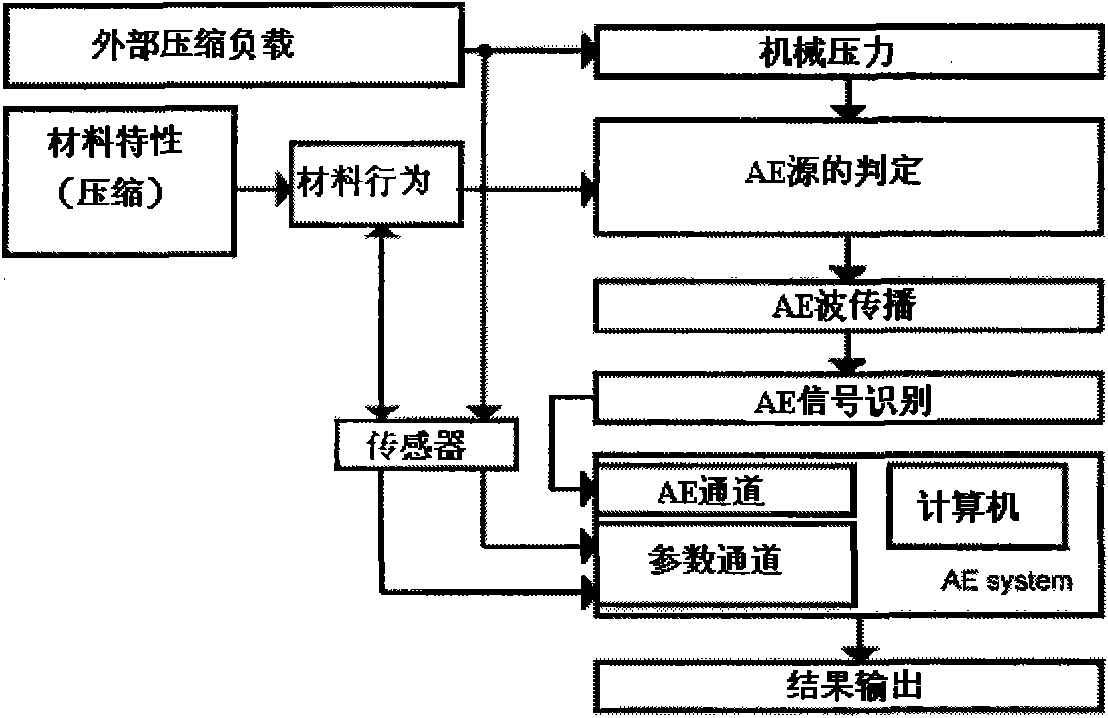

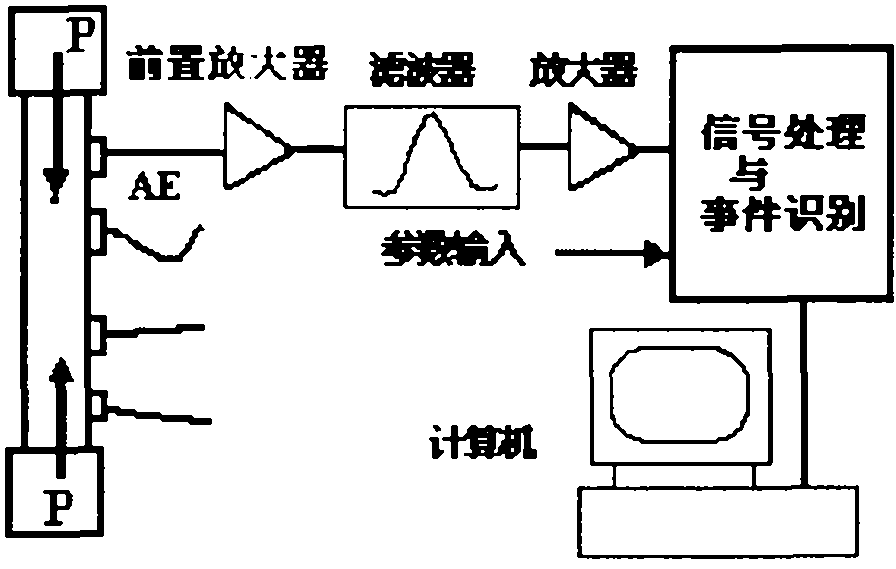

Nondestructive testing system and testing analysis method for three-dimensional braided composite material

InactiveCN102109498ARealize the whole dynamic monitoringShow damage characteristicsMaterial analysis using acoustic emission techniquesFrequency spectrumAcoustic emission

The invention provides an acoustic-emission-technology-based nondestructive testing system and an acoustic-emission-technology-based nondestructive testing method for a three-dimensional braided composite material. In the method, an acoustic emission signal generated by the composite material under external loading is received by an acoustic emission sensor and then is digitized, and the damaged condition of the material is further analyzed. By the method, a unilateral stretching experiment of the carbon fiber three-dimensional braided composite material is dynamically monitored all the way by the acoustic emission technology; and the method proves that the number of the acoustic emission events has good correlation with damage evolution of the carbon fiber composite material; through the spectrum analysis of the carbon fiber three-dimensional braided composite material, the final damage to the material is caused by fibrous fracture and damage frequencies show the damage characteristics of the material; different types of damage modes are well described through the spectrum analysis, and frequency ranges of all peak values can be detailed further, so that more detailed explanation for damage types and mechanisms can be given; and the fracture modes of the material can be analyzed by using acoustic emission characteristic parameters.

