Patents

Literature

60218 results about "Coal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements; chiefly hydrogen, sulfur, oxygen, and nitrogen. Coal is formed when dead plant matter decays into peat and is converted into coal by the heat and pressure of deep burial over millions of years. Vast deposits of coal originates in former wetlands—called coal forests—that covered much of the Earth's tropical land areas during the late Carboniferous (Pennsylvanian) and Permian times.

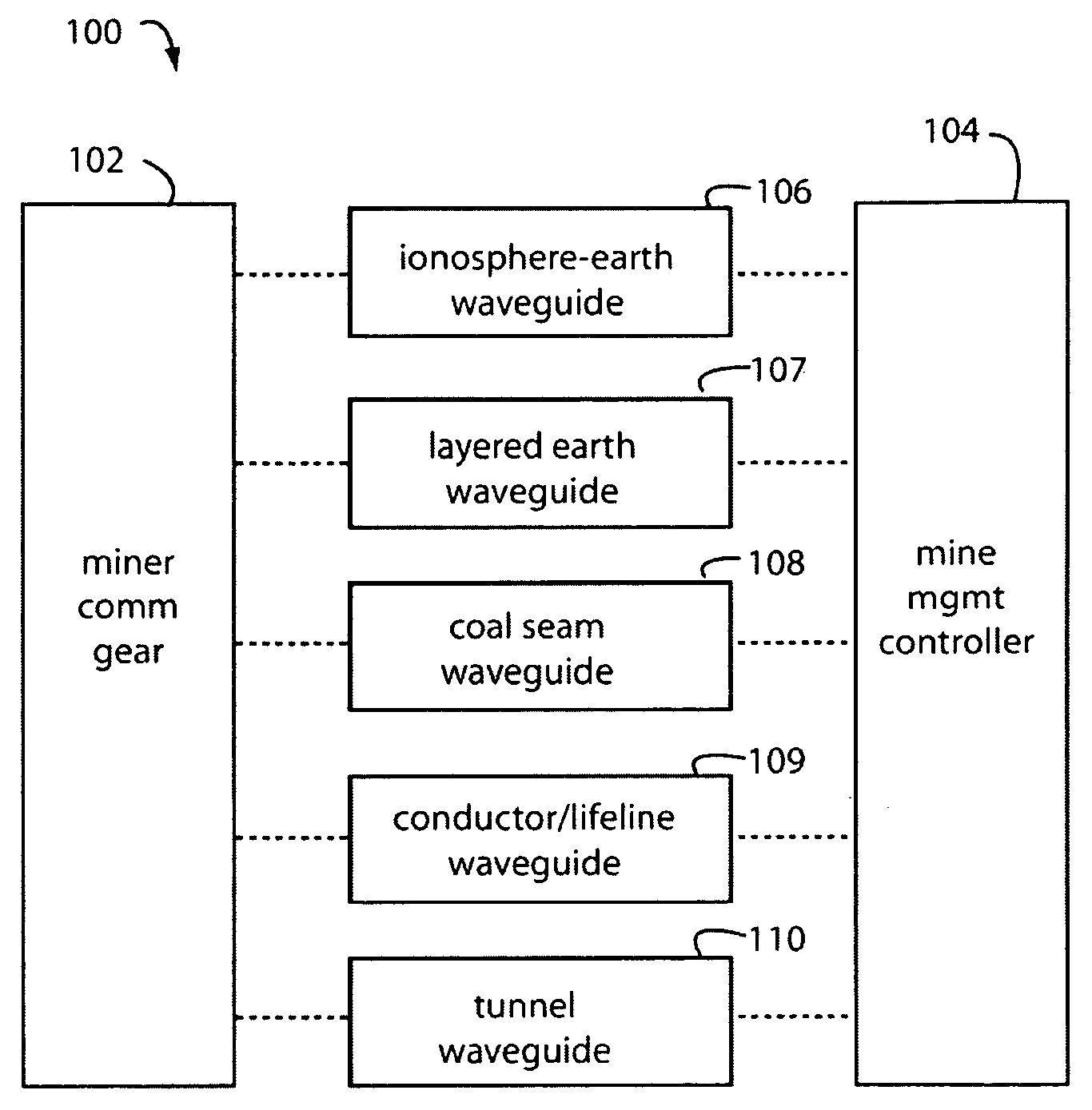

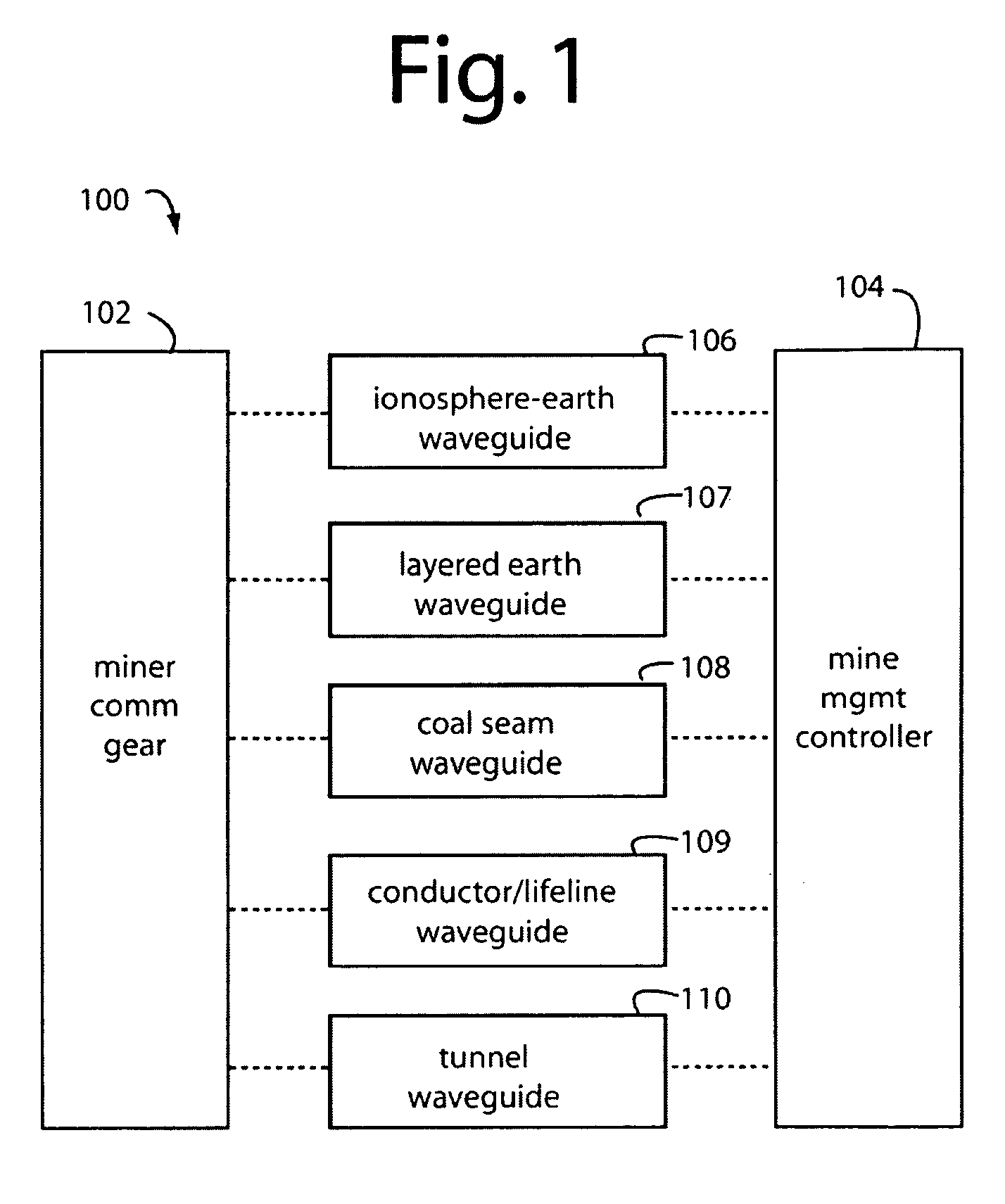

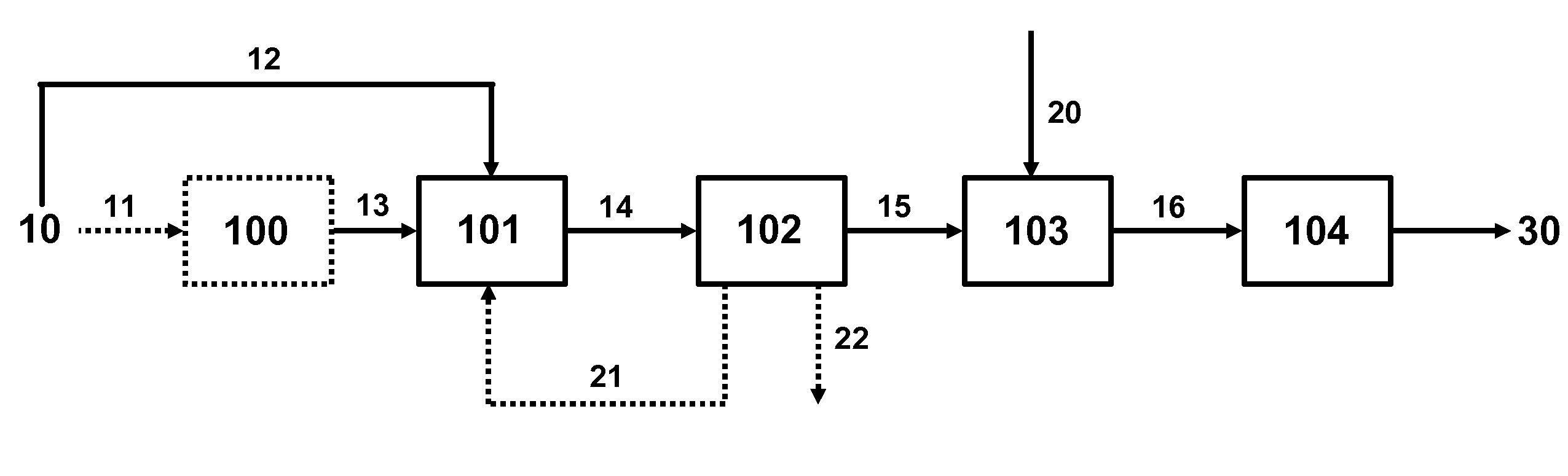

Underground radio communications and personnel tracking system

InactiveUS20090140852A1Function providedSubaqueous/subterranean adaptionElectric signalling detailsTransceiverElectrical conductor

An underground radio communications and personnel tracking system uses a portable communications device worn by a miner when underground in a mine. A cap-lamp transceiver provides voice and text communication on ultra-low frequency (ULF) to ultra-high frequency (UHF) carrier frequencies and modulation adapted by programming of a software defined radio to making selective and agile radio contacts via through-the-earth, conductor / lifeline, coal seam, tunnel, and ionosphere / earth-surface waveguides for transmission of electromagnetic waves. These waveguides comprise layered earth coal and mineral deposits, and manmade mining complex infrastructures which serendipitously form efficient waveguides. Ultra-Low Frequency F1 / F1 repeaters are placed underground in the mine, and providing for extended range of communication of the cap-lamp transceiver with radios and tracking devices above ground of the mine.

Owner:STOLAR

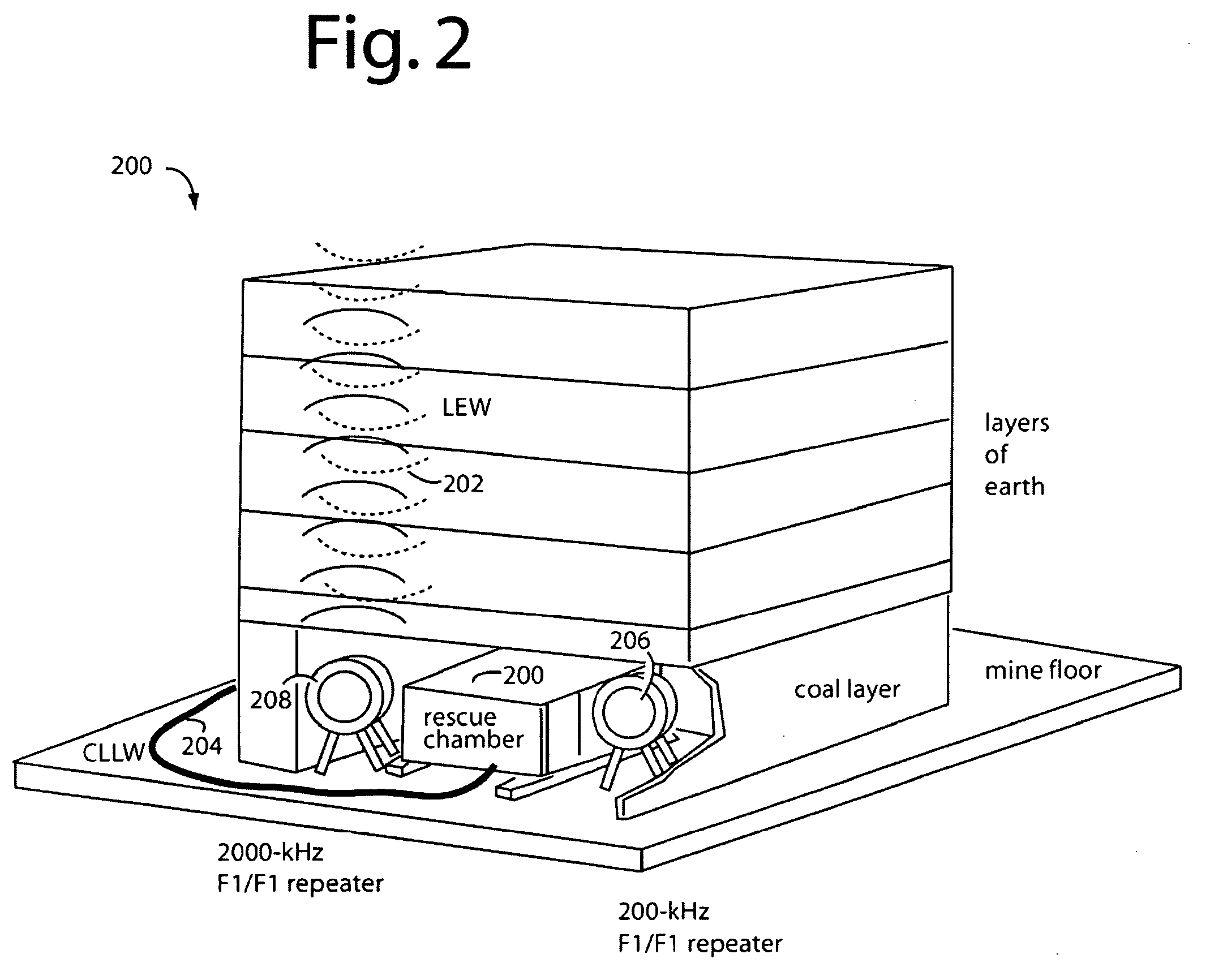

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

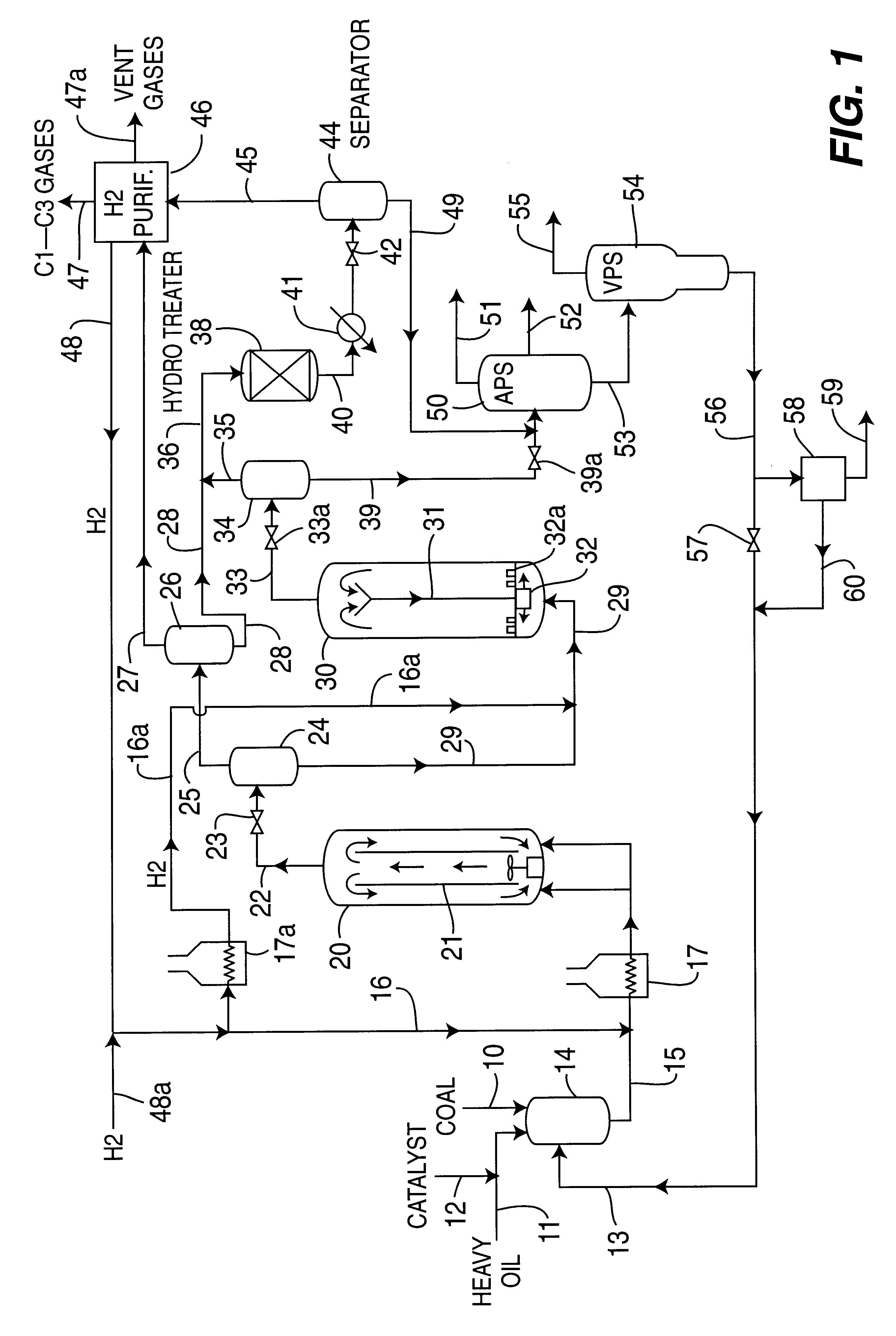

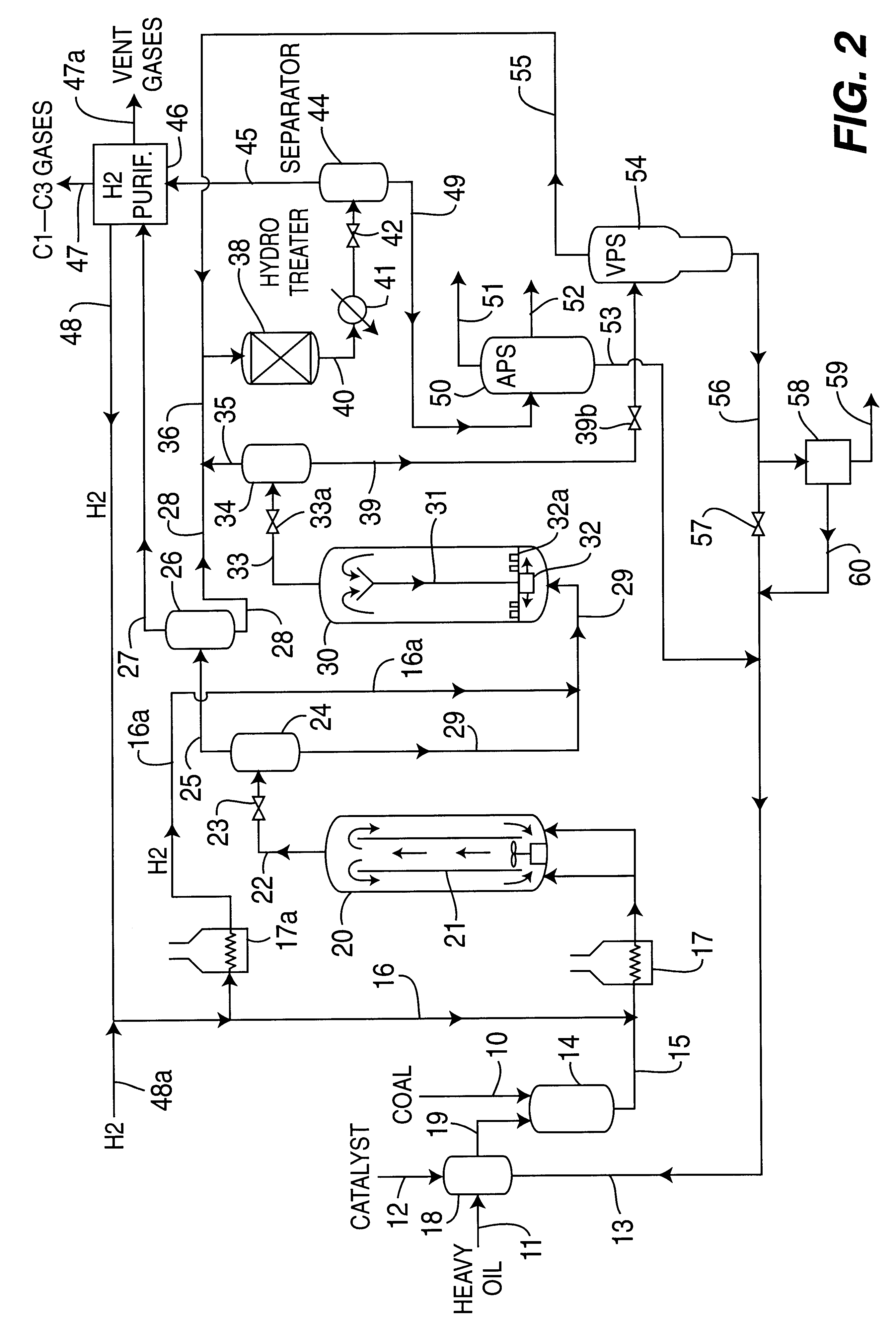

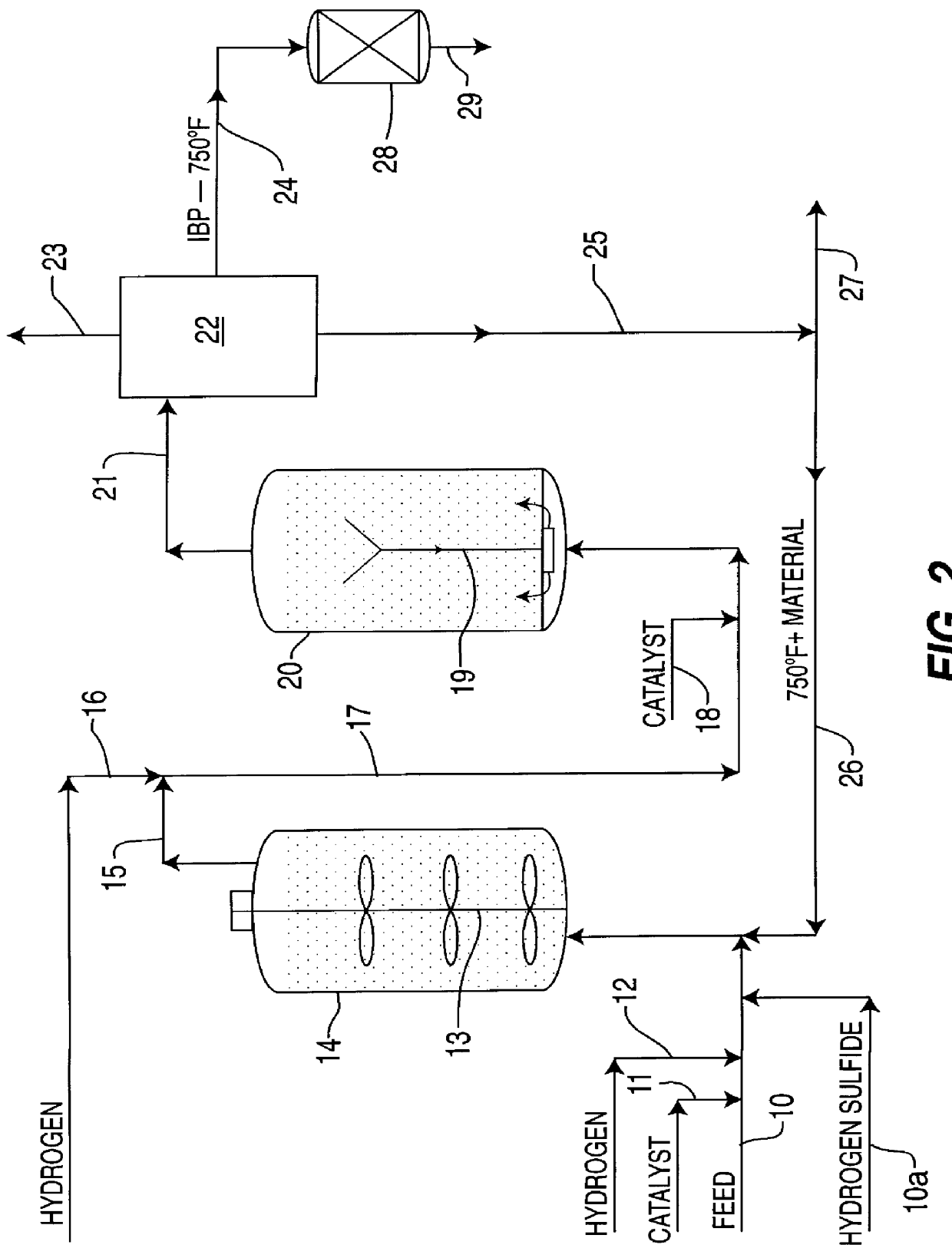

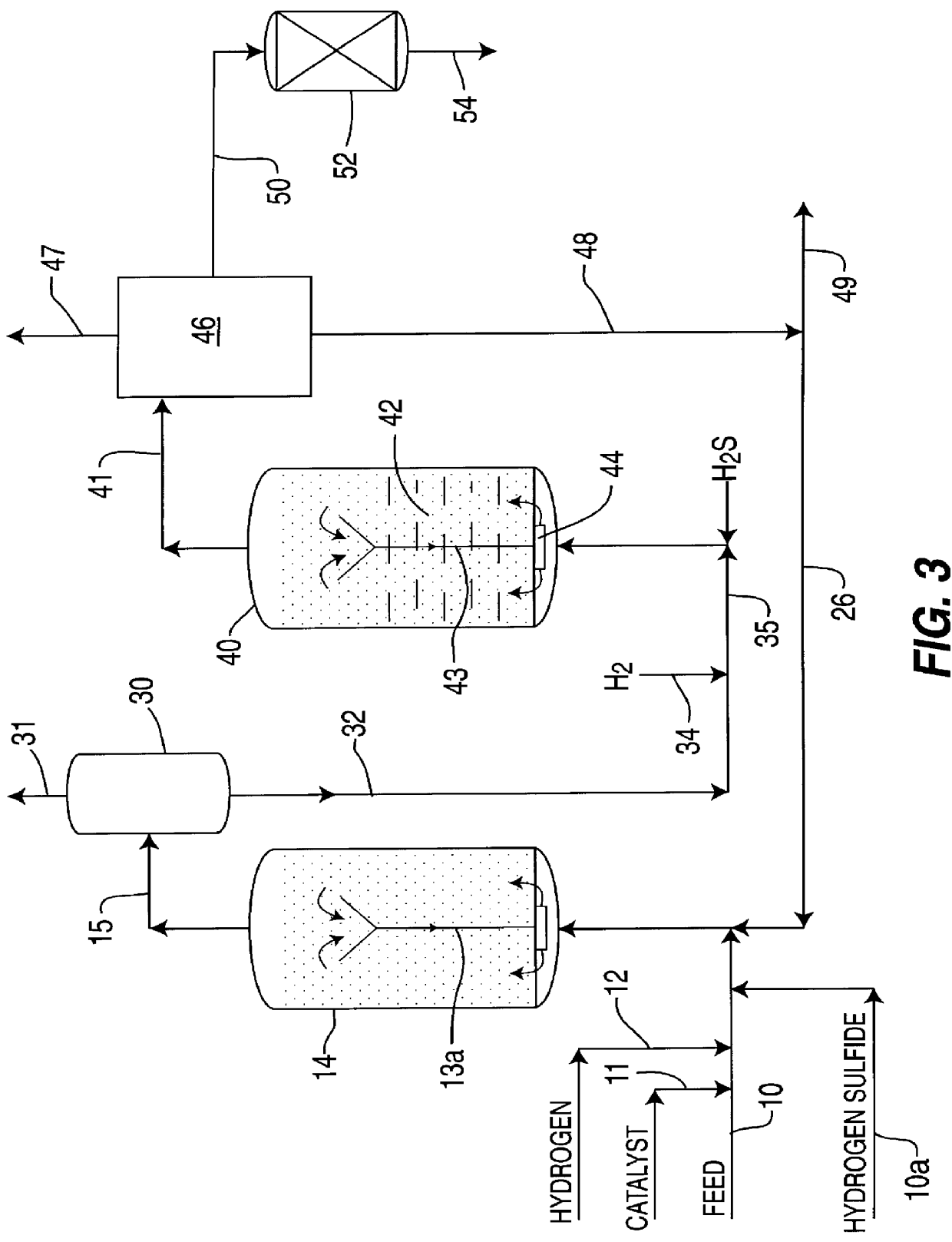

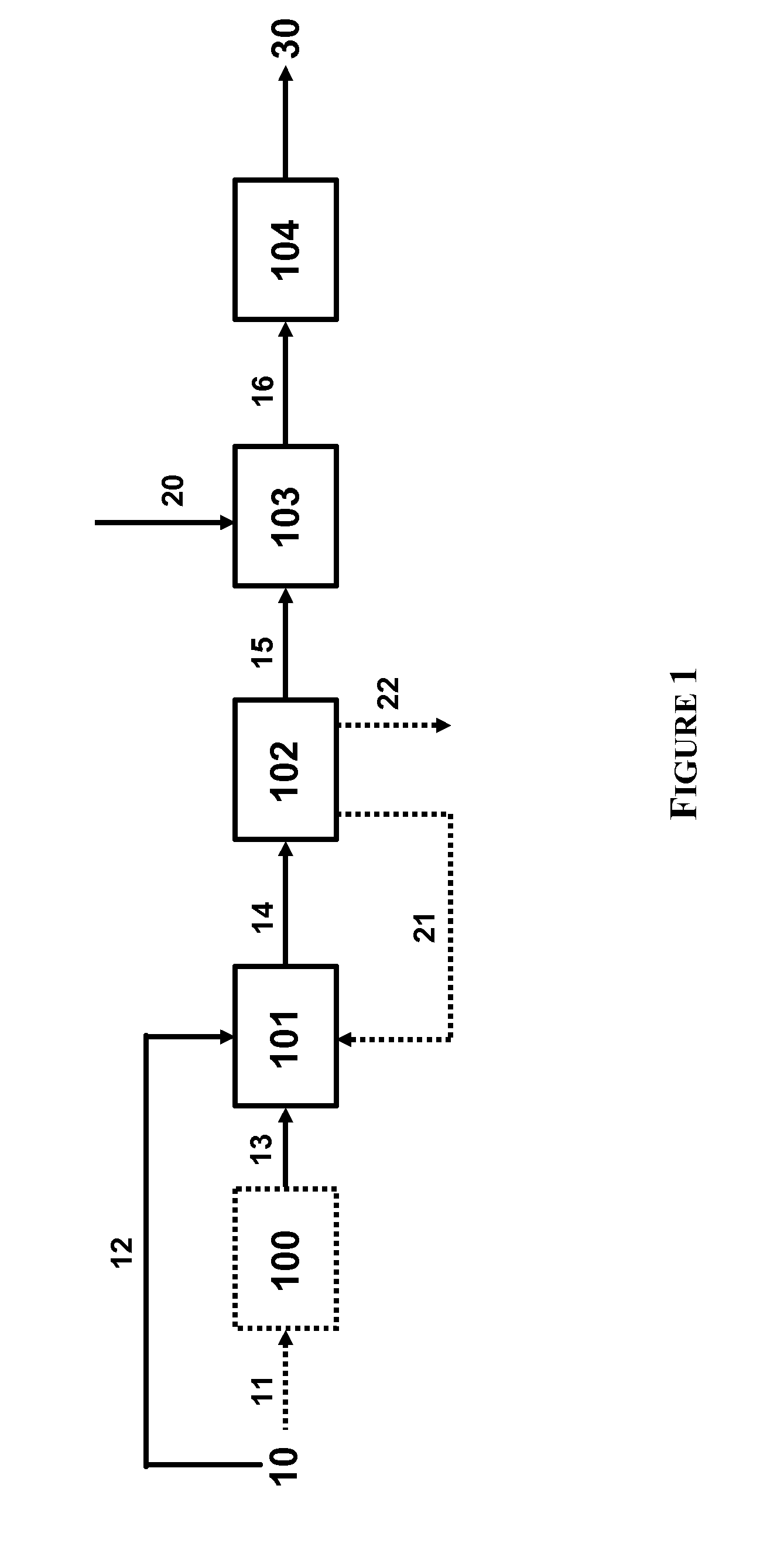

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

Method of generating and recovering gas from subsurface formations of coal, carbonaceous shale and organic-rich shales

