Patents

Literature

67results about How to "Improve distillation yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

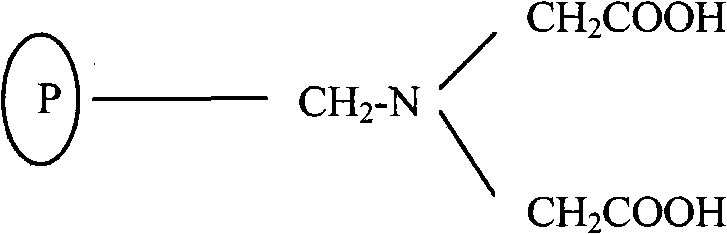

Novel chelate resin and production method and application thereof

ActiveCN101735372AHigh removal rateSimple process controlOther chemical processesMetal impuritiesChloroacetic acids

The invention provides a chelate resin and a production method and the application thereof, and the novel chelate resin can effectively remove impurities in trichlorosilane; the preparation method provided by the invention comprises the following steps: (1) zinc chloride is used as catalyzer, a white ball and chloromethyl ether are reacted to obtain chloromethylate white ball; (2) the chloromethylate white ball and hexamine are reacted, and then concentrated hydrochloric acid-ethanol mixing solution is used for decomposing, so as to obtain primary amine resin; (3) the primary amine resin is added in the chloroacetic acid aqueous solution, and the reaction is carried out for 10-30 hours at 55-70 DEG C to obtain the chelate resin; the chelate resin can effectively remove the metal impurities such as boron, phosphorus, calcium, magnesium, copper, ferrum and other impurities in trichlorosilane, the removal rate can reach more than 99 percent; the chelate resin has high processing capacity with 200t per cube and is the optimal choice for improving the product quality.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

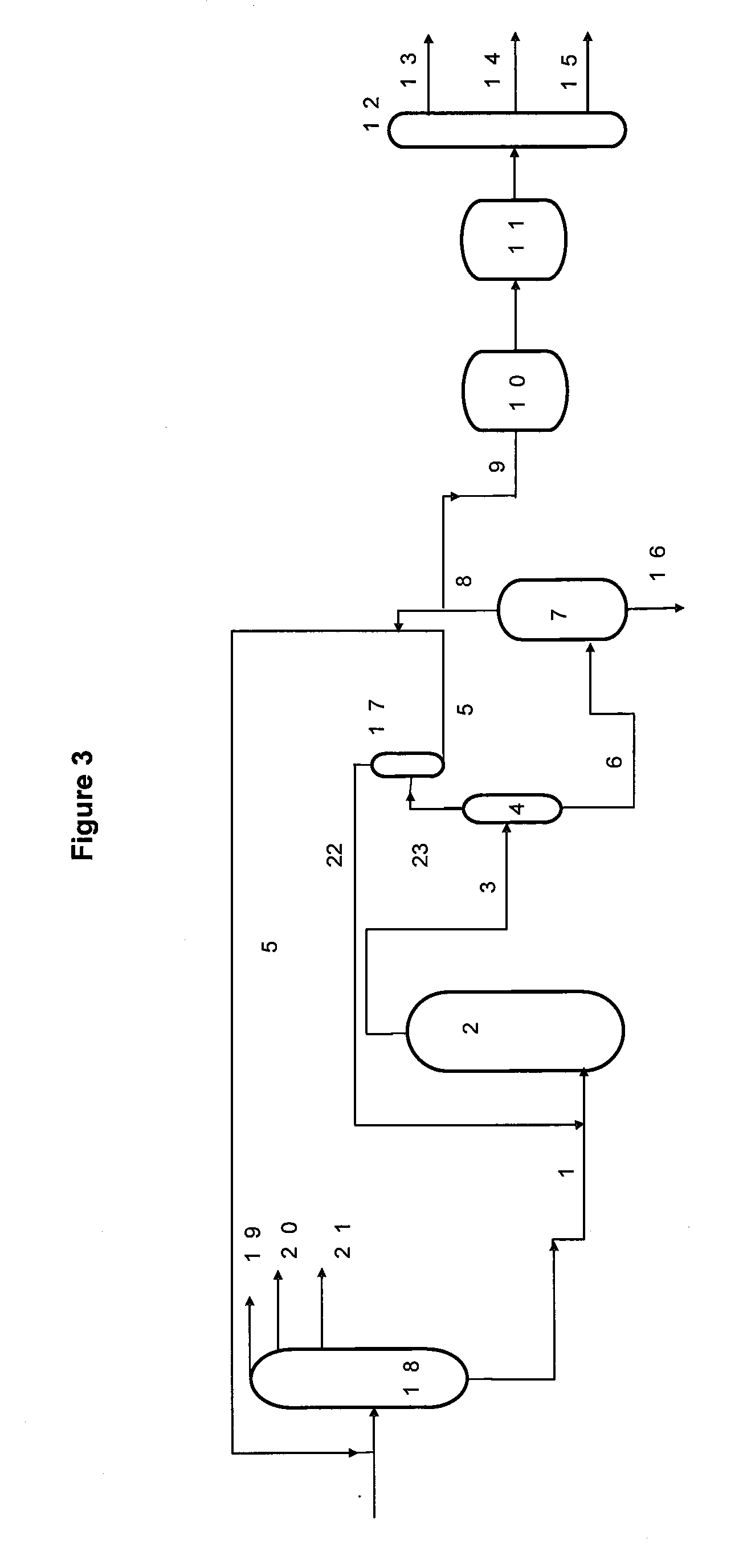

Residue conversion process that includes a deasphalting stage and a hydroconversion stage with recycling of deasphalted oil

ActiveUS20120061292A1Improve product qualitySimple and economical processTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsBoiling pointThree-phase

Owner:INST FR DU PETROLE

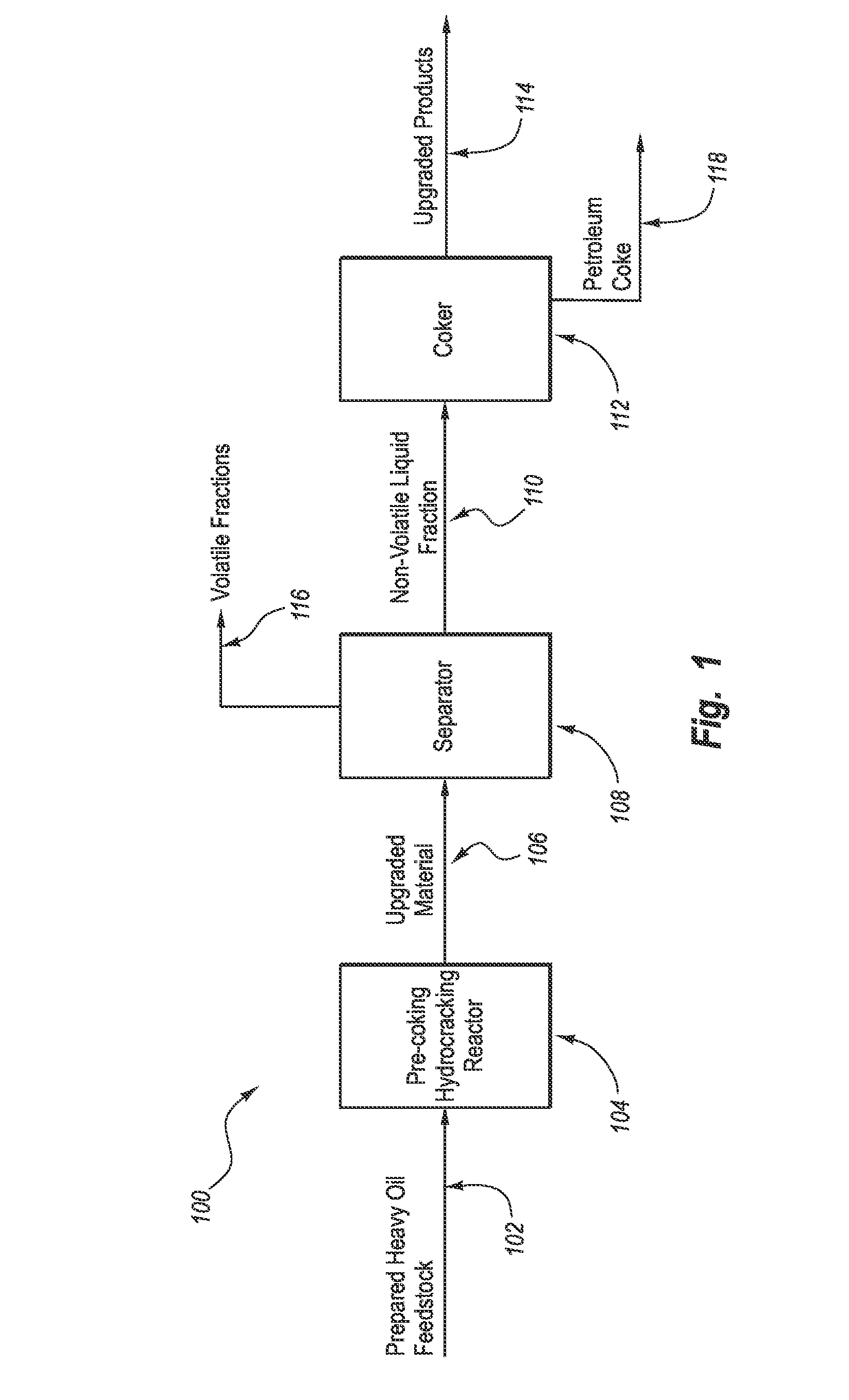

Integrated Slurry Hydrocracking and Coking Process

InactiveUS20100122932A1High value distillateIncrease valueThermal non-catalytic crackingTreatment with plural serial cracking stages onlyParticulatesHydrogen

Integrated slurry hydrocracking (SHC) and coking methods for making slurry hydrocracking (SHC) distillates are disclosed. Representative methods involve passing a slurry comprising a recycle SHC gas oil, a coker gas oil, a vacuum column resid, and a solid particulate through an SHC reaction zone in the presence of hydrogen to obtain the SHC distillate. Recovery of an SHC pitch from fractionation of the SHC reaction zone effluent provides an additional possibility for integration with the coker, and particularly via the upgrading of the SHC pitch in the coker to provide coke and lighter hydrocarbons such as SHC vacuum gas oil (VGO).

