Patents

Literature

1334 results about "Hexamethylene diisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexamethylene diisocyanate (HDI) is the organic compound with the formula (CH₂)₆(NCO)₂. It is classified as an diisocyanate. It is a colorless liquid.

Polyurethane foams with decreased aldehyde emissions, a process for preparing these foams and a method for decreasing aldehyde in polyurethane foams

This invention relates to polyurethane foams which exhibit decreased aldehyde emission, to a process of preparing these polyurethane foams, and to a method of decreasing aldehyde emissions in foams. The polyurethane foams herein additionally comprise a small quantity of a polyhydrazodicarbonamide dispersion polyol to the isocyanate-reactive component, or a trimerized hexamethylene diisocyanate to the polyisocyanate component.

Owner:COVESTRO LLC

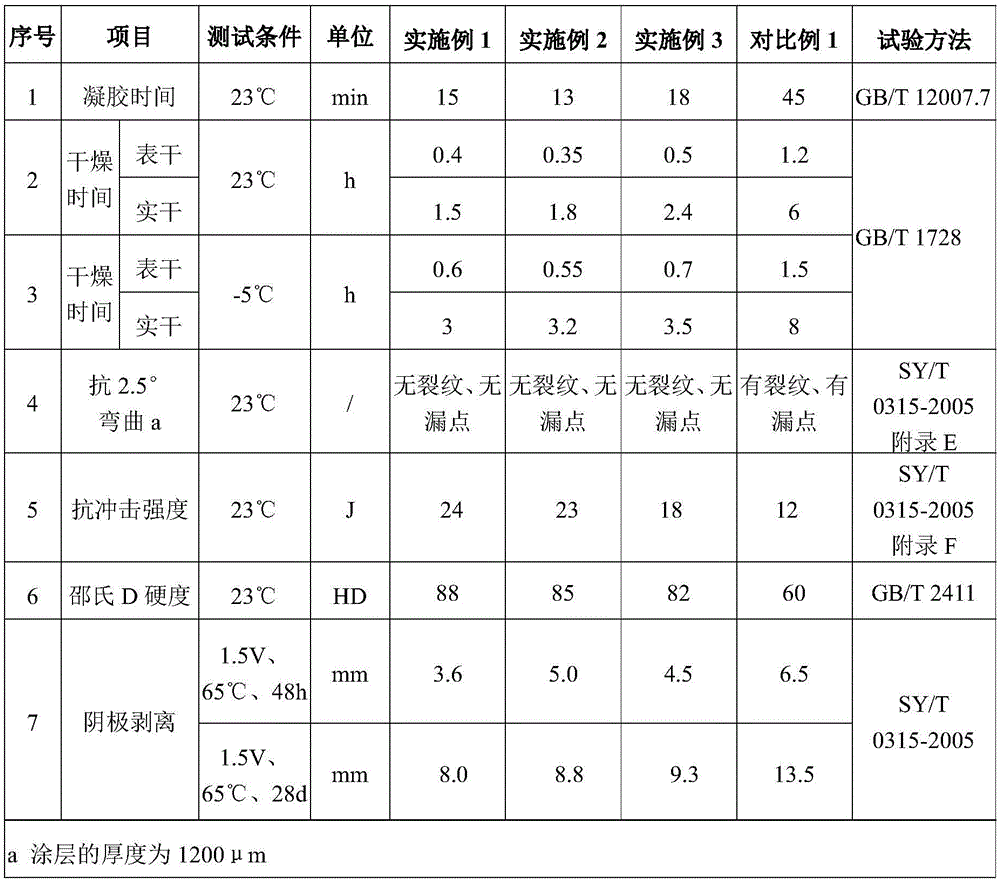

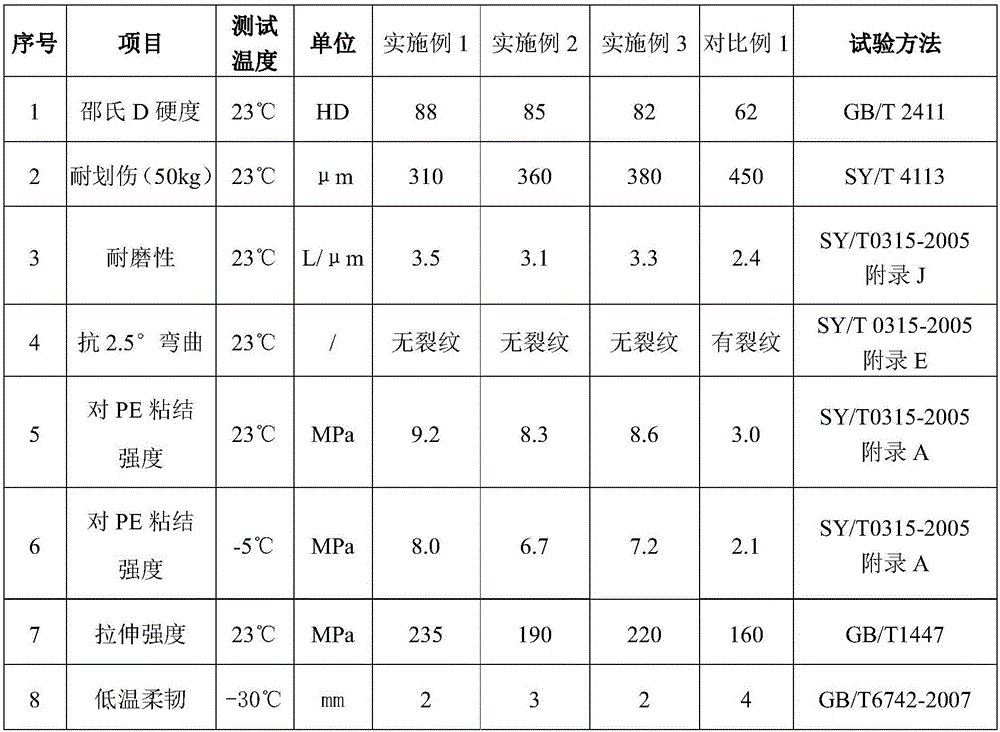

Solvent-free polyaspartate polyurea paint, and preparation method and application thereof

ActiveCN105670475AExcellent low temperature curingImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsLow temperature curingSolvent free

The invention provides a solvent-free polyaspartate polyurea paint, and a preparation method and application thereof. The solvent-free polyaspartate polyurea paint comprises a component A and a component B. The component A comprises the following ingredients in percentage by weight: 60-80% of hexamethylene diisocyanate and 20-40% of urethano modified HDI (hexamethylene diisocyanate) tripolymer. The component B comprises the following ingredients in percentage by weight: 60-70% of polyaspartate, 5-10% of pigment and filler, 10-20% of modified silicon micropowder, 1-3% of defoaming agent, 1-3% of leveling agent, 2-5% of adhesion promoter and 1-3% of coupling agent. The mass ratio of the component A to the component B is (3-5):1. The technical scheme provided by the invention greatly improves the low-temperature curing performance of the product and enhances the binding strength with the nonpolar material polyethylene; and the solvent-free polyaspartate polyurea paint has the advantages of high flexibility, high mechanical strength and high chemical corrosion resistance.

Owner:CYG CHANGTONG NEW MATERIAL

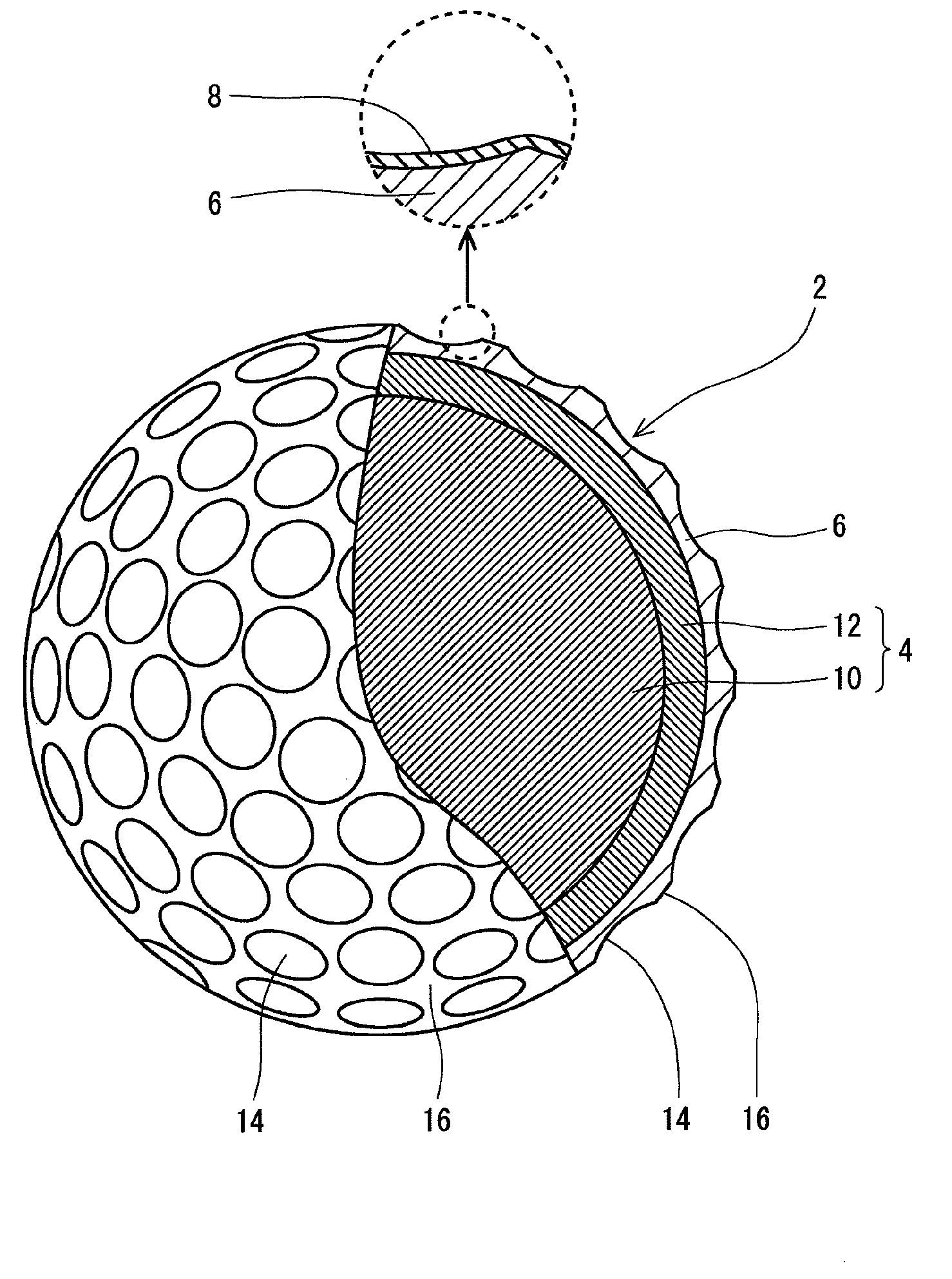

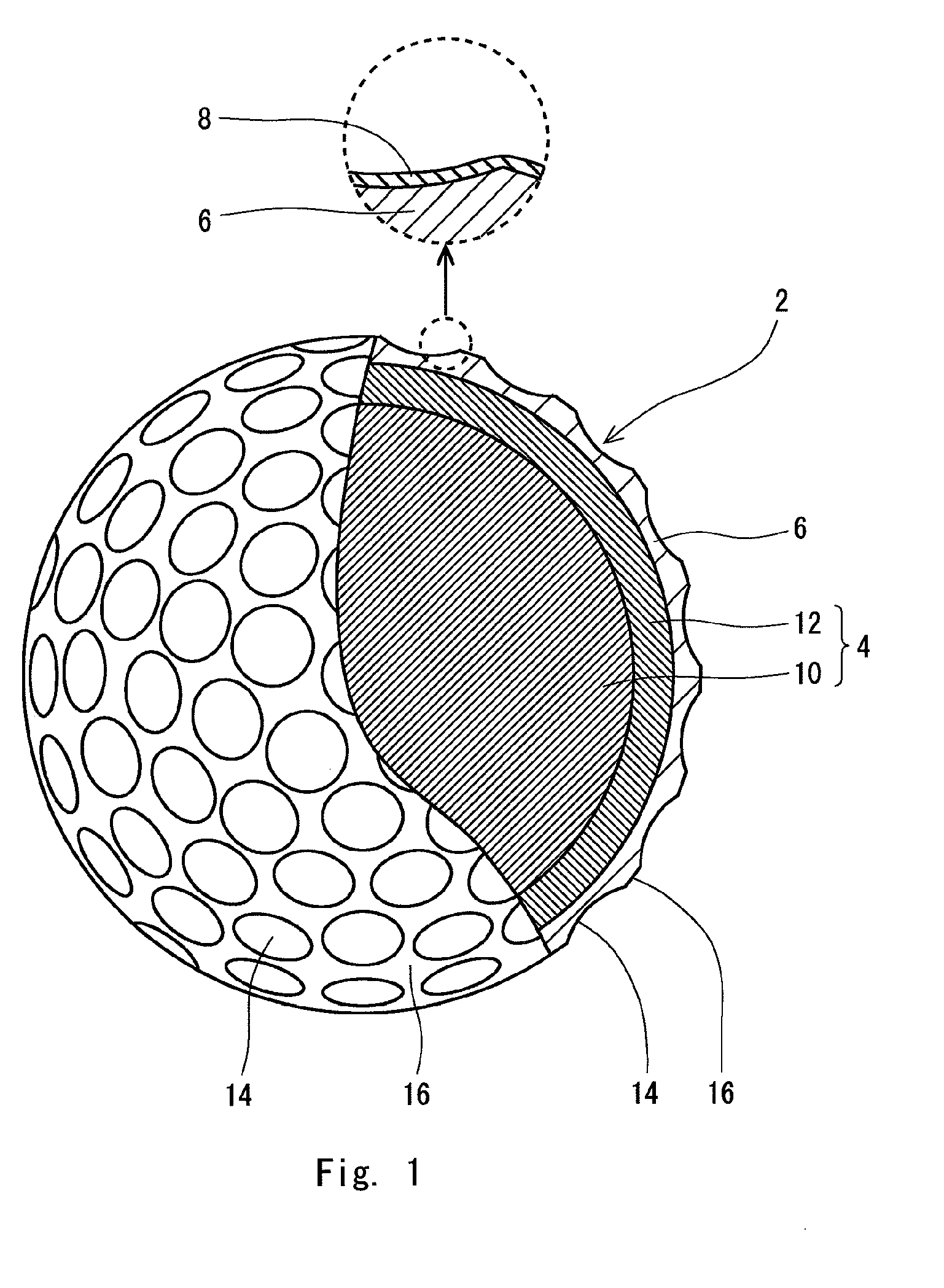

Golf ball

InactiveUS20110053708A1Prevent slippingFast rotationPolyurea/polyurethane coatingsGolf ballsPolyolEngineering

Golf ball 2 has spherical core 4, cover 6 situated on the external side of the core 4, and paint layer 8 situated on the external side of the cover 6. The cover 6 has a Shore D hardness of no greater than 61. The paint layer 8 has a Martens hardness of no greater than 2.0 mgf / μm2. The base polymer of the paint layer 8 is a polyurethane obtained by a reaction of a polyol with a polyisocyanate. The polyisocyanate contains a buret-modified form of hexamethylene diisocyanate. The cover 6 has a thickness of 0.3 mm or greater and 1.0 mm or less. The paint layer 8 has a thickness of 5 μm or greater and 40 μm or less.