InactiveUS20040033557A1Maximizes bacterial degradationStable and economically favorable and environmentally cleanMicrobiological testing/measurementGas production bioreactorsOrganic compoundCoal

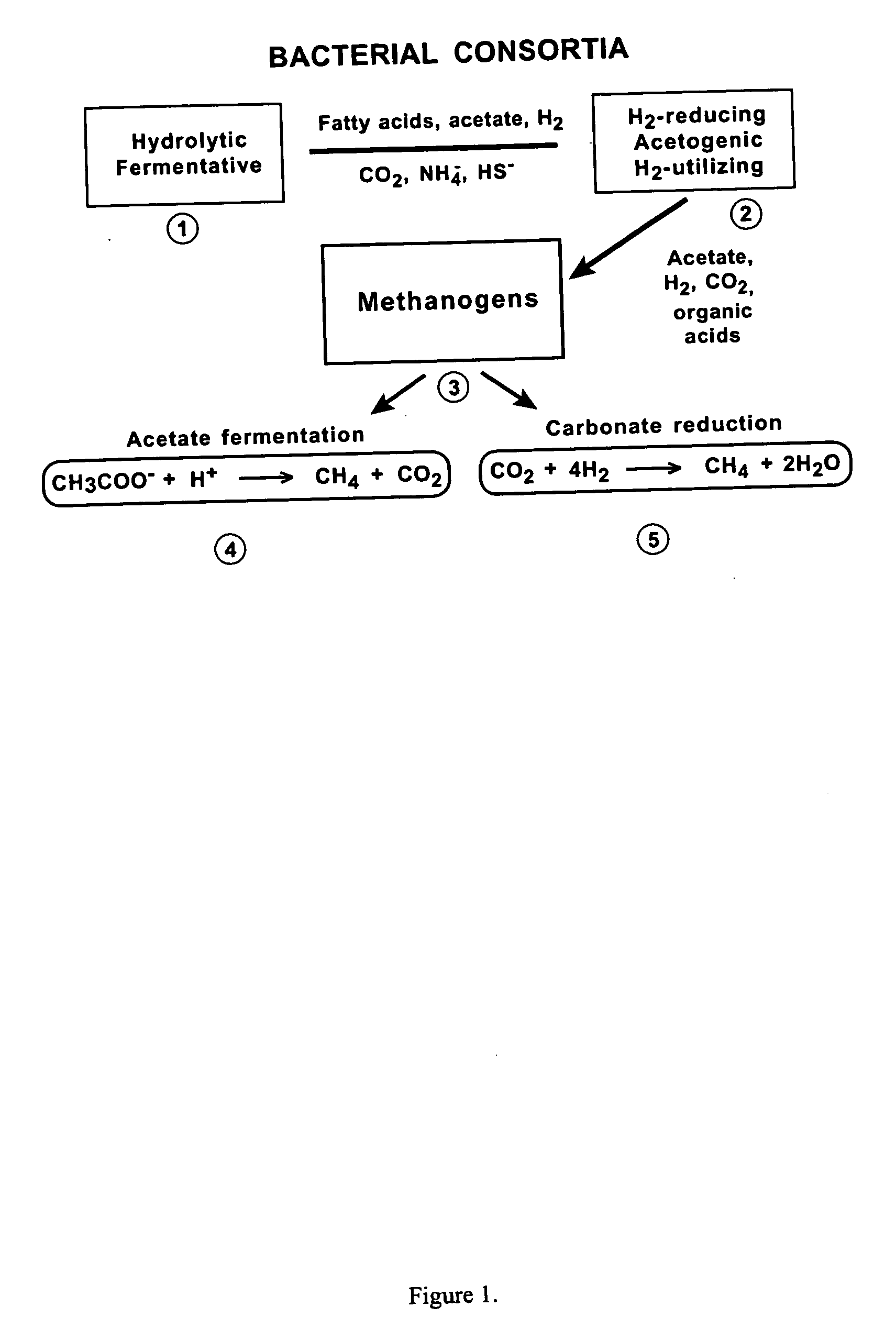

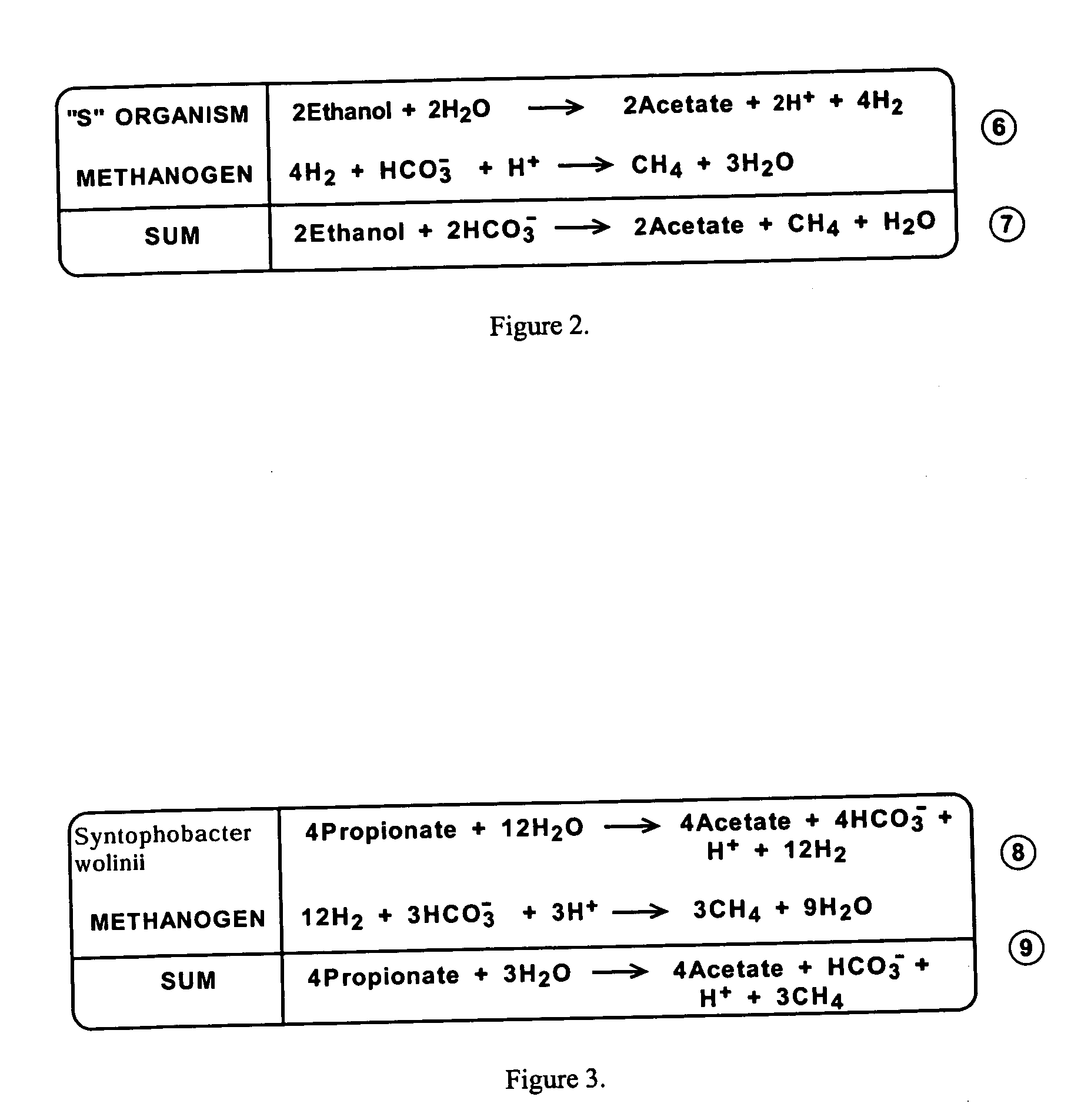

A method of generating and recovering gas from naturally existing subsurface formations Of coal, carbonaceous shale or organic-rich shales comprising the steps Of: injecting into fracture of the subsurface formation, under substantially anaerobic conditions, a consortia of selected anaerobic, biological microorganisms for in situ conversion of organic compounds in said formation into methane and other compounds; and producing methane through at least one well extending from said subsurface formation to the surfaces.

Owner:SCOTT ANDREW R +1

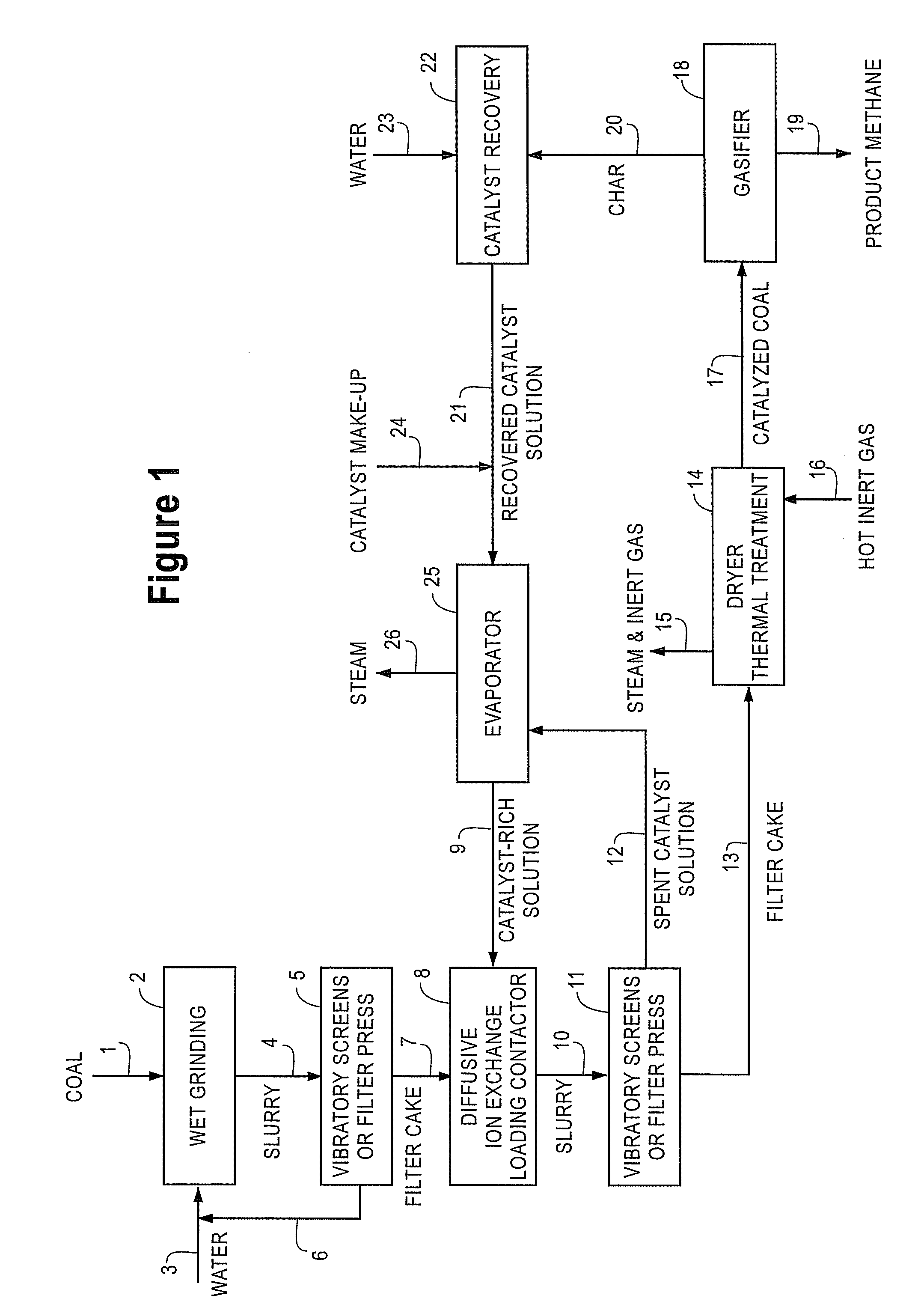

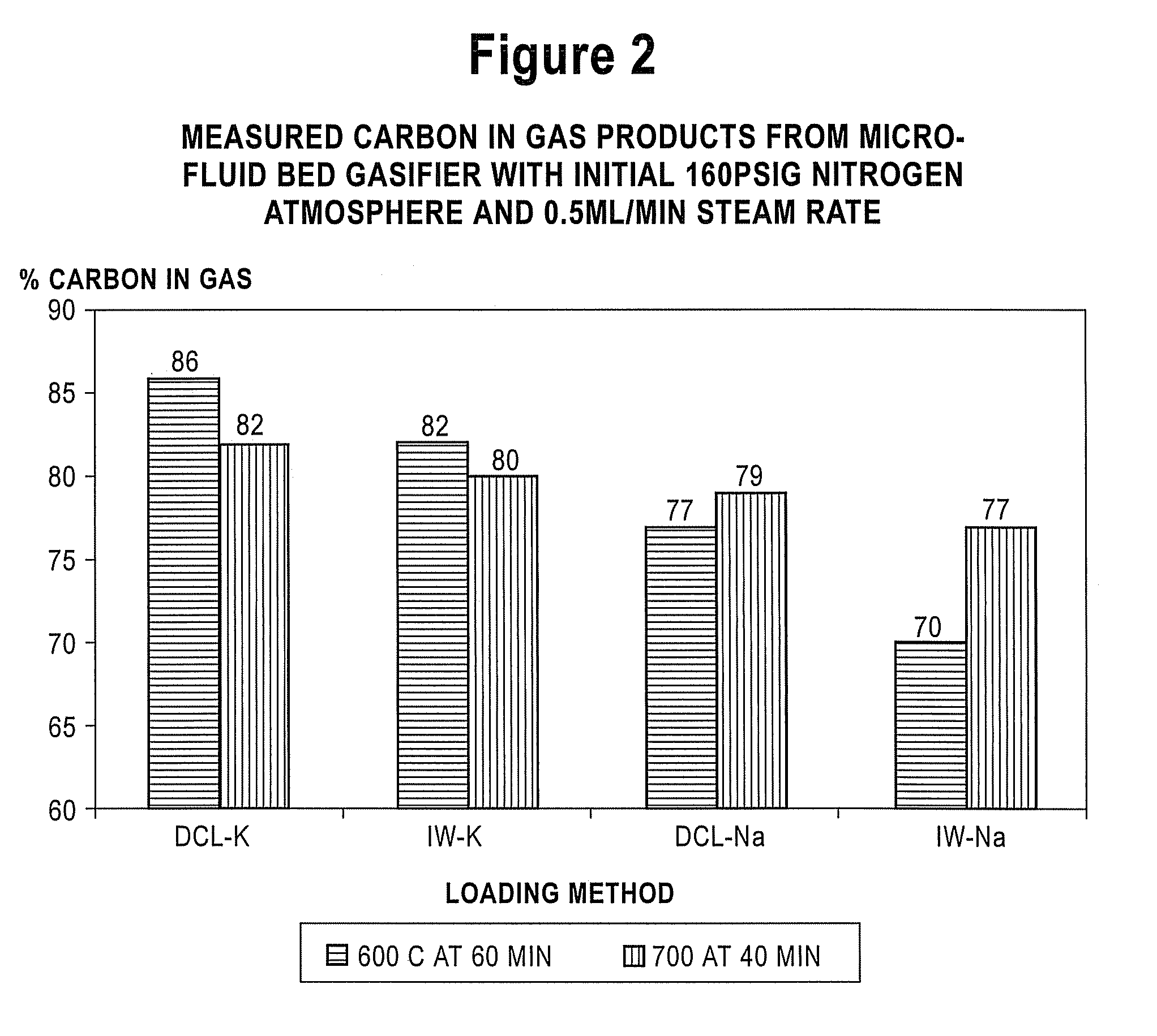

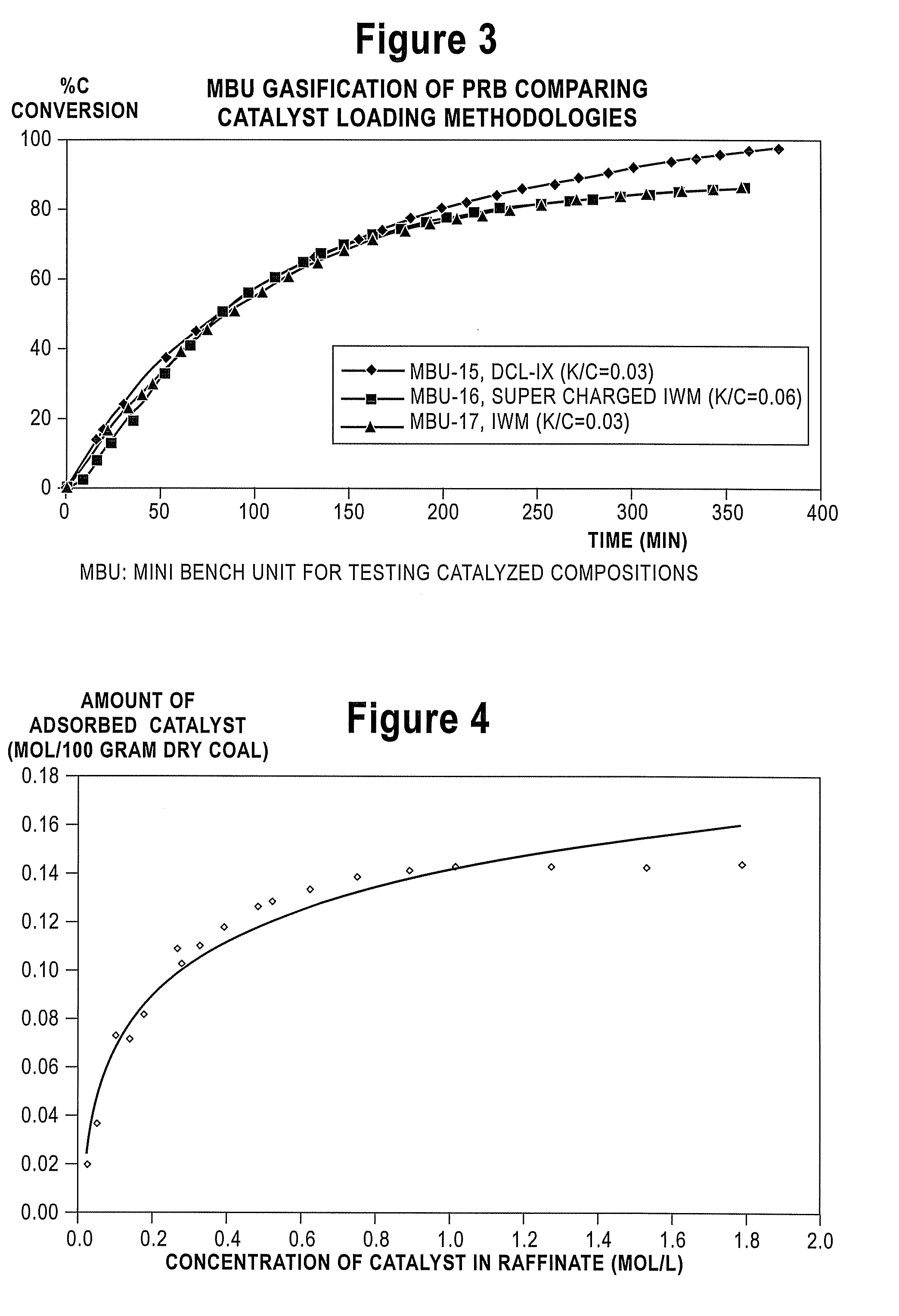

Catalyst-Loaded Coal Compositions, Methods of Making and Use

ActiveUS20090048476A1Efficient and high-yielding gasificationHigh yield productionCatalyst regeneration/reactivationSolid fuelsPtru catalystCoal matrix

The present invention relates to catalyst-loaded coal compositions having a moisture content of less than about 6 wt %, a process for the preparation of catalyst-loaded coal compositions, and an integrated process for the gasification of the catalyst-loaded coal compositions. The catalyst-loaded coal compositions can be prepared by a diffusive catalyst loading process that provides for a highly dispersed catalyst that is predominantly associated with the coal matrix, such as by ion-exchange.

