Patents

Literature

6513 results about "Thermal dilatation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

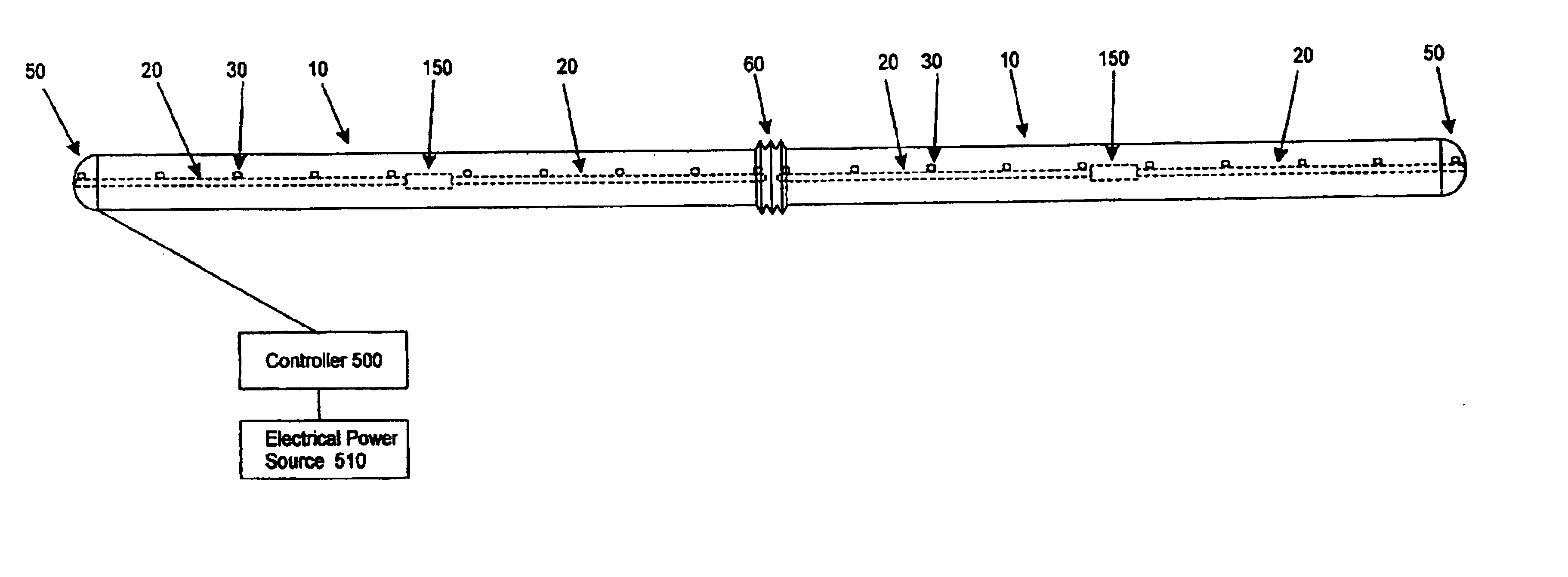

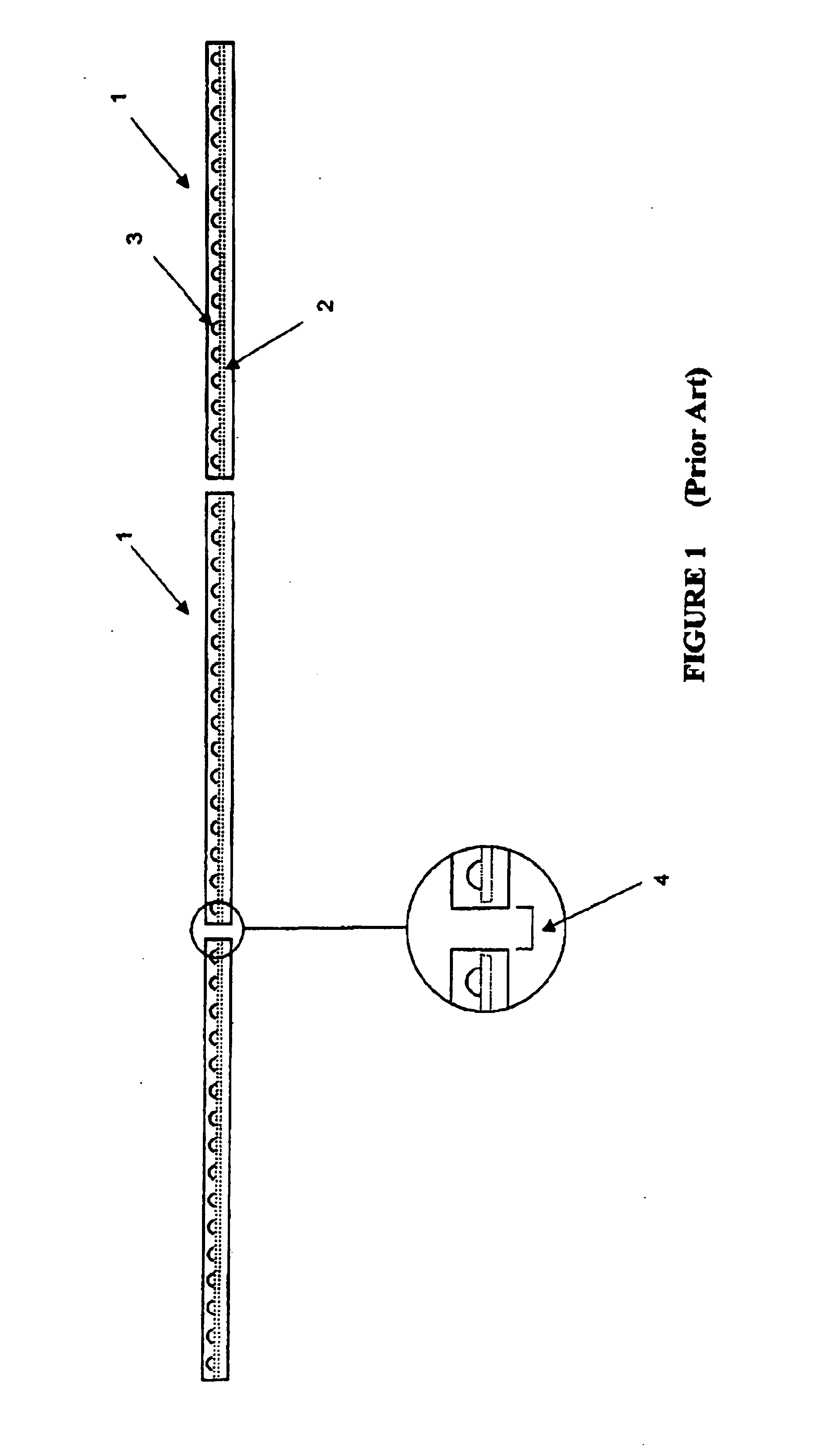

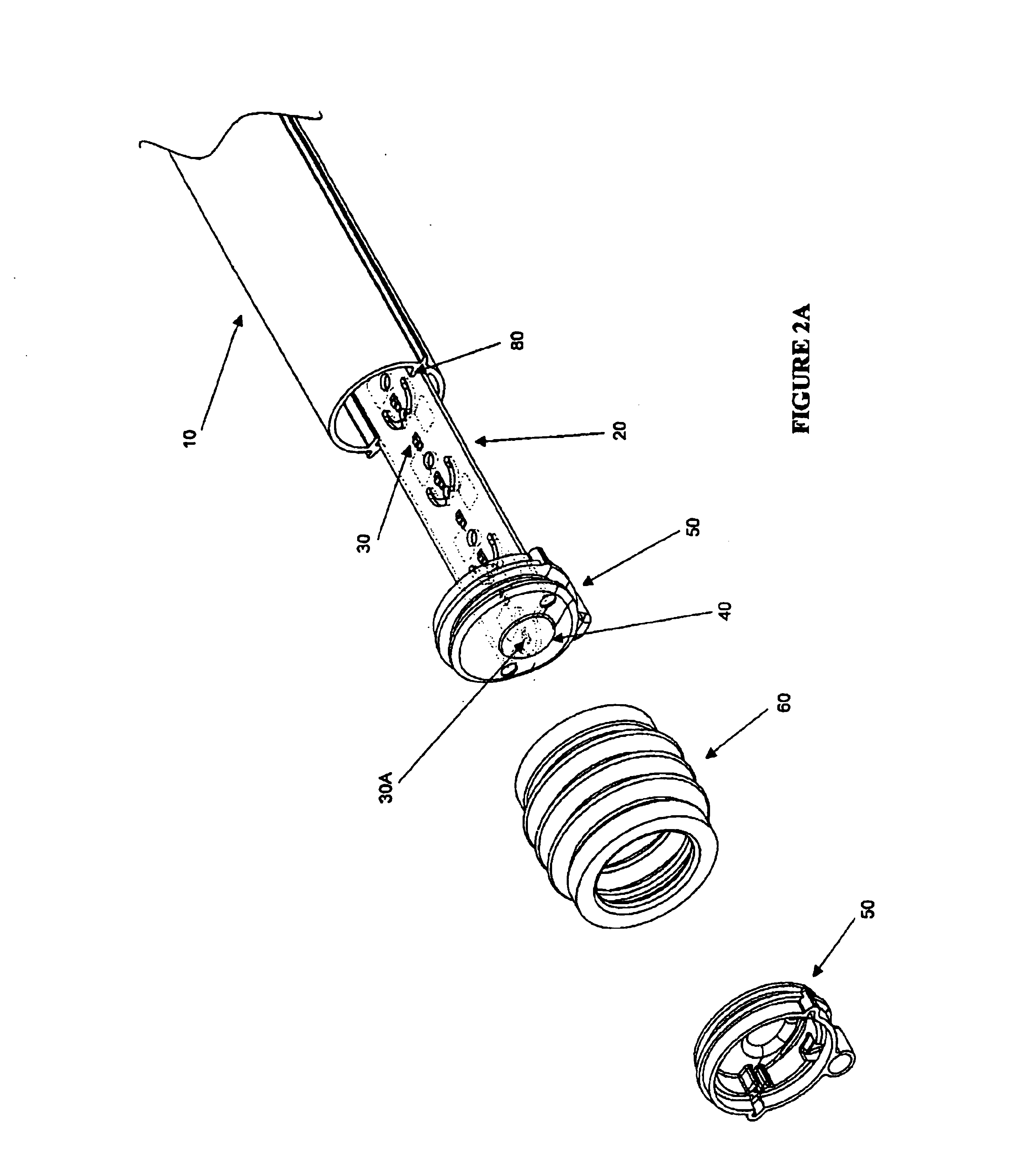

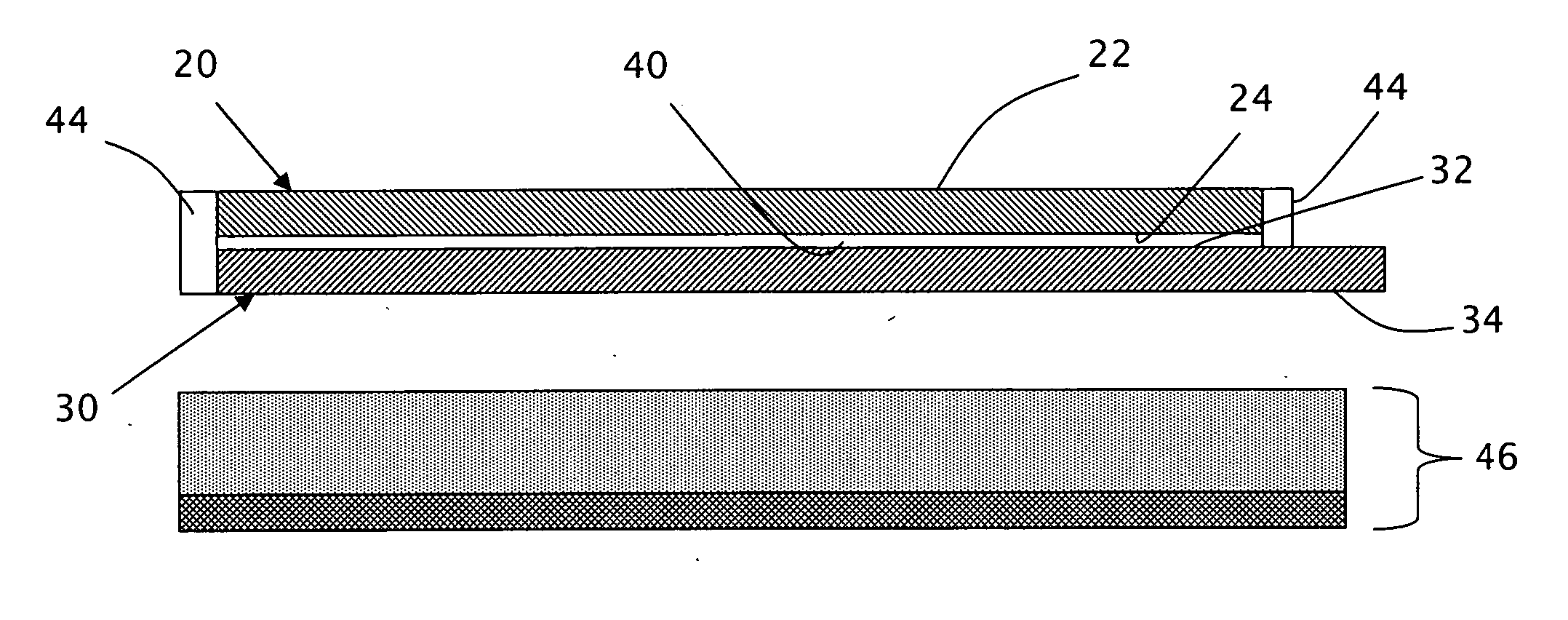

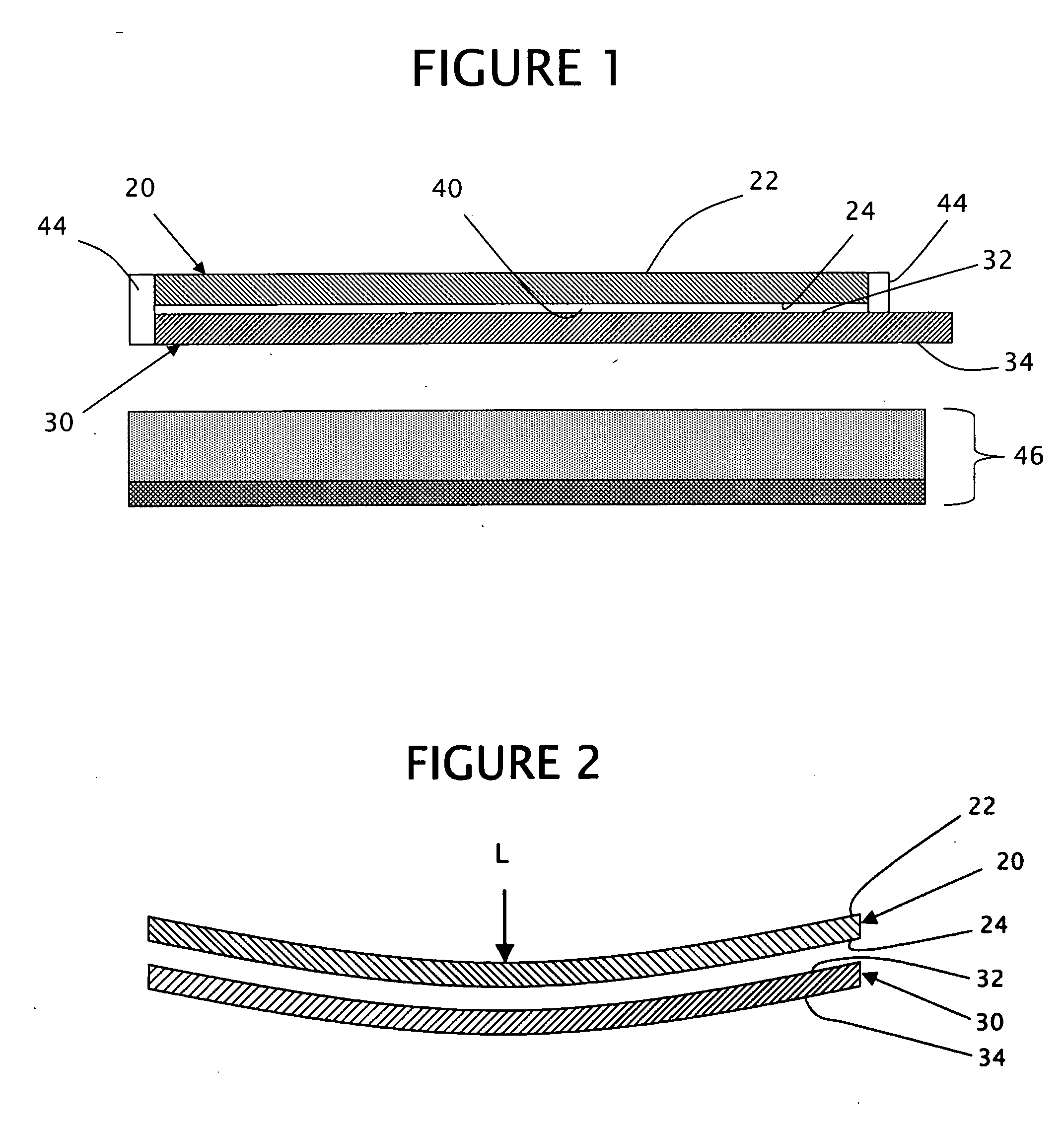

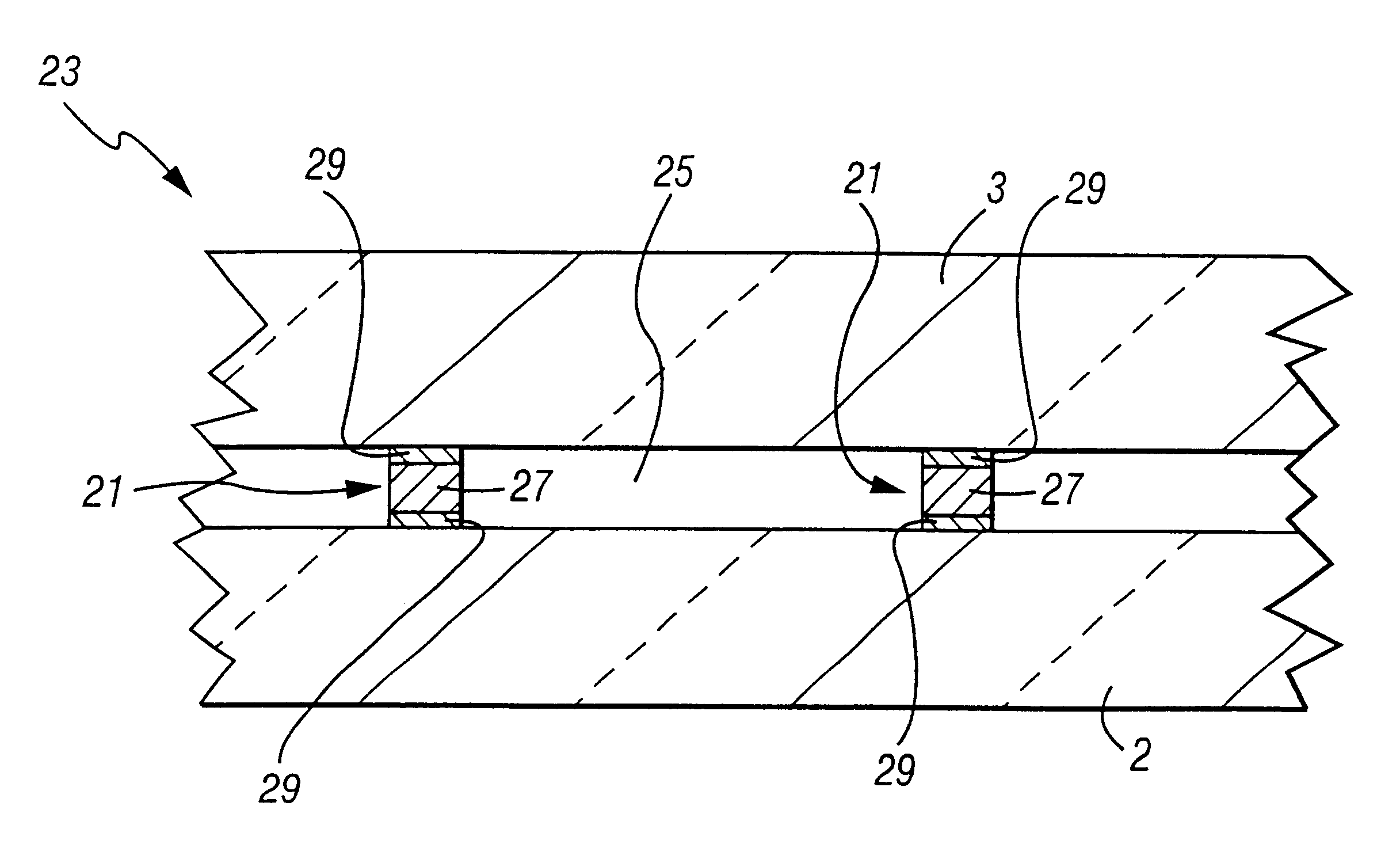

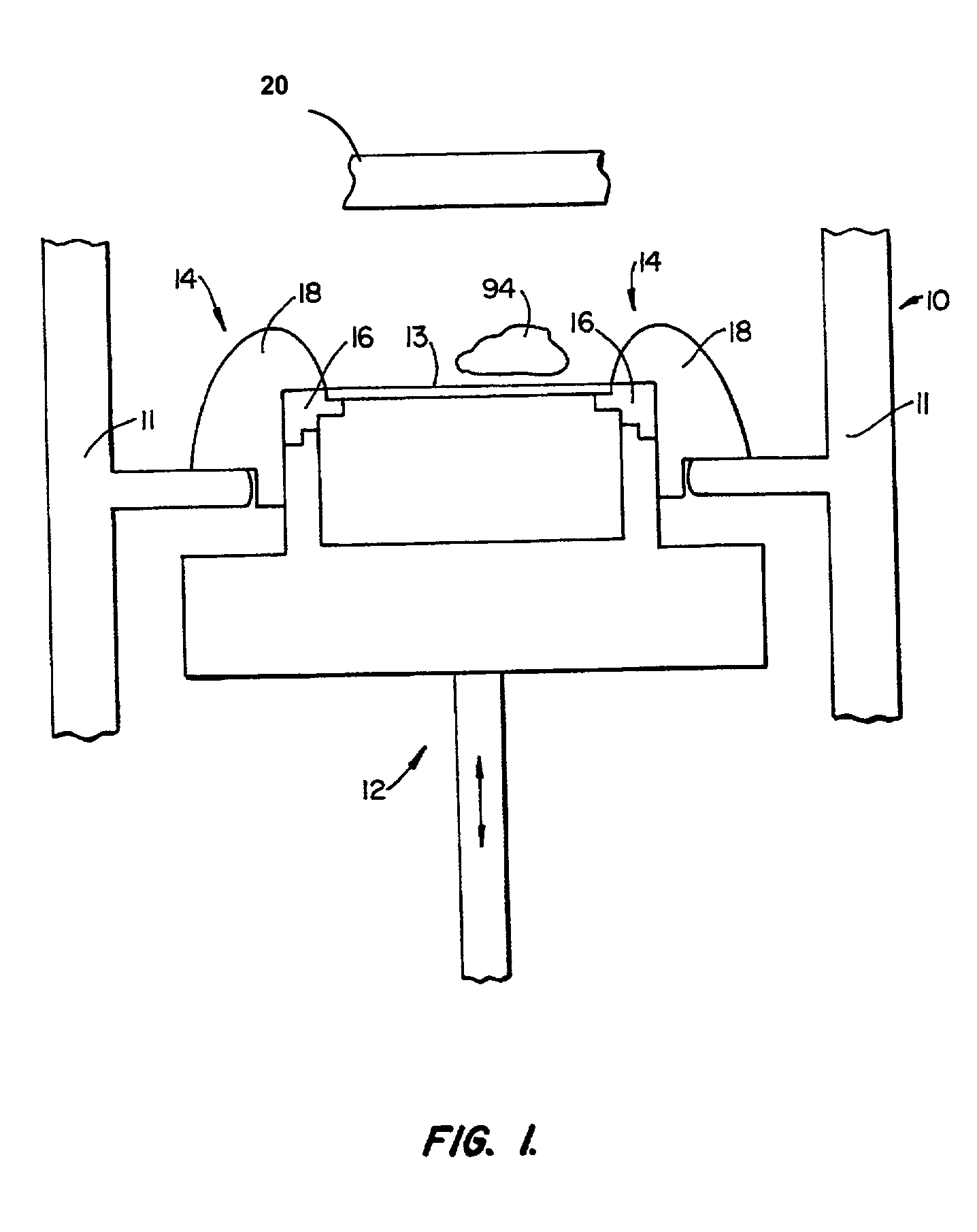

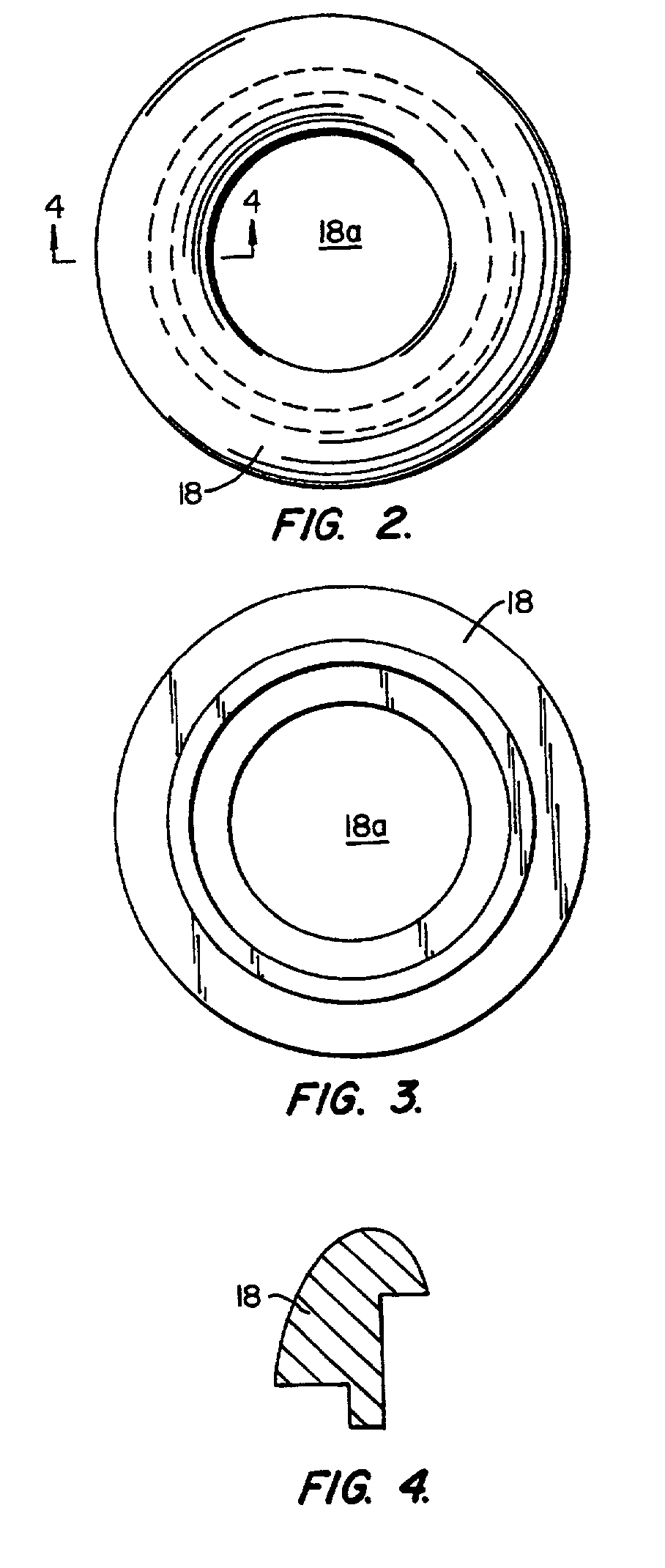

Strip lighting system incorporating light emitting devices

The invention provides an elongated lighting apparatus that can withstand temperature fluctuations. The elongated lighting apparatus comprises of the following elements: at least two elongated tubular members fabricated from translucent material. These elongated tubular members are fixed in an end-to-end configuration, separated by a region enabling for thermal expansion / contraction of the members. A substrate upon which a plurality of light emitting devices is placed, is slidably positioned inside each tubular member. End caps seal the open ends of the elongated tubular members. At least one of these end caps has a translucent protrusion that projects towards the region of separation. At least one light emitting device is positioned proximate to an end cap protrusion, thereby illuminating this region. A flexible interconnector encloses and visually conceals separating the adjacent members. The light emitting devices are electrically interconnected. An external power source provides a system to energize the light sources.

Owner:SIGNIFY HLDG BV

Glass laminate substrate having enhanced impact and static loading resistance

ActiveUS20060127679A1Increased resistance to impactIncrease static loadLiquid crystal compositionsGas-filled discharge tubesDisplay deviceThermal expansion

A glass laminate substrate for electronic substrates, such as flat panel displays, includes a transparent glass core bounded by transparent glass skin layers, wherein the coefficient of thermal expansion of the core is greater than the coefficient of thermal expansion of the skin layers thereby forming a residual compressive stress in the skin layers and a residual tensile stress in the core. The relative thickness of the skin layers can be selected to enhance the strength of the glass laminate substrate while maintaining a sufficiently low residual tensile stress in the core to allow scribing and separating of the substrate to size. Interlayers can be located between the core and the skin layers, wherein the interlayers include a residual compressive stress, and produce a reduced residual tensile stress in the core.

