Patents

Literature

310results about How to "Excellent reworkability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for high-strength heat-proof polythene composite material

InactiveCN101367973AHigh strengthGood strength, heat resistanceHeat resistanceUltimate tensile strength

The invention relates to a method for preparing high heat-resisting polyethylene composite materials. The method takes advantage of the feature that thermosetting resin has sound rigidity and strength under high temperature after curing, and by adding reaction compatibilizing agent to act with thermosetting resin to form a semi-interpenetrating network of polyethylene and thermosetting resin, and thereby preparing novel polyethylene composite materials. The polyethylene, thermosetting resin, curing agent, accelerating agent, reaction compatibilizing agent and antioxidant which are premixed evenly in a high-speed agitator are added into a double screw extruder, and reactively blended at a proper temperature and rotation speed, the produced granules are extruded out, and the desired high heat-resisting polyethylene composite materials are achieved. Compared with the common polyethylene, the heat resistance and the strength of the materials under normal temperature and high temperature are improved remarkably, and the materials can be applied to the fields of civil buildings, auto parts, household electrical appliances as well as wires and cables, and the like.

Owner:SHANGHAI JIAO TONG UNIV

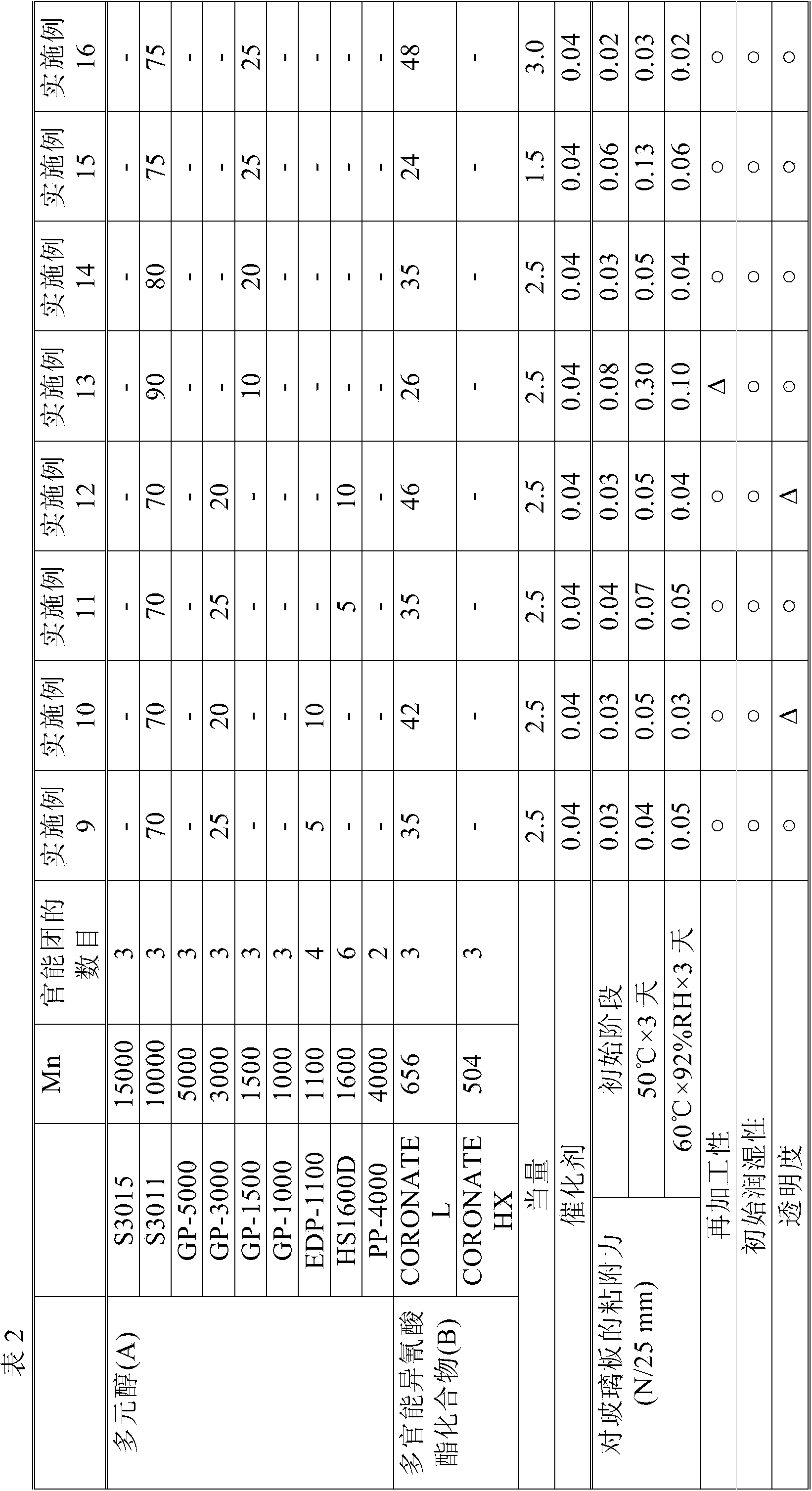

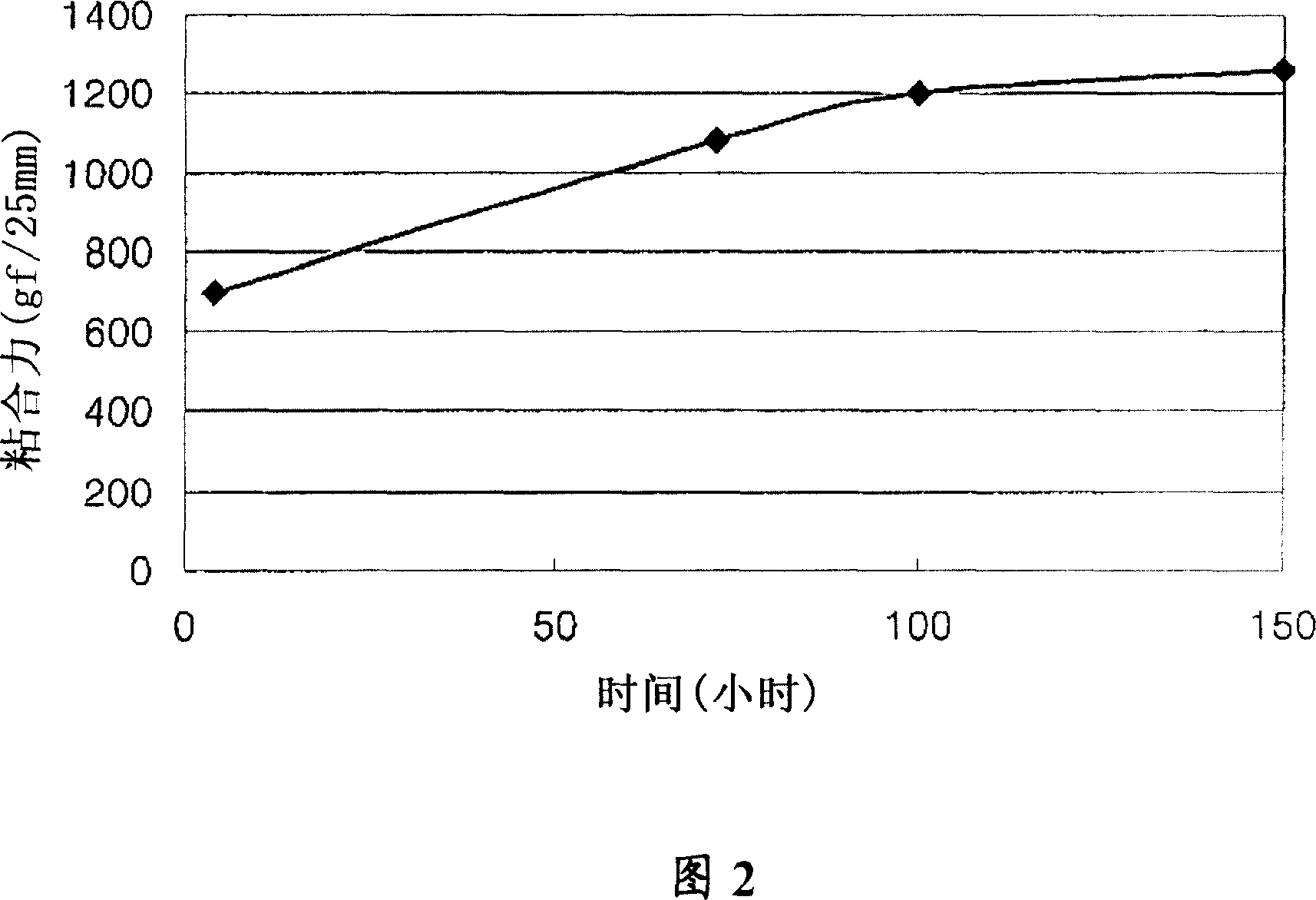

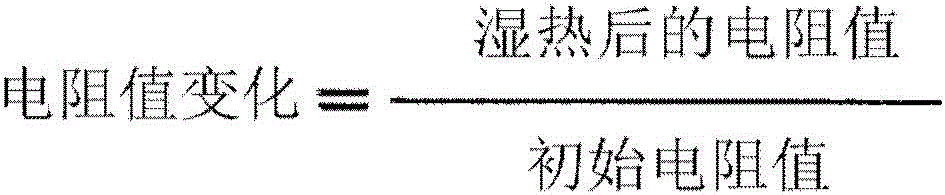

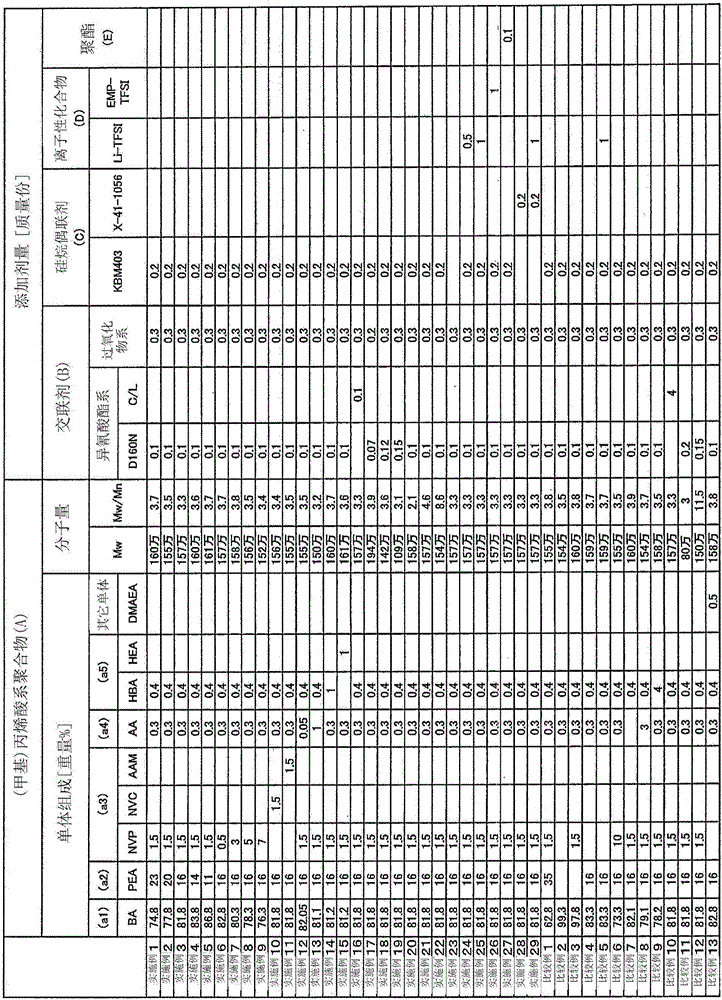

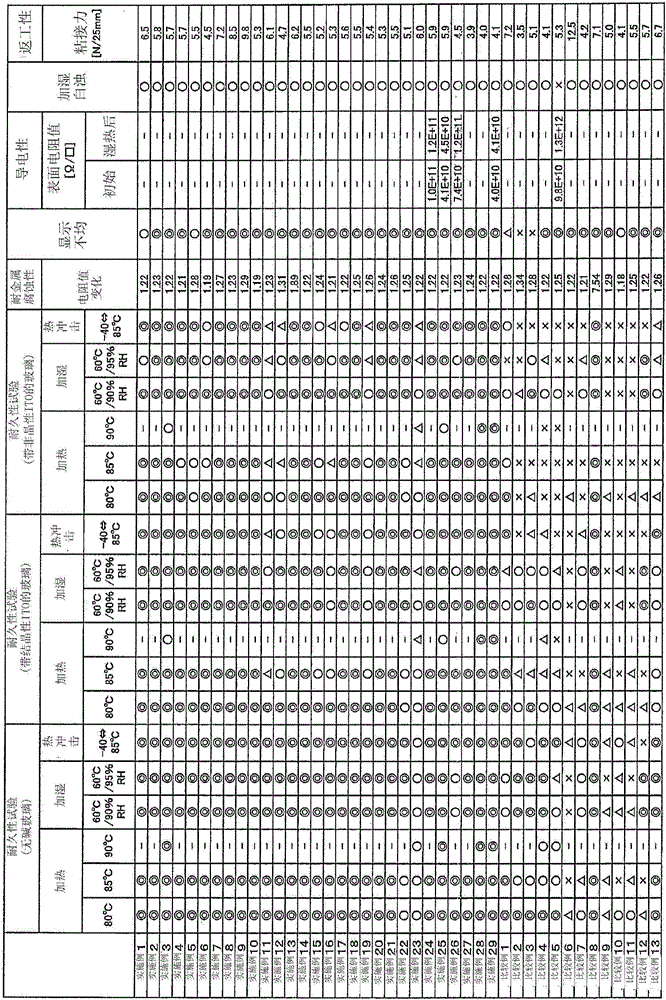

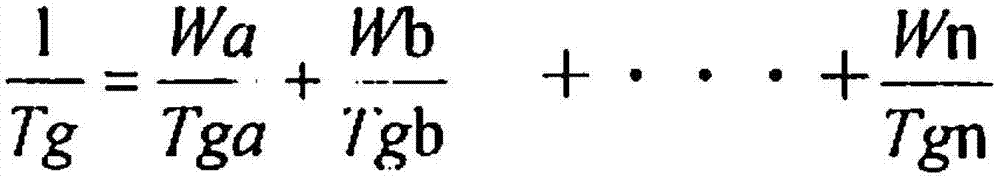

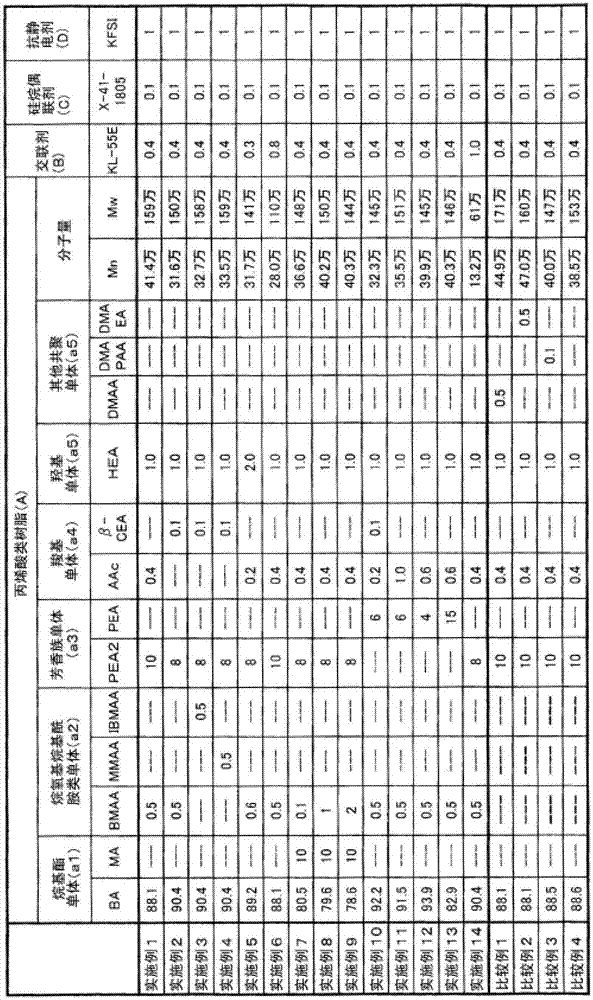

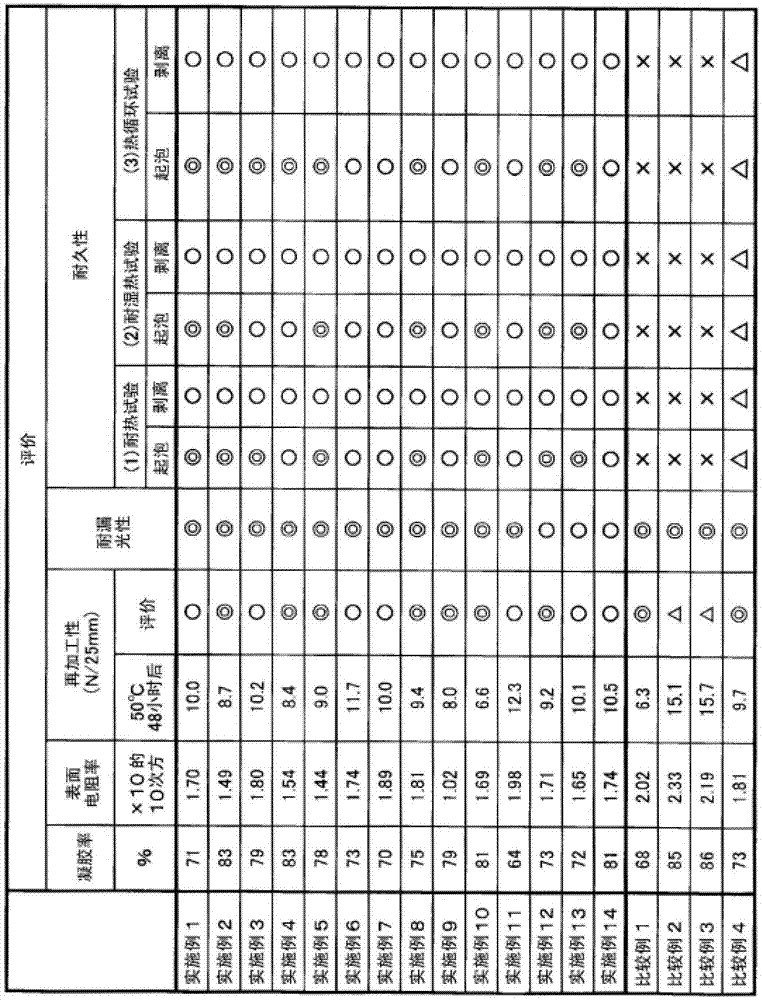

Adhesive Composition for Optical Film, Adhesive Sheet, and Optical Member Using Such Adhesive Composition

InactiveUS20090270557A1Avoid pollutionExcellent reworkabilityFilm/foil adhesivesPolyureas/polyurethane adhesivesMeth-Polymer science

An adhesive composition for optical films, which inhibits contamination in the re-release process and peeling under severe conditions while favorably maintaining its durability and light leakage prevention properties. The adhesive composition includes: (A) an acrylic-based polymer which is obtained by copolymerizing at least the following monomer components: (a1) a (meth)acrylic acid alkyl ester and / or a (meth)acrylic acid alkoxyalkyl ester, (a2) an aromatic ring-containing monomer, (a3) a hydroxyl group-containing monomer, and optionally, (a4) a carboxyl group- or amino group-containing monomer, and which has a weight-average molecular weight of 800,000 to 1,600,000 and a value (Mw / Mn), as obtained by dividing the weight-average molecular weight of the copolymer by the number-average molecular weight thereof of 10 to 50, (B) an isocyanate-based crosslinking agent, (C) a silane coupling agent, and optionally, (D) a crosslinking accelerator.

Owner:SOKEN CHEM & ENG CO LTD

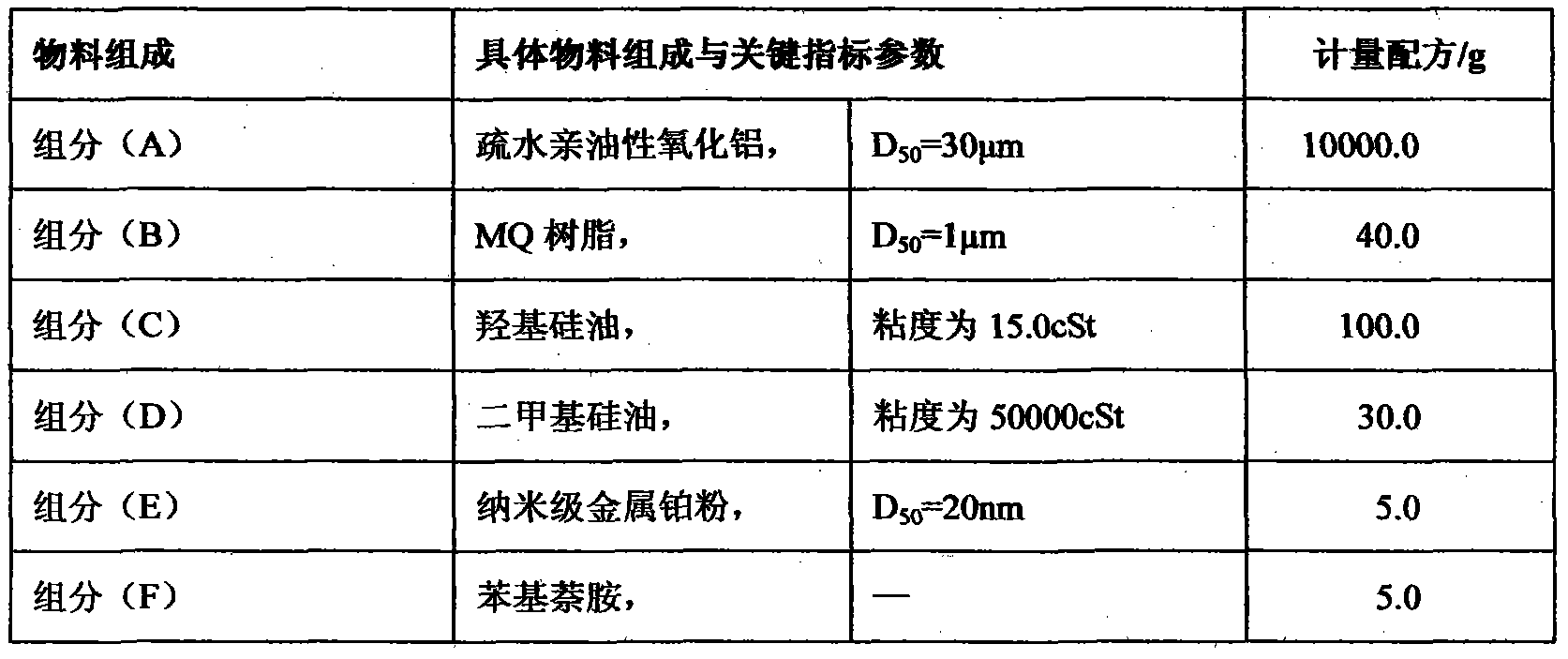

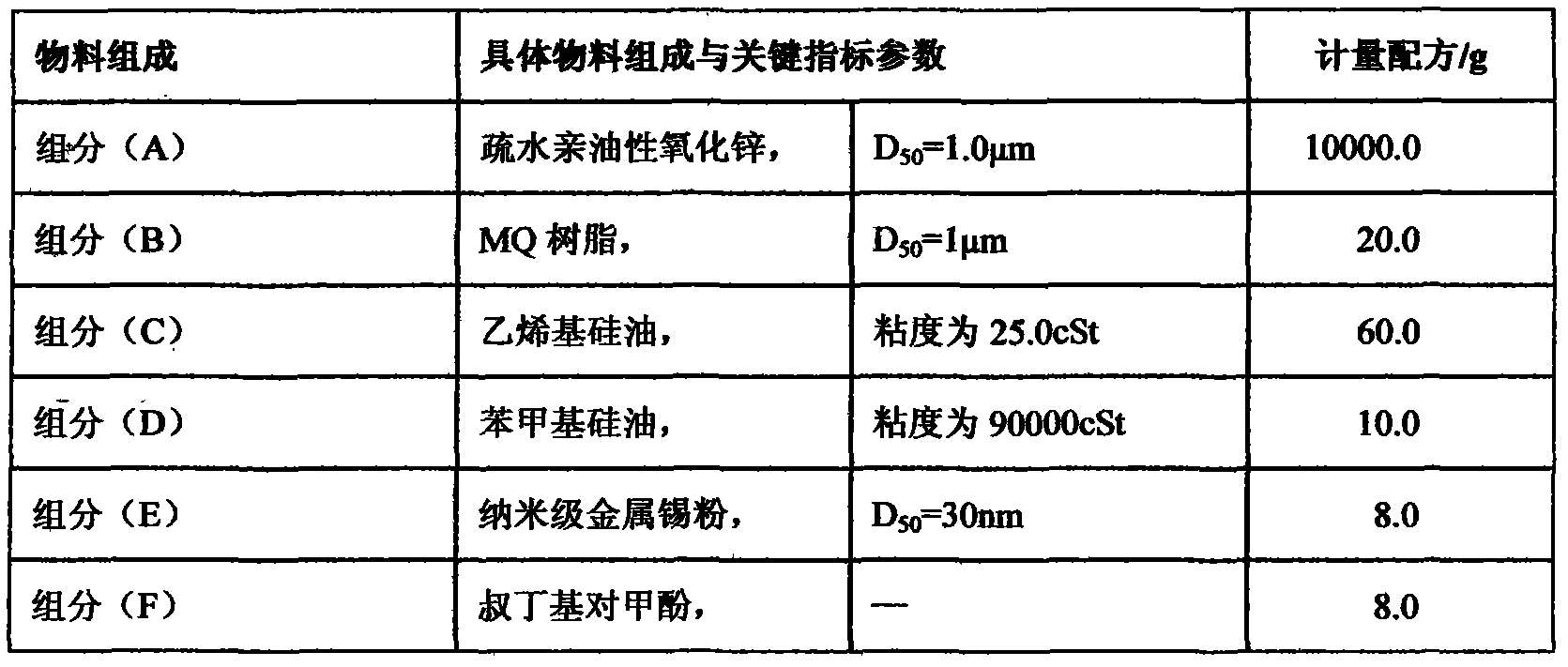

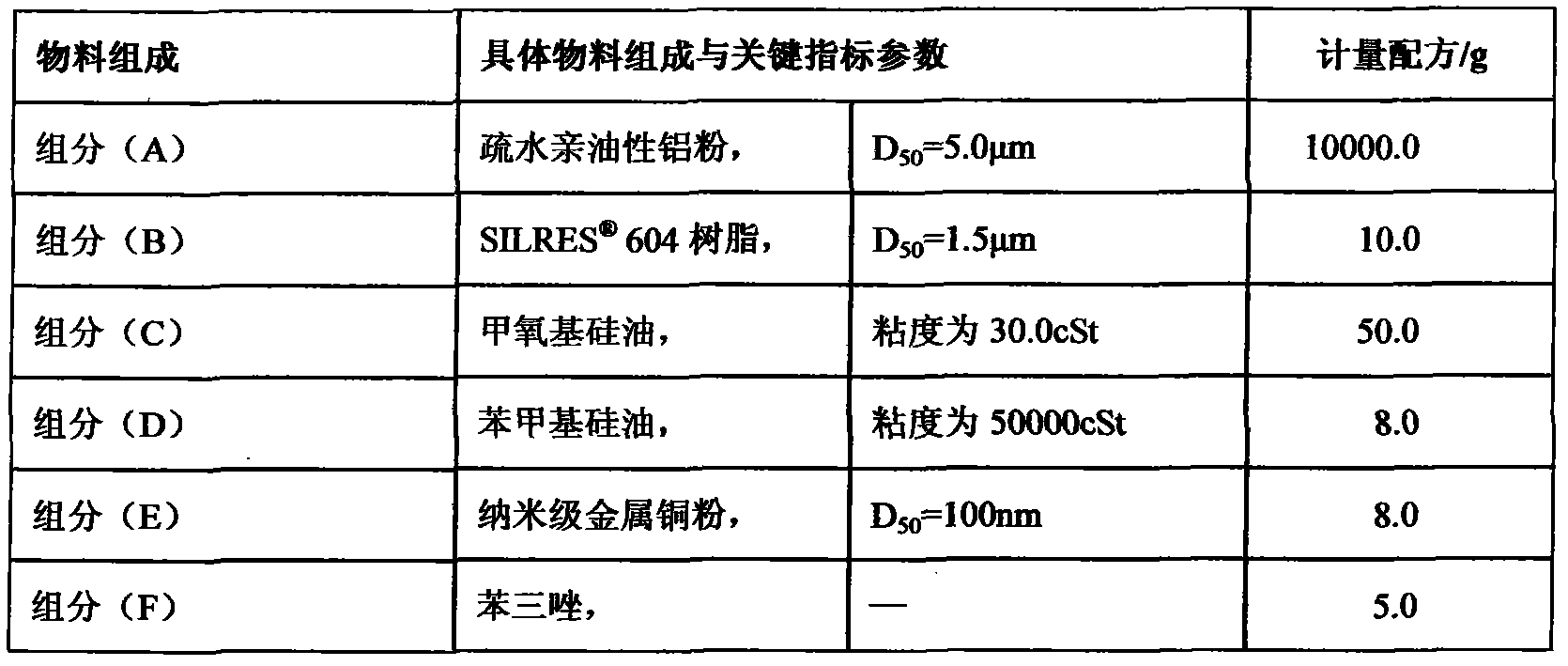

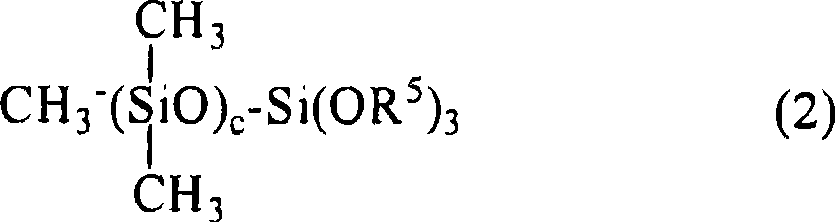

Thermal grease composition

ActiveCN102134474ASolve the chalking problemResolve fragmentationHeat-exchange elementsNano catalystThermal grease

