Patents

Literature

2425 results about "Natural rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural rubber, also called by other names of India rubber, latex, Amazonian rubber, caucho or caoutchouc, as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds, plus water. Thailand and Indonesia are two of the leading rubber producers. Forms of polyisoprene that are used as natural rubbers are classified as elastomers.

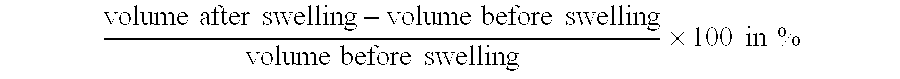

Sealing material which swells when treated with water

InactiveUS6358580B1Safely preventingRapid and sizable and controlled swellingCosmetic preparationsOrganic detergent compounding agentsElastomerCallose

The invention relates to an optionally foamed sealing composition for preformed seals which can swell when treated with water. The invention also relates to a method for the production thereof out of natural rubber and / or elastomers with a matrix comprised of natural rubber / elastomer components and particle-shaped water absorbing material stored therein. The water absorbing material is a combination of (A) polysaccharide(s) selected from cellulose, starch, starch derivatives removed from grafted starch, amylose, amylopectin, dextran, pectin, inulin, chitin, xanthan, alginic acid, alginates, carrageenan, pustulan, callose, laminarin, guluronic acid, pullulan, lichenin or mixtures of the same with (B) a highly water absorbent synthetic polymer selected from polymers based on (meth)acrylate, poly(meth)acrylic acid and the salts thereof, polyacrylamide, polyalcohols or copolymers of said synthetic polymers. The invention also relates to additional cross-linking and processing auxiliary agents and to property improving agents. It is possible to securely seal superstructures, substructures, tunnels and canals with the assistance of the inventive sealing compositions.

Owner:DAETWYLER AG CH +1

Antimicrobial medical articles containing a combination of anti-infective compounds, octoxyglycerin, salicylic acid, and sesquiterpenoids

Medical articles impregnated with antimicrobial compositions containing synergistic combinations of octoxyglycerin and other anti-infective compounds are disclosed. Such medical articles may include urinary catheters, central venous catheters, tracheal catheters, arterial grafts, wound dressings, sutures, or any other medical articles derived from polymeric substrates such as biomedical polyurethane, biomedical polyvinylchloride (PVC), biomedical silicon, biodegradable polymers, polytetrafluoroethylene (PTFE), etc. or from natural products including natural rubber, silk or cotton fiber. Antimicrobial compositions comprising salicylic acid and sesquiterpenoids are also disclosed.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

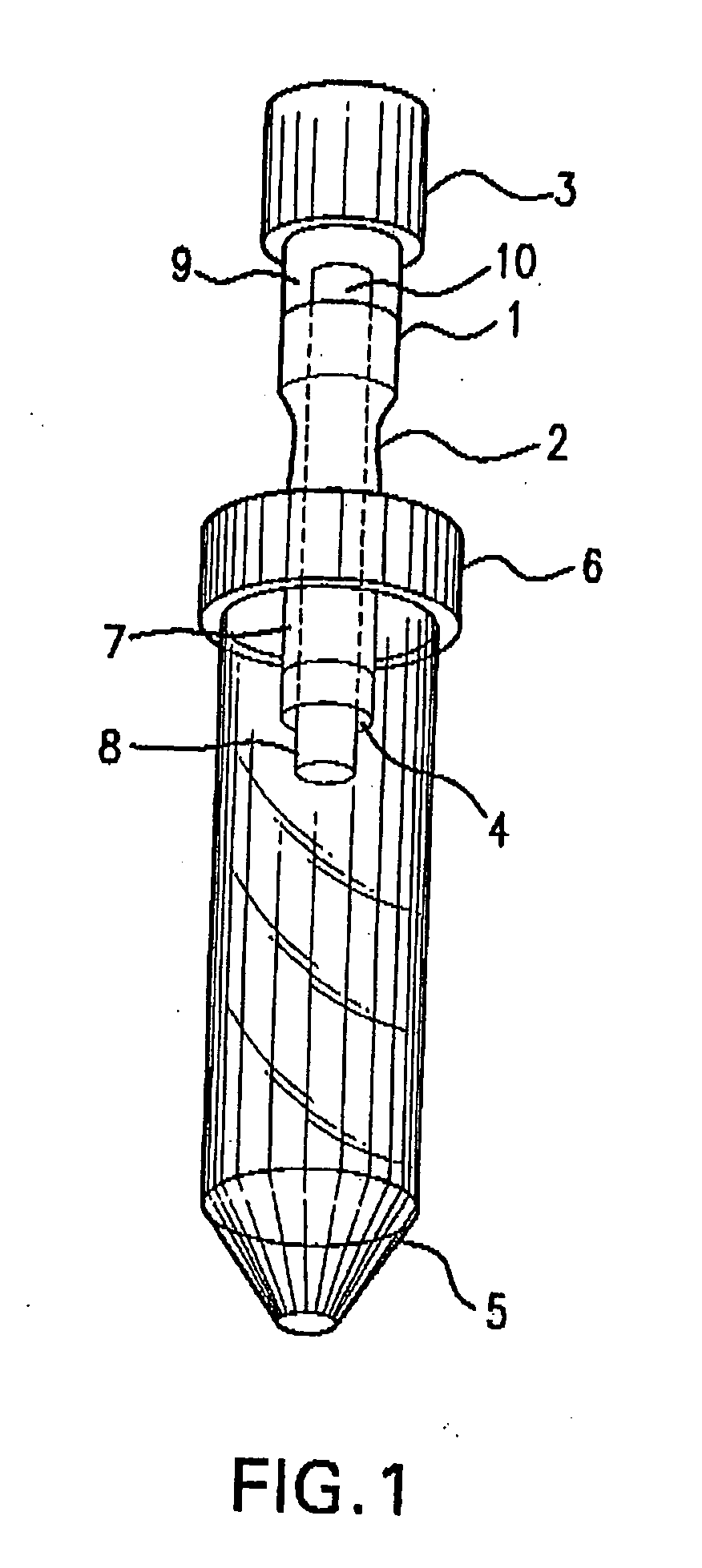

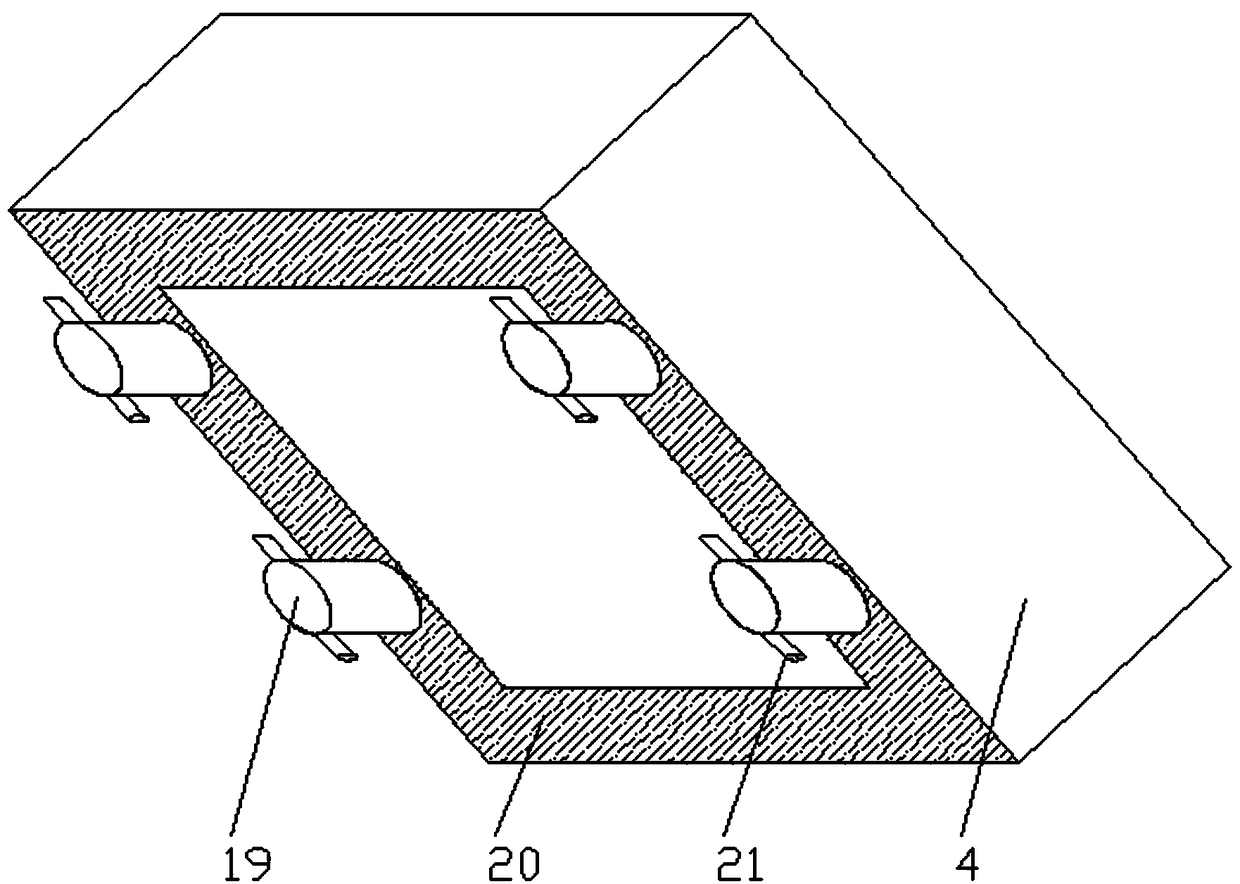

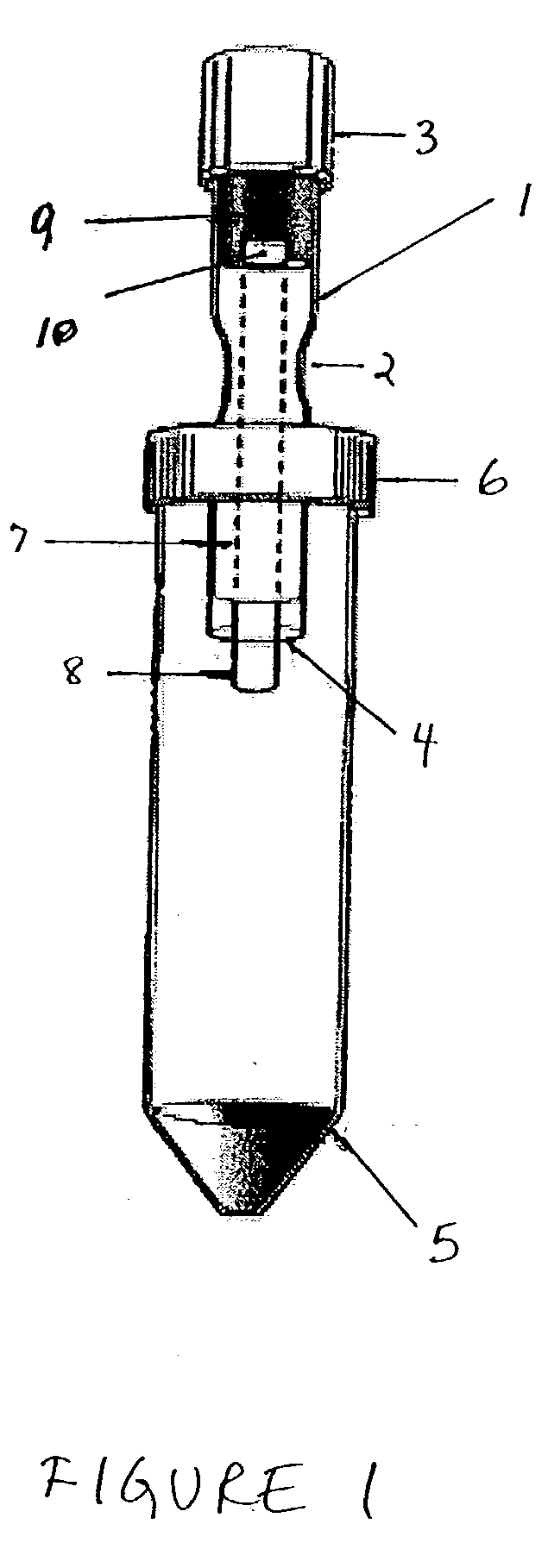

Electric pressure cooker vapor exhausting device

InactiveCN108577514AEasy to install and disassembleEasy to usePressure-cookersWater vaporEngineering

The invention discloses an electric pressure cooker vapor exhausting device which structurally comprises an electric pressure cooker, a pot cover, a water collecting tank, an exhausting device and a control panel. The control panel is arranged at the front portion of the electric pressure cooker. A power line is arranged at the rear portion of the electric pressure cooker. The left side of the electric pressure cooker is connected with the water collecting tank through a buckle. A silica gel seal ring is arranged on the top of the electric pressure cooker by a circle. The pot cover is arrangedon the top of the electric pressure cooker. The right portion of the pot cover is in threaded connection with a fixed base. A handle is arranged on the top of the fixed base. The left portion of thehandle is connected with the exhausting device. The water collecting tank is composed of a liquid level sensor, an alarm device, a concave hole and a natural rubber seal ring. The exhausting device comprises a fixed column, a synthesized rubber seal ring, a telescopic elastic head, a vapor inlet, a vapor guide pipe, a liquefied device and an exhaust pipe. The electric pressure cooker vapor exhausting device is convenient to install and detach, high in sealing performance and high in intelligence and efficiently senses the vapor liquid level.

Owner:黄文才

Composite material of modified micro plant fiber powder and natural rubber and its prepn process and application

The present invention discloses one kind of composite material of modified micro plant fiber powder and natural rubber and its preparation process and application. The composite material includes natural rubber or latex 100 weight portions, modified micro plant fiber powder 1-60 weight portions, sulfur 0.5-3.3 weight portions, promoter 1.2-4.3 weight portions, antiager 1-3 weight portions and other assistant. The preparation process includes mixing, forming, vulcanizing and other steps. The composite material has high tensile strength, high tearing strength, high ageing resistance, high virus permeation resistance, etc. and may be used widely in making urinary catheter, blood transfusion tube, condom, medical gloves and other products.

