Patents

Literature

1135 results about "Lead sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

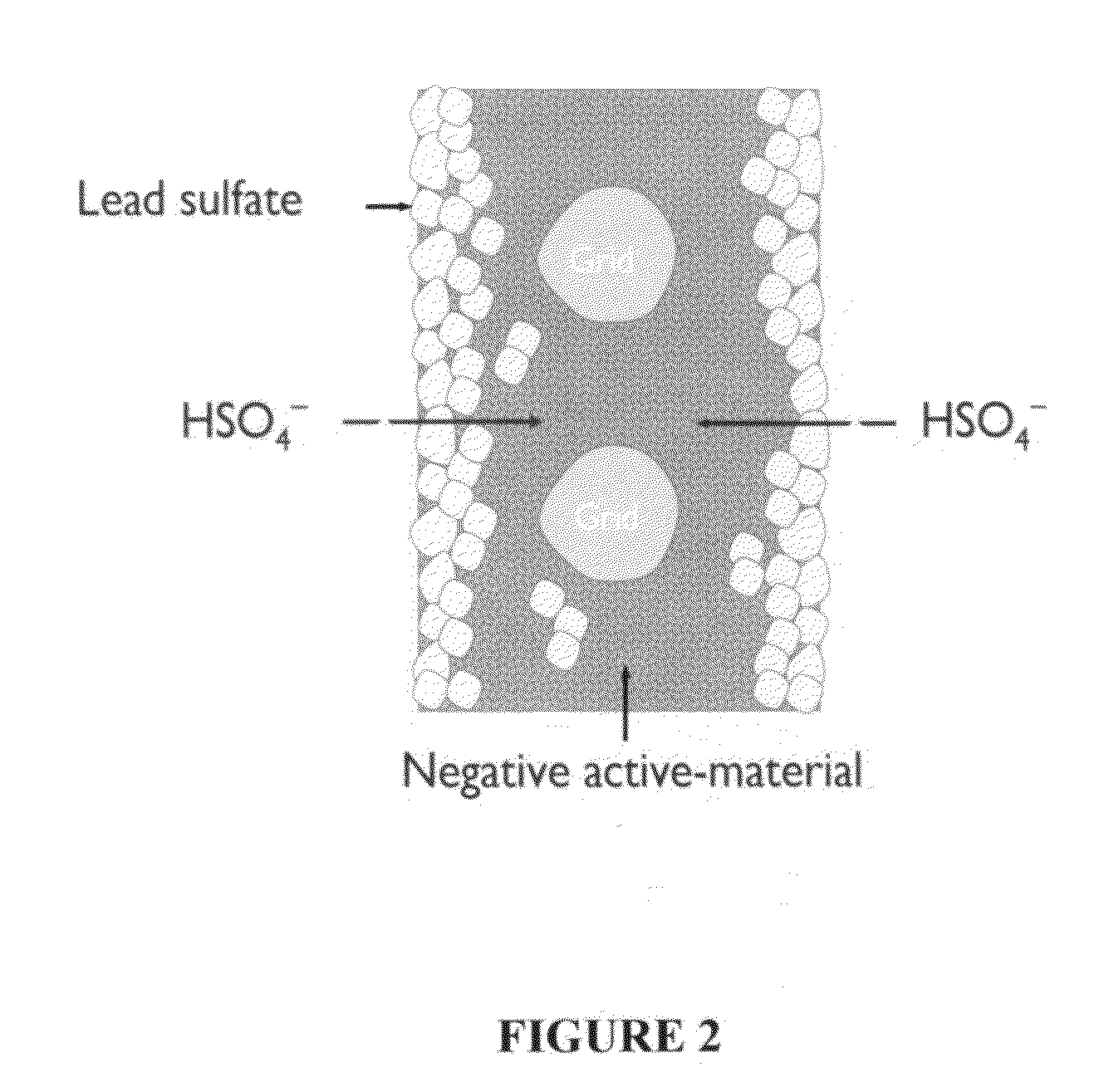

Lead(II) sulfate (PbSO 4) is a white solid, which appears white in microcrystalline form.It is also known as fast white, milk white, sulfuric acid lead salt or anglesite.. It is often seen in the plates/electrodes of car batteries, as it is formed when the battery is discharged (when the battery is recharged, then the lead sulfate is transformed back to metallic lead and sulfuric acid on the ...

Electric double layer capacitor

InactiveUS6466429B1Lower internal resistanceInhibit sheddingHybrid capacitor electrolytesHybrid capacitor electrodesActivated carbonLead dioxide

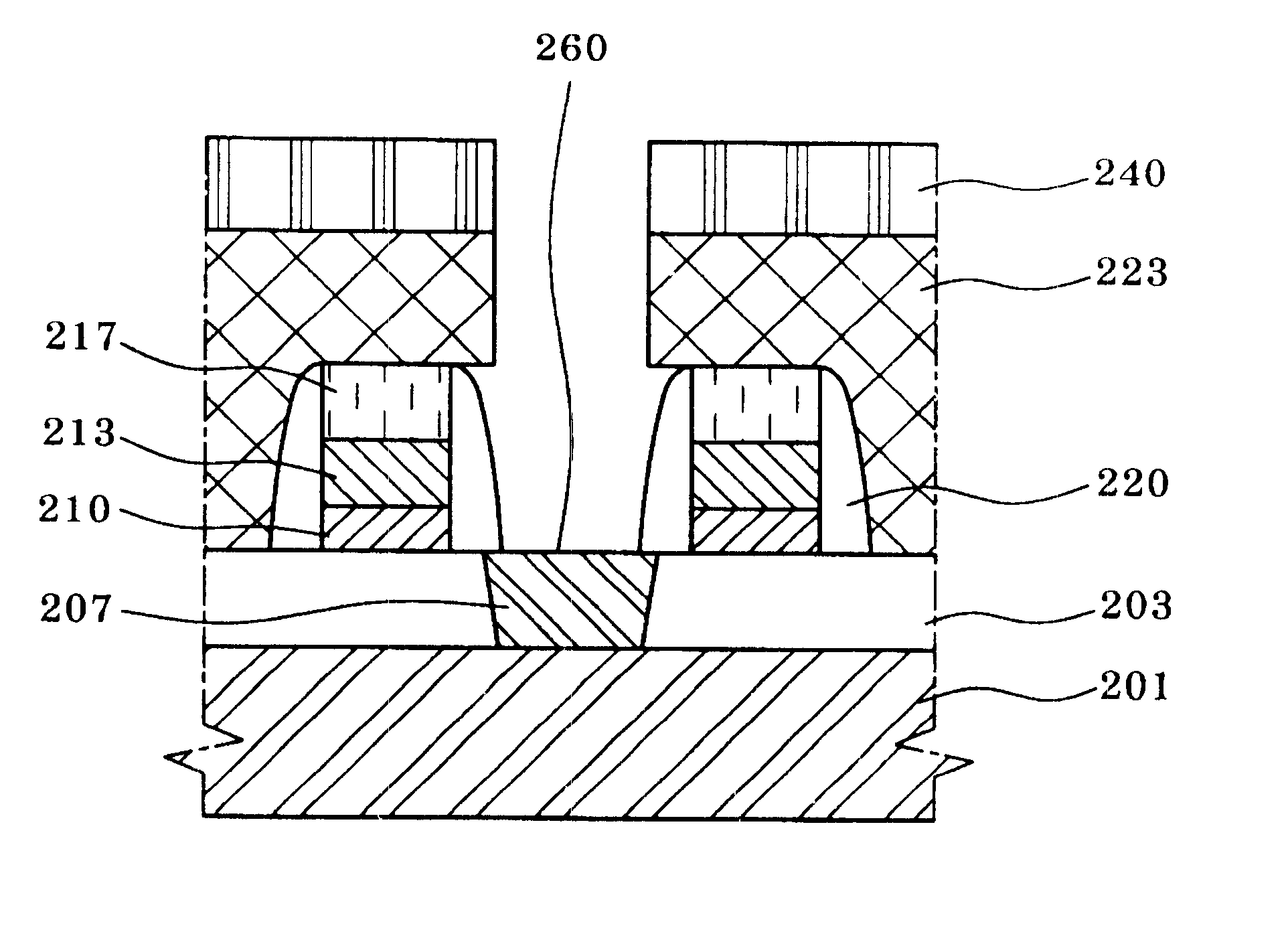

The present invention is directed to a novel capacitor. The capacitor may be used in electric double layer capacitors. The capacitors include a polarizable electrode including activated carbon and a non-polarizable electrode including lead dioxide and lead sulfate. The capacitors of the present invention provide considerably higher electric capacity, higher durability, and low resistance, while maintaining high conductivity. Additionally, the electrodes may be produced more quickly and inexpensively.

Owner:WAINWRIGHT D WALKER

Waste lead recovering method for lead-acid storage batteries

InactiveCN101608264AAvoid harmLower decomposition temperaturePhotography auxillary processesProcess efficiency improvementLead dioxideEngineering

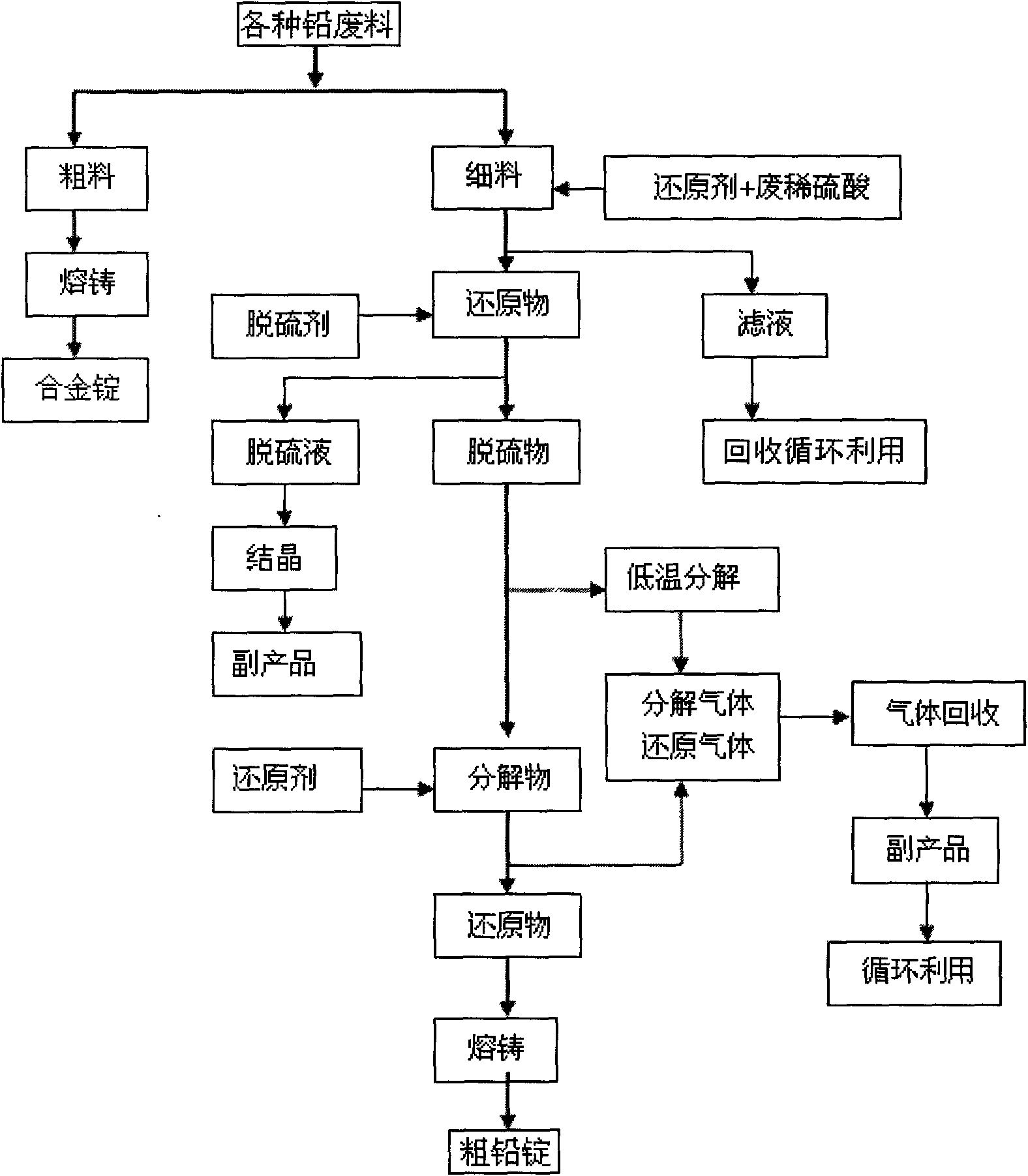

The invention discloses a waste lead recovering method for lead-acid storage batteries. The method comprises the following steps: fine stuff such as diachylon and the like are added in a reaction kettle with a stirring device; reducing agent (FeSO4) and dilute sulfuric acid are simultaneously added; stirring reaction is carried out at the temperature of 50-60 DEG C for 50-70 minutes so as to reduce lead dioxide into lead sulfate; the lead sulfate is added into the reaction kettle with the stirring device; water is simultaneously added into the reaction kettle for size mixing; then sodium carbonate is added; desulfuration is carried out at the temperature of 50-60 DEG C so as to obtain solid lead carbonate; the lead carbonate is put into a smelting furnace and then decomposed at the temperature of 320-350 DEG C so as to obtain lead oxide; and reducing agent (carbon) is added into the smelting furnace to reduce the lead oxide into metal lead at the temperature of 700-800 DEG C. The method recovers the lead by means of the combination of the wet and the dry processes, thereby avoiding the harm to the environment caused by lead dust, lead vapor, lead skim, sulfur dioxide gas, and the like by adopting fire smelting. The method has the advantages of high lead recovery rate, low energy consumption and no environment pollution.

Owner:张天任

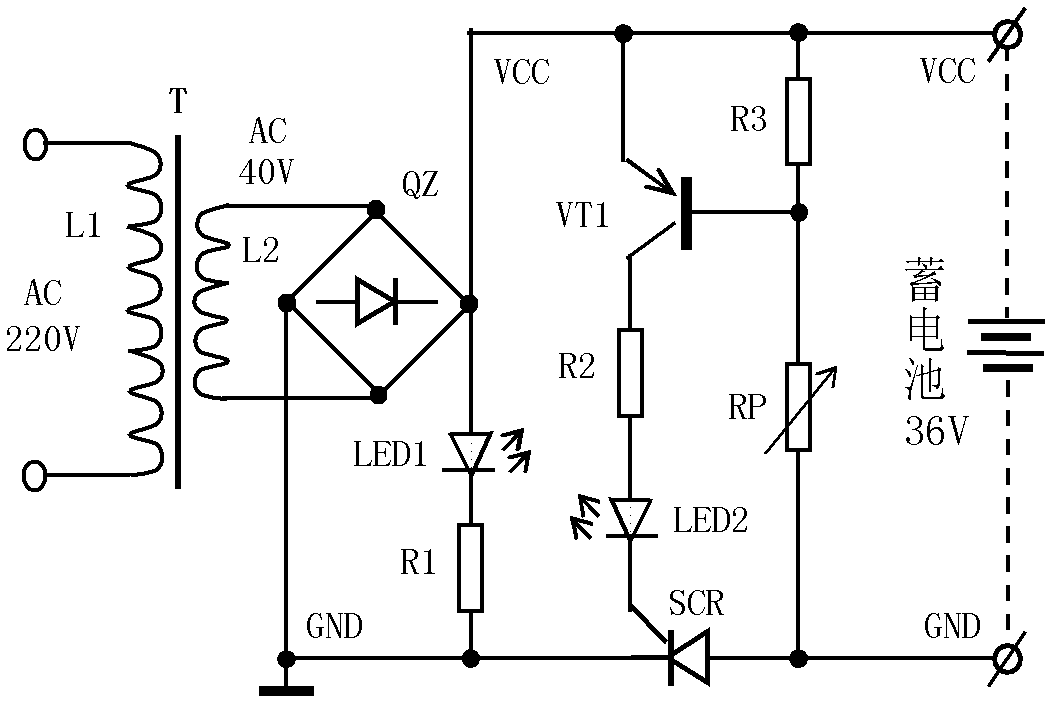

Intelligent charger for storage battery of electric vehicle

InactiveCN102545360AEasy to useBatteries circuit arrangementsEmergency protective circuit arrangementsTransformerFull wave

The invention belongs to the electronic technique field and storage battery charging, and relates to an intelligent charger for a storage battery of an electric vehicle. The intelligent charger for the storage battery consists of 220V alternating current, a power transformer T, a full-wave rectification circuit, a pulse direct current indicating circuit, unidirectional controllable silicon and a trigger circuit thereof, a biasing circuit of a PNP triode VT1, a charging output terminal and a charging state indicating circuit. The intelligent charger for the storage battery of the electric vehicle has multiple protective functions of preventing a polar plate of the storage battery from falling off or electrodes of the storage battery from being disconnected, preventing the storage battery from being subjected to short circuit, preventing inverted connection of a positive electrode and a negative electrode of the storage battery, preventing nominal voltage of a storage battery module from being deflected, preventing the polar plate of the storage battery from being subjected to lead sulfate formation, charging quickly, self-stopping until the storage battery is full of power and the like, so that a great convenience is supplied to a storage battery user; and the intelligent charger is suitable to be extensively used by an electric vehicle user and also suitable for developing charging and maintenance services in a shop or a stall.

