Patents

Literature

295 results about "Methylene diisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

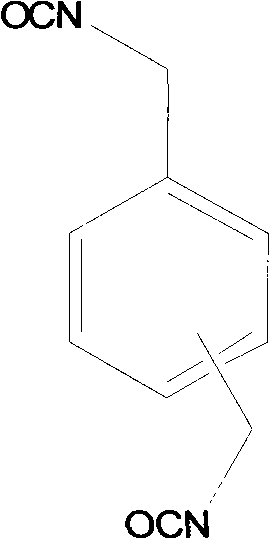

Synthesis process of phenyl dimethylene diisocyanate

InactiveCN1931834AEasy to storeEasy to transportIsocyanic acid derivatives preparationOrganic compound preparationLiquid mediumMethylene diisocyanate

The synthesis process of phenyl dimethylene diisocyanate belongs to the field of isocyanate synthesizing technology. In inert liquid medium, phenyl dimethylamine or its hydrochloride or carbonate reacts with bis(trichloromethyl) carbonate at the temperature of -20 deg.c to -60 deg.c, before heating and reflux reaction for 0.5-5 hr to synthesize phenyl dimethylene diisocyanate. The amount of bis(trichloromethyl) carbonate is 0.5-15 times that of phenyl dimethylamine or its hydrochloride or carbonate. The present invention has stable solid crystal materials, and is environment friendly and suitable for industrial production.

Owner:杭州崇舜化学有限公司

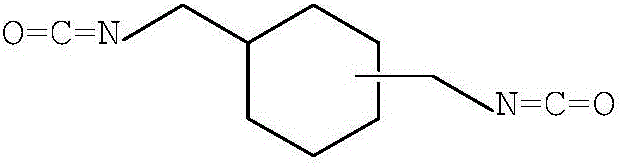

Preparation method of hydrogenated xylylene diisocynate

ActiveCN106674056AGood dispersionImprove liquidityOrganic compound preparationIsocyanic acid derivatives purification/separationXylyleneN dimethylformamide

The invention discloses a preparation method of hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate comprises the following steps: (1) performing salt forming reaction on 1,3-cyclohexanol dimethylamine and concentrated hydrochloric acid in a two-phase reaction solvent to obtain amine salt, wherein the two-phase reaction solvent consists of water and an inert organic solvent insoluble in water ; (2) performing photochemical reaction on the ammonium salt obtained in the step (1) and phosgene in an inert solvent by taking N,N-dimethylformamide or N,N-dimethylacetamide as a catalyst to obtain reaction liquid, and performing aftertreatment on the reaction liquid to obtain the hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate has the advantages of complete ammonium salt formation, small grain size of the ammonium salt, low viscosity of the ammonium salt, high space-time conversion rate of photochemical reaction, simple process, low cost and the like.

Owner:HUNAN HAILI CHEM IND

Method for preparing xylylene diisocyanate based on salification-phosgenation reaction

ActiveCN102070491ALarge particle sizeIncrease the rate of the phosgenation reactionIsocyanic acid derivatives preparationOrganic compound preparationXylyleneHigh concentration

The invention discloses a method for preparing xylylene diisocyanate (XDI) based on salification-phosgenation reaction. The method comprises the following steps of: (a) a salification reaction process of amine solution which is formed by xylylene diamine in an inert organic solvent and hydrogen chloride; (b) a hydrochloride centrifugal concentration process; (c) a high-pressure phosgenation process; and (d) a low-pressure phosgenation process. In the method, the salification reaction of the amine is kept performing in low-concentration hydrochloride solution all the time; and high-concentration hydrochloride solution participates in the phosgenation reaction to prepare the XDI. The process has a high time-space conversion rate and simultaneously ensures a good salification effect.

Owner:WANHUA CHEM GRP CO LTD +1

Room-temperature self-crosslinking water-soluble polyurethane acrylic resin and preparation method and application thereof

InactiveCN101544738ALow viscosityImprove conversion ratePolyureas/polyurethane adhesivesInksPolymer scienceAcrylic resin

The invention discloses a room-temperature self-crosslinking water-soluble polyurethane acrylic resin and a preparation method and an application thereof. The preparation method adopts an in-situ emulsion polymerization method and improves the prior preparation method, introduces tetramethyl benzene dimethylene diisocyanate or 2, 4 methyl cyclohexyl diisocyanate, and dipropylene glycol or neopentyl glycol functioning as chain extendor in raw materials, thereby lowering the viscosity of polyurethane prepolymer, and achieving the purpose of performing the synthetic reaction without organic solvent; oil-soluble evocating agent and water-soluble evocating agent are adopted to together evocate radical copolymerization so that oil-soluble monomer and water-soluble monomer can more effectively perform the radical copolymerization, thereby improving the reaction conversion rate. In addition, the combination of the two evocating agents also leads emulsion in the reaction to keep stable without easily jellifying and layering. The resin can be used for preparing plastics, aluminum foil package compound gel, paper-plastics compound gel, water color ink, water oil polish, water wooden ware paint or water plastic paint.

