Nano-wollastonite powder modified ethylene propylene diene copolymer cable material

A technology of EPDM rubber and wollastonite powder, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., to improve flame retardancy and heat resistance, improve thermal stability, excellent flame retardancy and non-delay flammability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

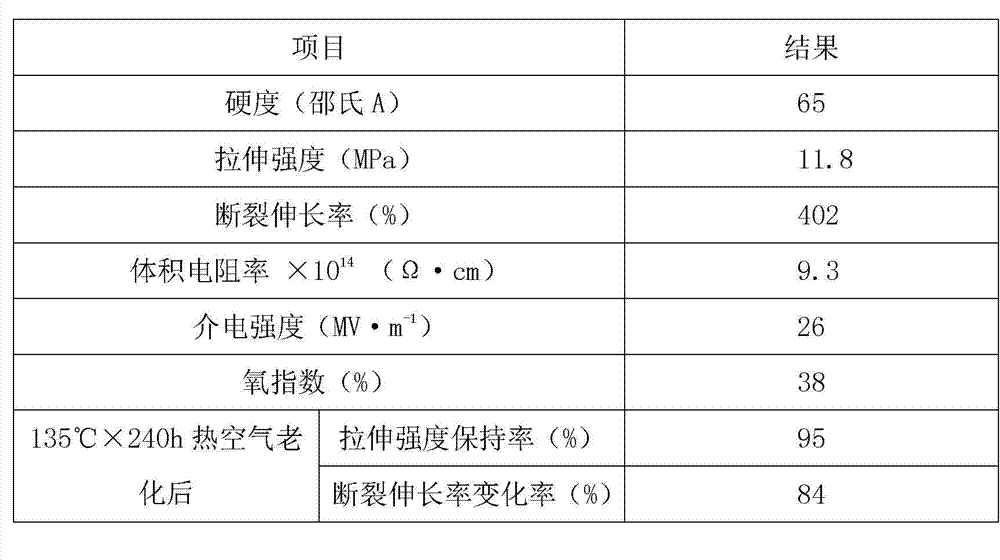

[0013] A kind of EPDM cable material modified by nano wollastonite powder, made of the following raw materials in parts by weight: Germany LANXESS EPDM 3950 115 parts, Butyl rubber BBK232 25 parts, 12 parts of SG-3 type PVC resin, 10 parts of trioctyl trimellitate, 4 parts of propylene glycol sebacate polyester, 5 parts of epoxy soybean oil, 8 parts of polyethylene wax, 0.36 parts of bisphenol A, 1.5 parts of zinc stearate, 0.8 parts of tribasic lead sulfate, 1.8 parts of sulfur, 4 parts of zinc oxide, 36 parts of nano wollastonite powder, 12 parts of organic bentonite, 15 parts of nano dolomite powder, 8 parts of carbon black N550, carbon black 12 parts of N220, 5 parts of antimony trioxide, 1.5 parts of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate, 1 part of crosslinking agent TAC, 0.8 parts of antioxidant 168, vinyl triethoxy 1.5 parts of base silane, 1 part of anti-aging agent RD, 2 parts of anti-aging agent TPPD, 1 part of accelerator CZ, 4 parts of accelerator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com