Patents

Literature

3964results about How to "Good solvent resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

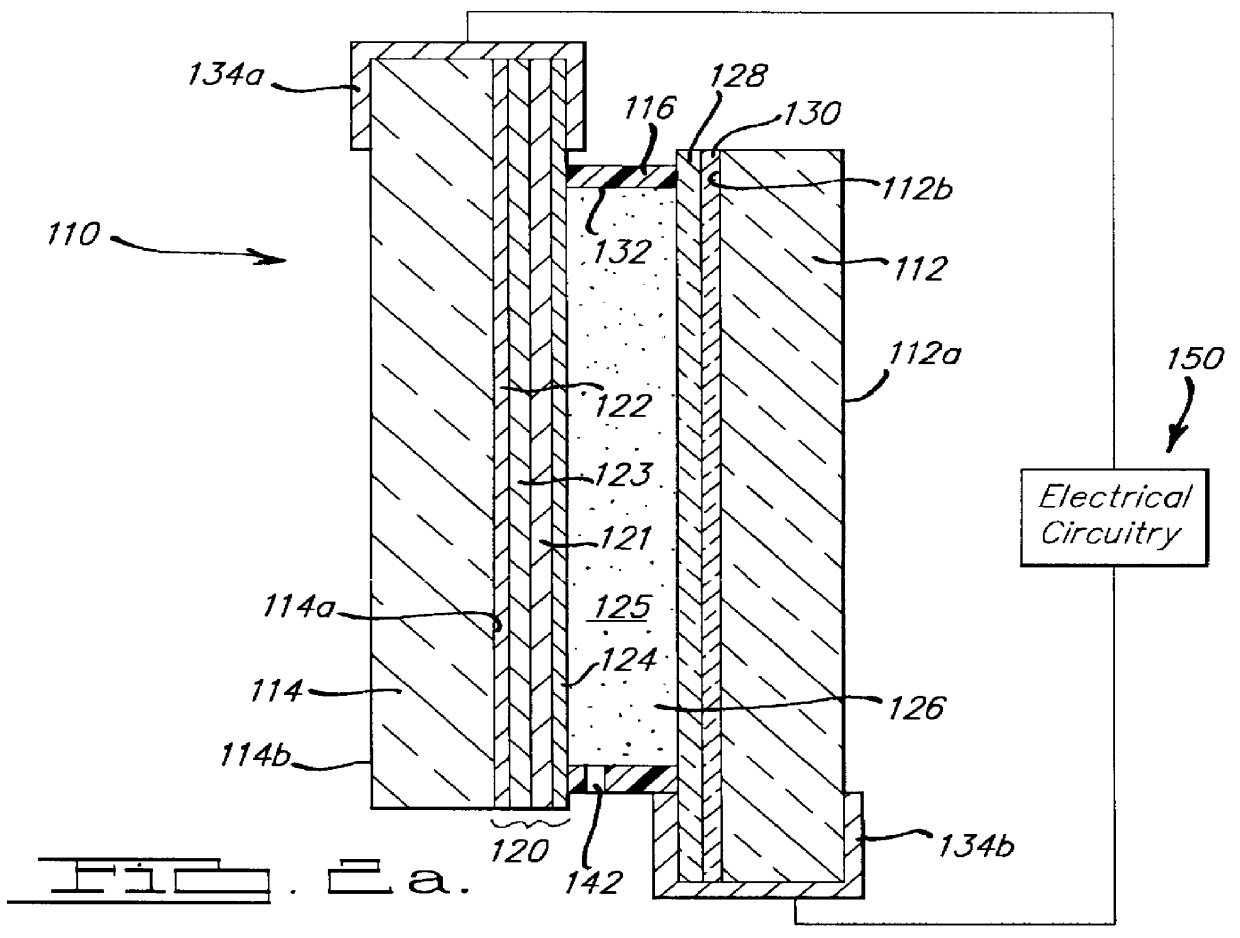

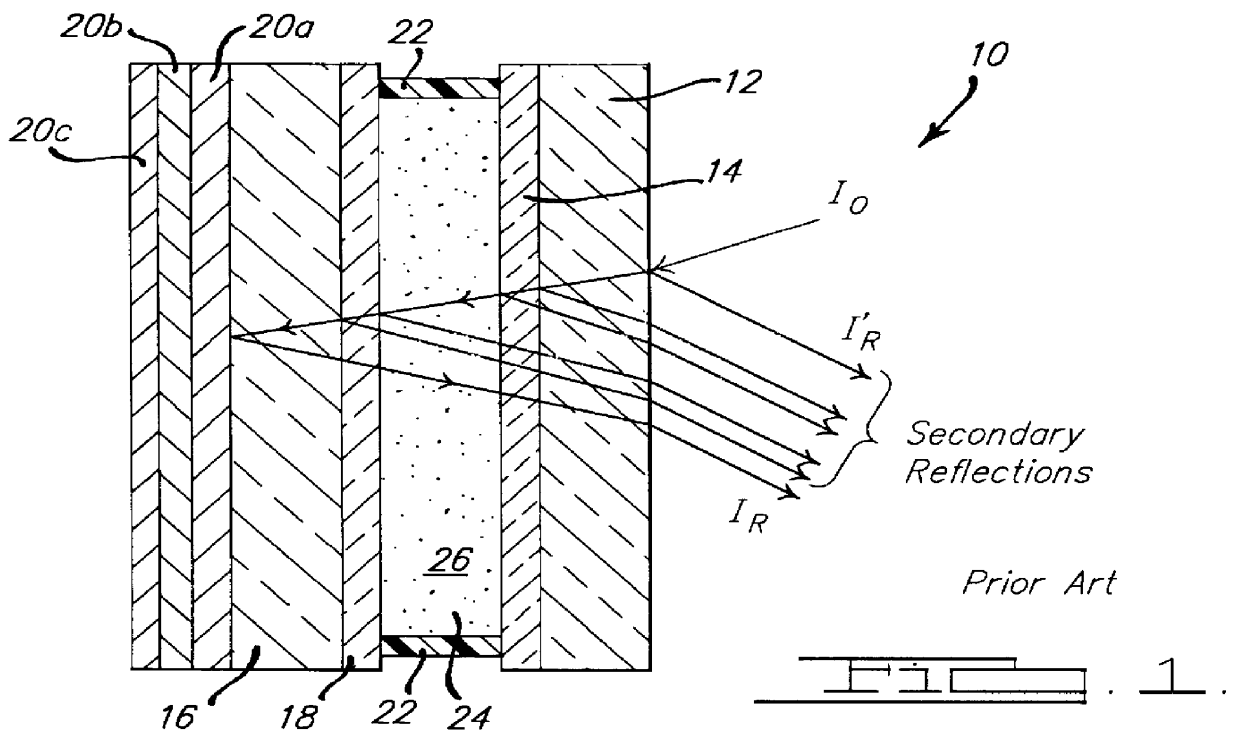

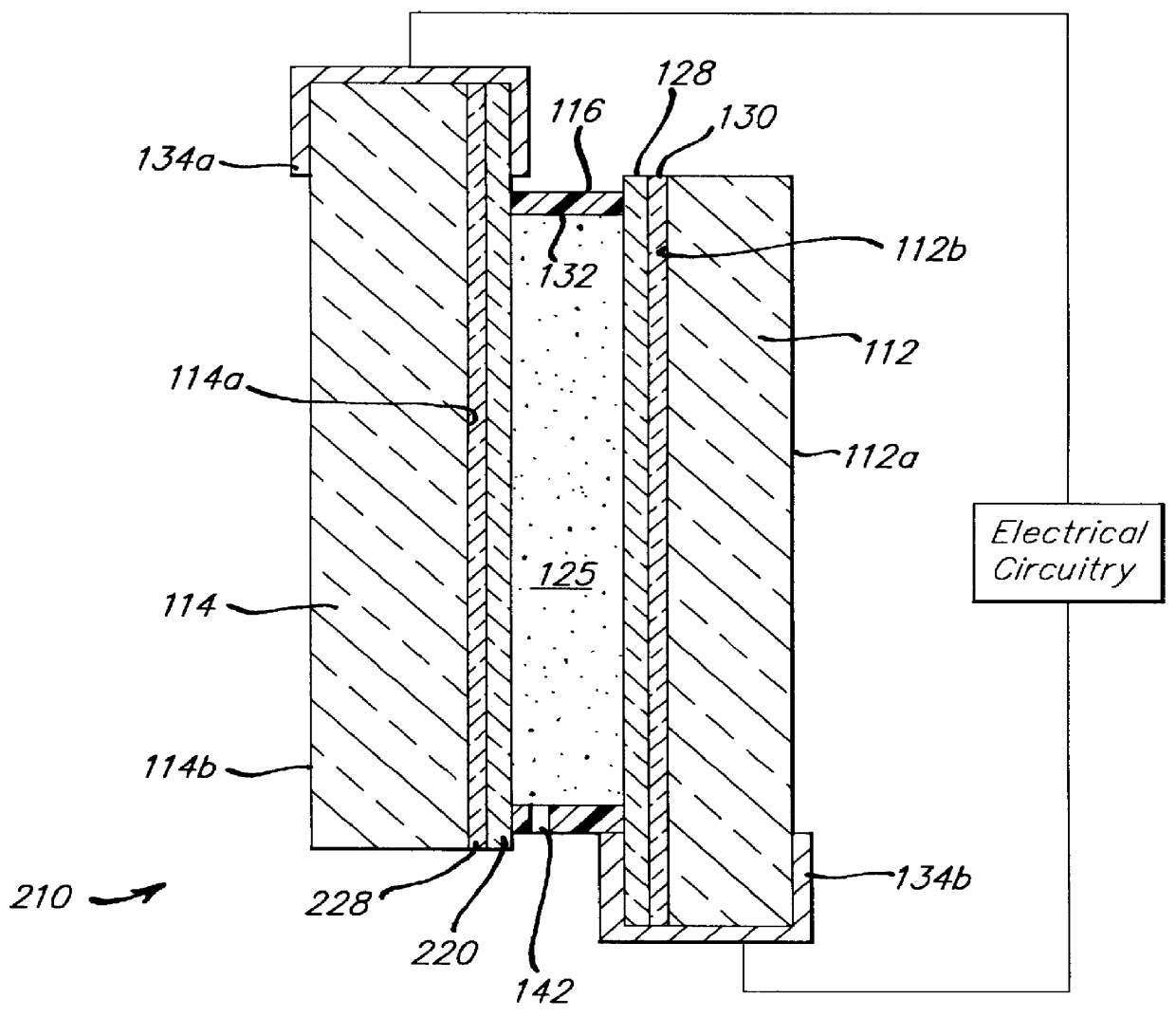

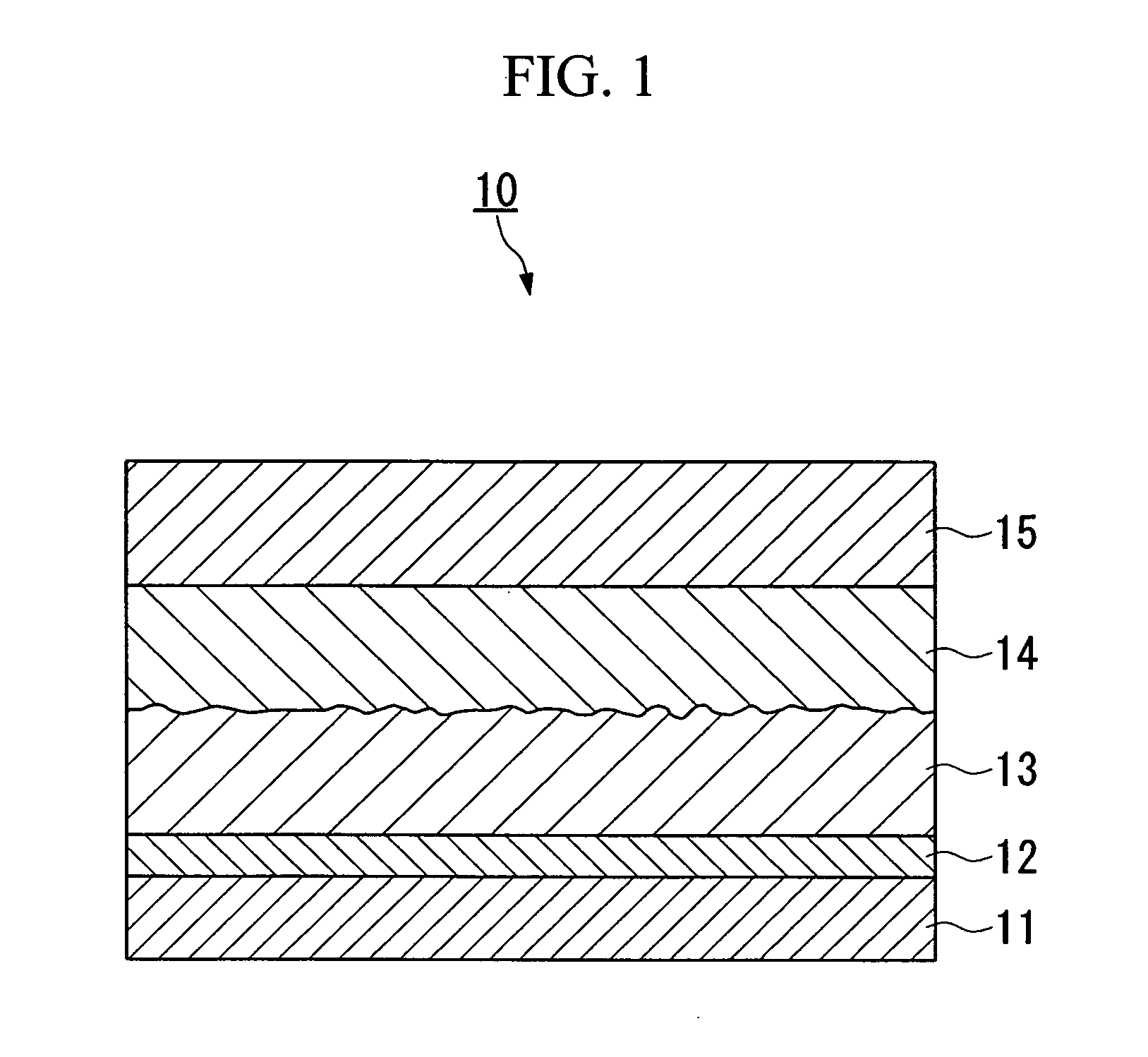

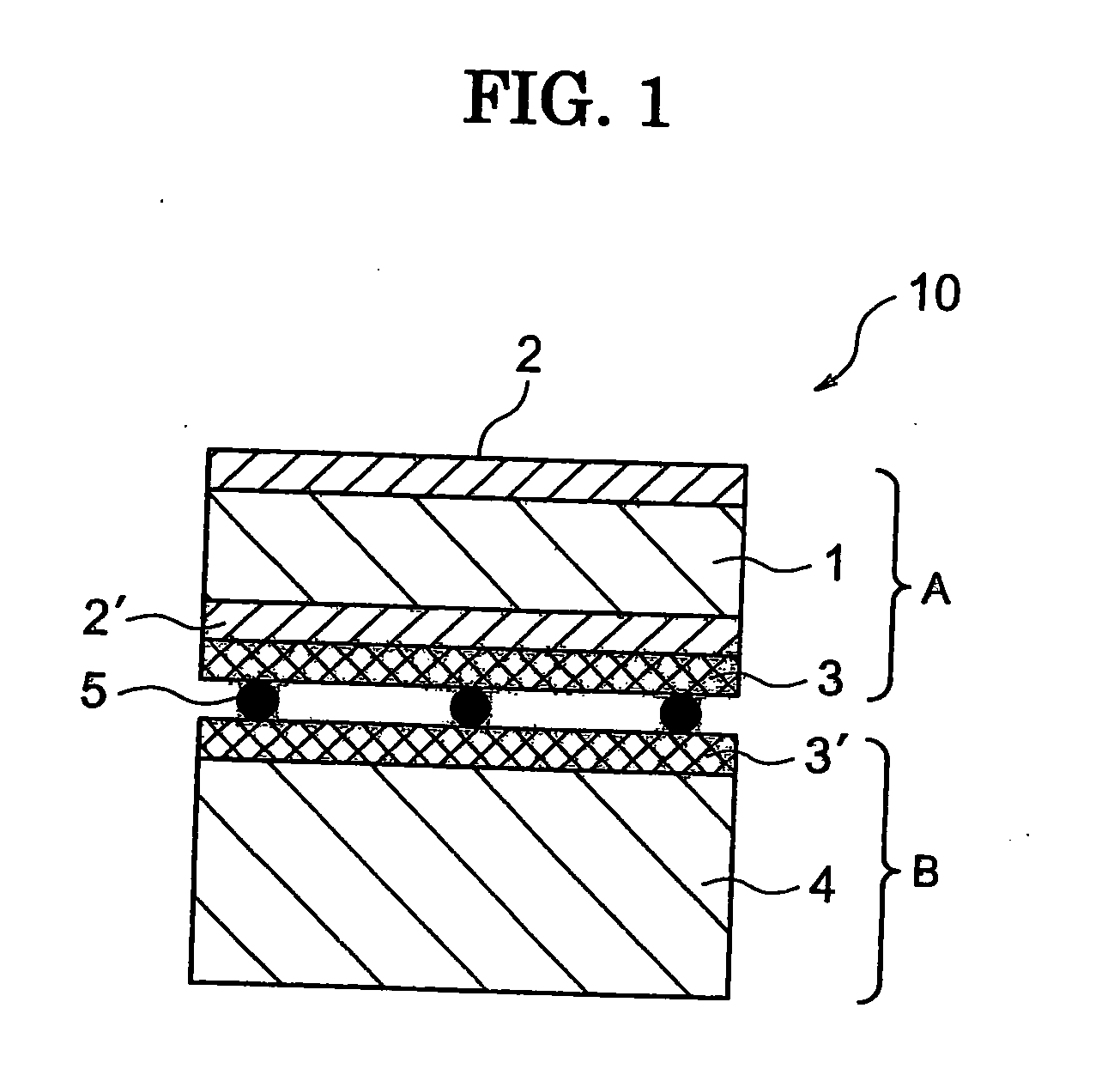

Seal for electrochromic devices

An improved seal member is provided as a part of an electrochromic device to bond two glass elements together in a spaced-apart relationship. In one embodiment the seal member provides improved adhesion to a reflector / electrode on the third surface of an electrochromic mirror, or to a layer of metal on the second or third surface for an electrochromic light filter. This seal member comprises a mixture of an organic resin sealing system and an adhesion promoter, where the adhesion promotor comprises a first and a second region, where the first region interacts with the reflector / electrode or the metal layer, and a second region that interacts with the organic resin sealing system, and may even chemically react with the organic resin sealing system. In another embodiment the seal member is provided with a coefficient of thermal expansion that is closer to glass than a standard epoxy sealing system.