Owner:SURE CHAMPION INVESTMENT LTD

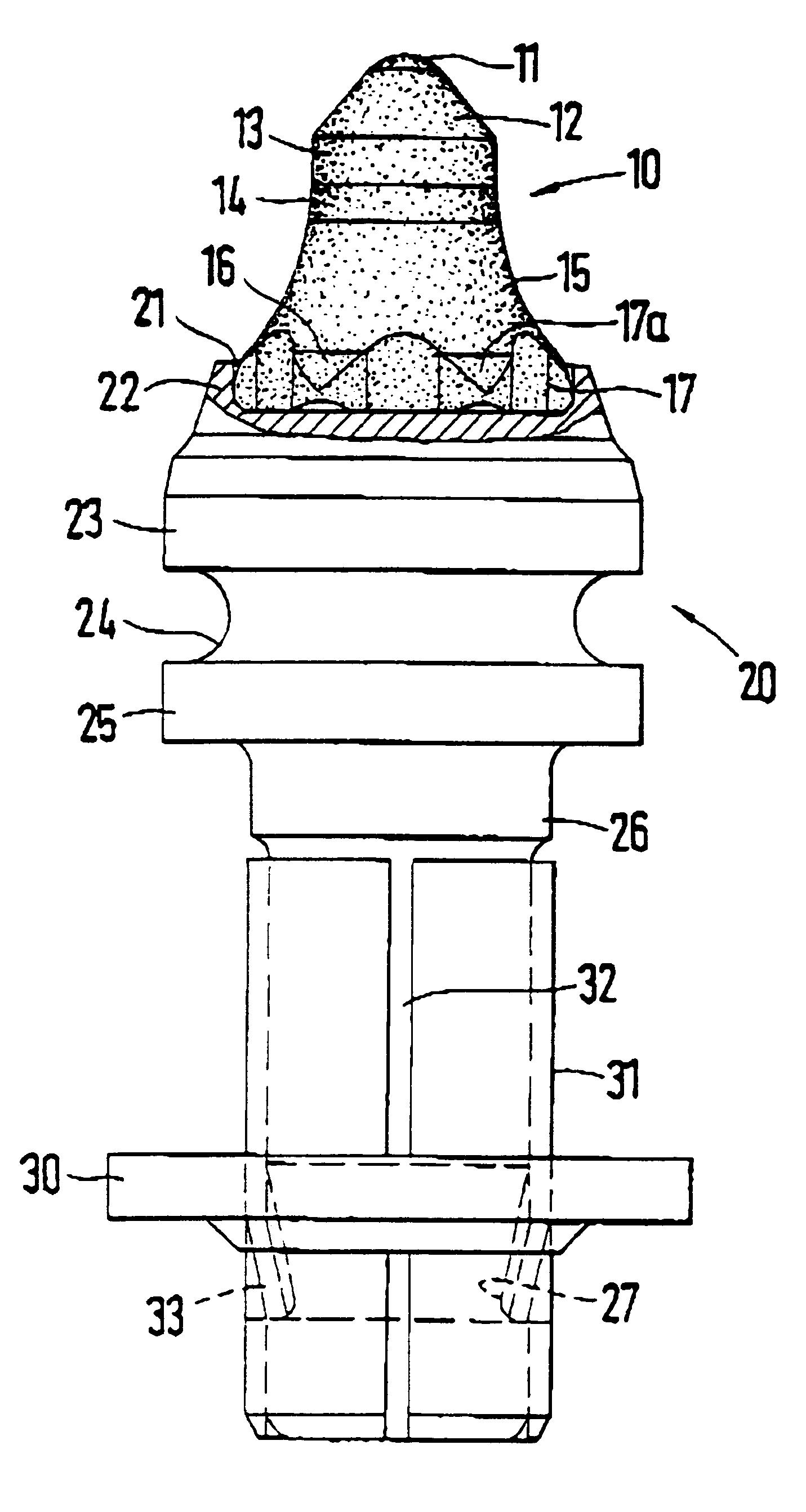

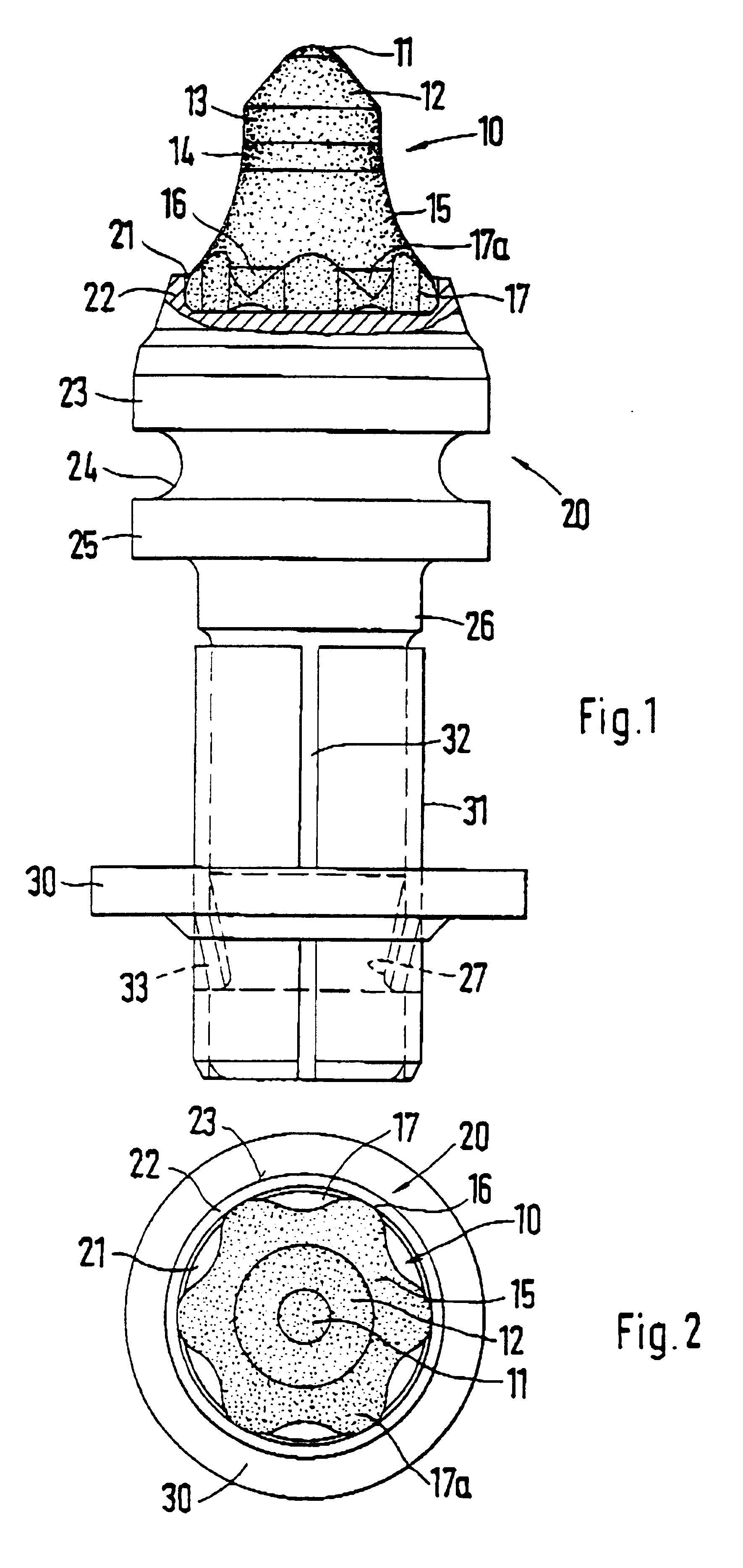

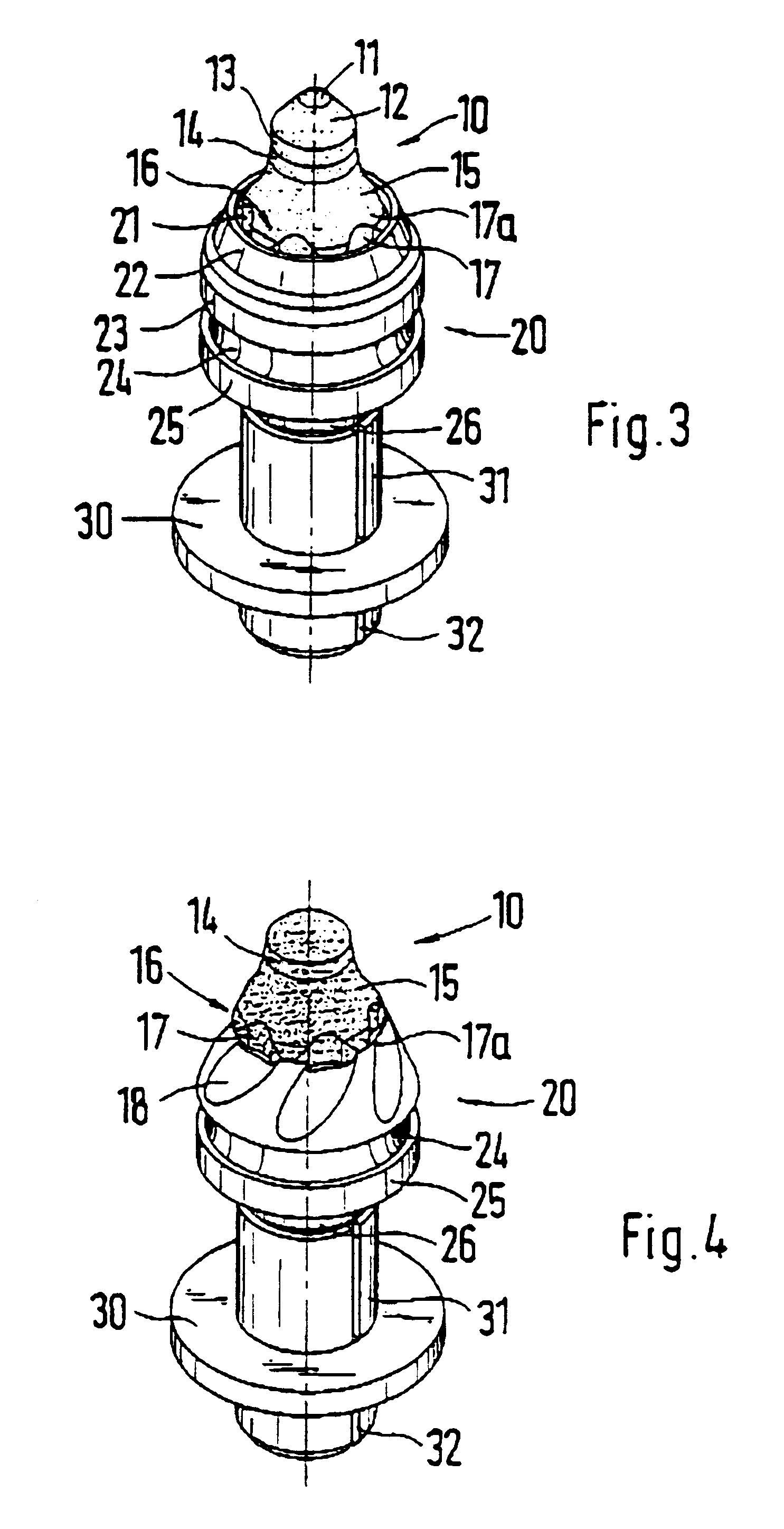

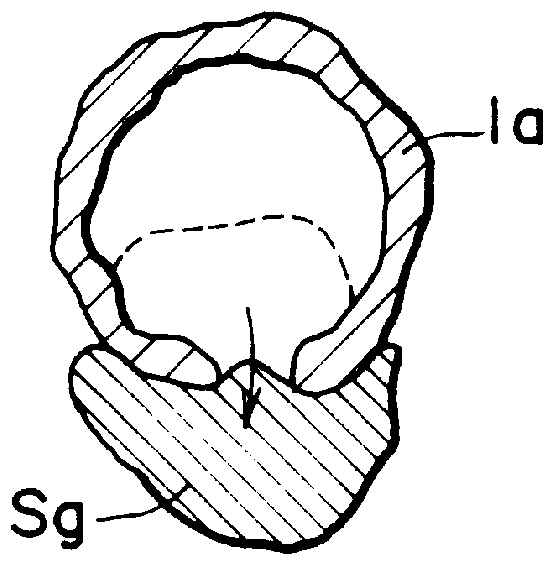

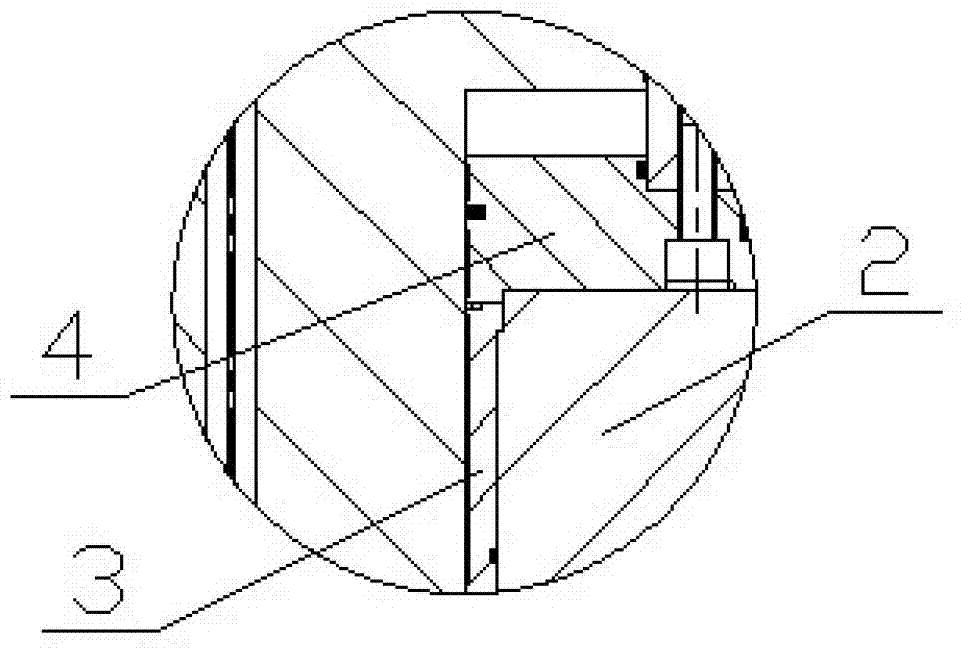

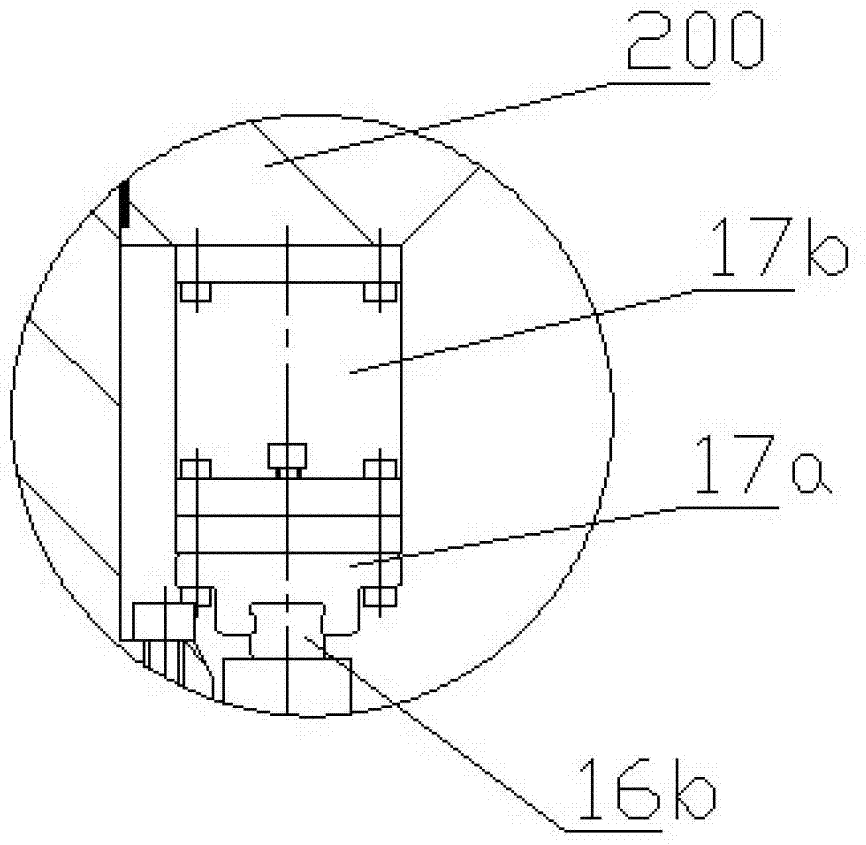

Round-shank bit for a coal cutting machine

InactiveUS6199956B1Sufficient supportLess stressPolishing machinesRevolution surface grinding machinesMaximum diameterEngineering

A round-shank bit for a coal cutting machine or the like, having a bit head and a bit shank, wherein the bit head has a bit tip, maintained by a base element in a receptacle of the bit head. Starting at the base element, the bit tip tapers in a direction toward the free end of the bit tip, wherein the base element forms a maximum diameter of the bit tip, and wherein the bit tip has recesses on its outer contour. In order to assure good rotational behavior over the entire length of the operating time, the base element has the recesses on an outer circumference forming the maximum diameter.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

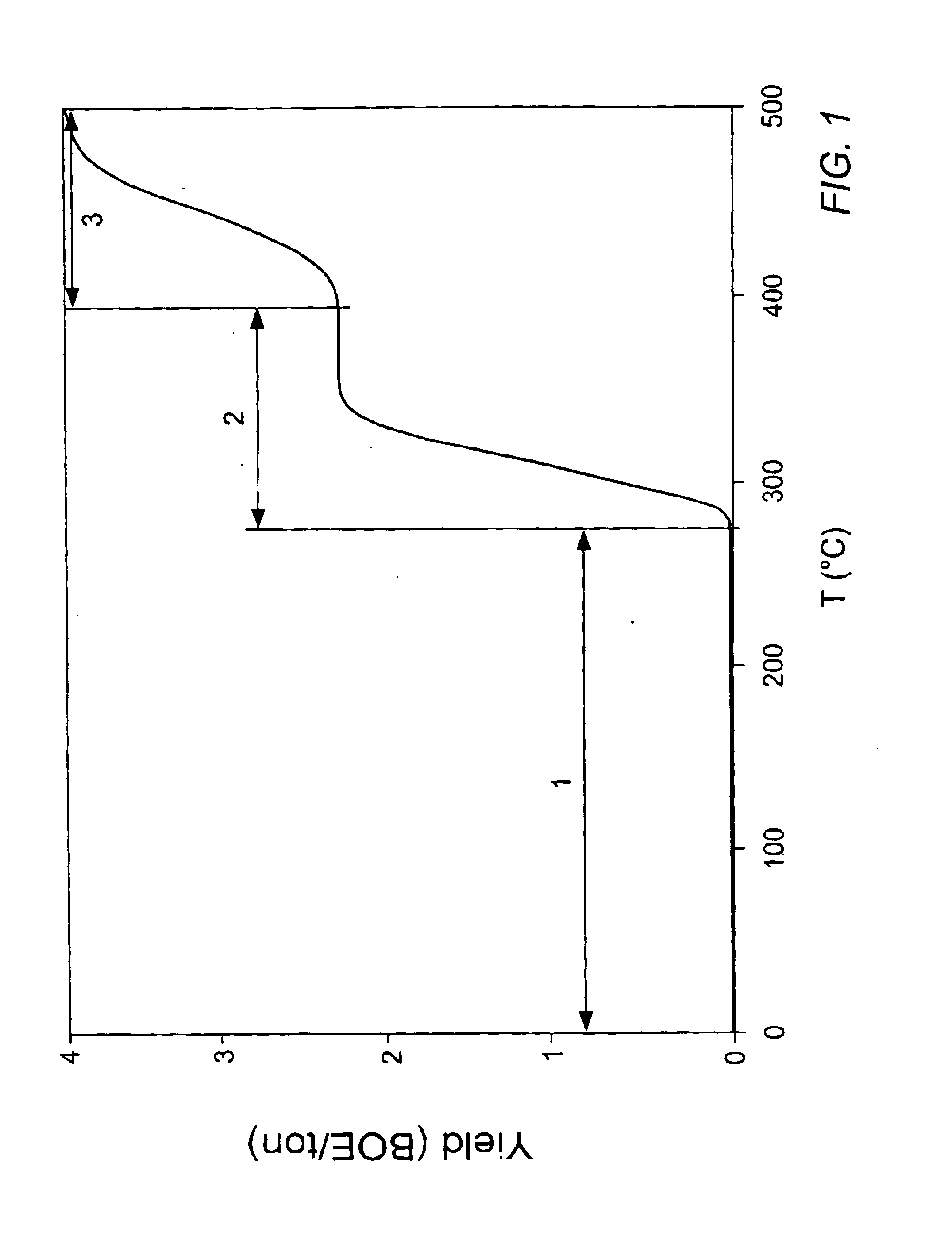

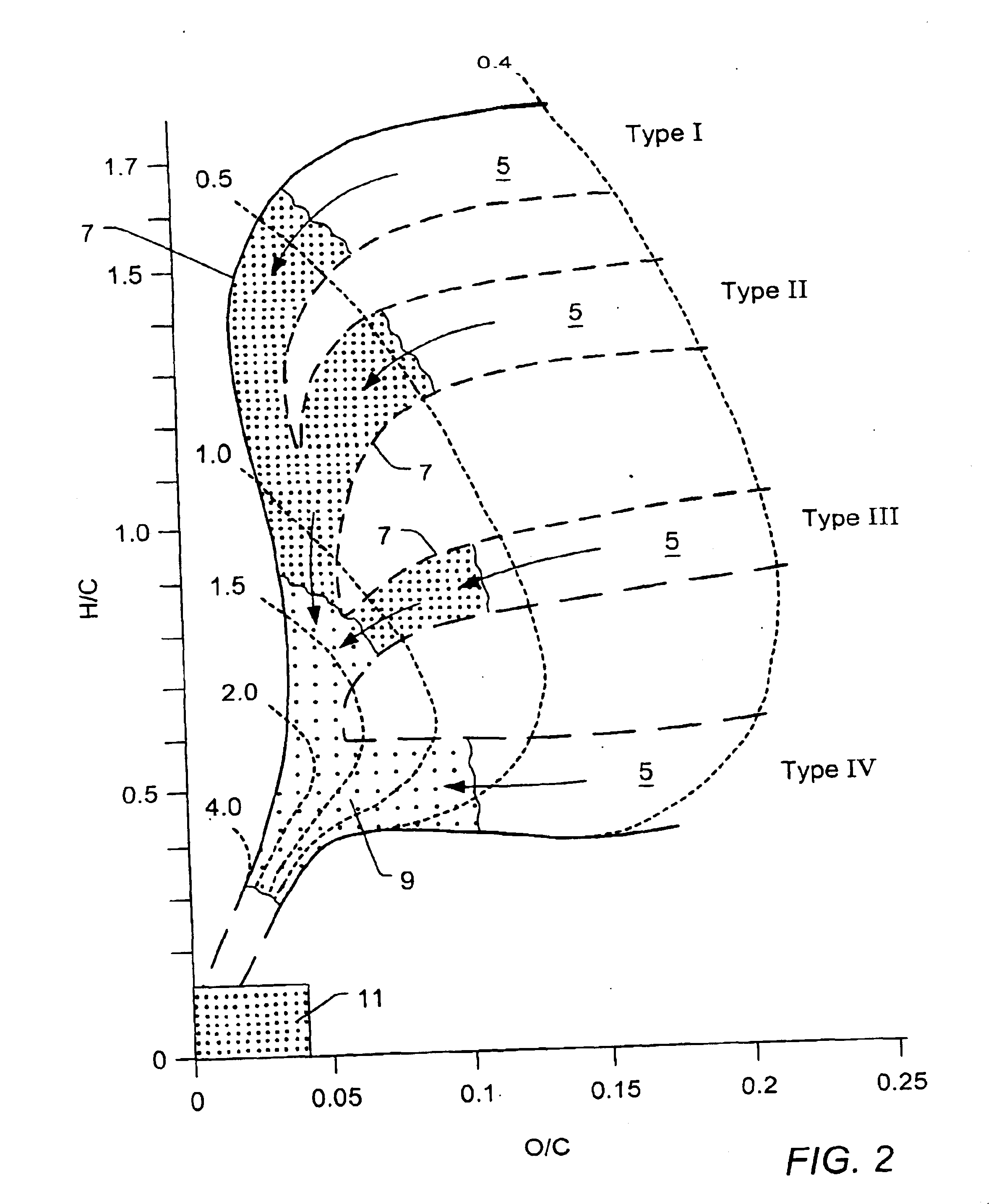

In situ thermal processing of a coal formation to increase a permeability/porosity of the formation

InactiveUS6866097B2Reduce the temperatureHigh strengthSurveyCombustion processPorosityInitial permeability

Owner:SHELL OIL CO

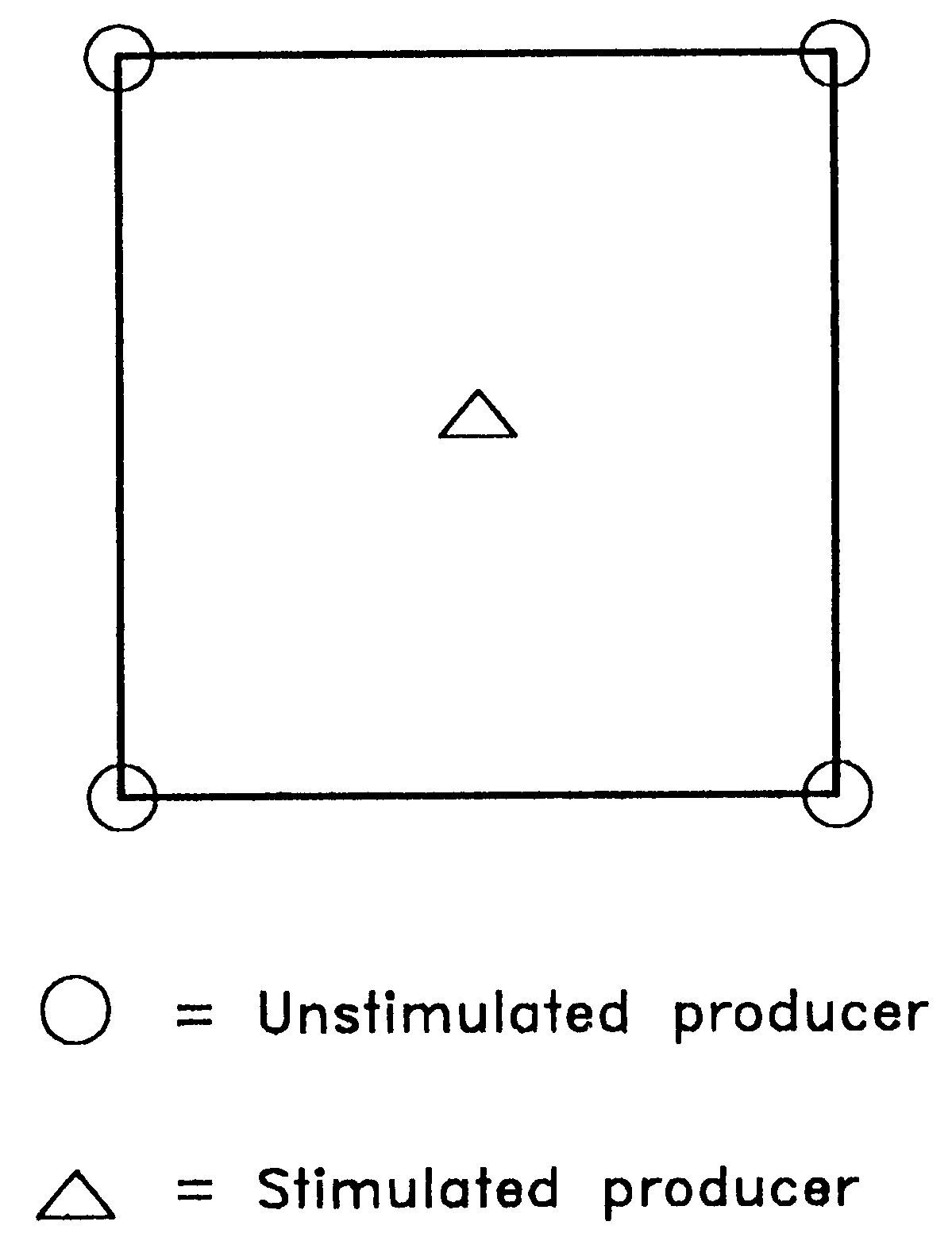

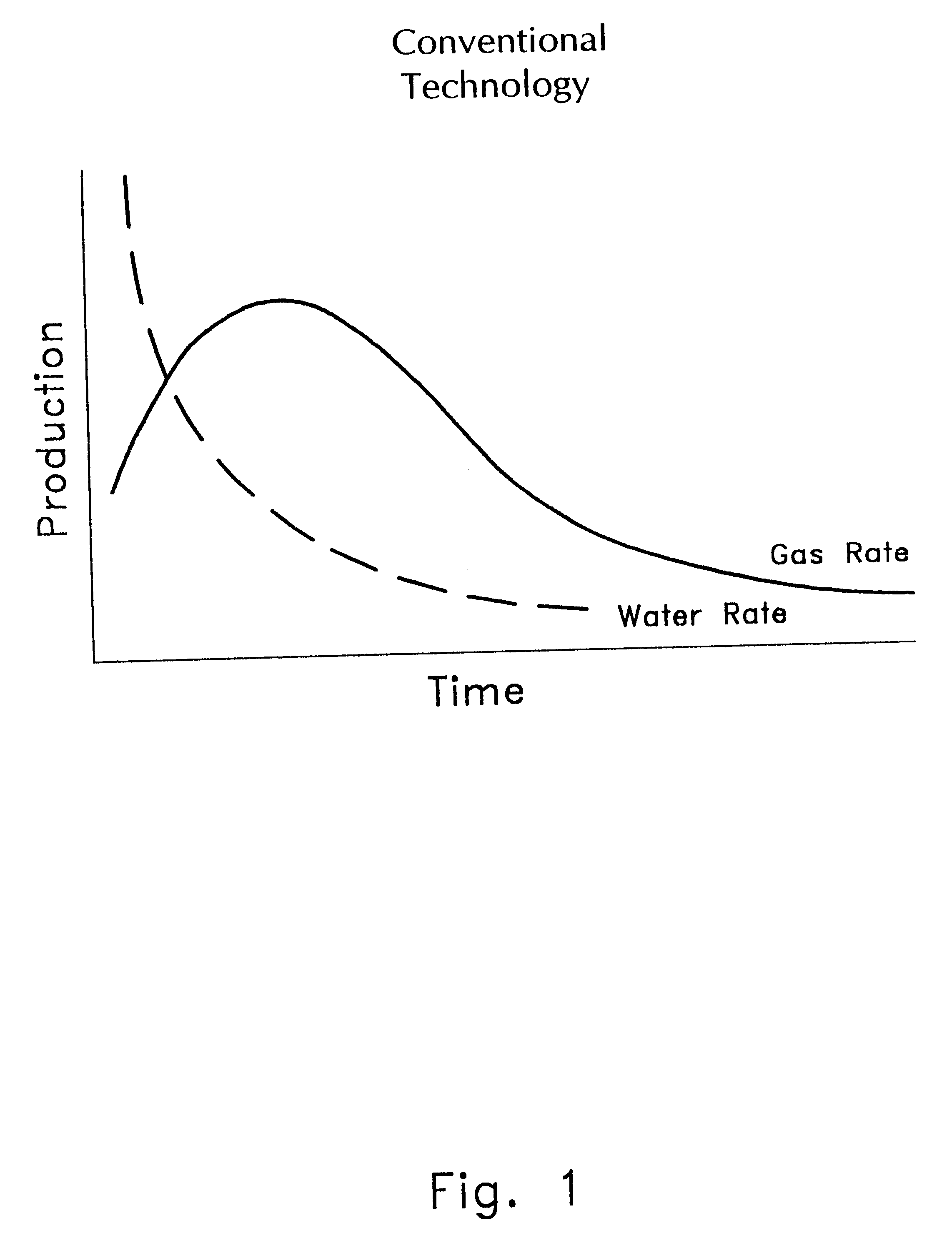

System for improving coalbed gas production

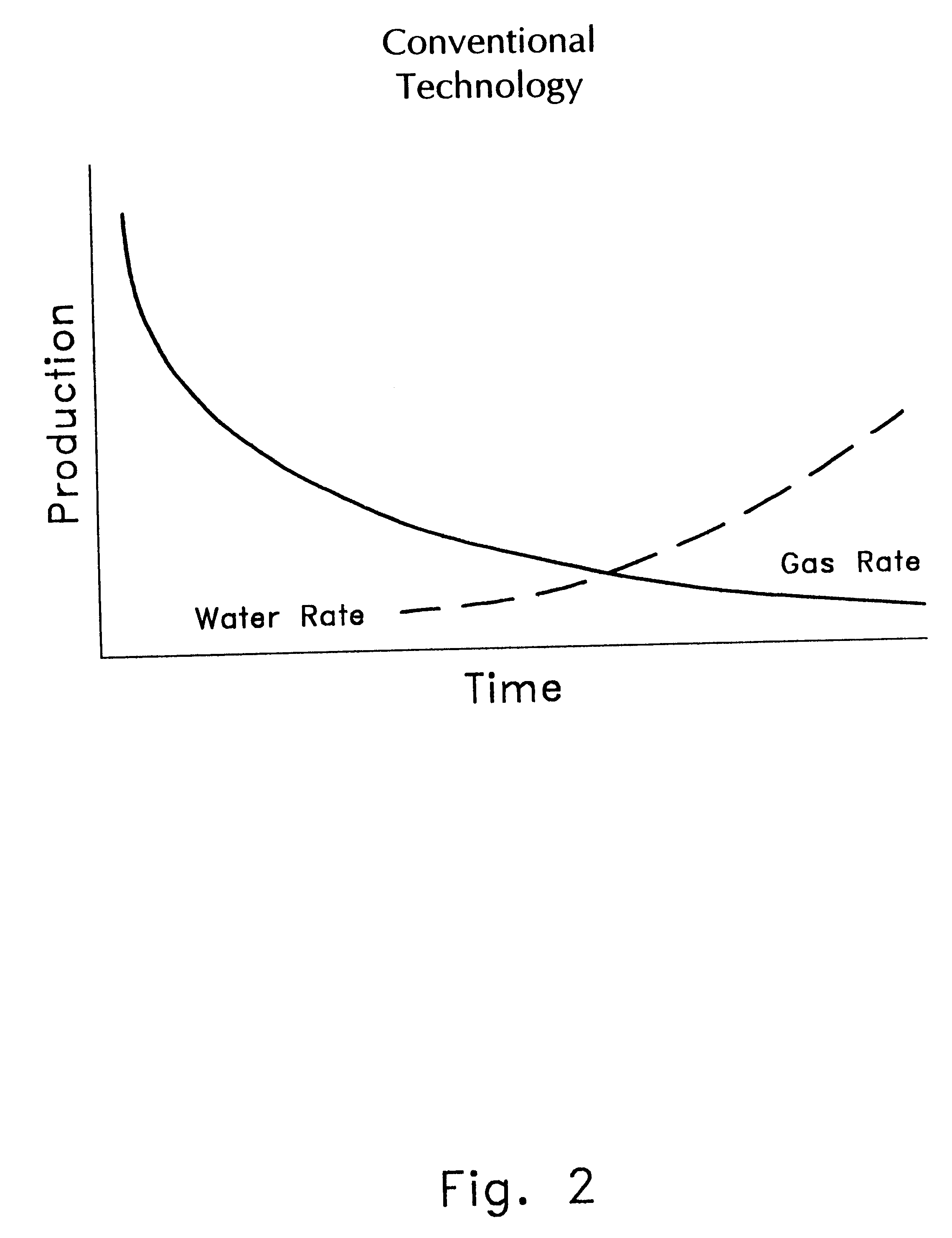

InactiveUS6244338B1Change in permeabilityPromote recoverySurveyDrilling rodsCoal matrixWater production

A method of stimulating coalbed methane production by injecting gas into a producer and subsequently placing the producer back on production is described. A decrease in water production may also result. The increase in gas production and decrease in water production may result from: (1) the displacement of water from the producer by gas; (2) the establishment of a mobile gas saturation at an extended distance into the coalbed, extending outward from the producer; and (3) the reduction in coalbed methane partial pressure between the coal matrix and the coal's cleat system.