Owner:JINAN UNIVERSITY

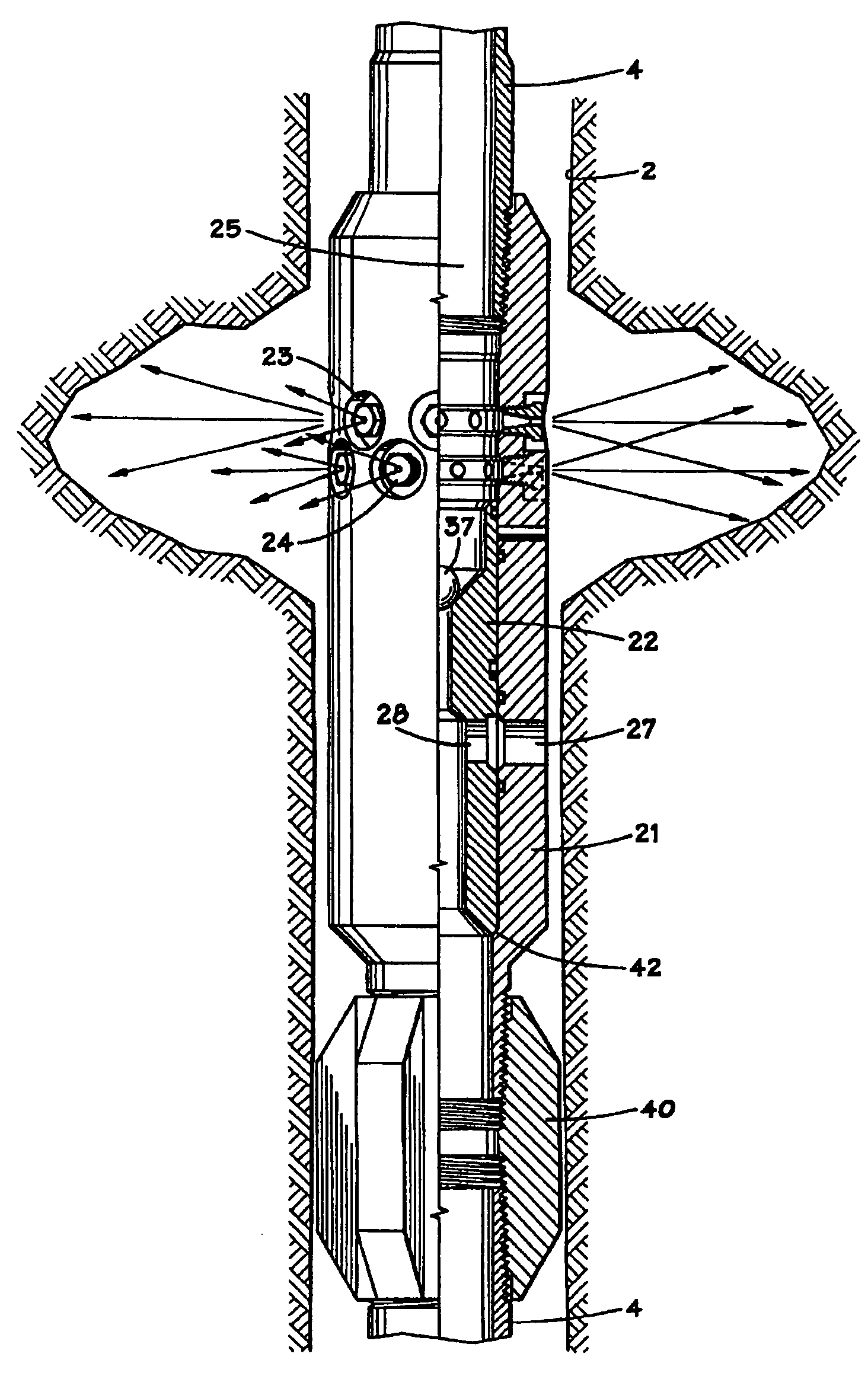

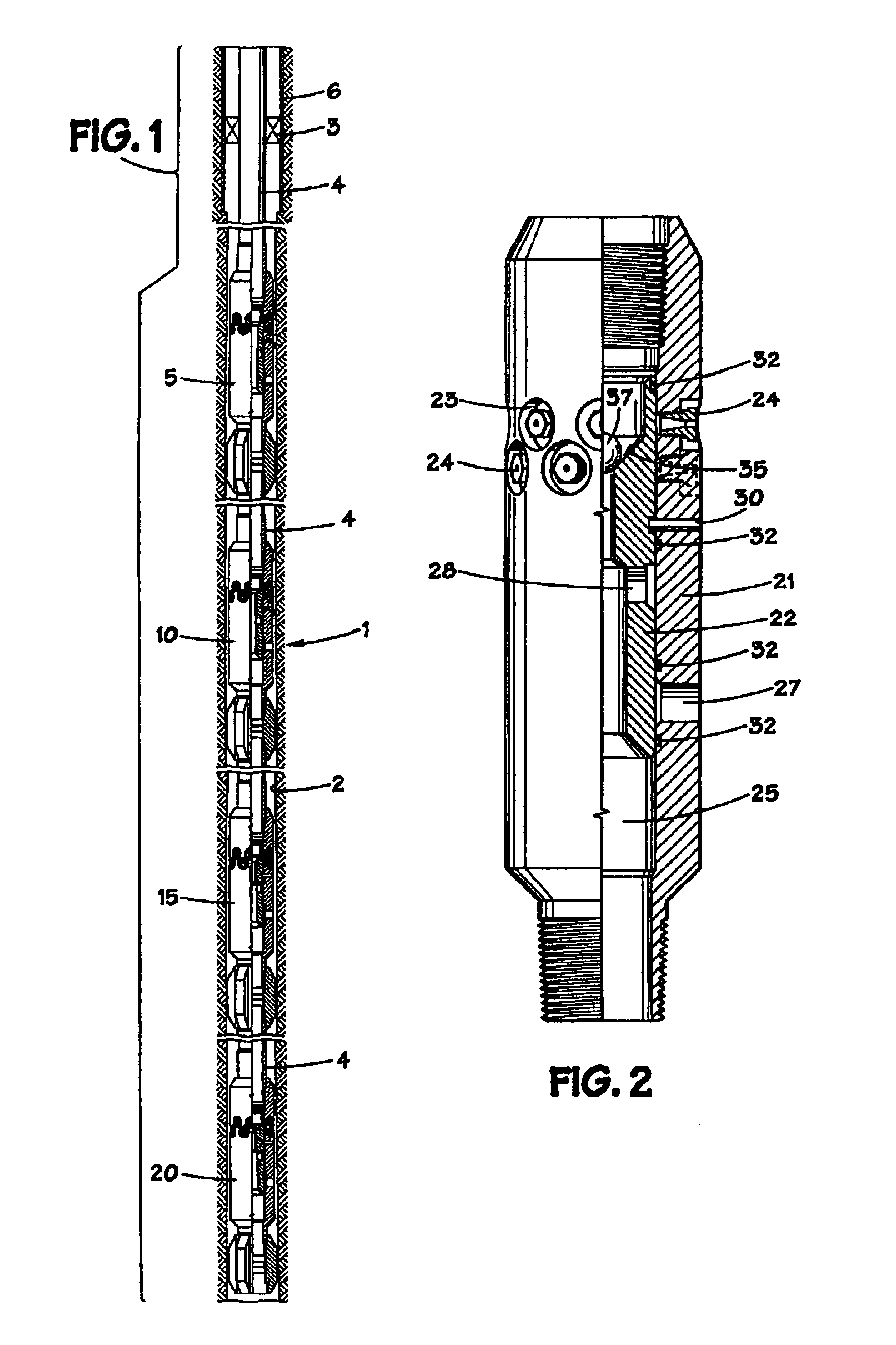

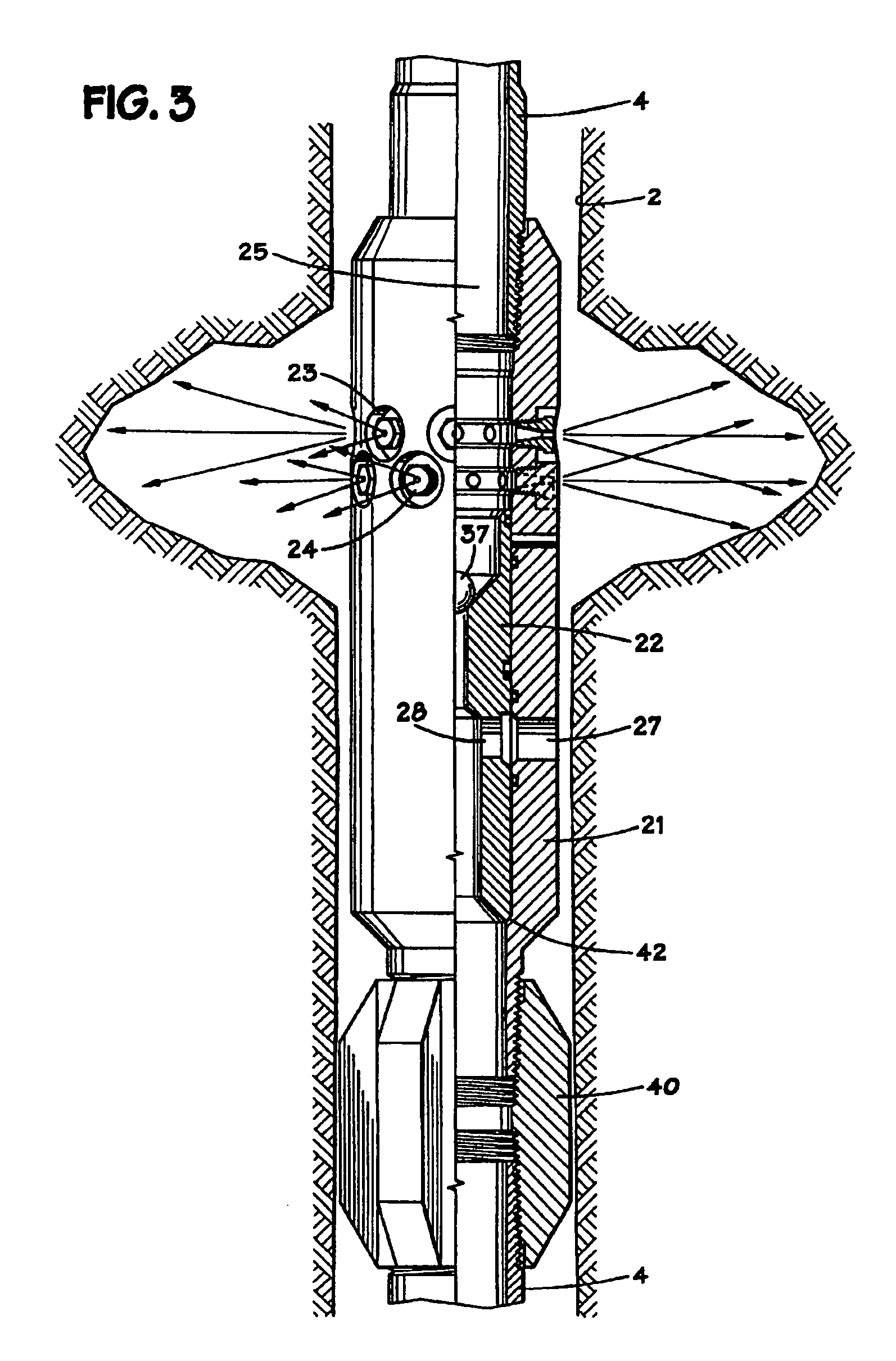

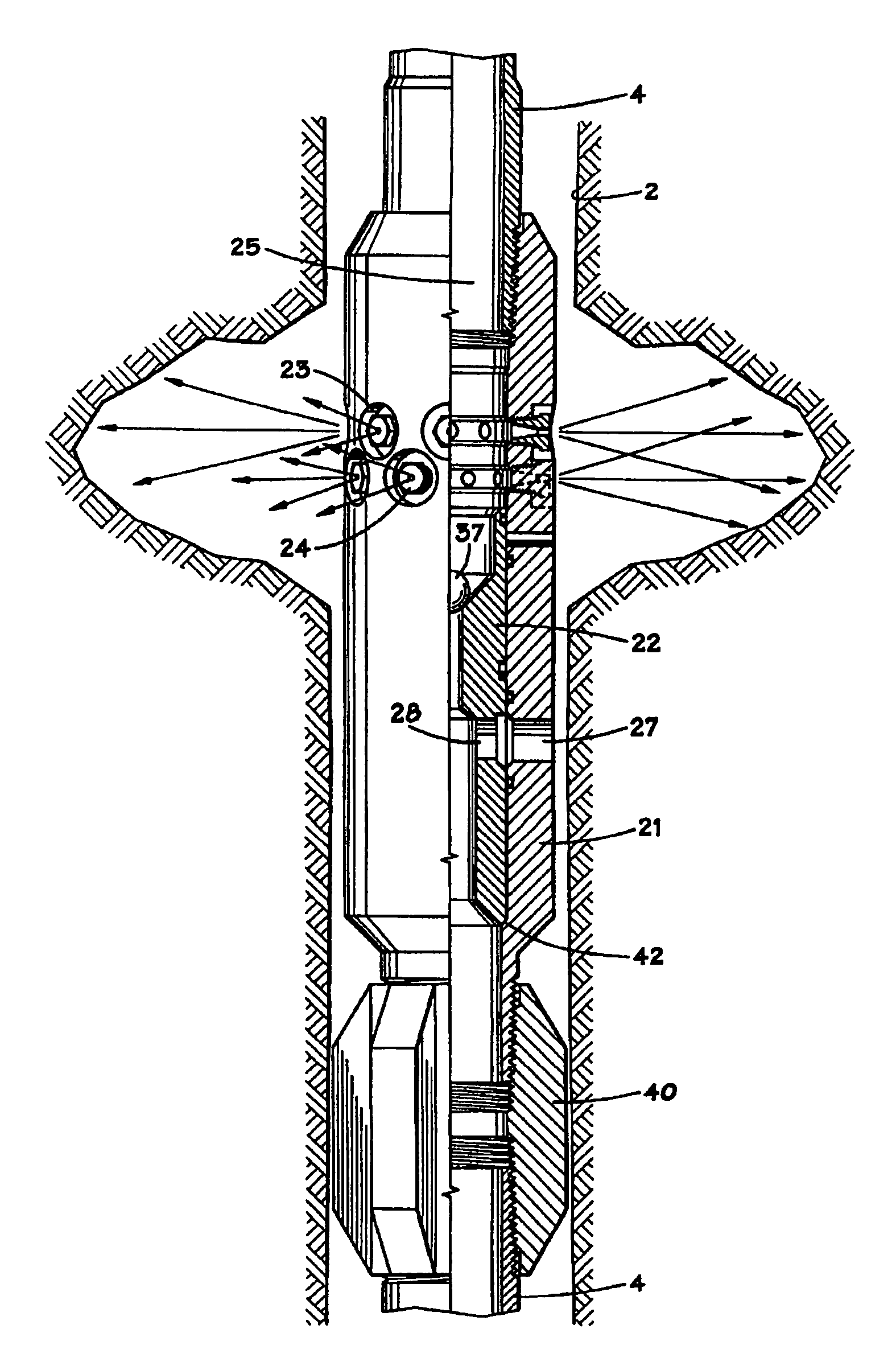

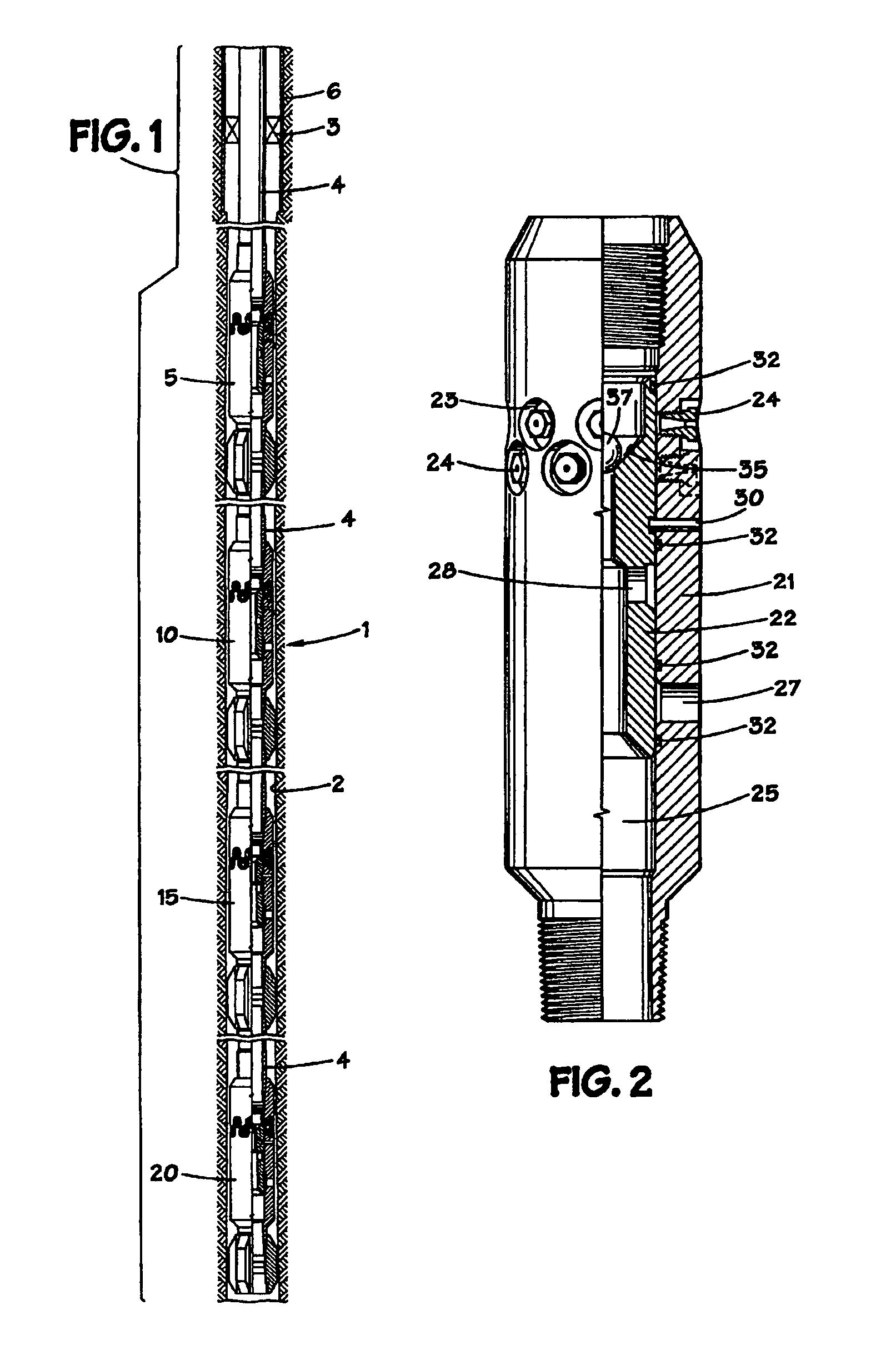

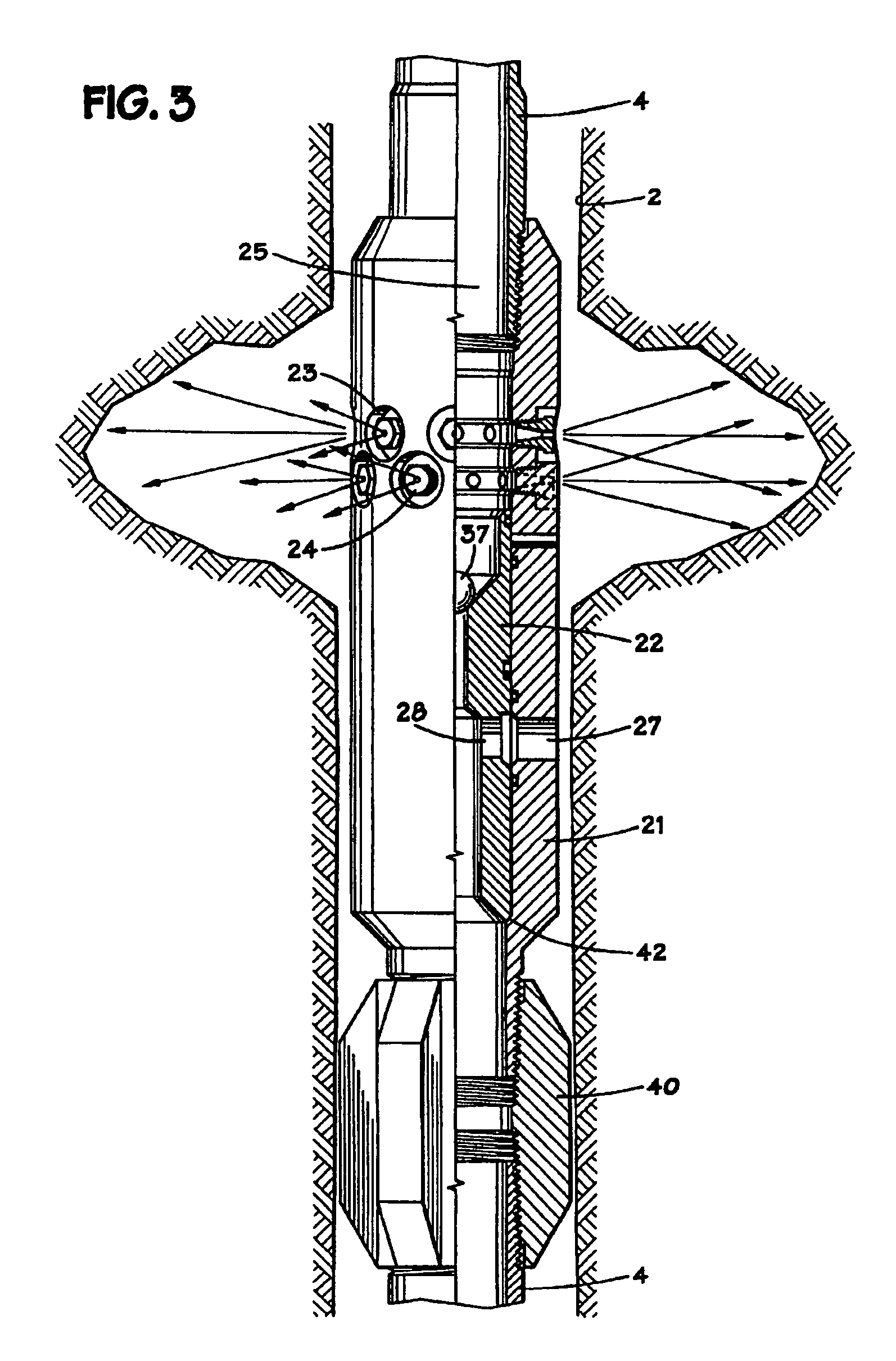

System and method for stimulating multiple production zones in a wellbore

ActiveUS20080210429A1Prevent curingFluid removalWell/borehole valve arrangementsNatural rubberOil well

A system and method for selectively stimulating a plurality of producing zones of a wellbore in oil and gas wells, the system being cemented within the wellbore. The system includes a plurality of modules connected in a string wherein the modules can be selectively actuated to stimulate producing zones adjacent the modules. Each module includes a sleeve shiftable between a closed position and a treating position where a plurality of radial passageways are exposed to the central passageway of the assembly. The system includes a wiper plug that is adapted to pass through ball seats of various sizes in the plurality of modules and an acid solution pumped into the string to break down the cement at the producing zones. The system may include at least one natural rubber wiper ball to remove residual cement from the string.

Owner:BAKER HUGHES INC

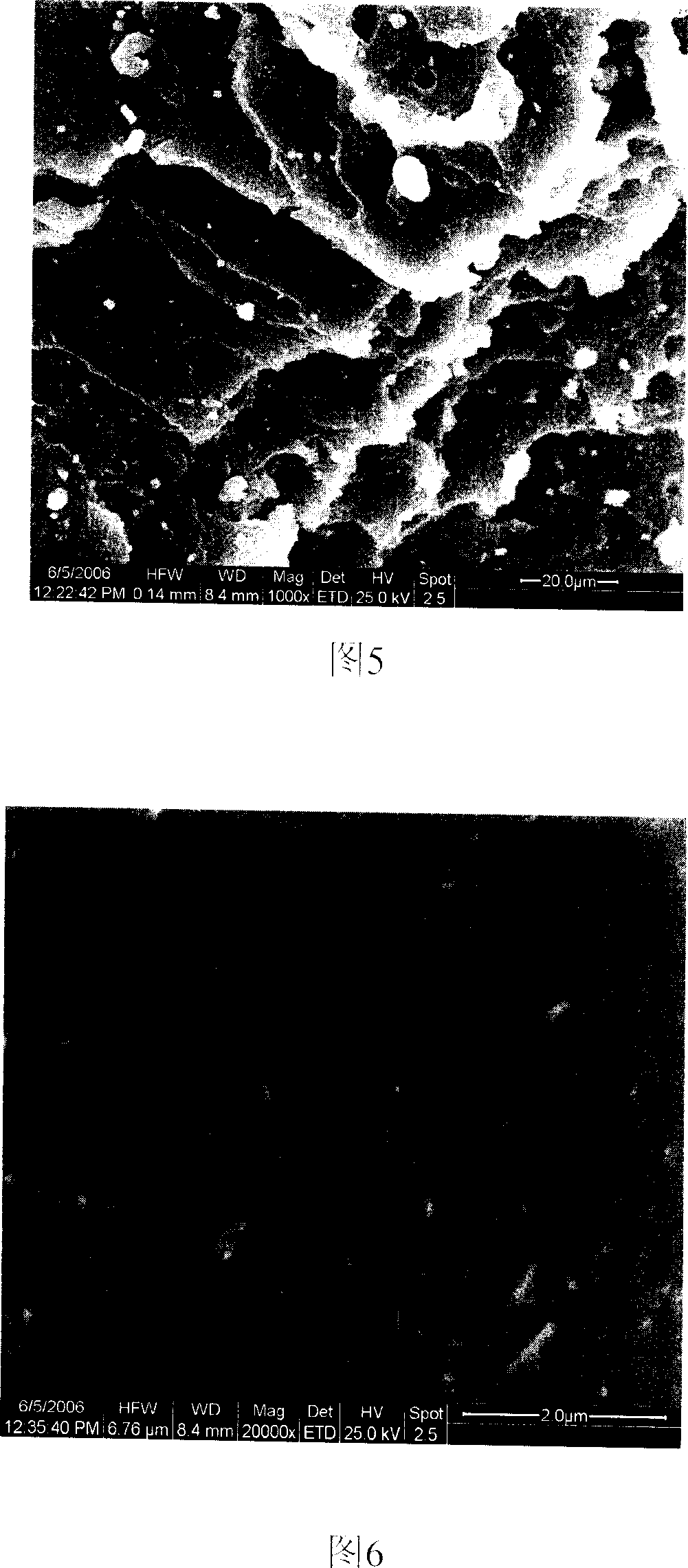

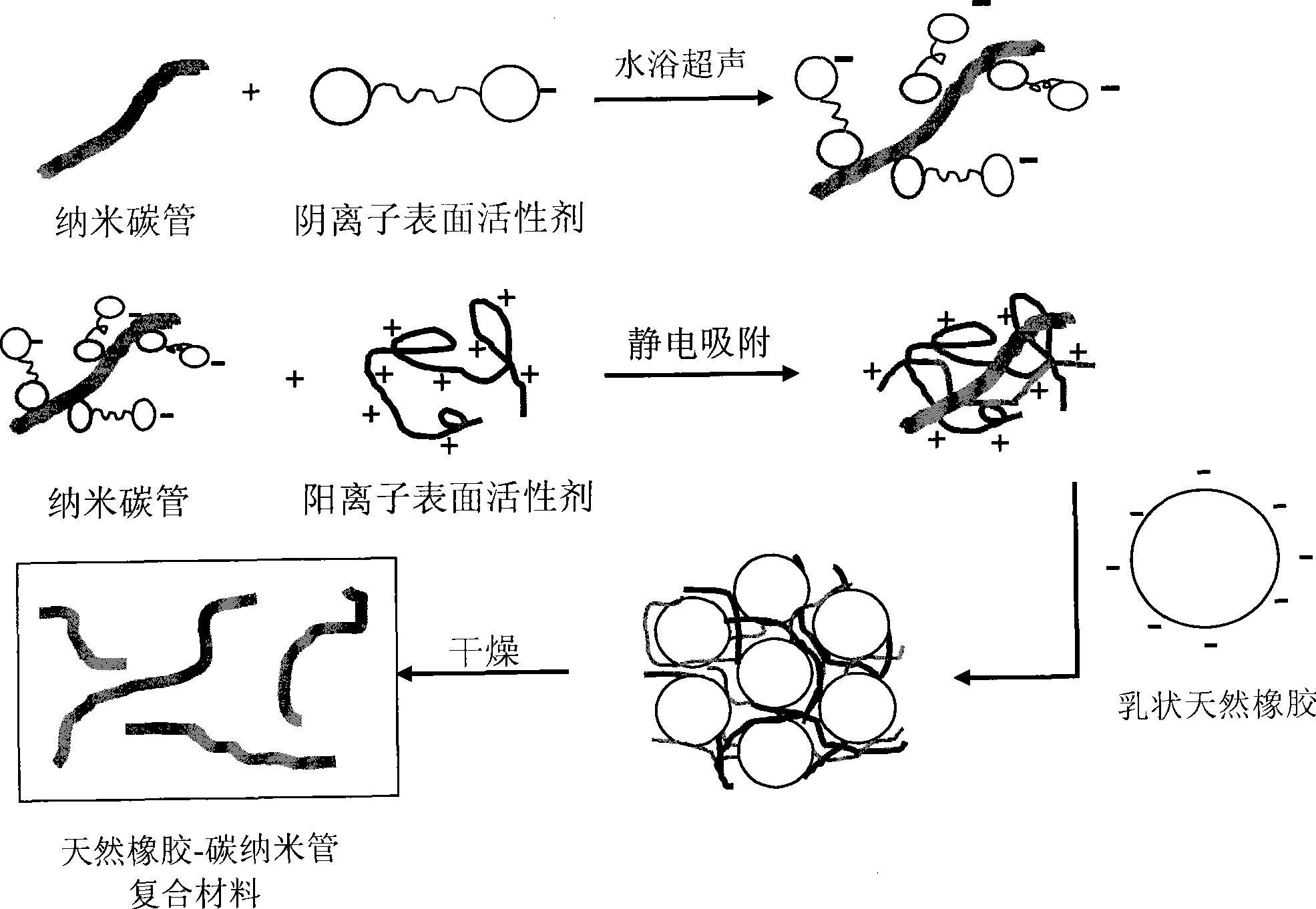

Method for preparing carbon nanotube-natural rubber compound material

The invention provides a method for preparing carbon nano tube-natural rubber composite materials, which is characterized in that the method takes epoxidised natural rubber as a compatilizer between a carbon nano tube and natural rubber, utilizes the excellent compatibility