Owner:TIANJIN POLYTECHNIC UNIV

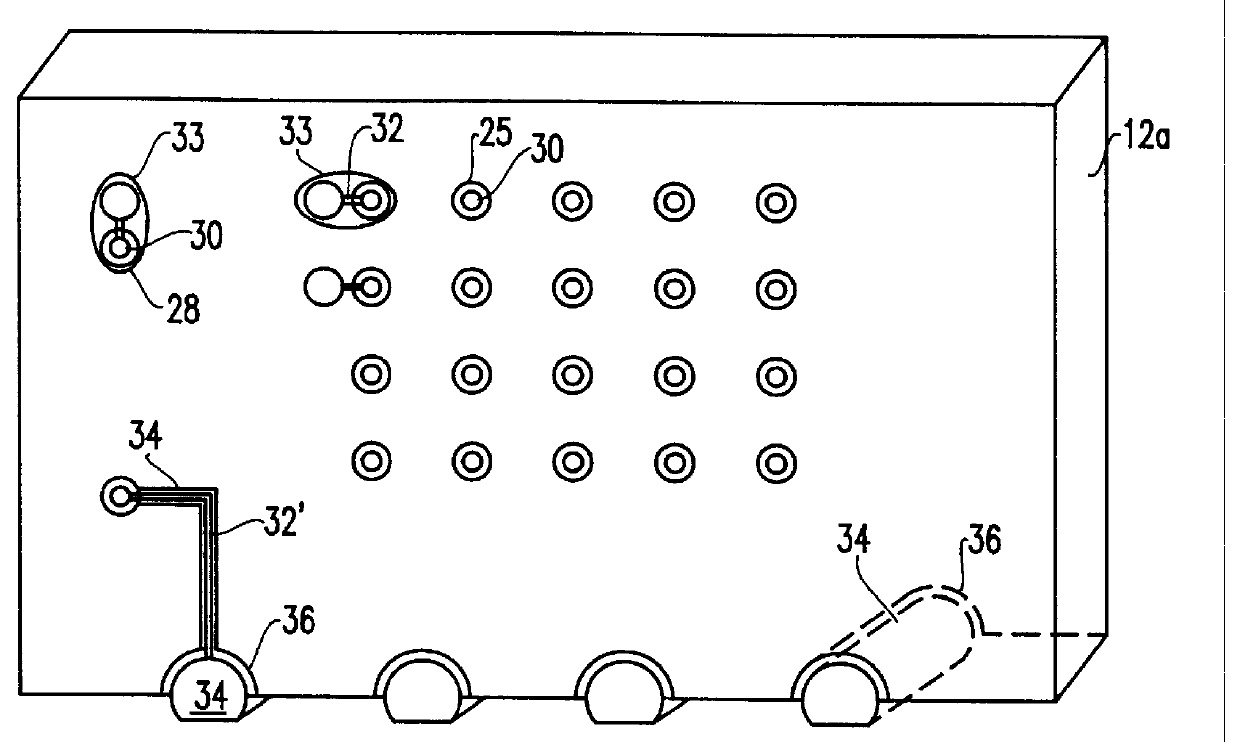

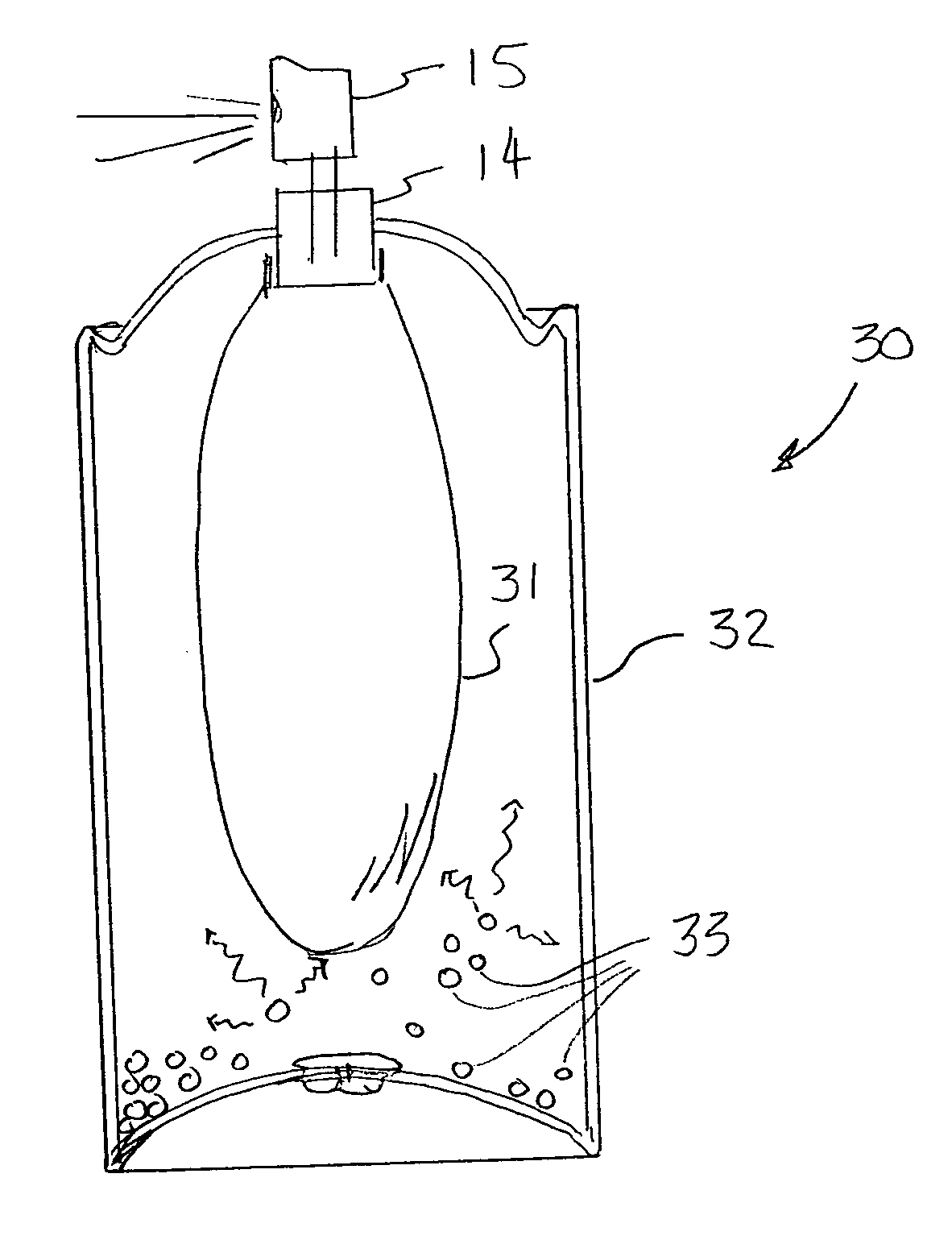

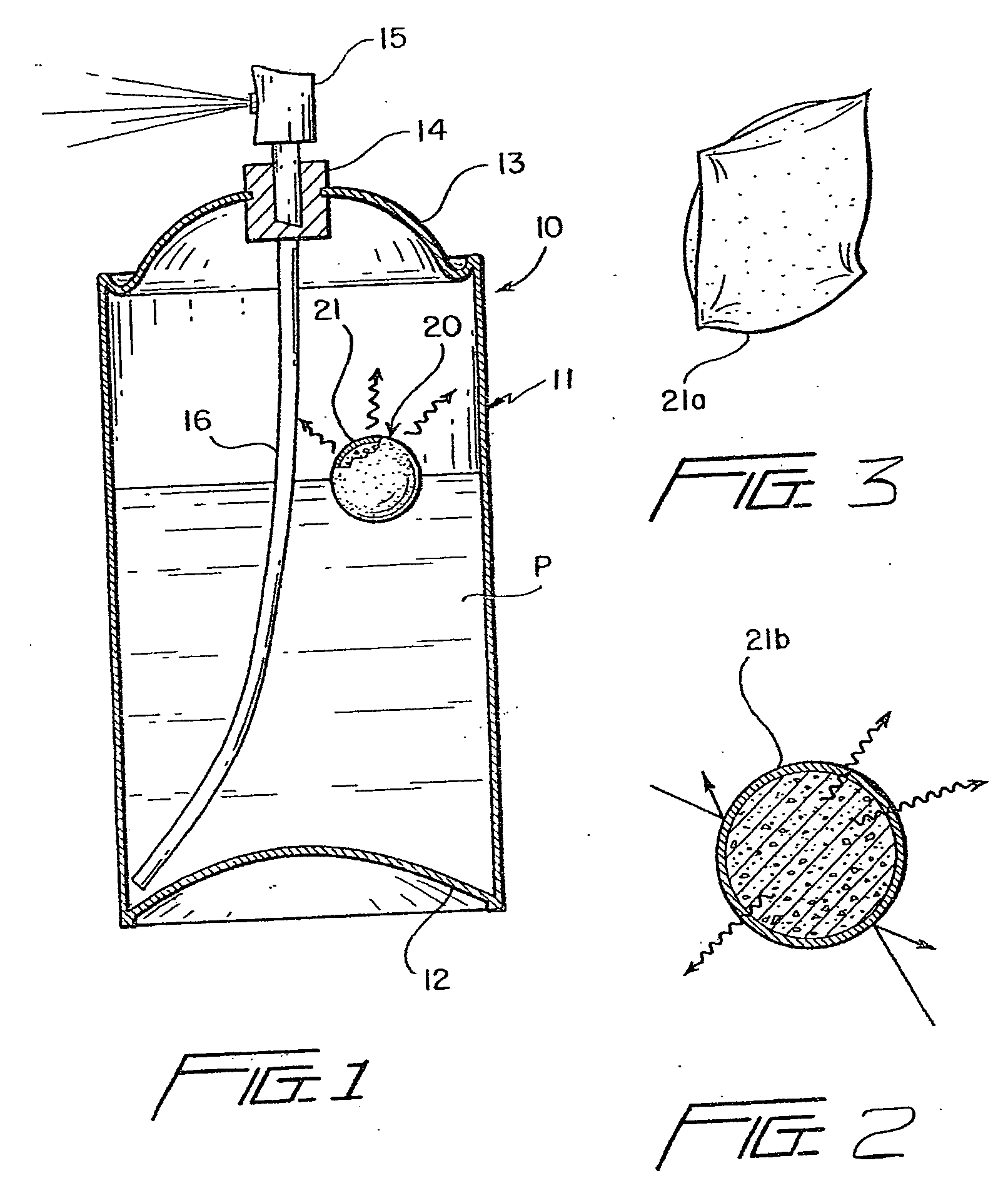

Gas storage and delivery system for pressurized containers

InactiveUS20050274737A1Consistent and uniform and acceptable spray patternFine foamOpening closed containersBottle/container closureSodium bicarbonateDesorption