Owner:刘德军

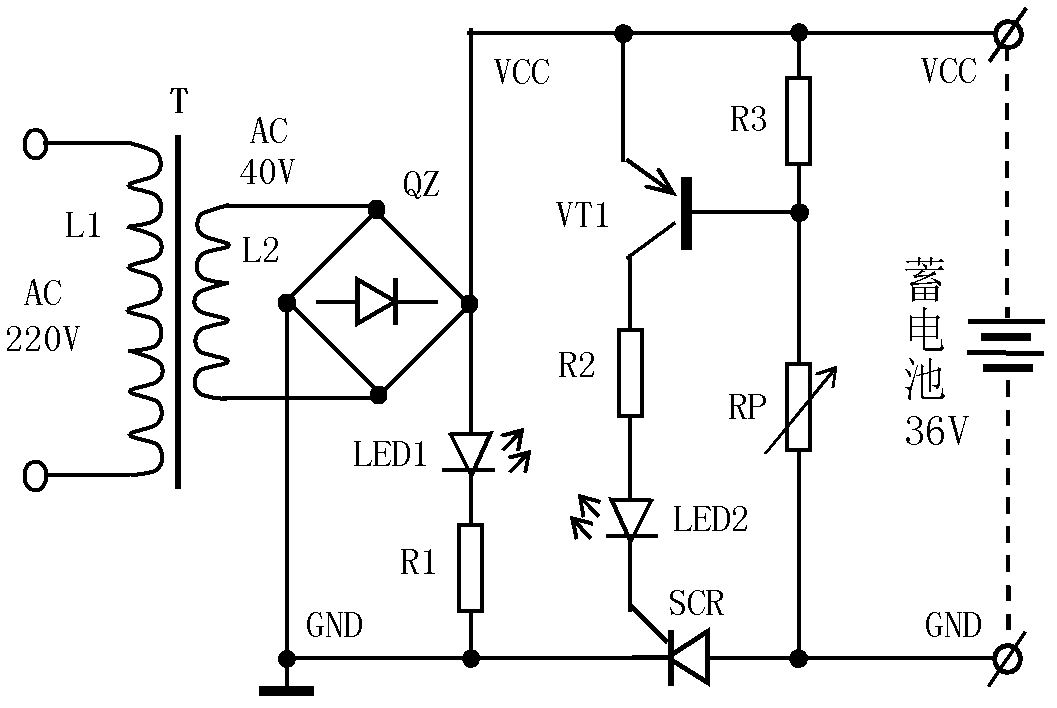

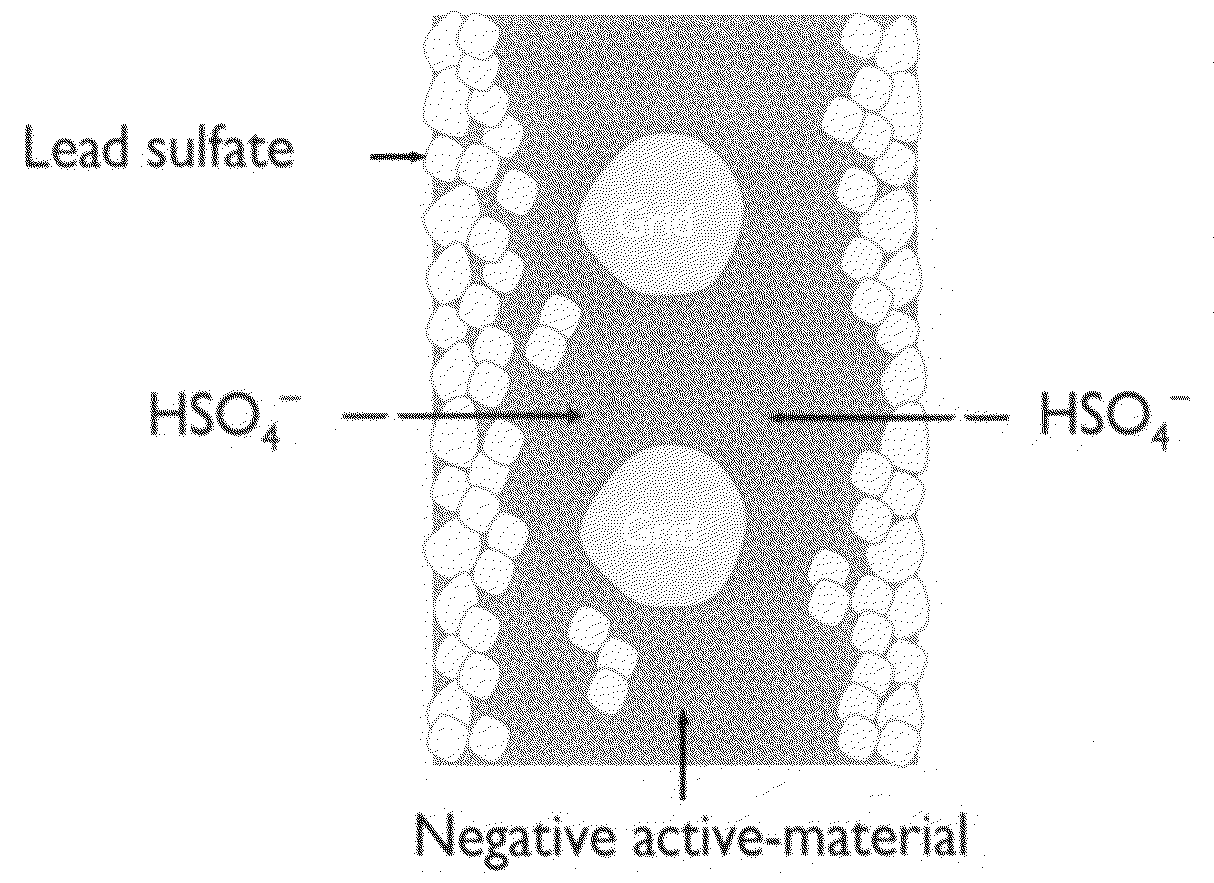

Expanders for lead-acid batteries

InactiveUS20090325068A1Increase battery capacityImprove efficiencyLead-acid accumulatorsNegative electrodesHigh rateGraphite

An expander formulation used in battery paste compositions. The expander formulation incorporates effective amounts, or elevated concentrations of up to 6% of graphite and mixtures of carbon black and graphite to lessen or minimize the accumulation of lead sulfate on the surface of the negative plate during high rate PSOC battery operation, and / or to increase the electrochemical efficiency, the reserve capacity, the cold cranking performance and the cycle life of lead-acid batteries.

Owner:HAMMOND GRP INC

High and low-temperature resistant porcelain glaze for enamel

InactiveCN103274764AImprove smoothnessGood high and low temperature resistanceTemperature resistanceLead sulfate

The invention relates to porcelain glaze and in particular relates to high and low-temperature resistant porcelain glaze for enamel. According to the technical scheme, the highnd low-temperature resistant porcelain glaze for enamel is prepared from the following raw materials in parts by weight: 22-38 parts of sodium silicate with the modulus of 2-3.8, 11-19 parts of aluminum oxide, 10-20 parts of manganese dioxide, 6-9 parts of palladium oxide, 6-9 parts of high-boron calcium borate, 23-29 parts of lead sulfate, 2-4 parts of talc, 7-13 parts of calcium carbonate, 8-12 parts of barium sulfate, 12-19 parts of zinc sulfate and 2-9 parts of titanium oxide. The high and low-temperature resistant porcelain glaze has excellent ultralow-temperature resistance and high-temperature resistance.

Owner:XIANGFENG ZHEJIANG METAL PROD

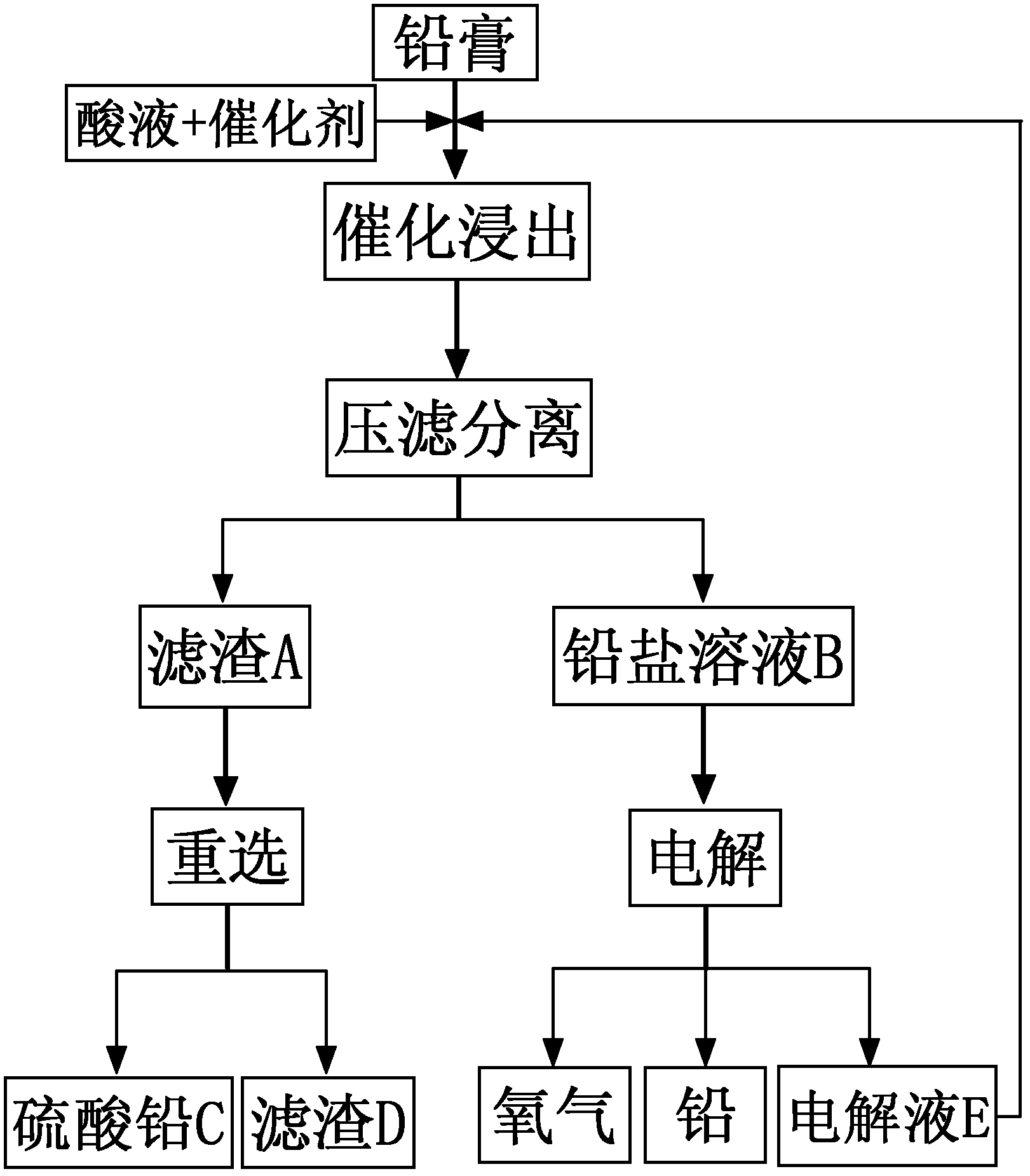

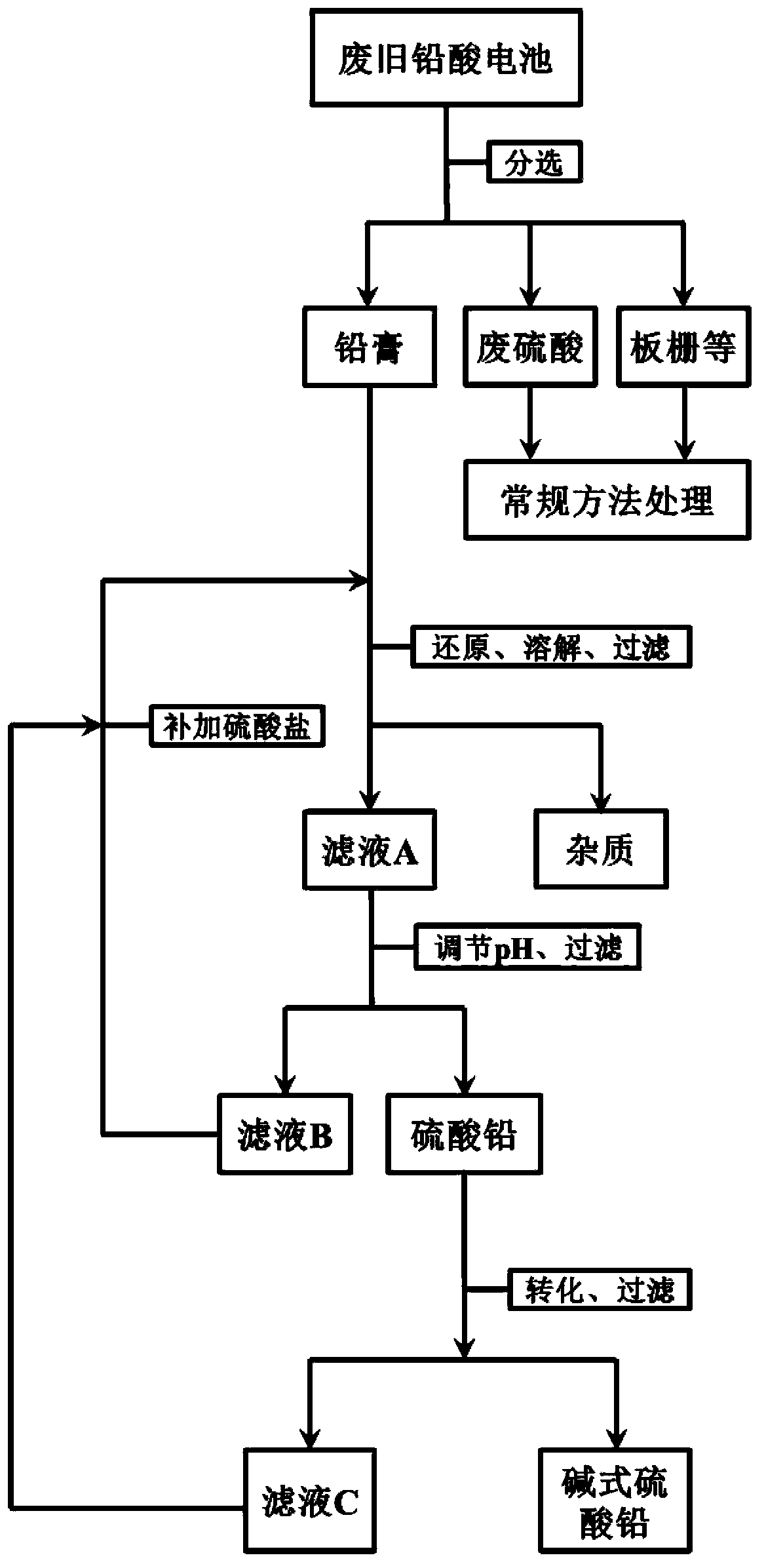

Lead regeneration method for recovering lead paste from waste lead acid storage battery by wet method

ActiveCN102618884AAvoid churnHigh recovery ratePhotography auxillary processesProcess efficiency improvementElectrolysisLead dioxide

The invention discloses a lead regeneration method for recovering lead paste from a waste lead acid storage battery by a wet method, and belongs to the field of lead regeneration from the lead paste of the waste lead acid battery. The lead regeneration method comprises the following steps of: adding the lead paste into an acid liquor reaction kettle containing a catalyst to perform oxidation reduction reaction on lead and lead dioxide in the lead paste to obtain soluble lead salt solution; meanwhile, reacting lead oxide with acid to obtain lead salt; separating to obtain insoluble filter residue mainly containing soluble lead salt solution and lead sulfate; and electrolyzing the lead salt solution to obtain lead, oxygen and acidic electrolyte, wherein the electrolyte can be returned to a leaching process for recycling, and the filter residue A is treated by the conventional reselection process to obtain the lead sulfate and the filter residue D. According to the lead regeneration method, the production cost is reduced, and high comprehensive lead recovery rate is obtained.

Owner:北京绿色引领环保科技研究院有限公司

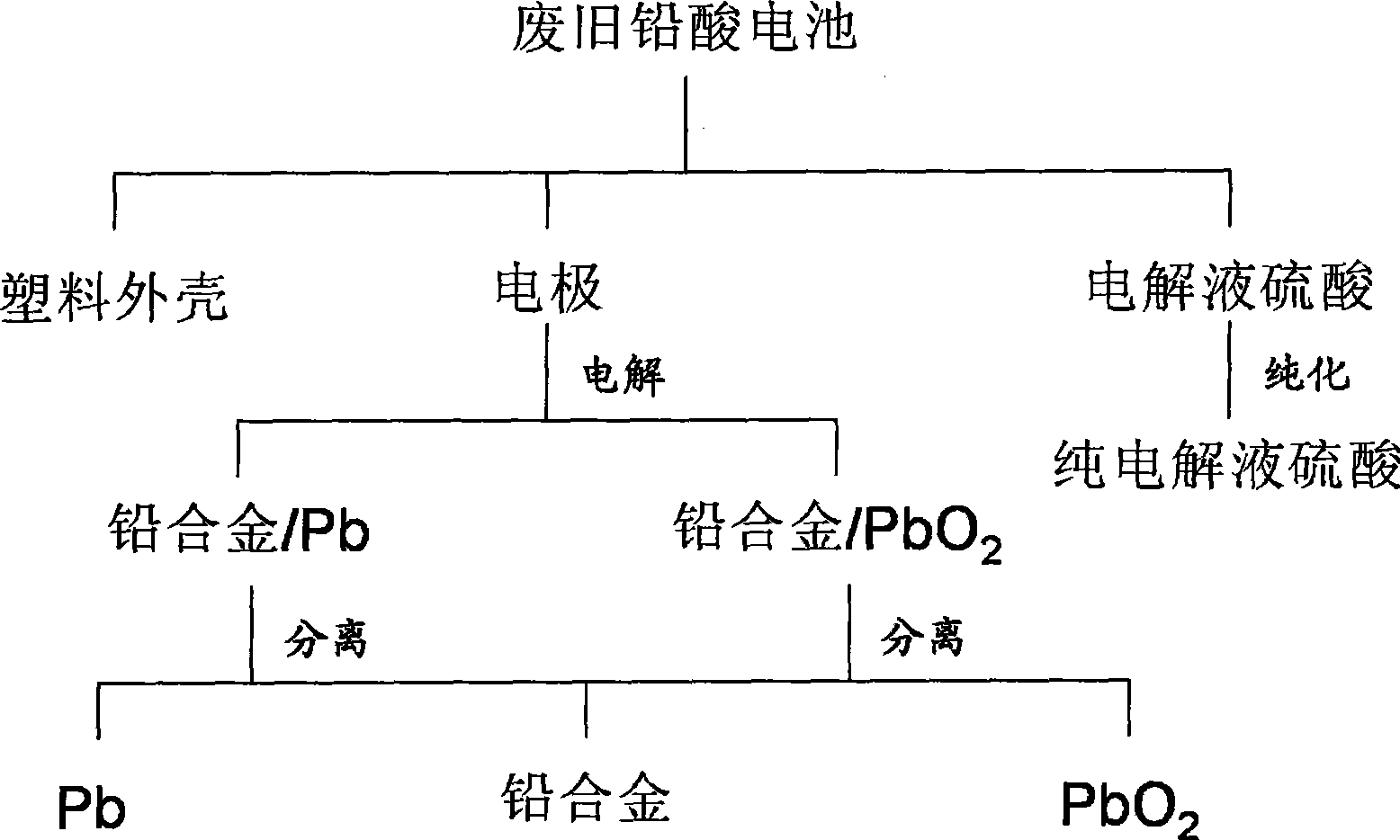

Method for waste lead-acid cell resourcization and lead-acid cell cyclic production

InactiveCN101488597AEliminate pollutionReserve availabilityWaste accumulators reclaimingBattery recyclingLead dioxideAlloy

The invention discloses a method for circularly producing lead acid batteries, aiming at thoroughly eliminating possible hazard of the lead acid battery on environment and leading the lead acid battery to be continuously useful in social life without causing negative effect. The method includes: the positive and negative plates of old and useless batteries are separated by a mechanical method, and then the positive and negative plates are subjected to electrochemical treatment, thus obtaining raw material for producing new lead acid battery and achieving the circular production of the lead acid battery including disassembly of the old and useless lead acid battery, purification of sulphuric acid electrolyte, the production of lead metal and lead dioxide by electrolyzing lead sulfate, the separation and regeneration of lead alloy as well as the production of new lead acid battery by the produced lead alloy, lead and lead dioxide. In theory, by the proposal, the raw material can be totally reused, thus achieving the aim of circularly producing the lead acid battery.

