Bicompenent high solid content aqueous polyurethane, its preparation method and application

A water-based polyurethane, high solid content technology, used in polyurea/polyurethane adhesives, adhesive types, textiles and papermaking, etc., can solve the problems of high product viscosity, difficult dispersion, poor hydrophilicity, etc. Less dosage, simple process, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

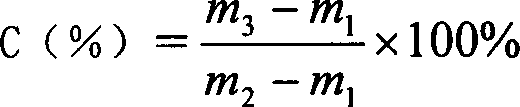

Method used

Image

Examples

Embodiment 1

[0066] raw material:

[0067] 1000.0g polyester diol (prepared by adipic acid, 1,4-butanediol, molecular weight 3000)

[0068] 32.9 Dimethylolpropionic acid (DMPA)

[0069] 24.8g triethylamine (TEA)

[0070] 65.7g hexamethylene diisocyanate (HDI)

[0071] 86.8g isophorone diisocyanate (IPDI)

[0072] 8.5g ethylenediamine (EDA)

[0073] 0.3g dibutyltin dilaurate

[0074] 400g acetone

[0075] 1210.0g deionized water

[0076] Preparation method: In a glass reactor equipped with an electric stirrer, a reflux condenser, and a thermocouple thermometer, add polyester diol and DMPA, and melt at 90-100°C. Then lower the temperature to about 70°C, add IPDI and HDI, dropwise add 0.3g of dibutyltin dilaurate catalyst, and in the presence of 400g of acetone, stir and react at 70°C for 5 hours to obtain a prepolymer. Cool the prepolymer to 50°C, add TEA to neutralize and form a salt. Disperse the prepolymer obtained after neutralization into a deionized medium under high-speed she...

Embodiment 2

[0078] raw material:

[0079] 1000.0g polyester diol (prepared by adipic acid, 1,4-butanediol, molecular weight 3000)

[0080] 45.0g 1,4-butanediol (BDO)

[0081] 37.9g dimethylolpropionic acid (DMPA)

[0082] 28.6g triethylamine (TEA)

[0083] 456.3.0g isophorone diisocyanate (IPDI)

[0084] 33.4g Ethylenediamine (EDA)

[0085] 0.3g dibutyltin dilaurate

[0086] 400.0g acetone

[0087] 1600.0g deionized water

[0088]In a glass reactor equipped with an electric stirrer, a reflux condenser, and a thermocouple thermometer, add polyester diol, BDO, and DMPA. After melting at 90-100°C, cool down to about 70°C and add IPDI, dropwise 0.3 g of dibutyltin dilaurate catalyst, in the presence of 400 g of acetone, stirred and reacted at 70° C. for 4 hours to obtain a prepolymer. After the temperature of the prepolymer is lowered to 50°C, TEA is added to neutralize and form a salt. Disperse the prepolymer obtained after neutralization into a deionized medium for emulsification...

Embodiment 3

[0090] raw material:

[0091] 1000.0g polyester diol (prepared by adipic acid, 1,4-butanediol, molecular weight 1000)

[0092] 42.1g dimethylolpropionic acid (DMPA)

[0093] 31.4g triethylamine (TEA)

[0094] 107.0g hexamethylene diisocyanate (HDI)

[0095] 329.9g isophorone diisocyanate (IPDI)

[0096] 34.0g ethylenediamine (EDA)

[0097] 0.3g dibutyltin dilaurate

[0098] 450.0g acetone

[0099] 1550.0g deionized water

[0100] Preparation method: See Example 1 to obtain a stable milky white water-based polyurethane dispersion with the following properties: solid content: 51.5%; pH: 6.9; viscosity: 475 mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com