between the epoxidised natural rubber and the natural rubber and the chemical reaction between the epoxidised natural rubber and the carbon nano tube, and improves the dispersion effect of the carbon nano tube in the natural rubber and strengthening the interaction between the carbon nano tube and the natural rubber to prepare the high-performance carbon nano tube-natural rubber composite materials. The tensile strength of vulcanized films of the composite materials is between 26 and 30 MPA; the elongation at break is between 750 and 900 percent; and the 300 percent stress at definite elongation is between 4.0 and 6.0 MPa.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Carbon nanotube modified powder natural rubber and method for preparing same

Disclosed is a powder natural rubber modified by carbon nanostructured pipe and the preparing method, relating to the field of modifying macromolecular material with CNTs. Said powder natural rubber is characterized in that it possesses carbon nanostructured pipe which is 1%~50% of the glue of natural latex in mass.The method comprises conducting surface treatment forCNTs to make it hydrophilism: mixing it with dispersant and deionized water and getting the CNTs-water slurry; modifying the pH value to 9~12; mixing with natural latex and getting the natural rubber liquid latex added with CNTs. Then preparing modified powder natural rubber containing CNTs with the method of spray-drying, the quantity of input is 5%~30%, the temperature is 100~180DEG C. The prepared powder rubber is characterized by the adequate distribution of the CNTs in the product, the small size, and the dramatically increased mechanics property compared with the traditional powder rubber.

