Patents

Literature

733results about How to "No bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resisting heat-insulation coating as well as preparation method and application thereof

ActiveCN103725074AEasy to use in constructionPlay the role of saving energy and reducing consumptionReflecting/signal paintsPetroleumEnergy consumption

The invention relates to the field of functional coatings and particularly relates to a high-temperature-resisting heat-insulation coating and a preparation method thereof. The high-temperature-resisting heat-insulation coating is composed of the following raw materials in percentage by mass: 10%-40% of high-reflection paint with a shell-core structure, 10%-40% of heat-insulation powder with the shell-core structure, 1%-5% of a toughening agent, 10%-50% of a high-temperature bonding agent, 1%-10% of a coating auxiliary agent, and the balance of water. The preparation method comprises the following steps: mixing, dispersing and grinding raw materials; carrying out homogenization to enable an average grain diameter to be 325-400 meshes; and filtering and packaging to obtain a finished product. The high-temperature-resisting heat-insulation coating can be applied to high-temperature fields of industrial furnaces, industrial boilers, high-temperature steam pipelines, petroleum cracking equipment, engine parts, high-temperature smelting, sintering furnaces and the like, and can be used under a higher temperature for long time; the energy consumption can be saved and the service life of the furnaces is prolonged.

Owner:武汉双虎涂料股份有限公司

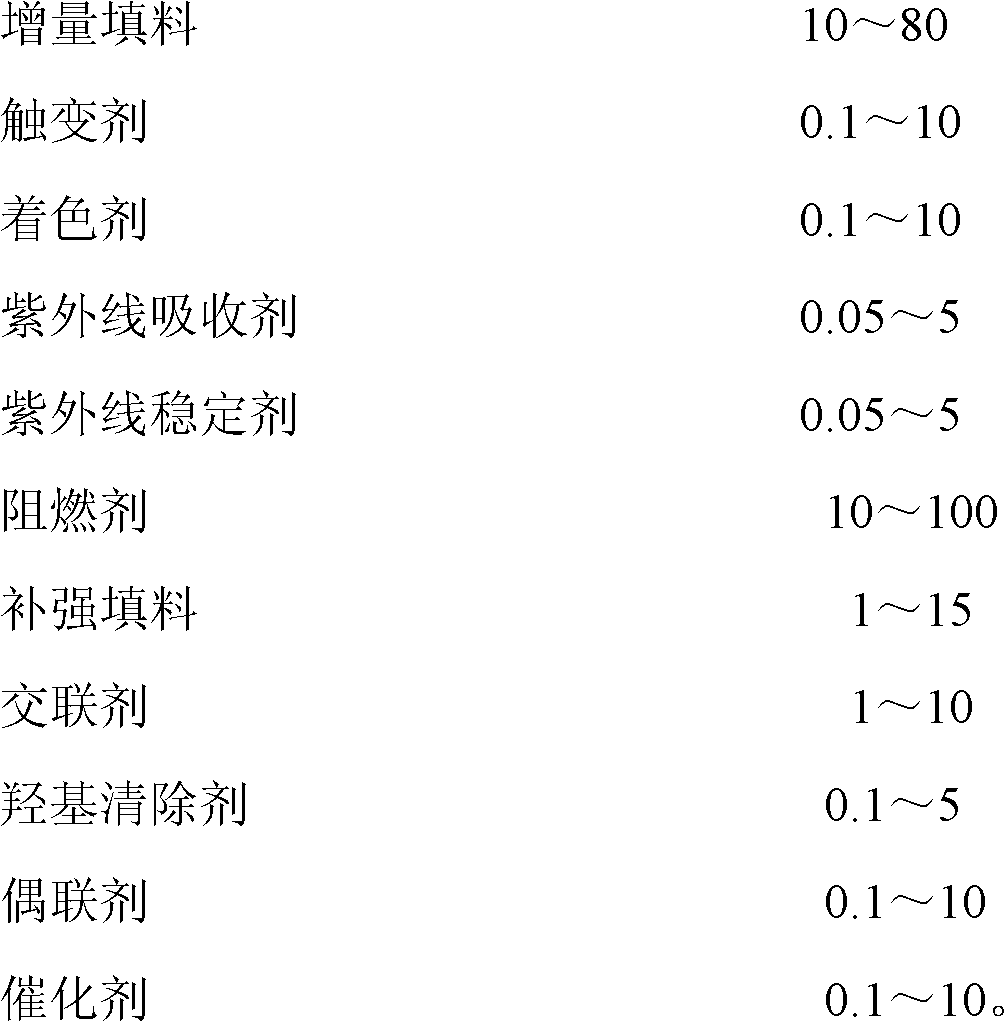

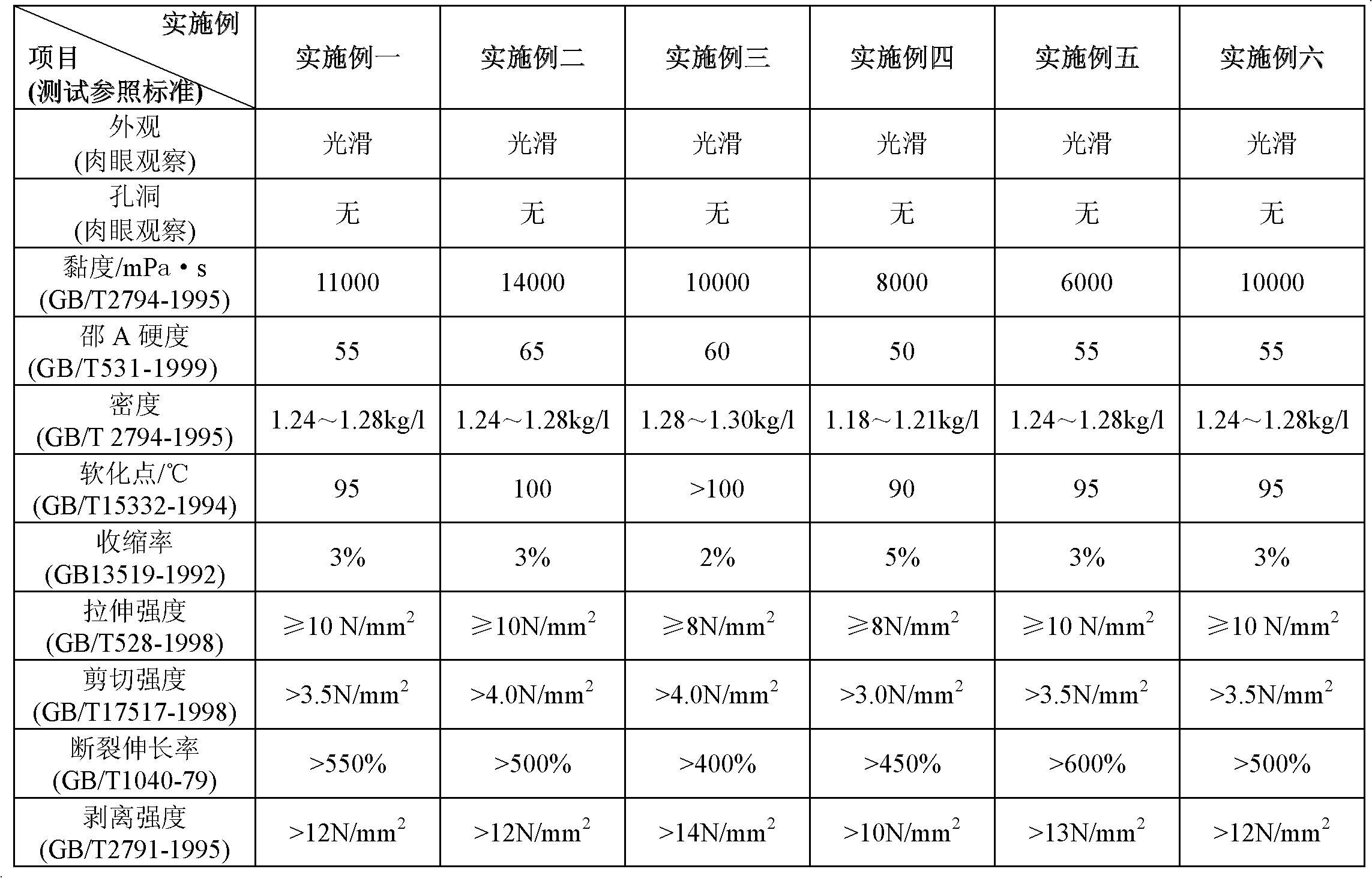

Monocomponent flame-retardant silane modified polyether sealant and preparation method thereof

InactiveCN102660214AImprove flame retardant performanceFast curingNon-macromolecular adhesive additivesPolyether adhesivesPolymer resinWeather resistance

The invention relates to a monocomponent flame-retardant silane modified polyether sealant and a preparation method thereof. The sealant of the invention comprises an MS-polymer resin, a plasticizer, a reinforcement filler, a thixotropic agent, an ultraviolet ray absorbing agent, an ultraviolet ray stabilizing agent, a flame retardant, a crosslinking agent, a hydroxy group scavenger, a coupling agent, an organic tin catalyst and the like. The obtained monocomponent flame-retardant silane modified polyether sealant has the advantages of flame retardation, fast solidification, strong strength, and high weather resistance.