The invention relates to the field of thermal interface materials, and more particularly, provides a thermal grease composition, which contains the following components: (A) 100.0 parts by weight of thermally conductive filler, (B) 0.1 to 8.0 parts by weight of active solid silicone resin, (C) 0.1 to 15.0 parts by weight of active silicone oil, (D) 0.1 to 9.0 parts by weight of macromolecular polysiloxane, (E) 0.1 to 3.0 parts by weight of nano catalyst, and (F) 0.1 to 3.0 parts by weight of additive. The thermal grease composition provided by the invention has good thermal conductivity and using weatherability, can effectively solve the technical difficulty that the thermal grease composition in the prior art is pulverized and crushed and the thermal conductivity is therefore reduced as the service time increases. The manufacturing process has simple, convenient and easy steps and the thermal grease composition is suitable for large-scale match production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

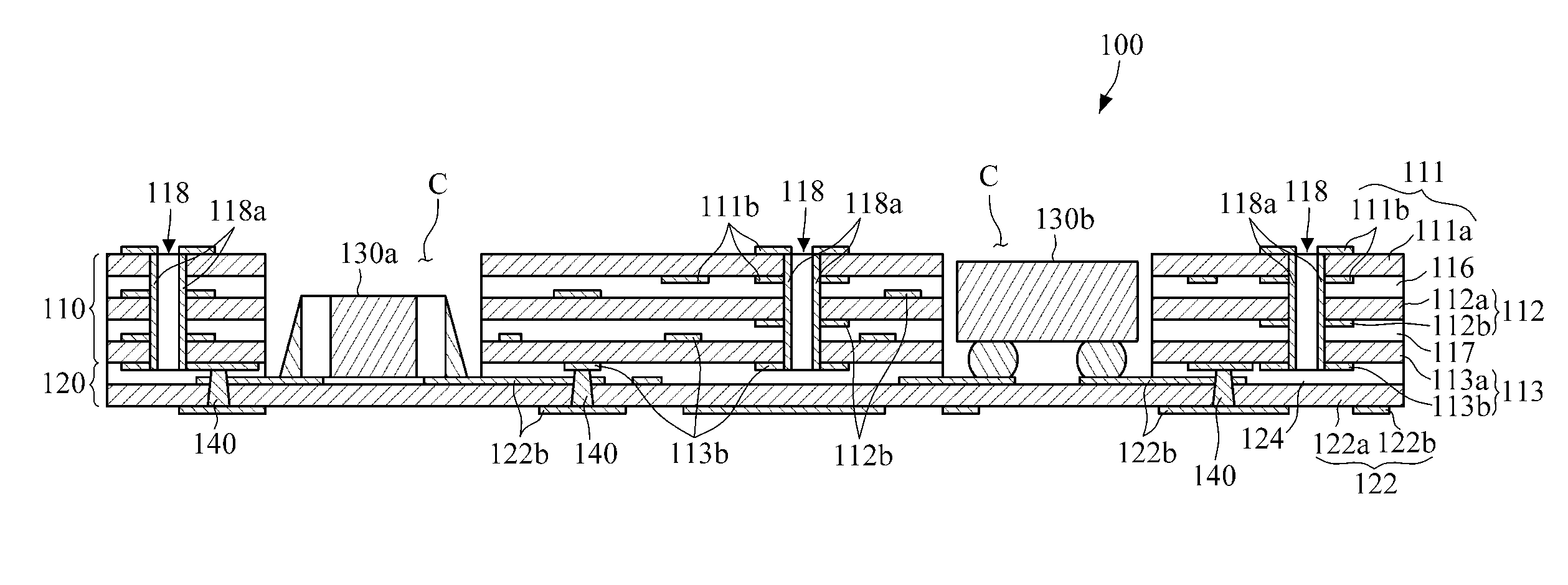

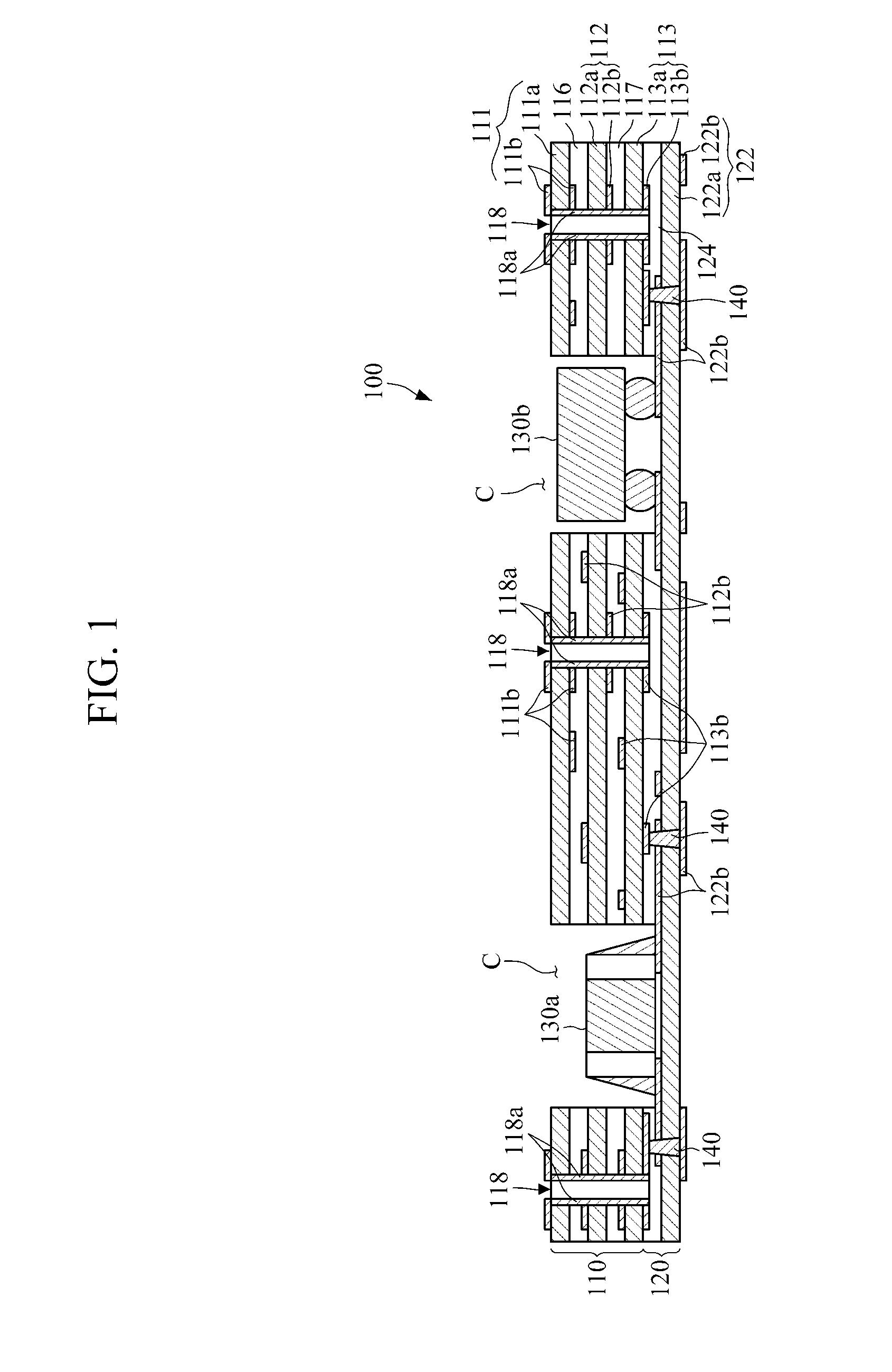

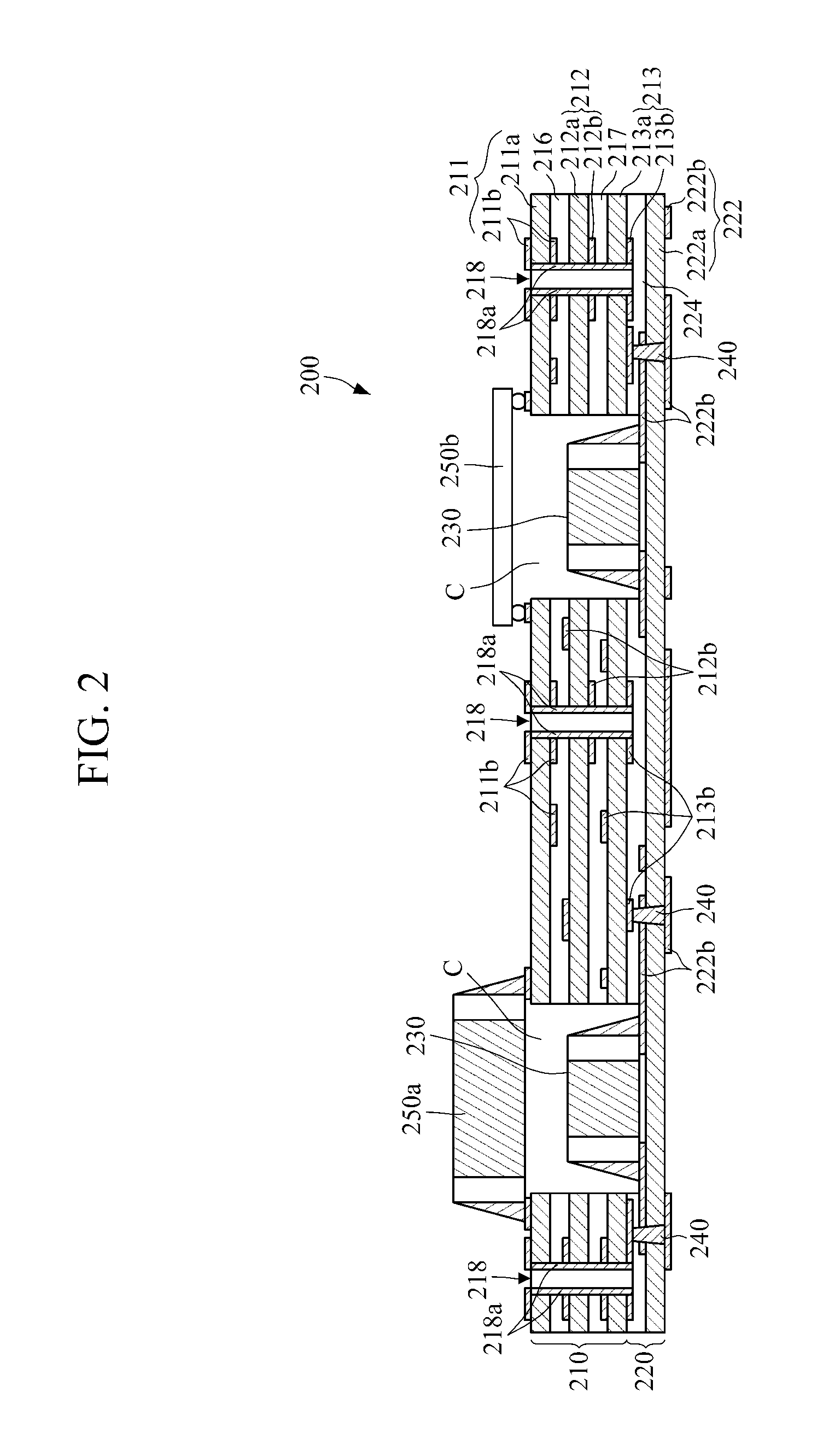

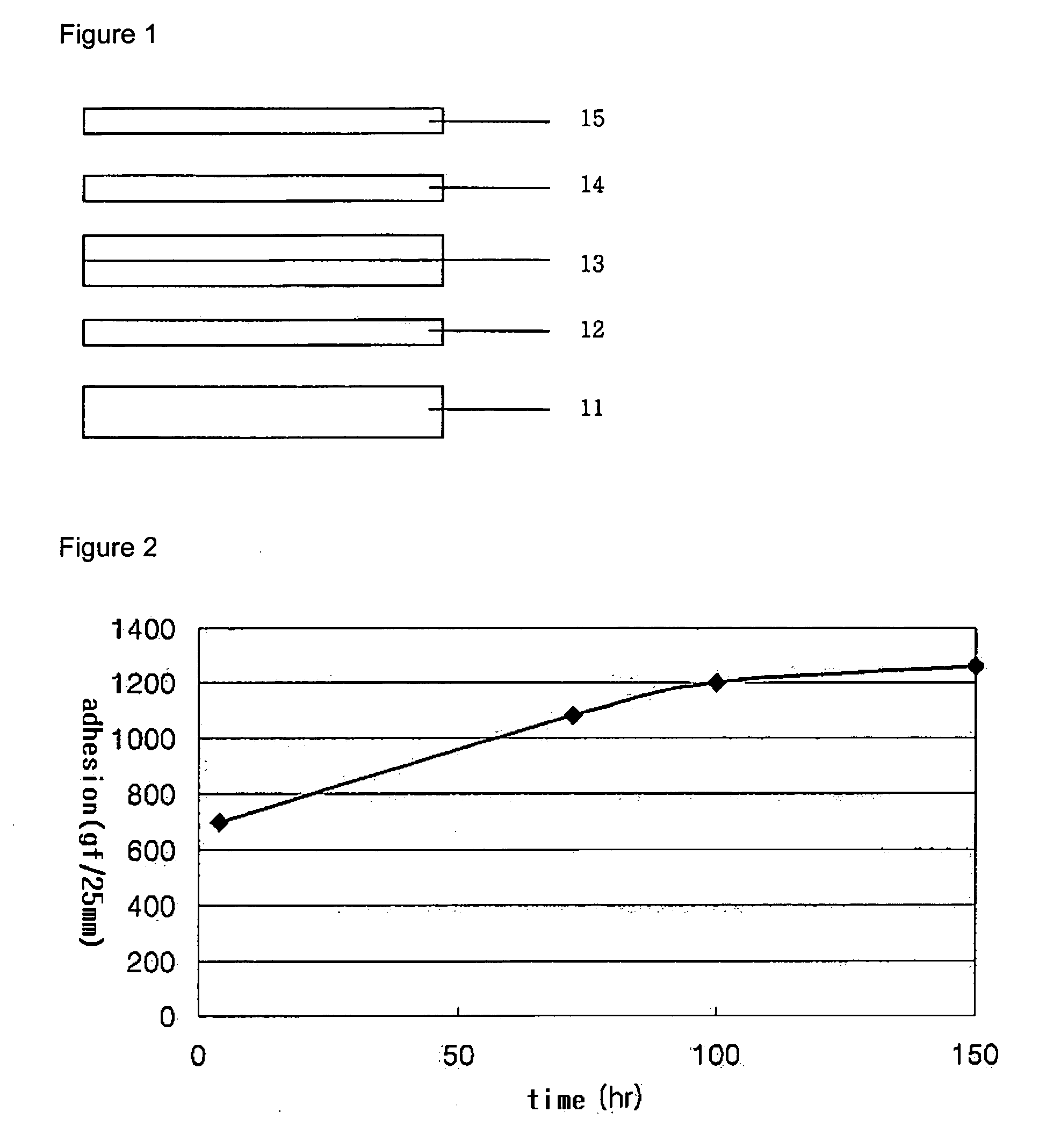

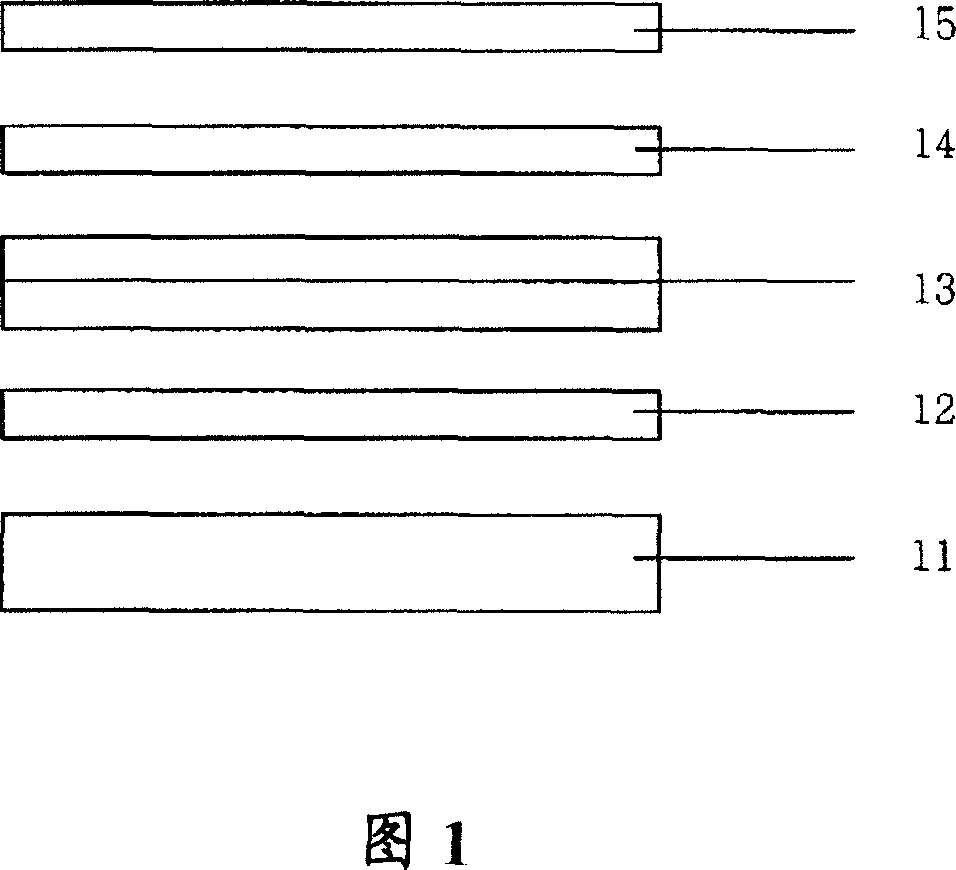

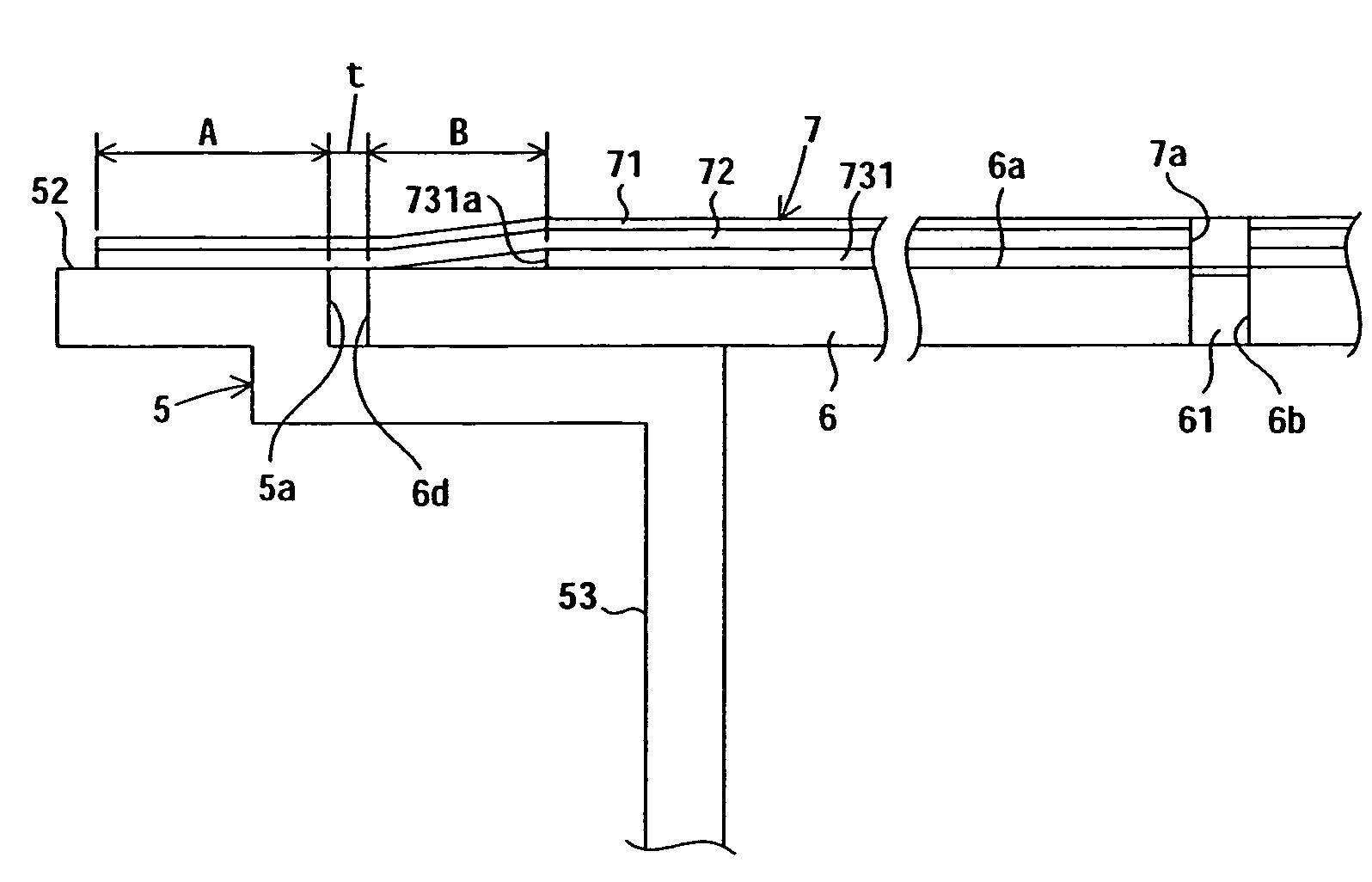

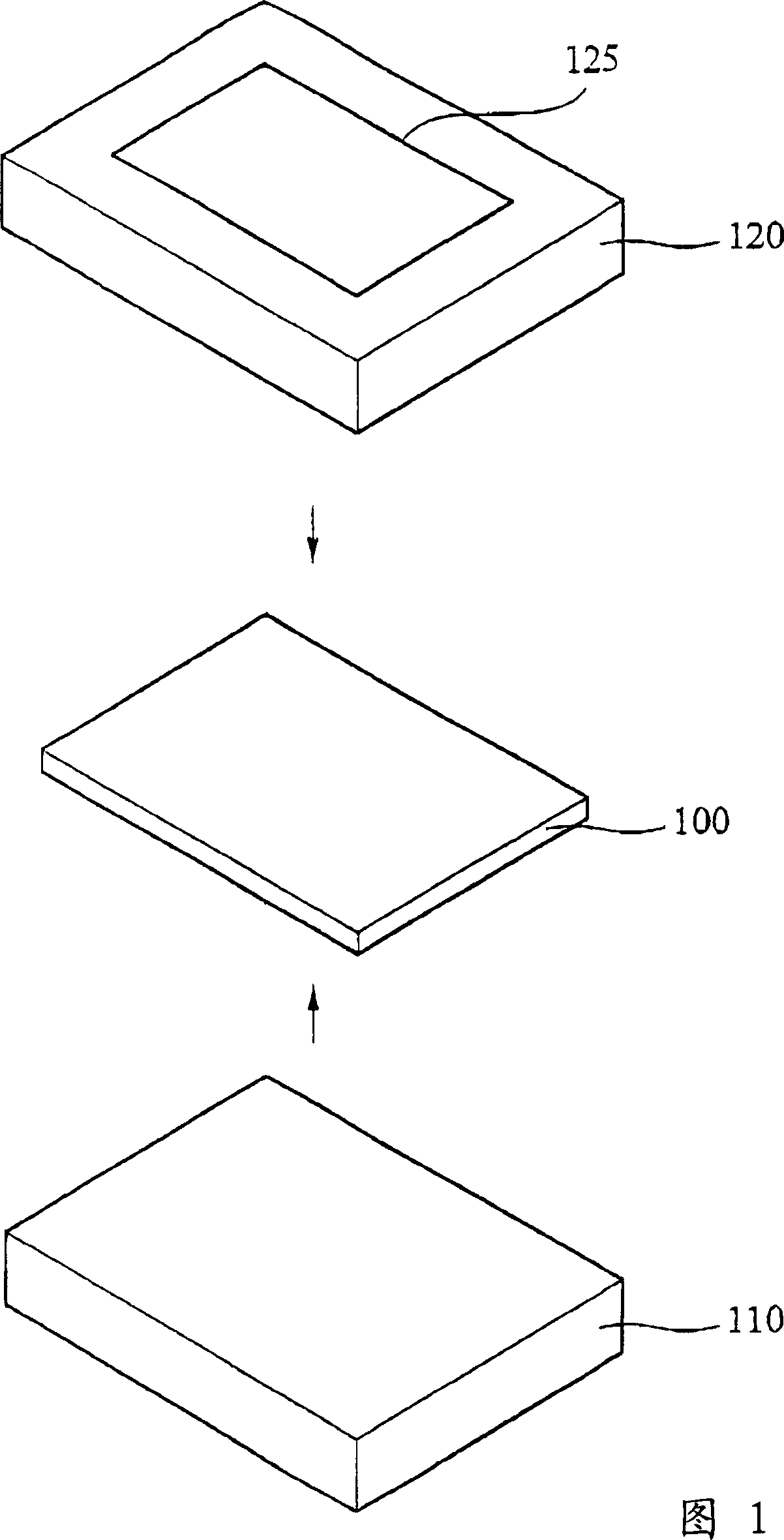

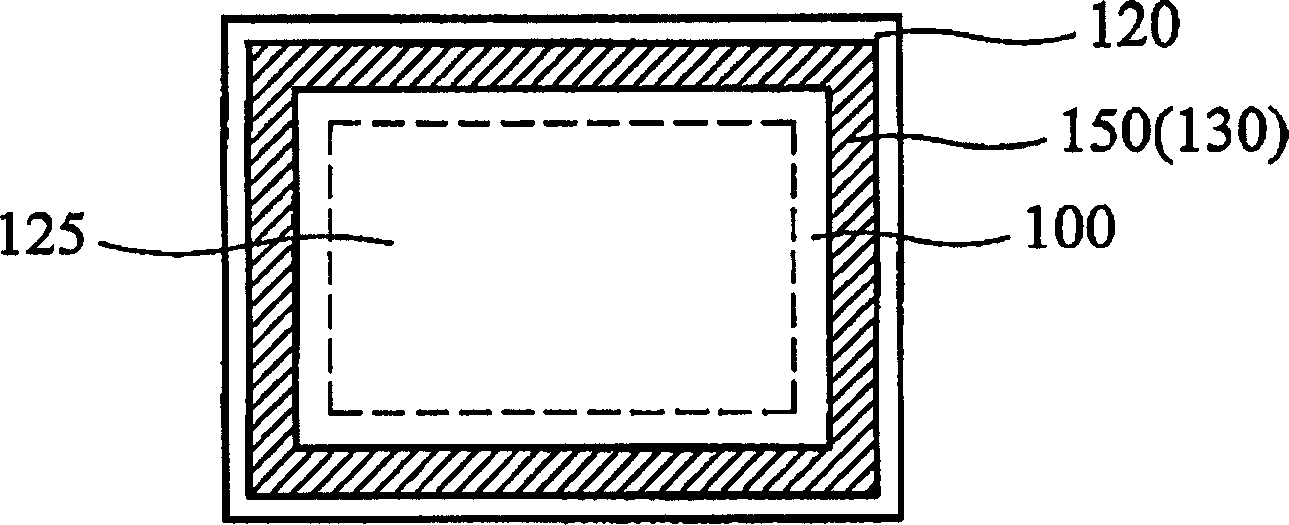

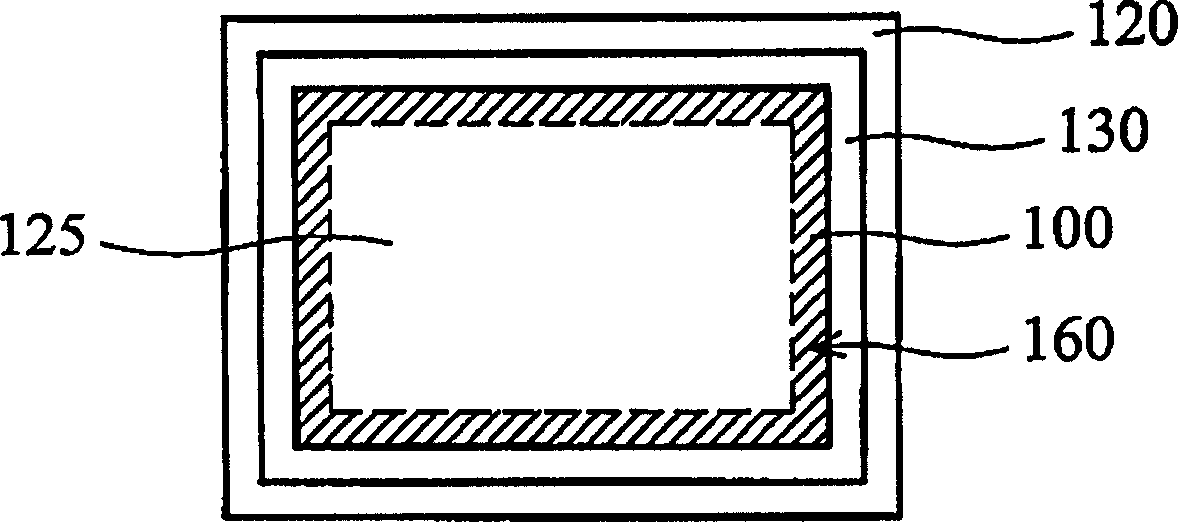

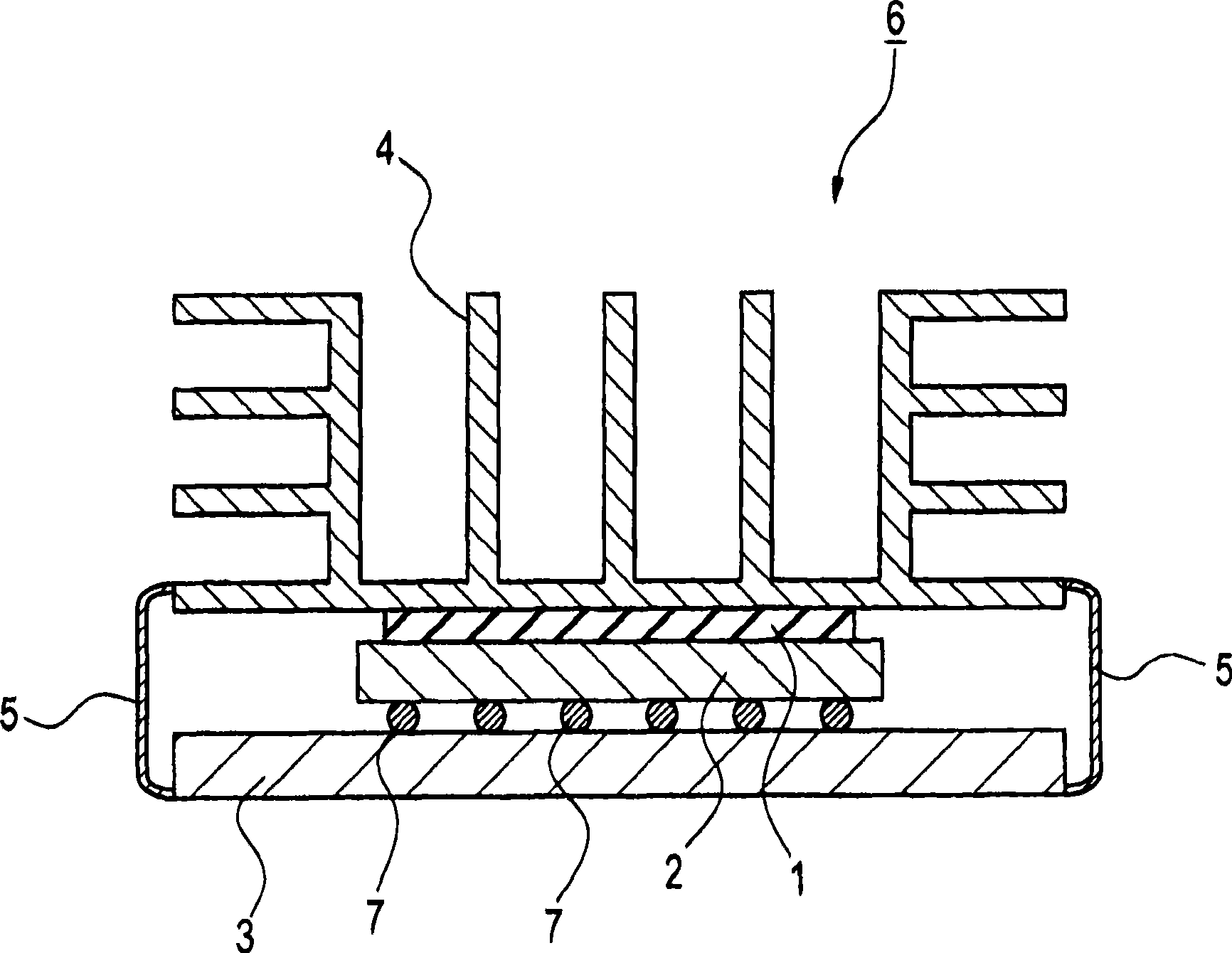

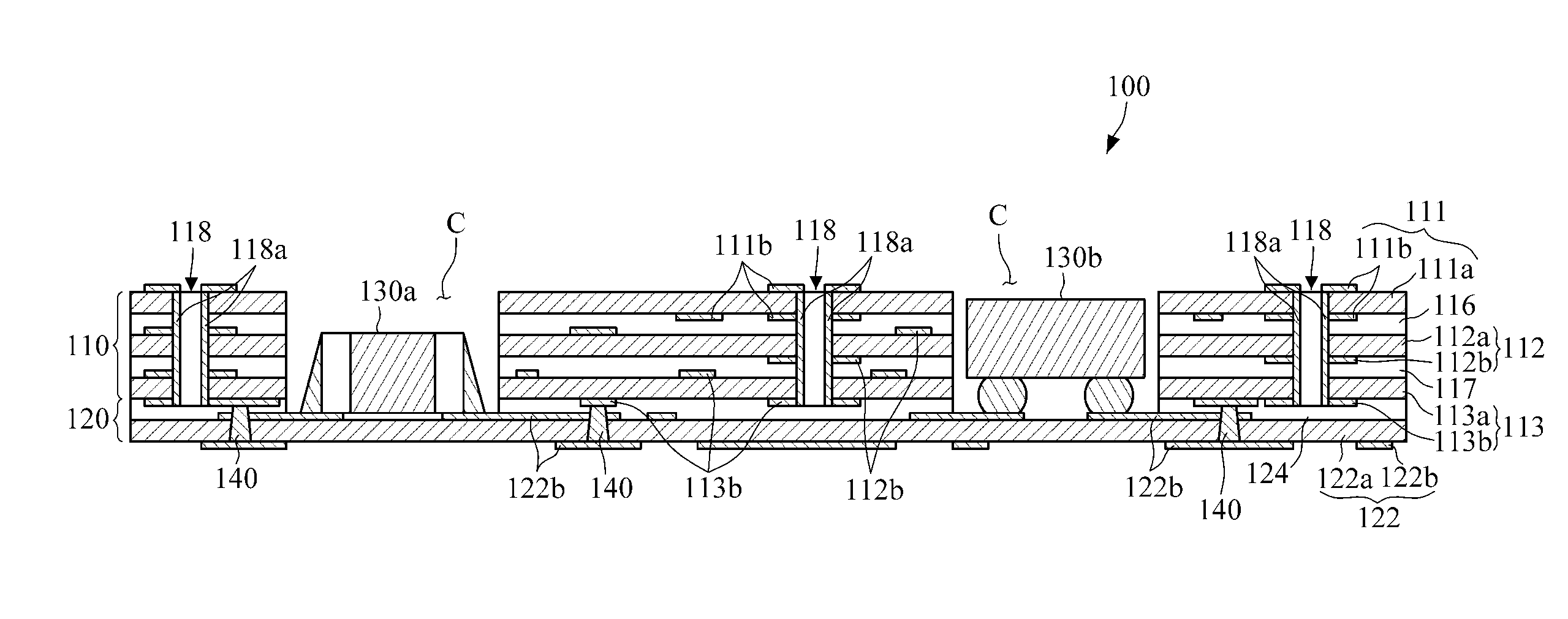

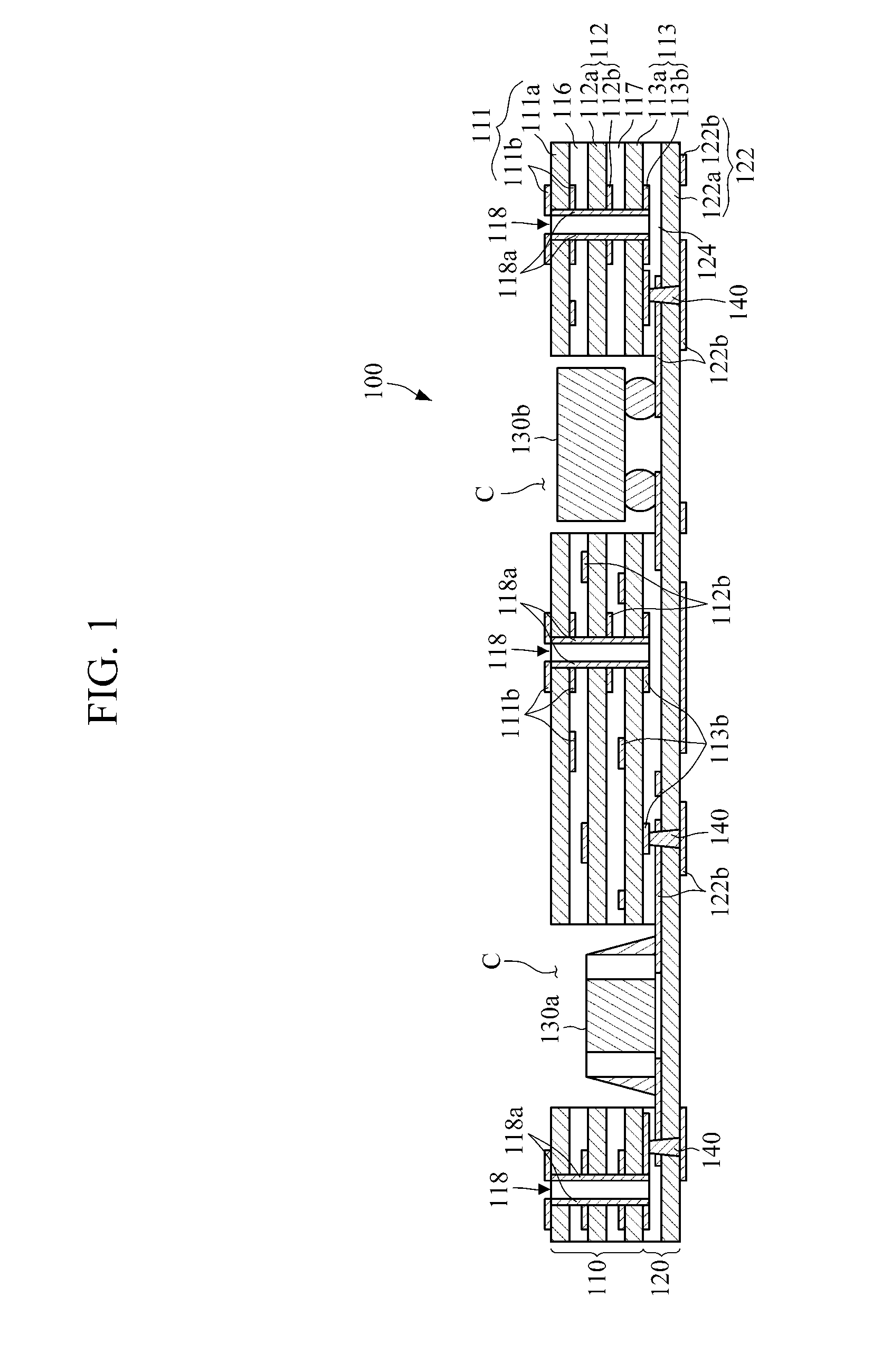

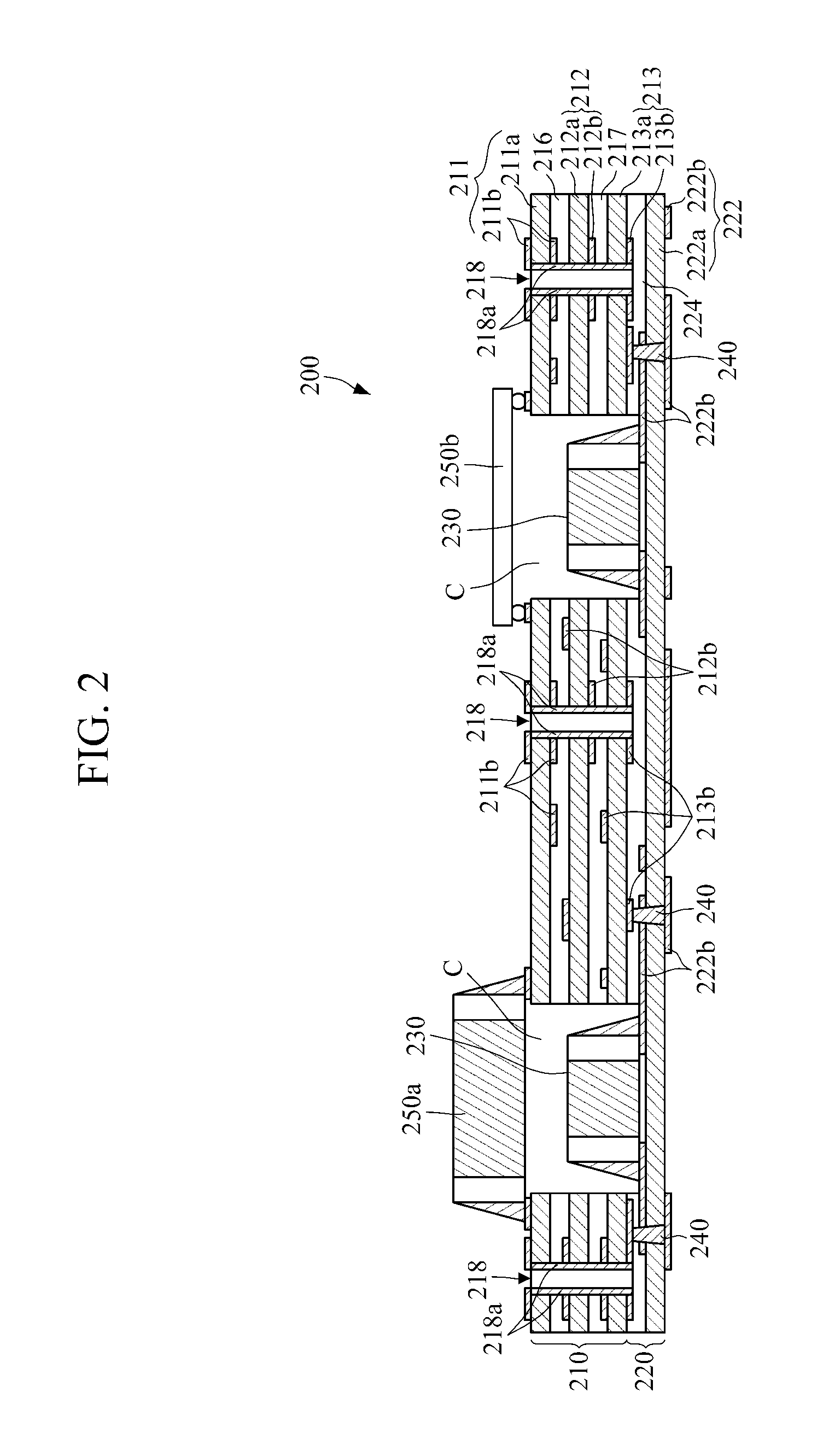

Multilayer laminate package and method of manufacturing the same

InactiveUS20120024583A1Excellent reworkabilityHigh yieldPrinted circuit assemblingPrinted electric component incorporationEngineeringElectronic component

