Single-component asphalt polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof, single-component technology, applied in coatings, etc., can solve the problems of pollution, irritating odor environment of polyurethane waterproof coatings, etc., to reduce costs, avoid irritating odors and environmental pollution, water resistance and waterproof performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

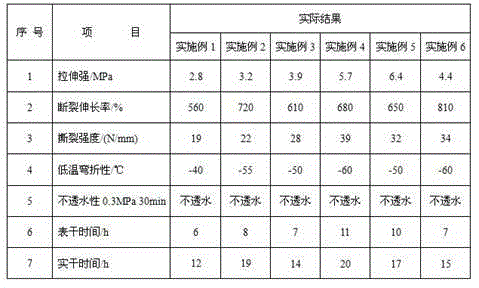

Examples

Embodiment 1

[0035] (1) Add 30 parts of polyether diol DL-2000 and 18 parts of polyether triol EP-330N into the reaction kettle, stir and heat to 110±5 ℃, and decompress at a vacuum pressure of -0.08 MPa Dehydration for 2 h, nitrogen protection, and cooling to 70 °C; then add 0.25 parts of benzoyl chloride and 12 parts of diphenylmethane diisocyanate in sequence, keep warm and stir for 3 h; finally lower the temperature to room temperature to obtain the polyurethane prepolymer Polymer, cool and set aside.

[0036] (2) Heat 29 parts of petroleum asphalt to 150 ? C, metered into the reaction kettle; then add 23 parts of talcum powder, 16 parts of heavy calcium carbonate, and 8 parts of kaolin, and keep stirring for 3 hours to fully disperse the filler; then cool down to 75 ? C, add 8 parts of glyceryl tricaprylate, 16 parts of dibutyl phthalate and 0.6 parts of dibutyltin dilaurate in sequence, stir for 4 h to disperse evenly; finally cool down the obtained asphalt mixture to about 40 ℃ to ...

Embodiment 2

[0039] (1) Add 41 parts of polyether diol DL-2000, 5 parts of polyether diol DL-1000 and 16 parts of polyether triol MN-3050 into the reactor, stir and heat to 110 °C, The vacuum pressure is -0.09 MPa and dehydration under reduced pressure for 2 h, and then cooled to 75 °C after being protected by nitrogen; then 0.4 parts of triphenyl phosphate and 24 parts of diphenylmethane diisocyanate are added in sequence, and the reaction is kept for 2.5 h with stirring; The temperature is lowered to room temperature to obtain a polyurethane prepolymer, which is cooled for later use.

[0040] (2) Heat 47 parts of petroleum asphalt to 120 ? C, metered into the reaction kettle; then add 42 parts of talcum powder and 19 parts of lime powder, keep warm and stir for 4 hours to fully disperse the filler; then cool down to 80 ? C. Add 23 parts of fatty acid glyceride (type 34), 22 parts of dibutyl phthalate and 1.2 parts of triethylenediamine in sequence, and stir for 3.5 hours to disperse eve...

Embodiment 3

[0043] (1) Add 31 parts of polyether diol DL-2000 and 21 parts of polyether triol MN-3050 into the reaction kettle, stir and heat to 110±5 °C, and dehydrate under vacuum pressure of -0.07 MPa After 3 h, it was cooled to 70 °C after nitrogen protection; then 0.5 parts of tartaric acid and 19 parts of liquefied MDI were added in sequence, and kept stirring for 2.5 h; finally, the temperature was lowered to room temperature to obtain a polyurethane prepolymer, which was cooled for later use.

[0044] (2) Heat 35 parts of petroleum asphalt to 180 ? C, metered into the reaction kettle; then add 35 parts of talcum powder and 11 parts of light calcium carbonate, heat and stir for 2 h to fully disperse the filler; then cool down to 90 ? C, add 13 parts of pentaerythritol cetanoic acid, 15 parts of dioctyl phthalate and 0.8 parts of triethylamine in sequence, stir for 2 hours to make it evenly dispersed; finally cool down to about 40 ℃ to get the asphalt composite system.

[0045] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com