Owner:SUN YAT SEN UNIV

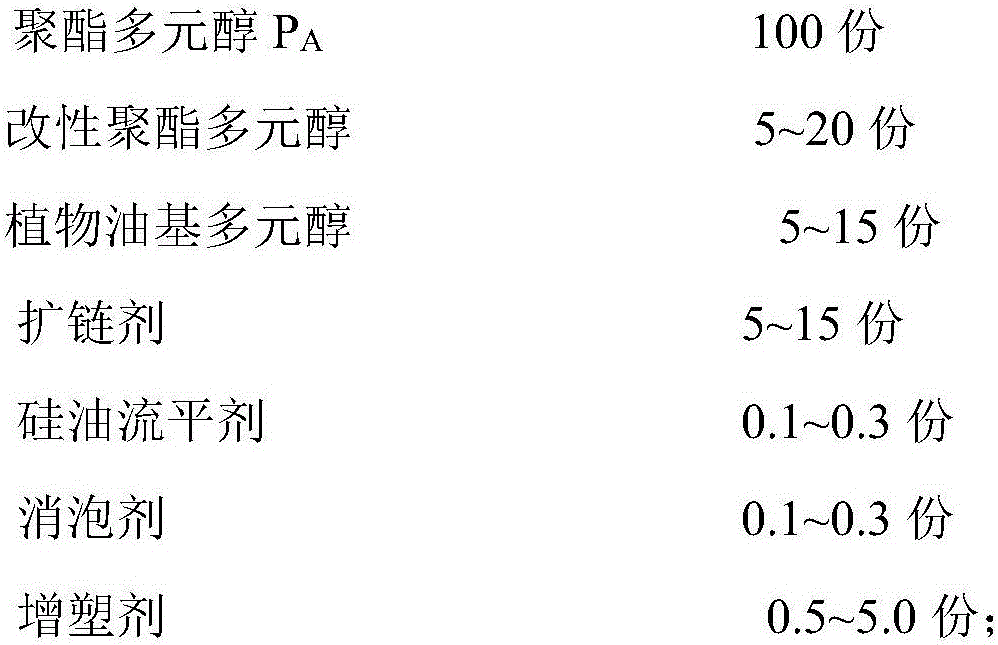

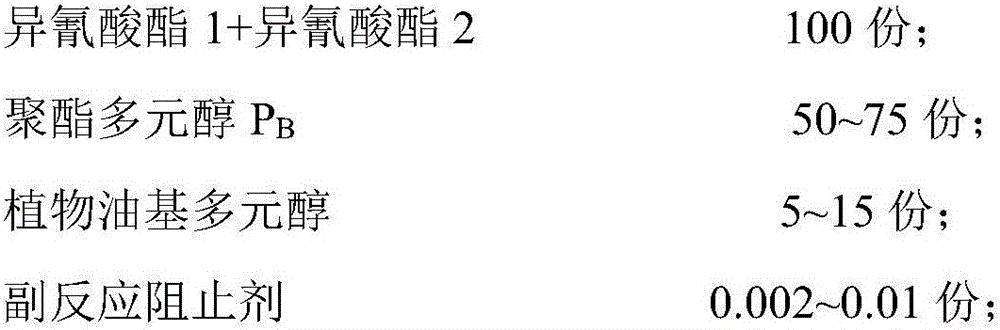

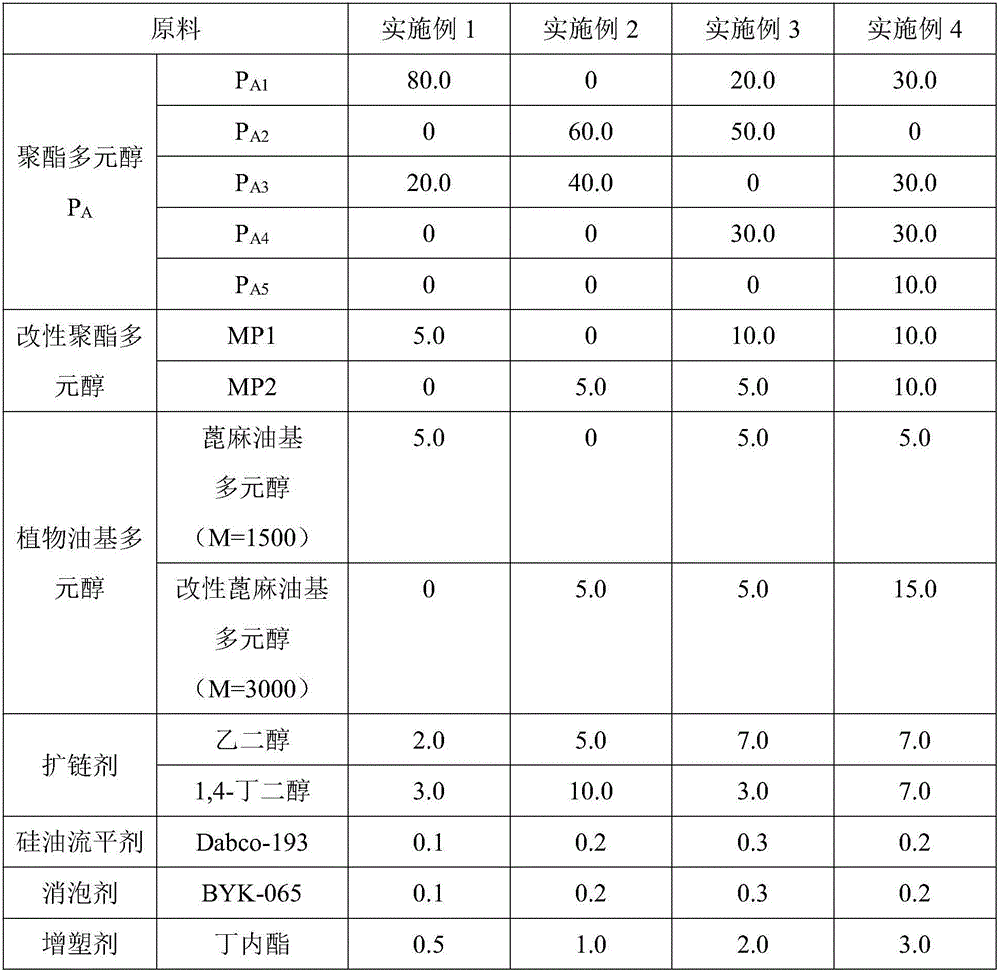

Environment-friendly polyurethane adhesive, and preparation method and applications thereof

ActiveCN106634778AOrderly rowsGood physical propertiesPolyureas/polyurethane adhesivesPolyurethane adhesiveOperability

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Preparation method of methylene diphenyl diisocyanate

ActiveCN106748887AImprove conversion rateInhibition of byproductsIsocyanic acid derivatives preparationOrganic compound preparationReaction rateOrganic phosphorus

The invention provides a preparation method of methylene diphenyl diisocyanate. The method comprises the following steps: performing a salt forming reaction on m-xylylenediamine and hydrogen chloride gas to obtain m-xylylenediamine hydrochloride; mixing the m-xylylenediamine hydrochloride, an organic phosphorus compound and solid phosgene for reaction to obtain methylene diphenyl diisocyanate. In a process of preparing methylene diphenyl diisocyanate, according to the application, an organic phosphorus compound additive is introduced, so that the reaction of m-xylylenediamine hydrochloride is promoted, therefore, the reaction rate and the effective conversion rate are improved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Method for synthesizing hexamethylene diisocyanate (HDI) biuret

InactiveCN101475680AReduce HDI contentReduce use toxicityIsocyanic acid derivatives purification/separationDissolutionHigh pressure

The invention relates to a method for synthesizing hexamethylene diisocyanate (HDI) biuret through a spray method. The method comprises the following steps: adopting the high pressure to inject water in the form of fog drops into an HDI contained reaction kettle, setting the temperature to be between 60 and 130 DEG C, setting the mol ratio of HDI to water 2 to 15, setting the water spraying time to be between 0.5 and 8 hours, carrying out heat preservation at a temperature of between 80 and 150 DEG C for 0 to 5 hours, and then carrying out the separation through a separating device; setting the separation temperature to be between 70 and 200 DEG C and the pressure to be between 0.5 and 50,000Pa; and pumping the separated steaming residue into a dilution container with a stirrer for dissolution, adding a metered solvent into the dilution container in advance, continuously adding the metered solvent into the dilution container with the pumping of the steaming residue, and carrying out the dilution to obtain an HDI biuret product with 25 to 100 percent of solid content. The method improves the reaction efficiency for producing the HDI biuret product, reduces the generation of polyurea, reduces the HDI content in the HDI biuret, and reduces the use toxicity of the HDI biuret. In addition, the production process is economical and has environmental protection.

Owner:JIANGMEN YIYUAN BIOCHEM ENG

Polymerizable composition for optical material, optical material and method for producing optical material

Disclosed is a polymerizable composition for o an optical material containing tolylene diisocyanate, hexamethylene diisocyanate, and one or more polythiol compounds selected from the group consisting of 4-mercaptomethyl-1,8-dimercapto-3,6-dithiaoctane,4,8-, 4,7- or 5,7-dimercaptomethyl-1,11-dimercapto-3,6,9-trithiaundecane, pentaerythritol tetrakismercaptoacetate, pentaerythritol tetrakismercaptopropionate, 2,5-bis(mercaptomethyl)-1,4-dithiane, bis(mercaptoethyl)sulfide, 1,1,3,3-tetrakis(mercaptomethylthio)propane, 4,6-bis(mercaptomethylthio)-1,3-dithiane and 2-(2,2-bis(mercaptomethylthio)ethyl)-1,3-dithietane.

Owner:MITSUI CHEM INC

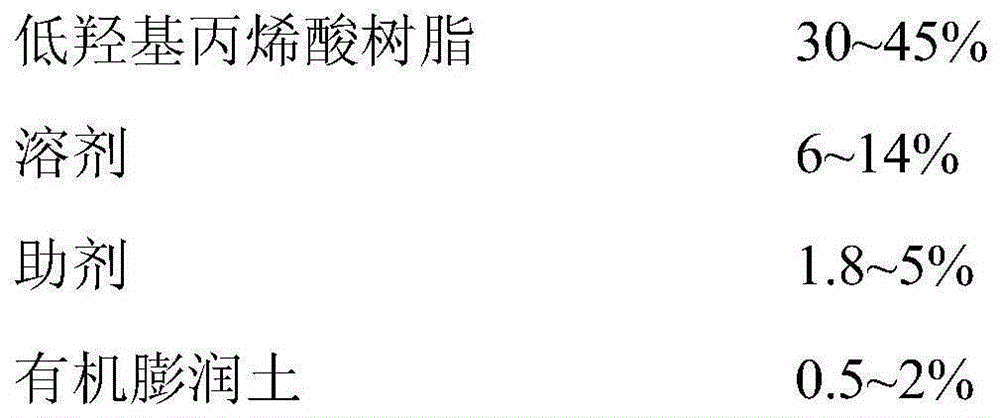

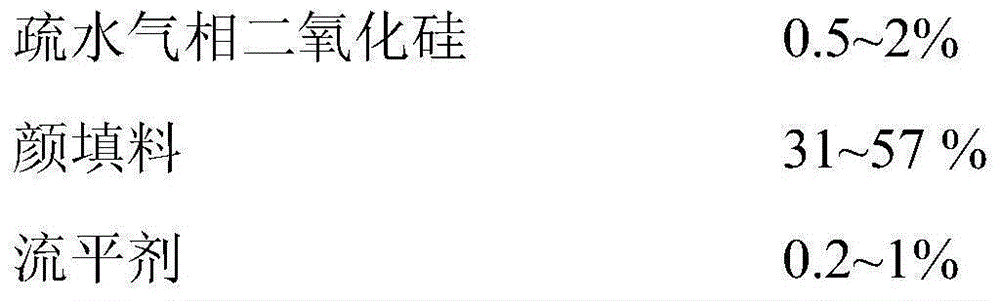

Primer-topcoat combined anti-corrosion paint suitable for various base materials and preparation method thereof

InactiveCN105111908AStrong adhesionWith salt spray resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsGas phaseSolvent

The invention discloses primer-topcoat combined anti-corrosion paint suitable for various base materials. The anti-corrosion paint is prepared from, by weight, 7-10 parts of components A and 1 part of components B in a combined mode, wherein the components A is prepared from, by weight, 30-45% of low hydroxyl acrylic acid resin, 6-14% of solvent, 1.8-5 parts of auxiliaries, 0.5-2% of organic bentonite, 0.5-2% of hydrophobic fumed silica, 31-57% of pigment filler and 0.2-1% of leveling agent; the components B is prepared from, by weight, 45-55% of hexamethylene diisocyanate tripolymer and 45-55% of solvent. A preparation method includes the steps that the solvent is added into the low hydroxyl acrylic acid resin, the auxiliaries, the organic bentonite, the hydrophobic fumed silica and the pigment filler are added, stirring and grinding are performed, the viscosity is adjusted, impurities are removed, and then the components A are obtained; the hexamethylene diisocyanate tripolymer and the solvent are mixed to obtain the components B, and the components A and the components B are mixed according to the proportion. The primer-topcoat combined anti-corrosion paint has excellent adhesive force for aluminum products, stainless steel plates and galvanized sheets, has physical and mechanical properties of salt spray resistance and others of anti-corrosion primers, and is excellent in water resistance, acid and alkali resistance and weather resistance, wherein the weather resistance is over 1200 hours.

