Patents

Literature

160results about How to "Excellent productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

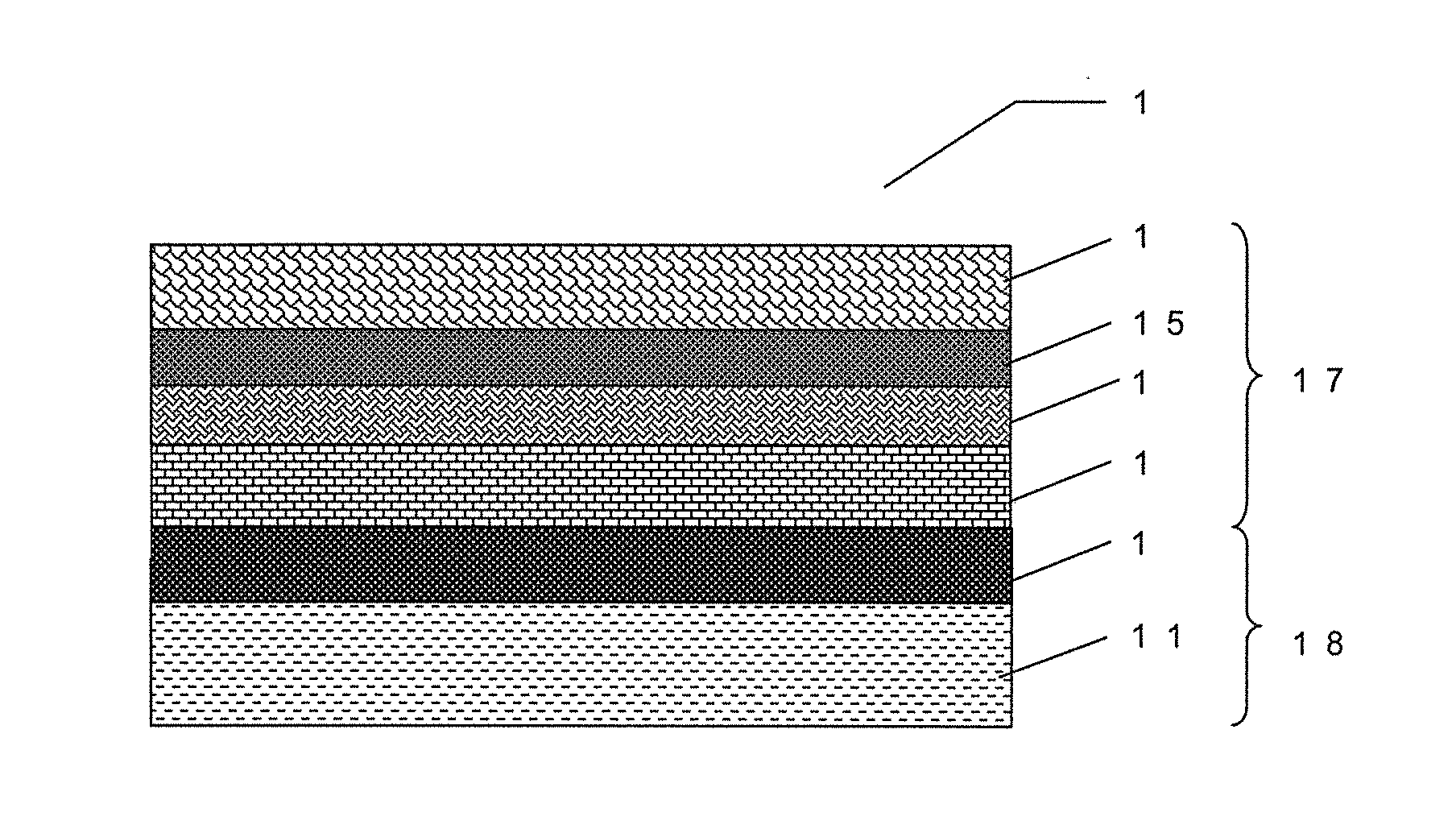

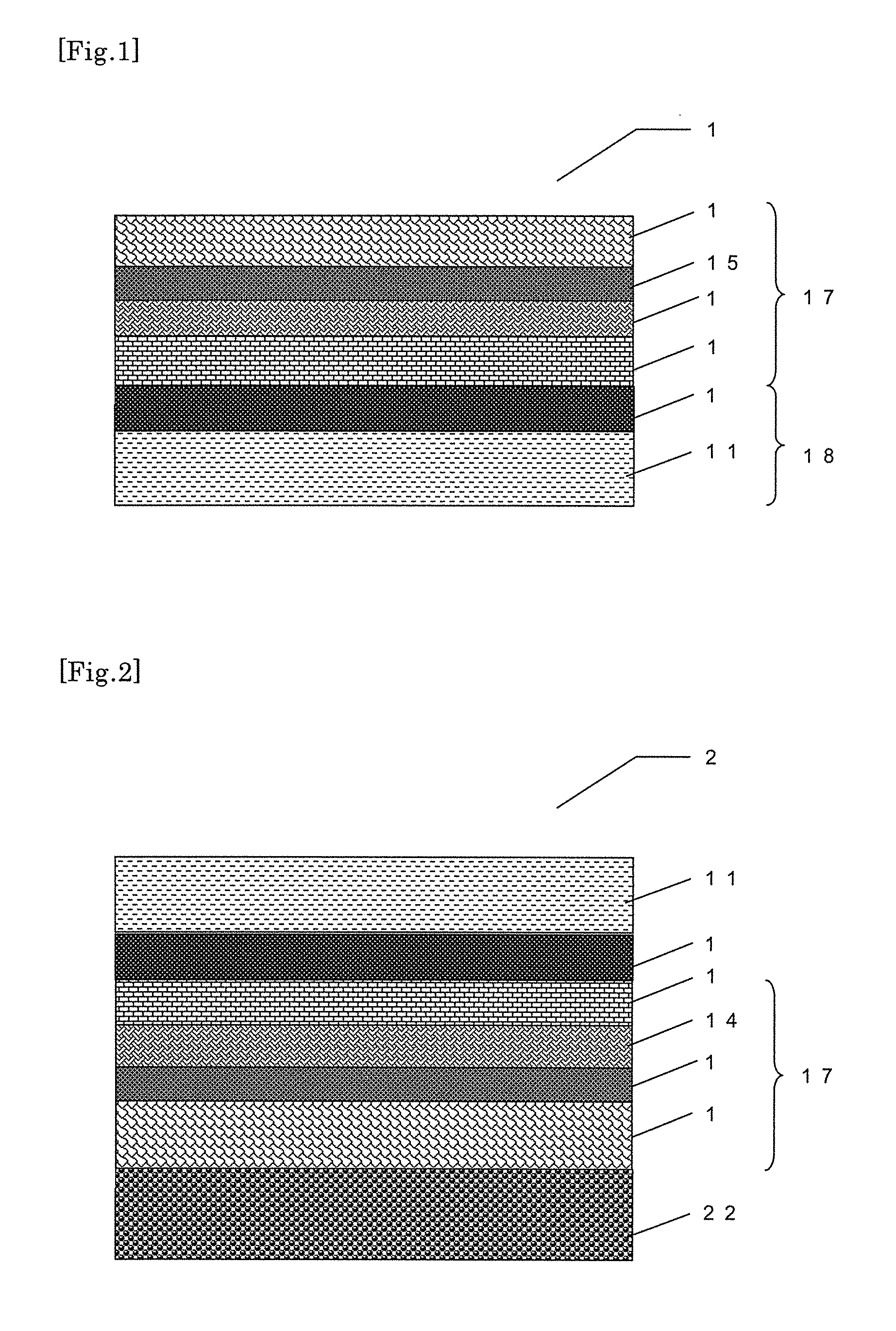

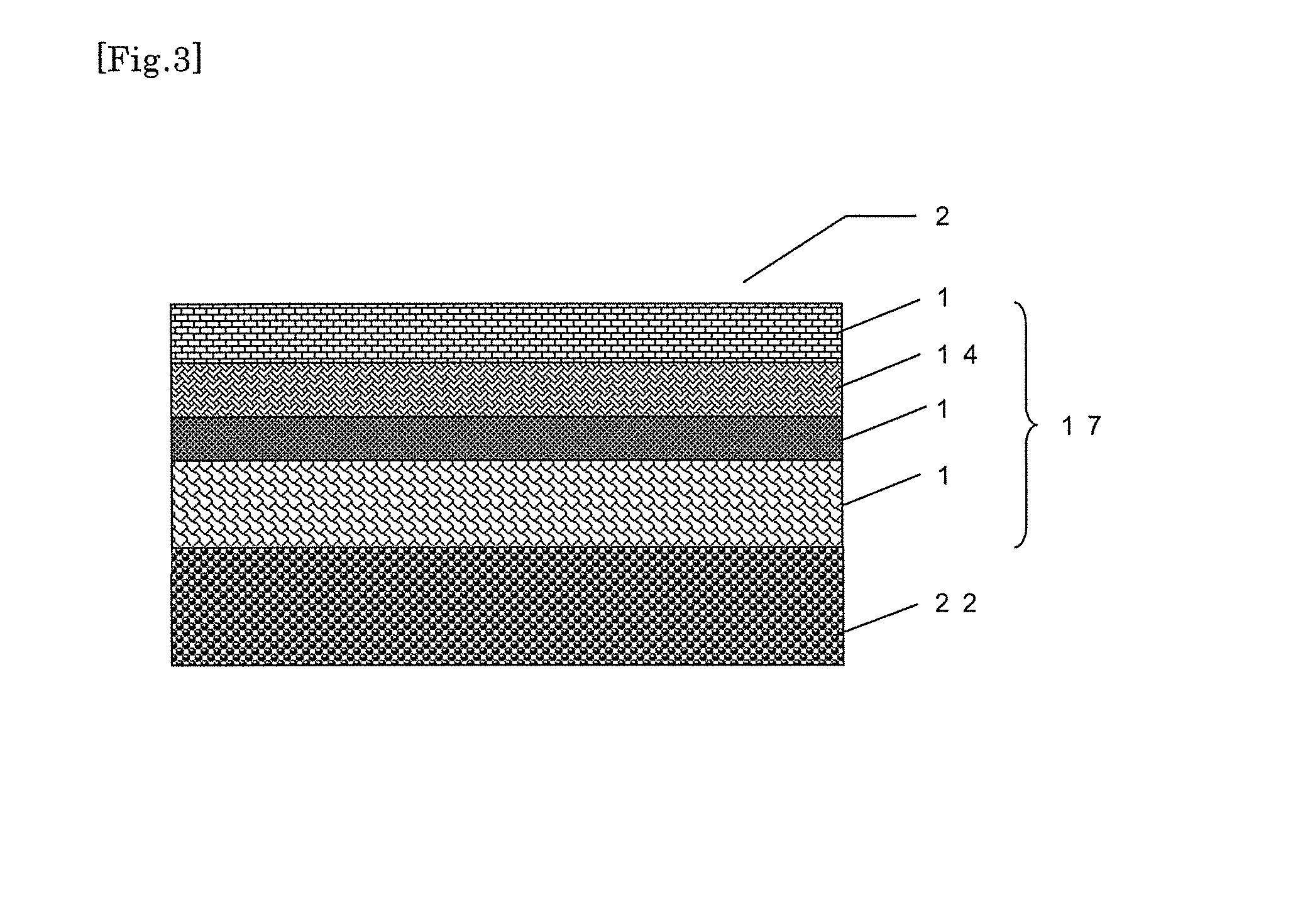

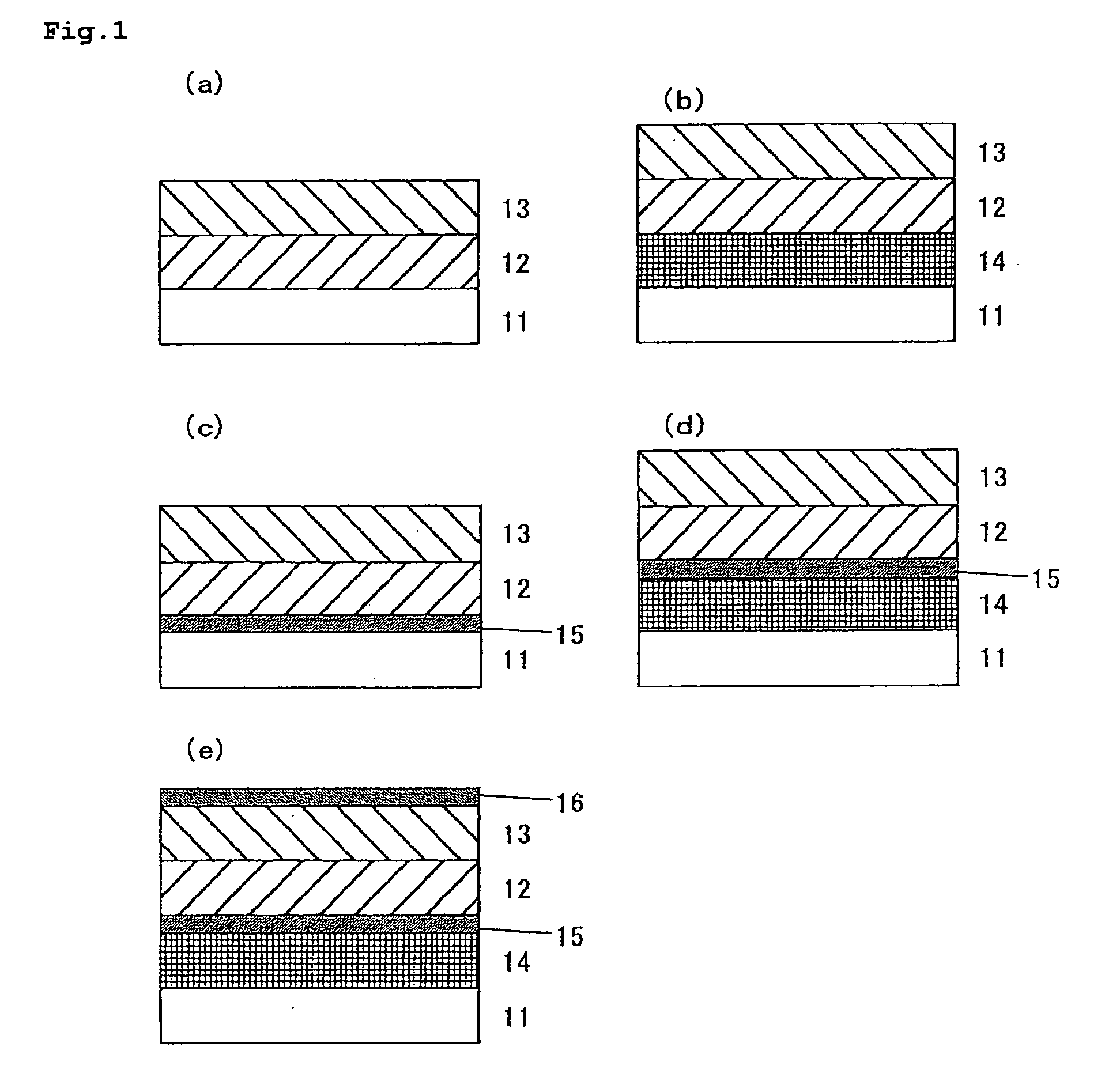

Production method of laminate, laminate, polarizing plate and image display device

InactiveUS20080038472A1Good scratch resistanceExcellent productivityPretreated surfacesSpecial surfacesChemical compoundChemical bond

A method for producing a laminate comprising a support; and at least two layers provided by coating at least two kinds of coating compositions, respectively, the method comprising: simultaneously coating at least two kinds of coating compositions on a support; and drying the at least two kinds of coating compositions, wherein the at least two kinds of coating compositions each comprises a compound having a polymerizable functional group capable of forming a chemical bond to each other.

Owner:FUJIFILM CORP

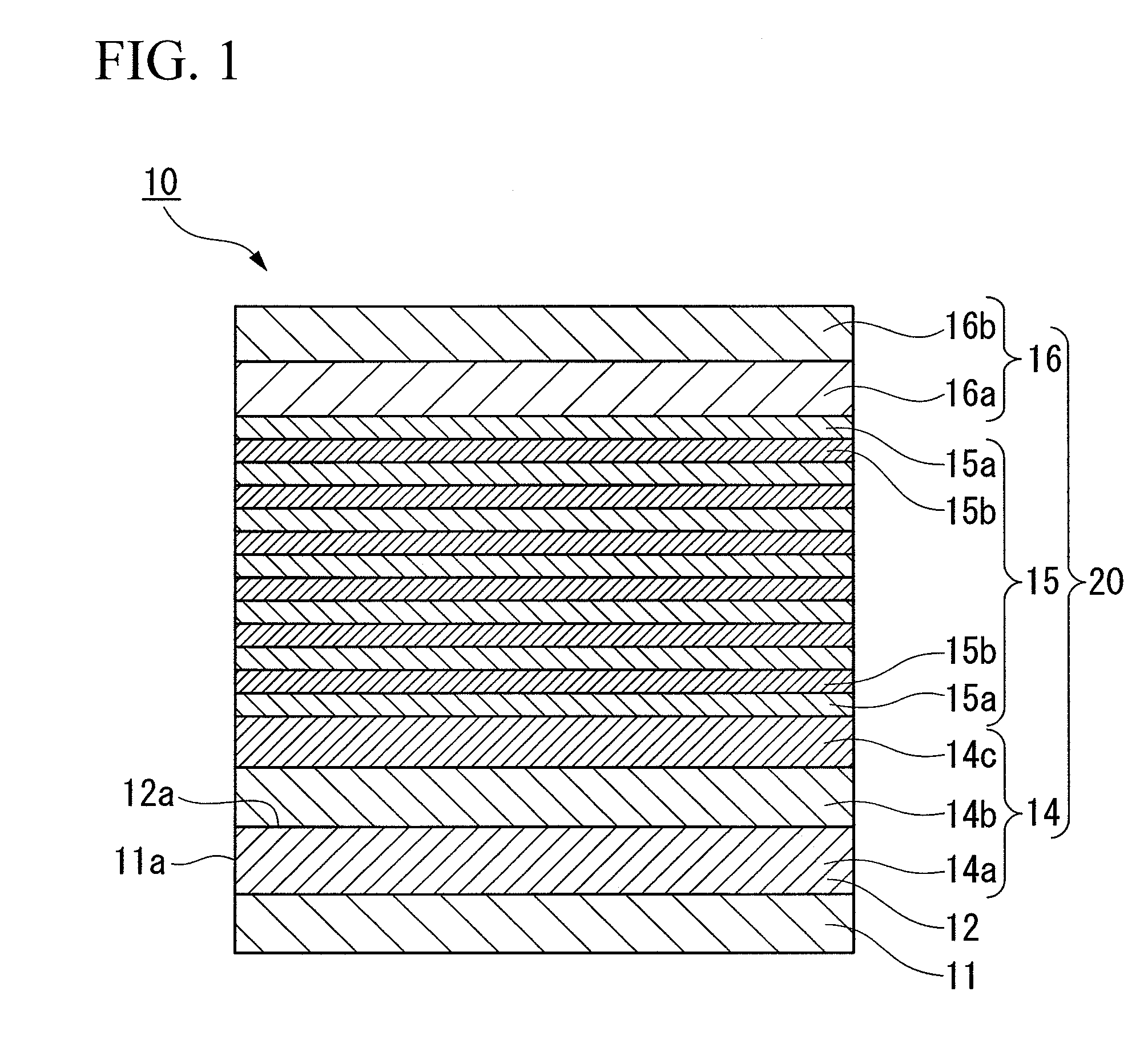

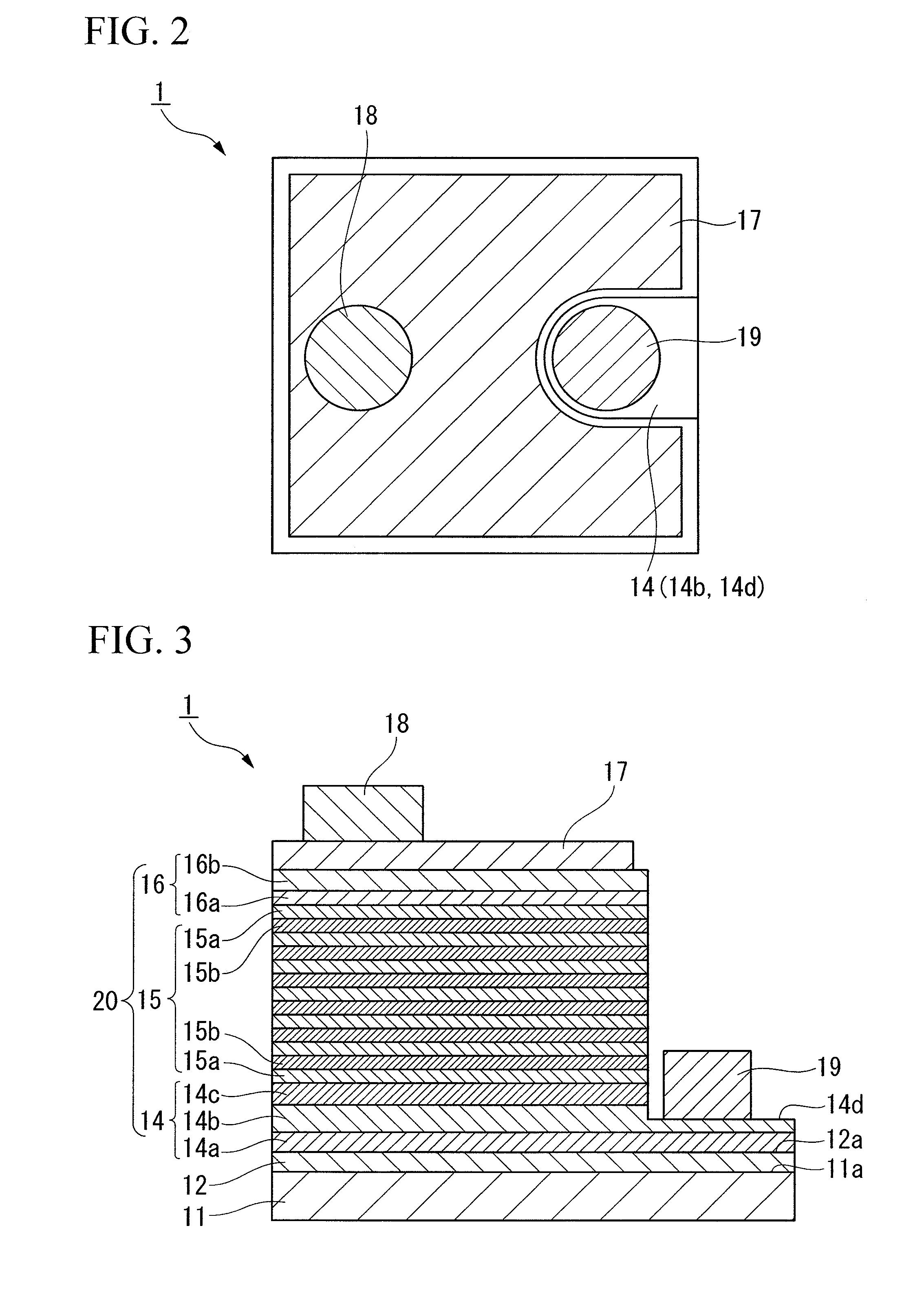

Method for producing group iii nitride semiconductor light emitting device, group iii nitride semiconductor light emitting device, and lamp

ActiveUS20090283795A1Favorable levelExcellent productivitySolid-state devicesSemiconductor/solid-state device manufacturingProduction rateNitride semiconductors

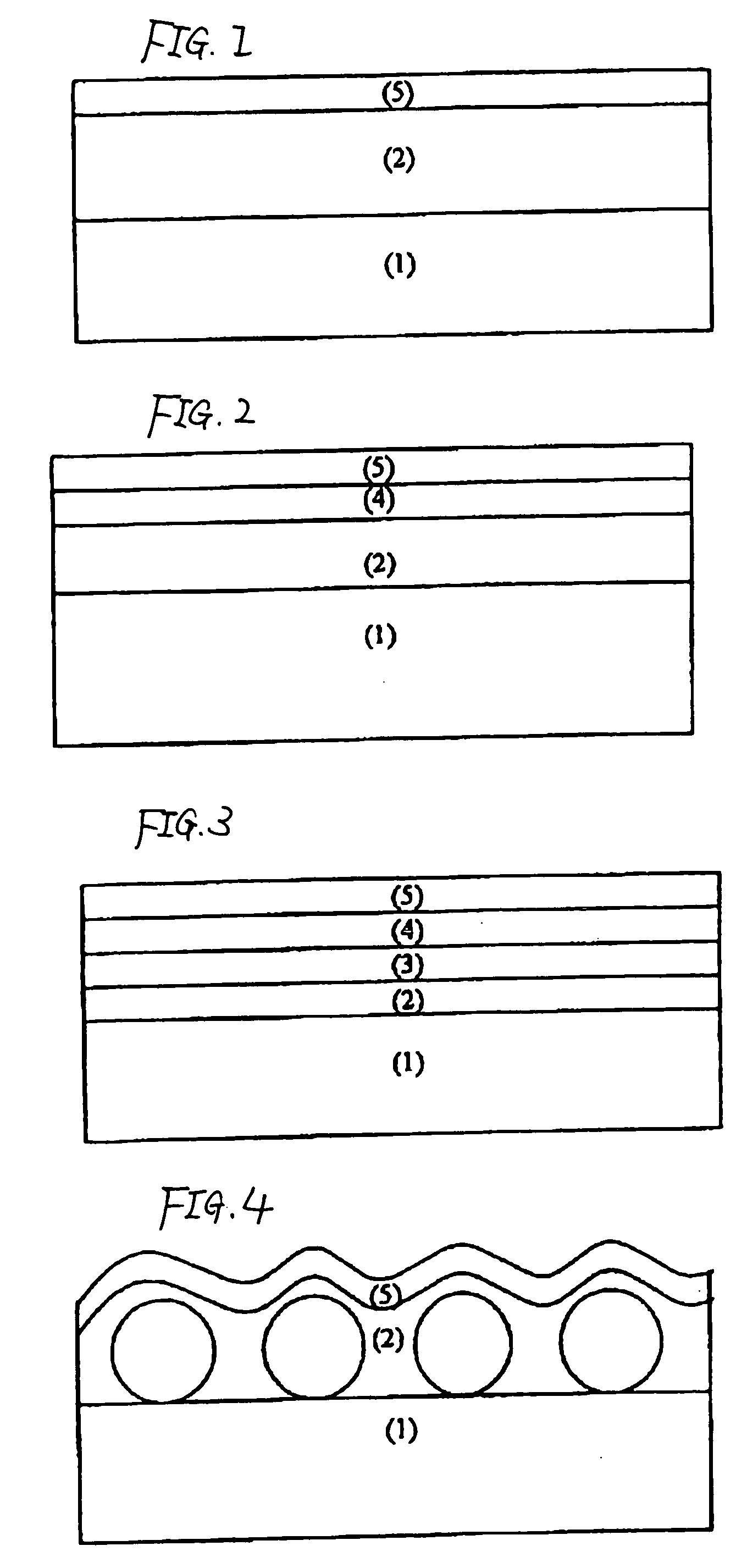

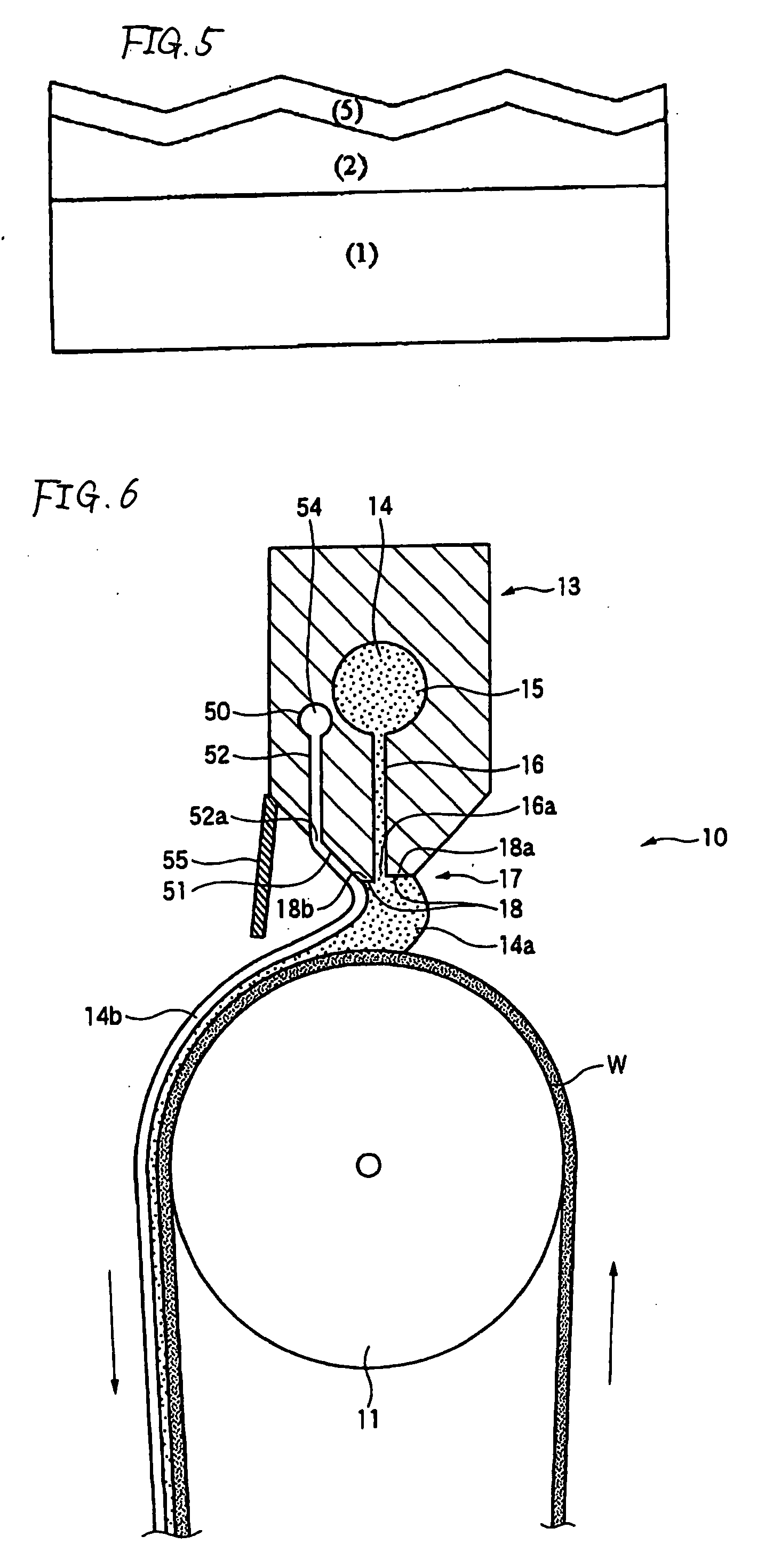

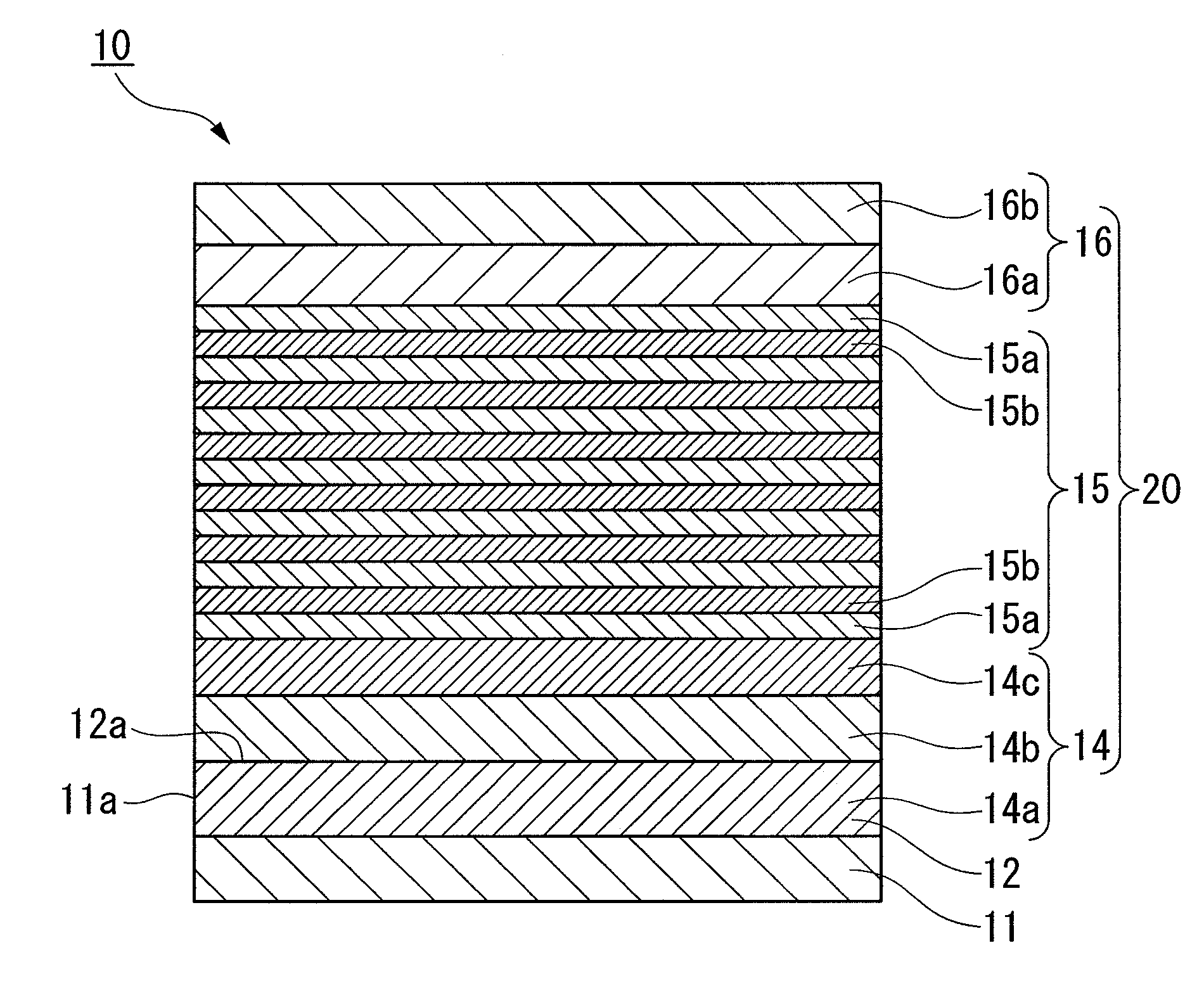

Provided is a method for producing a group III nitride semiconductor light emitting device capable of producing a group III nitride semiconductor light emitting device with excellent light emitting properties with excellent productivity; a group III nitride semiconductor light emitting device; and a lamp.Provided is a method in which a buffer layer 12 composed of a group III nitride compound is laminated on a substrate 11 and then an n-type semiconductor layer 14 provided with an underlying layer 14a, a light emitting layer 15, and an p-type semiconductor layer 16 are sequentially laminated on the buffer layer 12, and is a method in which the buffer layer 12 is formed so as to have a composition of AlXGa1-XN (0≦X<1) by activating, with plasma, and thereby reacting at least a metallic Ga source and a gas containing a group V element, and the underlying layer 14 is formed on the buffer layer 12.

