Patents

Literature

517 results about "Insulated pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

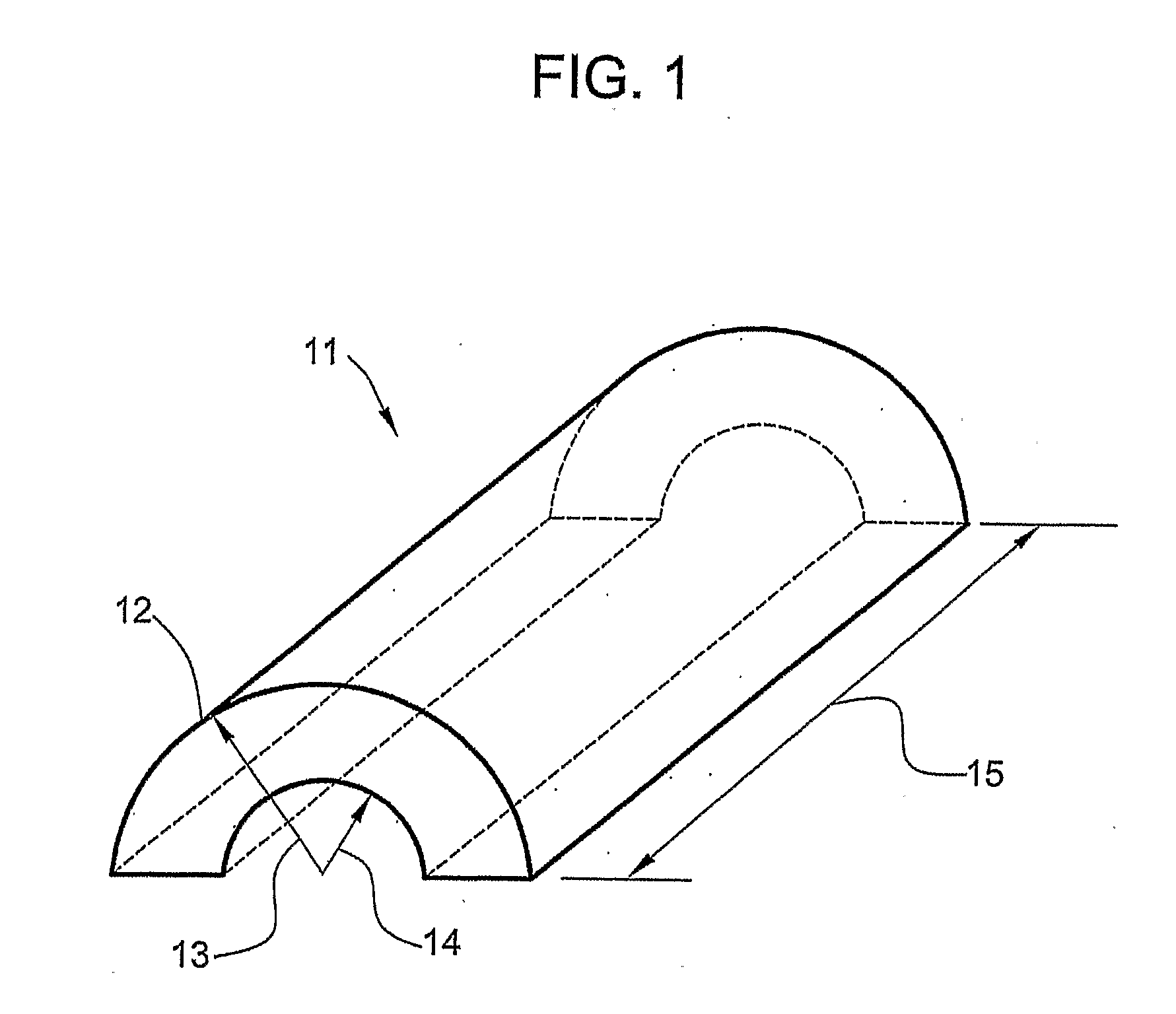

Insulated pipes (called also preinsulated pipes or bonded pipe ) are widely used for district heating and hot water supply in Europe. They consist of a steel pipe, an insulating layer, and an outer casing. The main purpose of such pipes is to maintain the temperature of the fluid in the pipes. A common application is the hot water from district heating plants. Most commonly used are single insulated pipes, but more recently in Europe it is becoming popular to use two pipes insulated within the same casing. By using insulated pipe supports, direct heat transfer between pipes and their supports are prevented.

Insulated pipe and method for preparing same

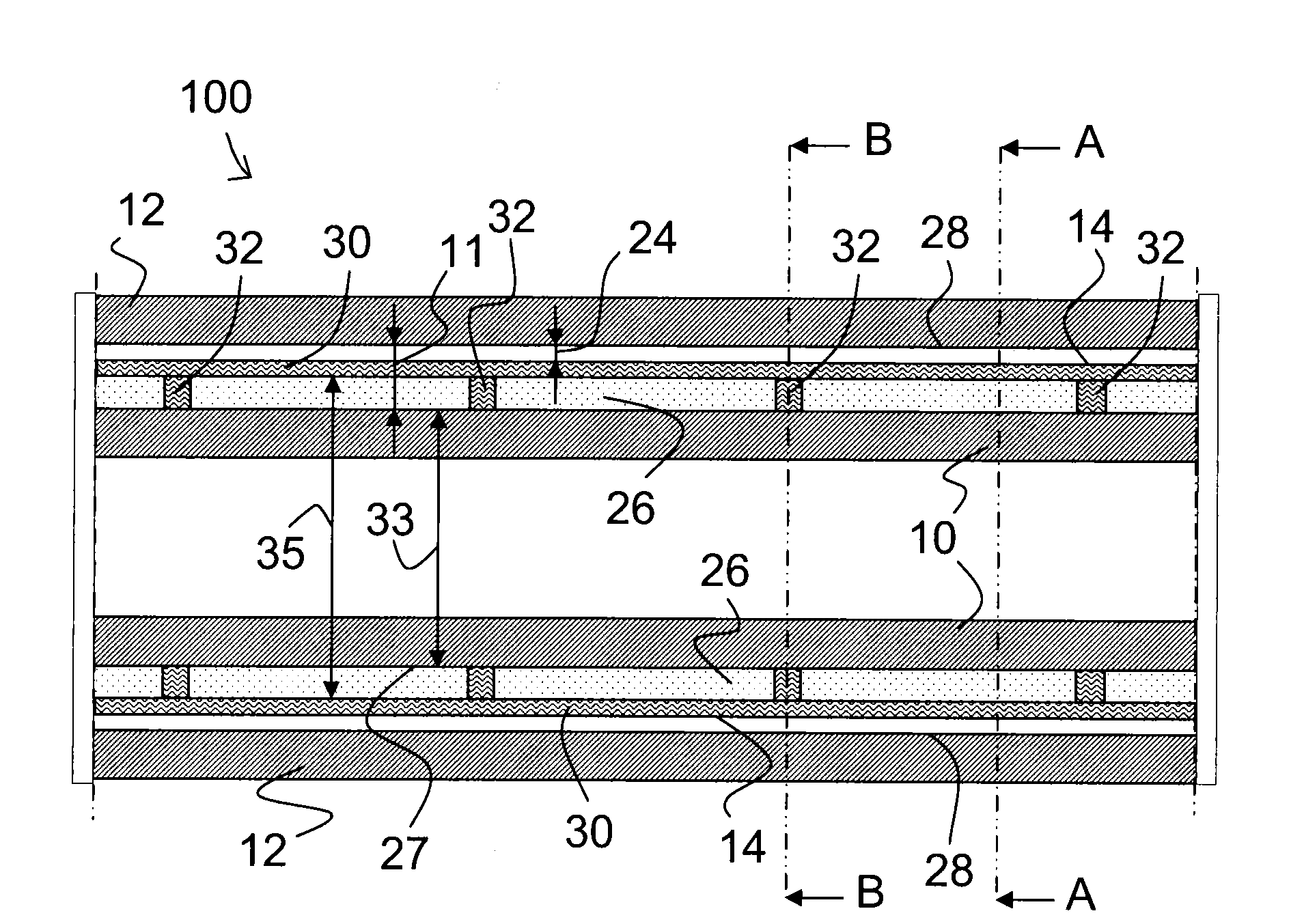

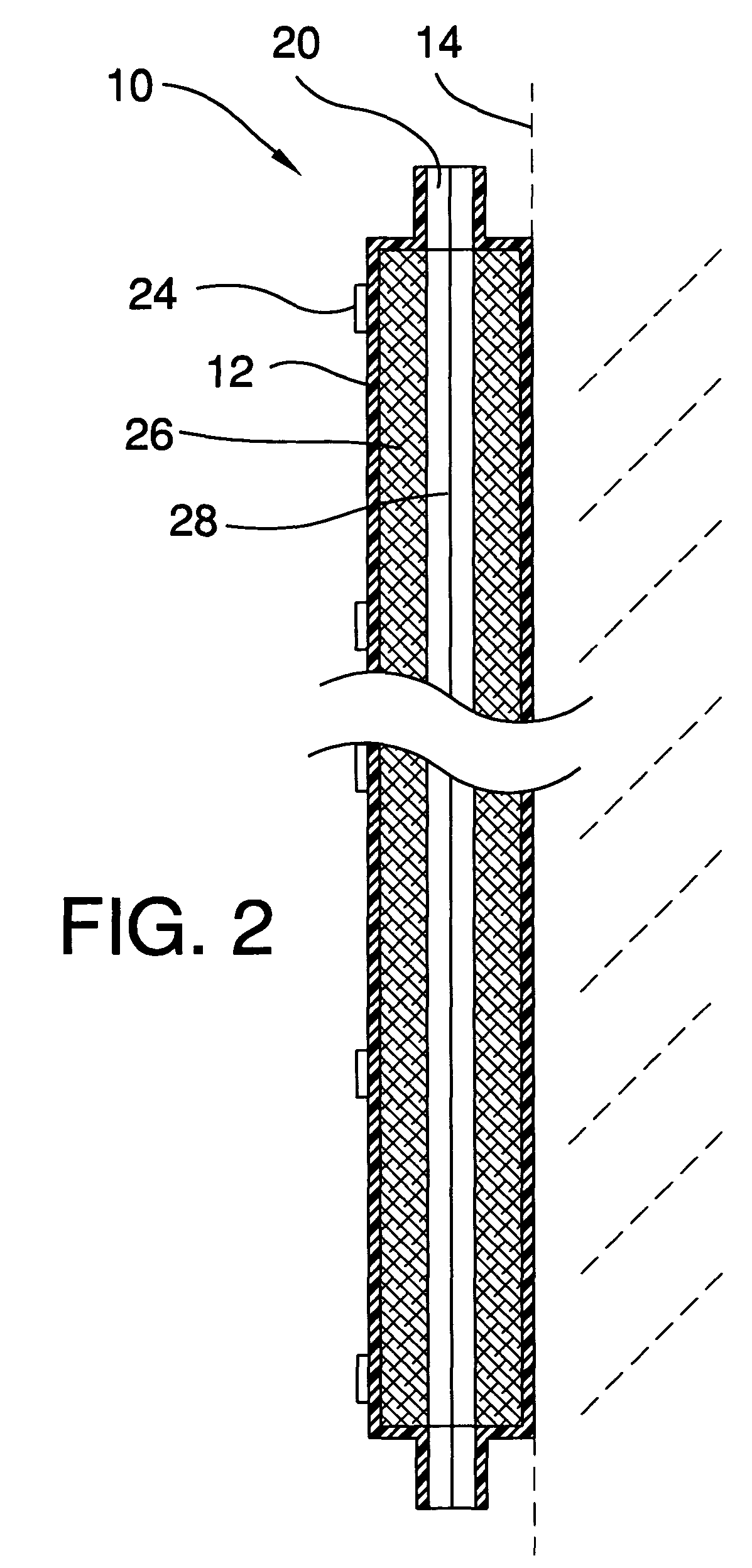

The invention provides an insulated pipe-in-pipe assembly comprising (a) at least one inner pipe, (b) an outer pipe disposed around the at least one inner pipe so as to create an annular space between the outer and inner pipes, (c) porous, resilient, compressible material disposed in the annular space, and (d) a remnant of a container that previously was positioned in the annular space and previously held the compressible material in a volume less than the volume of the compressible material in the annular space. The invention also provides a method for making such an insulated pipe-in-pipe assembly.

Owner:CABOT CORP

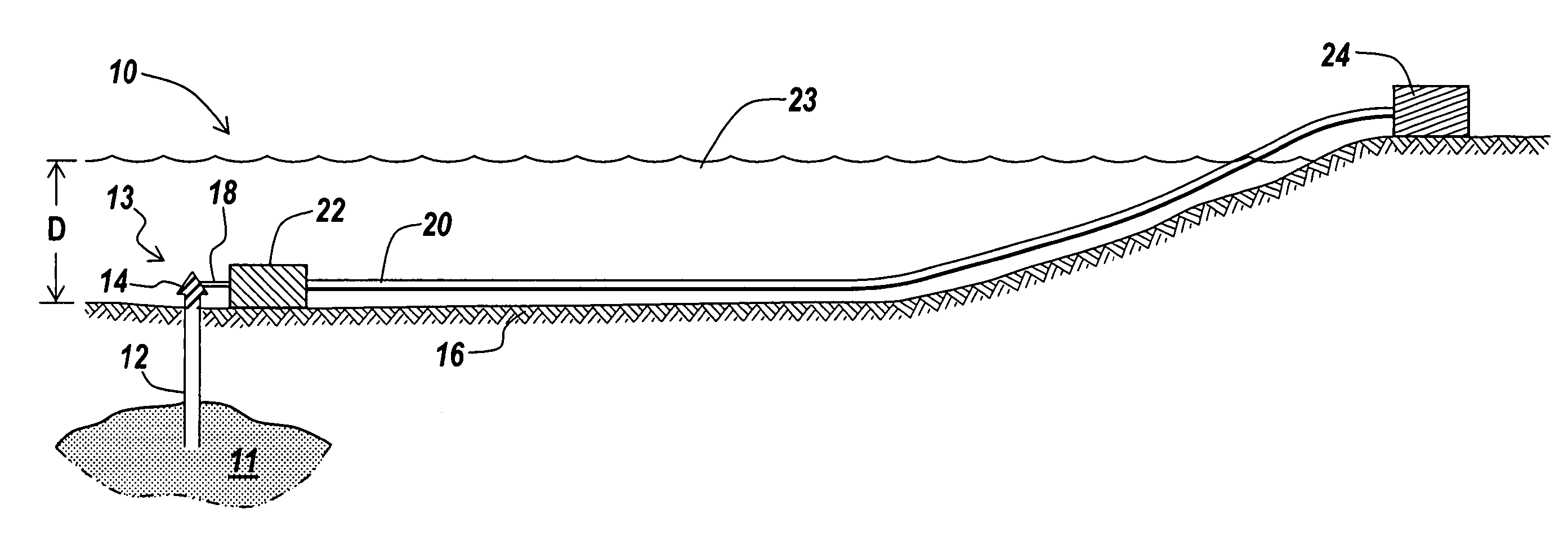

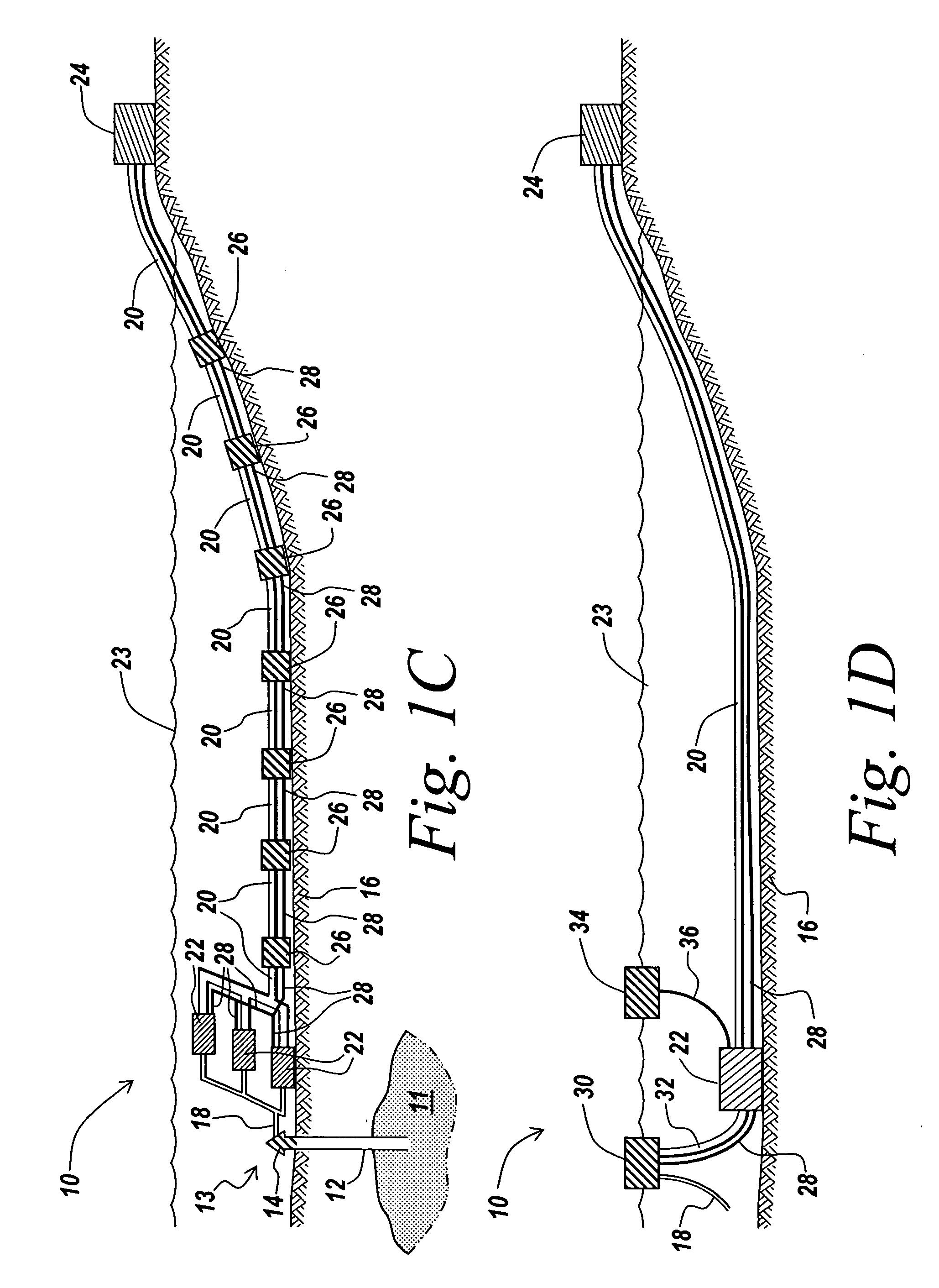

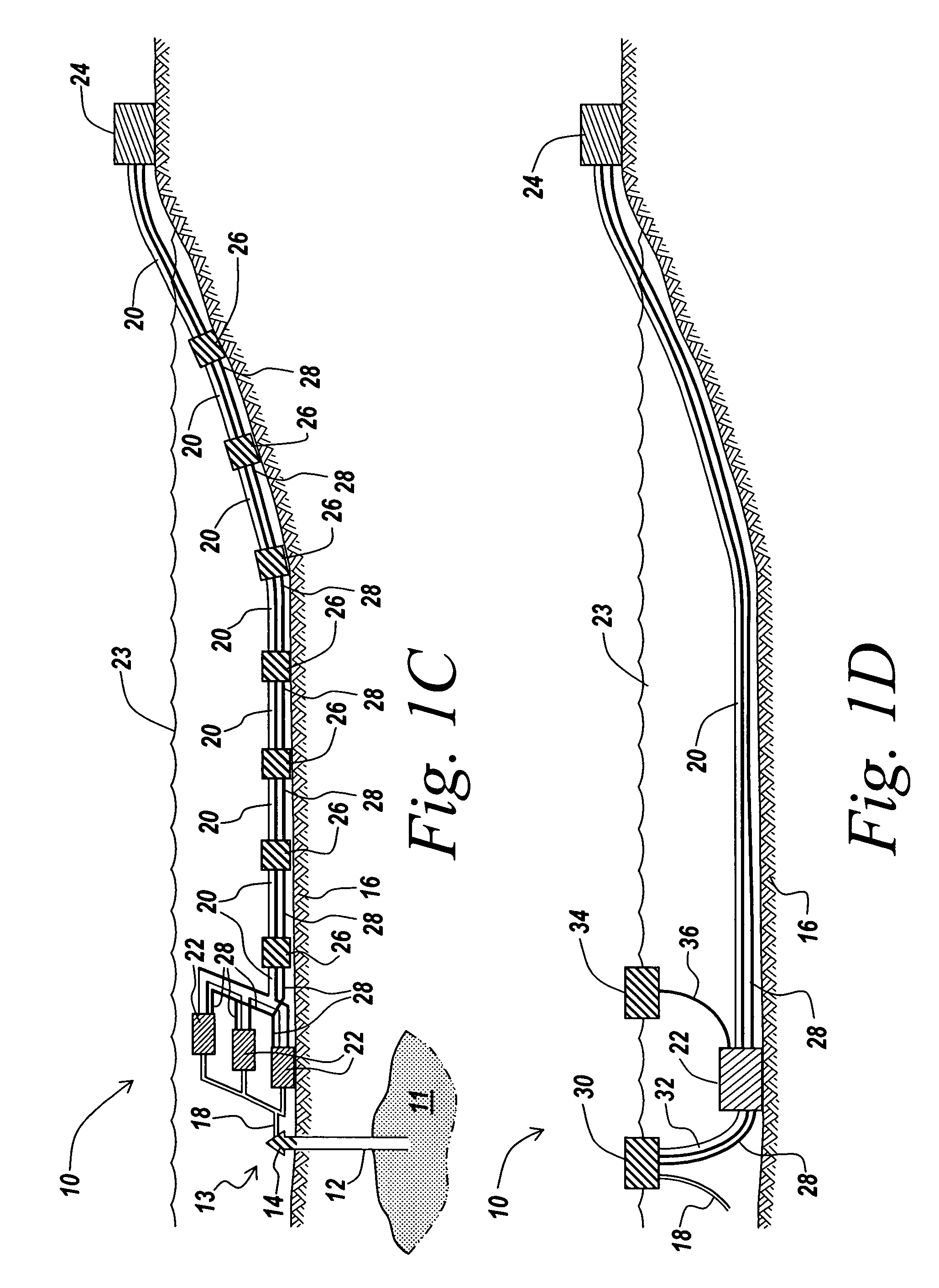

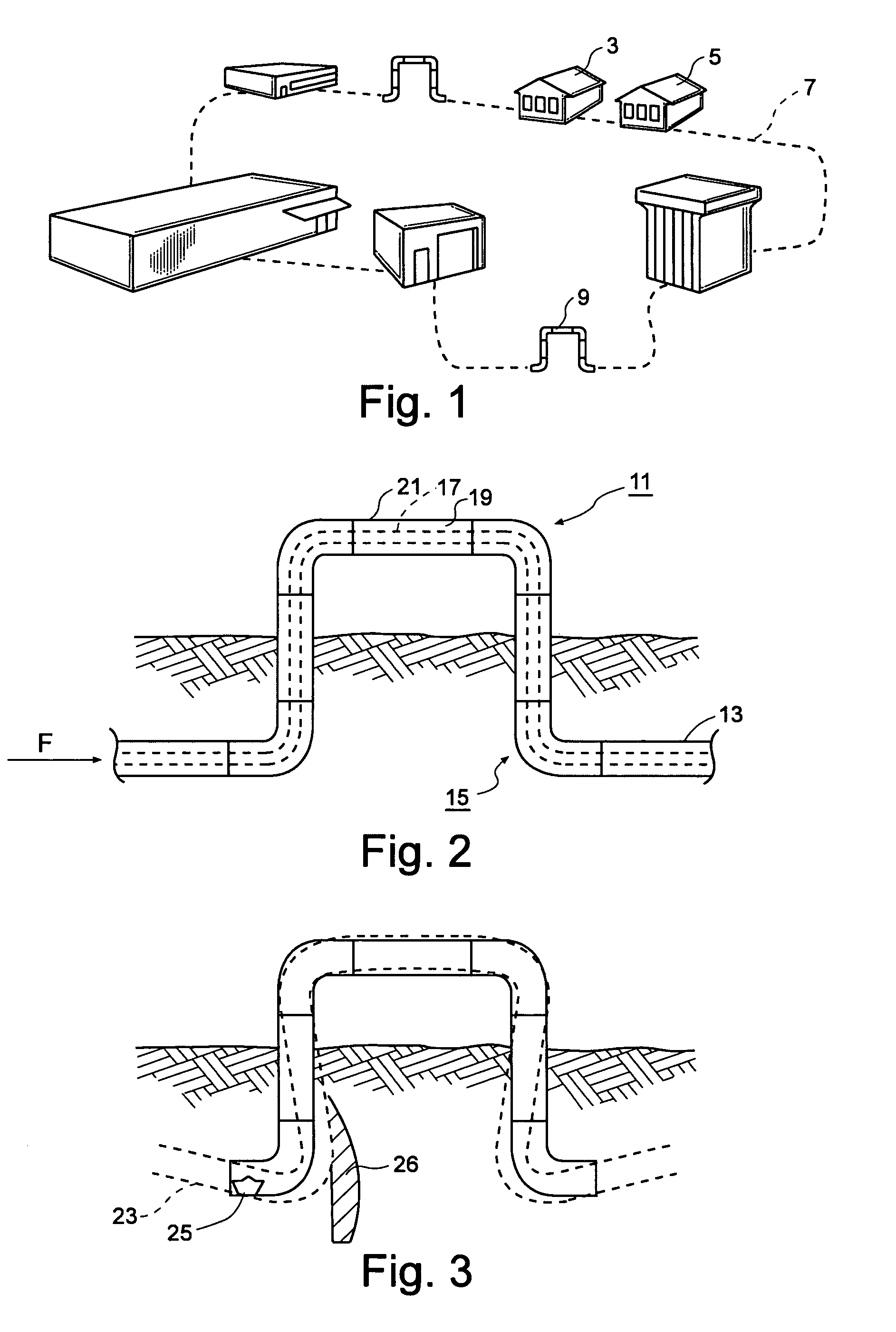

Undersea well product transport

InactiveUS20060175062A1Reduce and eliminate needEliminate and minimizeDrilling rodsInsulationHydrocotyle bowlesioidesShore

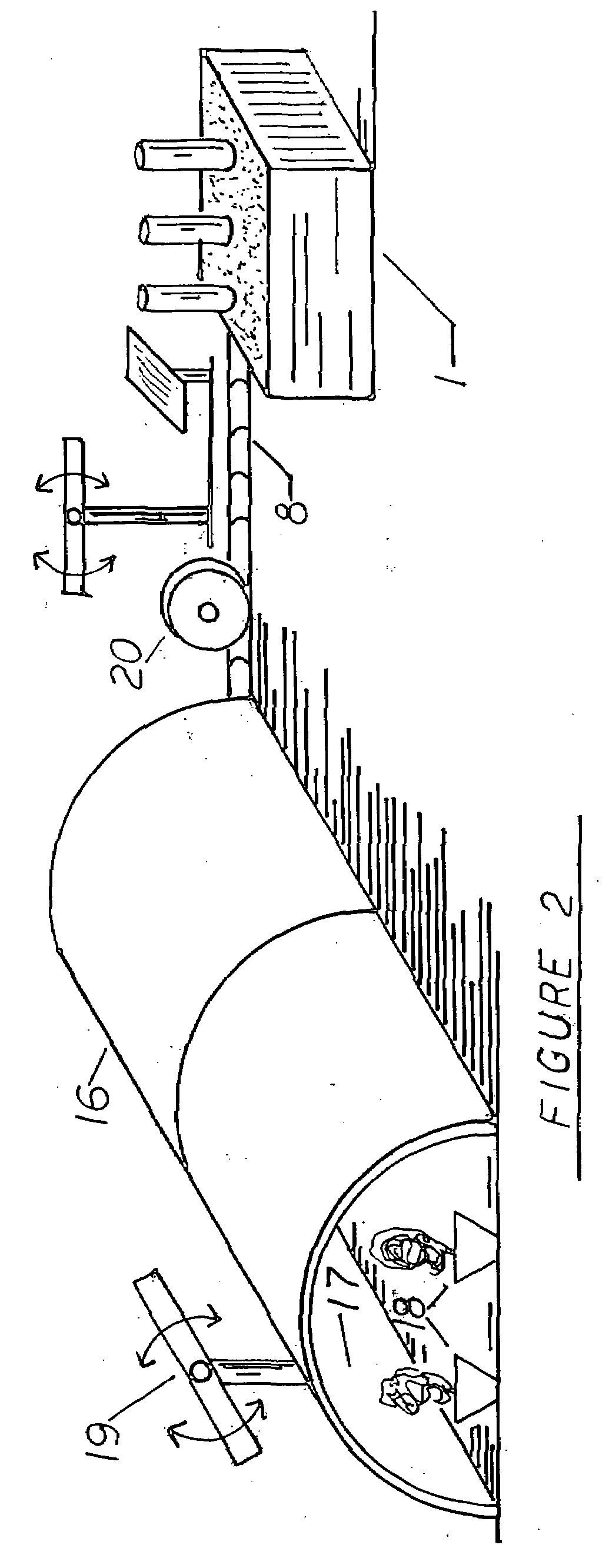

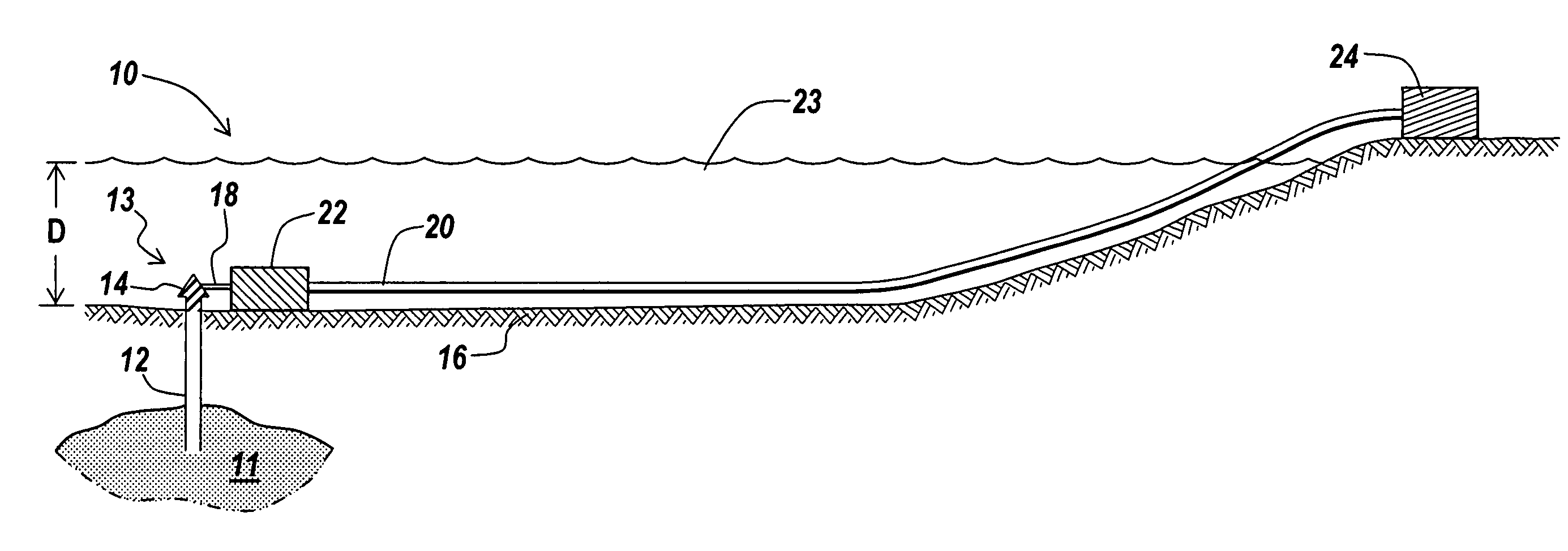

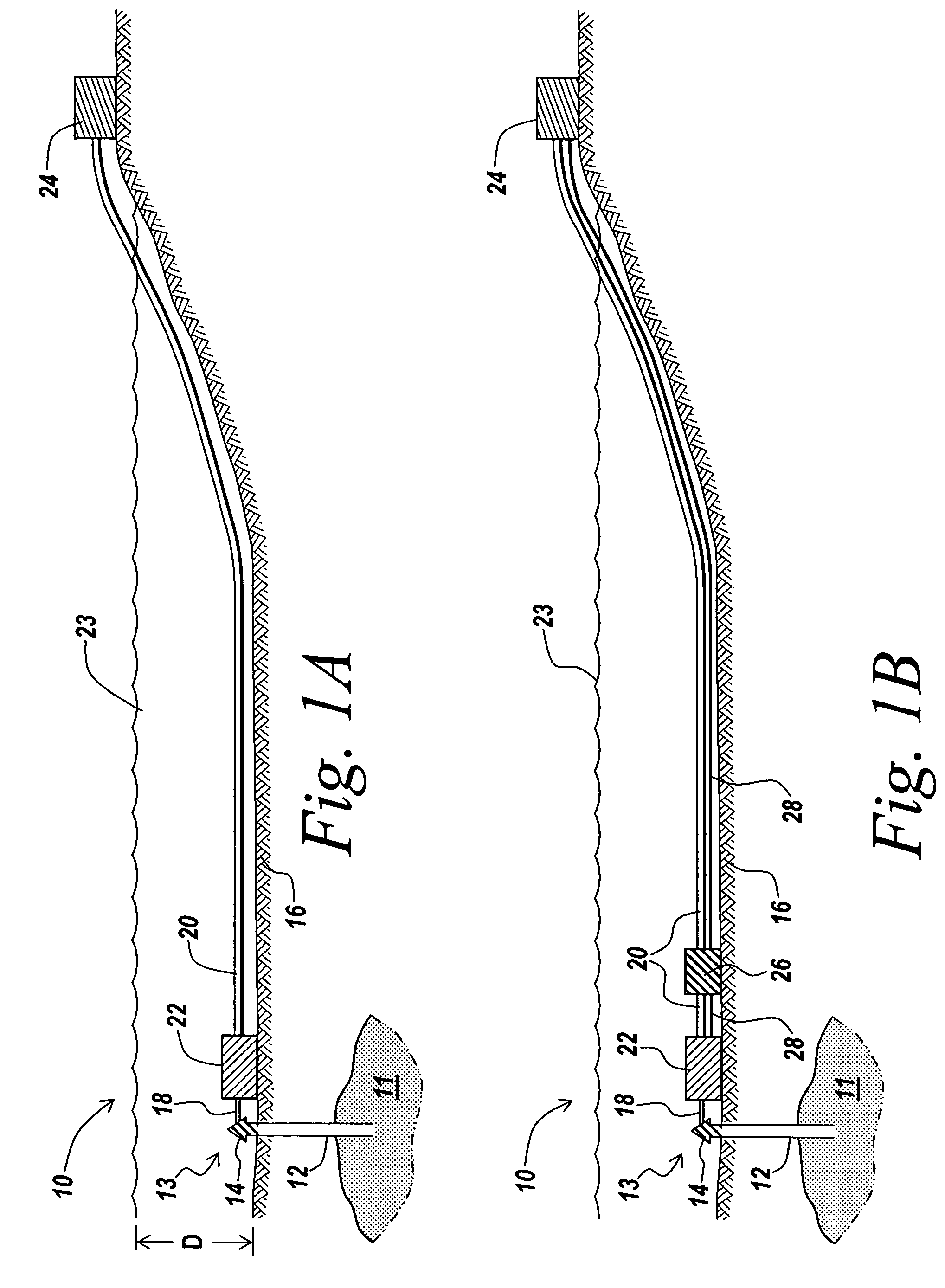

An apparatus and corresponding method of use extracts, cools, and transports effluents from subterranean, sub-sea oil formations to distant shore based processing facilities. The effluents, mostly crude oil, are conveyed rapidly to a cold flow generator near the oil wellhead on the sea bottom using the cold seawater to chill the effluents to a dispersed mixture including generated solids. The mixture is transported close to sea bottom temperatures, slowly, with small pressure drops, in low-cost submerged bare pipes over long distances to on or near shore processing facilities that can produce useful hydrocarbon products more cost effectively than at sea processing facilities. The apparatus eliminates or minimizes the need for heated or insulated pipe, the need for large floating processing structures, the need for sub-sea processing equipment, and / or the need for chemical additions to production flow.