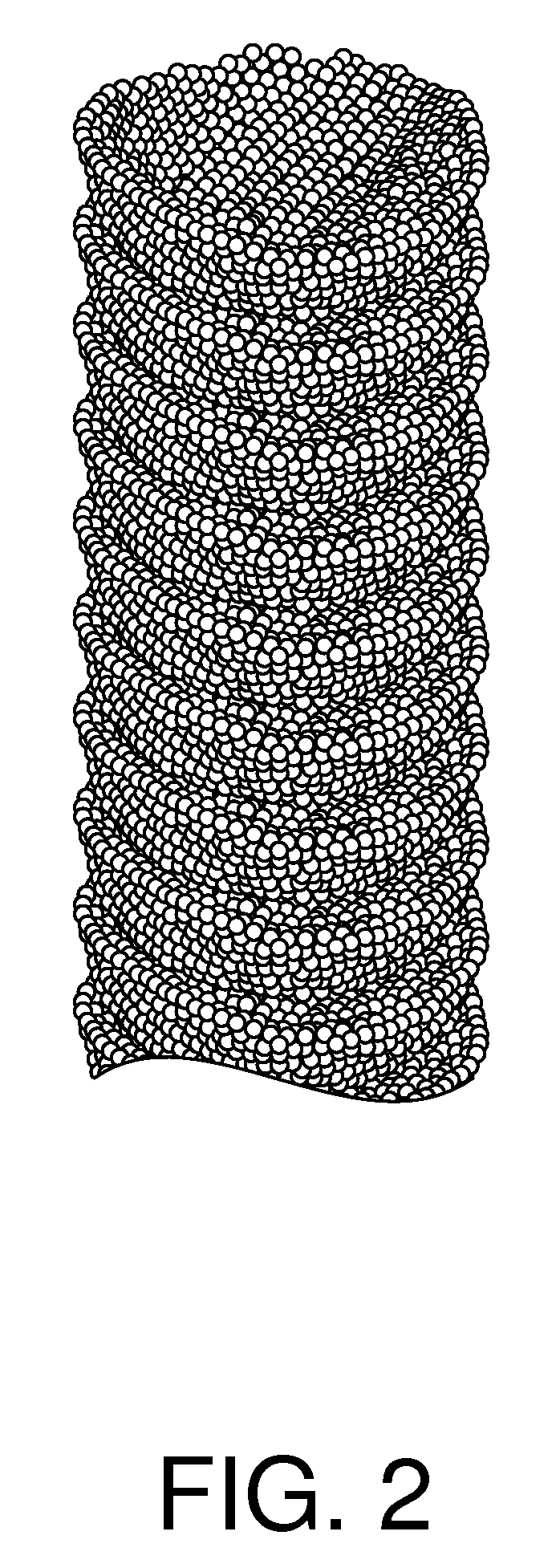

A gas adsorption material containing a desired quantity of gas is placed in a pressurized container along with a product to be dispensed, and as pressure in the container is depleted during use, stored gas is released into the container to maintain pressure in the container within a predetermined range. The material may be in contact with the product, or it may be isolated from the product, and is known as a pressure swing adsorption (PSA) system, wherein adsorption of gas into the material occurs at a high pressure, and desorption of gas from the material occurs at a low pressure. Such devices are capable of storing under pressure a volume of gas 18 to 20 times the volume of the material. A preferred adsorbent gas storage material is granular activated carbon, or a carbon fiber composite molecular sieve (CFCMS). Other materials, such as zeolite, starch-based polymers, activated alumina, silica gel, and sodium bicarbonate, or mixtures thereof, may be used, although they generally are not as effective as activated carbon. The adsorbent material may be in granular, powdered, or pellet form, or a mass of the material may be formed into variously shaped cohesive bodies, such as balls, tubes, cubes or rods, or sheets or screens which may be flat or curved or folded into various shapes, such as, for example, an accordion-like fold.

Owner:LIM WALTER K

Method for recovering carbon fiber by cracking waste carbon fiber composite material

The invention relates to a method for recovering carbon fiber by cracking a waste carbon fiber composite material, which comprises the following steps: (1) putting a waste carbon fiber composite material into the furnace cavity of a cracking device, fastening the furnace door, and introducing nitrogen gas for several minutes until air in the furnace cavity is completely discharged to form an oxygen-free inert environment; (2) heating the material in the furnace cavity to 350-900 DEG C, keeping for 0.5-5.0 hours, and blowing out the furnace to naturally cool the material in the furnace cavity, wherein the resin is subjected to thermal cracking reaction in the furnace cavity; and (3) opening the cooled furnace cavity, and taking out the product. Compared with the prior art, the carbon fiber obtained by the invention is beneficial to subsequent cutoff or pulverizing processing, and can be easily dispersed into single fiber after processing. According to the invention, the obtained carbon fiber is high in recovery rate and low in performance reduction degree; and the operating process is simple and suitable for industrial production.

