Patents

Literature

718results about How to "Reduce internal pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

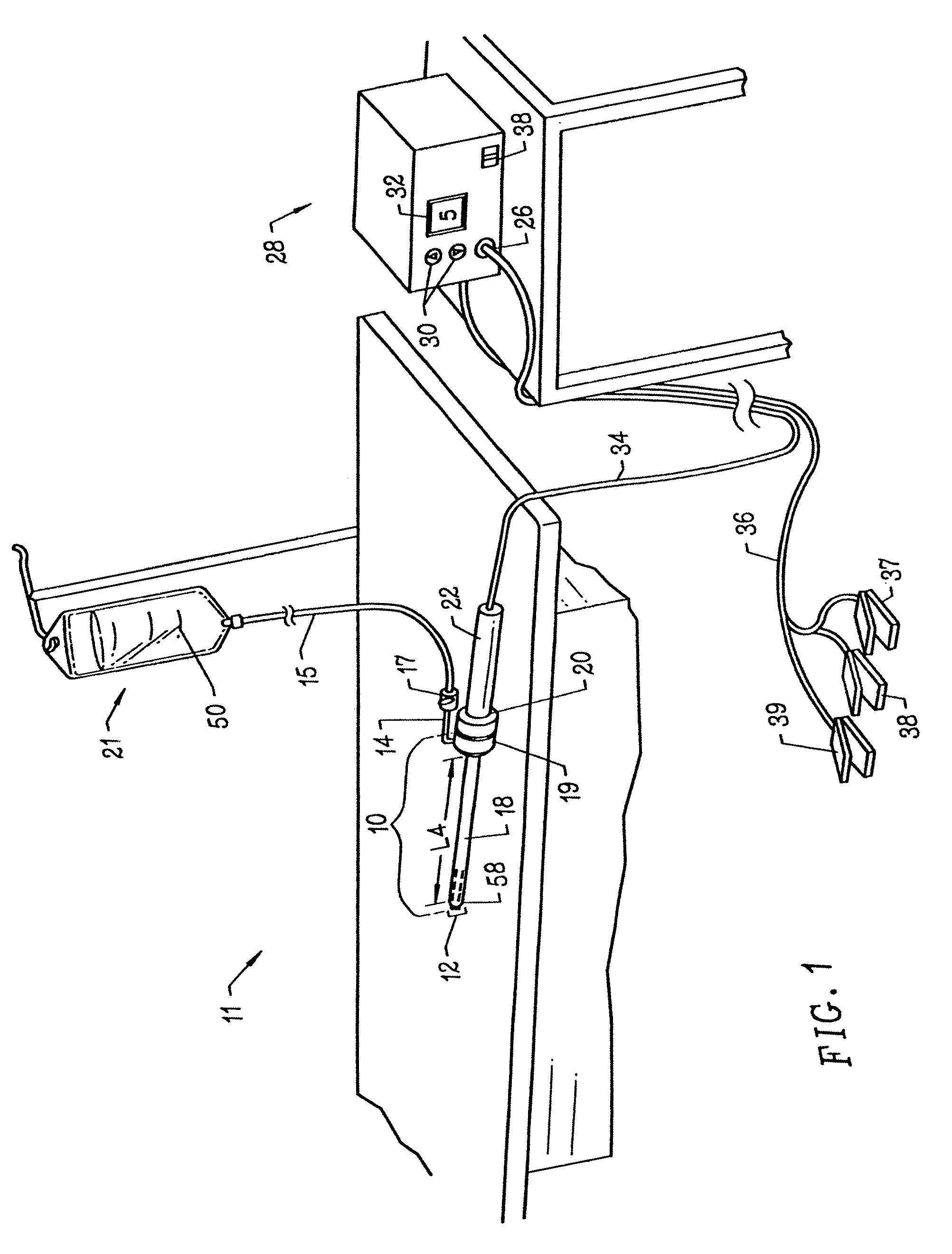

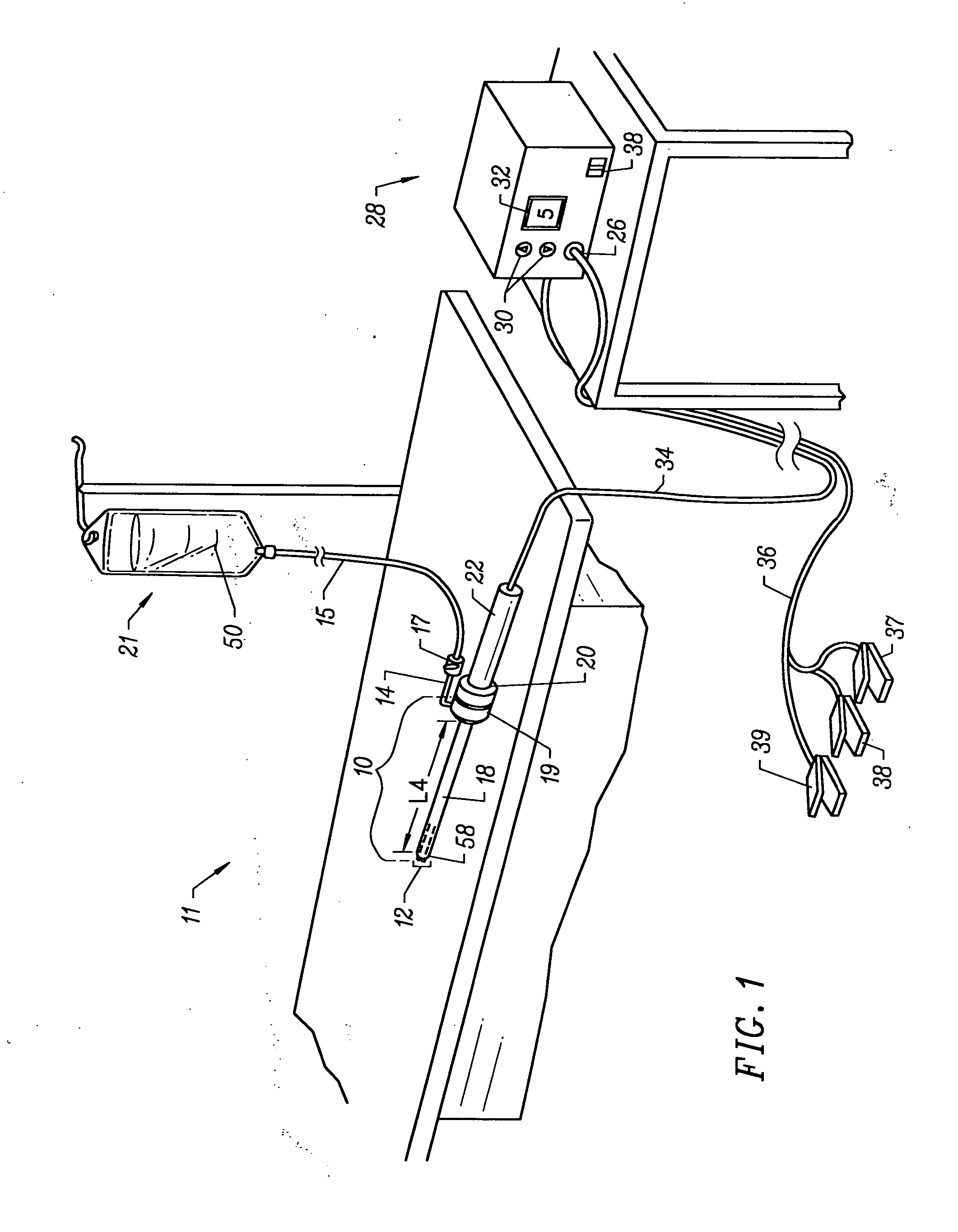

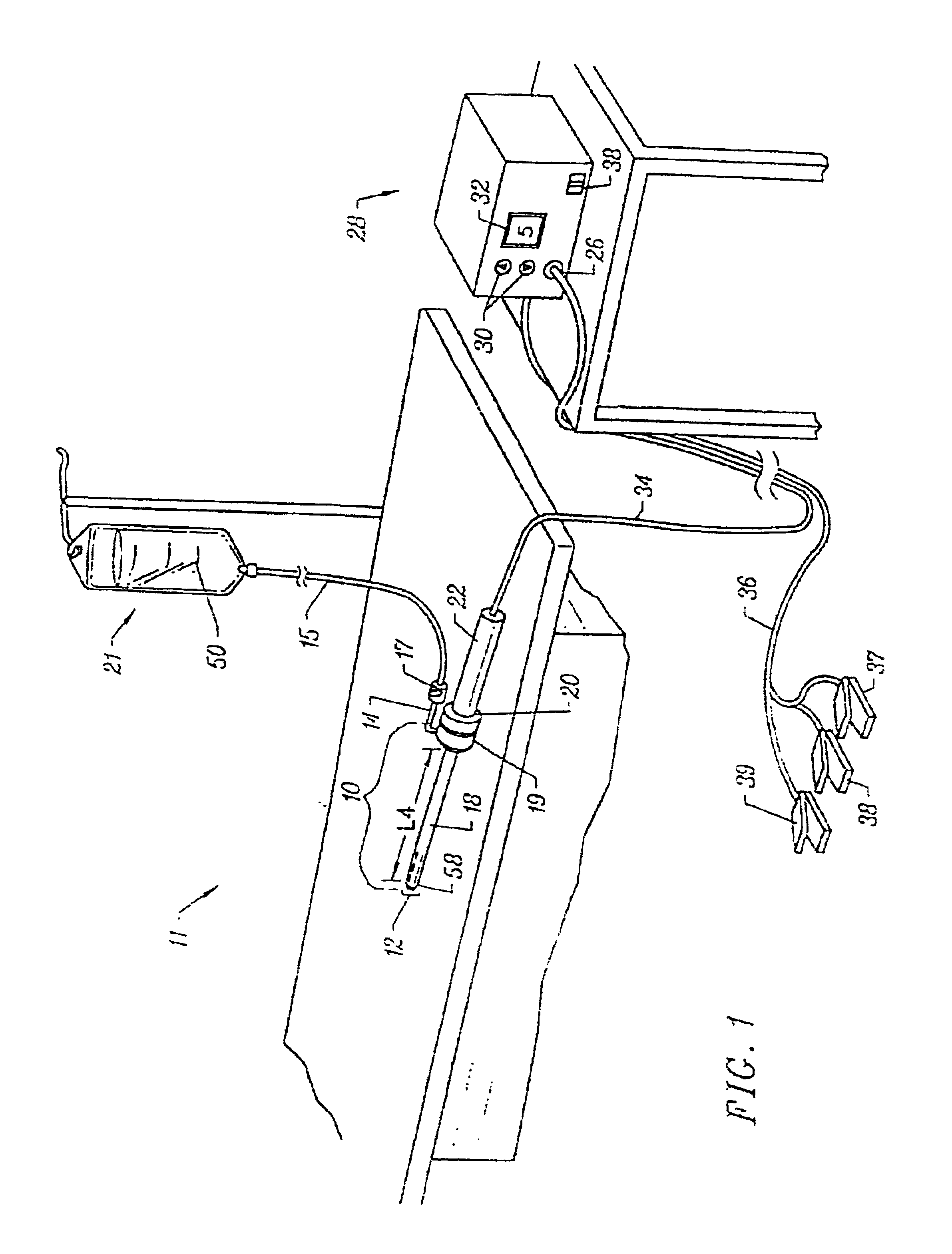

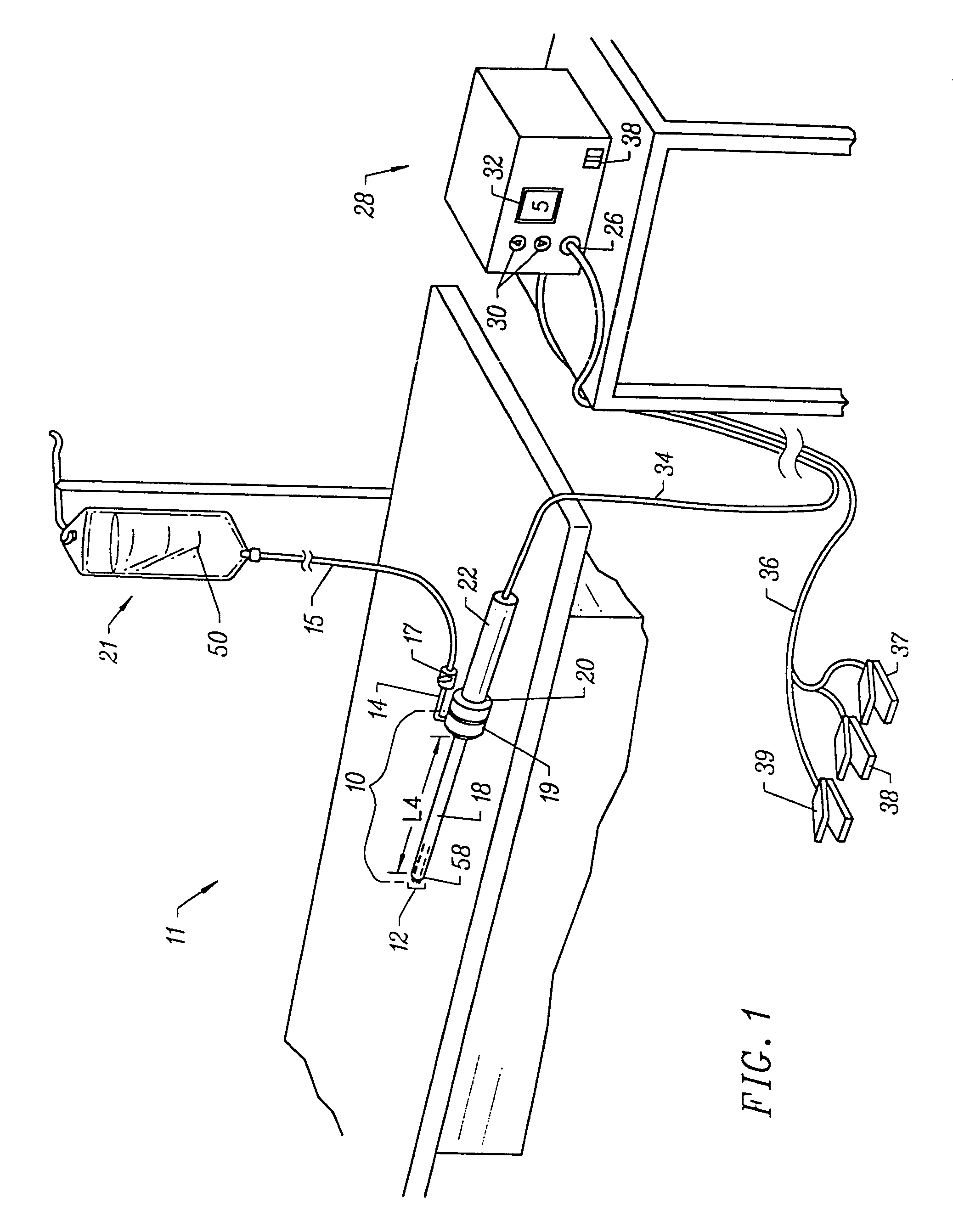

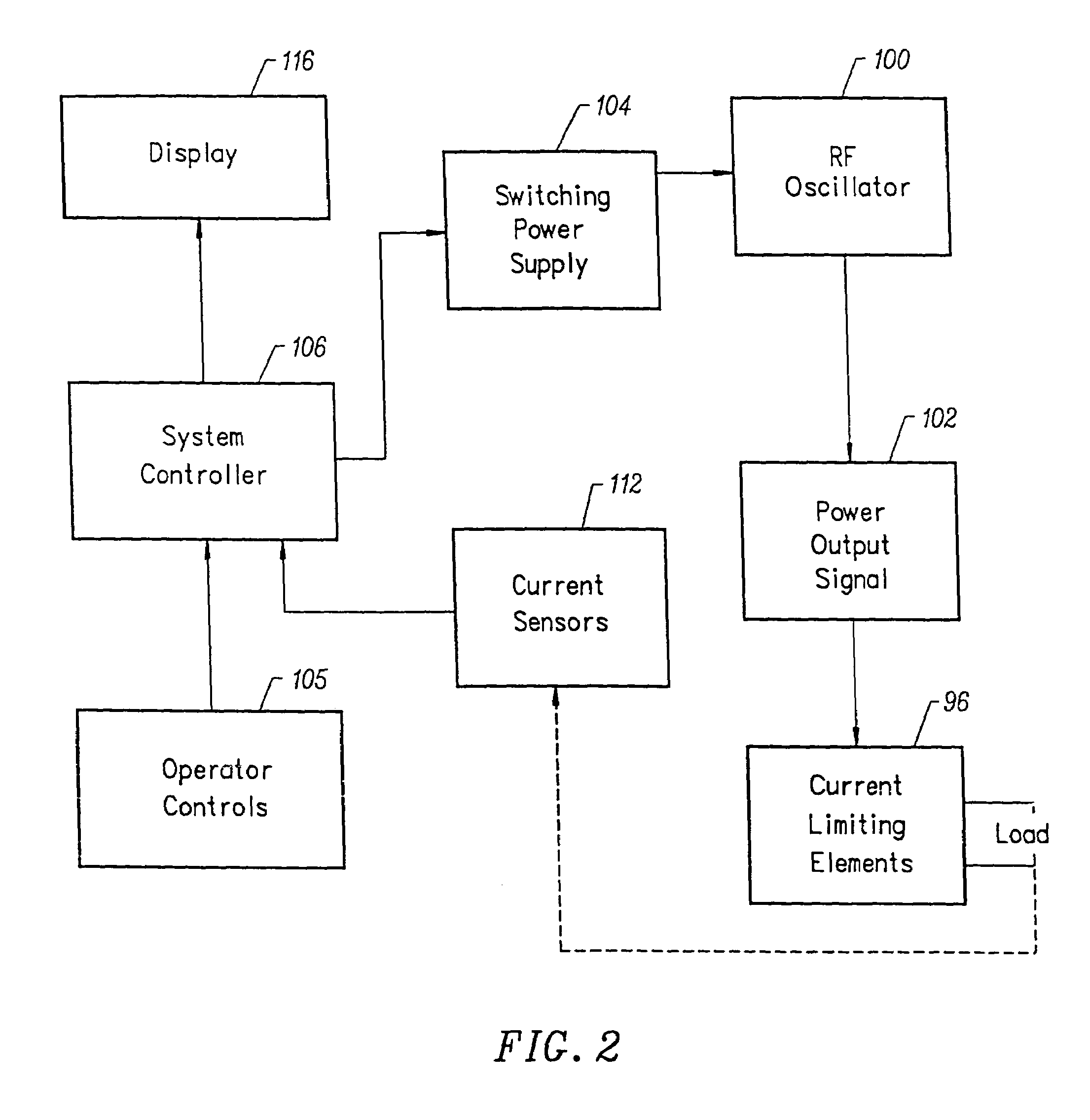

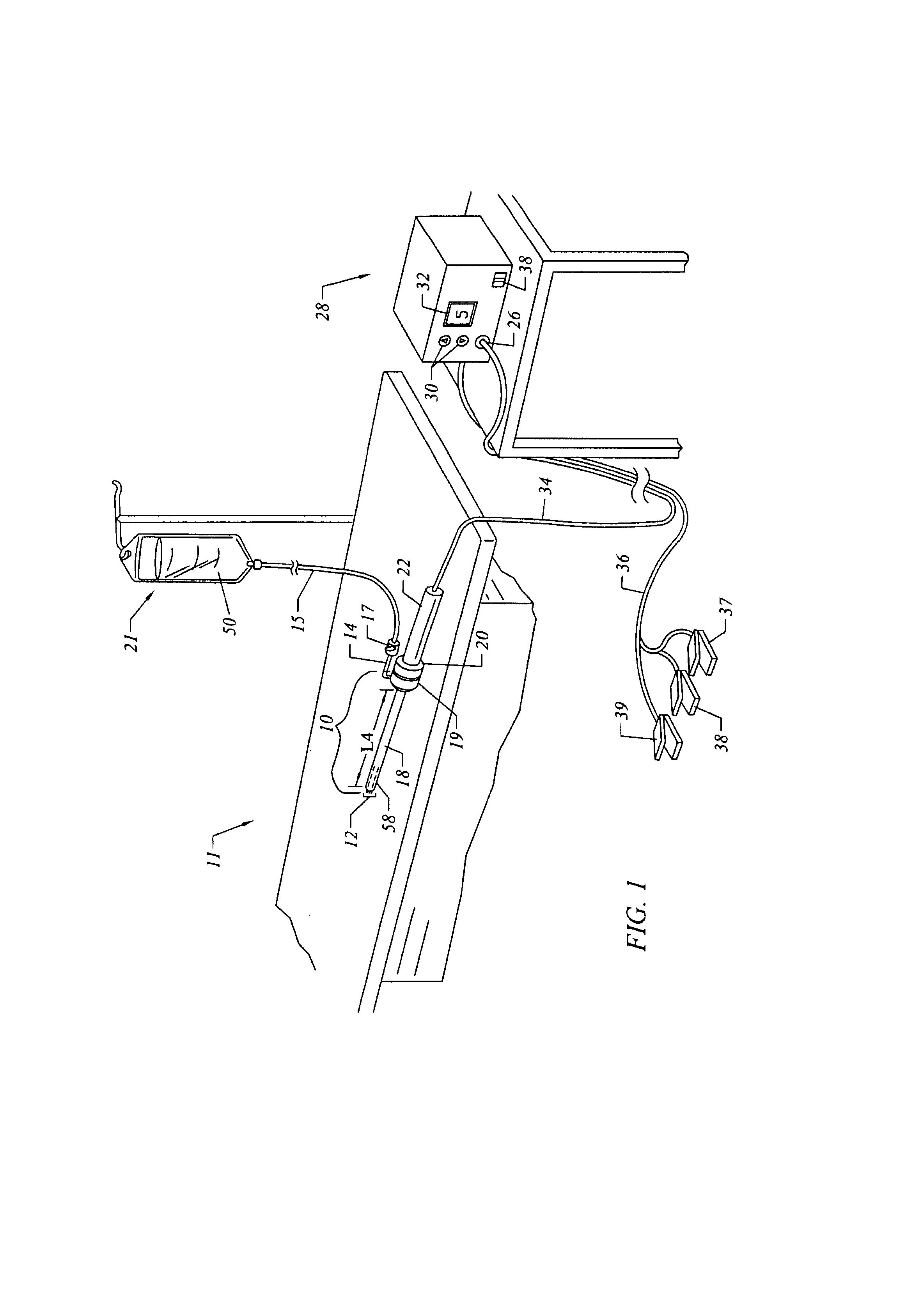

Methods for targeted electrosurgery on contained herniated discs

InactiveUS7179255B2Reduce pressureReduced neckingEnemata/irrigatorsHeart valvesFibrous ringCorneal ablation

