Patents

Literature

1773results about How to "Prevent burst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

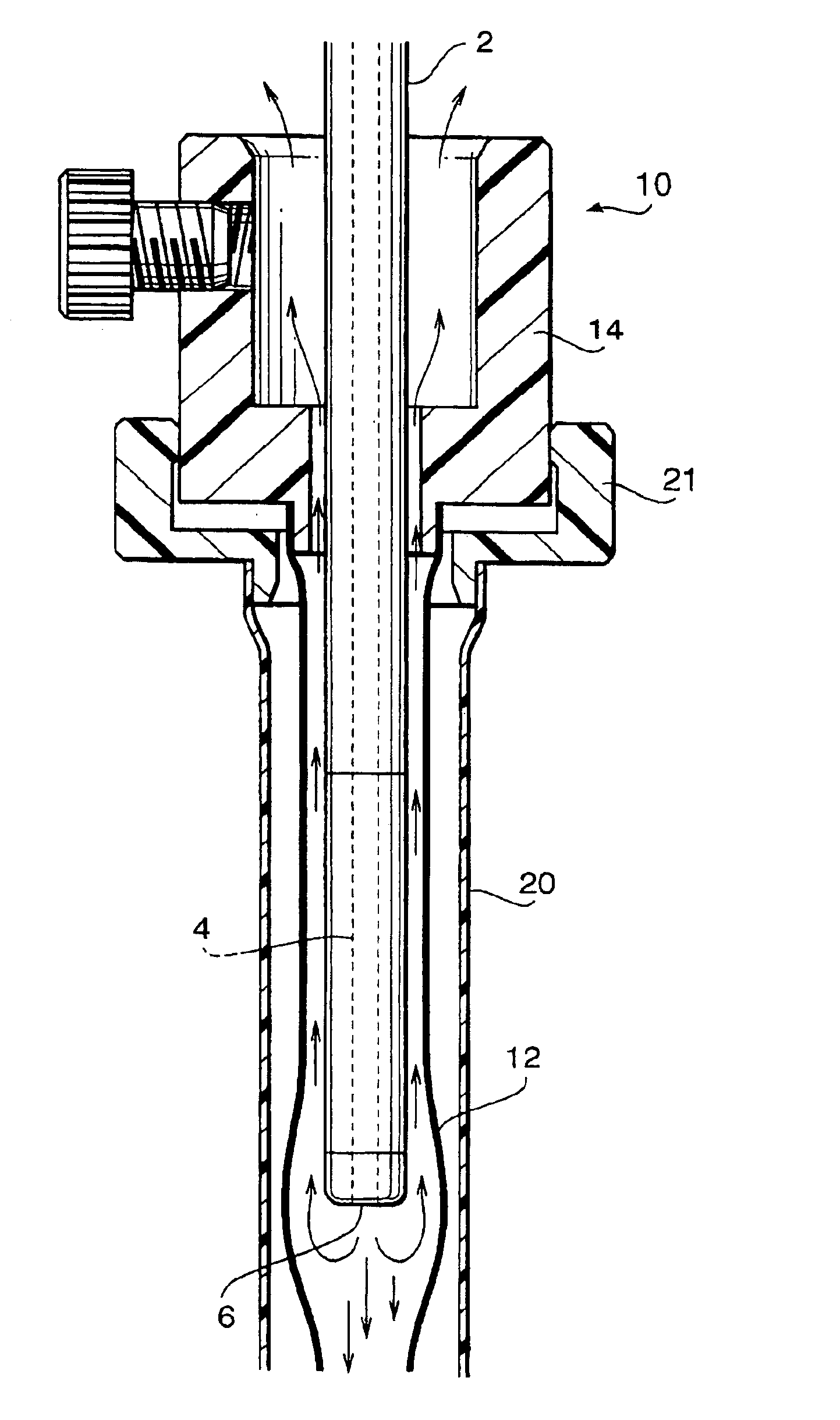

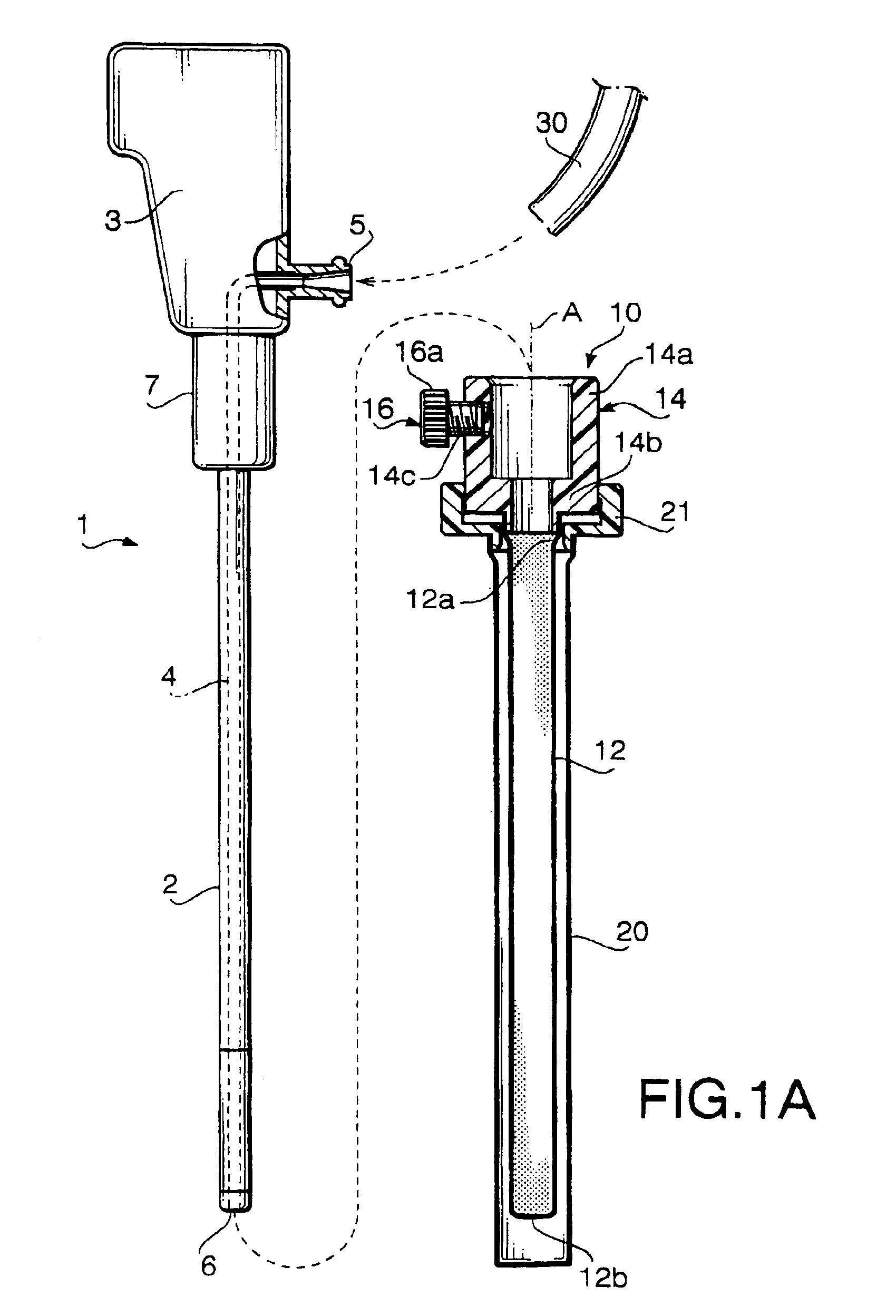

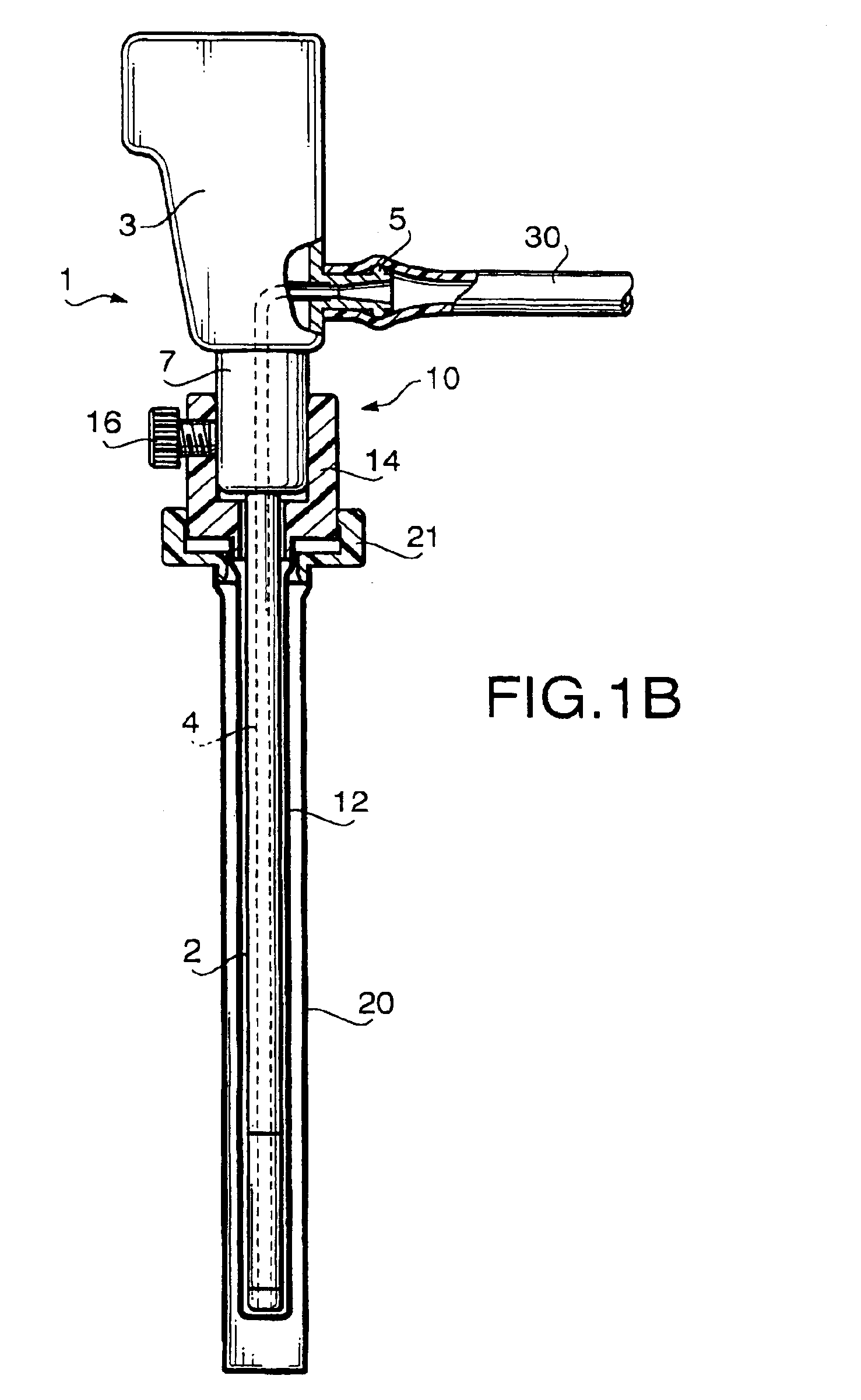

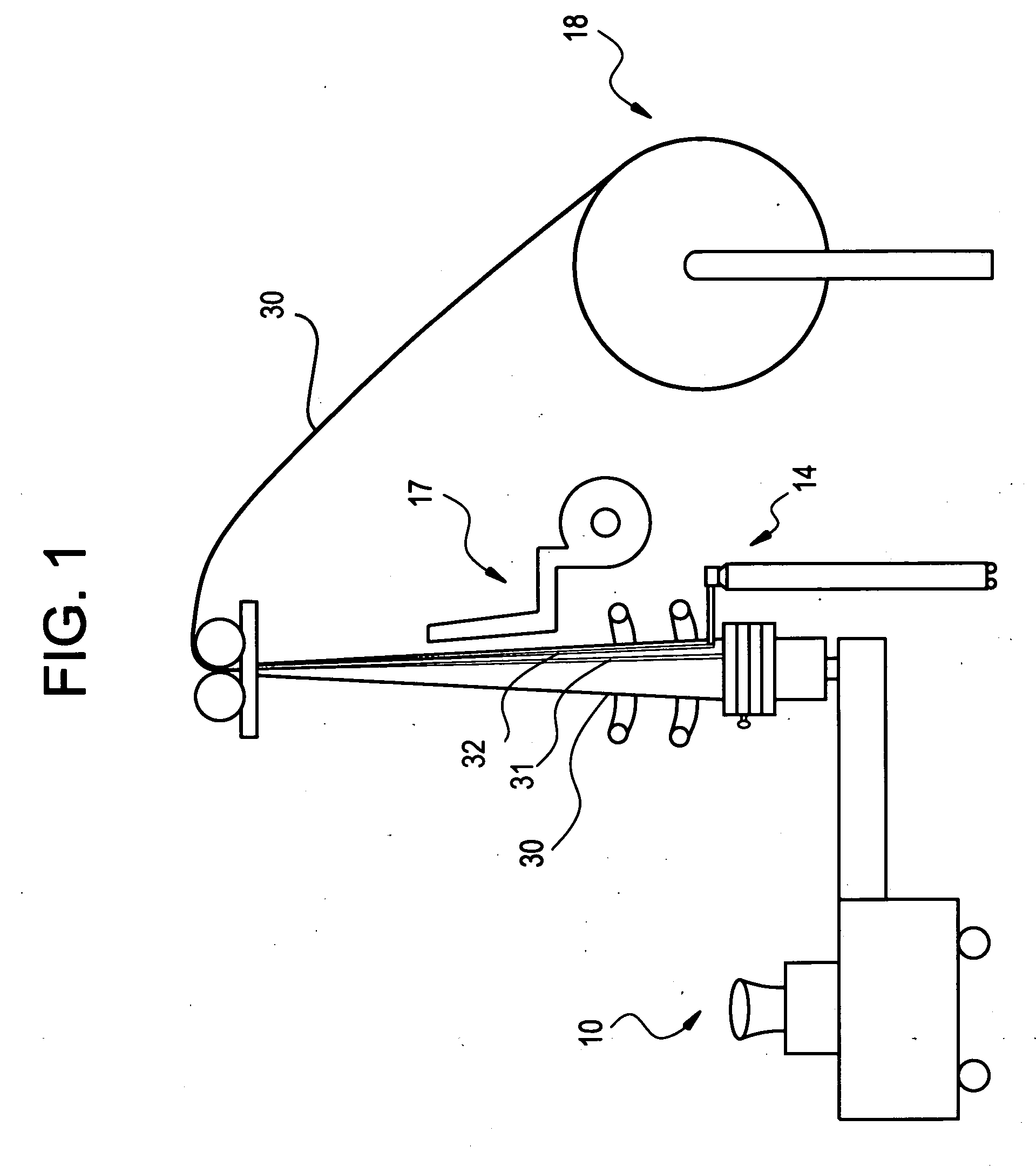

Endoscope with detachable sheath

Combination of an endoscope and a sheath for covering an inserting tube of the endoscope, the sheath includes an elastic tubular member having an open proximal end and a closed distal end, and the endoscope is provided with an air feeding tube for feeding air from a distal end of the inserting tube to inflate the tubular member when the inserting tube is inserted into the tubular member to be covered therewith.

Owner:ASAHI KOGAKU KOGYO KK

Controlled release formulations using intelligent polymers

InactiveUS6893661B1Promote absorptionMaintenance of therapeutically effective blood levelPowder deliveryOrganic active ingredientsSmart polymerWater contact

An extended release dosage composition of pharmaceutically active substances that have a water contact angle (θ) such that cos θ is between +0.9848 and −0.9848 presented as a matrix tablet containing the said pharmaceutically active substances, with / without suitable pharmaceutical excipients in intimate mixture with two groups of intelligent polymers having opposing wettability characteristics, one demonstrating a stronger tendency towards hydrophobicity and the other a stronger tendency towards hydrophilicity, the polymer combination being between the ratios of 1:50 and 50:1 amounts effective to control the release of said pharmaceutically active substances in a mathematically predictable manner, wherein the polymer demonstrating a stronger tendency towards hydrophobicity is not less than 5% wt / wt and preferably between 5-70% wt / wt of the final formulation composition. The intelligent polymers being ethylcellulose (EC) as a more strongly hydrophobic and hydroxyethylcellulose (HEC) and / or hydroxypropyl methylcellulose (HPMC) as more strongly hydrophilic (the ratio of HEC to HPMC being between 1:100 and 100:1). The matrix tablet is optionally coated with an enteric coat, 0-5%-15% wt / wt to prevent the initial burst effect seen in such systems and to impart gastrointestinal tract (GIT) “stealth” characteristics especially in the presence of food.

Owner:VALEANT INT BERMUDA

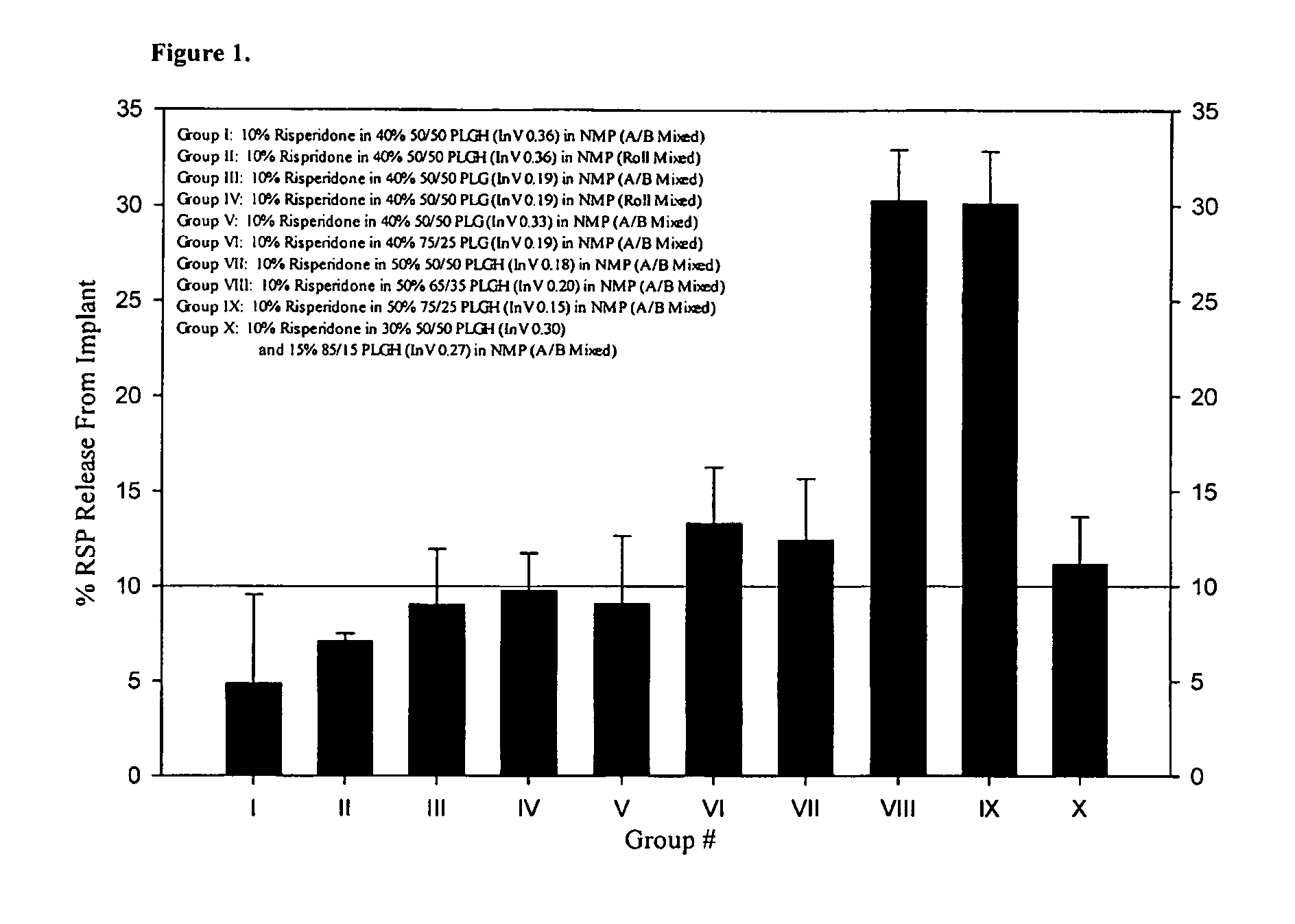

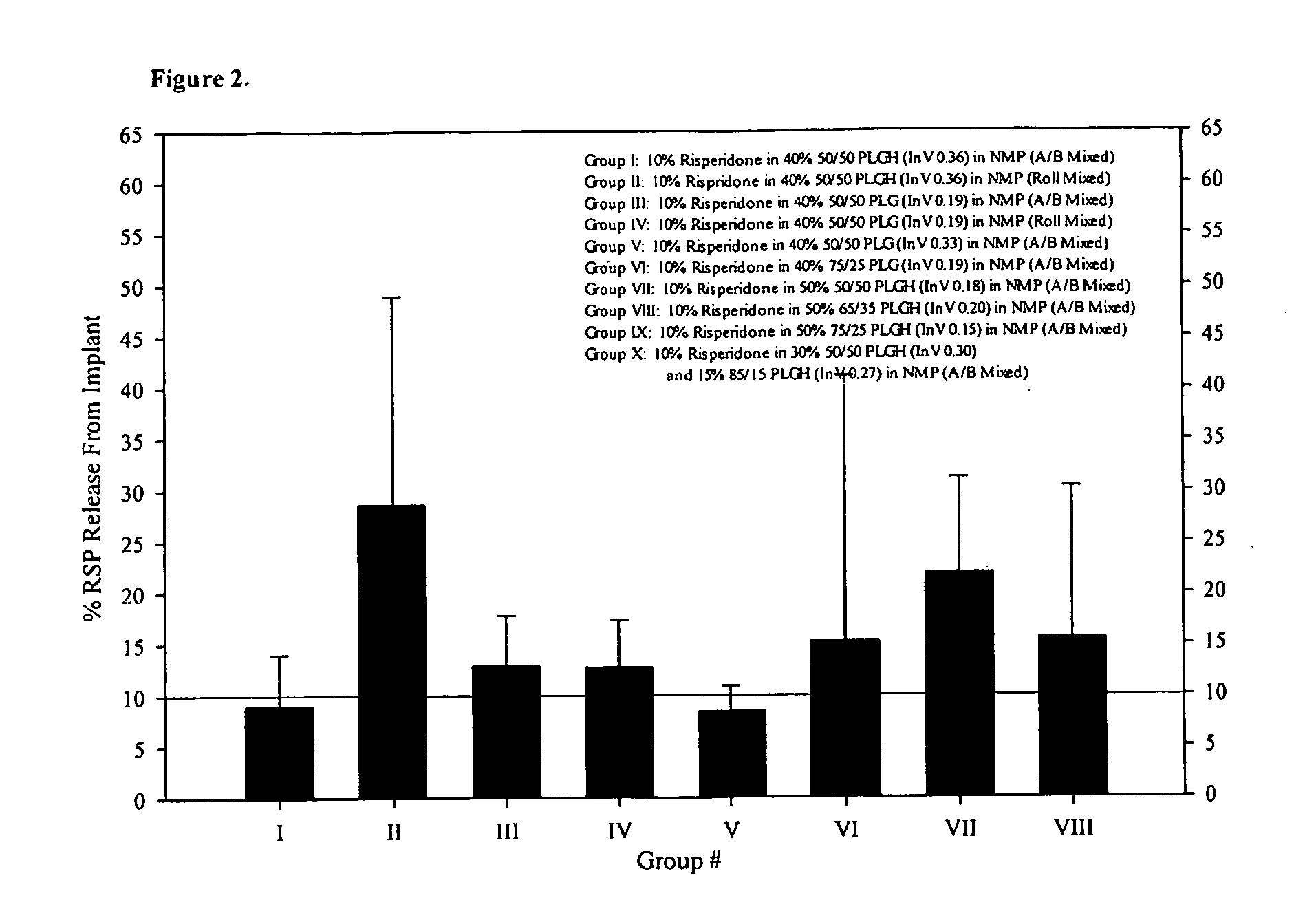

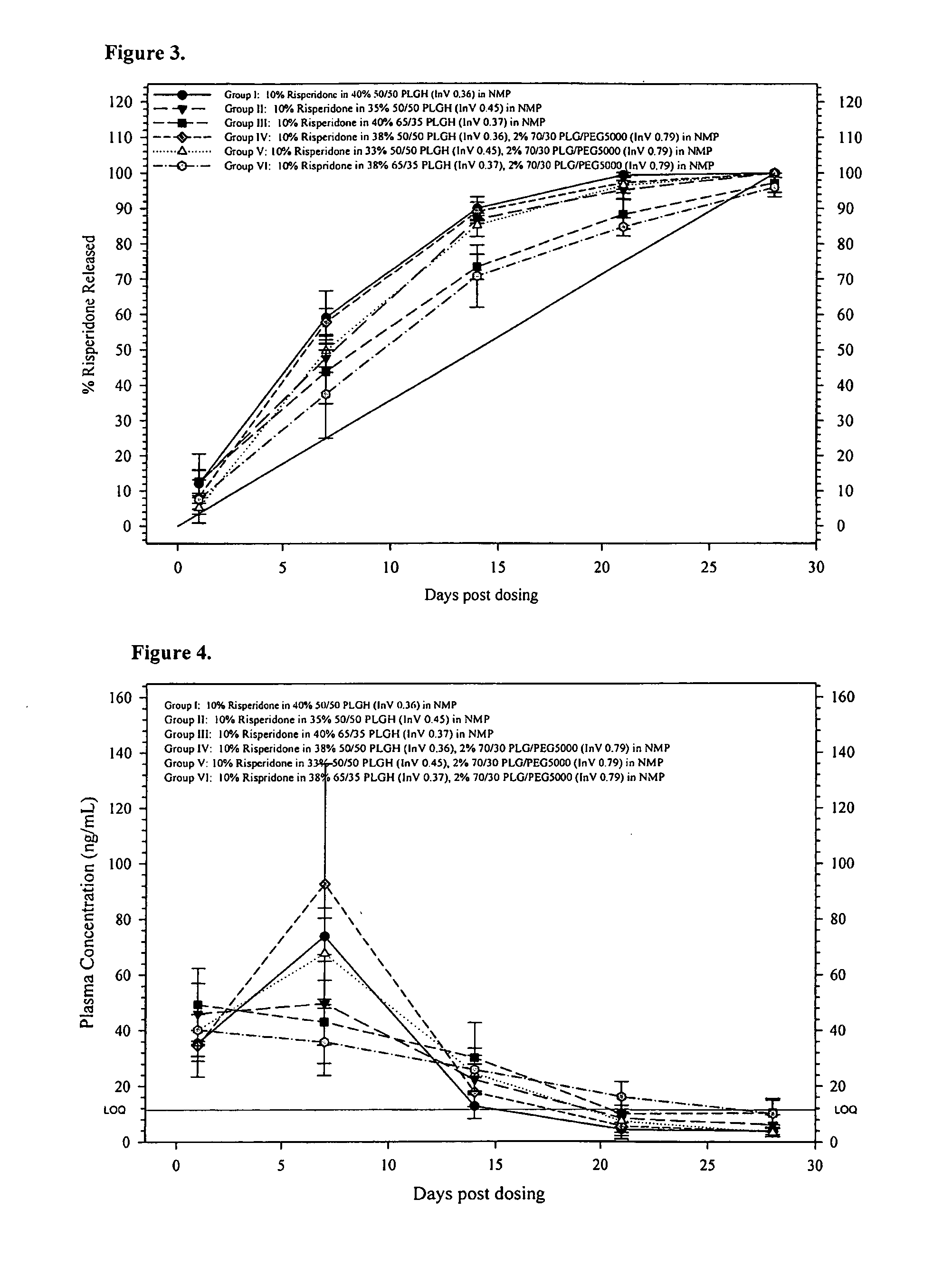

Sustained delivery formulations of risperidone compounds

ActiveUS20100266655A1Improve bioavailabilityLeast riskBiocideOrganic active ingredientsMetaboliteOrganic fluid

The present invention relates to a risperidone sustained release delivery system for treatment of medical conditions relating delusional psychosis, schizophrenia, bipolar disorder, psychotic depression, obsessive-compulsion disorder, Tourette syndrome, and autistic spectrum disorders. The sustained release delivery system includes a flowable composition containing risperidone, a metabolite, or a prodrug thereof and an implant containing risperidone, a metabolite, or a prodrug thereof. The flowable composition may be injected into tissue whereupon it coagulates to become the solid or gel, monolithic implant. The flowable composition includes a biodegradable, thermoplastic polymer, an organic liquid, and risperidone, a metabolite, or a prodrug thereof.