A multilayer laminate package and a method of manufacturing the same are provided. The multilayer laminate package includes a cavity layer, a non-cavity layer, an electronic component, and a metalized blind via. The cavity layer includes a first adhesive layer and two first circuit layers, which are stacked with the first adhesive layer between, and an opening. The non-cavity layer includes a second adhesive layer and a second circuit layer. The non-cavity layer is bonded to the cavity layer with the second adhesive layer so as to close one side of the opening. The electronic component is mounted in the opening and is electrically connected to the non-cavity layer exposed through the opening. The metalized blind via electrically connects the non-cavity layer to one of the circuit layers of the cavity layer.

Owner:SAMSUNG ELECTRONICS CO LTD

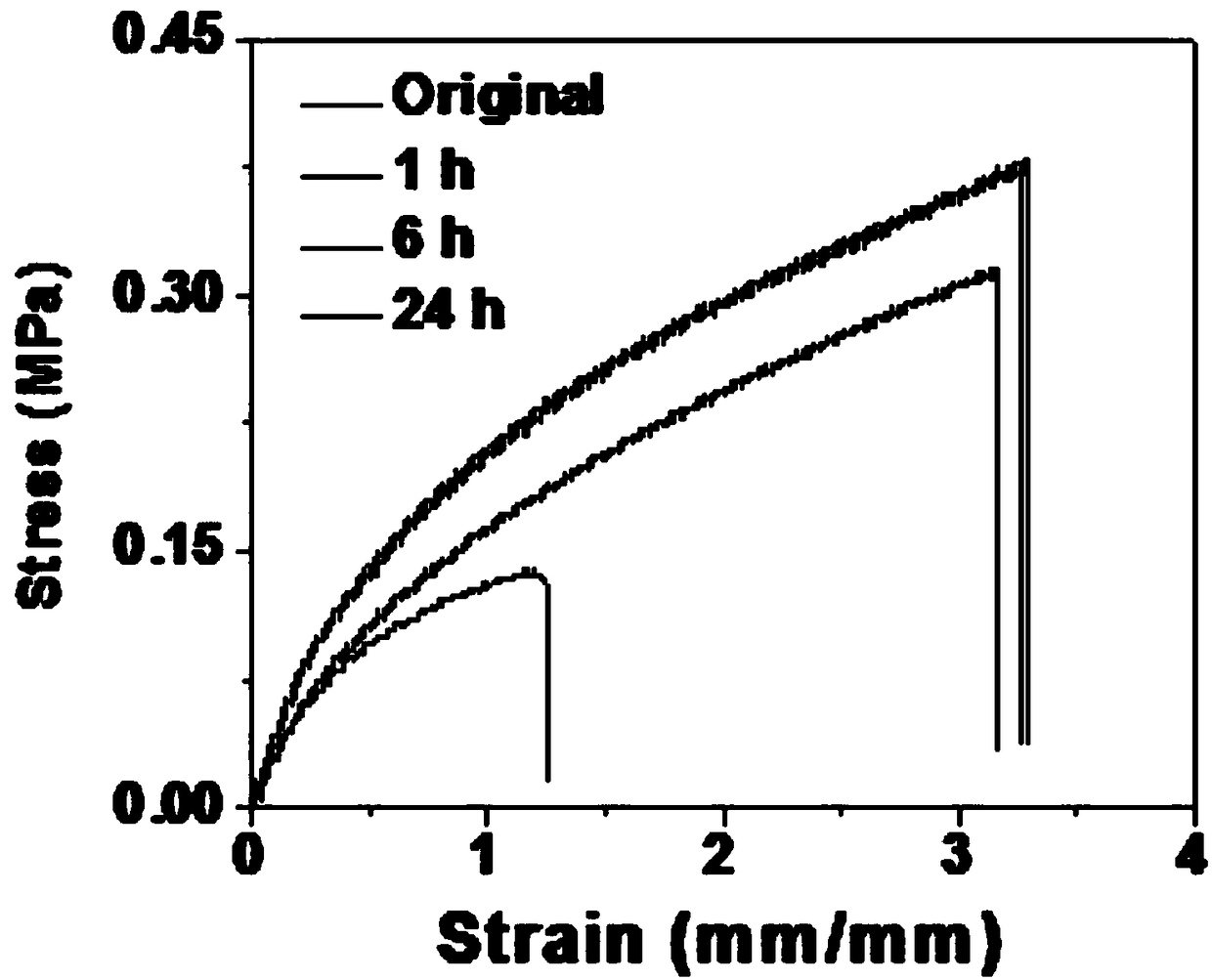

Self-repairing reprocessable polyurea material as well as preparation method and application

InactiveCN108559045AGood mechanical propertiesHave transparencyAdditive manufacturing apparatusAnti-corrosive paintsMechanical propertyPolyurea

The invention relates to the field of new materials, in particular to a self-repairing reprocessable polyurea material as well as a preparation method and application. The self-repairing reprocessablepolyurea material comprises the following raw materials in parts by weight: 3 to 13 parts of a cross-linking agent, 79 parts of amino-terminated polyetheramine, 8 to 18 parts of diisocyanate, and 1 to 5 parts of a catalyst. The polyurea material is obtained by reacting an amino group with isocyanate, and is a novel heat-responsive dynamic bond under the action of high temperature or the catalyst,so that the material can be self-repaired at 80 DEG C, and the interaction of hydrogen bonds between urea bonds can improve the mechanical strength of the material; and the polyurea material is excellent in mechanical properties, endowed with certain transparency, good in reworking properties, high in self-repairing efficiency, relatively low in repair temperature, simple in preparation technology, and low in relative cost.