Owner:SOUTHEAST UNIV

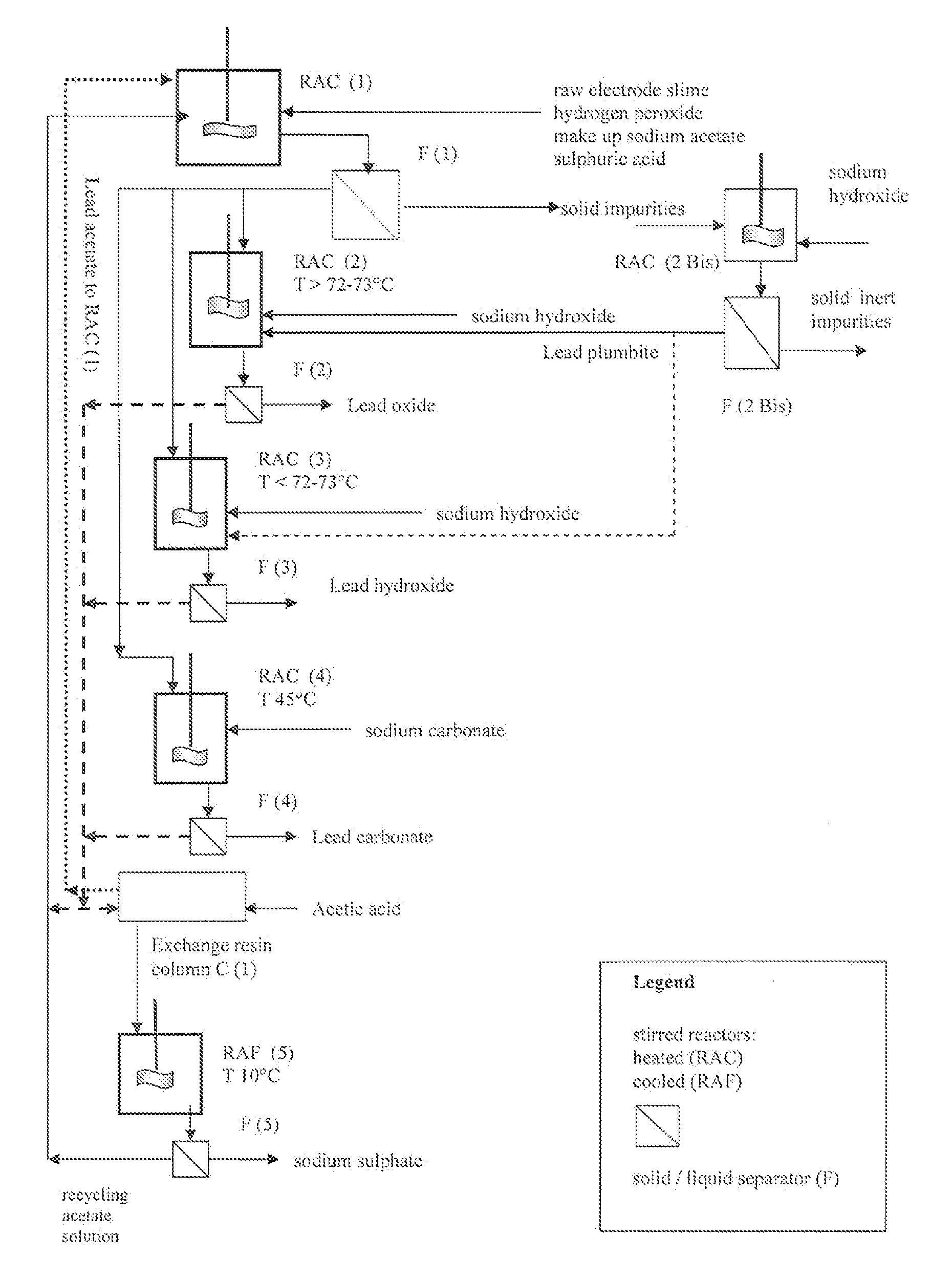

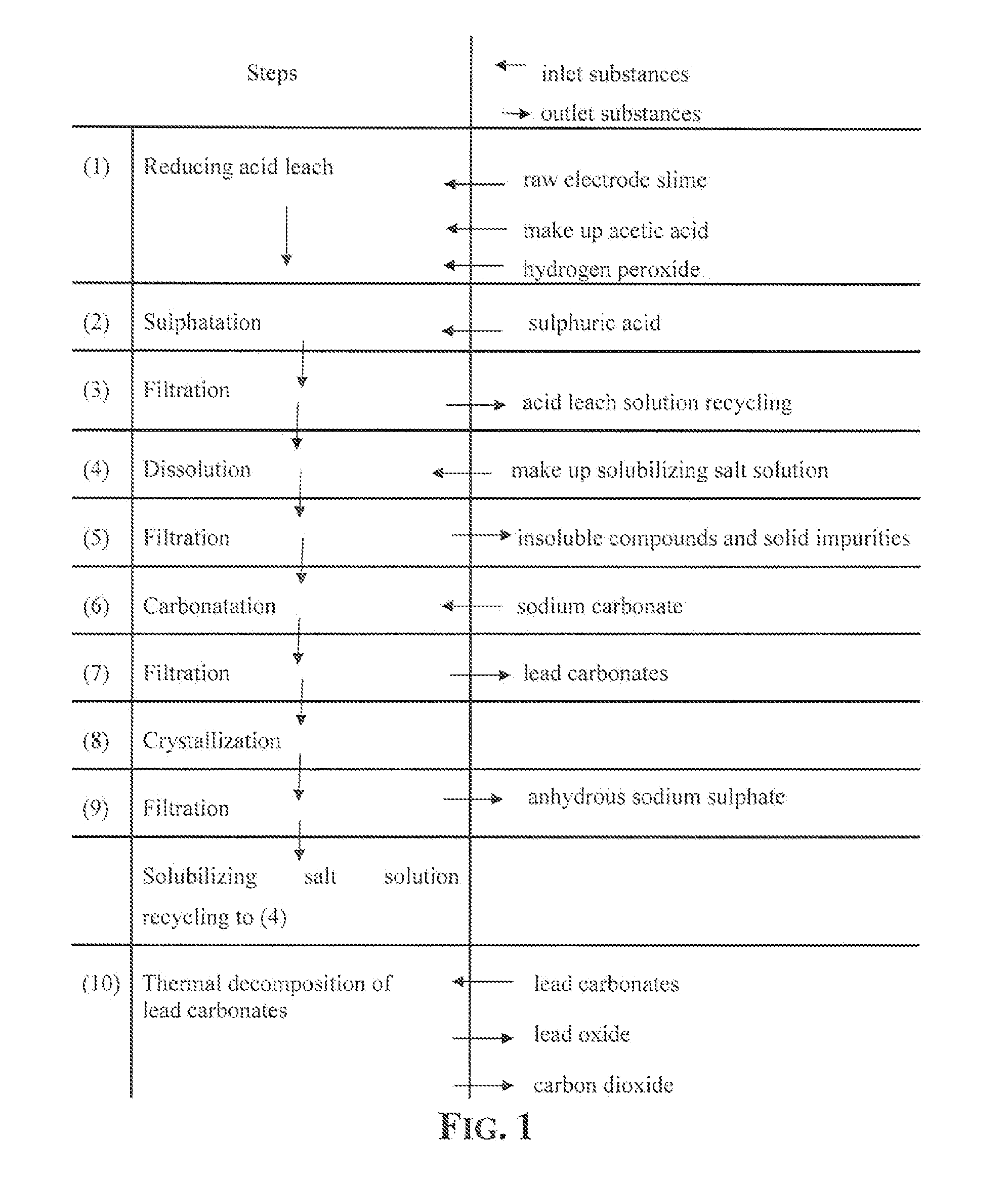

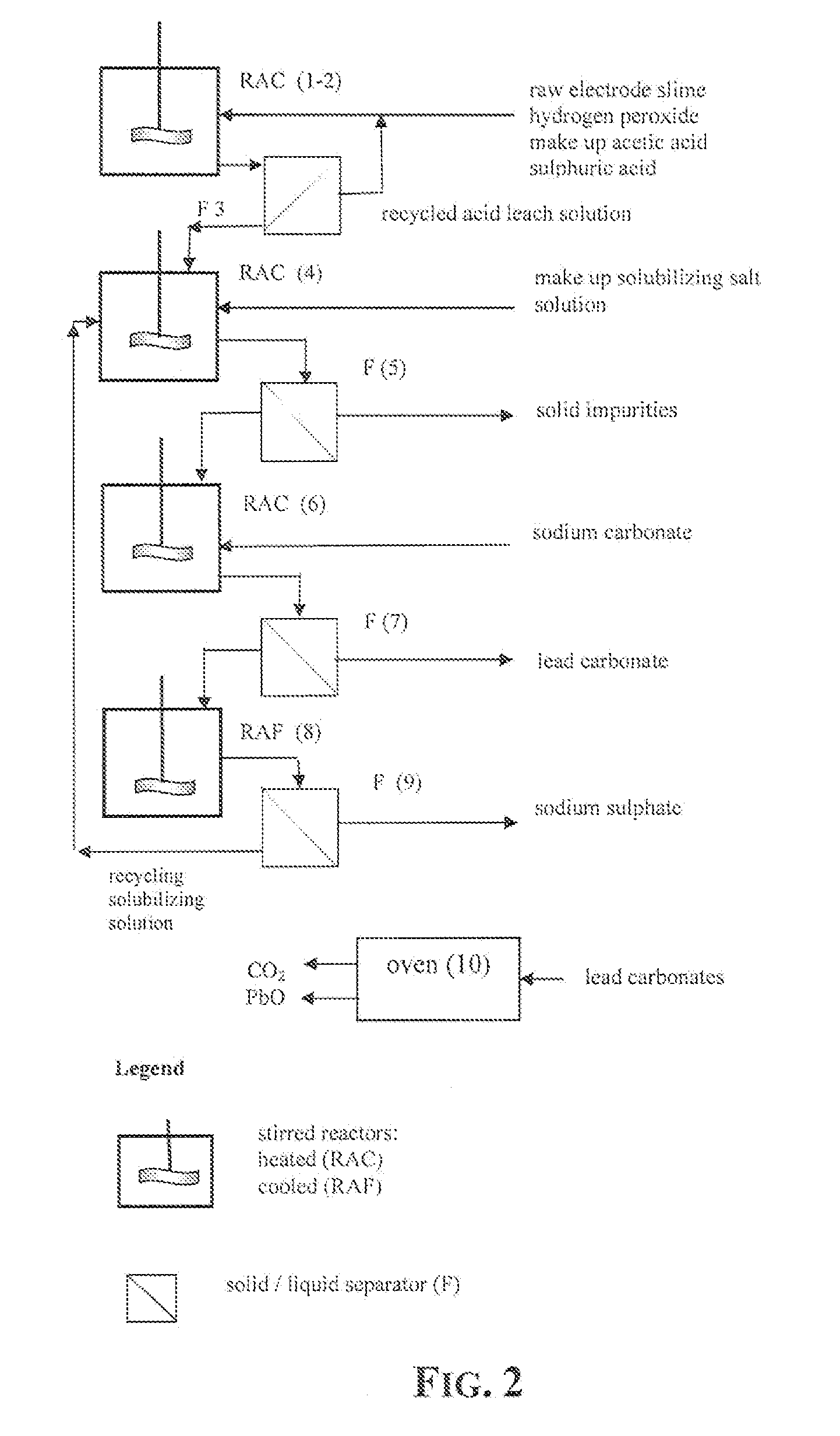

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

An outstandingly low environmental impact wet process recovers the lead content of an electrode slime and / or of lead minerals in the valuable form of high purity lead oxide or compound convertible to highly pure lead oxide by heat treatment in oven at relatively low temperature, perfectly suited for making active electrode pastes of new batteries or other uses. The process basically comprises the following treatments:a) suspending the impure lead containing material in an aqueous bath containing at least a lead oxide dissolving acid;b) reducing any insoluble lead dioxide to lead oxide by introducing in the suspension either hydrogen peroxide, a sulphite or sulphurous anhydride;c) converting all dissolved lead oxide to lead sulphate in the aqueous bath;d) obtaining a solution of lead sulphate obtained in an aqueous solution containing an acetate salt;e) precipitating and separating a purified lead compound in the form of either carbonate / oxycarbonate or of oxide / or hydroxide by adding to said acetate salt solution a carbonate salt or a hydroxide of the same cation of said acetate salt, respectively.Exemplary flow sheets according to several alternative embodiments and related processing plant diagrams are disclosed.

Owner:MILLBROOK LEAD RECYCLING TECH

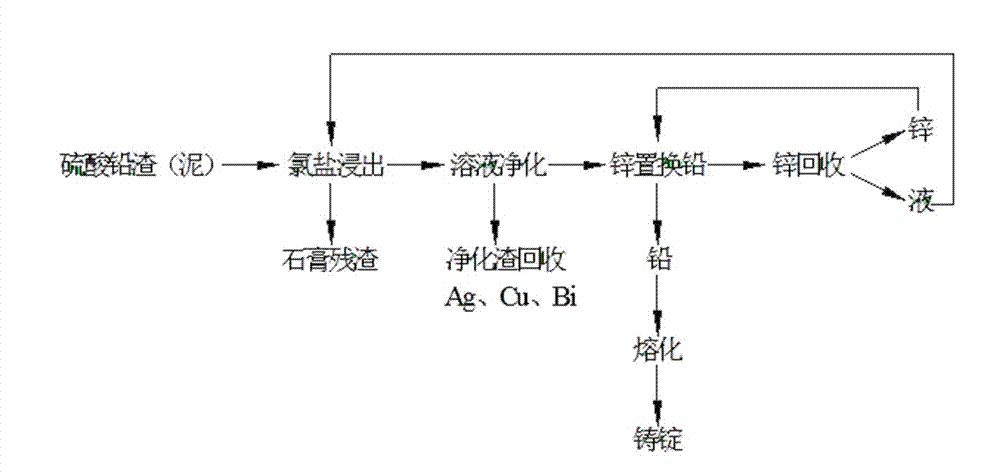

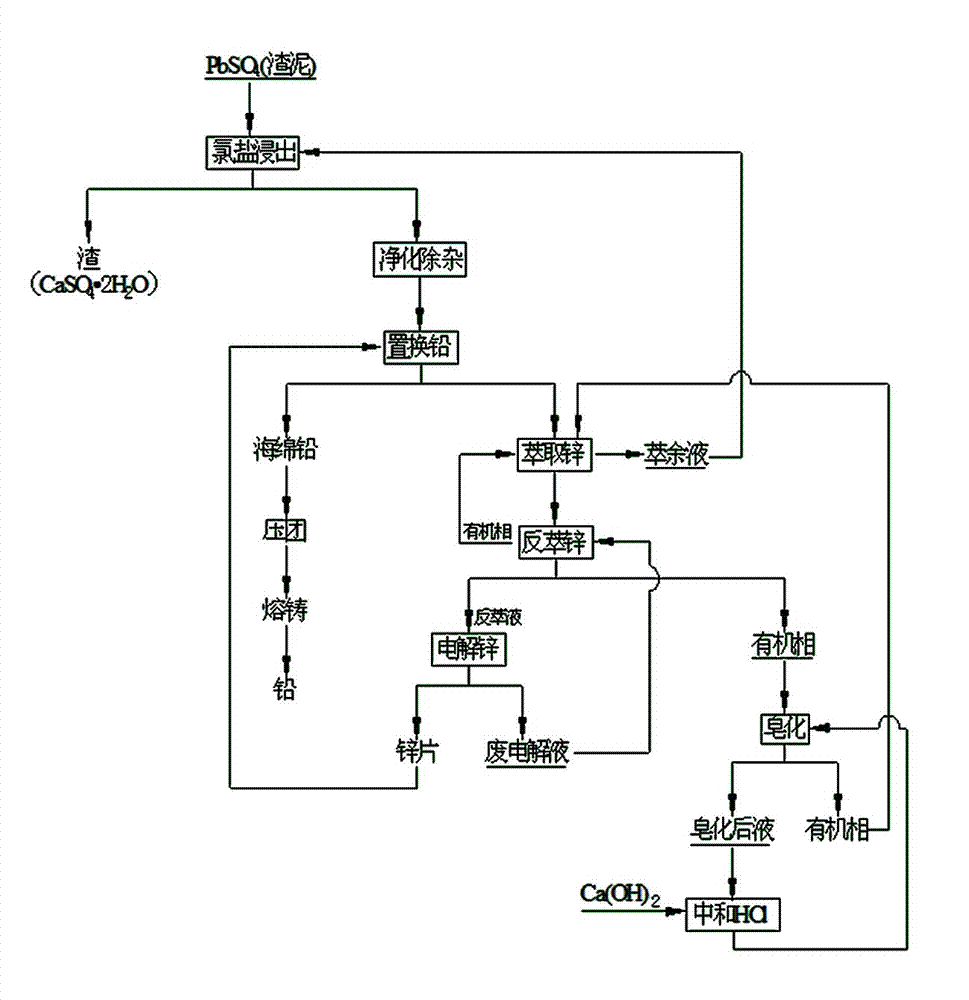

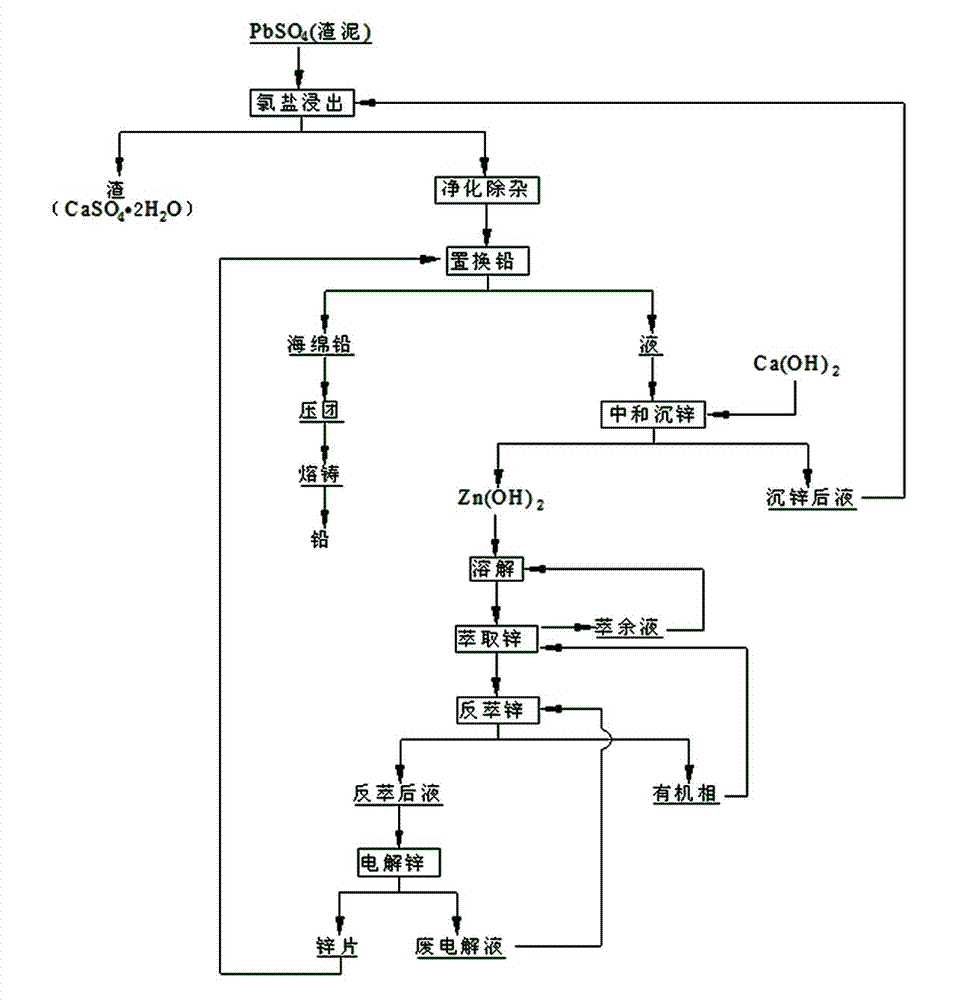

Lead hydrometallurgical technology through utilizing lead sulfate

The invention discloses a lead hydrometallurgical technology through utilizing lead sulfate, belongs to a hydrometallurgical technology, and relates to a technology which adopts a full-hydrometallurgical technology to produce lead through lead sulfate residuals or lead storage battery lead slime which is additionally produced in a zinc hydrometallurgical process. The method comprises steps of: with CaCl2 and NaCl as a leaching solvent; leaching high leaching residuals generated by zinc hydrometallurgy and containing lead sulfate, lead skims generated by leaching zinc out of lead-containing zinc oxides or the lead slimes generated by dismantling lead-acid storage batteries; using zinc to replace lead in the leaching solution; recovering zinc from the replacing solution; returning the recovered zinc to a lead replacement process; and circulating a Cl<->-containing liquid after zinc recovery to a lead sulfate chloride leaching process. The technology has the characteristics of low energy consumption, low cost and easiness in popularization and application; and smoke pollutions such as lead fume, lead dust and SO2 are thoroughly eliminated by utilizing the technology.