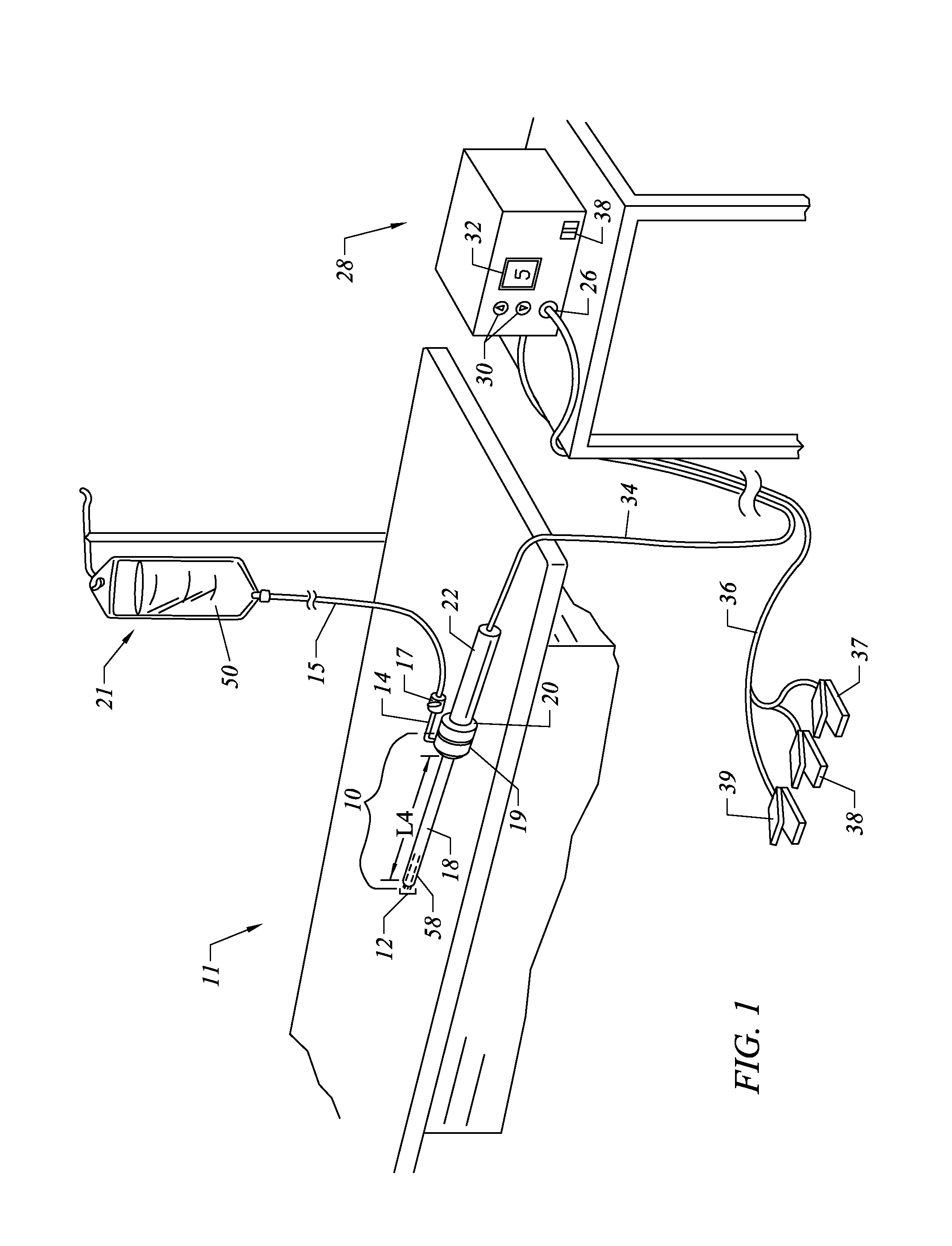

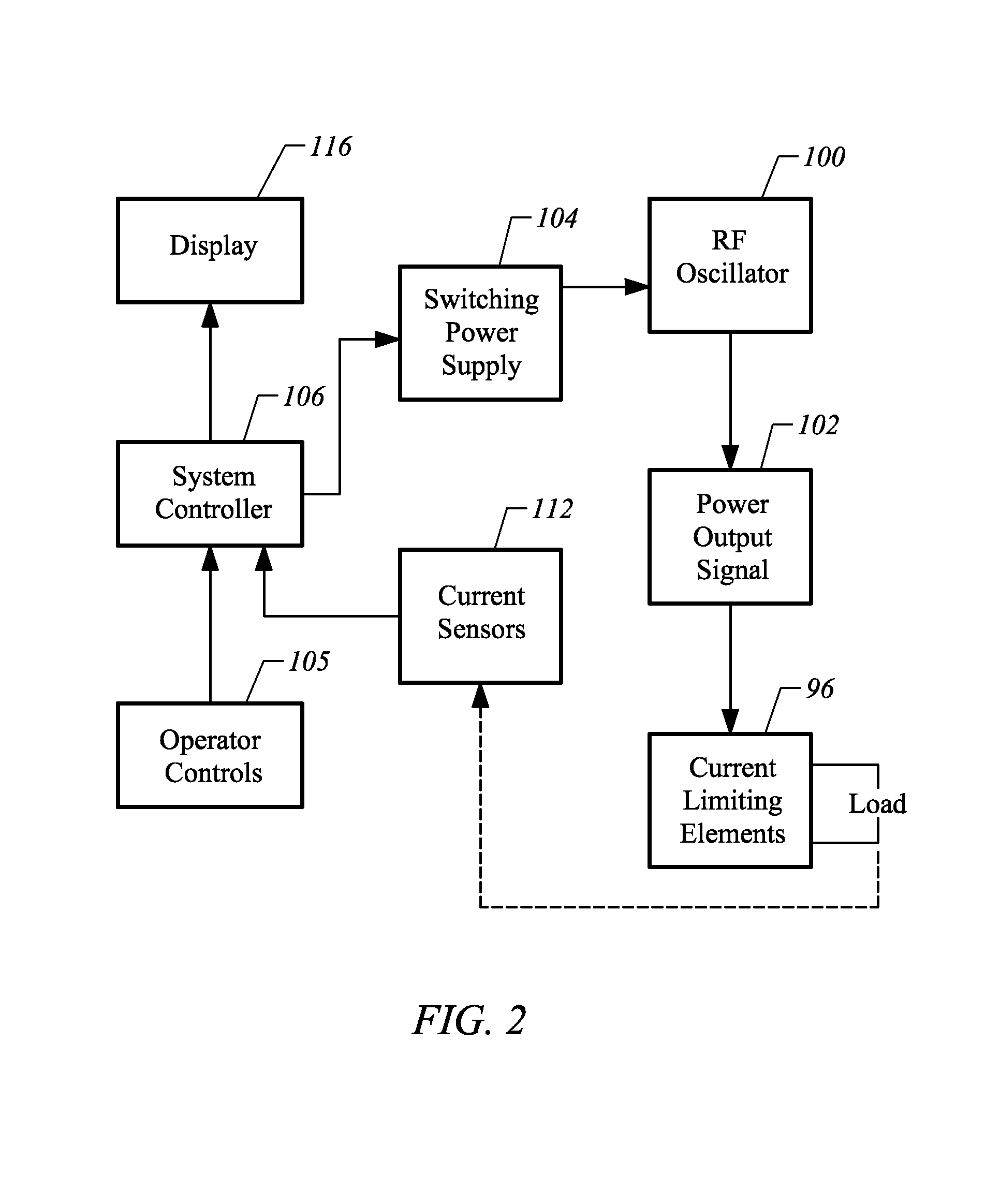

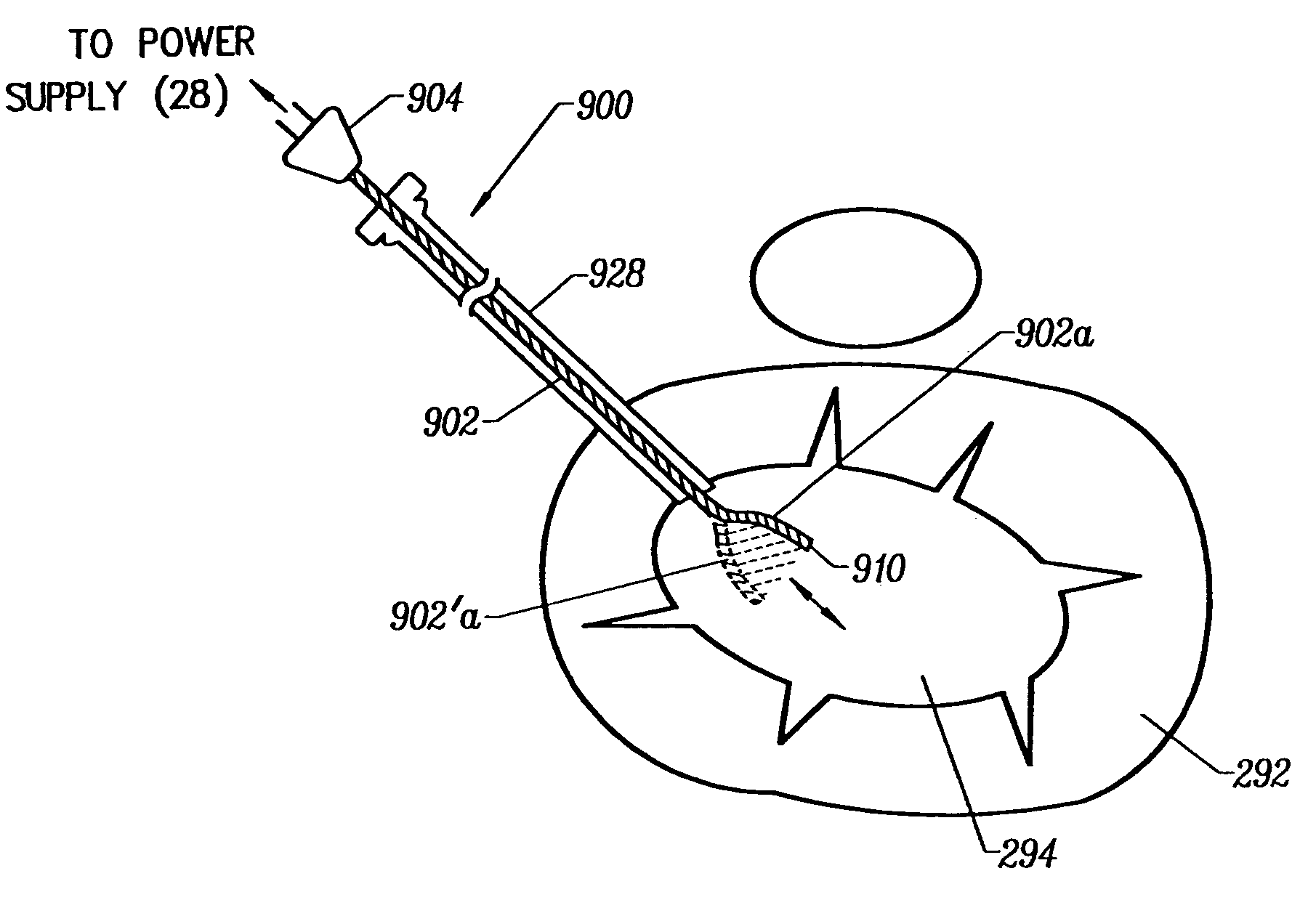

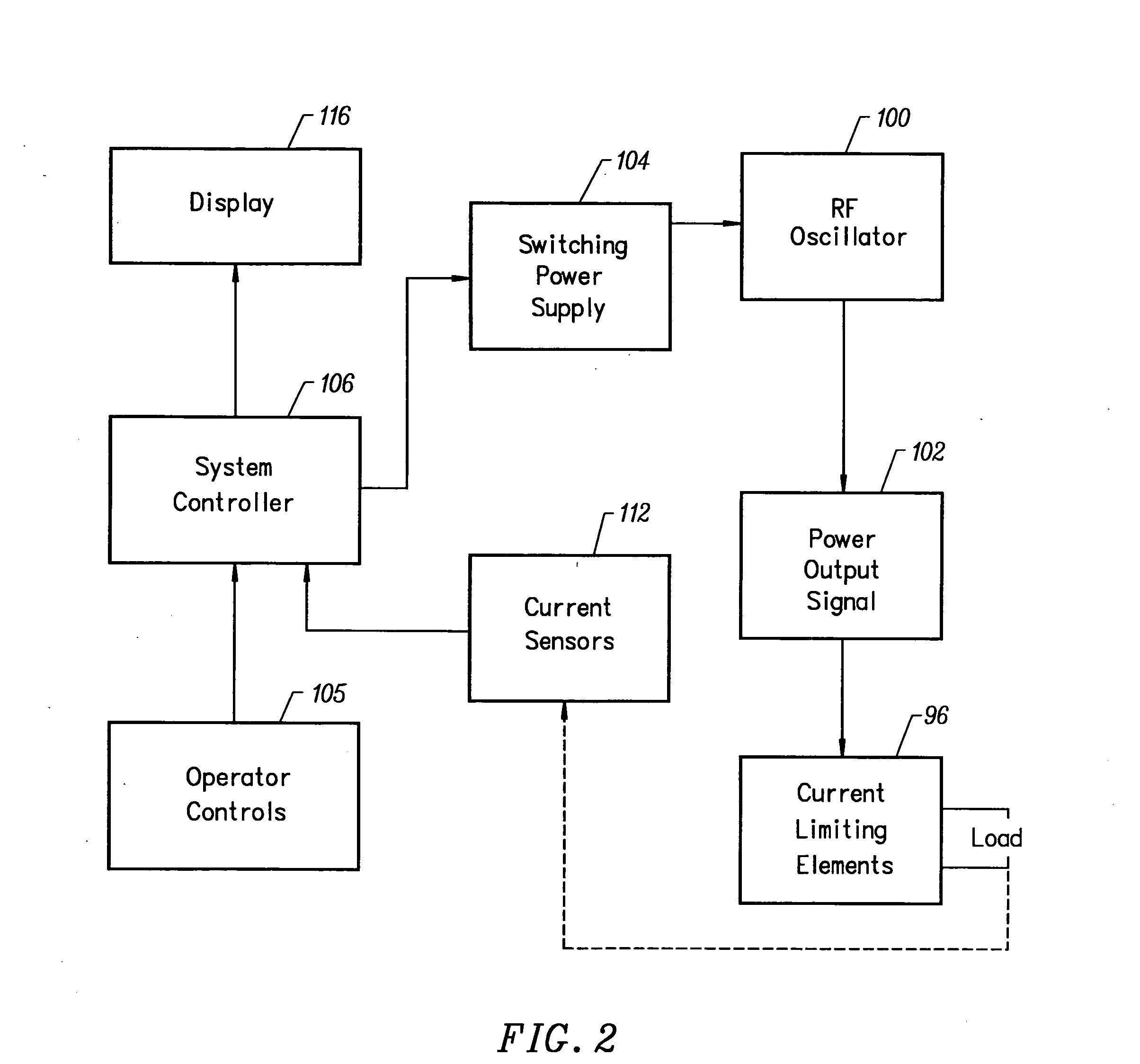

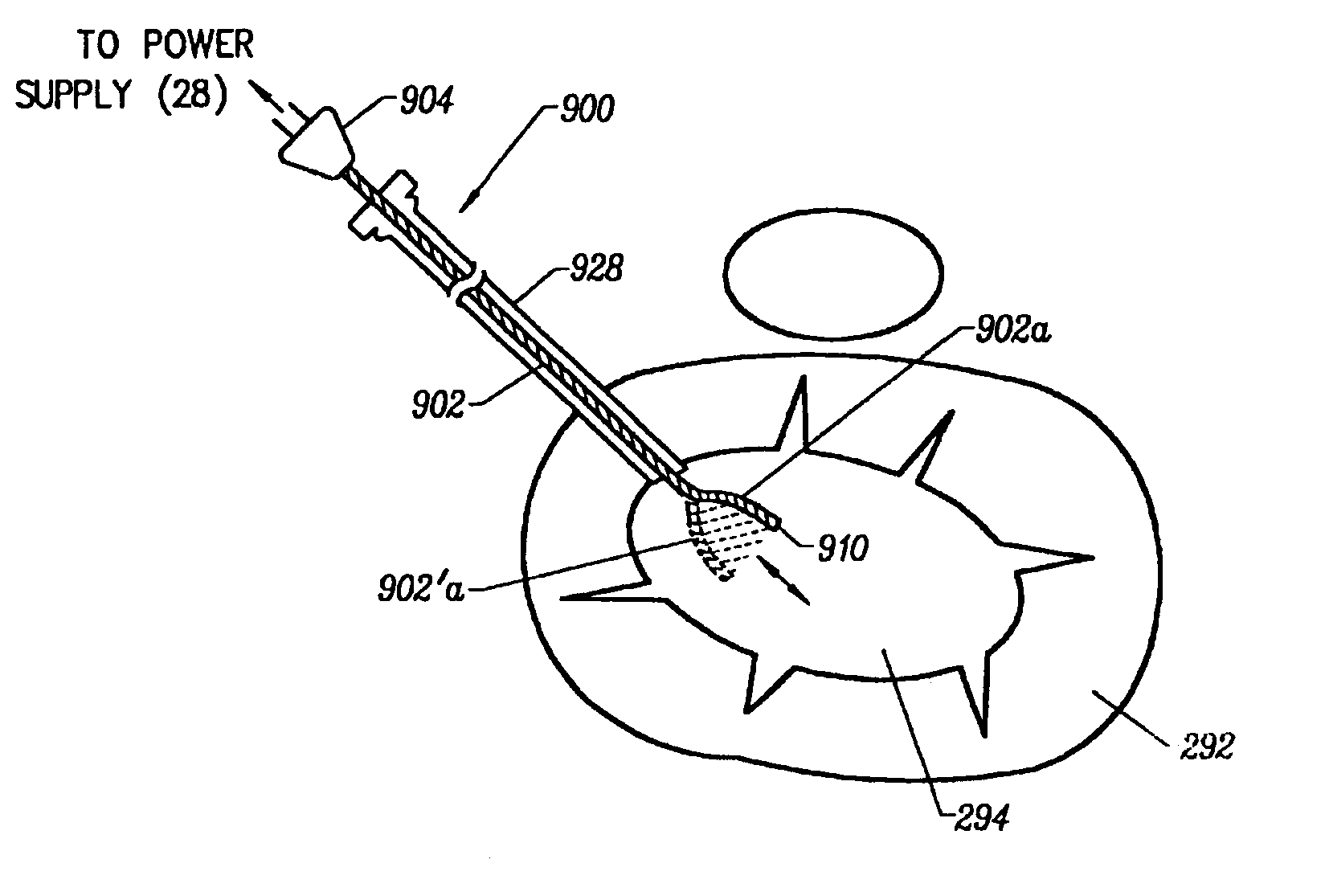

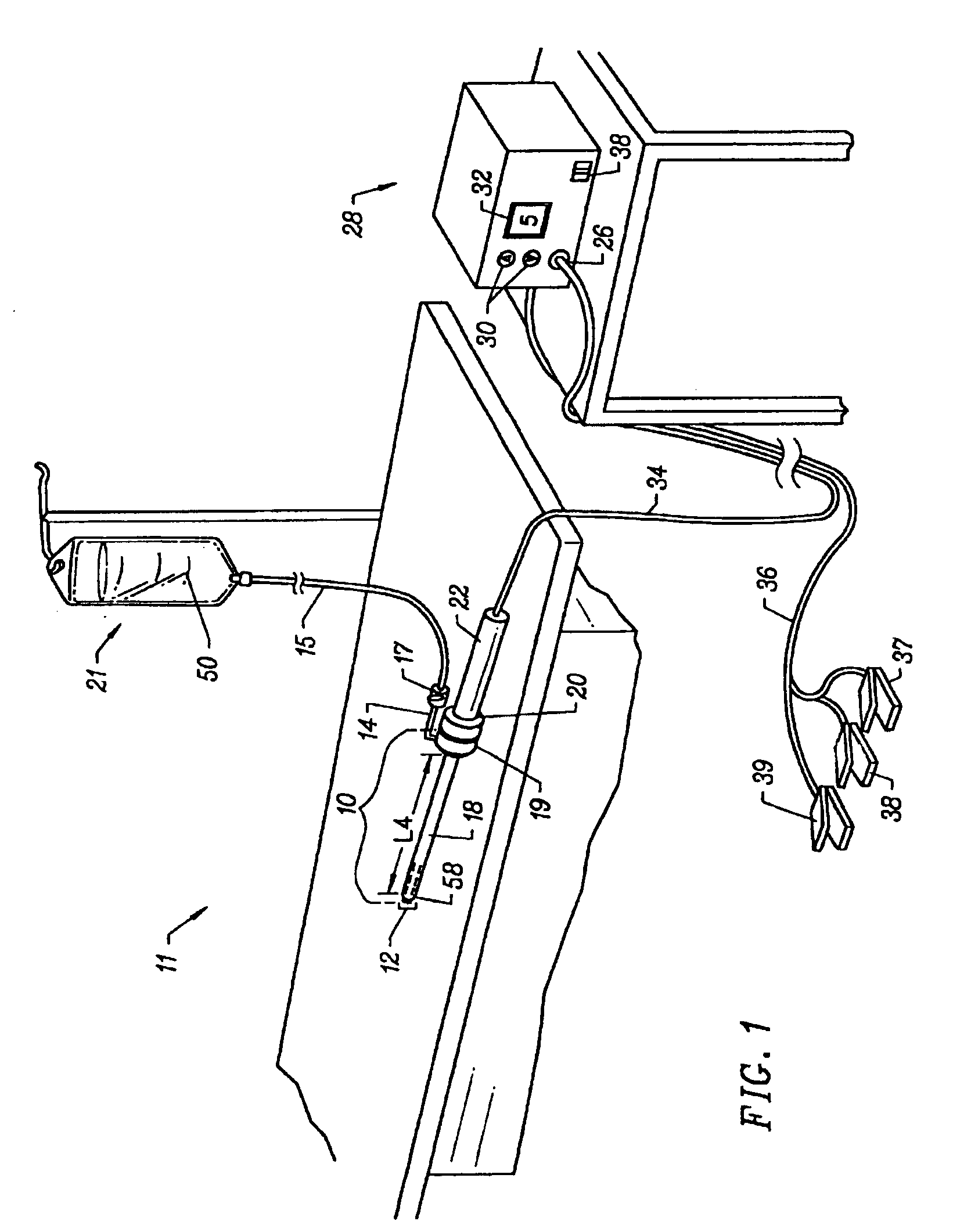

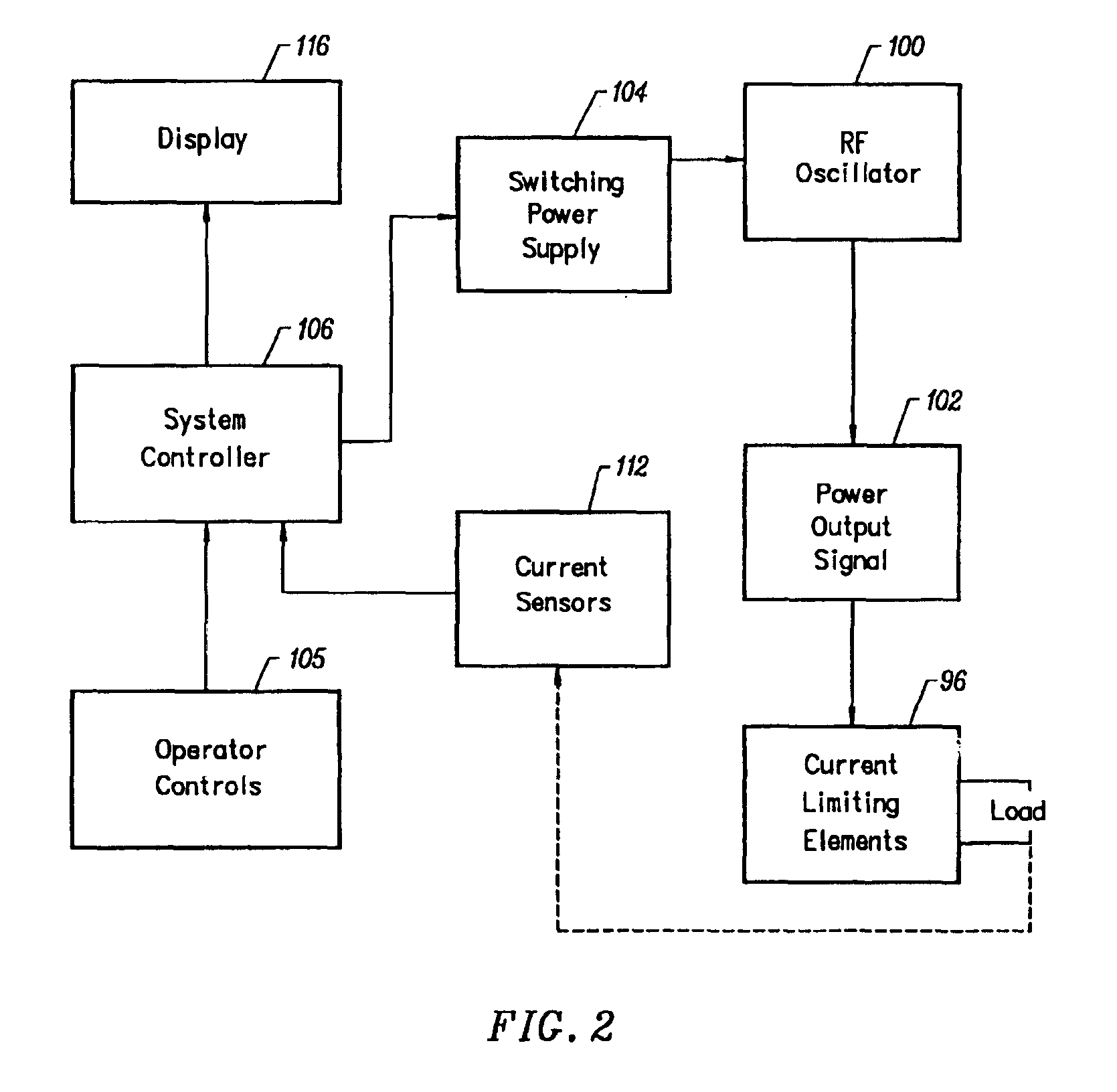

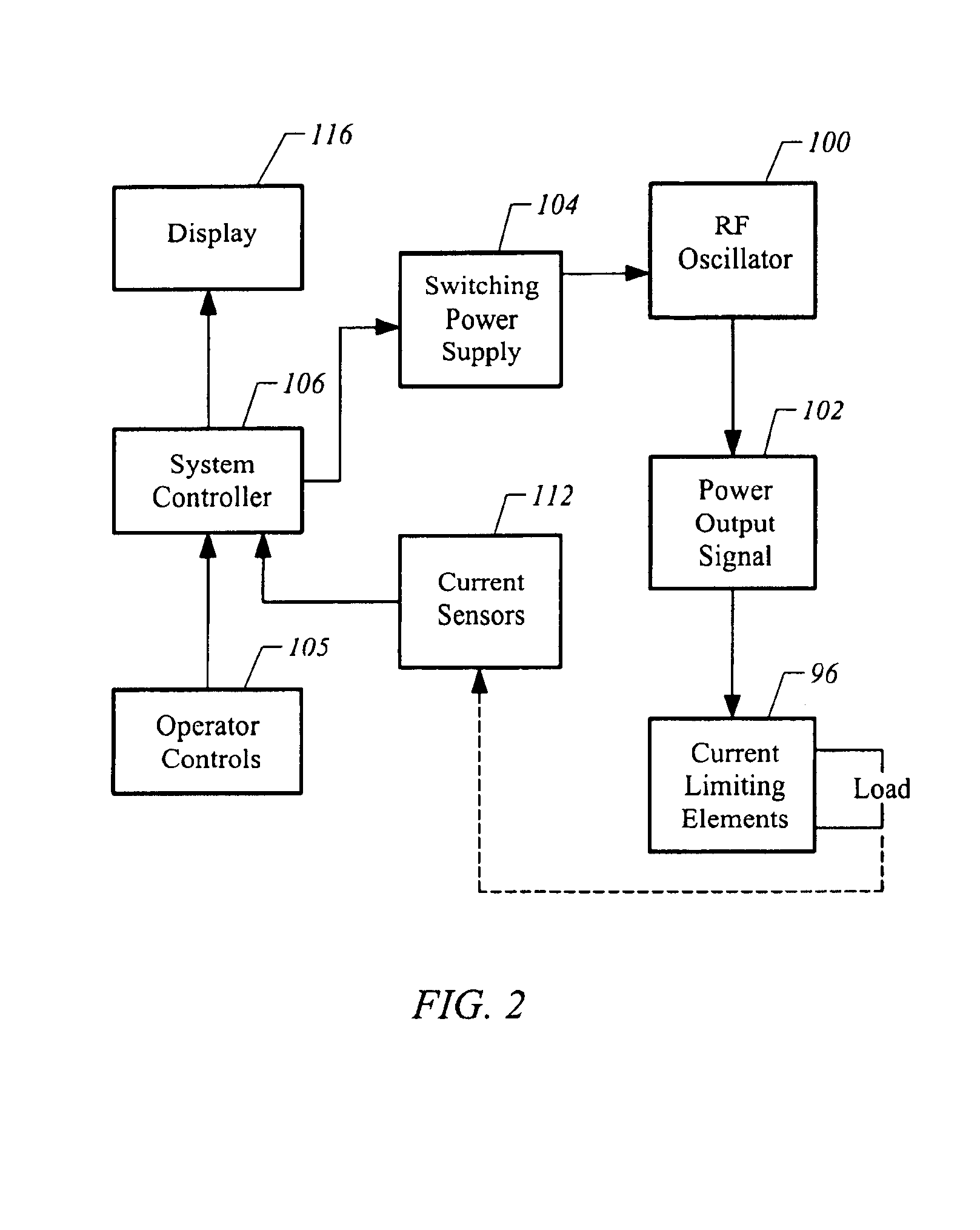

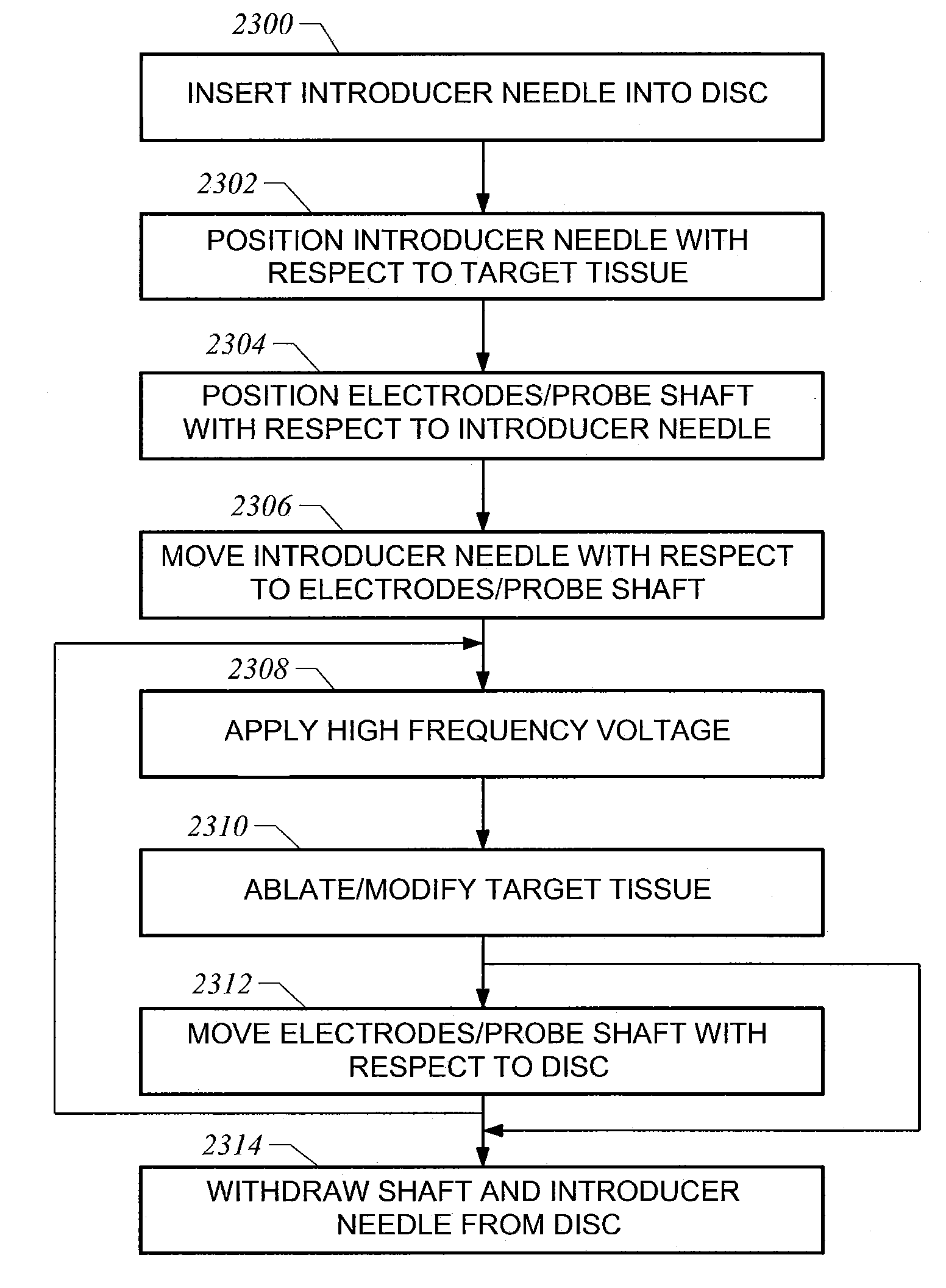

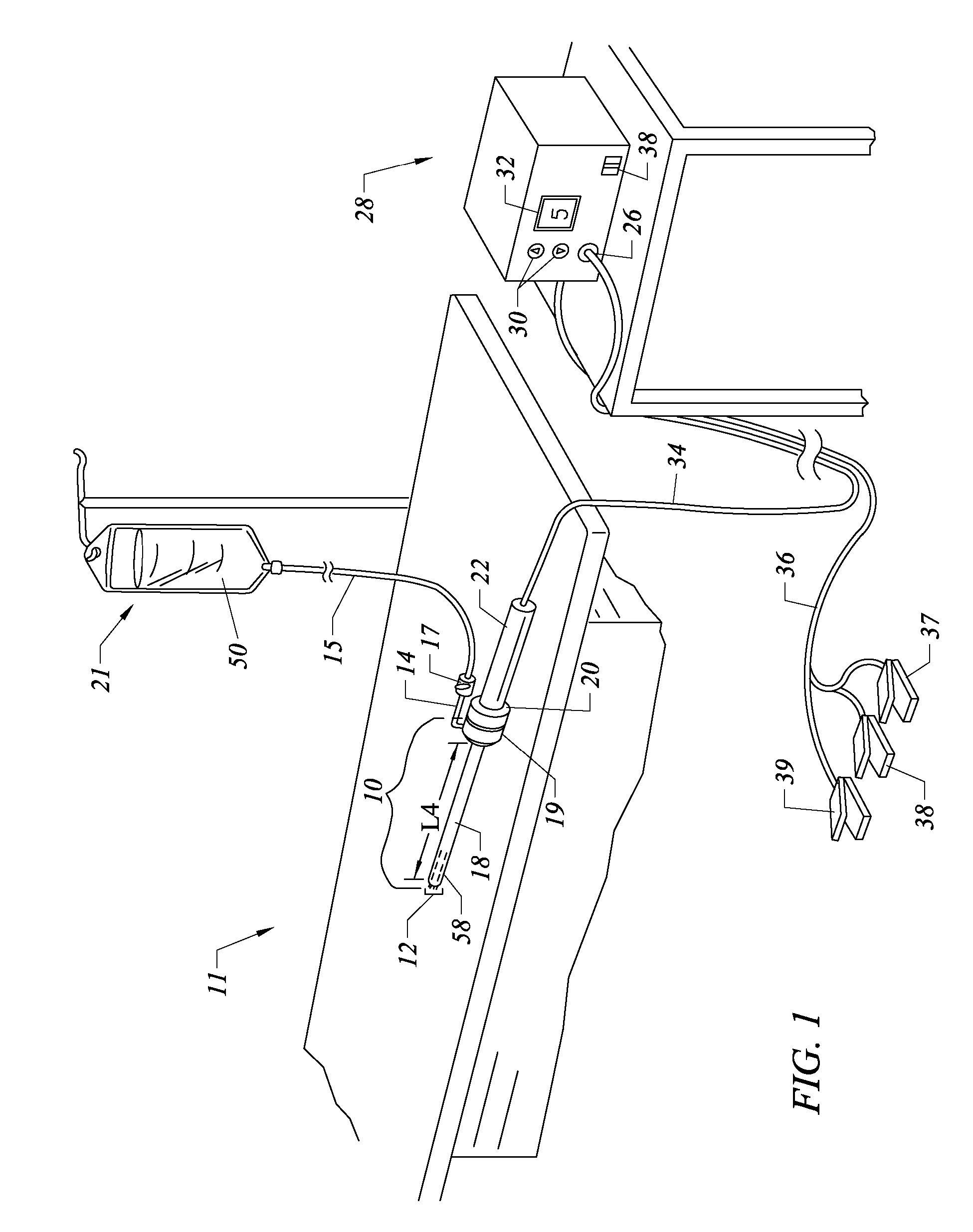

Apparatus and methods for treating an intervertebral disc by ablation of disc tissue. A method of the invention includes positioning at least one active electrode within the intervertebral disc, and applying at least a first high frequency voltage between the active electrode(s) and one or more return electrode(s), wherein the volume of the nucleus pulposus is decreased, pressure exerted by the nucleus pulposus on the annulus fibrosus is reduced, and discogenic pain of a patient is alleviated. In other embodiments, a curved or steerable probe is guided to a specific target site within a disc to be treated, and the disc tissue at the target site is ablated by application of at least a first high frequency voltage between the active electrode(s) and one or more return electrode(s). A method of making an electrosurgical probe is also disclosed.

Owner:ARTHROCARE

Methods for repairing damaged intervertebral discs

InactiveUS7318823B2Reduce internal pressureReduce moistureBiocideOrganic chemistryIntervertebral discActive electrode

Apparatus and methods for treating an intervertebral disc by ablation of disc tissue. A method of the invention includes positioning at least one active electrode within the intervertebral disc, and applying at least a first high frequency voltage between the active electrode(s) and one or more return electrode(s), wherein the volume of the nucleus pulposus is decreased, pressure exerted by the nucleus pulposus on the annulus fibrosus is reduced, and discogenic pain of a patient is alleviated. In other embodiments, a curved or steerable probe is guided to a specific target site within a disc to be treated, and the disc tissue at the target site is ablated by application of at least a first high frequency voltage between the active electrode(s) and one or more return electrode(s). A method of making an electrosurgical probe is also disclosed.

Owner:ARTHROCARE

Methods and apparatus for treating intervertebral discs

InactiveUS20050010205A1Minimal and collateral damageLower the volumeDiagnosticsSurgical needlesMedicineIntervertebral disc

Apparatus and methods for treating a target tissue by delivering a fluid at a defined temperature to a patient's body. An apparatus of the invention includes a fluid delivery unit for delivering fluid in at least close proximity to the target tissue, an aspiration unit for withdrawing the fluid, and a fluid source unit for providing the fluid at the defined temperature. A method of the invention includes forming a void in at least close proximity to the target tissue, and circulating a preheated fluid through the void, wherein the target tissue undergoes adjustment from body temperature to a treatment temperature due to heat exchange between the fluid and the target tissue.

Owner:ARTHROCARE

Methods for repairing damaged intervertebral discs

InactiveUSRE40156E1Reduce internal pressureReduce moistureBiocideOrganic chemistryIntervertebral discActive electrode

Apparatus and methods for treating an intervertebral disc by ablation of disc tissue. A method of the invention includes positioning at least one active electrode within the intervertebral disc, and applying at least a first high frequency voltage between the active electrode(s) and one or more return electrode(s), wherein the volume of the nucleus pulposus is decreased, pressure exerted by the nucleus pulposus on the annulus fibrosus is reduced, and discogenic pain of a patient is alleviated. In other embodiments, a curved or steerable probe is guided to a specific target site within a disc to be treated, and the disc tissue at the target site is ablated by application of at least a first high frequency voltage between the active electrode(s) and one or more return electrode(s). A method of making an electrosurgical probe is also disclosed.