Owner:DUNLOP SPORTS CO LTD

Preparation method of photo-moisture dual cured hot melt polyurethane sealant

InactiveCN105255435AImprove the shortcomings of low initial strengthRapid positioningNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to a preparation method of a photo-moisture dual cured hot melt polyurethane sealant. The preparation method comprises following steps: firstly, an HDI (hexamethylene diisocyanate) trimer reacts with a hydroxyl acrylate monomer, after the reaction, polyether polyol is added for continuous reaction, and a prepolymer A is obtained; bifunctional isocyanate reacts with crystalline polyester polyol and non-crystalline polyester polyol, and a prepolymer B is obtained; the prepolymer A and the prepolymer B are mixed in a certain ratio, then a photoinitiator, a catalyst, a coupling agent and the like are added, and the photo-moisture dual cured hot melt polyurethane sealant is obtained. The preparation method improves the defects of failure in rapid positioning of UV glue, low initial strength of the hot melt polyurethane sealant and the like, rapid positioning can be realized, the hot melt polyurethane sealant can achieve higher strength in a short time, and the hot melt polyurethane sealant can be used for bonding of appliances, furniture, electronic components and the like.

Owner:YANTAI DARBOND TECH

Room temperature super-fast curing double-component solvent-free polyurethane structural adhesive and preparation method and use method thereof

The invention discloses a room temperature super-fast curing double-component solvent-free polyurethane structural adhesive including A and B components; the A component comprises the following components in parts by weight: 50-90 parts of polyols, 0-50 parts of a chain extender, 0.5-15 parts of a catalyst, 0-30 parts of a filler and 5-10 parts of a stabilizer; the B component includes the following two parts: 50-100 parts of polyaryl polymethylene isocyanate and 0-50 parts of hexamethylene diisocyanate. The structural adhesive prepared by the method can be rapidly cured at room temperature.

Owner:WENZHOU INST OF BIOMATERIALS & ENG

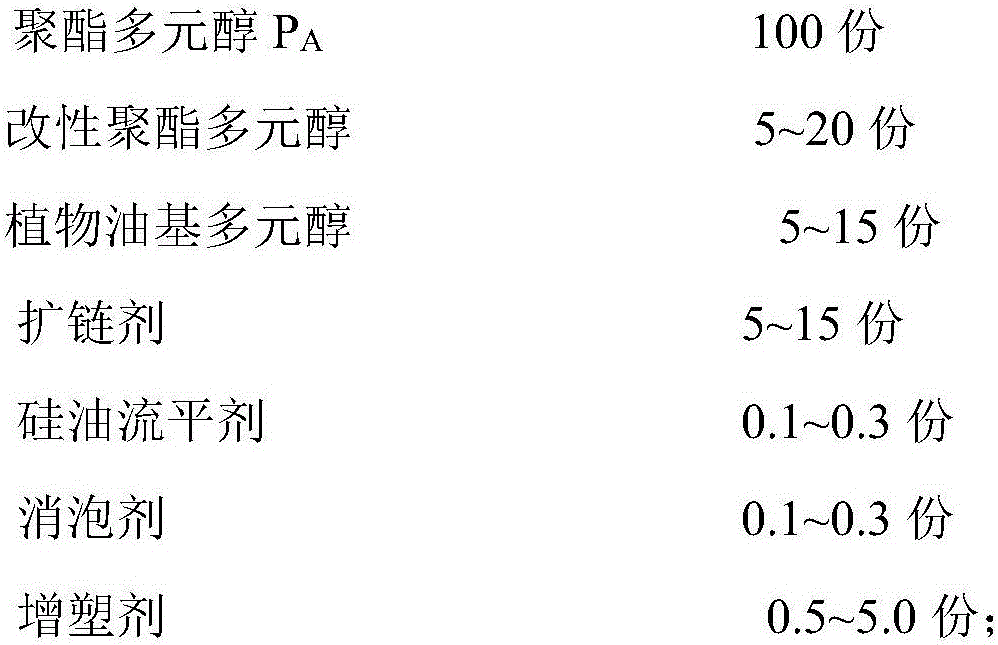

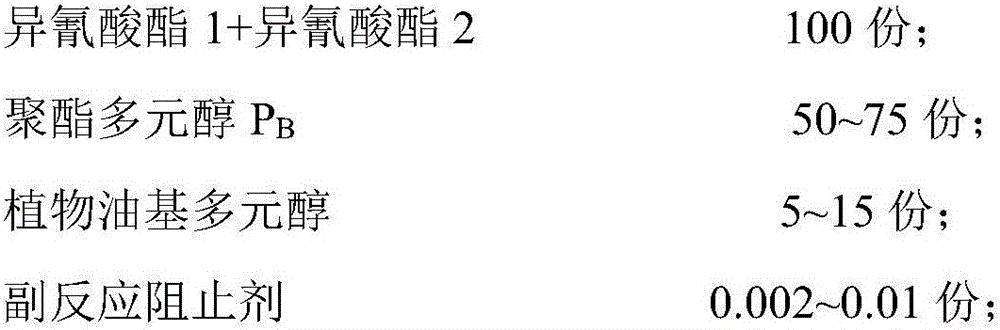

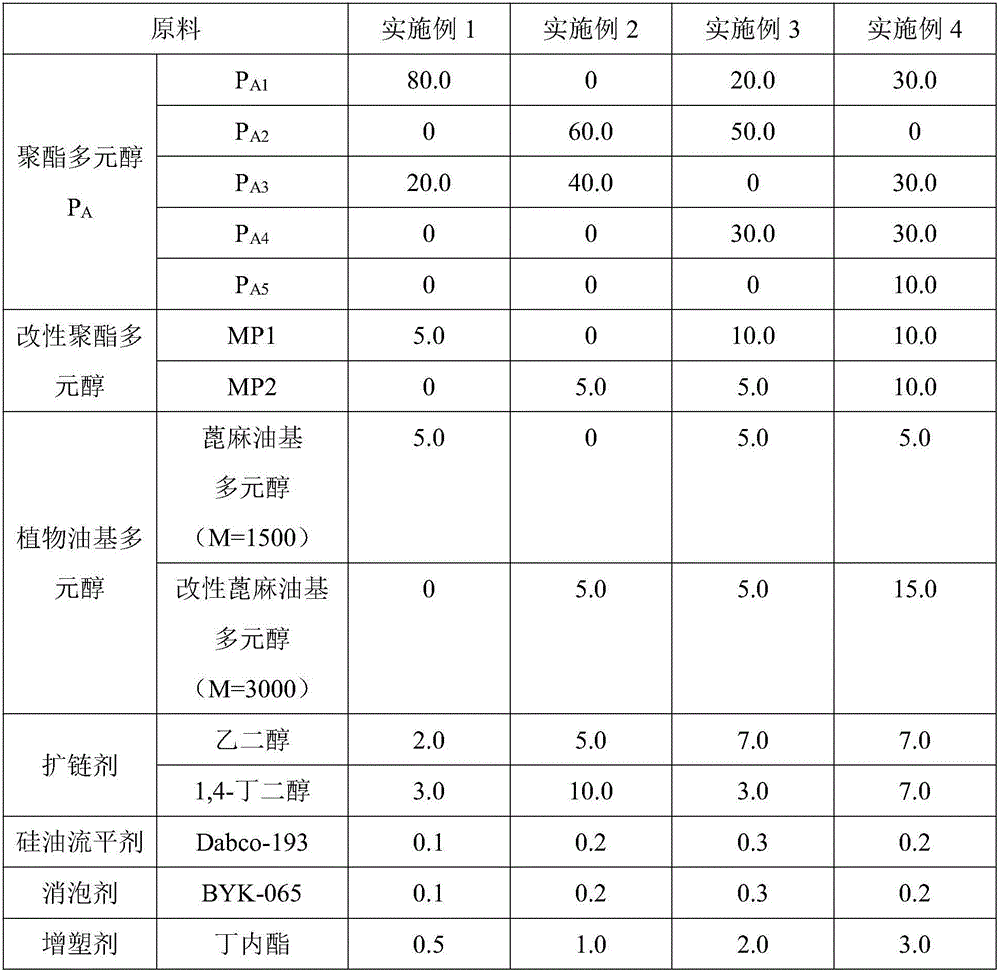

Environment-friendly polyurethane adhesive, and preparation method and applications thereof

ActiveCN106634778AOrderly rowsGood physical propertiesPolyureas/polyurethane adhesivesPolyurethane adhesiveOperability

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Preparation method of scratch-resistant polyurethane matt black finish for woodware

ActiveCN103013325AEliminate Bubble ProblemsNo surface foggingPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a preparation method of a scratch-resistant polyurethane matt black finish for woodware. The scratch-resistant polyurethane matt black finish comprises a resin paint component A and a curing agent component B in the weight ratio of 1: 0.5, wherein the resin paint component A comprises alkyd resin, extinction powder, a dispersing agent, carbon black paste, a modifying flatting agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B comprises a TDI-HDI (Toluene Diisocynate-Hexamethylene Diisocyanate) mixed tripolymer or a TDI / TMP (Trimethylolpropane) affixture, an HDI tripolymer and a solvent. The scratch-resistant double-component polyurethane matt black finish for woodware, prepared by the preparation method provided by the invention, brings no precipitate during being stored, is high in solidity, low in viscosity and excellent in leveling property; and the filming can be realized at one time, and the film is thick, free from sagging, and soft, full, fine, smooth, slippery in hand feel, shows alternate kindness with severity, is given the effect of full decoration like a mirror plane, brings a graceful and comfortable feel, and is adapted to modern aesthetic view and widely popular with the market and customers. The scratch-resistant polyurethane matt black finish is widely applied to protective decoration of surfaces of products such as the woodware, metals and plastics.

Owner:UNION FOSHAN CHEM +1

Yellowing-resistant quick-drying polyurethane wood paint and using method thereof

ActiveCN101619194AGood weather resistanceGood yellowing resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsAcrylic resinDiluent

The invention provides a yellow-resistant quick-drying polyurethane wood paint and a using method thereof. The polyurethane wood paint is prepared by mixing a main paint, a curing agent and a diluent, wherein the main paint comprises 30 to 45 weight percent of hydroxylated acrylic resin; and the curing agent comprises 40 to 50 weight percent of hexamethylene diisocyanate prepolymer. The paint film of the yellow-resistant quick-drying polyurethane wood paint provided by the invention has excellent yellowing resistance; and the yellowing resistance delta E is less than 0.5 when the polyurethane wood paint is radiated by UVA for 168 hours or naturally stored indoors for three years; and the paint film overcomes the defect that the hexamethylene diisocyanate prepolymer and the hydroxylated acrylic resin reacts slowly, and the surface dry time and the pressure dry time of the paint film are respectively 0.5 hour and 1.5 hours (at a temperature of 25 DEG C and a humidity of 50 percent).