Owner:TOYODA GOSEI CO LTD

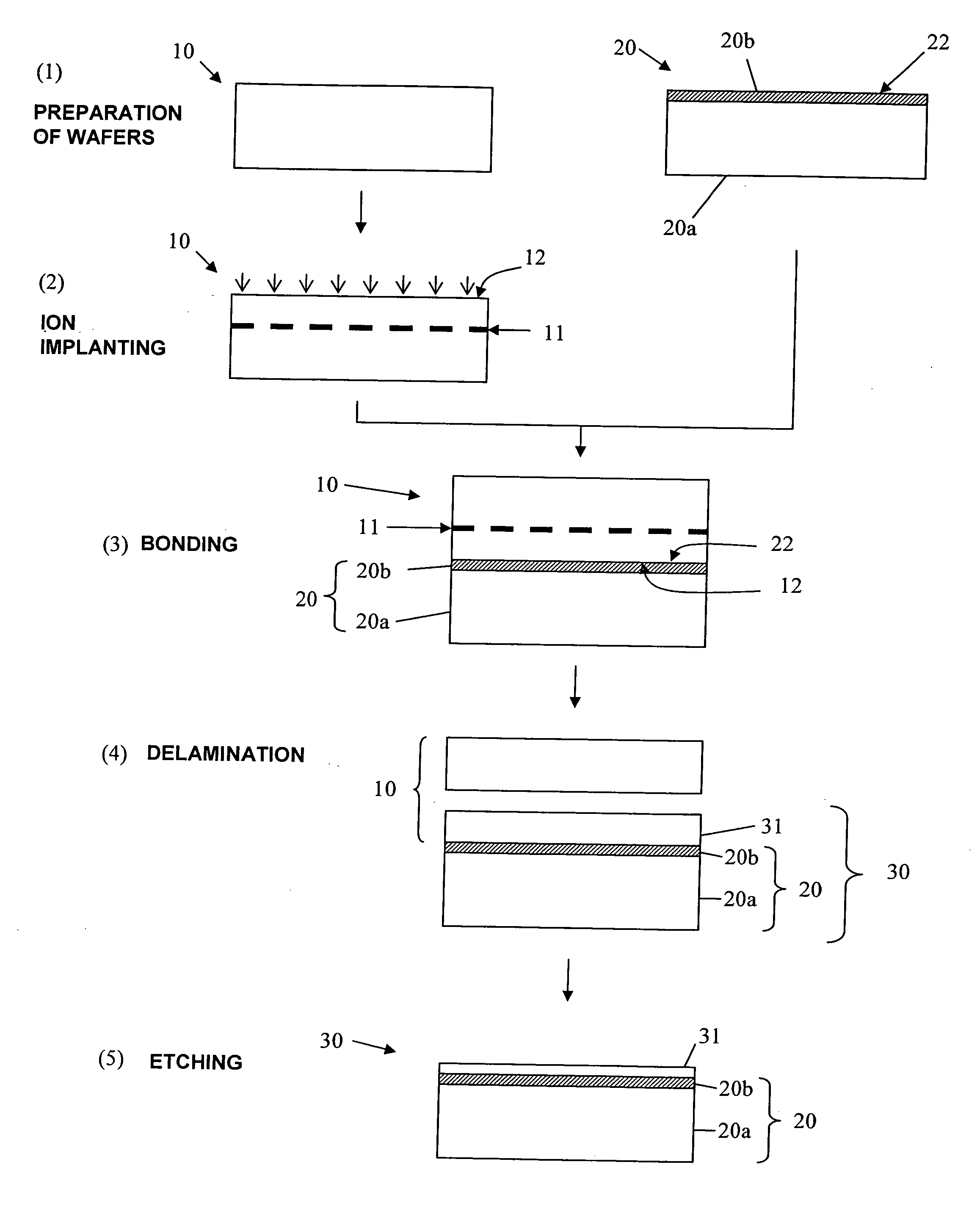

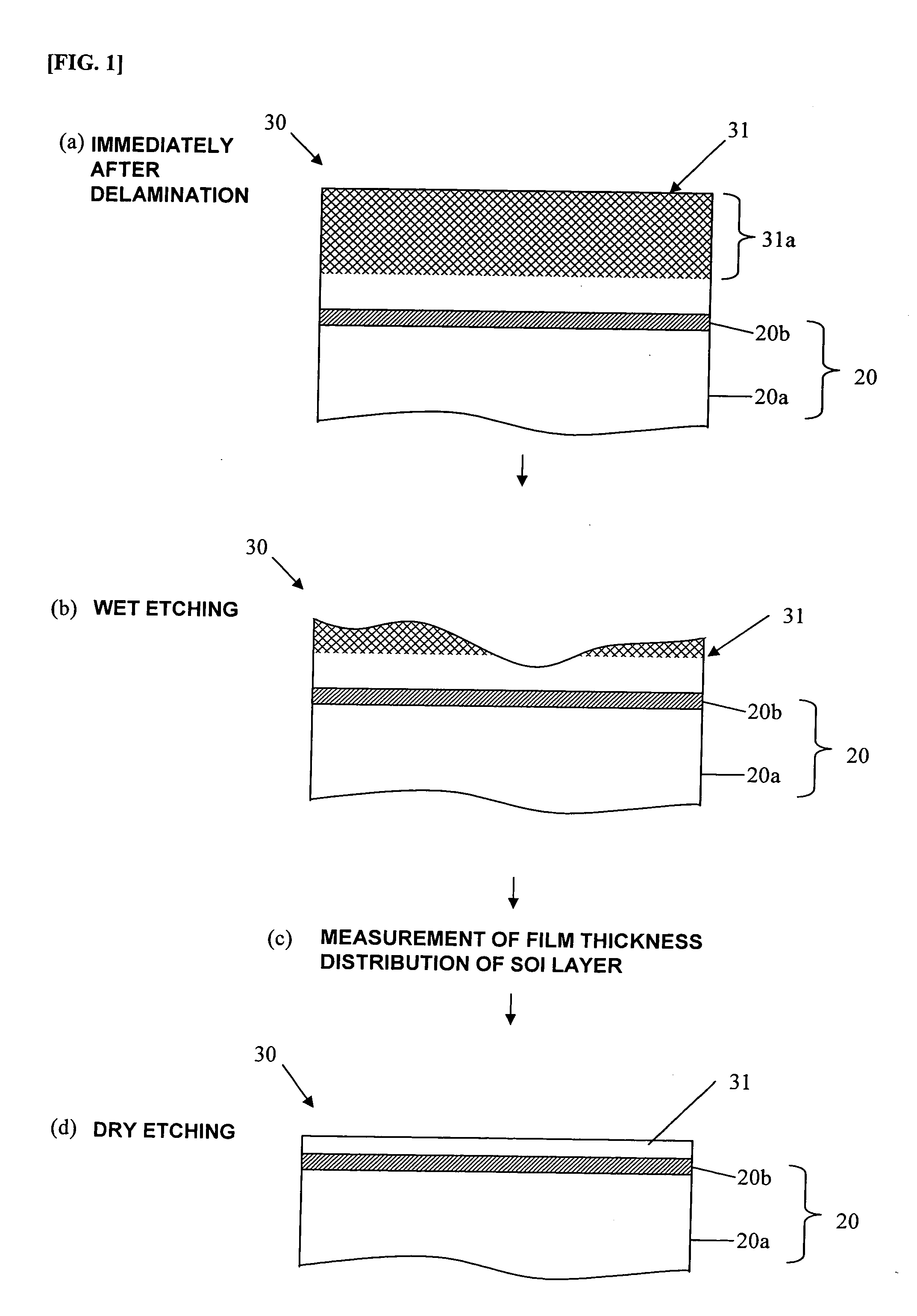

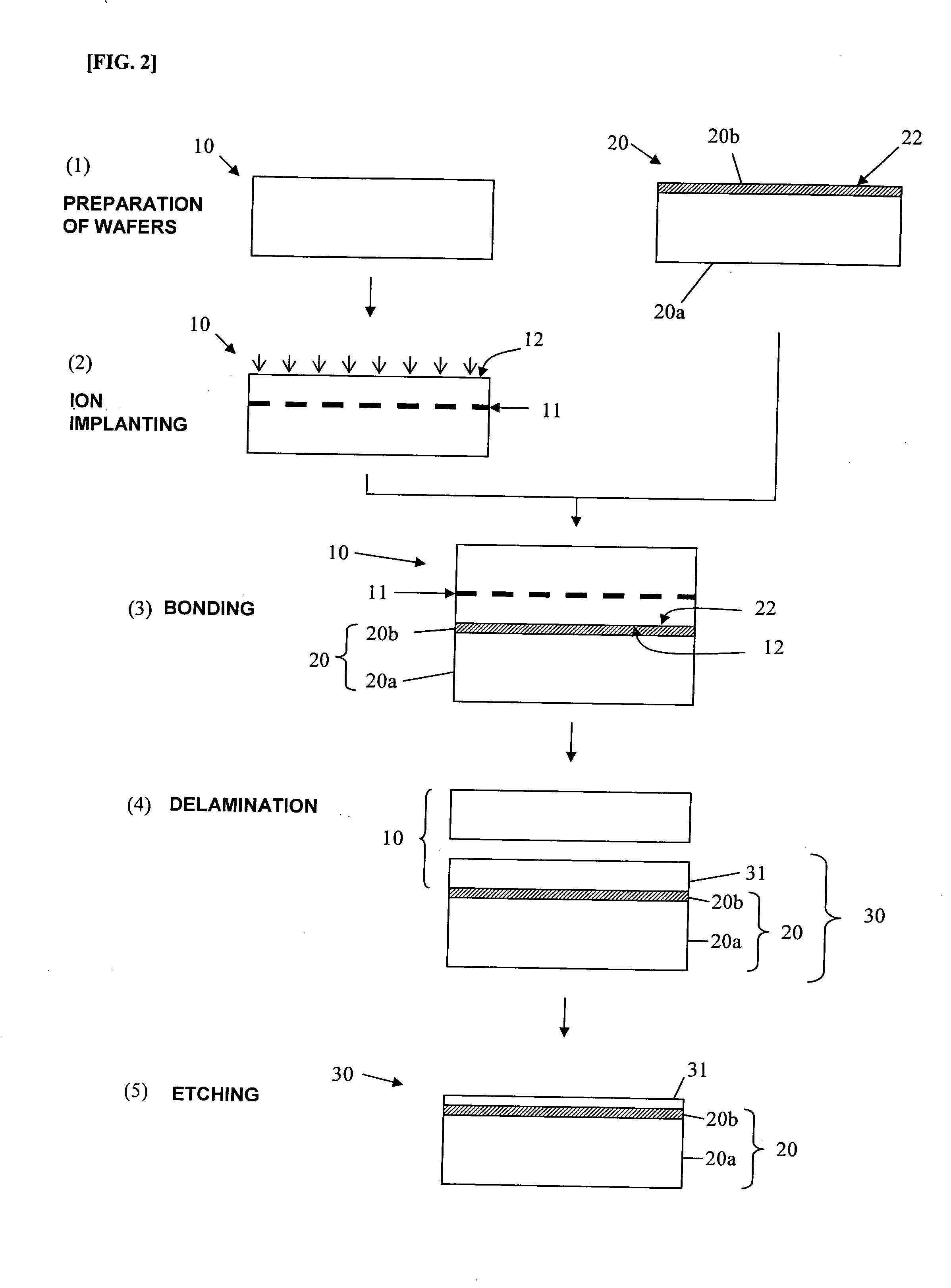

Method for manufacturing SOI wafer

ActiveUS20080299742A1Excellent productivityHigh etch rateSemiconductor/solid-state device testing/measurementSolid-state devicesChemistryProduction rate

There is disclosed a method for manufacturing an SOI wafer comprising: a step of implanting at least one of a hydrogen ion and a rare gas ion into a donor wafer to form an ion implanted layer; a step of bonding an ion implanted surface of the donor wafer to a handle wafer; a step of delaminating the donor wafer at the ion implanted layer to reduce a film thickness of the donor wafer, thereby providing an SOI layer; and a step of etching the SOI layer to reduce a thickness of the SOI layer, wherein the etching step includes: a stage of performing rough etching as wet etching; a stage of measuring a film thickness distribution of the SOI layer after the rough etching; and a stage of performing precise etching as dry etching based on the measured film thickness distribution of the SOI layer. There can be provided A method for manufacturing an SOI wafer having high film thickness uniformity of an SOI layer with excellent productivity.

Owner:SHIN ETSU CHEM CO LTD

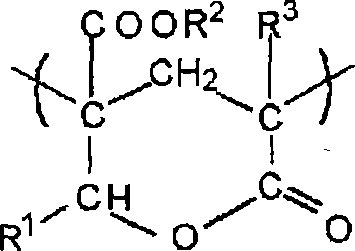

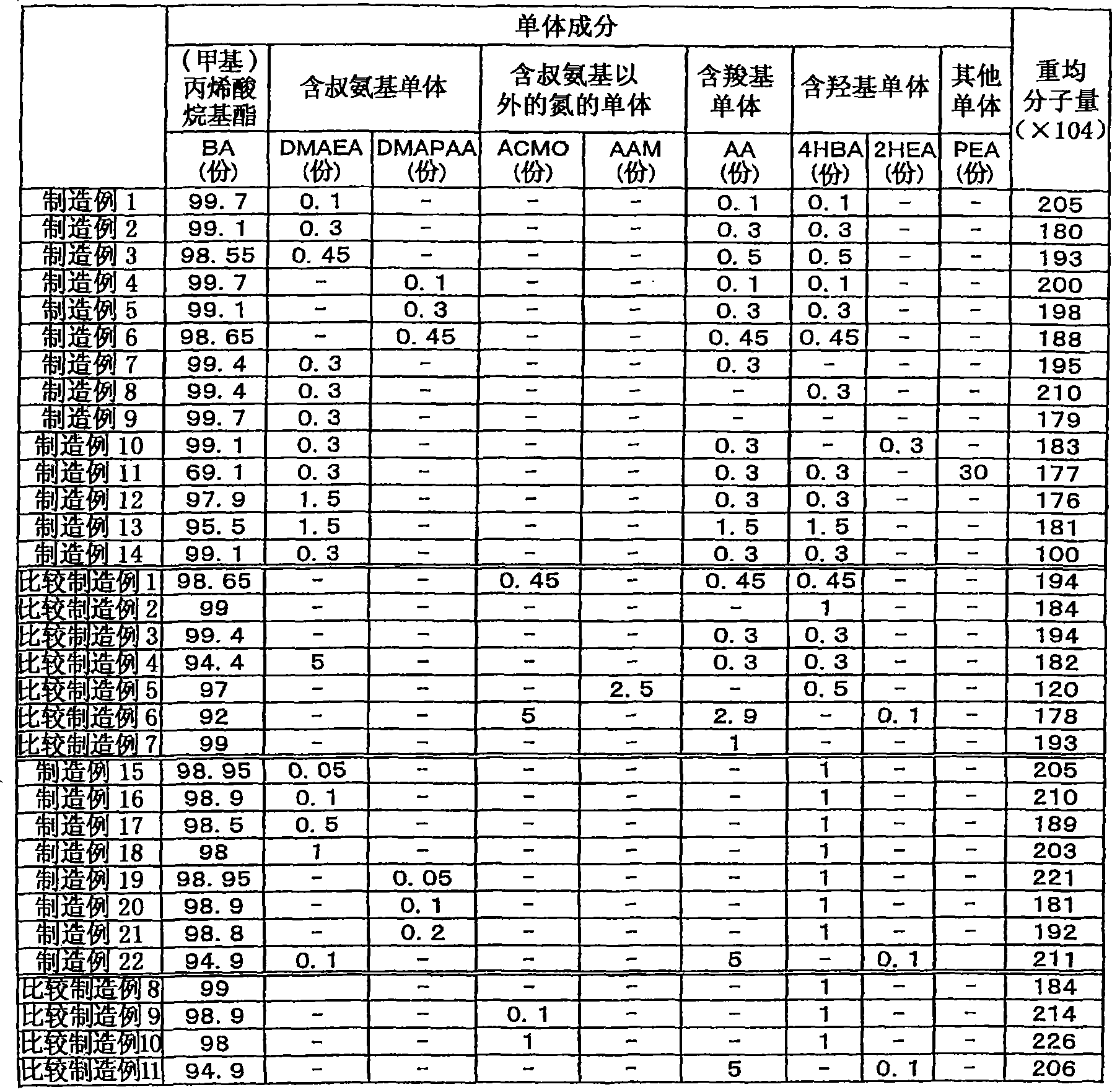

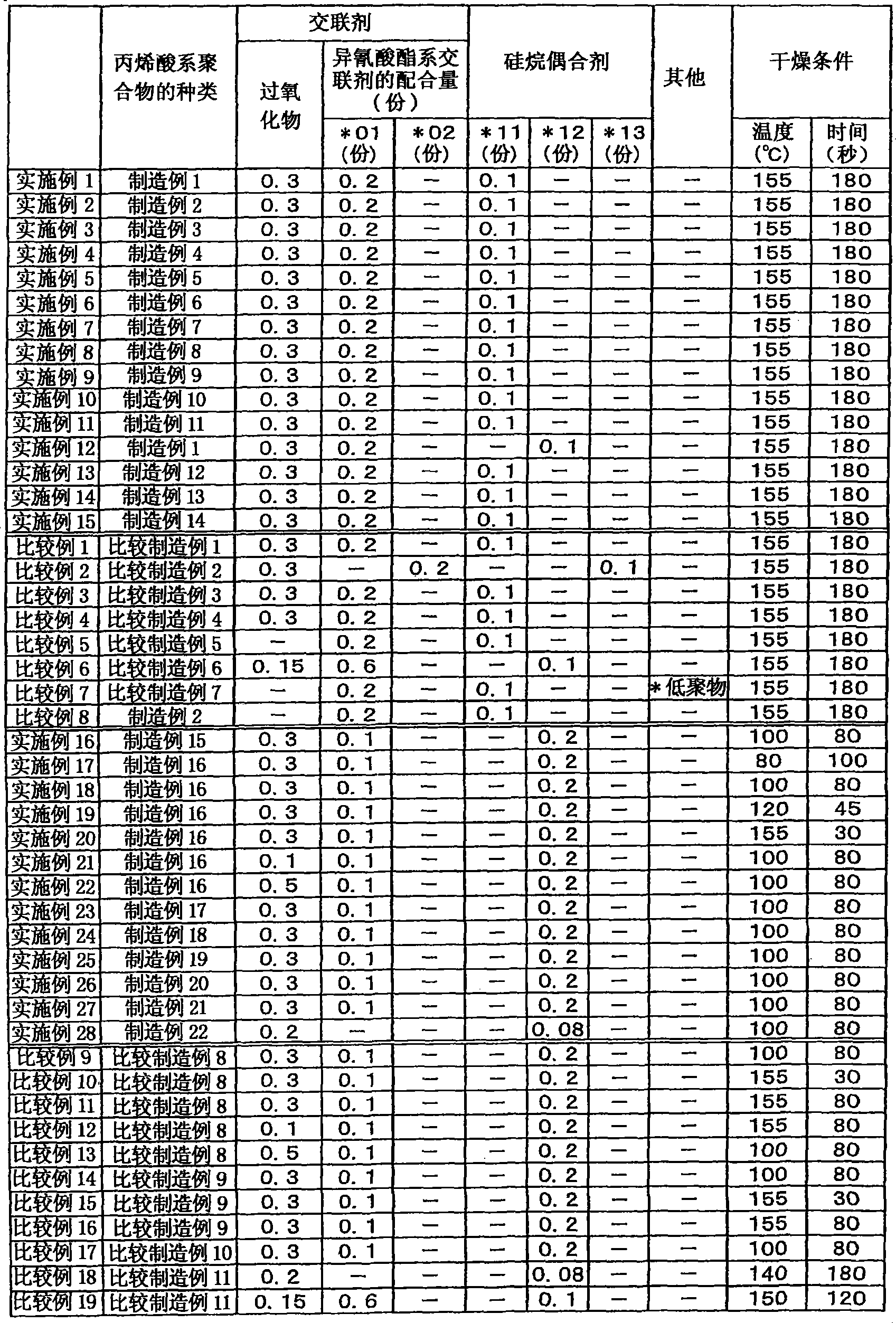

Pressure-sensitive adhesive composition for optical film, pressure-sensitive adhesive layer for optical film, production method thereof, pressure-sensitive adhesive optical film and image display

ActiveCN101418198AExcellent productivityImprove machinabilityFilm/foil adhesivesPolarising elementsMeth-Optical thin film

A pressure-sensitive adhesive composition can form an pressure-sensitive adhesive layer that has satisfactory reworkability such that optical films can be easily peeled from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be worked without pressure-sensitive adhesive fouling or dropout. The pressure-sensitive adhesive composition for an optical film of the present invention comprises 100 parts by weight of a (meth)acrylic polymer comprising 45 to 99.99% by weight of an alkyl (meth)acrylate monomer unit and 0.01 to 2% by weight of a tertiary amino group-containing monomer unit; and 0.01 to 2 parts by weight of a peroxide as a crosslinking agent.

