Patents

Literature

151results about How to "Fully biodegradable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

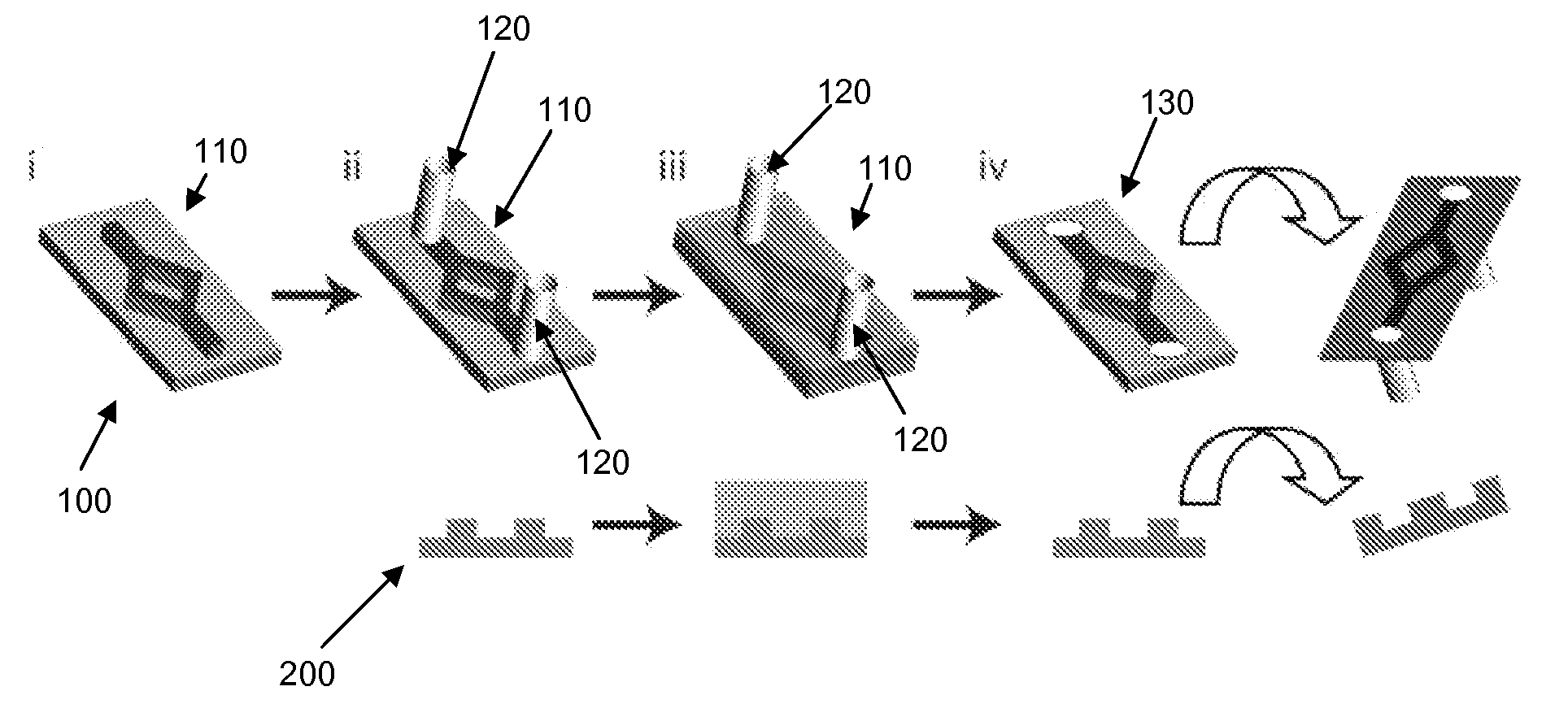

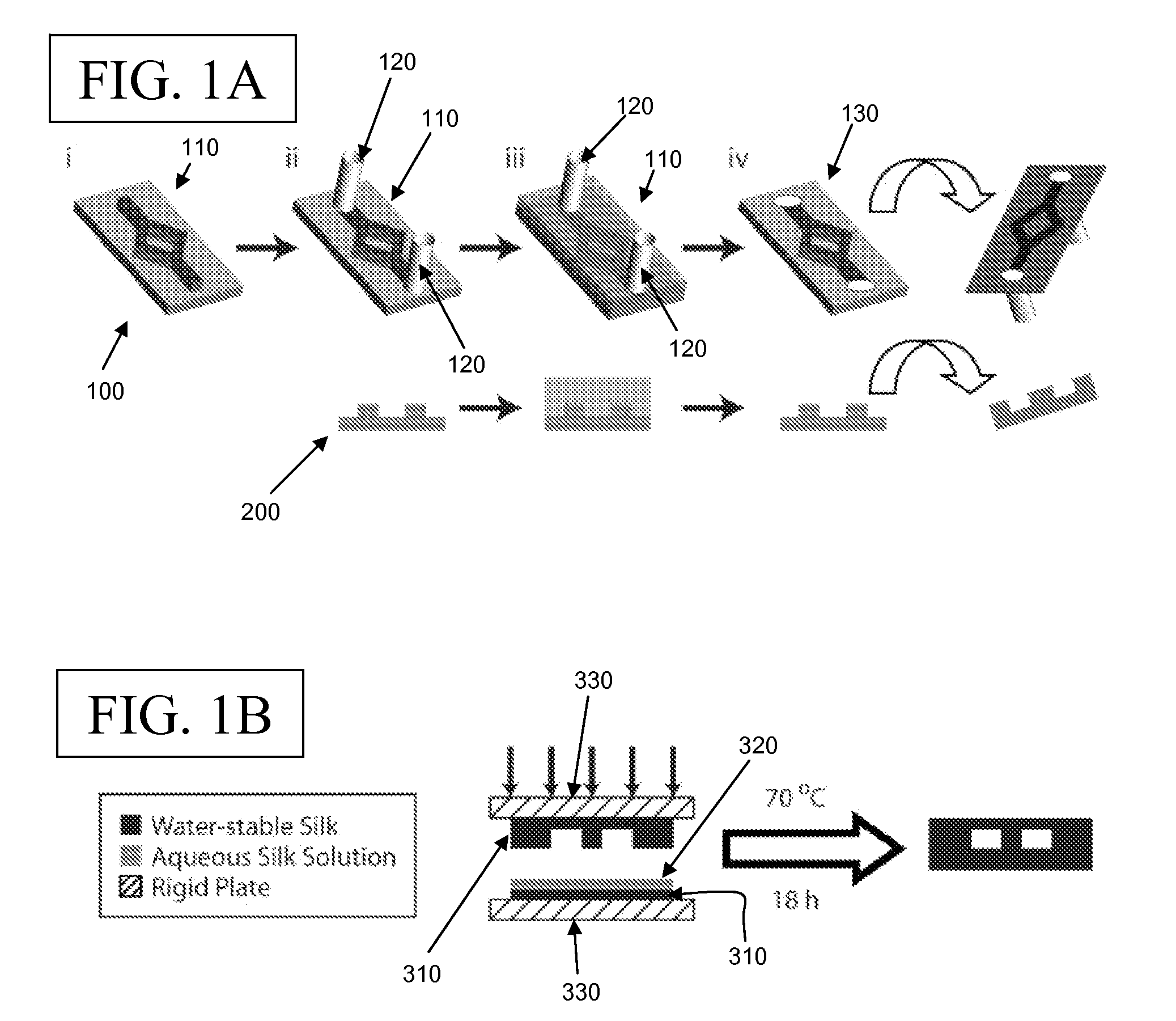

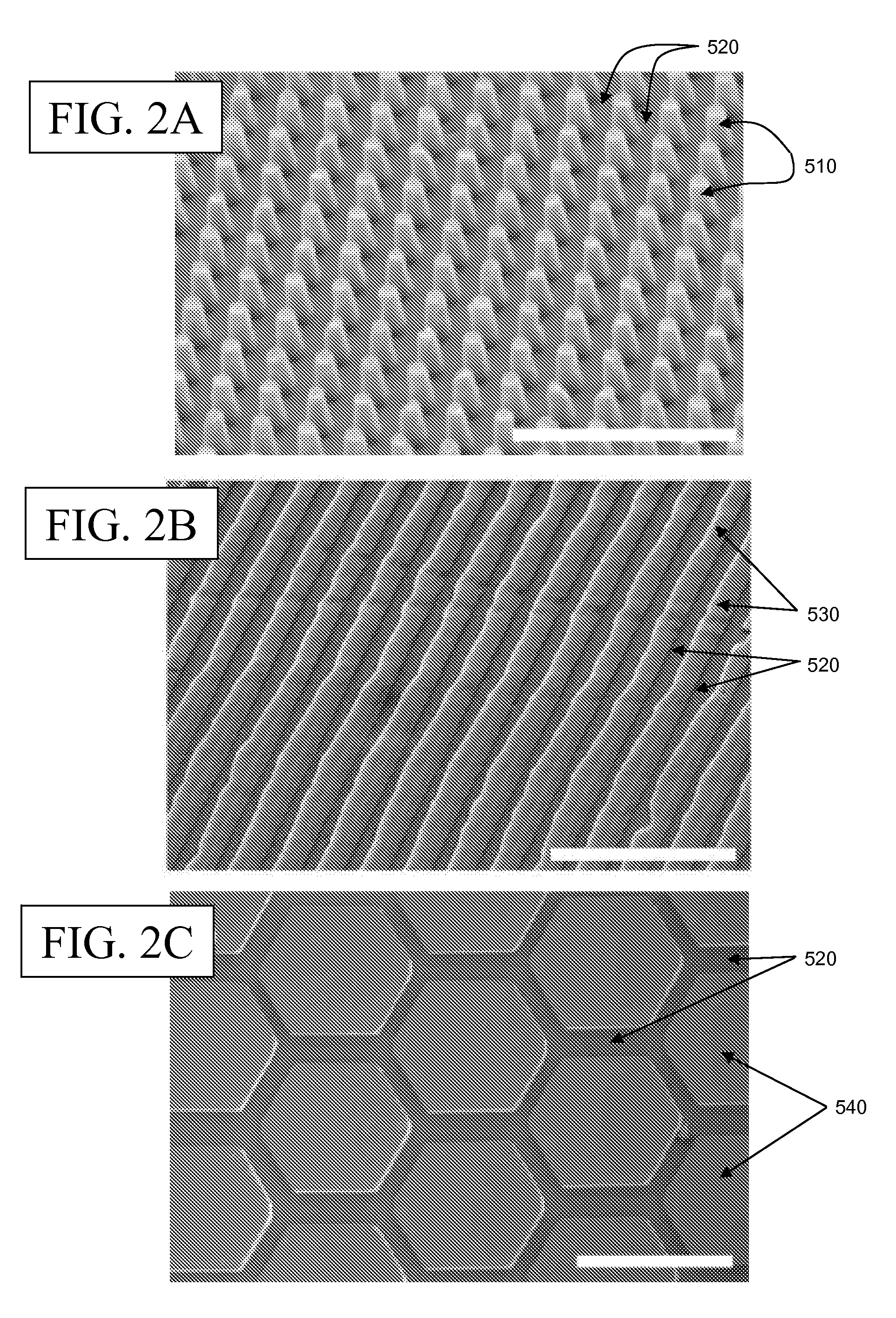

Microfluidic Devices and Methods for Fabricating the Same

ActiveUS20090004737A1Mechanically robustRobust mechanical propertyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringElectrical and Electronics engineering

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV +1

Method for preparing crosslinked aliphatic series polycarbonate

ActiveCN1775828AImprove mechanical properties and heat resistanceOvercome viscous flowSide chainDouble bond

The invention belongs to cross-linking type aliphatics polycarbonate preparation method. The method is used containing double bond epoxy compound, epoxy propane, and carbon dioxide ternary polymerization to make polycarbonate with side chain double bond and cross linking type polycarbonate by the cross linking of the side chain double bond. Compare with the non cross-linking polycarbonate, the heat resistance and mechanical property of the ternary polymerization carbonate is improved obviously after cross- linking. The copolymer not only will not be viscous flow at room temperature, but also can be long time use under 60 centigrade degree.