Owner:UOP LLC

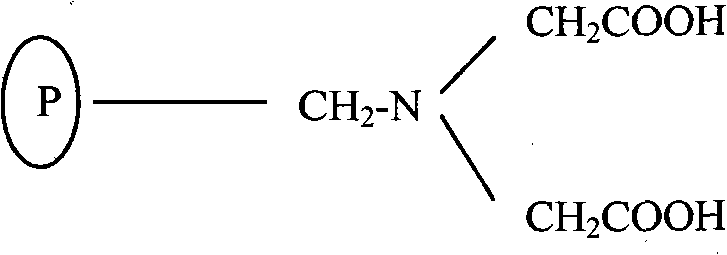

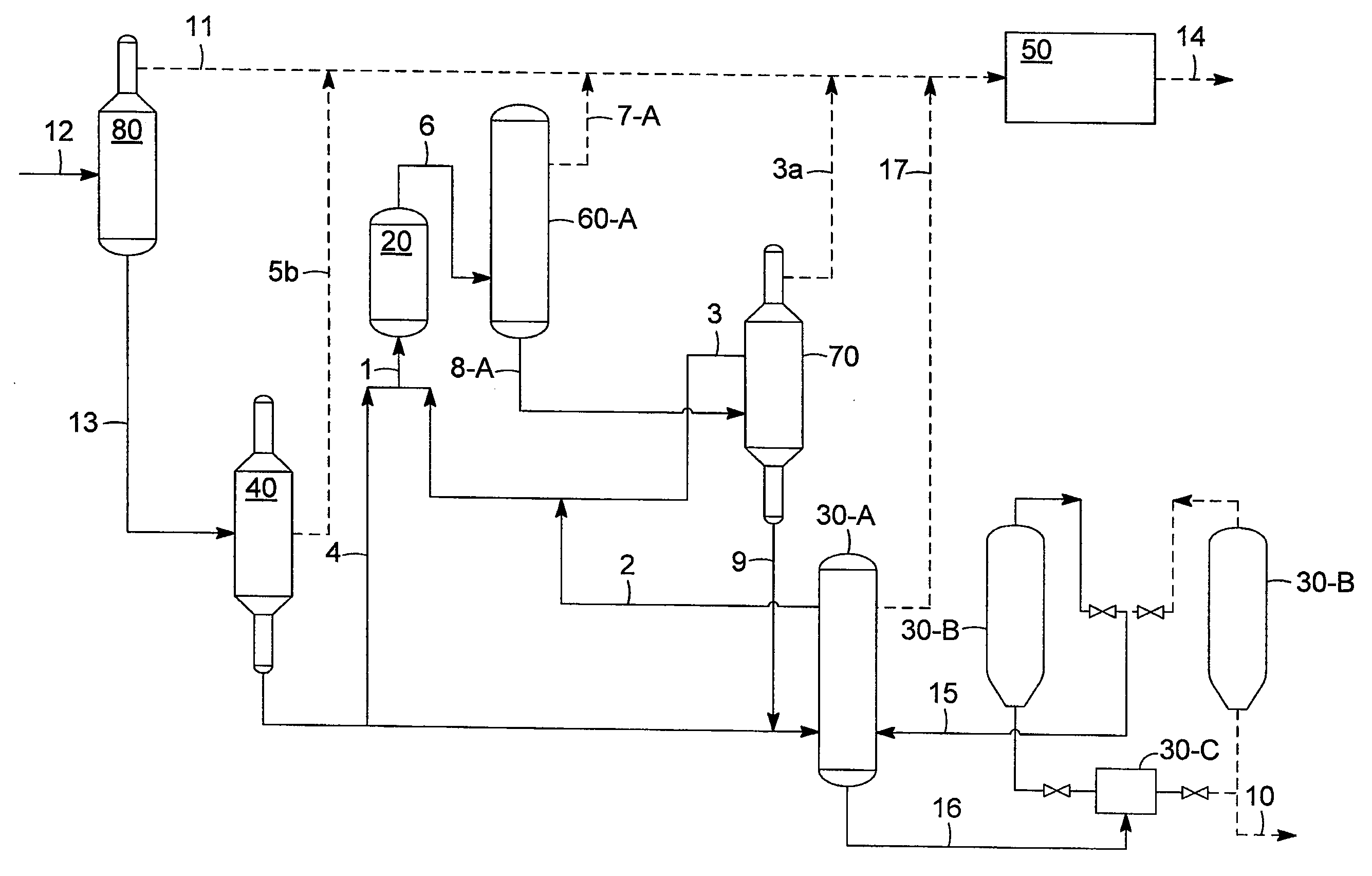

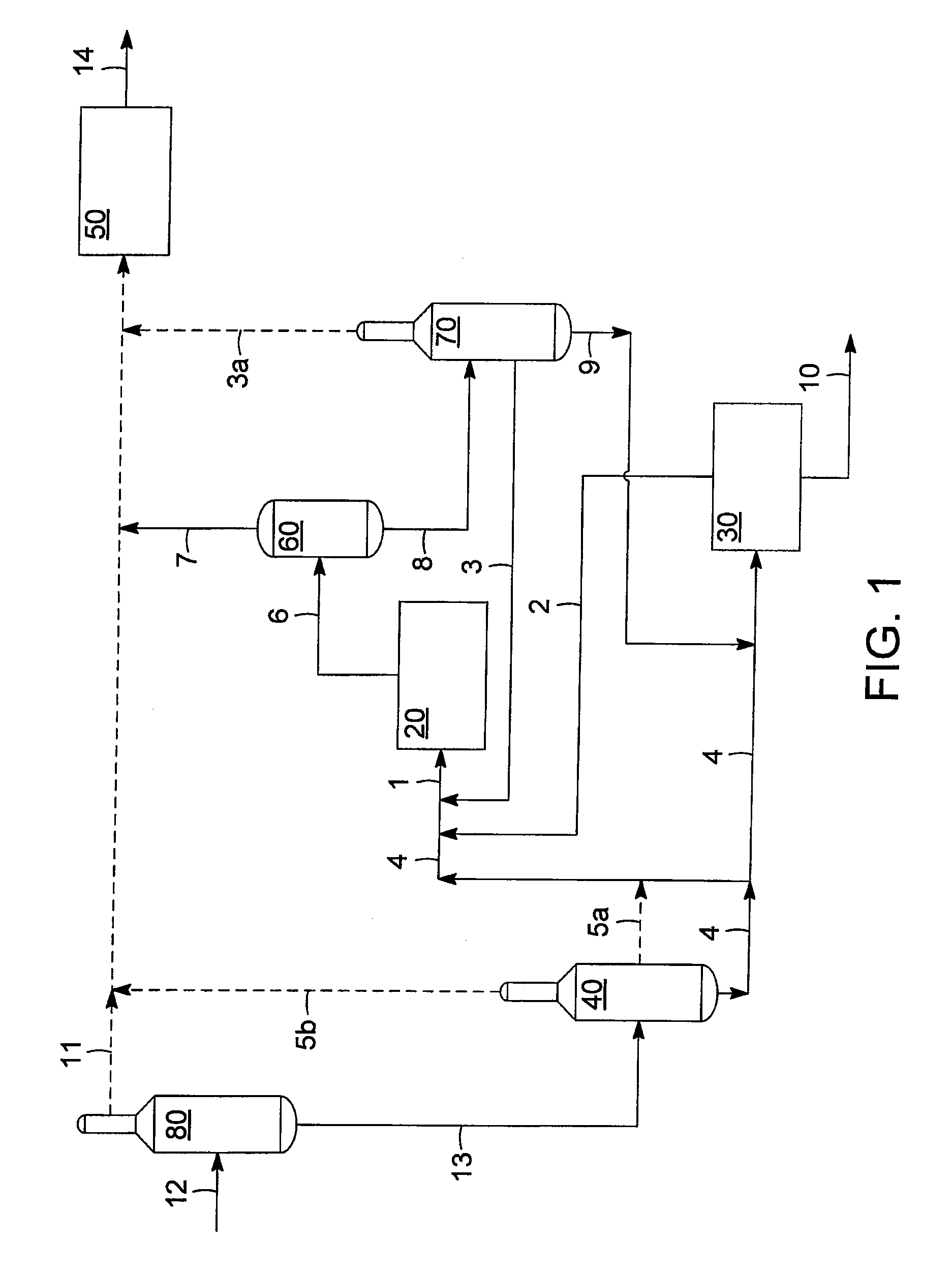

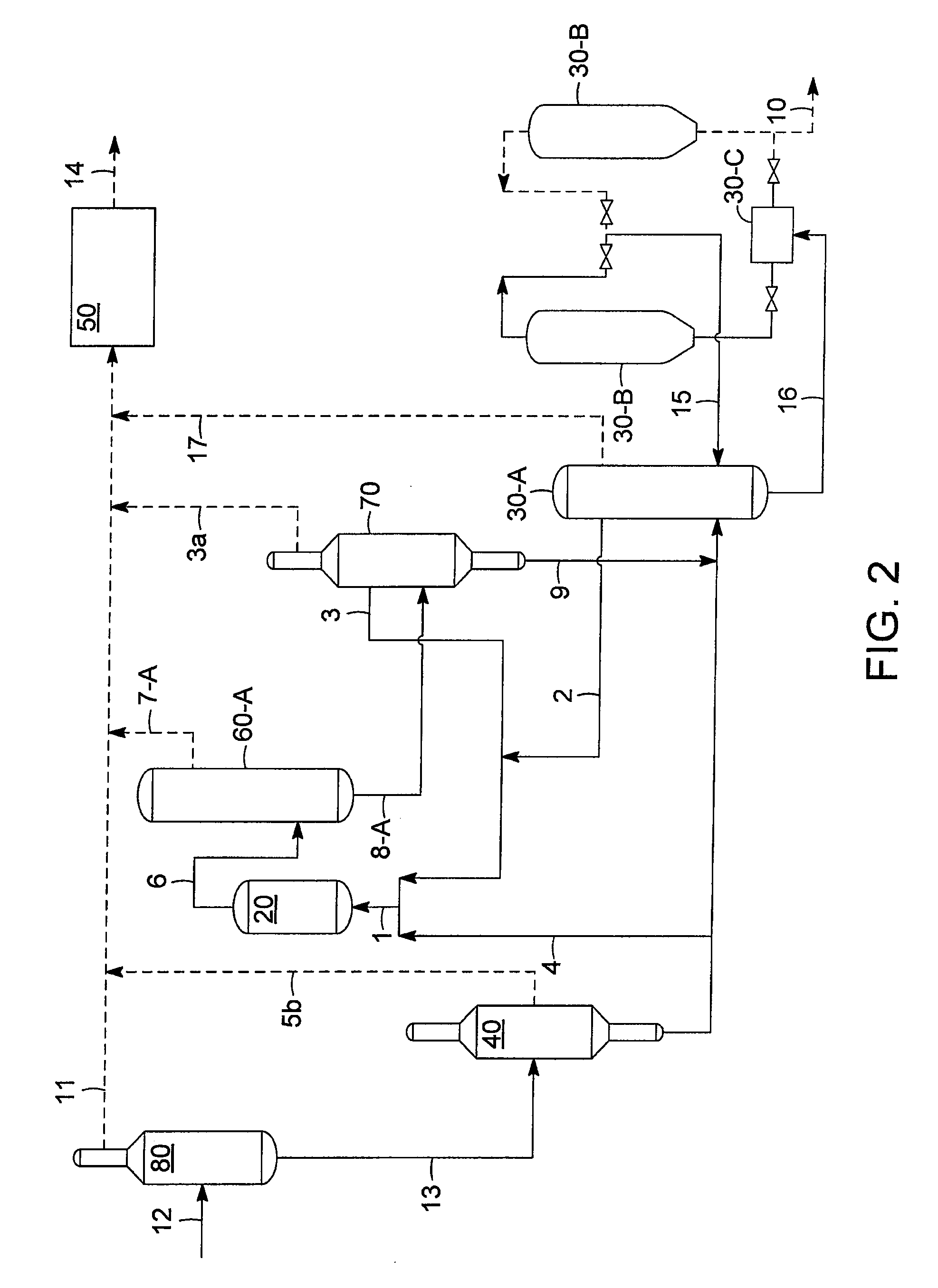

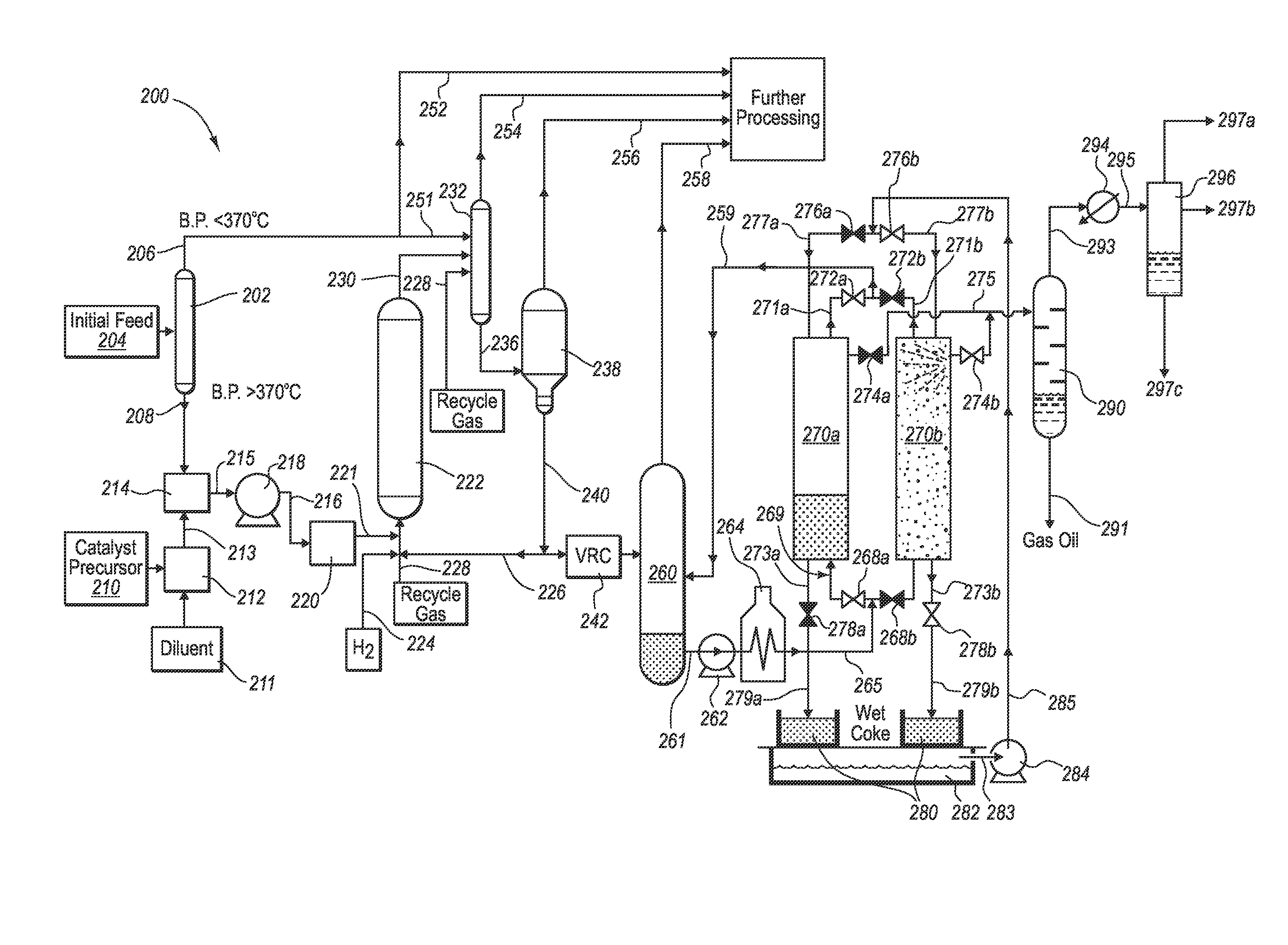

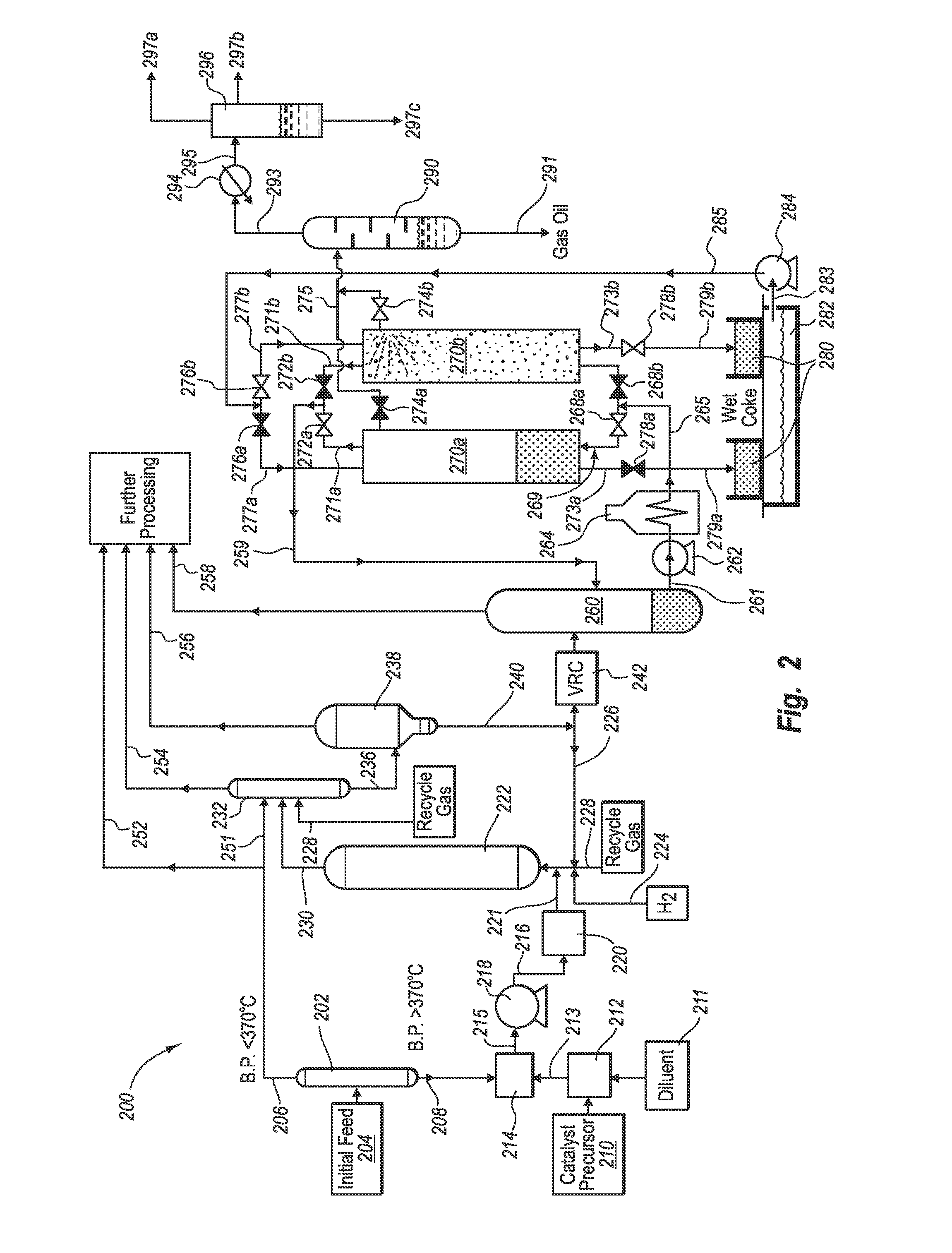

Apparatus and systems for upgrading heavy oil using catalytic hydrocracking and thermal coking

ActiveUS20150361360A1Increase conversionsImprove distillation yieldThermal non-catalytic crackingCatalyst activation/preparationThermodynamicsPtru catalyst

Methods and systems for hydroprocessing heavy oil feedstocks to form an upgraded material involve the use of a colloidal or molecular catalyst dispersed within a heavy oil feedstock, a pre-coking hydrocracking reactor, a separator, and a coking reactor. The colloidal or molecular catalyst promotes upgrading reactions that reduce the quantity of asphaltenes or other coke forming precursors in the feedstock, increase hydrogen to carbon ratio in the upgraded material, and decrease boiling points of hydrocarbons in the upgraded material. The methods and systems can be used to upgrade vacuum tower bottoms and other low grade heavy oil feedstocks. The result is one or more of increased conversion level and yield, improved quality of upgraded hydrocarbons, reduced coke formation, reduced equipment fouling, processing of a wider range of lower quality feedstocks, and more efficient use of supported catalyst if used in combination with the colloidal or molecular catalyst, as compared to a conventional hydrocracking process or a conventional thermal coking process.