Owner:JIANGSU TIANCHEN NEW MATERIALS

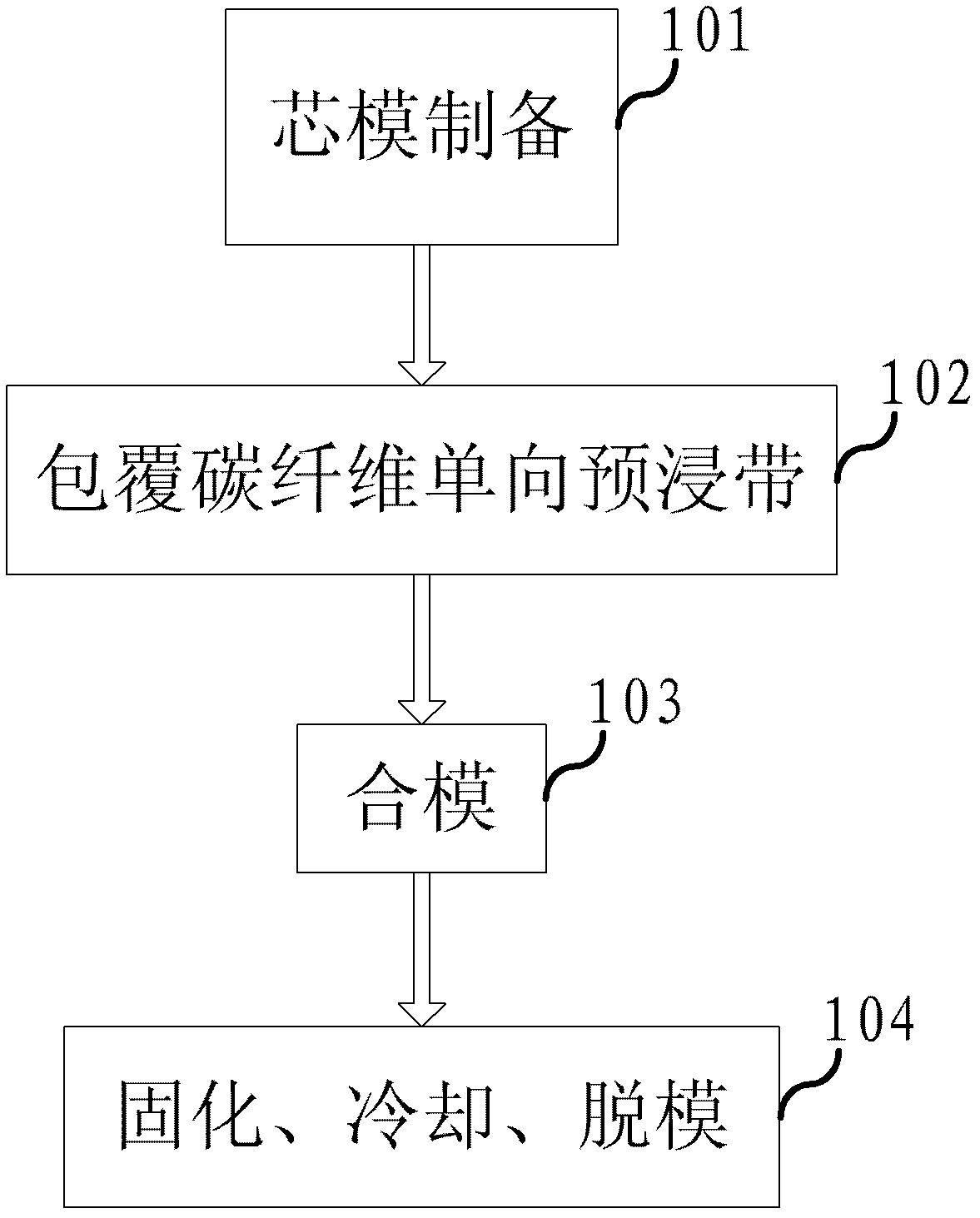

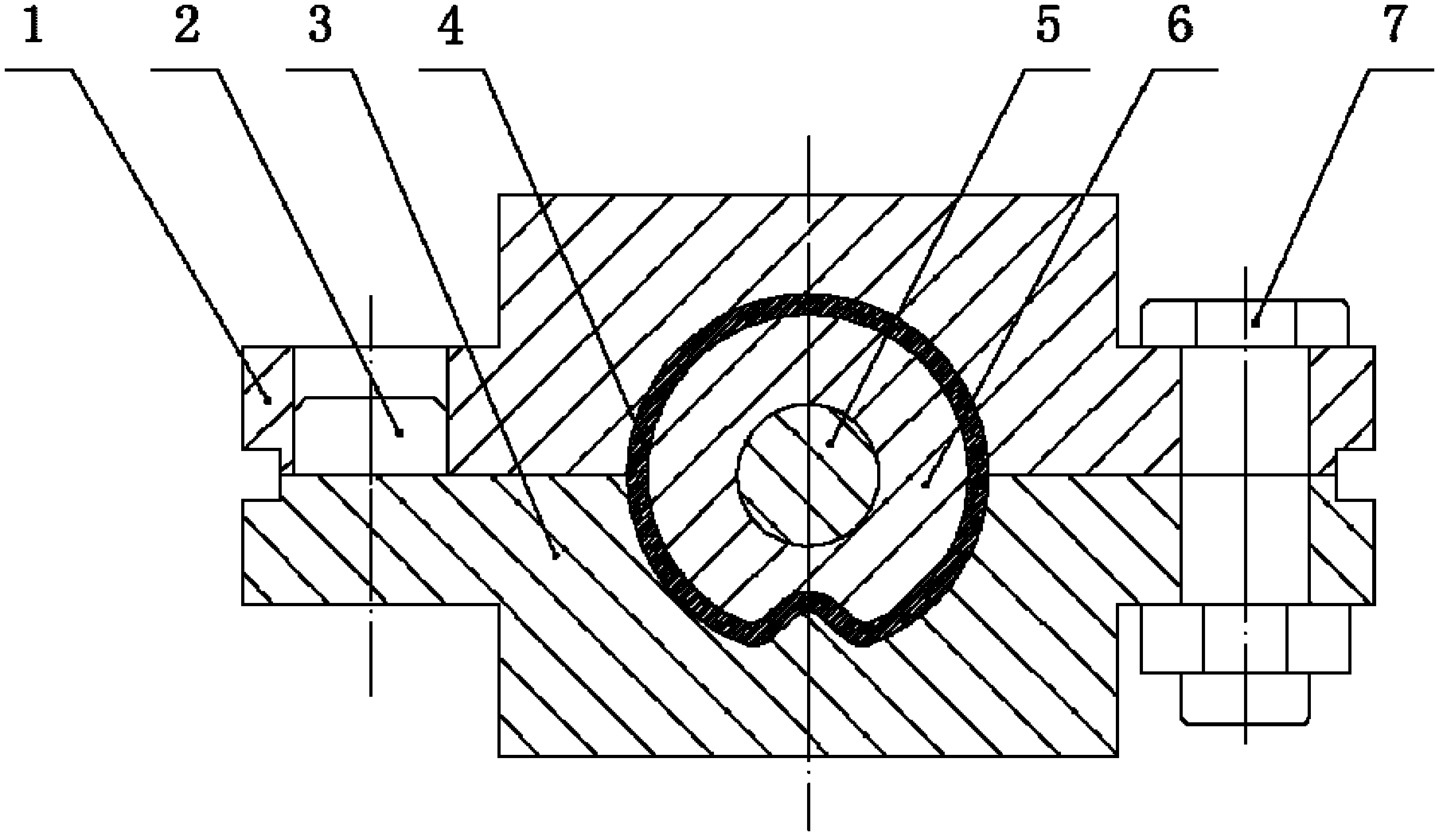

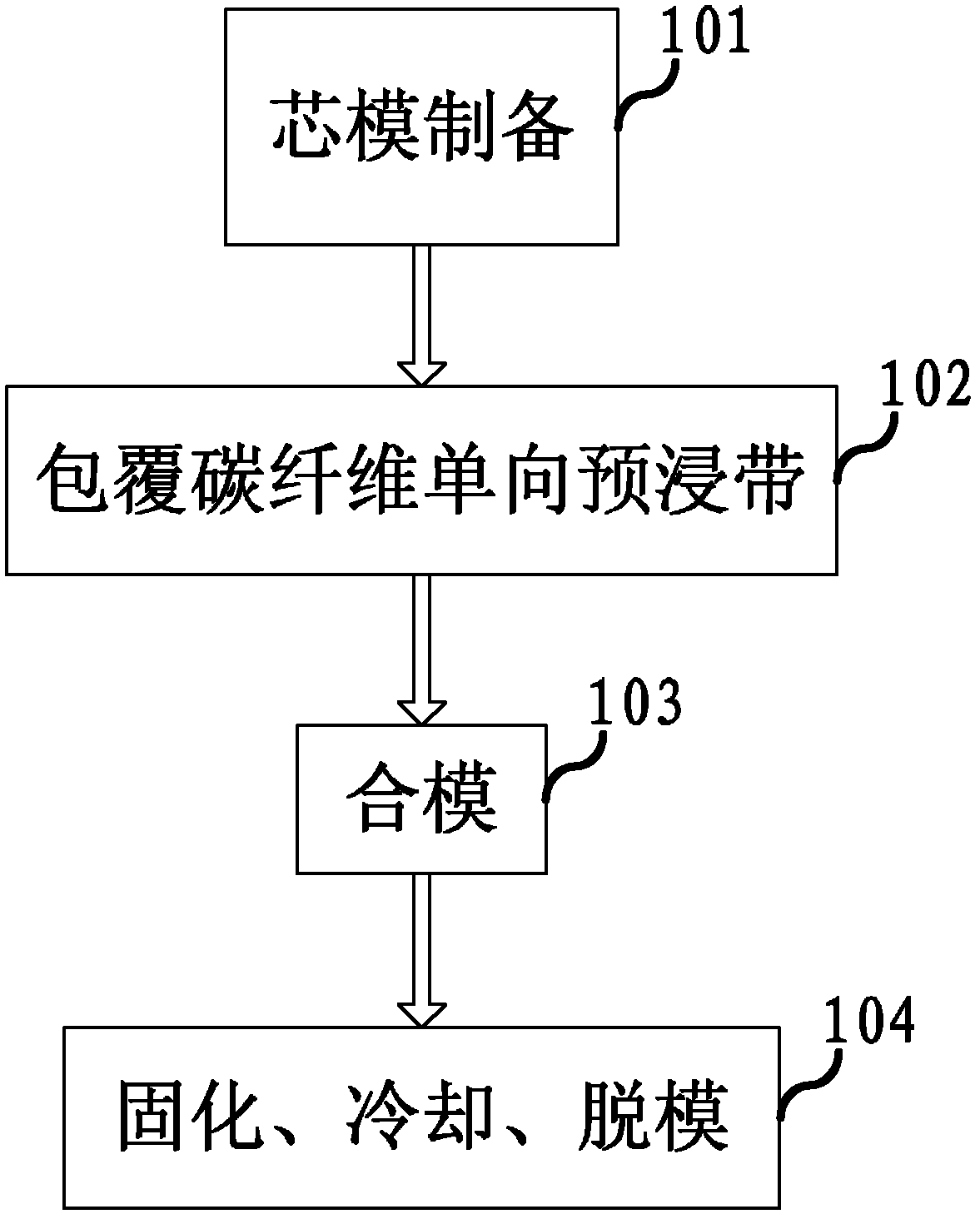

Method for forming carbon fiber pipe and die thereof

The invention discloses the technical field of carbon fiber composite materials, and discloses a method for forming a carbon fiber pipe. The method comprises the following steps of: preparing a core mould, namely preparing the core mould for wrapping carbon fiber one-way preimpregnation belts, wherein the core mould comprises a metal core rod and a rubber material wrapping the metal core rod; paving and coating the carbon fiber one-way preimpregnation belts, namely after coating a release agent on the surface of the core mould, paving and coating a plurality of layers of carbon fiber one-way preimpregnation belts according to different angles; closing the die, namely positioning the core mould in which the carbon fiber one-way preimpregnation belts are paved and coated and putting into a female die, closing the die, and fastening; and curing, cooling and demoulding, namely putting the die which is closed into a drying oven, curing, cooling with a furnace, and demoulding to form the required finished piece. The method for forming the carbon fiber pipe has the advantages of simple process, high production efficiency, low manufacturing cost, uniform wall thickness of the product, high quality and stability and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

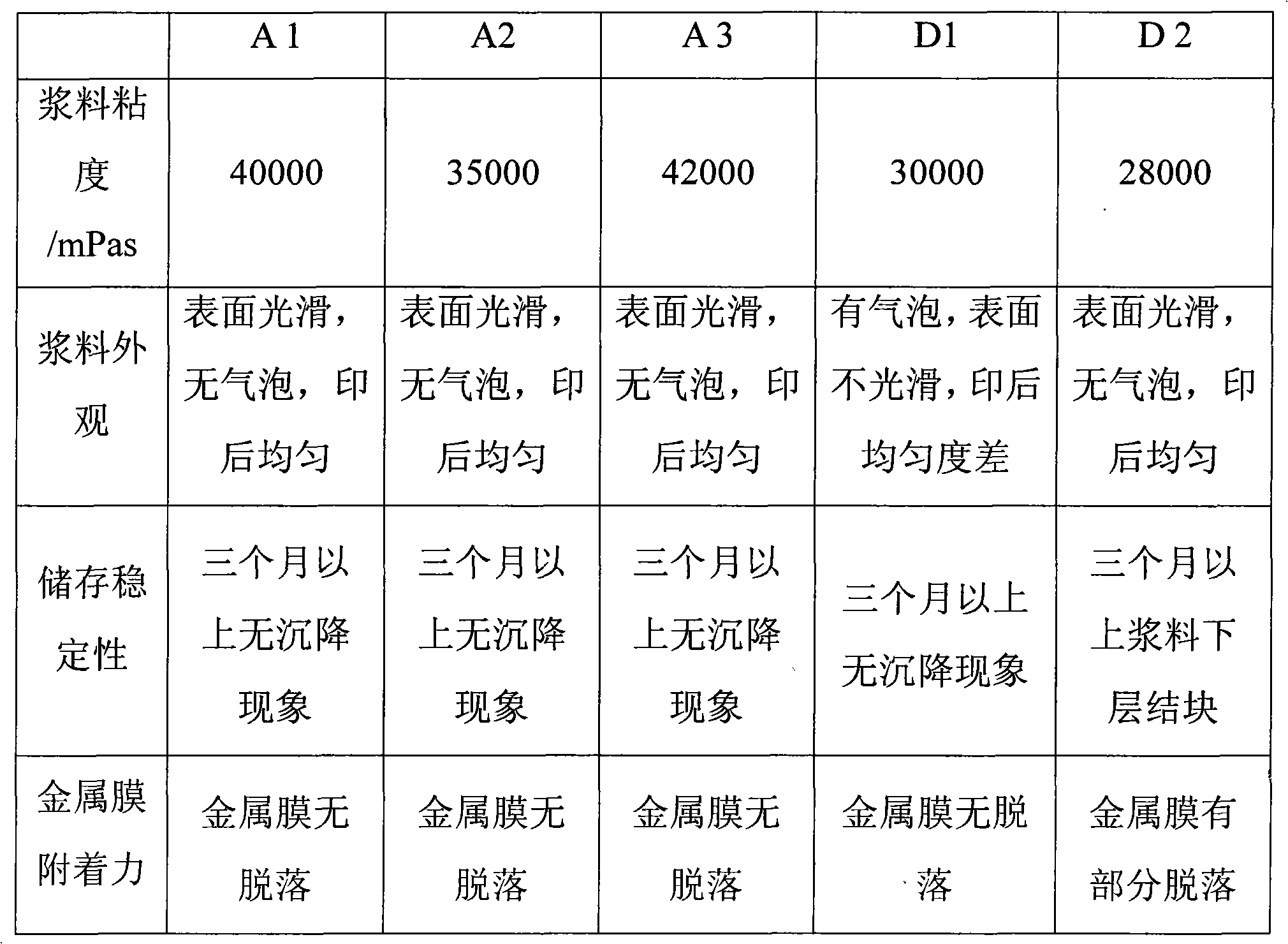

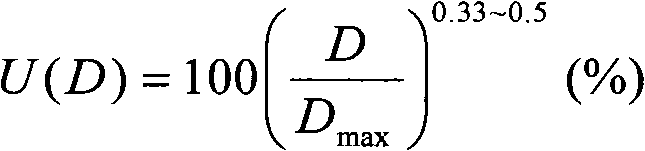

Conductive slurry for solar battery and preparation method

ActiveCN101931014AStrong adhesionReduce bendingFinal product manufactureSemiconductor devicesElectrical batterySlurry

The invention discloses conductive slurry for a solar battery and a preparation method thereof. The conductive slurry comprises conductive metal powder, an inorganic binder, an organic carrier and an additive, wherein the conductive metal powder comprises two kinds of metal powder with different grain sizes, the grain size of the large-grain-size metal powder is 4 to 6 mum and that of the small-grain-size metal powder is 1 to 100nm. The photoelectric conversion efficiency of the solar battery prepared by the conductive slurry provided by the invention is obviously improved; and the conductiveslurry has a homogenous appearance texture, a smooth surface and no air bubbles and generates no precipitates after long-time standing.