Owner:GENTEX CORP

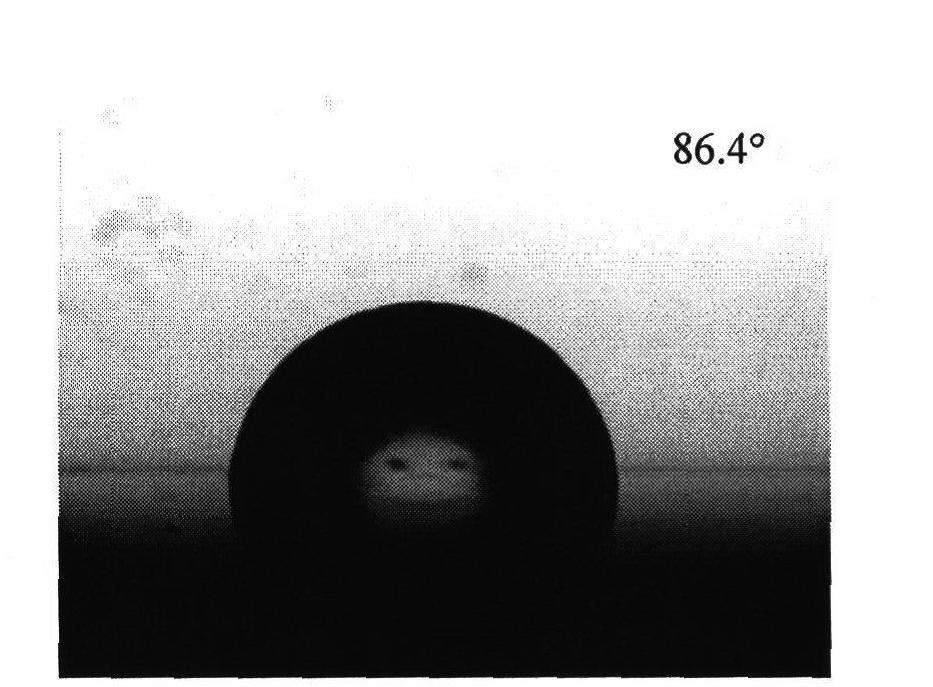

Nanocomposite ice-coating-proof paint having properties of superhydrophobicity and low adhesive strength

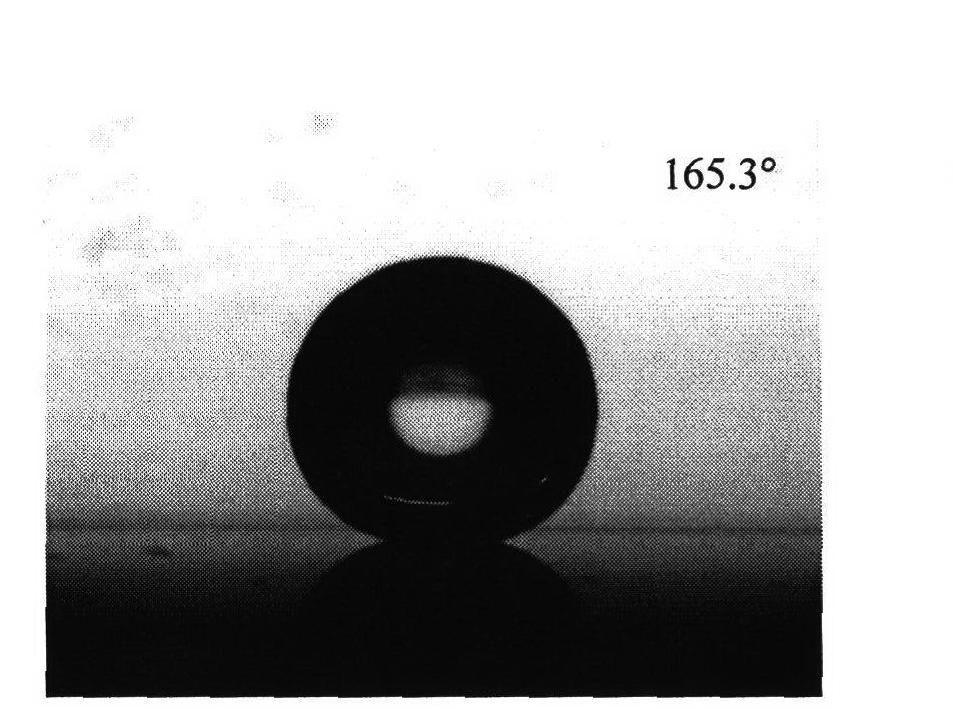

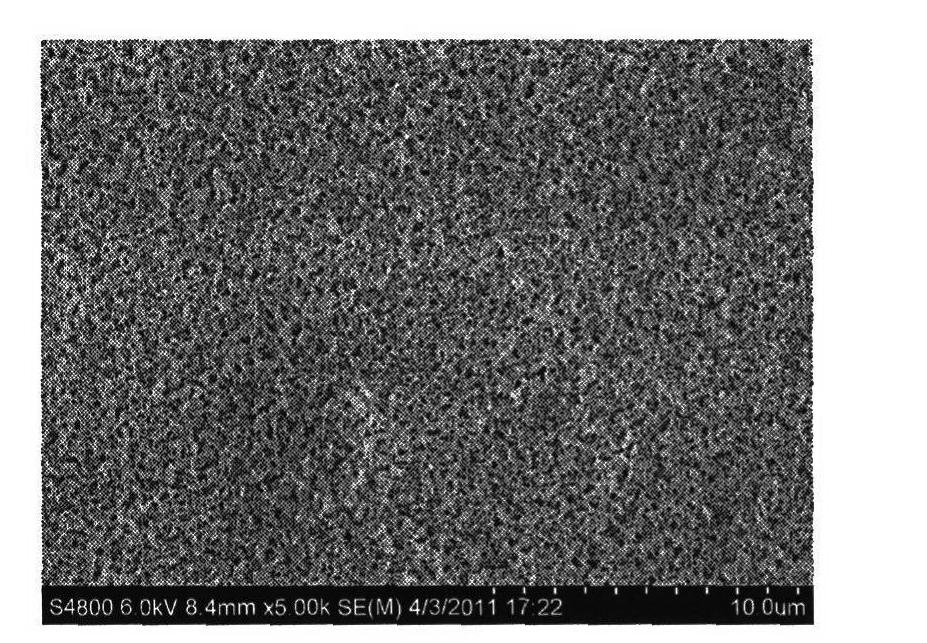

The invention relates to a nanocomposite ice-coating-proof paint having properties of superhydrophobicity and low adhesive strength and a preparation method thereof. The nanocomposite ice-coating-proof paint is characterized by comprising such raw materials, by mass, as 3%-30% of a fluorine-containing polyacrylate copolymer, 40%-80% of a solvent, 0.05%-1.5% of a defoamer, 0.05%-1% of an anti-setting agent, 1%-15% of nanoparticles, and 1%-20% of a crosslinking-curing agent. Film thickness of an ice-coating-proof coating prepared by adopting the nanocomposite ice-coating-proof paint provided by the invention is 5-10 mum, the water contact angle is over 150 degrees and the maximum angle is up to 169 degrees, and the adhesive strength of ice on the coating surface is 1.43*10<-2>MPa. The coating has a significant effect on ice-coating proofing, and can be used for preventing ice-coating on such components as telegraph pole towers, heat pump air-conditioners, low-temperature refrigeration devices, aircraft components, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

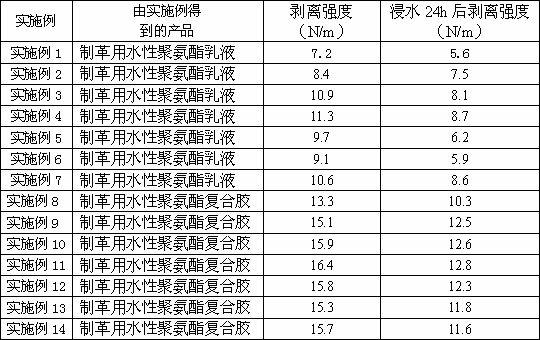

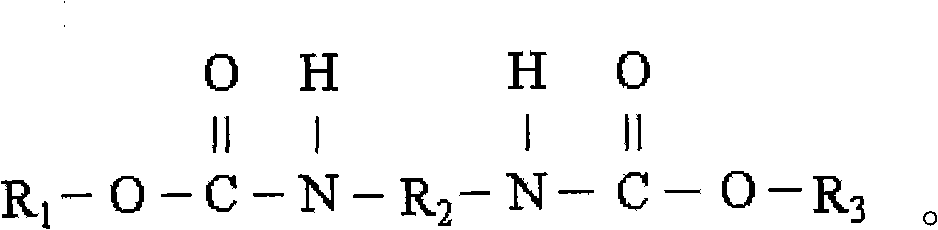

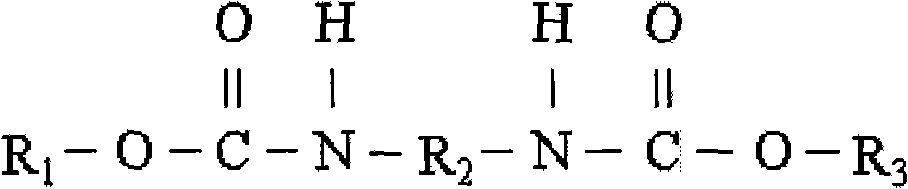

Water-based polyurethane composite adhesive for tanning and preparation method and application of composite adhesive

InactiveCN102618202ATroubleshoot MigrationOvercome the problem that the performance cannot fully meet the requirements of useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention discloses water-based polyurethane composite adhesive for tanning and a preparation method and application of the composite adhesive, belongs to the technical field of water-based polyurethane composite adhesive preparation methods, and in particular relates to a method for preparing composite adhesive in the fields of artificial leather and synthetic leather. The method for preparing the water-based polyurethane composite adhesive for tanning is characterized by comprising the following steps of: reacting polyol polymer and isocyanate, adding chain extender, hydrophilic chain extender, cross linker, catalyst and solvent, reacting, cooling and emulsifying, to obtain emulsion; and mixing the emulsion, curing agent, wetting agent, tackifier, adsorbent and thickening agent uniformly, and thus obtaining the hot-melt adhesive for artificial leather adhesive layers. The water-based polyurethane composite adhesive for tanning is used for compounding polyvinyl chloride (PVC) / cloth for artificial leather of luggage and clothes. The prepared water-based polyurethane composite adhesive for tanning has high adhesive fastness and good water and solvent resistance, and can be applied to processes of knife coating, roll coating and the like of binding materials of middle layers of artificial leather and synthetic leather in the fields of textiles, leather processing and the like.

Owner:江阴市诺科生物新材料科技有限公司

Production method for liner gloves aqueous polyurethane coating connection material

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

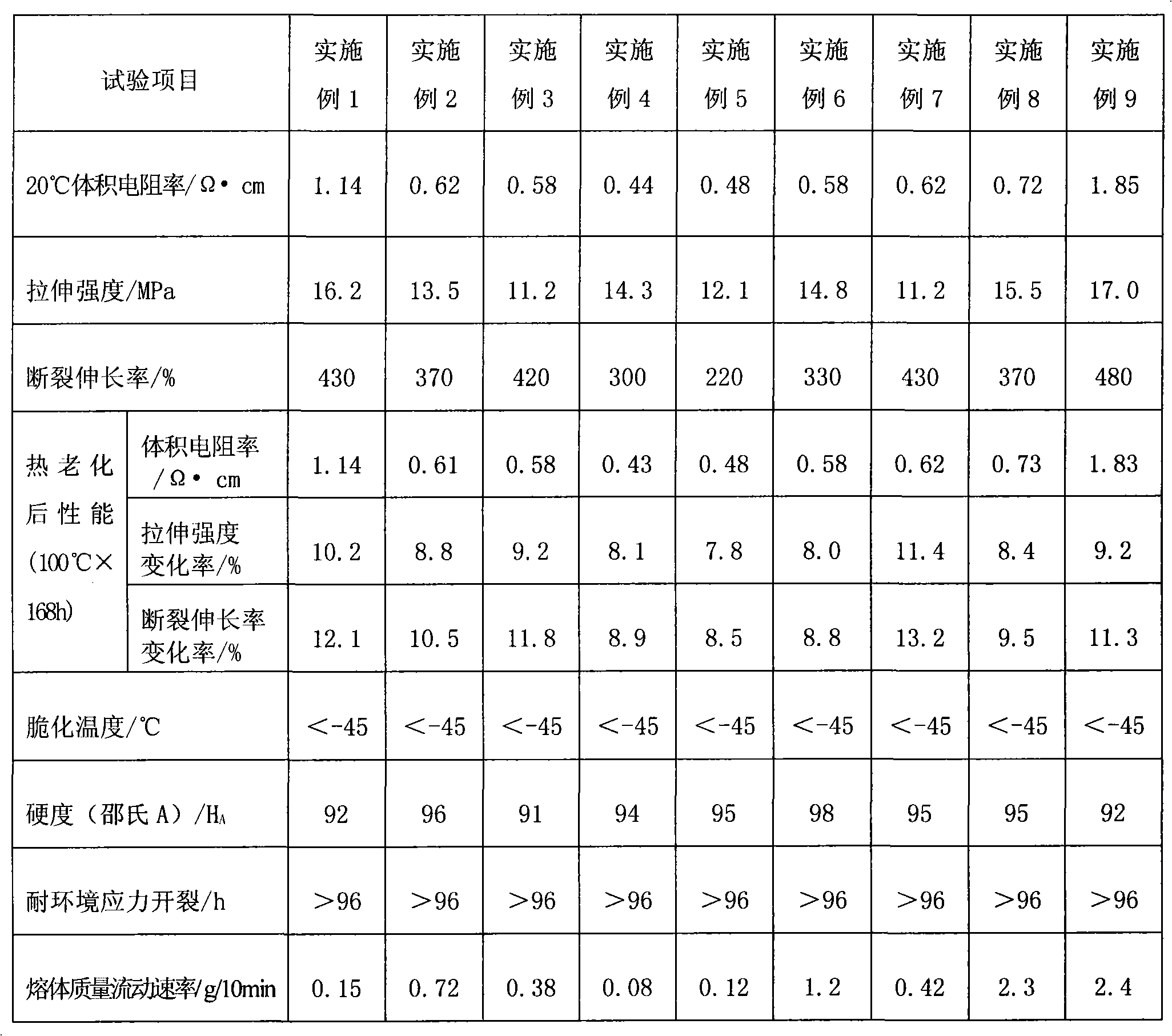

Composite type high-conductivity polymer material and preparation method thereof

ActiveCN101891914AImprove conductivityAvoid damageNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

The invention discloses a composite type high-conductivity polymer material and a preparation method thereof, which belongs to the technical field of new materials. The composite type high-conductivity polymer material is characterized by comprising the following raw materials in percentage by weight: 40-62 wt% of base resin compositions, 18-25 wt% of super conductive carbon black, 10-30 wt% of rubber filling oil, 1-3 wt% of low molecular wax, 0.2-0.8 wt% of fluoroelastomer processing aid (PPA), 0.5-2 wt% of lubricant, 1.5-3 wt% of inorganic filler and 0.5-2.5 wt% of other aids. The compositetype high-conductivity polymer material has the advantages of excellent high conductivity, environmental stress cracking resistance, weatherability, ozone resistance, ultraviolet resistance, favorable high temperature resistance, high impact resistance, oil resistance, solvent resistance and mechanical property, and can be used as an environment-friendly conductive polymer sheath material of an combined through earth line, a metal anticorrosive material of other ground cable, a conductive plastic cladding material of a conductive plastic cable positive wire, an optical cable flexible sheath material, and the like.