Owner:HEADWATERS HEAVY OIL

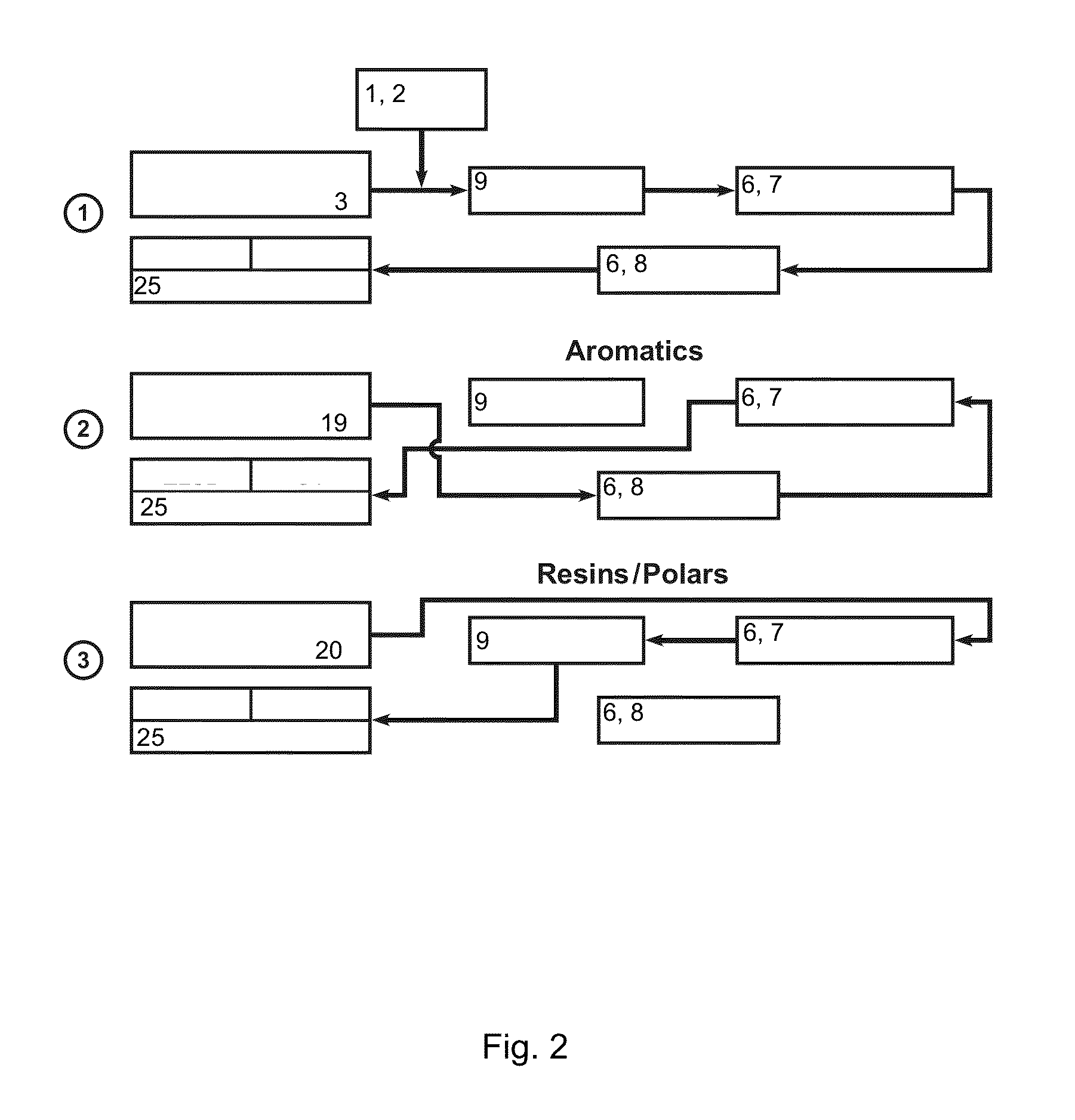

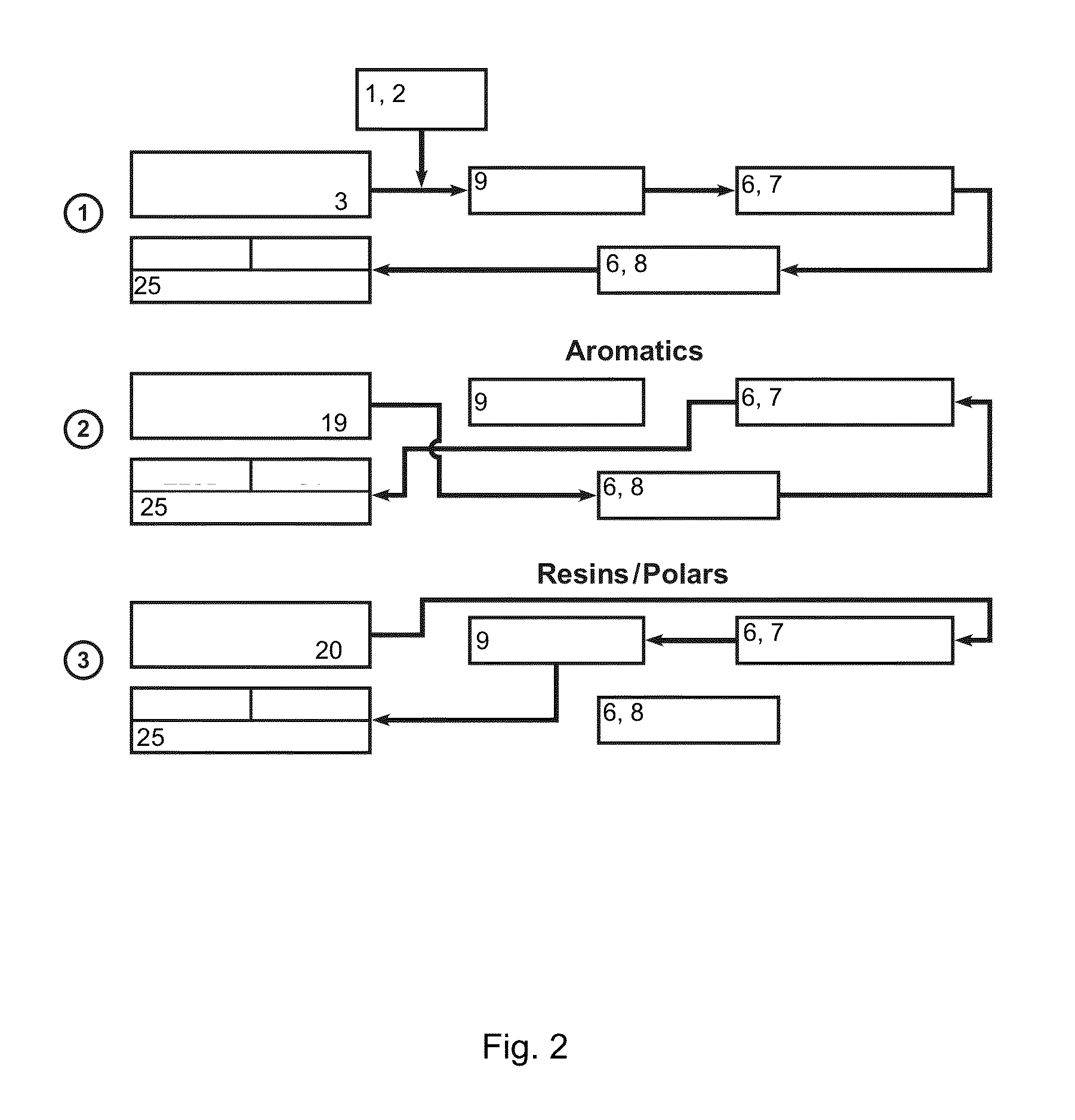

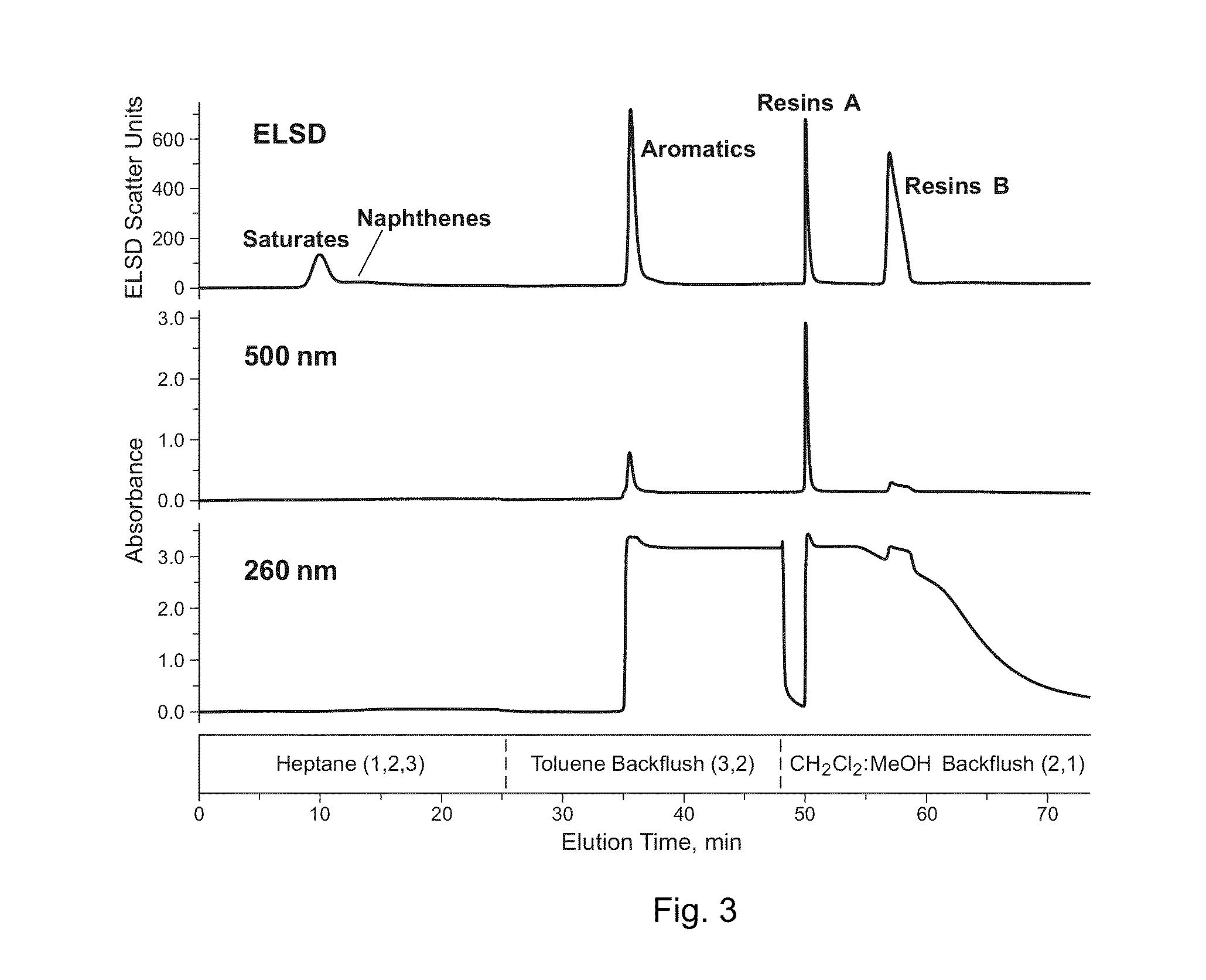

Hydrocarbon Separation and Analysis Apparatus and Methods

ActiveUS20130067991A1EasilyPromote resultsWorking-up pitch/asphalt/bitumen by selective extractionData processing applicationsSolubilityStationary phase

The inventive technology may involve, in particular embodiments, novel use of a non-porous, high surface energy stationary phase to adsorb, in reversible fashion, the most polar component of a resins fraction of an input hydrocarbon when a mobile phase is passed over the stationary phase. Such reversible adsorption prevents irreversibly adsorption of such components on active stationary phase(s) downflow of the non-porous, high surface energy stationary phase, thereby conserving stationary phase costs and increasing resolution of resins elutions, and accuracy of hydrocarbon component results. Aspects of the inventive technology may also involve a novel combination of a solubility based asphaltene component fractionating and analysis method and an adsorption chromatography method for separating and / or analyzing saturate, aromatics and resins components of an input hydrocarbon.

Owner:WESTERN RES INST INC

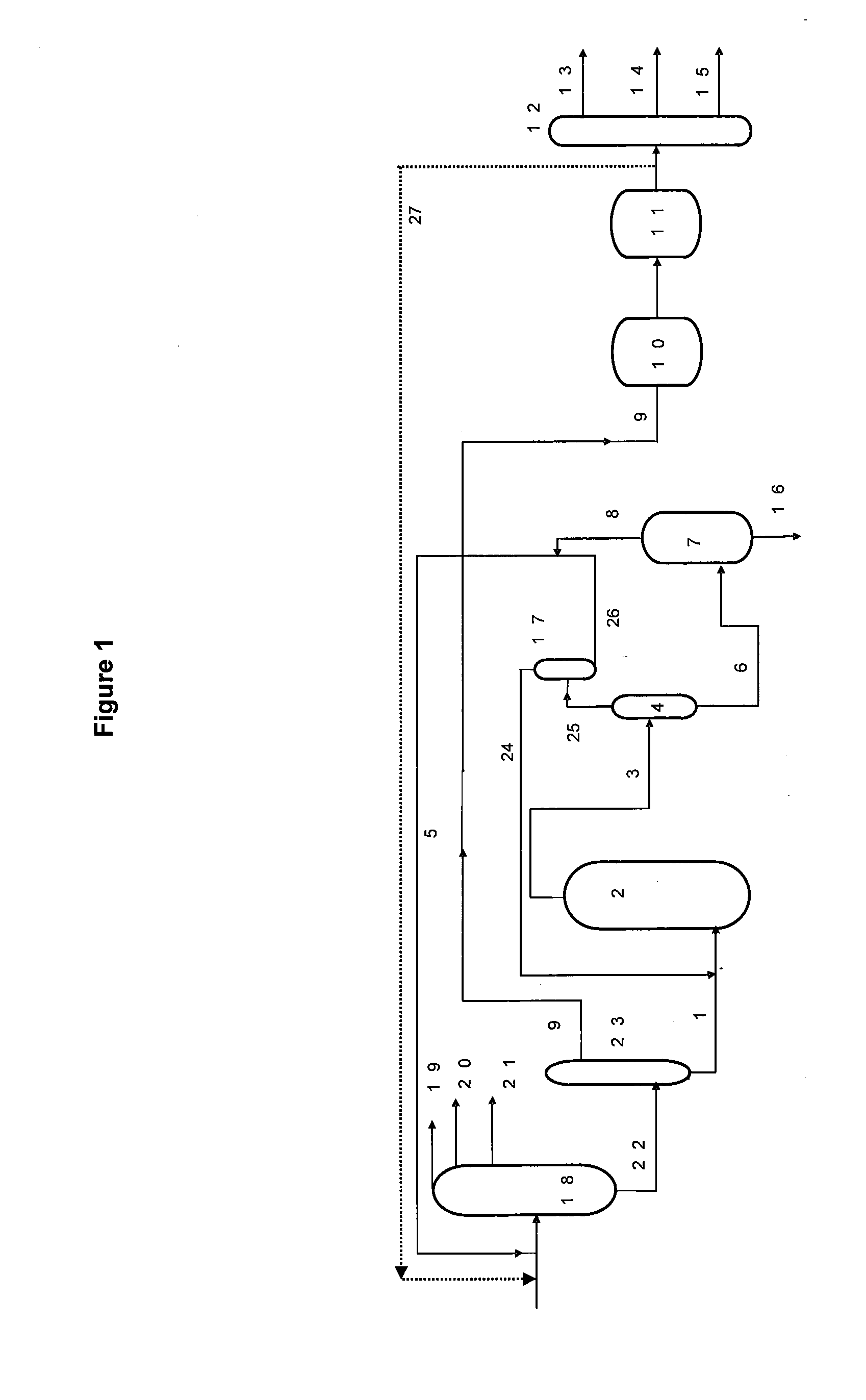

Novel integrated process for the treatment of oil feeds for the production of fuel oils with a low sulphur and sediment

InactiveUS20160312130A1Improve distillation yieldIncrease productionLiquid carbonaceous fuelsTreatment with hydrotreatment processesBoiling pointSulfur

Treating a hydrocarbon feed having a sulphur content of at least 0.5% by weight, an asphaltenes content of at least 1% by weight, an initial boiling point of at least 340° C. and a final boiling point of at least 480° C., in order to obtain at least one deasphalted oil fraction with a sulphur content of 0.5% by weight or less and a sediment content of 0.1% by weight or less.

