Patents

Literature

1847 results about "Adipate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adipates are the salts and esters of adipic acid. The anionic (HO₂C(CH₂)₄CO₂⁻) and dianionic (⁻O₂C(CH₂)₄CO₂⁻) forms of adipic acid are also referred to as adipate.

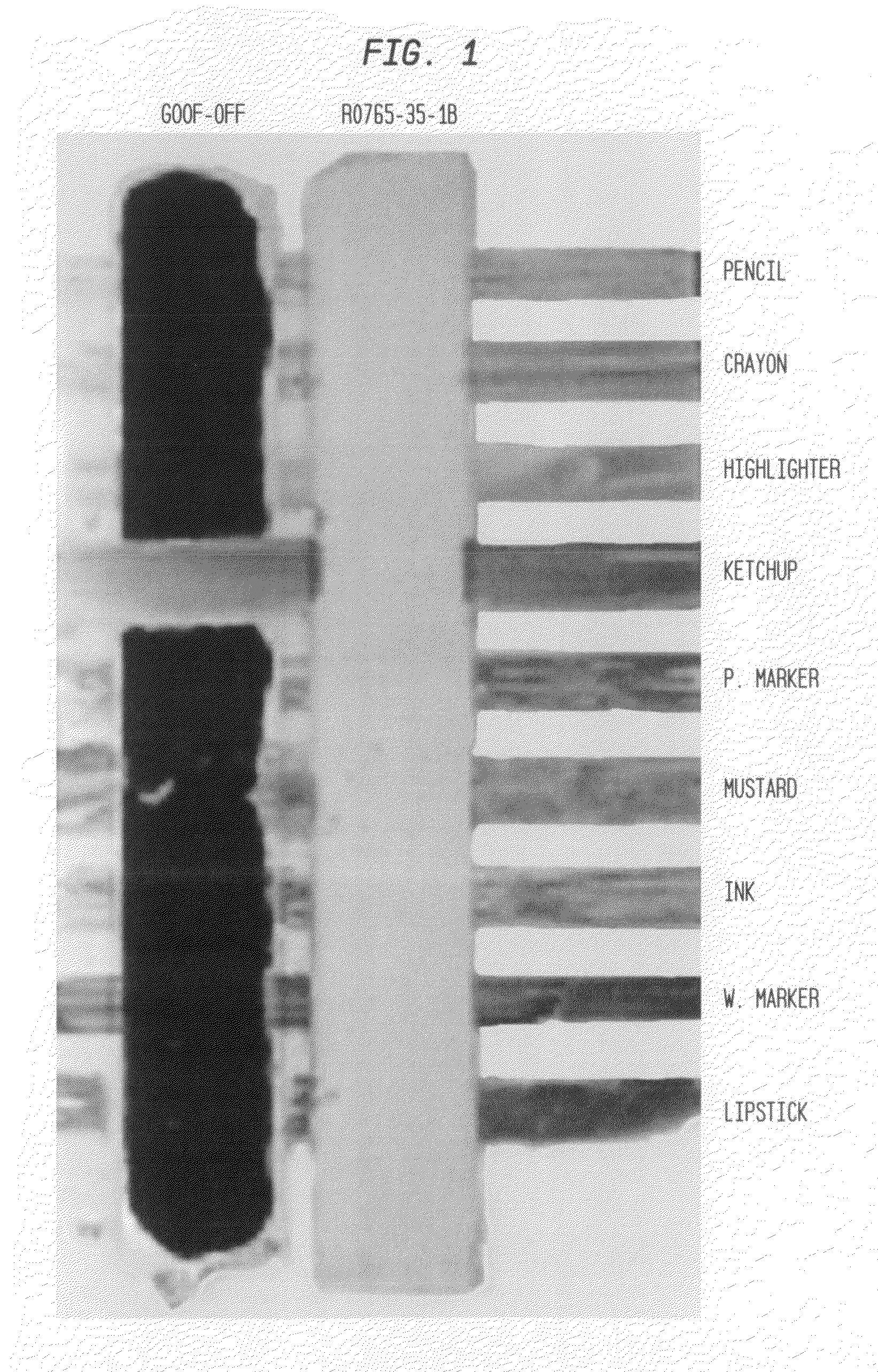

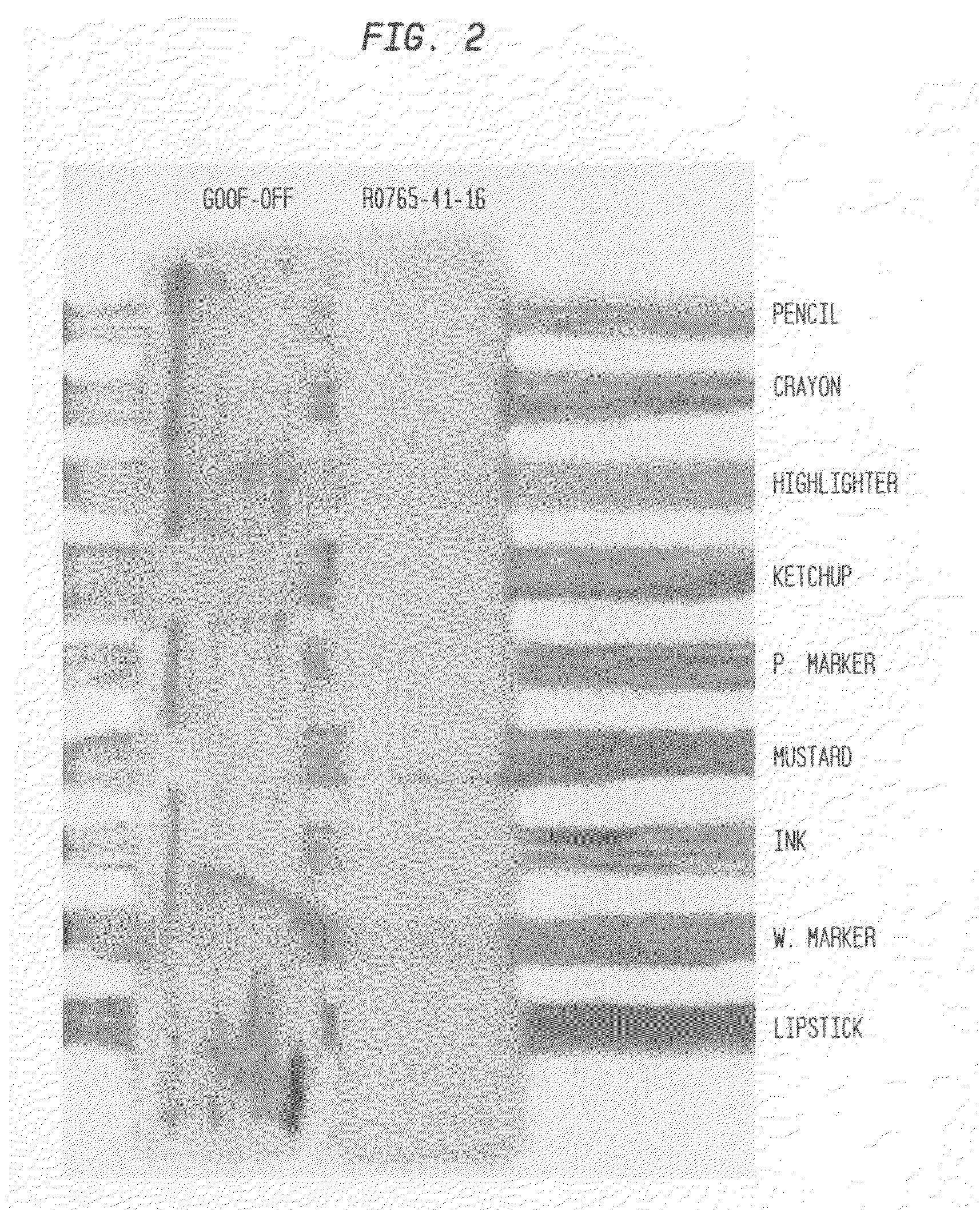

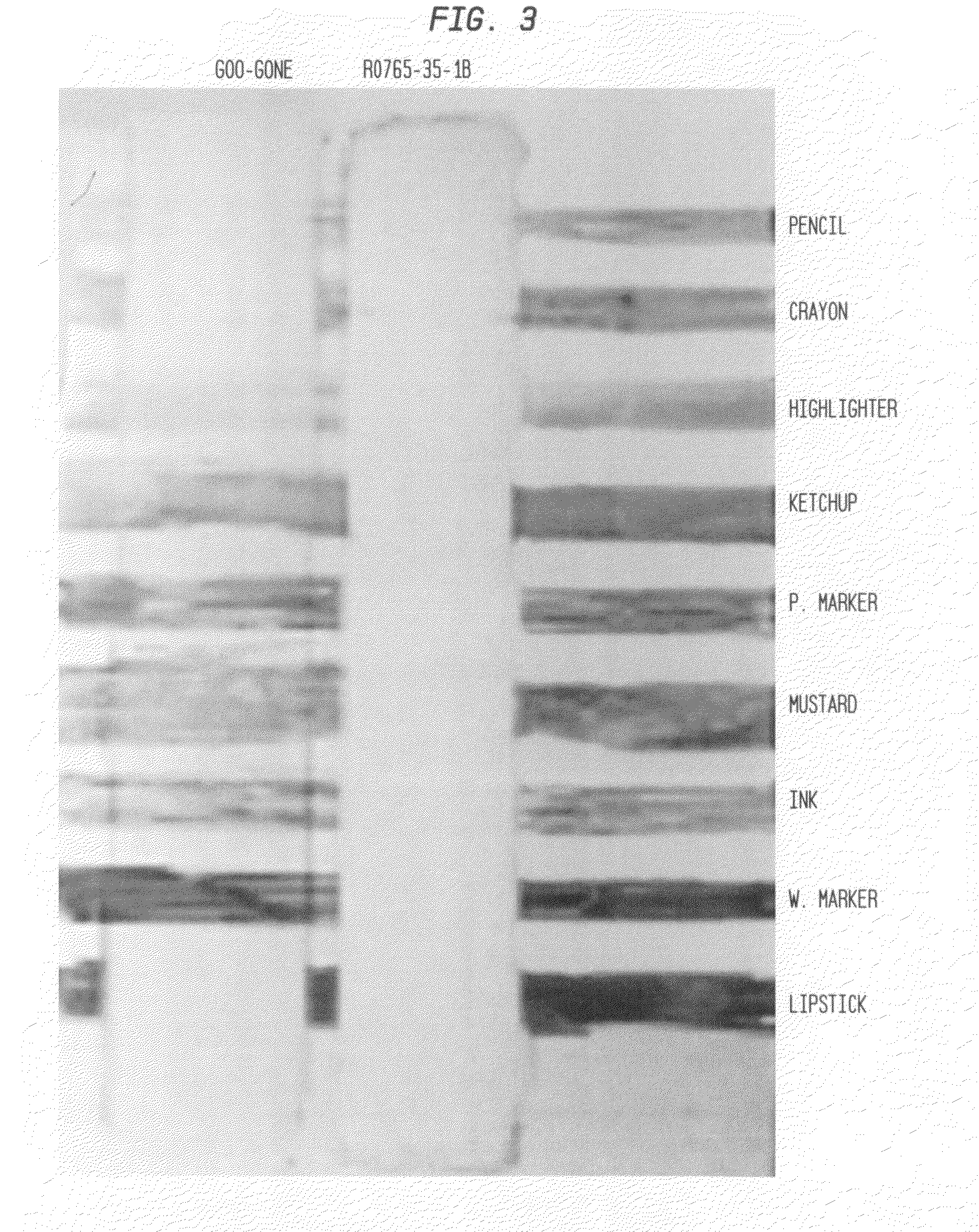

Cleaning compositions incorporating green solvents and methods for use

ActiveUS20090281012A1High flash pointLow vapor pressureOrganic detergent compounding agentsDetergent mixture composition preparationGlutaric acidActive agent

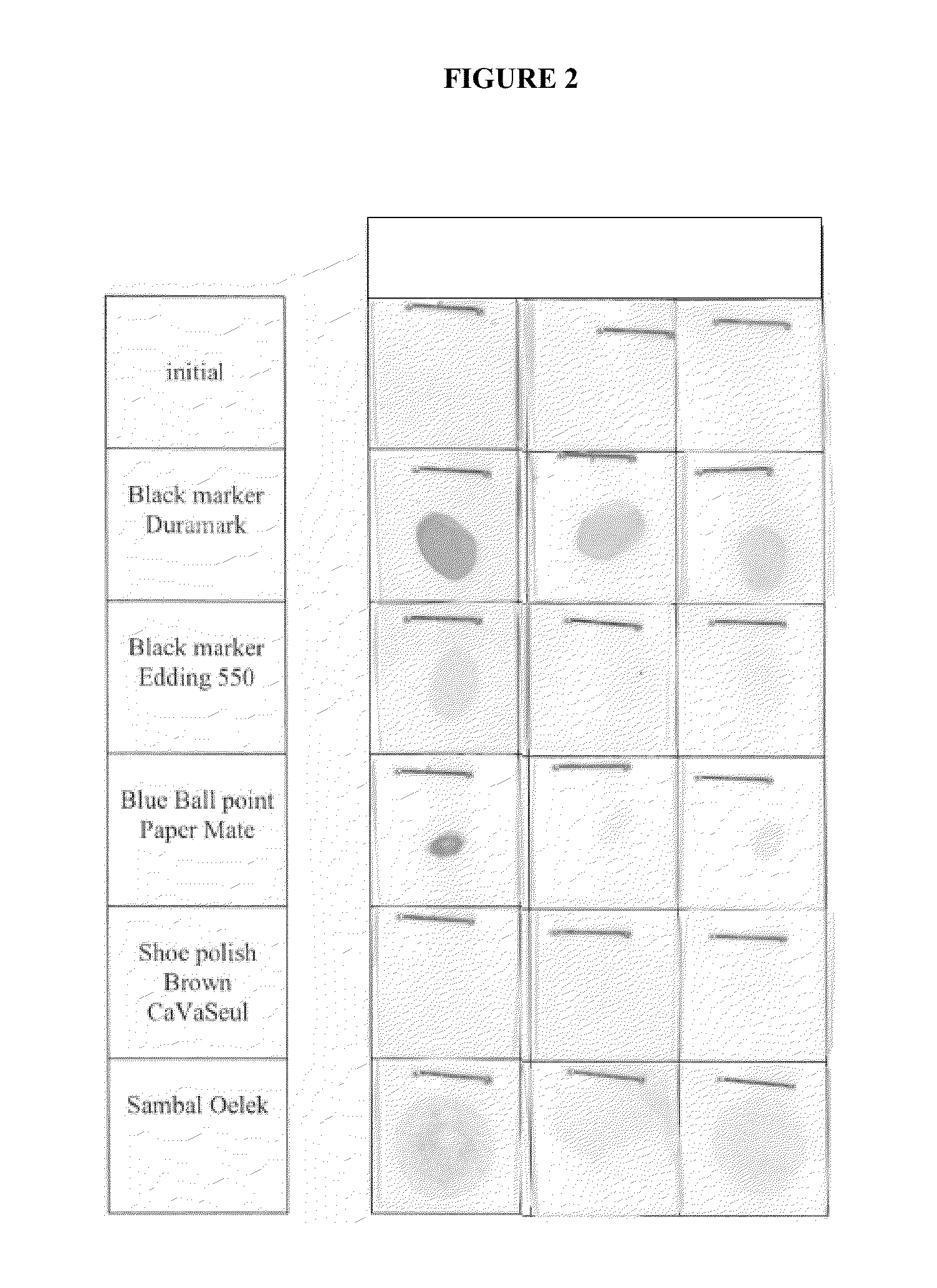

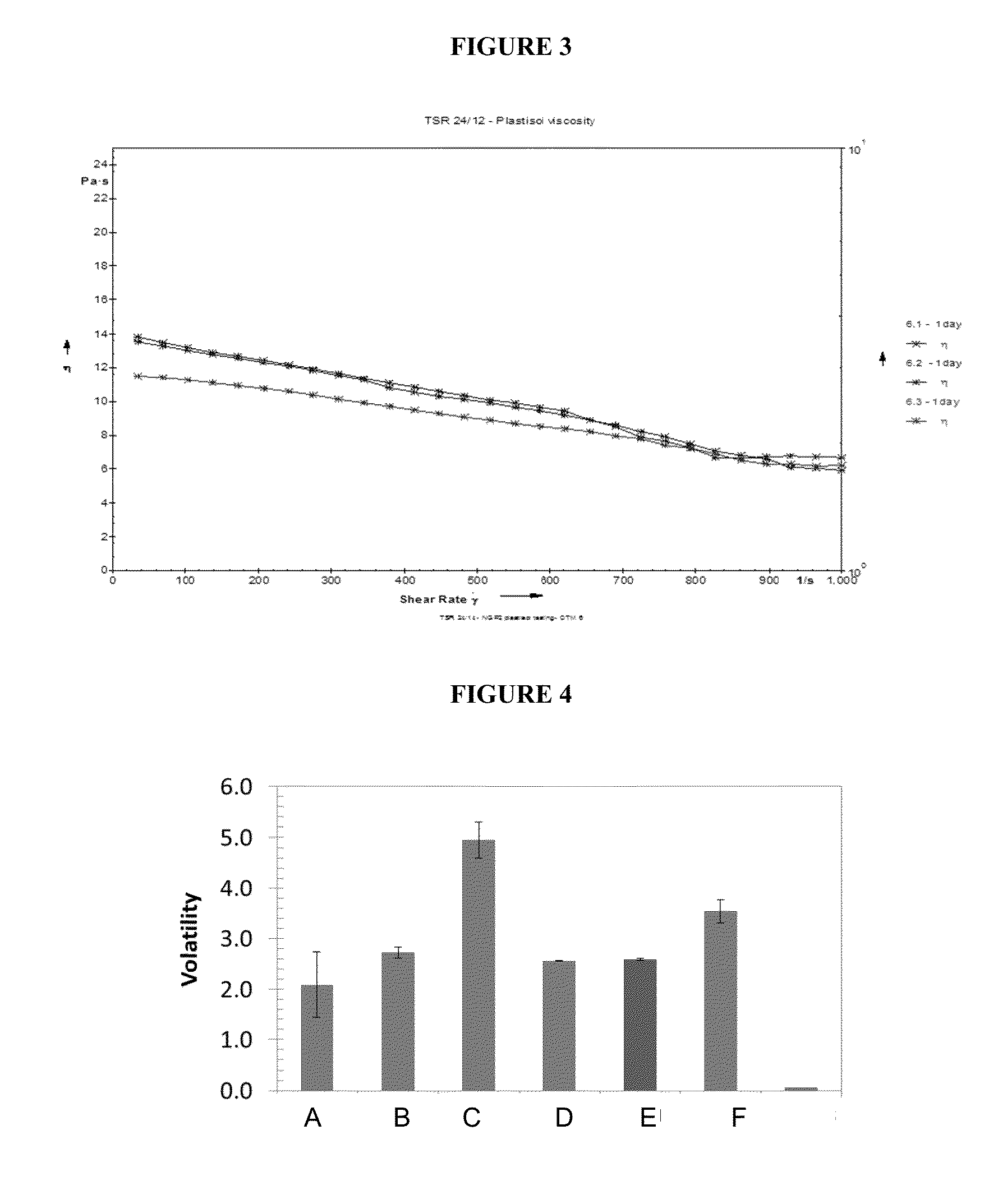

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

Biodegradable bicomponent fibers with improved thermal-dimensional stability

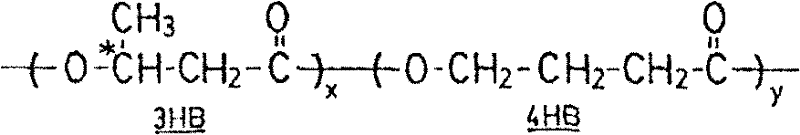

InactiveUS6953622B2Improve wettabilityImprove bindingConjugated synthetic polymer artificial filamentsYarnFiberPolyester