Owner:SICHUAN UNIV

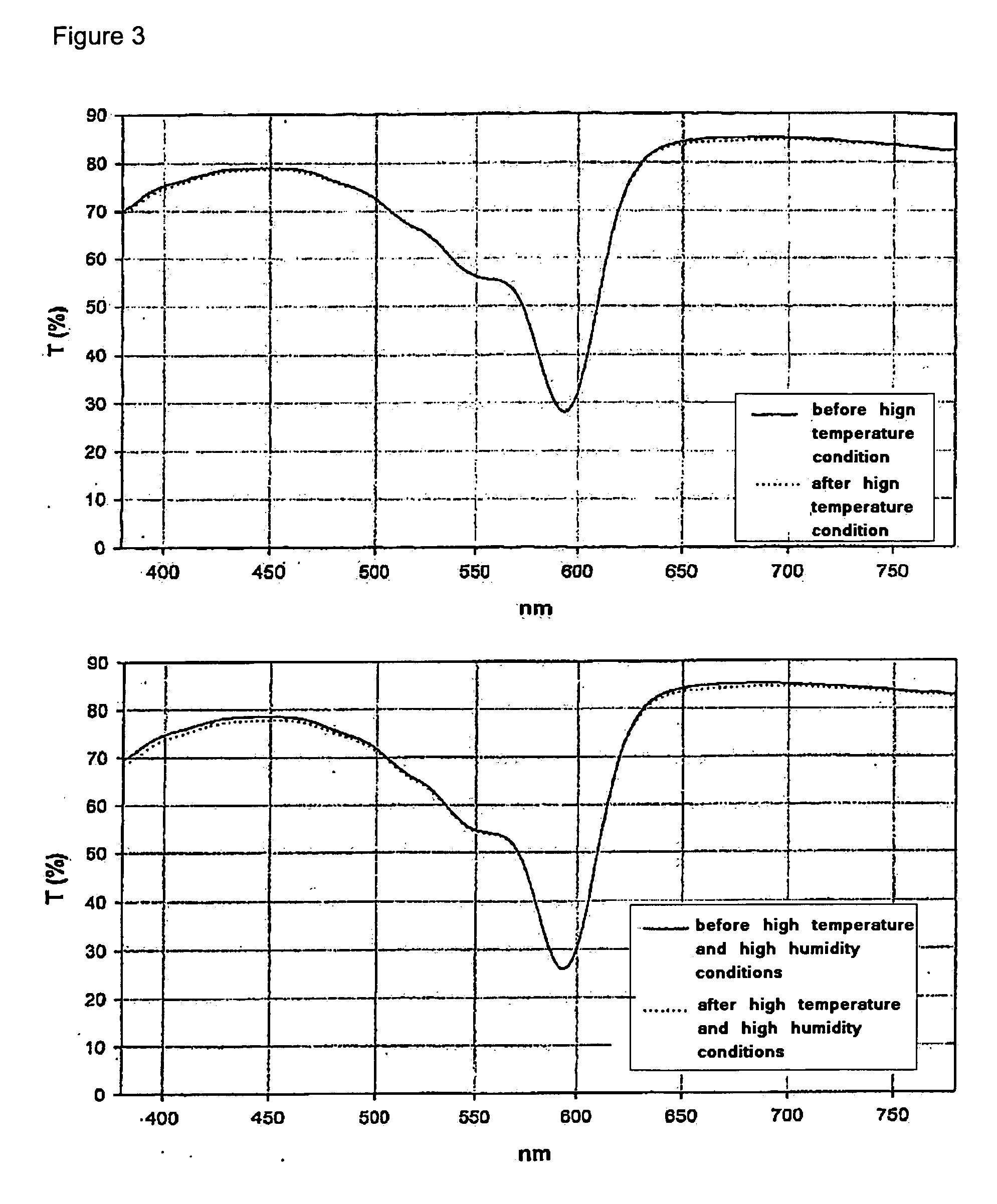

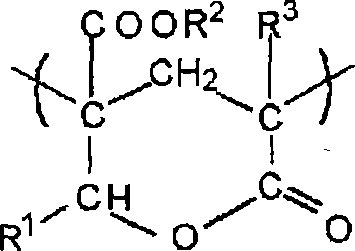

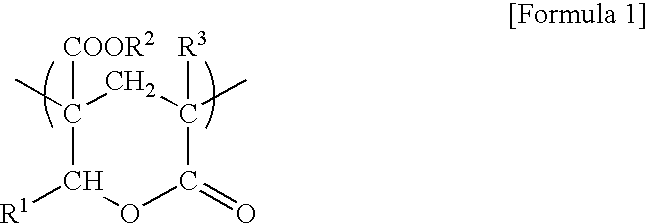

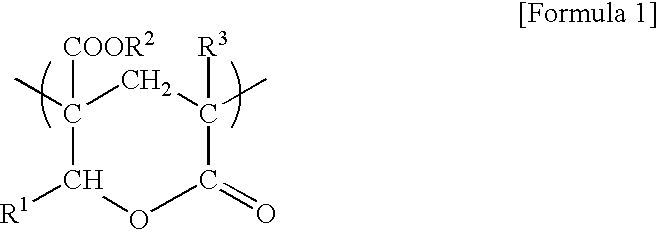

Acrylic pressure-sensitive adhesive composition with good re-workability

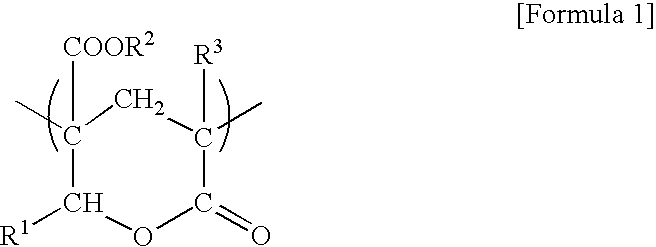

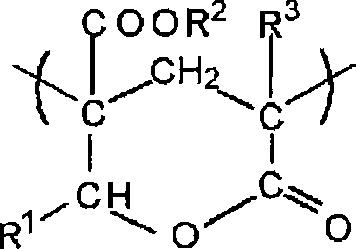

InactiveUS20060159915A1Excellent reworkabilityElectric discharge tubesFilm/foil adhesivesHydroxy groupPolydimethylsiloxane

This invention relates to an acrylic pressure-sensitive adhesive composition, including a) 100 parts by weight of an acrylic copolymer containing a hydroxy group without a carboxyl group; b) 0.01˜10 parts by weight of a cross-linkging agent; and c) 0.01˜5 parts by weight of a polyether modified polydimethylsiloxane copolymer having HLB of 4˜13 and having the structure of Formula 1, and to an adhesive sheet formed thereby. The adhesive composition and adhesive sheet according to this invention may exhibit excellent re-workability, durability, and reliability.

Owner:LG CHEM LTD

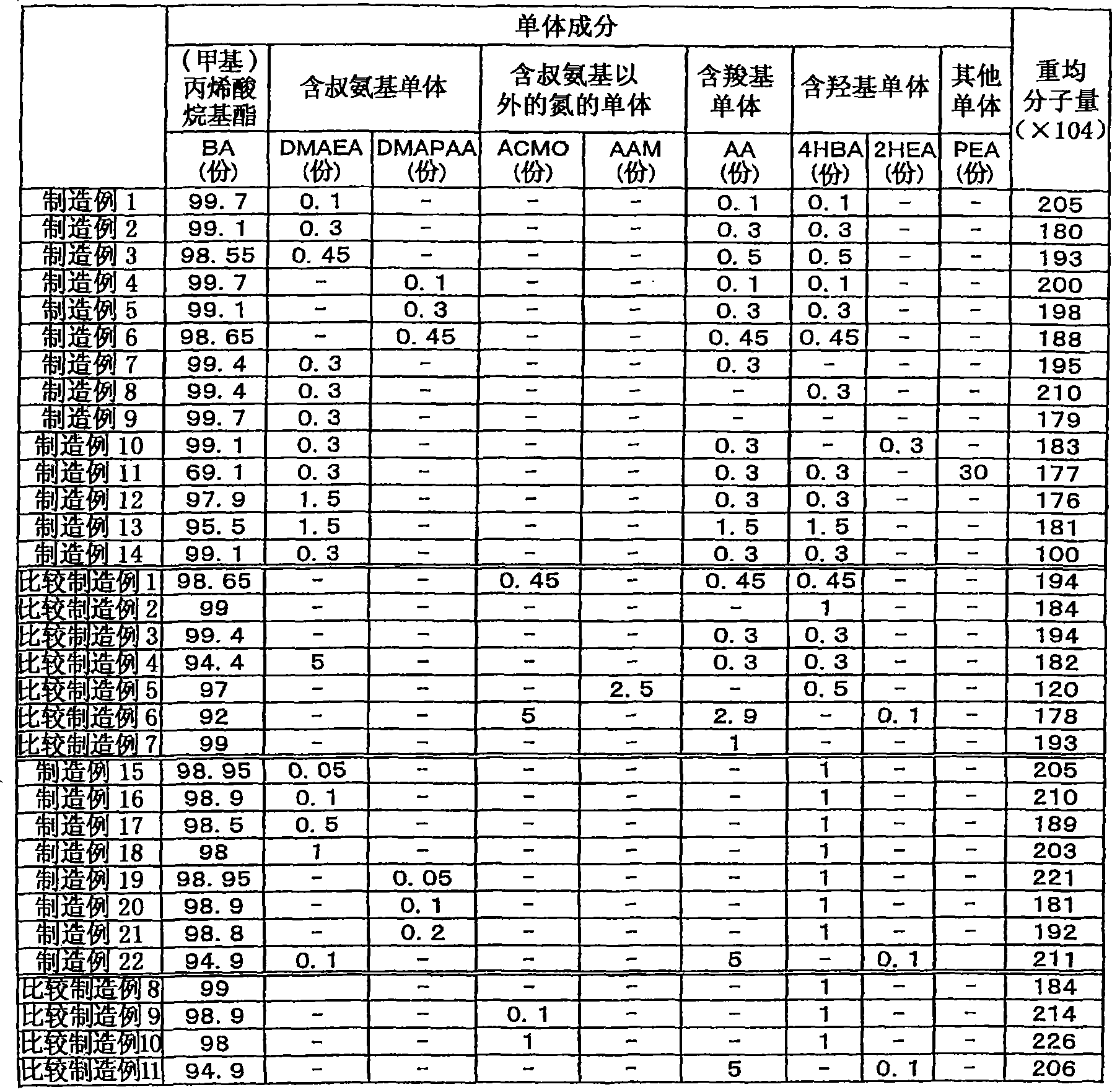

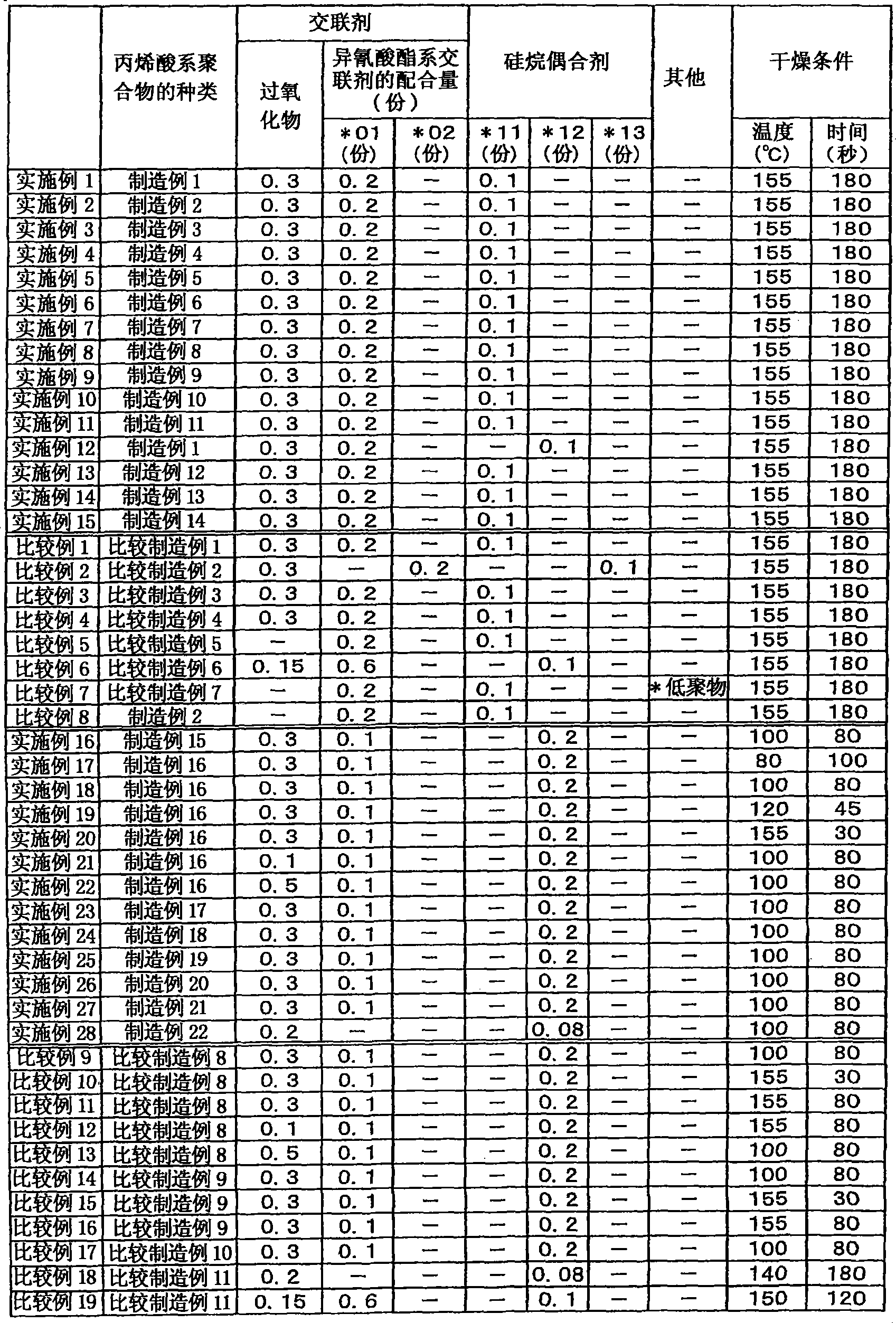

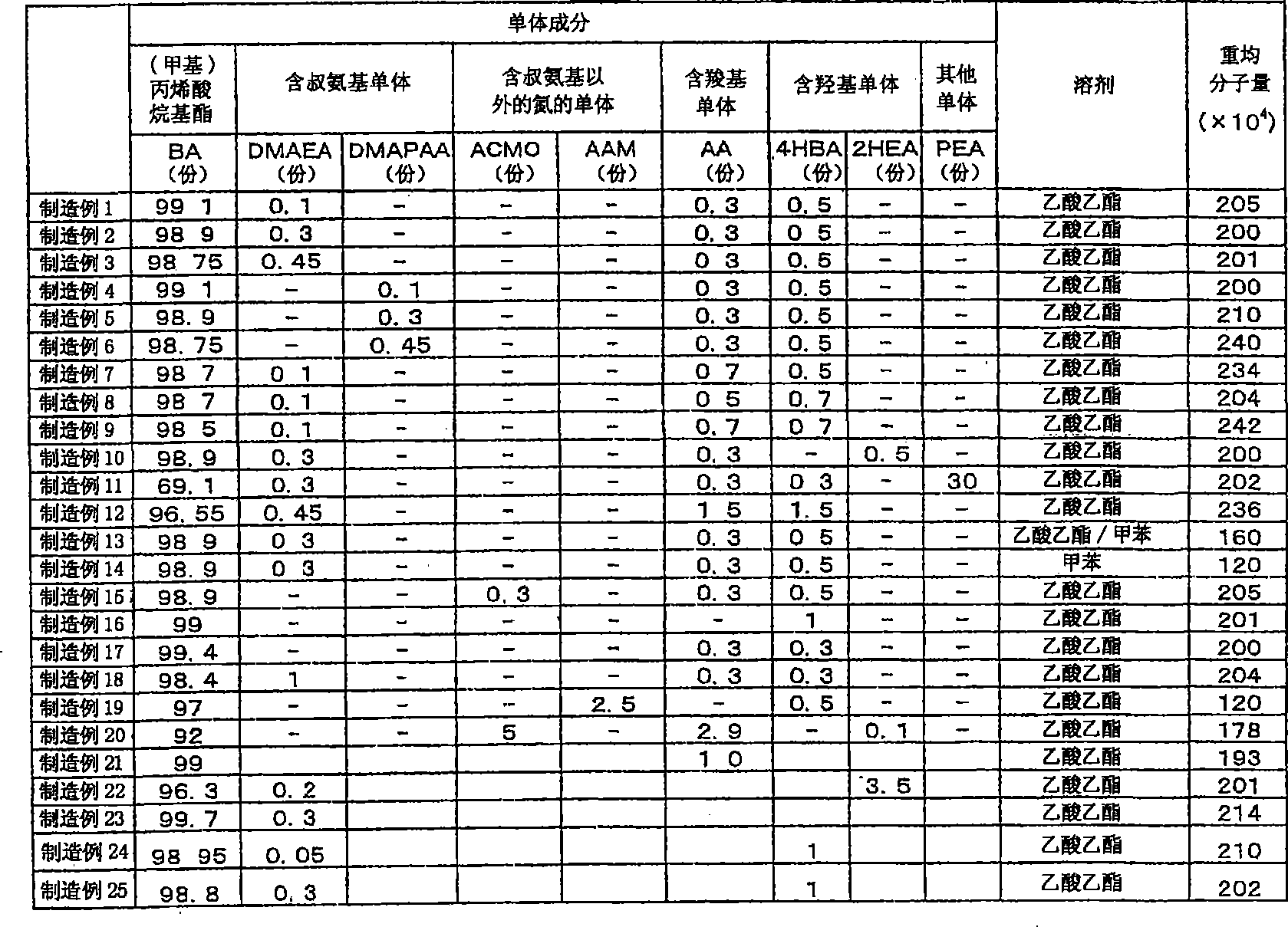

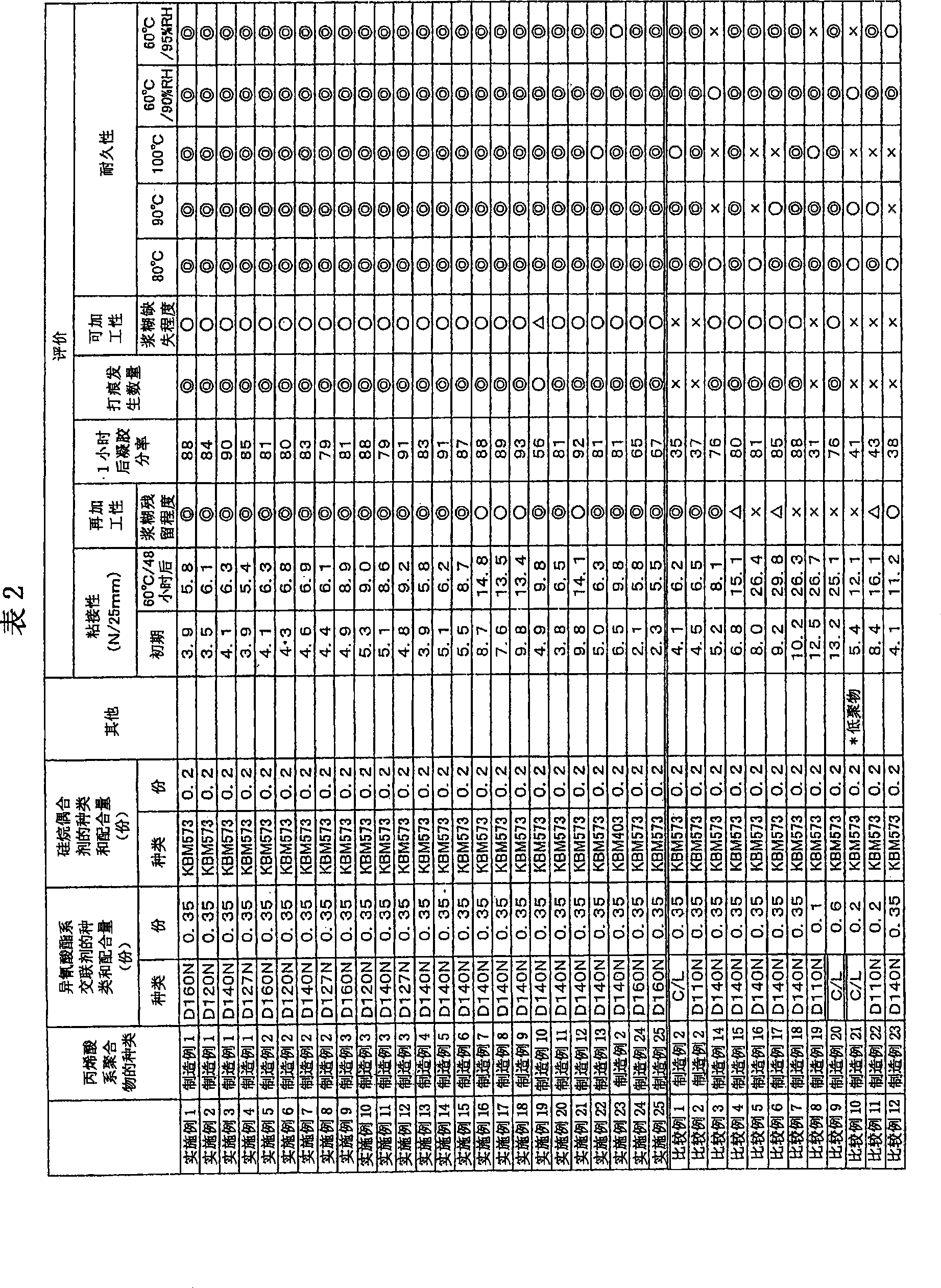

Pressure-sensitive adhesive composition for optical film, pressure-sensitive adhesive layer for optical film, production method thereof, pressure-sensitive adhesive optical film and image display

ActiveCN101418198AExcellent productivityImprove machinabilityFilm/foil adhesivesPolarising elementsMeth-Optical thin film

A pressure-sensitive adhesive composition can form an pressure-sensitive adhesive layer that has satisfactory reworkability such that optical films can be easily peeled from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be worked without pressure-sensitive adhesive fouling or dropout. The pressure-sensitive adhesive composition for an optical film of the present invention comprises 100 parts by weight of a (meth)acrylic polymer comprising 45 to 99.99% by weight of an alkyl (meth)acrylate monomer unit and 0.01 to 2% by weight of a tertiary amino group-containing monomer unit; and 0.01 to 2 parts by weight of a peroxide as a crosslinking agent.