Owner:INST FR DU PETROLE

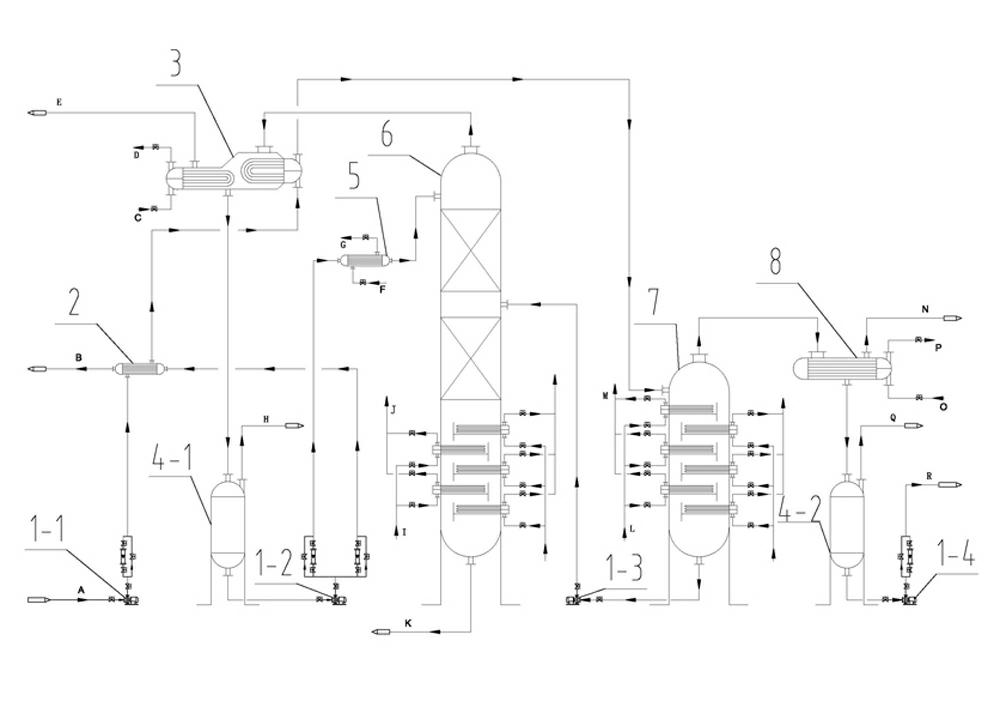

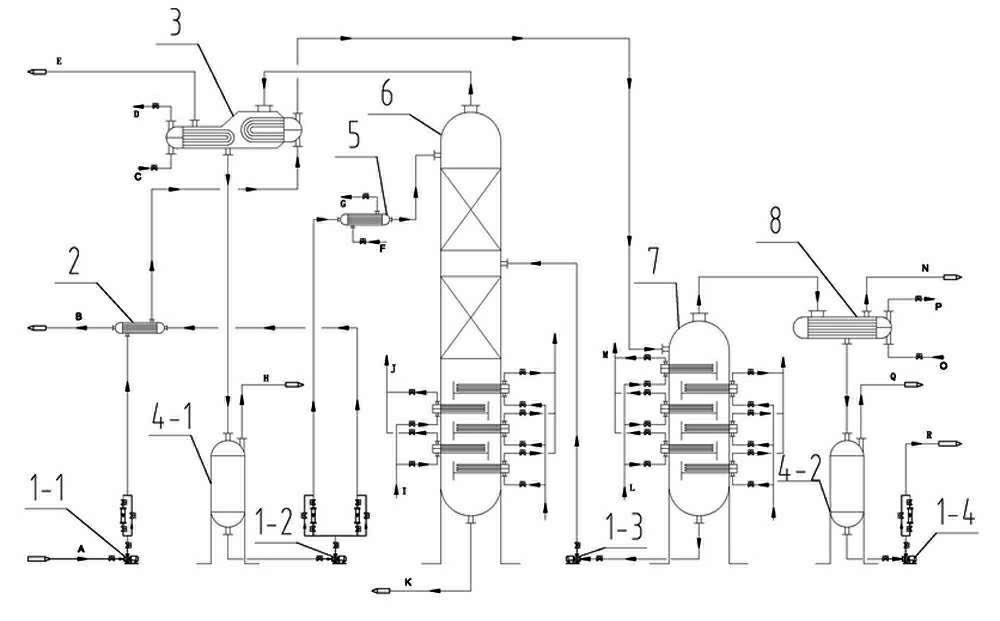

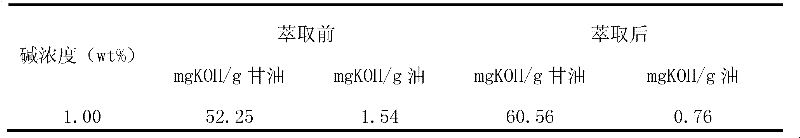

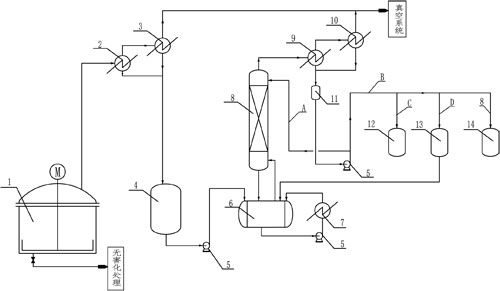

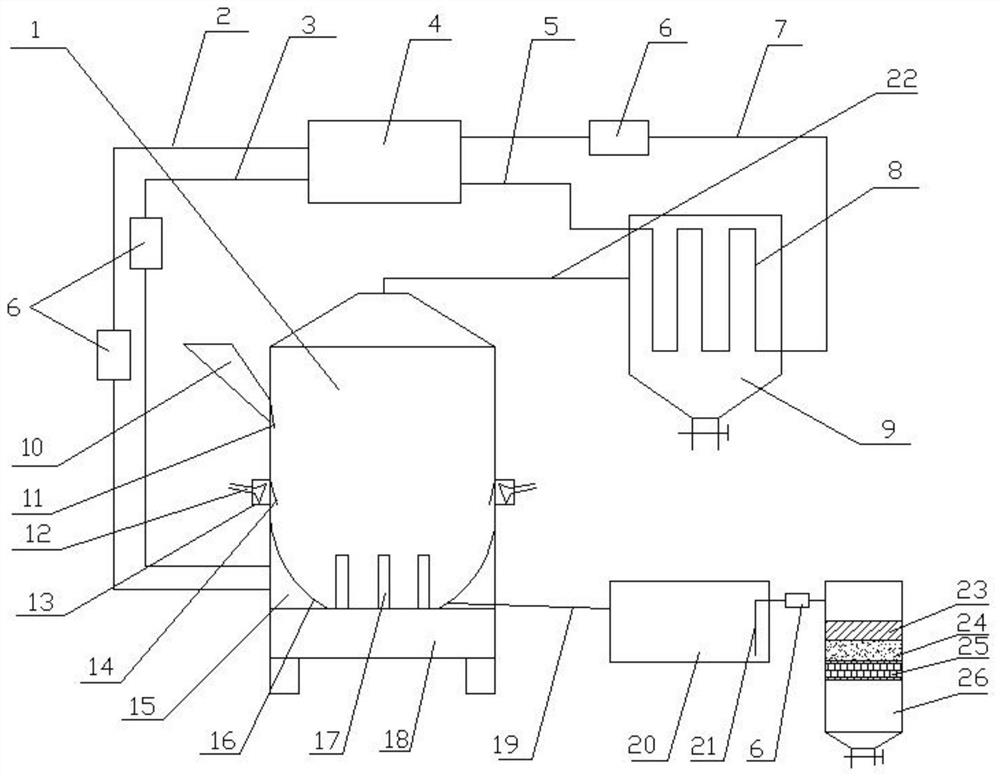

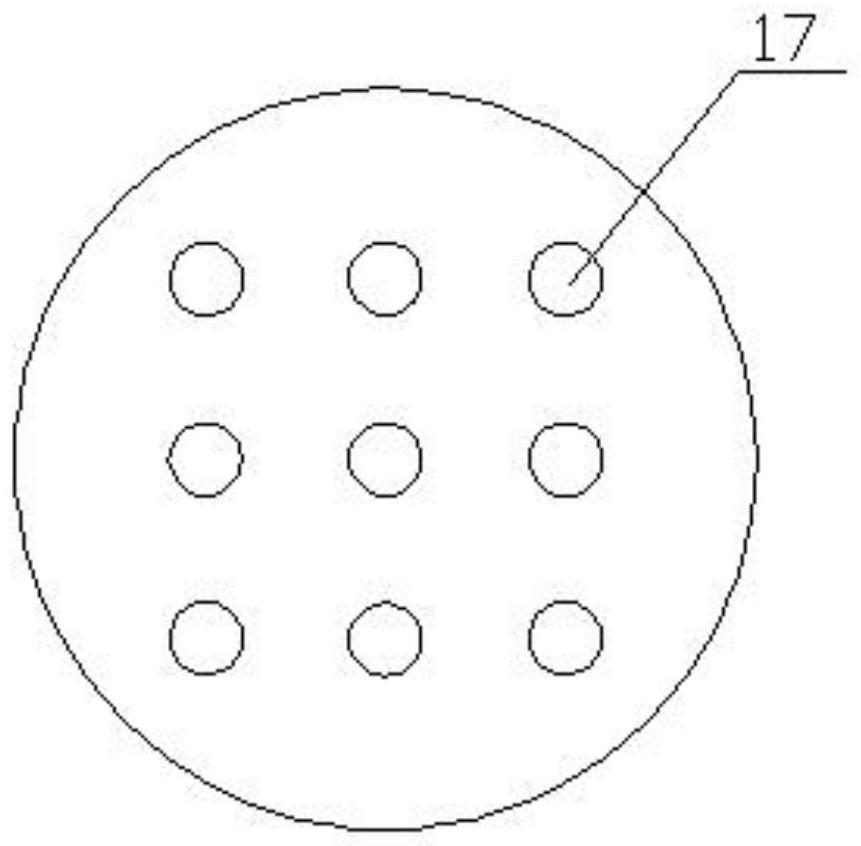

Multilayer-evaporation-based bio-diesel continuous rectification system and process

ActiveCN102604665AImprove distillation yieldIncrease vacuumHydrocarbon distillationLiquid hydrocarbon mixture productionBiodieselEvaporation

The invention relates to a multilayer-evaporation-based bio-diesel continuous rectification system and a multilayer-evaporation-based bio-diesel continuous rectification process. The system comprises a charging pump which is connected with a product-raw material heat exchanger. The product-raw material heat exchanger is connected with a multilayer evaporator through a combined condenser. A condenser is connected with the upper part of the multilayer evaporator, and is connected with a product intermediate tank which is connected with a discharging pump. A rectification column is connected with the lower part of the multilayer evaporator through an intermediate charging pump. A light component intermediate tank is connected with the upper part of the rectification column through the combined condenser, and is connected with the product-raw material heat exchanger and a preheater through a reflux pump. The preheater is connected with the rectification column. The system and the process have the beneficial effects that: after light components such as low-carbon methyl ester are removed from crude bio-diesel through the multilayer evaporator, a subsequent rectification column system can maintain a higher vacuum degree, the productivity is improved, the energy consumption is reduced, and the yield of a product is improved.

Owner:ZHEJIANG UNIV OF TECH

Method for extracting cinnamomum longepaniculatum leaf essential oil

InactiveCN109609276AHigh extraction rateImprove qualityEssential-oils/perfumesWater bathsOrganic solvent

The invention provides a method for extracting cinnamomum longepaniculatum leaf essential oil. The method comprises the following steps of A, pulverizing, wherein dried cinnamomum longepaniculatum leaves are pulverized and screened to obtain cinnamomum longepaniculatum leaf powder; B, enzymolysis, wherein an appropriate amount of water and cellulase are added into the cinnamomum longepaniculatum leaf powder obtained in the step A, water bath treatment is executed after even stirring, and continuous stirring is executed in the process; C, simultaneous distillation and extraction, wherein the mixture obtained in step B is simultaneously distilled and extracted in an organic solvent; D, oil-water separation and solvent removal, wherein an organic solvent phase is obtained through separation after the treatment in the step C, and then the organic solvent is removed to obtain crude extracted essential oil; E, dehydration, wherein the crude extracted essential oil obtained in the step D is subjected to dehydration treatment to obtain the essential oil. The essential oil in the cinnamomum longepaniculatum leaves can be fully released out by pulverization and cellulase treatment; meanwhile, the essential oil which is dissolved in a water phase by a conventional steam distillation can be extracted out by adopting a distillation extraction method. Thereby, the extraction rate of the cinnamomum longepaniculatum leaf essential oil can be significantly improved, and a cinnamomum longepaniculatum leaf essential oil product with better quality can be obtained.

Owner:SHANGHAI JIAO TONG UNIV

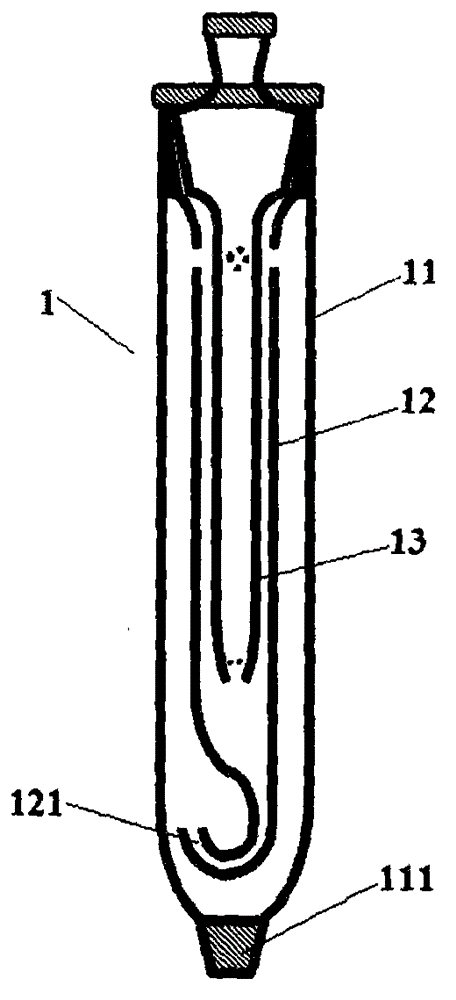

Combined rectifying column and application thereof

The invention relates to a combined rectifying column and application thereof, in particular to a combined rectifying column which is characterized by comprising an outer column body, a middle casing pipe and an inner casing pipe, wherein the main body parts of the outer column, the middle casing pipe and the inner casing pipe are tubular parts which are arranged with a same axis center. The invention further relates to a rectifying device with the combined rectifying column, and a method for rectifying a material to be rectified by using the combined rectifying column and the rectifying device. The device and the method provided by the invention have the characteristics that the washing is easy, the replacement is convenient when multiple fillers are used, the purity of a product is high, the quality is stable, the rectification yield is relatively high, the separation cost is low, and no potential safety hazard is generated in the rectification process, and moreover the types and the use amounts of the fillers can be changed according to different demands, so that the combined rectifying column has multiple functions of solvent purification and recycling, natural production extraction, and the like.

Owner:李桂芳

Preparation method of tetrachlorpyridine

ActiveCN103739543AImprove distillation yieldOrganic chemistryChemical recyclingAluminium chlorideDistillation

The invention discloses a preparation method of tetrachlorpyridine. The method comprises the following steps: in the presence of a catalyst, performing a contact reaction between a low-chloropyridine compound and chlorine gas to obtain a product after the contact reaction, wherein the catalyst is one or more of iron chloride, zinc chloride, magnesium chloride and aluminum chloride; introducing inactive gas into the product after the contact reaction, and distilling. By adopting the method disclosed by the invention, the distillation yield of tetrachlorpyridine can exceed 92%, and the obtained product tetrachlorpyridine does not contain the component of the catalyst; moreover, the residue after the distillation can be further applied to a catalytic synthesis reaction of tetrachlorpyridine.