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

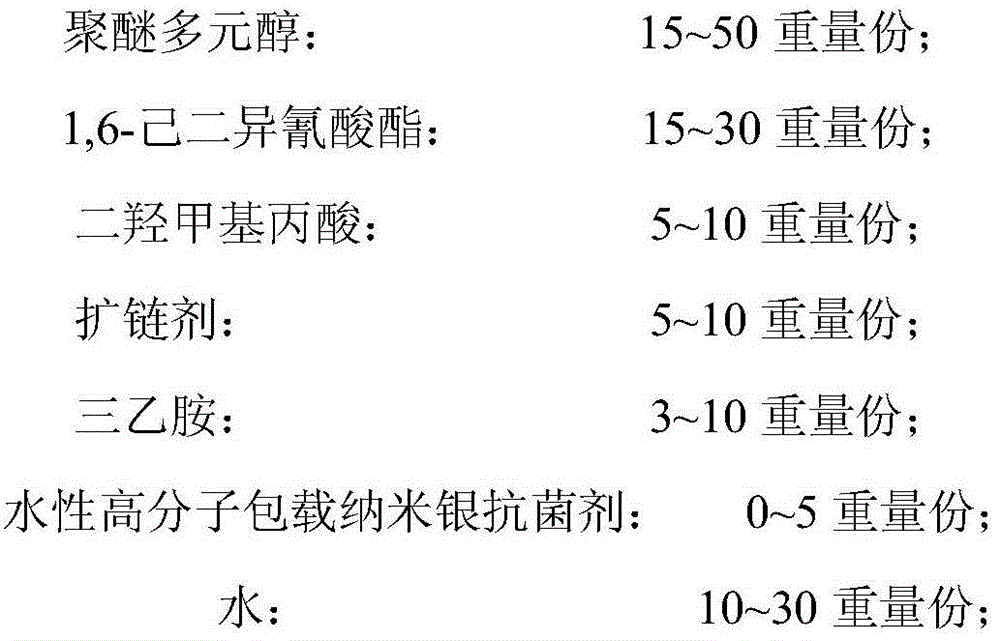

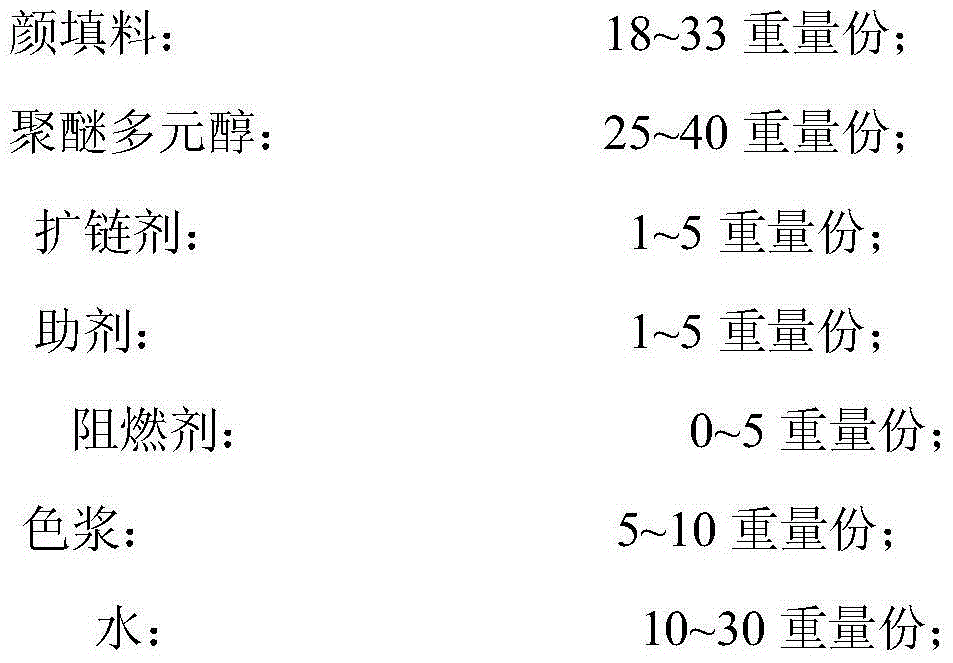

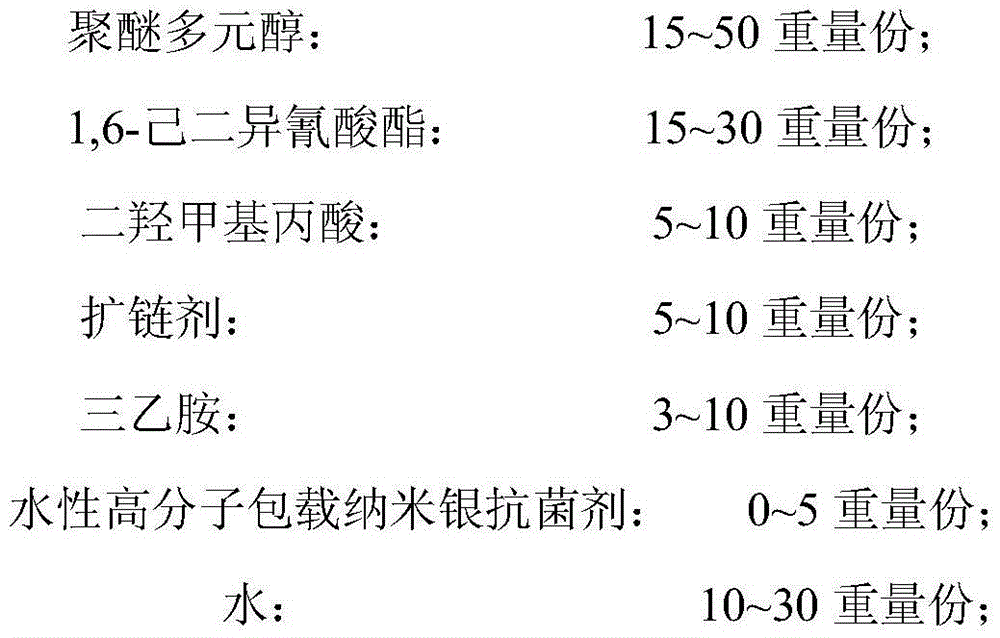

Efficient antibacterial waterborne polyurethane floor coating and preparation method thereof

The invention discloses an efficient antibacterial waterborne polyurethane floor coating and a preparation method thereof. The method comprises the following steps: firstly, reacting 1,6-hexamethylene diisocyanate (HDI) with polyether polyol, DMPA, a chain extender and the like to obtain a polyurethane prepolymer; then adding triethylamine for neutralization; adding an appropriate amount of auxiliaries and a waterborne antibacterial agent, and emulsifying at high speed to obtain the waterborne polyurethane floor coating. The waterborne polyurethane floor coating has excellent weather resistance, wear resistance and anti-microbial-adsorption performance. The waterborne polyurethane floor coating not only keeps good adhesive force to the floor, good water resistance and good chemicals resisting performance, but also has good antibacterial performance.

Owner:上海维度化工科技有限公司

Optical resin composition having excellent impact resistance and method for fabricating optical lens using the same

Disclosed herein are an optical resin composition with superior impact resistance and a method for producing an optical lens from the composition. More specifically, the optical resin composition for a plastic optical lens has superior impact resistance as well as light-weight, superior moldability, excellent dyeing ability, a high Abbe number and good transparency. The optical lens produced from the composition exhibits superior impact resistance even after multi- coating. The optical resin composition with superior impact resistance has a solid refractive index (nD) of 1.53 to 1.57, an Abbe number of 35 to 48, a liquid specific gravity of 0.97 to 1.25 and a solid specific gravity of 1.10 to 1.35, by which the composition comprises a mixture of isophorone diisocyanate and hexamethylene diisocyanate, pentaerythritol tetrakis(3-mercaptopropionate), a UV absorber, a release agent and a polymerization initiator. The optical lens is produced by thermally curing the composition.

Owner:KOC SOLUTION

UV-hardenable dispersions based on polyisocyanates

ActiveUS20080194775A1Good re-emulsifiabilityImprove responsePolyurea/polyurethane coatingsHydroxylamineMeth-

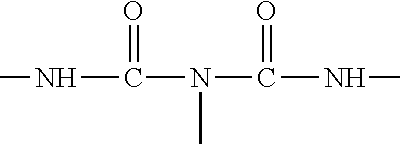

Aqueous UV-hardenable dispersions are provided, as well as their use for the production of coating agents, in particular coatings for ligneous substrates. The dispersions comprise the reaction product of a) one or more polyisocyanates of which at least one polyisocyanate is an oligomeric polyisocyanate of hexamethylene diisocyanate with urethane, biuret, iminooxadiazindione and / or isocyanurate structural units, b) one or more monohydroxy-functional compounds containing (meth)acryloyl groups, c) at least one component c1), which has a hydrophilising effect on the basis of incorporated (potentially) ionic groups and comprises at least one further isocyanate-reactive group and / or at least one component c2) which contains non-ionically hydrophilically acting groups and comprises at least one further isocyanate-reactive group, d) one or more difunctional and / or polyfunctional amines or hydroxyamines as chain extender, and e) optionally other monomeric, oligomeric and / or polymeric substances, which may optionally also contain further unsaturated groups.

Owner:COVESTRO DEUTSCHLAND AG

Luminant white paint and preparation method thereof

ActiveCN102533070AHigh hiding powerGood filling effectPolyester coatingsKetone solventsToluene diisocyanate

The invention discloses a luminant white paint. The luminant white paint is obtained by mixing a main paint, a curing agent and a diluent according to a mass ratio, wherein the main paint comprises the following components in parts by weight: 35-40 parts of alkyd resin, 3-5 parts of dispersing agent, 30-40 parts of titanium white powder, 10-20 parts of extender pigment, 0.2-0.5 parts of anti-setting agent, 0.2-0.4 parts of leveling agent, 0.2-0.5 parts of antifoaming agent, 0.5-1.0 parts of anti-yellowing agent and 20-25 parts of main paint solvent; the curing agent comprises the following components in parts by weight: 10-20 parts of curing agent solvent, 0.1-0.2 parts of dehydrating agent, 60-70 parts of HDI (Hexamethylene Diisocyanate) type curing agent and 30-40 parts of TDI (Toluene Diisocyanate) type curing agent; and the diluent comprises the following components in parts by weight: 60-70 parts of ester solvent and 30-40 parts of ketone solvent. The luminant white paint disclosed by the invention has the advantages of rapidness for leveling after being sprayed, full paint film, rockiness and scratch resistance. Meanwhile, the invention also discloses a preparation method of the luminant white paint.

Owner:NIPPON PAINT GUANGZHOU

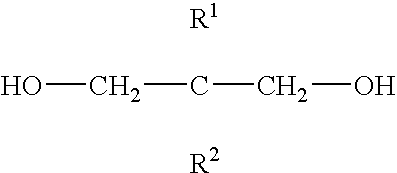

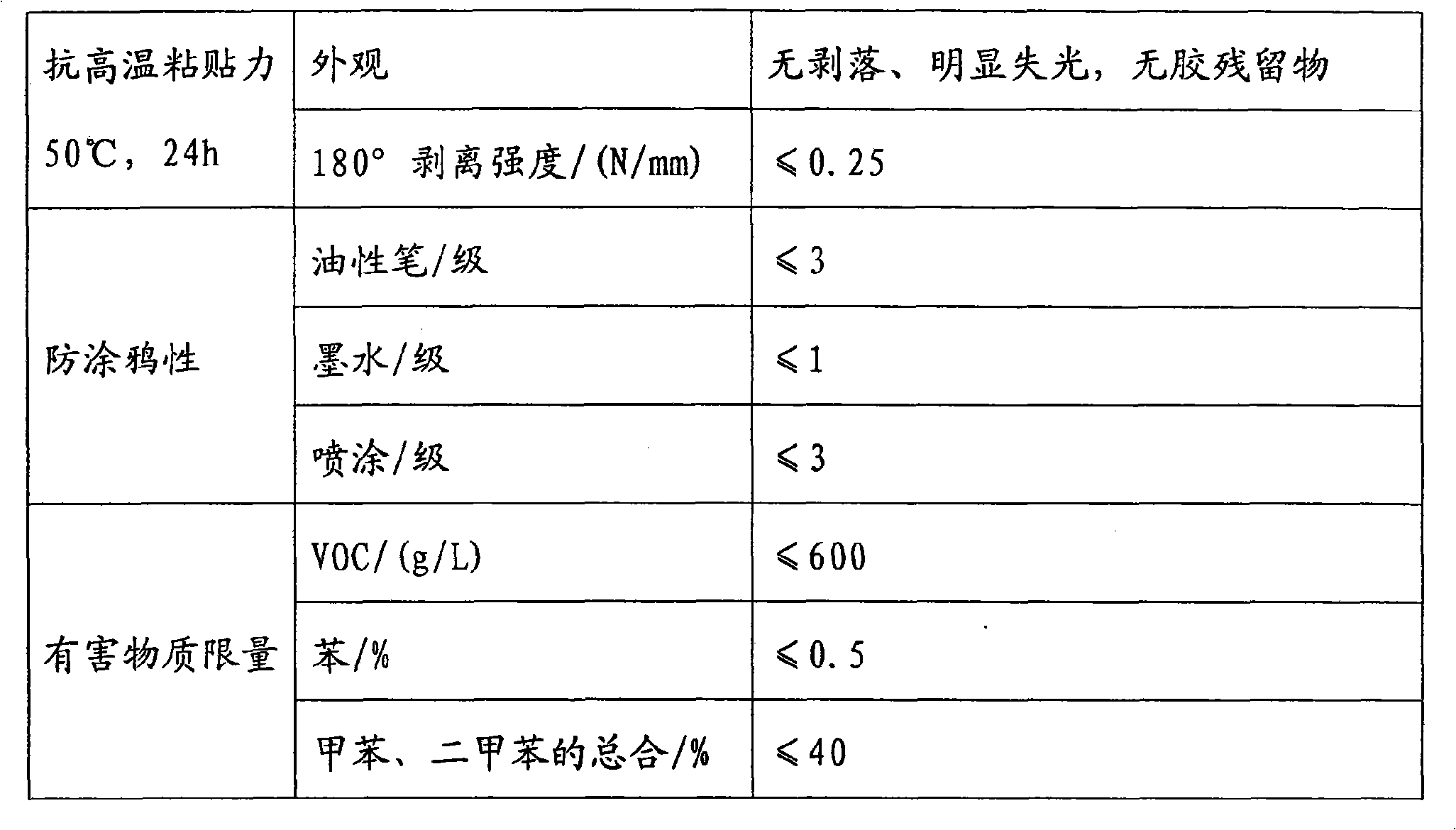

Coating compositions having improved early hardness

InactiveUS20070190257A1Improve efficiencyHigh glossPolyurea/polyurethane coatingsSpecial surfacesIsophorone diisocyanateAcrylic polymer

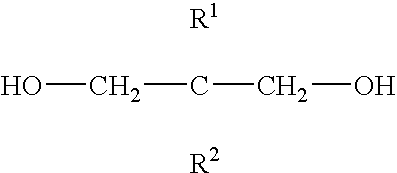

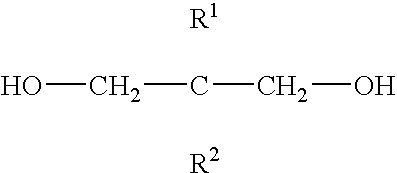

A fast hardening clear coating composition for repairing a clear coat / color coat finish or a pigmented mono-coat of a vehicle comprising a film forming binder and an organic liquid carrier, where the binder contains a hydroxyl polymer component comprising (A) hydroxyl-containing acrylic polymer, (B) at least one hydroxyl-terminated component selected from the group consisting of (1) an organic diol having the formulawhere R1 and R2 are individually selected from the group of hydrogen and an alkyl group having 1, 3-5 carbon atoms and (2) a hydroxyl terminated reaction product of trimethylol propane and a lactone; (C) an organic polyisocyanate crosslinking component, at least portion of which comprises a trimer of isophorone diisocyanate or hexamethylene diisocyanate and the composition further contains, a curing catalyst, of a dialkyl tin aliphatic carboxylate, a tertiary aliphatic mono or diamine, an aliphatic carboxylic acid, and optionally, a zinc or calcium organic acid salt in an effective amount such that the coating composition on curing at ambient temperatures is in a water spot free and sufficiently hard state for sanding or buffing within about 2 hours after application or on cool down when baked under normal conditions.