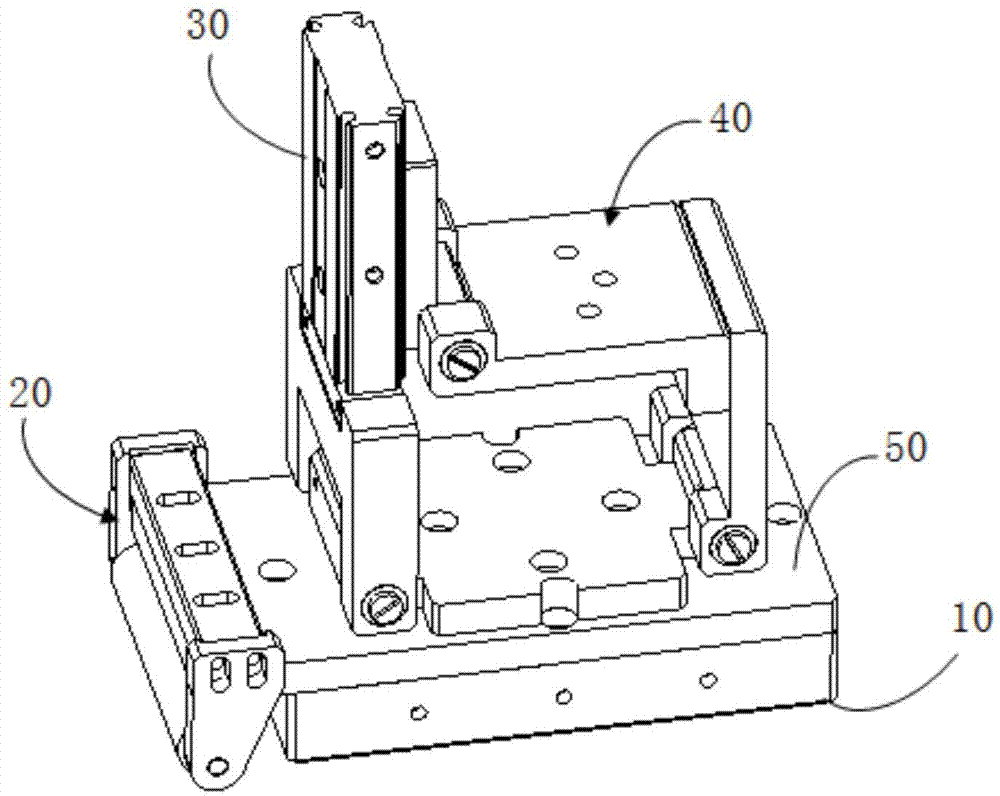

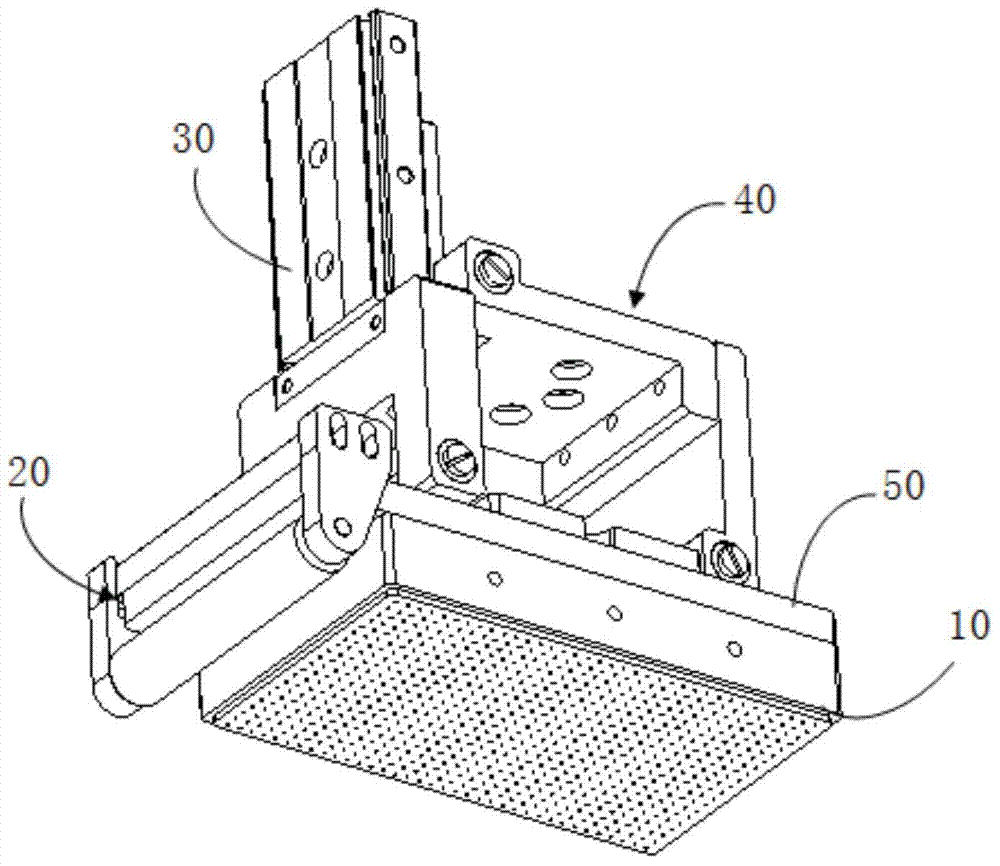

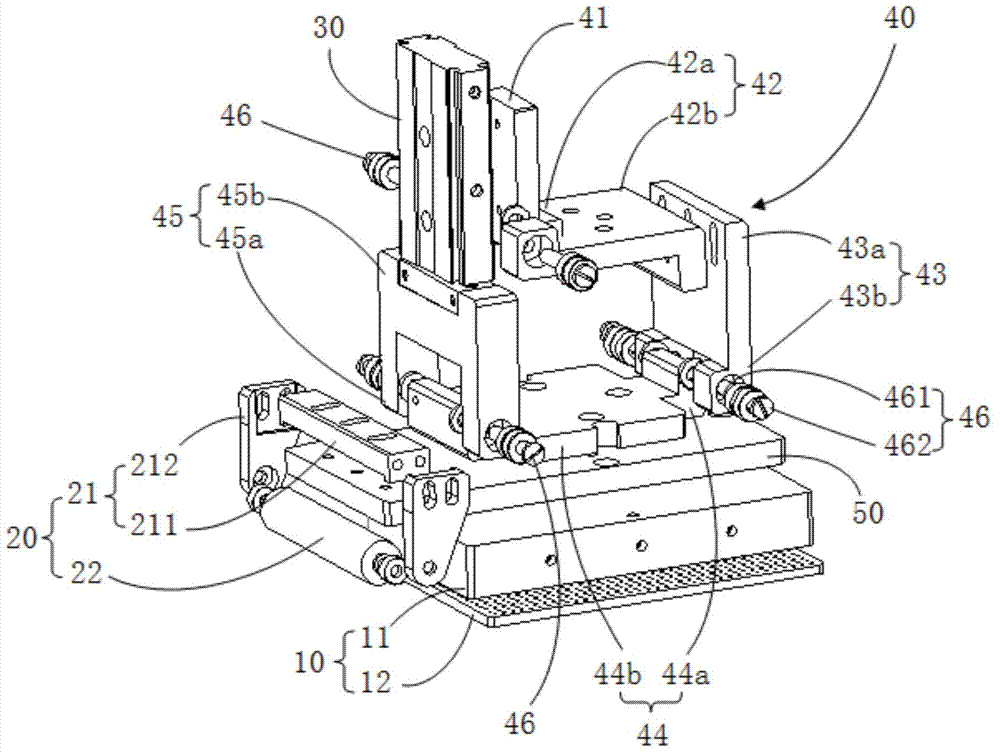

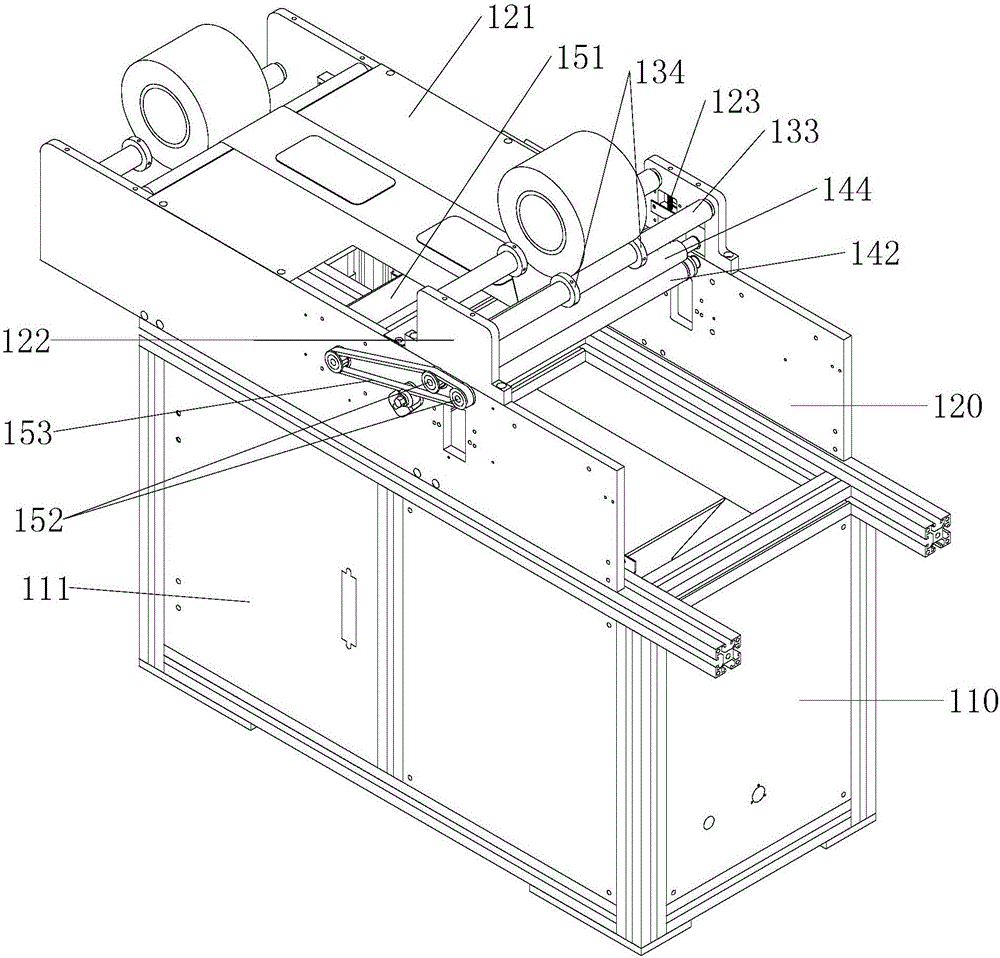

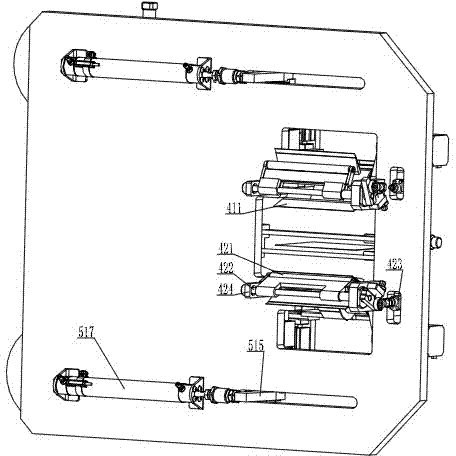

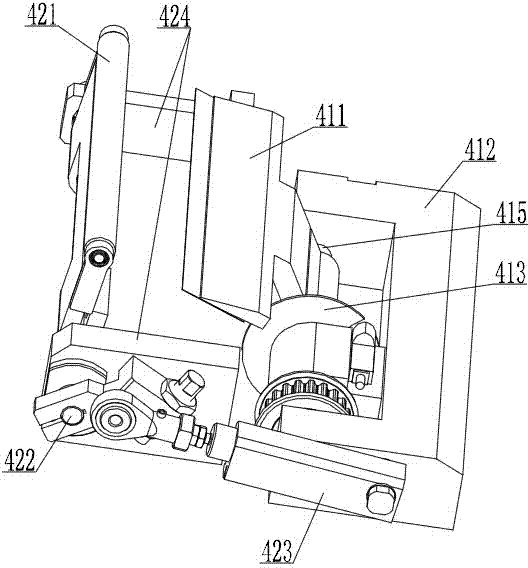

Film pasting device

InactiveCN104724312ACompact structureSimple and fast operationPackaging machinesTectorial membraneElectrical and Electronics engineering

The invention discloses a film pasting device. The film pasting device comprises a vacuum adsorbing assembly, a pressing roller mechanism, an air cylinder, a hinged connection assembly and a power mechanism, wherein the vacuum absorption assembly is used for adsorbing a protective film, the pressing roller mechanism comprises a fixing support and a rubber roller, the rubber roller is fixed on one side face of the vacuum adsorbing assembly through the fixing support, the hinged connection assembly is connected to the vacuum adsorbing assembly, one end of the hinged connection assembly is connected with the movable end of the air cylinder, the other end of the hinged connection assembly is fixedly connected with the air cylinder, and the power mechanism is used for supplying power to the film pasting device to enable the film pasting device to be capable of moving in the vertical direction or in the horizontal direction. When the air cylinder is in an upward contraction state, the bottom face of the vacuum adsorbing assembly is in a horizontal state and adsorbs the protective film; when the air cylinder is in a downward stretching state, the air cylinder drives the hinged connection assembly to rotate, the bottom face of the vacuum adsorbing assembly is in an inclined state, and the rubber roller rolls to paste the protective film on a product needing film pasting. The film pasting device is simple and exquisite in structure and flexible in motion, and the film pasting effects of being free of bubbles or damage can be achieved.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

Production process of aluminum alloy section

The invention discloses a production process of an aluminum alloy section. The aluminum alloy section having a smooth surface and high compactness is produced through the process steps such as aluminum alloy cast rod preparation, hot extrusion and molding, on-line quenching, stretch rolling, saw cutting, artificial aging, finished product saw cutting, packaging and the like. By strictly controlling the preheating temperature of the whole process, the aluminum alloy section produced through quenching and stretch rolling has no scratch, no bubble, no extrusion streak and no corrosion spot on the surface, has a smooth and level surface, and is high in ductility, strength and internal compactness.

Owner:HENAN HUILONG ALUMINUM IND

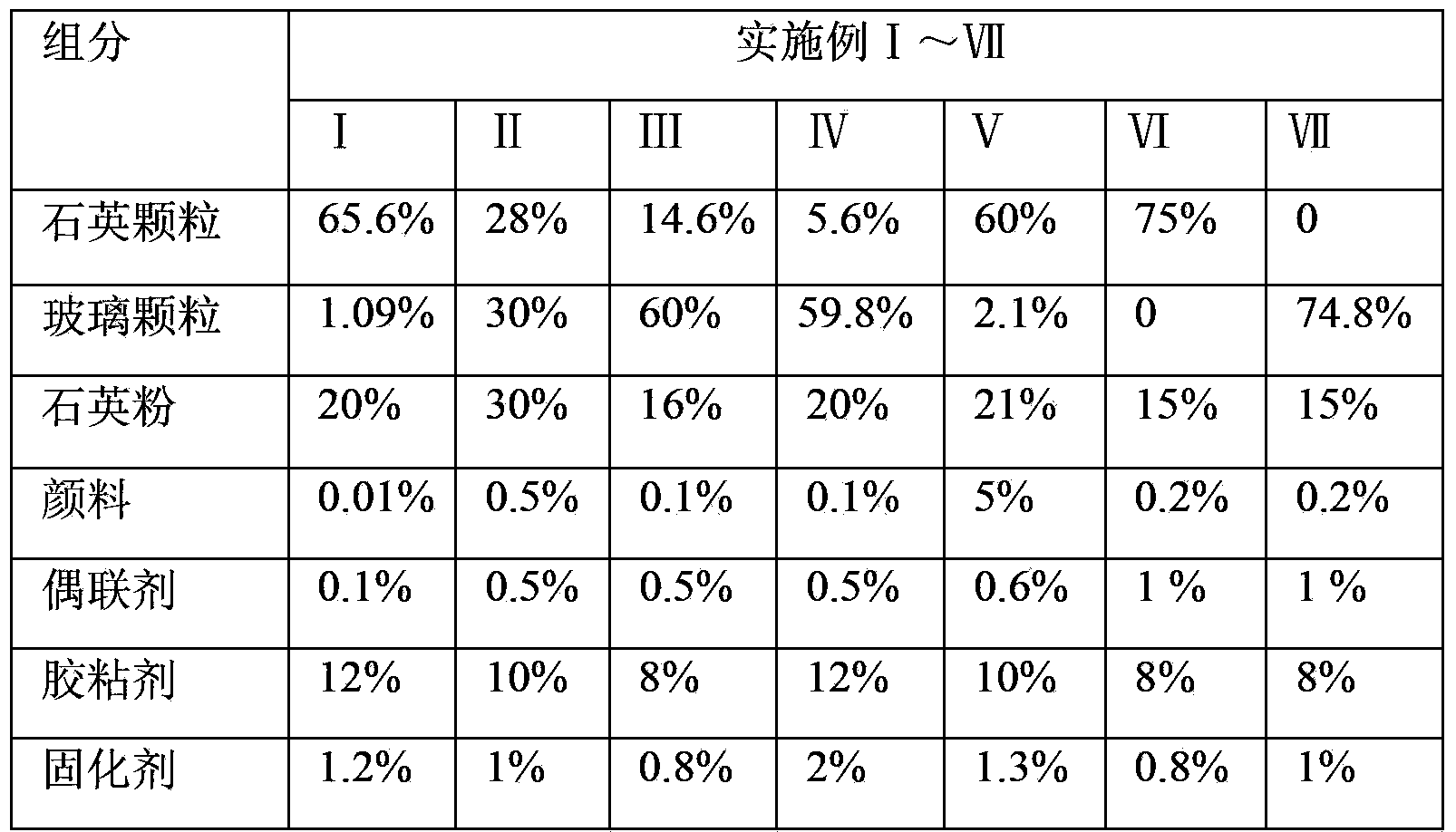

High-impact toughness man-made quartzite slab and preparation method thereof

The invention provides a high-impact toughness man-made quartzite slab and a preparation method thereof. The man-made quartzite slab comprises the following components in percentage by weight: 58-75 percent of particle raw materials, 15-33 percent of quartz powder, 0.01-10 percent of paint, 0.1-1 percent of coupling agent, 8-12 percent of adhesive and 0.8-2 percent of curing agent, wherein the particle raw materials are quartz particles, glass particles, or a mixture of the two. The man-made quartzite slab provided by the invention has the characteristics of low probability of cracking and deformation, and the like.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