Owner:SHANDONG KEHONG WIRE & CABLE TECH CO LTD

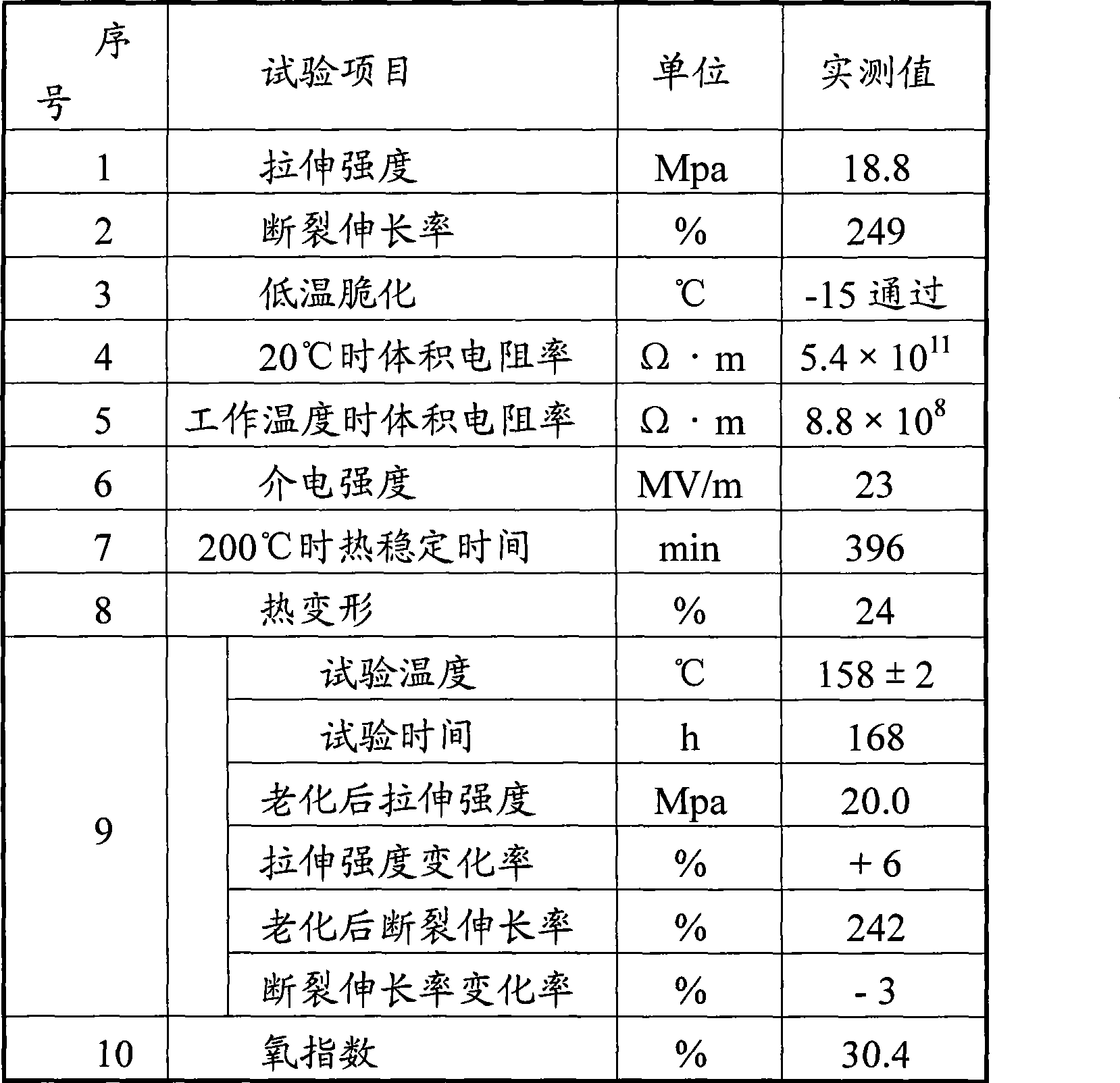

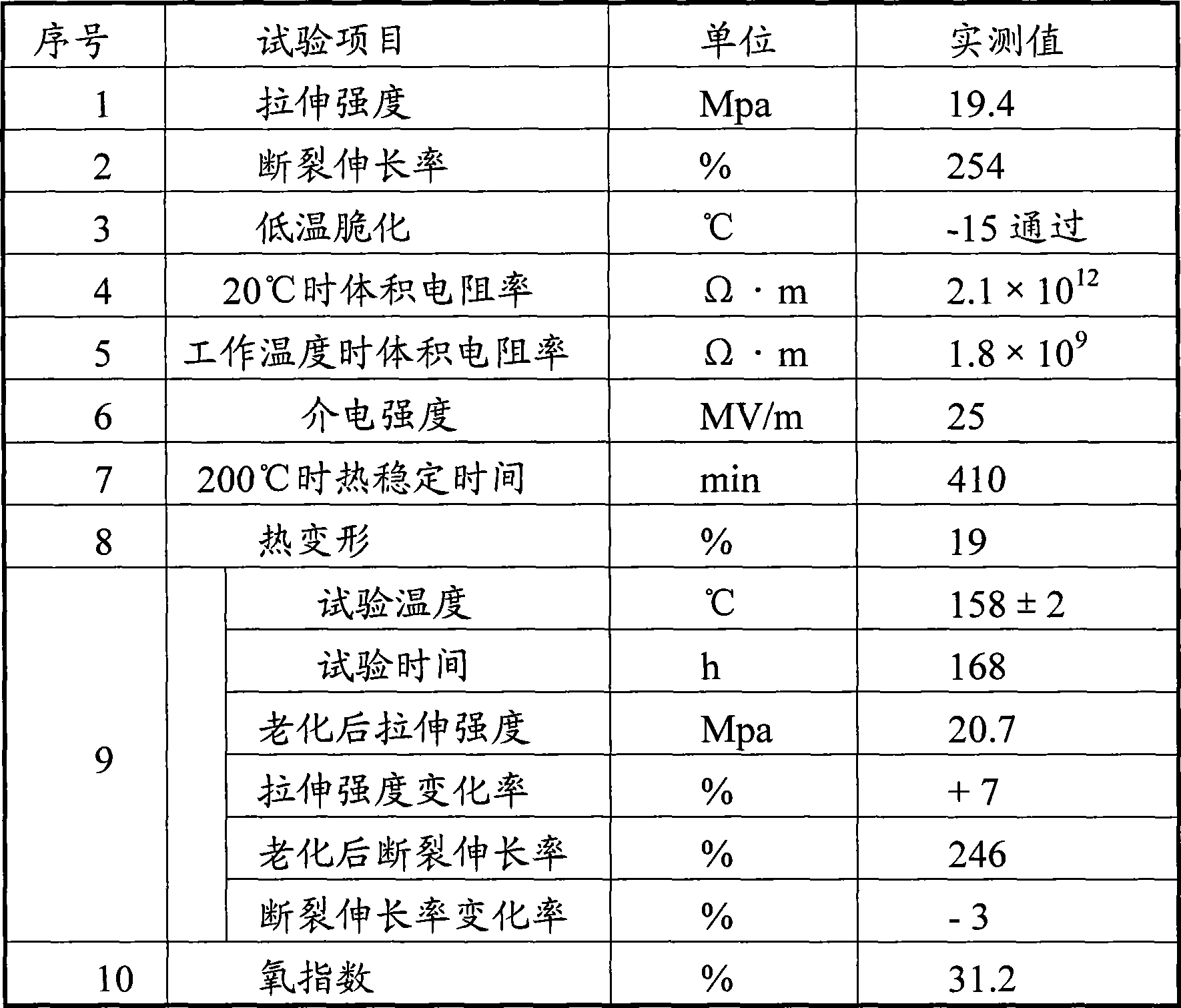

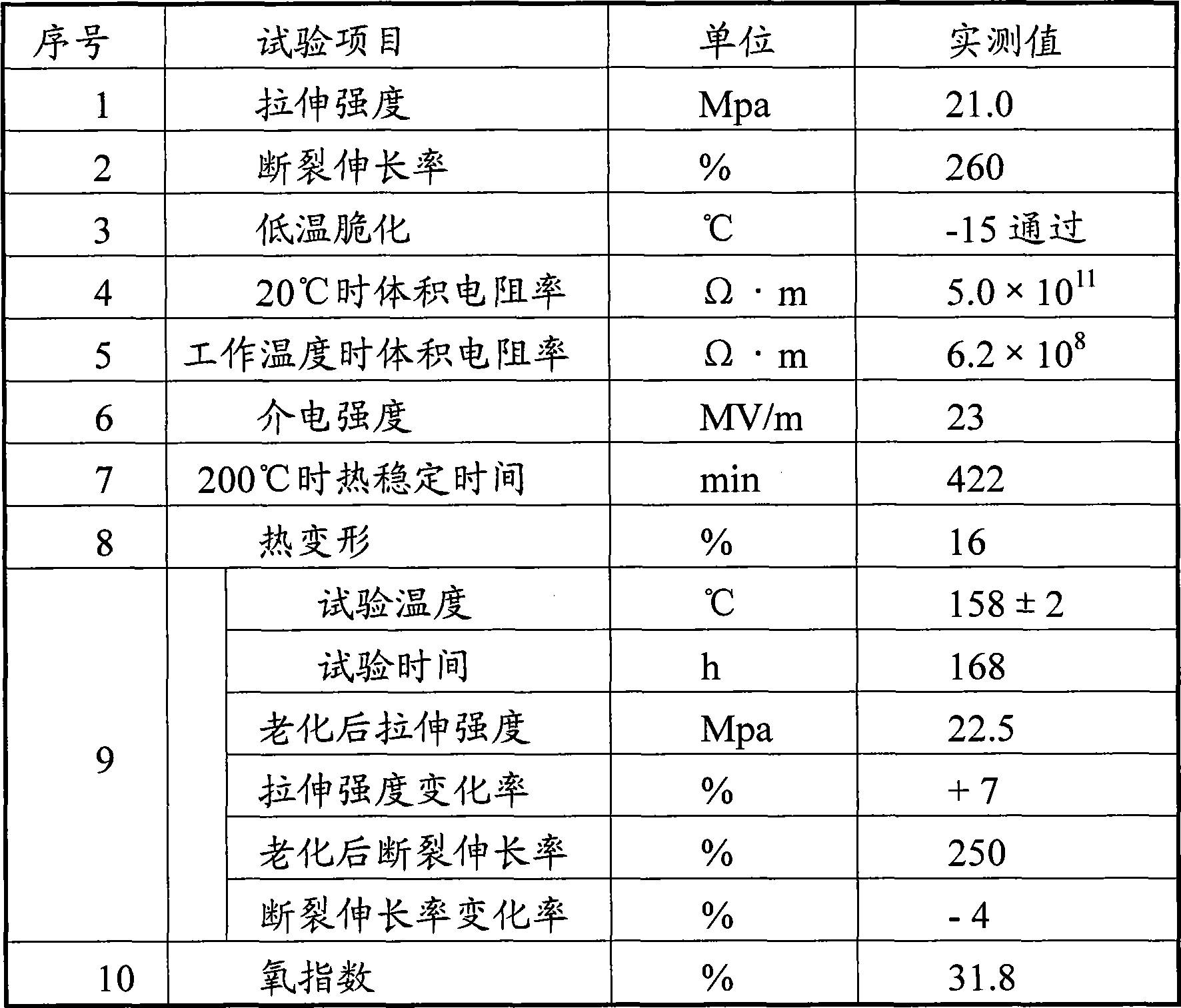

High temperature resistant environment-protective polychloroethylene material for electric wire and cable

InactiveCN101412834AImprove mechanical propertiesImprove insulation performancePlastic/resin/waxes insulatorsInsulated cablesPolyesterPolyvinyl chloride

The invention provides a high-temperature resistant environment-friendly polyvinyl chloride material for wires and cables. A raw material formulation mainly comprises the following materials in weight portion: 80 to 120 portions of loose-type polyvinyl chloride resin, 20 to 55 portions of tetraoctyl pyromellitate, 5 to 35 portions of polyester plasticizer and 12 to 18 portions of calcium-zinc stabilizer, wherein the polymerization degree of the loose-type polyvinyl chloride resin is between 2,000 and 3,000; in the calcium-zinc stabilizer, the total content of lead, cadmium, mercury and hexavalent chromium is less than or equal to 10 ppm of the total weight of the calcium-zinc stabilizer; the polyester plasticizer is polypropylene-1, 2-glycol adipate or polypropylene-1, 3-butylene terephthalate; and the molecular weight of the polyester plasticizer is between 3,000 and 4,000. After the material is aged in a hot-air oven for 168 hours at 158 DEG C, the retention rate of tensile strength is up to 106 percent; the retention rate of elongation at break is 97 percent; and the material is good in mechanical physical properties and insulating property. Therefore, the material meets the temperature-resistant requirement on long-term operating temperature at 125 DEG C in UL1581.

Owner:中广核三角洲(江苏)塑化有限公司

Seal for electrochromic devices

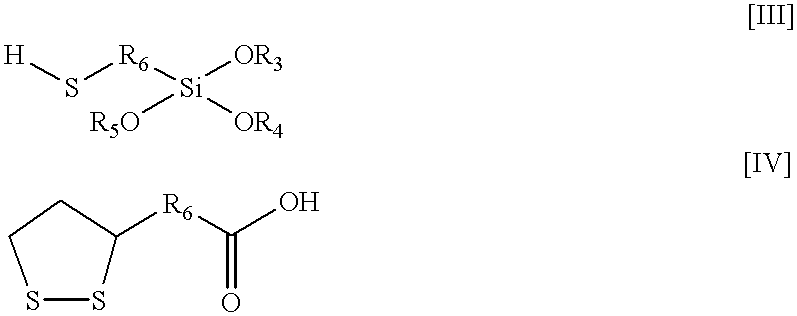

An improved seal member is provided as a part of an electrochromic device to bond two glass elements together in a spaced-apart relationship. In one embodiment the seal member provides improved adhesion to a reflector / electrode on the third surface of an electrochromic mirror, or to a layer of metal on the second or third surface for an electrochromic light filter. This seal member comprises a mixture of an organic resin scaling system and an adhesion promoter, where the adhesion promotor comprises a first and a second region, where the first region interacts with the reflector / electrode or the metal layer, and a second region that interacts with the organic resin sealing system, and may even chemically react with the organic resin sealing system. In another embodiment the seal member is provided with a coefficient of thermal expansion that is closer to glass than a standard epoxy sealing system.

Owner:GENTEX CORP

Photo-curable conductive adhesive and method for making same

InactiveCN1699492ALow curing temperatureLow resistivityPolyureas/polyurethane adhesivesEster polymer adhesivesPolymer scienceSilver plate

Disclosed is a photo-curable conductive adhesive and method for preparation, which is prepared from light-sensitive high molecular polymer, reactive dilution monomer, conducting particles, light-summing heat initiating agent and anti-oxidant through mixing and grinding, wherein the light-sensitive high molecular polymer is epoxy acrylic resin or / and polyurethane-acrylate, the reactive dilution monomer is the single, double and multiple functional monomers of acrylic acid, the conducting particle is silver powder, copper powder or silver-plated copper powder, the light initiating agent is alpha-amine alkyl methyl ketone, benzoin (or substituted benzoin) ether or acyl phosphines, the heat initiating agent is azocompound or peralcohol, the antioxidant is hydroquinone, p-hydroxybenzene methyl ether, 2,6-ditertiary-butyl-4-methylphenol.

Owner:DALIAN POLYTECHNIC UNIVERSITY

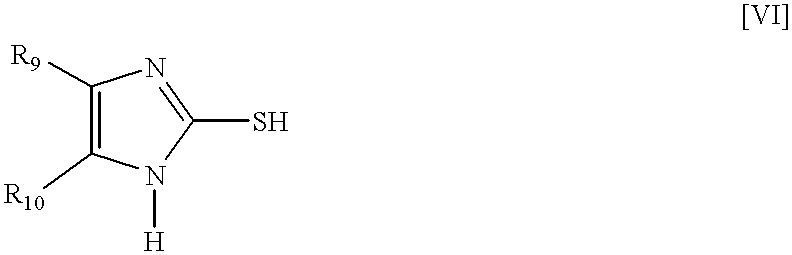

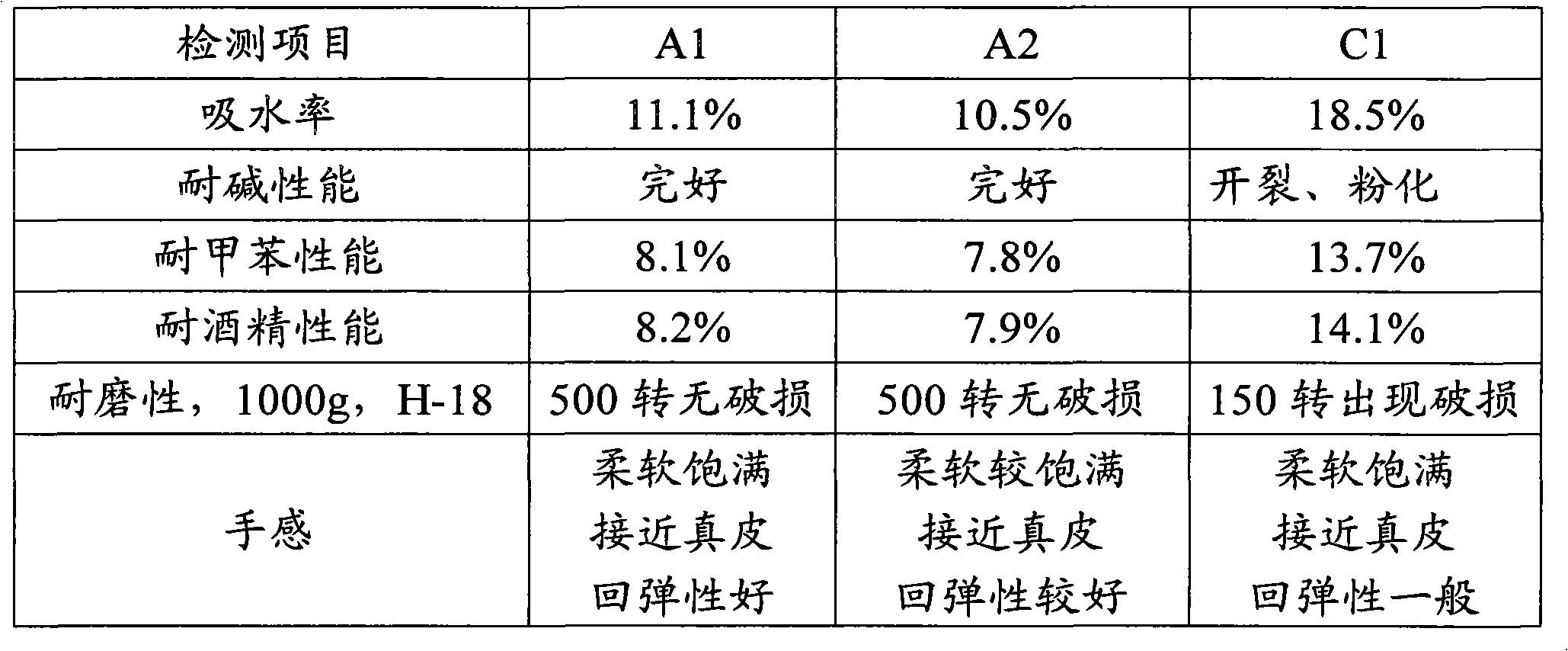

Method for manufacturing synthetic leather and synthetic leather

InactiveCN101941321AAchieving water-basedRealize cleaner productionSynthetic resin layered productsTextiles and paperLeather industryPolymer science