Owner:NITTO DENKO CORP

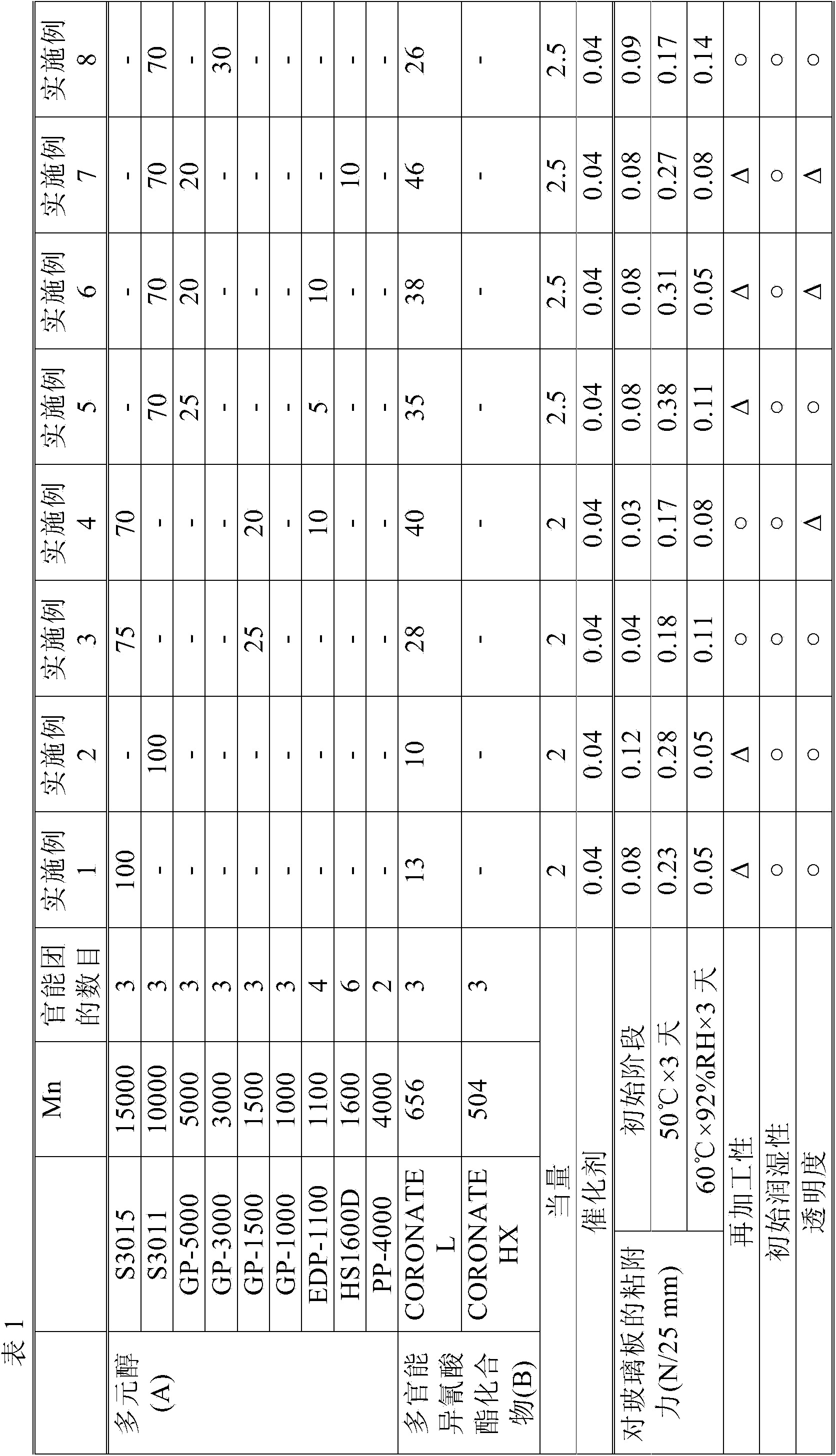

Urethane-based pressure-sensitive adhesive and surface protective film using the pressure-sensitive adhesive

ActiveCN103666360AExcellent reworkabilityHigh transparencyLayered productsPolyureas/polyurethane adhesivesPolyolPressure sensitive

Owner:NITTO DENKO CORP

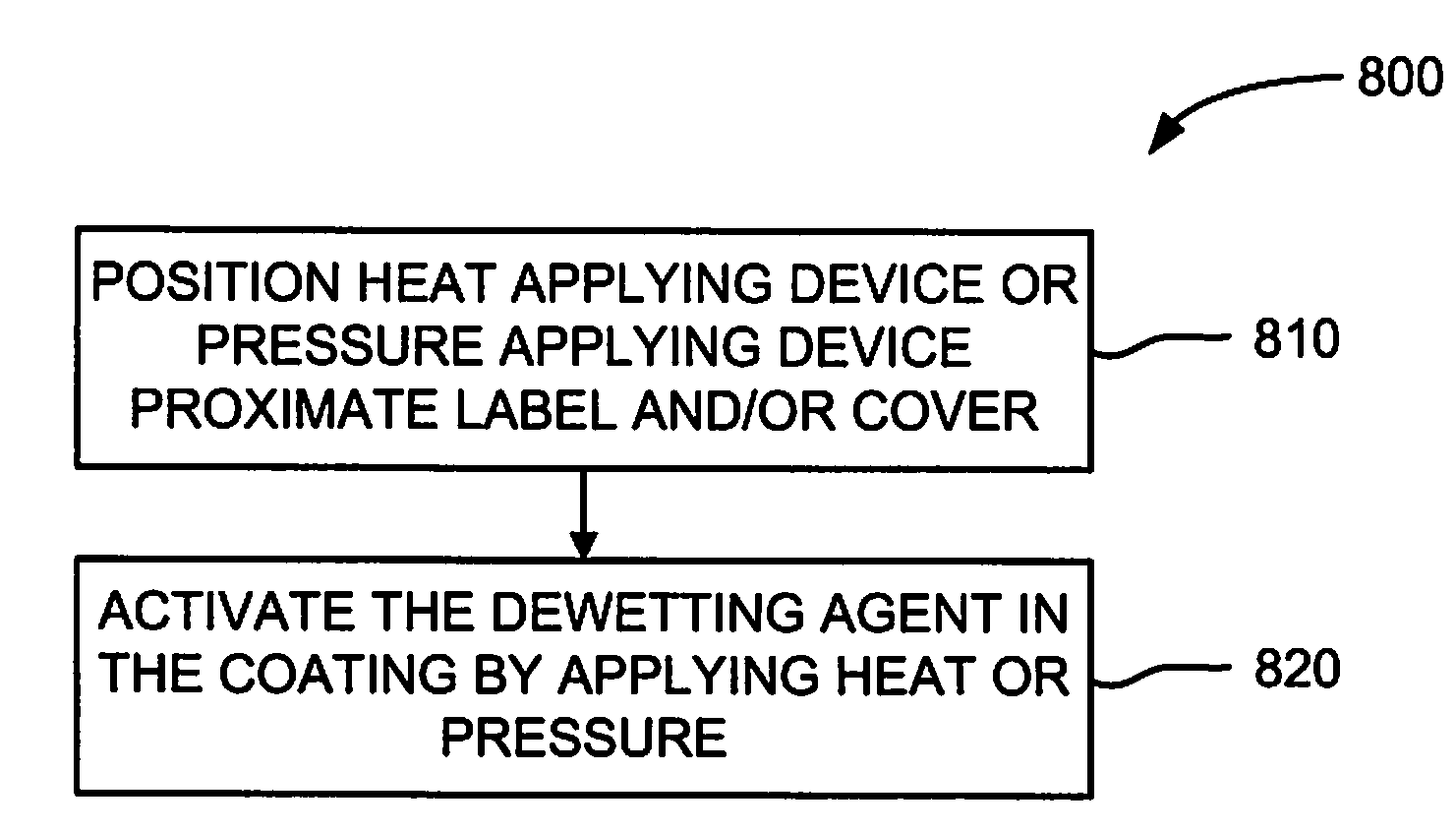

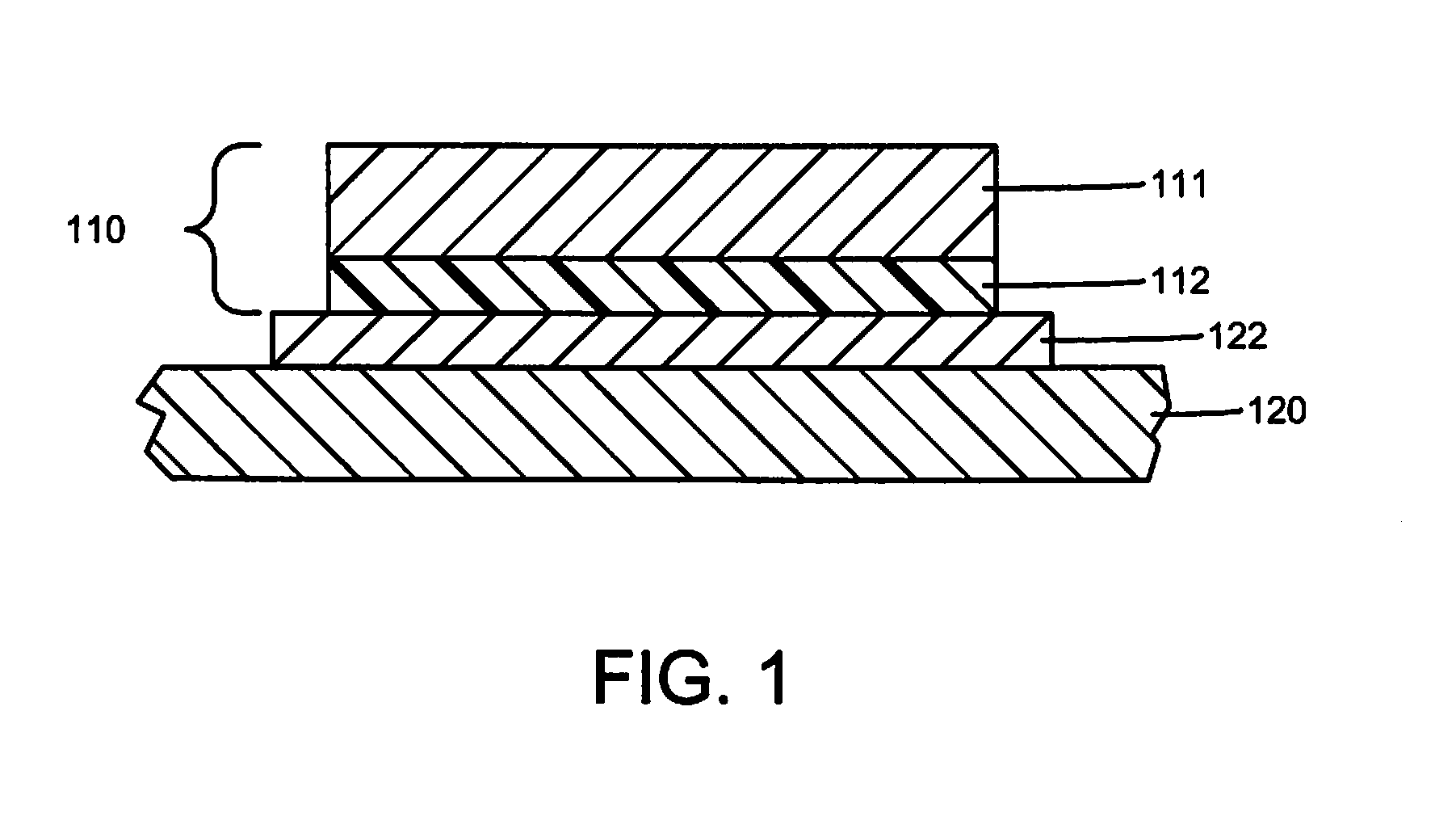

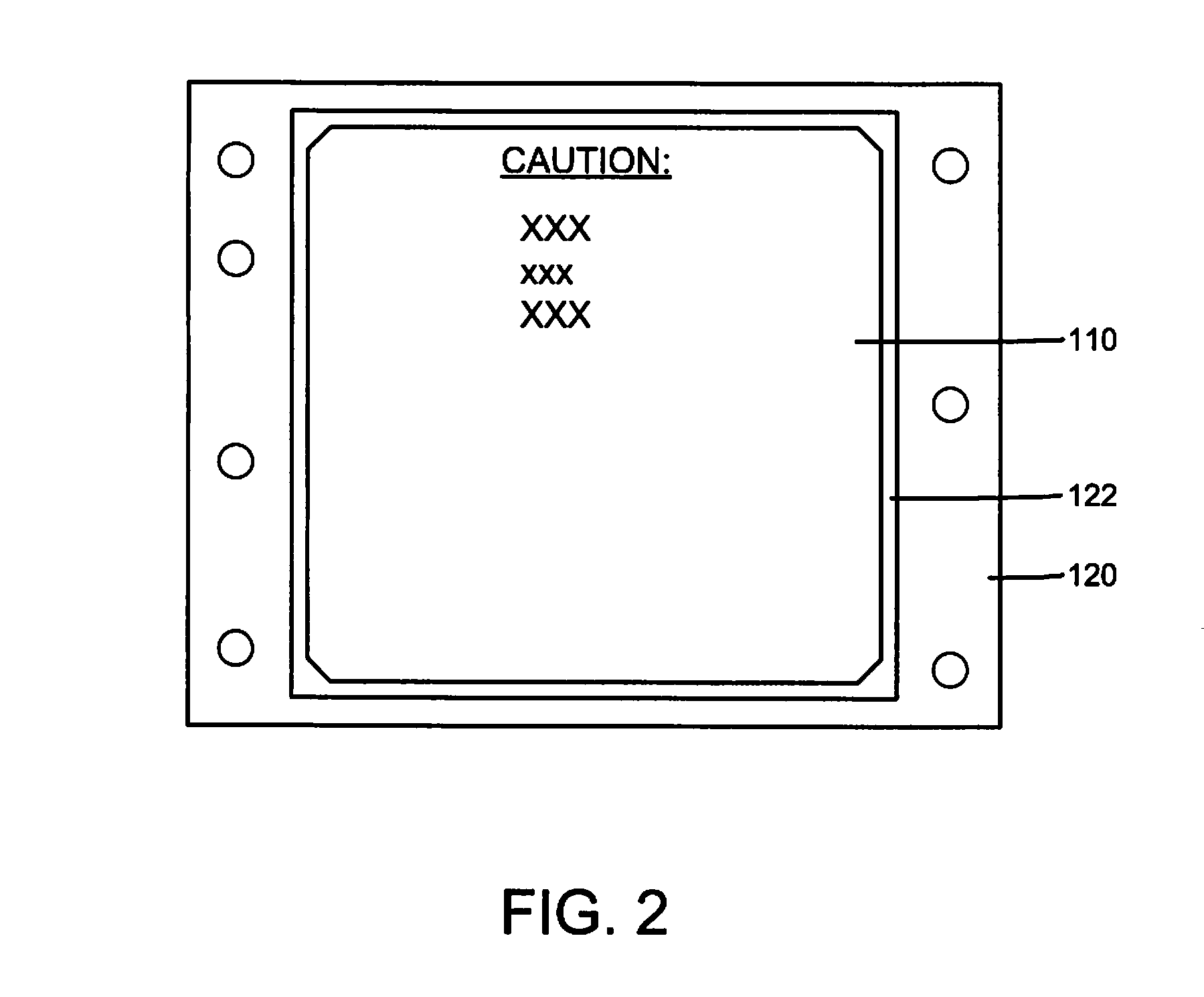

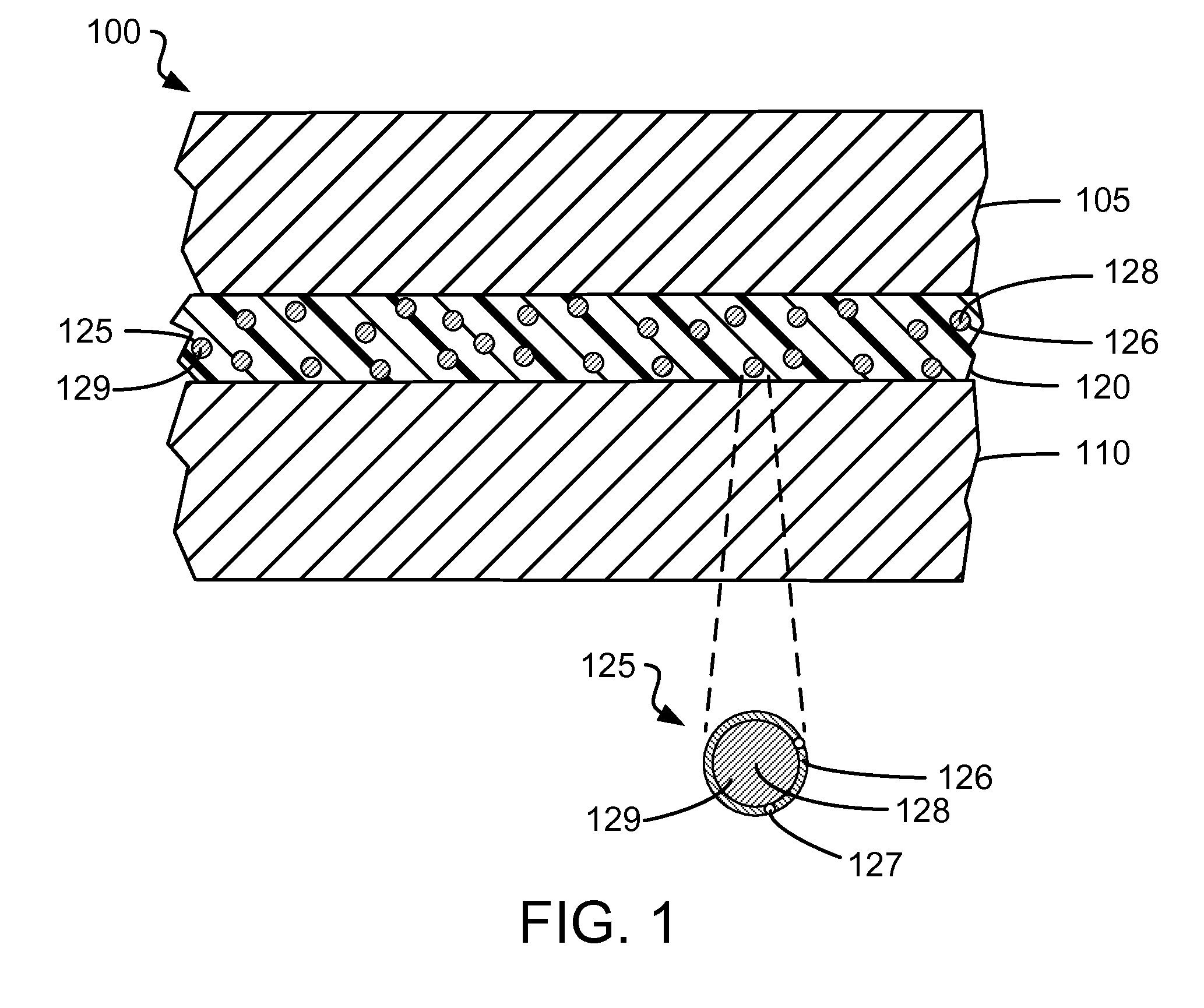

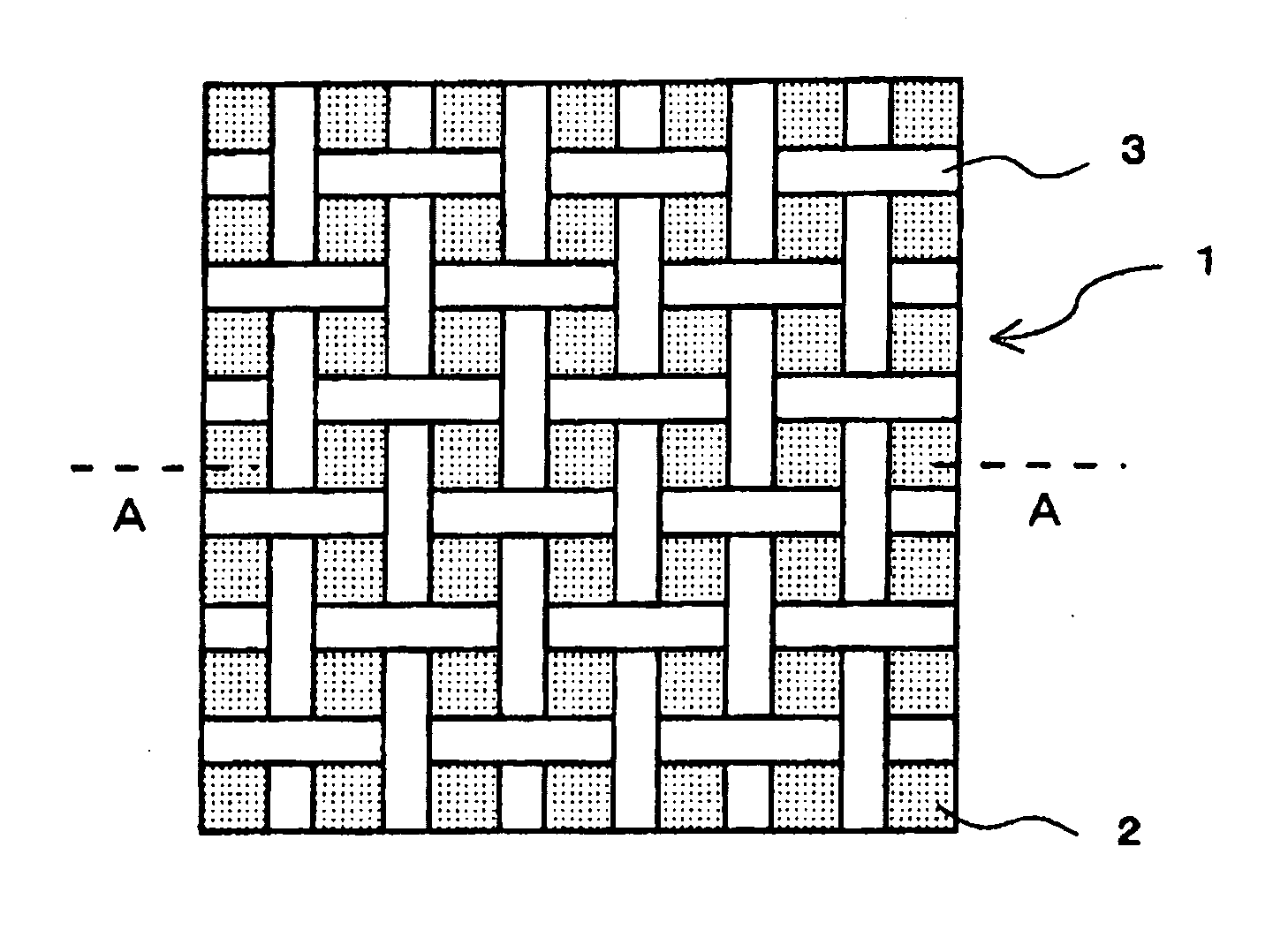

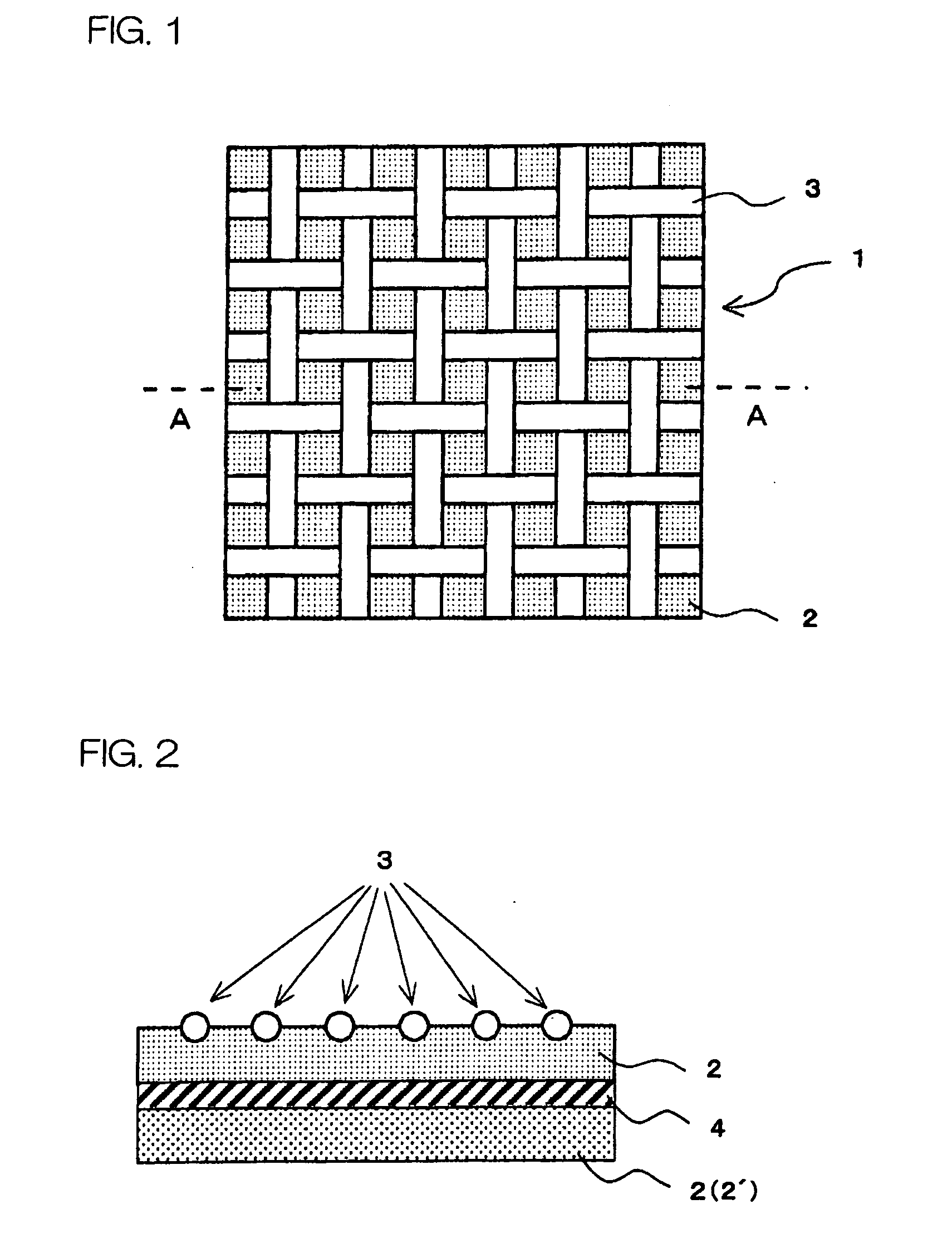

Apparatus and Method to Enable Easy Removal of One Substrate from Another for Enhanced Reworkability and Recyclability

InactiveUS20080264563A1Excellent reworkabilityAchieve recyclabilityLayered productsDomestic articlesMicrosphereDecomposition

A method and apparatus enables easy removal of a first substrate (e.g., a label, EMC gasket, etc.) from a second substrate (e.g., a cover of a computer enclosure) for enhanced reworkability or recyclability. An adhesive layer affixes the substrates to each other. A coating that includes a dewetting agent (DA) is interposed between the second substrate and the adhesive layer. Removal is facilitated by applying heat and / or pressure to activate the DA. Preferably, the DA thermally decomposes to form gaseous products at a predefined temperature. Heat may be applied through one or more of the substrates to drive the DA to decomposition, which forms bubbles that lift the first substrate relative to the second substrate. Optionally, the DA may be encapsulated in microspheres. For example, the DA may be silicone oil and / or an adhesive solvent encapsulated in microspheres and may be activated by applying pressure sufficient to crush the microspheres.

Owner:IBM CORP

Acrylic pressure-sensitive adhesive composition with good re-workability

InactiveCN1977015AExcellent reworkabilityIncreased durabilityElectric discharge tubesFilm/foil adhesivesHydroxy groupPolydimethylsiloxane

This invention relates to an acrylic pressure-sensitive adhesive composition, including a) 100 parts by weight of an acrylic copolymer containing a hydroxy group without a carboxyl group; b) 0.01~10 parts by weight of a cross-linkging agent; and c) 0.01~5 parts by weight of a polyether modified polydimethylsiloxane copolymer having HLB of 4~13 and having the structure of Formula 1, and to an adhesive sheet formed thereby. The adhesive composition and adhesive sheet according to this invention may exhibit excellent re-workability, durability, and reliability.