Owner:南通复源新材料科技有限公司

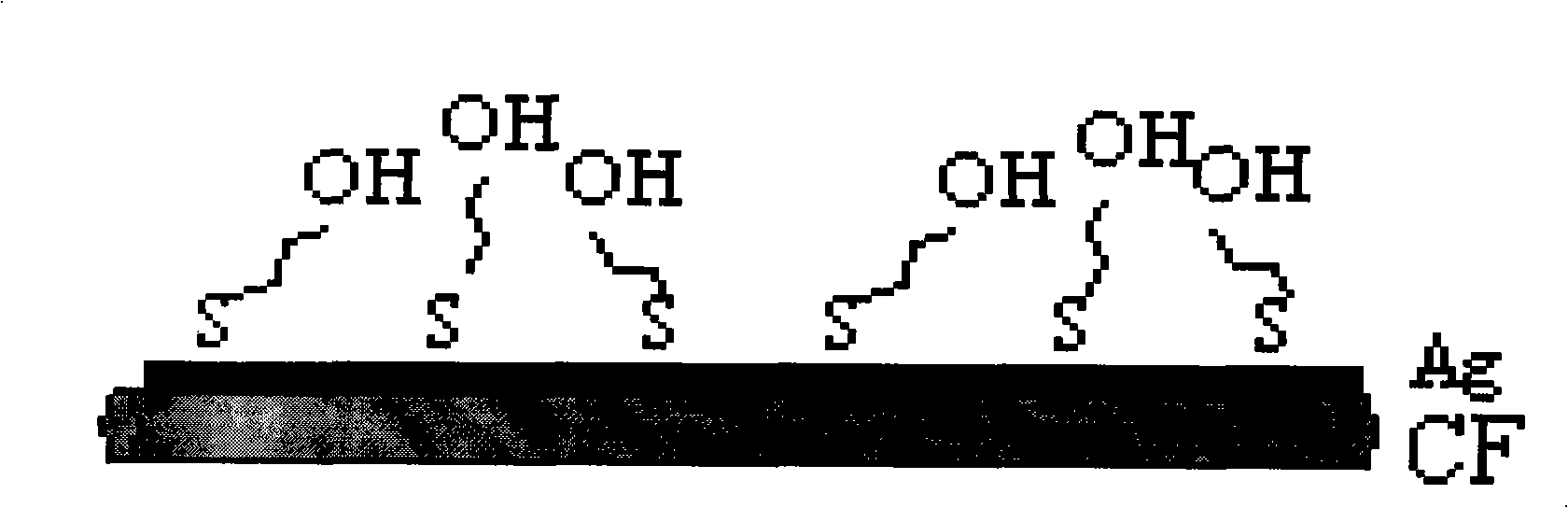

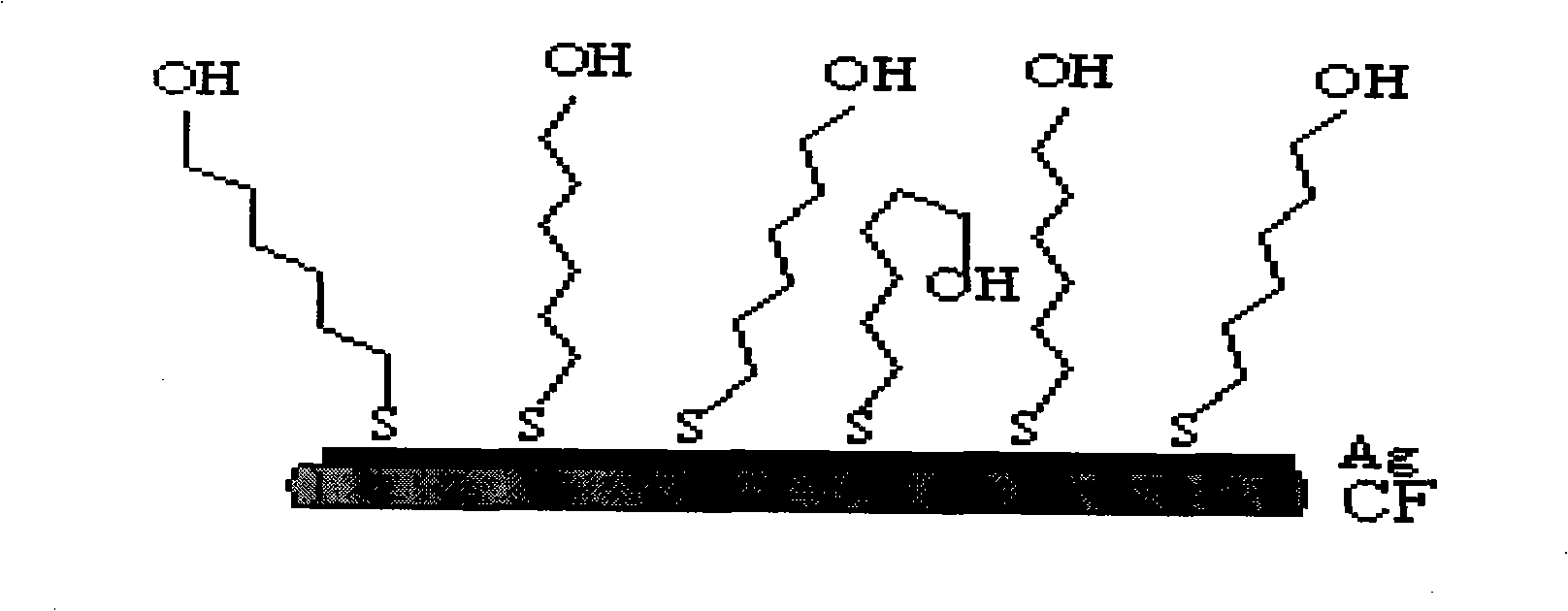

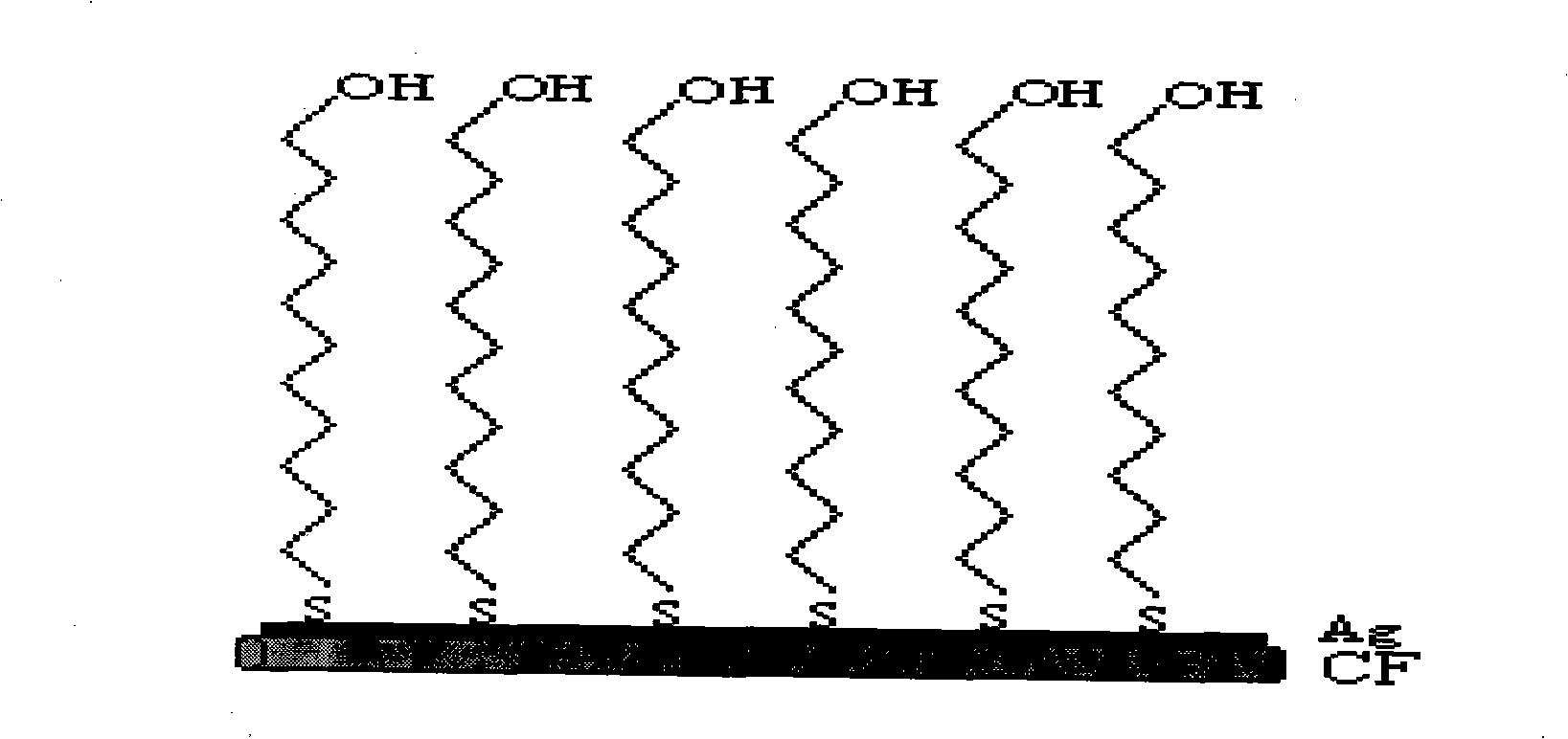

Carbon fiber surface modification method

The invention discloses a carbon fiber surface modification method, and relates to a carbon fiber modification method. The invention solves the problem of the uncontrollability of the distribution and arrangement of a carbon fiber surface functional group, which is not propitious to the study of the mechanism of a carbon fiber interface. The carbon fiber is plated with silver after surface pre-processing, then the carbon fiber with the silver-plated surface is infused in the dilute solution of thiol molecule containing sulfur element; depending on the coactions of the bonding reaction of sulfur atoms and metb and the force among self-assembly molecules, the thiol molecule has chemical absorption on the fiber surface and forms a closely arranged and ordered two-dimensional self-assembly single molecule membrane; two procedures are as follows: 1. the chemical plating of silver on the carbon fiber surface; and 2. the self assembly of molecules of organic sulfide on the silver-plating carbon fiber. The carbon fiber surface modification method has the advantages of realizing controllable, directional and ordered arrangement on the carbon fiber surface functional group from the molecule level, thus being beneficial to the study of the mechanism of the carbon fiber composite material interface.