Owner:ARTHROCARE

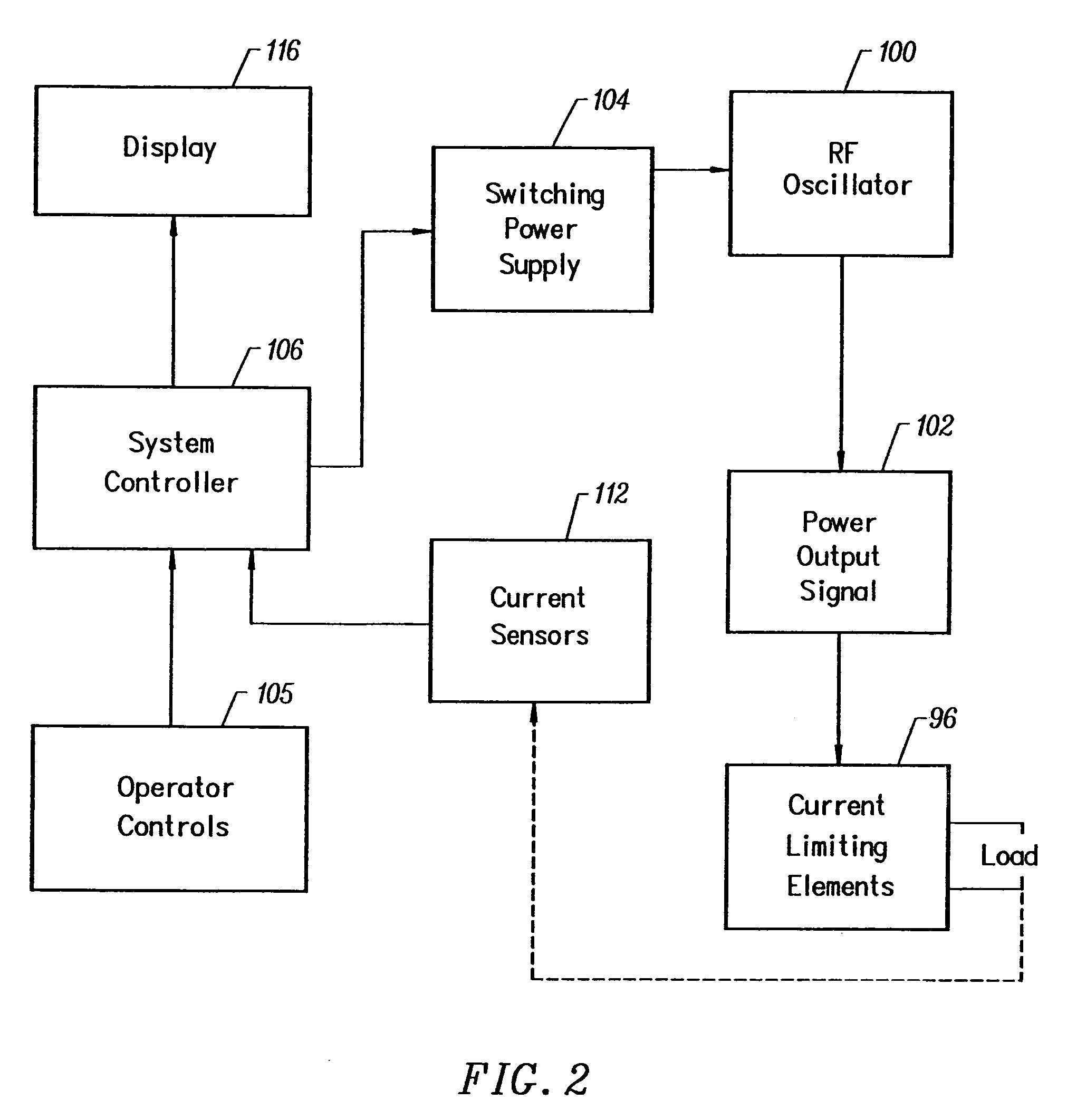

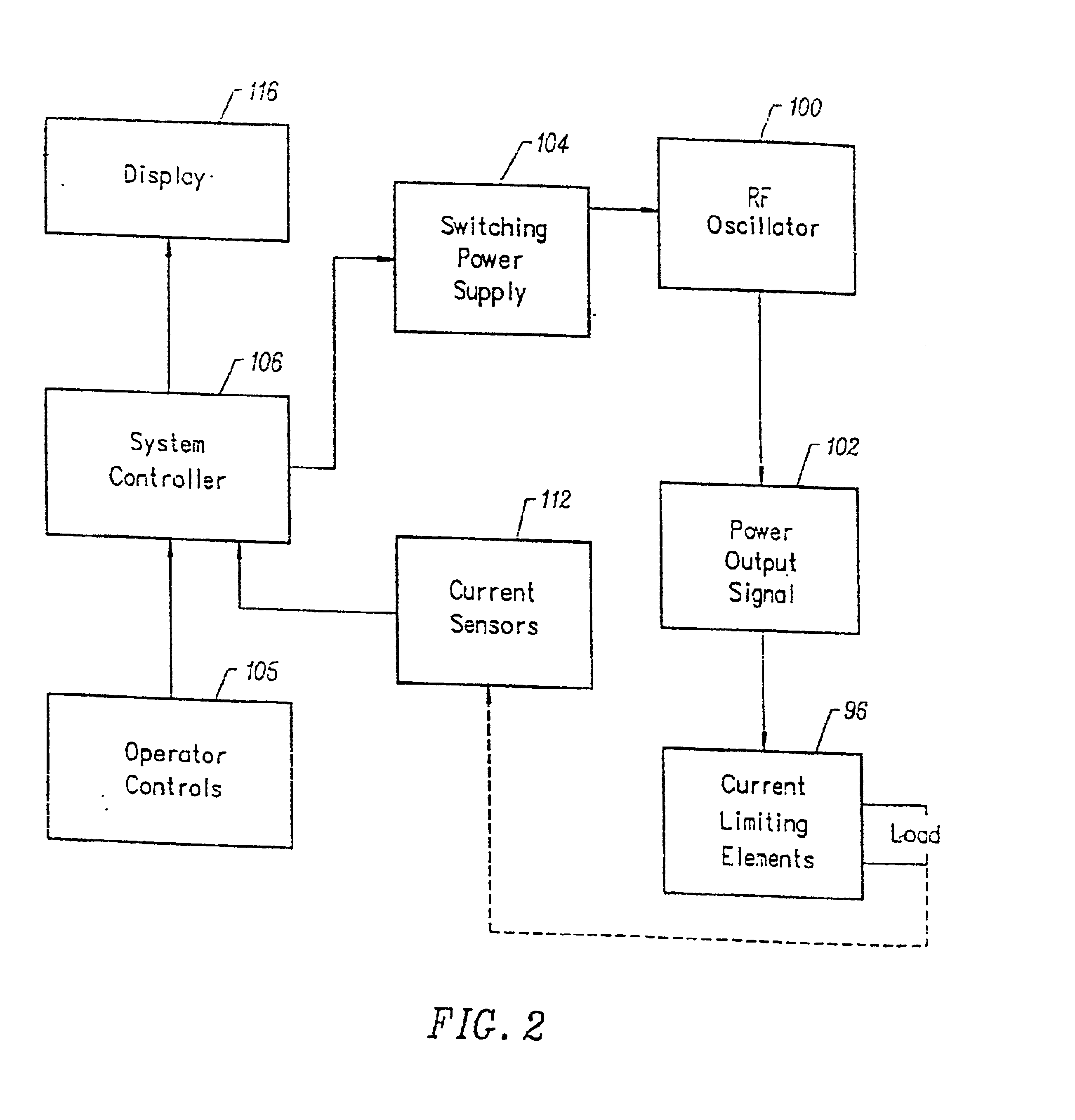

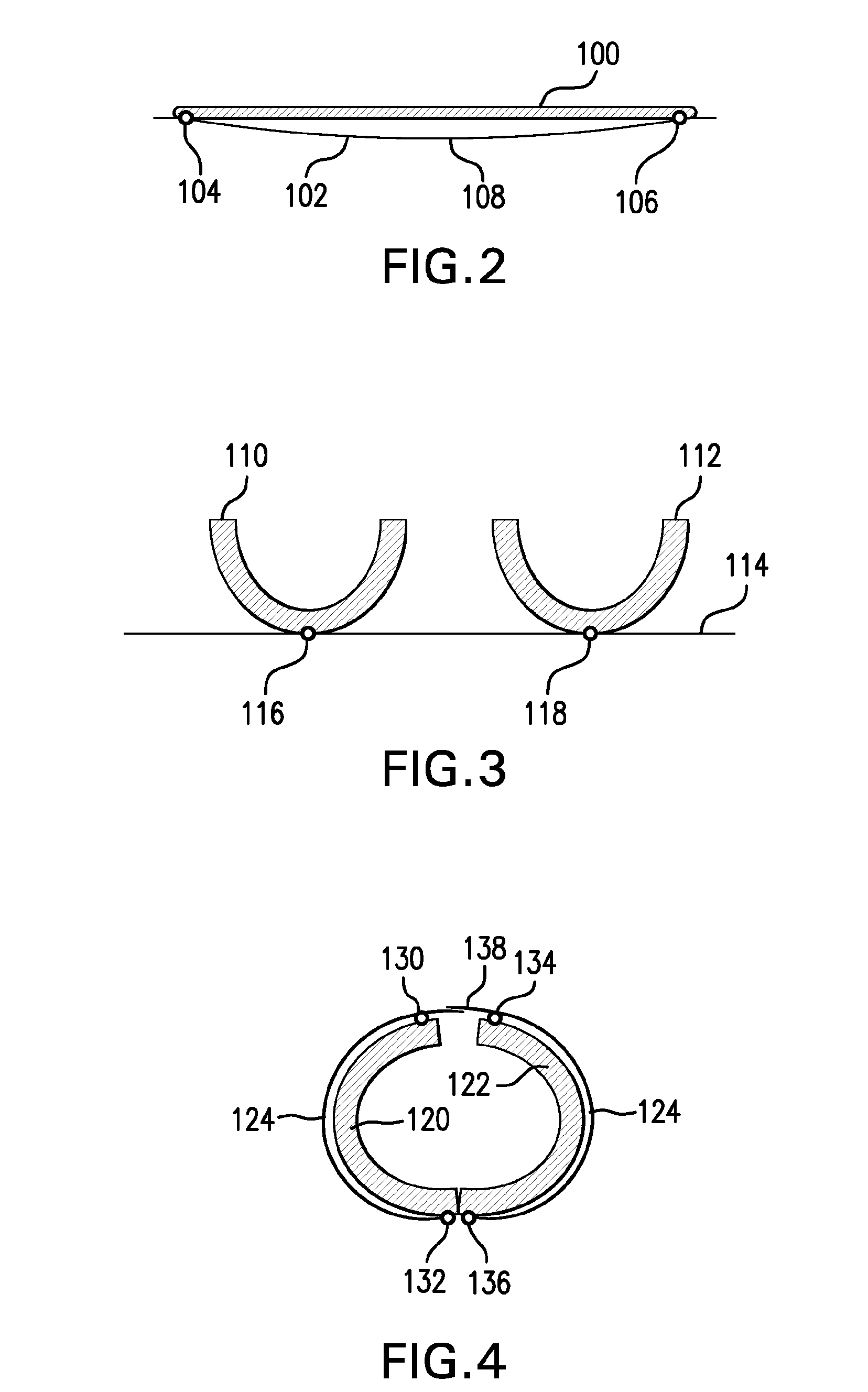

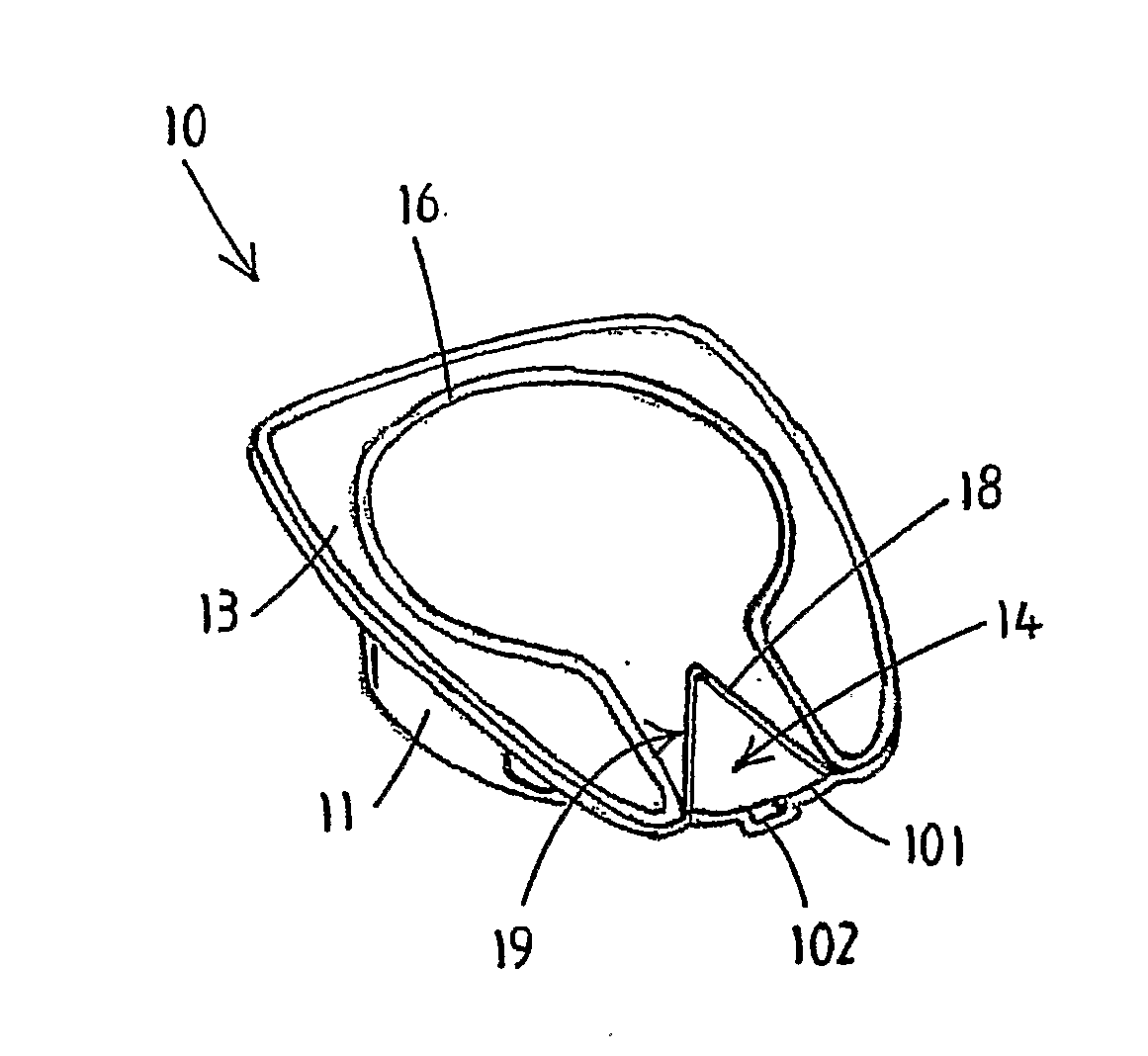

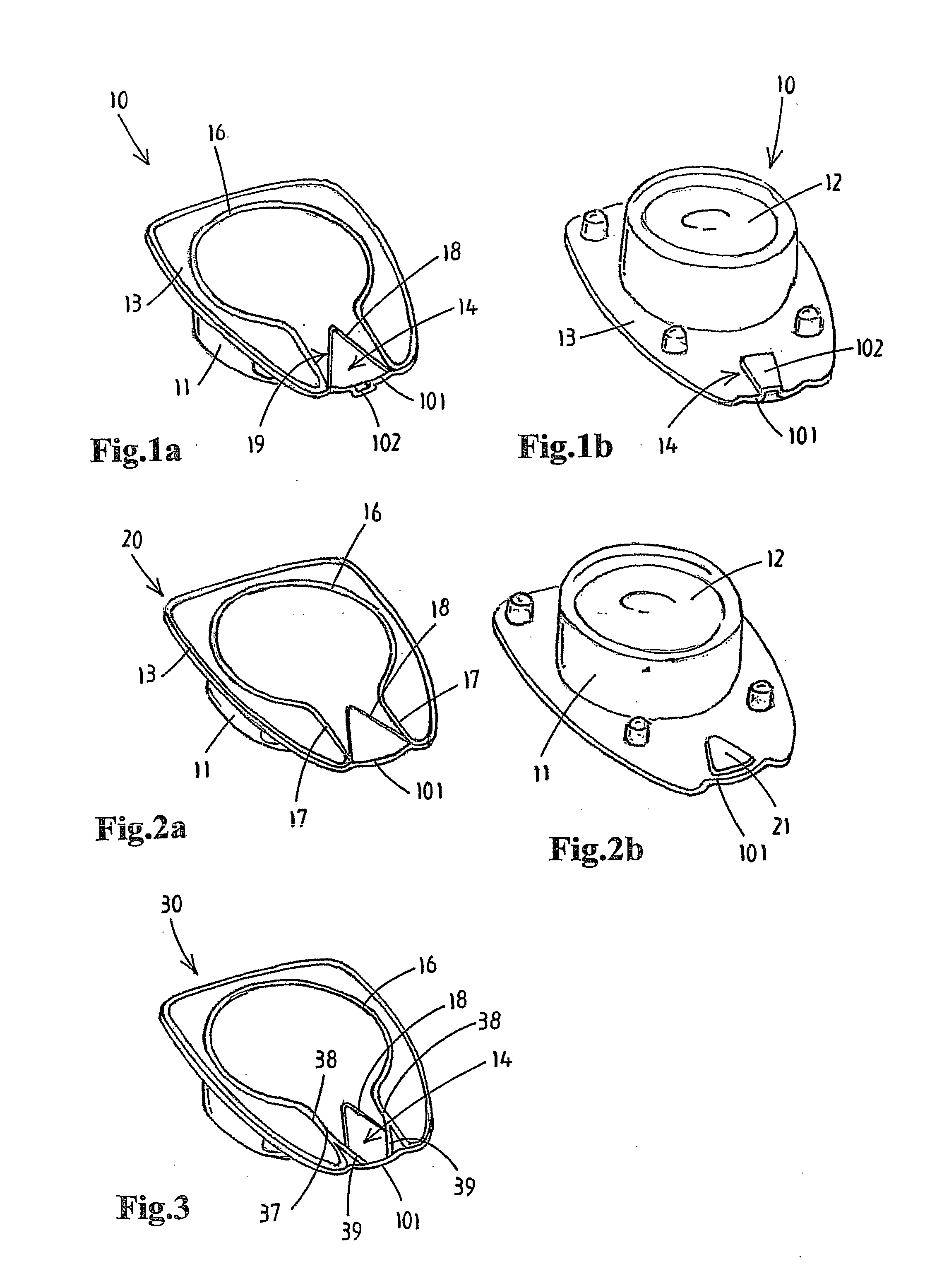

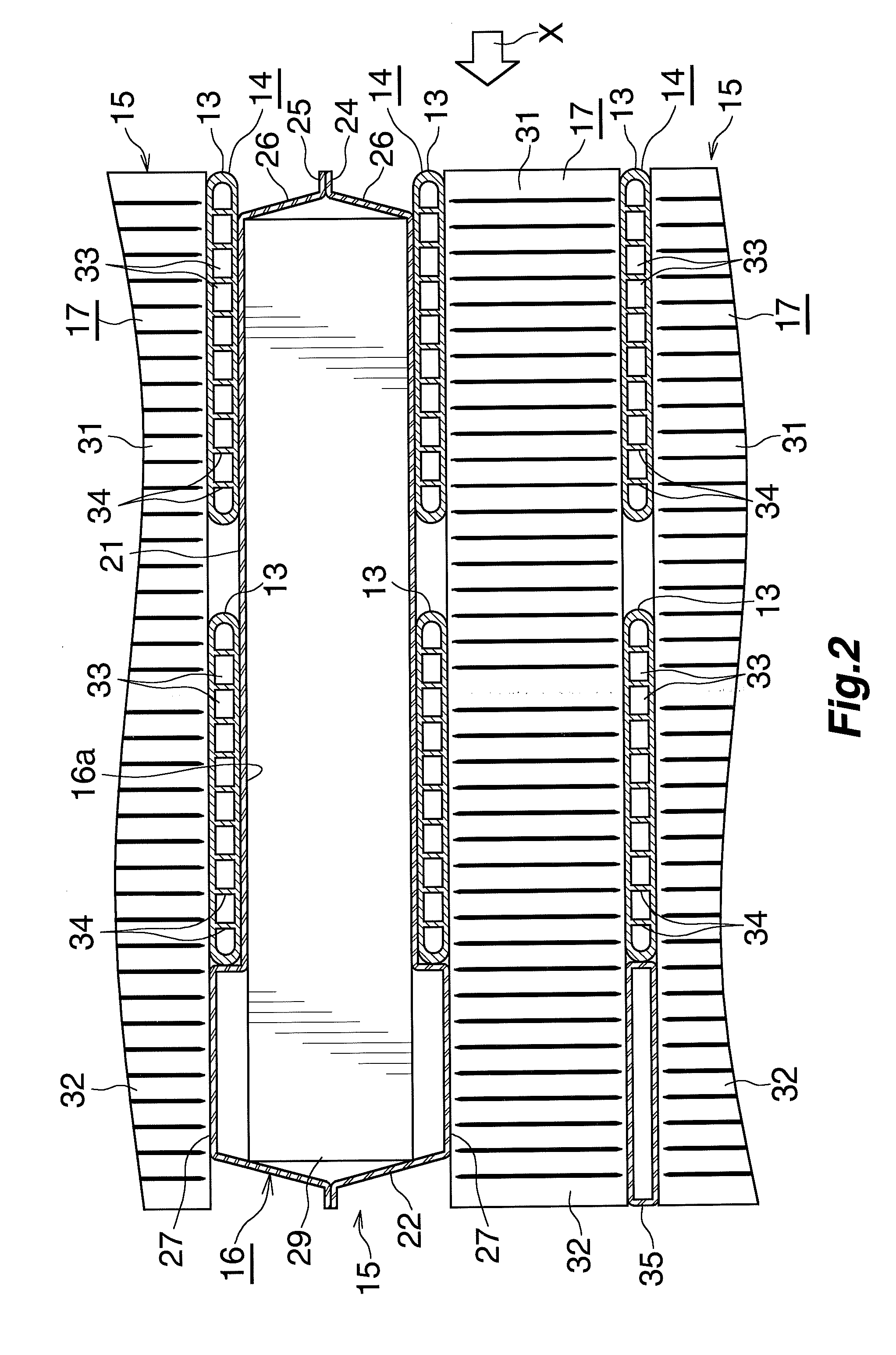

Electrosurgical apparatus having compound return electrode

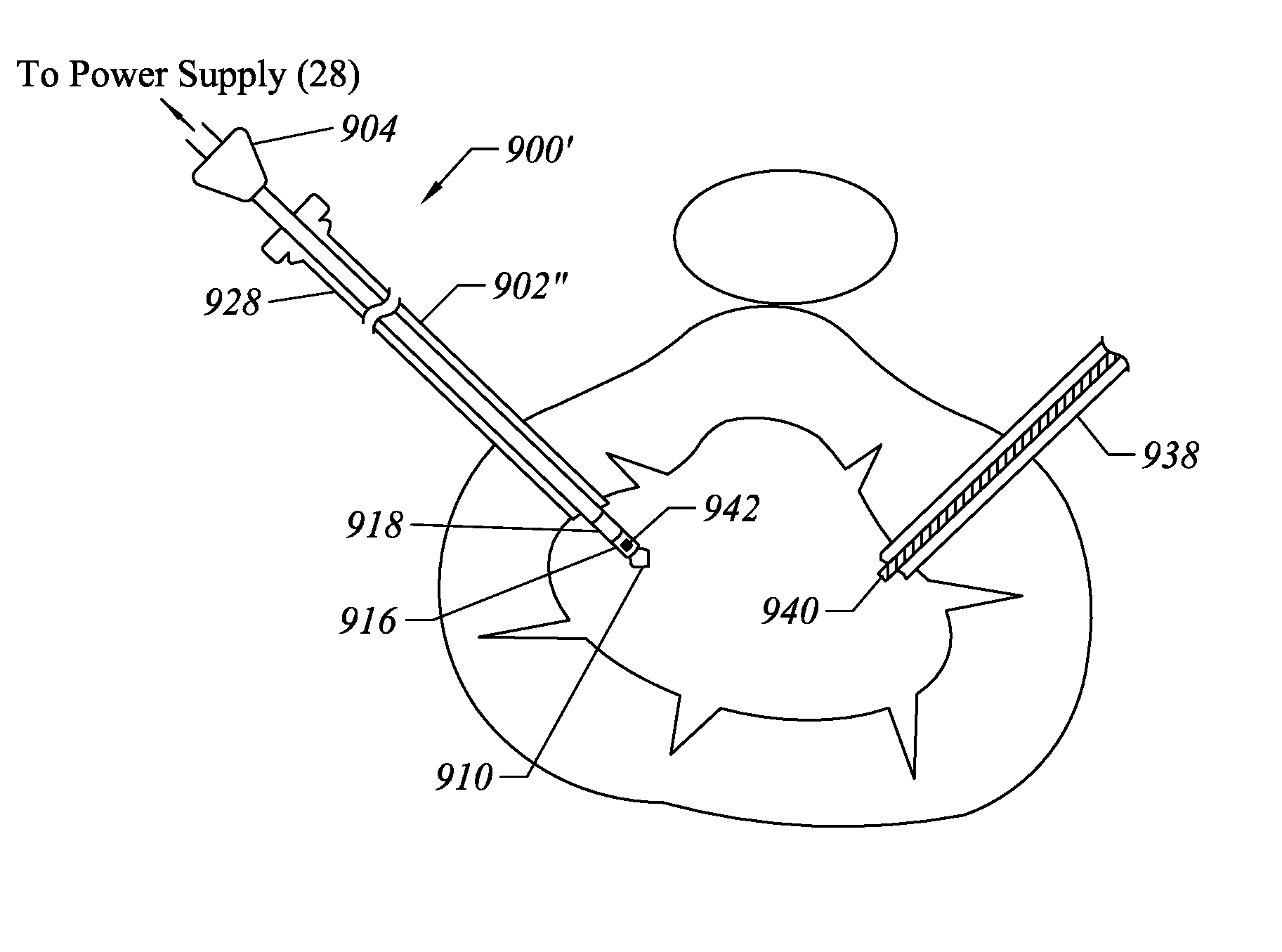

InactiveUS6837884B2Reduce the overall diameterAvoid arcingSurgical needlesSurgical instruments for heatingMedicineActive electrode

Electrosurgical apparatus and methods for ablating, coagulating, shrinking, stiffening, or other treatment of a target tissue of a patient. An apparatus of the invention includes an electrosurgical probe, and an introducer needle adapted for passing the distal end of the probe therethrough, wherein the probe includes an uninsulated shaft which makes electrical contact with the introducer needle when the shaft is engaged within a lumen of the introducer needle. The apparatus further includes an active electrode and a return electrode, wherein the return electrode comprises the shaft in combination with the introducer needle. In one embodiment, the active electrode includes an expandable electrode head.

Owner:ARTHROCARE

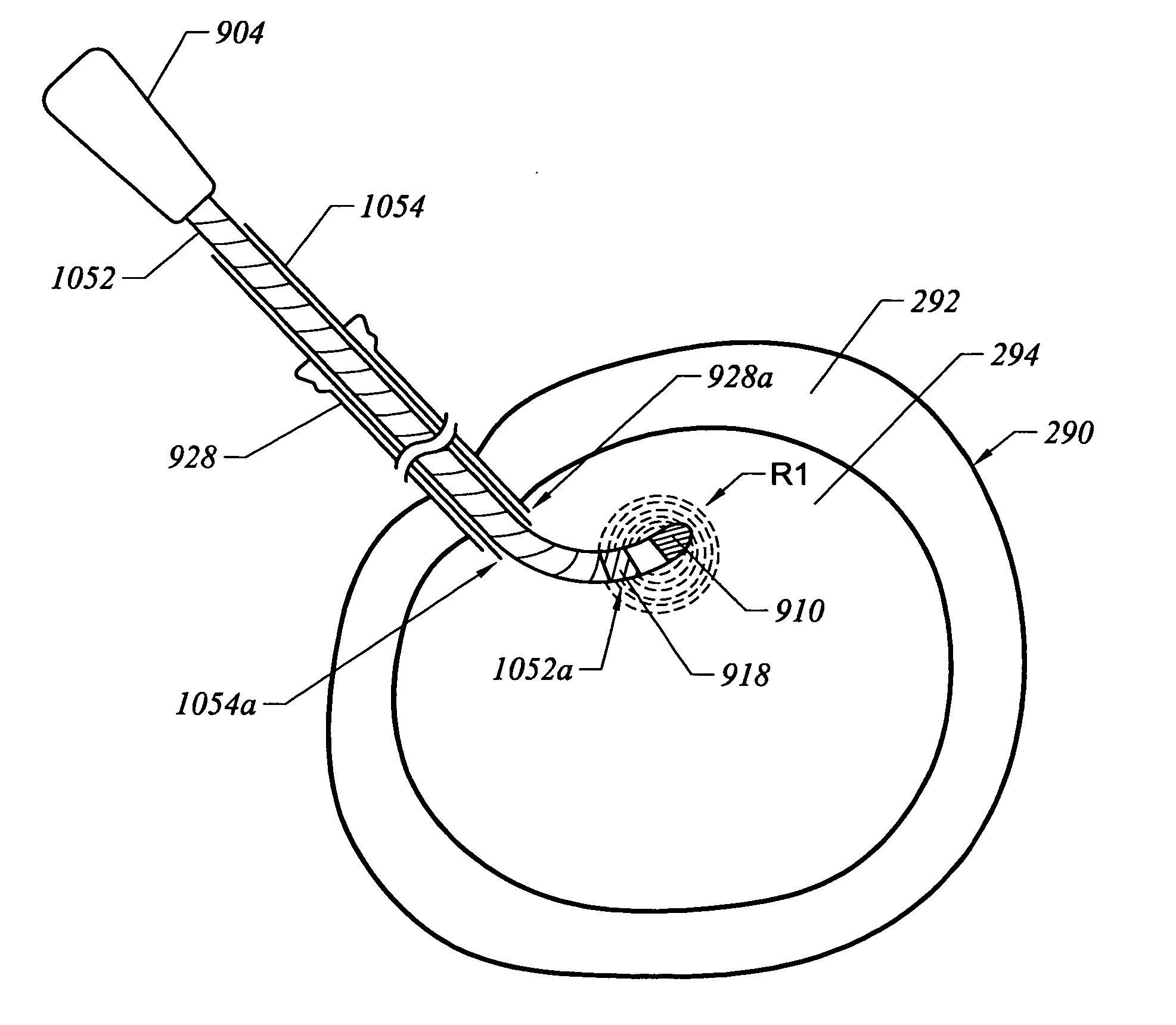

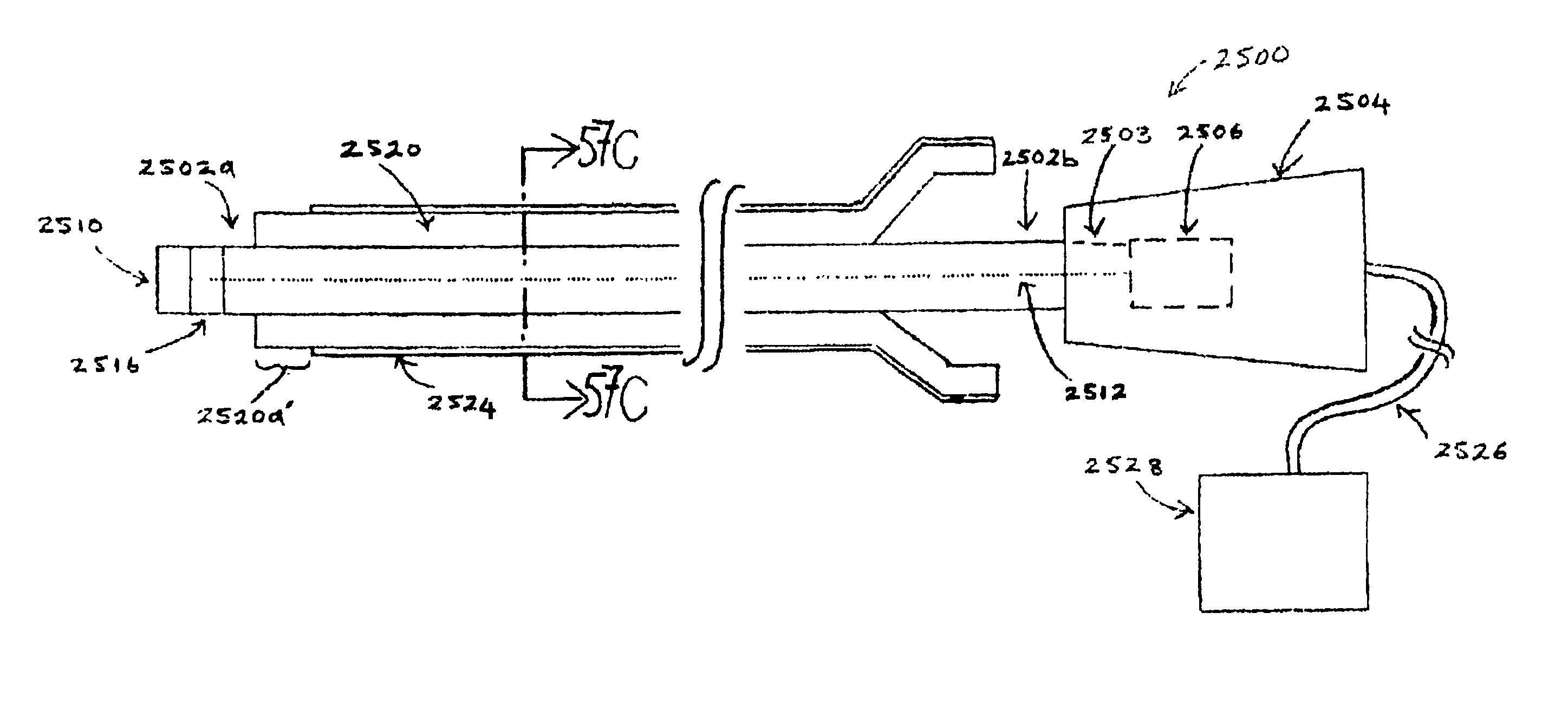

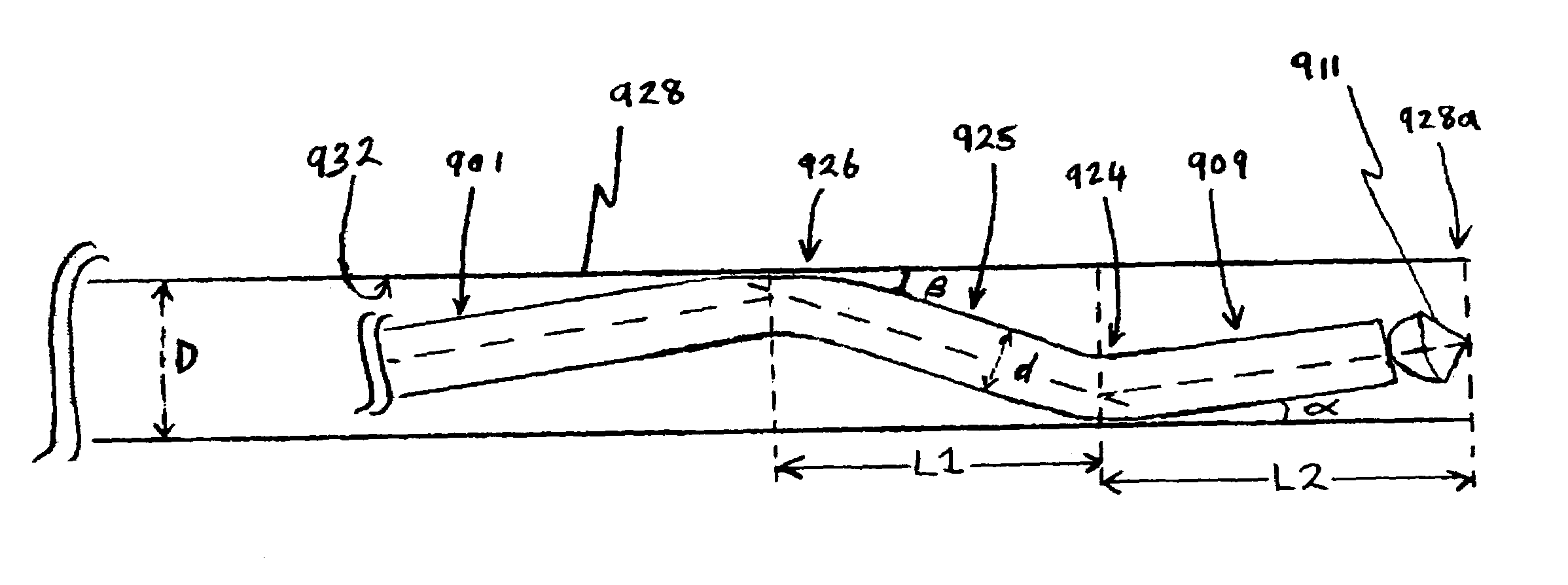

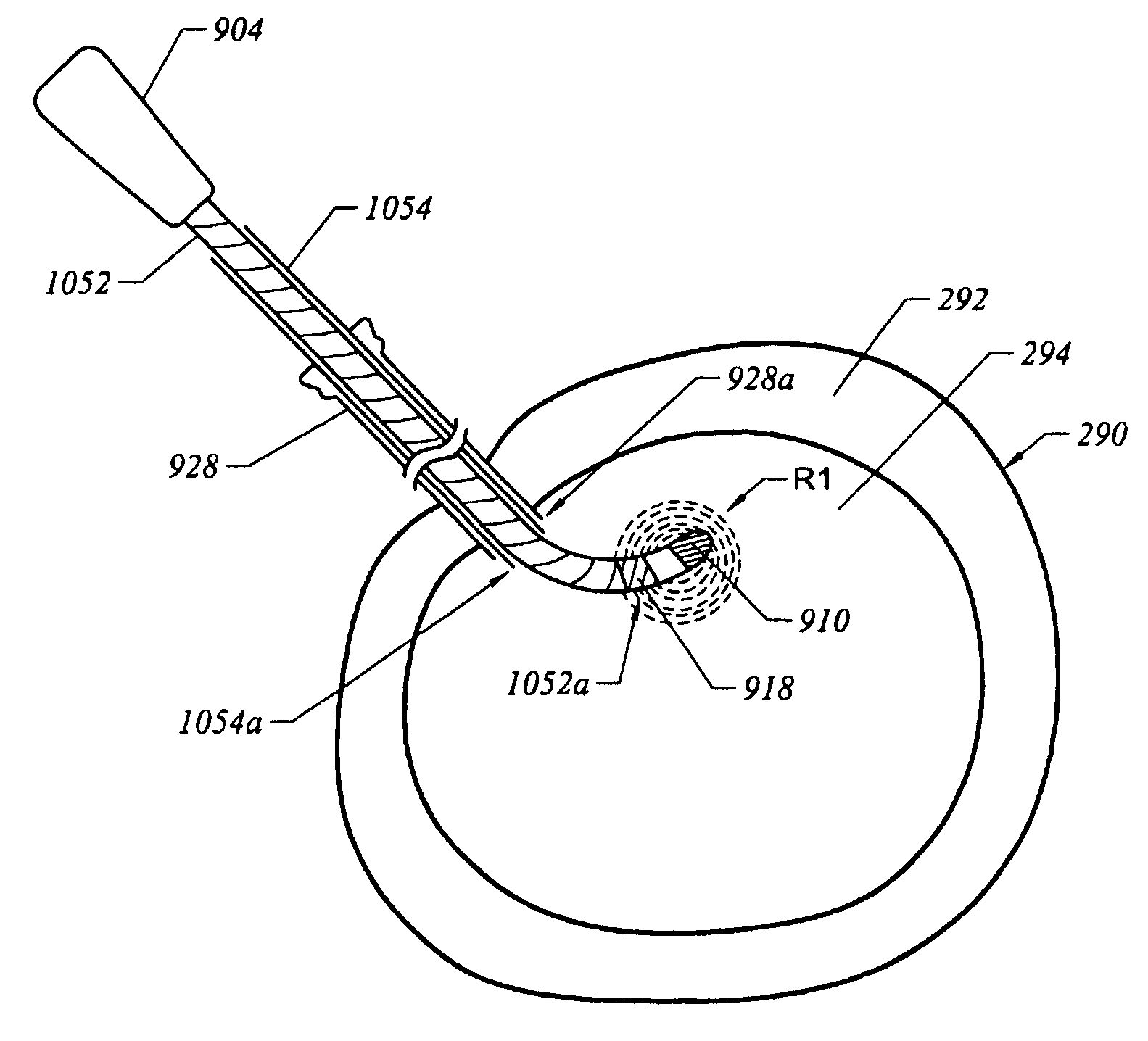

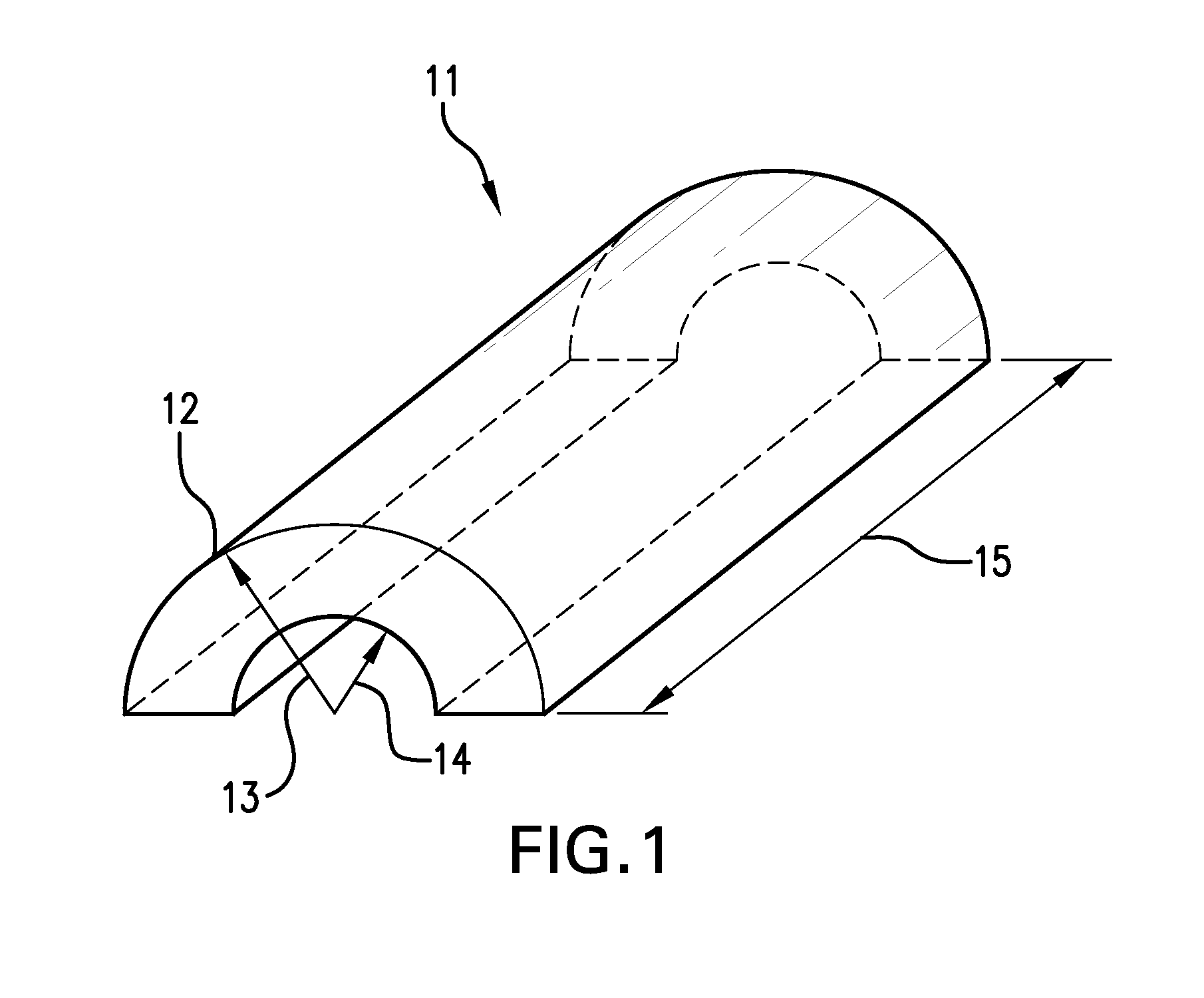

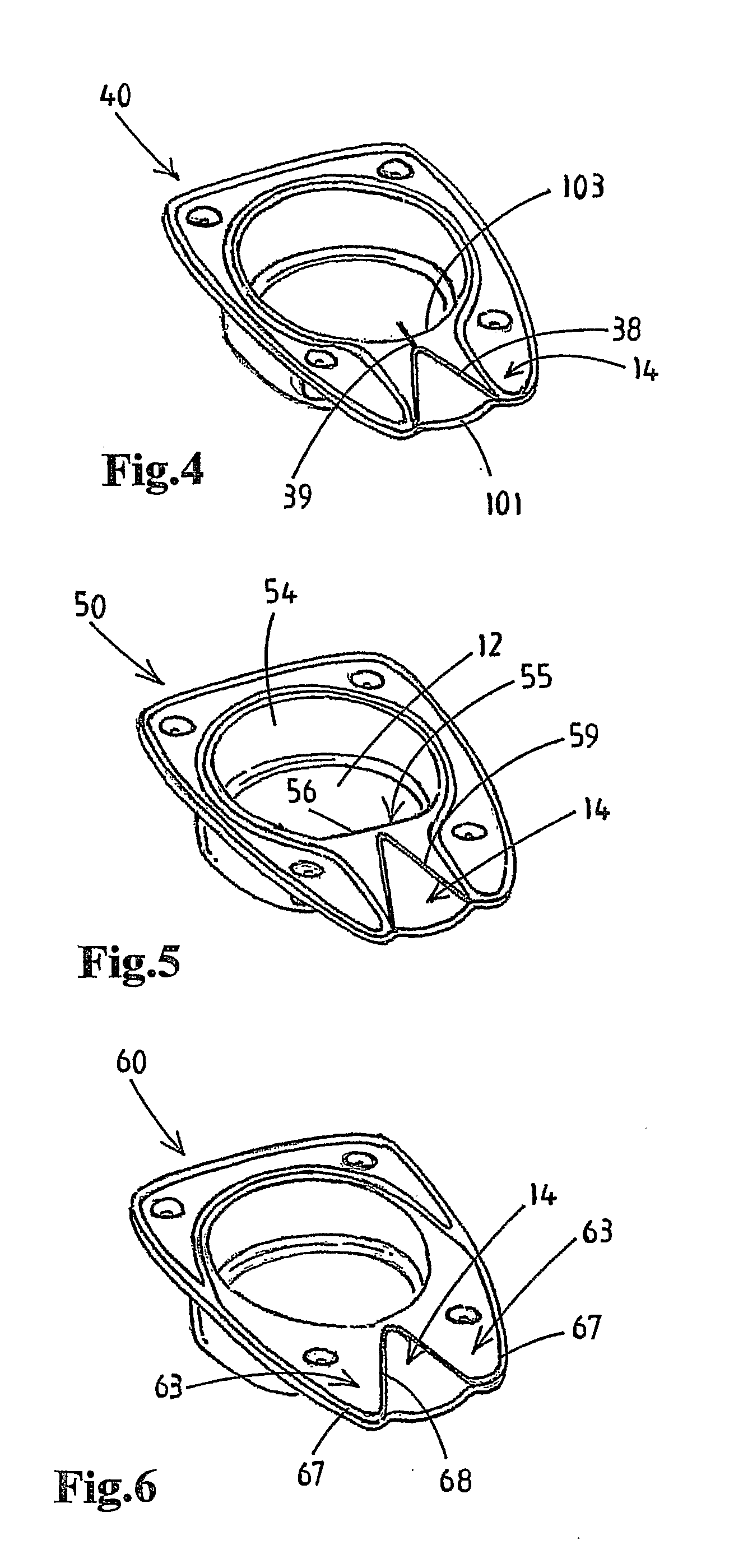

Electrosurgical apparatus having a curved distal section

InactiveUS7070596B1Reduce pressureReduced neckingDiagnosticsSurgical needlesIntervertebral discActive electrode

Apparatus and methods for advancing and retracting a medical instrument within an introducer device, wherein the instrument includes a distal tip, a distal linear portion, a first distal curve, a substantially linear inter-curve portion, and a second proximal curve. The length of the distal linear portion and the angle of the first curve determine the position of the distal tip within a lumen of the introducer device, such that the distal tip occupies a substantially central transverse location within the lumen and the distal tip avoids contact with the introducer device. The length of the inter-curve portion and the angle of the second curve determine deflection of the distal tip from a longitudinal axis of the shaft when the second curve is extended distally beyond a distal end of the introducer device. Also, methods and apparatus for treating an intervertebral disc by ablation of disc tissue. A method of the invention includes positioning at least one active electrode within the intervertebral disc, and applying at least a first high frequency voltage between the active electrode(s) and one or more return electrode(s), wherein the volume of the nucleus pulposus is decreased, pressure exerted by the nucleus pulposus on the annulus fibrosus is reduced, and discogenic pain of a patient is alleviated. In other embodiments, a curved or steerable probe is guided to a specific target site within a disc to be treated, and the disc tissue at the target site is ablated by application of at least a first high frequency voltage between the active electrode(s) and one or more return electrode(s). A method of making an electrosurgical probe is also disclosed.

Owner:ARTHROCARE

Methods and apparatus for treating intervertebral discs

InactiveUS7387625B2Reduce internal pressureReduce moistureDiagnosticsSurgical needlesIntervertebral discTreatment targets

Apparatus and methods for treating a target tissue by delivering a fluid at a defined temperature to a patient's body. An apparatus of the invention includes a fluid delivery unit for delivering fluid in at least close proximity to the target tissue, an aspiration unit for withdrawing the fluid, and a fluid source unit for providing the fluid at the defined temperature. A method of the invention includes forming a void in at least close proximity to the target tissue, and circulating a preheated fluid through the void, wherein the target tissue undergoes adjustment from body temperature to a treatment temperature due to heat exchange between the fluid and the target tissue.

Owner:ARTHROCARE

Apparatus and methods for treating cervical inter-vertebral discs

InactiveUS7393351B2Reduce the overall diameterAvoid arcingCannulasEnemata/irrigatorsMedicineActive electrode

Apparatus and methods for treating an inter-vertebral disc by ablation, coagulation, shrinking, stiffening, or other treatment of disc tissue. A method of the invention includes positioning at least one active electrode within the inter-vertebral disc, and applying at least a first high frequency voltage between the active electrode(s) and one or more return electrode(s), wherein the volume of the nucleus pulposus is decreased, pressure exerted by the nucleus pulposus on the annulus fibrosus is reduced, and discogenic pain of a patient is alleviated. An apparatus of the invention includes an electrosurgical probe, an introducer needle adapted for passing the distal end of the probe therethrough, and a positioning unit for monitoring a position of the probe in relation to the introducer needle.

Owner:ARTHROCARE

Battery electrolytic solution with fluoride-ion-dissociating salt and battery using the same

InactiveUS6306540B1Improve stabilityAvoid conductivitySolid electrolyte cellsLi-accumulatorsSupporting electrolyteDecomposition

The present invention relates to an electrolytic solution excellent in stability, and also relates to a battery excellent in battery performance and having an outer structure having light weight. The electrolytic solution contains a supporting electrolyte and a gas formation inhibitor in the solvent. The gas formation inhibitor contains a decomposition product of the supporting electrolyte with formation of a gas in the solvent. It functions as controlling to solution equilibrium in the electrolytic solution participating in decomposition reaction of the supporting electrolyte. A battery is obtained by filling the electrolytic solution between a positive electrode and a negative electrode.