Owner:LG CHEM LTD

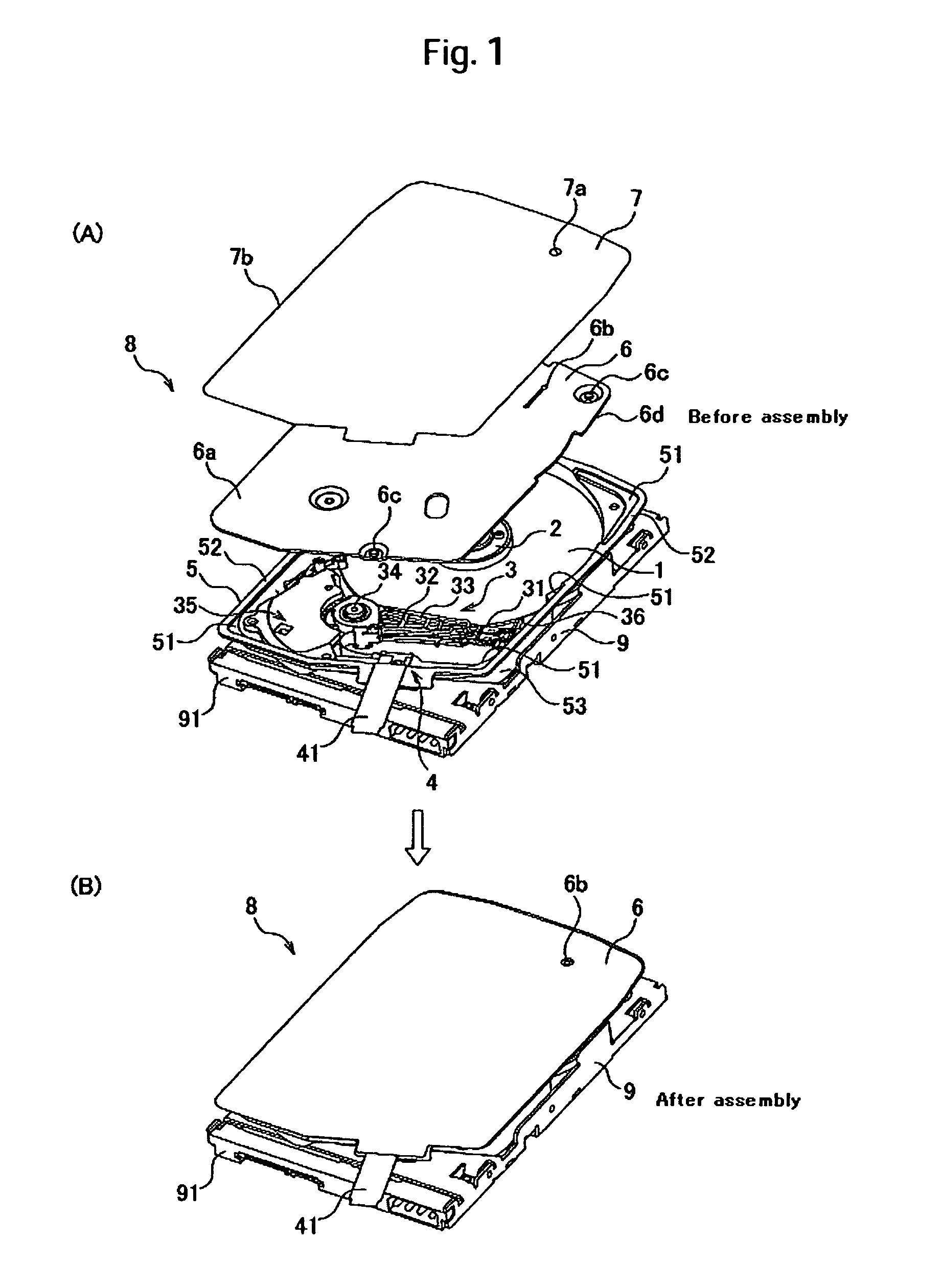

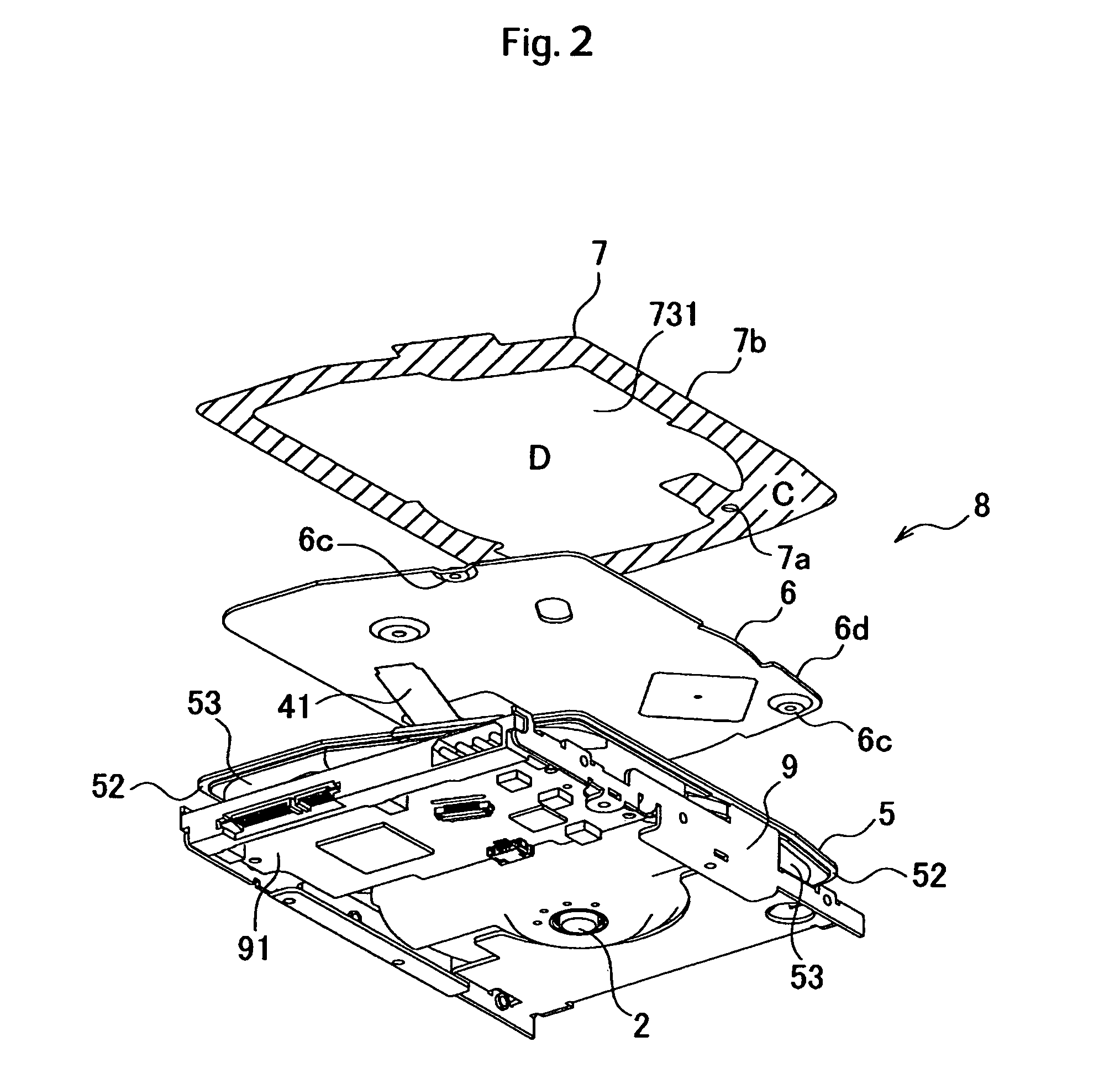

Magnetic disk drive with cover seal and method for fabricating same

InactiveUS7522375B2Long working timeAdditional drawbackApparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionWork timeElectrical and Electronics engineering

Owner:WESTERN DIGITAL TECH INC

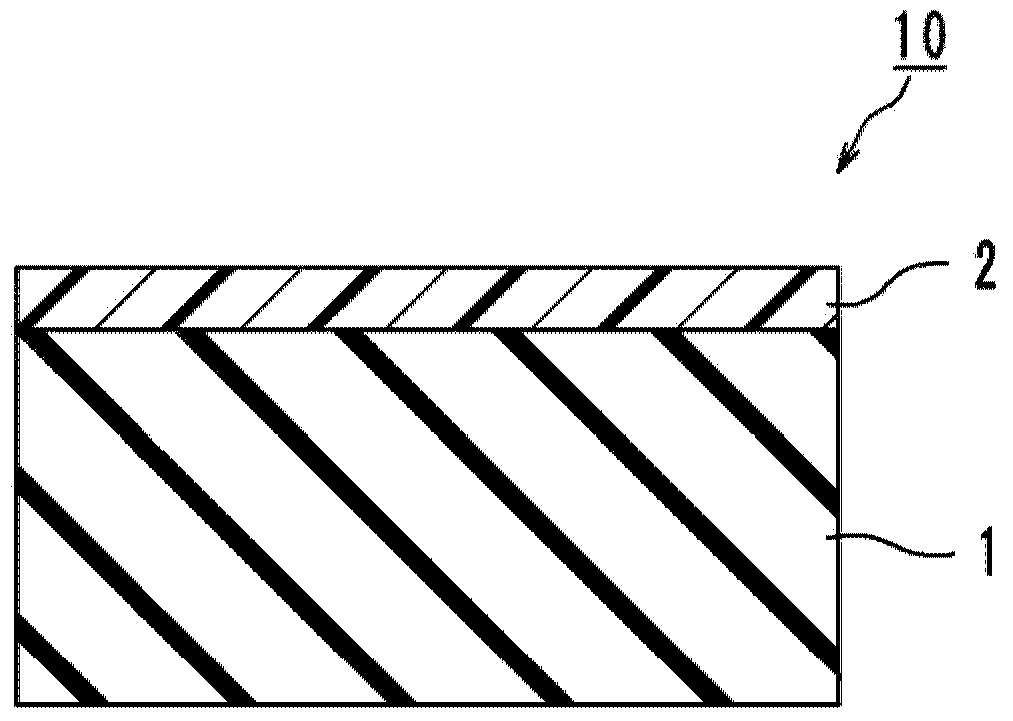

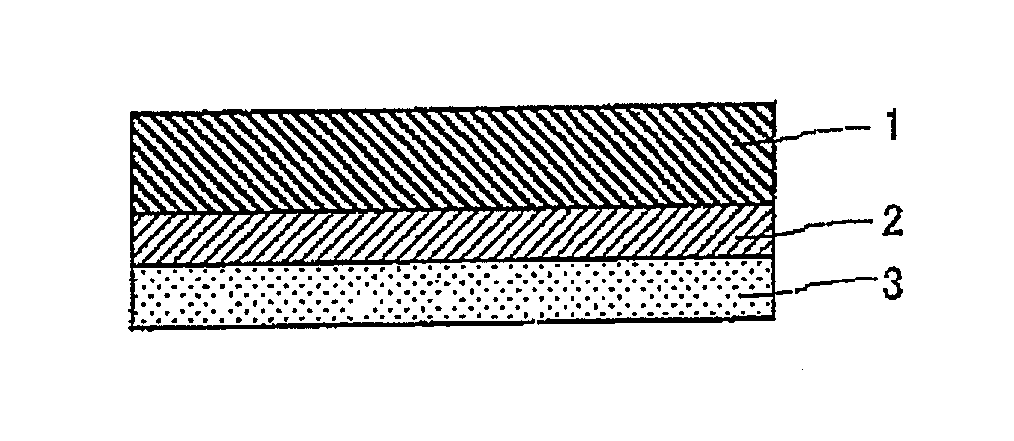

Adhesive agent composition for optical films, adhesive agent layer for optical films, optical film having adhesive agent layer attached thereto, and image display device

ActiveCN106133096AIncreased durabilityPrevent peelingNon-macromolecular adhesive additivesPolarising elementsPolymer scienceMeth-

An adhesive agent composition for optical films, which comprises: a (meth)acrylic polymer (A) that contains, as monomer units, 70% by weight or more of an alkyl (meth)acrylate (a1), 3 to 25% by weight of an aromatic-ring-containing (meth)acrylate (a2), 0.1 to 8% by weight of an amide-group-containing monomer (a3), 0.01 to 2% by weight of a carboxyl-group-containing monomer (a4) and 0.01 to 3% by weight of a hydroxyl-group-containing monomer (a5) and meets such requirements that the weight average molecular weight (Mw) is 1,000,000 to 2,500,000 and the Mw / (number average molecular weight (Mn)) ratio is 1.8 to 10 inclusive; and a cross-linking agent (B) in an amount of 0.01 to 3 parts by weight relative to 100 parts by weight of the (meth)acrylic polymer (A). The adhesive agent composition can be formed into an adhesive agent layer which satisfies durability to such an extent that the adhesive agent layer does not undergo foaming, is not detached or does not get clouded under humidified conditions when applied onto a glass or a transparent conductive layer, and which can prevent the occurrence of display unevenness due to leakage of light, and which has excellent metal corrosion resistance.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive composition for optical films, pressure-sensitive adhesive optical film and image display

InactiveUS20090162577A1Easy to processExcellent reworkabilityMonocarboxylic acid ester polymer adhesivesLiquid crystal compositionsXylyleneMeth-

There is provided an optical film pressure-sensitive adhesive composition capable of forming a pressure-sensitive adhesive layer that has reworkability such that optical films therewith can be easily separated from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be processed without causing adhesive stain or dropout after it is formed on an optical film. The optical film pressure-sensitive adhesive composition includes 100 parts by weight of a (meth)acrylic polymer including, as monomer units, (a) 50 to 99.79% by weight of an alkyl (meth)acrylate monomer, (b) 0.01 to 0.45% by weight of a tertiary amino group-containing monomer, and (c) 0.1 to 3% by weight of a hydroxyl group-containing monomer; and 0.01 to 2 parts by weight of a crosslinking agent that is at least one selected from the group consisting of hexamethylene diisocyanate, hydrogenated xylylene diisocyanate, and isophorone diisocyanate, or a polyisocyanate compound derived therefrom.

Owner:NITTO DENKO CORP

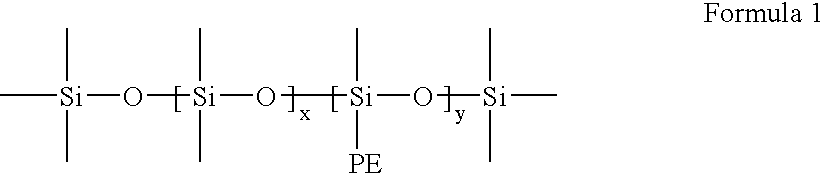

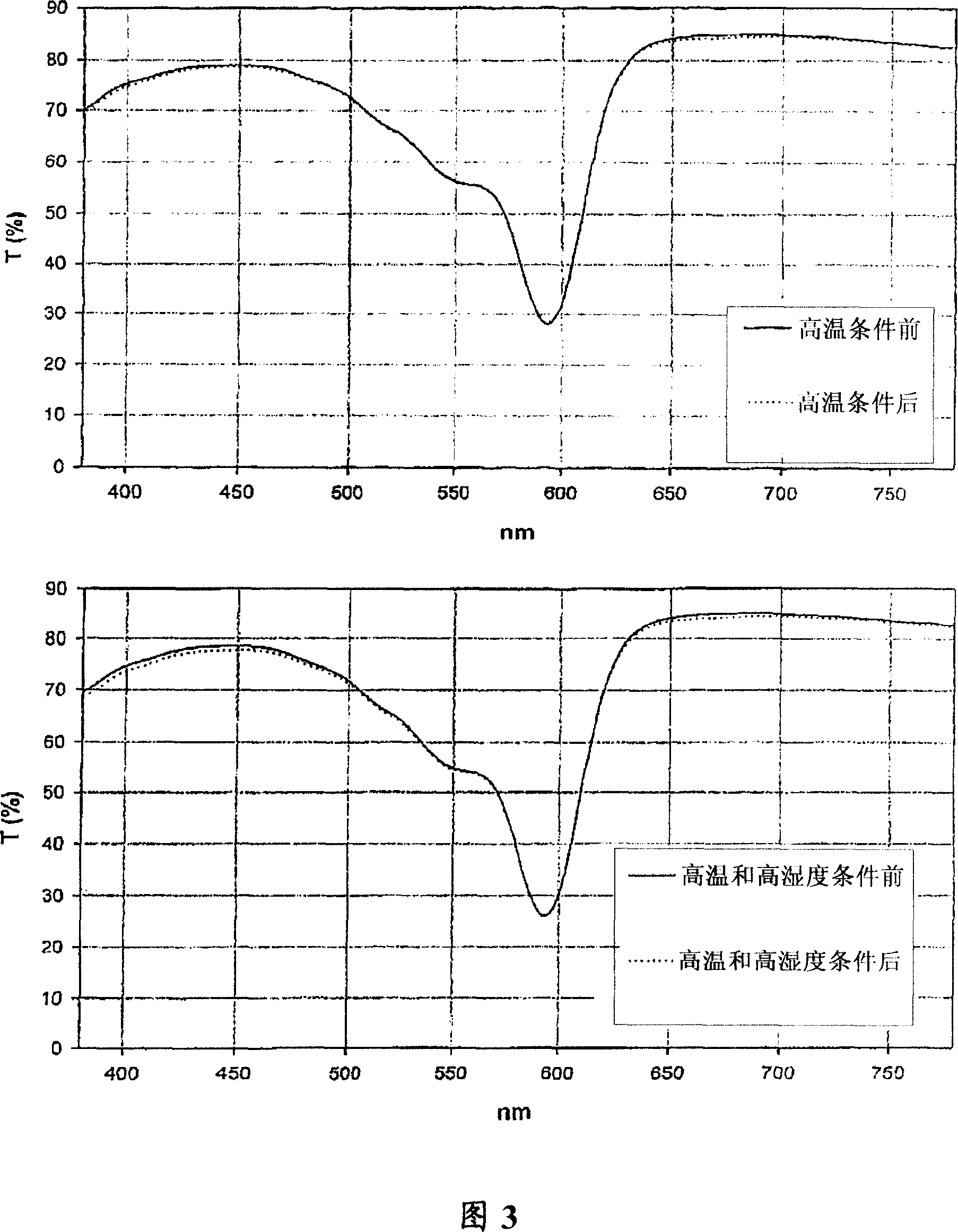

Charge-Preventing Optical Film, Charge-Preventing Adhesive Optical film, Manufacturing Method Thereof, and Image Display Device

InactiveUS20080044674A1Good effectImprove transmittanceElectroluminescent light sourcesSynthetic resin layered productsConductive polymerTransmittance

The present invention aims at providing an antistatic optical film having excellent antistatic effect and high light transmittance, wherein an antistatic layer laminated on at least one side of the optical film. An antistatic optical film having an antistatic layer laminated on at least one side of the optical film, wherein rubbing treatment is performed on a surface of the optical film on which the antistatic layer is laminated, and a conductive polymer in the antistatic layer is aligned.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive composition for optical film, pressure-sensitive adhesive layer for optical film, production method thereof, pressure-sensitive adhesive optical film and image display

InactiveUS20090104450A1Easy to processExcellent reworkabilityFilm/foil adhesivesSynthetic resin layered productsMeth-Display device

A pressure-sensitive adhesive composition for an optical film of the present invention comprises 100 parts by weight of a (meth)acrylic polymer comprising 45 to 99.99% by weight of an alkyl (meth)acrylate monomer unit and 0.01 to 2% by weight of a tertiary amino group-containing monomer unit; and 0.01 to 2 parts by weight of a peroxide as a crosslinking agent. The pressure-sensitive adhesive composition can form an pressure-sensitive adhesive layer that has satisfactory reworkability such that optical films can be easily peeled from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be worked without pressure-sensitive adhesive fouling or dropout.

Owner:NITTO DENKO CORP

Adhesive composition for optical films, adhesive optical film and image display

ActiveCN101463234AInhibit sheddingPollution suppressionNon-macromolecular adhesive additivesFilm/foil adhesivesXylyleneMeth-

The present invention provides an optical film pressure-sensitive adhesive composition, pressure-sensitive optical films and an image display device. The invention particularly provide an optical film pressure-sensitive adhesive composition capable of forming a pressure-sensitive adhesive layer that has reworkability such that optical films therewith can be easily separated from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be processed without causing adhesive stain or dropout after it is formed on an optical film. The optical film pressure-sensitive adhesive composition includes 100 parts by weight of a (meth)acrylic polymer including, as monomer units, (a) 50 to 99.79% by weight of an alkyl (meth)acrylate monomer, (b) 0.01 to 0.45% by weight of a tertiary amino group-containing monomer, and (c) 0.1 to 3% by weight of a hydroxyl group-containing monomer; and 0.01 to 2 parts by weight of a crosslinking agent that is at least one selected from the group consisting of hexamethylene diisocyanate, hydrogenated xylylene diisocyanate, and isophorone diisocyanate, or a polyisocyanate compound derived therefrom.

Owner:NITTO DENKO CORP

Adhesive composition for optical components, adhesive for optical components, optical component with adhesive layer, and image display device

ActiveCN103168083AExcellent reworkabilityGood durabilityNon-macromolecular adhesive additivesPolarising elementsChemistryLiquid-crystal display

The present invention provides an adhesive composition for optical components that is capable of achieving both reworkability and durability and that is capable of inhibiting unevenness in color and light leakage when applied to image display devices such as liquid crystal display panels. The present invention relates to an adhesive composition for optical components that contains an acrylic resin (A) obtained by copolymerizing a copolymerization component [I] containing, as the principal component thereof, an alkyl (meth)acrylate ester monomer (a1), wherein the adhesive composition is characterized by containing a N-(alkoxyalkyl)(meth)acrylamide monomer (a2) as the copolymerization component [I].

Owner:MITSUBISHI CHEM CORP +1

Liquid crystal display device

ActiveCN1558279AImprove the protective effectReduce volumeNon-linear opticsLiquid-crystal displayEngineering

The liquid crystal display device includes one liquid crystal panel, one back light assembly, one outer frame and one light inducing adhering layer. The back light assembly and the outer frame are set on two sides of the liquid crystal panel separately; the outer frame covers the liquid crystal panel and the back light assembly; and the light inducing adhering layer is set between the liquid crystal panel and the outer frame to adhere the liquid crystal panel and the outer frame. When being irradiated with specific light, the light inducing adhering layer will lose its adhesiveness and the liquid crystal panel may be separated from the outer frame.

Owner:AU OPTRONICS CORP

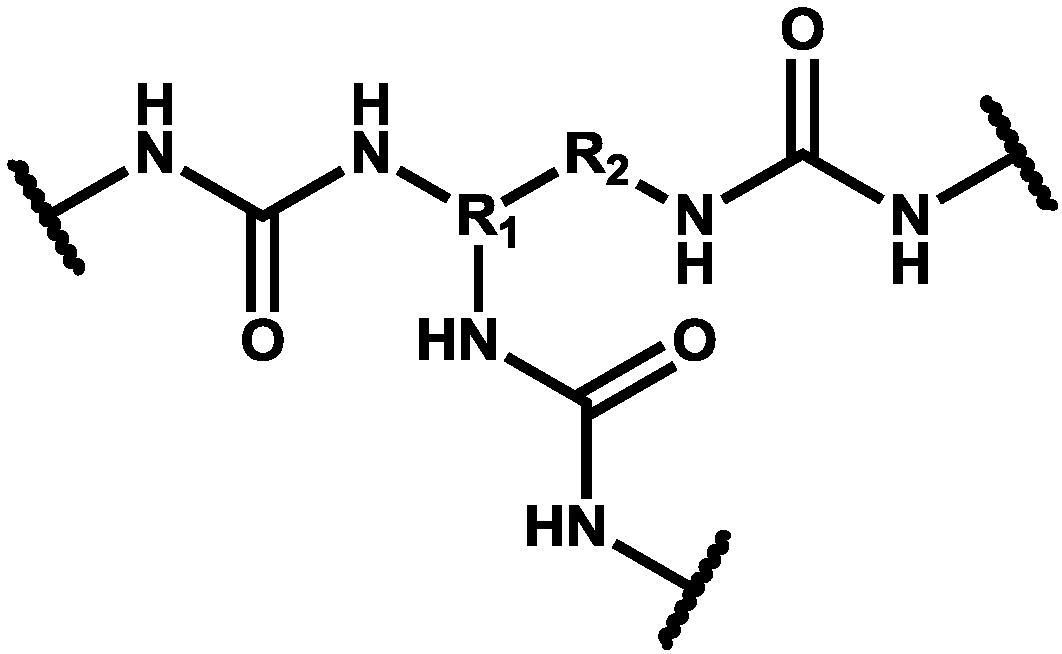

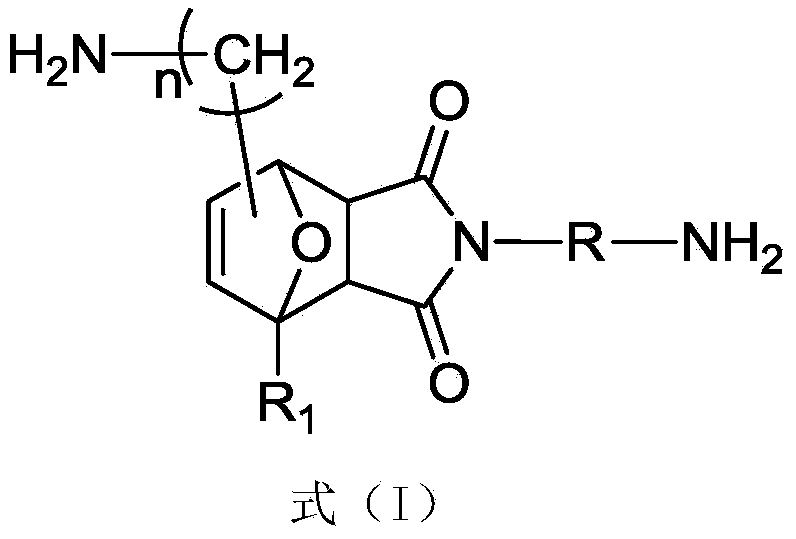

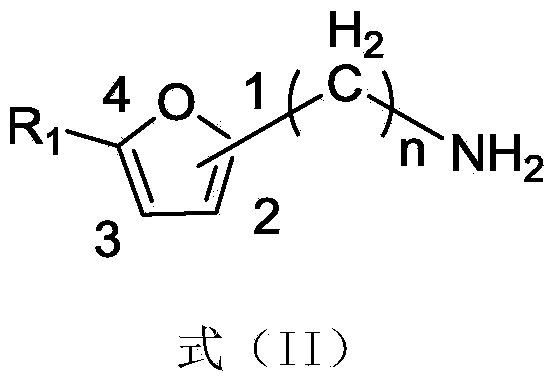

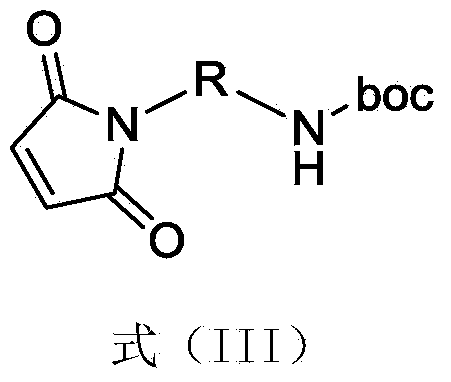

Diamine addition crosslinking agent and preparation method thereof, as well as composition for preparing thermal reversible crosslinking epoxy resin and composite material of thermal reversible crosslinking epoxy resin

The invention belongs to the technical field of epoxy resin based chemical crosslinking material preparation, and particularly relates to a diamine addition crosslinking agent and a preparation method thereof, as well as a composition for preparing thermal reversible crosslinking epoxy resin and a composite material of the thermal reversible crosslinking epoxy resin. The structure of the diamine addition crosslinking agent is as shown in the formula (I), wherein R1 is methyl or H, and n is 1-3; and R is non-aromatic radical. The epoxy resin and the composite material prepared from the composition containing the crosslinking agent have all excellent performance of traditional chemical crosslinking epoxy resin at a low temperature, have re-processing forming performance of thermoplastic materials at a high temperature, restore crosslinking characteristics after being cooled, and are called 'thermosetting-thermoplastic' materials. The reversible crosslinking epoxy resin and the composite material thereof have a self-recovery capability, and the performance of the re-processing forming material can be regulated by means of thermal treatment, so that the diamine addition crosslinking agent is applicable to preparation of self-restoring paint, electronic packaging materials, thermal reversible adhesives and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