Owner:TSINGHUA UNIV

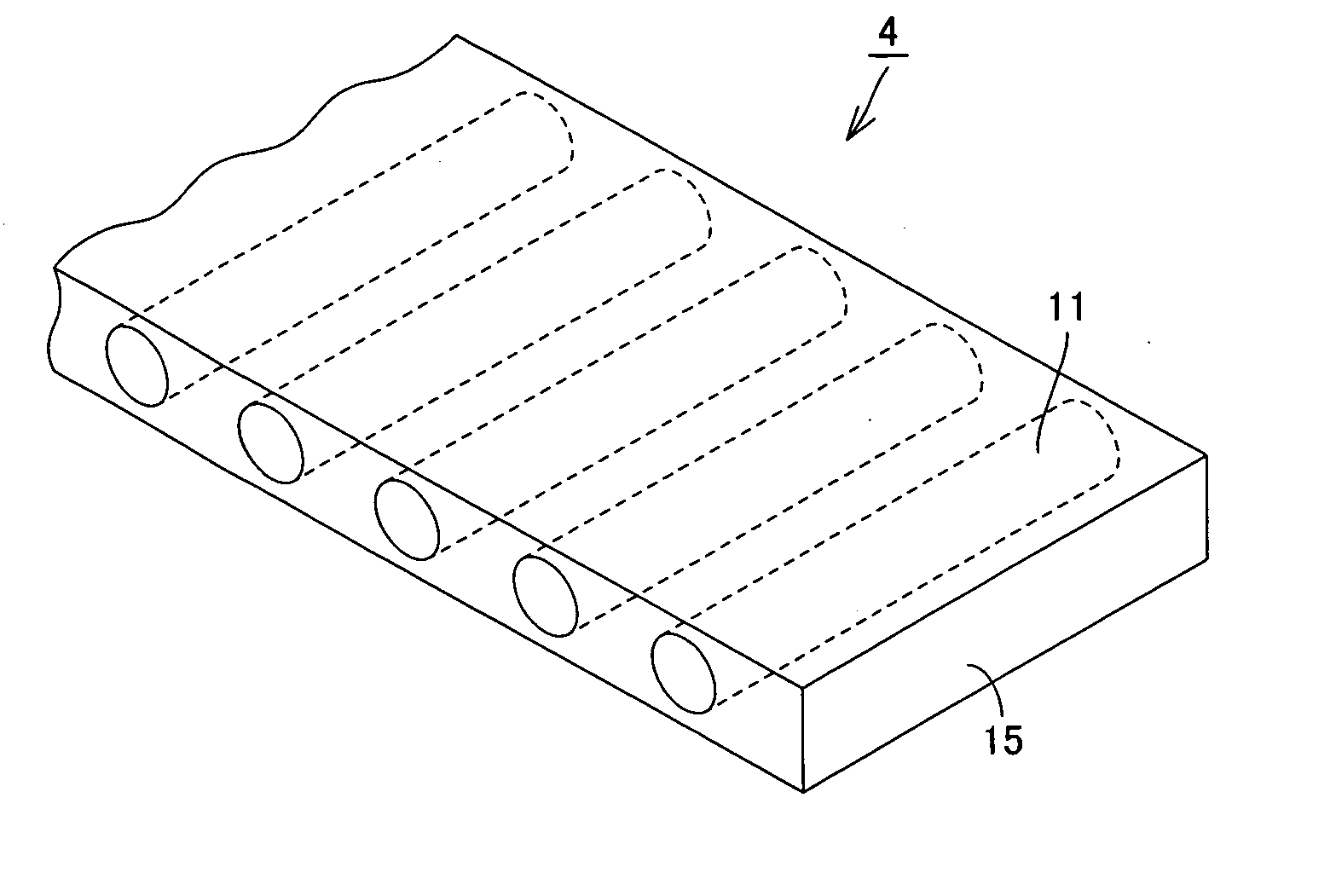

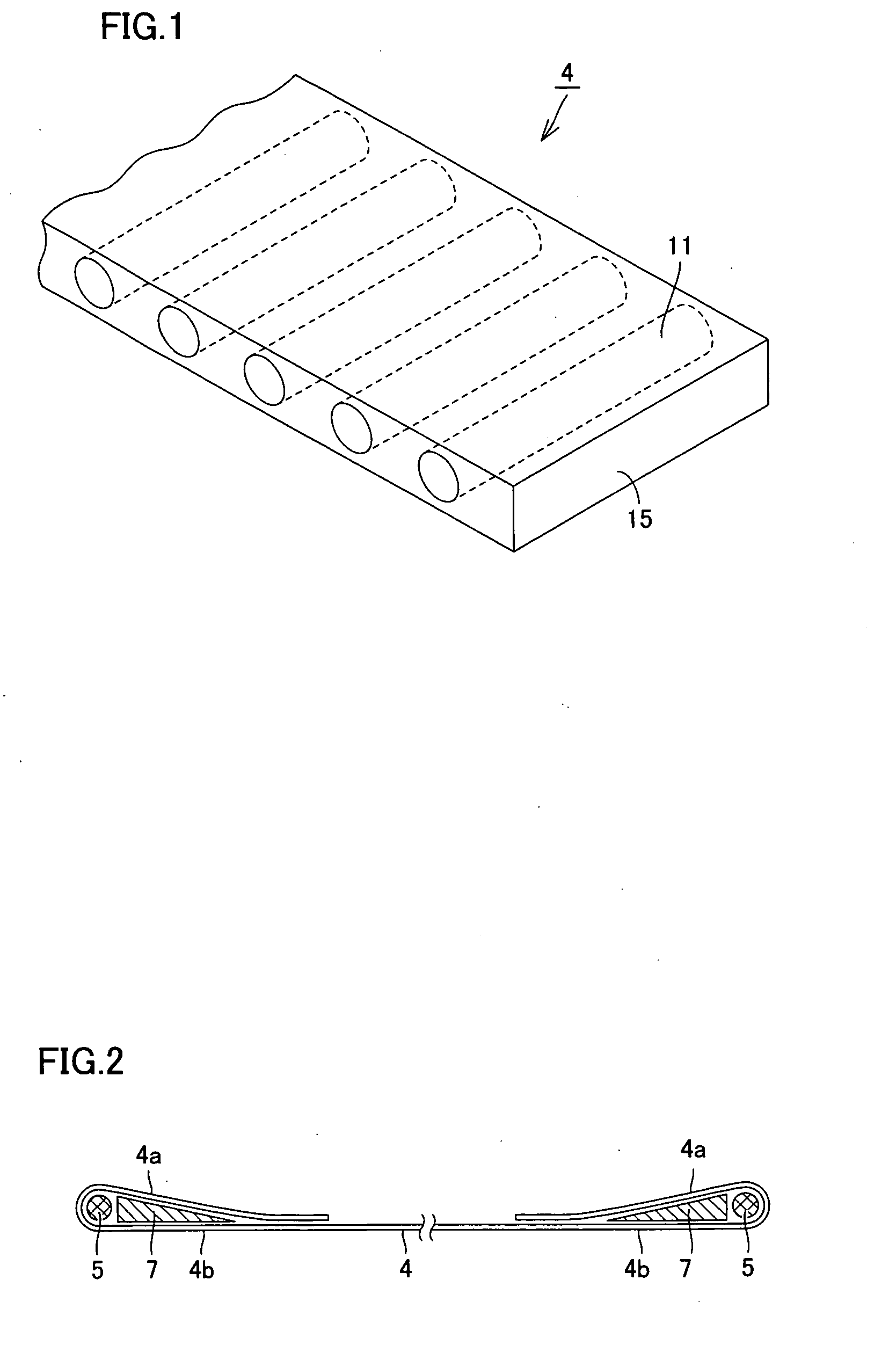

Rubber composition for tire and studless tire

InactiveUS20110166254A1Improve economyImprove performanceSilicaSpecial tyresNatural rubberEngineering

An object of the present invention is to provide a rubber composition for a tire, which can achieve well-balanced improvement in fuel economy, abrasion resistance, and performance on ice and snow, and a studless tire for a passenger vehicle using the rubber composition. The present invention relates to a rubber composition for a tire, including a rubber component and silica, wherein the rubber component contains a modified natural rubber with a phosphorus content of 200 ppm or less, and butadiene rubber, and the silica has a CTAB specific surface area of 180 m2 / g or more and a BET specific surface area of 185 m2 / g or more.

Owner:SUMITOMO RUBBER IND LTD

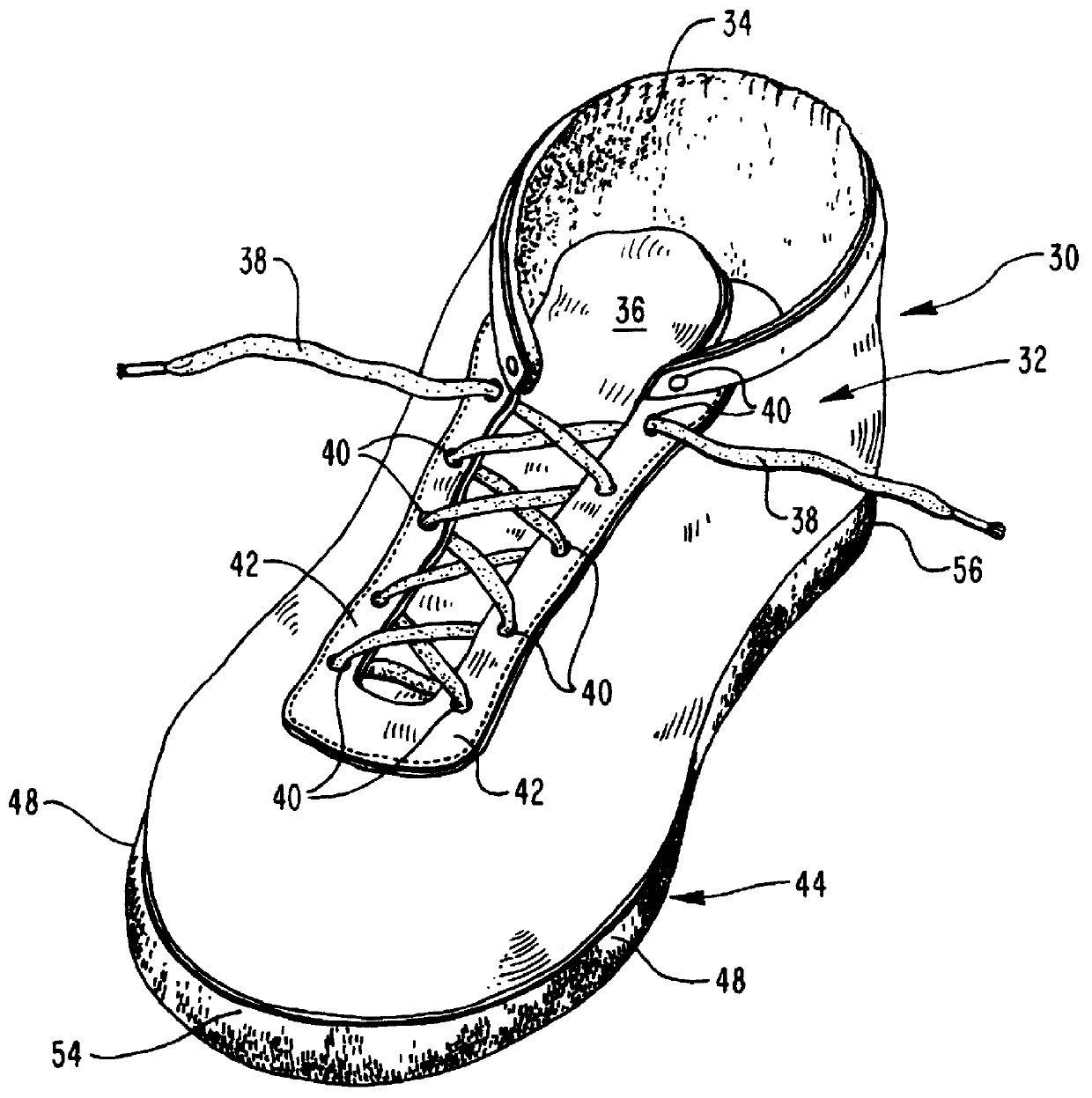

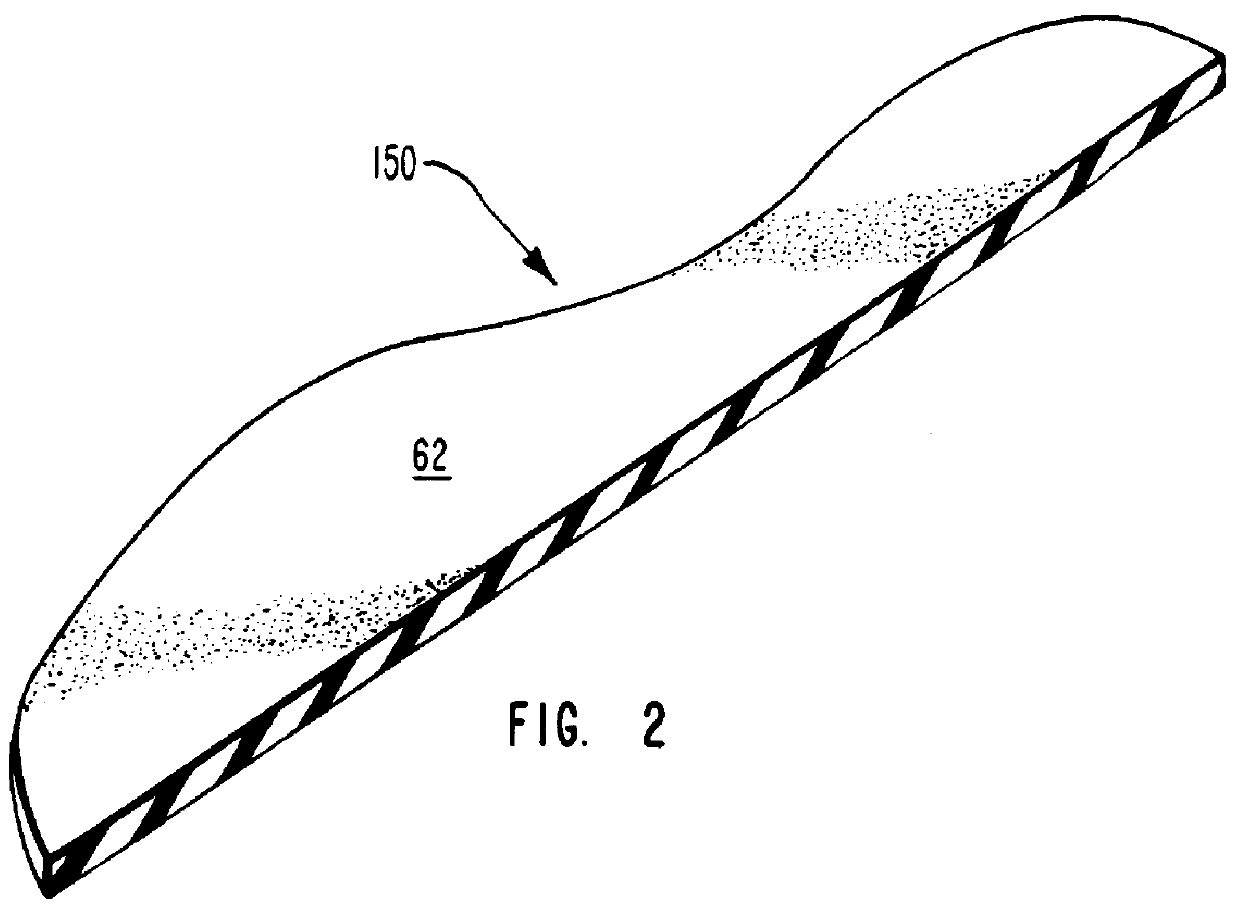

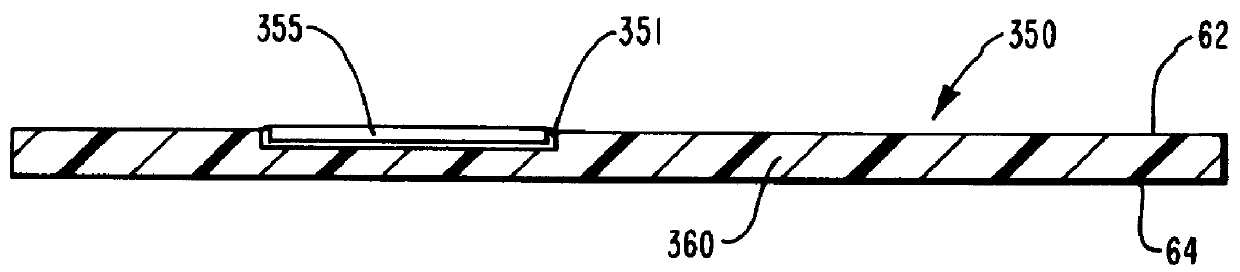

Performance enhancing athletic shoe components and methods

The present invention provides performance enhancing shoe components. The invented shoe component includes an upper layer of 1,4-polybutadiene and, optionally, a rubber such as natural rubber, synthetic isoprene rubber or polyisoprene. The first layer is attached to a resilient layer which extends substantially the length of the shoe. Optionally, a third layer or a coating may be attached to the resilient layer. The invented shoe components may be formed as shoe inserts, insoles, midsoles or shoe soles.

