Patents

Literature

13504 results about "Accelerant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Accelerants are substances that can bond, mix or disturb another substance and cause an increase in the speed of a natural, or artificial chemical process. Accelerants play a major role in chemistry—most chemical reactions can be hastened with an accelerant. Accelerants alter a chemical bond, speed up a chemical process, or bring organisms back to homeostasis. Accelerants are not necessarily catalysts as they may be consumed by the process.

Cement compositions with improved corrosion resistance and methods of cementing in subterranean formations

InactiveUS6904971B2Improve corrosion resistanceSolid waste managementDrilling compositionPhosphateSlurry

Owner:HALLIBURTON ENERGY SERVICES INC

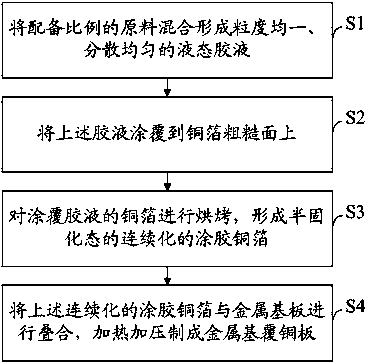

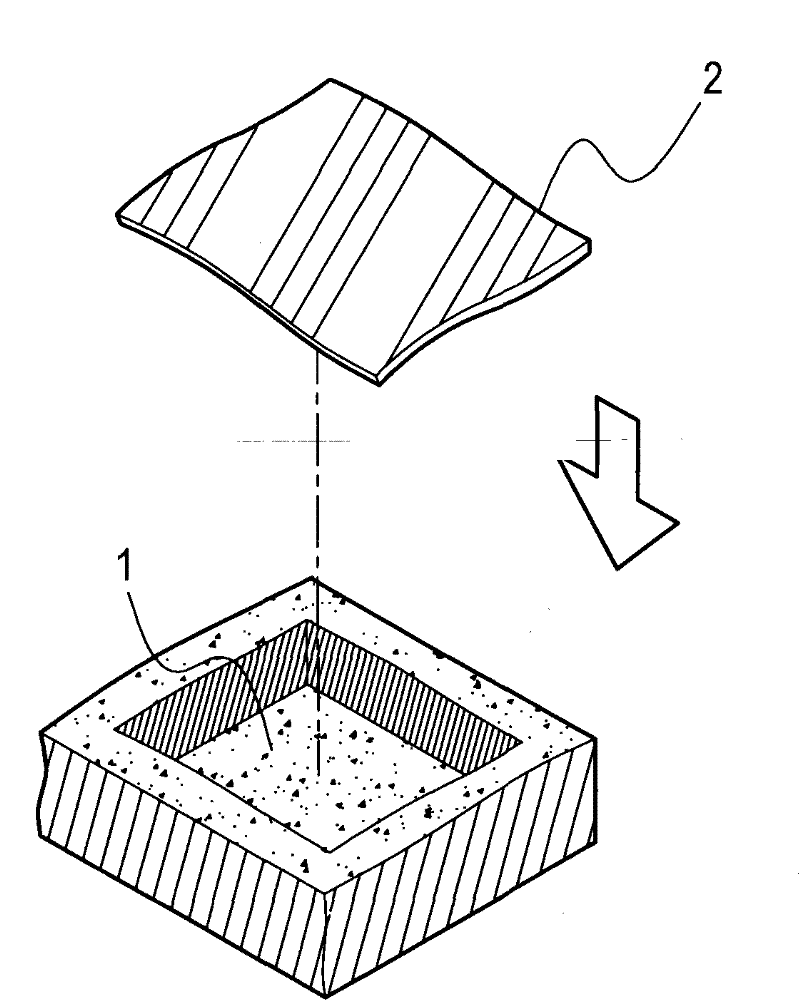

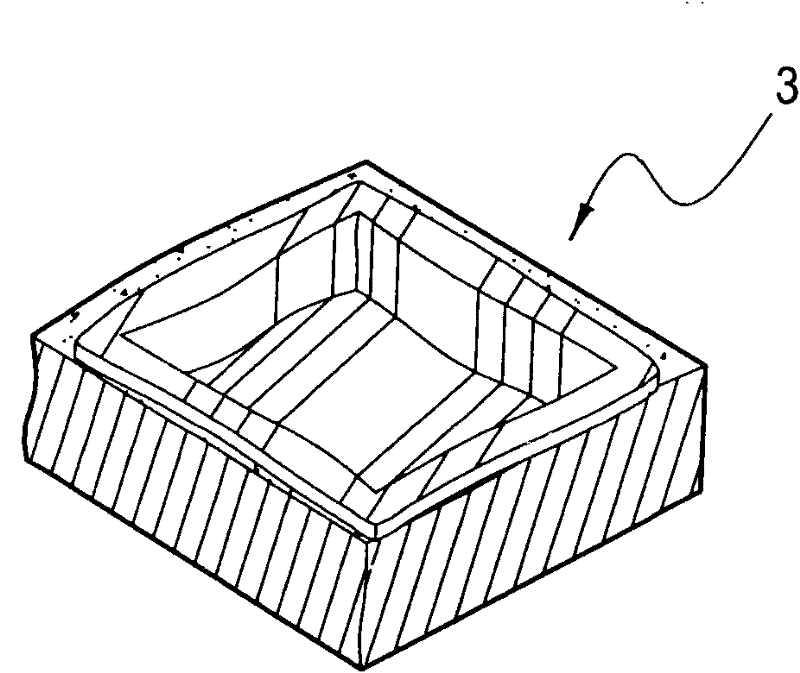

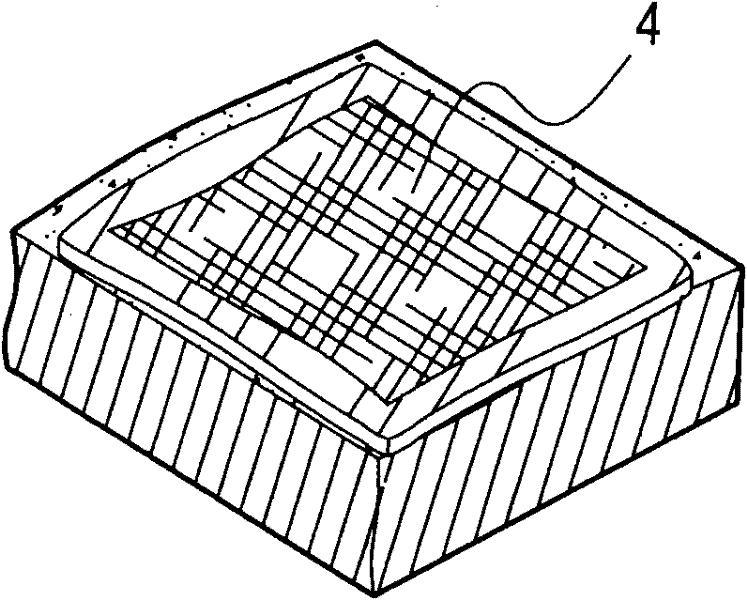

Epoxy resin composition, metal-based copper-clad plate and manufacturing method thereof

ActiveCN103694644AHigh thermal conductivityImprove thermal conductivityFilm/foil adhesivesLaminationEpoxyOrganic solvent

The invention discloses an epoxy resin composition, a metal-based copper-clad plate and a manufacturing method thereof. The epoxy resin composition comprises the following components by mass: 90-110 parts of epoxy resin, 10-50 parts of thermoplastic resin, 1-100 parts of a curing agent, 0.05-5 parts of a curing accelerant, 1-10 parts of an additive, 20-500 parts of heat conduction filler and 0-30 parts of an organic solvent. The metal-based copper-clad plate has the characteristic that 1, the heat conductivity is high; 2, the insulation property is high as the puncture-withstand voltage is higher than 6KV; 3, the anti-bending property is high, so that the metal-based copper-clad plate can be used for manufacturing a three-dimensional aluminum substrate; 4, the thickness of the insulation layer is uniform, the coating thickness tolerance can be controlled at + / - 2 microns, and the press-fit thickness tolerance can be controlled at + / - 5 microns, so that the performance of a product can be guaranteed; 5, the production efficiency is high; 6, the cost is low and is about 1 / 4-1 / 3 of the cost of an imported product.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

Organic cultivation medium and application method thereof

InactiveCN102217469ARefined grain structurePromote proliferationPlant cultivationCultivating equipmentsRoot growthSludge

The invention discloses an organic cultivation medium and an application method thereof. The organic cultivation medium is formed by fermenting a mixture comprising organic wastes (comprising straws, animal manures and organic garbage), sludge soil (urban sludge and substrate sludge of rivers and lakes) and composite soil microorganism preparations. The organic cultivation medium can be applied to plant and crop planting, and can be mixed with microelements, water-retaining agents and root-growth accelerants according to proportions in accordance with the nutrition requirement characteristics of plants and crops to form organic soil with common soil, and then the organic soil can be arranged in a manual anti-leakage cultivation slot or a specific container cultivation system to cultivate crops, vegetables and fruits, flowers or Chinese herbal medicine plants, etc.

Owner:陆振冈 +1

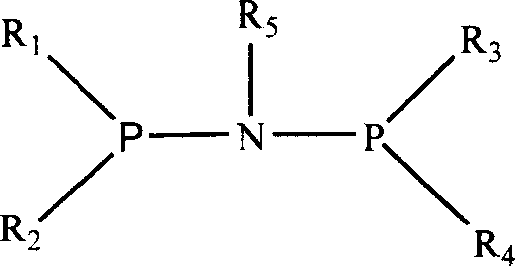

Catalyst composition of ethylene oligomerization and the application

ActiveCN101032695AHigh activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionAryl1-Octene

The present invention relates to catalyst composition for oligomerizing ethylene and its application. The catalyst composition includes complex of acetylacetone chromium, tetrahydrofuran chromium chloride and / or chromium isooctanate; ligand containing P and N; activator of methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; and promoter of X1R6X2, where, each of X1 and X2 is F, Cl, Br, I or alkoxyl, and R6 is alkyl or aryl group; with the molar ratio of the complex, the ligand, the activator and the promoter being 1 to 0.5-10 to 50-3000 to 0.5-10. The catalyst composition is used in oligomerizing reaction of ethylene to prepare 1-octene, and has high catalytic activity and high 1-octene selectivity.

Owner:PETROCHINA CO LTD

Multimetal oxide materials

Owner:BASF SE

Poly alcohol-based binder composition

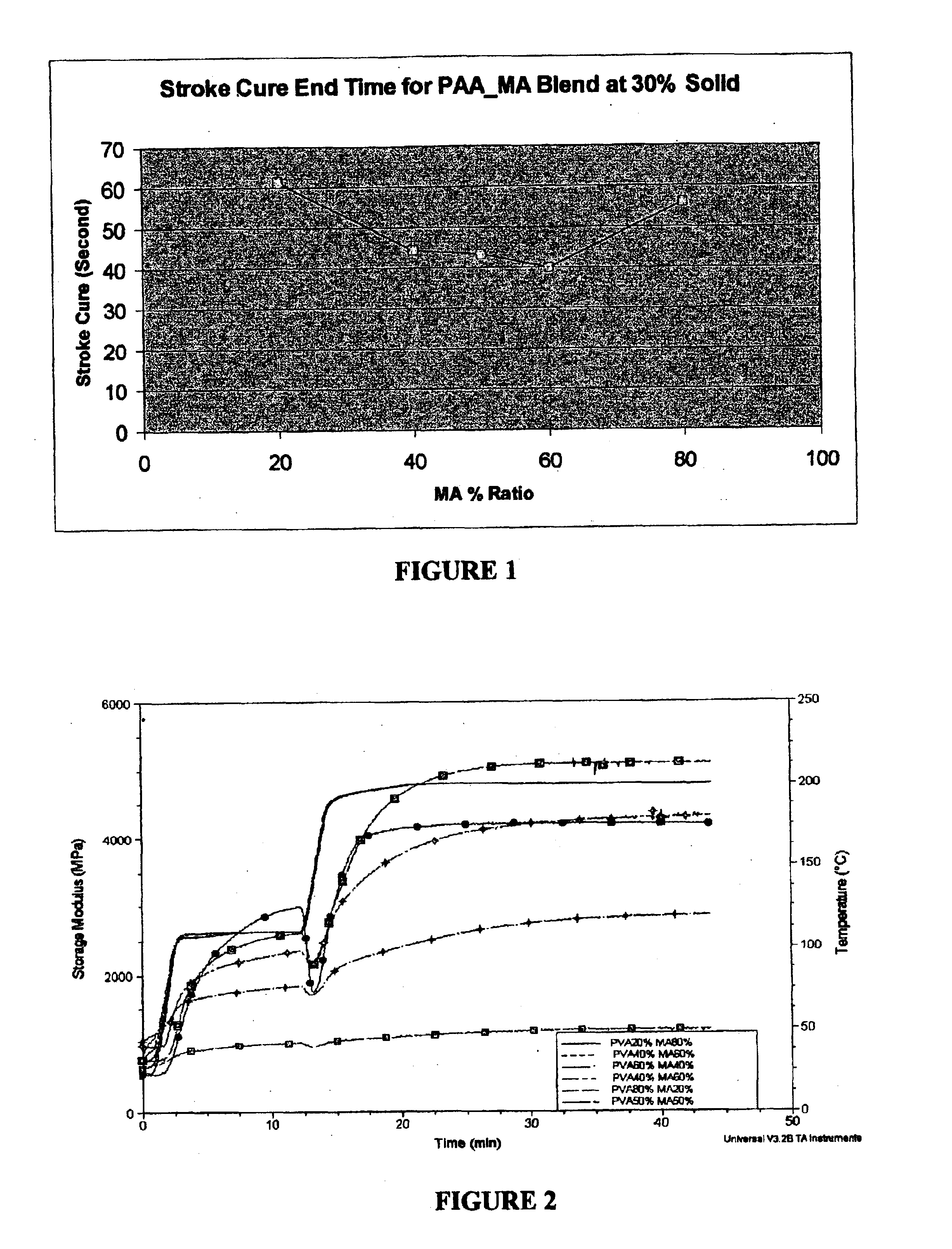

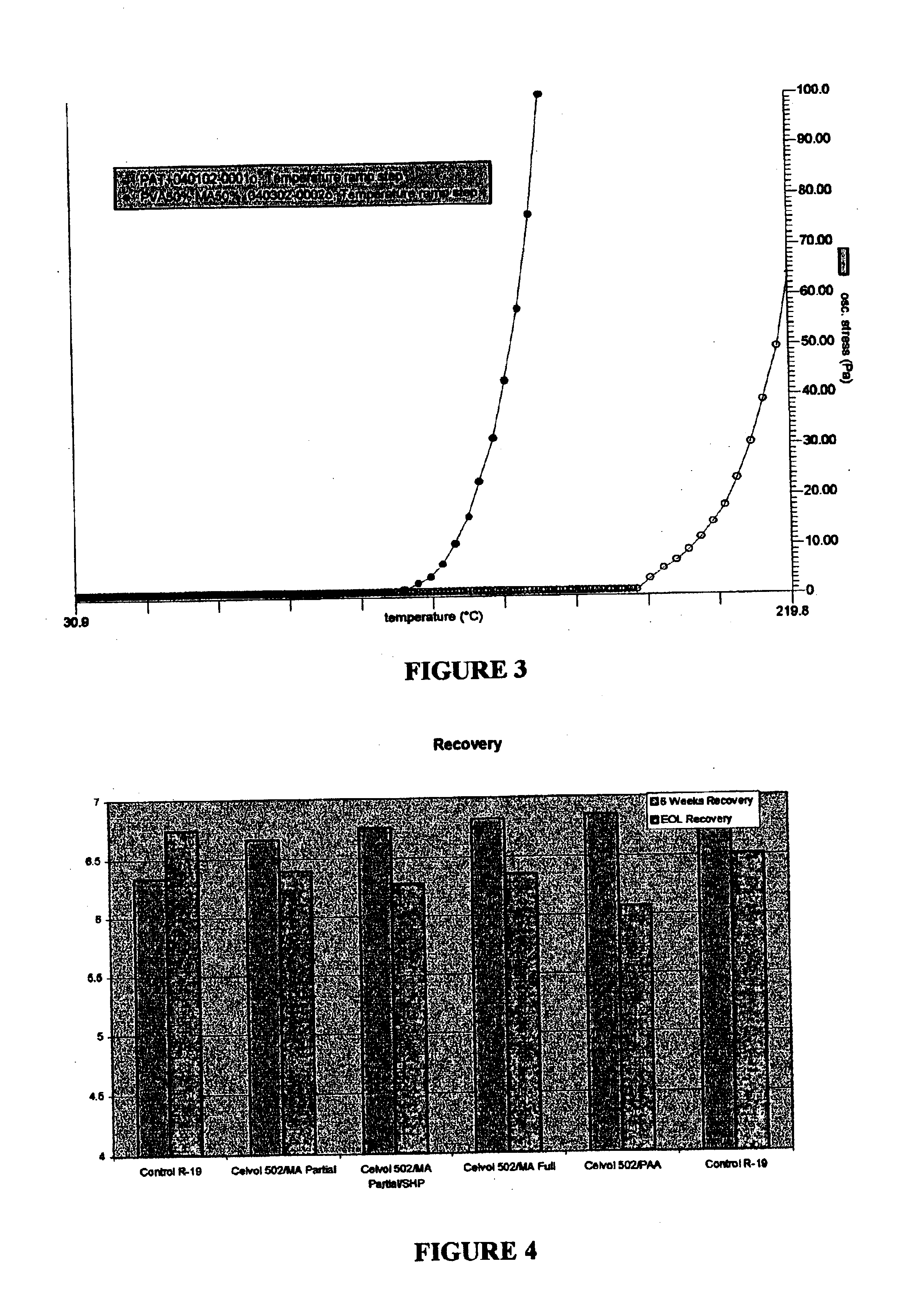

InactiveUS6884849B2Improve curing effectEmission reductionNon-fibrous pulp additionSynthetic resin layered productsAlcoholCarboxylic acid

The present invention provides a binder composition comprising a low molecular weight polycarboxylic acid, such as maleic anhydride, and a low molecular weight poly alcohol, such as polyvinyl alcohol, that exhibits improved cure performance with reduced emissions without sacrificing the performance of the final product or complication the manufacturing process. The binder composition may also incorporate a cure catalyst or accelerant such as sodium hypophosphite.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