Owner:BENSON ROBERT A

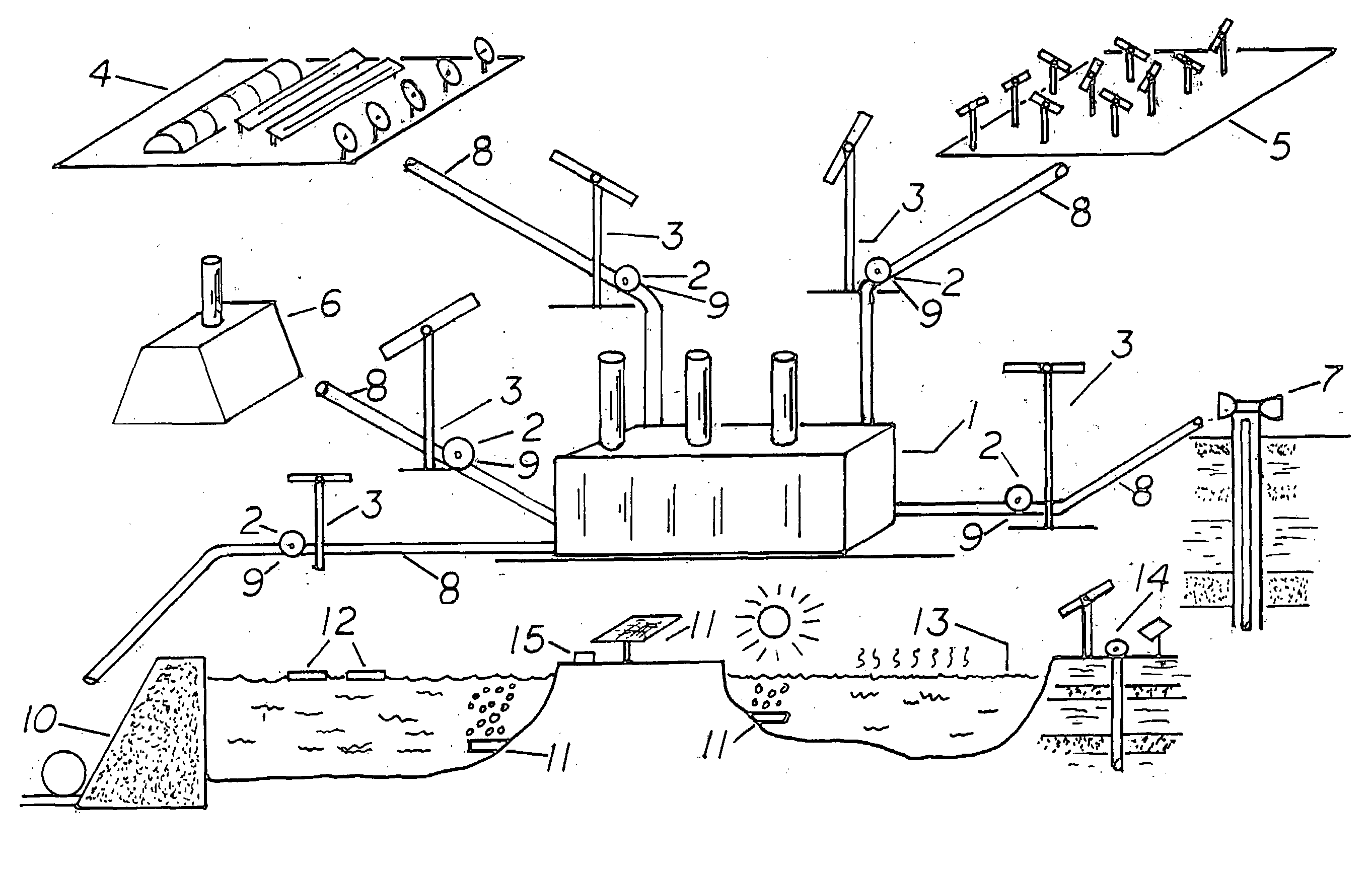

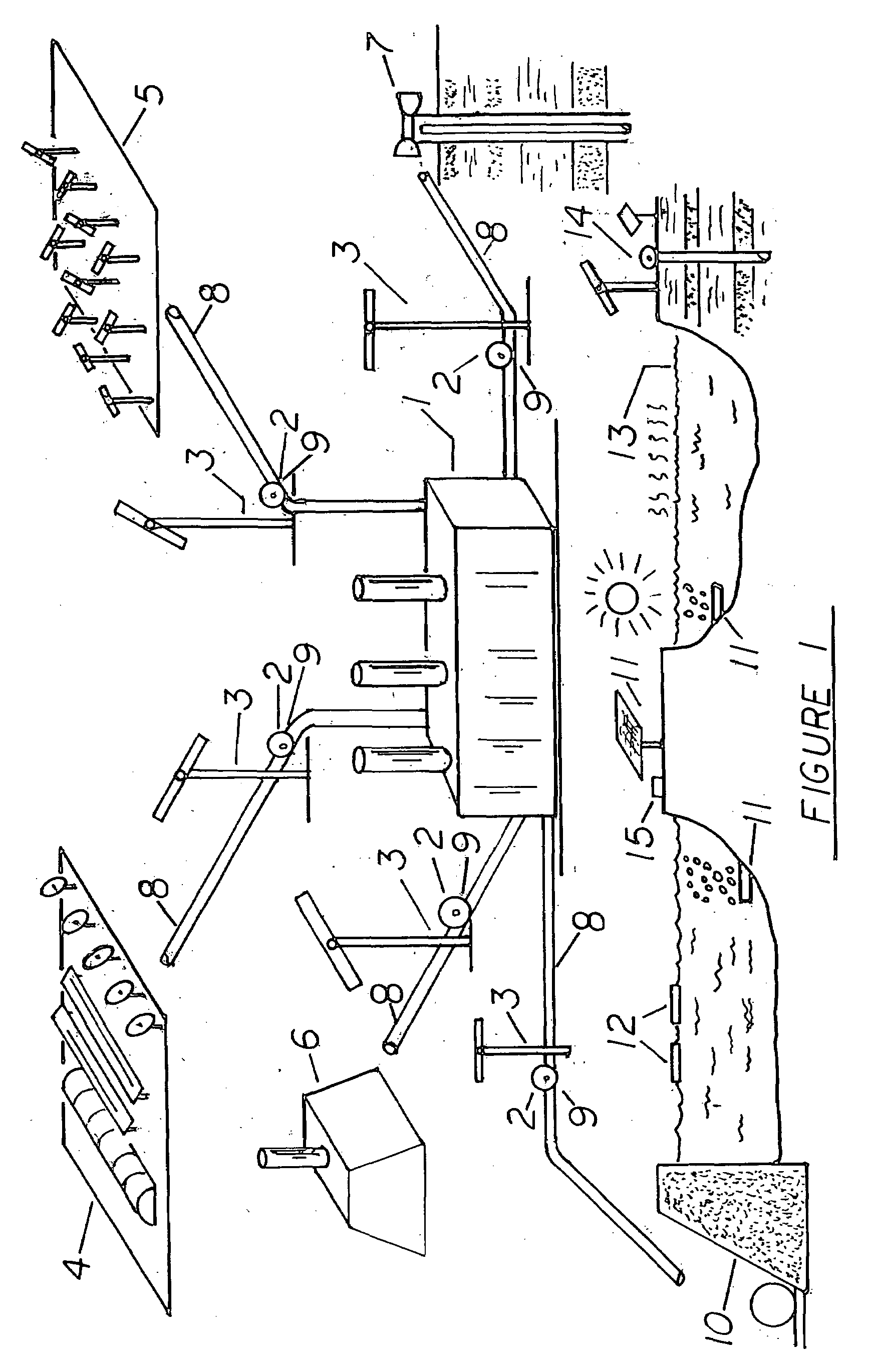

Use of renewable energy like solar, wind, geothermal, biomass, and hydropower for manufacturing combustion air for a fossil fuel burner and firebox

InactiveUS20080131830A1Reduce the amount requiredCarbon reductionSolar heating energyFuel heating with wind energyCombustion chamberEvaporation

Invented is a method of making combustion air for a fossil fuel burner, as a coal burning power plant, oil refinery or gas fired household appliance. Combustion air is made from solar, wind, biomass, hydropower or geothermal. A staged progression using lower cost greenhouses, or flatplates, or solarponds, feed warm air to higher cost concentrator solar collectors. Wind energy, biomass, geothermal energy heat and compress combustion air. Hydropower also heats and compresses combustion air. Solar evaporation from salt or impure water creates water or local rain for the hydropower system. Combustion air thus is made economically hot, compressed and high velocity, and placed into a heavily insulated pipes for long distance transmission to a distant power plant.

Owner:NIX MARTIN E

Thermally insulated pipe for use at very high temperatures

InactiveUS20100154917A1Thermal insulationPipe protection by thermal insulationOcean bottomInsulation layer

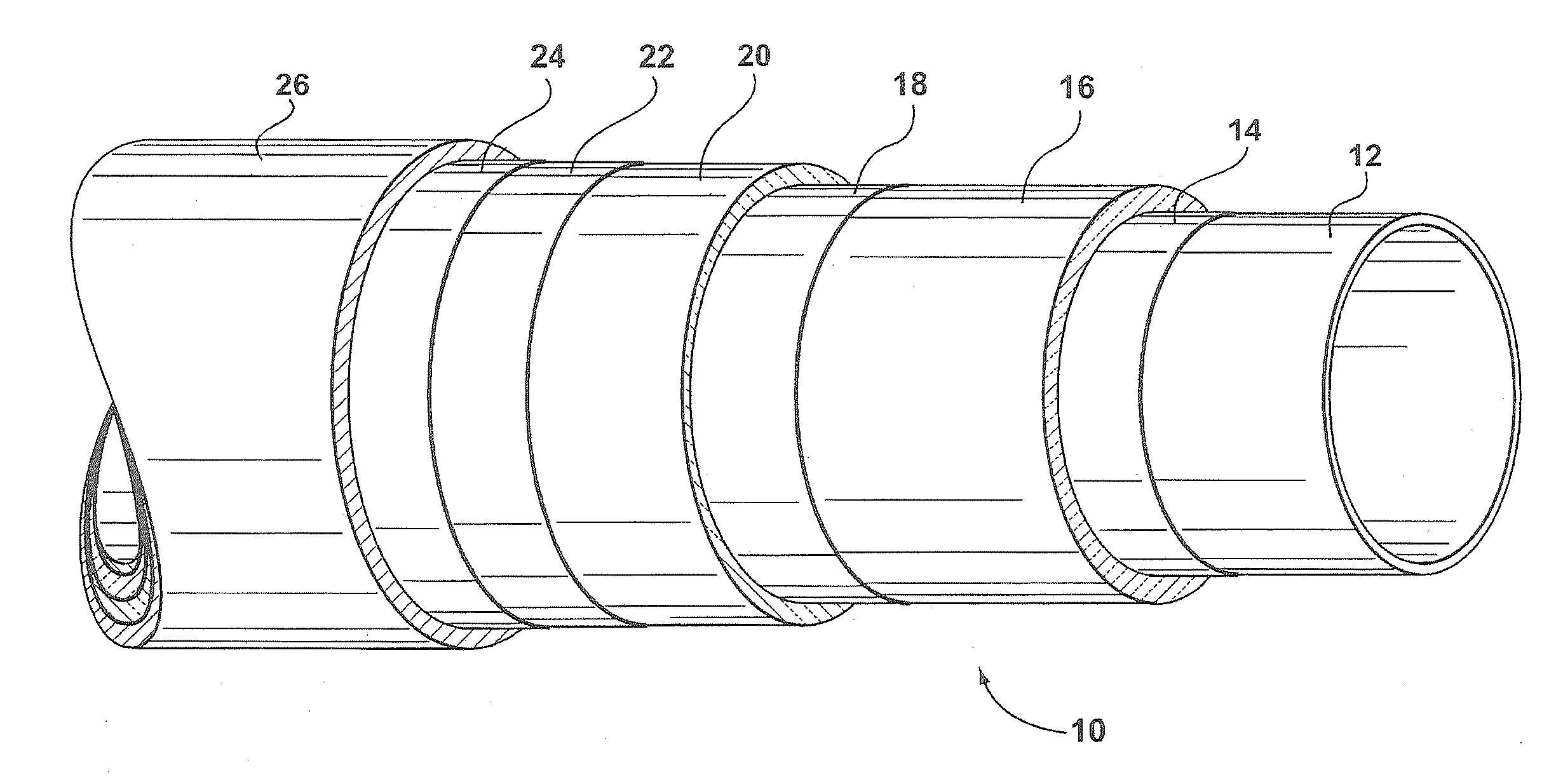

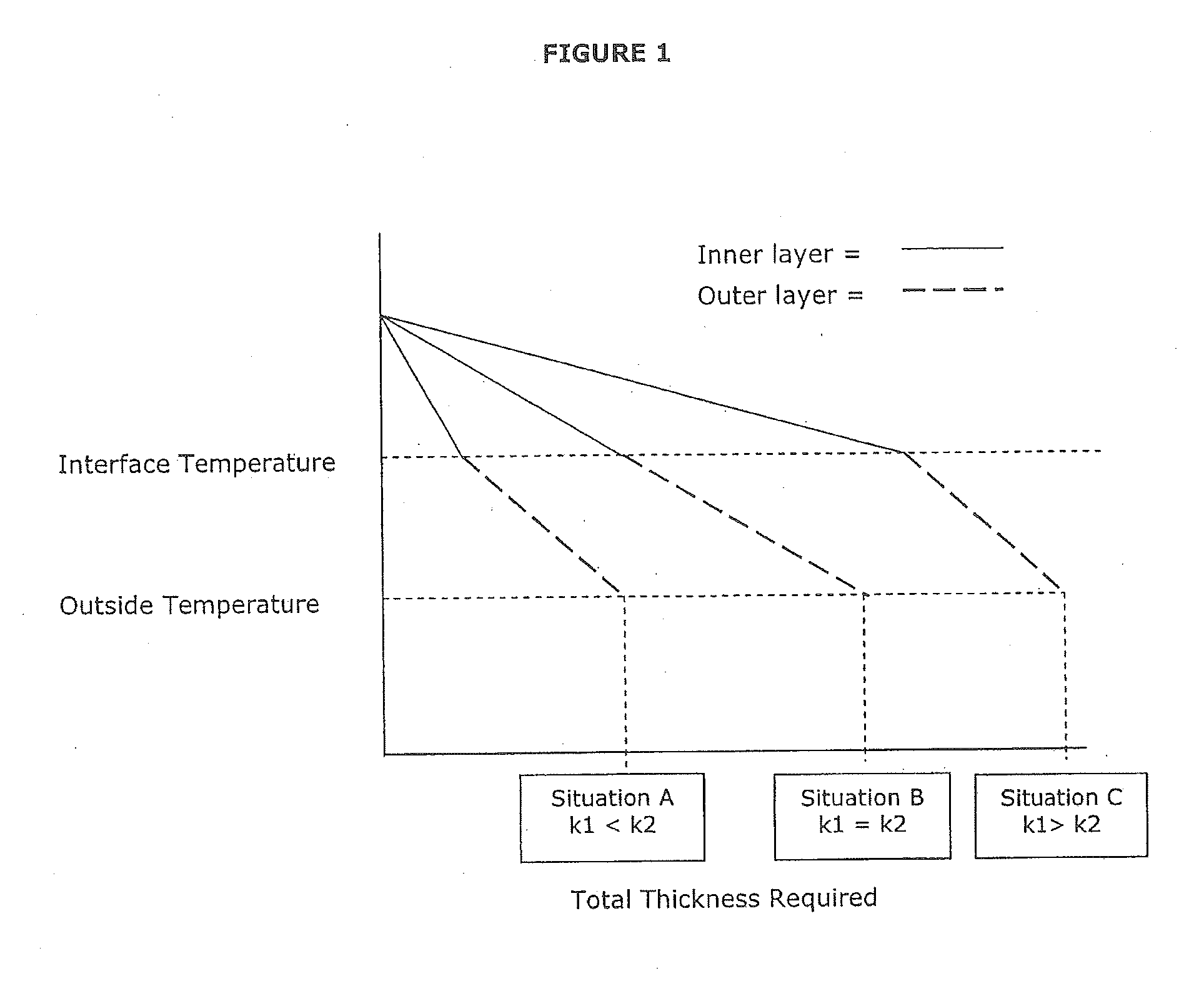

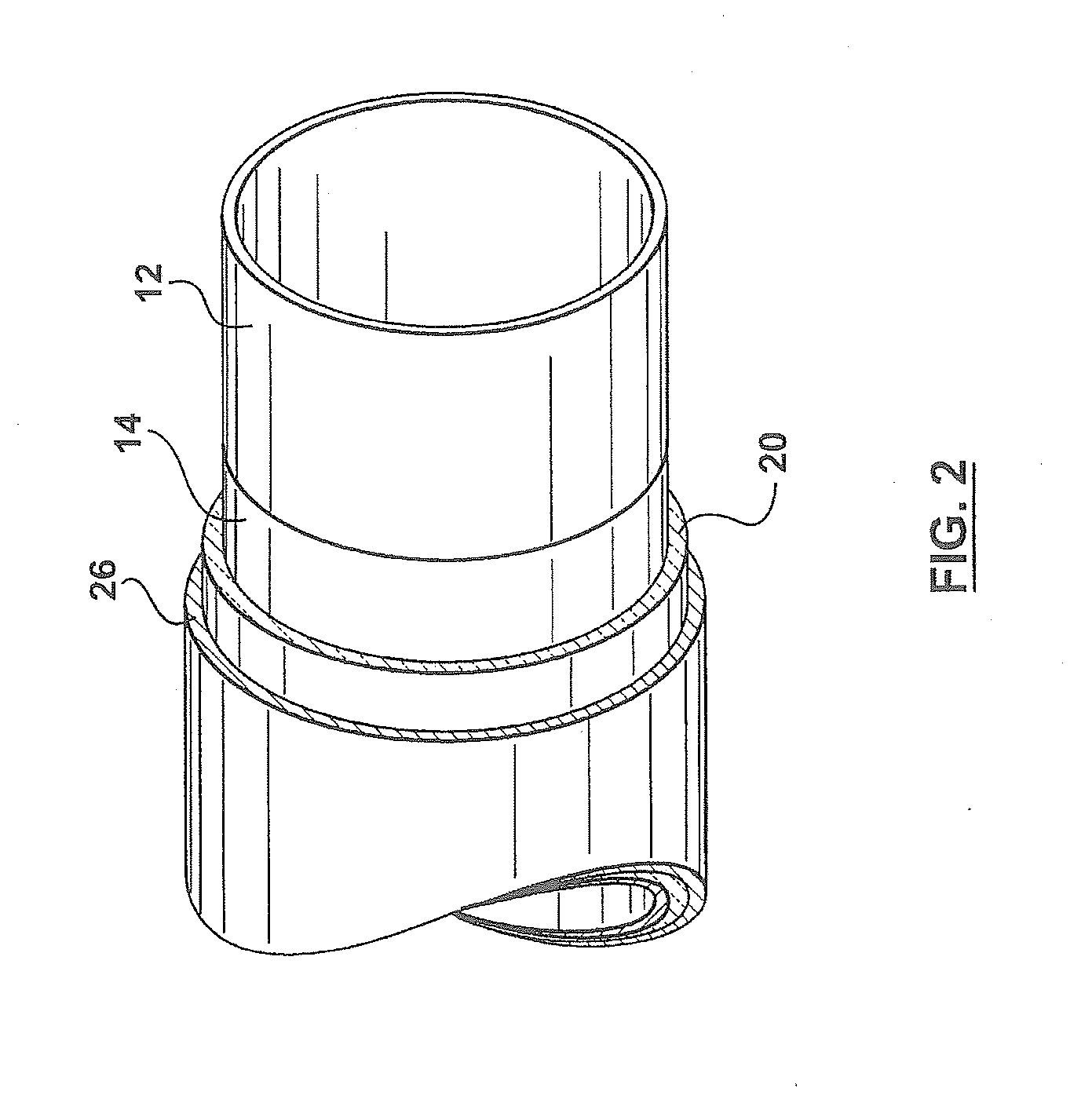

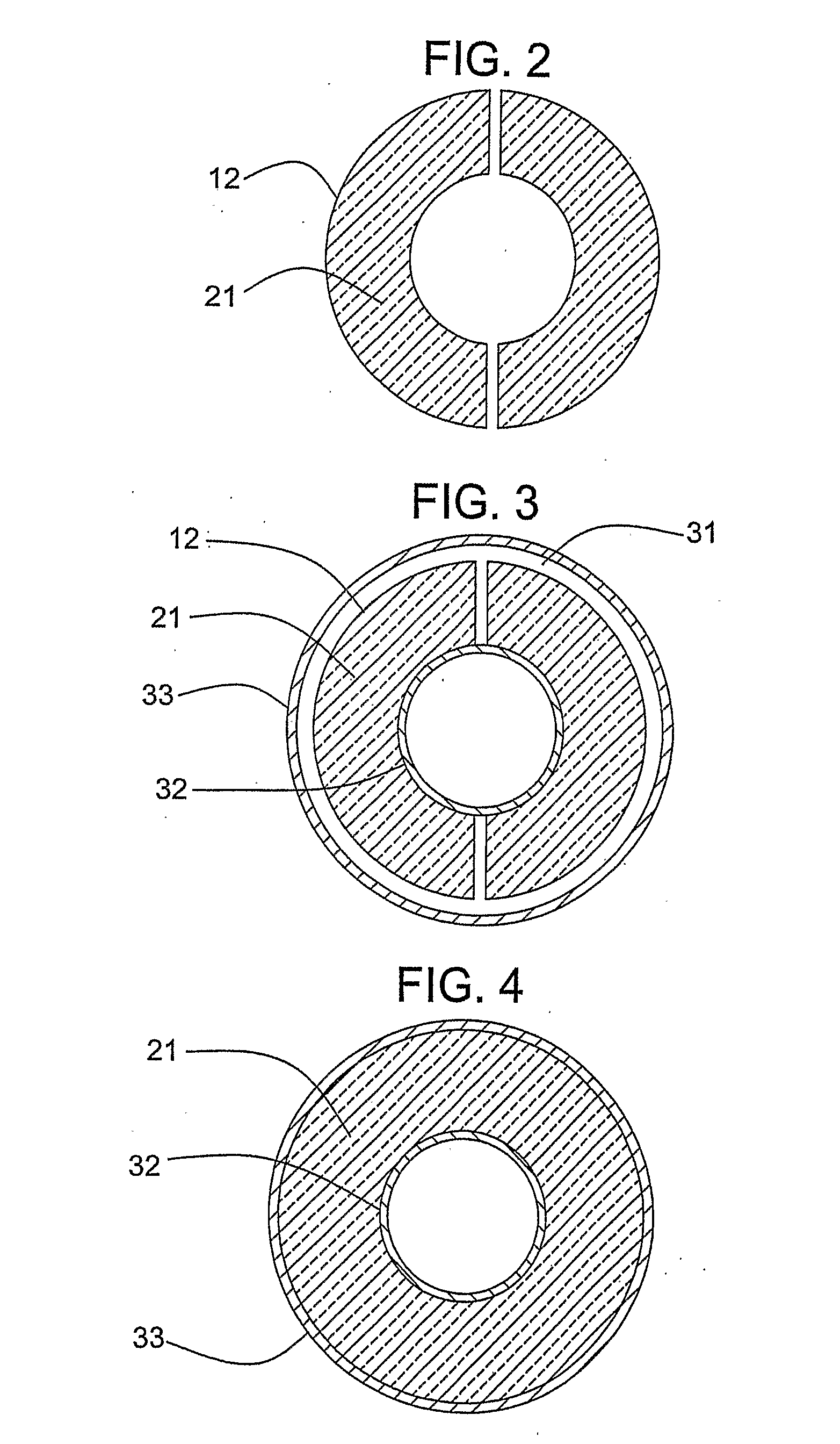

The present invention provides an insulated pipe comprising a pipe and a composite insulation system, said composite insulation system comprising: (a) a first insulation layer comprising a first insulation material having a thermal conductivity k-factor value of less than 0.023 W / m-K at 38° C.; and (b) at least one additional insulation layer comprising an insulation material having a thermal conductivity k-factor greater than that of the first insulation material and a maximum operating temperature limit less than that of the first insulation layer. The composite insulation system is bonded to an exterior surface of the pipe with the first insulation layer facing towards said exterior surface of the pipe. At least one of said first insulation layer or said at least one additional layer extends continuously about the exterior surface of the pipe. The present invention further provides an insulated pipe for use in an undersea pipeline and an insulated pipe for use in a subterranean pipeline.

Owner:SHAWCOR LTD

Low temperature method and system for forming field joints on undersea pipelines

A method for forming a field joints between sections of coated or insulated pipe which are to be welded together and incorporated into an undersea pipeline for carrying single or multi-phase fluids such as oil, gas and water. The method includes the application of a liquid epoxy layer which overlaps a lip of the factory-applied FBE coating protruding beyond a chamfered end of the factory-applied insulation layer, and which may be applied over the entire weld joint area. The liquid epoxy layer is partially cured by application of heat, and a layer of powdered adhesive is applied onto the partially cured liquid epoxy layer. The adhesive is subsequently sintered and activated by application of heat to its outer surface. The outer surfaces of the adhesive layer and the chamfers are then preheated and the thermal joint insulation is injection molded over the entire joint area. Throughout the entire method the temperature of the factory-applied FBE coating is maintained below its glass transition temperature so as to avoid weakening the bond between the FBE coating and the underlying steel pipe. The number and sequence of steps can be varied, depending at least partly on whether the liquid epoxy and adhesive layers are applied in a pipe coating facility or in the field.

Owner:SHAWCOR LTD

Manufacturing and Installation of Insulated Pipes or Elements Thereof

InactiveUS20110197987A1Easy to processEasy to installThermal insulationPipe protection by thermal insulationParticulatesAerogel

Insulated pipe systems or assemblies include a particulate, composite or monolithic insulating aerogel material. Techniques for installing or manufacturing such systems or assemblies are described, as are components useful in the installation or manufacture processes.

Owner:CABOT CORP

Undersea well product transport

InactiveUS7703535B2Reduce and eliminate needEliminate and minimizeDrilling rodsInsulationShoreSeawater

An apparatus and corresponding method of use extracts, cools, and transports effluents from subterranean, sub-sea oil formations to distant shore based processing facilities. The effluents, mostly crude oil, are conveyed rapidly to a cold flow generator near the oil wellhead on the sea bottom using the cold seawater to chill the effluents to a dispersed mixture including generated solids. The mixture is transported close to sea bottom temperatures, slowly, with small pressure drops, in low-cost submerged bare pipes over long distances to on or near shore processing facilities that can produce useful hydrocarbon products more cost effectively than at sea processing facilities. The apparatus eliminates or minimizes the need for heated or insulated pipe, the need for large floating processing structures, the need for sub-sea processing equipment, and / or the need for chemical additions to production flow.