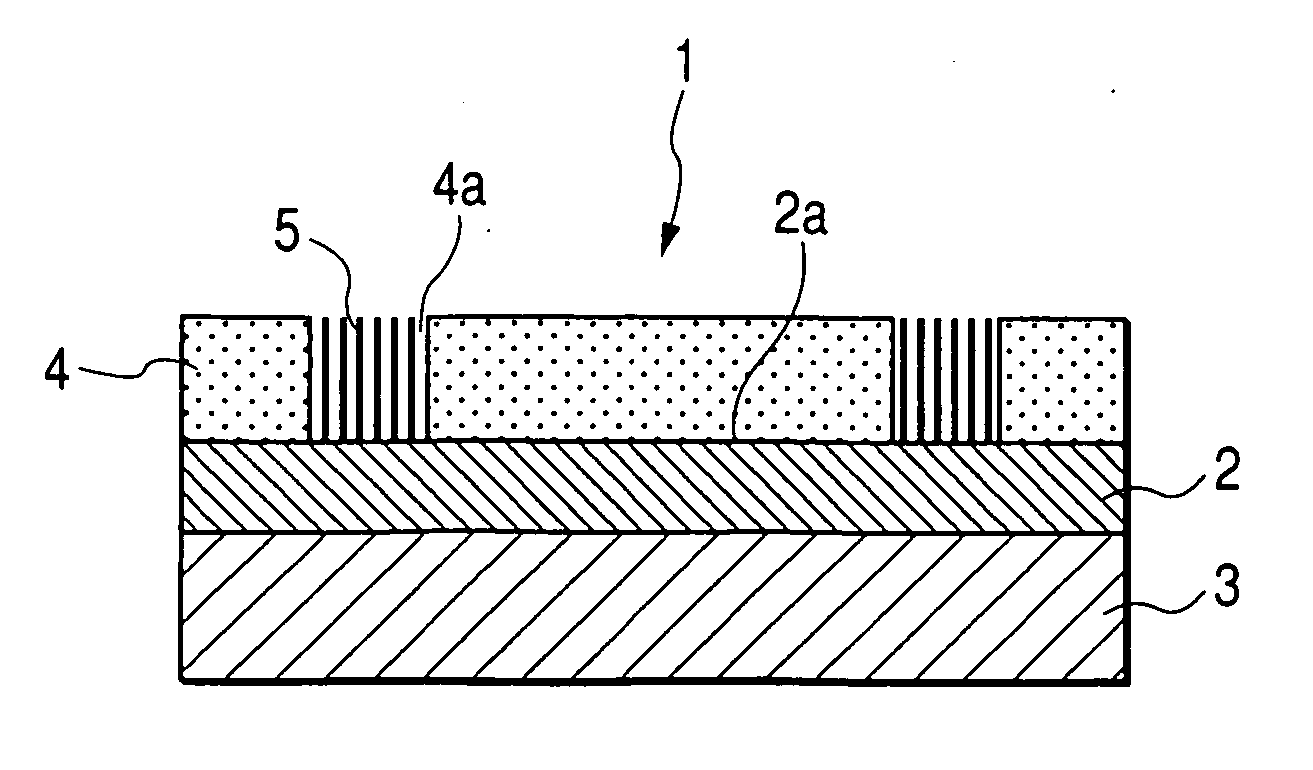

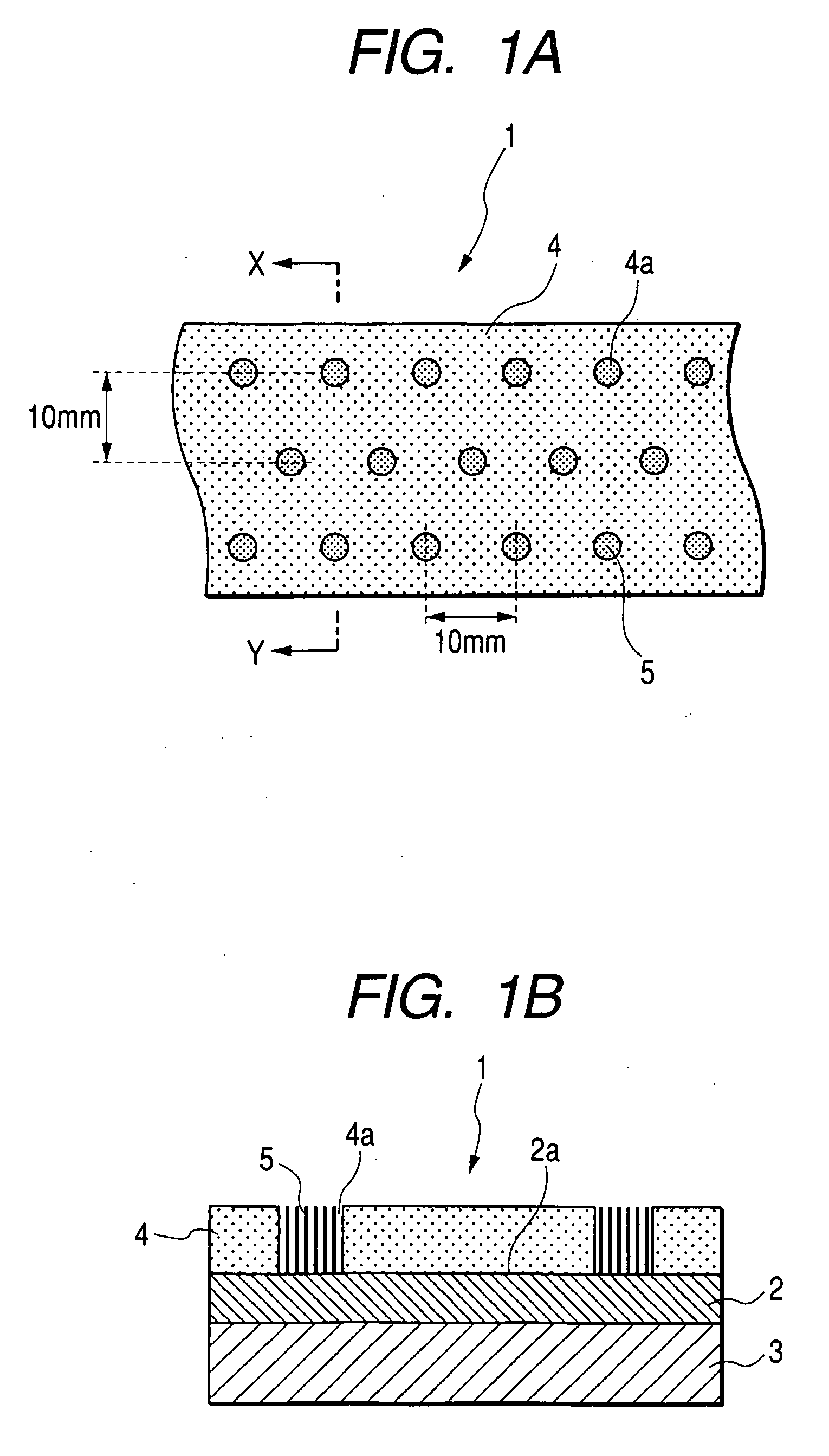

Foamed member, foamed member laminate, and electric or electronic device using foamed member

InactiveUS20090061206A1High expansion rateExcellent reworkabilitySynthetic resin layered productsThin material handlingThermoplasticPolyester

The present invention provides a foamed member capable of inhibiting or preventing foam breakage at the time when the foam member is peeled from a carrier tape, even when the foamed member has a high expansion ratio. The foamed member has a thermoplastic resin foam layer containing a thermoplastic resin foam formed through a step of impregnating a high-pressure inert gas into a thermoplastic resin and subsequently reducing pressure, and at least one of a thermoplastic polyester-based resin layer and a thermoplastic elastomer resin layer disposed on at least one side of the thermoplastic resin foam layer.

Owner:NITTO DENKO CORP

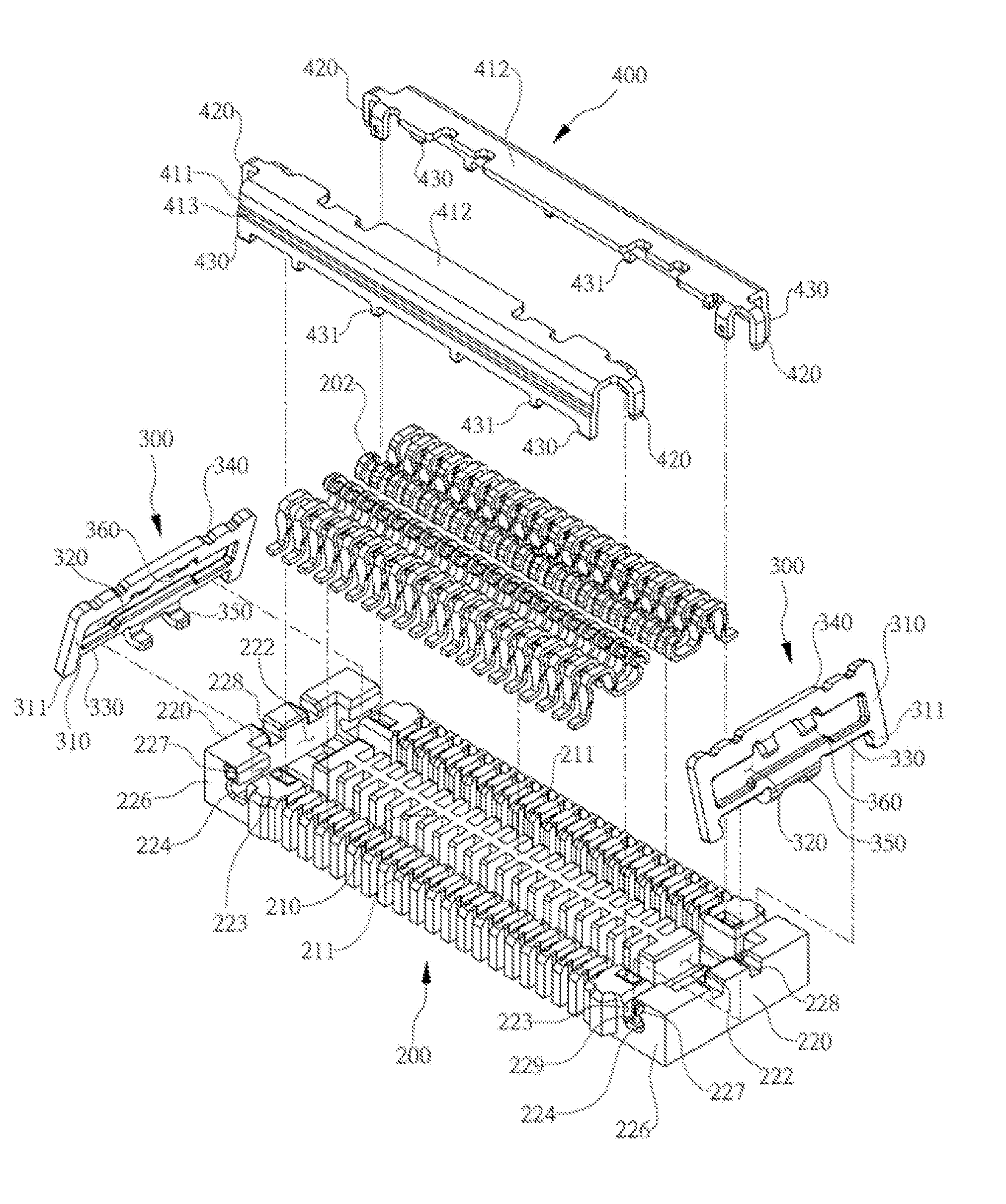

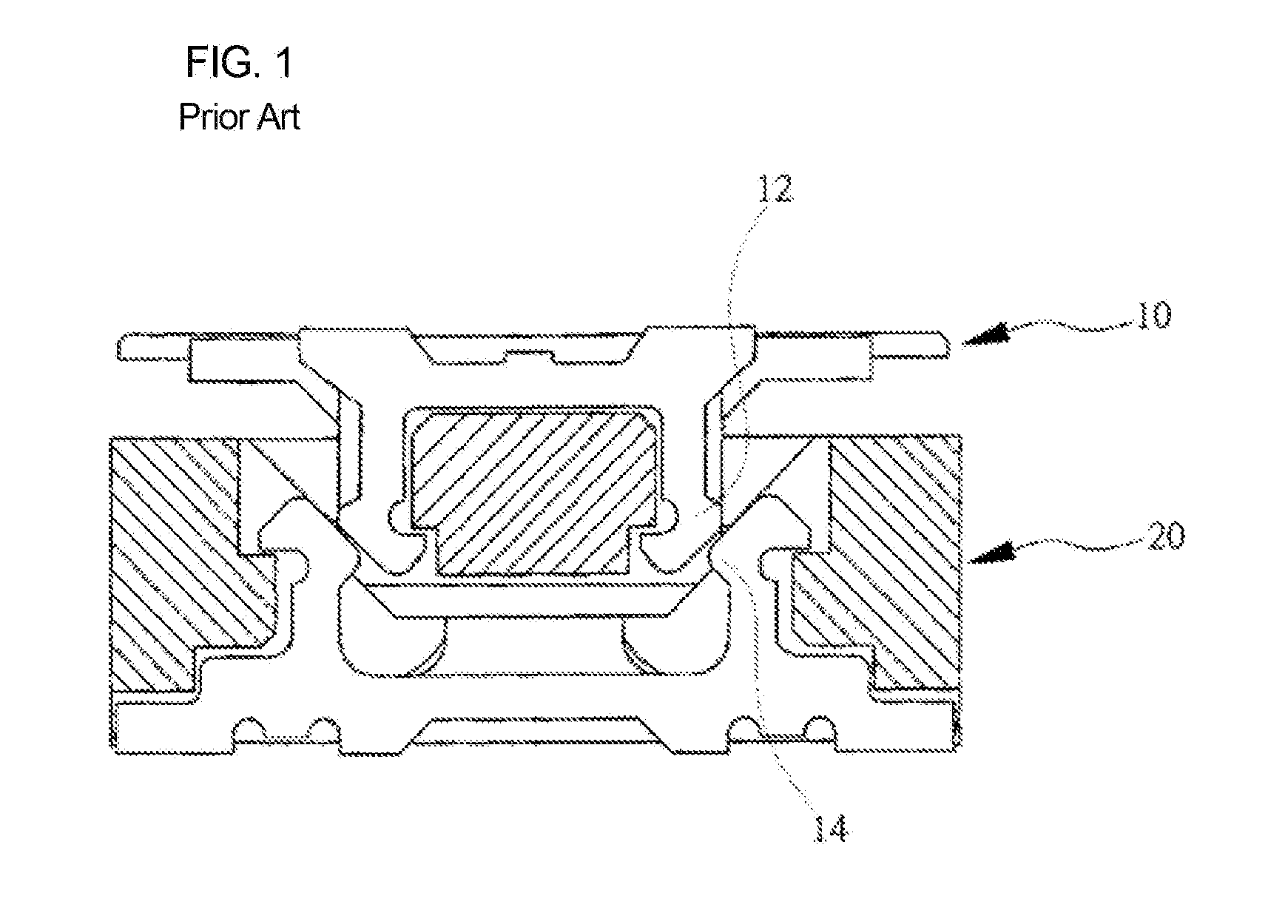

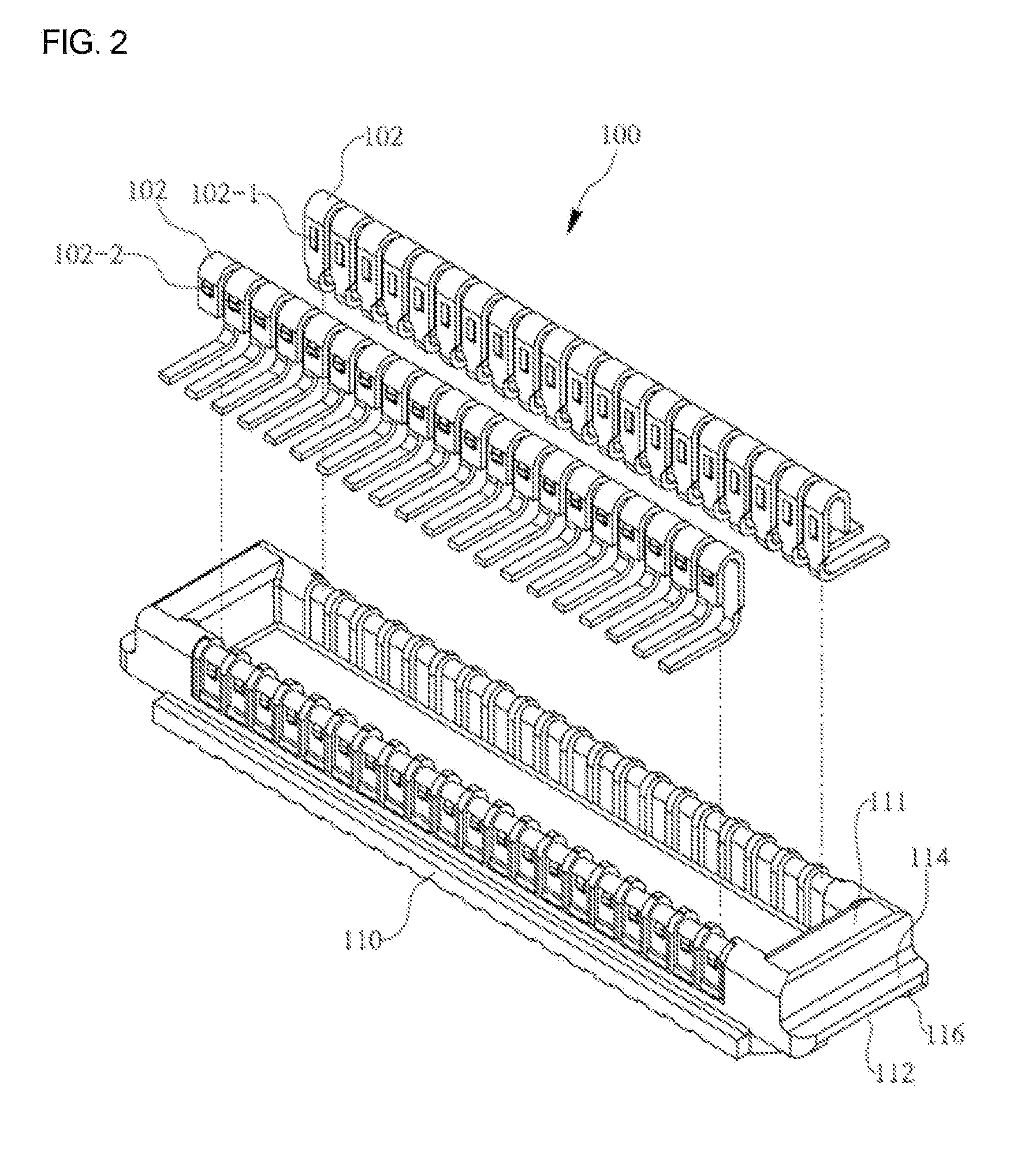

Shield and locking type board to board connector

ActiveUS20150132985A1High mechanical strengthSimple and convenient designCoupling contact membersClamped/spring connectionsOn boardElectromagnetic interference

A shield and locking type board to board connector functioning to connect a first board and a second board to each other, the connector including: a first connector unit having both a first base and a first terminal; a second connector unit having a second base and a second terminal; two shield members each having a shell shape, the shield members respectively provided on front and rear bases facing the second base such that the shield members arrest EMI (electromagnetic interference) noise; and a locking member provided in the second connector unit so as to prevent the first connector unit from being removed outward by an outward movement thereof after the first connector unit is combined with the second connector unit in a close contact state.

Owner:UJU ELECTRONICS

Heat-conductive laminated material and manufacturing method thereof

InactiveCN101544089AExcellent reworkabilityEasy to fixSemiconductor/solid-state device detailsSynthetic resin layered productsHydrogenElectronic component

The present invention relates to a heat-conductive laminated material and a manufacturing method thereof. The heat-conductive laminated material which comprises a first solidified product layer that is obtained through solidifying a silicone composition 1 and a second solidified product layer that is obtained through solidifying a silicone composition 2 and is formed on the first solidified product layer. The silicone composition 1 comprises the following components: (a) organopolysiloxane with alkenyl, (b) heat-conductive filler, (c) organic hydrogen polysiloxane, (d) platinum group metal base catalyst, (e) reaction retarder and (f) organosilicon resin. The silicone composition 2 comprises the components (a) to (f) but has a formula different from that of the silicone composition 1. The heat-conductive sheet of the invention has satisfactory viscosity and can be fixed to a heat-generating electronic component or heat-dissipating component by means of the self viscosity. The heat-conductive laminated material represents advantageous reprocessing property.

Owner:SHIN ETSU CHEM IND CO LTD

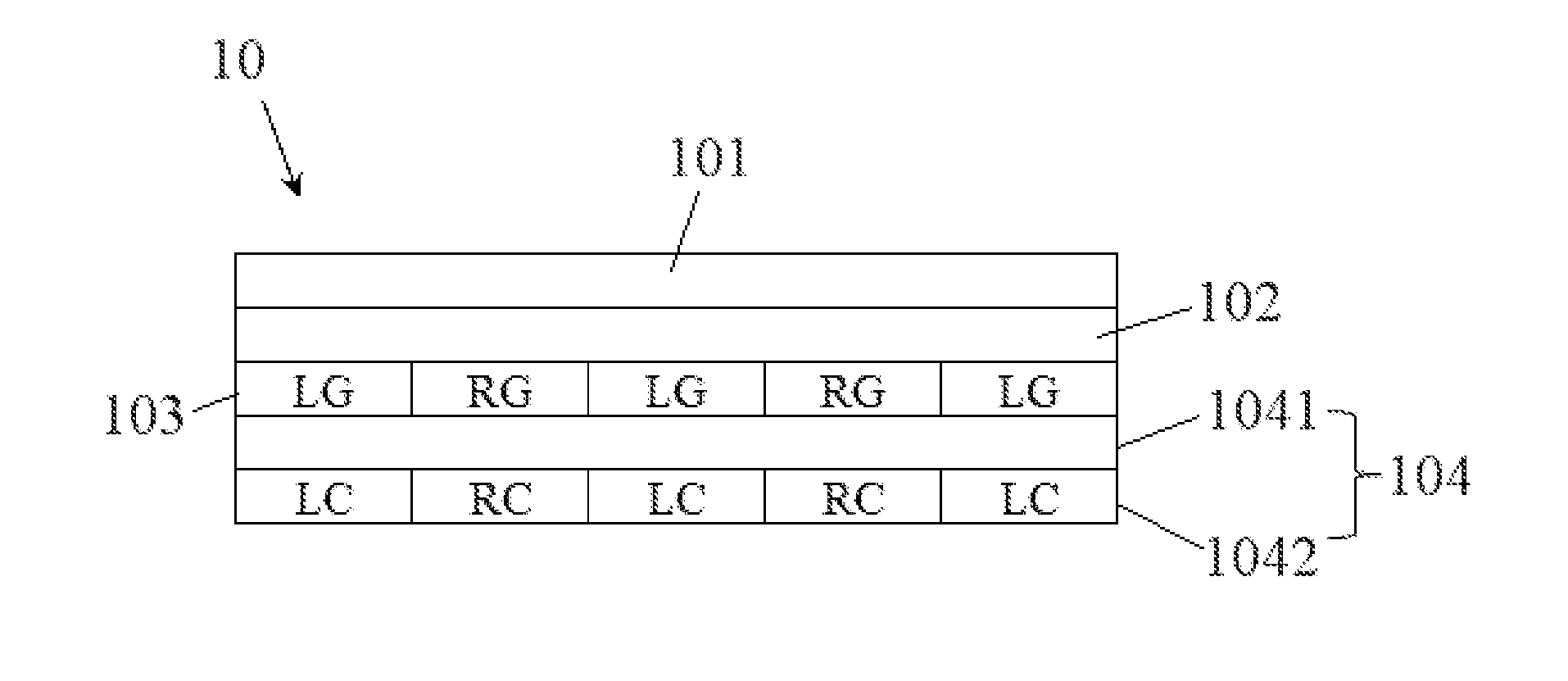

Optical device

ActiveUS20120262639A1Increased durabilityStable light division propertyLiquid crystal compositionsPolarising elementsOpticsPhysics

Owner:LG CHEM LTD

Pressure-sensitive adhesive optical film, production method thereof, and image display

InactiveUS20090116111A1Lower dissociation energyPromote decompositionSolid-state devicesSemiconductor/solid-state device manufacturingMeth-Acrylic polymer

A pressure-sensitive adhesive optical film of the present invention comprises an optical film; and a pressure-sensitive adhesive layer laminated on at least one side of the optical film, wherein the pressure-sensitive adhesive layer is formed from an acrylic pressure-sensitive adhesive comprising a (meth)acrylic polymer comprising 30 to 99.99% by weight of an alkyl (meth)acrylate monomer unit and 0.01 to 15% by weight of a functional group-containing monomer unit, and the (meth)acrylic polymer in the acrylic pressure-sensitive adhesive is crosslinked by electron beam irradiation. The pressure-sensitive adhesive optical film has a high level of reworkability, durability and workability.

Owner:NITTO DENKO CORP

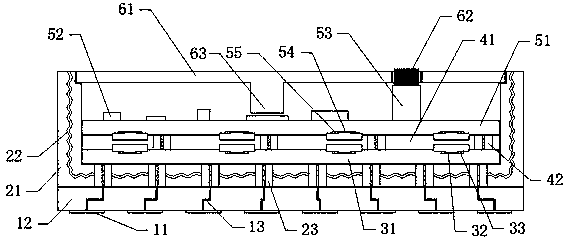

Multilayer laminate package and method of manufacturing the same

InactiveUS8872041B2Excellent reworkabilityHigh yieldPrinted circuit assemblingCircuit arrangements on support structuresEngineeringElectronic component

A multilayer laminate package and a method of manufacturing the same are provided. The multilayer laminate package includes a cavity layer, a non-cavity layer, an electronic component, and a metalized blind via. The cavity layer includes a first adhesive layer and two first circuit layers, which are stacked with the first adhesive layer between, and an opening. The non-cavity layer includes a second adhesive layer and a second circuit layer. The non-cavity layer is bonded to the cavity layer with the second adhesive layer so as to close one side of the opening. The electronic component is mounted in the opening and is electrically connected to the non-cavity layer exposed through the opening. The metalized blind via electrically connects the non-cavity layer to one of the circuit layers of the cavity layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Pressure-sensitive adhesive tape or sheet, and method for producing it

InactiveUS20060240209A1Good repositionabilityExcellent reworkabilityDecorative surface effectsDuplicating/marking methodsFiberEngineering

A pressure-sensitive adhesive tape or sheet having a pressure-sensitive adhesive layer formed on at least one surface of the support thereof, wherein the surface of the pressure-sensitive adhesive layer on at least one surface of the support partly has projected spots of fibers. The projected spots of fibers are preferably raised spots of fibers that are raised from the surface of the pressure-sensitive adhesive layer. The pressure-sensitive adhesive tape or sheet is favorable for flooring material fixation. The pressure-sensitive adhesive tape or sheet is produced according to a flocking method that comprises flocking the surface of the pressure-sensitive adhesive layer on at least one surface of the support to thereby form projected spots of fibers partly in the surface of the pressure-sensitive adhesive layer.