Owner:MITSUBISHI ELECTRIC CORP

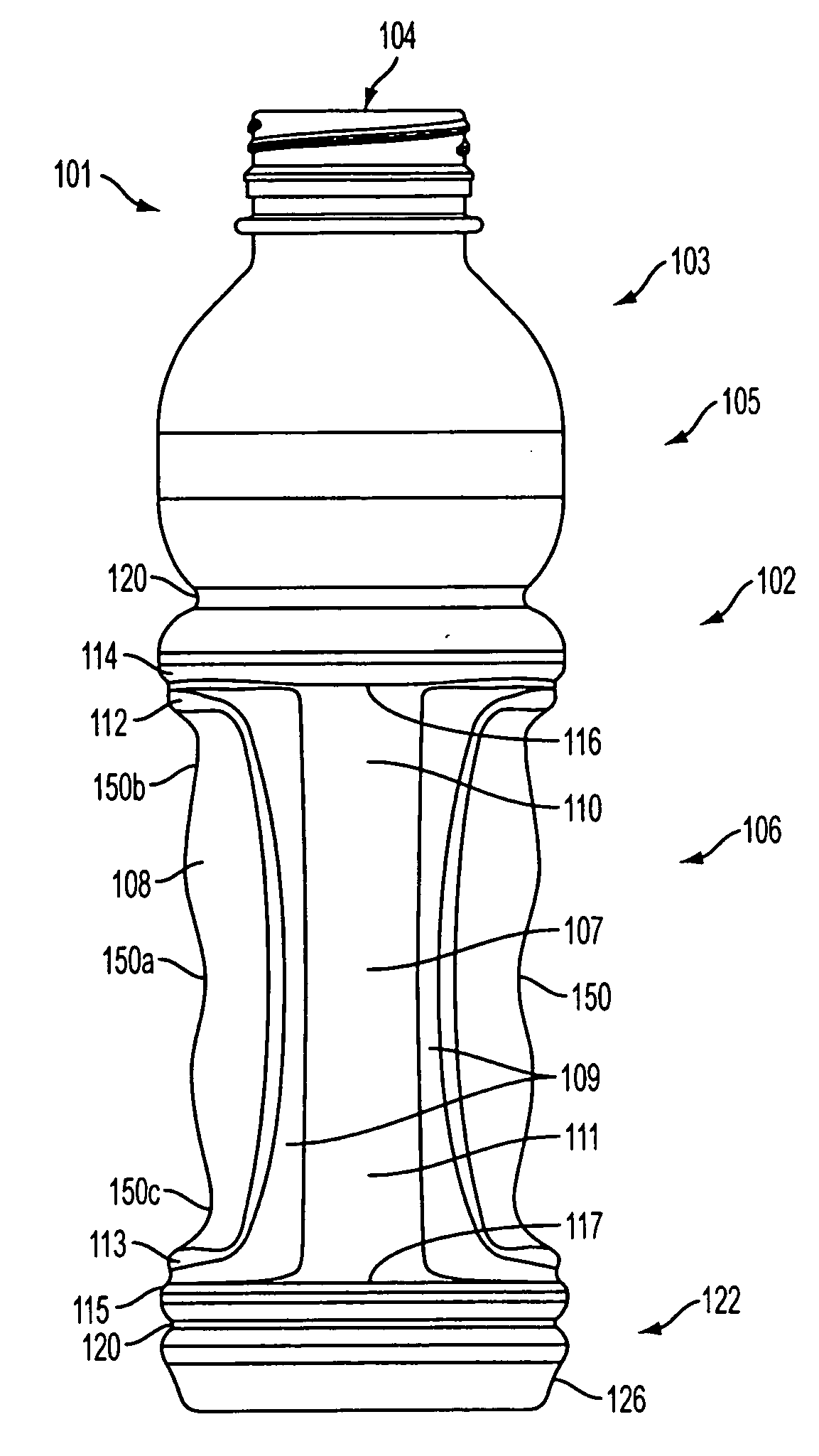

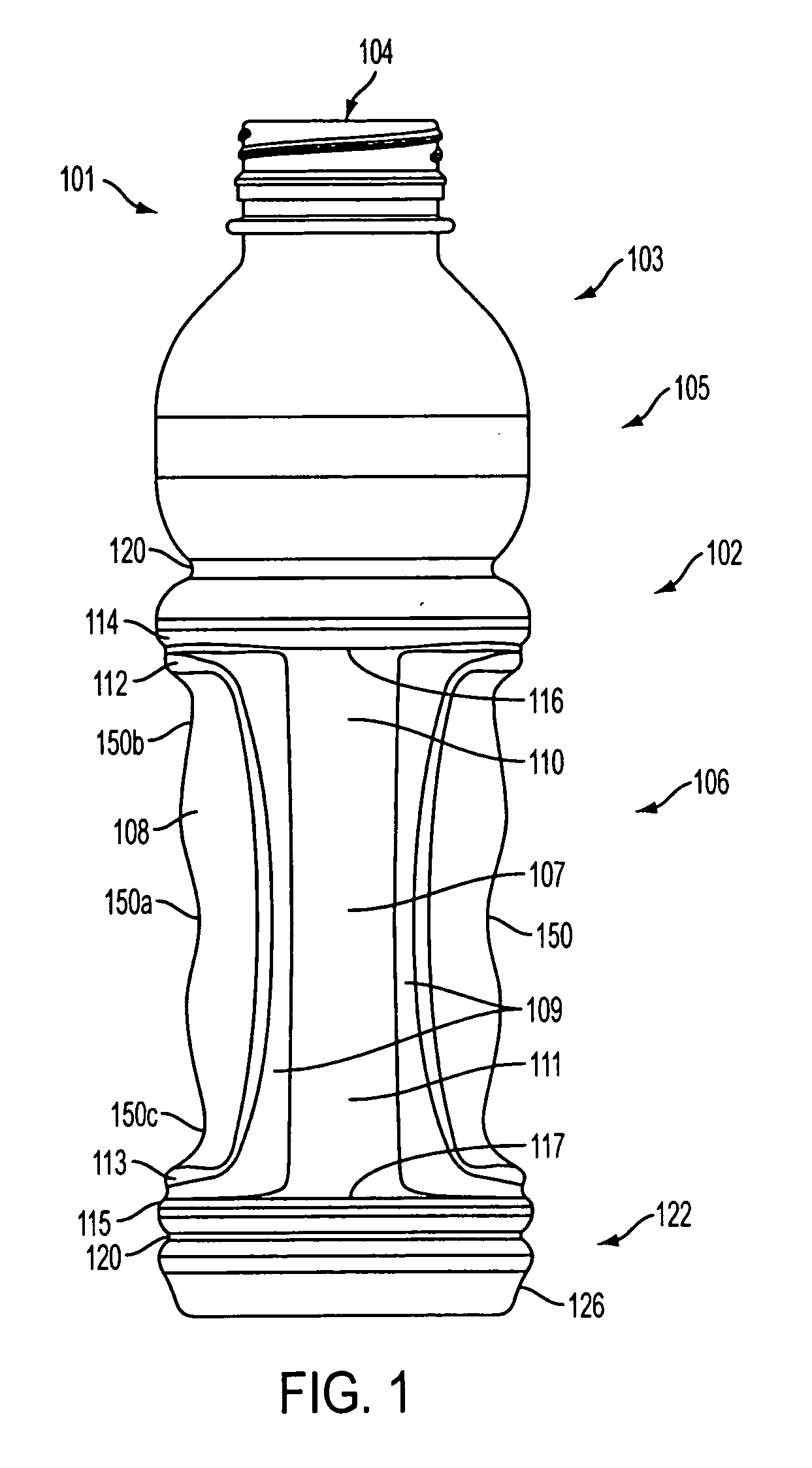

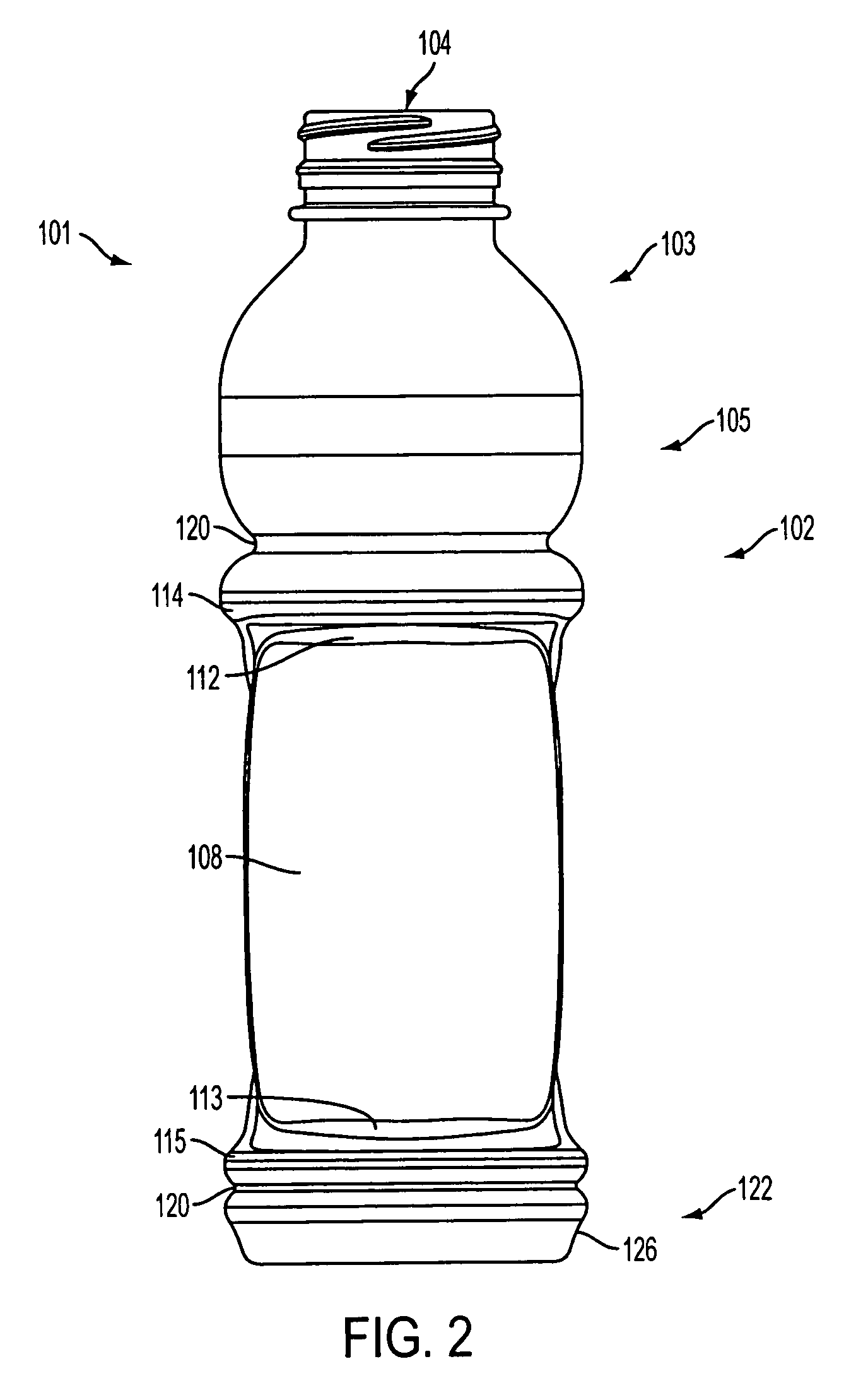

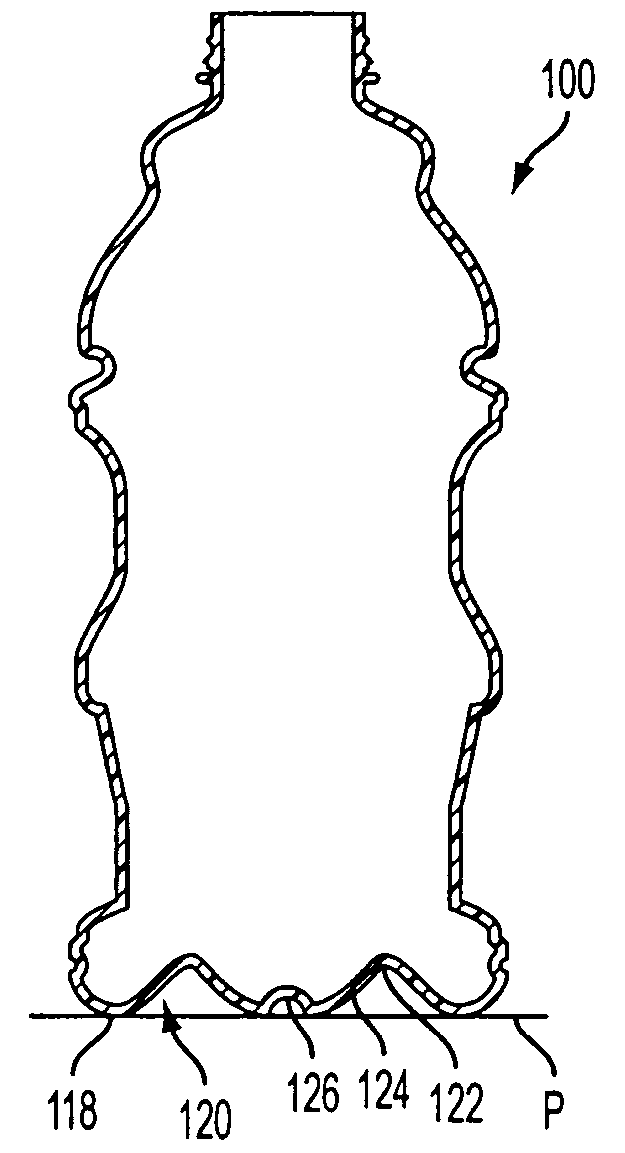

Squeezable multi-panel plastic container

ActiveUS20070090083A1Resistant to damageReduce impactLarge containersRigid containersDistortionSurface plate

The present invention relates to a plastic container comprising two substantially smooth opposing squeezable panels, separated by a vacuum panel and having at least one arcuate indentation adapted to allow flexure of the respective panel without permanent distortion or creasing when a force is applied to the panel toward the container interior.

Owner:MELROSE DAVID MURRAY

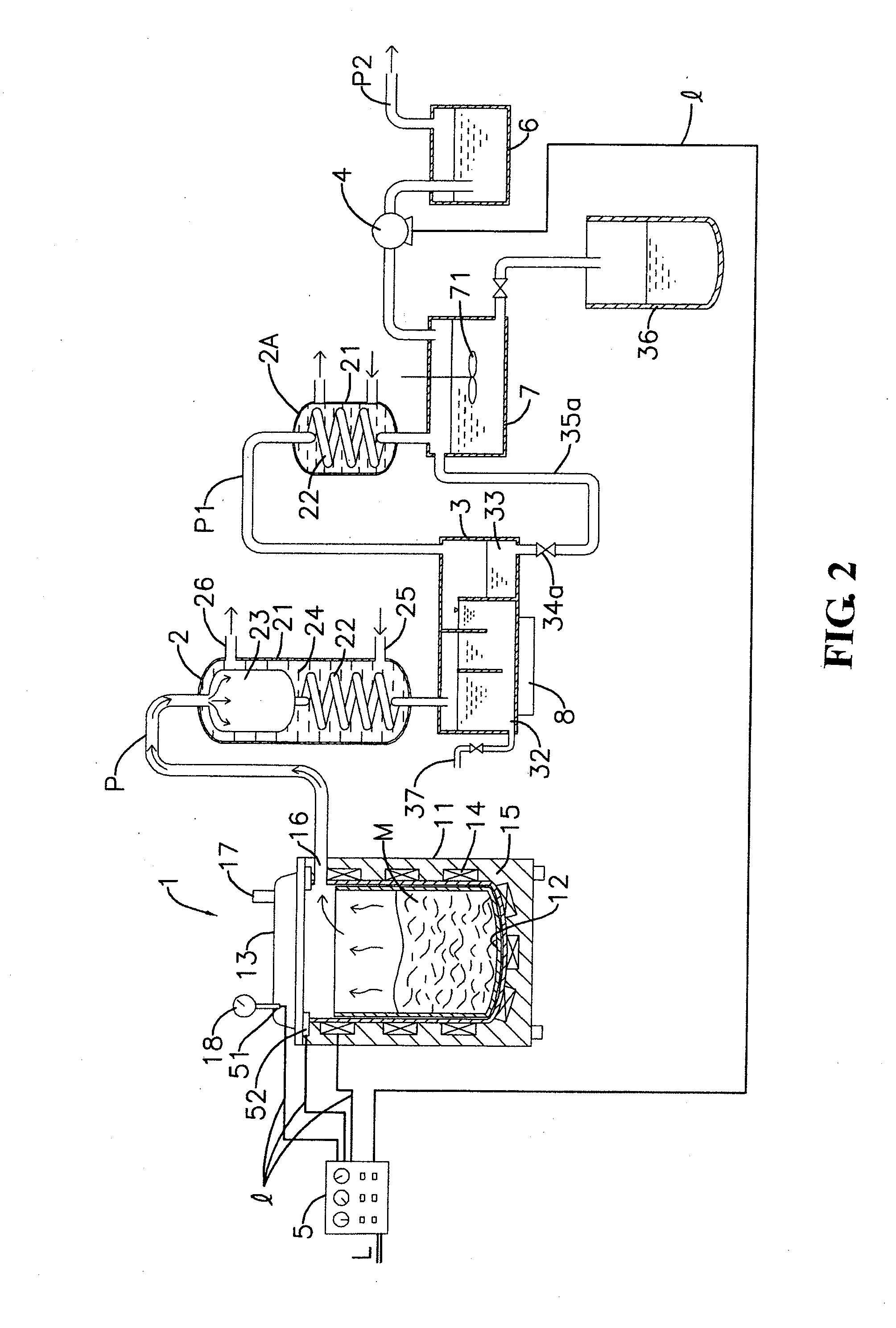

Vacuum pumping of conductor-in-conduit heaters

InactiveUS20050269092A1Reducing pressure insideReduce pressureInsulationFluid removalVacuum pumpingVapour pressure of water

Certain embodiments provide a method that includes placing a heater element in an opening in a subsurface formation. The heater element is in a conduit. A pressure is reduced inside the conduit to a pressure below the vapor pressure of water at the temperature in the conduit.

Owner:SHELL OIL CO

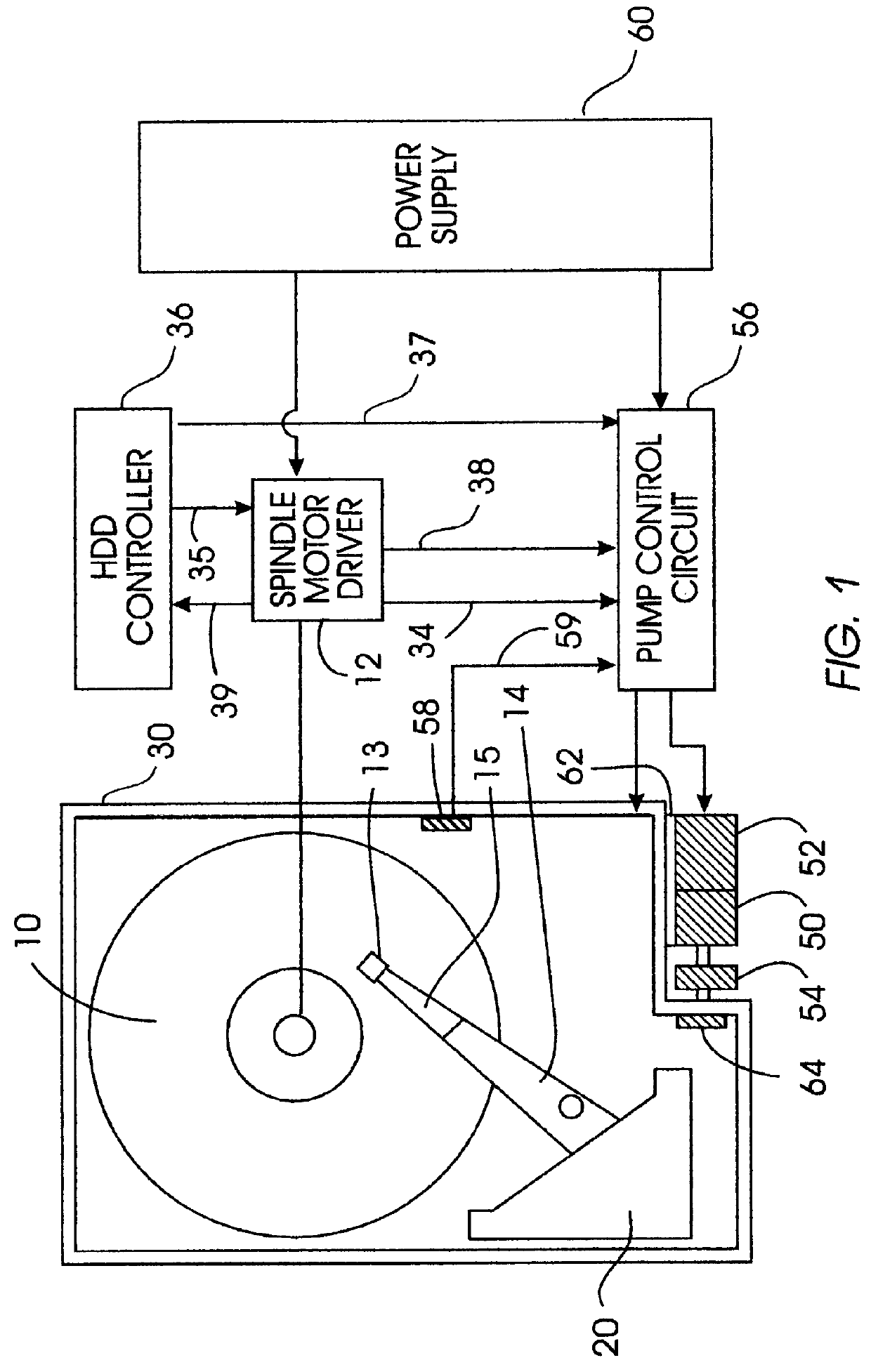

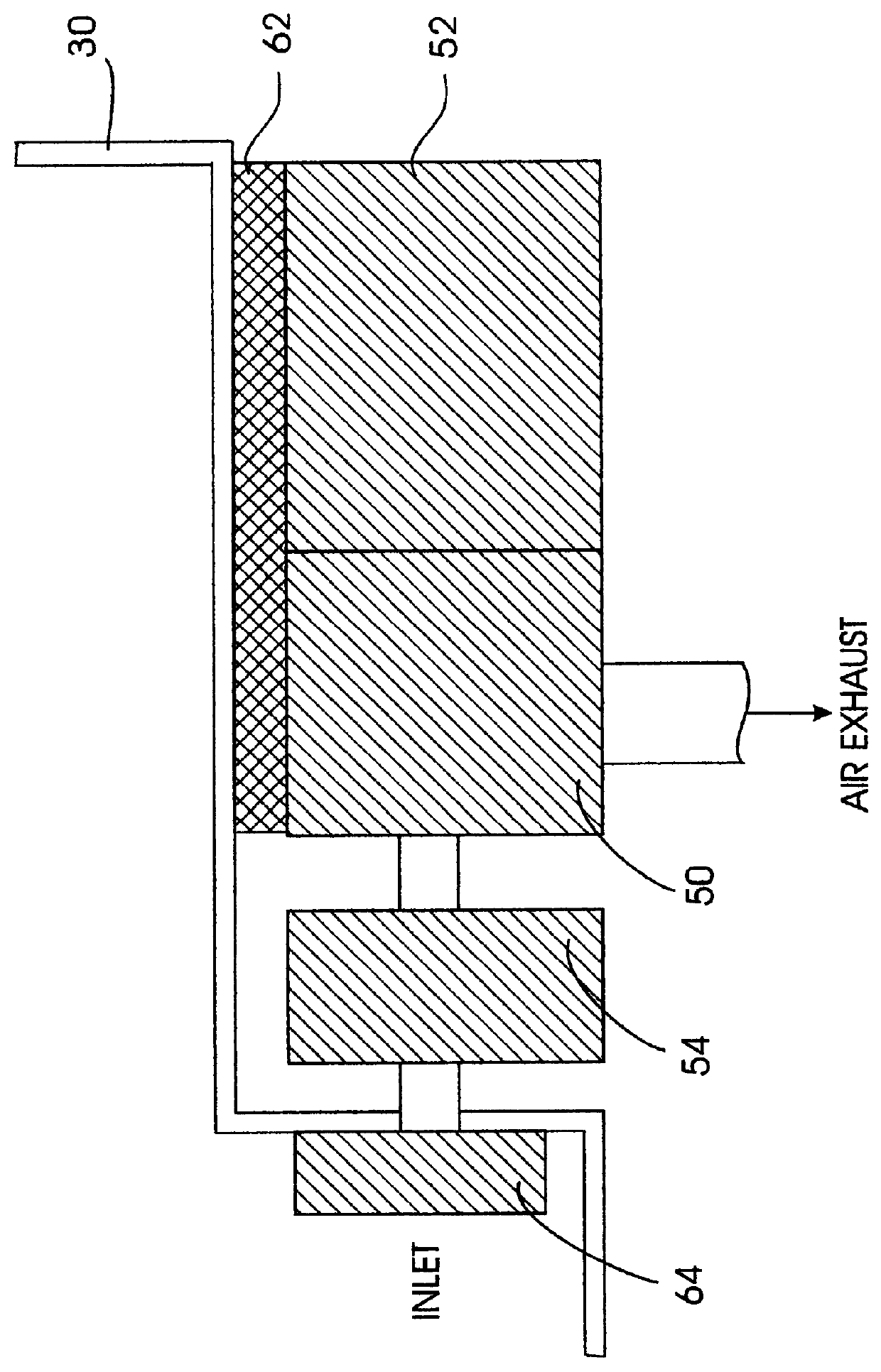

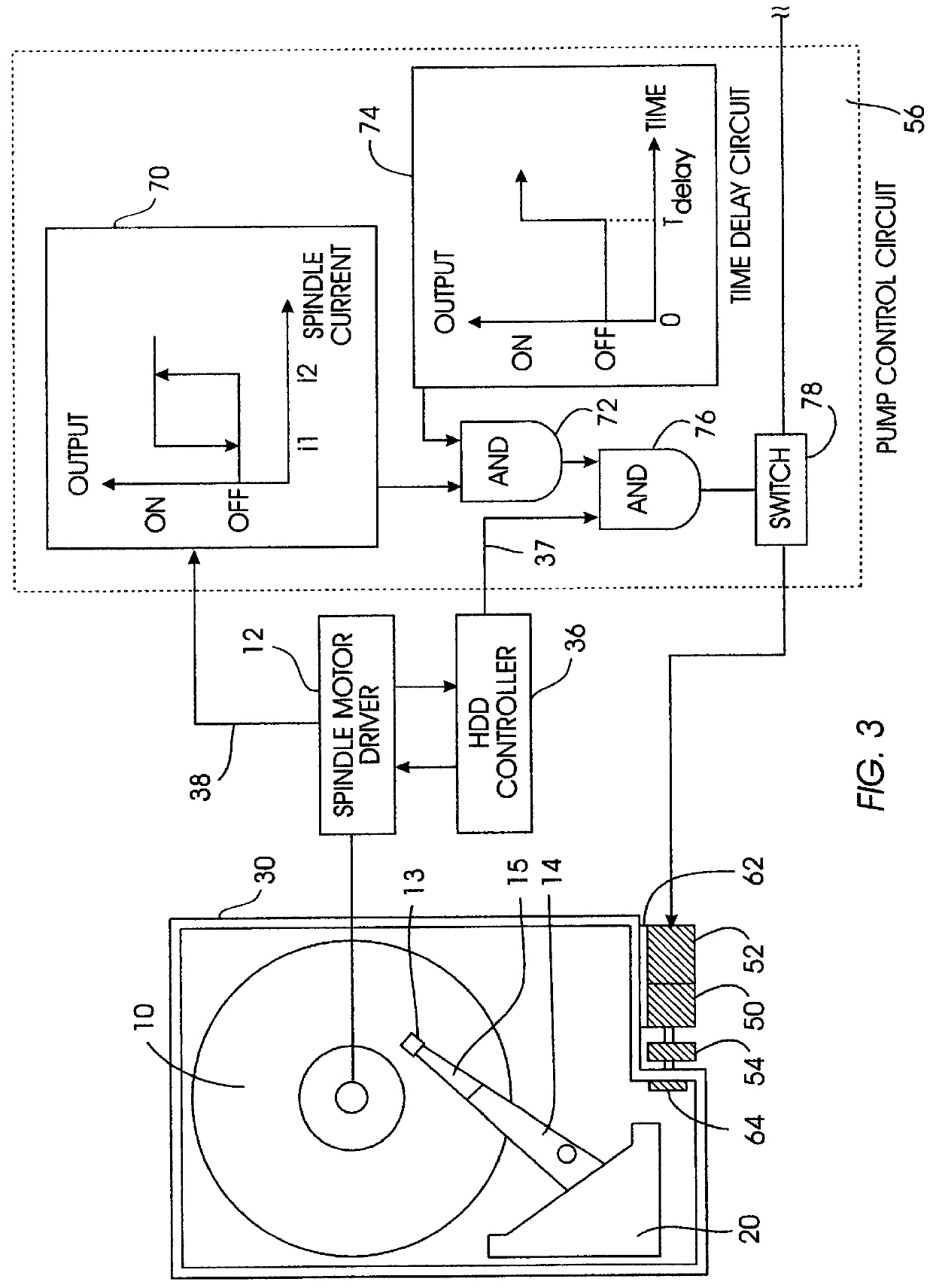

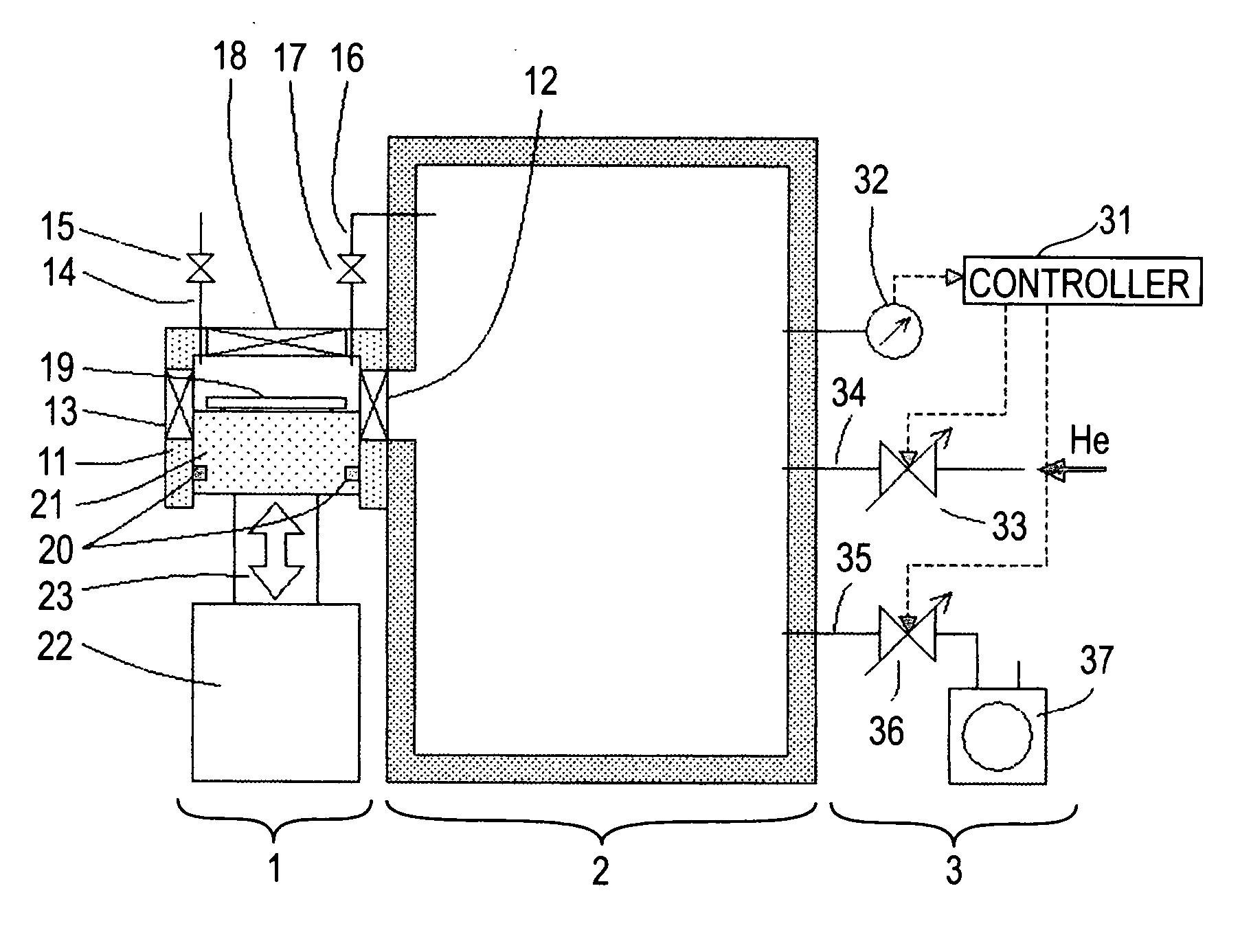

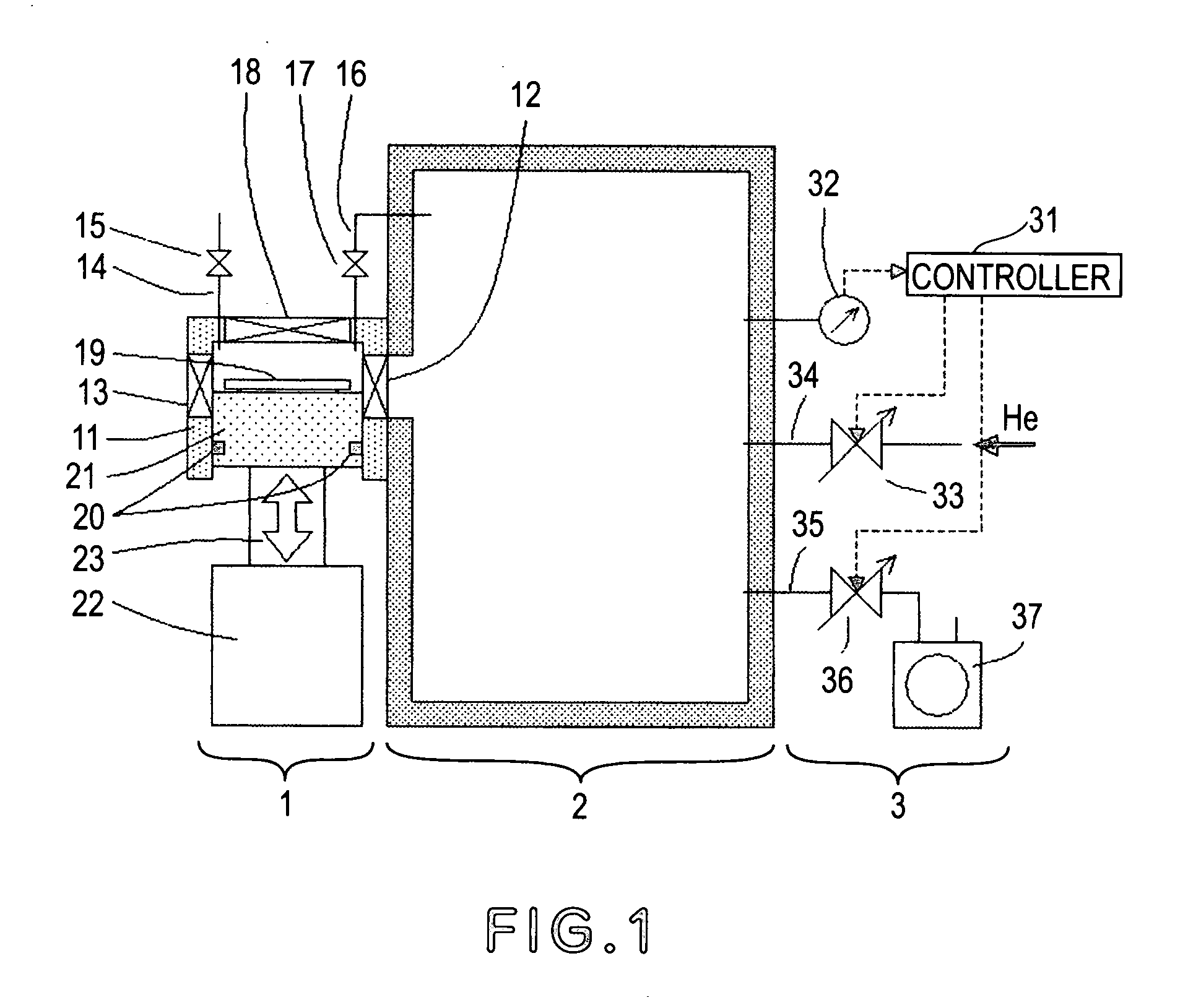

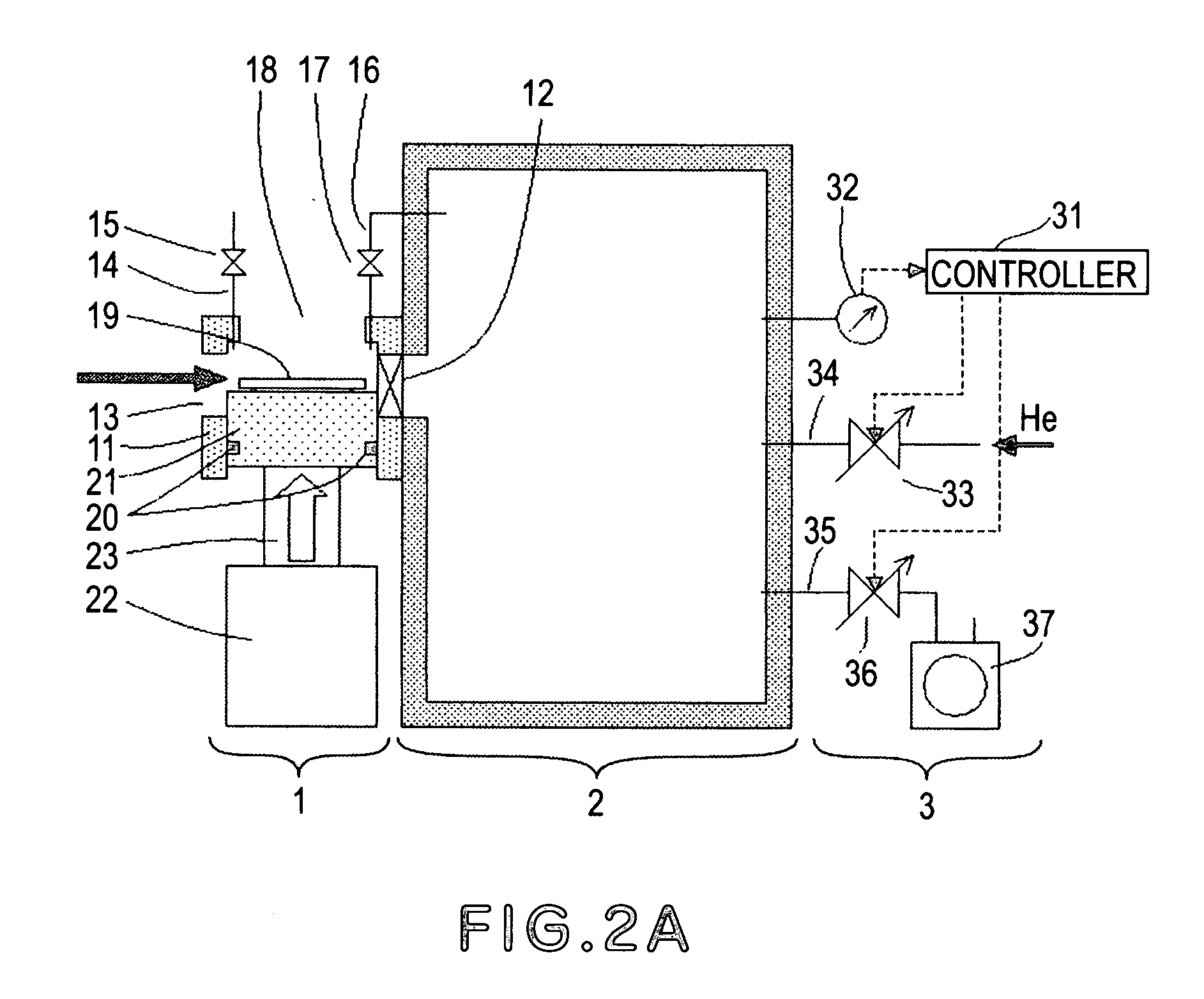

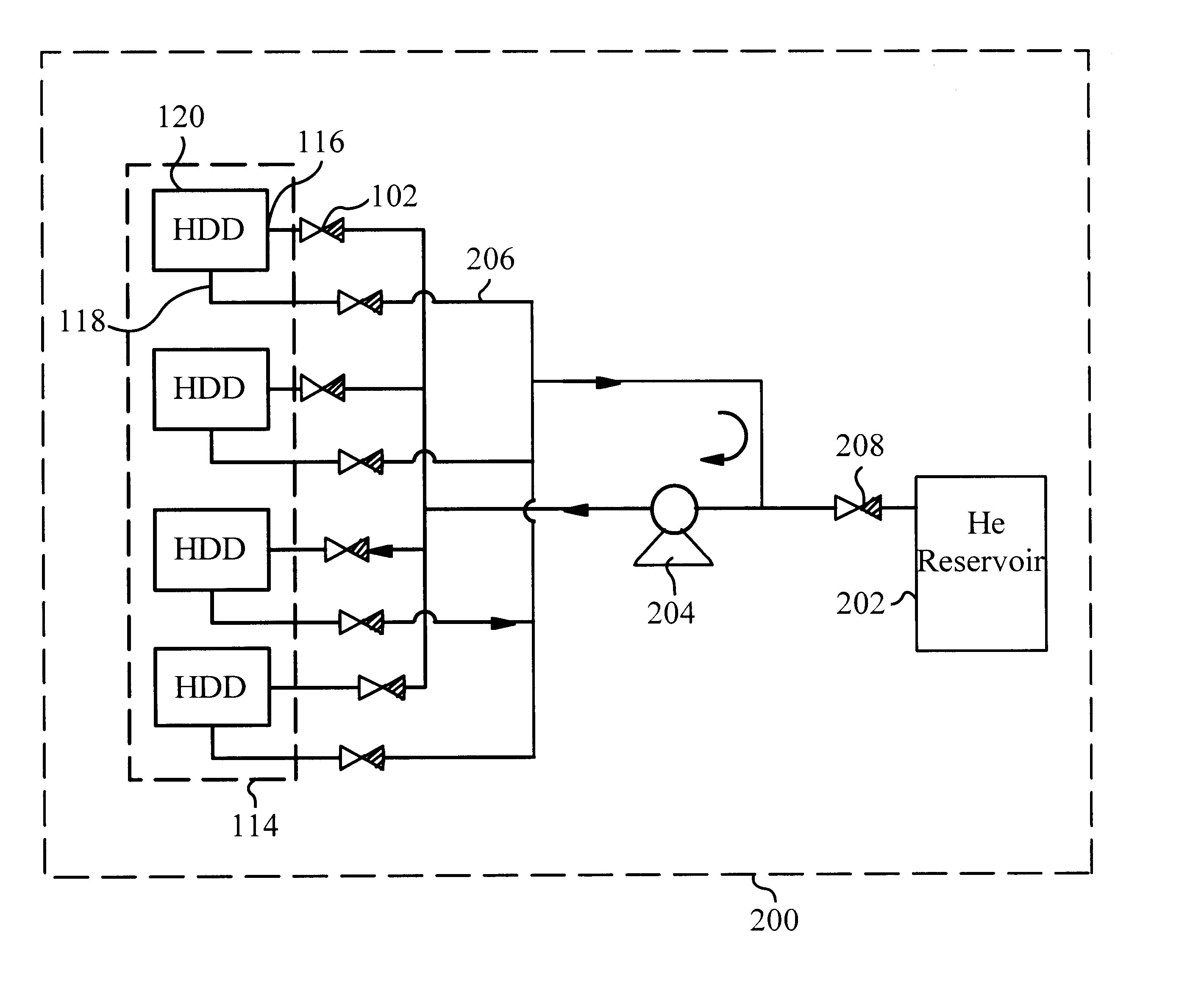

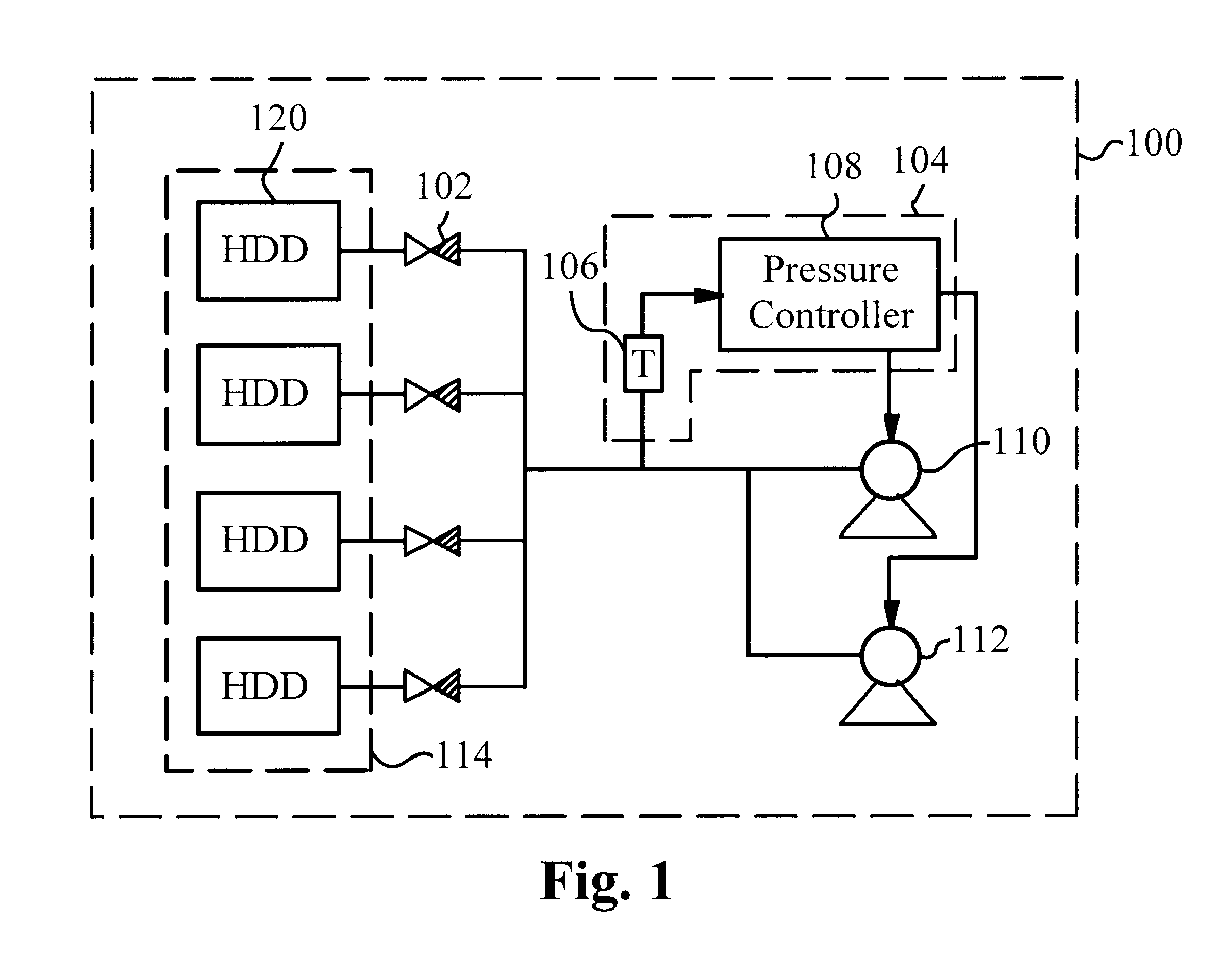

Disk drive with controlled reduced internal pressure

InactiveUS6144178AReduce internal pressureIncrease speedDC motor speed/torque controlElectrical testingInternal pressureElectric machine

A rigid magnetic recording disk drive includes a vacuum pump attached to the disk drive housing for removing air from within the housing so that the disk drive is operated at a reduced internal gas pressure. The pump motor is controlled by control circuitry that receives an input signal representative of the pressure within the housing to enable the pressure to be maintained within a predetermined reduced pressure range. Because spindle motor current has been directly correlated with internal pressure, a signal representative of the spindle motor current is used as the input to the pump control circuitry. The pump control circuitry also prevents the pump from turning on until the spindle motor has reached its stable operating speed, and from turning on when the disk drive is reading or writing data. Because of the reduced internal pressure the disk drive operates at a significantly higher disk RPM with only a minimal increase in power consumption and without any increase in track misregistration.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Method for handling a hot-filled container having a moveable portion to reduce a portion of a vacuum created therein

Systems and methods for vacuum compensation in hot-filled and cooled containers. Each container reduces, via one or more vacuum panels, a first portion of a vacuum created in the container. Each container also has a repositionable portion to reduce a second portion of the vacuum. During hot-filling, no portion of the repositionable portion extends below a standing or bearing surface of the container.

