Patents

Literature

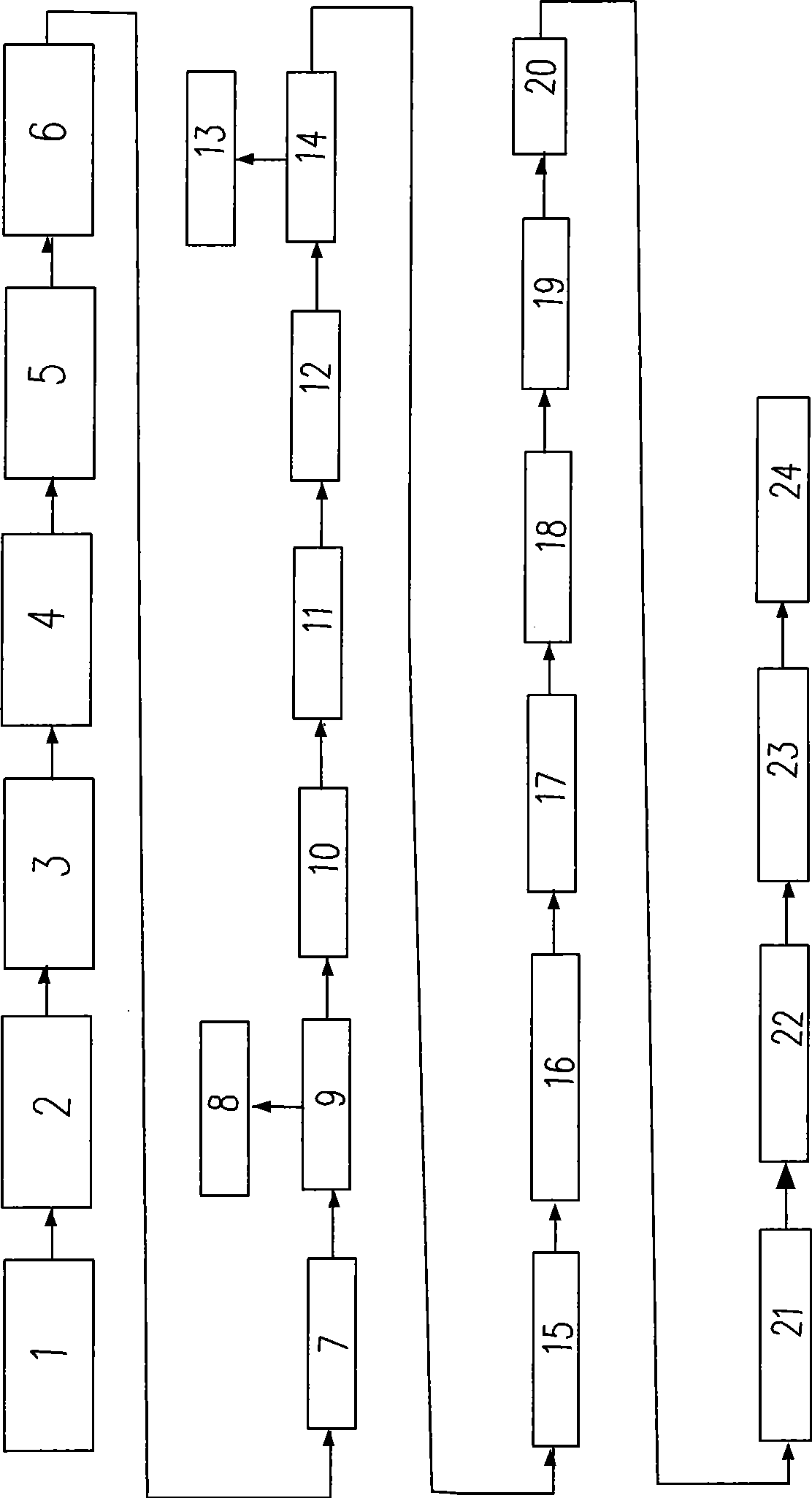

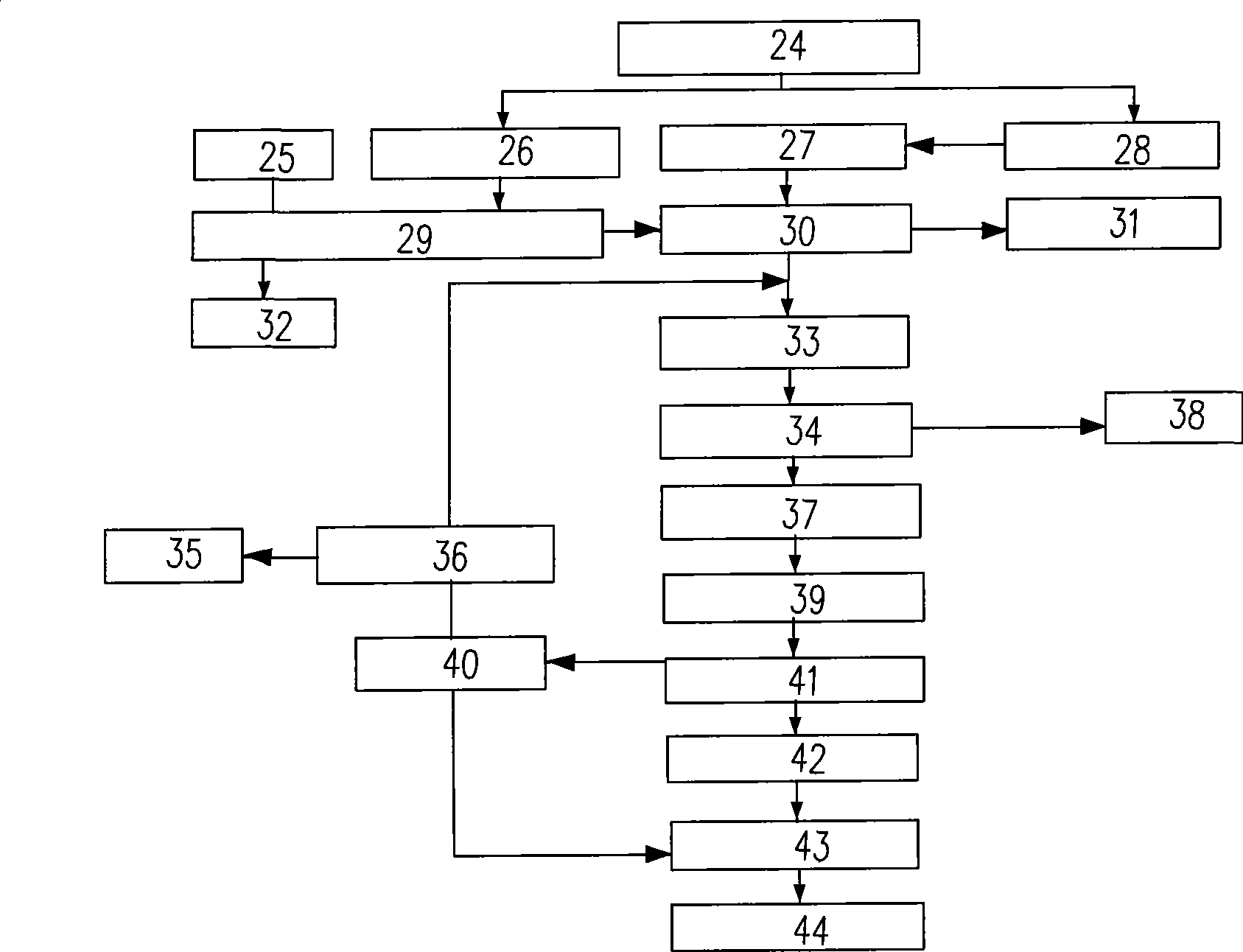

307 results about "Investment material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An Investment Material can be described as a ceramic material which is suitable for forming a mold into which metal or alloy is cast.

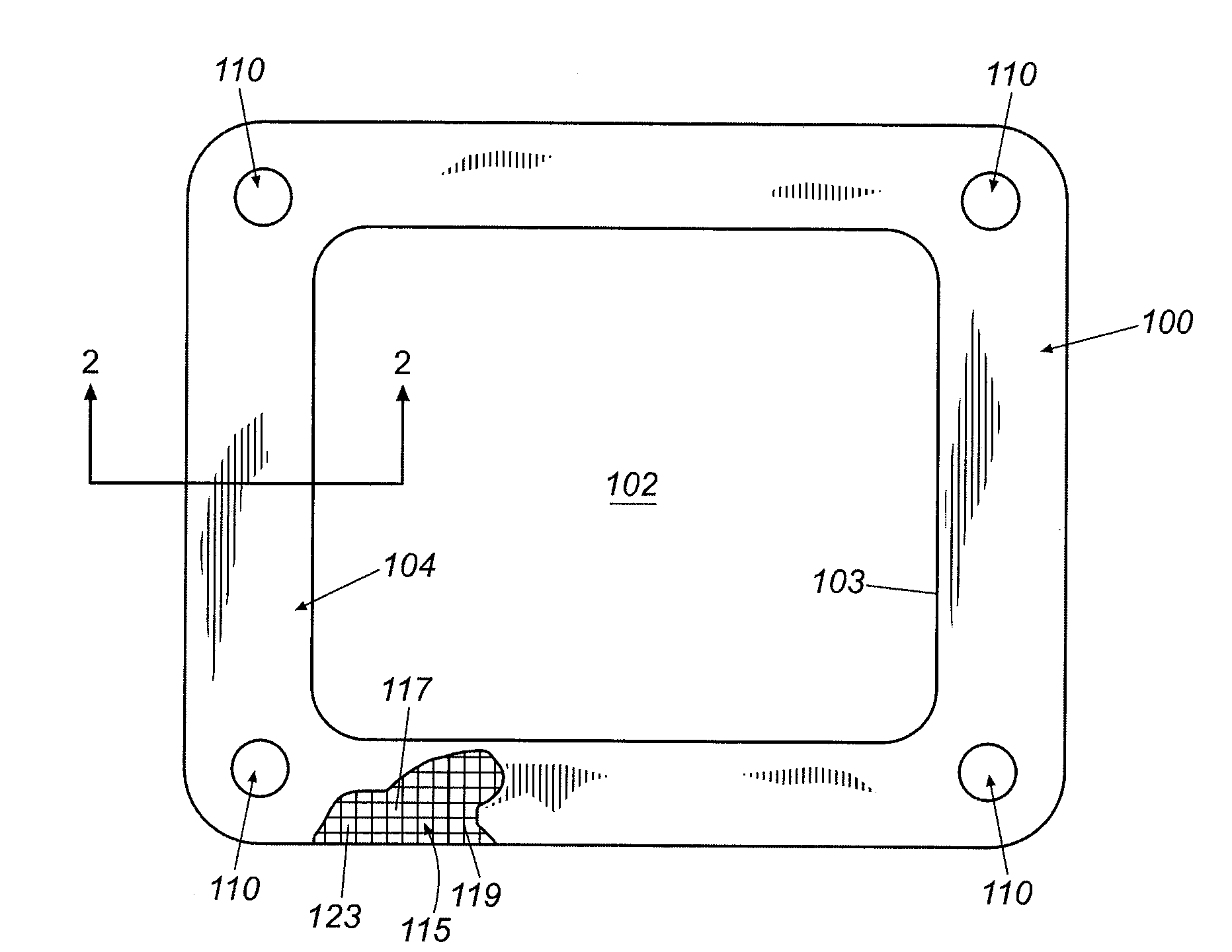

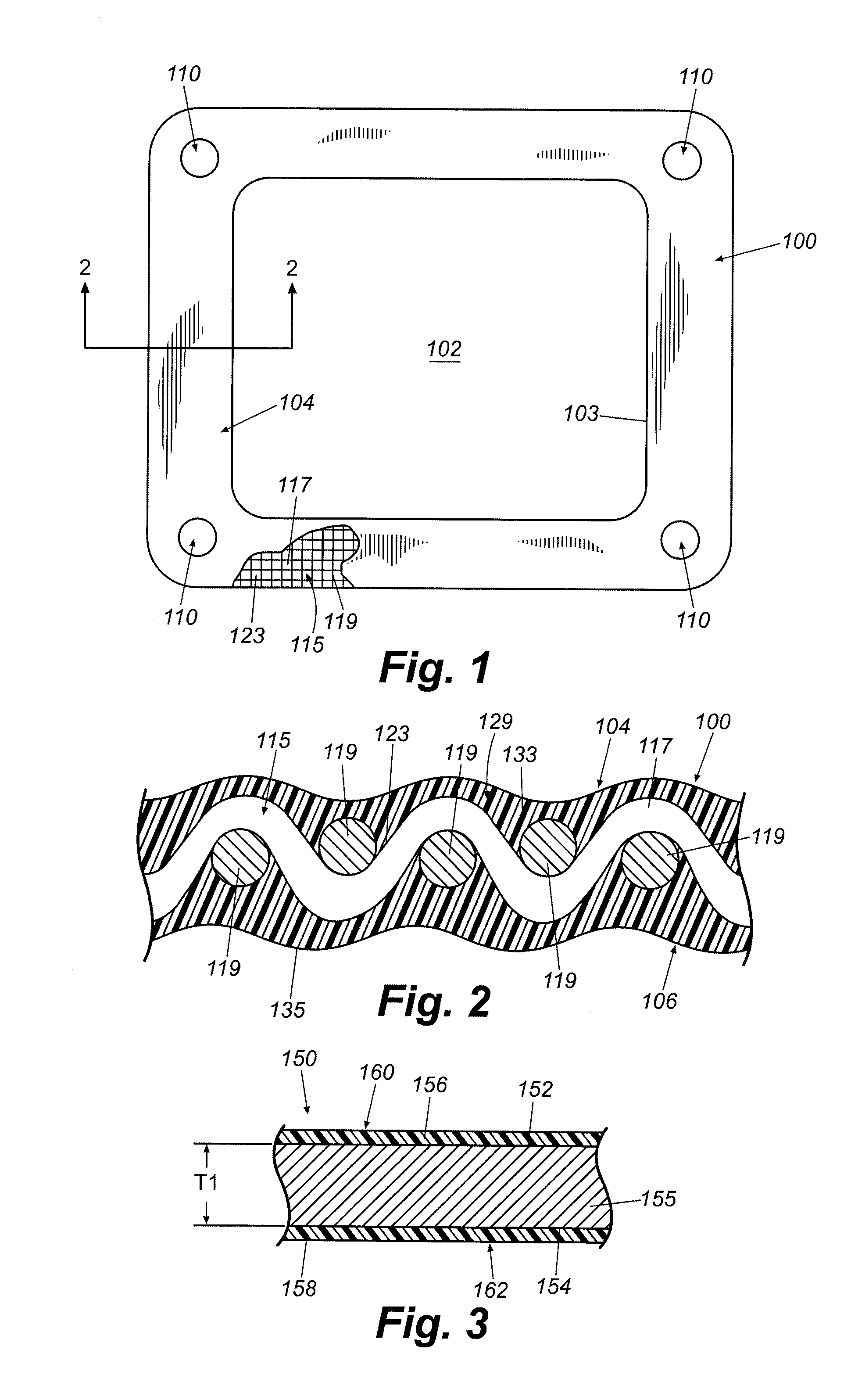

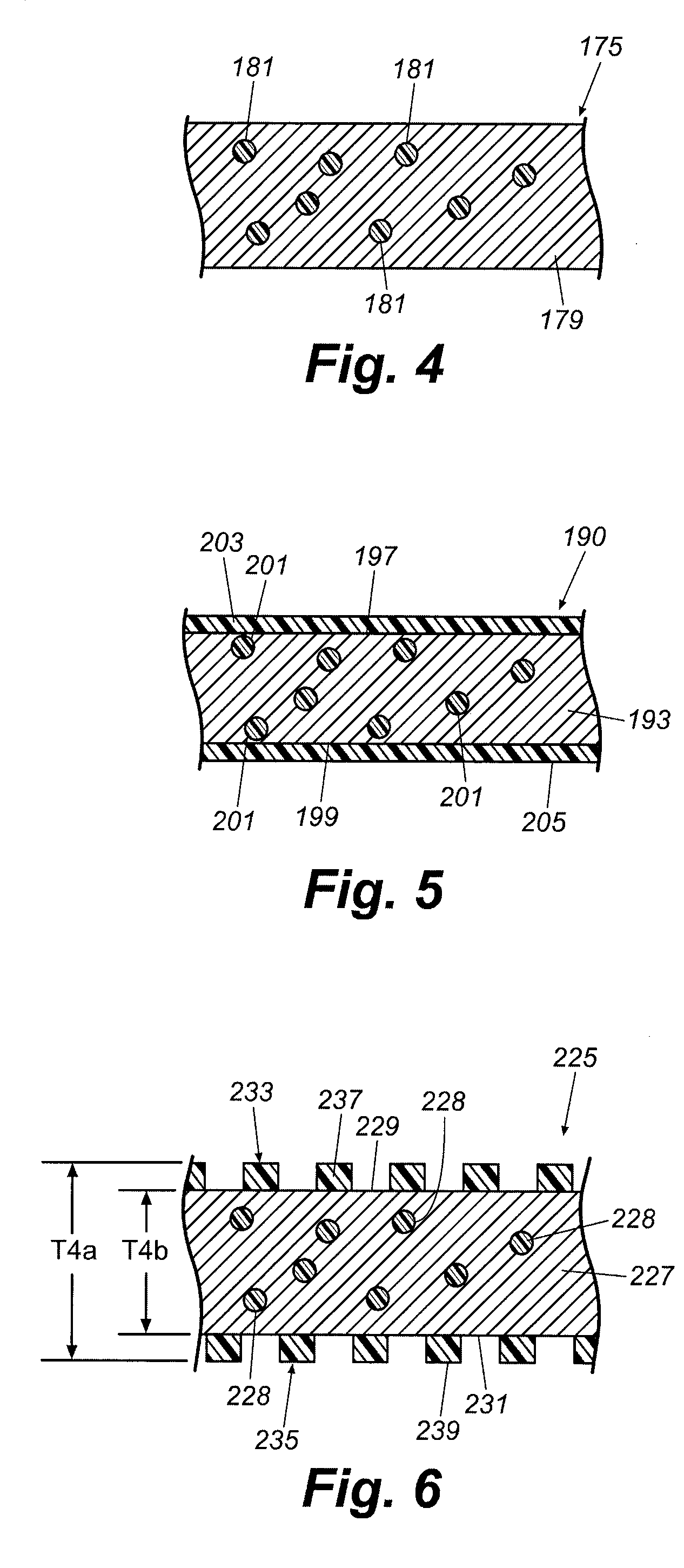

Gasket Formed From Various Materials And Methods Of Making Same

InactiveUS20080280040A1Highly controllable mannerDesigned and quickly and efficientlyEngine sealsSpecial surfacesInvestment materialEngineering

A gasket is provided for creating a seal between two surfaces. The gasket may include a pervious base sheet and a permeating material applied to or incorporated into the base sheet. The gasket is formed by various methods disclosed herein. The gasket may include a base sheet, a primary sealing material covering and / or impregnated the base sheet, and a secondary sealing material covering the primary sealing material. The secondary material may be applied in a predetermined pattern of raised and lowered sections or may be applied as a bead of sealing material. The secondary material may be applied through a variety of techniques including jetting and dispensing using robots such that beads with custom engineered and changing configurations along their lengths are possible. These custom engineered sealing beads provide optimum sealability over the entire area of a joint to be sealed.