Owner:THE UNIVERSITY OF WYOMING RESEARCH CORPORATION DBA WESTERN RESEARCH INSTITUTE

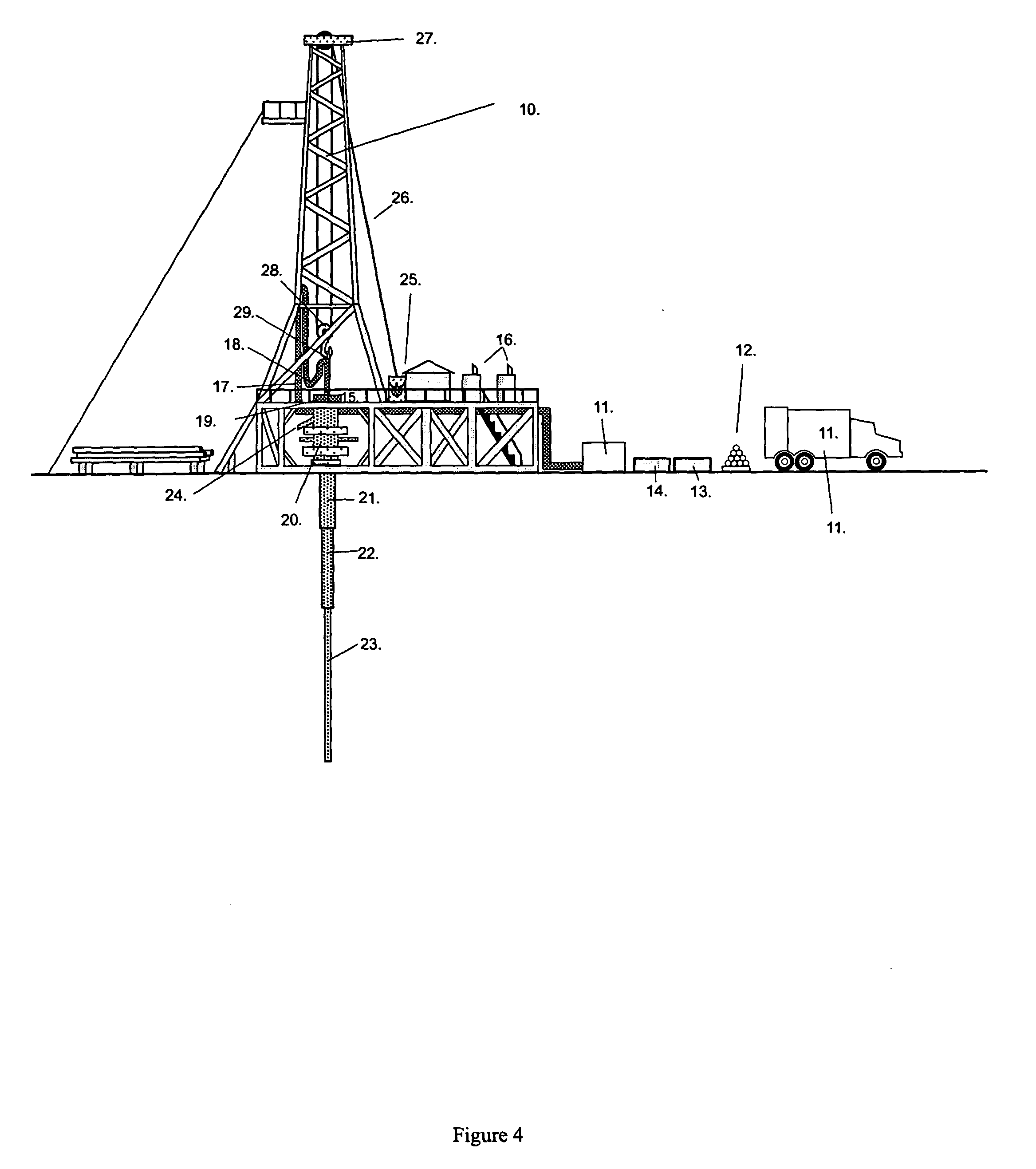

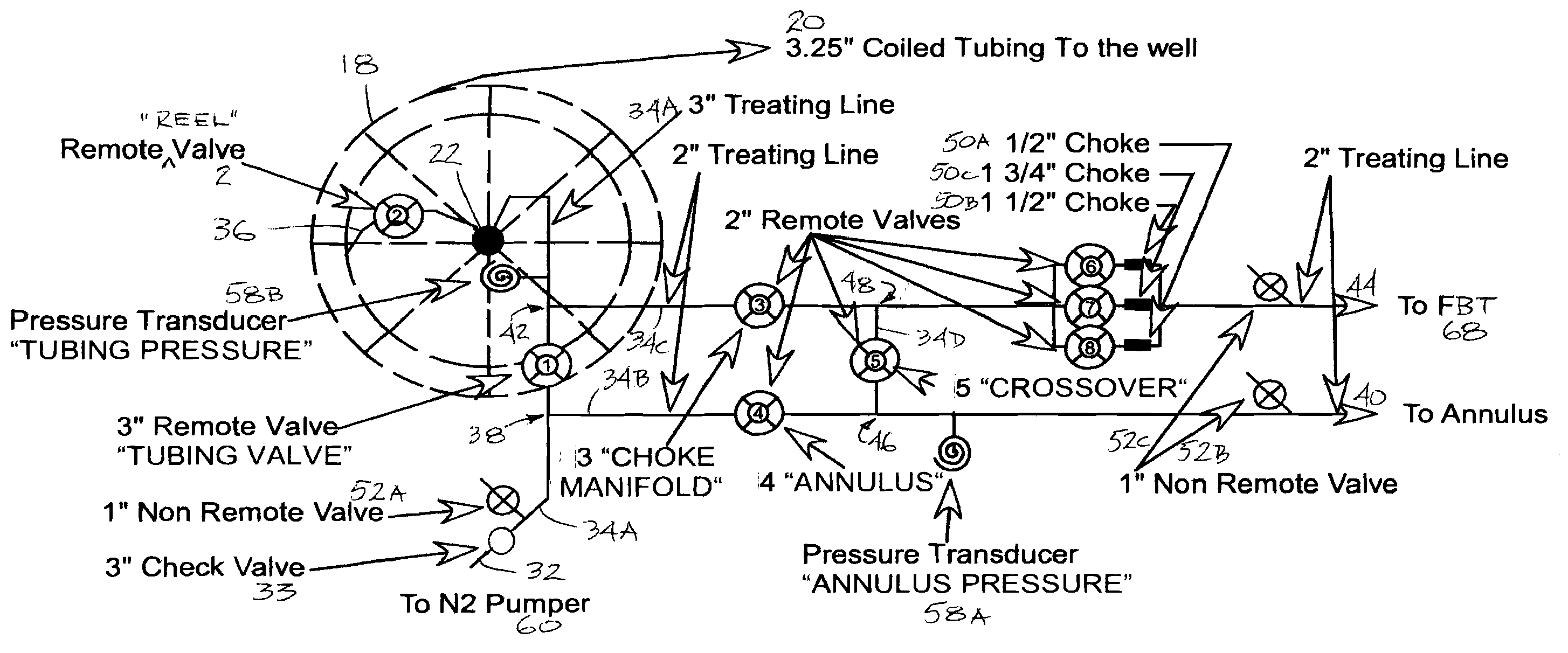

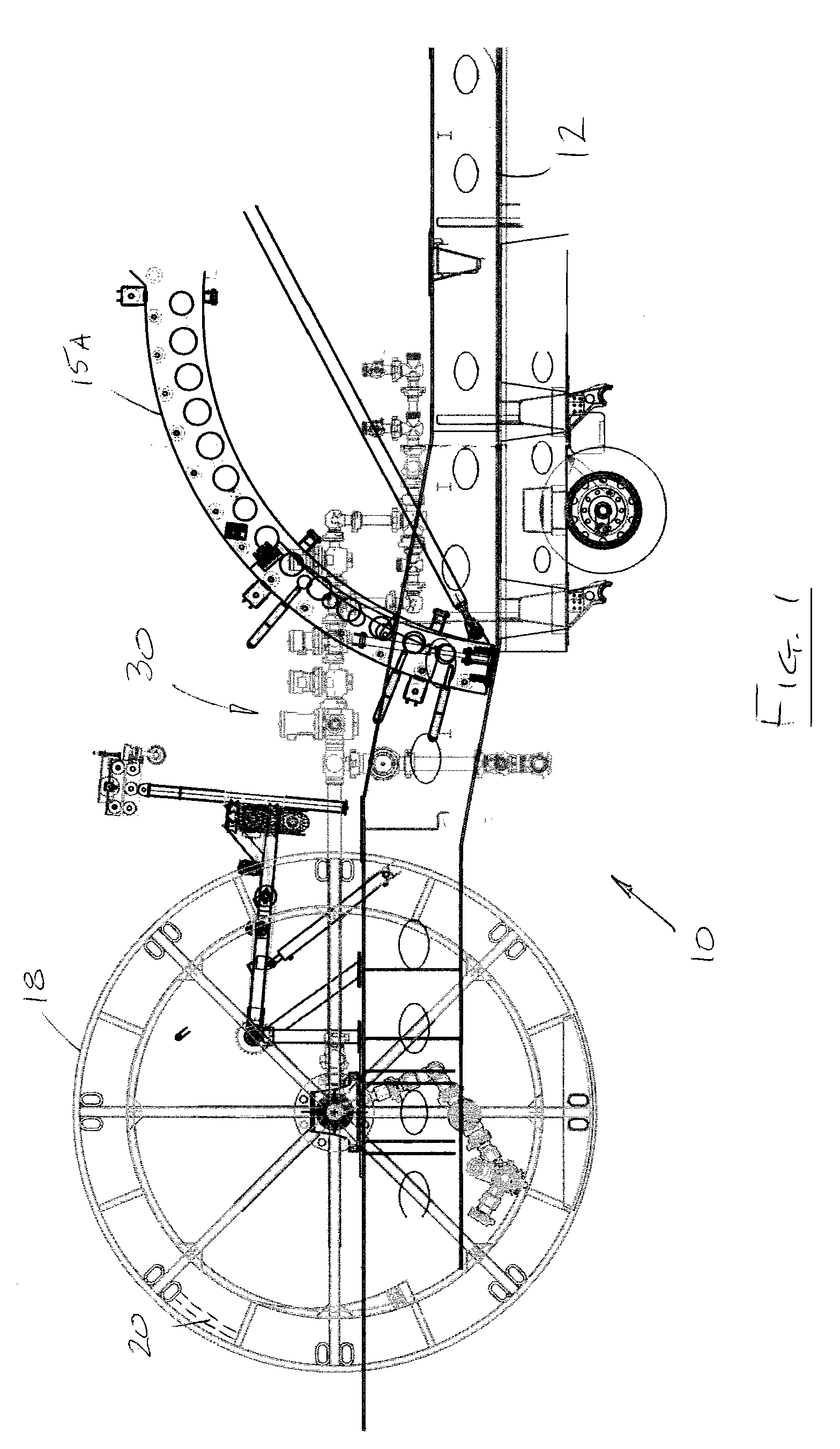

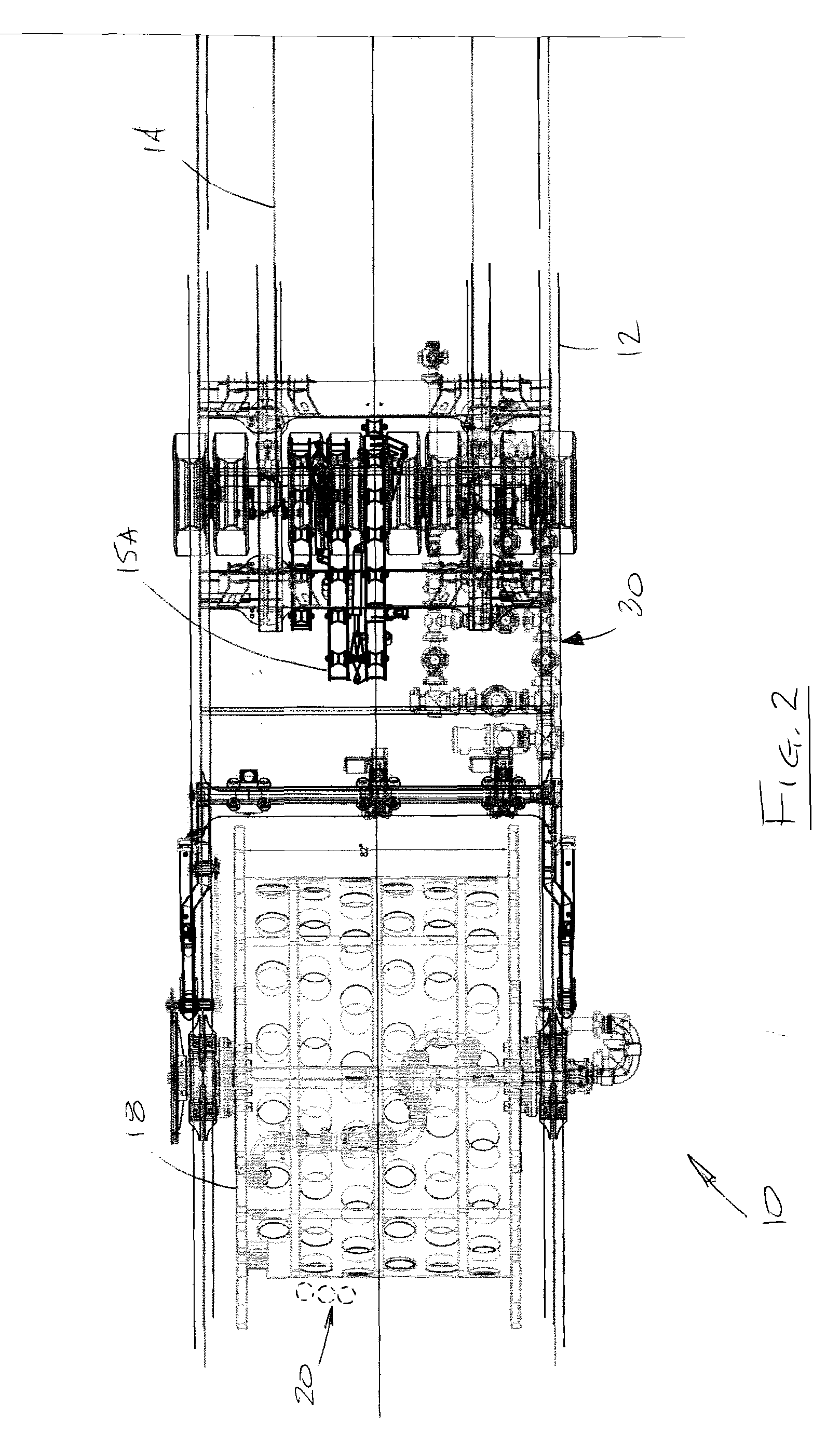

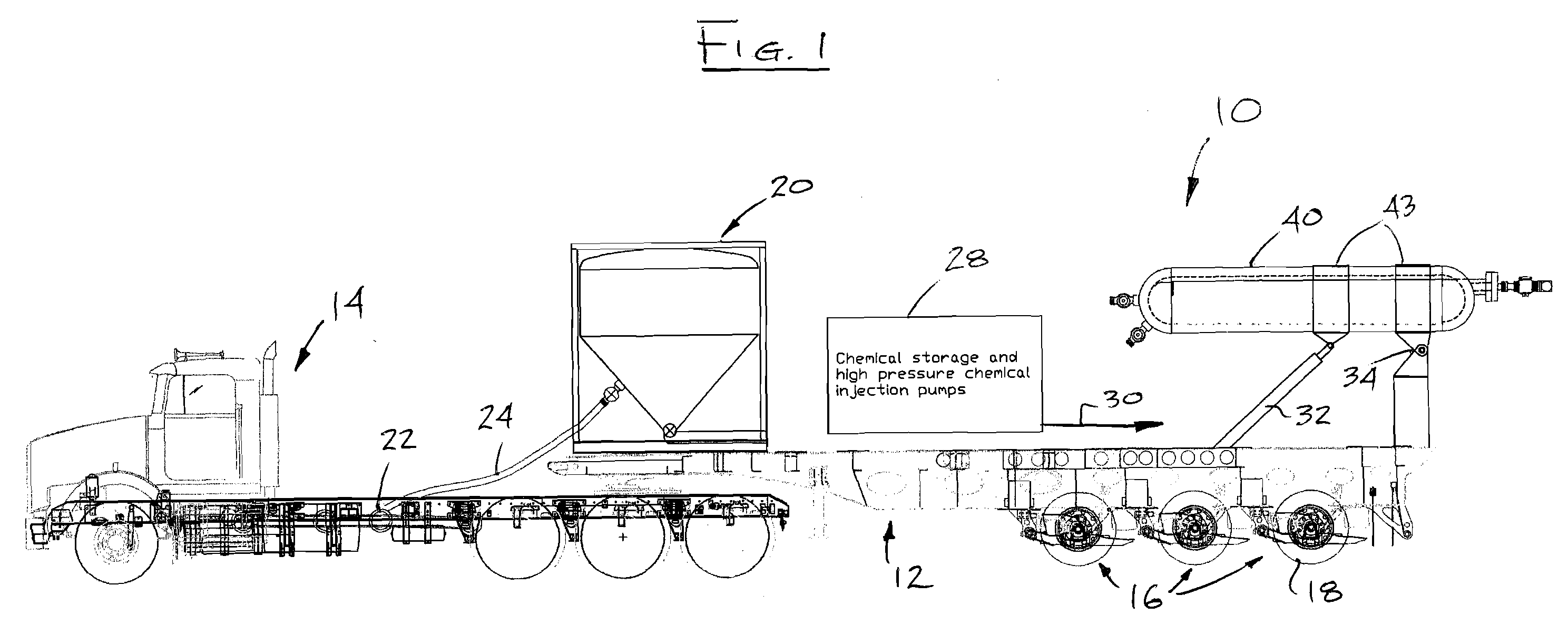

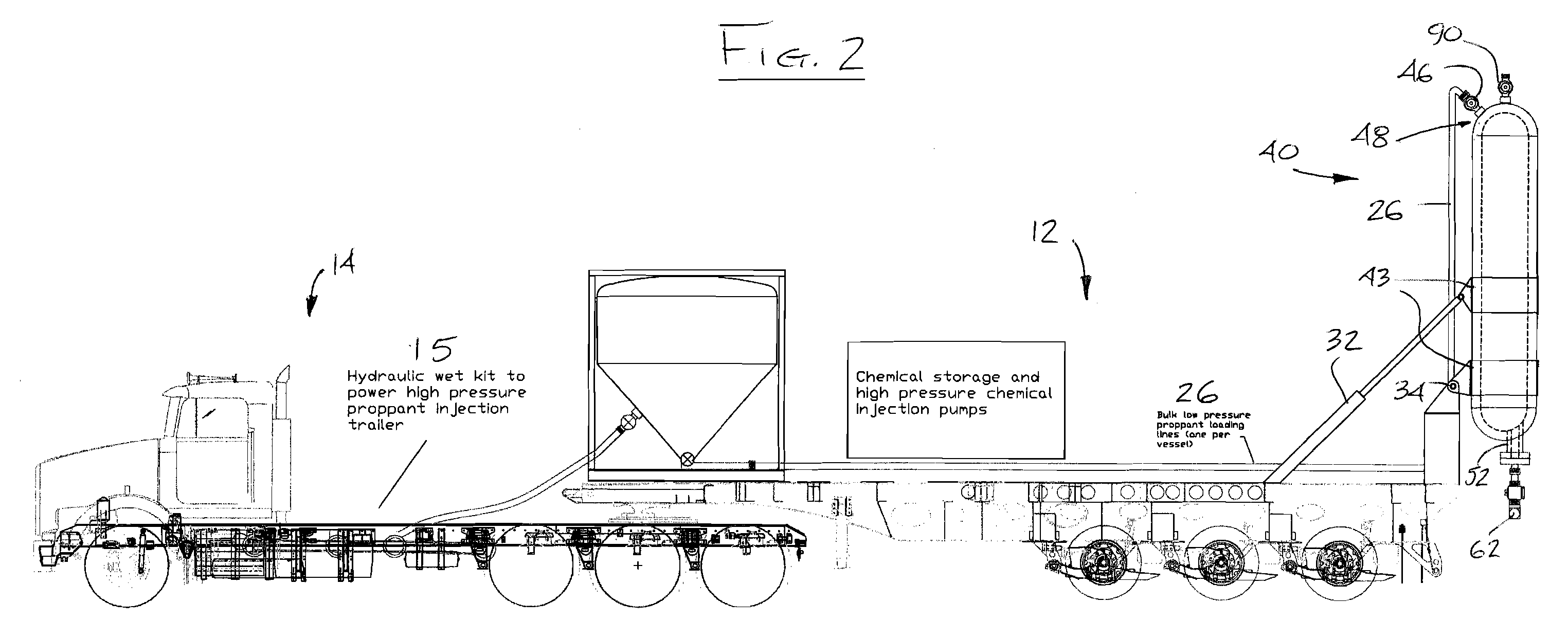

Well Servicing Rig and Manifold Assembly

A well servicing rig for communicating with a fluid source and an effluent reservoir (such as a flow back tank) has an apparatus for holding and dispensing coiled tubing. A manifold assembly is advantageously located on the rig for routing the pressurized fluid (such as nitrogen gas mixed with proppant) from the fluid source between the coiled tubing apparatus, the well and the effluent reservoir. The manifold assembly controls the flow of the fluid to perform fracturing operations, for reverse fluid circulation, for a common coiled tubing operation, for pressure testing, and the like. The assembly includes remotely controlled valves and pressure transducers for controlling the fluid flow, and chokes for diffusing fluid energy prior to entering the effluent reservoir. The rig, fluid source, effluent reservoir and a fluid pumper provide a novel method of servicing an underground formation (such as a coal bed) for natural gas.

Owner:FRAC SOURCE

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst. The particulate compositions are gasified in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Coal Compositions for Catalytic Gasification

ActiveUS20090217590A1Drying solid materials with heatGaseous fuelsPtru catalystHydrocotyle bowlesioides

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

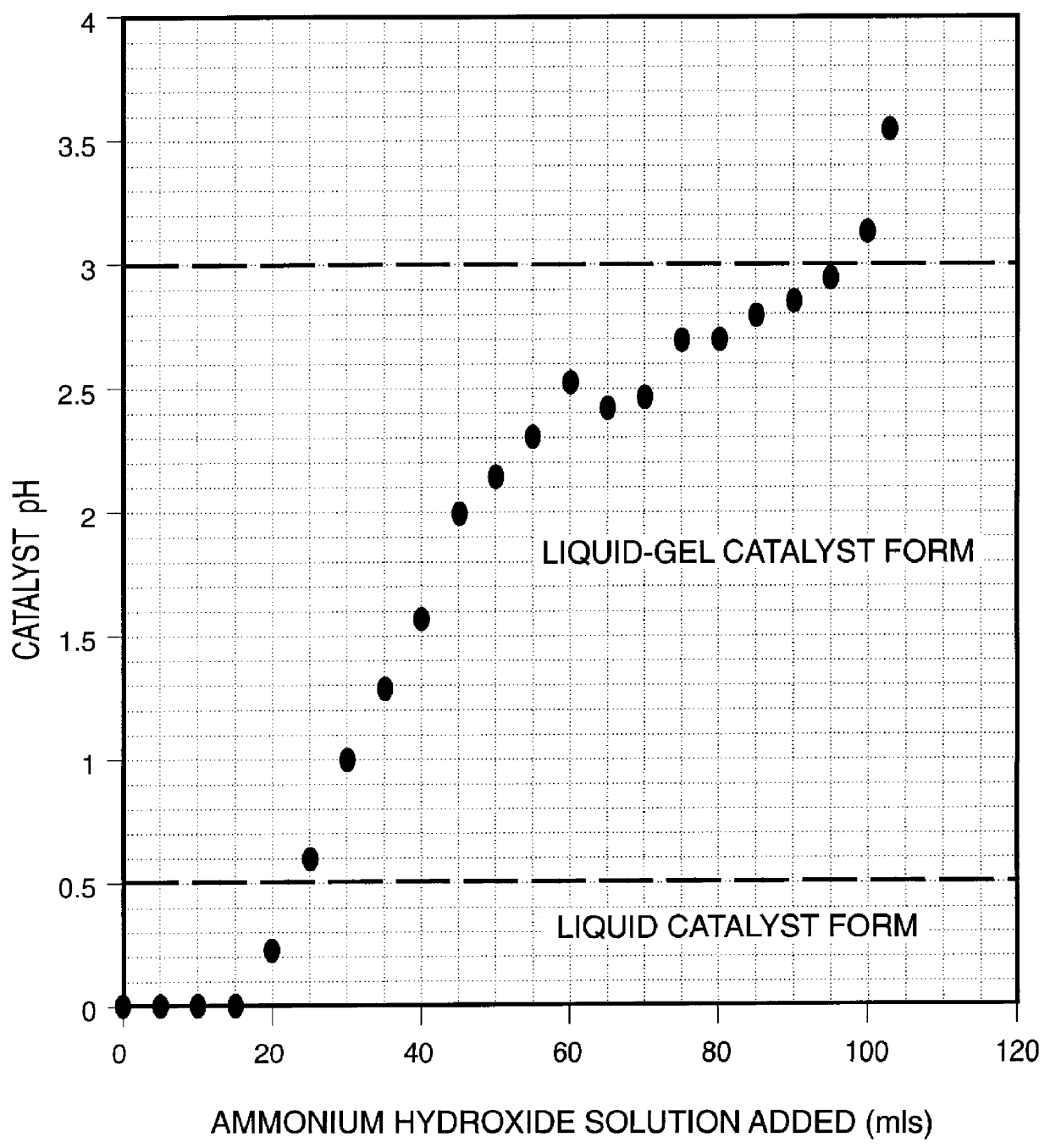

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

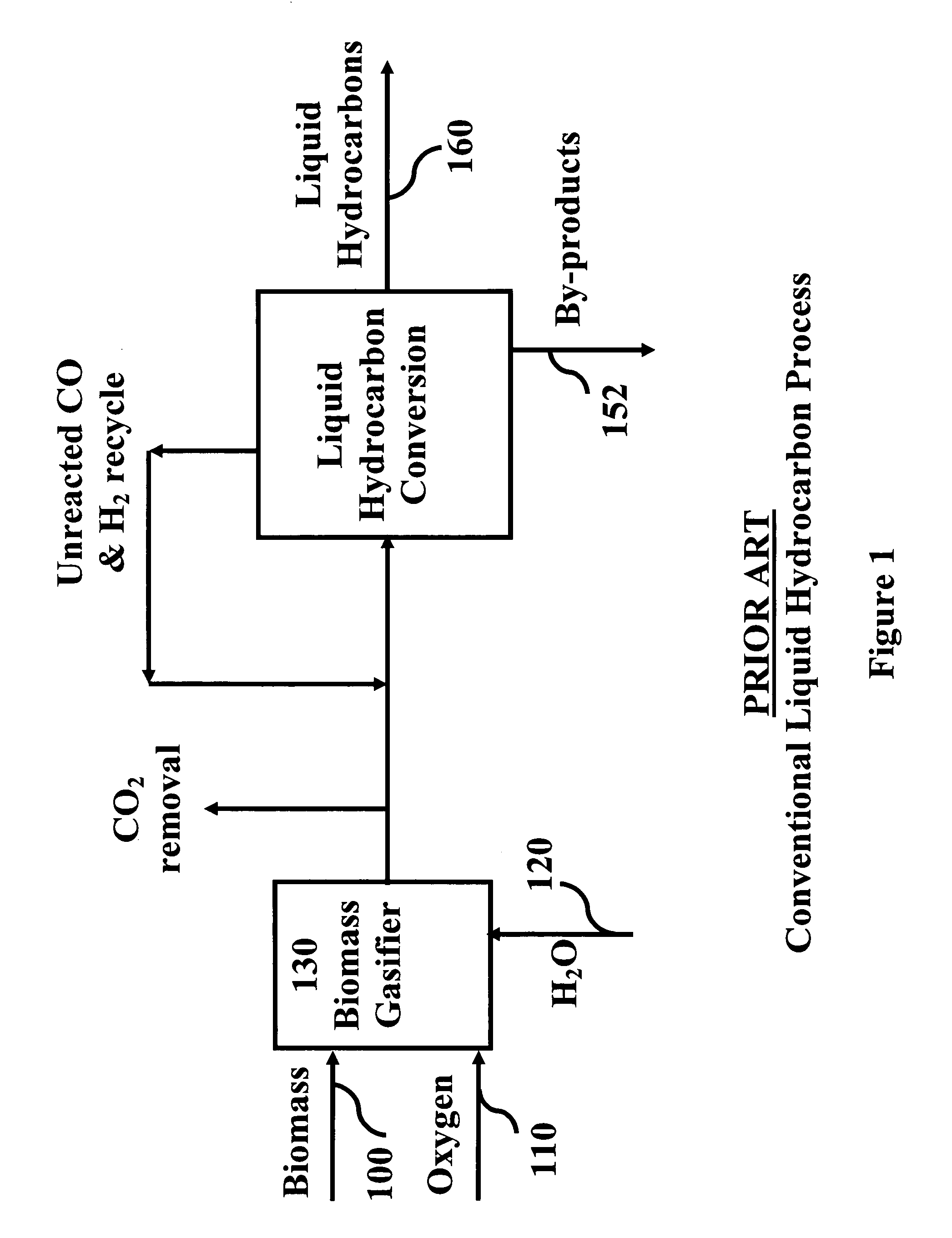

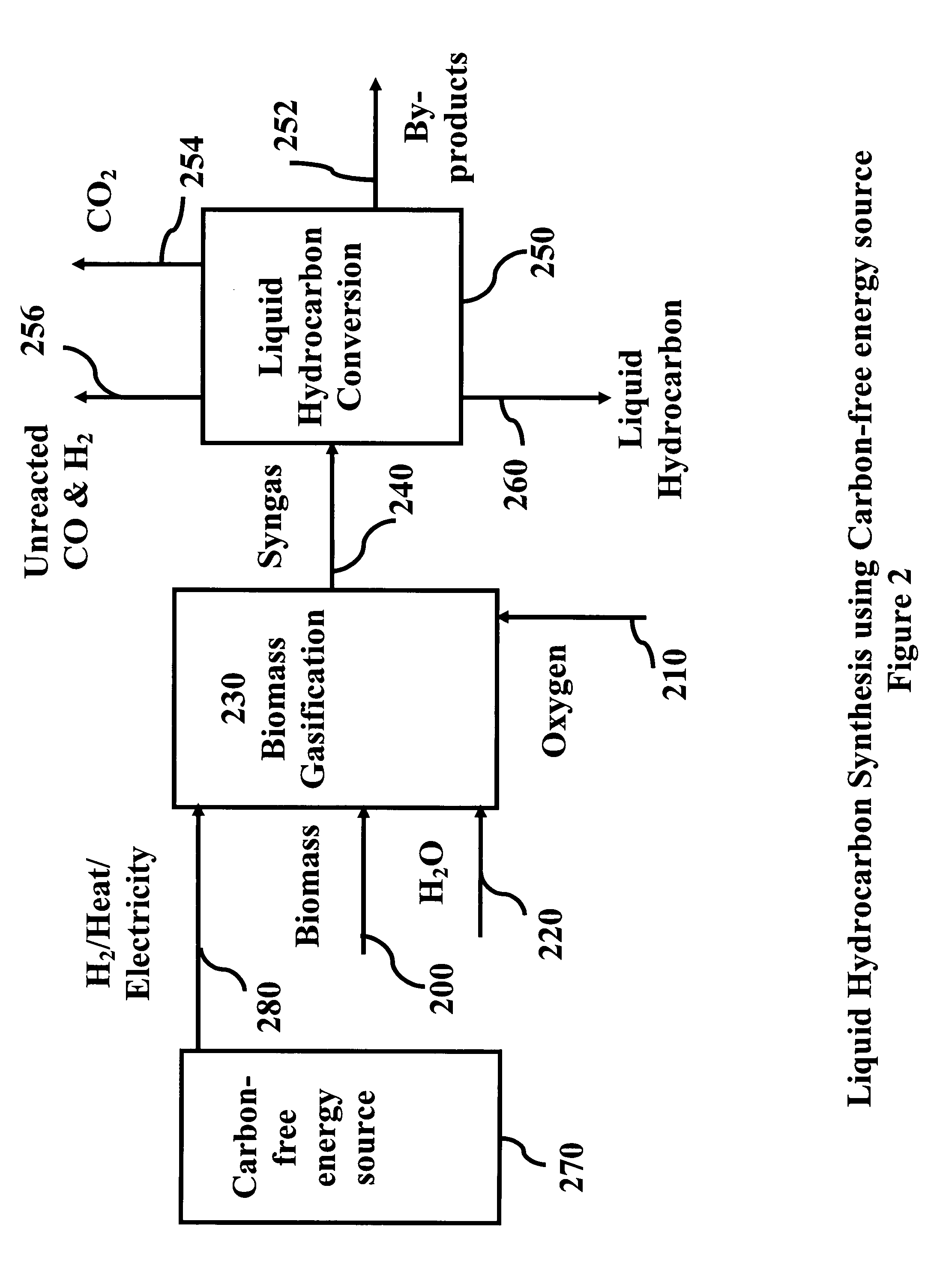

System and process for producing synthetic liquid hydrocarbon

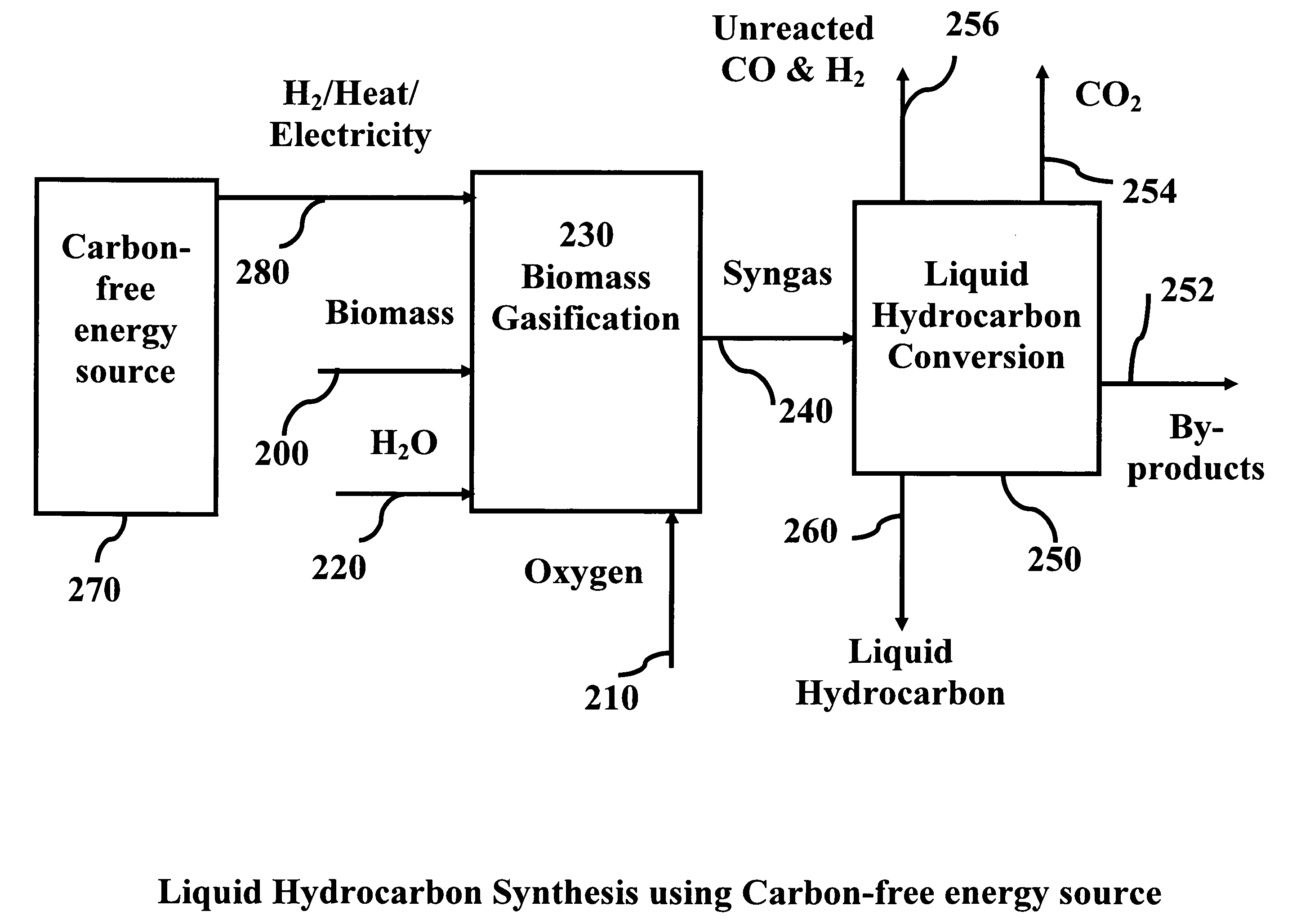

ActiveUS20080115415A1Improve carbon efficiencyReduce area requirementsMuffle furnacesCarbon compoundsOxygenElectrolysis of water

Production of synthetic liquid hydrocarbon fuel from carbon containing moieties such as biomass, coal, methane, naphtha as a carbon source and hydrogen from a carbon-free energy source is disclosed. The biomass can be fed to a gasifier along with hydrogen, oxygen, steam and recycled carbon dioxide. The synthesis gas from the gasifier exhaust is sent to a liquid hydrocarbon conversion reactor to form liquid hydrocarbon molecules. Unreacted CO & H2 can be recycled to the gasifier along with CO2 from the liquid hydrocarbon conversion reactor system. Hydrogen can be obtained from electrolysis of water, thermo-chemical cycles or directly by using energy from carbon-free energy sources.

