Method for preparing biodegradable polylactic acid foaming material

A polylactic acid foaming and biodegradable technology, applied in the field of foaming materials, can solve the problems that have not occurred before

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

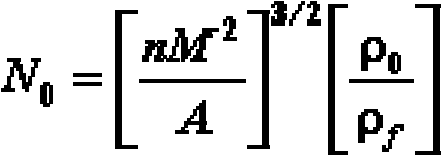

Method used

Image

Examples

Embodiment 1

[0032] PLA and PBAT are placed in a screw extruder, and the weight ratio of the two is 90% of PLA and 10% of PBAT. The extrusion temperature is 155°C, the extrusion time is 30min, and the screw speed is 70 rpm. 2 Foaming after swelling in the state. Extrude to obtain PLA / PBAT blend material.

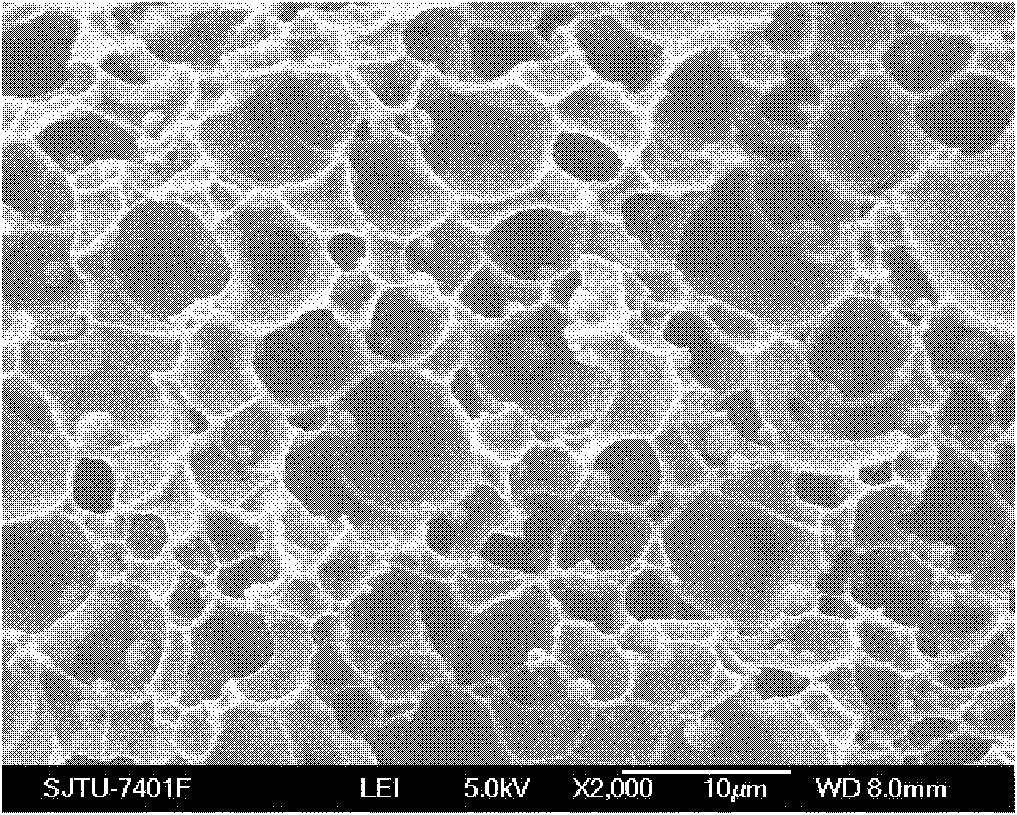

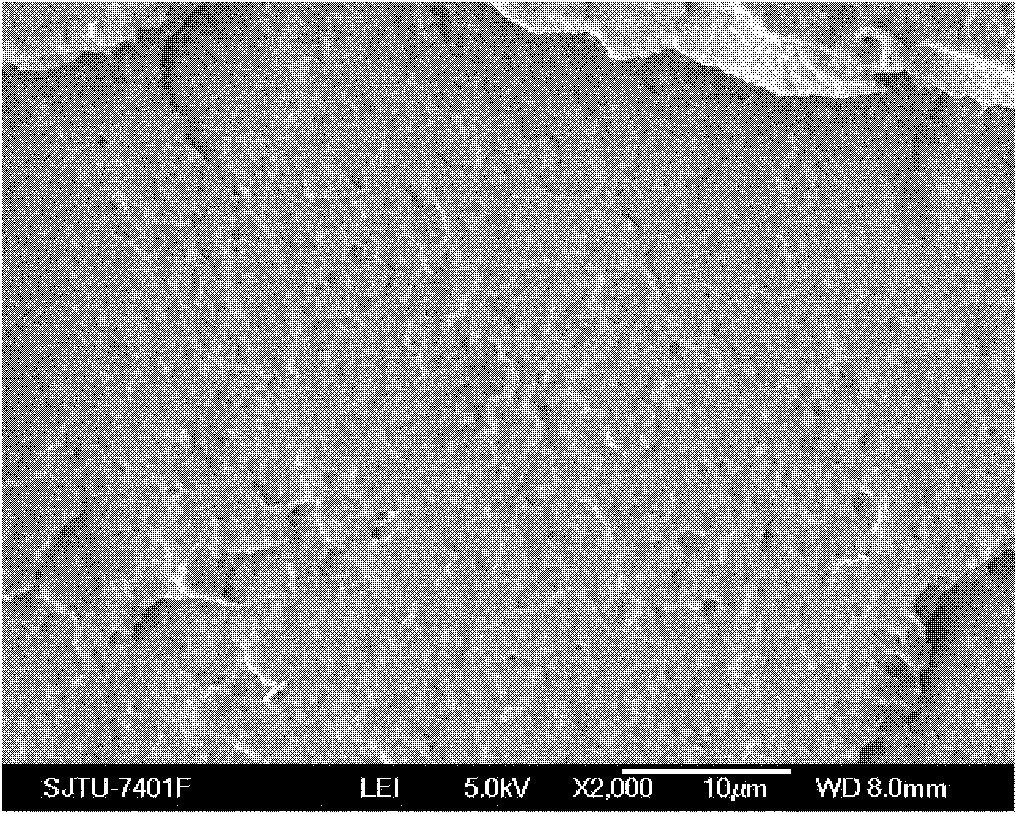

[0033] Place the PLA / PBAT blended material in an autoclave, in which the volume of the material is not greater than one-twentieth of the volume of the autoclave to ensure sufficient space for foaming. Close the autoclave and fill the autoclave with low-pressure CO 2 Purge for several minutes to displace the air in the kettle. Place the autoclave in a water bath at 40°C, and use a high-pressure pump to pump CO 2 Fill the autoclave until the pressure reaches 18MPa, and swell for 1 hour. Then quickly relieve the pressure until the gauge pressure is normal pressure, and the pressure relief rate is 2MPa / s. Take out the sample. Foam in a water bath at 100°C for 10s. Scanning electron m...

Embodiment 2

[0035] PLA and PBAT are placed in the screw extruder, and the weight ratio of the two is 70% of PLA and 30% of PBAT. The extrusion temperature was 155° C., the extrusion time was 30 minutes, the screw speed was 70 revolutions / min, and the PLA / PBAT blend material was obtained by extrusion.