Owner:AXALTA COATING SYST IP CO LLC

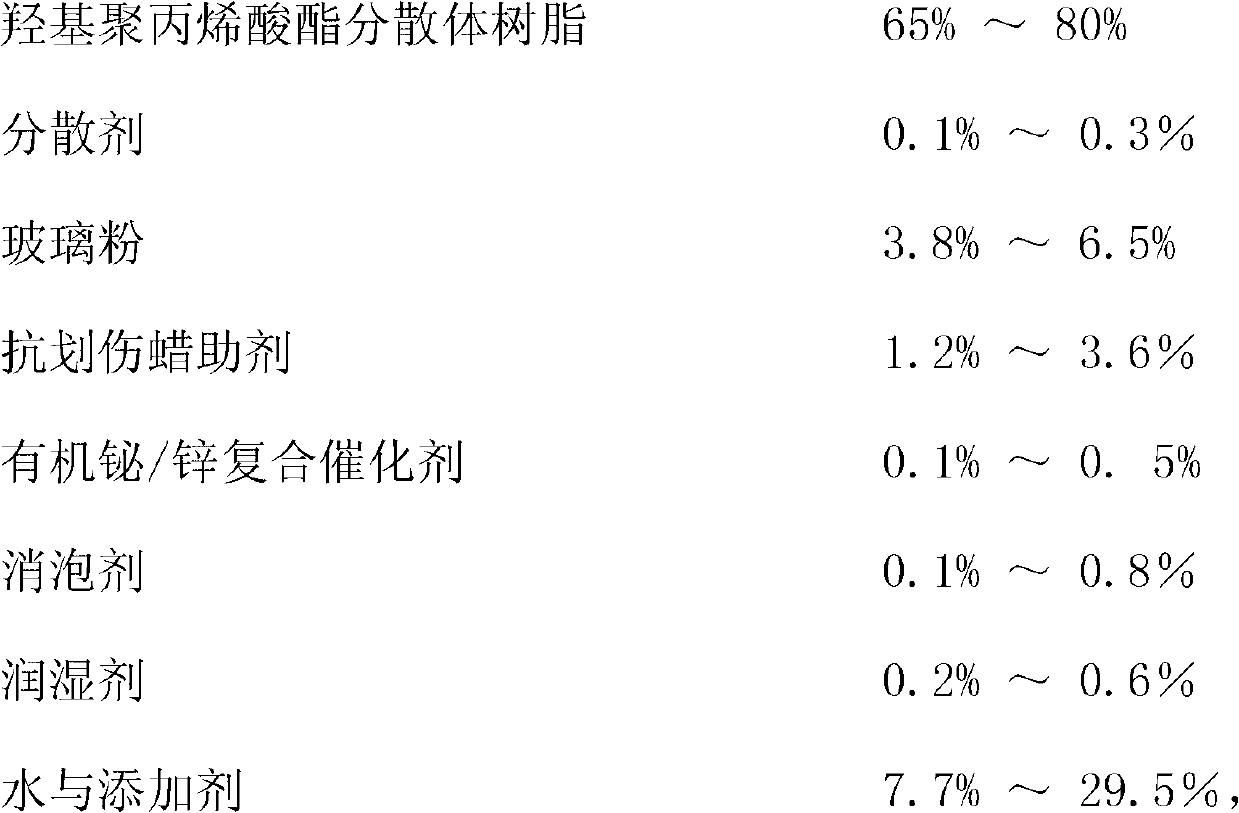

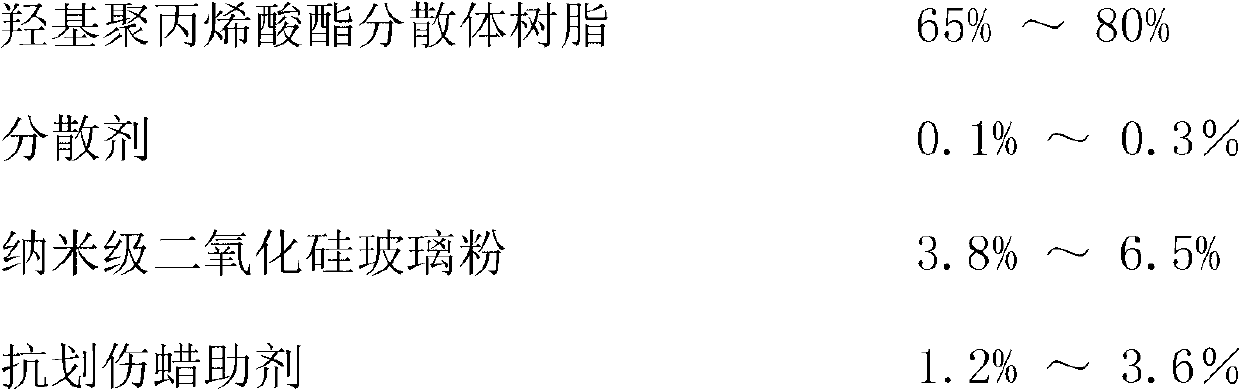

High-hardness scratch-resistant double-component waterborne polyurethane woodwork varnish and preparation method thereof

InactiveCN102898937AImprove scratch resistanceShorten the timeAnti-corrosive paintsPolyurea/polyurethane coatingsOperabilityDrying time

The invention discloses high-hardness scratch-resistant double-component waterborne polyurethane woodwork varnish and a preparation method thereof. The varnish consists of double components, i.e., a primer and a curing agent, wherein the primer consists of hydroxyl polyacrylate dispersion resin, dispersant, nano-scale silicon dioxide glass powder, a scratch-resistant wax auxiliary agent, an organic bismuth / zinc composite catalyst, an antifoaming agent, a wetting agent, water and an additive, wherein the sum of the weight percentages of the A components is 100 percent; the curing agent consists of propylene glycol ethyl ether acetate and allophanate modified HDI (Hexamethylene Diisocyanate) tripolymer; the sum of the weight percentages of the B components is 100 percent; and the A components and the B components are mixed according to the equivalent molar ratio of n-NCO:n-OH as 1.38:1.62. The varnish has the advantages of high hardness, shortened surface drying time and hard drying time, long activation period, superior performance, environmental friendliness of the product and high operability.

Owner:中山蓝海洋水性涂料有限公司

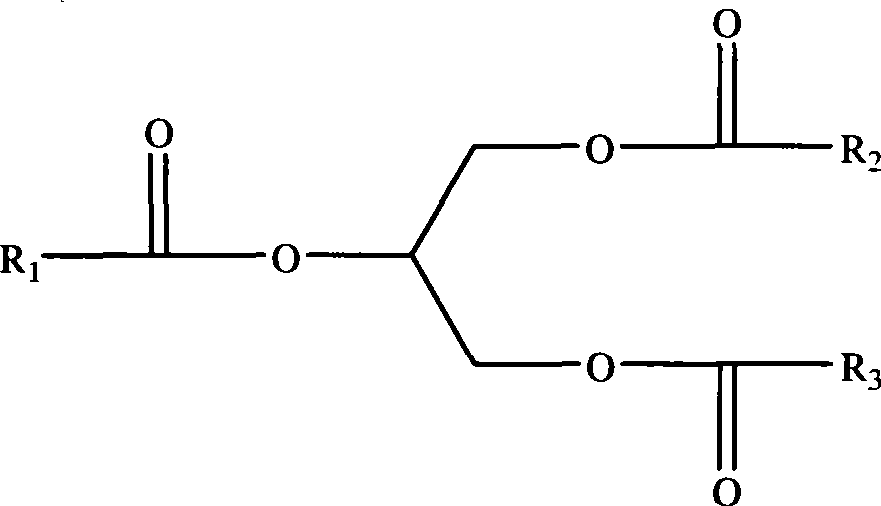

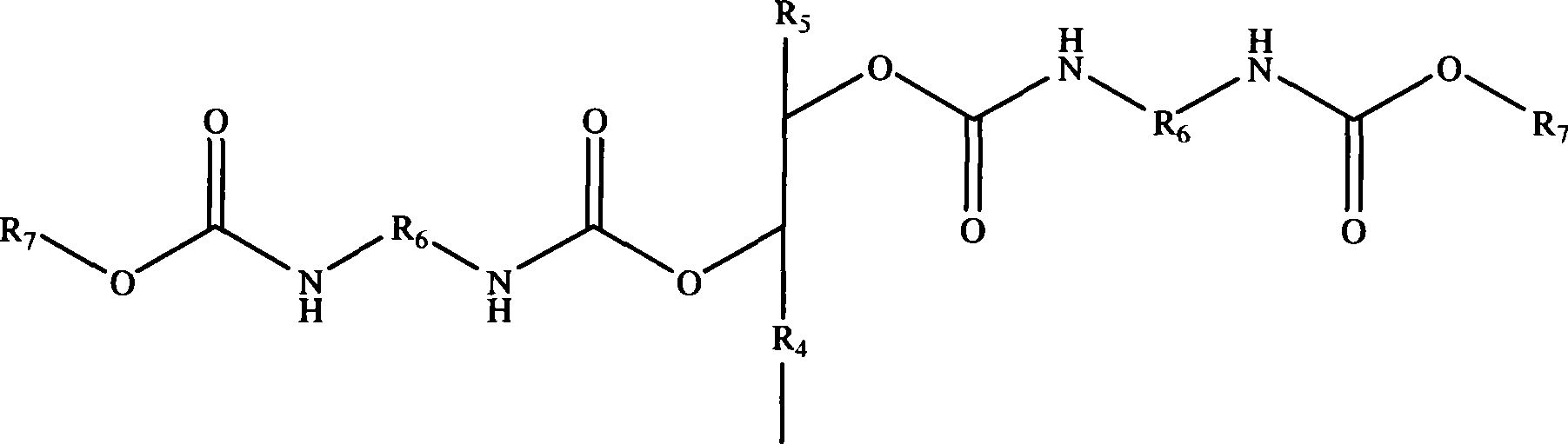

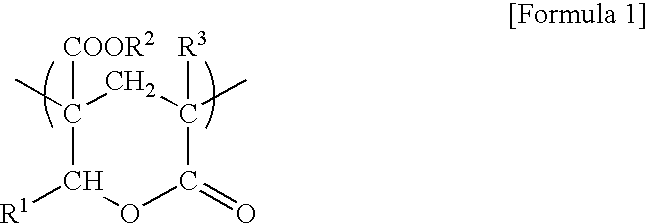

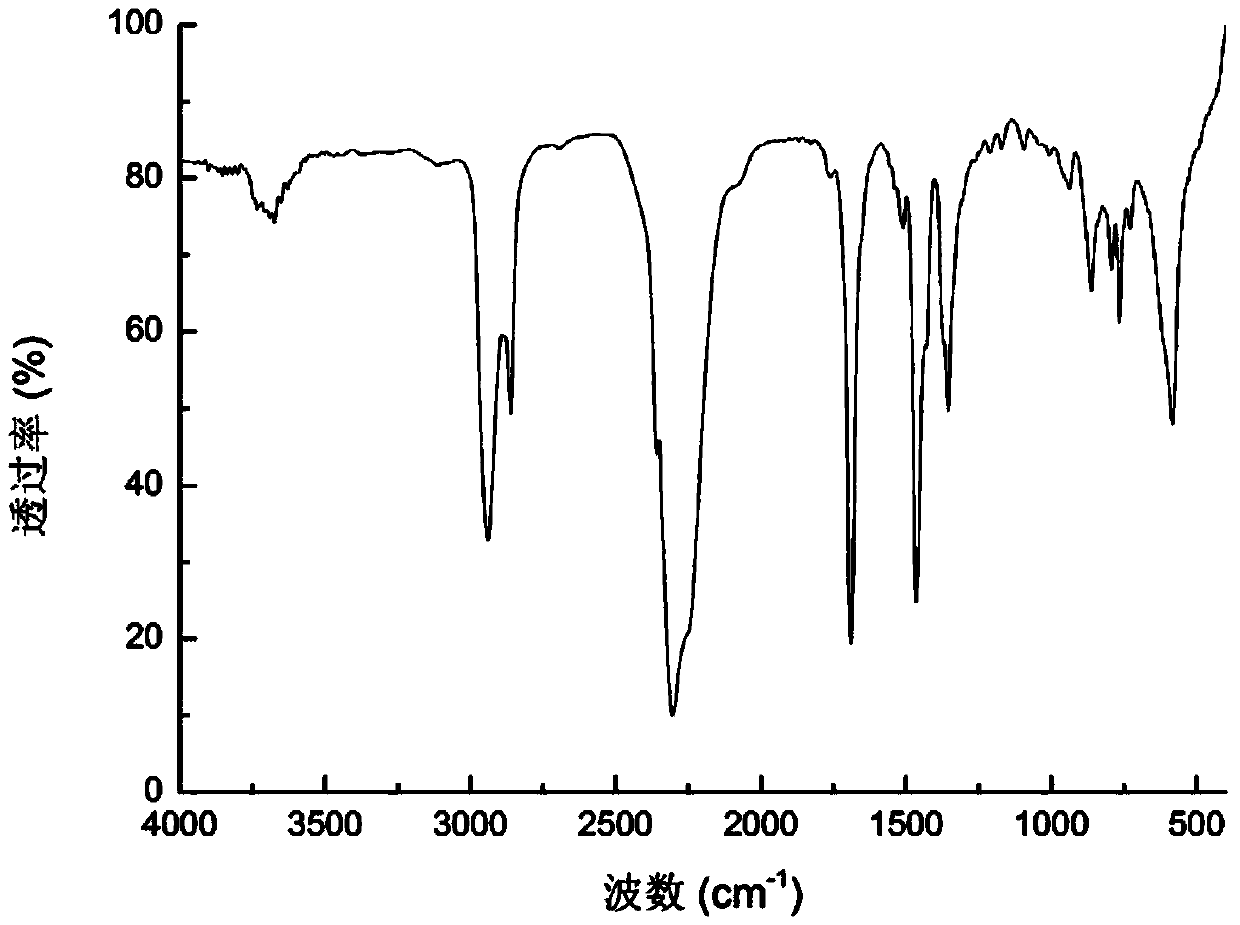

Vegetable oil based polyurethane acrylic ester, preparing process and use thereof

InactiveCN101497684AWide variety of sourcesEasy to makePolyurea/polyurethane coatingsSurface treatment compositionsAlkaneVegetable oil

The invention relates to vegetable oil based polyurethane acrylic ester, belonging to the field of photosensitive polymer material. The vegetable oil based polyurethane acrylic ester is characterized in that the general chemical formula is Formula I, wherein R1, R2 and R3 are respectively chosen from alkane of C1-C18, at least one of the alkane is chosen from Formula II, R4 and R5 are respectively chosen from alkane of C1-C16, R6 is diphenyl methane-4,4'-diisocyanate, or hexamethylene diisocyanate, or isophorone diisocyanate or residue of 2,4-toluene diisocyanate with two isocyanate functional group removed, and R7 is 2-hydroxyethyl acrylate, or hydroxypropyl acrylate, or residue of pentaerythritol triacrylate with hydroxy functional group removed.