A biodegradable hydrophilic binder fiber. These fibers may be produced by co-spinning an aliphatic polyester material in a side-by-side configuration with a polylactide polymer to obtain a fiber with improved material attributes. A multicarboxylic acid may be incorporated into either or both components of the fiber. The aliphatic polyester polymer may be selected from a polybutylene succinate polymer, a polybutylene succinate-co-adipate polymer, or a blend of these polymers. The biodegradable bicomponent fiber exhibits substantial biodegradable properties, yet has improved thermal stability and has significantly reduced shrinkage. The bicomponent fiber may be used in a disposable absorbent product intended for the absorption of fluids such as body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

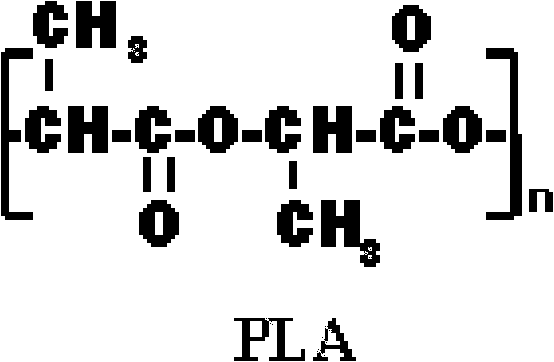

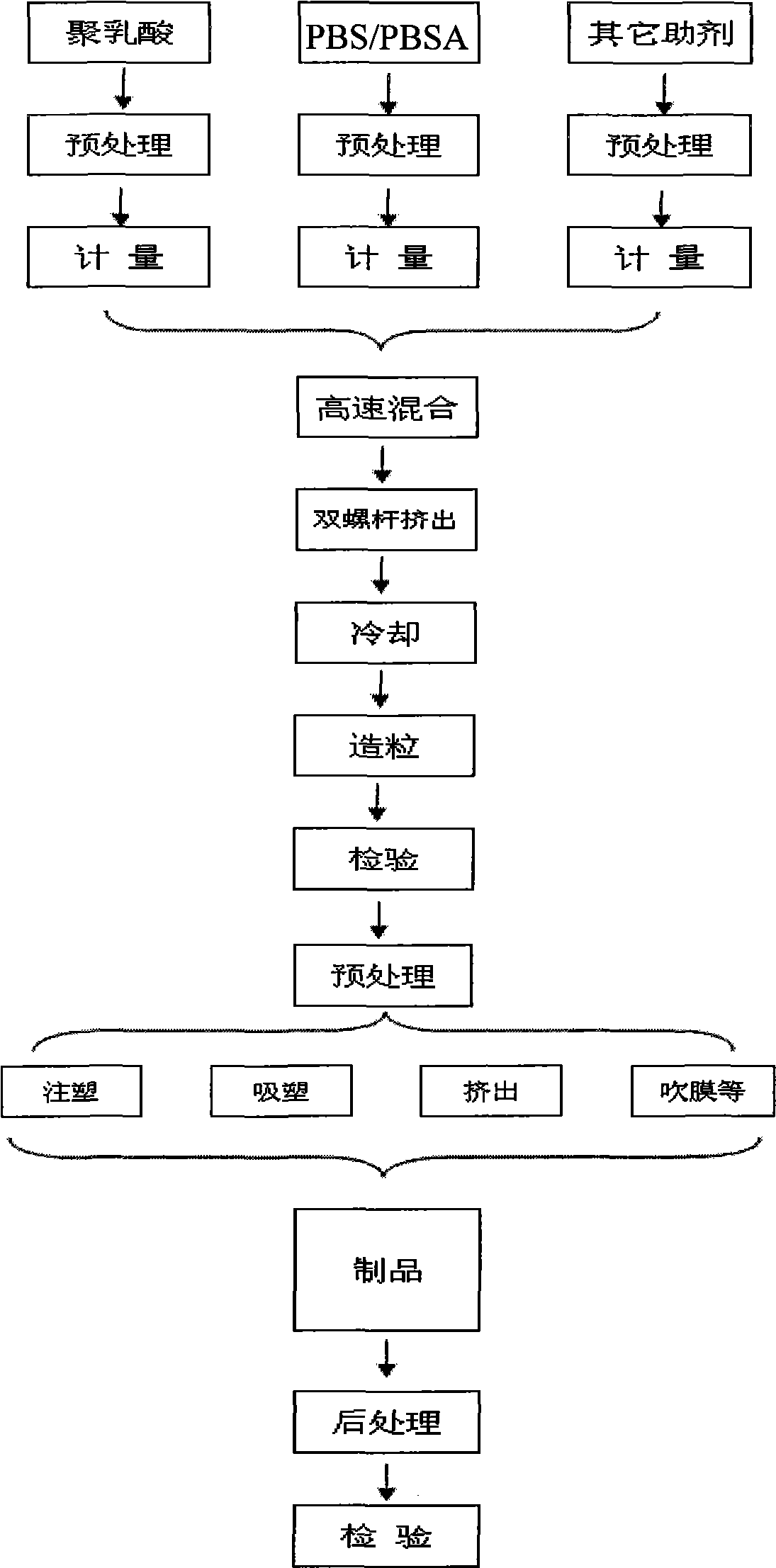

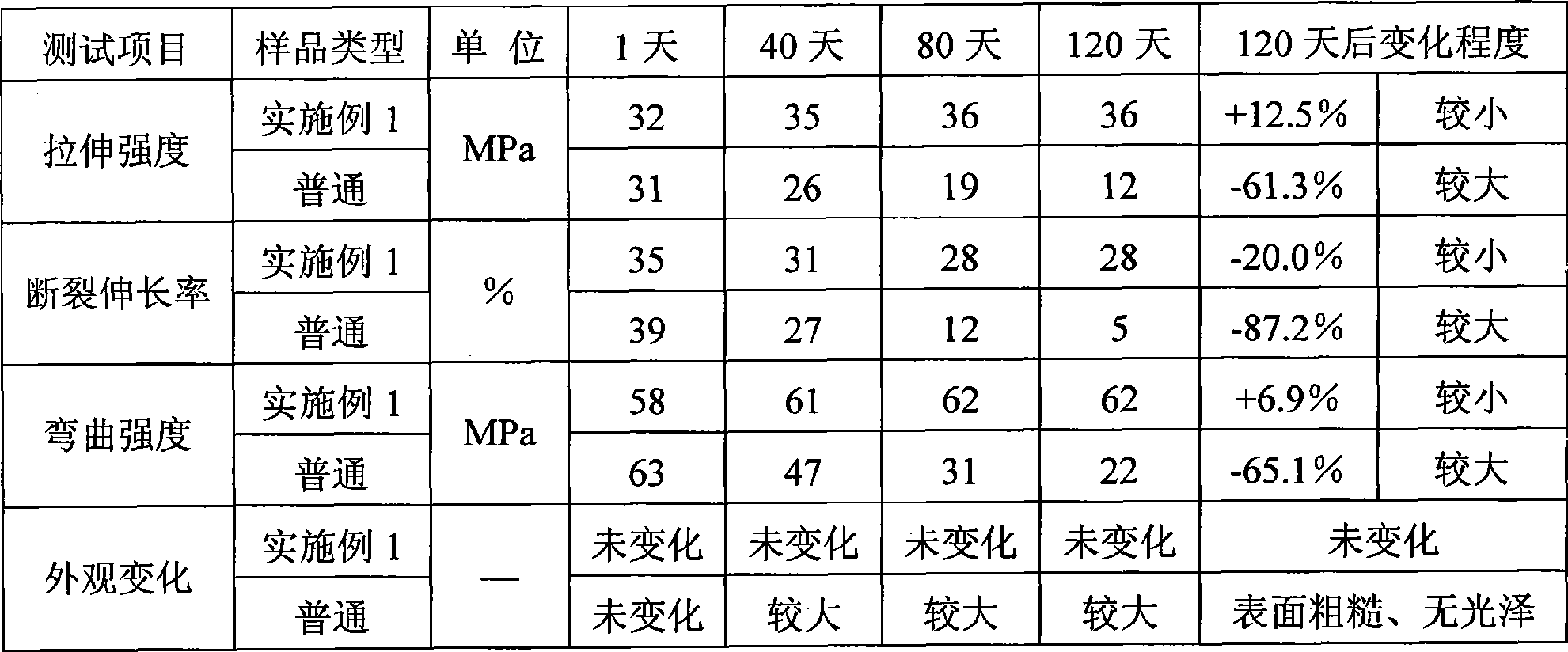

Entire biodegradation PLA/PBAT composite material and preparing method therefor

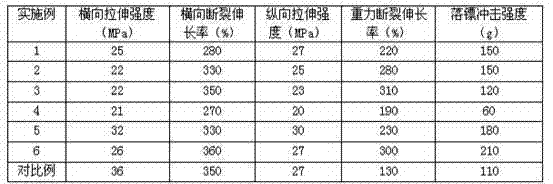

The invention belongs to the technical field of polymer materials, and relates to an entire biodegradation PLA / PBAT composite material and a preparing method therefor. The composite material comprises, by weight, 10-90 parts of polylactic acid, 10-90 parts of poly(butylene adipate-co-butylene terephthalate)ester, 10-80 parts of thermoplastic starch, 0.01-1.5 parts of compatilizer A, 0.1-10 parts of compatilizer B, and 1-40 parts of filling materials. The preparing method and an operation process for the composite material are simple, product manufacturing cost is relatively low, the composite material has excellent mechanical properties, is of excellent flexibility, is entirely biodegradable, and can be widely used in the field of consumer products such as packaging materials and disposable tableware.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

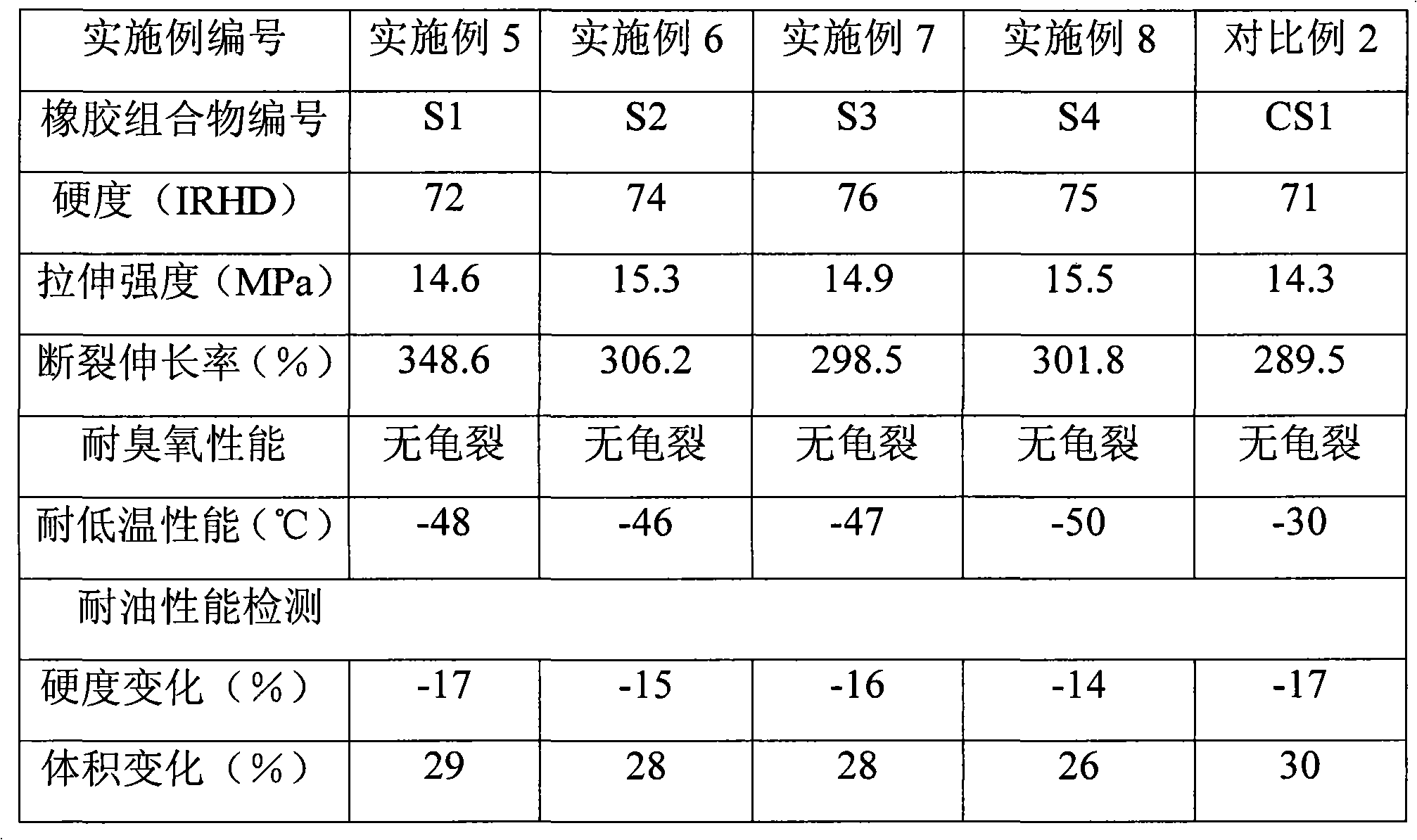

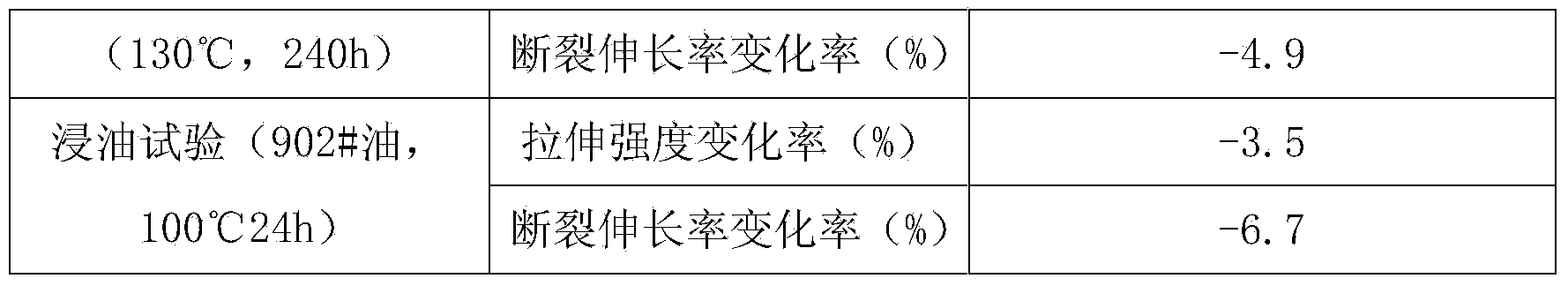

Oil resistant low temperature resistant rubber composition

InactiveCN101353451AGuaranteed oil resistanceGuaranteed ozone resistancePolymer scienceNitrile rubber

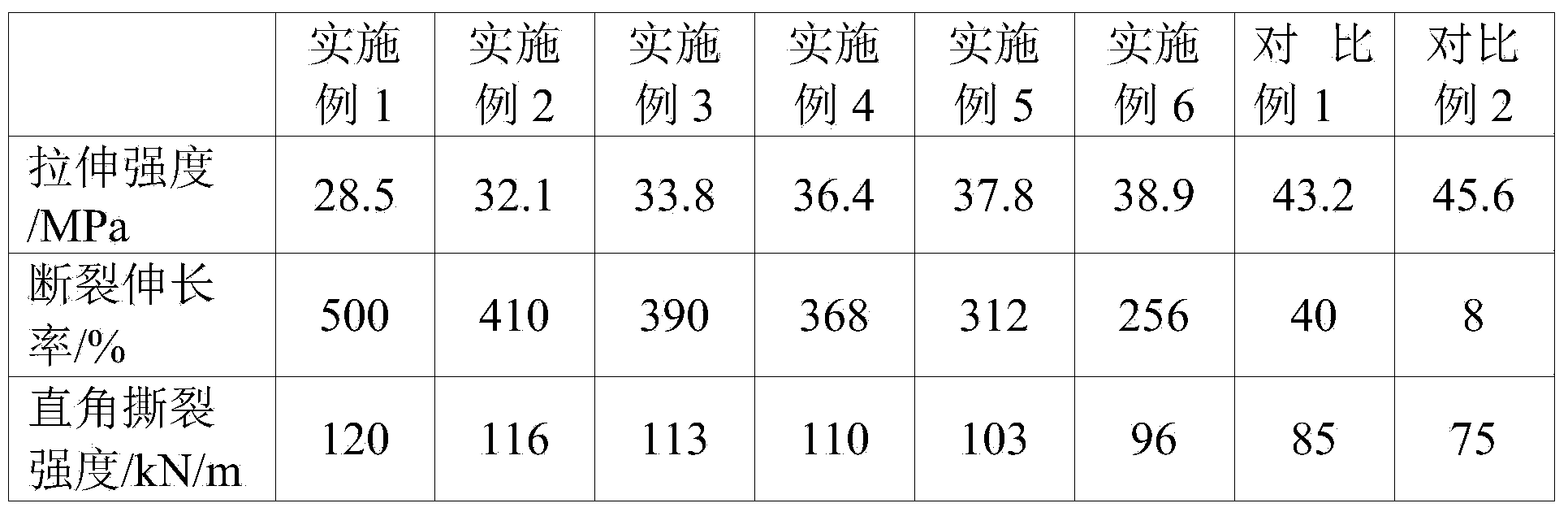

The invention relates to a rubber composite, comprising nitrile rubber, polyvinyl chloride, carbon soot, activator, vulcanizator, age inhibitor, antiscorcher, accelerant and plasticizer, wherein, the plasticizer is ethylhexyl sebacate and adipate. The rubber composite of the invention obviously improves the anti-low temperature performance of the rubber composite while ensuring the anti-oil performance, anti-ozone performance, tensile strength and elongation at break.