Owner:BENSON ROBERT A

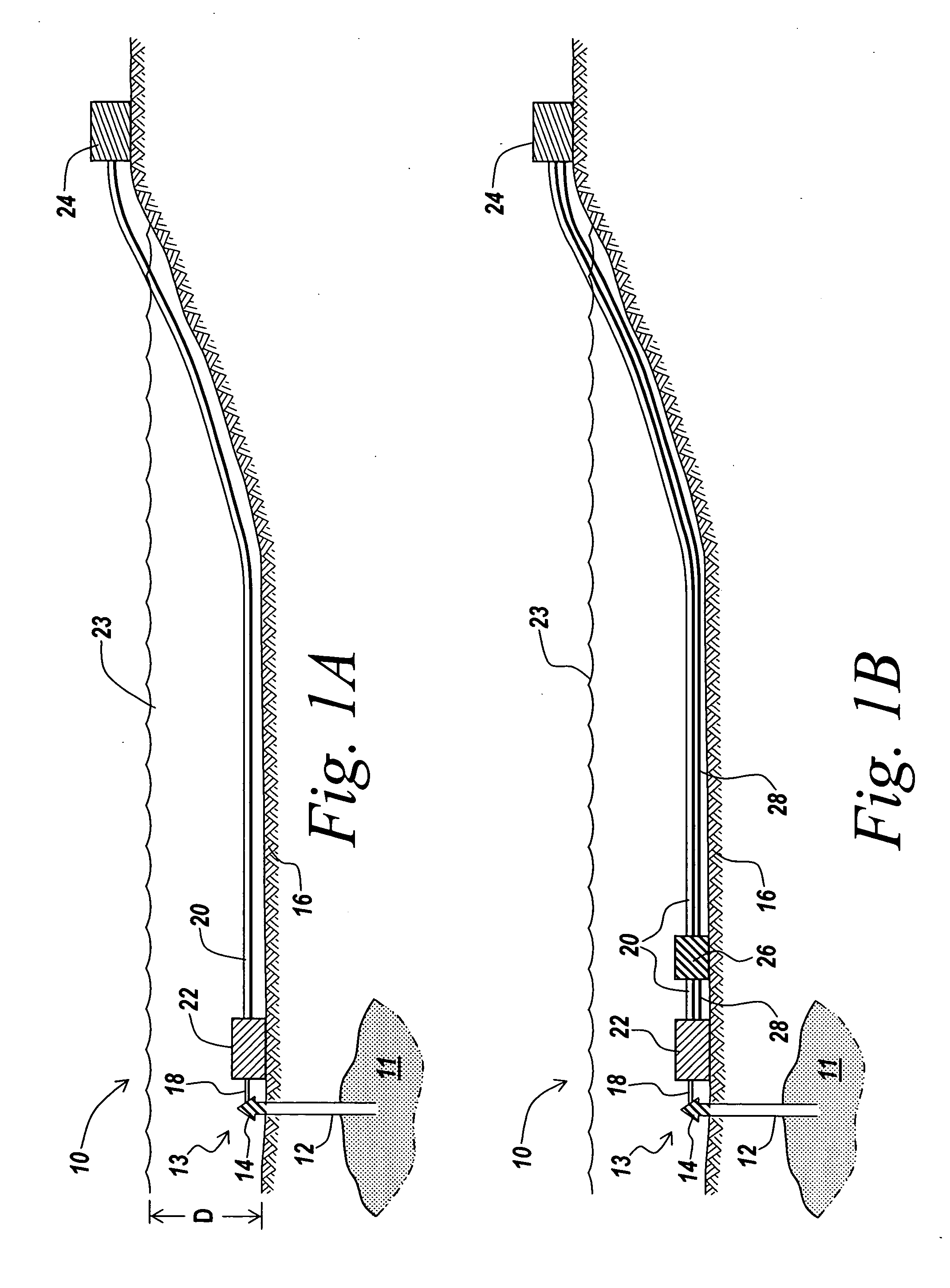

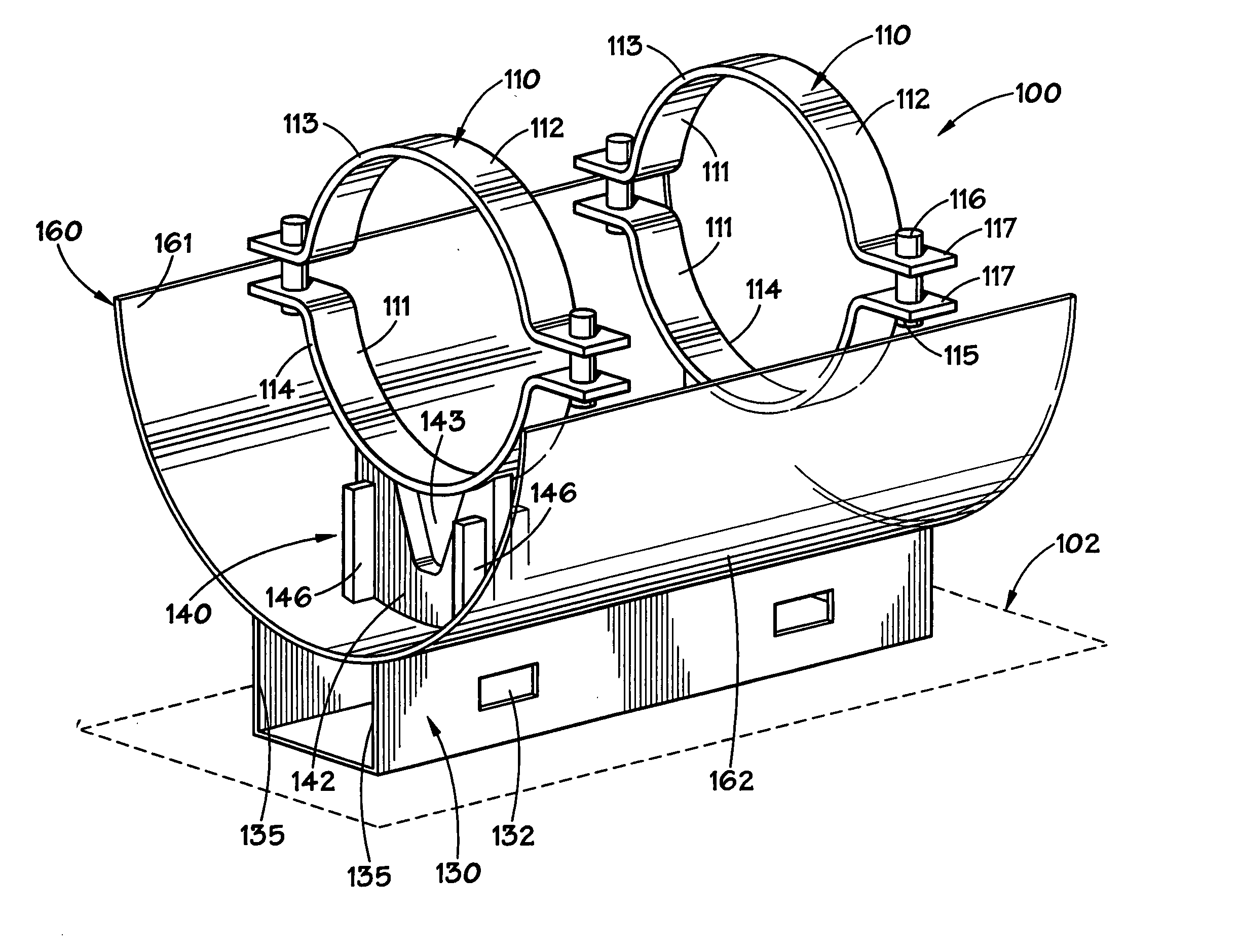

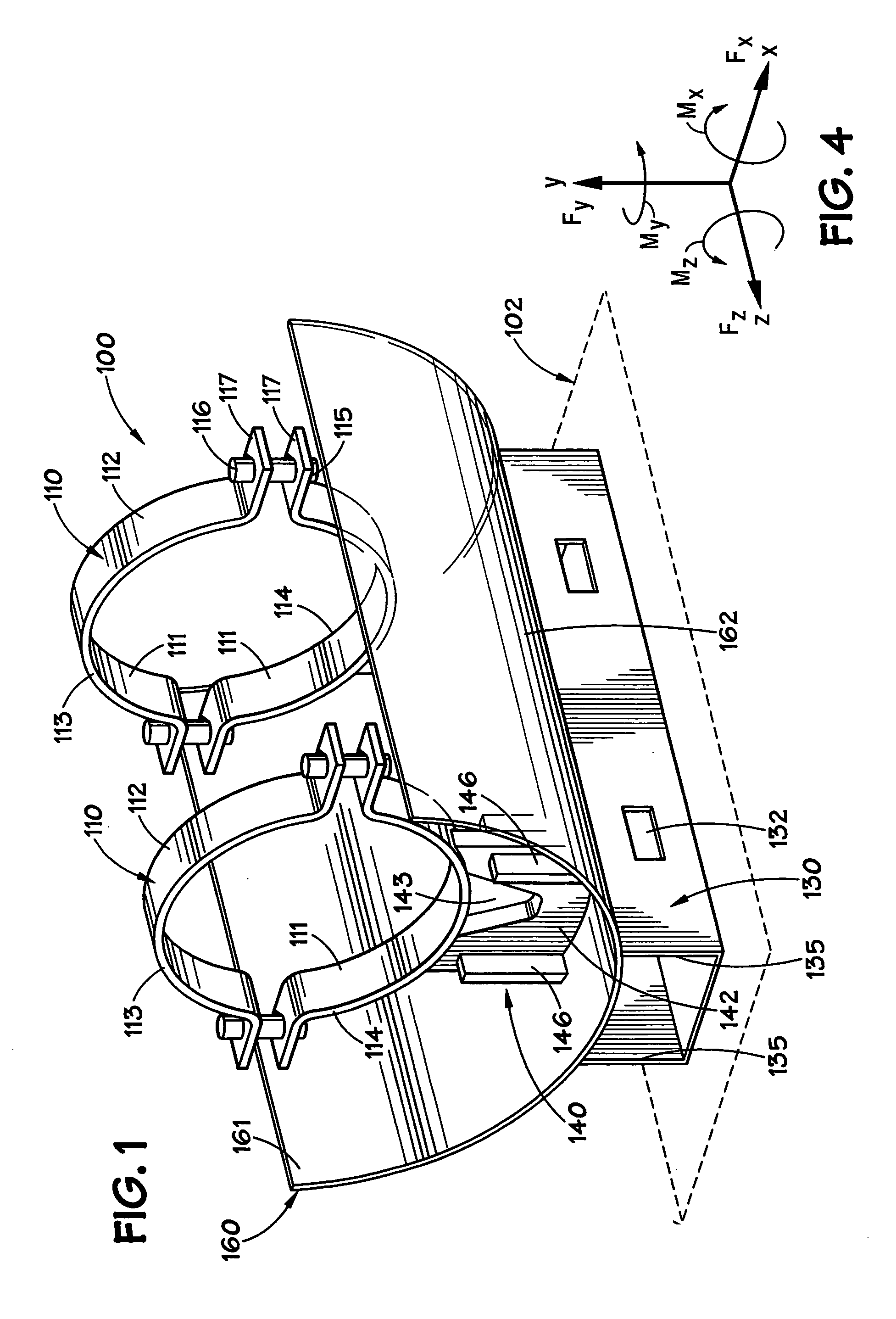

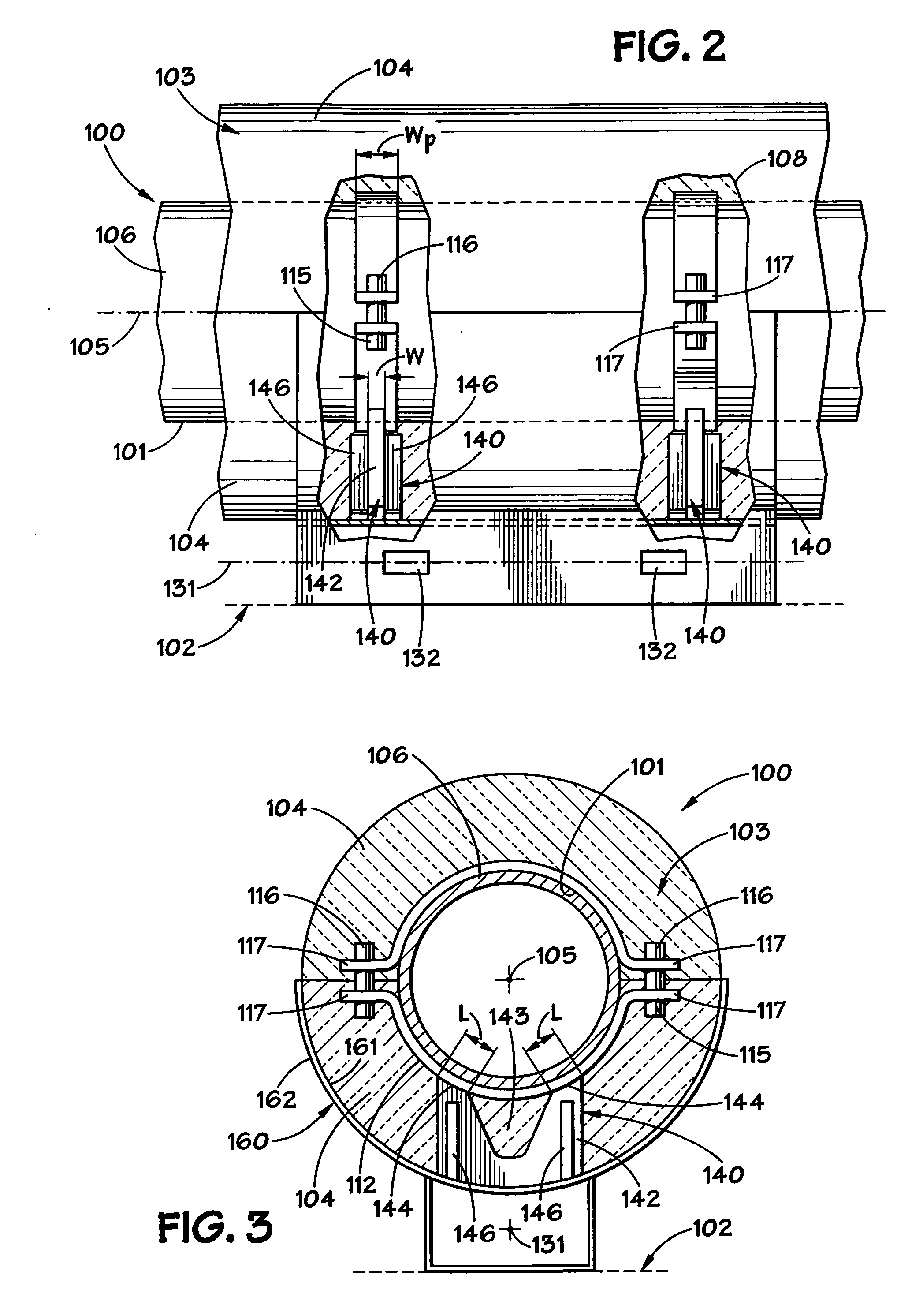

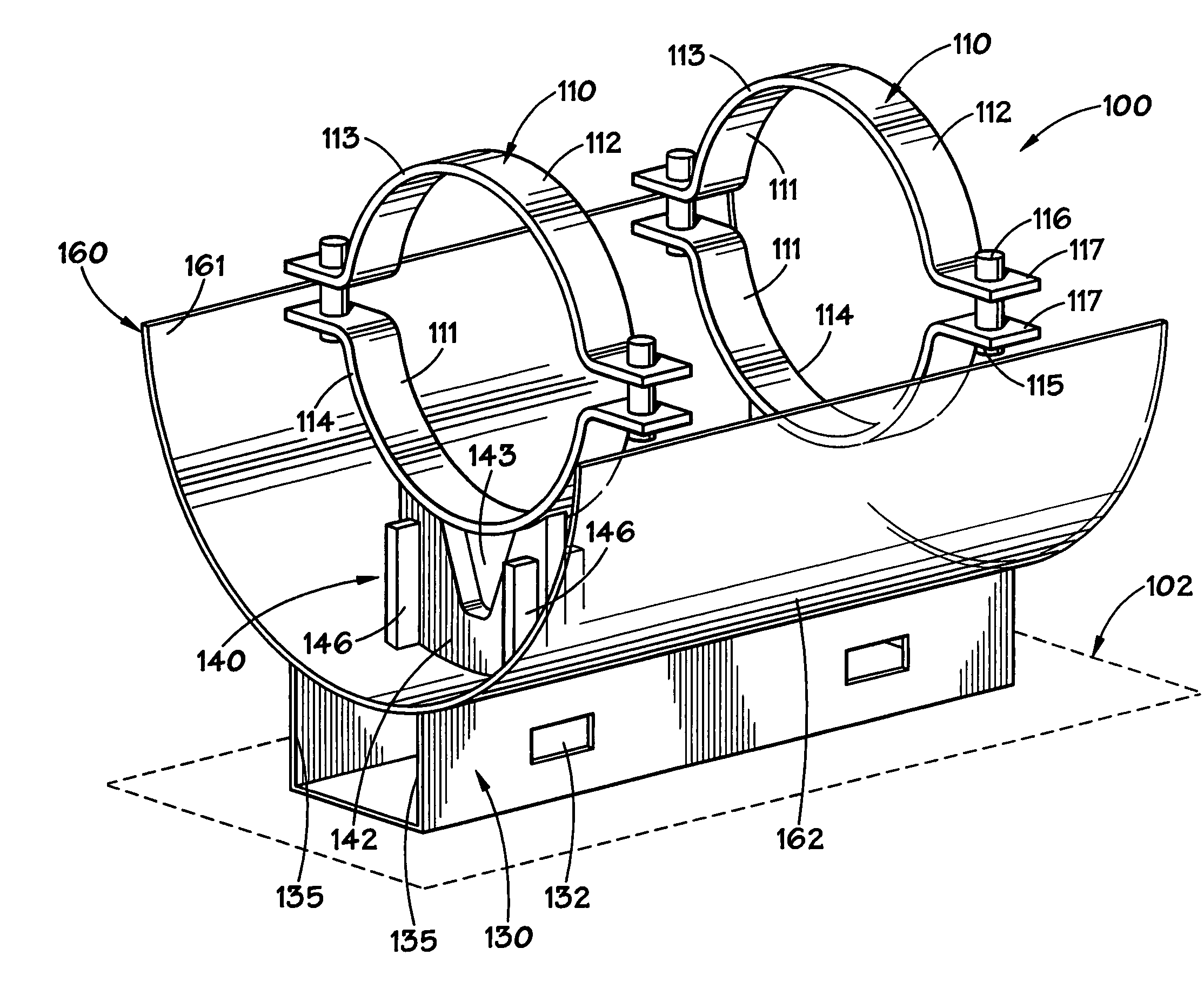

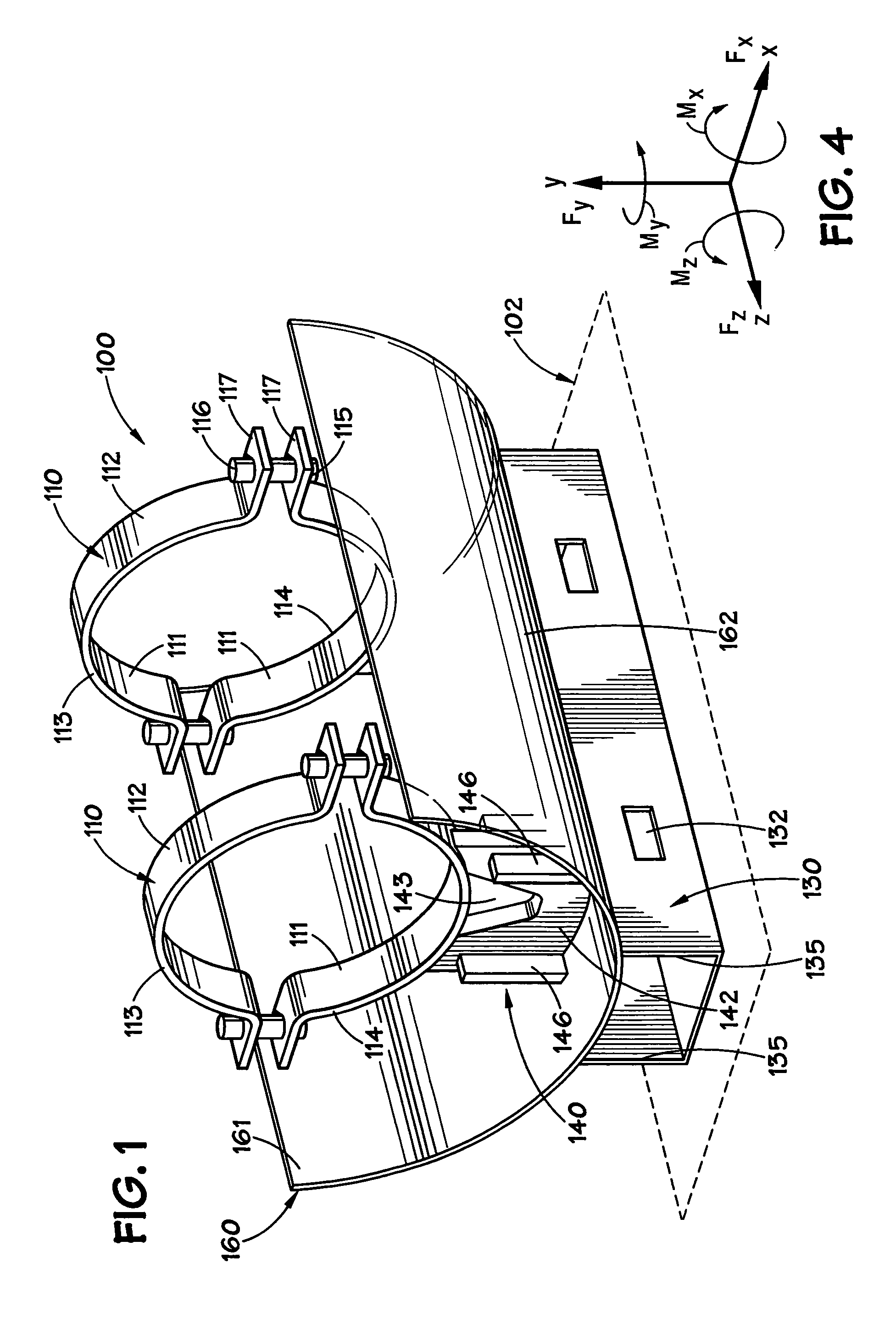

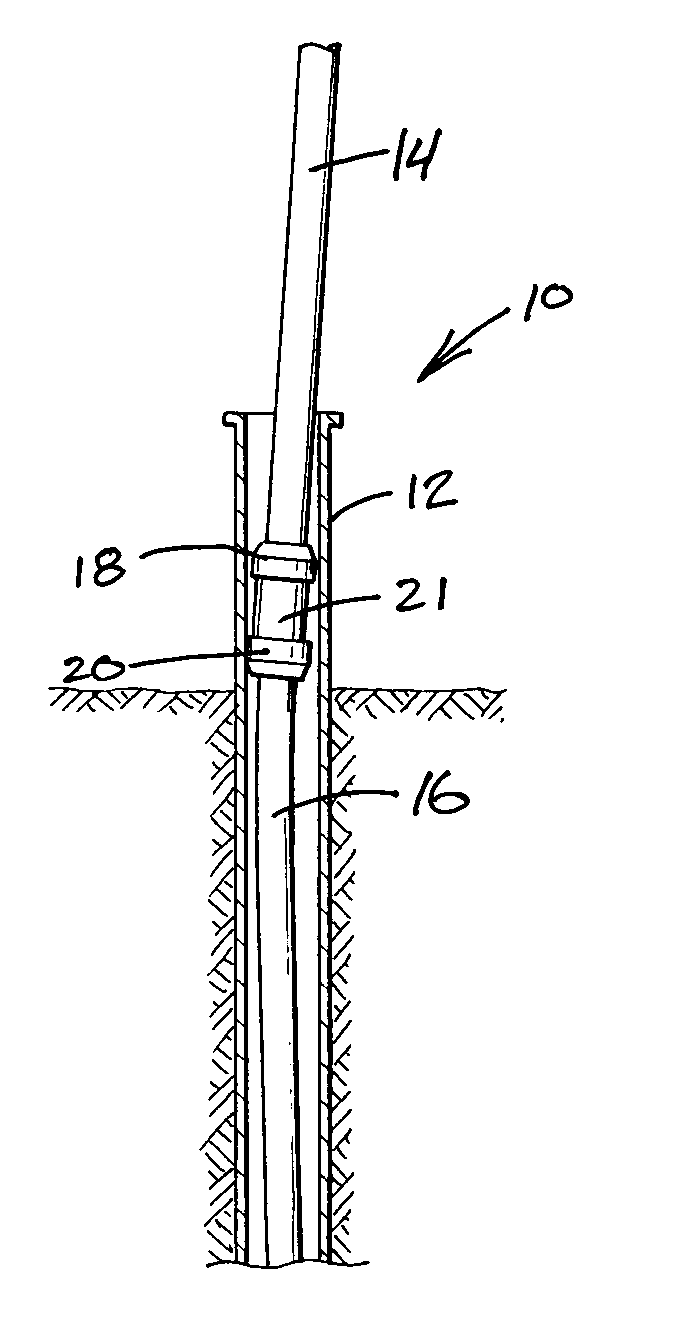

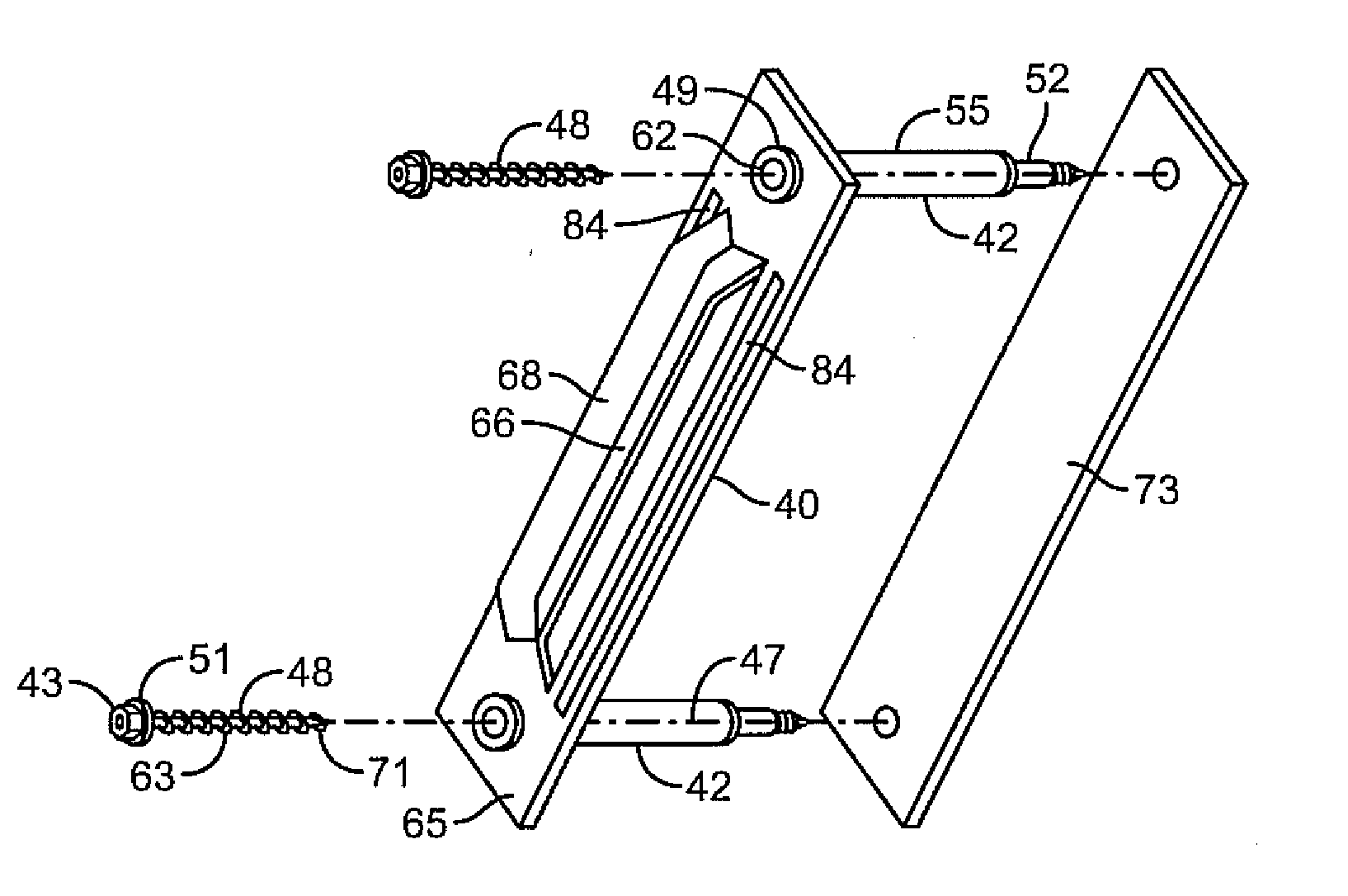

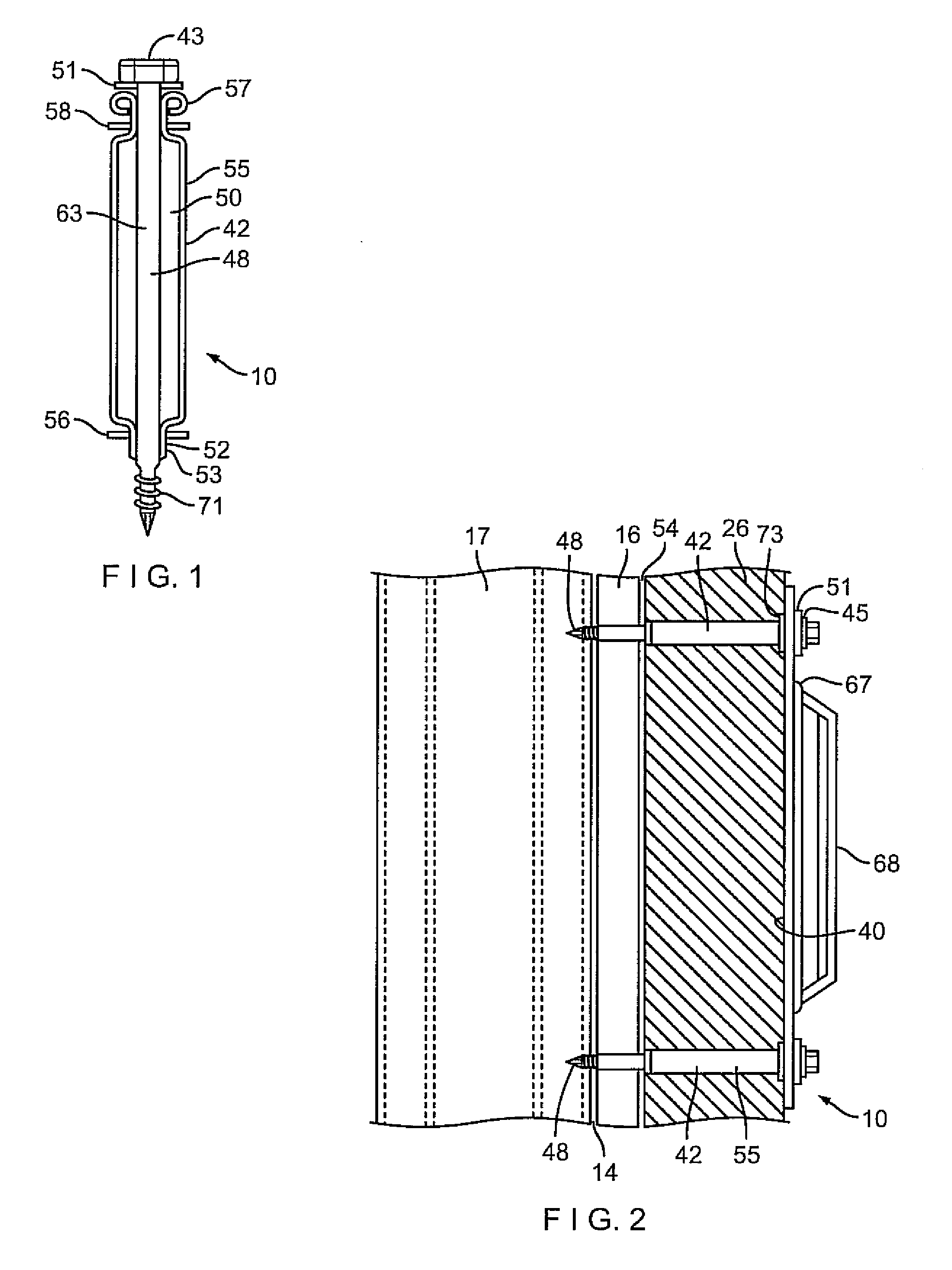

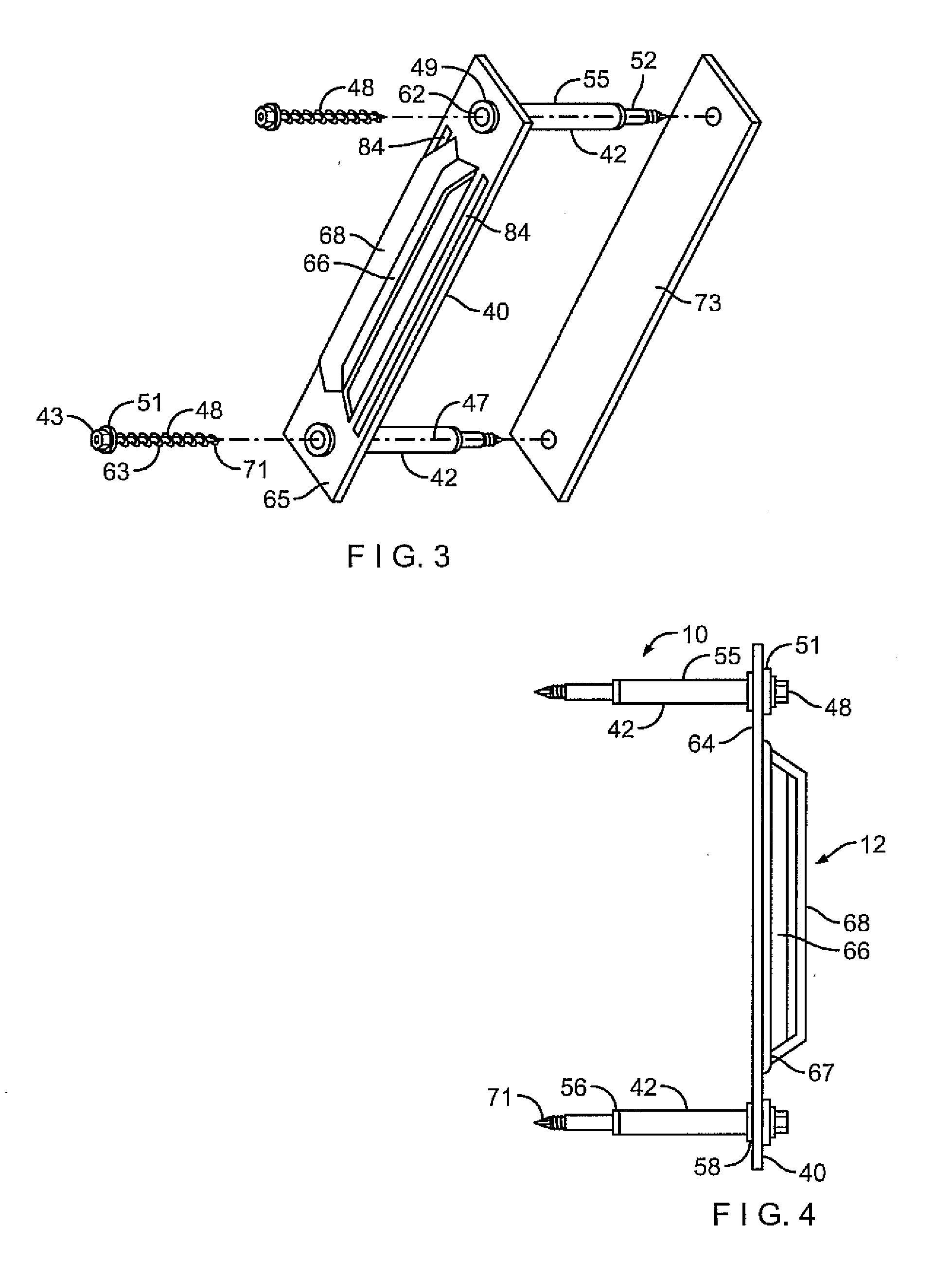

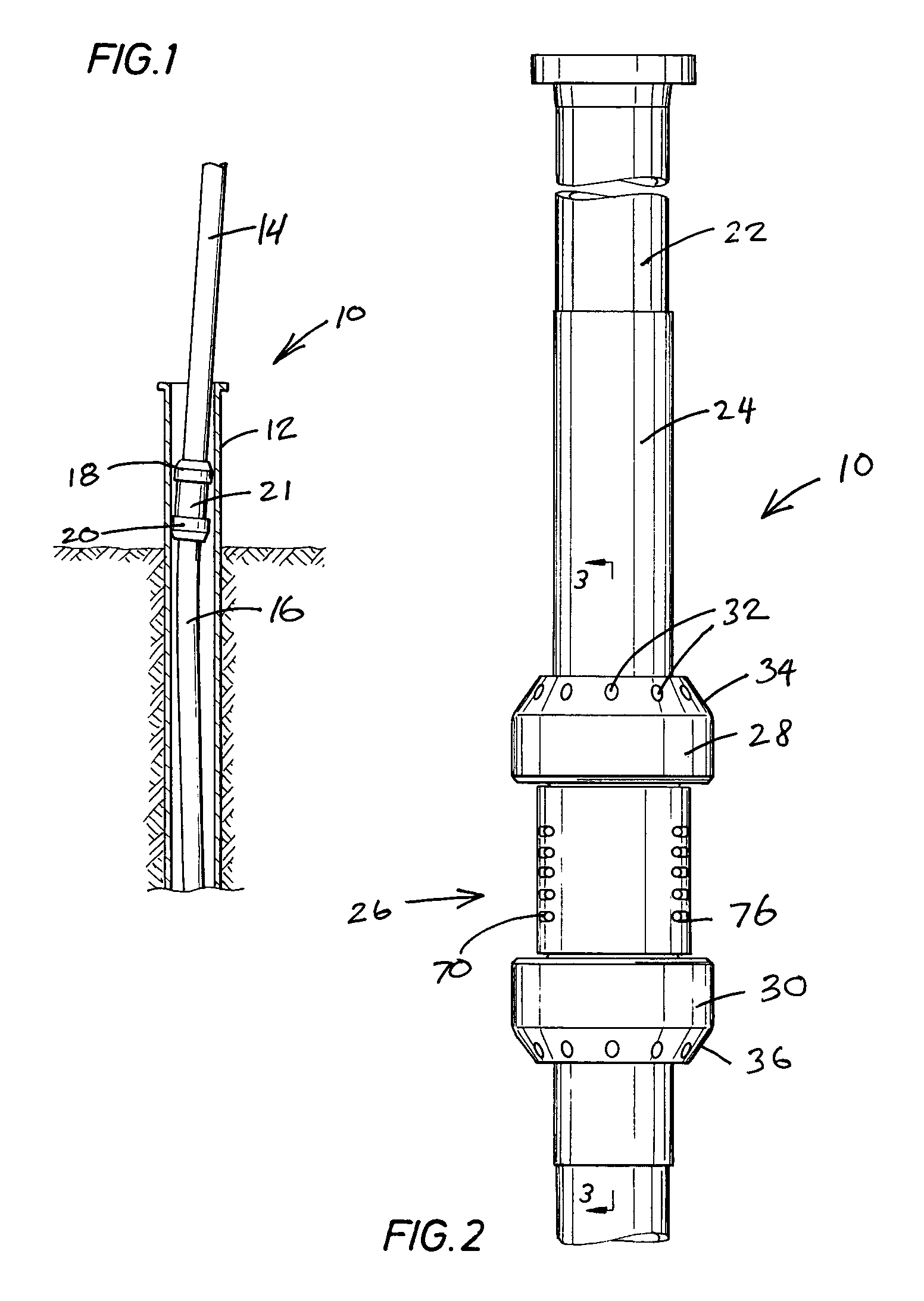

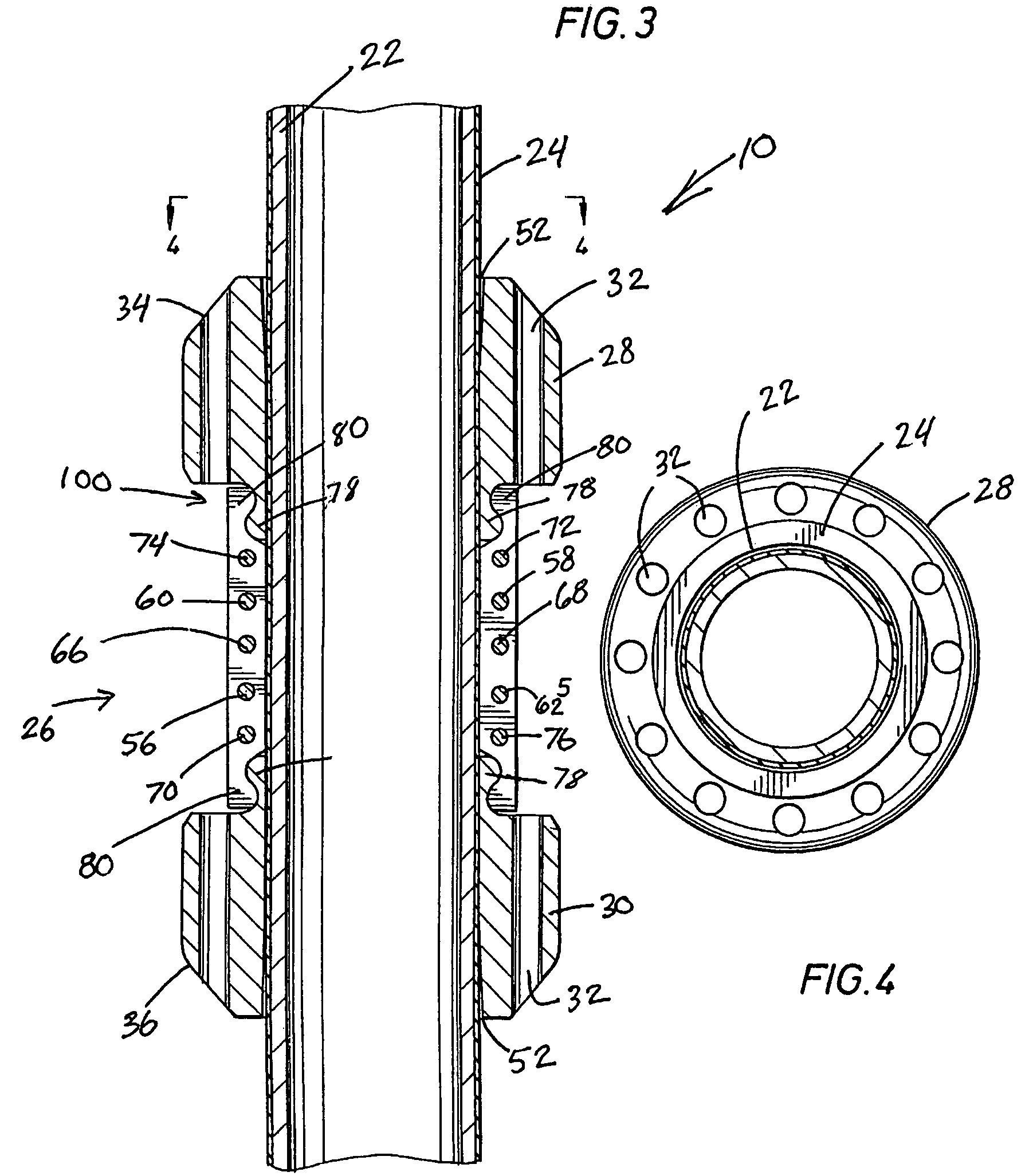

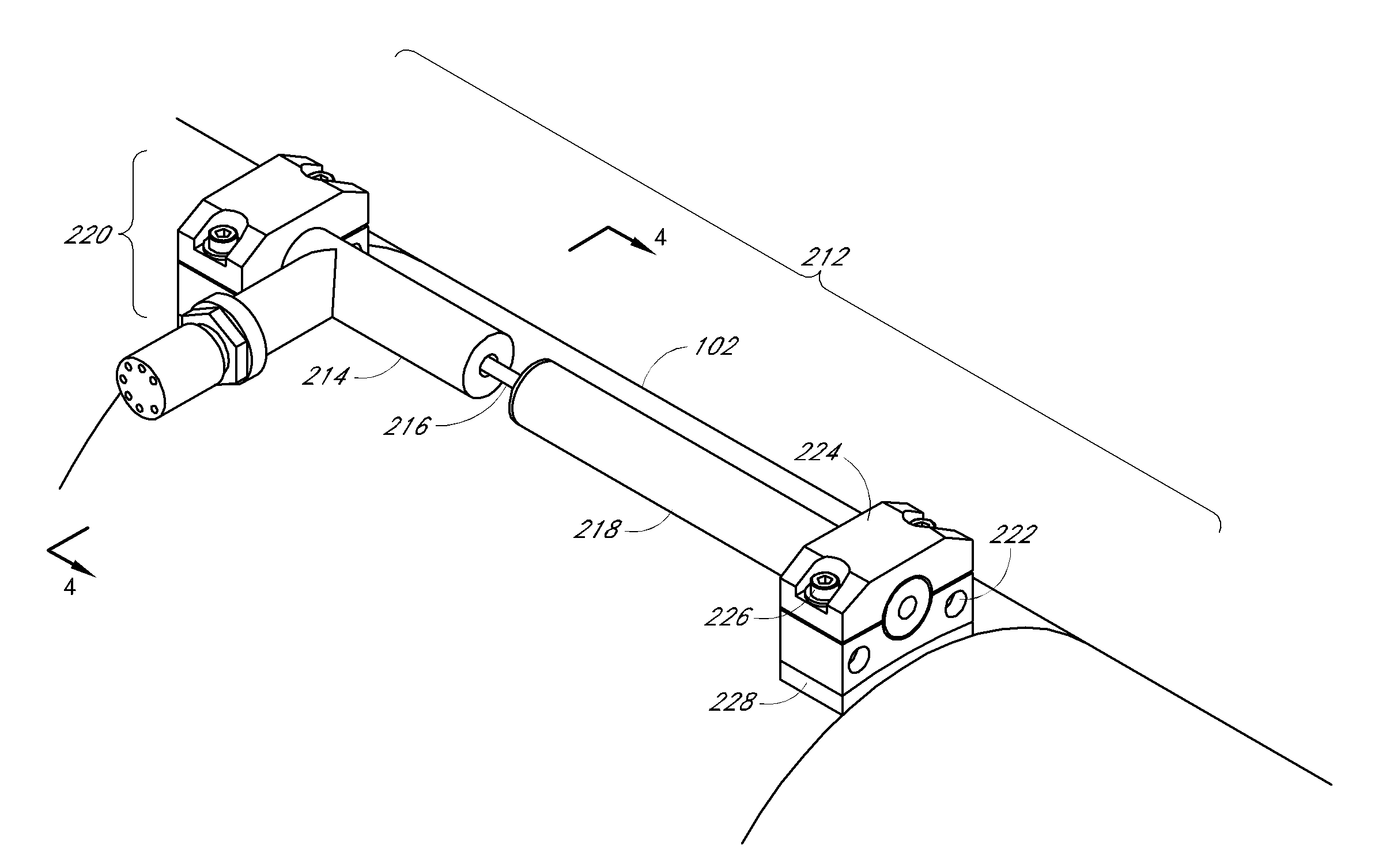

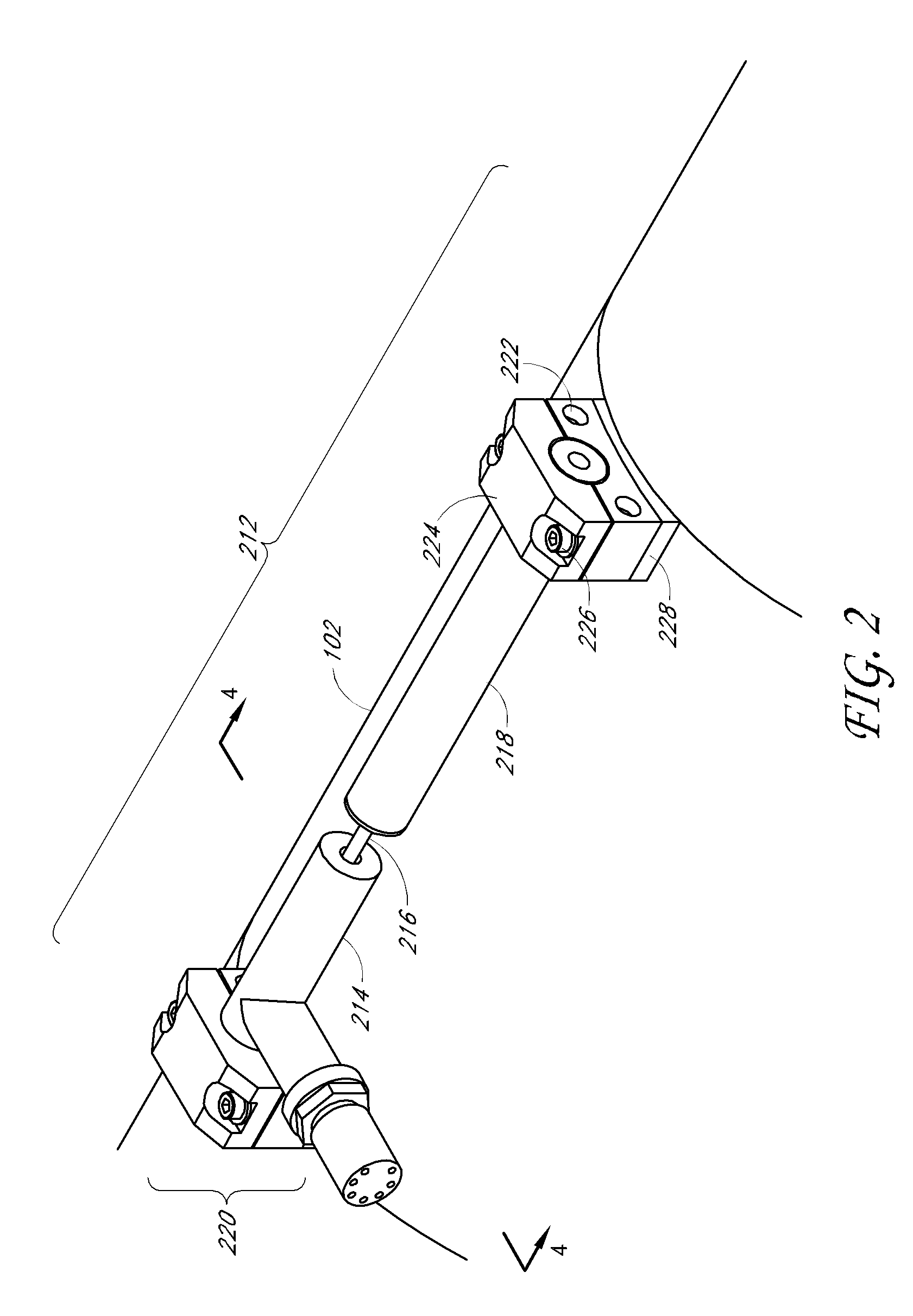

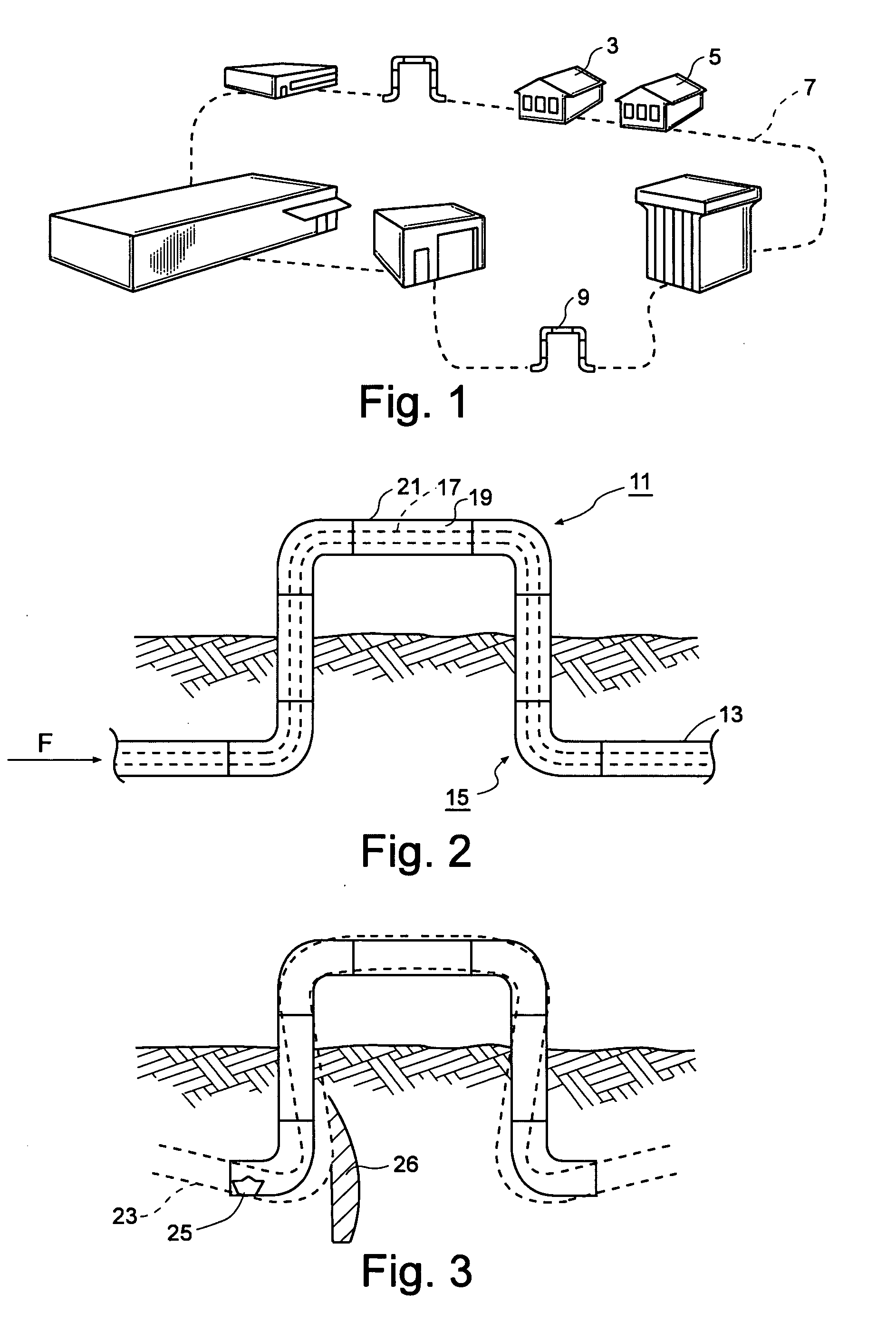

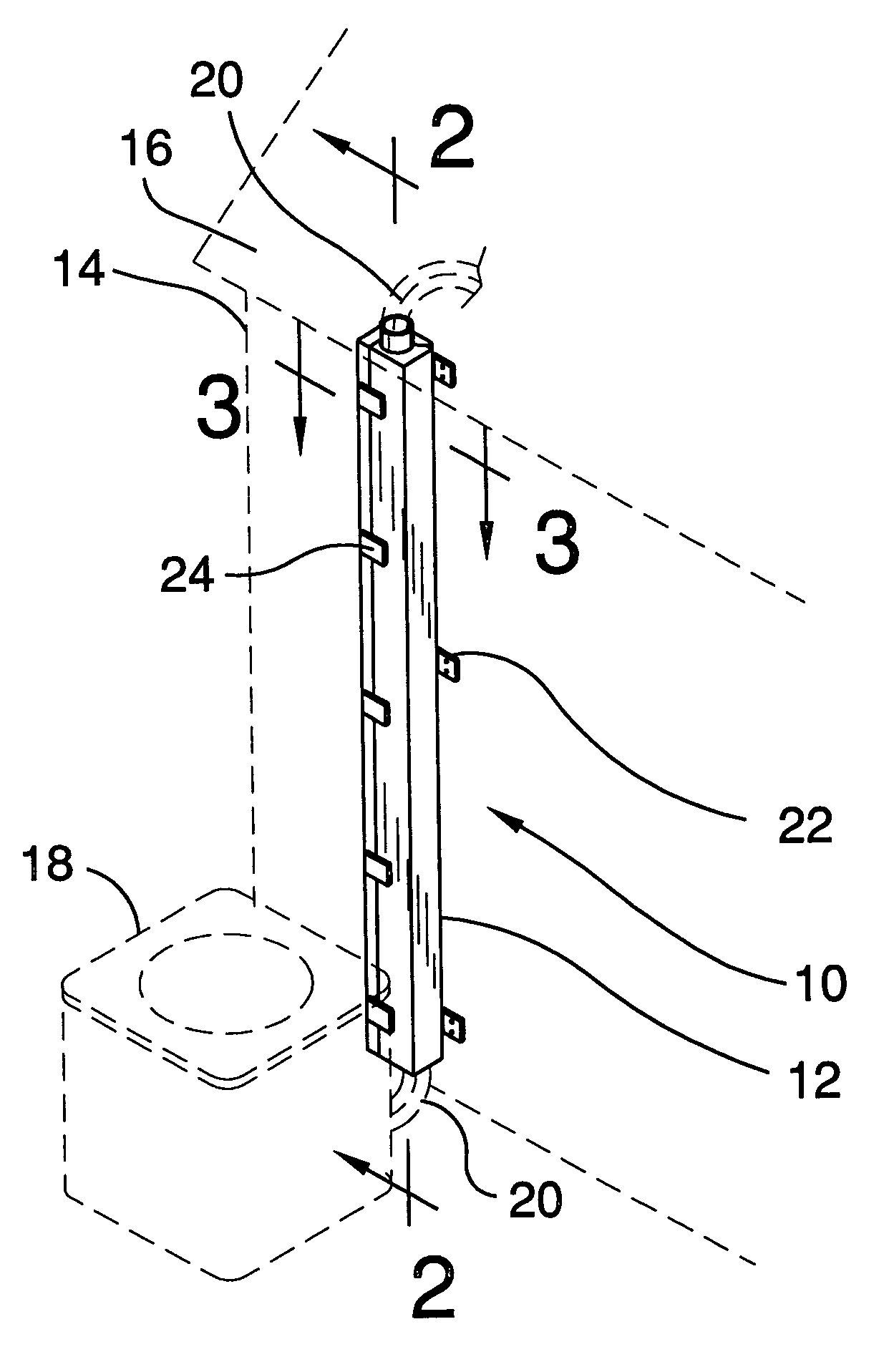

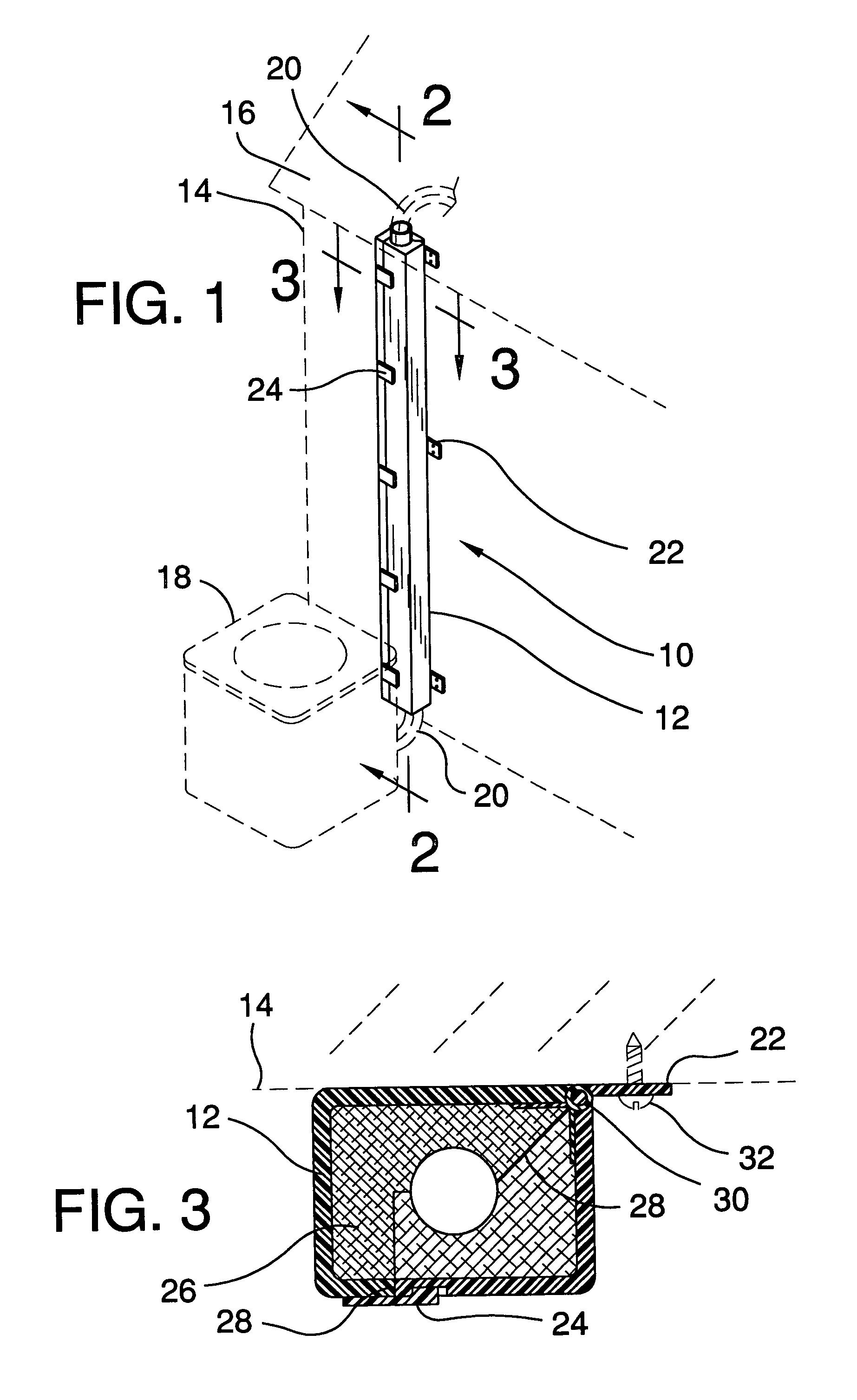

Method and apparatus for supporting an insulated pipe

ActiveUS20050116123A1Easy and economical to and installEasy and economical to manufacturePipe supportsThermal insulationEngineeringInsulated pipe