Owner:CROW WILLIAM R

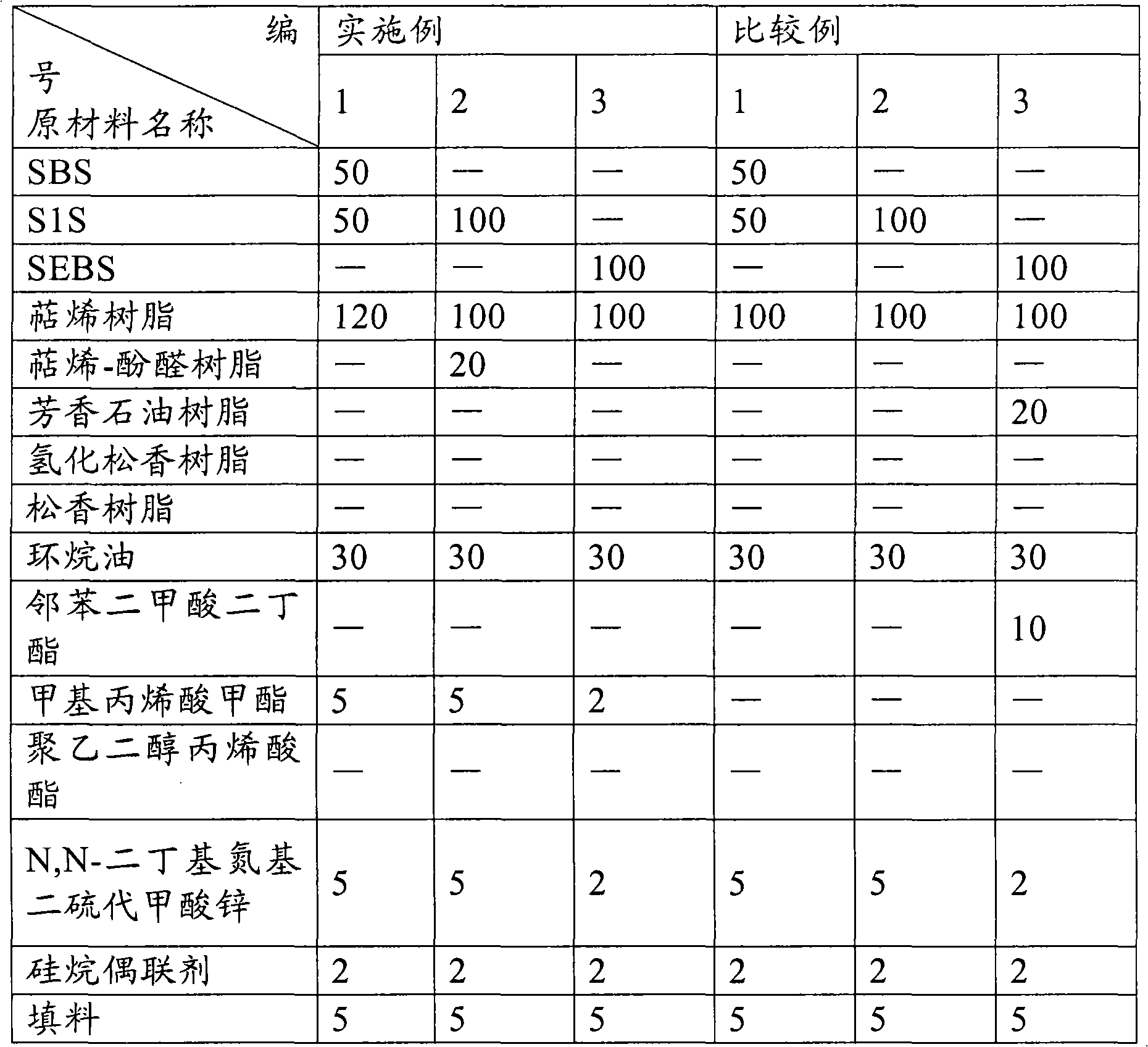

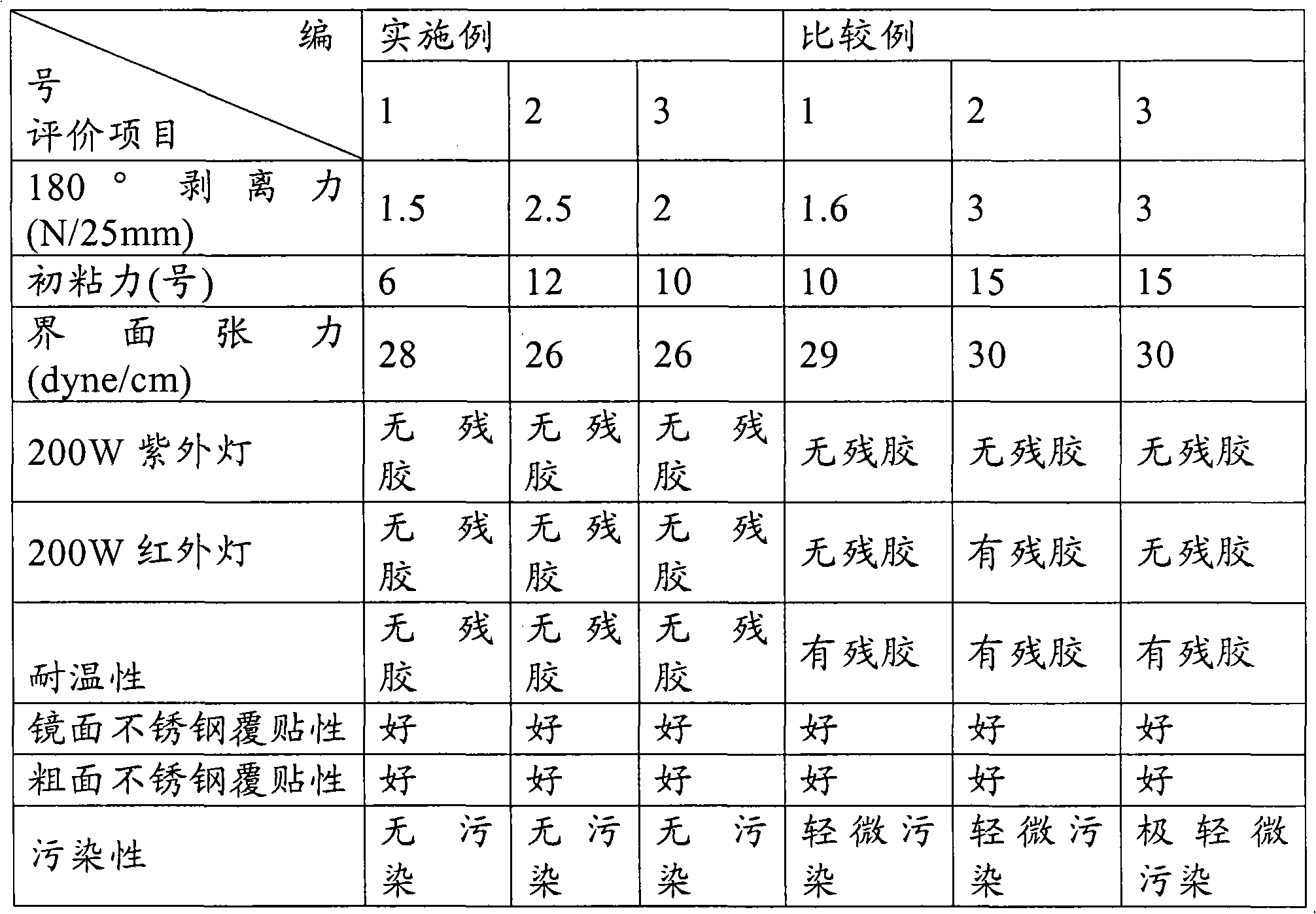

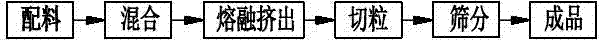

Preparation methods of hot melt pressure-sensitive adhesive and protective film as well as hot melt pressure-sensitive adhesive

ActiveCN102051149AImprove heat resistanceGood weather resistanceLiquid surface applicatorsNon-macromolecular adhesive additivesTectorial membranePolyolefin

The invention discloses preparation methods of a hot melt pressure-sensitive adhesive and a protective film as well as the hot melt pressure-sensitive adhesive. The preparation method of the hot melt pressure-sensitive adhesive comprises the following steps: adding thermoplastic elastomers, a tackifier, a plasticizer, an antiager, an antioxidant, a crosslinker, a filler and the like into a double-mixed column mixer, stirring, heating until the materials are melted down, and uniformly mixing to obtain the pressure-sensitive adhesive. The preparation method of the protective film comprises the following steps: directly pumping the melted and uniformly mixed pressure-sensitive adhesive into a coating roll of the a hot melt coating machine by a heat transfer pump, coating the pressure-sensitive adhesive onto one face of a polyolefin plastic film or thin plastic-coated paper, cooling, and rolling to obtain the protective film (paper). The hot melt pressure-sensitive adhesive disclosed by the invention can obtain good initial stickiness, cohesion and age stripping property by changing the different ratio of the thermoplastic elastomer as well as the variety and usage amount of the tackifier. The prepared polyethylene (PE) film substrate protective film has low interfacial tension, good initial stickiness, high cohesion and high temperature resistance, light resistance and weather resistance, and the comprehensive performance and product cost of the hot melt pressure-sensitive adhesive disclosed by the invention are better than those of the traditional solvent pressure-sensitive adhesive taking natural rubber as the main material.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