Owner:NITTO DENKO CORP

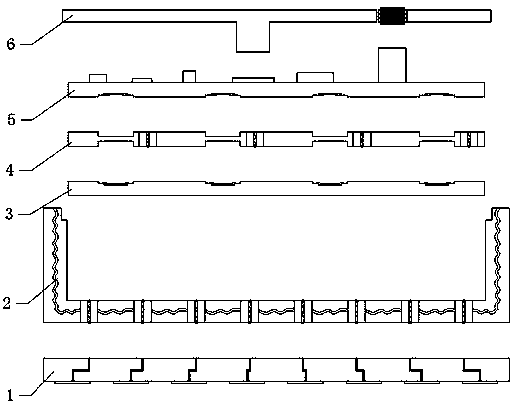

Integrated tile active phased-array antenna

ActiveCN111541001AReduce volumeLight in massParticular array feeding systemsRadiating elements structural formsRadio frequency signalPhase array antenna

The invention discloses an integrated tile active phased-array antenna. The antenna comprises an array antenna layer, a heat dissipation cavity, a radio frequency layer, a transition layer, a power supply and control layer and a cover plate layer. A plurality of first slots are formed in one side, close to the transition layer, of the radio frequency layer, first radio frequency chips are arrangedin the first slots, a plurality of second slots are formed in one side, close to the transition layer, of the power supply and control layer, and second radio frequency chips are arranged therein; acontrol device is arranged on one side, close to the cover plate layer, of the power supply and control layer and used for power supply and signal control; the transition layer plays a role in radio frequency signal transition and radio frequency isolation; the array antenna layer is electrically connected with the radio frequency layer at high frequency through a first radio frequency connectionstructure arranged on the heat dissipation cavity; the radio frequency layer is electrically connected with the power supply and the control layer at high frequency through a second radio frequency connection structure arranged on the transition layer; the cover plate layer is electrically connected with the power supply and control layer. According to the antenna, the multi-channel, multi-polarization or multi-frequency multifunctional high-integration integrated design is achieved, the overall size is small, the weight is light, and the thickness is small.

Owner:成都雷电微力科技股份有限公司

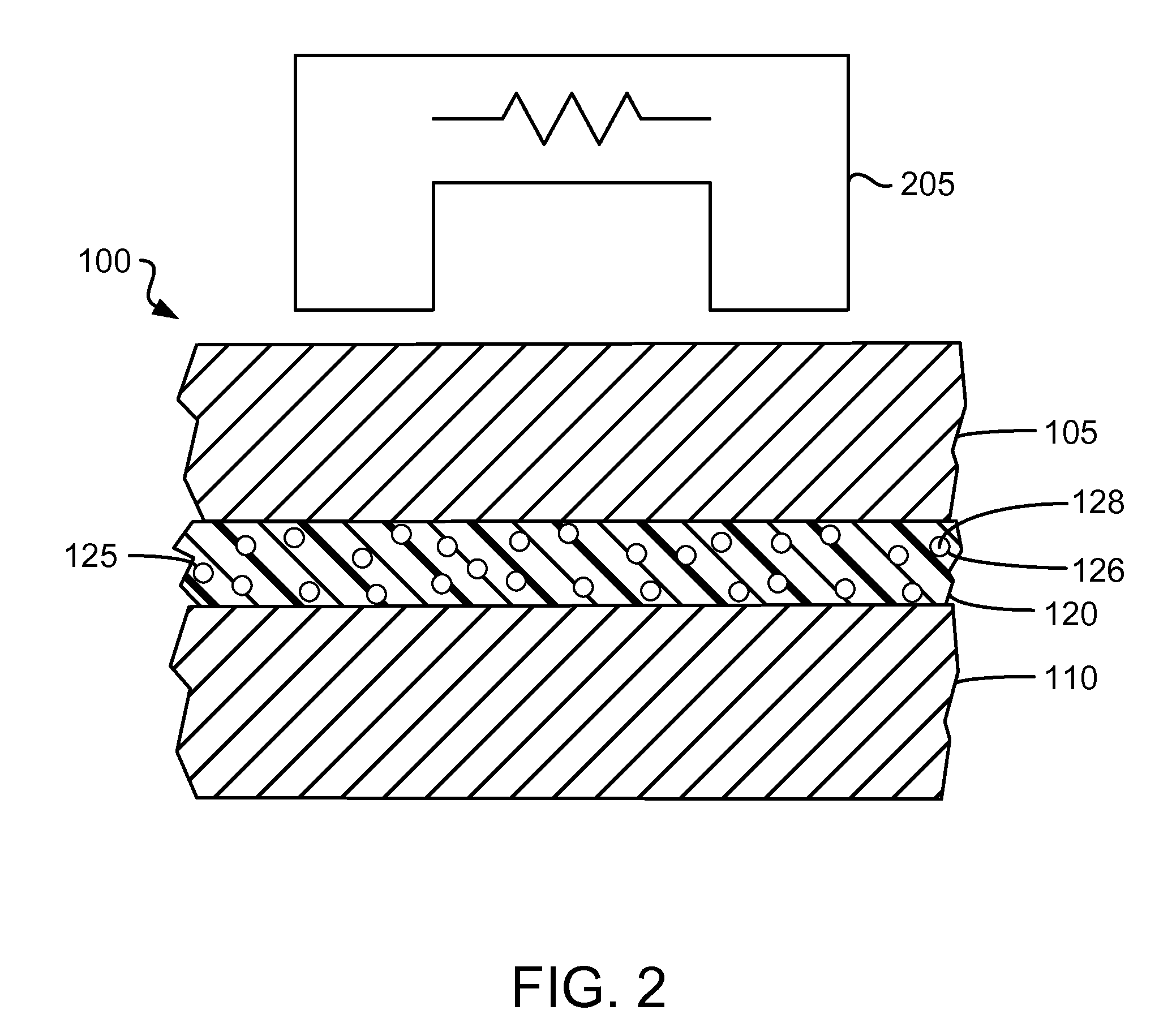

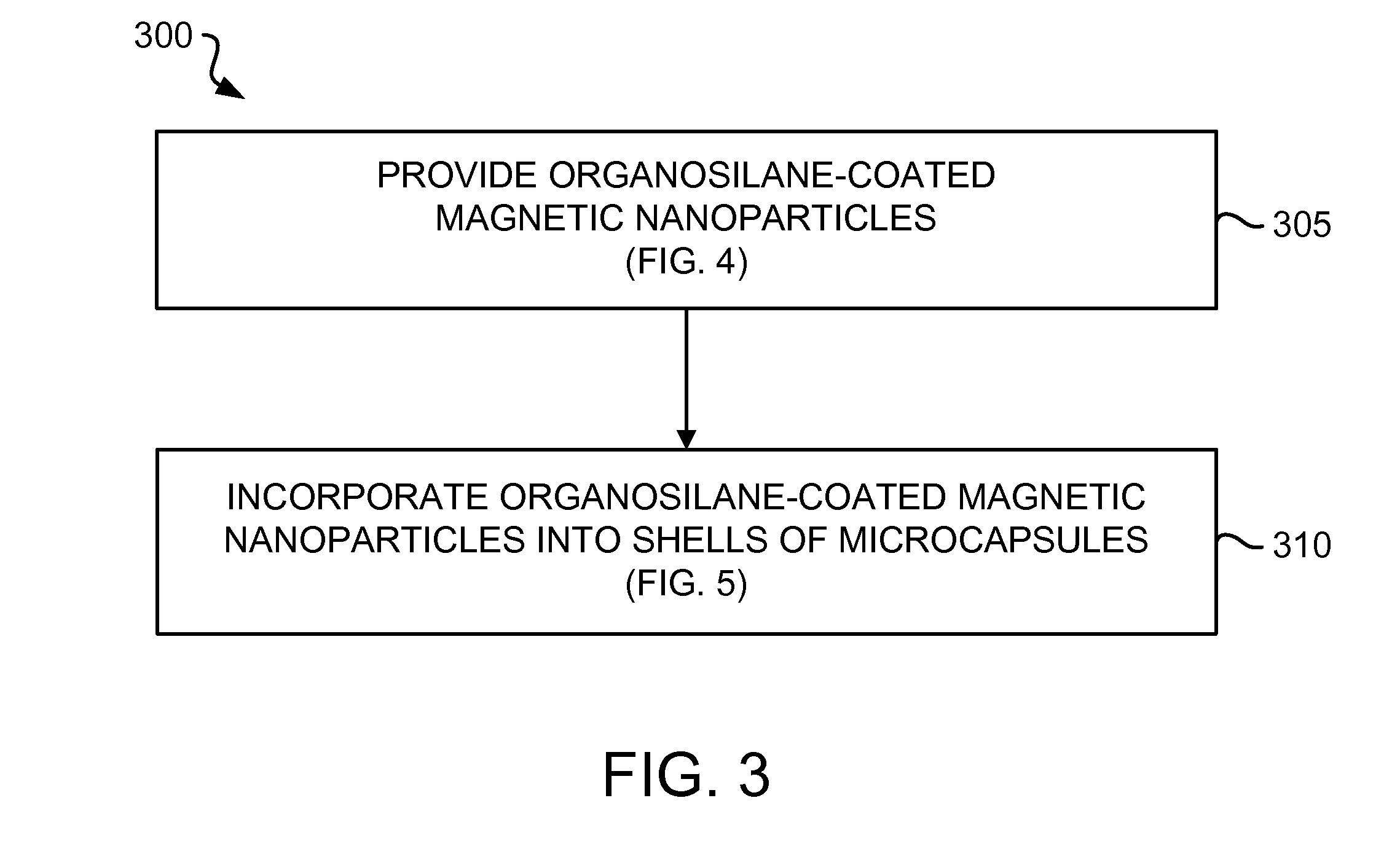

Microcapsules adapted to rupture in a magnetic field to enable easy removal of one substrate from another for enhanced reworkability

ActiveUS9186641B2Excellent reworkabilityReduce bond strengthLayered productsLaminationIn situ polymerizationTrimethylsilane

Owner:INT BUSINESS MASCH CORP

Adhesive seal material for end portion of solar cell panel, sealed structure of end portion of solar cell panel, sealing method, solar cell module, and producing method thereof

InactiveUS20110088756A1Easy to processEasy to stickPhotovoltaic supportsPV power plantsEngineeringSolar cell

An adhesive seal material for an end portion a solar cell panel is an adhesive seal material which is bonded to an end portion of a solar cell panel. The adhesive seal material includes a rubber-based adhesive layer, and a non-adhesive layer partially covering a surface of the rubber-based adhesive layer.

Owner:NITTO DENKO CORP

Carbon nanotube aggregate

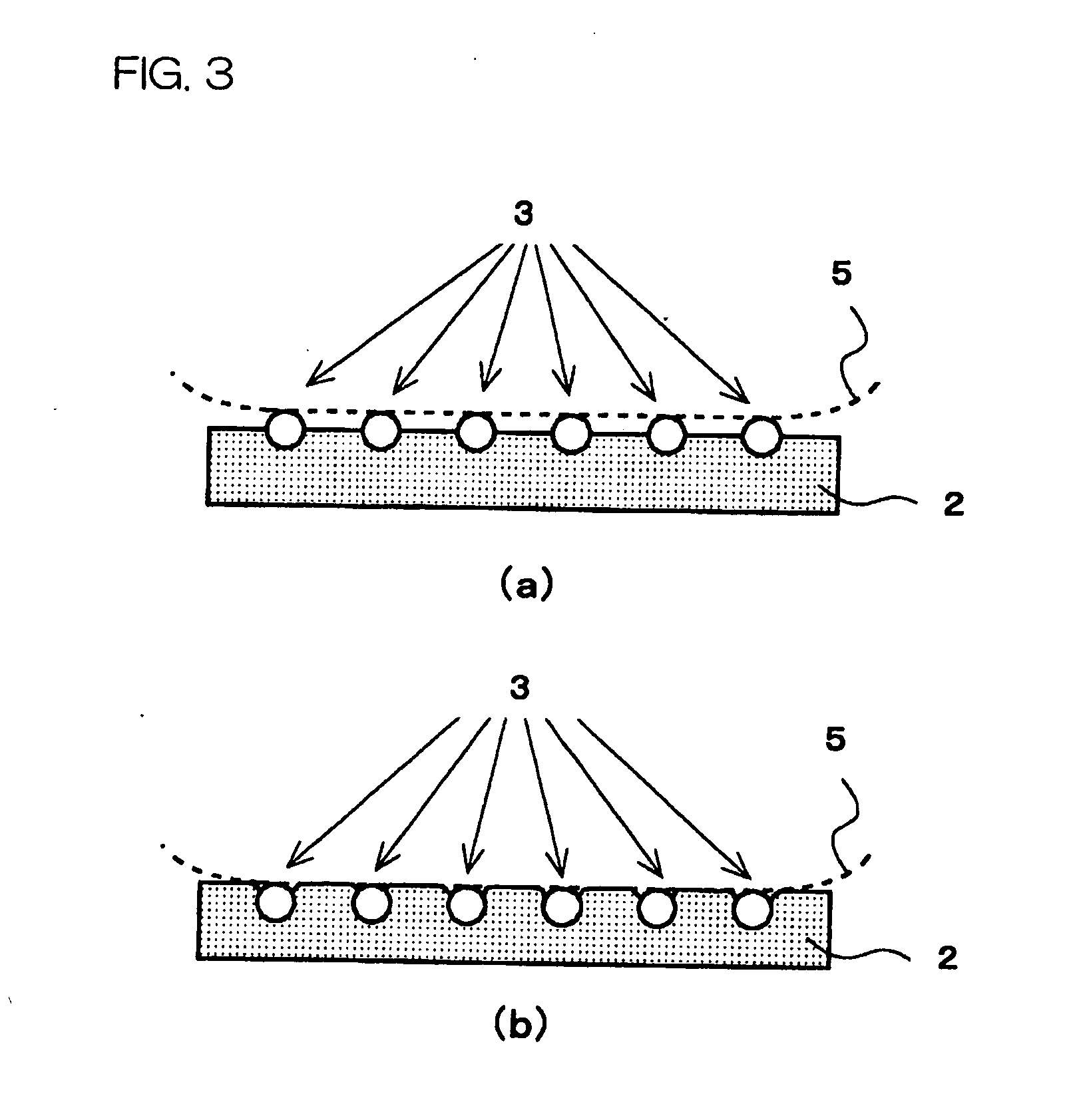

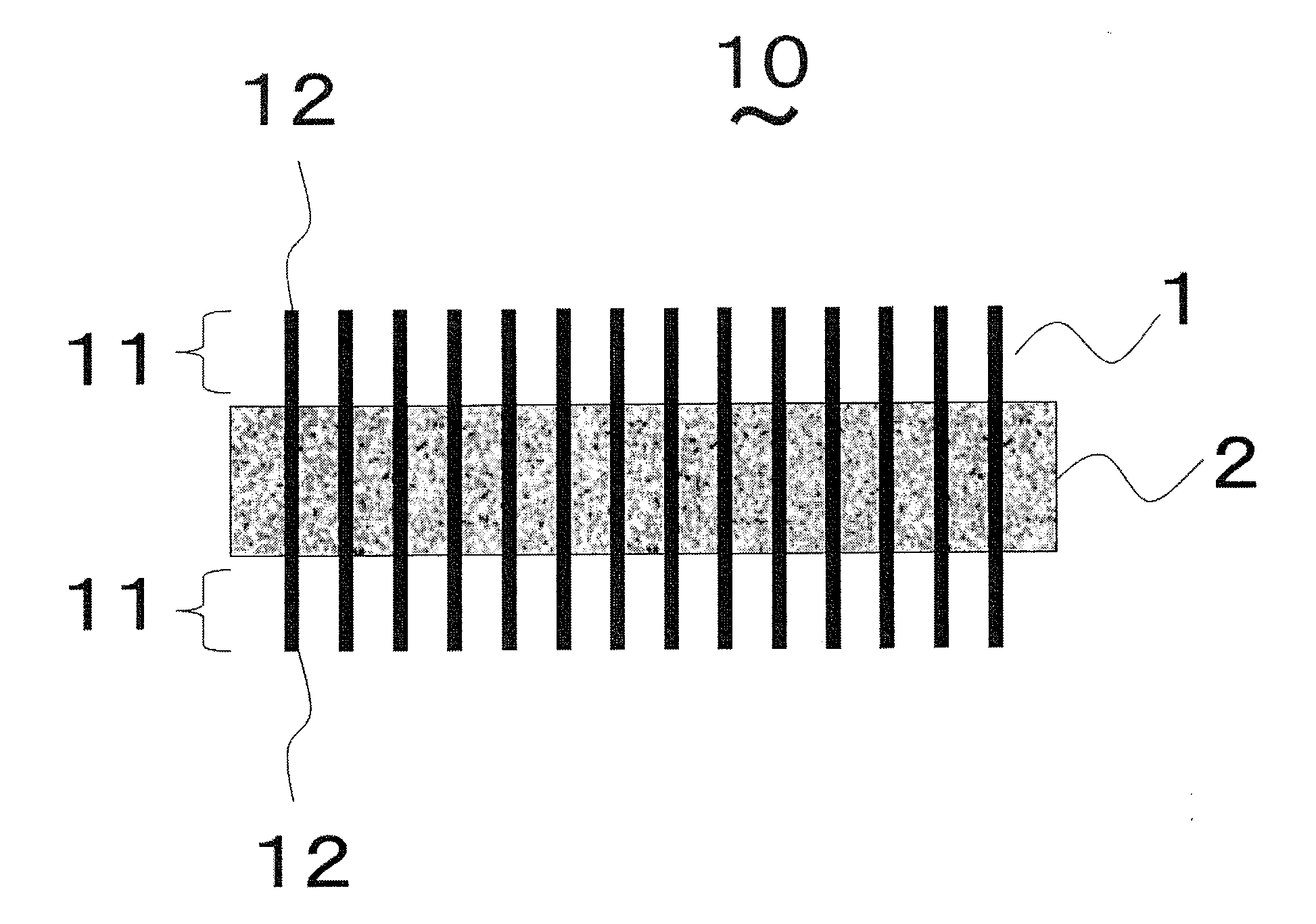

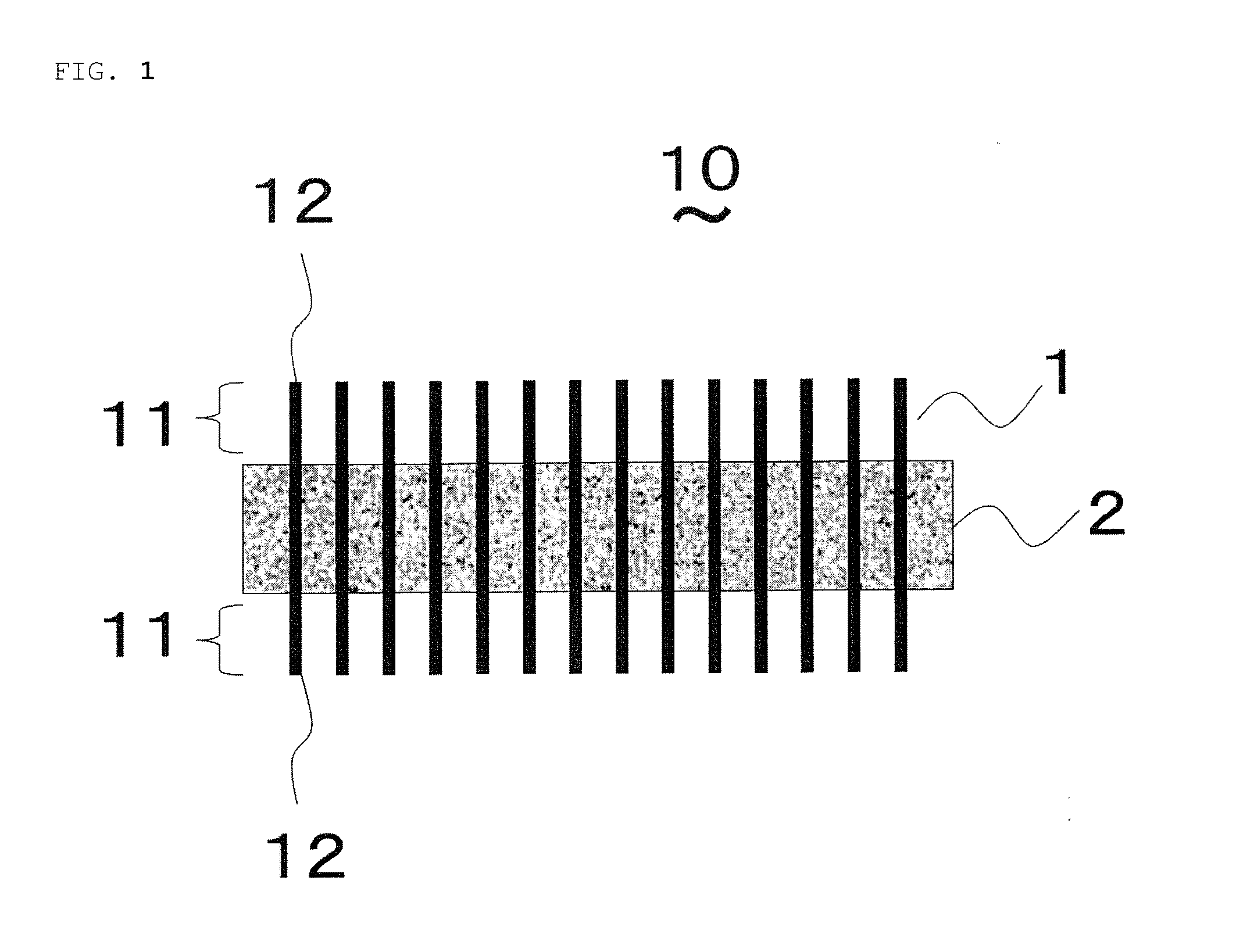

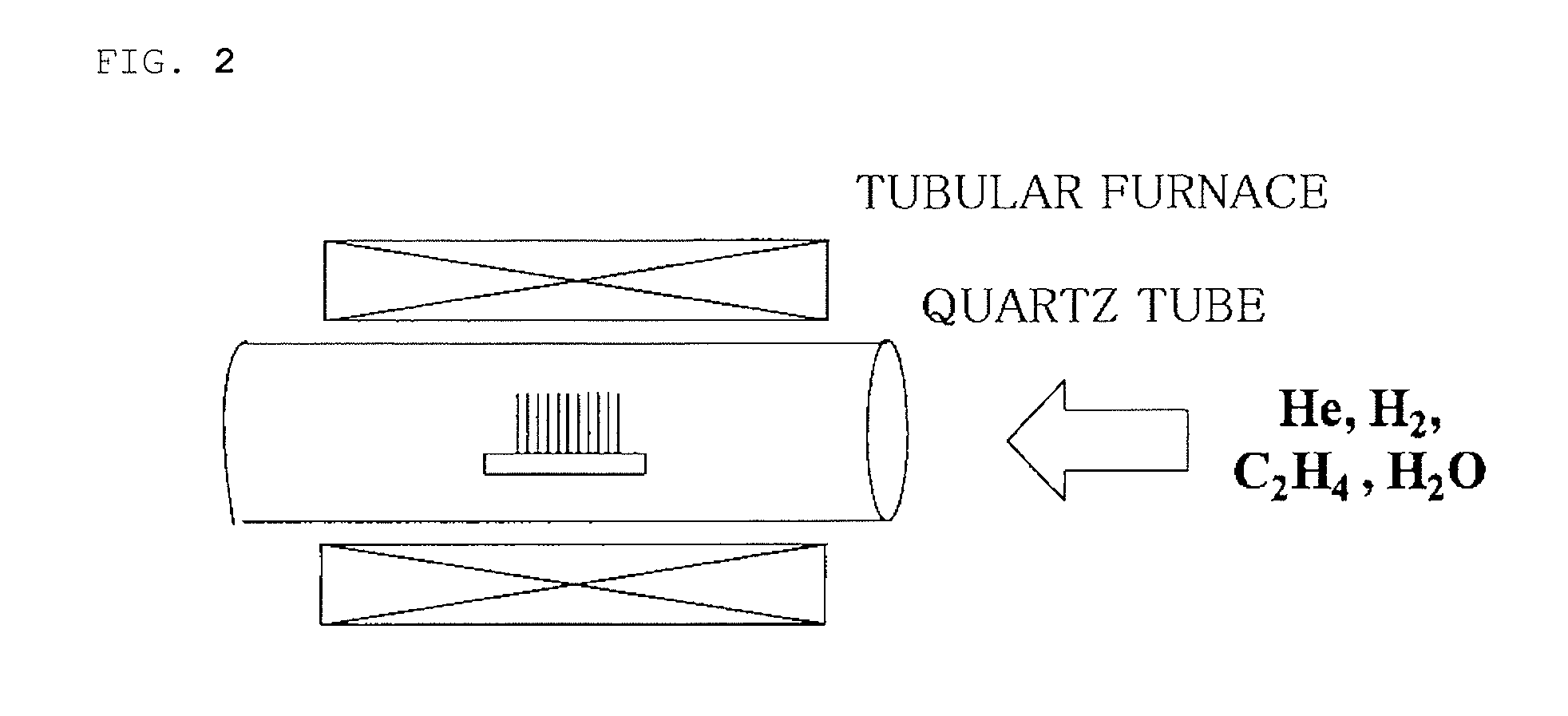

InactiveUS20110133135A1Improve heat spreading abilityHigh bonding strengthNon-metal conductorsMaterial nanotechnologyCarbon nanotubeUltimate tensile strength

Provided is a composite material useful as a material for a thermal contact surface in a microprocessor which can express extremely high thermal diffusion property and extremely high conductivity, can express a sufficient adhesive strength in its surface, and is excellent in reworking property at the time of a bonding operation. The carbon nanotube aggregate of the present invention is a carbon nanotube aggregate where a plurality of carbon nanotubes each having a plurality of walls penetrate a resin layer in a thickness direction of the resin layer, in which both terminals of the carbon nanotube aggregate each have a shear adhesive strength for glass at 25° C. of 15 N / cm2 or more.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com