Owner:盐城恒盛化工有限公司

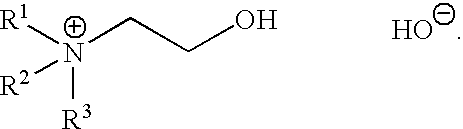

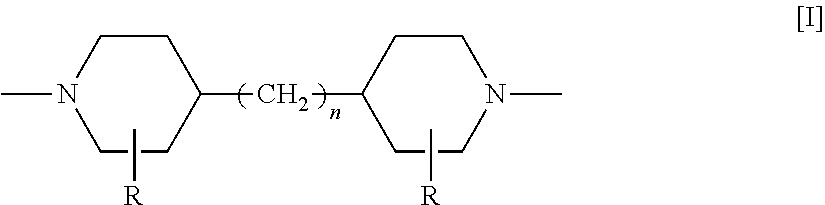

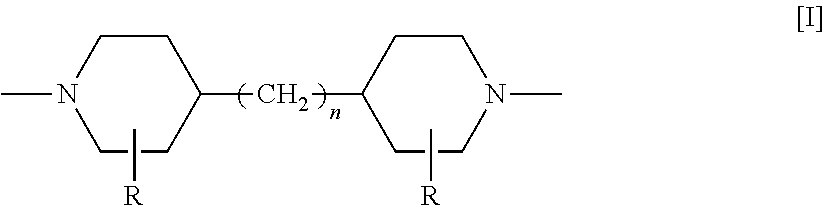

Methods of treating triethanolamine with acid components and basic components, and triethanolamine compositions containing the same

InactiveUS7550632B2Improve color qualityReduce discolorationAmino compound purification/separationOrganic compound preparationPhosphorous acidAlkaline earth metal

Methods for improving color properties of triethanolamine, and triethanolamine compositions treated thereby, are disclosed, wherein the methods comprise: (a) providing a composition comprising triethanolamine; and (b) contacting the composition with an acid component and a basic component; wherein the acid component comprises an acid selected from the group consisting of phosphorous acid, hypophosphorous acid and mixtures thereof; and wherein the basic component comprises a compound selected from the group consisting of alkali metal hydroxides, alkaline earth metal hydroxides, ammonium hydroxides according to general formula (I), and mixtures thereof:[R1R2R3(2-hydroxyethyl)ammonium] hydroxide (I)wherein R1, R2 and R3 each independently represents a C1-30 alkyl or a C2-10 hydroxyalkyl; with the proviso that where the basic component comprises an alkali metal hydroxide, the molar ratio of acid component: basic component is 1:0.1 to 1:1, and where the basic component comprises an alkaline earth metal hydroxide, the molar ratio of acid component: basic component is 1:0.05 to 1:0.5.

Owner:BASF AG

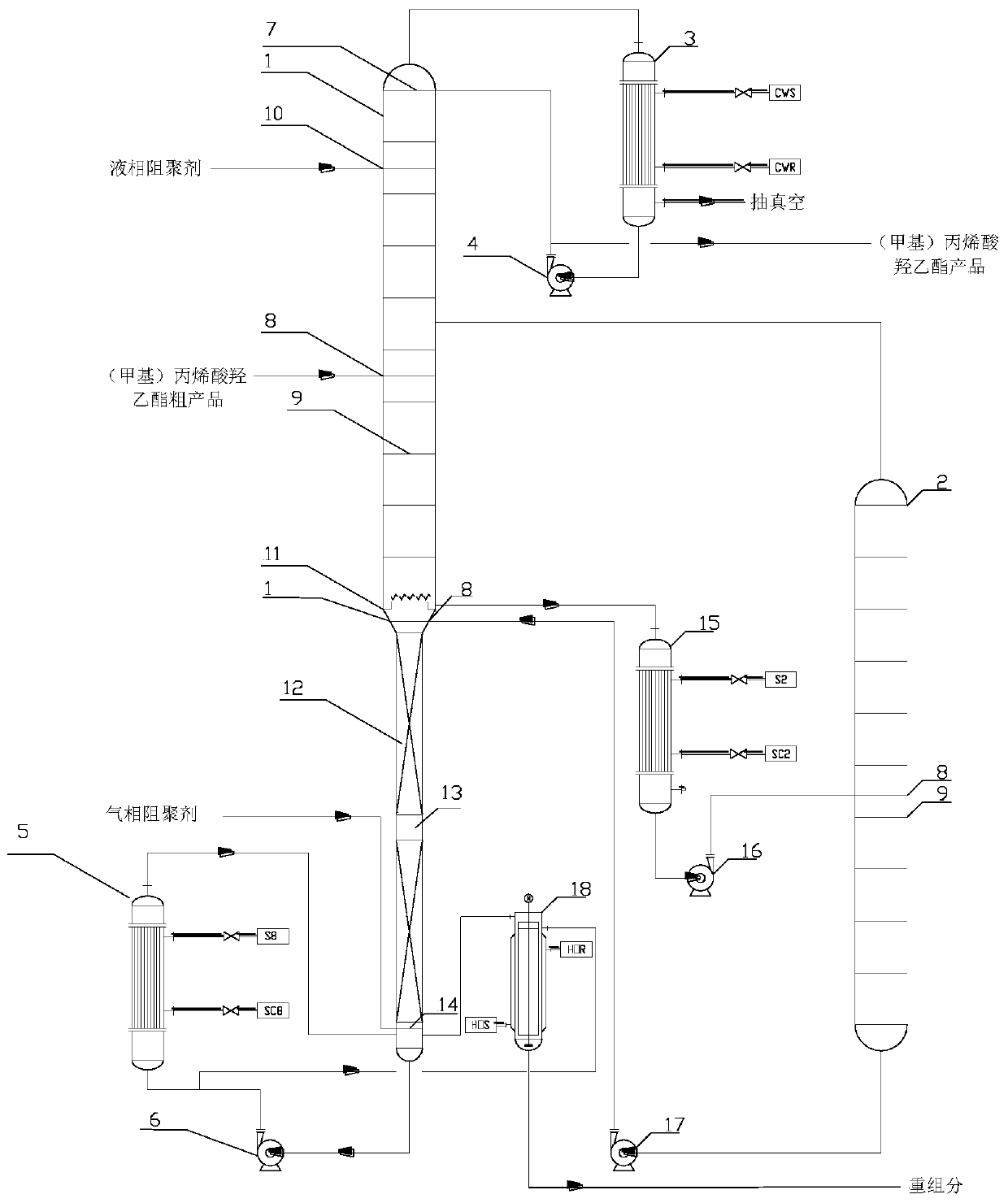

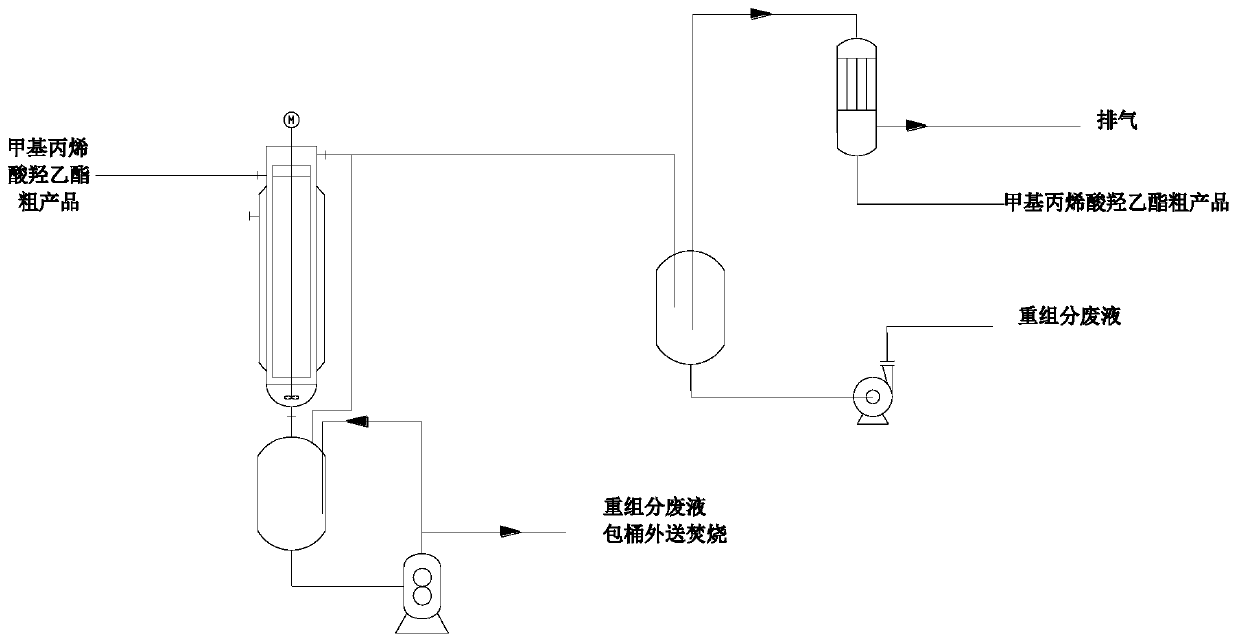

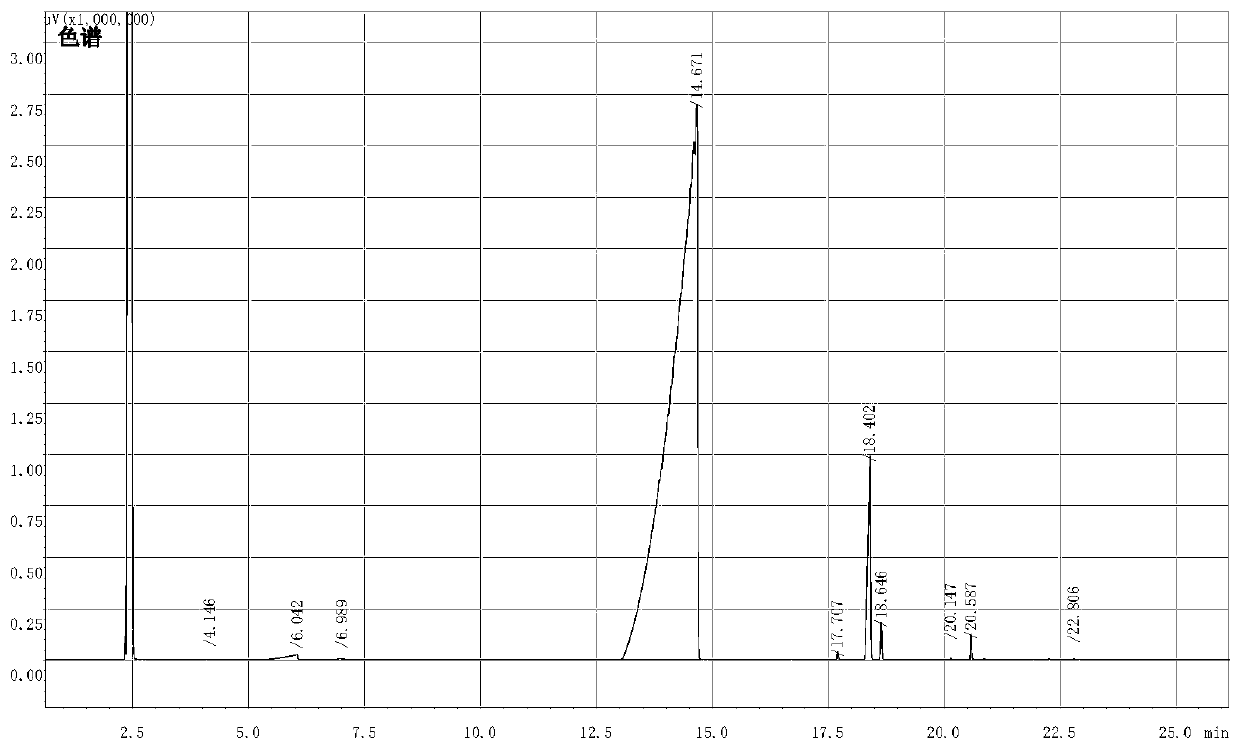

Continuous rectification separation method and device for (methyl) hydroxyethyl acrylate crude product

ActiveCN110935188AReduce aggregationReduce generationOrganic compound preparationCarboxylic acid esters preparation(Hydroxyethyl)methacrylateMeth-

The invention relates to a continuous rectification separation method and a continuous rectification separation device for a (methyl) hydroxyethyl acrylate crude product crude product, and mainly solves the problems of short device operation period and high cleaning frequency caused by high byproduct generation amount, high purification difficulty, low product rectification yield and severe polymerization after heating of the (methyl) hydroxyethyl acrylate crude product crude product in a rectification system in the prior art. According to the technical scheme, a (methyl) hydroxyethyl acrylatecrude product separation device is adopted, heavy components are removed in a thermocouple rectifying tower, the problems are well solved, and the method can be used for separation of the (methyl) hydroxyethyl acrylate crude product.

Owner:WANHUA CHEM GRP CO LTD

Hydrocarbon separation and analysis apparatus and methods

ActiveUS9353317B2EasilyPromote resultsComponent separationSolvent extractionStationary phaseSolubility

The inventive technology may involve, in particular embodiments, novel use of a non-porous, high surface energy stationary phase to adsorb, in reversible fashion, the most polar component of a resins fraction of an input hydrocarbon when a mobile phase is passed over the stationary phase. Such reversible adsorption prevents irreversibly adsorption of such components on active stationary phase(s) downflow of the non-porous, high surface energy stationary phase, thereby conserving stationary phase costs and increasing resolution of resins elutions, and accuracy of hydrocarbon component results. Aspects of the inventive technology may also involve a novel combination of a solubility based asphaltene component fractionating and analysis method and an adsorption chromatography method for separating and / or analyzing saturate, aromatics and resins components of an input hydrocarbon.