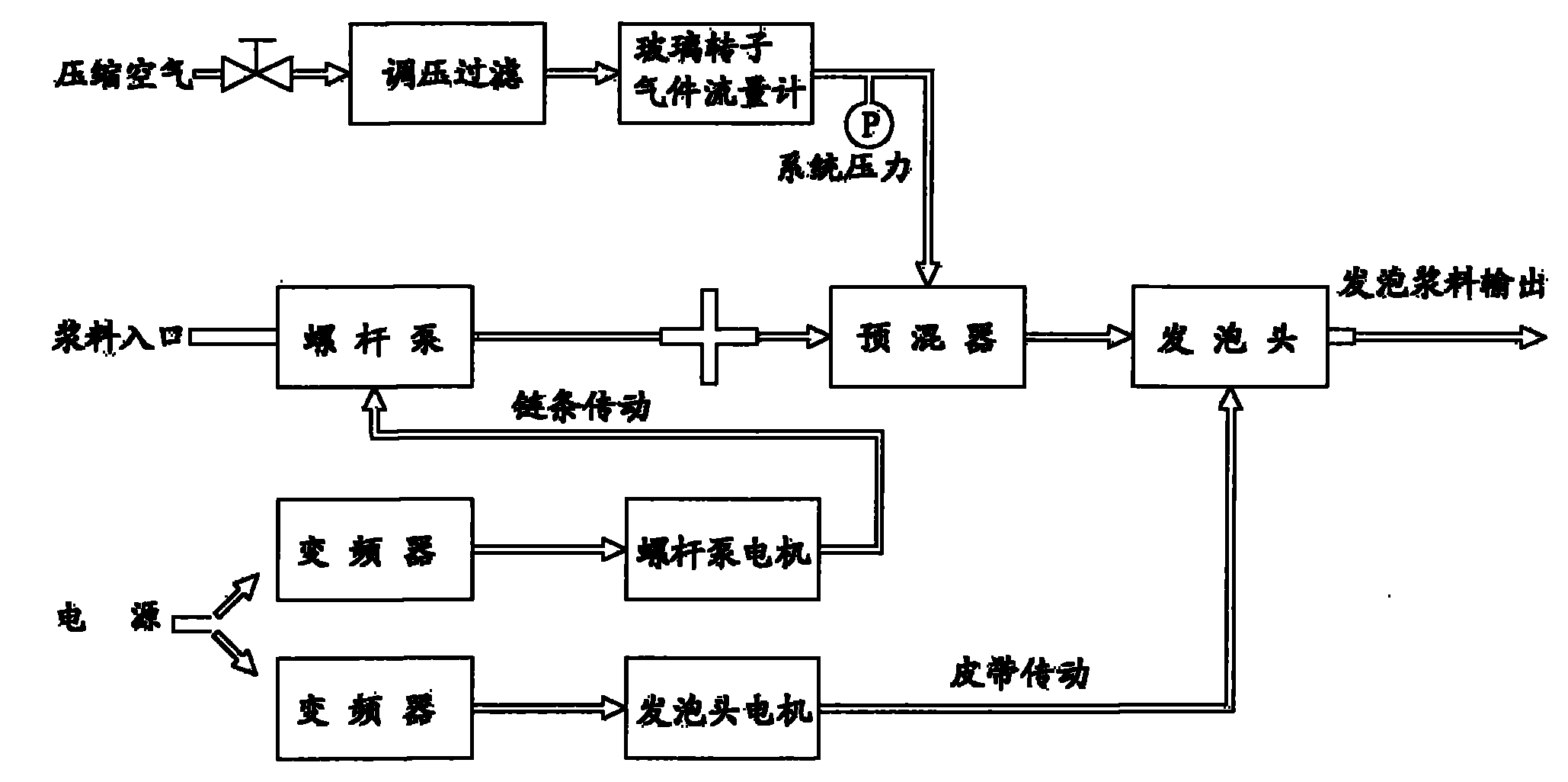

The invention provides a method for preparing synthetic leather and the synthetic leather prepared by the method. The method comprises the following steps: (1) coating slurry containing surface waterborne polyurethane resin on the surface of release paper, and drying to form a finishing coat; (2) mixing and foaming the slurry containing the foaming waterborne polyurethane resin with air by using a foaming machine, and coating the foamed slurry on the surface of the finishing layer, and drying to form a medium foaming layer; and (3) adhering the surface of the foaming layer and a basic fabric by using an adhesive containing waterborne polyurethane resin, and drying. The method uses the waterborne resin foaming layer to replace the Base leather manufacturing process, avoids using toxic and harmful organic solvents, such as dimetbyl formamide (DMF), toluene and the like, solves the pollution problem in the synthetic leather industry, and realizes clean manufacture of the synthetic leather.

Owner:丽水市优耐克水性树脂科技有限公司

Composite semipermeable membrane and method for producing same

ActiveUS20120248027A1Improve performanceGood removal effectSemi-permeable membranesMembranesOrganic solventPolyamide

A composite semipermeable membrane comprising a porous support membrane on which a separating functional polyamide layer resulting from the polycondensation reaction of polyfunctional aromatic amines with polyfunctional acid halides is formed, wherein the separating functional polyamide layer has carboxy groups, amino groups, phenolic hydroxyl groups, and azo groups, wherein XA, the ratio of the amino groups (molar equivalent of the amino groups / (molar equivalent of the azo groups+molar equivalent of the phenolic hydroxyl groups+molar equivalent of the amino groups)) on a feed water contact surface of the separating functional polyamide layer (an A surface), is in the range 0.5 or less, and XB, the ratio of the amino groups (molar equivalent of the amino groups / (molar equivalent of the azo groups+molar equivalent of the phenolic hydroxyl groups+molar equivalent of the amino groups)) on a permeate-side surface of the separating functional polyamide layer (a B surface), i.e., the opposite side to the A surface, is in the range of 0.5 to 1. The present invention provides a composite semipermeable membrane that achieves a balance between high solute removal properties and a high permeate flow rate and has high organic-solvent resistance, and a method for producing same.