Owner:天津市天骄辐射固化材料有限公司

Preparation method for perylene bisimide polyurethane liquid crystal non-covalent modified graphene

ActiveCN104059395AWide variety of sourcesLow pricePigment treatment with macromolecular organic compoundsPerylenemonoimidePtru catalyst

The invention discloses a preparation method for perylene bisimide polyurethane liquid crystal non-covalent modified graphene. The preparation method comprises the following steps: adding perylene and zinc acetate into N-methyl pyrrolidone, stirring and heating to 150-160 DEG C, adding diglycolamine, reacting for 12 hours, pouring into absolute ethyl alcohol for precipitating and discharging, filtering, and drying in vacuum to obtain hydroxyl-terminated perylene bisimide; taking and dissolving the hydroxyl-terminated perylene bisimide into N, N-dimethyl formamide, adding hexamethylene diisocyanate and a catalyst, heating to 60-65 DEG C and reacting for 6 hours under protection of N2, adding polyethylene glycol, heating to 90-95 DEG C and reacting for 8 hours, pouring reaction liquid into distilled water for precipitating and discharging, filtering, and drying in vacuum to obtain perylene bisimide polyurethane liquid crystals; and taking and dissolving the perylene bisimide polyurethane liquid crystals into chloroform, adding graphene, ultrasonically treating for 2-3 hours, carrying out suction filtration, washing by chloroform, and drying in vacuum to obtain the perylene bisimide polyurethane liquid crystal non-covalent modified graphene. The method disclosed by the invention has the advantages of being wide in material source, simple in process, low in price, small in pollution and the like.

Owner:绍兴盖诺超菱润滑材料有限公司

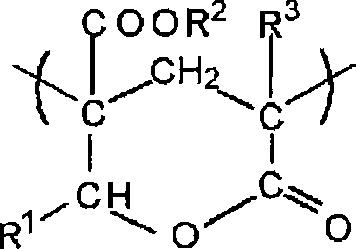

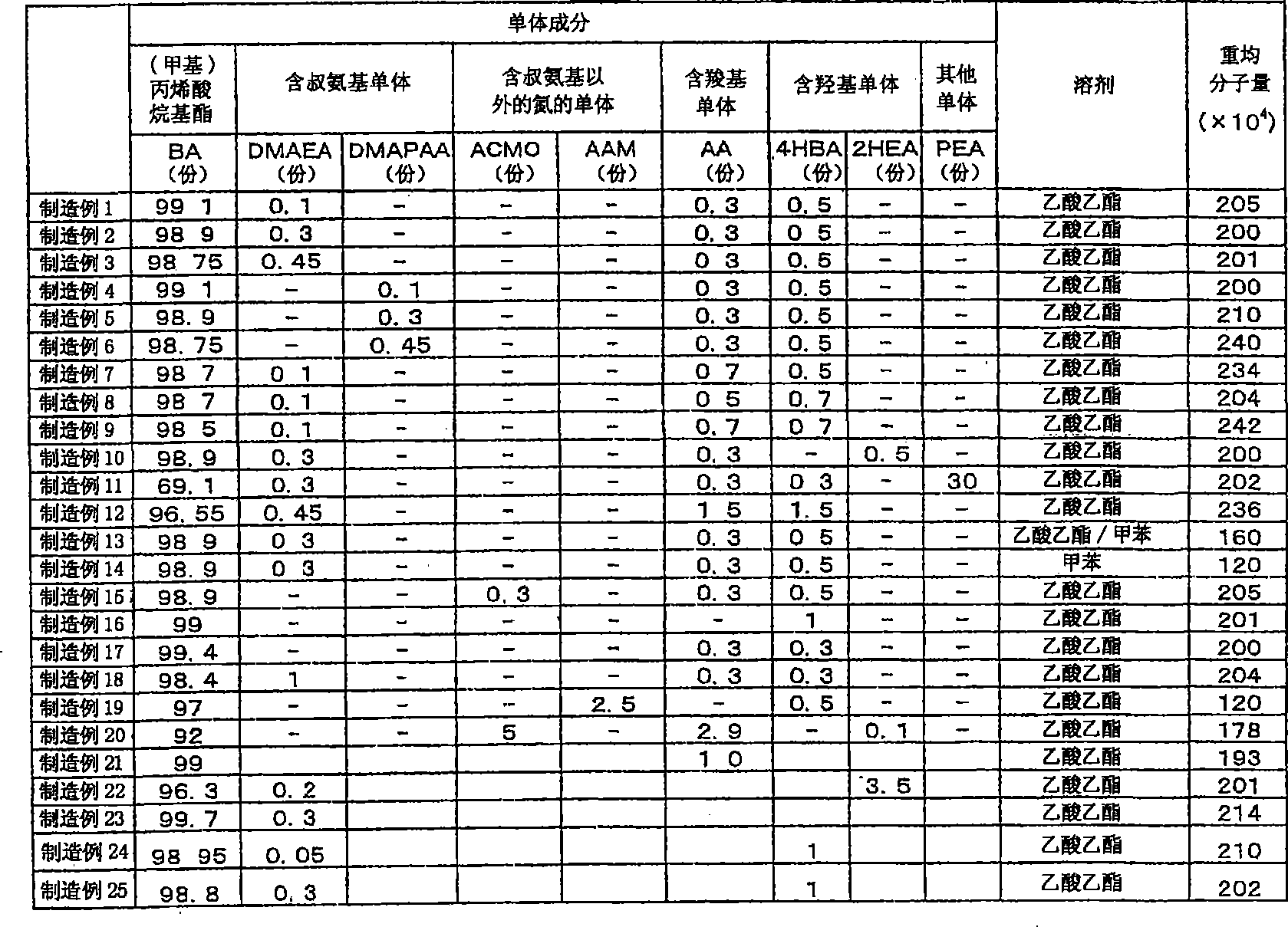

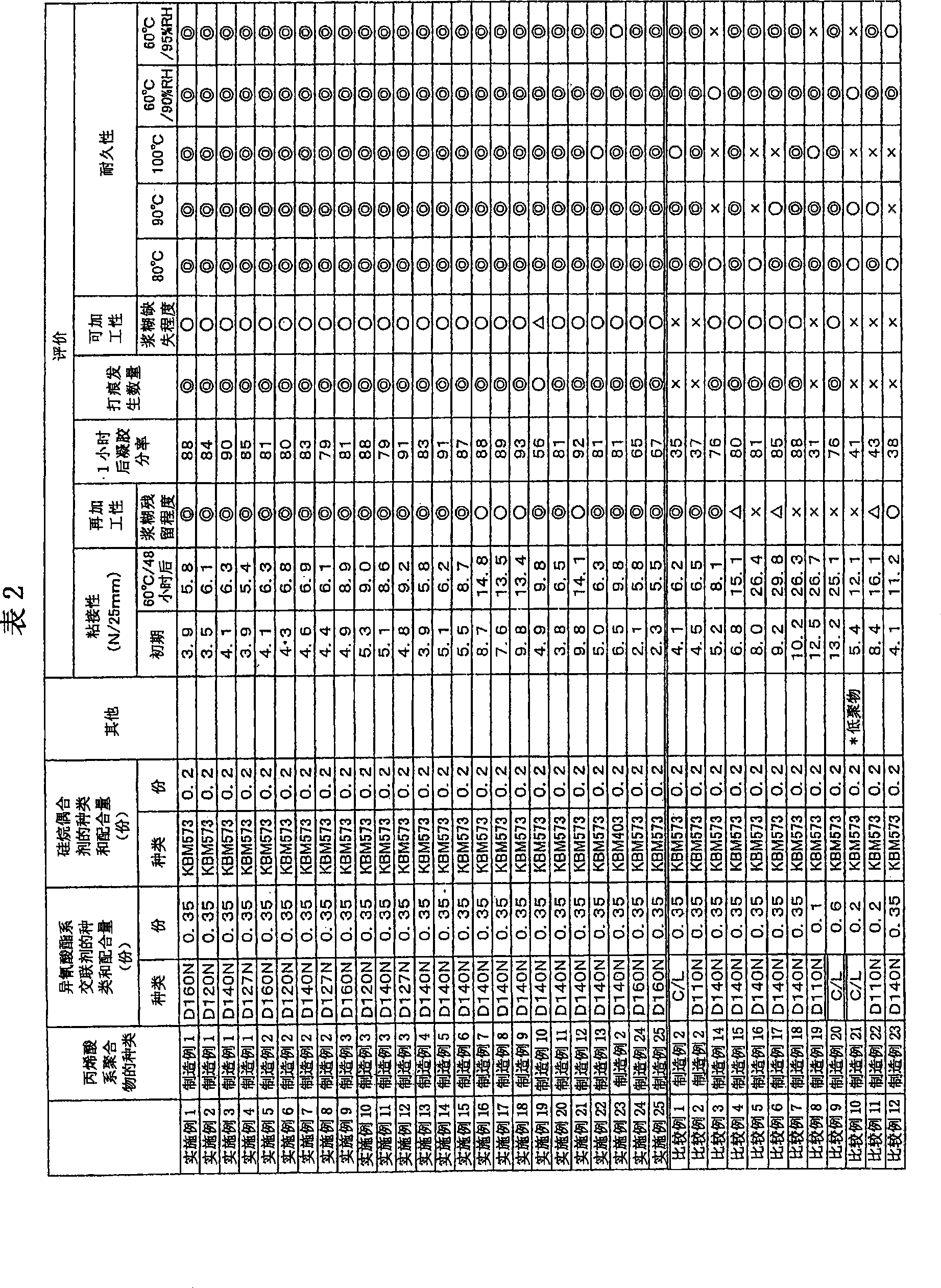

Pressure-sensitive adhesive composition for optical films, pressure-sensitive adhesive optical film and image display

InactiveUS20090162577A1Easy to processExcellent reworkabilityMonocarboxylic acid ester polymer adhesivesLiquid crystal compositionsXylyleneMeth-

There is provided an optical film pressure-sensitive adhesive composition capable of forming a pressure-sensitive adhesive layer that has reworkability such that optical films therewith can be easily separated from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be processed without causing adhesive stain or dropout after it is formed on an optical film. The optical film pressure-sensitive adhesive composition includes 100 parts by weight of a (meth)acrylic polymer including, as monomer units, (a) 50 to 99.79% by weight of an alkyl (meth)acrylate monomer, (b) 0.01 to 0.45% by weight of a tertiary amino group-containing monomer, and (c) 0.1 to 3% by weight of a hydroxyl group-containing monomer; and 0.01 to 2 parts by weight of a crosslinking agent that is at least one selected from the group consisting of hexamethylene diisocyanate, hydrogenated xylylene diisocyanate, and isophorone diisocyanate, or a polyisocyanate compound derived therefrom.

