Moisture-cured silicone modified polyurethane and hot melt adhesive composition and preparation method thereof

A polyurethane hot-melt adhesive and silane modification technology, which is applied in the field of adhesives, can solve problems such as environmental and human hazards, reduced strength, and long-term use, so as to achieve enhanced heat resistance and mechanical strength, and improved bonding performance. Effect of crosslinking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

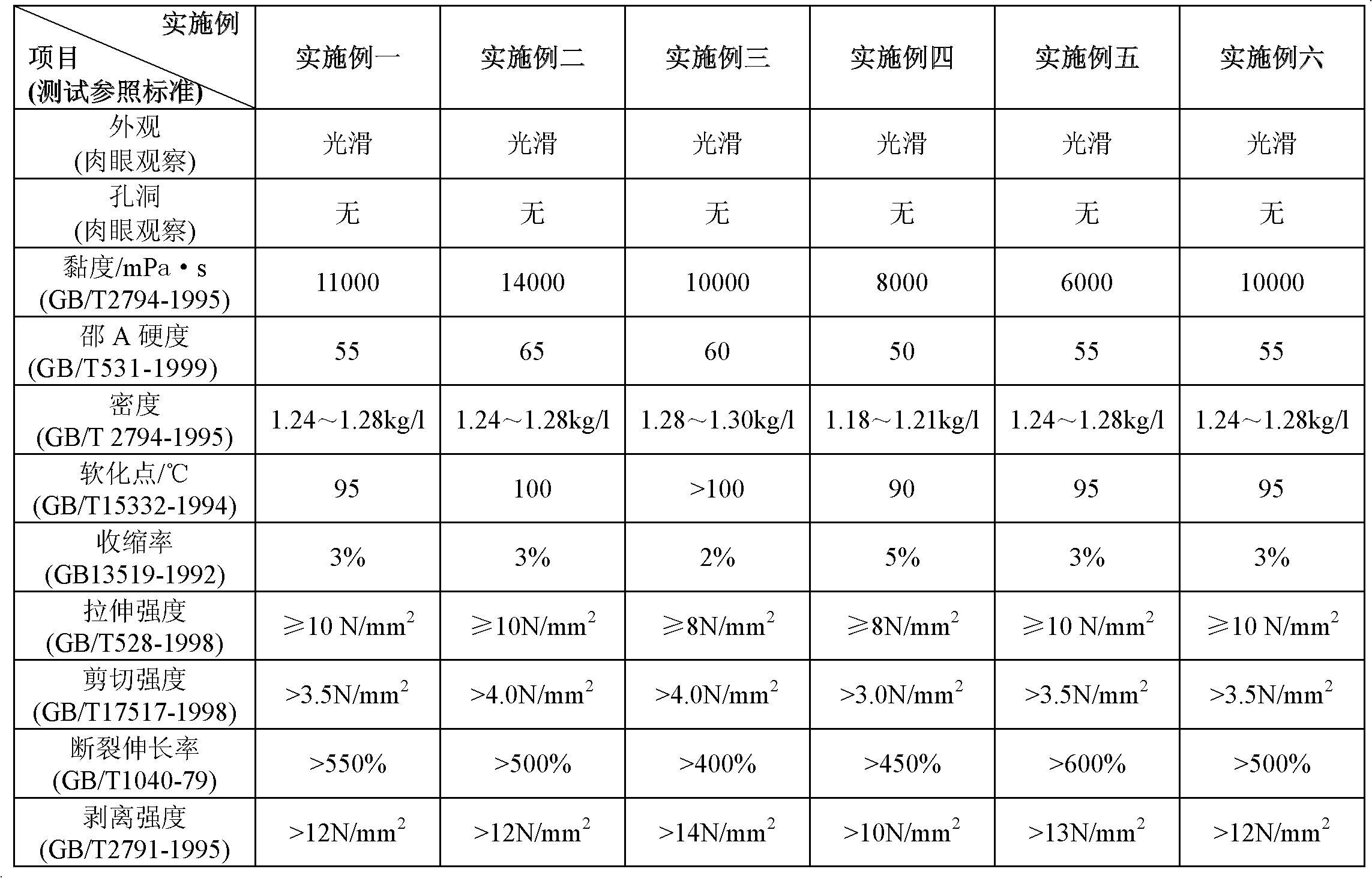

Examples

Embodiment 1

[0040] 1. The composition of the moisture-curing silane-modified polyurethane hot-melt adhesive in this embodiment is shown in Table 1 by weight percentage.

[0041] Table 1 Example 1 Moisture-curing silane-modified polyurethane hot-melt adhesive composition formula composition

[0042] components

name / model

Dosage

Silane modified polyurethane

80.0

BYK-9076

0.5

tackifying resin

10.0

DOP

5.0

Silicone additives

Q4-3667

0.3

Silica H15

4.0

Antioxidants

B-215

0.1

UV-328

0.1

[0043] 2. The preparation method of the moisture-curing silane-modified polyurethane hot-melt adhesive composition in this embodiment, first, the silane-modified polyurethane is prepared by reacting the polyurethane prepolymer containing terminal NCO groups with amino or mercapto silane,...

Embodiment 2

[0051] The difference between this example and Example 1 is: the preparation method of the moisture-curing silane-modified polyurethane hot-melt adhesive composition in this example, in the preparation of step (1) polyurethane prepolymer, the molar ratio of NCO / OH is 8 : 1.

Embodiment 3

[0053] The difference between this embodiment and Example 1 is: the preparation method of the moisture-curing silane-modified polyurethane hot-melt adhesive composition in this embodiment, in the preparation of step (1) polyurethane prepolymer, polyols with a molecular weight of 2000 are used A mixed alcohol of polyoxytetramethylene glycol (PTMG) and poly(diethanol adipate) in a molar ratio of 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com