Patents

Literature

1835 results about "Toluene diisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

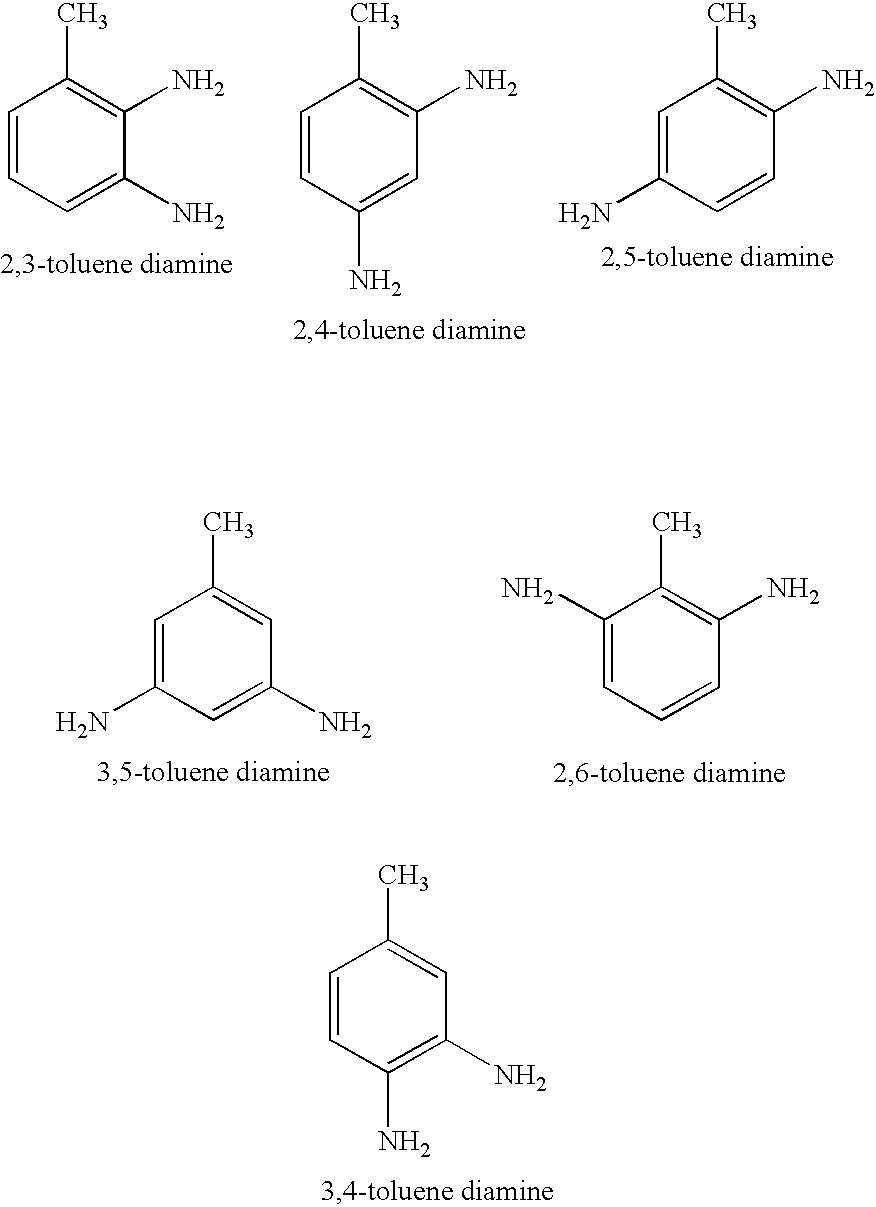

Toluene diisocyanate (TDI) is an organic compound with the formula CH₃C₆H₃(NCO)₂. Two of the six possible isomers are commercially important: 2,4-TDI (CAS: 584-84-9) and 2,6-TDI (CAS: 91-08-7). 2,4-TDI is produced in the pure state, but TDI is often marketed as 80/20 and 65/35 mixtures of the 2,4 and 2,6 isomers respectively. It is produced on a large scale, accounting for 34.1% of the global isocyanate market in 2000, second only to MDI. Approximately 1.4 billion kilograms were produced in 2000. All isomers of TDI are colorless, although commercial samples can appear yellow.

Compositions with Improved Adhesion to Low Surface Energy Substrates

InactiveUS20080113094A1Excellent low surface energyImprove adhesionSynthetic resin layered productsOrganic dyesOligomerEnd-group

Acrylic-based pressure sensitive adhesives are modified with a telechelic hydrocarbon oligomer. The oligomer comprises a hydrocarbon polymer chain or backbone and a functional end group, e.g., an oligomer prepared from a mono hydroxyl polybutadiene polymer and toluene diisocyanate. The oligomer attaches to the acrylic backbone of the polymer as a pendant group and in a preferred embodiment, the oligomer is mixed with the PSA shortly before the PSA is coated.

Owner:BRADY WORLDWIDE INC

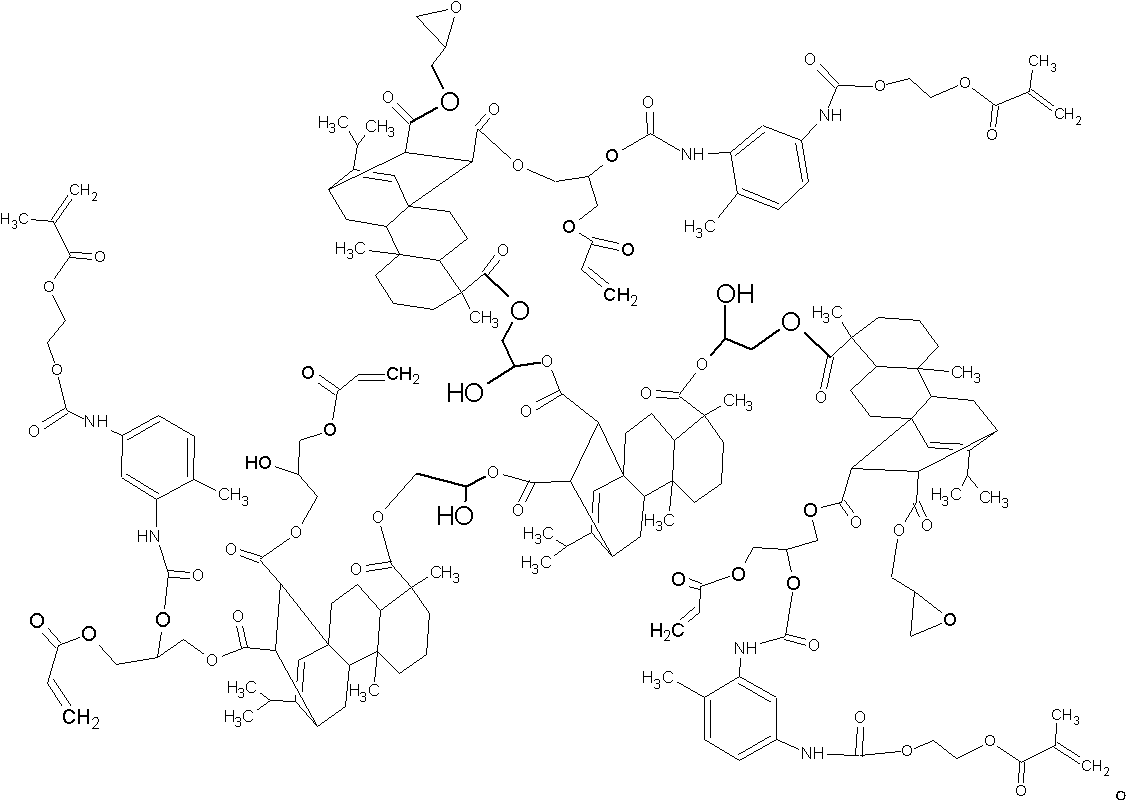

High-toughness photosensitive resin for 3D printing and preparation method thereof.

The invention provides a high-toughness photosensitive resin for 3D printing and a preparation method thereof. The photosensitive resin comprises a photosensitive resin (maleable photosensitive resin and rigid photosensitive resin), an active diluent, a light initiator and an additive. The method first synthesizes the toughness photosensitive resin (maleable polyurethane acrylate and epoxy modified polyurethane), and then the maleable photosensitive resin is mixed with the rigid photosensitive resin, active diluent, light initiator and additive. The maleable photosensitive resin is prepared from a polymer soft segment, which is a mixture of one or more selected from of polypropyleneoxide glycol ether, PTMG, hydroxyl-terminated polybutadiene, hydroxyl-terminated styrene butadiene rubber, hydroxyl-terminated butadiene acrylonitrile rubber and hydroxyl-terminated polysiloxane, and a polymer hard segment of toluene diisocyanate or isophorone diisocyanate, through hydroxyethyl acrylate or epoxypropanol termination. The photosensitive resin is applicable to DLP or SLA type 3D printers for modification of the existing 3D printing photosensitive resin, has excellent bending strength, and can directly print out elastic models.