Owner:紫荆花制漆(成都)有限公司

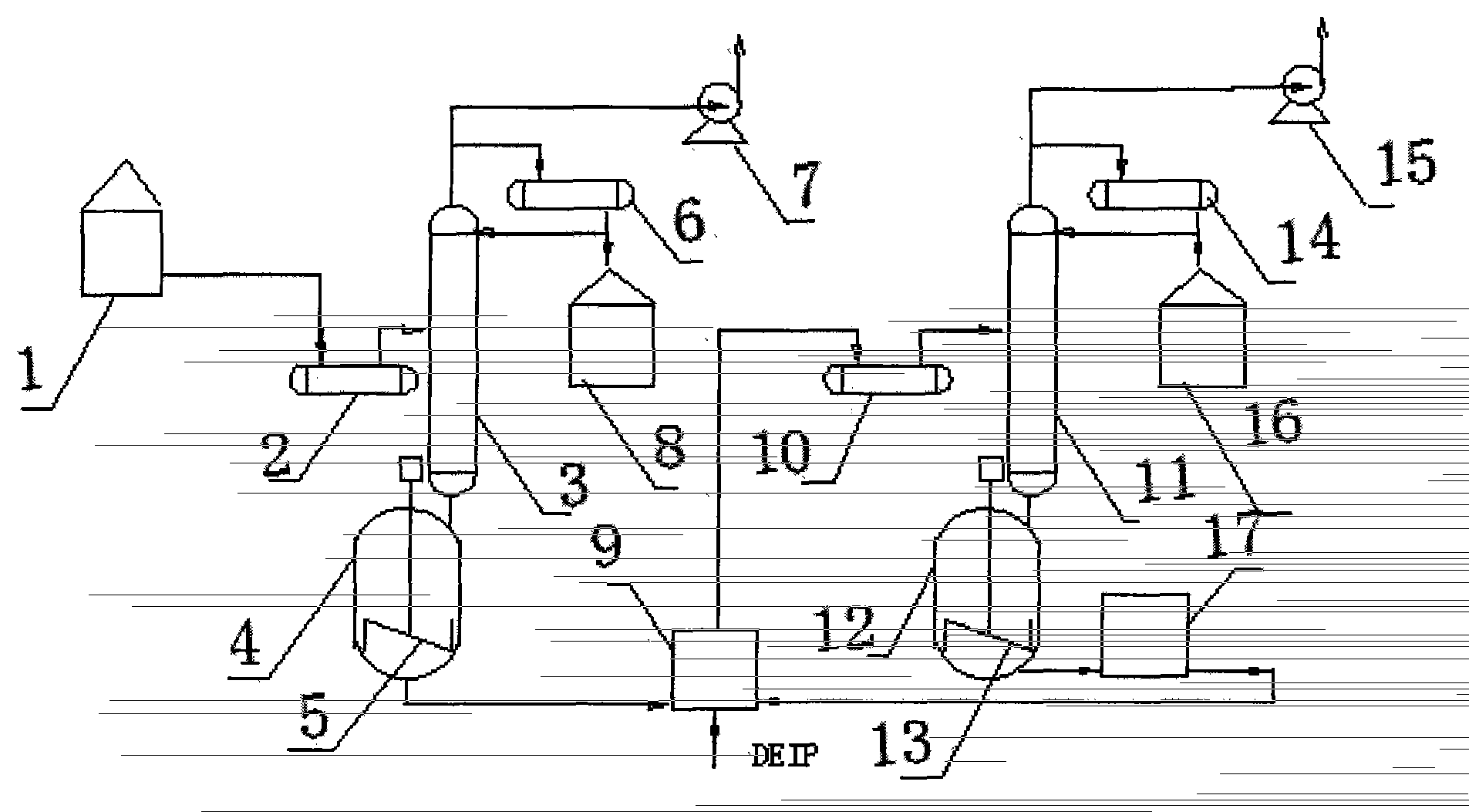

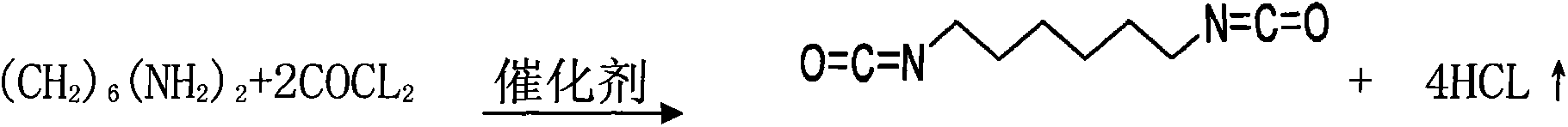

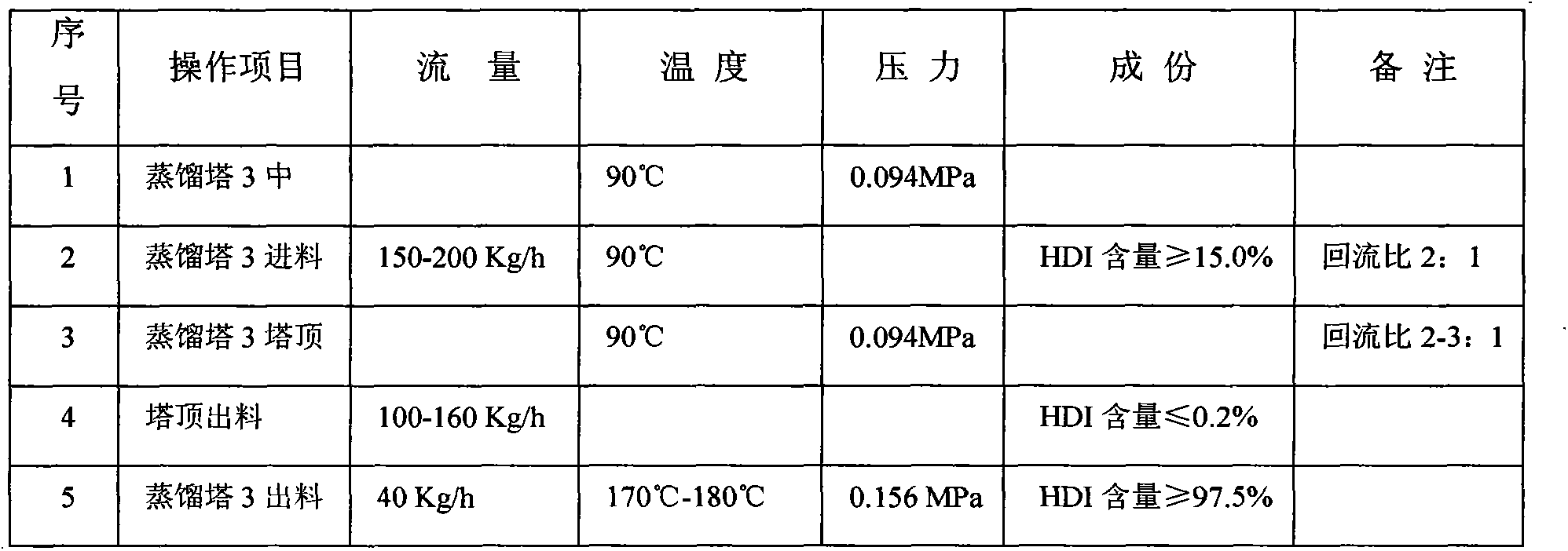

Device for refining hexamethylene diisocyanate and method thereof

The invention specifically relates to production equipment for refining hexamethylene diisocyanate and a method thereof. A stirrer is respectively arranged in the middle of the bottom of both a distillation column and a rectifying tower which are provided with a stirring device, and stirring wings are a frame type. The method for refining hexamethylene diisocyanate comprises the following steps: (1) letting an synthesized HDI solution enter a distillation column through a heat exchanger, starting a first vacuum pump, and starting a first stirrer in the column bottom while the agitation speed is less than or equal to 60rpm / min; Starting a first condenser on the tower top, evaporating all o-dichlorobenzene, continuously discharging by the distillation column and entering a mixing tank; and (ii) adding a DEIP solvent into the mixing tank, uniformly mixing crude HDI and the DEIP solvent according to the HDI-DEIP ratio of 1:1-1.5, sending the mixture into the rectifying tower to firstly evaporate mono-isocyanate chloride and continuously evaporate the HDI, drawing forth the DEIP for recycling, stirring high polymer residue in a heating vessel and discharging regularly, and carrying out burning treatment. The device and method provided by the invention can be applied in distillation separation and purification production technology which is easy to generate auto-agglutination phenomenon under the distillation condition.

Owner:甘肃银光聚银化工有限公司

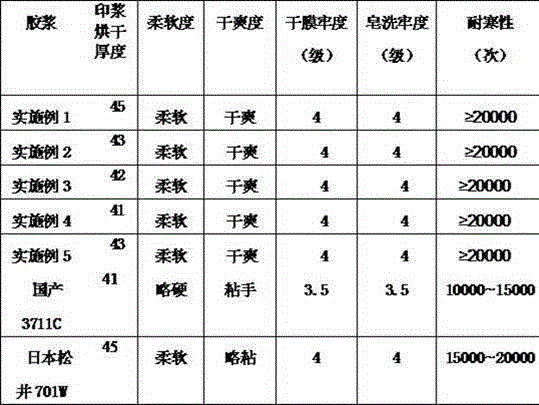

Waterborne polyurethane latex emulsion for nylon fabric and preparation method thereof

The invention provides a waterborne polyurethane latex emulsion for a nylon fabric and a preparation method thereof. The waterborne polyurethane latex emulsion comprises the following raw materials by weight: 20 to 50 of hydrogenated methyl diphenylene diisocyanate, 5 to 35 of hexamethylene diisocyanate, 50 to 70 of polytetramethylene ether glycol, 40 to 70 of polycarbonate glycol, 10 to 25 of polyethylene glycol, 25 to 35 of acetone, 5 to 15 of chain extender, 5 to 20 of micromolecular chain extender and 100 to 300 of deionized water. The preparation method comprises the following steps: prepolymerization; chain extension; and emulsification. The waterborne polyurethane latex emulsion is used for printing of the nylon fabric and has the advantages of soft handle, dryness, high elasticity, good fastness to washing, excellent cold resistance and good compatibility with color paste.

Owner:LIAONING FIXED STAR FINE CHEM

High transparency scratch-resisting matt clear paint

ActiveCN103131321AImprove the decorative effectImprove protectionPolyurea/polyurethane coatingsPolymer scienceToluene diisocyanate

The invention discloses high transparency scratch-resisting matt clear paint which is composed of a host agent, a curing agent and a diluent agent. The host agent comprises 65.5 % - 75.5% of short oil alkyd resins, 16 % - 25 % of solvent, 0.1 % - 0.3 % of antifoaming agents, 0.1 % - 0.3 % of flatting agents, 0.1 % - 0.5 % of anti-settling agents, 0.1 % - 0.3 % of dispersing agents, 1 % - 3 % of scratch-resisting assistant agents, and 4 % - 8 % of delustering agents. The curing agent comprises 40 % - 50 % of toluene diisocynate (TDI) trimer, 10 % - 20 % of TDI- hexamethylene diisocyanate (HDI) mixed trimer, 20 % - 30 % of TDI- trimethylolpropane adduct, and 20 % - 30 % of butyl acetate. The diluent agent comprises 40 % - 50 % of butyl acetate, 20 % - 30 % of dimethylbenzene, and 20 % - 30 % of propylene glycol methyl ether acetate. The high transparency scratch-resisting matt clear paint is good in transparency and scratch-resisting performance, and is easy to process.