Owner:INDIVIOR UK

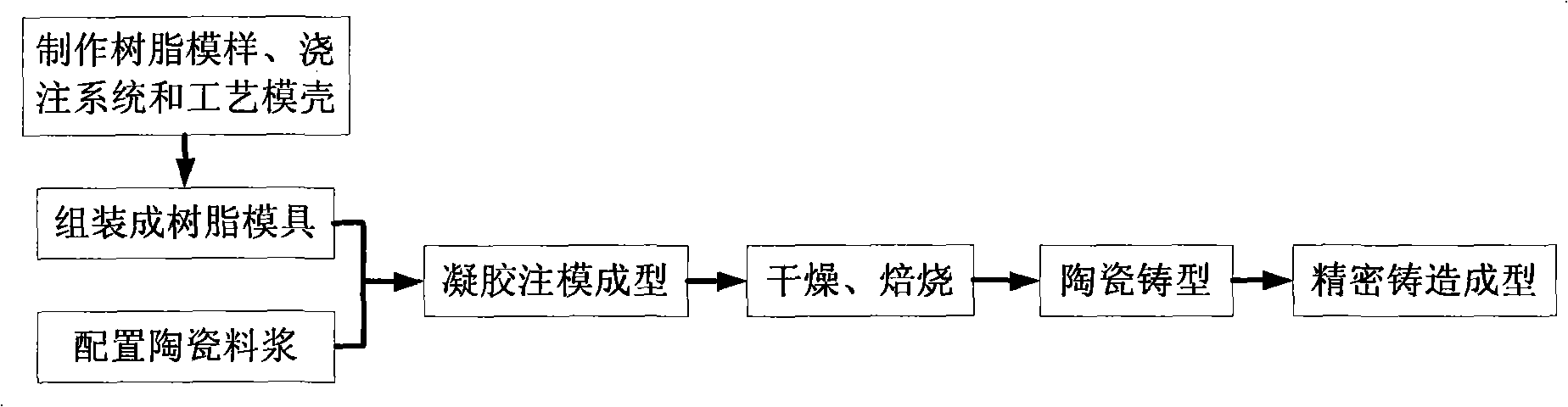

Method for quickly and precisely casting complex parts

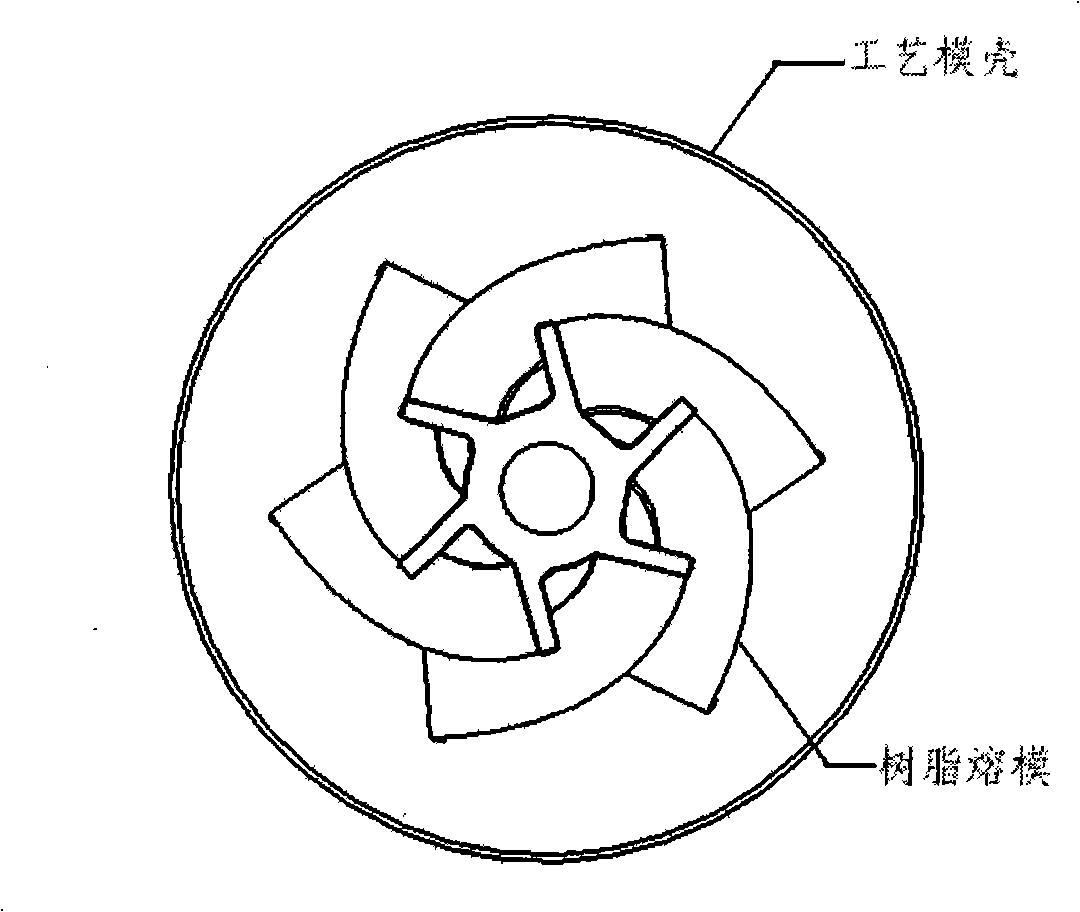

InactiveCN101301677APrevent burstShorten the production cycleFoundry mouldsCeramic shaping apparatusSolid phasesPolyresin

The invention provides a quick precision casting method for complex parts. The method uses a photosensitivity rapid prototyping technique to prepare a resin part prototype, a pouring system resin prototype and a resin process die shell which are then combined together to form a die; the method uses a gel-casting processing technique to pour ceramic slurries with high solid-phase and low viscosity into the die cavity so as to form a ceramic casting blank by quick in-situ solidification; the ceramic casting blank is dried and the resin prototype is burned and sintered to obtain the ceramic casting which contains the downsprue; finally, high-temperature metal liquid is poured into the ceramic casting; after being cooled, the ceramic casting is mechanically destroyed to obtain the precision casting. The method requires no manufacturing of metal dies, uses the ceramic casting prototyping which has high efficiency, good precision and short production period, and is especially suitable for the quick manufacture of middle and small batches and the trial-manufacture of new products in the precision castings with complex shapes.

Owner:XI AN JIAOTONG UNIV

Thermal-shock-resistant corundum-spinel refractory castable and preparation method thereof

The invention discloses thermal-shock-resistant corundum-spinel refractory castable which comprises the following raw materials in percentage by weight: 65-80% of corundum particles and fine powder, 3-10% of aluminum oxide fine powder, 2-8% of materials containing Zr, 10-15% of magnesium-aluminum spinel fine powder, 3-8% of bonding agent, 0.05-0.1% of organic fiber (additional) and 0.2-0.6% of water reducing agent (additional). The preparation method of the corundum-spinel refractory castable comprises the following process steps of burdening, mixing, molding, maintaining, drying, storage and transportation, using and the like. Compared with the prior art, the thermal-shock-resistant corundum-spinel refractory castable provided by the invention has high thermal-shock-resistant property, and favorable high-temperature resistance and anti-erosion capability, and is suitable for steel ladles, intermediate ladles, RH (relative humidity) immersion tubes, cement high-temperature kilns and the like.

Owner:LUOYANG LIER REFRACTORY MATERIAL +2

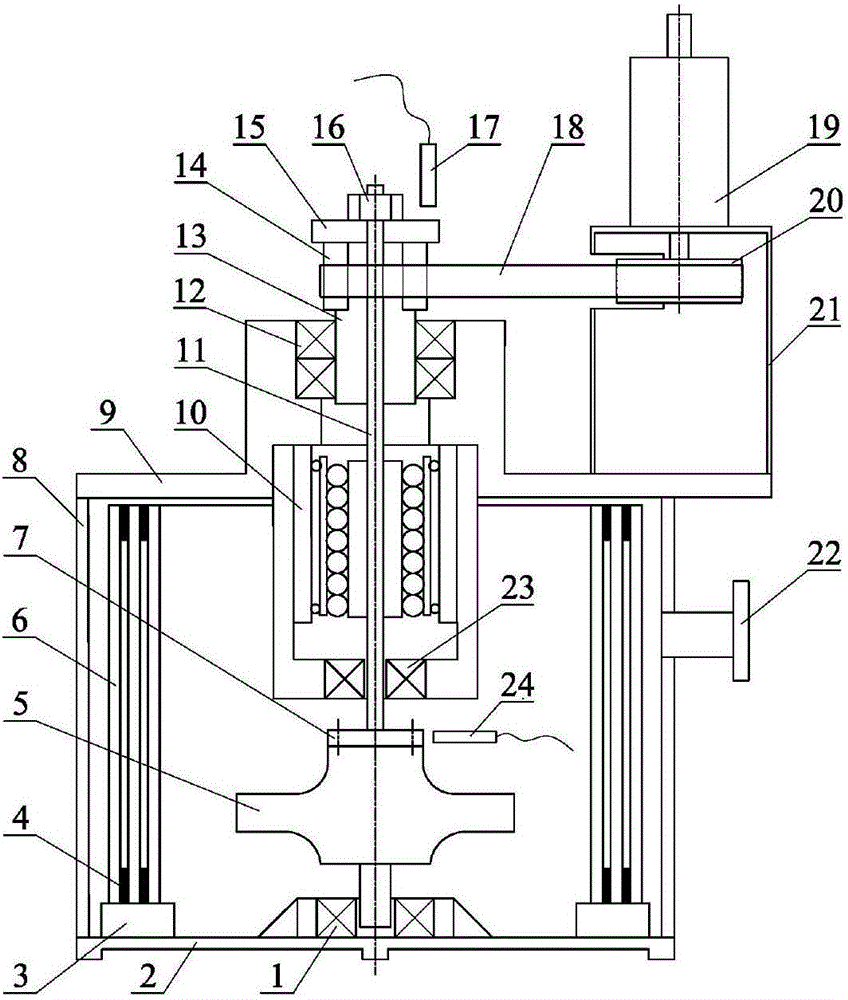

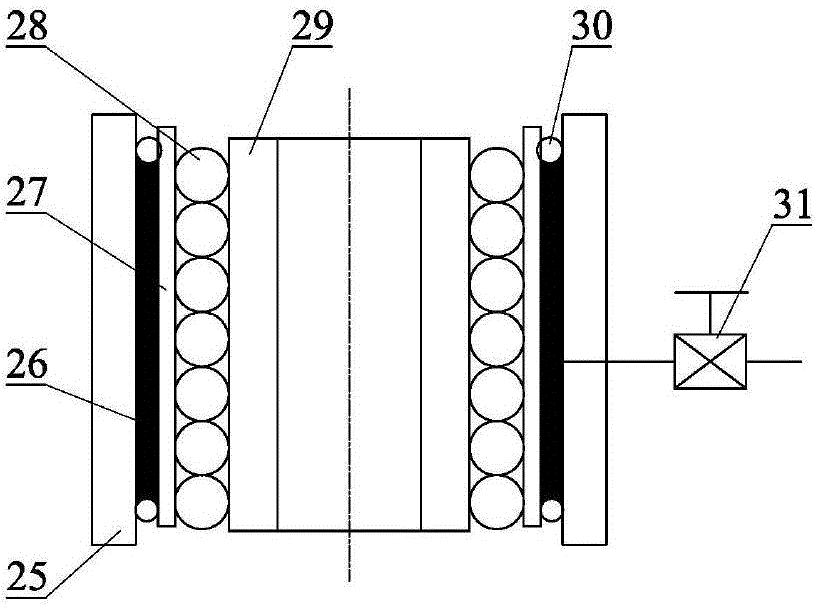

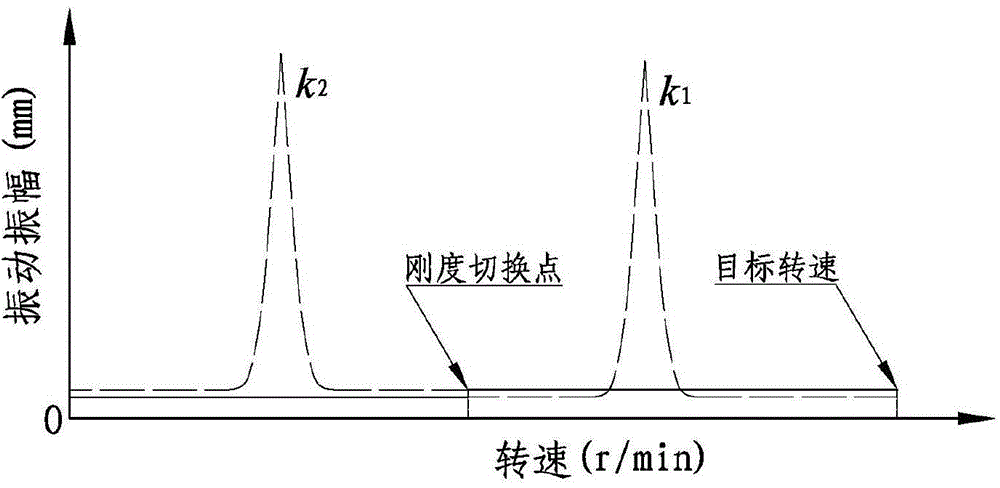

High-speed rotation testing machine and method for testing high-speed rotation strength performance of rotor

InactiveCN103604587ALarge single bearing capacityGood stabilityMachine part testingTest objectDrive motor

The invention discloses a high-speed rotation testing machine and a method for testing the high-speed rotation strength performance of a rotor. The high-speed rotation testing machine comprises a test cavity, a rotor system which is accommodated in the test cavity and used for testing the test rotor, a driving system that drives the rotor system and a rotating speed control system that controls the rotating speed of the rotor system, wherein the driving system includes a driving motor and a speeder which is connected with the driving motor and drives the rotor system to rotate at a high speed, the rotor system includes a test rotor fixed part, a main shaft connected with the test rotor fixed part and driven to rotate by the speeder, and a damper which is sleeved outside the main shaft and supports the main shaft, the test cavity is equipped with a vacuumizing opening, a plurality of layers of containing rings is arranged in the test cavity and surround the rotor system, and the containing rings are connected through spacing blocks arranged at tail ends of the containing rings. The high-speed rotation testing machine uses a high-speed rotating rotor as a test object, the rotor is speeded up through the speeder system, the working condition of the rotor in high-speed rotation is simulated, and the performance requirement of high speed centrifugal load effect resistance of the rotor is tested.

Owner:HANGZHOU HAILUOMA SCI & TECH

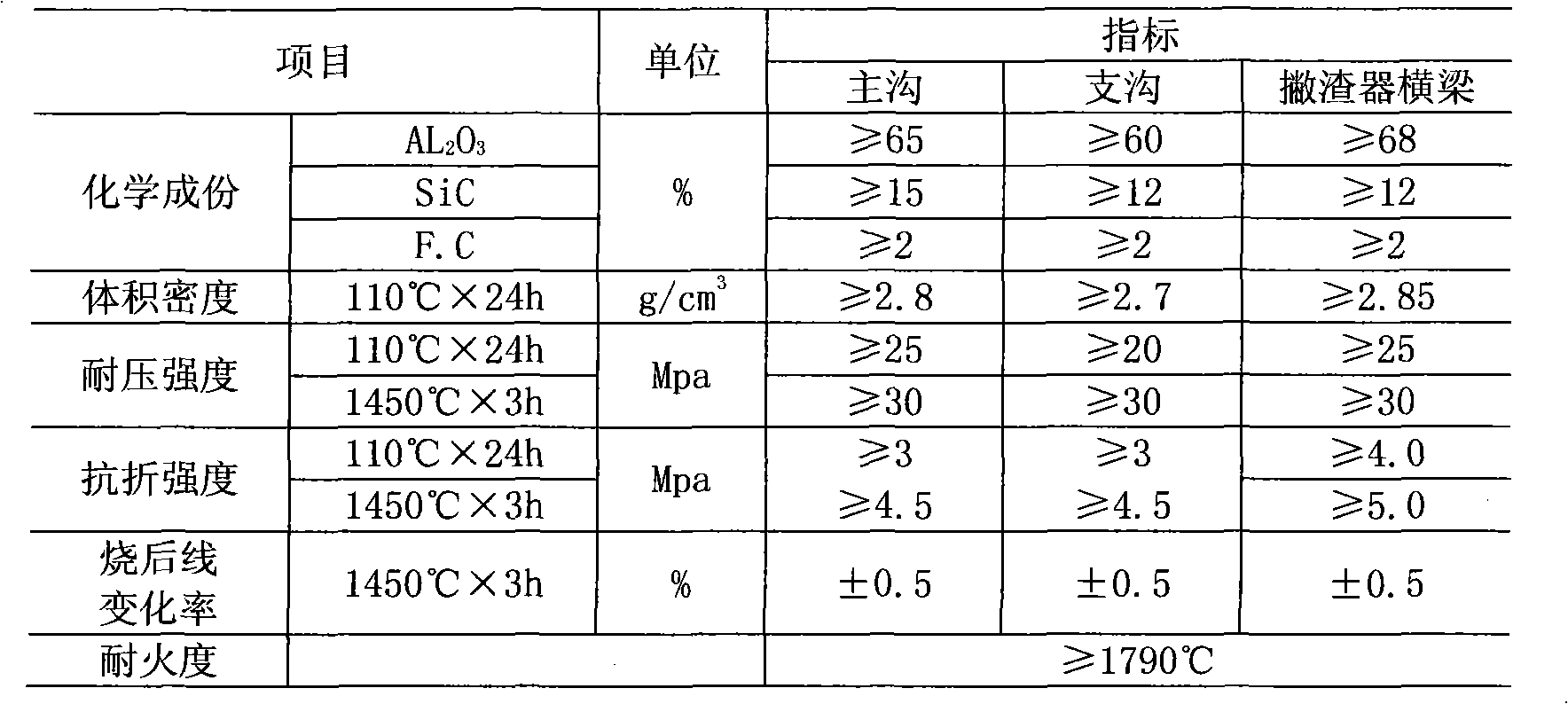

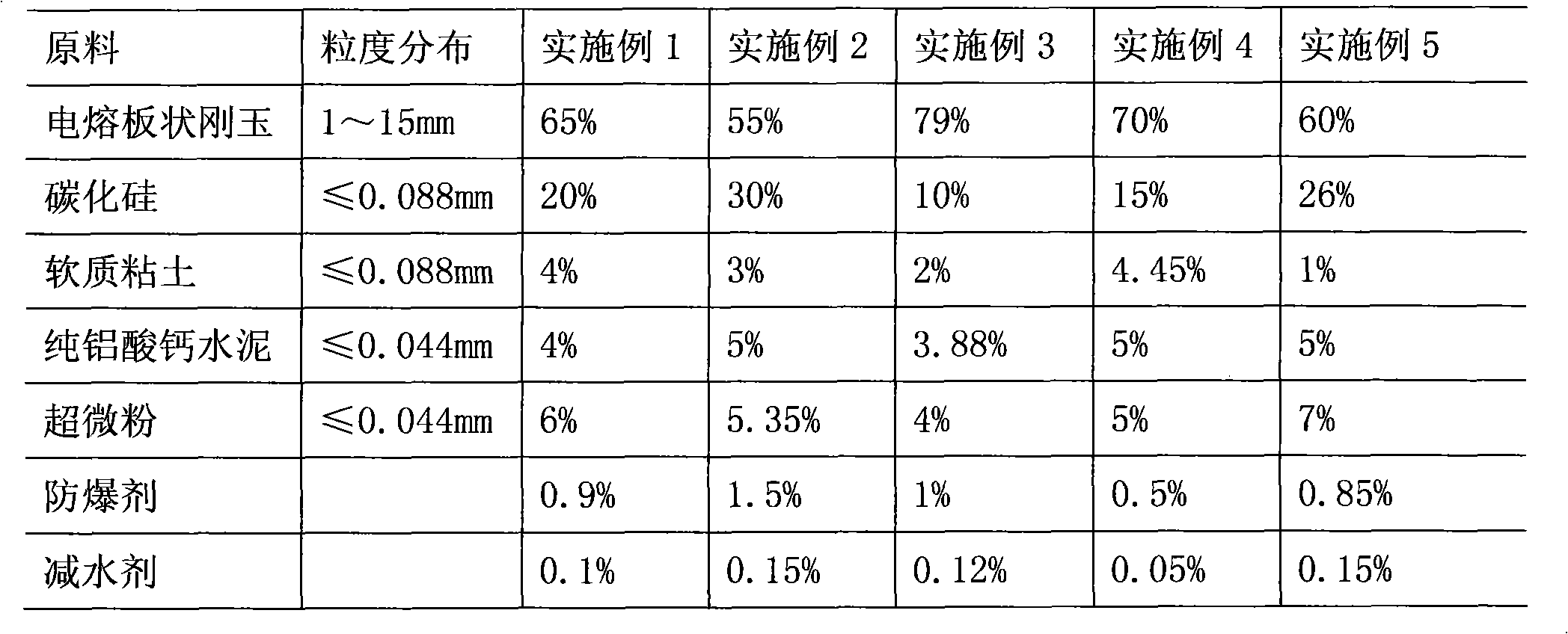

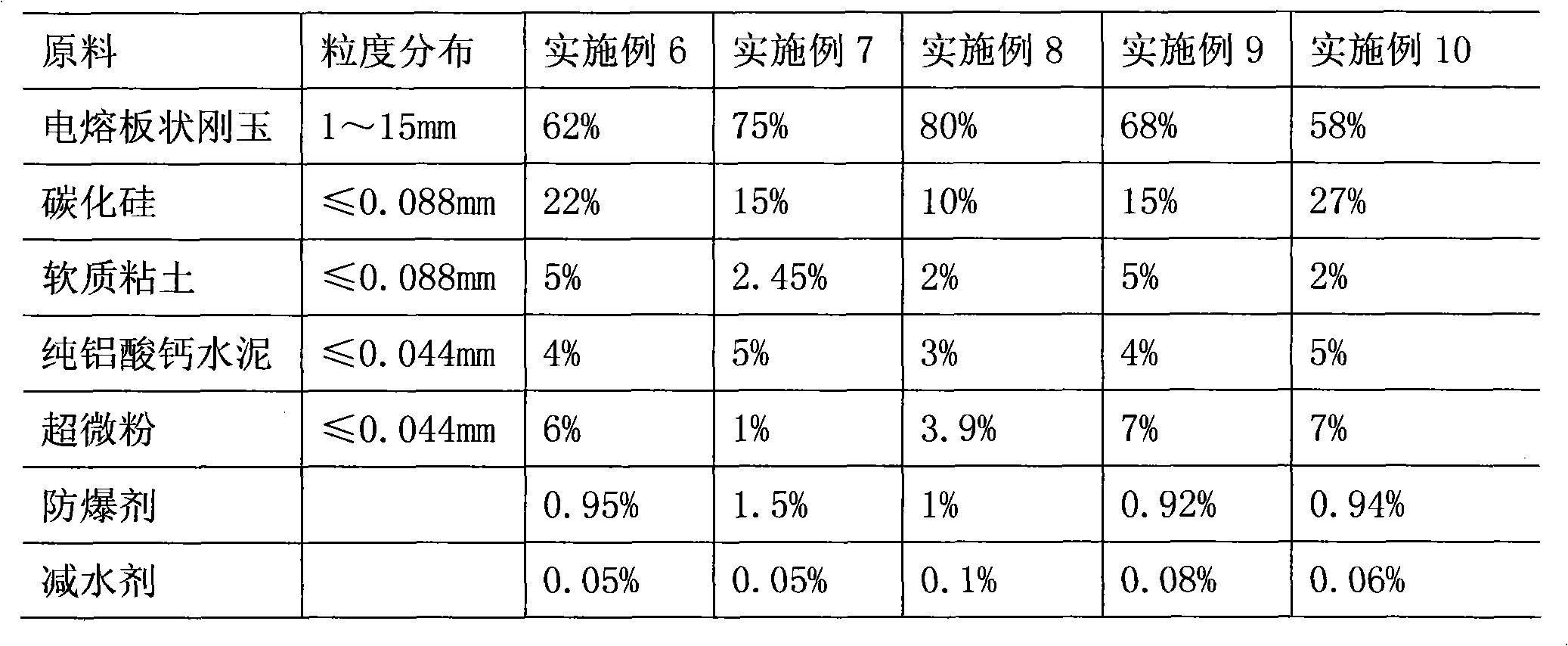

Explosion-proof iron runner castable

The invention relates to an explosion-proof iron runner castable which comprises the following raw materials in percentage by weight: 55-80 percent of fusion tabular corundum, 10-30 percent of silicon carbide, 1-5 percent of soft clay, 2-5 percent of pure calcium aluminate cement, 1-7 percent of submicron powder, 0.5-1.5 percent of explosion-proof agent and 0.05-0.15 percent of water reducing agent, wherein the explosion-proof agent is a mixture of aluminum powder, aluminum lactate, explosion-proof fiber and boron carbide powder with the weight ratio of 1-2:2.5-4:1-2.5:2-4. The castable of the invention has no cracks after demoulding and drying and no spalling during baking, has the safe explosion-proof temperature of 800 DEG C increased from 500 DEG C, can be subjected to construction under heat state and rapid temperature rise without spalling and can meet the operating requirements of rapid construction of middle and small size blast furnace iron runner. The castable has long service life, can improve the environment of a casting house, greatly reduces the labor intensity of the workers, improves the quality of molten iron and enhances the application safety factor of the iron runner.

