Multilevel porous polylactic acid material and preparation method thereof

The technology of a polylactic acid material and a macroporous material is applied in the field of multi-level porous polylactic acid material and its preparation, which can solve the problems such as no reports related to the multi-level porous polylactic acid material, and achieves wide application, easy operation and good heat resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

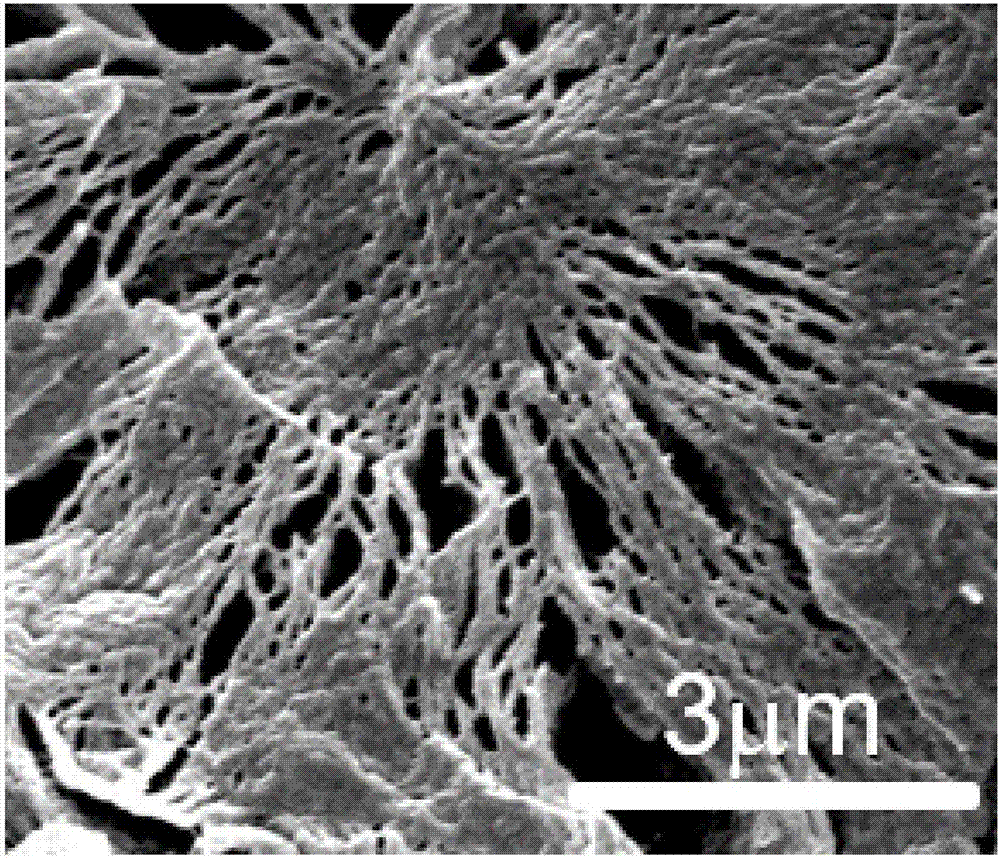

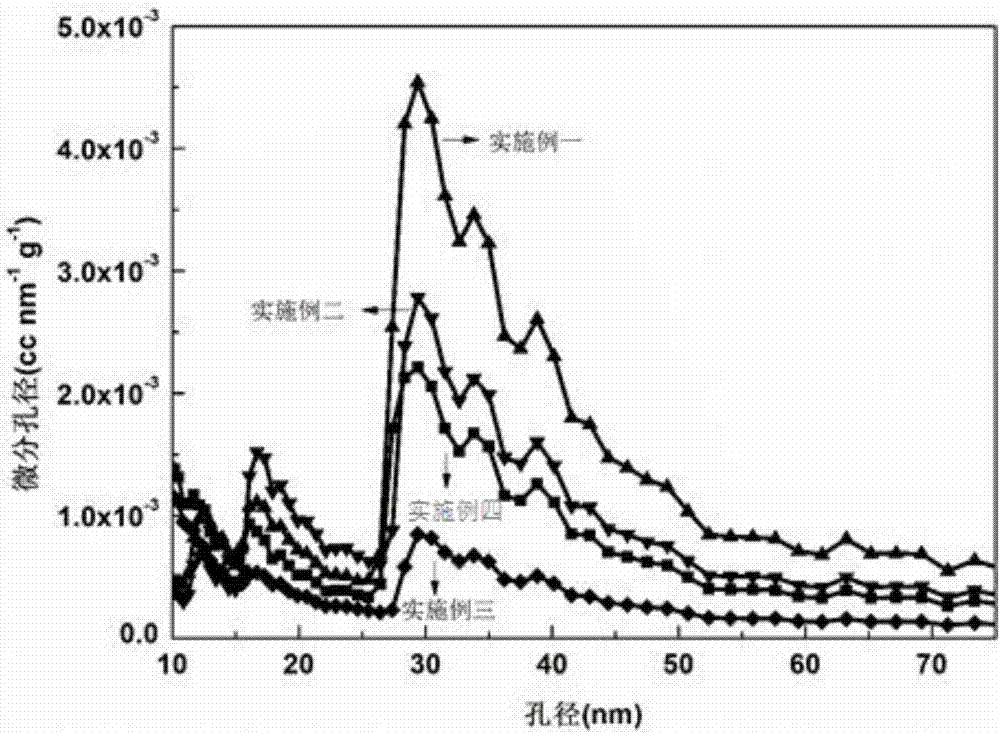

Embodiment 1

[0043] (1) Using melt blending method, add dry and weighed 14.4g PLLA, 3.6gPDLA and 12gPEO to the torque rheometer at the same time, melt and blend for 5 minutes under the processing conditions of 180°C and 60 rpm, room temperature Cool down to obtain a blend.

