Patents

Literature

326results about How to "Good low temperature flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water curing asphalt polyurethane composite waterproof coating and preparation method thereof

ActiveCN102775900AEnvironmentally friendlySimple manufacturing processPolyurea/polyurethane coatingsMoisture resistancePetroleum

A water curing asphalt polyurethane composite waterproof coating mainly comprises a component A and a component B. In terms of mass part, the component A consists of 60-85 parts of polyether polyol, 10-25 parts of isocyanate and 2-10 parts of plasticizer; and the component B consists of 40-70 parts of petroleum asphalt, 5-20 parts of compatilizer, 6-25 parts of plasticizer, 0.5-4 parts of stabilizer, 1-12 parts of water, 25-55 parts of filler, 8-20 parts of calcium hydroxide, 0.1-2 parts of catalyst and the like. When the water curing asphalt polyurethane composite waterproof coating is in use, the component A and the component B are uniformly mixed and the mixture is directly smeared on a waterproof datum plane of a building and is cured to form a waterproof film with the advantages of high strength, high elasticity and favorable low-temperature flexibility. The water curing asphalt polyurethane composite waterproof coating disclosed by the invention is simple in production process, low in cost and free from of tar or any organic solvent, meets the requirement of environment friendliness, is suitable for water resistance, seepage resistance and moisture resistance of construction engineering such as roofs, basements, bridges, tunnels and culverts and is especially suitable for waterproof engineering of damp datum planes.

Owner:HUBEI ENG UNIV

Spraying quick-setting rubber asphalt waterproof coating material

ActiveCN103627258AWith anti-adhesive effectImprove adhesionConjugated diene hydrocarbon coatingsNatural rubber coatingsComposite constructionWater based

The invention relates to a spraying quick-setting rubber asphalt waterproof coating material. A special technology is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material. The spraying quick-setting rubber asphalt waterproof coating material is a water-based spraying paint prepared according to a ratio, and a preparation method of the spraying quick-setting rubber asphalt waterproof coating material comprises following steps: a liquid rubber asphalt latex emulsion is prepared by mixing superfine, suspended and micro-emulsion modified emulsified asphalt with high-molecular polymer rubber latex; and the liquid rubber asphalt latex emulsion is mixed with a coagulant. Cold spraying construction is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material; elastic coating film elongation is more than 1000%; restoration ratio is more than 95%. The spraying quick-setting rubber asphalt waterproof coating material possesses ultraviolet resistance, high construction efficiency, high bonding strength, excellent high-temperature resistance, excellent low temperature flexibility, and better quick setting effect; and is capable of forming films in 3 seconds. The spraying quick-setting rubber asphalt waterproof coating material is water based; is friendly to the environment; possesses no toxicity, and excellent endurance; is quick and convenient for construction; and is a novel environmental friendly waterproof paint with a wide application range. The spraying quick-setting rubber asphalt waterproof coating material is mainly used for various waterproof and anticorrosion projects. The spraying quick-setting rubber asphalt waterproof coating material is used for individual construction of waterproof projects, for composite construction of waterproof projects together with waterproof roll, and for individual construction of anticorrosion projects.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

C7-C12 Secondary Alcohol Esters of Cyclohexanoic Acid

InactiveUS20100305250A1Easy to processGood low temperature flexibilityAlcoholCyclohexanecarboxylic acid

C7-C12 secondary alcohol esters of cyclohexanecarboxylic acids are especially useful as plasticizers for PVC and other plasticizable polymers. In embodiments, these plasticizers are useful in plastisol formulations to help improved processability of flexiblePVC material. In other embodiments these same plasticizers can be used in blends with other plasticizers to improve processability. In preferred embodiments these same plasticizers can be used to prepare flexible PVC compounds with enhanced low temperature flexibility, low toxicity, and improved resistance to outdoor aging.

Owner:EXXONMOBIL CHEM PAT INC

Elastic plastics blended antioxidation modified bituminous water-proof coiled material

InactiveCN1354203AGood low temperature flexibilityImprove high temperature resistanceOther chemical processesBuilding insulationsBituminous waterproofingThermoplastic elastomer

The present invention relates to a modified water-proofing asphalt roll material (called SA roll material for short), and is characterized by that in the raw material formula of asphalt 4-15% of thermoplastic elastomer polystyrene-butadiene-styrene block copolymer (SBS), 3-12% of atactic polypropylene (APP), 1-8% of light shielding agent, 0.05-3% of antioxidant, 0.05-3% of light stabilizer and 0.05-3% of UV absorbing agent. Said water-proofing roll material possesses low-temp. resistance, high-temp. resistance. UV-resisting property and good ageing resistance.

Owner:CHONGQING CITY NEW TYPE WATER PROOFING MATERIAL

High strength cold state asphalt fissure cementation water-proof glue and preparation thereof

ActiveCN101475748AGood anti-aging performanceImprove high temperature performanceOther chemical processesBuilding insulationsTO-18Adhesive