Owner:YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

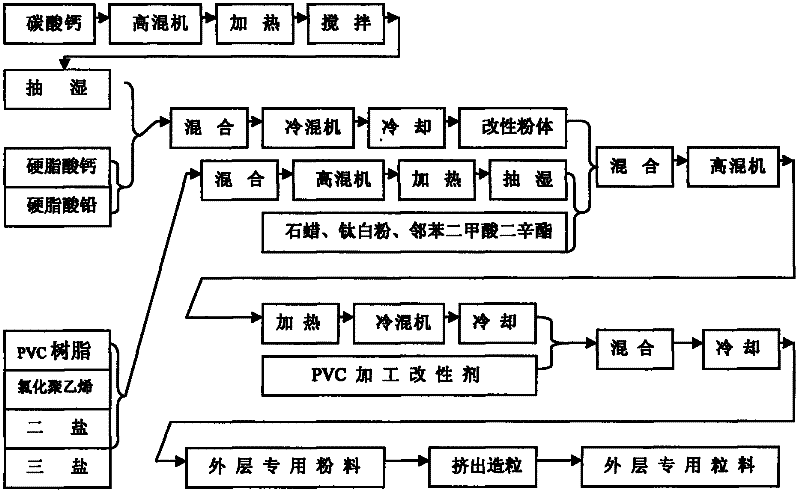

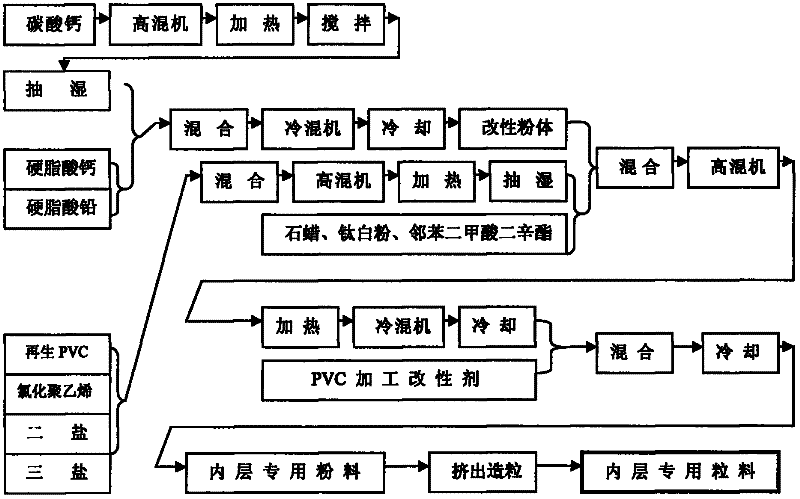

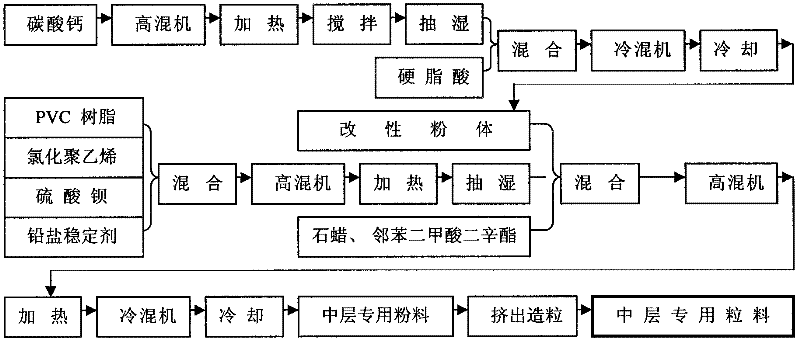

Three-layer noise reduction drainage pipe and manufacture method thereof

InactiveCN102313084AHigh strengthReduce impact noiseDomestic plumbingRigid pipesManufacturing cost reductionPolyvinyl chloride

The invention discloses a three-layer noise reduction drainage pipe, which comprises a drainage pipe body, wherein the drainage pipe body is a three-layer co-extrusion composite pipe formed by an impact-resistance outer layer, a noise reduction middle layer and an impact-resistance inner layer through co-extrusion. The noise reduction middle layer is a sound-absorbing middle layer or a sound insulation middle layer made of expandable polyvinyl chloride composition materials. The above layers are prepared with the following materials. The impact-resistance outer layer is made of polyvinyl chloride resin, chlorinated polyethylene, dibasic lead phosphite, tribasic lead sulfate, calcium stearate, lead stearate, paraffin, PVC processing and modifying agent, active light calcium carbonate, titanium dioxide and dioctyl phthalate. The sound-absorbing middle layer is made of polyvinyl chloride resin, chlorinated polyethylene, lead salt stabilizer, calcium stearate, stearic acid, paraffin, dioctyl phthalate, active light calcium carbonate and barium sulfate. The sound insulation middle layer is made of polyvinyl chloride resin, methacrylic ester polymer and inorganic foaming agent. Compared with the outer layer, the impact-resistance inner layer comprises the same components with the outer layer, except that PVC is adopted instead of polyvinyl chloride resin. The noise of the drainage pipe can be effectively reduced and the intensity of the drainage pipe is enhanced.

Owner:ZHEJIANG SANLENG PLASTIC

Method for recovering lead-containing raw material by using wet process

ActiveCN103526016AEnvironmentally Friendly Recycling MethodsEfficient recycling methodProcess efficiency improvementRecovery methodLead dioxide

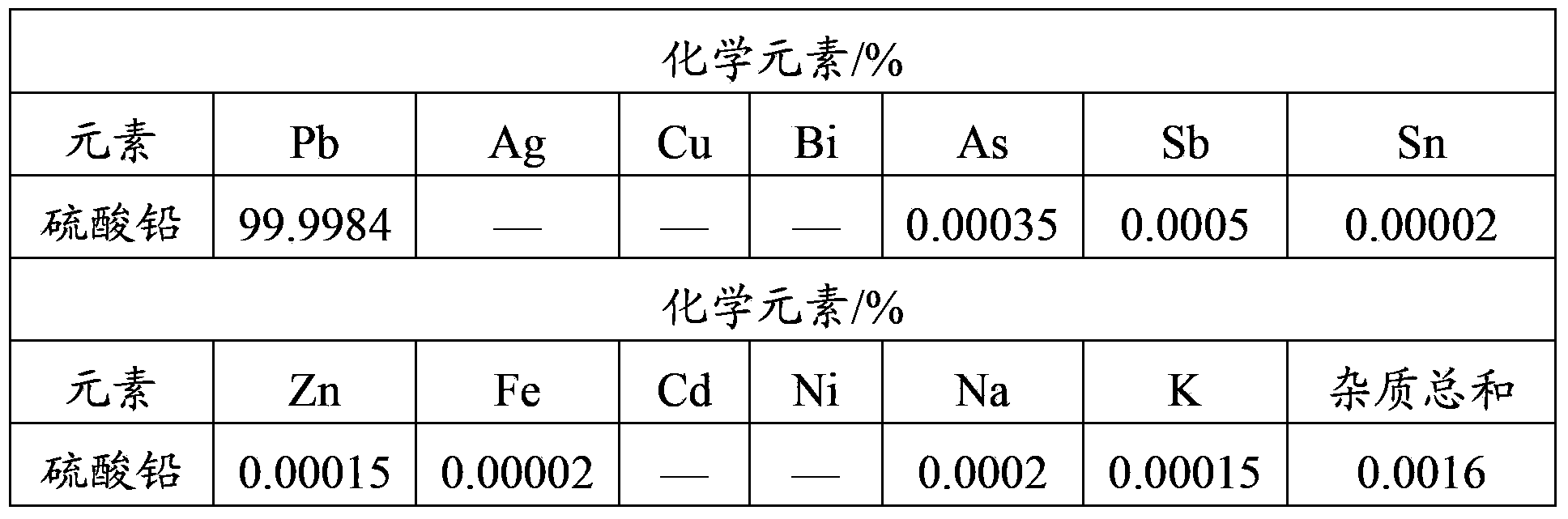

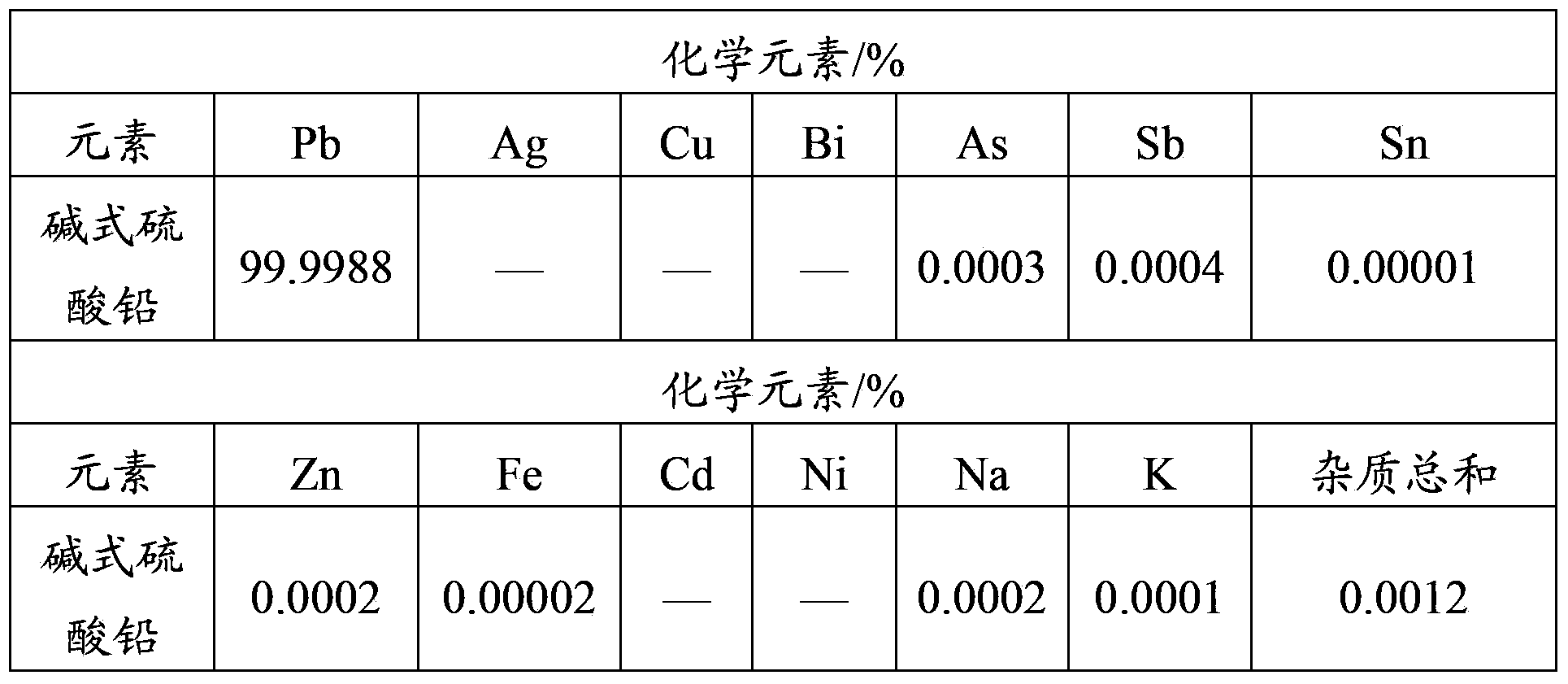

The invention discloses a method for recovering a lead-containing raw material by using a wet process. The method comprises the steps: (1) leaching the lead-containing raw material by using a solution, adding a reducing agent to reduce lead dioxide or lead orthoplumbate in the lead-containing raw material into a soluble lead salt, after a lead compound is completely dissolved, filtering the solution, and separating to obtain a filtrate A and an insoluble substance, wherein the solution contains sulfate, a complexing agent and a catalyst; (2) adjusting the pH value of the filtrate A, separating to obtain lead sulfate and a filtrate B, and returning the filtrate B to the step (1) after sulfate radicals are replenished and the pH value is adjusted; (3) directly using lead sulfate as battery materials or commodities, subjecting a sulfate-containing alkaline solution and lead sulfate to reaction, and separating to obtain basic lead sulfates and a filtrate C, wherein the basic lead sulfates include tribasic lead sulfate and tetrabasic lead sulfate. The method can be used for purifying the lead-containing raw material to form lead sulfate and basic lead sulfates directly used for producing lead-acid batteries, thereby being an environment-friendly wet-process recovery method.

Owner:北京中金瑞丰环保科技有限公司

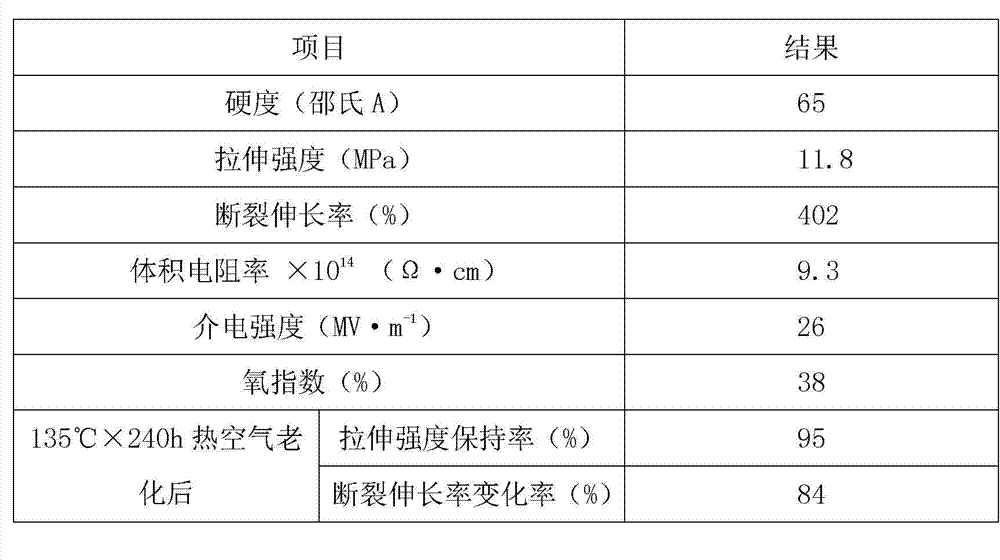

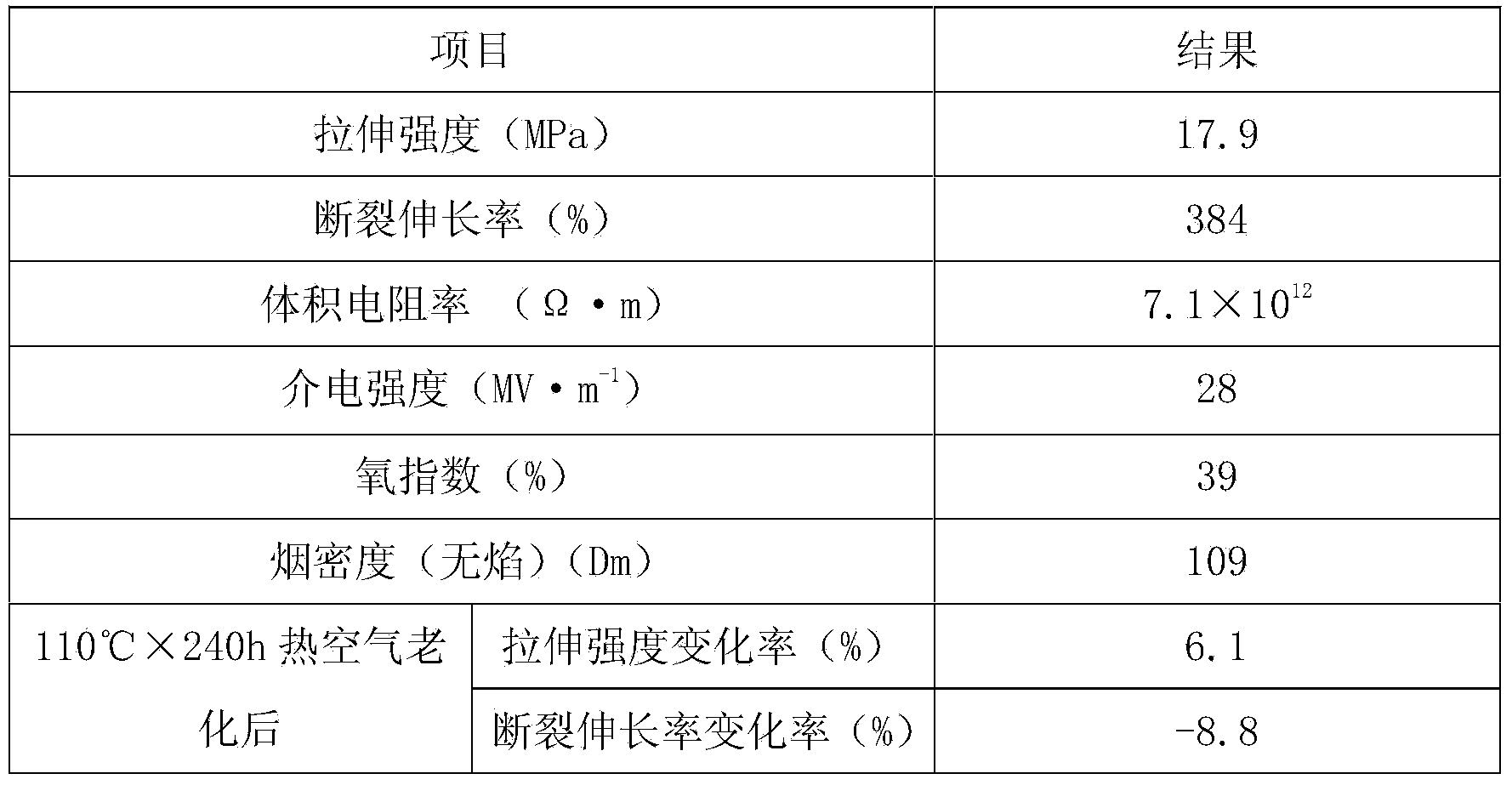

Novel low-smoke zero-halogen flame-retardant cable sheath material

InactiveCN102532649AReduce dosageDosage reachedInsulated cablesInsulated conductorsLow-density polyethyleneHigh carbon

The invention relates to a novel low-smoke zero-halogen flame-retardant cable sheath material, which comprises the following components in percentage by weight: 15-35 percent of low-density polyethylene, 15-35 percent of ethylene-vinylacetate copolymer, 8-30 percent of modified nano magnesium hydroxide, 2-6 percent of microencapsulated red phosphorus, 8-19 percent of thermoplastic phenolic resin, 1.8-3 percent of dicumyl peroxide as a crosslinking agent, 0.1-0.25 percent of antioxidant 1010, 1-3.5 percent of lead sulfate tribasic as a lead compound and 0.1-1 percent of N-salicyl aminophthalimide as a copper inhibitor. According to the novel low-smoke zero-halogen flame-retardant cable sheath material, the consumption of the modified nano magnesium hydroxide is reduced by adding the thermoplastic phenolic resin and the microencapsulated red phosphorus on the basis of ensuring the performance of mechanical energy, and the purpose of synergically retarding flame is achieved. When the cable sheath material burns, the microencapsulated red phosphorus absorbs a great deal of water decomposed and released when the modified nano magnesium hydroxide burns, to generate phosphoric acid, metaphosphoric acid, polymetaphosphoric acid and the like which cover the surface of the thermoplastic phenolic resin with higher carbon content, so that the surface of the thermoplastic phenolic resin can be dehydrated and carbonized in an accelerating way to form a thick liquid film layer for isolating oxygen and heat from the inside sheath material, and thus burning can be weakened or interrupted, and the flame-retardant effect of the cable sheath material is enhanced; meanwhile, the novel low-smoke zero-halogen flame-retardant cable sheath material disclosed by the invention has the advantages of zero halogen, low smoke formation amount during burning and little pollution to environment.