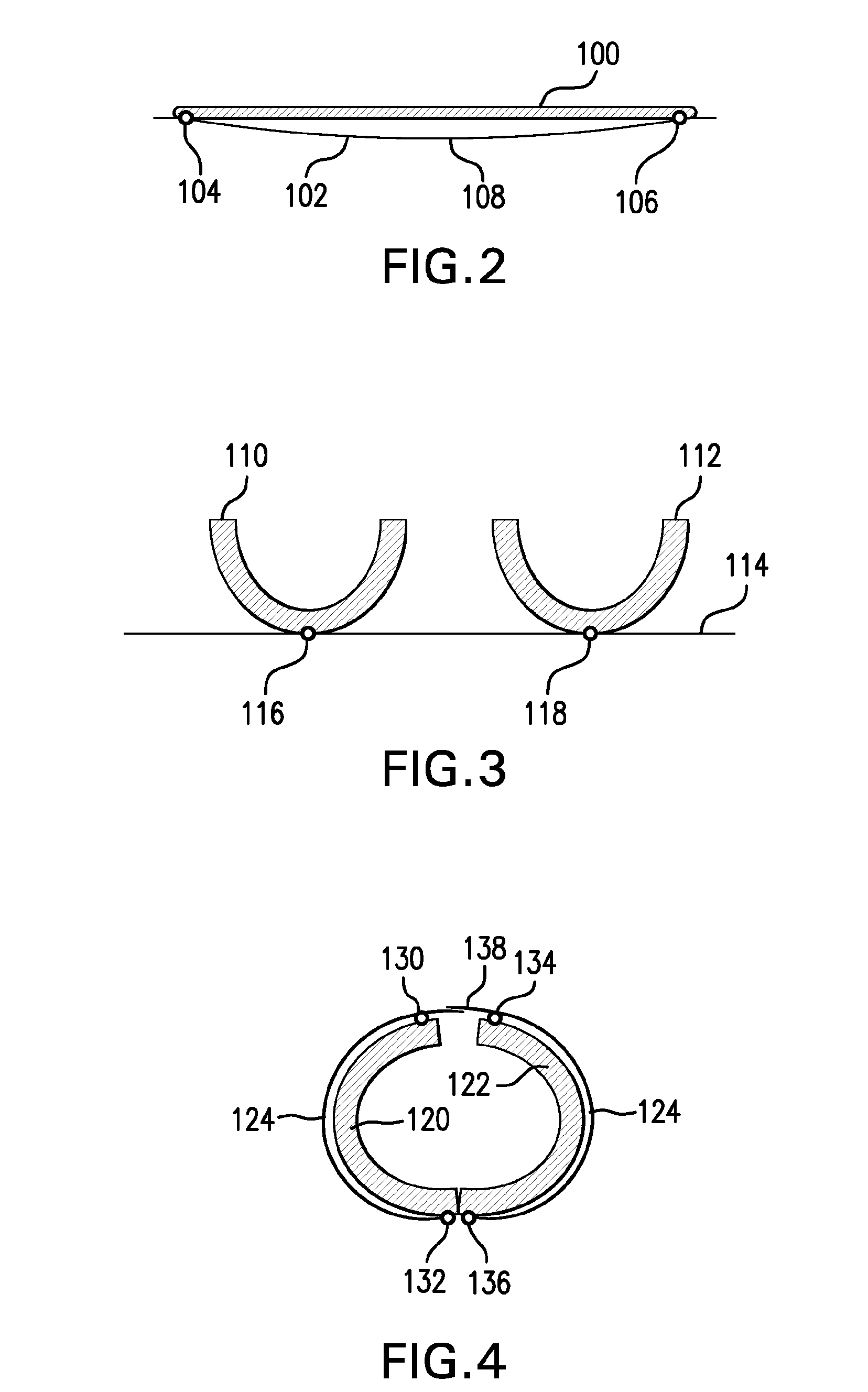

A method and apparatus for supporting a portion of a length of insulated pipe by a girder or other support structure, includes at least two pipe clamps, a base member, and a load transfer member attached to each of the at least two pipe clamps, wherein substantially none of the load, or forces and moments, exerted by the pipe, are carried, or transmitted, by the insulation disposed about the pipe.

Owner:PIPING TECHNOLOGY AND PRODUCTS

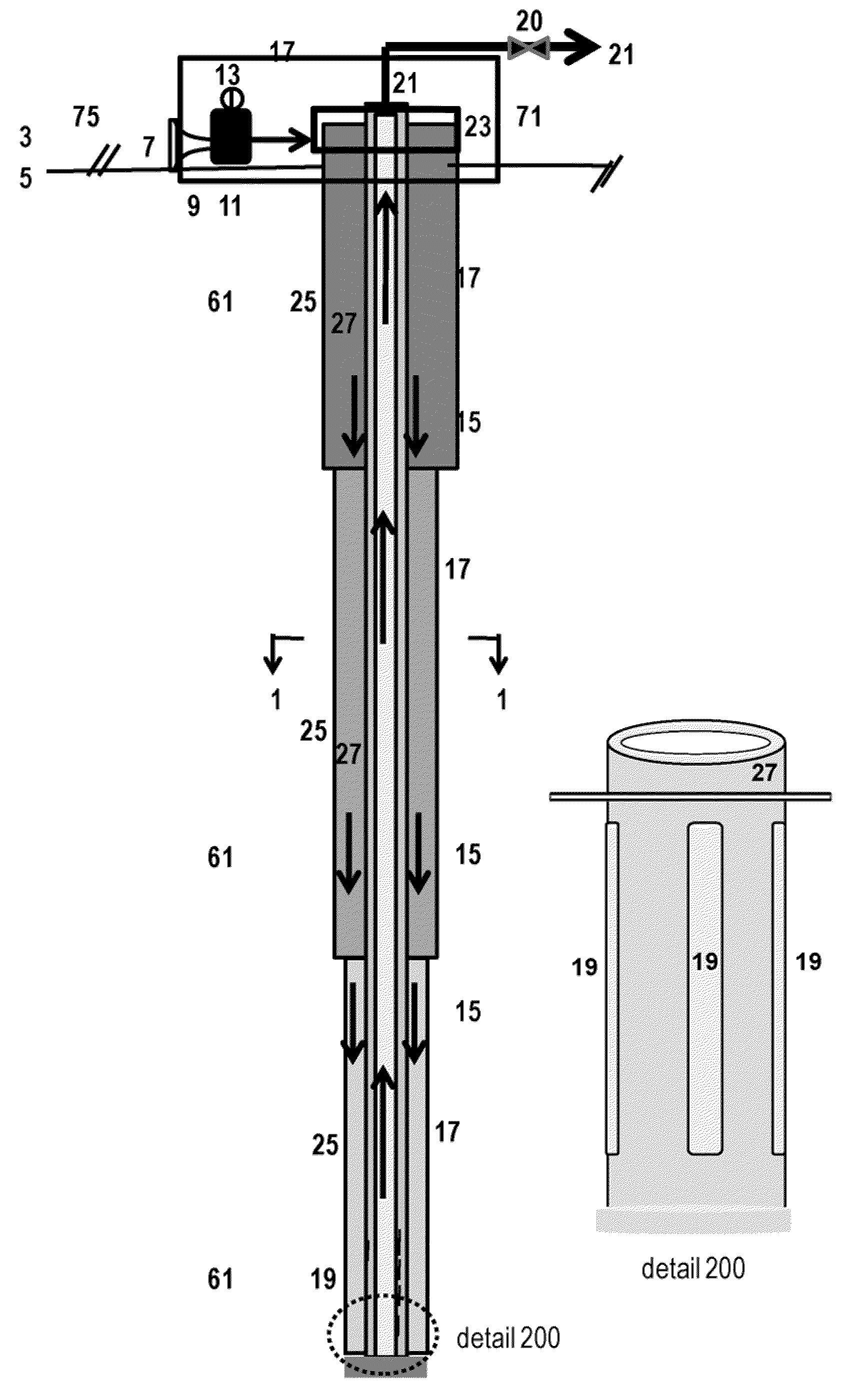

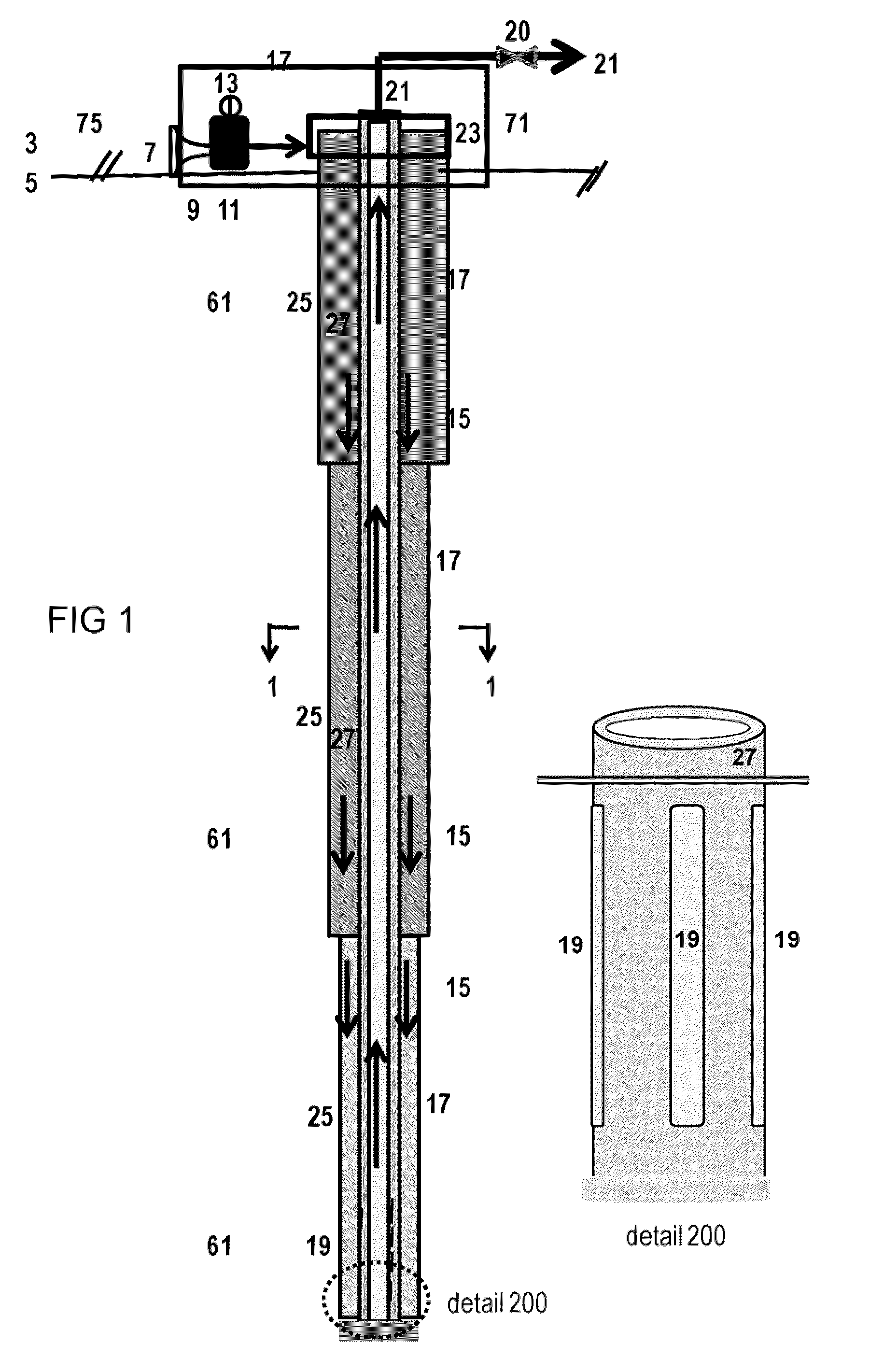

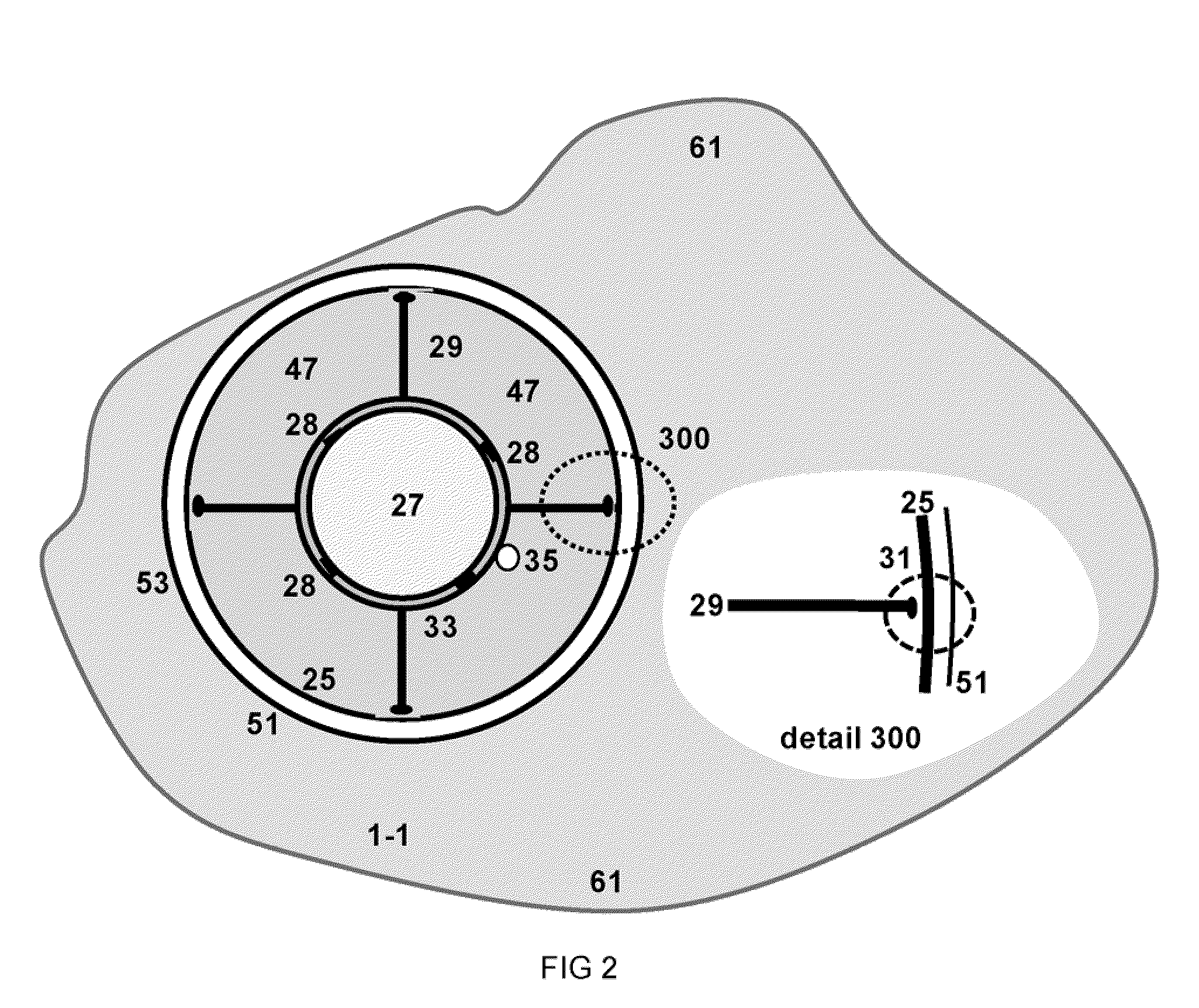

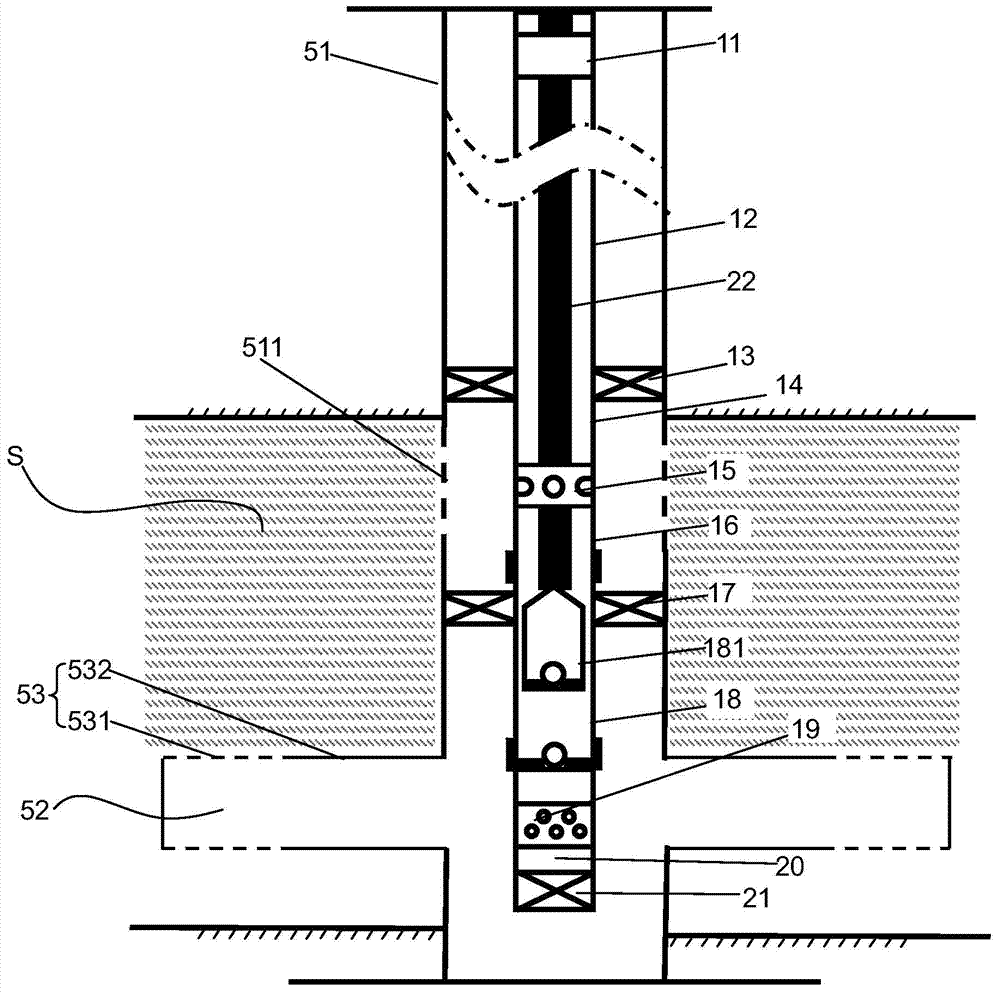

Two-concentric pipe system to heat fluids using the earth's interior thermal energy (DEEP)

ActiveUS20100270003A1Limit amplitudeDrilling rodsGeneral water supply conservationThermal energyDesalination

A method and apparatus for heating fluids using the Earth's inner heat to generate power and desalinate water. Fluids include fresh water and sea water to be desalinized. The method involves passing a filtered fluid down a channel formed by two concentric tubes in a deep well defining inner and outer channels, to a depth at which the fluid reaches the needed temperature. Hot fluids pass into an inner channel and flow to surface with small heat loss, through an insulated pipe. The hot fluid may be vaporized to produce power, and returned to the system when condensed, forming a closed system, or it may be desalinize seawater in an integrated process that also produces electrical power.

Owner:CLIMENT DE SARRIA MARIA ISABEL

Method and apparatus for supporting an insulated pipe

ActiveUS7213790B2Heat flow through the load transfer members is minimizedEasy and economical to and installPipe supportsThermal insulationInsulated pipeEngineering

A method and apparatus for supporting a portion of a length of insulated pipe by a girder or other support structure, includes at least two pipe clamps, a base member, and a load transfer member attached to each of the at least two pipe clamps, wherein substantially none of the load, or forces and moments, exerted by the pipe, are carried, or transmitted, by the insulation disposed about the pipe.