Owner:INTERFACE SOLUTIONS

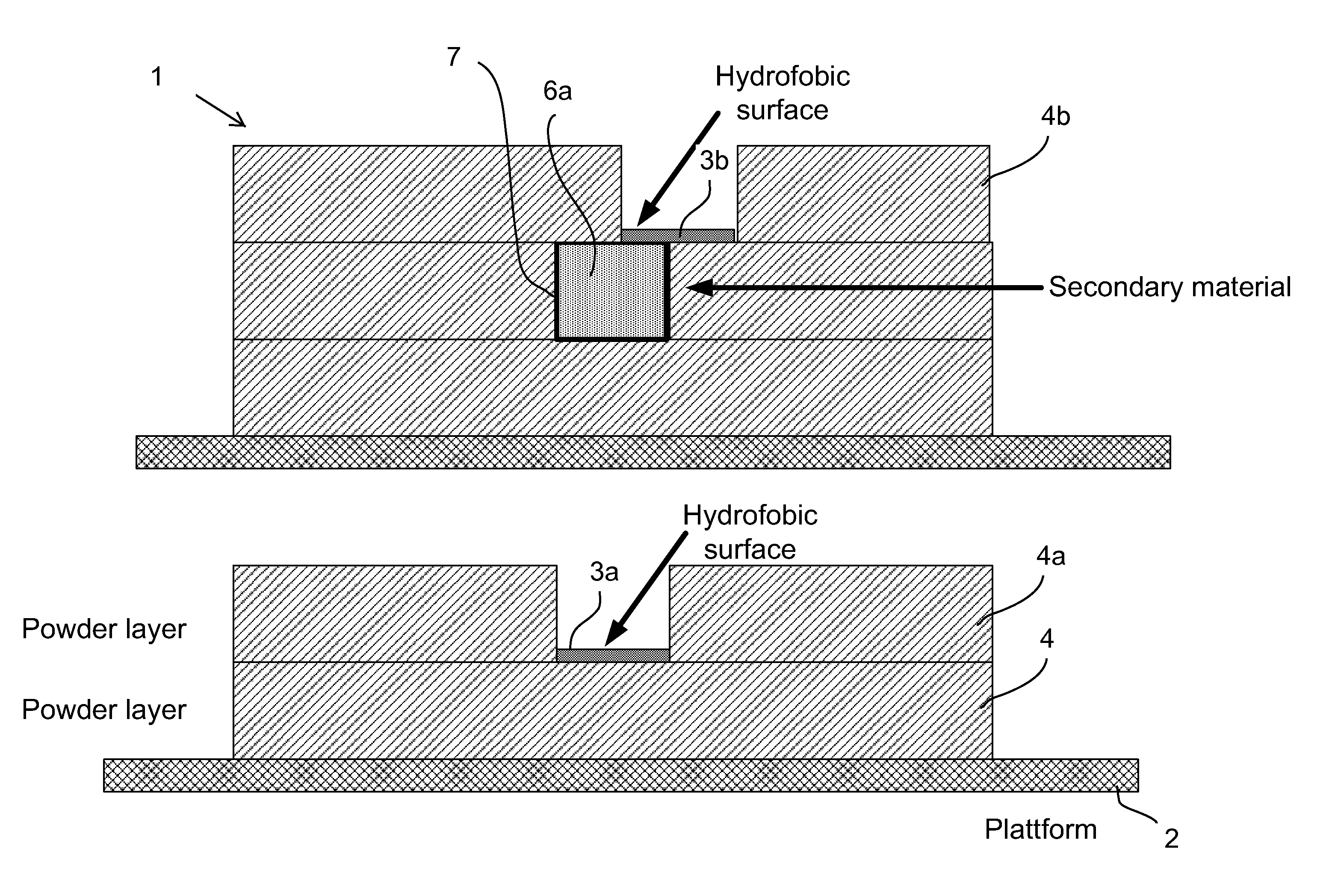

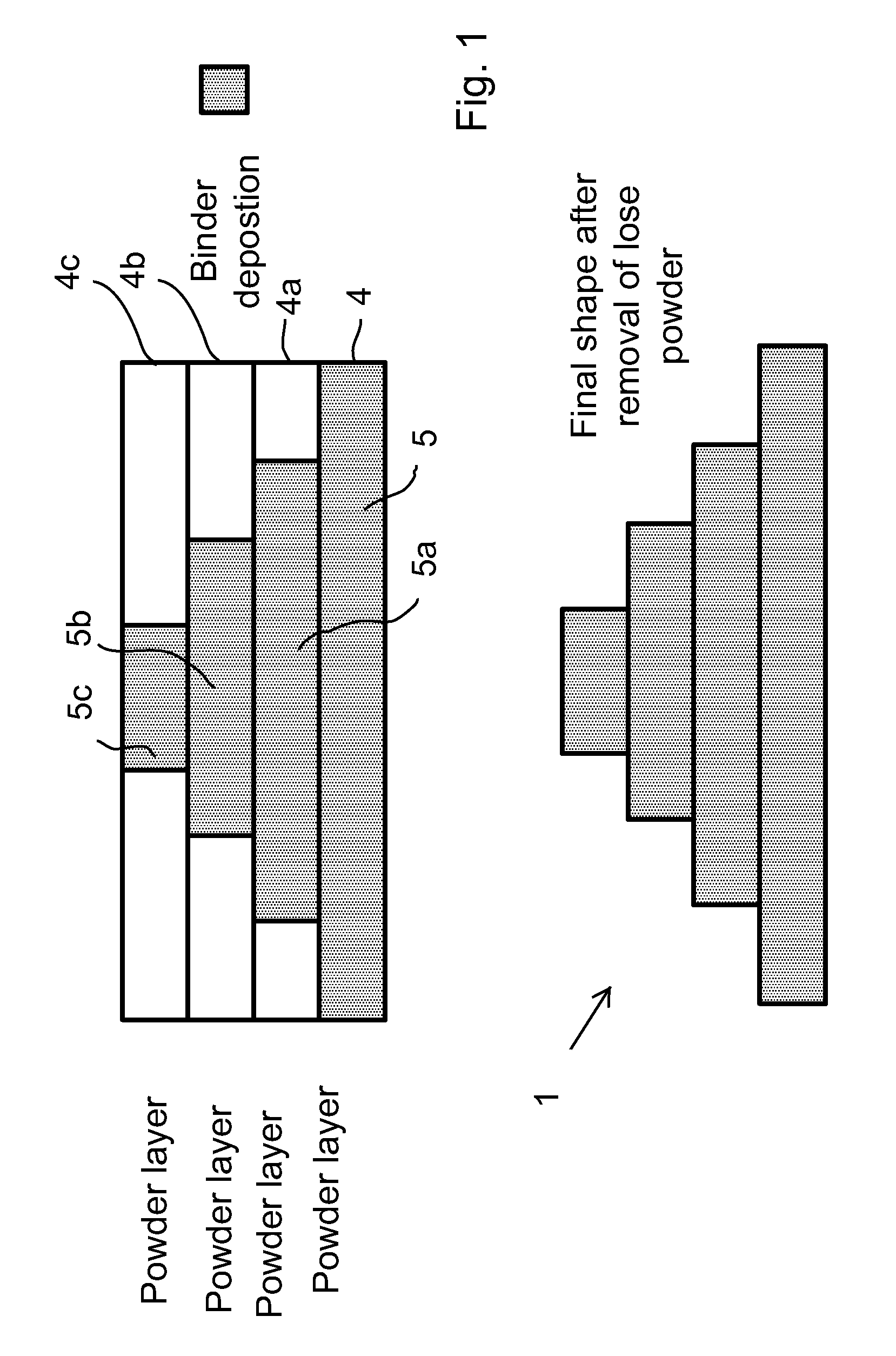

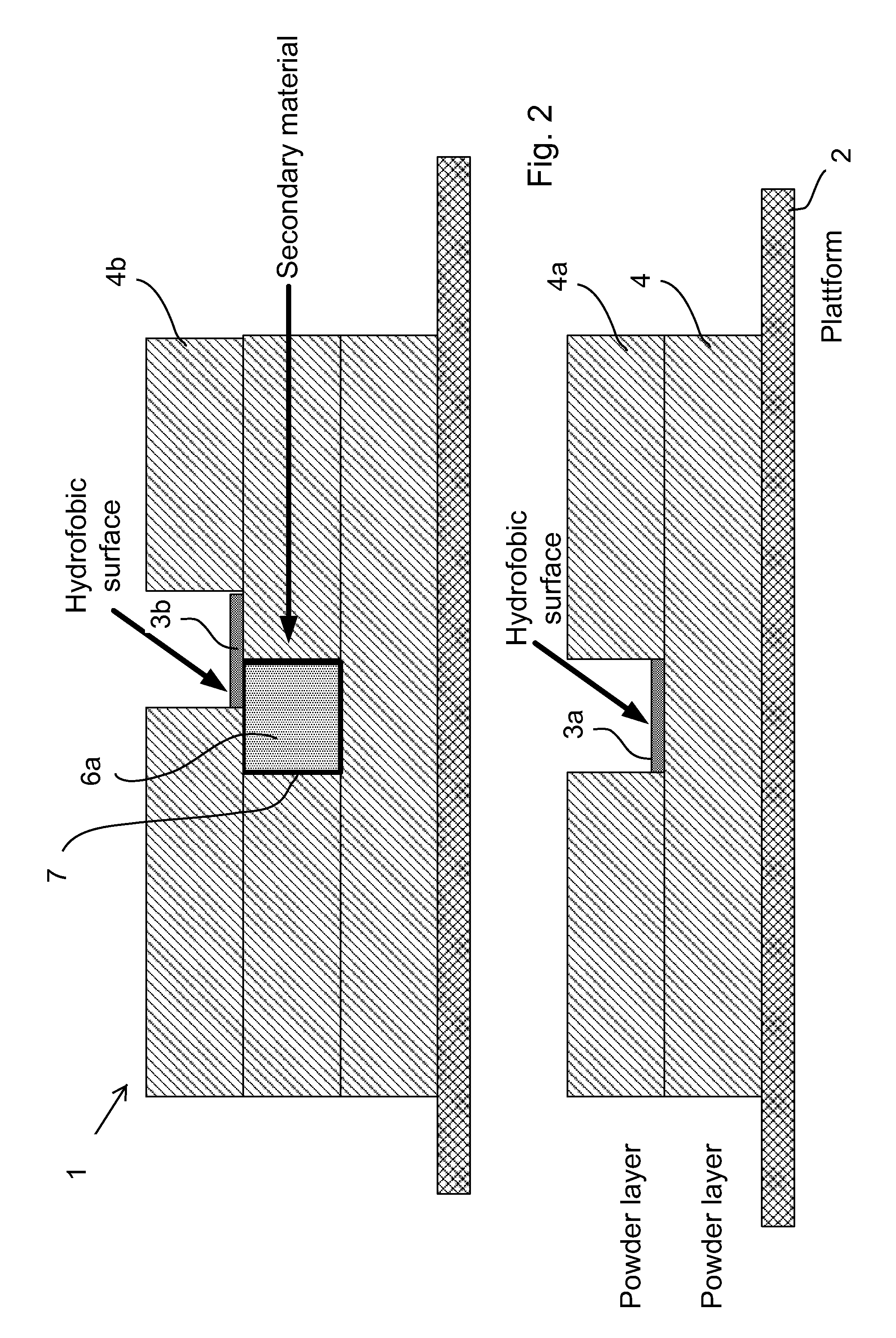

Layered manufacturing of free-form multi-material micro-components

ActiveUS20150306664A1Efficient productionAdditive manufacturing apparatusCircuit optical detailsMulti materialElectricity

The present invention relates to layer manufacturing, more particularly to a method for additive layer manufacturing of objects comprised of more than one material with free-form capability for all included materials. The invention can for example be used for producing packaging for Microsystems where the ceramic acts as an insulator and the secondary material is used to produce electrical or optical 3D conductor lines or electrical or optical 3D vias. The fine powder used in this method enables it to be used for building components with small feature size and demand for high precision. Other intended uses for this method is to build small mechanical precision parts or grinding tools, dental objects or medical implants.