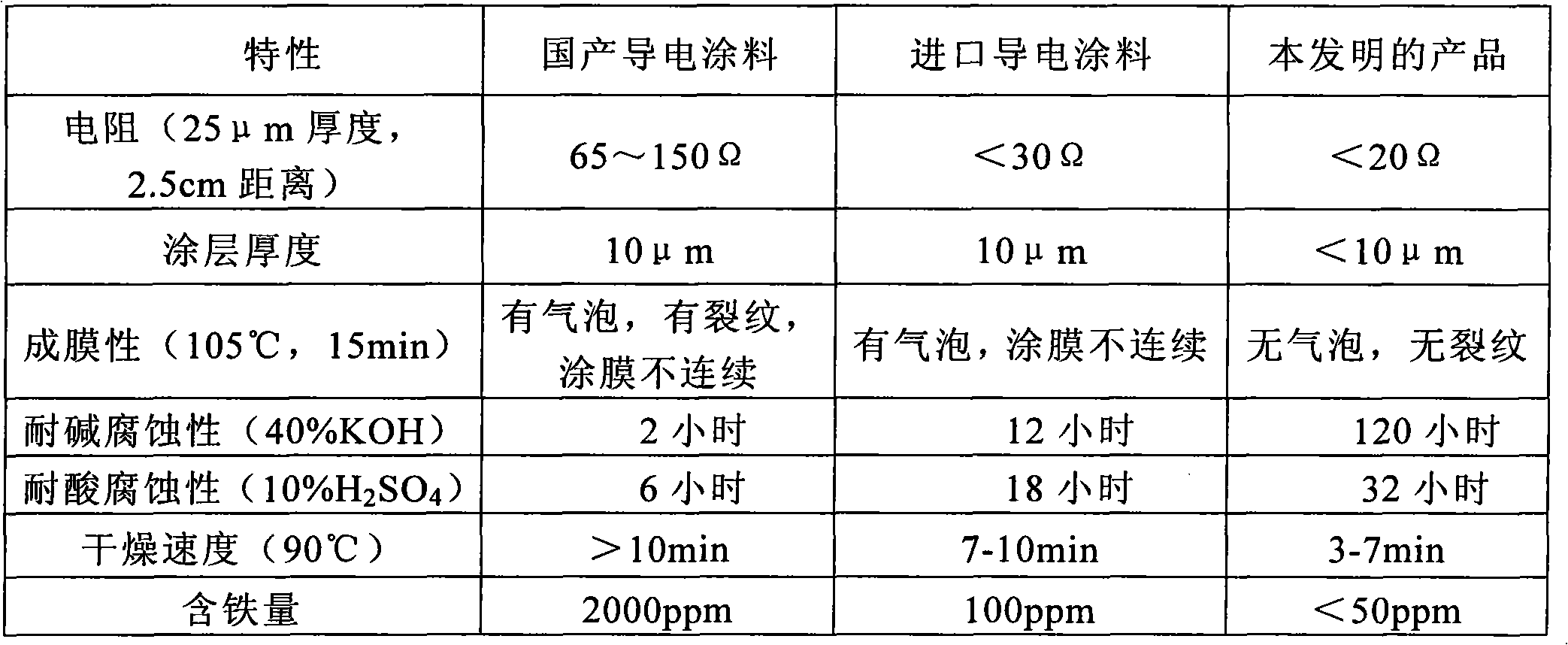

Supercapacitor electrode corrosion-resistant conductive coating

ActiveCN101899233AImprove conductivityReduce volumeAlkali metal silicate coatingsElectrolytic capacitorsConductive coatingSupercapacitor

The invention discloses a supercapacitor electrode corrosion-resistant conductive coating, which comprises the following components in percentage by weight: 10 to 35 percent of conductive agent, 0.1 to 3.5 percent of dispersing agent, 2.0 to 15 percent of binder, 0.1 to 8.0 percent of pH regulator, and 50 to 70 percent of pure water. The supercapacitor electrode corrosion-resistant conductive coating is prepared by the following steps of: fully mixing and uniformly stirring the components, adding the components into a ball mill for peptizing and dispersing, and discharging to obtain the supercapacitor electrode corrosion-resistant conductive coating. Compared with the conventional like products at home and abroad, the supercapacitor electrode corrosion-resistant conductive coating has the advantages of greatly improving the acid and alkali corrosion resistance, having no bubbles, falling off, corrosion and other phenomena after being soaked in alkaline solution for 120 hours and in acid solution for 32 hours, and improving the conductivity, adhesiveness and drying speed. The product can be diluted and adjusted according to need during use.

Owner:SHANGHAI HANBO ENTERPRISE +1

Downconversion frequency shift infrared radiation enhanced coating and preparation method thereof

InactiveCN101712816AHigh heat conversion efficiencyImprove absorption rateCoatingsEmissivityFrequency shift

The invention relates to an infrared radiation enhanced coating and a preparation method thereof. The downconversion frequency shift infrared radiation enhanced coating is characterized by consisting of the following components in percentage by mass: 20 to 50 percent of radiation synergistic enhancer, 1 to 7 percent of downconversion frequency shift additive, 15 to 45 percent of high-temperature resistant base stock, 32 to 50 percent of high-temperature binder, 1 to 4 percent of flexibilizer and 1 to 4 percent of coating auxiliary agent, and the sum of the mass percentage of the components is 100 percent. The coating not only has high emissivity and good thermal shock resistance, but also can convert visible light into infrared radiation; and the thermal conversion efficiency of the coating is effectively improved.

Owner:WUHAN YINFURUI NEW MATERIAL

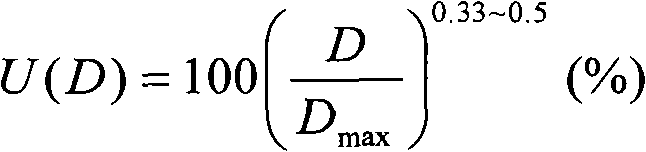

Method for growing tabular gallium oxide crystals through edge-defined film-fed growth process

InactiveCN103290471AOvercome bubblesOvercoming polycrystalline problemsPolycrystalline material growthBy pulling from meltSurface finishIridium

The invention discloses a method for growing tabular gallium oxide crystals through an edge-defined film-fed growth process. The method comprises the following steps of: by taking high-purity gallium oxide powder as a raw material, selecting an iridium die with the top end having such a surface smoothness so that mirror face effect is achieved; by selecting beta-Ga2O3 single crystals with an end-face normal direction (010) as seed crystals and taking a (100) surface as a main growth surface, melting the material in a high-purity CO2 atmosphere for growing, increasing the temperature to the range from 10 to 20 DEG C after melting of the material is finished, keeping the temperature constant for 1-2 hours and then entering a growth stage; dividing the whole crystal growth into four parts: seeding, necking down, shouldering and isodiametric growth; employing different technical parameters at different growth stages until the whole growth process is completed, thereby obtaining tabular beta-Ga2O3 crystals. The tabular beta-Ga2O3 crystals prepared by the method provided by the invention has the characteristics of regular appearance, flat surface, no bubbles, no polycrystal and no stress fringes.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Novel acrylic acid modified alkyd resin and method for preparing same

ActiveCN102993424AImprove drynessGood weather resistancePolyester coatingsLiquid mediumAging resistance

The invention aims to provide an acrylic acid modified alkyd resin which is improved in hardness, dryness, abrasion resistance and aging resistance and also maintains particular flexibility, pigment wettability and the like. Simultaneously, the acrylic acid modified alkyd resin provided by the invention solves the problem that the common acrylic acid modified alkyd resin in the market is poor in acid and alkali resistance. The acrylic acid modified alkyd resin provided by the invention is characterized that a paint film is free of bubbling, rusting, crazing and falling in 48 hours when being measured through a liquid medium resistance experiment according to GB / T 9274-1988; and the acrylic acid modified alkyd resin is obviously superior to the traditional soybean oil alkyd resin and the common acrylic acid modified alkyd resin.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

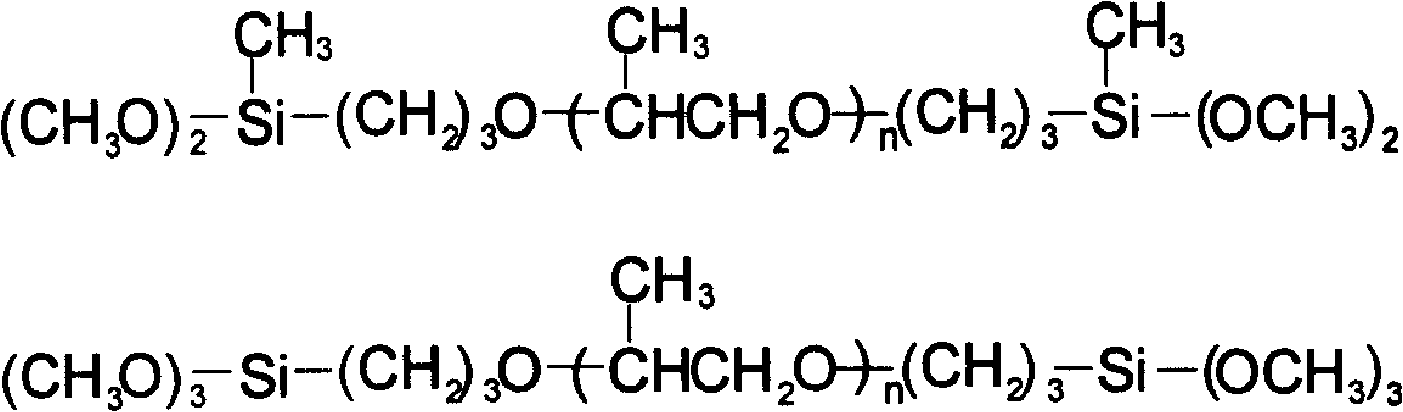

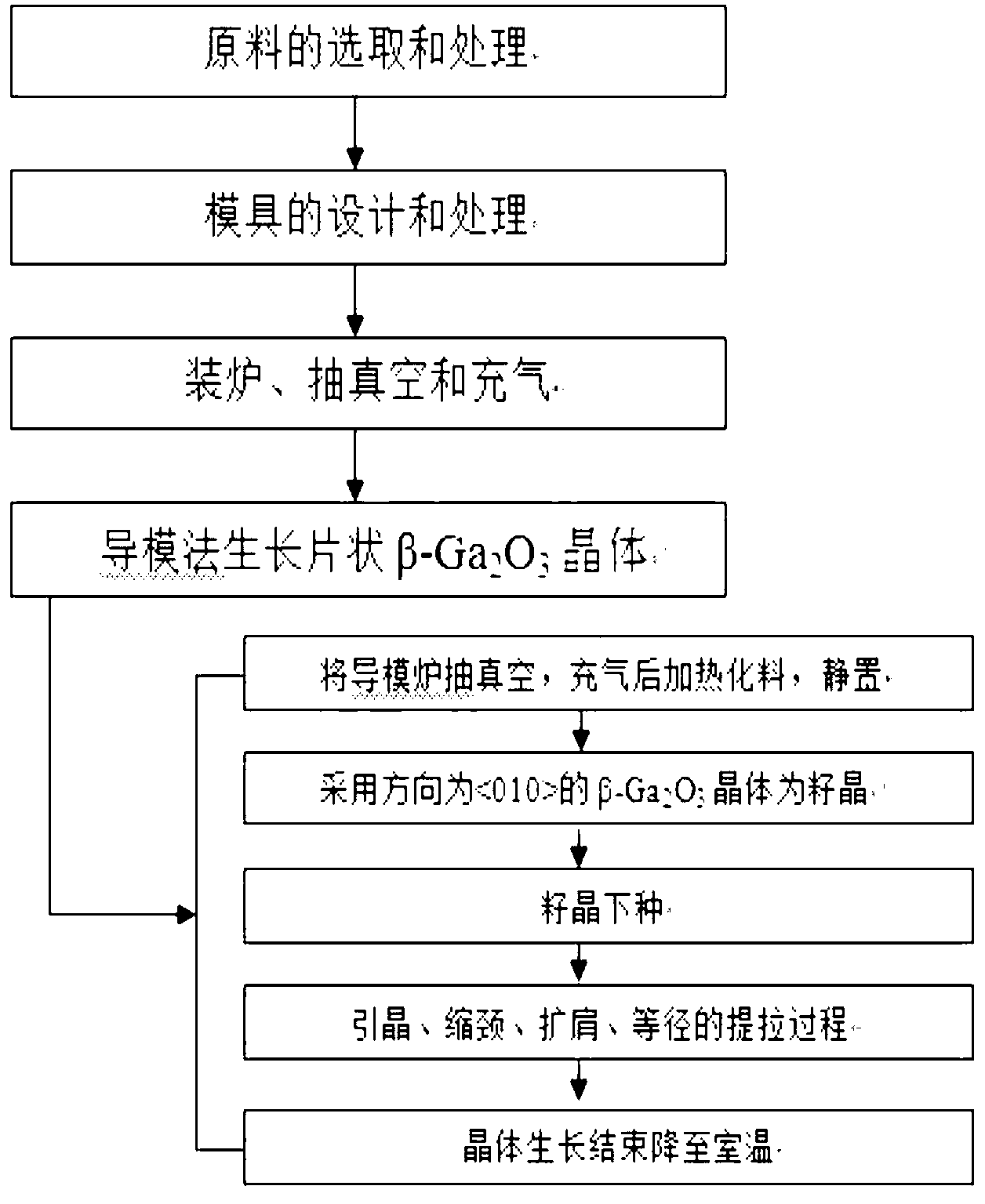

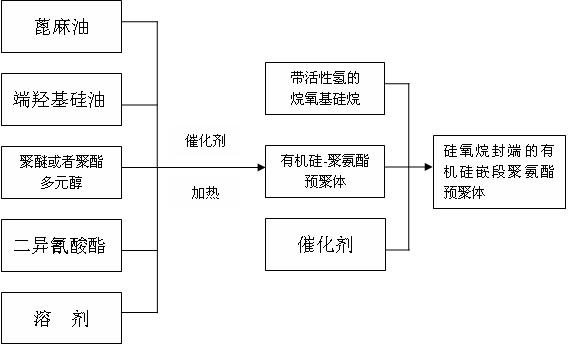

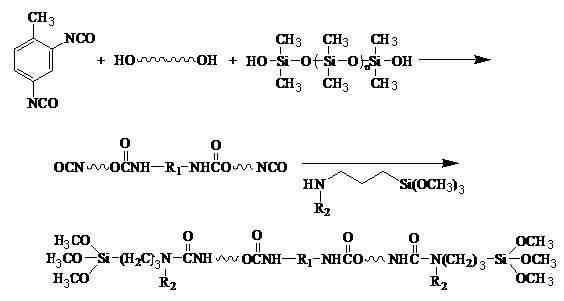

Preparation method for siloxane-terminated organosilicon block polyurethane prepolymer

ActiveCN102633983ATake full advantage of performanceGood adhesionPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a preparation method for siloxane-terminated organosilicon block polyurethane prepolymer. The method includes the following steps: polyester polyol or polyether polyol, hydroxy-terminated silicone oil, castor oil and the like are dripped into aromatic or aliphatic diisocyanate, so that organosilicon block polyurethane prepolymer is obtained; and afterwards, under organic tin catalyst, siloxane with activated hydrogen is added into the organosilicon block polyurethane prepolymer to react, so that the stable siloxane-terminated organosilicon block polyurethane prepolymer is obtained. The cured film of the prepolymer prepared by the method has the advantages of high elasticity, low-temperature flexibility, high water resistance, high adhesive force, high wear resistance and high aging resistance. The siloxane-terminated organosilicon block polyurethane prepolymer can be widely applied in sealing or coating materials for environment protection, buildings, electronics and other industries and other fields.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

Production of pure soya-bean lactacidase fermenting beverage

InactiveCN1644112AFine tissuePure bean flavorFood preparationMilk substitutesStreptococcus thermophilusBiology

A fermented lactobacillus beverage is prepared from soybean through preparing soybean milk, inoculating thermophilic streptococcus and lactobacillus, fermenting, dispensing, homogenizing and sterilizing. Its advantages are agreeable taste, not containing cholesterine and lactose, and high nutritive value.