Owner:NITTO DENKO CORP

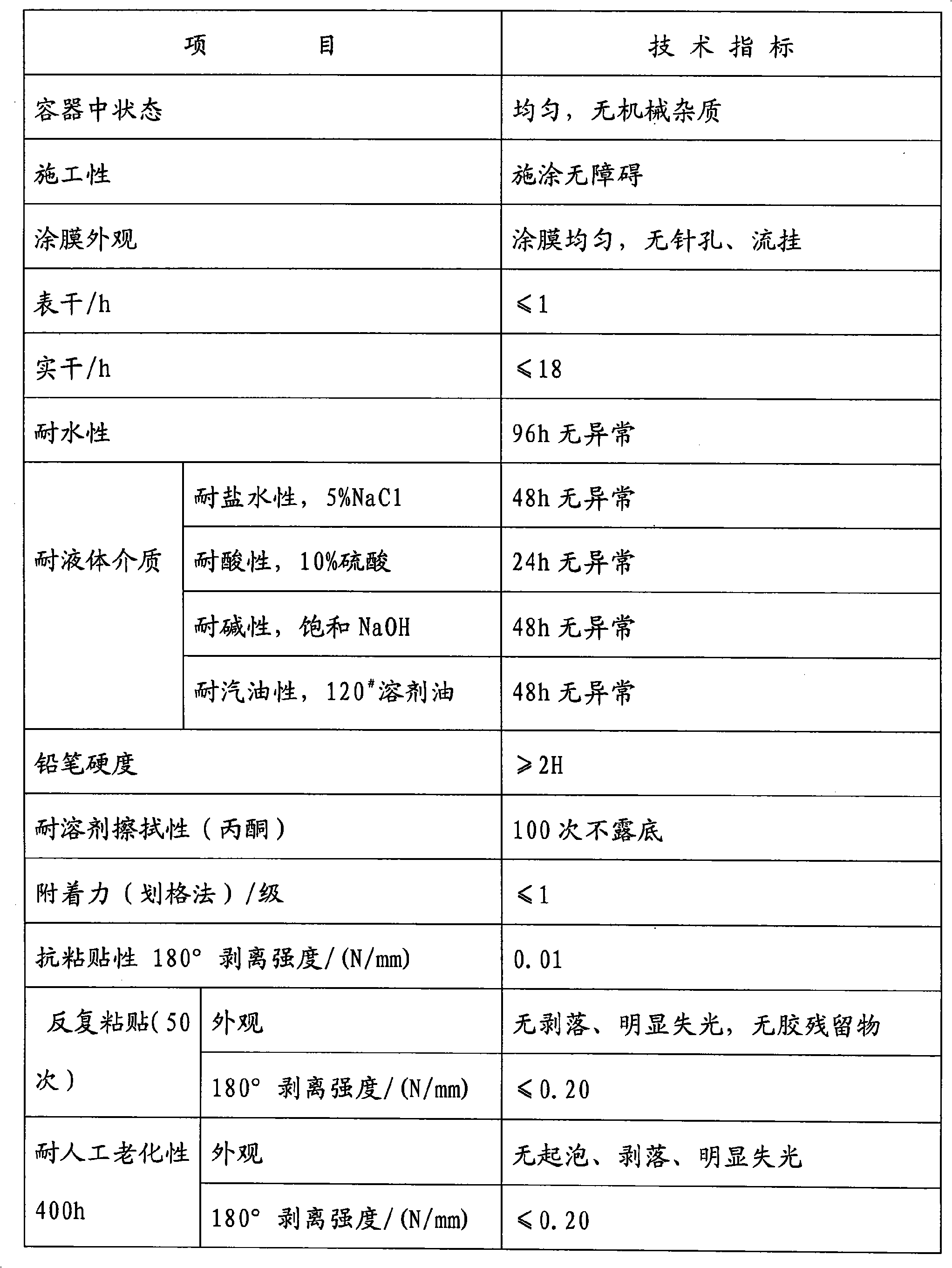

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995AHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, modified polydimethyl siloxane resin, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

Ultrathin expansion steel-structure fireproofing coating

InactiveCN1488692AGood fire and heat insulationImprove adhesionFireproof paintsPolymer scienceAcrylic resin

The present invention provides a fire-retardant coating capable of forming ultrathin coating layer and having high fire-resisting limit. Its composition comprises (by weight portion) 50-60 portions of modified acrylic resin, 12-16 portions of pentaerythritol, 9-12 portions of trimeric cyanamide, 19-21 portions of polyammonium phosphate, 6-8 portions of zinc borate, 9-11 portions of titanium pigment, 1.25-15 portions of chlorinated paraffin (in which chlorine content is 70%) and 8-15 portions of 200# solvent gasoline. The above-mentioned modified acrylic resin is a chlorinated rubber modified acrylic resin made up by using 1.4-1.8 portions of chlorinated rubber, 2.2-2.7 portions of xylene, 0.9-1.1 portions of hexamethylene-diisocyanate and 1.6-1.8 portions of hydroxyl-bearing acrylic resin. Its coating layer thickness is 1.71-2.69 mm, and its fire-resisting limit can be up to 69-147 min.

Owner:应急管理部四川消防研究所

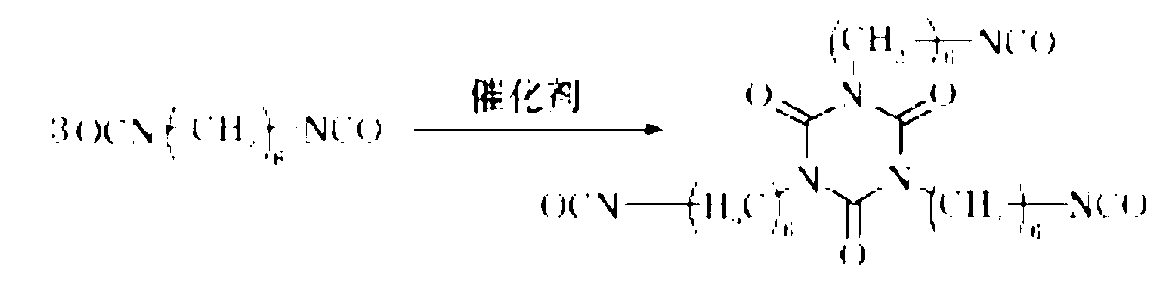

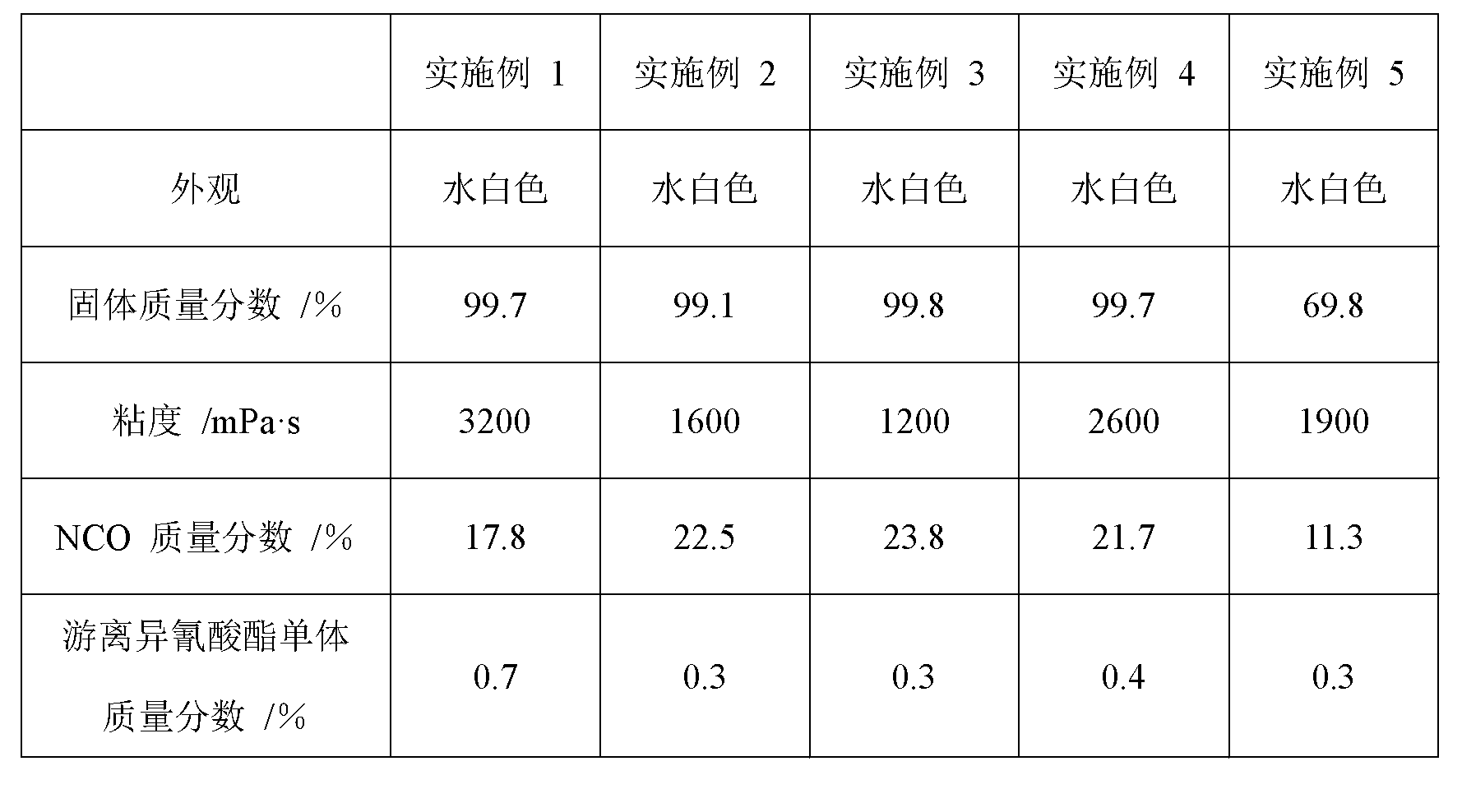

Polyurethane curing agent with low free isocyanate monomer and preparation method thereof

InactiveCN103224605AAdd one step polymerization reactionLow free HDI contentPolyurea/polyurethane coatingsPolymer scienceMeth-

The present invention relates to a polyurethane curing agent with low free isocyanate monomer and a preparation method thereof. The polyurethane curing agent comprises the raw materials in weight percentage as following: 80 - 88 parts of hexamethylene diisocyanate monomer; 12 - 20 parts of polyhydric alcohol; 0.1-0.5 part of catalyst; and 0.1-1.0 part of terminating agent. The invention adopts a two-step chemical conversion reaction, namely, adds one step of polymerization reaction based on one-step addition reaction to remove free isocyanate monomer by a trimer method so as to obtain the 100% solid content, wherein the NCO content is between 21 and 22 %, and the free HDI content is between 0.1 and 1.0 %. According to the present invention, the preparation process of polyurethane curing agent is simplified without post-processing . The polyurethane curing agent of the invention is matched with hydroxyl acrylic resin and polyester resin etc., and the paint film will not be yellowed, and has excellent light resistance, weathering resistance, chemical resistance and gorgeous gloss.