Owner:QINGDAO UNIV OF SCI & TECH

High temperature polyurethane/urea elastomers

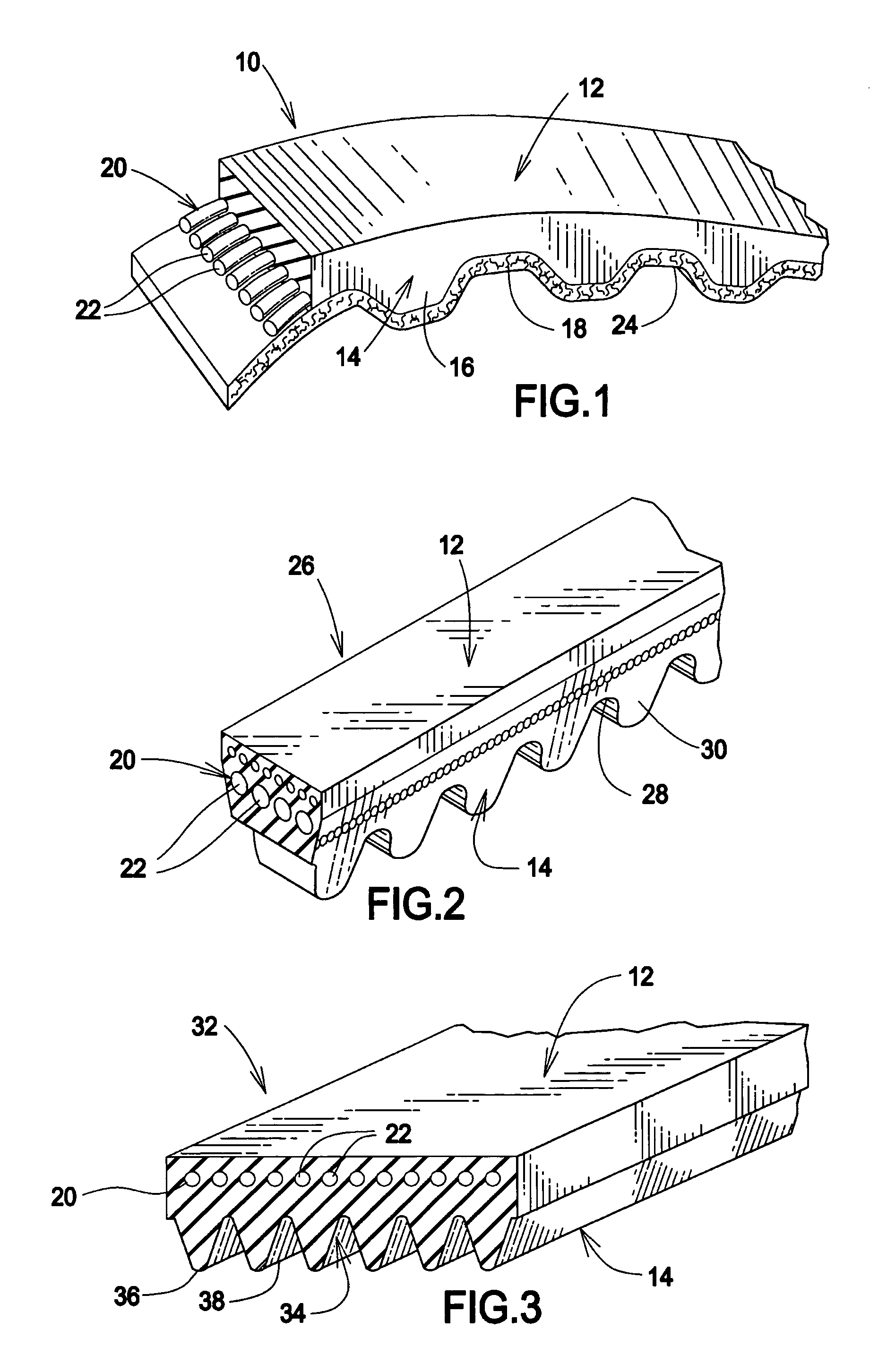

InactiveUS6964626B1High and low temperature resistance propertiesHigh and low temperature resistance propertyV-beltsRopes and cables for vehicles/pulleyElastomerPolyester

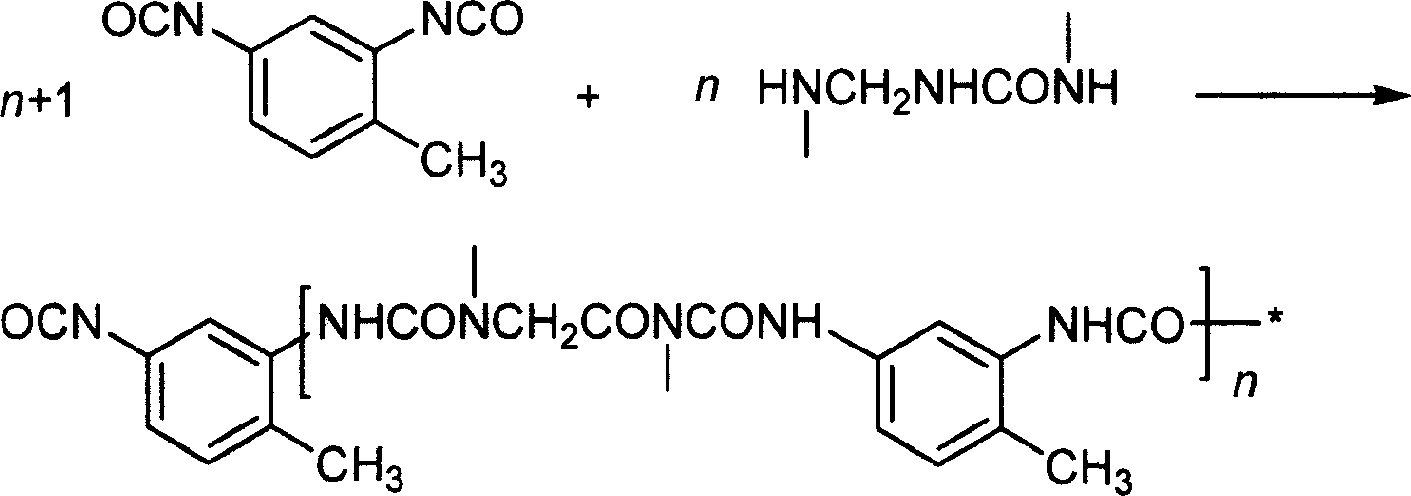

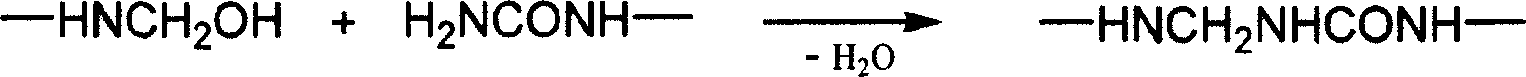

The present invention relates to molded polyurethane / urea elastomers, and specifically to improved polyurethane / urea elastomers having high temperature stability to about 140–150° C. and low temperature flexibility at about −35–(−40)° C., for use in dynamic applications. These elastomers are particularly useful for application in belts, specifically in automotive timing or synchronous belts, V-belts, multi V-ribbed or micro-ribbed belts, flat belting and the like. The polyurethane / urea elastomers of the present invention are prepared by reacting polyisocyanate prepolymers with symmetric primary diamine chain extenders, mixtures of symmetric primary diamine chain extenders and secondary diamine chain extenders, or mixtures of symmetric primary diamine chain extenders and non-oxidative polyols, which are all chosen to eliminate the need for catalysts via standard molding processes, and to improve phase separation. The polyisocyanate prepolymers are reaction products of polyols which are nonoxidative at high temperatures, such as polycarbonate polyols, polyester polyols, or mixtures thereof, with organic polyisocyanates which are either compact, symmetric and aromatic, such as para-phenylene diisocyanate, 1,5-naphthalene diisocyanate, and 2,6-toluene diisocyanate, or are aliphatic and possess trans or trans,trans geometric structure, such as trans-1,4-cyclohexane diisocyanate and trans,trans-4,4′-dicyclohexylmethyl diisocyanate.

Owner:THE GATES CORP

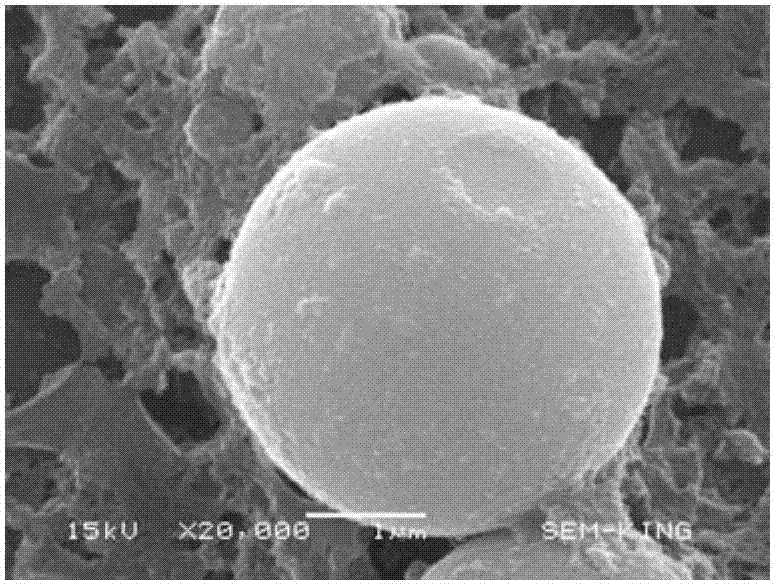

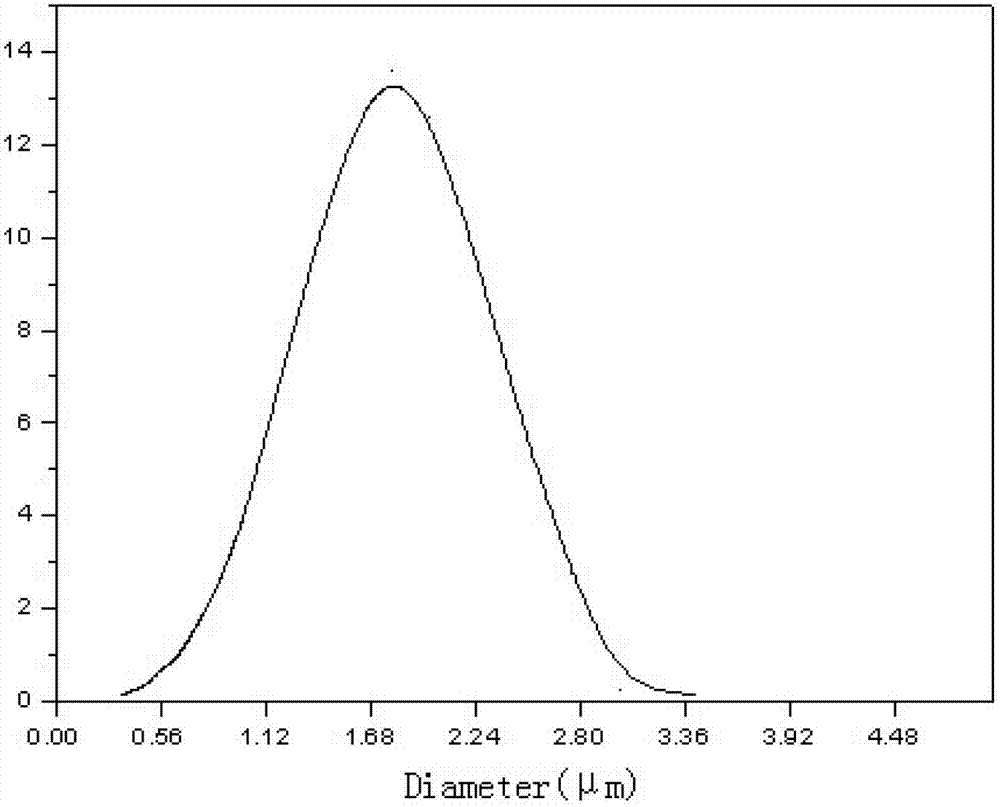

Preparation method of phase transformation material microcupsule

InactiveCN101045857AHigh mechanical strengthRaw materials are easy to getHeat-exchange elementsMicroballoon preparationParaffin waxToluene diisocyanate

This invention relates to preparation method of a facies change stuff microcapsule. It takes paraffin as phase-change material, takes toluene diisocyanate and urea-formaldehyde resin as cyst wall stuff, by interfacial polymerization and in situ polymeric method to carry out microencapsulate, to prepare double deck, microcapsule packed paraffin phase-change material. This method could prepare microcapsule phase-change material that contain any specification paraffin from 1% to 70%. Transformation temperature of this phase-change material is adjustable from 0 to 70 deg.C. This compound phase-change material can directly apply to construction region, textile region, and martial region and so on.