Owner:HENAN HUAXI FURNACE REFRACTORY

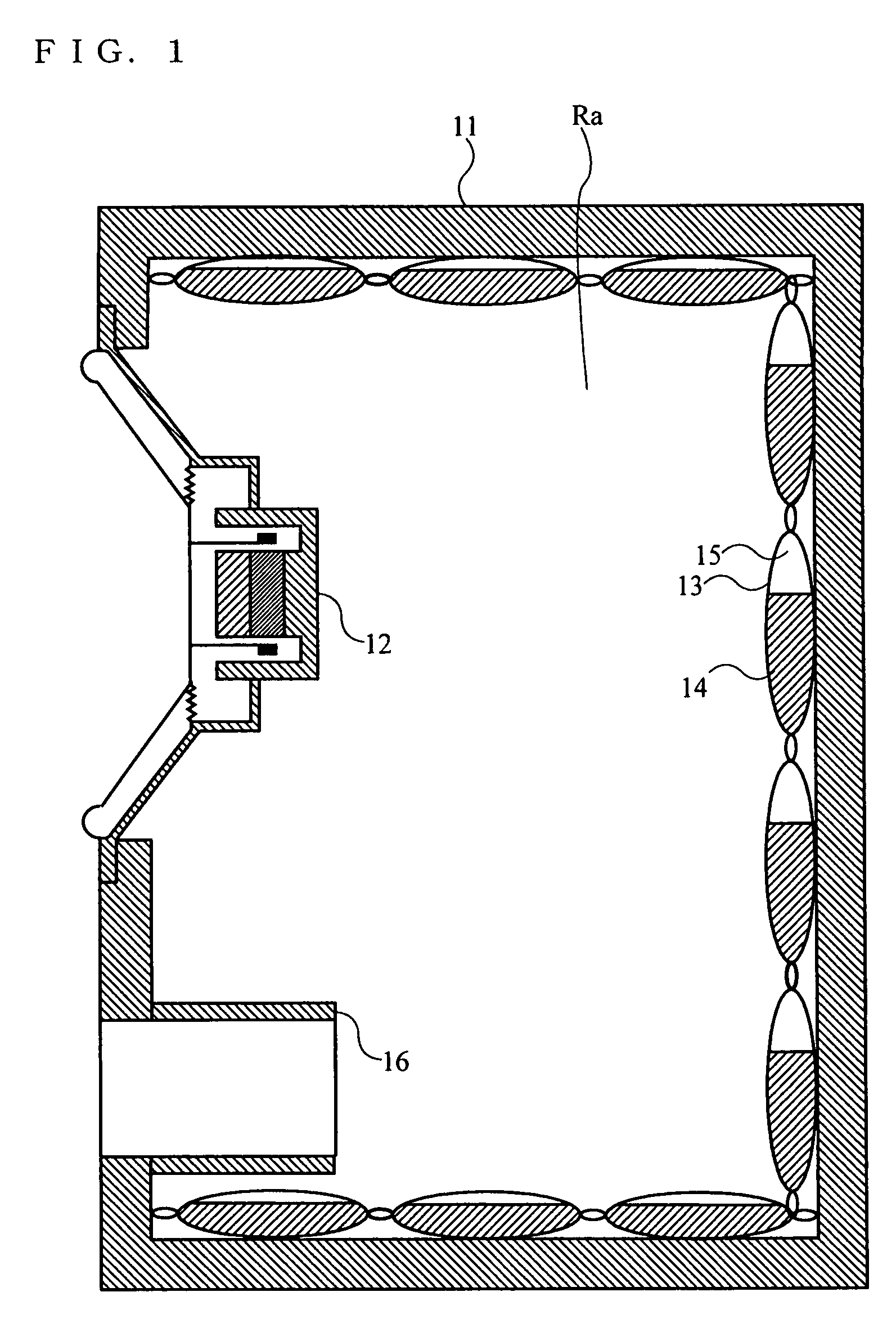

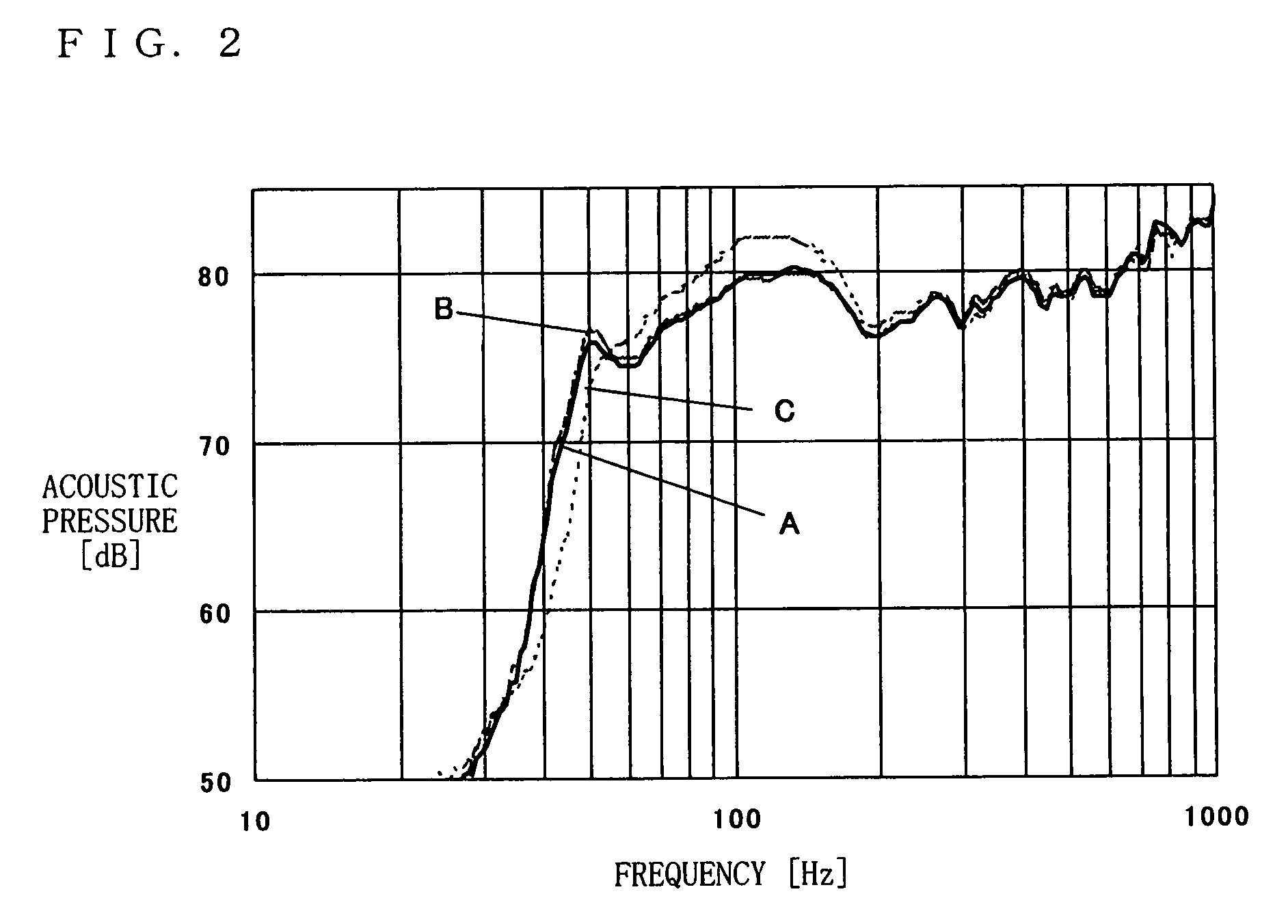

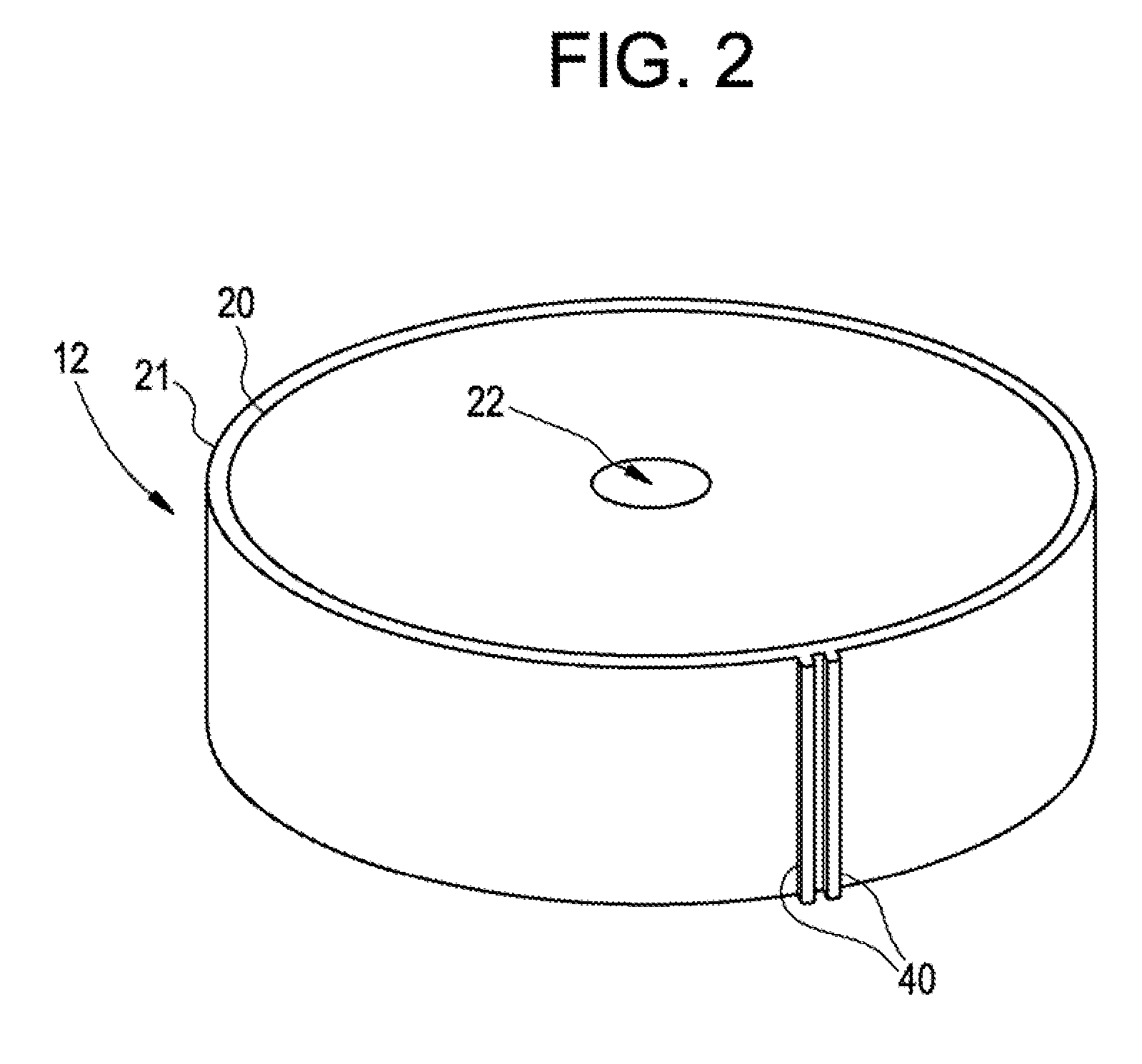

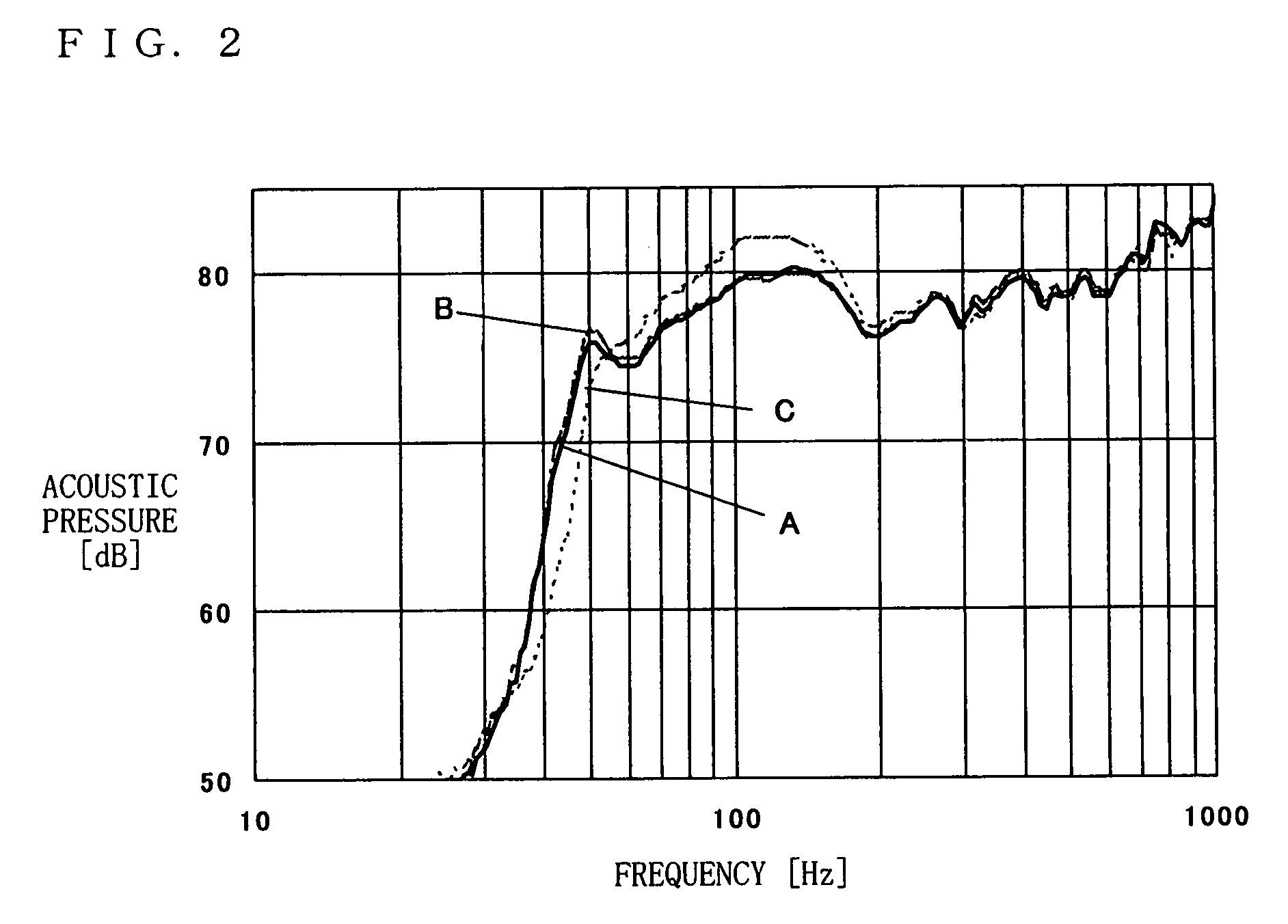

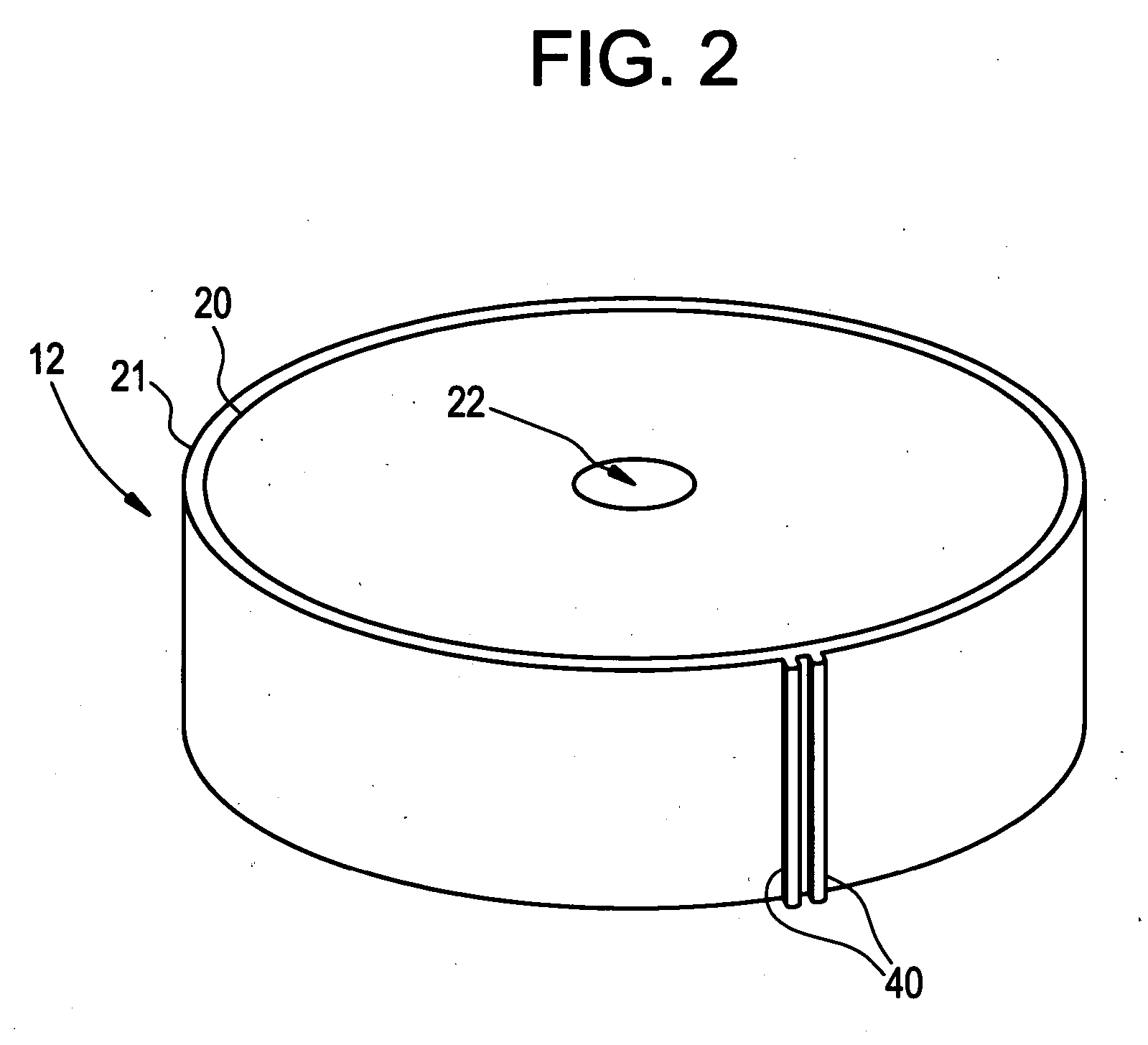

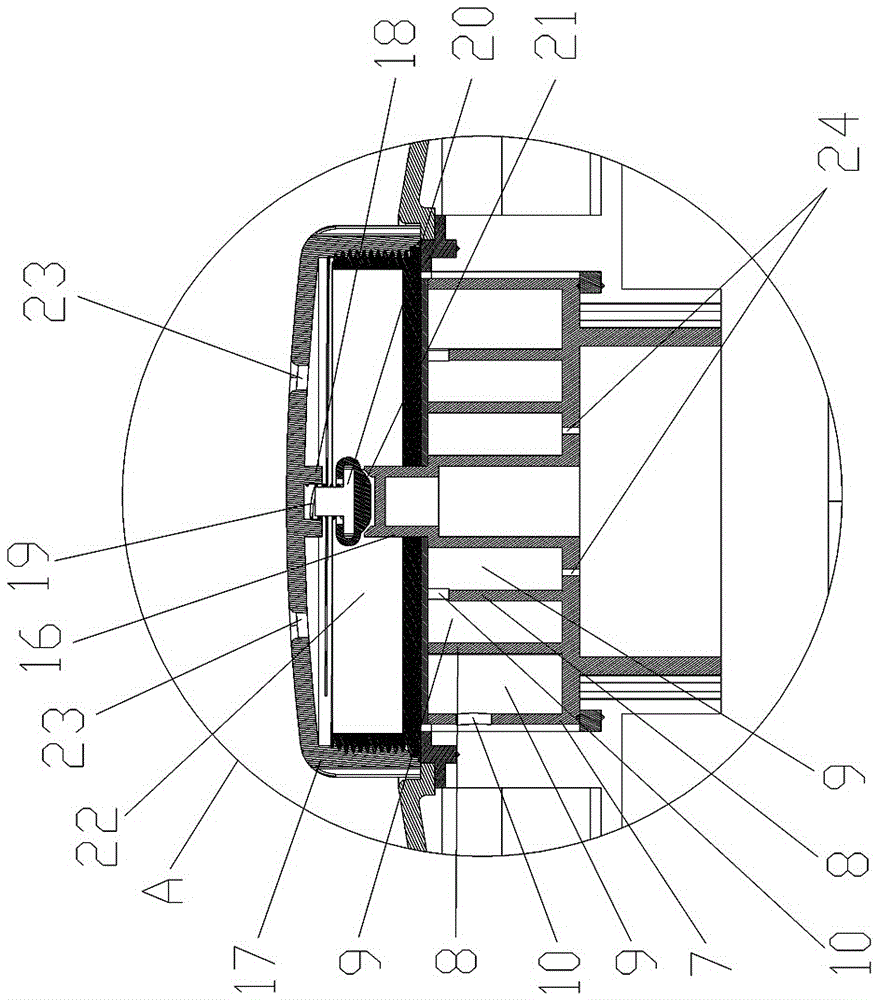

Loudspeaker system

ActiveUS7974423B2Improve performanceAdjustable pressureSubstation equipmentFrequency/directions obtaining arrangementsAeroshellLoudspeaker

A loudspeaker system comprises a cabinet, a speaker unit, a package body, a filler gas, and an absorbent. The speaker unit is mounted in the cabinet. At least one package body is disposed in a vacant space inside of the cabinet and is structured by a bag body for sealing materials thereinto from outside thereof. A predetermined amount of the filler gas is sealed into the package body. A predetermined amount of the absorbent is sealed into the package body and physically absorbs the filler gas.

Owner:PANASONIC CORP

Controlled release formulations using intelligent polymers

InactiveUS20050214368A1Promote absorptionMaintain levelOrganic active ingredientsBiocideSmart polymerWater contact

A controlled release pharmaceutical composition comprises (a) at least one pharmaceutically active substance having a water contact angle (θ) such that cos θ is between +0.9848 and −0.9848, (b) a first intelligent polymer component; and (c) a second intelligent polymer component having opposite wettability characteristics to the first intelligent polymer component, the first and second polymer components being present in a ratio in the range of about 1:100 to about 100:1 by weight. The polymer components are effective for controlled release of the pharmaceutically active substance from the composition.

Owner:BIOVAIL LAB INT SRL

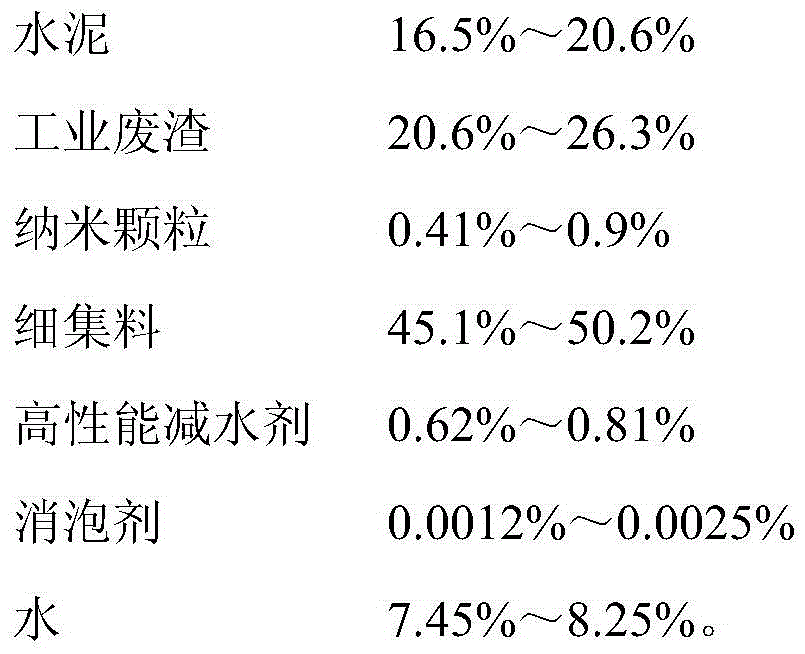

Cement-based composite material with high-temperature resistance and superhigh performance and preparation method thereof

InactiveCN102092996AReduce burstImprove compactnessSolid waste managementMetal fiberAggregate (composite)

The invention discloses a cement-based composite material with high-temperature resistance and superhigh performance and a preparation method thereof. The cement-based composite material comprises the raw materials of a gelled material, an aggregate, fibers, a water reducing agent and water, wherein the gelled material is a mixture of cement and active mineral admixture, the aggregate is yellow sand or a mixture of yellow sand and pebbles, and the fibers are organic fibers or mixtures of organic fibers and metal fibers. The cement-based composite material is produced through improvement on the basis of common concrete manufacturing, has the properties of superhigh mechanical property and high-temperature resistance, is applicable to high-temperature resistant engineering structures, and is favorable for preventing the collapse and the destruction of the construction structures in a fire disaster.

Owner:NANJING UNIV OF SCI & TECH

Bag for crushing objects

InactiveUS20070098308A1Quantity minimizationReduce the amount requiredEnvelopes/bags making machineryBag making operationsEngineeringPlastic bag

The invention relates to a plastic bag suitable for crushing and dispensing an object, such as medicinal pill. The bag has an open end, is strong enough to withstand crushing forces, and includes a bottom seal that forms an angle of greater than 90° with the sides of the bag. For example, the bottom seal may be curved and concave toward the open end of the bag. The bag may also include a lip near the opening and formed by one of the bag walls The bag may also include a gripper on any of (1) the interior or exterior surfaces of the lip or (2) the interior or exterior surface of the other wall. The bag may also include an indicator mark, e.g., a colored line near the opening to serve as a visual and / or tactile indicator for the user of the bag.

Owner:THE BAGCO

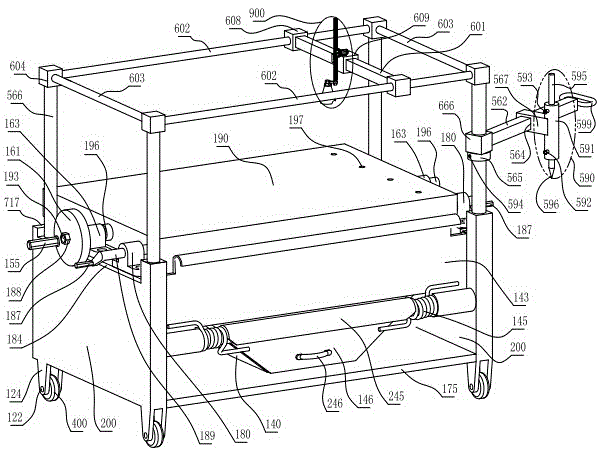

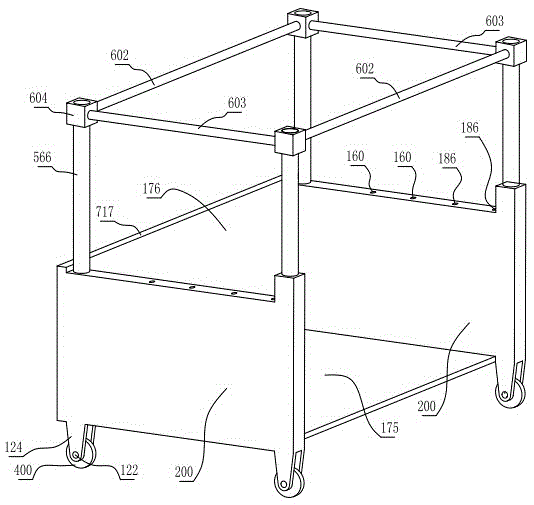

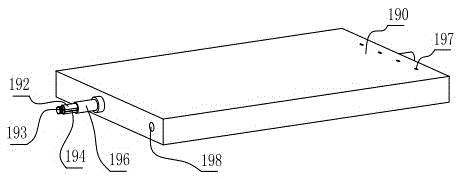

Disk wheel rotating bench rack shooting V-shaped clamping plate nickel alloy glass examination apparatus

InactiveCN105527156AEasy to moveEasy to removeMaterial strength using repeated/pulsating forcesMobile cameraNickel alloy

The invention relates to a toughened glass test examination apparatus, and concretely relates to a disk wheel rotating bench rack shooting V-shaped clamping plate nickel alloy glass examination apparatus. The apparatus is characterized in that a bench plate rotating shaft at one side is fixedly provided with a hand-operated disk wheel, a disk wheel flat key is arranged between the bench plate rotating shaft and the hand-operated disk wheel, and the outer side surface of the hand-operated disk wheel is provided with a disk wheel cranking handle; two transverse horizontal rods are in sliding fit with shooting transverse slide blocks, a shooting square bar is fixedly arranged between the two shooting transverse slide blocks, the shooting square bar is provided with a mobile camera assembly, an impact cross bar is fixedly provided with a cylinder impacter in a slidable manner, the upper plane of a test bench plate is fixedly provided with a coplanar V-shaped groove clamping plate assembly, and a broken glass recovery container is fixedly arranged between an entirety of bench plate bearers and lock pin bearers and the upper plane of a supporting side plate; and an integral frame is provided with a rack elevating industry camera, a disk wheel overturns test bench plates, a screw thread lock pin is arranged to fasten, and especially the coplanar V-shaped groove clamping plate assembly and the cylinder impacter are also arranged to form an automatic whole-course detection base apparatus.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Method for preparing tungsten carbide abrasion resistant composite coating by penetration brazing method

ActiveCN101637838AHigh bonding strengthFast heat conductionSoldering apparatusWelding/soldering/cutting articlesEpoxyBond interface

The invention relates to a method for preparing tungsten carbide abrasion resistant composite coating by a penetration brazing method, belonging to the field of coating preparation in materials processing engineering. The invention comprises the following steps: (1) pasting coating metal powder cloth containing tungsten carbide-cobalt (WC-Co), nickle (Ni) and chromium (Cr) mixed powder on a metalsubstrate by using epoxy resin bonding agent; (2) preparing welding material metal powder cloth from BNi-2 brazing material and pasting the welding material metal powder cloth on the coating metal powder cloth obtained in the step (1); and (3) carrying out penetration brazing in a vacuum furnace to form a metallurgical bonded interface. The tungsten carbide abrasion resistant composite coating canbe applicable to protection of mechanical elements in the field of generating plant, petroleum, aviation, food, plastics and the like.