Owner:NITTO DENKO CORP

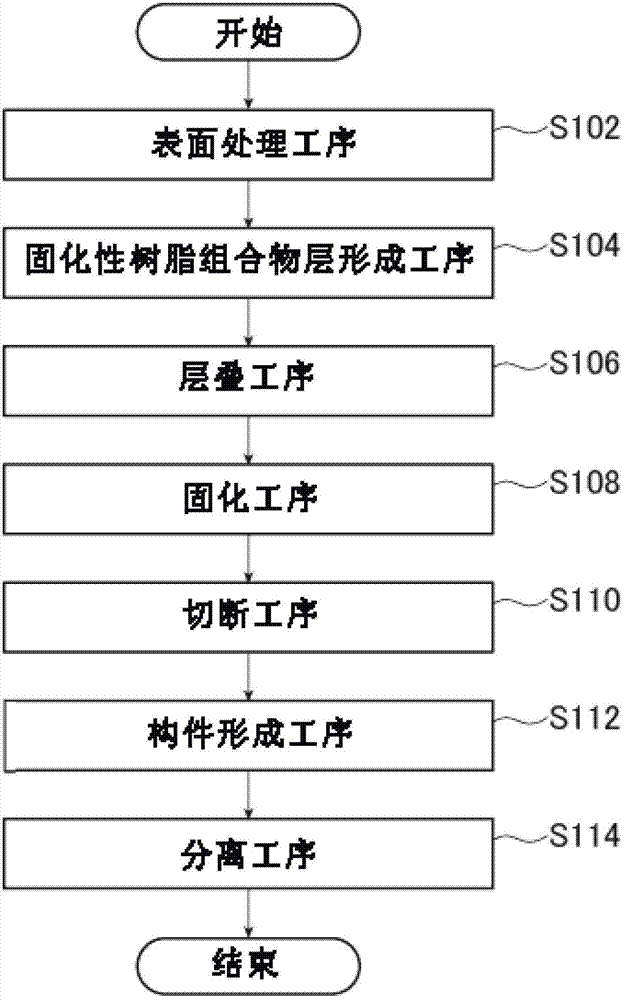

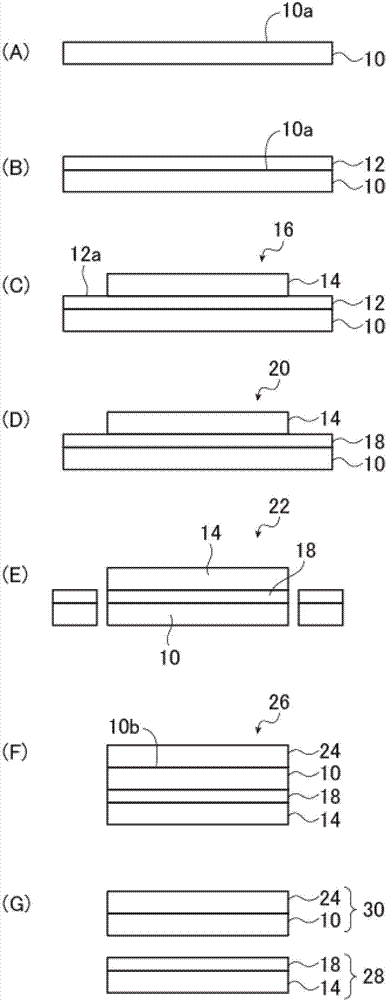

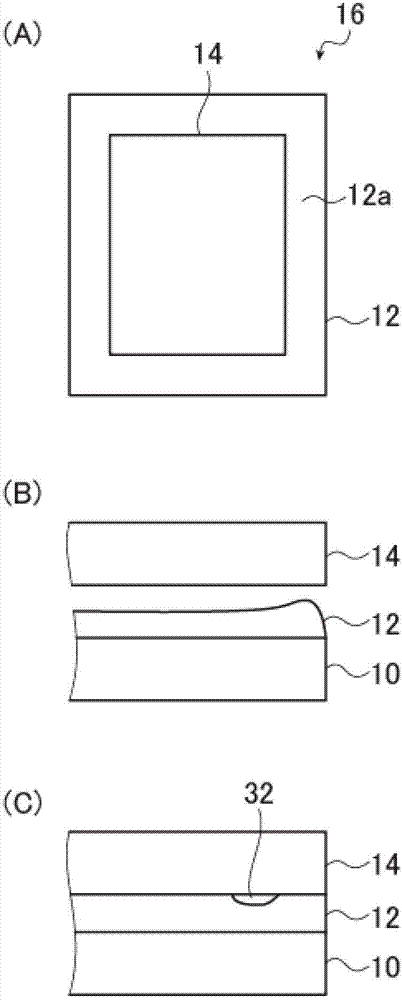

Method for producing electronic device

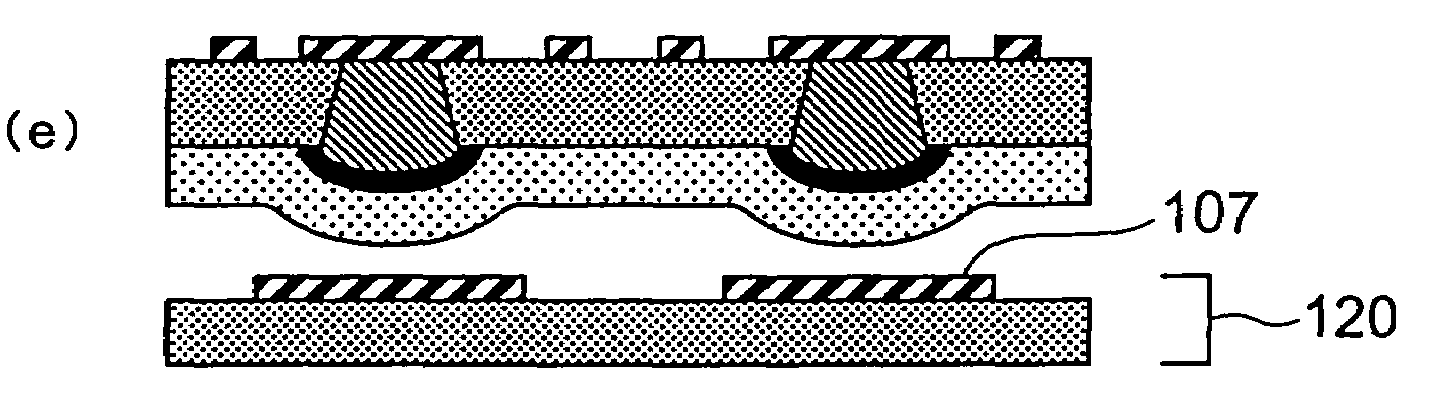

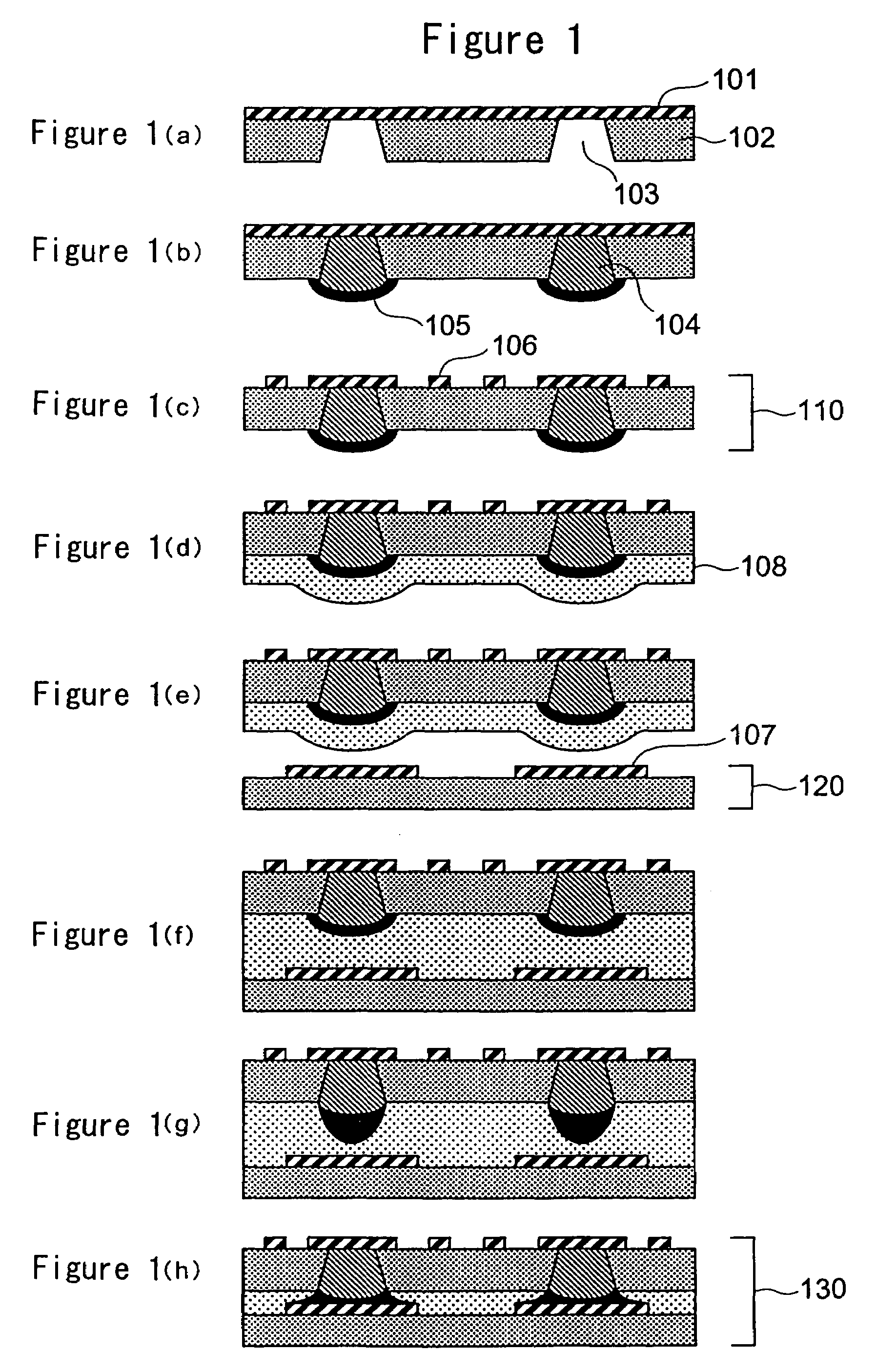

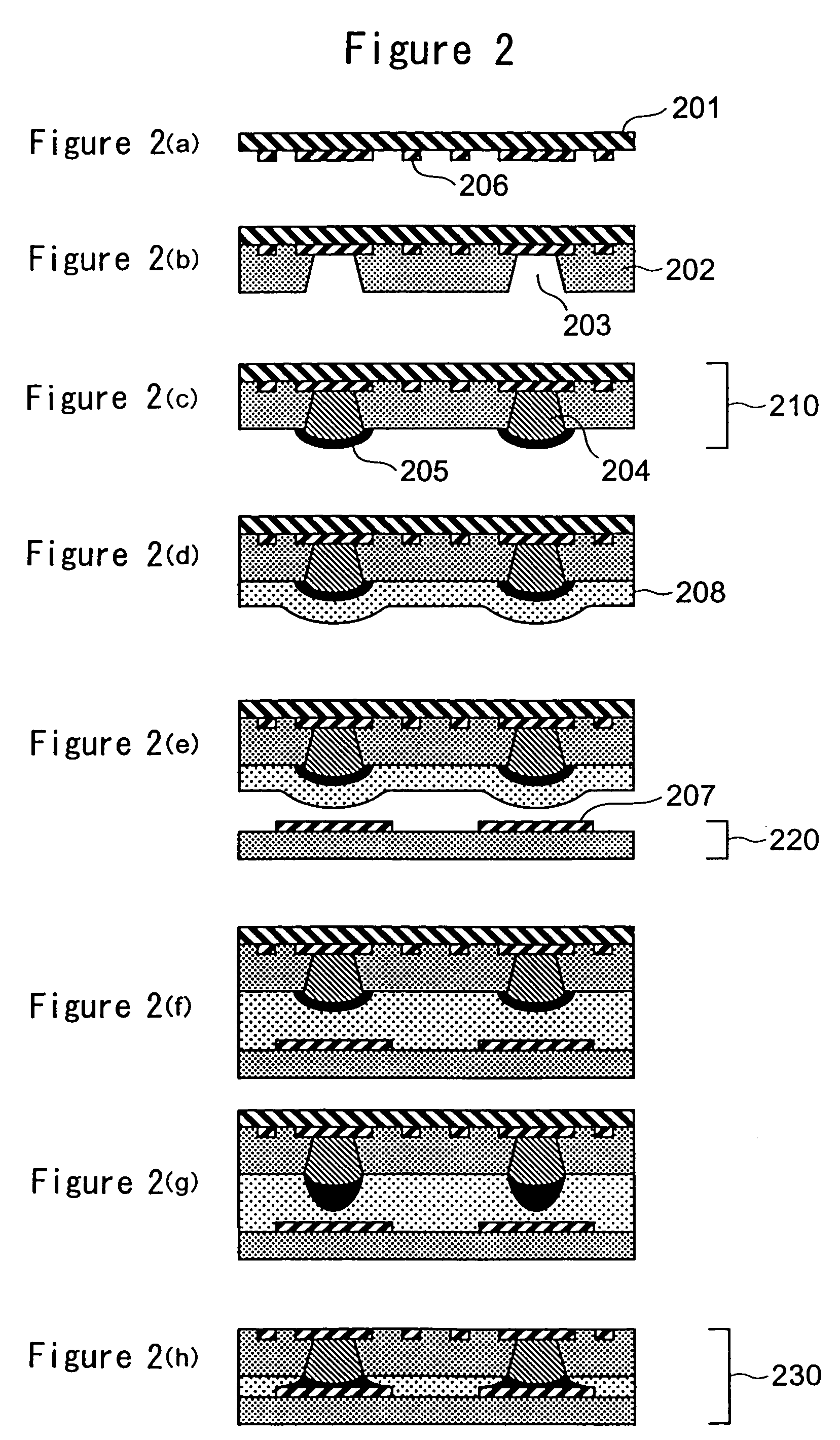

InactiveCN103042803AExcellent productivityImprove flatnessLamination ancillary operationsLaminationSeparation processSurface finishing

The invention relates to a method for producing an electronic device, which is the method for producing a peeling glass substrate and components for the electronic device. The method for producing the electronic device includes the processes as following: a surface treatment process, a curable resin composition layer formation process, an overlapping process, a curing process, a cutting process, a component formation process and a separation process.

Owner:ASAHI GLASS CO LTD

Method for preparing grinding silk

InactiveCN101994167AExcellent productivityReduce wearOther chemical processesArtifical filament manufactureInvestment materialContact phase

The invention relates to a method for preparing a super-tough super-strong specific grinding silk. In the invention, the performance of a polyamide resin slice is adjusted through adjusting auxiliary materials, such as antioxidant, a flexibilizer and / or a reinforcing agent and the like, artificial diamond grinding particles subjected to coupling agent treatment is added to produce the grinding silk with excellent performance. A contact phase of the artificial diamond grinding particles subjected to the coupling agent treatment and the polyamide resin slice is solid-liquid blending by means of segment charging, so as to reduce the abrasion of a building-block type single screw rod extruder by using the artificial diamond grinding particles, and feed volumes are respectively regulated to obtain a plurality of grinding silks having the proportion content of grinding materials, so that the product meets the requirement on various trenchant use environment. The product developed by the process has the advantage of better grinding performance, and can be normally used in the environment of high temperature and acid base.

Owner:慈溪市洁达纳米复合材料有限公司

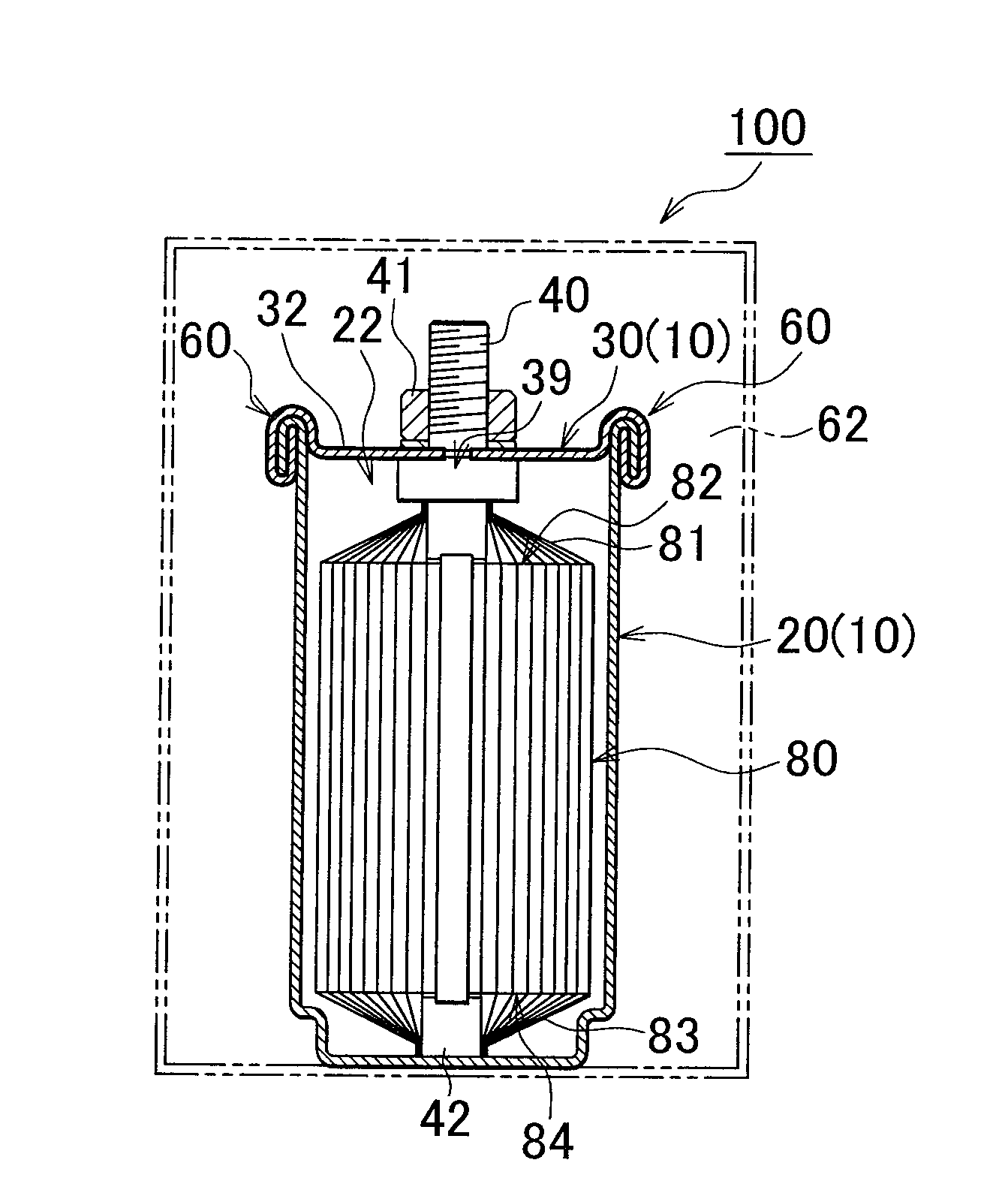

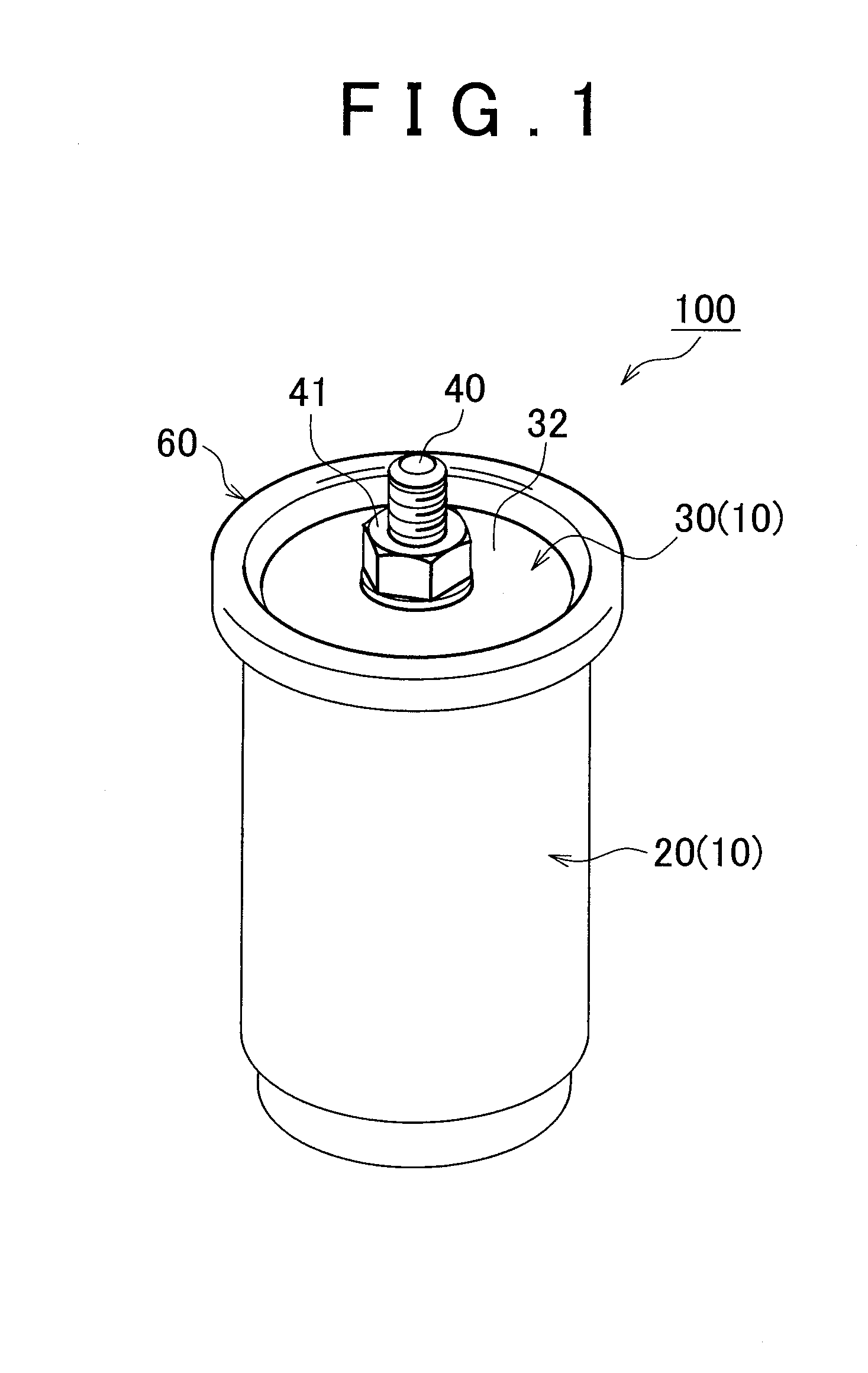

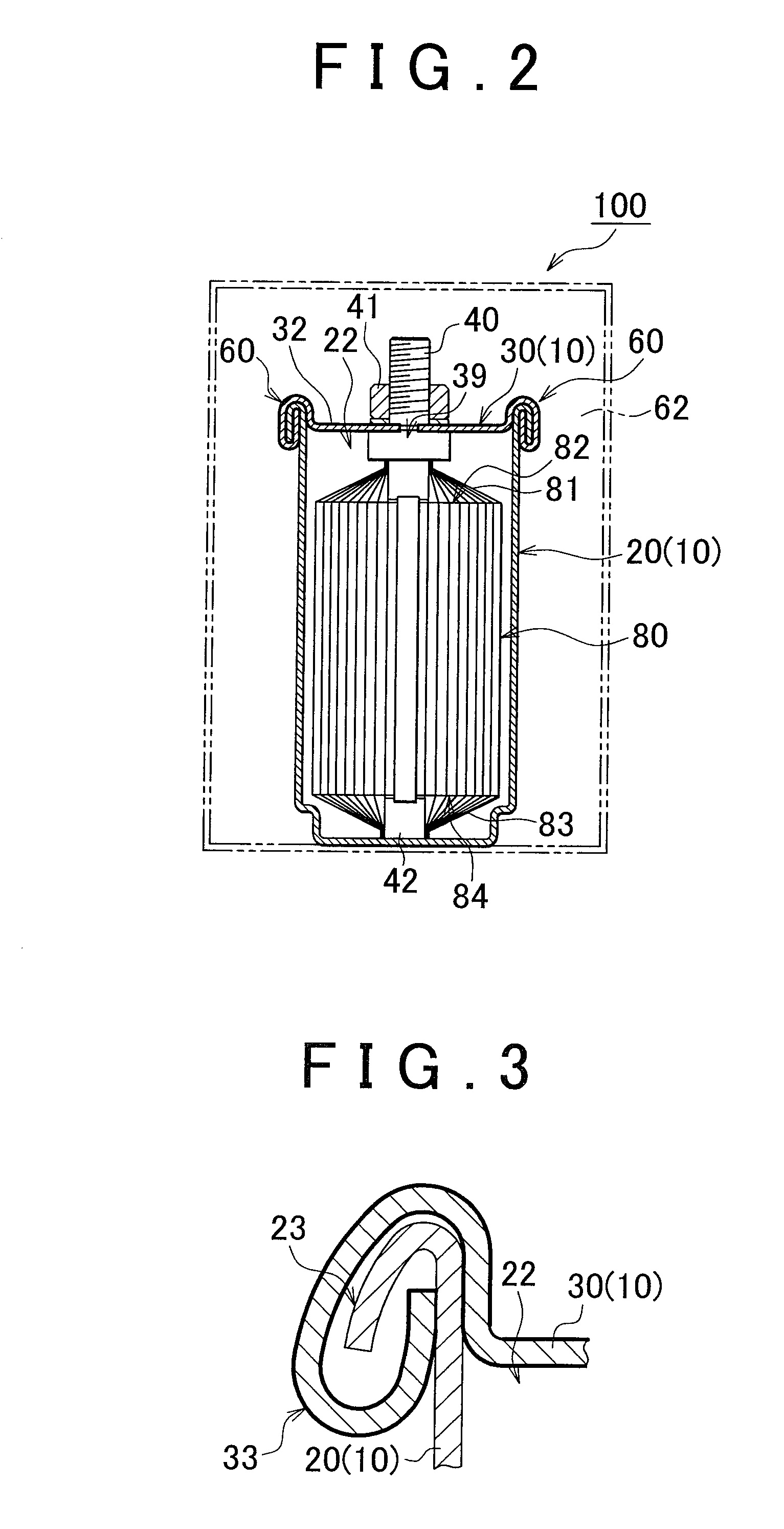

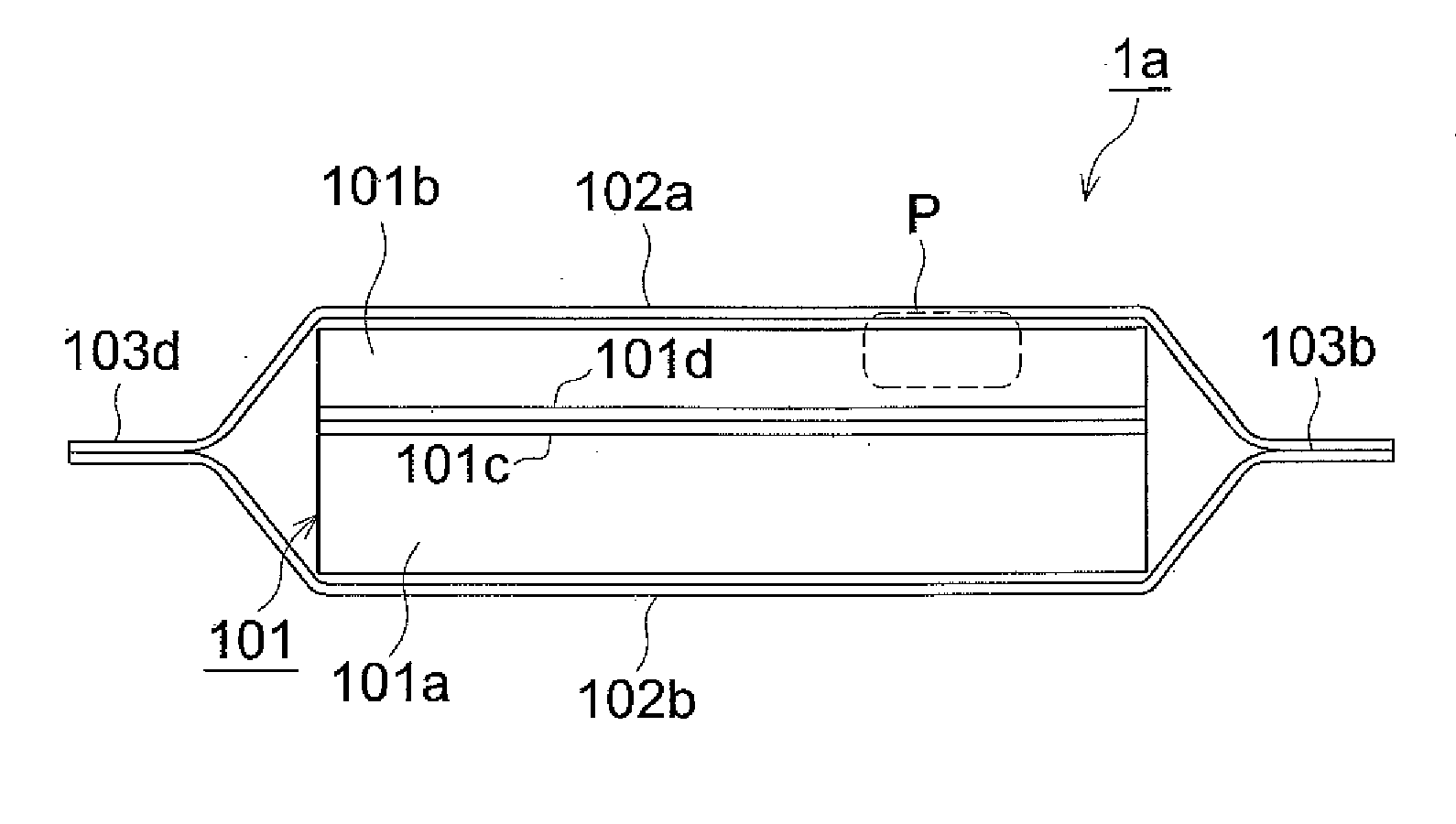

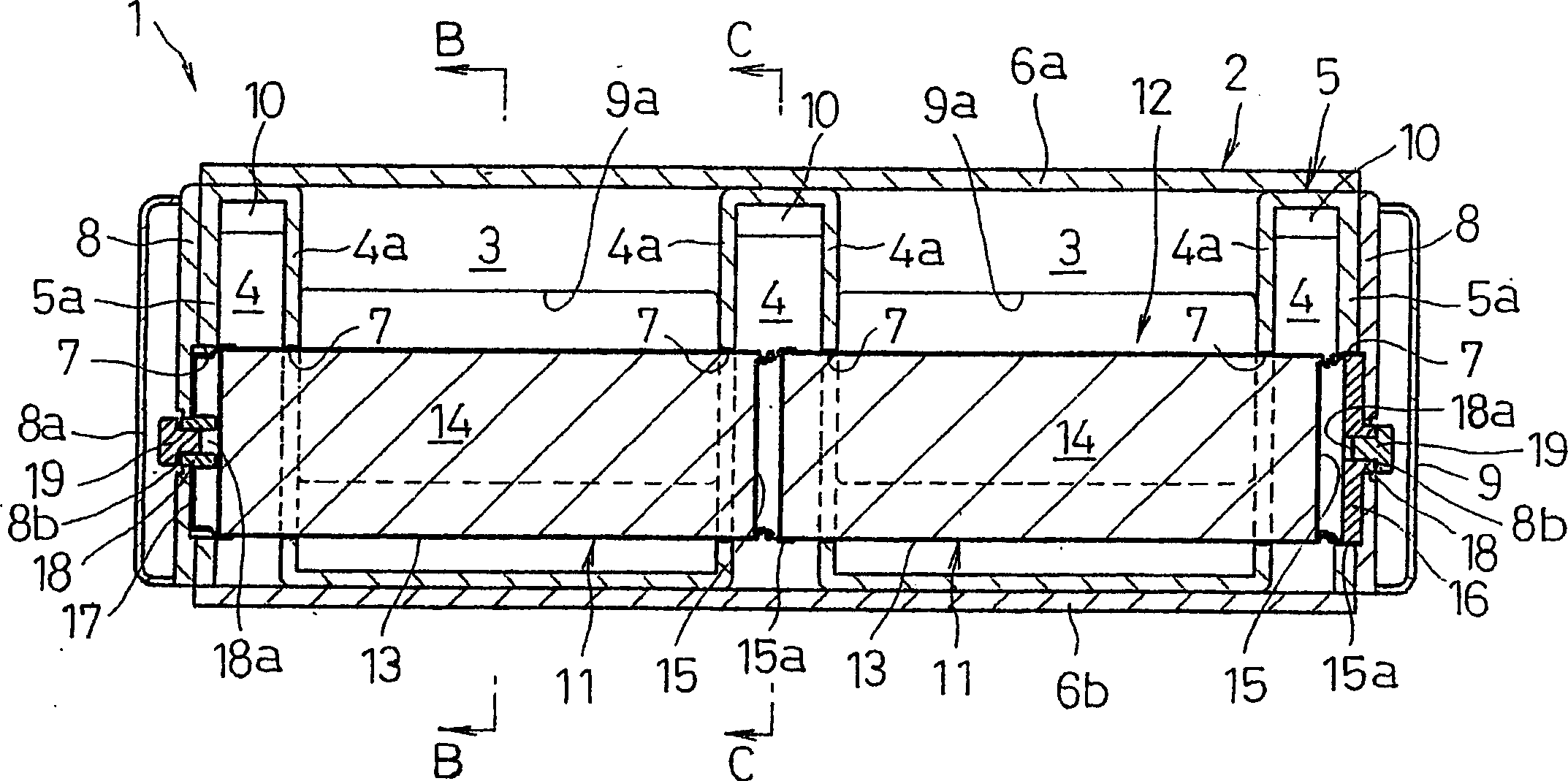

Sealed battery, and vehicle equipped therewith

InactiveUS20090142660A1Efficiently carry-outExcellent productivityFinal product manufactureCell temperature controlMechanical engineeringEngineering

A sealed battery includes: a battery container having in at least an end portion thereof an opening portion, and a container folded-back portion formed in a peripheral edge of the opening portion; a lid having in its outer periphery a lid folded-back portion, and being attached to the opening portion of the battery container; a junction portion in which the container folded-back portion and the lid folded-back portion are integrally joined by a double-rolled seam method; a first seal member closing a first gap between a distal end portion of the container folded-back portion clamping a distal end portion of the lid folded-back portion and an inside of a folded curve portion of the lid folded-back portion; and a second seal member closing a second gap between the distal end portion of the lid folded-back portion and an inside of a folded curve portion of the container folded-back portion.

Owner:TOYOTA JIDOSHA KK

Decorative sheet and decorative molded product

InactiveUS20130209819A1Excellent productivityExcellent contamination resistance and moldabilityLamination ancillary operationsDecorative surface effectsThermoplasticProduction rate

Provided are a decorative sheet and a decorative molded product with excellent productivity that impart the decorative molded product with superior stain resistance and moldability. The decorative sheet and the decorative molded product sequentially have a releasable layer and a surface protecting layer on one side of a base sheet, the surface protecting layer composed of an ionizing radiation-curable resin composition containing a polyfunctional (meth)acrylate monomer and a thermoplastic resin with a molecular weight of 175 to 1000, the thermoplastic resin having a predetermined weight average molecular weight, and the polyfunctional (meth)acrylate monomer and the thermoplastic resin being of predetermined mass ratios.

Owner:DAI NIPPON PRINTING CO LTD

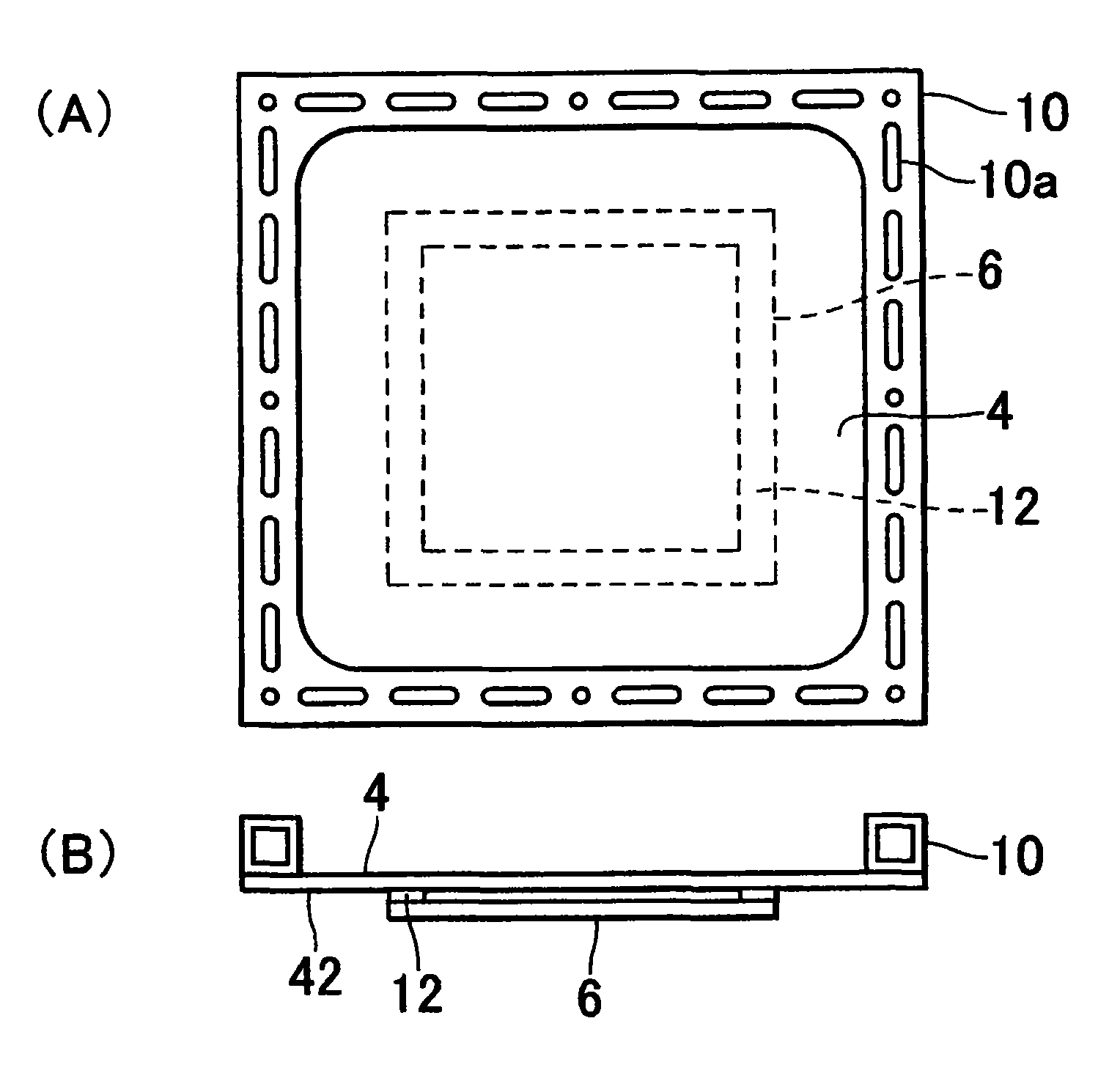

Scintillator plate, scintillator panel and flat panel radiation detector by use thereof

InactiveUS20100314547A1Excellent productivityImprove light extractionPhotometrySolid-state devicesProduction rateOptoelectronics

There is provided a scintillator plate which is superior in productivity, exhibits enhanced light extraction efficiency of a scintillator and enhanced sharpness and results in reduced deterioration in sharpness between flat light-receiving element surfaces. There are also provided a scintillator panel and a flat panel radiation detector by use thereof.The scintillator plate comprises a reflection layer, a resinous anticorrosion layer and a scintillator layer provided sequentially in this order on a heat-resistant resin substrate, wherein the scintillator plate is employed, as a component for a flat panel radiation detector, without being physicochemically adhered to the surface of a flat light-receiving element.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Spunbonded nonwoven fabric

ActiveUS20090022956A1Excellent productivityHigh strengthLayered productsAbsorbent padsWoven fabricFineness

There is provided by the present invention a spunbonded nonwoven fabric which is formed from fibers comprising a propylene-based polymer and has MFR of 65 to 150 g / 10 min and a fineness of 0.01 to 1.5 deniers, wherein the basis weight is in the range of 5 to 40 g / m2 and the embossed area ratio is in the range of 6.5 to 25%.