Owner:PURDUE RES FOUND INC

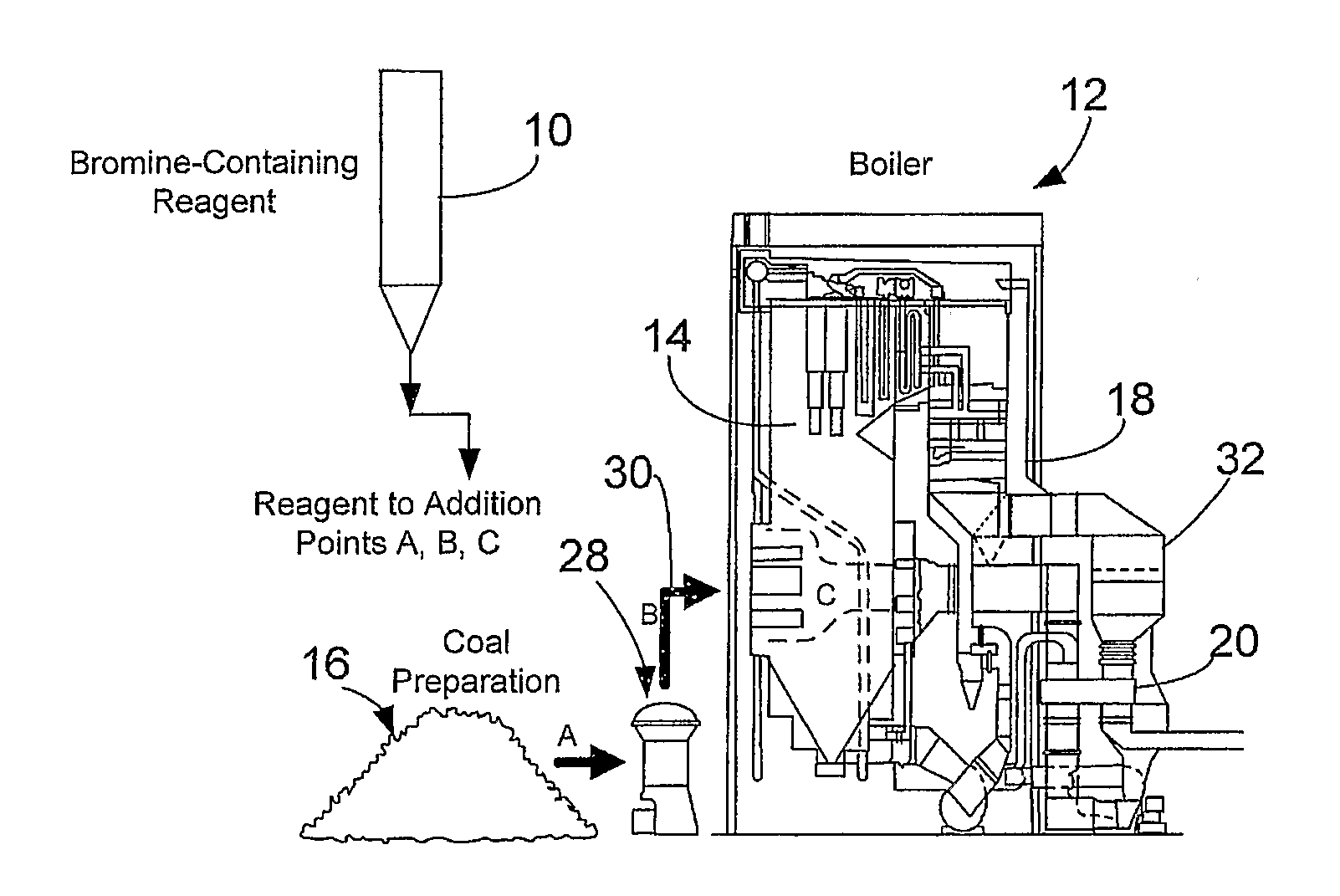

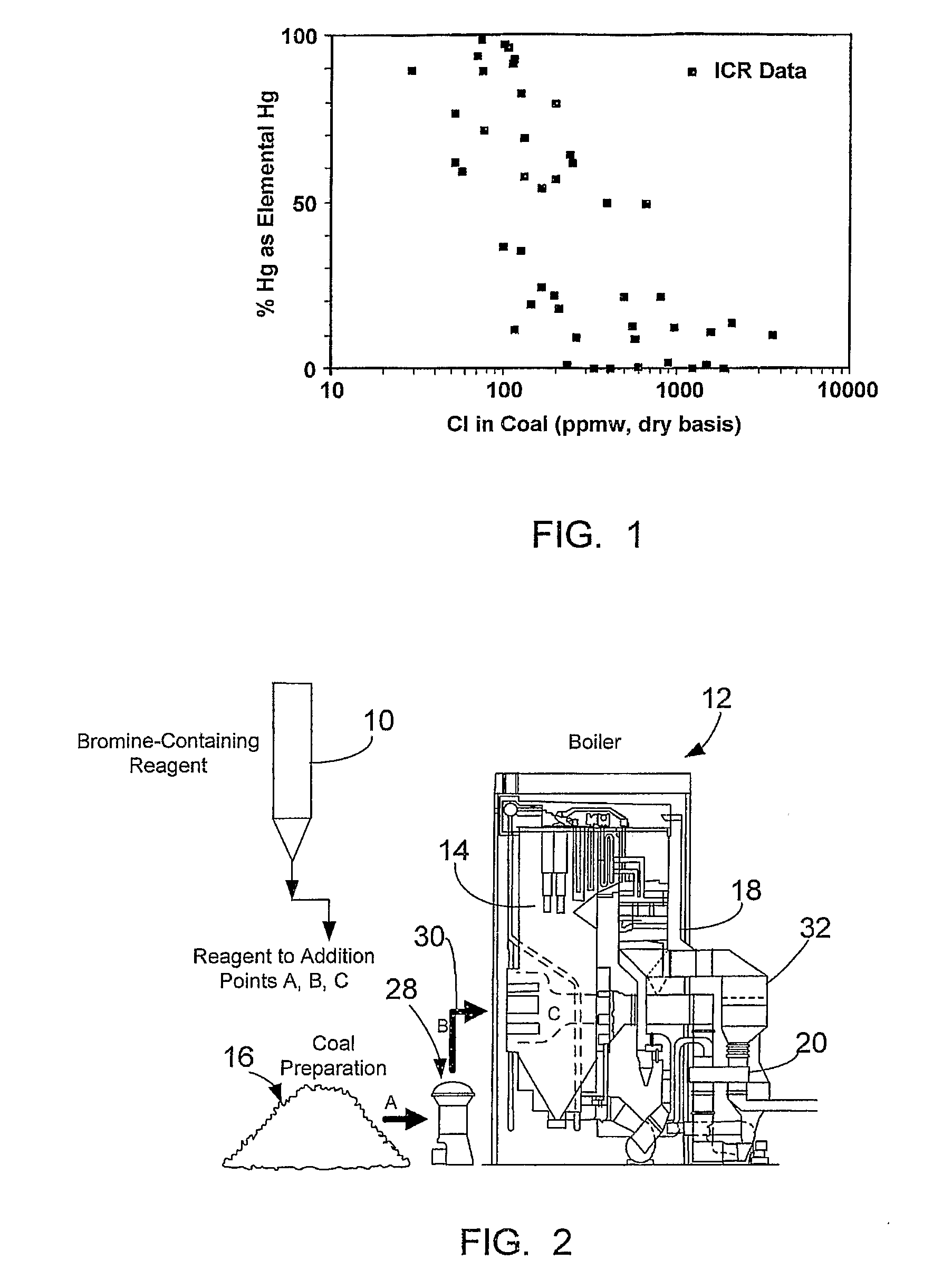

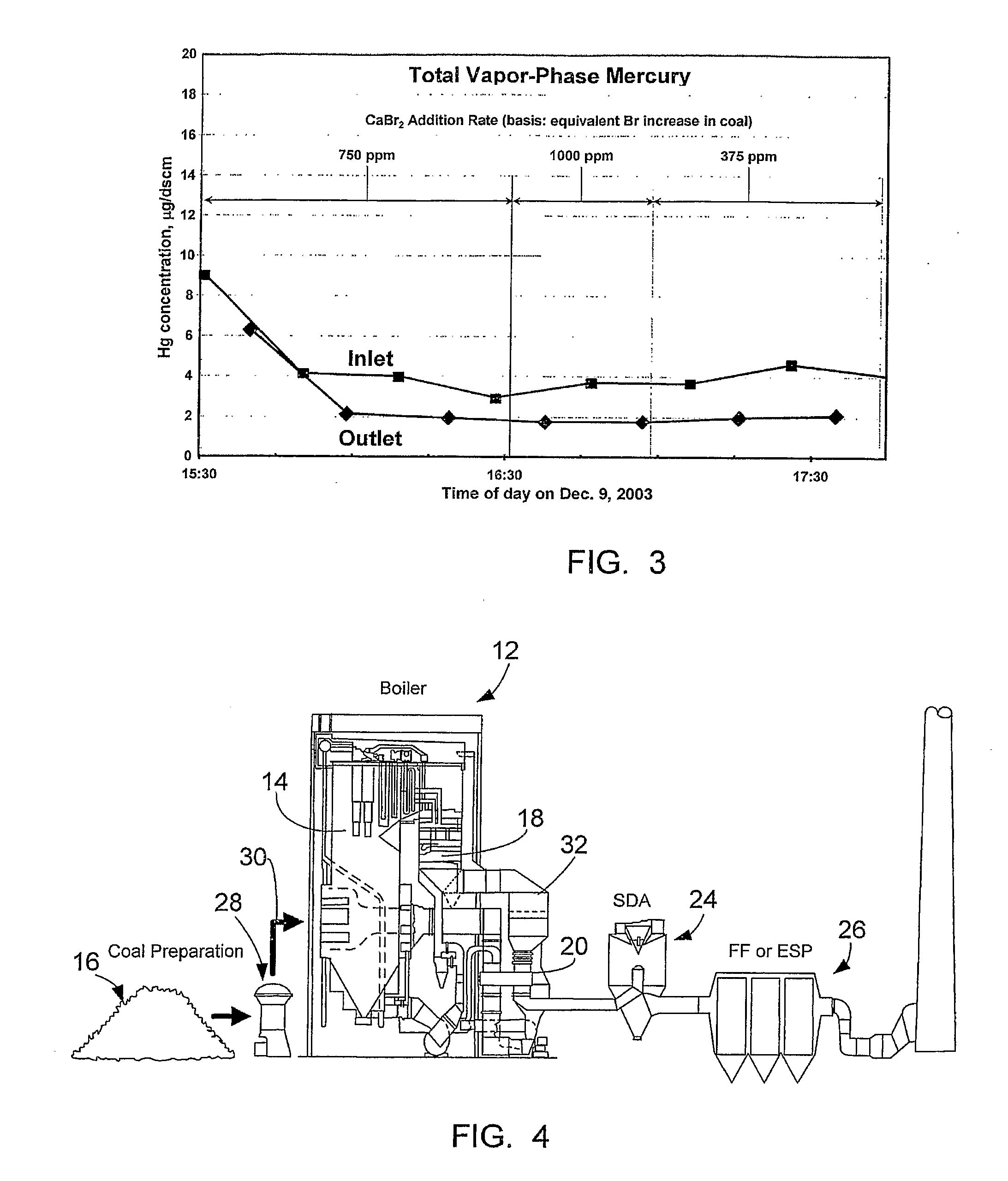

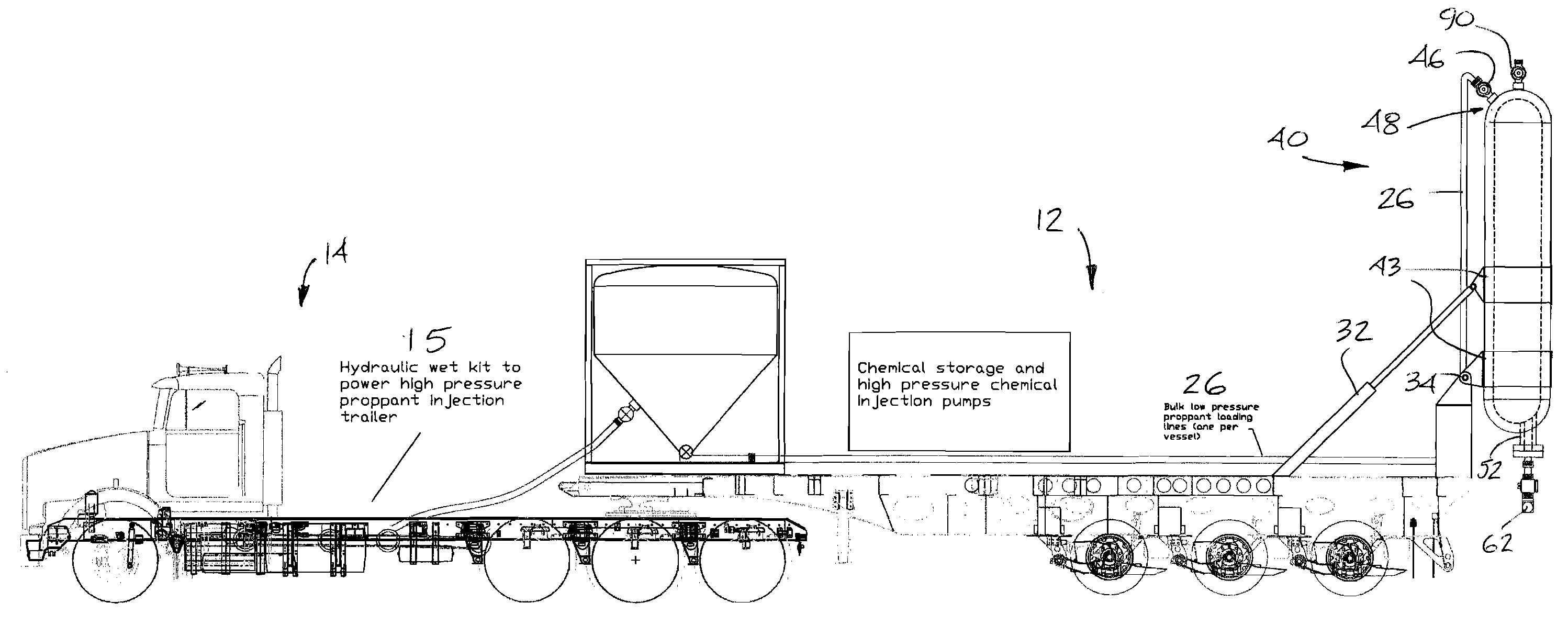

Bromine Addition for the Improved Removal of Mercury from Flue Gas

InactiveUS20080107579A1Significant technicalSignificant commercial advantageGas treatmentUsing liquid separation agentCombustionFlue gas

Bromine-containing compounds, added to the coal, or to the boiler combustion furnace, are used to enhance the oxidation of mercury, thereby enhancing the overall removal of mercury in downstream pollution control devices. The method is applicable to utility power plants equipped with wet FGD systems, as well as those plants equipped with spray dryer absorber FGD systems.

Owner:THE BABCOCK & WILCOX CO

High-pressure Injection Proppant System

Owner:FRAC SOURCE

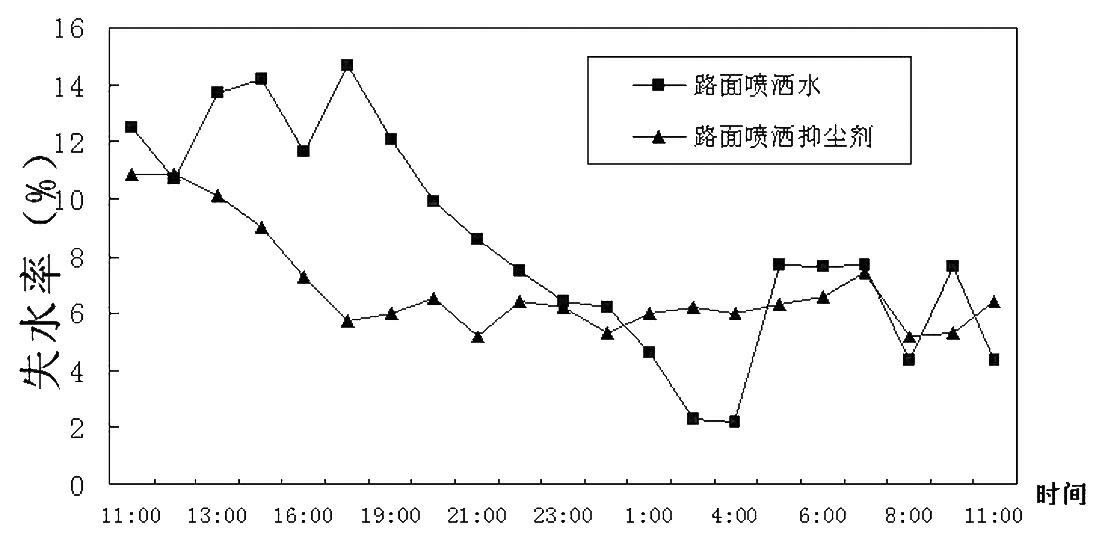

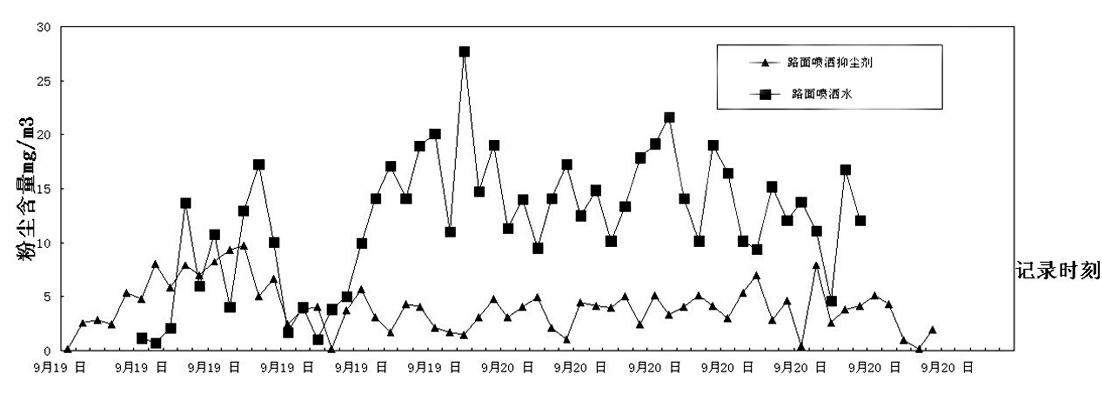

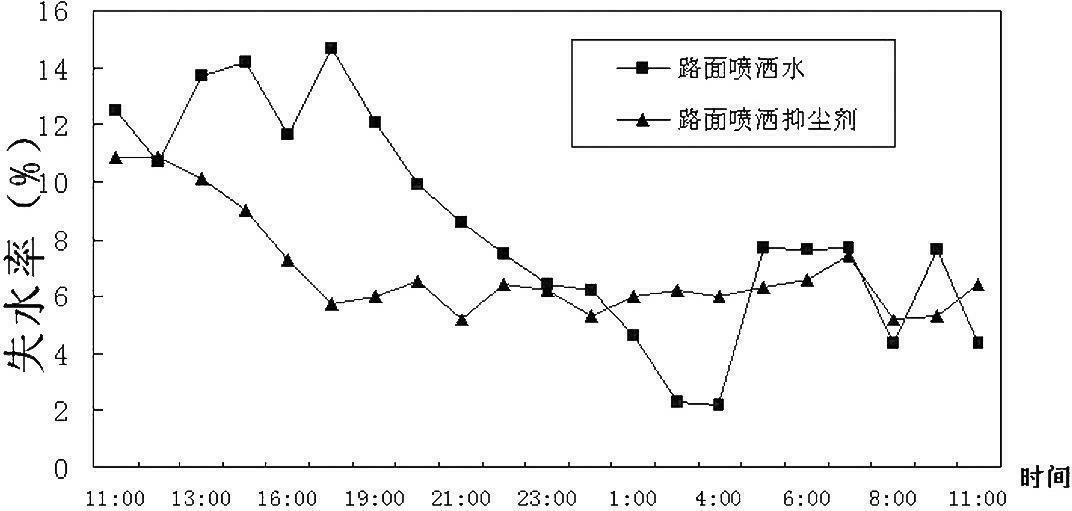

Road dust suppressant

ActiveCN102660227AStrong anti-pressure functionLarge particle sizeOther chemical processesLiquid productEvaporation

The invention discloses a road dust suppressant, which is prepared by mixing and blending 0.1-2.0% of water-soluble high molecular polymer, 20-50% of moisture absorption humectant, 1.0-5.0% of preservative, 0.5-5.0% of penetrating agent and the balance water. The road dust suppressant is a dynamic dust-proof and dust-suppressing liquid product which combines functions of wetting, bonding, permeating, adsorbing moisture and the like into a whole and has extremely strong pressurization-resistant function. The road dust suppressant has the advantages of obvious anti-evaporation performance and good water retention hygroscopicity, and dust on the road surface can be coagulated and is unlikely to fly. The road dust suppressant disclosed by the invention not only can be applied to road dust suppressing but also can be simultaneously used for the aspects, such as the mine exploration and transportation environment, storage yards of coal ash, coal and other ores, and the treatments of municipal construction earthwork dust raise.

Owner:山西兴源盛科技有限公司

Processes for Preparing a Catalyzed Coal Particulate

Processes are provided for preparing a substantially free-flowing alkali metal gasification catalyst-loaded coal particulate suitable for use as a feedstock for the production of gaseous products, and in particular methane, via the catalytic gasification of the catalyst-loaded coal particulate in the presence of steam.

Owner:SURE CHAMPION INVESTMENT LTD

Fuel Composition

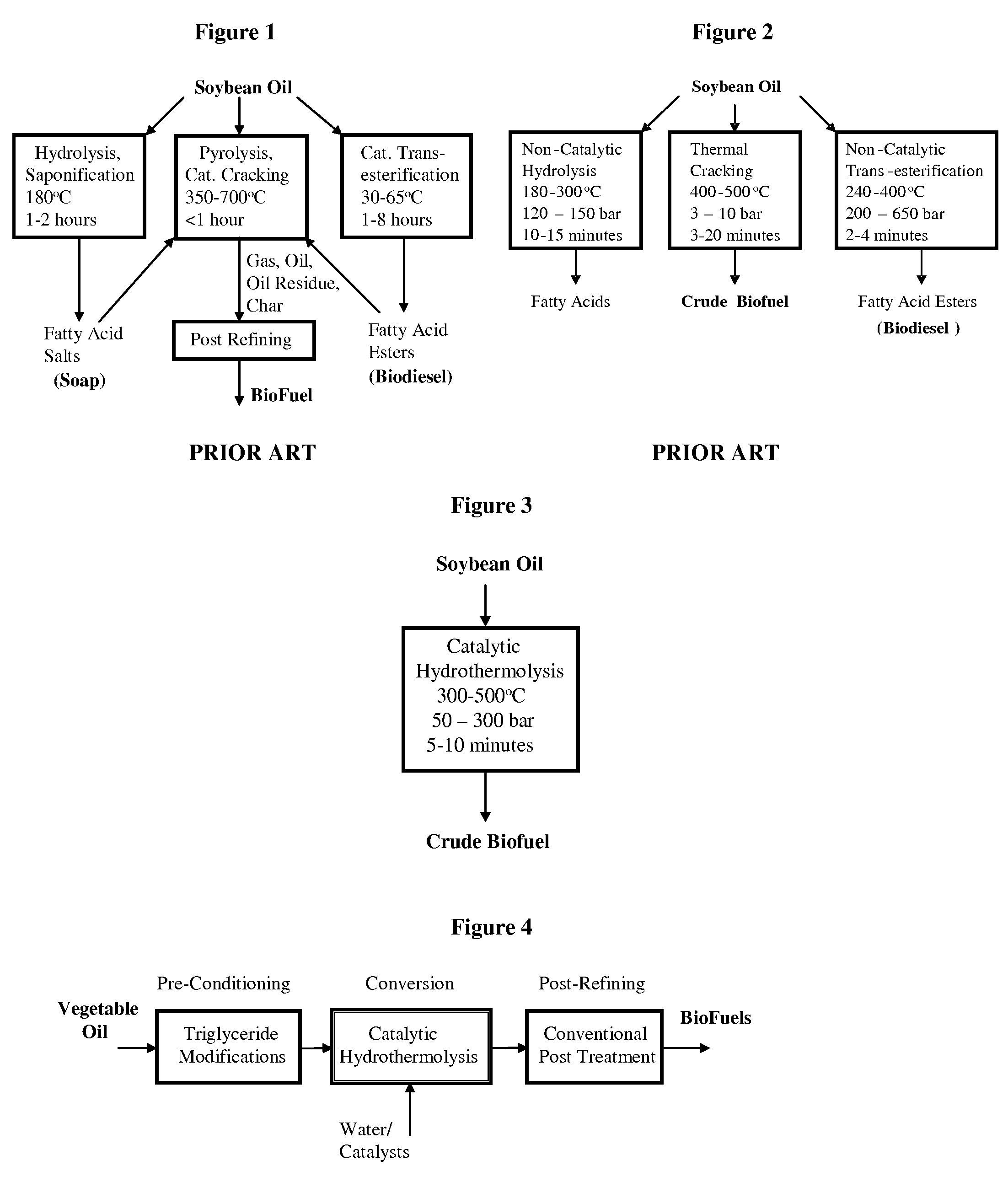

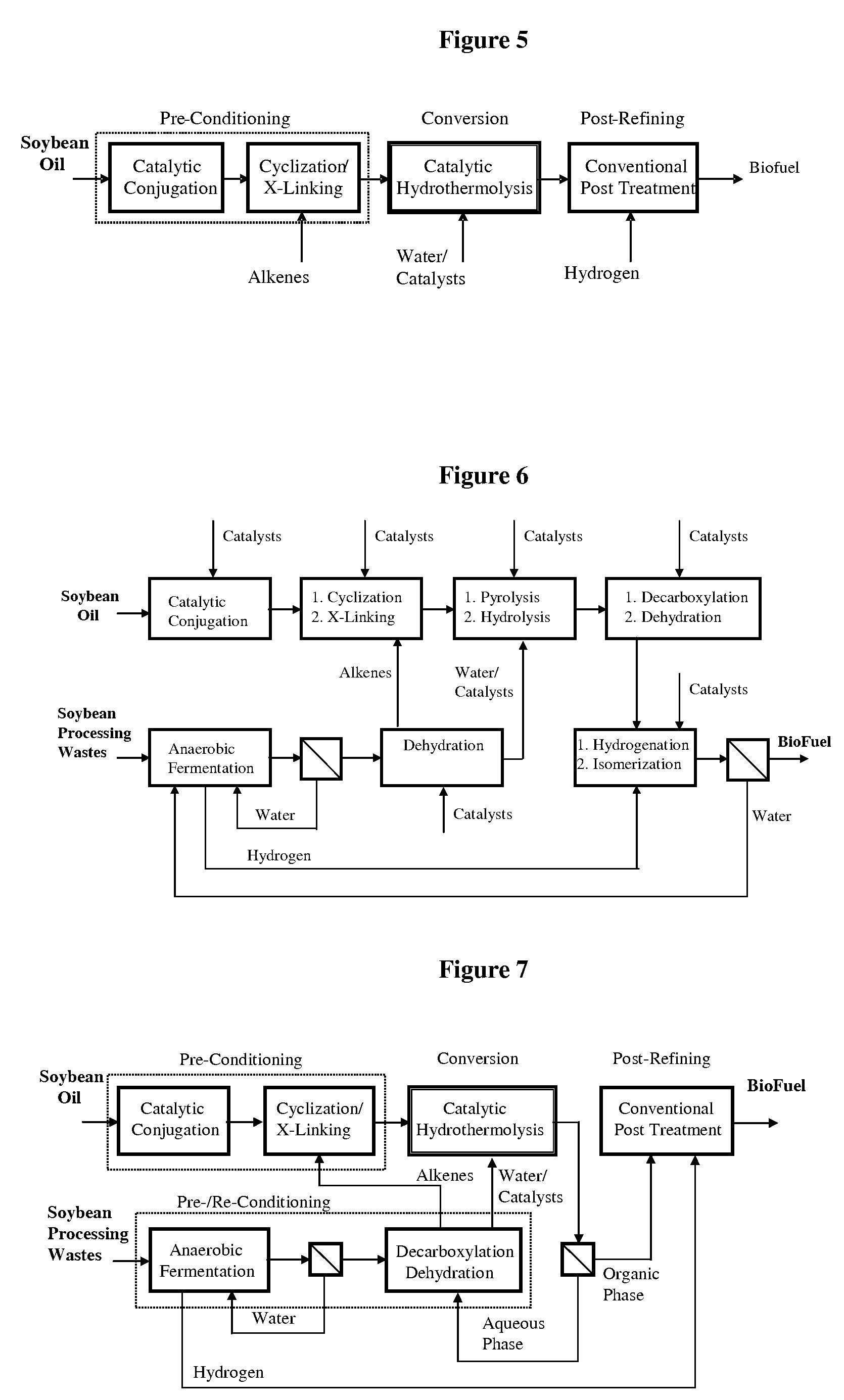

ActiveUS20080229654A1Maximize product yieldYield maximizationFatty acid isomerisationFatty acid oxidationIsomerizationVegetable oil

Compositions and methods for forming hydrocarbon products from triglycerides are disclosed. In one aspect, the methods involve the thermal decomposition of fatty acids, which can be derived from the hydrolysis of triglycerides. The thermal decomposition products can be combined with low molecular weight olefins, such as Fischer-Tropsch synthesis products, and subjected to molecular averaging reactions. Alternatively, the products can be subjected to hydrocracking reactions, isomerization reactions, and the like. The products can be isolated in the gasoline, jet and / or diesel fuel ranges. Thus, vegetable oils and / or animal fats can be converted using water, catalysts, and heat, into conventional products in the gasoline, jet and / or diesel fuel ranges. These products are virtually indistinguishable from those derived from their petroleum-based analogs, except that they can have virtually no aromatic, sulfur or nitrogen content, they are derived, in whole or in part, from renewable resources, and can also be derived from domestically available coal and / or natural gas.