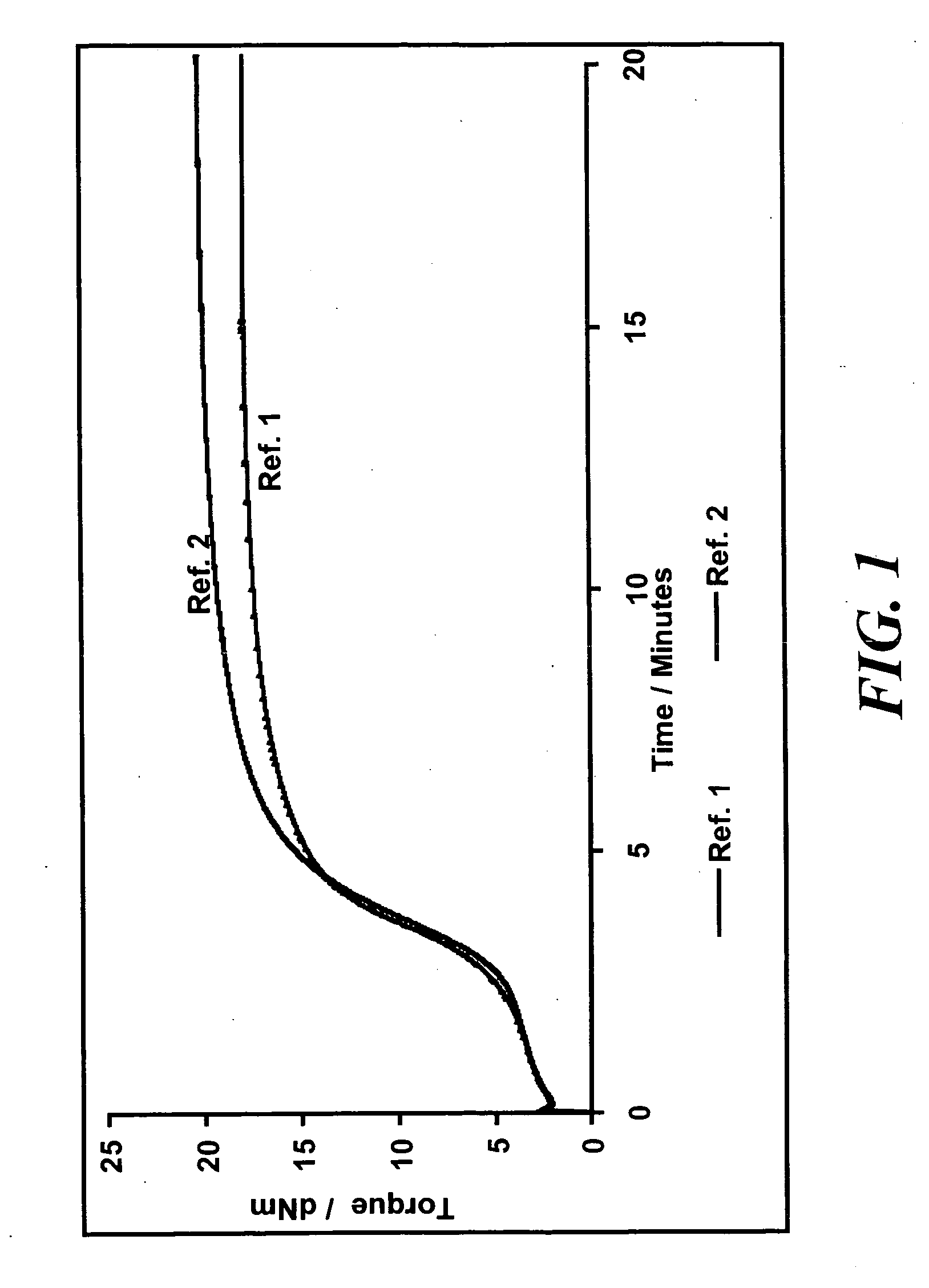

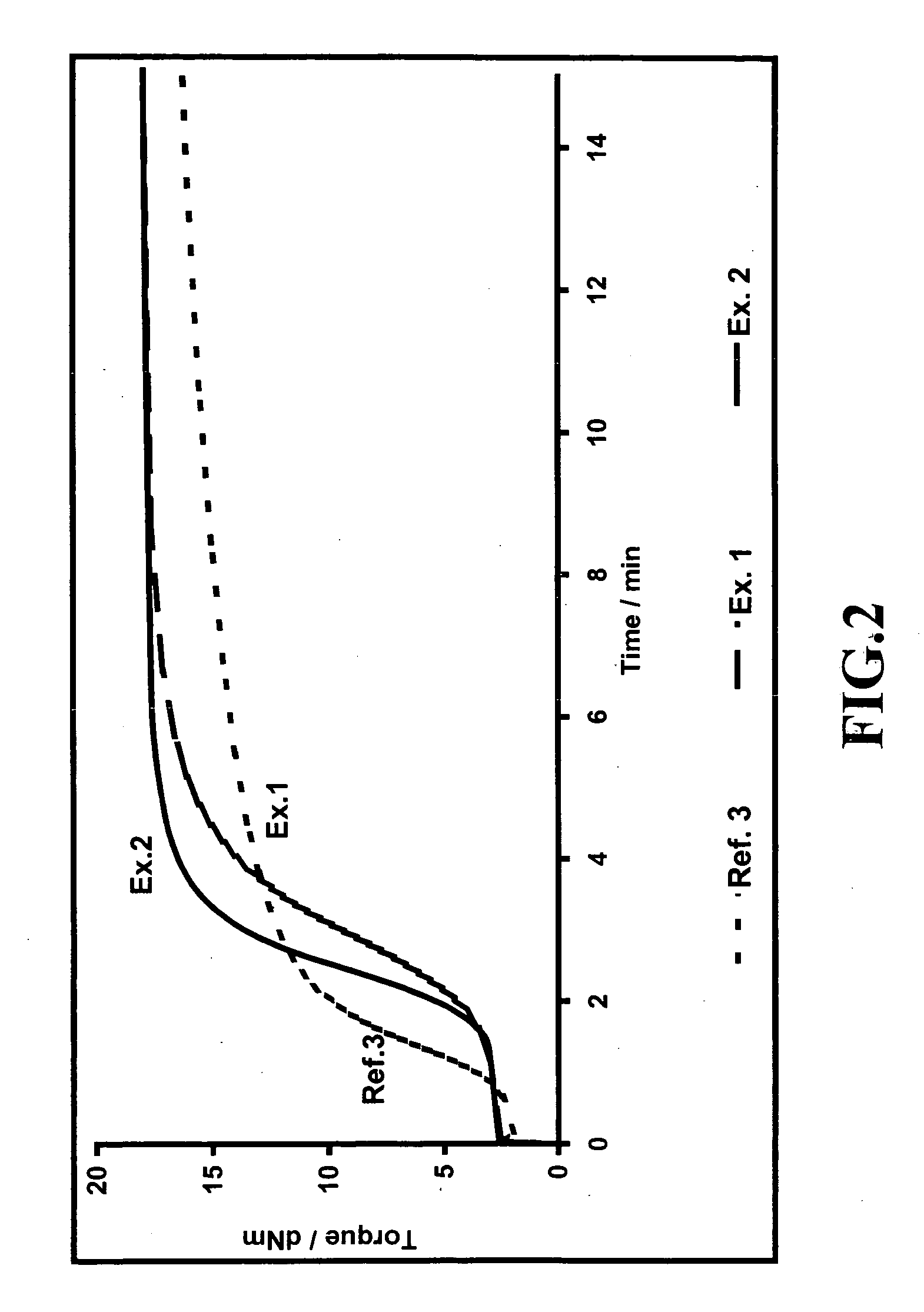

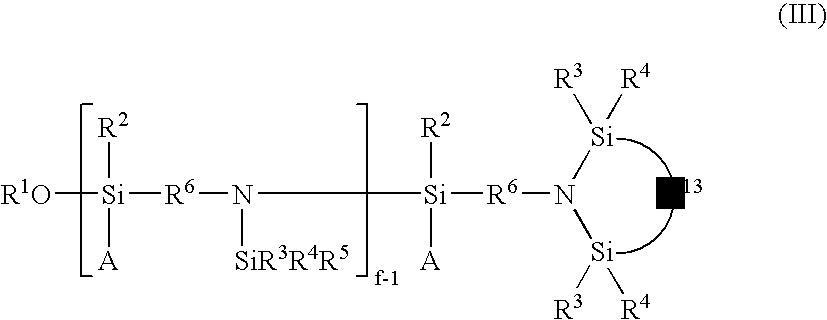

Rubber mixtures

A rubber mixture which exhibits reliable processability contains (A) a rubber or mixture of rubbers, (B) a filler, (C) at least one organosilane, (D) a thiuram accelerator, and (E) a nitrogen-containing co-activator. A weight ratio of thiuram accelerator (D) to nitrogen-containing co-activator (E) is equal to or greater than 1.

Owner:EVONIK DEGUSSA GMBH

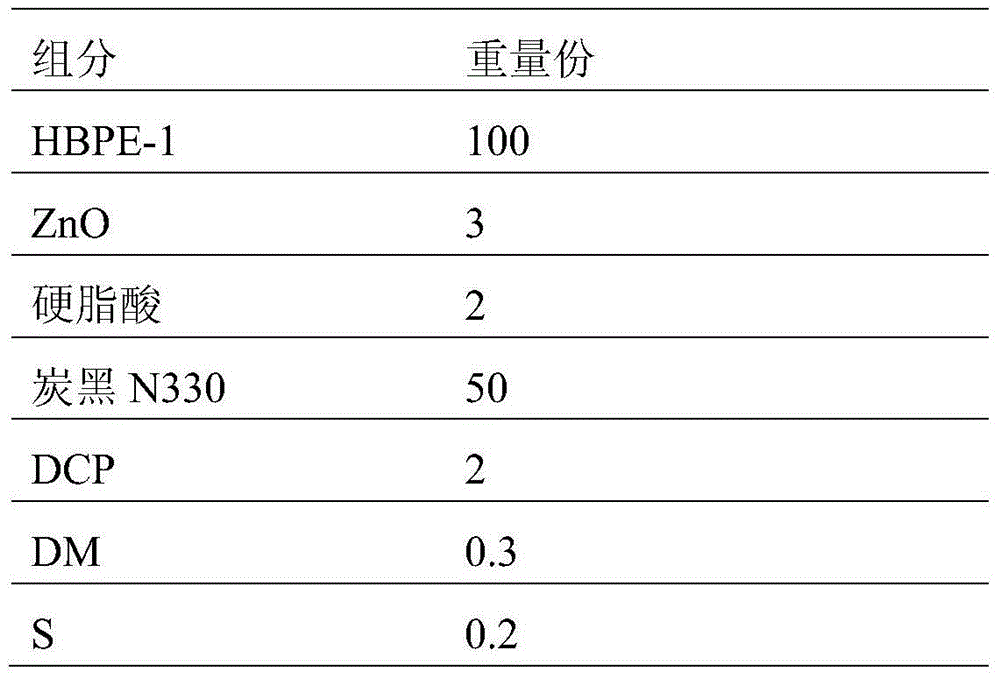

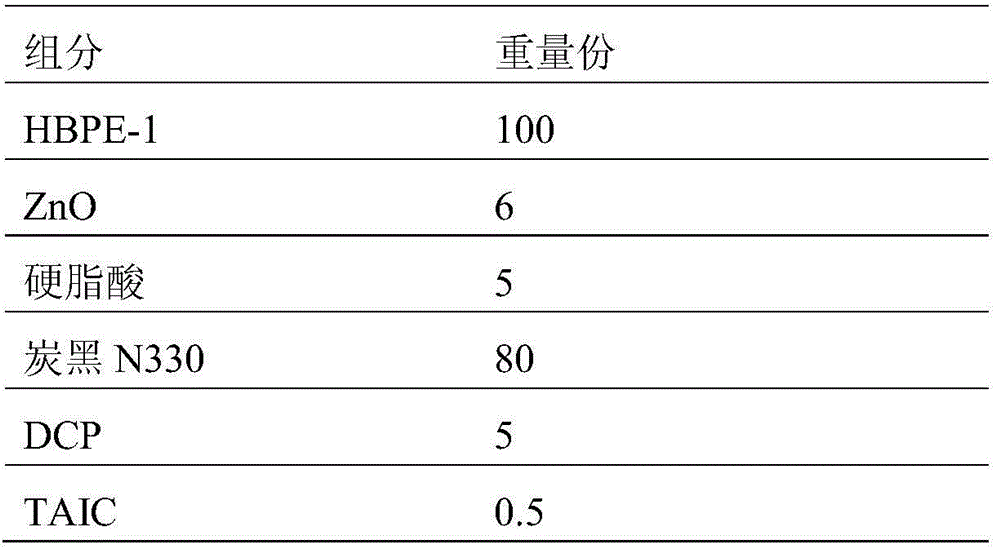

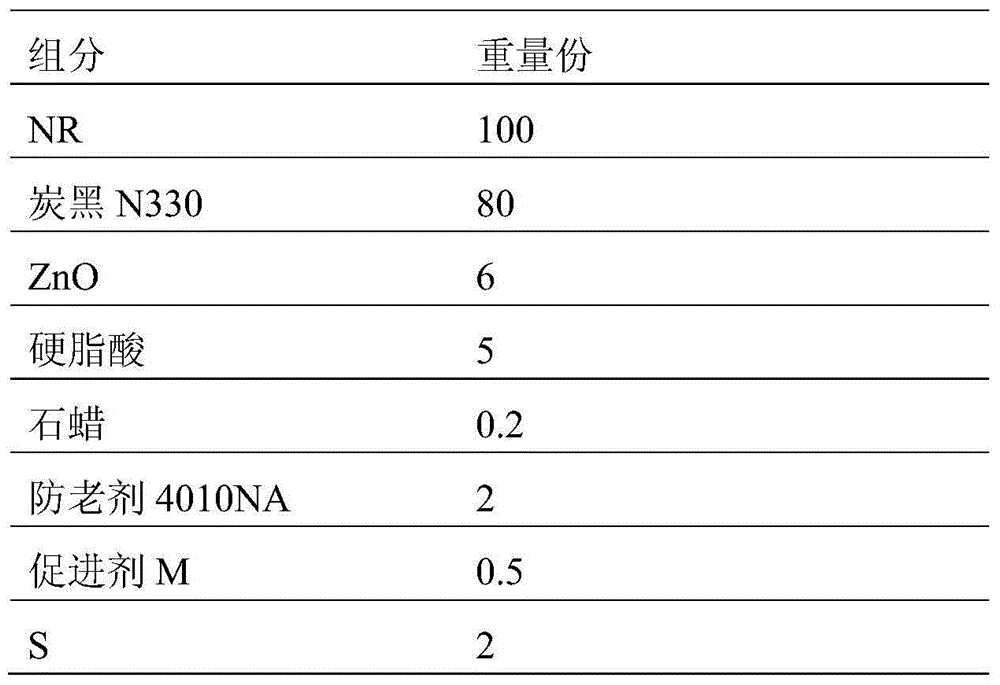

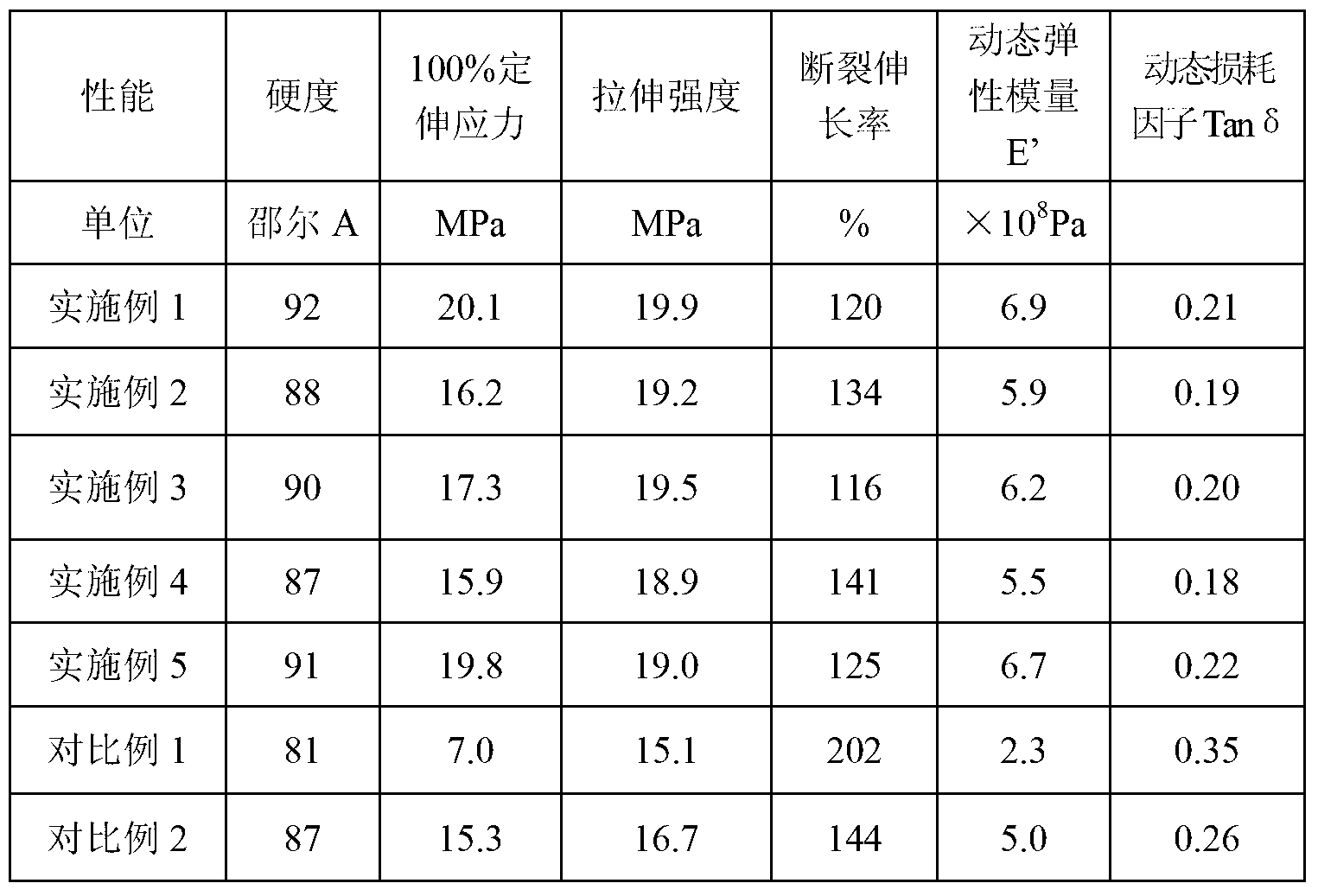

Polyethylene rubber and processing method thereof

The invention belongs to the technical field of rubber, and particularly relates to polyethylene rubber and a processing method thereof. The polyethylene rubber comprises following raw materials by weight: 100 parts of hyper branched polyethylene, 50-80 parts of carbon black, 2-5 parts of a peroxide crosslinking agent, 0-6 parts of zinc oxide, 0-5 parts of a lubricant, 0.3-0.5 part of an accelerant, and 0-0.2 part of sulfur. Beneficial effects of the polyethylene rubber and the processing method thereof are that: the hyper branched polyethylene (HBPE) is sulfurized by utilization of a peroxide sulfurization system, has good mechanical performances through stress-strain performance tests, and has a characteristic of high elasticity of rubber. The processing method of the polyethylene rubber is totally different from preparation methods of chlorinated polyethylene rubber and chlorosulfonated polyethylene rubber at present. The polyethylene rubber and the processing method thereof break the limit that polyethylene can be only used for making plastic products, expand the application scope of the polyethylene, and largely increase the additional value of polyethylene homopolymers.

Owner:ZHEJIANG UNIV

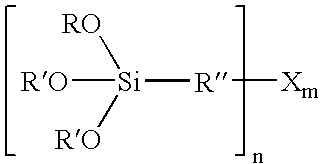

Organic-inorganic hybrids surface adhesion promoter

An organic-inorganic hybrid surface adhesion promoter having the general formula, A-B, wherein A is hydrolyzed and polycondensed from a trioxysilane R-Si(OR')3 or its mixture with one or two more silanes, where R' is methyl, ethyl or propyl, and where R is an organic group of methacrylate, epoxy, amine, isolyante, hydroxide or non-halogens or halogens containing alkyl, alkenyl, aryl, alkylary or arylalky, and wherein B is hydrolyzed and polycondensed from an alkoxy silane, chloride silane, or alkoxy or chloride metal compound, whereby B reacts with a substrate to form a uniting group which is selected from the group consisting of Si-O-Si, M-O-M, M-O-S and Si-O-M, M being a metal atom.

