Synergistic flame-retardant low-smoke halogen-free polyolefin cable material and preparation method thereof

A polyolefin cable material and synergistic flame-retardant technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of volume resistivity, breakdown strength decrease, material lack of flexibility, and dielectric loss increase. Achieve the effects of good uniformity and surface finish, superior flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

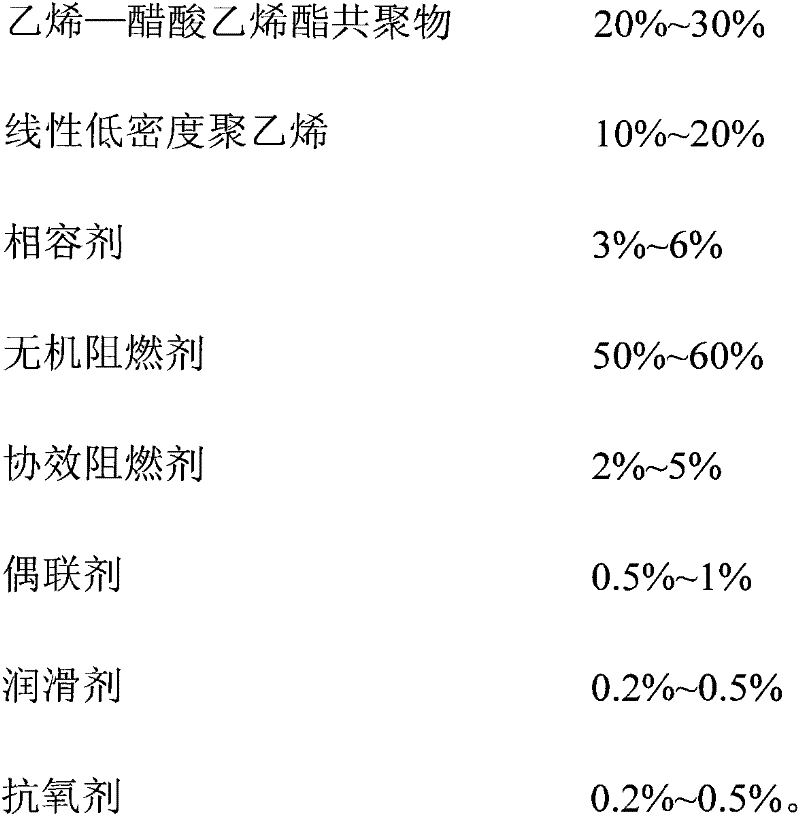

Method used

Image

Examples

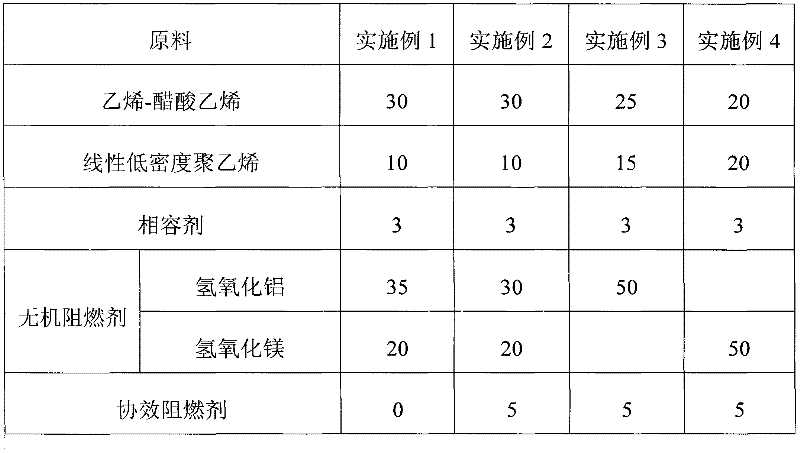

Embodiment 1

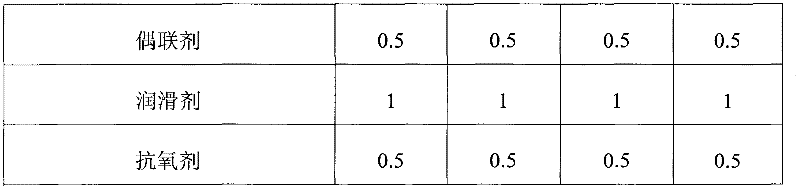

[0029] Embodiment 1: The compatibilizer adopts maleic anhydride grafted ethylene-vinyl acetate copolymer, the coupling agent adopts γ-(2,3-epoxypropoxy) propyltrimethoxysilane, and the lubricant adopts stearin Magnesium acid, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester as antioxidant, without synergistic flame retardant.

Embodiment 2

[0030] Example 2: The compatibilizer adopts maleic anhydride grafted ethylene-vinyl acetate copolymer, and the mass percentage of the synergistic flame retardant consists of: linear low density polyethylene 35%, ultra-high molecular weight organosilicon polymer with a molecular weight of 800,000 45%, ammonium polyphosphate 15%, pentaerythritol 5%, the coupling agent adopts γ-(2,3-epoxypropoxy)propyltrimethoxysilane, the lubricant adopts magnesium stearate, and the antioxidant adopts four [β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester.

Embodiment 3

[0031] Example 3: The compatibilizer uses maleic anhydride grafted ethylene-octene copolymer, and the mass percentage of the synergistic flame retardant consists of: 35% linear low density polyethylene, 45% ultra-high molecular weight silicone polymer with a molecular weight of 800,000 %, ammonium polyphosphate 10%, pentaerythritol 10%, the coupling agent adopts γ-(2,3-epoxypropoxy) propyltrimethoxysilane, the lubricant adopts magnesium stearate, and the antioxidant adopts four [ β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com