Owner:迁安市宏奥低碳科技有限公司

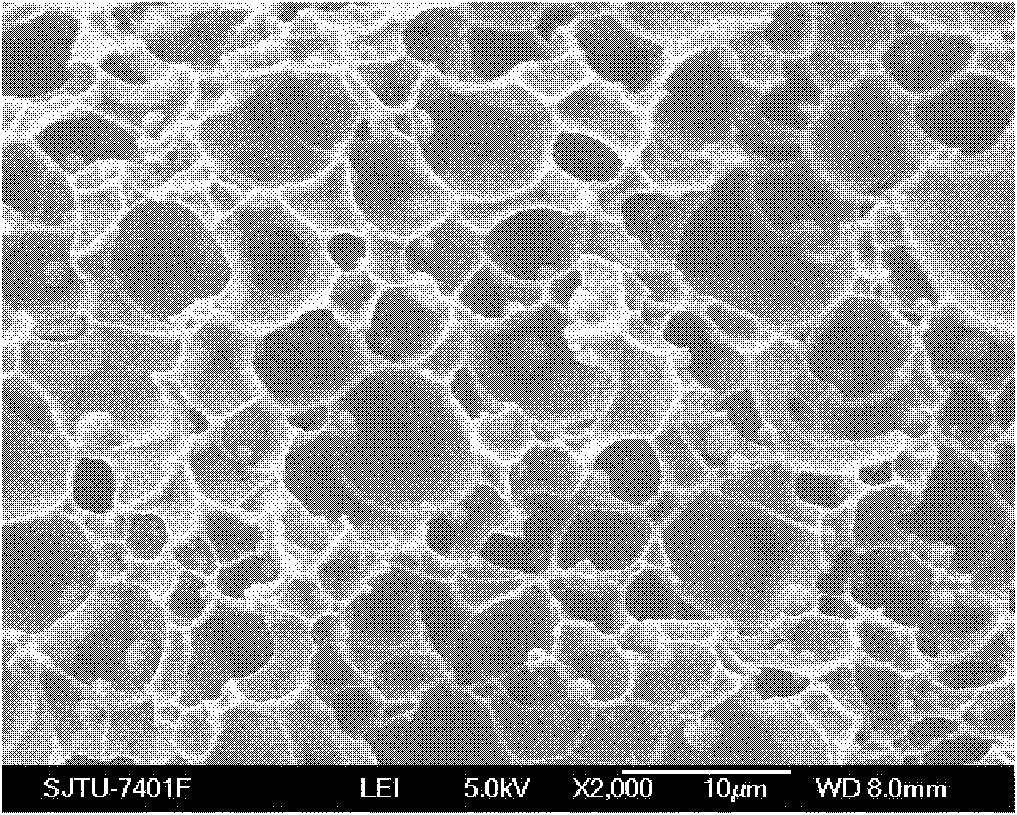

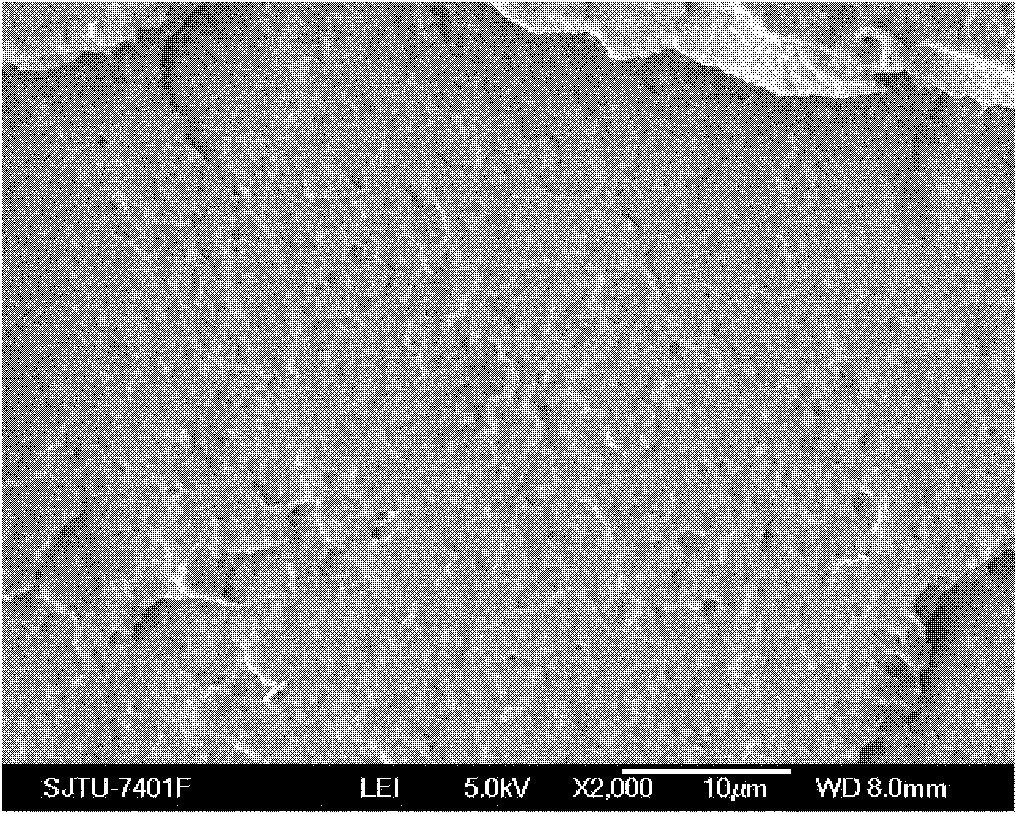

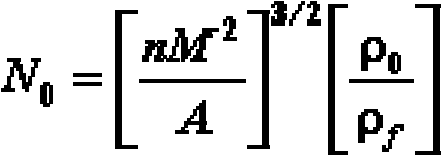

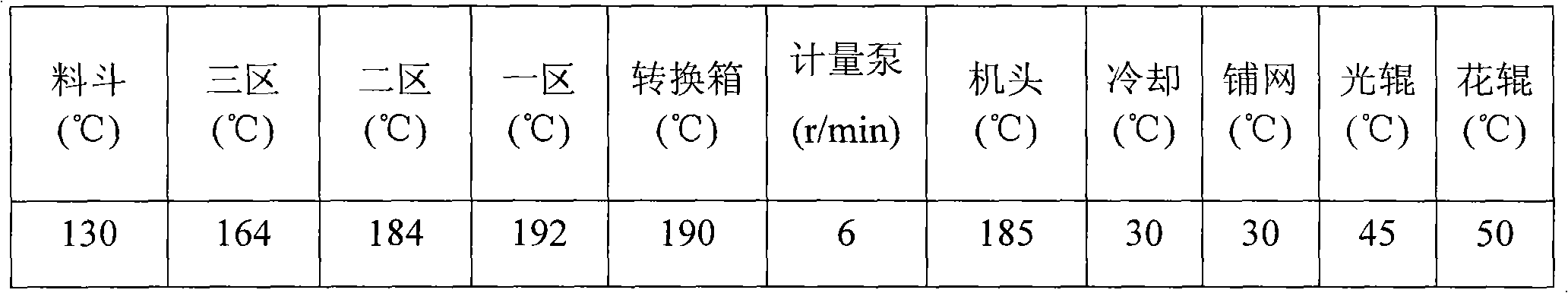

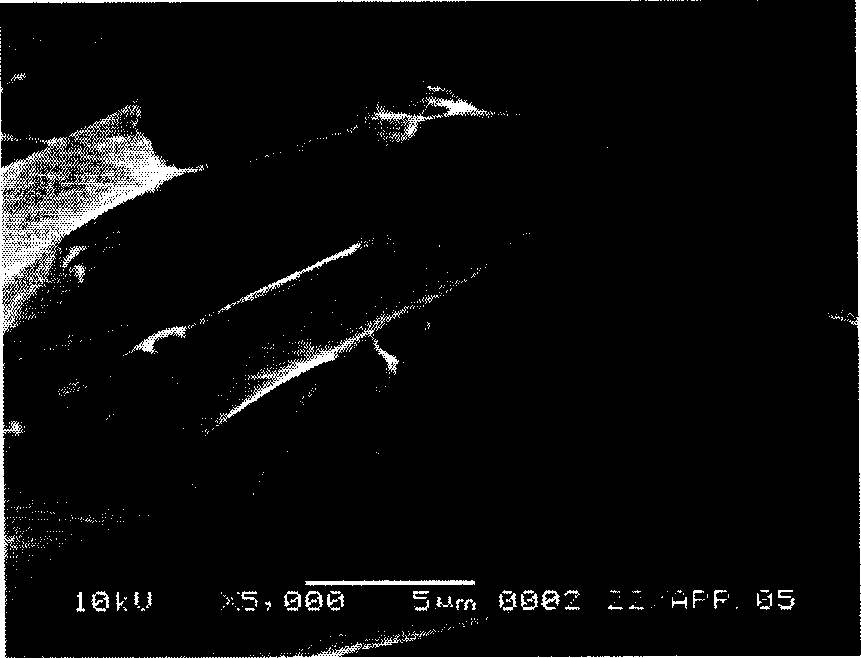

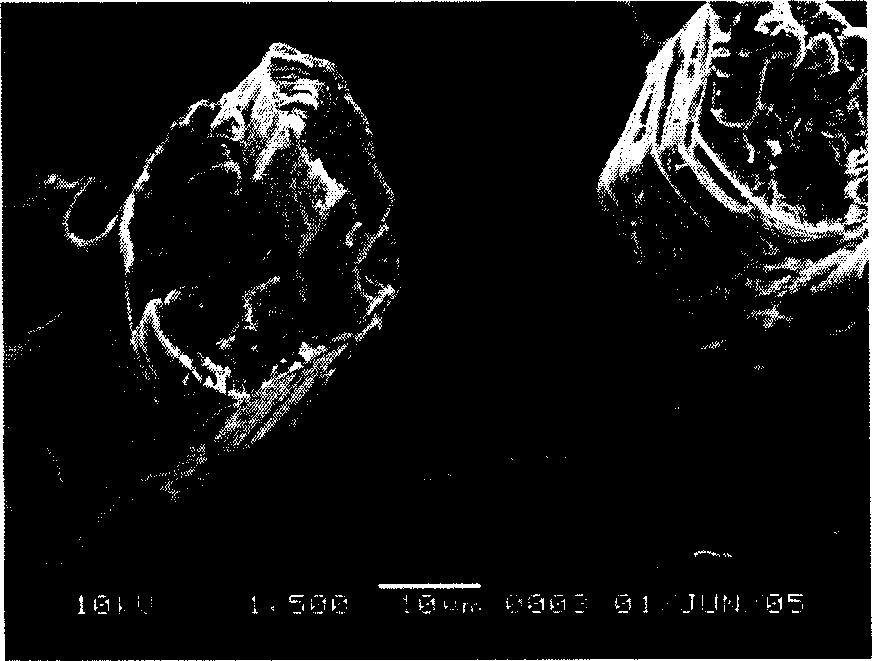

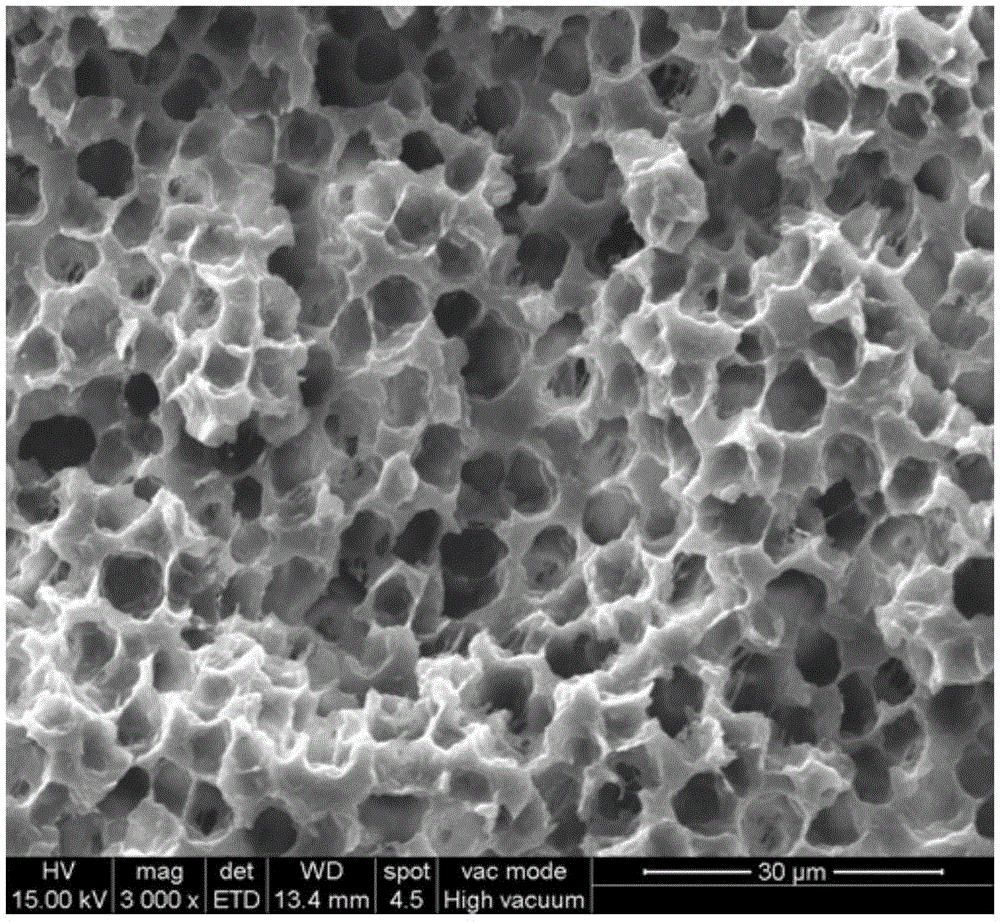

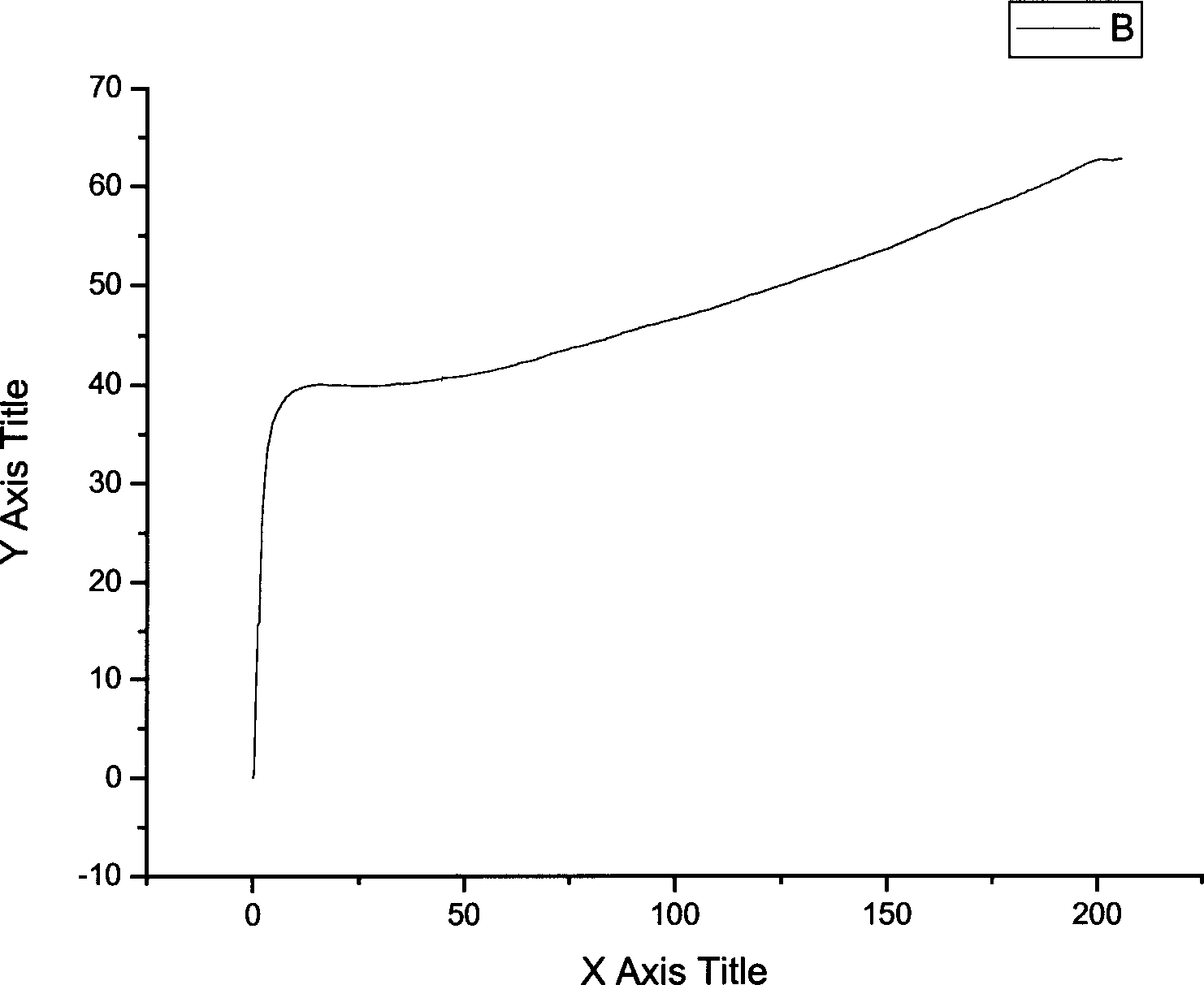

Method for preparing biodegradable polylactic acid foaming material

The invention discloses the composition of a biodegradable polylactic acid (PLA) foaming material and a preparation method thereof. The method for preparing the biodegradable polylactic acid foaming material comprises the following steps: blending polylactic acid (PLA) and aliphatic-aromatic co-polyester toughening agent in a screw extruder; loading the extrudate into the fluid of supercritical CO2 to swell, so that the CO2 can be fully dissolved in the blended materials; then, releasing the pressure at a high rate, so as to supersaturate the CO2 in the composite material, thus achieving the thermodynamic instability; and nucleating and foaming to obtain the biodegradable PLA foaming material, wherein the toughening agent is particularly poly(butylenes adipate-co-terephthalate) (PBAT) in the invention. The method of the invention is capable of preparing the PLA foaming material with the cell diameter thereof being 0.9056mu m to 5.250mu m and the cell density thereof being 2.05*1,019 pieces / cm<3> to 2.01*1,022 pieces / cm<3>. The invention as a green and environment-friendly technique can improve the material performance and reduce the cost.

Owner:SHANGHAI JIAO TONG UNIV

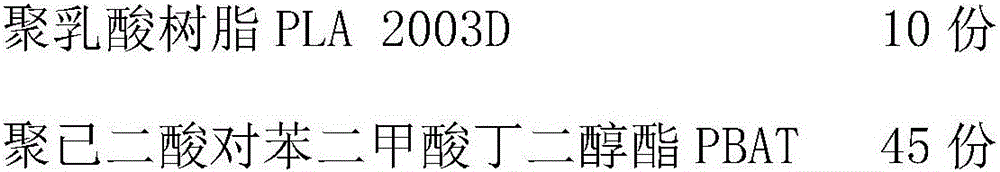

Biodegradable modified polylactic acid material and preparation method thereof and method for preparing non-woven fabric by same

InactiveCN101914272AGenerate good effectThe preparation process is environmentally friendlyNon-woven fabricsPolymer scienceNonwoven fabric

The invention relates to a biodegradable modified polylactic acid material, prepared by the following raw materials by parts by weight: 100 parts of polylactic acid resin; 10-50 parts of ternary copolyester obtained by polymerization of terephthalic acid, aliphatic hydrocarbon diacid and aliphatic hydrocarbon dihydric alcohol; 5-40 parts of inorganic filler and 1-20 parts of plasticizer. The raw materials are subject to mixing, refining and extrusion pelleting, thus obtaining the modified polylactic acid material. The biodegradable modified polylactic acid material of the invention has the following advantages: the material can be completely biodegraded and is environmentally friendly, and the non-woven fabric prepared by the material has good elasticity, mechanical strength and flexibility and can be popularized and applied in multiple fields.