Owner:BYD CO LTD

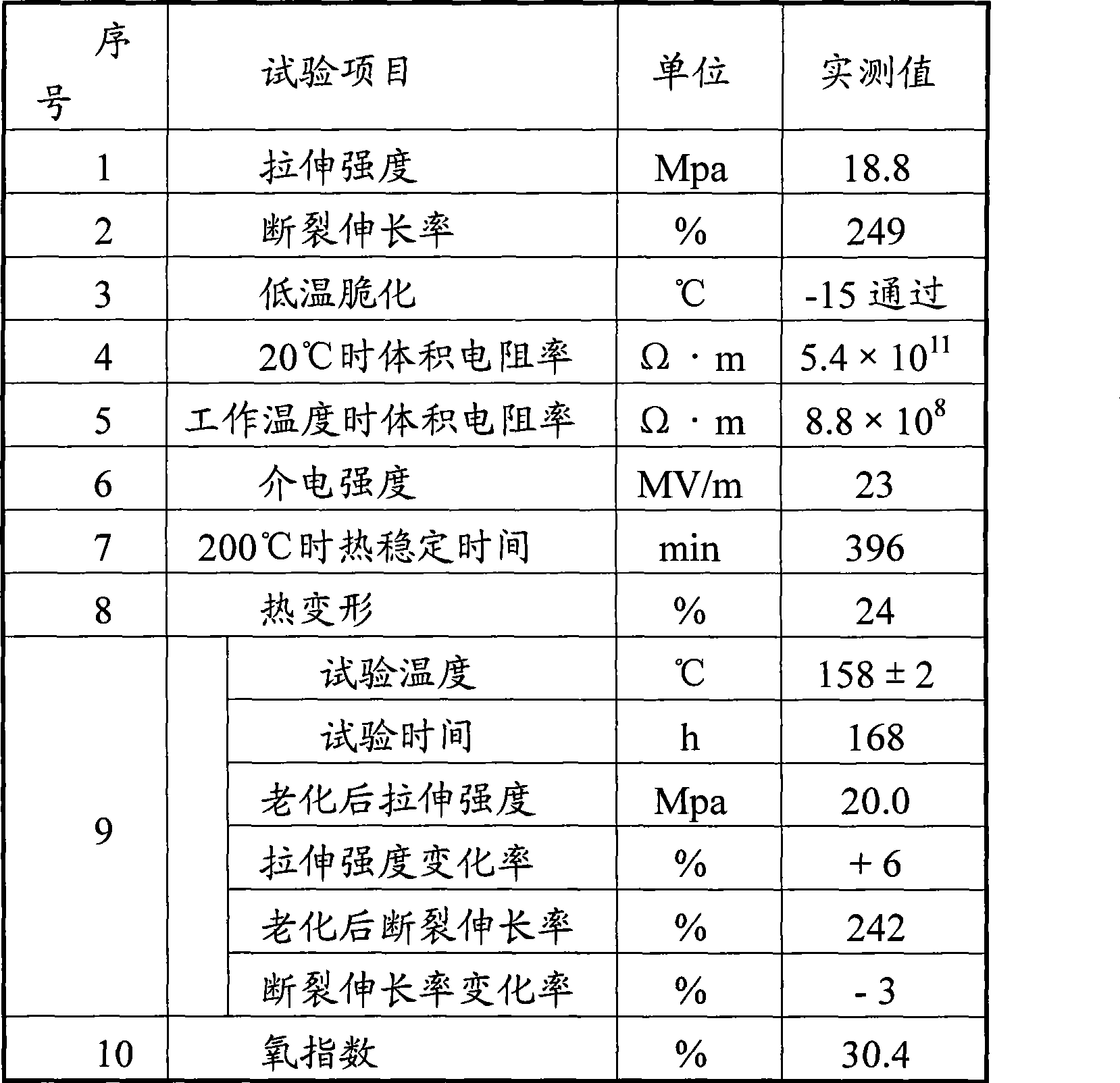

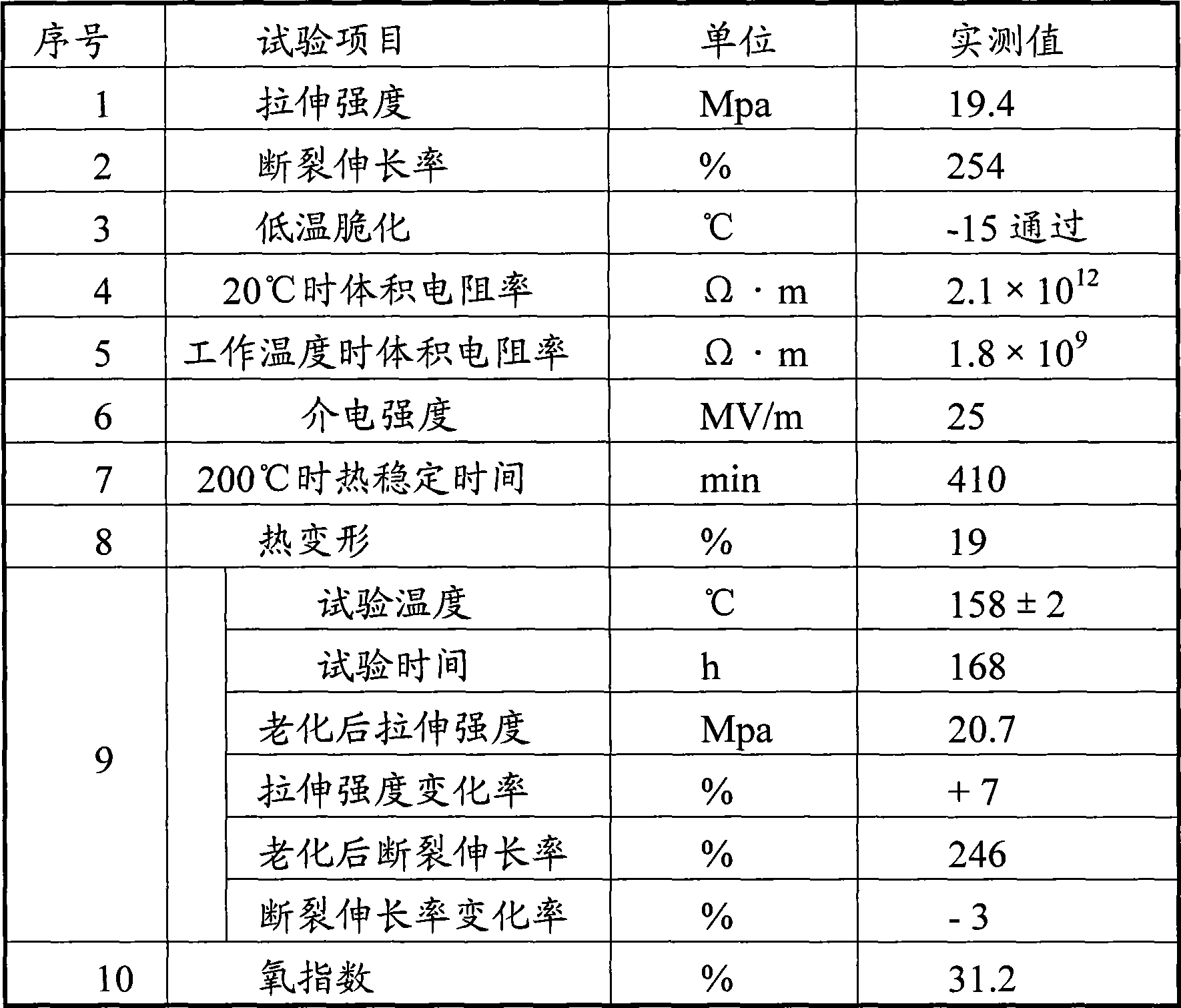

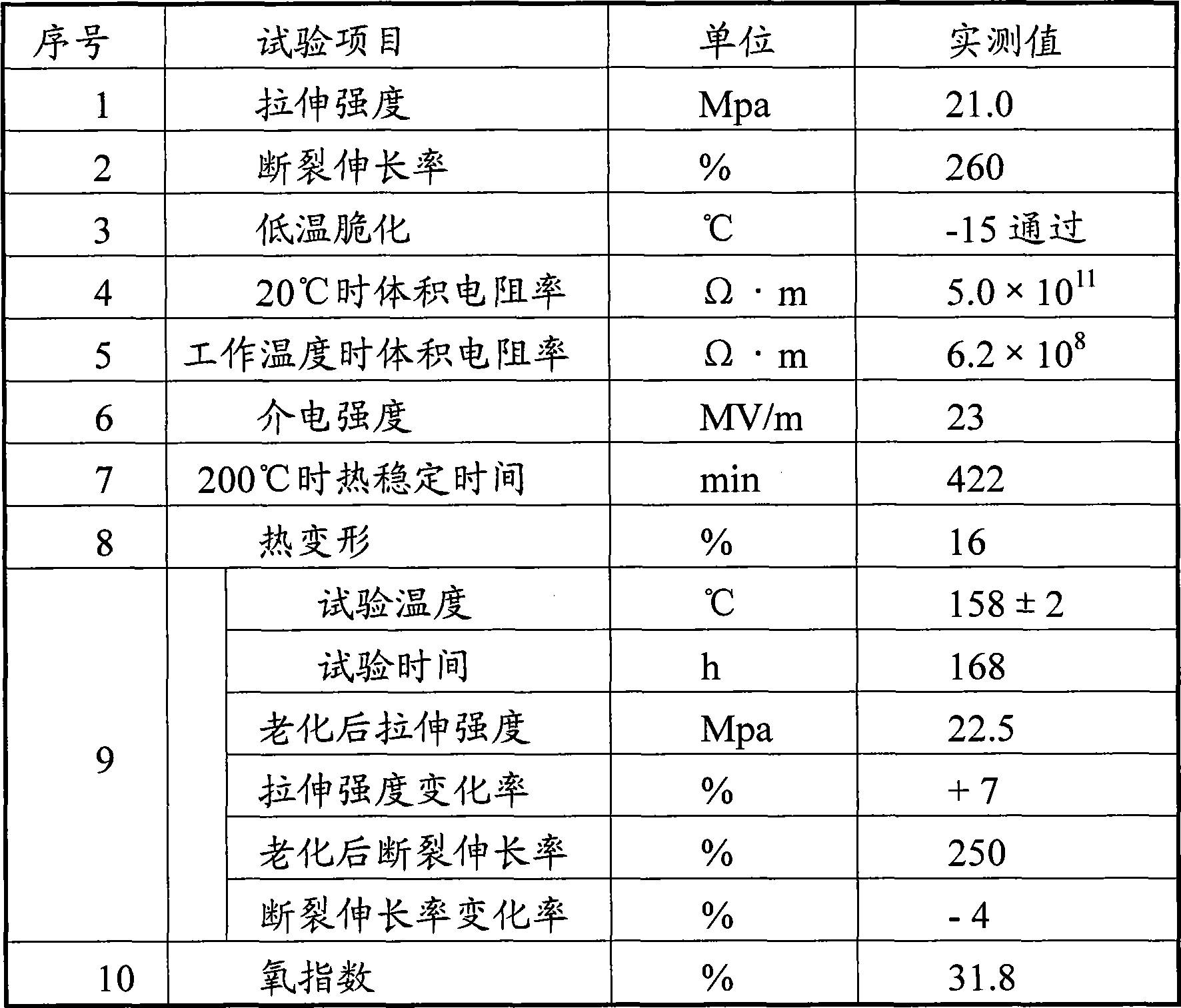

High temperature resistant environment-protective polychloroethylene material for electric wire and cable

InactiveCN101412834AImprove mechanical propertiesImprove insulation performancePlastic/resin/waxes insulatorsInsulated cablesPolyesterPolyvinyl chloride

The invention provides a high-temperature resistant environment-friendly polyvinyl chloride material for wires and cables. A raw material formulation mainly comprises the following materials in weight portion: 80 to 120 portions of loose-type polyvinyl chloride resin, 20 to 55 portions of tetraoctyl pyromellitate, 5 to 35 portions of polyester plasticizer and 12 to 18 portions of calcium-zinc stabilizer, wherein the polymerization degree of the loose-type polyvinyl chloride resin is between 2,000 and 3,000; in the calcium-zinc stabilizer, the total content of lead, cadmium, mercury and hexavalent chromium is less than or equal to 10 ppm of the total weight of the calcium-zinc stabilizer; the polyester plasticizer is polypropylene-1, 2-glycol adipate or polypropylene-1, 3-butylene terephthalate; and the molecular weight of the polyester plasticizer is between 3,000 and 4,000. After the material is aged in a hot-air oven for 168 hours at 158 DEG C, the retention rate of tensile strength is up to 106 percent; the retention rate of elongation at break is 97 percent; and the material is good in mechanical physical properties and insulating property. Therefore, the material meets the temperature-resistant requirement on long-term operating temperature at 125 DEG C in UL1581.

Owner:中广核三角洲(江苏)塑化有限公司

Biological degradable film and laminated material

ActiveCN102675839AImprove mechanical propertiesHigh elongationSynthetic resin layered productsNon-woven fabricsMicroorganismPolymer science

The invention discloses a biological degradable film, enhancement type biological degradable fabrics and a laminate material, and the enhancement type biological degradable fabrics and the laminate material are made of the laminated biological degradable film. The biological degradable film mainly comprises polybutylene adipate terephthalate (PBAT) or poly butylenes succinate (PBS) or a mixture of PBAT and PBS, and polylactic acid (PLA) and other degradable macromolecular polymers such as PBSA, PCL, PCL-BS and PHA, and accordingly the PLA, and a novel mixture of PLA and polyhydrooxyalkonates (PHAs), or a mixture of PLA, PBAT and PBS, or a mixture of PLA, PHAs, PBAT and PBS or other degradable macromolecular polymers are made. The enhancement type biological degradable fabrics and the laminate material have strong biological degradable performances in the environment containing microorganisms and can have good quality guarantee period, strength, flexibility and toughness.