Owner:ZENASTRA PHOTONICS INC

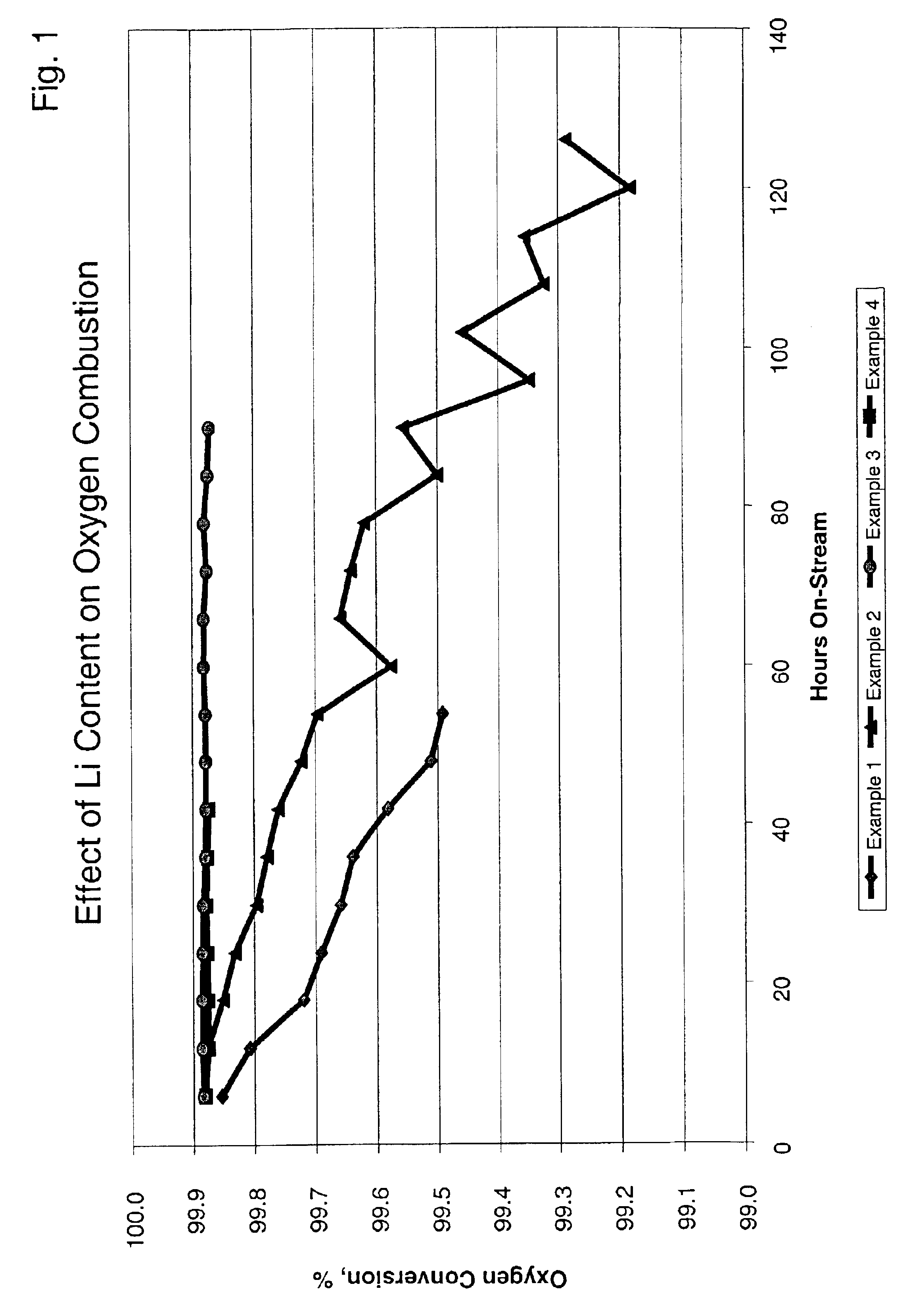

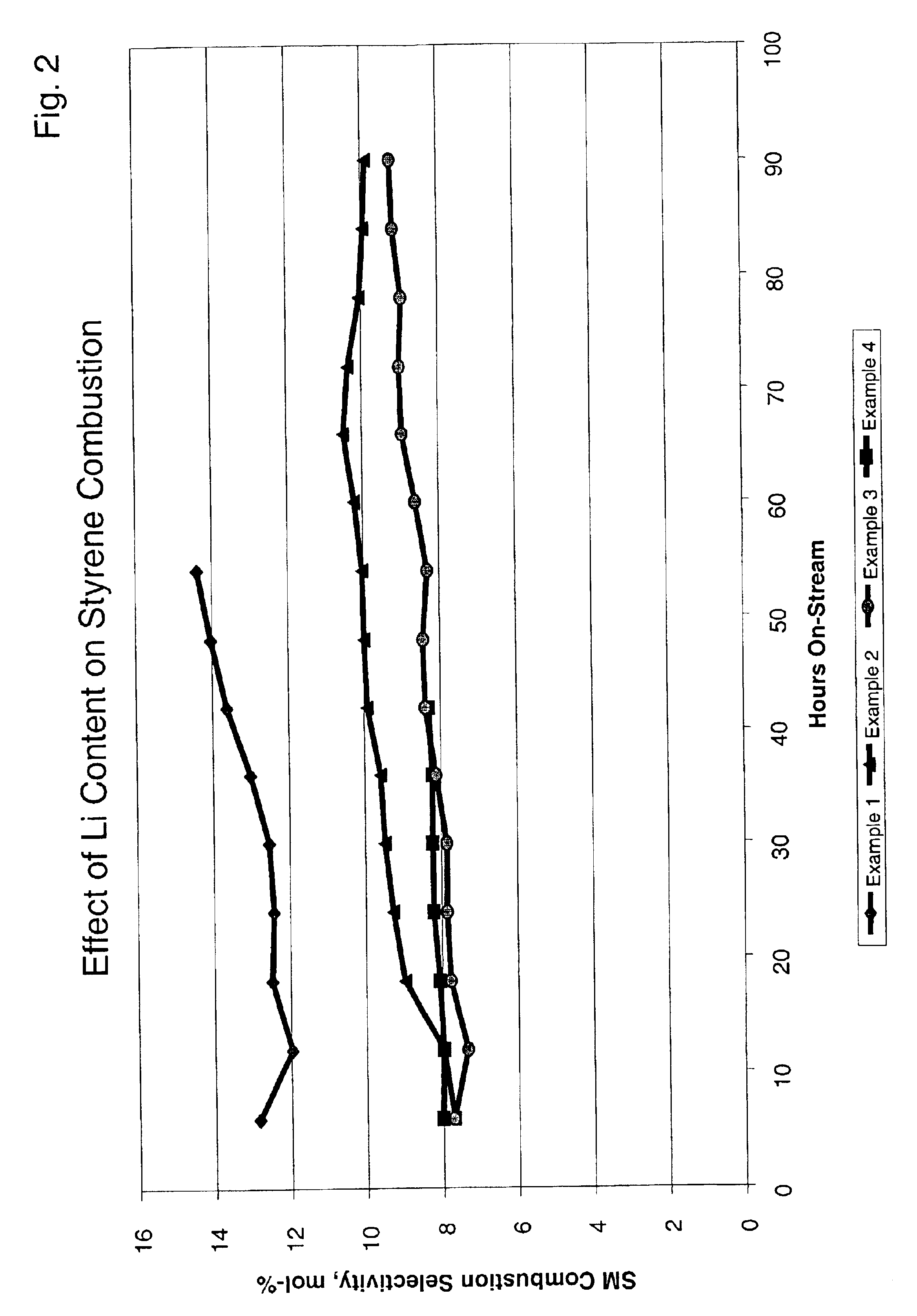

Lithium aluminate layered catalyst and a selective oxidation process using the catalyst

InactiveUS6858769B2Thermal non-catalytic crackingHydrocarbon by isomerisationHydrogenDehydrogenation

A catalyst for the selective oxidation of hydrogen has been developed. It comprises an inert core such as cordierite and an outer layer comprising a lithium aluminate support. The support has dispersed thereon a platinum group metal and a promoter metal, e.g. platinum and tin respectively. This catalyst is particularly effective in the selective oxidation of hydrogen in a dehydrogenation process.

Owner:UOP LLC

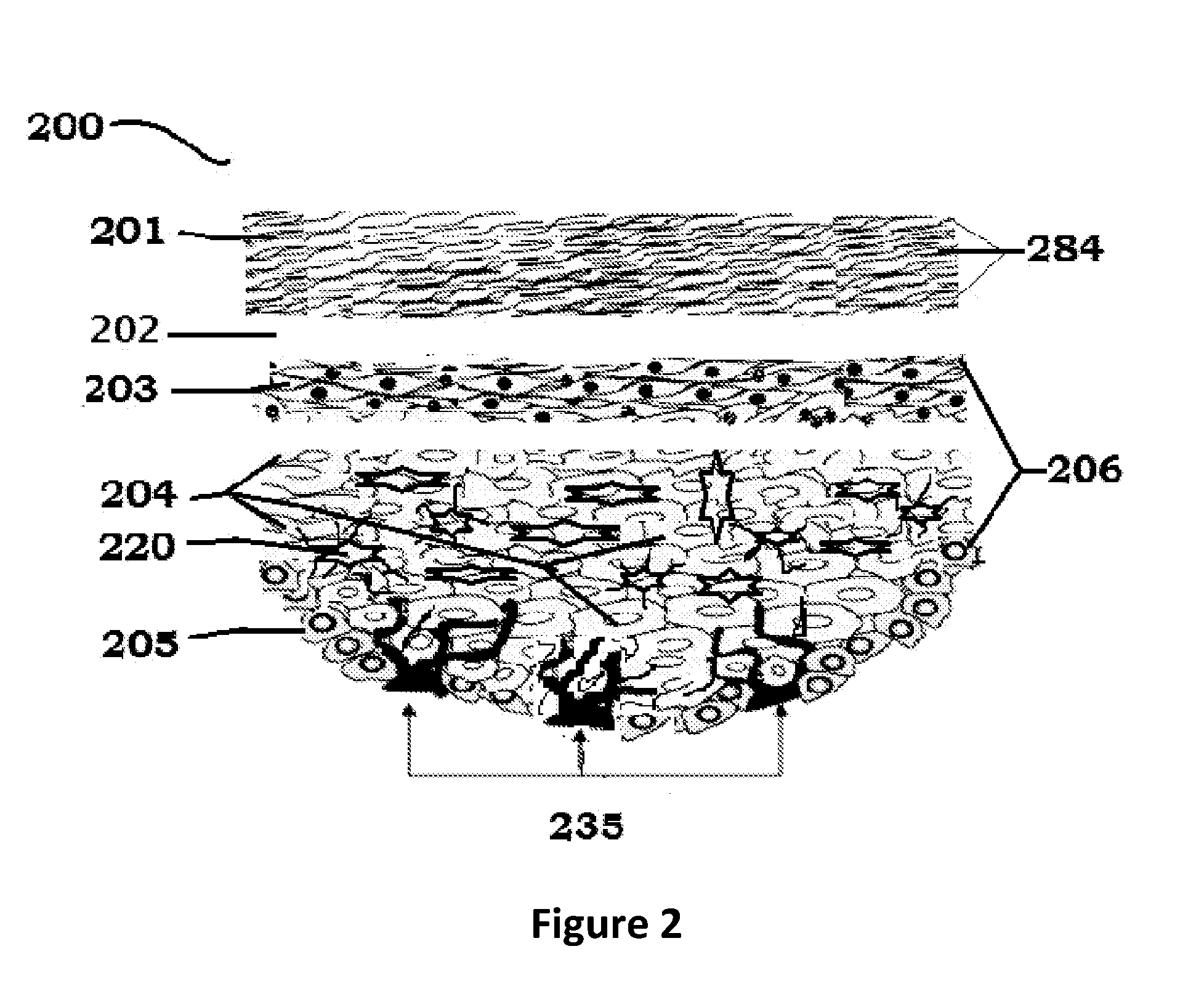

Implantation of encapsulated biological materials for treating diseases

The present invention relates to compositions and methods of treating a disease, such as diabetes, by implanting encapsulated biological material into a patient in need of treatment. This invention provides for the placement of biocompatible coating materials around biological materials using photopolymerization while maintaining the pre-encapsulation status of the biological materials. Several methods are presented to accomplish coating several different types of biological materials. The coatings can be placed directly onto the surface of the biological materials or onto the surface of other coating materials that hold the biological materials. The components of the polymerization reactions that produce the coatings can include natural and synthetic polymers, macromers, accelerants, cocatalysts, photoinitiators, and radiation. This invention also provides methods of utilizing these encapsulated biological materials to treat different human and animal diseases or disorders by implanting them into several areas in the body including the subcutaneous site. The coating materials can be manipulated to provide different degrees of biocompatibility, protein diffusivity characteristics, strength, and biodegradability to optimize the delivery of biological materials from the encapsulated implant to the host recipient while protecting the encapsulated biological materials from destruction by the host inflammatory and immune protective mechanisms without requiring long-term anti-inflammatory or anti-immune treatment of the host.

Owner:NOVOCELL

Preparation method and application of anti-pollution hydrophilic separating membrane

ActiveCN103480278AReduce dosageMeet the needs of hydrophilic immobilizationSemi-permeable membranesMembrane permeabilizationMicrofiltration membrane

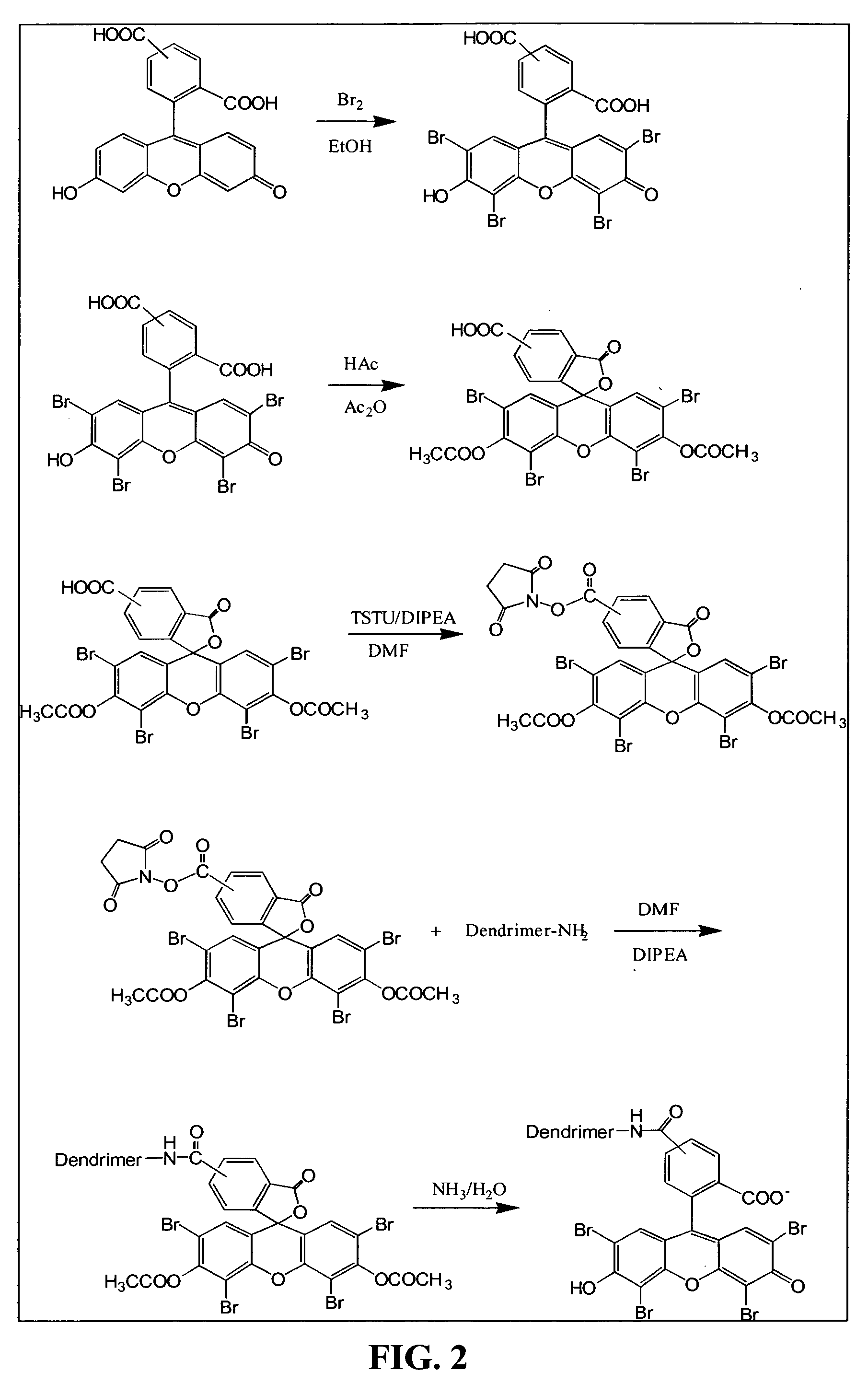

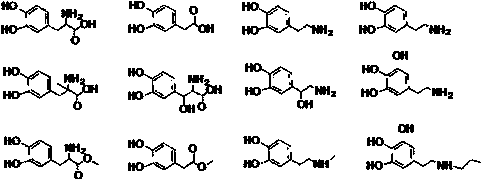

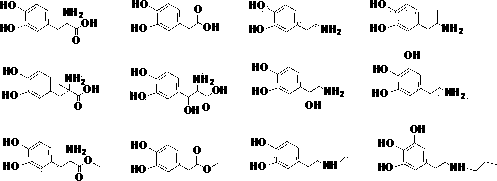

The invention discloses a preparation method and an application of an anti-pollution hydrophilic separating membrane. The preparation method is characterized in that a pyrocatechol derivative is used as an accelerant and a curing agent between a separating membrane material and a hydrophilic material, when blending casting film liquid of the separating membrane is prepared, the pyrocatechol derivative is added to blending liquid of the separating membrane material and the hydrophilic material, and the pyrocatechol derivative is subjected to polymerization cross-linking in a phase conversion process of the membrane preparation, so that the effect of fixing the hydrophilic material is achieved. The preparation method of the anti-pollution hydrophilic separating membrane has strong universality and is suitable for the blending of multiple hydrophilic materials and multiple membrane materials. The preparation method is simple, easy to operate, mild in conditions, economic, high-efficiency, environmentally-friendly, easy for industrialization and suitable for the preparation of multi-functional hydrophilic micro-filtration membranes, ultra-filtration membranes, nano-filtration membranes, reverse-osmosis membranes, positive-osmosis membranes, pressure-delay osmosis membranes, pervaporation membranes and the like which are used for liquid and gas separation and membrane reactors.