Owner:IER BUSINESS DEV CENT +1

Fully biodegradable and multi-functional plastic mulch

ActiveCN103289134AFully biodegradableCreate pollutionClimate change adaptationPlant protective coveringsEcological environmentAdditive ingredient

The present invention provides fully biodegradable and multi-functional plastic mulch. The plastic mulch comprises, by weight percent: natural biopolymers of starch or derivatives thereof, biodegradable synthetic polymers, an interfacial reinforcer, a compound plasticizer with urea as a main ingredient, a nitrogen phosphorus and potassium compound fertilizer, pesticides, herbicides and trace fertilizers. The plastic mulch of the present invention not only has heat and moisture preservation functions, and is fully biodegradable after use, eliminating the contamination to soil causes by residual plastic mulch debris; and functional additives of fertilizers and nutrients, pesticides, herbicides etc. in the plastic mulch are sustainedly released as the plastic munch degrading, so the plastic mulch has long lasting effects of weed controlling, pest killing, and sustainedly released fertilizing, significantly reducing the use amount of fertilizers and pesticides, decreasing costs, and protecting the ecological environment. The invention also provides a method for preparing the multi-functional plastic mulch.

Owner:ANHUI XUELANG BIOTECHNOLOGY CO LTD

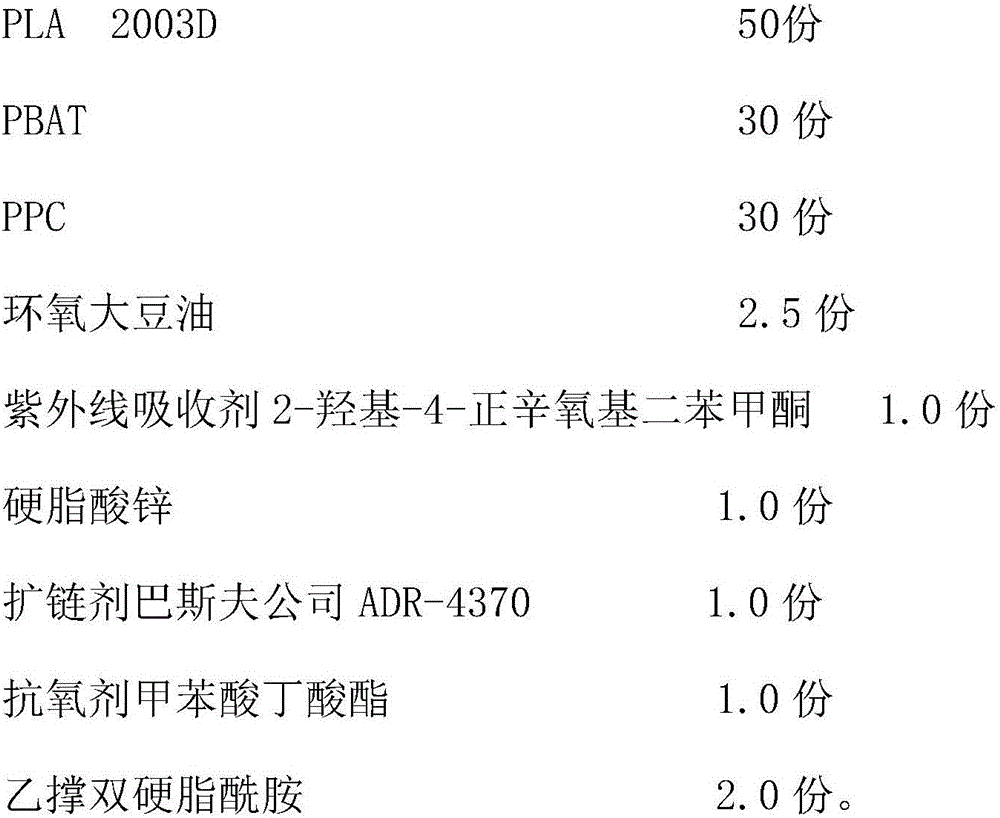

High-barrier-property biodegradable mulching film and preparation method thereof

InactiveCN106046725AFully biodegradableGood mechanical propertiesLow-density polyethyleneAntioxidant

The invention relates to a high-barrier-property biodegradable mulching film and a preparation method thereof, belonging to the field of high-polymer materials. The high-barrier-property biodegradable mulching film is prepared from a polylactic acid resin, a toughener, a heat stabilizer, an ultraviolet absorbent, a chain extender, an antioxidant, an opening agent and the like by using a film blowing machine set. The high-barrier-property biodegradable mulching film can be automatically degraded under the actions of rich oxygen and microbes, does not pollute the environment, has higher barrier property than the LDPE (low-density polyethylene) film with the same thickness by 1.5-2.0 times, and satisfies the functions of moisture retention, water preservation and yield increase for crops. The method has the advantages of simple production technique and high production efficiency, and can easily implement industrial production.

Owner:JILIN COFCO BIOCHEM

Method for preparing toughened calcium carbonate filling polylactic acid

The invention discloses a method for preparing toughened calcium carbonate filling polylactic acid, which comprises steps of: firstly, mixing 1-10 parts of ester polymer coating treated agent and 5-50parts of calcium carbonate for 5-15 minutes in a high speed mixer with the speed more than 4000rpm / min to cause the treating agent to form thin layer distribution on the surface of the calcium carbonate; melting and mixing 100 parts of dried polylactic resin particles and treated calcium carbonate in an internal mixer of 110-175 DEG C ora two roll rubber mixing mill for 3-15 minutes, or adding dried polylactic resin particles and treated calcium carbonate into a double-screw extruder, melting and mixing in the temperature of 110-190 DEG C, and finally extruding pelleting to obtain toughened calcium carbonate filling polylactic acid. The method has simple technique, convenient treatment, short production period and low energy consumption; the prepared calcium carbonate gas good disperse effect in the polymer, has low cost and easily realizes the industrialization production of the coated calcium carbonate.

Owner:SICHUAN UNIV

Degradable bacteriostatic food packing material and preparation method thereof

ActiveCN101974213AFully biodegradableSimple processFlexible coversWrappersAntibacterial activityFilm material

The invention discloses a degradable bacteriostatic food packing material and a preparation method thereof. The preparation method comprises the following steps: irradiating chitosan by a radiation method for degradation; adding coupling agent aid solution into the degraded chitosan, mixing and stirring; drying the mixture to remove the solvent and then adding a degradable polymer material and mixing; and adding lubricant and plasticizer and finally preparing a film product. The invention adopts chitosan as an antibacterial raw material. The chitosan has high antibacterial activity and can suppress the growth and breeding of certain fungi, bacteria and viruses; and a small amount of the chitosan is used, and the toxic side effect is avoided; polylactic acid and polycaprolactone can be degraded completely, and the film forming performance and the processability are high; the film material prepared by combining the chitosan is used as bacteriostatic preservative material, and compared with the common packing material, has good bacteriostatic effect and strong preservation power and can prolong the shelf life of the food; moreover, the bacteriostatic long-term effectiveness of the bacteriostatic plastic can be synchronized with the service life of the product, thus being convenient and economic; and after the using period, the bacteriostatic plastic can be either recycled or degraded and assimilated with the nature without causing environmental pollution.

Owner:SICHUAN KUIKE BIOTECH

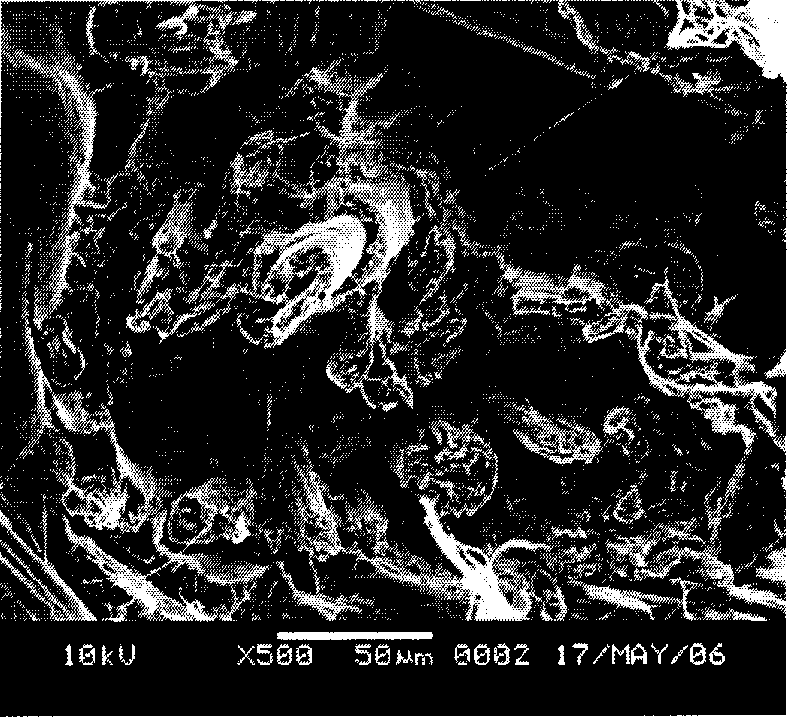

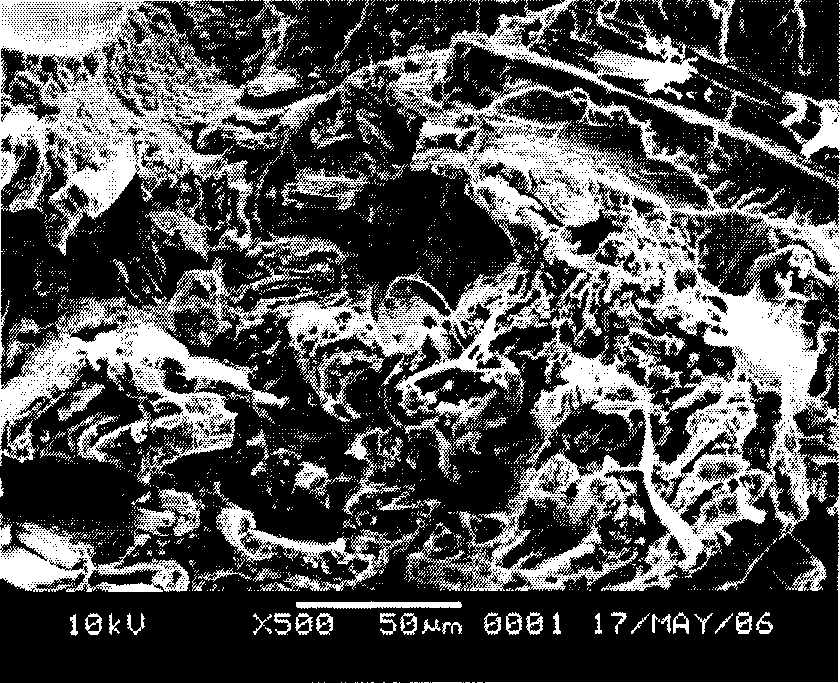

Method for preparing composite material of poly lacltic acid enhanced by ramie fiber

InactiveCN1760266AFully biodegradableImprove interface performanceVegetal fibresPrepolymerPolylactic acid

A ramie fiber reinforced polylactic acid composition is prepared through respectively dissolving the prepolymer of polylactic acid polycaprolactone in organic solvent, immersing the ramie fibers in the solution of polycaprolactone, adding another solution, sealing, and in-situ polymerizing at 60-100 deg.C for 0.5-4 hr. It has excellent interface and mechanical performance.

Owner:DONGHUA UNIV

Polylactic acid pressure-sensitive bonding adhesive tape capable of complete biodegradation and preparation method thereof

InactiveCN101104779AEnergy savingReduce manufacturing costFilm/foil adhesivesPressure sensitiveChemistry

The invention relates to a polylactic pressure sensitive adhesive tape which can be completely biodegraded and the preparation method. The adhesive tape comprises a back material of polylactic biaxial film, a pressure sensitive adhesive layer on one major surface and a release agent layer on another major surface. The polylactic pressure sensitive adhesive tape is provided with biodegradability and has no pollution to the environment. The invention also provides a method of making the polylactic pressure sensitive adhesive tape, wherein the temperature drops from 100-140 DEG C to 40-70 DEG C in the drying technology, which reduces energy consumption and production cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

