Elastomer modified PVC (polyvinyl chloride) waterproof roll and production process thereof

A waterproof membrane and production process technology, applied in the field of elastomer chlorinated polyethylene (CPE) modified PVC waterproof membrane, elastomer modified PVC waterproof membrane, can solve the problem of poor flexibility at low temperature, short service life, degumming And other problems, to achieve the effect of good low temperature flexibility, long service life and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

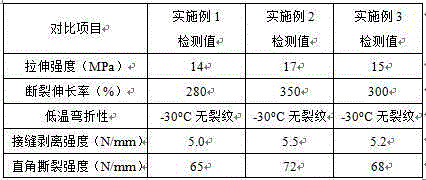

Embodiment 1

[0034] Embodiment 1 A kind of elastomer modified PVC waterproof coiled material

[0035] The waterproof roll material includes the following raw materials, in parts by mass:

[0036] Raw material parts by mass

[0037] PVC resin 98 parts

[0038] 30 parts plasticizer

[0039] Heat stabilizer 5.8 parts

[0040] 4 parts epoxy soybean oil

[0041] Elastomer CPE25 parts

[0042] Filling 30 parts

[0043] Titanium dioxide 5 parts

[0044] 1 part stearic acid

[0046] Antioxidant 10100.5 parts

[0047] 0.5 part of ultraviolet absorber;

[0048] The PVC resin: SG-3 type;

[0049] The plasticizer: DOP;

[0050] The heat stabilizer is formed by compounding tribasic lead sulfate (referred to as trisalt) and dibasic lead phosphite (referred to as disalt) in a mass ratio of 2:1;

[0051] Described elastomer is CPE, and its chlorine content is 35~37%;

[0052] The filler is active light calcium carbonate with a mesh number of 2500-5000 mesh. Th...

Embodiment 2

[0055] Embodiment 2 A kind of elastomer modified PVC waterproof membrane

[0056] The waterproof roll material includes the following raw materials, in parts by mass:

[0057] Raw material parts by mass

[0058] PVC resin 100 parts

[0059] 35 parts plasticizer

[0060] 6 parts heat stabilizer

[0061] 5 parts epoxy soybean oil

[0062] Elastomer CPE38 parts

[0063] Filling 40 parts

[0064] Titanium dioxide 5.6 parts

[0065] 1.5 parts of stearic acid

[0066] Barium stearate 1.5 parts

[0067] Antioxidant 10101.2 parts

[0068] 1.1 parts of ultraviolet absorber;

[0069] The PVC resin: SG-3 type;

[0070] The plasticizer: DOP;

[0071] The heat stabilizer is formed by compounding tribasic lead sulfate (referred to as trisalt) and dibasic lead phosphite (referred to as disalt) in a mass ratio of 2:1;

[0072] Described elastomer is CPE, and its chlorine content is 35~37%;

[0073] The filler is active light calcium carbonate with a mesh number of 2500-5000 mesh...

Embodiment 3

[0076] Embodiment 3 A kind of elastomer modified PVC waterproof membrane

[0077] The waterproof roll material includes the following raw materials, in parts by mass:

[0078] Raw material parts by mass

[0079] PVC resin 102 parts

[0080] 40 parts of plasticizer

[0081] Heat stabilizer 6.2 parts

[0082] 6 parts epoxy soybean oil

[0083] Elastomer CPE50 parts

[0084] Filling 50 parts

[0085] Titanium dioxide 6 parts

[0086] 2 parts stearic acid

[0087] 2 parts barium stearate

[0088] Antioxidant 10101.5 parts

[0089] 1.5 parts of ultraviolet absorber;

[0090] The PVC resin: SG-3 type;

[0091] The plasticizer: DOP;

[0092] The heat stabilizer is formed by compounding tribasic lead sulfate (referred to as trisalt) and dibasic lead phosphite (referred to as disalt) in a mass ratio of 2:1;

[0093] Described elastomer is CPE, and its chlorine content is 35~37%;

[0094] The filler is active light calcium carbonate with a mesh number of 2500-5000 mesh. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com