Owner:JIANGNAN UNIV

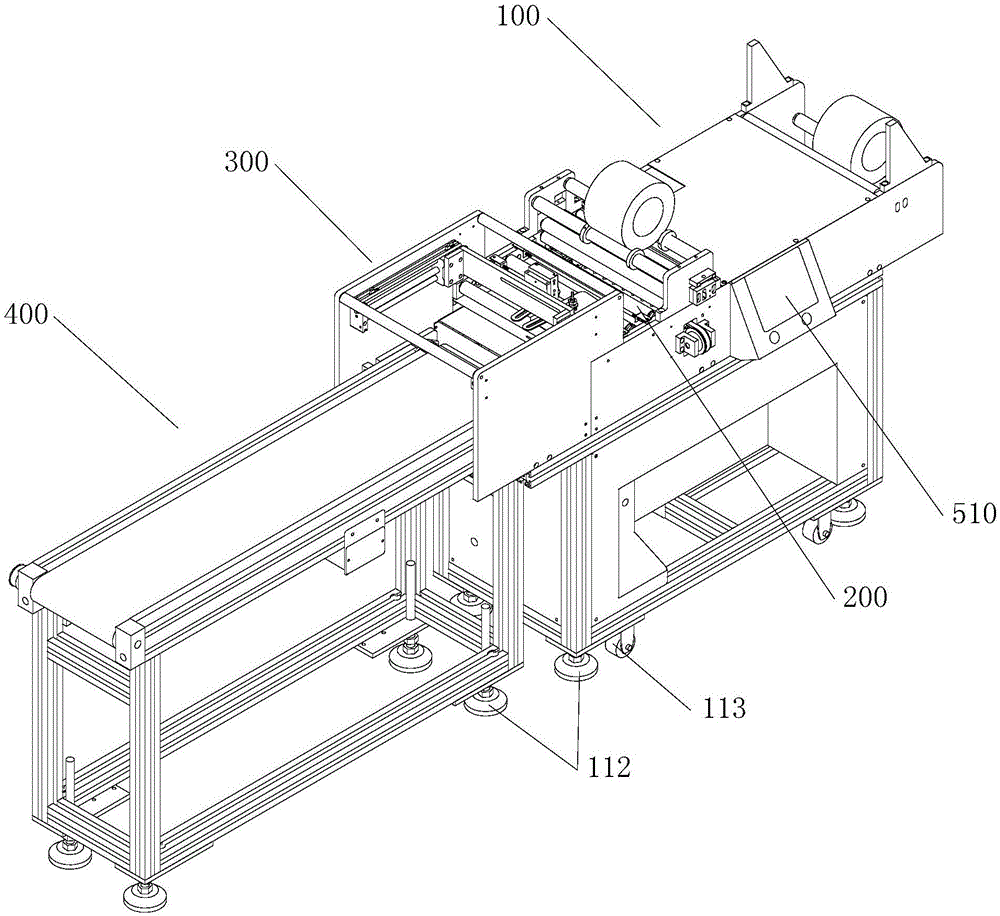

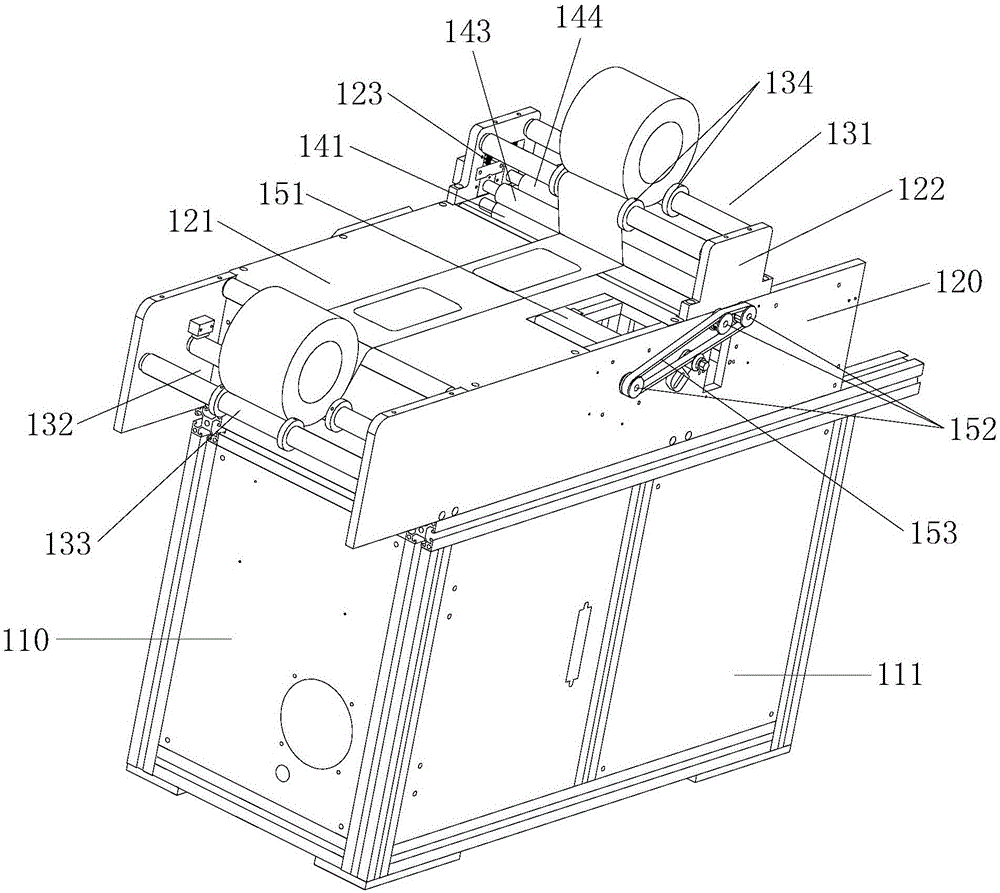

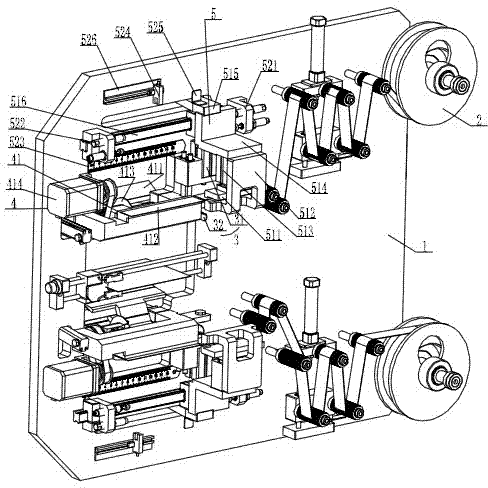

Automatic coating and cutting machine

ActiveCN106079810ALow costReduce labor costsLamination ancillary operationsLaminationGlass coverControl system

The invention relates to an automatic coating and cutting machine. The automatic coating and cutting machine mainly comprises a coating mechanism and a cutting mechanism successively used for processing materials, a collecting mechanism for collecting the coated and cut material, a transport mechanism for transporting the material and an electric control system, wherein the material such as a glass cover plate is fed from one side of the coating mechanism and is collected after being coated with a film and cut, and finally the material is output from one side of the transport mechanism. The automatic coating cutting machine can substitute a great amount of labor, so that the labor cost is saved; the efficiency is improved, and the automation degree is high; the equipment stability is high, the coating effect is tidy and has no bubble, the cutting is standard and orderly, the material can be effectively and orderly collected and transported, and the qualification rate of products can be guaranteed.

Owner:深圳市银浩自动化设备有限公司

Moisture-cured silicone modified polyurethane and hot melt adhesive composition and preparation method thereof

InactiveCN102492389AGood adhesionHigh molecular weightPolyureas/polyurethane adhesivesPolymer scienceUltraviolet lights

The invention discloses a moisture-cured silicone modified polyurethane and hot melt adhesive composition. The composition comprises the following raw materials by weight: 60 to 80 percent of silicone modified polyurethane, 10 to 20 percent of tackifying resin, 1 to 8 percent of plasticiser, 0.5 to 2 percent of viscosity reducing additive, 0.2 to 1 percent of organosilicon additive, 3 to 8 percent of inorganic filler, 0.05 to 0.5 percent of anti-oxidant, and 0.05 to 0.5 percent of ultraviolet light absorber. The invention further discloses a preparation method of the composition. The invention has the advantages that the composition can be cross-linked fast and completely; the viscosity, the solidification foaming phenomenon and the bonding performance of a hot melt adhesive system are improved; the purposes of no bubble, no odor, low construction viscosity and the like are realized; the final strength is favorable; and solidification without bubbles can be realized on the condition that a layer is 2 mm in thickness.

Owner:GUANGZHOU BAIYUN CHEM IND

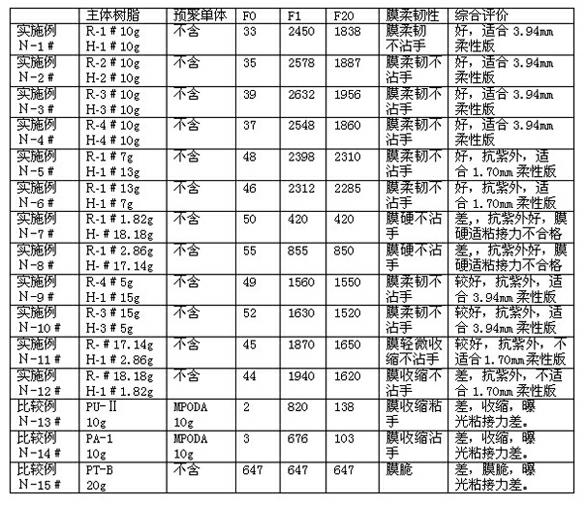

Ultraviolet curing adhesive

ActiveCN102079961ASolve the problem of unexposed initial tackHigh softening pointPolyureas/polyurethane adhesivesPhotosensitive materials for photomechanical apparatusAcrylic resinAdhesive

The invention discloses an ultraviolet curing adhesive comprising a resin main body, a dissolvent, an ultraviolet light initiator and an addition agent, wherein the resin main body is composed of a resin R and a resin H; the R resin is an active polyurethane acrylic resin with a main chain containing a polyether structure and a branch chain containing a vinyl optical active group as well as with a lower molecular weight; and the H resin is an inert polyurethane acrylic resin with a main chain containing a polydiene and aryloxide structure and with a relatively higher molecular weight. The adhesive contains no monomer or prepolymer, has high softening point, can be precoated on a base material, has super strong cohesive force on a high-oilness contact surface and has characteristics of high-temperature resistance, small internal stress and good flexibility.

Owner:LUCKY HUAGUANG GRAPHICS

Fluorine rubber seal element and preparing method thereof

ActiveCN101168656AExtended service lifeGood process performanceOther chemical processesCarbon blackCalcium hydroxide

The invention provides a fluorinated rubber sealing element; the invention is characterized in that the sealing element is produced by the raw material with the following quality parts: binary fluorinated elastomer of 60 to 80 parts, tetrafluoroethlene propylene rubber of 20 to 40 parts, carbon black of 20 to 40 parts, calcium hydroxide of 3 to 5 parts, metal oxide of 3 to 6 parts, hexafluoride sonitroso propyl diphenol of 1.5 to 2 parts, benzyl triphenyl phosphorus chloride of 0.3 to 0.5 part, processing aid of 0.5 to 2 part, dicumyl peroxide of 0.5 to 1.2 parts, and triene propyl isocyan urate of 0.5 to 1.2 parts. The invention has the preparation method that sulphation for 8 to 12 minutes is molded on a compression machine under 165 to 180 DEG C through being extruded and formed after the raw material with the quality parts are added in mixing equipment to be mixed uniformly under 60 to 80 DEG C, and then the sealing element is produced after performing secondary cure for 8 to 24 hours in hot air of 200 to 250 DEG C. The fluorinated rubber sealing element produced has long service life and can be high temperature water vapor resistant and high and low impact resistant.

Owner:广州国机智能橡塑密封科技有限公司

Forming method of wall-flow type honeycomb ceramic carrier

ActiveCN101117289AHigh temperature resistantNon-deformableCatalyst carriersExhaust apparatusMicrowave ovenMethylcellulose Powder

The invention relates to a forming method of a wall flow type honeycomb ceramics carrier billet for collection of diesel engine tail gas particles. A mixture power of pure silicon carbide and methylcellulose is stirred evenly and is poured into a stirring mill and then is stirred to make the silicon carbide power and the methylcellulose mix ed evenly; a flour water solution of water and flour is stirred evenly and poured into the stirring mill with stirring and makes the pug stirred evenly enough; tung oil is added into the stirred pug, and is stirred for a plurality of minutes, when the pug can be felted together, the pug is put into a container and is sealed to guarantee that the water in the pug can not be vaporized, and is kept musty for one day; after milled and extruded to be formed, the pug is dried by a microwave oven, finally holes are filled, after the pug is parched, dried and fired, then the billet is obtained.