Owner:MITSUI CHEM INC

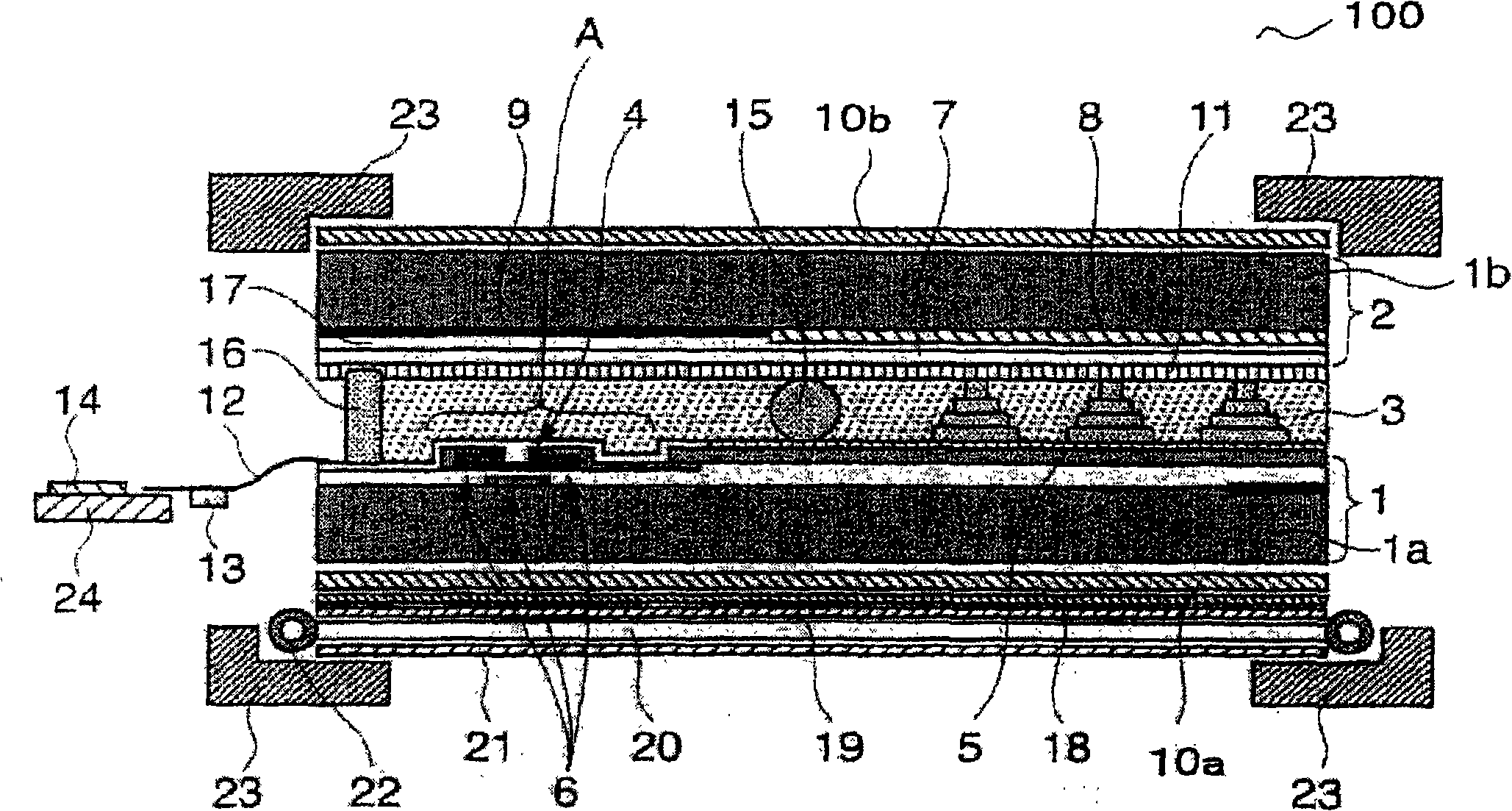

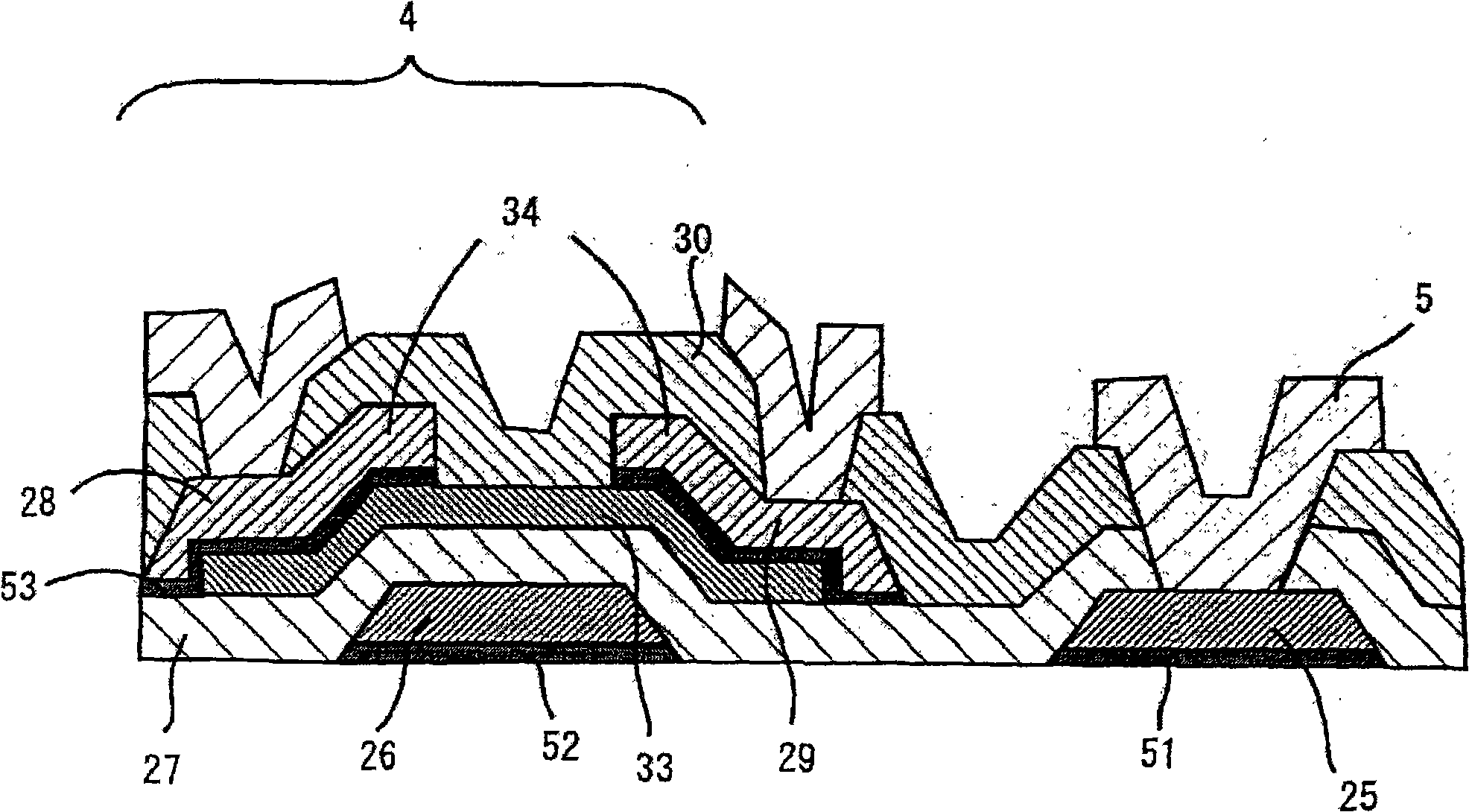

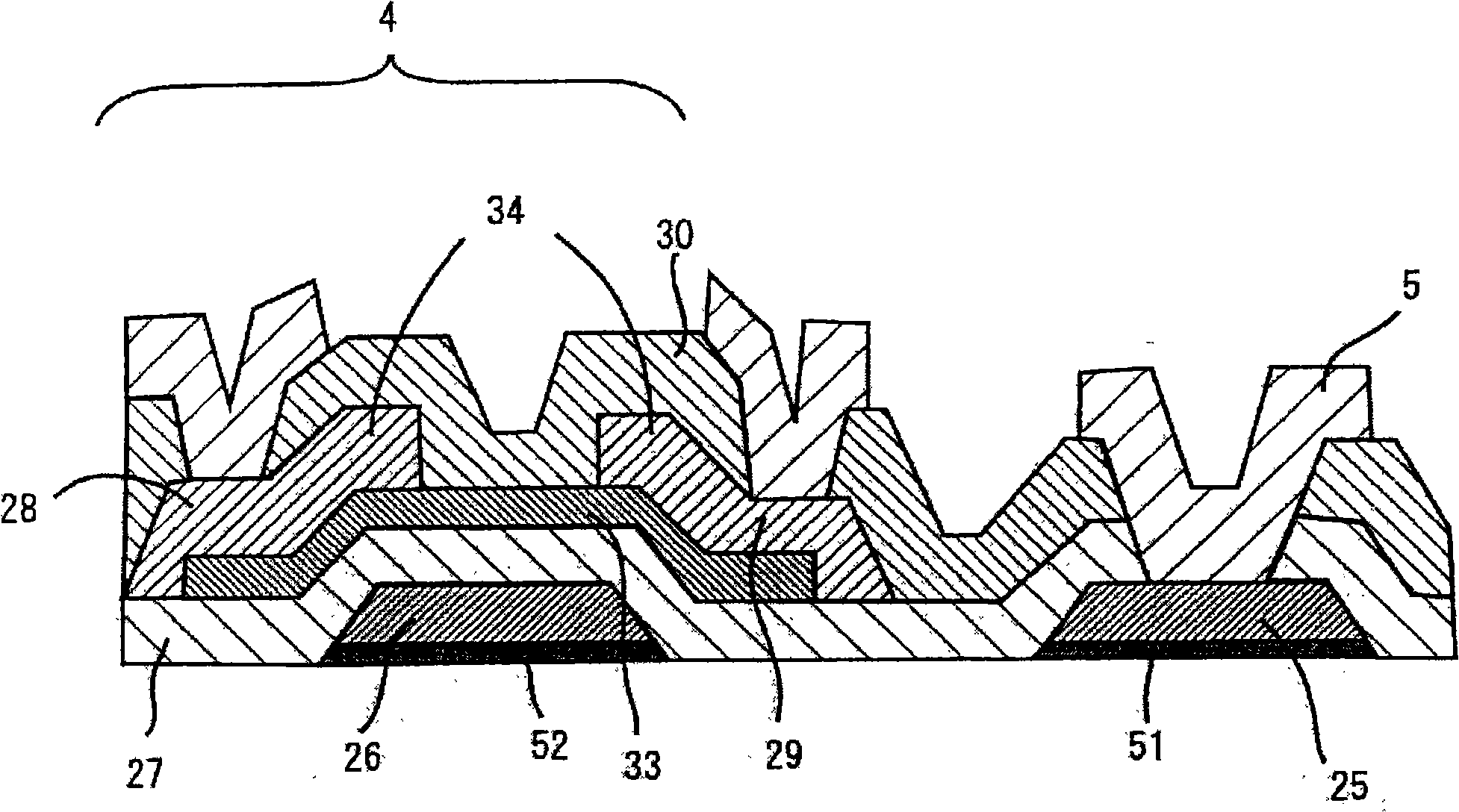

Thin film transistor substrate and display device

InactiveCN101330102AExcellent TFT characteristicsExcellent productivityTransistorSolid-state devicesSemiconductorDisplay device

Disclosed herein is a TFT substrate which exhibits good characteristic properties despite the omission of the barrier metal layer to be normally interposed between the source-drain electrodes and the semiconductor layer in the TFT. The thin film transistor substrate has a semiconductor layer (33) and source-drain electrodes (28, 29). The source-drain electrodes are composed of oxygen-containing layers (28a, 29a) and thin films (28b, 29b) of pure copper or a copper alloy. The oxygen-containing layer contains oxygen such that part or all of oxygen combines with silicon in the semiconductor layer (33). And, the thin films (28a, 29a) of pure copper or a copper alloy connect with the semiconductor layer (33) of the thin film transistor through the oxygen-containing layers (28a, 29a).

Owner:KOBE STEEL LTD

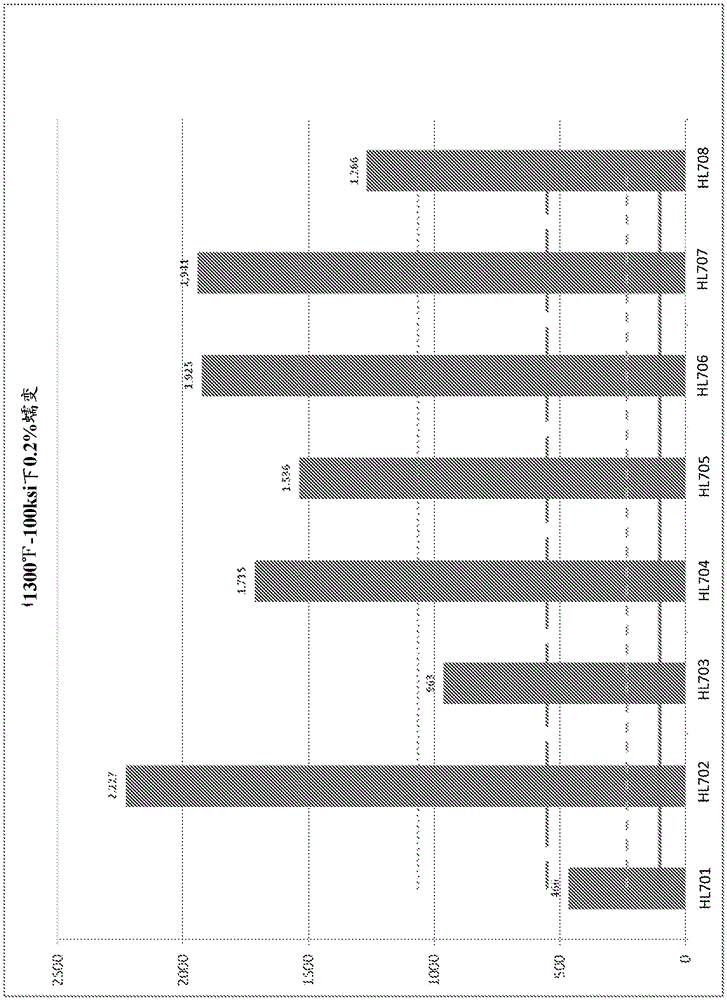

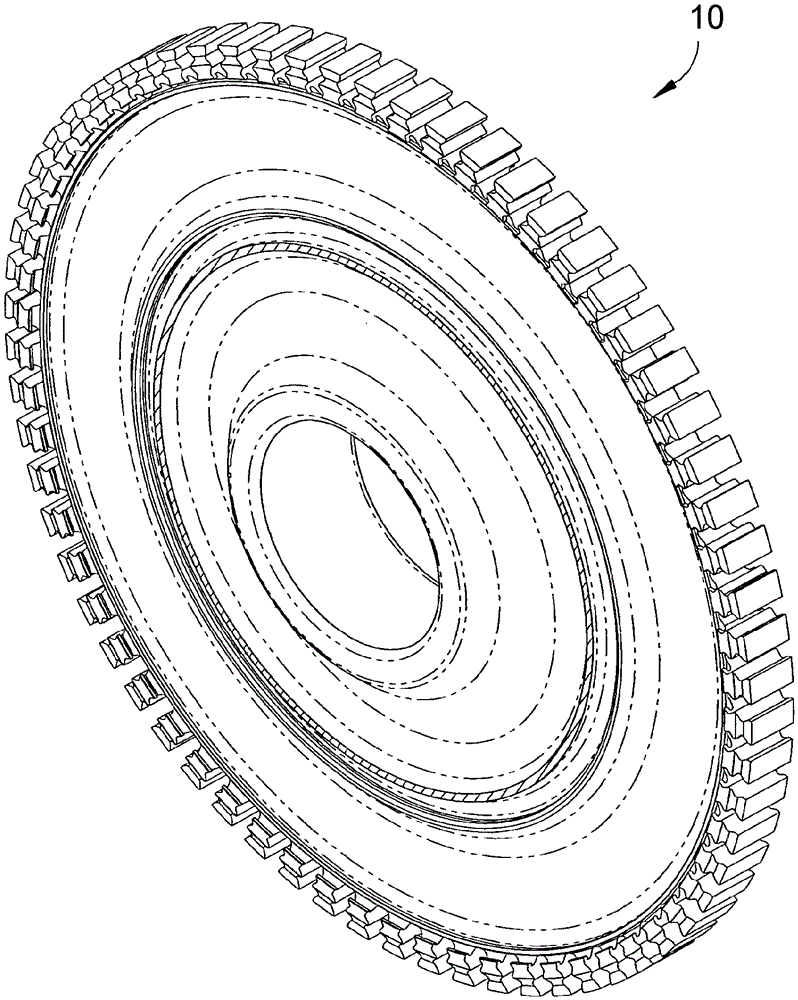

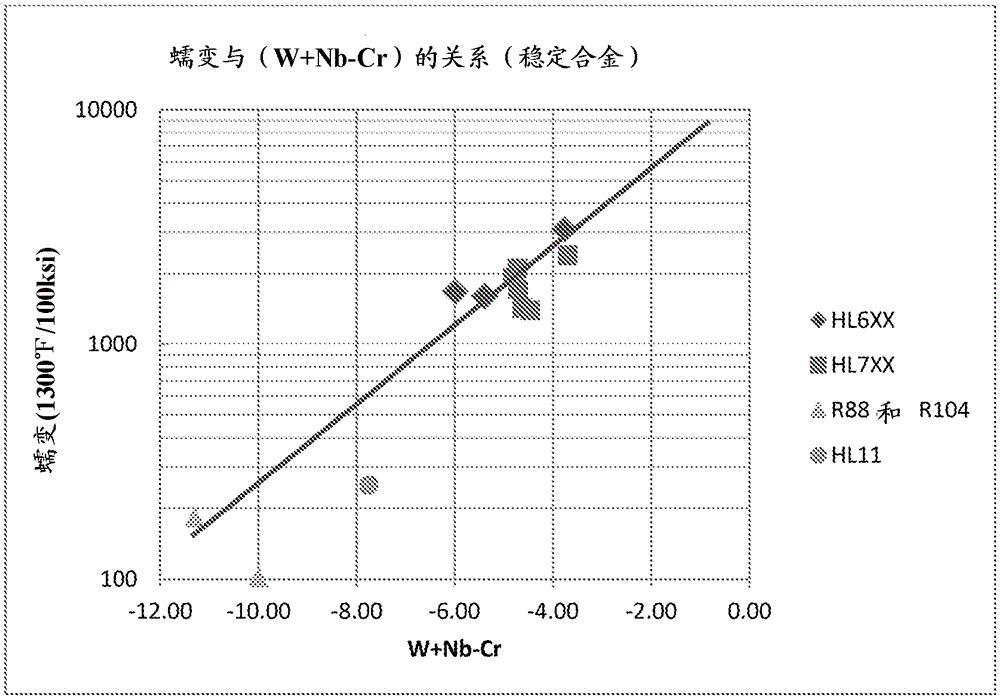

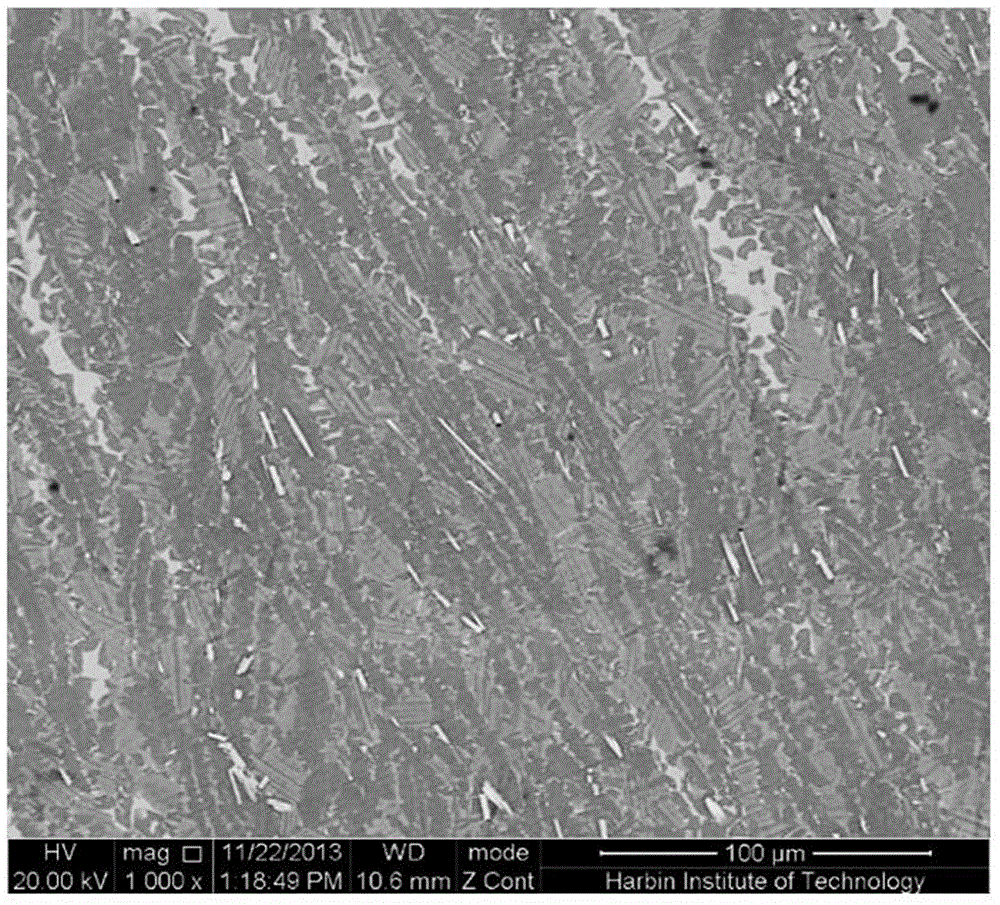

Superalloys and components formed thereof

ActiveCN105492639AImproved high temperature and pressure holding propertiesImproved creep characteristicsEfficient propulsion technologiesNiobiumHafnium

A gamma prime nickel-base superalloy and components formed therefrom that exhibit improved high-temperature dwell capabilities, including creep and hold time fatigue crack growth behavior. A particular example of a component is a powder metallurgy turbine disk of a gas turbine engine. The gamma-prime nickel-base superalloy contains, by weight: 16.0 to 30.0% cobalt; 9.5 to 12.5% chromium; 4.0 to 6.0% tantalum; 2.0 to 4.0% aluminum; 2.0 to 3.4% titanium; 3.0 to 6.0% tungsten; 1.0 to 4.0% molybdenum; 1.5 to 3.5% niobium; up to 1.0% hafnium; 0.02 to 0.20% carbon; 0.01 to 0.05% boron; 0.02 to 0.10% zirconium; the balance essentially nickel and impurities. The superalloy has a W+Nb-Cr value of at least-6, is free of observable amounts of sigma and eta phases, and exhibits a time to 0.2% creep at 1300 Fahrenheit and 100 ksi of at least 1000 hours.