Owner:JIANGXI HENGDA HI TECH CO LTD

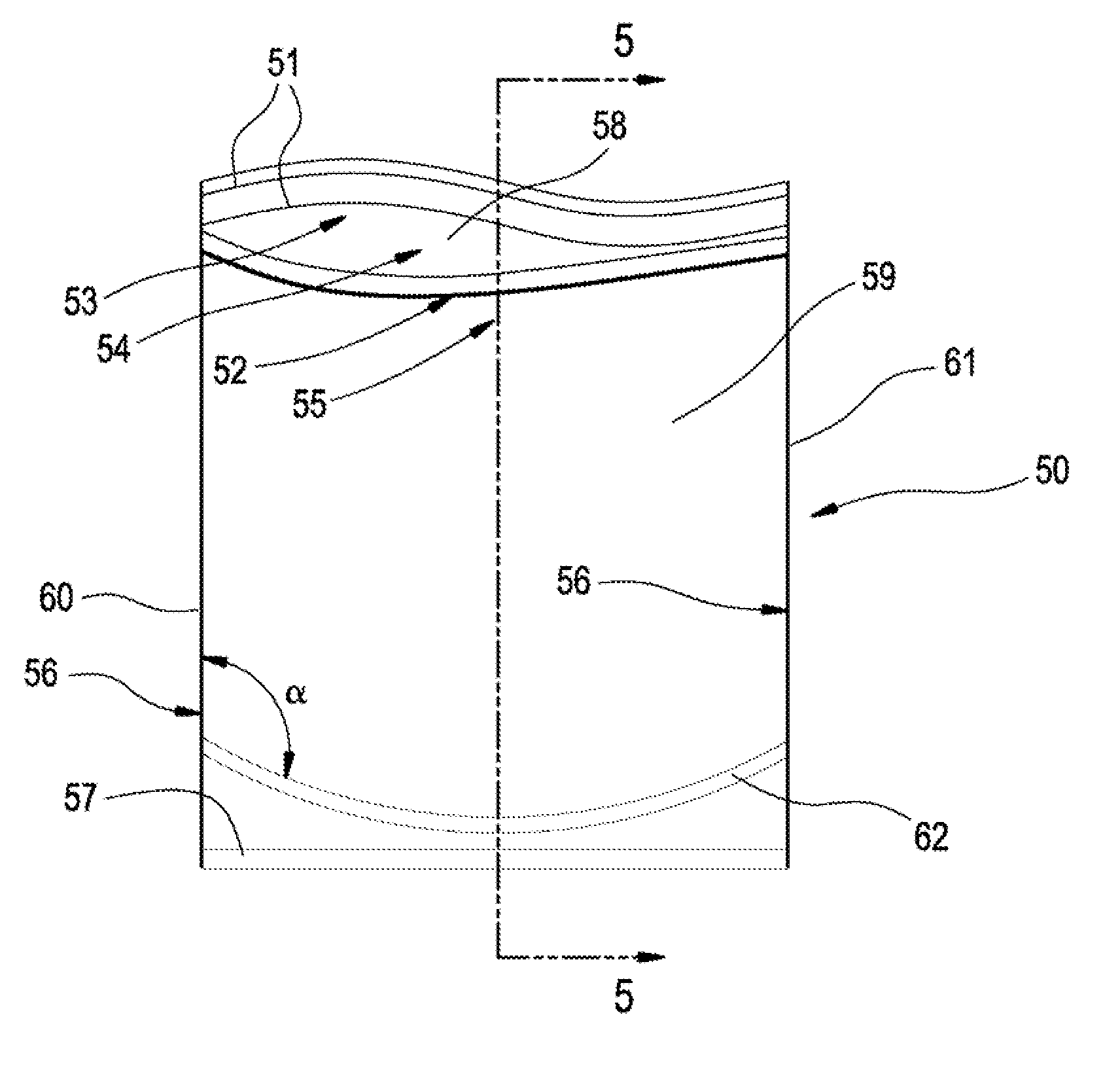

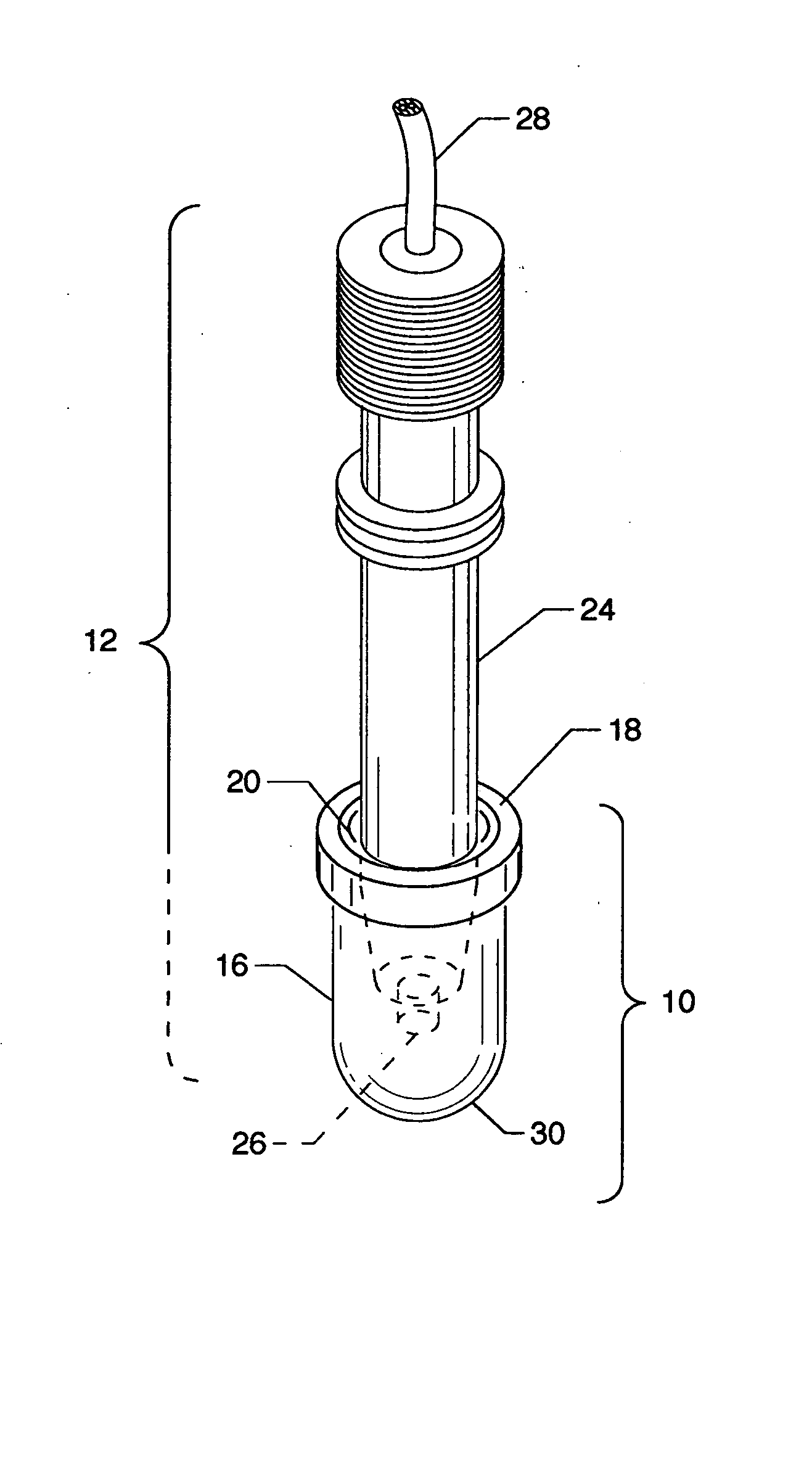

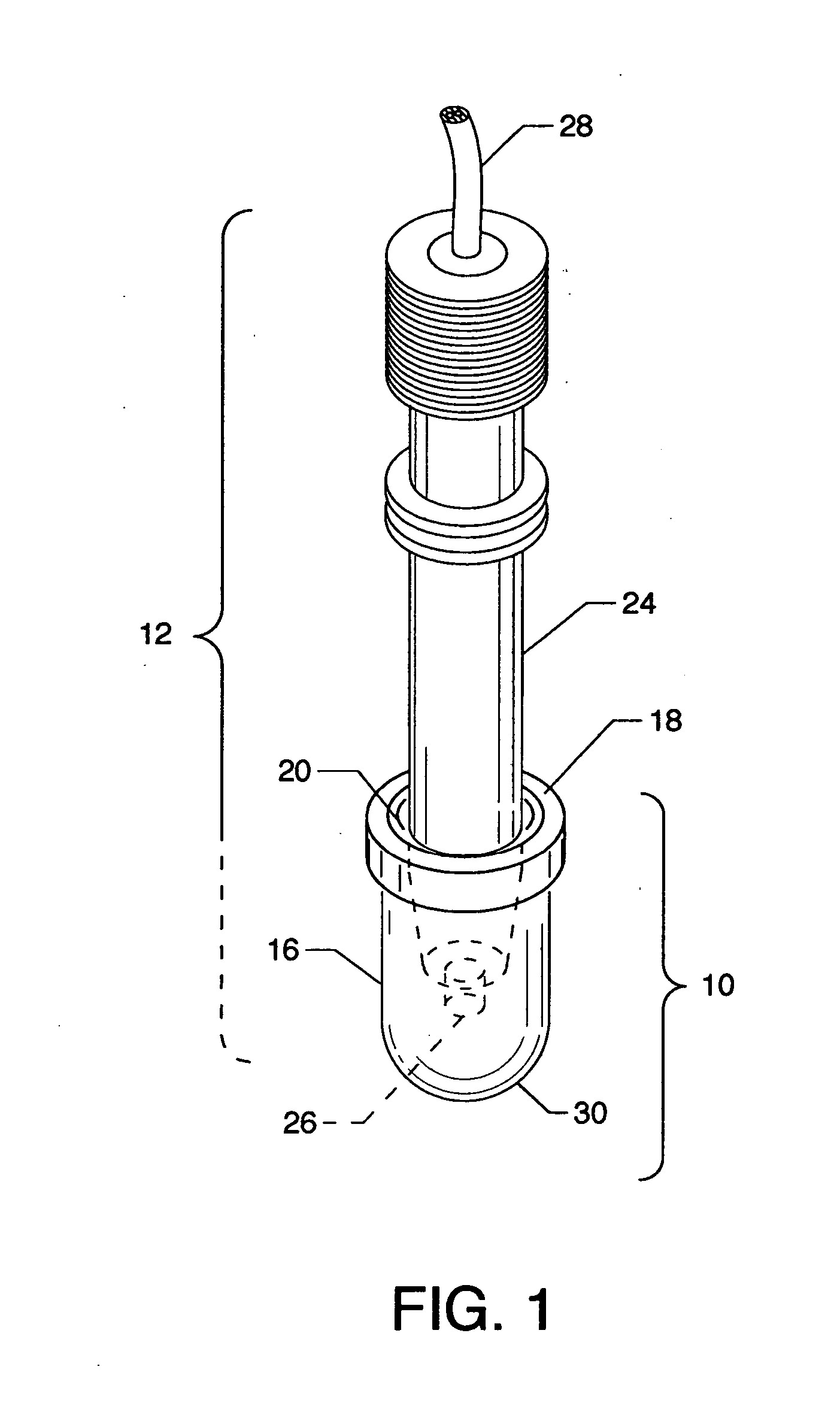

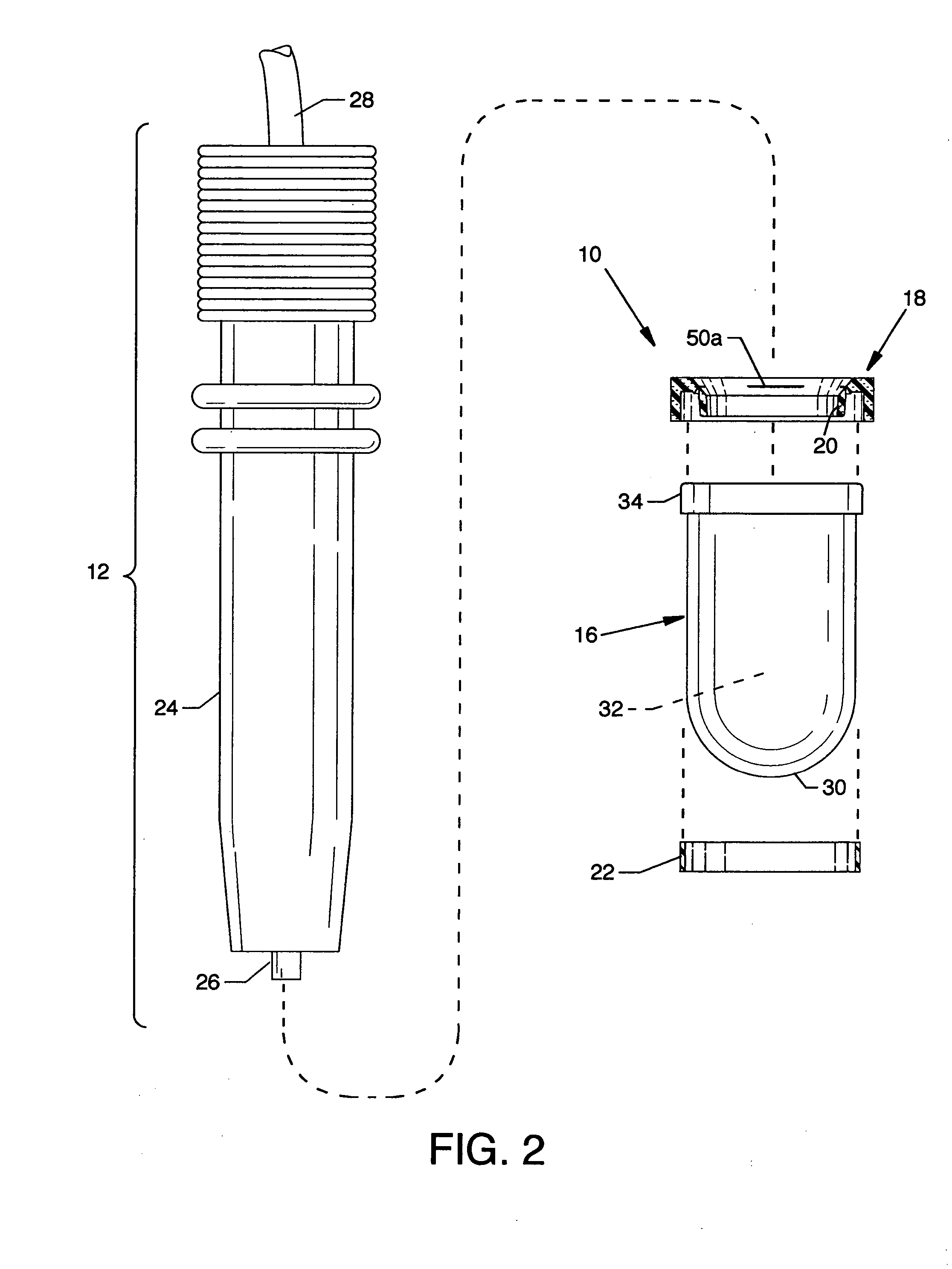

Immersion bag system for use with an ultrasound probe

ActiveUS20070239030A1No minimal abrasive contactAvoid soakingUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringVertical axis

An immersion bag system for use with an ultrasound probe to overcome near field artifact includes a flexible thin wall thickness immersion bag with an attached flexible collar having an integral internal seal. The immersion bag contains a gel or other ultrasound transmission medium and is sealingly and removably attached to the tip end of an ultrasound probe by use of the flexible collar having the integral internal seal. The immersion bag is able to conform to a cornea as well as to other surfaces whether flat or irregular, thereby enabling an ultrasound probe to be used easily on such surfaces. An ultrasound probe in use with the immersion bag system is maintained at a distance above the contact surface of the immersion bag and is positionable about the vertical axis while the immersion bag maintains stationary conformal contact with the structure against which it is in contact.