Owner:U S PACIFIC NONWOVENS IND

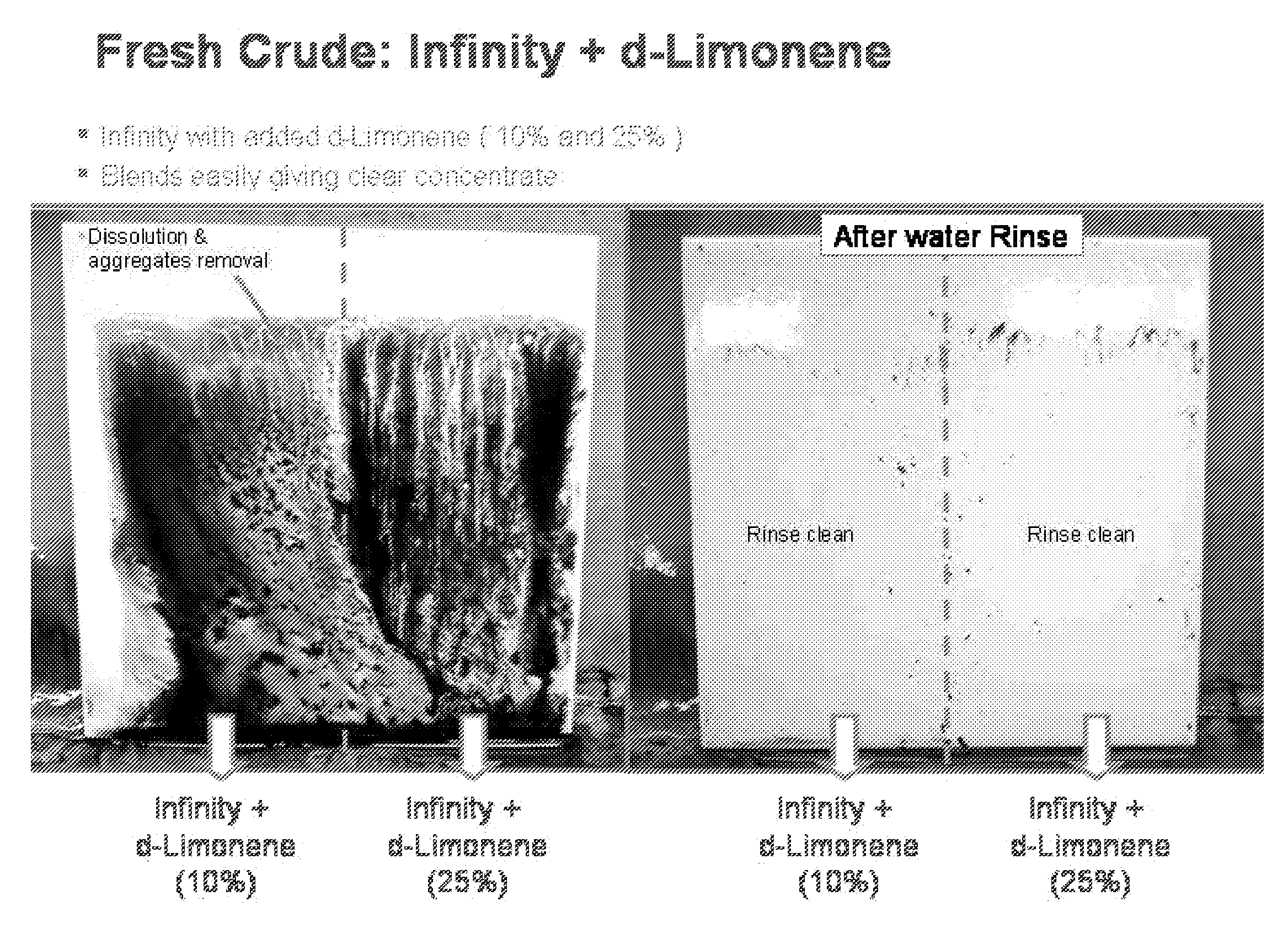

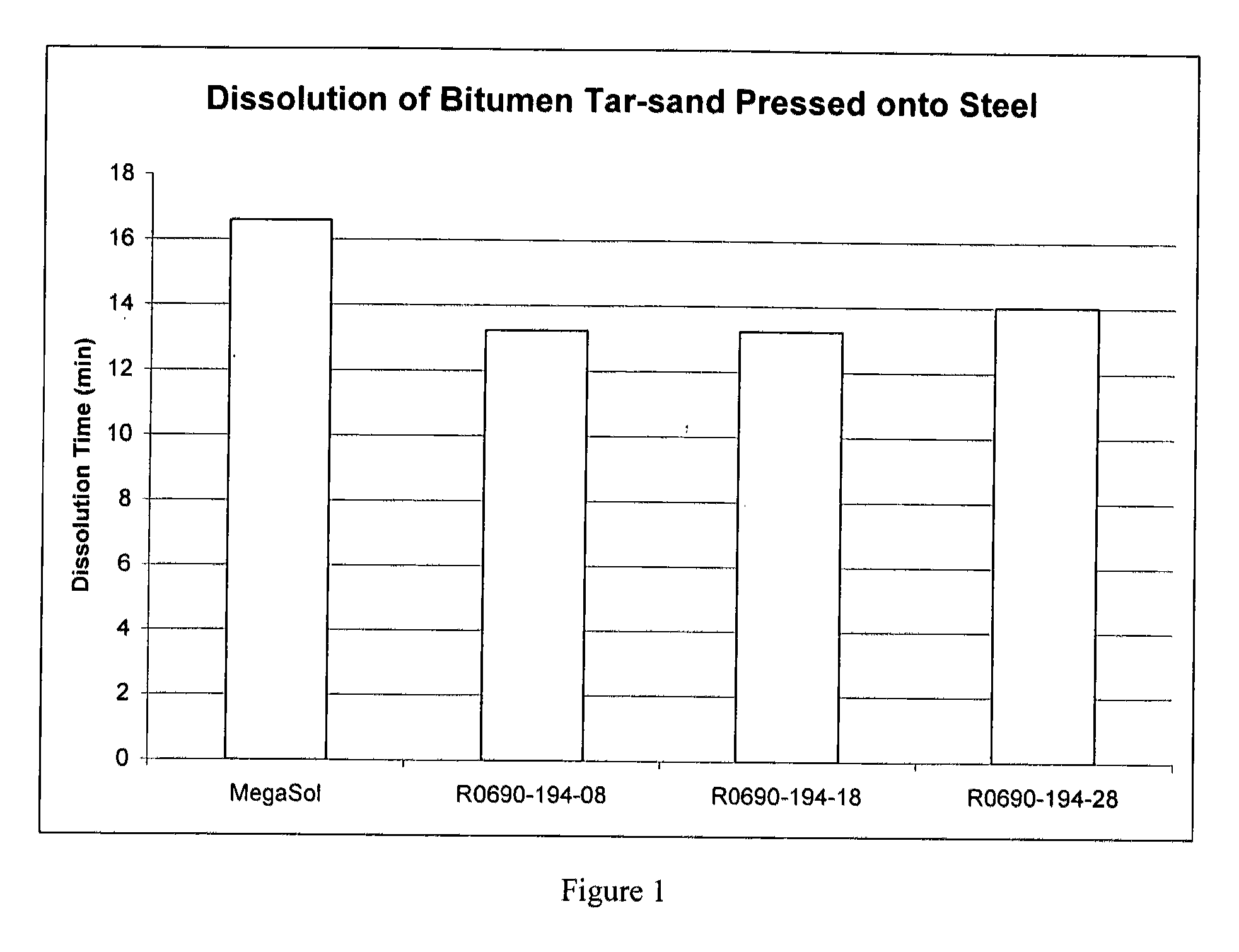

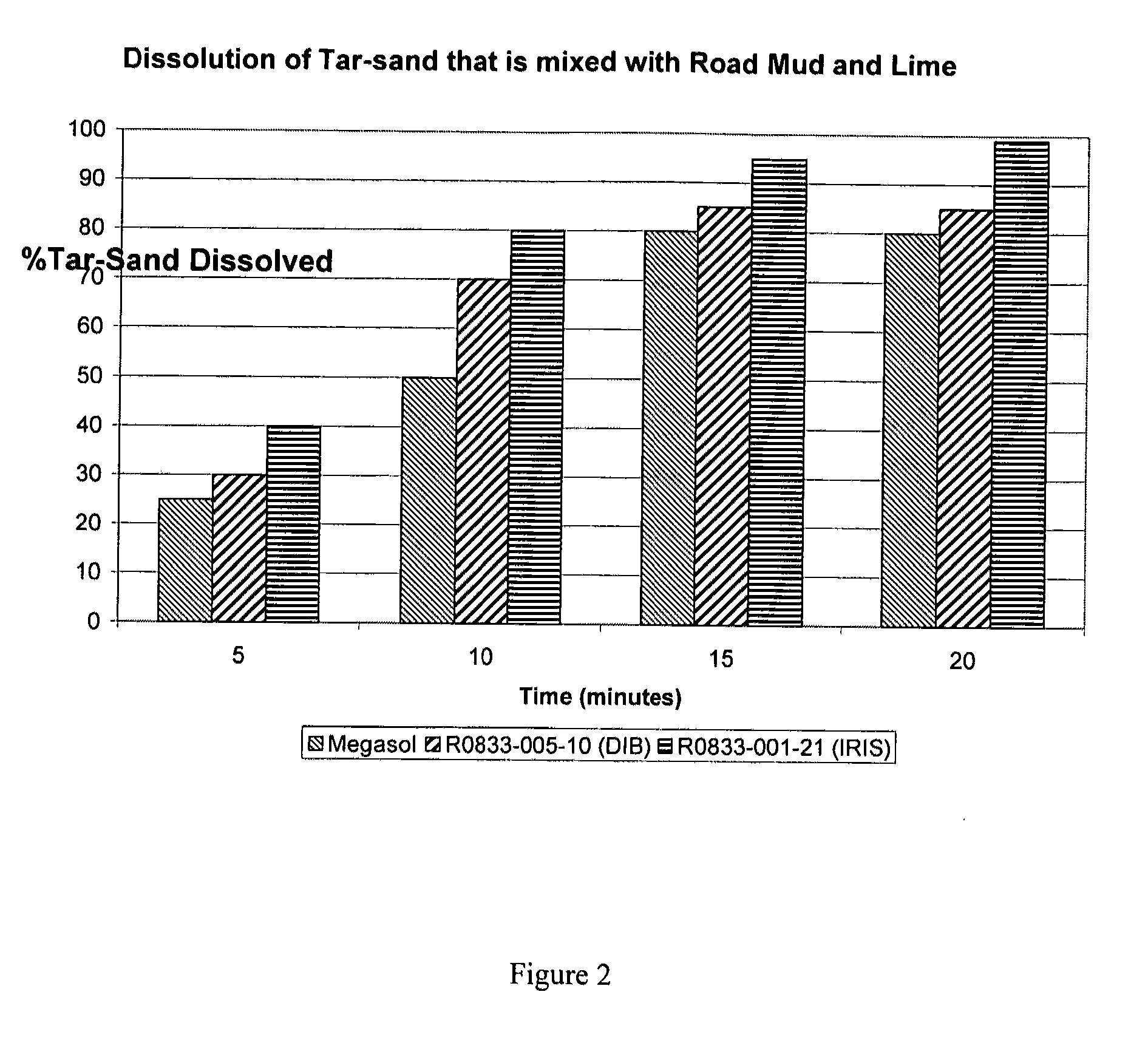

Dibasic esters utilized as terpene co-solvents, substitutes and/or carriers in tar sand/bitumen/asphaltene cleaning applications

ActiveUS20120149626A1Reduce concentrationImprove environmental conditionsOrganic detergent compounding agentsNon-ionic surface-active compoundsCarrier fluidFuel oil

A heavy oil cleaning composition comprising: a) a blend of dibasic esters comprising dialkyl methylglutarate and at least one of a dialkyl adipate or dialkyl ethylsuccinate; b) at least one terpene; and c) at least one surfactant. Also described are methods for delivering a solvent at reduced concentration comprising the steps of: a) obtaining a terpene-based solvent; and b) mixing the terpene-based solvent with a carrier fluid (the carrier fluid comprising a microemulsion of i) a blend of dibasic esters selected from the group consisting of dialkyl methylglutarate, dialkyl adipate, dialkyl ethylsuccinate, dialkyl succinate, dialkyl glutarate and any combination thereof, ii) at least one surfactant selected from the group consisting of a terpene alkoxylate, an alcohol alkoxylate and any combination thereof; and iii) water) in order to obtain a mixture to clean heavy oils.

Owner:RHODIA OPERATIONS SAS

Environmentally Friendly Solvent Systems/Surfactant Systems For Drilling Fluids

InactiveUS20140005079A1Good for healthImprove securityFlushingDrilling compositionGlutaric acidActive agent

A oil field production fluid, namely a drilling mud composition, comprising a mixture of: (a) at least one base oil component; and (b) an additive component comprising a blend of dibasic esters. The functional fluid can optionally comprise additional additive components. The blend of dibasic esters comprises two or more of dialkyl methylglutarate, dialkyl adipate, dialkyl ethylsuccinate, dialkyl succinate, dialkyl glutarate.

Owner:RHODIA OPERATIONS SAS

Use of eco-friendly microemulsions in oil cleaning applications

InactiveUS20130146545A1Easily biodegradablePoint becomes highSurface-active detergent compositionsTransportation and packagingDibasic esterPhenol

An environmentally-friendly cleaning composition for oil cleaning comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition.

Owner:RHODIA OPERATIONS SAS

Full-biodegradable film and preparation method thereof

The invention relates to a composition of a high-tenacity full-biodegradable film and a preparation method thereof. The film is prepared from polylactic acid (PLA), poly propylene carbonate (PPC), polybutylene adipate terephthalate (PBAT) and a heat stabilizer. Blending modification sections are prepared by adopting a twin-screw extruder, blow molding is carried out by adopting a single-screw extruder, the prepared film has excellent tenacity and full biodegradable performance, and meanwhile the cost is low, so that the film is an ideal substitute for a current non-degradable film packing material.

Owner:NANTONG LONGDA BIO TECH NEW MATERIALS CO LTD

Modified polylactic acid material and preparation method and application thereof

The invention provides a modified polylactic acid material and a preparation method and application thereof. The modified polylactic acid material comprises the following raw materials in part by weight: 40 to 70 parts of polylactic acid, 10 to 20 parts of thermoplastic polyester elastomer, 10 to 20 parts of plasticizer and 10 to 20 parts of organic or inorganic filler, wherein the thermoplastic polyester elastomer is polyester thermoplastic polyurethane; the plasticizer is one or two of tributyl acetocitrate, epoxidized soybean oil, propylene glycol polyester adipate or dioctyl maleate; and the organic or inorganic filler is one or more of starch, talcum powder, calcium carbonate, mica, montmorillonite, clay or titanium dioxide. The modified polylactic acid material has the advantages of improving the flexibility of a polylactic acid material and reducing the cost of a biodegradable material. A mechanical performance test shows that in the modified polylactic acid material, the tensile strength is 15 to 70 MPa and the fracture tensile rate is 20 to 38 percent.

Owner:江苏天仁生物材料有限公司

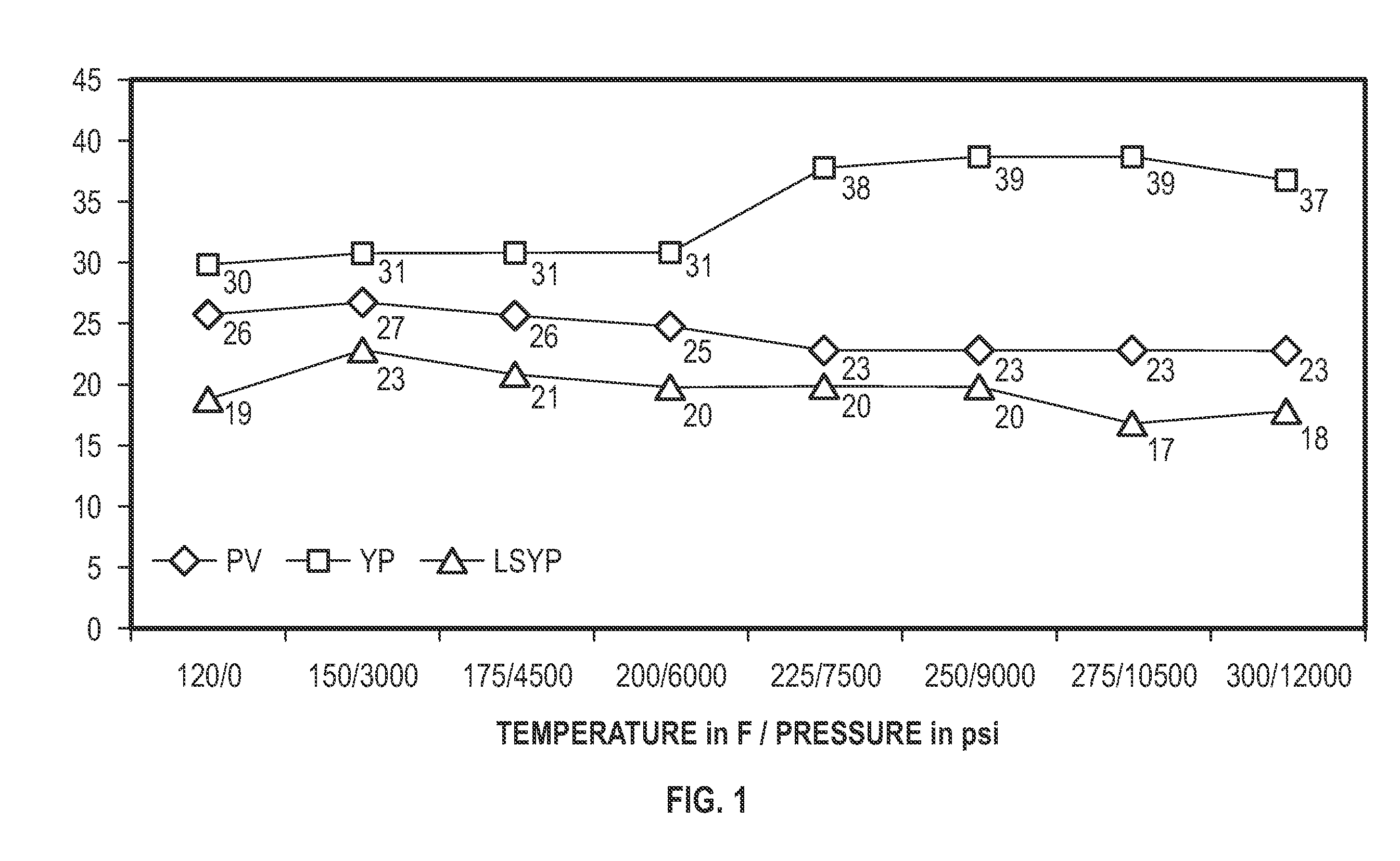

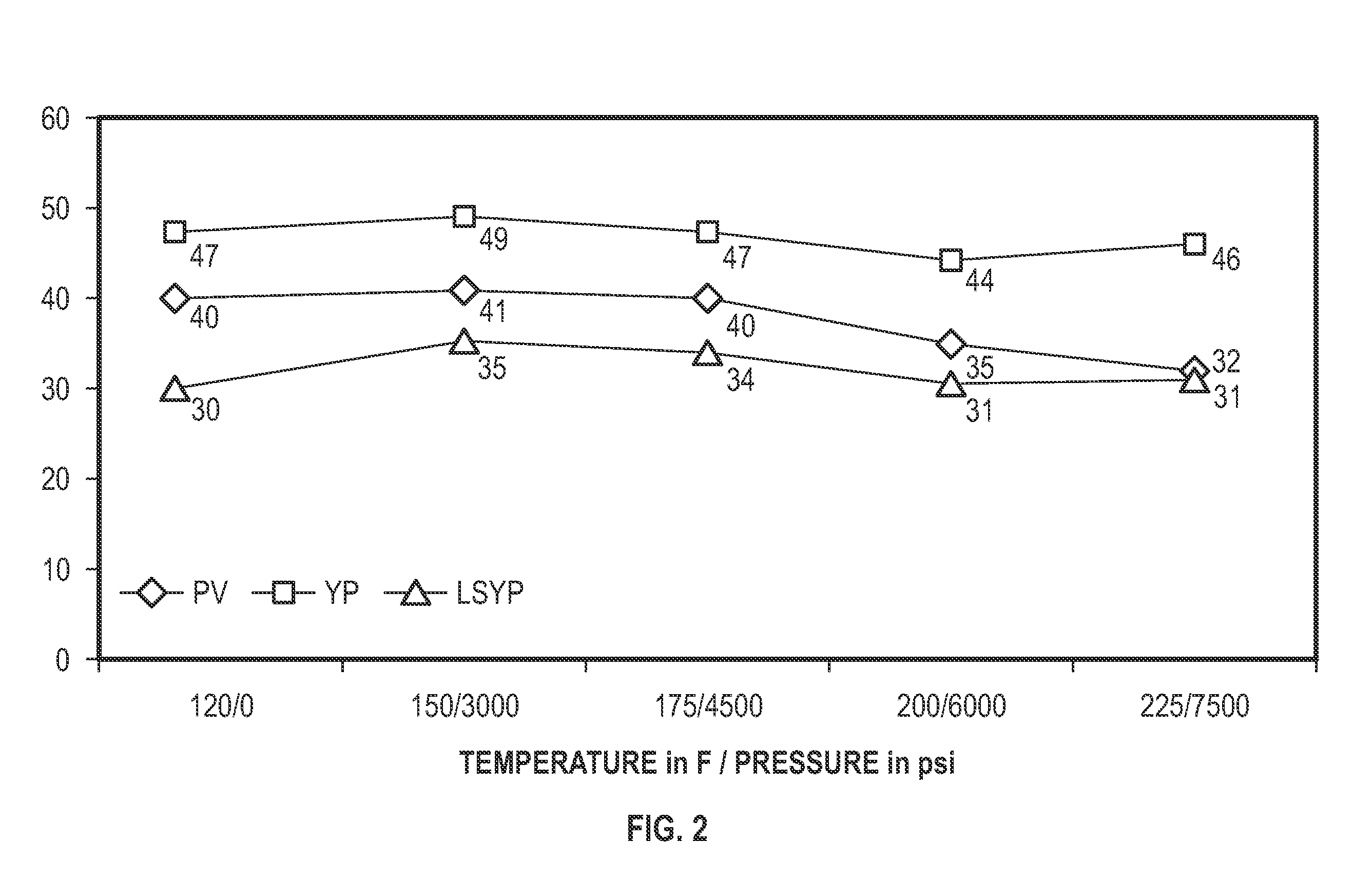

Methods and Materials to Enhance High Temperature Rheology in Invert Emulsions

ActiveUS20130303411A1Quantity minimizationLow pour pointFlushingDrilling compositionOrganic acidEmulsion