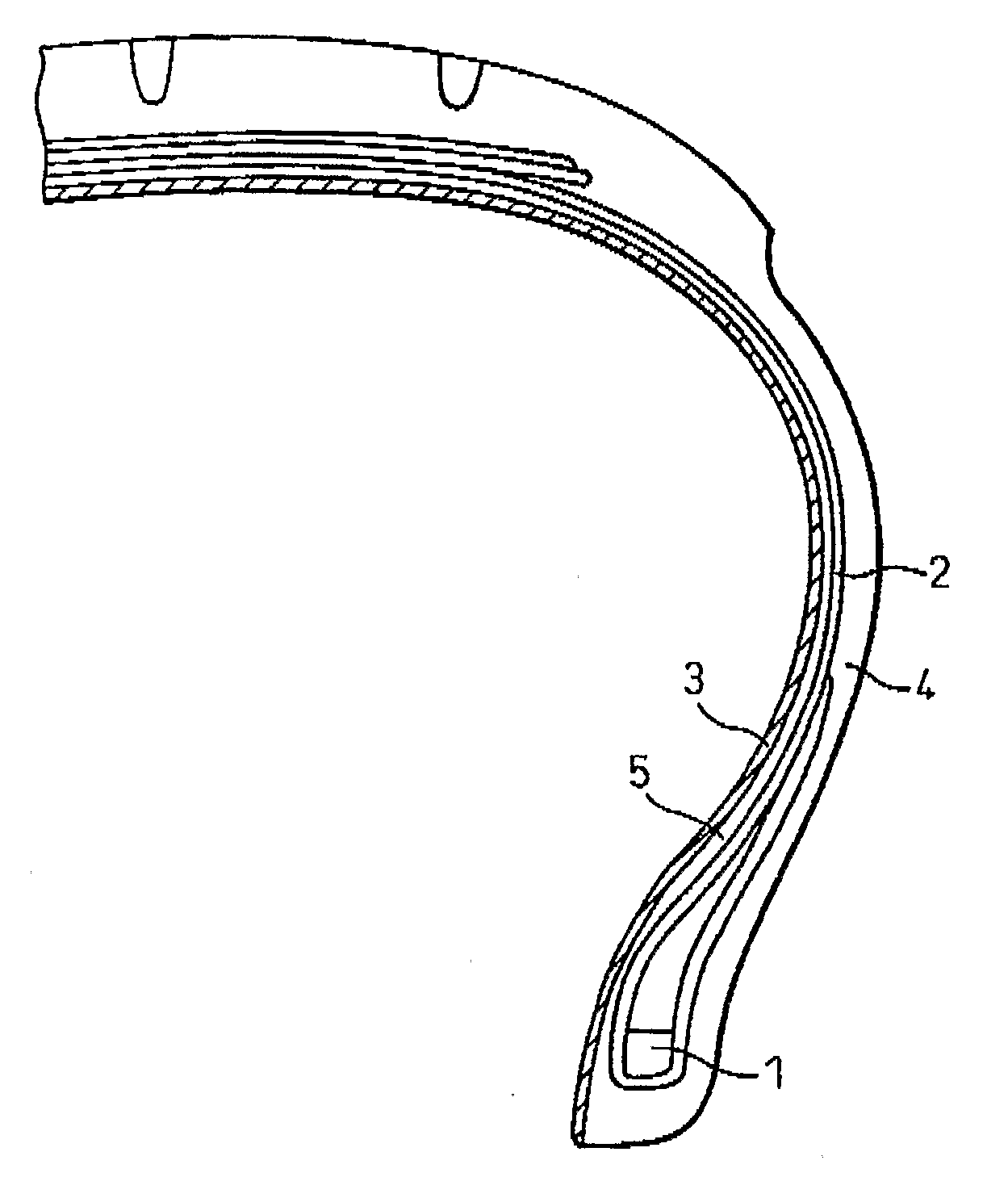

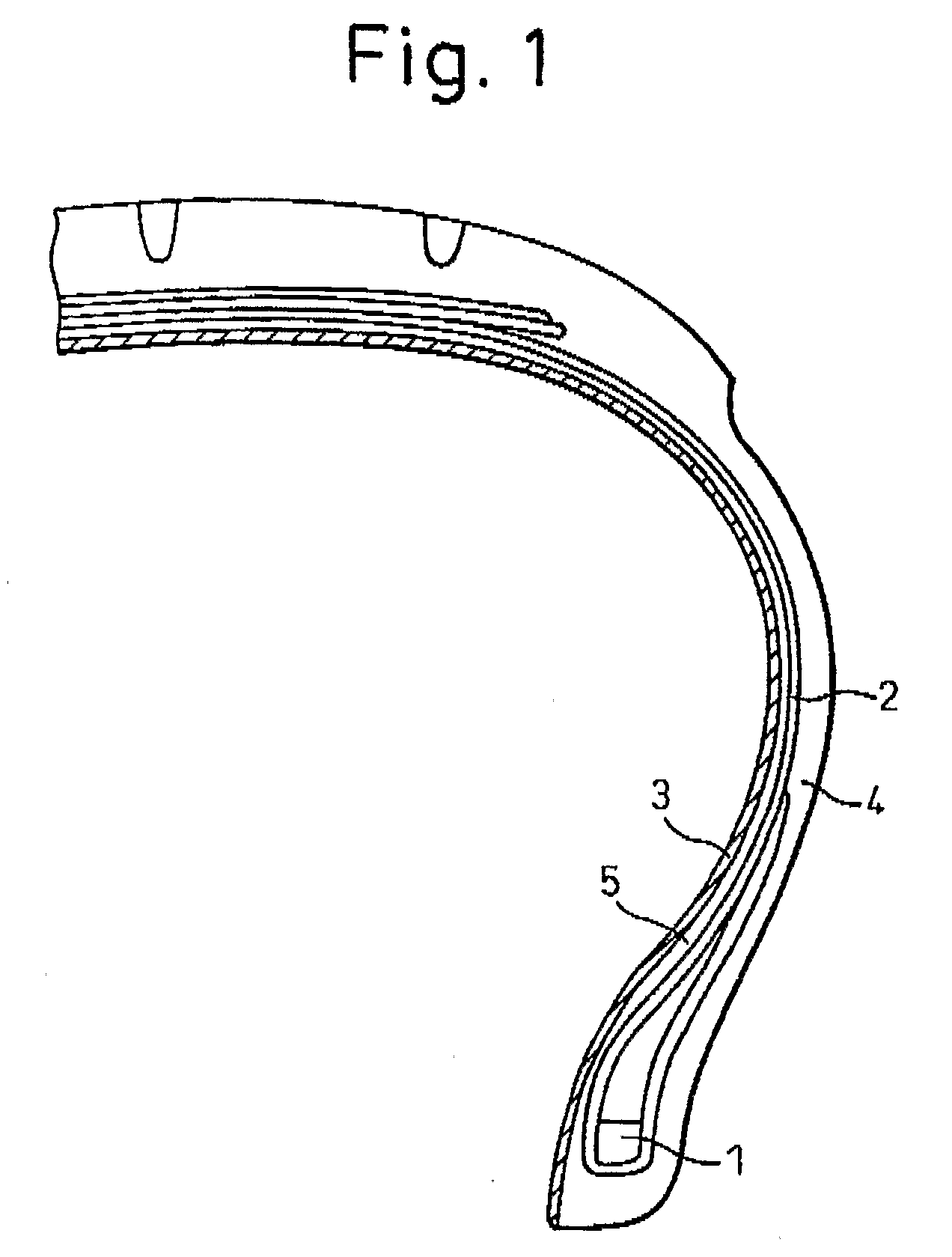

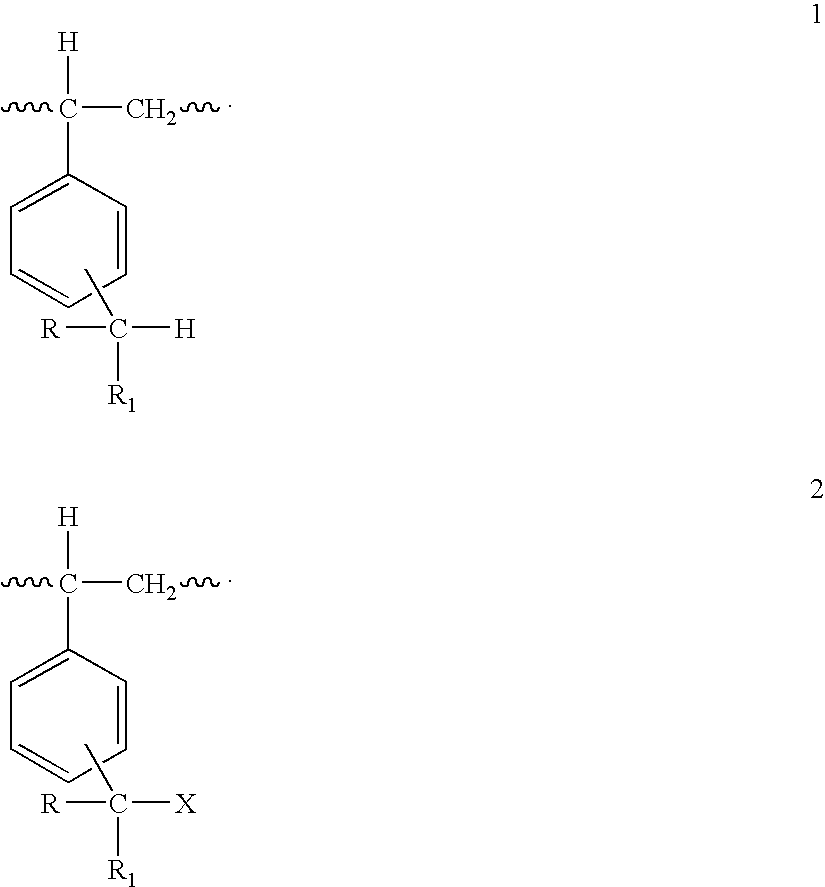

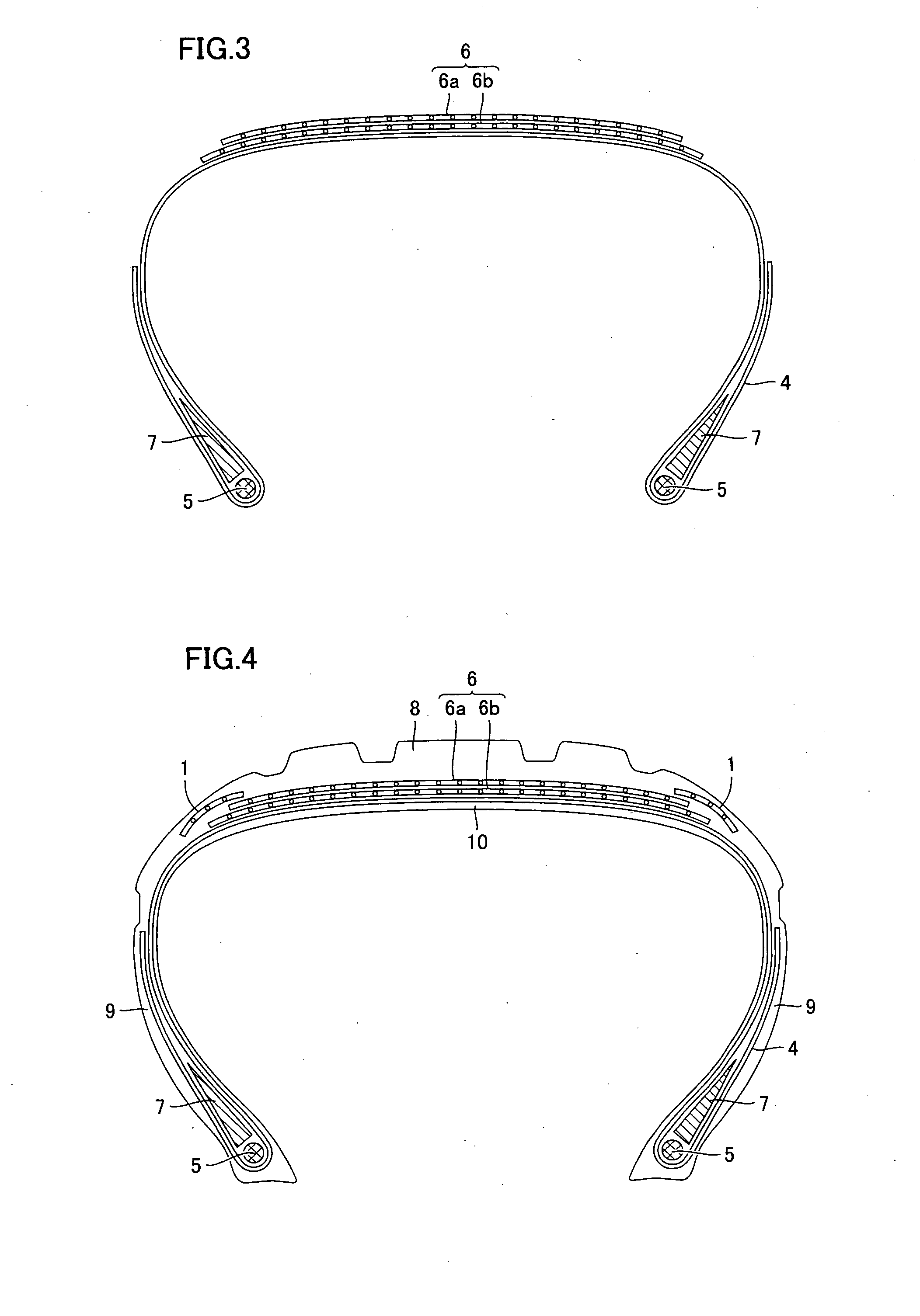

Construction Comprising Tie Layer

ActiveUS20080314491A1Without separate inflatable insertsWith separate inflatable insertsElastomerTackifier

This disclosure relates to a vulcanizable layered composition comprising at least two layers and at least one tie layer. The first of the two layers comprises a fluid permeation prevention layer and the second comprises at least one high diene rubber. The tie layer comprises, a mixture, in parts by weight relative to 100 weight parts of rubber of: (1) 10 to 70 parts by weight of epoxidized natural rubber; (2) 30 to 90 parts by weight of at least one high diene elastomer; (3) 20 to 90 parts by weight of at least one filler; (4) 1 to 20 parts by weight of at least one tackifier, —and (5) at least 0.2 to 15 parts by weight of curing system for the elastomers and rubbers; The fluid permeation prevention layer comprises: (A) at least one thermoplastic engineering resin component; and (B) at least one elastomer component, wherein (B) is dispersed in a vulcanized or partially vulcanized state, as a discontinuous phase, in a matrix of component (A).

Owner:YOKOHAMA RUBBER CO LTD +1

Agronomic crop stalk medium density fiberboard using natural rubber and manufacturing method therefor

InactiveCN101367227AIncrease profitInhibition releaseFlat articlesDomestic articlesFiberStearic acid

The invention provides a crop straw medium density fiberboard by natural gum. Raw materials of the medium density fiberboard comprise crop straw fiber, a bonding agent, a waterproof and lubricating agent and a flame retardant, wherein the bonding agent is natural gum and comprises plant gum and animal gum; the waterproof and lubricating agent is natural wax, stearic acid or stearate; and the flame retardant is non-toxic and harmless flame retardant. The mixture ratio for all the raw materials by weight percent is: 75 to 93 percent of the crop straw fiber, 1 to 8 percent of the bonding agent (dried), 0.5 to 8 percent of the waterproof and lubricating agent, and 5.5 to 23.5 percent of the flame retardant. All the raw materials are produced into a finished product through mixing, sizing, spreading, prepressing, hot pressing and edge cutting; and microwave is used for auxiliary heating in the hot pressing phase. The crop straw medium density fiberboard by the natural gum can realize complete degradation under natural condition after the medium density fiberboard is abandoned or destroyed without any nonreversible destruction to the environment, so the production and application of the crop straw medium density fiberboard realize complete sustainability and recyclability, and have significant realistic and historic significance.

Owner:张东旭

System and method for stimulating multiple production zones in a wellbore

Owner:BAKER HUGHES INC

Antimicrobial medical articles containing a synergistic combination of anti-infective compounds and octoxyglycerin

Medical articles impregnated with antimicrobial compositions containing synergistic combinations of octoxyglycerin and other anti-infective compounds are disclosed. Such medical articles may include urinary catheters, central venous catheters, tracheal catheters, arterial grafts, wound dressings, sutures, or any other medical articles derived from polymeric substrates such as biomedical polyurethane, biomedical polyvinylchloride (PVC), biomedical silicon, biodegradable polymers, polytetrafluoroethylene (PTFE), etc. or from natural products including natural rubber, silk or cotton fiber.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Rubber composition and pneumatic tire using the same

InactiveUS20070123636A1Improve performanceIn situ pavingsFilm/foil adhesivesPolymer sciencePlasticizer

A high performance rubber composition using a plasticizer derived from resources other than petroleum and a pneumatic tire using the same are provided. A rubber composition comprising a rubber component containing at least 50% by weight of a natural rubber and / or a modified natural rubber and a terpene (co)polymer having a number average molecular weight of at most 700, and a pneumatic tire using the same.

Owner:SUMITOMO RUBBER IND LTD

Antistatic gloves and process for making same

InactiveUS20080306200A1Desirable antistatic propertyDesirable propertyGlovesConjugated diene hydrocarbon coatingsPolymer scienceAntistatic agent

The present invention is directed to antistatic elastomeric articles and methods of making the same. The articles can be single layered or multilayered. The single layered articles possess desirable antistatic properties and desirable properties of comfort and feel. The multilayered articles have an outermost layer / surface that possesses desirable antistatic properties and an innermost layer / surface that exhibits desirable properties of comfort and feel. In preferred embodiments, the elastomeric articles are made form a nitrile / natural rubber blend. Articles of the present invention have antistatic properties measured as having a surface resistivity below about 1014 Ω / sq and a static decay time of less than about 60 seconds.

Owner:ALLEGIANCE CORP

Polyolefin film for use in cold seal cohesive applications

A polyolefin multilayer film containing a polyolefinic core layer and a first polyolefin skin layer of a blend, wherein the first polyolefin skin layer does not contain a thermoplastic or natural rubber and provides a cold seal receptive surface for a cold seal adhesive is disclosed. The blend includes an ethylene propylene random copolymer at 50-90 wt. % of the skin layer and metallocene catalyzed plastomer at 10-50% wt. % of the skin layer, a metallocene catalyzed isotactic polypropylene polymer or a butene propylene copolymer that contains from 5 wt % to 22 wt % of butene.

Owner:TORAY PLASTICS AMERICA

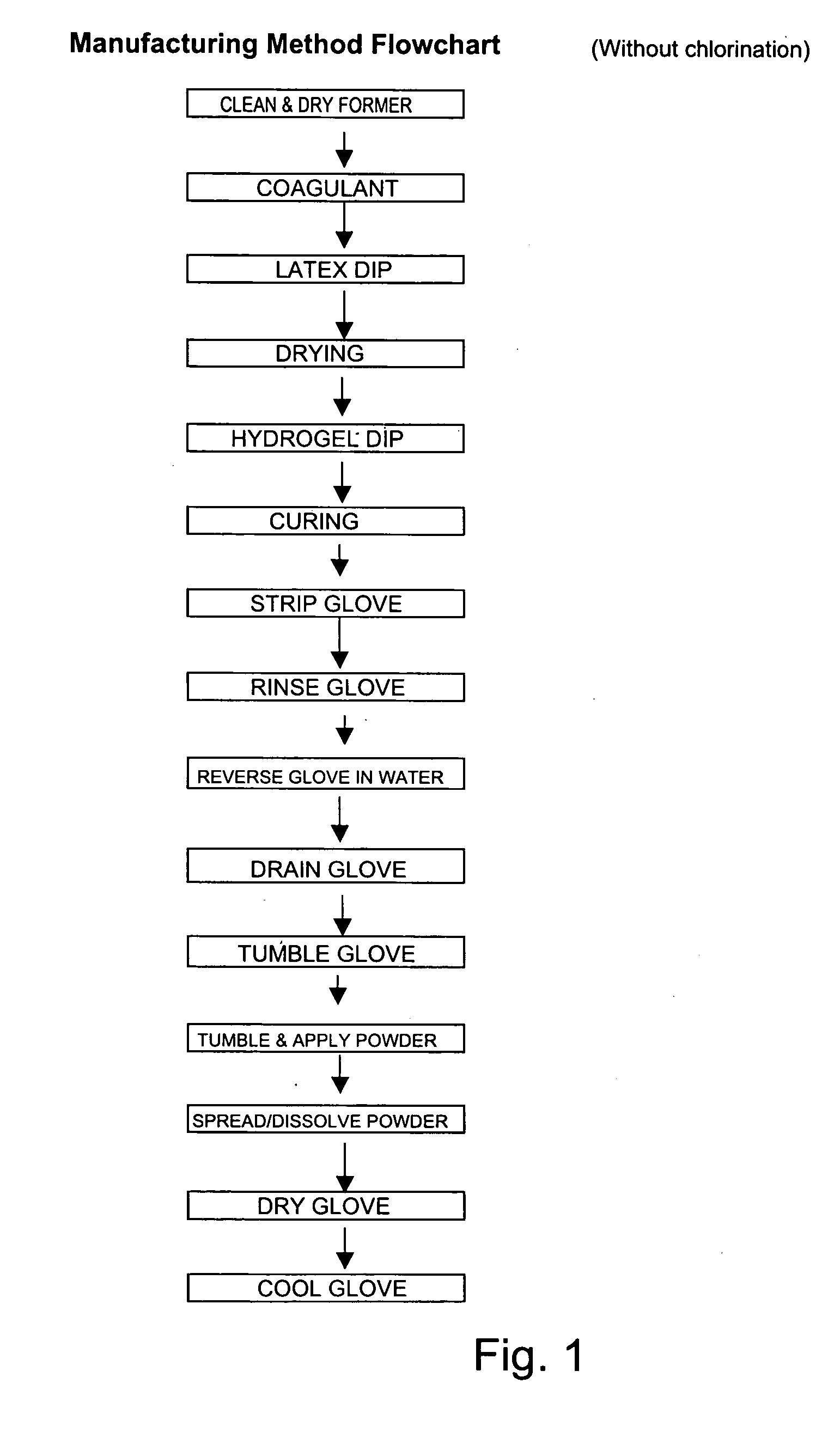

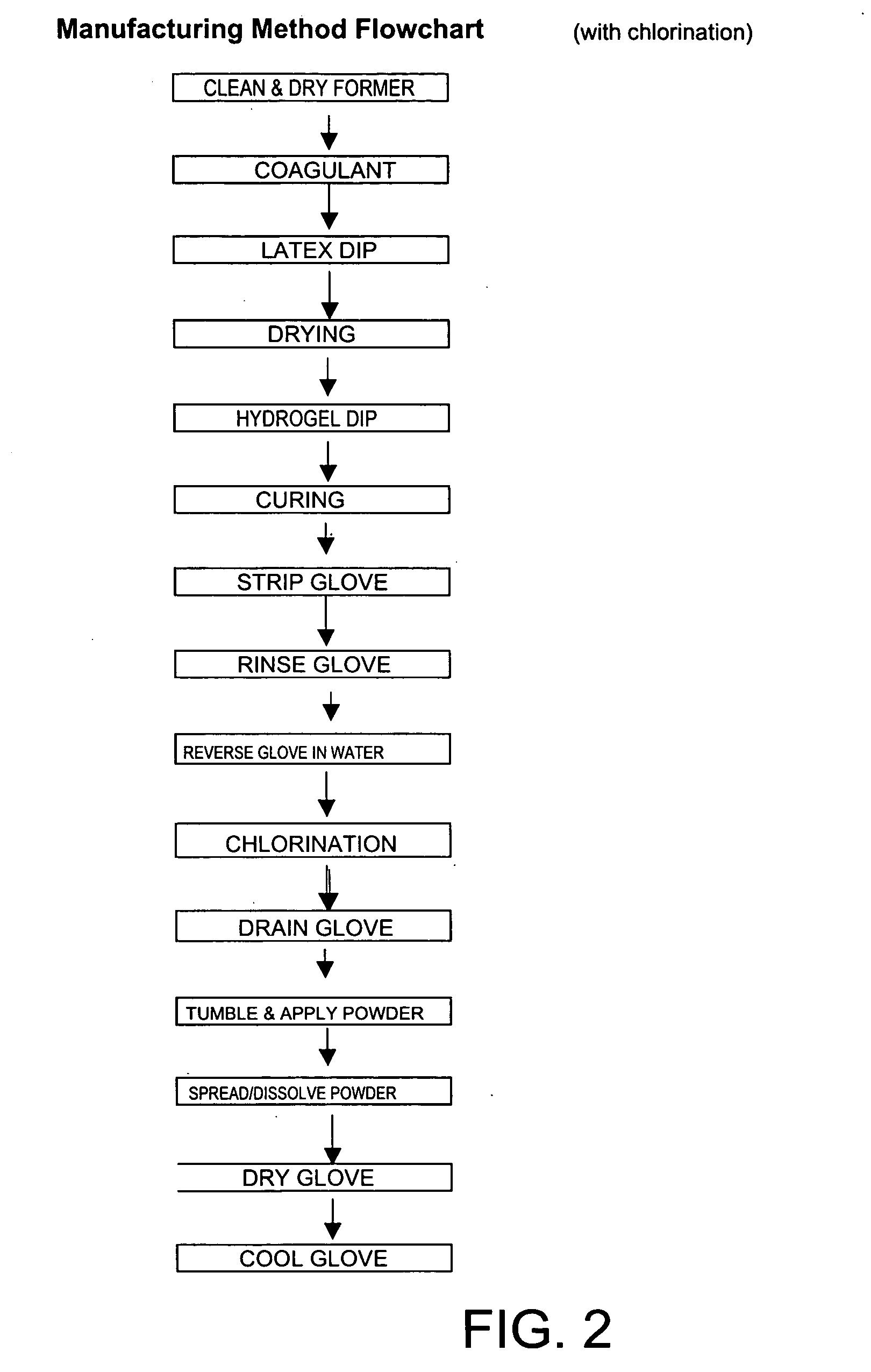

Skin-care protective gloves and manufacturing method

InactiveUS20050222543A1Easy to controlMinimize time of exposureGarment special featuresGlovesPerspirationSkin contact

Protective natural rubber and synthetic elastomeric gloves are disclosed which have an inner skin-contacting absorbent layer. The inner layer is impregnated with skin care compositions. During application of the gloves, the inner layer absorbs perspiration from the hand and readily and slowly releases skin care compositions to soothe and condition the hand. Methods of manufacture are described.