Owner:YANTAI LVSHUIFU MEMBRANE MATERIAL

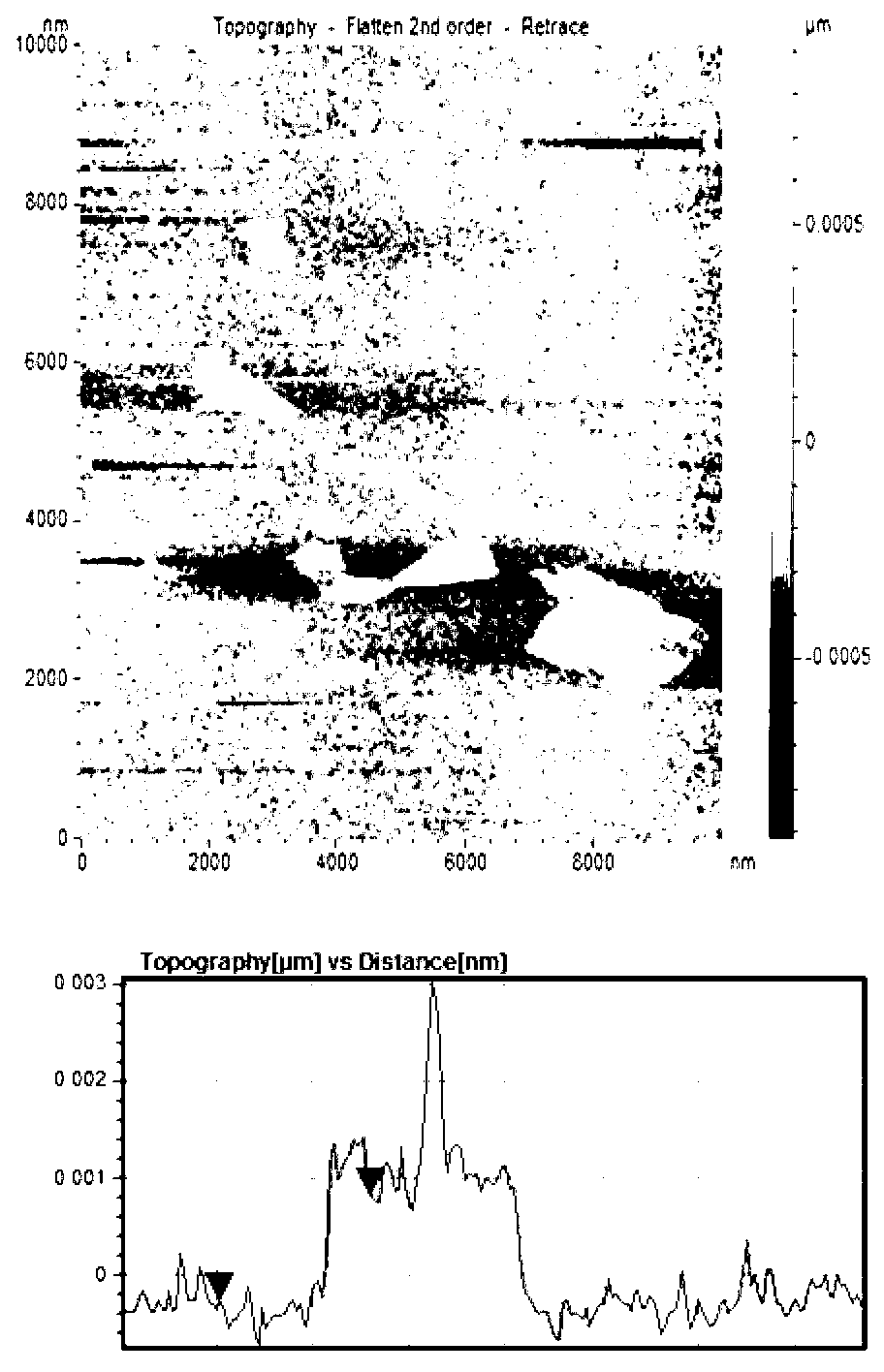

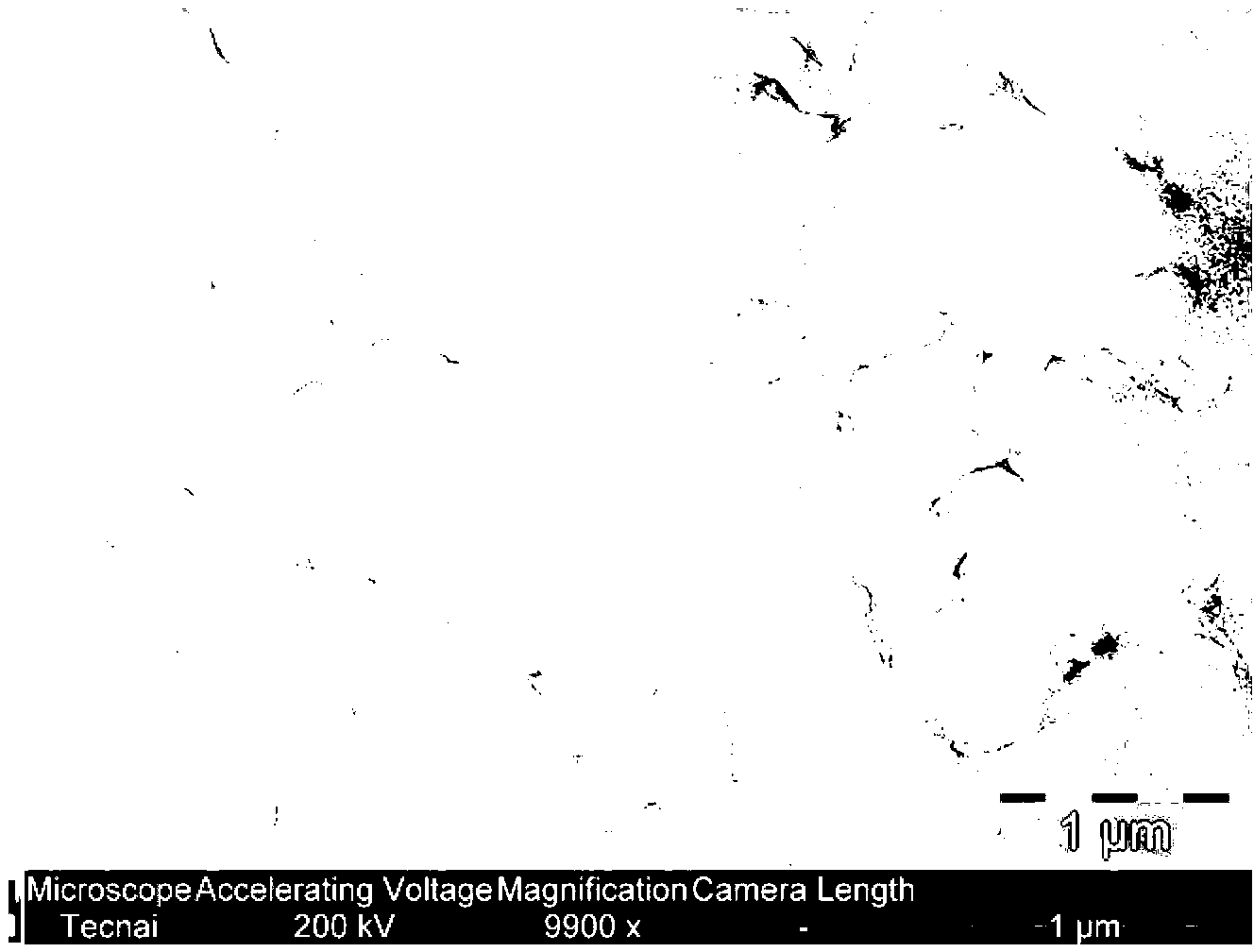

Oxidized grapheme/carbon black rubber nanocomposite and preparation method thereof

The invention provides an oxidized grapheme / carbon black rubber nanocomposite and preparation method thereof, which belongs to the field of rubber nanocomposite technology. The nanocomposite comprises the following basic compositions by mass: 100 parts of diene series rubber matrix, 0.5-5 parts of oxidized grapheme, 30-70 parts of hard carbon black of average particle size 11-30nm, 1-10 parts of plasticizer, 6-10 parts of activator, 0.5-4 parts of anti-aging agent, 1-4 parts of sulfuration promoter and 1-6 parts of insoluble sulphur; oxidized grapheme modifier. The oxidized grapheme powder is dispersed in deionized water for ultrasound, and a natural rubber emulsion is added, and masterbatch after flocculation, washing and drying is mixed uniformly with other additives, after sulfuration, the product is obtained. The oxidized grapheme / carbon black rubber nanocomposite has the advantages of excellent processing performance and obviously reduced dynamic themogenesis, thereby improving the usage life of tyre.