Owner:TORAY IND INC

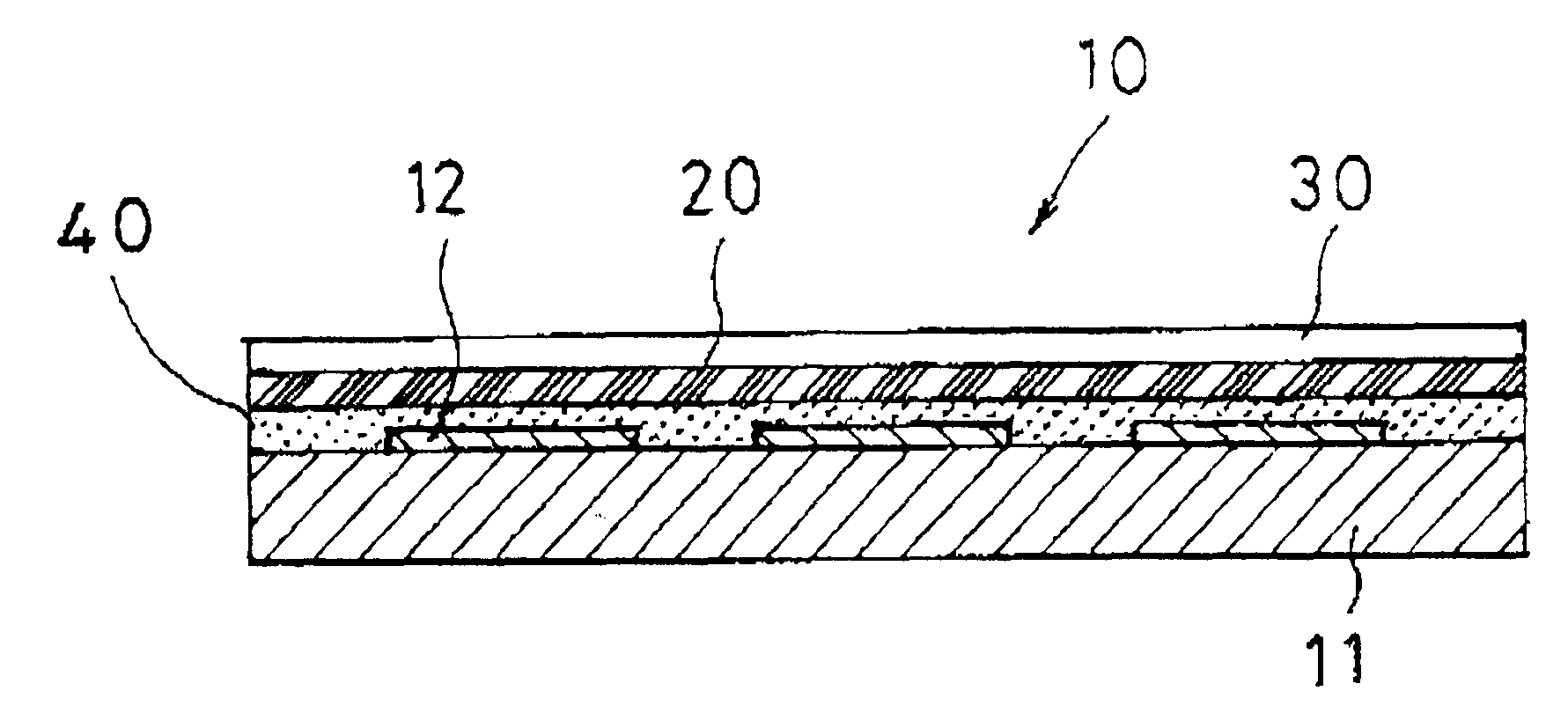

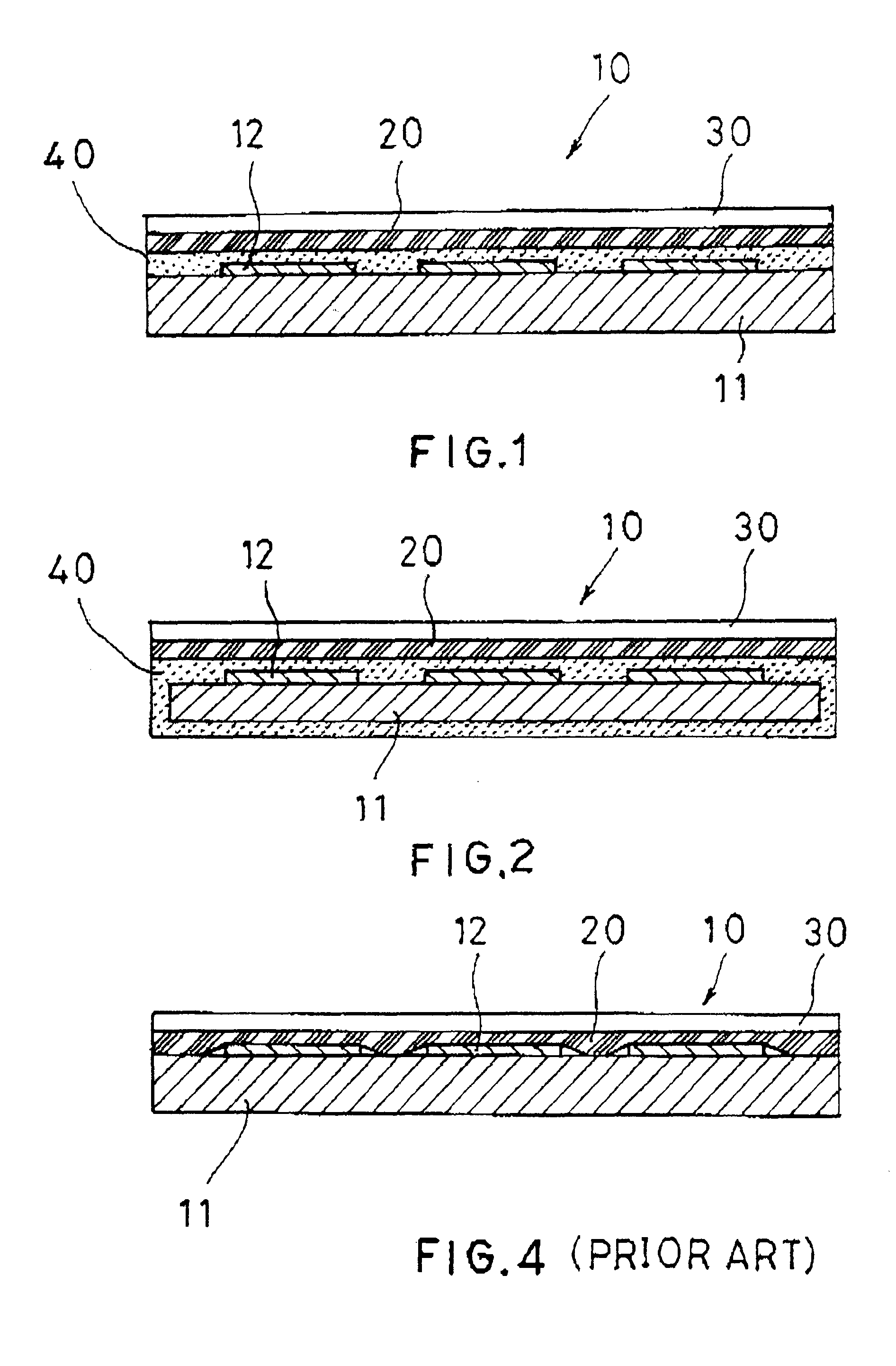

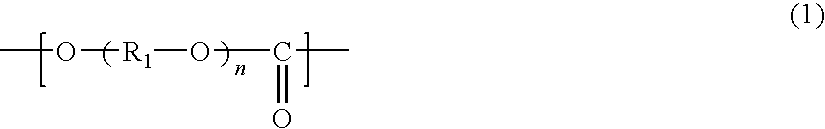

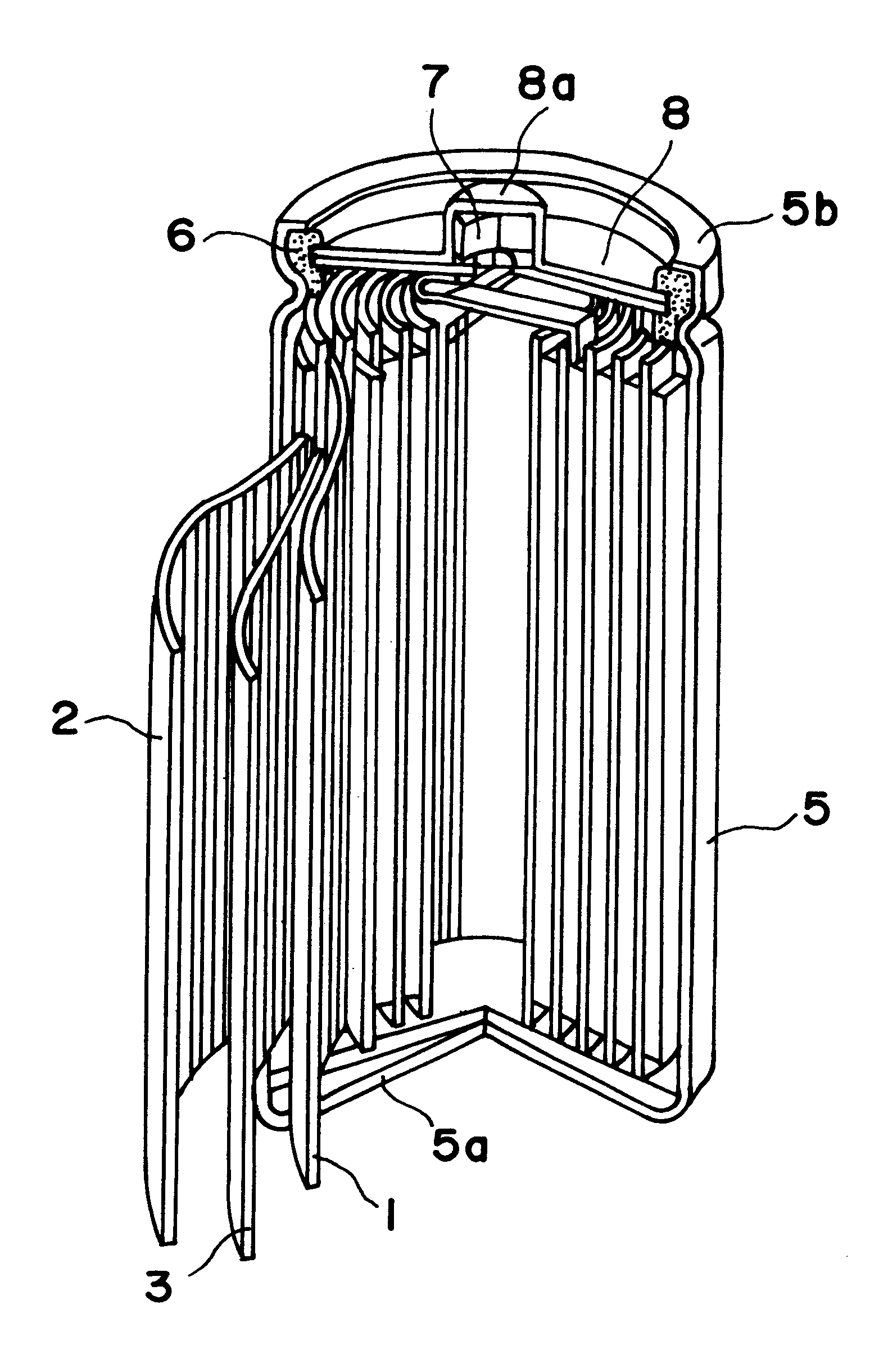

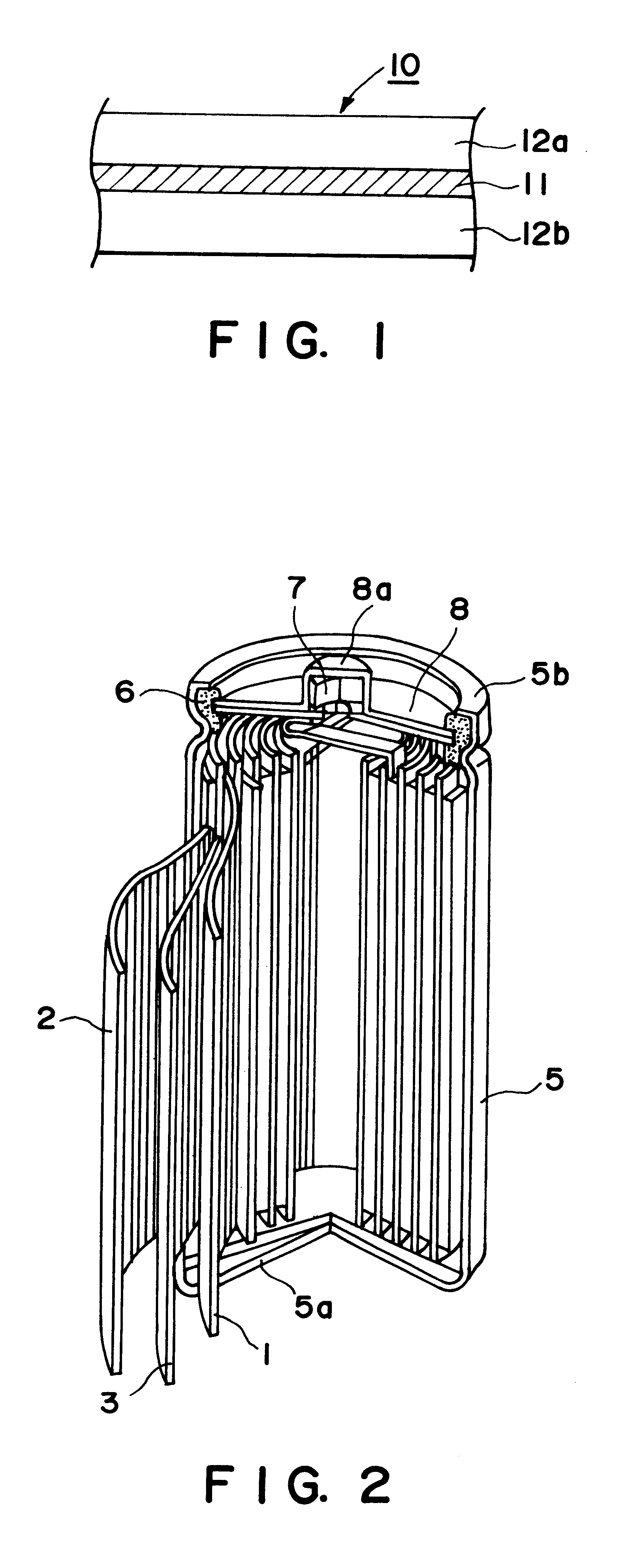

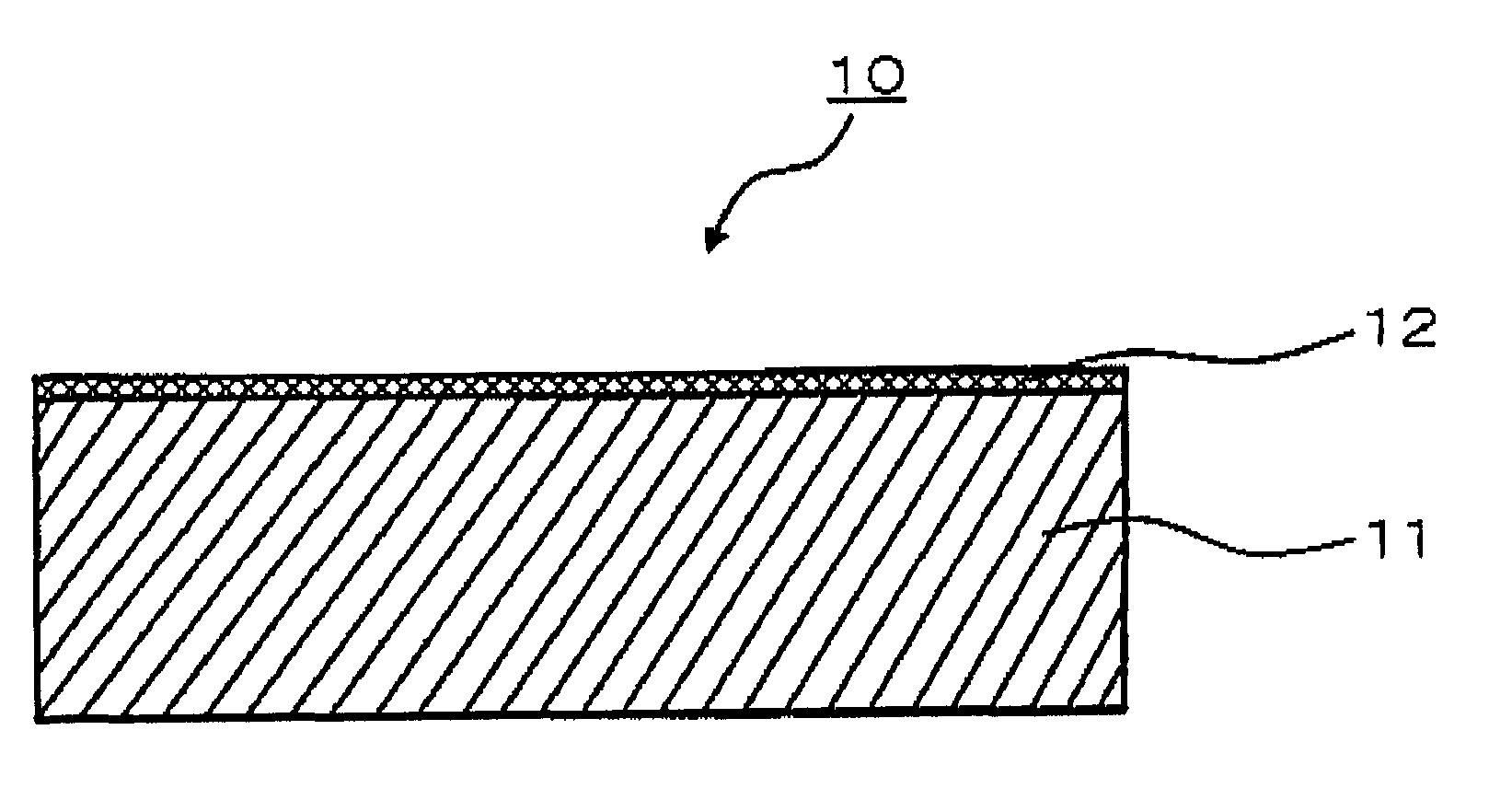

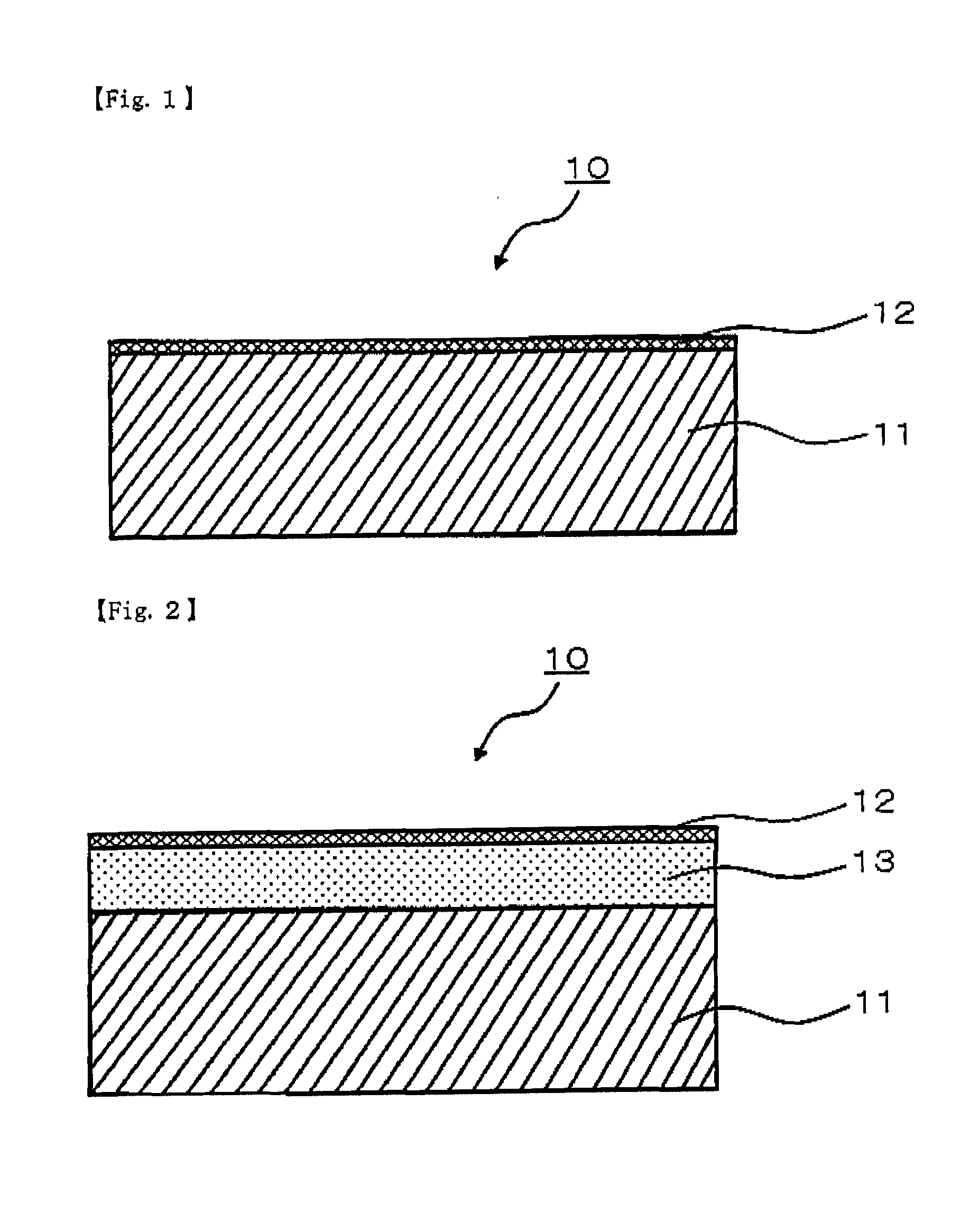

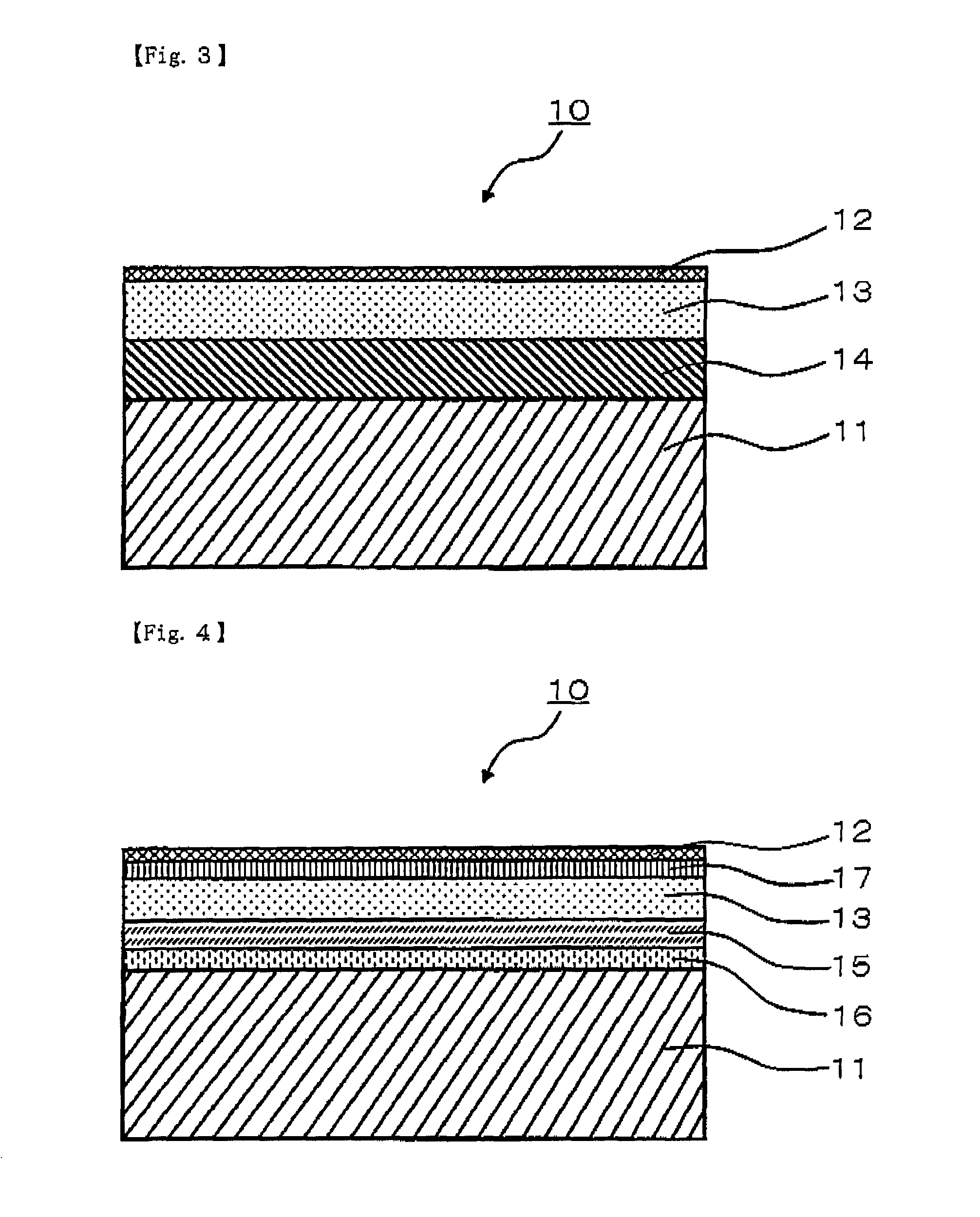

Scale on an apparatus for measuring displacement

InactiveUS6675491B2Good solvent resistanceImprove adhesionWalking sticksSlide gaugesAdhesive beltGrating