Owner:CO2 PAC

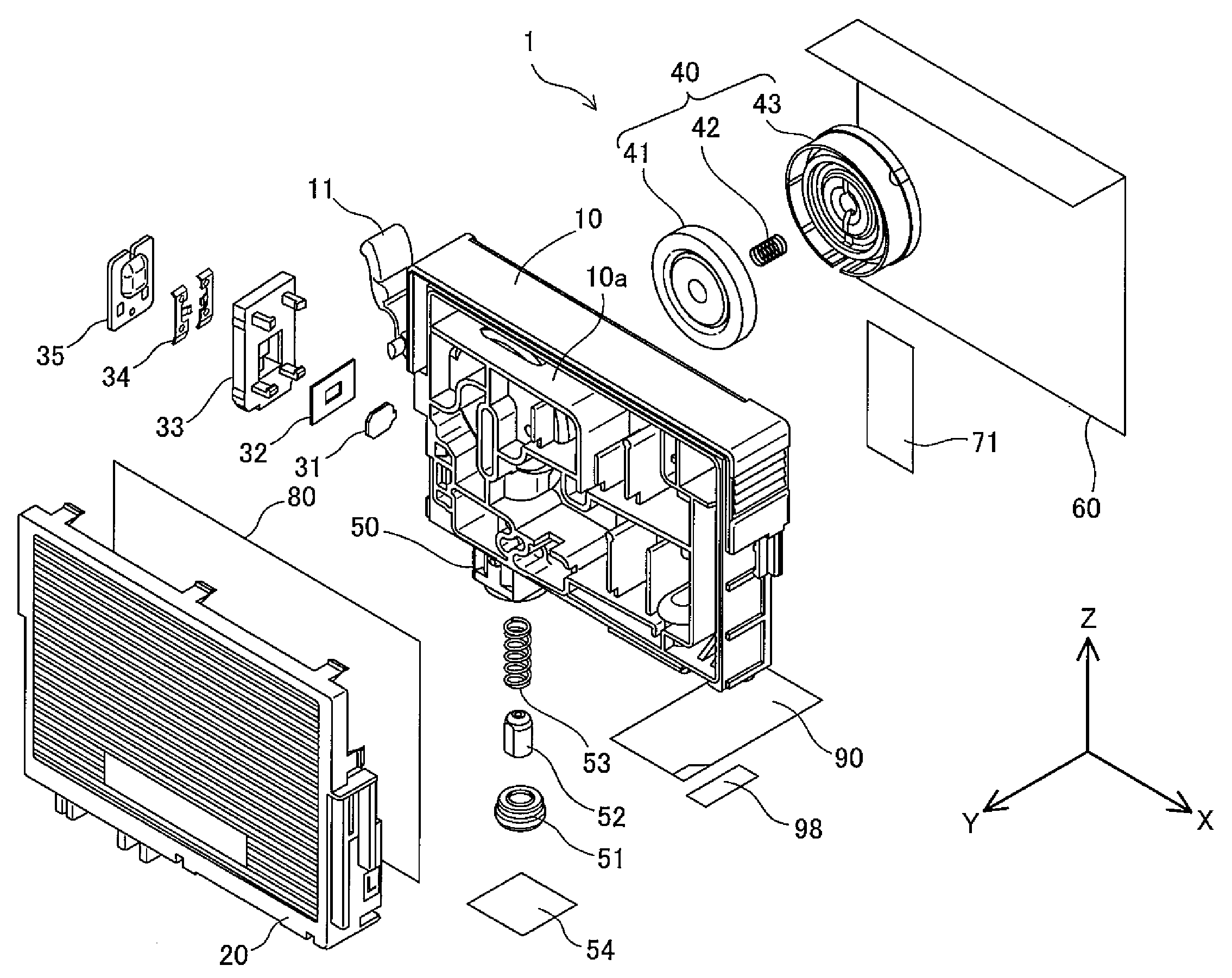

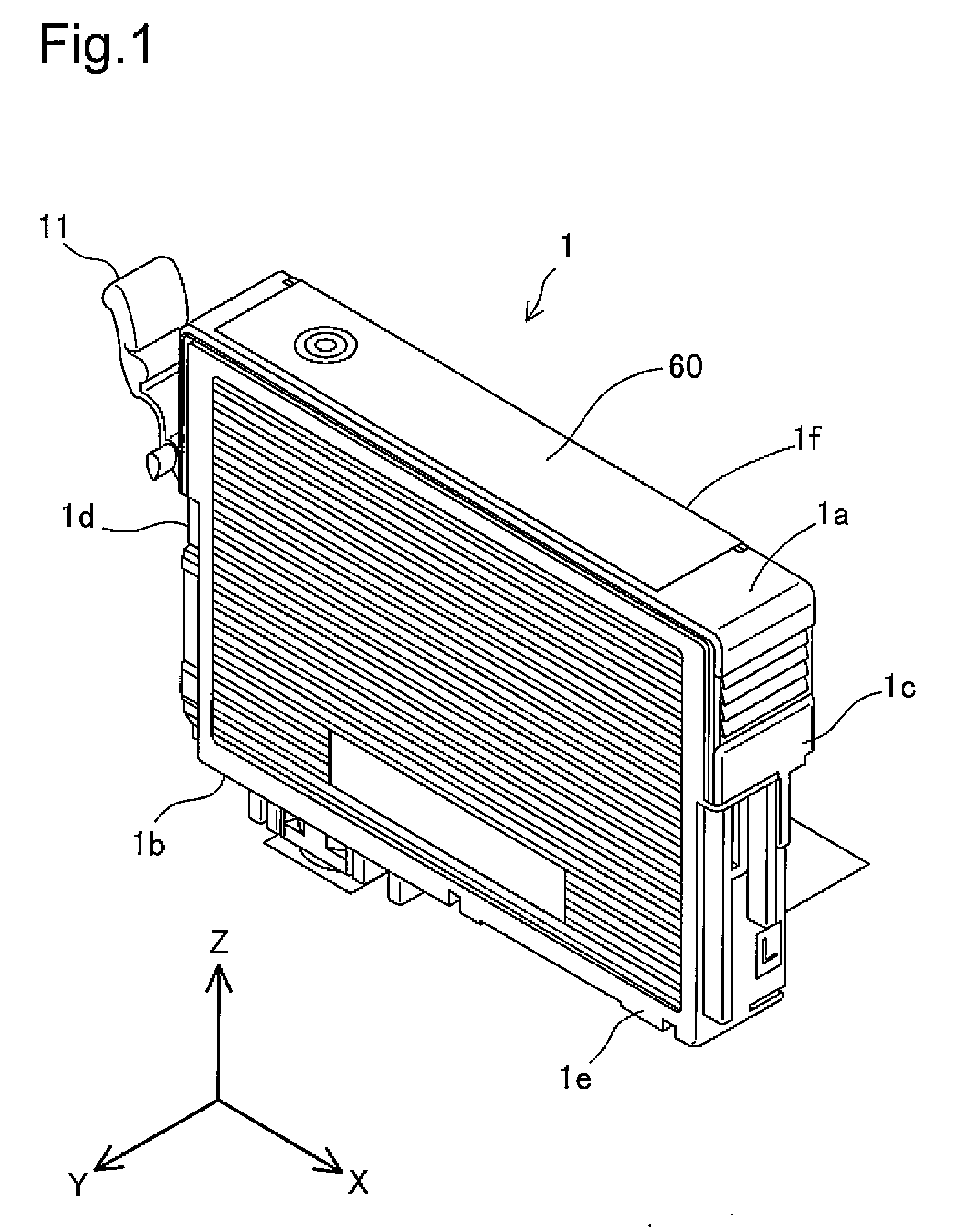

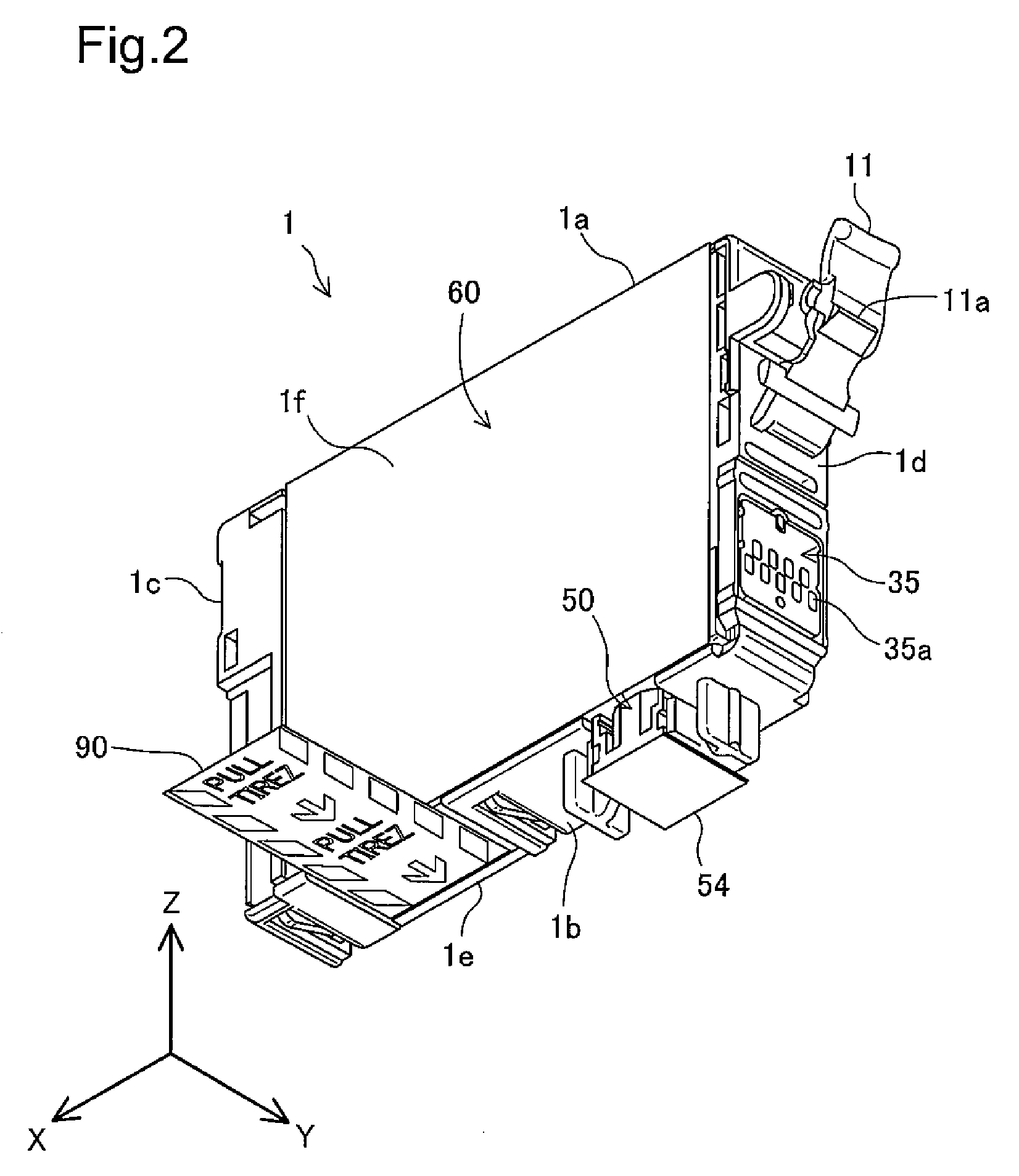

Liquid container and remanufacturing method of liquid container

ActiveUS20090322838A1Increase resistanceIncrease capacityWriting implementsMetal-working apparatusOpen structure

According to one aspect of the invention, a remanufacturing method of a liquid container forms an inlet in a downstream wall surface of a second chamber, which defines part of a bottom face of the liquid container. In the state of closing a liquid feeder and opening an air open structure, the remanufacturing method injects a liquid through the inlet to fill the second chamber with the liquid. In the state of opening the liquid feeder and closing the air open structure, the remanufacturing method injects the liquid through the inlet to fill a space from the second chamber to the liquid feeder with the liquid. The remanufacturing process seals the inlet after completion of the injection of the liquid. This arrangement enables the liquid to be efficiently refilled into the liquid container without damaging the functions of the liquid container.

Owner:SEIKO EPSON CORP

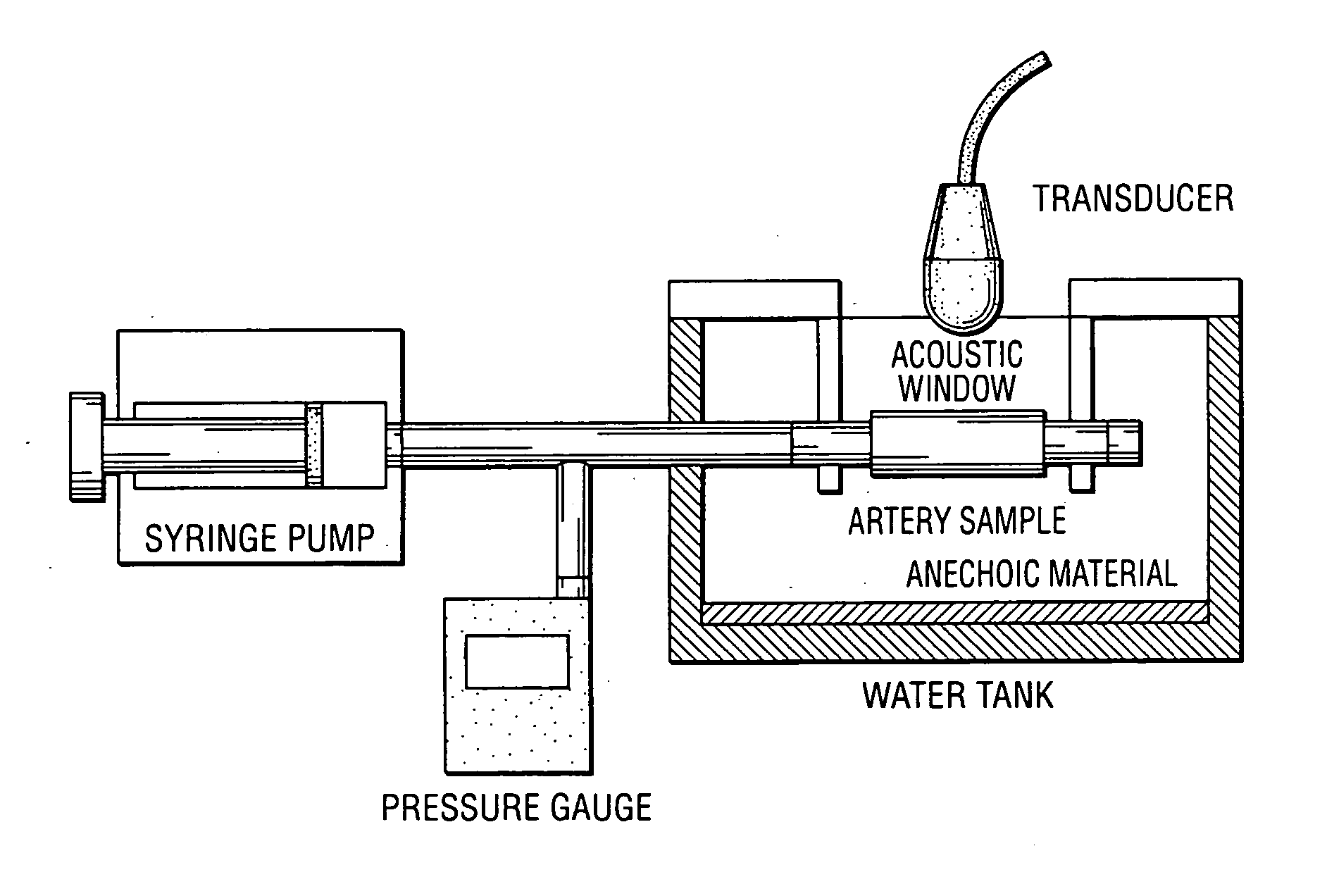

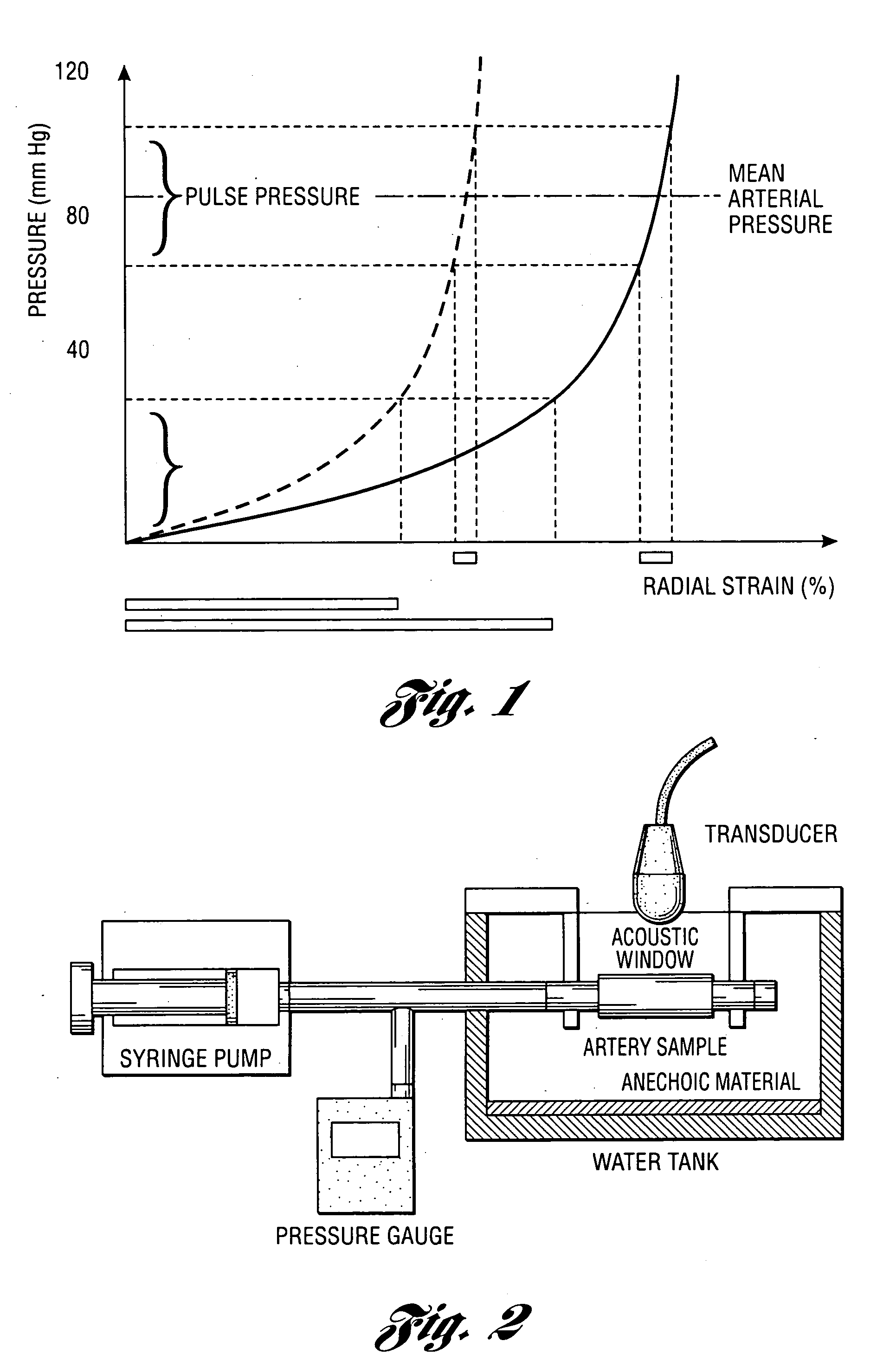

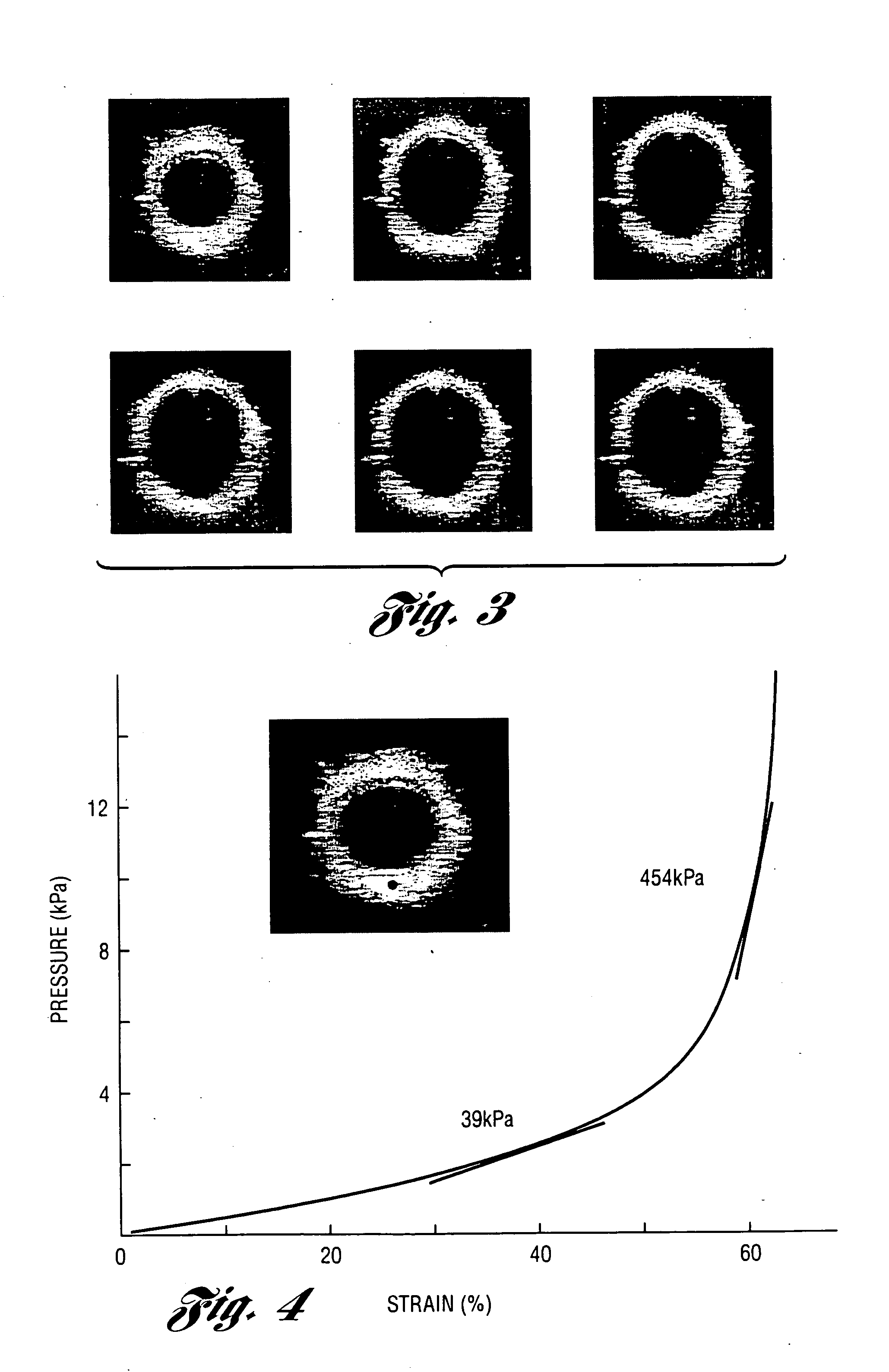

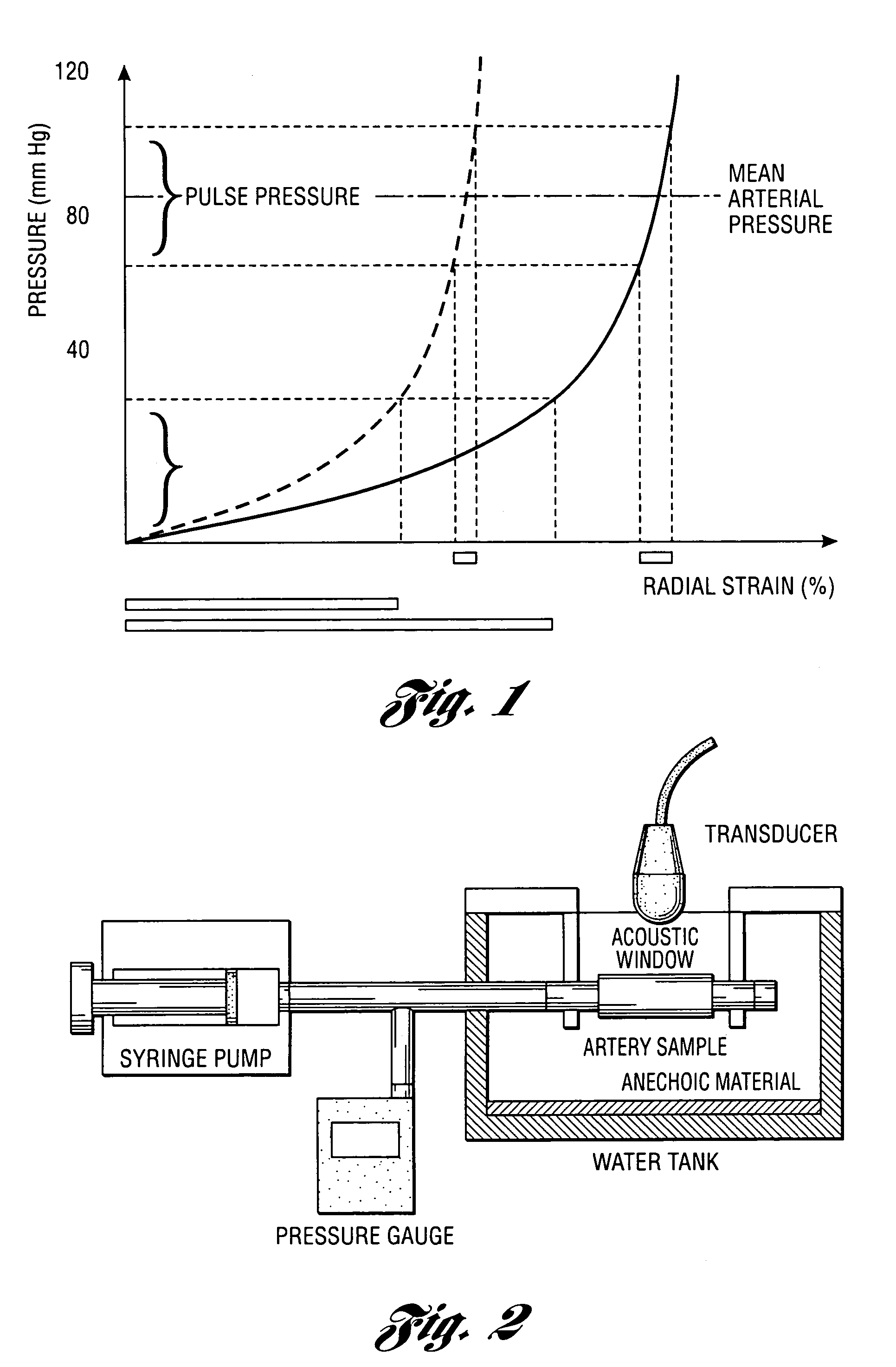

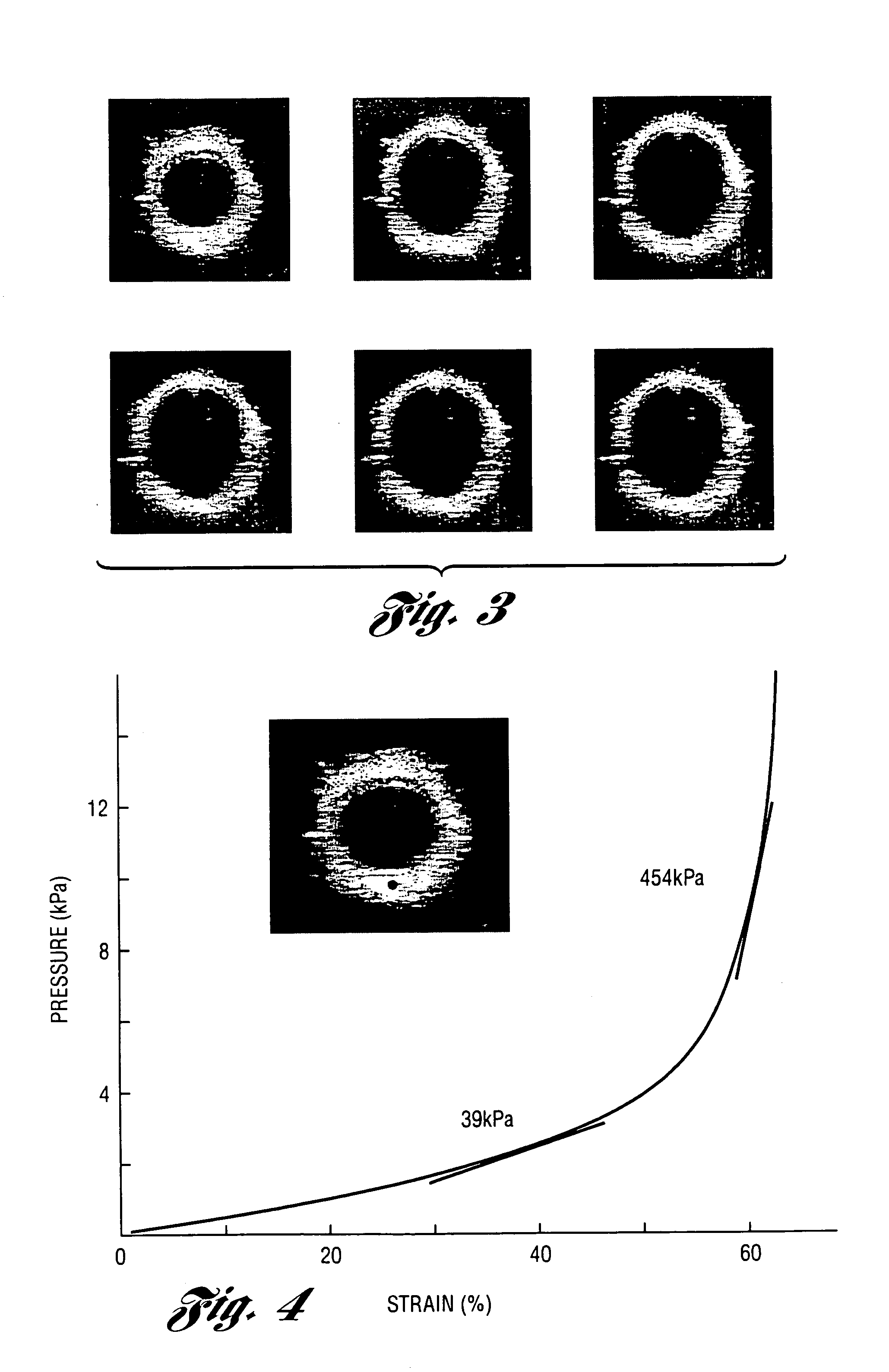

Methods and systems for measuring mechanical property of a vascular wall and method and system for determining health of a vascular structure

InactiveUS20050124892A1Reduce internal pressureBlood flow measurement devicesOrgan movement/changes detectionCardiac cyclePhase sensitive

Methods and systems for measuring mechanical property of a vascular wall and a method and system for determining health of a vascular structure are provided wherein local deformation of a vessel wall resulting from physiologic pressures with altered transmural forces is measured. A non-invasive free-hand ultrasound scanning-procedure was performed to apply external force, comparable to the force generated in measuring a subject's blood pressure, to achieve higher strains by equalizing the internal arterial baseline pressure. When the applied pressure matched the internal baseline diastolic pressure, strain and strain rate increased by a factor of 10 over a cardiac cycle. Radial arterial strain was assessed in the vessel wall over the entire deformation procedure using a phase-sensitive, two-dimensional speckle-tracking algorithm. An elastic modulus reconstruction procedure was developed to estimate the non-linear elastic properties of the vascular wall.