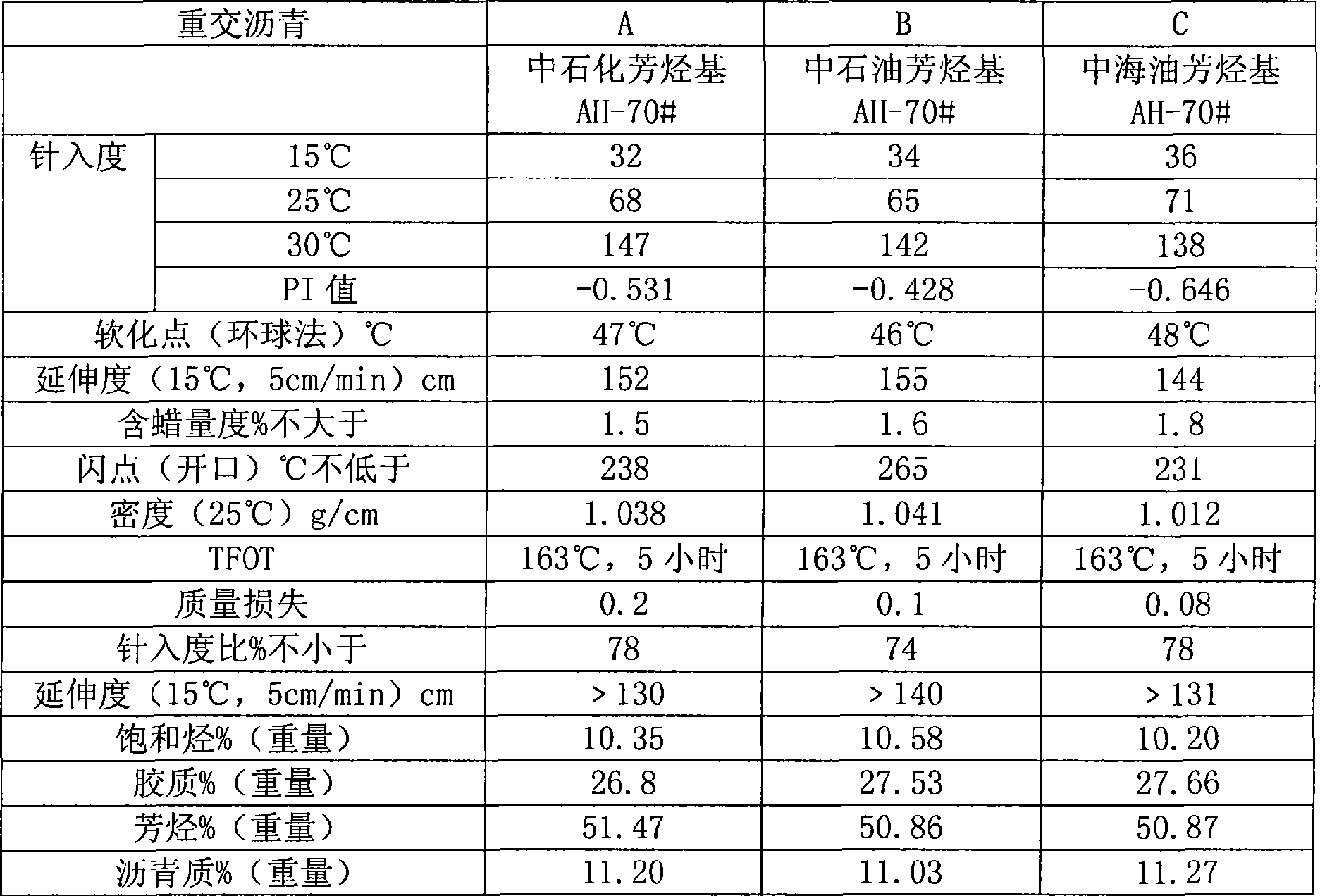

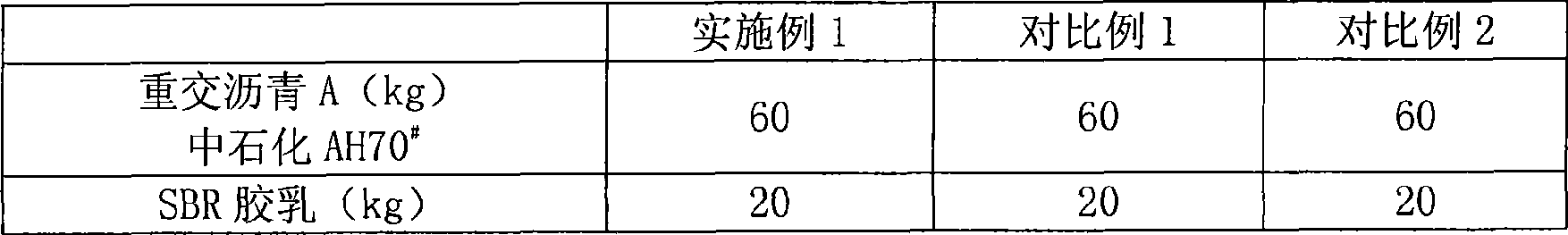

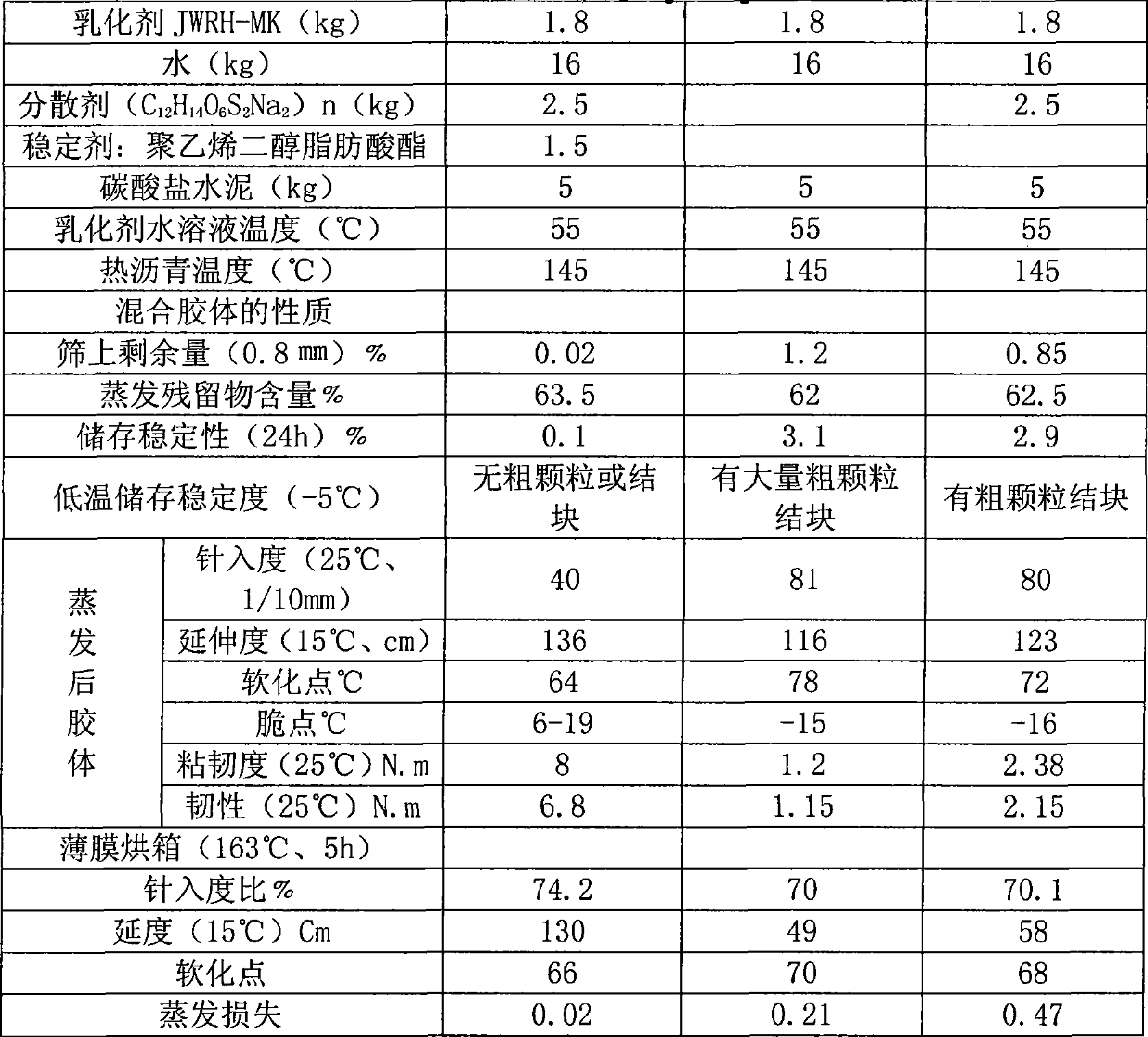

The invention relates to high-strength cold asphalt crack-pouring waterproof adhesive and a preparation method thereof. The waterproof adhesive comprises the following components in portion by weight: 15 to 20 portions of modifier polymer, 2.0 to 3 portions of dispersant, 0.5 to 2.0 portions of stabilizing agent, 50 to 60 portions of heavy rubber asphalt, 1.5 to 2.0 portions of emulsifying agent, 15 to 18 portions of purified water, and 4 to 16 portions of curing agent. The waterproof adhesive has the advantages of simple preparation, reliability and excellent properties, can be widely applied to crack pouring for large traffics in cities and countryside, heavy loading high-grade roads, stress absorbing structural layers, waterproof and mist sealing layers or layer sealing mat coats and the like, and remarkably improves water proofing, skid resistance, flatness and abrasion resistances of the roads.

Owner:钦兰成

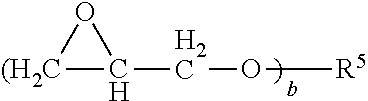

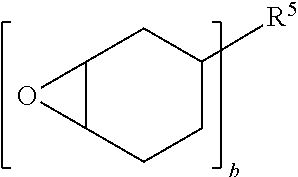

Elastomeric epoxy materials and the use thereof

Thermoset elastomer compositions are disclosed. Such elastomers are the reaction product of (a) an ambient temperature liquid epoxy-terminated prepolymer formed by reacting a polyoxyalkyleneamine having a molecular weight of from 3000 to 20,000 with an excess of epoxide, wherein the polyoxyalkyleneamine has at least 3 active hydrogen atoms and (b) a curing agent comprising at least one amine or polyamine having an equivalent weight of less than 200 and having 2 to 5 active hydrogen atoms. Such elastomers can be used in applications such as for sealants, adhesives, coatings, gaskets, jointing and cast elastomers.

Owner:DOW GLOBAL TECH LLC

Elastomer modified PVC (polyvinyl chloride) waterproof roll and production process thereof

InactiveCN105419162AImprove mechanical propertiesGood low temperature flexibilityElastomerPolymer science

The invention provides an elastomer modified PVC (polyvinyl chloride) waterproof roll and a production process thereof. The waterproof roll is prepared from the following raw material components in parts by weight: 98 to 102 parts of PVC resin, 30 to 40 parts of plasticizer, 5.8 to 6.2 parts of heat stabilizer, 4 to 6 parts of epoxidized soybean oil, 25 to 50 parts of elastomer CPE, 30 to 50 parts of filler, 5 to 6 parts of titanium dioxide, 1 to 2 parts of stearic acid, 1 to 2 parts of barium stearate, 0.5 to 1.5 parts of antioxygen 1010 and 0.5 to 1.5 parts of ultraviolet light absorber. The modified PVC waterproof roll provided by the invention is good in mechanical property, and long in service life.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

EVA/LLDPE composite polymer waterproof board and manufacturing process thereof

InactiveCN102010543AGood low temperature flexibilityImprove puncture resistanceLinear low-density polyethyleneAntioxidant

The invention relates to a composite polymer waterproof board, which is prepared from the following components in part by weight: 30 to 90 parts of ethylene-vinyl acetate (EVA) copolymer, 20 to 50 parts of linear low density polyethylene (LLDPE) and 0.5 to 1.5 parts of antioxidant. The composite polymer waterproof board has high seepage resistance, high barrier property, high puncture resistance, no chemical pollution, and resistance to acid, alkali and various chemical substances. The invention discloses a synthetic resin polymer waterproof board with high elongation and wear resistance and a preparation method thereof. The waterproof board is suitable for water and seepage resistance of civil engineering such as various tunnels, underground civil engineering, urban subways, water conservation, artificial lakes, refuse landfills, petrochemical plant waste residue treatment sites, sewage regulating tanks and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

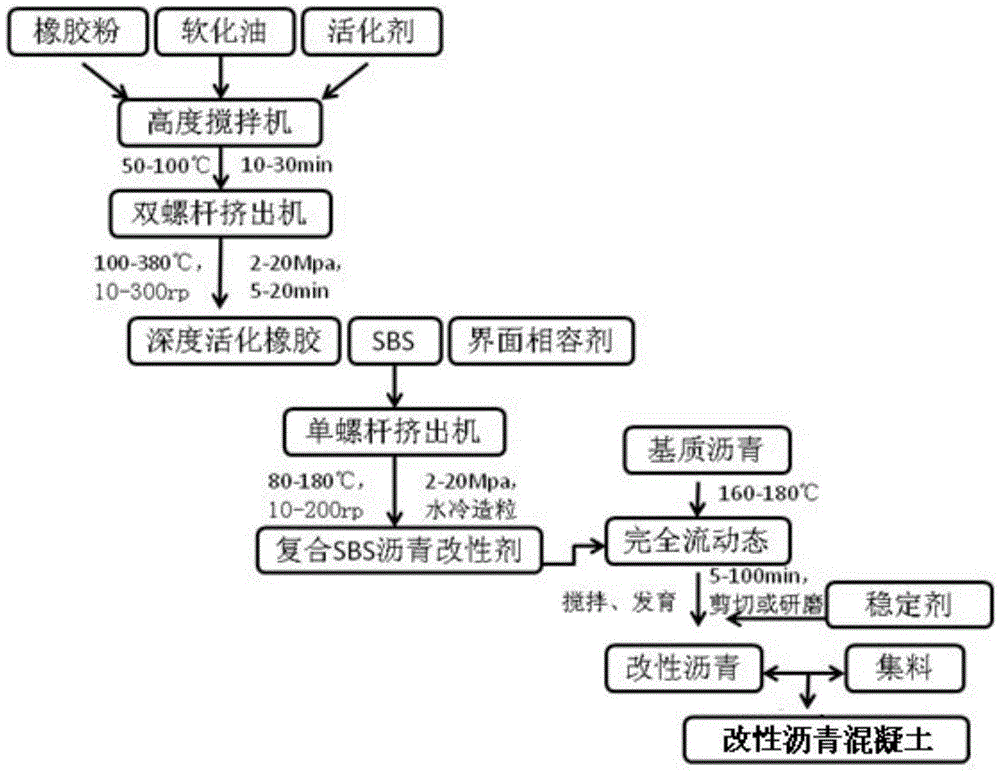

Composite-SBS (Styrene Butadiene Styrene block polymer)-particle asphalt modifier with storage stability and aging resistance and preparation method thereof

ActiveCN104693819AControl "Secondary Pollution"Low costBuilding insulationsPolymer scienceAging resistance

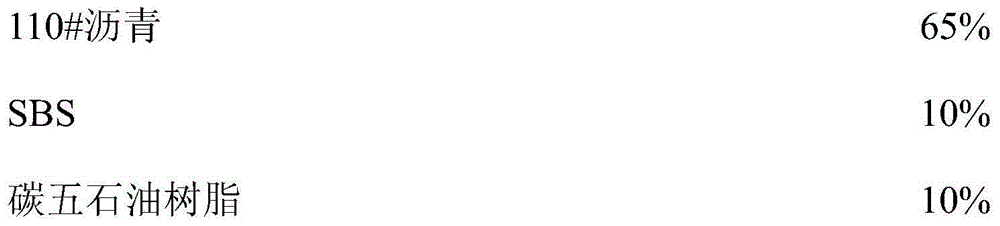

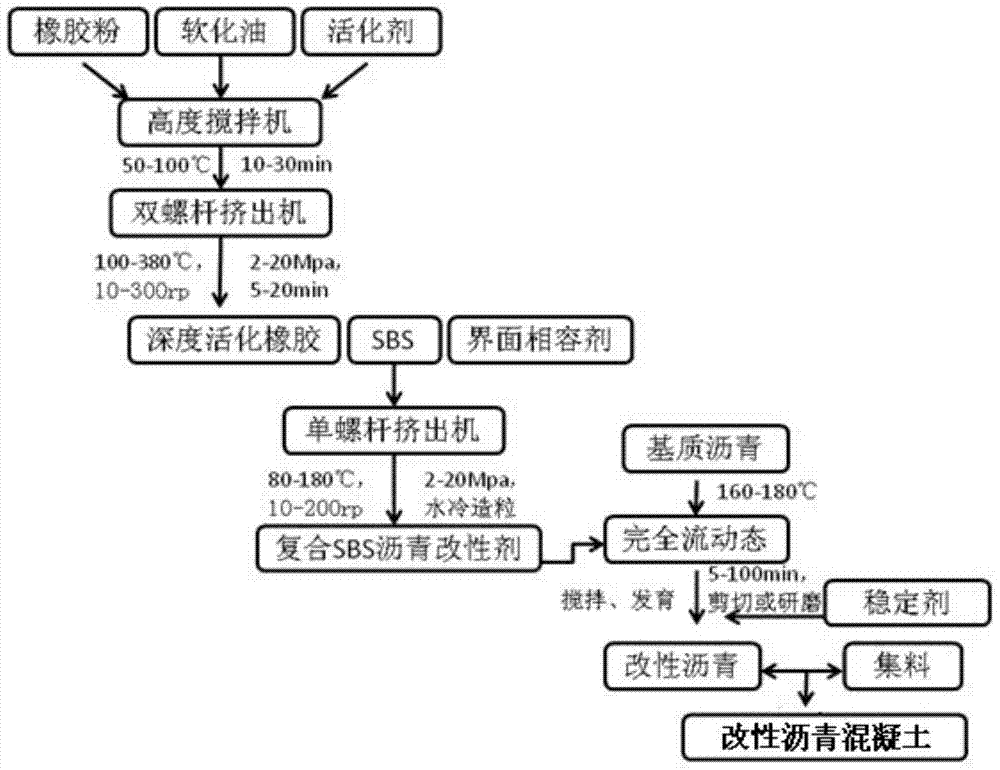

The invention relates to composite-SBS (Styrene Butadiene Styrene block polymer)-particle asphalt modifier with storage stability and aging resistance and a preparation method thereof. The composite-SBS-particle asphalt modifier contains the ingredients in percentage by mass: 15-38% of SBS, 56-82% of deep-activated rubber powder and 3-6% of an interface compatibilizer, wherein the deep-activated rubber powder consists of rubber powder, softening oil and an activator. The method comprises the steps: preparing the deep-activated rubber powder from waste rubber powder by using the high-temperature and high-shear action of a twin-screw extruder; thoroughly mixing the SBS particles and the deep-activated rubber powder by using the blending action of screws, and granulating, thereby preparing the asphalt modifier. Compared with asphalt modified by ordinary SBS modifiers, asphalt prepared by using the composite-SBS-particle asphalt modifier disclosed by the invention has the advantages that the ageing resistance is excellent, and heat storage does not separate out basically. Waste / used tires can be massively consumed, so as to relieve black pollution. According to the asphalt modifier, urban noise pollution and road surface microstructure can be lowered, road surface drainage is facilitated, water splashing is reduced, and the safety performance of driving is improved.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