Owner:WESTERN RES INST INC

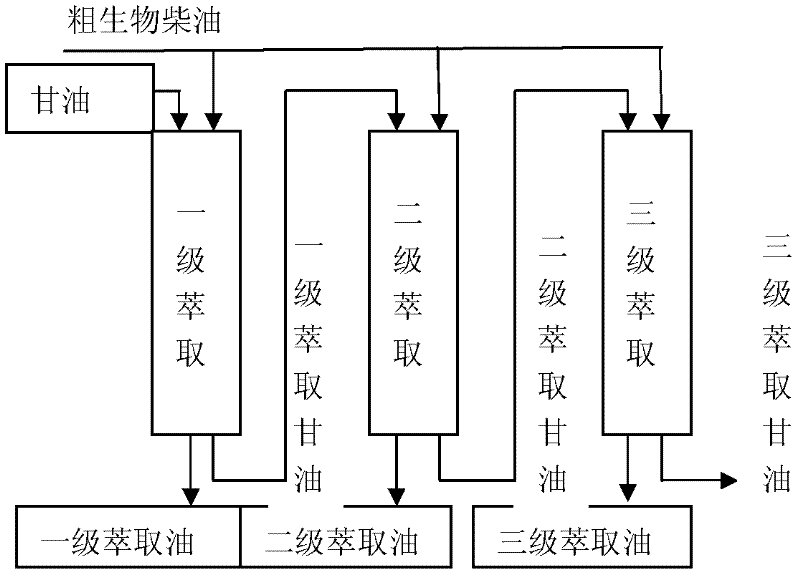

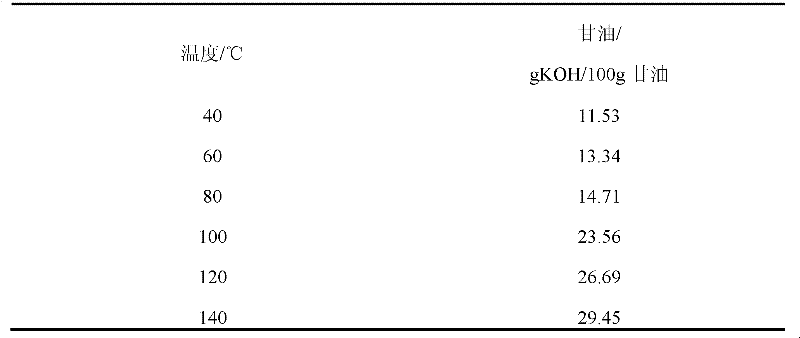

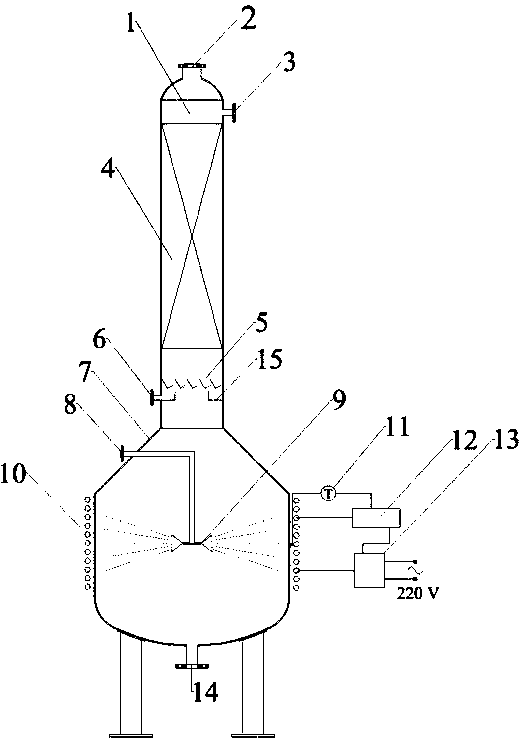

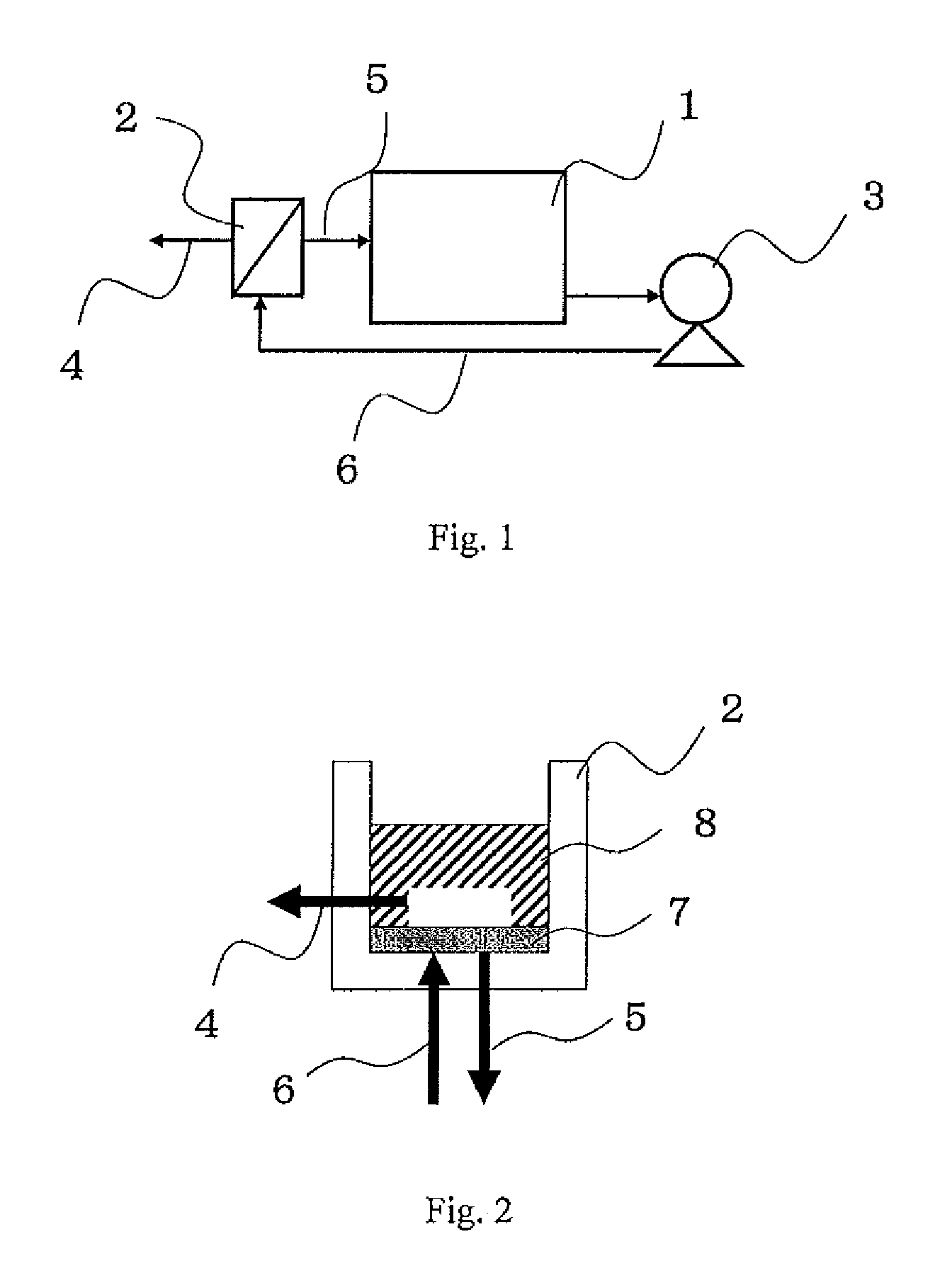

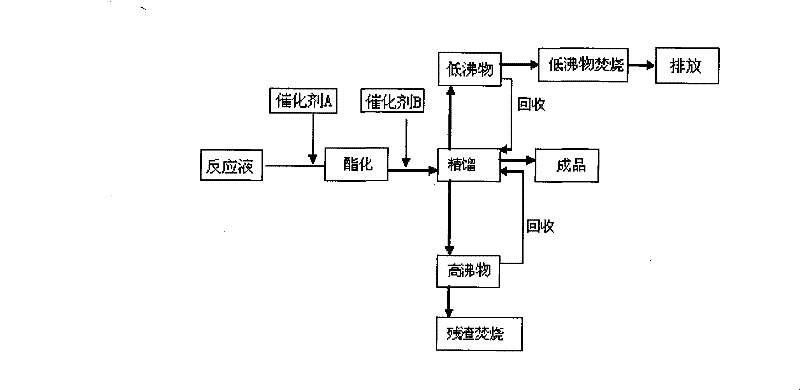

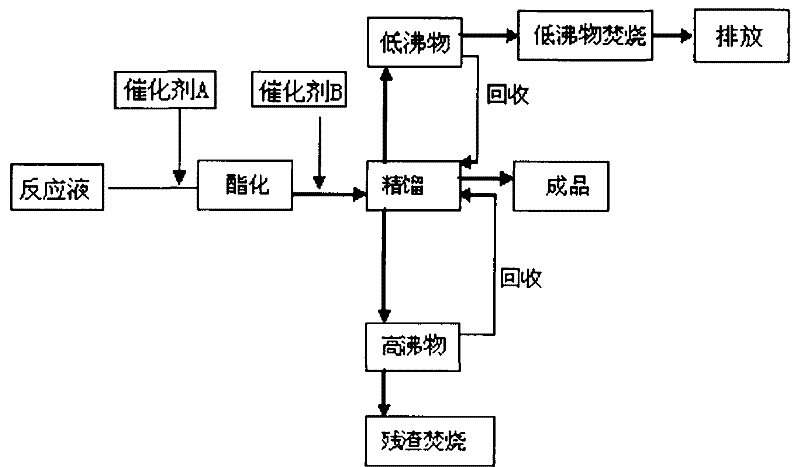

Method for removing base catalyst from crude biodiesel

ActiveCN102586012AAvoid alcoholysisImprove distillation yieldBiofuelsFatty-oils/fats refiningBiodieselGlycerol

The invention relates to a method for removing a base catalyst from crude biodiesel. The method comprises the following step of: removing the base catalyst from the crude biodiesel by taking glycerin as an extracting agent, wherein the extraction temperature is 60-150DEG C, the operating pressure is normal pressure, and a mass ratio of the crude biodiesel to the glycerin is 10-1. Compared with the prior art, the method has the advantages that: 1, the method for removing the base catalyst from the biodiesel by taking the biodiesel byproduct glycerin as the extracting agent avoids a problem of wastewater caused by a water washing process; 2, the base catalyst dissolved in the glycerin phase is separated in a cooling crystallization mode, the glycerin and the base catalyst can be cyclically applied to a production process mechanically, and production cost is reduced; and 3, the base catalyst is effectively removed, alcoholysis in the high temperature vacuum rectification process of the biodiesel is avoided, and the biodiesel rectification yield is improved.

Owner:ZHEJIANG UNIV OF TECH

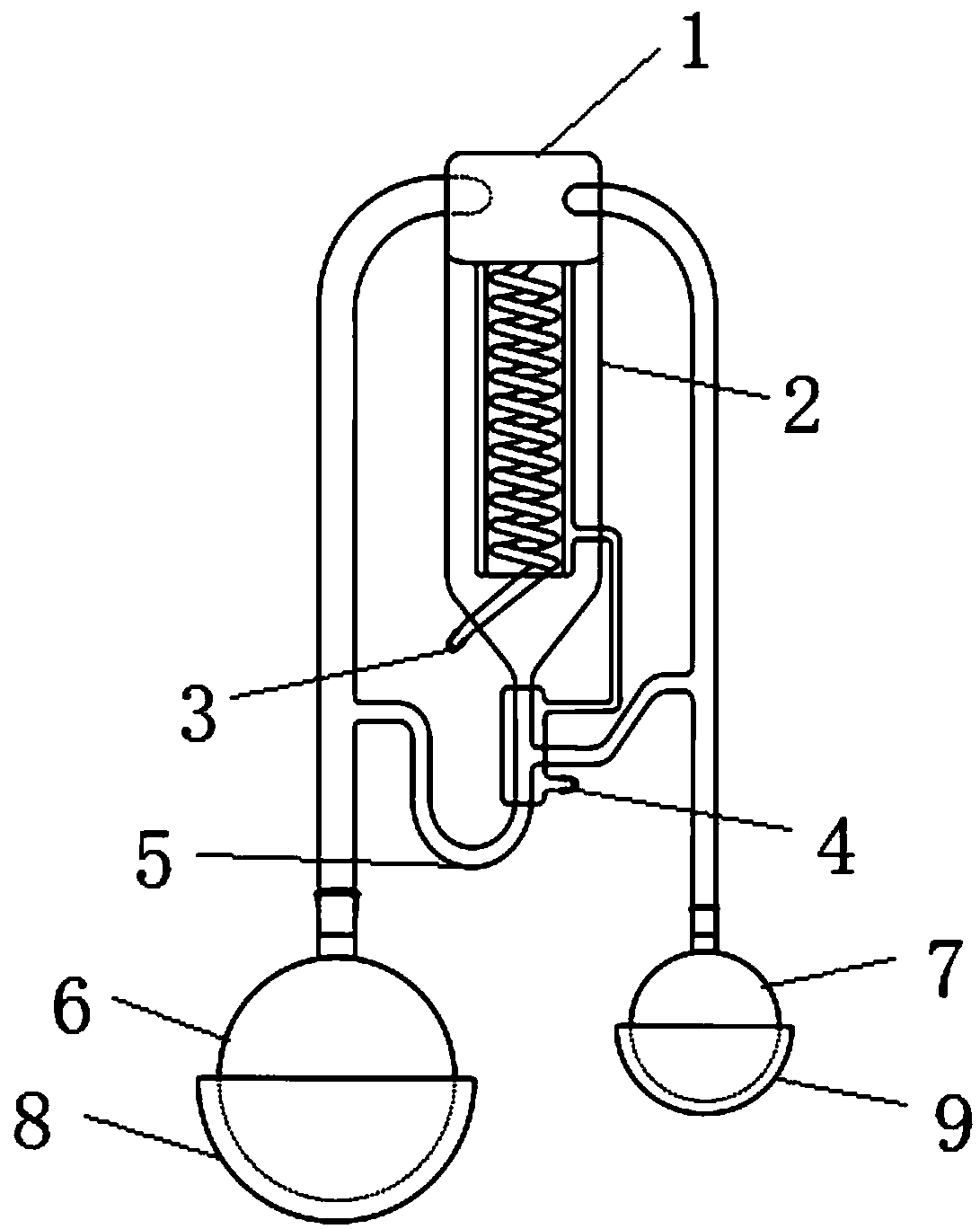

Rectification tower capable of rapidly heating and vaporizing material

ActiveCN109011676AImprove thermal efficiencyUniform temperatureFractional distillationTemperature controlLiquid layer

The invention discloses a rectification tower capable of rapidly heating and vaporizing a material. The rectification tower comprises a rectification tower body, a tower bottom heating vessel and an atomizer arranged in the tower bottom heating kettle, the rectification tower body is provided with a tower top rising gas port and a tower top return port, and the rectification tower body is filled with a packing; the tower bottom heating kettle is provided with a feed inlet and a kettle bottom discharge outlet, an electromagnetic coil is arranged around the outer wall of the tower bottom heatingkettle, and two ends of the electromagnetic coil are connected with a temperature control circuit system; and the atomizer is connected with a feed inlet pipeline of the tower bottom heating kettle,and jet orifices are arranged at the side parts of the atomizer. The rectification tower is especially suitable for rectification separation of high-boiling point heat-sensitive materials, atomizes the material during rectification, and makes atomized liquid drops in direct contact with a heating surface without generating a liquid layer thickness in order to realize high-vacuum vaporization of the material; and the heating and vaporizing are carried out in the form of liquid drops, so the heat exchange efficiency is high, rapid heating and vaporizing of the material are achieved, the residence time of the material on the high temperature surface is shortened, and the material is prevented from denaturing and coking.

Owner:ZHEJIANG UNIV OF TECH

Method of producing diol or triol

ActiveUS9018424B2High purityImprove distillation yieldOrganic compound preparationOxygen compounds purification/separationPolyamideDiol

A method for producing a diol or triol, which has a step of removing impurities contained in a diol- or triol-containing solution, is provided. In the method, a diol- or triol-containing solution is filtered through a nanofiltration membrane having a polyamide-containing functional layer. The diol- or triol-containing solution is then collected from the permeate flow of the nanofiltration membrane.

Owner:TORAY IND INC

Heliotropin rectification method

The invention relates to a rectification method of piperonal. The specific steps are as follows: add 500 g of crude piperonal (wherein the raw material piperonyl ring contains 10%), 200 ml of inert solvent, connect a 10 cm rectification column, a fractionation device, and a receiving bottle into a 1000 ml single-necked flask ;Turn on the vacuum, measure the vacuum degree to be 30Pa, start to heat up, carry out total reflux at the beginning, and start to accept the previous fraction after half an hour of total reflux, the acceptance temperature of the former fraction is 100-150°C, higher than 150°C, lower than 180°C is the product pepper Aldehyde, get piperonal aldehyde rectification product 445g, content is higher than 98%. The addition of an inert solvent forms a protective layer on the surface of piperonal, which isolates the oxidation and polymerization of piperonal by a small amount of oxygen, and plays a protective role. It also reduces the risk of explosion and improves the distillation yield. .