Owner:BRADIN DAVID

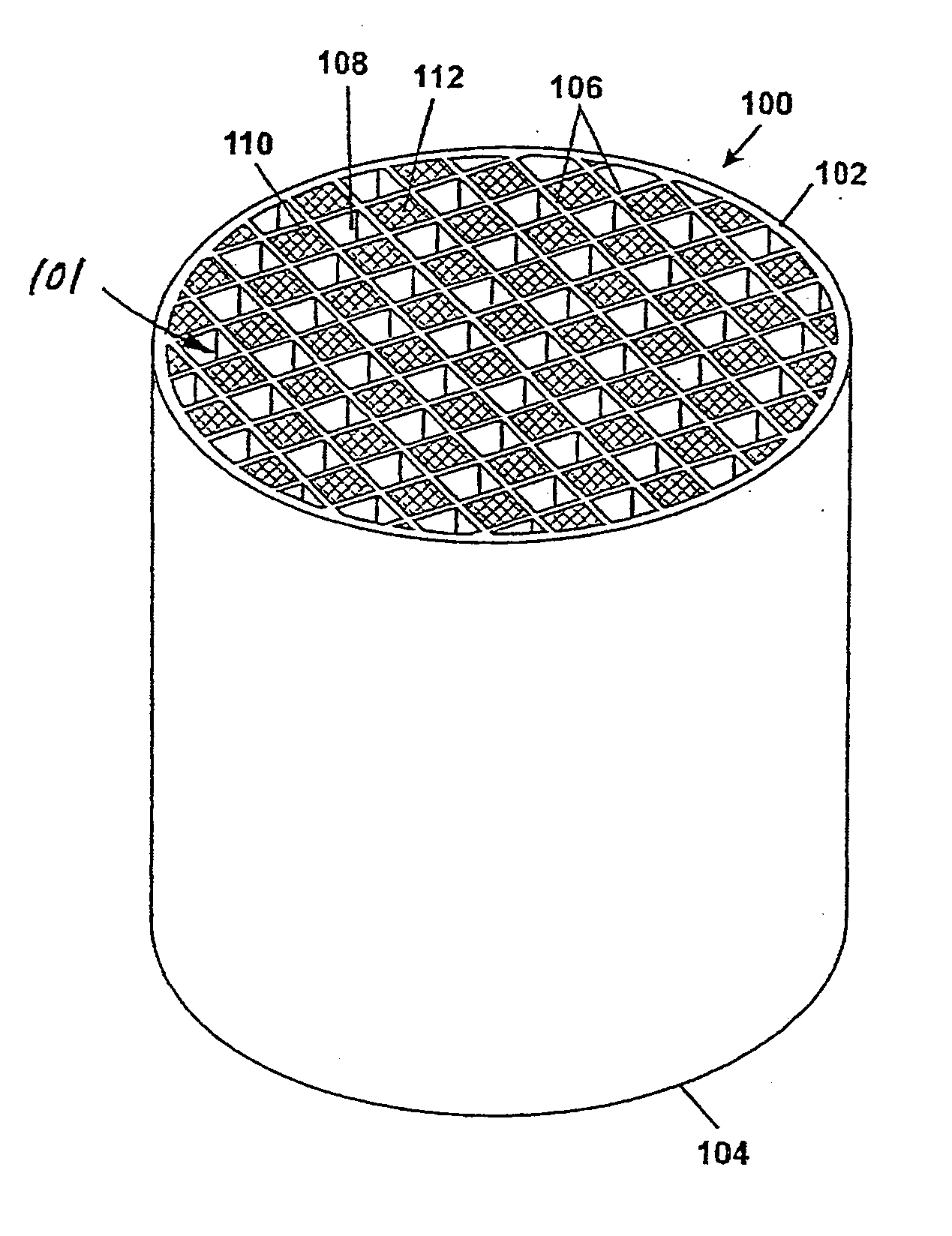

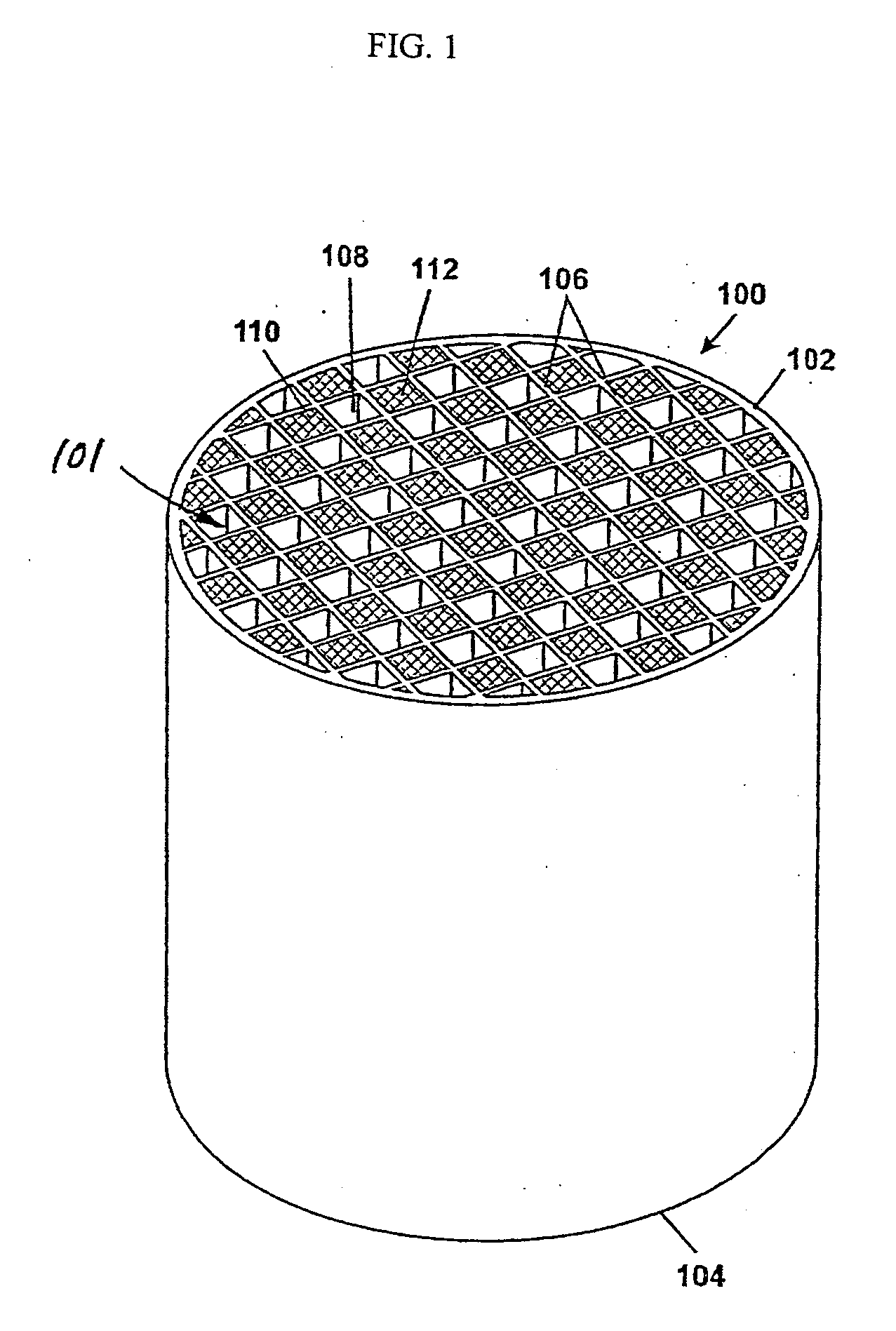

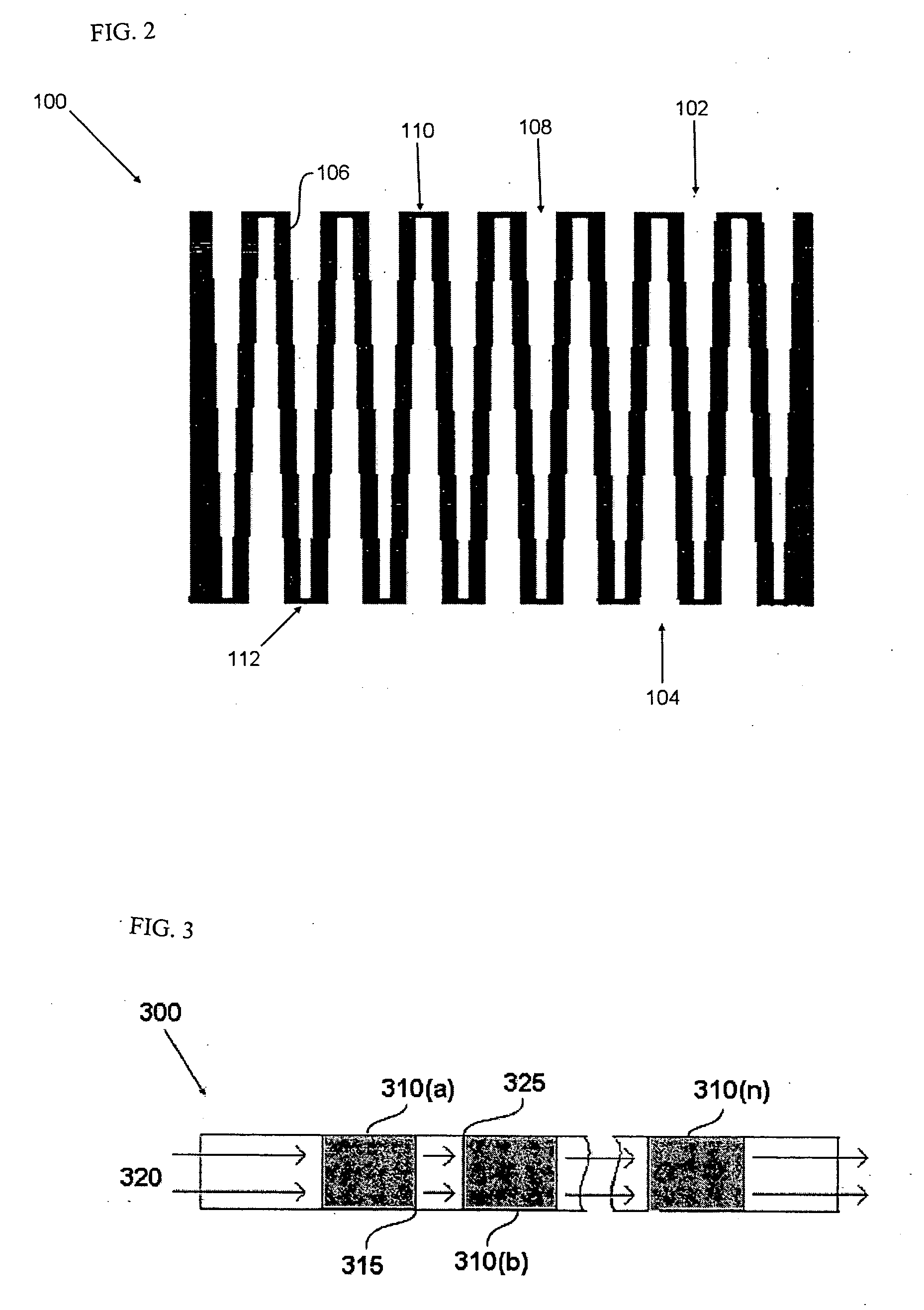

Activated carbon honeycomb catalyst beds and methods for the use thereof

InactiveUS20070261557A1Simple designLow costGas treatmentCarbon compoundsActivated carbonCombustion system

Disclosed herein, without limitation, are activated carbon honeycomb catalyst beds and systems for removing mercury and other toxic metals from a process stream, i.e, from flue gas of a coal combustion system. The activated carbon honeycomb can for example remove greater than 90% mercury from flue gas with a simple design and without adding material to the flue gas. Also disclosed herein, and without limitation, are methods for manufacturing and using the disclosed honeycomb catalyst beds and systems.

Owner:CORNING INC

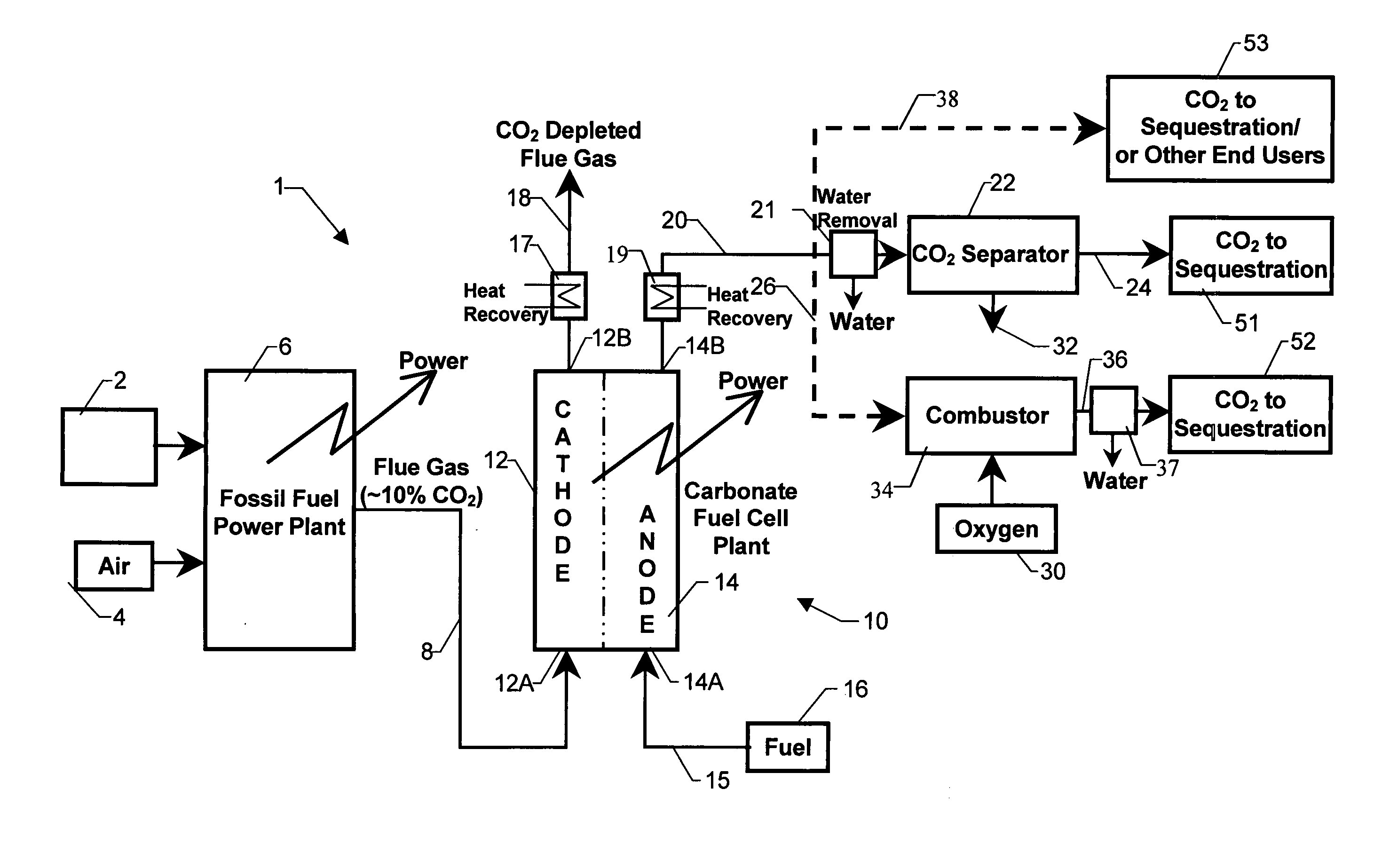

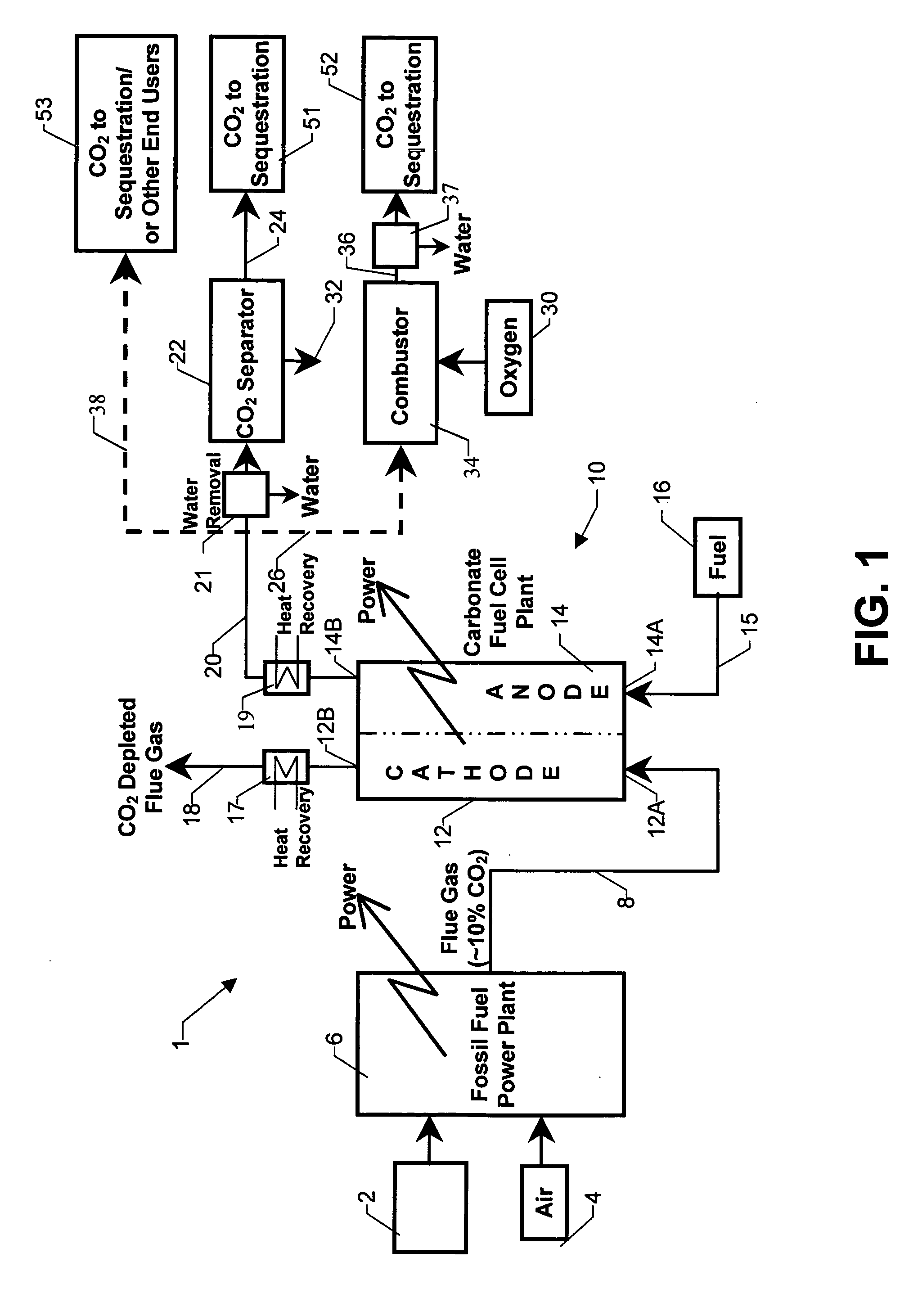

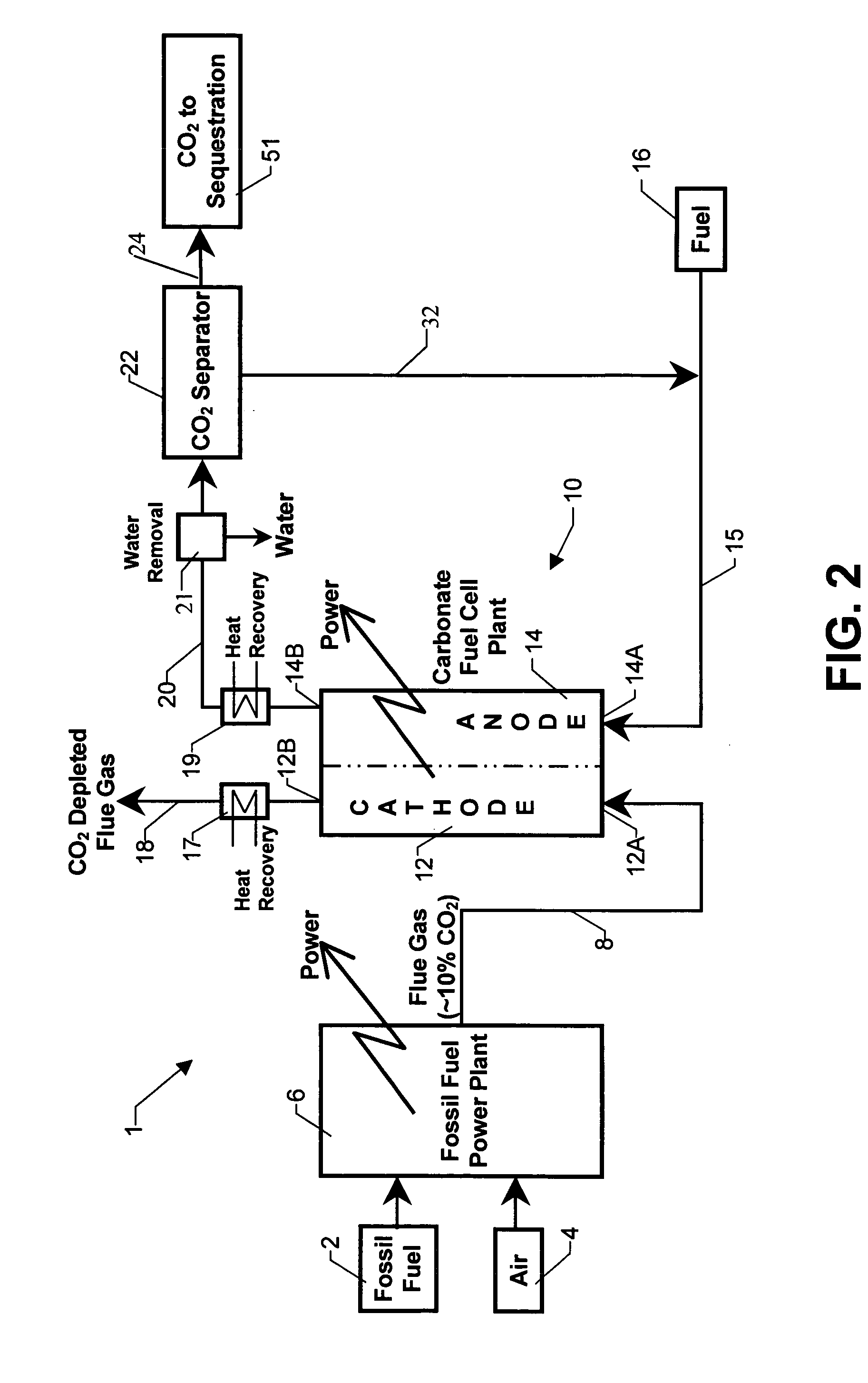

Integrated high efficiency fossil fuel power plant/fuel cell system with CO2 emissions abatement

An integrated power production system including a fossil fuel power plant for processing fossil based fuel such as coal or natural gas arranged in tandem with a carbonate fuel cell having an anode and a cathode section. The flue gas of the power plant serves exclusively as the inlet gas for the cathode section of the fuel cell. Anode exhaust gas leaving the anode section of the fuel cell is subjected to processing including sequestration of the carbon dioxide in the exhaust gas.

Owner:FUELCELL ENERGY INC

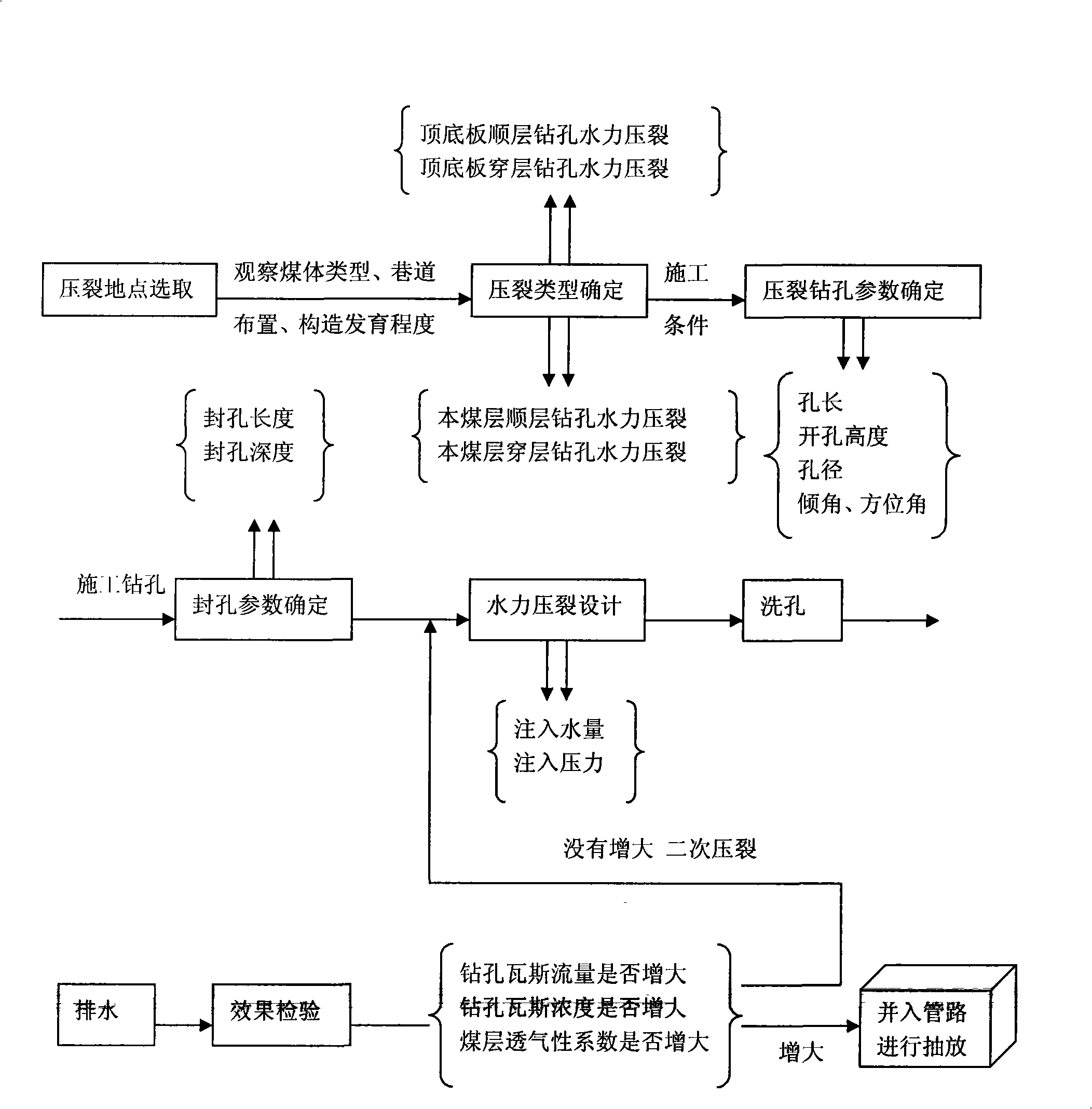

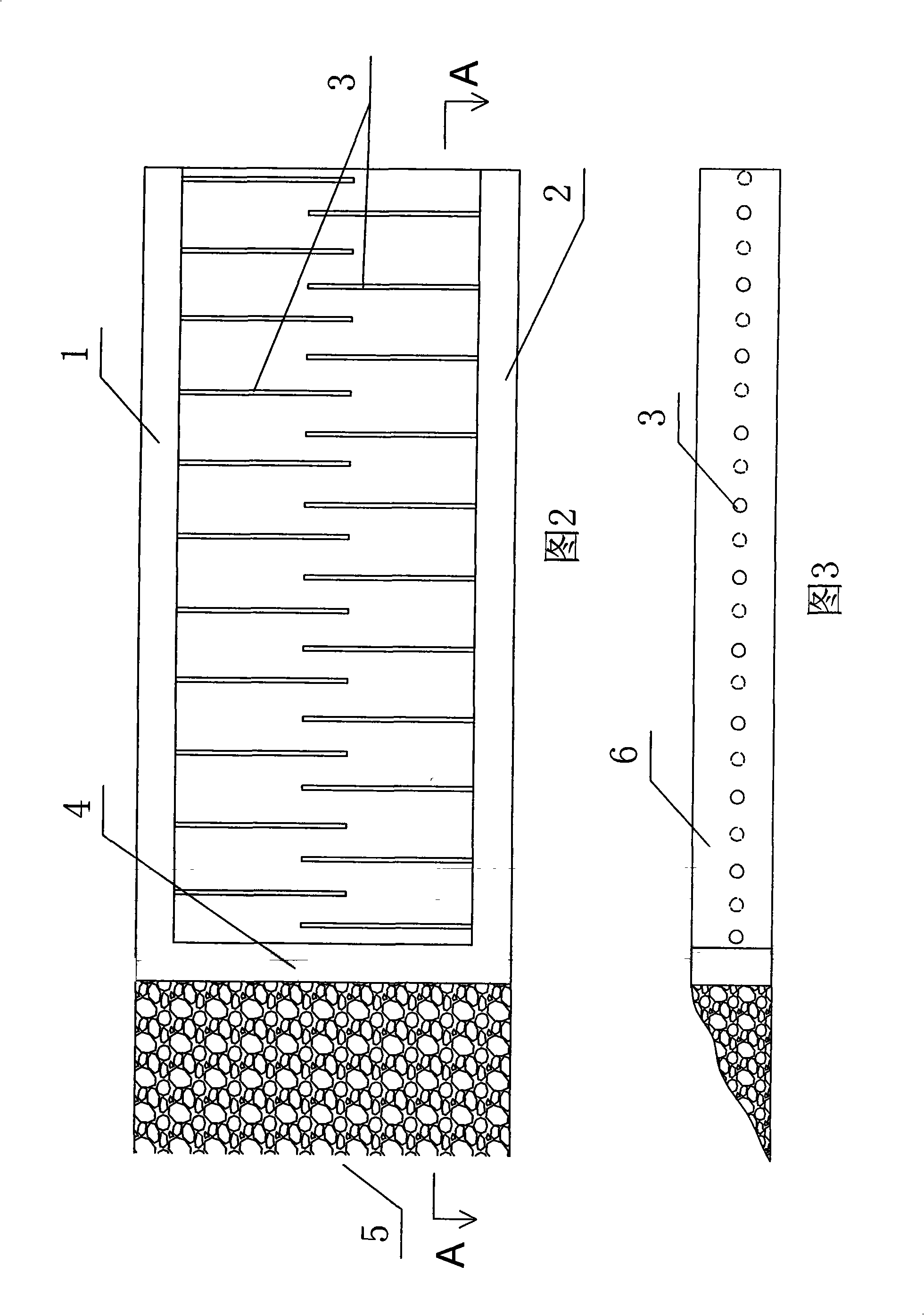

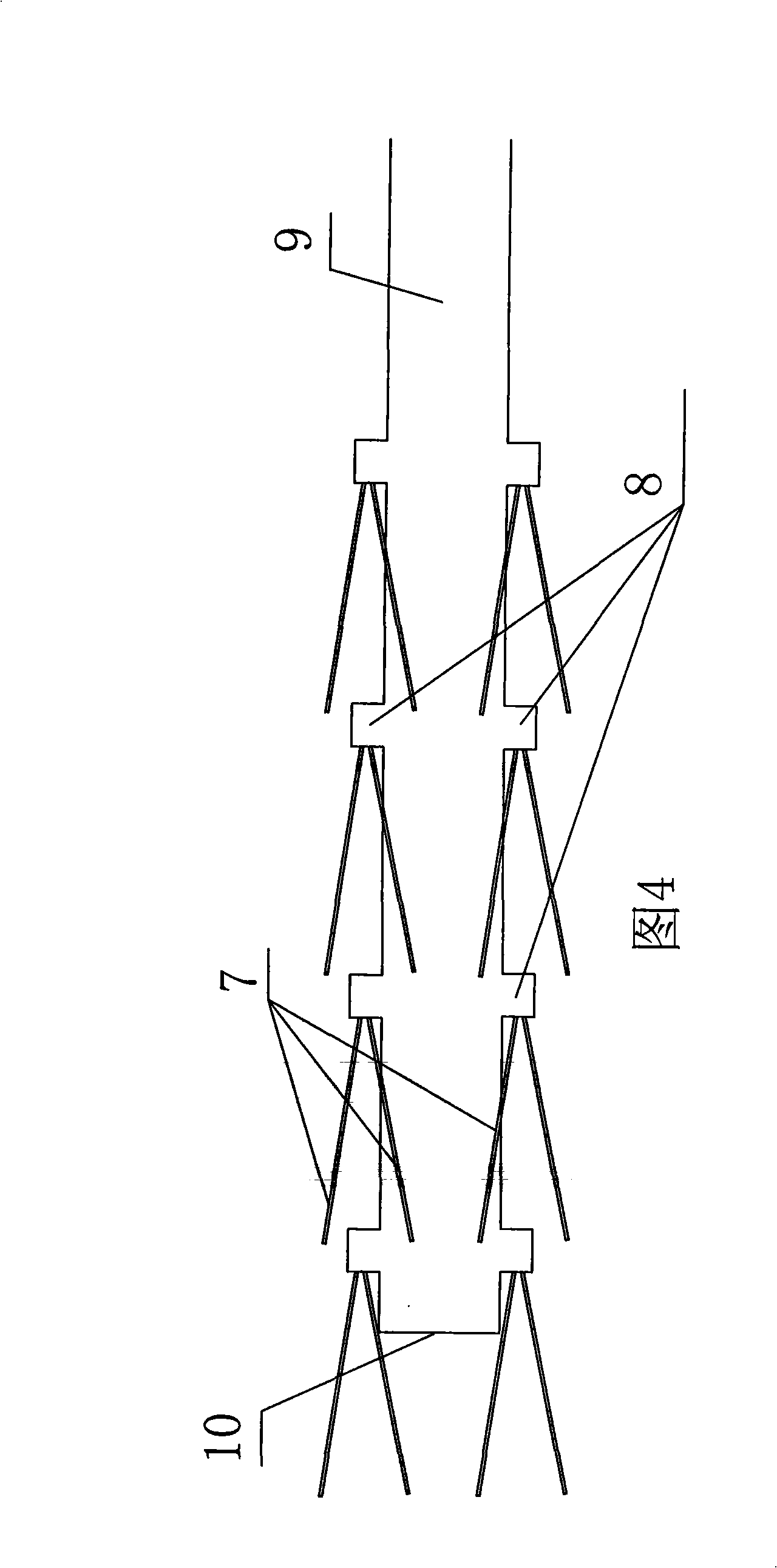

Coal mine down-hole drilling hydraulic fracturing anti-reflection mash gas extraction technique