Owner:RGT UNIV OF MICHIGAN

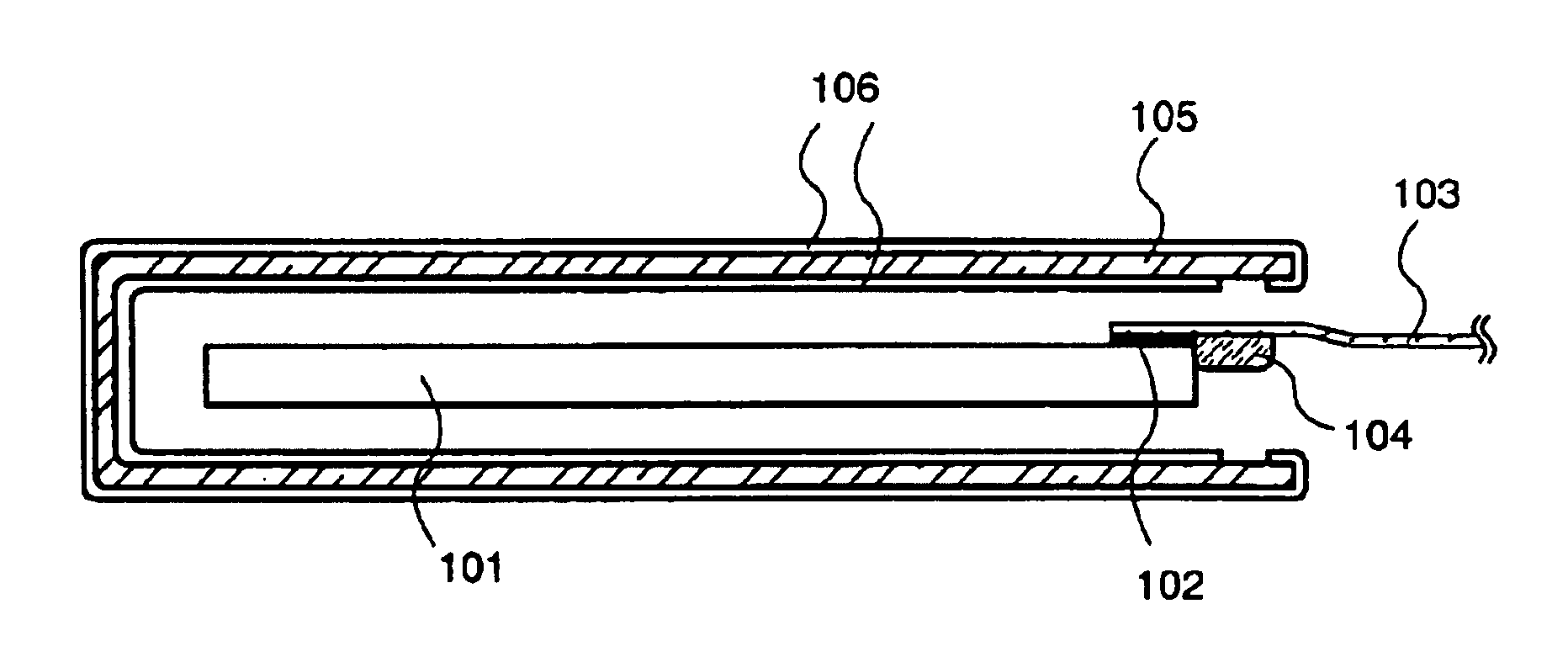

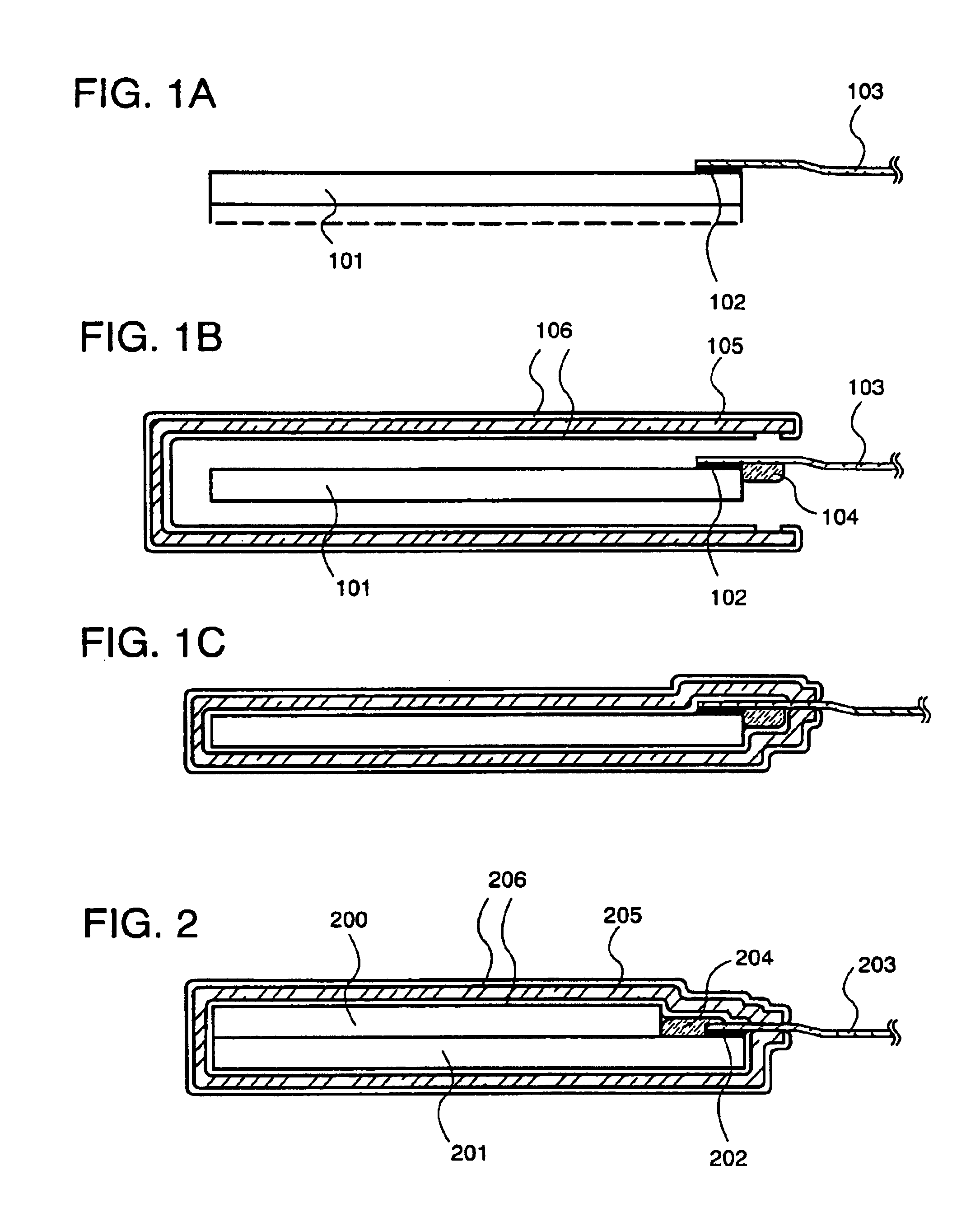

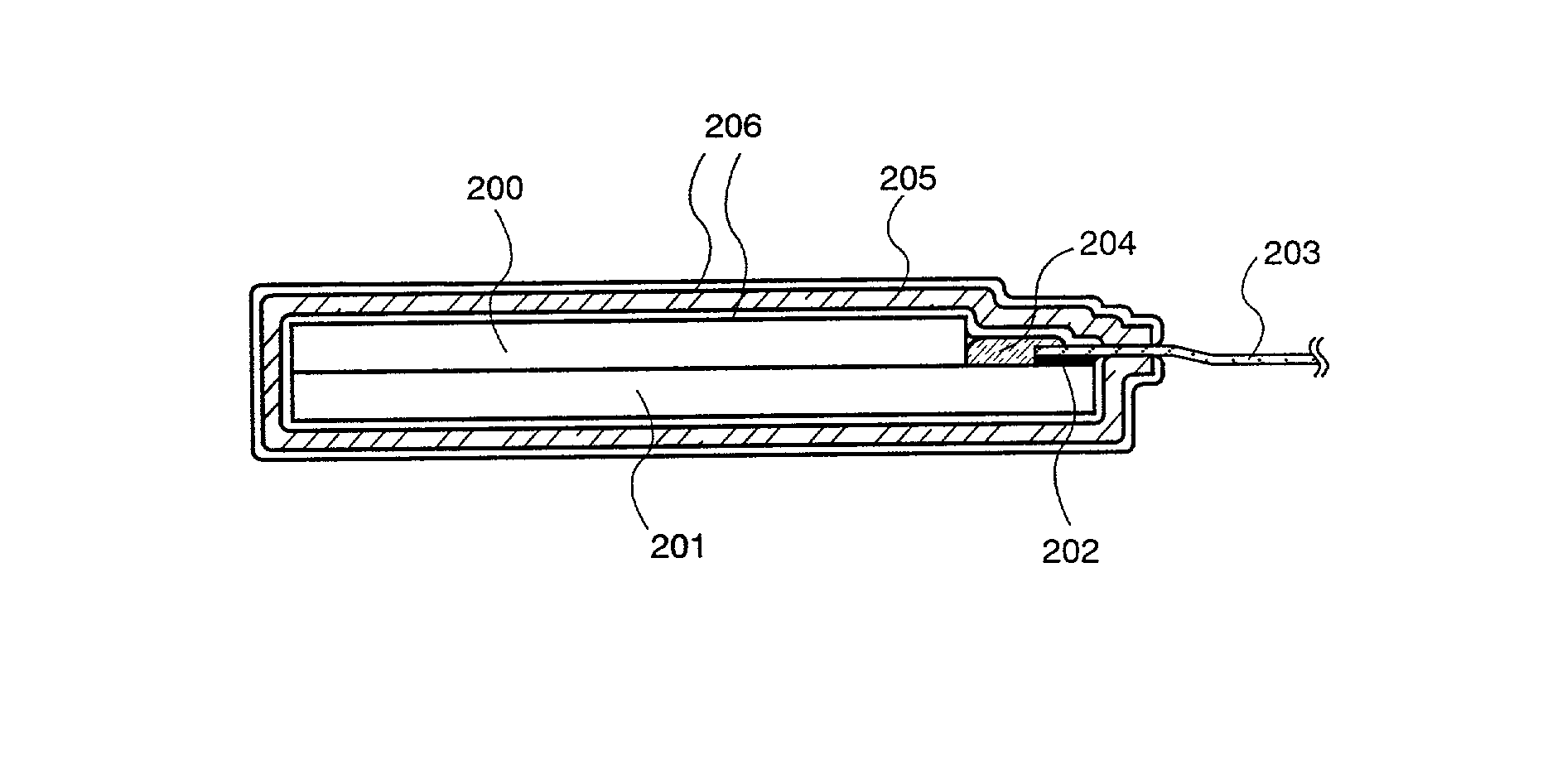

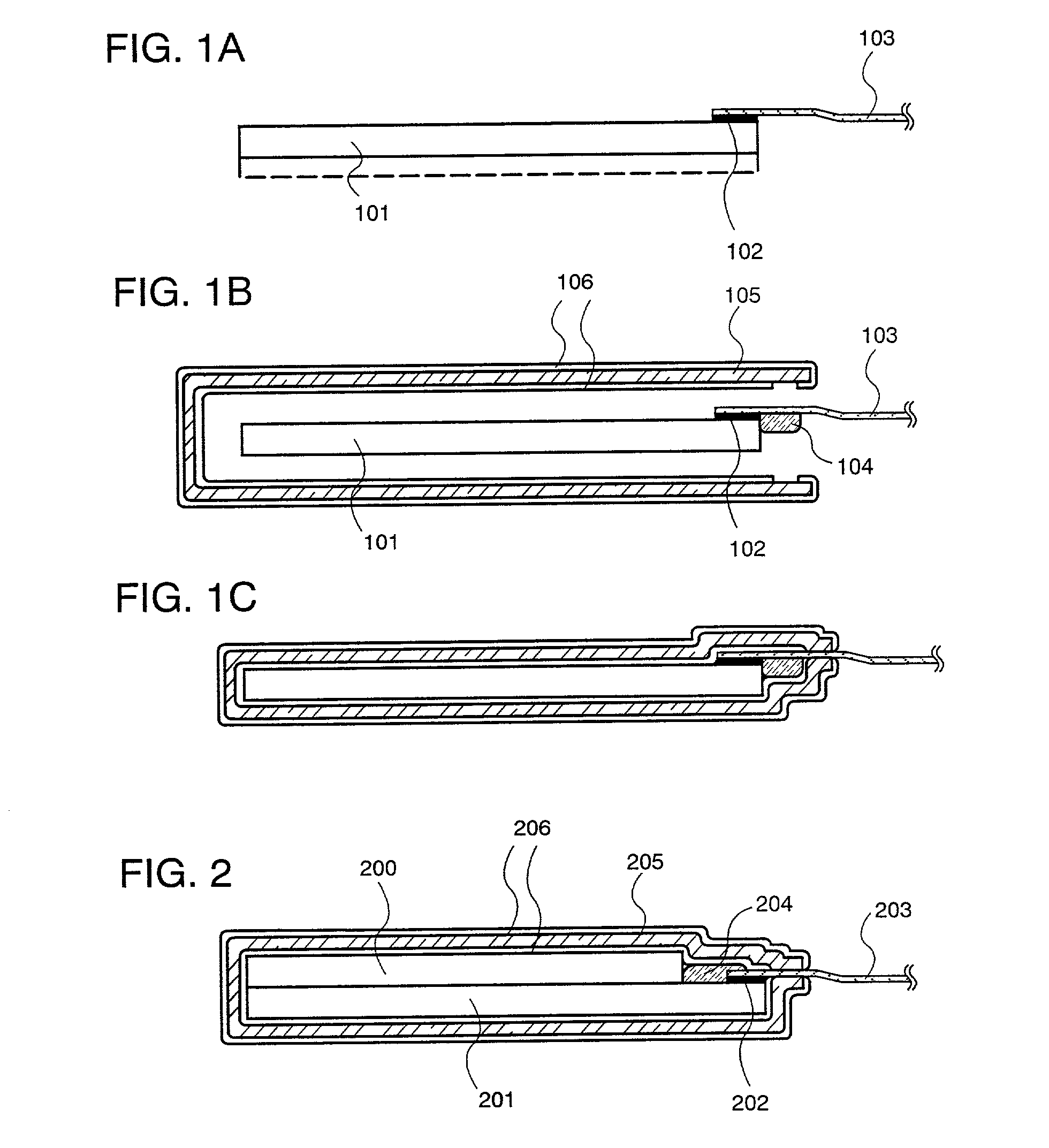

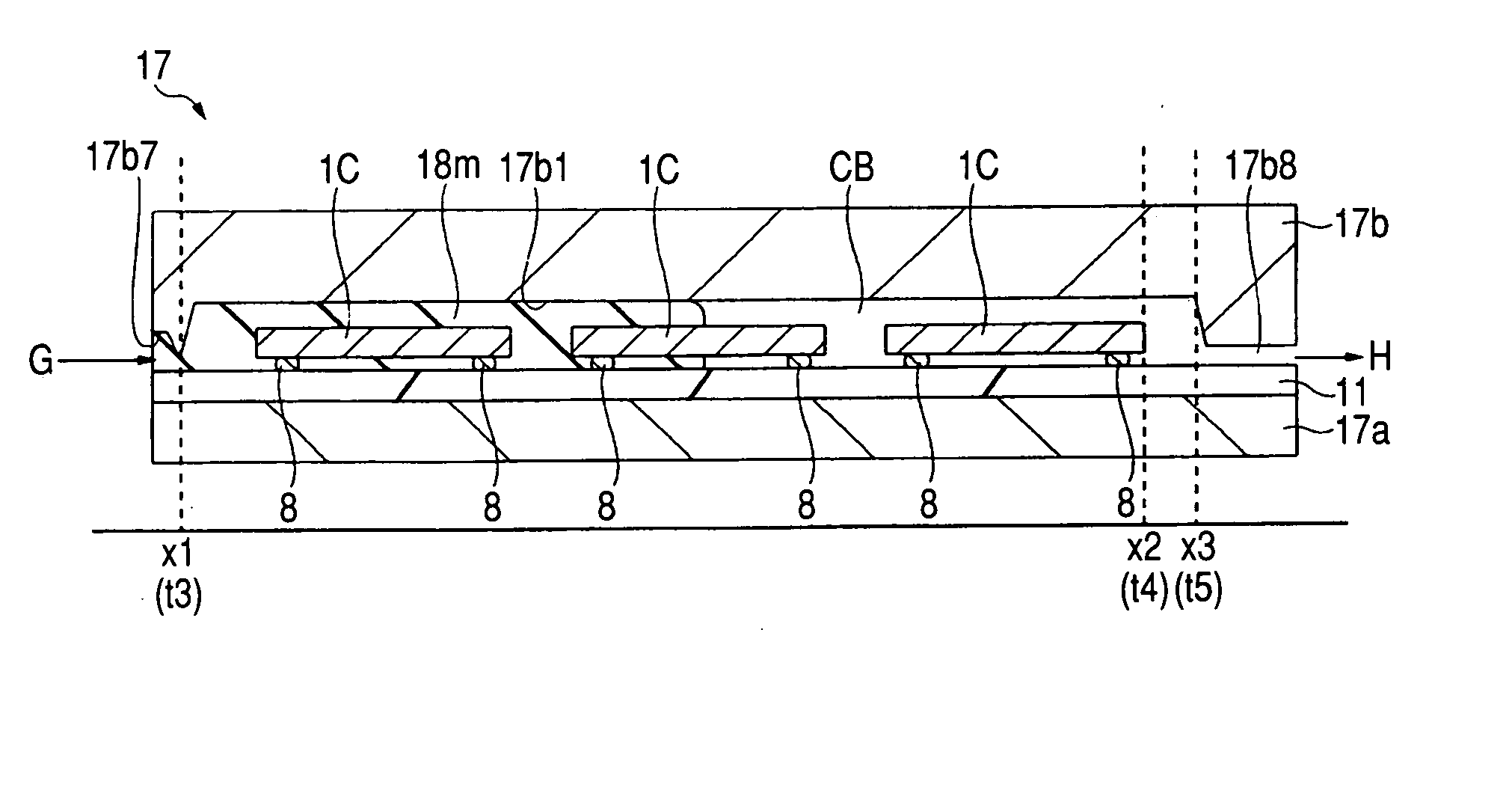

Light emitting device, electronic equipment, and method of manufacturing thereof

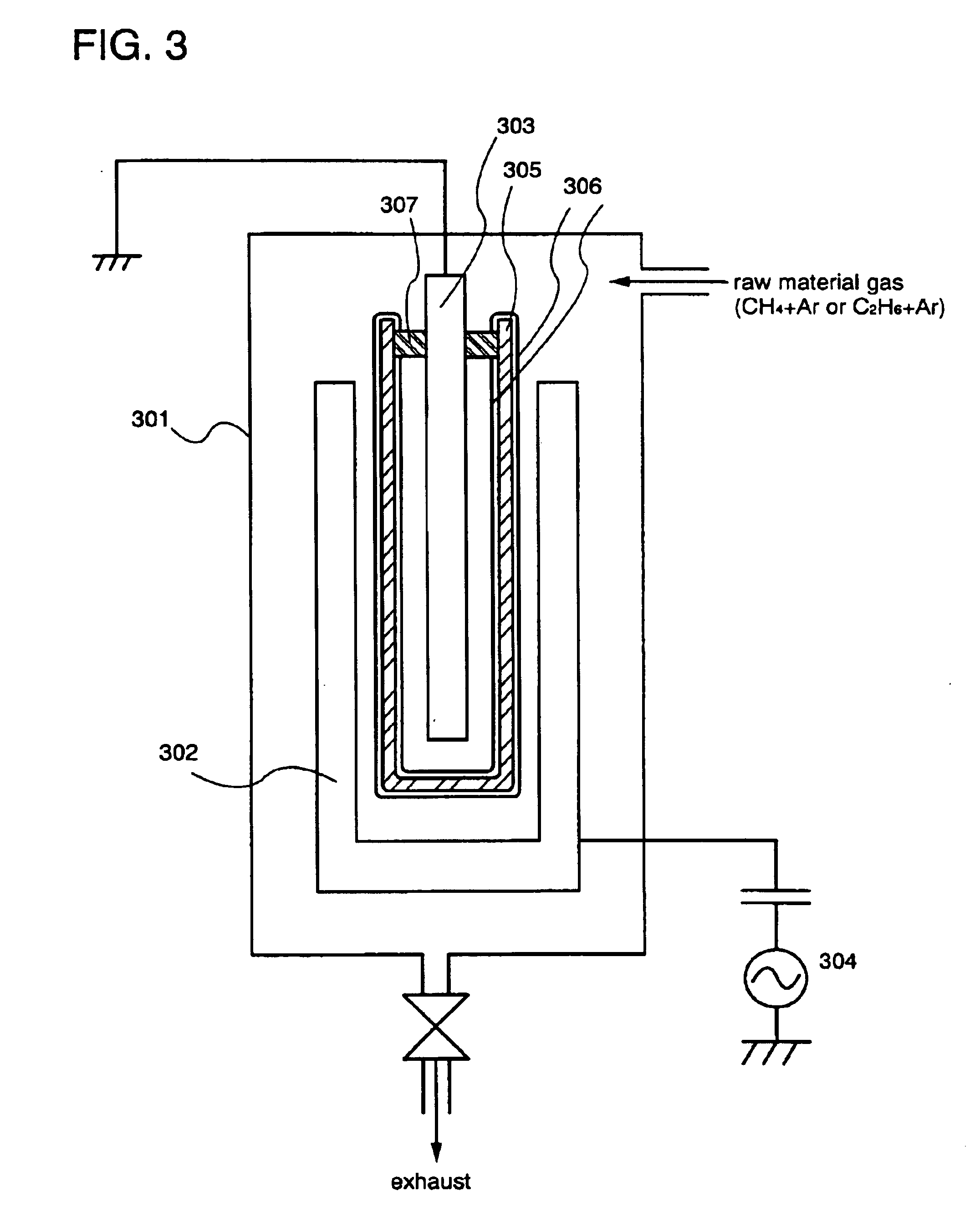

InactiveUS6822391B2Easy to reachReduce internal pressureDischarge tube luminescnet screensLamp detailsOrganic light emitting deviceOxygen

A highly reliable light-emitting device is provided in which an organic light-emitting device is not degraded by oxygen, moisture, and the like. The organic light-emitting device is press-fit in vacuum using a wrapping film (105) that is covered with a DLC film (or a silicon nitride film, an AlN film, a film of a compound expressed as AlNXOY) (106) containing Ar. The organic light-emitting device thus can be completely shut off from the outside, and moisture, oxygen, or other external substances that accelerate degradation of an organic light emitting layer can be prevented from entering the organic light-emitting device.

Owner:SEMICON ENERGY LAB CO LTD

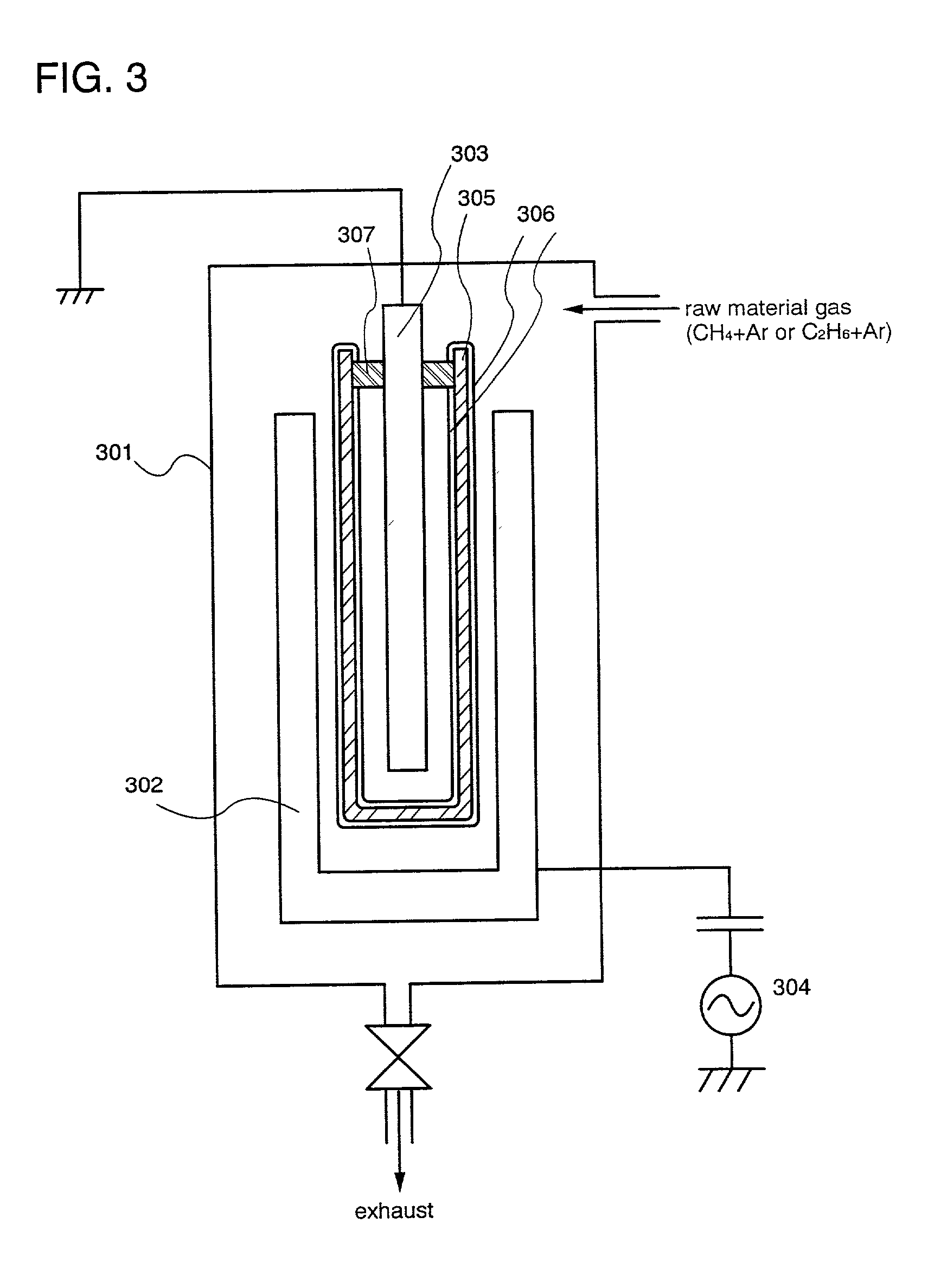

Load-lock technique

InactiveUS20050186716A1Reducing and suppressing contaminationReducing and suppressing and temperatureVacuum evaporation coatingSemiconductor/solid-state device manufacturingEngineering

Disclosed is a load-lock system, an exposure apparatus having the same, and a load-lock method. In one preferred form, the load-lock system includes a chamber housing, and a capacity changing system for changing the capacity of the chamber housing. The load-lock method includes the steps of conveying an object into a chamber housing, reducing the capacity of the chamber housing after the conveying step, and reducing the pressure inside the chamber housing after the capacity reducing step.

Owner:CANON KK

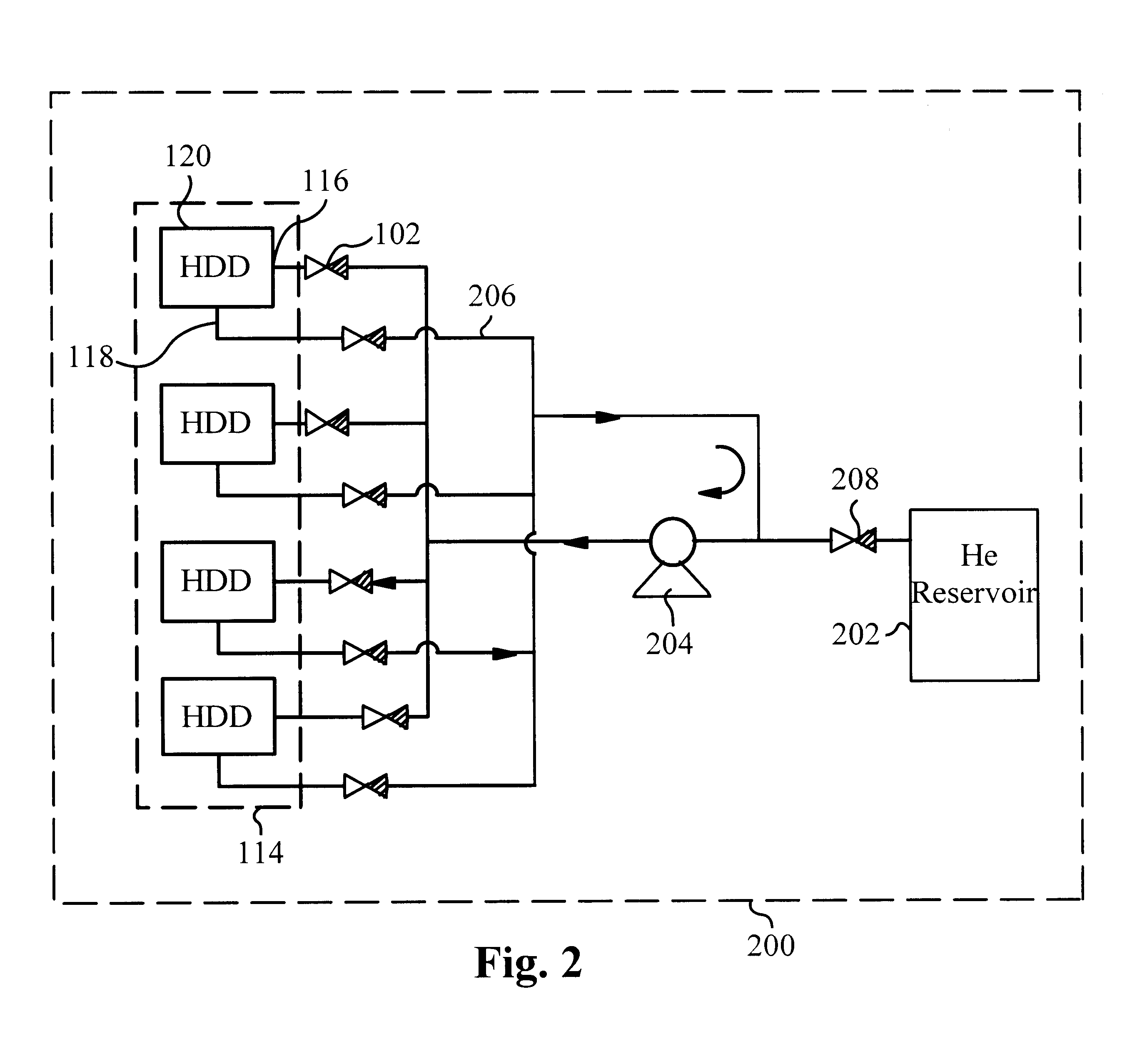

Disk array system with internal environmental controls

InactiveUS6560064B1Reduce consumptionReduce vibrationReducing temperature influence on carrierUndesired vibrations/sounds insulation/absorptionInternal pressureEngineering

A disk drive array system using a vacuum pump to reduce the disk drive internal pressures and / or a helium circulator to fill and circulate helium in a disk drive array to reduce vibrations, reduce power consumption, and increase cooling (when helium is used). The disk drive array system is also configured such that individual disk drives can be removed from the disk drive array without affecting the internal pressures of the remaining disk drives in the array.

Owner:IBM CORP

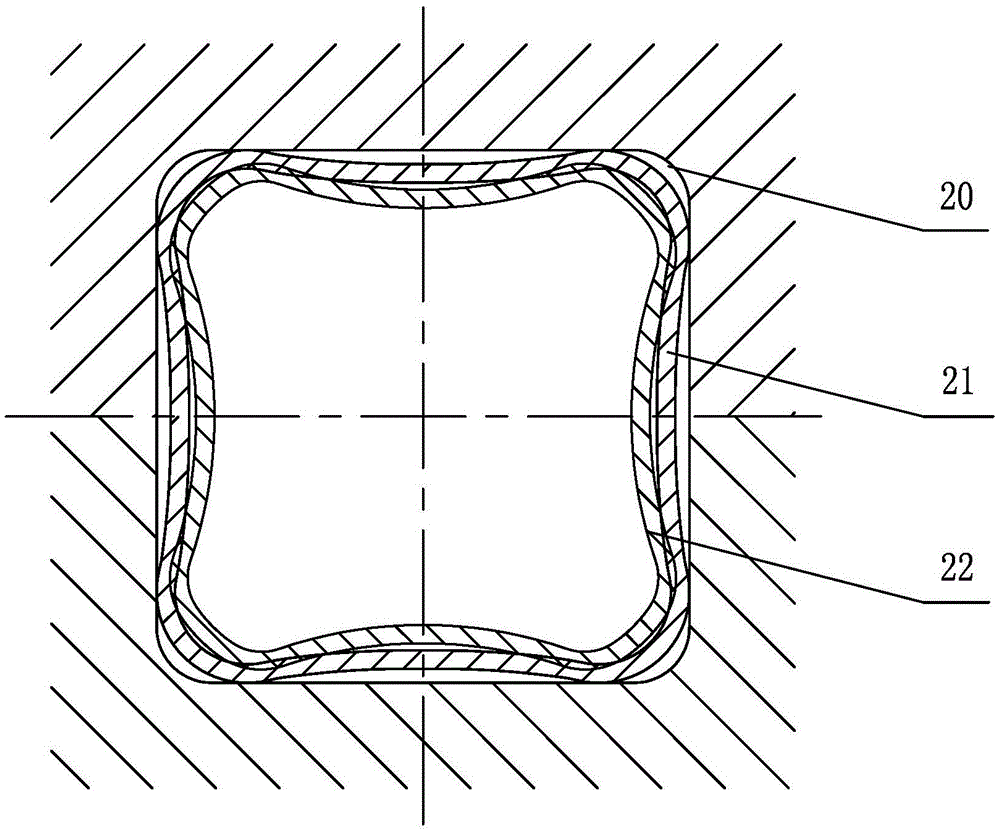

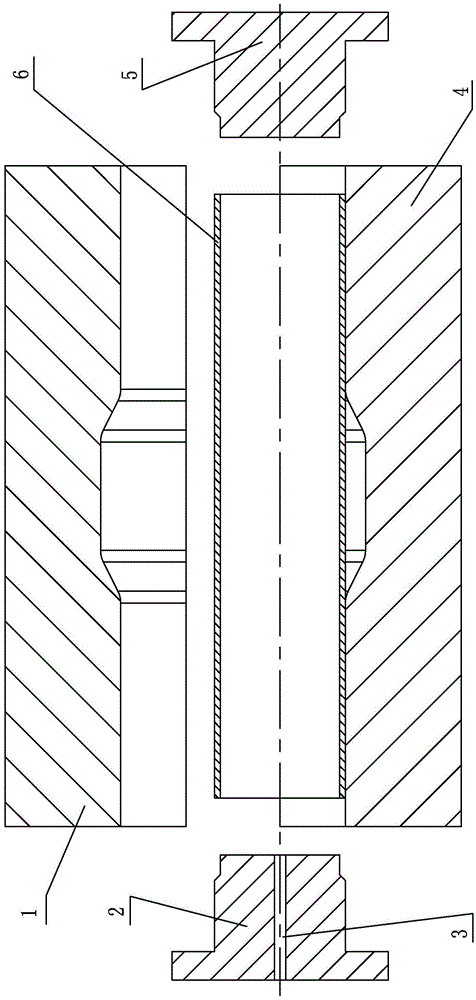

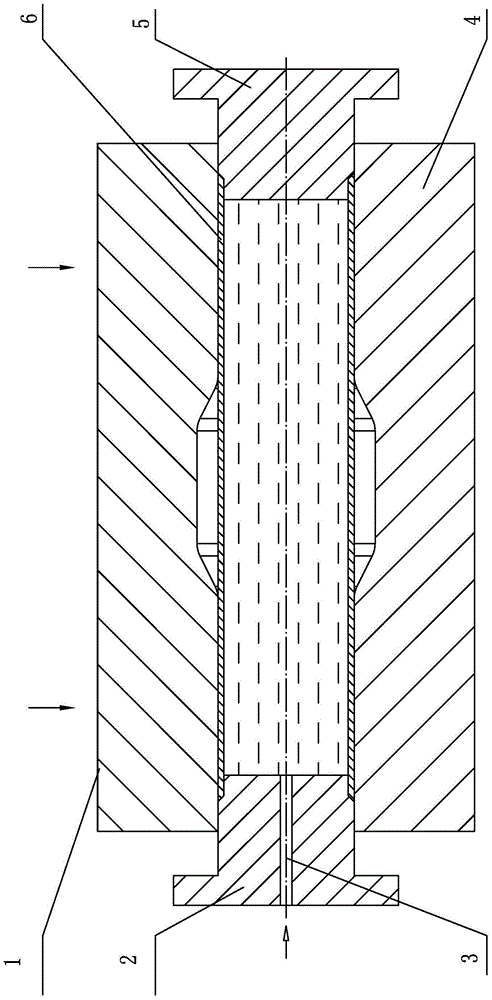

Charging pressing forming method for variable-cross-section special-shaped pipe

The invention discloses a charging pressing forming method for a variable-cross-section special-shaped pipe, and relates to a forming manufacturing method of a metal pipe. The problems that an existing low-internal-pressure forming technology only can form a pipe with the unchangeable section perimeter, and meanwhile, in the internal-high-pressure forming process of an advanced high-strength steel variable-cross-section pipe, the pressure is high, springback is large, and a mold is seriously worn are solved. The forming method comprises the steps that firstly, an upper expansion mold and a lower expansion mold are assembled on a pressure machine; secondly, the upper expansion mold descends to perform mold assembly, a pipe blank is subject to charging, and the pipe blank expands until the pipe blank is attached to the mold; thirdly, the internal pressure of the pipe blank is relieved; fourthly, an upper pressing block and a lower pressing mold are assembled on a pressure machine; fifthly, the upper pressing block descends to perform mold assembly; sixthly, under the joint action of mechanical pressure of the mold and hydraulic pressure of an inner cavity of a variable-cross-section round pipe, mold attaching is carried out, the variable-cross-section round pipe is formed into the variable-cross-section special-shaped pipe, and the forming process is finished; and seventhly, the internal pressure of the variable-cross-section special-shaped pipe is relieved, and the variable-cross-section special-shaped pipe is cut, so that the variable-cross-section special-shaped pipe meeting the design requirement is obtained. The method is used for forming the variable-cross-section special-shaped pipe.