Owner:安徽名士达新材料有限公司

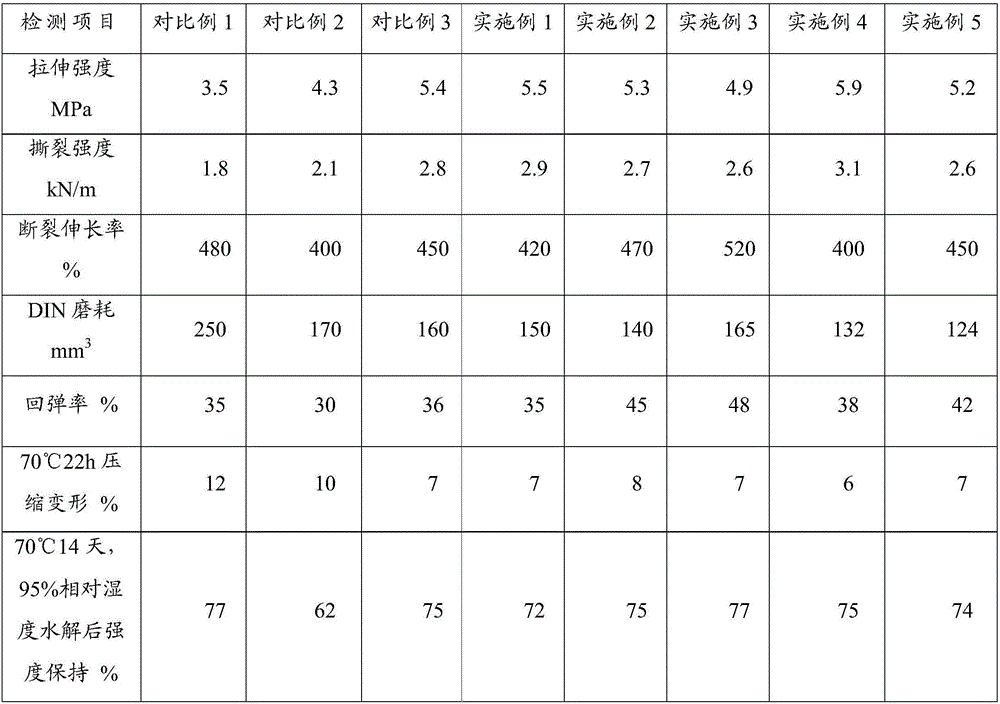

B component isocyanate prepolymer and polyurethane double components for preparing microcellular polyurethane elastomer and application

The invention discloses a B component isocyanate prepolymer for preparing a microcellular polyurethane elastomer. The B component isocyanate prepolymer is prepared from isocyanate, polyether polyol and polyester polyol. The polyester polyol comprises polyethylene adipate glycol diethylene glycol trimethylpentanediol trimethylolpropane ester polyols and poly dimer acid ethanediol 1,4-butanediol 1,3-butanediol trimethyl pentanediol ester polyols. The polyether polyol comprises polytetrahydrofuran ether glycol and ethylene oxide and propylene oxide copolyether. Isocyanate comprises 4,4-diphenyl methane diisocyanate, carbodiimide-ketonuria imine modified liquidation 4,4-diphenyl methane diisocyanate and cyclohexane tetramethylxylylene diisocynate. The invention further provides double components for preparing a microcellular polyurethane elastomer and a microcellular polyurethane elastomer. The microcellular polyurethane elastomer prepared from the B component isocyanate prepolymer has excellent mechanical property and hydrolysis resistance.

Owner:XUCHUAN CHEM SUZHOU

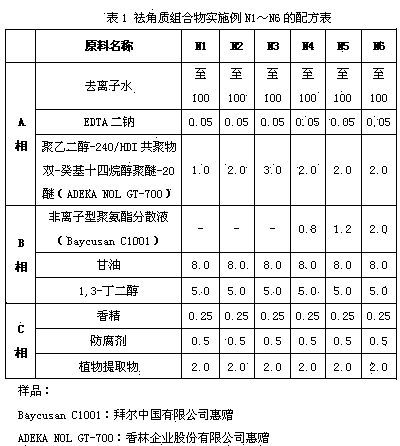

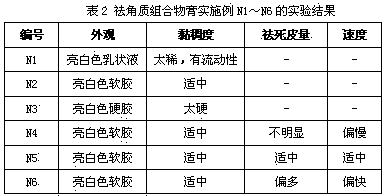

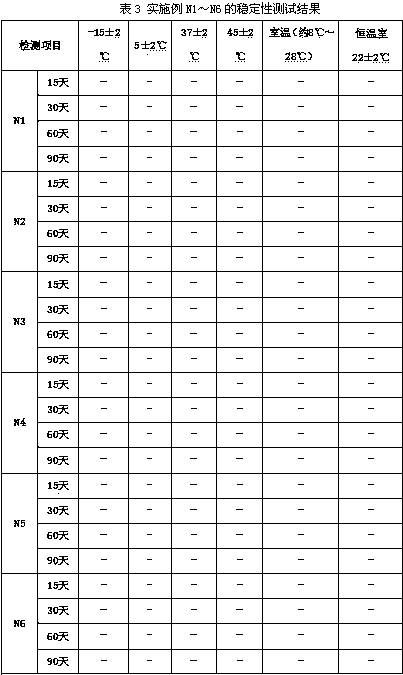

Non-ionic composition used for removing keratin and preparation method of non-ionic composition

ActiveCN103705428ABrighten the appearanceGood experienceCosmetic preparationsToilet preparationsPolymer scienceCutin

The invention relates to a non-ionic composition used for removing keratin. The non-ionic composition comprises the following components by weight percent: 0.5-5% of non-ionic polyurethane dispersion liquid, 0.5-5% of non-ionic emulsifier, 0.5-5% of plant extract, 5-20% of moisturizer and the balance of deionized water and additive, wherein the non-ionic emulsifier is polyethylene glycol-240 / hexamethylene diisocyanate copolymer dual-decyl tetradecane alcohol polyether-20 ether; active ingredient in the plant extract is gallogen. According to the non-ionic composition, the non-ionic polyurethane dispersion liquid is used as a film-forming agent to be twisted, the non-ionic emulsifier is used for thickening, non-ionic safe raw material is adopted, feeling is close to skin, a zwitterion complex doe not need to be formed, matrix with low pH value is not needed, and the non-ionic composition is safe, non-irritation, bright white in appearance, smooth and elastic, good in use experience feeling, obvious in immediate effect, moderate and safe, and has the effect of softening the keratin for a long time.

Owner:SHANGHAI INOHERB COSMETIC

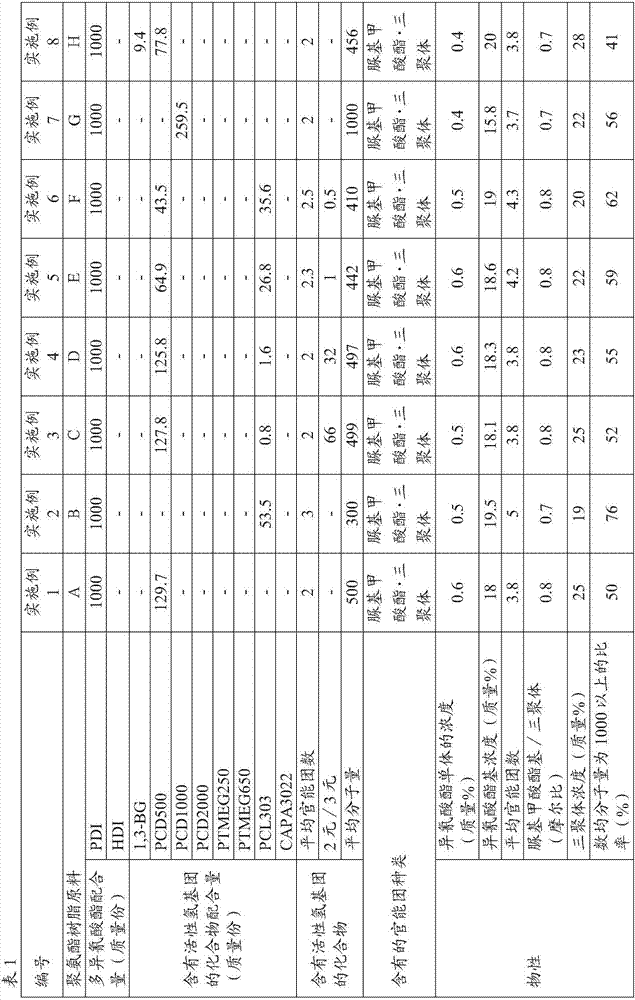

Self-repairing polyurethane resin material, self-repairing polyurethane resin, self-repairing coating material, self-repairing elastomer material, method for producing self-repairing polyurethane resin material, and method for producing self-repairing polyurethane resin

InactiveUS20170342189A1Good chemical resistanceMaintain good propertiesPolyurea/polyurethane coatingsElastomerHydrogen

In a self-repairing polyurethane resin material produced by reaction of pentamethylenediisocyanate with an active hydrogen group-containing compound, the active hydrogen group-containing compound contains a polyol compound having a number average molecular weight of 100 to 2000 and an average functionality of 2 to 3.