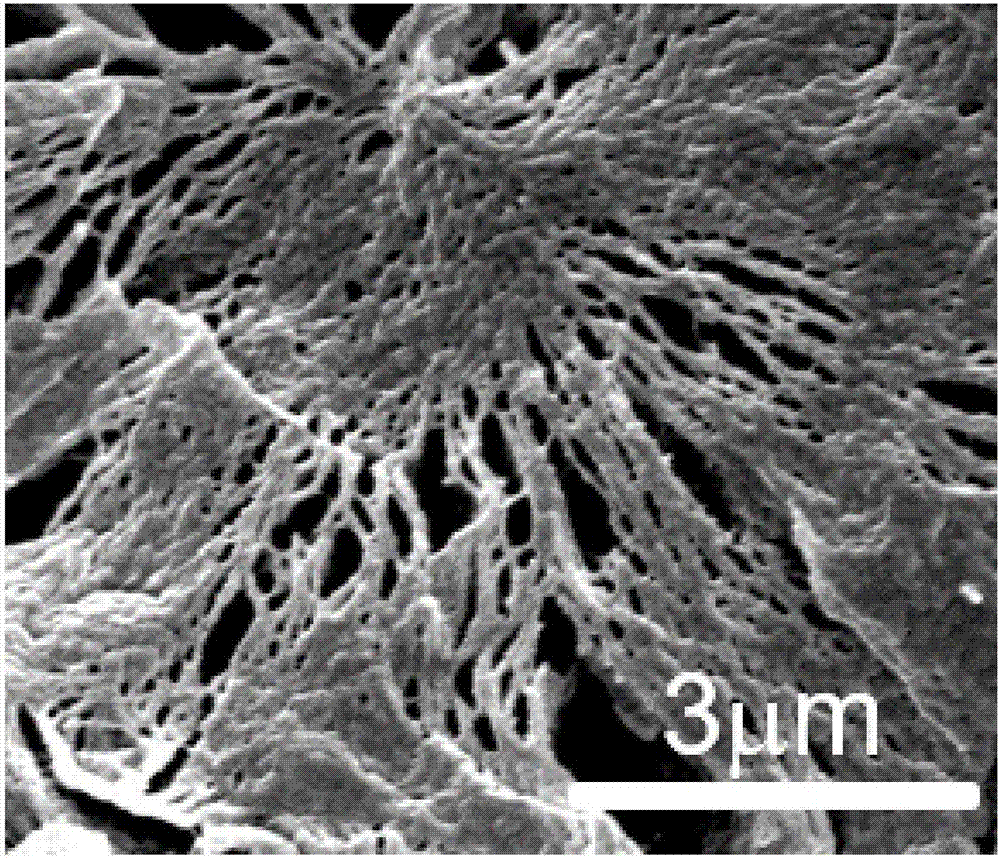

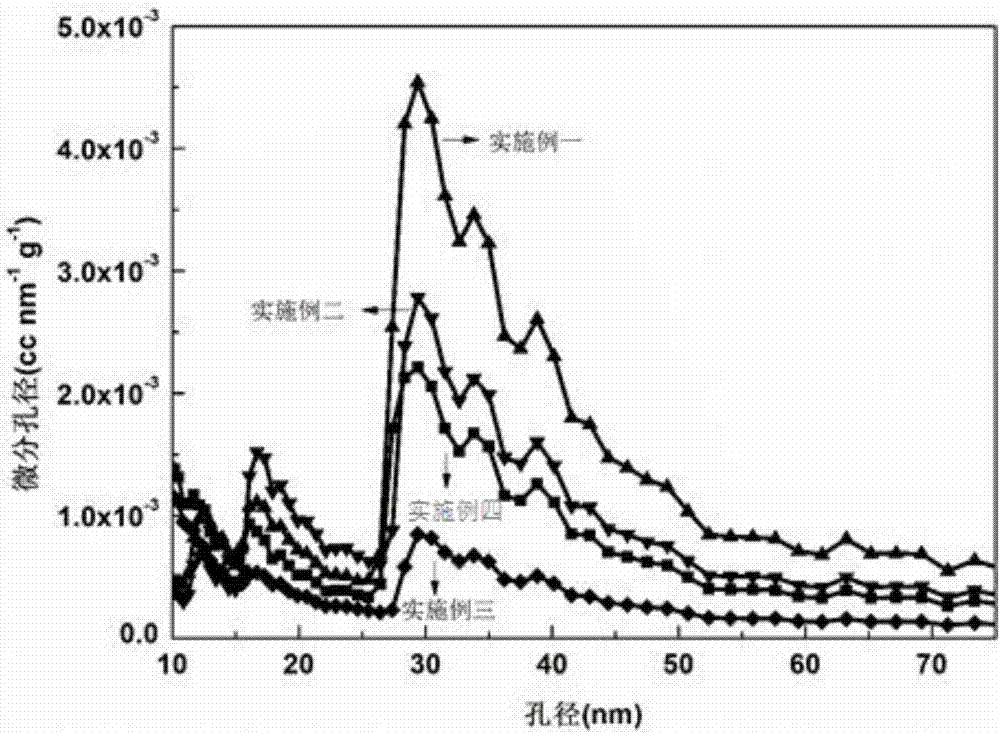

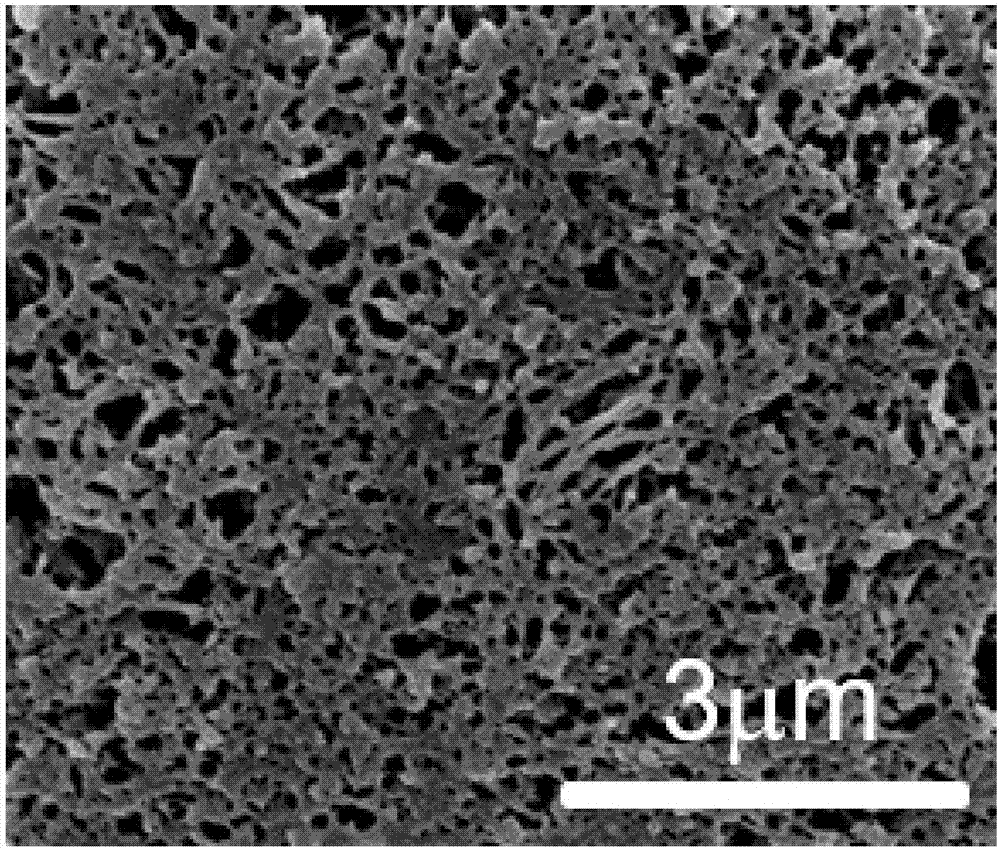

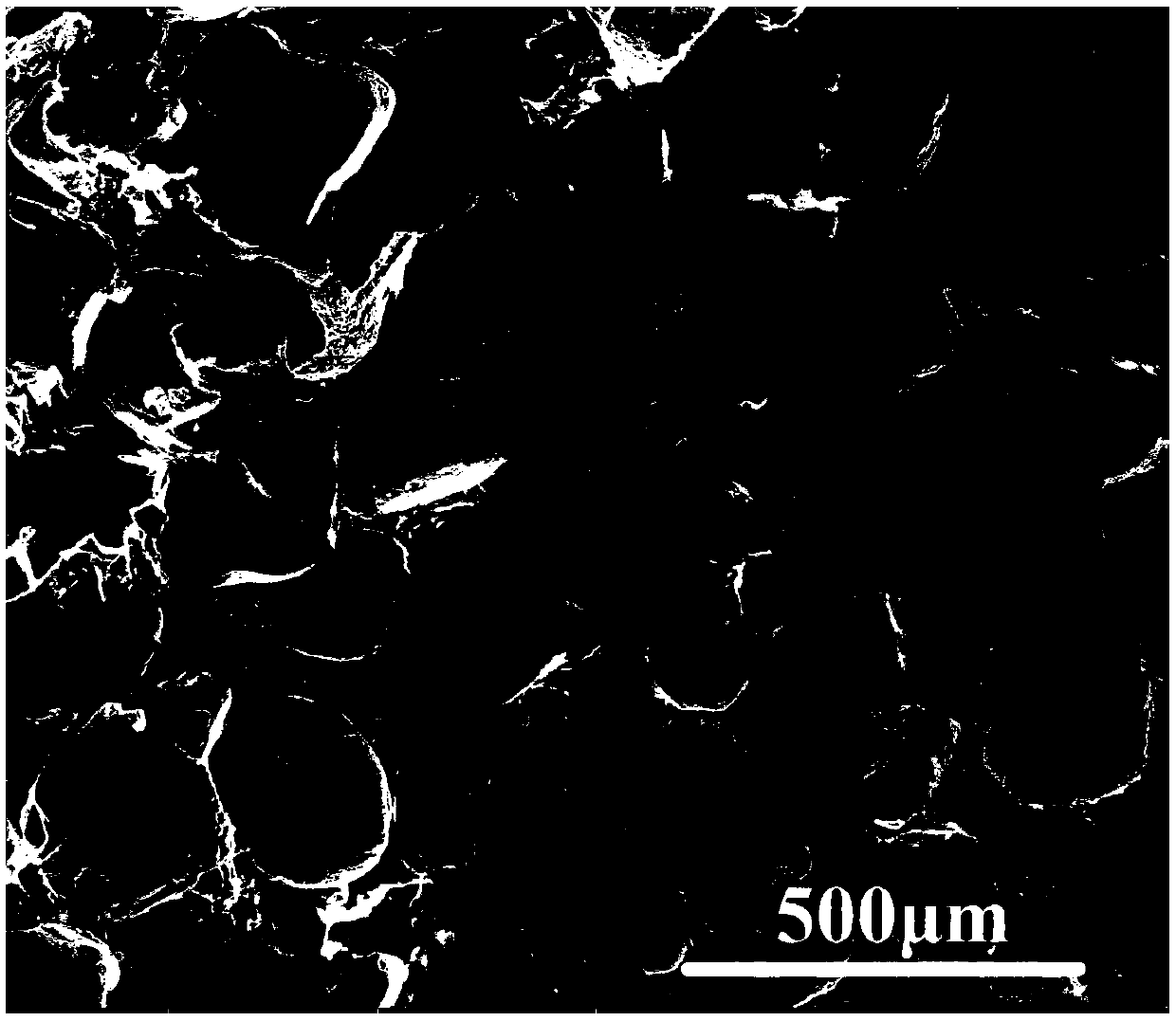

Multilevel porous polylactic acid material and preparation method thereof

ActiveCN106947228AIncrease productivityThe removal process is safe and environmentally friendlyOil waterAcetonitrile

The invention belongs to the field of multilevel porous materials and particularly relates to a multilevel porous polylactic acid material and a preparation method thereof. The invention provides a polylactic acid material which is a mesoporous-macroporous material. The invention provides the multilevel porous polylactic acid material which can be degraded. The porous material has a controllable shape and a controllable pore size. The porous material can be applied to selective oil and water separation because of excellent hydrophobicity (a water contact angle can be up to 135 degrees) and lipophilicity. The multilevel porous material still has very good size stability and very good solvent resistance under an environment of which the temperature is up to 210 DEG C, and is still integral in structure when being stood in an acetonitrile solution with 80 DEG C-temperature for 24 hours; and the adsorption quantity of chloroform in an aqueous solution by the multilevel porous material can be up to 1.87 + / - 0.20gg<-1>.

Owner:SICHUAN UNIV

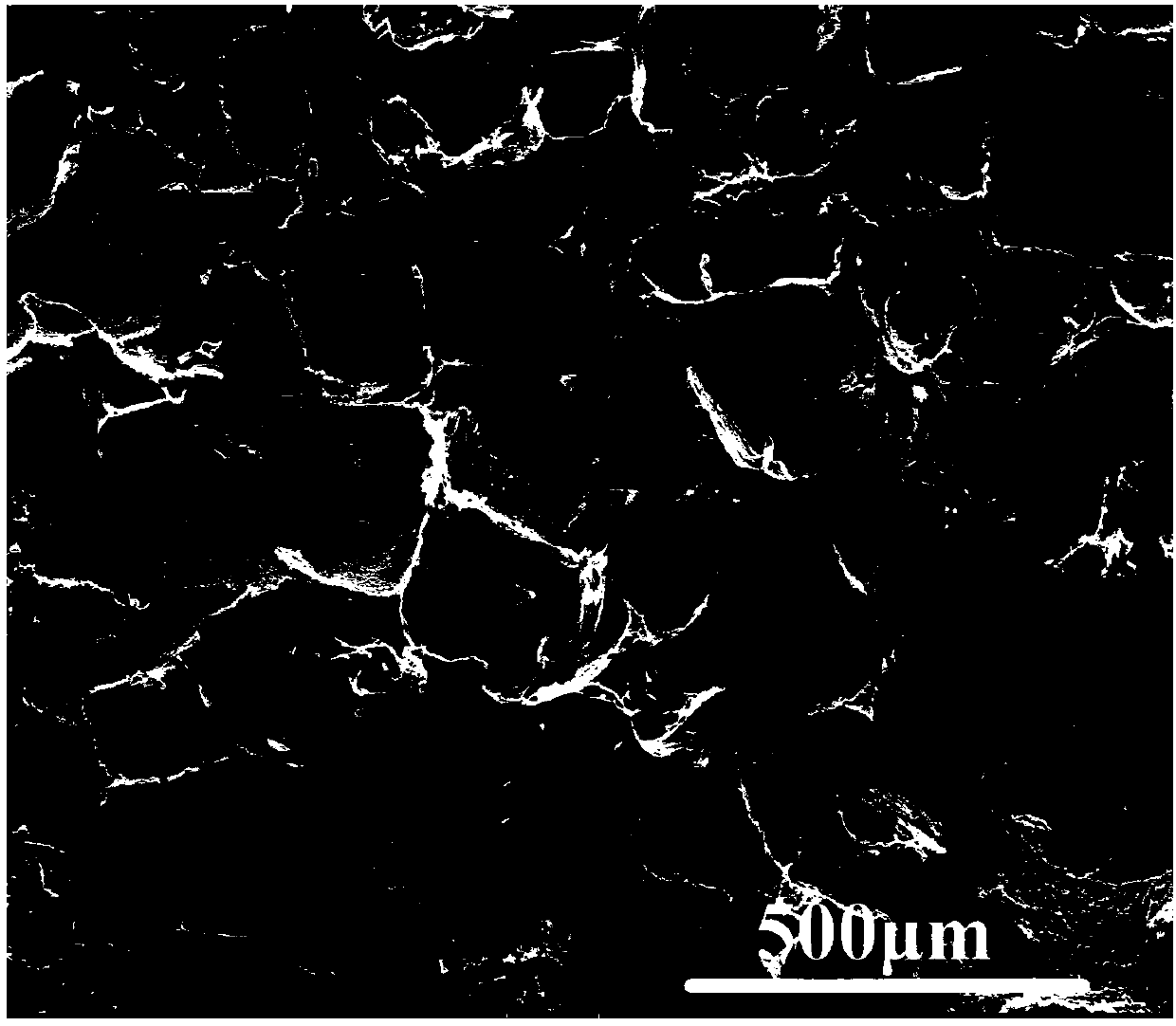

Porous polylactic acid material for scaffold for tissue engineering and preparation method thereof

InactiveCN107670108AMeet special shape requirementsMeet shape requirementsPharmaceutical delivery mechanismProsthesisPorosityBiocompatibility Testing

The invention belongs to the field of polymer material processing and biomedicine and relates to a porous polylactic acid material for a scaffold for tissue engineering and a preparation method thereof. The preparation method of the porous polylactic acid material for the scaffold for tissue engineering comprises the steps that poly-L-lactic acid, poly-D-lactic acid and a pore-foaming agent are prepared into a polylactic acid steric blend through a solution casting method; the pore-foaming agent in the polylactic acid steric blend is removed, and then the porous polylactic acid material for the scaffold for tissue engineering is obtained through drying. The mass ratio of the poly-L-lactic acid to the poly-D-lactic acid is 1:9 to 9:1, the mass ratio of polylactic acid to the pore-foaming agent is 1:6 to 1:2, and the polylactic acid contains the poly-L-lactic acid and the poly-D-lactic acid. The obtained porous polylactic acid material for the scaffold for tissue engineering has highly controllable pore structure and pore size and very high aperture ratio, the porosity of the scaffold is 70-82%, and energy storage modulus can be up to 630-3327 MPa at the temperature of 37 DEG C. In addition, the porous polylactic acid material has very good biocompatibility.