Owner:ESI

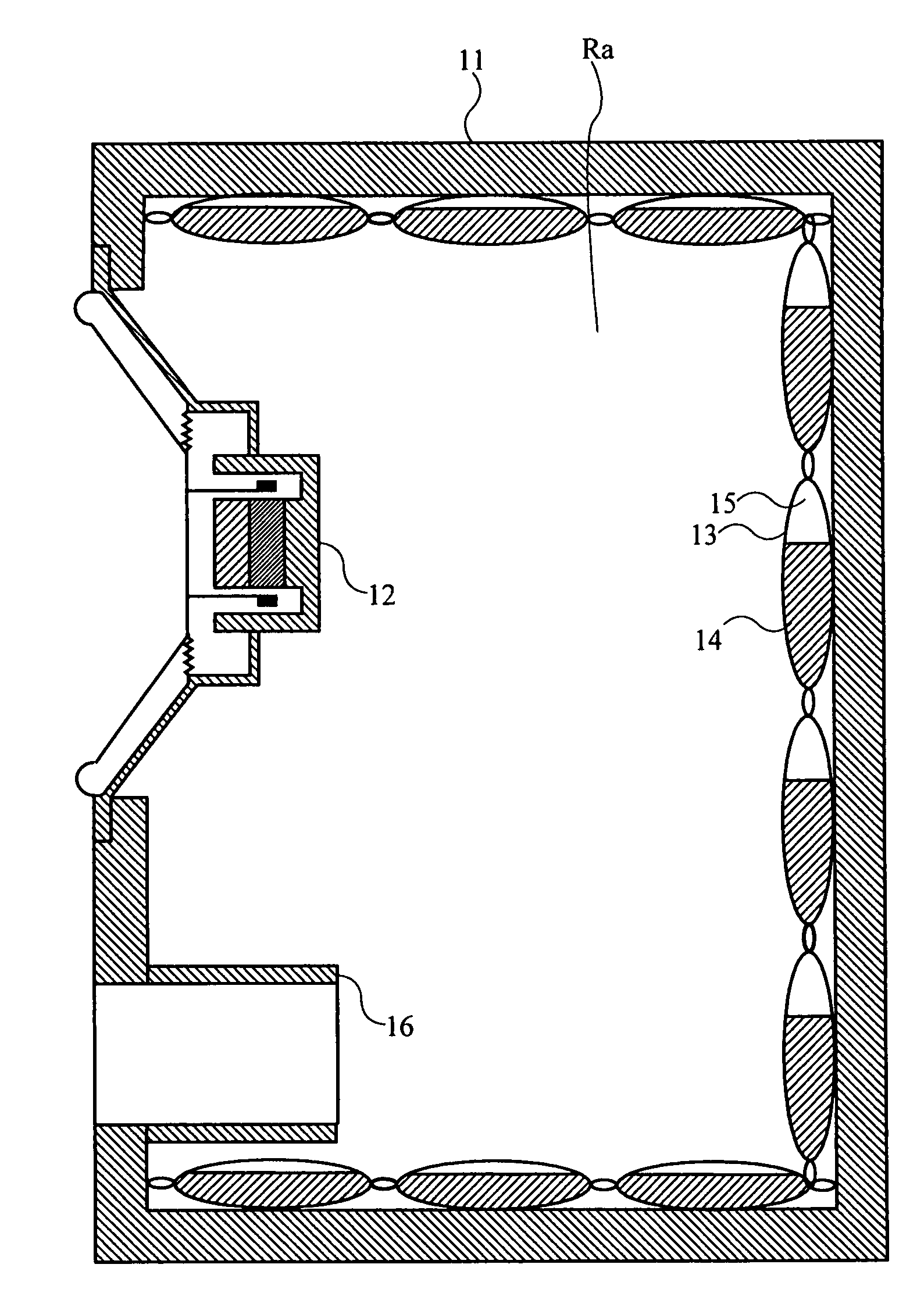

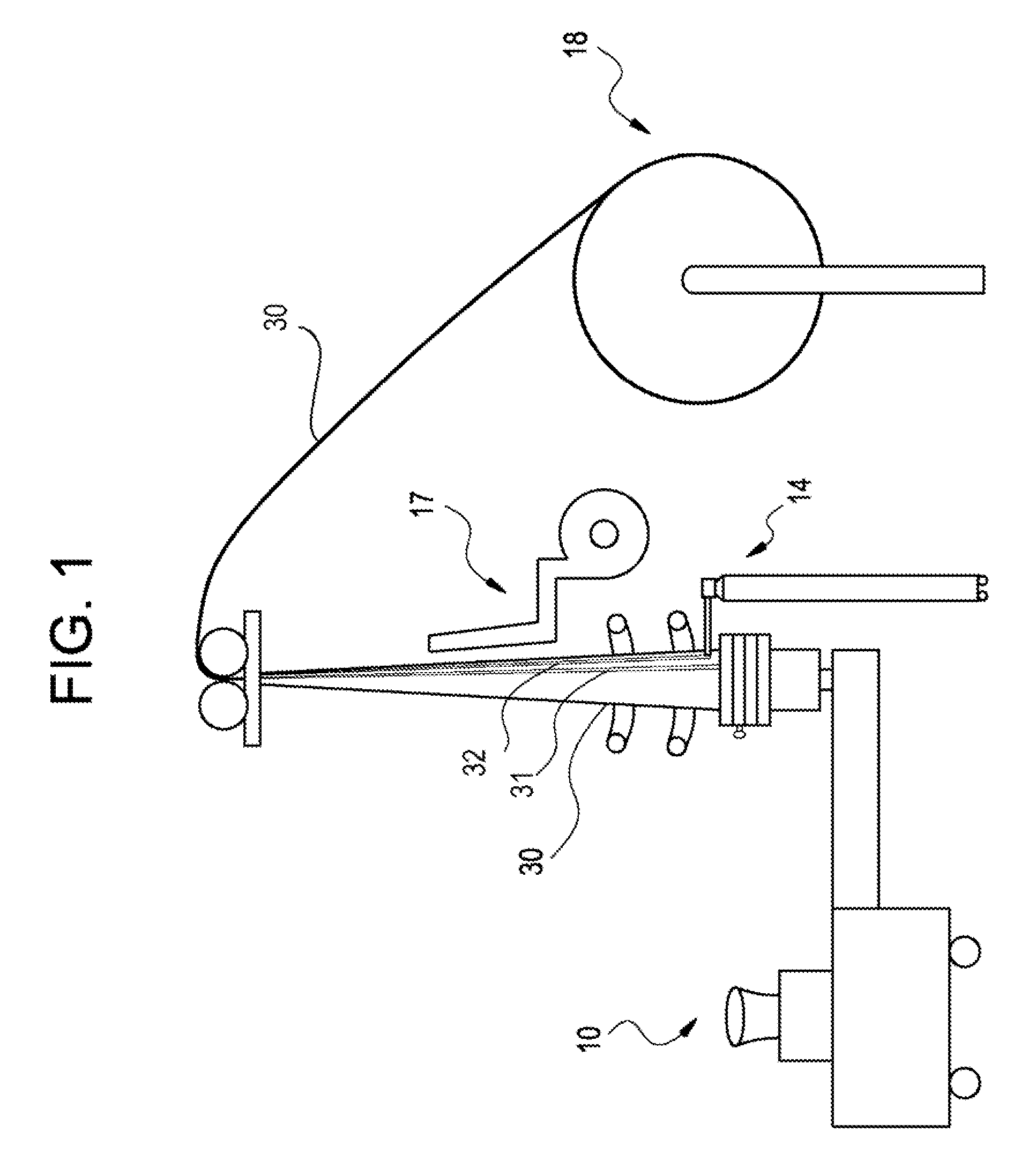

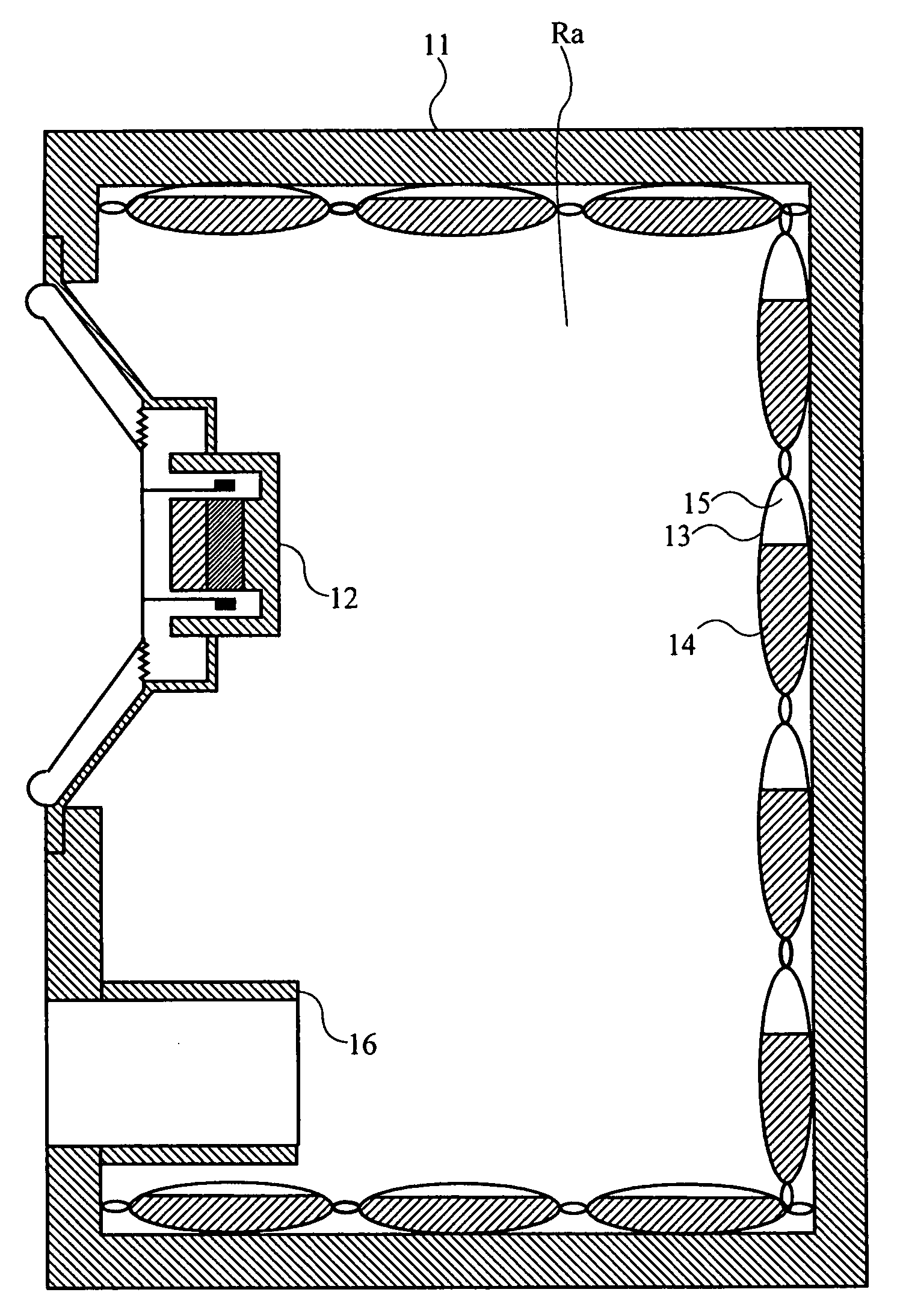

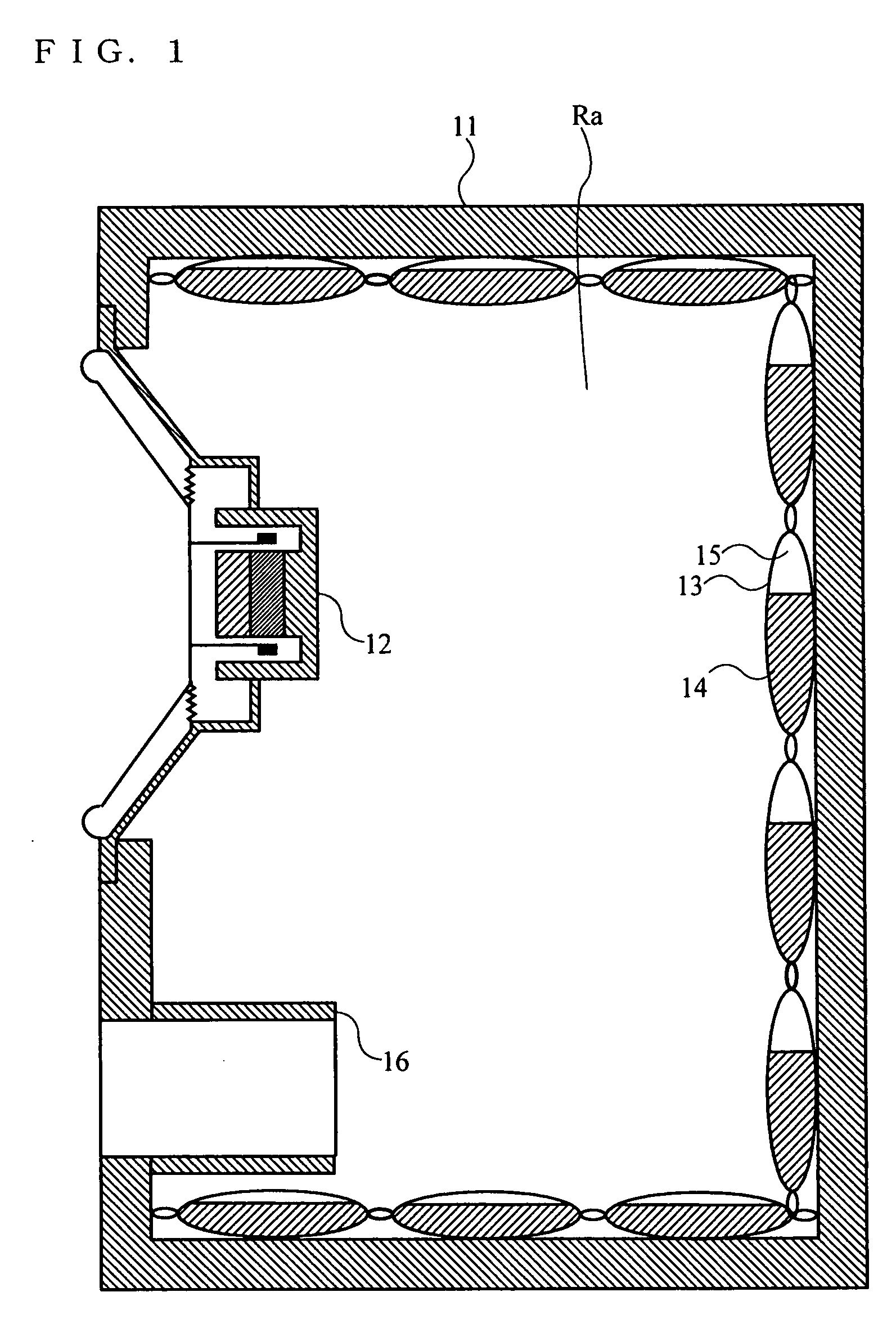

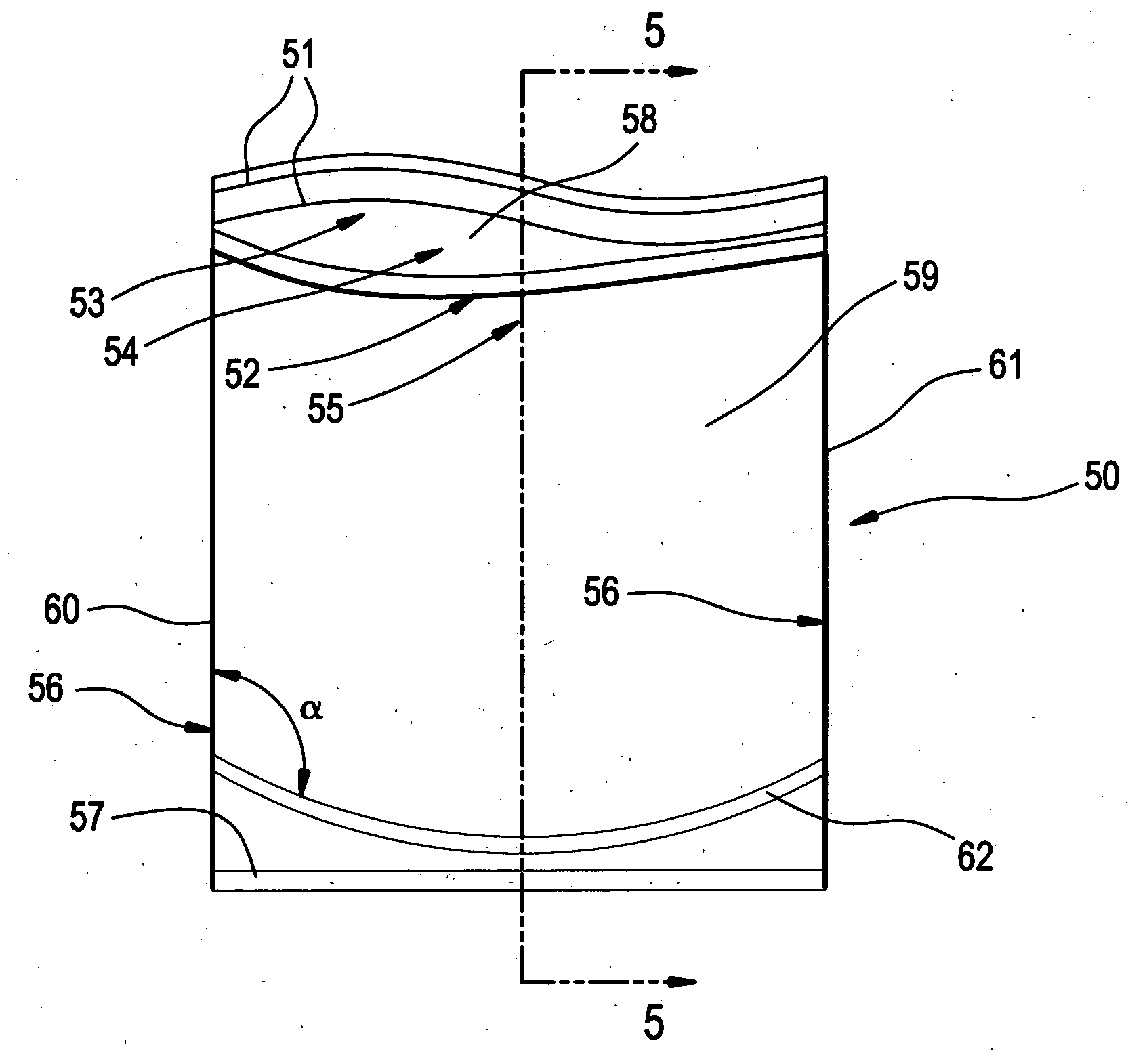

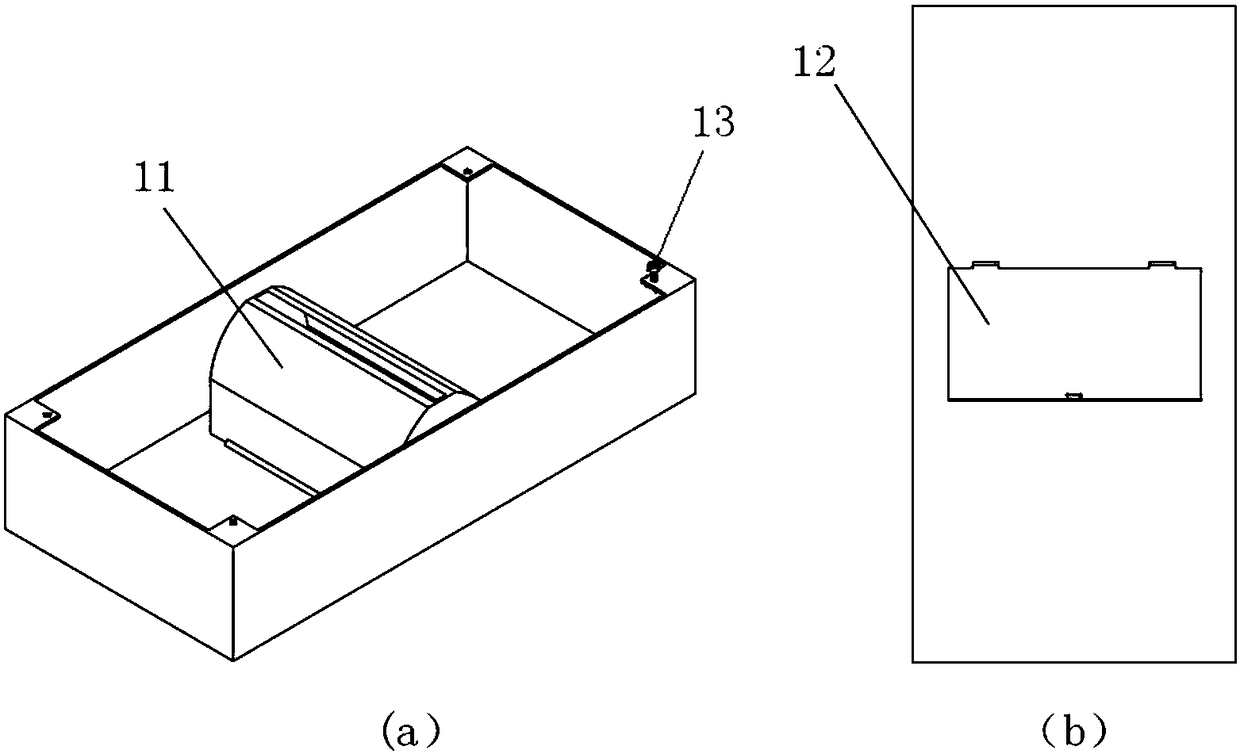

Loudspeaker System

ActiveUS20070286449A1Improve performanceAdjustable pressureSubstation equipmentFrequency/directions obtaining arrangementsEngineeringLoudspeaker

A loudspeaker system comprises a cabinet (11), a speaker unit (12), a package body (13), a filler gas (15), and an absorbent (14). The speaker unit (12) is mounted in the cabinet (11). At least one package body (13) is disposed in a vacant space (Ra) inside of the cabinet (11) and is structured by a bag body for sealing materials thereinto from outside thereof. A predetermined amount of the filler gas (15) is sealed into the package body (13). A predetermined amount of the absorbent (14) is sealed into the package body (13) and physically absorbs the filler gas (15).

Owner:PANASONIC CORP

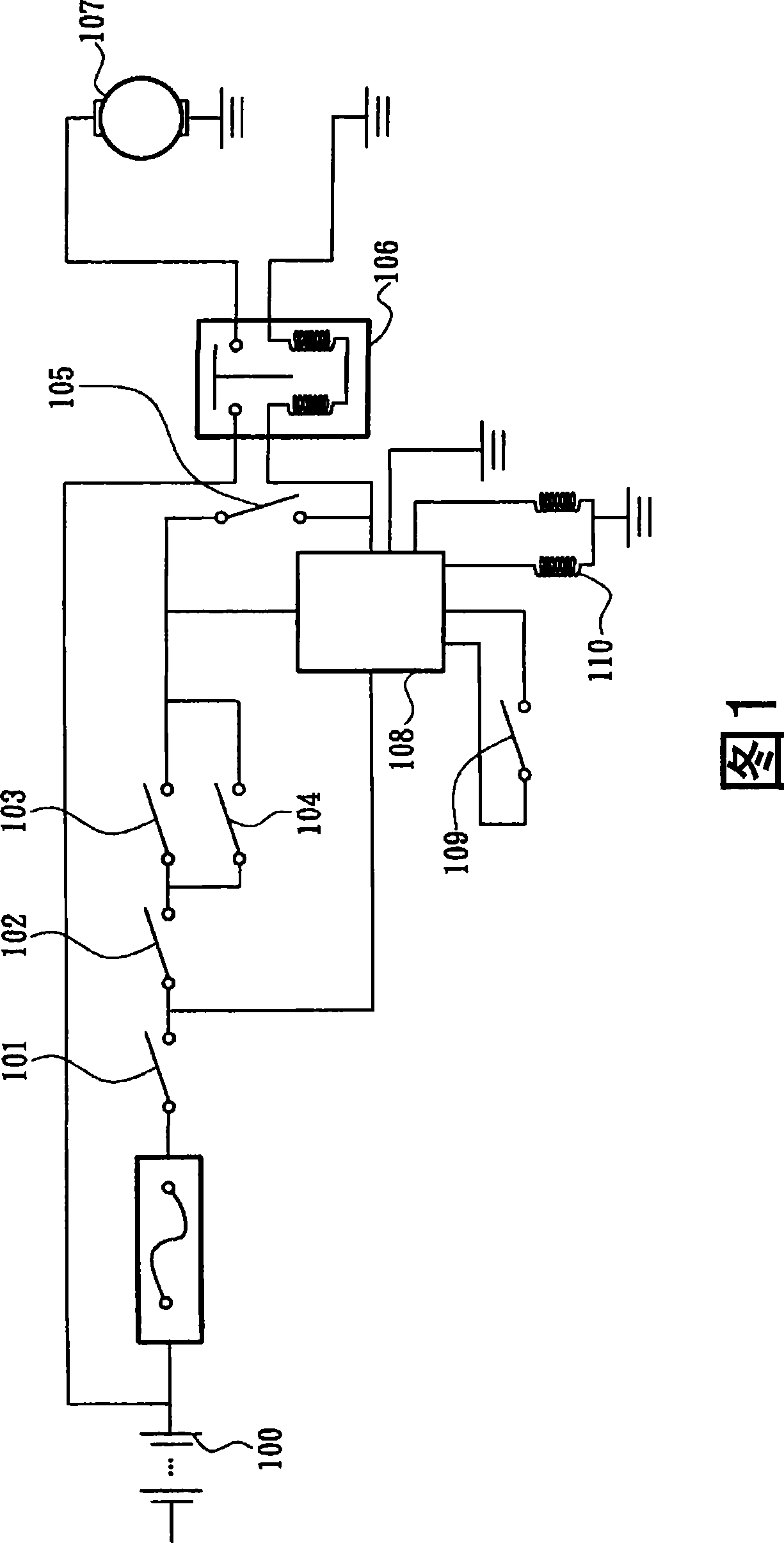

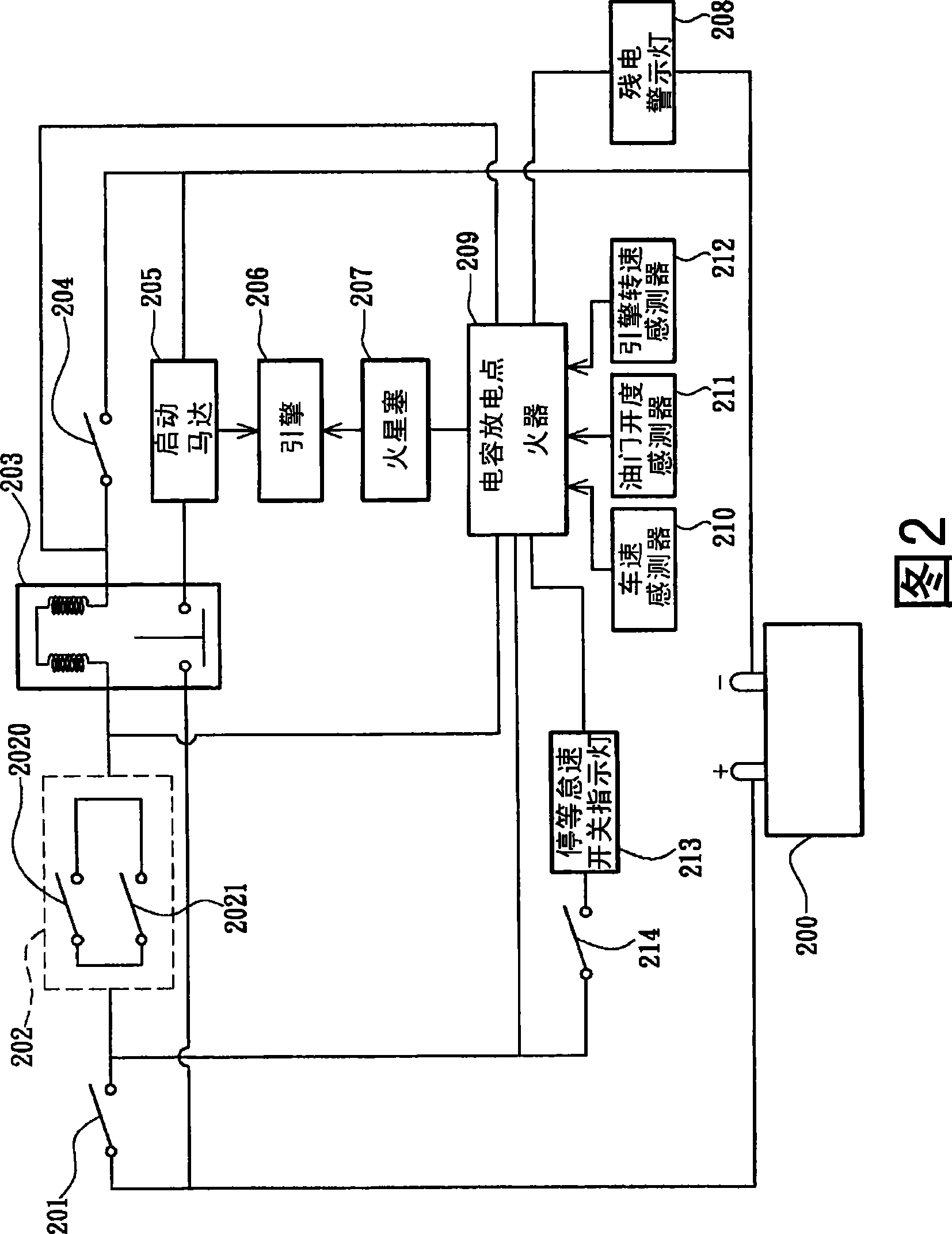

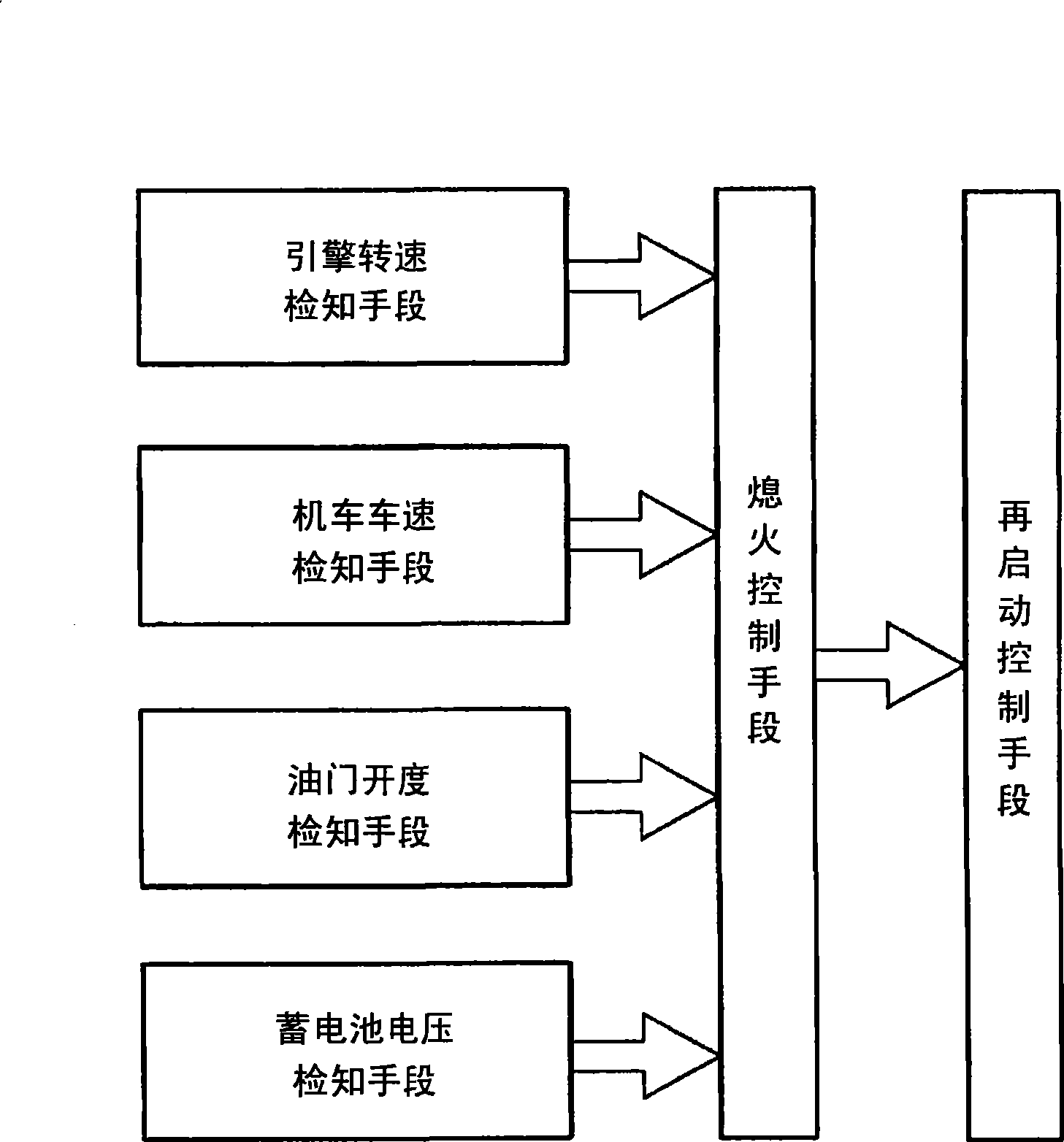

Motorcycle engine control method and device thereof

InactiveCN101382093AReduce pollutionReduce fuel consumptionElectrical controlInternal combustion piston enginesFlameoutIdle speed

The invention discloses a method and a device for controlling a motorcycle engine. The device is used for judging an operating state of a motorcycle, controlling automatic flameout of the engine and re-starting the engine so as to reduce oil consumption in a process of stopping and operating the motorcycle at an idle speed. The invention checks operation information of the motorcycle through an ignition control chip module to judge a current operation state of the motorcycle. When the ignition control chip module checks that the motorcycle is in a static state, the engine operates at the idlespeed, and a position of throttle opening of the motorcycle is a default value of an origin point, after the conditions are satisfied, the position of the throttle opening is a default value of the time of the automatic flameout, the ignition control chip module controls the automatic flameout of the engine. When the ignition control chip module checks that the throttle opening of the motorcycle is changed to be more than a default value of the voltage of the throttle opening, the ignition control chip module controls a relay to act and starts up a motor to operate, and controls a spark plug to ignite and re-start the engine.

Owner:KYMCO

Method for manufacturing an air permeable composite film

InactiveUS7077923B2Increase resistanceHigh strengthPackage recyclingPackaging foodstuffsComposite filmDifferential pressure