An invert emulsion drilling fluid, and a method of drilling with such fluid, having improved rheology at low mud weights and high temperatures. The improved rheology is effected with addition of a rheology additive of the invention comprising fatty dimer diamines or dimer diamines and an organic acid or ester of the acid. A nonlimiting example of such a rheology additive comprises a C36 fatty dimer diamine and adipic acid or dimethyl adipate.

Owner:HALLIBURTON ENERGY SERVICES INC

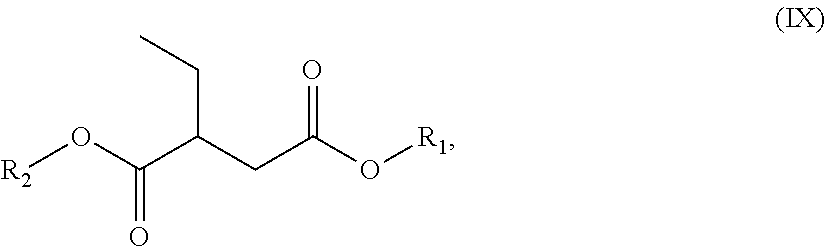

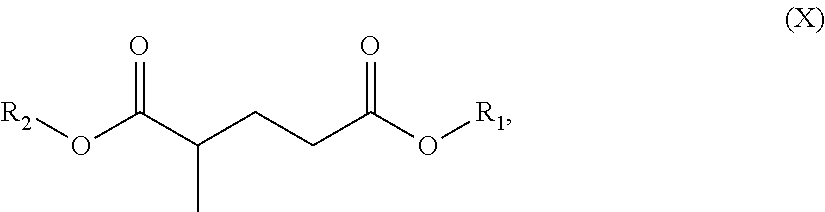

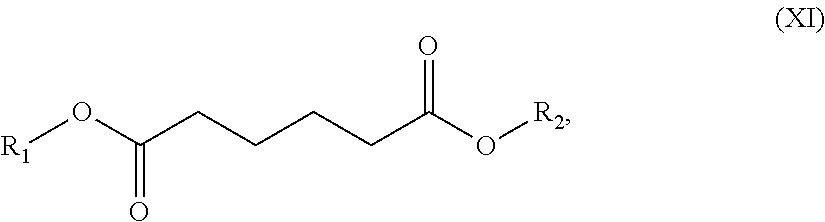

Plasticizer Blends and Use Thereof

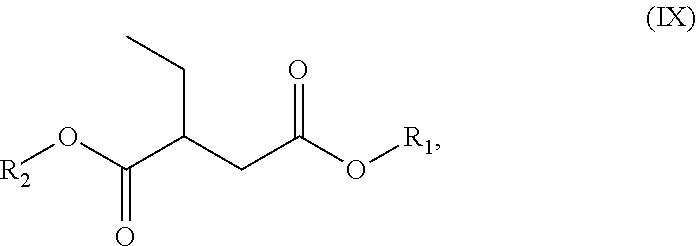

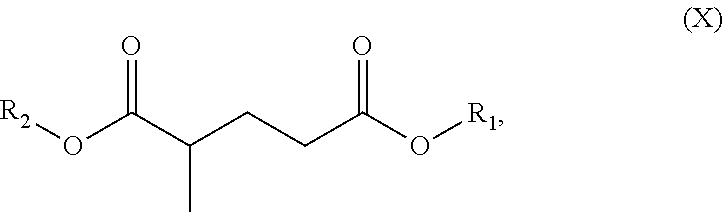

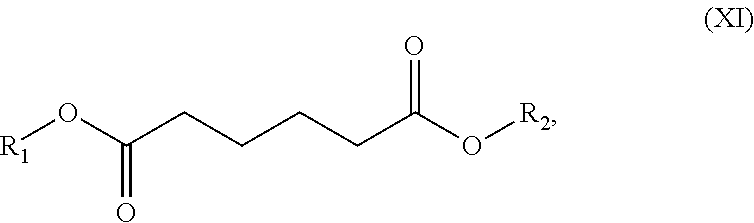

Provided are mixtures of 1) compounds of the formula:wherein R1 is a saturated or unsaturated cyclic hydrocarbon optionally substituted with an alkyl and / or an OXO-ester, and R2 is a C4 to C14 hydrocarbyl; and 2) one or more second plasticizers selected from the group consisting of alkyl terephthalates, alkyl phthalates, alkyl benzoate esters, di-benzoate esters, esters of cyclohexane polycarboxylic acids, and dialkyl adipates. Also provided are plasticized polymer compositions containing said mixtures.

Owner:EXXONMOBIL CHEM PAT INC

Polylactic acid foaming material and preparation method thereof

The invention provides a polylactic acid foaming material and a preparation method thereof. The polylactic acid foaming material is prepared from the following ingredients according to parts by weight: 45-93 parts of polylactic acid, 5-28 parts of toughener, 1-5 parts of nucleating agent and 1-10 parts of foaming agent. The polylactic acid is one of poly-L-lactic acid, poly-D-lactic acid and poly-DL-lactic acid or a mixture or a polymer thereof, and has the weight average molar mass of 0.8-3.5 million, molecular weight distribution of 1.2-2.5, and degree of crystallinity of 15-60 percent. The toughener is one of poly succinic acid butyl ester and poly adipate / butylene terephthalate or a mixture of two with random ratio. Other accessory ingredients can also be added. The preparation method comprises the following steps: evenly mixing the polylactic acid, the toughener, the nucleating agent, the foaming agent, the accessory ingredients and the like in a high mixing machine according to a certain proportion, then milling for 5-25 minutes at the temperature of 100-170 DEG C, and carrying out die pressing foaming on obtained materials at the temperature of 120-210 DEG C on a vulcanizing machine for 2-10 minutes to prepare the polylactic acid foaming material. The polylactic acid foaming material prepared by using the preparation method has the advantages of high resistance to shock, high elongation at break, high tensile strength and complete biodegradation after used.

Owner:南京冠创生物科技有限公司

Material capable of completely biodegrading and preparation method thereof

The invention relates to a material capable of completely biodegrading, containing the following parts by weight:100 of polyester resin, 5-100 of polylactic resin and the multipolymer thereof, 10-80 of compounding converted starch, 10-60 of inorganic fillers and 0.1-0.9 of resin acceptor, wherein the polyester resin is at least one of polybutylene succinate resin, polybutylene adipate resin and the multipolymer thereof. The invention also provides a preparation method of the material. The material capable of completely biodegrading can combine the advantages of each component and has high intensity, modules, elongation at break and toughness, good heat resistance, and the like, thereby meeting the property requirements of a plurality of plastic products in the market and in particular products, such as non-returnable containers, mess kits, agricultural films, and the like, which cause serious white pollution, retaining the complete biodegradability of the material and reducing the production cost under the precondition of no influence on the property requirement.

Owner:深圳市未名北科环境材料有限公司 +1

Preparation method of thermoplastic polyurethane elastomer

InactiveCN103059554AImprove mechanical propertiesImprove heat resistancePolyethylene glycolHydrolysis

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

Controllable bio-based full-degradable mulching film

InactiveCN104559087ASolve the interface compatibility problemSolve the problem of the controllability of the degradation film cyclePlant protective coveringsAntioxidantPolyethylene terephtalate

The invention discloses a controllable bio-based full-degradable mulching film which is prepared from the following raw materials in parts by weight: 15-60 parts of polylactic acid (PLA), 40-85 parts of polyterephthalic acid-butanediol adipate, 0.1-0.5 part of reactive assistant, 0.1-0.5 part of antioxidant, 0.1-0.5 part of lubricant, 0.1-0.5 part of ultraviolet absorbent and 0.1-0.5 part of light stabilizer. The novel reactive assistant is adopted to solve the problem of interface compatibility between PLA and PBAT; by adjusting the PLA / PBAT proportion and adding other ultraviolet absorbents and light stabilizers, the problem of controllability on mulching film degradation period is solved; and by utilizing the characteristic of high mechanical strength of the PLA in combination with favorable flexibility of the PBAT, the controllable-degradation-period full-biodegradable low-cost agricultural mulching film based on PLA multielement composite modification technique, of which the thickness is down to 6 mu m and the maximum bio-base content is up to 60%, is developed. The controllable bio-based full-degradable mulching film has favorable quality, and has wide popularization application prospects in promoting national soil pollution treatment and developing ecological agriculture.

Owner:JIANGSU UNIV OF SCI & TECH

Controllable fully biodegradable mulching film and preparation method thereof

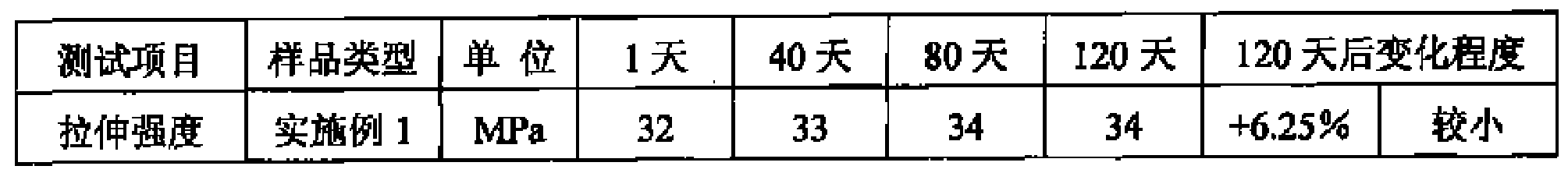

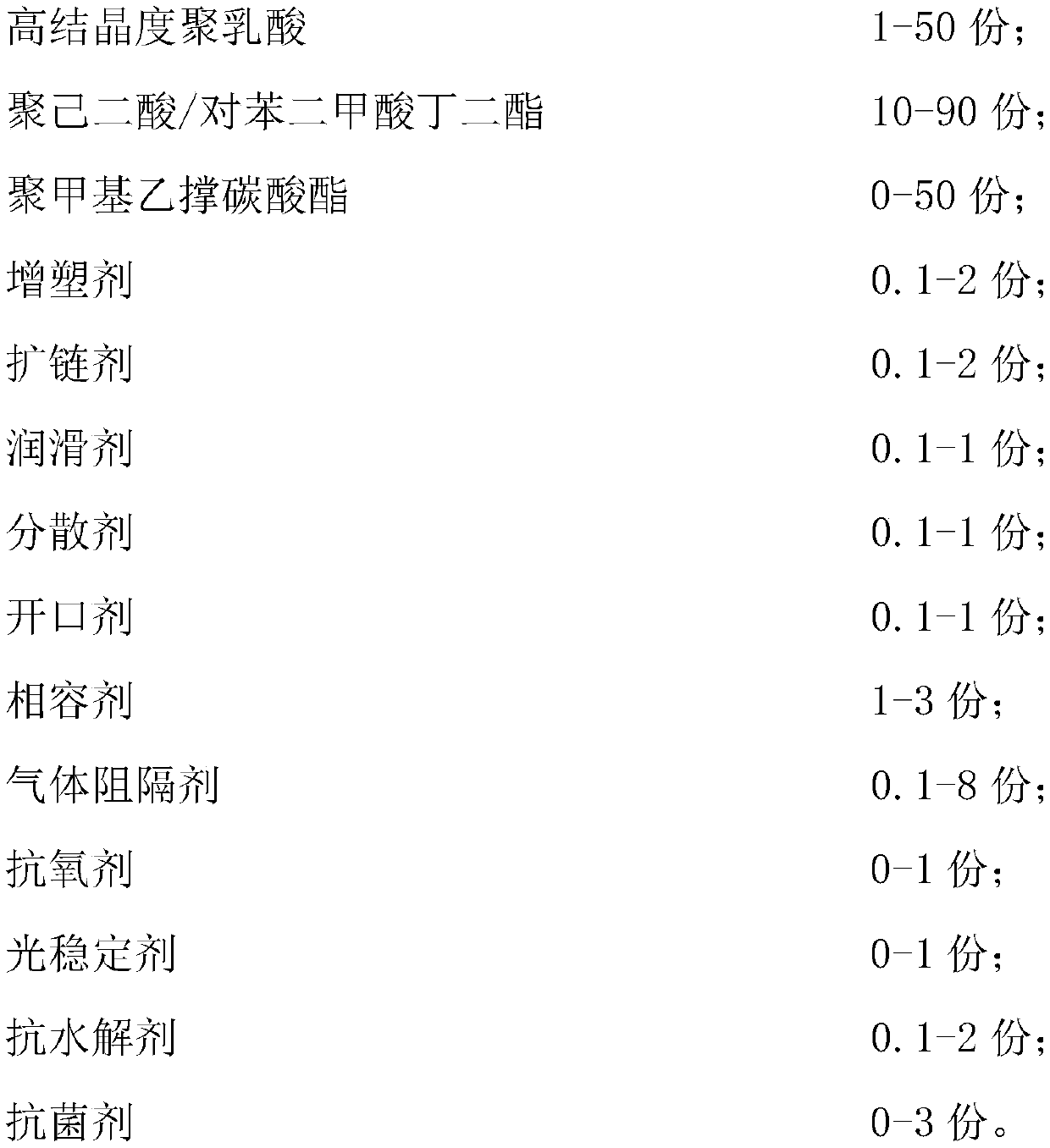

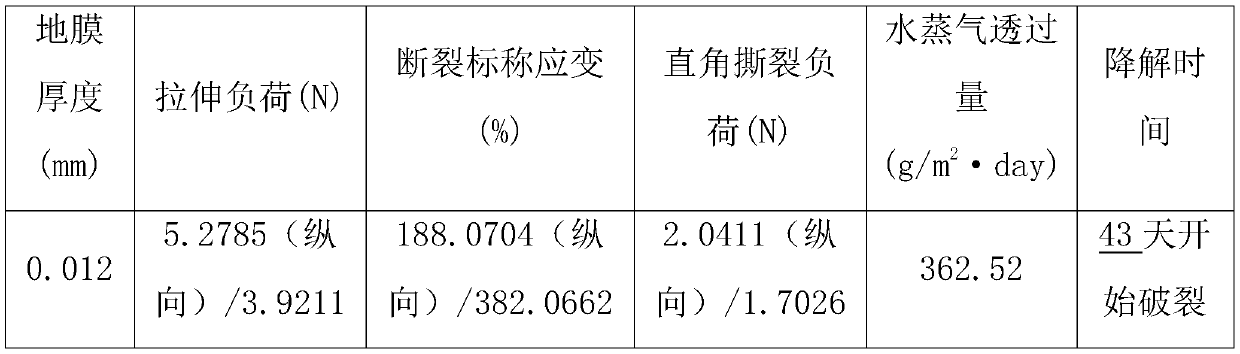

InactiveCN110330773AHigh water vapor barrierHigh tensile strengthClimate change adaptationPlant protective coveringsPolymer sciencePolybutylene

The invention belongs to the technical fields of biodegradable material modification and application, and relates to a controllable fully biodegradable mulching film and a preparation method thereof.The controllable fully biodegradable mulching film comprises the following raw materials in parts by weight: 1-50 parts of high-crystallinity polylactic acid, 10-90 parts of polybutylene adipate / butylene terephthalate, 0-50 parts of poly propylene carbonate, 0.1-2 parts of a plasticizer, 0.1-2 parts of a chain extender, 0.1-1 part of a lubricant, 0.1-1 part of a dispersant, 0.1-1 part of an opening agent, 1-3 parts of a compatibilizer, 0.1-8 parts of a gas barrier, 0-1 part of an antioxidant, 0-1 part of a light stabilizer, 0.1-2 parts of an anti-hydrolysis agent and 0-3 parts of an antibacterial agent. The raw materials are pretreated and uniformly mixed, the controllable fully biodegradable mulching film is obtained by extrusion and blow molding, and the thickness of the mulching film is0.005 to 0.020 mm. The fully biodegradable mulching film provided by the invention has good mechanical properties, excellent heat preservation and moisture retention performance, and can be completely degraded by itself; the mulching film degradation rate can be regulated according to the 'mulching film function period' of different crop mulching films in different regions to meet the needs of different crops in different regions.