Owner:GUIZHOU HUANGDI DIESEL ENGINE CLEANER

Polyvinylchloride (PVC) plastic wood plank and preparation method thereof

The invention provides a polyvinylchloride (PVC) plastic wood plank and a preparation method thereof. The PVC plastic wood plank consists of the following ingredients: PVC, calcium carbonate, wood flour, azodicarbonamide (AC) foaming agents, stabilizing agents, coupling agents, acrylicester (ACR), paraffin wax, stearic acid and fire retardants. By means of the PVC plastic wood plank, appending proportion of the calcium carbonate is enhanced by reducing the amount of the wood flour, and at the same time, by adjusting the amount of the PVC, and the type and amount of other additives, not only can hardness of the plank be greatly enhanced, but also appropriate toughness can be possessed. Therefore, the plank is guaranteed to be not only possess enough hardness when used as wood floors in public places so that damage and sinking of the surface of the plank are not prone to occurring, but also meet requirements of the wood floors due to the toughness of the plank so that the plank can be ensured to be not easy to crack.

Owner:江西铁木真装饰材料有限公司

Ultralow-expansion coefficient high transparent glass-ceramics and method for producing its product

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

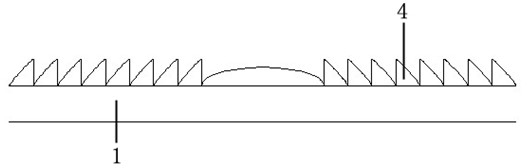

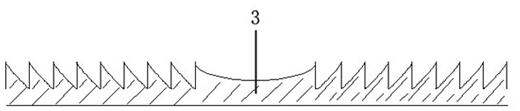

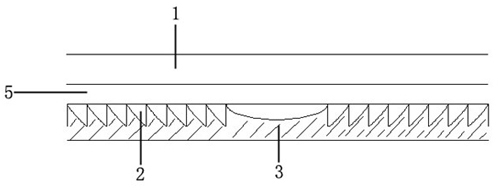

Glass silica gel Fresnel lens and manufacture method thereof

The invention discloses a glass silica gel Fresnel lens and a manufacture method thereof, which resolve the problem that the existing glass silica gel Fresnel lens has bubbles. The glass silica gel Fresnel lens is formed by fixedly bonding a bubble-free silica gel Fresnel lens layer (4) to tempering super white glass (1). The manufacture method includes utilizing the tempering super white glass (1) as a base material, conducting mould assembly on the tempering super white glass (1) and a Fresnel lens mould (3) evenly and smoothly coated with silica gel (2) when vacuum degree is 0.05-0.08Pa after vacuumizing processing, enabling mould assembly pressure to be 50-200kilogram / cm<2>, heating the mould after mould assembly, enabling the temperature to be 90-100 DEG C, conducting solidification for certain time with the vacuum degree, the mould assembly pressure and the heating temperature unchanged, enabling the bubble-free silica gel Fresnel lens layer (4) to be fixedly bonded to the tempering super white glass (1) and then conducting air discharge, decompression, mould moving and demoulding to obtain the glass silica gel Fresnel lens.

Owner:广东金天阳光电有限公司

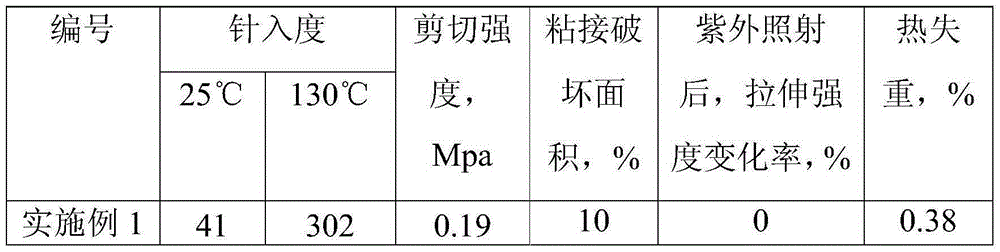

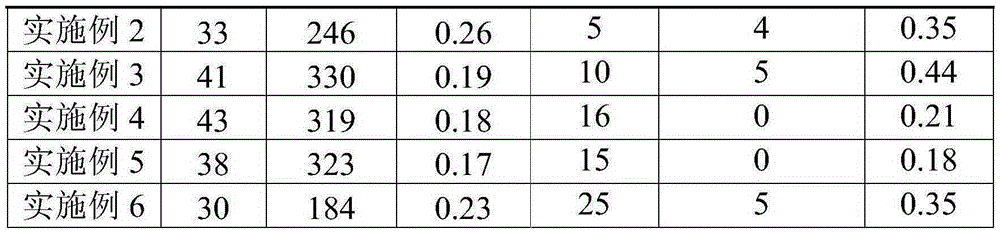

Butyl hot melt adhesive and preparation method thereof

ActiveCN105385388ALow water vapor transmission rateGood UV aging resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAlloyButyl rubber

The invention discloses a butyl hot melt adhesive and a preparation method thereof. The preparation method comprises the following steps that in a high temperature kneader, the temperature is set at 130 DEG C-150 DEG C, 180-600 parts by weight of polyisobutene, 100 parts by weight of butyl rubber and 30-120 parts by weight of tackifying resin are firstly added into the kneader, the temperature is increased to 110 DEG C-130 DEG C, and stirring is performed until the materials are uniform; 450-1000 parts by weight of packing, 0-7 parts by weight of an anti-aging agent and 1-25 parts by weight of a softening agent are sequentially added, vacuumizing and stirring are performed for 0.5-2.5 hours, 20-100 parts by weight of the retained polyisobutene is added, vacuumizing and continuous stirring are performed for 0.5-2 hours, and the butyl hot melt adhesive is prepared. The butyl hot melt adhesive prepared through the method is excellent in anti-ultraviolet property and easy to construct, has the excellent adhesive property on hollow glass materials and aluminum alloy strips and can not only meet usage of hollow glass, but also be applied to the fields such as photovoltaic backboard adhesion.

Owner:CHENGDU GUIBAO SCI & TECH

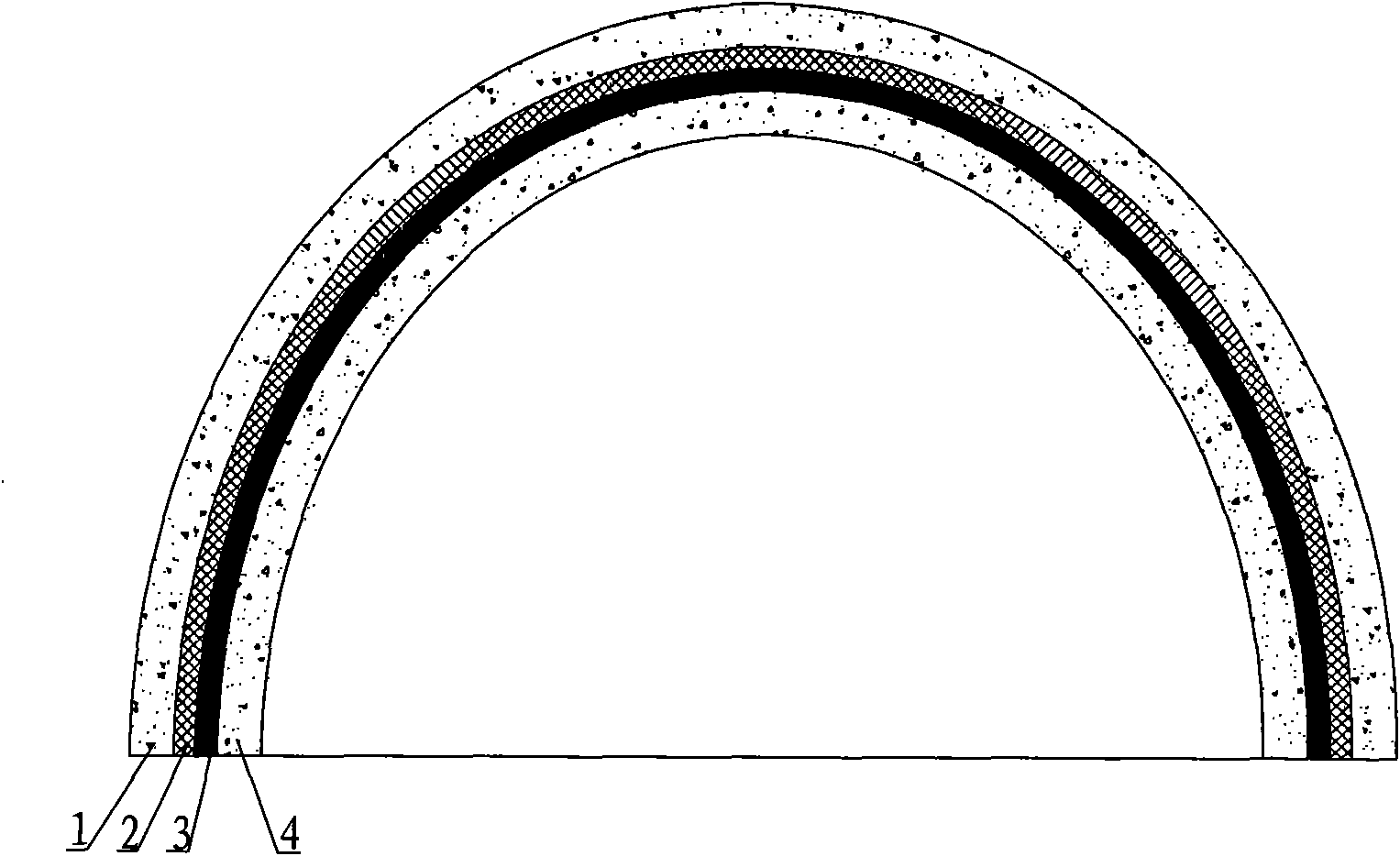

Construction method of tunnel waterproof and water drainage system

InactiveCN101614129AWill not harmWill not sputterUnderground chambersDrainageStructural deformationGeomorphology

The invention discloses a construction method of a tunnel waterproof and water drainage system, comprising the following steps: (1) preparing raw materials on a drainage layer; (2) injecting the drainage layer; (3) injecting a waterproof layer. The drainage layer and the waterproof layer of the invention all adopt the construction technology of injection. On the basis of water conductivity function, the drainage layer also has the functions of leveling and adapting to structural deformation, the waterproof layer adopts the construction mode of instantaneous film forming by ultraspeed curing and injecting, and the formed film is an integral structure, thus realizing that the integral structure is seamless and waterproof, the injection surface is free of flow, the film surface is smooth without bubbles and the construction produces no volatile organic compounds, simultaneously greatly improving the construction efficiency and reducing the labor intensity of workers.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

High-temperature-resisting coating and its production

A high-temperature-resisting coating and its production are disclosed. The coating consists of solid material and liquid material. The solid material comprises yttrium oxide, jargonia, rare-earth mixture, glass flour, sodium silicate and active clay and the liquid material consists of borax, sodium hydrate, water glass and water. It has better high-temperature-resisting, oxidation-resisting, anti-corrosive performances and excellent adhesion. It can be used for metal industrial furnace coating.

Owner:金柏林 +1

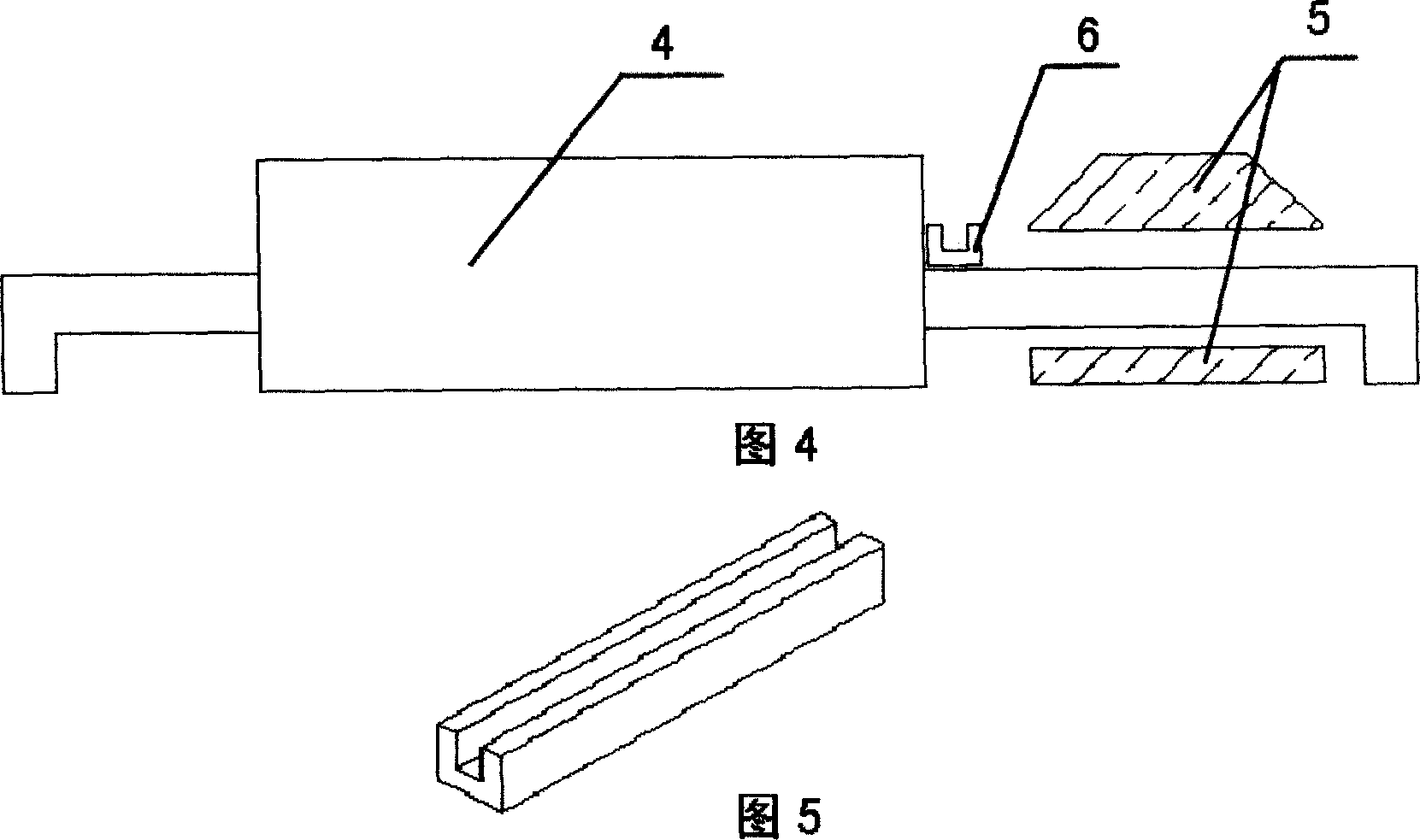

Gluing device and gluing method

ActiveCN103579577ANo bubblesWrinkle freeElectrode manufacturing processesElectrical and Electronics engineering

The invention discloses a gluing device. The gluing device comprises a gluing mechanism. The gluing mechanism comprises gluing rollers and movable gluing plates opposite to the gluing rollers. The movable gluing plates are used for transferring a glue tape towards a pole piece. The gluing rollers cooperate with the movable gluing plates and evenly rolling-paste the glue tape on the pole piece. The invention also discloses a gluing method utilizing the gluing device. The gluing rollers are used for gluing and can evenly rolling-paste the glue tape on the pole piece along with pole piece feeding without bubble and fold production.