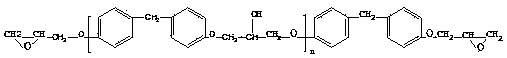

Multiple curable aqueous hyperbranched polyurethane inorganic nanomaterial hybrid coating agent and preparation method thereof

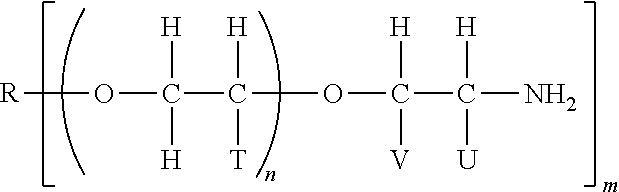

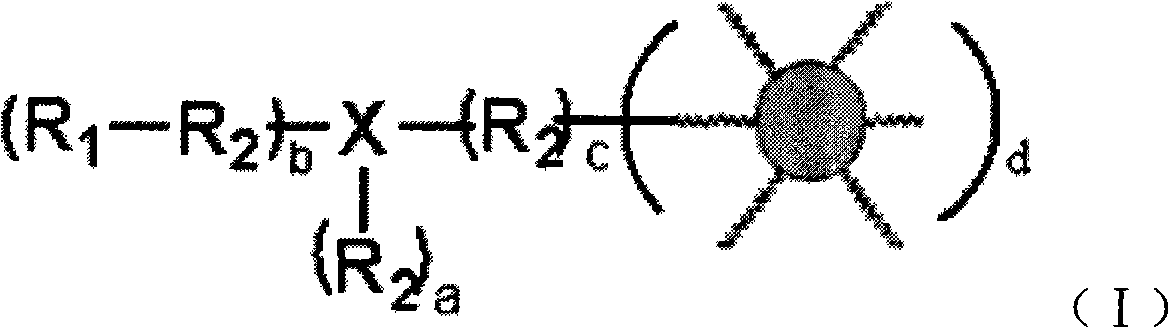

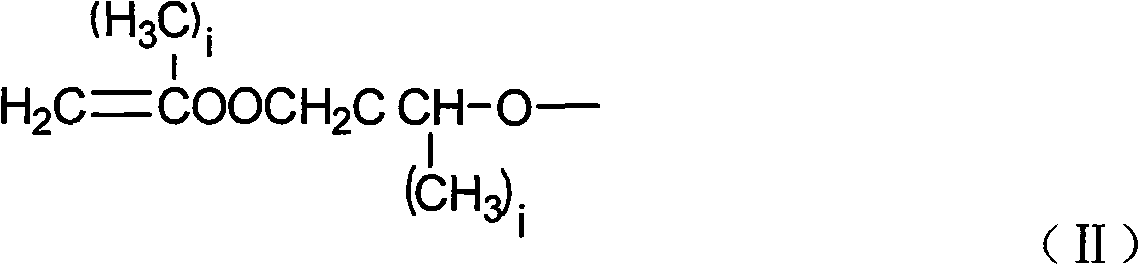

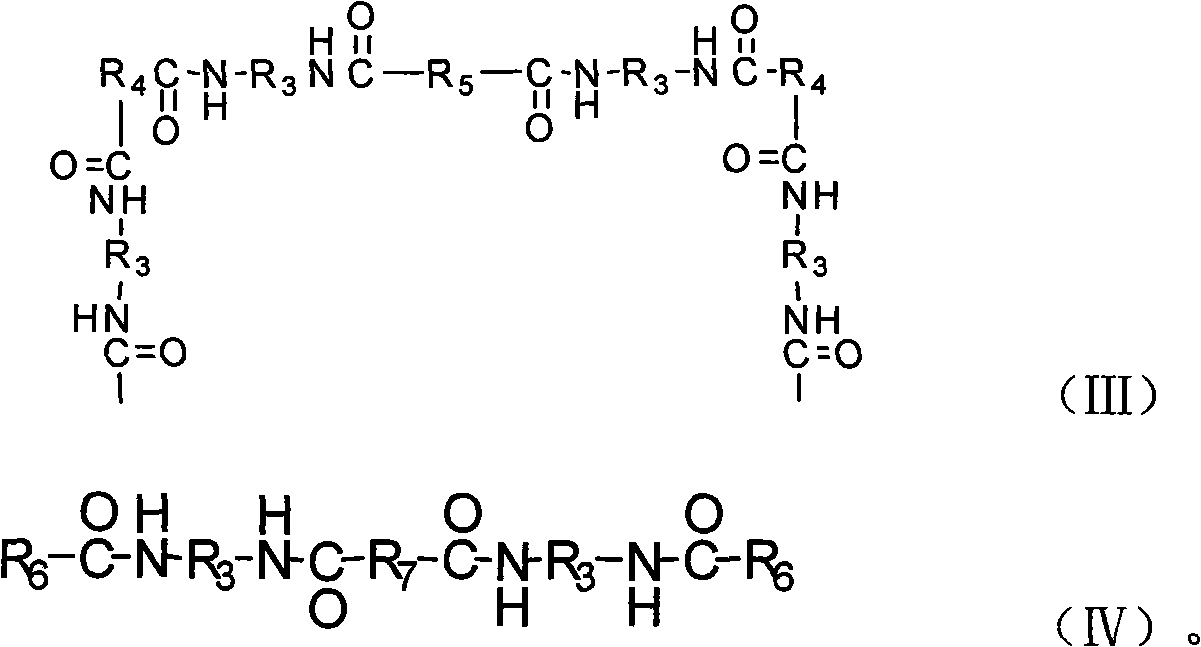

InactiveCN101597461AHigh strengthImprove rigidityPolyurea/polyurethane coatingsLeather surface finishingStructural formulaTemperature resistance

The invention relates to a multiple curable aqueous hyperbranched polyurethane inorganic nanomaterial hybrid coating agent and a preparation method thereof. The coating agent comprises the following compositions in percentage by mass: 20 to 45 percent of polyurethane shown in a structural formula below, and 55 to 80 percent of deionized water. A film coated by the coating agent has the characteristics of flatness, smoothness, temperature resistance, oil resistance and the like, and has excellent low-temperature toughness performance. Leather coated by the coating agent has the characteristics of high gloss, good hand touch, abrasion resistance, difficult cracking, good elasticity, excellent water resistance and deflection resistance, and the like.

Owner:ZHEJIANG DONGHUA IND

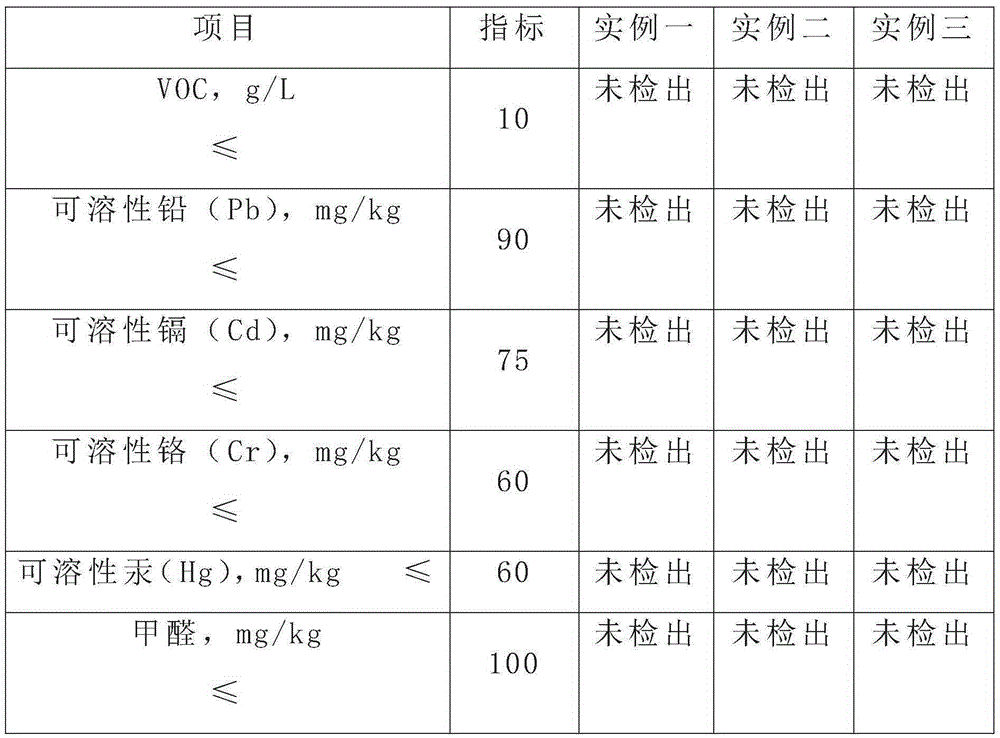

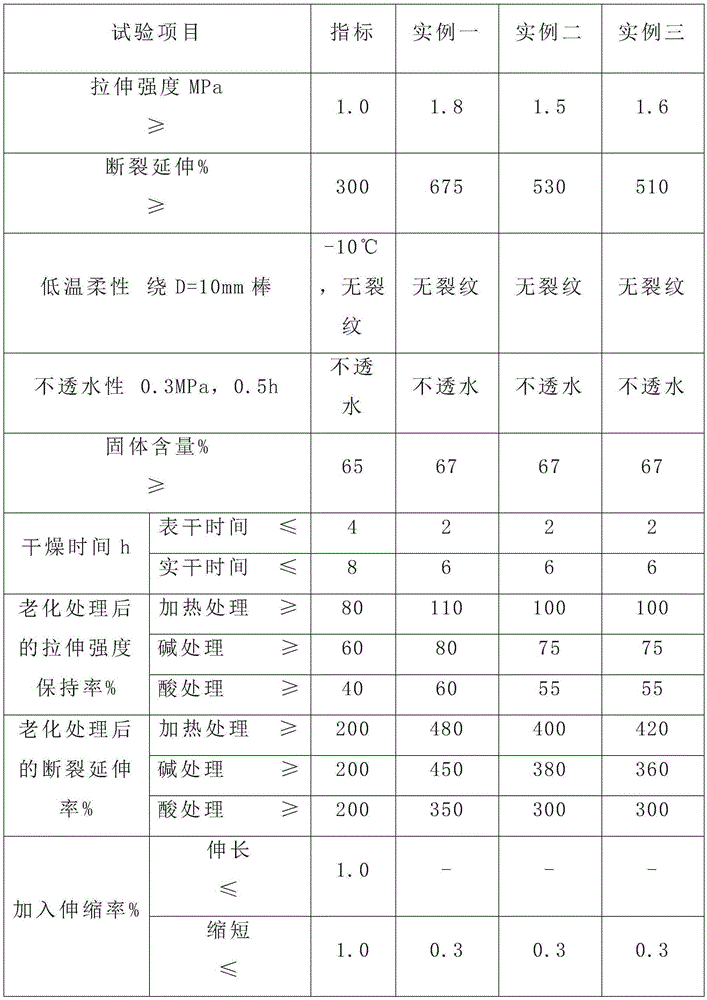

Environment-friendly building waterproof paint with low content of VOC and preparation method thereof