Owner:DIGITAL METAL

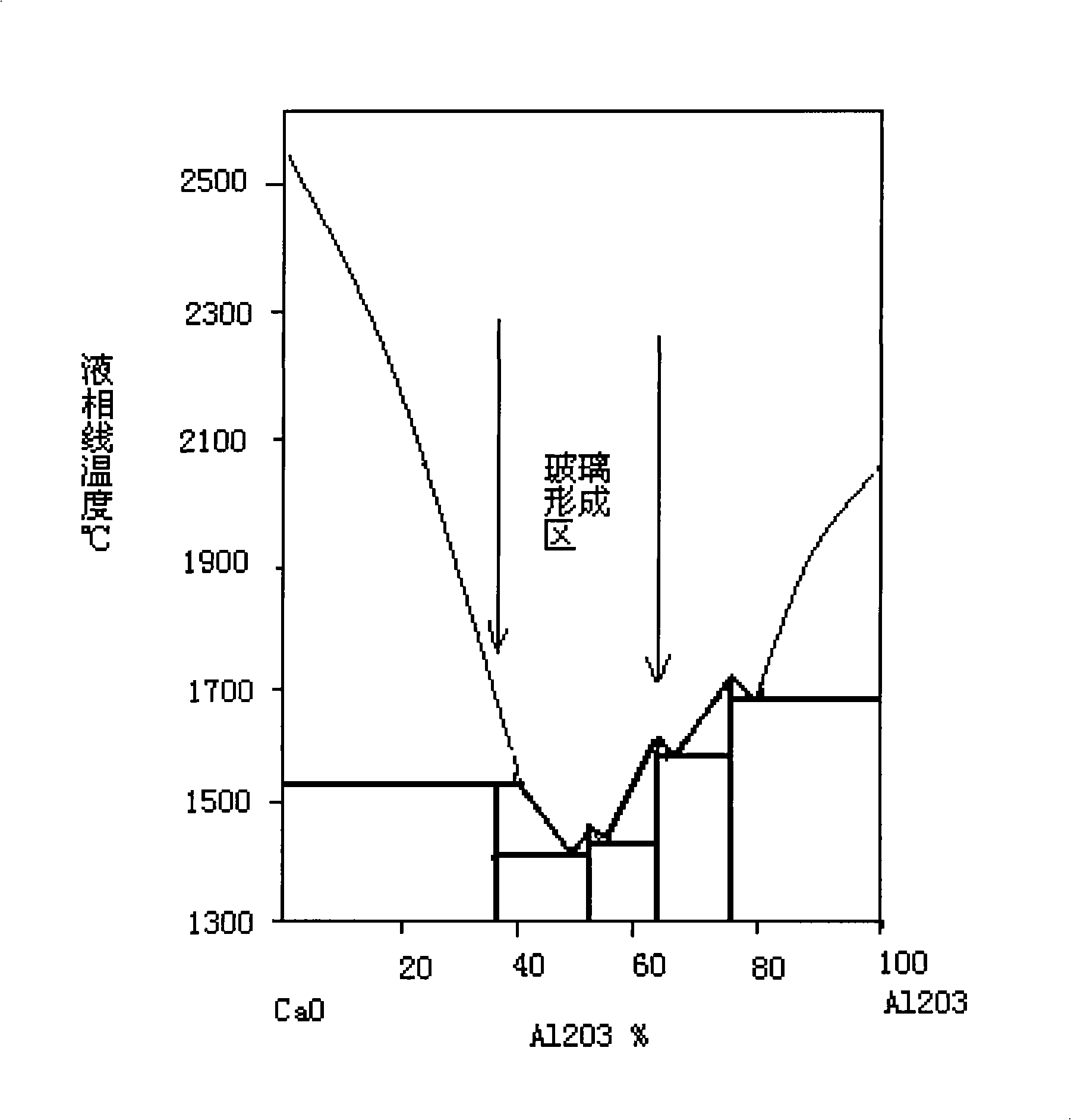

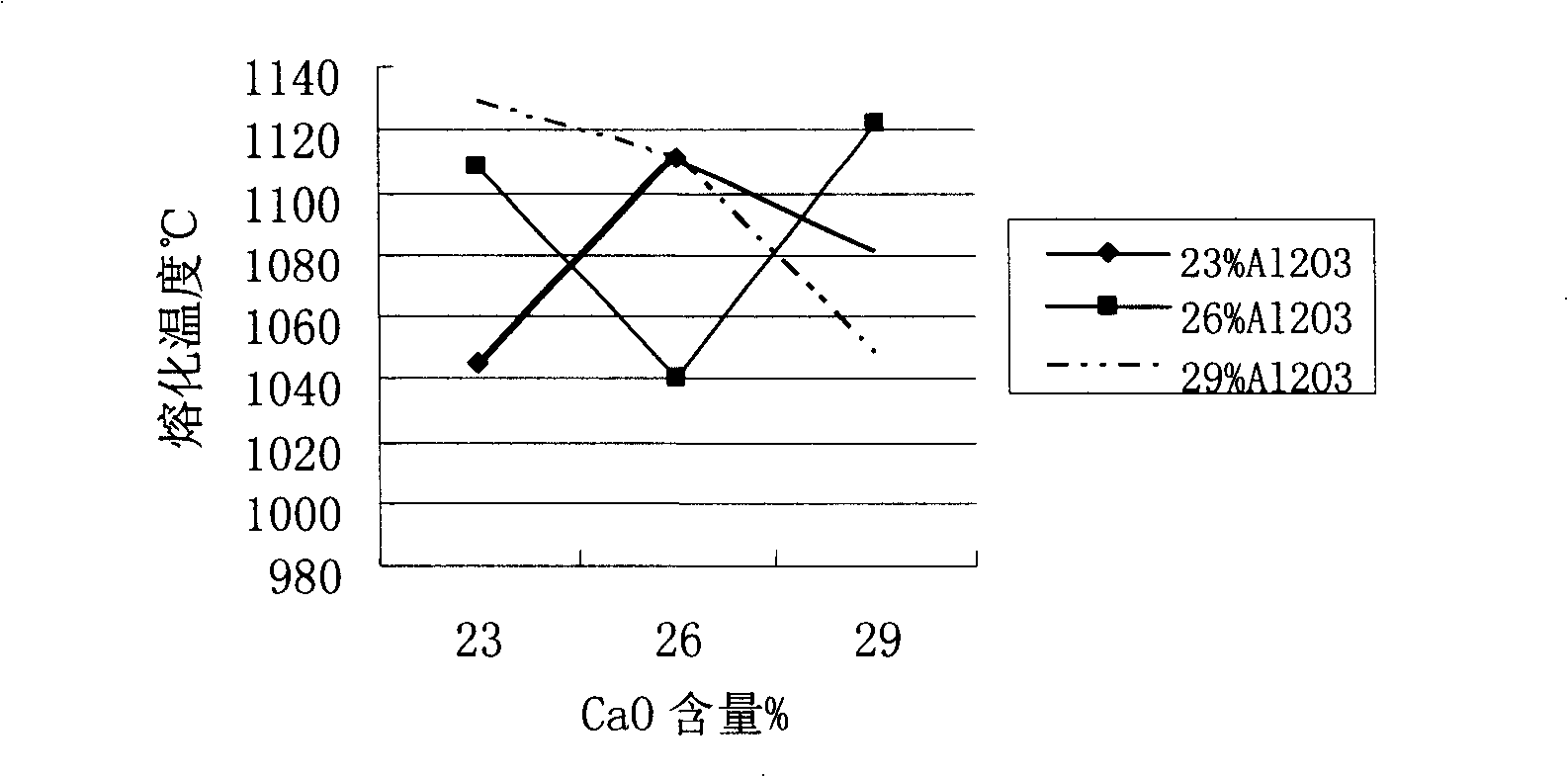

Continuous casting protection slag for high-alumina steel and manufacture method thereof

InactiveCN101332497ASolving Continuous Casting ProblemsInhibit denaturation of slagChemical compositionSlag

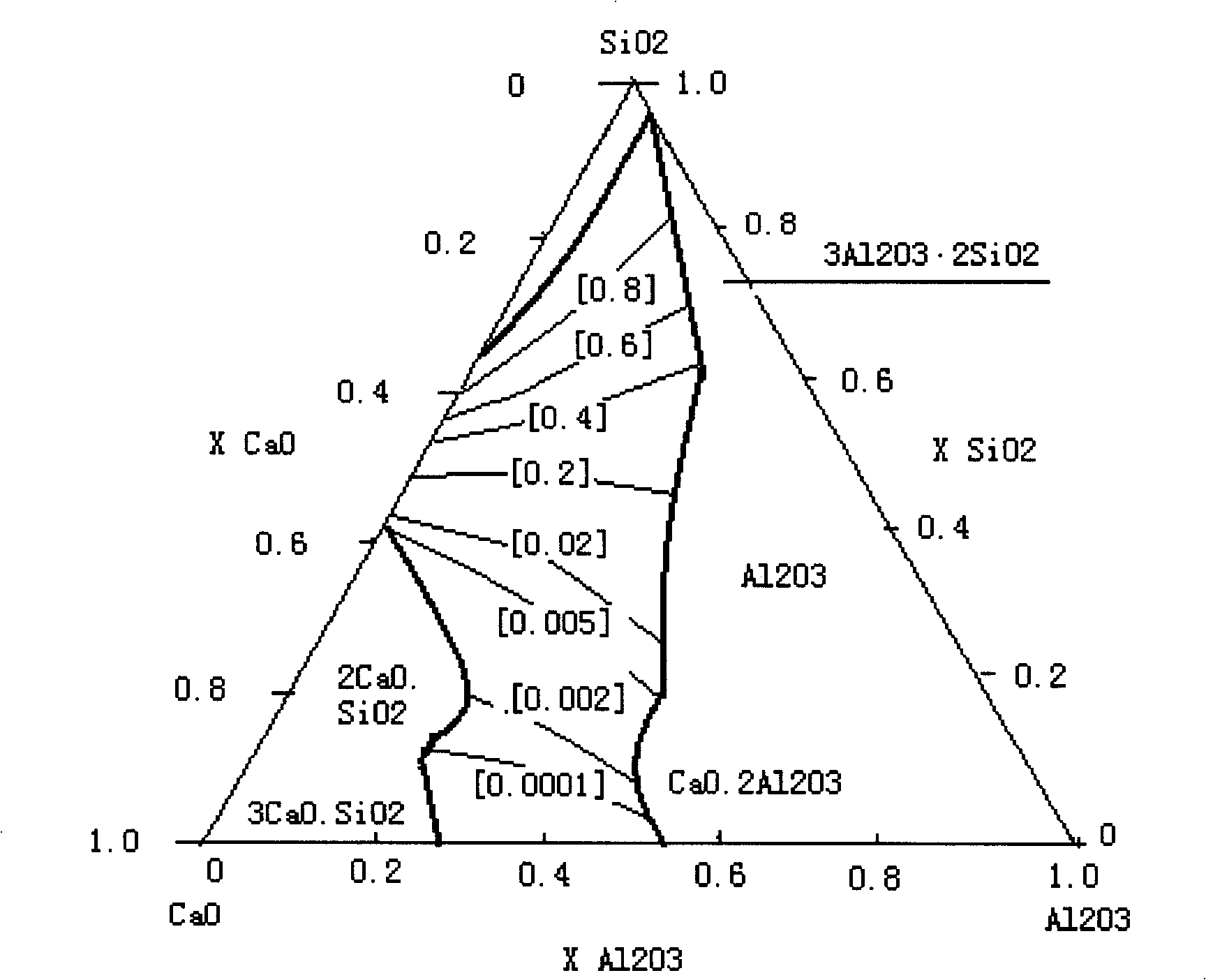

The invention relates to a steel-making auxiliary material and a production method thereof, in particular to a continuous casting powder for high-aluminum steel and a production method thereof. The invention is mainly technically characterized in that the casting powder raw material is prepared by using the following chemical components with the percentage: CaO+Al2O3 accounts for 50%-60%, and the ratio of CaO to Al2O3 is 0.7-1.3, SrO accounts for 4-10%, BaO accounts for 2-5%, MgO accounts for 1-3%, fluxing agent is composed of Na2O which accounts for 10-16%, Li2O accounting for 2-5%, F accounting for 6-12%, and SiO2 which is kept less than or equal to 2%. The casting powder is produced by the steps of melting, water quenching, drying and crushing and by adding a carbon material. The continuous casting powder can inhibit the oxidized strong reducing elements from entering the slag to cause the slag denaturation; and can ensure smooth continuous casting production of steel products containing high aluminum, Ti and rare earths, and good surface quality of casting blank.

Owner:BAOSHAN IRON & STEEL CO LTD

Cement based capillary crystalline high-performance waterproofing powder and application thereof

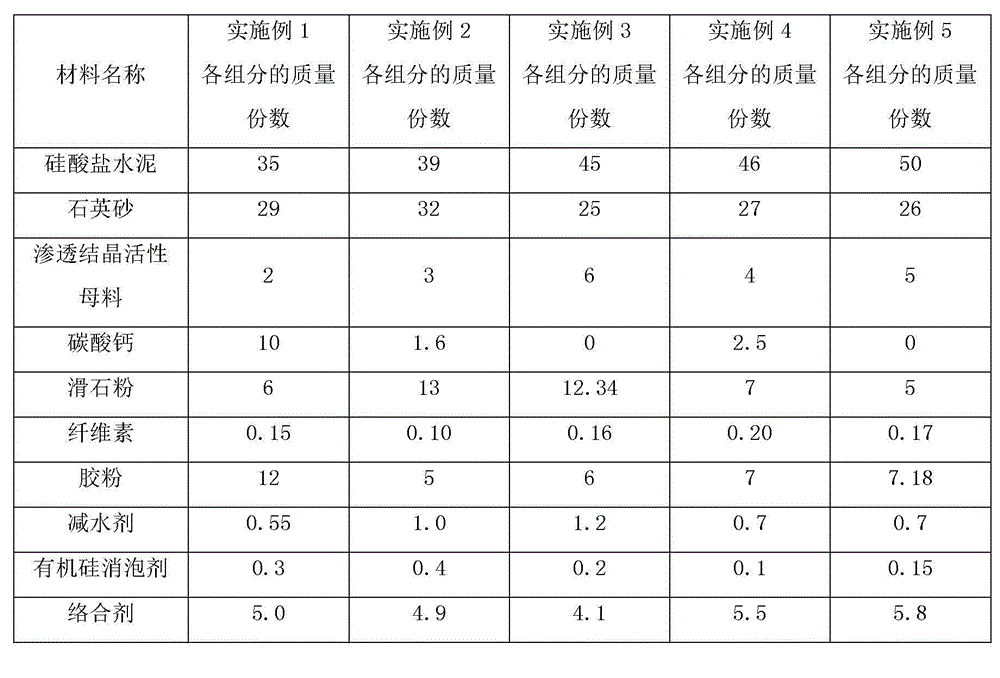

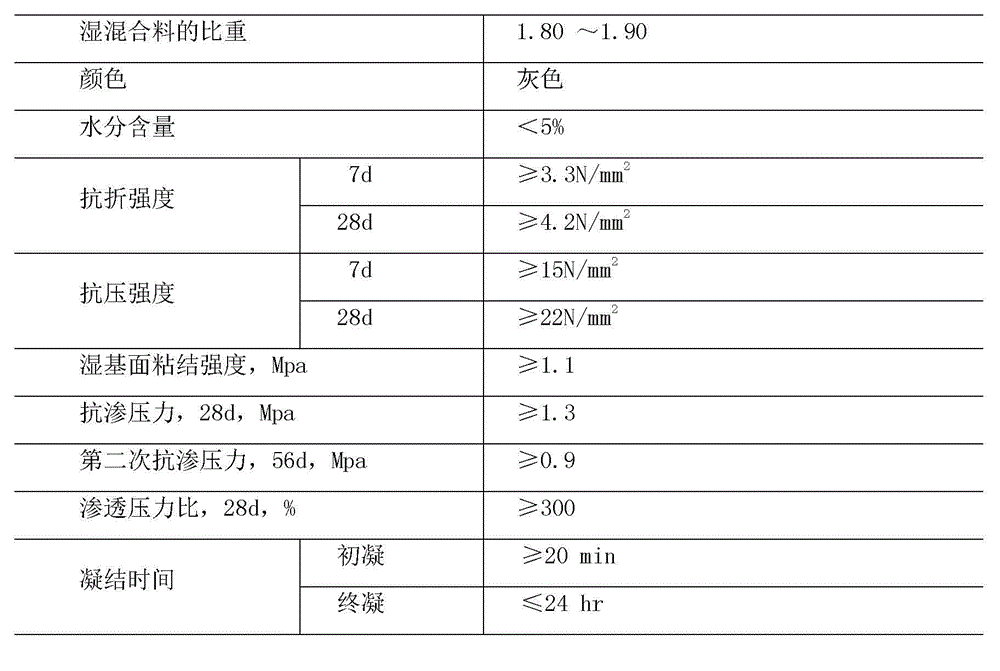

The invention discloses a cement based capillary crystalline high-performance waterproofing powder and an application thereof. The cement based capillary crystalline high-performance waterproofing powder is characterized in that inorganic materials of Portland cement, quartz sand and the like serve as a base, active compound capillary crystalline master batch, polymers and other various auxiliarymaterials are added and mixed to prepare powder waterproofing materials; and the cement based capillary crystalline high-performance waterproofing powder includes, by weight, 35-50 parts of the Portland cement, 25-32 parts of the quartz sand, 2-6 parts of the capillary crystalline active master batch, 0-10 parts of calcium carbonate, 5-13 parts of talcum powders, 0.1-0.2 part of cellulose, 6-12 parts of rubber powders, 0.55-1.2 parts of water reducers, 0.1-0.4 part of power organic silicon defoamer and 4.1-5.8 parts of complexing agents. Various raw materials are uniformly stirred in a mixer to obtain the cement based capillary crystalline high-performance waterproofing powder, and the cement based capillary crystalline high-performance waterproofing powder is mixed with a certain amount of clear water to prepare the waterproofing materials. The cement based capillary crystalline high-performance waterproofing powder is simple in preparing, convenient to use and good in water resistance and anti-permeability.