Owner:HARBIN INST OF TECH

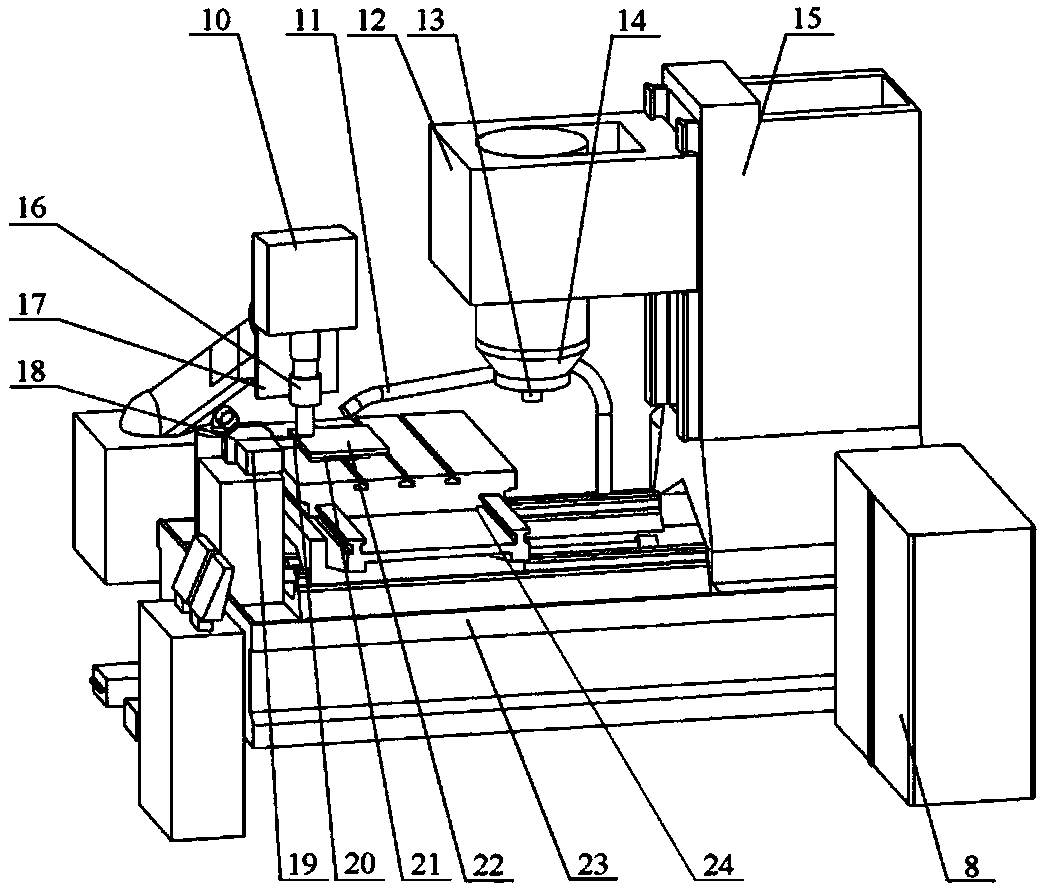

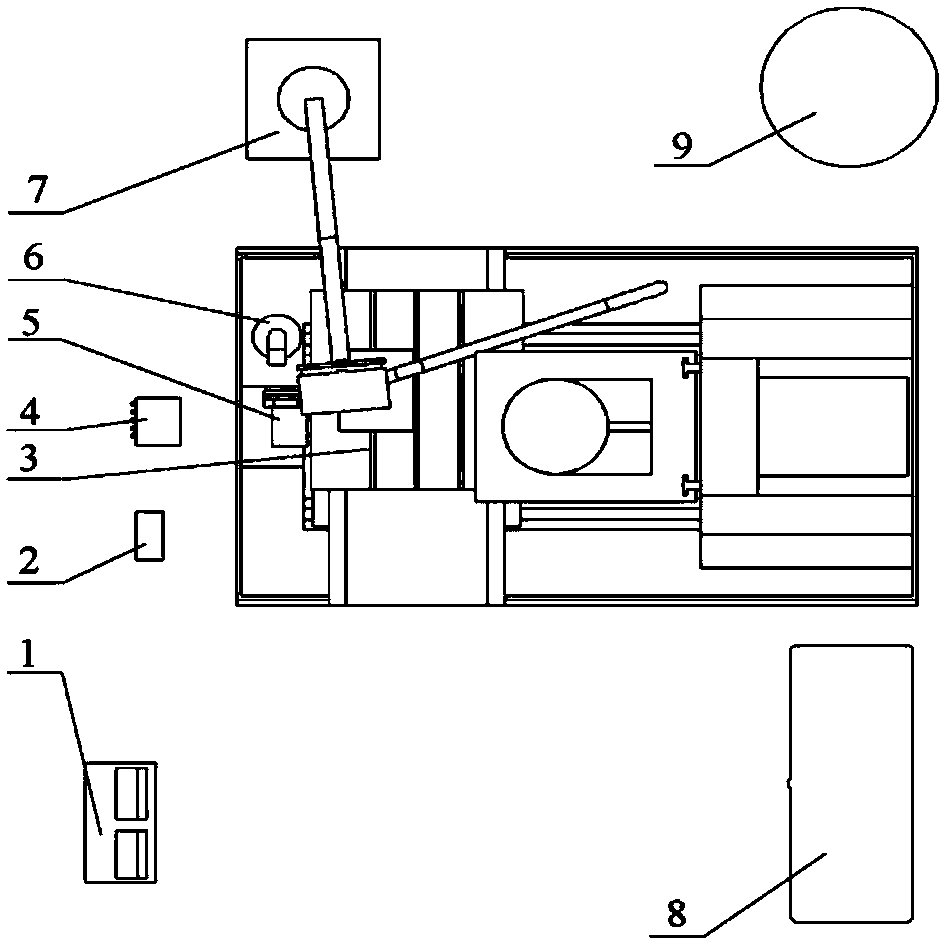

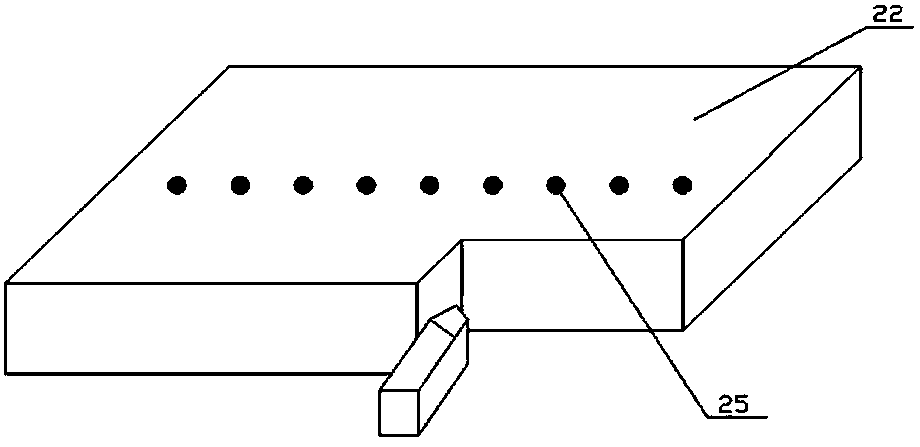

Experimental device for cutting off carbon fiber composite material

InactiveCN103837422ASave spaceThe cutting experiment is orderly and accurateInvestigating machinabilityTemperature controlMaterial removal