Owner:HARBIN INST OF TECH

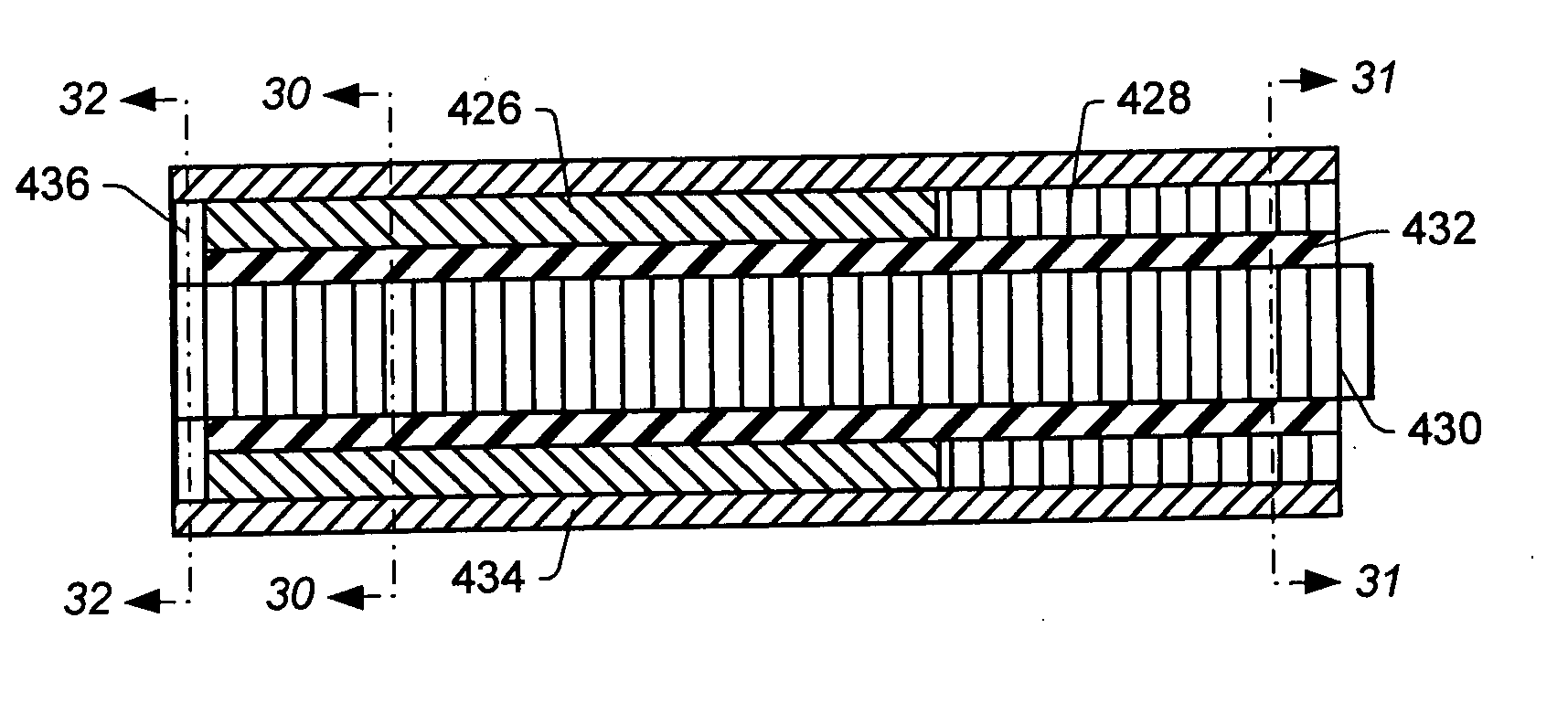

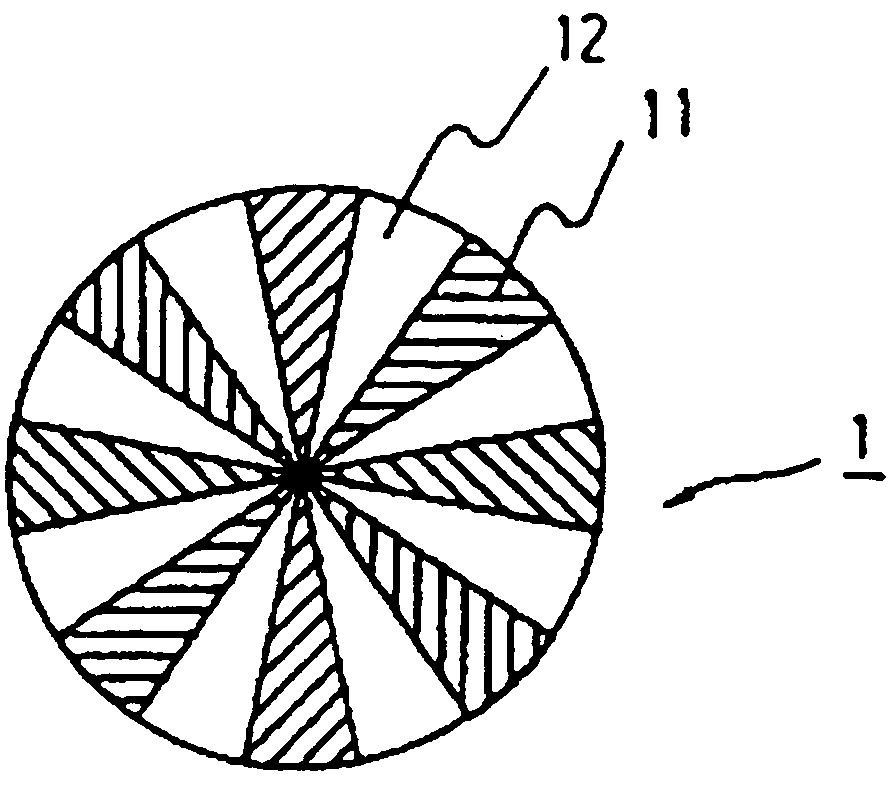

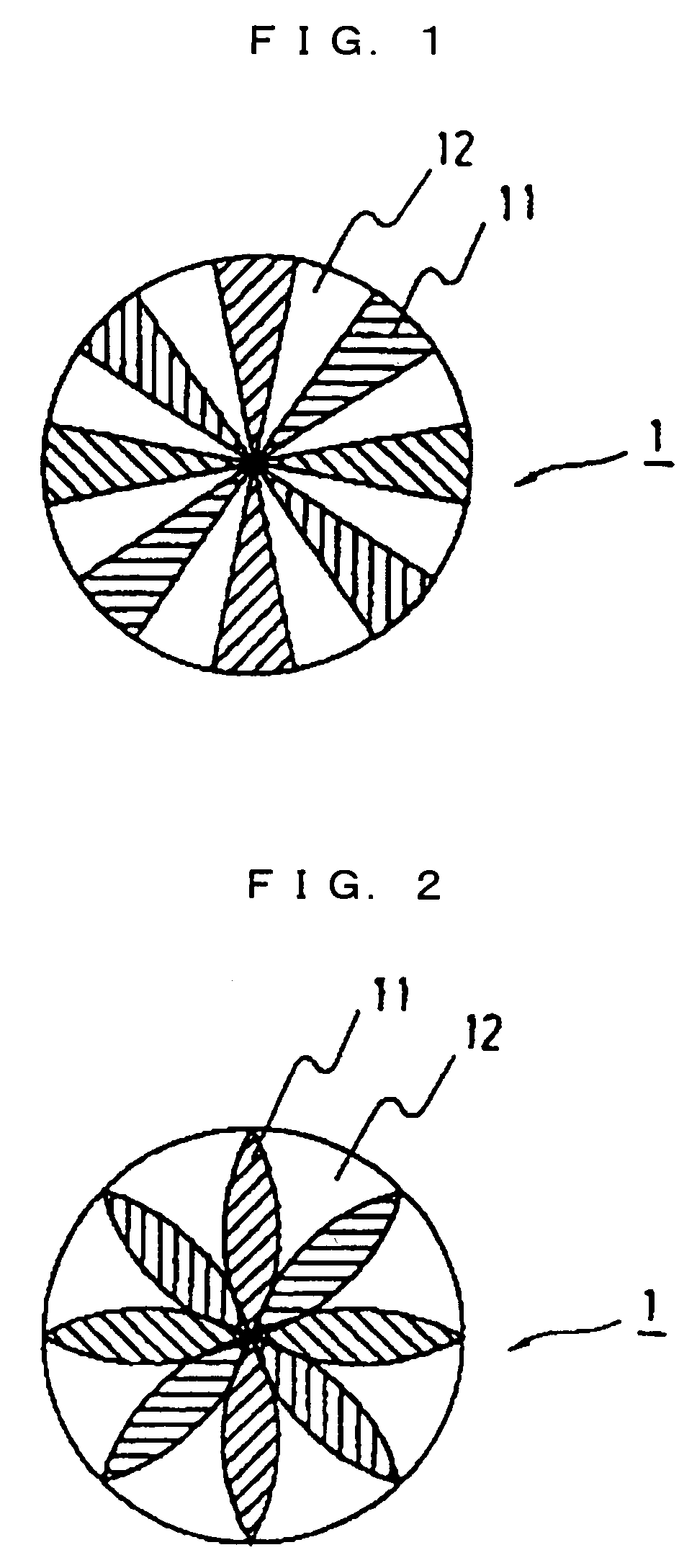

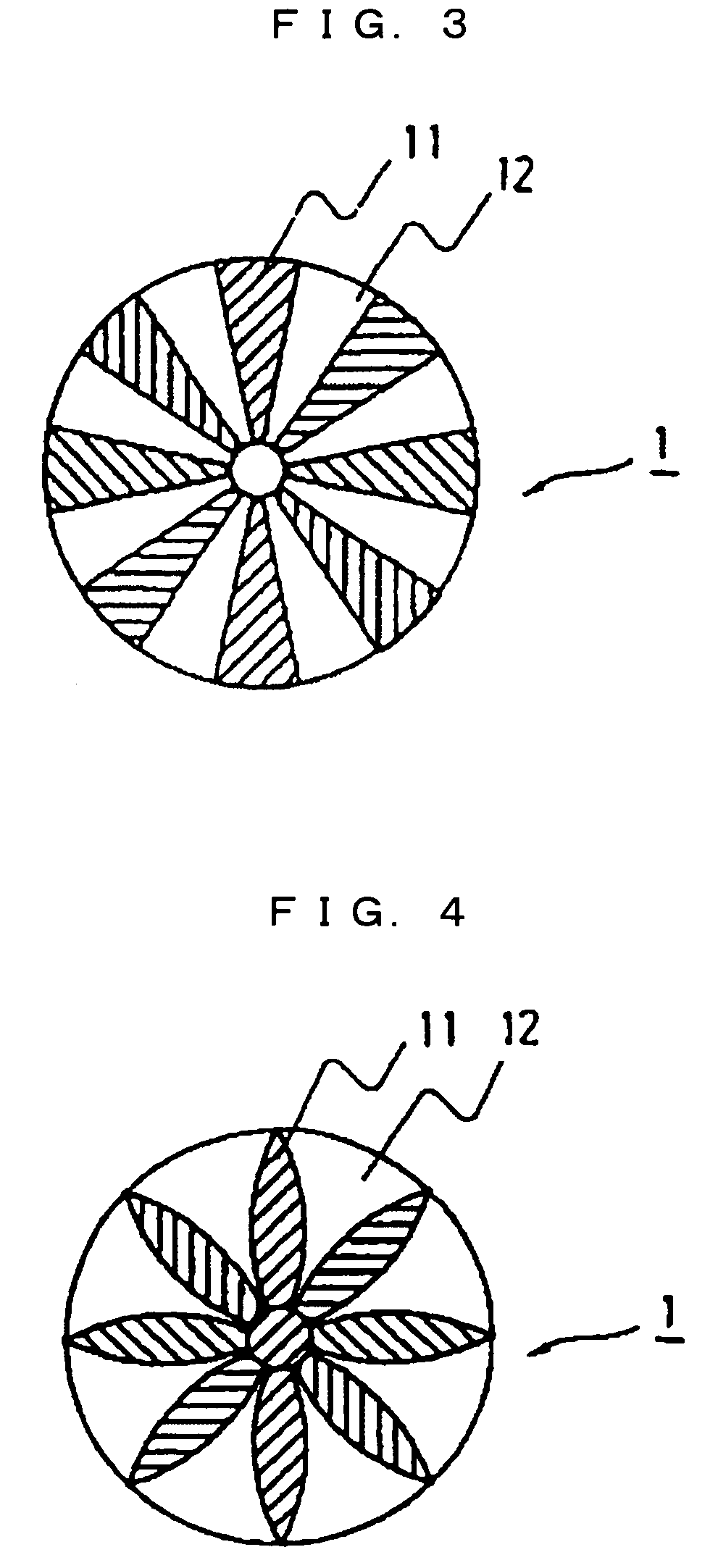

Battery separator and battery comprising same

InactiveUS7923143B2Poor dispersibilityEffectively prevent a short circuitSynthetic cellulose/non-cellulose material pulp/paperCell component detailsPolymer scienceHigh intensity

A battery separator comprising a nonwoven fabric, wherein the nonwoven fabric contains (1) superfine fibers having a fiber diameter of 3 μm or less, (2) noncircular fine fibers having a noncircular cross-sectional shape and having a fiber diameter of 3 to 5 μm (excluding 3 μm), the fiber diameter meaning a diameter of a circle having an area the same as that of the noncircular cross-sectional shape, and (3) polypropylene based high-strength composite fibers containing a fusible component on the surface thereof and having a tensile strength of 4.5 cN / dtex or more, and the fusible component contained in the polypropylene based high-strength composite fibers is fused, and a battery comprising the battery separator are disclosed. A battery separator of the present invention has a high electrolyte-holding capacity and is capable of effectively preventing a short circuit, even if the separator is designed to be thinner to enhance the capacity of a battery.

Owner:JAPAN VILENE CO LTD

Light emitting device, electronic equipment, and method of manufacturing thereof

InactiveUS20020113549A1Easy to reachReduce internal pressureDischarge tube luminescnet screensLamp detailsOrganic light emitting deviceOxygen

A highly reliable light-emitting device is provided in which an organic light-emitting device is not degraded by oxygen, moisture, and the like. The organic light-emitting device is press-fit in vacuum using a wrapping film (105) that is covered with a DLC film (or a silicon nitride film, an AlN film, a film of a compound expressed as AlNXOY) (106) containing Ar. The organic light-emitting device thus can be completely shut off from the outside, and moisture, oxygen, or other external substances that accelerate degradation of an organic light emitting layer can be prevented from entering the organic light-emitting device.

Owner:SEMICON ENERGY LAB CO LTD

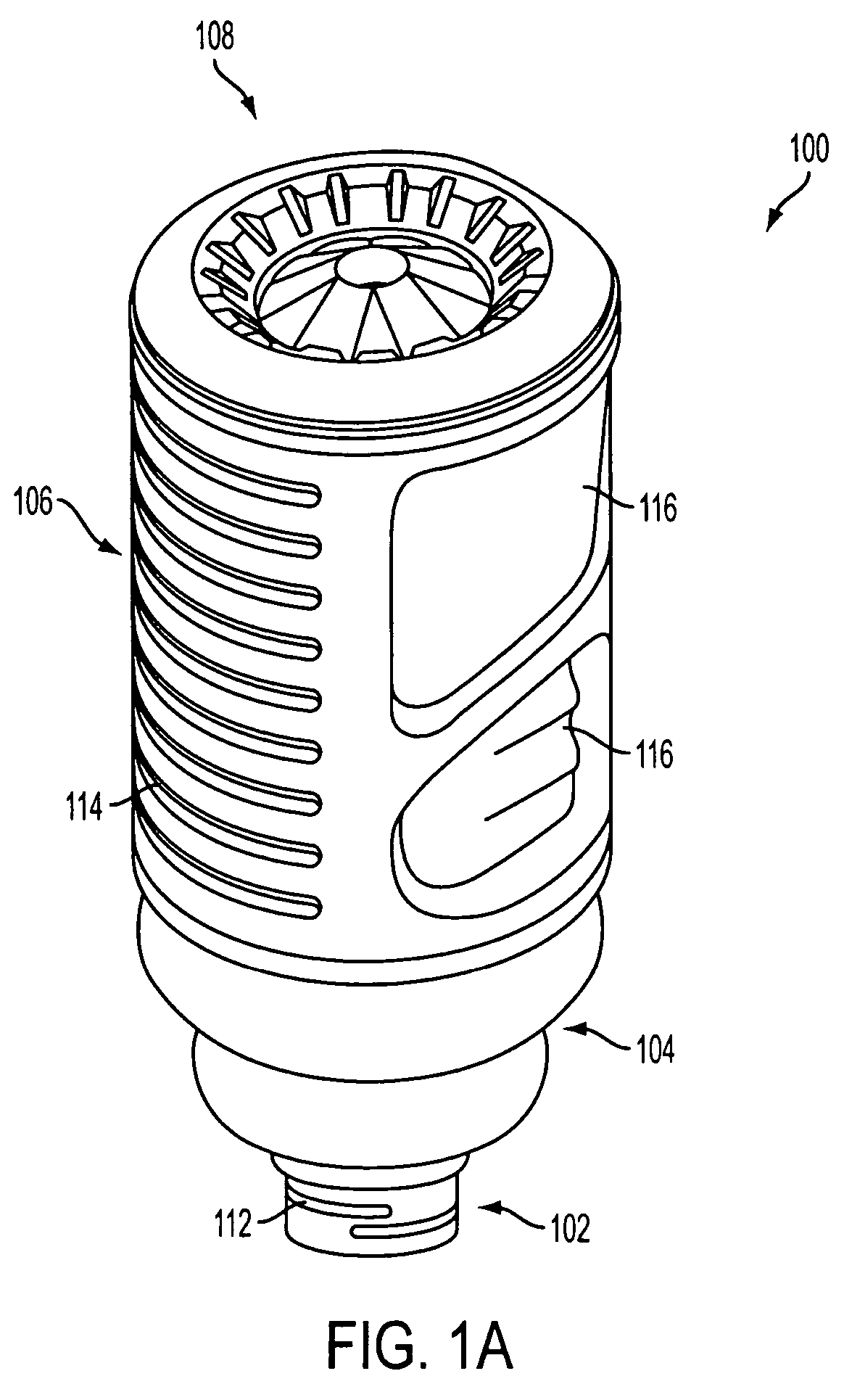

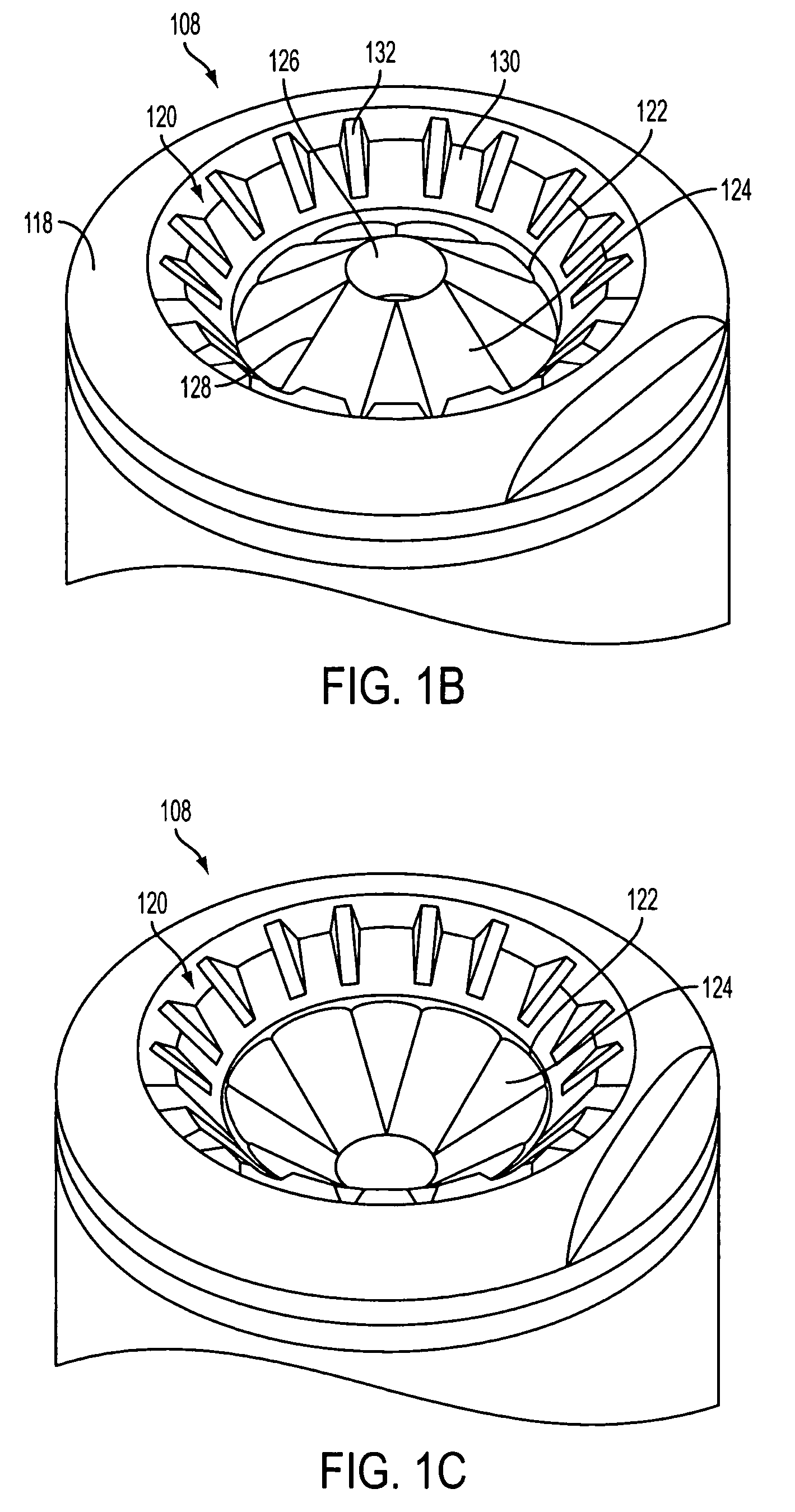

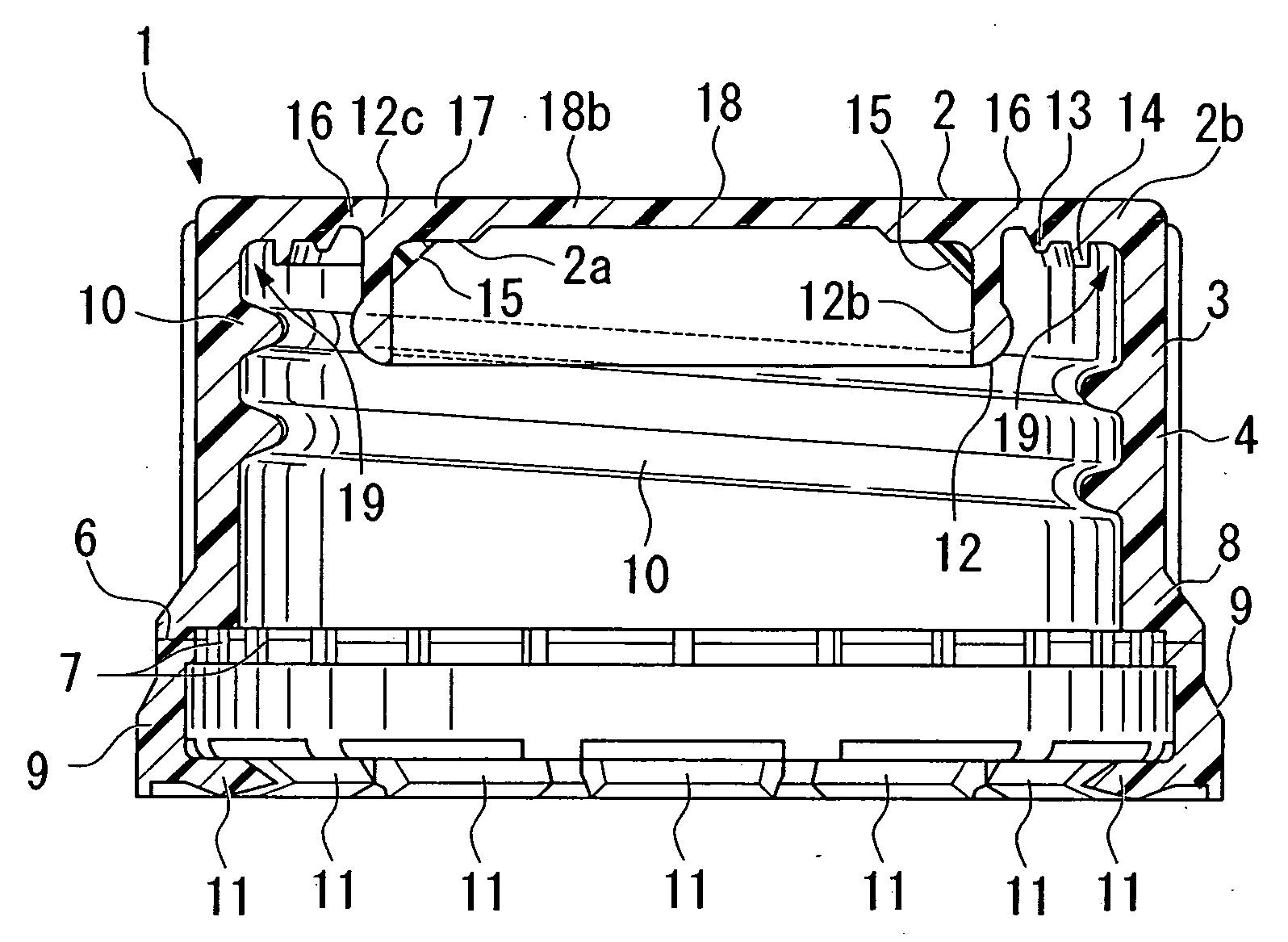

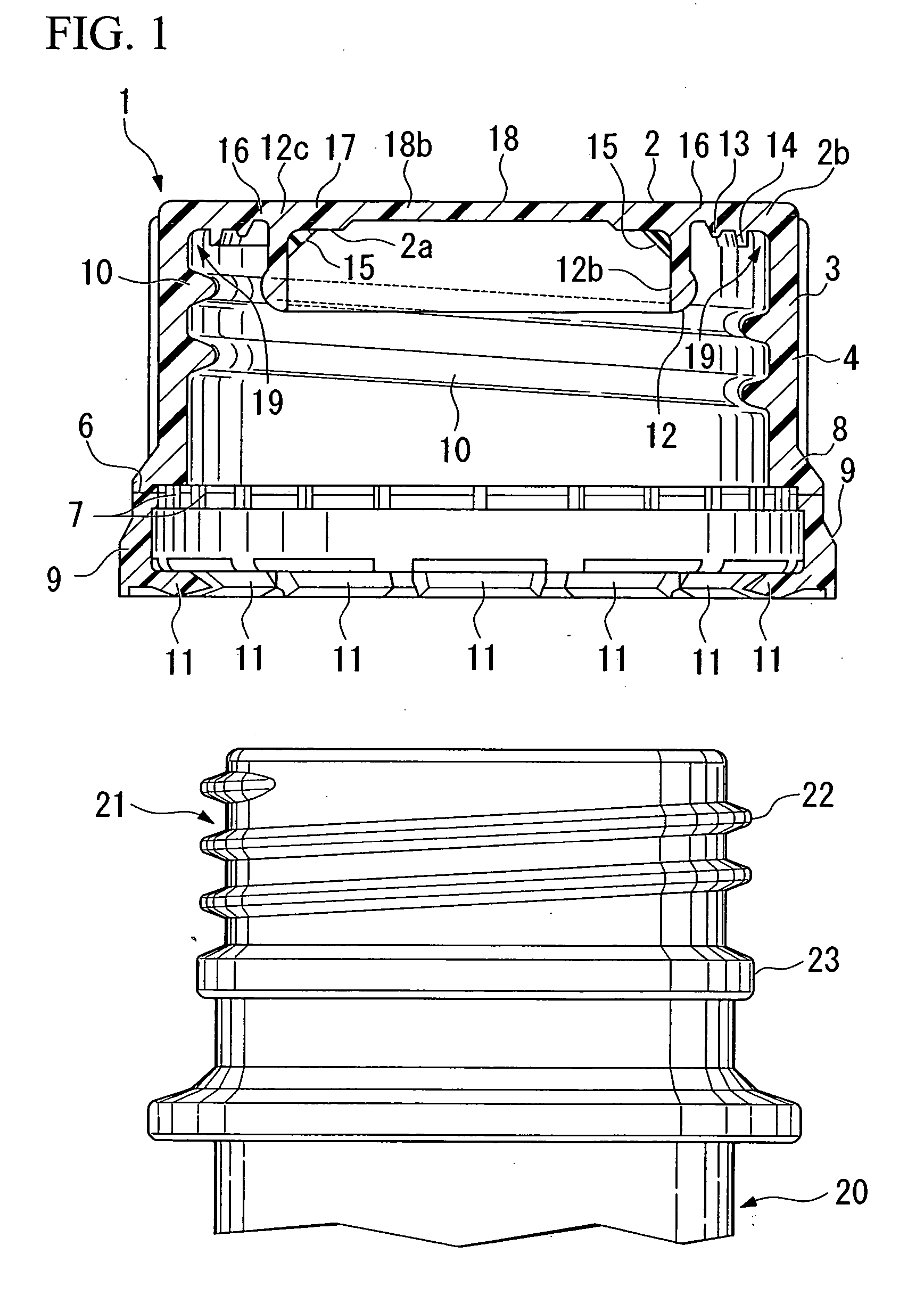

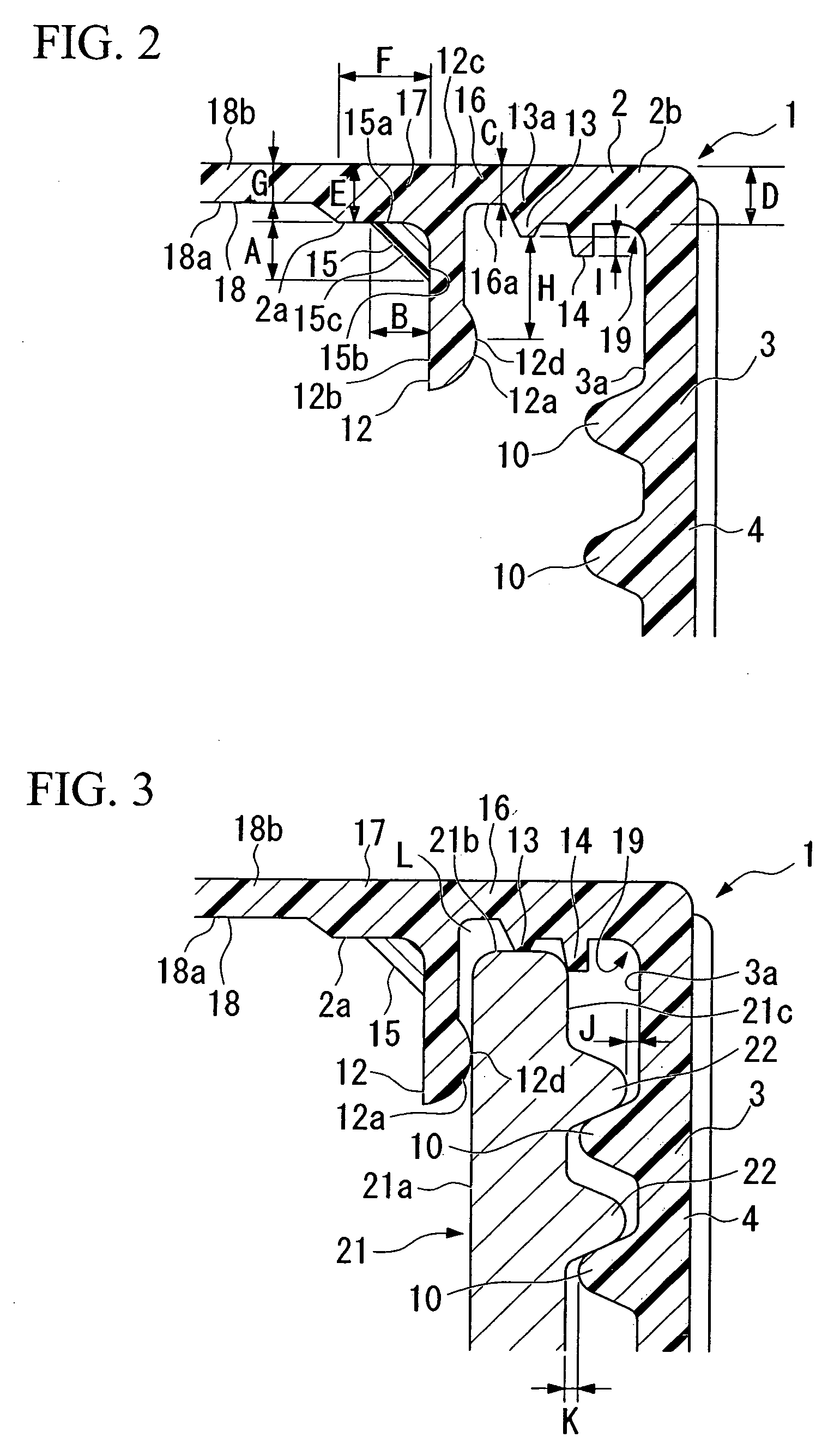

Synthetic resin cap, closing device, and container-packed beverage

ActiveUS20060255002A1Reduce internal pressureIncrease pressureCapsClosure using stoppersInternal pressureEngineering

The present invention provides a synthetic resin cap comprising: a cap body (4) having a top plate portion (2) and a cylinder portion (3) hanging from a circumferential edge portion (2b) thereof; an annular inside seal projection (12) to be fitted to a container mouth portion (21); a connector portion (15) formed between the top plate portion (2) and the inside seal projection (12); and an outside thin wall portion (16) formed on the top plate portion (2), and provides a closing device using thereof, and a container-packed beverage. When the internal pressure of the container has risen, the top plate portion (2) is deformably swelled upward, and an inward tensile force is applied to the inside seal projection (12) by the connector portion (15). Since the outside thin wall portion (16) undergoes bending deformation, the portion positioned inside the outside thin wall portion (16) to undergo significant bulging deformation upward, and the slope of the top plate portion (2) at the portion where the inside seal projection (12) is formed is increased. Thus, the inside seal projection (12) is displaced inward, and gas in the container may be easily discharged to the outside.

Owner:CLOSURE SYST INT INC

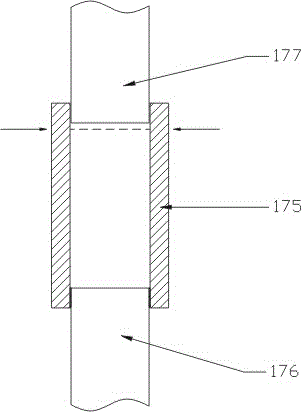

Manufacturing and Installation of Insulated Pipes or Elements Thereof

InactiveUS20110197987A1Easy to processEasy to installThermal insulationPipe protection by thermal insulationParticulatesAerogel

Insulated pipe systems or assemblies include a particulate, composite or monolithic insulating aerogel material. Techniques for installing or manufacturing such systems or assemblies are described, as are components useful in the installation or manufacture processes.

Owner:CABOT CORP

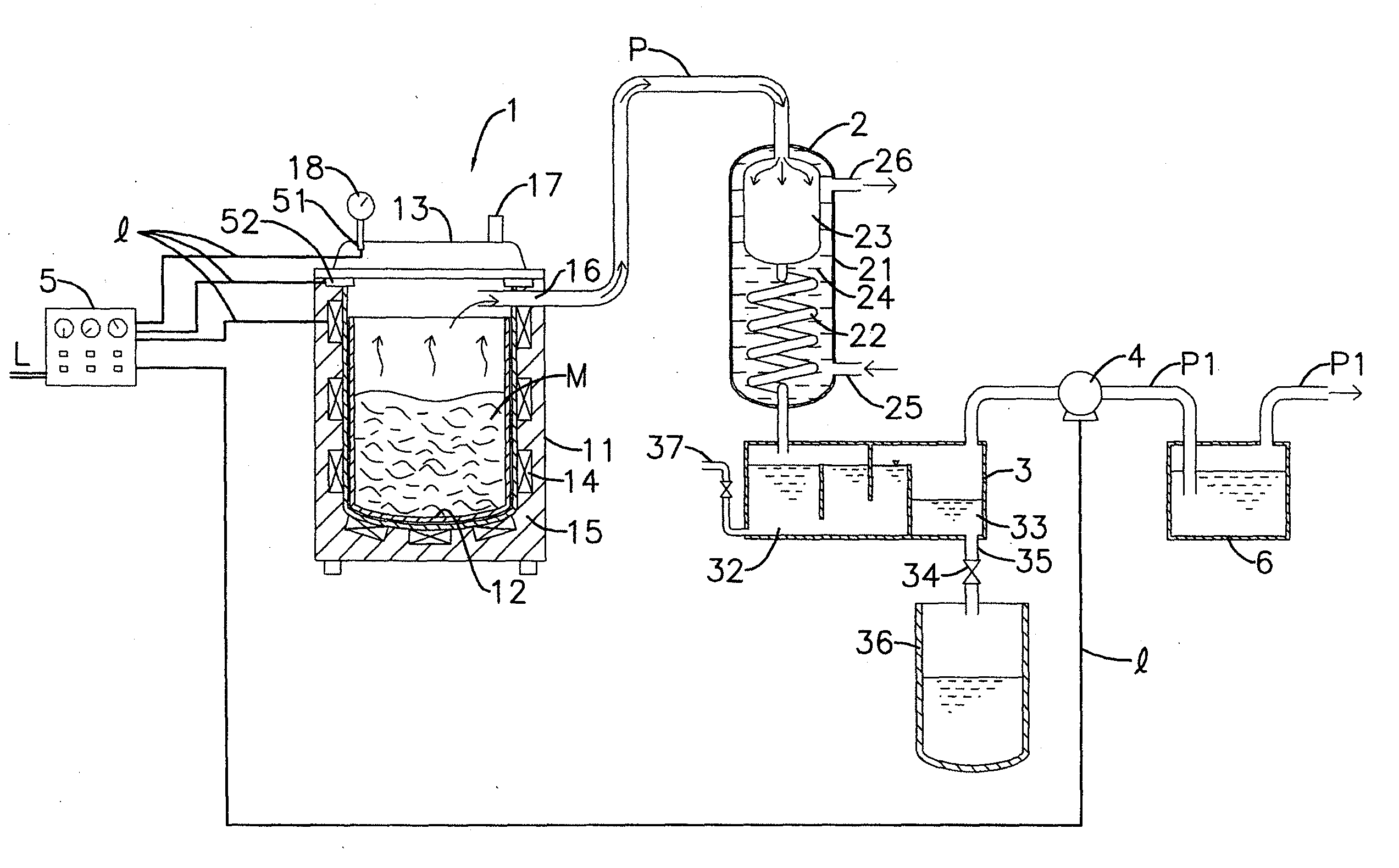

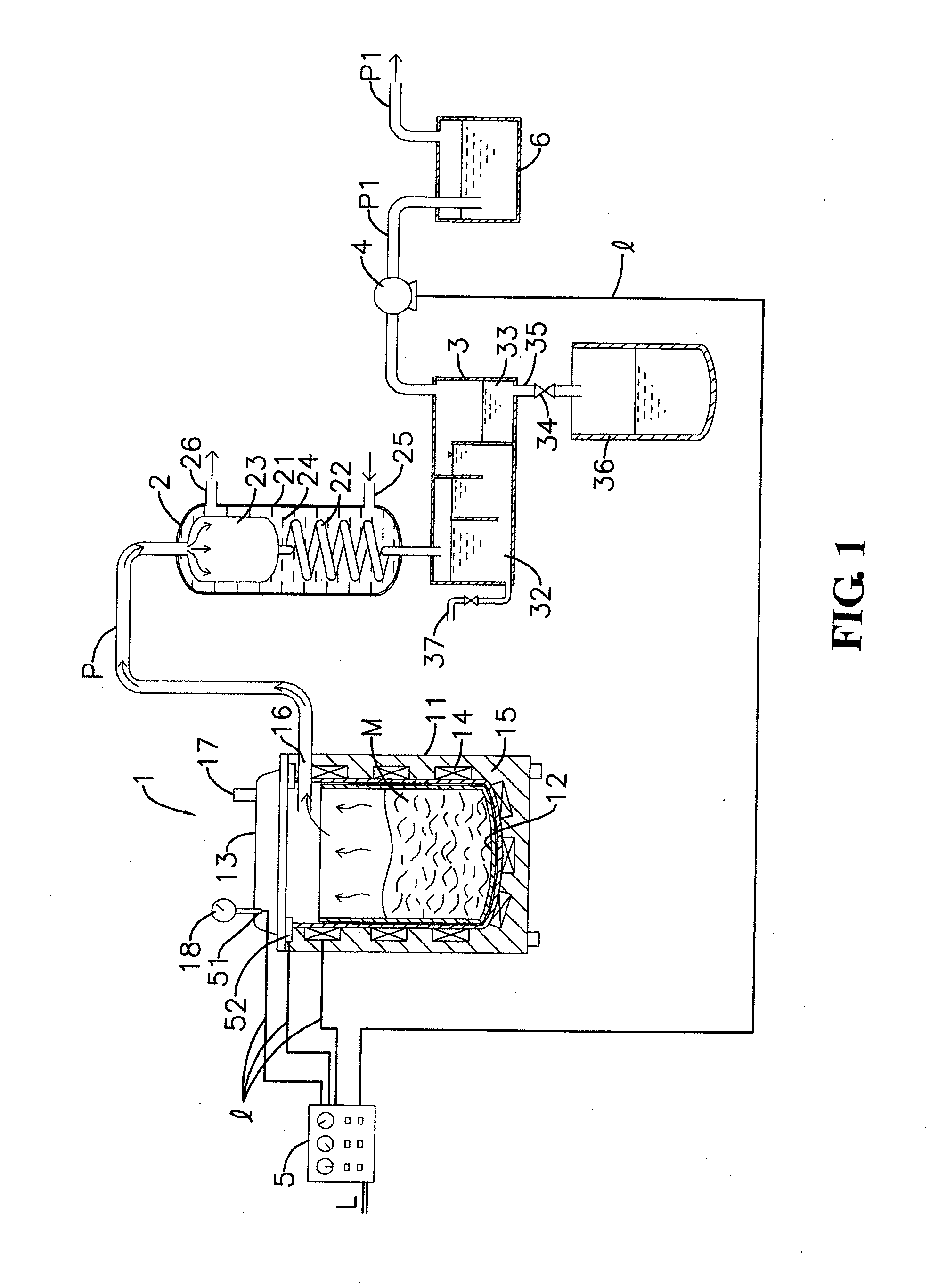

Method of extracting essential oil from biomass wastes and a device thereof

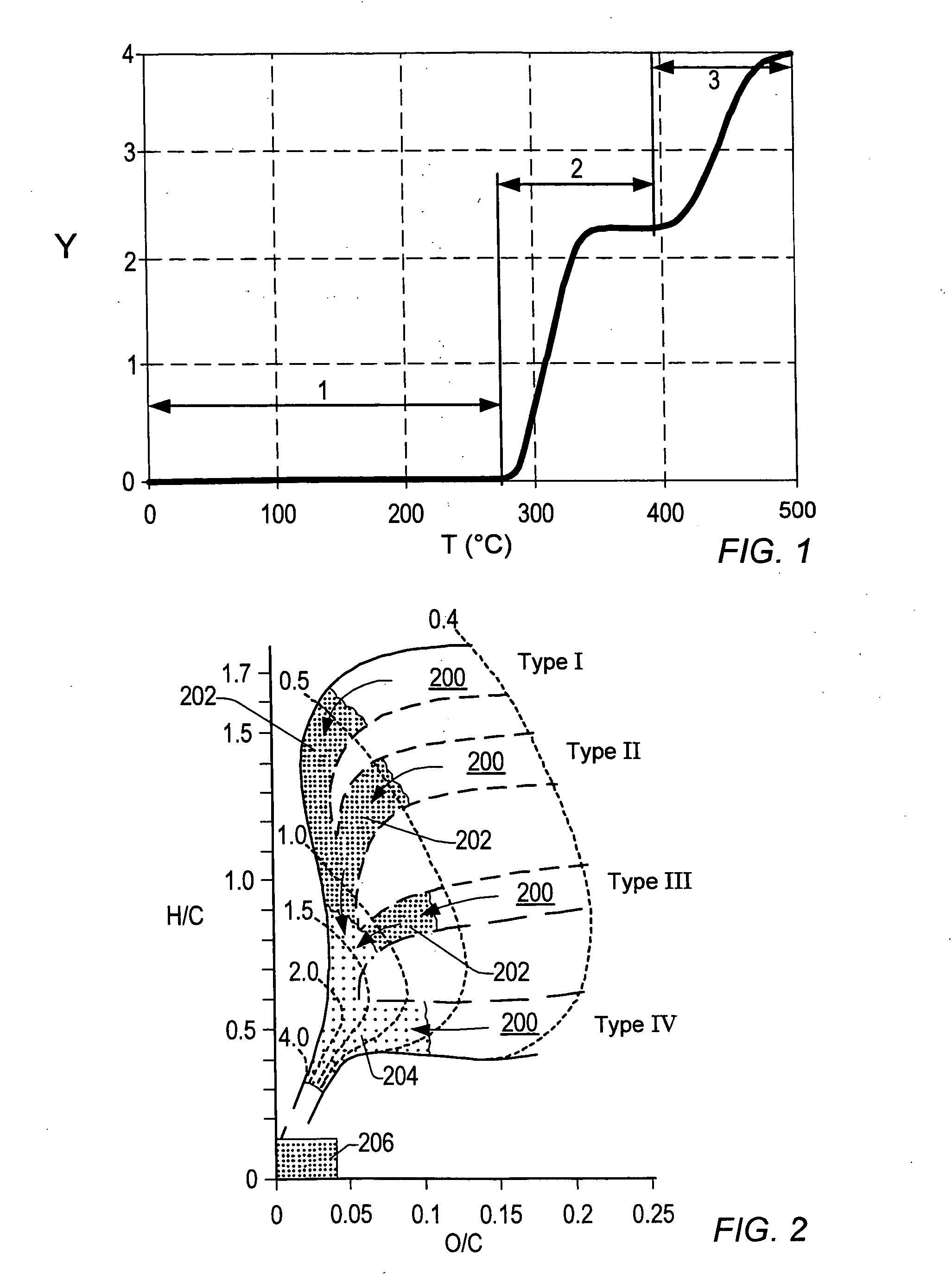

InactiveUS20110034712A1Reduce processing timeQuality improvementRetortsLiquid hydrocarbon mixture productionEngineeringOxygen

A method of extracting essential oil from biomass wastes puts biomass wastes, such as wood residuals, wood chips or other plants, in an air-tight oxygen-free reaction vessel to be heated up indirectly, for conducting a thermal pyrolysis cracking reaction (i.e. dry distillation); and guides volatile gas which is distilled when the processed wastes disintegrate, into a condenser to be condensed as liquid which is then separated into water and oil through an oil-water separation tank. Whereas, non-liquefied gas is discharged outside after deodorizing, and residuals in the reaction vessel are processed with high-temperature dry distillation once to become activated carbons. In processing, temperature and pressure in the reaction vessel are controlled in multiple phases, along with using a suction pump of a changeable speed and a changeable flow rate to suck out air in high speed in phases, to keep internal pressure of the reaction vessel at a low pressure condition, thereby shortening a processing time and acquiring high quality essential oil and activated carbons as by-products.The present invention also includes a system device to implement this method. In the oil-water separation tank of this device, an ultrasonic generator is provided to re-disintegrate tars, which improves quality of the oil products.