Owner:深圳利峰达科技发展有限公司

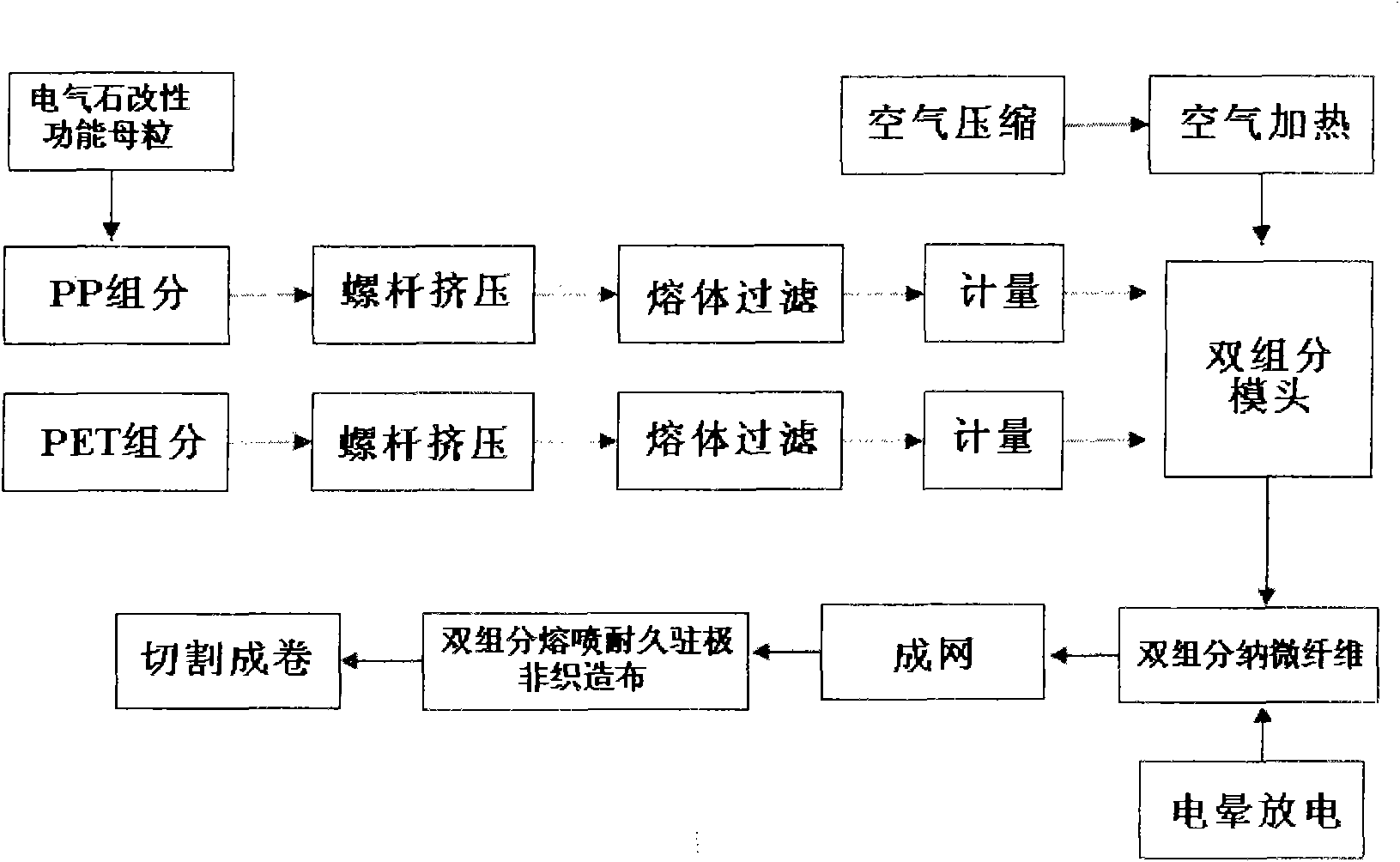

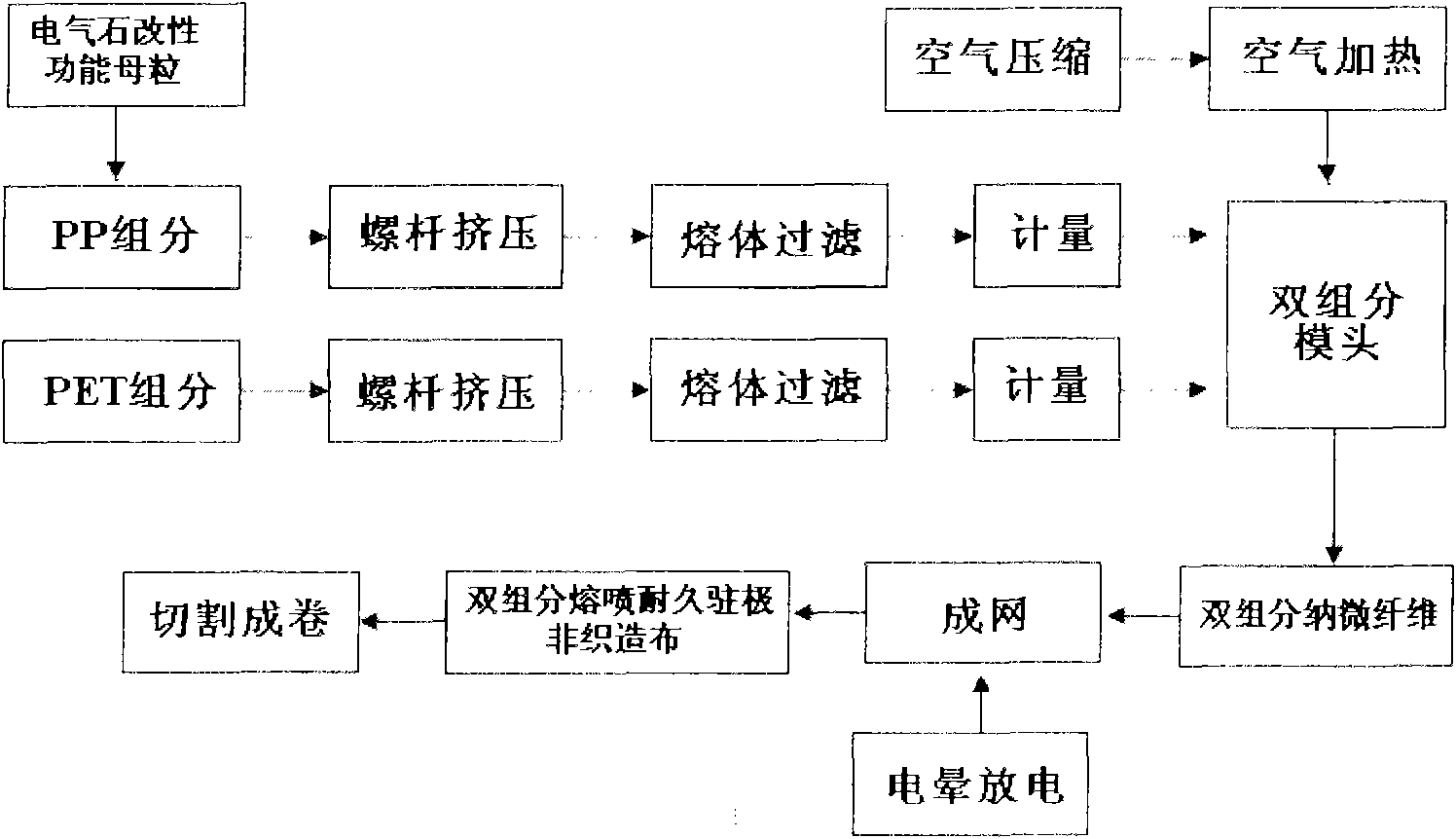

Double-component melt-blown durable electret non-woven fabric and manufacturing method thereof

InactiveCN101591837ASoft touchImprove breathabilityElectroconductive/antistatic filament manufactureArtificial filament physical treatmentFiltrationThermal insulation

The invention relates to a double-component melt-blown durable electret non-woven fabric and a manufacturing method thereof. The non-woven fabric consists of tourmaline modified polypropylene / polyethylene glycol adipate (tourmaline modified PP / PET) parallel double-component melt-blown nano microfiber; and the fiber has the following components in percentage by mass: 20 to 80 percent of tourmaline modified PP, and 80 to 20 percent of PET. The method for manufacturing the non-woven fabric adopts the components in percentage by mass and the process steps of: (1) performing drying pre-treatment on the PET first; (2) then preparing a double-component melt-blown non-woven fabric by tourmaline modified PP / PET melt-blown composite spinning technology; and (3) finally obtaining the double-component melt-blown durable electret non-woven fabric by performing high-voltage corona discharge electret treatment on the non-woven fabric. The non-woven fabric can be used for durable high-efficiency filtration materials, and can also be applied to thermal insulation materials, antibacterial medical materials, oil absorption materials and the like.

Owner:TIANJIN POLYTECHNIC UNIV

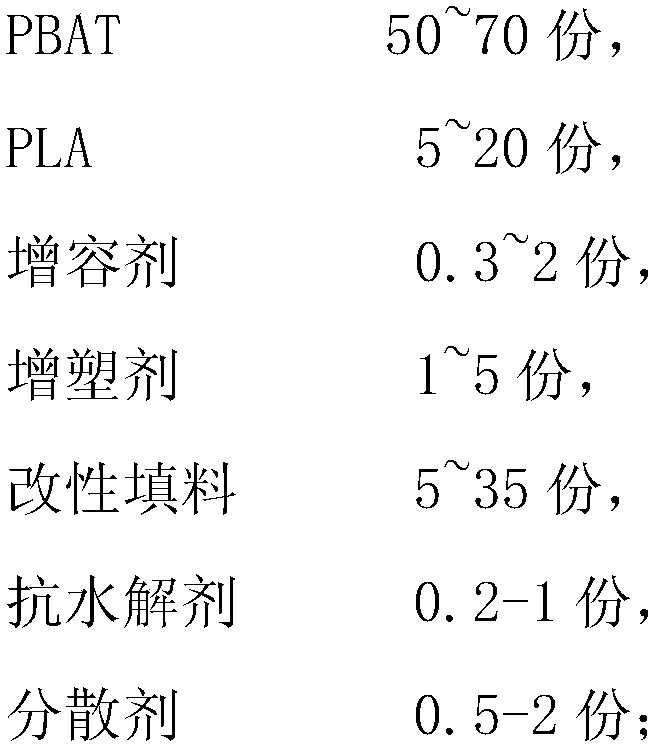

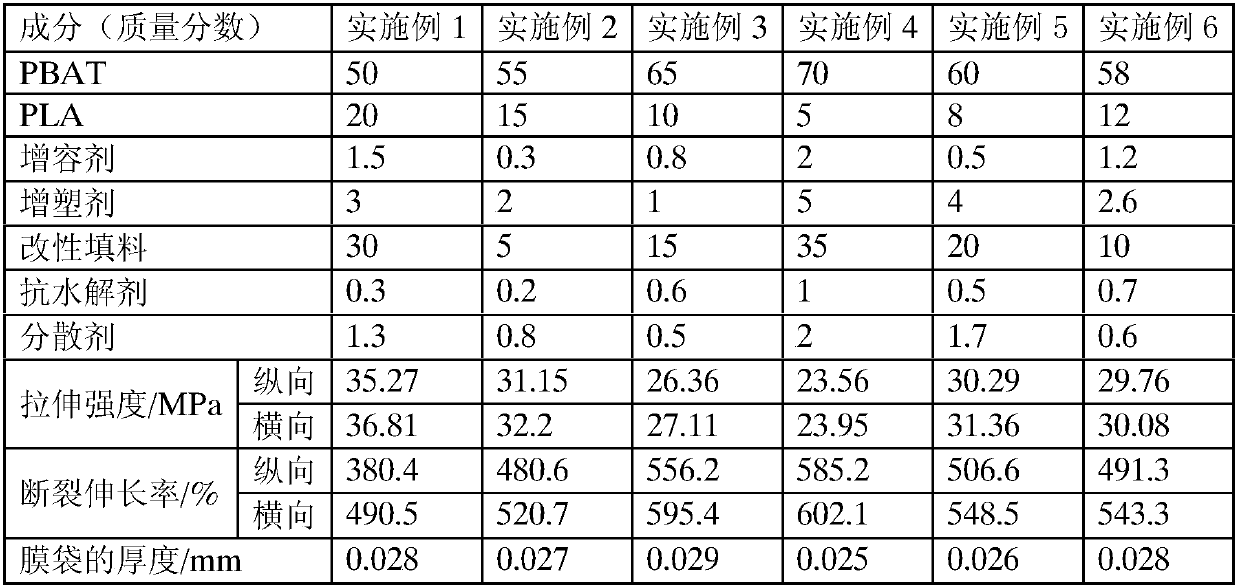

Completely-biodegradable film bag material and preparation method of film bag

The invention relates to a completely-biodegradable film bag material and a preparation method of a film bag. The completely-biodegradable film bag material is prepared from mixing the following raw materials in parts by weight: 50 to 70 parts of PBAT (poly-butylene adipate-co-terephthalate), 5 to 20 parts of PLA (poly-lactic acid), 0.3 to 2 parts of a compatilizer, 1 to 5 parts of a plasticizer,5 to 35 parts of modified filler, 0.2 to 1 part of an anti-hydrolysis agent, and 0.5 to 2 parts of a dispersant, wherein the modified filler is prepared by adding an inorganic filler or organic fillerinto a mixing machine, stirring, sequentially adding a surface modifying additive in the stirring process, and mixing. When the modified filler is added into the material, the property of the film bag product is not degraded; however, the production cost is greatly reduced. The completely-biodegradable film bag material and the preparation method of the film bag has the advantages that the production technology is simple; the forming stability, opening property, puncturing-resistant property, dispersing property of color master batch are good; the surface is smooth, and the completely-biodegradable film bag material can be used for producing shopping bags, rolling bags, express bags, garbage bags and the like.

Owner:WUHAN HUALI BIOLOGY CO LTD

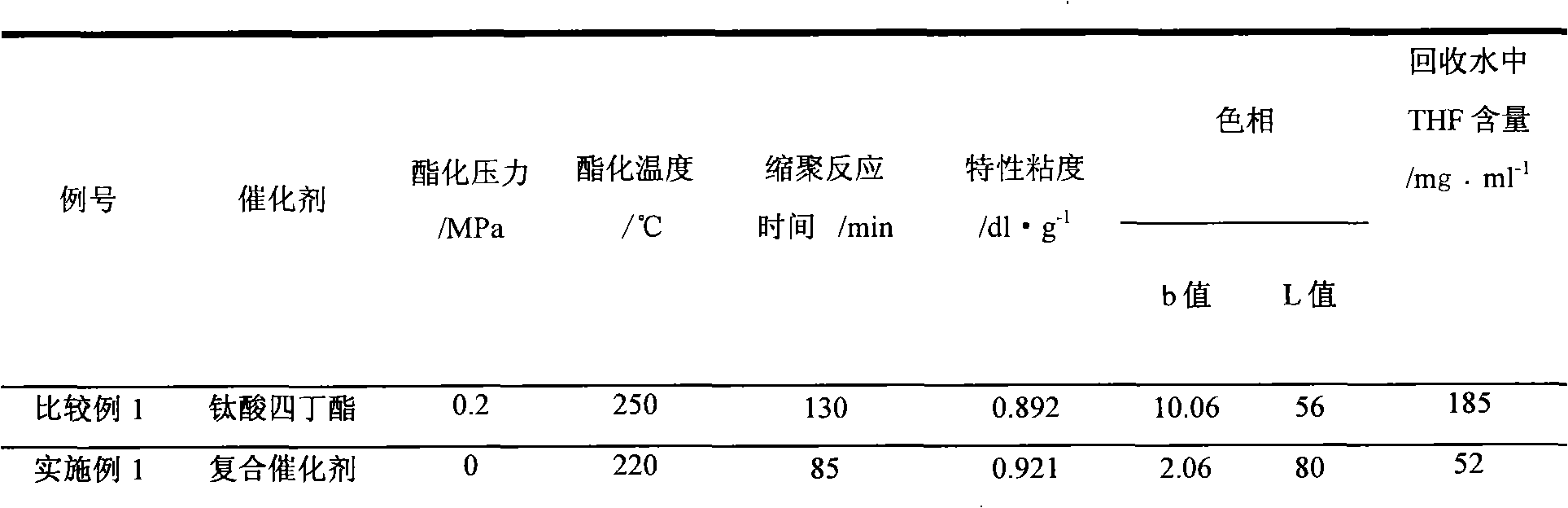

Preparation method of polybutylene terephthalate/adipate butanediol copolyester

The invention relates to a preparation method of polybutylene terephthalate / adipate butanediol copolyester, which utilizes a titanium compound and an antimony compound as the composite catalyst, the mole ratio of terephthalic acid to adipate is 3:7-8:2, the ratio of the total mole of the terephthalic acid and the adipate to the mole of 1,4-butanediol is 1:1.0-1.8, esterification is carried out at normal pressure and the temperature of 150-220 DEG C, the pressure is reduced to high vacuum 10-150 Pa for the reaction, the final temperature for the reaction is 265-280 DEG C, and inert gas is utilized to recover the pressure to be normal to obtain the copolyester. The reaction time is shortened, the production amount of tetrahydrofuran is small, the intrinsic viscosity of copolyester chips is 0.90-1.32 dL / g, the hue b value of the product is between 0 and 8, the L value is between 68 and 85, and the product of the polybutylene terephthalate / adipate butanediol copolyester can be used in the fields of various soft package plastic products.