Owner:BEIJING UNIV OF CHEM TECH

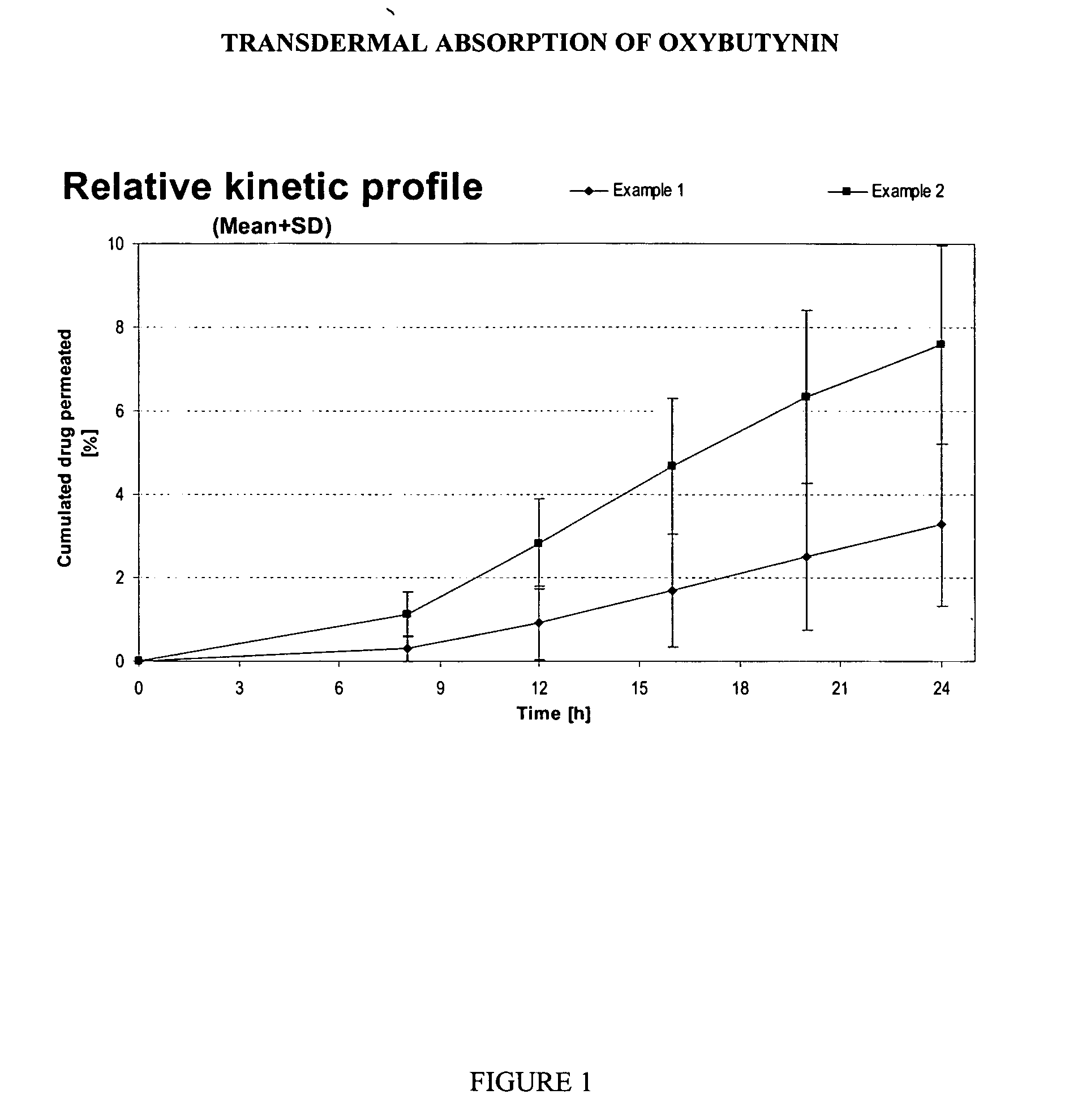

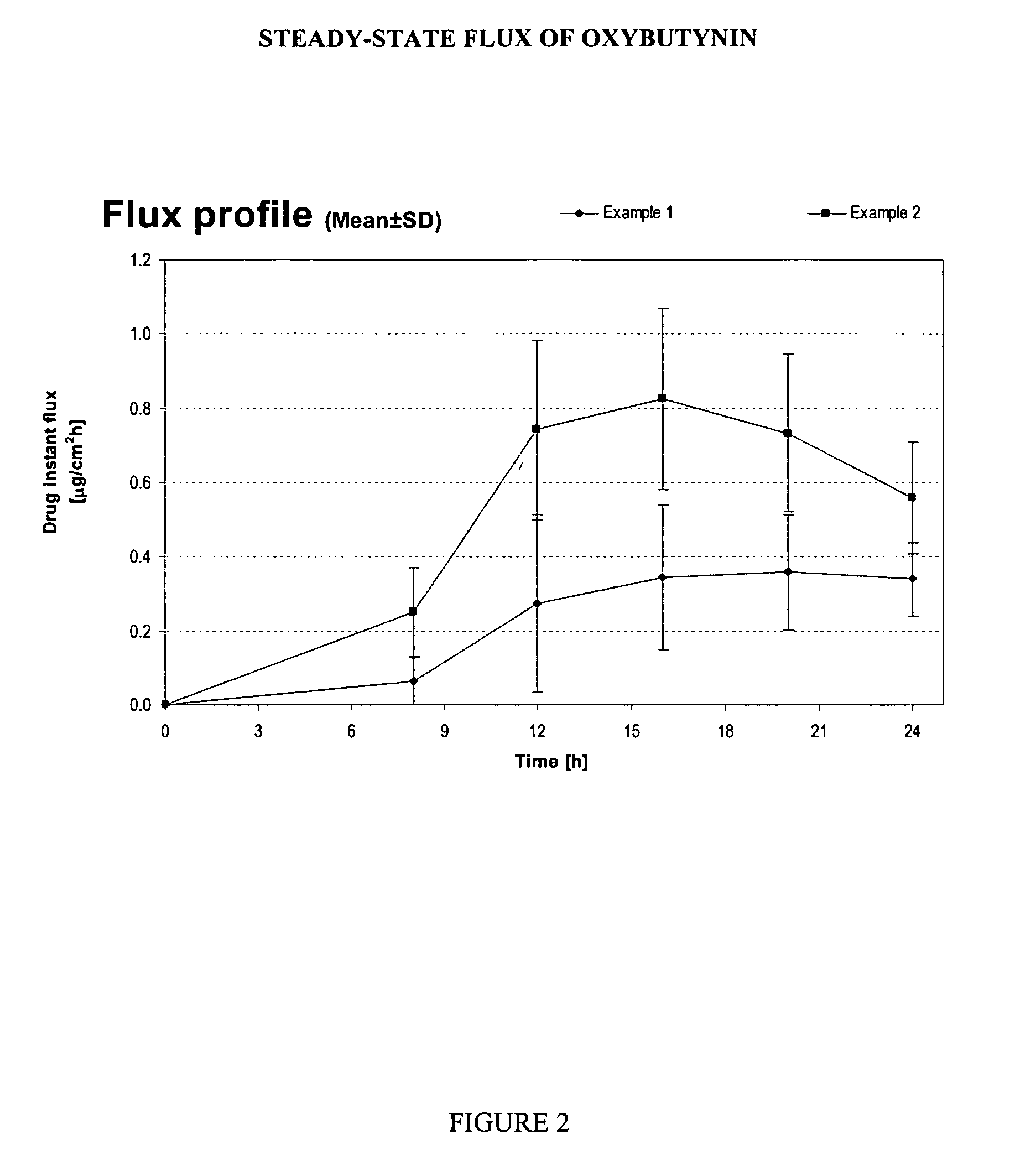

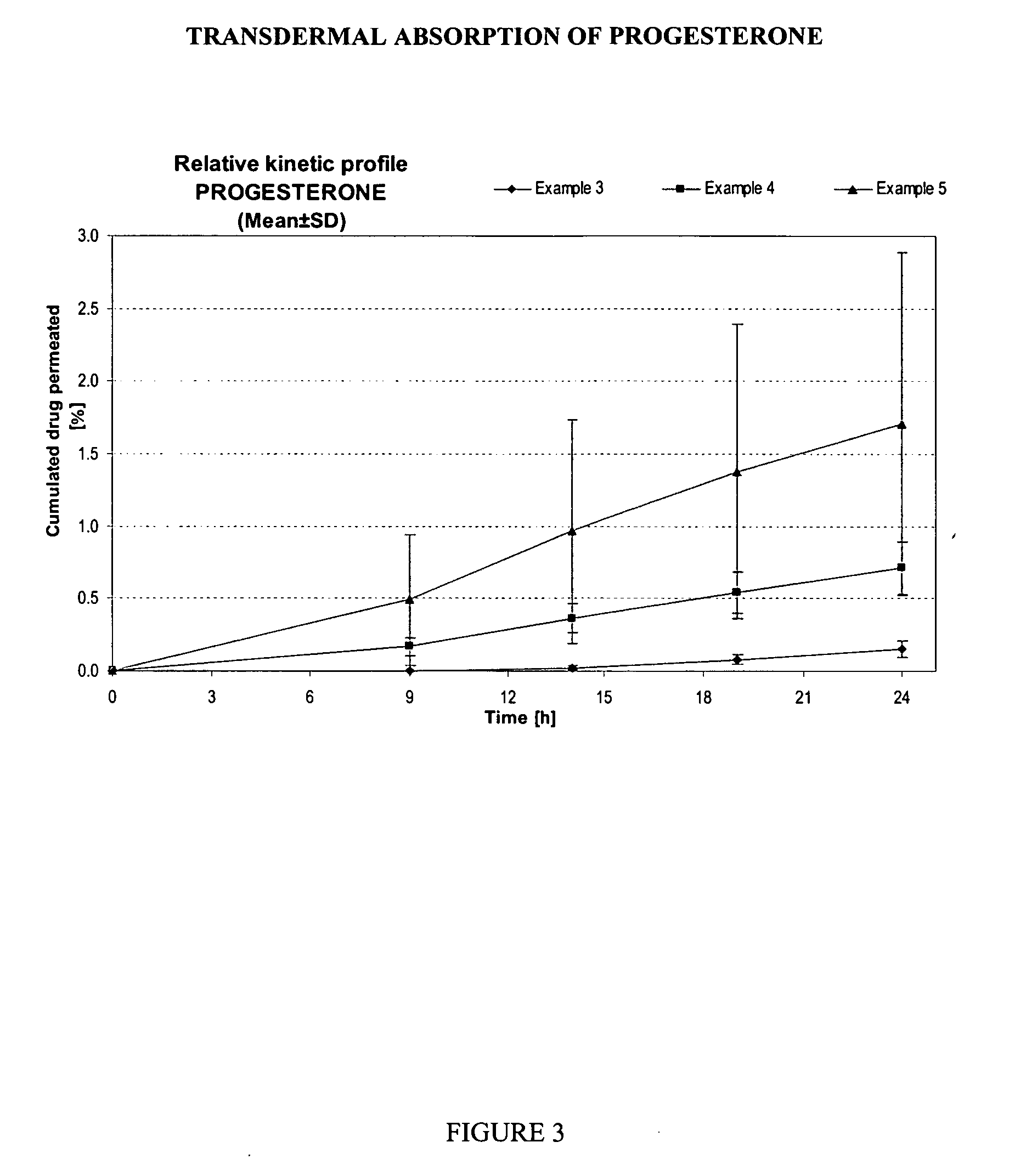

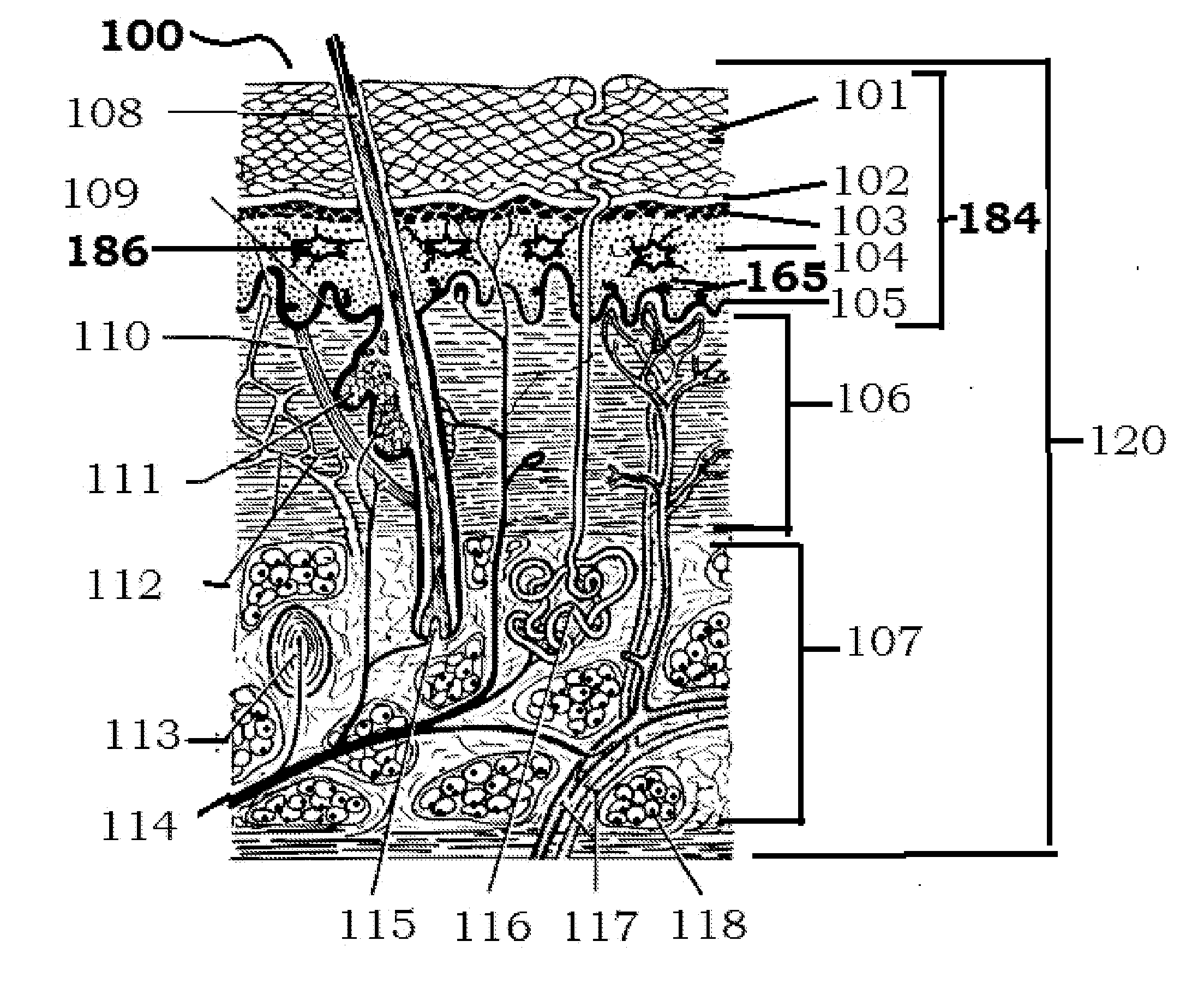

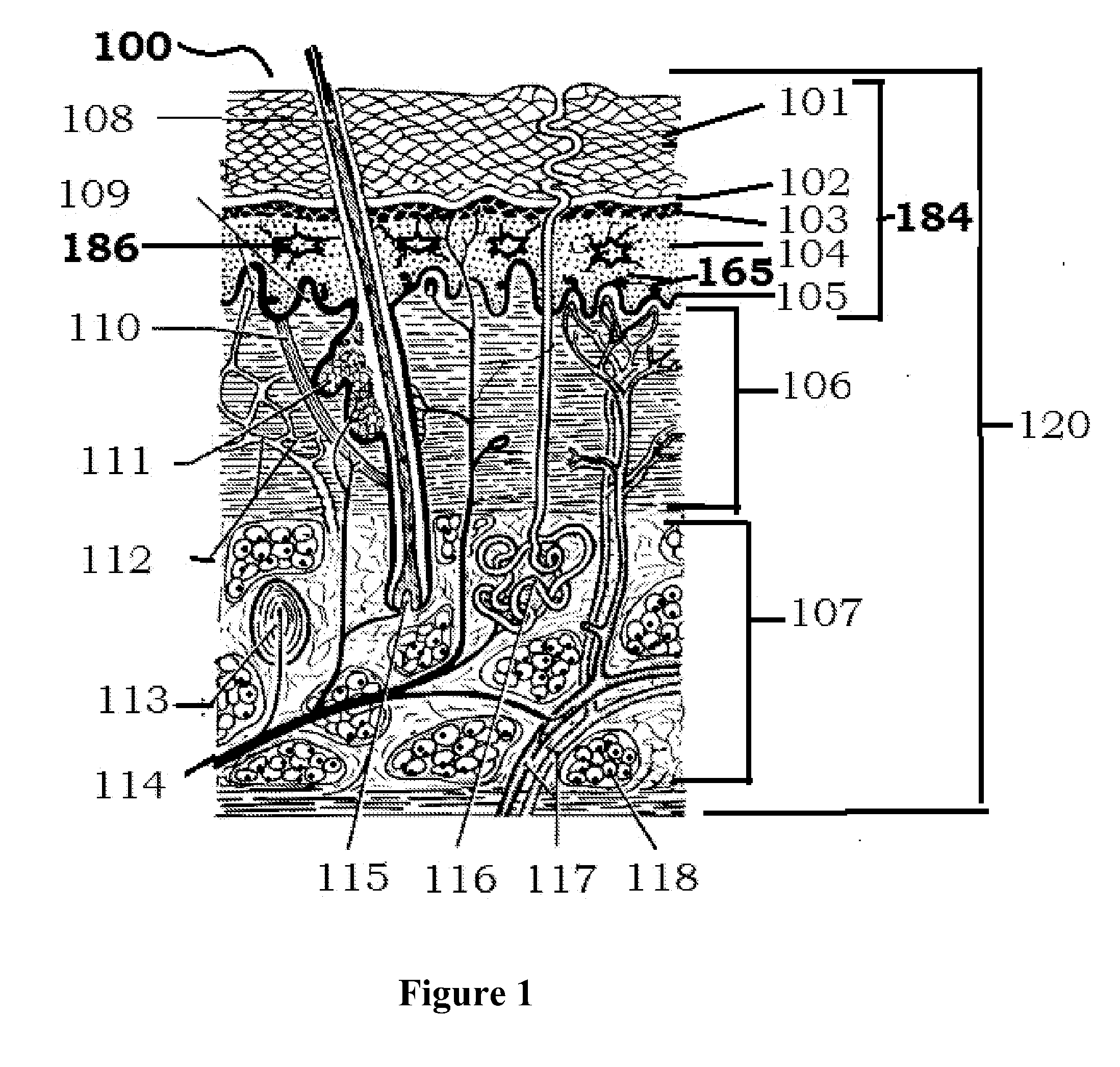

Permeation enhancer comprising genus Curcuma or germacrone for transdermal and topical administration of active agents

InactiveUS20050244522A1Increase permeationImprove permeabilityBiocideOrganic active ingredientsTetraglycolGermacrone

A formulation, method and system for the topical, transdermal or transmucosal administration of a therapeutically effective active agent. Particularly, the invention provides a formulation, system and method for enhancing the permeation or penetration of active agents across the dermal or mucosal surfaces of a mammalian subject. The formulation includes a plant extract of the genus Curcuma of the family Zingiberaceae, a germacrone, or a natural or synthetic constituent thereof, which has been found to increase penetration of the active agent across the dermal or mucosal surface. If desired, a secondary permeation enhancer of a polyalcohol, a monoalkyl ether of diethylene glycol, a tetraglycol, or a mixture thereof can be used for certain active agents for optimal permeation enhancement.

Owner:ANTARES PHARMA IPL

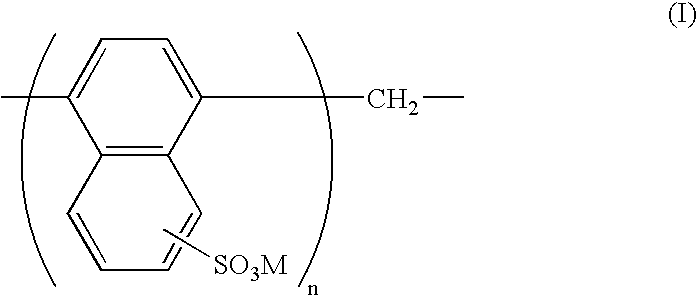

High hydroxyethylated starch and high dispersant levels in gypsum wallboard

InactiveUS20080070026A1High strengthReduce weightSynthetic resin layered productsPaper/cardboard layered productsGlass fiberFiber

The invention generally provides gypsum-containing slurries including stucco, a hydroxyethylated starch, naphthalenesulfonate dispersant, and sodium trimetaphosphate. The naphthalenesulfonate dispersant is present in an amount of about 0.1%-3.0% by weight based on the weight of dry stucco. The hydroxyethylated starch is present in an amount of from about 0.5% by weight to about 10% by weight based on the weight of dry stucco in the formulation. The sodium trimetaphosphate is present in an amount of about 0.1%-0.4% by weight based on the weight of dry stucco. Other slurry additives can include accelerators, binders, paper fiber, glass fiber, and other known ingredients. The invention also comprises the gypsum-containing products made with such slurries, for example, lightweight gypsum wallboard, and a method of making lightweight gypsum wallboard.

Owner:UNITED STATES GYPSUM CO

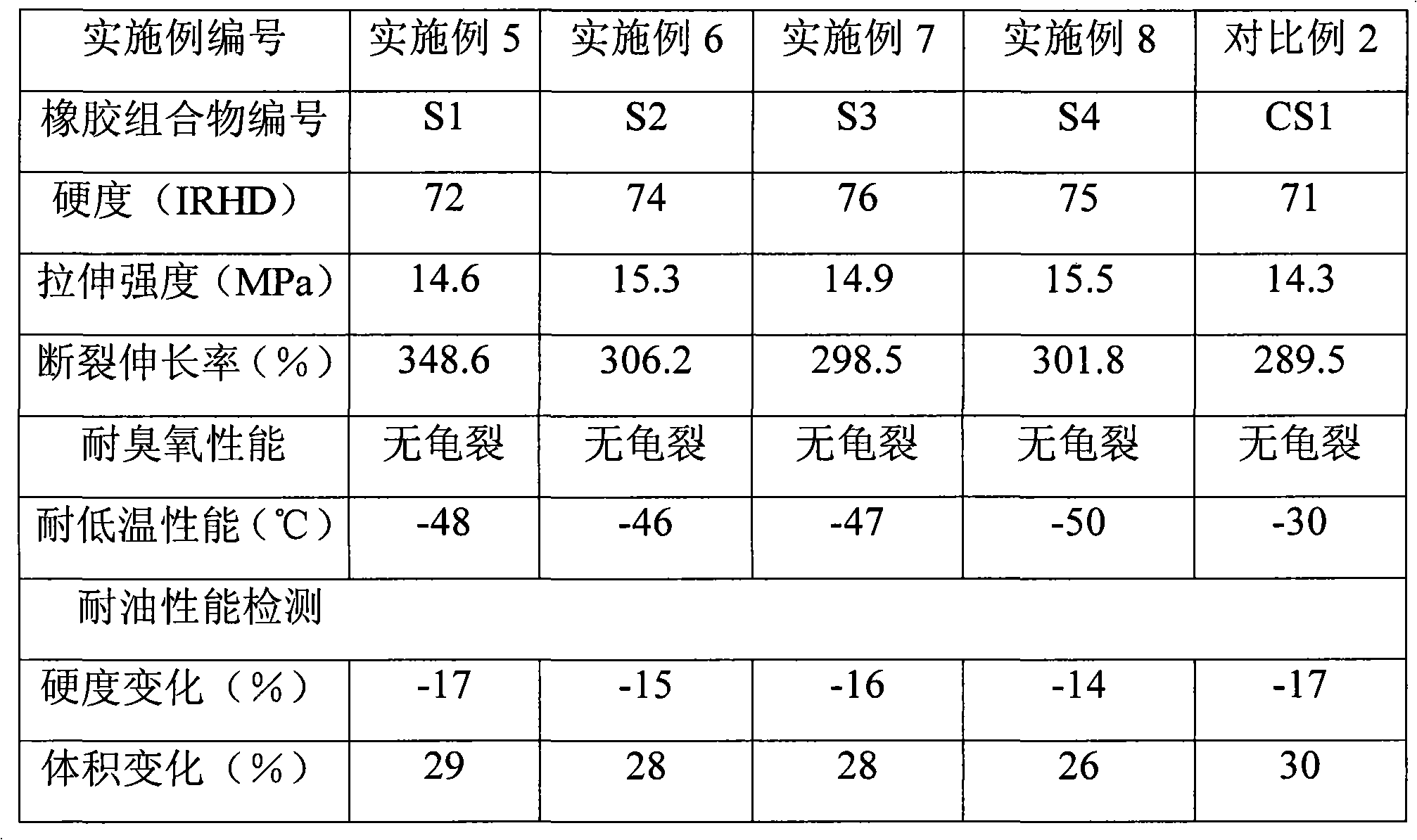

Oil resistant low temperature resistant rubber composition

InactiveCN101353451AGuaranteed oil resistanceGuaranteed ozone resistancePolymer scienceNitrile rubber

The invention relates to a rubber composite, comprising nitrile rubber, polyvinyl chloride, carbon soot, activator, vulcanizator, age inhibitor, antiscorcher, accelerant and plasticizer, wherein, the plasticizer is ethylhexyl sebacate and adipate. The rubber composite of the invention obviously improves the anti-low temperature performance of the rubber composite while ensuring the anti-oil performance, anti-ozone performance, tensile strength and elongation at break.

Owner:BYD CO LTD

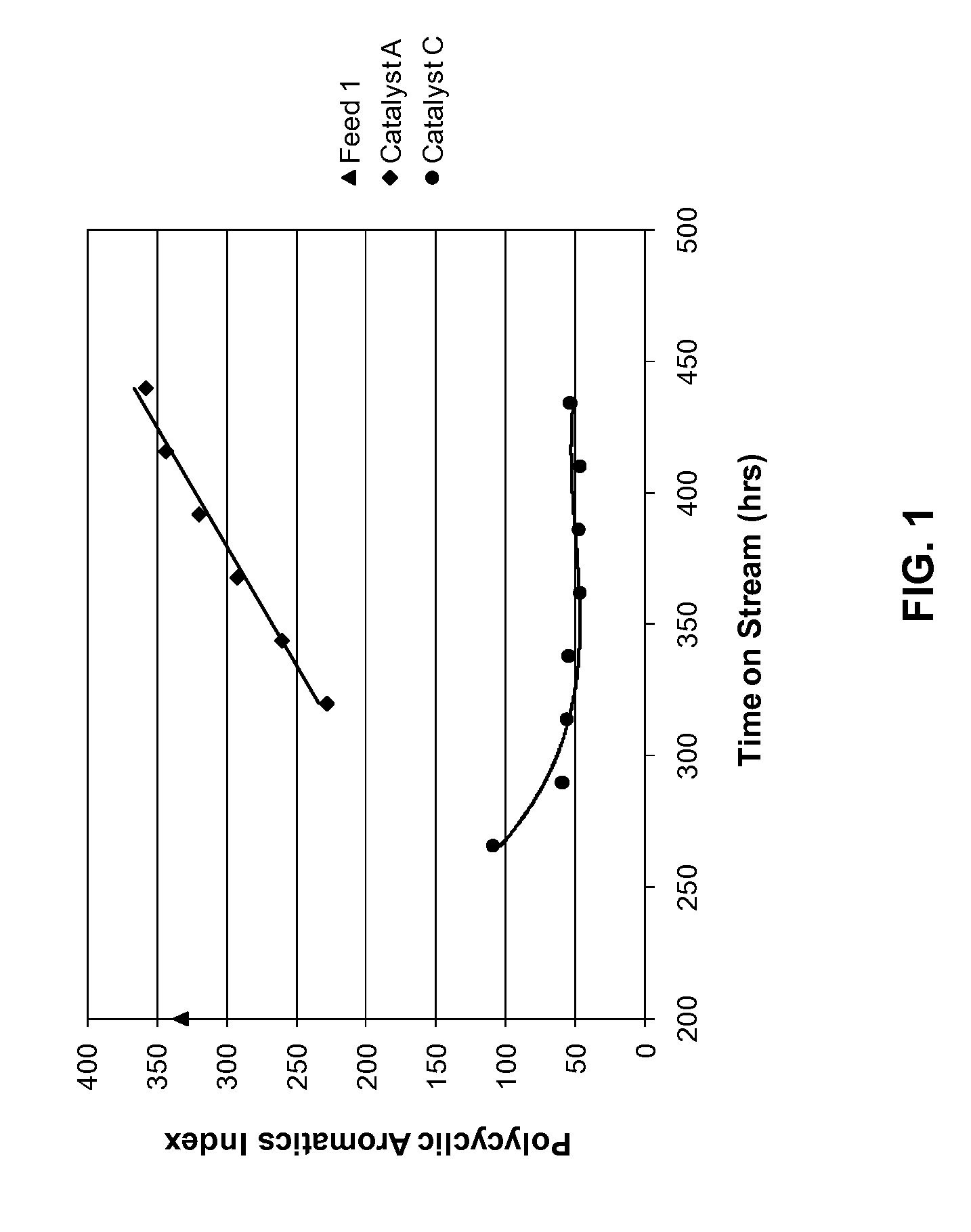

Desulfurization process and novel bimetallic sorbent systems for same

Novel sorbent systems for the desulfurization of cracked-gasoline and diesel fuels are provided which are comprised of a bimetallic promotor on a particulate support such as that formed of zinc oxide and an inorganic or organic carrier. Such bimetallic promotors are formed of at least two metals of the group consisting of nickel, cobalt, iron, manganese, copper, zinc, molybdenum, tungsten, silver, tin, antimony and vanadium with the valence of same being reduced, preferably to zero. Processes for the production of such sorbents are provided wherein the sorbent is prepared from impregnated particulate supports or admixed to the support composite prior to particulation, drying, and calcination. Further disclosed is the use of such novel sorbents in the desulfurization of cracked-gasoline and diesel fuels whereby there is achieved not only removal of sulfur but also an increase in the olefin retention in the desulfurized product. Such sorbents can also be utilized for the treatment of other sulfur-containing streams such as diesel fuels.

Owner:CHINA PETROCHEMICAL CORP

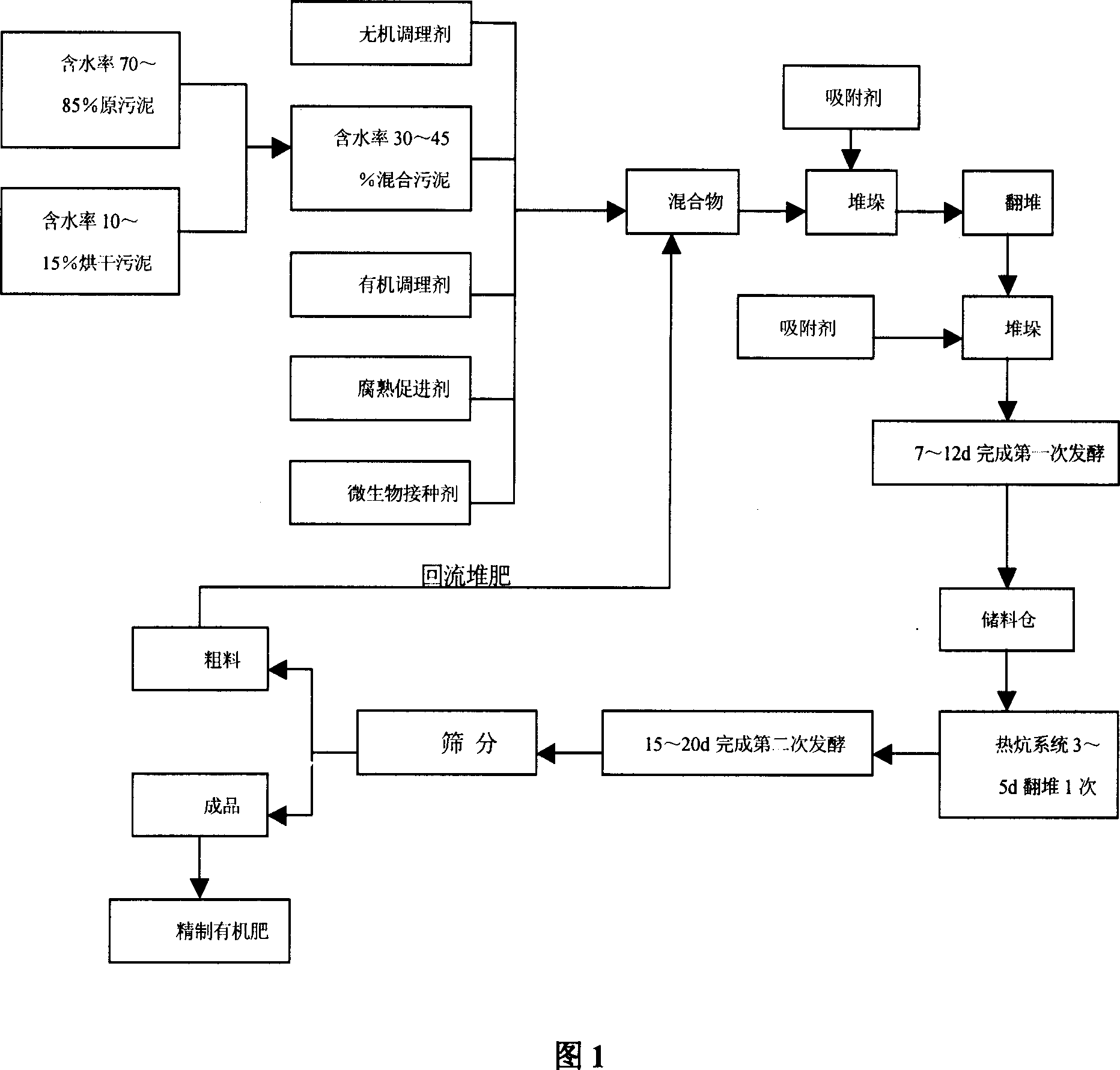

Refined fertilizer produced from sludge and producing method thereof

InactiveCN1923759AAchieve reuseReduce lossesBio-organic fraction processingClimate change adaptationSorbentSludge

The invention discloses a refined organic fertilizer and preparing method of sludge, which comprises the following steps: compounding piled raw materials; piling; turning the pile; ripening; drying in the hot cavity; sieving to obtain the product. The refined organic fertilizer contains composite sludge, organic amendment, inorganic amendment, matured accelerant, microbe grafting agent and adsorbant, which are blended completely according to certain proportion, wherein these materials are fermented for the second time, which are prepared into refined organic fertilizer.