Owner:ANHUI LENCAQI BUILDING MATERIAL

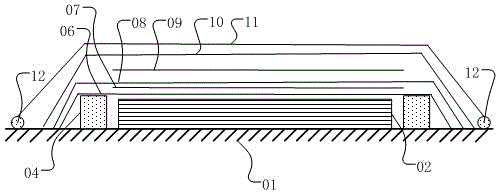

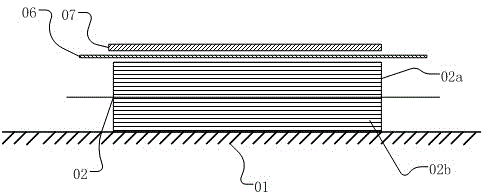

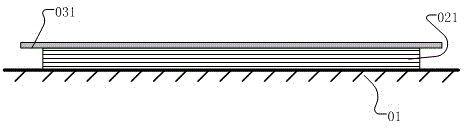

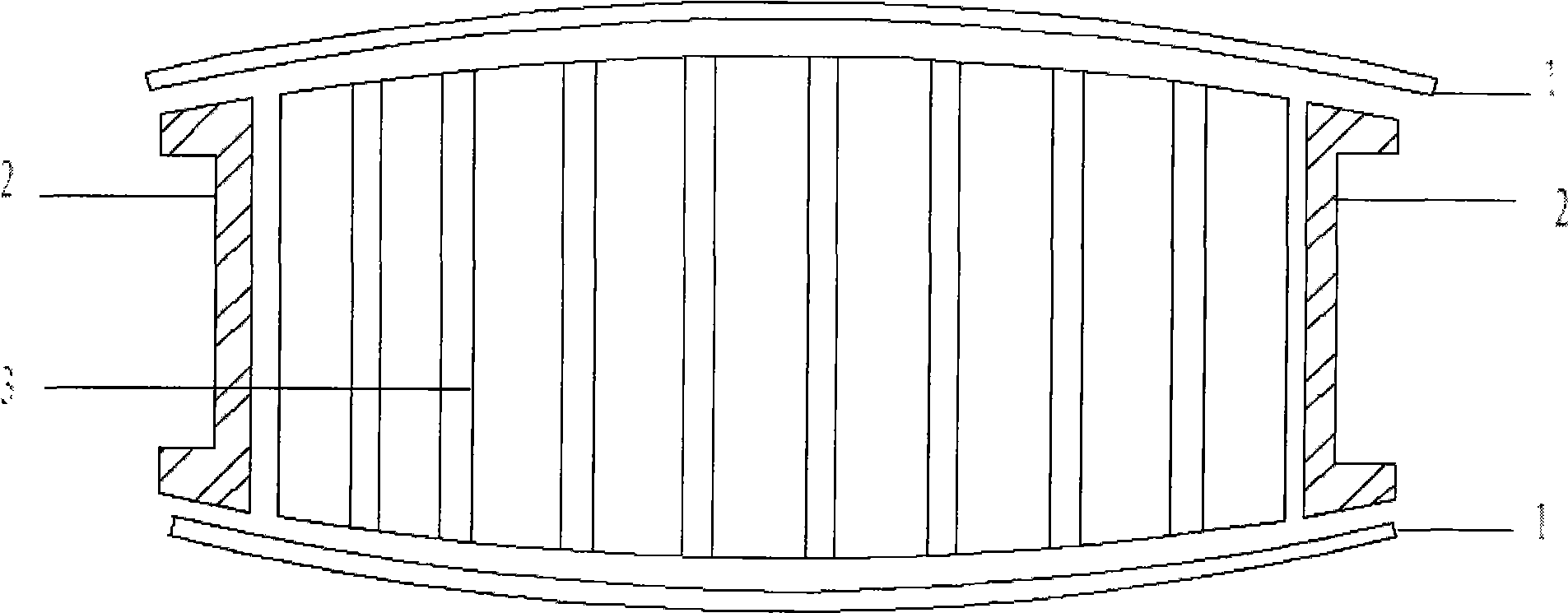

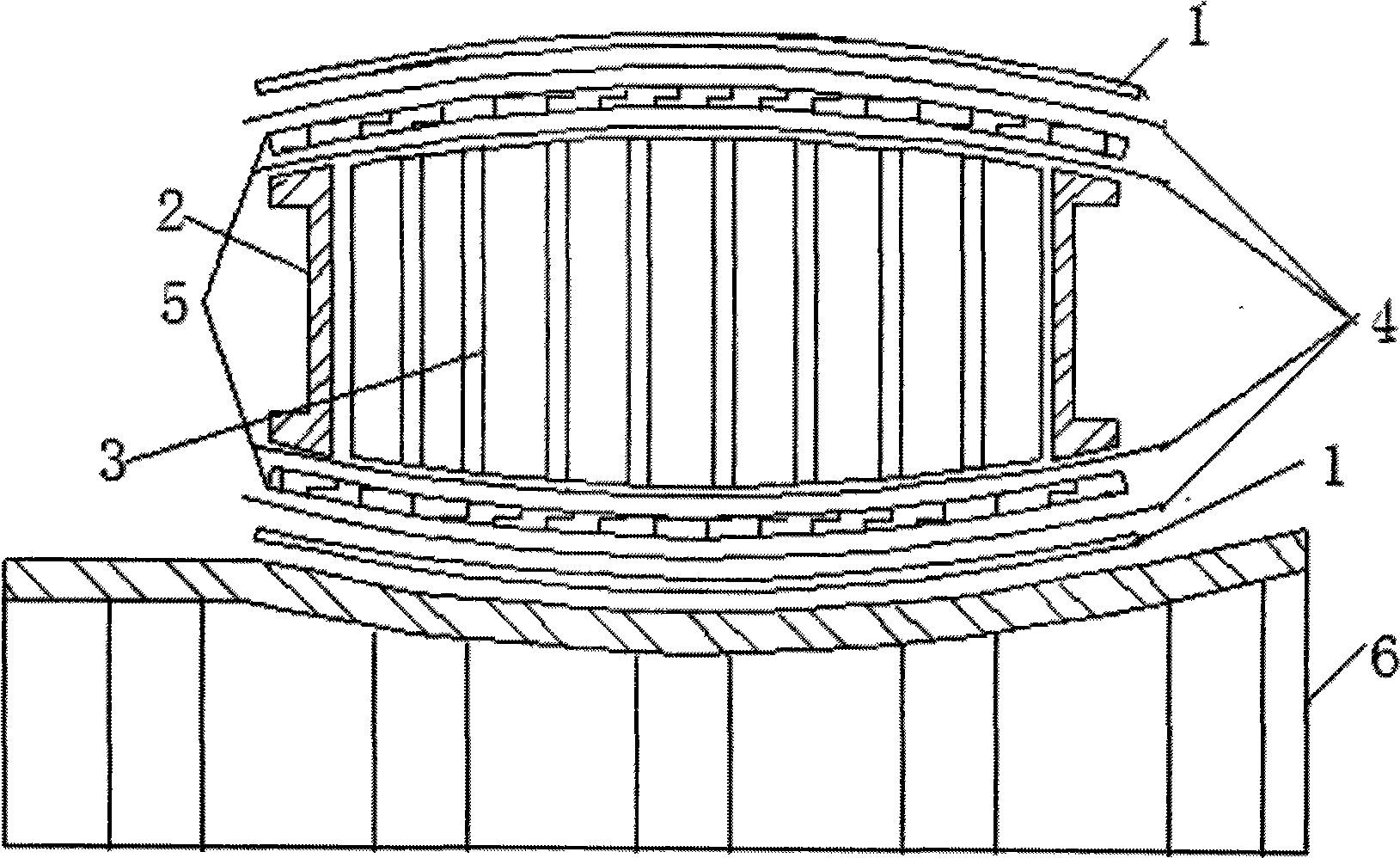

Curing formation method for non-flat plate composite product and shaping mould

The invention discloses a curing forming method and a forming die used for a non-slab composite material part. The method comprises the steps as follows: composite material part blank is arranged on a rigid die body which has the same shape with the processing shape and gluing and layer-paving are carried out according to the required dimension; after the layer-paving is finished, the composite material part blank is arranged on the rigid die body; furthermore, surfaces with plane are provided with elastic soft layers; corner pure rubber layers which are connected with elastic soft layer joint seams are arranged at corner profile so as to form a soft die surface; subsequently, vacuum bag auxiliary material is arranged on the soft die surface so as to prepare the vacuum bag curing forming composite material part. By the flexible soft die consisting of rubber-fabrics, the method arranges the composite material part blank on the surface of the soft die after the layer-paving is finished; the method for preparing the vacuum bag curing forming part solves the surface quality problems in the prior art that the non-die surface of the bag-pressing forming composite material part is crapy, accidented and has no gloss and the like, and improves the working efficiency.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

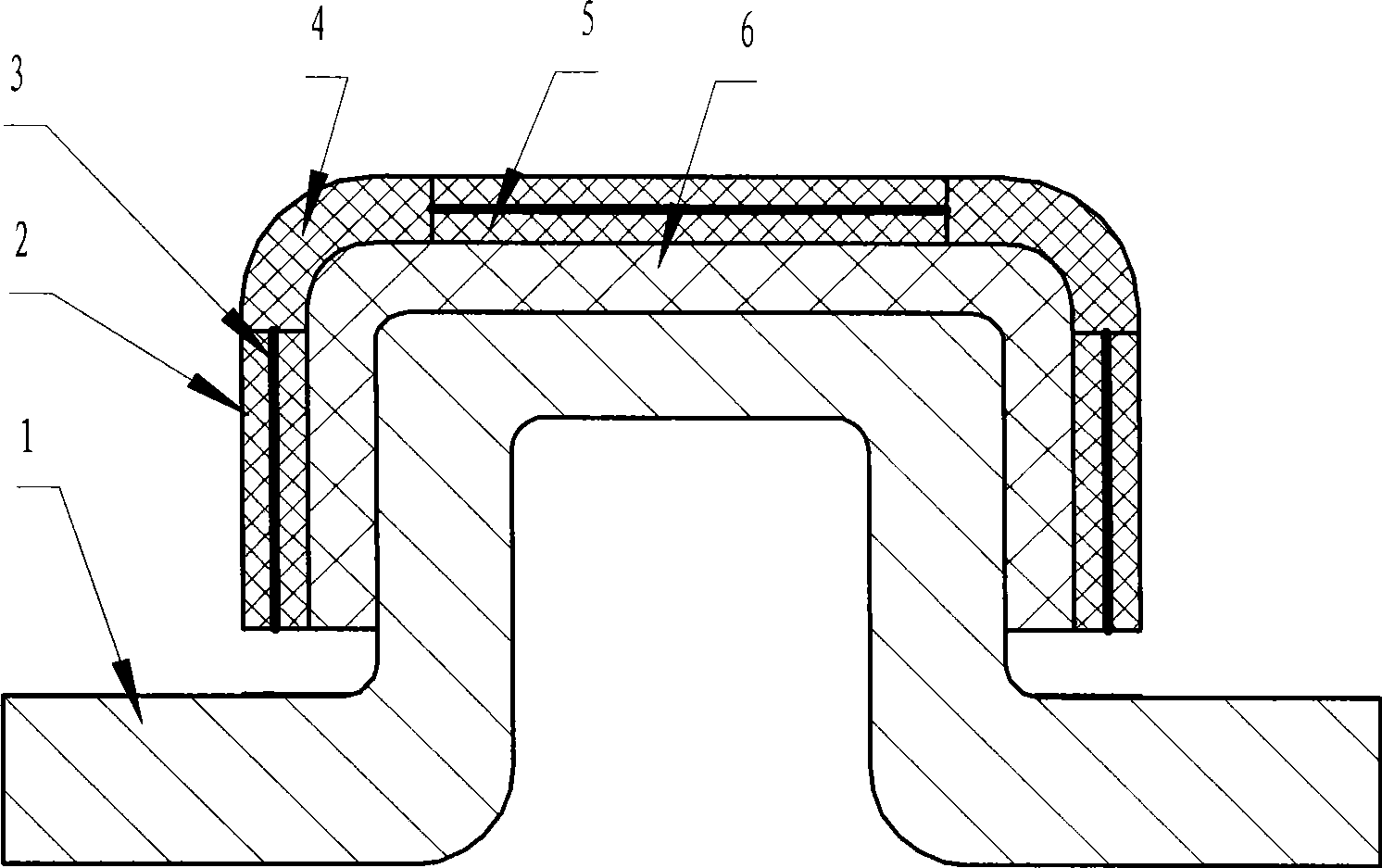

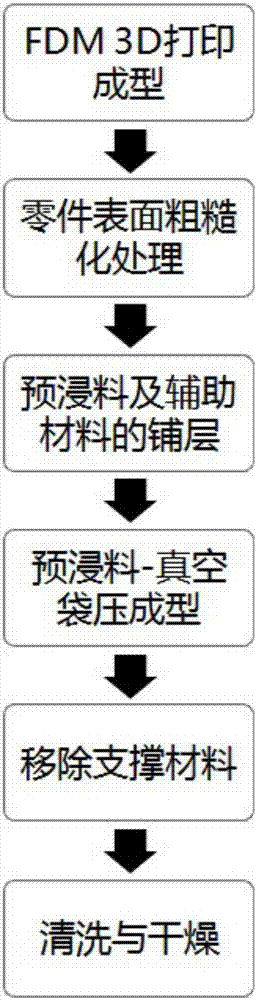

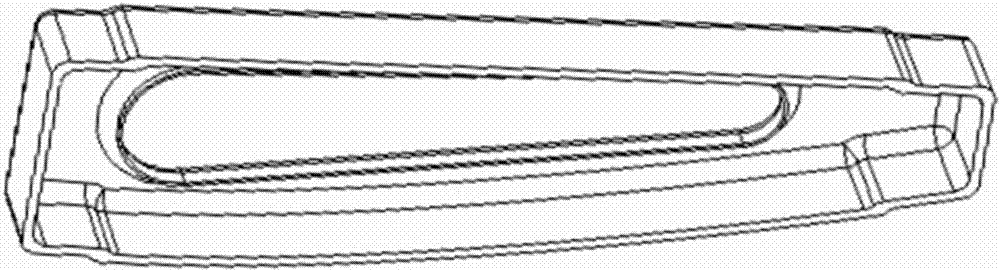

3D printing assisted forming method for fiber reinforced composite material

ActiveCN107187020AImprove surface roughnessIncrease mechanical bite forceAdditive manufacturing apparatus3D object support structuresFiber-reinforced compositeInvestment material

Provided is a 3D printing assisted forming method for a fiber reinforced composite material. An FDM 3D printing forming method and a continuous fiber composite material forming method are combined, a prepreg coating and an assisting material are laid on the surface of a part in a prepreg-vacuum bag molding composite material forming mode with an FDM 3D formed part as a forming mold, curing of prepreg is completed under a certain degree of temperature and pressure, and a supporting material is removed, cleaned and dried. By integrating the advantages of the flexibility and high precision of FDM 3D printing forming and the advantages of low weight and high strength of the composite material, the defects that FDM 3D printing forming is low in strength while the composite material is can not be separated from the mold easily are overcome, and the fiber reinforced composite material of a complex structure can be formed and manufactured into parts.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Cap assembly having storage chamber for secondary material with inseparable working member

InactiveUS20100163442A1Conveniently openedCapsClosure using stoppersSecondary componentInvestment material

A cap assembly mounted on a neck of a container for containing a ingredient different from that in accommodated in a container comprises a cap body having an inner housing formed with a chamber for storage of a secondary ingredient and a working member adapted to open a low end opening of the chamber to allow the secondary ingredient in the chamber of the inner housing to be mixed with a primary ingredient in the container. The mixed ingredients may be discharged through an opening.

Owner:LEE IN OK

Metal, ceramic powder and polymer mixture used for manufacturing metal and ceramic products and method for hydrolyzing and removing polymer from moldings

The invention discloses a polymer material, metal and ceramic powder mixture used for manufacturing metal, ceramic and compound (mixed) material (material component) products and a method for hydrolyzing and removing polymer materials from moldings. The mixture comprises the following materials in volume ratio: 40-70% of material components and 60-30% of polymer material adhesives (being composed of the following materials in mass ratio: 50-95% of main materials that can be hydrolyzed and removed at a relatively low temperature, 46-4.5% of ancillary materials that can be thermally removed at a relatively high temperature and 4-0.5% of additives); the mixture is used for molding by mixing, banburying, squeezing and granulating; main polymer materials are hydrolyzed and removed from molded green bodies at a relatively low temperature, auxiliary polymer materials and additives are thermally removed at a relatively high temperature, and the green bodies are sintered to obtain target products. The polymer material and the method have the advantages that adhesive removing is low in temperature and short in time, and the catalyst is water; removed materials are reusable by recycling, condensing and separating, and are environment-friendly; after molding, pouring gate and flow passage rejecting materials can be repeatedly recycled; the product cost is lowered.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

Preparation method of zirconia grinding fluid

InactiveCN102250585ASmall particle sizeLow shape requirementOther chemical processesMetallurgyInvestment material

The invention discloses a preparation method of a zirconia grinding fluid, and relates to the technical field of new materials applied in precision grinding and polishing technical fields. The preparation method comprises the processes: adding a wetting and dispersing agent to high-speed dispersed water in parts by weight, then adding zirconia powder and auxiliary materials, fully dispersing, introducing into a high-speed sanding machine for sanding to grind the edge of zirconia powder into a round spherical shape, adding functional additives when the particle size of the zirconia powder reaches a certain value, and then adding a coloring agent to adjust the color. The zirconia grinding fluid has the characteristics of free from influence of particle size and shape of zirconia raw materials, lower production cost and good stability, is suitable for the precision grinding and polishing of liquid crystal electroconductive glass, flat optical glass, optical spherical and optical lens glass, filters, filter windows and glass plate substrates, and is especially suitable for the grinding and polishing of soft material spherical glass.