Owner:CORNING INC

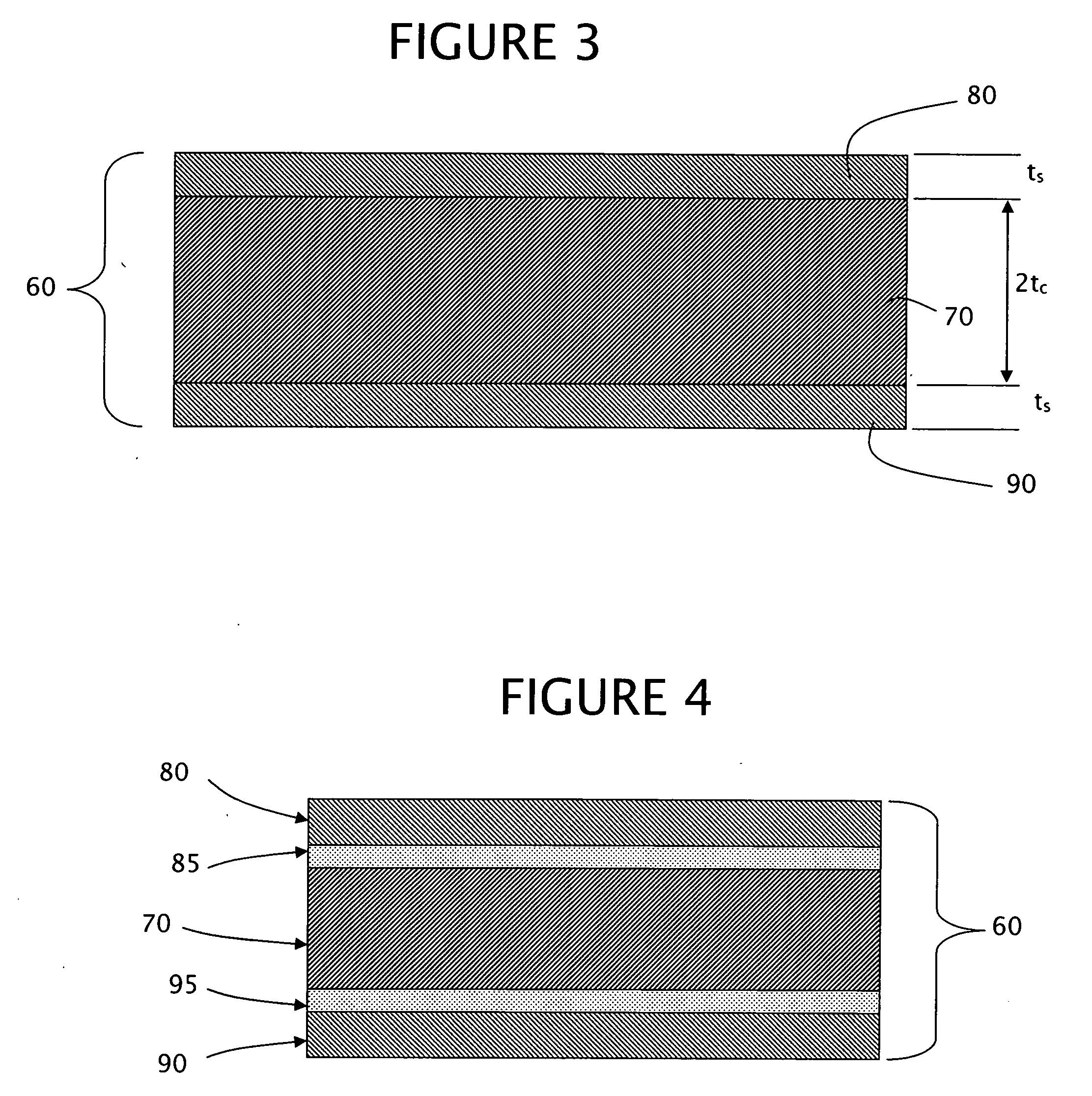

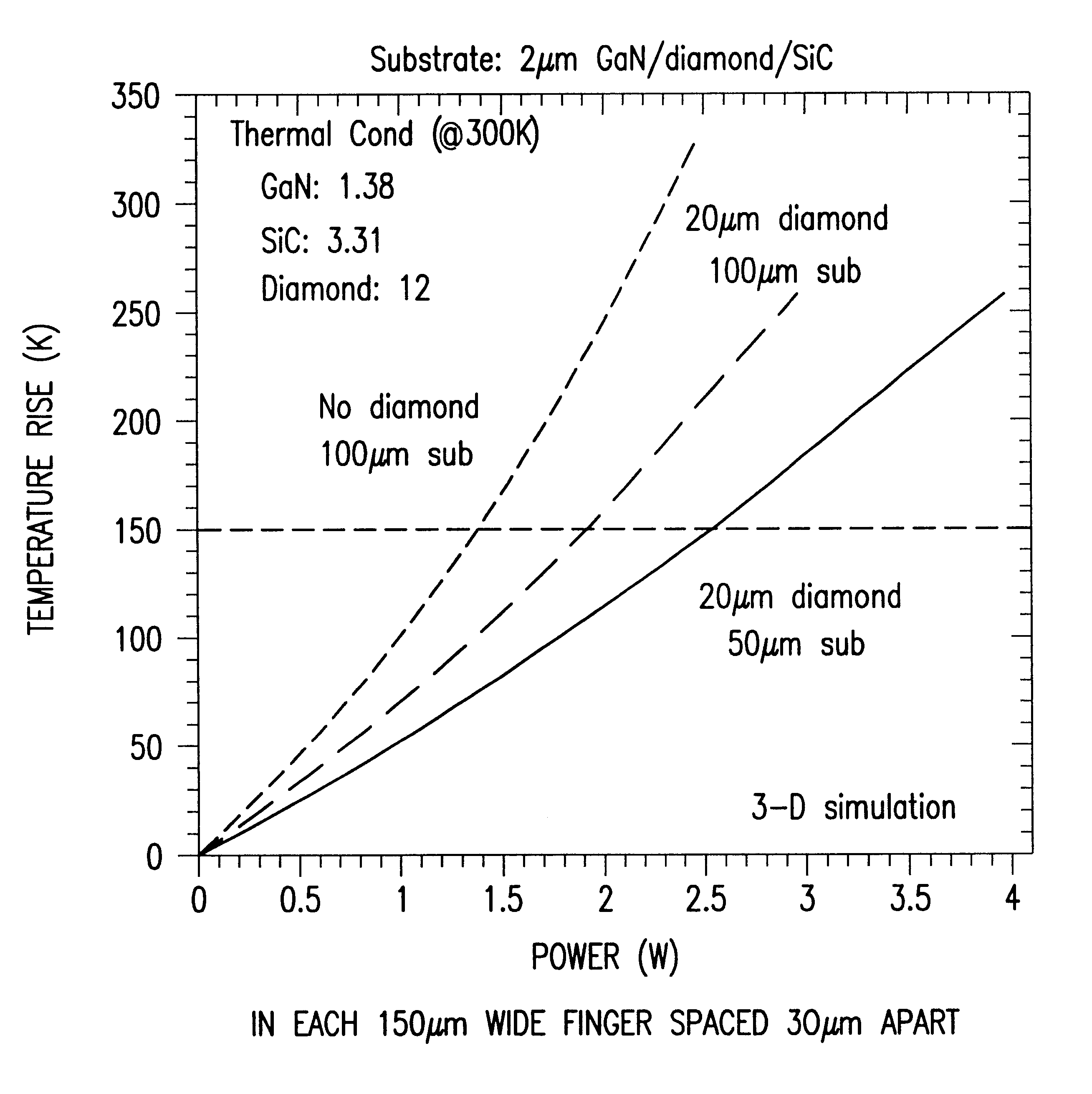

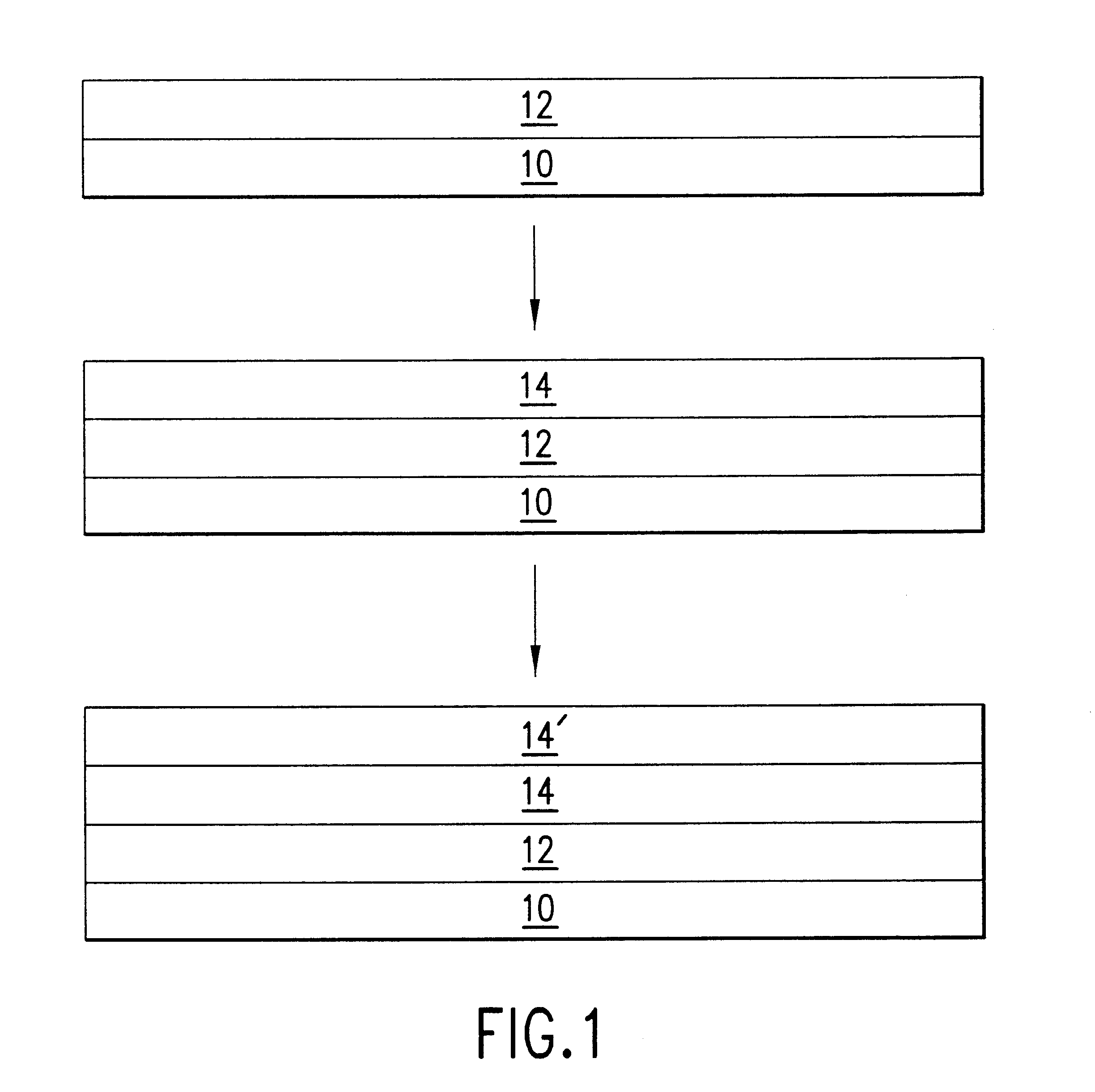

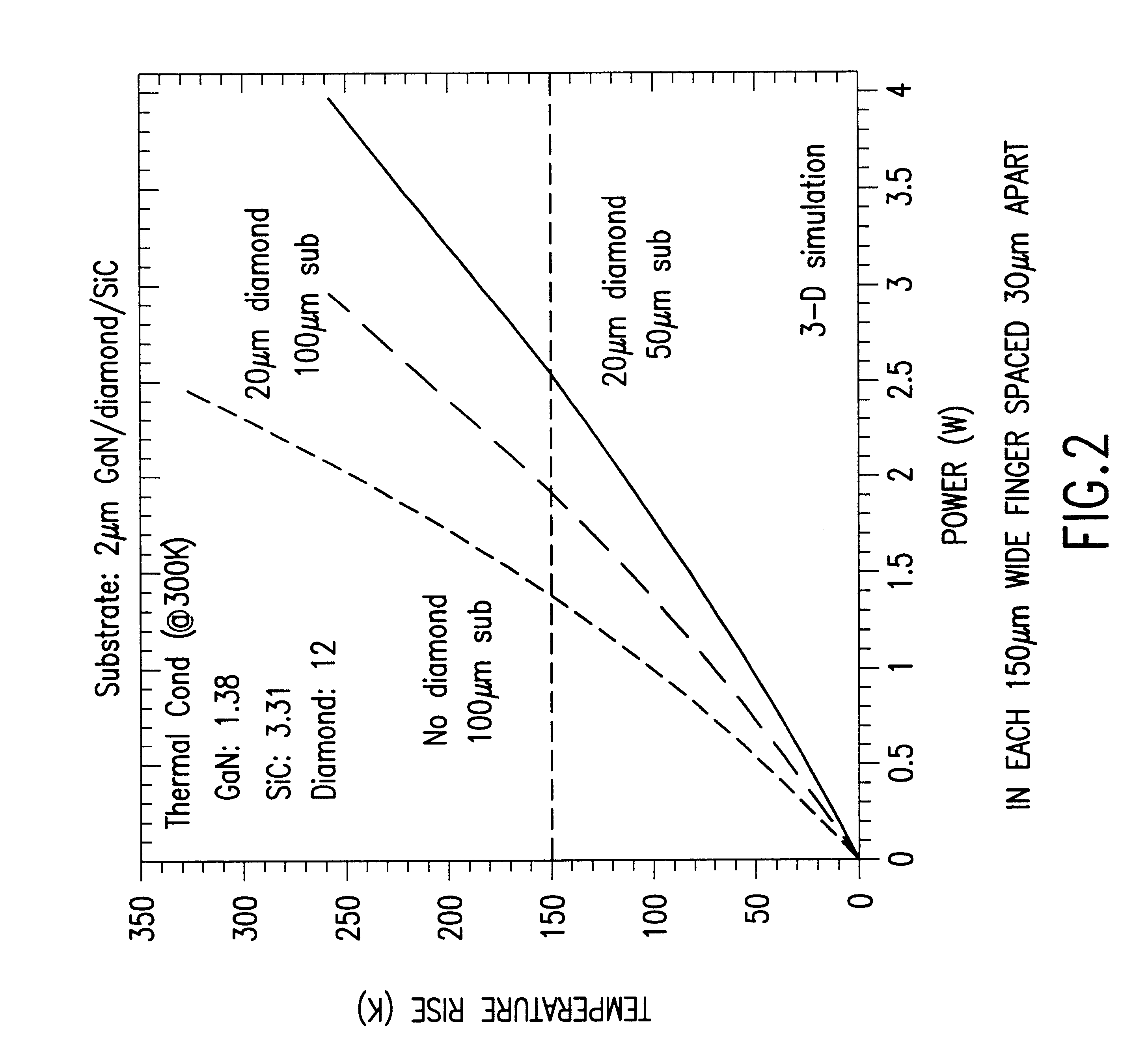

Electronic device with composite substrate

InactiveUS6497763B2Improve scalabilityImprove electronic performancePolycrystalline material growthSemiconductor/solid-state device manufacturingThermal coefficientComposite substrate

A method for making a multilayered electronic device with at least one epitaxial layer grown on a single-crystal film bonded to a composite wherein at least one layer is polycrystalline, the method includes the step of bonding a single-crystal film at least one of the epitaxial layers on the single-crystal film wherein thermal coefficients of expansion for the substrate and the epitaxial layer are closely matched.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