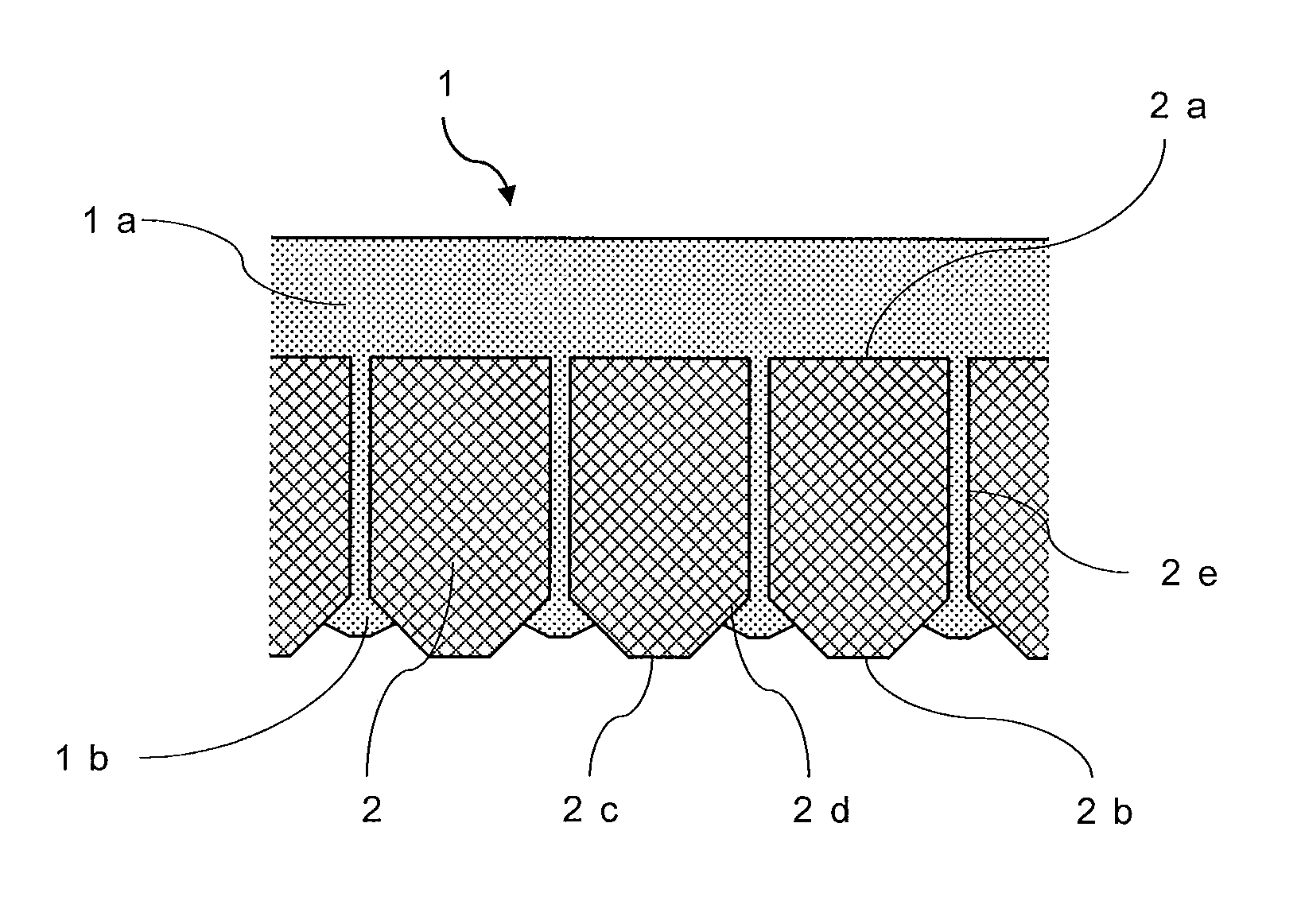

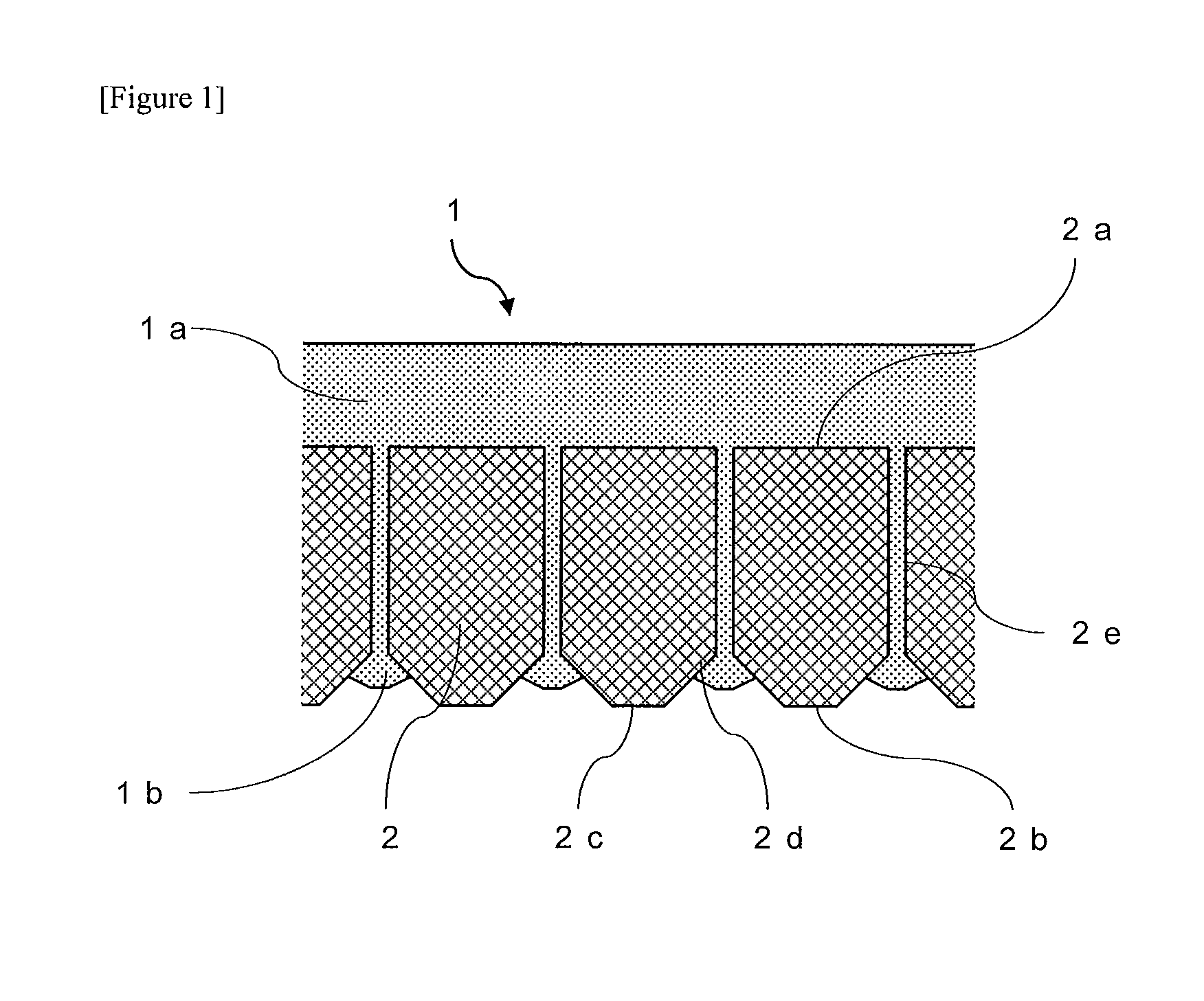

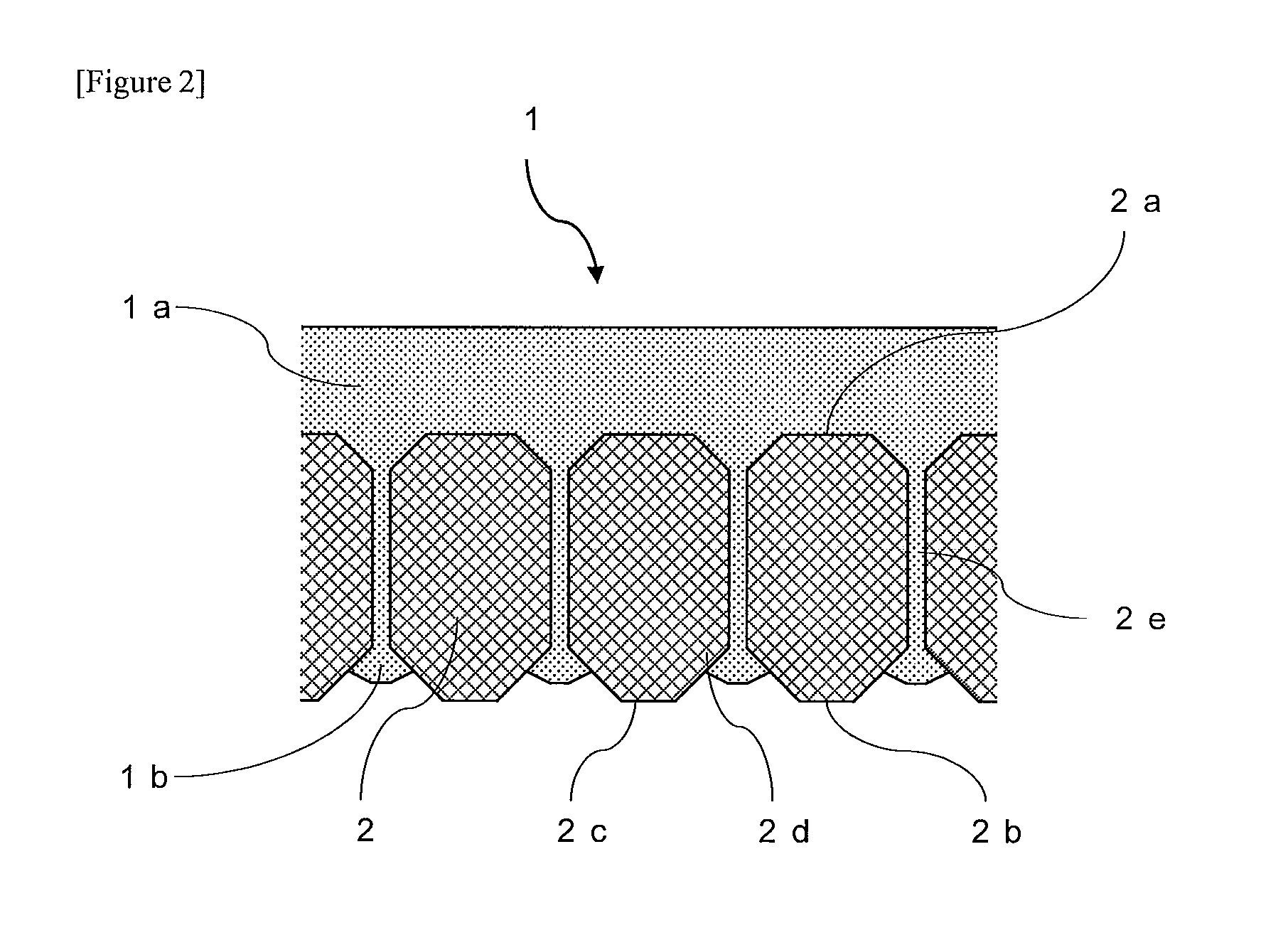

A scale for an apparatus for measuring displacement is enclosed. It comprises a scale member having a plurality of rectangular gratings arranged in a periodic pattern on the glass epoxy substrate and the like, a coating layer covered on the side of the scale member on which a plural of the rectangular gratings are formed, a scale cover (film layer) which functions as a protective layer, and a scale forming material bonded to the outer portion of the coating layer by an adhesive layer so as to keep contaminants, oil or particles from intruding between the rectangular grating and the adhesive layer, for example an adhesive tape and the like.

Owner:MITUTOYO CORP

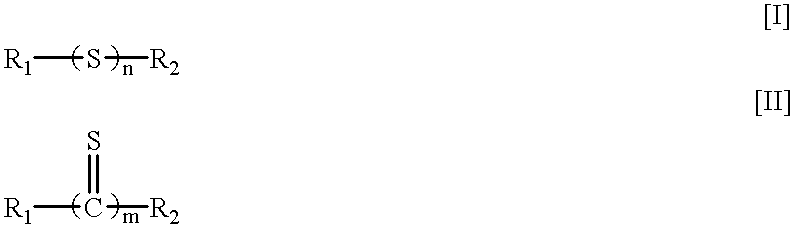

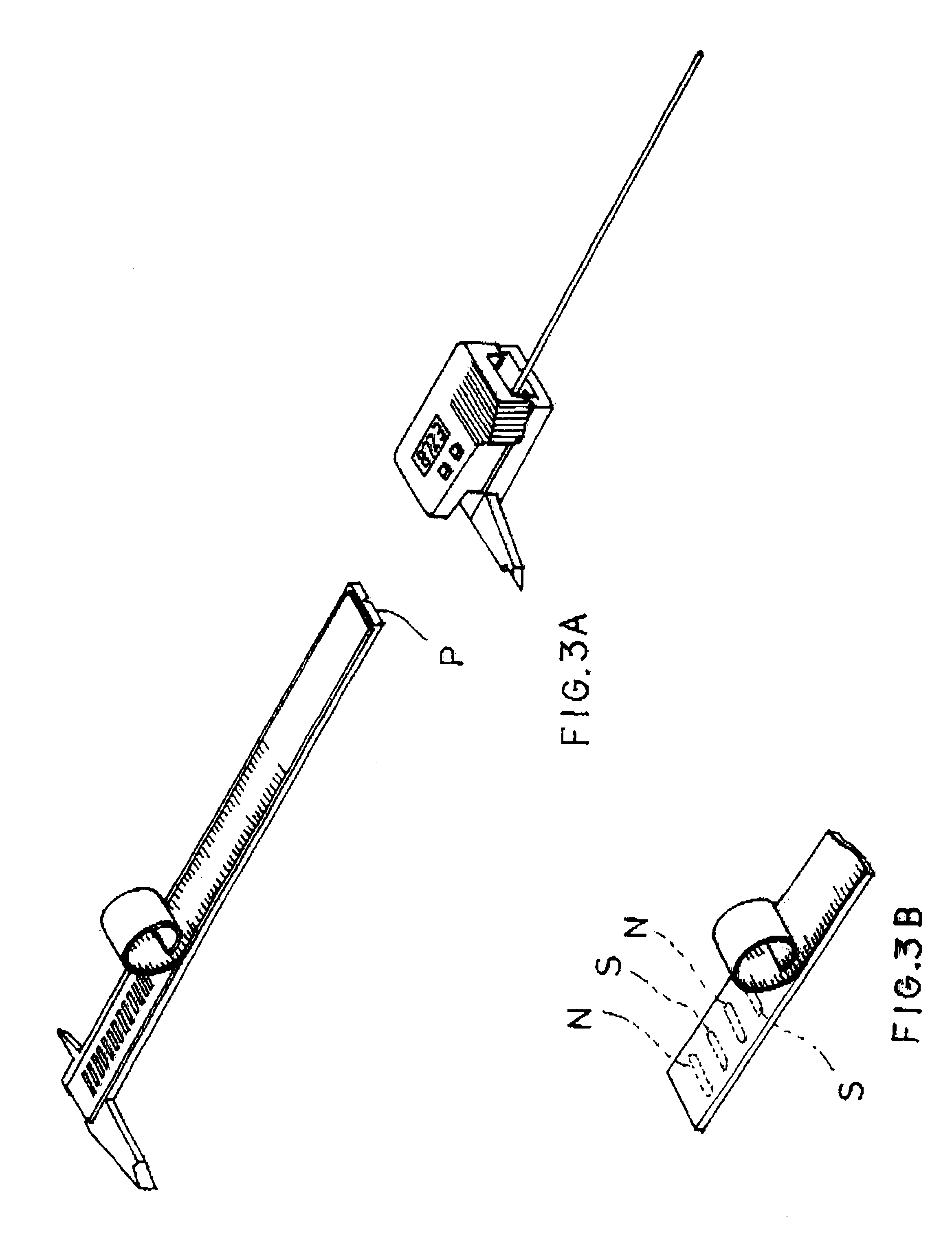

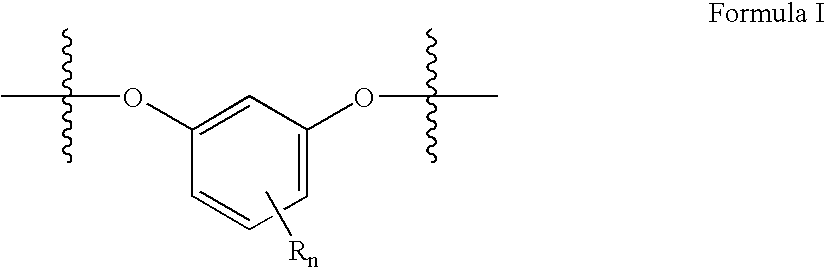

Resin composition for printing plate

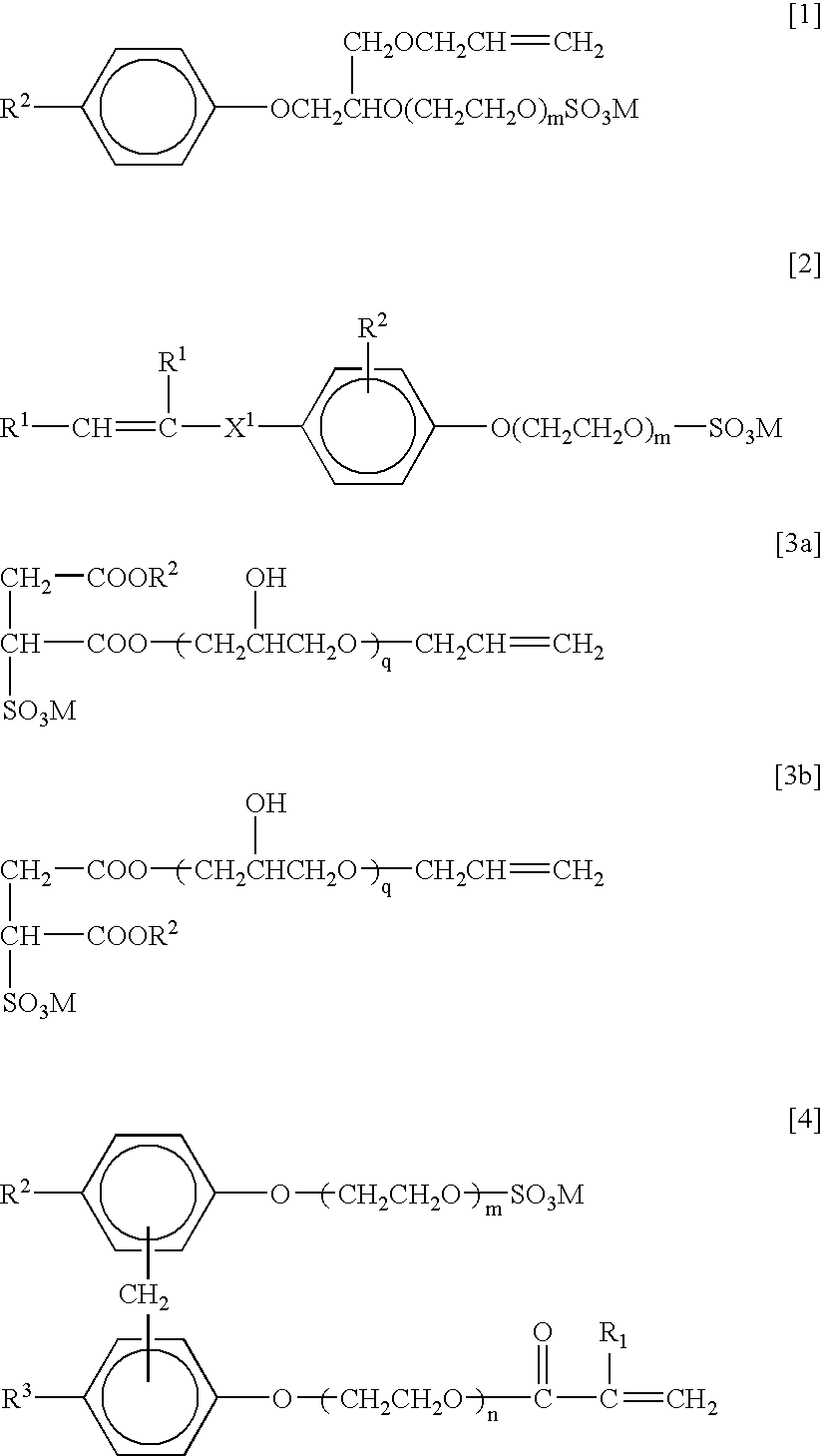

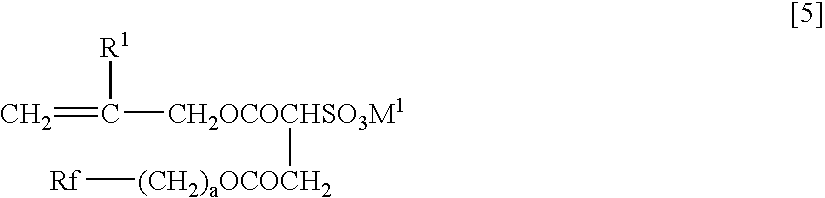

InactiveUS20100093119A1Good solvent resistanceImprove the immunityPhotosensitive materialsLayered productsPolymer sciencePolycarbonate