Owner:湖南皓志新材料股份有限公司

Method for preparing non-woven fabric polishing abrasive tool with high abrasion resistance

InactiveCN101913121AHigh viscosityImprove adhesionFibre typesGrinding devicesSilanesMagnesium stearate

The invention relates to a method for preparing a non-woven fabric polishing abrasive tool with high abrasion resistance. The method comprises the following steps of: taking 20 to 40 mass parts of epoxy resin, adding 4 to 25 mass parts of curing agent, 20 to 45 mass parts of abrasive, 8 to 15 mass parts of diluent, 2 to 8 mass parts of toughening agent, 1 to 3 mass parts of silane coupling agent and 3 to 8 mass parts of auxiliary materials into the epoxy resin, mixing the materials uniformly, then spraying the mixture onto a non-woven fabric, curing the mixture at a high temperature, and then performing punch forming, wherein the toughening agent comprises reactive epoxy toughening agent, terminal carboxyl liquid nitrile rubber and / or terminal carboxyl polybutadiene liquid rubber; the silane coupling agent comprises gamma-aminopropyltriethoxysilane, gamma-glycidyl ether oxypropyl trimethoxy silane and / or gamma-(methacryloyloxy) propyltrimethoxysilane; and the other auxiliary materials comprise 2,4,6-tri(dimethylaminomethyl) phenol DMP-30 accelerator, wax powder, graphite, pigment, magnesium stearate and / or zinc stearate. The non-woven fabric polishing abrasive tool is mainly used for polishing treatment of metal surfaces.

Owner:SOUTH CHINA UNIV OF TECH +1

High intensity straight-line joint pipeline steel tube fabrication technique using high-frequency electric resistance welding

InactiveCN101474644AHigh geometric accuracy of appearanceImprove mechanical propertiesHigh frequency current welding apparatusManufacturing technologyPerformance index

The invention relates to the manufacturing technical field of steel pipes for long-distance transport pipes for petroleum, natural gas, mineral powder and the like, in particular to a pipeline steel pipe manufacturing technology employing straight high-frequency resistance welding. Raw materials meeting requirements are purchased, wherein, the requirements comprise physical properties, chemical compositions and mechanical properties of the raw materials. The raw materials are inspected to determine whether the physical properties, the chemical compositions and the mechanical properties meet the requirements. The technology comprises steel pipe manufacturing preparation, determination of production line moulding process parameters, determination of welding process parameters and determination of auxiliary material parameters. The pipeline steel pipe manufacturing technology employing the straight high-frequency resistance welding can help manufacture 632.2X11.1-60 pipeline steel pipes, various performance indexes of the steel pipes meet the requirements of pipeline steel pipes (USA API SPEC 5L PSL2 44 Standard), the heights of an inside seam and an outside seam are identical with the pipe wall of a parent material, and the technology perfectly solves the engineering anti-corrosive difficulties. The straight high-frequency pipeline pipe manufacturing technology has the advantages of high manufacturing efficiency, fast speed and low cost.

Owner:中冶辽宁德龙钢管有限公司

Method for smelting base metal of low phosphorous stainless steel by using low-grade limonite of containing nickel-chromium

ActiveCN101092656ARich sourcesLow priceBlast furnace detailsManufacturing convertersAdhesiveHigh pressure

This invention relates to a method for smelting low-phosphorus stainless steel base material from nickel and chrome-containing low-grade limonite. The method comprises: (1) pre-treating nickel and chrome-containing low-grade limonite via sieving, pulverizing and drying to obtain ore powder and ore blocks with different particle sizes, and mixing with fuel and flux to obtain sinter ore; (2) mixing various dedusted ashes, sintered return fines, and ore powder with an adhesive and a reductant, and passing into cold-pressed balls or carbon-containing balls under high pressure; (3) drying the carbon-containing balls, adding into a converter, and reducing to obtain pre-reduced balls; (4) mixing the sinter ore with partial ore blocks, the cold-pressed balls, the carbon-containing balls, the pre-reduced balls, the fuel, the flux and auxiliary materials, and smelting in a blast furnace to obtain molten nickel and chrome-containing alloy or molten iron; (5) mixing with the cold-pressed balls, the carbon-containing balls and the pre-reduced balls, and smelting in an electric furnace or a converter to reduce, decarbonizes, dephosphorize and obtain clean molten stainless steel base material that can be directly used in steel making; (6) casting with a continuous caster to obtain solid stainless steel base material that can be directly used in steel making. The method has such advantages as low cost, little pollution, abundant raw materials, high recovery rate of alloy elements, and few harmful elements.

Owner:前海索新发展科技(深圳)有限公司

Solid propping agent and its preparation method

The present invention relates to an improvement on solid supporting agent for deep-seated oil ang gas well fracture process, and is characterized by that it adopts kaoline and red mud as clay material, and increases its dose, so that on the premise of ensuring strength it can obviously reduce the apparent density of product, it not only is favorable for carrying construction of fracturing fluid, but also its volume dose is small, and can reduce use cost. Said ivnention adopts rotary kiln rolling dynamic firing process, its product can be uniformly fried, and its fried time is short.

Owner:宜兴东方石油支撑剂有限公司

Method of preparing bamboo wood complementary composite material

The present invention belongs to the technical field of artifical boards and composite materials. The present invention applies the following processing steps: the collection of bamboo materials, the processing of bamboo culms, the slicing of bamboo strips, the processing of bamboo filament, the processing of a bamboo filament curtain, the glue dipping of the bamboo filament curtain, the glue trickling and drying of the glue-dipped bamboo filament curtain, the peeling and slicing of wood veneers, the removal of wood scars, the production of glulam, the glue dipping and drying of the wood veneers, unidirectional bamboo-wood laminating assembly, pressing, etc. By utilizing the characteristics of bamboo and wood and the performance complementation of bamboo as the main material and wood as the auxiliary material, a high-quality composite material with an excellent performance and without inside defects is produced.

Owner:国际竹藤网络中心

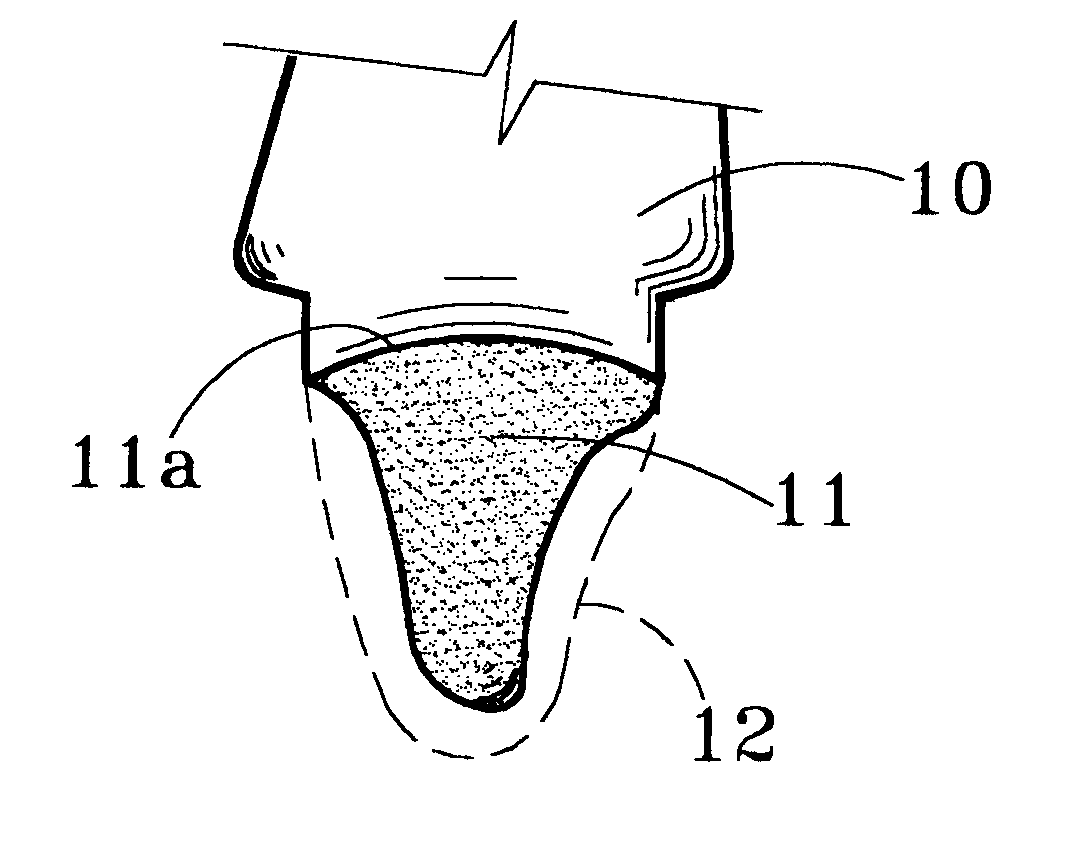

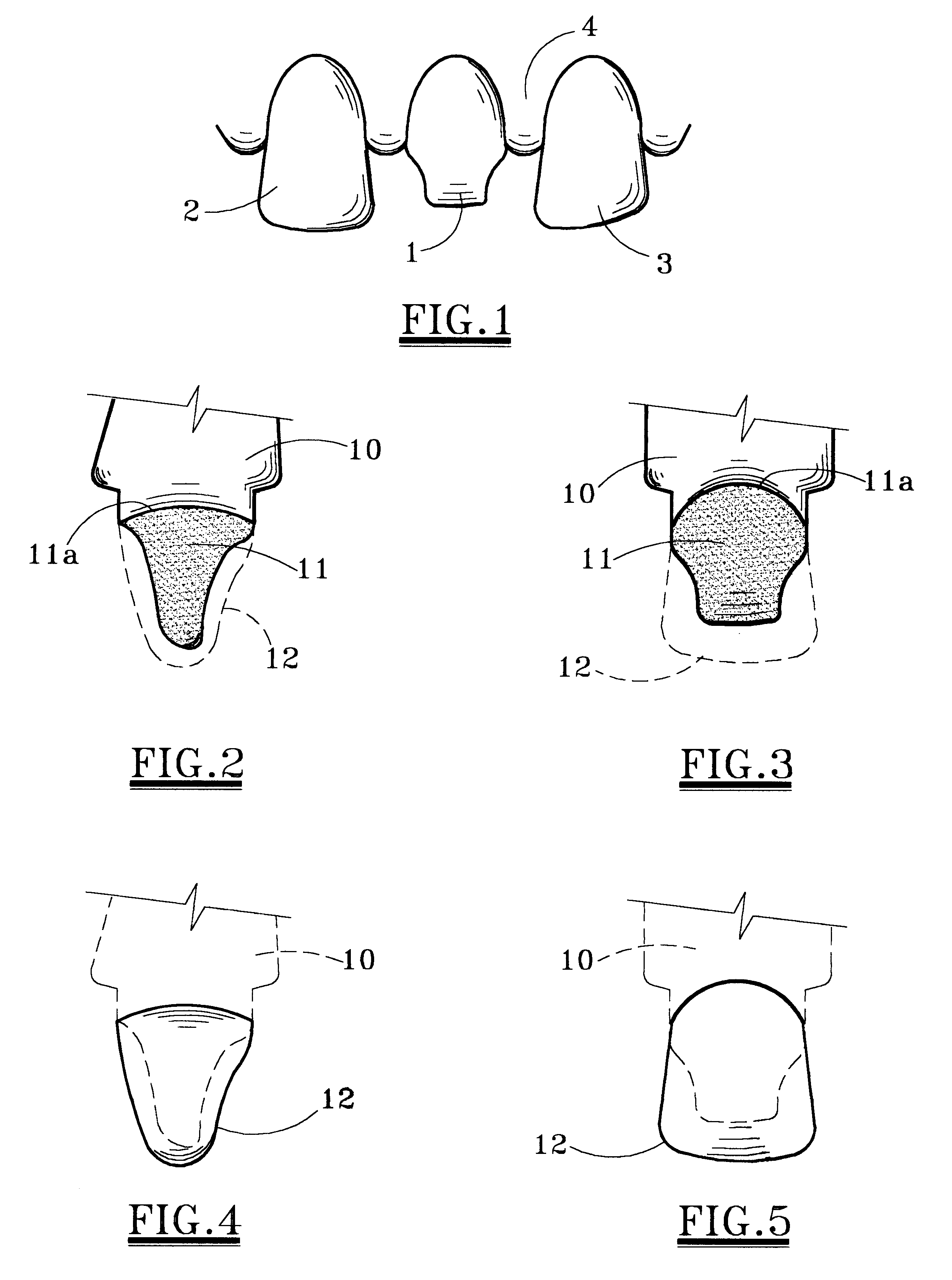

Method of forming tooth restoration

InactiveUS6361721B1Tendency for the porcelain to crack or debond will be eliminated or greatly reducedReduce incompatibilityOther chemical processesTooth crownsInvestment materialColloid

Refractory investment material and method for forming a positive replication of a tooth structure on which a high-alumina based porcelain tooth restoration is to be formed, the material being formed from a refractory powder which includes calcined alumina mixed with a liquid carrier comprising an aqueous colloidal dispersion of silicon dioxide. The method comprises the steps of: preparing a negative impression of the tooth structure on which a tooth restoration is to be placed; forming a positive replication of the tooth structure by pouring the mixture of refractory powder and aqueous dispersion into the negative impression; allowing the positive replication to harden; removing the positive replication from the negative impression for degassing and cooling; and coating the positive replication with a mixture of high-alumina porcelain in an aqueous carrier to form a core layer of porcelain on which subsequent layers of high-alumina porcelain may be applied.

Owner:STERN ALVIN L

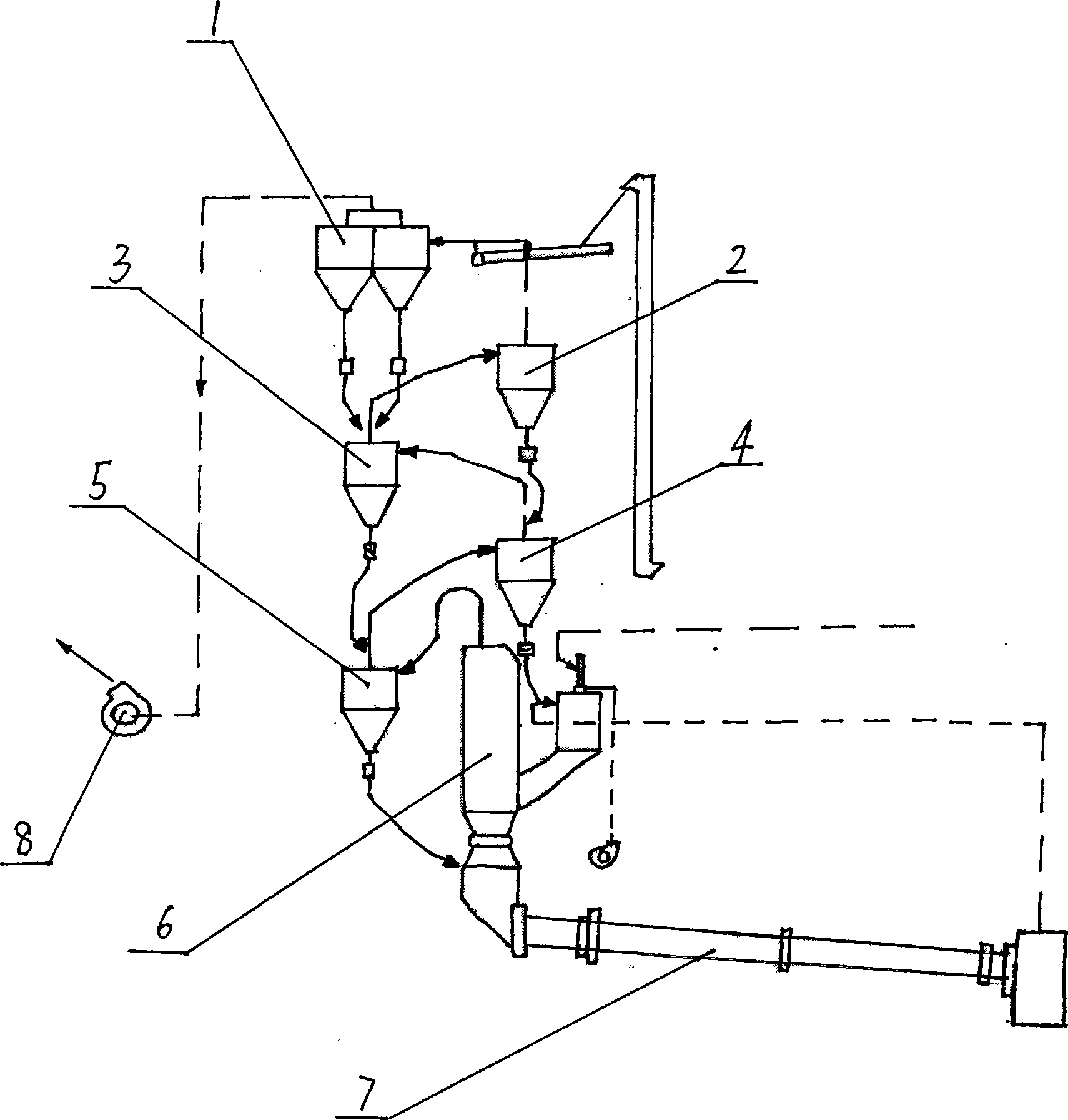

Technological process for producing cement clinker by dry burning carbide slag

The invention discloses a process method for manufacturing cement clinker through dry combustion of carbide slag. A mixture of the carbide slag subjected to drying and pulverizing treatment and an auxiliary material is used as a green stock and is gradually pyrolyzed by a five-stage cyclone preheater, wherein hot wind at a temperature of between 500 and 600 DEG C is supplied in a second-stage or a third-stage cyclone preheater to complete the decomposition of Ca(OH)2 into CaO; the green stock discharged from a discharge pipe of a fourth-stage cyclone preheater enters a decomposing furnace; the decomposing furnace is connected with a wind port for dispersing and rotating the green stock; the green stock and airflow burning in the decomposing furnace at a temperature of between 900 and 1,000 DEG C are fully mixed; the temperature of the green stock is further improved in order to gradually decompose a carbonate composition; and finally the green stock enters a rotary kiln and is calcined to form the cement clinker. By the method, the decomposition rate of the green stock of the carbide slag reaches between 90 and 95 percent; the specification and the length of the rotary kiln are not needed to amplify; thermal efficiency is high; and the system has stable operation.