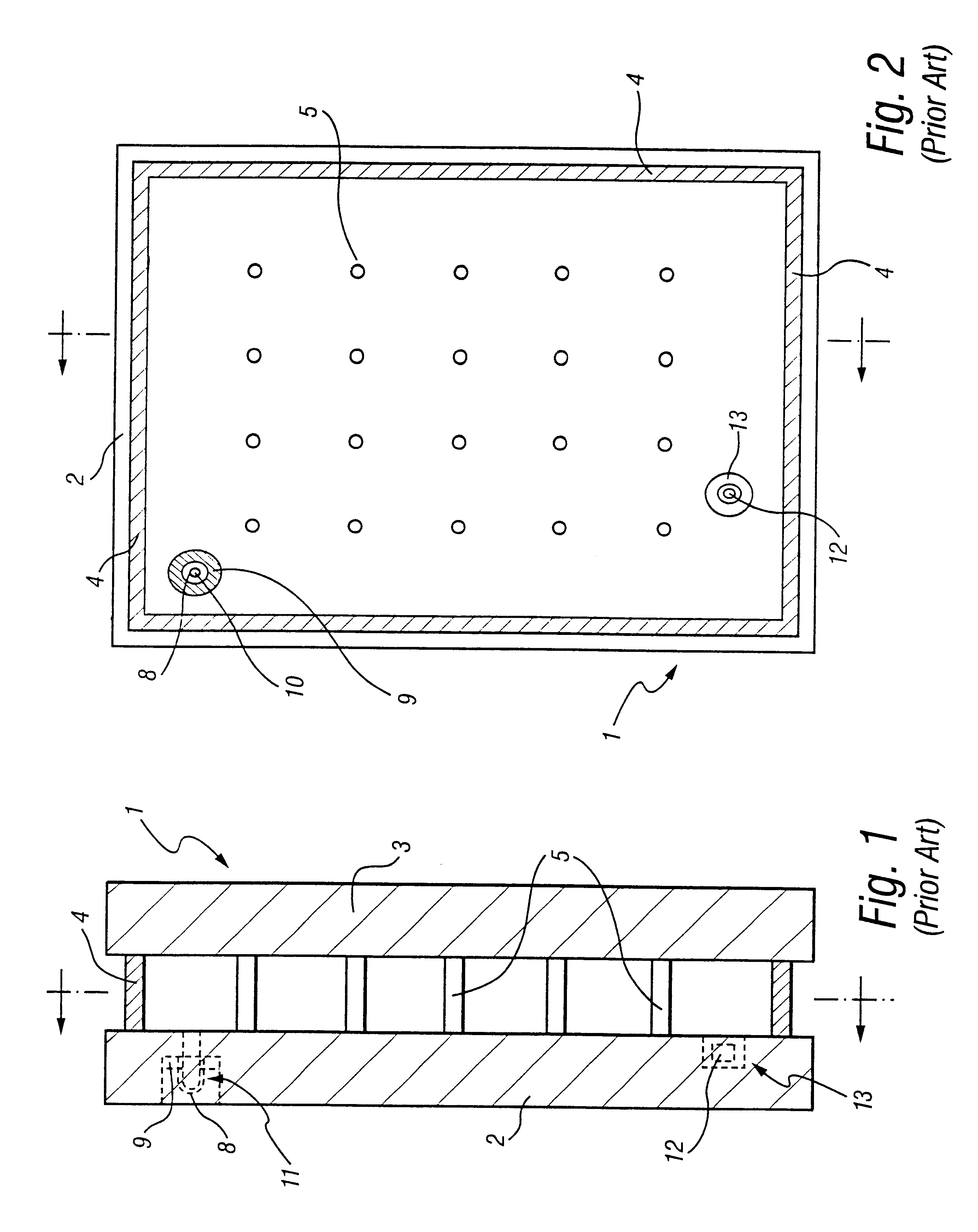

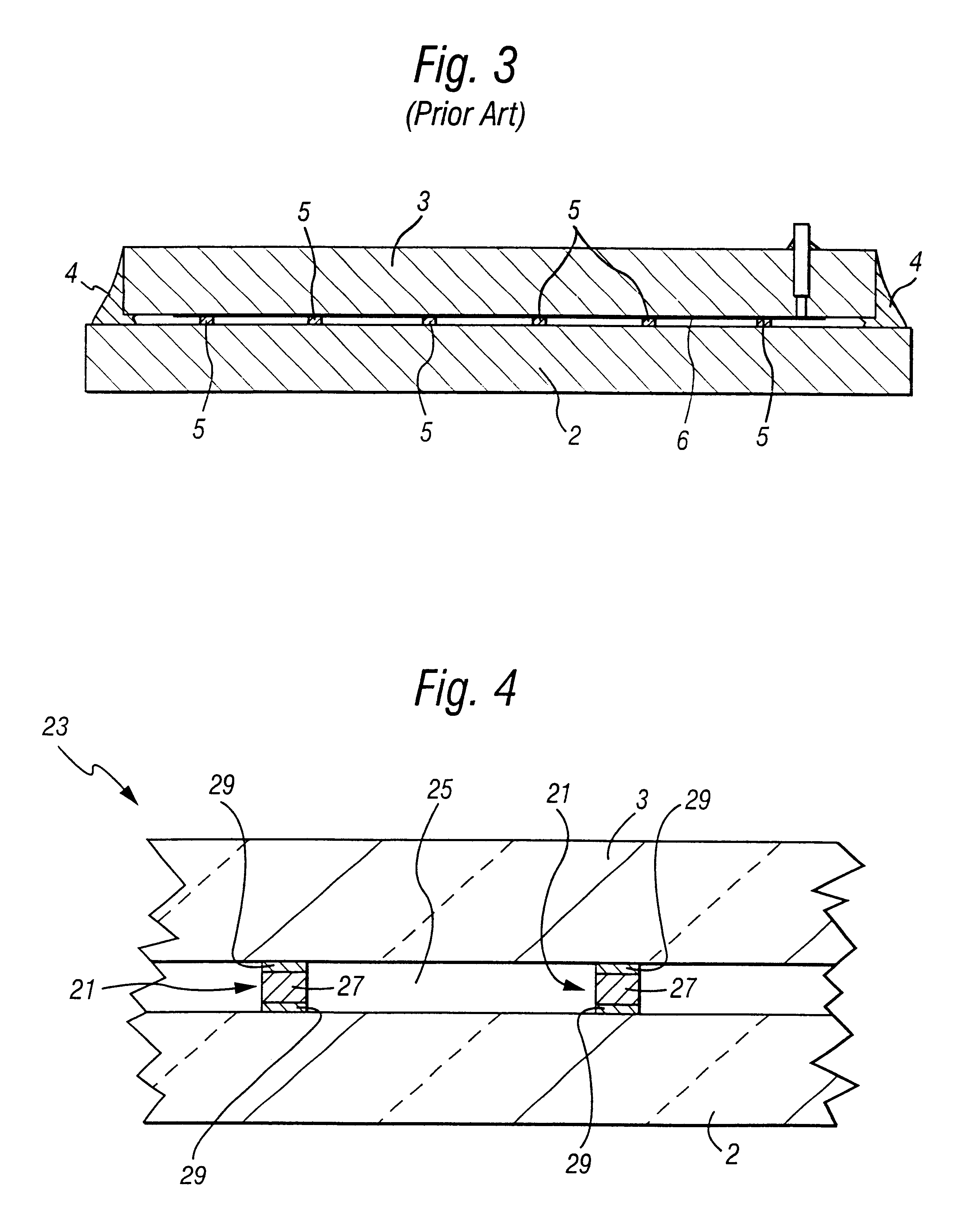

Vacuum IG pillar with lubricating and/or reflective coating

InactiveUS6946171B1Less visibly obtrusiveMinimize cracksClimate change adaptationWindows/door improvementChemical reactionThermal expansion

A vacuum insulating glass (IG) unit is provided with an array of spacers / pillars between opposing glass sheets. At least some of the spacers / pillars are coated on at least one surface thereof with a dry lubricant and / or reflective material such as silver. This coating permits the glass sheet(s) to move relative to one another during thermal expansion while minimizing the degree to which the spacers / pillars scratch or crack the glass during such relative movement. A method of making an exemplary spacer / pillar includes transforming by chemical reaction silver ions on a core into a metallic silver coating thereby resulting in a coated spacer / pillar.

