Use of renewable energy like solar, wind, geothermal, biomass, and hydropower for manufacturing combustion air for a fossil fuel burner and firebox

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

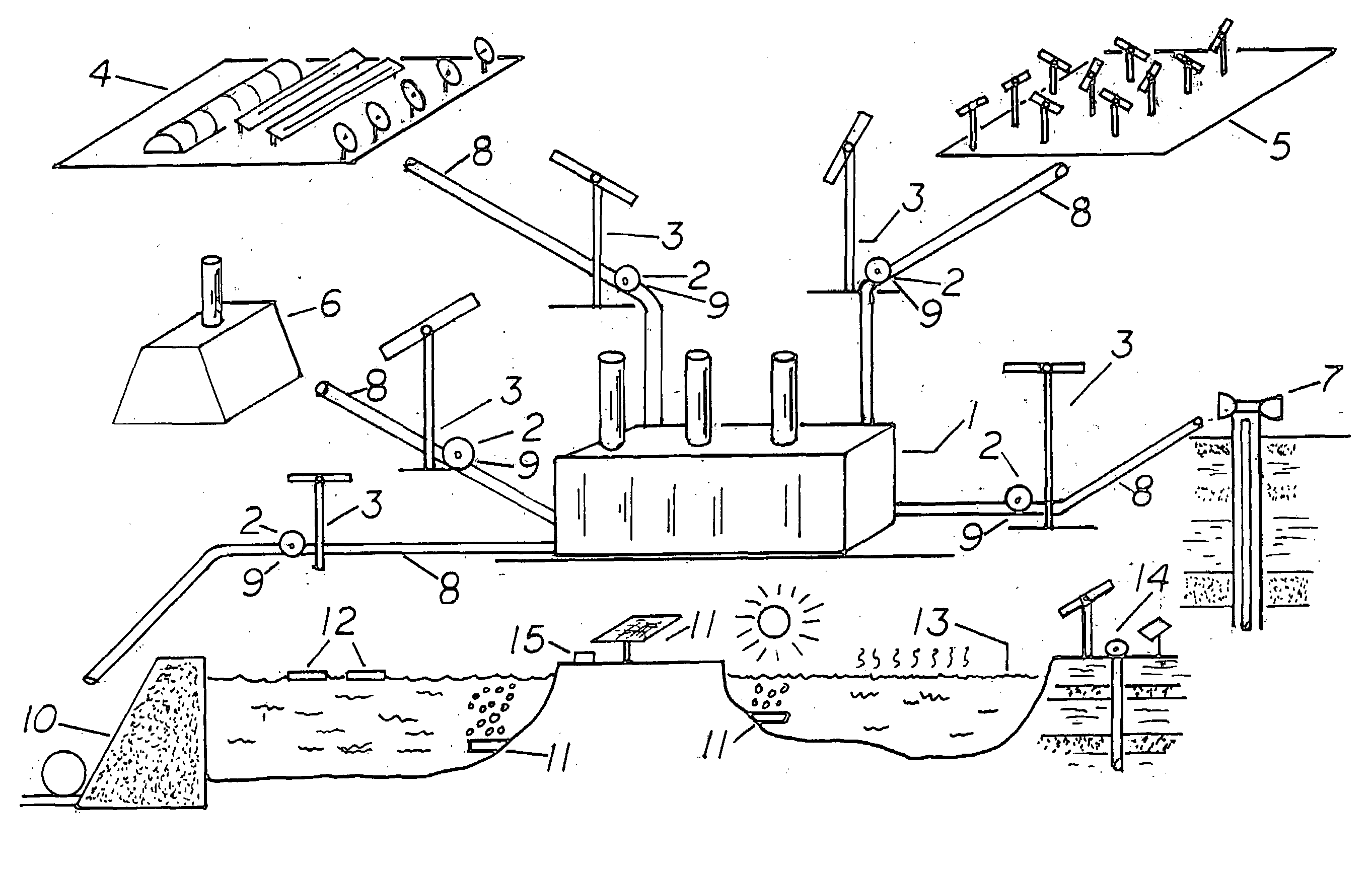

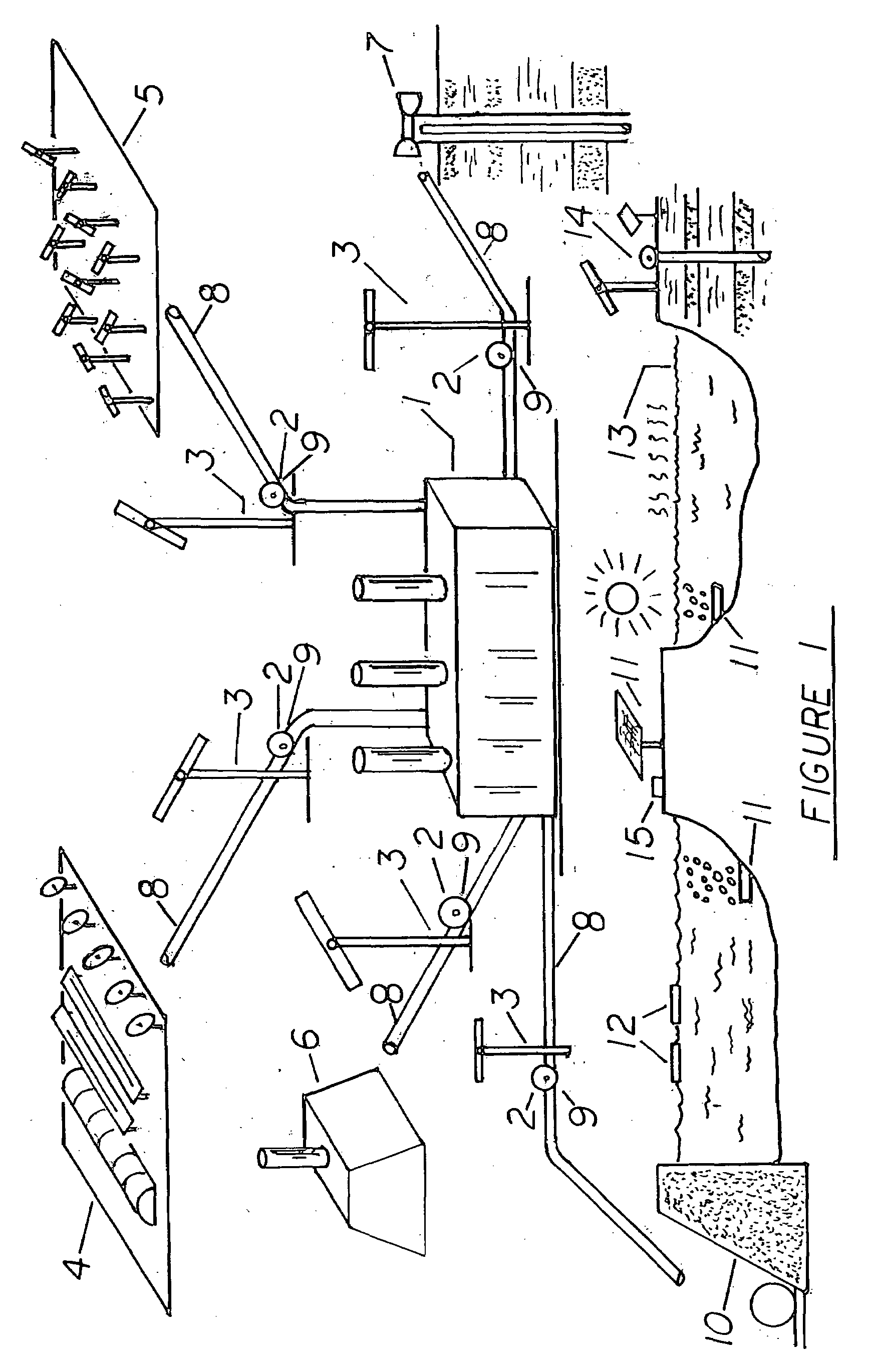

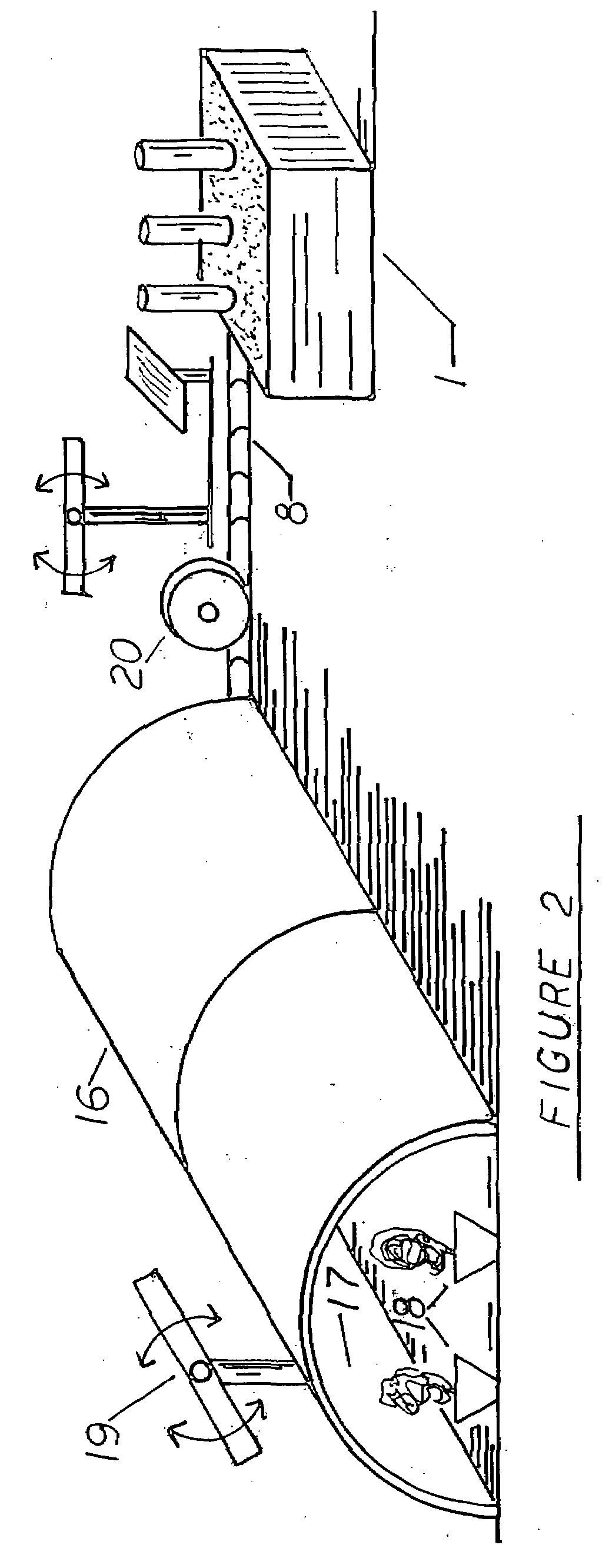

[0201]FIG. 1 illustrates an overview of the invented device. Shown is a system for manufacturing hot and compressed air for a distant power plant, like a coal burning power plant (1). Located next to the power plant could be large wind turbines (3), which power centrifuge compressors (2). From the surrounding region, various energy sources (4,5,6,7) create combustion air, and put the air into a heavily insulated pipe system (8) for long distance transmission. Along the way extra centrifuge compressors, with flywheels (9), can be located to compress and move the combustion air through the transmission system. Solar farms (4) with various types of solar collectors make and concentrate combustion air. Various types of solar collectors can be employed: solar greenhouses, sandbox solar collectors, solar ponds, evacuated tube type solar collectors, line focus and point focus type solar collectors, heliostats with towers, solar smelters, and so on. Wind energy (5) can be employed to power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com