Owner:HUBEI TRASION CHEM IND CO LTD

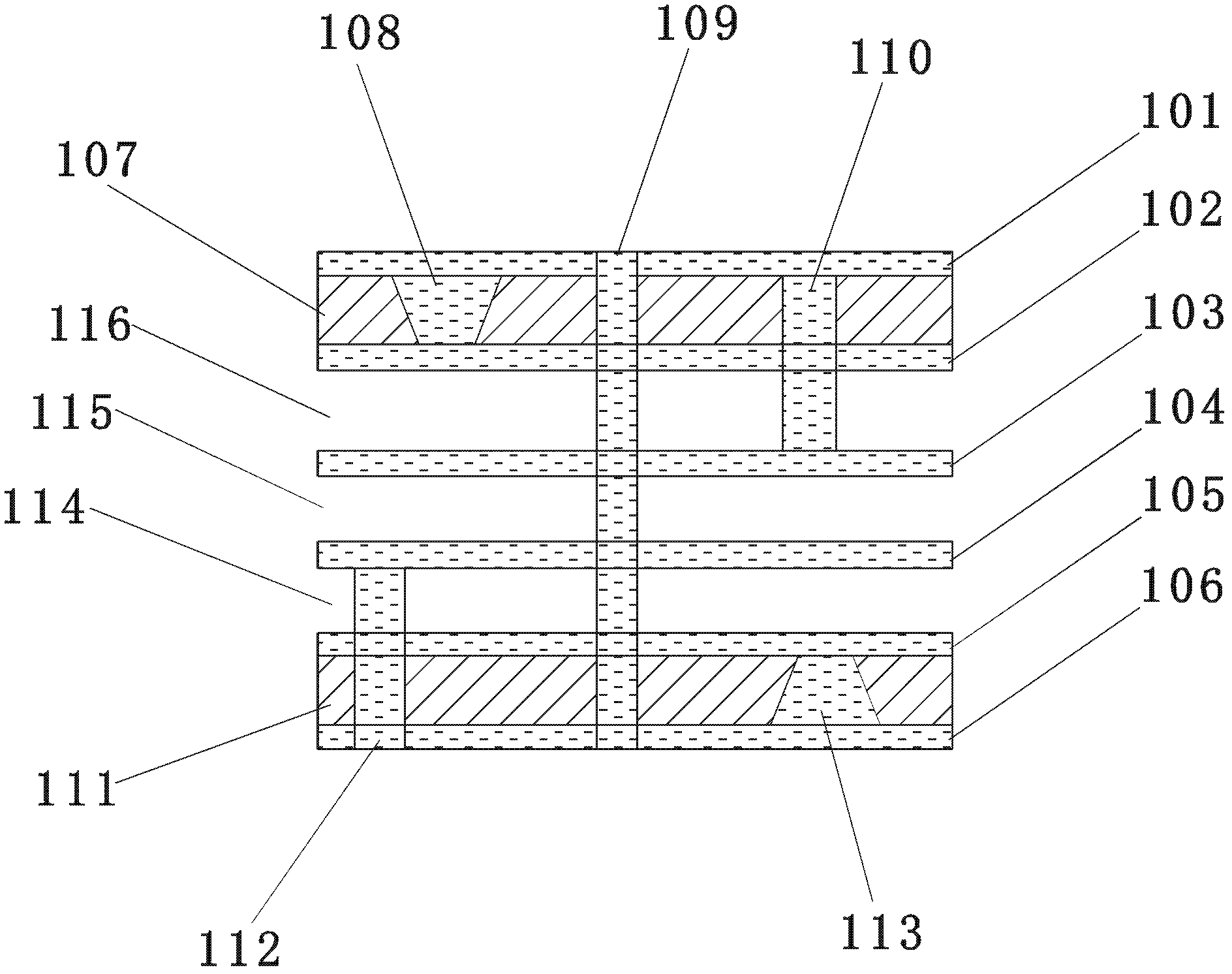

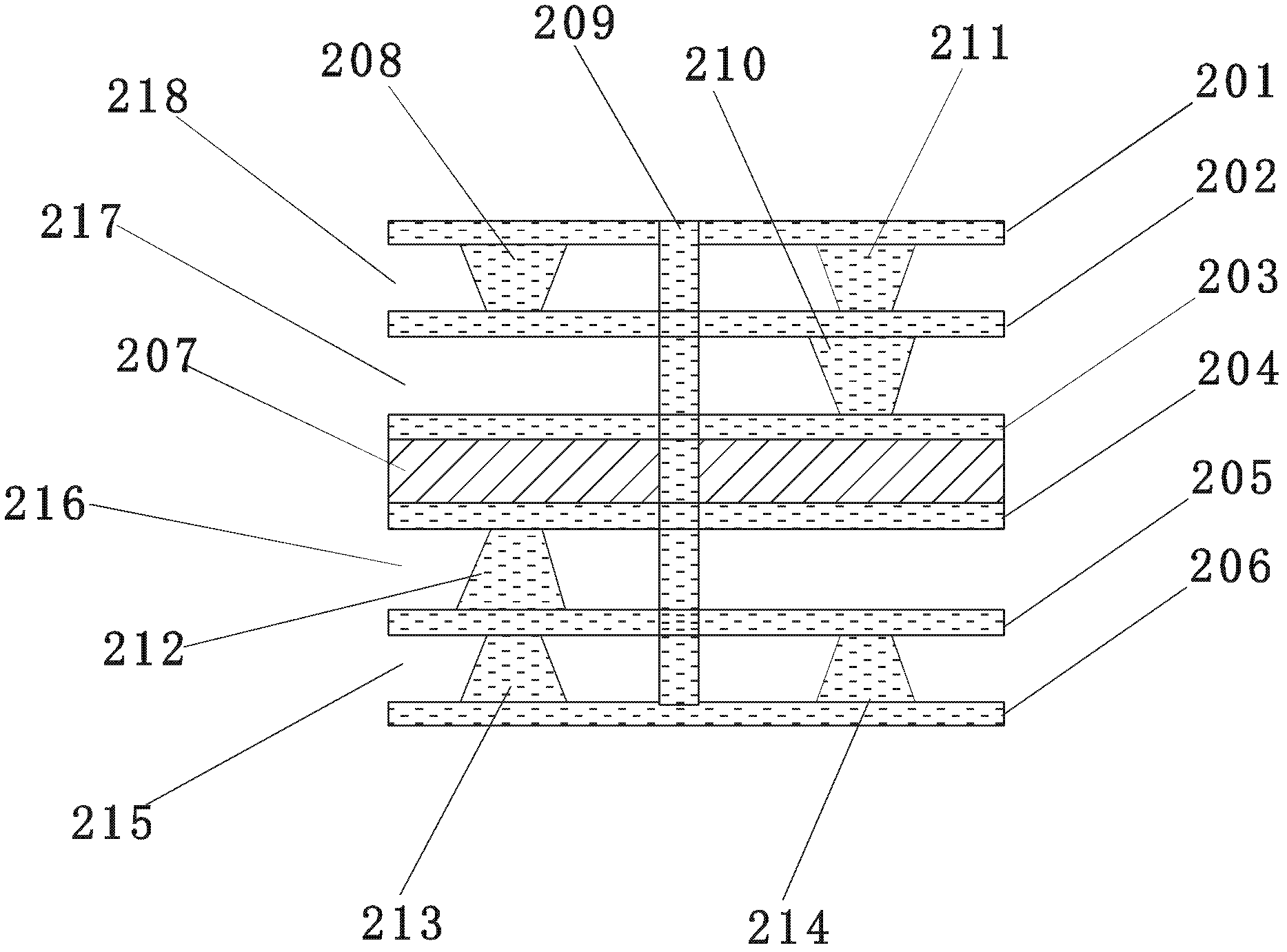

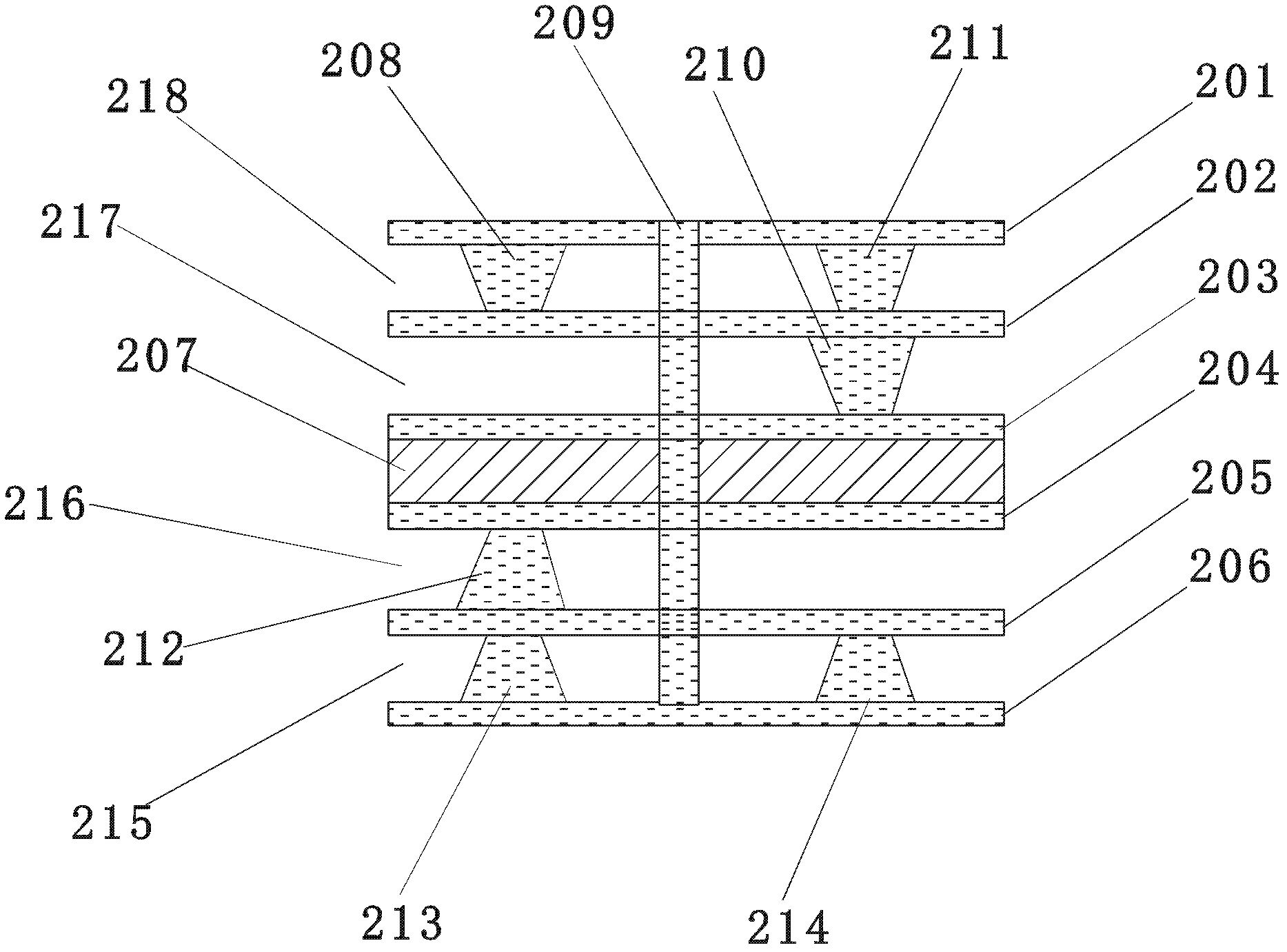

Hexamethylene diisocyanate (HDI) plate with symmetrically pressed structure and manufacturing method thereof

InactiveCN102548186AExpansion and contraction are difficult to controlEasy to expand and contractPrinted circuit detailsMultilayer circuit manufactureOptoelectronicsCopper foil

The invention discloses a hexamethylene diisocyanate (HDI) plate with a symmetrically pressed structure and a manufacturing method thereof. The manufacturing method comprises the following steps of: A, pressing a second copper foil layer on the upper side of a core plate, and pressing a fifth copper foil layer on the lower side of the core plate; B, performing laser hole drilling on the second copper foil layer to form a second laser blind hole, and performing laser hole drilling on the fifth copper foil layer to form a fourth laser blind hole; C, pressing a first copper foil layer on the second copper foil layer, and pressing a sixth copper foil layer on the fifth copper foil layer; and D, performing laser hole drilling on the first copper foil layer to form a first laser blind hole and a third laser blind hole, performing laser hole drilling on the sixth copper foil layer to form a fifth laser blind hole and a sixth laser blind hole, wherein the third laser blind hole is stacked with the second laser blind hole, and the fifth laser blind hole is stacked with the fourth laser blind hole. Compared with the prior art, the HDI plate has the advantages that the pressed stacked structure is changed; asymmetric pressing is replaced by symmetric pressing; after pressing for the first time, one core plate replaces two core plates; the expansion and contraction of the HDI plate are easy to control during manufacturing; and furthermore, layer deflection is improved greatly, the manufacturing difficulty is reduced greatly, and the production period is shortened.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Method for synthesizing hexamethylene diisocyanate (HDI) biuret

InactiveCN101475680AReduce HDI contentReduce use toxicityIsocyanic acid derivatives purification/separationDissolutionHigh pressure

The invention relates to a method for synthesizing hexamethylene diisocyanate (HDI) biuret through a spray method. The method comprises the following steps: adopting the high pressure to inject water in the form of fog drops into an HDI contained reaction kettle, setting the temperature to be between 60 and 130 DEG C, setting the mol ratio of HDI to water 2 to 15, setting the water spraying time to be between 0.5 and 8 hours, carrying out heat preservation at a temperature of between 80 and 150 DEG C for 0 to 5 hours, and then carrying out the separation through a separating device; setting the separation temperature to be between 70 and 200 DEG C and the pressure to be between 0.5 and 50,000Pa; and pumping the separated steaming residue into a dilution container with a stirrer for dissolution, adding a metered solvent into the dilution container in advance, continuously adding the metered solvent into the dilution container with the pumping of the steaming residue, and carrying out the dilution to obtain an HDI biuret product with 25 to 100 percent of solid content. The method improves the reaction efficiency for producing the HDI biuret product, reduces the generation of polyurea, reduces the HDI content in the HDI biuret, and reduces the use toxicity of the HDI biuret. In addition, the production process is economical and has environmental protection.

Owner:JIANGMEN YIYUAN BIOCHEM ENG

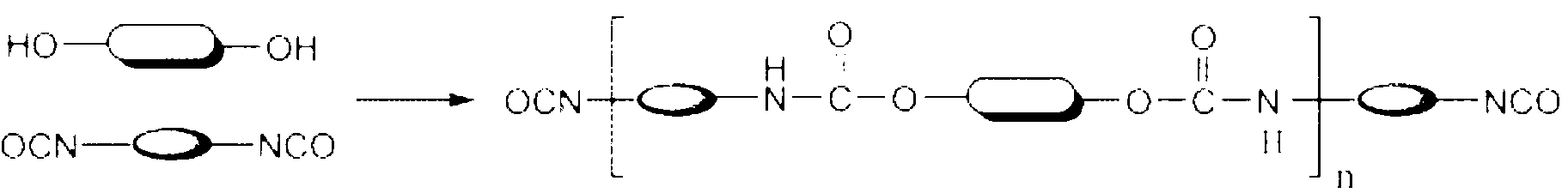

Waterborne polyurethane grouting material and preparation method thereof

InactiveCN102093537AConvenient sourceAvoid poisoningOther chemical processesIsophorone diisocyanatePolymer chemistry

The invention discloses a preparation method of a waterborne polyurethane grouting material. The method is as follows: isocyanate, retarding agent and hydrophilic polyether polyol are mixed to react and obtain the finished product, wherein isocyanate is selected from diphenylmethane diisocyanate, liquefied diphenylmethane diisocyanate, polymethylene polyphenyl isocyanate isophorone diisocyanate, dicyclohexylmethylmethane-4,4'-diisocyanate, hexamethylene diisocyanate and polymethylene polyphenyl isocyanate or the mixture of toluene diisocynate and the isocyanates; and the degree of functionality of hydrophilic polyether polyol is 2-6, the ratio of ethylene oxide to propylene oxide is 99 / 1-60 / 40 and the molecular weight is 1000-20000. The invention also relates to the hydrophilic polyurethane grouting material prepared by the method. The preparation method of the invention is simple and convenient and has wide raw material sources; the prepared hydrophilic polyurethane grouting material does not contain organic solvent, thus avoiding the damage on the health of the constructor and promoting environmental protection; and the grouting material can have lower viscosity and good permeability and waterproof and leaking stoppage effect.

Owner:SHANGHAI DONGDA CHEM

Adhesive composition for optical films, adhesive optical film and image display

ActiveCN101463234AInhibit sheddingPollution suppressionNon-macromolecular adhesive additivesFilm/foil adhesivesXylyleneMeth-

The present invention provides an optical film pressure-sensitive adhesive composition, pressure-sensitive optical films and an image display device. The invention particularly provide an optical film pressure-sensitive adhesive composition capable of forming a pressure-sensitive adhesive layer that has reworkability such that optical films therewith can be easily separated from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be processed without causing adhesive stain or dropout after it is formed on an optical film. The optical film pressure-sensitive adhesive composition includes 100 parts by weight of a (meth)acrylic polymer including, as monomer units, (a) 50 to 99.79% by weight of an alkyl (meth)acrylate monomer, (b) 0.01 to 0.45% by weight of a tertiary amino group-containing monomer, and (c) 0.1 to 3% by weight of a hydroxyl group-containing monomer; and 0.01 to 2 parts by weight of a crosslinking agent that is at least one selected from the group consisting of hexamethylene diisocyanate, hydrogenated xylylene diisocyanate, and isophorone diisocyanate, or a polyisocyanate compound derived therefrom.

Owner:NITTO DENKO CORP

Scratch-resistant double-component waterborne glossy varnish and preparation method thereof

The invention belongs to the field of coatings and relates to double-component waterborne glossy varnish and a preparation method thereof, in particular to scratch-resistant double-component waterborne glossy varnish and a preparation method thereof. The double-component waterborne glossy varnish comprises a component A and a component B, wherein the component A comprises hydroxyl polyacrylate containing secondary dispersoid, waterborne polyurethane dispersoid, a defoaming agent, a coalescing agent, a wax emulsion, a leveling agent, a thickener and water; the component B comprises propylene glycol diacetate and hydrophilic aliphatic polyisocyanate containing hexamethylene diisocyanate. The varnish has the characteristics of excellent glossiness, high fullness, good varnish film surface effect and the like and also has outstanding scratch resistance.