Owner:PIPING TECHNOLOGY AND PRODUCTS

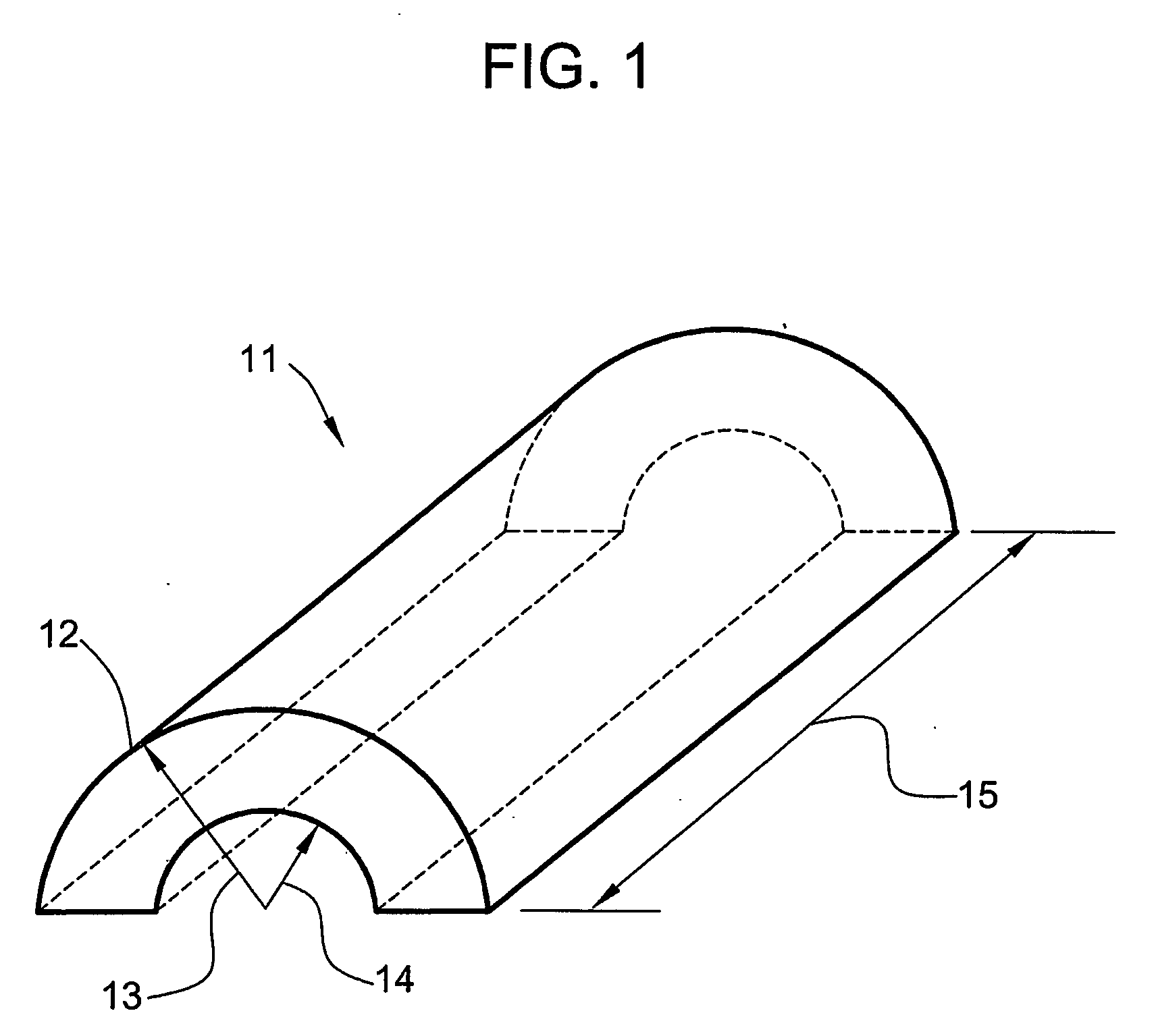

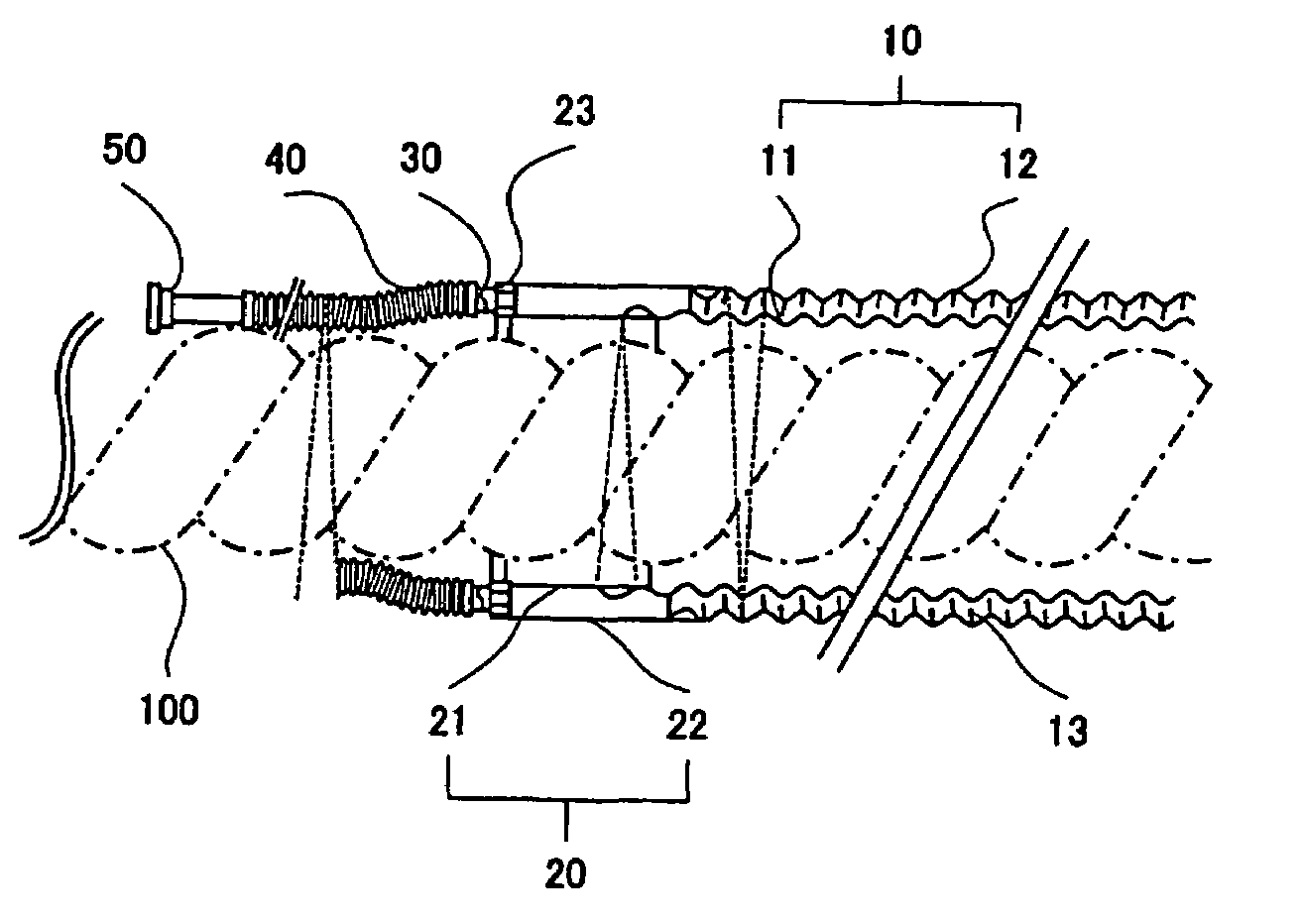

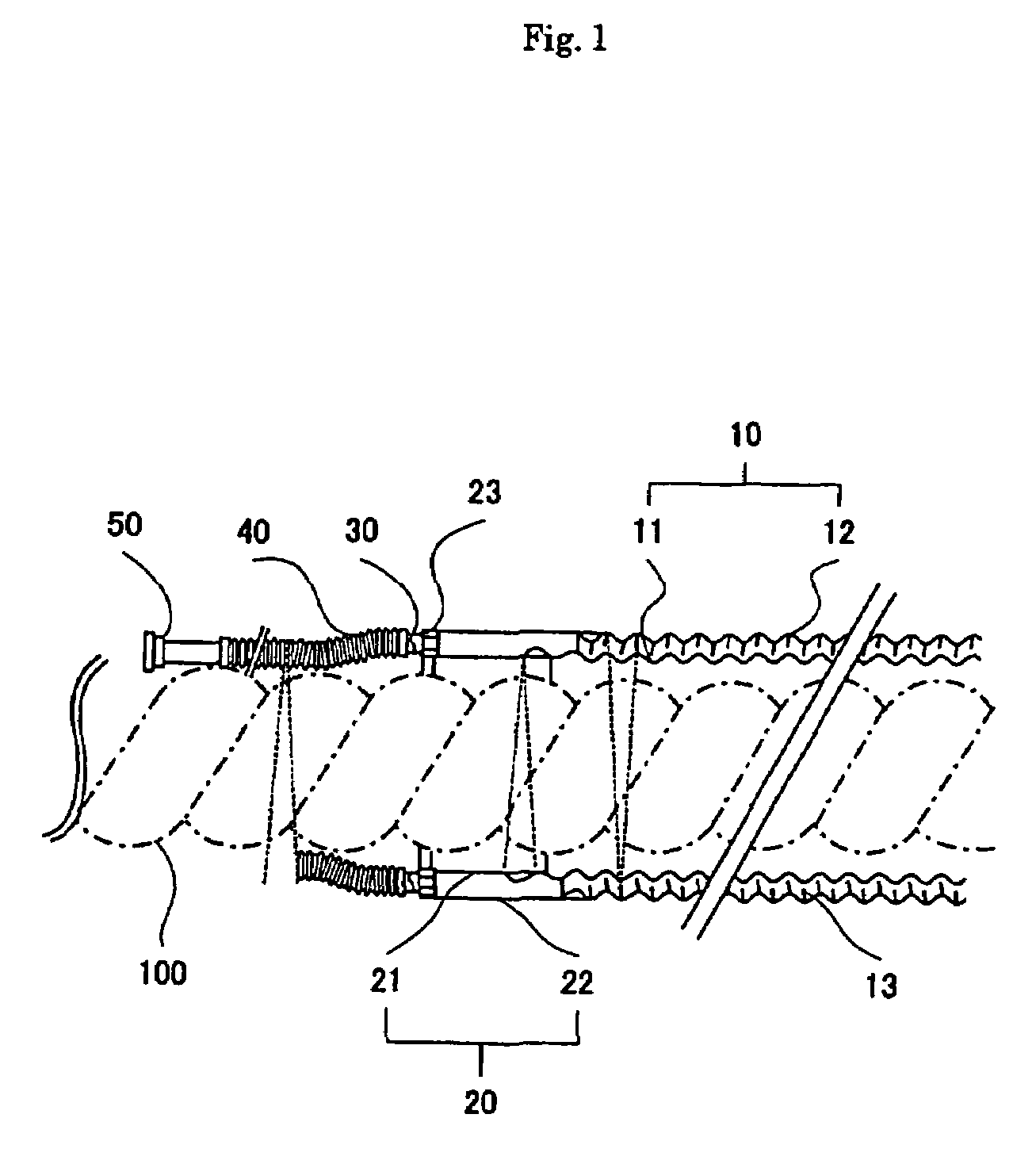

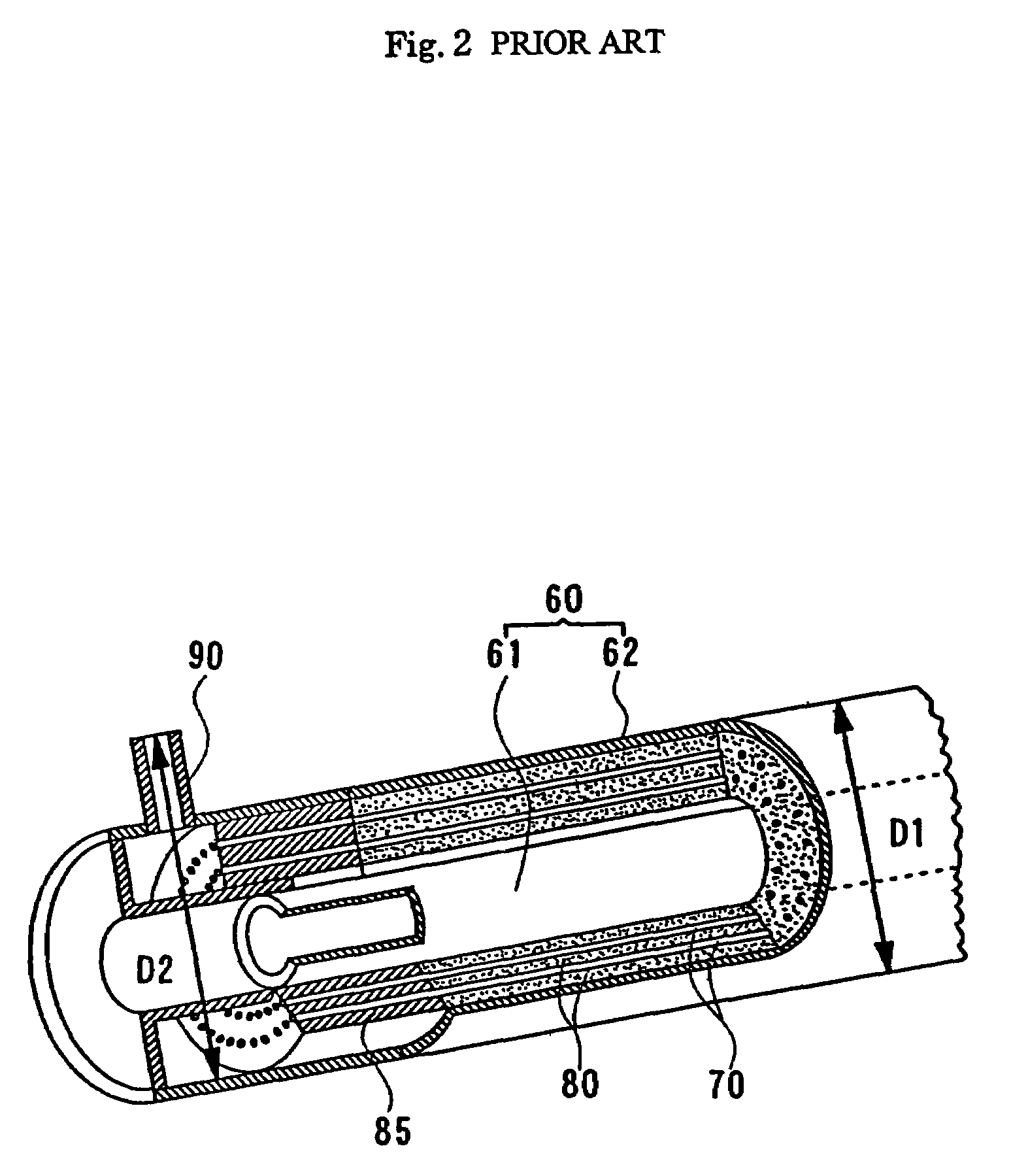

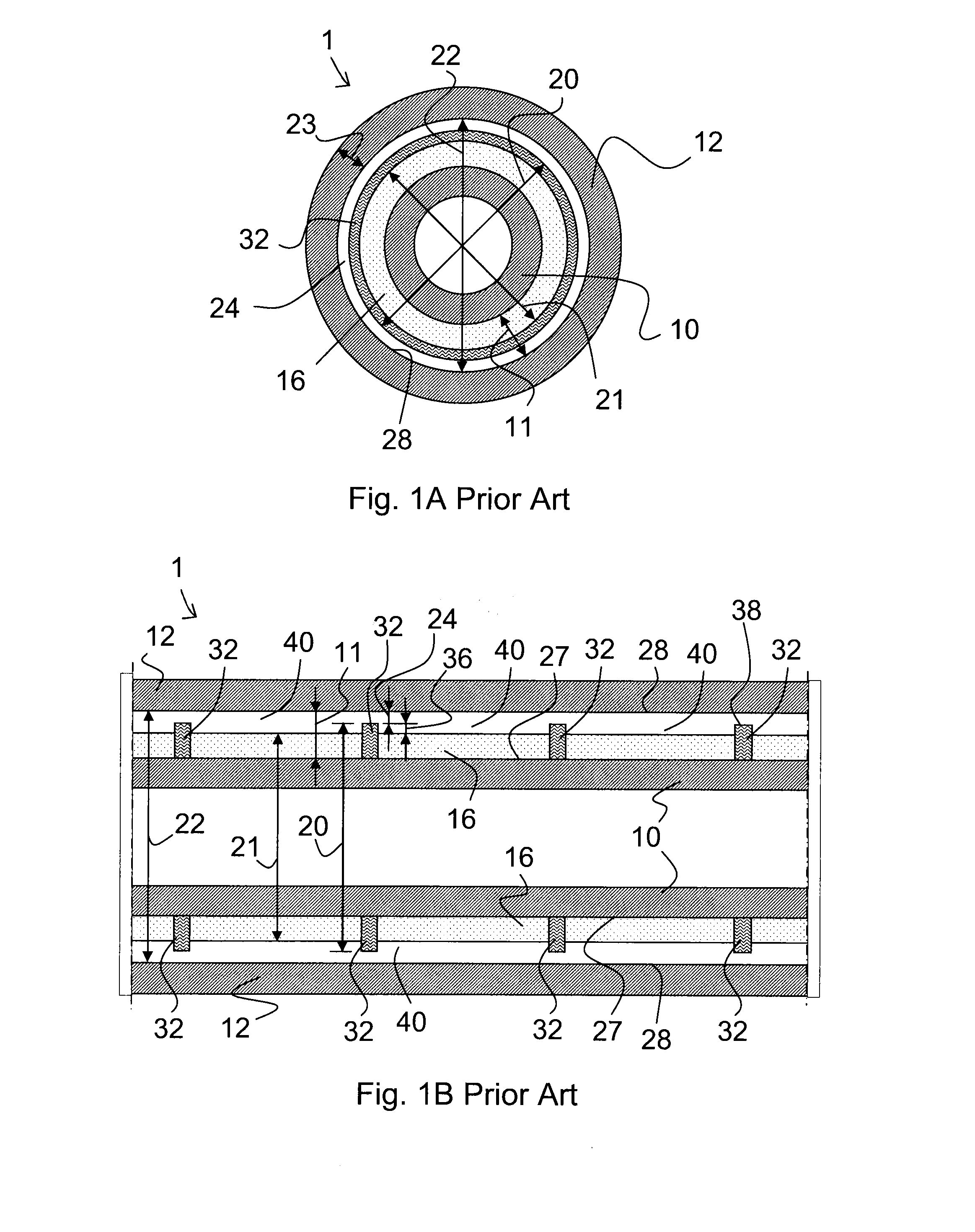

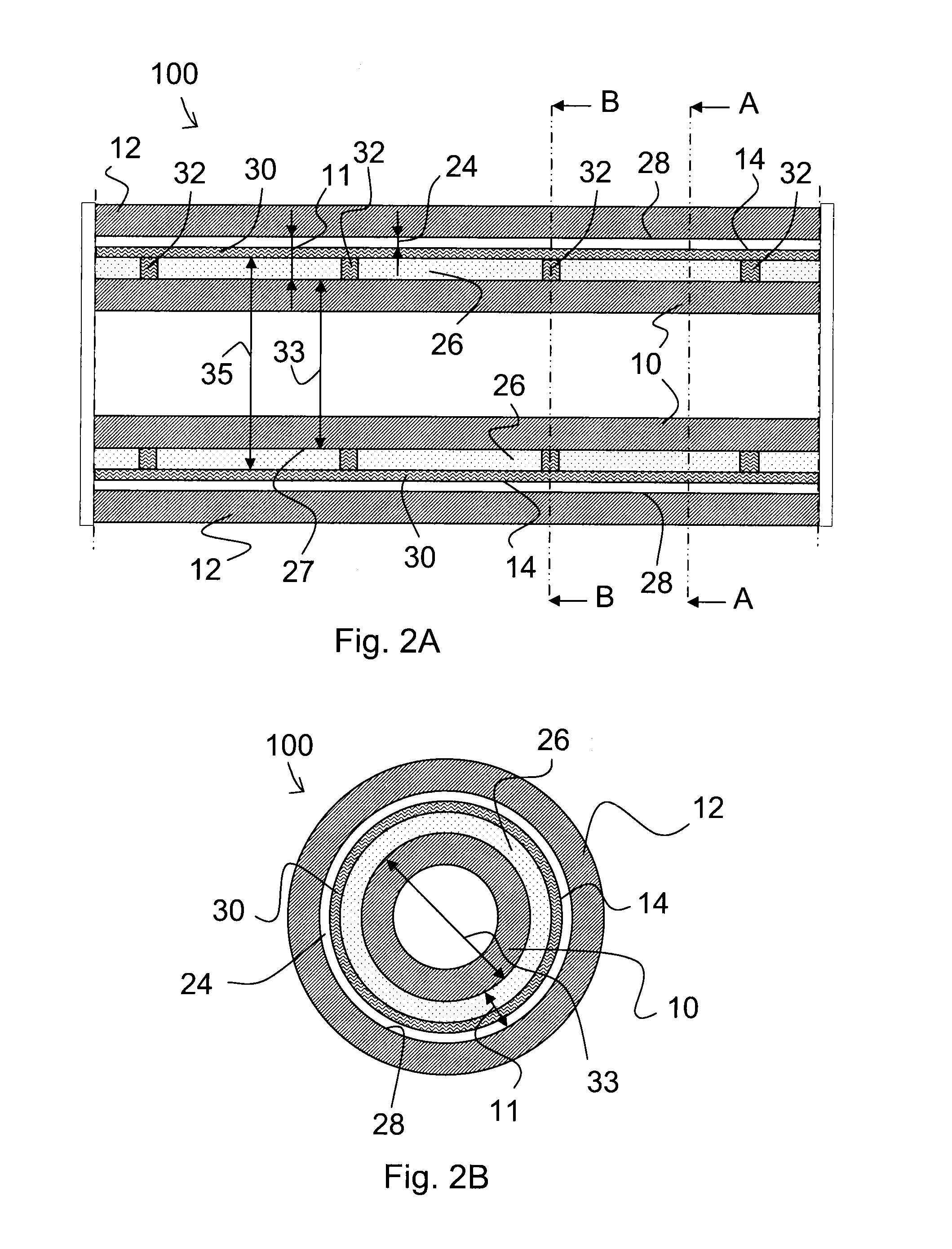

Vacuum-insulated pipe

InactiveUS7093619B2Easy to installInsert smoothlyThermal insulationPipe elementsPosition toleranceThermal insulation

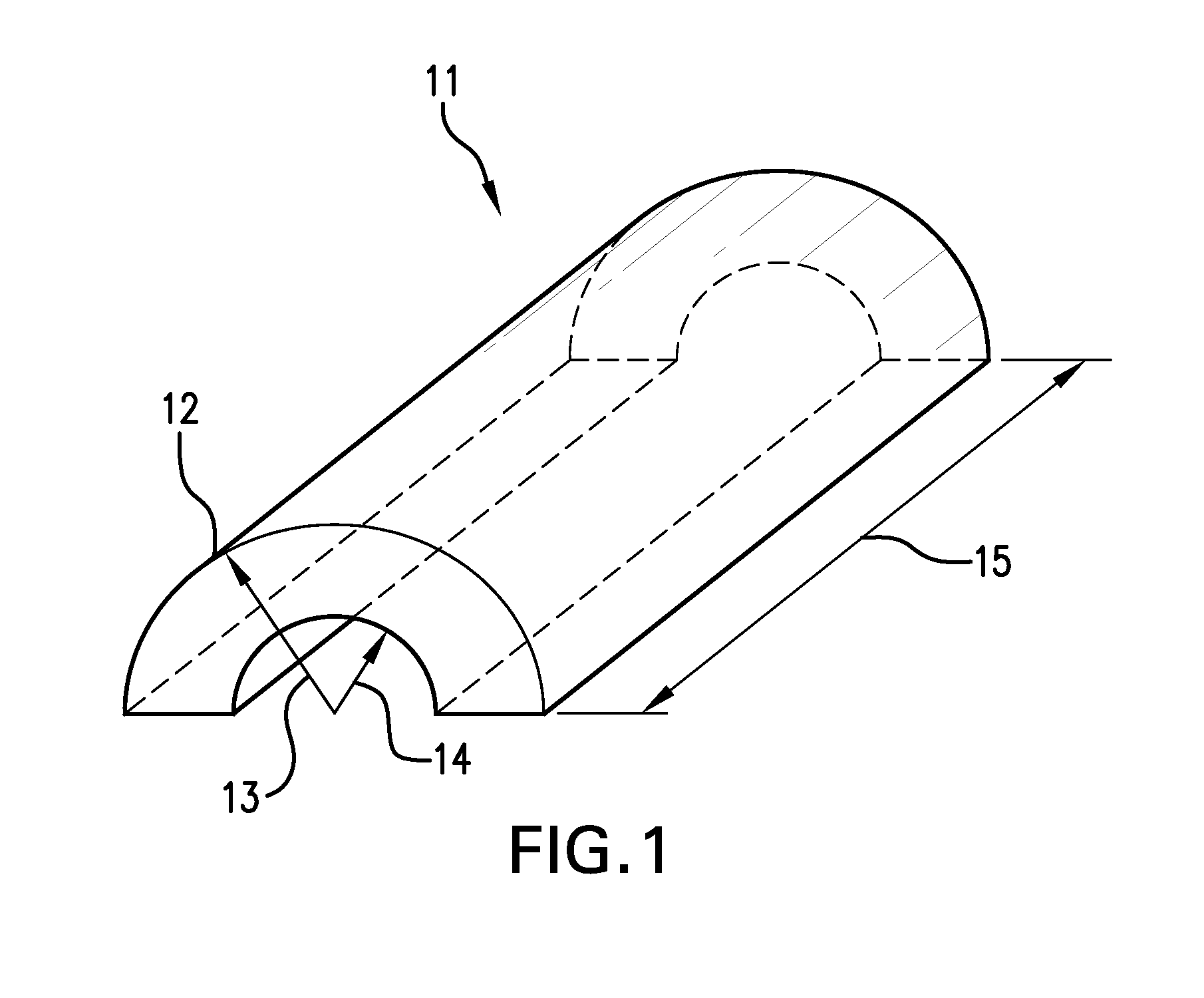

To provide a thermal insulation piping with no radially projecting part from a periphery thereof, so as to facilitate insertion of the thermal insulation piping into a pipeline or equivalent. In a thermal insulation tube 10 having a vacuum layer between an inner tube 11 and an outer tube 12, an evacuation port 30 for vacuum evacuation is oriented parallel with a longitudinal direction of the thermal insulation piping at an end of the thermal insulation tube 10. This construction can produce the thermal insulation tube 10 with no radially projecting part from a periphery thereof, thus providing improved workability when the thermal insulation piping is contained in the pipeline or equivalent. Further, a flexible pipe(s) 40 is / are preferably connected to the evacuation port(s) 30. This can allow increased positional tolerances in the connection of the evacuation port(s) to a vacuum evacuation device.

Owner:SUMITOMO ELECTRIC IND LTD +1

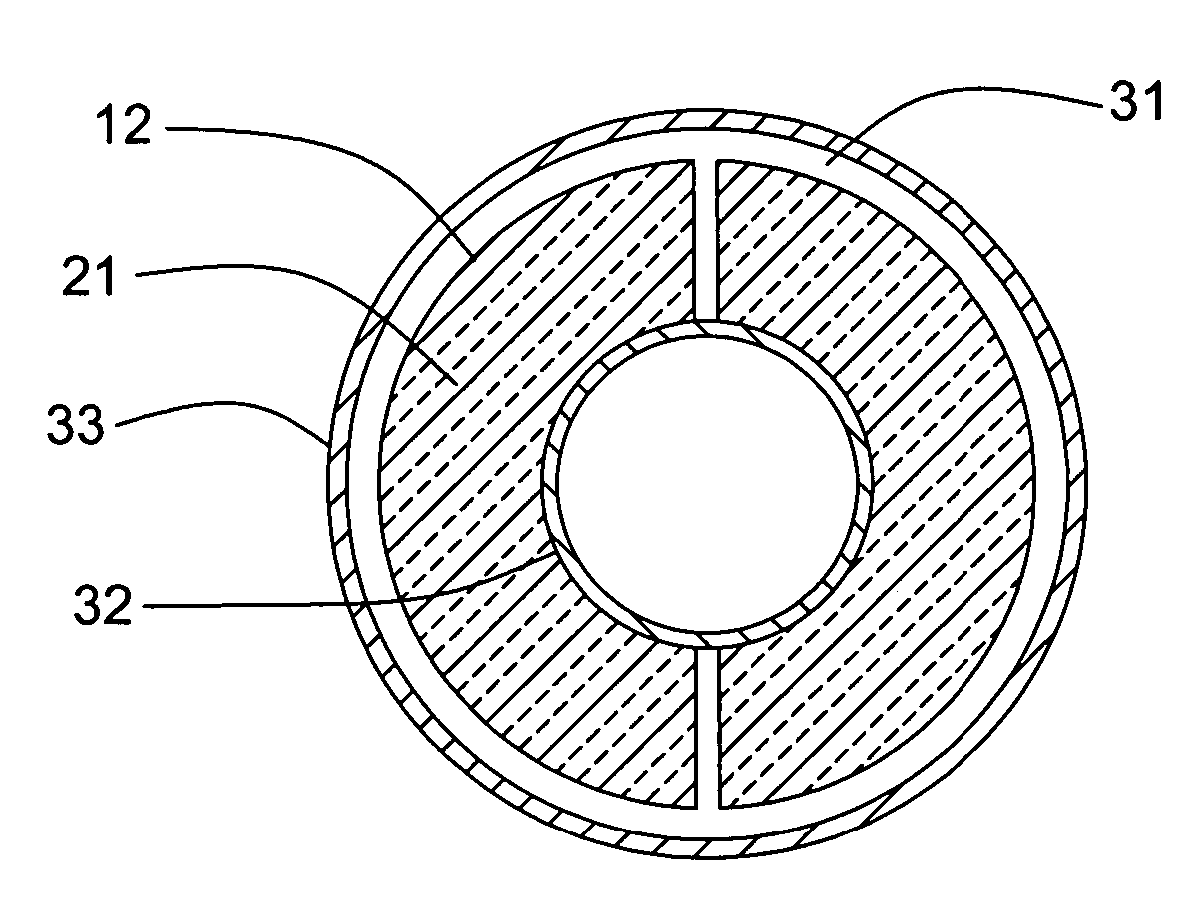

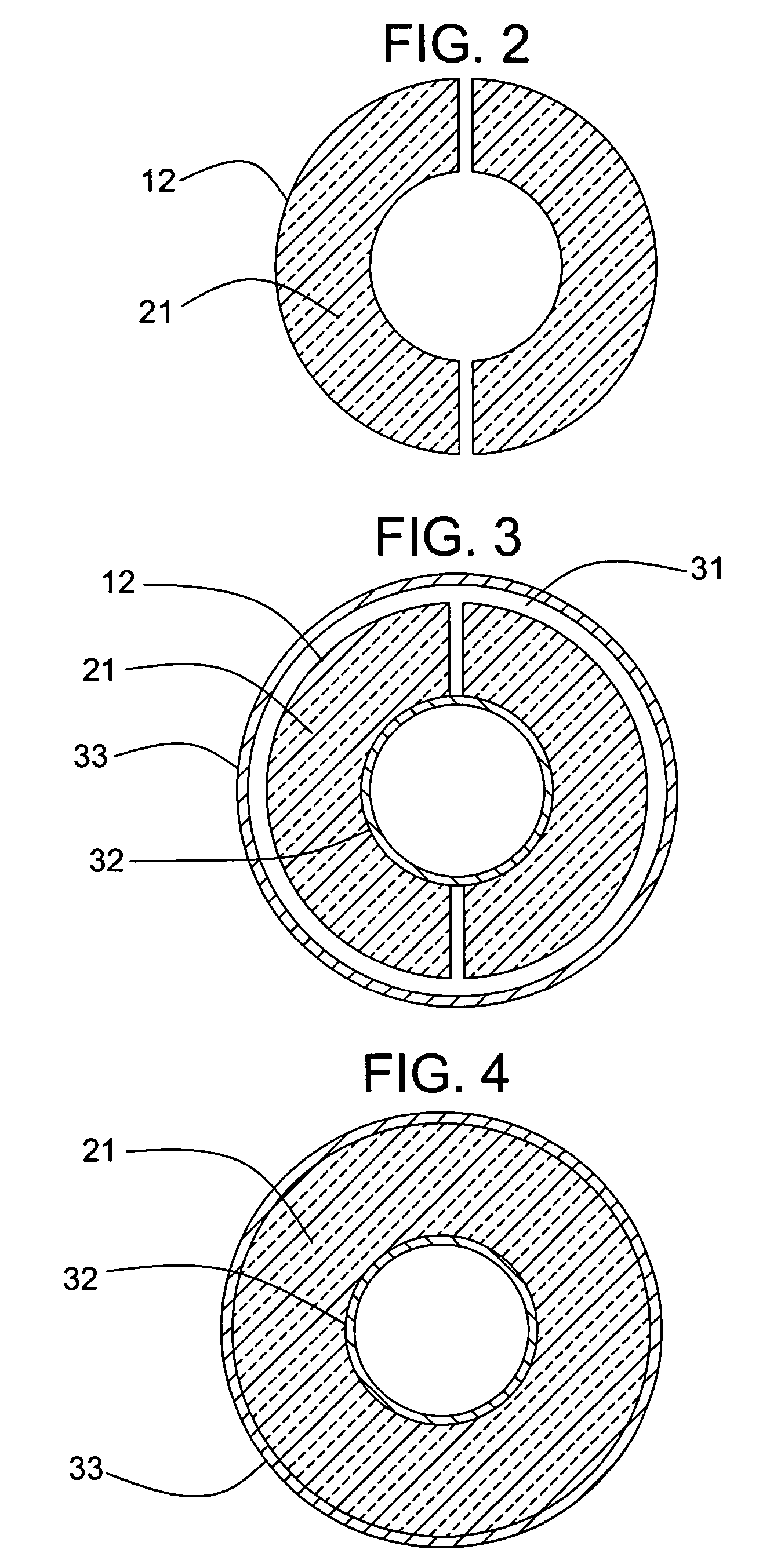

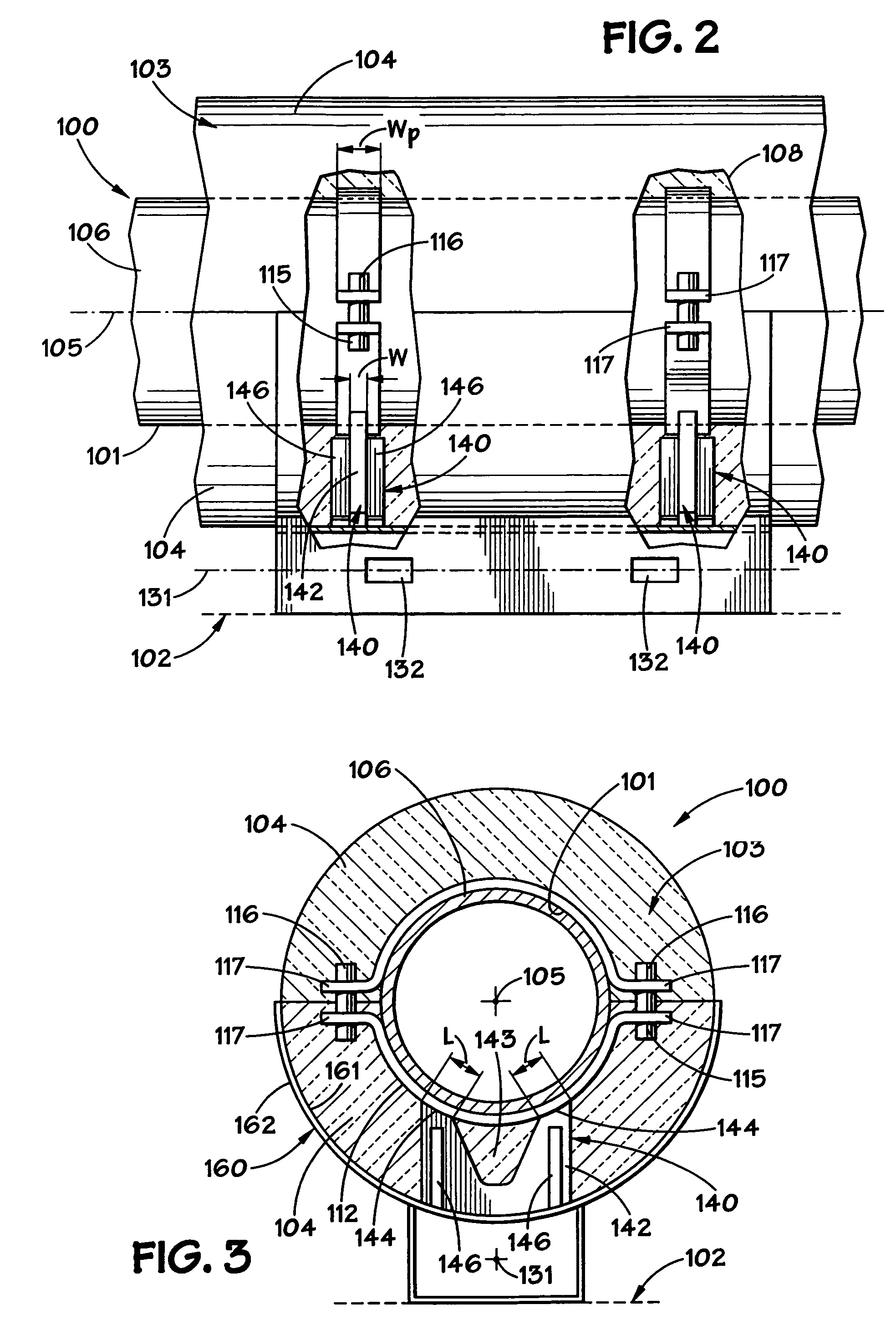

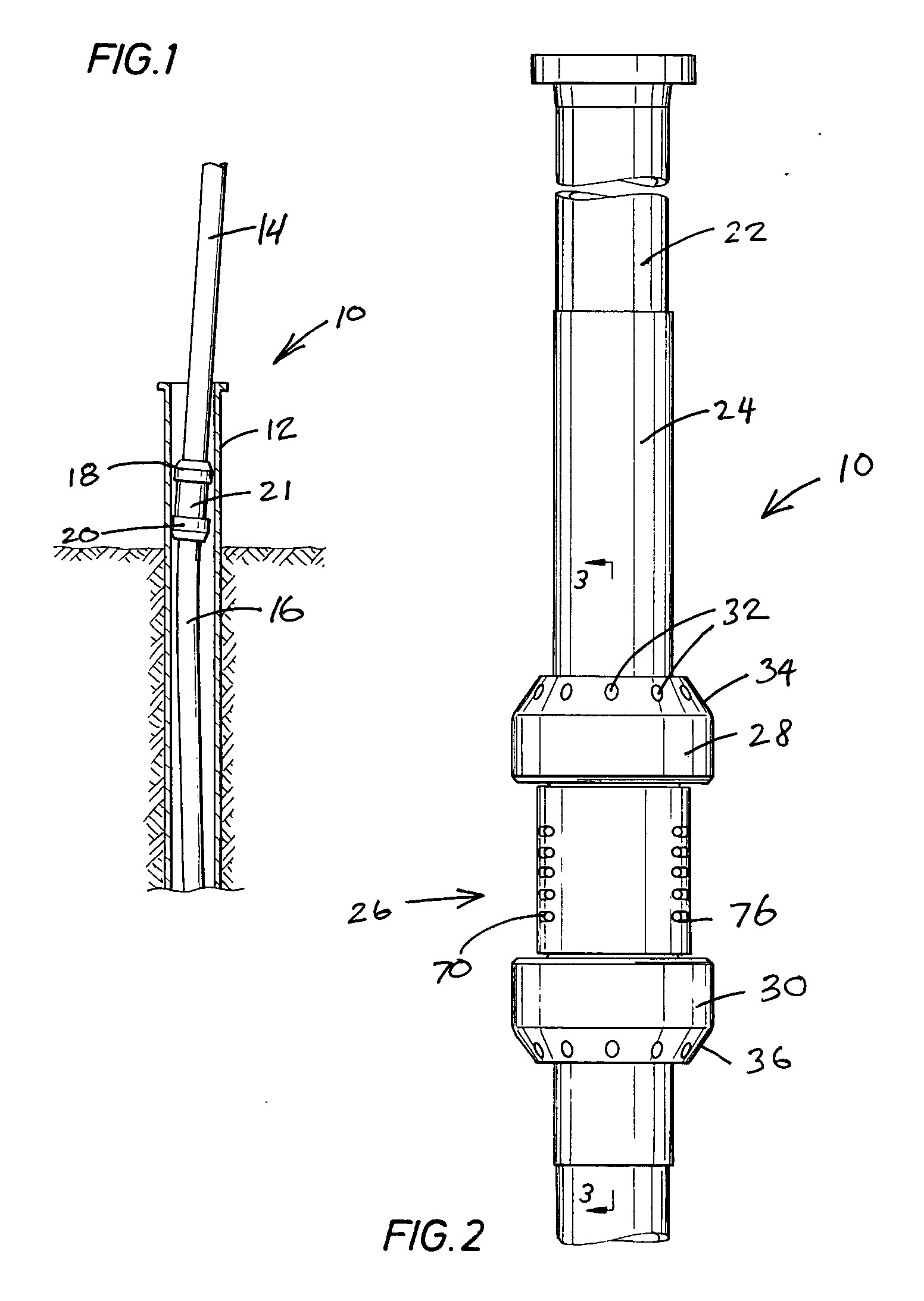

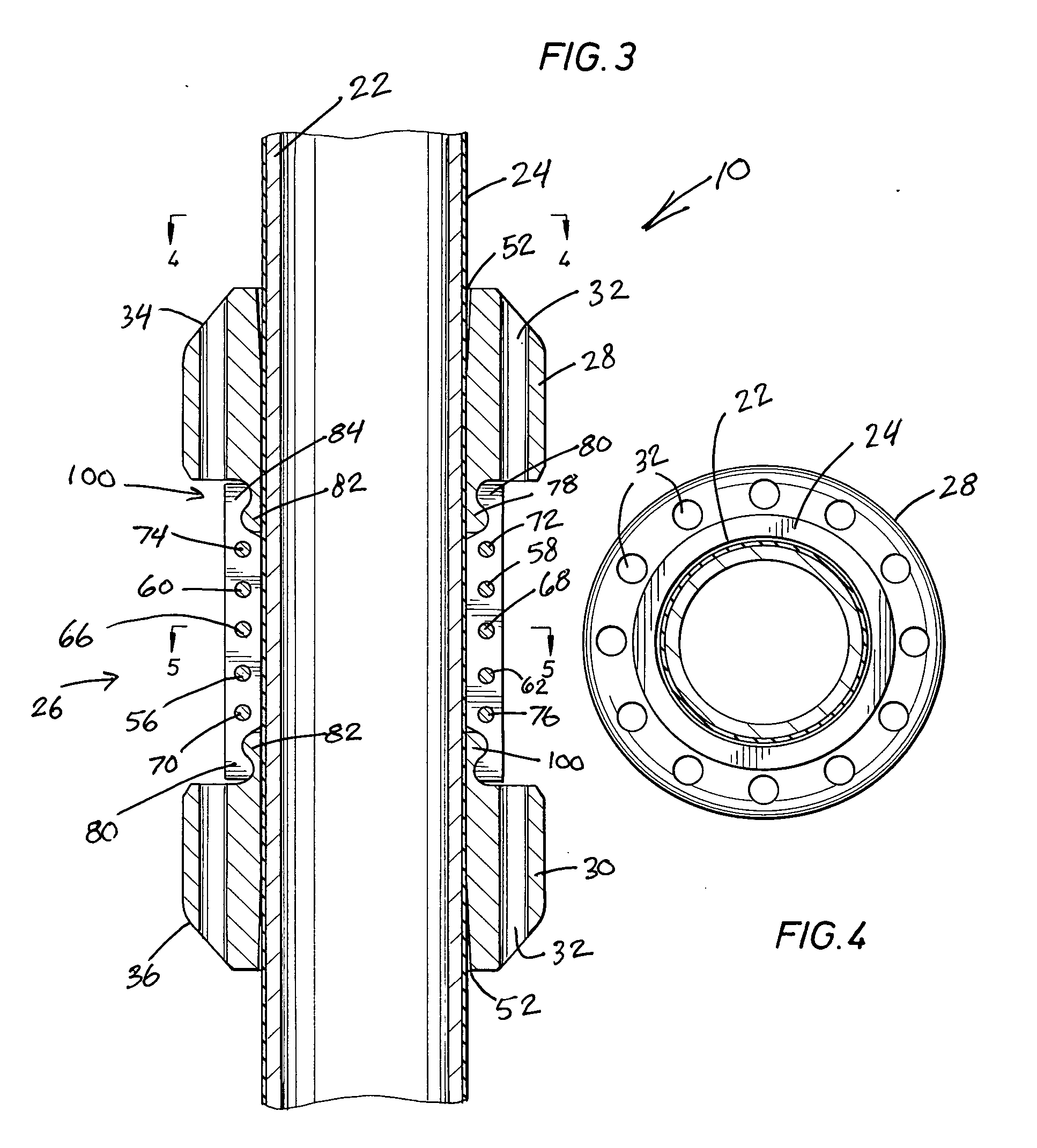

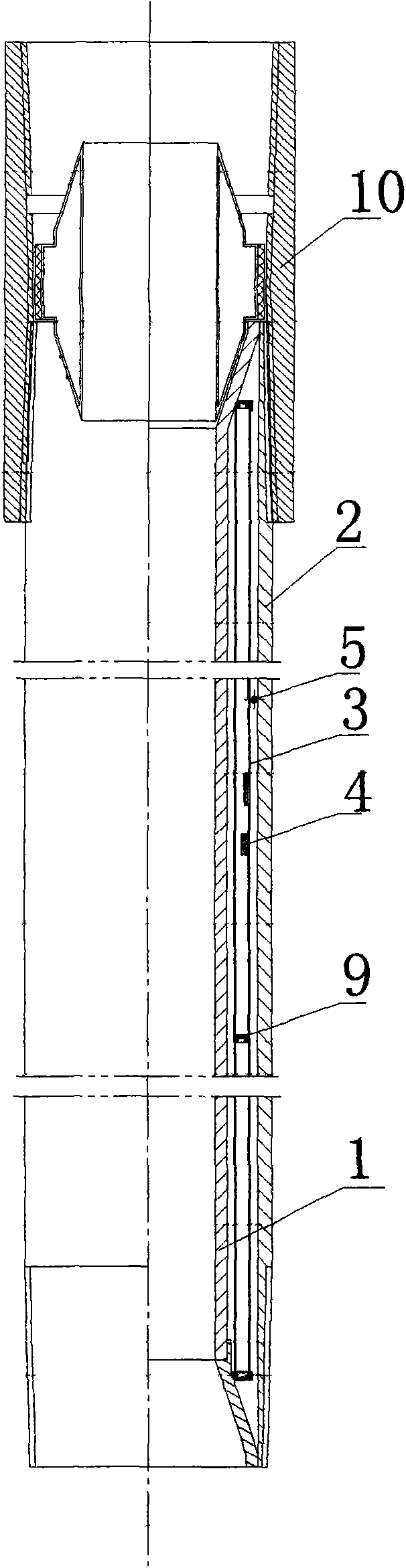

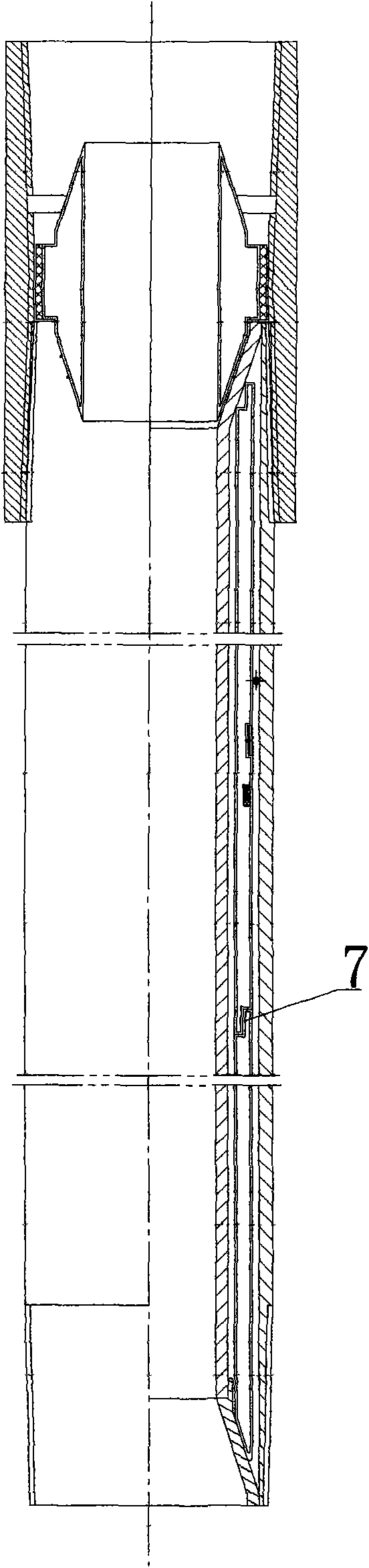

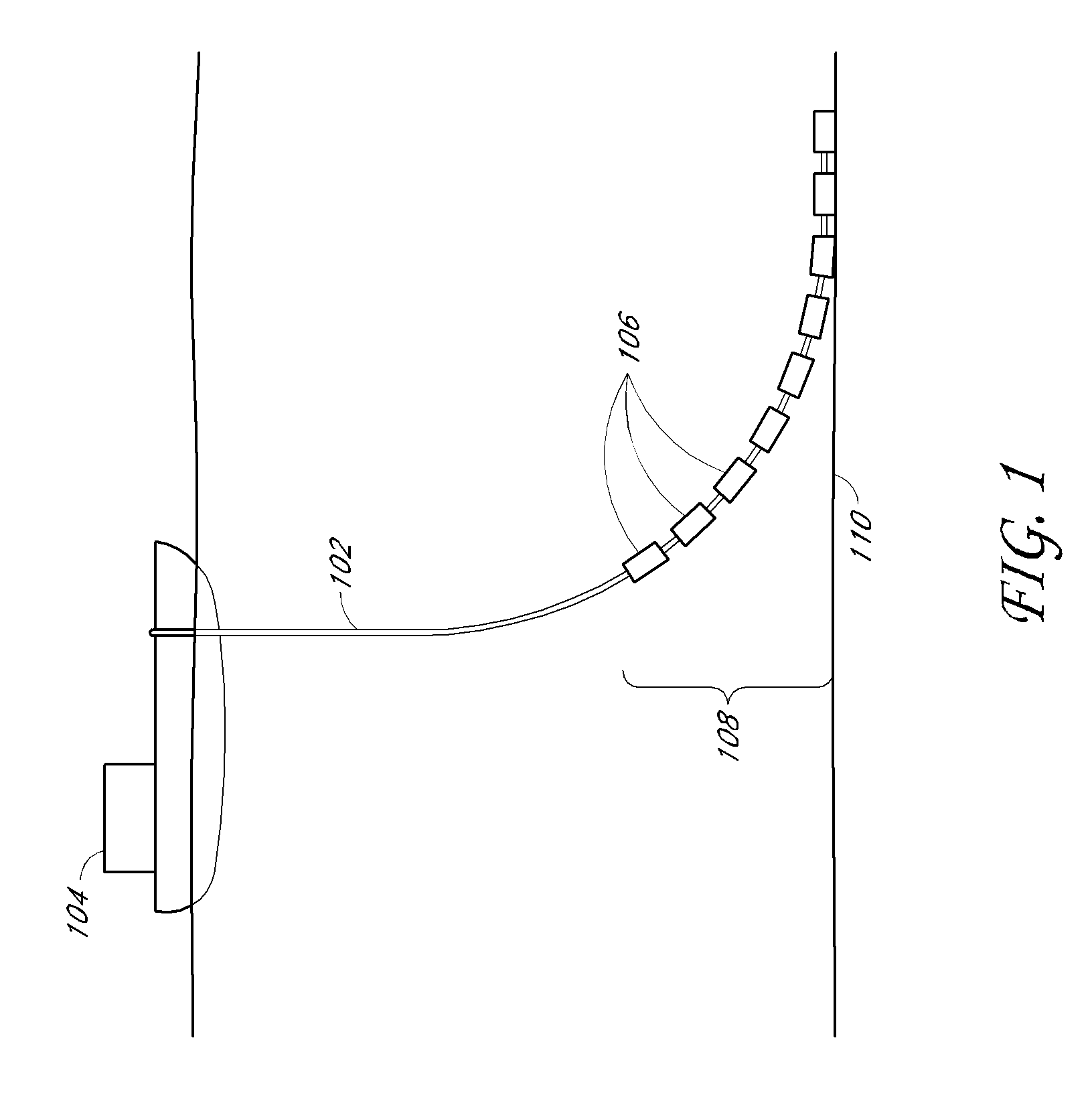

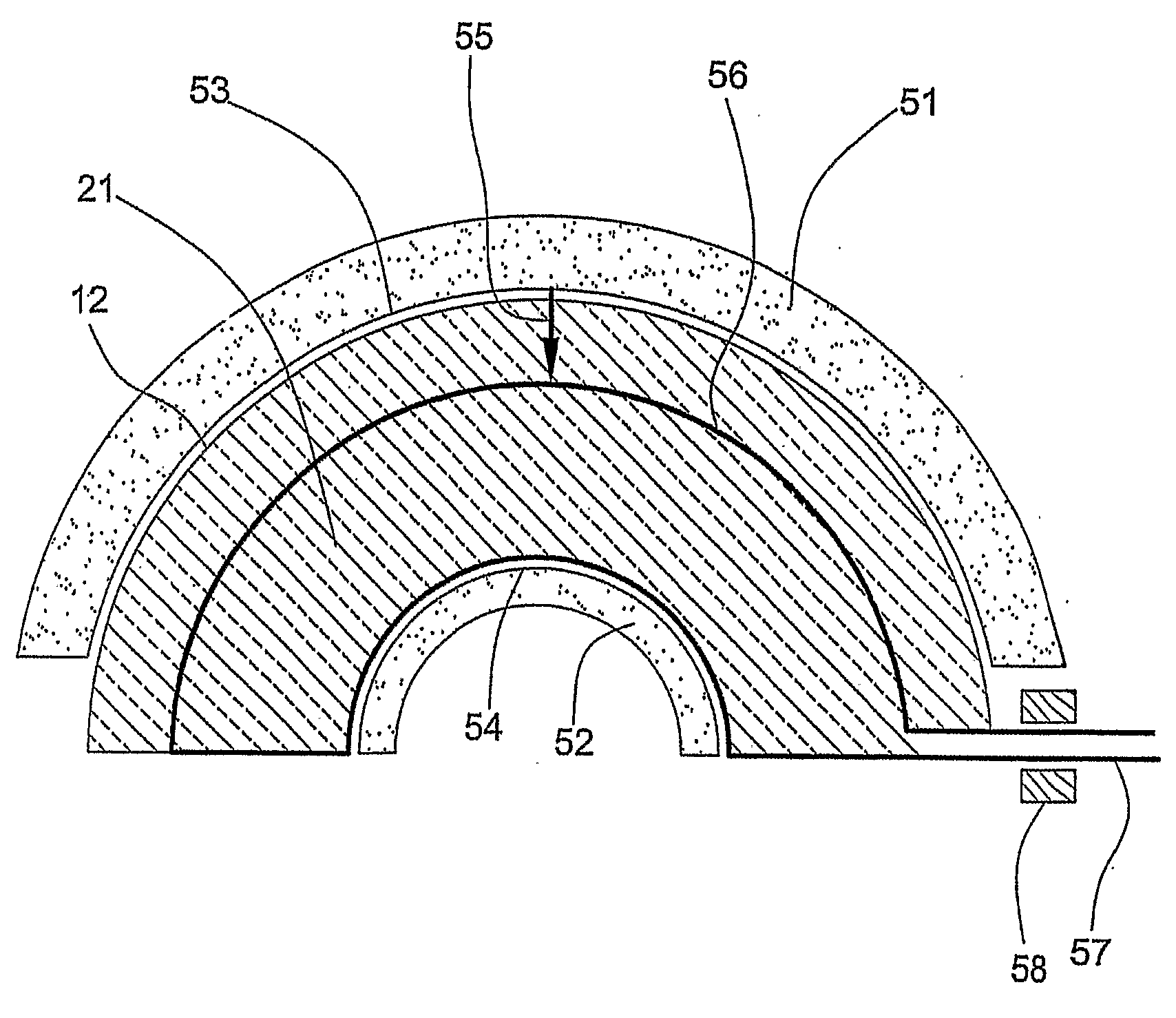

Centralizer system for insulated pipe

ActiveUS20050082056A1Prevent movementPrevent rotationDrilling rodsDrilling casingsInsulation layerBiomedical engineering

A centralizer system is provided for use in a marine riser system with an insulated pipe, which may be a titanium stress joint. The centralizer system utilizes one or more centralizers mounted such that insulation material is provided in an annulus between the one or more centralizers and the stress joint. A clamp is utilized to axially affix either one centralizer or multiple centralizers to the stress joint. The clamp is comprised of a plurality of sections with cylindrical interior surfaces which are tightened together using fasteners. The cylindrical interior surfaces avoid damage to the insulation layer which may be elastomeric. The clamp and each centralizer have radially directed projections thereon which interlock the clamp with each centralizer. Because the clamp is axially affixed, the centralizer is then also axially affixed. In one embodiment, the centralizer is axially moveable to a desired axial position prior to being interlocked to the tightened clamp.