Owner:SICHUAN UNIV

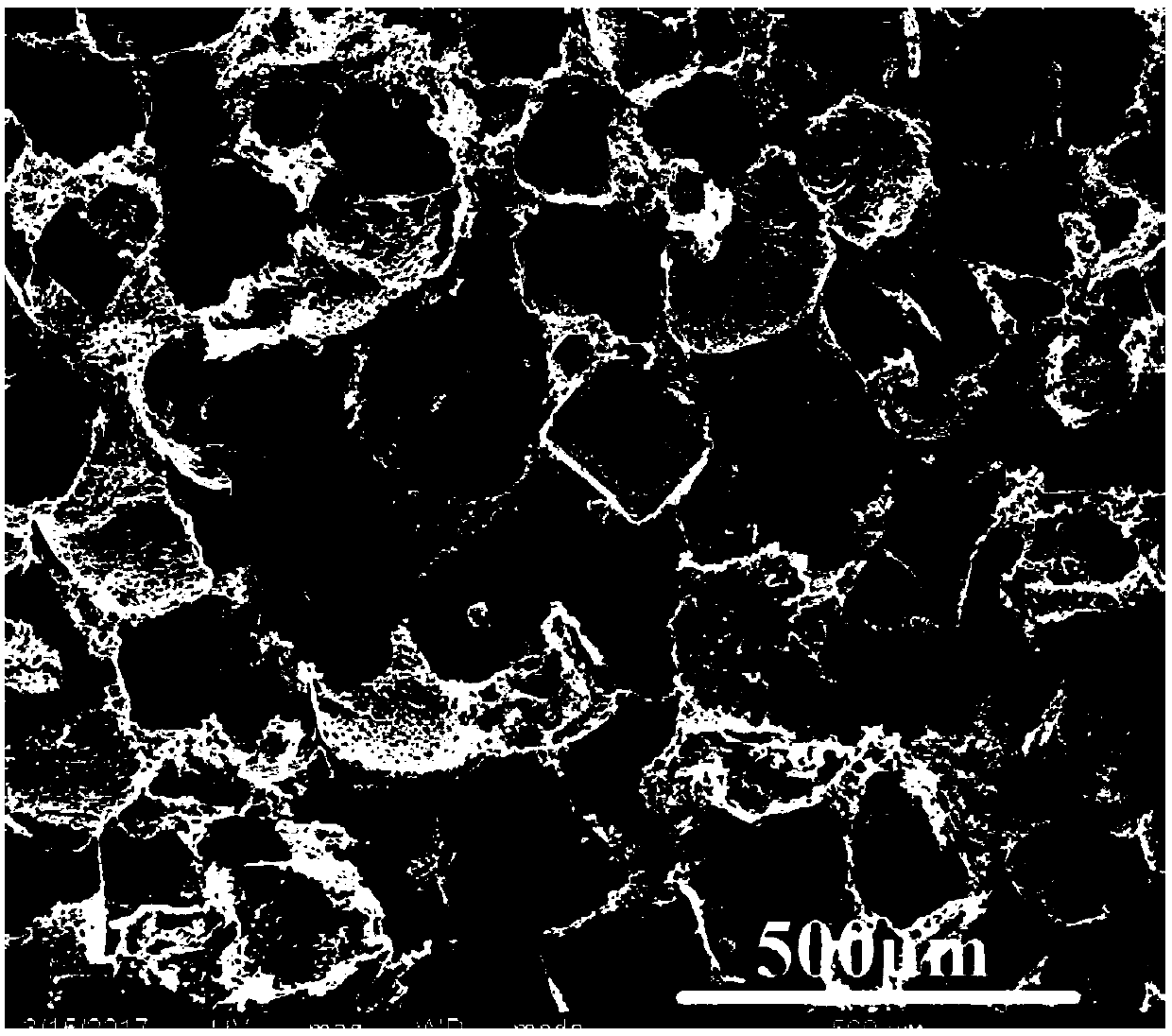

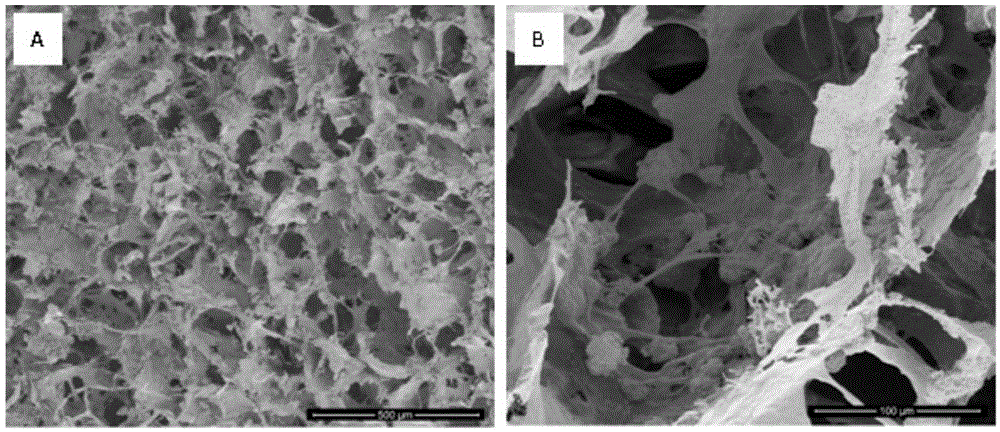

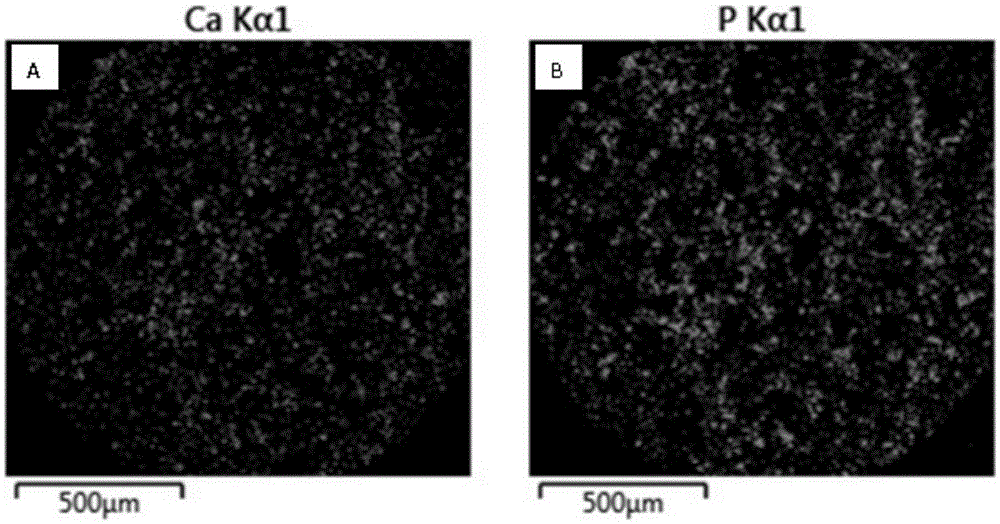

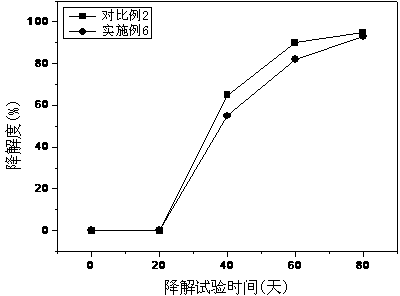

Bone repair composite material based on acellular biological tissue matrix material and preparation method of bone repair composite material

ActiveCN105412989AImprove adsorption capacityVarious ingredientsPharmaceutical delivery mechanismSkeletal disorderAcellular matrixBiocompatibility Testing

The invention relates to a bone repair composite material based on an acellular biological tissue matrix material and a preparation method of the bone repair composite material. According to the bone repair composite material disclosed by the invention, a micro-fibrotic animal tissue acellular matrix material is taken as an organic component, and a calcium salt biological ceramic material or other inorganic bioglass is taken as an inorganic component. According to the bone repair composite material prepared by the method disclosed by the invention, additional physical crosslinking or chemical crosslinking is not needed, and the bone repair composite material has a complete three-dimensional porous net structure; the protein component in the biological tissue matrix material has the natural triplex structure; the bone repair composite material has the excellent biocompatibility, the complete biodegradability, the excellent osteoconduction, as well as the excellent osteoinductivity and the excellent osteogenesis, also has certain mechanical strength and shape memory function, and can be used as a bone filling material with bioactivity or a repair material for large-area bone defect.

Owner:HANGZHOU HUAMAI MEDICAL DEVICES CO LTD

Preparation method of degradable glycolic acid copolyester

The invention discloses a preparation method of degradable glycolic acid copolyester. Glycolic acid copolyester with high molecular weight is obtained by condensation polymerization of glycollic acid, adipic acid and ethylene glycol. The direct condensation polymerization is adopted, so that the whole process is short in procedure, less in side reaction and low in energy consumption during production; glycollic acid, adipic acid and ethylene glycol are taken as raw materials, so that the cost of the raw materials is low. Thus, the finally obtained glycolic acid copolyester is low in production cost. The prepared glycolic acid copolyester is high in intrinsic viscosity, good in mechanical property and excellent in practicability. In addition, the glycolic acid copolyester is completely prepared by the condensation polymerization of biodegradable monomers, so that the glycolic acid copolyester has the complete biodegradability; catalysts containing stannum, plumbum and the like, which have large toxicity, are not adopted in the preparation process, so that the glycolic acid copolyester is nonhazardous to a human body. As a result, the glycolic acid copolyester disclosed by the invention is a safe and environment-friendly high molecular material.

Owner:JIANGSU JINJU ALLOY MATERIAL

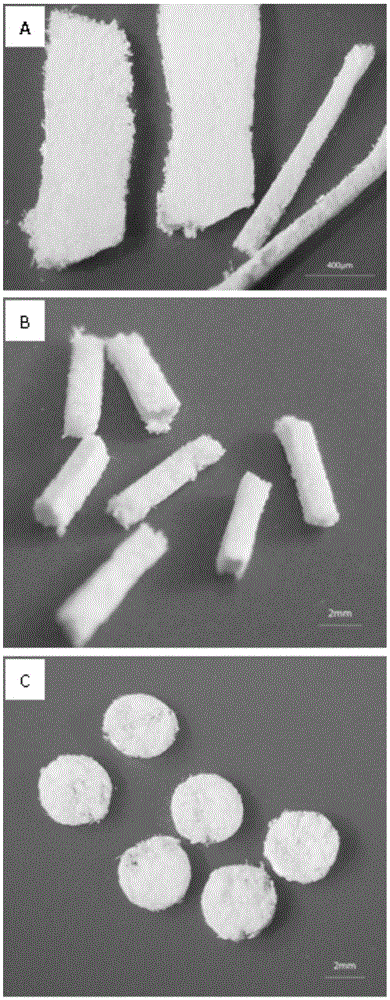

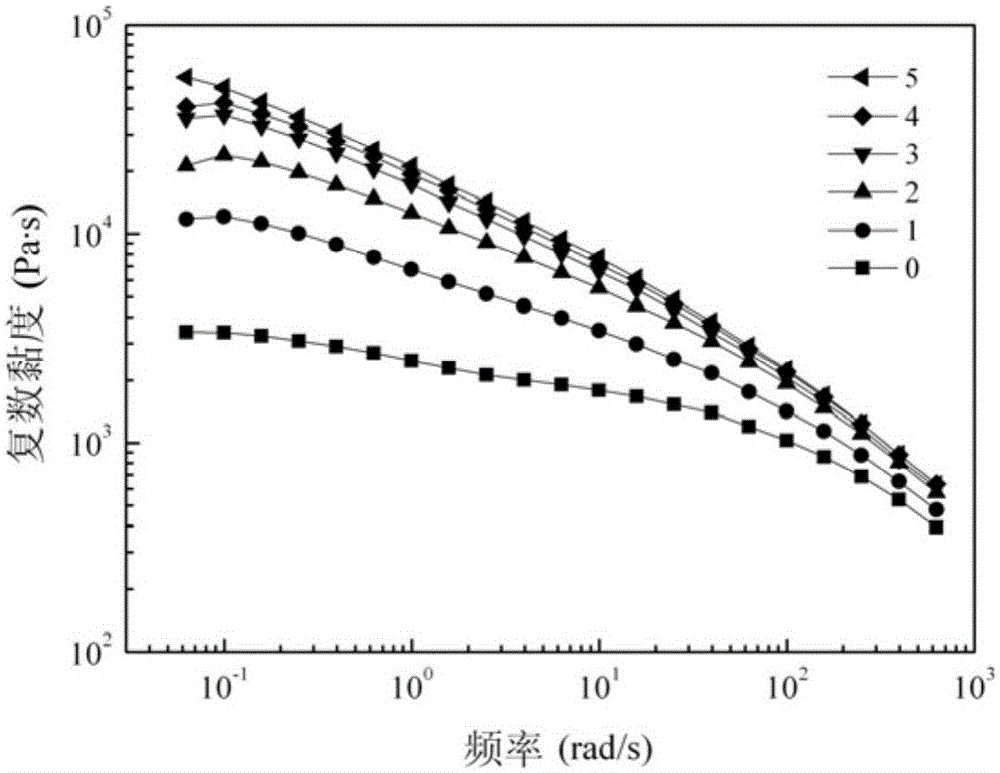

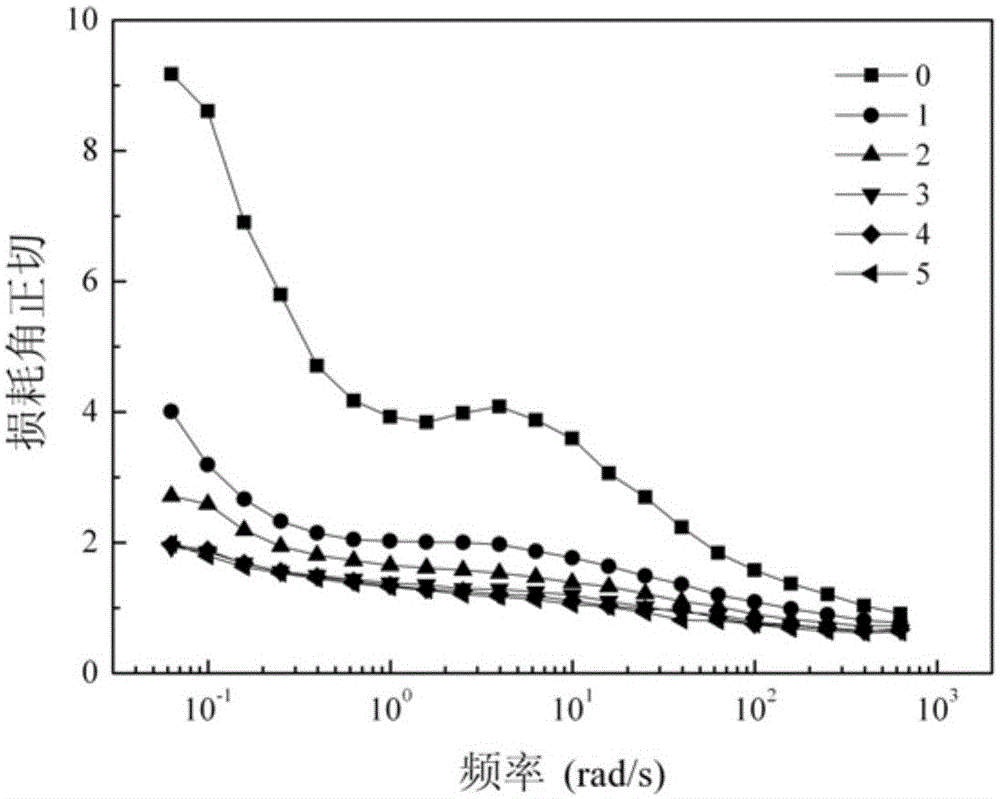

Polylactide-based blended material, preparation method thereof and method for preparing foam material from polylactide-based blended material

The invention discloses a polylactide-based blended material, a preparation method thereof and a method for preparing a foam material from the polylactide-based blended material. The mass ratio of PLA to an elastomer in main components of the blended material is (70-90):(30-10), and the mass percentage of a chain extender is 0.2-2.0% calculated according to the fact that the mass sum of PLA and the elastomer is 100%. The preparation method of the blended material comprises the following steps: mechanically mixing PLA, the elastomer and the chain extender according to the ratio to form a premix; then, placing the premix into an extruder; and reacting and carrying out melt blending to obtain the polylactide-based blended material. According to the preparation method of the foam material, the prepared polylactide-based blended material is placed in a high-pressure kettle cavity and is foamed through introducing a supercritical fluid, or the prepared polylactide-based blended material is added into an injection molding machine or extruder and is foamed through introducing the supercritical fluid. The blended material prepared by using the preparation method not only has very high toughness, but also remains the original strength of a polylactic acid material.