Owner:LIN IRENE

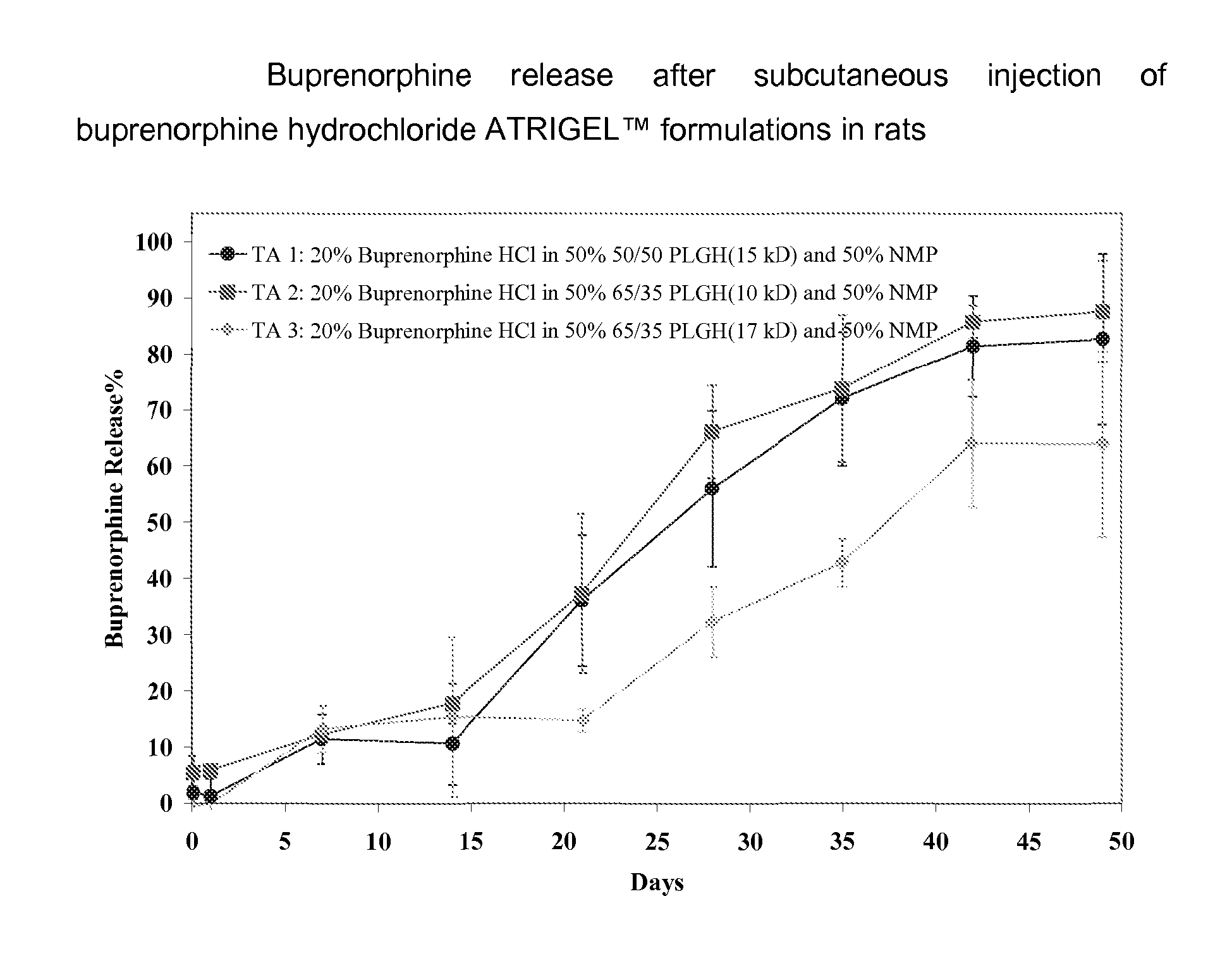

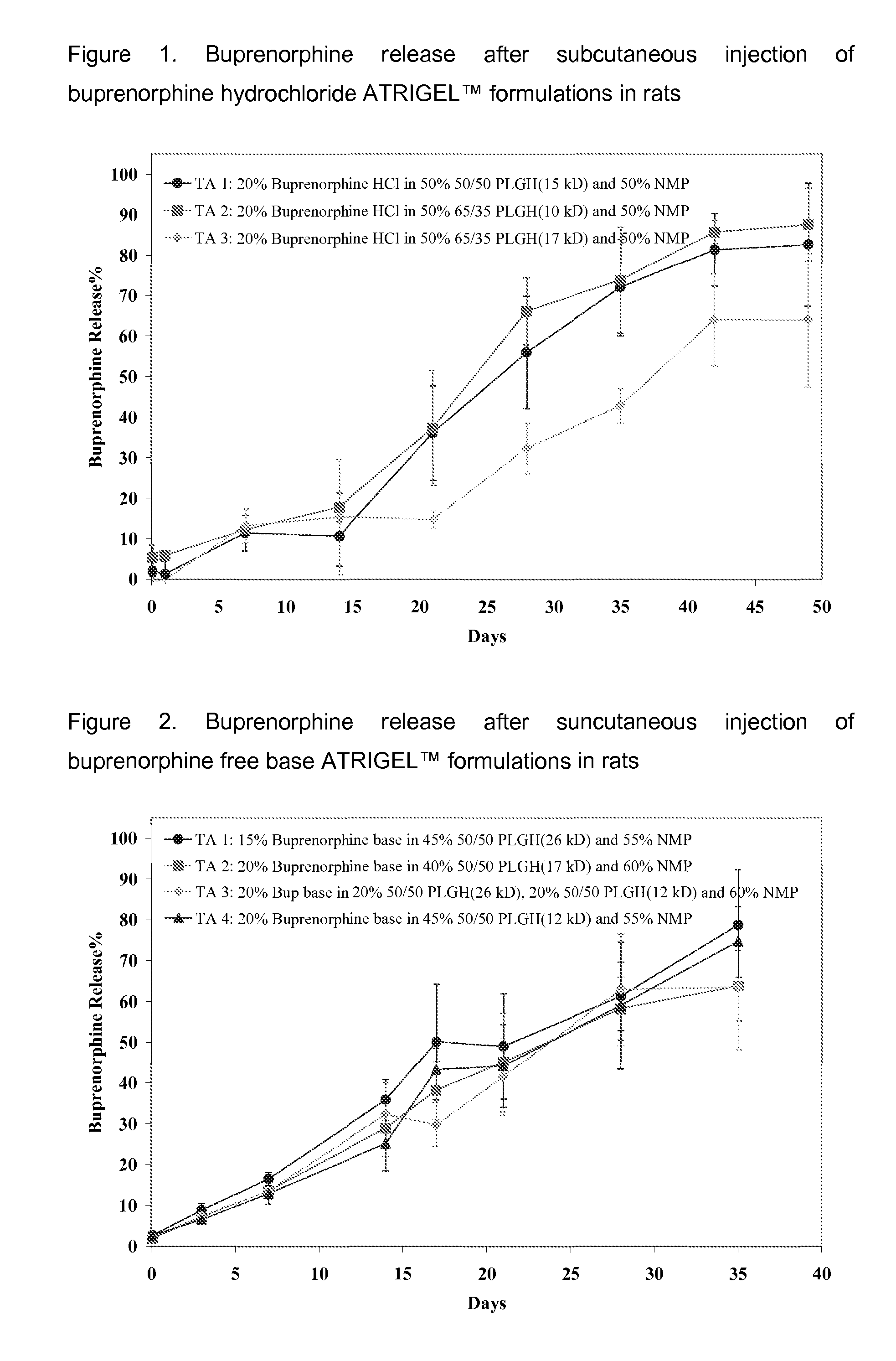

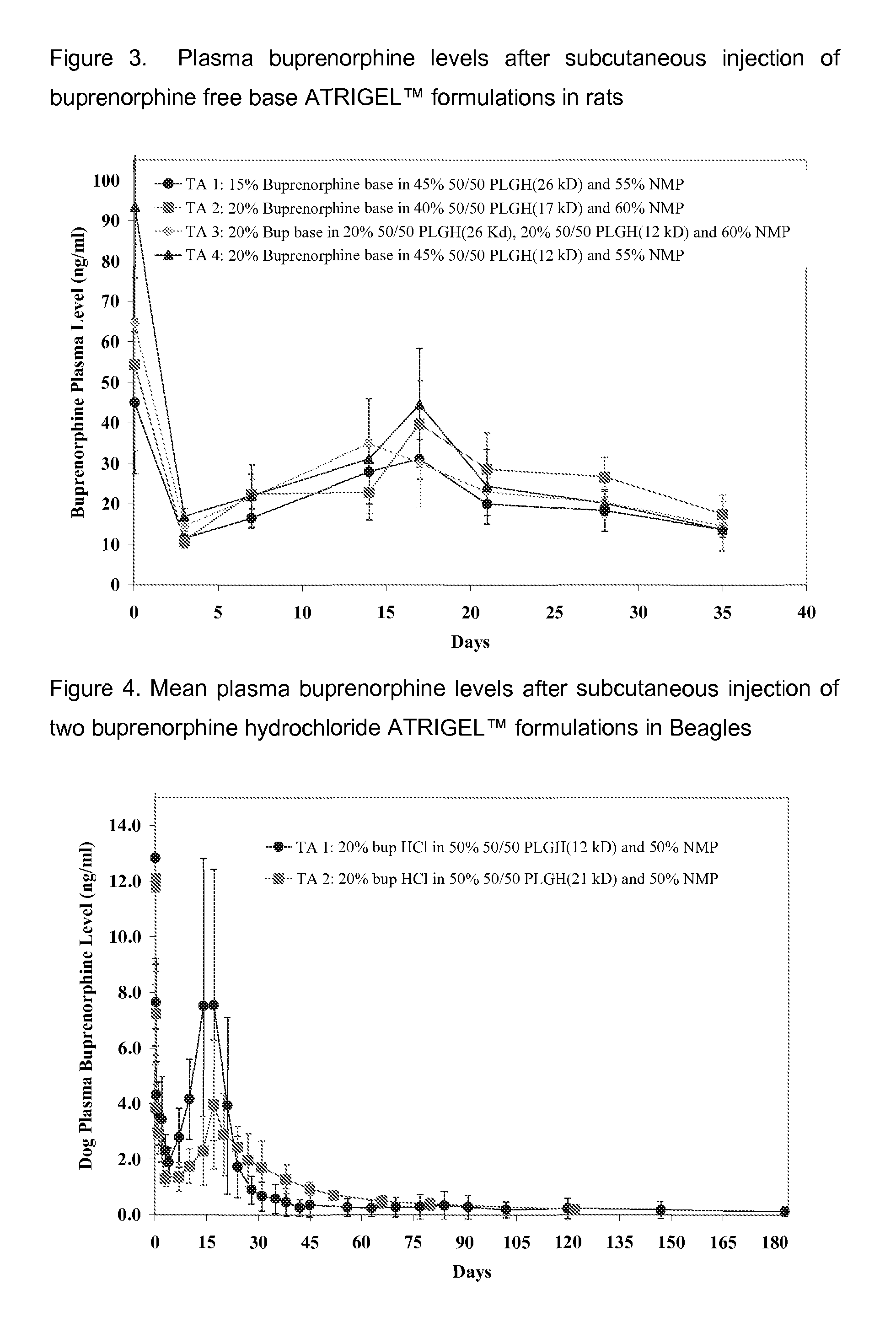

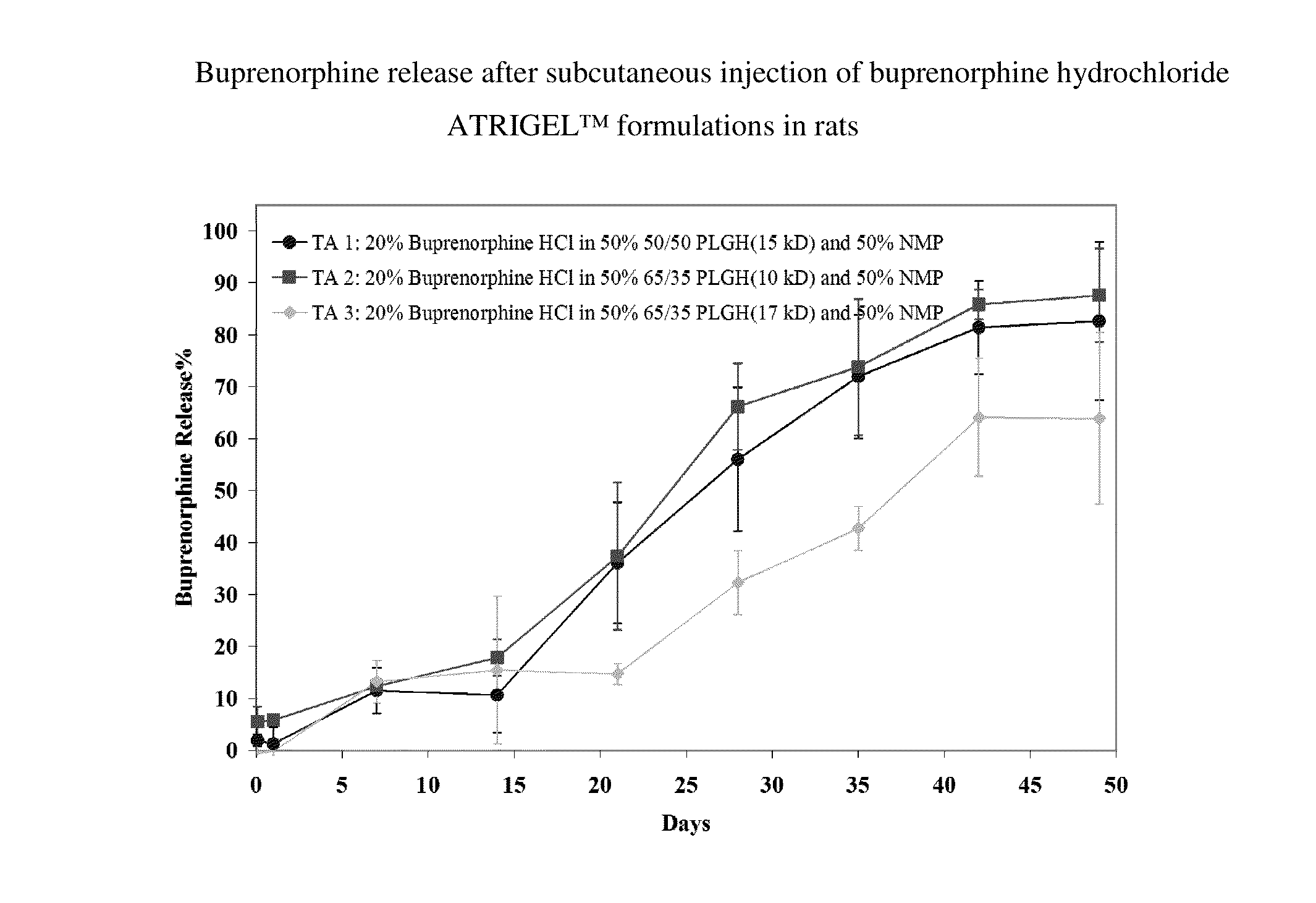

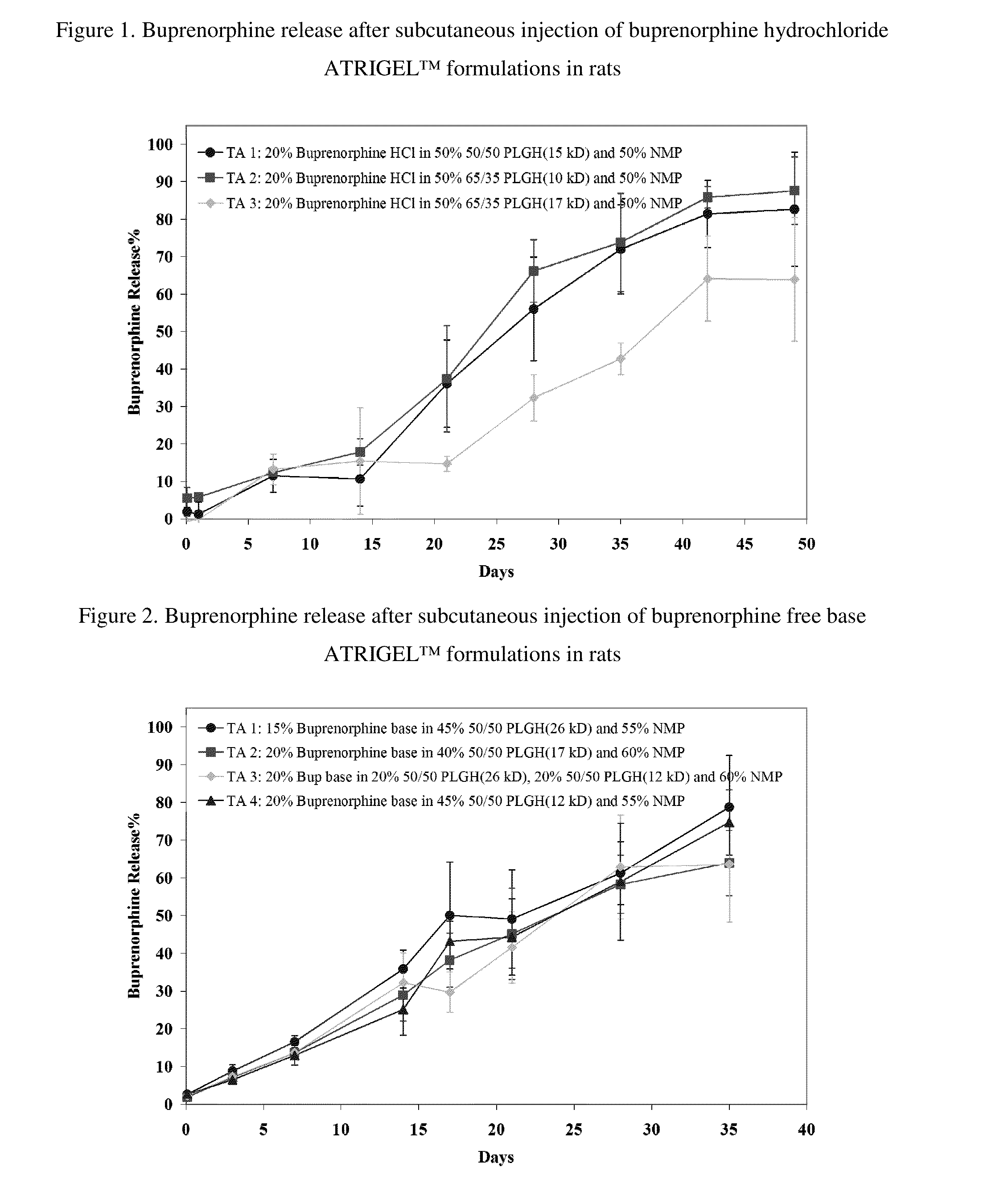

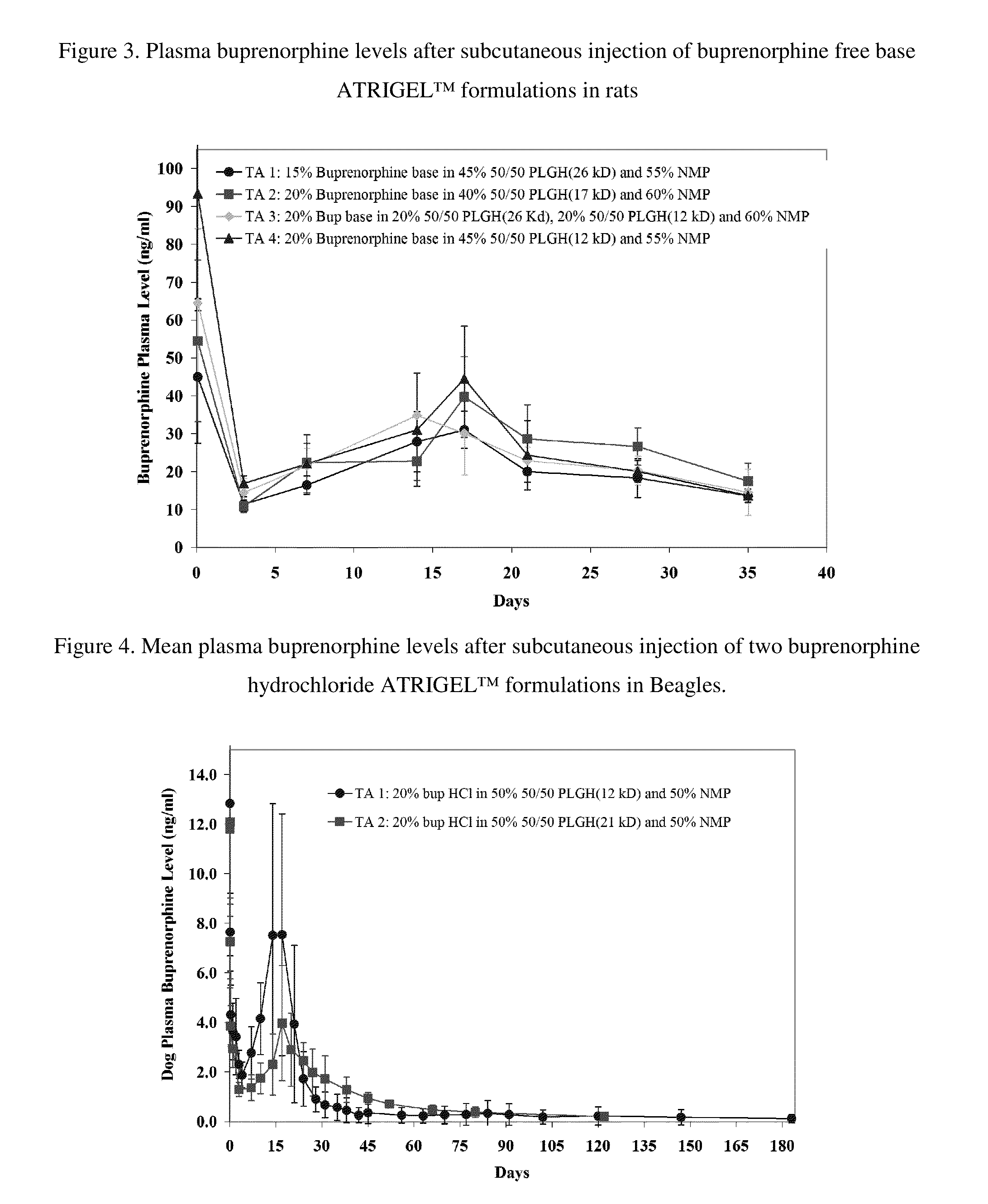

Injectable flowable composition comprising buprenorphine

The present invention is directed to a buprenorphine sustained release delivery system capable of delivering buprenorphine, a metabolite, or a prodrug thereof for a duration of about 14 days to about 3 months. The buprenorphine sustained release delivery system includes a flowable composition and a solid implant for the sustained release of buprenorphine, a metabolite, or a prodrug thereof. The implant is produced from the flowable composition. The buprenorphine sustained release delivery system provides in situ 1-month and 3-month release profiles characterized by an exceptionally high bioavailability and minimal risk of permanent tissue damage and typically no risk of muscle necrosis.

Owner:INDIVIOR UK

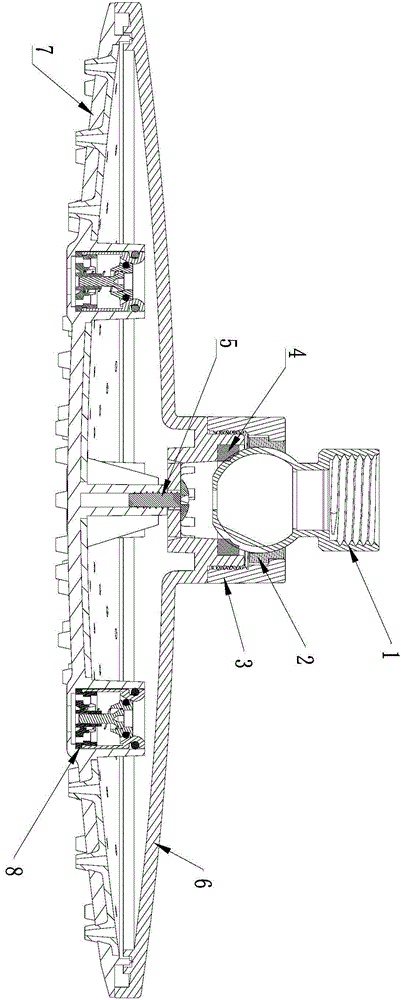

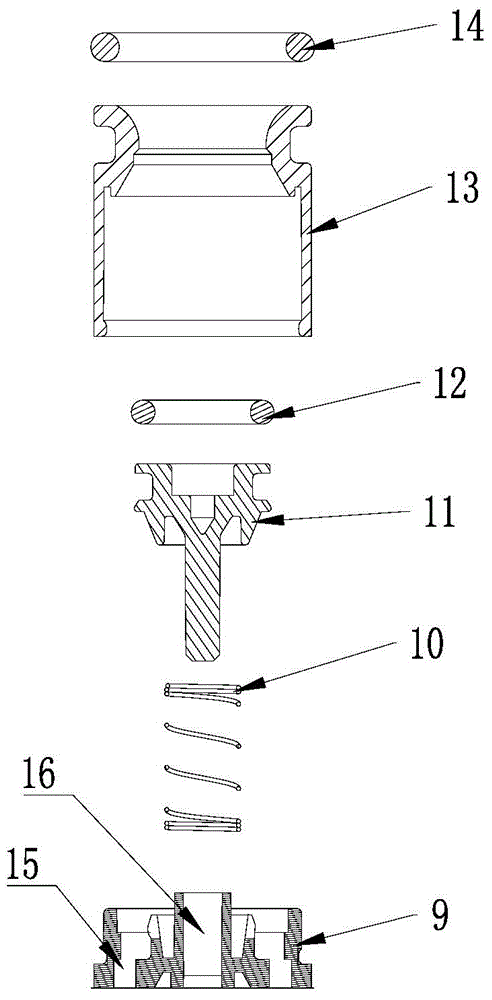

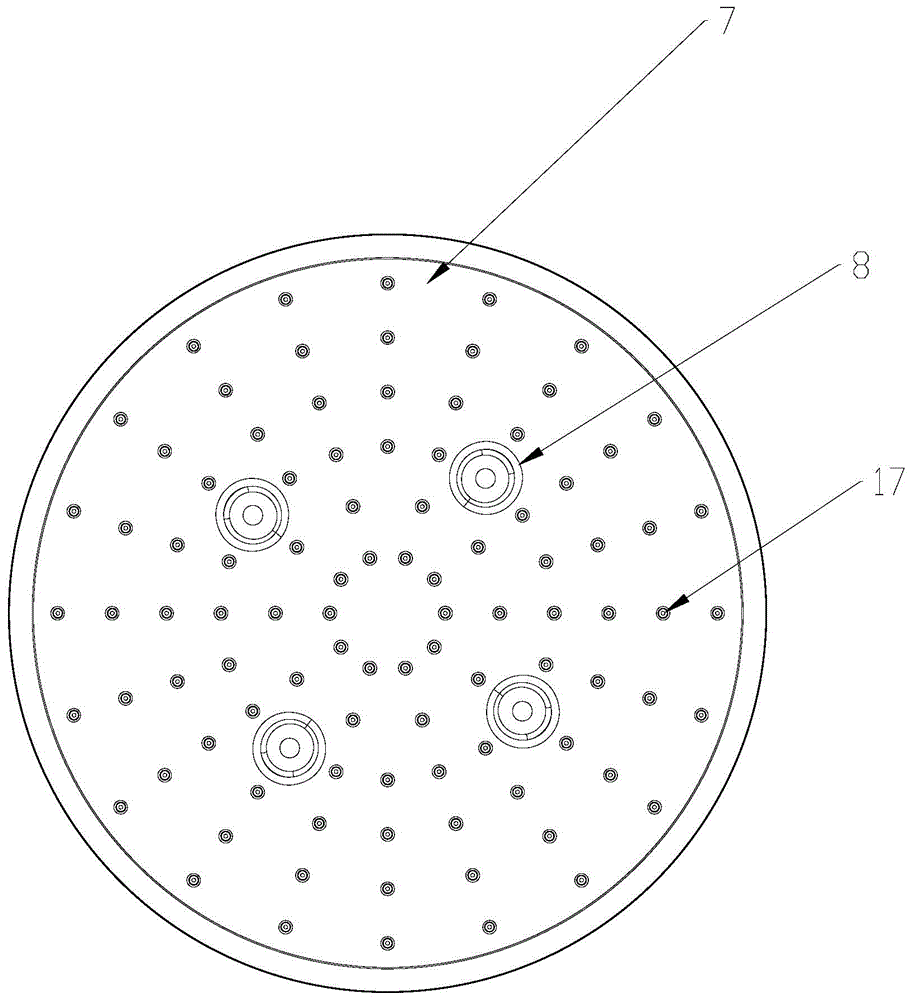

Anti-explosion shower head

The invention relates to an anti-explosion shower head. The problem of burst of shower heads caused by the facts that water spraying holes become small or are blocked or water pressure rises abnormally is solved. According to the technical scheme, an anti-explosion valve is positioned in a shower head disc. The anti-explosion valve can be automatically opened or closed along with the changes of water pressure in the shower head, so as to achieve the effect of adjusting the water pressure in the shower head. The anti-explosion shower head can avoid users' personal injury caused by shower head burst caused by too high water pressure in the shower head.

Owner:KAIPING HANSHUN SANITARY WARE IND

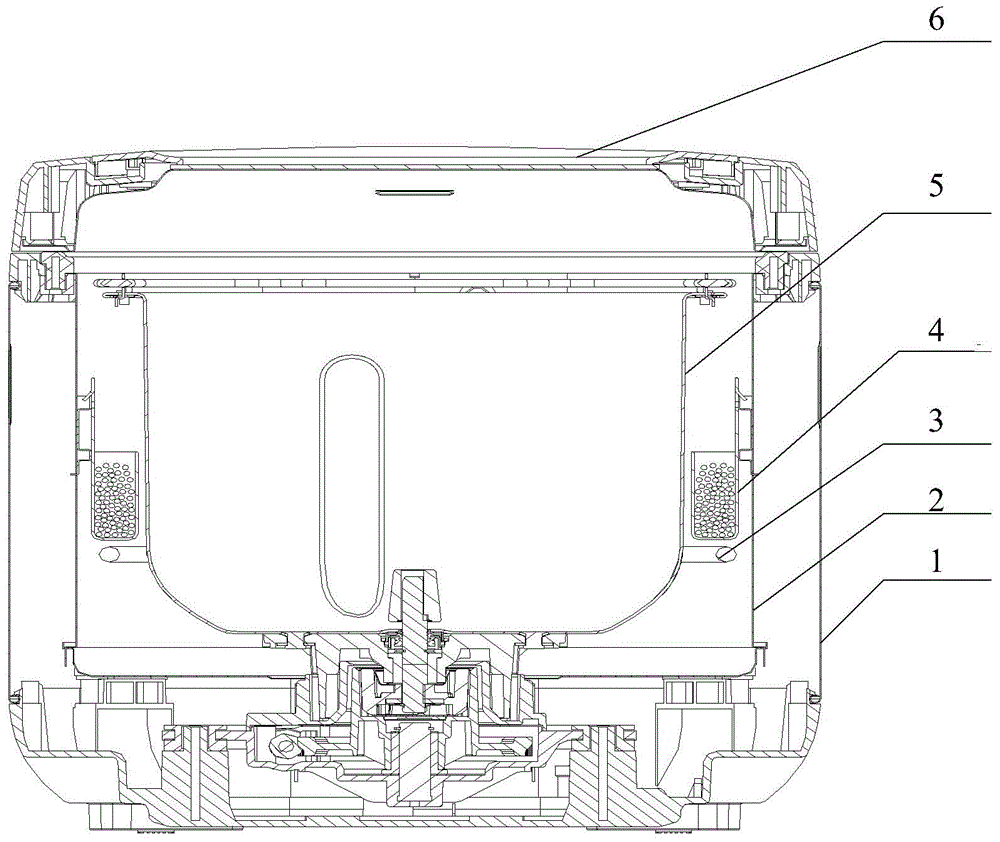

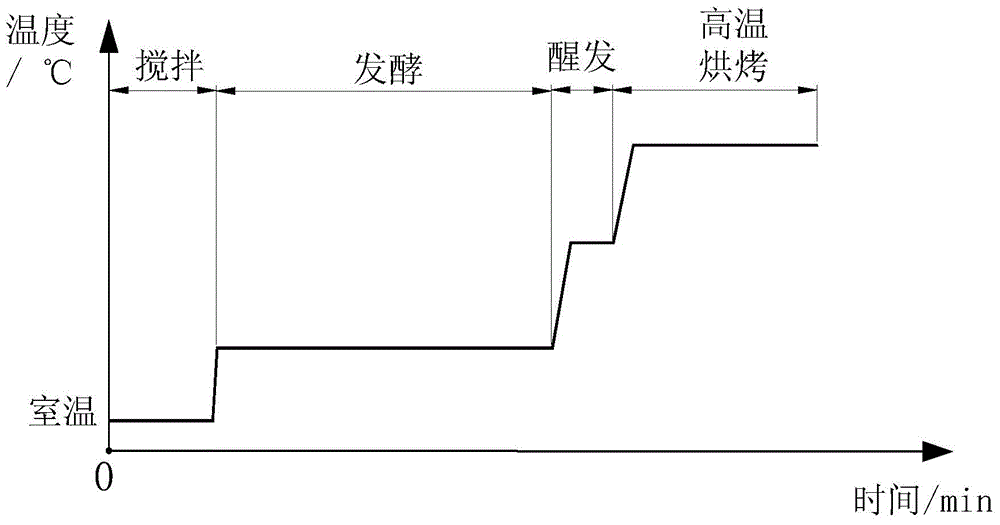

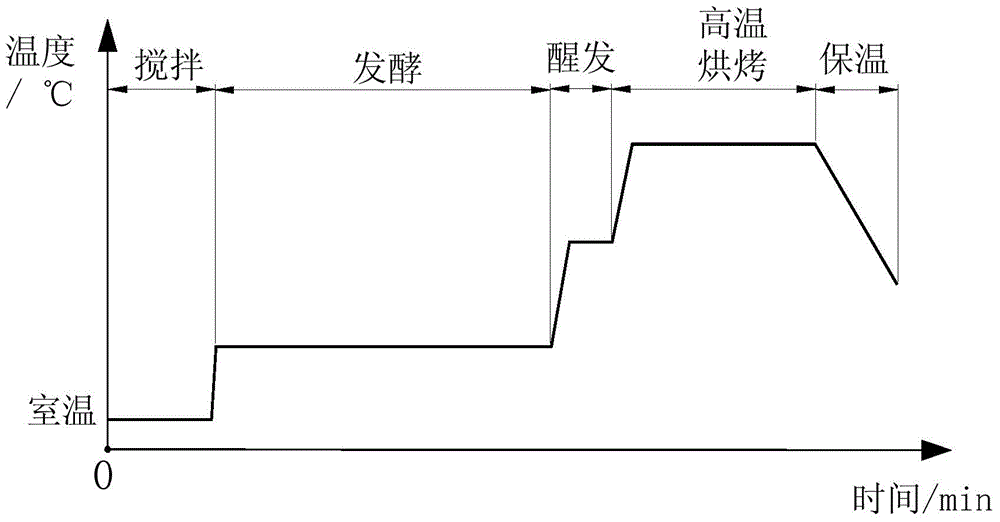

Bread making method

The invention provides a bread making method. A bread machine is used for making bread, the bread machine consists of a bread bucket and an oven bucket, a steam device is arranged between the bread bucket and the oven bucket, and the steam device is used for generating steam under the heating action of a heating element arranged on the inner side wall of the oven bucket. The making method comprises the following steps: firstly, putting bread raw materials in the bread bucket, and forming a bread dough under the stirring action of a stirring piece, wherein the stirring time is 20 to 40 min; secondly, controlling the temperature inside the bread machine to be 28 to 35 DEG C, and fermenting the bread blanks for 50 to 90 min; thirdly, controlling the temperature inside the bread machine to be 50 to 80 DEG C and the relative humidity to be 80% to 90%, and finally fermenting the fermented bread dough for 20 to 30 min; fourthly, controlling the temperature inside the bread machine to be 110 to 140 DEG C, and carrying out high-temperature baking on the bread dough after final fermentation to make the bread. The bread making method provided by the invention solves the technical problem that bread skins of the bread made by an existing bread making method are relatively thick as well as brown and crisp.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