Owner:GUARDIAN GLASS LLC

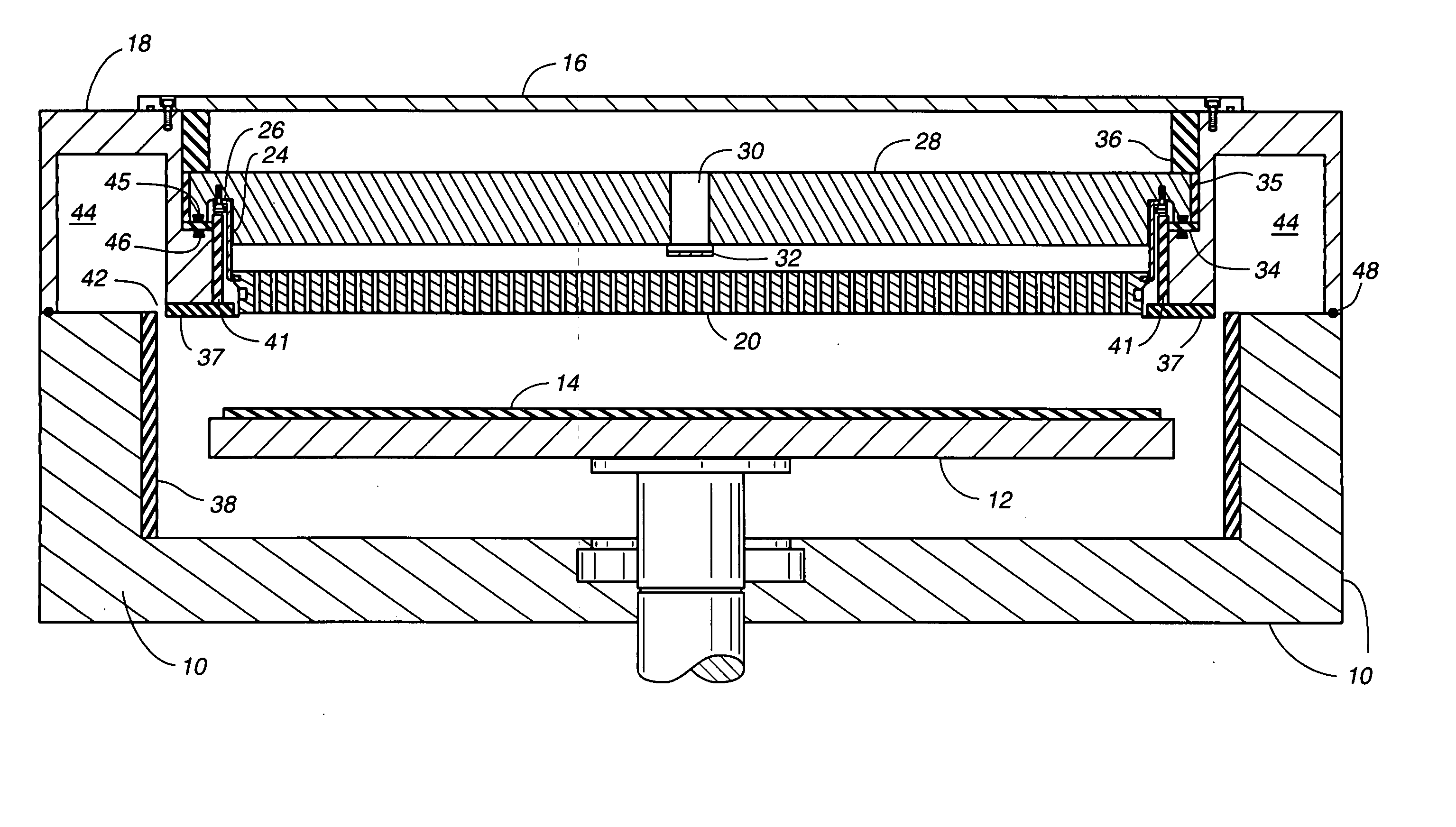

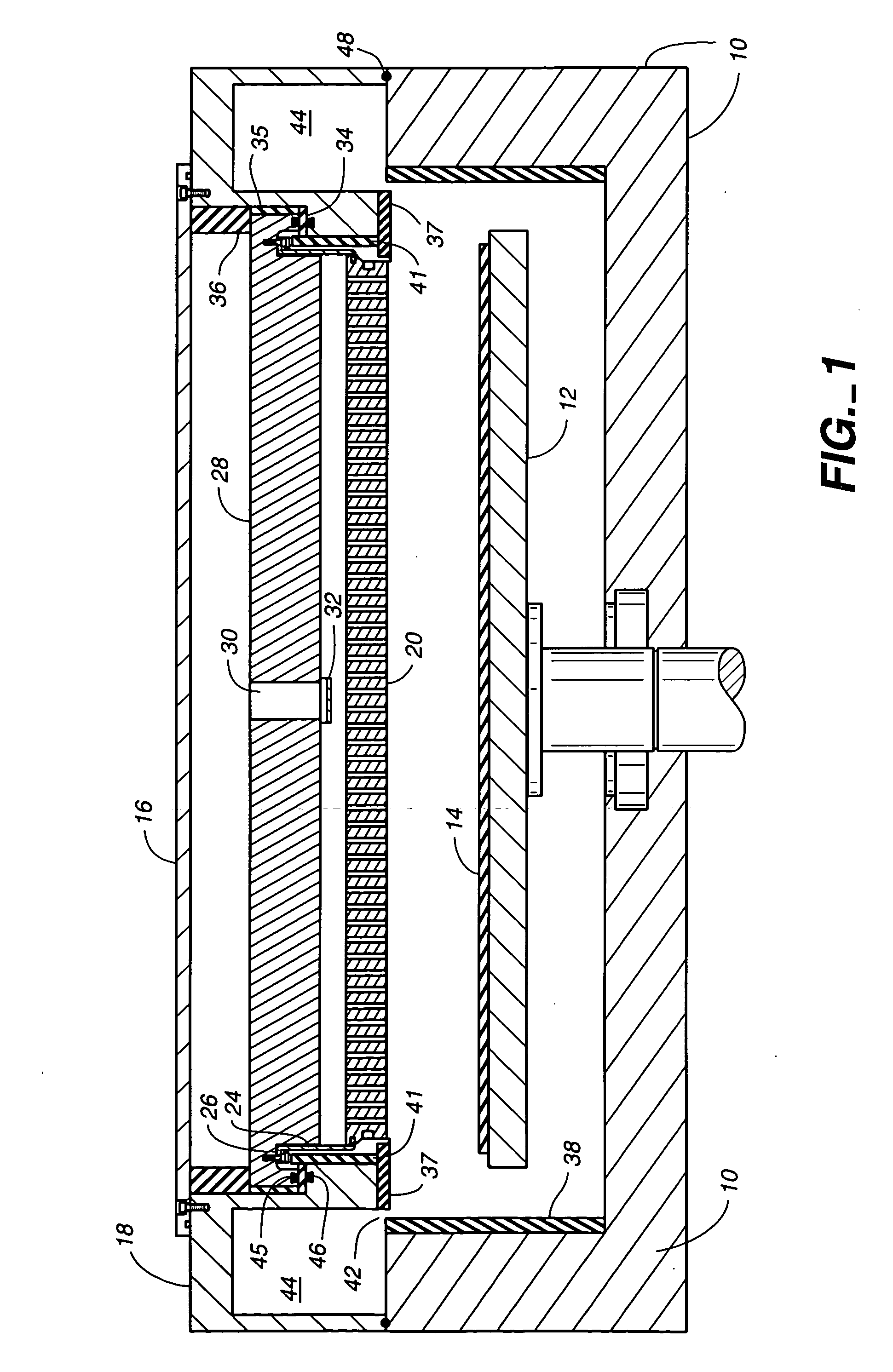

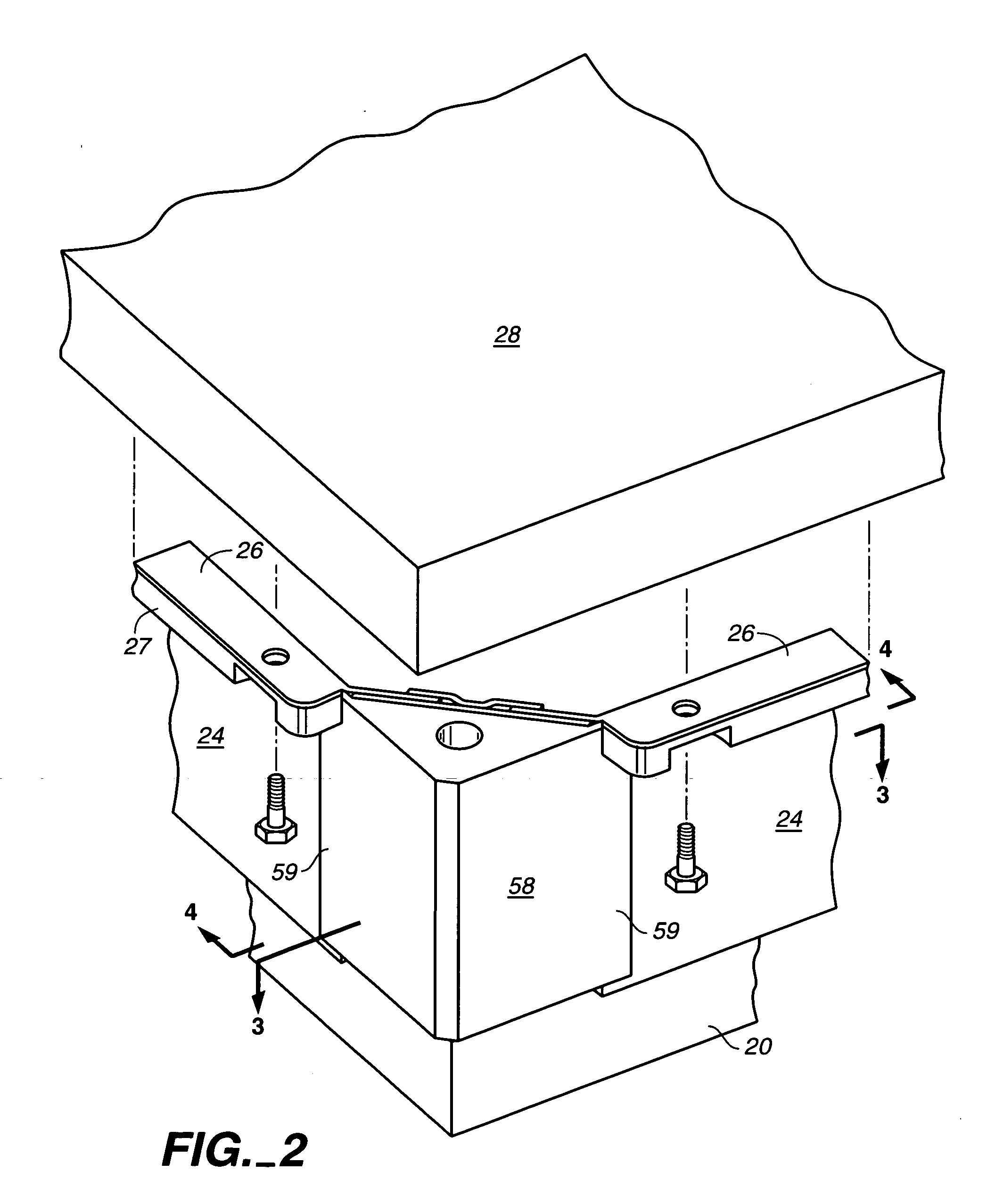

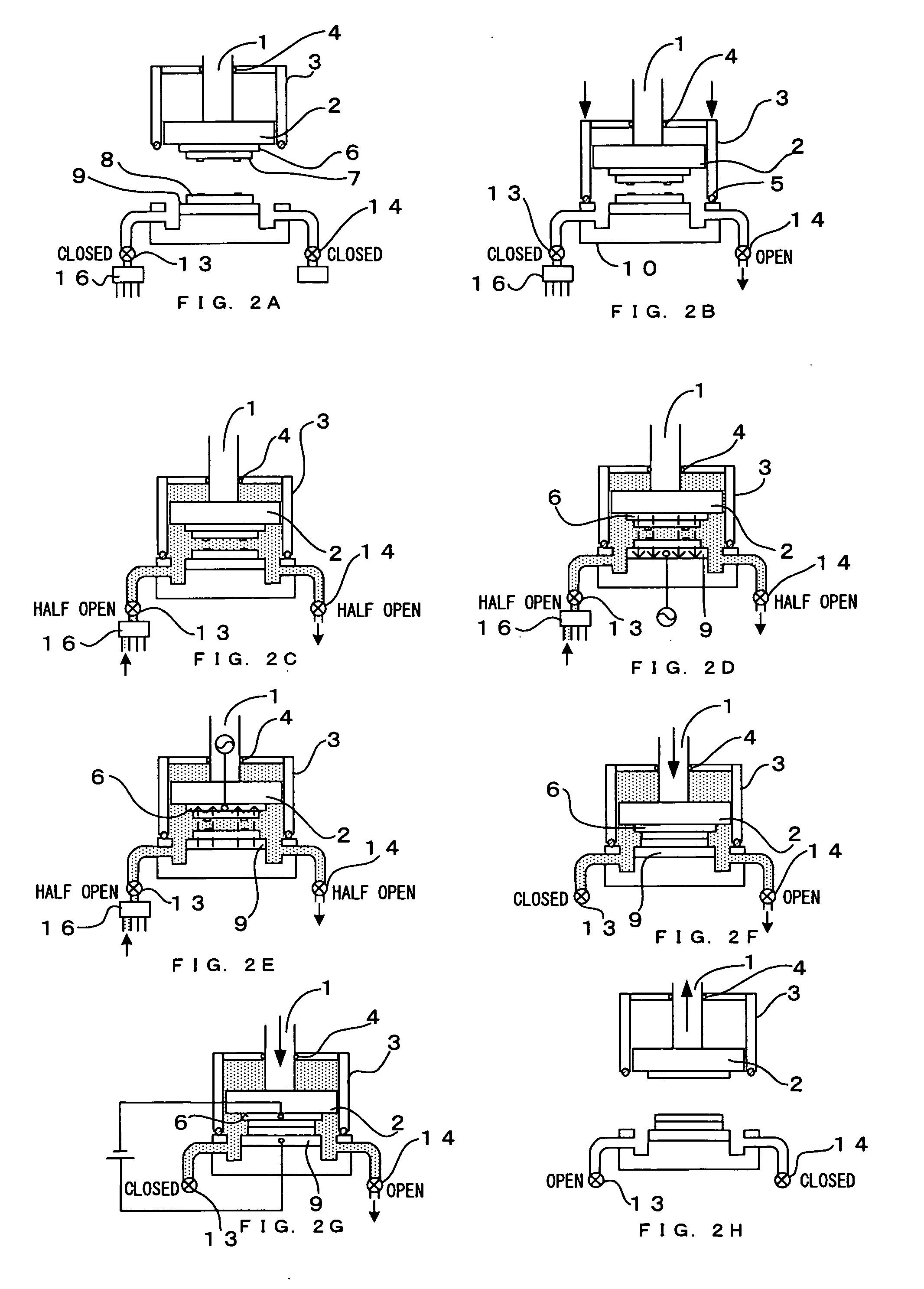

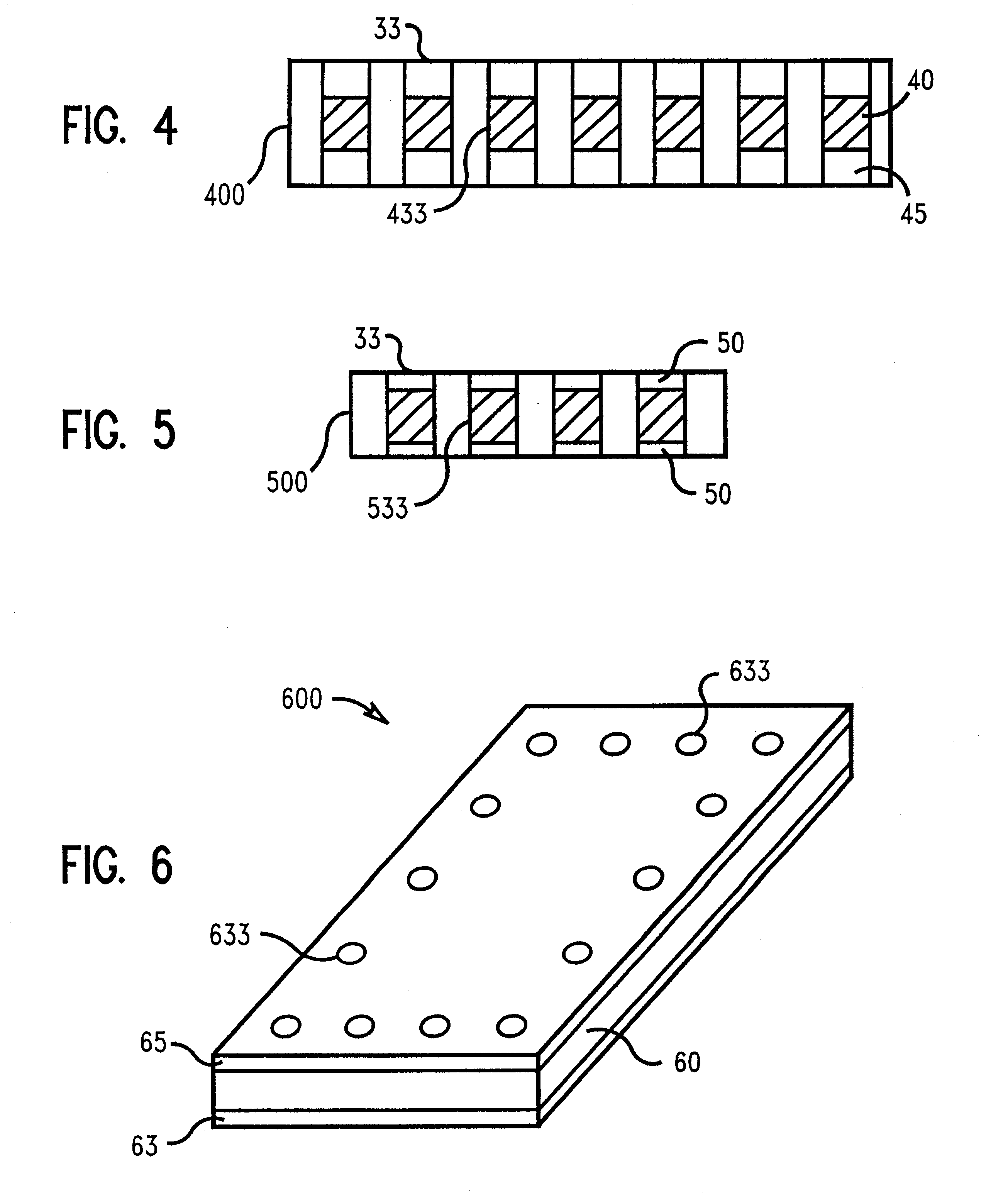

Suspended gas distribution manifold for plasma chamber

InactiveUS20050000432A1Minimize gas leakagePermit some movementElectric discharge tubesSemiconductor/solid-state device manufacturingThermal dilatationThermal isolation

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by a side wall comprising one or more sheets. The sheets preferably provide flexibility to alleviate stress in the gas distribution plate due to thermal expansion and contraction. In another aspect, the side wall provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

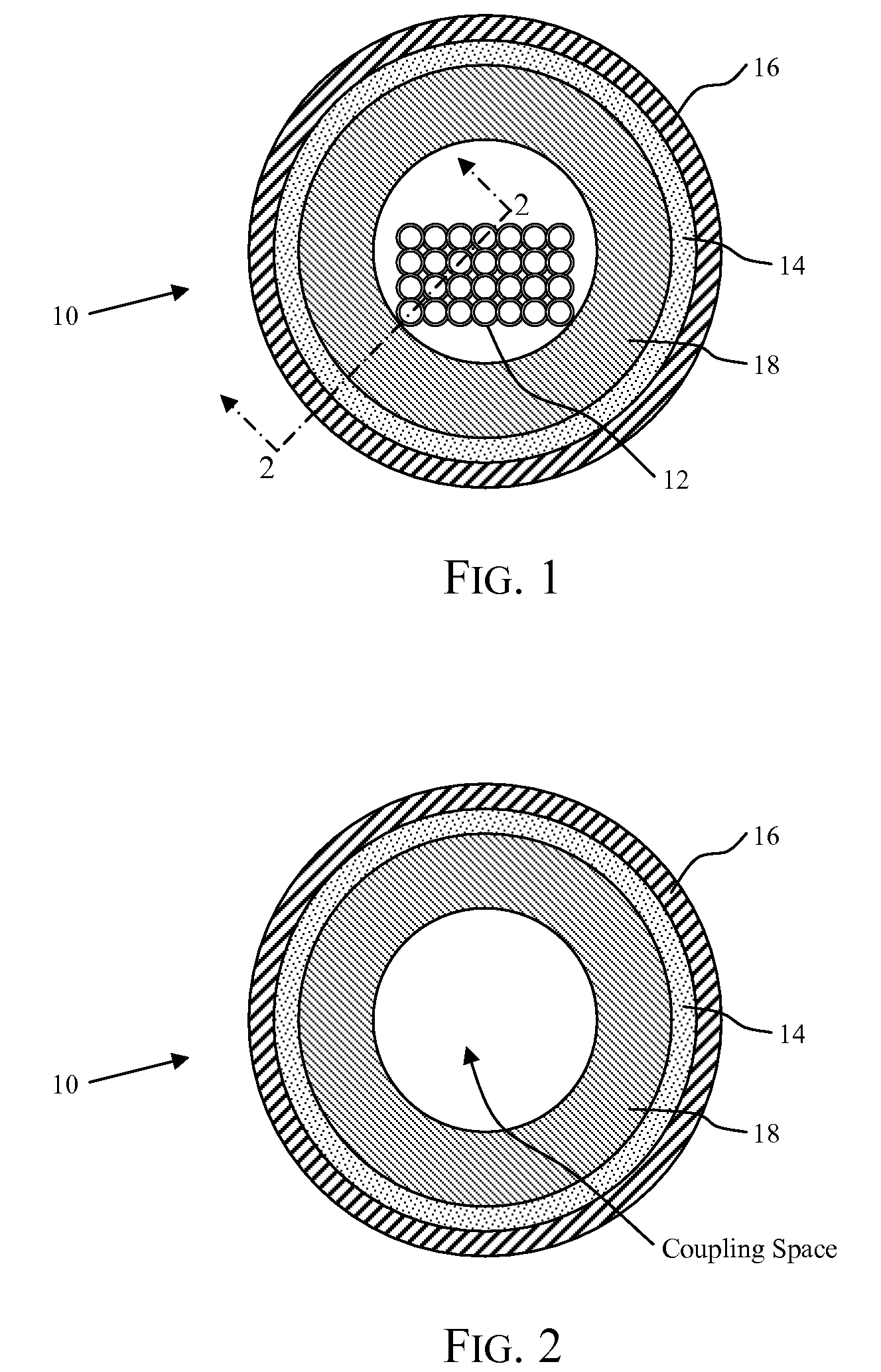

Optical fiber cable having a deformable coupling element

InactiveUS7639915B2Reduce collectionInhibitionGlass making apparatusFibre mechanical structuresThermal dilatationEngineering

Disclosed is an optical fiber cable that includes optical fibers and a deformable coupling element enclosed within a buffer tube. The coupling element is formed from a deformable yet substantially incompressible material that is capable of releasably and intermittently coupling the optical fibers to the buffer tube in various orientations. The design of the coupling element layer permits coupling of the optical fibers to the buffer tube without the use of a compressive cushioning layer and yet permits localized movement the optical fibers relative to the buffer tube to account for disparate thermal expansion and to accommodate optical fiber placement.