Owner:MITSUI CHEM INC

Encapsulating polyurethane material recipe and encapsulating material containing said recipe

ActiveCN1986641AImprove the safety of useEasy to useOther chemical processesMoisture cure polyurethaneHigh intensity

The encapsulating polyurethane material consists of polyether polyol and diphenyl methylene diisocyanate, and the diphenyl methylene diisocyanate is liquefied 4, 4'-diphenyl methylene diisocyanate. The encapsulating polyurethane material as one kind of high strength single component wet cured encapsulating polyurethane material has excellent storage stability, short curing period, convenient use, excellent adhesion and no bubble produced during wet curing. It is suitable for sealing and adhering glass, PVC, PP, ABS and other plastics, especially memory card.

Owner:靖江德方科技服务有限公司

Process for the production of polyurethane di(METH)acrylates

A process for the production of polyurethane di(meth)acrylates in which a diisocyanate component, a diol component and hydroxy-C2-C4-alkyl(meth)acrylate in the molar ratio x:(x-1):2 are reacted without solvent and without subsequent purification operations, wherein x means any desired value from 2 to 5, wherein 50 to 80 mol % of the diisocyanate component is formed by 1,6-hexane diisocyanate, and 20 to 50 mol % by one or two diisocyanates, each forming at least 10 mol % of the diisocyanate component and being selected from the group consisting of toluylene diisocyanate, diphenylmethane diisocyanate, dicyclohexylmethane diisocyanate, isophorone diisocyanate, trimethylhexane diisocyanate, cyclohexane diisocyanate, cyclohexanedimethylene diisocyanate and tetramethylenexylylene diisocyanate, wherein the mol % of the respective diisocyanates add up to 100 mol %, wherein the diol component comprises no more than four different diols, and 20 to 100 mol % of the diol component is formed by at least one linear aliphatic alpha,omega-C2-C12-diol, and 0 to 80 mol % by at least one (cyclo)aliphatic diol that is different from linear aliphatic alpha,omega-C2-C12-diols, wherein each diol of the diol component forms at least 10 mol % within the diol component, and wherein the mol % of the respective diols add up to 100 mol %.

Owner:EI DU PONT DE NEMOURS & CO

Process for production of wood composites using mixed PMDI/solid novolac resin binder

InactiveCN1330668AImprove water resistanceLess tendency to stick to platenPolyureas/polyurethane adhesivesWood veneer joiningMethylene diisocyanateComposite lumber

This invention relates to a process for the production of composite wood products. This process comprises a) applying a binder composition to wood particles, and b) molding or compressing the wood particles treated with the binder to form a composite wood product. Suitable binder compositions comprise a polymethylene poly(phenyl isocyanate) and a solid novolac resin.

Owner:HEXION SPECIALTY CHEM INC

Waterborne silane modified polyurethane bonding agent and preparation method thereof

ActiveCN105462536AImprove performanceHigh strengthPolyureas/polyurethane adhesivesEpoxyPolyurethane adhesive

The invention discloses a waterborne silane modified polyurethane bonding agent and a preparation method thereof. The waterborne silane modified polyurethane bonding agent is prepared from the following raw materials in parts by weight: 15-20 parts of polyether glycol, 8-10 parts of diisocyanate, 1-2 parts of an acid, 2-5 parts of a silane coupling agent, 8-10 parts of epoxy resin, 5-10 parts of acetone, 0.5-1 part of a catalyst, 2-5 parts of an end-capping agent, 1-2 parts of trimethylamine, 10-15 parts of 1-methyl-2-pyrrolidinone and 45-50 parts of deionized water. According to the waterborne silane modified polyurethane bonding agent provided by the invention, the silane coupling agent and polyurethane resin are compounded, and the silane coupling agent has the characteristics of being fast to cure, free of foaming during curing, and excellent in dampness-heat and aging resistance, so that the performance of a polyurethane bonding agent is improved; meanwhile, through addition of tetramethyl isophthalylidene diisocyanate, the strength, bonding force, appearance, flexibility and durability of the a waterborne polyurethane adhesive can be improved. Therefore, the developed waterborne silane modified polyurethane can be resistant to 60 minutes' boiling at 100 DEG C, and has high bonding strength to various hydrophilic and hydrophobic substrates.

Owner:SHANGHAI JINQIANG ADHESIVE

High peel strength adhesive for shoes

InactiveCN105238323AHigh viscosityHigh tensile strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAdhesive

The present invention discloses a high peel strength adhesive for shoes, wherein the raw materials comprise, by weight, 90-105 parts of modified polyurethane, 25-28 parts of carboxy styrene-butadiene rubber, 20-23 parts of water-soluble chlorosulfonated polyethylene, 30-35 parts of a water-soluble epoxy resin, 5-10 parts of a calcium zinc stabilizer, 3-8 parts of an anti-aging agent, and 50-80 parts of water, and during the modified polyurethane preparation method, graphene oxide is subjected to acidification and ultrasound treatment, the obtained material is grafted with cyclohexanedimethylene diisocyanate to obtain modified diisocyanate, and the modified diisocyanate, an anionic hydrophilic chain extender and other materials are combined to generate the modified polyurethane. According to the present invention, the high peel strength adhesive for shoes has characteristics of excellent peel resistance, high toughness and good bonding property, and adopts water as the solvent, such that the environmental protection is good, and the high peel strength adhesive can not harm the health.