Owner:GENERAL ELECTRIC CO

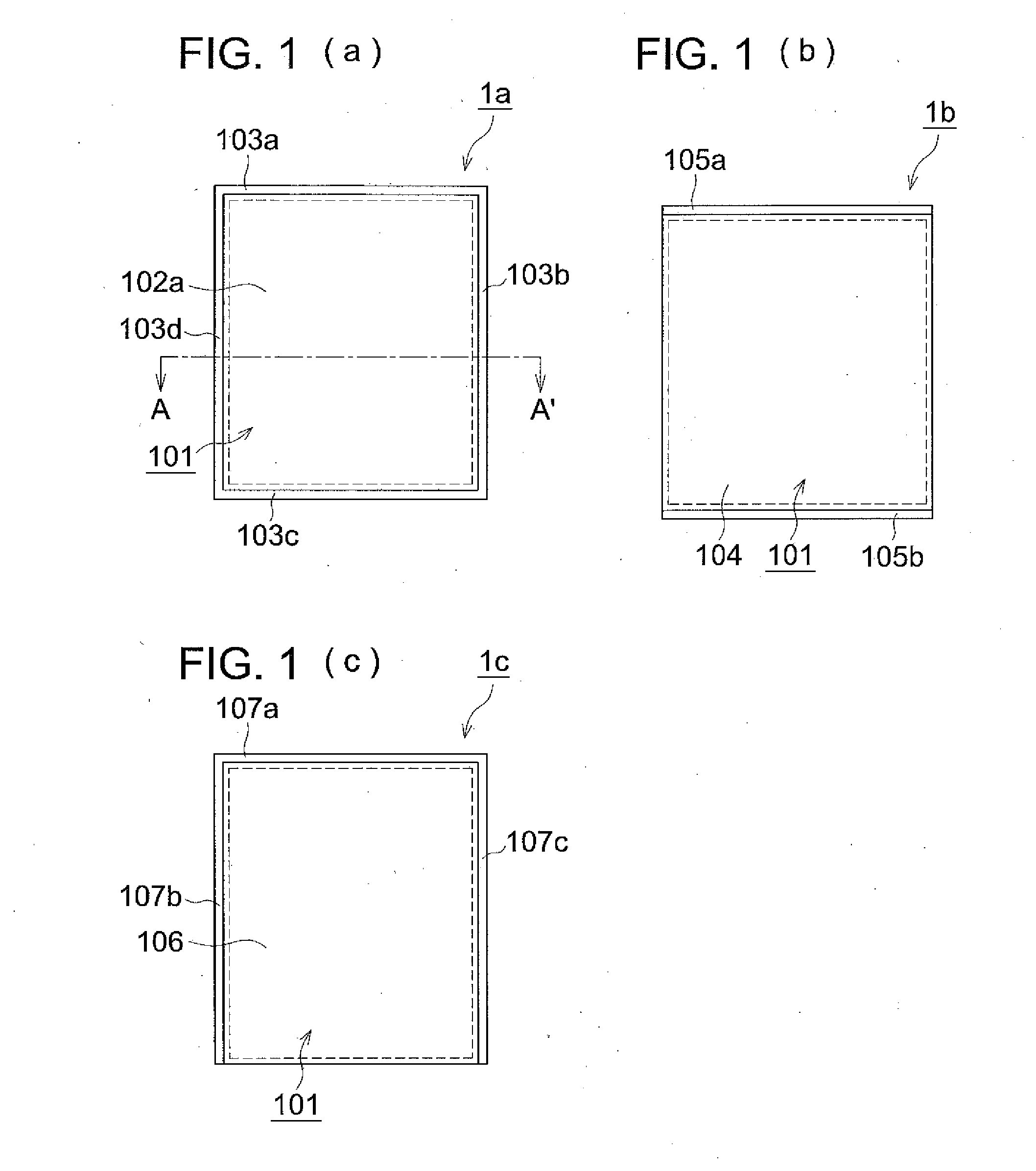

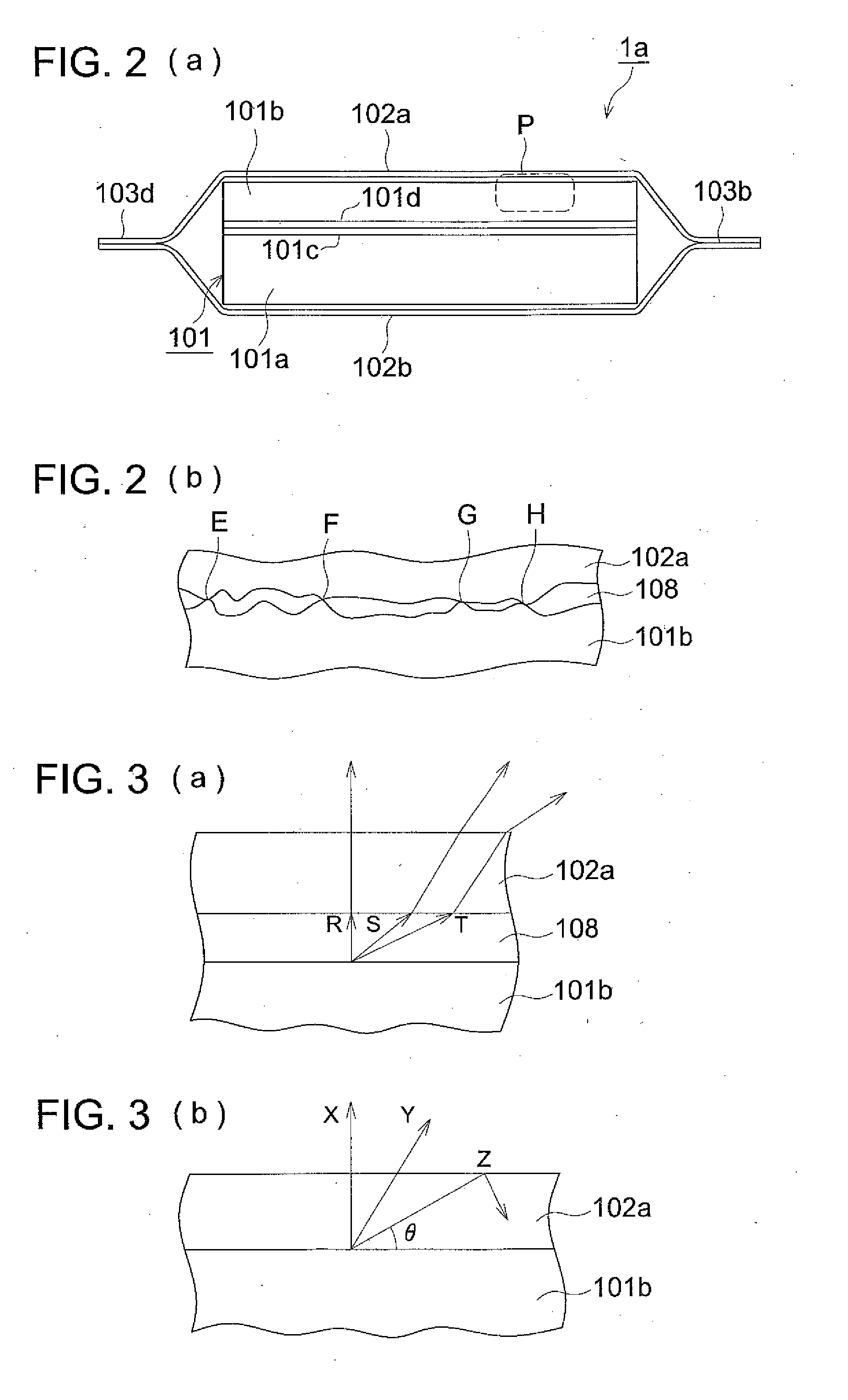

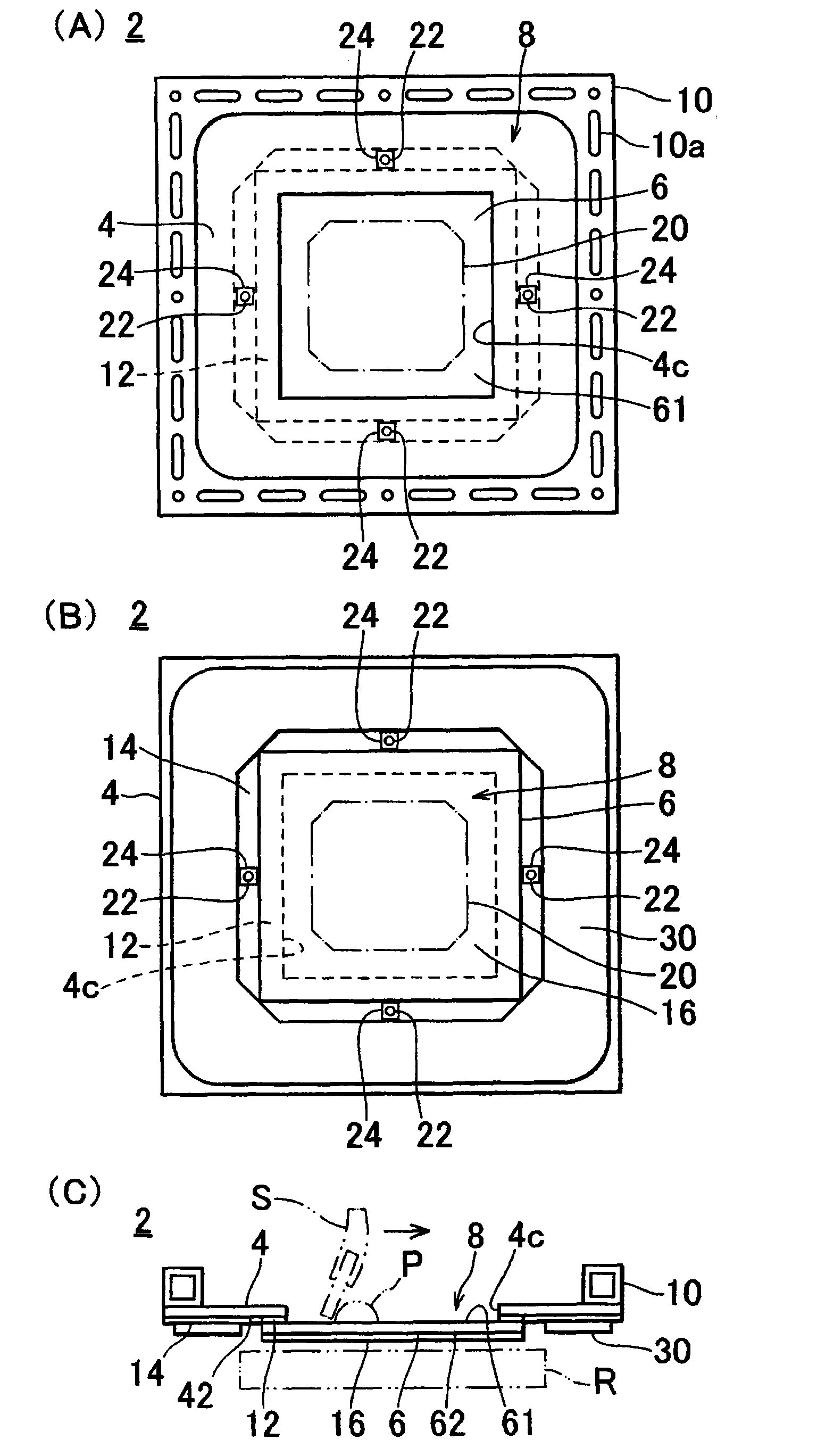

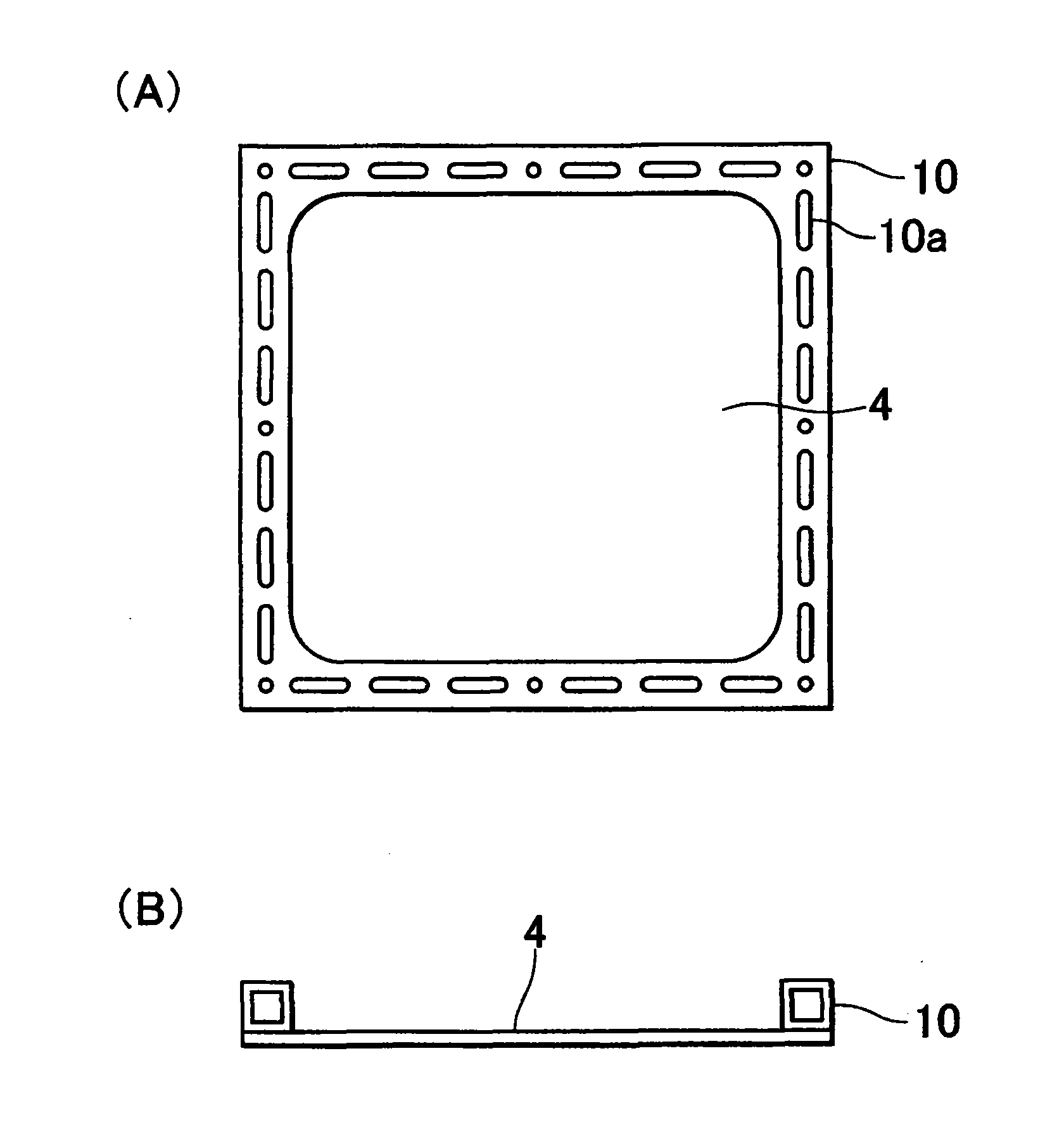

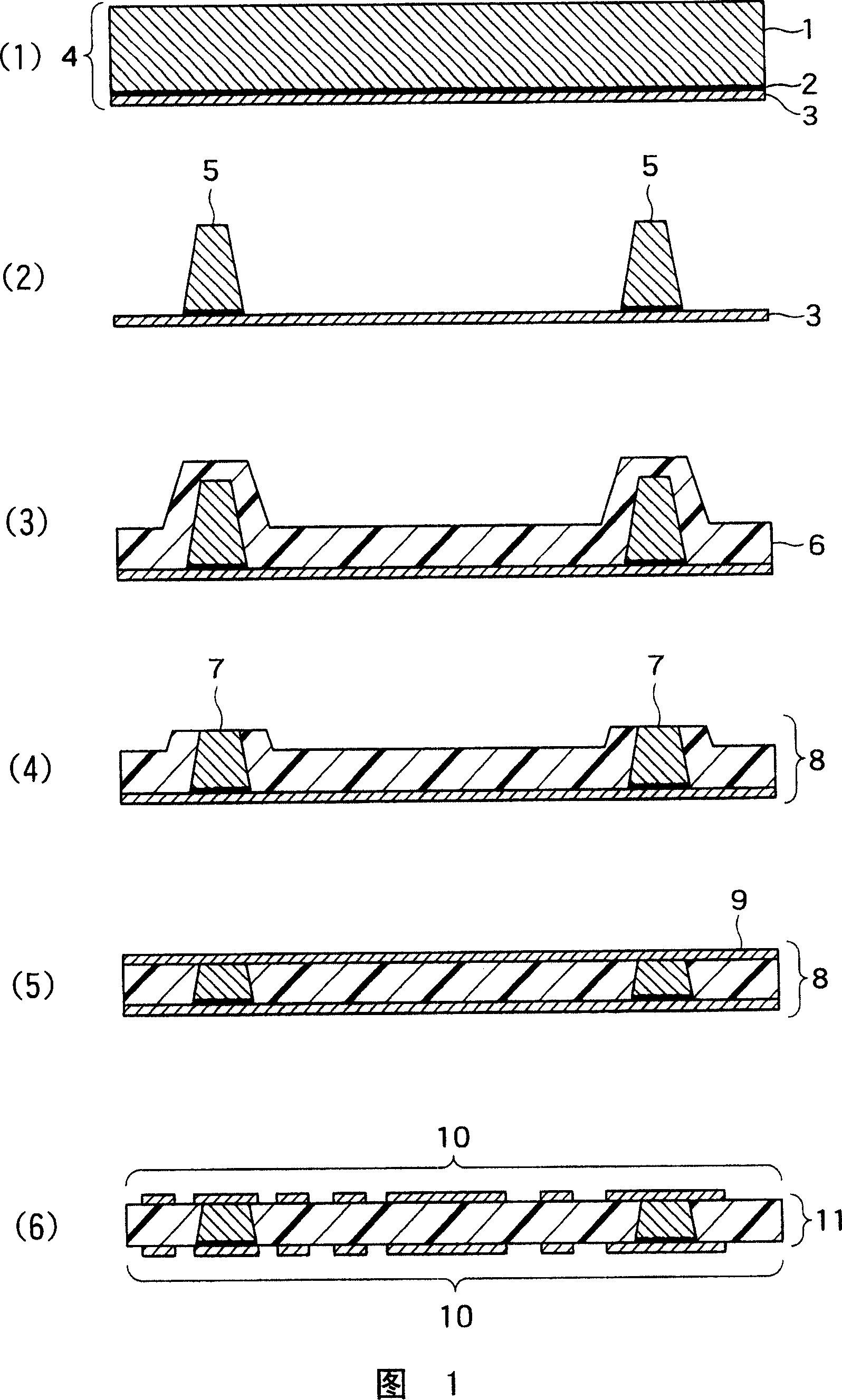

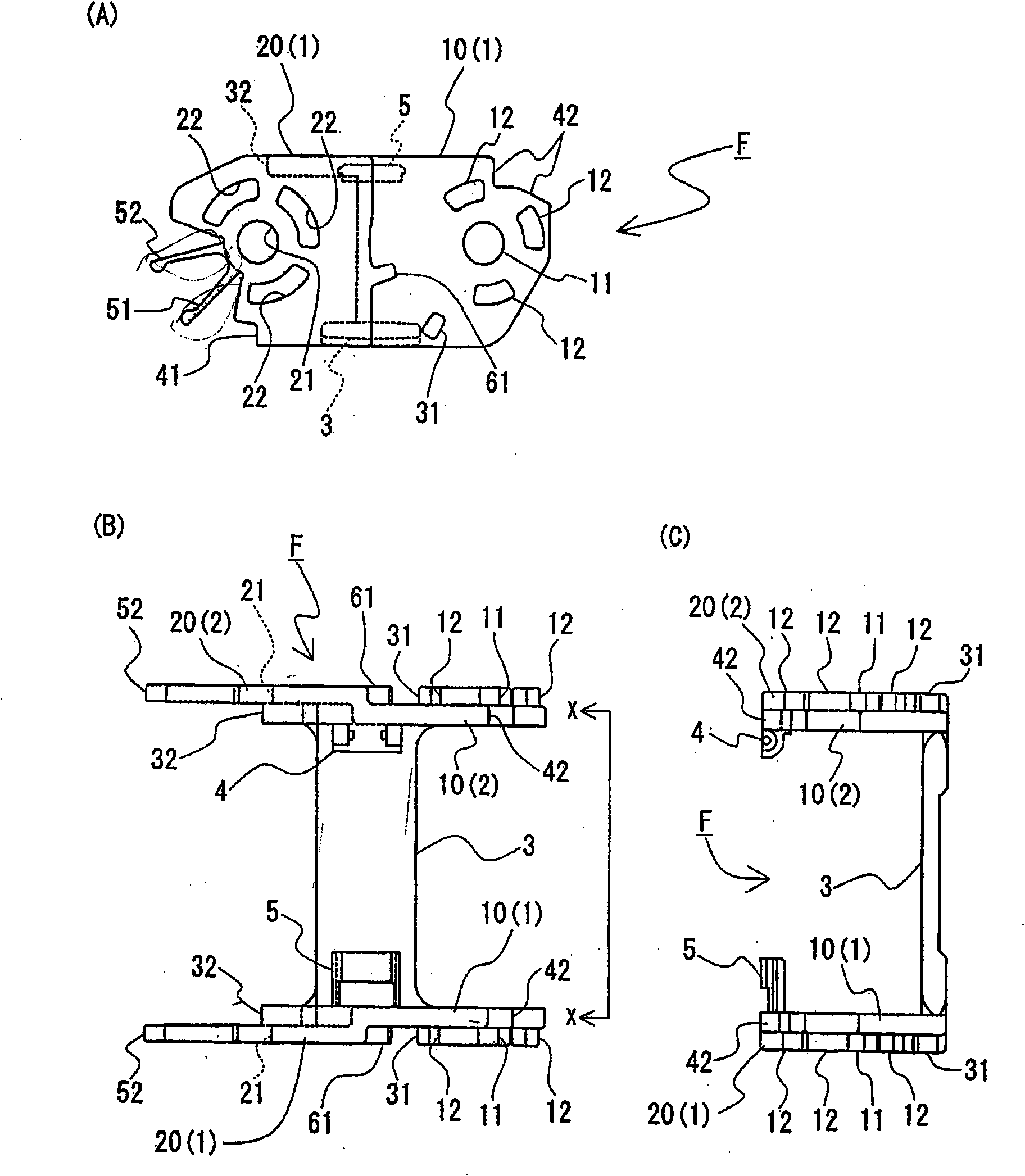

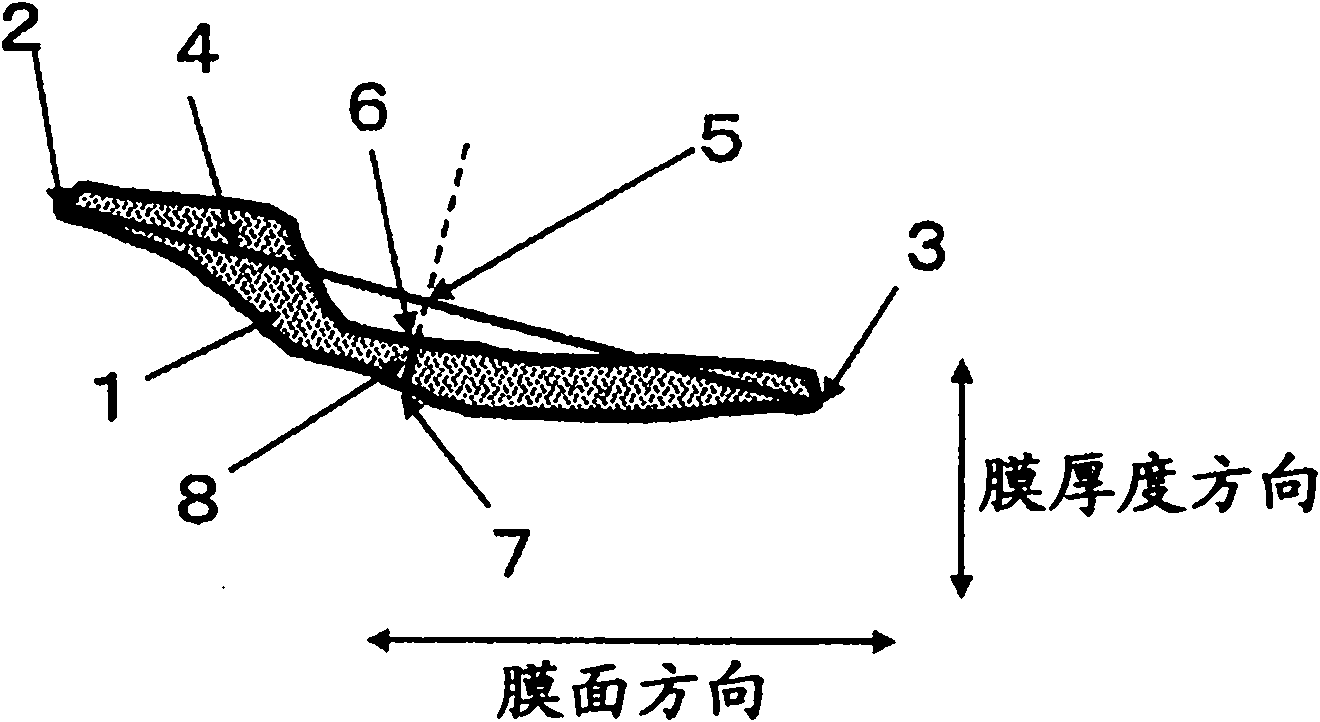

Screen printing plate and manufacturing method thereof

ActiveCN102211446ANo deterioration in exposure accuracy occursExcellent productivityScreen printersForme preparationYarnRelative displacement

The invention provides a screen printing plate and a manufacturing method thereof. The screen printing plate (2) comprises an outer yarn (4) of an opening part (4c) made of resin net; an inner yarn (6) matched with the outer yarn (4) of the opening part (4c) and made of metal net; an emulsion layer (16) for printed patterns made of phototonus resin and formed with printed patterns (20) on the inner yarn (6); an emulsion layer (14) for alignment marks made of phototonus resin and formed with alignment marks (22) on the outer yarn (4). The printed patterns (20) and the alignment marks (22) being separated by a photo mask (F) are formed by exposing and developing the emulsion layer (16) for printed patterns and the emulsion layer (14) for alignment marks. Therefore, the relative displacement between the printed patterns of the inner yarn and the alignment marks of the outer yarn is avoided and the manufacturing cost is low.

Owner:MURATA MFG CO LTD

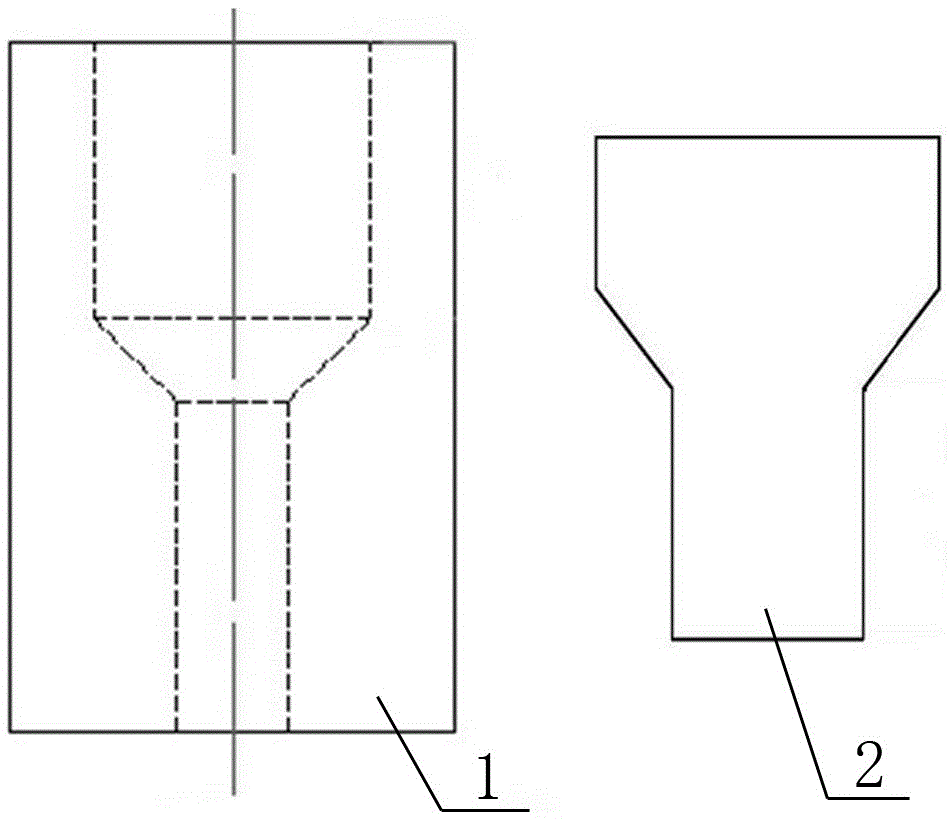

Preparation method for TiAl alloy bar

ActiveCN106636741ASolve the problem of severe segregationPrevent surface oxidationExtrusion diesIngotSkull

The invention discloses a preparation method for a TiAl alloy bar and relates to a preparation method for a bar. The preparation method for the TiAl alloy bar aims at solving the problems that according to a TiAl alloy bar prepared through an existing method, the preparation process is complex, the surface of the bar cracks, the diameter is nonuniform, the bar structure grain size is nonuniform, and TiAl alloy reacts with package materials and is molten when the extrusion temperature is too high. The preparation method for the TiAl alloy bar comprises the specific steps that 1, all raw material components are weighed; 2, a cast ingot is prepared through water cooling copper crucible induction skull melting; 3, pretreatment is conducted on an extrusion blank; and 4, bar extrusion is conducted, and thus the TiAl alloy bar can be obtained. The surface of the TiAl alloy bar obtained through the preparation method is free of cracking, the diameter is uniform, the bar structure grain size is uniform, and the process is simple.

Owner:山西中工重型锻压有限公司

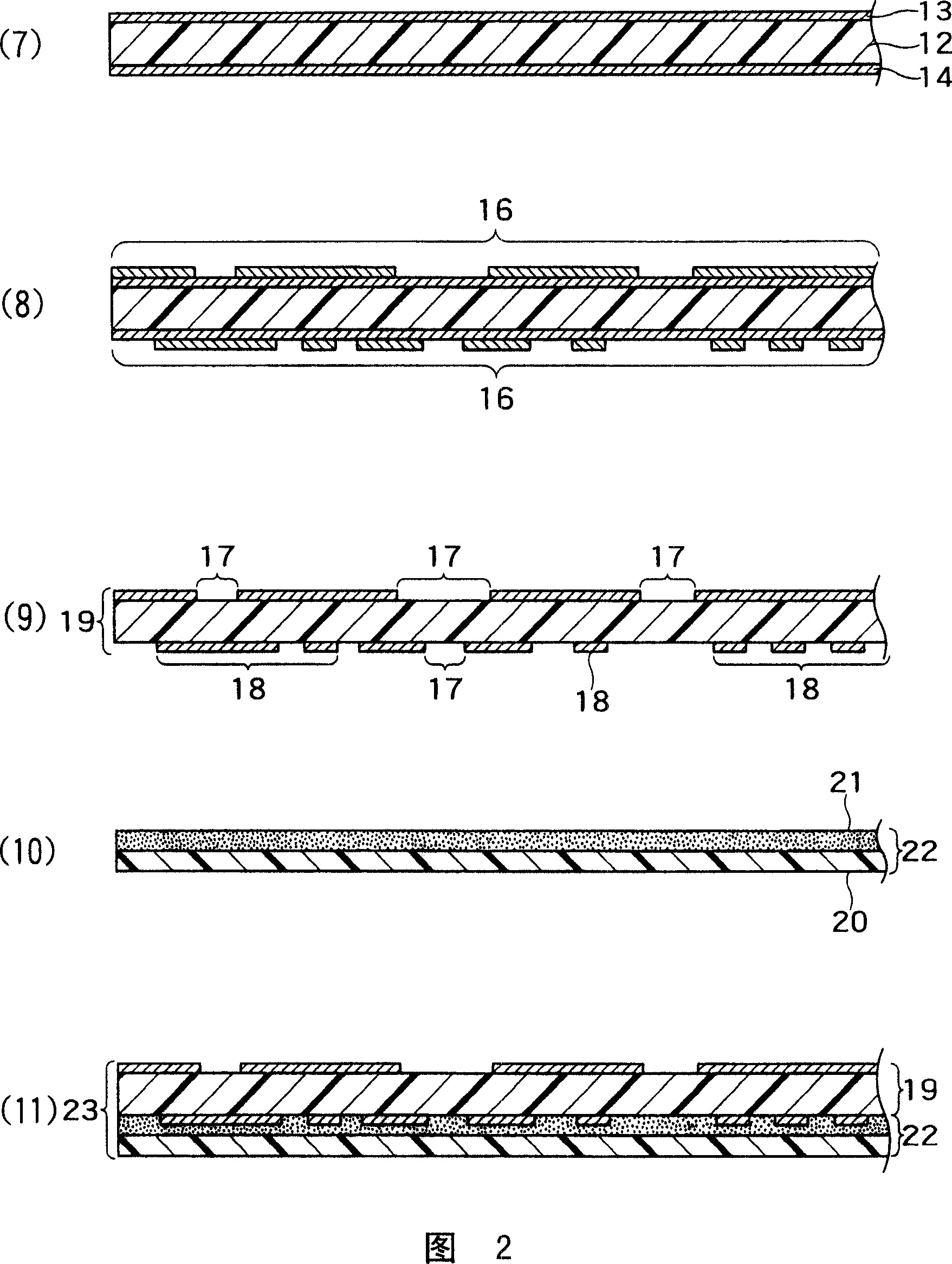

Method for manufacturing multilayer wiring substrate with cable

InactiveCN1972571AWiring miniaturizationEnsure flatnessMultilayer circuit manufacturePrinted element electric connection formationLaser processingEngineering

The invention provides a method for inexpensively and stably manufacturing a multilayer wiring board having a cable section with a high integration degree capable of loading narrow pitch CSP. The manufacturing method of the multilayer flexible wiring board having the cable section in at least an outer layer, includes a) a process for manufacturing an inner layer core substrate (8, 58); b) a process for forming an opening of copper foil in a conduction hole forming part on an outer layer side in a double sided copper clad laminate having flexibility, and forming a circuit pattern (10, 60) comprising an opening of a conduction hole forming part on an inner layer side of the double sided copper clad laminate; c) a process for forming a cover ray (22, 70) on the circuit pattern to make it to be an outer layer built-up layer (23, 67); d) a process for laminating the outer layer built-up layer by turning a side where the cover ray is formed to a side of the inner layer core substrate, and forming the lamination circuit substrate (25, 73); e) a process for performing laser processing on the conduction hole forming part of the outer layer side through the opening of copper foil, and forming a conduction hole (26, 27, 28, 74, 75, 76) in the lamination circuit substrate; f) a process for performing laser processing on the conduction hole forming part of the outer layer side by acting the opening of the copper foil and the opening of the conduction hole forming part as a mask for shielding laser, and forming the conduction hole in the lamination circuit substrate; and g) a process for performing a conduction processing on the conduction hole, and forming a via hole (29, 30, 31, 77, 78, 79) with electrolytic plating. The double sided copper clad laminate can be replaced by a single sided copper clad laminate.

Owner:NIPPON MEKTRON LTD

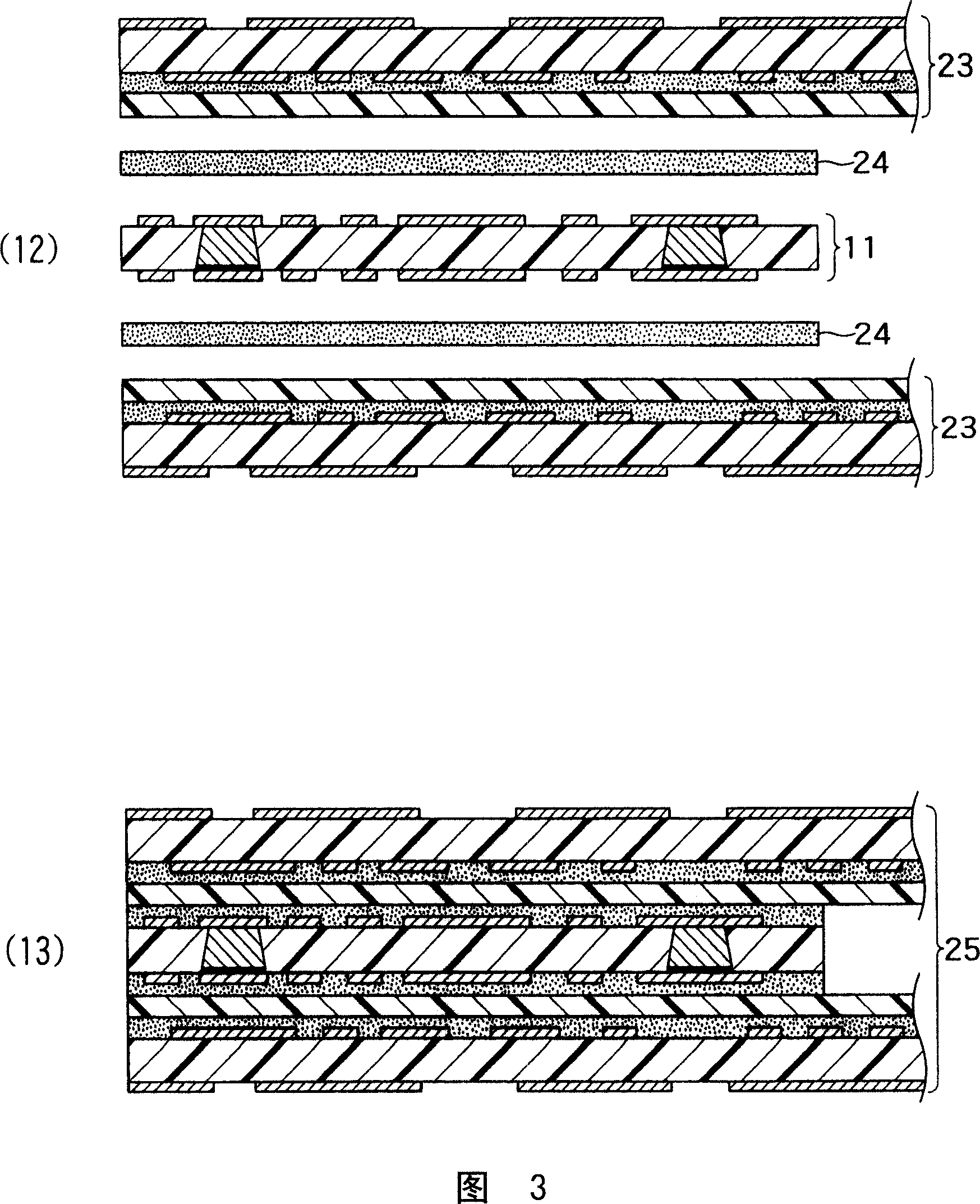

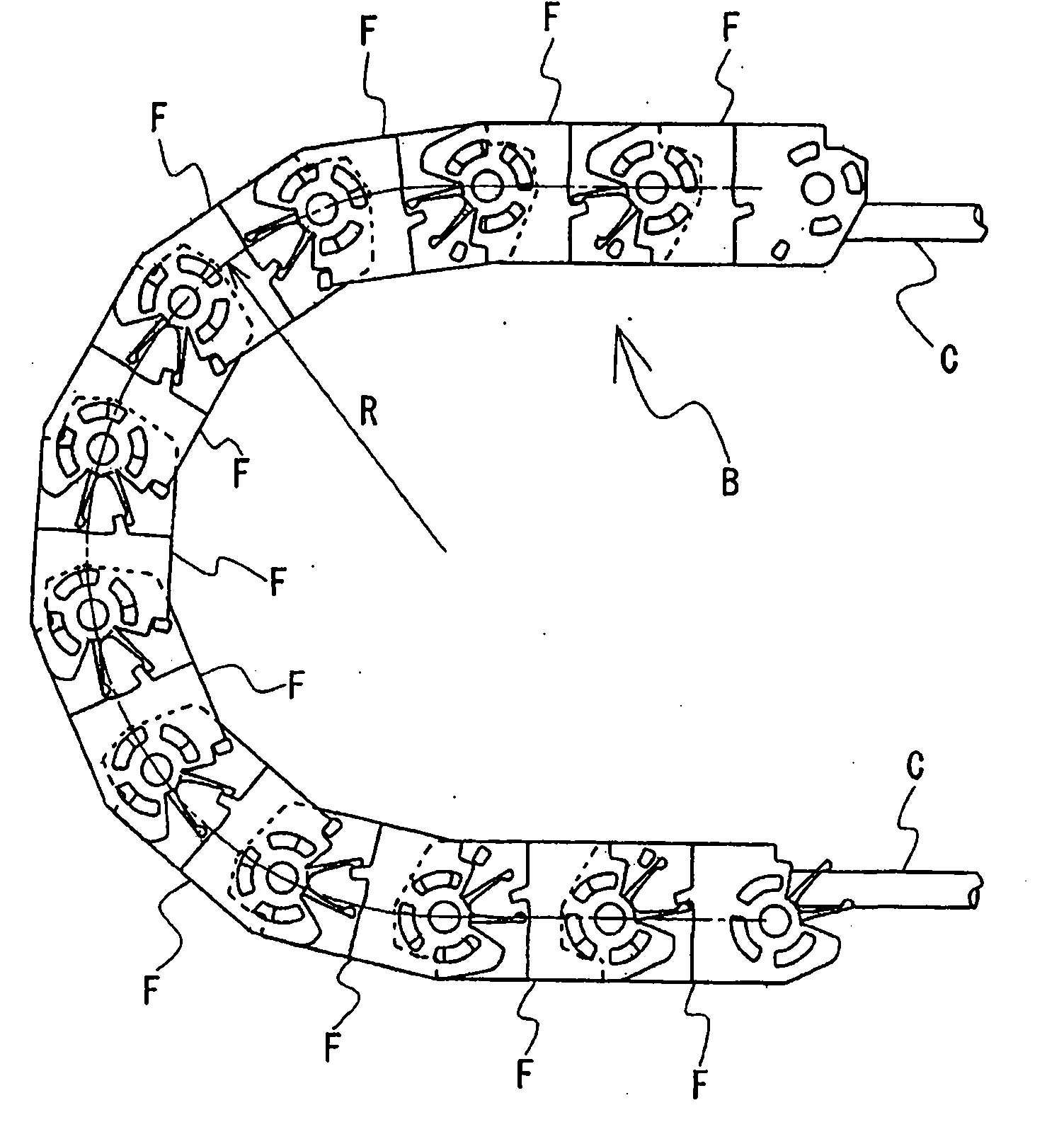

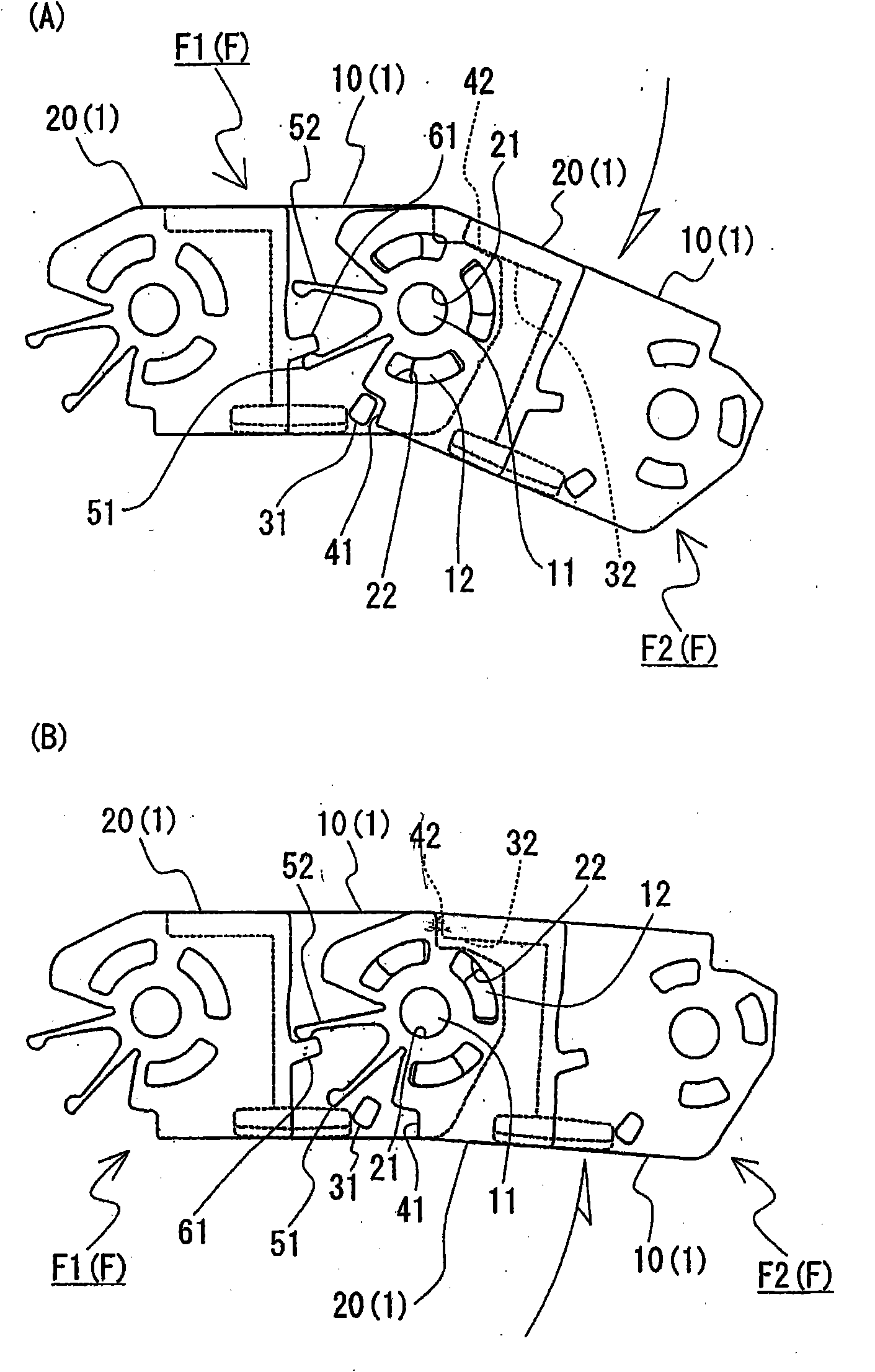

Cable drag chain

InactiveCN101952617AExcellent productivityReduce crashHauling chainsHoisting chainsMultiple frameMechanical engineering