Owner:HEFEI CEMENT RES DESIGN INST

Method for preparing grinding silk

InactiveCN101994167AExcellent productivityReduce wearOther chemical processesArtifical filament manufactureInvestment materialContact phase

The invention relates to a method for preparing a super-tough super-strong specific grinding silk. In the invention, the performance of a polyamide resin slice is adjusted through adjusting auxiliary materials, such as antioxidant, a flexibilizer and / or a reinforcing agent and the like, artificial diamond grinding particles subjected to coupling agent treatment is added to produce the grinding silk with excellent performance. A contact phase of the artificial diamond grinding particles subjected to the coupling agent treatment and the polyamide resin slice is solid-liquid blending by means of segment charging, so as to reduce the abrasion of a building-block type single screw rod extruder by using the artificial diamond grinding particles, and feed volumes are respectively regulated to obtain a plurality of grinding silks having the proportion content of grinding materials, so that the product meets the requirement on various trenchant use environment. The product developed by the process has the advantage of better grinding performance, and can be normally used in the environment of high temperature and acid base.

Owner:慈溪市洁达纳米复合材料有限公司

Manufacturing method of carbon fiber girder for fan blade

The invention relates to a manufacturing method of a carbon fiber girder for a fan blade, which is a carbon fiber vacuum pouring method. The manufacturing method comprises the following steps of: laying carbon fiber unidirectional cloth in a girder die according to the design requirement; laying a vacuum pouring auxiliary material according to the design requirement; carrying out sealing treatment by a carbon fiber girder covering vacuum bag; and vacuumizing, injecting glue and finally curing to obtain the carbon fiber girder. According to the invention, the method is simple and is convenient to operate; the production efficiency is effectively improved; the structure strength of a product is also ensured; and the appearance quality and the mechanical property of a composite material part are also ensured.

Owner:GUODIAN UNITED POWER TECH LIANYUNGANG CO LTD

Method of making hull of fishing boat and yacht with basalt fiber reinforced material

InactiveCN1421351AIncrease loading capacityReduce resistanceNon-magnetic metal hullsHeat stabilityFishing

The present invention is the method of making hull of fishing boat and yacht with basalt fiber reinforced material. The material used includes twist-less basalt rove or fabric, unsaturated polyester resin or epoxy resin, promoter and other supplementary material. The making process includes spreading the basalt material, spraying resin, curing, demolding and other steps. The basalt fiber has acidand alkali resistance, heat stability, tensile strength and other mechanical performance superior to those of common glass fiber. Making hull of fishing boat and yacht with basalt fiber reinforced material can result in improved performance and lowered cost.

Owner:周献刚 +1

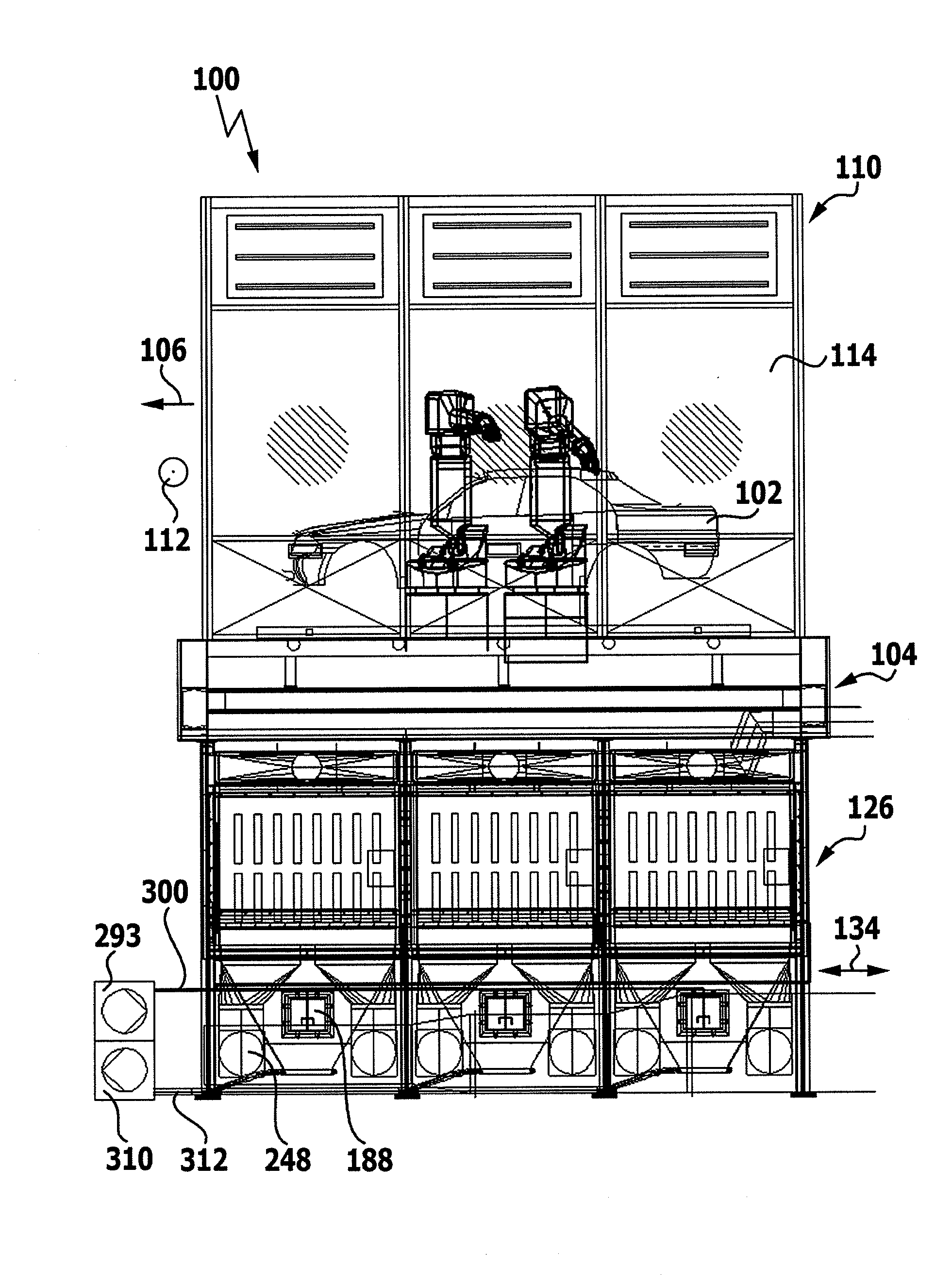

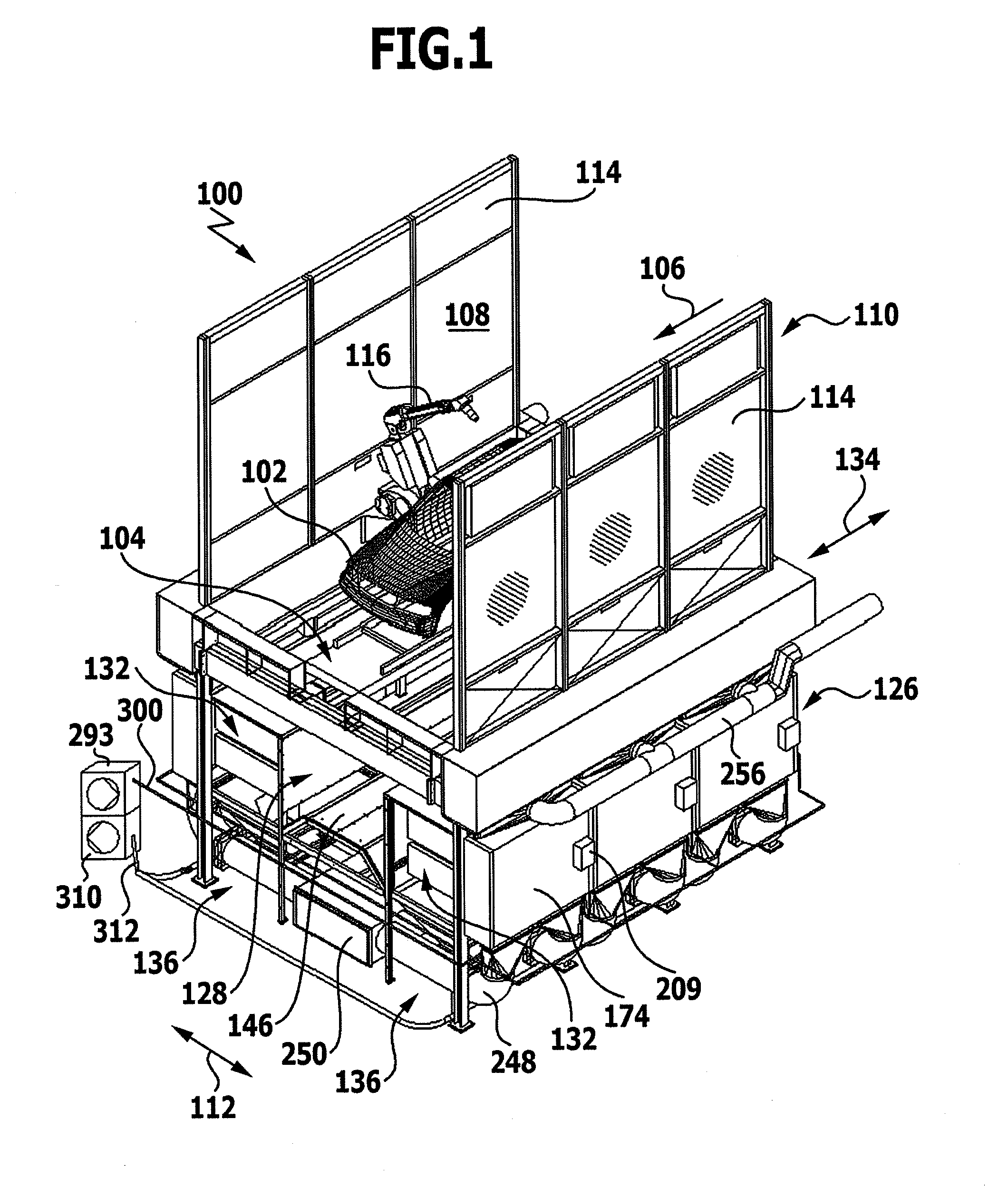

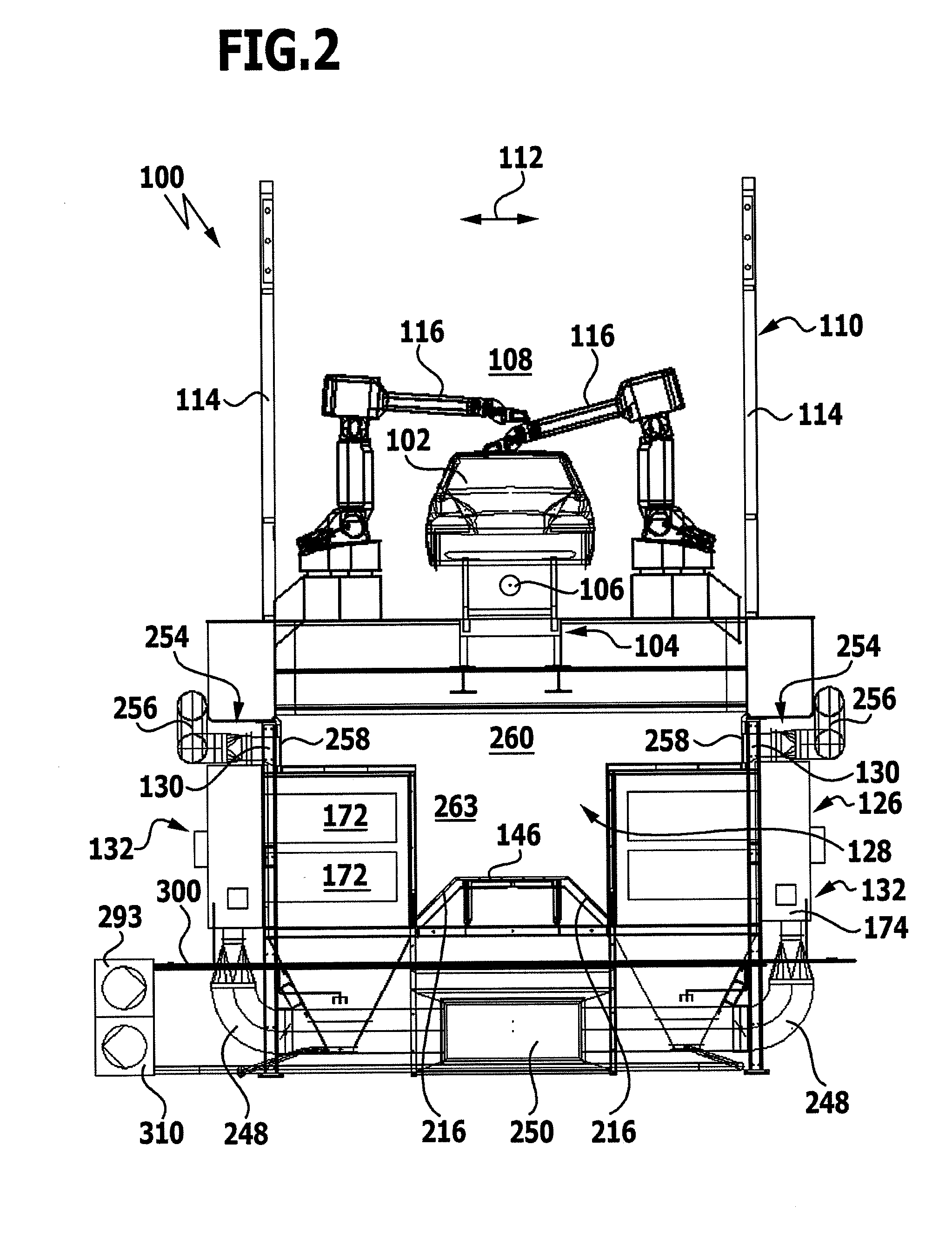

Method and apparatus for introducing auxiliary material

ActiveUS20100197213A1Avoid introducingReliable preventionLiquid surface applicatorsLiquid degasificationLacquerInvestment material

In order to provide a method of introducing auxiliary material into the flow path of a crude gas stream charged with wet-paint overspray before the crude gas stream passes through at least one filter element for separating the overspray from the crude gas stream, with which method an introduction of auxiliary material into the application region of a paint shop is reliably prevented even in the event of incorrect operation, a method is proposed, which comprises the following method steps: detecting whether there is an adequate crude gas flow through the at least one filter element; and blocking the introduction of auxiliary material into the flow path of the crude gas stream if it is determined that there is not an adequate crude gas flow.

Owner:DUERR SYST AG

Method for preparing series titanium-iron alloy by smelting titanium raw material

A method to produce a series of ferrotitanium by smelting the titanium material in Panxi area. The technology steps are as following: the titanium material in Panxi area, calcareous metallurgy accessories and calcium-sodium treatment reagent will be delivered into the revolving burner, they will be warm-up fast, and then will be delivered into blendor by connecting barn to be uniformly mixed. And then aluminium, iron system material, auxiliary reducers and potassium chlorate will be orderly added in from the batch bin, when the material and the auxiliary material in the blendor have been uniformly mixed, they will drop into the smelting furnace, which has been warmed up, by the connecting barn, the igniter will be added in, and the inhibiting agent will be added when the reaction get over for about 2-3 minutes, they will be cooled for 20-40h, and at last the residue and the ferrotitanium will be separated. The ferrotitanium product will enter warehouse after being checked and paclaged. The material source of this patent is assured, and the production technology is on the safe side, the product quality of the ferrotitanium made by it is stable, and it fulfills the different needs of all kinds of steel industry, so it the myth that the Panxi vanadium-titinium magnetite can not produce high ferrotitanium because the impurity of it is high, and it fills up the blank in our country.

Owner:攀枝花市银江金勇工贸有限责任公司

Production method of polyethylene terephthalate graft copolymerized resin and molded product thereof

The present invention provides a method of producing a polyethylene terephthalate graft copolymerized resin, comprising subjecting the following mixture to a homogeneous reaction at a temperature of 250° C. or higher to impart a high melt viscosity to the mixture, the mixture containing (A) 100 parts by weight of a polyethylene terephthalate polyester as a main material, (B) 0.01 to 2 parts by weight of a polymeric polyfunctional epoxy compound containing 7 to 100 epoxy groups in a molecule and having a molecular weight of 1,000 to 300,000 as a coupling agent, (C) 0.01 to 1 part by weight of a metal salt of an organic acid as a coupling reaction catalyst, and (D) 0 to 100 parts by weight of an aromatic alicyclic polyester and / or an aromatic aliphatic polyester each having a carboxyl group in an aromatic nucleus as an auxiliary material.