The invention provides an experimental device for cutting off a carbon fiber composite material, and belongs to the field of research on hardly machined material cutting devices. The experimental device is provided with experiment functional devices by taking a cutting device as a basic structure, wherein the experiment functional devices comprise a work piece quick assembling-clamping and temperature control device, a high-speed micro-examination device, a temperature and cutting force online measuring device and a dust remover. In the high-speed micro-examination device, a lens is connected with a high-speed camera, the high-speed camera is arranged on a single-axis precision displacement platform pedestal which is arranged on a camera support, a light source is aligned to a cutting area and the high-speed camera is connected with a computer system. The experimental device for cutting off the carbon fiber composite material, which is disclosed by the invention, can effectively realize the observation on a cutting process, precisely measures the temperature and the cutting force in real time, controls the temperatures of a sample and a cutter, and studies on material breakage forms, material removal mechanisms and cutter abrasion mechanisms under different cutting conditions, so as to provide experimental support for the explanation of the carbon fiber composite material cutting basic theory.

Owner:DALIAN UNIV OF TECH

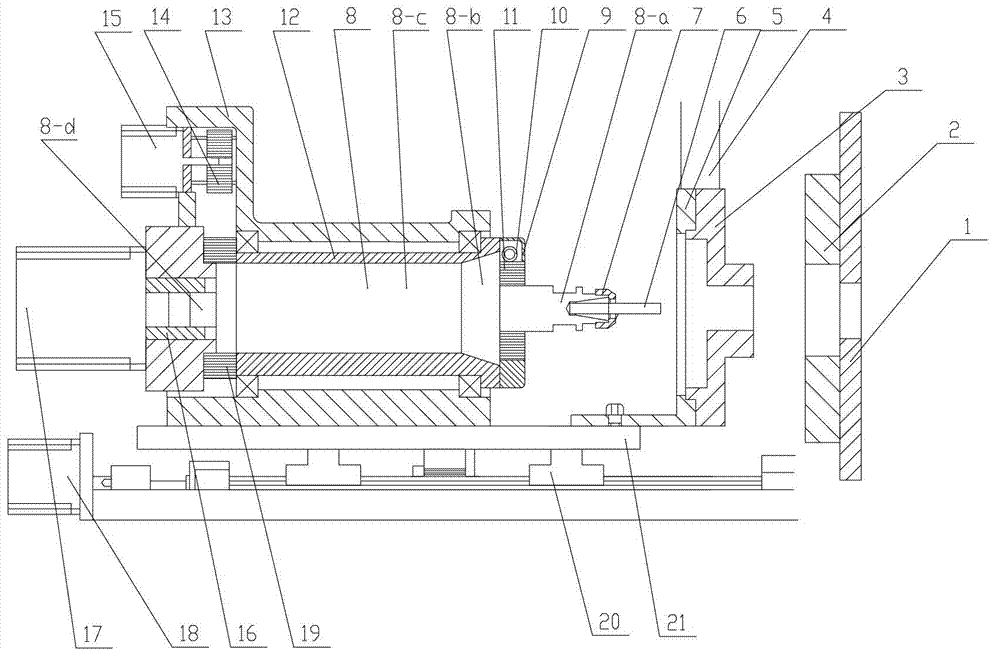

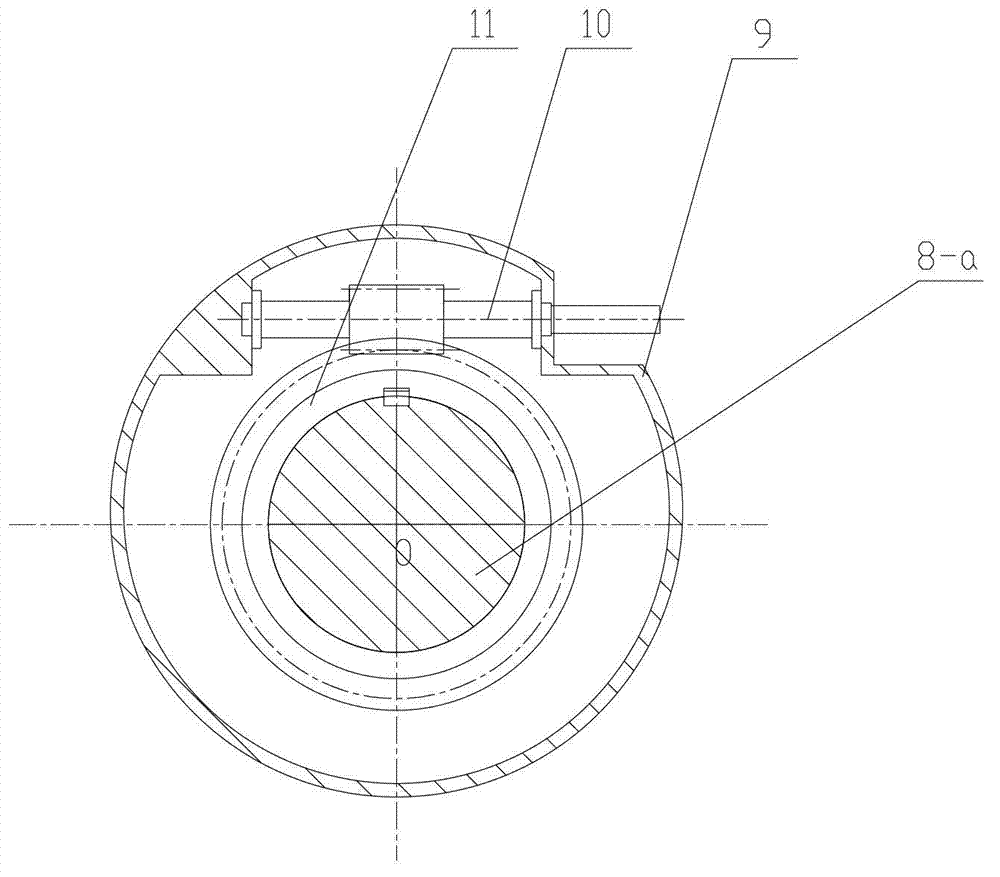

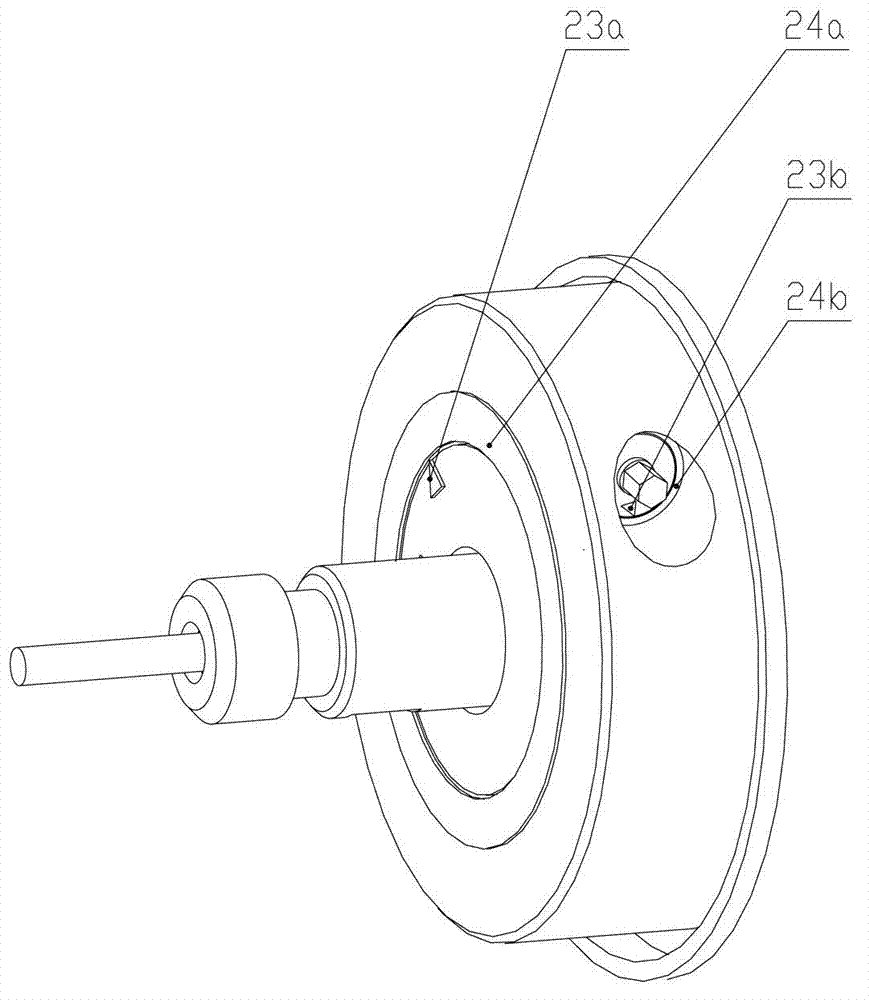

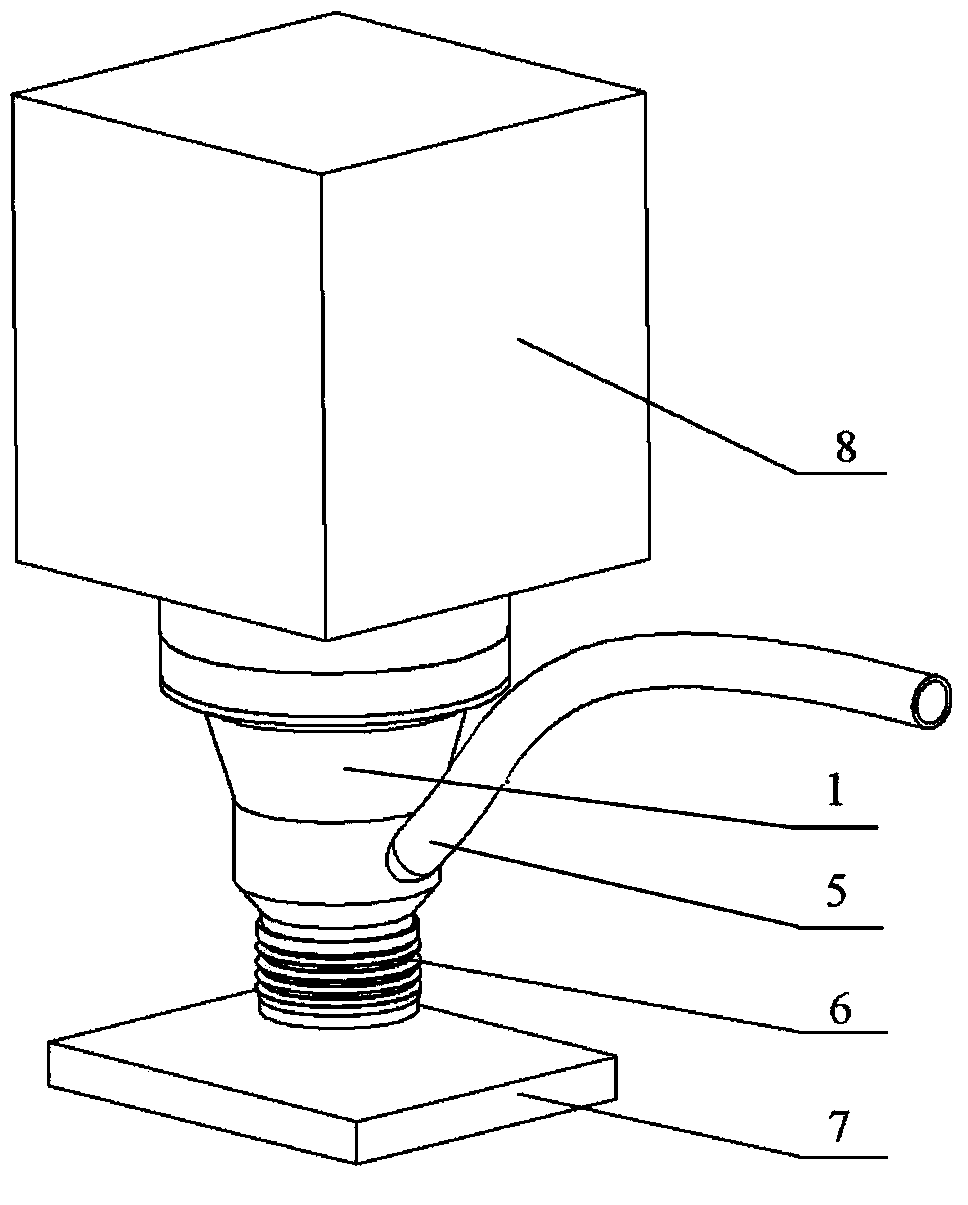

Portable spiral hole milling device and machining method

ActiveCN103192125AAccurate adjustmentImprove processing qualityAutomatic control devicesFeeding apparatusFiberTitanium alloy

The invention provides a portable spiral hole milling device and a machining method, which belong to the technical field of spiral hole milling machining, and are applied to new materials such as carbon fiber composites, aluminum alloy, titanium alloy and other hard machined materials. The portable device consists of a cutter self-rotation mechanism, a revolution mechanism, a radial shifting