Provided is a cable drag chain wherein braking can be applied to frame pivoting, and that furthermore has excellent producibility. The cable drag chain is constructed such that multiple frames (F) are formed coupled to be mutually pivotable, and a long body, such as a cable, is arranged in a guide part enclosed by each frame. The cable drag chain has a construction wherein, between the coupled frames (F1, F2), the pivot angle of the frame (F2) is restricted by contact between a stopper piece 31 (stopper receiver 42) of the one frame (F1) and a stopper receiver (41) (stopper piece 32) of the other frame (F2). The cable drag chain also has a construction wherein elastic projections (51, 52) of the one frame (F2) contact a receiver part (61) of the other frame (F1) when the coupled frames (F) are pivoted, and braking is applied to the relative rotation of the two frames (F1, F2) by the elasticity of the elastic projections (51, 52).

Owner:SHIMA SEIKI MFG LTD

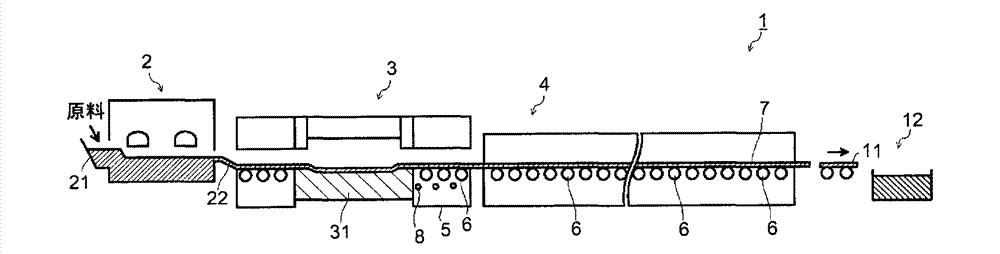

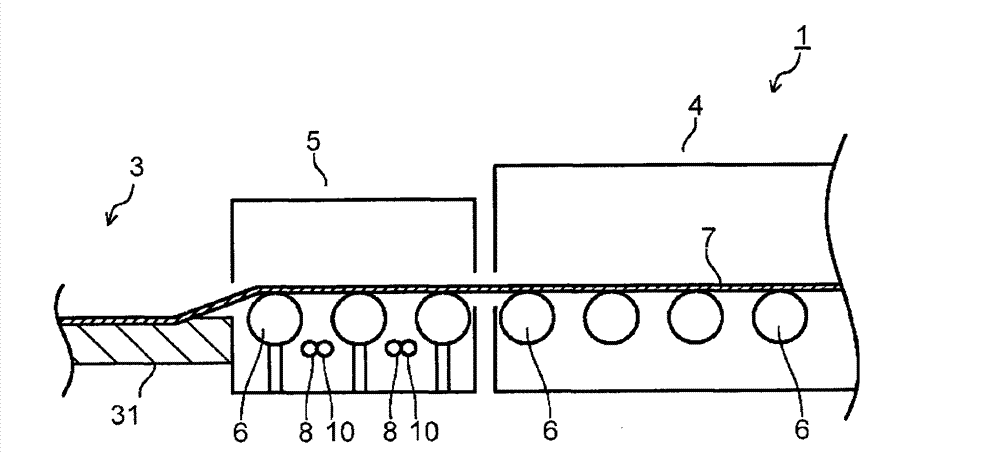

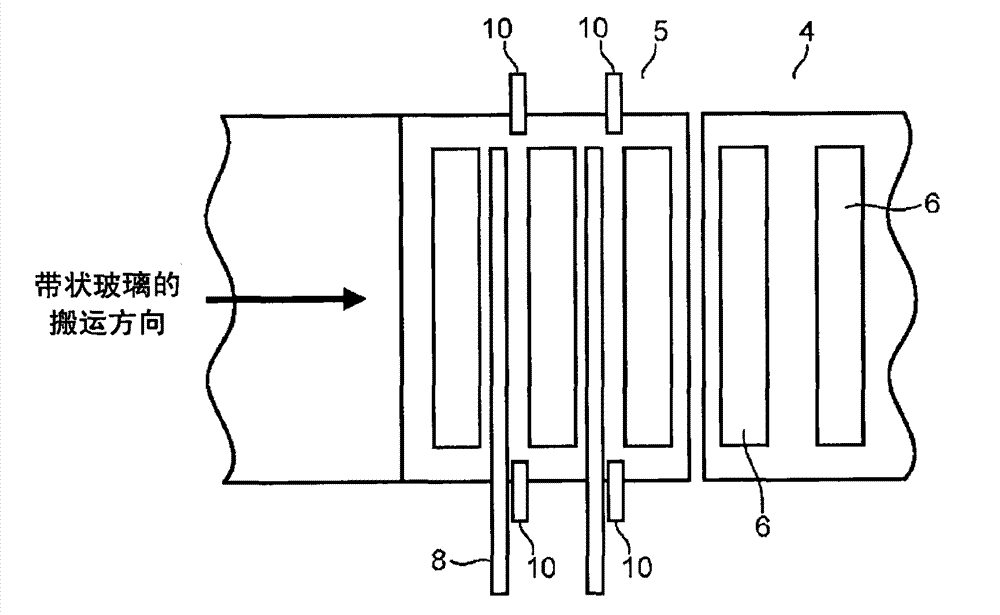

Method for manufacturing glass and glass

InactiveCN102775050AHigh strengthIncrease the surface compressive stressGlass tempering apparatusIdentification meansCompound (substance)Potassium ions

The invention provides a method for manufacturing glass capable of producing glass substrates which have good performances and high strength and good protective functions even the substrates are thin. In the method of manufacturing glass, after a sodium concentration reduction process for making sodium concentration on a glass surface lower than sodium concentration in the central part of glass, a chemical reinforcement processing process is performed in which the glass is dipped in fuse salt containing potassium ions to replace part of sodion in the glass with the potassium ion.

Owner:ASAHI GLASS CO LTD

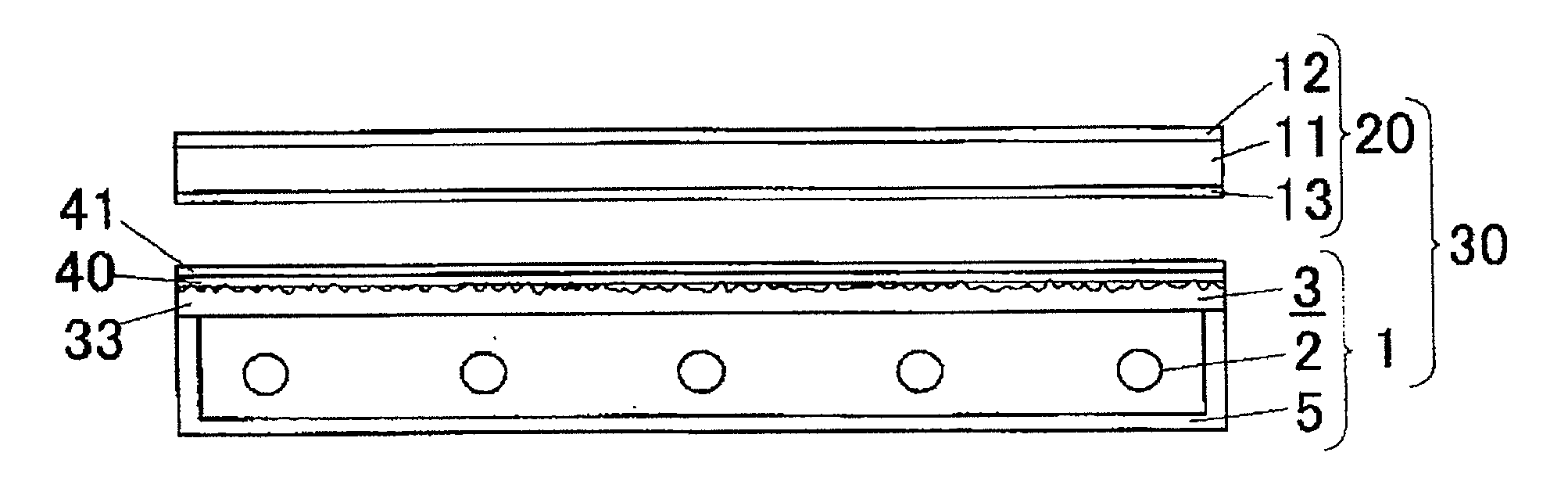

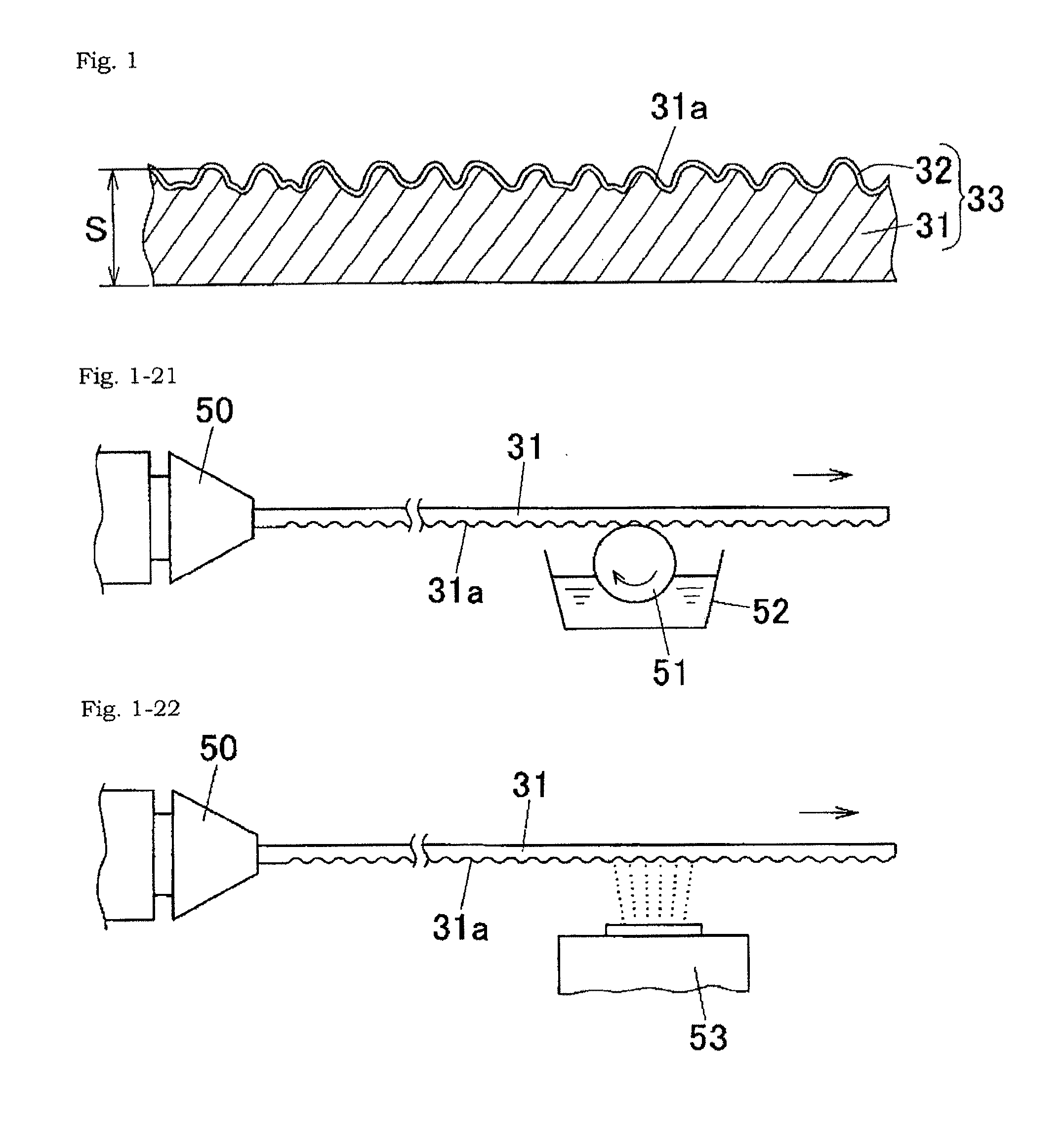

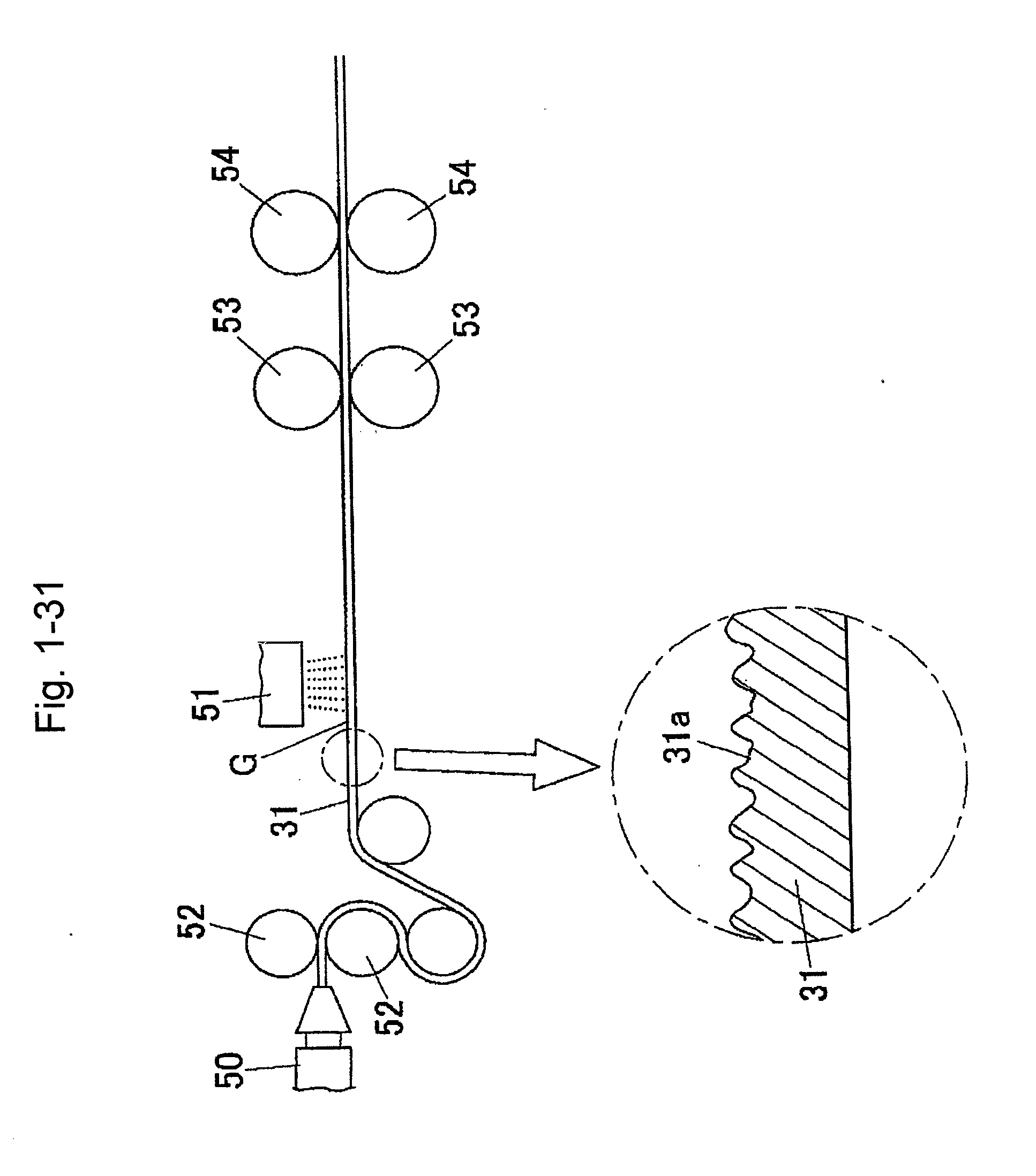

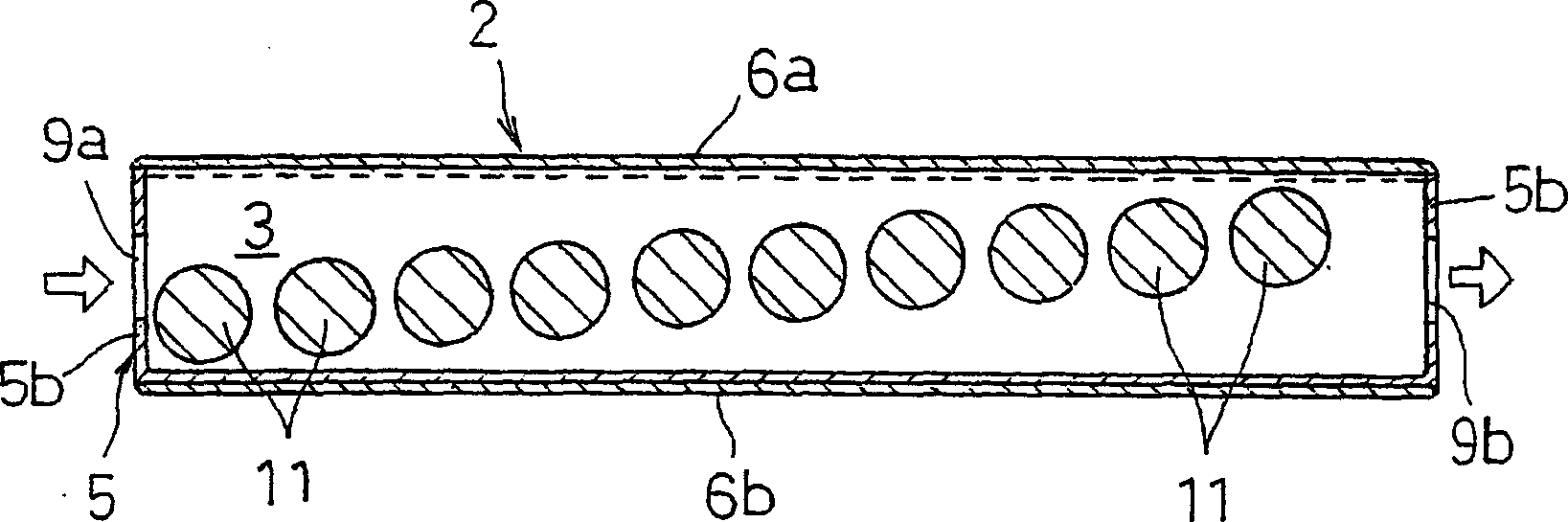

Light diffuser plate with primer layer, process for producing the same, laminated optical member, surface light source apparatus and liquid crystal display

InactiveUS20090296024A1Handle efficiency be improveExcellent productivityDiffusing elementsSynthetic resin layered productsLiquid-crystal displayEngineering

The present invention relates to a light-diffuser-plate-with-primer-layer, which permits lamination of an optical film or the like thereon with a sufficient bonding strength, and a process for producing the same efficiently and at a lower cost.

Owner:SUMITOMO CHEM CO LTD

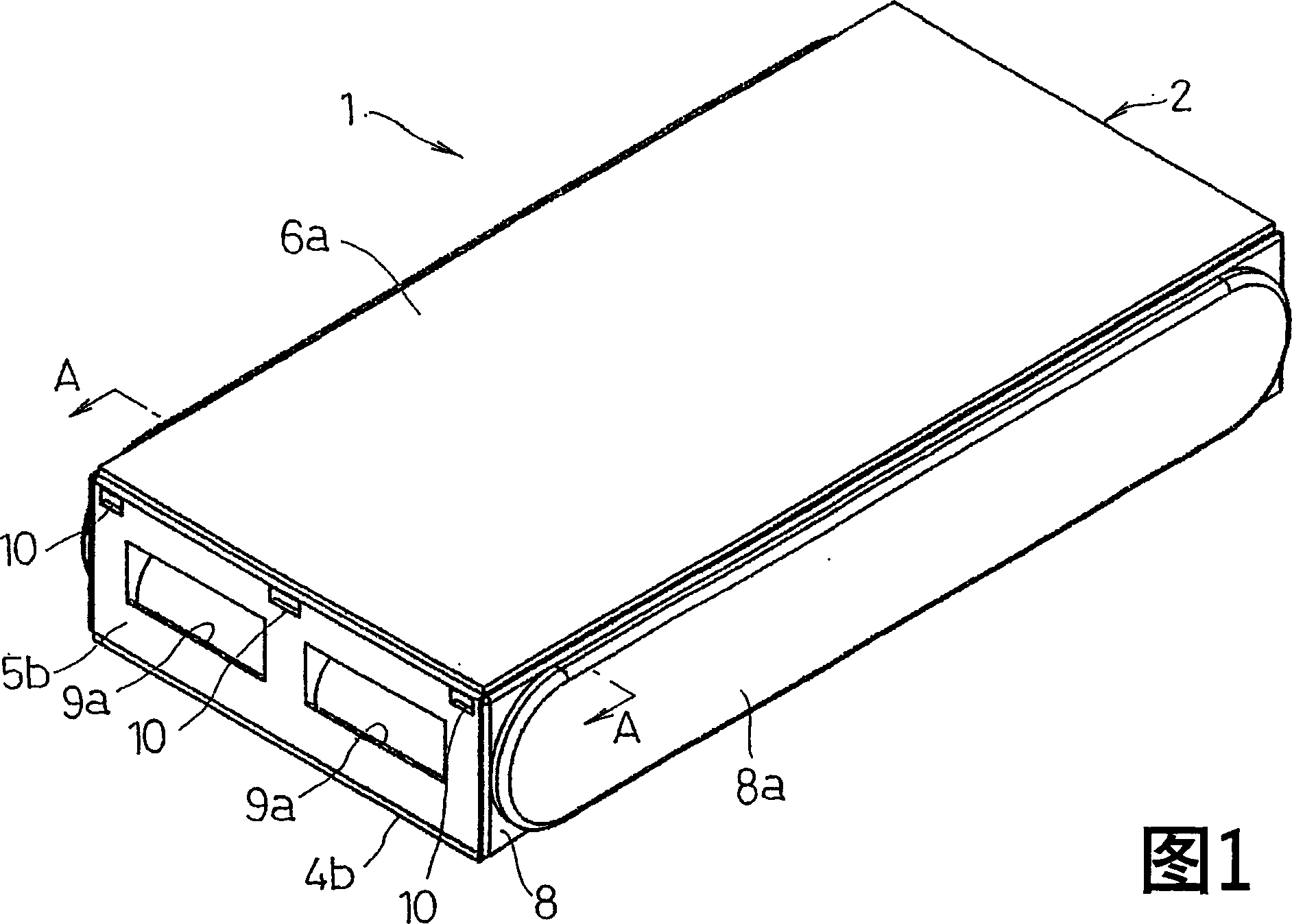

Battery pack

InactiveCN1659739AAvoid exceptionReliable dischargePrimary cell to battery groupingCell temperature controlEngineeringBattery pack

In a battery pack ( 1 ) that accommodates a plurality of batteries ( 11 ) arranged in parallel in a case ( 2 ) that forms a cooling-air passage ( 3 ), the cooling-air passage ( 3 ) and a gas-discharge passage ( 4 ) for discharging gas leaking from the battery ( 11 ) when the battery ( 11 ) falls into abnormal state are formed and separated from each other in the case ( 2 ).

Owner:PANASONIC CORP

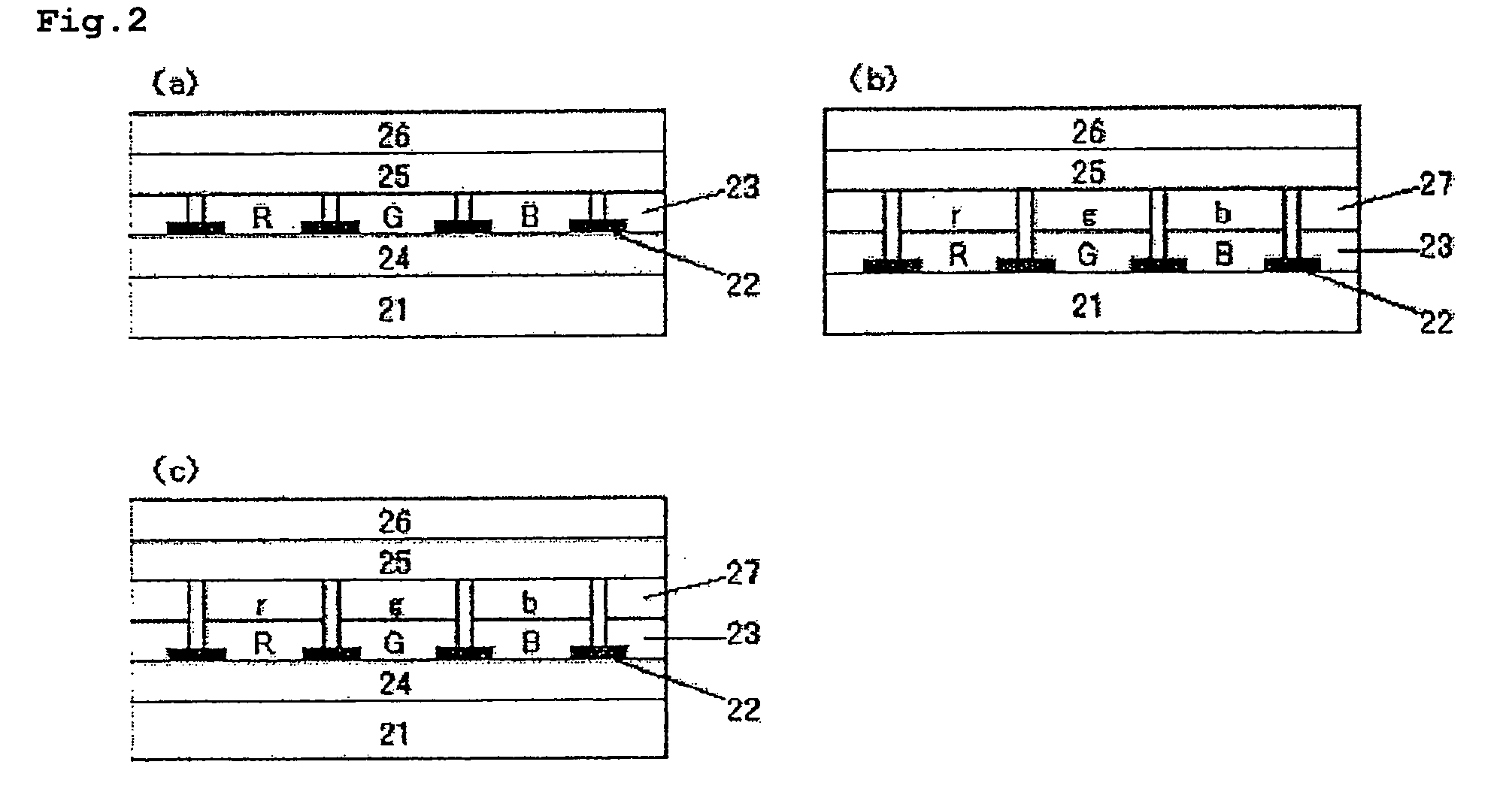

Transfer Material, and Process for Producing Liquid Crystal Cell Substrate and Liquid Crystal Display Device Using the Same

InactiveUS20090174857A1Improvement in view angle dependence of colorExcellent productivityLiquid crystal compositionsOptical filtersChemistryPhotosensitive polymer

A novel transfer material is disclosed. The transfer material comprises, at least, a support, and, thereon, an optically uniaxial or biaxial anisotropic layer and a photosensitive polymer layer. A novel process for producing a liquid crystal cell substrate is also disclosed. The process comprises, at least, [1] laminating a transfer material as set forth in any one of claims 1 to 11 on a substrate; [2] removing the support from the transfer material laminated on the substrate; and [3] exposing the photosensitive polymer layer disposed on the substrate to light.