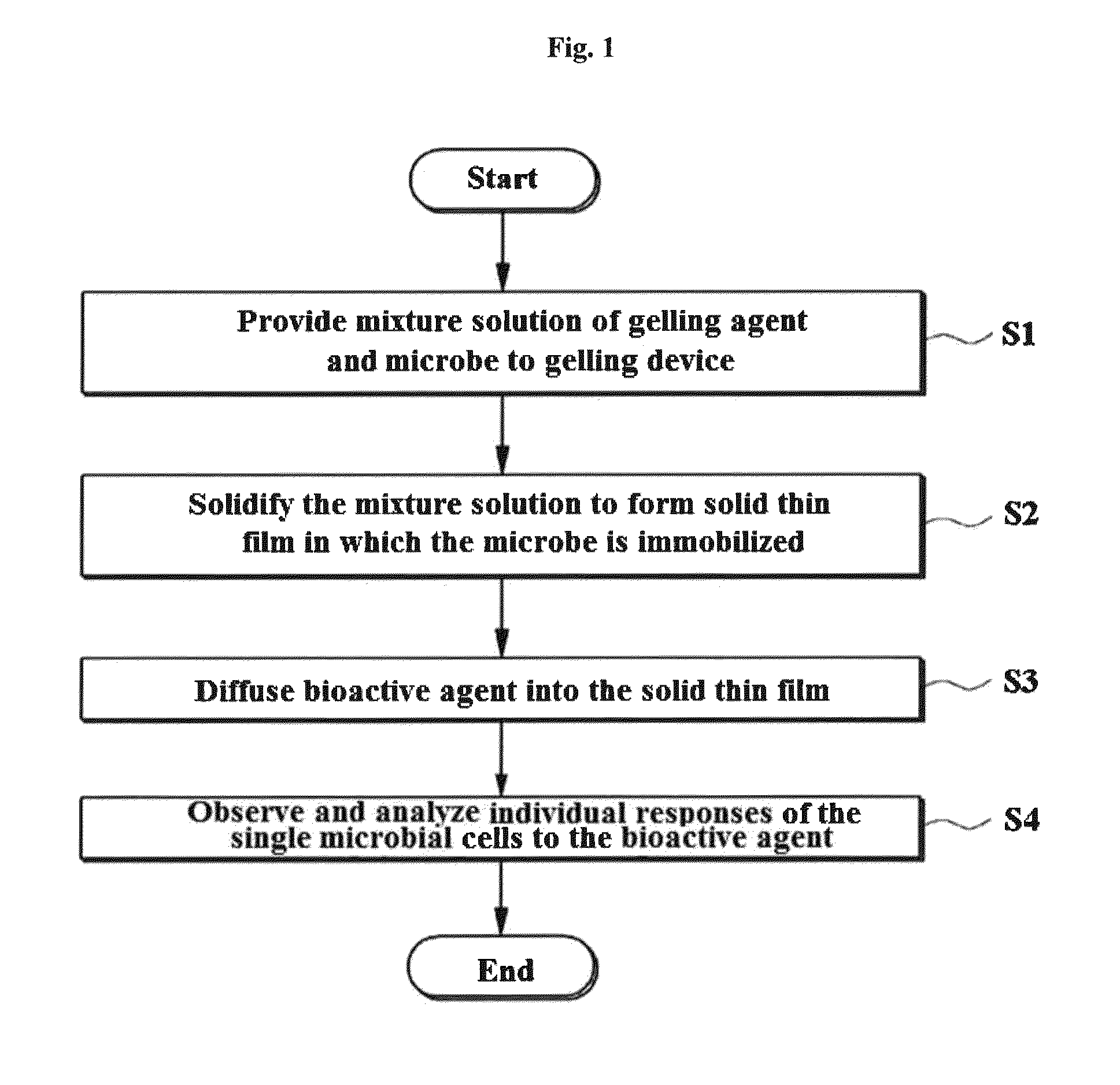

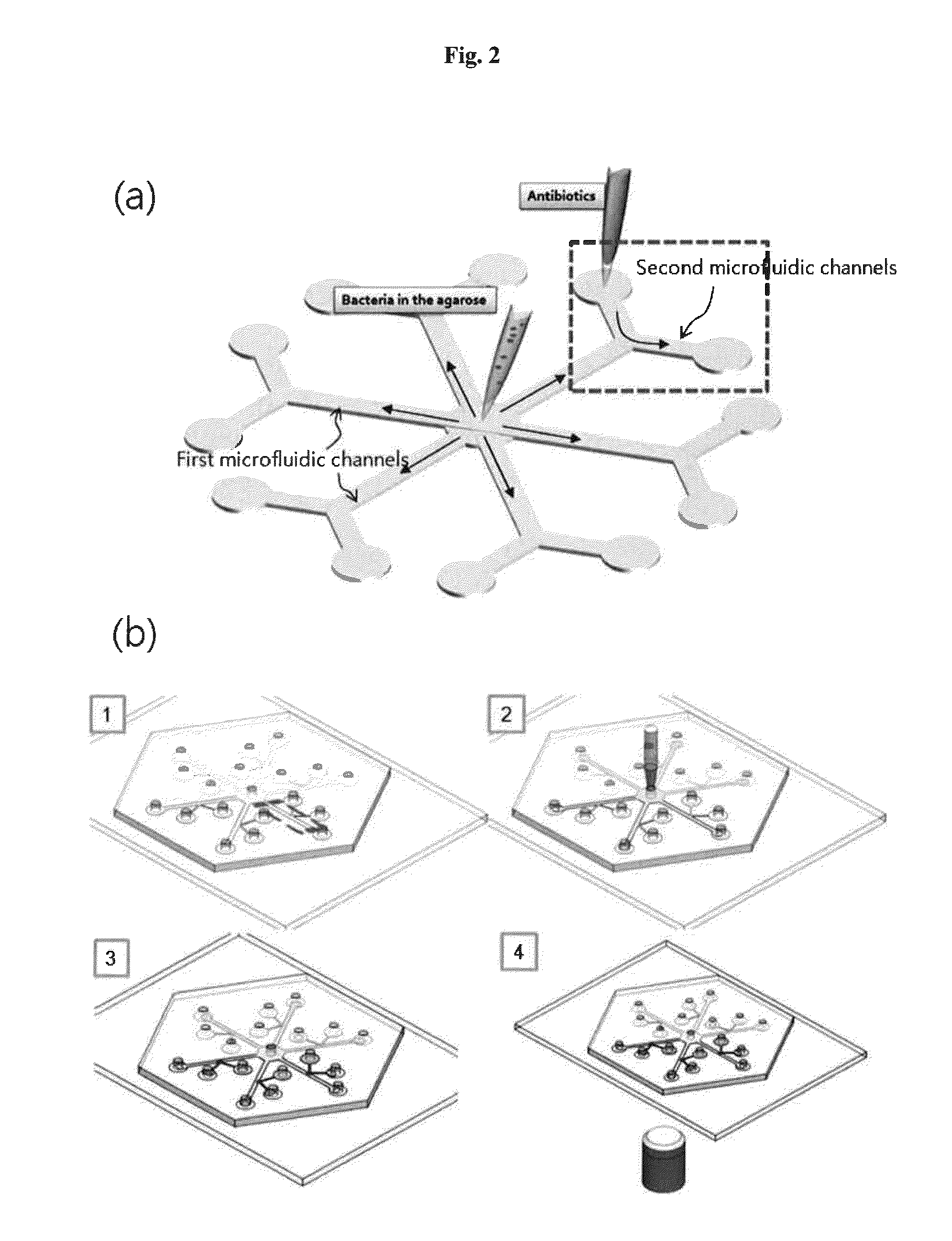

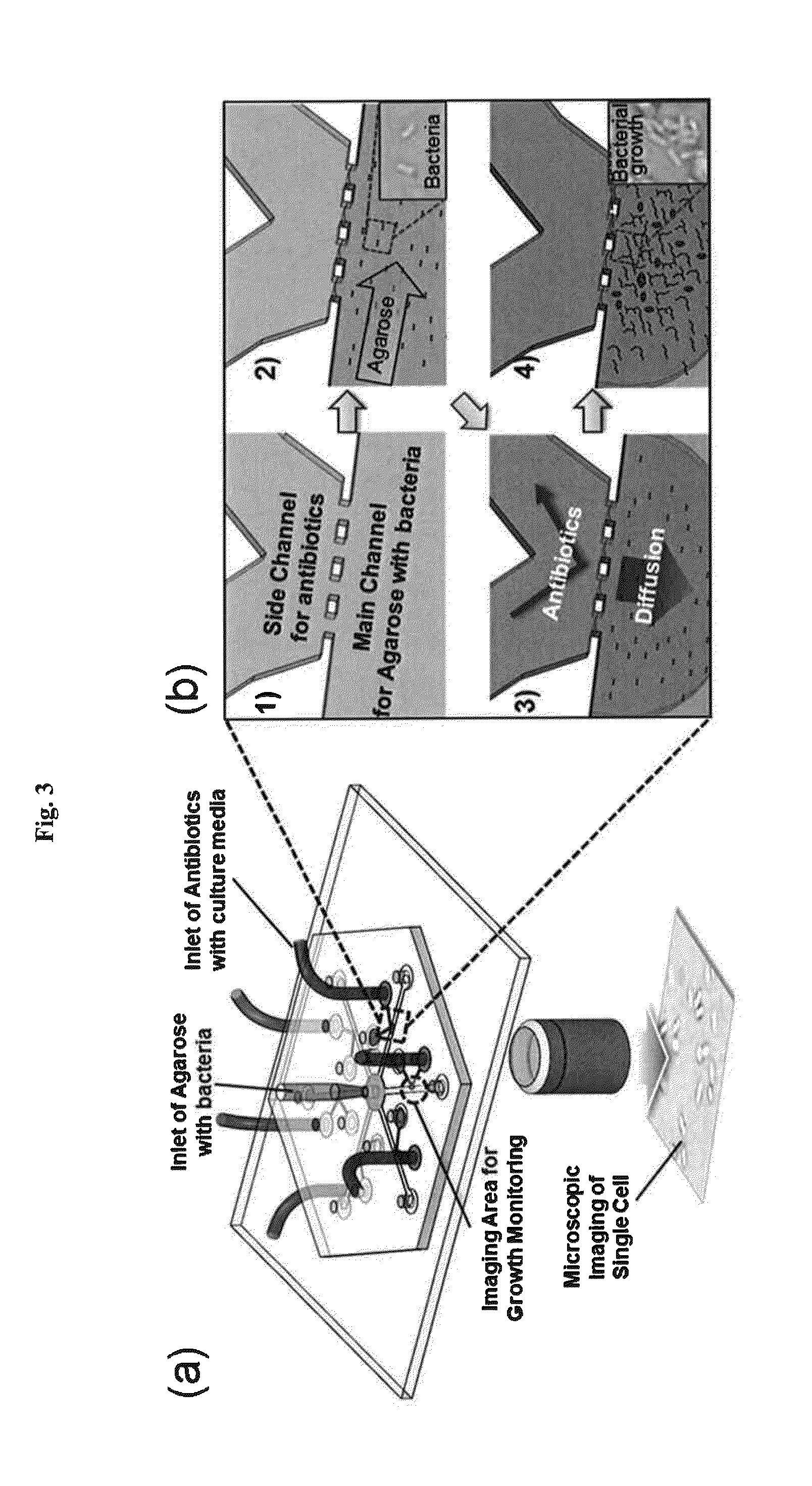

Rapid antibiotic susceptibility testing system based on bacterial immobilization using gelling agent, antibiotic diffusion and tracking of single bacterial cells

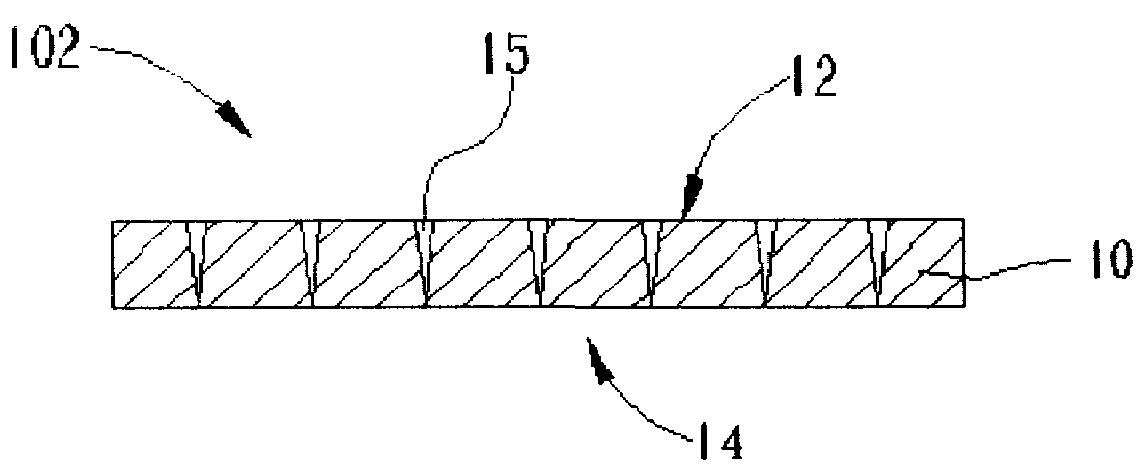

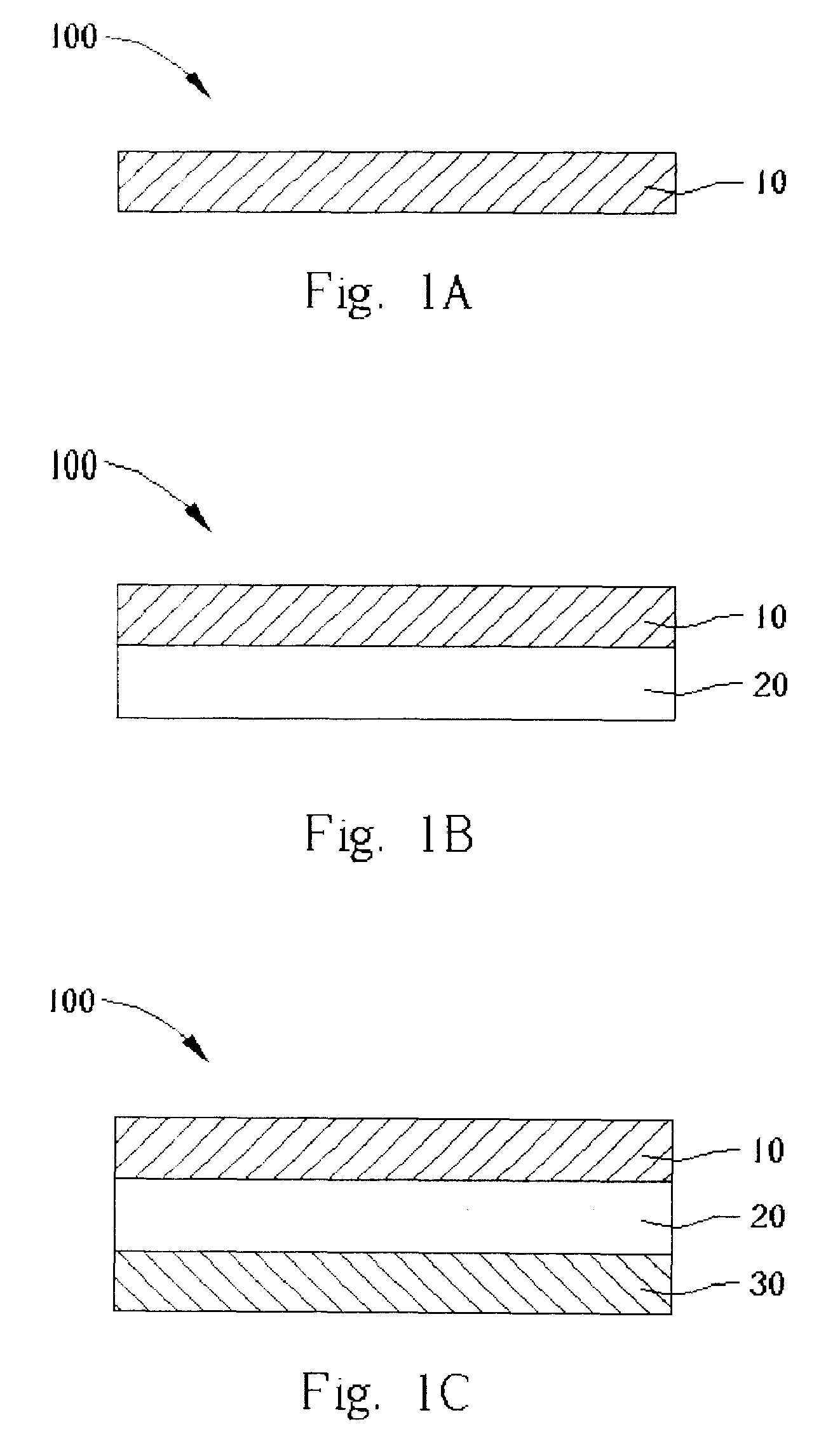

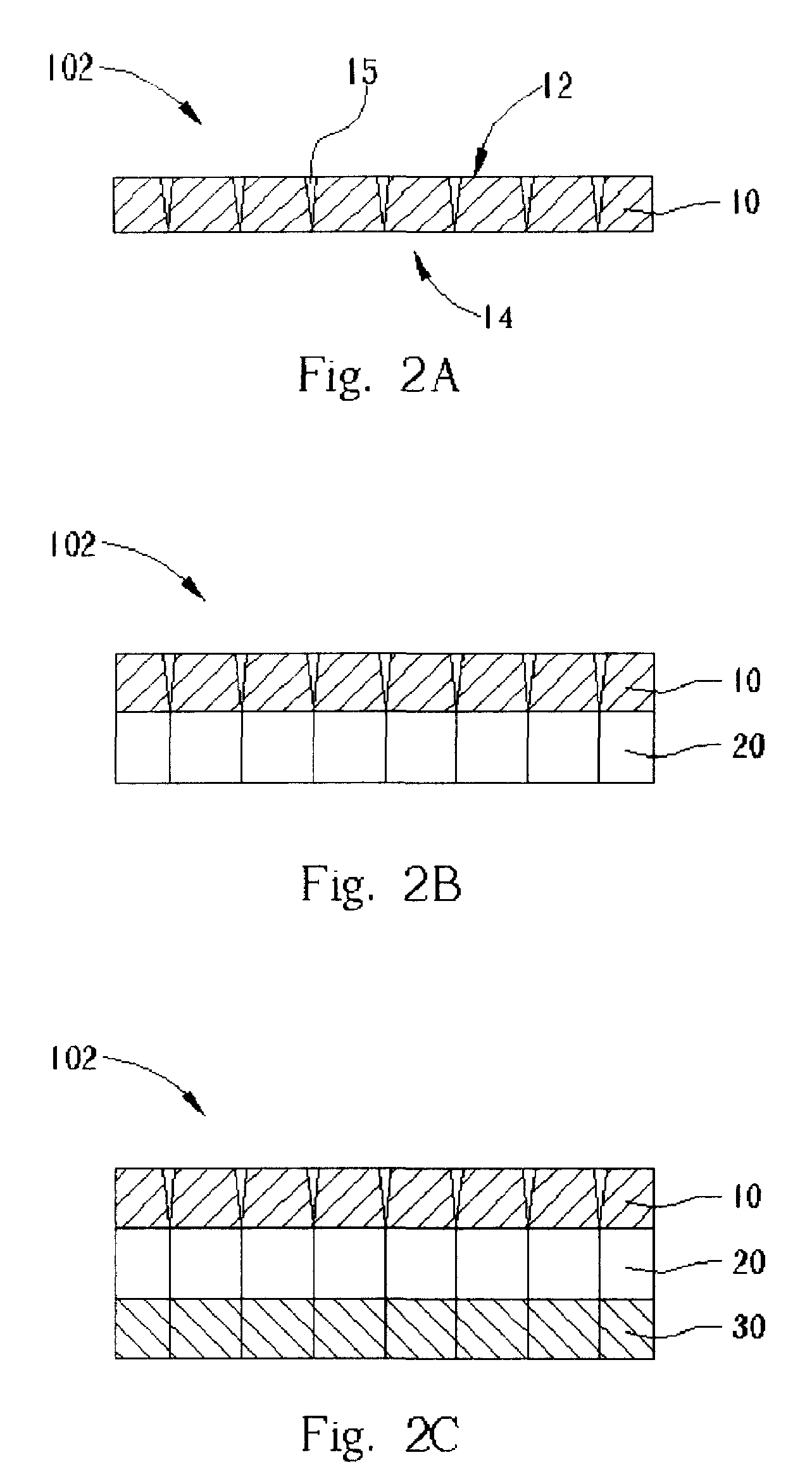

ActiveUS9133498B2Prevent burstBioreactor/fermenter combinationsImage analysisDiffusionMinimum inhibitory concentration

A testing method is disclosed. The testing method includes: providing a mixture solution of a gelling agent and a microbe to a gelling device; solidifying the mixture solution to form a solid thin film in which the microbe is immobilized; supplying a bioactive agent to the solid thin film and allowing the bioactive agent to diffuse into the solid thin film; and imaging the individual responses of the single microbial cells to the bioactive agent, and determining the minimum inhibitory concentration (MIC) of the bioactive agent based on the analysis of the images to obtain AST results.

Owner:QUANTA MATRIX

Bag for crushing objects

InactiveUS20050078888A1Quantity minimizationReduce the amount requiredEnvelopes/bags making machineryBag making operationsEngineeringPlastic bag

The invention relates to a plastic bag suitable for crushing and dispensing an object, such as medicinal pill. The bag has an open end, is strong enough to withstand crushing forces, and includes a bottom seal that forms an angle of greater than 90° with the sides of the bag. For example, the bottom seal may be curved and concave toward the open end of the bag. The bag may also include a lip near the opening and formed by one of the bag walls. The bag may also include a gripper on any of (1) the interior or exterior surfaces of the lip or (2) the interior or exterior surface of the other wall. The bag may also include an indicator mark, e.g., a colored line near the opening to serve as a visual and / or tactile indicator for the user of the bag.

Owner:THE BAGCO

Ru porcelain tea-dust glaze and preparation technology thereof

The invention discloses a Ru porcelain tea-dust glaze and a preparation technology thereof. The Ru porcelain tea-dust glaze comprises, by weight, 28-32 parts of white feldspar, 12-14 parts of calcite, 8-10 parts of quartz stone, 50-53 parts of Ru drug, 1.0-1.5 parts of bone meal and 0.5-1.0 part of talcum powder, and the Ru drug is kaolin from Mangchuan Country in Ruzhou City in Henan Province. The glaze color of the Ru porcelain tea-dust glaze is a tea-dust color, and tea-dust-like tawny fine points flash on the background color of ochre color, so the glaze is unsophisticated, elegant, beautiful and interesting, and porcelains sintered by using the glaze are beautiful, thereby the glaze increases a new glaze color for Ru porcelain, and improves the economic benefit of the Ru porcelain.

Owner:姚瑞平

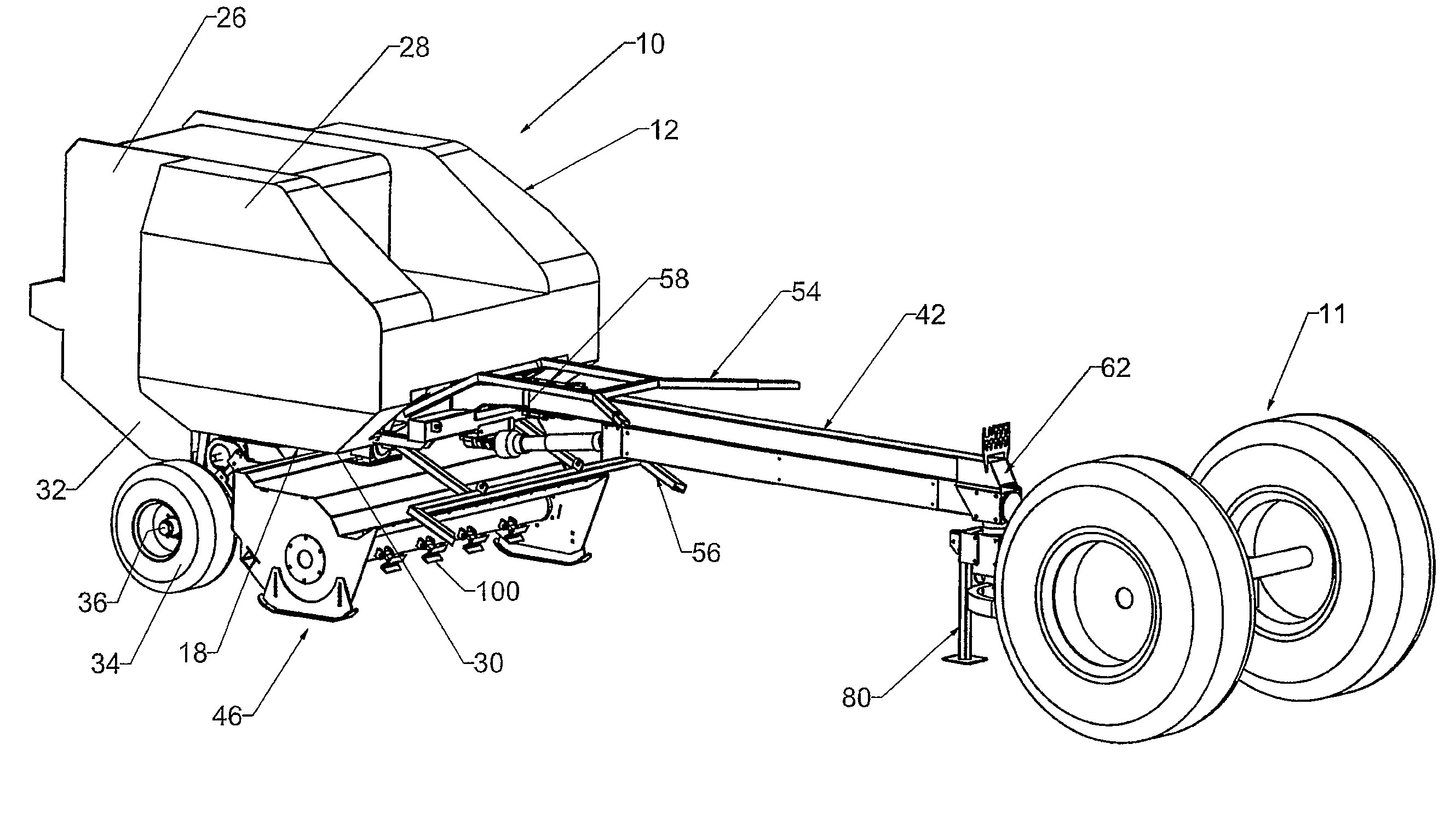

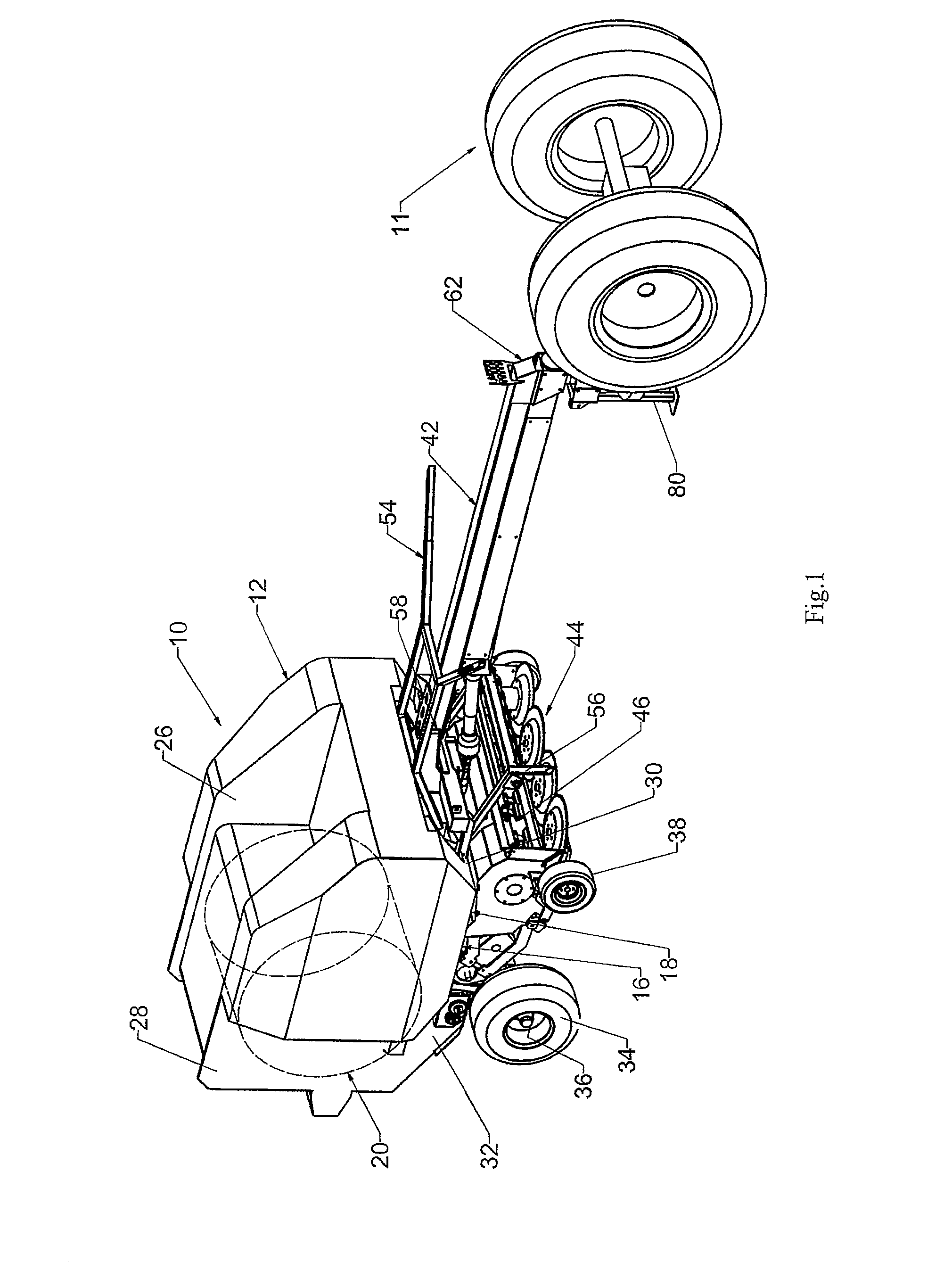

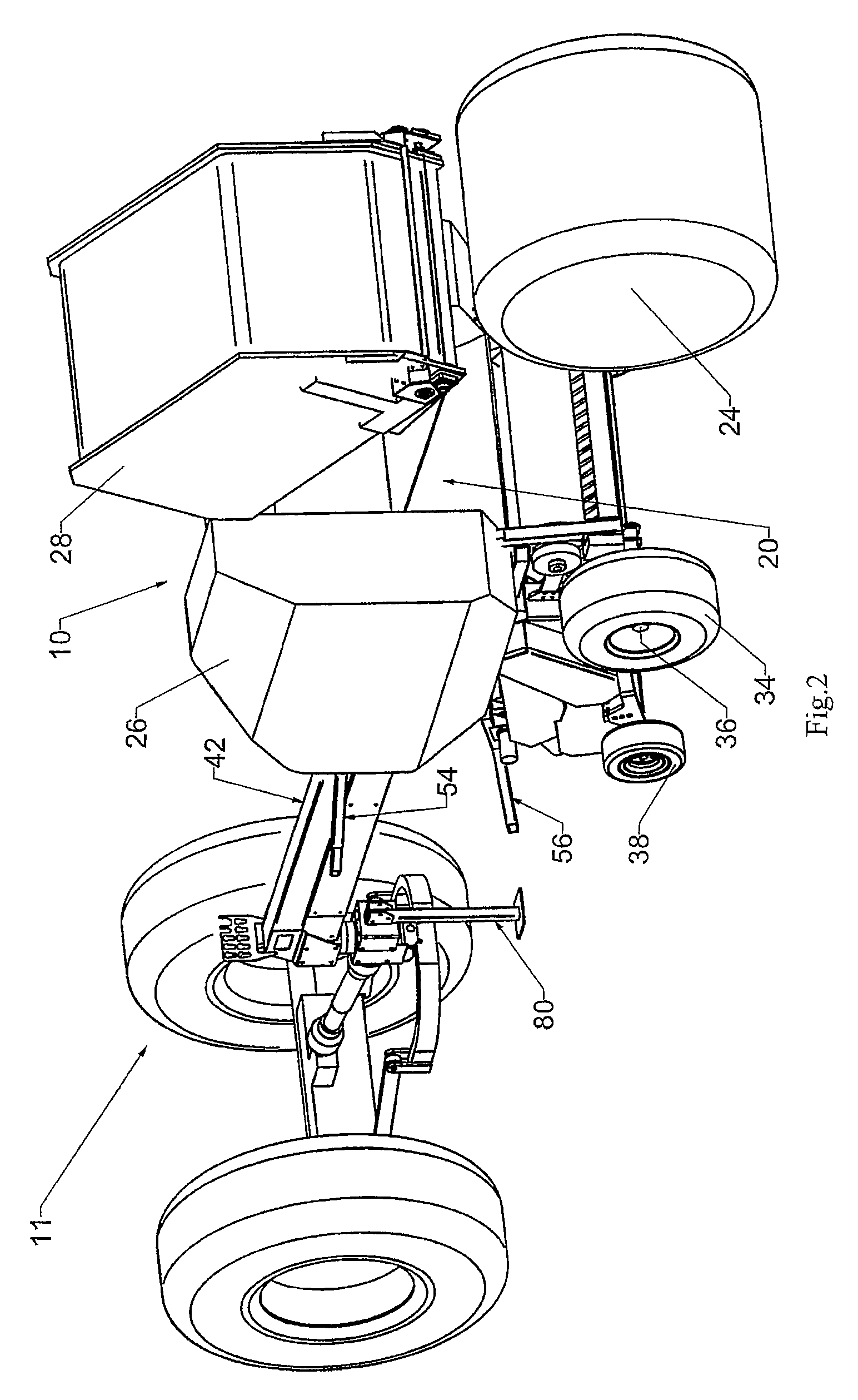

Device and method for harvesting woody crops

ActiveUS7743595B2Reduces difficulty and disadvantageContinuously workingLoadersMowersEngineeringContinuous operation

A device for harvesting crops comprising woody material including a processor arranged to mechanically work the woody material and to feed the mechanically worked woody material to a bale-forming mechanism, the bale-forming mechanism being arranged to form a bale of the mechanically worked woody material. The present invention also extends to a method for harvesting crops comprising woody material in a continuous operation including the steps of: (a) mechanically working the woody material using a processor of a harvesting device; (b) feeding the mechanically worked woody material to a bale-forming mechanism of the harvesting device; and (c) forming a bale from the mechanically worked woody material.