[0044] (2) The obtained blend was put into deionized water to dissolve PEO, the deionized water was replaced every 8 hours, dissolved at room temperature and stirred, and the dissolution time was 3 days.

[0045] (3) Put the extracted sample into a vacuum oven at 40°C for 24 hours to dry to obtain the mesoporous-macroporous polylactic acid material.

[0046] The results of the raw materials and their proportions and water contact angles of each embodiment and comparative example are shown in Table 1.

[0047] Table 1 Raw materials and their proportions, water contact angles and porous structures of Examples and Comparative Examples

[0048]

[0049] "-" in the table means not added

Embodiment 2

[0051] (1) Using the melt blending method, add the dried and weighed 12.6g PLLA, 5.4gPDLA and 12gPEO to the torque rheometer at the same time, melt and blend at 180°C, 60 rpm for 5 minutes, room temperature Cool down to obtain a blend.

[0052] (2) The obtained blend was put into deionized water to dissolve PEO, the deionized water was replaced every 8 hours, dissolved at room temperature and stirred, and the dissolution time was 3 days.

[0053] (3) Put the extracted sample into a vacuum oven at 40°C for 24 hours to dry to obtain the mesoporous-macroporous polylactic acid material.

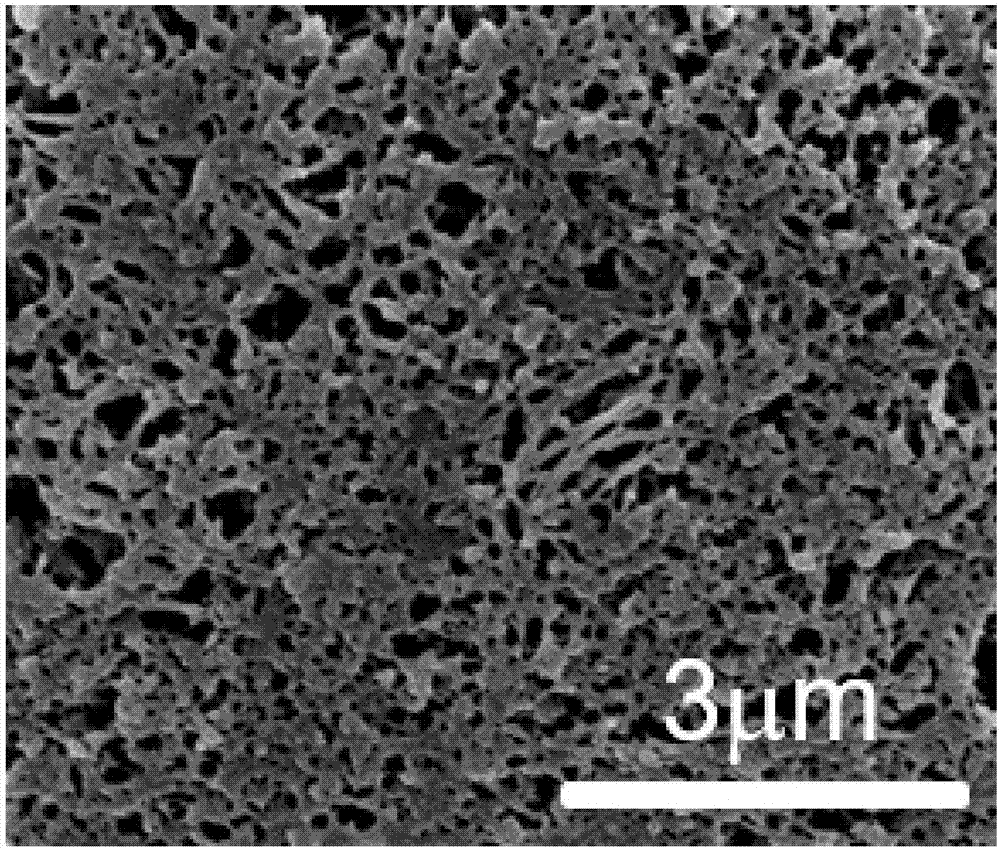

Embodiment 3

[0055] (1) Using melt blending method, add dry and weighed 10.8g PLLA, 7.2gPDLA and 12gPEO to the torque rheometer at the same time, melt blending at 180°C, 60 rpm for 5 minutes, room temperature Cool down to obtain a blend.

[0056] (2) The obtained blend was put into deionized water to dissolve PEO, the deionized water was replaced every 8 hours, dissolved at room temperature and stirred, and the dissolution time was 3 days.

[0057] (3) Put the extracted sample into a 40° C. vacuum oven and dry for 24 hours to obtain the mesoporous-macroporous polylactic acid material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com