Owner:NAT COUPLING

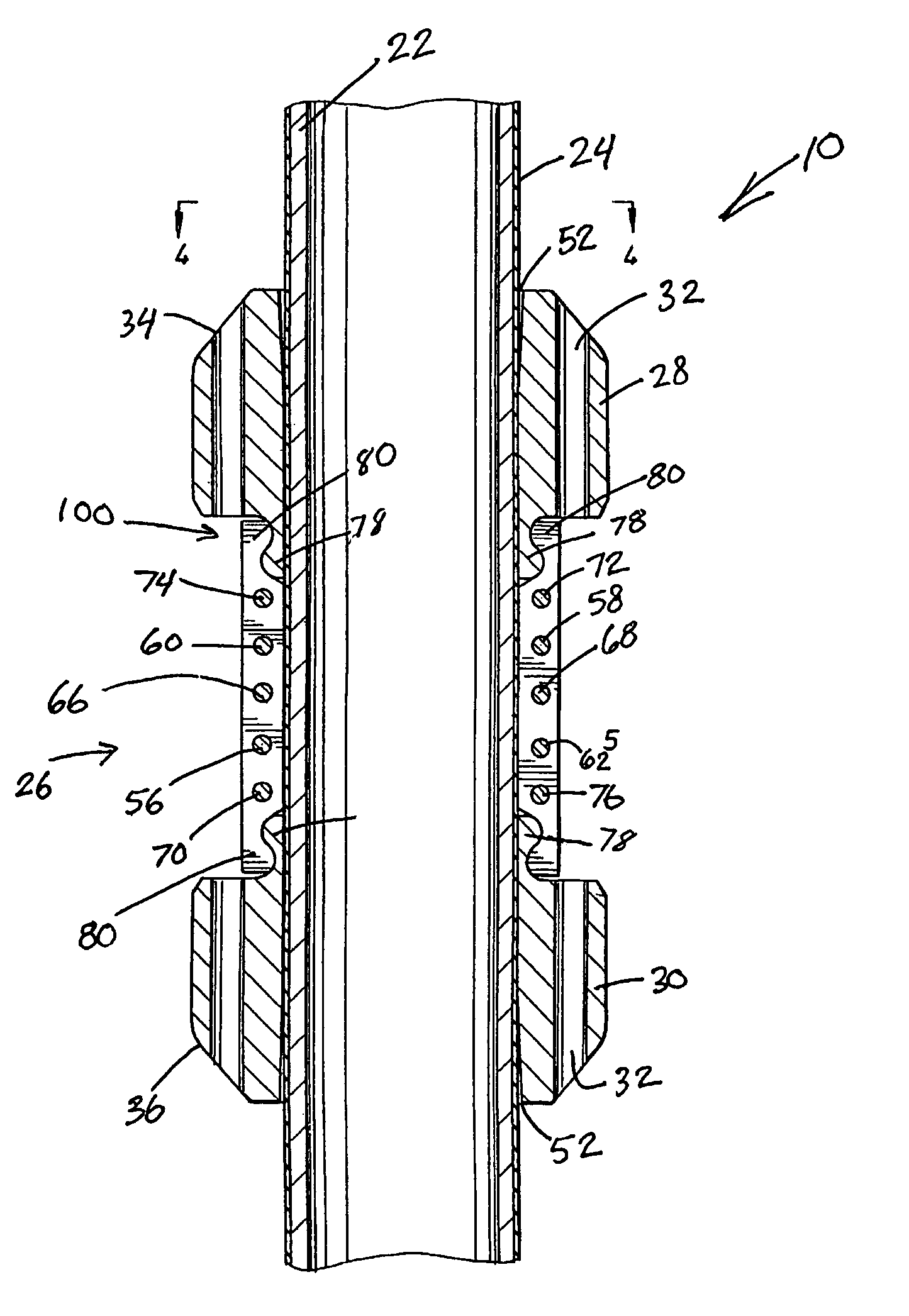

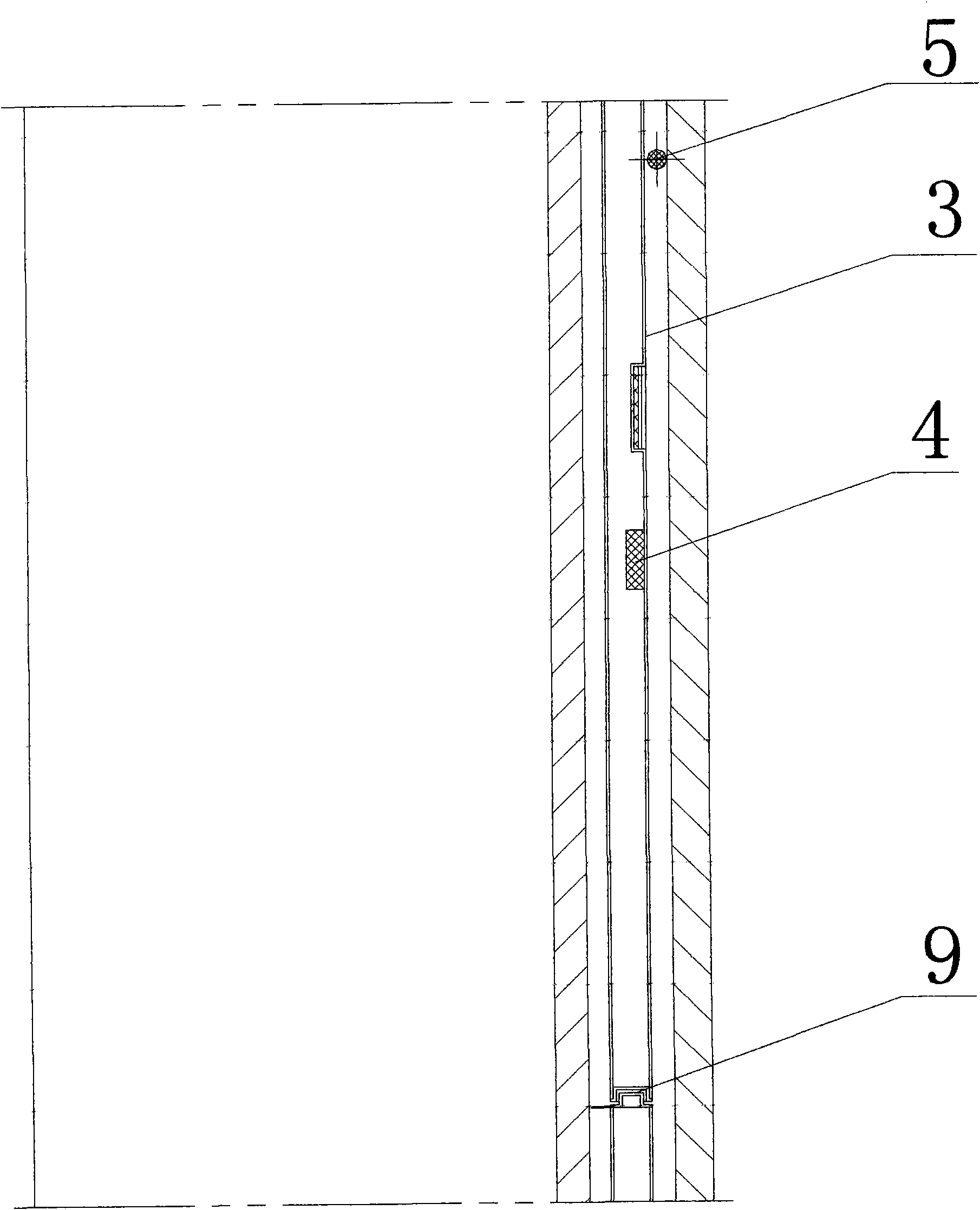

Thermally isolating tubule for wall anchor

ActiveUS20120308330A1Prevent disengagementPrevent water penetrationConstruction materialWashersSurface mountingWater vapor

A tubule assembly for thermally isolating a surface-mounted wall anchor and an anchoring system employing the same are disclosed. The thermally-isolated tubule assembly is adaptable to varied anchor structures and for use with interlocking veneer ties and reinforcement wires to provide a high-strength surface mounted anchoring system for cavity walls. The stepped cylinders sheath the mounting hardware to limit insulation tearing and resultant loss of insulation integrity. The tubule assembly is thermally-isolated through the use of a series of strategically placed compressible nonconductive fittings and set within the perimeter of the anchor base. Seals are formed which preclude penetration of air, moisture, and water vapor into the wall structure.

Owner:HOHMANN & BARNARD INC

Centralizer system for insulated pipe

ActiveUS7096940B2Prevent movementPrevent rotationDrilling rodsDrilling casingsInsulation layerBiomedical engineering

A centralizer system is provided for use in a marine riser system with an insulated pipe, which may be a titanium stress joint. The centralizer system utilizes one or more centralizers mounted such that insulation material is provided in an annulus between the one or more centralizers and the stress joint. A clamp is utilized to axially affix either one centralizer or multiple centralizers to the stress joint. The clamp is comprised of a plurality of sections with cylindrical interior surfaces which are tightened together using fasteners. The cylindrical interior surfaces avoid damage to the insulation layer which may be elastomeric. The clamp and each centralizer have radially directed projections thereon which interlock the clamp with each centralizer. Because the clamp is axially affixed, the centralizer is then also axially affixed. In one embodiment, the centralizer is axially moveable to a desired axial position prior to being interlocked to the tightened clamp.

Owner:NAT COUPLING

Vacuum compound heat insulating pipe

ActiveCN101644372AEasy to processGuaranteed insulation effectDrilling rodsThermal insulationVacuum pumpingCarbon steel

The invention relates to a vacuum compound heat insulating pipe which comprises an inner pipe and an outer pipe and is characterized in that at least one layer of independent stainless steel or carbonsteel vacuum heat insulating pipe is arranged between the inner pipe and the outer pipe, and the vacuum heat insulating pipe is a double-layer vacuum pumping pipe only formed by welding a stainless steel plate or a carbon steel plate. The vacuum compound heat insulating pipe has the heat insulating life of more than eight years, and the heat insulating effect can be ensured. In addition, when theinner pipe and the outer pipe of the vacuum compound heat insulating pipe are damaged, the stainless steel vacuum heat insulating pipe is conveniently replaced, can be repeatedly used and reduces themaintenance cost in a subsequent maintenance process.

Owner:湖北贵族真空科技股份有限公司

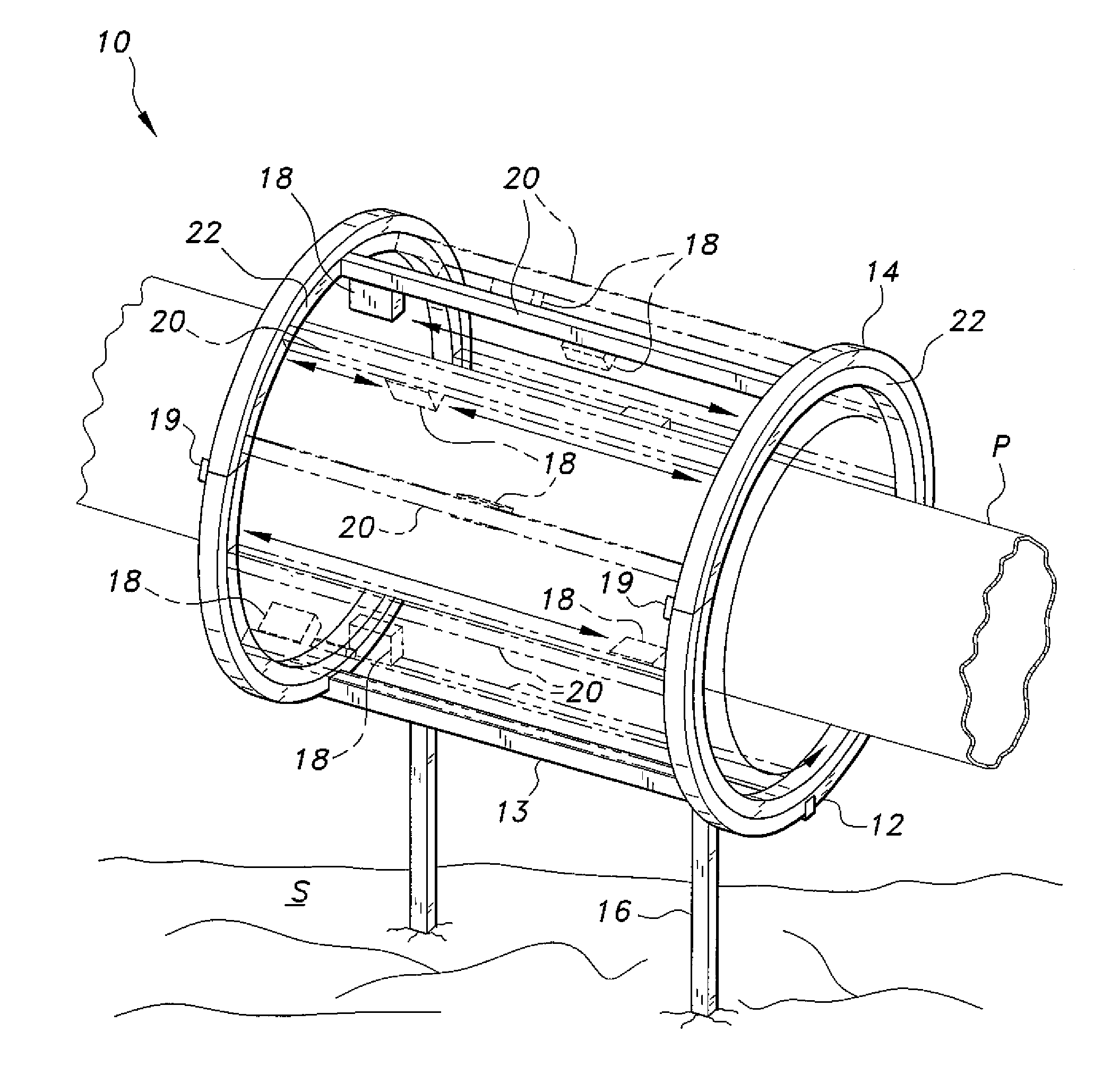

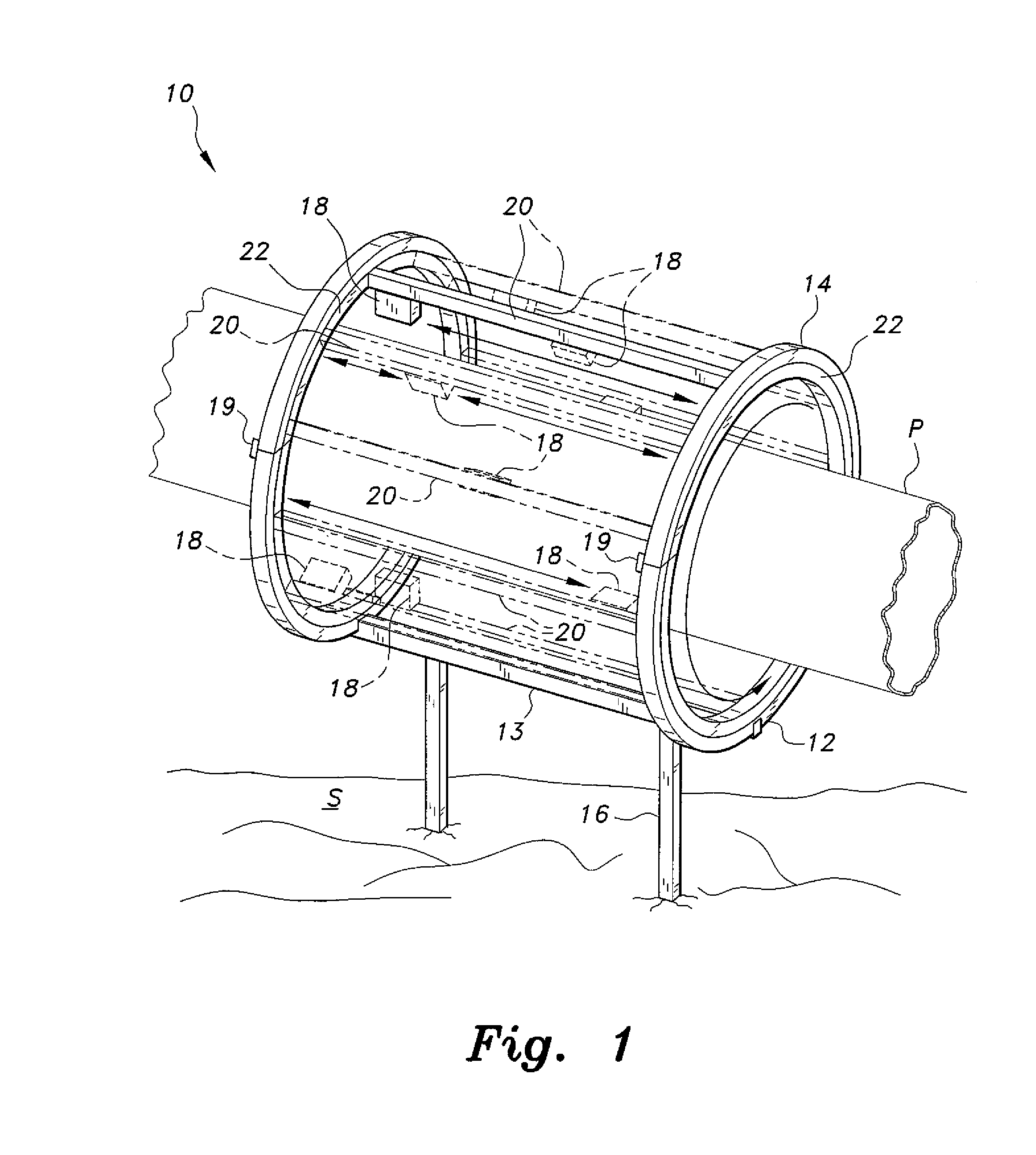

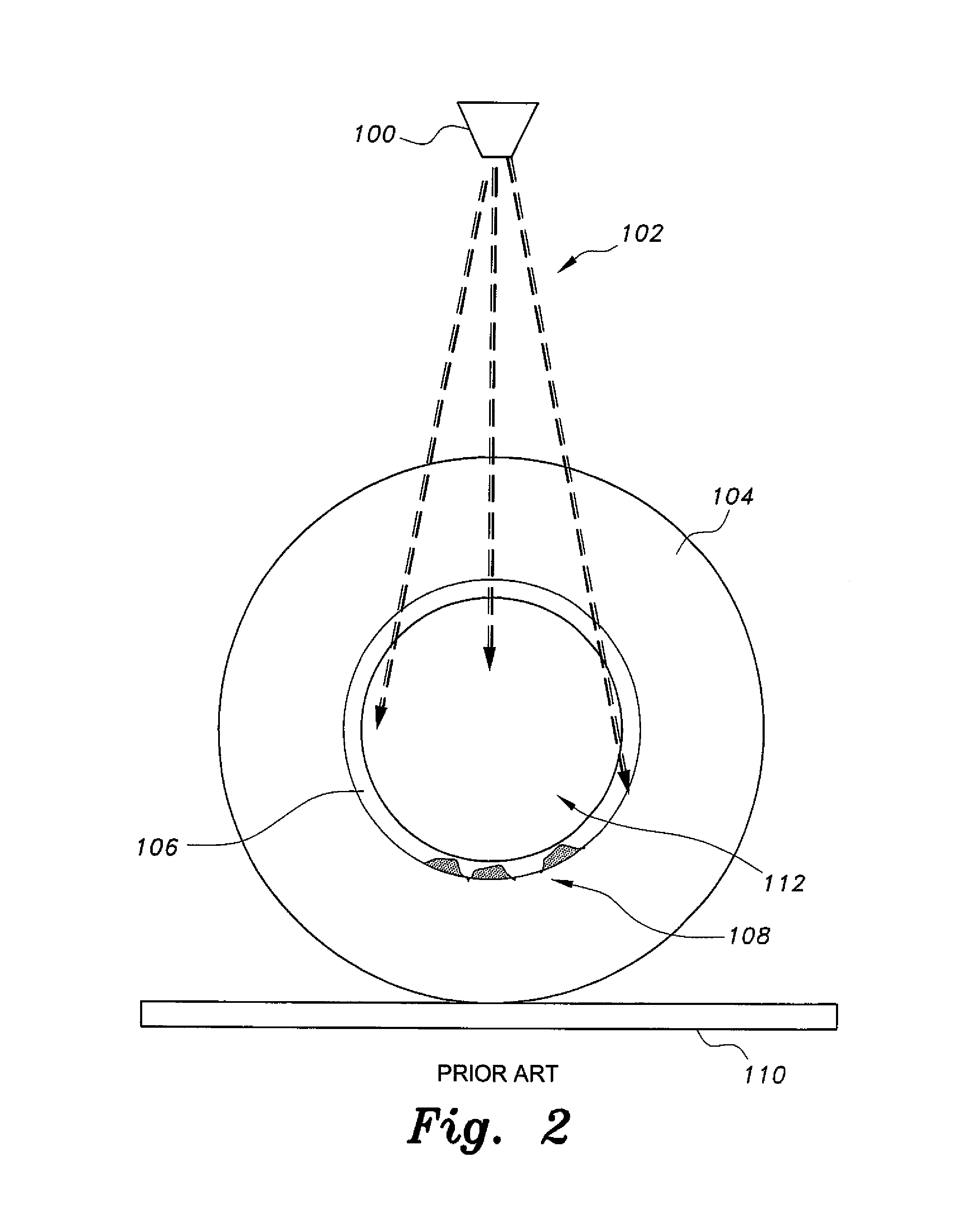

System for inspection and imaging of insulated pipes and vessels using backscattered radiation and X-ray fluorescence

InactiveUS8767912B1Readily apparentX-ray spectral distribution measurementUsing wave/particle radiation meansEngineeringX-ray fluorescence

The system for the inspection and imaging of insulated pipes and vessels using backscattered gamma radiation and X-ray fluorescence includes a frame having a pair of coaxial rings adapted for coaxial mounting about the insulated pipe, vessel or the like. A pair of rotating supports are rotatably mounted within the pair rings for driven rotation thereof. A plurality of horizontal supports are secured to, and extend between, the pair of rotating supports such that each of the horizontal supports extends along a direction parallel to an axis of the insulated pipe. A plurality of inspection modules are slidably mounted to the horizontal supports. Each inspection module includes at least one radiation source, an X-ray fluorescence detector and a backscattered gamma radiation detector. The plurality of inspection modules are linearly translated along the axial direction of the pipe, and also circumferentially rotated therearound for simultaneous, three-dimensional inspection of the pipe body.

Owner:KING ABDULAZIZ UNIV

Device and method for providing strain measurements of insulated pipes

ActiveUS20080303382A1Avoid damageReduced and eliminated disruptionDrilling rodsPiezoelectric/electrostriction/magnetostriction machinesInsulation layerEngineering

This disclosure provides methods and apparatuses to monitor strain in a steel pipe with reduced or eliminated disruption of the insulative and anti-corrosive layers or coatings that cover the pipe. The methods and apparatuses can include an attachment scheme that is less intrusive and less sensitive to dilation of the insulation layer on the pipe than previous strain monitoring solutions. Additionally, methods and apparatuses can reduce corrosion by virtue of the reduction in the number and volume of metallic components.

Owner:BMT SCI MARINE SERVICES

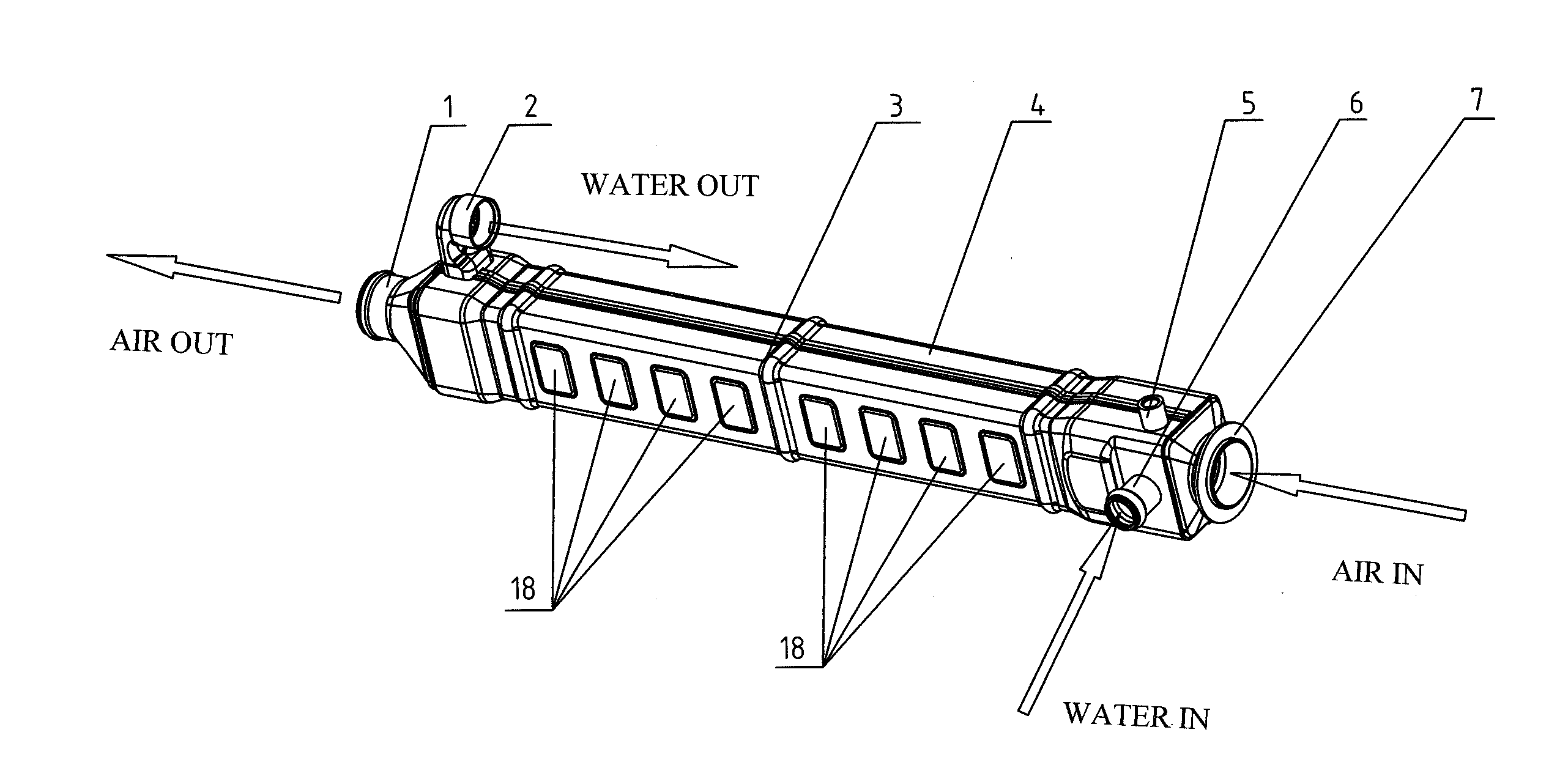

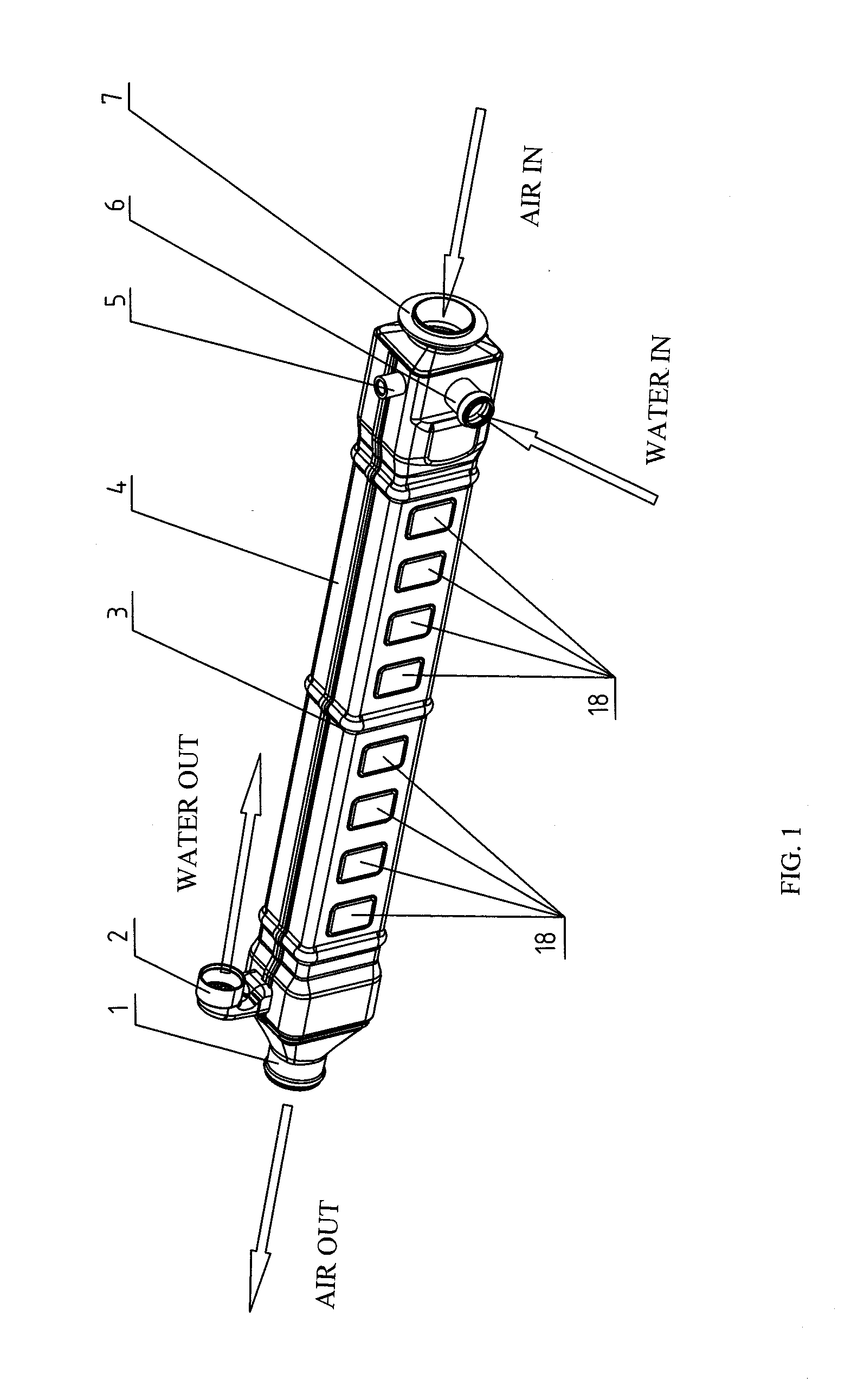

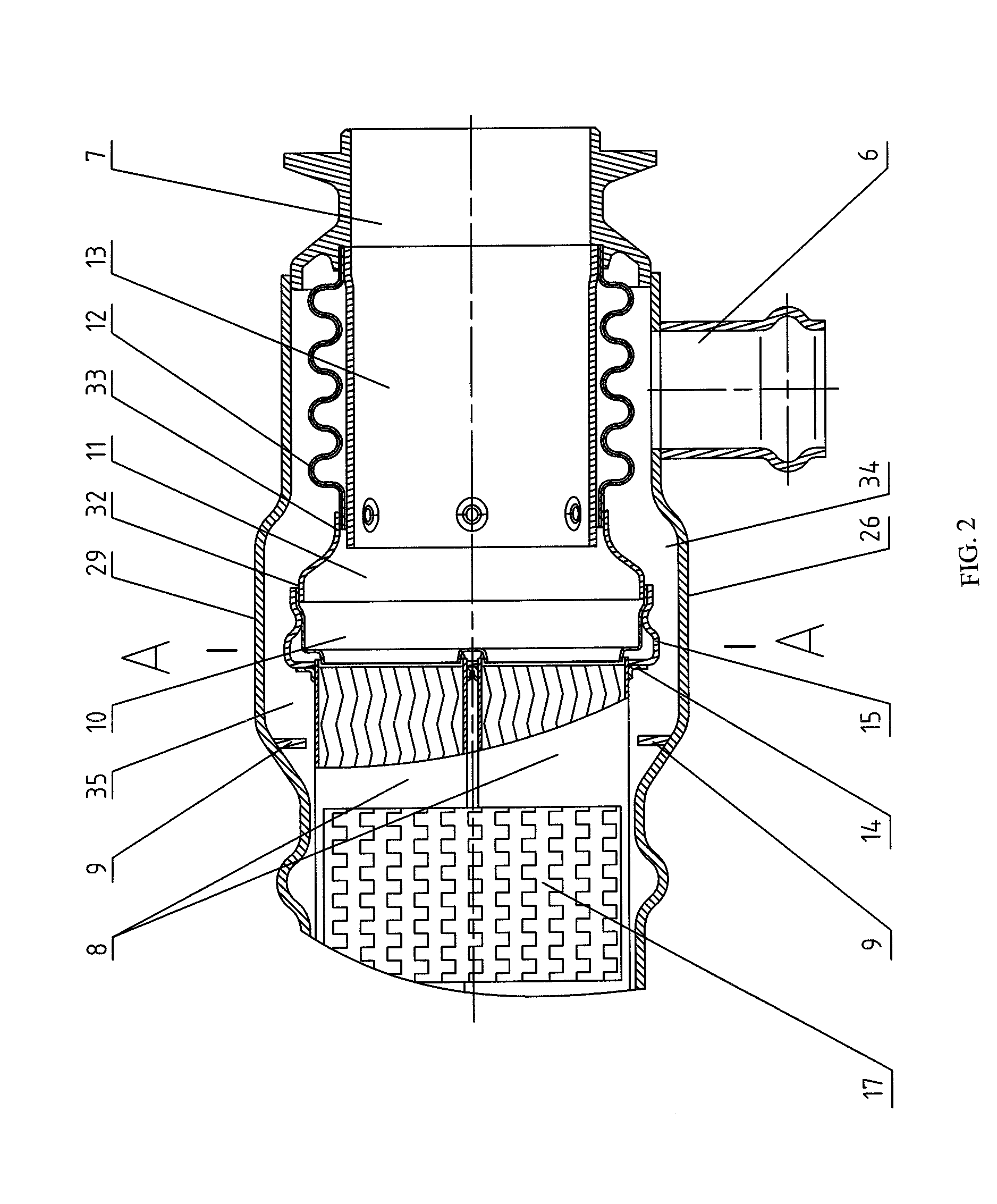

Plate-fin structure exhaust gas recirculation cooler with heat-insulation function

ActiveUS20140034028A1High strengthImprove cooling effectInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringExhaust gas recirculation

The present invention discloses a plate-fin structure EGR cooler with heat-insulation function includes shell. The two ends of the shell are equipped with an air inlet flange and a discharge chamber. A water inlet pipe and a water outlet pipe are set on the shell near the air inlet flange and the discharge chamber. A cooling core assembly, an air chamber and a bellow are set in the shell. The main board at one end of the cooling core assembly is connected to the shell and the discharge chamber and the main board at another end is connected to one end of the air chamber. The other end of the air chamber is connected to one end of the bellow. The other end of the bellow is connected to the shell and the air inlet flange. A heat-insulating pipe connected to the air inlet flange is set within the bellow. Since the main board at the other side of the cooling core assembly is flexibly connected to the shell via the air chamber and the bellow, the axial deformation generated in the flat pipe unit can be transferred to and absorbed by the bellow through the air chamber and thus the axial heat stress generated from the heat deformation of the flat pipe unit is eliminated.