[0036] Place the PLA / PBAT blended material in an autoclave, in which the volume of the material is not greater than one-twentieth of the volume of the autoclave to ensure sufficient space for foaming. Close the autoclave and fill the autoclave with low-pressure CO 2 Purge for several minutes to displace the air in the kettle. Place the autoclave in a water bath at 40°C, and use a high-pressure pump to pump CO 2 Fill the autoclave until the pressure reaches 18MPa, and swell for 1 hour. Then quickly relieve the pressure until the gauge pressure is normal pressure, and the pressure relief rate is 2MPa / s. Take out the sample. Foam in a water bath at 100°C for 10s. Scanning electron microsco...

Embodiment 3

[0038] PLA and PBAT are placed in the screw extruder, and the weight ratio of the two is 50% of PLA and 50% of PBAT. The extrusion temperature was 155° C., the extrusion time was 30 minutes, the screw speed was 70 revolutions / min, and the PLA / PBAT blend material was obtained by extrusion.

[0039] Place the PLA / PBAT blended material in an autoclave, in which the volume of the material is not greater than one-twentieth of the volume of the autoclave to ensure sufficient space for foaming. Close the autoclave and fill the autoclave with low-pressure CO 2 Purge for several minutes to displace the air in the kettle. Place the autoclave in a water bath at 40°C, and use a high-pressure pump to pump CO 2 Fill the autoclave until the pressure reaches 18MPa, and swell for 1 hour. Then quickly relieve the pressure until the gauge pressure is normal pressure, and the pressure relief rate is 2MPa / s. Take out the sample. Foam in a water bath at 100°C for 10s. Scanning electron micros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com