Owner:JIANGSU HENGTONG POWER CABLE

Gel electrolyte capable of prolonging service life of lead-acid battery

InactiveCN104091968APrevent gelAvoid reunionLead-acid accumulatorsElectrolyte immobilisation/gelificationElectrochemical responseElectrolytic agent

The invention discloses gel electrolyte capable of prolonging the service life of a lead-acid battery. The gel electrolyte contains the following raw materials in percentage by weight: 0.1 to 0.5 percent of polyethylene glycol, 0.1 to 1 percent of stannous sulfate, 0.5 to 1.5 percent of sodium sulfate, 0.5 to 1 percent of phosphoric acid, 0.05 to 2 percent of an organic silicon polymer, 0.5 to 8 percent of fumed silica, 35 to 45 percent of sulfuric acid and the balance being de-ionized water. According to the gel electrolyte, the polyethylene glycol is used as a colloid stabilizer and can prevent colloids from being gelled or agglomerated before being filled into the battery and enhance the stability of the colloids to form a stable three-dimensional mesh structure; the stannous sulfate can be oxidized into stannic tin to improve the electrical conductivity of an active substance and the recharging capability of the battery which is discharged; the sodium sulfate can provide a certain quantity of sulfate radicals for electrochemical reaction in the electrolyte to reduce the degree of supersaturation of lead sulfate crystals; silicon-oxygen bonds and hydrogen bonds in the organic silicon polymer can effectively reduce the softening speed of the active substance, inhibit the passivation of the active substance on the surface layer and prolong the service life of the battery.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU NEW ENERGY

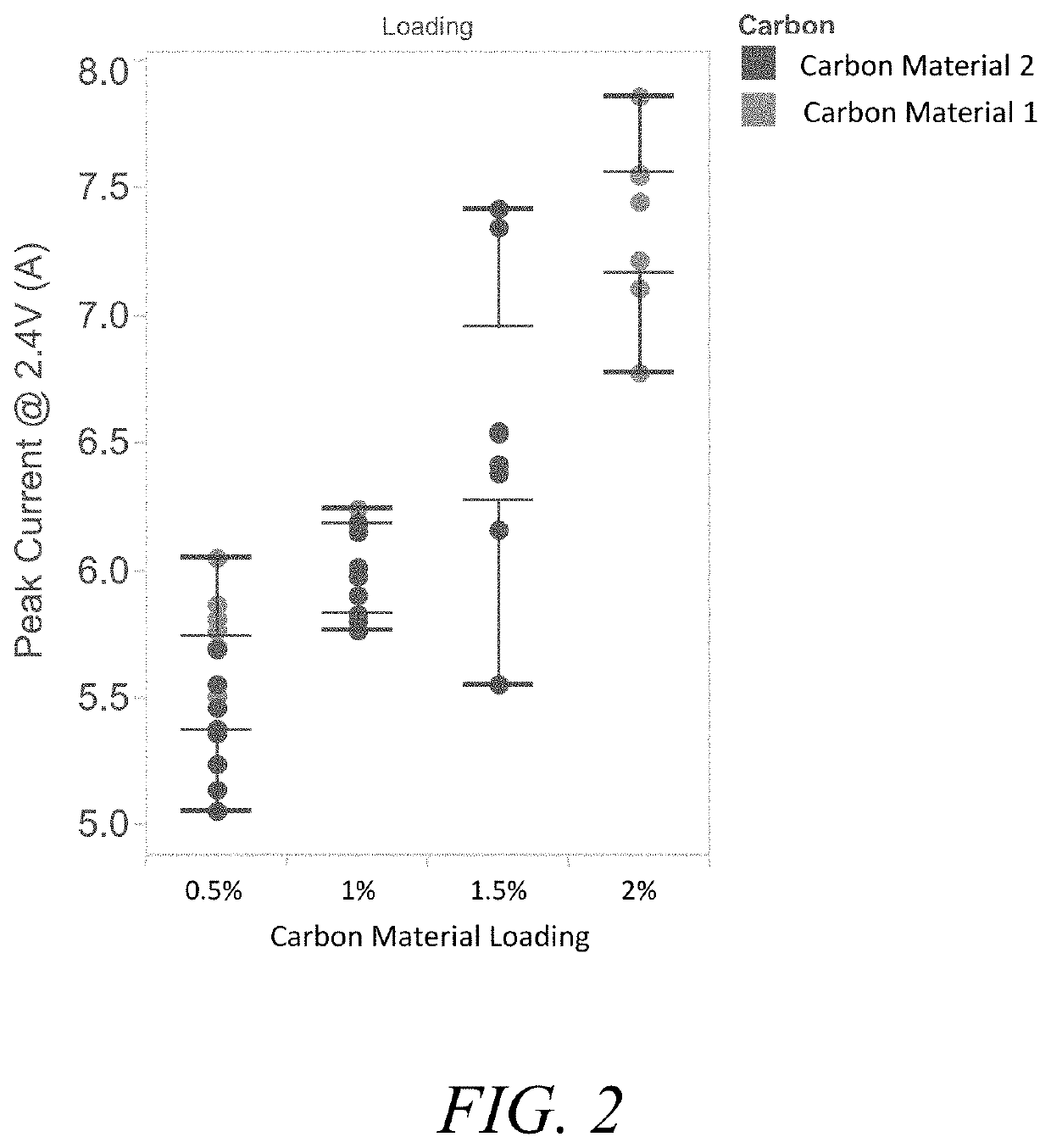

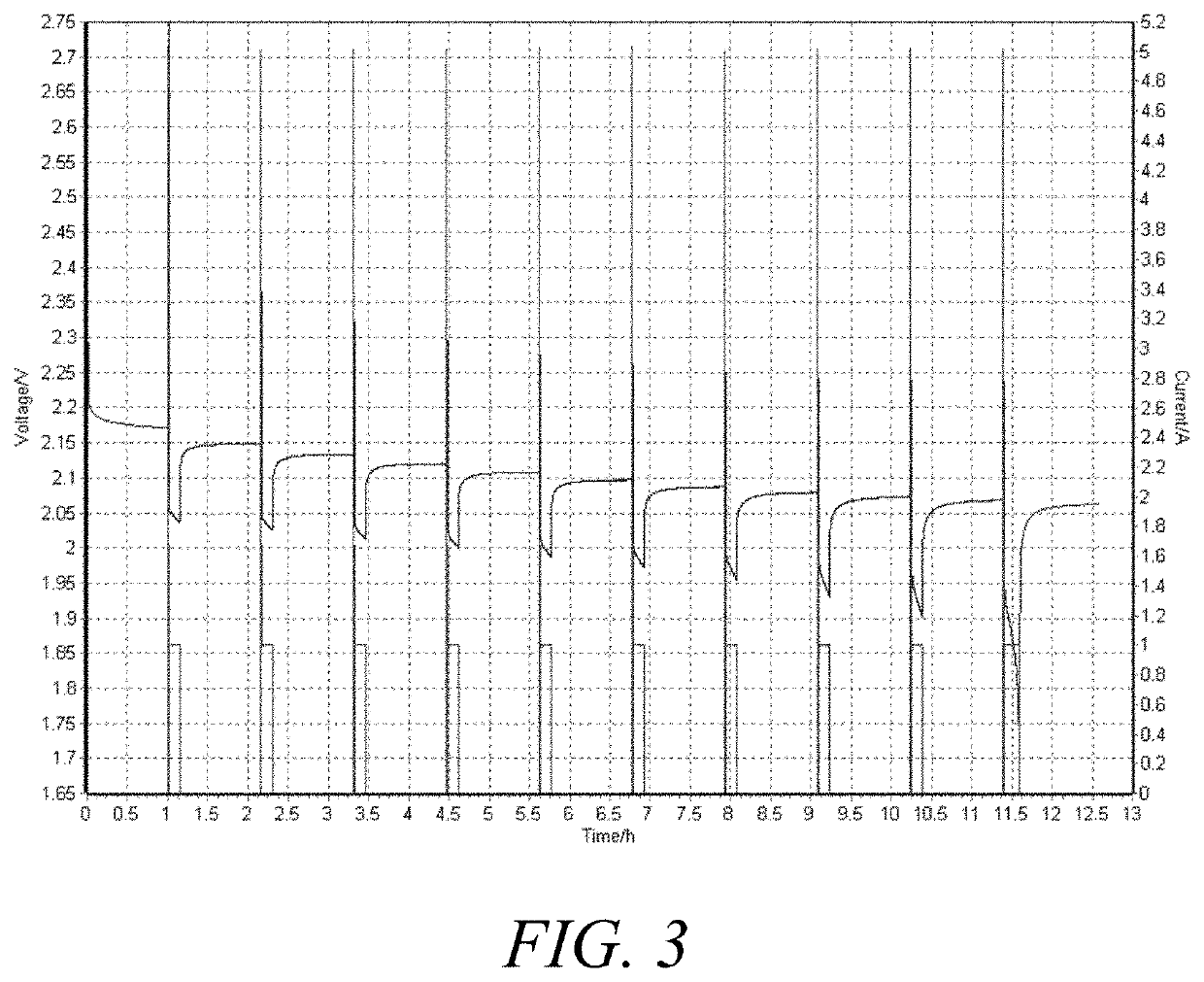

Carbon materials for improving performance of lead acid batteries

InactiveUS20200144619A1Improve charge acceptanceImproved profileLead-acid accumulator electrodesAcid electrolytesLead oxideLead sulfate

A composition comprising a lead species (e.g., leady oxide, porous metallic lead, metallic lead, lead sulfate) a carbon material and an expander are described herein. Also disclosed are electrodes, devices (e.g., batteries) including the same. Methods for making and using the disclosed novel composition are also detailed herein.

Owner:BASF AG

Polyvinyl chloride elastomer formula for flame-retarded mining flexible cable and its processing method

InactiveCN1676546AOvercome stickiness and blackeningOvercomes defects that can cause electrical crackingInsulated cablesInsulated conductorsElastomerRubber material

This invention relates to PVC elastomer formula for flame retarding mine use sofe cable and its processing technique. The formula includes the following contents(weight share): high polymerized PVC 100, low polymerized PVC 10-50, the plasticizer 60-120, tri-salt lead sulfate 2-5, disalt lead phosphate 2-5, disalt lead stearate 0.5-1.5 barium stearate 0.5-1.0, inflaming retarding agent 10-20, assistant retarding agent 2-7, antioxidant 0.1-1.0, bulking agent 10-30. The processing technique is as follows: match every group according to weight ratio and then past them; knead the pasting and powder under 90-110deg.C for 4-10 minutes, plasticize the kneaded mixture and particlize the processed rubber material and storage them. The elasticity of PVC of this invention can arrive the elasticity of rubber, and its electrical performance, hot endurance, inflaming retarding performance and tensile and breaking elongation are up to the standards.

Owner:JIANGWAN SPECIAL CABLE SHANGHAI

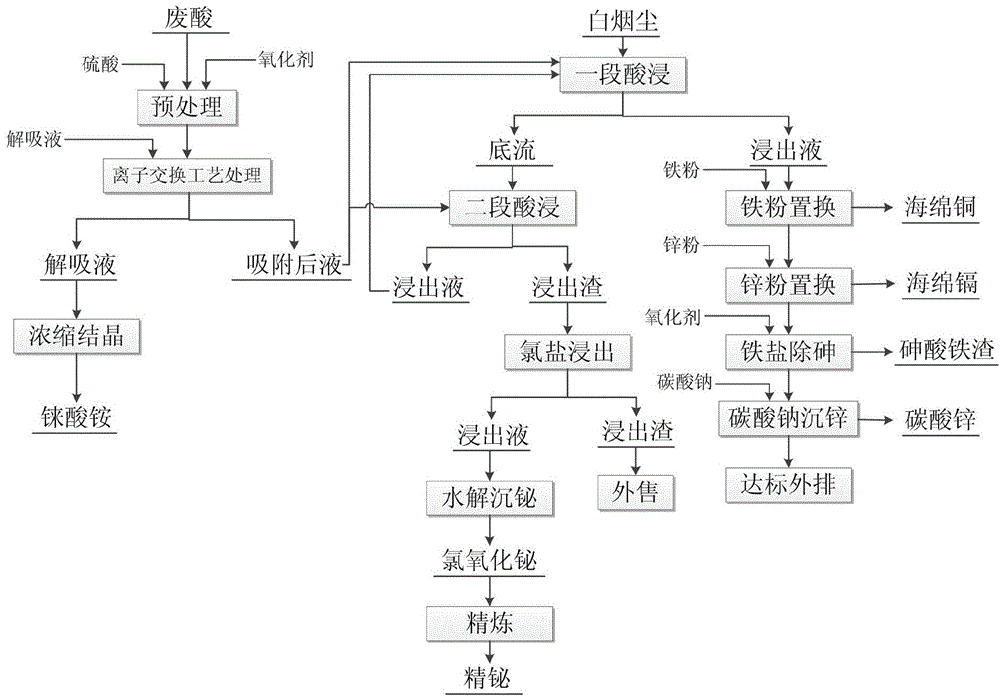

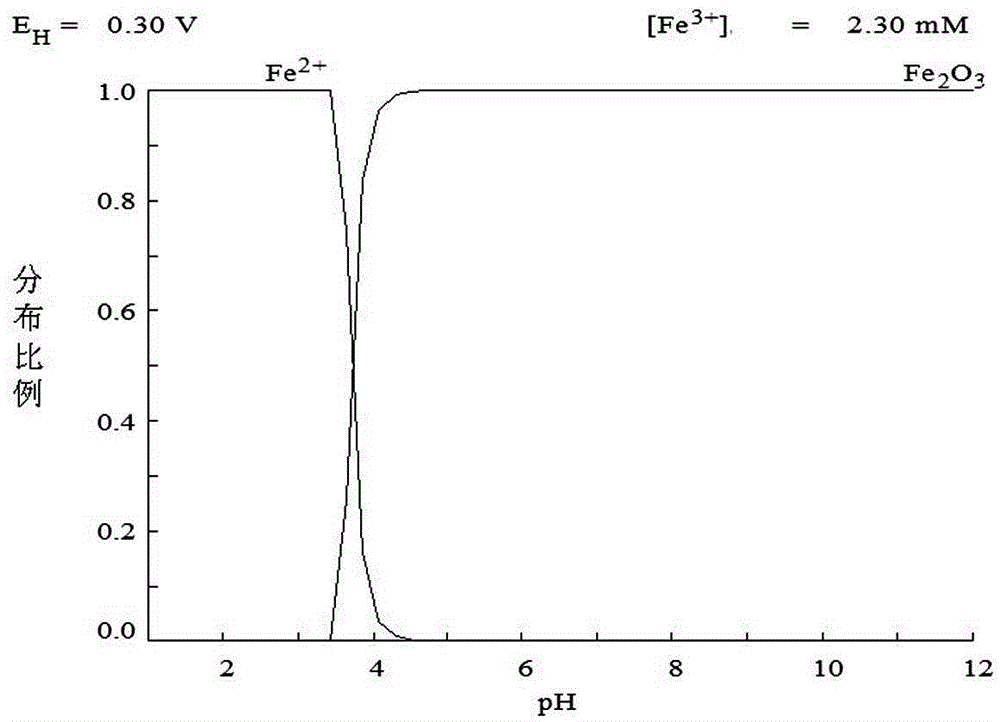

Process of recovering copper smelting waste acid and white smoke dusts

InactiveCN104593604AEfficient selective adsorptionEasy to handleProcess efficiency improvementParticulatesWater treatment

The invention provides a process of recovering copper smelting waste acid and white smoke dusts. The process comprises the following steps: removing suspended particulate matters in the waste acid, regulating the acidity and the redox potential of the liquid, and enabling ions including molybdenum ions in the liquid to exist in a high positive ion mode; then selectively adsorbing rhenium by utilizing ion exchange resin, after adsorption is saturated, carrying out desorption to obtain a rhenate liquid, and carrying out concentration and crystallization to obtain rhenate; using the waste acid after adsorbing the rhenium for leaching the white smoke dusts; treating the white smoke dusts by adopting two segments of countercurrent acid leaching-chloride leaching process, recovering valuable metals including copper, zinc and cadmium of an acid leaching liquid, carrying out harmless treatment on harmful elements including arsenic by virtue of a molysite method, recovering valuable metals including bismuth of a chloride leaching liquid, and selling lead sulfate, serving as a main component of chloride leaching residues, to a lead smelting plant. According to the process provided by the invention, the rhenium in the waste acid can be efficiently separated and recovered, the leaching white smoke dusts of the waste acid can be fully utilized, and the waste acid and white smoke dust leaching liquids can be comprehensively treated by utilizing a set of copper recovering and arsenic harmless treatment system, so that the process matching ability is good, the comprehensive recovery rate of the valuable metals is high, the waste water treatment effect is good, the investment is little, the production cost is low, and the economical benefit is good.

Owner:ZIJIN MINING GROUP

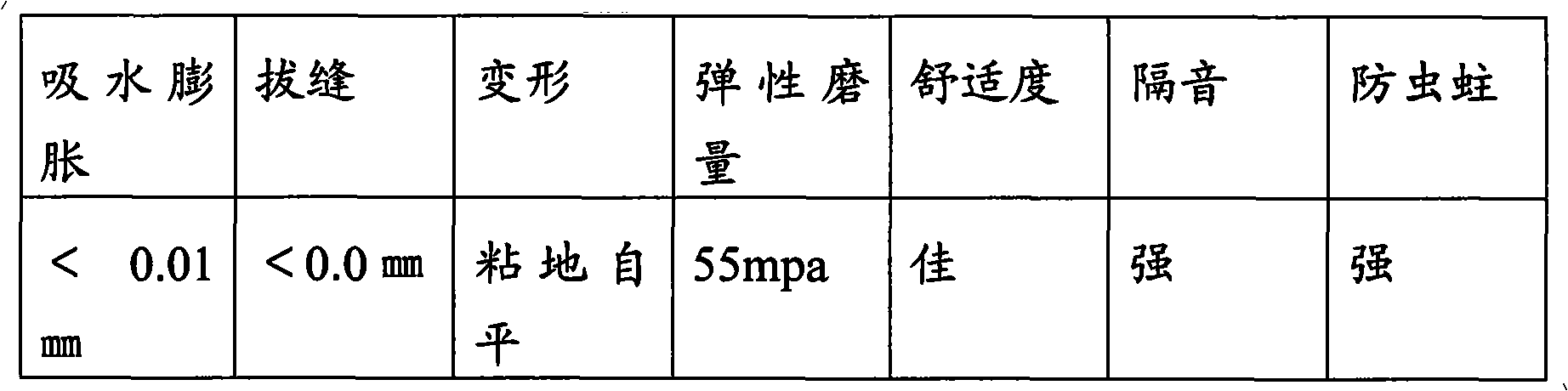

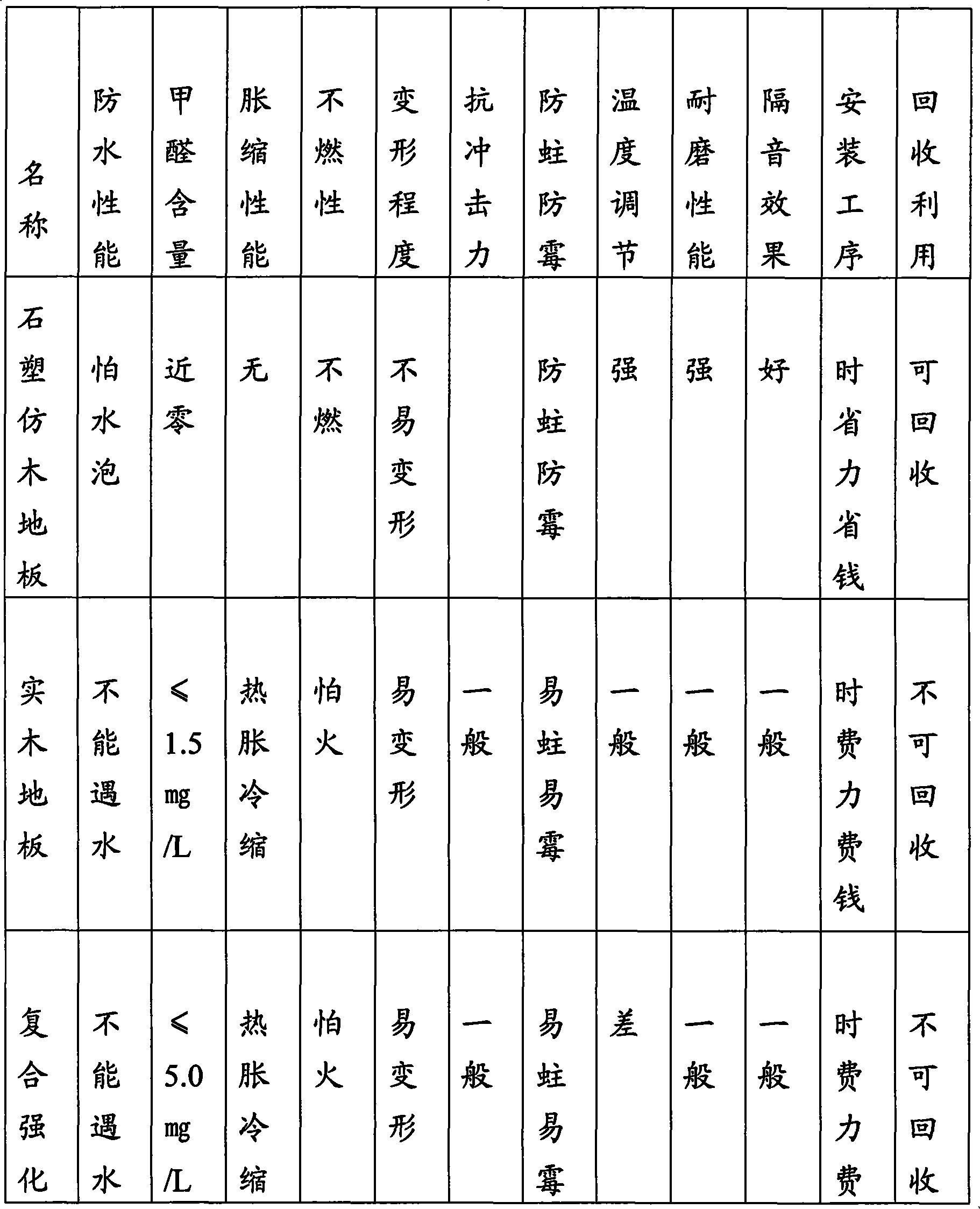

Stone-plastic simulated wood floor and manufacturing method thereof

The invention provides a stone-plastic simulated wood floor and a manufacturing method thereof. The stone-plastic simulated wood floor comprises the following components in percentage by mass: granular calcium carbonate mineral powder or tailing residue powder (containing over 50 percent of calcium carbonate), waste polyvinyl chloride (PVC) granules, polyamino modified silicone oil, polyether silicone oil, dibutyl ester, paraffin, complex stabilizers, tribasic lead sulfate, lead stearate, barium stearate and stearic acid. The stone-plastic simulated wood floor manufactured from wastes from industrial and mining enterprises and life saves resources, is insusceptible to sliding and radiation generation and solves the problems of low fire resistance, low water resistance, deformation, insect damage and troublesome maintenance and the like.