Owner:SOUTH CHINA UNIV OF TECH

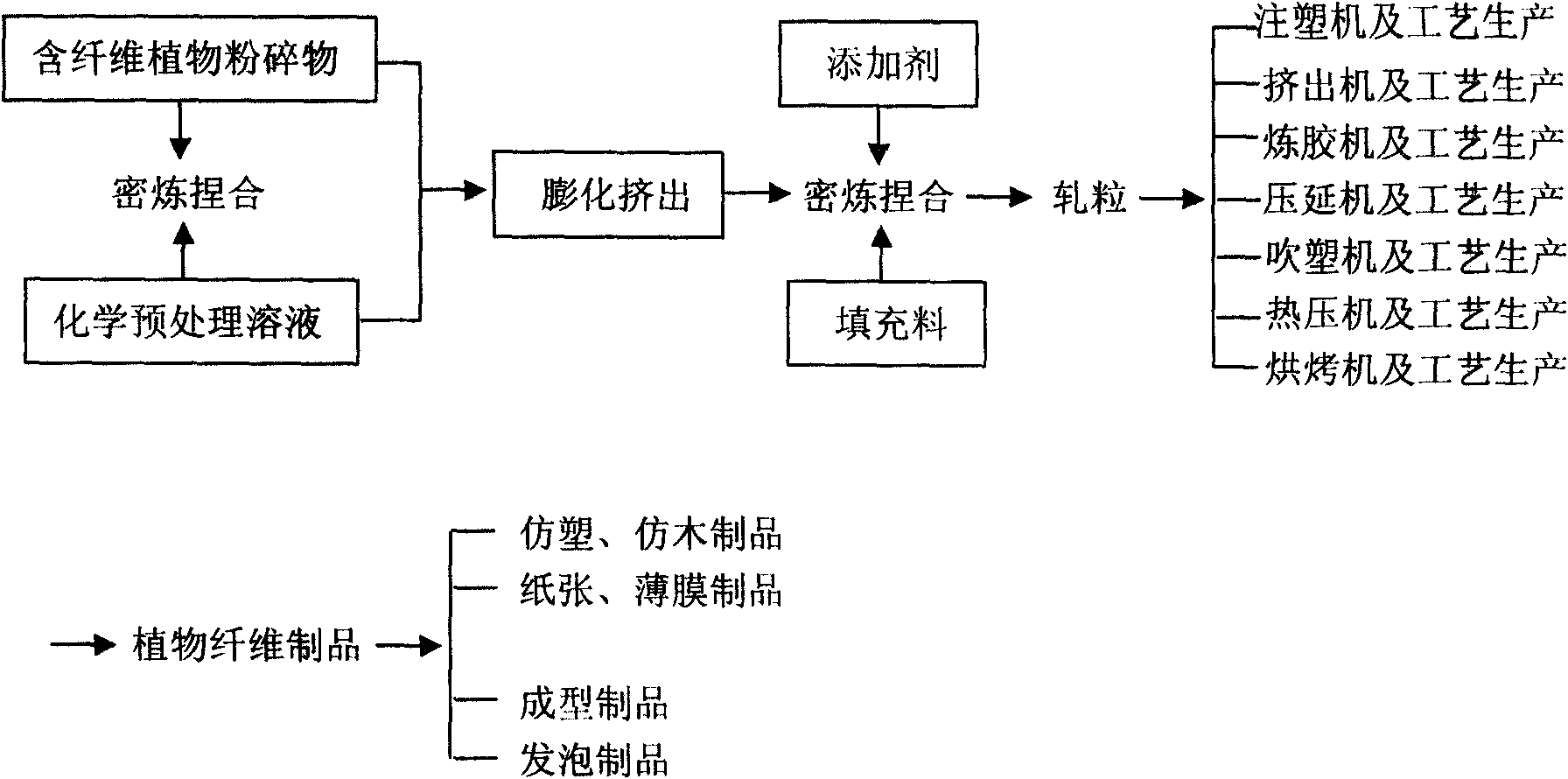

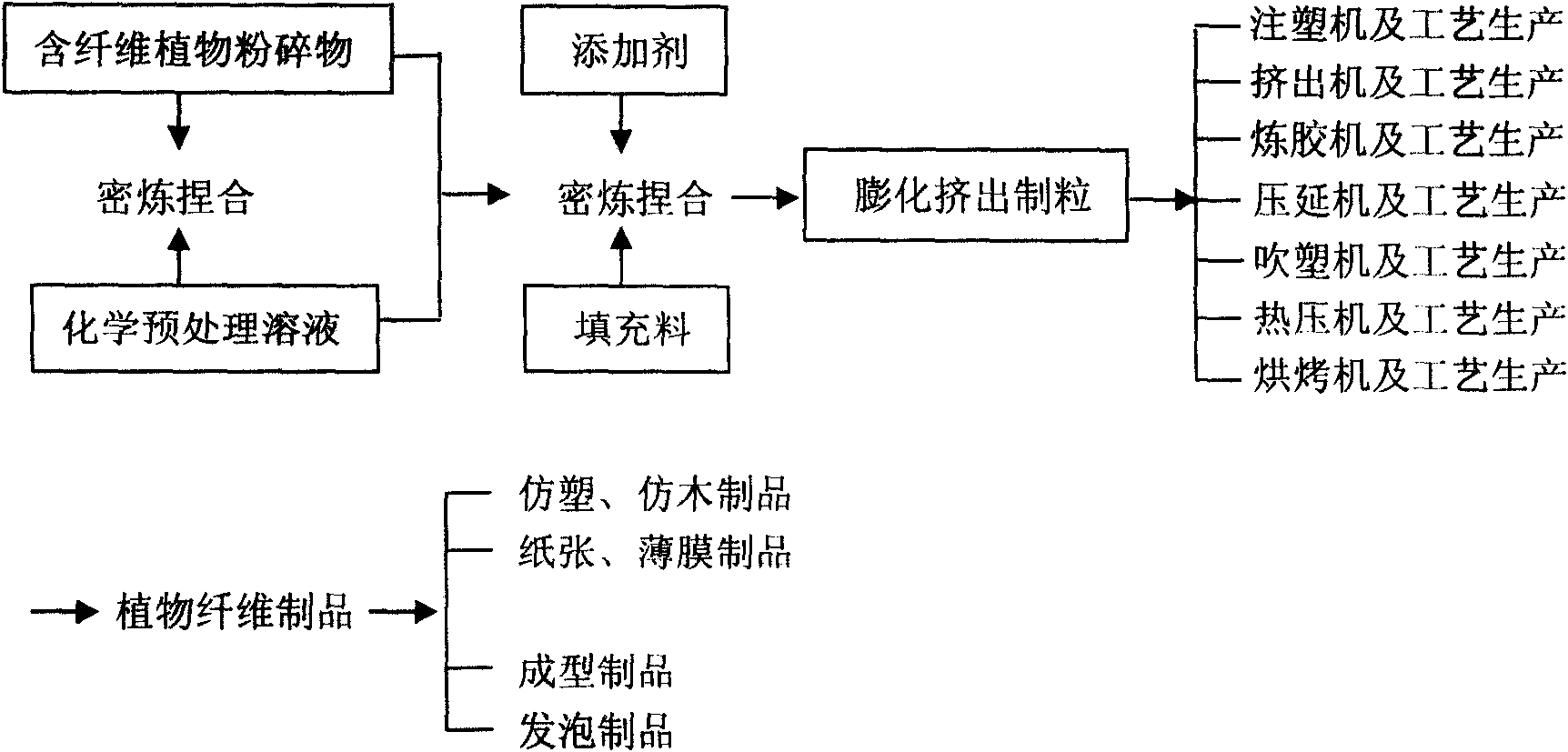

Manufacturing method of plant fibre products

The invention relates to a manufacturing method of plant fibre products, which comprises the steps: pulverized substances containing textile plants are poured into a banburying kneader and chemical pretreatment solution is added, so the fibre pretreatment chemical modification is realized simultaneously when mechanical physics modifying is realized; after entering into an expansion extruder for expansion modification, the pulverized substances are added with various additives and fillings, which are banburied and kneaded together, and the banburying kneading substance is rolled into particles by a particle rolling machine; or plant fibre subjected to banburying kneading chemical modification and various additives and fillings are directly and together banburied and kneaded and then are extruded and produced to form particles or extrusion sectional materials by the expansion extruder; the produced particles or sectional materials can be used for producing plant fibre products of various types and performances and plant fibre products of sheets, sectional materials, paper, membranes, and the like by utilizing the prior plastic injection machine, extruder, blow moulding machine, rubber refining machine, calander, hot press, and equipment and technology principles of microwave and infrared, steam drying, and the like so as to replace plastic, plastic foam, woodworks, paper and membranes.

Owner:朱秀刚

Porous silicon

InactiveUS20130034714A1High pore volumeImprove solubilityCosmetic preparationsPaper/cardboard articlesMaterials sciencePorous silicon

Owner:PSIMEDICA

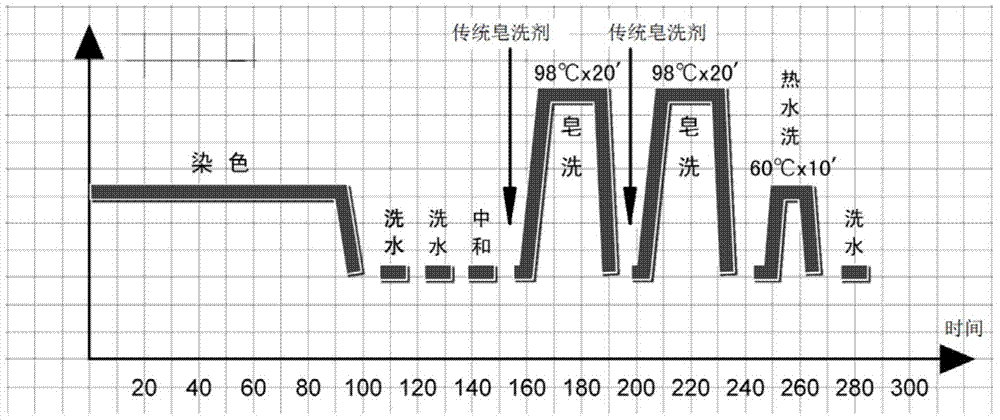

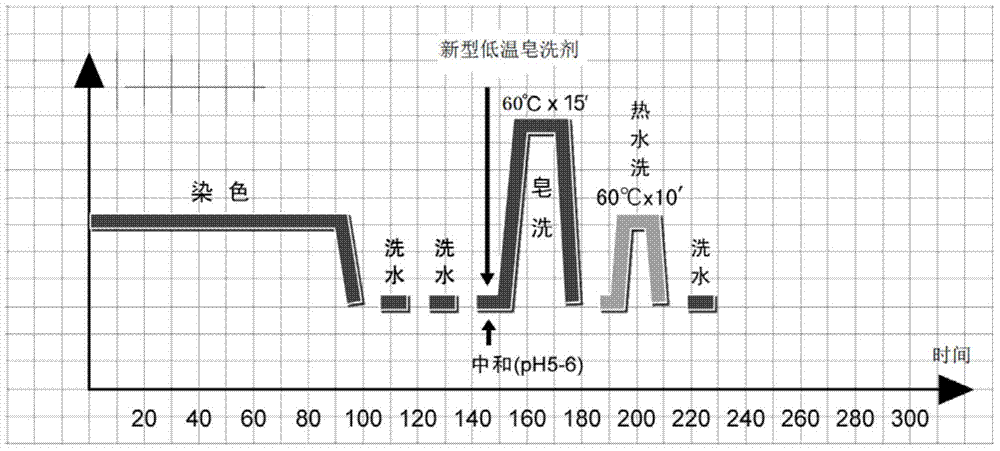

Novel cryogenic soaping agent and preparation method thereof

InactiveCN103571645AReduce dosageEffective dissolutionNon-ionic surface-active compoundsOrganic/inorganic per-compounds compounding agentsCarboxymethyl celluloseSulfate

The invention discloses a novel cryogenic soaping agent. The novel cryogenic soaping agent is characterized by comprising the following components in percentage by weight: 5-25% of laccase, 25-45% of persulfate, 15-35% of alkali, 15-25% of polyvinylpyrrolidone, 15-25% of sodium polyacrylate and 5-10% of sodium carboxymethyl cellulose. The novel cryogenic soaping agent is applied to a soaping process after reactive dyeing, and can effectively remove a flooding color, a paste material and an auxiliary agent on fabric at a relatively low temperature to improve the color brilliance, color fastness and cleanliness of the fabric.

Owner:上海德桑精细化工有限公司

Preparation method of reinforced polylactic acid composite material for ramie-fabric

InactiveCN1869107AFully biodegradableImprove interface performanceFibre treatmentOrganic solventPrepolymer

A ramie fabric reinforced polylactic acid composition able to be fully biodegradated is prepared through respectively dissolving the polylocatic acid and polycaprolactone in organic solvent, treating the surface of ramie fabric, immersing it in said polycaprolactone solution, adding the solution of polylactic acid, sealing and in-situ polymerizing.

Owner:DONGHUA UNIV

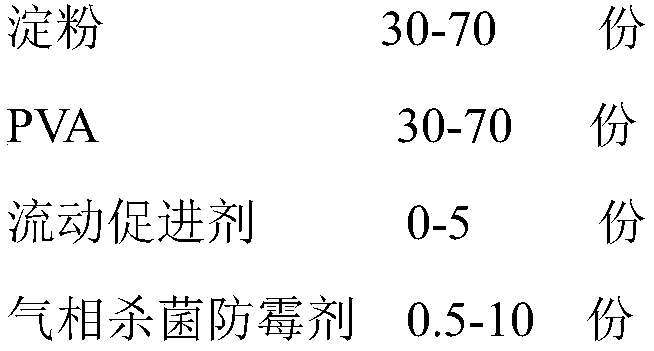

Degradable gas-phase fruit and vegetable preservative film and preparation method thereof

InactiveCN108314805AIncrease productivityProduct quality is stableFlexible coversWrappersAnti bacterialPlasticizer

The invention relates to a degradable gas-phase fruit and vegetable preservative film and a preparation method thereof, and belongs to the technical field of fruit and vegetable preservative packagingmaterial modification. The degradable gas-phase fruit and vegetable preservative film is prepared from the following raw materials in parts by weight: 30 to 70 parts of starch, 30 to 70 parts of PVA,0 to 5 parts of a flowing accelerant, 0.5 to 10 parts of a gas-phase anti-bacterial mildew preventive, 0.1 to 10 parts of an ethylene inhibitor, 0.1 to 5 parts of a negative oxygen ion slow-release agent, 10 to 25 parts of a plasticizer and 0.5 to 10 parts of an accessory ingredient. The degradable gas-phase fruit and vegetable preservative film is low in raw material cost, wide in source, atmosphere-controlled and breathable, and the biological degradability and preservation effect are excellent; and moreover, the invention provides a simple and practicable preparation method, and the preservative film is beneficial to industrial production.

Owner:朱春英

Completely biodegradable resin made of non-staple grain plant modified starch and its preparation method

ActiveCN102408588AIncrease the amount addedHigh resource substitutionBiodegradable copolymersTemperature and pressure

The invention discloses a preparation method of a completely biodegradable resin made of non-staple grain plant modified starch. The method comprises the steps of: first putting non-staple grain plant starch into a reaction vessel, adding water to prepare it into starch milk, and heating it to a proper temperature, conducting stirring and washing, then adding chemicals into a water solution for modification grafting treatment, and then separating water and starch through centrifugation, and conveying the separated modified starch to an airflow drying system for dewatering and drying, then taking 100 parts of dried modified starch, adding 5-50 parts of a compatilizer, 2-15 parts of an anti-block agent, 0-100 parts of polylactic acid, and 150-250 parts of a completely biodegradable copolymer of dibasic acid and dibasic alcohol, and mixing them uniformly, carrying out extrusion granulating or tabletting under an appropriate temperature and pressure, thus obtaining a resin material or sheet special for complete biodegradation. The resin of the invention has both the usage function similar to ordinary plastic products and a complete biodegradability. And after being used and abandoned, the resin can be degraded into carbon dioxide and water that can be consumed by the environment.

Owner:SUZHOU HANFENG NEW MATERIAL

Preparation method of fresh water composite microorganism base modifier

The invention discloses a preparation method of a fresh water composite microorganism bottom modifier. The preparation method comprises the steps of preparation of a fermentation culture medium, fermentation, adsorption and crosslinking. The method comprises the following specific steps: firstly, mixing bran powder, corncob powder, starch wastewater and a fermentation synergist to obtain the fermentation culture medium; introducing a mixed bacterial solution of rhodococcus erythropolis, saccharomyces cerevisiae and bacillus subtitles for fermentation culture, and purifying to obtain a microbial flocculant; then, adsorbing sesame straw activated carbon, enzymatic liquid, the microbial flocculant and a microbial preparation; performing crosslinking with a crosslinking agent to obtain the fresh water composite microorganism base modifier. The preparation method has the beneficial effects of easiness and feasibility, higher yield and productive rate of polysaccharides in a preparation process, higher mechanical strength and stability of a final product, and higher mass transfer performance and pelletizing performance. The fresh water composite microorganism base modifier modifies culturing sewage through the three strong effects of fluctuation, enzymatic degradation and microbial degradation, and has the advantages of comprehensive biodegradability, high security, nontoxicity, harmlessness and freeness from secondary pollution.