ActiveCN101403314ALess gushEliminate disastersFluid removalGas removalDischarge efficiencyInjection pressure

The invention relates to a hydraulic fracturing anti-reflection technology for pumping and exploring gas by drilling a hole in a coal mine well, comprising the following steps sequentially: (1) selecting a fracturing location; (2) determining the pressure type according to observed coal type, laneway arrangement and construction development degree, and ways of top soleplate bedding plane borehole hydraulic fracturing, top soleplate translamellar borehole hydraulic fracturing, the coal bed bedding plane borehole hydraulic fracturing or the coal bed translamellar borehole hydraulic fracturing can be adopted; (3) determining borehole parameters for constructing drilling, wherein, the borehole parameters include borehole length, borehole height, aperture, obliquity angle and azimuth angle; (4) designing the hydraulic fracturing, including injected water volume and injection pressure; (5) borehole washing; (6) draining; (7) examining the fracturing effect, if the fracturing effect is in accordance with the requirement, the following step is carried out, if not, turning to step (4); and (8) entering a pipeline for pumping and discharging. The technology enhances the air permeability of the coal bed, reduces the gas emission rate of an excavation working face, and obviously promotes the pumping and exploring capability and the pumping and exploring effect of the single borehole. The pumping and discharging efficiency is improved, the pumping and discharging time is shortened and the damage of the gas is maximally eliminated.

Owner:HENAN POLYTECHNIC UNIV

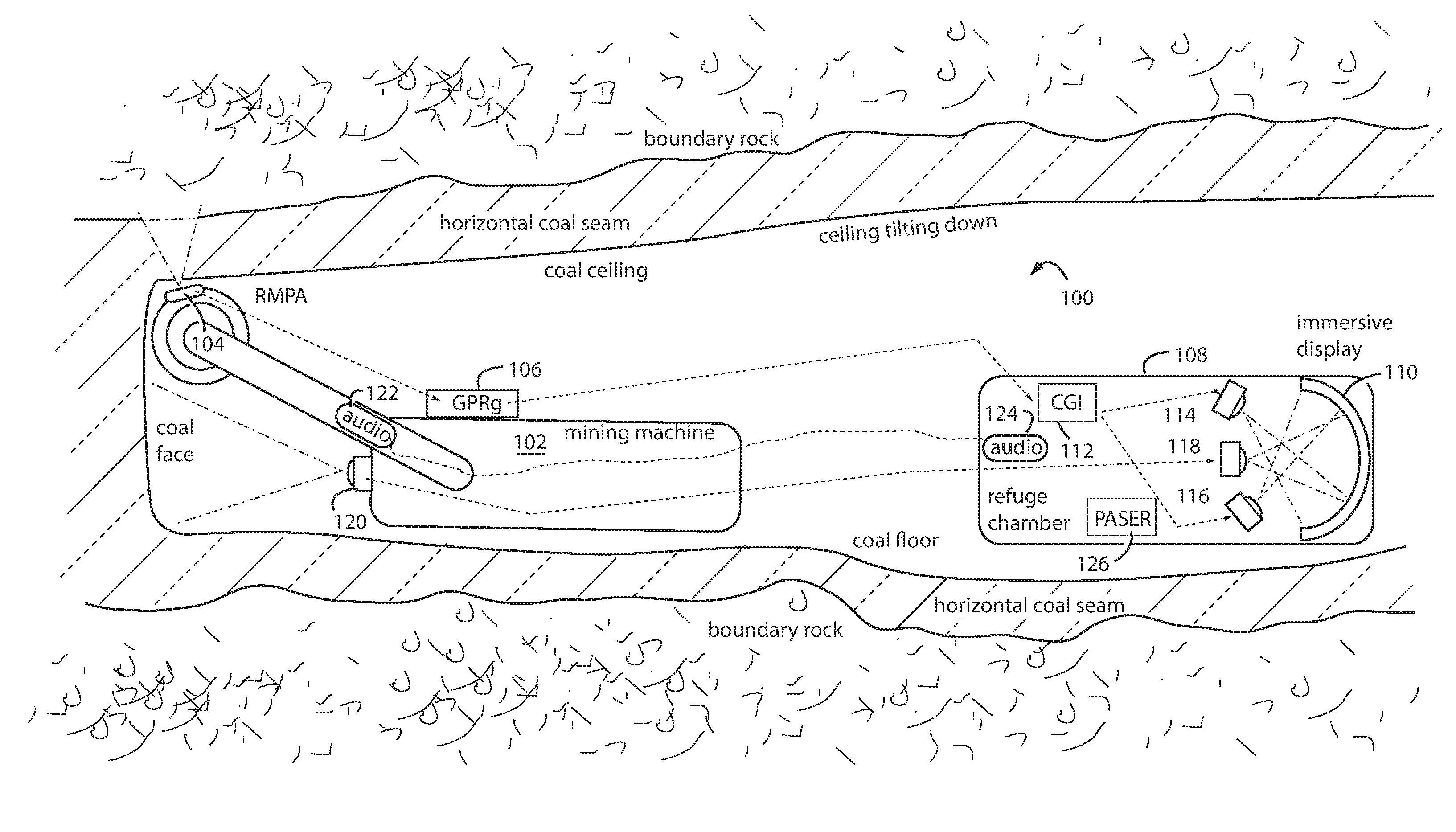

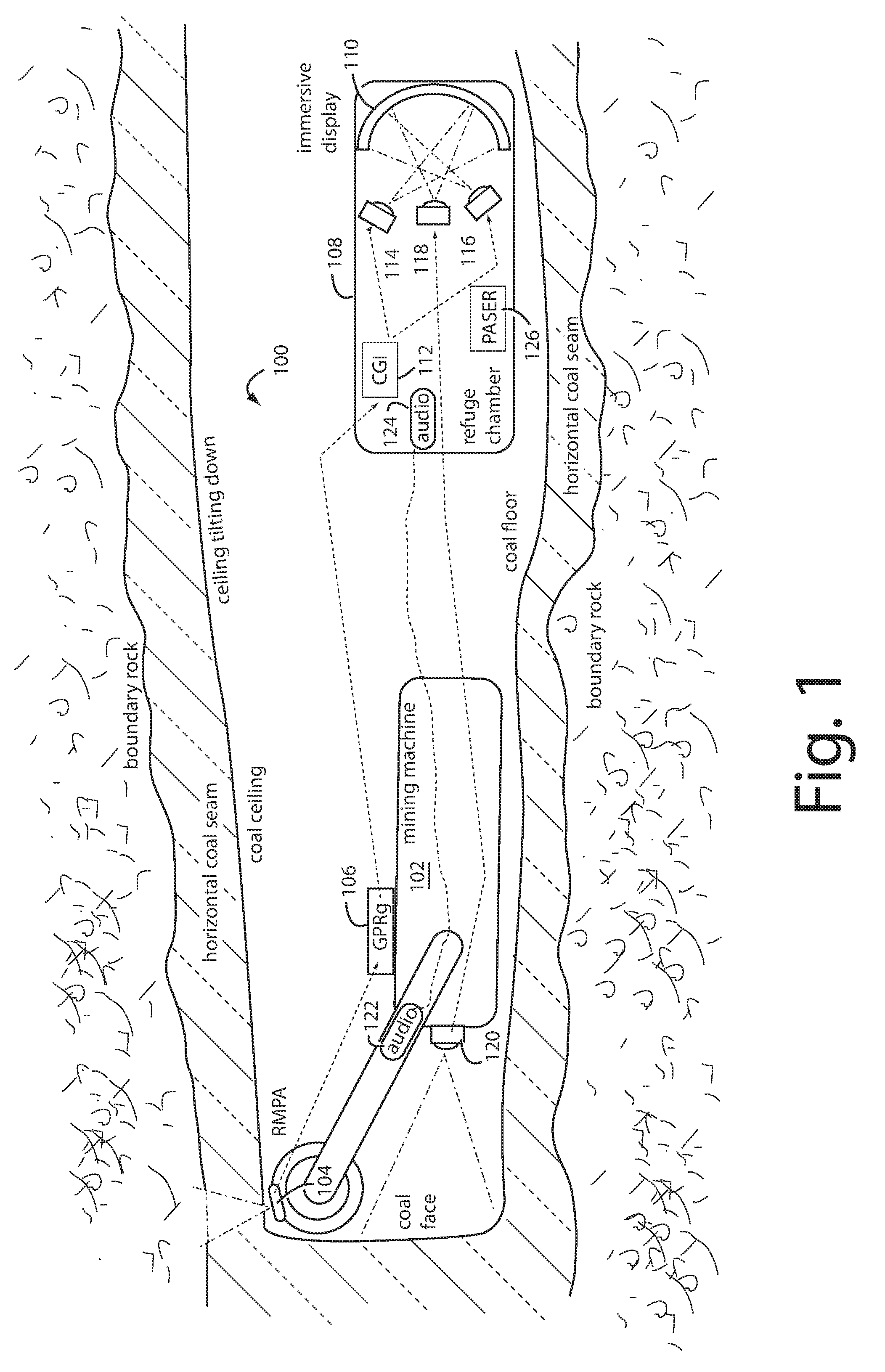

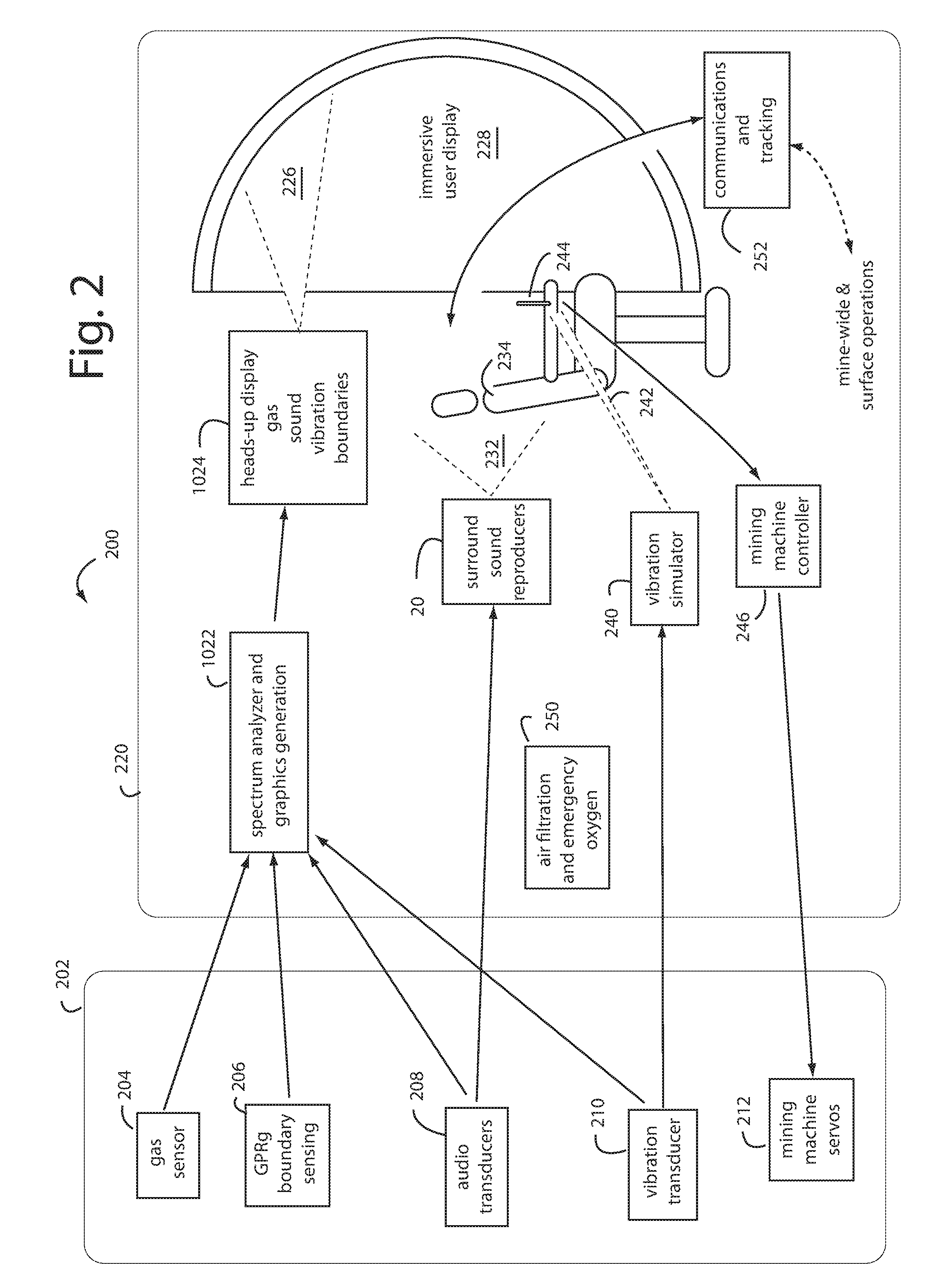

Method of protecting the health and well-being of coal mine machine operators

A method of operating coal mine machinery that protects and maintains machine operators' health and well-being removes the machine operators to a clean, low-noise environment inside a refuge chamber. Inside, are controls, cameras, audio, and informational displays needed to run continuous mining machines nearby and communicate mine-wide with other personnel. Cameras fitted to the mining machines provide straight-ahead views, ground penetrating radars fitted to the cutting drums measure the coal depths in the ceilings above, the floors below, and the coal face ahead. Guidance data is presented on informational displays, and the data from the ceilings and floors is used to drive computer graphics special effects to graphically represent the coal ceilings and coal floors overlaying boundary rock. Audio pickups on the mining machine allow the operator to hear and feel how the machine is functioning, just as operators have always employed their other senses.

Owner:STOLARCZYK LARRY G

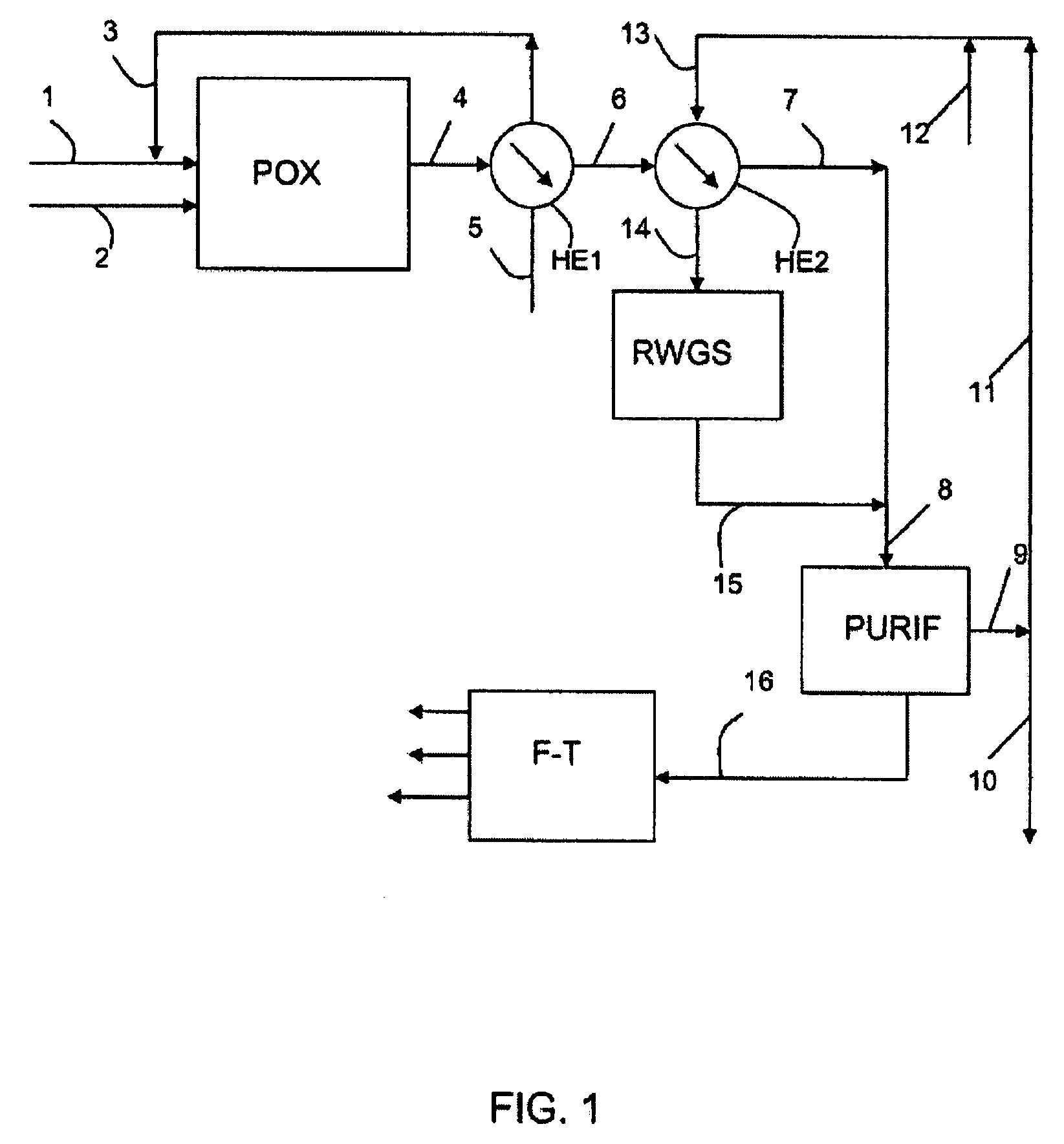

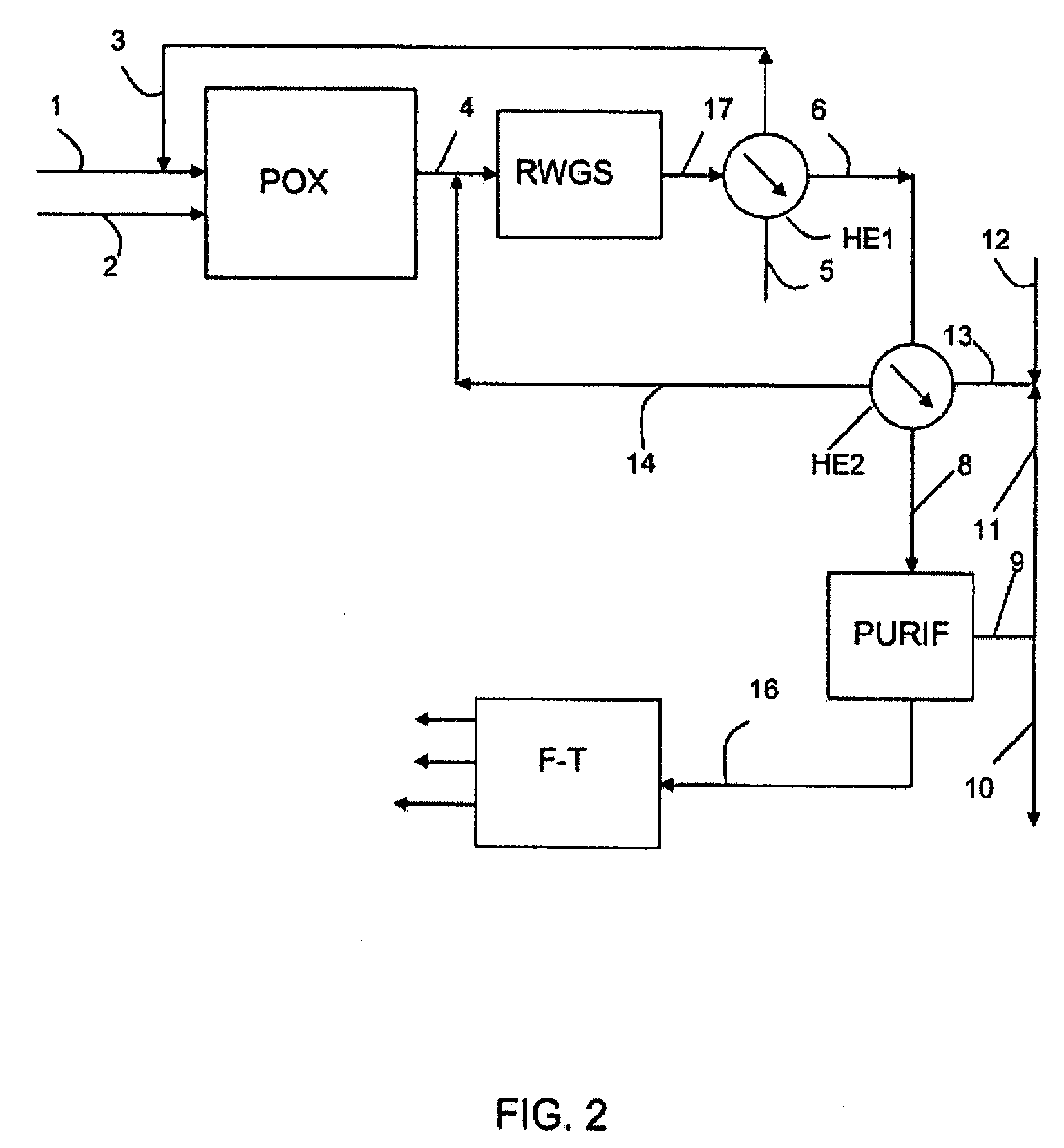

Process for the production of synthesis gas with conversion of CO2 into hydrogen

ActiveUS7846979B2Useful thermal recovery on the gasification effluentCombustible gas chemical modificationProductsSteam reformingPartial oxidation

Process for the production of liquid hydrocarbons from a feedstock that comprises at least one elementary feedstock from the group of biomass, coal, lignite, petroleum residues, methane, and natural gas, comprising: at least one stage a) for gasification of the feedstock by partial oxidation and / or steam reforming to produce a synthesis gas SG; a stage b) for separating CO2 from SG and a portion of the effluent of the subsequent stage c); the mixing of a portion of the CO2 that is separated with a gas of an H2 / CO ratio of more than 3; a stage c) for partial conversion with hydrogen, thermal or thermocatalytic, of the CO2 that is present in said first mixture according to the reaction: CO2+H2→CO+H2O in a specific reaction zone that is separated from said gasification zone or zones; a stage d) for Fisher-Tropsch synthesis on a synthesis gas that comprises at least a portion of SG and at least a portion of the CO that is produced by the conversion of CO2 into hydrogen.

Owner:INST FR DU PETROLE

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

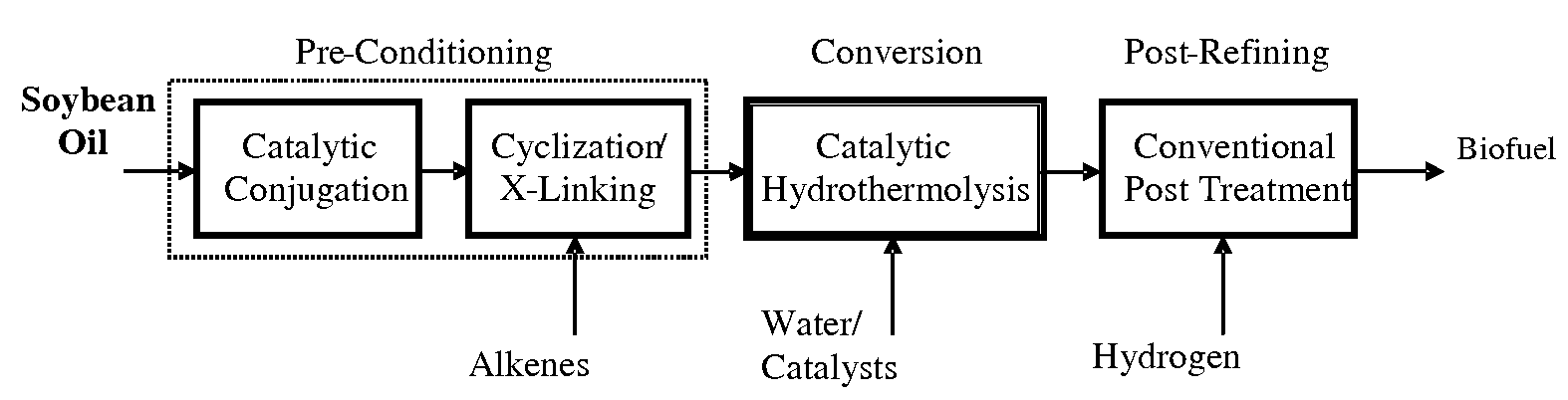

Method of converting triglycerides to biofuels

ActiveUS7691159B2Improve chemical and physical and combustion qualityImprove thermal stabilityFatty acid chemical modificationOrganic compound preparationCross-linkIsomerization

A triglyceride-to-fuel conversion process including the steps of (a) preconditioning unsaturated triglycerides by catalytic conjugation, cyclization, and cross-link steps; (b) contacting the modified triglycerides with hot-compressed water containing a catalyst, wherein cracking, hydrolysis, decarboxylation, dehydration, aromatization, or isomerization, or any combination thereof, of the modified triglycerides produce a crude hydrocarbon oil and an aqueous phase containing glycerol and lower molecular weight molecules, and (c) refining the crude hydrocarbon oil to produce various grades of biofuels. A triglyceride-to-fuel conversion process further including the steps of (a) carrying out anaerobic fermentation and decarboxylation / dehydration, wherein the anaerobic fermentation produces hydrogen, volatile acids, and alcohols from fermentable feedstocks, and the decarboxylation / dehydration produces alkenes from the volatile acids and alcohols, respectively; (b) feeding the alkenes to the cyclization process; (c) feeding the hydrogen to the post refining process; and (d) recycling the aqueous phase containing glycerol to the decarboxylation / dehydration process. A biofuel composition including straight-chain, branched and cyclo paraffins, and aromatics. The paraffins are derived from conversion of triglycerides. The aromatics are derived from conversion of either triglycerides, petroleum, or coal.

Owner:APPLIED RES ASSOCS INC

Method and apparatus for making metallic iron

InactiveUS6036744AHigh purityReadily and efficiently madeBlast furnace componentsRotary drum furnacesMolten slagCoal

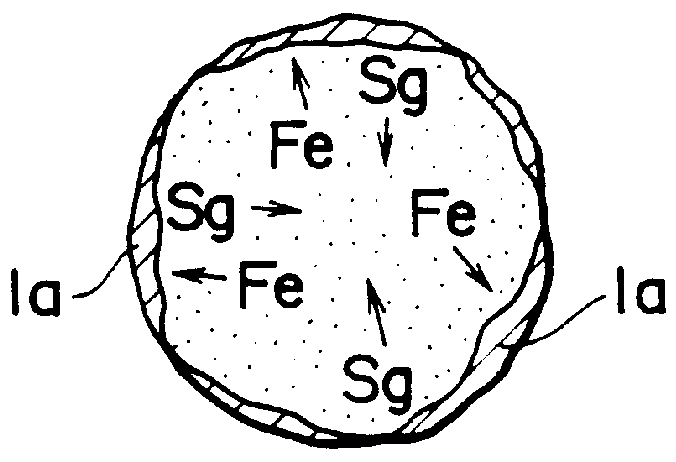

A method of making metallic iron in which a compact, containing iron oxide such as iron ore or the like and a carbonaceous reductant such as coal or the like, is used as material, and the iron oxide is reduced through the application of heat, thereby making metallic iron. In the course of this reduction, a shell composed of metallic iron is generated and grown on the surface of the compact, and slag aggregates inside the shell. This reduction continues until substantially no iron oxide is present within the metallic iron shell. Subsequently, heating is further performed to melt the metallic iron and slag. Molten metallic iron and molten slag are separated one from the other, thereby obtaining metallic iron with a relatively high metallization ratio. Through the employment of an apparatus for making metallic iron of the present invention, the above-described method is efficiently carried out, and metallic iron having a high iron purity can be made continuously as well as productively not only from iron oxide having a high iron content but also from iron oxide having a relatively low iron content.