Owner:SHENZHEN YINGHE TECH

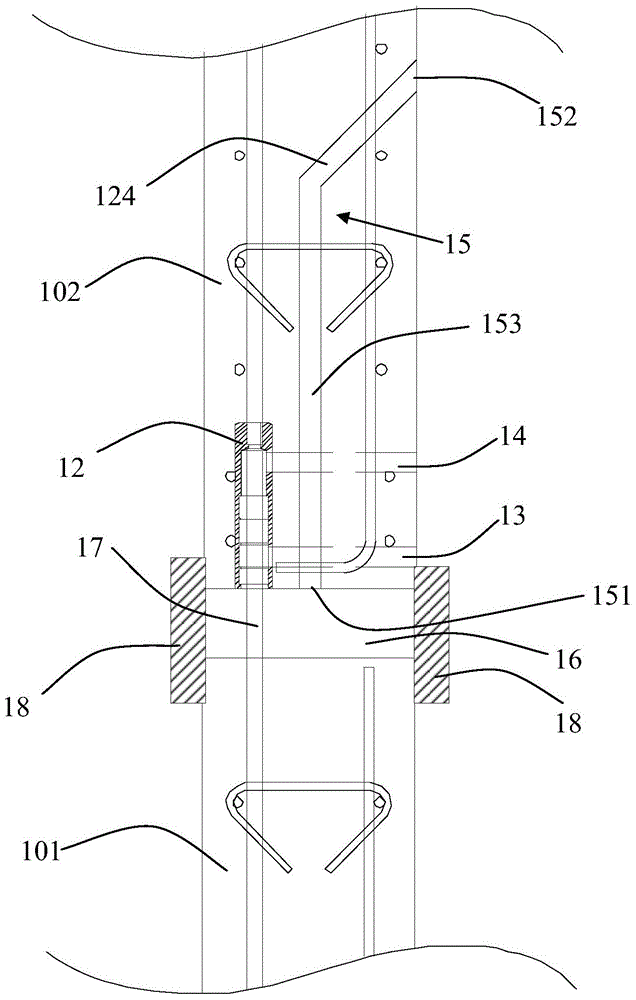

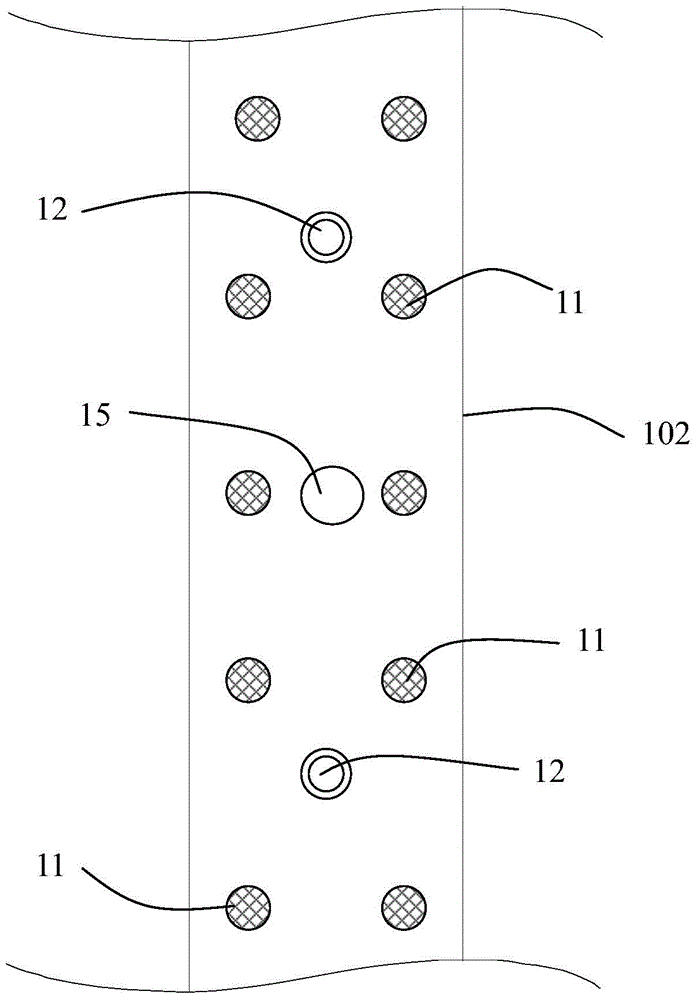

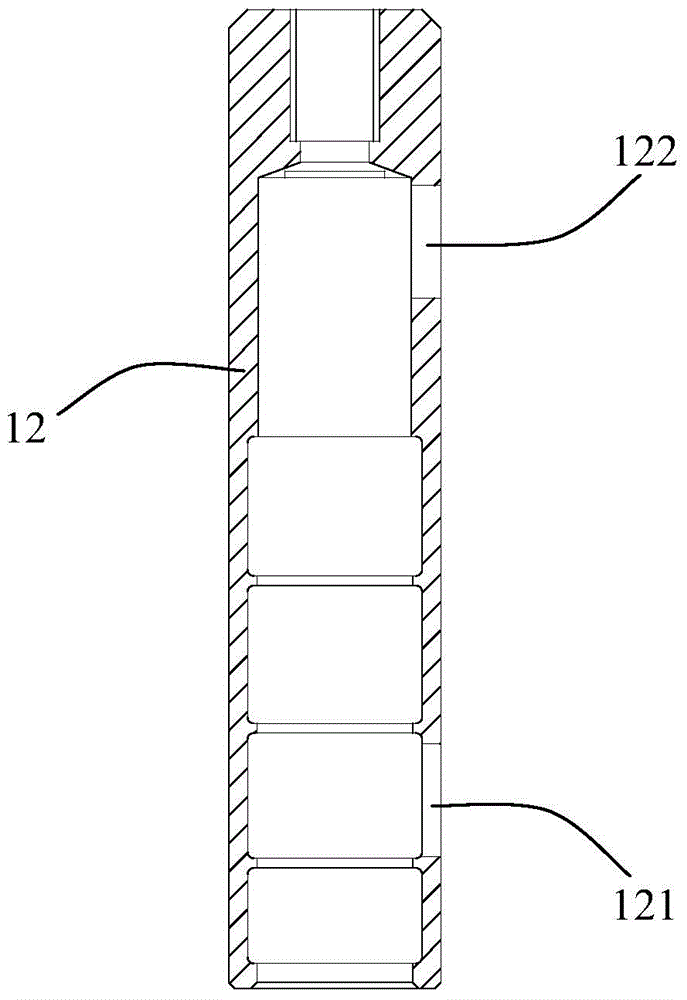

Detection method and detection structure for grouting density of prefabricated part

ActiveCN104865352AMake sure to fillNo bubblesBuilding reinforcementsMaterial analysisSlurryComputer science

The invention discloses a detection method and a detection structure for grouting density of prefabricated parts. The detection method comprises the following steps: providing at least one first prefabricated part and a second prefabricated part, preserving a grouting construction gap between the first prefabricated part and the second prefabricated part, and forming opposite grouting interfaces between the first prefabricated part and the second prefabricated part; arranging prefabrication testing points on the grouting interfaces of the first prefabricated part or / and the second prefabricated part, and connecting the prefabrication testing points with a signal receiver; grouting size into the grouting construction gap; when the size in the grouting construction gap triggers the prefabrication testing points, transmitting signals to the signal receivers from the prefabrication testing points; based on the signals transmitted from the prefabrication testing points, judging the grouting density degree of the grouting construction gap. As the prefabrication testing points are arranged on the grouting interfaces, the density degree of size grouting in the grouting construction gap can be detected, the size can be completely filled without bubble, and the grouting connection quality between the prefabricated parts can be ensured.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Building heat preservation material

InactiveCN106588108AReduce weightImprove insulation effectCeramicwareCelluloseEnvironmental resistance

The invention discloses a building heat preservation material. The building heat preservation material is mainly prepared from, by weight, 15-30 parts of bentonite, 15-30 parts of coal ash, 10-20 parts of mica, 2-5 parts of polyacrylamide, 12-27 parts of kaolin, 11-25 parts of expanded perlite, 7-15 parts of phenolic resin, 0.5-2 parts of calcium stearate, 1-3 parts of foaming agent, 6-13 parts of soapstone, 35-55 parts of modified environment-friendly adhesive, 3-6 parts of starch ether, 6-13 parts of centrifugal glass fibers, 2-8 parts of hydroxymethyl propyl cellulose, 15-25 parts of cement, 8-17 parts of ceramsite and 11-23 parts of diatomite. The building heat preservation material is low in weight, can replace a traditional building heat preservation material, and can be used for coating protection of building side walls. The heat conductivity coefficient of the material is tested based on the GB / T10297-1998 standard, the heat conductivity coefficient is only 0.038-0.040, the heat preservation performance is extremely excellent, high acid-base corrosion resistance is achieved, no abnormities exist after the experimental test is carried out for 150 h, superhigh weather fastness is achieved, and no discoloring or pulverization or bubbles or stripping or cracks are generated 420 h later.