Owner:PETROCHINA CO LTD

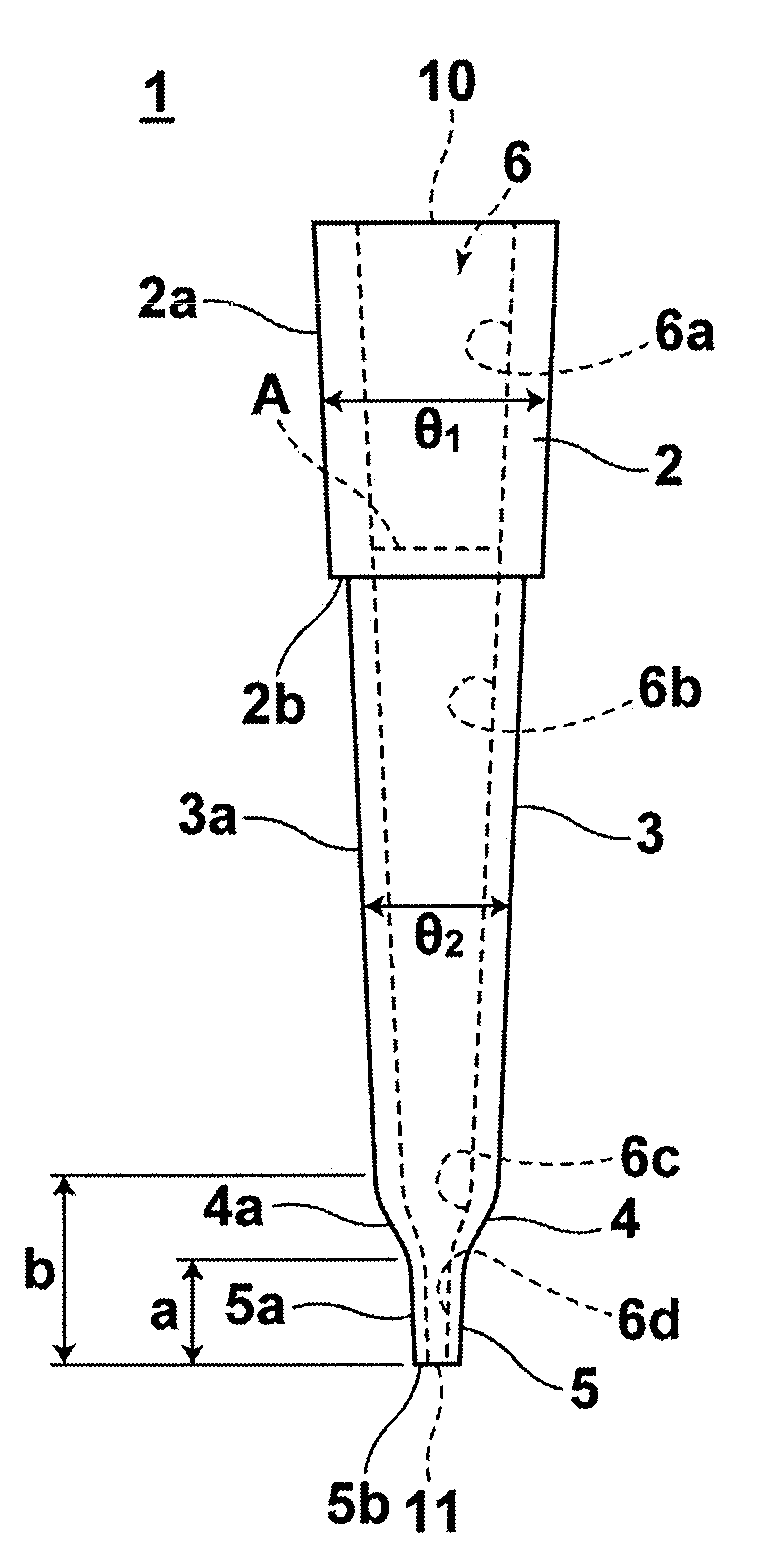

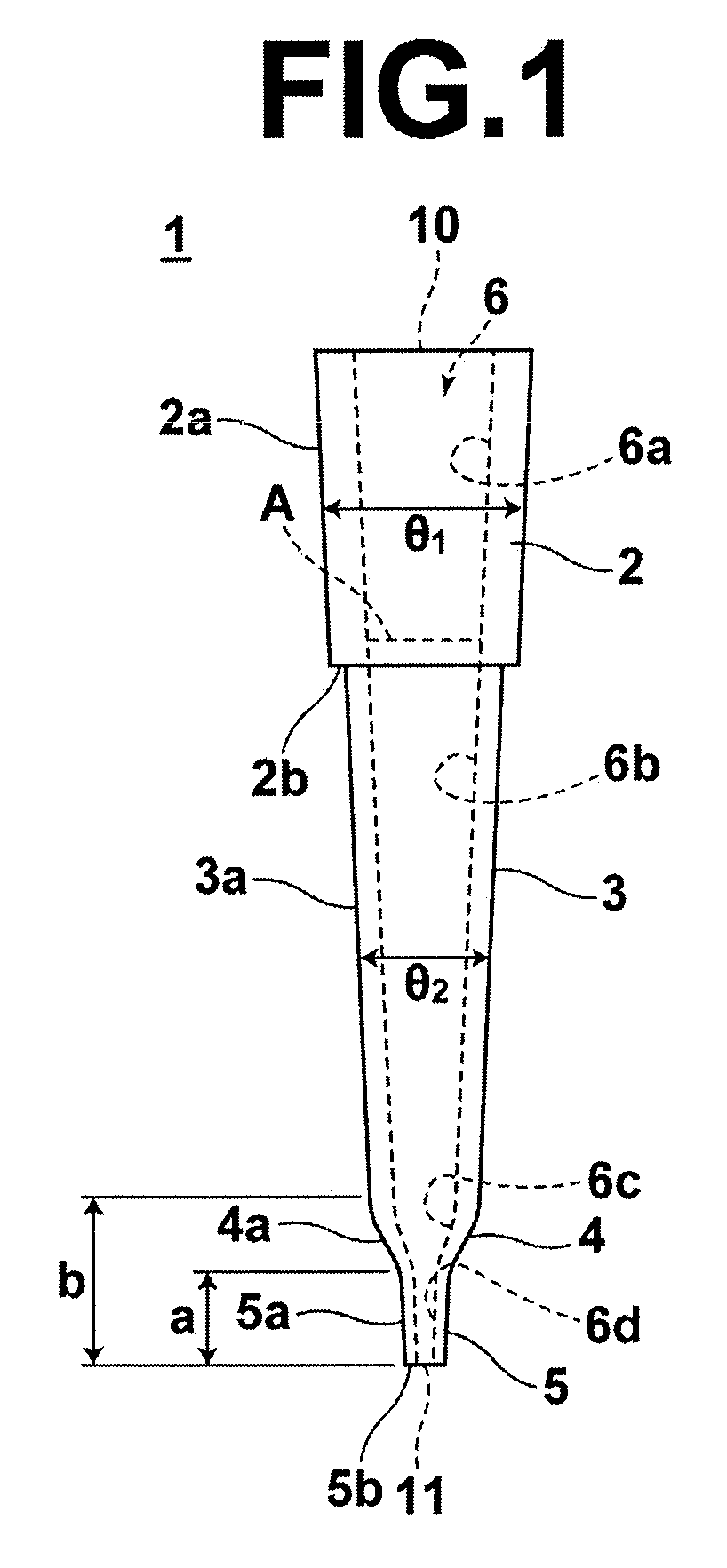

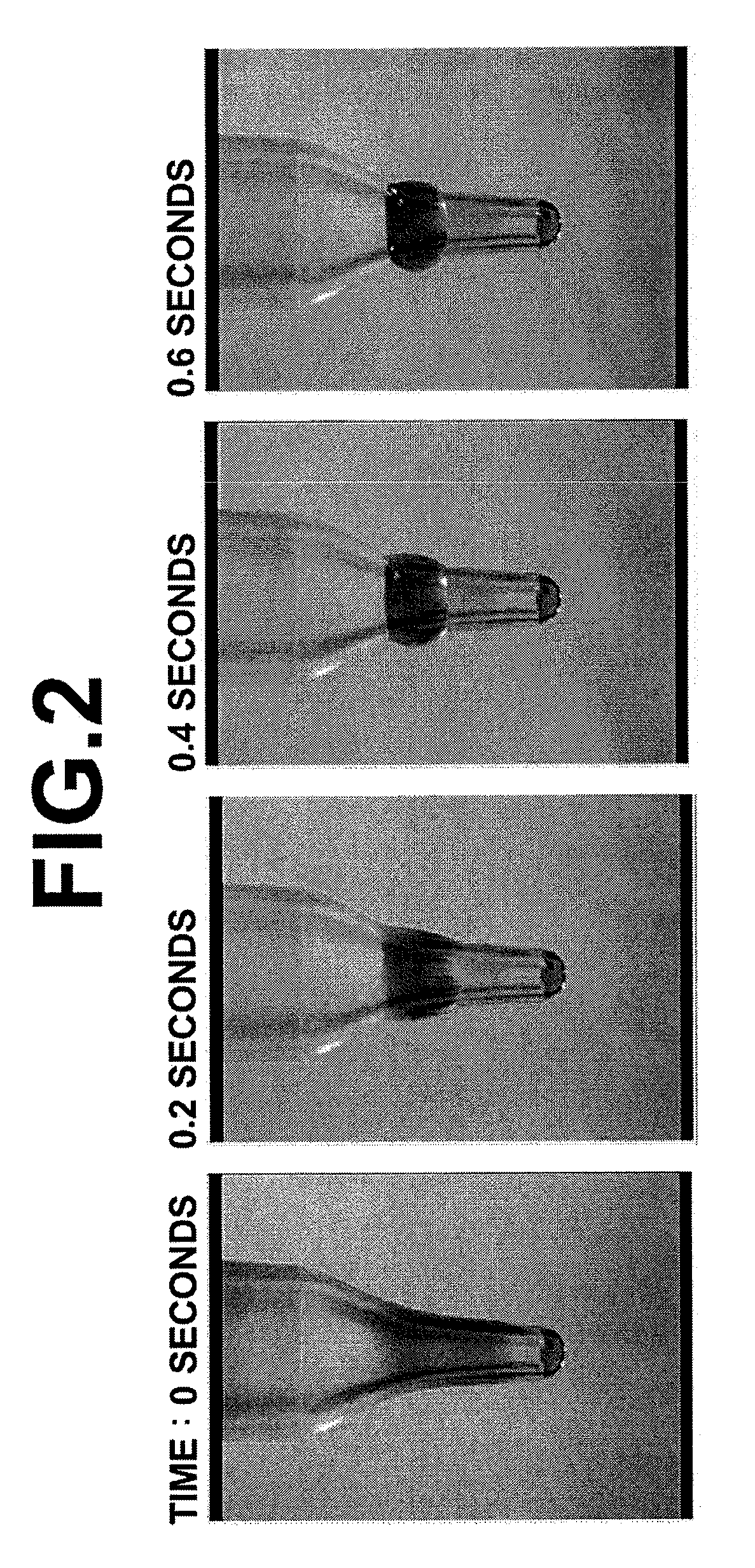

Pipette tip

InactiveUS20090202392A1Reliable distributionAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPipette1,3-Butanediol

A pipette tip formed by a polypropylene substrate coated with a water repellent agent. The water repellent agent contains a silicone resin containing at least one specific substance selected from the group consisting of diisononyl phthalate, diisodecyl phthalate, trioctyl trimellitate and poly (1,3-butanediol adipate). The total mass of the specific substance is 1-30 mass % of the silicone resin.

Owner:FUJIFILM CORP

Method for preparing biodegradable polylactic acid foaming material

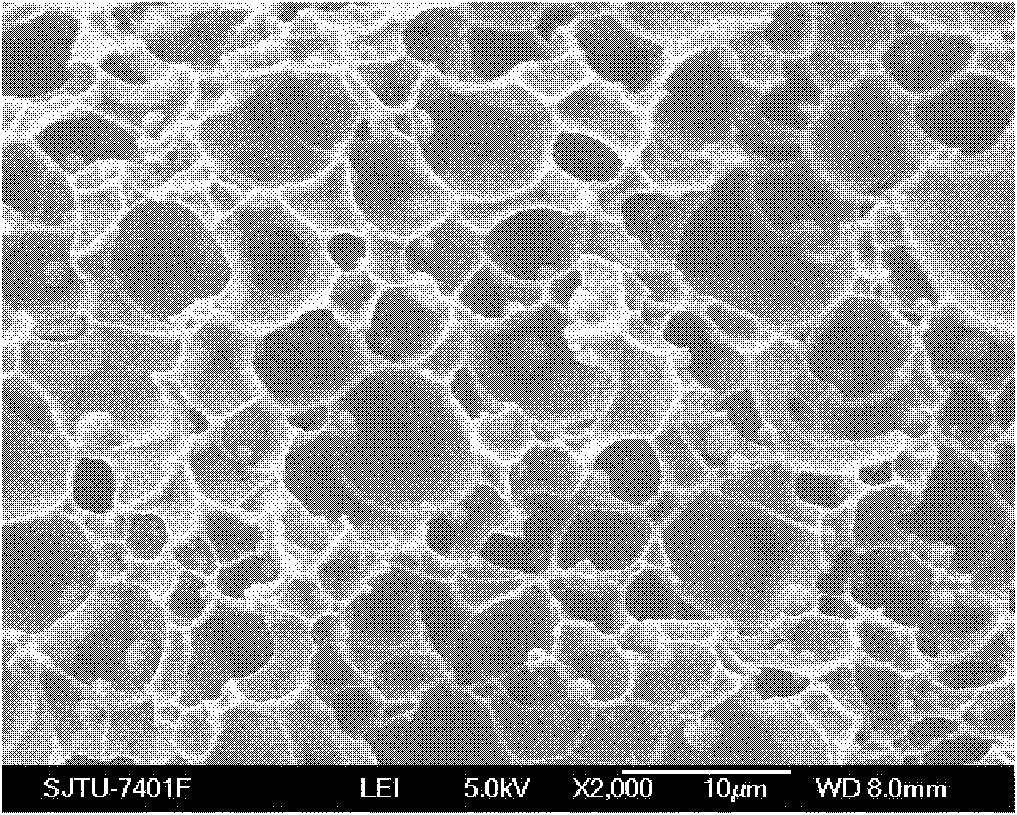

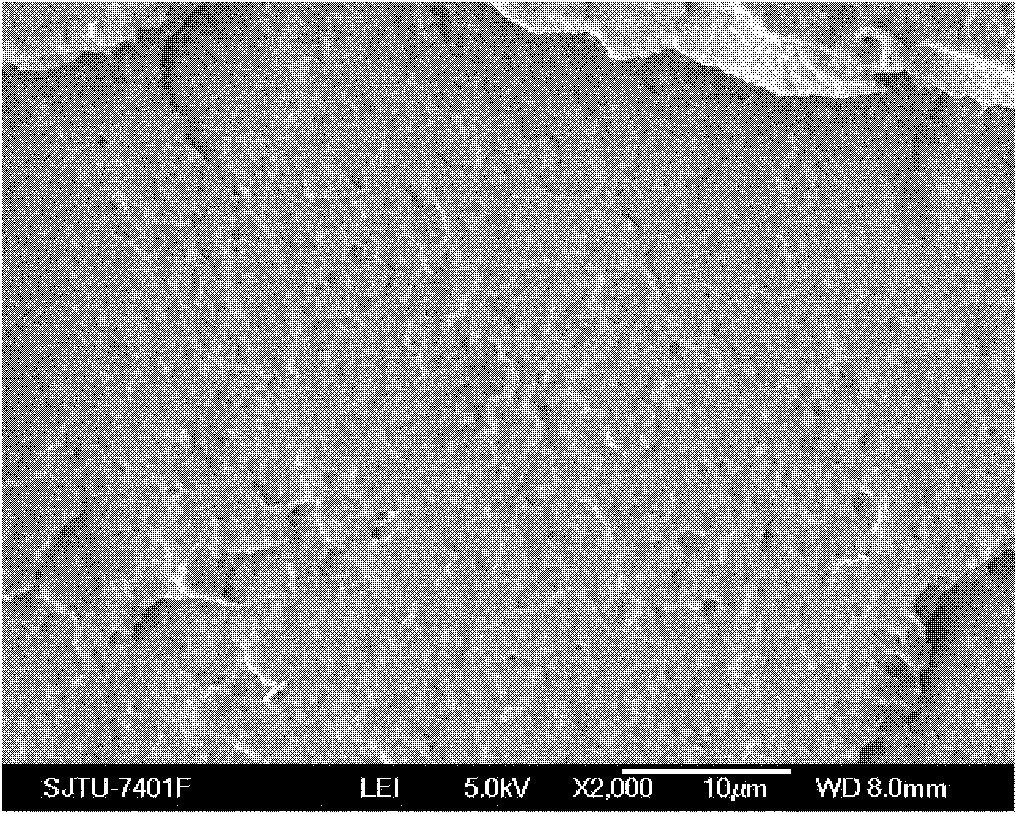

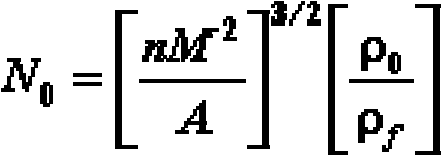

The invention discloses the composition of a biodegradable polylactic acid (PLA) foaming material and a preparation method thereof. The method for preparing the biodegradable polylactic acid foaming material comprises the following steps: blending polylactic acid (PLA) and aliphatic-aromatic co-polyester toughening agent in a screw extruder; loading the extrudate into the fluid of supercritical CO2 to swell, so that the CO2 can be fully dissolved in the blended materials; then, releasing the pressure at a high rate, so as to supersaturate the CO2 in the composite material, thus achieving the thermodynamic instability; and nucleating and foaming to obtain the biodegradable PLA foaming material, wherein the toughening agent is particularly poly(butylenes adipate-co-terephthalate) (PBAT) in the invention. The method of the invention is capable of preparing the PLA foaming material with the cell diameter thereof being 0.9056mu m to 5.250mu m and the cell density thereof being 2.05*1,019 pieces / cm<3> to 2.01*1,022 pieces / cm<3>. The invention as a green and environment-friendly technique can improve the material performance and reduce the cost.

