Aqueous polyurethane flocking glue and preparation method thereof

A water-based polyurethane and flocking adhesive technology, which is applied in the field of polyurethane flocking adhesive and its preparation, can solve the problems of non-cold resistance, solvent resistance, unsafe use of adhesives, poor air and moisture permeability, etc., and achieve high hydrophilic efficiency, Reduced washing resistance and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

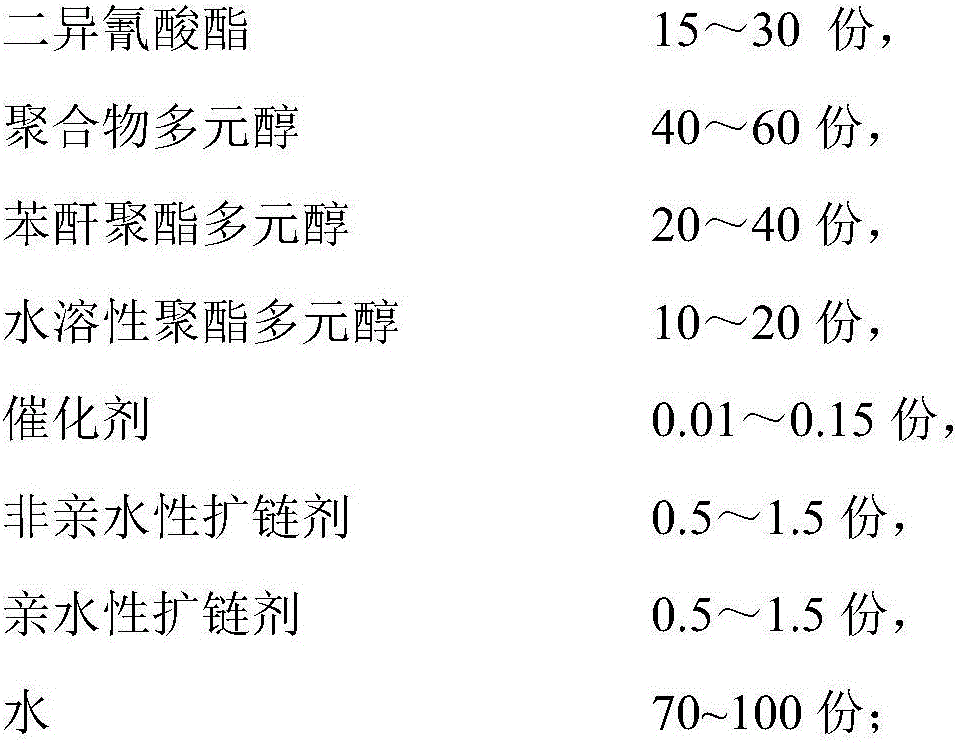

Method used

Image

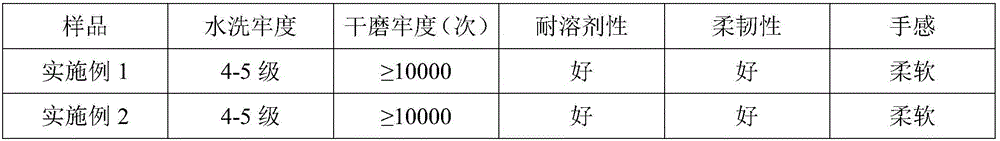

Examples

Embodiment 1

[0051] (1) Under the protection of dry nitrogen, 230g of PBA after vacuum dehydration, 25g of isophorone diisocyanate, 50g of 1,6-hexamethylene diisocyanate, 100g of HF8356, 55g of BY3301, 0.02g of Add it into the reaction vessel, and react at 90°C for 1.5 hours under mechanical stirring to obtain a prepolymerization reaction system;

[0052] (2) Reduce the temperature of the above-mentioned prepolymerization reaction system to below 60°C, add acetone, the viscosity when the temperature is lowered to 25°C is 5000cP, then add 2.5g of 1,4-butanediol and 0.03g of Under mechanical stirring, control the temperature at 60°C for 2 hours to obtain a chain extension reaction system;

[0053] (3) Reduce the temperature of the above-mentioned chain extension reaction system to below 50°C, add 3.5g of hydrophilic chain extender A95 to react for 2 minutes, add 500g of water to emulsify and disperse, and obtain a milky white and bluish polyurethane emulsion, and distill under reduced pres...

Embodiment 2

[0055] (1) Under the protection of dry nitrogen, vacuum dehydrated 100g of PBA, 100g of PBNA, 25g of isophorone diisocyanate, 60g of 1,6-hexamethylene diisocyanate, 150g of HF8356, 50g of BY3301, 0.05 g's Add it into the reaction vessel, and react at 90°C for 1.5 hours under mechanical stirring to obtain a prepolymerization reaction system;

[0056] (2) Reduce the temperature of the above-mentioned prepolymerization reaction system to below 60°C, add acetone and cool down to 25°C when the viscosity is 4000cP, then add 6.0g of 1,4-butanediol and 0.05g of Under mechanical stirring, control the temperature at 65°C for 2 hours to obtain a chain extension reaction system;

[0057] (3) Reduce the temperature of the above-mentioned chain extension reaction system to below 50°C, add 2.5g of hydrophilic chain extender A95 to react for 4 minutes, add 520g of water to emulsify and disperse, and obtain a milky white and bluish polyurethane emulsion, and remove the solvent by distillati...

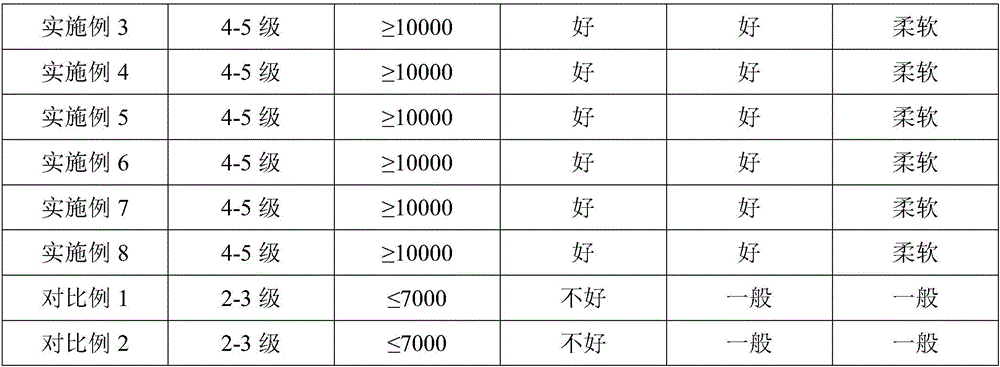

Embodiment 3

[0059] (1) Under the protection of dry nitrogen, 200g of PNA after vacuum dehydration, 30g of isophorone diisocyanate, 100g of 1,6-hexamethylene diisocyanate, 100g of HF8356, 50g of BY3301, 0.05g of Add it into the reaction vessel, and react at 95°C for 1.5 hours under mechanical stirring to obtain a prepolymerization reaction system;

[0060] (2) Reduce the temperature of the above-mentioned prepolymerization reaction system to below 60°C, add acetone and cool down to 25°C when the viscosity is 2500cP, then add 7.0g of 1,6-hexanediol and 0.1g of Under mechanical stirring, control the temperature and react at 70°C for 2 hours to obtain a chain extension reaction system;

[0061] (3) Reduce the temperature of the above-mentioned chain extension reaction system to below 50°C, add 3.0g of hydrophilic chain extender A95 to react for 4min, add 480g of water to emulsify and disperse to obtain a milky white and bluish polyurethane emulsion, and distill under reduced pressure to rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com