Owner:张家口德高森板业有限公司

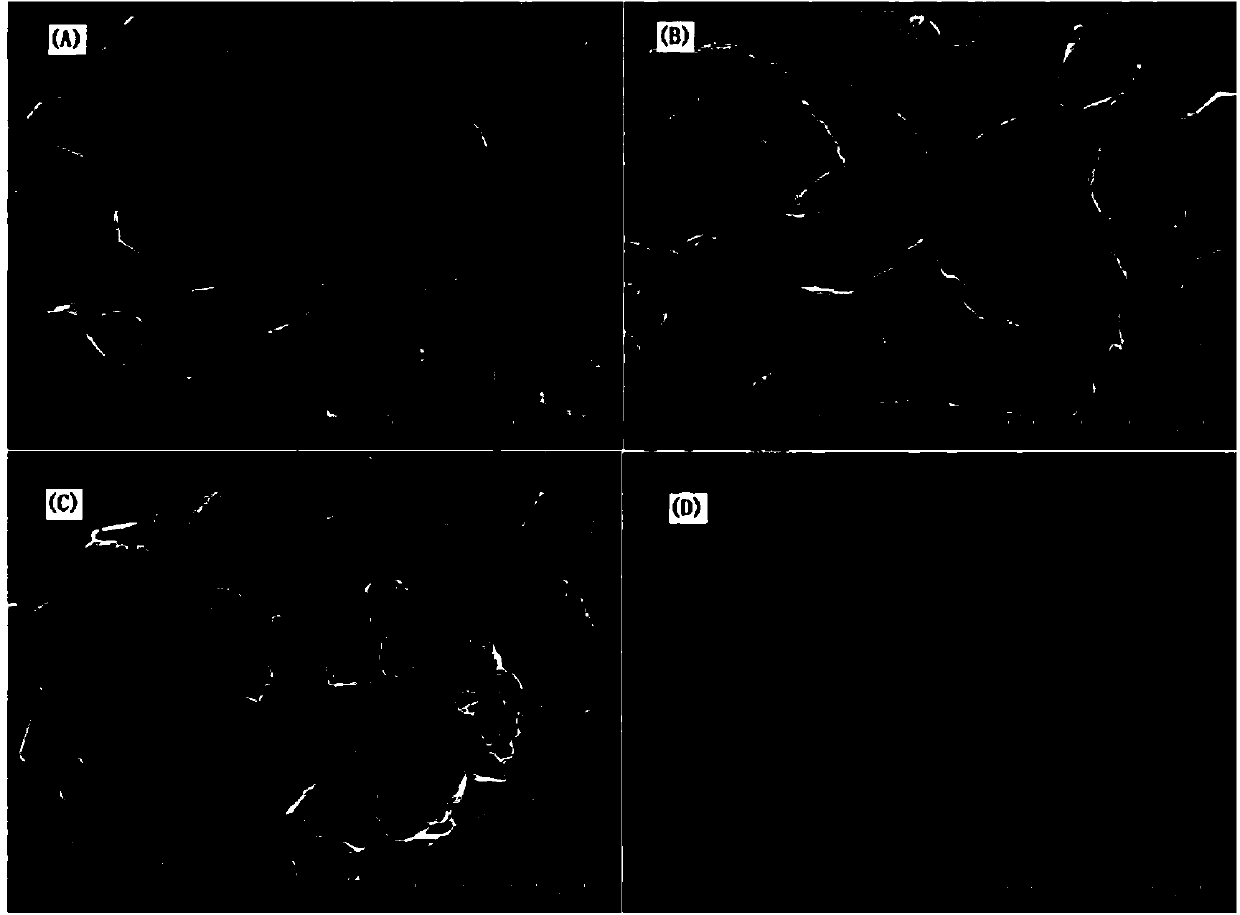

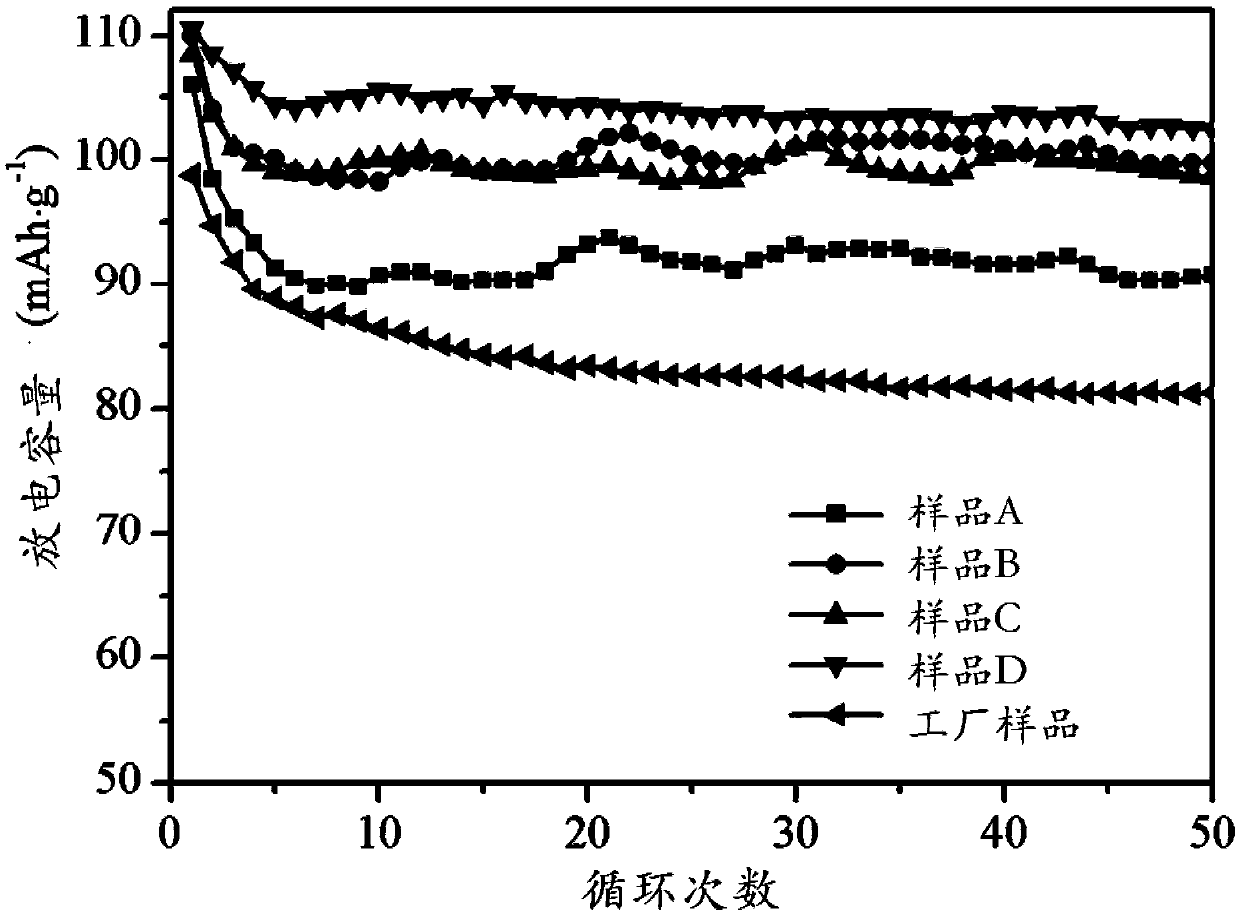

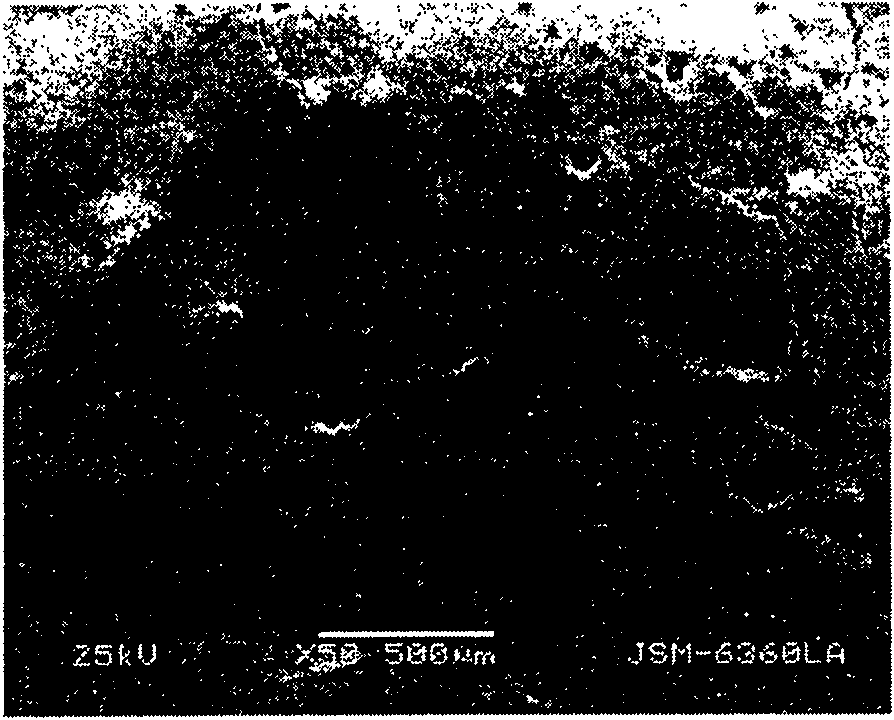

Preparing method for nano micron lead sulfate with electrochemical activity and method adopting lead sulfate to prepare lead-acid cell

ActiveCN103723761AShorten the production cycleShorten board making timeMaterial nanotechnologyLead-acid accumulator electrodesFiberSulfate

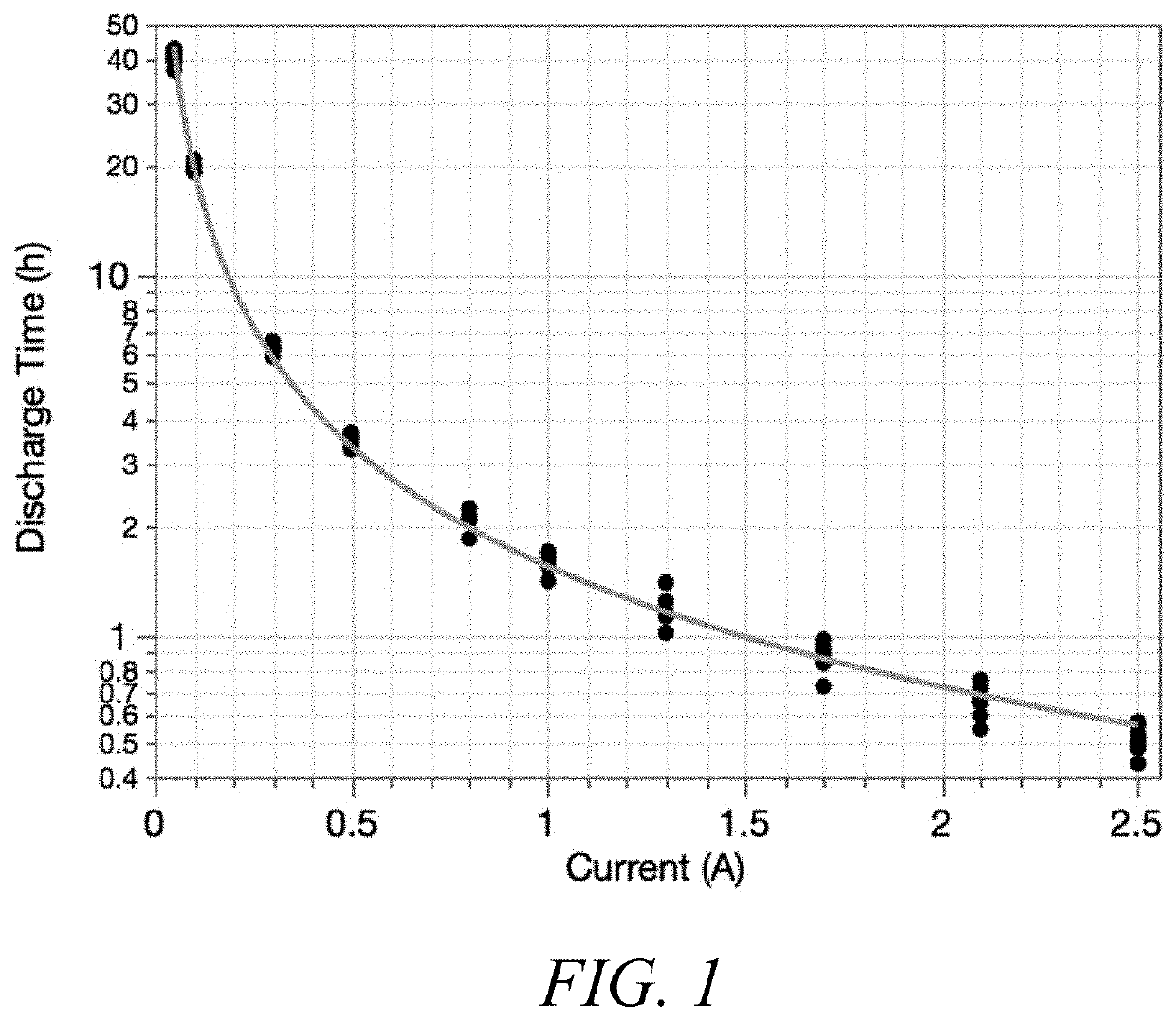

The invention discloses a preparing method for nano micron lead sulfate with electrochemical activity and a method adopting the lead sulfate to prepare a lead-acid cell. The preparing method for nano micron lead sulfate includes the following steps: using a morphological control agent for controlling the crystal growth of lead sulfate; enabling a water solution of soluble lead salt to react with a water solution of soluble sulfate / sulfuric acid, or enabling an aqueous dispersion of lead elementary substance / insoluble lead compound to react with a water solution of sulfuric acid in a clash flow reactor; finally obtaining the nano micron lead sulfate. The preparing method for the lead-acid cell includes the following steps: adopting the lead sulfate as active substances for an anode and a cathode; preparing a positive plate and a negative plate through adding fibers, a conductive agent, an expanding agent and the like; adding membranes between the two poles; then placing the two plates in a cell box for battery charging and formation. The invention has the advantages that the nano micron lead sulfate is high in electrochemical activity; the performance of the lead-acid cell is high and the service life of the lead-acid cell is long after the nano micron lead sulfate is adopted as the active substances of the lead-acid cell; besides, the preparing methods for the lead sulfate and the lead-acid cell are simple and feasible and have the characteristics of energy conservation and environmental protection.

Owner:SOUTHEAST UNIV

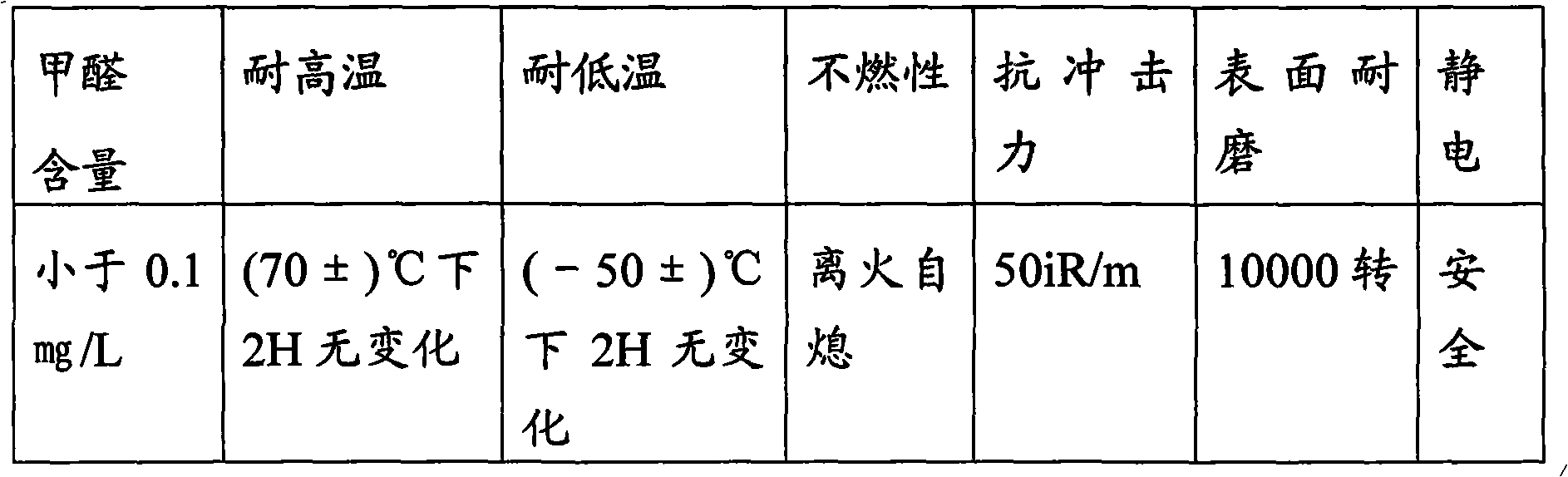

Nano-wollastonite powder modified ethylene propylene diene copolymer cable material

ActiveCN102964697AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsPolyesterPolymer science

The invention discloses a nano-wollastonite powder modified ethylene propylene diene copolymer cable material, which is prepared FROM the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland ethylene propylene diene copolymer 3950, 20-30 parts of butyl rubber BBK232, 10-15 parts of SG-3 PVC (polyvinyl chloride) resin, 10-15 parts of trioctyl trimellitate, 2-5 parts of propanediol sebacate polyester, 2-5 parts of epoxidized soybean oil, 5-10 parts of polyethylene wax, 0.2-0.5 part of bisphenol A, 1-2 parts of zinc stearate, 0.5-1 part of lead sulfate tribasic, 1-2 parts of sulphur, 3-5 parts of zinc oxide, 30-40 parts of wollastonite powder, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Method for recycling waste lead storage battery

InactiveCN102306856AThe conversion process is simpleImprove conversion rateWaste accumulators reclaimingProcess efficiency improvementElectrolytic agentProcess engineering

Owner:重庆市铜梁区诚信电极板厂

Lead-acid storage battery lead paste and preparation method thereof

InactiveCN107230777AIncrease the speed of chargingIncrease the discharge speedLead-acid accumulator electrodesFiberPolyester

The invention discloses a lead-acid storage battery lead paste, comprising a positive lead paste and a negative lead paste, wherein the positive lead paste comprises the following components: regenerated lead powder, red lead, polytetrafluoroethylene, ultra-fine tetrabasic lead sulfate, sodium perborate, graphite, polyester staple fiber, glass fiber, antimonous oxide, dilute sulfuric acid and deionized water; and the negative lead paste comprises the following components: regenerated lead powder, red lead, barium sulfate, barium stearate, sodium lignosulfonate, humic acid, semi-carbonized wood chips, polyester staple fiber, modified graphene, dilute sulfuric acid and deionized water. According to the lead-acid storage battery lead paste disclosed by the invention, the problem of poor over-discharge performance and charge acceptance capability of a storage battery can be improved, and the service life of the storage battery can be prolonged.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