Owner:安徽大松树脂有限公司

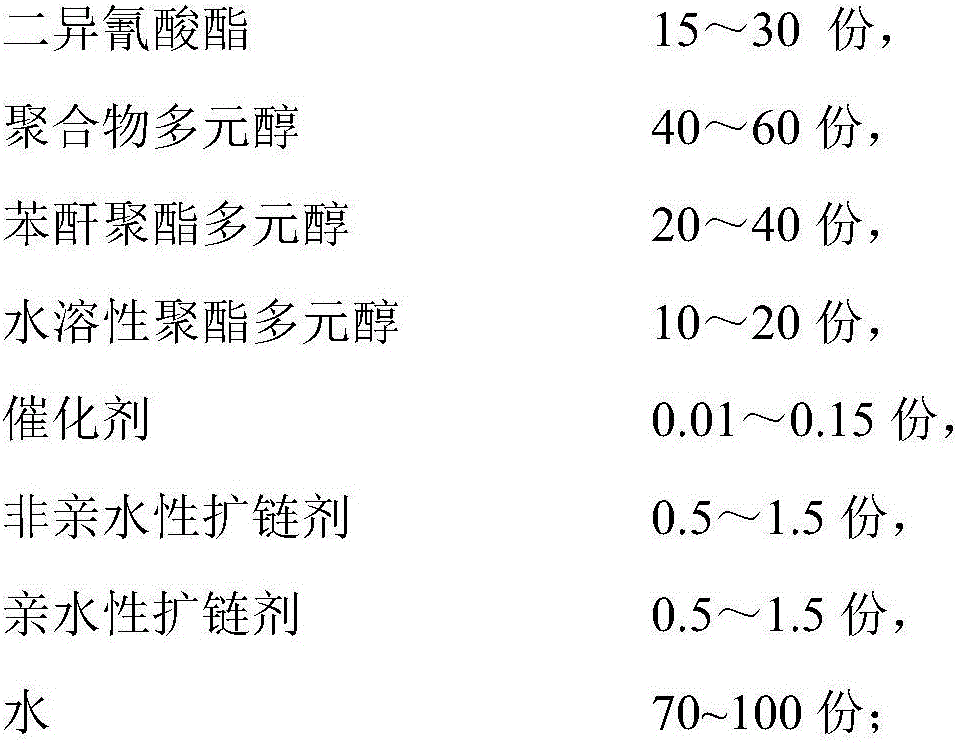

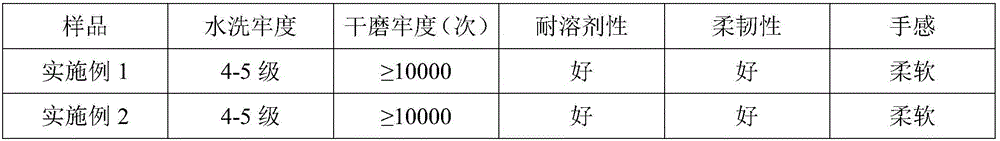

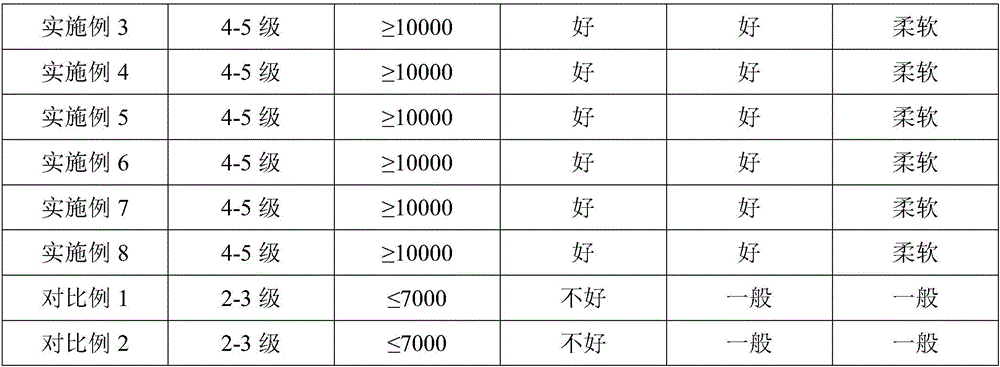

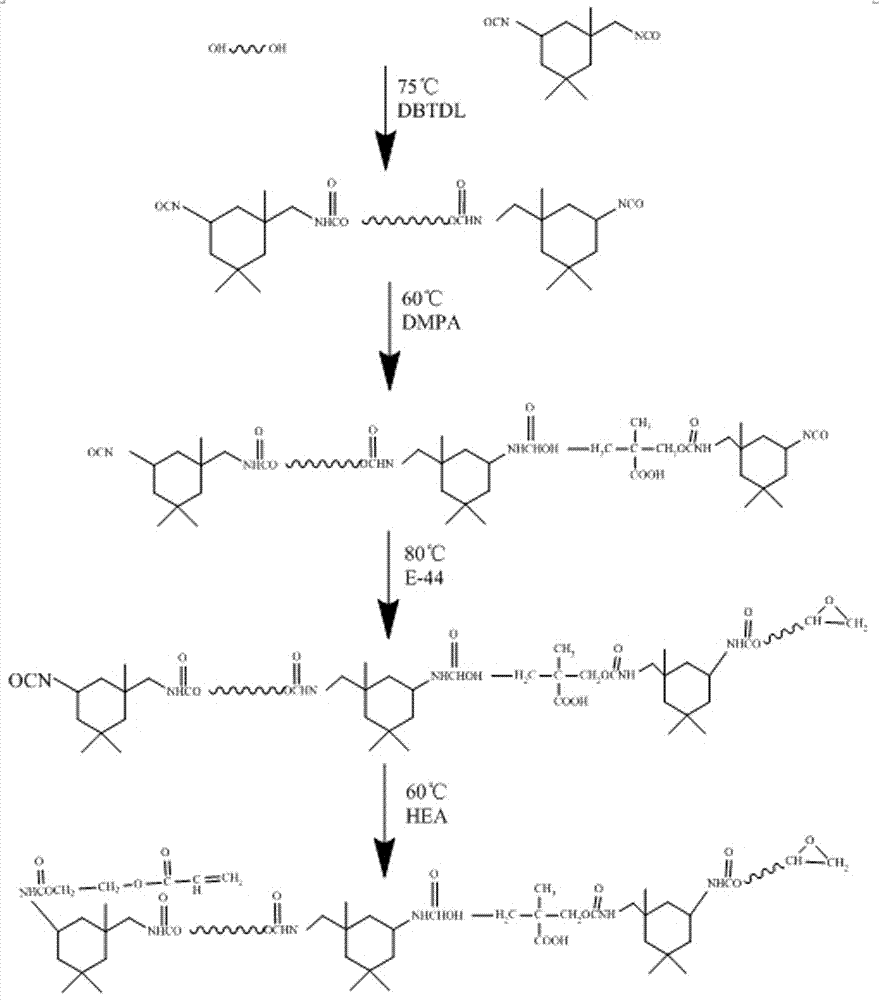

Aqueous polyurethane flocking glue and preparation method thereof

InactiveCN106753160AImprove hydrophilicityImprove bonding fastnessPolyureas/polyurethane adhesivesDiphenylmethanePolyester

The invention discloses aqueous polyurethane flocking glue and a preparation method thereof. The aqueous polyurethane flocking glue is prepared from 15 to 30 parts by weight of diisocyanates, 40 to 60 parts by weight of polymer polyol, 20 to 40 parts by weight of diethylene glycol phthalic anhydride polymer, 10 to 20 parts by weight of water-soluble polyester polyol, 0.01 to 0.15 parts by weight of a catalyst, 0.5 to 1.5 parts by weight of a non-hydrophilic chain extender, 0.5 to 1.5 parts by weight of a hydrophilic chain extender and 70 to 100 parts by weight of water, wherein the diisocyanates comprise at least two of toluene diisocyanate, 1, 6-hexamethylene diisocyanate, isophorone diisocyanate, diphenylmethane-4, 4-diisocyanate, dicyclohexylmethane diisocyanate and tetramethylbenzenedimethylene diisocyanate, and the polymer polyol comprises at least one of adipic acid-type polyester polyol having number-average molecular weight of 1000 to 3000, polycaprolactone, polycarbonate and polyether polyol. The aqueous polyurethane flocking glue has good resistance to water washing, adhesion fastness, solvent resistance, safety, environmental friendliness, good product flexibility and feeling.

Owner:SHANGHAI HUAFENG MATERIAL TECH RES INST LLP

Modified urethane acrylate copolymer, photoresist and preparation method of photoresist

The invention discloses a modified urethane acrylate copolymer. The modified urethane acrylate copolymer is prepared from 16.1 to 50.9 parts by mass of polyisocyanate, 15.4 to 40.2 parts by weight of polyether polyol, 0. 01 to 0.09 parts by weight of a catalyst, 3.1 to 11.6 parts by weight of carboxylated diol, 5.3 to 20.8 parts by weight of epoxy resin, 0.1 to 0.5 parts by weight of a polymerization inhibitor, 10.7 to 35.5 parts by weight of hydroxyl group-containing acrylate, and 10 to 80 parts by weight of a solvent. The polyisocyanate is a mixture of one or more of hexamethylene diisocyanate, tolylene diisocyanate, 1, 6-hexamethylene diisocyanate, isophorone diisocyanate, diphenylmethane diisocyanate, xylylene diisocyanate, and polymethylene polyphenyl polyisocyanate. The modified urethane acrylate copolymer has the advantages of simple operation and short production period. The modified urethane acrylate copolymer has the advantages of adjustable acid value, good heat resistance, strong corrosion resistance, good adhesion to the substrate and stable performance. The prepared photoresist has good comprehensive performances and is easy to promote and use.

Owner:SHENZHEN DALTON ELECTRONICS MATERIAL CO LTD

Method for synthesizing pentamethylene diisocyanate

InactiveCN106045882AAccurate measurementAvoid reactionCarbamic acid derivatives preparationOrganic compound preparationHigh pressureMethylene diisocyanate

The invention discloses a method for synthesizing pentamethylene diisocyanate. 1,5-pentanediamine or salt produced by 1,5-pentanediamine and dry carbon dioxide or 1,5-pentanediamine and dry hydrogen chloride reacts with solid-state phosgene, a middle product is produced, carbon dioxide or hydrogen chloride is exhausted, and the middle product is pentamethylene dimethylcarbamoyl chloride. The middle product is decomposed at the high temperature to produce pentamethylene diisocyanate and hydrogen chloride. The synthesis method adopts a solid-state phosgene method for synthesis, and solid-state phosgene is in a solid form at the normal temperature, has a higher melting point and a stable property and can be accurately metered during a reaction; high temperature and high pressure are not required in the technological process, the operation is simple and the cost is low.