Owner:金华市呗力水产养殖技术有限公司

Preparation method of fully degradable polyglycolic acid composite packaging materials

InactiveUS20200339804A1Good microbial degradabilityImprove mechanical propertiesFlexible coversWrappersFiberPoly dl lactide

The present disclosure provides a fully degradable Polyglycolic acid (PGA) composite packaging material comprises, by weight part, the following: PGA, polycaprolactone, poly(L-lactide-ε-caprolactone), anti-blocking agent, slipping agent, flexibilizer, waterproofing agent, chitosan, reinforced fibers and the like. The present disclosure further provides a preparation method of the fully degradable modified polyglycolic acid composite packaging materials. The present disclosure has the following advantages. The packaging material of the present disclosure has good microbial degradation and hydrolysis. With complete biodegradation, it would result in end-products, water and carbon dioxide, which are environmentally friendly, non-toxic and pose no threat to human- and animal-health. The packaging material of the present disclosure has good mechanical properties, and can fully meet various application requirements of packaging materials. Inexpensive and environmental pollution-free fillers can be added without influence on mechanical properties. The cost can be effectively reduced. The preparation process is simple.

Owner:REBERET CHINA CO LTD

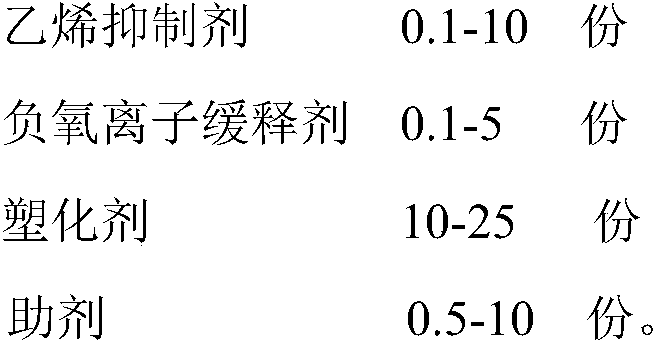

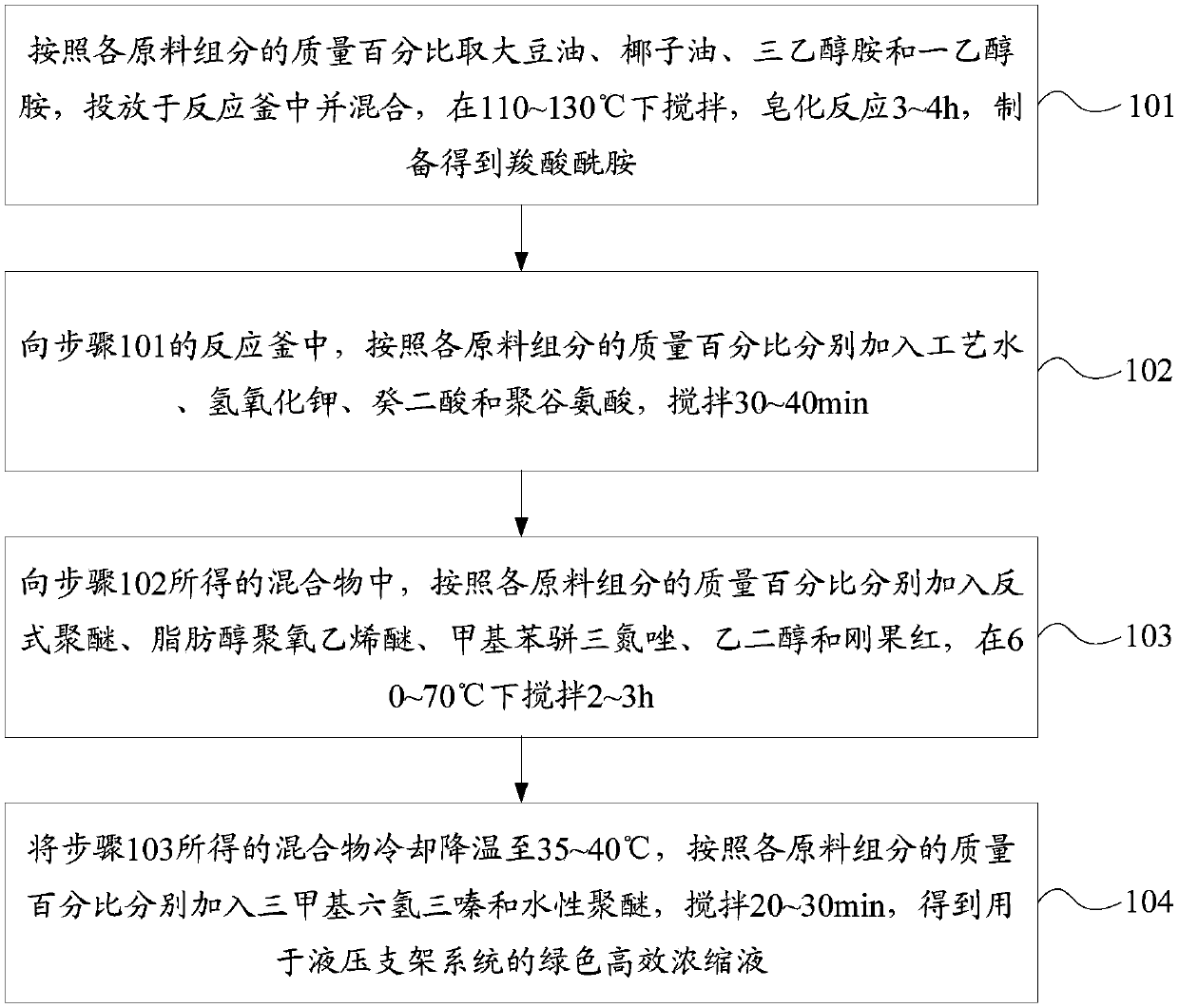

Green and efficient concentrated solution for hydraulic support system and preparation method of green and efficient concentrated solution

ActiveCN107557132AFully biodegradableGood corrosion inhibitionLubricant compositionPotassium hydroxideCarboxylic acid

The invention provides a green and efficient concentrated solution for a hydraulic support system and a preparation method of the green and efficient concentrated solution. The concentrated solution is prepared from components in percentage by mass as follows: 5%-8% of soybean oil, 3%-5% of coconut oil, 4%-6% of potassium hydroxide, 2%-3% of trans-polyether, 7%-10% of polyglutamic acid, 10%-12% ofsebacic acid, 1%-2% of fatty alcohol polyoxyethylene ether, 6%-10% of triethanolamine, 2%-4% of monoethanolamine, 10% of glycol, 0.1%-0.3% of methylbenzotriazole, 1%-2% of trimethyl hexahydrotriazine, 0.1%-0.3% aqueous polyether, 0.01%-0.02% of Congo red and the balance of reagent process water. The concentrated solution is obtained through multiple steps as follows: carboxylic acid amide is prepared from the soybean oil, the coconut oil, triethanolamine and monoethanolamine through a saponification reaction, and methylbenzotriazole, the sebacic acid and carboxylic acid amide are compounded with a metal sustained release agent.

Owner:CCTEG CHINA COAL RES INST

Degradable packaging material based on orange peel dregs and preparation method and application thereof

InactiveCN102133967AHigh in nutrientsImprove physical and chemical propertiesFlexible coversWrappersAdhesive cementMaterials science

The invention discloses a degradable packaging material based on orange peel dregs, which is mainly prepared by mixing orange peel dreg particles and an adhesive and performing thermal forming on the mixture, wherein the mass ratio of the orange peel dreg particles to the adhesive is 1:(0.15-5). The degradable packaging material is prepared by the following steps of: drying to obtain dry orange peel dregs; crushing to obtain the orange peel dreg particles; mixing the orange peel dreg particles with the adhesive to obtain the mixture; and injecting the mixture into a forming mould for hot-forming processing. The degradable packaging material can be applied to nutrition bowls, seedling-throwing disks, fruit trays or egg trays and has the advantages of high product quality, high strength, artistic appearance, low cost, environmental friendliness and the like.

Owner:HUNAN AGRI PRODS PROCESSING INST

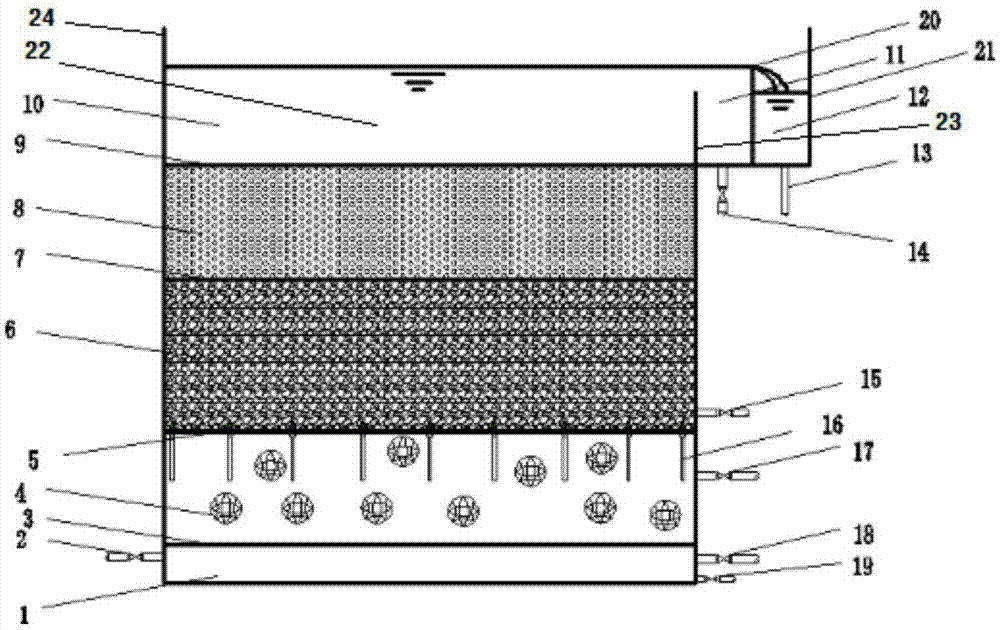

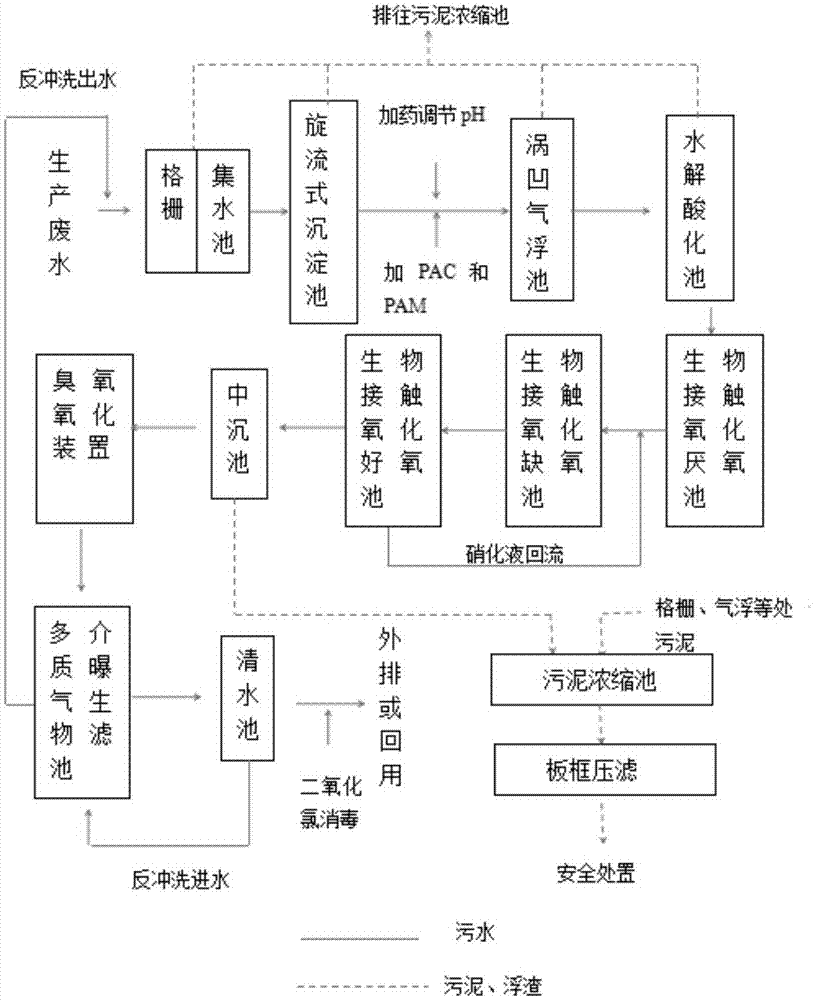

Multi-medium biological aerated filter and method for treating traditional Chinese medicine decoction piece wastewater using same

InactiveCN106892499AFully biodegradableReduce pollutant loadTreatment using aerobic processesTreatment involving filtrationActivated sludgeWater filter

The invention relates to a multi-medium biological aerated filter and a method for treating traditional Chinese medicine decoction piece wastewater using the same in the technical field of water treatment. The multi-medium biological aerated filter is characterized in that in the direction perpendicular to the bottom of the filter, a back flush water outlet weir plate and a normal water outlet weir plate are arranged to sequentially divide the multi-medium biological aerated filter into a filter body, a back flush water outlet chamber and a normal water outlet chamber; in the direction parallel to the bottom of the filter, a primary filter screen, a primary filter plate, a secondary filter plate and a secondary filter screen are sequentially arranged in the water filtering direction to divide the filter body into a water inlet chamber, a suspension filler chamber, a biological ceramsite filter material chamber, an activated carbon filler chamber and a clear water layer; and the suspension filler chamber provides a space for growth and propagation of activated sludge, thereby ensuring that products generated after ozone oxidizes heterocyclic and aromatic organic matters can be sufficiently subjected to biodegradation. According to the traditional Chinese medicine decoction piece wastewater treatment process provided by the invention, grit and inorganic salt particles in wastewater can be effectively removed and cleaned, thereby ensuring effective removal of pollutants in the wastewater, reducing energy consumption, and lowering the cost.