Owner:SHANGHAI JIAO TONG UNIV

Completely-biodegradable mulching film material and mulching film

InactiveCN103937179ANo residueTo increase productionClimate change adaptationPlant protective coveringsPlastic mulchPoly(butylene succinate)

The invention discloses a completely-biodegradable mulching film material which contains one kind or several kinds of compounds which are selected from a group consisting of polyhydroxy alkanoates, polylactic acid, poly(butylene adipate-co-terephthalate), poly(butylene-scuccinate / adipate) and poly(butylene-scuccinate). By adopting the completely biodegradable mulching film material, the yield of crops can be greatly improved, the mulching film material can be completely biodegradable without residues of a mulching film, and the yield of crops can be continuously increased.

Owner:山东省意可曼科技有限公司

PLA (polylactic acid) modified material, preparation method thereof and PLA biodegradable mulching film

The invention discloses a PLA (polylactic acid) modified material, a preparation method thereof and a PLA biodegradable mulching film. The modified material contains the following raw materials in percentage by weight: 58-80wt% of PLA, 15-40wt% of PBAT (poly(butylene adipate-co-terephthalate)), 0.1-5wt% of modified talcum powder, 0.1-2wt% of antioxidant, 0.1-1wt% of ultraviolet absorption agent, 0.1-2wt% of light stabilizer, 0.1-2wt% of antiblocking agent, 0.1-1wt% of chain extender and 0.0005-0.05wt% of initiator. The PBAT is added into the PLA, and meanwhile the chain extender is used to compatibilize the polymer, so that the prepared material keeps the characteristics of high strength, high transmittancy and high cost performance of the PLA after blow molding and film forming, and meanwhile, the flexibility is enhanced.

Owner:ANHUI JUMEI BIOLOGICAL TECH

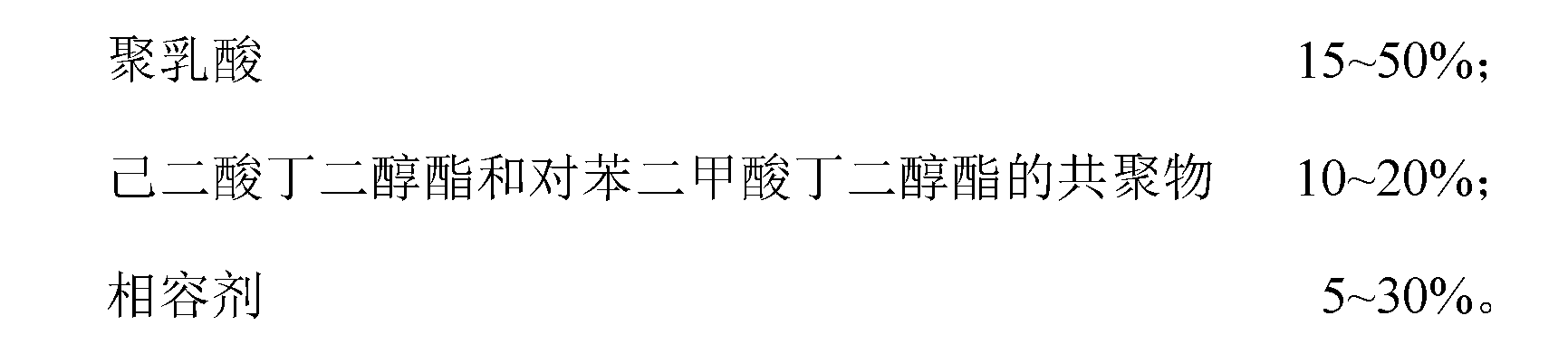

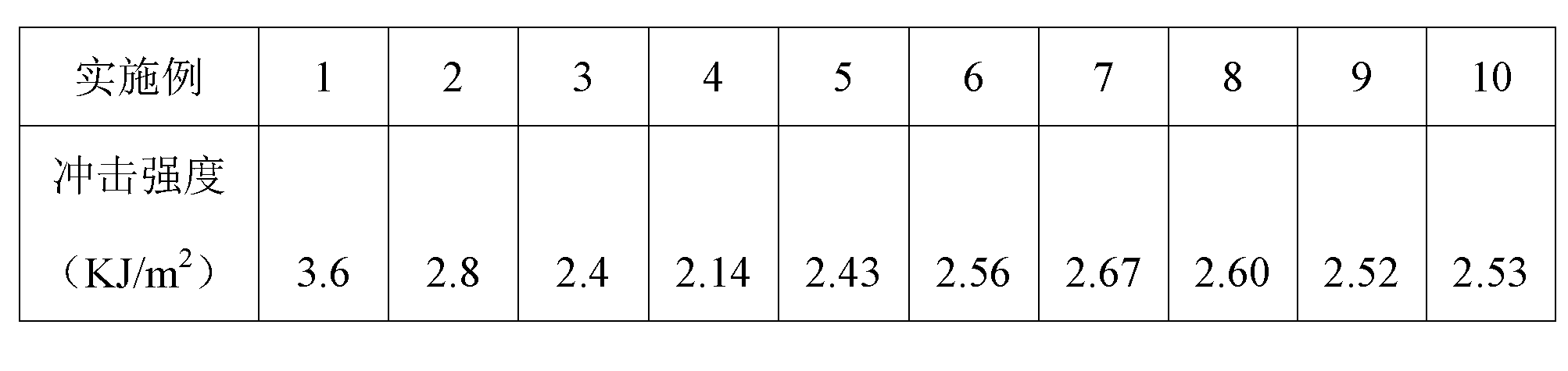

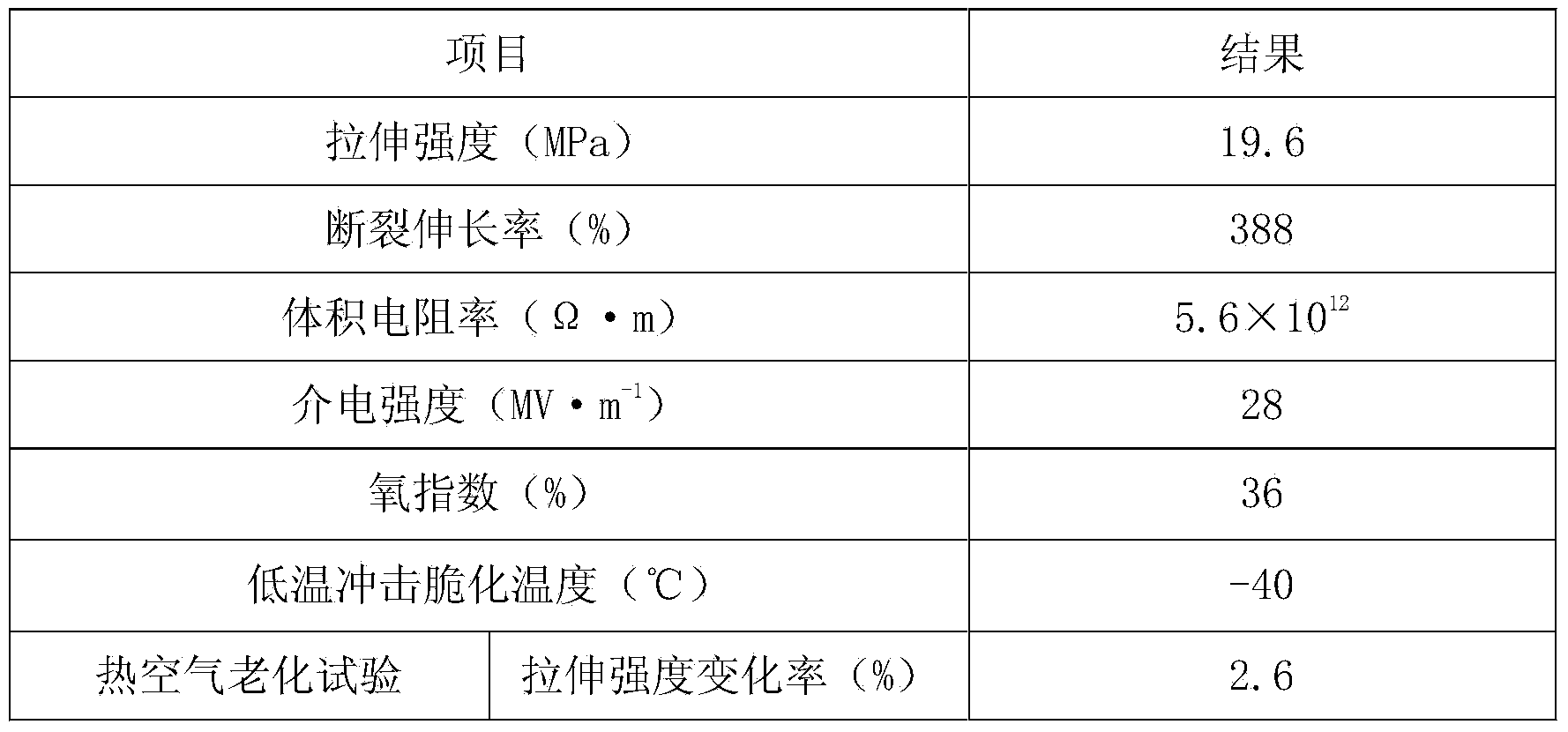

Full-biodegradable material and preparation method thereof

The invention relates to a full-biodegradable material which is characterized by comprising the following raw materials in percentage by weight: 30-65% of starch, 5-15% of vegetable oil, 15-50% of polylactic acid, 10-20% of polybutylene adipate-polybutylene terephthalate copolymer and 5-30% of compatilizer. Preferably, the compatilizer accounts for 5-20% of the total weight of the raw materials. The full-biodegradable material has the advantages of excellent and stable properties and low cost, is biodegradable, well gives consideration to economic benefit and environmental benefit, and has wide application prospects. The invention also provides a preparation method of the full-biodegradable material. The preparation method is easy to implement, operate and control, can easily implement industrial production, and is beneficial to lowering the cost of the full-biodegradable material.

Owner:ECOTA ENVIRONMENTAL TECH

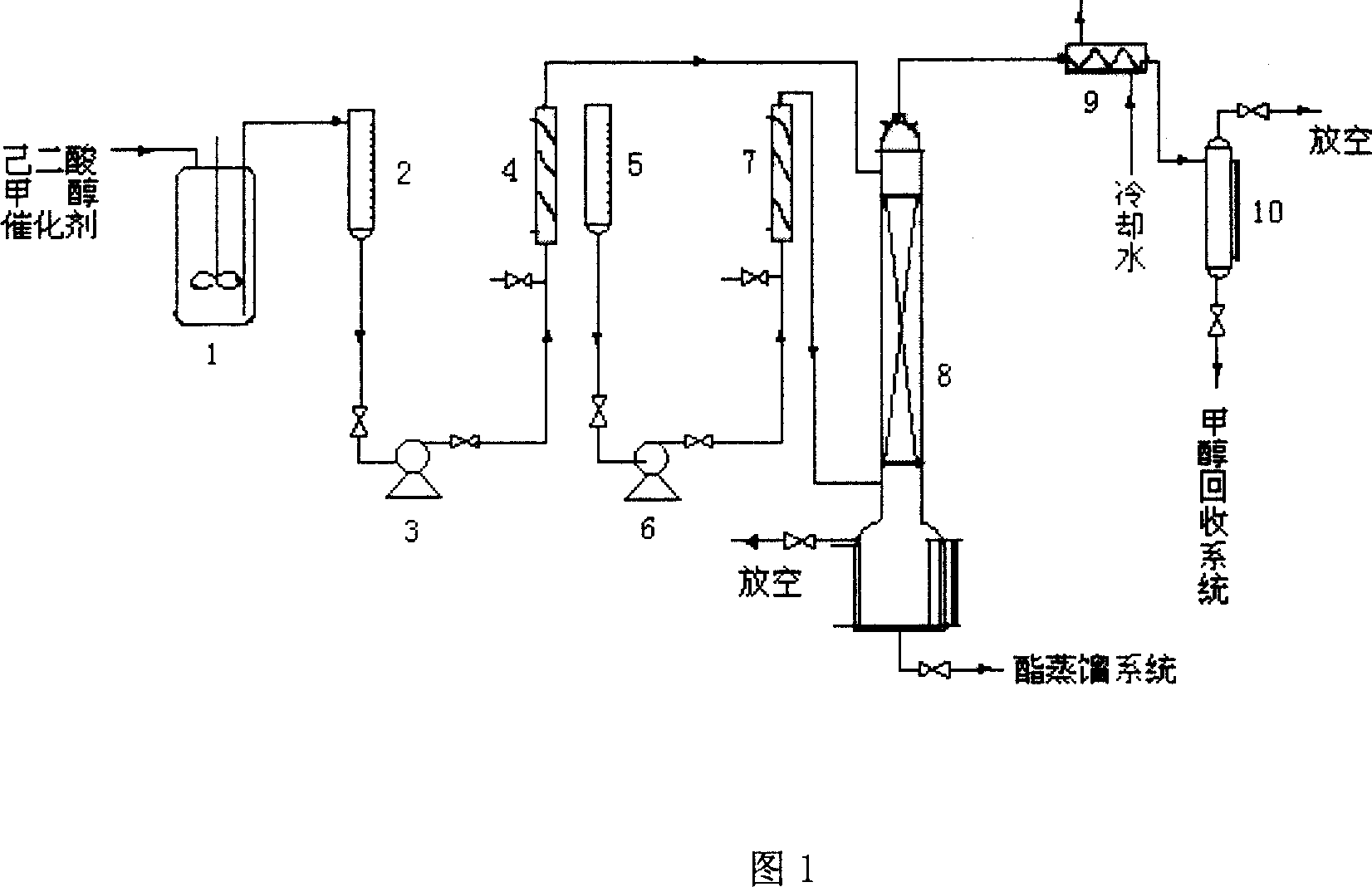

Method and equipment for continuous esterification production of adipic acid dimethyl ester

ActiveCN101134725ABreak down the esterification rateImprove the conversion rate of esterificationOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterReaction temperature

The present invention relates to continuous esterification process and apparatus for producing dimethyl adipate in the presence of solid acid catalyst. The process includes the following steps: setting solid acid catalyst, adipic acid and methanol into pre-esterifying kettle; heating to 50-100 deg.c to react at normal pressure to obtain lean ester; feeding the supernatant with lean ester to the upper part of one continuous esterifying tower and methanol vapor to its lower part for countrecurrent reaction in the catalyst section at the temperature of 70-150 deg.c, liquid space velocity of 0.1-0.7 kg / kg.hr and methanol space velocity of 0.1-1.0 kg / kg.hr; rectifying the resultant at operation pressure of 0-0.01 MPa to obtain dimethyl adipate. The present invention has adipic acid converting rate up to 99 % and dimethyl adipate purity up to 99.8 %.

Owner:PETROCHINA CO LTD

Oil-resistant cold-resistant ultraviolet-proof polyvinyl chloride/nitrile rubber composite cable material and preparation method thereof

InactiveCN103509274AImprove mechanical propertiesImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsDiethylene glycol monobutyl etherPolymer science

A disclosed oil-resistant cold-resistant ultraviolet-proofpolyvinyl chloride / nitrile rubber composite cable material is prepared from the following raw materials in parts by weight: 60-80 parts of SG-2 type polyethylene, 20-30 parts of POE, 30-50 parts of nitrile rubber, 15-20 parts of fluorubber, 10-15 parts of dioctyl phthalate, 5-10 parts of di(butylcarbitol)adipate, 0.5-1 part of dicumyl peroxide, 2-3 parts of triallyl isocyanurate, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of titanium dioxide, 5-10 parts of paraffin oil, 2-3 parts of zinc oxide, 4-8 parts of microcrystalline paraffin and the like. The cable materials of the invention ahs excellent thermoset rubber apparence and thermoplastic elastomer characteristics, and good mechanical properties and low-temperature flexibility; the long-term suitable operation temperature is -40 DEG C to 105 DEG C; the cable material is capable of retarding flame, resisting oil, resisting acid and base, resisting wear, resisting weather, resisting ozone, resisting thermal aging and resisting ultraviolet ray, and is applicable as high-oil-resistance weatherable cable sheath materials.

Owner:安徽天民电气科技有限公司

Low cost bio-based full degradable film and preparation method thereof

The present invention discloses a low cost bio-based full degradable film and preparation method thereof, the ratio of each component in parts by mass of the film is as follows: 15-25 parts of a polyglycolic acid, 25-35 parts of corn starch, 35-55 parts of poly(butylene adipate-co-terephthalate), 5 parts of a compatilizer, 3.75-12.25 parts of a starch plasticizer, 0.5-0.7 part of citric acid, 0.75-1.25 parts of acetyl tributyl citrate, 0.3-0.5 part of maleic anhydride, 0.2 part of antioxidant 164, and 0.2 part of 2-(2″-hydroxyl-5″-methylphenyl)benzotriazole. The low cost bio-based full degradable film provided by the present invention has a bio-based content, which can reach 30% or more, a lower cost, and a tensile strength exceeding a traditional PE thin film, and has very important significance for solving the problem of “white pollution” and promoting the popularization and application of full biodegradable materials.

Owner:JIANGSU JINJU ALLOY MATERIAL

Poly(butylene adipate terephthalate)/starch high-barrier composite membrane and preparation method of poly(butylene adipate terephthalate)/starch high-barrier composite membrane

ActiveCN106881929AHigh oil contentReduce manufacturing costSynthetic resin layered productsDomestic containersFood packagingAdipate

The invention relates to the field of food packaging and in particular provides a poly(butylene adipate terephthalate) / starch high-barrier composite membrane and a preparation method of the poly(butylene adipate terephthalate) / starch high-barrier composite membrane. The membrane adopts a sandwiched structure and takes a poly(butylene adipate terephthalate) as an outer layer; a sandwiched layer is a starch nano composite material layer; the thickness of the sandwiched layer accounts for 40 percent to 90 percent of the whole composite membrane; the composite membrane with the structure has a good barrier performance and is widely applied to packaging of products which are easy to oxidize, especially packaging of fresh agricultural products and high-oil foods; meanwhile, the production cost of a full degradable packaging membrane is remarkably reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com