Owner:ZHEJIANG YINLUN MACHINERY

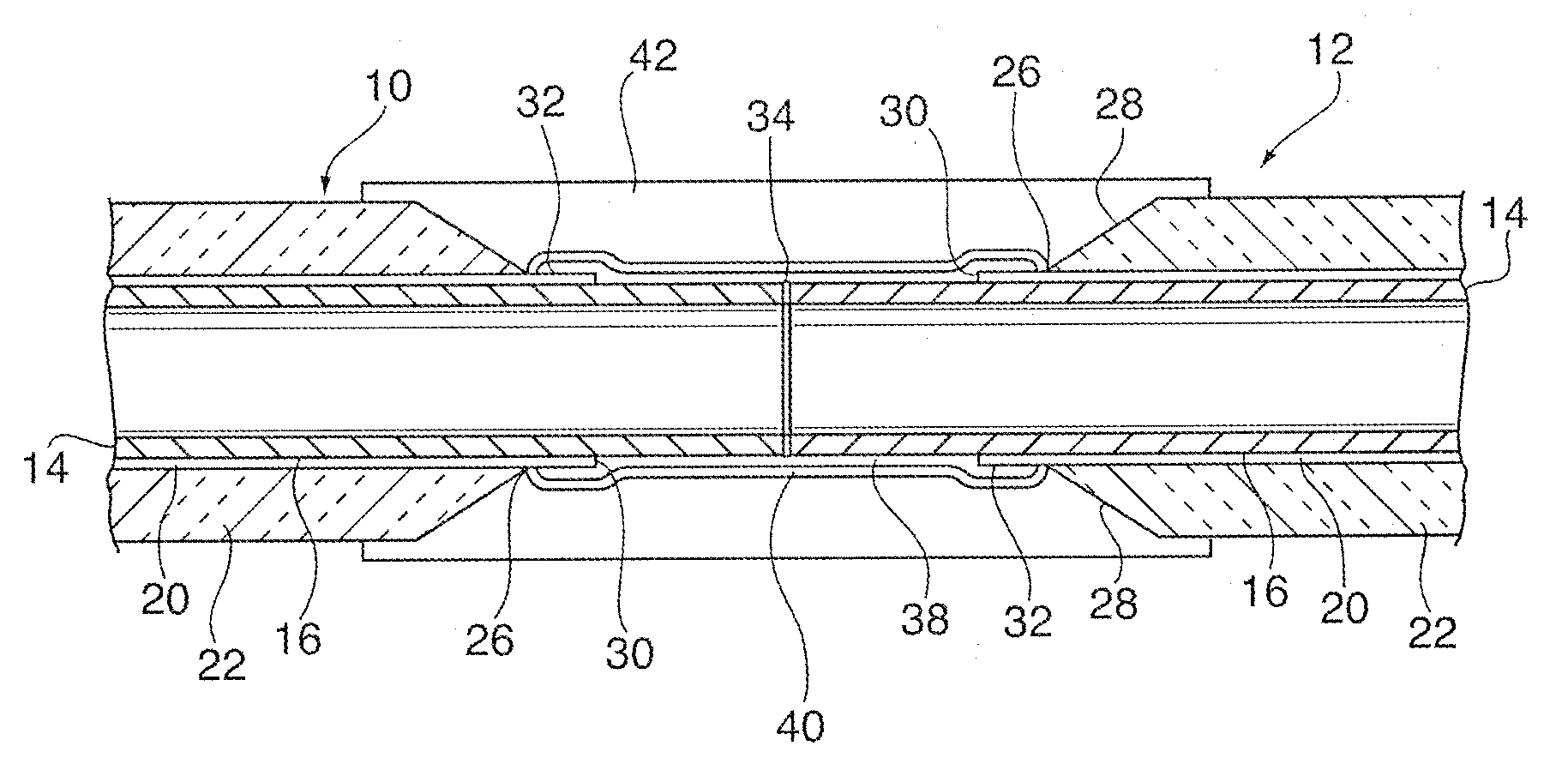

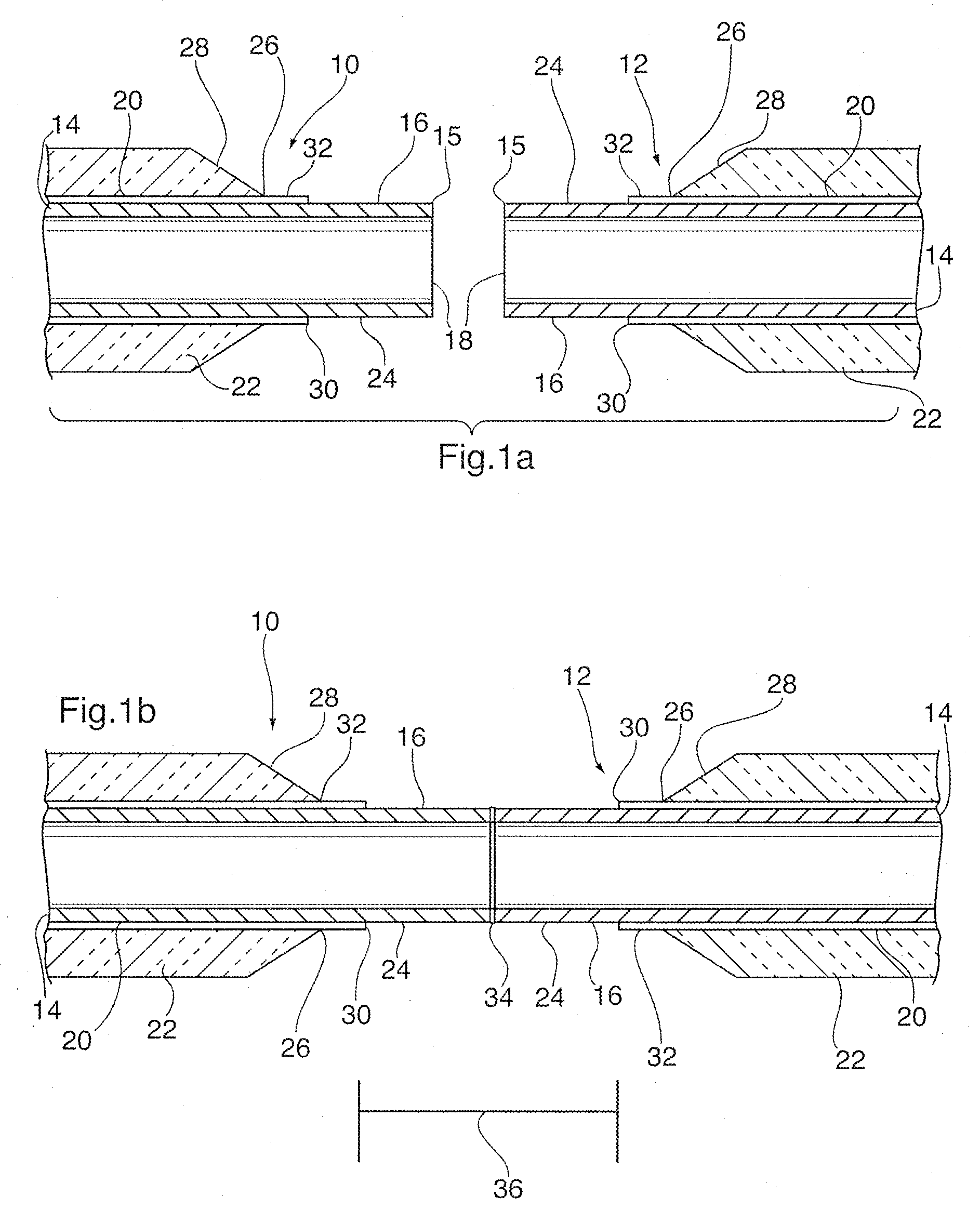

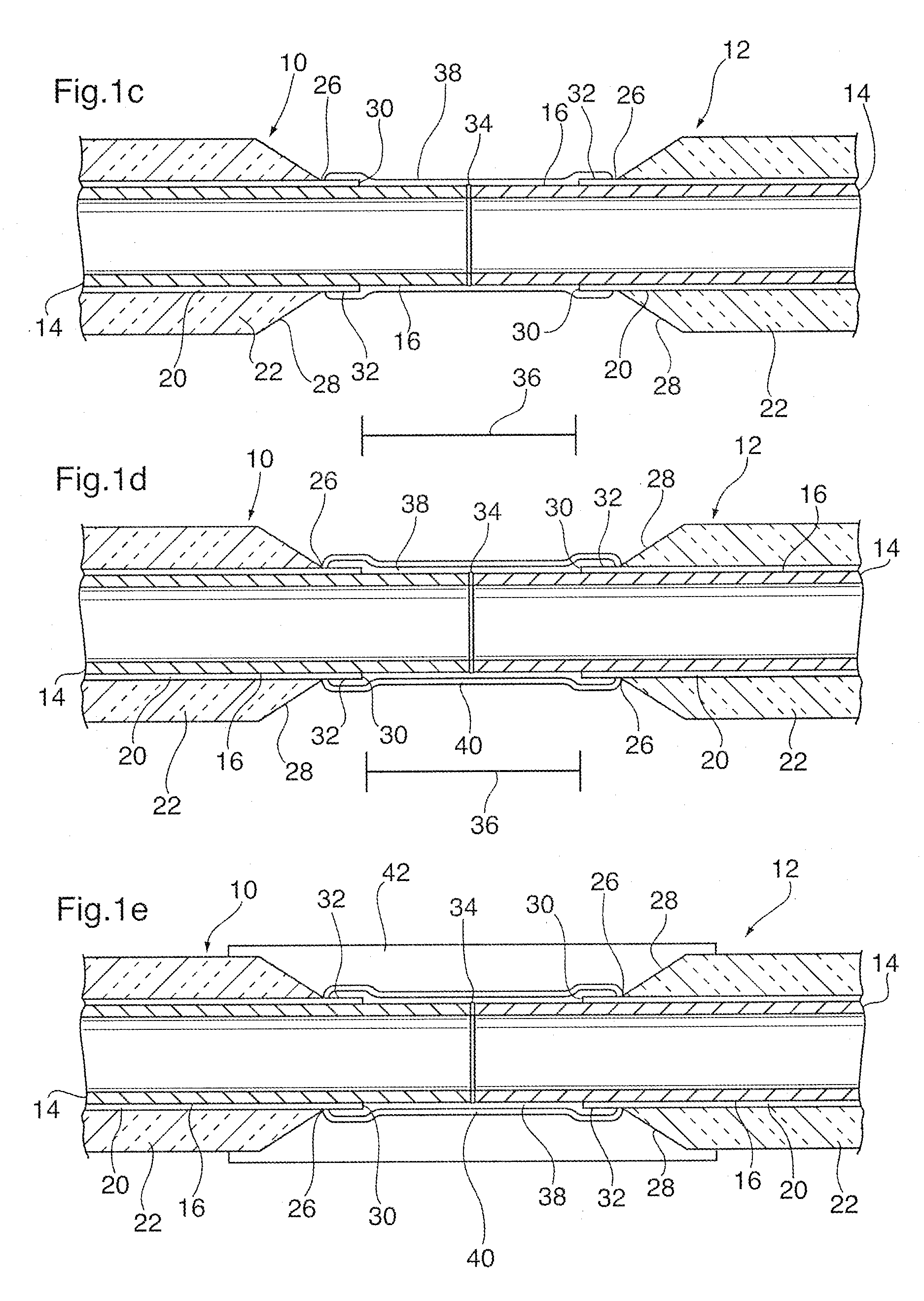

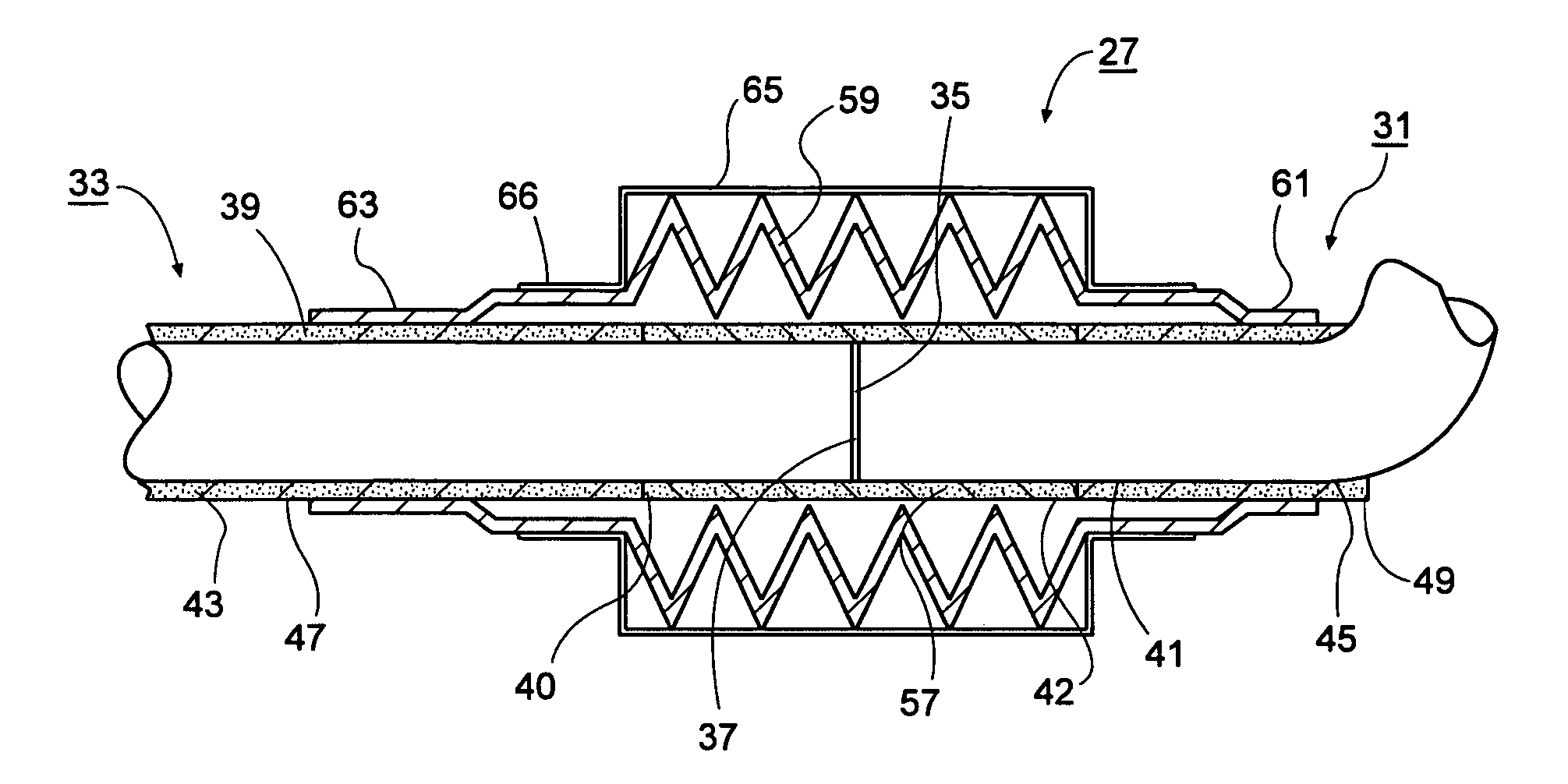

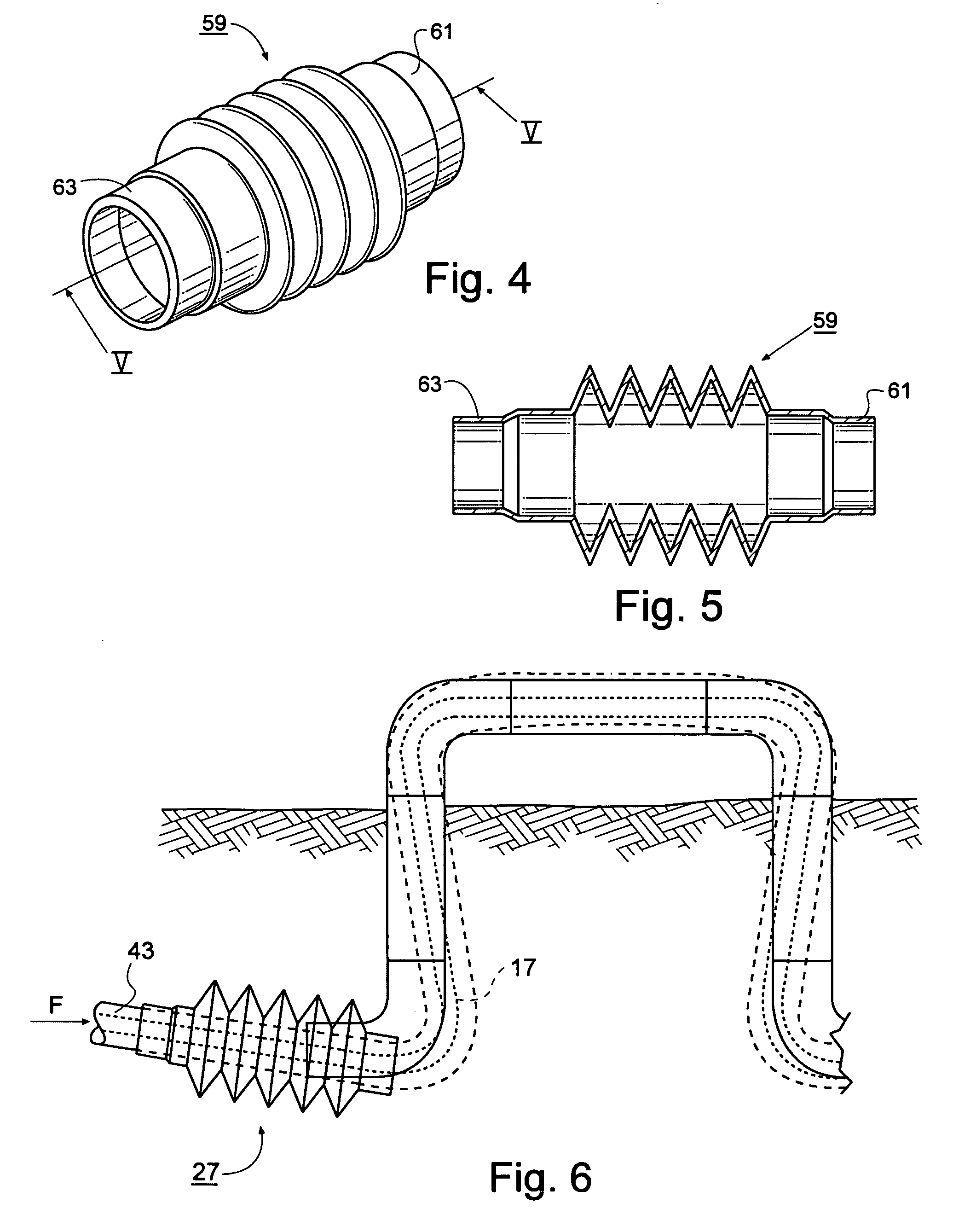

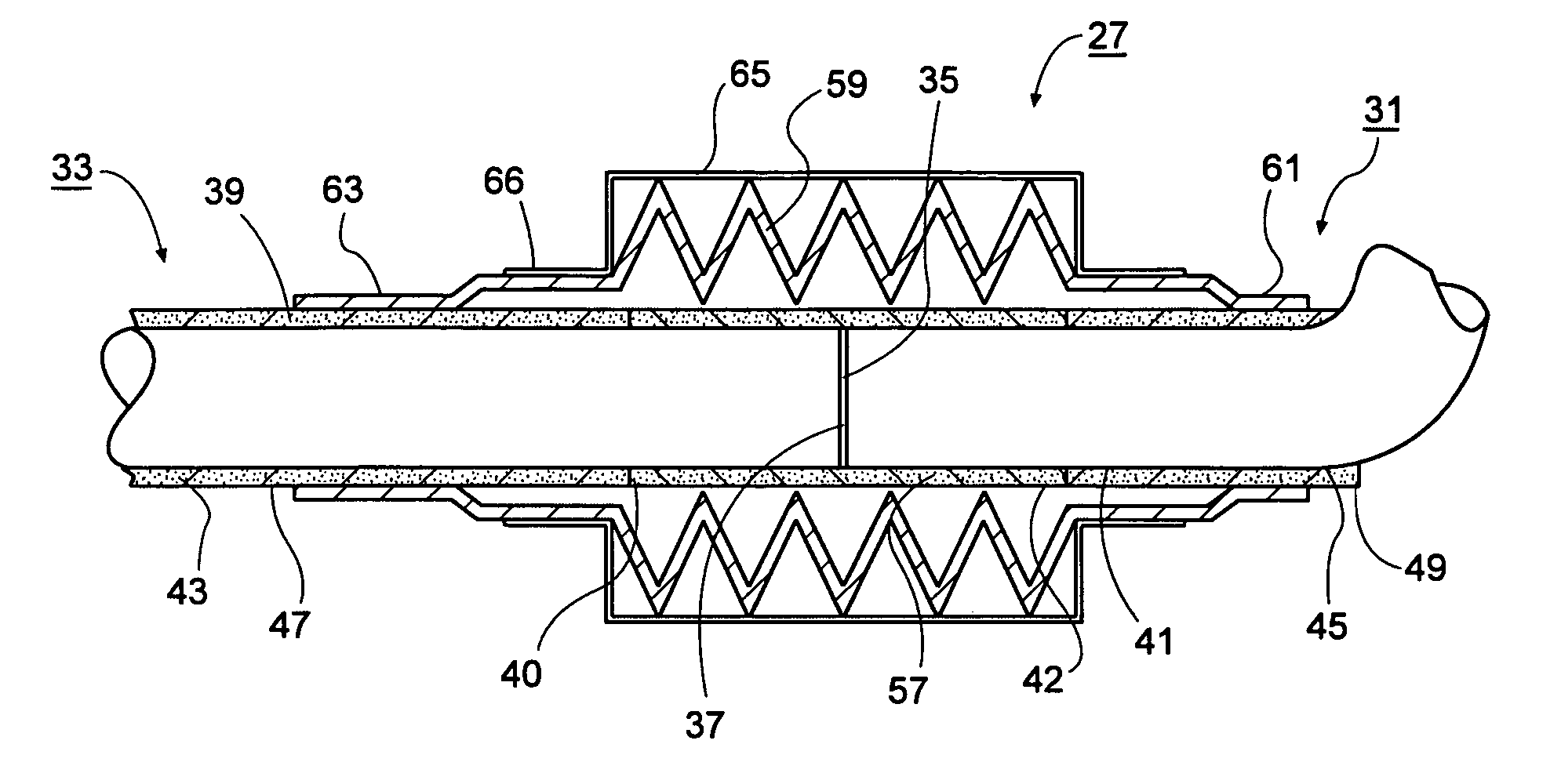

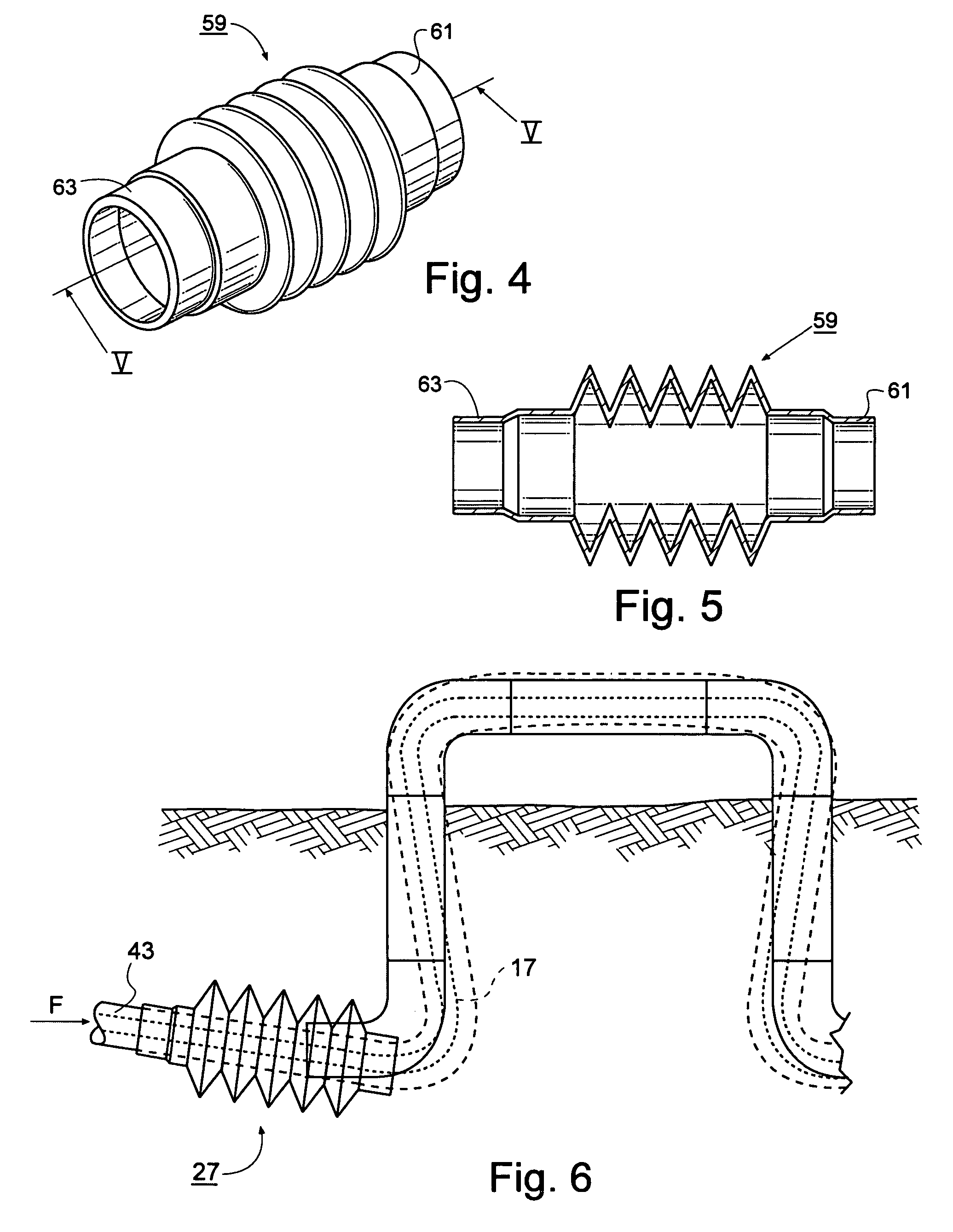

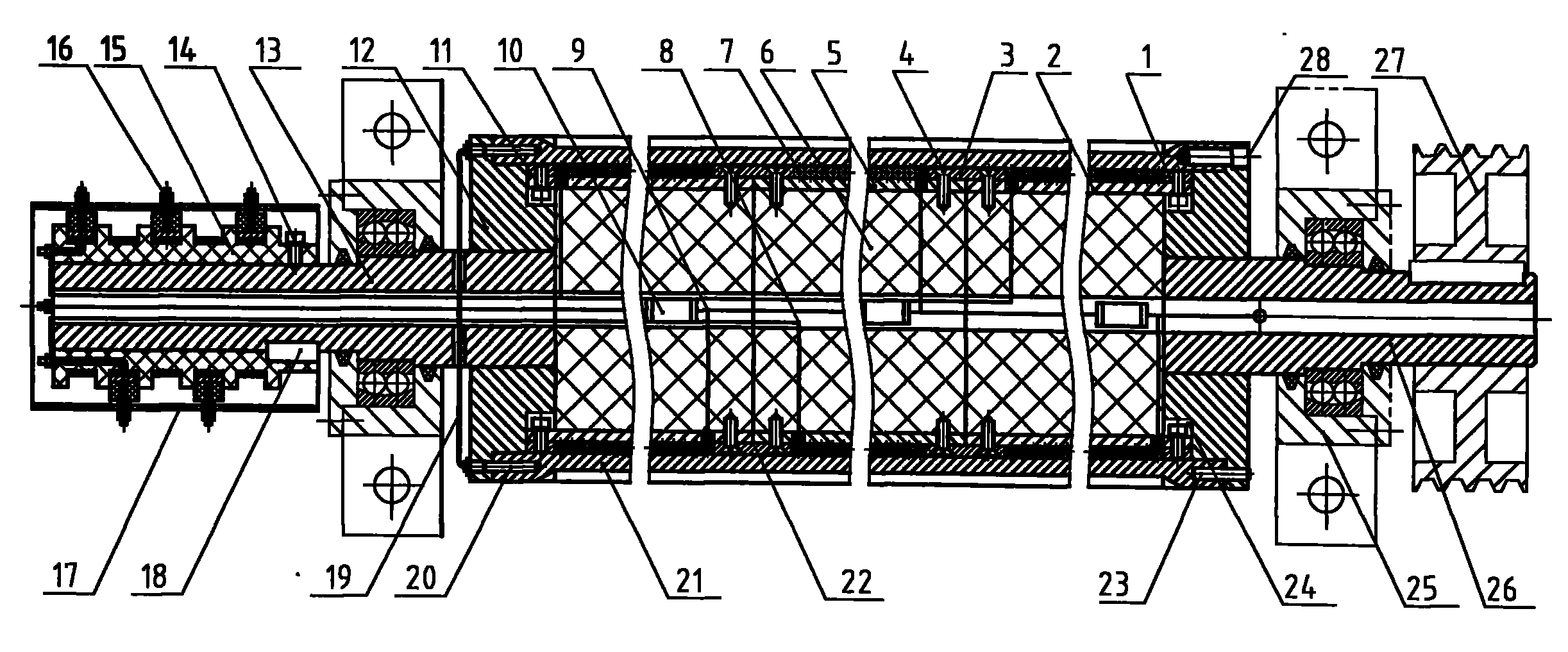

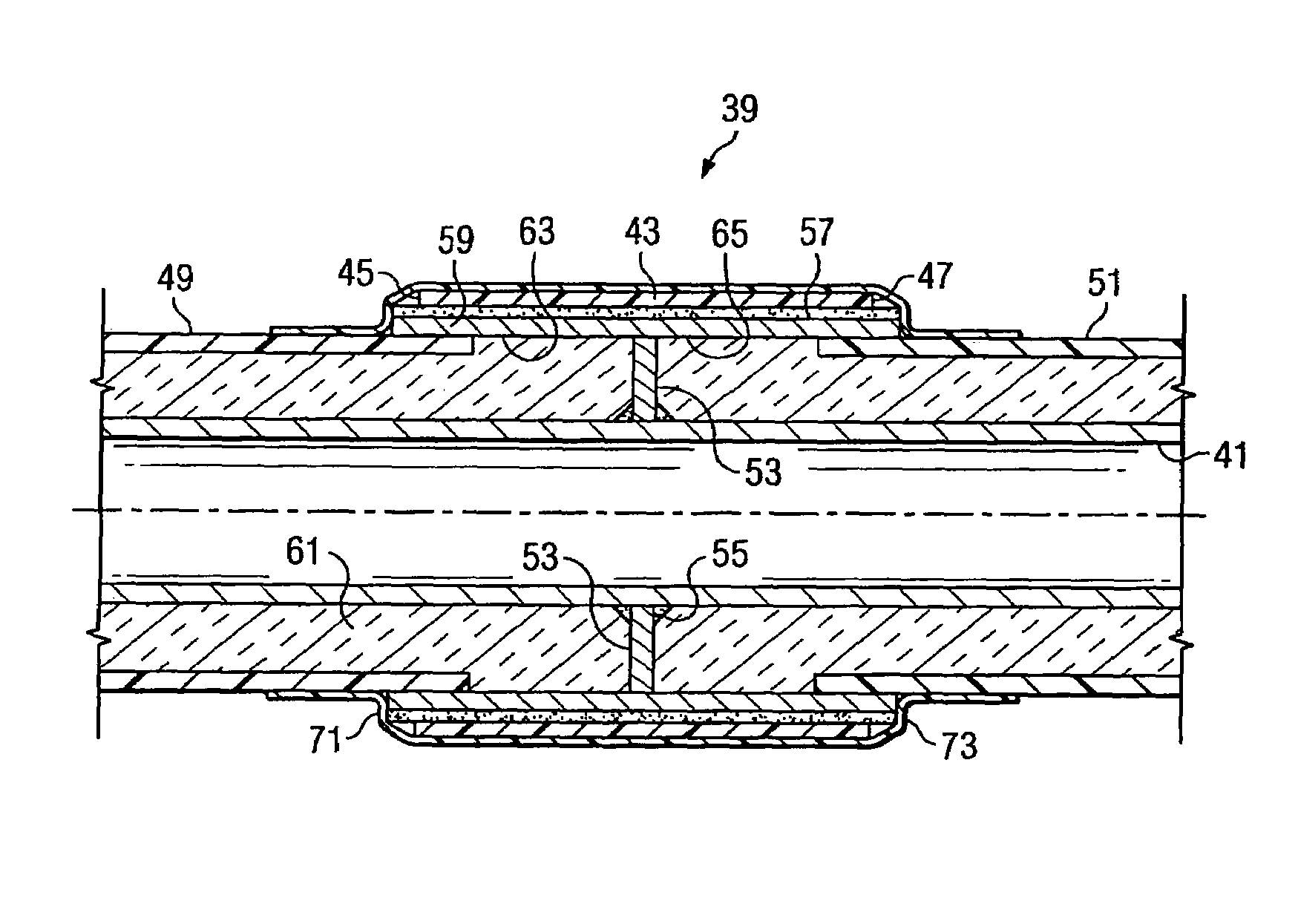

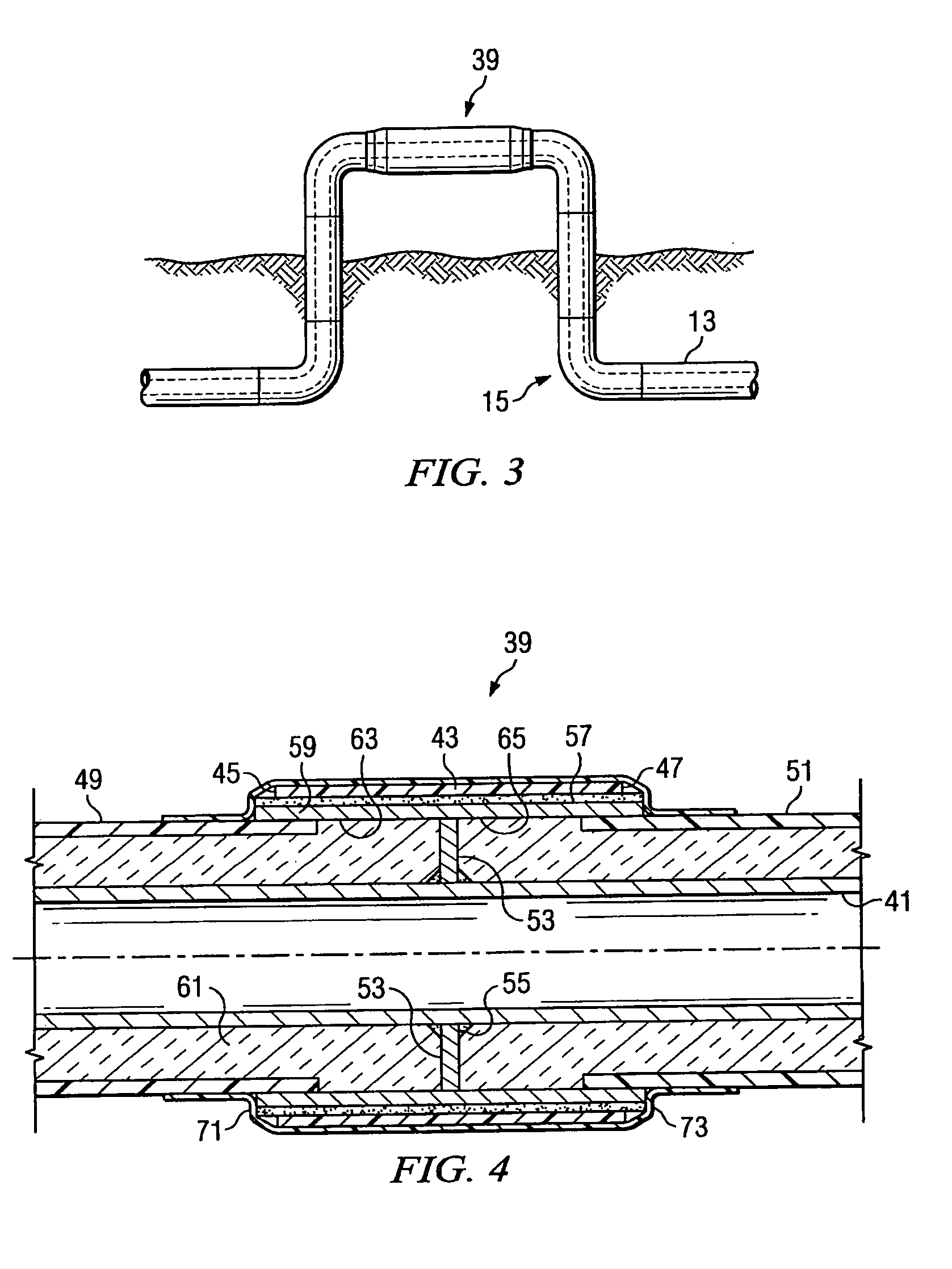

High temperature line expansion installation with bellows

An flexible coupling is shown for an insulated piping system of the type used to convey steam and other high temperature fluids. The coupling uses a flexible bellows and additional insulating and joining components to couple conventional lengths of insulated pipe. The bellows arrangement compensates for any relative movement of the inner fluid conveying pipes with respect to the outer layers of insulating material and outer jacket in order to protect the integrity of the assembly and prevent the intrusion of water or other contaminants which could lead to corrosion or early failure of the piping system.

Owner:THERMACOR PROCESS

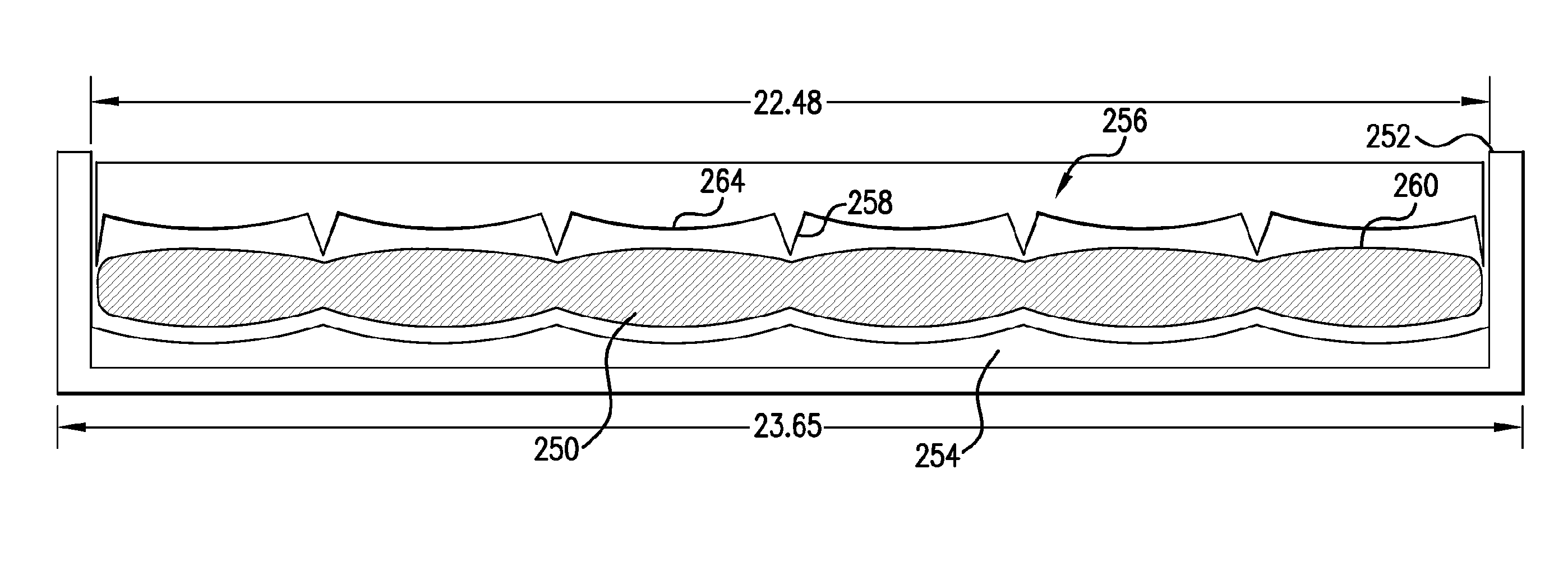

Insulation for pipe-in-pipe systems

InactiveUS20090301596A1Big cost advantageQuick assemblyThermal insulationFlexible pipesThermal insulationThick wall

A method of providing an insulated pipe-in-pipe assembly includes providing an inner pipe; providing a thermal insulation layer of a highly porous solid formed from a gel, the highly porous solid having pores smaller than 100 nanometre, the thermal insulation layer being provided around the inner pipe for thermal insulation of the inner pipe; providing a protective layer on the outer surface of the thermal insulation layer for protecting the thermal insulation layer, and providing a thick walled outer pipe around the protective layer. A Pipe-in-pipe assembly and a pipe-in-pipe section made by the method are also provided.

Owner:HEEREMA MARINE CONTRACTORS NEDERLAND

High temperature line expansion installation with bellows

InactiveUS7143788B2Poses problemSleeve/socket jointsPipeline expansion-compensationCouplingEngineering

An flexible coupling is shown for an insulated piping system of the type used to convey steam and other high temperature fluids. The coupling uses a flexible bellows and additional insulating and joining components to couple conventional lengths of insulated pipe. The bellows arrangement compensates for any relative movement of the inner fluid conveying pipes with respect to the outer layers of insulating material and outer jacket in order to protect the integrity of the assembly and prevent the intrusion of water or other contaminants which could lead to corrosion or early failure of the piping system.

Owner:THERMACOR PROCESS

Insulated pipe and method for preparing the same

The invention provides an insulated pipe-in-pipe assembly comprising (a) at least one inner pipe, (b) an outer pipe disposed around the at least one inner pipe so as to create an annular space between the outer and inner pipes, (c) porous, resilient, compressible material disposed in the annular space, and (d) a remnant of a container that previously was positioned in the annular space and previously held the compressible material in a volume less than the volume of the compressible material in the annular space. The invention also provides a method for making such an insulated pipe-in-pipe assembly.