Owner:HUILIN SHENGDA ENERGY MATERIAL SCI & TECH DEV BEIJING

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

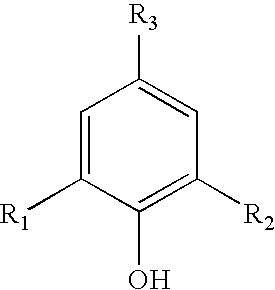

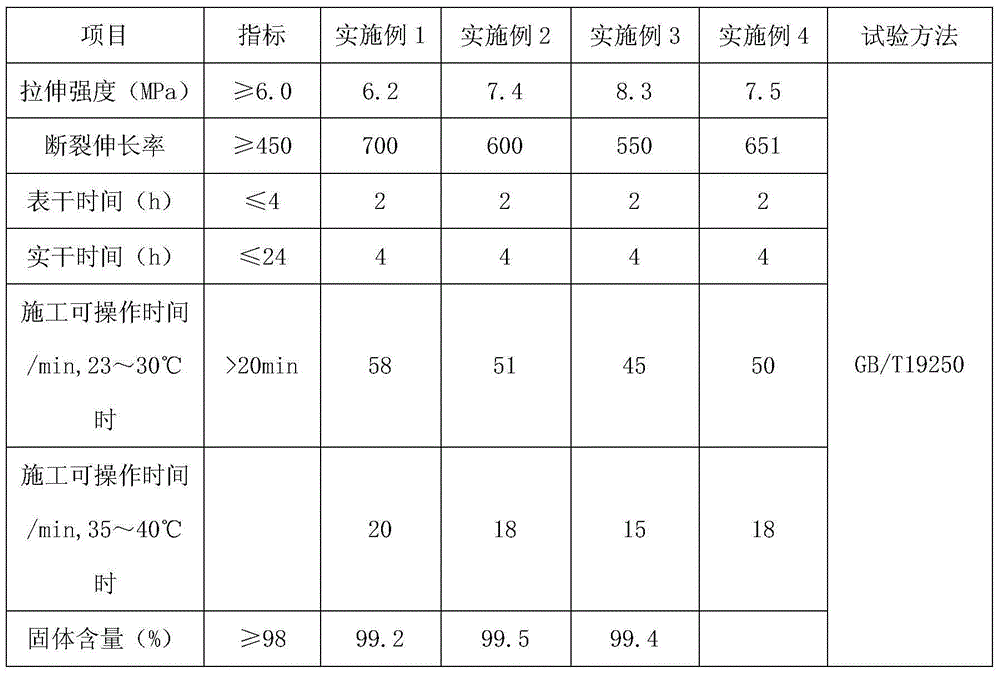

Bi-component high-strength polyurethane waterproofing paint

ActiveCN101100582AImprove performanceQuality improvementAntifouling/underwater paintsPaints with biocidesExtensibilityToluene diisocyanate

A dual-component high-strength polyurethane water proof coating contains A and B components; A component consists of polyether dibasic alcohol 120-200 proportion, polyether trivalent alcohol 40-180 proportion, toluene diisocyanate 47-80 proportion, dibutyl ester 1.5-3 proportion, and tartaric acid 0.1-1 proportion. B component consists of filling oil 50-90 proportion, paraffin chloride 20-50 proportion, dibutyl ester 10-30 proportion, 3,3-dichloro-4,4-diphenyl-methane-diamine 45-70 proportion, poly-ether trivalent alcohol 60-360 proportion, hydrated magnesium silicate 50-60 proportion, kaolin 10-50 proportion, heavy calcium carbonate 50-60 proportion, iron oxide brown or carbon black 3.5-4.5 proportion, de-foaming agent 0.2-0.5 proportion, and dibutyltin dilaurate 0.2-0.5 proportion. It's convenient and cheap, has excellent adhesion, strength and extensibility and more solid content and no environmental pollution. It can be used for foundation construction and municipal traffic engineering.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Urethane acrylate composite structure

InactiveUS20060051593A1Low viscosityExcellent resin curingSynthetic resin layered productsPolyurea/polyurethane coatingsToluene diisocyanateUrethane acrylate

A urethane acrylate composite structure includes a first layer that is a show surface of the urethane acrylate composite structure and a support layer. The support layer includes a urethane acrylate composition that includes a urethane acrylate adduct. The urethane acrylate adduct is the reaction product of an isocyanate component and a stoichiometric excess of a functionalized acrylate component. The isocyanate component includes toluene diisocyanate and polymeric polyphenylmethane polyisocyanate. The functionalized acrylate component is reactive with the isocyanate component. The urethane acrylate composition exhibits improved viscosity due to the isocyanate component. The combination of the toluene diisocyanate and the polymeric polyphenylmethane polyisocyanate results in the improved viscosity of the urethane acrylate composition while maintaining excellent resin curing and finished composite structure properties.

Owner:PEELER CALVIN T +3

Single-component asphalt polyurethane waterproof coating and preparation method thereof

InactiveCN102719187AAvoid pollutionNo pollution in the processPolyurea/polyurethane coatingsToluene diisocyanateMoisture

A single-component asphalt polyurethane waterproof coating mainly comprises the following raw materials in part by mass: 45-70 parts of polyether polyol, 10-35 parts of isocyanate, 0.2-1 part of stabilizer, 25-50 parts of petroleum bitumen, 6-25 parts of compatibilizing agent, 10-30 parts of plasticizer, 40-80 parts of filler and 0.5-2 parts of catalyst. The single-component asphalt polyurethane waterproof coating mainly takes the petroleum asphalt as a liquid softener, does not contain toluene diisocyanate, any organic solvent or other volatile components, and meets a requirement on environment friendliness; when in use, the single-component asphalt polyurethane waterproof coating is directly applied to a waterproof base surface of a building and solidified by moisture to form a waterproof coating with high strength and high elasticity, thus not only simplifying a construction process and but also avoiding nonuniform preparation and mixing of a multi-component asphalt polyurethane waterproof coating; the single-component asphalt polyurethane waterproof coating is applicable to water, seepage and moisture prevention of construction works such as a building roof, a basement, a bridge, a tunnel, a culvert, in particular to a waterproofing work of a wet base surface.

Owner:HUBEI ENG UNIV

Method for grafting SiO2 nanoparticles with graphene oxide modified epoxy resin

The invention discloses a method for grafting SiO2 nanoparticles with graphene oxide modified epoxy resin. The method comprises the following steps of: mixing ethyl orthosilicate with tetrahydrofuran, dropwise adding hydrochloric acid, stirring at the normal temperature, adding deionized water and sodium chloride, stirring uniformly, separating by using a separating funnel, removing a lower layer clear solution, adding anhydrous magnesium sulfate into an upper layer organic solution, standing over night, and filtering to obtain SiO2 sol; dropwise adding toluene diisocyanate into an ultrasonically-dispersed graphene oxide solution, adding the prepared SiO2 sol, performing suction filtration under reduced pressure, washing a product with absolute ethyl alcohol, and drying to obtain cinereous powder, i.e., SiO2 nanoparticle grafted graphene oxide; and adding the SiO2 nanoparticle grafted graphene oxide into an epoxy resin substrate, and carrying out a curing reaction to obtain a modified epoxy resin condensate. The method has the advantages of simple process, easiness in operating, environmental friendliness, simple equipment, contribution to reducing cost and applicability to mass production.

