Method for preparing non-woven fabric polishing abrasive tool with high abrasion resistance

A high wear-resistant and abrasive technology, applied in grinding/polishing equipment, grinding devices, manufacturing tools, etc., can solve the problems of complex manufacturing process and high equipment requirements, achieve simple preparation method, good toughness, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

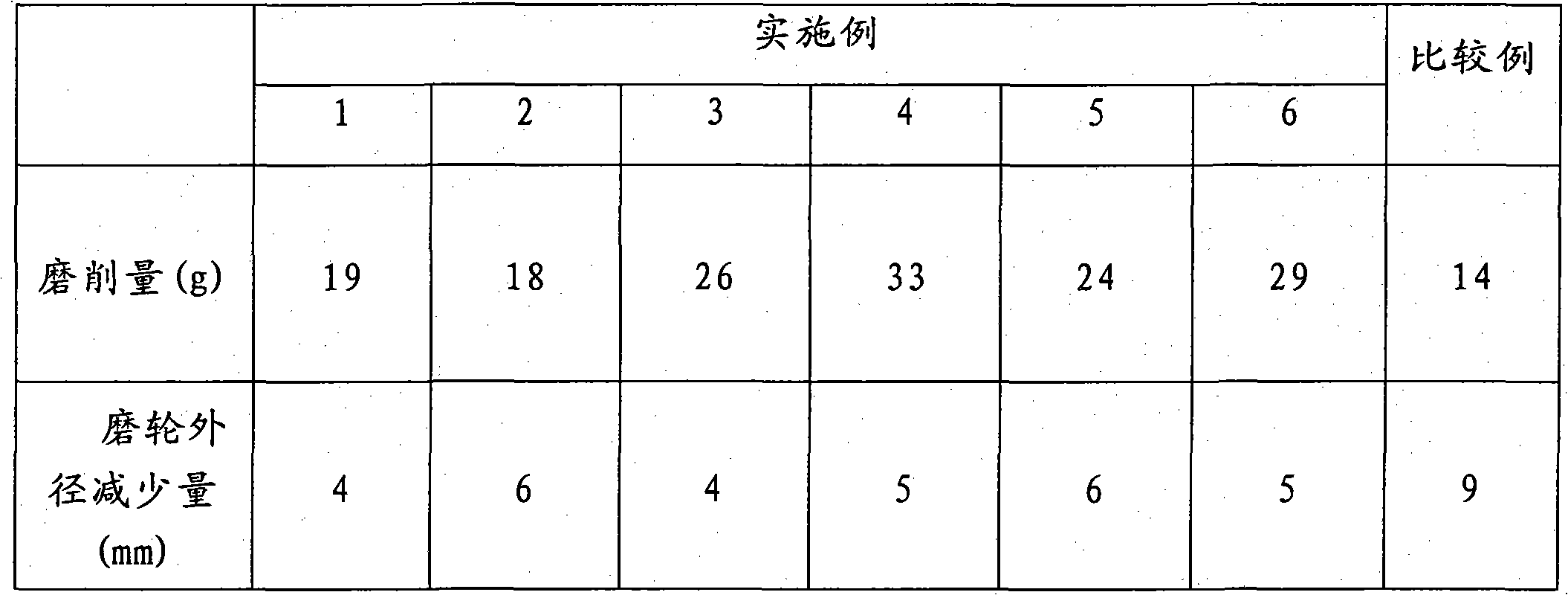

Examples

Embodiment 1

[0030] The first step is based on parts by mass, take 25 parts of epoxy resin, add 15 parts of polyamide 651, 20 parts of silicon carbide with a particle size of 200-1800 mesh, 10 parts of Hainan sand with a particle size of 200-1800 mesh, and 7 parts with a particle size of 200 -1800 mesh white corundum, 5 parts of nano-silica with a particle size of 20-350nm, 8 parts of industrial ethanol, 2 parts of magnesium stearate, 2 parts of wax powder of model TF-1780 (particle size of 0.5-70μm) , 1 part of silane coupling agent γ-aminopropyl triethoxysilane KH550, 0.5 part of phthalocyanine green, 4 parts of reactive epoxy toughening agent CYH-277, 0.5 part of accelerator 2,4,6-tri( Dimethylaminomethyl)phenol DMP-30, uniformly stirred at room temperature to prepare an oil phase slurry;

[0031] In the second step, the oil phase slurry obtained in the first step is added to the spraying machine, and the PP non-woven fabric (with a density of 50g / cm 3 ) Spray on both sides, the amount of ...

Embodiment 2

[0034] The first step is based on parts by mass, take 25 parts of epoxy resin, add 10 parts of methyl tetrahydrophthalic anhydride (MeTHPA), 20 parts of silicon carbide with a particle size of 200-1800 mesh, and 10 parts with a particle size of 200-1800 Purpose Hainan sand, 7 parts white corundum with a particle size of 200-1800 mesh, 10 parts industrial ethanol, 5 parts acetone, 1 part magnesium stearate, 3 parts model TF-1830 wax powder (particle size 0.5-70μm), 1 part of silane coupling agent γ-aminopropyl triethoxysilane KH550, 2 parts of chromium oxide green, 4 parts of reactive epoxy toughening agent CYH-277, 2 parts of accelerator 2,4,6-tri(two (Methylaminomethyl)phenol DMP-30, stir uniformly at room temperature to prepare an oil phase slurry;

[0035] In the second step, the oil phase slurry obtained in the first step is added to the spraying machine, and the PE type non-woven fabric (with a density of 100g / cm 3 ) Spraying on both sides, the spraying amount is 30% of the ...

Embodiment 3

[0038] The first step is based on parts by mass, take 35 parts of epoxy resin, add 15 parts of polyamide 651, 5 parts of 4,4'-diaminodiphenylmethane, 15 parts of silicon carbide with a particle size of 200-1800 mesh, 7 parts White corundum with particle size of 200-1800 mesh, 3 parts of nano-silica with particle size of 20-350nm, 6 parts of industrial ethanol, 2 parts of dimethyl carbonate, 1 part of magnesium stearate, 1 part of model TF-1778 Wax powder (particle size 0.5-70μm), 0.5 part of silane coupling agent γ-aminopropyltriethoxysilane KH550, 0.5 part of γ-glycidoxypropyltrimethoxysilane KH560, 1 part of γ-( Methacryloxy) propyl trimethoxysilane KH570, 0.5 parts of chromium oxide green, 7 parts of reactive epoxy toughening agent CYH-277, 0.5 parts of accelerator 2,4,6-tris(dimethylaminomethyl) (Base) phenol DMP-30, stir uniformly at room temperature to prepare an oil phase slurry;

[0039] In the second step, the oil phase slurry obtained in the first step is added to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com