Owner:DRAKA COMTEQ BV

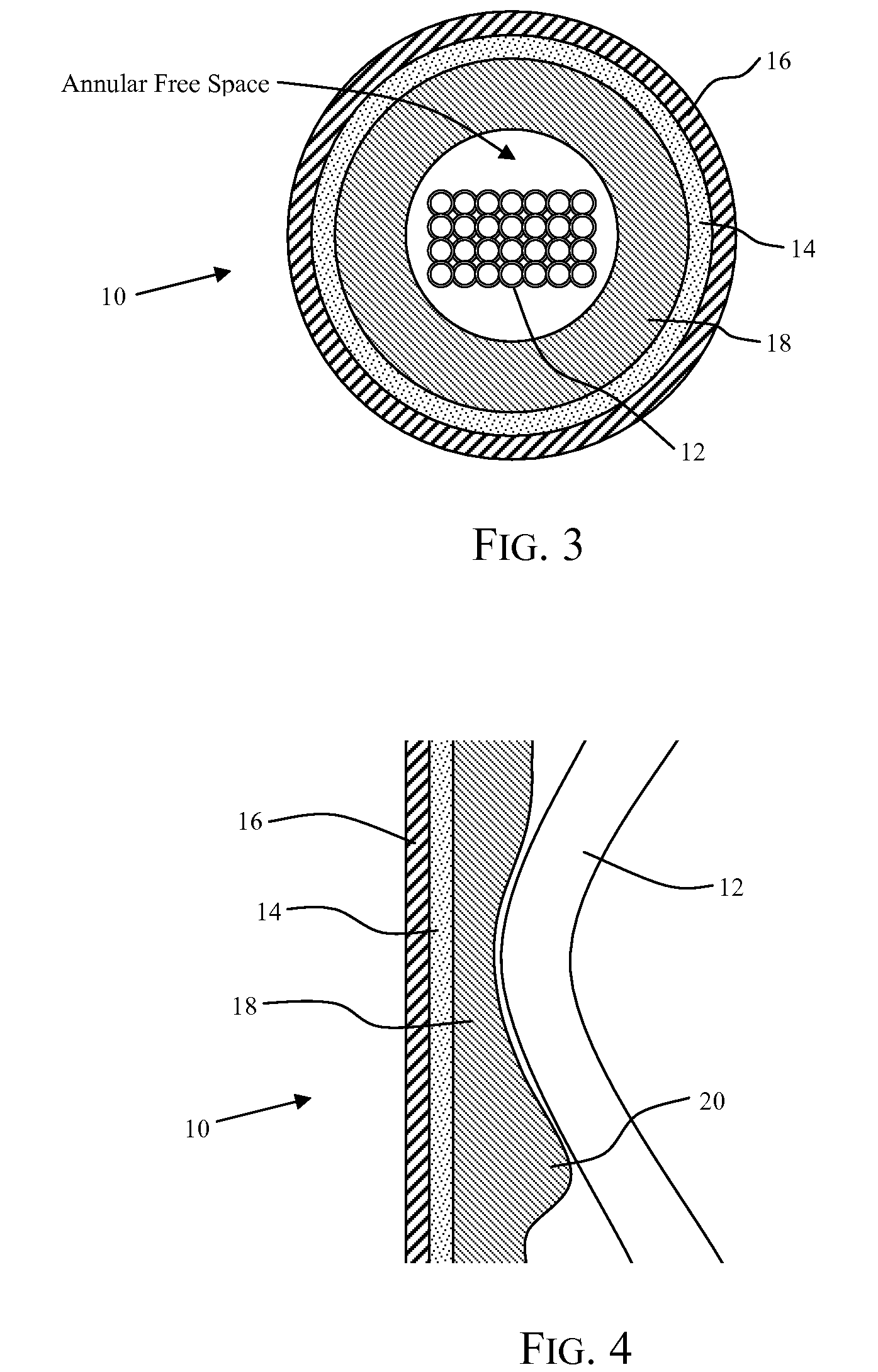

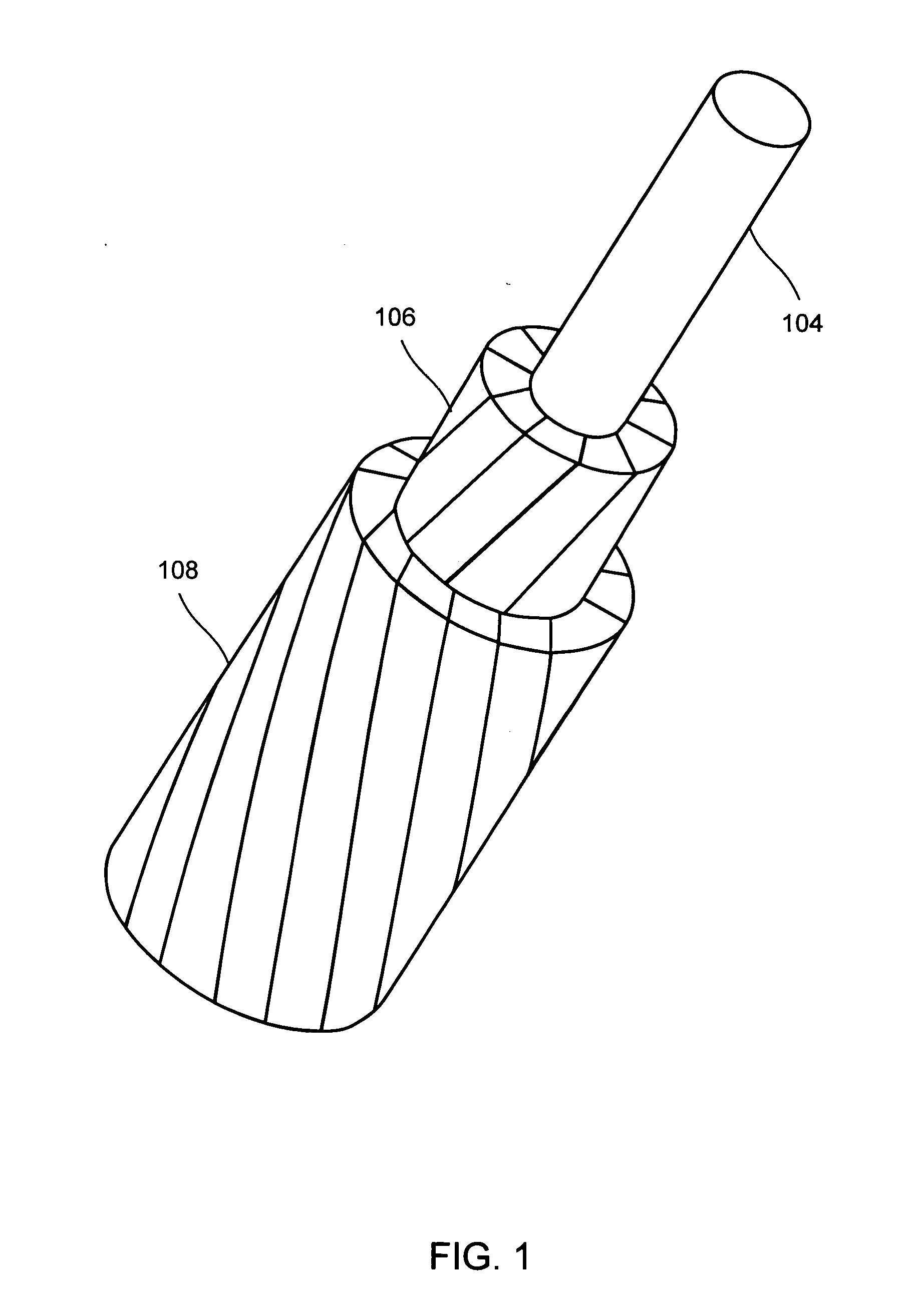

Aluminum conductor composite core reinforced cable and method of manufacture

This invention relates to an aluminum conductor composite core reinforced cable and method of manufacture. The composite core comprises a plurality of longitudinally extending fibers embedded in a resin matrix. The composite core comprises the following characteristics: tensile strength ranging from about 250 to about 350 Ksi; a tensile modulus of elasticity ranging from about 12 to about 16 Msi; and a coefficient of thermal expansion less than or equal to about 6×10−6 cm / cm·° C. The composite core is further manufactured according to a two die pultrusion system, the system comprising tooling designed in accordance with the processing speed, selection of composite core fibers and resin and desired physical characteristics of the end composite core.