Owner:山东崇舜新材料科技有限公司

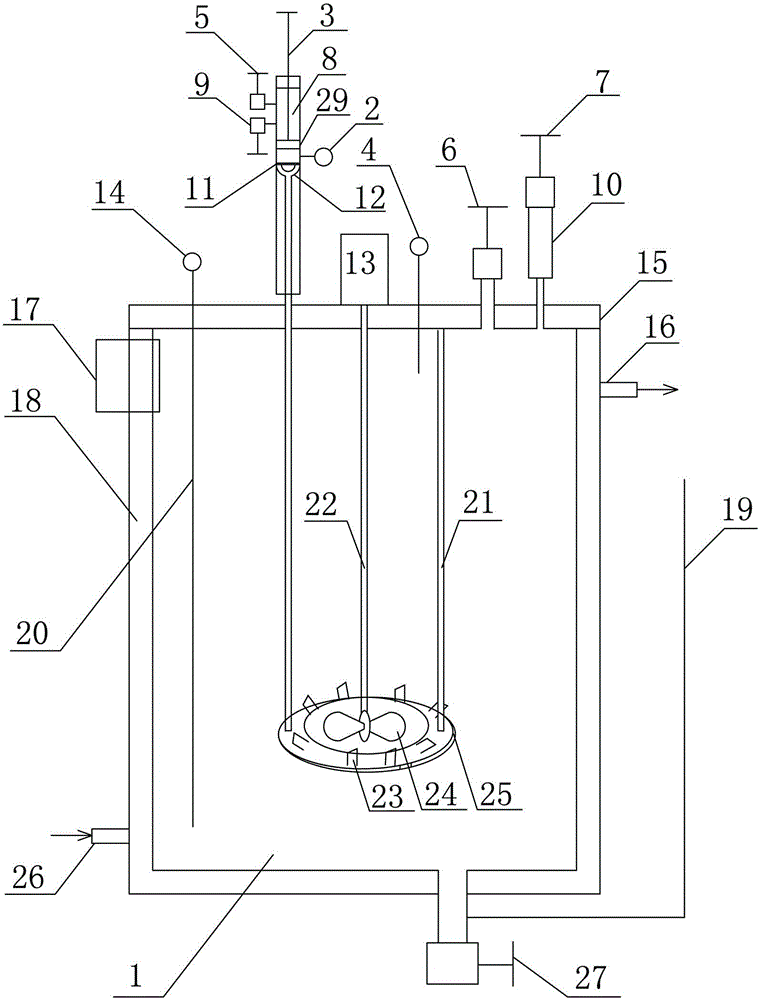

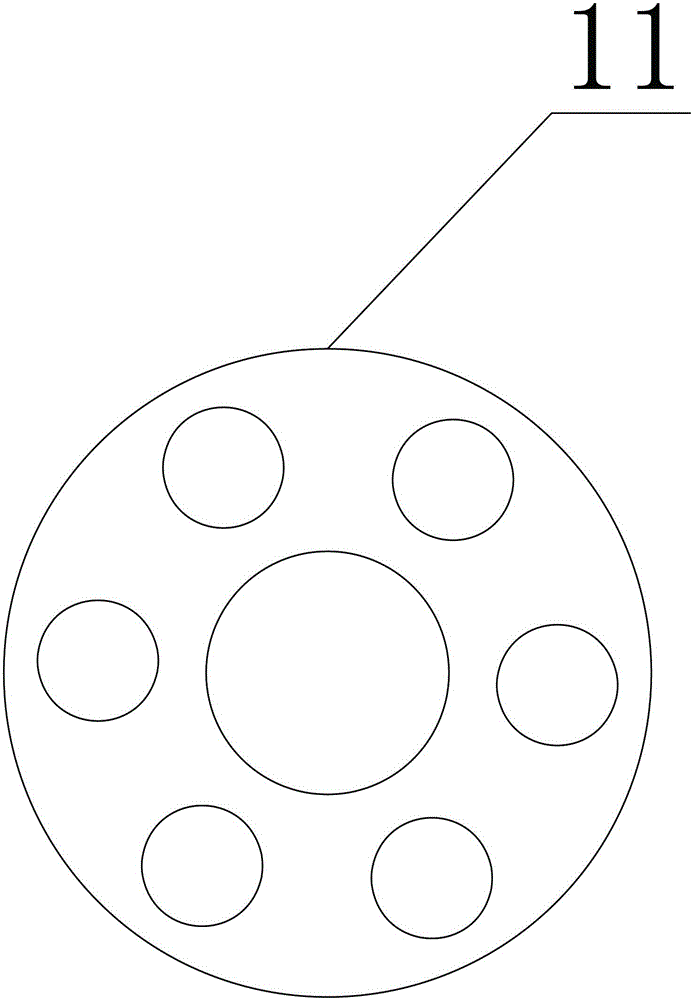

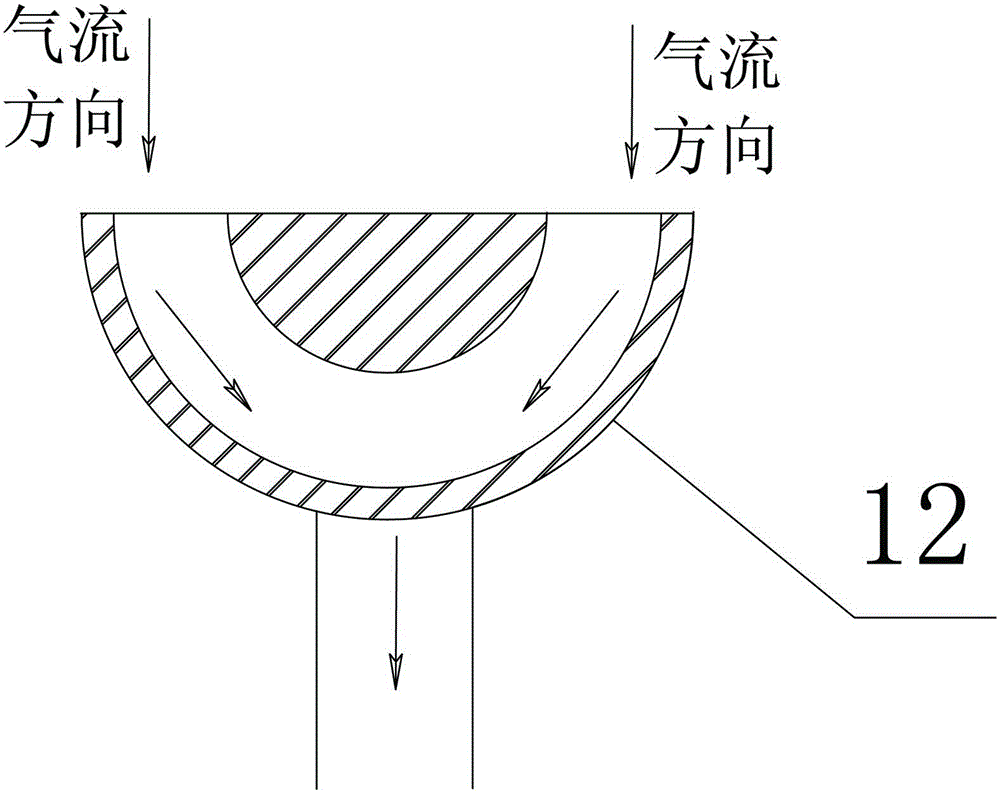

Synthesis device and method for xylylene diisocynate

ActiveCN105195080AIncrease productivityDesign scienceIsocyanic acid derivatives preparationOrganic compound preparationXylyleneProcess engineering

The invention provides a synthesis device for xylylene diisocynate. The synthesis device comprises a reaction kettle, a gas distributor mounted in the reaction kettle, and a phosgene feeding device communicated with the reaction kettle, wherein the phosgene feeding device comprises a mixed gas cavity, a pressure adjustment assembly for adjusting pressure in the mixed gas cavity, a multihole limiting flow division plate mounted in the mixed gas cavity, and a spherical control valve mounted in the mixed gas cavity, wherein the mixed gas cavity is provided with a phosgene inlet and an inert gas inlet; the multihole limiting flow division plate is arranged between the phosgene inlet and the spherical control valve and between the inert gas inlet and the spherical control valve; and the spherical control valve is communicated with the gas distributor. The synthesis device has the advantages of scientific design, reasonable structure, high production efficiency, reliable product quality. The invention further provides a method for synthesizing xylylene diisocynate by adopting the synthesis device.

Owner:开封华瑞化工新材料股份有限公司

Preparation method of beta-cyclodextrin modified loofah sponge adsorbent

InactiveCN105195100AGood physical and chemical stabilityHigh mechanical strengthOther chemical processesWater/sewage treatment by sorptionSilanesSorbent

The invention discloses a preparation method of a beta-cyclodextrin modified loofah sponge adsorbent. The preparation method comprises the steps that 1, a loofah sponge is organically treated; 2, the organic loofah sponge is modified through gamma-(2,3-glycidyl) propyl group trimethoxy silane; 3, by mass, 52-65% of dimethyl sulfoxide, 8-15% of beta-cyclodextrin and 8-15% of hexamethylene diisocyanate are added in a reactor, the temperature is increased to 55+ / -2 DEGC and kept constant, stirring is carried out, a backflow reaction is carried out for 2-4 h, then 15-25% of the organic loofah sponge modified through the gamma-(2,3-glycidyl) propyl group trimethoxy silane is added, the sum of the percentages of all the components is 100%, the constant temperature is kept to be 65+ / -2 DEG C, stirring is carried out, the backflow reaction is carried out for 6-8 h, acetone backflow washing is carried out after the reaction is finished, the mixture is taken out to be placed in a vacuum drying box to be dried, and the beta-cyclodextrin modified loofah sponge adsorbent is obtained. The beta-cyclodextrin modified loofah sponge adsorbent has the high adsorption capacity for perfluoro caprylic acid, and is low in cost and environmentally friendly.

Owner:UNIV OF JINAN

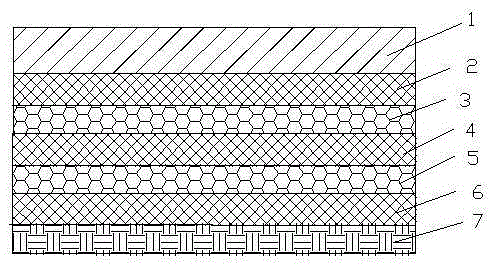

High-barrier-property photovoltaic backboard of multilayer structure

ActiveCN105419617AImprove barrier propertiesImprove insulation performanceSynthetic resin layered productsPolyurea/polyurethane coatingsPtru catalystMoisture barrier

The invention discloses a high-barrier-property photovoltaic backboard of a multilayer structure. The photovoltaic backboard sequentially comprises a weather-proof outer layer, a first obstruction coating, a first base layer, a second obstruction coating, a second base layer, a third obstruction coating and an inner layer from top to bottom. The first obstruction coating, the second obstruction coating and the third obstruction coating are all double-component polyurethane systems. A component A is prepared from 15-25 parts of fluorine resin, 20-40 parts of polypropylene oxide polyhydric alcohols, 1-2 parts of defoaming agent, 0.5-1 part of catalyst, 5-10 parts of inorganic filler and 10-30 parts of organic solvent. A component B is a mixture containing one or two of toluene diisocynate, isophorone diisocyanate and trimethyl 1,6-hexamethylene diisocyanate. The component A and the component B are mixed according to the ratio NCO / OH=0.5-1.1. According to the high-barrier-property photovoltaic backboard, by designing the two base layers and the three obstruction coatings, the moisture barrier property and the insulativity of the backboard are effectively improved.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS

Solid acid catalyst and use thereof in synthesizing 1,6-hexamethylene diisocyanate

ActiveCN101337189ALight colorHigh reactivityPhysical/chemical process catalystsPreparation from carbamatesCatalytic pyrolysisMethyl carbonate

The invention relates to a solid-acid catalyst, and the application thereof in the synthesis of 1, 6-hexamethylene diisocyanate (HDI). The solid-acid catalyst of the invention is characterized in that SO4<2-> / TiO2-ZnO-ZrO2-Al2O3 is prepared by the reaction of phthalate ester, water soluble zinc salt, water soluble aluminum salt, water soluble zirconium salt and H2SO4; the mole fraction of the phthalate ester is 8-45 percent; the mole fraction of the zinc salt is 30-60 percent; the mole fraction of the zirconium salt is 3-10 percent; and the mole fraction of the H2SO4 is 6-18 percent. The catalyst is applicable to the preparation of the 1, 6-hexamethylene diisocyanate (HDI), has higher reaction activity and higher selectivity, and can adopt the cheaper dimethyl carbonate as the raw material, besides, the aminolysis yield is as high as 95 percent, the pyrolysis yield can reach 88 percent, and the catalytic pyrolysis temperature is especially lower, and can decrease to be not higher than 230 DEG C, thereby obviously reducing the occurrence of side reactions, improving the yielding rate of the product, and enabling the total yielding rate of the product to be 83.6 percent.