Owner:南宁市大江保温材料有限公司

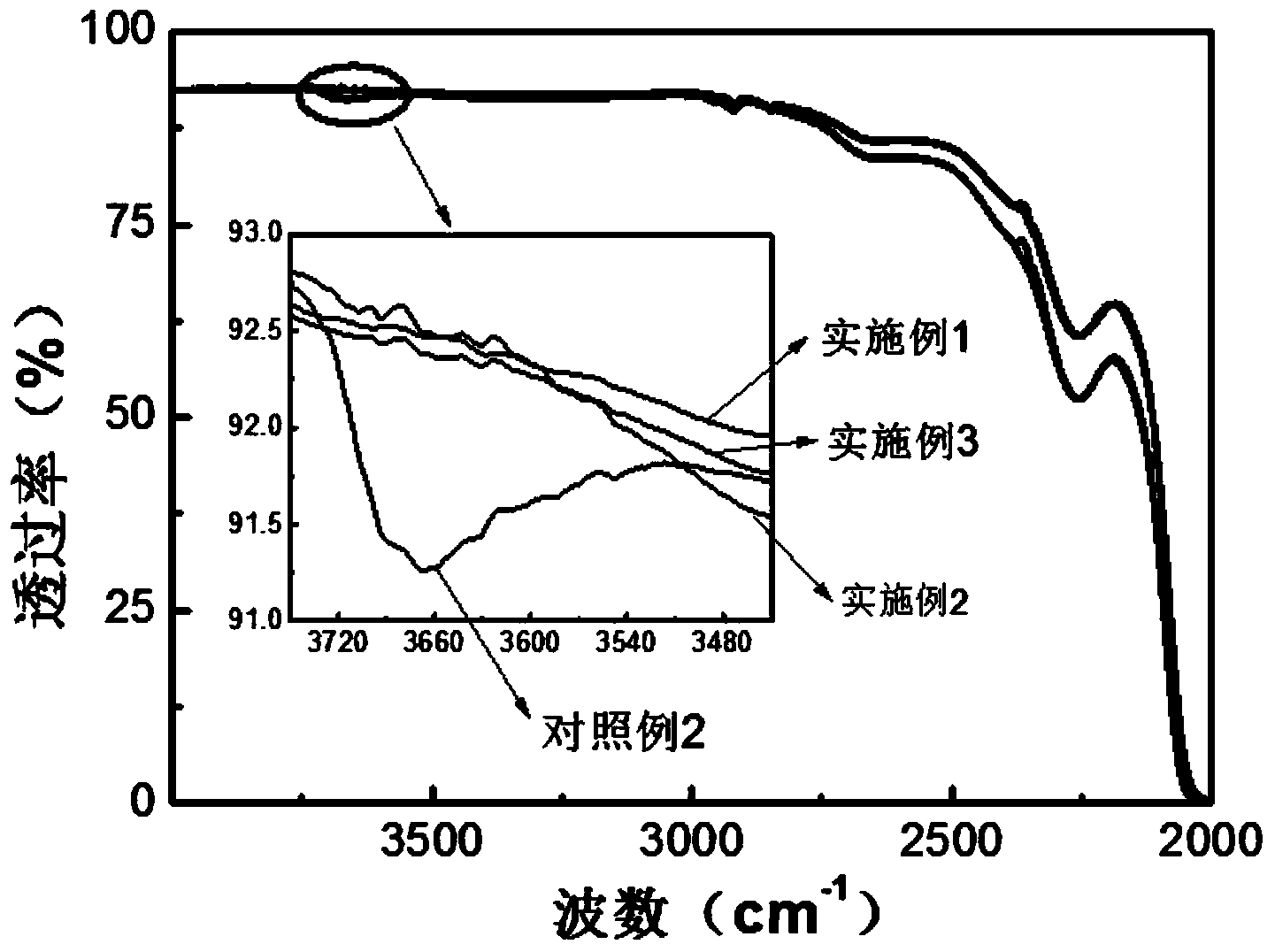

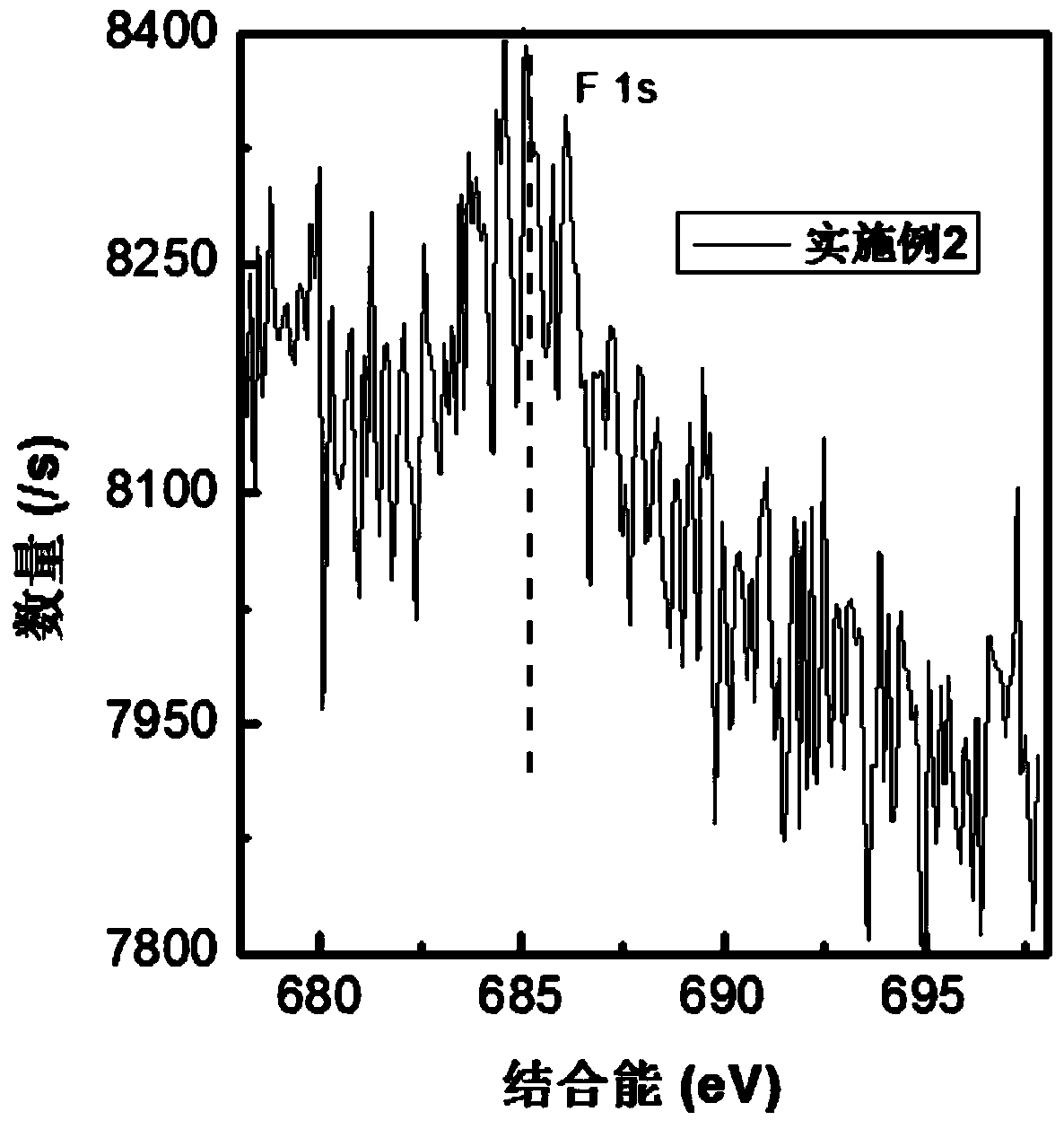

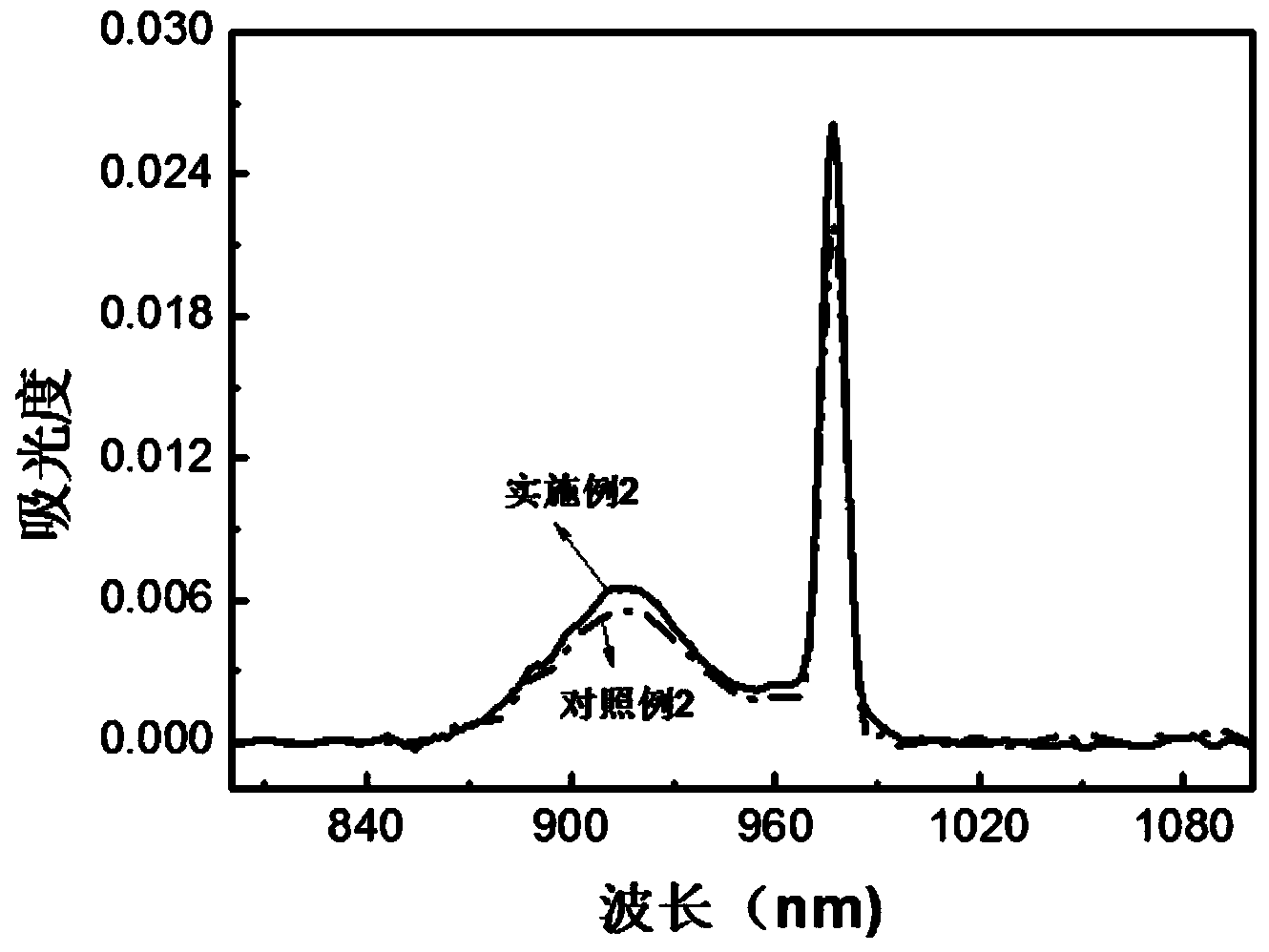

Preparation method for fluorine-containing low-refractivity Yb<3+>-doped quartz glass

The invention relates to a preparation method for fluorine-containing low-refractivity Yb<3+>-doped quartz glass. The method comprises the steps: starting from a solution, preparing evenly doped silicon oxide powder by using a sol-gel method; and carrying out decarbonization and dehydroxylation treatment on the powder, and finally sintering into glass. By applying the method, F<-> can be effectively introduced, and the rare earth-doped quartz glass with high uniformity, low hydroxyl content and the refractivity almost identical to that of the pure quartz glass can be obtained. The method can be applied to preparation of a high-brightness large-mode-field quartz optical fiber mandril.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

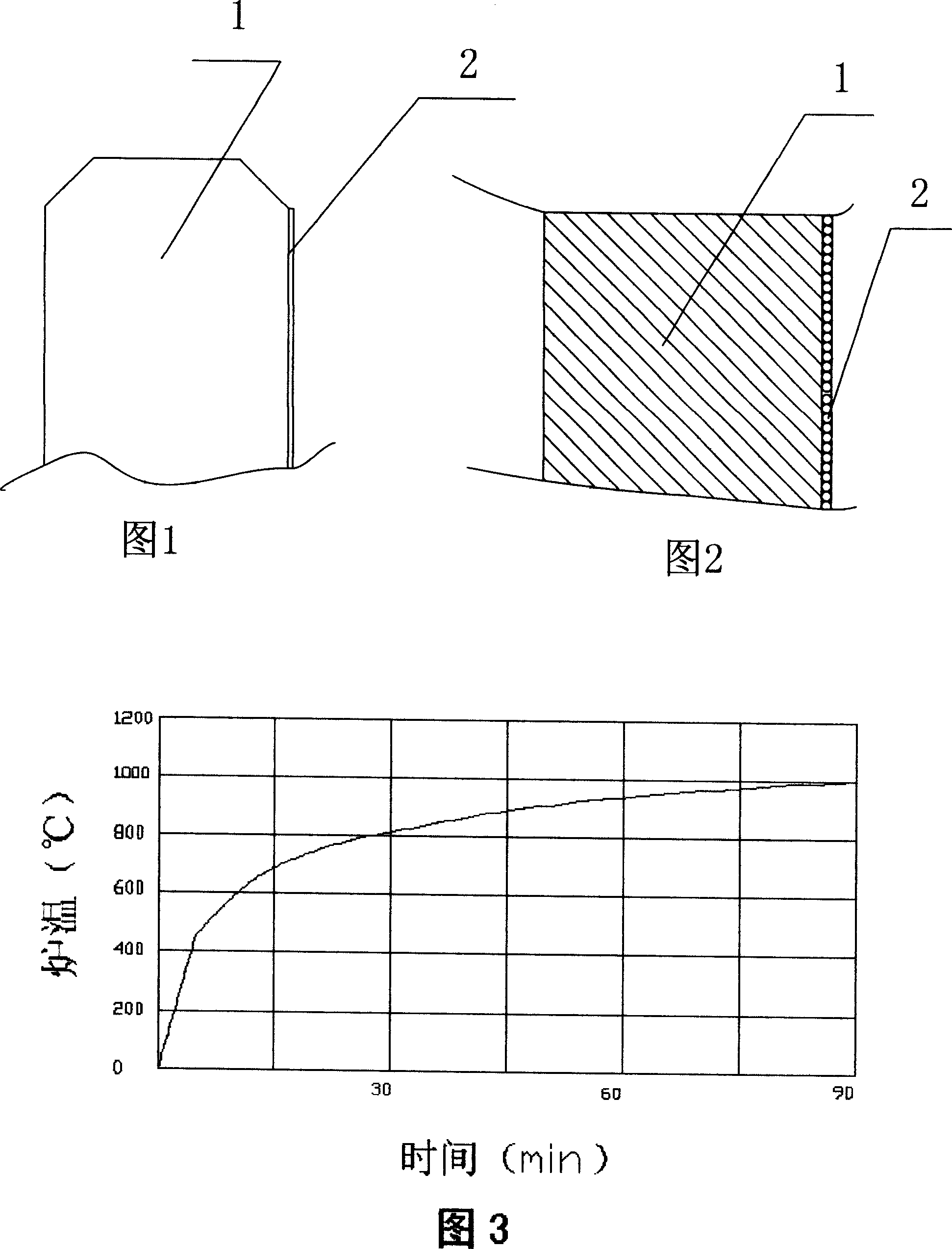

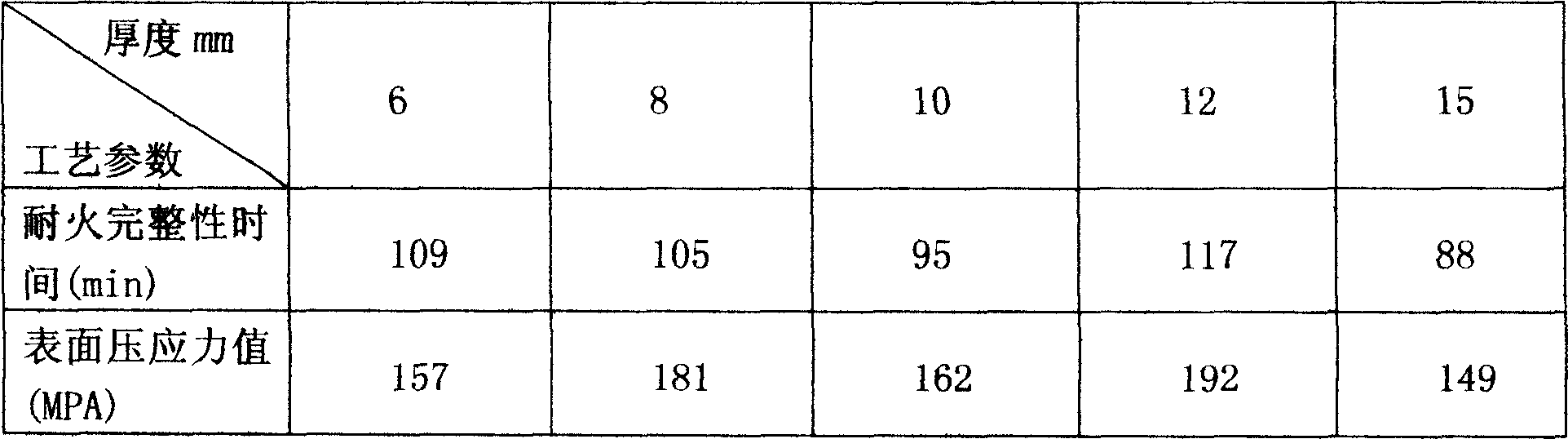

Method for producing fire-resisting glass and dedicated production equipment

ActiveCN101092286AAccelerates the ion exchange reaction processWon't peel off easilyGlass tempering apparatusGratingHeat resistance

This invention discloses method and specific apparatus for producing fireproof glass. The apparatus comprises: an upper stage plate, a furnace, a cooling wind grating and a lower stage plate. A baffle is set between the heating furnace and the cooling wind grating. The method comprises: (1) spray-coating a cesium / potassium salt solution onto glass at normal temperature; (2) naturally wind-drying the spray-coated glass at normal temperature, placing in a 680-725 deg.C tempering furnace, rapidly heating, cooling, circulating the glass between the heating furnace and the cooling wind grating by a roll so that the heating and cooling temperature is uniform, and unloading to obtain fireproof glass. The cesium / potassium salt solution comprises: cesium salt 0.8-1.2%, potassium salt 38-41%, acetone 40-45%, formic acid 8-13%, and Swiss-78 6-8%. The fireproof glass has such advantages as high heat resistance, low specific gravity, high light permeability, no yellowing, and no air bubbles.

Owner:新福兴玻璃工业集团有限公司

Protection method for rust removal, paint removal and anticorrosion of metal surface

InactiveCN102218386ASolve the work of rust removal and rust preventionReduce labor intensityPretreated surfacesCoatingsBenzeneKetone

The invention relates to a protection method for rust removal, paint removal and anticorrosion of a metal surface. The method comprises three steps of (1) metal surface lossless rust removal technology, (2) conversion of rust iron on a metal surface and antirust processing, (3) painting of anticorrosion paint on the metal surface. Compared with prior art, the protection processing on the metal surface of the invention employs a high-pressure water-sand blending technology to remove rust, so that rust removal efficiency is higher and the method is safe and environment-friendly. Free rust on the metal surface can be conversed into antirust priming paint when a rust removal transforming agent is being painted, so as to complete metal rust removal and rust prevention by one step, and solve problems, that harm antirust quality, such as local corrosion and free rust at one time. The rust transforming agent employed in the technology belongs to an aqueous system, is without harmful solvents of benzene, ketone, etc., or heavy metal compositions and is nontoxic and environmental-friendly, so that base materials with rust can be used in construction to save costs and raise efficiency. Anticorrosion coating on the metal surface employs a high-pressure air-free coating spraying, so that construction quality is more reliable and the efficiency is higher.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com