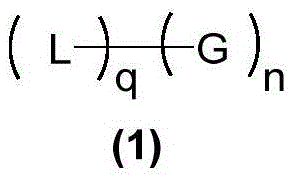

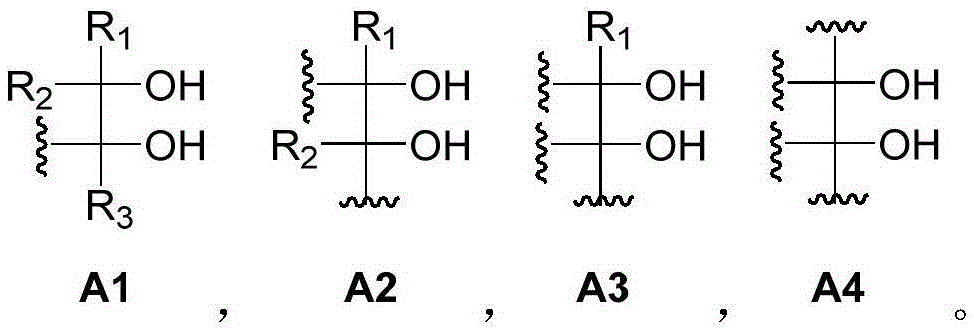

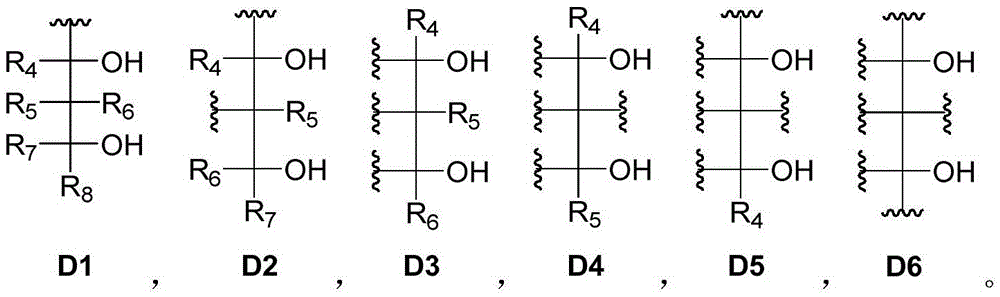

Disclosed is a polymer having excellent solvent resistance which can be produced by using a polycarbonate diol having a repeating unit represented by the formula (1) and / or (2), having a hydroxyl group at both termini, and having a number average molecular weight of from 300 to 50,000:wherein R1 represents a linear or branched hydrocarbon group having 2 to 50 carbon atoms; and n represents an integer of 2 to 50,wherein R2 represents a linear or branched hydrocarbon group having 10 to 50 carbon atoms.

Owner:ASAHI KASEI E-MATERIALS CORPORATION

Acrylate micro-emulsion with high solid content, its preparation method and use

The invention refers to a high-solid content acrylate micro-latex, its making method and its application to carpentry dope. It adopts the technique of half-continuous starvation feeding, and is obtained by the polymerizing method of seed latex. It leads into cross-linking groups in the course of polymerization such as amidogen, acetoacetyl and amido, depends on the reaction of the groups of form film, gets painting film with cross-linking construction, and improves the water and solvent resistance of the painting film.

Owner:SOUTH CHINA UNIV OF TECH

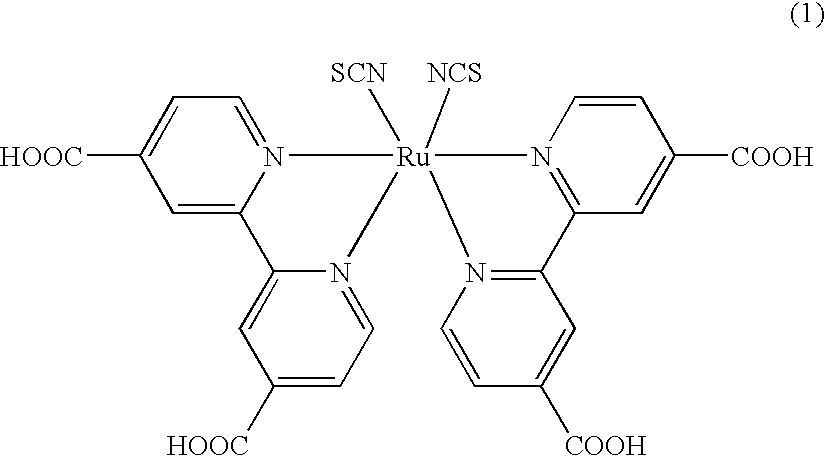

Conductive composition, conductive coating material, conductive resin, capacitor, photoelectric transducer, and their production method

InactiveUS20070096066A1No ionic conductivityImprove heat resistanceNon-metal conductorsHybrid capacitor electrodesConductive coatingConductive polymer

The present invention provides a conductive composition comprising (i) a cyano group-containing polymer compound which is a copolymer of a cyano group-containing monomer and a vinyl group-containing monomer, and n-conjugated conductive polymer.

Owner:SHIN-ETSU POLYMER CO LTD

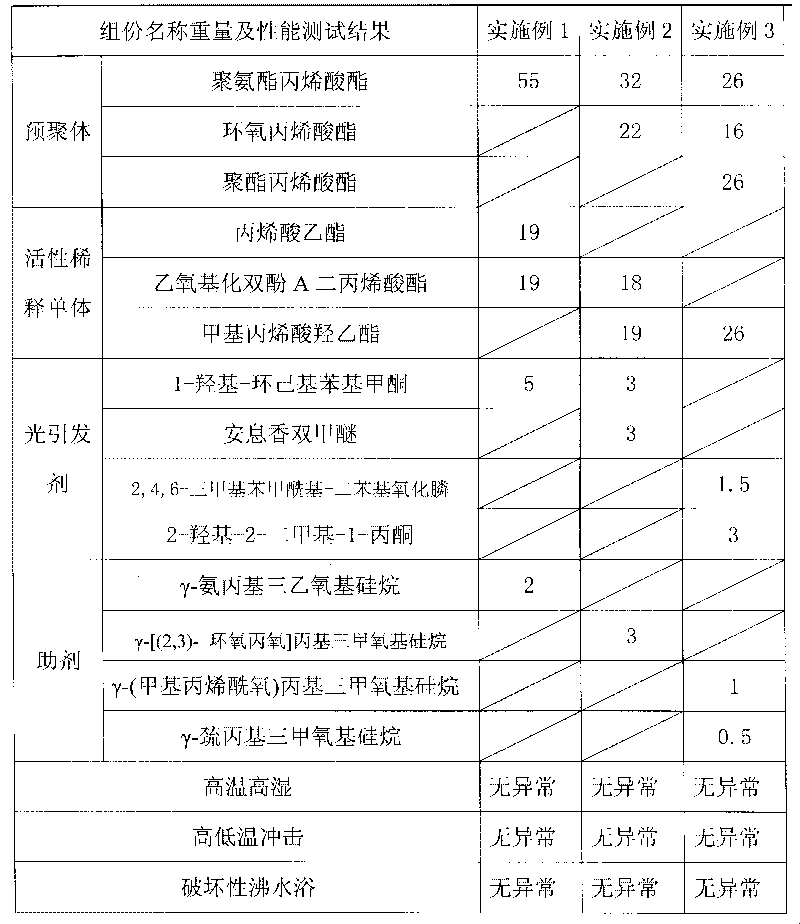

UV curing packaging adhesive for liquid crystal display

InactiveCN101724374AFast curingCuring shrinkage is smallOther chemical processesPolyureas/polyurethane adhesivesPrepolymerPhotoinitiator

The invention provides a UV curing packaging adhesive for a liquid crystal display. Based on 100 weight parts, the adhesive consists of following components: 40 to 70 parts of prepolymer, 20 to 50 parts of active diluent monomer, 1 to 8 parts of photoinitiator, and 0.1 to 5 parts of assistant. The prepolymer is one or a mixture of more of the urethane acrylate, epoxy acrylate and polyster acrylate. The UV curing packaging adhesive for the liquid crystal display has the characteristics of high curing speed, low shrinkage rate and excellent damp heat resistance.

Owner:BEIJING HYSTIC NEW MATERIALS

Preparation method of water-based polyurethane/nano-silicon dioxide composite emulsion

InactiveCN101845217AEliminate pollutionAddress pollution and damagePolyurea/polyurethane coatingsPrepolymerSolvent

The invention relates to a preparation method of a water-based polyurethane / nano-silicon dioxide composite emulsion, which comprises the following steps: uniformly mixing and stirring ethyl orthosilicate, absolute ethyl alcohol and octadecyl trimethyl ammonium chloride for reacting to obtain nano-silicon dioxide sol; heating polyglycol, and then, adding diisocyanate and dibutyltin dilaurate for reacting to form polyurethane prepolymer; adding a hydrophilic chain extender and a cross-linking agent into the polyurethane prepolymer for carrying out chain extending reaction, adding organic base for regulating the pH value to be 7.0-8.0, and then, adding deionized water to obtain 30% of water-based polyurethane emulsion; and mixing the nano-silicon dioxide sol and the water-based polyurethane emulsion in a water bath, and carrying out ultrasonic treatment to obtain the water-based polyurethane / nano-silicon dioxide composite emulsion. Harmful solvents and emulsifying agents do not need to be added in the preparation process of the invention, thereby solving the problems of polluting environment and injuring operators.

Owner:SHAANXI UNIV OF SCI & TECH

Flame retardant polymer blends

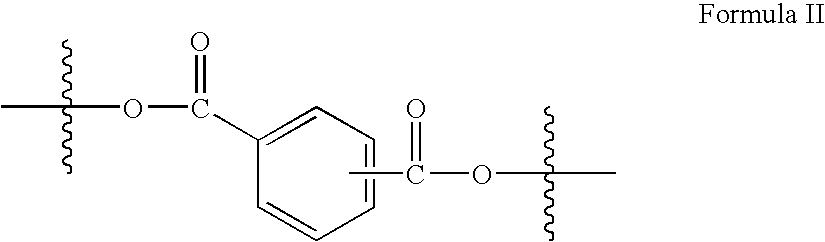

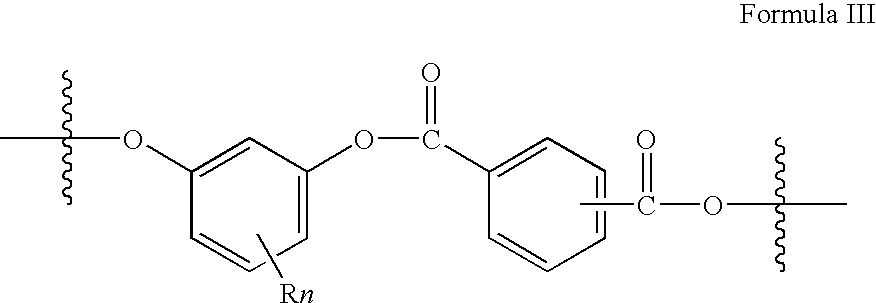

InactiveUS20070066737A1Improve flame retardant performanceGood solvent resistancePolyesterPolyetherimide

Blends of polyimides, polyetherimides or polyetherimide sulfones with resorcinol based polyesters, or resorcinol based polyester carbonate polymers, and silicone copolymers, have improved flame resistance. Peak heat release energy is reduced and the time to reach peak heat release is increased. In some instances the flame retardant blends show high percent transmission with low haze. Addition of metal oxides may further improve flame resistance.

Owner:SABIC GLOBAL TECH BV

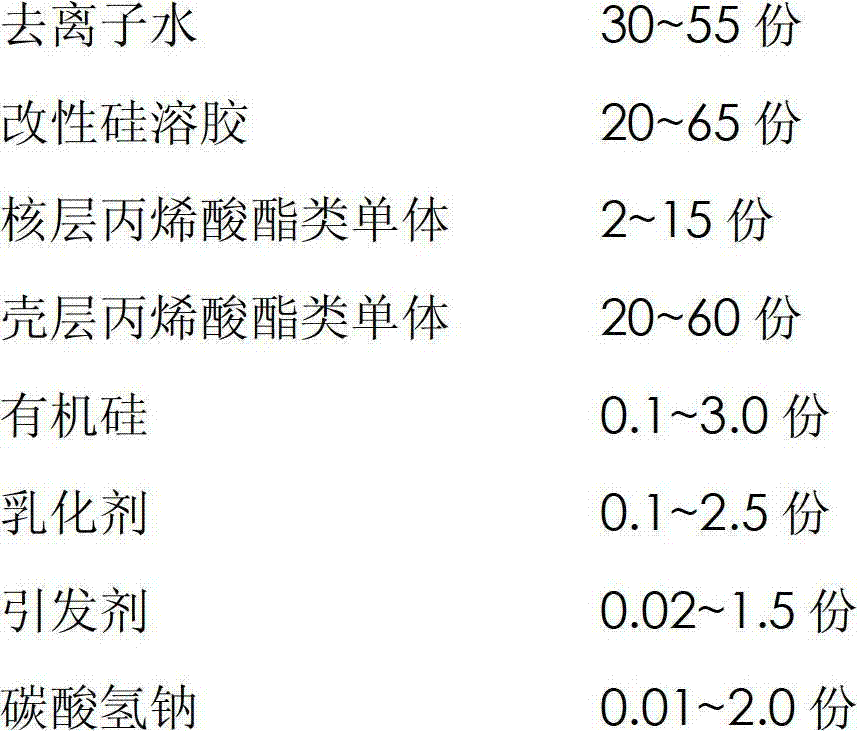

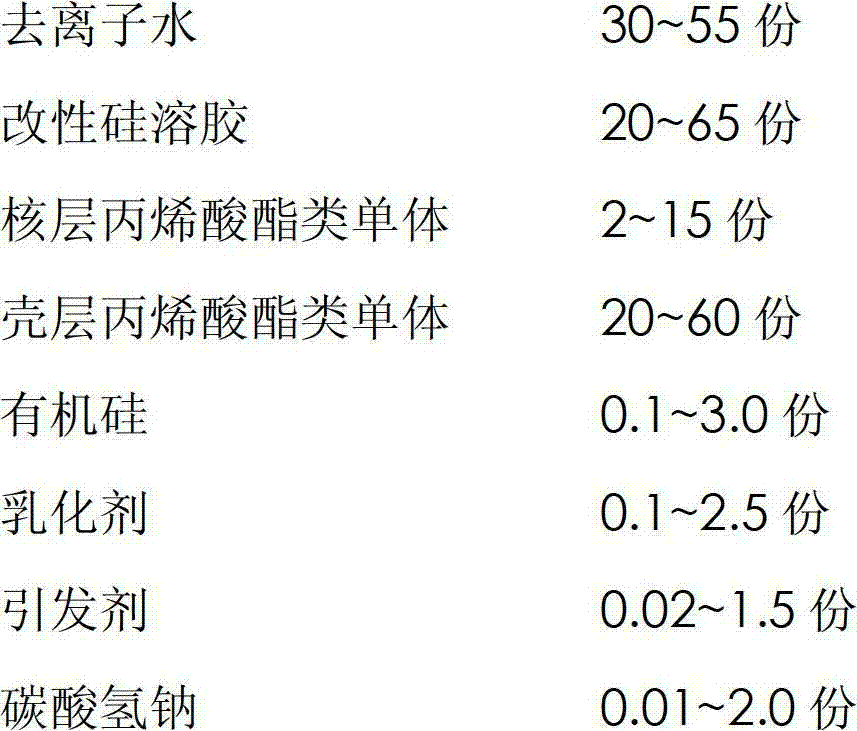

Organosilicon modified silica sol/polyacrylate composite emulsion and its preparation method

InactiveCN102731735AGood repeatabilityComposite emulsion has excellent performanceCoatingsSolventIon

The invention discloses an organosilicon modified silica sol / polyacrylate composite emulsion and its preparation method. The emulsion comprises the following raw materials, by mass, 30-55 parts of deionized water, 20-65 parts of a modified silica sol, 2-15 parts of a core acrylate monomer, 20-60 parts of a shell acrylate monomer, 0.1-3.0 parts of organosilicon, 0.1-2.5 parts of an emulsifier, 0.02-1.5 parts of an initiator, and 0.01-2.0 parts of sodium bicarbonate, wherein the Si (by SiO2) content in the organosilicon modified silica sol / polyacrylate composite emulsion is 15-25% by mass. The emulsion which has an excellent appearance is a white emulsion with obvious blue lights. A coat of the emulsion is transparent and smooth, and has a hardness reaching 5-6H and an adhesion being 0-1 level. The coat has an excellent water resistance, so the coat does not have whitening and foaming phenomena after immersed in water for 7-10 days; the coat has no changes after resisting neutral salt fog for 15-20 days; and the solvent wiping resistance of the coat can pass an MEK test 180-200 times.