Owner:FTEX INC (JP)

Novel prescription of CSP diversion agent and preparation method thereof

InactiveCN1994624AStable thicknessProportionally largeMelt-holding vesselsInvestment materialGraphite

The invention relates to a guide agent and relative preparation, used in CSP smelt factory, wherein it uses chromic sand, quartz sand, magnesium sand, feldspar sand, and graphite, to be screened, mixed and dried. Compared with present guide agent, it has better sinter degree, stable thickness, and better high-temperature resistance, etc. And the test proves that its steel pack self-open rate can reach 98-100%.

Owner:XIXIA TONGYU METALLURGICAL PROTECTION MATERIAL

Method for enabling carbon fiber composite thick laminated structure to uniformly absorb resin and laminated structure

ActiveCN104401092ASolve the problem of uneven suctionEvenly distributedLaminationLamination apparatusAdhesiveInvestment material

The invention provides a method for enabling a carbon fiber composite thick laminated structure to uniformly absorb resin and a laminated structure. The method comprises the following steps: alternately laying prepreg layers and resin absorbing layers on the surface of a mould till a required thickness design value, and enabling the peripheries of the resin absorbing layers to go beyond a main body prepreg laminated plate; arranging a baffling strip as high as the laminated plate around the laminated plate, connecting the resin absorbing layers by using a breathable material, and enabling the breathable material to penetrate through the baffling strip to allow the resin absorbing layers to be communicated with an external air pumping system; laying auxiliary materials on the laminated plate sequentially, tightly sealing a vacuum bag by using sealing adhesive, and putting a whole system into a hot pressing tank for curing so as to obtain a laminated plate structure with uniformly distributed resin. Through the adoption of the method, the problem that resin cannot be uniformly absorbed in the thickness direction in the curing process of the prepreg laminated plate with the thickness being larger than 5mm is solved; the resin is uniformly distributed inside the obtained thick laminated plate; the thick laminated plate has small defects; fatigue resistance, impact toughness and other mechanical properties of the thick laminated plate are greatly improved.