Owner:福州乐道知识产权运营有限公司

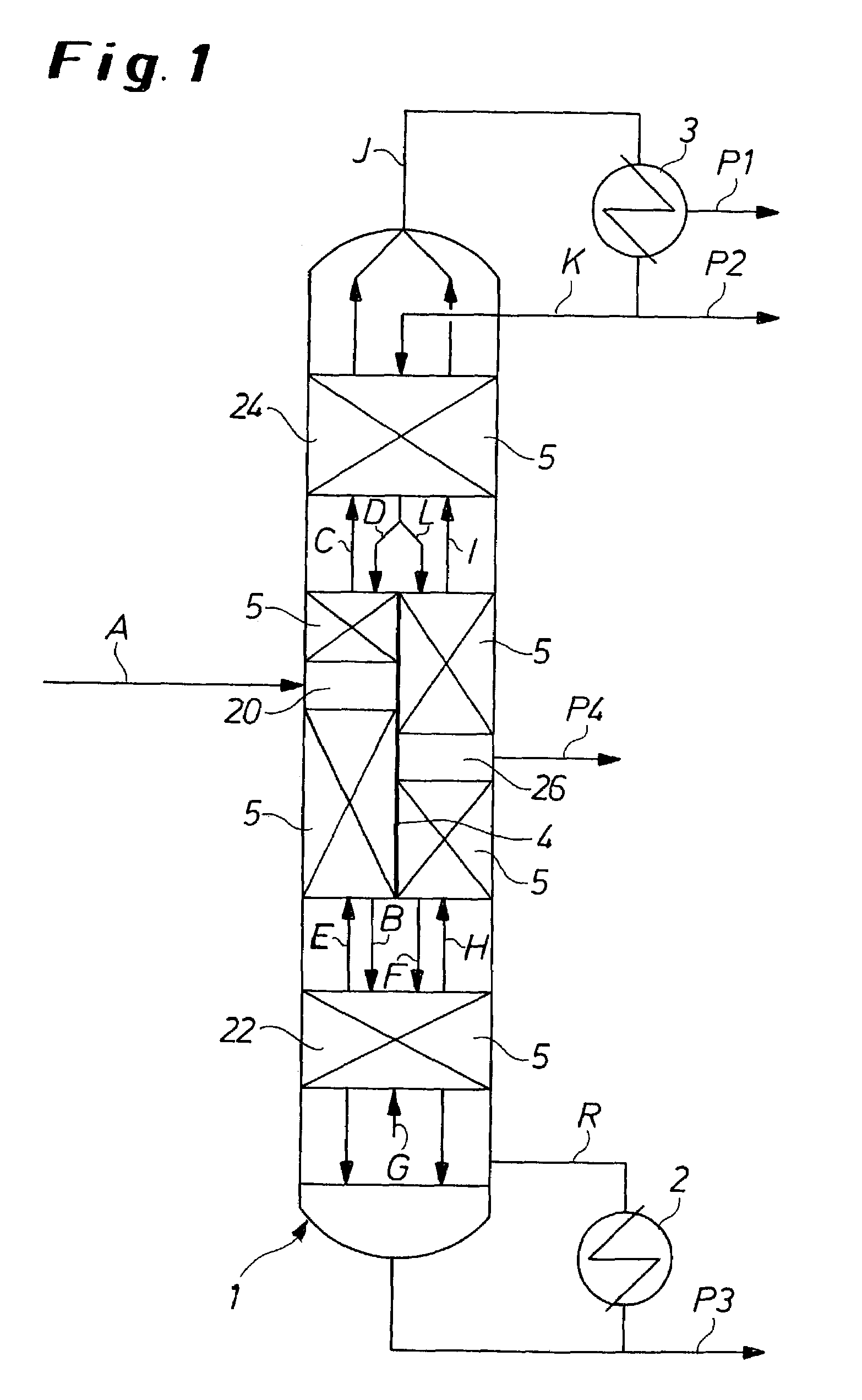

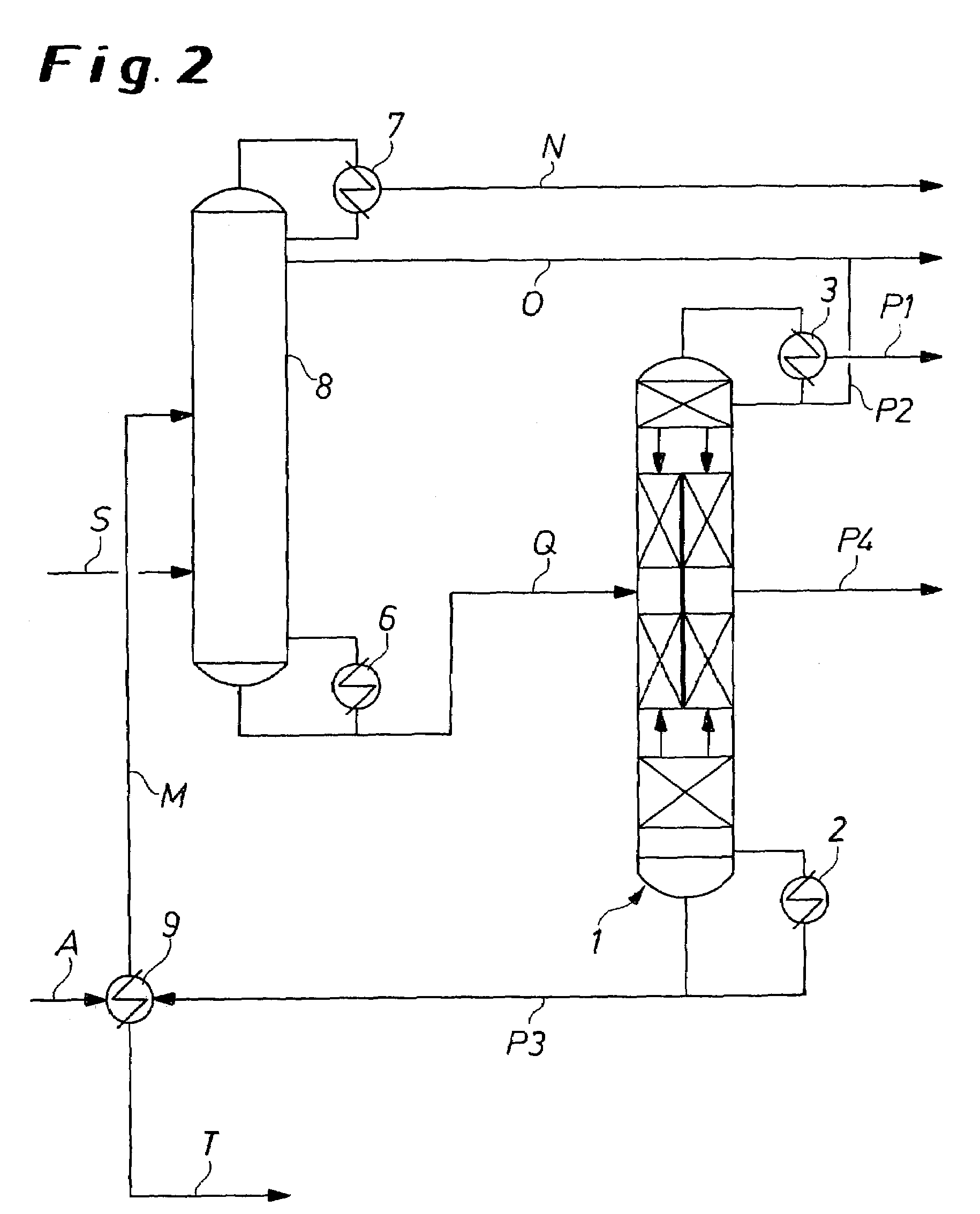

Process for the purification of mixtures of toluenediisocyanate incorporating a dividing-wall distillation column

InactiveUS7118653B2Lower energy requirementsLow investment costOrganic compound preparationIsocyanic acid derivatives purification/separationOrganic solventToluene diisocyanate

Owner:COVESTRO DEUTSCHLAND AG

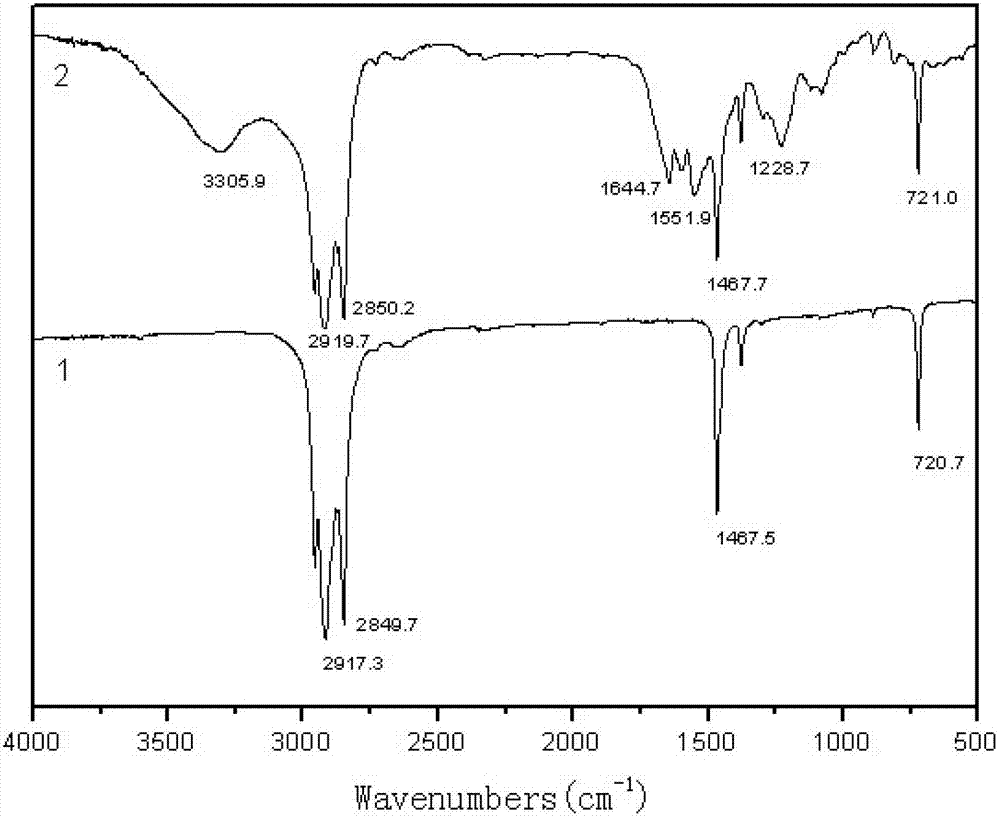

Hydrophilic trauma dressing made from polyurethane and its preparation method

InactiveCN1462614AImprove hydrophilicityNo foreign body reactionAdhesive dressingsAbsorbent padsToluene diisocyanatePolyethylene glycol

A hydrophilic polyurethane dressing for wound is composed of the soft foam chips of hydrophilic polyurethane and the water-proof bacteria-isolating air and moisture permeable polyurethane film. Its preparing process includes such steps as mixing polygolyol, toluene diisocyanate (TDI-80) and propanetriol, stirring, reaction at 80-90 deg.C for 90-120 min to obtain prepolymer of polyurethane, mixingit with polyether, organotin catalyst, alamine catalyst pore-forming agent, stabilizer and water, foaming and ageing to obtain said soft foam chips, preparing the solution of said prepolymer in acetone and / or N,N-dimethyl formamide, adding water, filming, removing solvent, and solidifying reaction to obtain polyurethane film.

Owner:SICHUAN UNIV +1

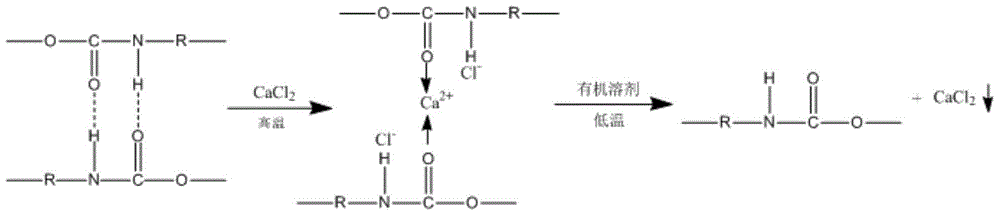

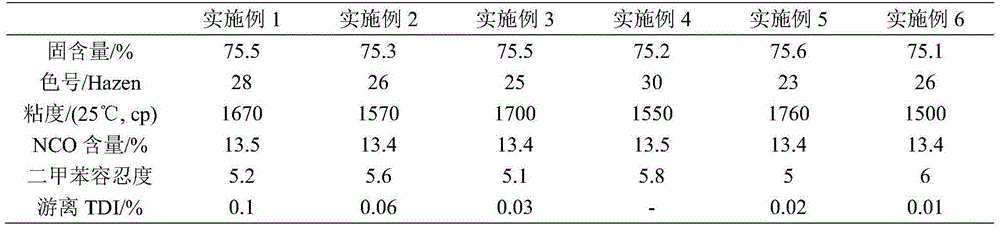

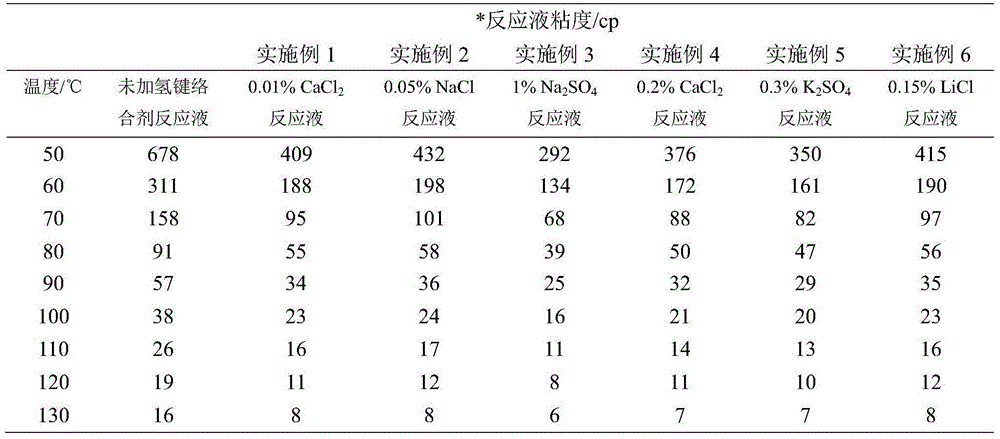

Preparation method of polyurethane curing agent

ActiveCN105218780ALow monomer contentUniform molecular weight distributionPolyurea/polyurethane coatingsToluene diisocyanateNitrogen gas

The invention relates to a preparation method of a polyurethane curing agent. The method comprises the steps of: 1, under the protection of nitrogen, adding mixed alcohol to a reaction kettle filled with toluene diisocyanate (TDI), and insulating for standby; 2, adding 0.01wt-1wt% of a hydrogen bond complexing agent based on toluene diisocyanate, stirring and dissolving; then separating by a thin film evaporator, diluting the prepolymer after separation to obtain a polyurethane curing agent; and cooling and stirring to precipitate a hydrogen bond complexing agent, filtering to obtain a polyurethane curing agent with solid content of 50-80 wt% and free TDI content of 0-0.1wt%. The invention has the advantages that the product has extremely low free isocyanate monomer content, is environment-friendly and non-toxic, and can reduce separation energy consumption and improve the separation efficiency, effectively recover TDI monomer and inorganic salt, improve the utilization rate, achieve cleaner production and reduce the cost of production.