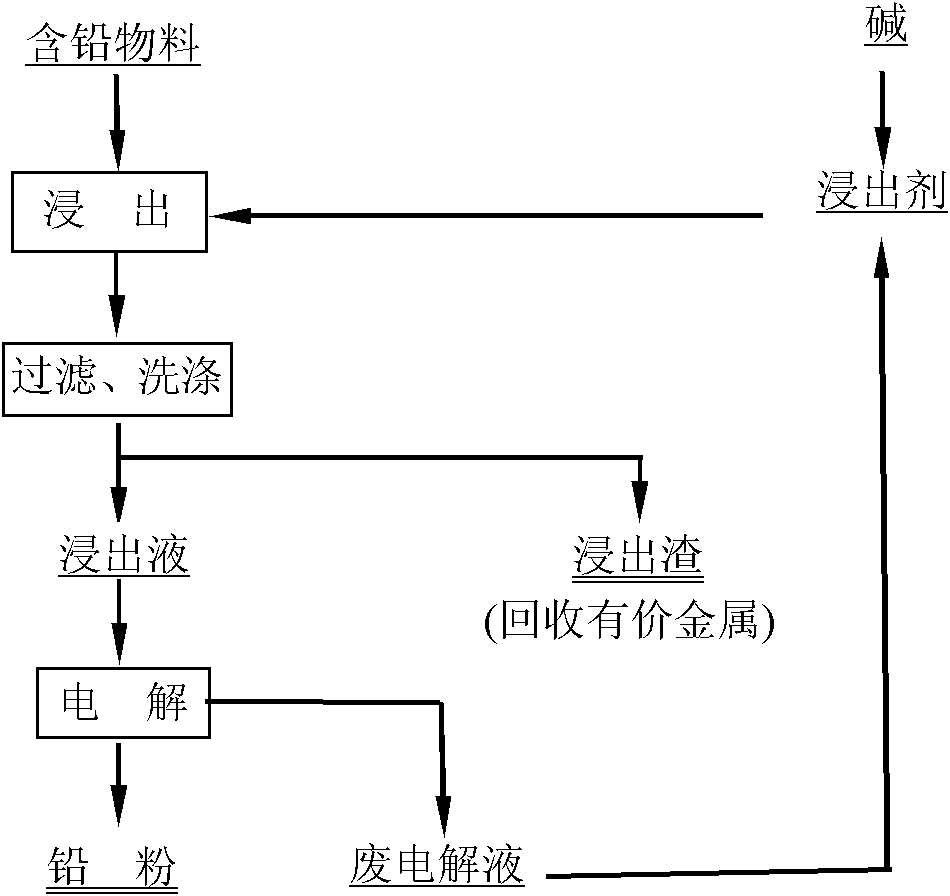

Method for recovering lead from lead-containing material by matching leaching-electrowinning method

InactiveCN102206750AEasy to separateImprove the efficiency of follow-up operationsPhotography auxillary processesProcess efficiency improvementSlagLead sulfate

The invention discloses a method for recovering lead from a lead-containing material by matching a leaching-electrowinning method. The method comprises the following steps of: selectively leaching the lead from the lead-containing material at the temperature of -95DEG C by using a mixture of 0.005-0.5M ethylenediaminotetraacetateedetate and 0.05-1.0M alkali as a leaching agent, and filtering and separating to obtain a lead-containing solution; and separating out metal lead powder from the solution by using an electrowinning method, blending electrowinning waste liquor, and returning to the leaching step. By leaching lead from secondary zinc oxide soot, the grade of zinc in secondary zinc oxide and the leaching rate of subsequent leaching can be improved, and subsequent treatment is facilitated; and by leaching lead from low-grade lead slag containing lead oxide, lead sulfate or lead chloride, the leached sewage in the slag piling process never contains lead or contains little lead, environment is not affected, the waste is changed into treasure, and the lead can be recovered from the lead slag. The method has the advantages of simple flow, simple operation, low energy consumption and the like, and can be widely used for treating lead-containing secondary zinc oxide materials and low-grade lead slag.

Owner:CENT SOUTH UNIV

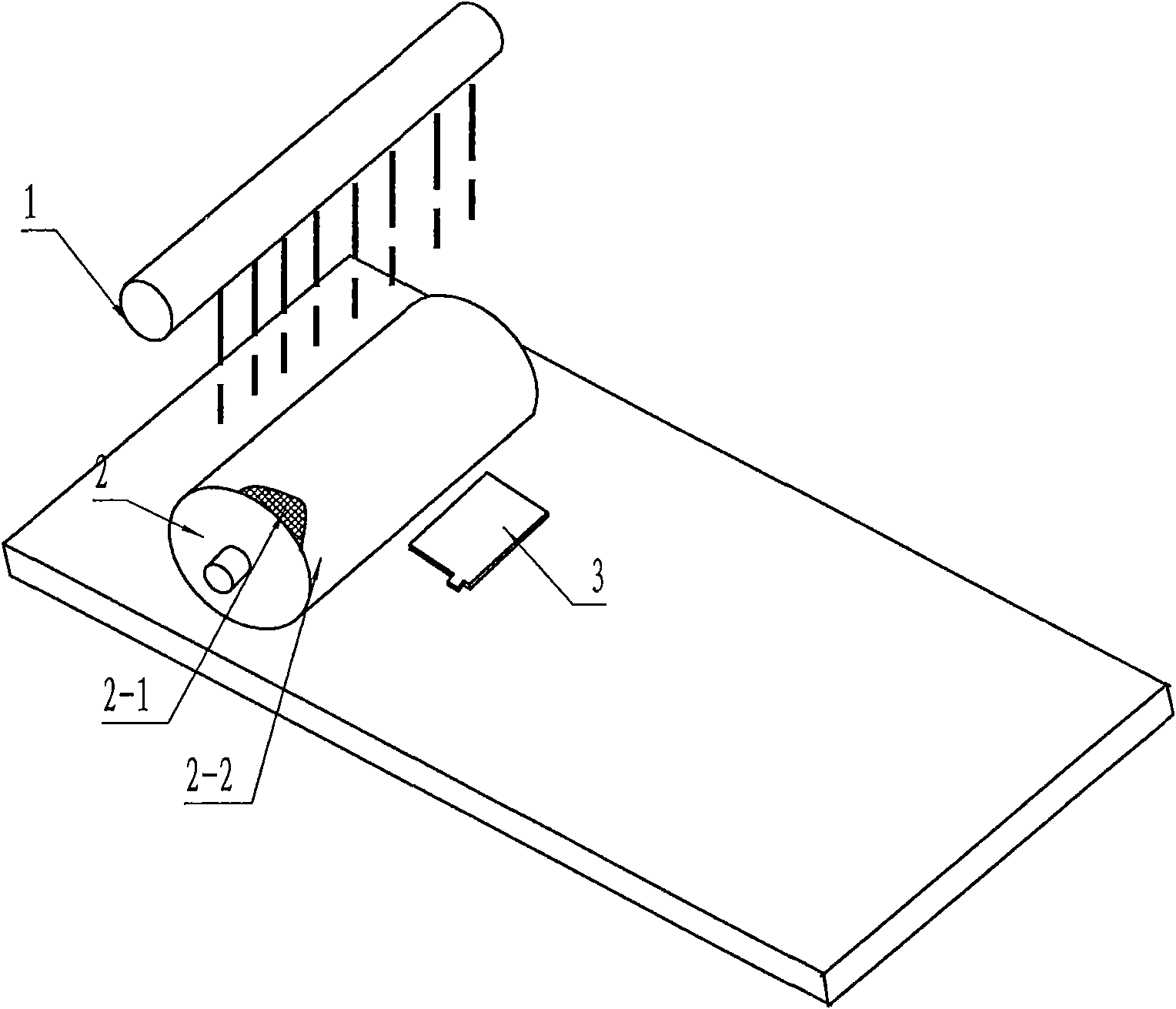

Preparation method of vale control lead-acid accumulator green plate without crackles

The invention discloses a preparation method of a vale control lead-acid accumulator green plate without crackles, for the purpose of removing crackles of plates. The improvement of the invention is characterized in that: a pasted green plate is processed by rolling and acid treatment, in which dilute sulphuric acid of 1.150 g / cm is sprinkled on a compression roller; the green plate is rolled under the compression roller; and the dilute sulphuric acid is attached uniformly to the green plate. Relatively high-density dilute sulphuric acid is used for sprinkling on the green plate by rolling, which leads to thicker lead sulfate coating; water loss of the plate is decreased due to quick drying; uncombined lead existing as active substance during solidifying and drying process reacts sufficiently with oxygen, thus producing better solidifying effect and enhancing the bonding force between the active substance and a slab lattice. The vale control lead-acid accumulator green plate made by the method has smooth plate surface without crackles. Therefore, the quality of the plate is significantly improved.

Owner:FENGFAN

Weather-proof polyolefin wire cable material and preparation method thereof

InactiveCN104109276AImprove flame retardant performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsEpoxyPolyolefin

The invention discloses a weather-proof polyolefin wire cable material and a preparation method thereof, the cable material comprises the raw material by weight: 60-80 parts of LDPE, 15-25 parts of EVA, 10-15 parts of SEBS, 14-18 parts of magnesium hydroxide, 2-4 parts of stearic acid, 1-2 parts of zinc oxide, 5-10 parts of zinc borate, 1-2 parts of lead sulfate tribasic, 1-2 parts of vinyltriethoxysilane, 4-8 parts of octyl epoxy stearate, 0.5-1 part of light stabilizing agent GW-4800.5, 1-1.5 parts of anti-oxidant 215, 0.5-1 part of dibutyltin dilaurate, 0.5-1 part of dicumyl peroxide, 20-25 part of aluminum silicon black, 10-15 parts of nano barite, 5-10 parts of nano diatomite and 4-8 parts of composite filling material. The polyolefin cable material has excellent flame retardation performance, physical and mechanical properties and weatherability, can be widely used in electric power cable, communication cable, control cable, optical cable , subway cable, insulation or sheath, electronic wire, automobile and the like, and has the advantages of environmental protection and durable performance.

Owner:ANHUI RONGJIU OPTICAL FIBER COMM

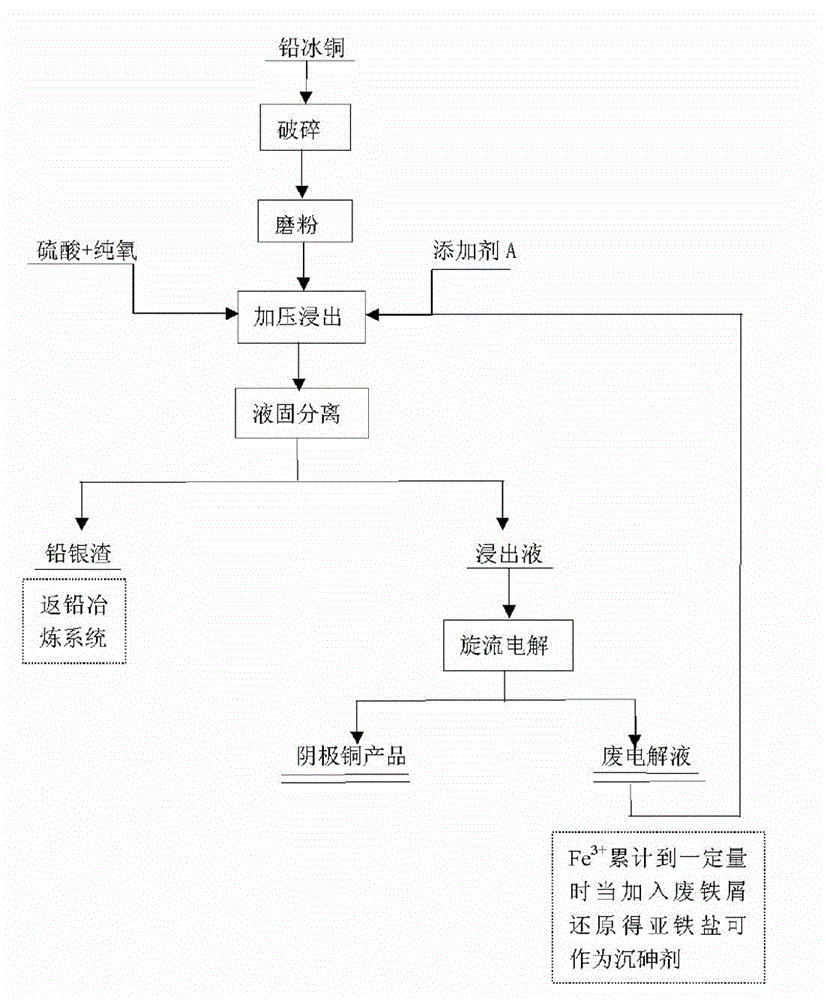

Process for selective efficient copper extraction and comprehensive recovery from lead copper matte

ActiveCN104789783ANo pollution to the environmentNo pollution in the processPhotography auxillary processesProcess efficiency improvementCycloneElectrolysis

The invention discloses a process for selective efficient copper extraction and comprehensive recovery from lead copper matte and belongs to the field of wet processes of non-ferrous metal metallurgy. According to the process disclosed by the invention, the lead copper matte is taken as a raw material, and the process comprises the following steps: crushing, grinding and screening the lead copper matte, performing pulp conditioning on the lead copper matte after screening and sulfuric acid (or a waste electrolyte), then pouring into a high-pressure kettle, performing leaching, adding an adjusting agent A and introducing pure oxygen; controlling technical conditions, oxidizing sulfur in the lead copper matte to elemental sulfur in the oxidization and leaching processes, and transferring into slag; oxidizing copper to enable the copper to enter a solution in the form of copper ions and enabling lead to leave in the slag in the form of lead sulfate with gold and silver; and enabling most of iron to enter into the slag in the forms of hematite and yellow calcium iron vitriol under high-temperature, high-pressure and high-acid conditions. After the completion of the leaching process, liquid-solid separation is performed to realize primary separation of the copper and other valuable elements; after acid adjustment of a leachate, cyclone electrolysis is directly performed to extract the copper in the leachate, and then a cathode copper product which is in line with a national standard can be obtained; and leaching residues are sent into a lead pyrometallurgy system for comprehensively recovering Pb, Ag, Au and other valuable elements.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Attapulgite-modified polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995446AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationEpoxySurface layer

The invention discloses attapulgite-modified polyvinyl chloride (PVC) synthetic leather. The attapulgite-modified PVC synthetic leather comprises a surface layer, a foamed layer, a bonding layer and a brushing fabric, and is characterized in that the surface layer is prepared by mixing the following raw materials in parts by weight to form slurry: 70 to 80 parts of SG-2 type PVC resin, 30 to 40 parts of SG-5 type PVC resin, 10 to 15 parts of triethyl citrate, 30 to 35 parts of epoxy butyl oleate, 20 to 25 parts of n-butyl methacrylate, 5 to 6 parts of PVC color paste, 1 to 2 parts of dibasic lead phosphate, 1 to 2 parts of tribasic lead sulfate and 5 to 10 parts of modified diatomite. Through the improvements of the formula and the process, the flexibility of the synthetic leather is improved, and the synthetic leather has a natural comfortable hand feeling similar to that of natural leather and is difficult to damage or tear after being used for 3 to 5 years.