mechanism, an axial feeding mechanism and a machining locating mechanism, wherein a main shaft of the cutter self-rotation mechanism is a mechanical main shaft and is provided with four shaft necks in different shapes, and the center O1 of the axial line of a right-end shaft neck of the main shaft deviates from the center O of the axial line of a main body shaft neck of the main shaft. The portable device is located by a driller template and a fixed bushing in a combination manner; when machining positions are changed, the process is simple and the location is precise; and meanwhile, the portable device has enough stability and rigidity during machining. According to the portable device disclosed by the invention, the end surfaces of a worm wheel and a worm rod for regulating eccentricity are respectively provided with an index plate and an indicator for indicating the eccentricity, so that the regulation of the eccentricity is more accurate and visual.

Owner:DALIAN UNIV OF TECH

Method for surface modification on carbon fibers

The invention belongs to the technical field of surface modification and relates to a method for surface modification on carbon fibers. The method is characterized in that a material containing a catechol structure is used as a surface modifier and the surface modifier is coated on surfaces of carbon fibers so that carbon fiber surface characteristics are improved. After surface modification on carbon fibers by the material containing the catechol structure, the carbon fibers can be further subjected to surface modification by other chemical materials according to demands. The method can be operated simply and conveniently, has obvious effects and realizes effective modification on a specific matrix by simple operation. Through simple operation, the carbon fibers can be subjected to hydrophilic modification and the surfaces of the carbon fibers have lipophilicity. Through use of a group or a substance having special a function, the carbon fibers have special functions of bacterium resistance and luminescence. The method has wide application prospects in the field of carbon-fiber composite materials and other functional materials.