Owner:CTC GLOBAL CORP

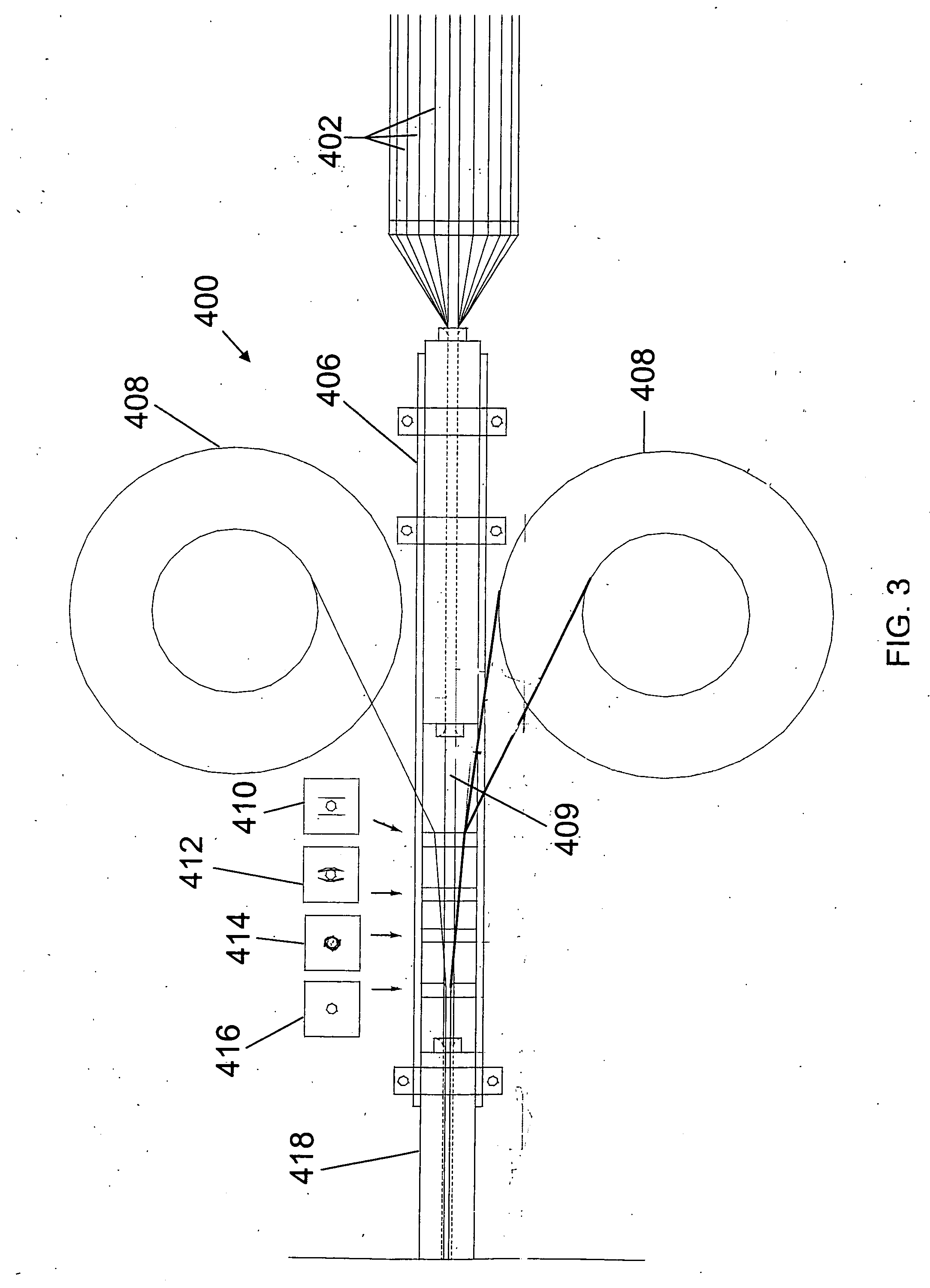

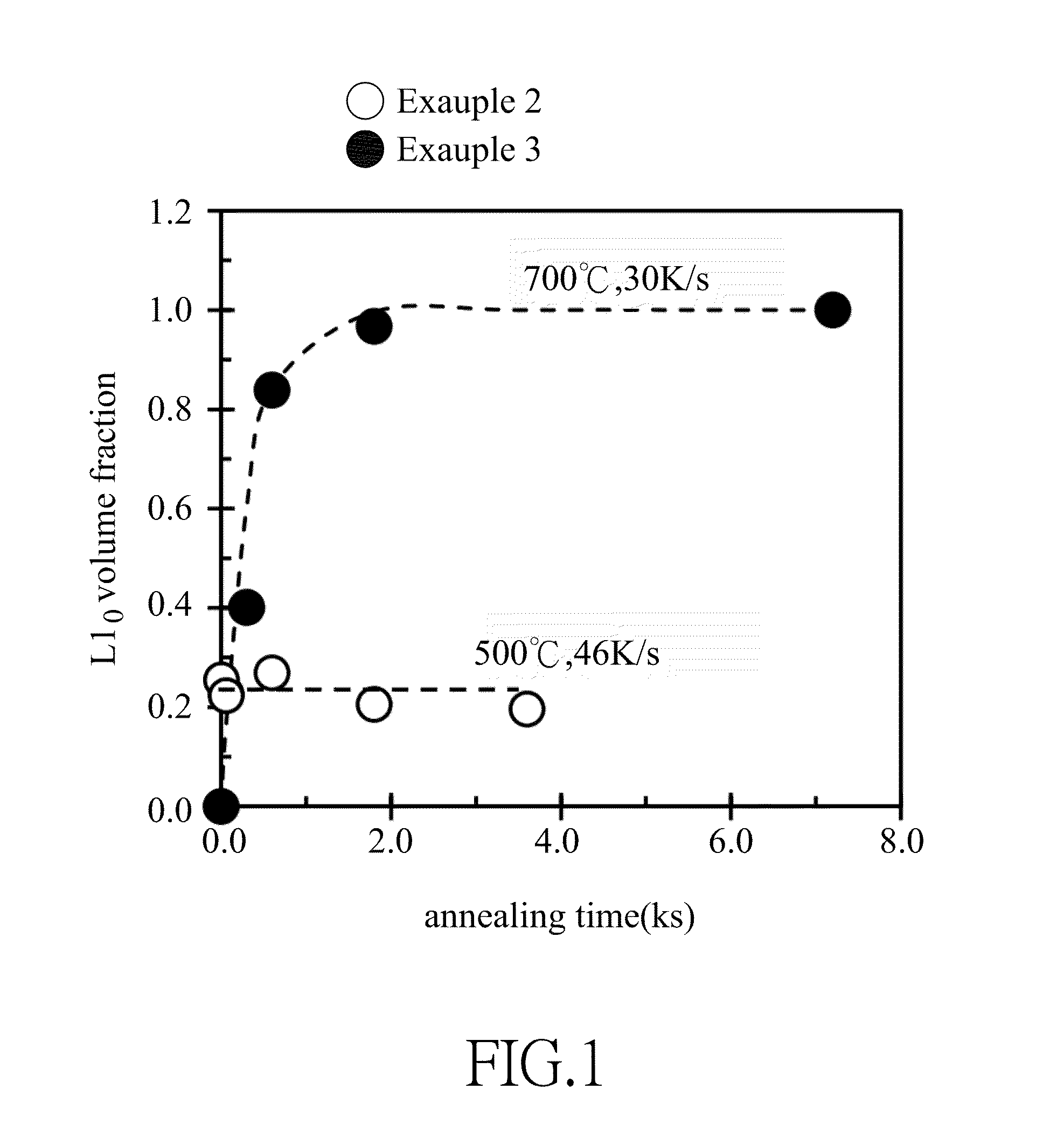

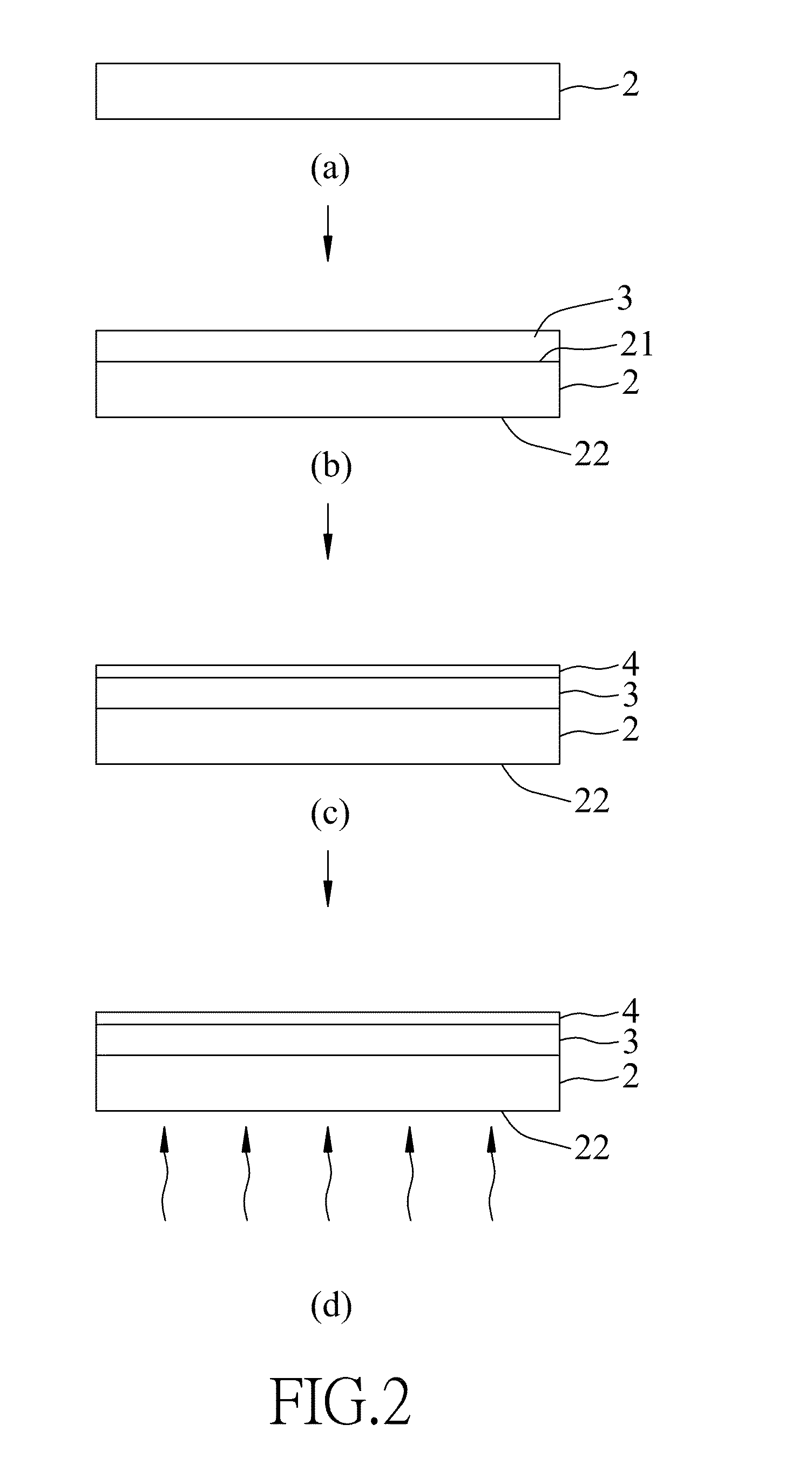

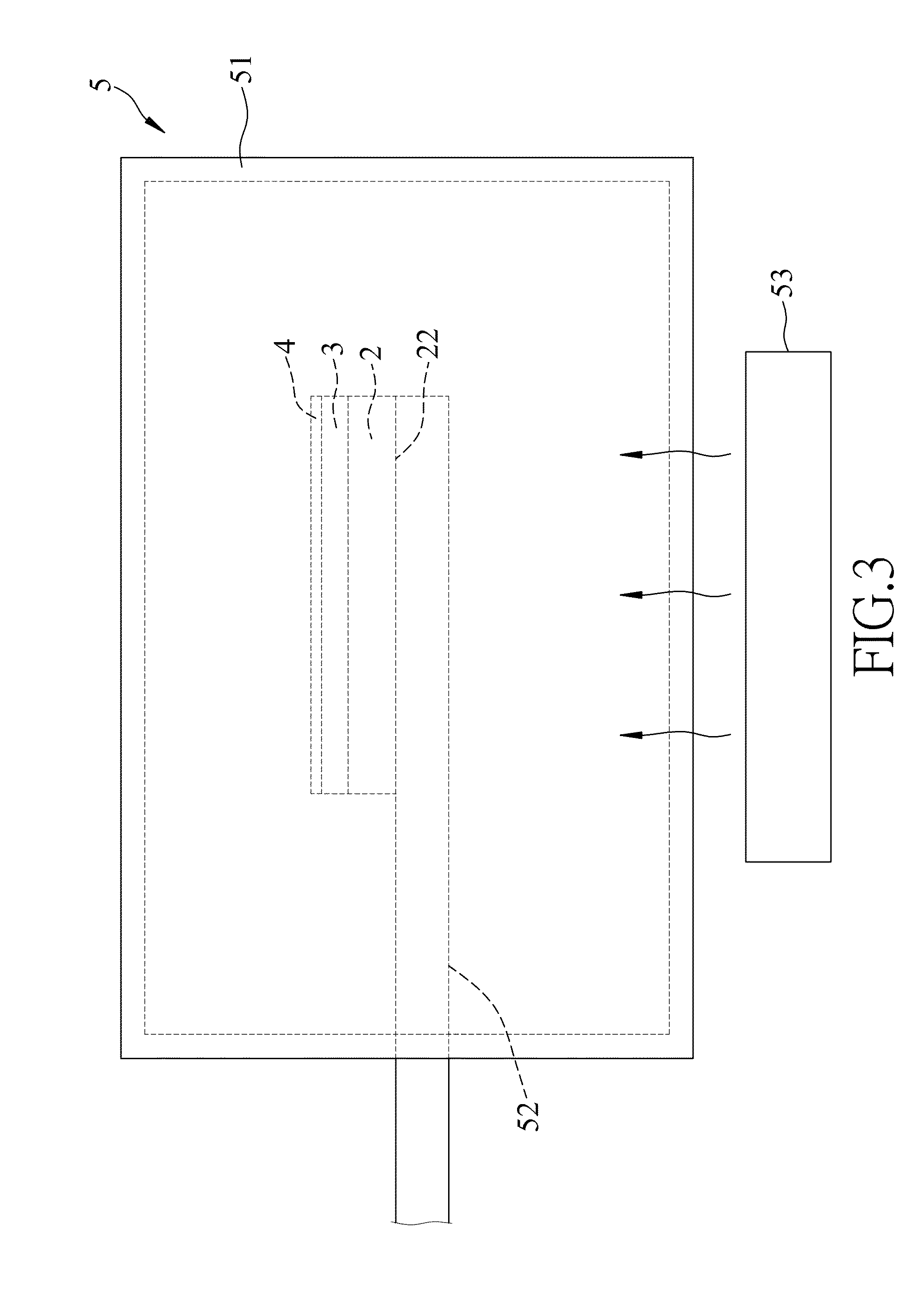

Method for making an ordered magnetic alloy

ActiveUS20140366990A1Rapid thermal expansionOvercomes drawbackChemical vapor deposition applicationHeat treatment applicationIn planeMetal

A method for making an ordered magnetic alloy includes (a) providing a thermally conductive base having opposite first and second surfaces; (b) forming a thermal barrier layer on the first surface of the thermally conductive base; (c) forming a disordered magnetic alloy layer on the thermal barrier layer, the disordered magnetic alloy layer being made from a disordered alloy which contains a first metal selected from Fe, Co, and Ni, and a second metal selected from Pt and Pd; and (d) after step (c), applying a transient heat to the thermally conductive base to cause rapid thermal expansion of the thermally conductive base, which, in turn, causes generation of an in-plane tensile stress in the disordered magnetic alloy layer.

Owner:NATIONAL TSING HUA UNIVERSITY

Mullite-aluminum titanate body and method for making same

InactiveUS20060021308A1Low thermal expansionHigh thermal shock resistanceInternal combustion piston enginesDispersed particle filtrationYttriumBismuth preparation

This invention relates to a mullite-aluminum titanate body having a low coefficient of thermal expansion of less than 15×10−7 C−1, a high porosity of at least 38% by volume, a median pore diameter of at least 8 microns, and a narrow pore size distribution as characterized by the relation (d50-d10) / d50 being less than 0.50 corresponding to a high degree of interconnected porosity. The inventive ceramic body also contains at least 0.10% by weight metal oxide, the metal being either yttrium, calcium, bismuth, a lanthanide metal or combinations of thereof. The inventive ceramic body is particularly useful as a wall-flow filter for diesel exhaust. A method of fabrication is provided where the sintering temperature is between 1375°-1550° C.