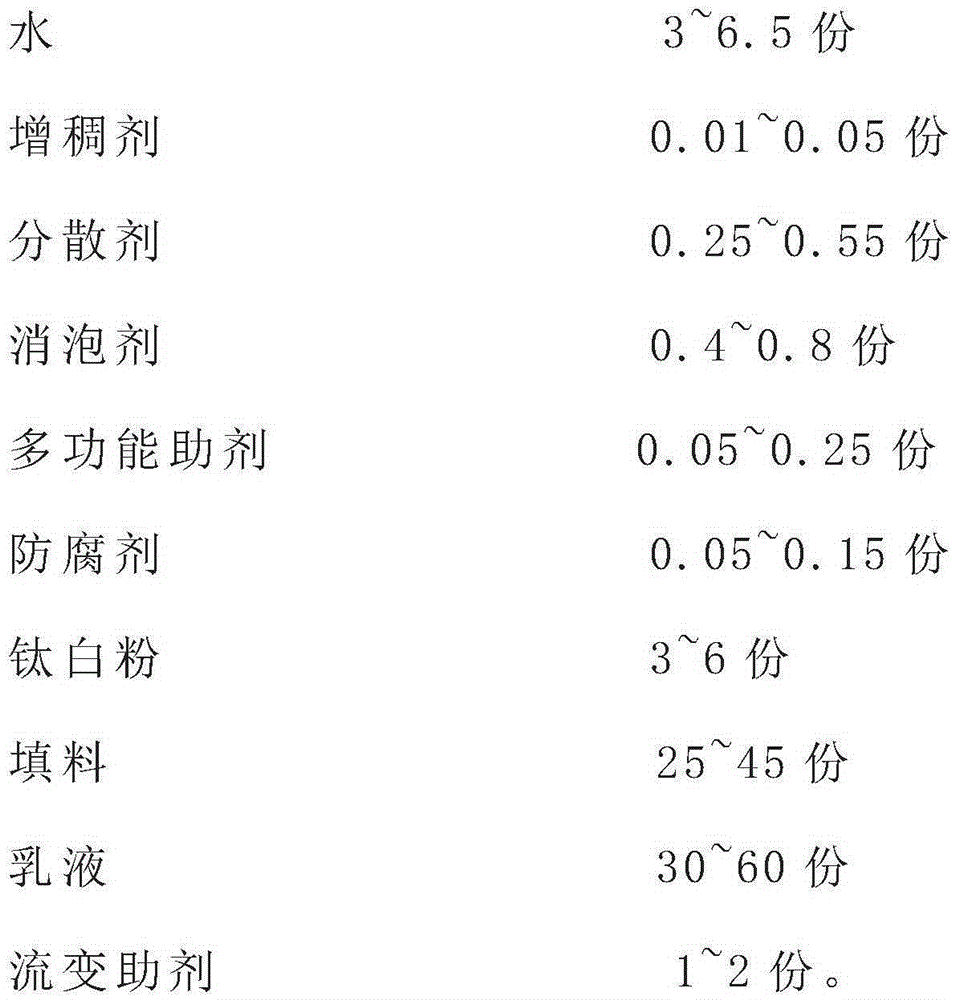

InactiveCN105385274ALow monomer residueLow content of volatile additivesAntifouling/underwater paintsPaints with biocidesSOAPMaterials science

The invention discloses an environment-friendly building waterproof paint with a low content of VOC (volatile organic compound) and a preparation method thereof. The paint comprises the following components in parts by weight: 3 to 6.5 parts of water, 0.01 to 0.05 part of thickening agent, 0.25 to 0.55 part of dispersant, 0.4 to 0.8 part of antifoaming agent, 0.05 to 0.25 part of multifunctional auxiliary agent, 0.05 to 0.15 part of antiseptic, 3 to 6 parts of titanium dioxide, 25 to 45 parts of filling material, 30 to 60 parts of emulsion, and 1 to 2 parts of rheological additive. The paint is prepared by a ternary compounding technology, which compounds three components: low-VOC pure acrylic emulsion, low-VOC vinyl acetate-ethylene emulsion, and soap-free organic silicon rubber emulsion; a VOC-free composite rheological system blending technology and a composite silver ion sterilizing and anticorrosion technology. The paint has the advantages of low VOC content, green, no toxicity, high strength, convenience in construction, and stableness in storage.

Owner:苏州市姑苏新型建材有限公司

Coating material for surface coating of waterproof membrane and preparation method thereof

ActiveCN101575475AHigh tensile strengthHigh elongationMulticolor effect coatingsPolymer sciencePolymer

The invention relates to a coating material for the surface coating of a waterproof membrane and a preparation method thereof. The coating material is prepared by the following method of: mixing and synthesizing a raw material consisting of a component A, a component B, a component C and a component D to obtain a polymer emulsion, wherein the component A comprises 90.0-130.0 weight portions of deionized water; the component B comprises 9.0-22.0 weight portions of deionized water, 0.5-1.5 weight portions of sulfate and 0.1-1.0 weight portion of polymerizing agent; the component C comprises 98.0-128.5 weight portions of deionized water, 0.2-5.0 weight portions of sulfate, and 2.5-4.5 weight portions of polymerizing agent; the component D comprises 150.0-260.0 weight portions of acrylic acid ester, 3.0-10.0 weight portions of methacrylic acid, 5.0-20.0 weight portions of organic fluorine and 5.0-20.0 weight portions of organosilicon; filling a filling material, a nano-material and an additive in the polymer emulsion and carrying out uniform dispersion simultaneously; adjusting the pH value to 8-9 by an ammonia; adding a thickener subsequently and filtering the solution, thus obtaining the colorful nano-fluorine silicone-acrylate coating materials. The coating materials are uniformly coated on the surface of the waterproof membrane, and the solidified and bonded colorful nano-fluorine silicone-acrylate coating has high tensile strength, large fracture elongation, good weathering resistance and low-temperature resistance, excellent heat resistance and stability and various color types.

Owner:KESHUN WATERPROOF TECH CO LTD

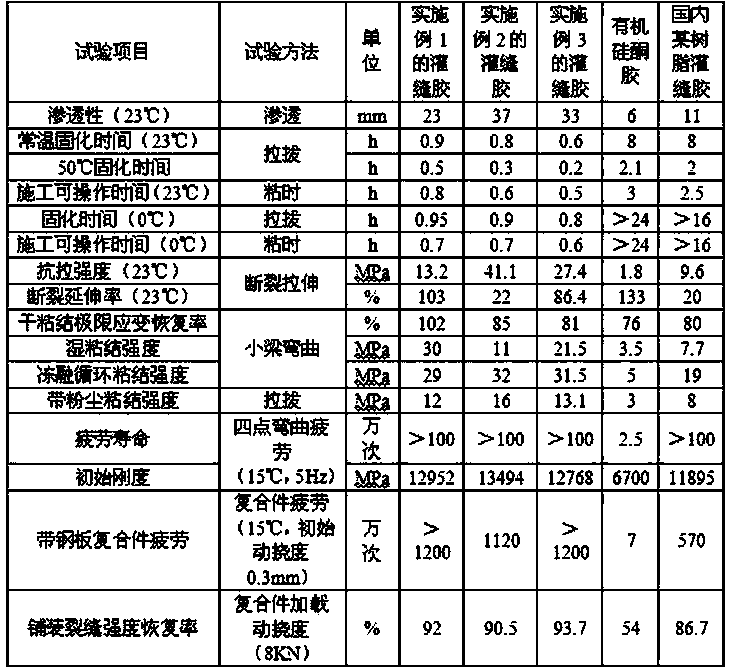

Low-temperature rapidly cured acrylic ester modified epoxy resin joint sealant used in road and bridge

ActiveCN104231995AExcellent low temperature permeabilityImprove adhesionNon-macromolecular adhesive additivesModified epoxy resin adhesivesPolymer scienceHexamethylenediamine

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

Novel high-temperature-resistant non-curing waterproof coating and preparation method thereof

InactiveCN110016291AImprove high temperature resistanceImprove adhesionFireproof paintsOther rubber coatingsPolymer sciencePolyamide

The invention belongs to the technical field of building materials, and provides a novel high-temperature-resistant non-curing waterproof coating. The coating is composed of the following components in percentage by weight: 25-35% of asphalt, 15-30% of rubber oil, 10-20% of waste tire rubber powder, 5-10% of styrene-butadiene rubber, 1-3% of styrene-butadiene-styrene (SBS), 4-10% of tackifying resin, 10-20% of fly ash, 2-5% of a high-temperature modifier and 2-5% of a viscosity reducer, wherein the high-temperature modifier is a BL modifier or polyamide wax. The preparation method is carried out by adopting a three-section-type feeding method and comprises the following steps: adding asphalt and rubber oil, carrying out heating to 150 DEG C, then adding the SBS, the styrene-butadiene rubber, the tackifying resin and the viscosity reducer, carrying out heating to 180 DEG C, then adding the fly ash and a high-temperature modifier, mixing the components at 180 DEG C to form a uniform liquid, and carrying out cooling and discharging to obtain the novel high-temperature-resistant non-curing waterproof coating. The invention solves the problem that a non-curing rubber asphalt waterproofcoating is poor in heat resistance.