Owner:FUJIFILM CORP

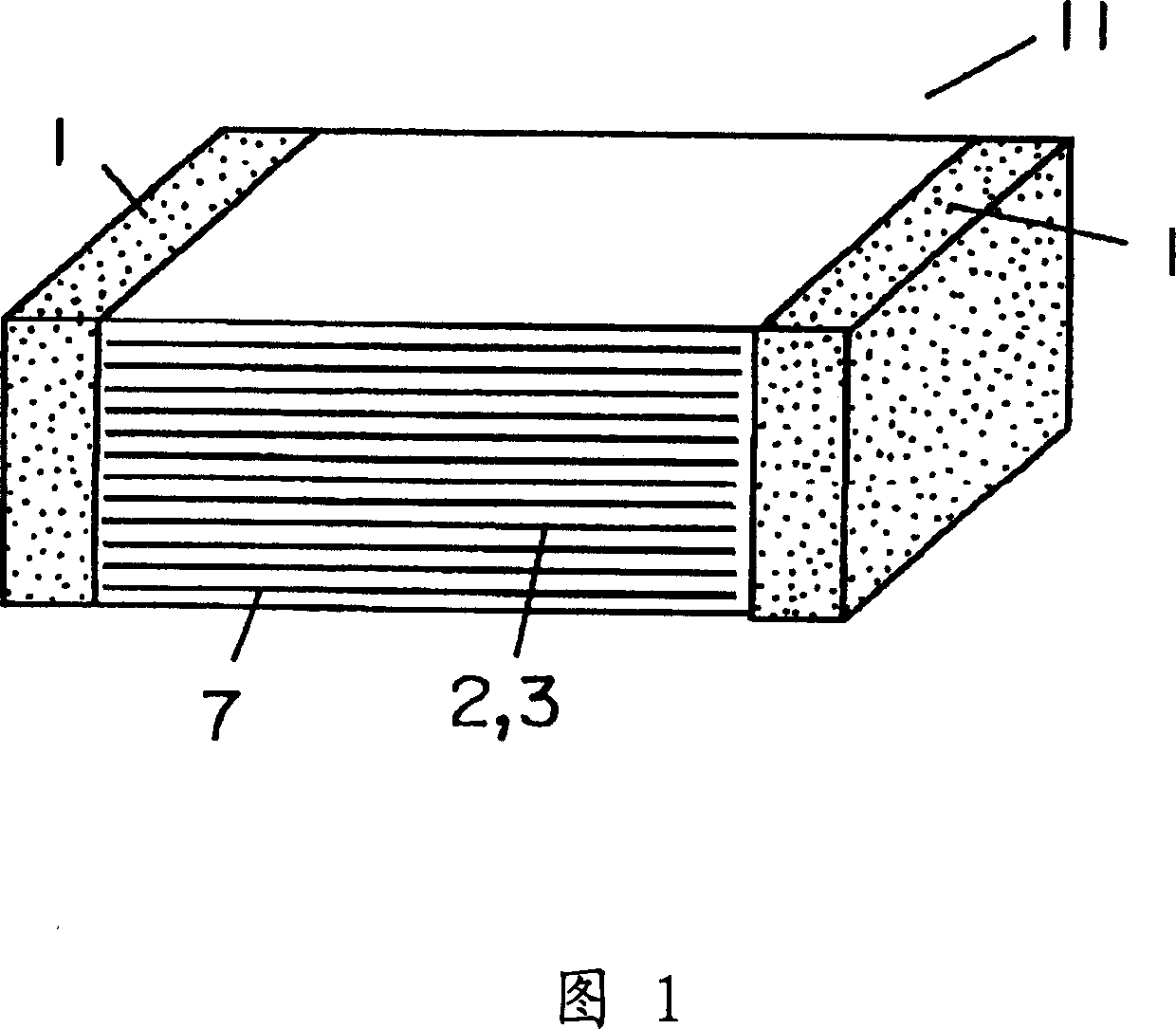

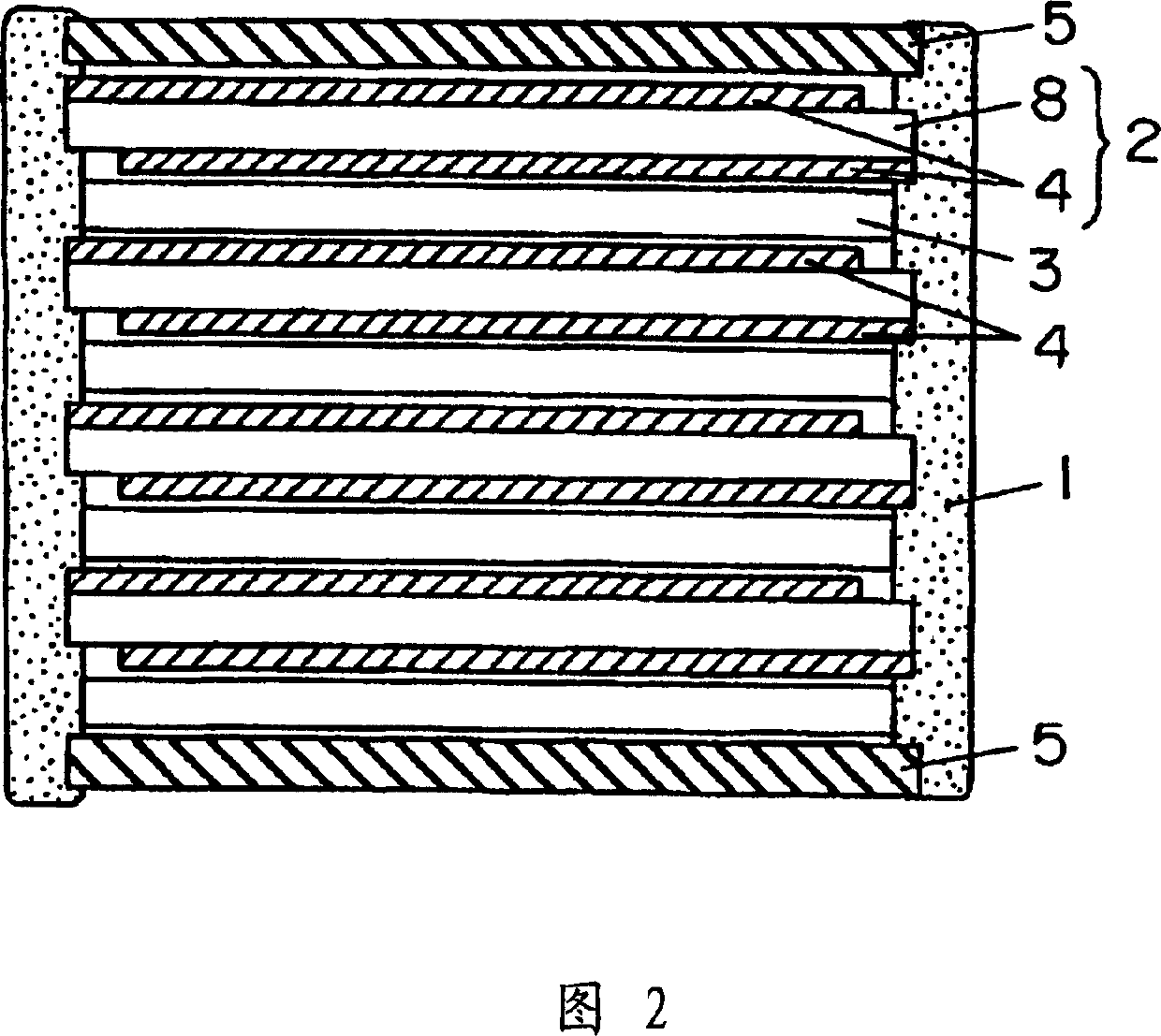

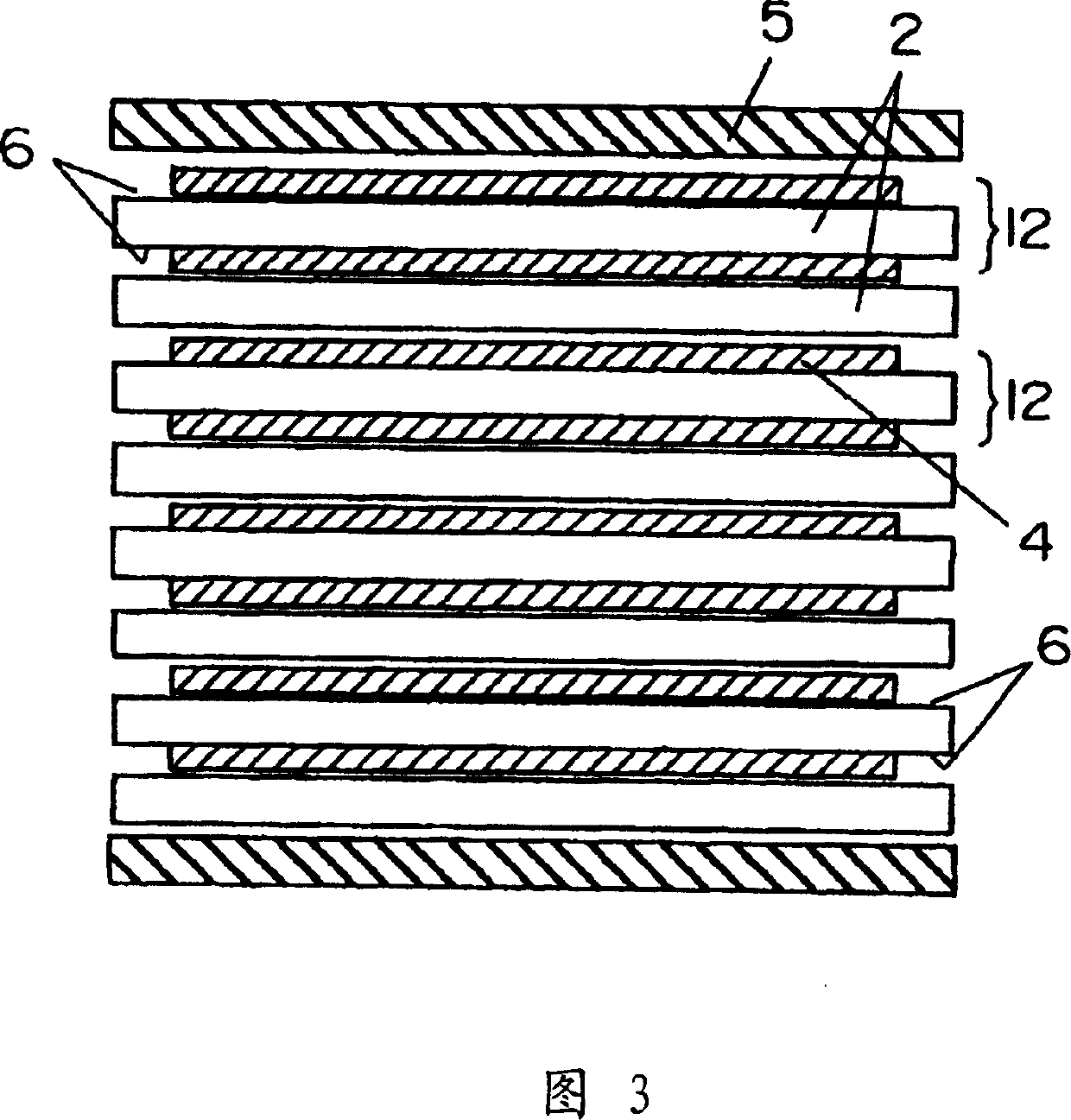

Multilayer fim capacitor and prodn. method thereof

InactiveCN1463451AImprove reliabilityExcellent productivityFixed capacitor electrodesFixed capacitor dielectricBobbinEngineering

A both-side-metallized polypropylene film having aluminum-zinc alloy evaporated on both sides of the film and a non-metallized polypropylene film are wound on a cylindrical bobbin plural times, thus providing a cylindrical winding body formed of multi-layer films. Then, sprayed-metal electrodes are formed on both sides of the cylindrical winding body. The cylindrical winding body is cut to obtain plural capacitor elements. Pulse laser beam is applied to a cut surface of the capacitor element, then metal exposed on the cut surface and metal evaporated on a surface of the films near the cut surface are removed by a distance not shorter than 0.05mm from the cut surface. This processes provides a multi-layer film capacitor usable at a voltage not lower than AC350V.

Owner:PANASONIC CORP

Method of manufacturing electronic part and electronic part obtained by the method

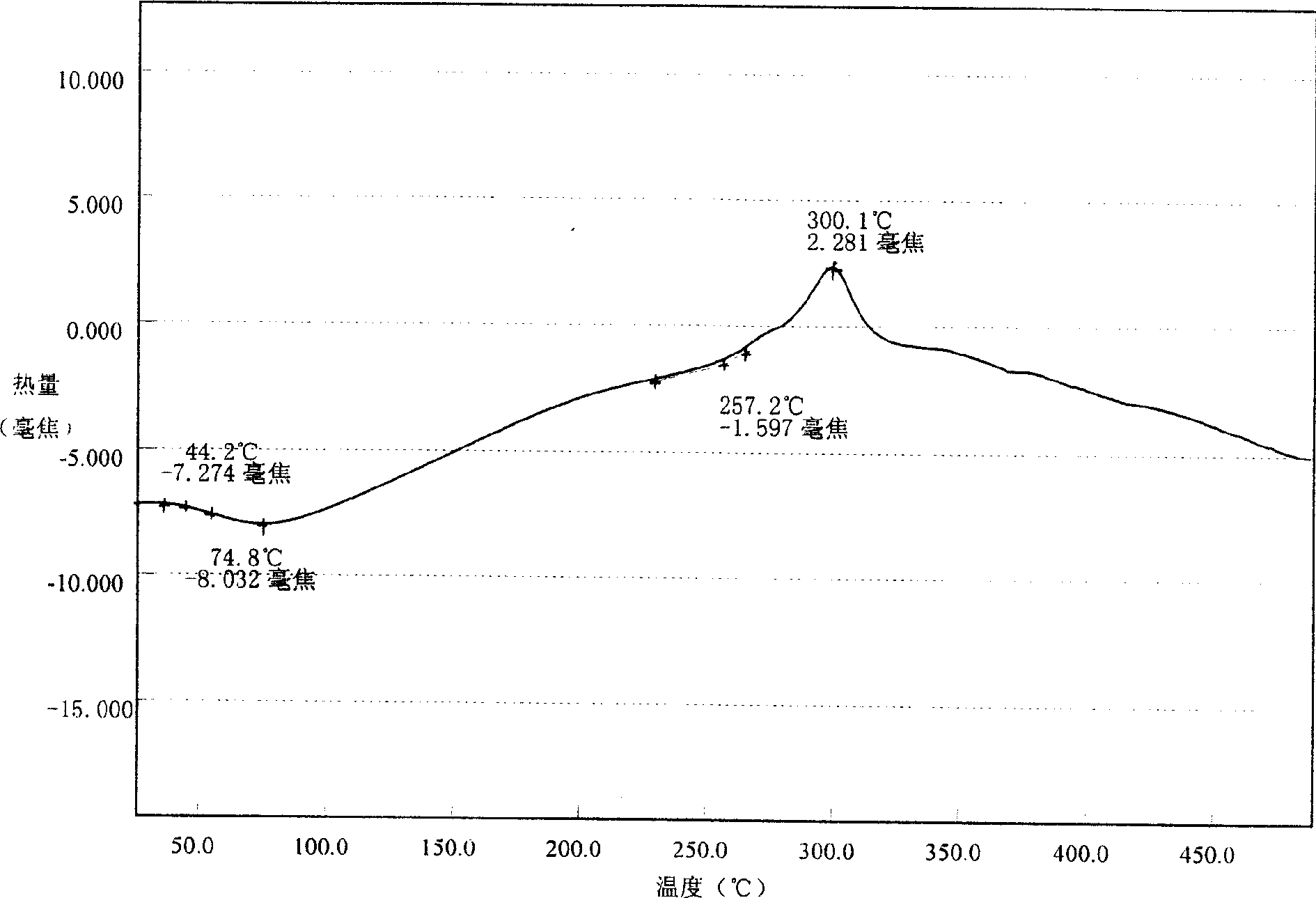

InactiveUS7331502B2High reliabilityExcellent productivityDigital data processing detailsFinal product manufactureProduction rateSoldering

In a process for producing an electronic part which comprises soldering (A) an electronic member having conductor portions I for electric connection having a solder layer or a solder bump (a solder portion) on a surface of a tip and (B) an electronic member to be connected having conductor portions II for electric connection arranged at positions corresponding to positions of conductor portions I by pressing (A) to (B) under heating via an adhesive layer, the solder portion is brought into contact with the adhesive layer, the solder portion is melted by heating at a temperature of or higher than a melting point of the solder, the soldering is conducted by pressing the melted solder portion, and the adhesive layer is cured. An electronic part is obtained in accordance with the process. Electric connection is surely achieved and a highly reliable electronic part can be obtained with excellent productivity.

Owner:SUMITOMO BAKELITE CO LTD

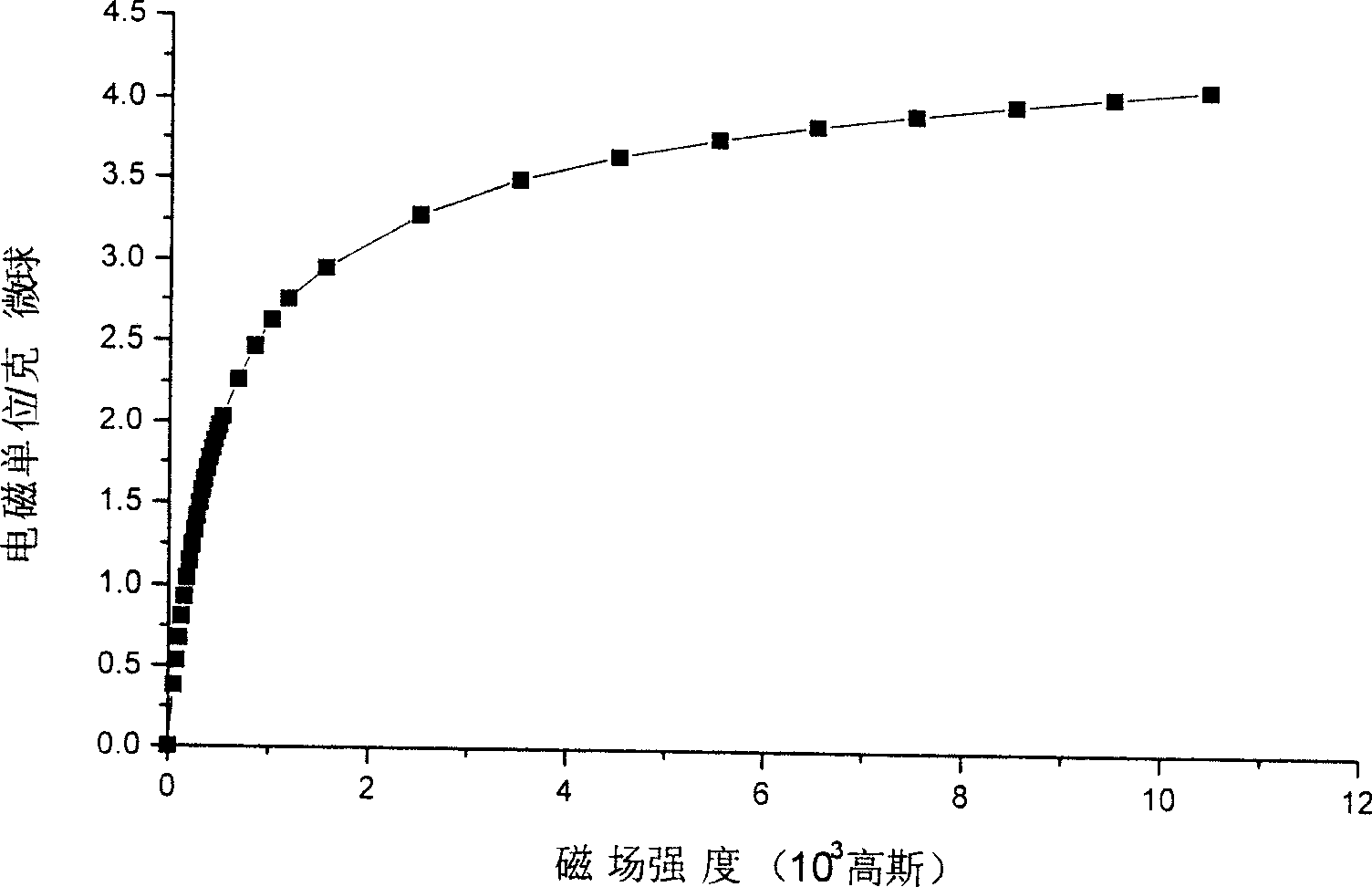

Composite biopolysaccharide magnetic microsphere preparation method

InactiveCN1763126AStrong acid and alkali resistanceSmall swelling coefficientCross-linkSulfanilic acid

The present invention relates to the preparation process of magnetic microballoon of composite polysaccharide. The magnetic microballoon with certain magnetic response property is prepared with tamarind gelatin or sweet wormwood gelatin and chitosan as material, ferroferric iron as magnetofluid, glutaraldehyde as cross-linking agent and o-aminobenzene sulfonic acid as aminating agent. The magnetic microballoon has surface functional radical of -OSO2(C6H4)N-C(CH2)3CHO. The magnetic microballoon of composite polysaccharide has less volume swelling, high acid tolerance and low cost.

Owner:NORTHWEST NORMAL UNIVERSITY

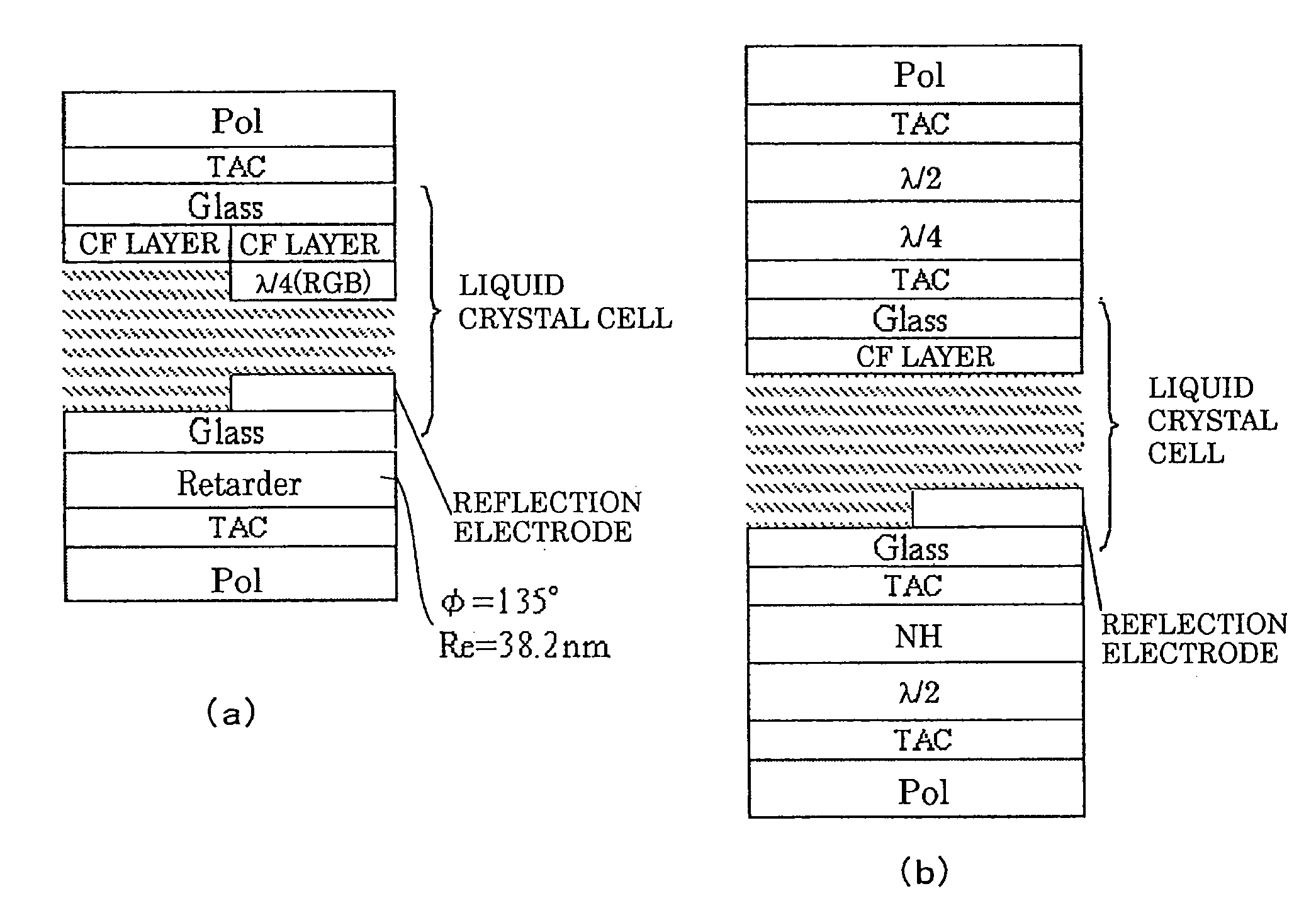

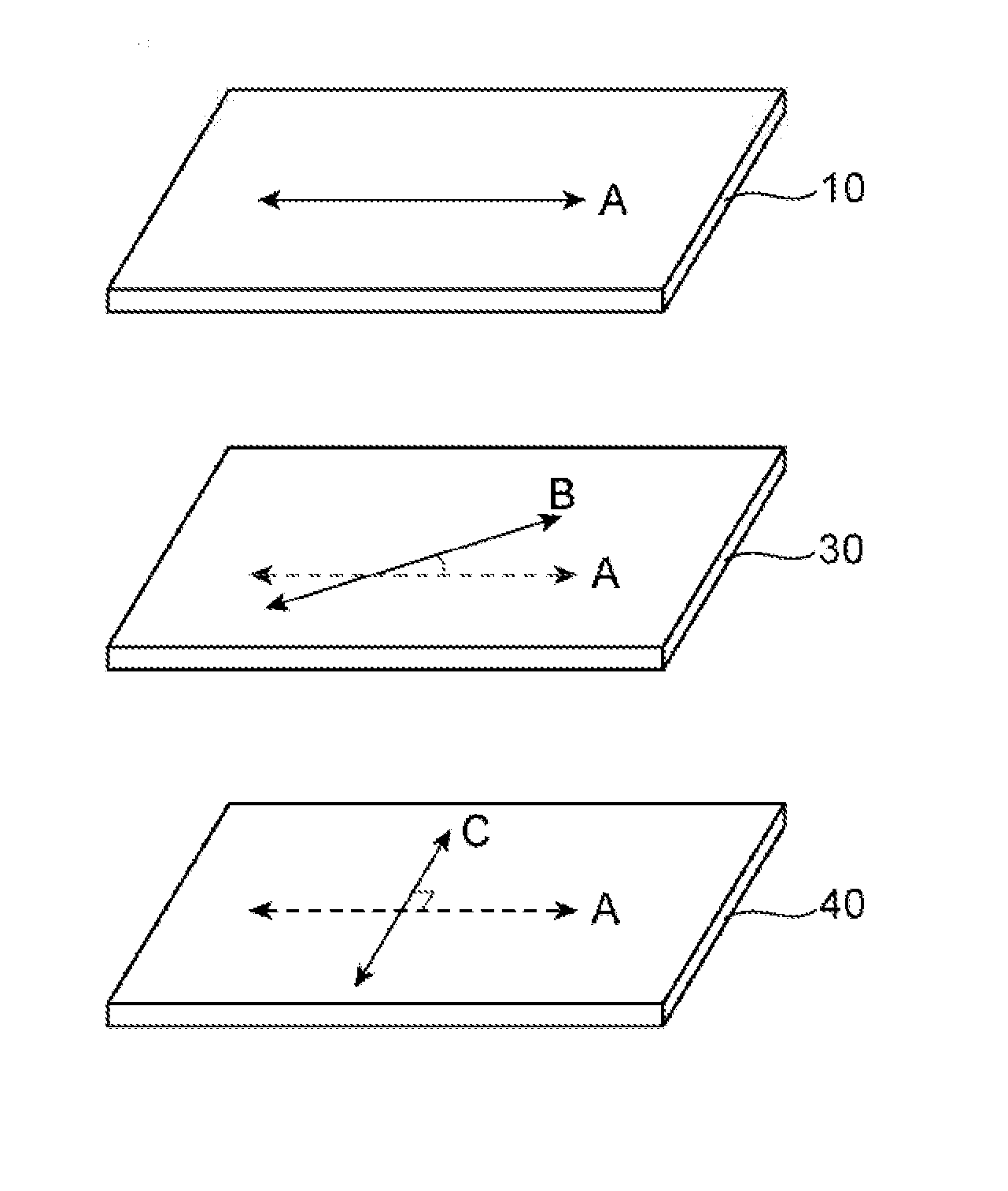

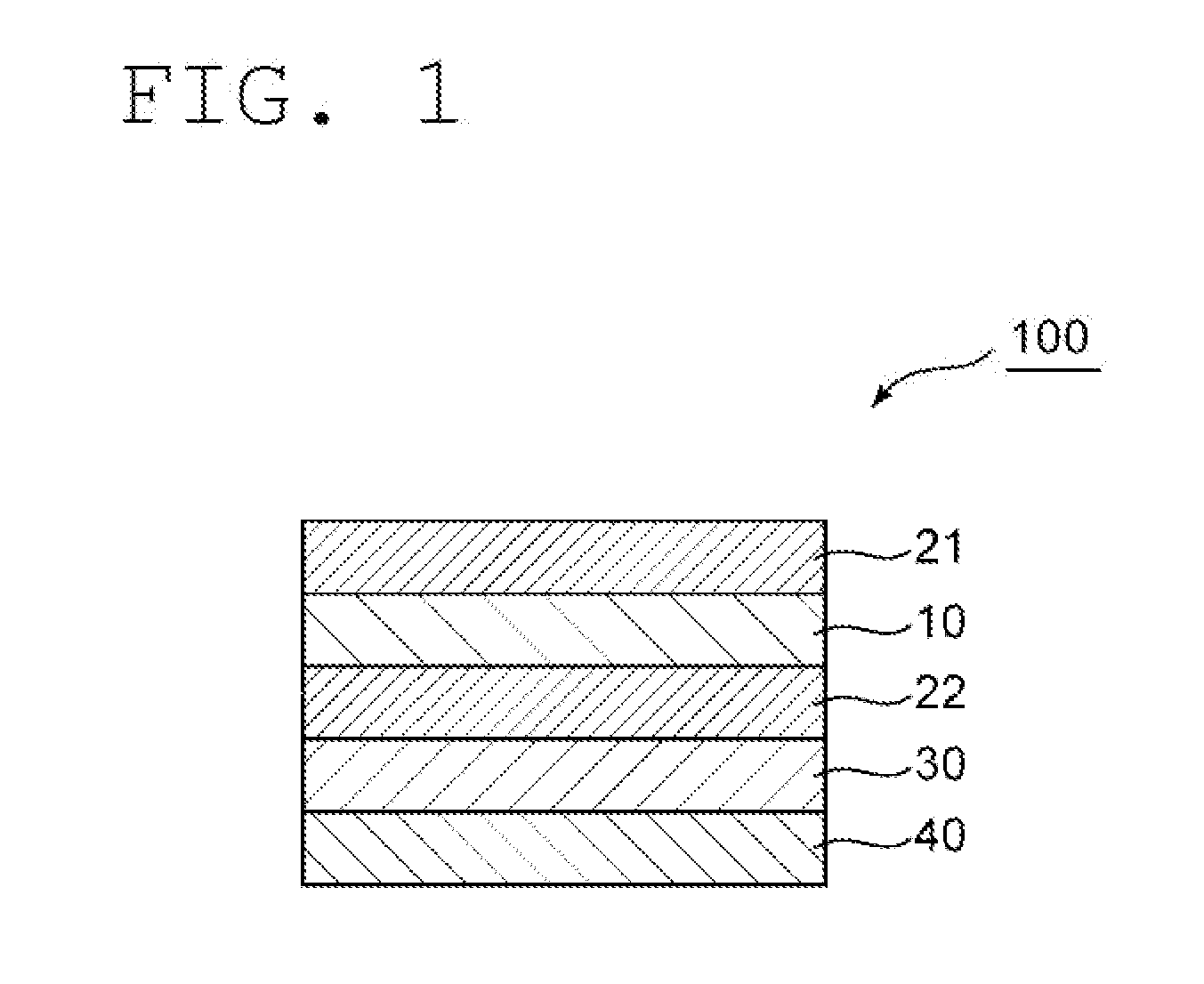

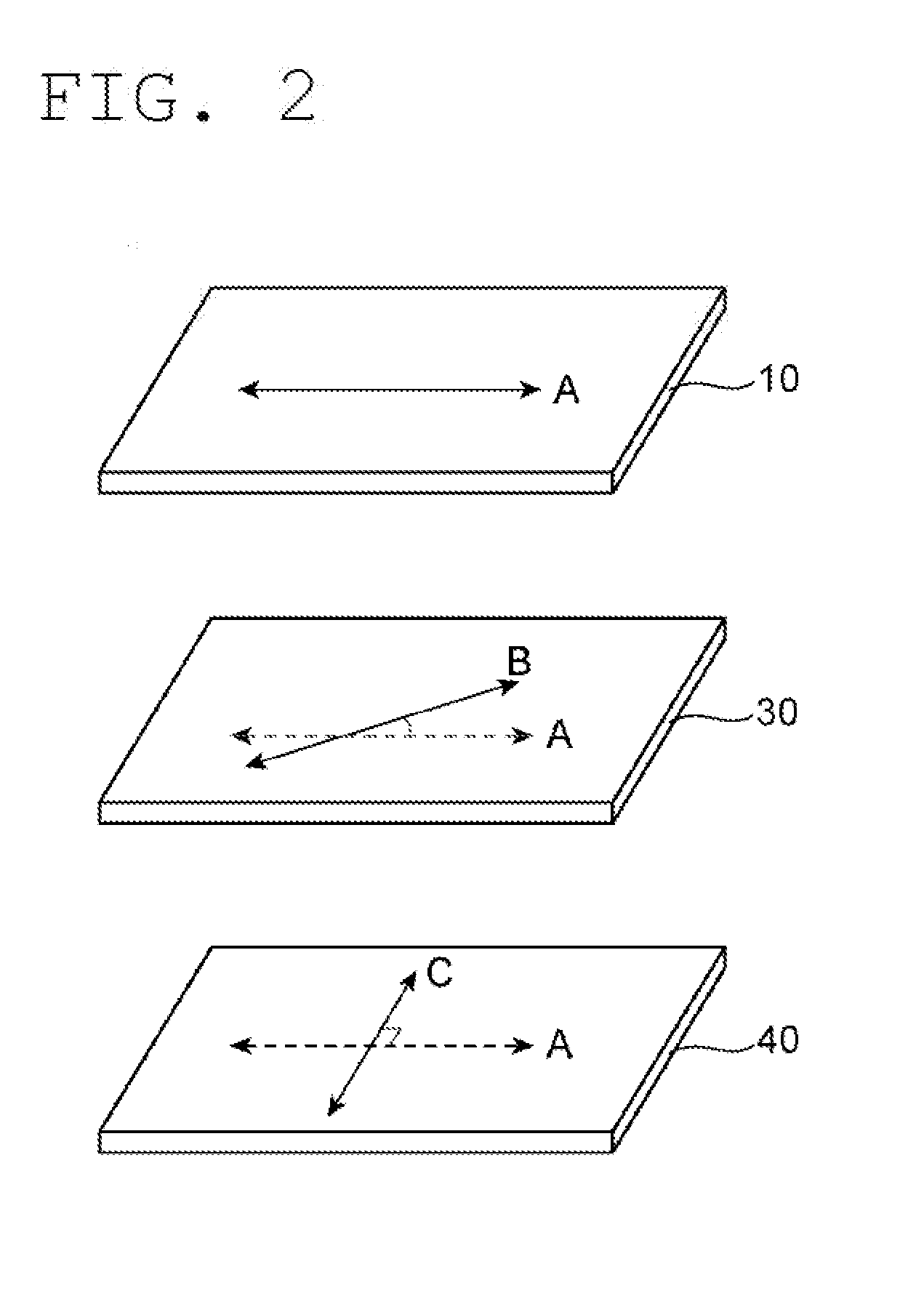

Circular polarizer for organic el display device, and organic el display device

ActiveUS20170052300A1Excellent tintExcellent productivityTransportation and packagingElectroluminescent light sourcesPolarizerOptoelectronics

There is provided a circularly polarizing plate for an organic EL display apparatus that is excellent in productivity, is prevented from warping, and can achieve an excellent tint. An elongated circularly polarizing plate for an organic EL display apparatus according to an embodiment of the present invention includes in the following order: an elongated polarizer having an absorption axis in a longitudinal direction thereof; an elongated first retardation layer functioning as a λ / 2 plate; and an elongated second retardation layer functioning as a λ / 4 plate. An angle formed between the absorption axis of the elongated polarizer and a slow axis of the elongated first retardation layer is front 15° to 30°; and the absorption axis of the elongated polarizer and a slow axis of the elongated second retardation layer are substantially perpendicular to each other.