Owner:江西科美香料有限公司

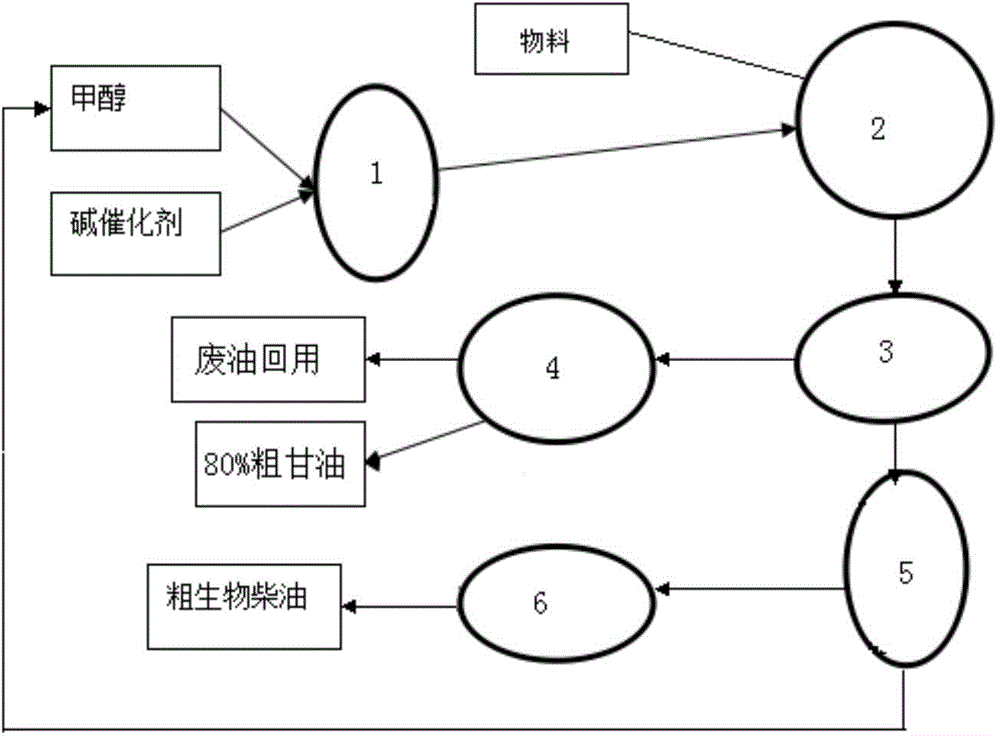

Biodiesel continuous ester interchange technology

ActiveCN104651060AReduce dosageAchieve serializationFatty acid esterificationBiofuelsGlycerolMetering pump

The invention discloses a biodiesel continuous ester interchange technology, which comprises the following steps: I. mixing methanol with an alkali catalyst in a mixer; II. continuously pumping the mixed solution in the step I and low-acid or esterified waste oil into a continuous ester interchange reactor through a metering pump; III. enabling materials discharged from the continuous ester interchange reactor to continuously flow into a continuous glycerine soap separator, and separating out glycerine soap and methanol-containing crude methyl ester; and IV. enabling the glycerine soap separated in the step III to enter a continuous glycerine separator, separating out glycerin and waste oil, and recycling the waste oil for production; and V. enabling the methanol-containing crude methyl ester separated from the step III to continuously enter a methanol recycler, and enabling the recycled methanol to be used for production, and crude methyl ester to enter a rectifying tower for rectifying, to obtain crude biodiesel. The ester exchange reactivity can achieve more than 95%, the continuous production can be realized,and the conversion rate of fatty acid methyl ester can be up to more than 98%.

Owner:江苏卡特环保科技有限公司

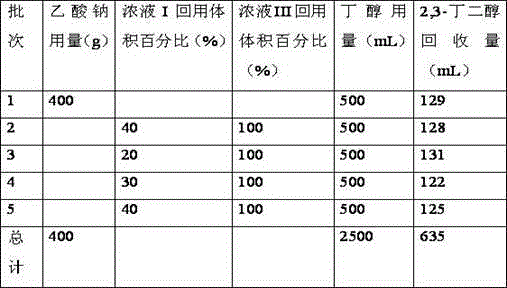

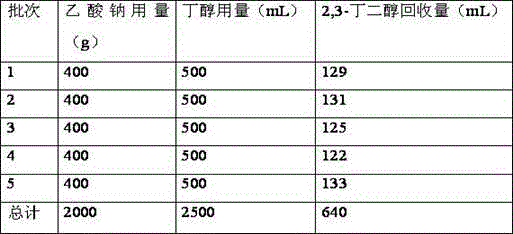

Method for separating 2,3-butanediol

ActiveCN105622342AAchieve recyclingImprove desalination performanceOrganic compound preparationHydroxy compound separation/purificationInorganic saltsOrganic acid

The invention discloses a method for separating 2,3-butanediol. The method comprises the following steps: (1) carrying out pretreatment on fermentation broth, so as to obtain clear fermentation broth; (2) adding an inorganic salt and / or an organic acid salt into the clear fermentation broth, carrying out thorough mixing, then, adding a low-polarity organic substance into the clear fermentation broth, carrying out thorough mixing, and then, carrying out standing layering, so as to obtain an upper phase, i.e., a 2,3-butanediol organic solution and a lower phase, i.e., a salt solution; and (3) carrying out electrodialysis desalination treatment on the upper phase, i.e., the 2,3-butanediol organic solution, and collecting a clear solution and concentrated liquor I; and carrying out electrodialysis desalination treatment on the lower phase, i.e., the salt solution by taking the concentrated liquor I as electrodialysis concentrated liquor circulating liquid, collecting and recycling concentrated liquor II, and distilling the clear solution, thereby obtaining the 2,3-butanediol product. According to the method, biomacromolecules such as thallus dissolved protein and lipids can be effectively removed from the fermentation broth so as to form a relatively uniform and pure liquid-phase system, and the implementation of next-step refining manners such as double-aqueous-phase and rectifying is facilitated, so that the method is applicable to large-scale production application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high-purity m-xylylene diisocyanate

InactiveCN113321599ASolve the problem of difficult separation of heavy phase componentsPrevent self-aggregationIsocyanic acid derivatives purification/separationFlash distillationXylyleneMethylene diisocyanate

The invention relates to a method for preparing high-purity m-xylylene diisocyanate (m-XDI). The method is characterized by comprising the following steps: feeding a crude product reaction liquid containing m-xylylene diisocyanate, a solvent and reaction byproducts into a light-phase flash evaporator operated at negative pressure for flash evaporation, and then feeding the above materials into a high-vacuum batch distillation tower for batch distillation, conducting refluxing with different reflux ratios for different fractions so as to finally obtain a qualified product. According to the method, the problem that heavy-phase components of the m-XDI reaction liquid are difficult to separate in a conventional rectification process is solved; and meanwhile, the self-agglutination phenomenon of the m-XDI reaction liquid containing the heavy-phase components in the rectification process is avoided, and the rectification yield of m-XDI can be improved.

Owner:甘肃银光聚银化工有限公司

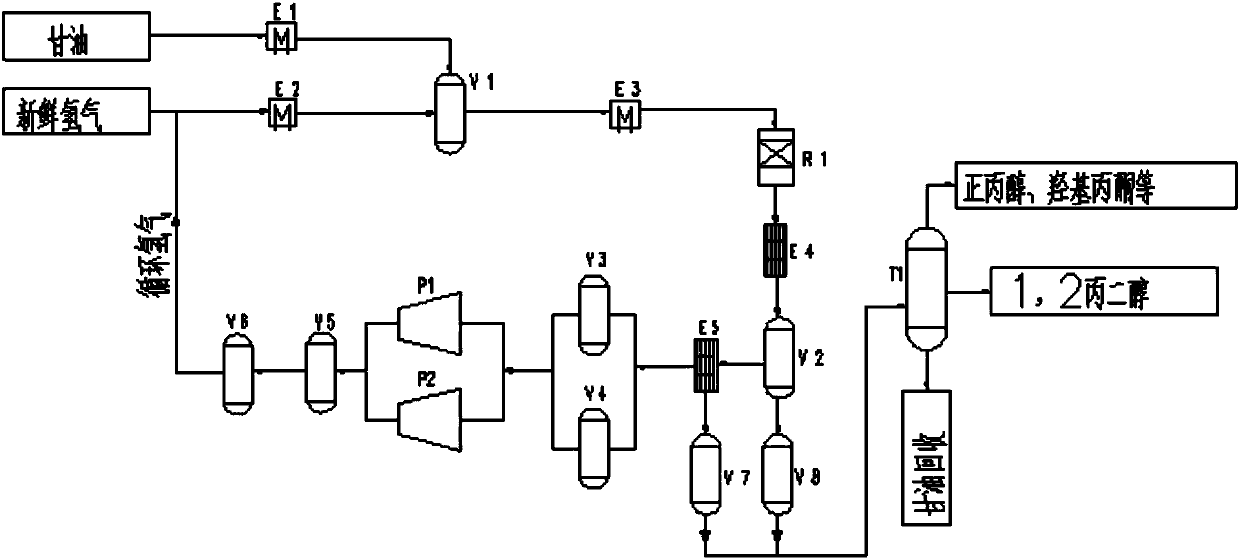

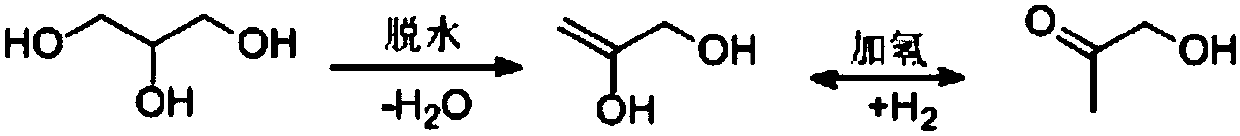

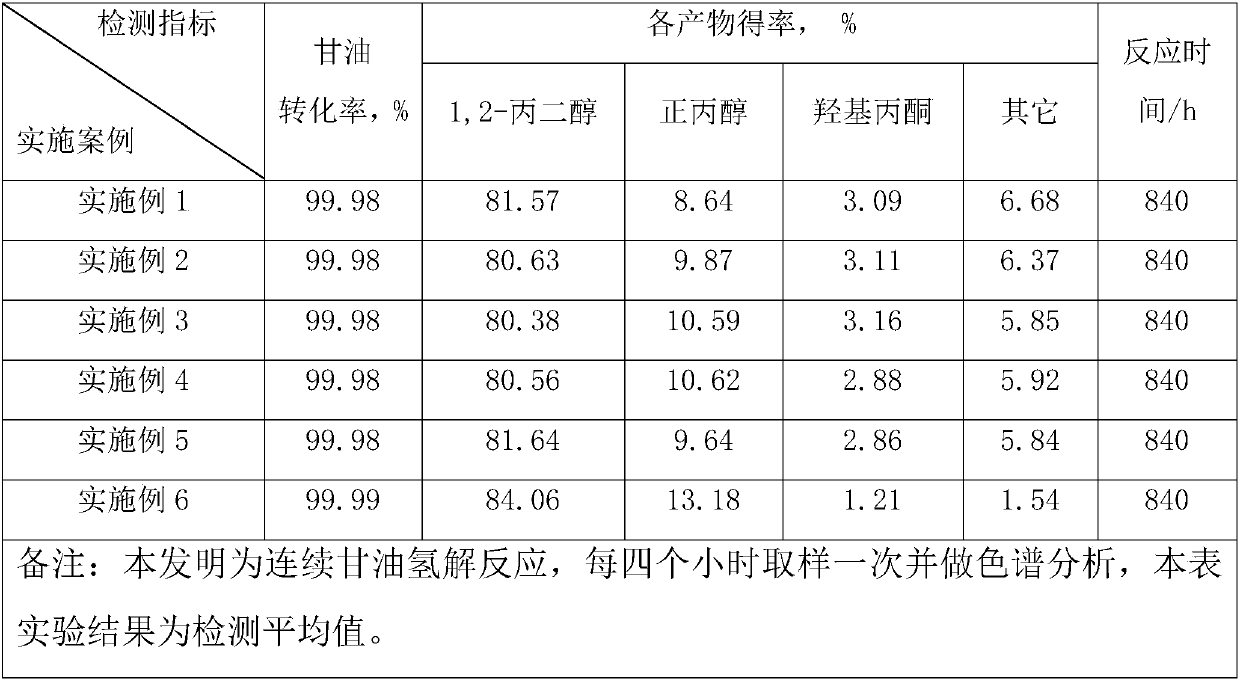

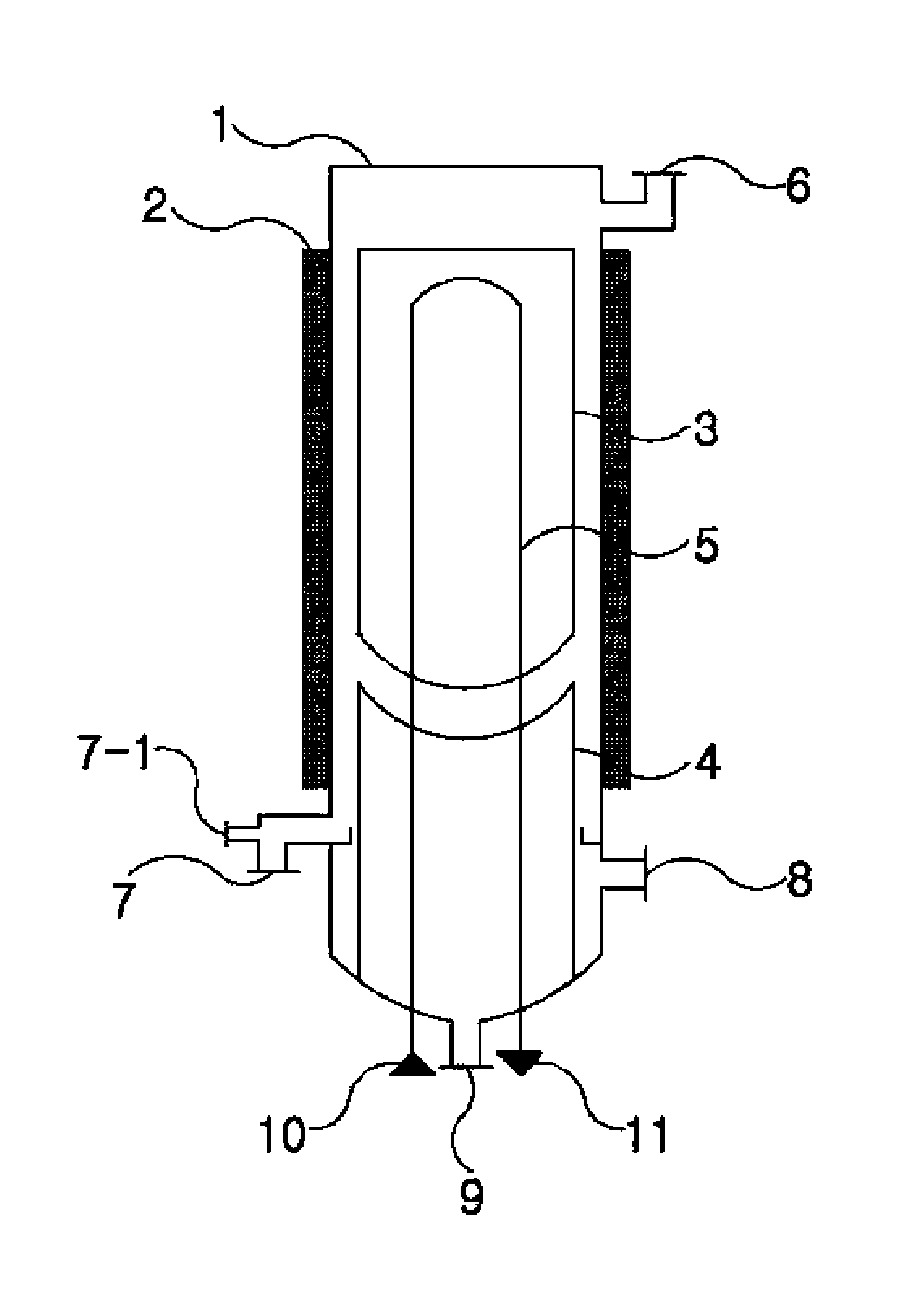

Method for preparing 1,2-propylene glycol and normal propyl alcohol by using biologic glycerol

InactiveCN107673952AReduce equipment costsSave on energy costsOrganic compound preparationHydroxy compound preparationRare earthGlycerol

The invention discloses a method for preparing 1,2-propylene glycol and normal propyl alcohol by using biologic glycerol. The method comprises the following steps: with biologic glycerol of which thepurity is more than or equal to 95% and hydrogen as main raw materials, by adopting a continuous reaction mode, first vaporizing glycerol, followed by atomizing with pre-heated hydrogen, and then carrying out a catalytic hydrogenolysis reaction on a fixed bed, wherein the reaction conditions are as follows: the temperature is 150-250 DEG C, the pressure is 0.8-2.5MPa, the molar ratio of hydrogen to glycerol is (10-50):1, and mass space velocity is 0.2-1.0 / h, and while the materials are vaporized, the vaporized materials are allowed to flow through a fixed reaction bed loaded with a hydrogenolysis catalyst to be subjected to a catalytic hydrogenolysis reaction; the hydrogenolysis catalyst is a copper-based catalyst, comprising the following components according to molar ratio: 10-20% of Cu,30-40% of Al, 30-40% of Si, and 1-10% of Zr and rare earth. The method for preparing 1,2-propylene glycol and normal propyl alcohol by using biologic glycerol disclosed by the invention has the advantages of few equipment investment, low production energy consumption and low product cost.