Owner:SOUTH CHINA UNIV OF TECH

Binder solution and electrode-forming composition for non-aqueous-type battery

InactiveUS6200703B1Good gelHigh affinityNon-aqueous electrolyte cellsNon-aqueous electrolyte accumulator electrodesOrganic acidOrganic solvent

A vinylidene fluoride polymer binder solution for forming an electrode for a non-aqueous-type battery is formed by adding an acid, preferably an organic acid, as a stabilizer to a solution of a vinylidene fluoride polymer in an organic solvent. The acid is preferably added in an amount sufficient to ensure a pH of at most 9 when measured with respect to a 10-times dilution of the binder solution with deionized water. The acid addition is effective for preventing a problematic viscosity increase in the binder solution and also gelling of an electrode-forming composition formed by adding a powdery electrode material in the binder solution.

Owner:KUREHA KAGAKU KOGYO KK

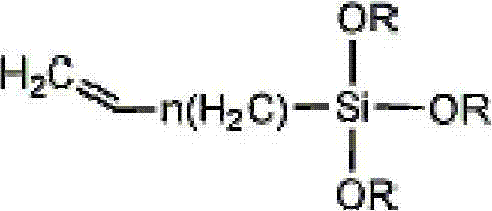

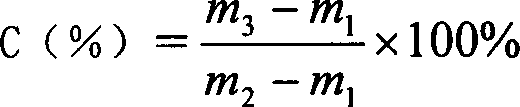

Method for preparing organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion

InactiveCN101735412AIncreased stability and solids contentImproves water resistance and adhesionSolventEmulsion

The invention relates to a method for preparing an organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion. According to the method, a reactive emulsifier is used to replace a conventional emulsifier, and the method comprises the steps of: performing soap-free emulsion polymerization on acrylic ester monomers, (methyl) acrylic acid, vinyl silicone oil and alkoxy silane containing double bonds; and then adding ethyl orthosilicate for a sol-gel reaction to obtain the organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion. The organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion is suitable to be taken as a leather finishing agent. The method can completely eliminate the adverse effect of a small molecular emulsifier on an acrylic resin emulsion finishing agent, introduce good characteristics of organosilicon and nano-silicon dioxide into an acrylic resin, overcome the disadvantages of hot sticking and cold shortness, poor waterproof performance and poor solvent resistance and the like of the acrylic resin, and improve the mechanical property, adhesive force and wear resistance of the acrylic resin.

Owner:山西佳宇丰化工科技有限公司

Initiator system and adhesive composition made therewith

InactiveUS6027813ALower Level RequirementsGood solvent resistanceSynthetic resin layered productsEster polymer adhesivesSolventAcid anhydride

Systems for initiating the polymerization of acrylic monomers comprising (1) organoborane amine complexes and (2) decomplexers comprising at least one anhydride group. Adhesive compositions prepared from the initiator systems advantageously exhibit low levels of mobile constituents, excellent solvent resistance, and good adhesion to low energy surfaces.

Owner:3M INNOVATIVE PROPERTIES CO

Thermo-sensitive discoloration material microcapsule and preparation method thereof

InactiveCN102477290AGood chemical stabilityGood solvent resistanceTenebresent compositionsMicroballoon preparationEmulsionChange color

The invention discloses a thermo-sensitive discoloration material microcapsule and a preparation method thereof. The microcapsule is composed of a core material and a wall material for covering the core material, wherein the core material comprises a thermo-sensitive discoloration compound composed of a chromogenic reagent, a color-developing agent and a solvent; the wall material is a melamine resin pre-polymer; the mass ratio of the thermo-sensitive discoloration compound to the melamine resin pre-polymer is 1:(1-2). The preparation method comprises the following steps of: mixing the chromogenic reagent, the color-developing agent and the solvent to form a thermo-sensitive discoloration solution under the heating condition; adding an emulsifying agent solution into the thermo-sensitive discoloration solution and emulsifying a commixed solution to obtain an emulsion; adjusting the pH value to 3-6 and adding the melamine resin pre-polymer into the emulsion; reacting at a temperature for 60-70 DEG C for 1-1.5 hours and then cooling to 30-40 DEG C; then adding a dispersant; and washing and drying to obtain the thermo-sensitive discoloration microcapsule. According to the method provided by the invention, the influences on human bodies and environments are greatly reduced; the operation is simple, the prepared microcapsule products can fast change color and fade and the effect is obvious, so that the thermo-sensitive discoloration material microcapsule can be widely applied in the fields of anti-counterfeiting textile and printing and the like.

Owner:BEIJING CTA TEX CHEM

Waterproof moisture permeation polyurethane paint used for textiles and preparation method

The invention relates to waterproof moisture permeation polyurethane paint used for textiles and a preparation method. The waterproof moisture permeation polyurethane paint is prepared from methyl diphenylene diisocyanate, toluene di-isocyanate, polyether glycol (with the molecular weight of 2000), linear dihydroxylated alkylsiloxane (with the molecular weight of 1000), polyester dihydric alcohol (with the molecular weight of 2000), trimethylolpropane, chain extending agents, sealing compounds, dibutyl tin laurate and solvents through the processes of pre-polymerization reaction, chain extension reaction and sealing reaction. The production process is simple, and the products have the advantages of self-crosslinking effect, soft hand feeling, good cold resistance performance, high moisture permeation performance, high water pressure resistance and little reduction after water pressure resistance washing.

Owner:郯城丰润粮机配件有限公司

Bicompenent high solid content aqueous polyurethane, its preparation method and application

InactiveCN1786055ASimple processReduce dosageFibre treatmentPolyureas/polyurethane adhesivesWater basedWater dispersible

The present invention relates to double-component high solid content water-based polyurethane, its preparation method and application. Said method includes the following procedures: preparing water-dispersible polyurethane adhesive; preparing water-dispersivity polyisocynate cross-linking agent; and before application mixing the water-dispersible polyurethane adhesive and water-dispersivity polyisocynate cross-linking agent, in which the preparation of polyurethane adhesive includes the preparation of prepolymer, the prepolymer is neutralized and dispersed into the deioniced water to obtain dispersion, then the dispersion is chain-extended so as to form water-based polyurethane.

Owner:SOUTH CHINA UNIV OF TECH

Dynamic polymer material

InactiveCN105646872ADynamic responsivenessMild reaction conditionsCoatingsPhenylboronic acidCross-link

The invention discloses a dynamic polymer material. The dynamic polymer material comprises a product obtained through reaction of the following components: at least one polyol compound containing two or more 1,2-diol motifs or 1,3-diol motifs as well as at least one phenylboronic acid compound containing two or more phenylboronic acid motifs provided with aminomethyl groups in ortho-positions. Dynamic reversible phenylborate bonds are formed through the reaction of the components and then constitute a dynamic cross-linked polymer. The polymer material has reusability and recoverability because of the dynamic reversibility of the special phenylborate bonds; besides, when the polymer material adopting a specific formula receives external force, dynamic bonds break preferentially to have energy dissipation and stress elimination functions, so that the material has good toughness. The material has broad application prospect in the fields of military space equipment, functional paint and coatings, biomimetic materials, biomedical materials and the like.

Owner:翁秋梅

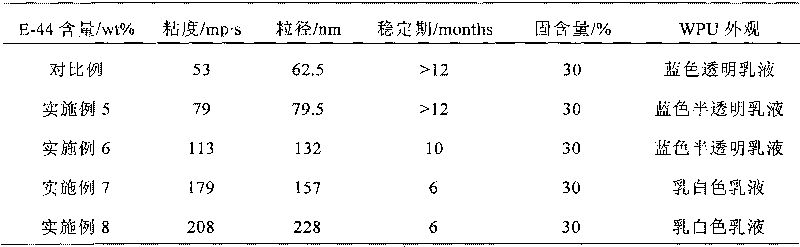

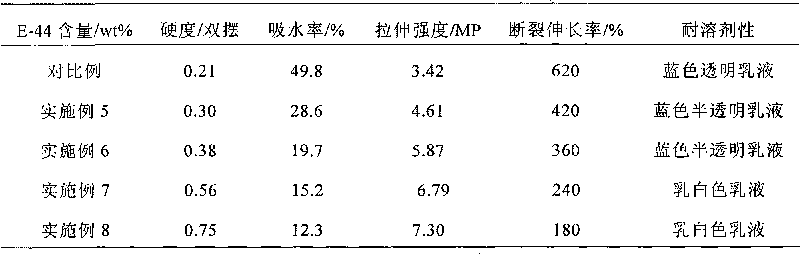

Epoxy resin modified water-based polyurethane emulsion and preparation method thereof

InactiveCN101717488AHigh molecular weightImprove cohesive energyPolyurea/polyurethane coatingsPolyesterWater based

The invention relates to an epoxy resin modified water-based polyurethane emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 20 to 40 percent of isophorone diisocyanate, 20 to 40 percent of polyester, 5 to 10 percent of hydrophilic chain extender, 2 to 10 percent of chain extender, 1 to 3 percent of crosslinker, 3 to 10 percent of neutralizing agent, 2 to 10 percent of epoxy resin and 10 to 20 percent of acetone. The preparation method comprises the steps of feed preparation, polyester dehydration, the synthesis and neutralization of prepolymer, and chain extension and emulsification. Compared with the prior art, the epoxy resin modified water-based polyurethane emulsion has the advantages of high hardness of film, good water resistance and solvent resistance and the like, and is widely applied in the field of packaging coatings.

Owner:SHANGHAI WEIKAI CHEM

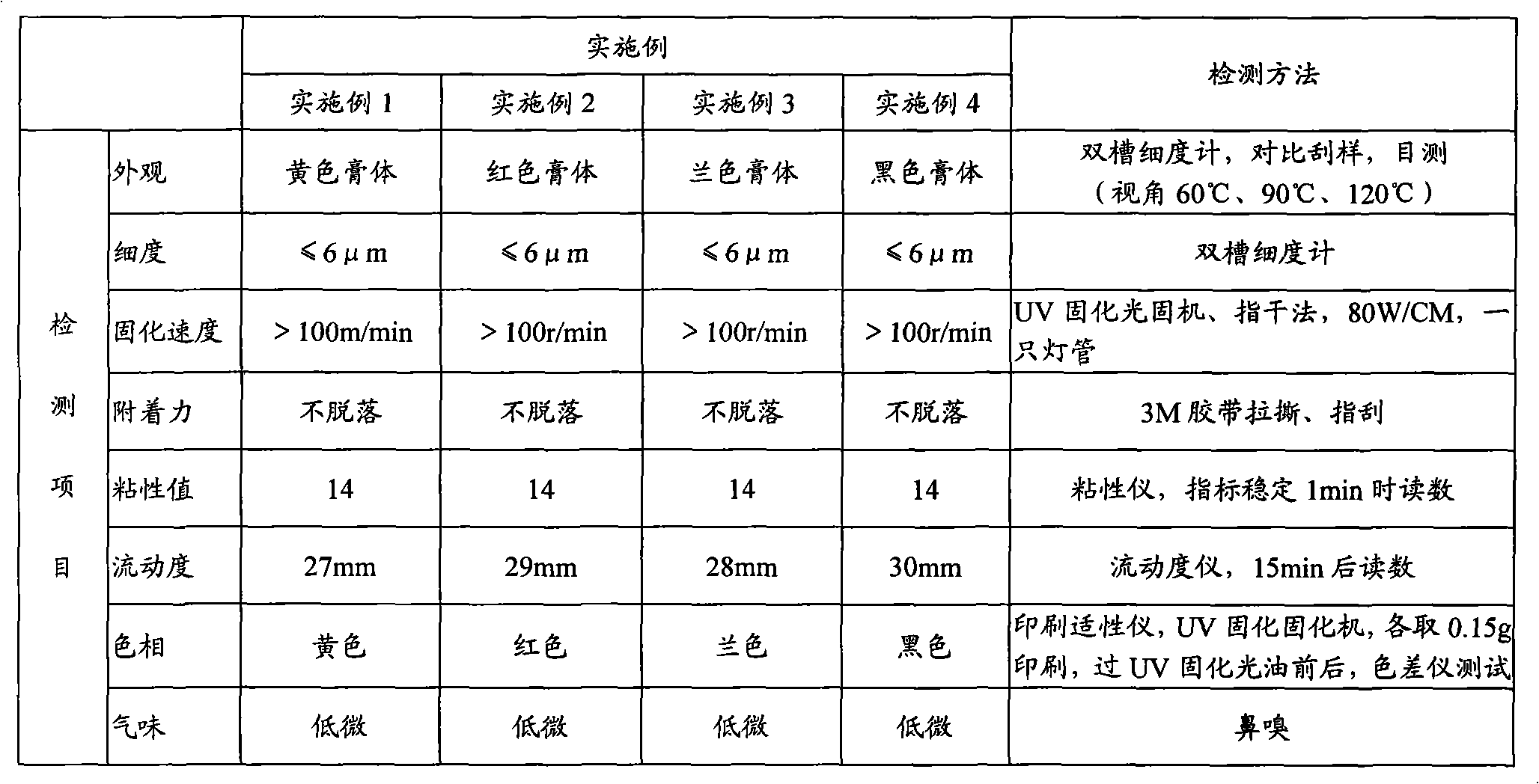

UV curing offset printing ink and use

The invention relates to UV cured lithographic ink and purposes thereof. The ink is a compound which comprises the following components by the weight percent: 30 to 50 of polyester acrylic ester, 0 to 15 of epoxy acrylic ester, 2 to 22 of high-viscosity monofunctional polyurethane acrylic ester, 0 to 10 of acrylic monomer, 10 to 15 of photoinitiator, 2 to 5 of filler and 16 to 22 of pigment. The UV curing glue printing ink of the invention can be cured at high speed, can meet the requirements of high-speed packaging, printing and environment protection, does not contain VOC, has little irritation to the human skin, and can be used as lithographic ink for the high-speed printing, and paper and plastic printing of packaging and printing.

Owner:深圳市美丽华科技股份有限公司

Decorative sheet for three-dimensional work

ActiveUS20110045284A1Good molding effectGood die releaseDecorative surface effectsSynthetic resin layered productsCross-linkHeat deflection temperature

Provided is a decorative sheet for three-dimensional processing comprising a support and at least a surface protective layer laminated thereon, wherein the above decorative sheet for three-dimensional processing has a breaking elongation (according to JIS K 7127) exceeding 300% at temperature higher by 40° C. than a thermal deformation temperature of the above support measured by an ASTM D648 method, and the above surface protective layer is obtained by cross-linking and curing an ionizing radiation curable resin composition and has a film thickness of 0.2 to 6.0 μm.Capable of being provided is a decorative sheet for three-dimensional processing which is improved in a molding property and has good die release and does not produce cracks and scratches on a surface in molding and which is improved as well in an abrasion resistance and a solvent resistance.

Owner:DAI NIPPON PRINTING CO LTD

Environment-friendly type moldable aqueous transfer coating, preparation and use thereof

ActiveCN101407656AReduce contentReduce manufacturing costCoatings with pigmentsPolyurea/polyurethane coatingsSolvent basedPolyresin

The invention relates to an environment-friendly moldable waterborne transfer coating, a preparation method and an application thereof, wherein, the waterborne transfer coating takes the following components with the contents (parts by weight) as raw materials: 40 to 70 parts of waterborne resin; 10 to 20 parts of cosolvent; 18 to 40 parts of deionized water; 0.1 to 2 parts of pH value regulator; 0.1 to 0.5 part of wetting agent; 0.1 to 0.2 part of leveling agent; and 0.05 to 0.2 part of defoamer. Compared with the prior art, the environment-friendly moldable waterborne transfer coating has the following advantages of environmental protection and cost advantages, good printing adaptability, relatively wide range of suitable molding temperature during the molding, good molding effect and easy production control; furthermore, the environment-friendly moldable waterborne transfer coating can be directly used for replacing the existing solvent laser transfer coating by the pilot scale production confirmation.

Owner:SHANGHAI WEIKAI CHEM

Hard coat film

InactiveUS20050142362A1Increase resistanceEasy to wearInput/output for user-computer interactionSynthetic resin layered productsDisplay deviceSolvent

A hard coat film exhibits excellent scratch resistance and wear resistance, provides the property for preventing attachment of finger prints and the property for removal of finger prints by a simple operation, is excellent in retaining these properties, exhibits excellent solvent resistance and is advantageously used as the hard coat film for touch panels and the hard coat film for protecting various types of display. The hard coat film comprises a transparent substrate film and a hard coat layer disposed at least on one face of the substrate film, wherein the hard coat layer comprises a cured product of a resin composition sensitive to an ionizing radiation which comprises a polymerizable surfactant.

Owner:LINTEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com