Owner:WANHUA CHEM GRP CO LTD

Ultraviolet curing liquid optical clear adhesive and preparation method thereof

InactiveCN103031105ASmall smellModerate viscosityPolyureas/polyurethane adhesivesAdhesiveToluene diisocyanate

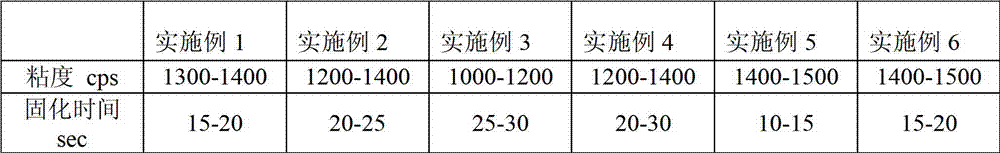

The invention relates to an ultraviolet curing liquid optical clear adhesive and a preparation method thereof, and belongs to the field of bonding adhesives. The method comprises the steps that toluene diisocyanate, polyethylene glycol and hydroxyethyl acrylate are taken as raw materials; a urethane acrylate prepolymer is synthesized through polystep reaction by a bulk method; the prepolymer is taken as a main body; a photoinitiator, a composite reactive diluent and other assistants are added; and then the ultraviolet curing liquid optical clear adhesive is prepared. The ultraviolet curing liquid optical clear adhesive prepared by the preparation method has the characteristics that the ultraviolet curing liquid optical clear adhesive is low in smell, moderate in viscosity, good in flexibility, high in light transmittance and refractive index, high in bonding strength, waterproof, and good in cold and heat shock resistance, weather resistance and ageing resistance. The ultraviolet curing liquid optical clear adhesive is completely transparent after being cured, and can keep stable high transparency and is free from yellowing, whitening and degumming for a long term in high-temperature and high-humidity environments.

Owner:SHENZHEN JINLIAN TECH

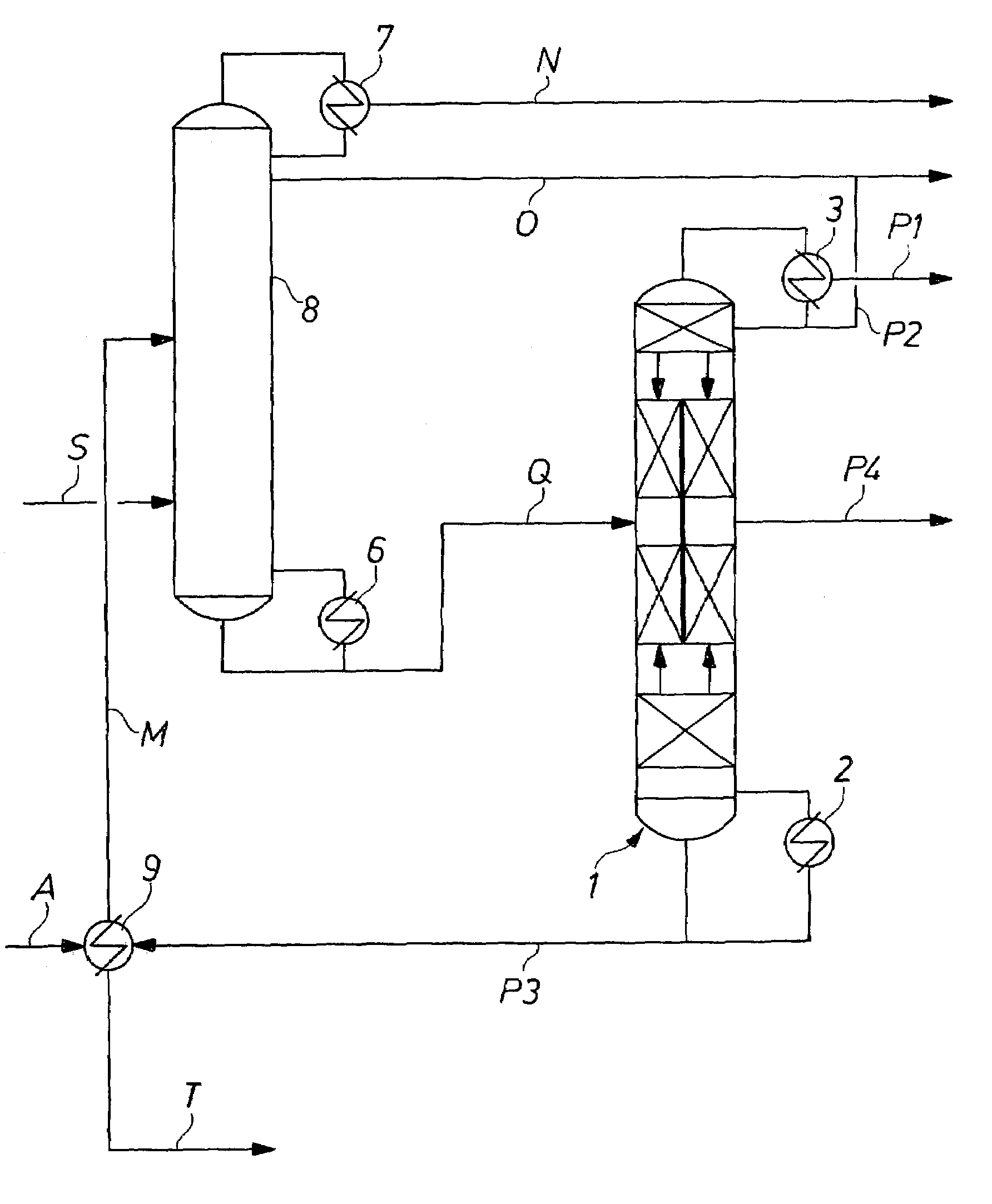

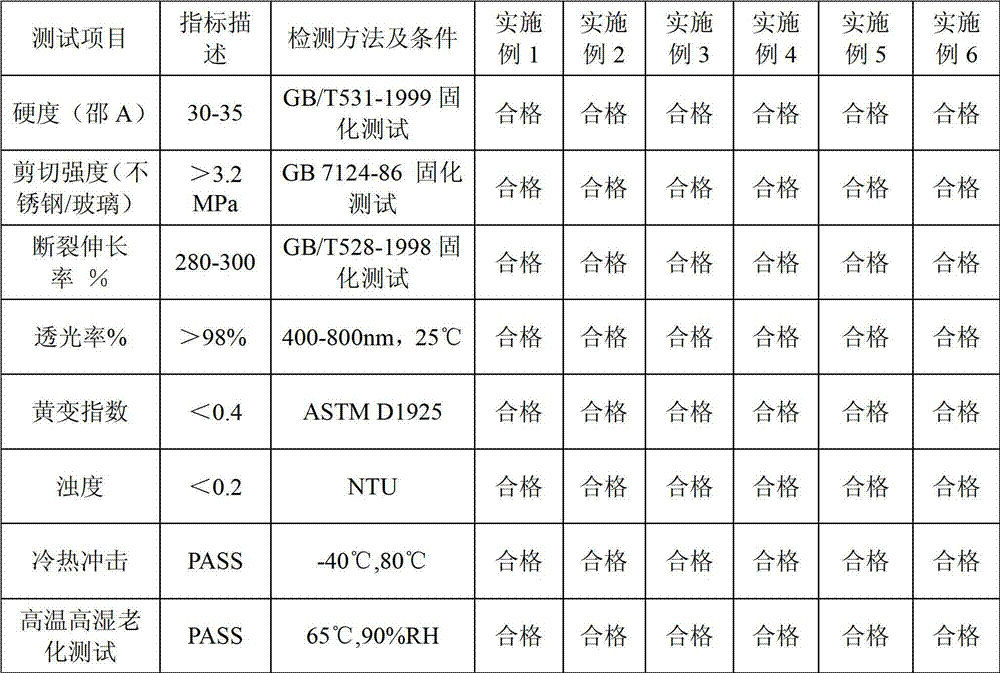

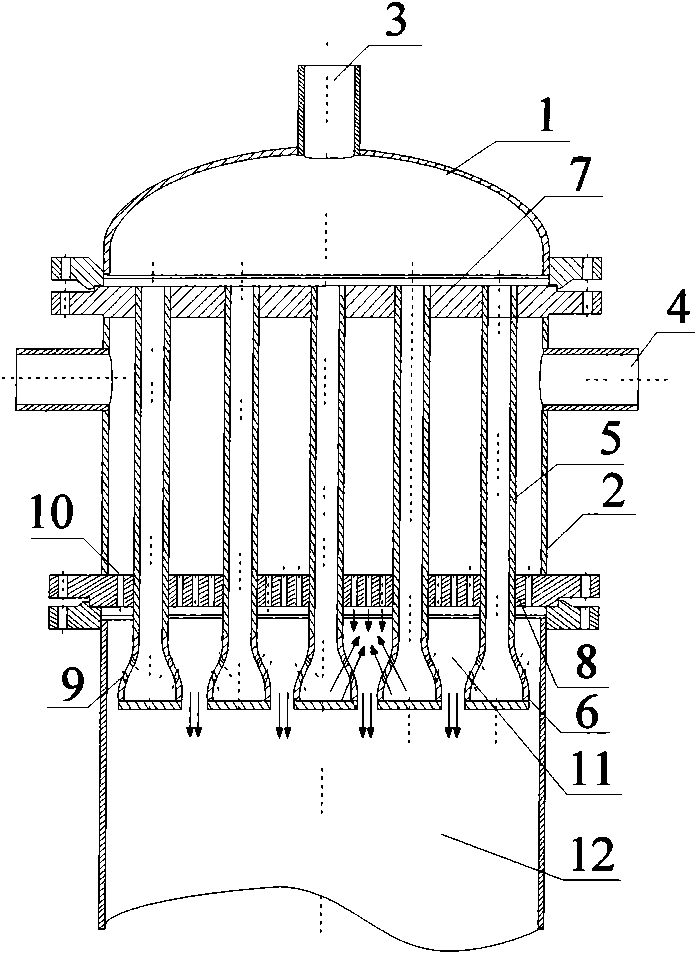

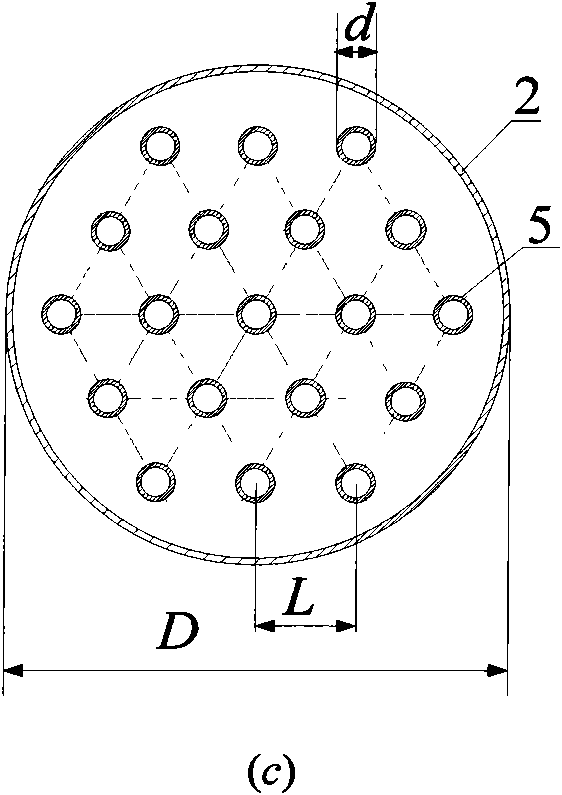

Column tube type impinging stream reactor and operating system for producing toluene diisocynate