Owner:SHAO ZECHUAN

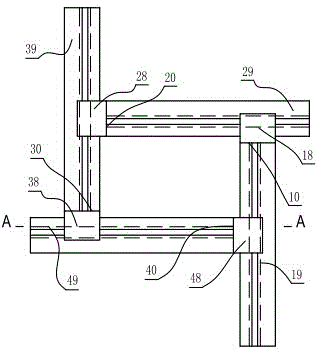

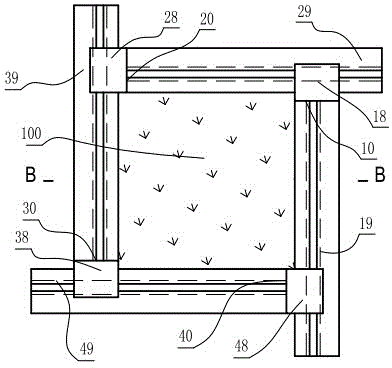

Natural rubber press plate with four edges capable of being adjusted to one plane through skewed slots

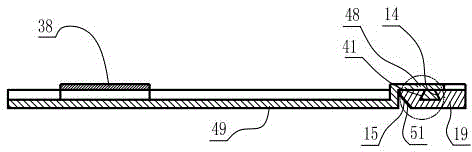

The invention relates to a press plate for glass testing, and especially relates to a natural rubber press plate with four edges capable of being adjusted to one plane through skewed slots. The press plate is composed of a clamping part and a sliding part. The improvements of the press plate are as follows: the sliding part is arranged on one end of the clamping part and is overlapped on the upper surface of the clamping part; the lower surface of the sliding part is taken as the sliding lower plane, the sliding lower plane is provided with a trapezoidal emboss, the upper surface of the clamping part is the clamping upper plane, and the clamping upper plane is provided with a trapezoidal groove. The sliding lower plane and the clamping upper plane are in the same height. The inner side of the clamping part is provided with a clamping slope, and a rubber press sheet is adhered on the clamping slope. The angle between clamping slope (15) and the clamping upper plane (16) is 51 to 53 degrees. A layer of rubber press sheet (51) is adhered on the clamping slope (15), and the thickness of the rubber press sheet (51) is 2.1 to 2.3 millimeters. When the width is adjusted to limit a tempered glass sheet (100) in the horizontal direction, and a downward force can be generated at the same time, so the tempered glass sheet (100) can be pressed against the flat plate (50) of a test platform so as to avoid the explosion of the tempered glass sheet (100) due to the uneven stress on the tempered glass sheet (100).

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

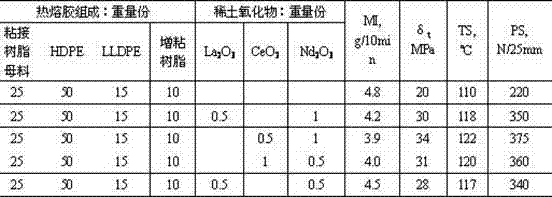

Hot-melt adhesive for steel-plastic composite pipe

ActiveCN102190984AImprove performanceExtended service lifeNatural rubber adhesivesNon-macromolecular adhesive additivesPolyolefinRare earth

The invention discloses a hot-melt adhesive for a steel-plastic composite pipe, which is prepared by blending and extruding the following components in percentage by weight by a parallel double screw extruder: 5-40% of binding resin master batch, 50-80% of polyolefin resin, 5-25% of tackifying resin and 0.02-5% of inorganic rare-earth oxide, wherein the binding resin is prepared by carrying out graft modification on polyethylene and / or ethylene copolymer, which is / are used as the matrix resin, and initiator (accounting for 0.01-0.2 wt% of the binding resin master batch) and unsaturated polar monomer (accounting for 0.1-5 wt% of the binding resin master batch); the polyolefin resin is used for adjusting the consumption of the binding resin master batch and the comprehensive properties of the hot-melt adhesive; and the tackifying resin is one or combination of SBS (styrene-butadiene-styrene), SEBS (styrene-ethylene-butadiene-styrene), SIS (styrene-isoprene-styrene), cis-1,4-polybutadiene rubber, nitrile-butadiene rubber and natural rubber. Since the rare-earth oxide is added, the grafting ratio of the binding resin master batch in the hot-melt adhesive is increased, thereby obviously enhancing the initial viscosity, enduring viscosity, binding strength and other properties.

Owner:河北金天塑胶新材料有限公司

Rubber composition for tire, tire member and tire

A rubber composition for a tire comprising a rubber component containing at least one of a natural rubber and an epoxidized natural rubber, not less than 15 parts by mass of silica based on 100 parts by mass of the rubber component, and not less than 0.5 part by mass of calcium stearate based on 100 parts by mass of the rubber component, a tire member made using the rubber composition for a tire, and a tire made using the tire member.

Owner:SUMITOMO RUBBER IND LTD

Composite shielding material for medical X-ray protection

InactiveCN101137285AImprove the protective effectReduce weightMagnetic/electric field screeningShieldingHigh energyX-ray

The invention provides a composite shielding material for shielding medical X-ray, which insists of ray absorbing material and carrier material, wherein, the ray absorbing material comprises mixing lanthanide, tungsten, bismuth, tin and / or antimony, the lanthanide which is extracted from natural ore can be oxide or formalization compound thereof, the tungsten, bismuth, tin and / or antimony can be metal power thereof, also can be formalization compound thereof. The carrier material can be natural rubber or artificial rubber, thermoplastic elastomer, as well as plastic. The composite shielding material for shielding medical X-ray provide by the invention has the advantages of good shielding performance, light weight, non-poisonous, no pollution, low cost and so on, not only overcomes defects of using single element barium or bismuth, but also overcomes defects that the lead equivalent is reduced when absorbing low and high energy X-ray in the lanthanide adding with tungsten technology.

Owner:魏宗源 +1

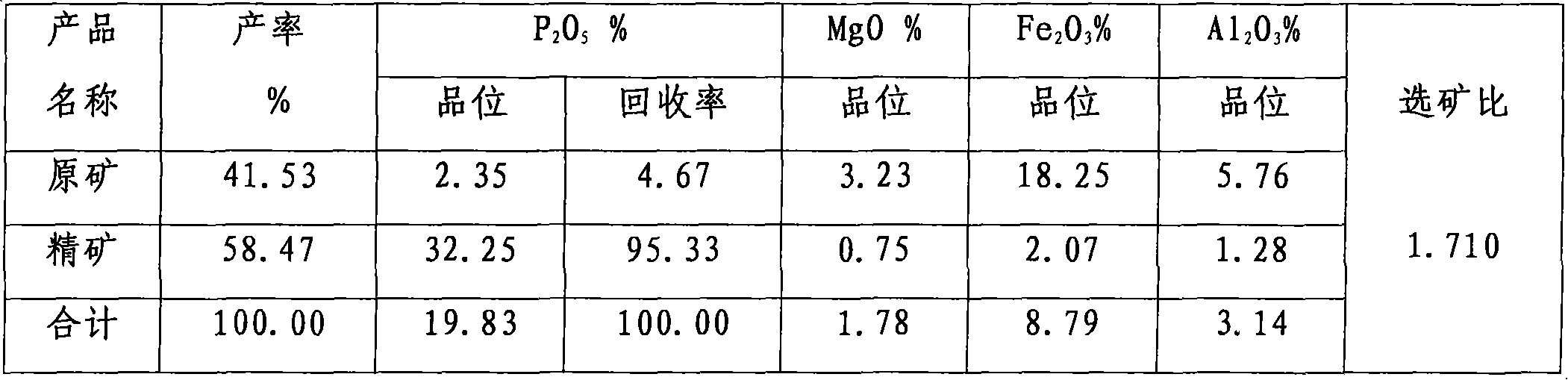

Collophanite flotation collector and method for preparing same

ActiveCN101797536AStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

Puncture sealing composition and tire

The present invention is a pneumatic tire of the tubeless type, embodying a layer of puncture sealant composition based on: A. a minor proportion of a low molecular weight elastomer (e.g., depolymerized natural rubber) in admixture with a tackifying or plasticizing substance (e.g., a resinous reaction product of a mineral oil purification residue with formaldehyde) and B. a major proportion of a high molecular weight elastomer (e.g., cis-polyisoprene); Containing a crosslinking agent (e.g., isopropyl titanate) in an amount sufficient to give a partial cure; and C. ground rubber from used tires in the amount of up to 5 percent by weight of the sealant composition.

Owner:MICHELIN RECH & TECH SA

Process for preparing attapulgite and natural rubber nano composite material

The invention discloses a making method of concave-convex bar-stone and natural rubber nanometer composite material, which comprises the following steps: dispersing through ultraviolet; modifying; blending; conglutinating; thinning; washing; dehydrating; melting; sulfurizing. The invention disperses nanometer crystal of concave-convex bar-stone in the natural rubber base, which improves rubber property.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

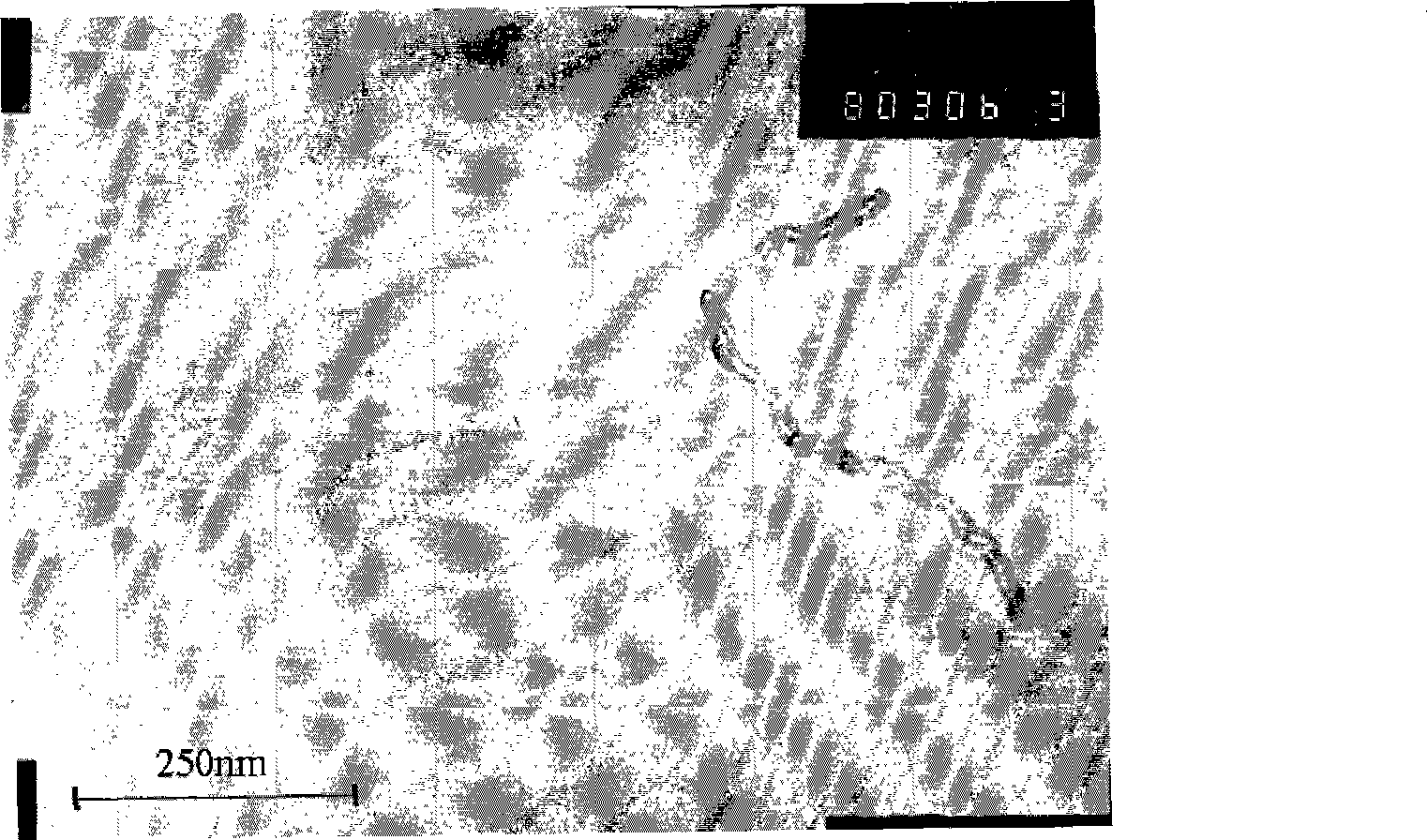

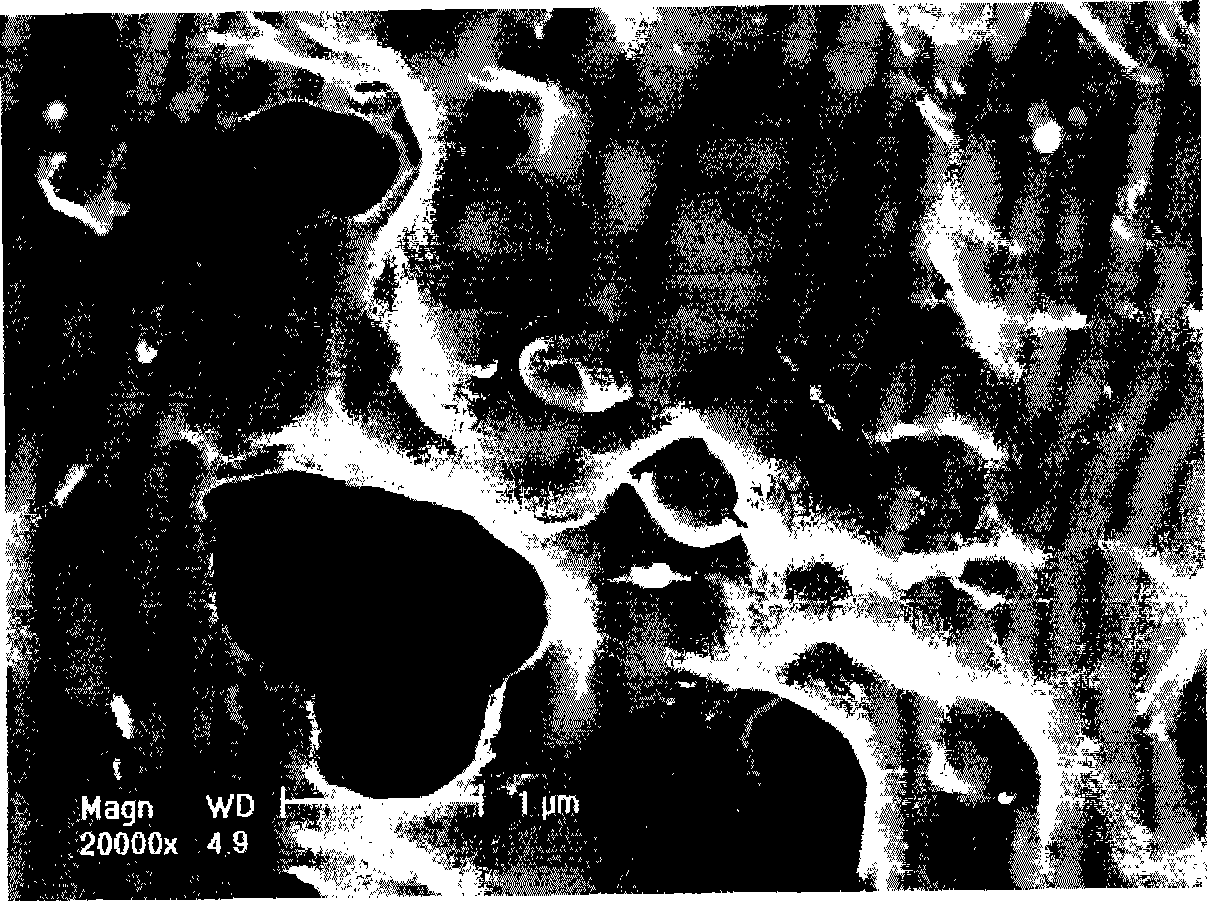

Method for preparing natural rubber-carbon nano tube composite material by using static electricity self-assembly

The invention provides a method for utilizing electrostatic self-assembly to prepare a natural rubber-carbon nano-tube composite material. The method comprises the following steps of adopting surfactant to modify the surfaces of carbon nano-tubes so as to enable the surfaces of the carbon nano-tubes to have positive charges, directly mixing the carbon nano-tubes with lacteous natural rubber with negative charges and utilizing self-assembly in an electrostatic adsorption principle to prepare the natural rubber-carbon nano-tube composite material. The preparation method realizes that the carbon nano-tubes are uniformly dispersed in the natural rubber and have good compatibility with the natural rubber, thereby providing technical guarantee for preparing nano-composite rubber products with excellent comprehensive properties.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Porous metal/organic polymeric composites

InactiveUS7632565B1Simple structureGood acoustic damping propertyLiquid surface applicatorsSynthetic resin layered productsEpoxyPt element

Metal foams are impregnated with resins. The metal foam / polymer composite formed upon curing has excellent acoustic dampening and structural properties. Foams of various metals, such as aluminum, titanium, nickel, copper, iron, zinc, lead, silver, gold, platinum, tantalum, and alloys based on these metals, may be used. The polymer component may be any polymeric resin, for example, epoxy, natural rubber, acrylic, or phenolic.