Owner:JIANGSU GUOLI CHEM TECH

Carbon nanotube modified polyurethane composite material

The invention discloses a carbon nanotube modified polyurethane composite material including the raw materials: hydroxyl-terminated polybutadiene, diphenyl methylene diisocyanate, polyisocyanurate, vinyltriethoxysilane, a silane coupling agent KH-560, hydroquinone dihydroxyl ethyl ether, dimethythiotoluene diamine, dibutyltin dilaurate, polyvinyl chloride, an acrylonitrile-styrene-butadiene copolymer, nano calcium carbonate, carbon nanotubes, organic modified montmorillonite, nano silica, nano barium titanate, calcium sulphate whiskers, dioctyl phthalate, pentaerythritol-tetra-[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate], and polybenzimidazole. The carbon nanotube modified polyurethane composite material provided by the invention has the advantages of good water resistance, high strength, excellent heat resistance, and aging resistance.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

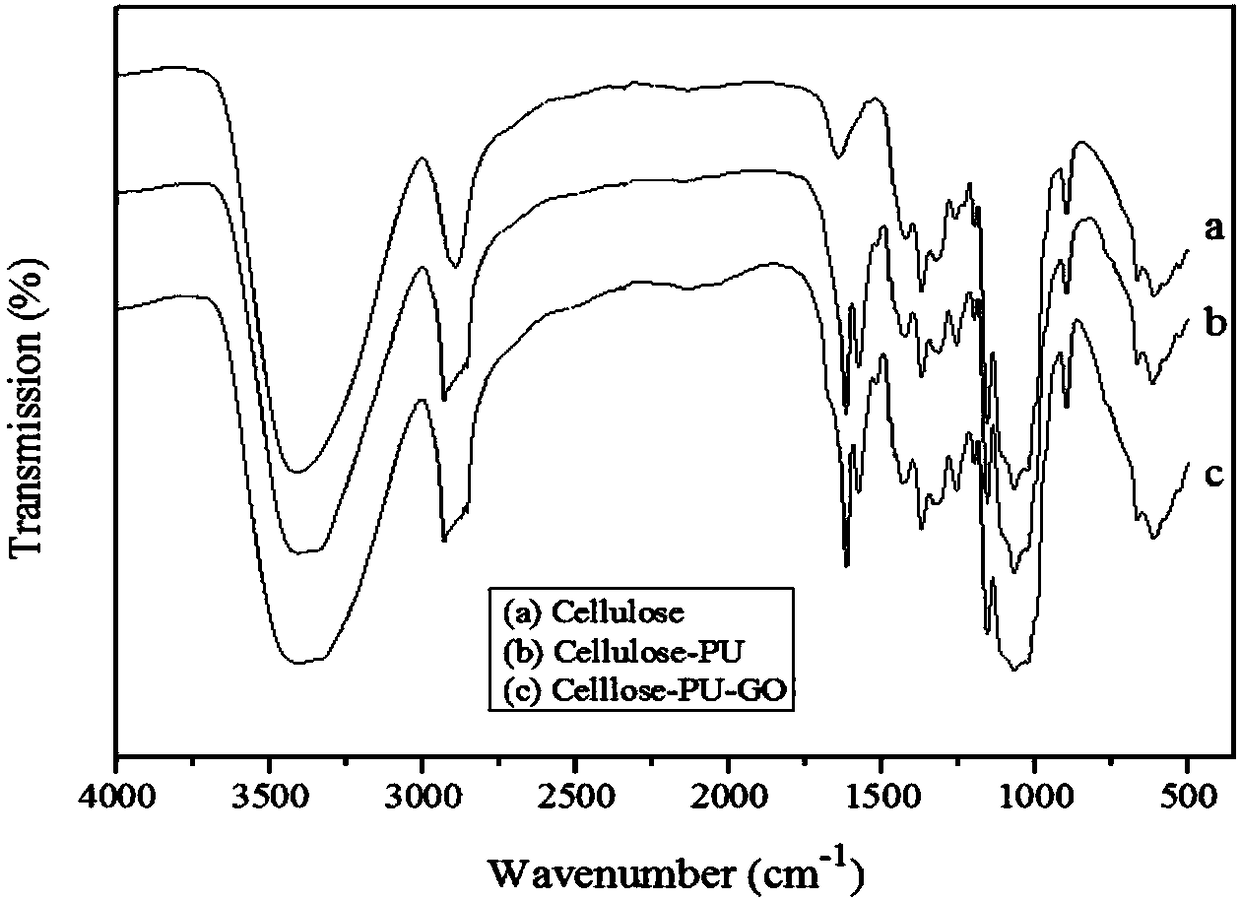

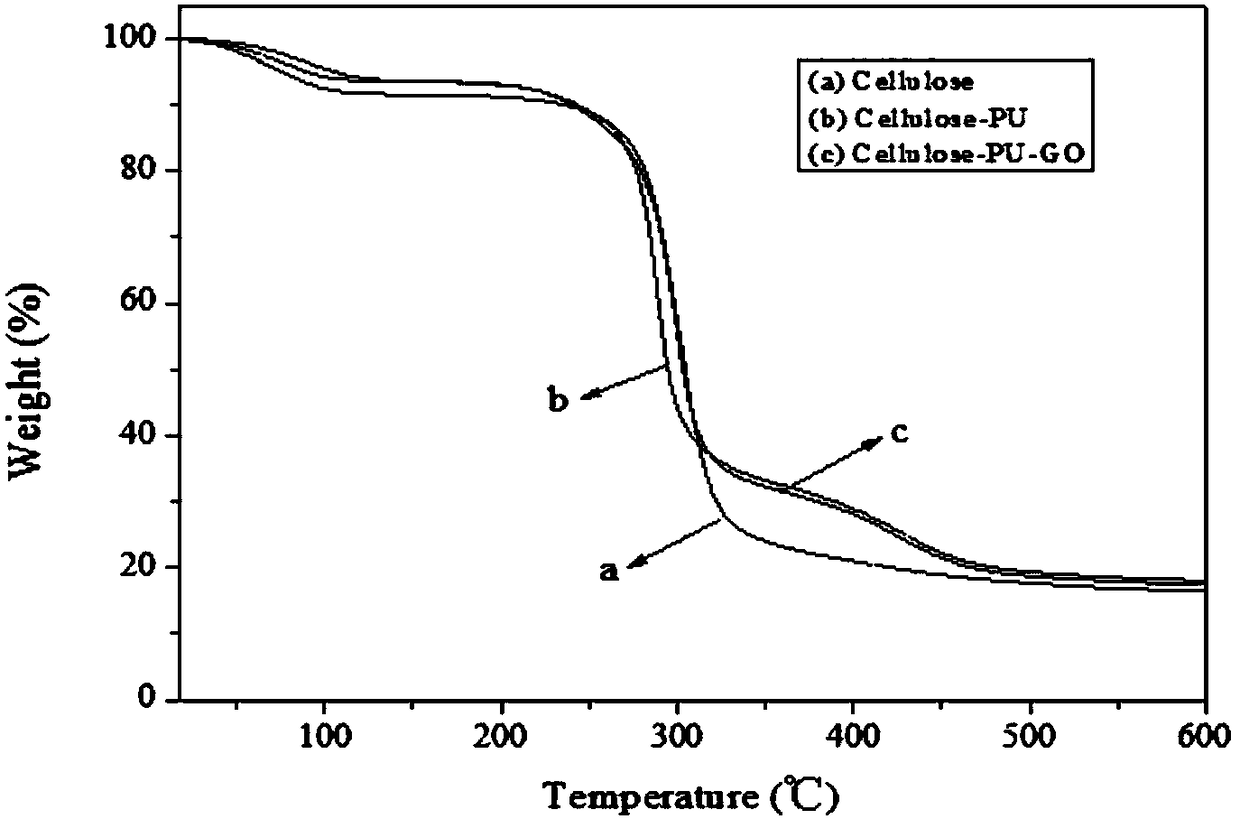

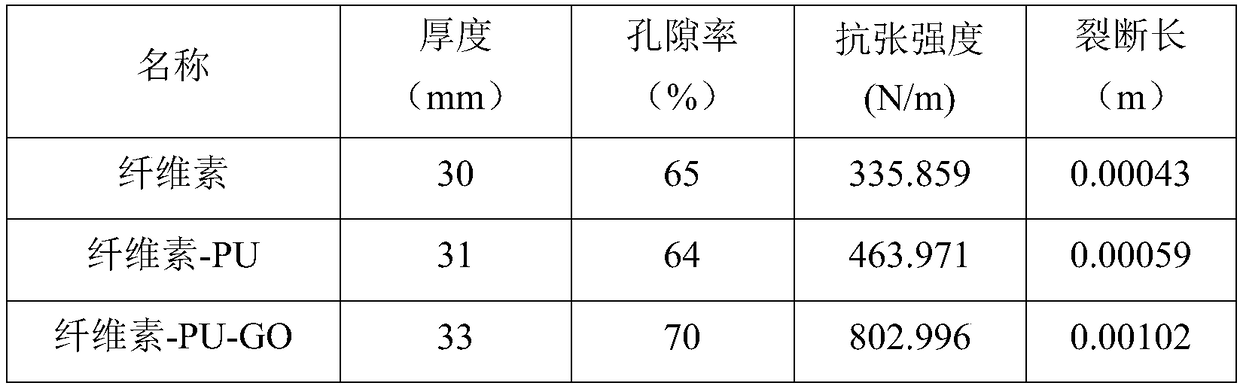

Graphene oxide-modified polyurethane-cellulose battery separator and preparation method thereof

InactiveCN108417765AThe material is cheap and environmentally friendlyConvenient sourceCell component detailsCelluloseSolvent

The invention discloses a graphene oxide-modified polyurethane-cellulose battery separator and a preparation method thereof, and belongs to the field of a lithium battery material. The composite cellulose separator is a wet-state graphene oxide-modified polyurethane-cellulose film material which is prepared by dissolving cellulose in an ionic liquid [Amin]Cl, performing crosslinking reaction with6-methylene diisocyanate and then mixing with graphene oxide, the separator is prepared by solvent replacement and drying, and the composite separator can be used for a non-aqueous lithium battery separator material. The separator prepared by the method has relatively good thermal resistance, chemical solvent resistance and mechanical property; and moreover, the regenerative cellulose is used as araw material, and the separator has the advantages of low cost and biological degradability.

Owner:BEIJING FORESTRY UNIVERSITY

Self-repairing polyurethane resin raw material, self-repairing polyurethane resin, self-repairing coating material, self-repairing elastomeric material, self-repairing polyurethane resin raw material production method and self-repairing polyurethane resin production method

InactiveCN107001557ASuitable for manufacturingExcellent self-healing performancePolyurea/polyurethane coatingsElastomerPolyol

Owner:MITSUI CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com