Owner:AGRI & AGRI FOOD

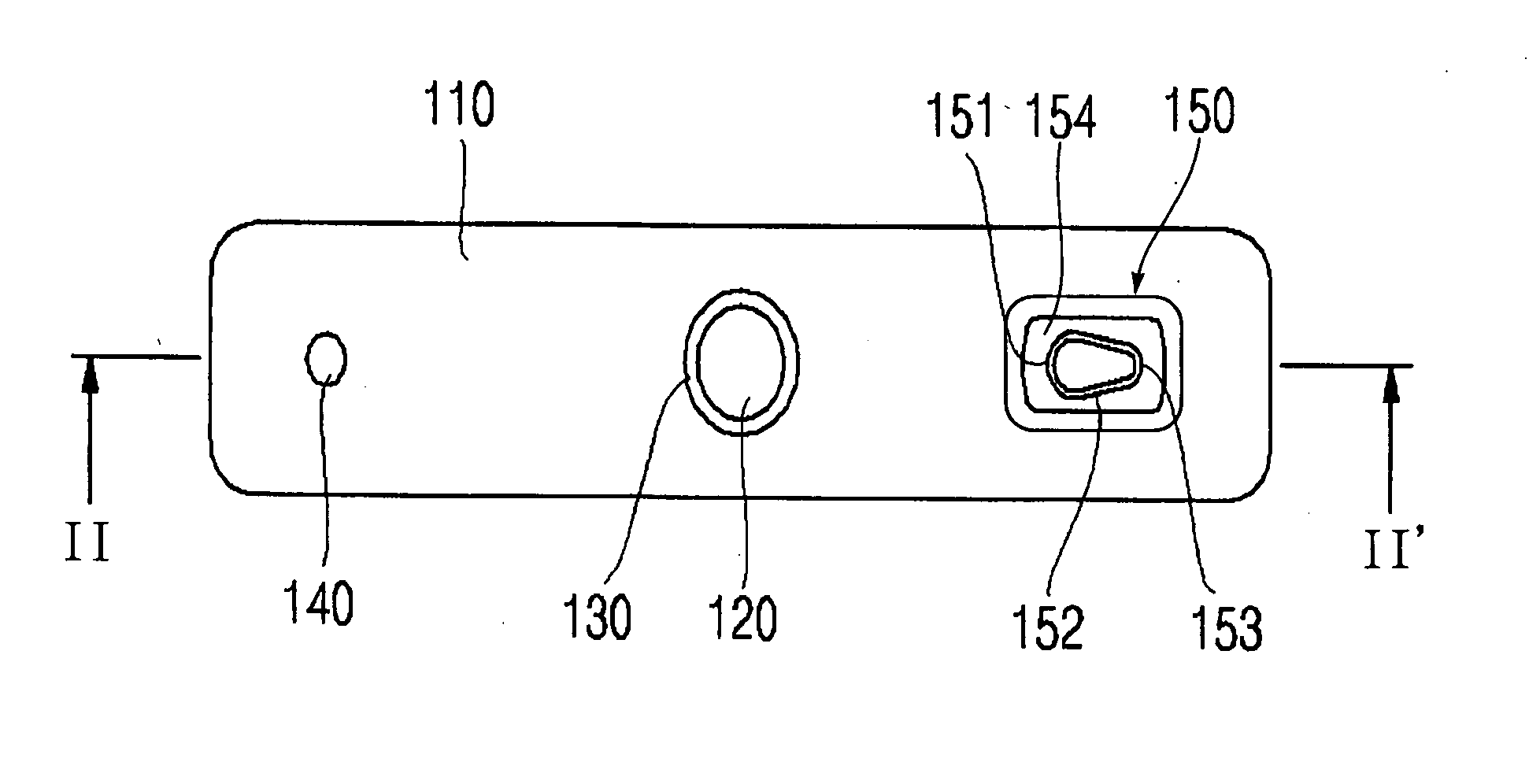

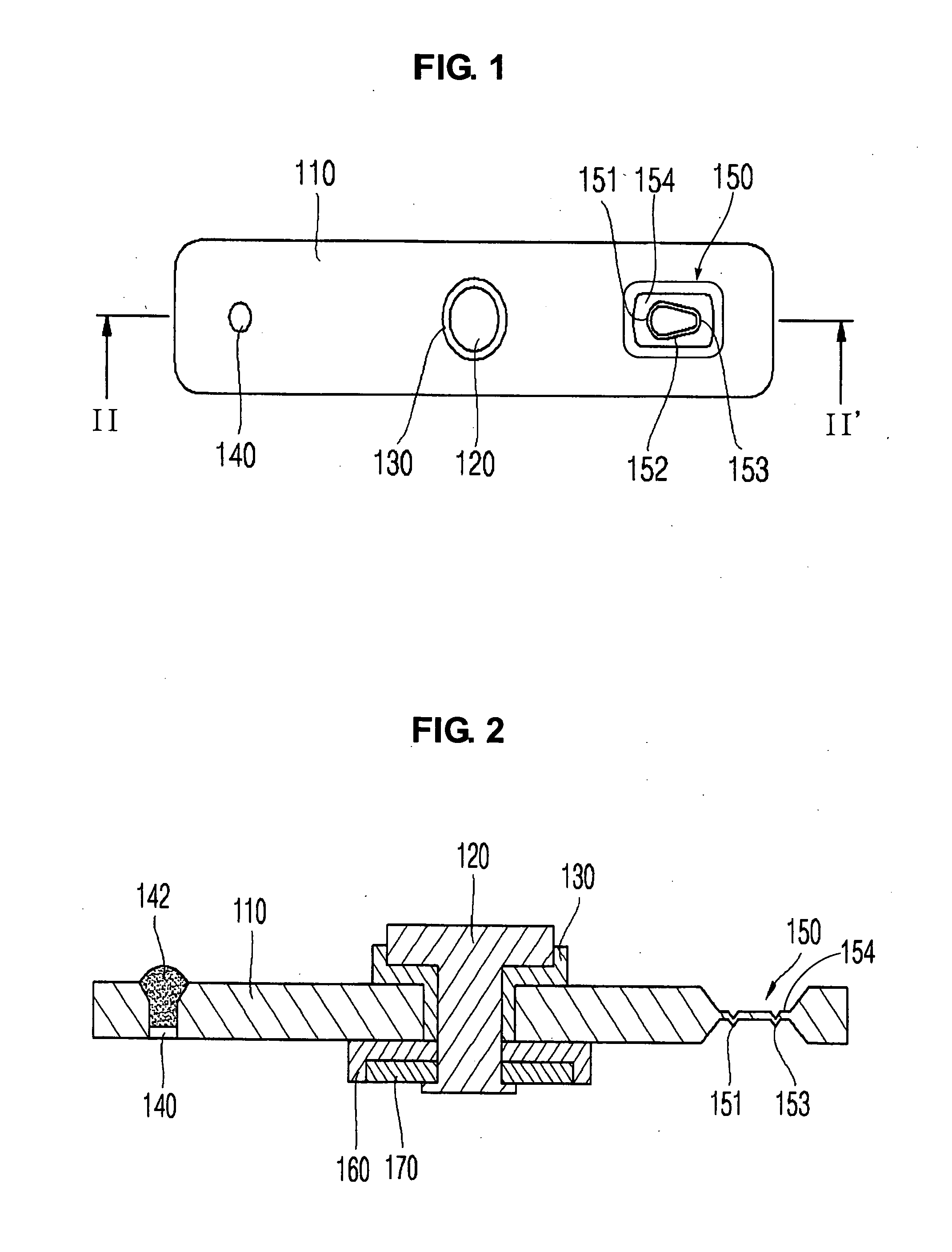

Secondary battery

ActiveUS20080145748A1Reduce internal pressureEasy dischargeFinal product manufactureSmall-sized cells cases/jacketsInternal pressureElectrical and Electronics engineering

A secondary battery has a safety vent which has an asymmetric structure and provides a substantial opening for the battery, instead of having a local crack, to rapid vent to atmosphere in order to prevent the secondary battery from bursting when the internal pressure of a battery increases excessively or external impact is applied thereto.The secondary battery includes an electrode assembly charging / discharging functions, a can housing the electrode assembly, a cap assembly that includes a cap plate closing up an open part of the can, and a safety vent having an asymmetric track shape that is provided in the cap plate of the cap assembly.

Owner:SAMSUNG SDI CO LTD

Injectable flowable composition comprising buprenorphine

ActiveUS8975270B2Least riskImprove bioavailabilityBiocidePharmaceutical delivery mechanismMetaboliteMUSCLE NECROSIS

The present invention is directed to a buprenorphine sustained release delivery system capable of delivering buprenorphine, a metabolite, or a prodrug thereof for a duration of about 14 days to about 3 months. The buprenorphine sustained release delivery system includes a flowable composition and a solid implant for the sustained release of buprenorphine, a metabolite, or a prodrug thereof. The implant is produced from the flowable composition. The buprenorphine sustained release delivery system provides in situ 1-month and 3-month release profiles characterized by an exceptionally high bioavailability and minimal risk of permanent tissue damage and typically no risk of muscle necrosis.

Owner:INDIVIOR UK

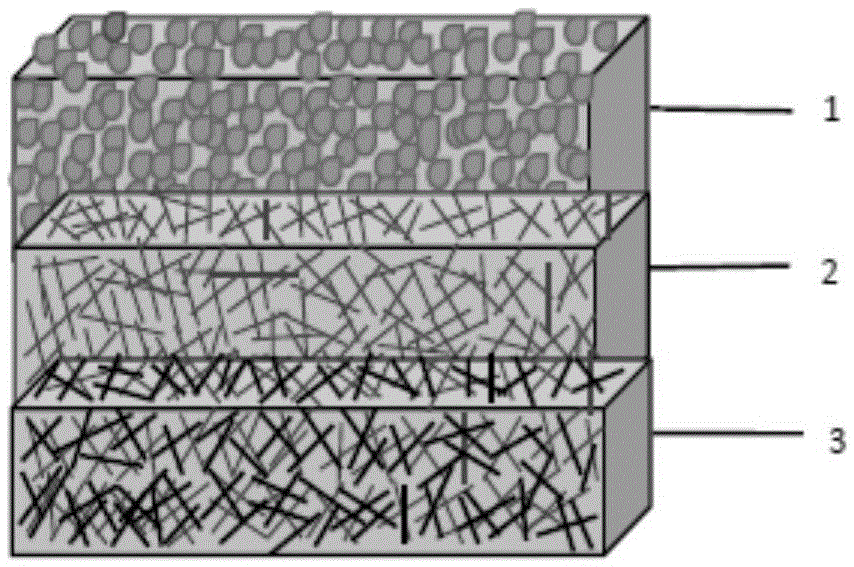

Anti-penetration and anti-explosion cement-based protective engineering material and preparation method thereof

ActiveCN105622018AWide variety of sourcesConducive to ecological sustainable developmentCrack resistanceCoupling

The invention discloses an anti-penetration and anti-explosion cement-based protective engineering material and a preparation method thereof. The protective engineering material is of a three-layer gradient structure made from very-high-performance mortar of the same proportioning ratio, a bottom layer is made from hybrid-fiber reinforced very-high-performance cement-based composite material, a middle layer is made from large-mixing-quantity steel-fiber reinforced very-high-performance cement-based composite material, a top layer is made from very-high-performance mortar-grouted high-strength coarse aggregate concrete, and the interfacial adhesivity is good. The very-high-performance mortar is prepared from cement, industrial residues, nanomaterials, fine aggregates, an antifoamer, a high-performance water reducing agent and water. According to the protective engineering material disclosed by the invention, hybrid fibers of the bottom layer can be used for improving the toughness and impact wave absorbing action of the structure and can also be used for improving crack resistance and high-temperature resistance; large-mixing-quantity steel fibers of the middle layer can be used for keeping the integrity of the structure and preventing bursting; high-strength coarse aggregates are added into the top layer, so that the penetration depth can be reduced, and the aim of anti-penetration and anti-explosion coupling action is achieved.

Owner:NANJING UNIV OF SCI & TECH

Simple method for manufacturing ceramic-metal composite wear-resistant part

The invention discloses a simple method for manufacturing a ceramic-metal composite wear-resistant part. The simple method for manufacturing the ceramic-metal composite wear-resistant part is characterized by comprising the following steps of obtaining a steel wire gauze, stamping a groove in the steel wire gauze, filling ceramic particles in the groove after surface wetting treatment is conducted on the ceramic particles, taking another steel wire gauze to cover the first steel wire gauze so that the groove can be shielded and scattering of the ceramic particles can be avoided, fixing the steel wire gauze with the ceramic particles fixed on a corresponding position, need to be enhanced, of the mold cavity wear-resistant part, and pouring and casting matrix metal liquid to obtain the wear-resistant part. The simple method for manufacturing the ceramic-metal composite wear-resistant part has the advantages of being even in distribution of the ceramic particles, firm in combination with matrix metal, capable of giving full play to the characteristics of ceramic and metal and achieving high-resistant performance and high-impact-resistant performance, simple, easy and convenient to operate, capable of being produced in large scale or in batch, and low in cost.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

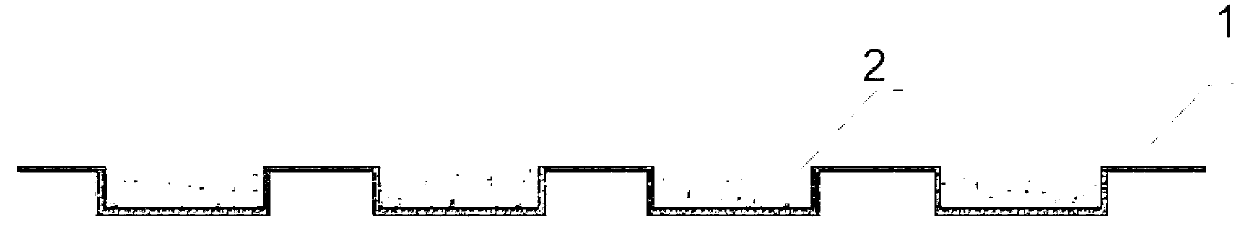

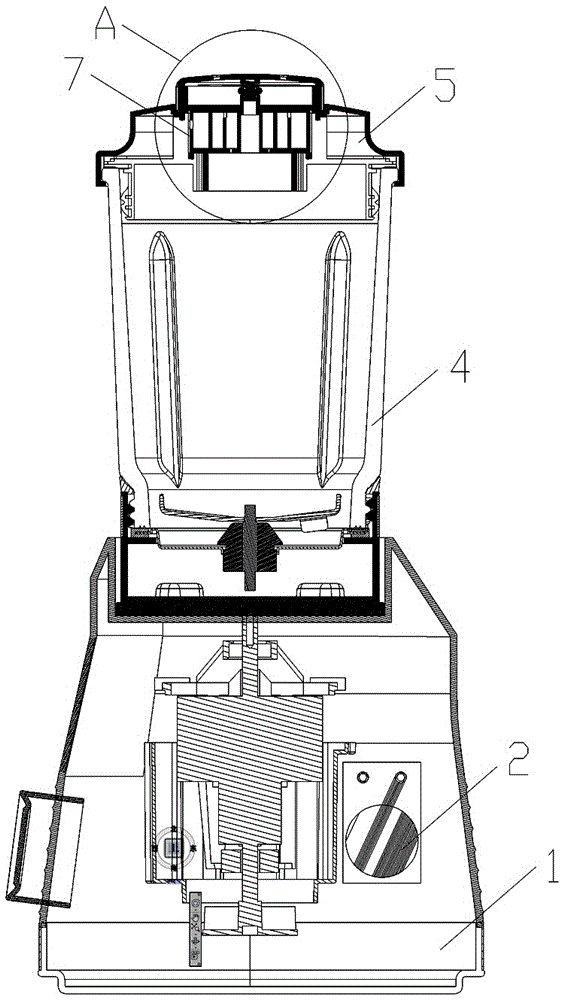

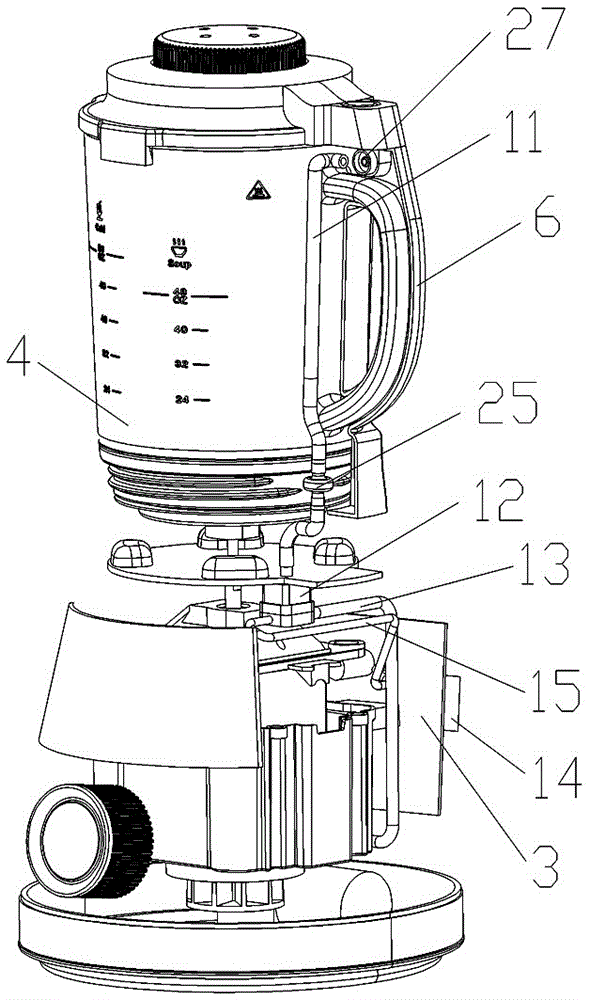

Novel vacuum food processor

The invention discloses a novel vacuum food processor which comprises a processor seat. A vacuumizing pump and a circuit board are arranged in the processor seat, a stirring cup is mounted on the processor seat, a cup cover is arranged on the stirring cup, a handle is arranged on one side of the stirring cup, an inner cover communicated with an inner cavity of the stirring cup is arranged on the cup cover and provided with an inner cavity, multiple concentric retaining rings are arranged in the inner cavity of the inner cover from inside to outside respectively, an annular filtering passage is formed between each two concentric retaining rings, each two adjacent annular filtering passages are communicated through openings in the corresponding concentric retaining rings, and the vacuumizing pump is communicated with the annular filtering passage on the outermost side through a vacuumizing pipe; the vacuumizing pipe is connected on the stirring cup, one end of the vacuumizing pump is communicated with the inside of the stirring cup while the other end of the vacuumizing pump is connected with a tapping seat, a first tapping pipe is arranged between the tapping seat and the vacuumizing pump, a sensor is arranged on the circuit board, and a second tapping pipe is arranged between the tapping seat and the sensor and communicated with the vacuumizing pipe.

Owner:ZHONGSHAN LOVAS ELECTRIC APPLIANCE CO LTD

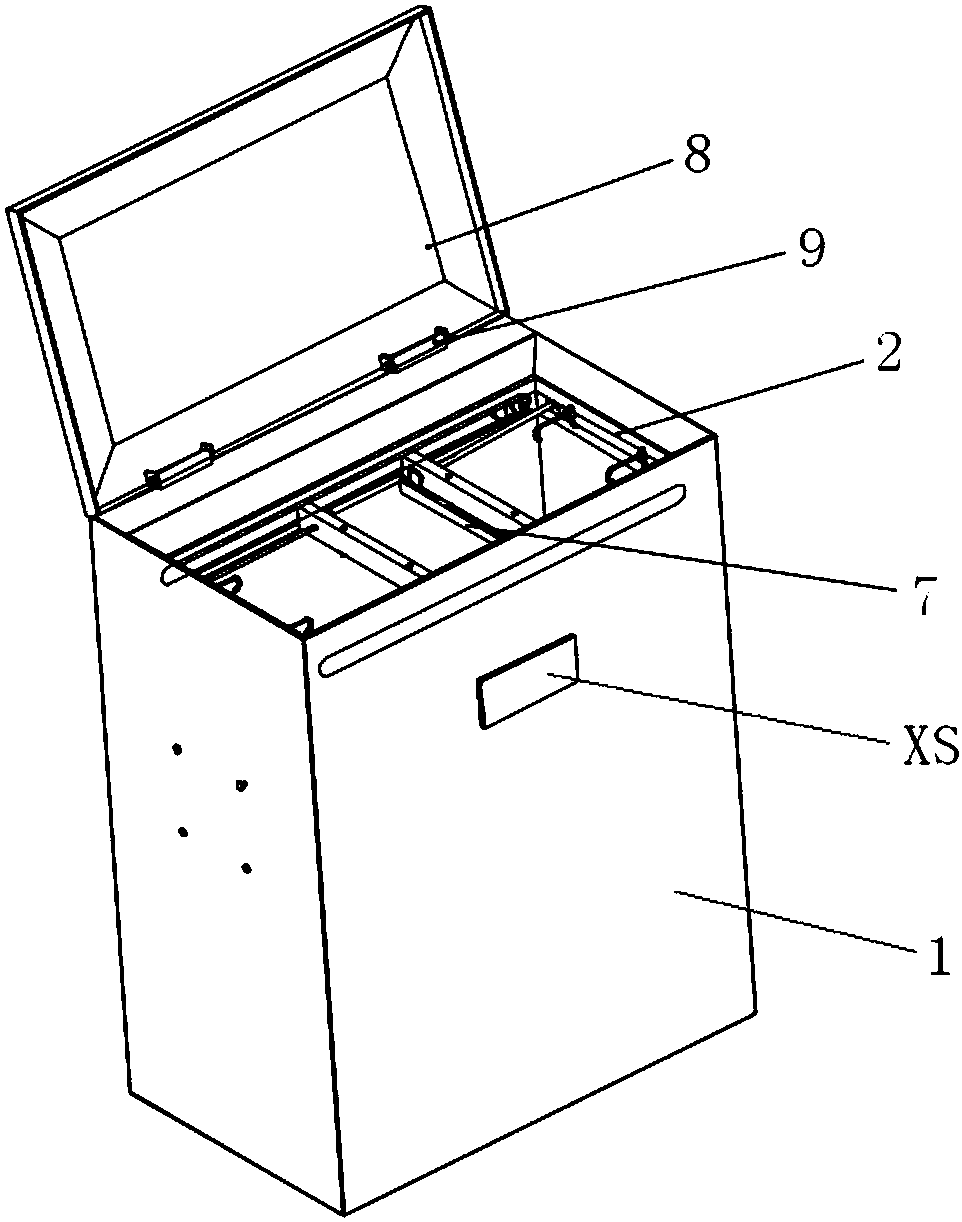

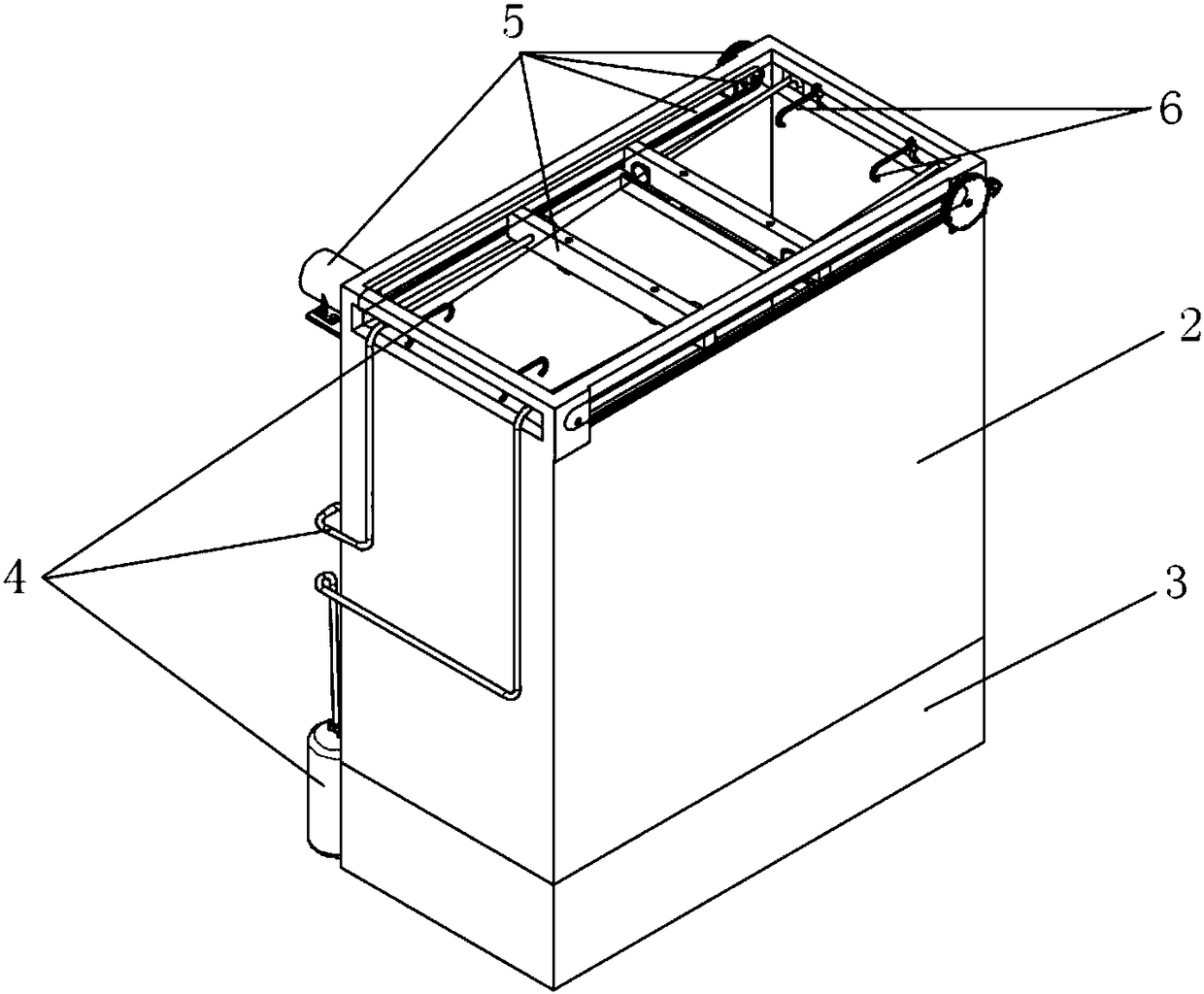

Multifunctional intelligent garbage can

The invention discloses a multifunctional intelligent garbage can. The multifunctional intelligent garbage can comprises an outer can, an inner can, a garbage bag opening and closing device and an intelligent controller, wherein the inner can is sleeved with the outer can, the garbage bag opening and closing device comprises a grabbing device and an opening and closing mechanism, the opening and closing mechanism comprises two parallel push rods and a push rod driving mechanism, the two ends of each push rod correspond to the upper edges of the front and rear walls of the inner can respectively, the grabbing device comprises vacuum pumps and multiple suckers, and the suckers are distributed and installed on the opposite surfaces of the two push rods and connected with the vacuum pumps through flexible air pipes. According to the multifunctional intelligent garbage can, a garbage can body is internally provided with the garbage bag opening and closing device controlled by the intelligent controller, so that automation of garbage bag opening and closing is achieved, not only are replacement and sealing of garbage bags convenient and fast, but also there is no need for a user to touchgarbage directly, and thus the life quality of the user is greatly improved; the garbage can is low in production cost and suitable for application and popularization.

Owner:TANGSHAN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com