Owner:KOBE STEEL LTD

Gas turbine system comprising closed system of fuel and combustion gas using underground coal layer

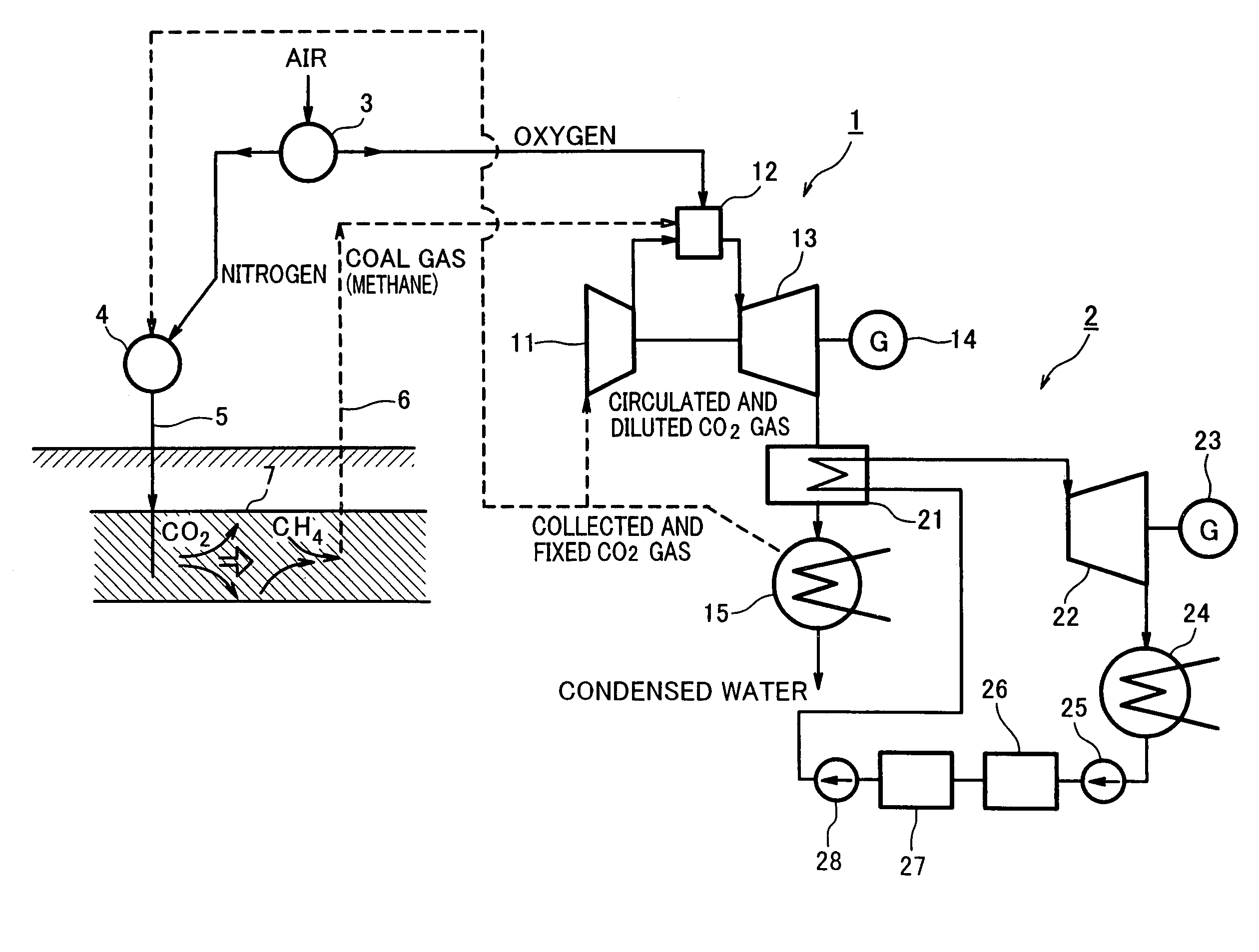

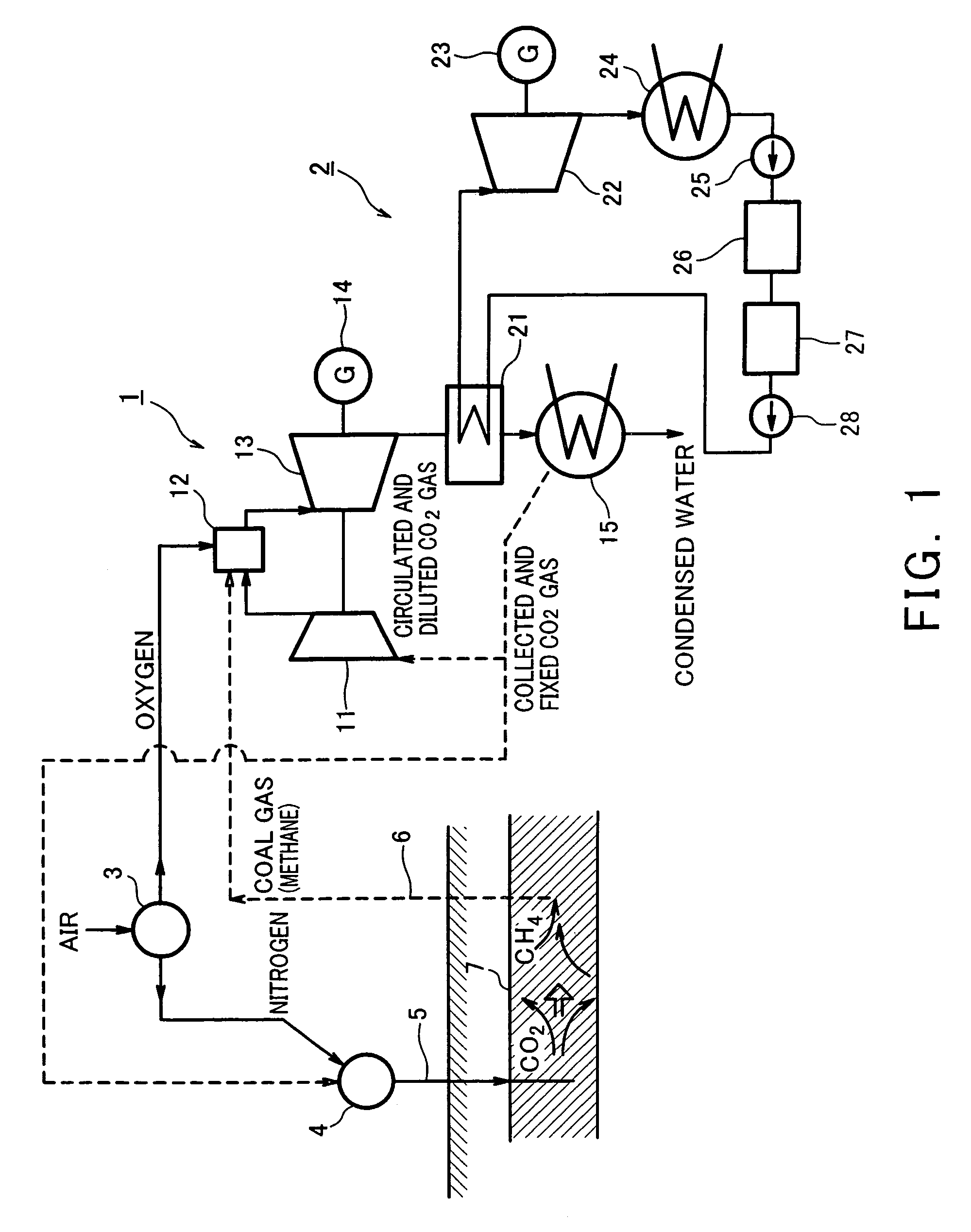

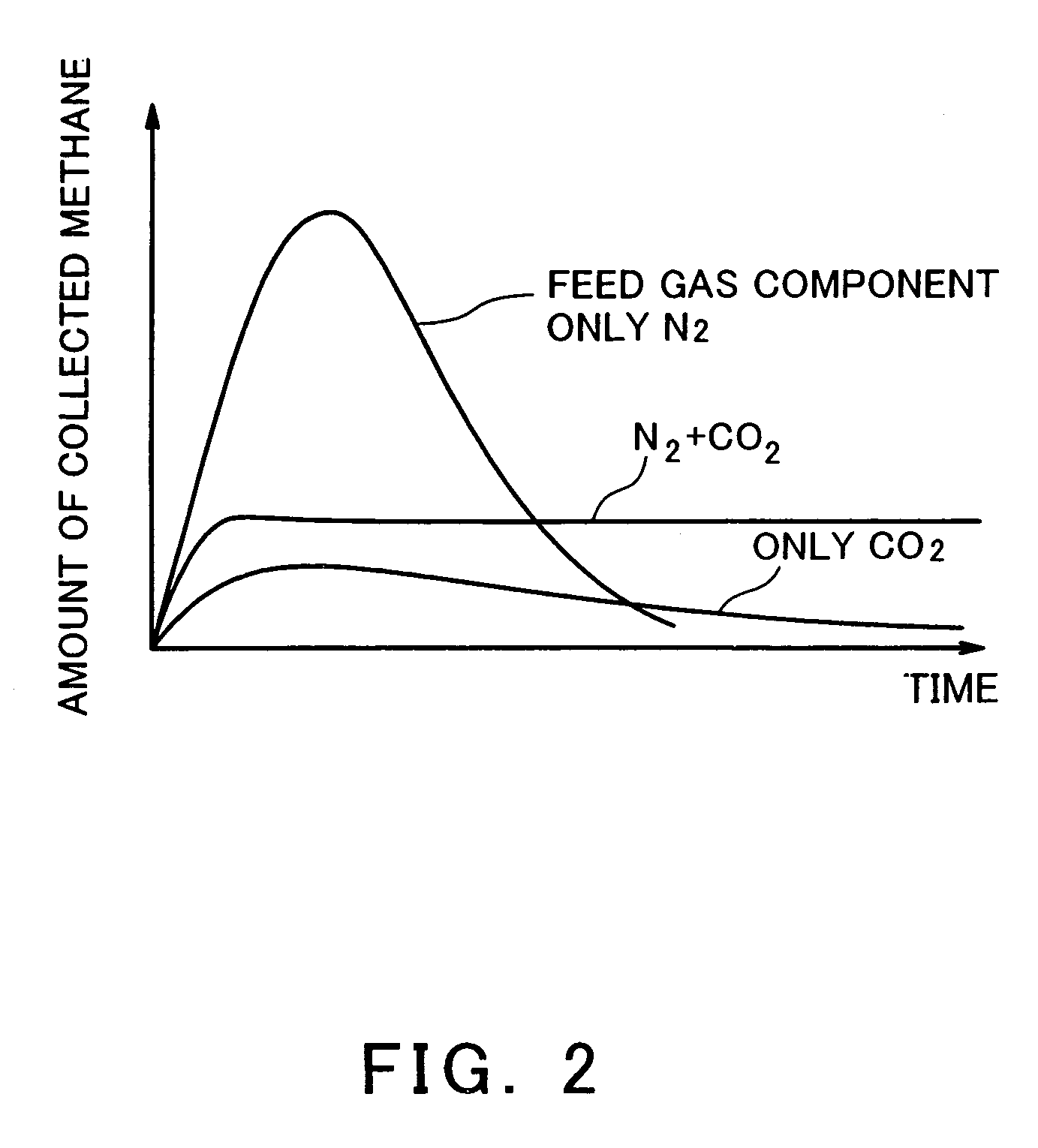

InactiveUS7143572B2Inhibition releaseTurbine/propulsion fuel supply systemsWorking fluid for enginesCombustionProduct gas

A gas turbine system is configured to inhibit release of carbon dioxide to the atmosphere in such a manner that methane is combusted with oxygen that has been separated from air by an oxygen generator to allow an oxygen combustion type gas turbine to be driven. Carbon dioxide emitted from the turbine is fed under pressure into an underground coal bed along with an air component after separating the oxygen from the air and fixed into the coal bed, and the coal bed methane is collected above the ground by a gas drive action of the gas and supplied to the gas turbine as fuel.

Owner:KAWASAKI HEAVY IND LTD +1

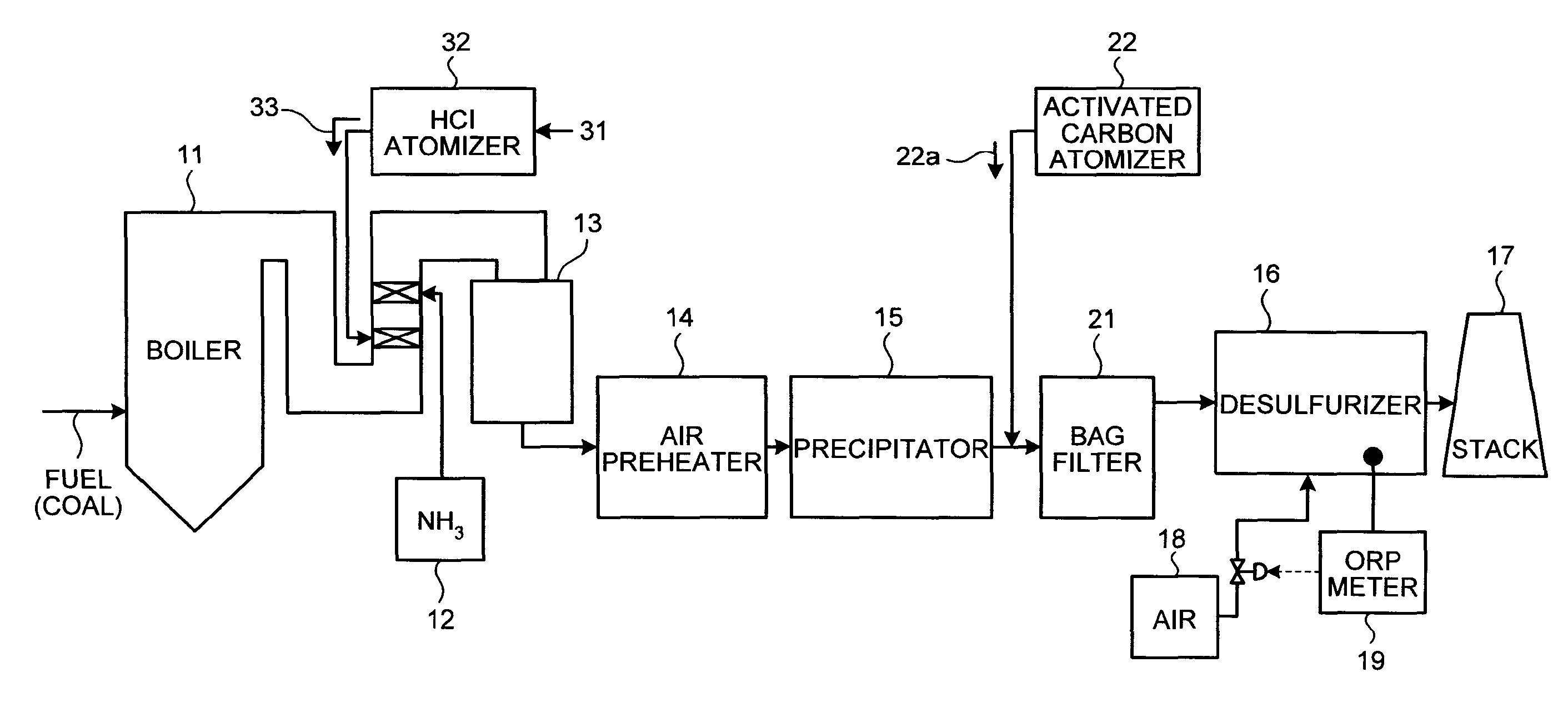

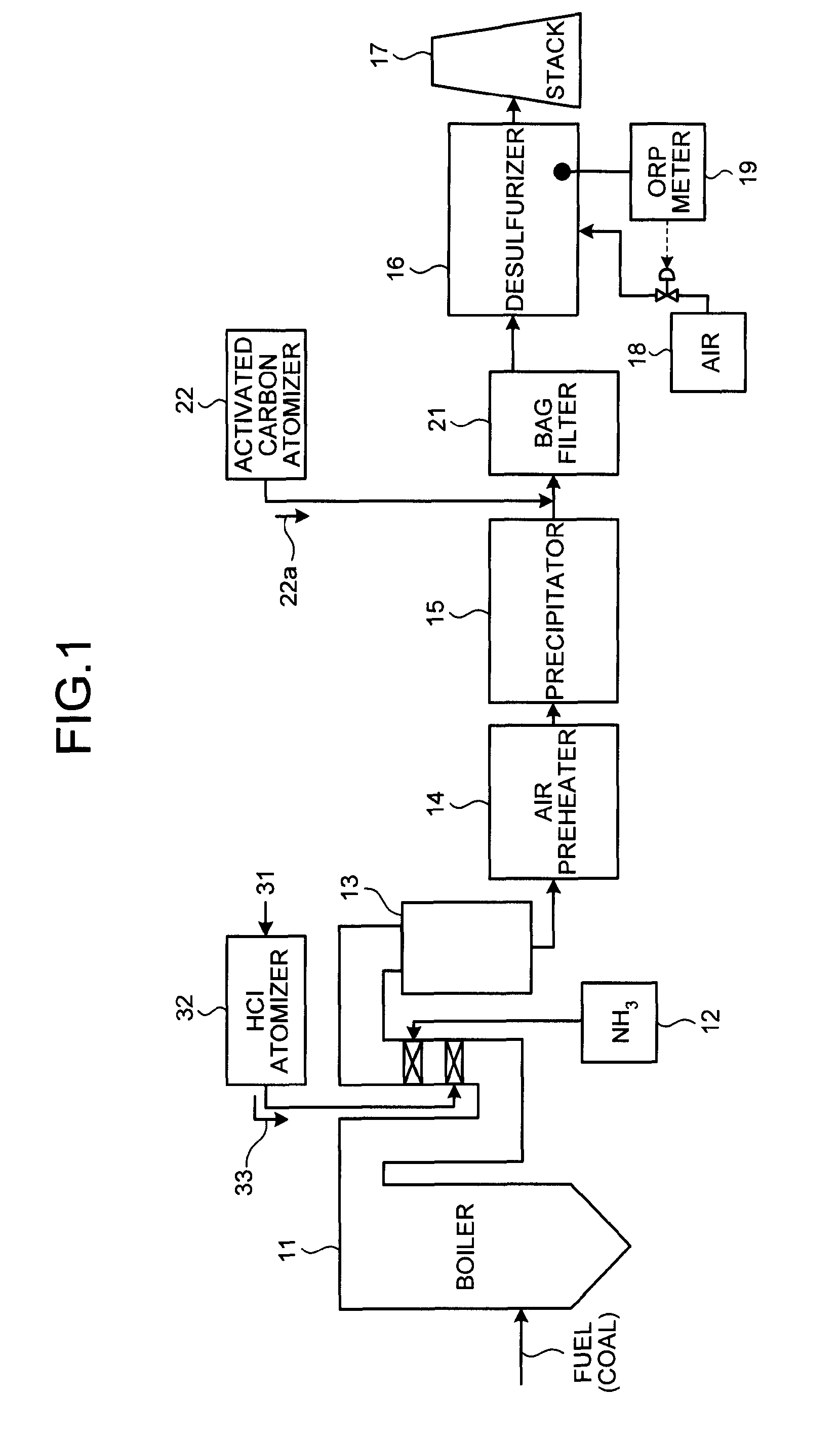

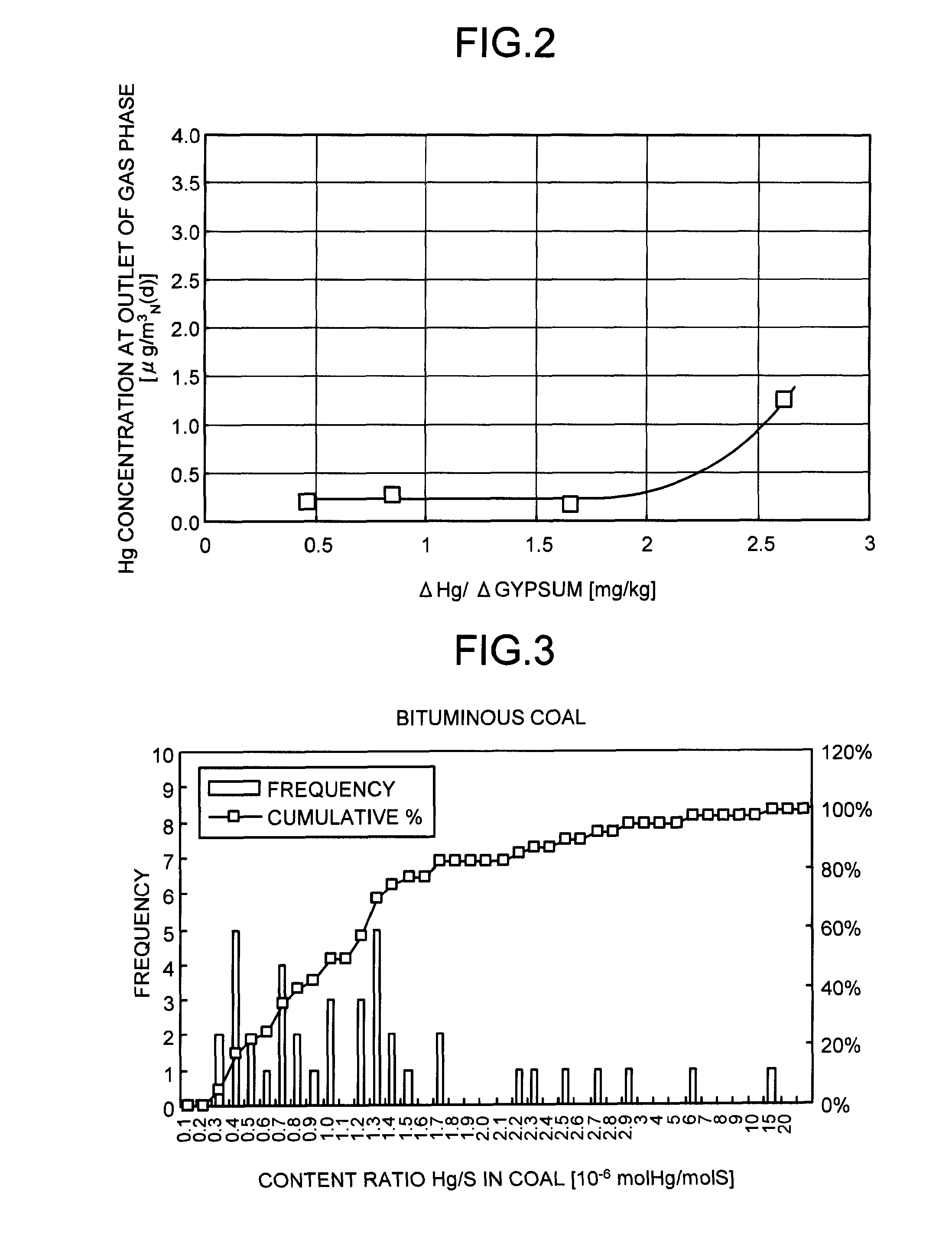

Flue gas control system of coal combustion boiler and operating method thereof

ActiveUS8071060B2Reduce operating costsCombination devicesNitrogen compoundsAir preheaterParticulates

A flue gas control system of a coal combustion boiler comprises an HCl atomizer that sprays hydrogen chloride to flue gas from a coal combustion boiler that uses coal as a fuel; NOx removing apparatus that removes nitrogen oxides by ammonia denitration by adding ammonia to the flue gas after spraying hydrogen chloride and oxidizes mercury; an air preheater that recovers heat in the gas after removal of nitrogen oxides; a precipitator that removes particulates in the gas; an activated carbon atomizer that sprays activated carbon into the gas after particulate collection; a bag filter that collects activated carbon having adsorbed mercury; a desulfurizer that removes sulfur oxides in the flue gas after removal of activated carbon; a stack that discharges the gas which has undergone desulfurization to outside; and an ORP meter that measures an oxidation reduction potential for feeding air to a slurry absorbent in the desulfurizer.

Owner:MITSUBISHI HEAVY IND LTD

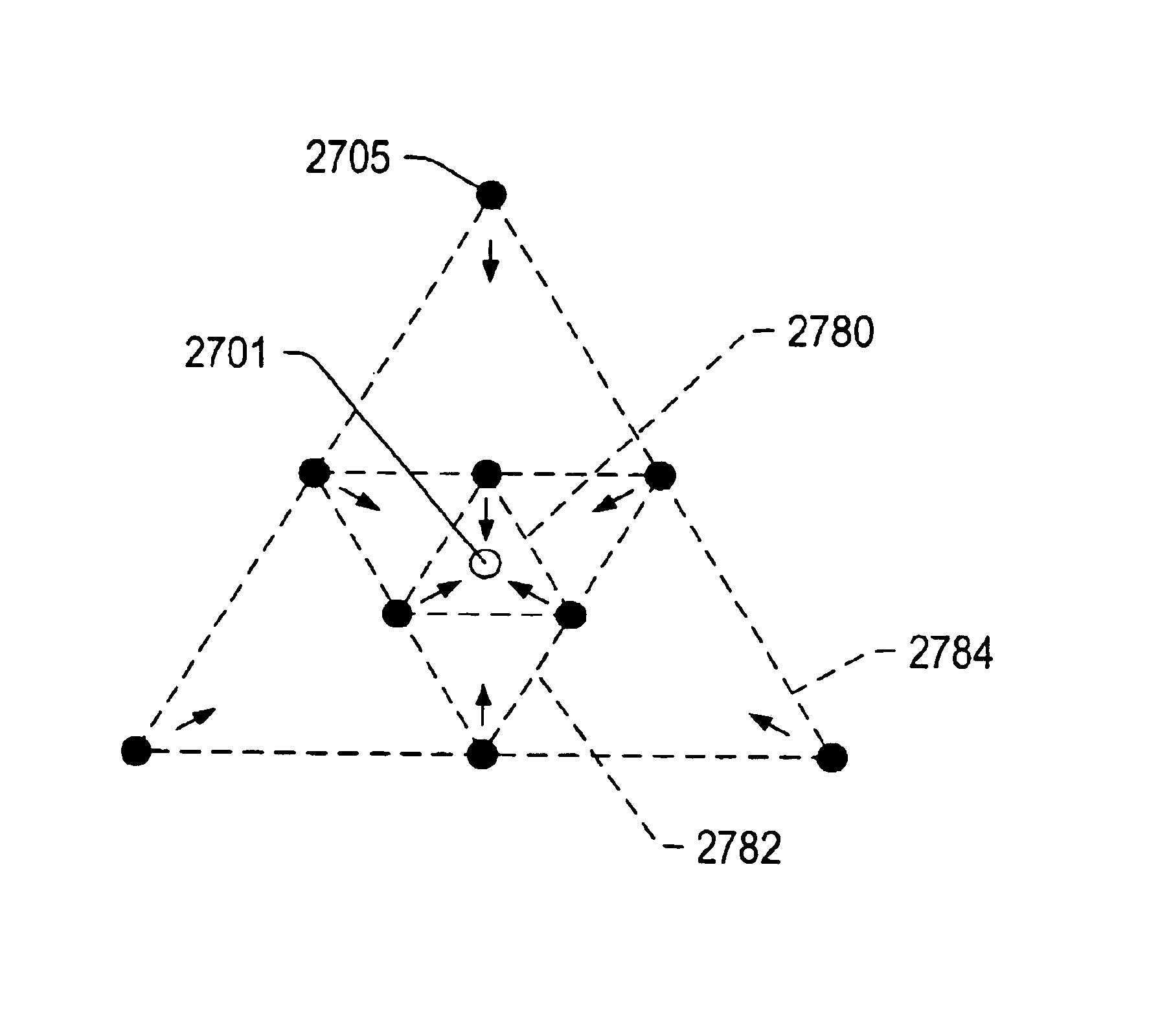

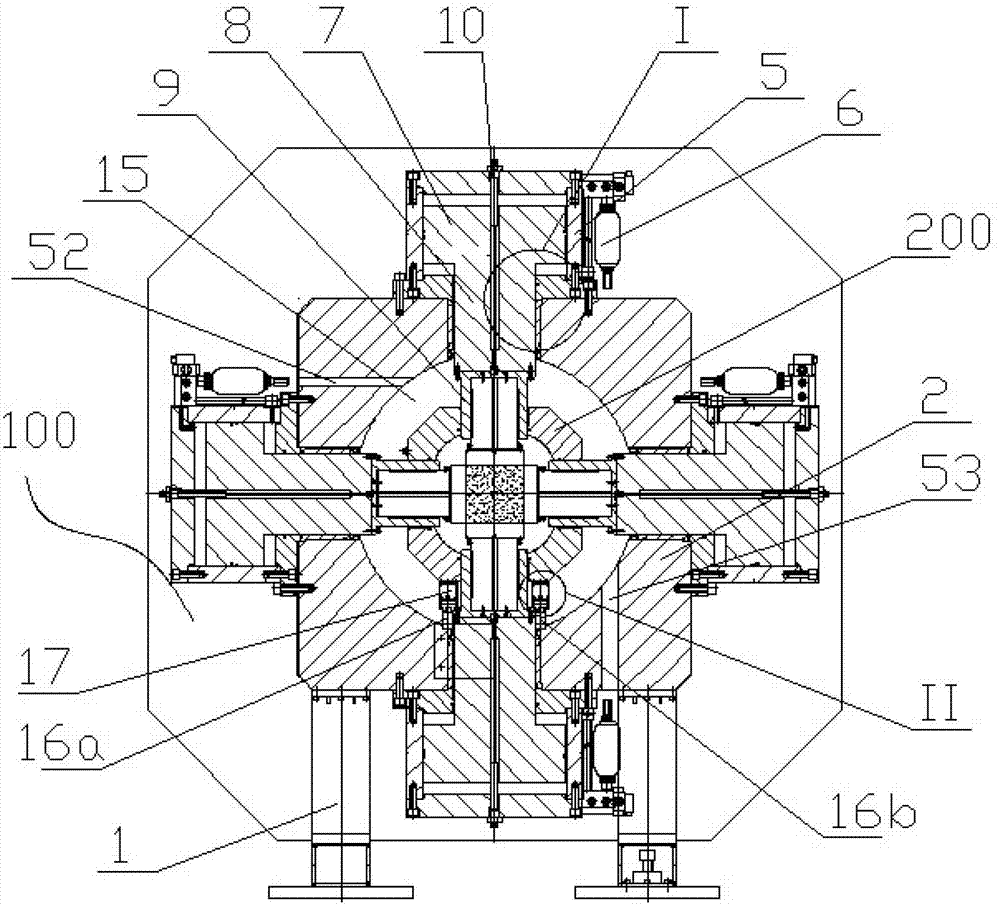

Coal-rock hydraulic fracturing testing method under true triaxial state

ActiveCN102735547AReveal deformationRevealing intensityMaterial strength using tensile/compressive forcesPermeability/surface area analysisFracture testingHydraulic fracturing

The invention discloses a coal-rock hydraulic fracturing testing method under a true triaxial state. The coal-rock hydraulic fracturing testing method under the true triaxial state comprises the following steps: 1) preparing a test piece; 2) installing the test piece; 3) pre-loading; 4) loading; 5) hydraulically fracturing; 6) unloading; 7) storing all data recorded by a data collection system, taking out the test piece and observing the shape of the test piece. According to the coal-rock hydraulic fracturing testing method, the real work condition can be more really simulated, and a theoretical basis is provided for solving on-site problems.

Owner:CHONGQING UNIV

System and method for atmospheric carbon sequestration

ActiveUS20100257775A1Increase carbon emissionsLiquid surface applicatorsSolid waste disposalCarbon sequestrationCoal

This invention relates to systems and methods for converting biomass into highly inert carbon. Specifically, some embodiments densify the carbon into anthracite-style carbon aggregations and store it in geologically stable underground deposits. The use of certain embodiments yield a net effect of removing atmospheric carbon via the process of photosynthesis and converting it into hard coal, which can be stored in underground beds that mimic existing coal deposits which are known to be stable for thousands of years.

Owner:COOL PLANET ENERGY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com