ActiveCN101612547ASmall amplification effectReduce generationIsocyanic acid derivatives preparationOrganic compound preparationJet flowReaction zone

The invention relates to a column tube type impinging stream reactor and an operating system for producing toluene diisocynate. The upper head of the column tube type impinging stream reactor is connected with a barrel body on which a barrel body feeding hole (4) is arranged, the column tubes pass through the barrel body and are evenly distributed on the upper tube-plate and the lower tube-plate in the barrel body, jet orifices (10) of the lower tube-plate are evenly distributed on the lower tube-plate; the lower end of the column tube is connected with an expanding section of the column tube; and the jet orifices (9) of the column tubes are arranged on the lower ends of the column tubes and the expanding sections of the column tubes. A stream of material is injected by the jet orifices (10) of the lower tube-plate in a jet current mode; around the jet orifices of the lower tube-plate, the column tubes and column tube expanding sections are arranged in parallel and are vertical to the lower tube-plate; the other stream of fluid is injected into an impinging mixed zone with a certain angle in a jet current mode by the jet orifices (9) of the column tubes arranged on the column tubes and the column tube expanding sections and is impacted with the first stream of material and then is quickly mixed; and the reaction material enters into a second reaction zone (12) for further reaction. The size of the impinging mixed zone can be flexibly changed by adjusting the structure parameters of the mixed zone, therefore, the reactor has strong adaptability.

Owner:SEDIN ENG +1

Dissolvant type polyurethane curing agent synthetic method for producing low free toluene diisocyanate content

ActiveCN101456940AReduce glossLow free toluene diisocyanate contentPolyurea/polyurethane coatingsAcetoacetatesPolyol

The invention relates to a synthesis method for preparing a solvent based polyurethane curing agent with low content of dissociated toluene di-isocyanate, which is characterized in that the reaction undergoes in two stages: stage one, the toluene di-isocyanate and polylol react in the solvent, the reaction degree is monitored by sampling and detecting the content of NCO from the reacted mixture during the reaction process; when the content of NCO is stable, the reaction reaches the endpoint of stage one; stage two, acetylacetic ester is added to the reacted mixture; after the reaction goes on, the reaction degree is monitored by sampling and detecting the content of NCO from the reacted mixture during the reaction process; when the content of NCO is stable again, the reaction reaches the endpoint of stage two, which is also the endpoint of the overall reaction; wherein, the reaction of the stage two is conducted at low temperature. The synthesis method is characterized by small investment, low content of dissociated toluene di-isocyanate monomer, low viscosity, good flexibility and stable product performance.

Owner:GUANGDONG HUARUN PAINT CO LTD

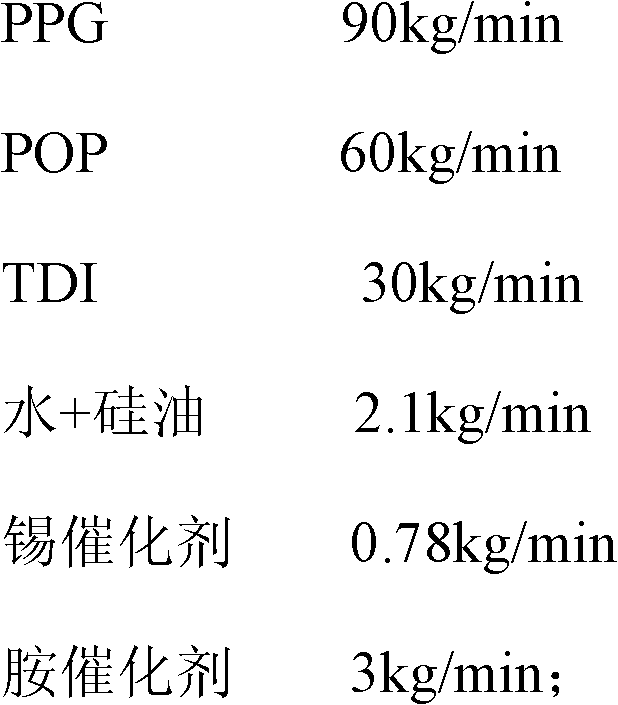

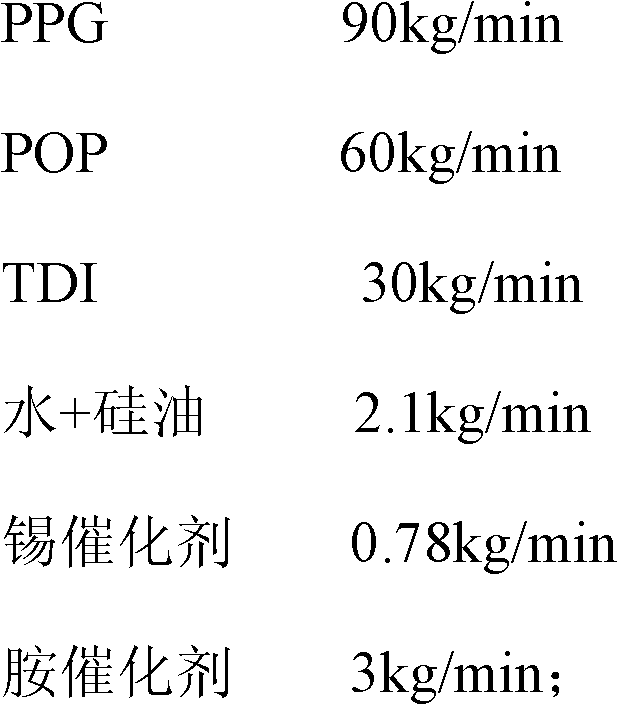

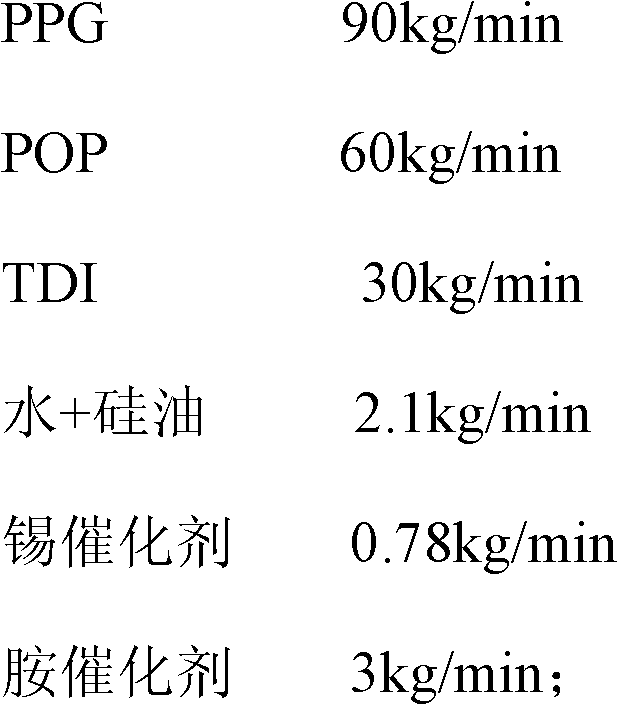

Flexible polyurethane foam and production process

The invention discloses flexible polyurethane foam and a production process for preparing the flexible polyurethane foam. A mixture of polyether, isocyanate, water, a catalyst and foam stabilizer is formed by reacting by means of one-step continuous foaming process, wherein the polyether consists of PPG (polypropylene glycol) and POP (polyether polyol), and the proportion of 2,4-TDI (toluene diisocyanate) to 2,6-TDI, which are isomers of TDI of isocyanate, ranges from 75-85:15-25. High-density foam with apparent density up to 80kg / m3 is produced by means of the one-step continuous foaming process and has the advantages of high production capacity and fine cell-opening performance as compared with molding foam. The foam produced by the process has high density up to 80kg / m3 under the condition of continuous production as compared with common block foam, so that the cell diameter of the foam is thick, and the foam is high in elasticity and bearing capacity.

Owner:ZHEJIANG CHUANYANG SPONGE

Monocomponent polyurethane waterproof paint and preparation method thereof

InactiveCN104087147AHigh strengthHigh elongation at breakPolyurea/polyurethane coatingsPolyolOrganic solvent

The invention provides a monocomponent polyurethane waterproof paint and a preparation method thereof. The monocomponent polyurethane waterproof paint comprises the following components in parts by weight: 200 to 300 parts of polyether polyol, 100 to 200 parts of toluene diisocyanate (TDI), 60 to 100 parts of organic solvent, 240 to 400 parts of filling material, 30 to 50 parts of defoaming agent, 200 to 250 parts of plasticizer, 50 to 80 parts of dispersing agent and 5 to 10 parts of catalyst. The monocomponent polyurethane waterproof paint is nontoxic, free of pollution, high in curing speed, short in construction period, low in cost and good in paintcoat performance.

Owner:STATE GRID CORP OF CHINA +1

Thermal storage and insulation microcapsule for building material and preparation method thereof

ActiveCN102732225AHydrophilicSimple preparation processHeat-exchange elementsMicroballoon preparationThermal energy storageToluene diisocyanate

The present invention relates to a thermal storage and insulation microcapsule for a building material and a preparation method thereof. An inner wall material employs toluene diisocyanate and polyethylene glycol as a polymerization monomer, which wraps a core material via interfacial polymerization; and an outer wall material employs toluene diisocyanate, diethylenetriamine, ethanediamine or piperazine as a polymerization monomer, which wraps an inner nuclear shell via interfacial polymerization. Capsule wall of the thermal storage and insulation microcapsule of the invention has advantages of thermosetting property, high mechanical strength, and improved abrasion resistance and durability.