Owner:FUDAN UNIV

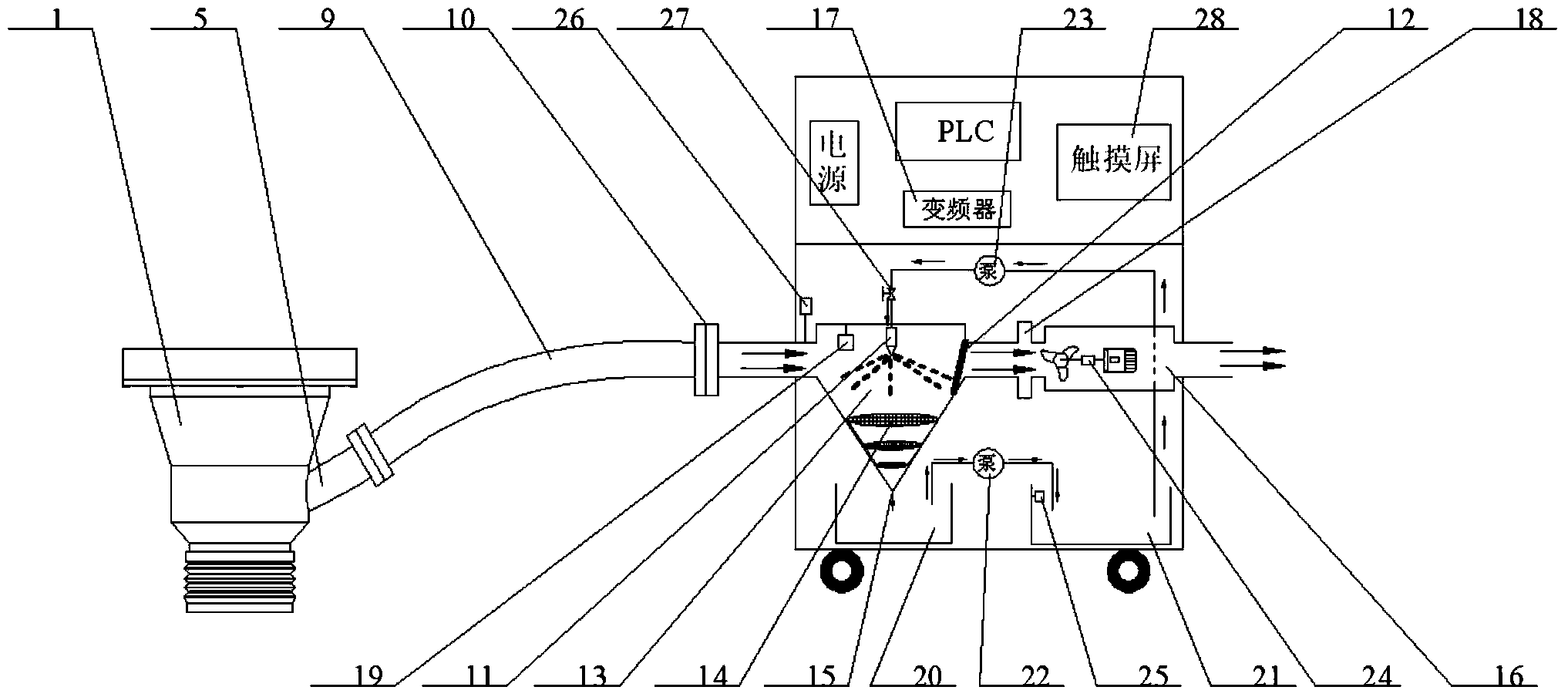

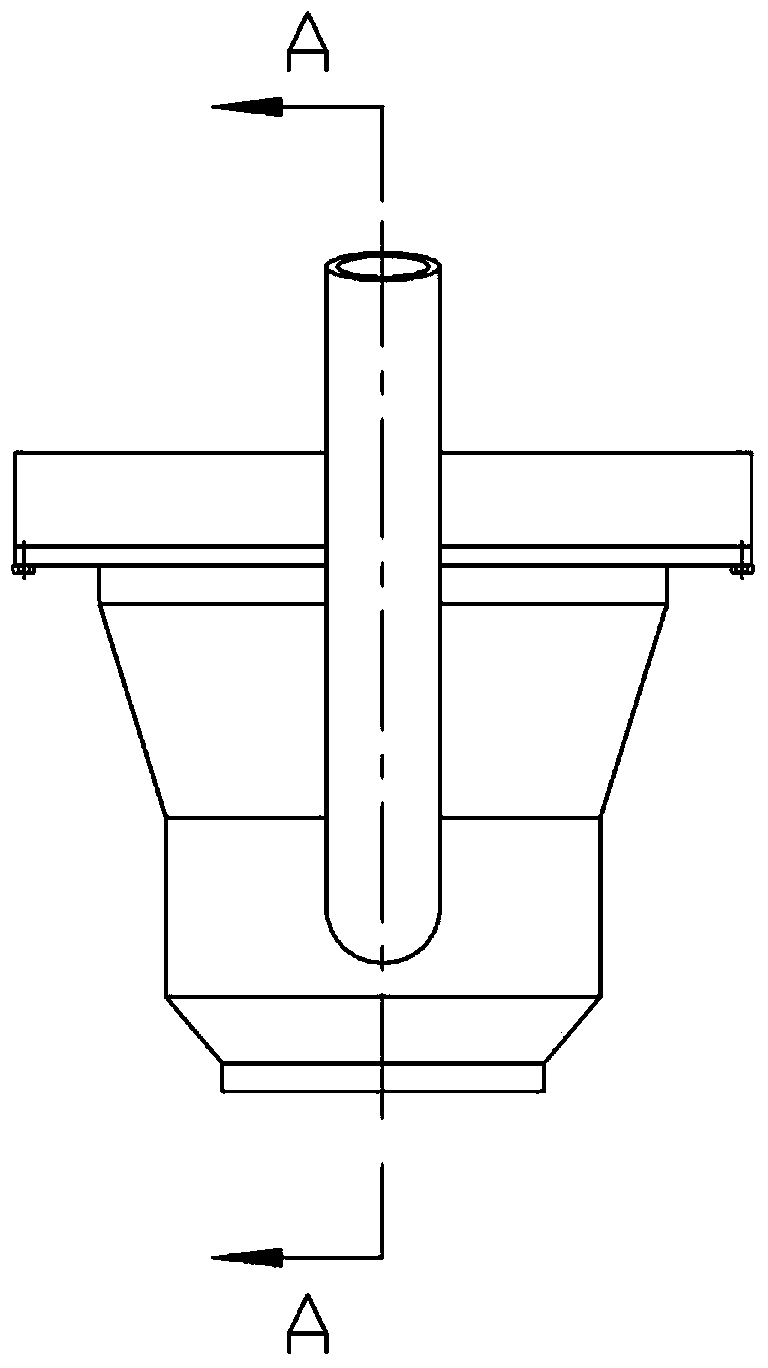

Drilling and milling carbon fiber composite material follow-up dust collection device

ActiveCN103769403AGuaranteed to stickAvoid pollutionUsing liquid separation agentDirt cleaningFiltrationProgrammable logic controller

The invention relates to a drilling and milling carbon fiber composite material follow-up dust collection device, belongs to the technical field of energy saving and environmental protection during the processing process of carbon fiber composite materials, and relates to a carbon fiber composite material dust removal and collection device. The device comprises a swarf collecting assembly, a wet process dust-settling device, a power part and a water filtration circulating device. A swarf collecting cover in the swarf collecting assembly is arranged on a machine tool spindle box, and an annular electromagnet sucking disc is positioned in an annular groove at the top of the swarf collecting cover; the device is fixed with bolts through a pressing plate; a power cord of the annular electromagnet sucking disc is connected with an I / O (Input / Output) module of a PLC (Programmable Logic Controller) through a contactor. The drilling and milling carbon fiber composite material follow-up dust collection device can sufficiently collect a great deal of dust during the drilling and milling process of carbon fiber composite material, the swarf collecting cover can synchronously feed along with a spindle tool, and pulls away and collects swarf and dust generated during the processing process in time, so that the swarf and the dust are prevented from floating anywhere to cause environmental pollution and damage to machine tool equipment.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com