Owner:CABOT CORP

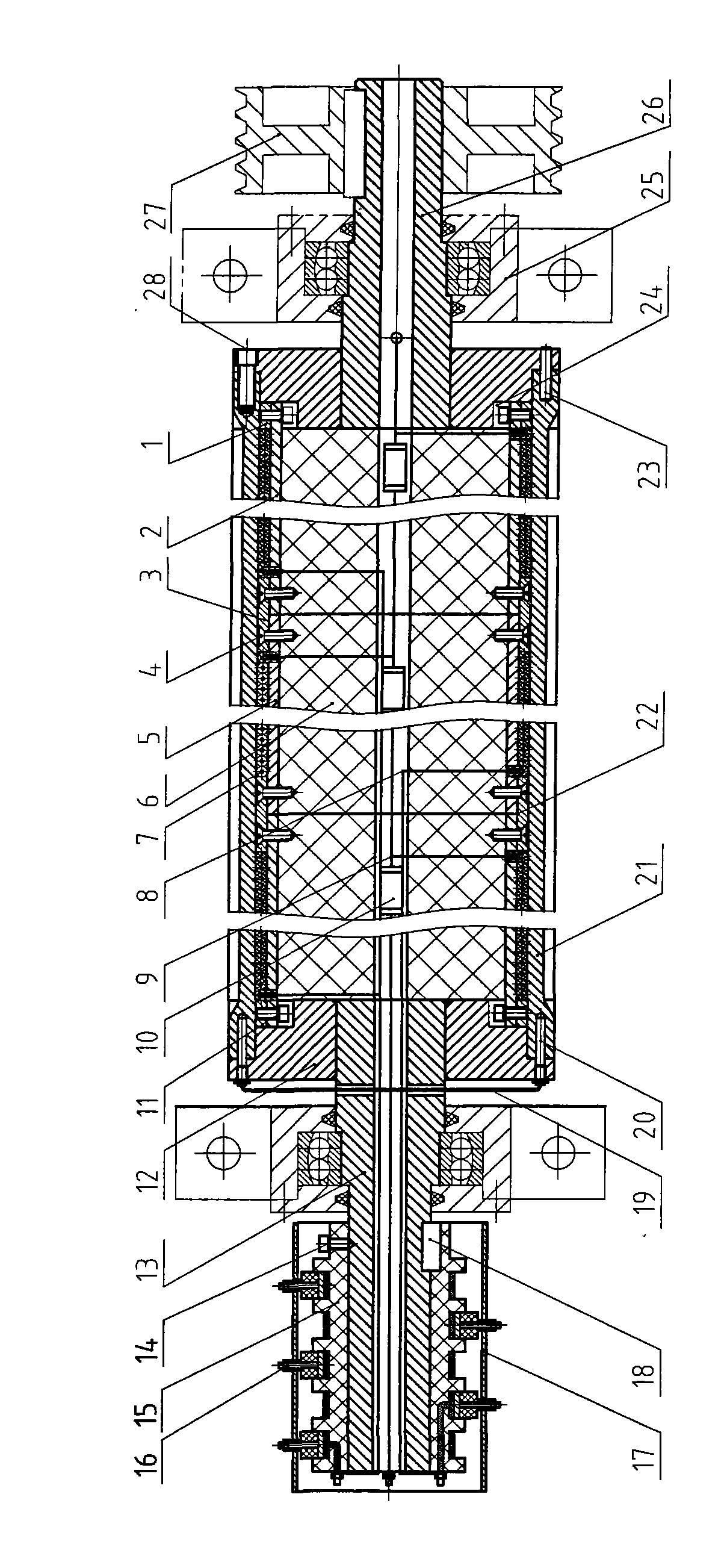

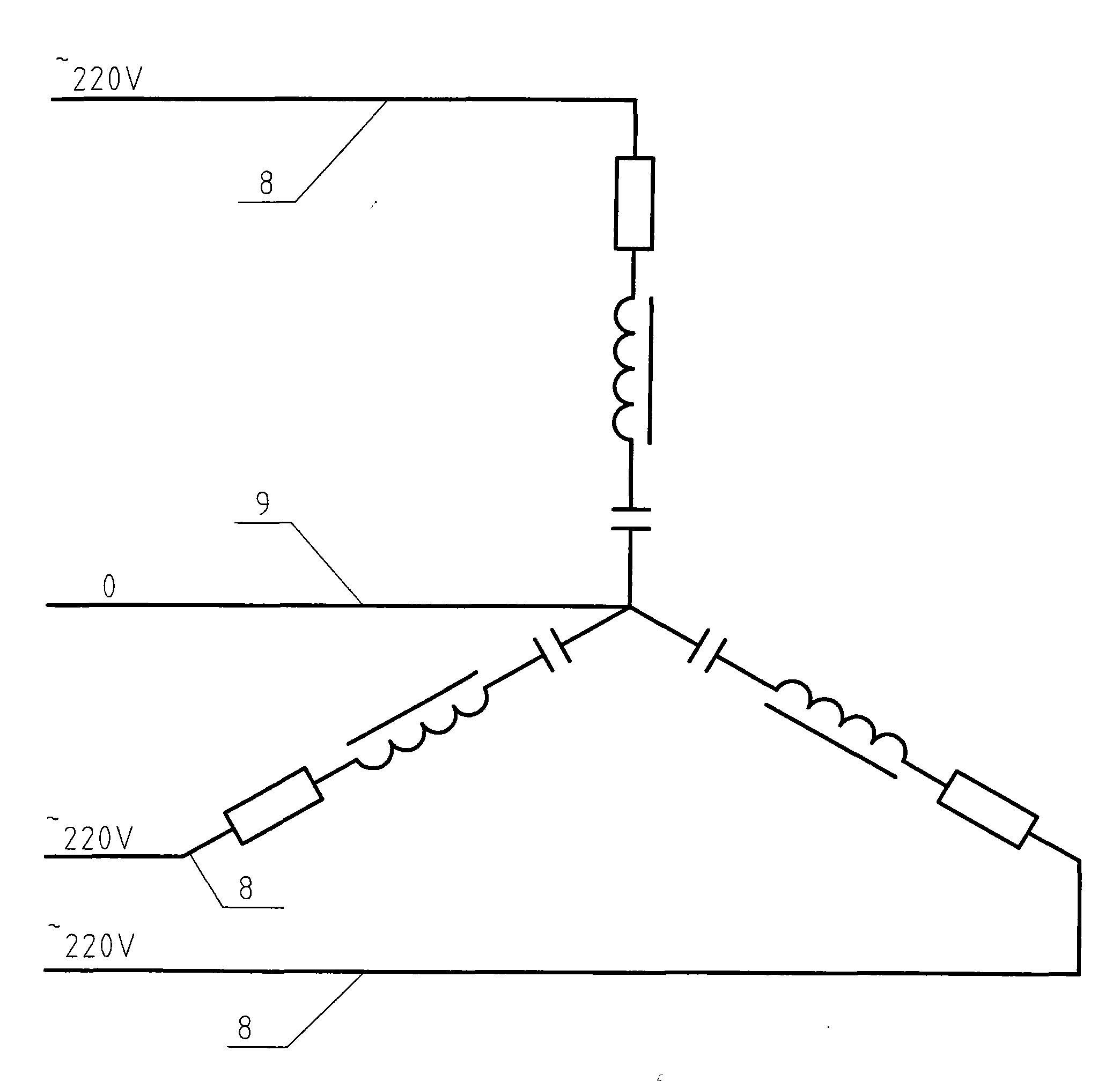

Natural luster finishing machine roller for electromagnetic and resistance heating by using power current

InactiveCN101775727AFast heatingFully absorbedOhmic-resistance heatingInduction heating apparatusCapacitanceHigh energy

The invention relates to a component used in textile machinery, in particular a natural luster finishing machine roller which comprises a roller body 21, a heating device and a rotary hook-up device, wherein the heating device comprises coils 7, a core barrel 22, a heat insulated pipe 6, a capacitor resistor 10, the core barrel 22, the heat insulated pipe 6 and the capacitor resistor 10 are sequentially arranged at the inner side of the roller body 21; the coil 7 formed by winding a rope-shaped heater is arranged in a groove of the core barrel 22; the starting end wire 8 of each group of coils 7 is connected with one live wire of a three-phase AC power supply on a carbon brush 16, the tail end wire 9 thereof is connected with a capacitor 10 in series and then connected with a shared neutral wire of the three-phase AC power supply on the carbon brush 16, and thus a star-shaped connection circuit combining resistor, inductance and capacitor is formed. By using the principle that power current can generate current while flowing through resistance wires and generate magnetic fields while flowing through magnetic fields to make magnetic conductors generate heat because of inductance, the natural luster finishing machine roller has the advantages of dual effects of electromagnetic and resistance heat, high heating speed, high energy utilization rate and few device failures.

Owner:JIANGSU JUNFENG TEXTILE MACHINERY

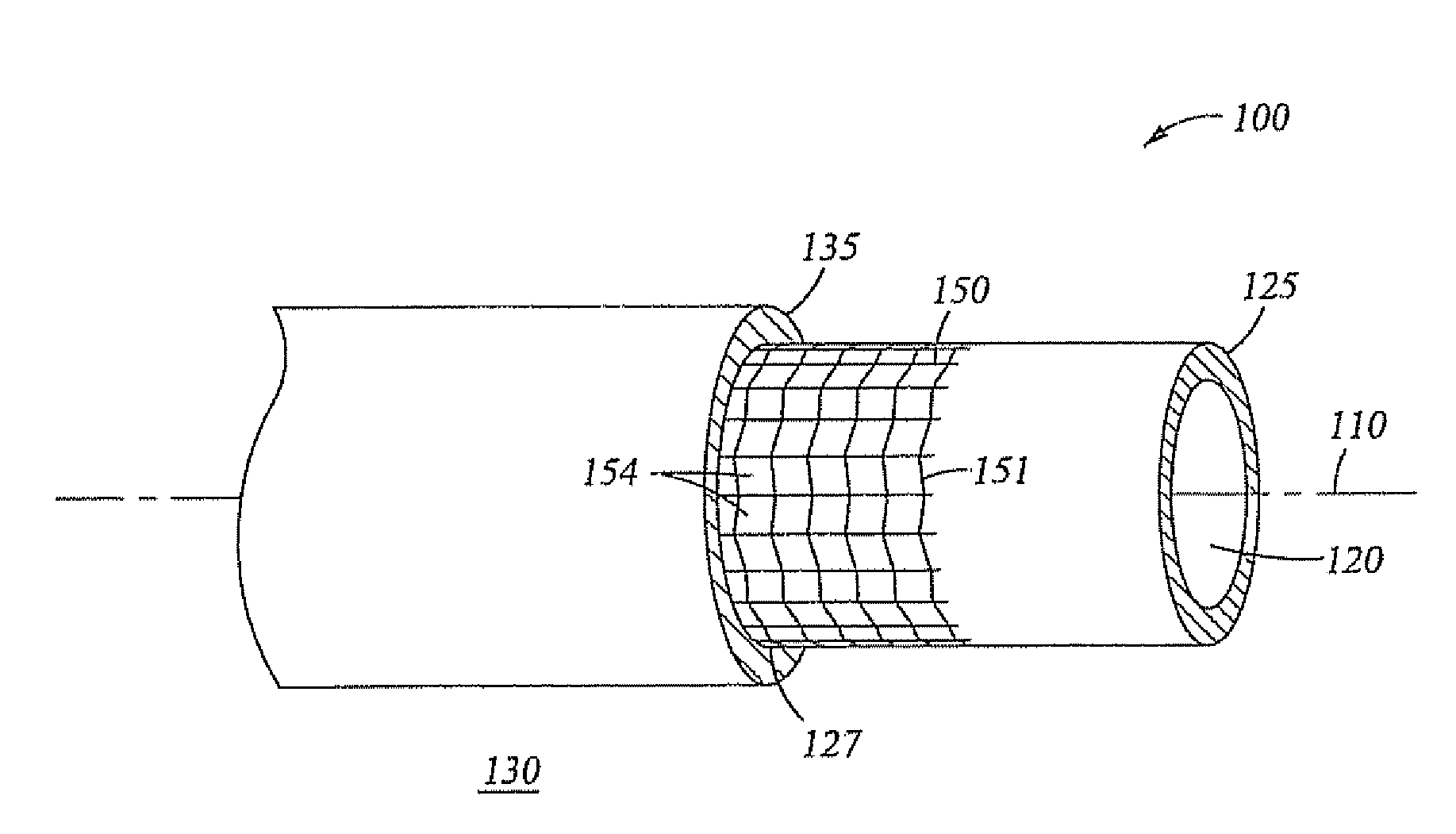

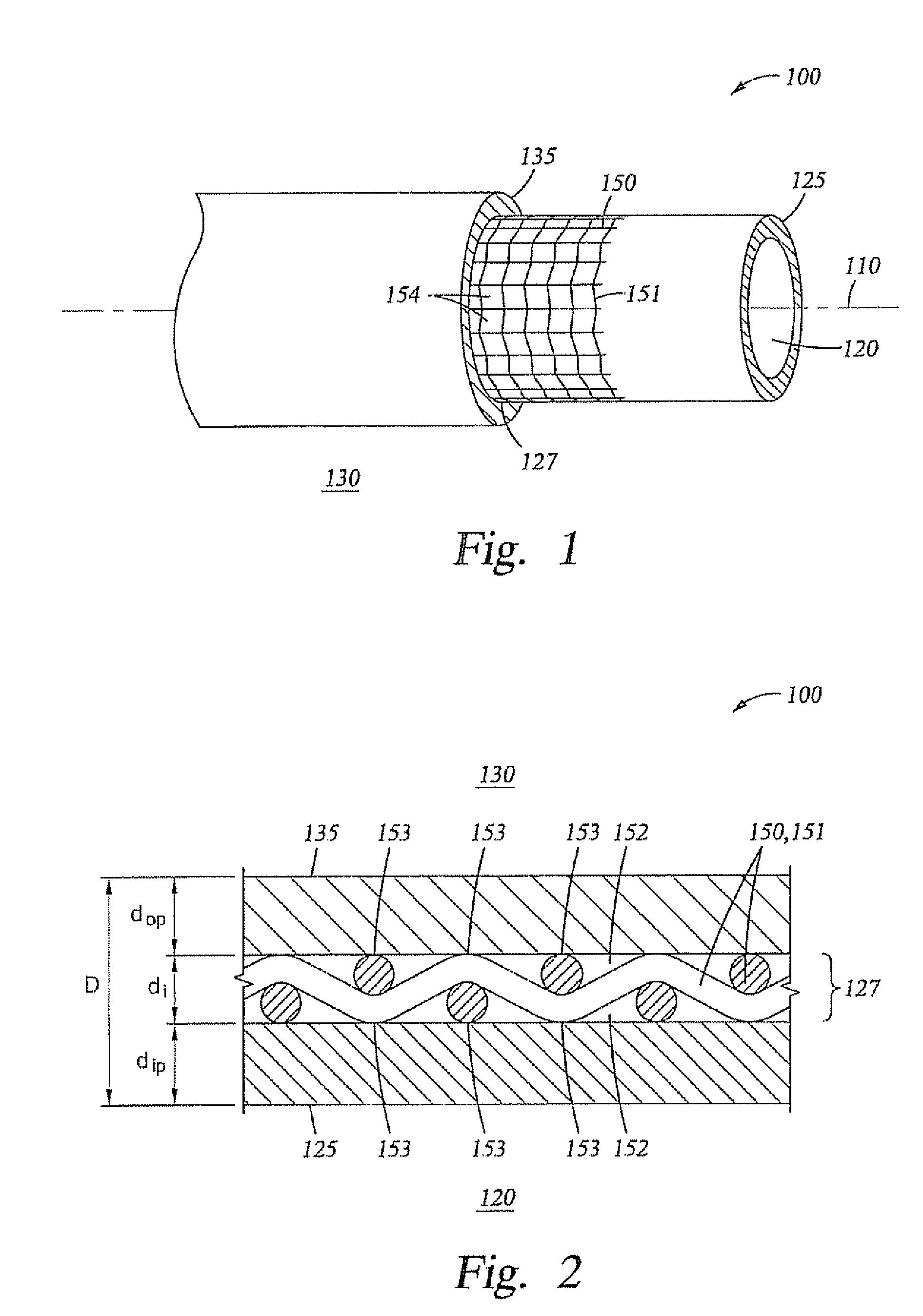

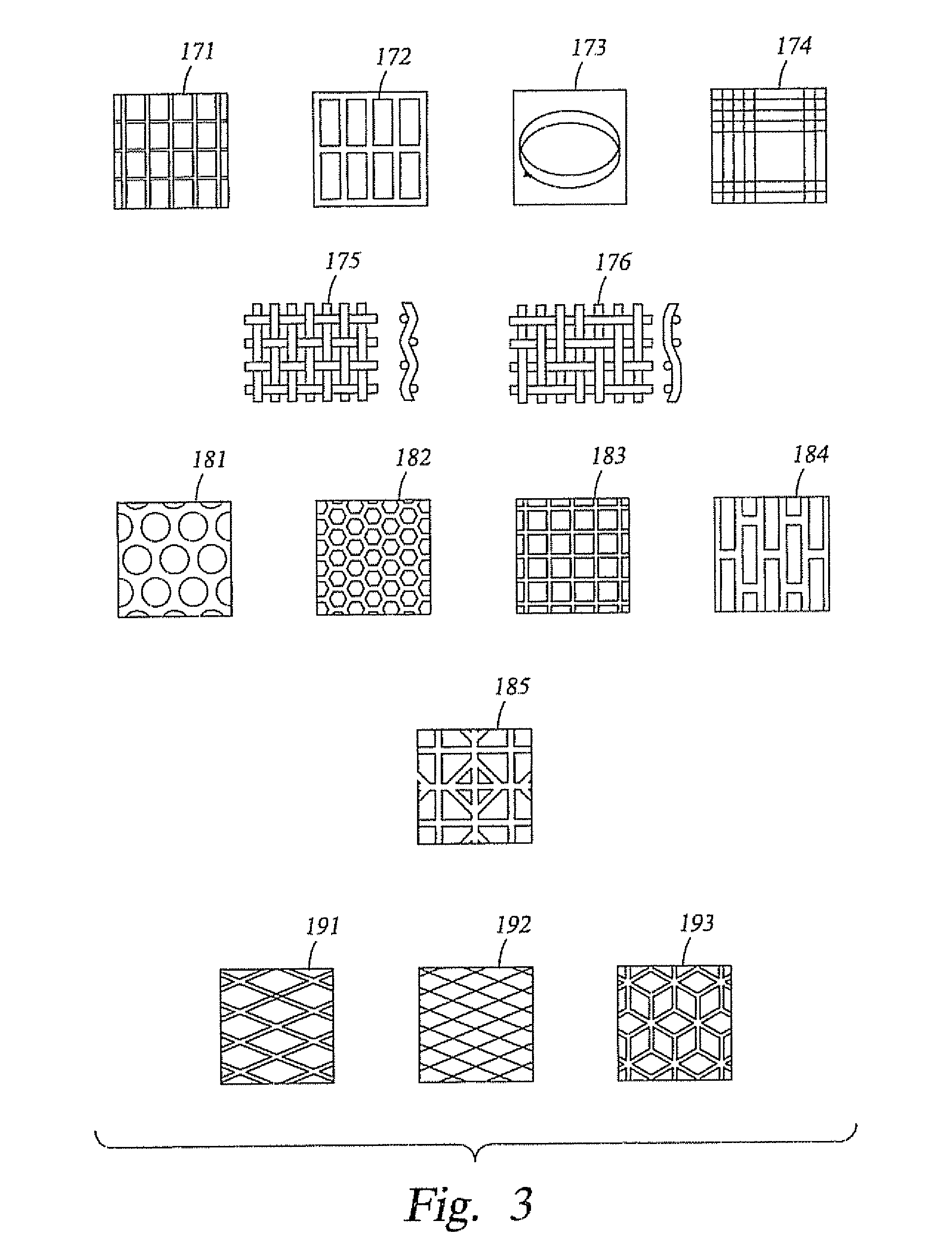

Interstitially Insulated Pipes and Connection Technologies

An interstitially insulated pipeline for flowing a hydrocarbon. In an embodiment, the pipeline comprises a first interstitially insulated pipe and a second interstitially insulated pipe. Each interstitially insulated pipe comprises an inner pipe, an outer pipe mounted coaxially around the inner pipe, an insulating interstice radially positioned between the inner pipe and the outer pipe, and a layer of screen mesh having a mesh size 10 or less disposed in the insulating interstice. In addition, the pipeline comprises a joint coupling the first interstitially insulated tubular and the second interstitially insulated tubular end-to-end. The joint includes a connection that couples the outer pipe of the first interstitially insulated pipe to the outer pipe of the second interstitially insulated pipe, and an annular seal member disposed between the inner pipe of the first interstitially insulated pipe and the inner pipe of the second interstitially insulated pipe.

Owner:TEXAS A&M UNIVERSITY

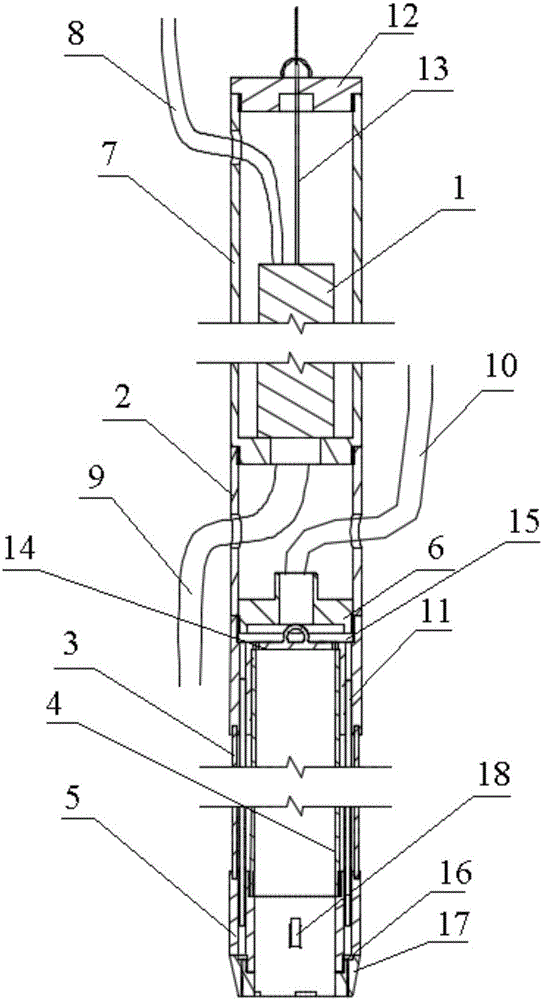

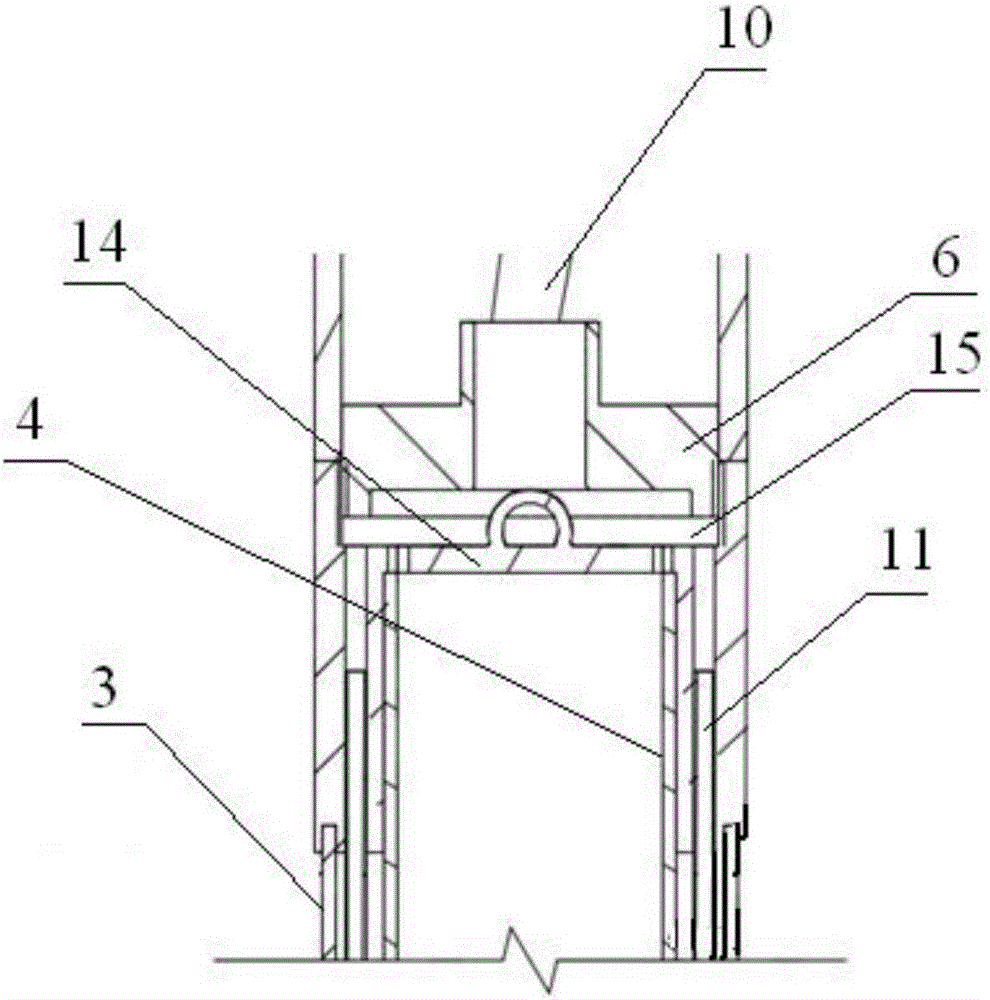

Hot water core drill used at glacier

The invention discloses a hot water core drill used at a glacier. The hot water core drill comprises a plunger pump, a two-way pipe, a heat insulation pipe, an ice core pipe, a drill bit and a flower divider, wherein the plunger pump is arranged in a pump storage pipe, the upper end of the plunger pump is connected with a water outlet pipe, the lower end of the plunger pump is connected with a water absorption pipe, the two-way pipe is connected to the lower end of the pump storage pipe, the lower end of the two-way pipe is connected with the heat insulation pipe, the ice core pipe is inserted in the heat insulation pipe, the drill bit is arranged below the heat insulation pipe and the ice core pipe, the flow divider is arranged on the lower portion of the two-way pipe and at the top end of the ice core pipe, the top end of the flow divider is connected with a hot water injection pipe, the lower portion of the flow divider is connected with a plurality of drainage pipes which are arranged in a gap between the heat insulation pipe and the ice core pipe, and hot water injected by the hot water injection pipe at the top end of the flow divider is injected into the drainage pipes through the flow divider. The hot water core drill has the advantages that due to the fact that the hot-melting drill bit is adopted for tapping and drilling of the hot water drill, and molten water is extracted to serve as a raw material of the hot water drill, cost is reduced, and the energy utilization rate is increased.

Owner:JILIN UNIV

Insulated pipe concealer

InactiveUS7757722B1Easily and efficiently manufactured and marketedLow priceHeating and ventilation casings/coversEngineering safety devicesRefrigerationInsulated pipe

An insulated pipe concealer is provided comprising an elongated plastic pipe sleeve with a left side and right side pivotally connected to each other and adapted to close. An elongated insulation element is found inside the pipe sleeve with a channel adapted to receive a pipe. Latches for fastening the two sides of the pipe sleeve together; and hinged flaps adapted for attachment to a wall are attached to the exterior of the pipe sleeve. This pipe concealer is particularly useful in covering refrigeration pipes found on building exteriors.

Owner:LESCH JR JAMES A +1

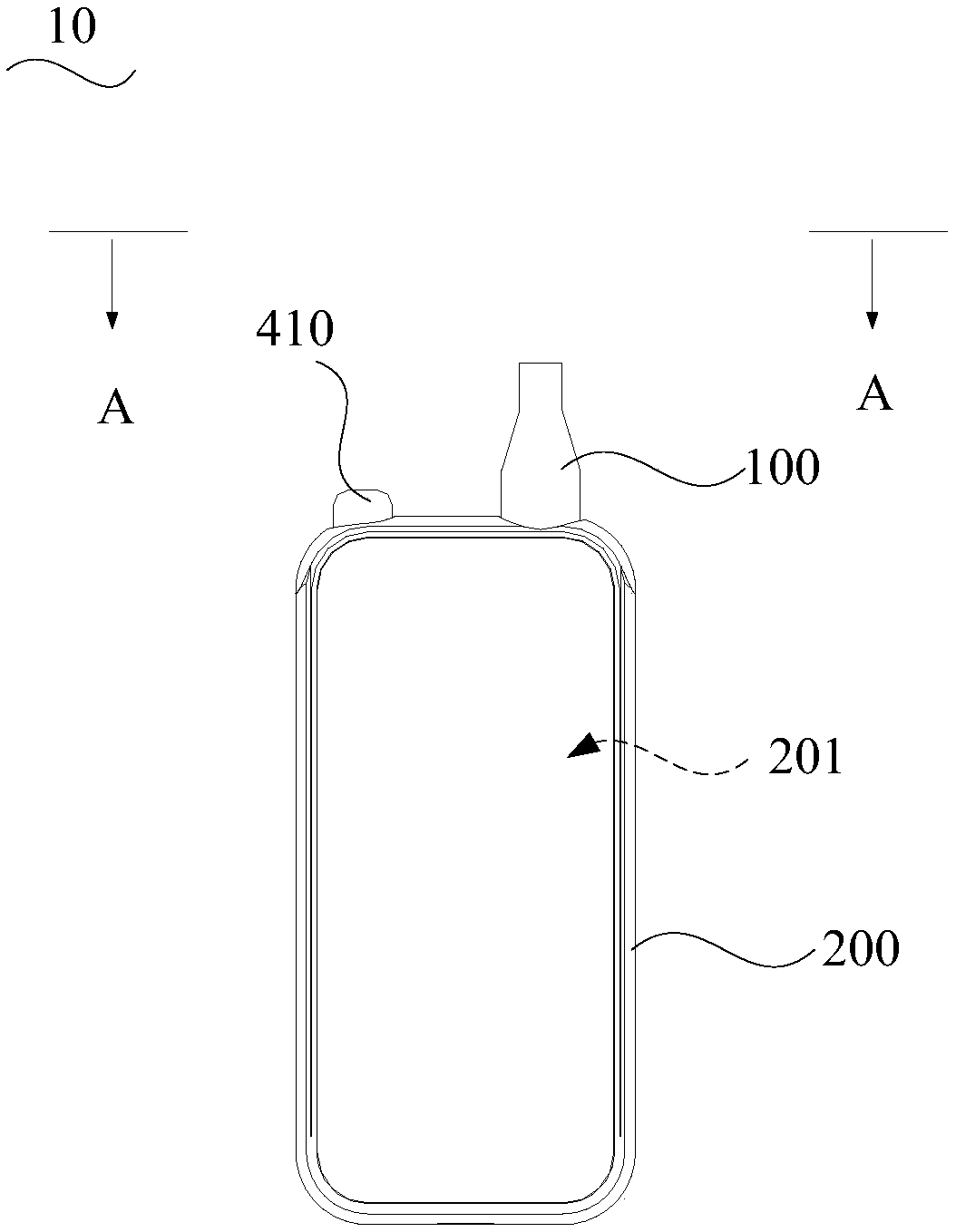

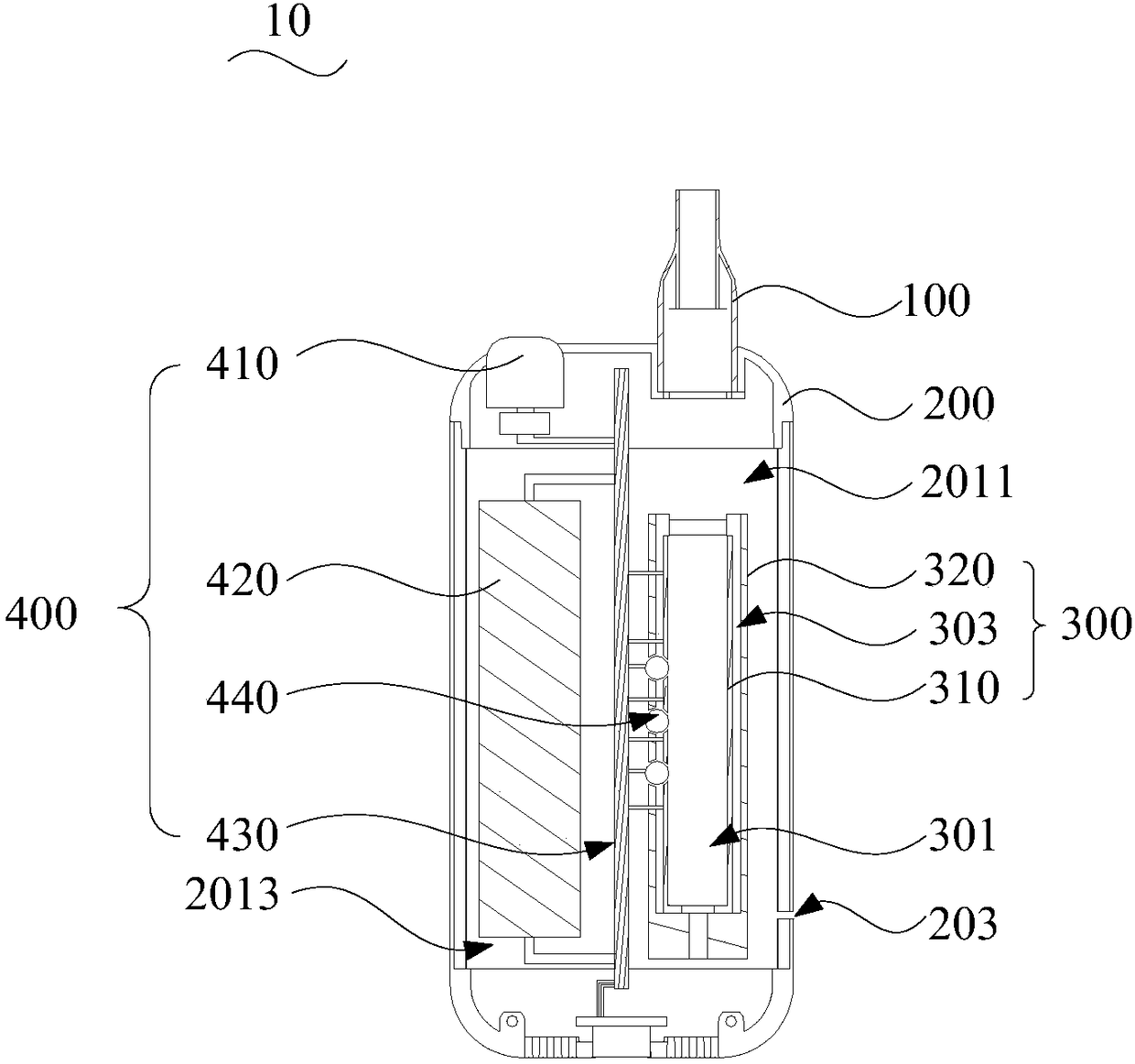

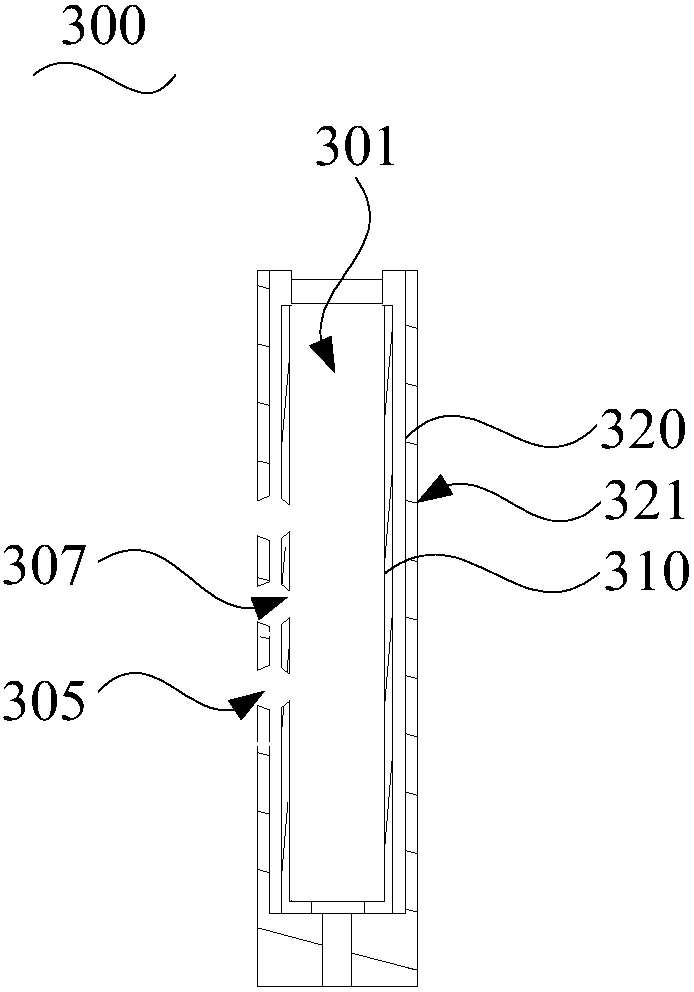

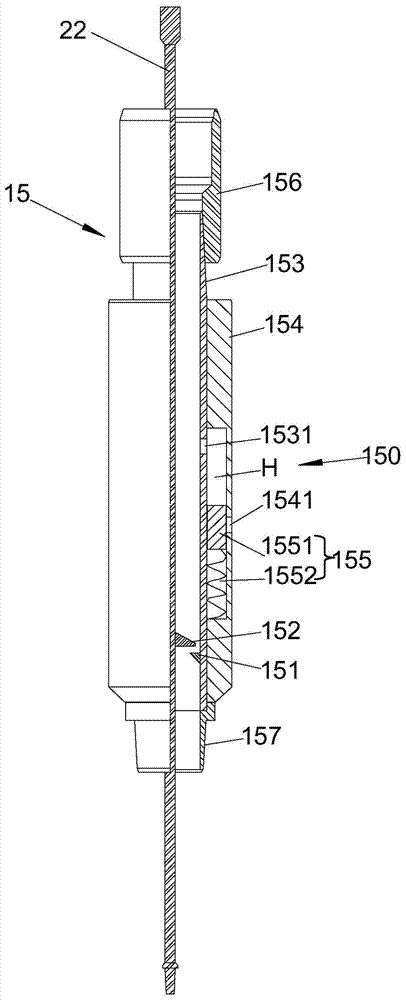

Electronic heating device

ActiveCN108208944ASimple structureGood heat insulationTobacco devicesReflecting/signal paintsCooking & bakingCold air

The invention relates to an electronic heating device, comprising a suction nozzle, a housing, a heating component and a power component. The heating component includes a heating pipe and a heat-insulating pipe; a baking cavity is arranged in the heating pipe; the wall of the heat-insulating pipe is coated with a heat-insulating coating layer; the heating pipe is sleeved with the heat-insulating pipe; a gap passage is formed between the heat-insulating pipe and the heating pipe in mutually spaced manner; the heat-insulating pipe is provided with a gas guide hole whereby a receiving cavity is communicated with the gap passage. The heat-insulating coating layer can reflect thermal radiation of the heating pipe so that heat in the baking cavity is avoided being directly transmitted to the housing. A gap is provided between the heat-insulating pipe and the heating pipe, external cold air can enter the receiving cavity from a gas inlet and may enter the gap passage via the gas guide hole, and the temperature of the heating pipe and the heat-insulating pipe is reduced during suction. The cooling design measures such as the heat-insulating coating layer and flow promotion enable the electronic heating device is simple in structure and good in heat-insulating effect.

Owner:SHENZHEN HANGSEN STAR TECH

Water stop for a loop installation in a pre-insulated pipeline

A high temperature pre-insulated piping system is shown which has a special water stop located along the length of the piping. The water stop has an internal disk which forms a pair of isolated chambers within the water stop. The internal disk is formed of a material which is impervious to the flow of water. As a result, the two internal chambers are isolated from one another and act as isolating elements to contain any breach in the exterior of the piping system to a specific location in the length of the pipe string.

Owner:THERMACOR PROCESS

Thermal oil production pipe column for injection-production in the same well for vertical well and oil production method thereof

ActiveCN104514535AIncrease profitImprove the effect of throughput miningFluid removalOil productionCheck valve

The invention discloses a thermal oil production pipe column for injection-production in the same well for a vertical well and an oil production method thereof. The oil production pipe column comprises a telescopic pipe, a first insulated pipe, an upper packer, a second insulated pipe, a steam injection check valve, an oil pipe, a lower packer, an oil well pump, a sieve pipe, a tail pipe and a screwed plug which are connected in sequence from the top to bottom, an oil pumping rod is placed in the oil production pipe column, and the lower end of the oil pumping rod is connected with a traveling valve in the oil well pump; a gas injection flow passage which connects the inside to the outside in one direction is formed in the side wall of the steam injection check valve, a fixed sealing ring plate and a movable sealing ring plate placed on the fixed sealing ring plate are arranged in the inner cavity of the lower side of the gas injection flow passage, the movable sealing ring plate sleeves the oil pumping rod, and the outer periphery thereof hermetically contacts with the upper surface of the inner periphery of the fixed sealing ring plate. The thermal oil production pipe column for the injection-production in the same well for the vertical well and the oil production method thereof are capable of effectively using the steam heat, improving the economical benefit and improving the cyclic steam stimulation effect for thickened oil.

Owner:PETROCHINA CO LTD

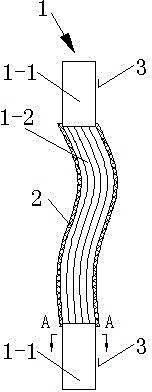

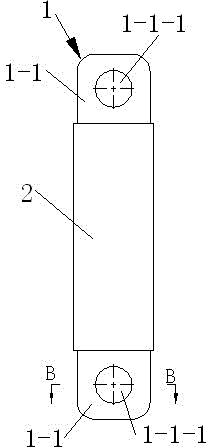

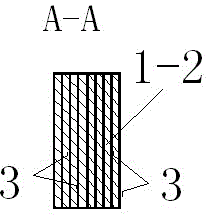

Manufacturing method for flexible soft copper bar assembly for electric connection

InactiveCN102945711AAvoid short circuitReasonable workmanshipLine/current collector detailsCable/conductor manufactureElectricityCopper

The invention relates to a manufacturing method for a flexible soft copper bar assembly for electric connection. The manufacturing method comprises two different forms, wherein the first form comprises the steps of blanking, sweat soldering, electroplating, sleeving of an insulated pipe and holing in sequence; and the second form comprises the steps of blanking, electroplating, sleeving of the insulted pipe, sweat soldering of one end, bending, sweat soldering of the other end and holing in sequence. The manufacturing method has the advantages of reasonable process, good quality of a finished product, practicality and convenience and the like.

Owner:AMPHENOL AUTOMOTIVE CONNECTION SYST CHANGZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com