Owner:常州汉诺斯生物科技有限公司

Polyurethane-encapsulated particle comprising polyol derived from aromatic amine-based initiator

ActiveUS7416785B2Efficient mixingBiocideBio-organic fraction processingToluene diisocyanatePhosphate

An encapsulated particle includes a core particle. The core particle includes a fertilizer selected from the group of nitrogen, phosphate, potash, and sulfur, and combinations thereof. The core particle may also include herbicides, insecticides, and fungicides. The encapsulated particle also includes a polyurethane layer disposed about the core particle. The polyurethane layer includes the reaction product of an aromatic isocyanate component and a polyol that is reactive with the aromatic isocyanate component. The aromatic isocyanate component includes methylene diphenyl diisocyanate, toluene diisocyanate, and mixtures thereof. The polyol that is reactive with the aromatic isocyanate component is derived from an aromatic amine-based initiator and includes a toluene diamine. The aromaticity of the aromatic isocyanate component and the polyol serves to insure complete miscibility between the aromatic isocyanate and the polyol thereby forming the polyurethane layer without defects preventing water from permeating the polyurethane layer and dissolving the core particle.

Owner:BASF CORP

Novel high-strength polyurethane waterproofing paint and preparation method thereof

InactiveCN104673076ALong construction timeHigh strengthPolyurea/polyurethane coatingsToluene diisocyanatePlasticizer

The invention discloses a novel high-strength polyurethane waterproofing paint which consists of a component A and a component B. The component A is prepared from the following components in parts by weight: 140-350 parts of polyether polyol, 20-60 parts of TDI (toluene diisocyanate), 20-60 parts of diphenylmethane diisocyanate and 50-100 parts of a plasticizer; the component B is prepared from the following components in parts by weight: 50-100 parts of polyether polyol, 40-200 parts of a plasticizer, 20-80 parts of a chain extender, 100-300 parts of pigment and filler, 0.1-0.5 part of a catalyst, 0.1-0.5 part of a polymerization inhibitor and 0.1-1 part of a high-performance accessory ingredient defoaming agent. The invention also comprises a preparation method of the high-strength polyurethane waterproofing paint. The high-strength polyurethane waterproofing paint disclosed by the invention has relatively long operable construction time and excellent physical and mechanical properties such as high strength, high elongation rate and high bonding strength, and is low in residual TDI and toxicity. The novel high-strength polyurethane waterproofing paint can be widely applied to infrastructure construction and municipal traffic engineering, and particularly to water resistance of important projects such as high-speed railways and highway bridges.

Owner:XUZHOU WONIUSHAN NEW WATERPROOF MATERIALS

Polyurethane matt varnish for benzene-free odor-less furniture

ActiveCN101684388AImprove mechanical propertiesGood gloss and color retentionPolyurea/polyurethane coatingsCyclohexanoneFoaming agent

The invention provides a polyurethane matt varnish for benzene-free odor-less furniture, which is composed of a main agent, a curing agent and a diluent. The main agent comprises 66.5-75.5% of hydroxyacrylic resin, 16.0-25.0% of solvent, 0.1-0.3% of defoarming agent, 0.05-0.1% of flatting agent, 0.1-0.5% of anti-settling agent, 0.1-0.5% of dispersing agent, and 4-8% of delustering agent; the curing agent comprises40.0-50.0% of toluene diisocyanate tripolymer, 20.0-30.0% of toluene diisocyanate-trimethylolpropane affixture, and 20.0-30.0% of butyl acetate; the diluent comprises 60.0-70.0% of butyl acetate, 15.0-20.0% of cyclohexanone, and 15.0-25.0% of propylene glycol methyl ether acetate. The product of the invention is favorable for construction, and no odor exists after the construction of the previous night.

Owner:上海展辰涂料有限公司 +1

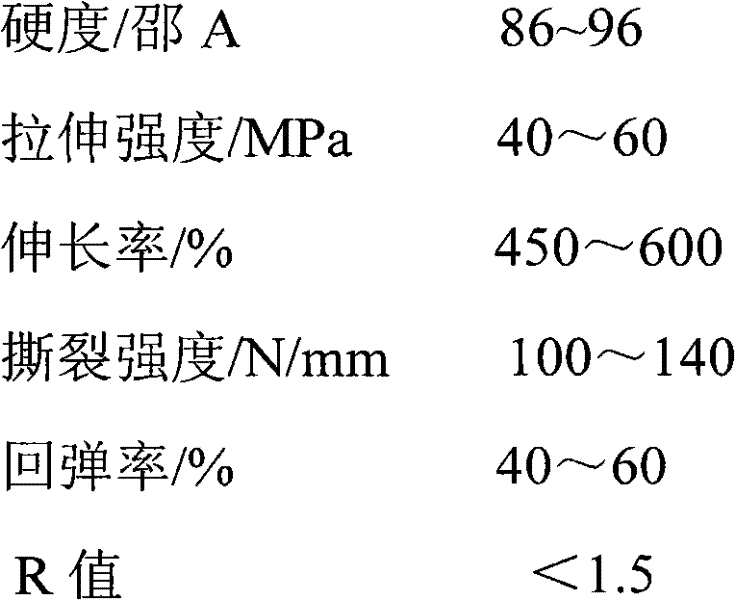

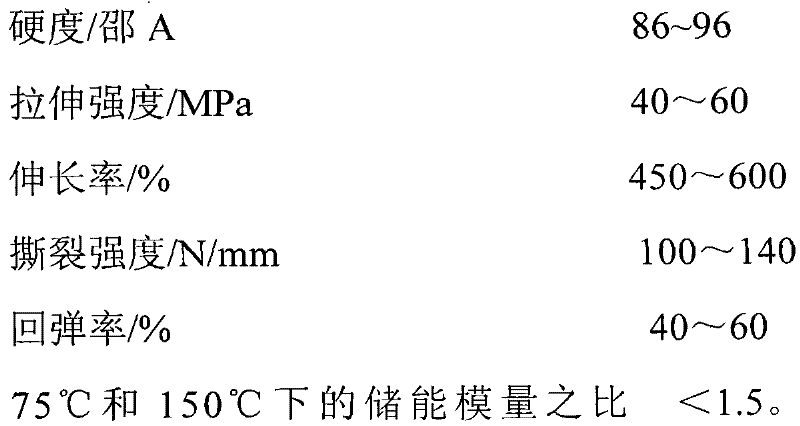

Heat-resistant thermoplastic polyurethane elastomer and preparation method thereof

ActiveCN102199269AImprove high temperature resistanceImprove mechanical propertiesPolyurethane elastomerAlcohol

The invention discloses a heat-resistant thermoplastic polyurethane elastomer and a preparation method thereof. The preparation method comprises the following steps of: dehydrating 55-80 parts of macromolecular dihydric alcohol, then adding the dehydrated macromolecular dihydric alcohol into TODI (Toluene Diisocyanate), reacting at the temperature of 75-120 DEG C to generate a prepolymer which has good storage stability and contains 3.0% to 9.0% of NCO; uniformly mixing 1.5-13 parts of chain extender, 0.001-0.1 part of catalyst, 0.05-1 part of oxidation inhibitor, 0.2-1 part of ultraviolet light absorbent and 0.2-2 parts of light stabilizer, and then mixing with the prepolymer in the step (a); vacuumizing and deforming the mixture in the step (b), and then pouring into a mould of 140-200 DEG C for demoulding for 10-25min; and curing the demoulded semi-finished products in a drying oven of 100-120 DEG C for 20-24 hours to obtain a finished product. The polyurethane elastomer has good high-temperature resistant property; the ratio of the storage modulus measured at 75 DEG C and 150 DEG C is less than 1.5; and the polyurethane elastomer has good integrated mechanical property and low cost.

Owner:LIMING RES INST OF CHEM IND

Luminant white paint and preparation method thereof

ActiveCN102533070AHigh hiding powerGood filling effectPolyester coatingsKetone solventsToluene diisocyanate

The invention discloses a luminant white paint. The luminant white paint is obtained by mixing a main paint, a curing agent and a diluent according to a mass ratio, wherein the main paint comprises the following components in parts by weight: 35-40 parts of alkyd resin, 3-5 parts of dispersing agent, 30-40 parts of titanium white powder, 10-20 parts of extender pigment, 0.2-0.5 parts of anti-setting agent, 0.2-0.4 parts of leveling agent, 0.2-0.5 parts of antifoaming agent, 0.5-1.0 parts of anti-yellowing agent and 20-25 parts of main paint solvent; the curing agent comprises the following components in parts by weight: 10-20 parts of curing agent solvent, 0.1-0.2 parts of dehydrating agent, 60-70 parts of HDI (Hexamethylene Diisocyanate) type curing agent and 30-40 parts of TDI (Toluene Diisocyanate) type curing agent; and the diluent comprises the following components in parts by weight: 60-70 parts of ester solvent and 30-40 parts of ketone solvent. The luminant white paint disclosed by the invention has the advantages of rapidness for leveling after being sprayed, full paint film, rockiness and scratch resistance. Meanwhile, the invention also discloses a preparation method of the luminant white paint.