Owner:HEFEI ANSHAN COATING FABRICS

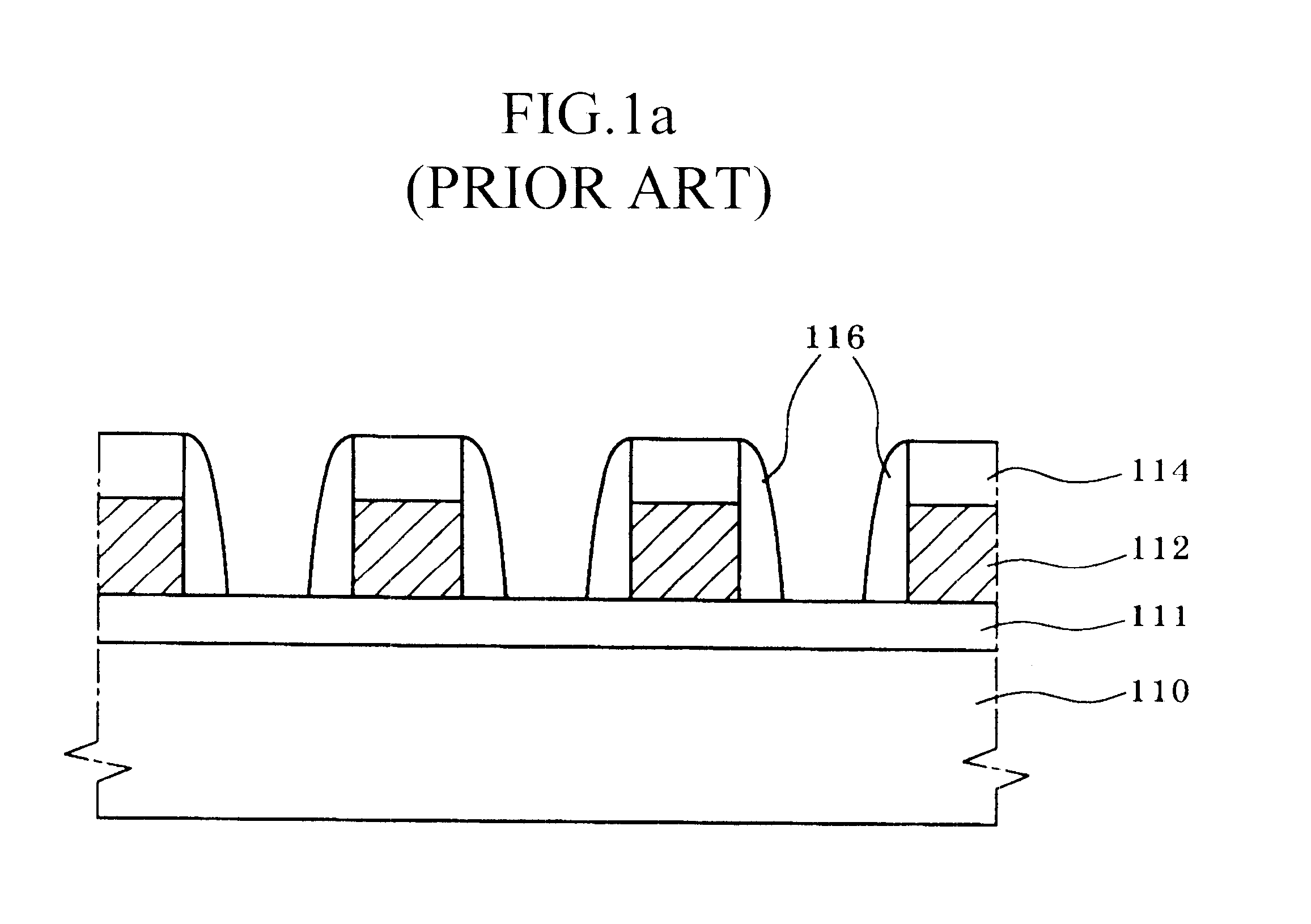

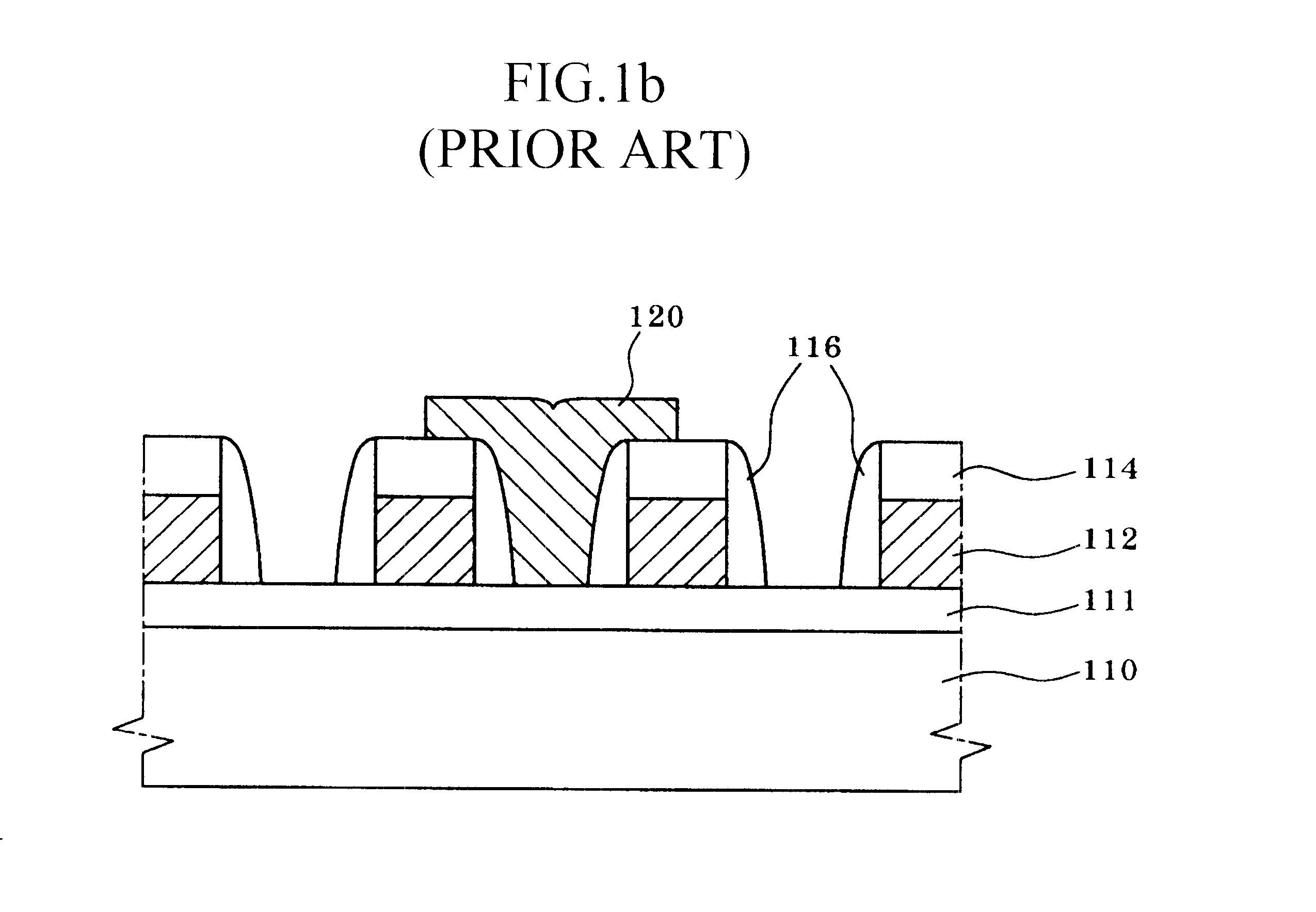

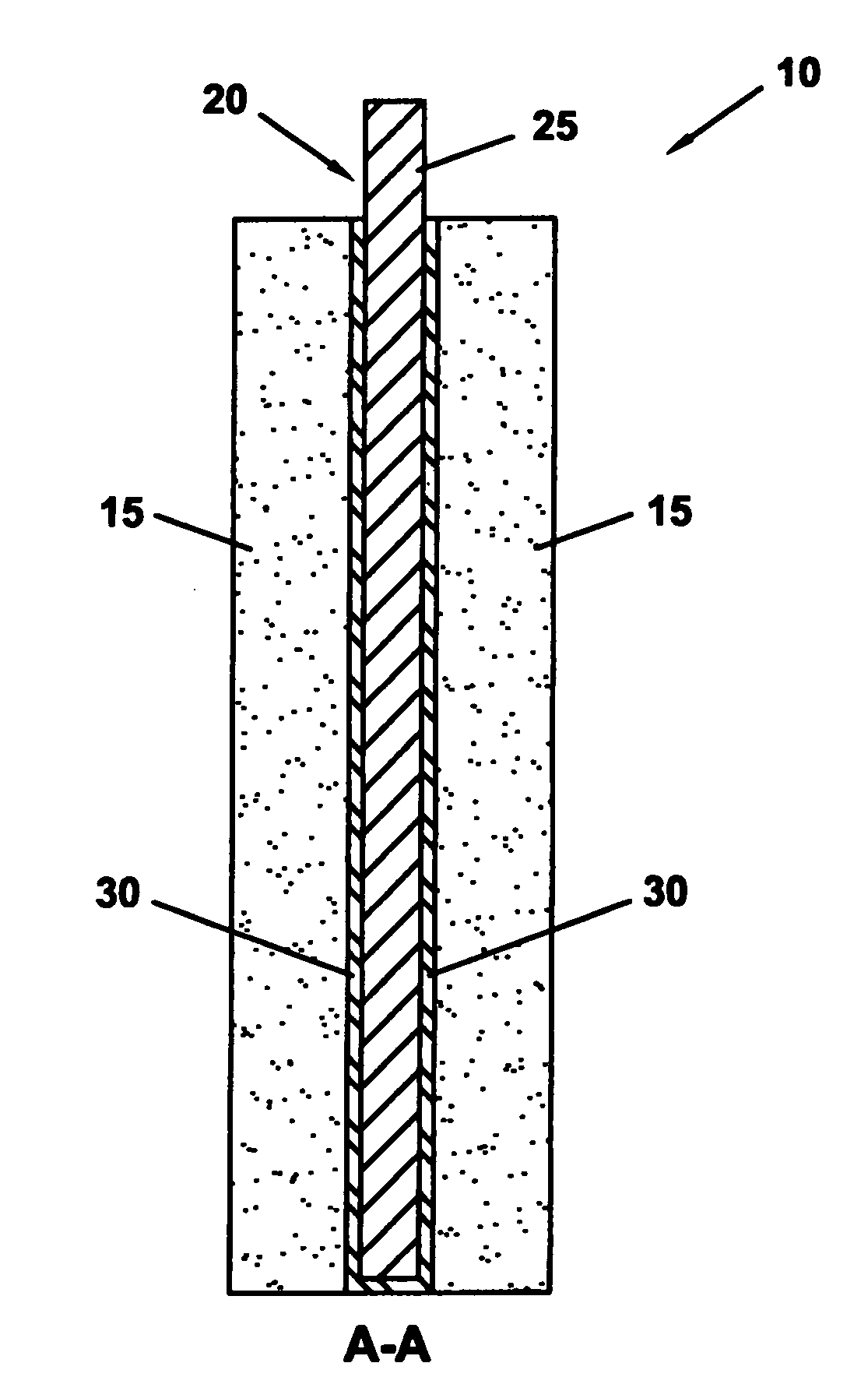

Electrode and current collector for electrochemical capacitor having double electric layer and double electric layer electrochemical capacitor formed therewith

An electrode and a DEL capacitor formed therewith. The electrode will typically be a polarizable electrode, and may be formed of an activated carbon material having a substantially zero ash percentage and a low percentage of transition metals. In constructing a DEL capacitor employing such an electrode, a non-polarizable electrode formed from a lead dioxide / lead sulfate compound is preferably also used. The DEL capacitor may utilize an acid-based electrolyte, such as an aqueous sulfuric acid electrolyte. Consequently, the present invention also includes a current collector that preferably comprises a base material formed from a lead or a lead compound and a protective coating material that is resistant to an acid-based electrolyte. Preferably, the protective coating material is formed from a polymer base and a conductive dope that may thereafter be applied to the current collector base material by a variety of methods.

Owner:UNIVERSAL SUPERCAPACITORS LLC

Oleophilic modificatioon method for tiny inorganic Nano powder

ActiveCN1872918ARich surface chargeRealize surface lipophilic modificationPigment treatment with organosilicon compoundsSilicon oxideLead sulfate

This invention relates to a method for lipophilic modification of inorganic micro / nanopowder. The method comprises: (1) uniformly depositing a layer of inorganic oxide (zirconium oxide, magnesium oxide, aluminum oxide, silicon oxide, titanium oxide, zinc oxide or ferric oxide, 2-5 wt. % of the micro / nanopowder) or its hydrate onto the surface of the micro / nanopowder; (2) coating the composite micro / nanopowder with an organic compound (anionic surfactant, silane coupler, phthalate coupler or aluminum coupler, 3-7 wt. % of the composite micro / nanopowder). The micro / nanopowder is calcium carbonate, barium carbonate, magnesium carbonate, barium sulfate or lead sulfate, or their mixture. The sizes of the micro / nanopowder are in the range of 1-50000 nm. The obtained lipophilic micro / nanopowder can be used to manufacture paints, rubbers and plastics with improved properties.

Owner:SHANGHAI UNIV

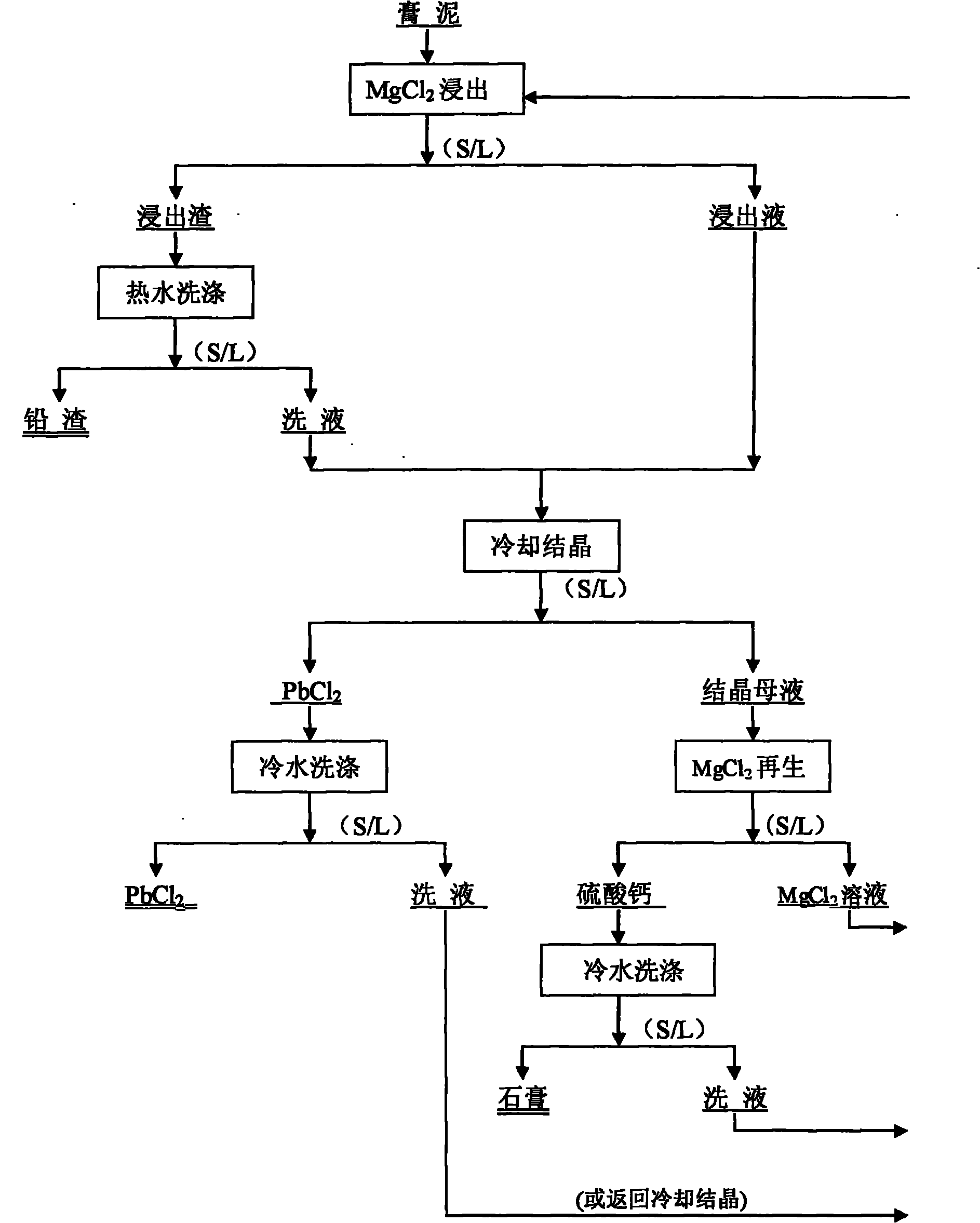

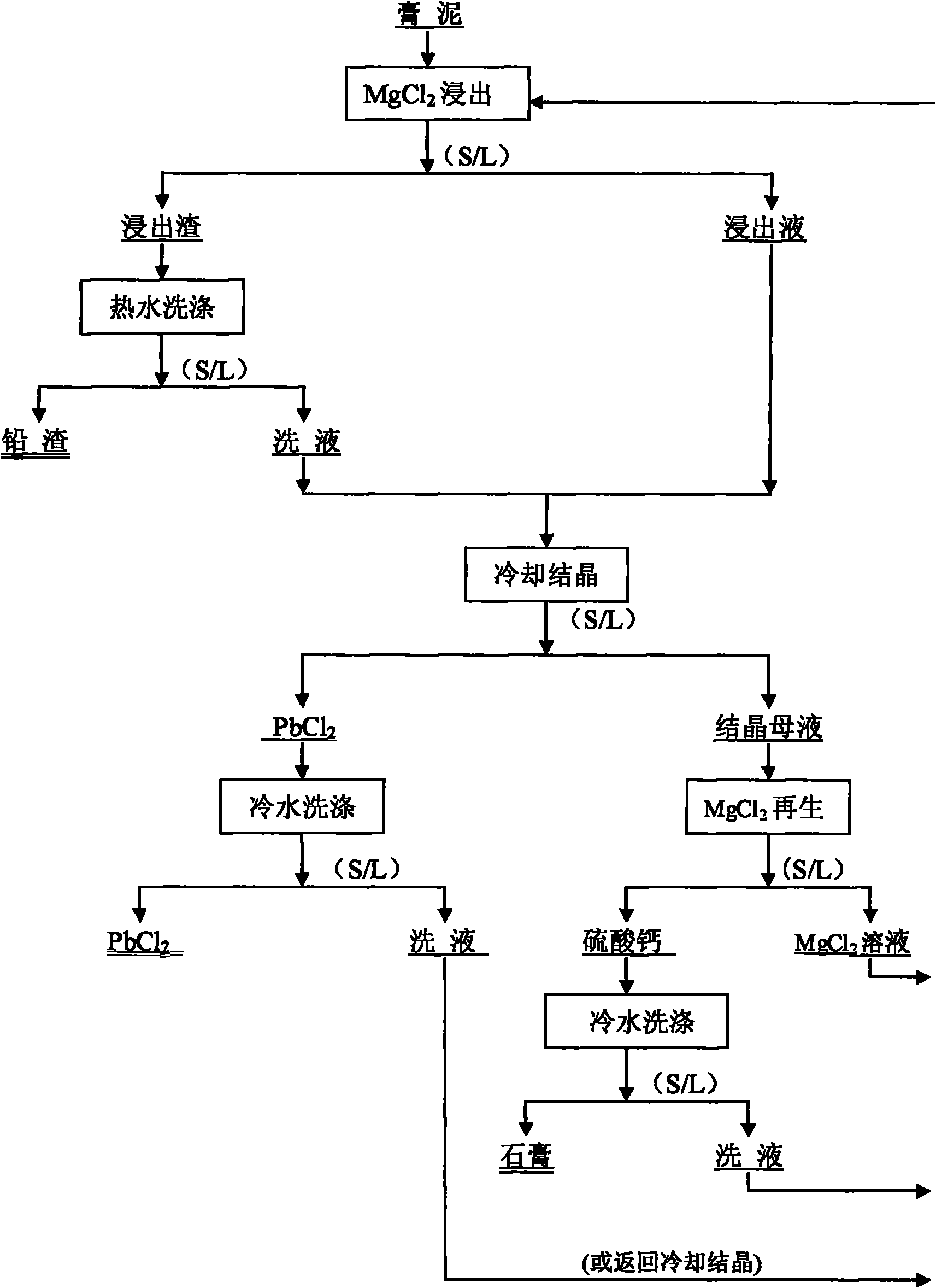

Method for removing sulfur from waste lead-acid storage battery gypsum mud by using magnesium chloride

The invention relates to a method for removing sulfur from waste lead-acid storage battery gypsum mud by using magnesium chloride, which is characterized by comprising the following steps of: firstly, decomposing a waste lead storage battery subjected to acid pouring to obtain the gypsum mud, and entering the next process for later treatment; then leaching the gypsum mud by using a magnesium chloride solution, converting lead sulfate in the gypsum mud into lead chloride entering into the solution, leaving other oxides of lead in leached slag, carrying out liquid-solid separation after leaching is ended, and smelting the leached slag at the low temperature to produce wet lead; cooling to crystallize a leachate to obtain solid lead chloride and crystallized mother liquor, smelting the solid lead chloride at low temperature to produce the wet lead, carrying out regeneration treatment on the crystallized mother liquor by using the crystallized mother liquor and then returning to the step of desulfurizing and leaching the gypsum mud; and finally, adding calcium chloride to the crystallized mother liquor to regenerate the magnesium chloride as a desulfurizing agent and simultaneously produce calcium sulfate as a byproduct. The invention has good desulfurizing effect, and the magnesium chloride as the desulfurizing agent has low price, is easy to regenerate and can be recycled. The invention does not have high requirement on production equipment, greatly reduces the production cost and has obvious advantages.

Owner:SHENYANG RES INST OF NONFERROUS METALS

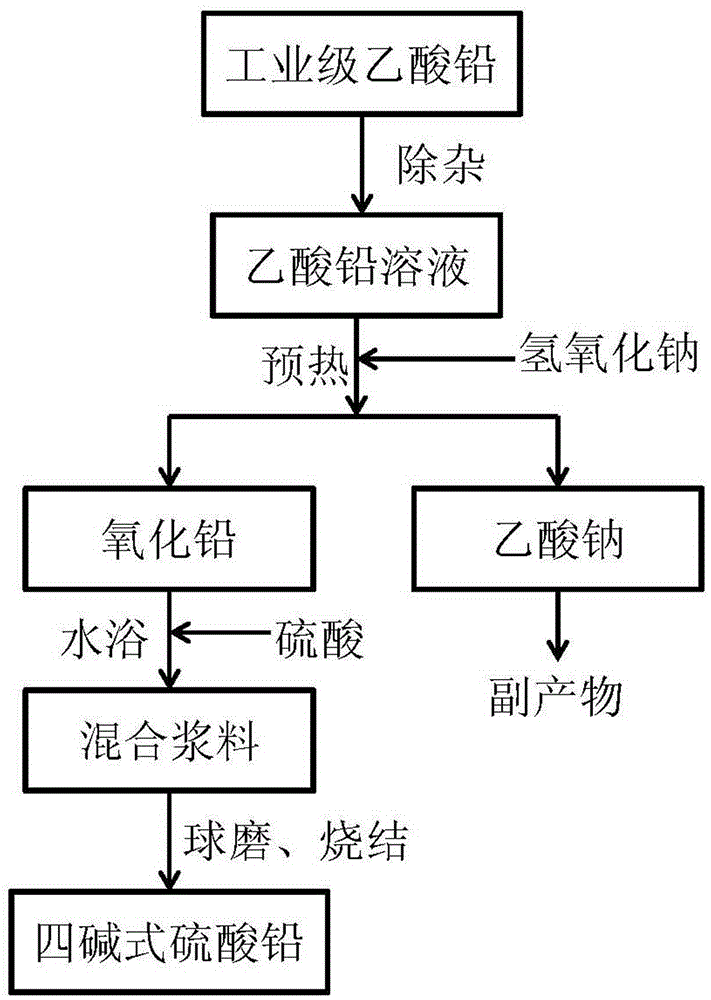

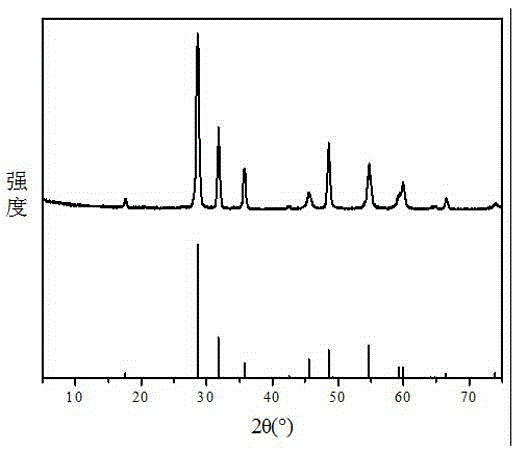

Method for preparing tetrabasic lead sulfate

ActiveCN105271375AHigh purityThe process is simple and easy to controlLead sulfatesAcetic acidLead acetate

The invention provides a method for preparing tetrabasic lead sulfate. The method comprises the following steps: S10. impurities are removed from a lead acetate stock solution, so as to obtain a lead acetate solution; S20. the lead acetate solution is mixed with an alkaline solution under a heated condition, and lead oxide is obtained after filtering; S30. the lead oxide is mixed with sulfuric acid, filtering is carried out after reaction, and ball milling is carried out after sintering to obtain the tetrabasic lead sulfate. The method provided by the invention has the advantages of simple and controllable processes, high product purity (above 99 percent), and uniform and controllable particle sizes; moreover, according to the method, the lead acetate serves as the initiator to prepare the high-purity tetrabasic lead sulfate, and multiple batches of measurements of the tetrabasic lead sulfate show that the contents of iron element and barium element, which are the impurities significantly affecting the battery performance, are below 20 ppm and below 2 ppm respectively.

Owner:SHENZHEN CENT POWER TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com