Owner:AODA KOALA PAINT HUIZHOU

Aqueous bi-component coating of vehicle rubber and plastic sealing strip and preparation method thereof

InactiveCN101824271AStrong adhesionAttachment meetsPolyurea/polyurethane coatingsPolyamide coatingsCross-linkPolyurethane dispersion

The invention relates to an aqueous bi-component coating of a vehicle rubber and plastic sealing strip and a preparation method thereof. A component A takes aqueous polyurethane as matrix resin, and a component B is a cross-linking agent. The component A contains the following components in percentage by weight: 26-55 percent of aliphatic aqueous polyurethane dispersoid, 0-5 percent of polyamide paraffin slurry, 0-20 percent of aqueous ethylene paraffin liquid, 0-12 percent of aqueous resin containing active functional group, 1-10 percent of functional material, 5-10 percent of slipping agent, 0.1-2 percent of stuffing, 0-3 percent of pigment slurry, 1.5-6 percent of special assistant and 15-45 percent of solvent, and the component B contains the following components in percentage by weight: 70-100 percent of hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate and 0-30 percent of diethylene glycol butylether acetate. The invention has the advantages that after thecross-linking reaction is carried out on the aqueous resin composition and the cross-linking agent, the aqueous bi-component coating has excellent adhesiveness and meets the adhering requirements on treated rubber and plastic surfaces, has superstrong abrasive resistance and moderate flexibility, can enhance the slipping performance and the abrasive resistance with glass, resists high temperature, does not deform or separate out and has permanent slipping effect.

Owner:吕相洋

Curing agent 1,6- hexamethylene diisocyanate prepolymer and preparation thereof

ActiveCN101274977AReduce consumptionOvercome the problems of high volatility and high toxicity of construction when used directlyPolyurea/polyurethane coatingsAlcoholOrganic solvent

The invention provides a curing agent of 1, 6-hexamethylene diisocyanate prepolymer and a preparation method thereof. The preparation method comprises that: HDI and an organic solvent are put in a reaction vessel, stirred evenly and added with vacuumized and dehydrated polybasic alcohol; with cold mix for 0.5 hour at room temperature and reaction for 2 to 5 hours at temperature of 60 to 100 DEG C, an HDI modifier is prepared; then the temperature is decreased to 50 to 80 DEG C and while stirring, the mixed solution of trimethylolpropane and the organic solvent are added into the reaction vessel in drops for 1 to 4 hours at temperature of 60 to 100 DEG C; then the reaction is incubated for 1 to 3 hours with heat preservation; again the temperature is increased to 80 to 100 DEG C and the reaction is incubated for 2 to 5 hours with heat preservation; finally the transparent viscous fluid of HDI prepolymer is prepared with temperature decreased to 60 DEG C; the organic solvent is added into dilute the required solid content. The invention has good weather resisting property and non-yellowing property under ultraviolet radiation and high temperature, simple product preparation technique, the molecular structure of the curing agent being able to be regulated according to the requirement of users, and can acquire products of high solid content and other advantages.

Owner:周建明

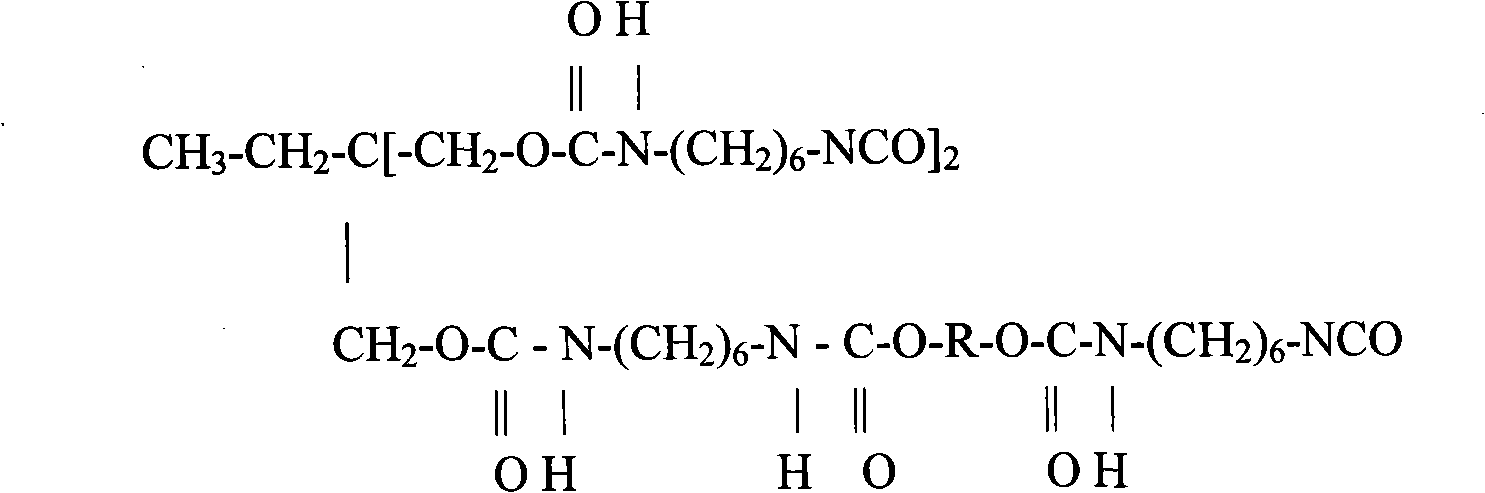

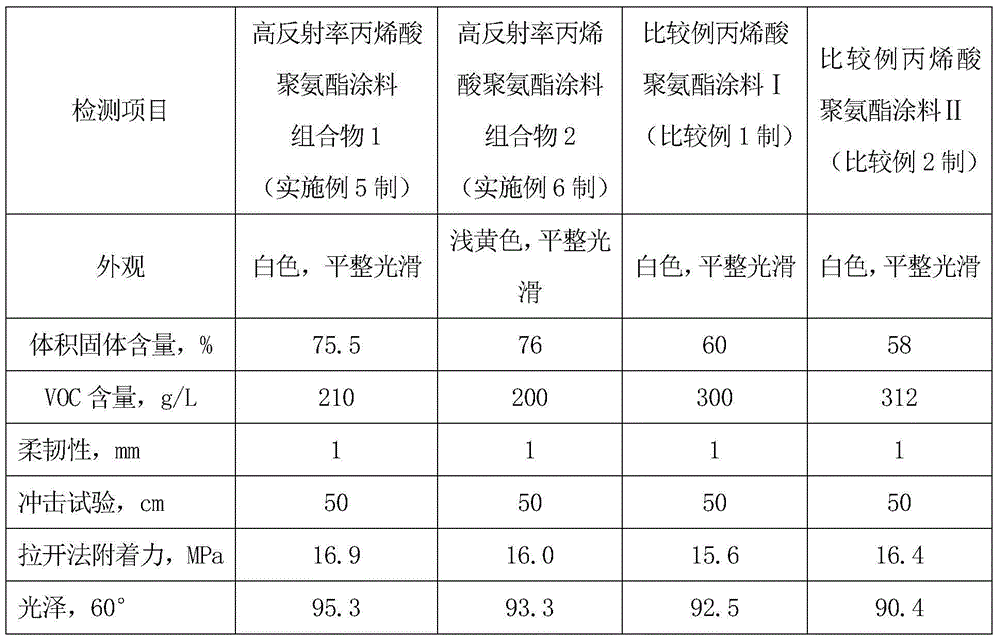

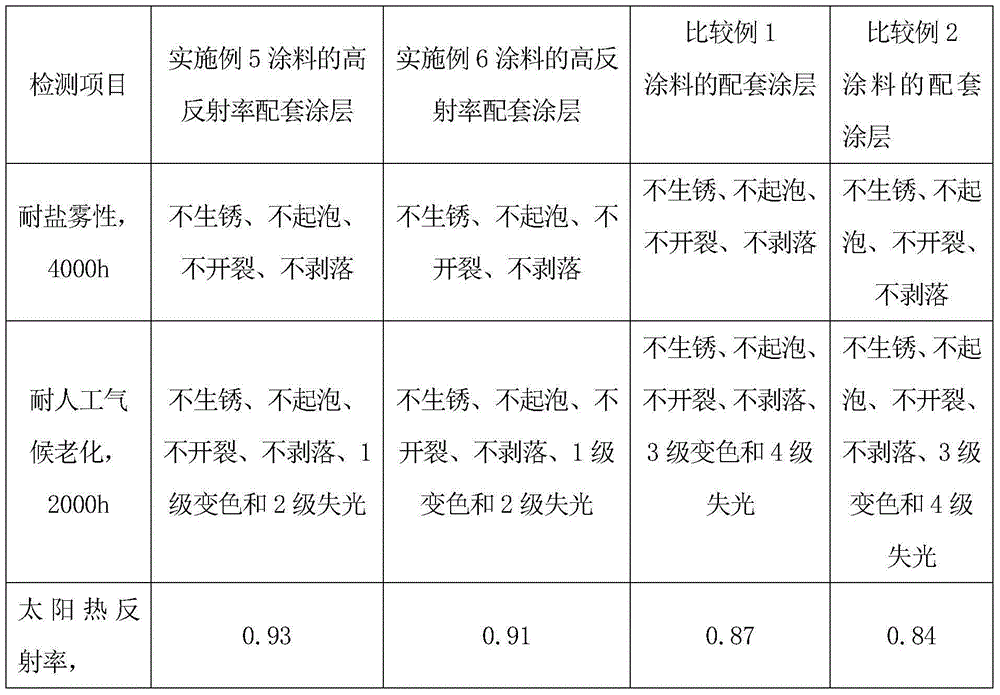

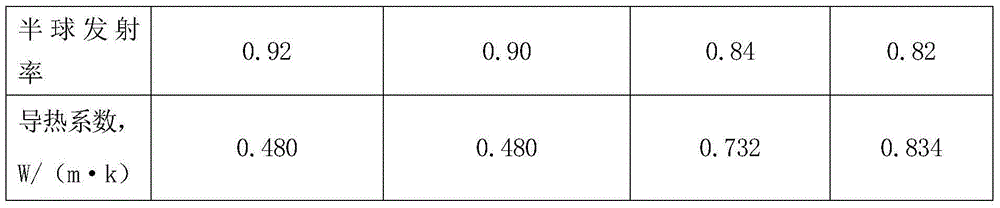

High-reflective acrylic polyurethane coating composition

ActiveCN104371531AHigh solid contentGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinIsophorone diisocyanate

The invention relates to a high-reflective acrylic polyurethane coating composition which comprises a component A and a component B in a mass part ratio of 20;3. The component A in 100 parts by mass comprises the following materials in part by mass: 30-50 parts of modified hydroxyl acrylic resin, 2-6 parts of auxiliaries, 35-45 parts of heat reflective pigments, 4-8 parts of aerogel and 10-15 parts of organic solvent. The component B in 100 parts by mass comprises the following materials in part by mass: 75-90 parts of polyisocyanate and 10-25 parts of organic solvent. The modified hydroxyl acrylic resin is obtained by cold-blending modified resin and hydroxyl acrylic resin in a mass part ratio of 1-3: 1; the solid content of the modified hydroxyl acrylic resin is greater than or equals to 75wt%; the particle size of heat reflective pigments ranges from 0.55 micron to 1.2 microns; the particle size of the aerogel ranges from 1 micron to 80 microns; the pore size of the aerogel ranges from 10 nanometers to 20 nanometers; and the heat conductivity coefficient of the aerogel is less than or equals to 0.015W / (m k). The polyisocyanate is one or more of HDI (hexamethylene diisocyanate) biuret, HDI trimer and IPDI (isophorone diisocyanate) trimer curing agents. The high-reflective acrylic polyurethane coating composition is high in reflective insulation quality; and the quantity of VOC (volatile organic compounds) of the high-reflective acrylic polyurethane coating component is low.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Preparation method of hexamethylene diisocyanate tripolymer curing agent

InactiveCN103435778AEasy to synthesizeGood effectOrganic chemistryPolyurea/polyurethane coatingsPolymer scienceAmmonium hydroxide

The invention discloses a preparation method of a hexamethylene diisocyanate tripolymer curing agent, which comprises the following steps: putting an isocyanate monomer into a reaction vessel in a nitrogen gas protective atmosphere, dropwisely adding an isocyanate trimerization catalyst containing 2-hydroxyalkyl quaternary ammonium hydroxide within 1-1.5 hours, reacting while stirring at 30-80 DEG C for 2-24 hours, wherein the mass of the isocyanate trimerization catalyst accounts for 0.01-0.5% of that of the isocyanate monomer; when the mass percent of free NCO groups is measured to be 30-40%, adding an isocyanate trimerization inhibitor, wherein the mass of the isocyanate trimerization inhibitor accounts for 0.1-1% of that of the isocyanate monomer; and feeding the obtained polyurethane tripolymer curing agent into a separation device through a distributor at a feed rate of 1-20g / min, and separating to obtain the hexamethylene diisocyanate tripolymer curing agent. The curing agent disclosed by the invention is favorably compatible with resin, and has ultraviolet irradiation resistance, high compatibility, low viscosity and high mechanical strength.

Owner:SOUTH CHINA UNIV OF TECH

UV-hardenable dispersions based on polyisocyanates

ActiveCN101240058APolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolymer scienceMeth-

Aqueous UV-hardenable dispersions are provided, as well as their use for the production of coating agents, in particular coatings for ligneous substrates. The dispersions comprise the reaction product of a) one or more polyisocyanates of which at least one polyisocyanate is an oligomeric polyisocyanate of hexamethylene diisocyanate with urethane, biuret, iminooxadiazindione and / or isocyanurate structural units, b) one or more monohydroxy-functional compounds containing (meth)acryloyl groups, c) at least one component c1), which has a hydrophilising effect on the basis of incorporated (potentially) ionic groups and comprises at least one further isocyanate-reactive group and / or at least one component c2) which contains non-ionically hydrophilically acting groups and comprises at least one further isocyanate-reactive group, d) one or more difunctional and / or polyfunctional amines or hydroxyamines as chain extender, and e) optionally other monomeric, oligomeric and / or polymeric substances, which may optionally also contain further unsaturated groups.

Owner:COVESTRO DEUTSCHLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com