Owner:河南驼峰防水科技有限公司

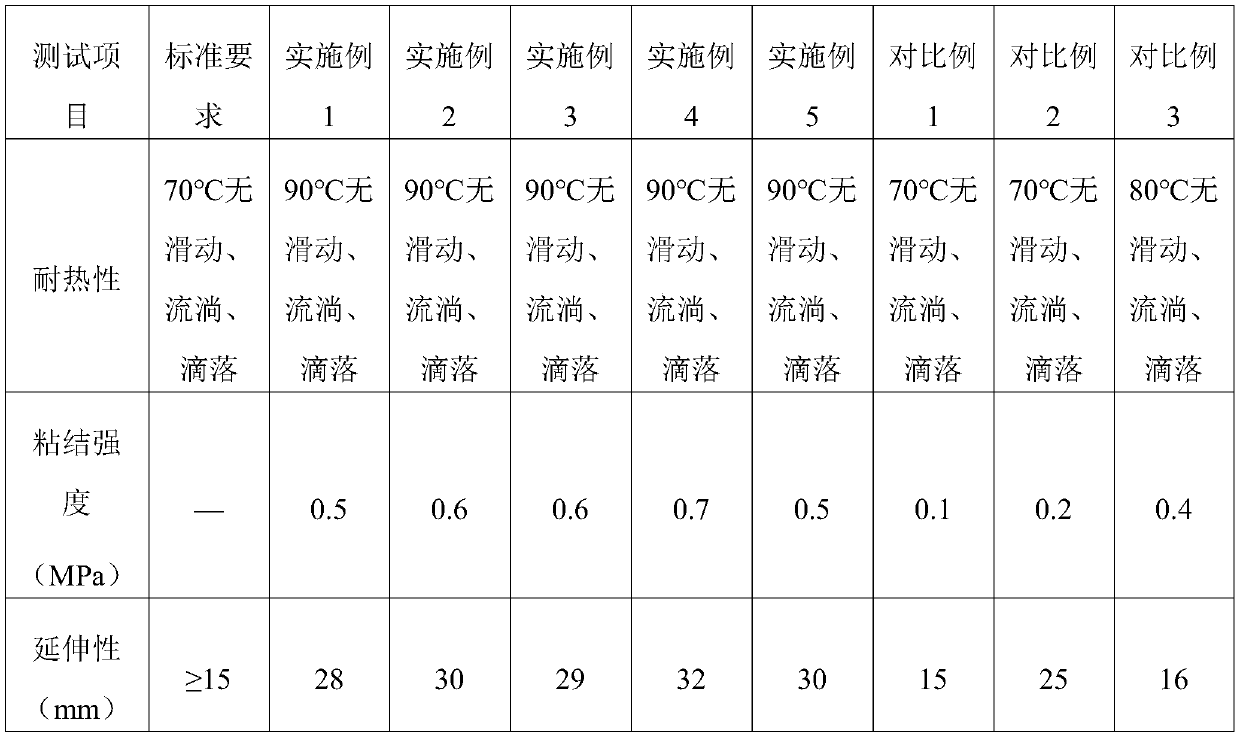

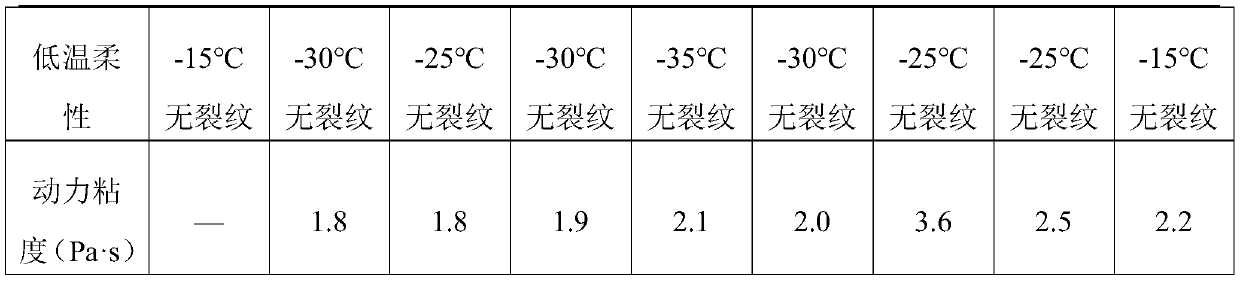

Polymer cement waterproof paint and preparing method thereof

InactiveCN105385279AGood cold resistanceImprove mechanical propertiesCoatingsPolymer scienceEmulsion

The invention discloses polymer cement waterproof paint and a preparing method thereof. The polymer cement waterproof paint is prepared from 100 parts of acrylate waterproof emulsion, 35-55 parts of cement, 35-55 parts of quartz sand, 15-35 parts of heavy calcium carbonate, 10-20 parts of water, 0.3-0.6 part of a defoaming agent and 0.1-0.3 part of preservative. Silane coupling agent KBM-503 organosilicone monomers are adopted to modify acrylate to obtain the acrylate waterproof emulsion. The polymer cement waterproof paint is excellent in low temperature flexibility and water resistance and good in mechanical property.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

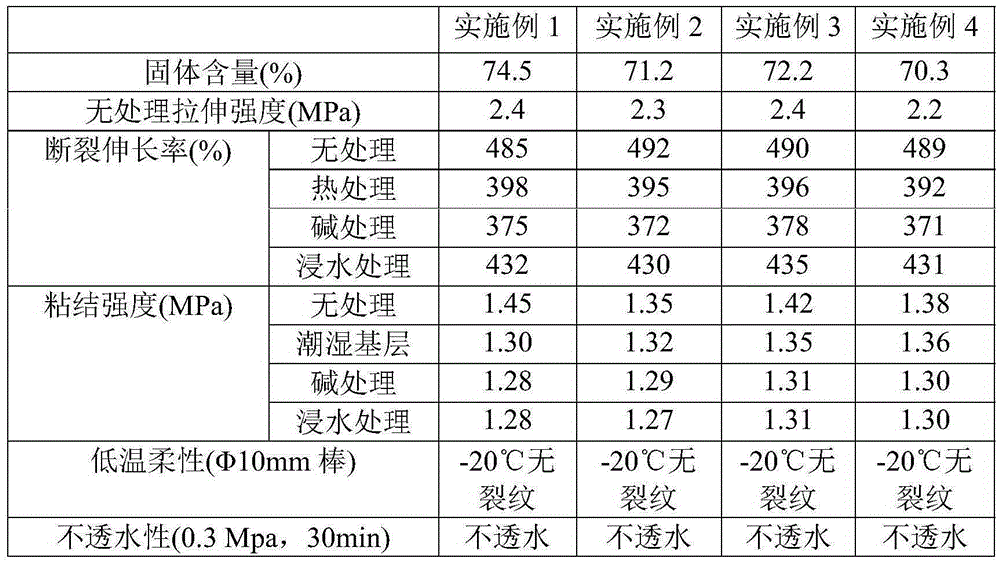

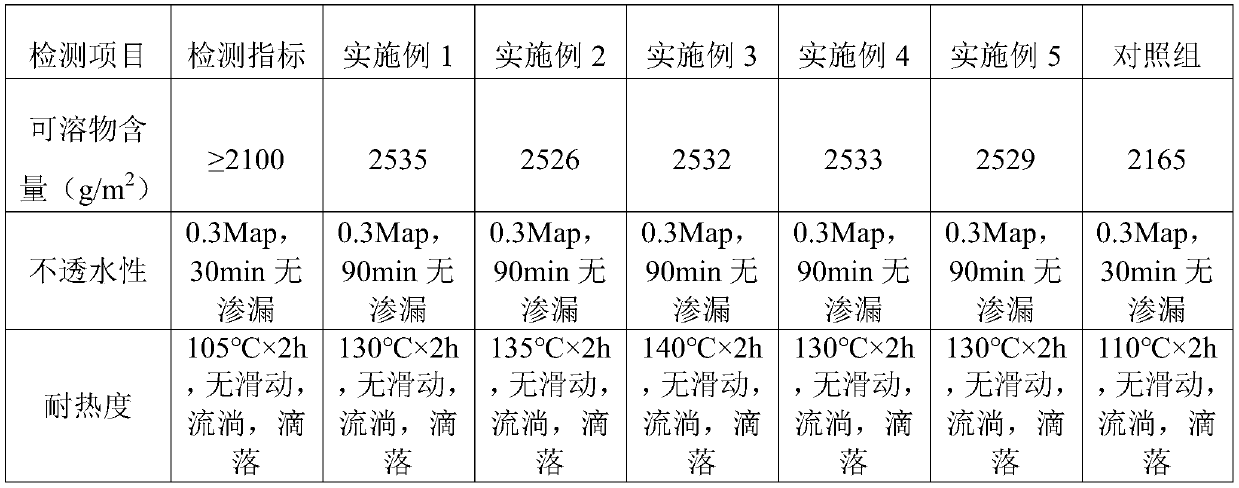

Novel modified asphalt waterproof coiled material and preparation method thereof

ActiveCN109881848AHigh soluble contentImprove impermeabilityRoof covering using flexible materialsProtective foundationElastomerBituminous waterproofing

The invention belongs to the technical field of building materials, and provides a novel modified asphalt waterproof coiled material. The novel modified asphalt waterproof coiled material comprises modified asphalt coating layers, a tire base layer and an isolation layer, wherein the material of the modified asphalt coating layer is modified asphalt, and the modified asphalt is prepared from the following components in parts by weight: 5-10 parts of 10# asphalt, 40-50 parts of 90# or 100# asphalt, 6-12 parts of softening oil, 4-6 parts of rubber powder, 3-5 parts of SBS, 2-4 parts of high density polyethylene, 0.2-0.6 part of triallyl isotactic cyanurate, 0.6-2 parts of dicumyl peroxide and 10-20 parts of filler. A preparation method comprises the following steps that firstly the modifiedasphalt is prepared by mixing materials and grinding twice; the modified asphalt is then coated on the upper surface and the lower surface of the tire base layer to obtain the tire base layer with themodified asphalt coating layers on both sides; and an isolation film is then coated to obtain the isolation layer, and forming by cooling is carried out to obtain the novel modified asphalt waterproof coiled material. The novel modified asphalt waterproof coiled material and the preparation method solve the problem of defects in high and low temperature resistance of elastomer modified asphalt and plastic modified asphalt waterproof coiled materials in the prior art.

Owner:包头市草原驼峰防水材料有限公司

Asphalt rubber material for producing SBS elastomer modified asphalt waterproof roll material as well as preparation method and application thereof

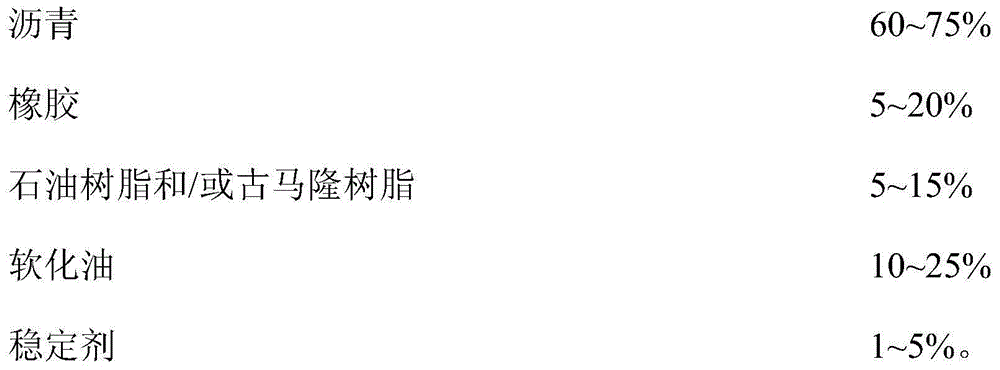

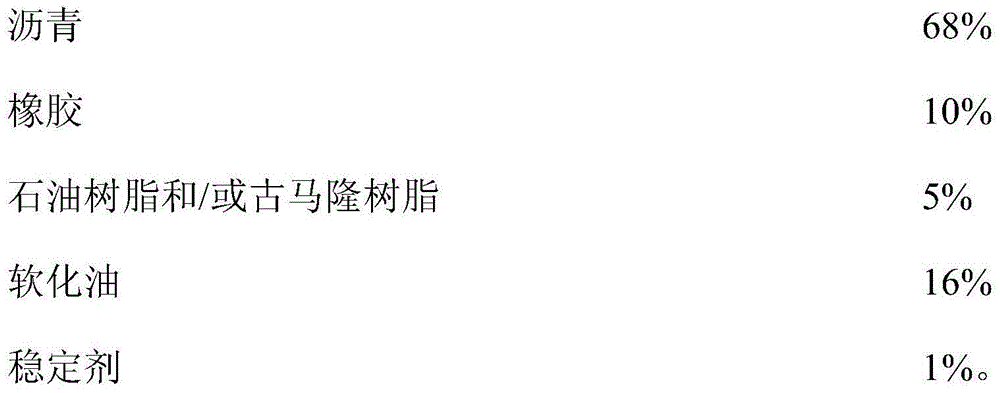

The invention provides an asphalt rubber material for producing an SBS elastomer modified asphalt waterproof roll material. The asphalt rubber material is prepared from the following main raw materials in percentage by mass: 60-75% of asphalt, 5-20% of rubber, 5-15% of petroleum resin and / or coumarone resin, 10-25% of softening oil and 1-5% of a stabilizer. The asphalt rubber is high in ductility, softening point and needle penetration. When the asphalt rubber is used for preparing SBS elastomer modified asphalt waterproof roll material, the low-temperature flexibility, high-temperature resistance, cohesive strength and waterproof performance of the waterproof roll material can be improved; the waterproof roll material shows excellent waterproof performance; the energy loss, the material loss, the labor cost and the production cost can be reduced; and the quality is very easy to control.