Owner:NIPPON PAINT GUANGZHOU

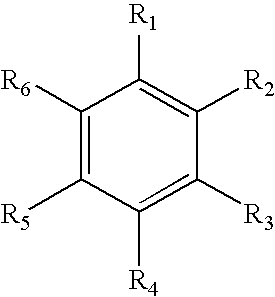

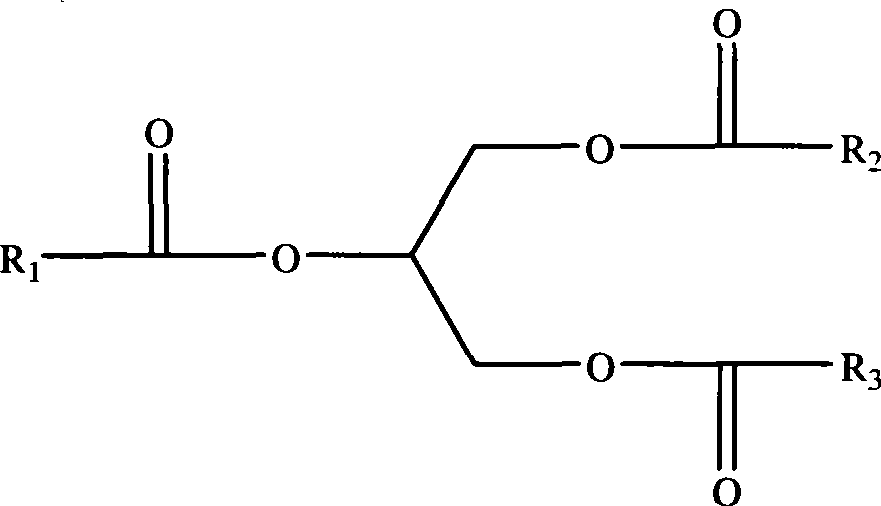

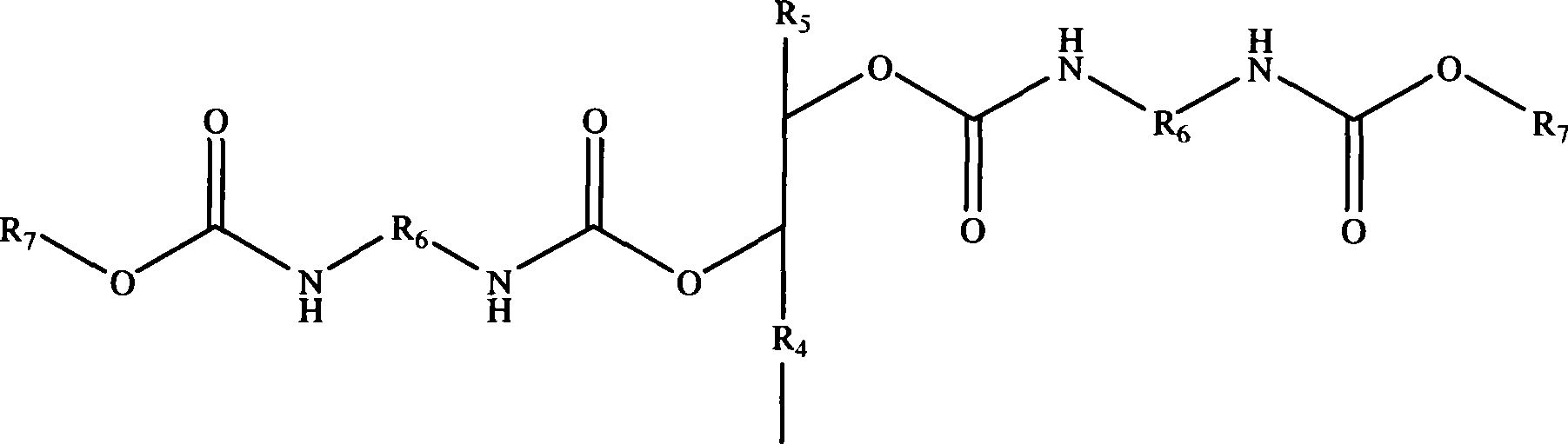

Vegetable oil based polyurethane acrylic ester, preparing process and use thereof

InactiveCN101497684AWide variety of sourcesEasy to makePolyurea/polyurethane coatingsSurface treatment compositionsAlkaneVegetable oil

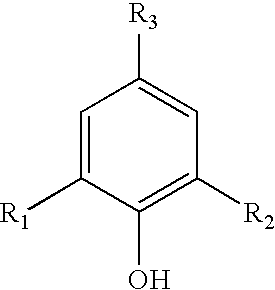

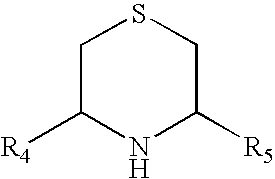

The invention relates to vegetable oil based polyurethane acrylic ester, belonging to the field of photosensitive polymer material. The vegetable oil based polyurethane acrylic ester is characterized in that the general chemical formula is Formula I, wherein R1, R2 and R3 are respectively chosen from alkane of C1-C18, at least one of the alkane is chosen from Formula II, R4 and R5 are respectively chosen from alkane of C1-C16, R6 is diphenyl methane-4,4'-diisocyanate, or hexamethylene diisocyanate, or isophorone diisocyanate or residue of 2,4-toluene diisocyanate with two isocyanate functional group removed, and R7 is 2-hydroxyethyl acrylate, or hydroxypropyl acrylate, or residue of pentaerythritol triacrylate with hydroxy functional group removed.

Owner:天津市天骄辐射固化材料有限公司

Two-component polyurethane waterproof coating and preparation method thereof

InactiveCN101418184AHigh solid contentHigh strengthPolyurea/polyurethane coatingsPolymer scienceToluene diisocyanate

The invention discloses a bicomponent polyurethane waterproof paint, which consists of a component A and a component B in weight portion, wherein the component A consists of 60 to 70 portions of toluene di-isocyanate(TDI), 7 to 10 portions of polyether N-330, 16.8 to 30.9 polyether N-220, 2 to 3 portions of amine-terminated polyether resin and 0.1 to 0.2 portion of stabilizing agent tartaric acid; and the component B consists of 20 to 30 portions of polyether N-330, 0.5 to 1 portion of antioxidant, 3 to 5 portions of tinting color, 4 to 8 portions of vulcanizing agent MOCA, 10 to 20 portions of vacuum distillate 4 line oil, 8 to 20 portions of chlorcosane, 4 to 8 portions of plasticizing agent DOP and 15 to 20 portions of sericite in powder. The invention also discloses a preparation method for the paint. The bicomponent polyurethane waterproof paint has the advantages of high solid content, high strength, and high elongation at break, and is especially suitable to be used as a waterproof layer of concrete bridge decks of high-speed railways, highways, lines for passenger transportation and lines for both passenger and freight transportation.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Method for preparing ultraviolet (UV)-curable polyisocyanate modified superbranched epoxy acrylate

ActiveCN102234268ALow viscosityGood alkali resistanceOrganic chemistryCoatingsEpoxyMaleopimaric acid

The invention relates to a method for preparing an ultraviolet(UV)-curable polyisocyanate modified superbranched epoxy acrylate, which comprises the following steps of: heating maleopimaric acid tri glycidyl ester, maleopimaric acid and a catalyst for esterification reaction to obtain rosin-based superbranched resin; cooling, and adding epoxy chloropropane, water and a catalyst for reaction to obtain superbranched epoxy resin; adding crylic acid, a catalyst and a polymerization inhibitor for reaction to obtain superbranched epoxy acrylic resin; and reacting the superbranched epoxy acrylic resin with ethylene glycol methacrylate terminated para toluene diisocyanate, a catalyst and a polymerization inhibitor to obtain the final product. Compared with the prior art, the method has the advantages that: rosinyl is introduced into superbranched polyester, and the hardness, strength and other special properties of the resin are improved and the curing speed is improved by utilizing the special rigid condensed ring structure of the rosin. The cured product has higher ultraviolet resistance; and by adjusting the using amount of raw materials, superbranched polyester for ultraviolet-curable coatings meeting different coating requirements can be prepared.

Owner:江苏金隆新材料有限公司

Transparent polyurethane elastomer component material and using method thereof

The invention provides a hypergolic transparent urethane elastomer combination material, wherein the polymer component comprises 2000-6000 molecular weight polyether polyol, aromatic diamine MOCA, accelerant and light-stability agent; the prepolymer (NCO%=7%-10%)is made by the mixture of 2000 molecular weight, 2 functionality polyether polyol and more than two-type diisocyanate with toluene diisocyanate at 70-90Deg. C. The weight ratio of prepolymer and polymer is 1:1, the mixing temperature is 25Deg. C-40Deg. C, and the vulcanizing temperature is 60Deg. C-75Deg. C. The elastomer not only guarantees transparency, but also is provided with the good mechanic property, which makes the light transmittance ratio of the product more than 85%, makes the product produce in the lower temperature, and is fit for manufacturing the transparent skating shoe wheel or the slide board wheel.

Owner:SHANDONG INOV POLYURETHANE

Polyurethane hot melt adhesive for high-grade lining cloth and preparation method thereof

InactiveCN101570676AOvercome difficult bonding problemsDoes not affect damagePolyureas/polyurethane adhesivesPolyesterToluene diisocyanate

The invention discloses the polyurethane hot melt adhesive for high-grade lining cloth, which is obtained through the reaction among polyester polyols with the relative molecular weight thereof being 2,000 to 2,200, 4,4-diphenylmethane diisocyanate (MDI), toluene diisocyanate (TDI), 1,4-butanediol (1,4-BDO) and aromatic diamine extender, wherein, the molecular weight of the polyurethane hot melt adhesive is 85,000 to 95,000. The polyurethane hot melt adhesive has the advantages of low thermal-bonding temperature and rapid crystallization, thereby facilitating the machining operations, preventing the polyurethane hot melt adhesive from being stuck to cloth and further preventing the polyurethane hot melt adhesive from penetrating and bleeding on ultra-thin loose base cloth; furthermore, the polyurethane hot melt adhesive has outstanding resistance to dry-cleaning and washing as well as washing under various caustic conditions. The invention further discloses a method for preparing the polyurethane hot melt adhesive for high-grade lining cloth.

Owner:长兴三伟热熔胶有限公司

Process for making a flexible polyurethane foam

Process for preparing a flexible polyurethane foam comprising reacting at an isocyanate index of 70 to 130, 1) 40-65 parts by weight of a polyisocyanate composition comprising a) 80-100% by weight of a diphenylmethane diisocyanate component comprising, based on 100 parts by weight of the diphenylmethane diisocyanate component, i) 75-100 parts by weight of diphenylmethane diisocyanate comprising 15-75 parts by weight of 4,4′-diphenylmethane diisocyanate, and 25 to 85 parts by weight of 2,4′-diphenylmethane diisocyanate, and 2,2′-diphenylmethane diisocyanate and / or a liquid variant of such diphenylmethane diisocyanate, and ii) 0 to 25 parts by weight of homologues of diphenylmethane diisocyanates having an isocyanate functionality of 3 or more; and b) 20-0% by weight of toluene diisocyanate; 2) 20 to 45 parts by weight of a polyether polyol having an average molecular weight of 4500-10000, an average nominal functionality of 2-6 and comprising oxypropylene and optionally oxyethylene groups, the amount of oxypropylene groups being at least 70% by weight calculated on the weight of this polyol; 3) 3 to 20 parts by weight of a polyether polyol having an average molecular weight of 700-4000, an average nominal functionality of 2-6 and an hydroxyl value of at most 225 mg KOH / g and comprising oxyethylene and optionally oxypropylene groups, the amount of oxyethylene groups being at least 70% by weight calculated on the weight of this polyol; and 4) 2-6 parts by weight of water, wherein the amount of the polyisocyanate composition, polyol 2), polyol 3), and water being 100 parts by weight.

Owner:HUNTSMAN INT LLC +1

Liquid partially trimerized and allophanized polyisocyanates based on toluene diisocyanate and diphenylmethane diisocyanate

InactiveUS7553963B2Urea derivatives preparationIsocyanic acid derivatives preparationPrenylationToluene diisocyanate

This invention relates to storage-stable, liquid, partially trimerized and allophanized polyisocyanates having an NCO group content of 15 to 41% by weight, and comprising 5 to 85% by weight of toluene diisocyanate, 5 to 85% by weight of a polyisocyanate of the diphenyl-methane series and an organic compound or mixture thereof. The present invention also relates to a process for the preparation of the storage-stable, liquid, partially trimerized and allophanized polyisocyanates; to storage-stable, liquid urethane prepolymers of these partially trimerized and allophanized polyisocyanates; and to a process for the production of these storage-stable, liquid, urethane prepolymers.

Owner:BAYER MATERIALSCIENCE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com