Owner:NAVY UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC THE

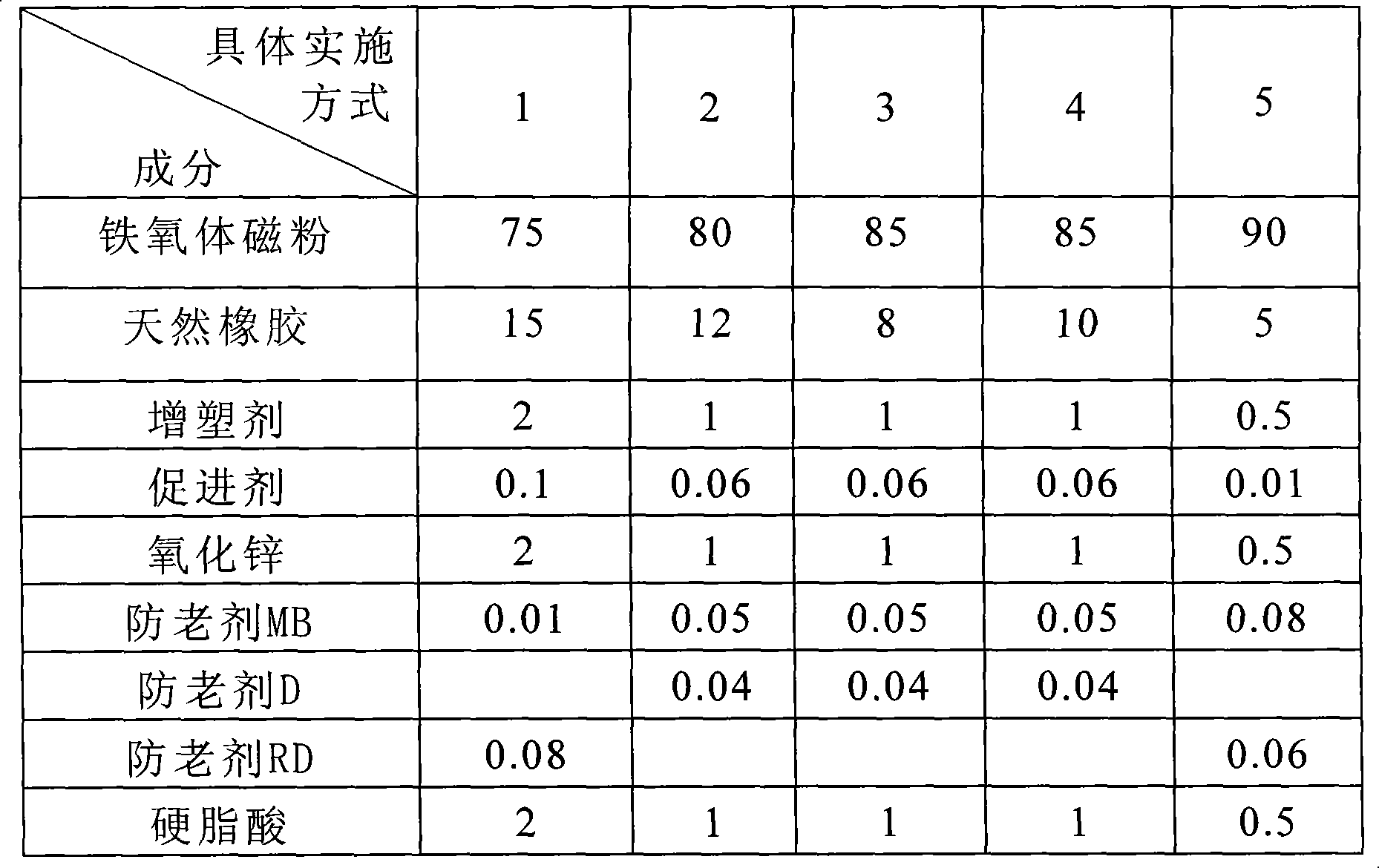

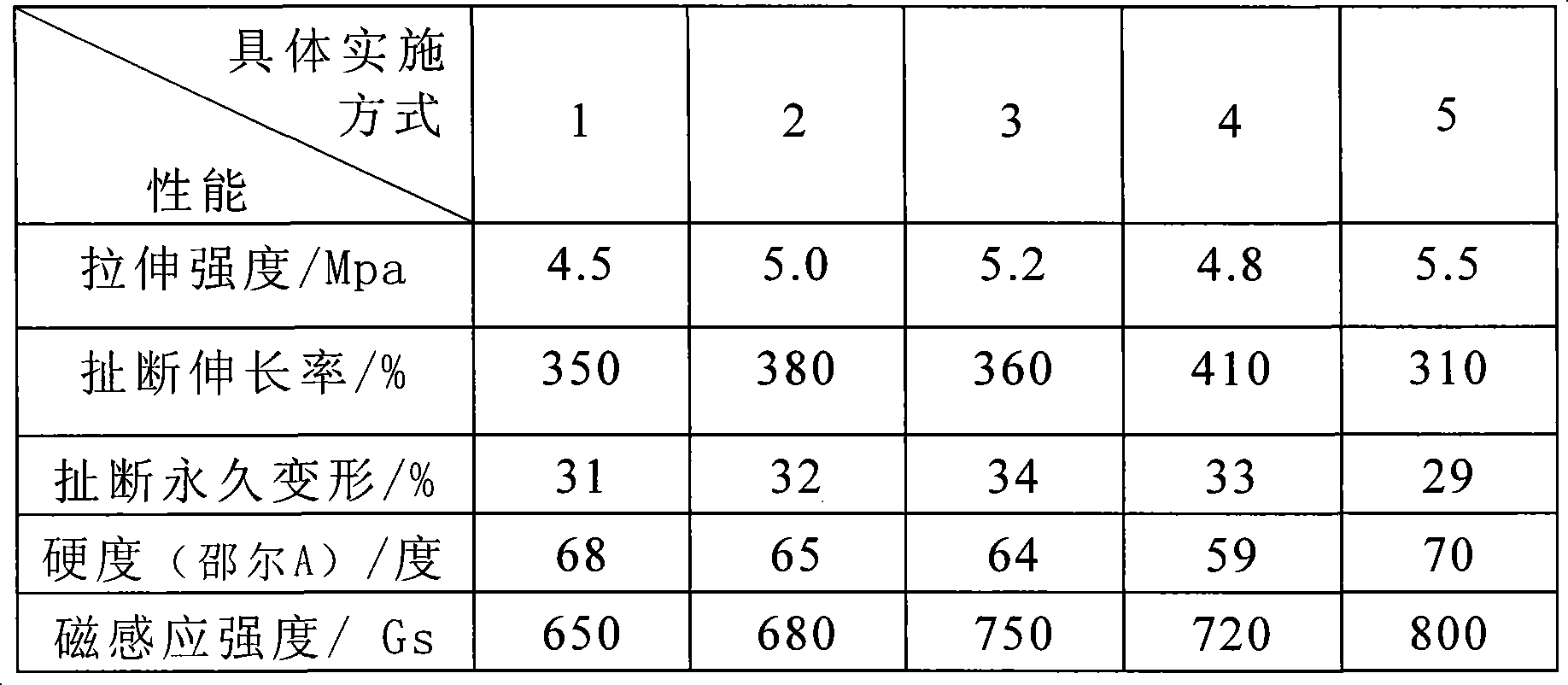

Magnetic rubber having high magnetic flux density and preparation method thereof

InactiveCN101230156ACompatibility is reasonableIncrease magnetic inductionOrganic/organic-metallic materials magnetismPlasticizerVolumetric Mass Density

The invention provides magnetic rubber with high magnetic induction intensity and the preparation method thereof, which belongs to the composite material technology field. The invention solves the problems in the prior production process that the production cost is high, the magnetic induction intensity of the produced special magnetic rubber product is low, and the elasticity performance is poor. The magnetic rubber with high magnetic induction intensity is made of ferromagnetic oxide powder, natural rubber, plasticizer, accelerator, activator, antioxidant and stearic acid which are prepared. The preparation method comprises the following steps: step A, grinding and blending; step B, rubber refining; step C, moulding, and step D, charging magnetism. The magnetic induction intensity of the magnetic rubber special product reaches above 600 gauss, and the elasticity performance is good; the preparation method and process is simple, and the production cost is low.

Owner:杨中联

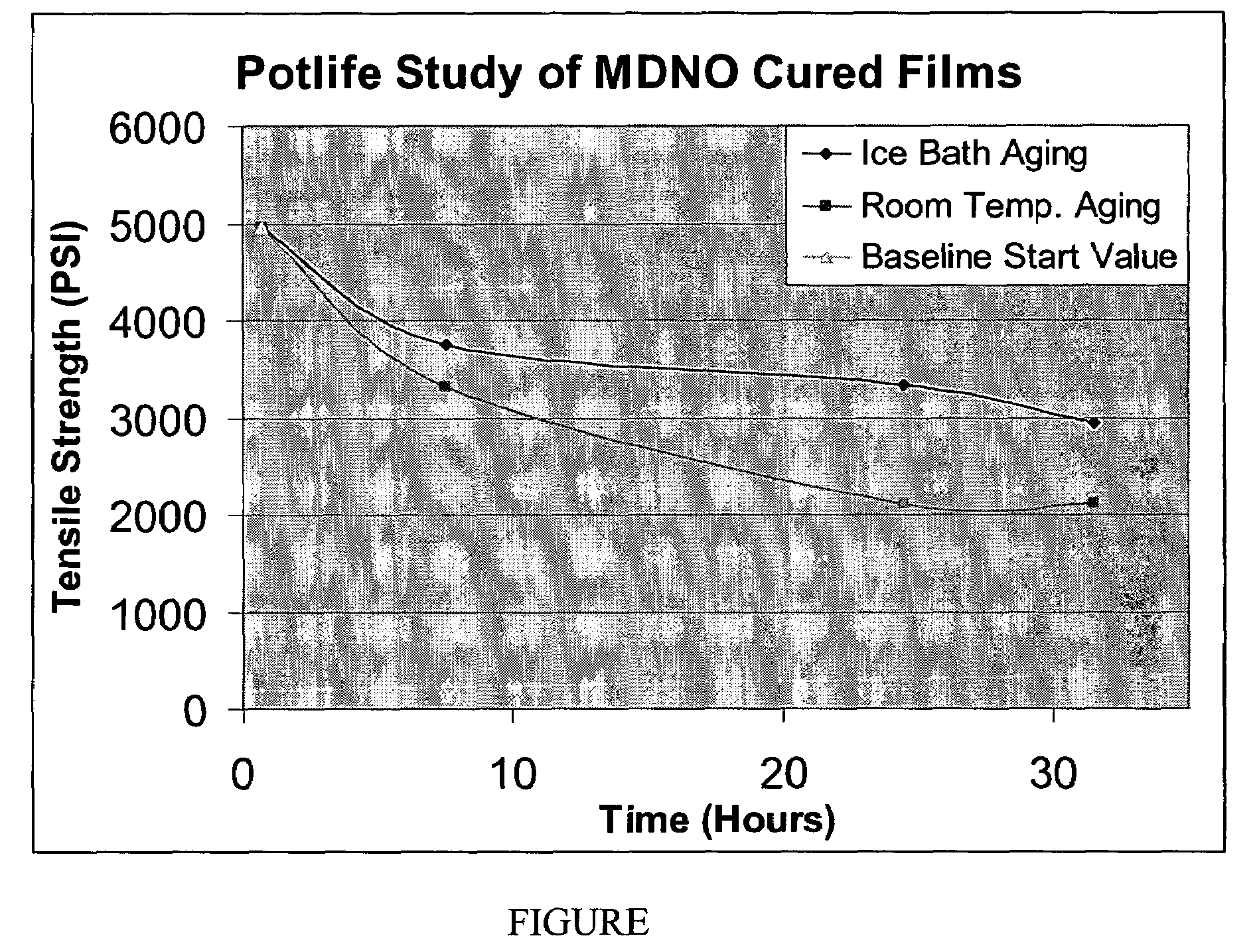

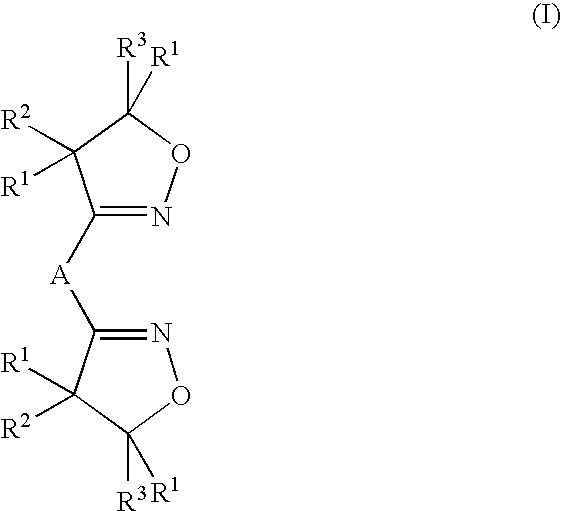

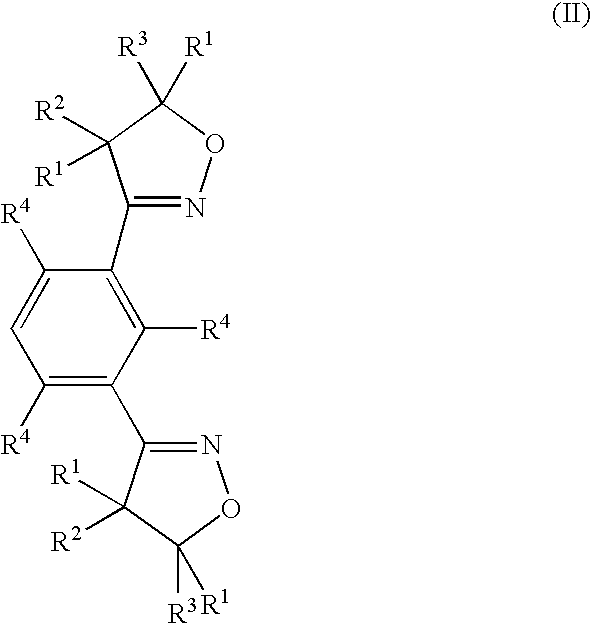

Thin walled polynitrile oxide crosslinked rubber film products and methods of manufacture thereof

Natural rubber and / or synthetic polyisoprene film products having enhanced tear strength and tensile strength crosslinked with a one polynitrile oxide, intended for direct or indirect contact with living tissue or fluids to be placed in living organisms.

Owner:APEX MEDICAL TECH A CORP OF THE STATE OF ILLINOIS

Natural rubber liquid slurry containing chitosan/sericin and preparation method thereof

The invention discloses a natural rubber liquid slurry containing chitosan / sericin and a preparation method thereof, and belongs to the field of high polymer chemistry. The invention is characterized in that the preparation method comprises the following steps: respectively preparing a chitosan water solution and a sericin water solution, mixing the two solution, and regulating the pH value of the mixture to 9-11 by using ammonia water and a citric acid solution; and adding the obtained chitosan / sericin mixed solution to a natural latex slurry, adding a laurate surfactant, and mechanically stirring the mixture uniformly to obtain the natural rubber liquid slurry containing chitosan / sericin. The invention has the advantages that the chitosan has the functions of adsorbing water soluble proteins in the latex, inhibiting bacteria and viruses from breeding, and the like; and the sericin has the functions of oxidation resistance, allergy resistance, hydrophilia, oil resistance and the like, thereby enhancing the emulsion phase stability and the preservation effect of the natural latex. In particular, the product obtained by using the method overcomes the defects of short service life, easy aging and sticking, poor oil resistance, initiation of protein allergy and the like in the traditional natural latex product.

Owner:湖南万橡新材料科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com