Owner:中油佳汇(广东)防水股份有限公司

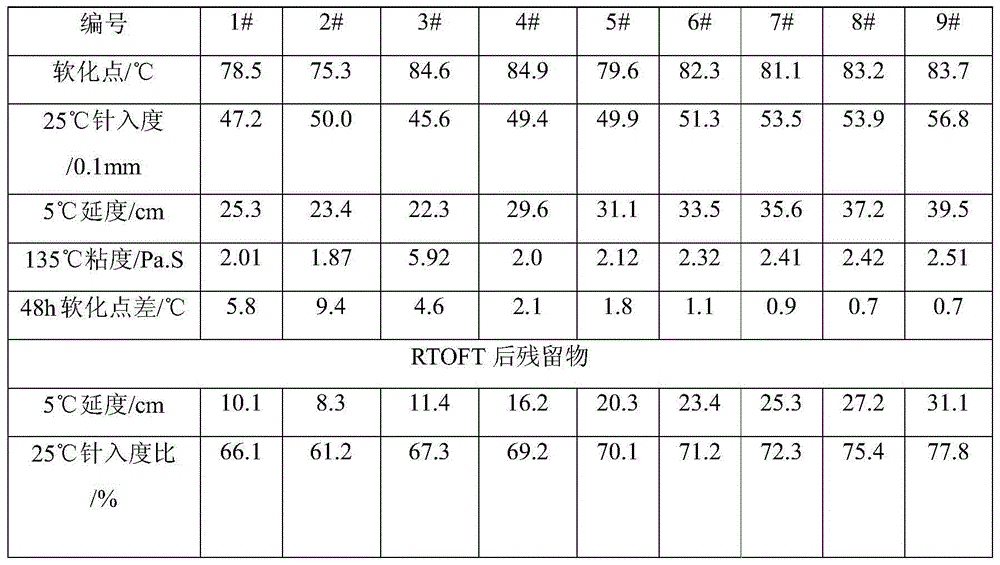

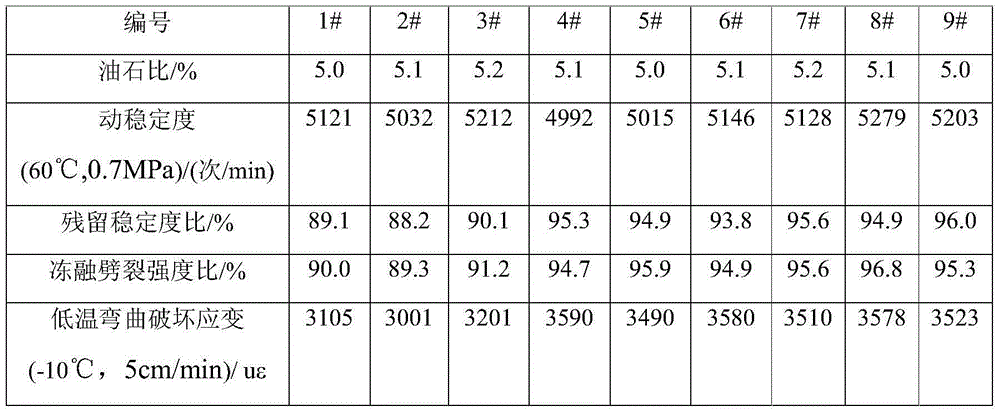

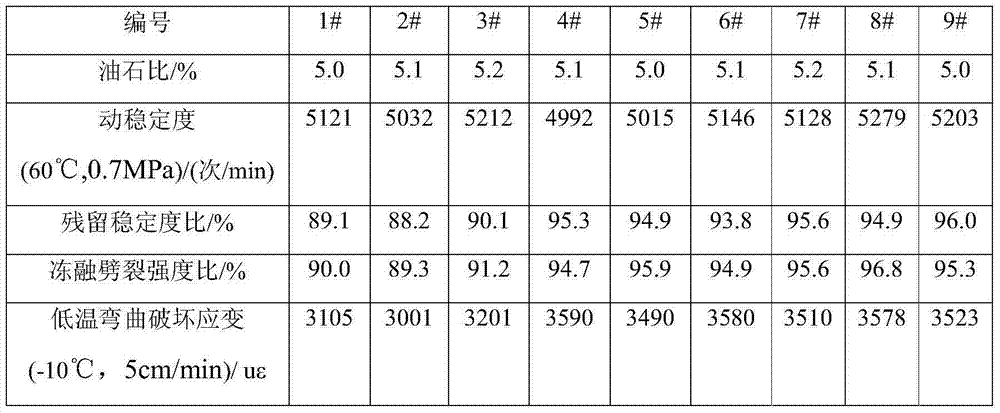

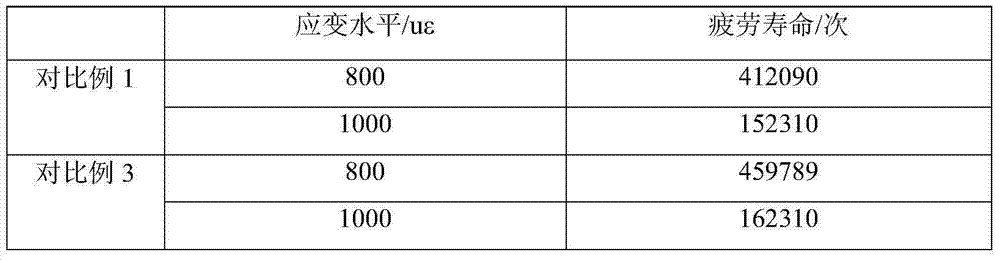

Storage-stable and ageing-resistant composite SBS particle modified asphalt concrete and preparation method thereof

ActiveCN104710134AControl "Secondary Pollution"Low costBuilding insulationsNoise pollutionMicrostructure

The invention discloses a storage-stable and ageing-resistant composite SBS particle modified asphalt concrete and a preparation method thereof. The composite SBS particles comprise 15%-38% of SBS, 56%-82% of deep activation rubber powder, and 3%-6% of an interface compatibilizer, wherein the deep activation rubber powder consists of rubber powder, softening oil and an activating agent. According to the storage-stable and ageing-resistant composite SBS particle modified asphalt concrete and the preparation method thereof, waste rubber power is processed through a double-screw extruder under the high-temperature and high shearing condition to obtain the deep activation rubber powder; and besides, the blending effect of screw rods is utilized to fully mix SBS particles with the deep activation rubber powder to prepare the composite SBS particles through granulation, and the composite SBS particles are utilized to prepare modified asphalt concrete; Compared with a common SBS modifying agent, the composite SBS particle modified asphalt concrete is better in ageing resistance, and has no heat storage evolution; junked tires can be excessively consumed, the black pollution is reduced, city noise pollution is reduced, and the surface drainage is facilitated, water splattering is alleviated, and the traffic safety performance is improved through the pavement surface microscopic structure.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

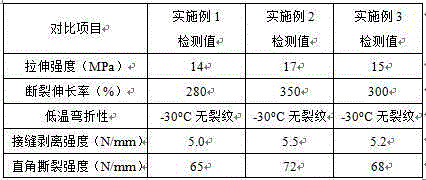

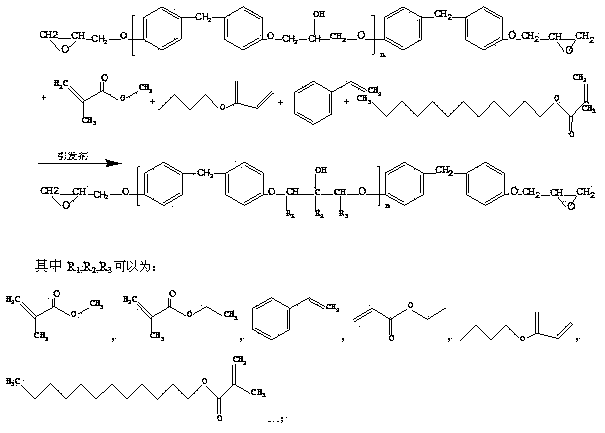

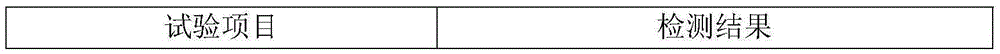

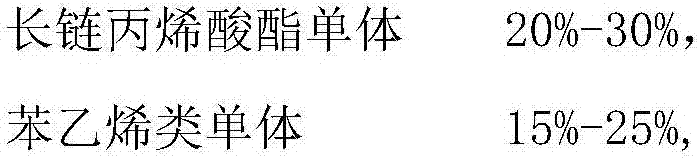

Emulsion for modifying water emulsion asphalt coating, preparation method of emulsion and coating

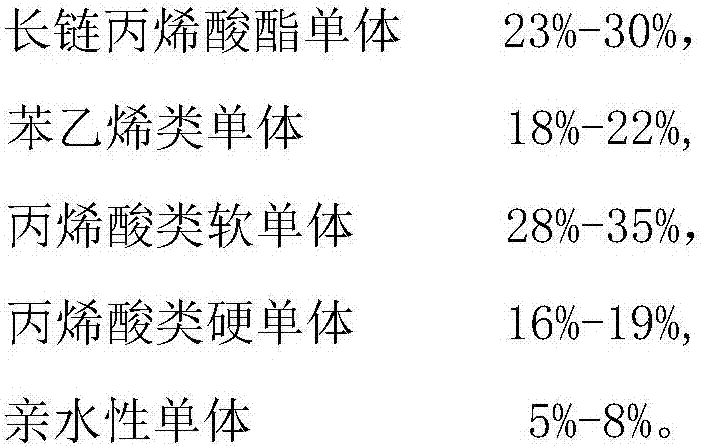

The invention discloses an emulsion for modifying a water emulsion asphalt coating, a preparation method of the emulsion, and the coating, relates to the field of building materials, and solves technical problems that the water emulsion asphalt coating cannot achieve high tensile strength, high elongation, high bonding strength and construction without blistering simultaneously. The emulsion of the invention comprises the following components by mass: 20%-30% of long chain acrylate monomers, 15%-25% of styrene monomers, 25%-35% of acrylic soft monomers, 15%-20% of acrylic hard monomers and 3%-8% hydrophilic monomers. The water emulsion asphalt coating prepared by adopted the emulsion provided by the invention has characteristics of high tensile strength, high elongation, high bonding strength and construction without blistering simultaneously.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