Owner:HENGSHEN

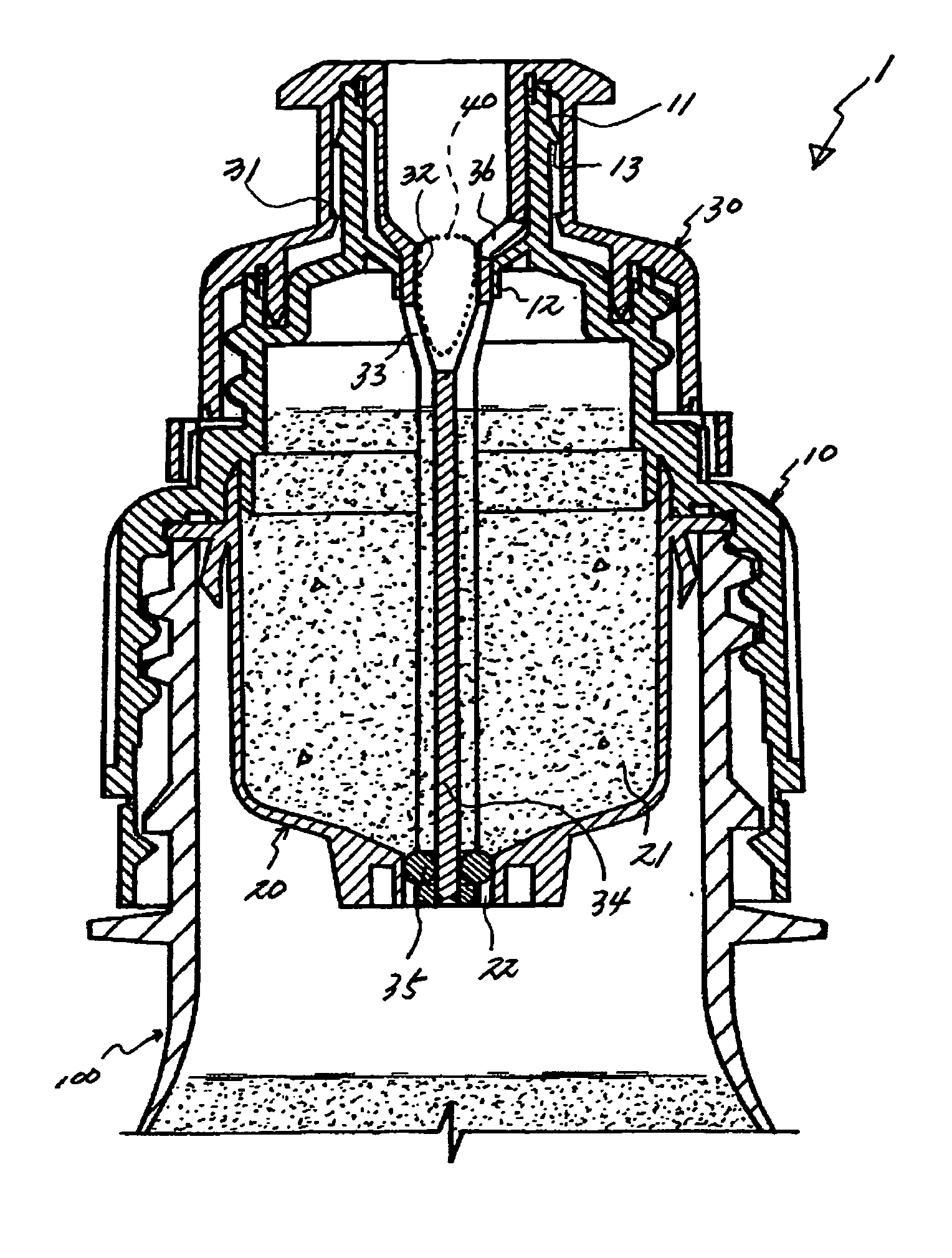

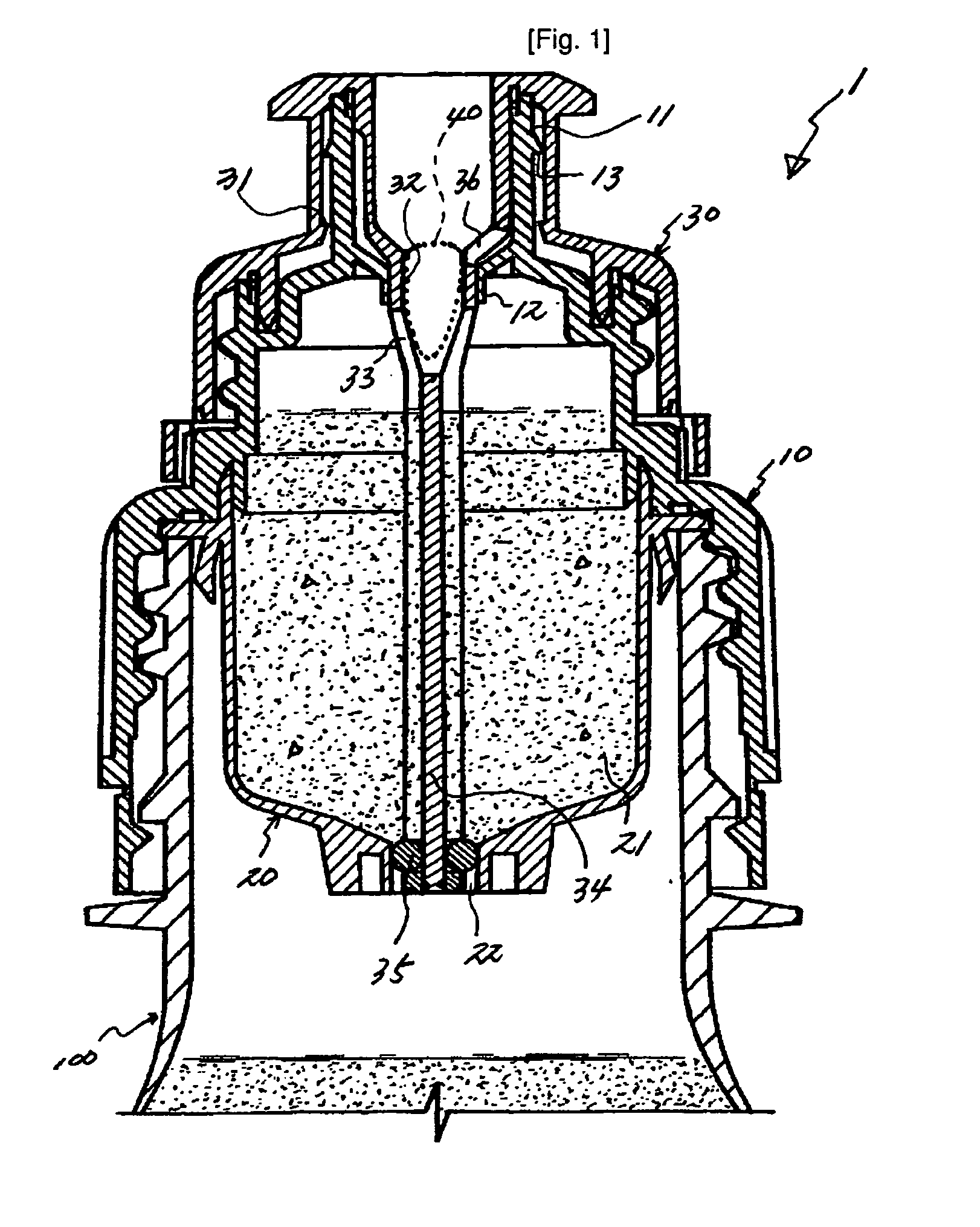

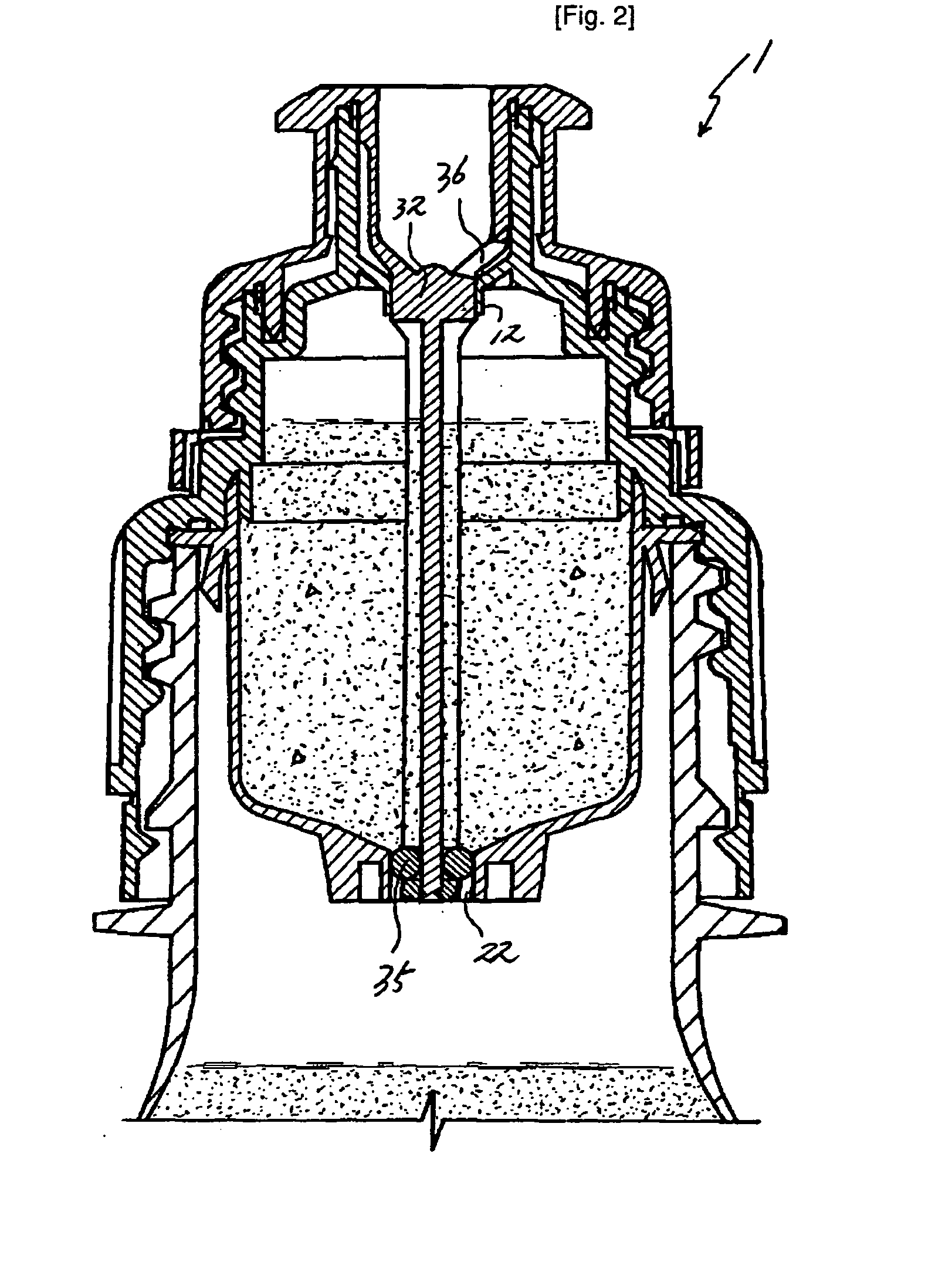

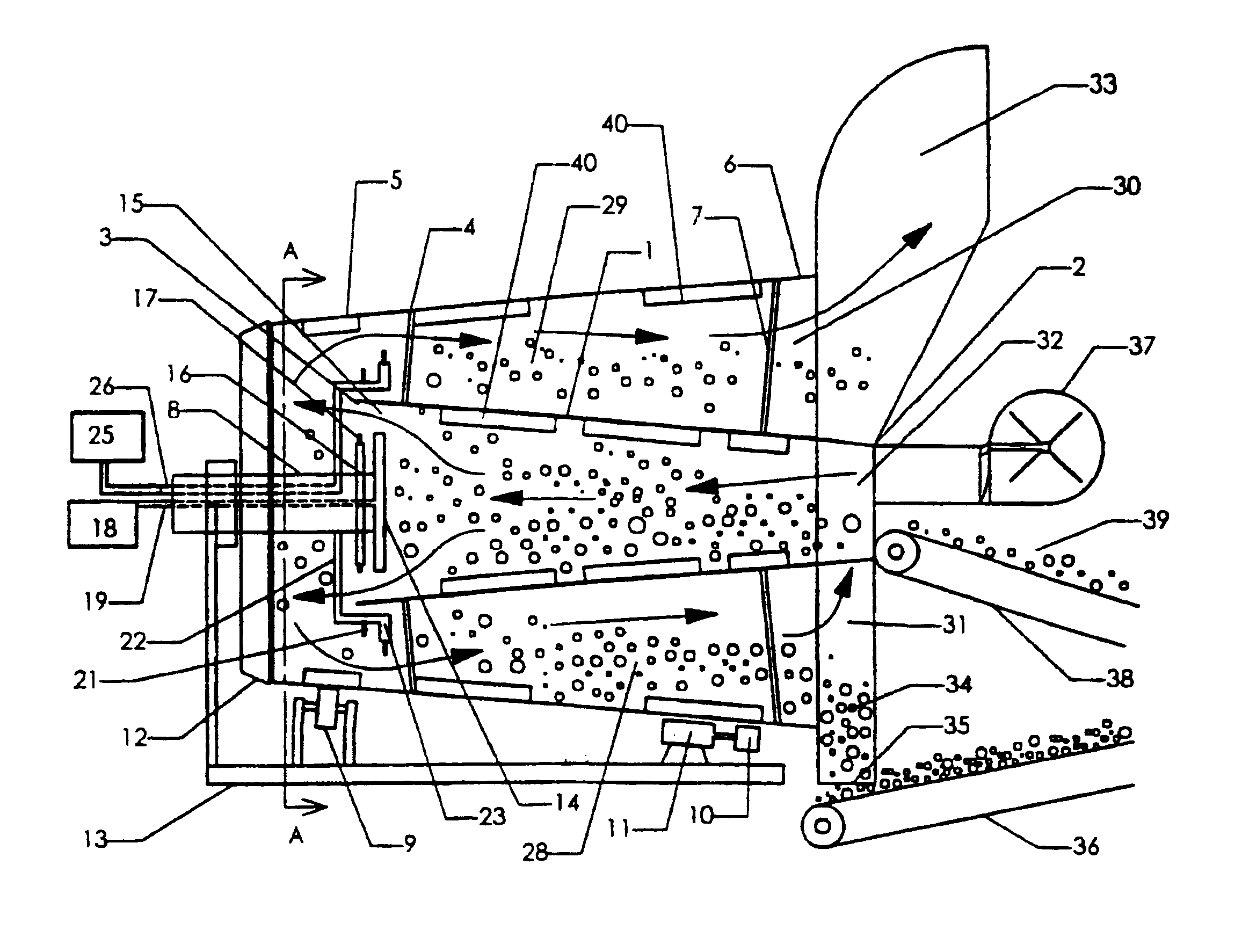

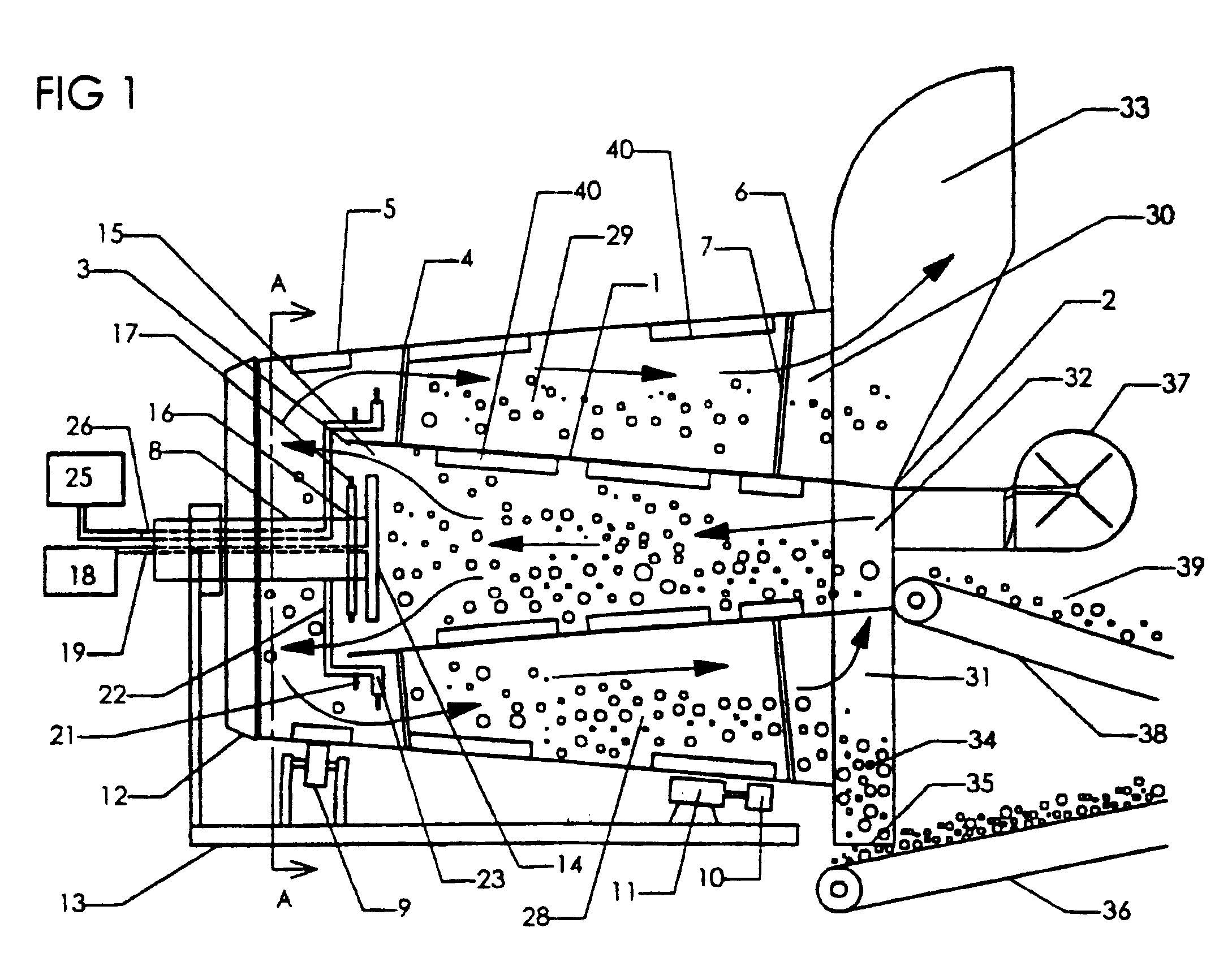

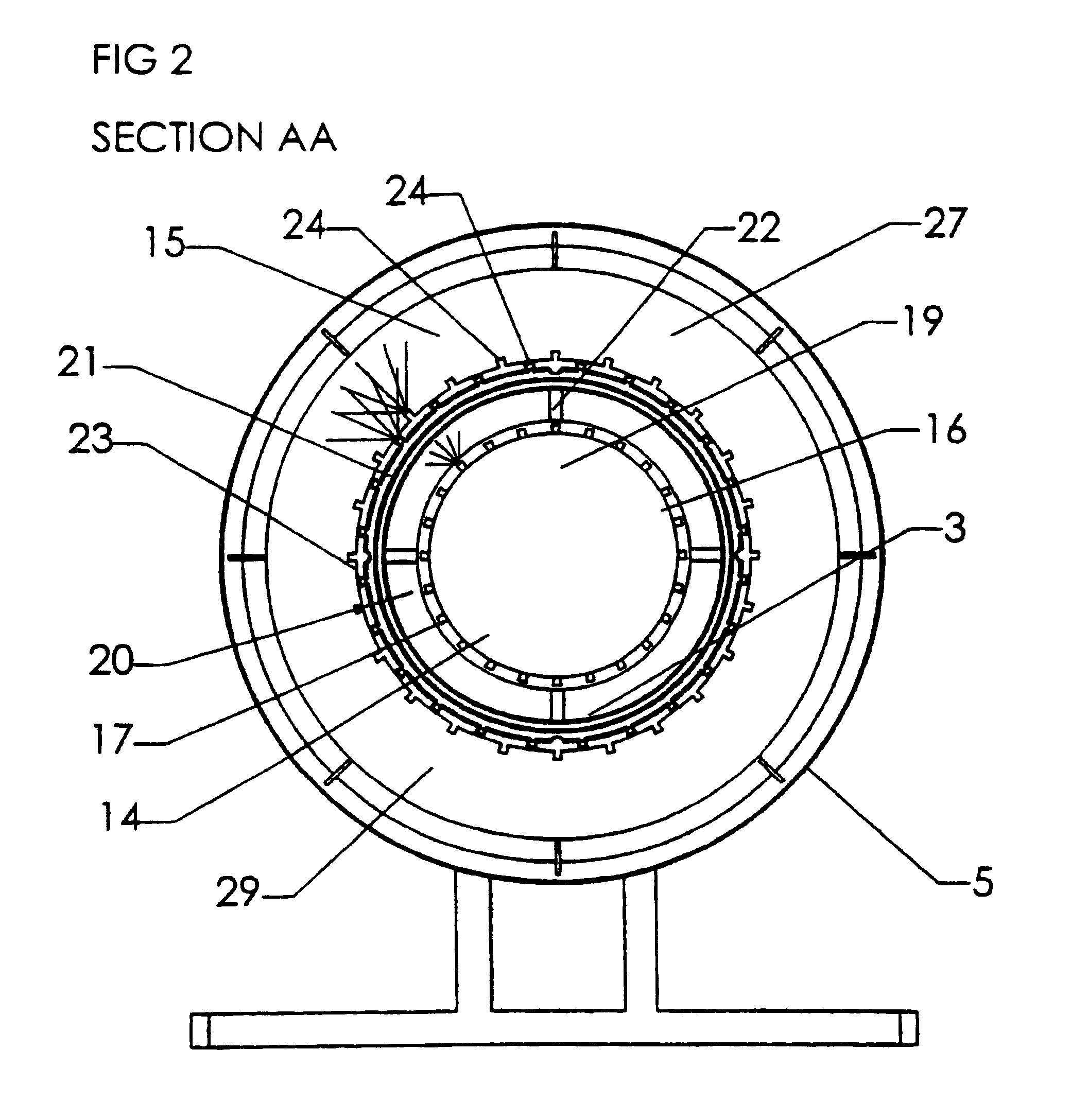

Multiple drum mixing system

InactiveUS6363625B1Reduce burnWell mixedBranding equipmentRotary drum furnacesImpellerInvestment material

A drying and mixing plant is provided comprising a tapered inner drum (1) and an oppositely tapered outer drum (4) attached together concentrically and rotated as a unit. A burner (37) directs a hot air stream into the small end (2) of the inner drum (1). Material is fed into the small end of the inner drum, where impellers (40) lift it and drop it into the hot air stream and move the material through the inner drum (1) aided by the downward taper of the inner drum. The material exits the inner drum and enters the outer drum (4) where an additive material is introduced and mixed with the material (42) as both move through the chamber (28) between the inner and outer drums to a material outlet. The receiving end (5) of the outer drum (4) is enclosed in a shroud (12), therefore the air stream is directed through the chamber (28) between the drums, the chamber having an expanding cross section which slows the air down allowing fines to precipitate out. The device may include nozzles (17) for spraying water across the path of the air stream and material flow, and further may include, for fluid additive materials, additive nozzles (21, 23) spraying the additive material across the path of the air and material. A third drum (43) may be provided inside the inner drum (1), allowing separate addition of a third material (47), and further reducing fines in the air. The device is particularly suitable for mixing asphalt paving mix.

Owner:NIEW INDS

Permeable fireproof materials for aluminium refining and process for preparing same

The invention discloses a poromeric fire-proof material and preparing method of refined aluminum, which comprises the following parts: 60-92 percent sintered compact calcium hexaluminate, 8-30 percent auxiliary material and 2.5-5.5 percent binder, wherein the auxiliary material is some or all of board-shaped corundum, electric melting white corundum, mild-clay, quartz, kyanite, chromium hemitrioxide green and zircon. The preparing method comprises the following steps: blending poromeric fire-proof material and binder completely; loading the material in the mould; placing the mould on the vibrating platform; pressurizing on the material at 10-20 ton; vibrating at 3-5 mm amplitude at 5-15 s; sintering at 1400-1700 deg.c.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

High-temperature wear-resisting ceramic composite fiber brake block

InactiveCN103122959AInhibition of devitrification changesImprove adhesionOther chemical processesFriction liningCeramic compositeBarium titanate

The invention relates to a high-temperature wear-resisting ceramic composite fiber brake block which is manufactured by processing framework materials and auxiliary materials through material mixing, mould pressing, hot press molding and solidification procedures, wherein the framework materials comprise bismaleimide modified phenolic resin, short aramid fiber, high-purity ceramic fiber, potassium titanate fiber, mineral fiber, barium titanate and nickel; the auxiliary materials comprise molybdenum sulfide and / or tin sulfide, graphite and / or coke, acrylonitrile-butadiene rubber, mica, zinc oxide, stearic acid, barium sulfate and 4010-type antiager. The high-temperature wear-resisting ceramic composite fiber brake block solves the problems existing in the prior brake blocks, can well avoid high-speed decay and high-temperature decay, has the advantages of being good in staibility and long in service life, and is a high-temperature wear-resisting ceramic composite fiber brake block which is low in noise, high in intensity and low in pollution.

Owner:山东金山汽配有限公司

Production of composite rubber track

A composite rubber racetrack is prepared from baypren, natural rubber, ethylene propylene rubber, the rubber powder made of used tyre, white carbon black, pottery clay, zinc oxide, stearic acid, naphthenic oil, dioctylester, flame retardant, ultraviolet absorbent and sulfurizing promoter through proportional mixing, adding sulfur, forming sheet, sticking the rubber liner made of regenerated rubber, sulfurizing, cutting for removing edges, grinding, examining and packing.

Owner:浙江绿环工程机械有限公司

Method for checking, correcting and compensating matching relationship of glued joint face between parts

InactiveCN101530890AGuaranteed bonding qualityGuarantee or improve bonding qualityMetal-working apparatusInvestment materialPressure sensitive

The invention provides a method for checking, correcting and compensating a matching relationship of a glued joint face between parts when a metal or a composite material component is subjected to bag-pressure glued joint, the method solves defect and problem that the surface of a non-gluing mould surface is uneven, the coating is subsided and the inner glued joint face is debonded when the metal and the composite material component are subjected to the glued joint. The inventive technical proposal comprises the steps of: at first, laying sequentially isolating thin films and pressure-sensitive plastics between the coating and a sandwich material and between the glued joint faces of the skeleton parts, and positioning the isolating thin films and the pressure-sensitive plastics, laying an auxiliary material of a vacuum-bag, then manufacturing the vacuum bag, simulating the pressure of the glued joint and pressing within a tank at low temperature; when the isolating thin films and pressure-sensitive plastics are out of the tank, checking the matching relationship between the parts, measuring deforming thickness of the pressure-sensitive plastics, and by means of the deformation of the pressure-sensitive plastics, checking the matching relationship of the glued joint face between parts in a quantized manner, and afterwards, in accordance with the quantized result of the proper, interferential or spaced matching relationship, correcting and compensating the matching situation, which causes the defects of the uneven surface of the non-gluing mould surface, the subsided coating and the debonded inner glued joint face in the glued joint parts, of the glued joint face between parts.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

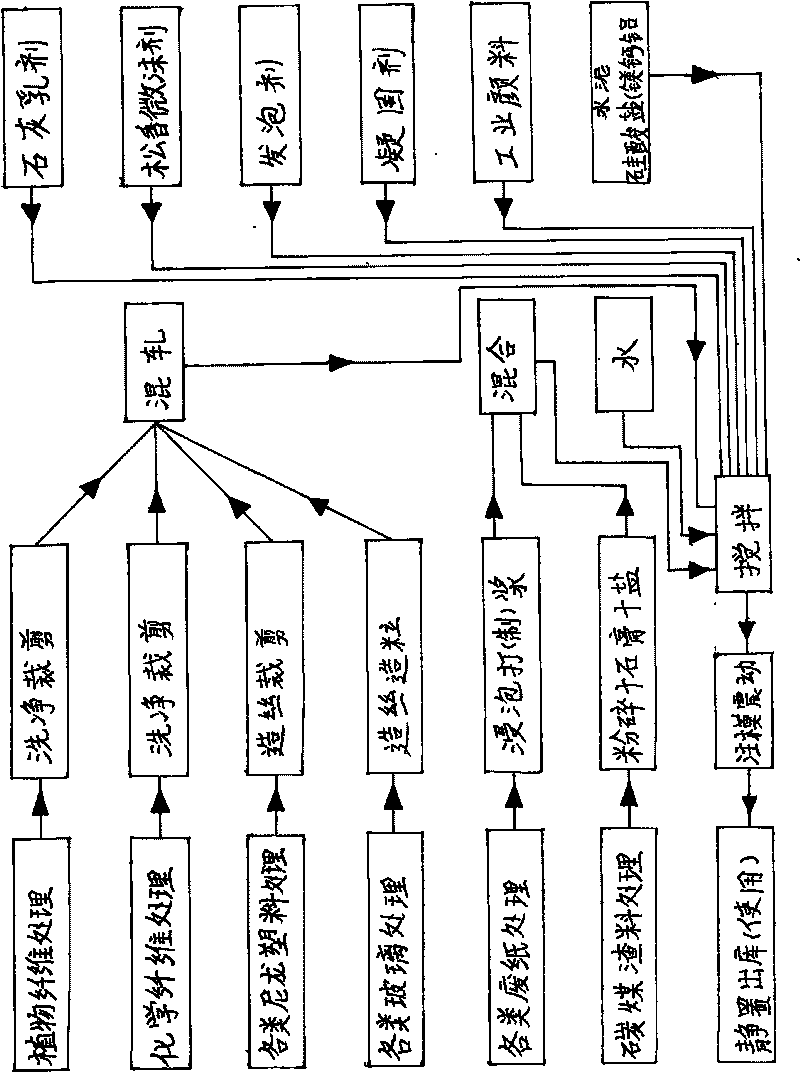

Technology for producing wall material by using waste

InactiveCN101723623ASave resourcesSave precious resourcesSolid waste managementHazardous substanceSlag

The invention discloses a technology for producing wall material (tile) by using waste. The invention comprises base material (calcium, magnesium, aluminum, silicon, acid, salt) cement and water and filler (chemical fiber, vegetable fiber, asbestos, glass fiber, carbonaceous coal slag, paper pulp and the like) and auxiliary materials (gypsum powder, salt, lime emulsion, rosin foam micronizing agent, foaming agent, coagulator, industrial pigment and other additive auxiliary materials needed by actual function). The invention is characterized by 1. burning-free property; 2. utilization of waste products; 3. usage of pouring into wall body or other objects by size or other raw materials, or producing into tile and other products; 4. greatly enhanced physical strength; 5. heat and voice insulation; 6. light mass and easy processing and trimming; 7. saving large quantities of clay (land) resources; 8. no three-waste pollution and energy saving; 9. purification of environment: materials such as waste plastic, rubber, nylon and the like can be buried underground for 200 years, and vegetable fiber and glass can be buried underground for 100 years, the material can slowly release toxic and harmful substances to cause the land where the materials are buried to lose use function permanently; 10. flexible formula proportioning and auxiliary material types according to actual requirements; and 11. simple and scientific technique, and easy implementation.

Owner:董四清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com