Owner:广东省农业科学院土壤肥料研究所

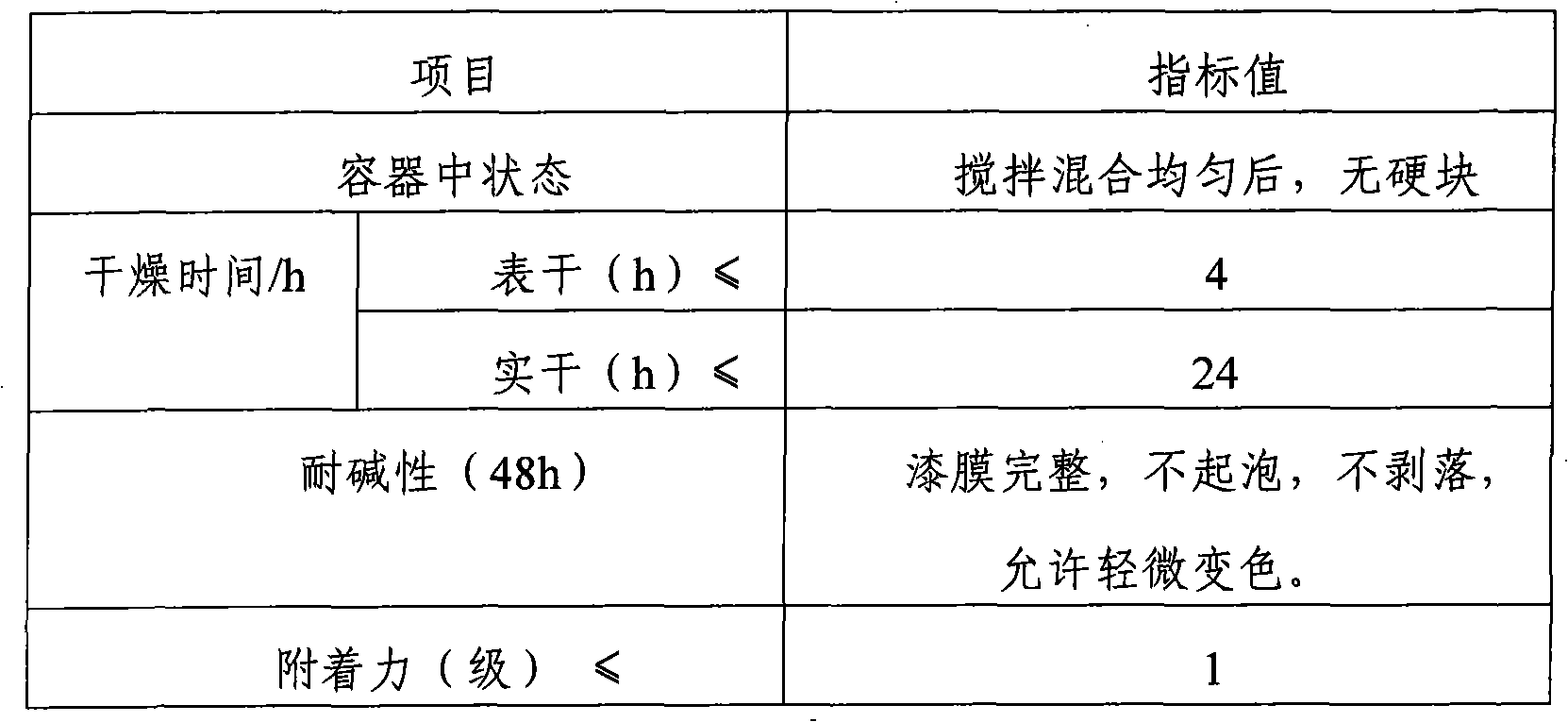

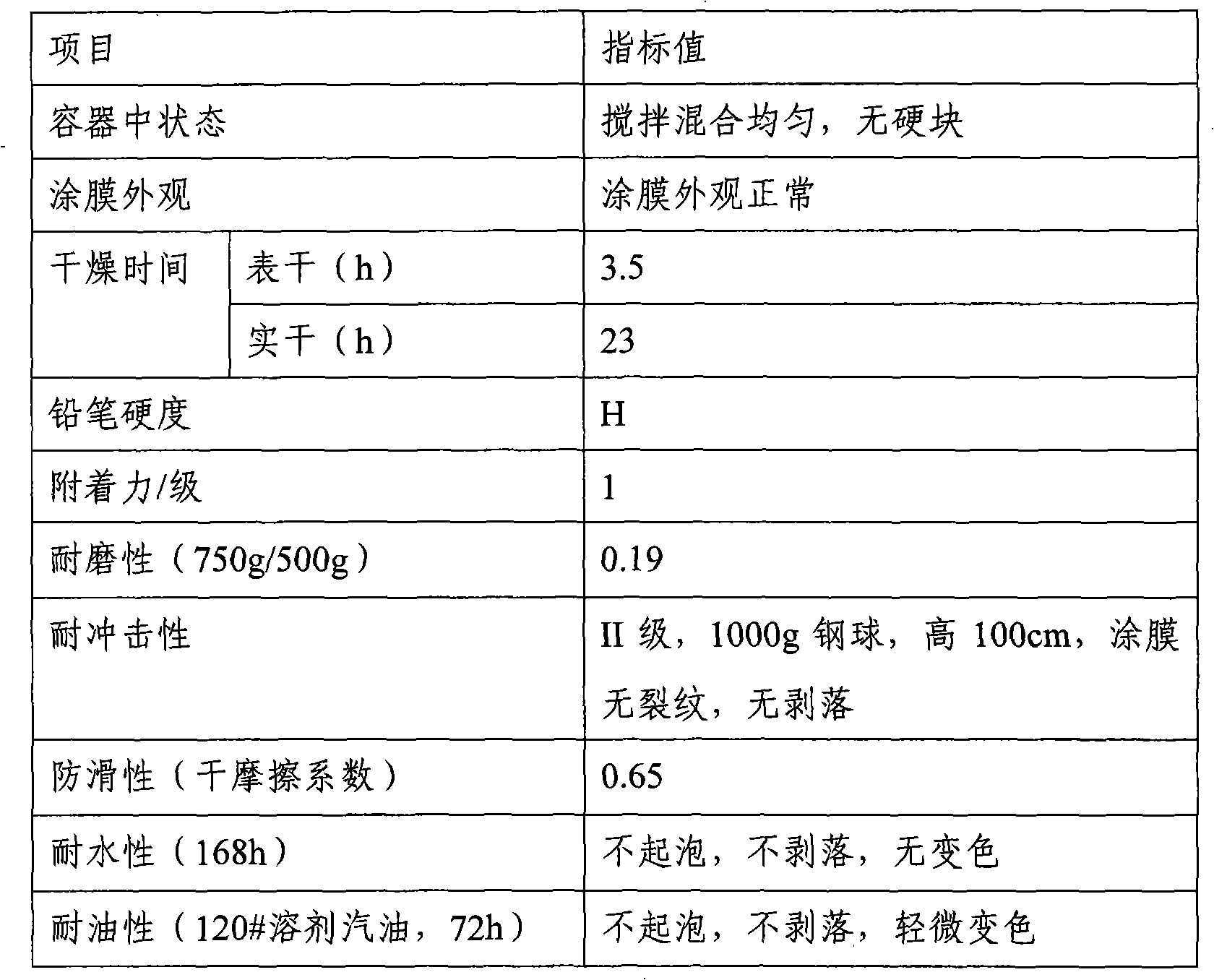

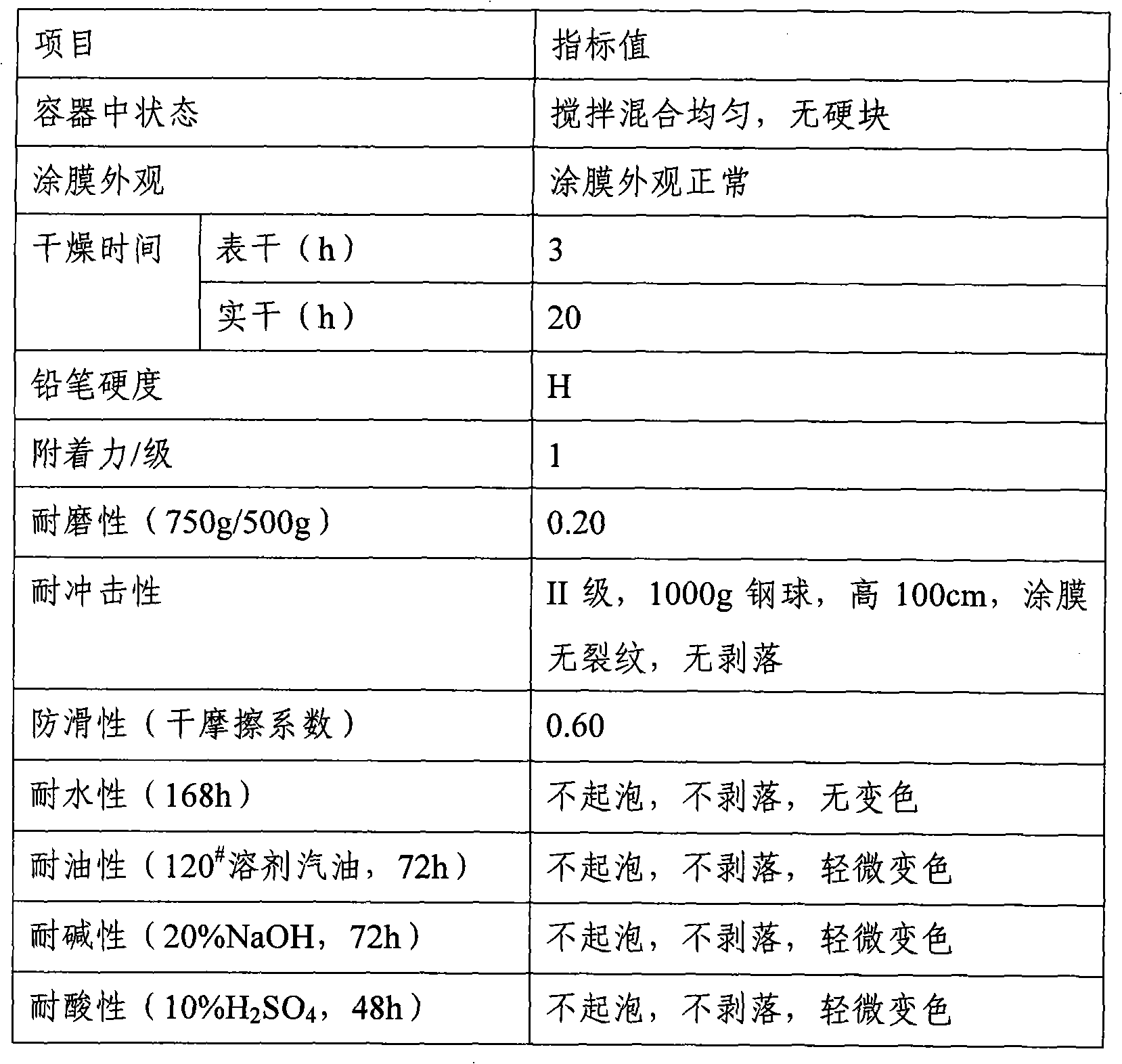

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

Preparation method of recycled polyester chip microfilaments and usage thereof

InactiveCN101747596ASimple compositionNo smellFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterLinear low-density polyethylene

The invention relates to a preparation method of recycled polyester chip microfilaments and a usage thereof, belonging to the field of plastic modification and category of composite material / alloy promoter. The polyester chip microfilament is an ideal promoter which has excellent performance, environment-friendliness, high added value, wide application range and broad market prospect and can change the mechanical property of the composite material / alloy. Recycled blow molding polyester (RPET / RPBT) is taken as main raw material, and the following formula and process are adopted for preparing the microfilament according to parts by weight: 100 parts of recycled polyester (RPET / RPBT), 5-30 parts of wire-drawing high-density polyethylene (HDPE) / polypropylene (PP) / linear low-density polyethylene (LLDPE), 0.1-4 parts of crosslinking agent / chain extender / anchoring agent, 0.1-0.8 part of antioxidant, 0.5-6 parts of nucleating agent, and 1-5 parts of nucleate accelerant, and other processing aids (such as lubricant and plasticizer) / functional aids (such as fire retardant and ultraviolet absorber) can be additionally and appropriately added. The microfilament is prepared through extrusion, cooling, drawing and granulating by the reaction under 90-260 DEG C under the action of mechanical shear. The recycled polyester (RPET / RPBT) microfilament prepared in the invention can endow the composite material / alloy with excellent mechanical property.

Owner:王世和

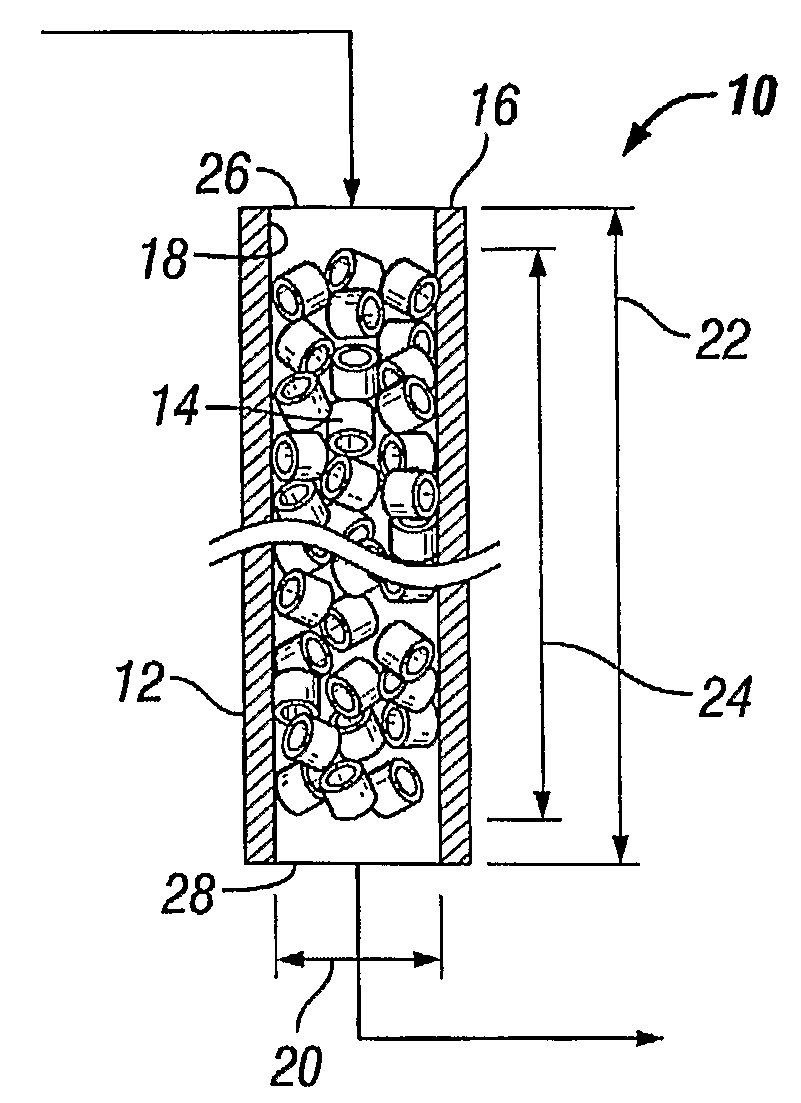

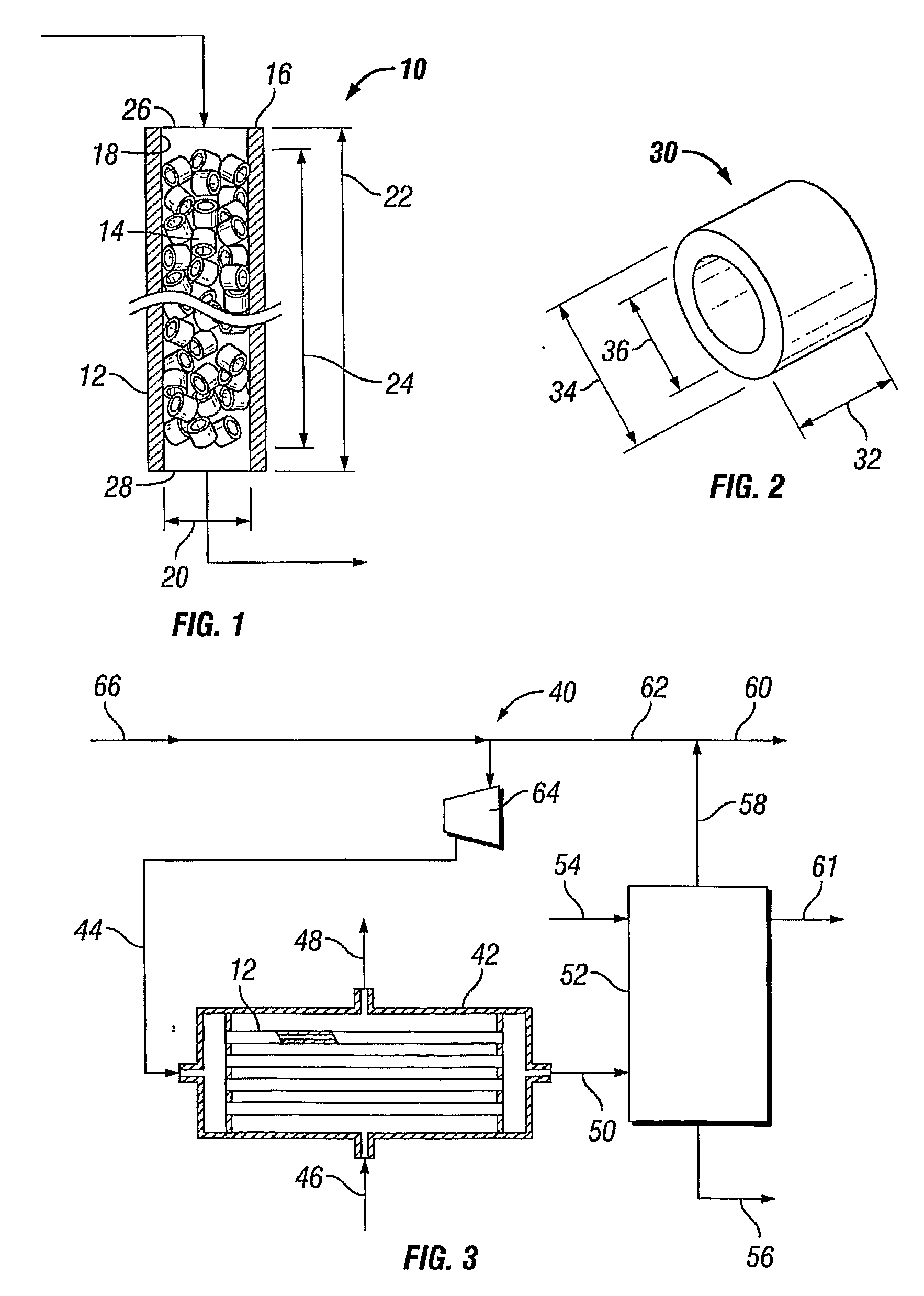

Reactor System and Process for the Manufacture of Ethylene Oxide

A reactor system for the epoxidation of ethylene, which reactor system comprises an elongated tube having an internal tube diameter of more than 40 mm, wherein contained is a catalyst bed of catalyst particles comprising silver and a promoter component deposited on a carrier, which promoter component comprises an element selected from rhenium, tungsten, molybdenum and chromium; a process for the epoxidation of ethylene comprising reacting ethylene with oxygen in the presence of the catalyst bed contained in the reactor system; and a method of preparing ethylene glycol, an ethylene glycol ether or an ethanol amine comprising obtaining ethylene oxide by the process for the epoxidation of ethylene, and converting the ethylene oxide into ethylene glycol, the ethylene glycol ether, or the ethanol amine. Preferably, the internal tube diameter is at least 45 mm.