Owner:LIN WEI CHIH

Methods and systems for measuring mechanical property of a vascular wall and method and system for determining health of a vascular structure

InactiveUS7318804B2Reduce internal pressureOrgan movement/changes detectionInfrasonic diagnosticsCardiac cyclePhase sensitive

Methods and systems for measuring mechanical property of a vascular wall and a method and system for determining health of a vascular structure are provided wherein local deformation of a vessel wall resulting from physiologic pressures with altered transmural forces is measured. A non-invasive free-hand ultrasound scanning-procedure was performed to apply external force, comparable to the force generated in measuring a subject's blood pressure, to achieve higher strains by equalizing the internal arterial baseline pressure. When the applied pressure matched the internal baseline diastolic pressure, strain and strain rate increased by a factor of 10 over a cardiac cycle. Radial arterial strain was assessed in the vessel wall over the entire deformation procedure using a phase-sensitive, two-dimensional speckle-tracking algorithm. An elastic modulus reconstruction procedure was developed to estimate the non-linear elastic properties of the vascular wall.

Owner:RGT UNIV OF MICHIGAN

Container for dispensing a substance

InactiveUS20120241455A1Solve the lack of spaceSpoiling of the dispensing apparatus is preventedOpening closed containersBottle/container closureEngineeringMechanical engineering

Owner:MDS GLOBAL HLDG

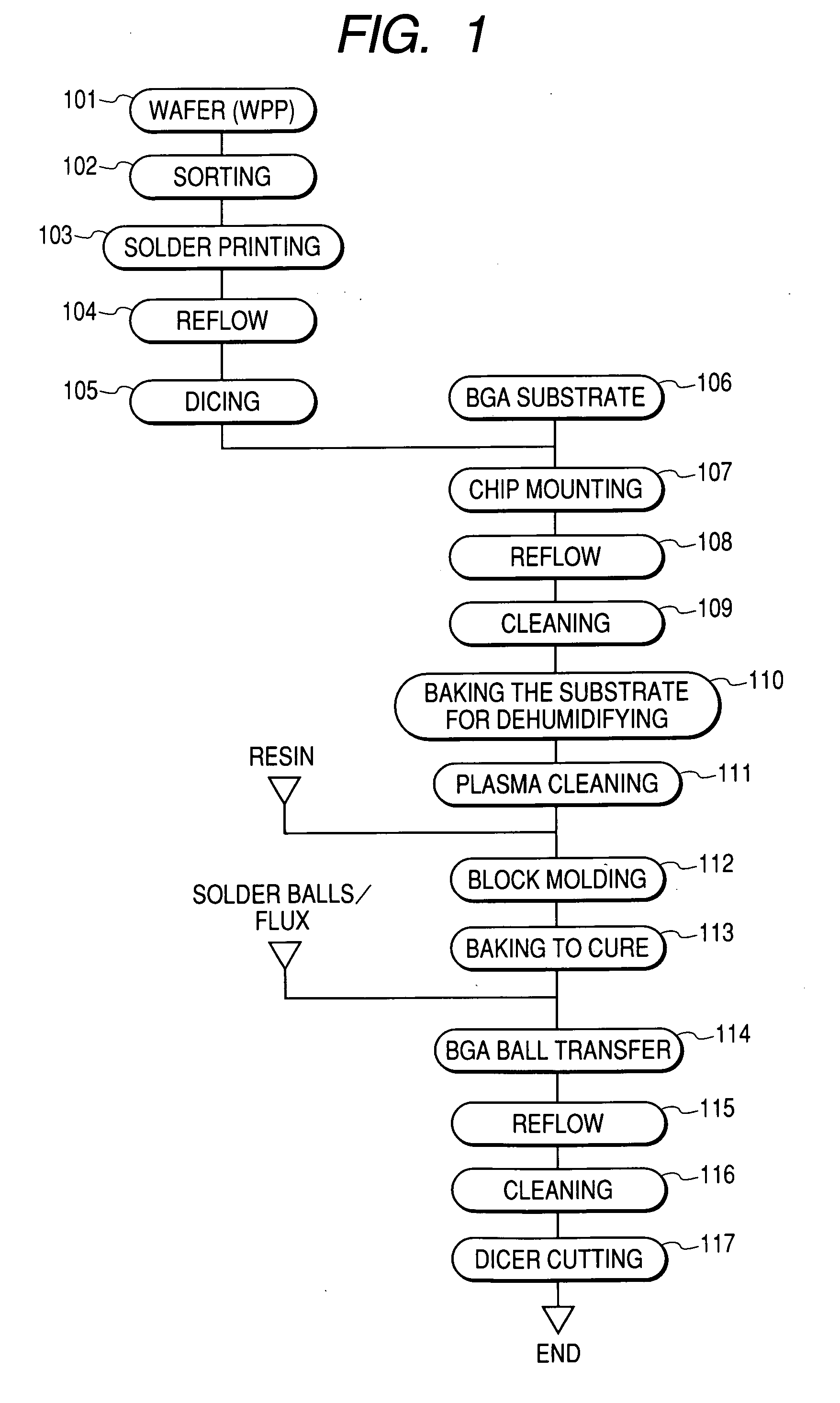

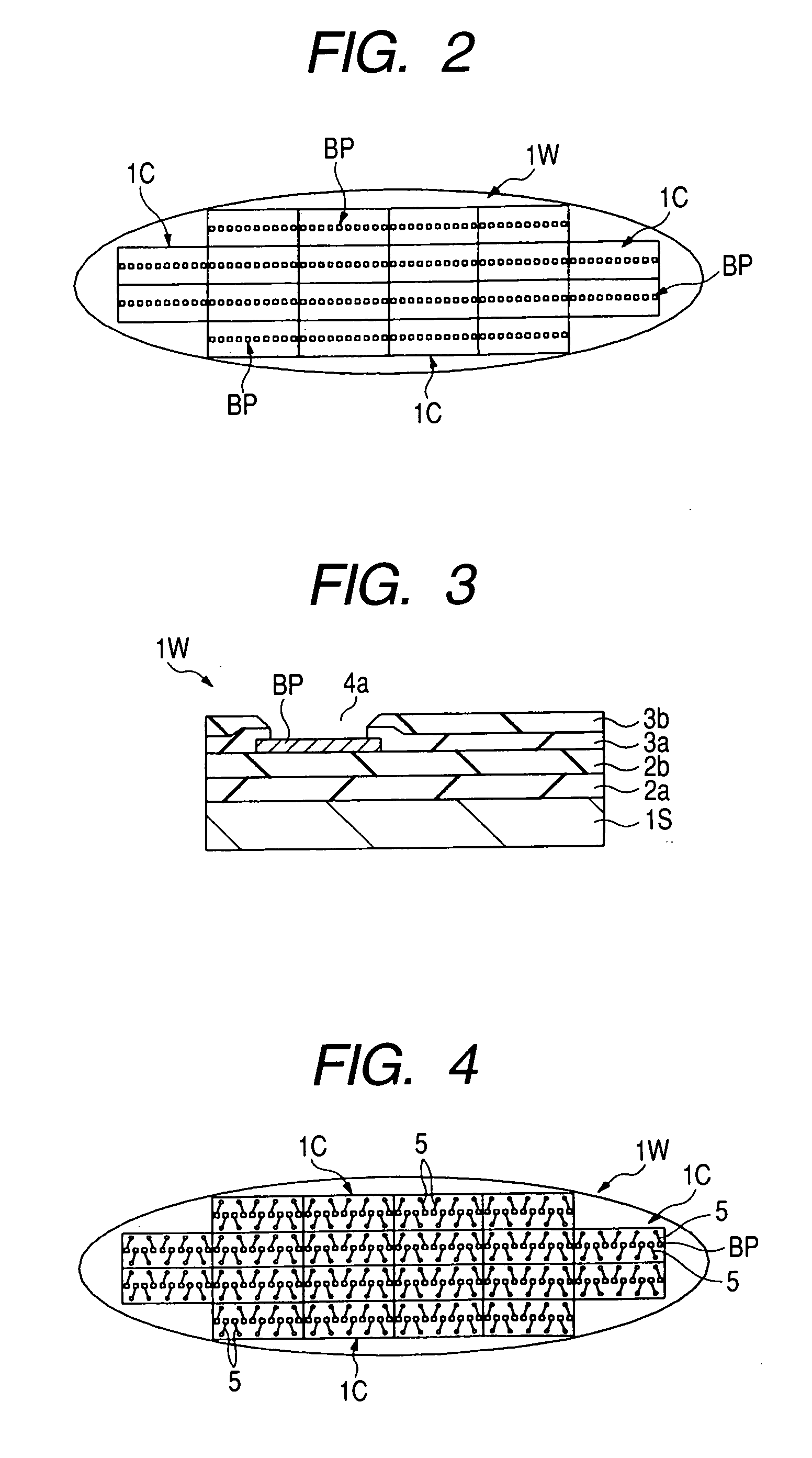

Manufacturing method of a semiconductor device

InactiveUS20050133895A1Increase productionReduce internal pressureSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsInternal pressureDevice material

The yield of a sealing process for a semiconductor device which adopts a flip-chip mounting method is to be improved. In a molding process wherein plural semiconductor chip ICs mounted on a parts mounting surface of a substrate matrix through bump electrodes are to be sealed all together with a sealing resin in a reduced state of the internal pressure of a cavity of a molding apparatus, a clamping pressure at the time of clamping the substrate matrix by both a lower die and an upper die of a molding die is set at a relatively low pressure in an initial stage of injection of the sealing resin and is changed to a relatively high pressure when the sealing resin has covered the semiconductor chip ICs located in a final stage in the resin injecting direction.

Owner:RENESAS ELECTRONICS CORP

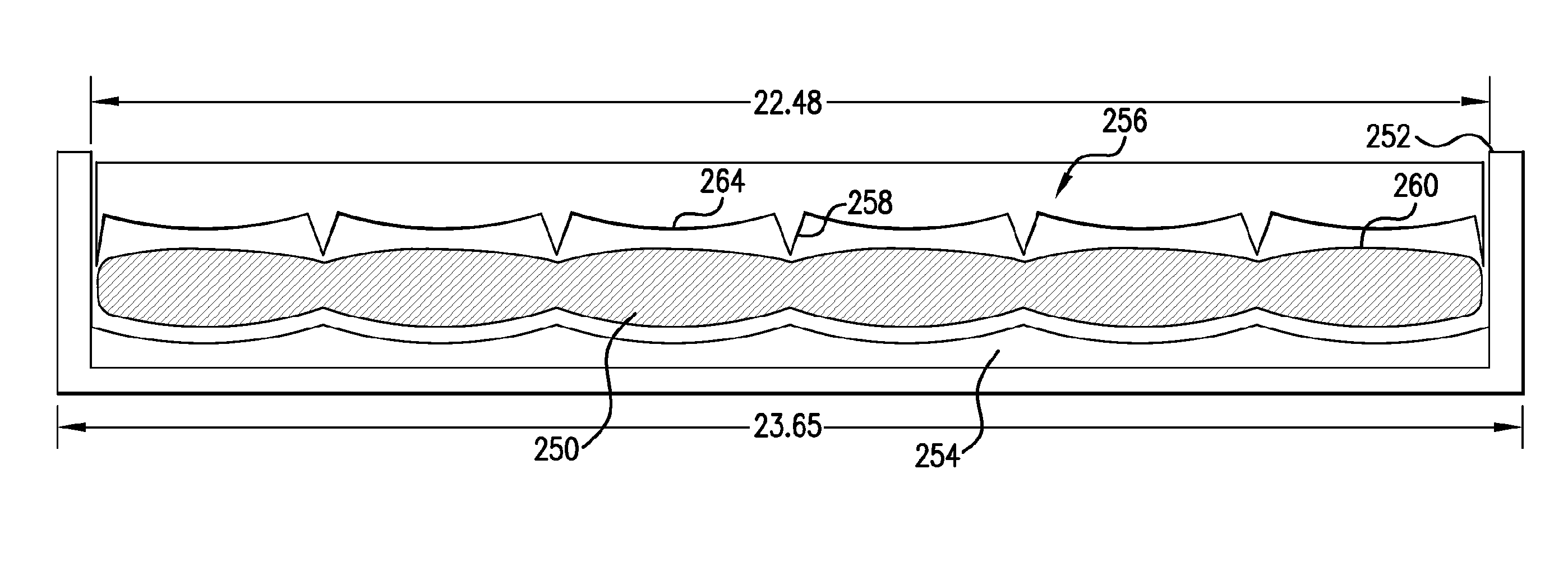

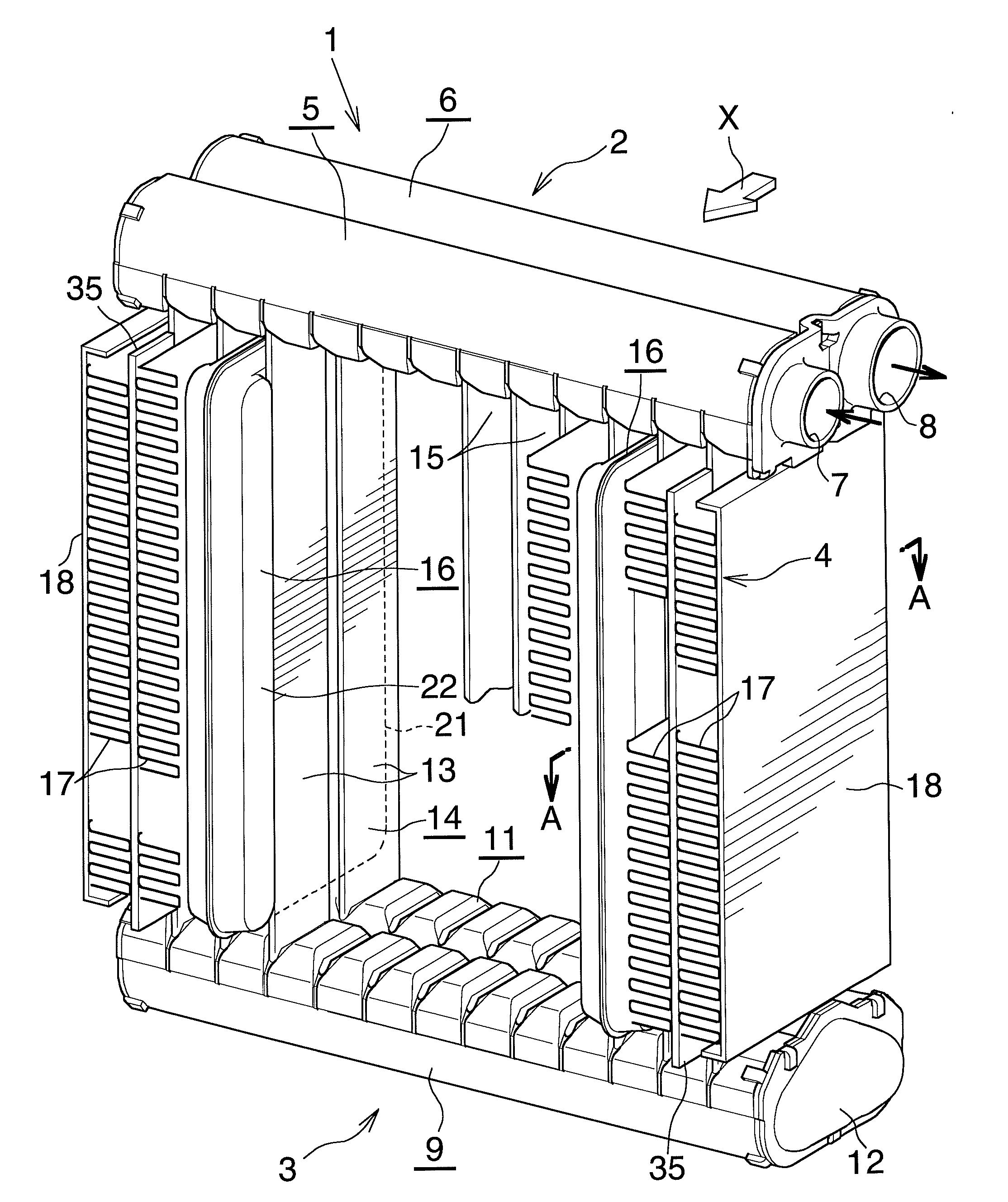

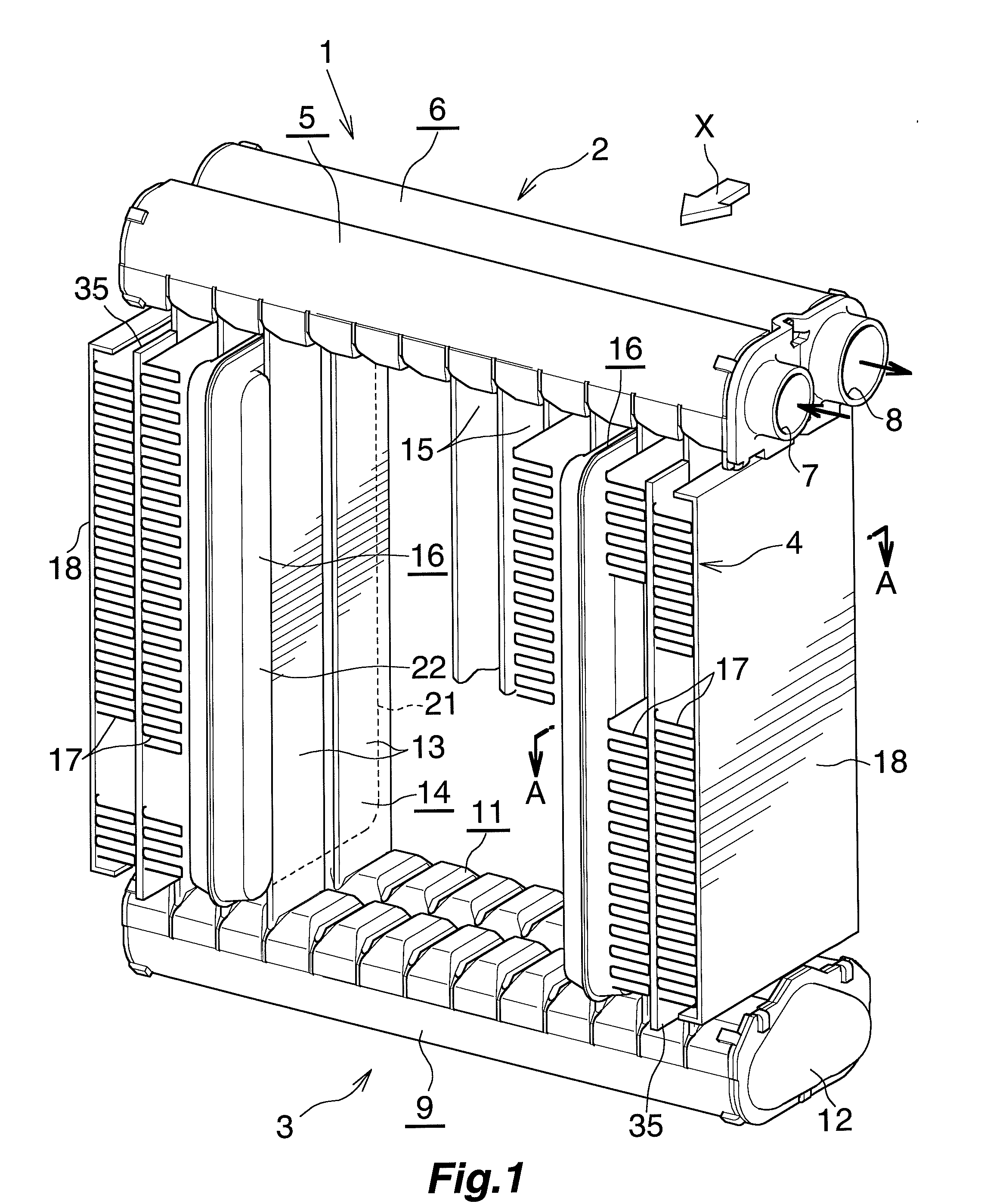

Evaporator with cool storage function

InactiveUS20120042687A1Reduce internal volumeSuppress mutationHeat storage plantsEvaporators/condensersCool storageFront edge

An evaporator with a cool storage function includes a cool storage material container disposed at least one of air-passing clearances formed between adjacent refrigerant flow tubes, and fins disposed in air-passing clearances on opposite sides of the cool storage material container. The cool storage material container includes a container body portion joined to the corresponding refrigerant flow tubes, and an outward extending portion which extends from the front edge of the container body portion and projects frontward in relation to the refrigerant flow tubes. Each of the fins has a fin body portion joined to the corresponding refrigerant flow tubes, and an outward extending portion which extends from the front edge of the fin body portion body and projects frontward in relation to the refrigerant flow tubes. The outward extending portions of the fins are brazed to opposite sides of the outward extending portion of the cool storage material container.

Owner:KEIHIN THERMAL TECH CORP

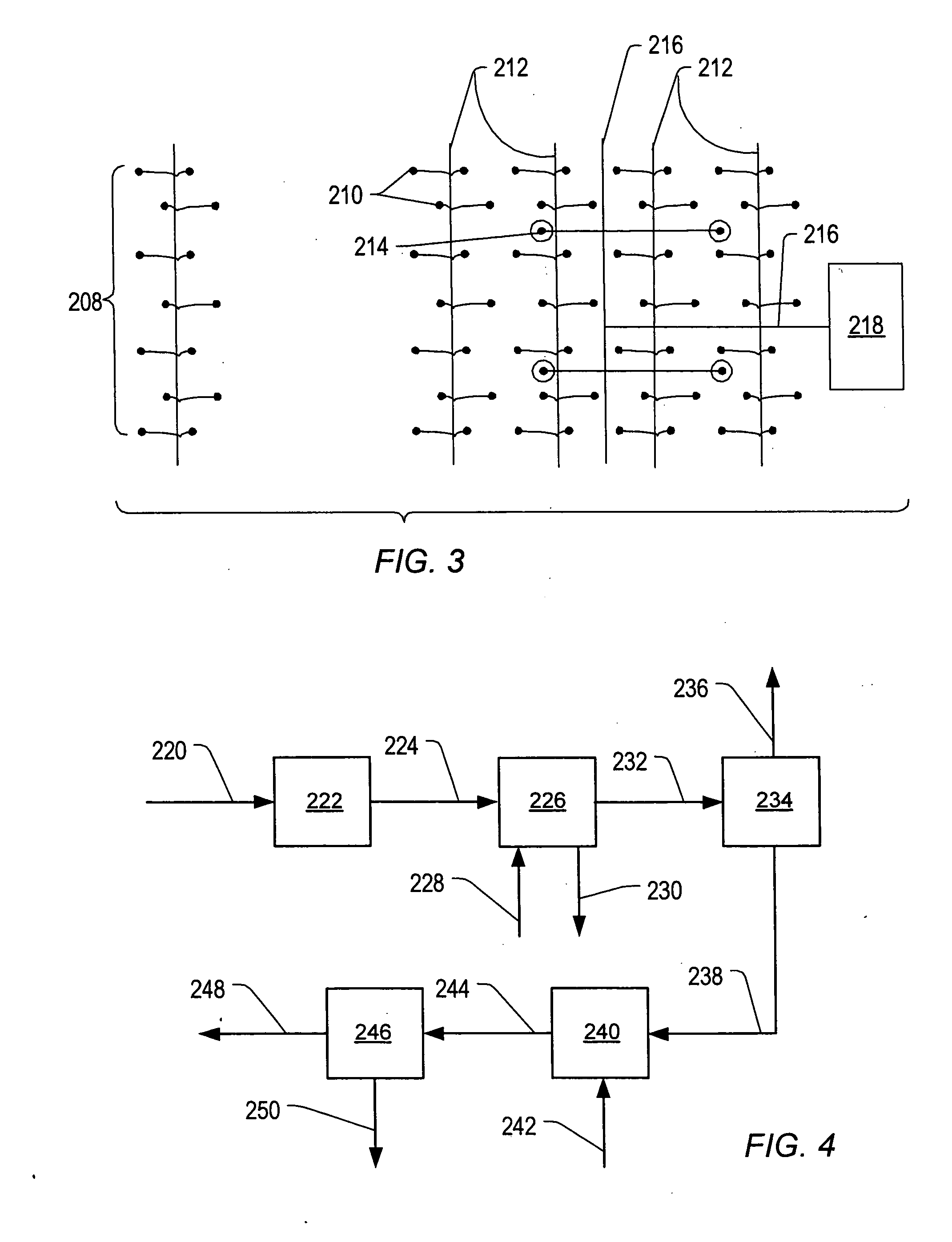

Fast reactor type coupling nuclear reaction implementation method and nuclear reactor for same

InactiveCN105023621AInherently safeReduce engineering difficultyFuel elementsNuclear energy generationNuclear reactor coreInherent safety

The present invention relates to a fast reactor type coupling nuclear reaction implementation method and a nuclear reactor for same. The main contents comprise: a fast reactor type coupling nuclear reaction implementation method, a reactor modular design approach, a fast reactor type coupling nuclear reactor, a reactor core, a fuel element, a nuclear control system, and a proliferation fuel system. The fast reactor type coupling nuclear reactor mainly combusts thorium and nuclear waste, and has inherent security. The reactor main container is composed of a fission pool and a moderating pool that are completely isolated from each other but coupling to each other. A primary coolant is separated from a moderator. A thermal insulation layer is disposed between the fission pool and the moderating pool so that both can perform neutron exchange but heat exchange is blocked. Fast neutrons produced by the fission pool and moderated neutrons reflected by the moderating pool may enable the reactor core to simultaneously perform coupling nuclear reaction of the two types of neutrons. The moderating pool may be provided with the nuclear control system, and ex-core coupling core control may be implemented. The moderating pool is provided with a thorium purification fuel system, and on-line extraction of the purification fuel can be performed, and separation of nuclide is safe and simple, thereby providing a solution to the technical bottleneck of "thorium reactor".

Owner:陈安海

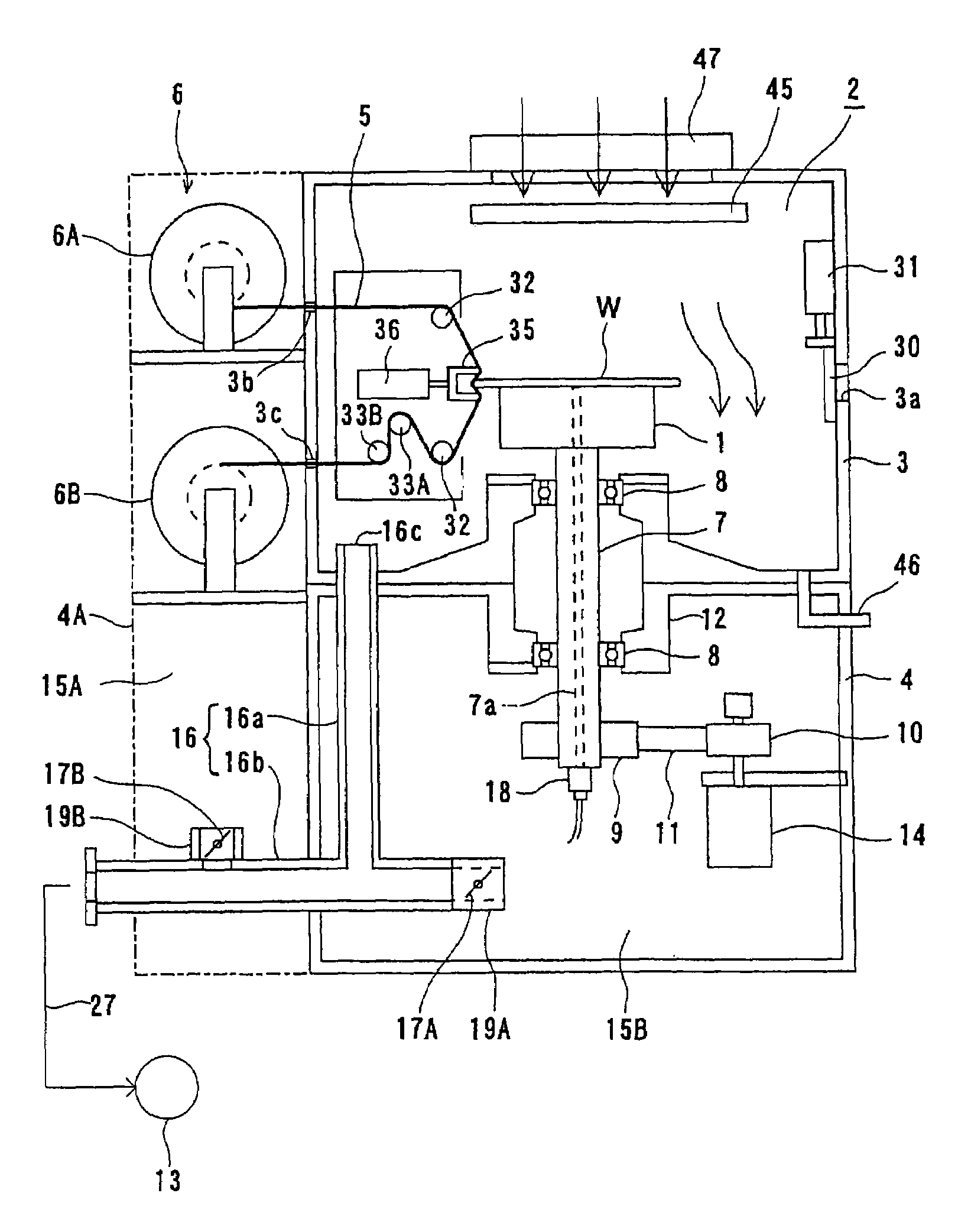

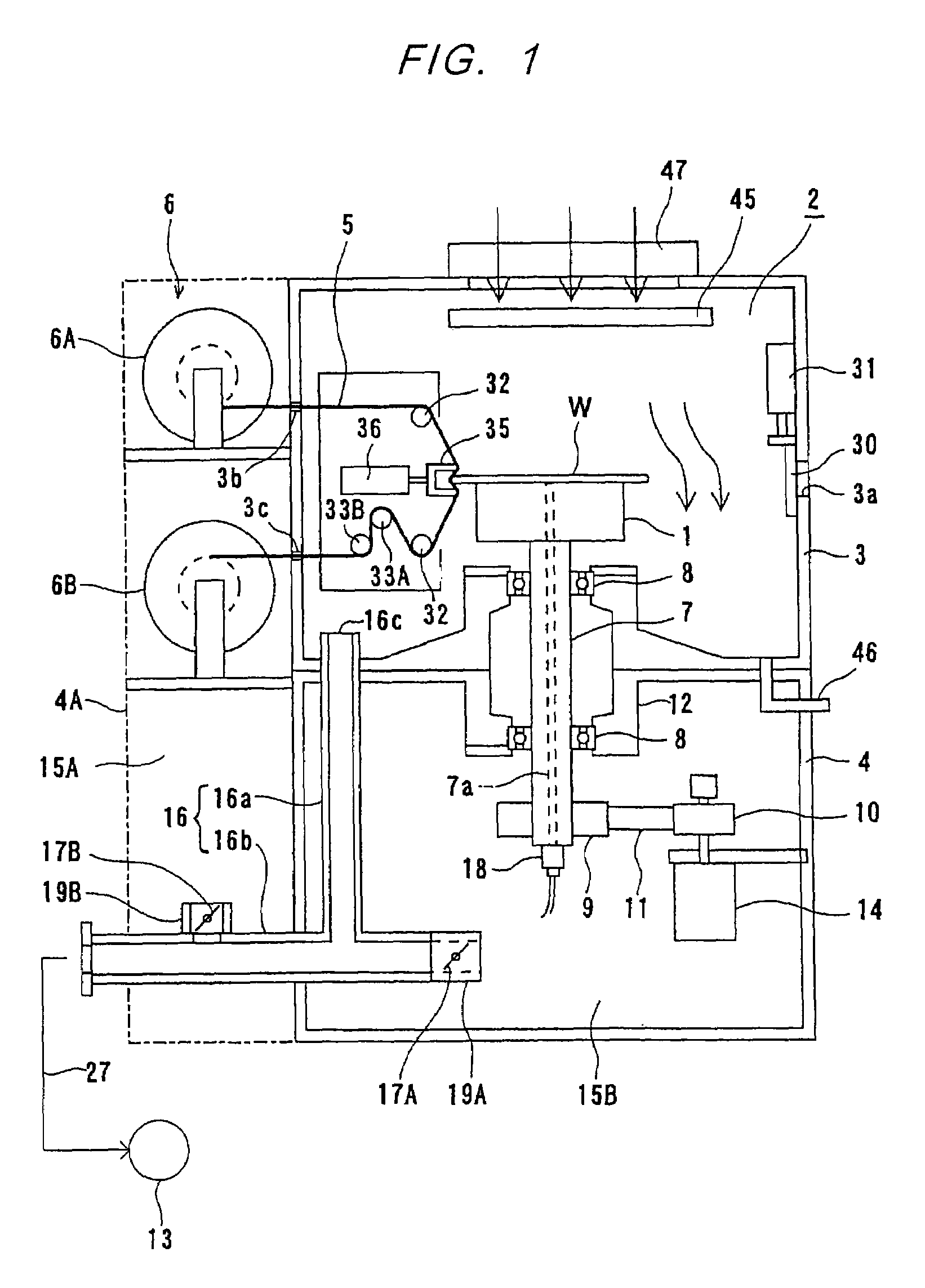

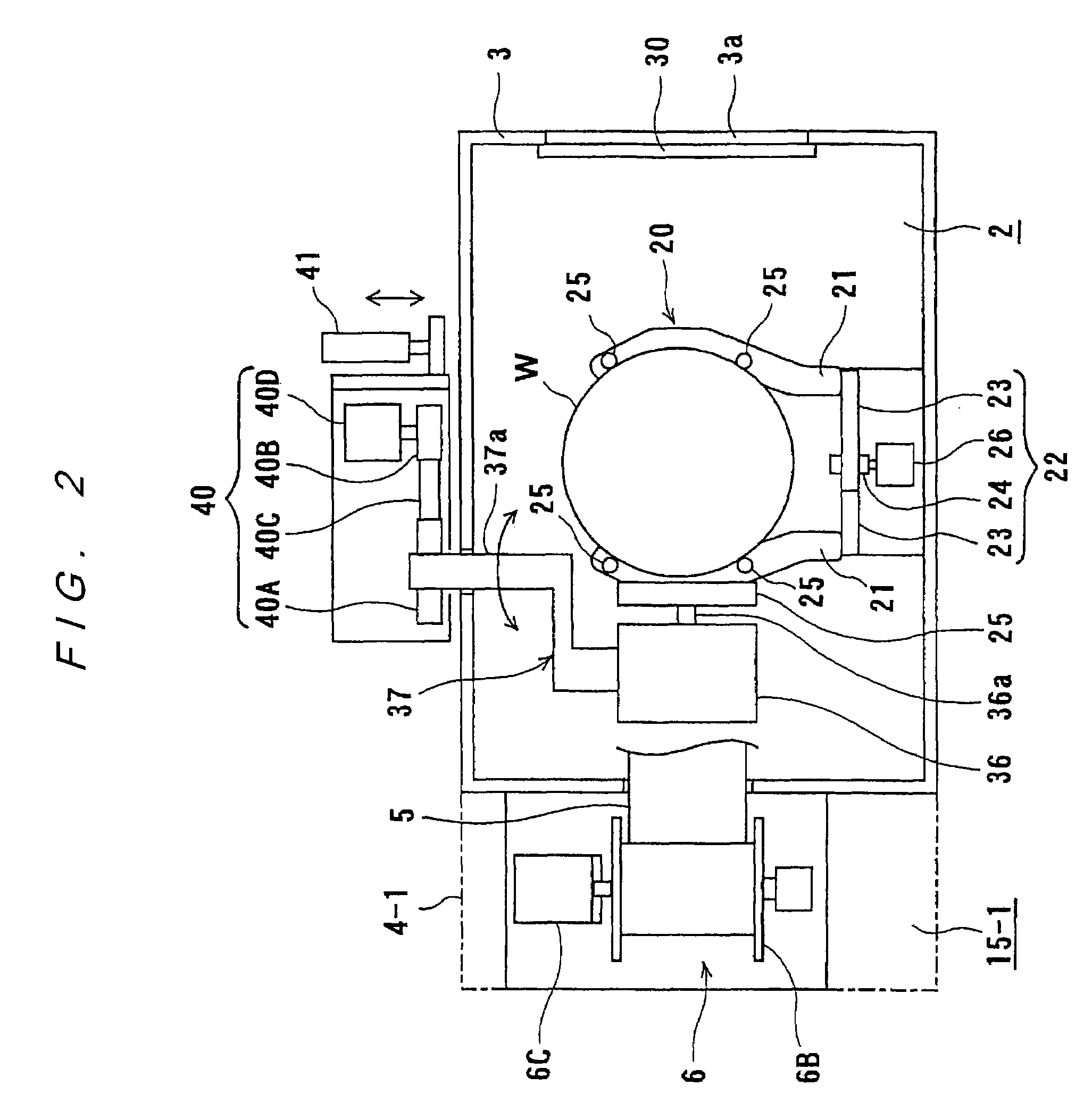

Polishing apparatus and substrate processing apparatus

ActiveUS7682225B2Inhibition of attachmentEasily be cleanEdge grinding machinesPolishing machinesInternal pressureSurface roughness

The present invention relates to a polishing apparatus for removing surface roughness produced at a peripheral portion of a substrate, or for removing a film formed on a peripheral portion of a substrate. The polishing apparatus includes a housing for forming a polishing chamber therein, a rotational table for holding and rotating a substrate, a polishing tape supply mechanism for supplying a polishing tape into the polishing chamber and taking up the polishing tape which has been supplied to the polishing chamber, a polishing head for pressing the polishing tape against a bevel portion of the substrate, a liquid supply for supplying a liquid to a front surface and a rear surface of the substrate, and a regulation mechanism for making an internal pressure of the polishing chamber being set to be lower than an external pressure of the polishing chamber.

Owner:EBARA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com