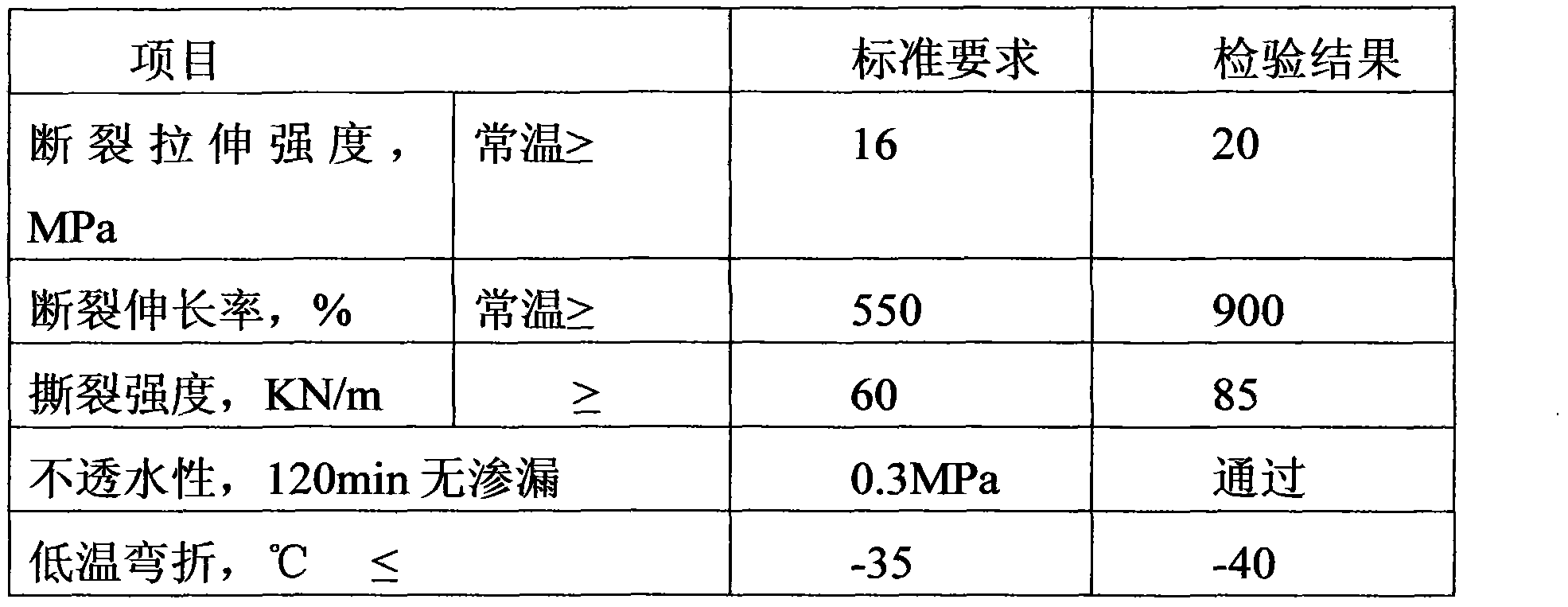

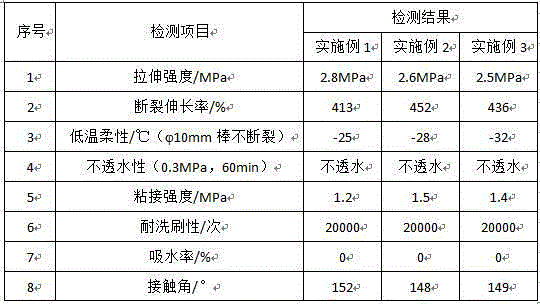

Fumed silica modified acrylate waterproof paint, and preparation method thereof

The invention provides a fumed silica modified acrylate waterproof paint. The fumed silica modified acrylate waterproof paint comprises, by weight, 40 to 50 parts of a polymer emulsion, 20 to 30 parts of modifying fumed silica, 0.2 to 0.6 part of a wetting dispersant, 0.2 to 0.5 part of an antifoaming agent, 0.1 to 0.2 part of a preservative, 0.2 to 0.5 part of a thickening agent, 5 to 10 parts of kaoline, 20 to 30 parts of heavy calcium carbonate powder, 2 to 5 parts of titanium dioxide powder, and 1 to 5 parts of water. Acrylate waterproof paint water resistance is improved greatly, water absorption rate is reduced, waterproofing is realized at 0.3MPa in 60min, and water absorption rate is zero.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

Abrasion-resisting mortar repairing material with high elasticity and construction technology

The invention mainly employs monocomponent polyurea as a cementing material, a small amount of thixotropic agents are added properly, and mixed with special-type sand materials to prepare an abrasion-resisting mortar with high elasticity and high cost performance. Through improvement of the construction technology, the construction problems of slow curing speed, difficult levelling of surfaces and the like are overcome. A novel concrete thin-layer abrasion-resisting repairing material is prepared. The novel mortar is a flexible repairing material with good performances, has excellent elasticity besides, and has high intensity, high abrasion-resistance and aging resistance. The repairing material solves the encountered problems during concrete thin layer repairing well, and has unique advantage in concrete thin layer defect repairing aspects. The repairing material has better performances compared to traditional polymer cement mortar and epoxy mortar, can replace the traditional polymer cement mortar and epoxy mortar, and has good repairing effects especially in the repairing of shallow-layer destroy of hydraulic concrete abrasion-resisting positions. The repairing material has good low temperature performance and can maintain certain flexibility at the temperature of minus 45 DEG C.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +2

Acrylic emulsion, preparation method and application thereof

ActiveCN102382235ASimple processing methodImprove performanceFibre treatmentPolymer scienceFunctional monomer

The invention relates to the field of materials, and specifically discloses an acrylic emulsion, a preparation method and application thereof. The acrylic emulsion comprises the following raw material in parts by weight: 35%swung dash45% of acrylate monomer, 7%swung dash10% of functional monomer, 1.0%swung dash2.5% of emulsifier, 0.2%swung dash0.6% of initiating agent and 42%swung dash55% of water; and the preparation method is a semicontinuous starvation feeding method. The prepared acrylic emulsion has high solid content, can be used for textile coating, and has good handfeel, high low temperature resistance and good fastness on cloth; and the preparation method is environmental friendly.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

Wild tea camellias cutting seedling raising method

ActiveCN104641920AImprove survival rateAvoid the problem of scrambling for nutrientsCultivating equipmentsPlant cultivationAxillary budDisease

The invention belongs to the field of tea tree seedling raising and specifically discloses a wild tea camellias cutting seedling raising method. The wild tea camellias cutting seedling raising method mainly comprises the following steps: within cutting time in May to June or October to November, scissoring new twigs which are 1.8-2.2mm in stem diameter and grown in the current year from selected excellent stock trees as cutting seedlings, wherein the branches become red from green, and the cutting seedlings are semi-lignified strong branch tips which are free of quarantine diseases and provided with axillary buds, preparing a seedling bed, cutting, shielding the sunshine, preventing freezing, performing field management after cutting, transplanting and the like. According to the characteristics that wild tea camellias is concentrated in a high altitude area with great diurnal temperature difference and cold winters, and has unique growth characteristics, improvements to the material selection, seedling bed preparation, seedling field management and the like, which are different from those of a common tea tree cutting technology, are made, so that the survival rate of the wild tea camellias is greatly increased.

Owner:湖北贡易德茶业有限公司

Waterproof polyurethane coating for woodware

InactiveCN104263220AIncrease elasticityGood low temperature flexibilityPolyurea/polyurethane coatingsEpoxyPolyvinyl alcohol

The invention relates to a waterproof polyurethane coating for woodware, which comprises the following components in parts by weight: 25 parts of polyurethane emulsion, 12 parts of bentonite, 5 parts of urea-formaldehyde resin, 6 parts of silicon dioxide, 5 parts of ethanol, 8 parts of epoxy resin, 4 parts of polyvinyl alcohol, 2 parts of formaldehyde, 2 parts of magnesium sulfate, 23 parts of talcum powder, 2 parts of a flame retardant, 12 parts of titanium dioxide, and 3 parts of a defoaming agent. Compared with the prior art, the waterproof polyurethane coating for woodware has good elasticity, low temperature flexibility, aging resistance, and no flowability at high temperature, and therefore, the quality of products can be improved, and the using temperature range of products can be expanded.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

C7-C12 secondary alcohol esters of cyclohexanoic acid

InactiveUS8669311B2Good low temperature flexibilityImprove stabilityPlastic/resin/waxes insulatorsLavatory sanitoryAlcoholCyclohexanecarboxylic acid

C7-C12 secondary alcohol esters of cyclohexanecarboxylic acids are especially useful as plasticizers for PVC and other plasticizable polymers. In embodiments, these plasticizers are useful in plastisol formulations to help improved processability of flexible PVC material. In other embodiments these same plasticizers can be used in blends with other plasticizers to improve processability. In preferred embodiments these same plasticizers can be used to prepare flexible PVC compounds with enhanced low temperature flexibility, low toxicity, and improved resistance to outdoor aging.

Owner:EXXONMOBIL CHEM PAT INC

High-modulus asphalt mixture additive and preparation method thereof

ActiveCN106633269AHigh temperature sensitivityGood low temperature flexibilityBuilding insulationsEpoxyMolecular sieve

The invention discloses a high-modulus asphalt mixture additive and a preparation method thereof. The additive comprises, by weight, 100 parts of plastic, 10-20 parts of EVA resin, 15-25 parts of butadiene-styrene rubber and / or derivative thereof, 10-20 parts of ethylene tar and 10-20 parts of composite modifier, wherein the composite modifier is composed of a mesoporous molecular sieve coated with epoxy grafted polyethylene wax. The additive has high compatibility with asphalt and a mixture, so that resistance to low-temperature cracking of a high-modulus asphalt mixture is improved remarkably, the additive has excellent resistance to track and water damage, and the mixture is low in blending temperature and high in construction peaceability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dual component type polyurea paint and spraying method thereof

ActiveCN109852213AMeet the curing internal stressImprove curing internal stressLiquid surface applicatorsPolyurea/polyurethane coatingsHardnessPolyurea

The invention provides a dual component type polyurea paint and a spraying method thereof. The provided polyurea paint comprises two components: a component A and a component B; wherein the main raw material of the component A is prepared through reactions between specific isocyanate and hydroxyl terminated compounds (or amino-terminated compounds) according to a certain ratio; the component B comprises amino terminated resin and an amino terminated chain extender according to a certain ratio. The polyurea paint can form a polyurea coating, which can well improve the low temperature performance of a PVC slush-moulded surface. When the PVC slush-moulded surface with a polyurea coating explodes at a low temperature, shattering or splashing will not happen; furthermore, the gelling time and surface drying time of the polyurea paint are short, thus the production efficiency is improved, proper hardness is guaranteed, and the phenomenon that the PVC slush-moulded surface is deformed due tolarge hardness is avoided.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