Owner:SHELL OIL CO

Hydroprocessing catalyst and method of making the same

ActiveUS20110000824A1Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveOrganic chemistry

The present invention is directed to a hydroprocessing catalyst containing at least one catalyst support, one or more metals, optionally one or more molecular sieves, optionally one or more promoters, wherein deposition of at least one of the metals is achieved in the presence of a modifying agent.

Owner:CHEVROU USA INC

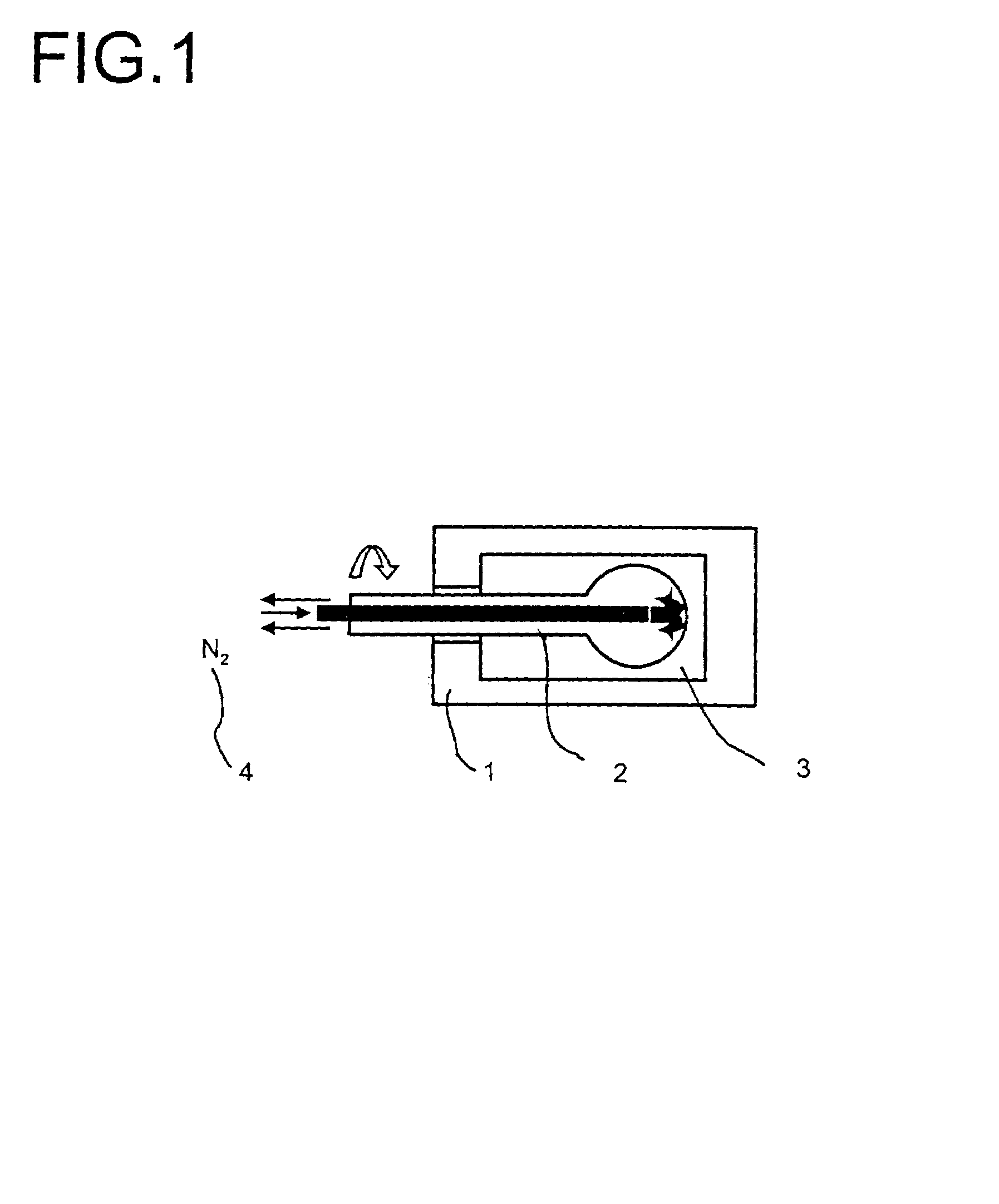

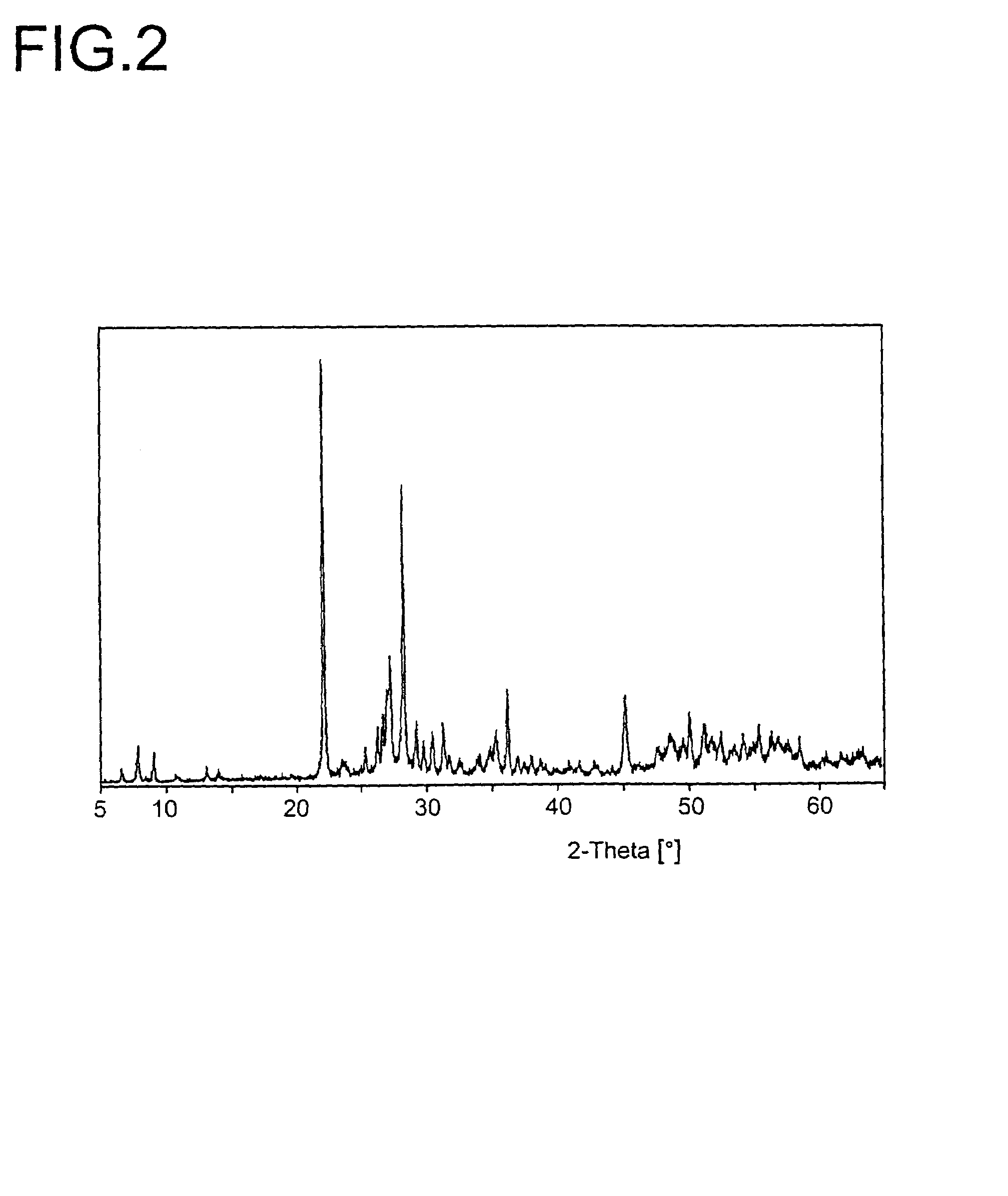

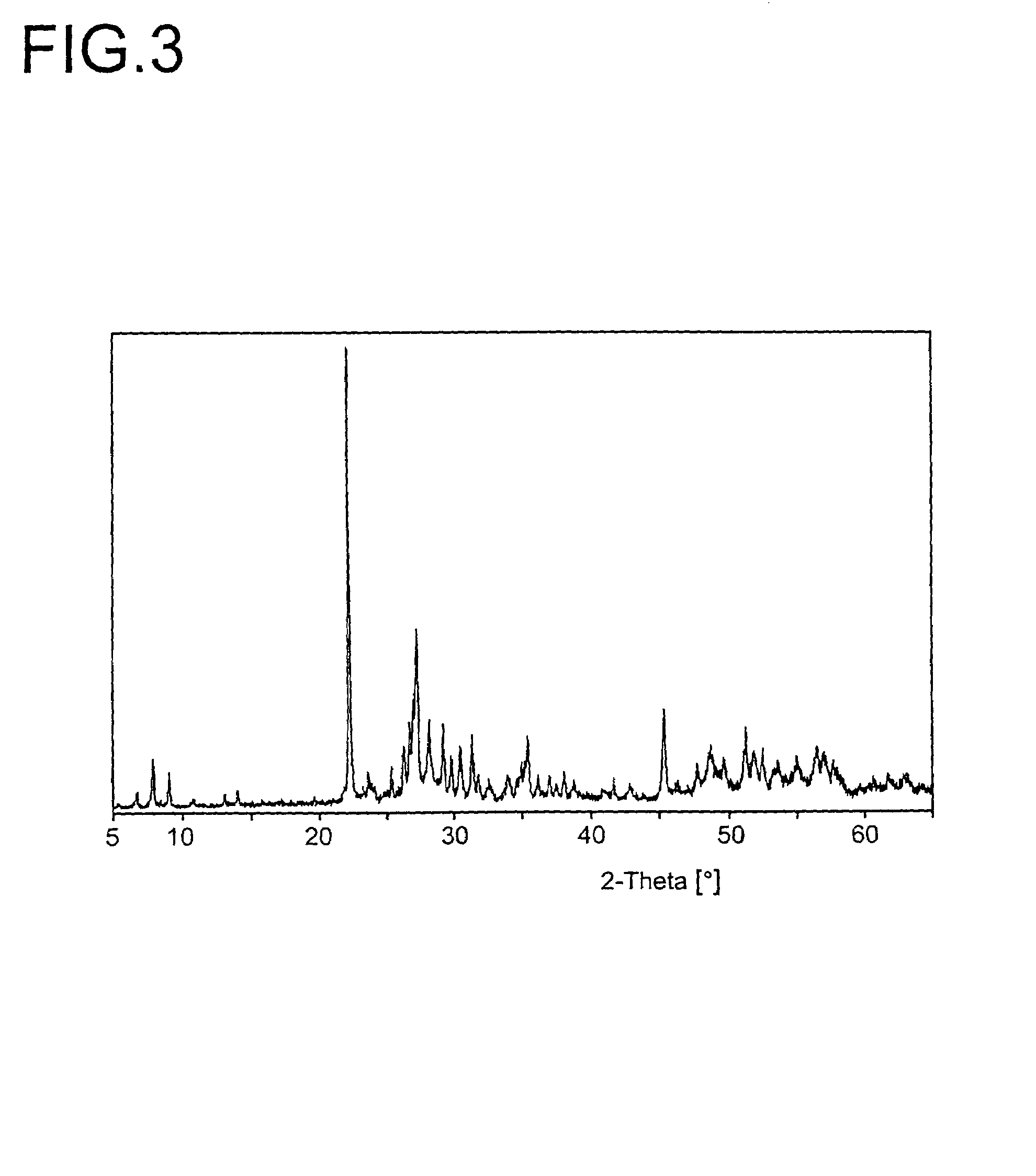

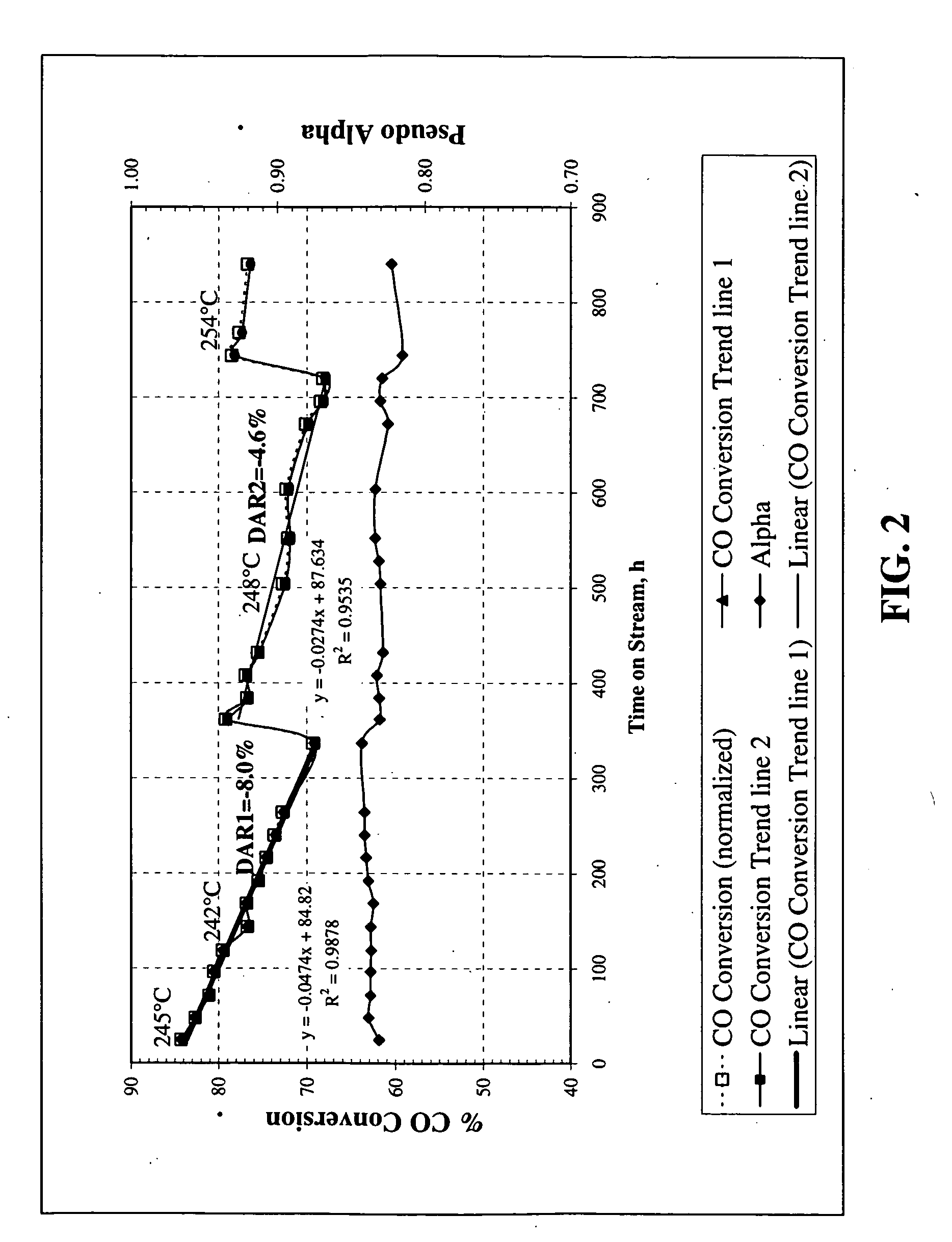

Strengthened iron catalyst for slurry reactors

ActiveUS20090062108A1Various problemOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSlurry reactorPotassium

A method of strengthening a precipitated unsupported iron catalyst by: preparing a precipitated unsupported iron catalyst containing copper and potassium; adding a solution comprising a structural promoter to the previously prepared catalyst; drying the mixture; and calcining the dried catalyst.A method for preparing an iron catalyst, the method comprising: precipitating a catalyst precursor comprising iron phases selected from hydroxides, oxides, and carbonates; adding a promoter to the catalyst precursor to yield a promoted precursor; drying the promoted precursor to yield dried catalyst; and calcining the dried catalyst, wherein the catalyst further comprises copper and potassium.A method of preparing a strengthened precipitated iron catalyst comprising: co-precipitating iron, copper, magnesium, and aluminum; washing the precipitate; alkalizing the precipitate; and drying the precipitate to yield a dried catalyst precursor. The dried catalyst precursor may be calcined and treated with a gas comprising carbon monoxide.