Owner:NANJING POLYTECHNIC INSITUTE

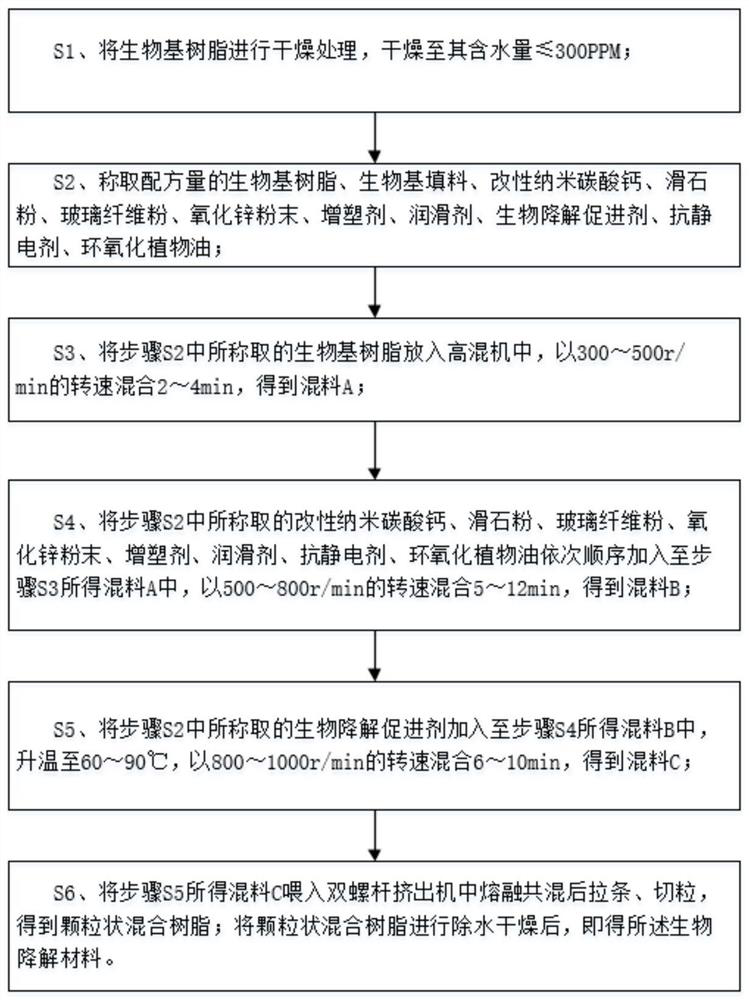

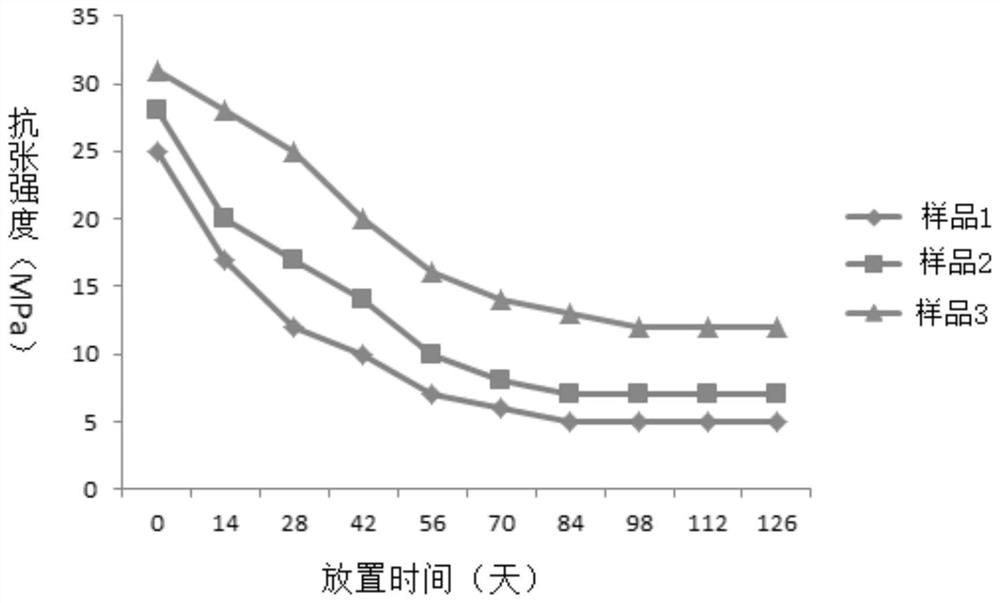

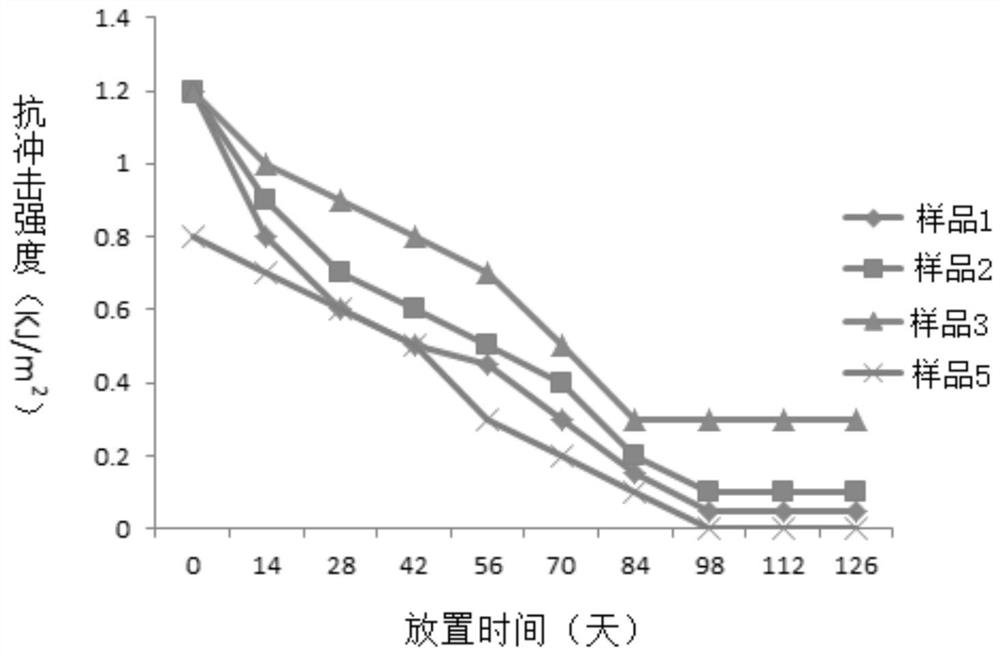

Biodegradable material and preparation method thereof

InactiveCN112029154AGood mechanical propertiesRealize the carbon cycleEnvironmental pressurePlasticizer

The invention discloses a biodegradable material and a preparation method thereof. The biodegradable material comprises the following raw materials in parts by weight: 10-79 parts of bio-based resin,5-45 parts of a bio-based filler, 3-20 parts of modified nano calcium carbonate, 5-15 parts of talcum powder, 5-15 parts of glass fiber powder, 6-18 parts of zinc oxide powder, 5-20 parts of a plasticizer, 1-5 parts of a lubricant, 0.5-5 parts of a biodegradation accelerator, 10-50 parts of an antistatic agent and 3-15 parts of epoxidized vegetable oil. The biodegradable material disclosed by theinvention is safe, environment-friendly and non-toxic, has complete biodegradability, relieves environmental pressure caused by large-scale use of fossil plastic, has excellent mechanical properties compared with an existing biodegradable material, and has the advantages that the temperature resistance, the wear resistance, the hydrophobicity, the creep resistance, the rigidity, the tensile property and the impact resistance are remarkably improved, and production cost is significantly reduced.

Owner:锐保新材料科技(上海)有限公司

Three-layer co-extrusion full-biodegradable delivery packaging bag and preparation method thereof

InactiveCN109229812AFully biodegradableImprove mechanical propertiesBio-packagingBagsBlow moldingEngineering

The invention relates to a three-layer co-extrusion full-biodegradable delivery packaging bag and a preparation method thereof, and belongs to the field of high polymer materials. Raw material components of an inner layer, a middle layer and an outer layer are mixed to be uniform respectively according to the formula, master batches are prepared through a twin-screw extruding machine, and then a three-layer full-biodegradable film is prepared through a three-layer co-extrusion blow molding process. The film is subjected to the gluing, heat sealing and cutting procedures of a delivery packagingbag making machine, and the delivery packaging bag is prepared. The material formula good in opening performance and film forming performance is adopted on the middle layer and the inner layer, and the material formula good in mechanical performance and film forming performance is adopted on the middle layer and the outer layer. The delivery packaging bag has full biodegradability, has excellentmechanical performance, heat sealing performance and seal adhesive sealing performance and can replace a delivery packaging bag prepare from a non-biodegradable plastic PE film.

Owner:JILIN COFCO BIOCHEM

Biodegradable ultraviolet-blocking weather-proof micro-nano composite material and application thereof

The invention discloses a biodegradable ultraviolet-blocking weather-proof micro-nano composite material and an application thereof. The material is obtained by carrying out melt blending on 1-100 parts by mass of micro-nano particles with a core-shell structure and 50-10000 parts by mass of a biodegradable polymer matrix at a temperature of 100-250 DEG C for 5-40 minutes, and can be used as various thin films, sheet materials or board materials with ultraviolet protection and weather resistance. The contained micro-nano particles are a core-shell modified bio-based material, wherein the shellmainly comprises a dopamine polymer, and the core is lignin. The mechanical property of the micro-nano particles can be effectively improved by regulating and controlling morphology and material composition of the shell layer, ultraviolet blocking performance and weather-proof stability of the micro-nano particles is improved, and compatibility of the micro-nano particles with the polymer matrixis improved. The coating disclosed by the invention has good ultraviolet blocking property and weather resistance and is economic and environmentally friendly, operation is simple, and a wide application prospect is achieved in the aspect of ultraviolet protection and weather-proof polymer material preparation.

Owner:ZHEJIANG UNIV

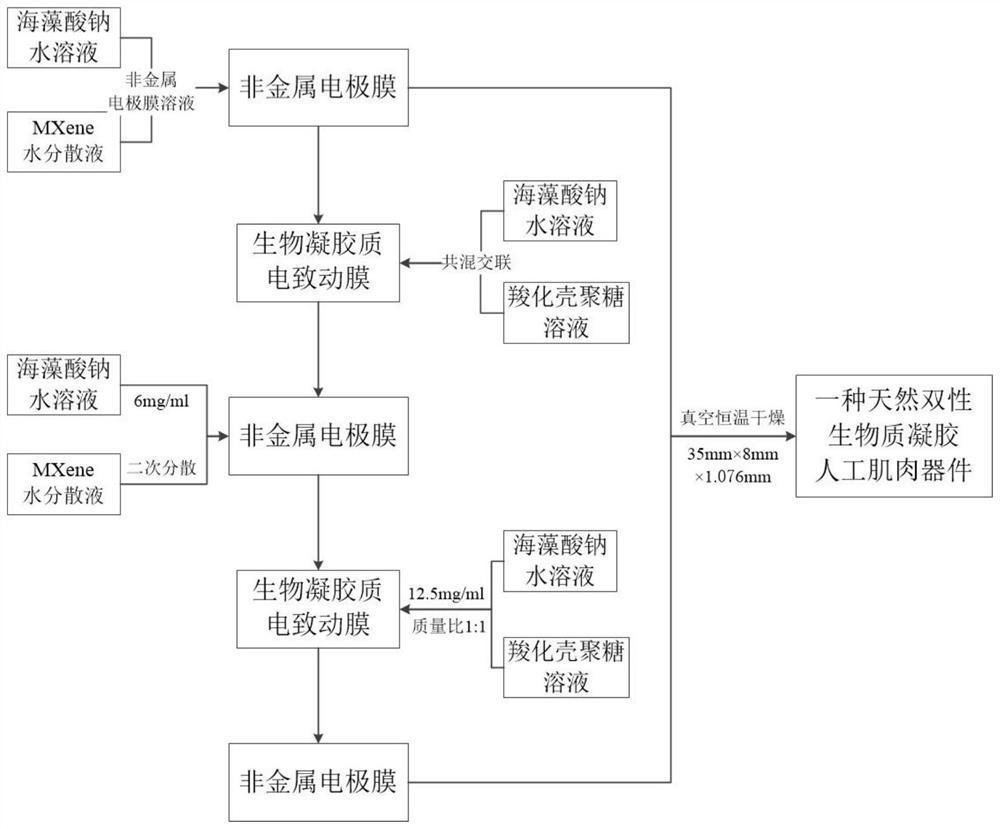

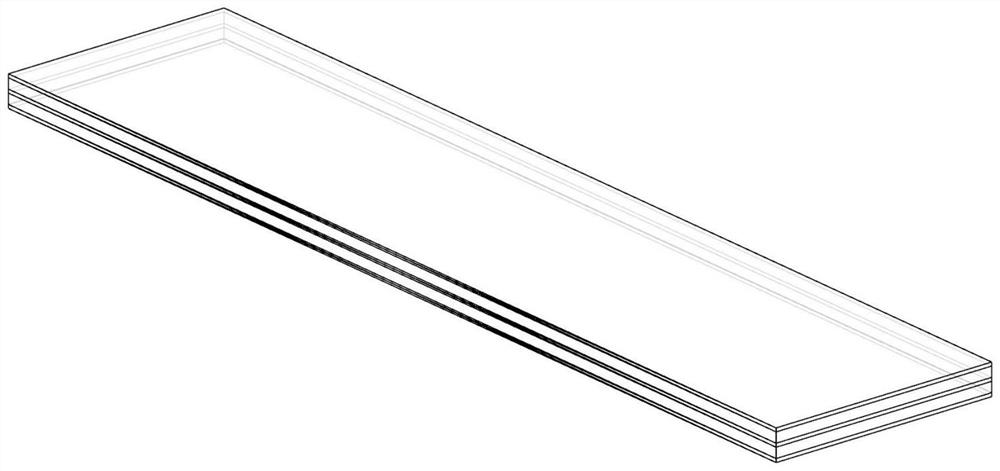

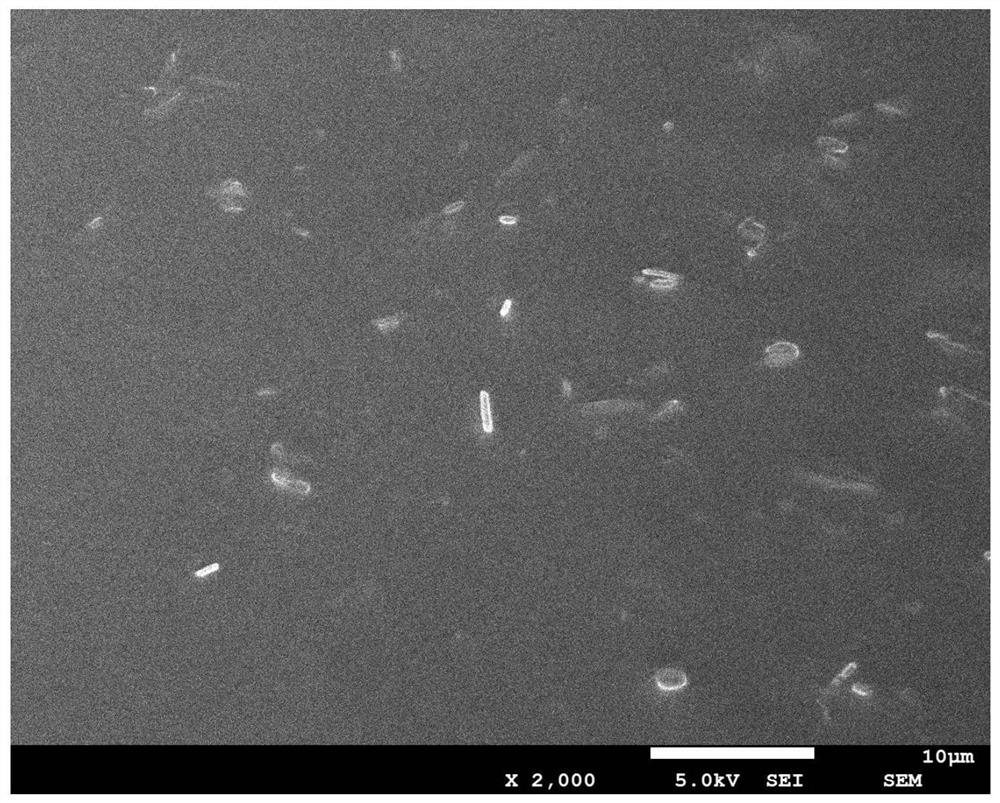

Construction method for natural bipolar biomass gel artificial muscle device

ActiveCN112644016AThe construction method is scientific and reasonableSimple and fast operationAdditive manufacturing apparatus3D object support structuresBiocompatibilityElectrochemistry

The invention provides a construction method for a natural bipolar biomass gel artificial muscle device. Theconstruction method is characterized by comprising the following three steps of: firstly, carrying out biological crosslinking reaction on natural a high-molecular polymer sodium alginate and carboxylated chitosan to obtain a biomass gel electricactive film with excellent biocompatibility and bipolar electric actuation behavior; secondly, by utilizing a hydrogen bond synergistic effect between sodium alginate and MXene surface functional groups, preparing a non-metal electrode membrane solution through direct water-bath blending, wherein the non-metal electrode membrane solution is high in conductivity, resistant to bending, safe and non-toxic after being formed into a membrane; and finally, sequentially and alternately laminating and constructing the electricactive film and the electrode film solution to form an artificial muscle device with a multi-layer hamburger-like structure, wherein an internal interface synthesis layer of the artificial muscle device is good in adhesion; the response deformation degree, the reversible actuation property and the movement range are increased; and very excellent electric-chemical-mechanical properties are shown. The construction method has the advantages of being scientific, reasonable, easy and convenient to operate, environmentally friendly, high in applicability and good in effect.

Owner:NORTHEAST DIANLI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com