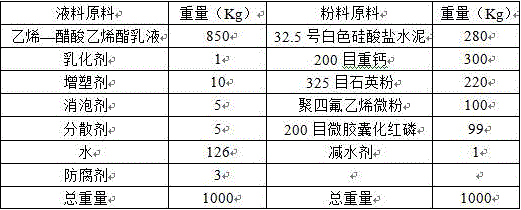

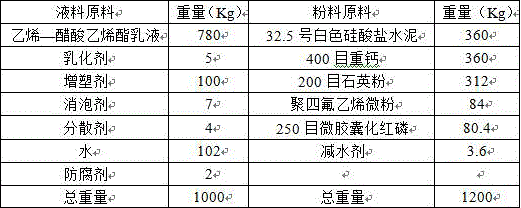

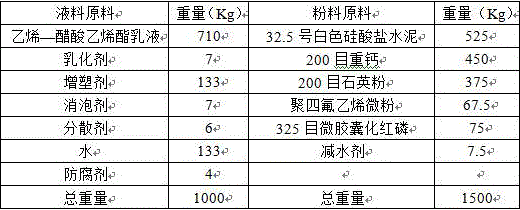

Environmentally-friendly flame-retardant polymer cement waterproof coating and production process therefor

The invention provides an environmentally-friendly flame-retardant polymer cement waterproof coating. The coating comprises a liquid material and a powder material. A weight ratio of the liquid material to the powder material is (1 to 0.8) to (1 to 1.5). The liquid material comprises the following components in parts by weight: 65-85 parts of ethylene-vinyl acetate emulsion, 0.1-0.7 parts of an emulsifier, 1-17 parts of a plasticizer, 0.3-0.7 parts of a defoamer, 0.4-0.6 parts of a dispersant, 10-15 parts of water and 0.1-0.4 parts of a preservative. The powder material comprises the following components in parts by weight: 25-35 parts of cement, 20-30 parts of heavy calcium carbonate, 20-30 parts of quartz powder, 5-10 parts of polytetrafluoroethylene micropowder, 5-10 parts of micro-capsulated red phosphorus and 0.1-0.5 parts of a water reducer. The waterproof coating is environmentally-friendly; no organic matters are volatilized; and the waterproof coating is a nonflammable material.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

Cementing material based on continuous elastic-plastic expansion joints of small-span and medium-span bridges and preparation method and application thereof

InactiveCN102504551AGood driving comfortContinuous deckBridge structural detailsBuilding insulationsMother liquorButadiene-styrene rubber

The invention discloses a cementing material based on continuous elastic-plastic expansion joints of small-span and medium-span bridges and a preparation method and application thereof. The cementing material is composed of matrix pitch, SBS (styrene butadiene styrene polymer), waste rubber powder, TOR (trans-polyoctenamer rubber) binder and aromatic hydrocarbon. The mass ratio of matrix pitch : SBS : waste rubber powder : TOR (trans-polyoctenamer rubber) binder : aromatic hydrocarbon is 100:8 to 10:15:2:3 to 5. The preparation method includes steps of mixing the waste rubber powder and TOR uniformly, then adding the mixture into the matrix pitch at the temperature of 170 DEG C to mix to form modified pitch mother liquor, adding the SBS and the aromatic hydrocarbon into the modified pitch mother liquor and mixing the same at the temperature of 180 DEG C to prepare composite modified pitch which is the cementing material based on the continuous elastic-plastic expansion joints of the small-span and medium-span bridges. The cementing material based on the continuous elastic-plastic expansion joints of the small-span and medium-span bridges is simple in preparation and applied to the small-span and medium-span bridge expansion joints and has the advantages of high comfortableness in running, high elastic recovery capability, low flexibility, fine high-temperature stability and waterproof performance, convenience in construction and repair, fast traffic opening and the like.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

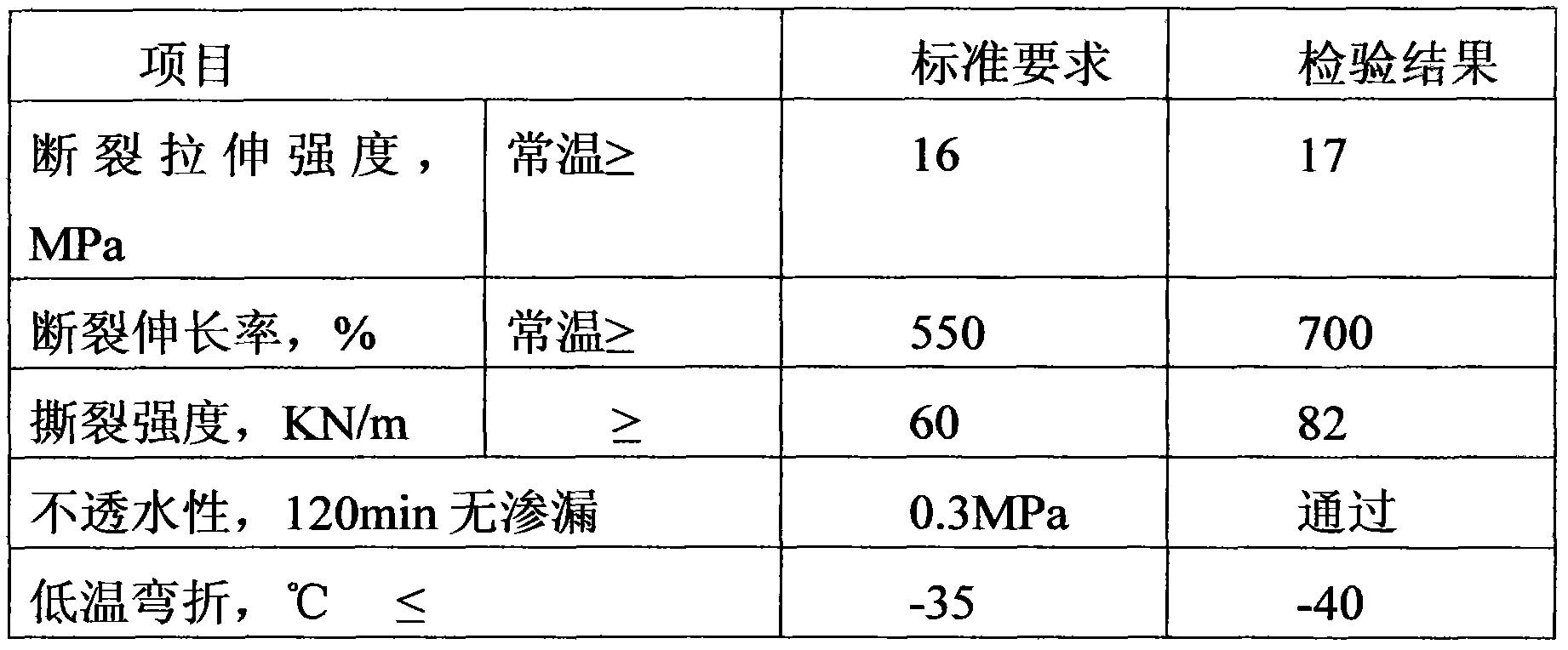

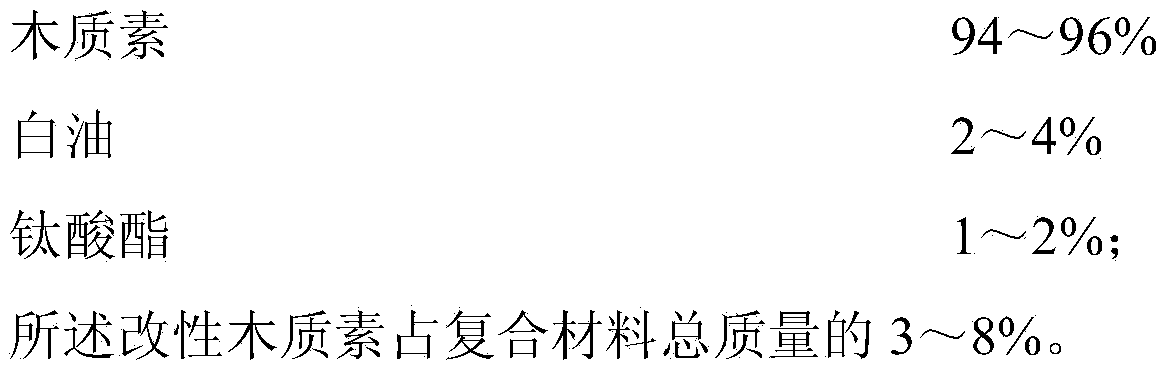

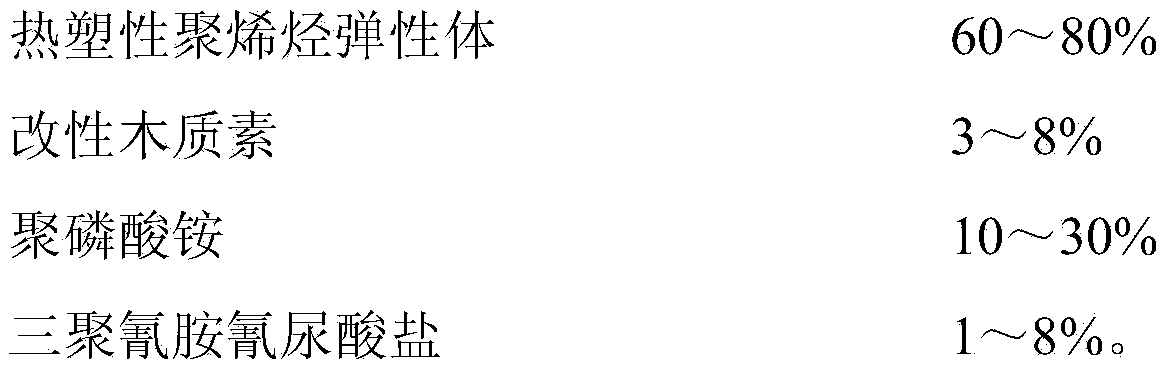

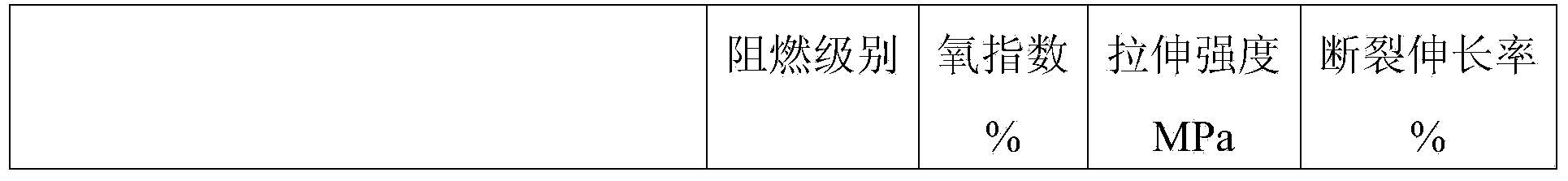

Modified lignin intumescent flame retardant TPO composite material as well as preparation method and application of composite material

InactiveCN103834107APromote environmental protectionHigh char formation ratePolyolefinAging resistance

The invention relates to a modified lignin intumescent flame retardant thermoplastic polyolefin (TPO) composite material as well as a preparation method and an application of the composite material. The composite material contains modified lignin, wherein the modified lignin consists of the following components in percentage by mass: 94-96% of lignin, 2-4% of white oil and 1-2% of titanate; and the modified lignin accounts for 3-8% in terms of total mass of the composite material. The prepared modified lignin intumescent flame retardant TPO composite material disclosed by the invention has the beneficial effects of being high in tensile strength at break, high in elongation at break, low in heating expansion amount, good in low temperature flexibility, good in penetration resistance and strong in chemical corrosion resistance; and the composite material is excellent in weather aging resistance, applicable to damp, hot and cold natural environments in a long term, and low in performance change.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com