Owner:NITTO DENKO CORP

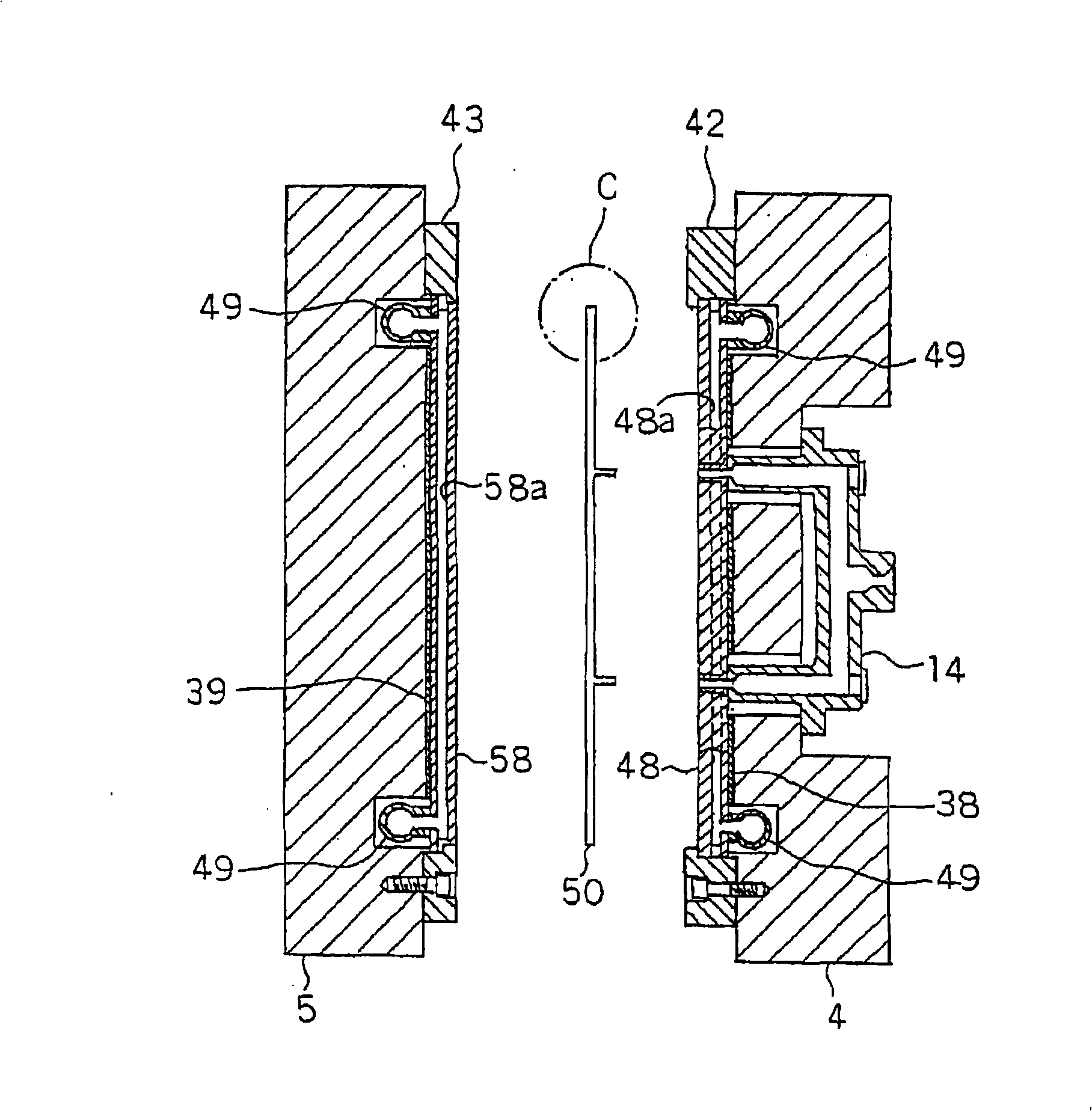

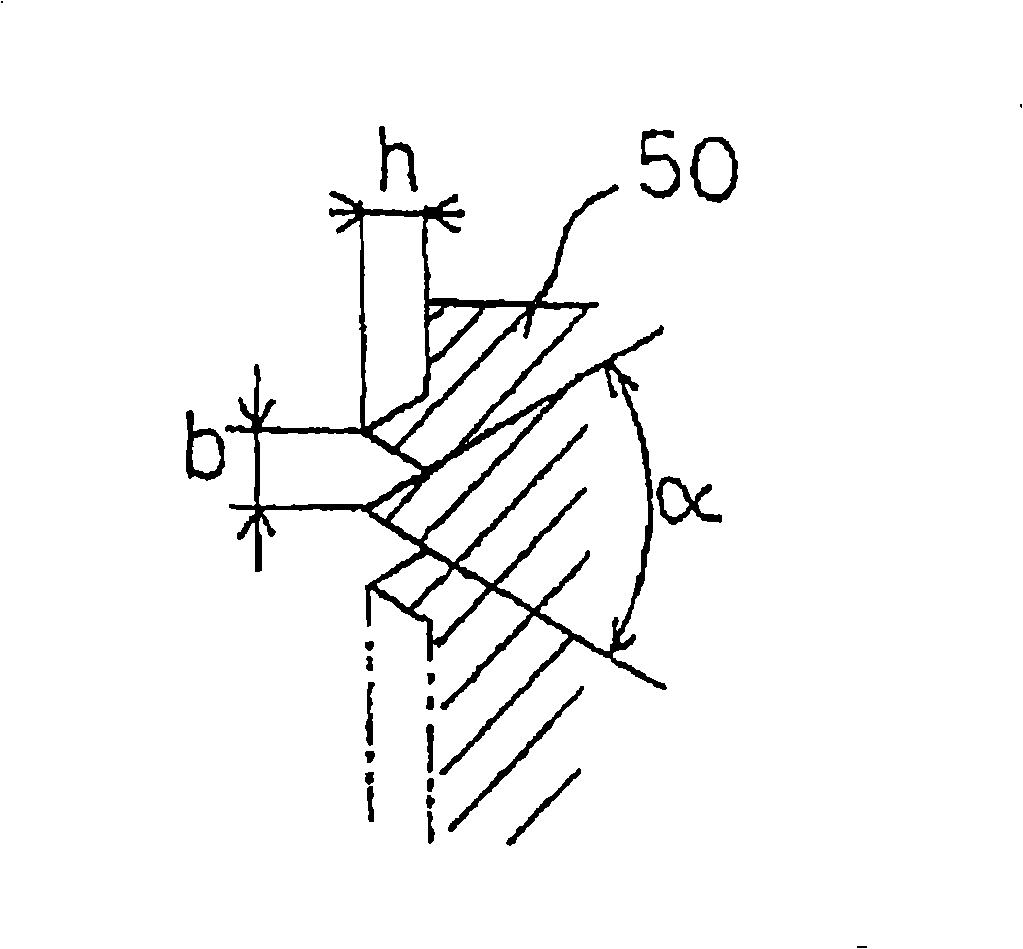

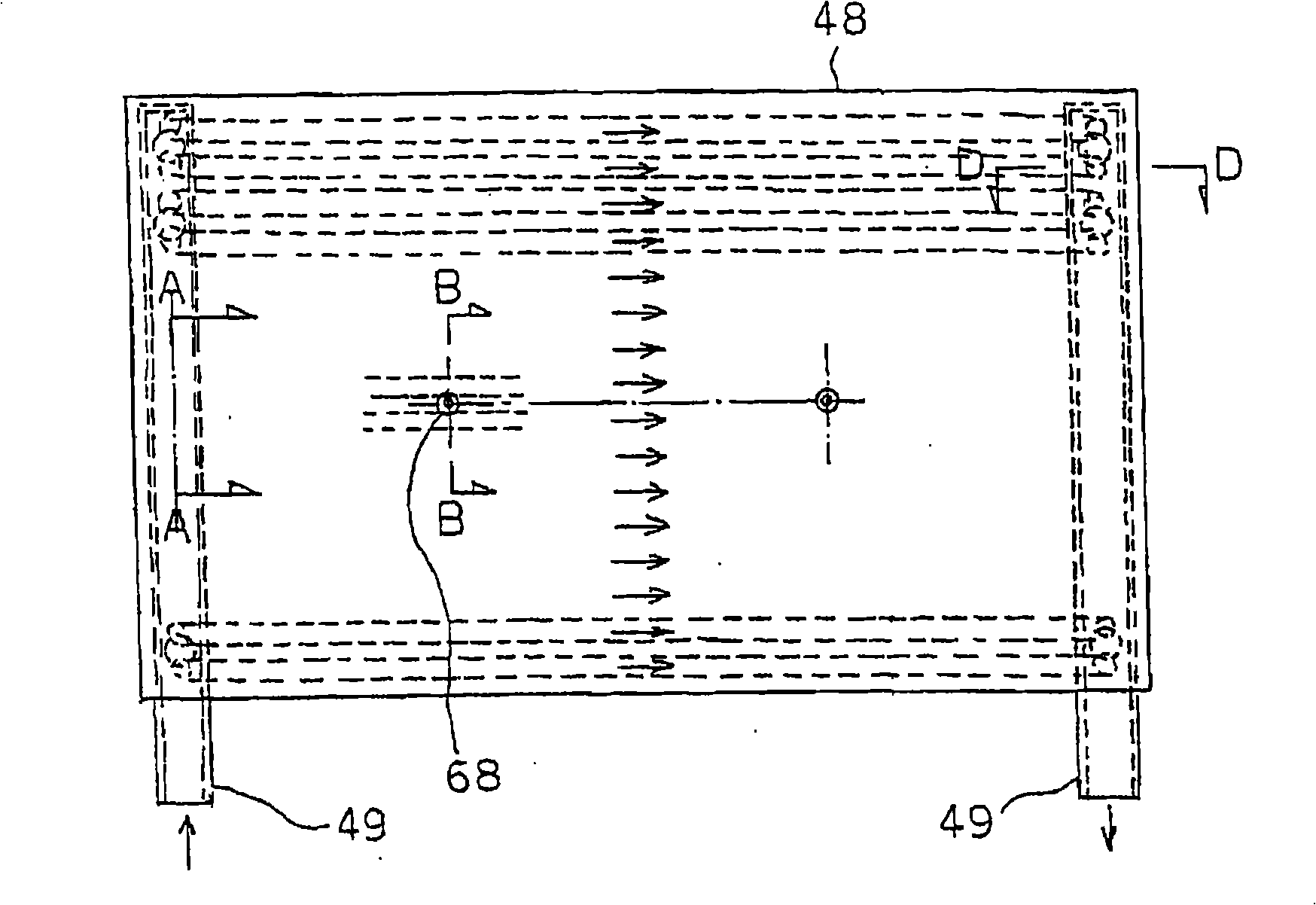

Mold, mold temperature regulation method, mold temperature regulation device, injection molding method, injection molding machine, and thermoplastic resin sheet

The present invention provides a mold, mold temperature regulation method, mold temperature regulation device, injection molding method, injection molding machine, and thermoplastic resin sheet, the mold made of by certain material can enhance the transferability of the surface of a molded product and can allow the molded product to be taken out immediately after the solidification, whereby molding cycle can be accelerated. In the mold, both a stationary side mold and a movable side mold are mounted within masters, and a cavity face is formed on a release side. A plurality of heating medium passages are bored at a position distant by a given distance from the cavity face. The mold comprises a 15 to 30 mm-thick rectangular bushes formed of a metal having a coefficient of thermal conductivity of 20 to 40 W / (m K), heat insulating plates having a coefficient of thermal conductivity of not more than 5 W / (m K) and held between the masters and the bushes, a pair of heating medium manifolds (mounted on both ends of the anticavity face of the bushes so as to be led to the heating medium passages of the bushes, and a plurality of pressing members for pressing four edges of the bushes to fix the bushes to the masters.

Owner:MITSUBISHI HEAVY IND LTD +1

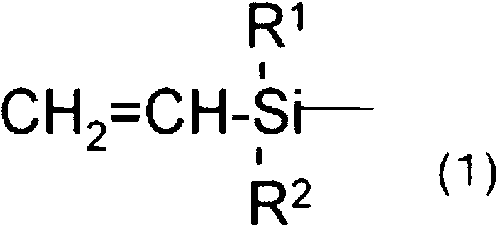

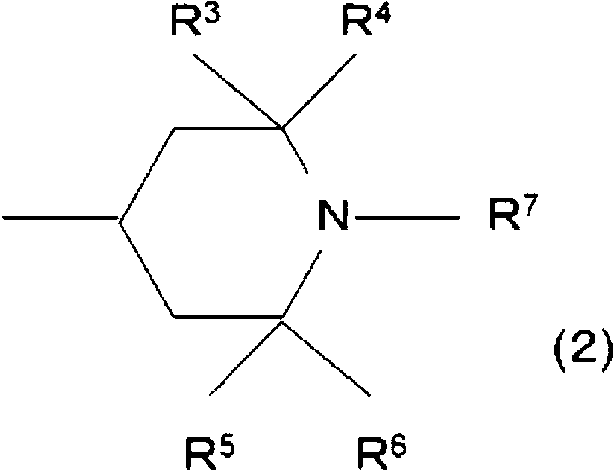

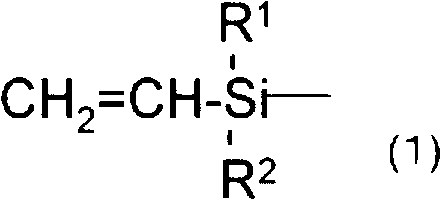

Photocurable silicone gel composition and application thereof

ActiveCN102869727ASoft deterioration does not occurExcellent photocurabilityAdhesive processesOther chemical processesSilicone GelsHydrogen

Disclosed is a photocurable silicone gel composition formed from 100 parts by mass of an organopolysiloxane (A) having at least one or more of a group shown by general formula (1), a mercaptoalkyl group-containing organopolysiloxane (B) in parts by mass such that the number of moles of the mercaptoalkyl group forms 0.01 - 1.0 moles per mole of the group for (A) shown in general formula (1), 0.01 - 20 parts by mass of a photopolymerization initiator (C) per 100 parts by mass of component (A), and 0.001 - 10 parts by mass of a hindered amine (D) compound having a group shown by general formula (2) per 100 parts by mass of component (A). (In general formula (1) R1 - R2 indicate hydrogen or C1-20 alkyl group.) (In general formula (2), R3 - R6 indicate hydrogen or a C1-20 alkyl group, and R7 indicates hydrogen or -CH2-R8 (R8 indicating hydrogen or a monovalent organic group).).

Owner:THREEBOND FINE CHEM CO LTD

Ultraviolet-ray solidified ink and printed matter using same

InactiveCN1454947AExcellent productivityExcellent gloss and abrasion resistanceInksPrinting inkVarnish

The present invention provides a printing ink which has good printing adaptability and easy treatment property of oiliness printing ink and can be solidified and instantaneously dried by UV-ray and printed matter printed by said printing ink. Besides, it also provides a printing ink used in the UV-ray solidified printing method for continuously cover-printing UV-ray solidification transparent varnish on the printing ink, and also provides the printed matter with excellent production property and excellent glossiness and frictional resistance. By regulating its carrier components said printing ink has good oleophilicity, good printing adaptability, easy treatment property and UV-ray instantaneous solidification property.

Owner:DAINIPPON INK & CHEM INC

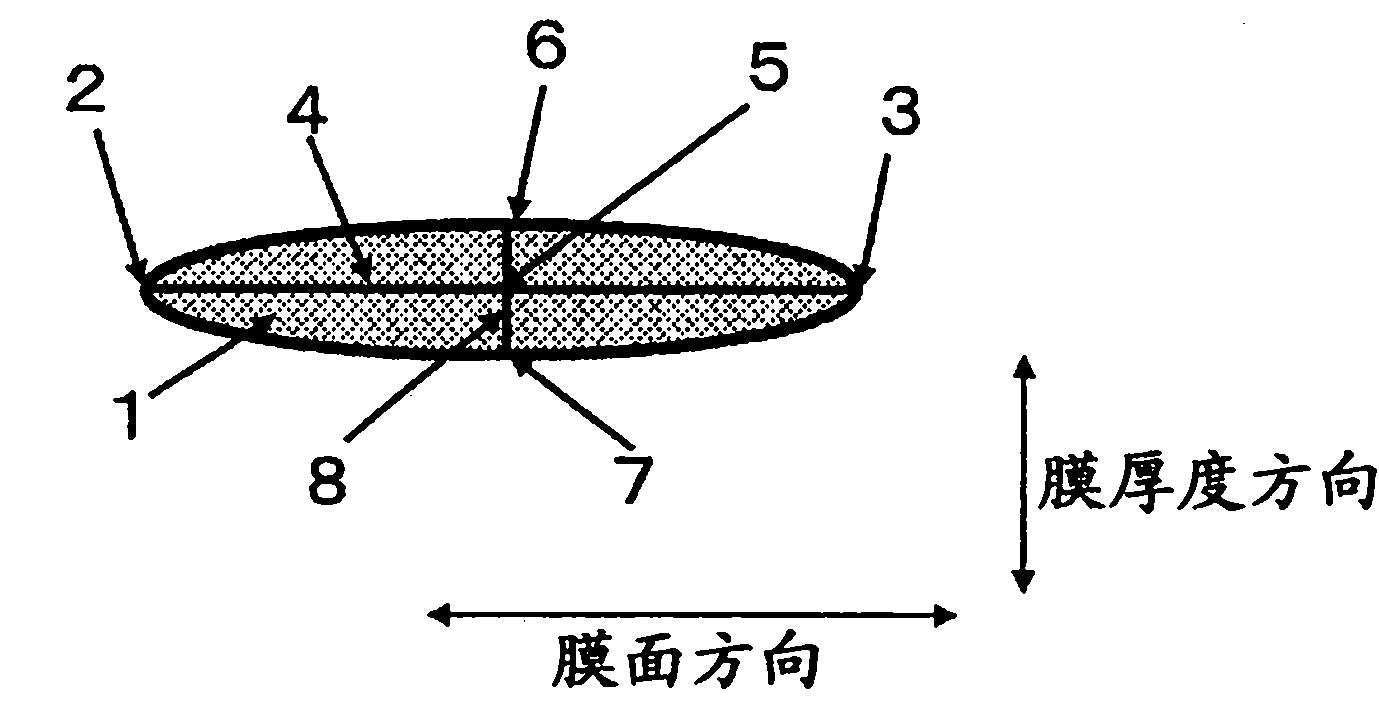

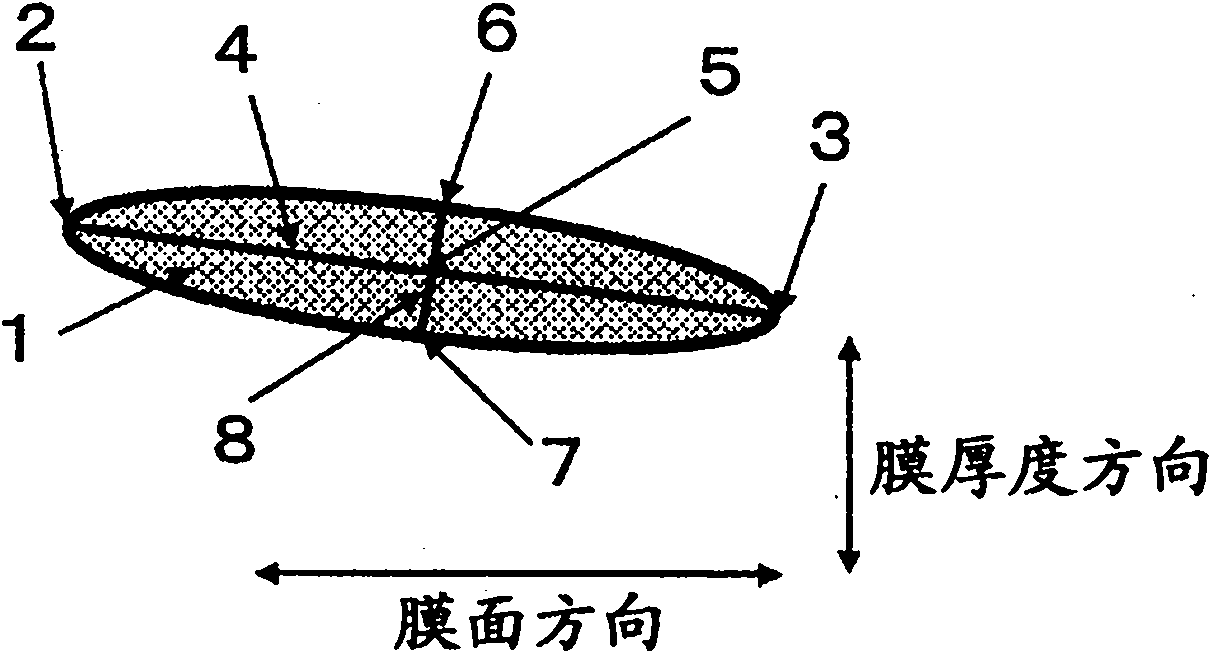

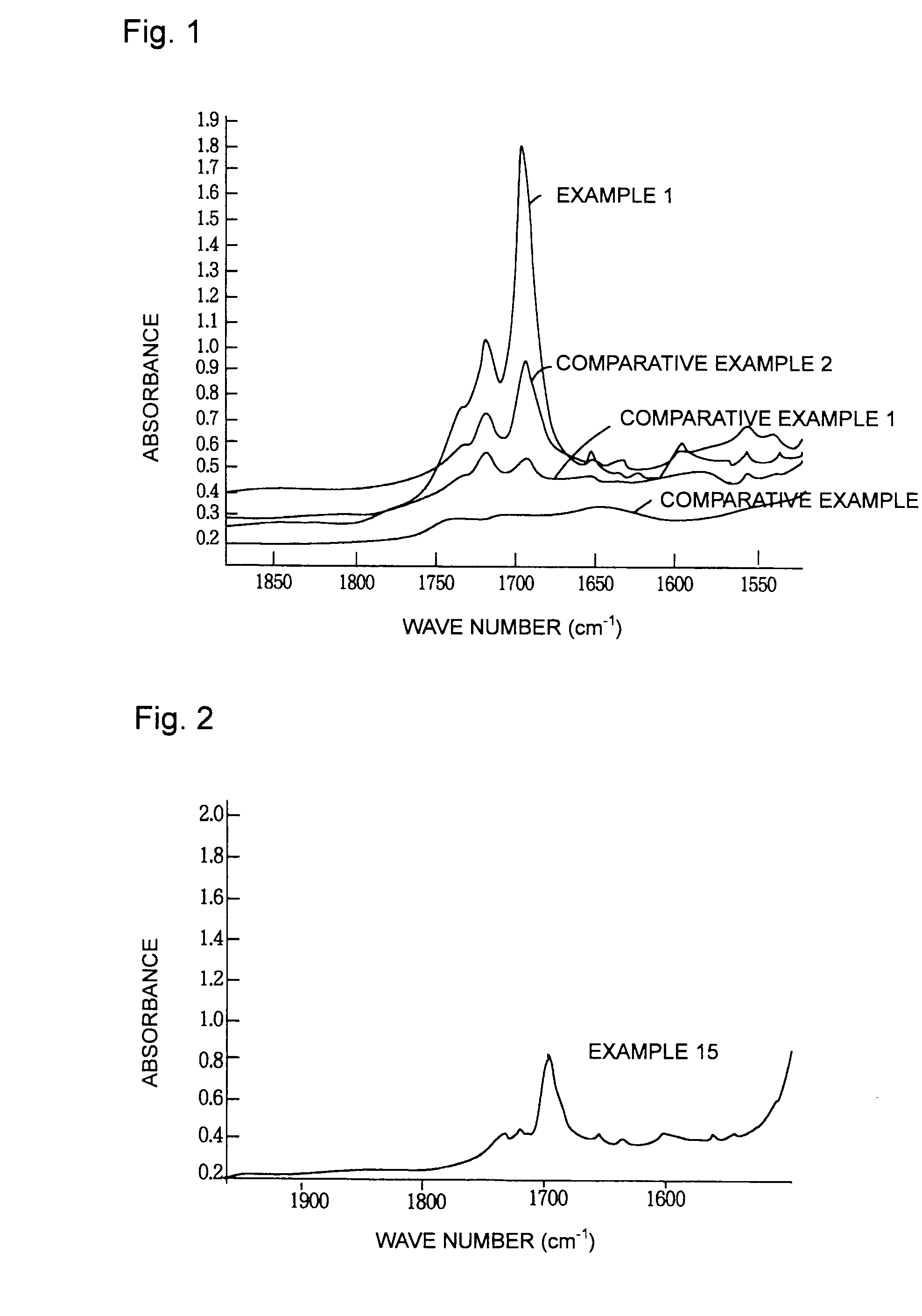

Polyester film, method for production of the same, and area light source, solar battery back-sheet and solar battery each comprising the same

InactiveCN101878251AExcellent productivityLayered productsThin material handlingTransmittanceChemistry

Disclosed is a polyester film having excellent mechanical strength, ray transmittance, gas barrier properties, molding easiness, mold releasability, UV resistance, insulation properties and productivity. Specifically disclosed is a film which comprises a polyester layer (layer W) comprising an aromatic polyester resin (A) and an incompatible component (B) that is incompatible with the polyester resin (A), wherein the incompatible component (B) comprises an acid-modified polyolefin resin (b2), wherein the incompatible component (B) is dispersed in the form of a dispersant having a flatness of 10 or more in the polyester layer (layer W), and wherein the dispersant makes up not less than 3% by volume and less than 50% by volume of the total volume of the polyester layer (layer W), and wherein air bubbles make up less than 3% by volume of the total volume of the polyester layer (layer W).

Owner:TORAY IND INC

Cross-linkable fluoroelastomer excellent in cross-linkability and method for its production

InactiveUS20100196709A1Excellent in cross-linkabilityExcellent productivityRubber insulatorsCellulosic plastic layered productsChemistryAliphatic alcohol

To provide a cross-linkable fluoroelastomer remarkably excellent in cross-linkability and a method for its production, a fluoroelastomer composition excellent in the cross-linked physical properties, and a cross-linked rubber.A cross-linkable fluoroelastomer having a Mooney viscosity of from 20 to 300, obtainable by heat-treating a mixture of a fluoroelastomer (A), an organic peroxide (B) and at least one additive (C) selected from the group consisting of a C12-28 higher fatty acid, a metal salt of a C12-28 higher fatty acid, an ester of a C12-28 higher fatty acid, an amide of a C12-28 higher fatty acid and a C12-28 higher aliphatic alcohol, at a temperature of from 110 to 380° C.

Owner:ASAHI GLASS CO LTD

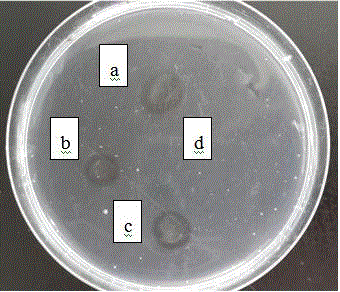

Method for culturing cordyceps militaris mycelium and plasmin

ActiveCN104911169AExtensive growth conditionsEnzyme production cycle is shortFungiMicroorganism based processesBiotechnologyNutrient solution

The invention discloses a method for culturing cordyceps militaris mycelium and plasmin. The used cordyceps militaris bacterial strain has a preservation number of CGMCC No.2577 in the General Microbiological Center of China Committee of Culture Collection for Microorganisms on 4th, July, 2008. The taxology name is cordyceps militaris. The culture method comprises bacterial classification activation, seed nutrient solution preparation and solid fermentation, a solid fermentation matrix contains cordyceps militaris and plasmi, its plasmin vitality can reach 927.77U / g. The method uses rice and wheat bran as culture matrix for culturing cordyceps militaris and producing cordyceps militaris mycelium and plasmin, bacterial classification and production raw material are safe and reliable, the raw material has the advantages of low cost and easy acquisition, compared with a traditional cultivation technology, the production period is shortened by 5 / 6, operation is simple, and realization is easy. The method provides a novel thinking and research base for research and development of health food for preventing and treating pulmonary thromboembolism, and provides a novel approach for producing cordyceps militaris mycelium.

Owner:QIQIHAR UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com