Owner:RES USA LLC

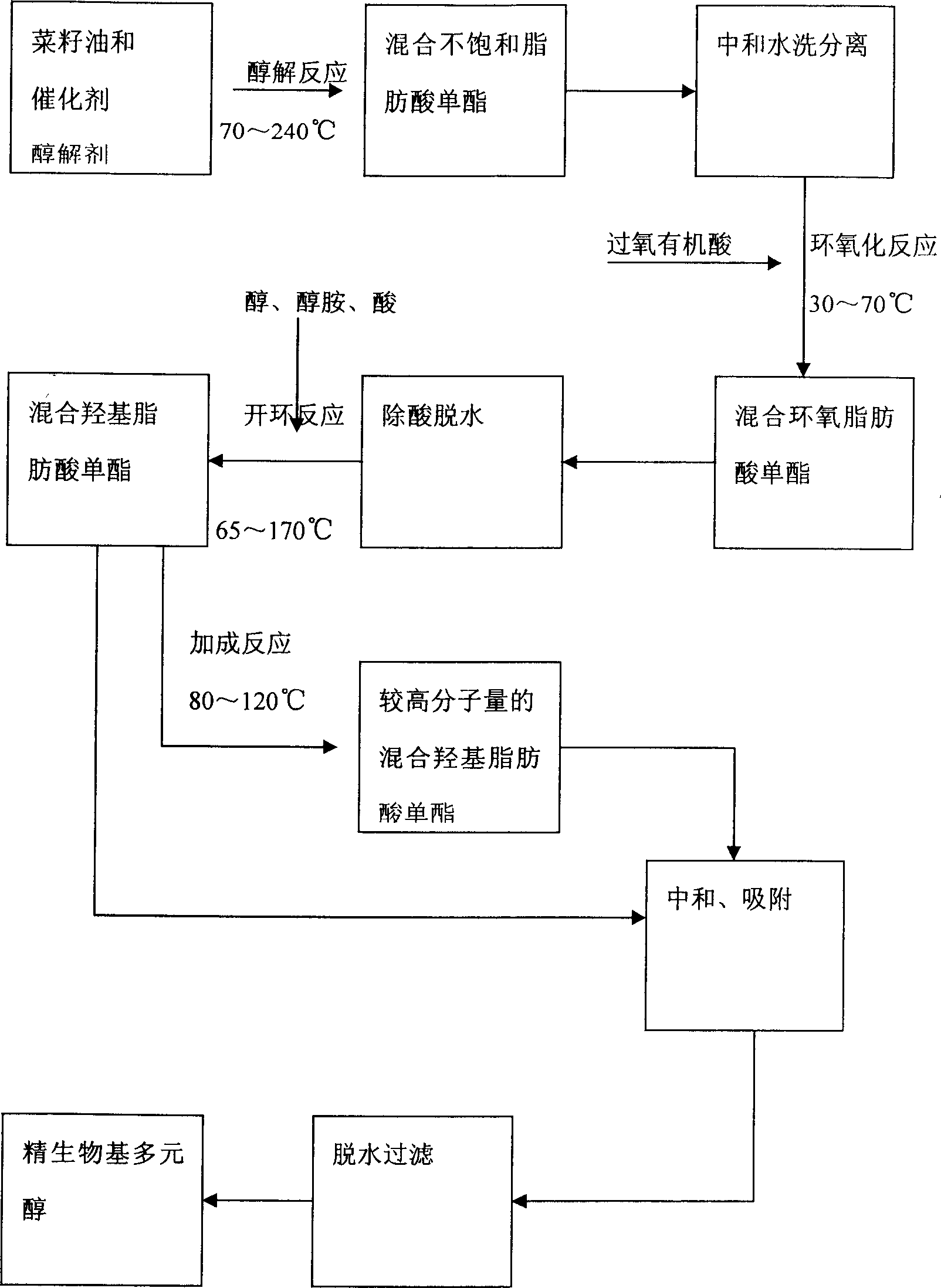

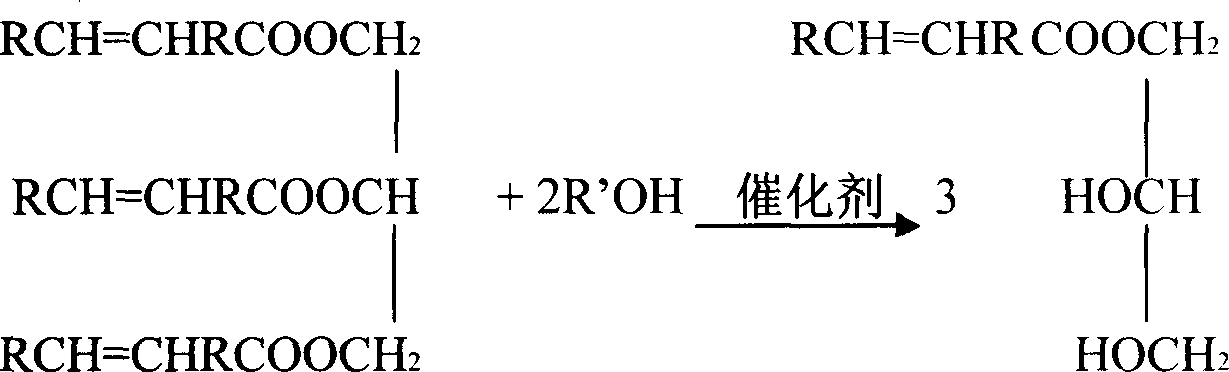

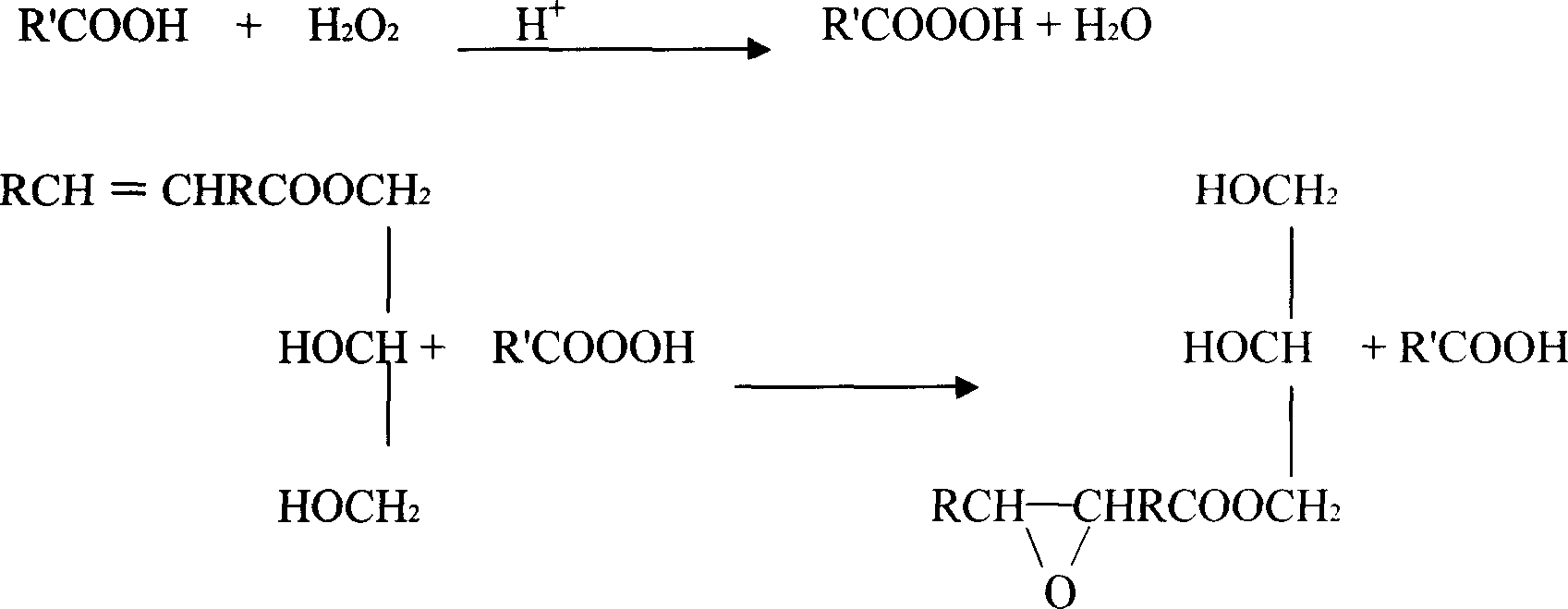

Bio-based polyhydric alcohol prepared by using rape seed oil

The invention discloses a rape oil preparing biological radical polyatomic alcohol, which comprises the following steps: carrying on alcoholysis reaction with rape oil alcohol and accelerant; generating mixed unsaturated fatty acid monoesters; adding in epoxidation agent to proceed epoxidation reaction; getting mixed epoxy aliphatic acid monoesters-biological radical polyatomic alcohol. The invention has high reaction active, which is convenience to prepare high-functionality product.

Owner:HONGBAOLI GRP CO LTD

Hydrolysis-resistant double-component polyurethane adhesive for structure adhesion

ActiveCN102559126AImprove hydrolysis resistanceHigh bonding strengthPolyureas/polyurethane adhesivesPolyesterAdhesion force

The invention relates to a hydrolysis-resistant double-component polyurethane adhesive for structure adhesion. The hydrolysis-resistant double-component polyurethane adhesive for structure adhesion consists of a component A and a component B, wherein the component A comprises the following components in part by weight: 30 to 70 parts of polyisocyanate resin, 5 to 20 parts of plasticizing agent, 0.25 to 5 parts of thixotropic agent, 10 to 50 parts of incremental filler and 0.25 to 1 part of water-removing agent; and the component B comprises the following components in part by weight: 5 to 30 parts of polyester polyol, 5 to 30 parts of vegetable oil polyol, 5 to 30 parts of polyether polyol, 3 to 15 parts of water-absorbing filler, 1 to 10 parts of thixotropic agent, 3 to 15 parts of incremental filler, 0.1 to 10 parts of pigment, 0.1 to 5 parts of adhesion force accelerator, 0.1 to 2 parts of chain extender and 0.01 to 0.2 part of catalyst. An adhesion system improves adhesion property, solves the problem that a thermosetting composite material is subjected to surface roughening treatment before adhesion and improves the using efficiency. Aiming at the problem of poor hydrolysis resistance of a polyester type polyurethane adhesive system, the hydrolysis resistance is improved through molecule design of polyurethane soft and hard sections.

Owner:TONSAN ADHESIVES INC

Method of long lasting human skin tanning

InactiveUS20110020252A1Durable UVRAvoid repeated contactCosmetic preparationsToilet preparationsHuman skinDermatology

The invention relates to the use of Rifampin and its related compound as a method of producing long-lasting, effective skin tanning for human and animal. The invention relates to methods of accelerating and facilitating the tanning of the skin using Rifampin along with use of the other tanning facilitators and accelerants with or without UVR.

Owner:SHANTHA TOTADA R +2

Sand consolidation and water plugging profile control agent made by oil sand

InactiveCN101451061ATo achieve the goal of emission reductionEnhanced overall recoveryDrilling compositionSealing/packingSlagGranularity

The invention relates to a sand-consolidating and water-blocking profile modifying agent for oil sludge sand. The profile modifying agent is prepared by mixing the following raw materials: oil sludge sand, 10 to 90 portions of consolidation agent or adding modifier, a consolidation accelerant or a consolidation retardant; the oil sludge sand is subjected to ball milling through a ball mill; part of large crude oil is separated off so as to reach the requirement of granularity of the profile control agent; therefore, the oil sludge sand with granularity of less than 200 meshes is less than 70 percent of the total mass of the oil sludge sand; and the consolidation agent is selected from one or a mixture of one or more of cement or cement clinker, steel slag, slag, pulverized coal ash, gypsum, lime and magnesia. In application, the profile control agent is prepared to a 1 to 20 percent suspension solution; and the suspension solution is injected into a deep part of stratum of an oilfield through profile modification equipment. The profile modifying agent fully utilizes mass oil sludge sand produced in the production process of various oilfields, realizes the aim of emission reduction; and the oil sludge sand is recycled and is used as the sand-consolidating and water-blocking profile modifying agent, thereby achieving the aim of consolidating sand, blocking water and improving extraction yield.

Owner:SHANDONG UNIV

Thermosetting adhesive compositions comprising a protein-based component and a polymeric quaternary amine cure accelerant

InactiveUS20050261404A1Fast tack-buildingFast curingProtein adhesivesLayered productsSynthetic resinEpichlorohydrin

Thermosetting adhesive compositions for use in e.g., particleboard or fiberboard, wherein the compositions comprise a blend of a protein-based component and a polymeric quaternary amine cure accelerant, can provide the fast tack-building and curing, as well as ultimately good bonding characteristics normally associated with synthetic resin compositions. Preferably, the polymeric quaternary amine cure accelerant is the reaction product of a polyamidoamine and epichlorohydrin.

Owner:GEORGIA PACIFIC CHEM LLC

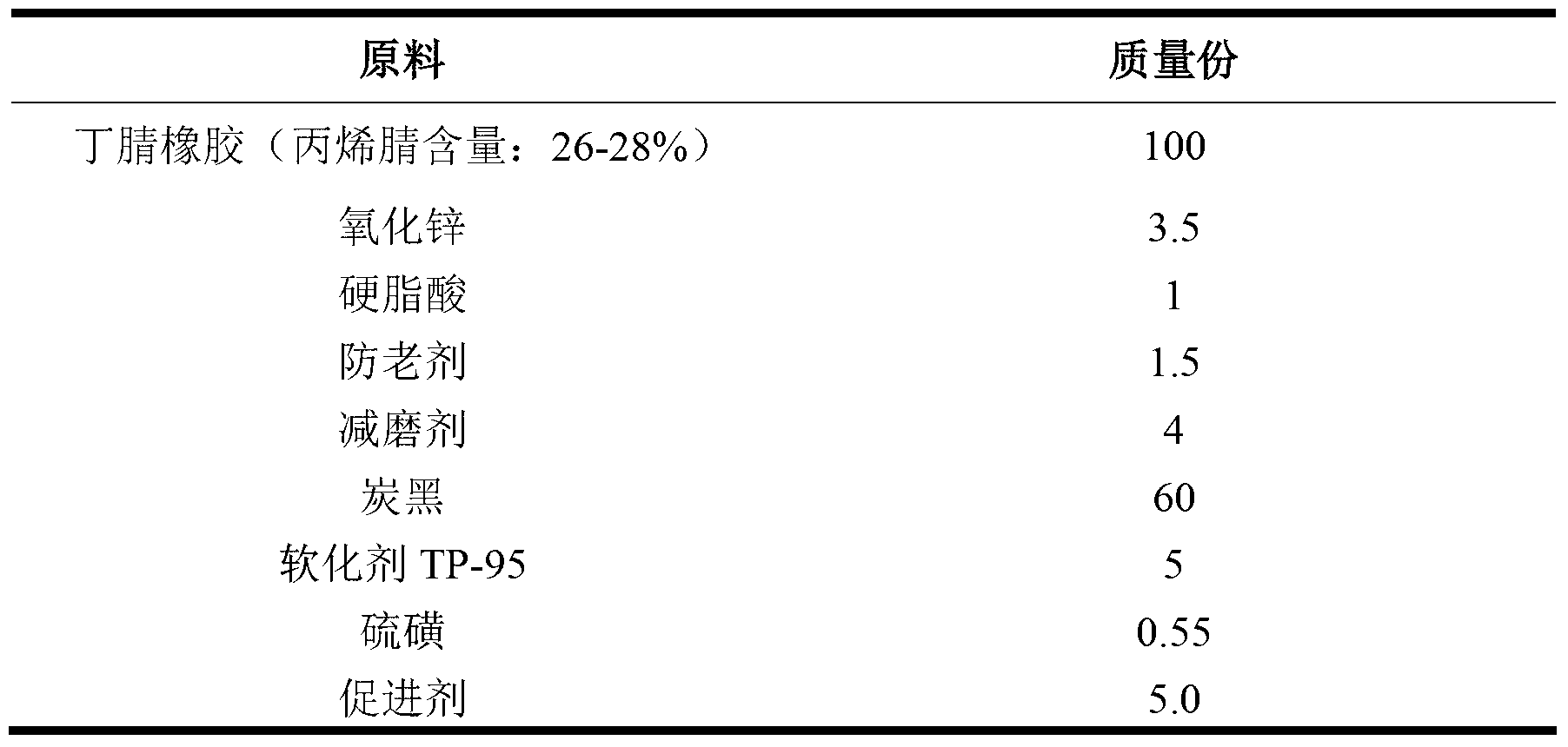

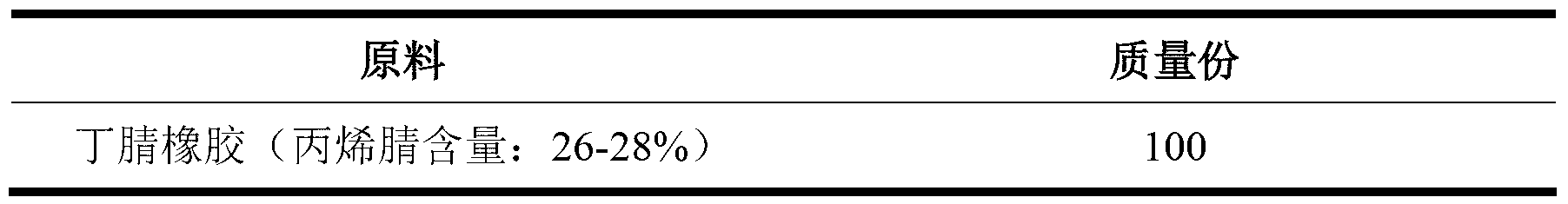

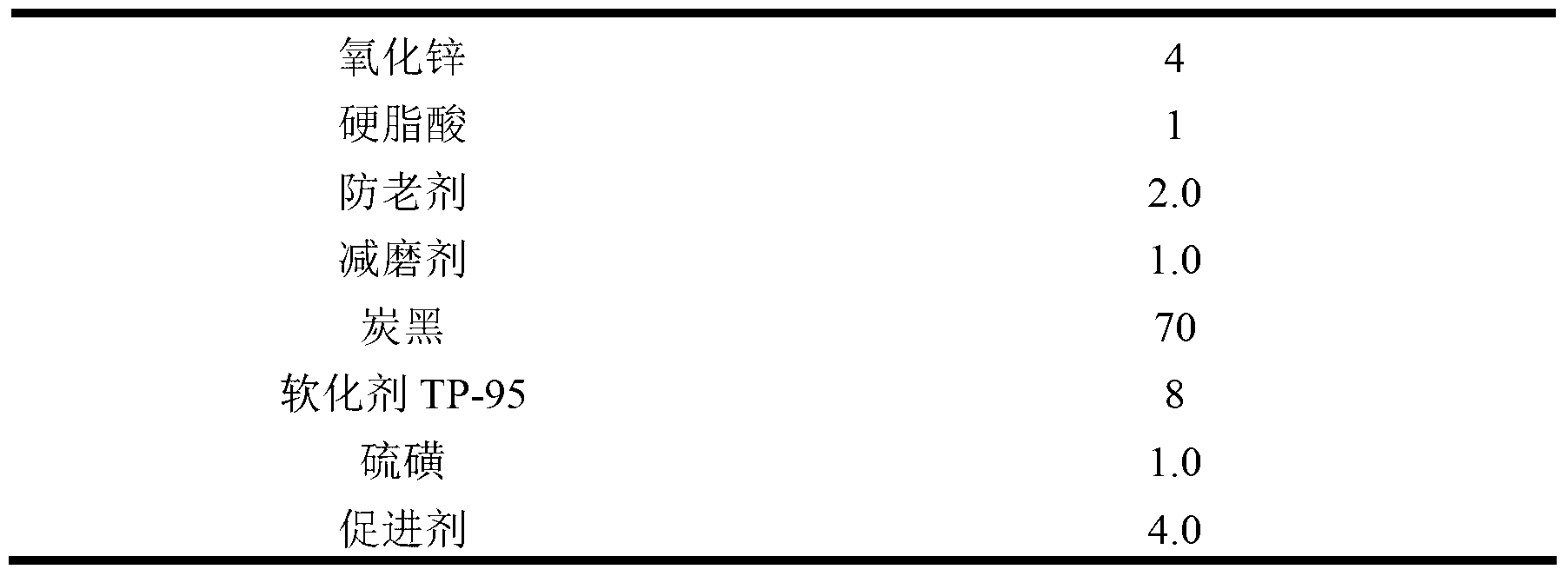

Cold-resistant wear-resistant nitrile rubber sealing material and preparation method thereof

ActiveCN103289150ACompatibility is reasonableImprove wear resistanceOther chemical processesPolymer scienceNitrile rubber

The invention discloses a cold-resistant wear-resistant nitrile rubber sealing material which comprises the following raw materials of: by weight, 100 parts of nitrile rubber, 3.5-8 parts of zinc oxide, 1 part of stearic acid, 1.5-3.5 parts of an antioxidant, 0.5-4.0 parts of an antifriction agent, 60-115 parts of carbon black, 2-10 parts of TP-95, 0.3-1.0 parts of a vulcanizing agent and 3.0-5.5 parts of an accelerant. A preparation method of the nitrile rubber sealing material comprises the steps of plasticating the nitrile rubber, adding the zinc oxide, the stearic acid, the antioxidant and the antifriction agent to carry out mixing, adding 1 / 2 of the carbon black to continue mixing after last mixing, then adding the residual carbon black and TP-95 to continue mixing, discharging glue stock and refining the glue stock with turning, obtaining a segment of rubber compound and placing the segment of the rubber compound, adding the rubber compound to a rubber covered roll of an open mill, adding the accelerant to carry out mixing, milling and packaging in a triangular bag, adjusting thickness and discharging material sheets. The nitrile rubber sealing material provided by the invention has better cold resistance and wear resistance.

Owner:GUANGZHOU JST SEALS TECH

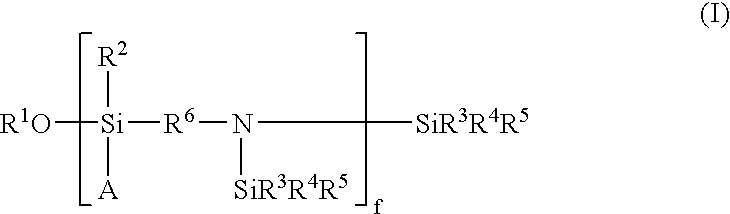

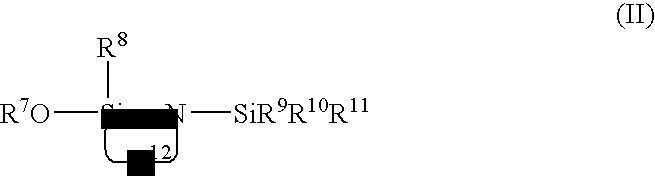

Process for producing modified conjugated diene based polymer, modified conjugated diene based polymer produced by the process, rubber composition, and tire

The invention provides a process for producing a modified conjugated diene based polymer which attains favorable interaction between a rubber component and carbon black and / or silica, thereby improving dispersibility of the fillers, and which exhibits excellent properties such as heat-buildup-suppressing performance, fracture characteristics, and wear resistance; a modified conjugated diene based polymer produced through the process; a rubber composition containing the diene polymer; and a tire produced from the rubber composition and exhibiting the above properties. The process for producing a modified conjugated diene based polymer includes a step (a) of reacting a silicon compound with a conjugated diene based polymer having an active end so that the reaction takes place at the active end, the silicon compound having a protected primary amino group in the molecule thereof and a bi-functional silicon atom to which a hydrocarbyloxy group and a reactive group including a hydrocarbyloxy group are bonded, to thereby modify the active end, and a step (b) of performing condensation reaction which involves the compound having a bi-functional silicon atom, in the presence of a titanium compound serving as a titanium-based condensation-accelerating agent.

Owner:BRIDGESTONE CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com