Owner:龙岩卓越生物基材料有限公司

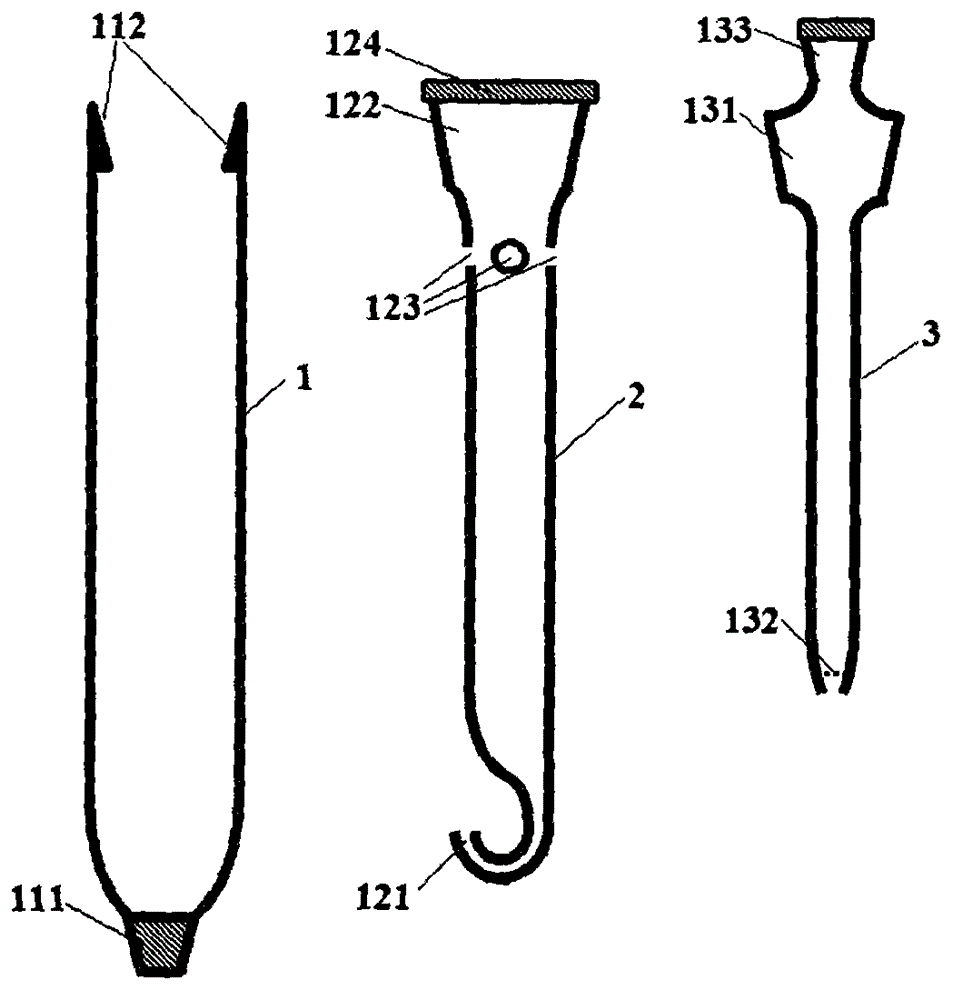

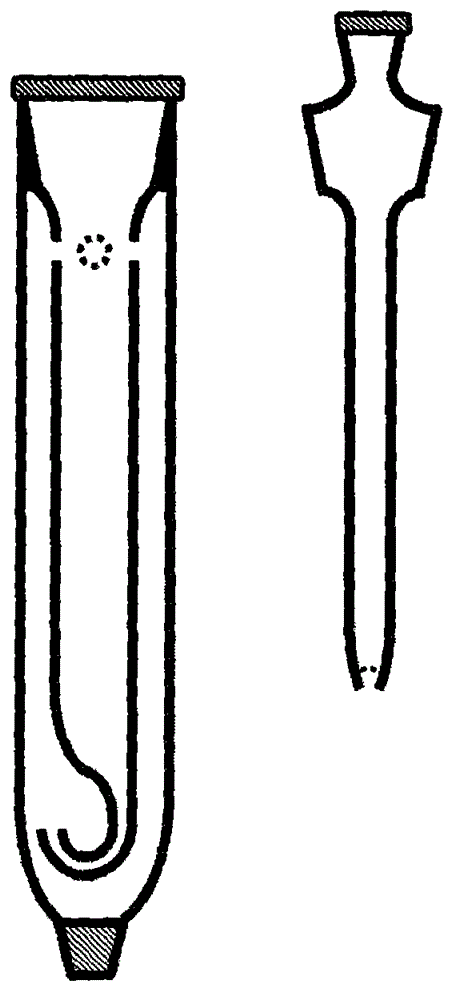

Method for preparing high-purity anhydrosugar alcohol using sequential combination of thin film distillation and short path distillation

ActiveUS9169263B1Easy to produceHigh purityOrganic compound preparationHydroxy compound preparationAlcoholSugar

The present invention relates to a technique for preparing an anhydrosugar alcohol using hydrogenated sugar as a raw material and, more specifically, to a technique for preparing a high-purity anhydrosugar alcohol (in particular, isosorbide, isomannide, isoidide, and the like) having a purity of 98% or higher and containing less than 0.1% of sorbitol and a sorbitan isomer, which are impurities, in a high total distillation yield of 94% or higher (more preferably, 95% or higher) by adding an acid to hydrogenated sugar (for example, hexitol) to convert same to an anhydrosugar alcohol, and then distilling the converted liquid over two or more stages by sequentially using a combination of an external condenser type wiped film evaporator and an internal condenser type short path evaporator.

Owner:SAMSANG CORP

Method for rectifying dimethyl phosphite

ActiveCN107722053AIncrease vacuumReduce corrosionGroup 5/15 element organic compoundsDimethyl phosphitePhosphate

The invention relates to a method for rectifying dimethyl phosphite. The method comprises the following steps that after raw materials are fully reacted in an esterification reaction kettle, crude ester enters the rectification kettle, a first rectifying tower and a second rectifying tower are arranged at the top of the rectifying kettle, and the first rectifying tower and the second rectifying tower are continuously heated; the first rectifying tower firstly collects low-boiling-point substances in the materials into a low-boiling-point substance storage tank, and tower bottom discharge liquid enters the second rectification tower for further separation; a vacuum unit is started for vacuum concentration, high-purity dimethyl phosphate is collected into a product storage tank, and tower bottom residual liquid is high-boiling-point substances. The technical process is simple, the production time is short, the product purity is high, the yield is high, continuous production can be achieved, the cost is low, the fuel utilization rate is high, emission is basically avoided, the environmental pollution is small, the reaction operation safety is high, the labor intensity is low, the labor efficiency is high, the product quality is good, and industrialization is facilitated.

Owner:HENAN HDF CHEM CO LTD

Preparation method of trichloropyridine

The invention discloses a preparation method of trichloropyridine. The method comprises the following steps: enabling a low chlorinated pyridine compound to react with chlorine in a contact manner in the existence of a catalyst, so as to obtain a contact reaction product, wherein the catalyst is one or more of ferric chloride, zinc chloride, magnesium chloride and aluminum chloride; and leading in an inactive gas to the contact reaction product to distill. By adopting the method disclosed by the invention, the distillation yield of the trichloropyridine can be up to over 90%, and the obtained product trichloropyridine does not contain a catalyst ingredient. In addition, the distilled residue can be applied to catalyzed synthesis of the trichloropyridine.

Owner:盐城恒盛化工有限公司

Method for preparing methyl acetoacetate by using novel composite catalyst

ActiveCN101337890BAvoid decompositionReduce decompositionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidBoiling point

The invention discloses a method for preparing methyl acetoacetate by using complex catalyst, which comprises the following steps: carrying out esterification reaction of methanol and diketene to generate crude methyl acetoacetate, wherein two different catalysts are added in the different stages of the esterification reaction; triethylenediamine catalyst is added before the esterification reaction; and diketene can be added directly dropwise without being heated by vapor, thereby overcoming the disadvantage that diketene is added dropwise after heating methanol to the boiling point in the conventional process and reducing the energy consumption; and cooling the generated liquid to 40 DEG C after the reaction, adding concentrated sulfur acid catalyst, keeping the temperature for half an hour, filtering, continuously rectifying the filtrate, and separating to obtain fine methyl acetoacetate with the content larger than 99%. Compared with the conventional intermittent rectification method, the continuous rectification method has greatly improved throughput and more convenient operation.

Owner:安徽天成新材料有限公司

Energy-saving and environment-friendly distillation recovery device

InactiveCN112742058ATake advantage ofNo pollutionFractional distillationProcess engineeringEnvironmental engineering

The invention provides an energy-saving and environment-friendly distillation recovery device which comprises a distillation tank, a middle tank, a material receiving tank, a recovery tank and a filtering tank, a feeding hopper is arranged on one side of the distillation retort, a distillation outlet is formed in the top end of the distillation tank, and a steam inlet pipe is communicated between the distillation outlet and the material receiving tank; a heating device is arranged at the bottom end of the distillation tank, a material containing cavity is fixed to the upper end of the heating device, the bottom end of the material containing cavity is communicated with the recovery tank through a recycling pipe, and the recovery tank is communicated with the filtering tank through a liquid pumping pipe. According to the invention, the water resource is fully utilized, the water is recycled, the middle tank is used for realizing multiple purposes of the water, the residual liquid after distillation is treated and can be reused, and even if the residual liquid finally needs to be discharged to the outside, the residual liquid is filtered, so that the environmental pollution is avoided. The device is energy-saving, environment-friendly and high in practicability.

Owner:新乡医学院三全学院

Preparation method of methyl acetoacetate

ActiveCN103450017BImprove stabilityReduce consumptionPreparation from ketenes/polyketenesAcetic acidNitrate

The invention provides a preparation method of methyl acetoacetate. The preparation method sequentially comprises the following steps of: (1) fully dissolving methanol and a catalyst, then adding the mixture into an esterification reaction kettle, heating up, and dropwise adding ketene dimer; (2) after completing dropwise addition, insulating, and cooling to produce crude methyl acetoacetate; (3) rectifying the crude product to obtain the finished methyl acetoacetate. The preparation method is characterized in that the catalyst in the step (1) is an amine type ionic liquid catalyst which is selected from one or more of n-butylamine nitrate, n-butylamine acetate, ethylamine nitrate, ethylamine acetate, propylamine nitrate and propylamine acetate. According to the preparation method of methyl acetoacetate, the amine type ionic liquid catalyst is researched and is good in stability, the stability of methyl acetoacetate is enhanced under the action of the catalyst, the rectification yield of a product can be improved, the technological operations are simple, the raw material consumption is reduced, and the catalyst has obvious advantages and a positive effect.

Owner:NANTONG ACETIC ACID CHEM

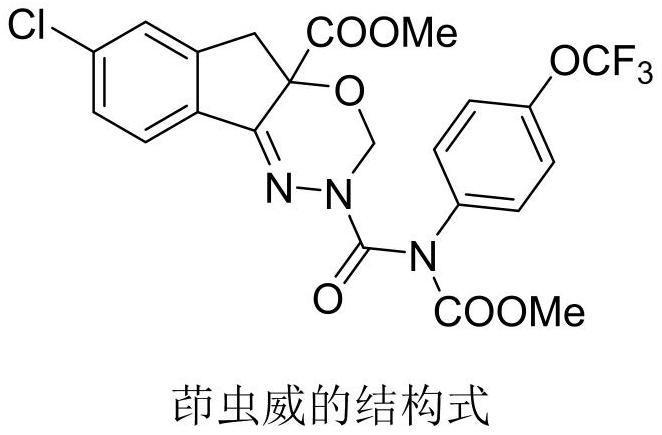

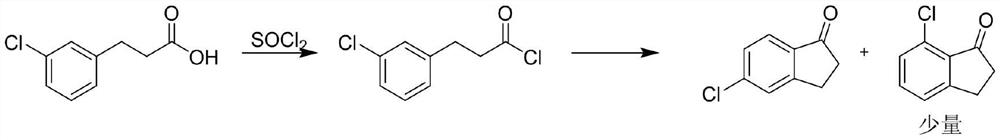

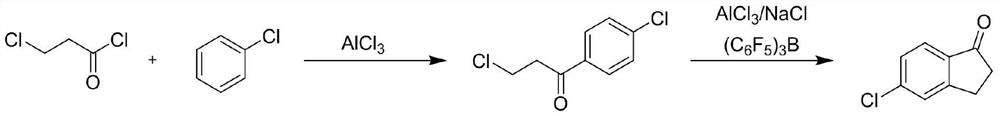

Improved process method for preparing 5-chloroindanone

ActiveCN112939756AReduce stepsShorten production hoursOrganic compound preparationCarbonyl compound preparation by condensationAluminum trichlorideOrganic synthesis

The invention discloses an improved process method for preparing 5-chloroindanone, and belongs to the technical field of organic synthesis. The method comprises the following steps: mixing chlorobenzene with anhydrous aluminum trichloride, adding 3-chloropropionyl chloride, and carrying out Friedel-Crafts acylation reaction to obtain 3,4'-dichloropropiophenone; then carrying out catalytic cyclization under the condition of anhydrous aluminum trichloride / sodium chloride or tri(pentafluorophenyl)borane; and after the reaction is finished, washing the product with water and directly rectifying the product to obtain the 5-chloroindanone. According to the process disclosed by the invention, the direct distillation is performed after water washing, so that no subsequent operation is performed, the operation steps are reduced, the production time is shortened, the production cost is saved, the extraction effect of the product is greatly improved, the yield of the product is improved by 15% or above, low-boiling-point substances and high-boiling-point substances can be effectively removed through direct distillation, and the content of the product is improved to 99.5% or above; meanwhile, cyclization is carried out under catalysis of tri(pentafluorophenyl)borane, so that the total dosage of aluminum trichloride can be reduced, the cyclization reaction temperature is reduced, the generation of tar is reduced, and the yield of the product is improved.

Owner:上海鼎素精细化工有限公司

Separation method of chloro isoamylene

InactiveCN100999440AReduce the amount of componentsReduce moistureHalogenated hydrocarbon preparationIsomerismsTower

This invention relates to a separation method of chlor-isoamylene. First preheats the output of isoprene react with hydrogen chloride; then send the output into the first tower central of continuous distillation tower which includes two series towers for vacuum distillation; the first tower pressure is -0.070 ~ - 0.100MPa, the top temperature of 30 ~ 60 deg C, the temperature of the tower reactor is 50 ~ 70 deg C, reflux ratio is 2 ~ 5; reflux pot of first tower has a Layered device for regular separating water; outputs component of reflux pot enter isomerism reactor for isomerism reaction, after water separating return to first tower; tower reactor components enter central of second tower, pressure is - 0.08 ~ 0.10MPa, the top temperature of 30 ~ 50deg, tower reactor temperature of 60 ~ 80 deg C, reflux ratio is 1-3, store the products of consecutive distillation in the tank with cooling jacket. Compared with existing technologies, this invention has energy-saving, high purity features.

Owner:上海博爱化工有限公司

Preparation method of ethyl acetoacetate

ActiveCN103450018BImprove stabilityReduce consumptionPreparation from ketenes/polyketenesAcetic acidNitrate

Owner:NANTONG ACETIC ACID CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com