Owner:CORNING INC

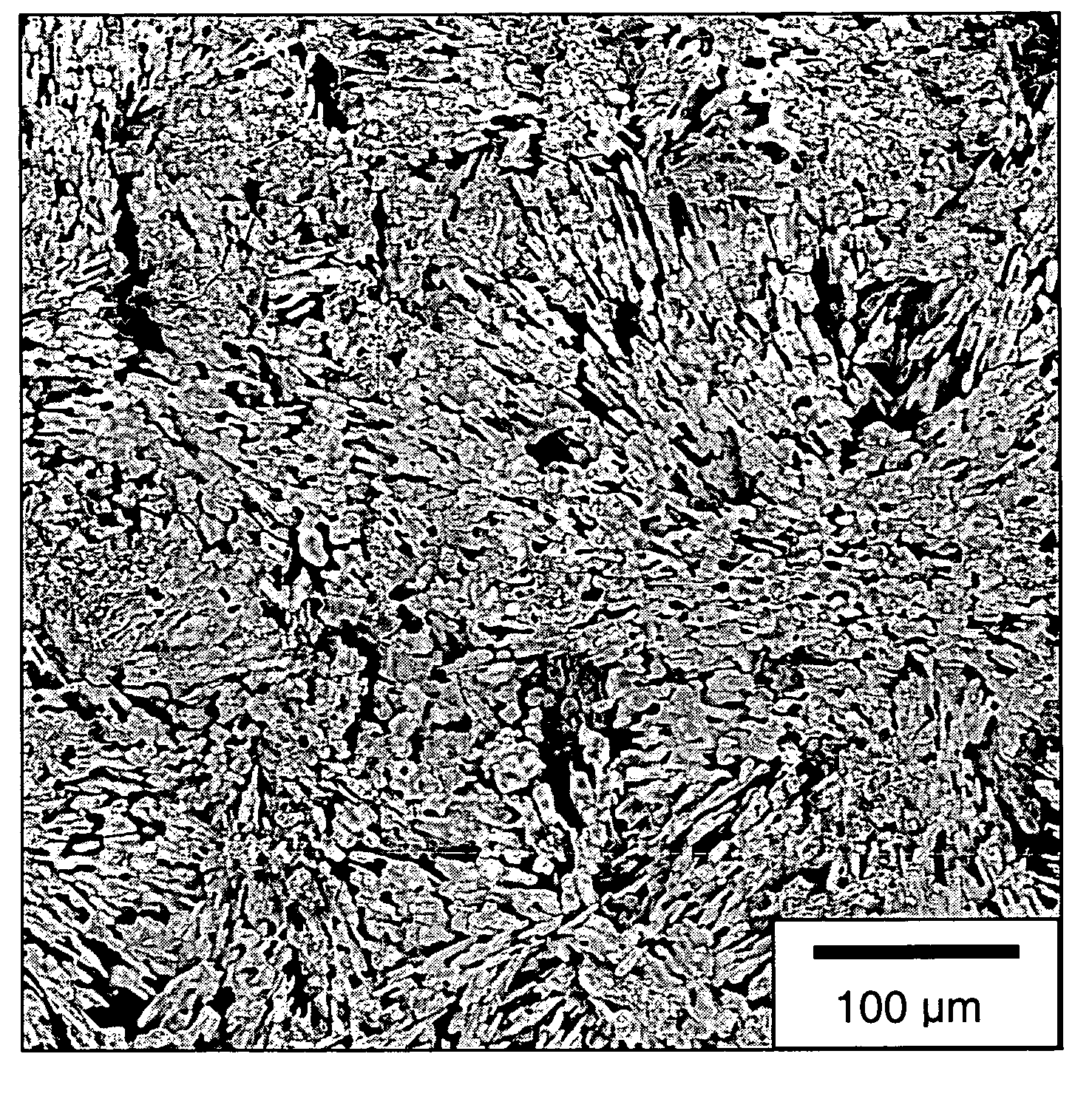

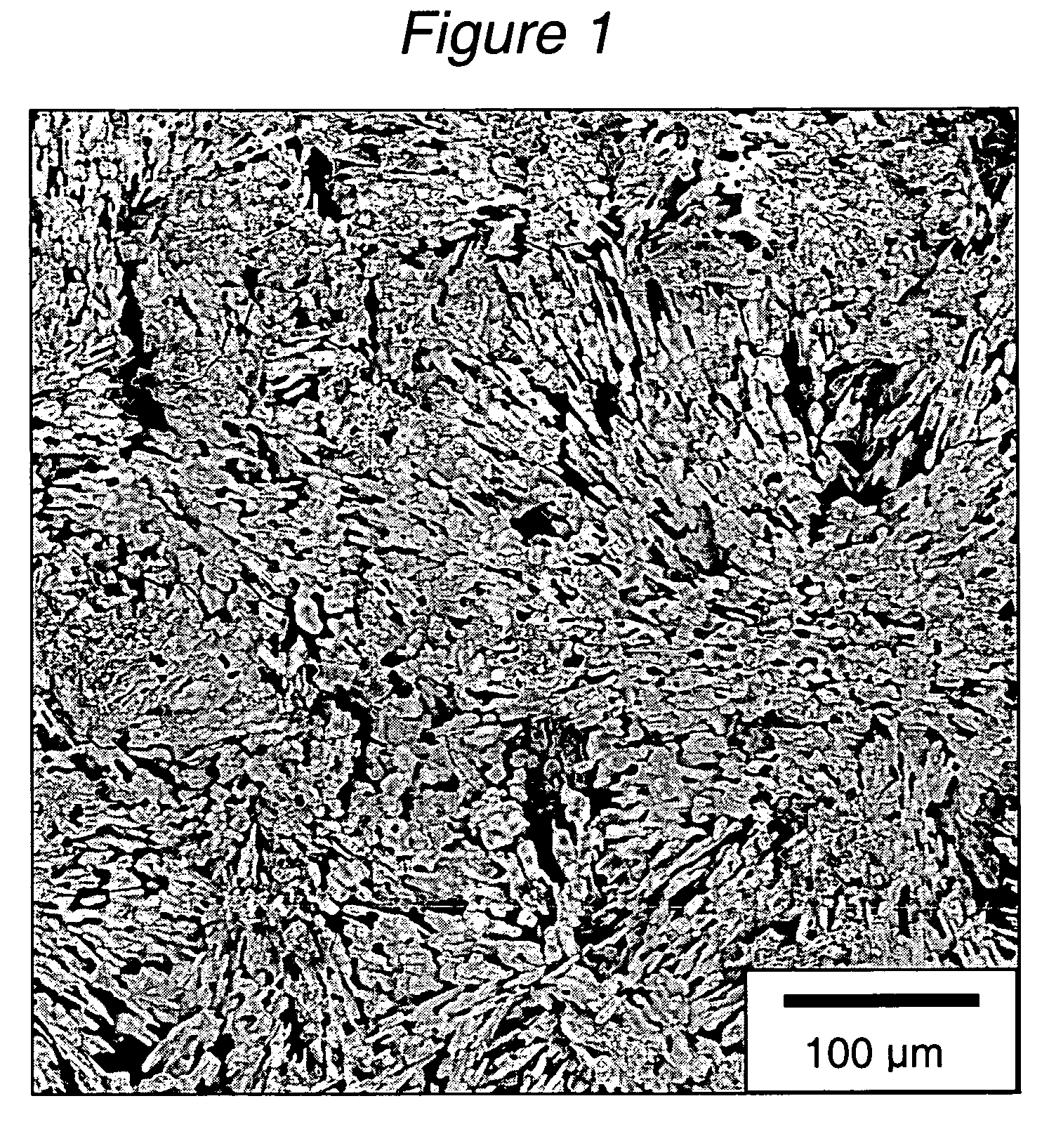

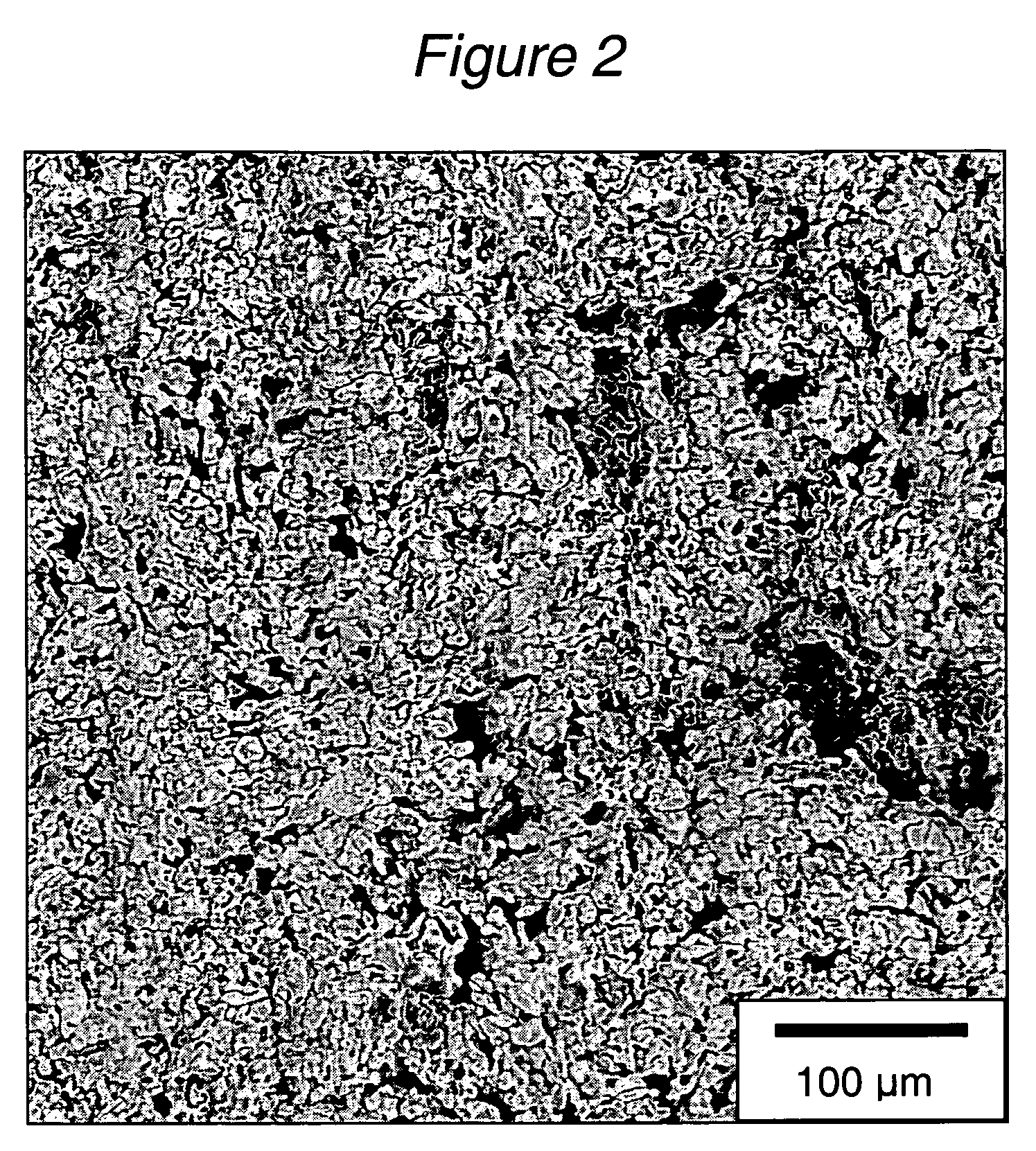

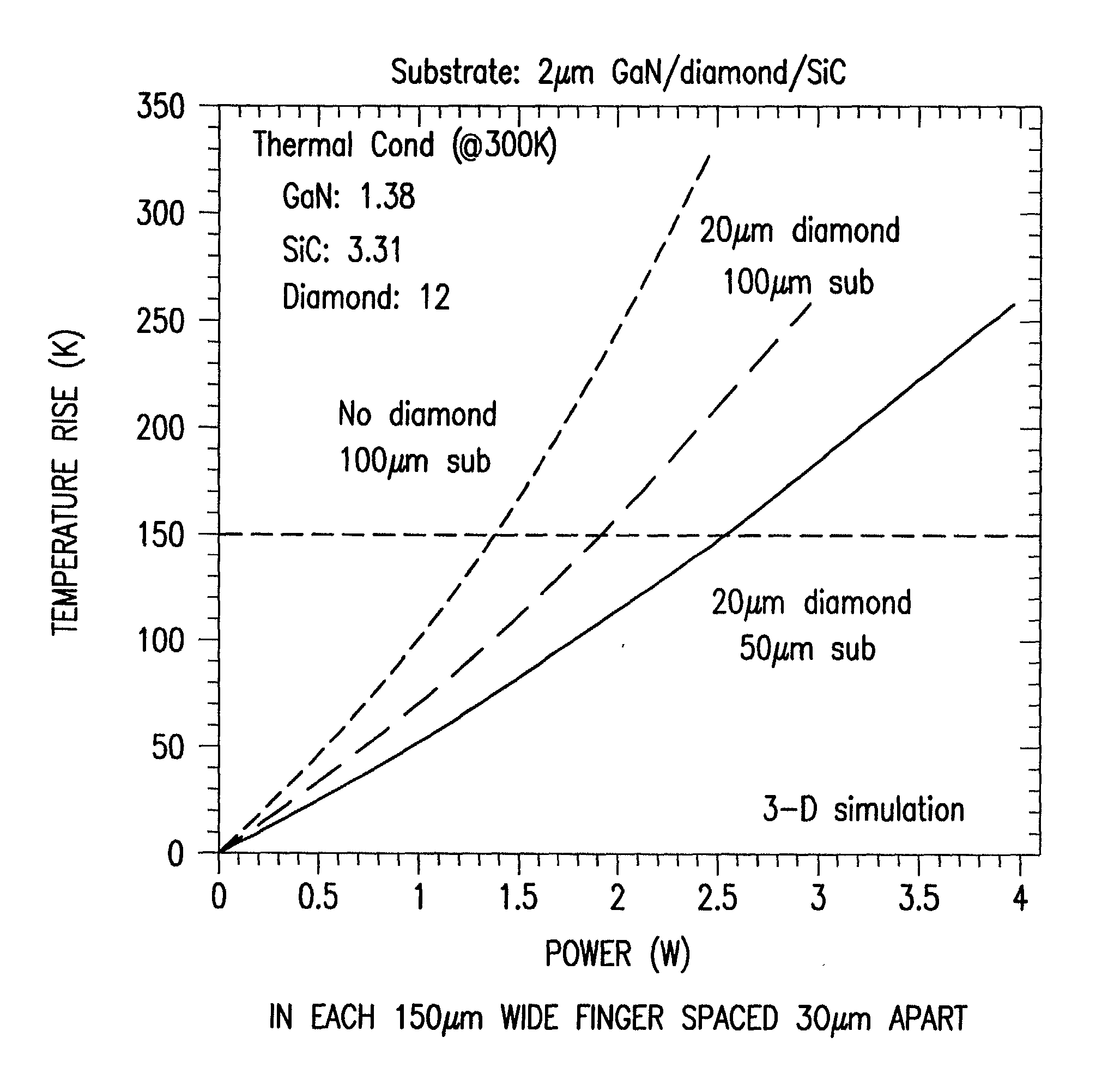

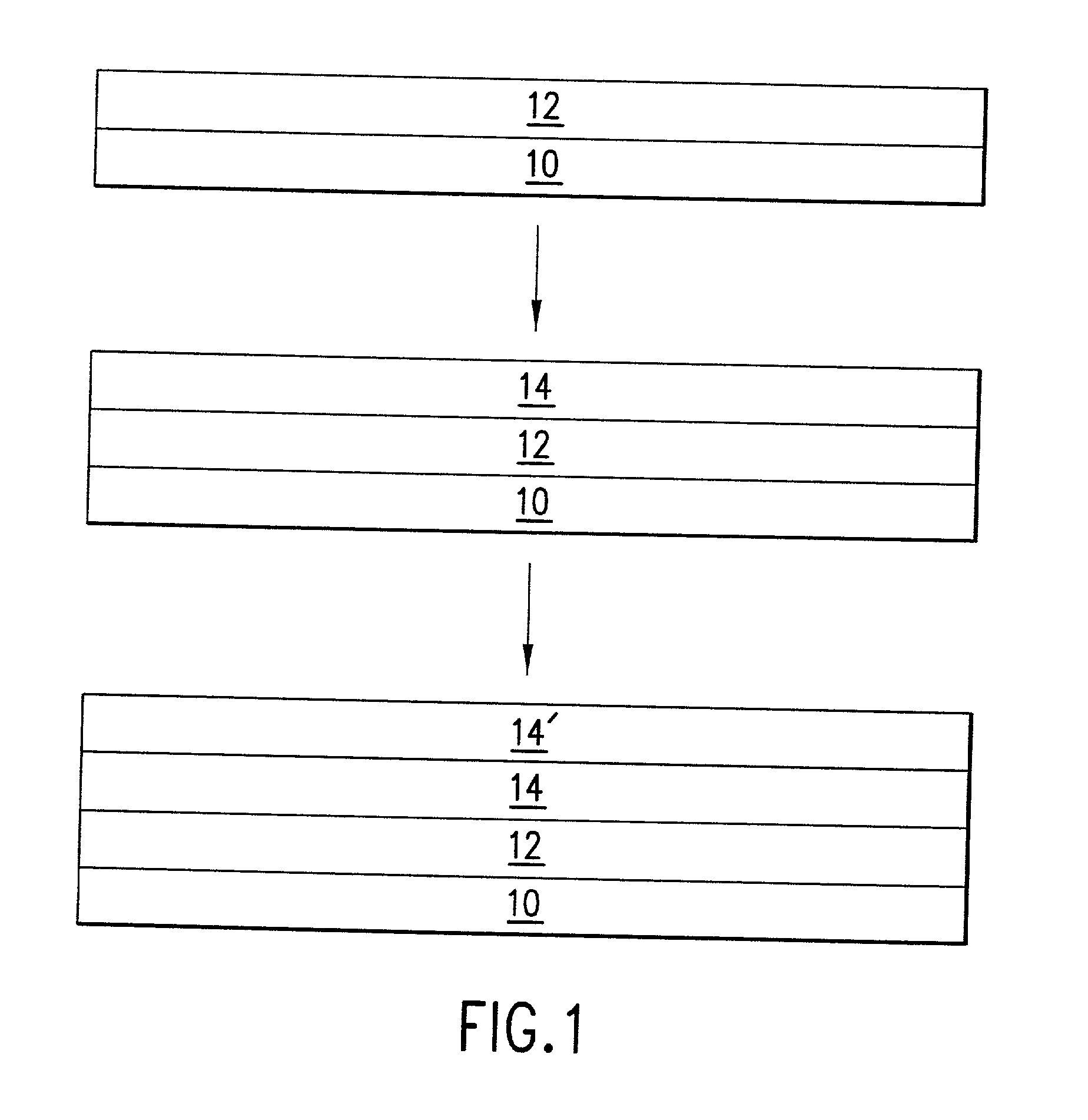

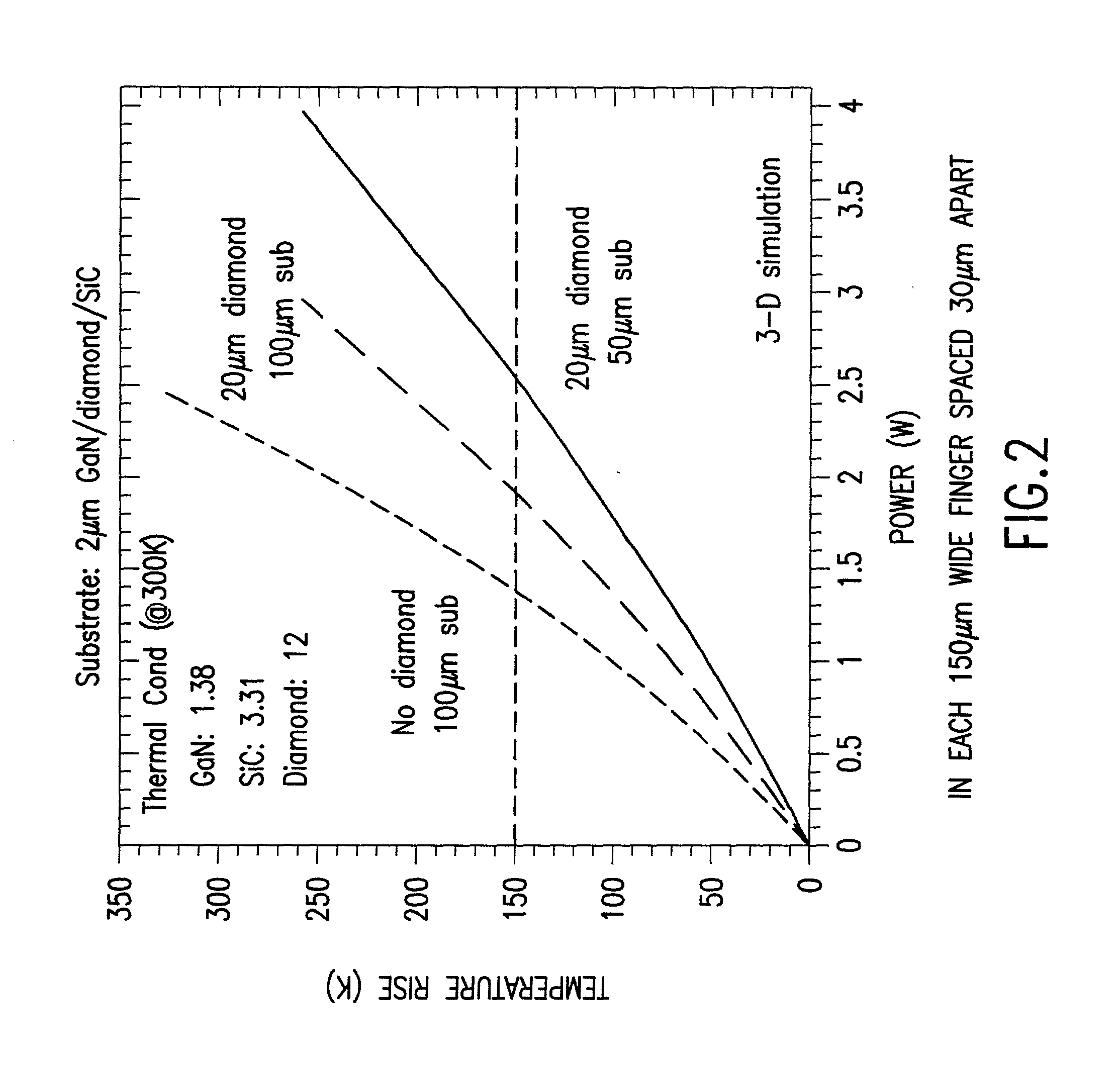

Electronic device with composite substrate

InactiveUS20020096106A1Fast heat conductionGood thermal expansionPolycrystalline material growthSemiconductor/solid-state device manufacturingThermal dilatationComposite substrate

A method for making a multilayered electronic device with at least one epitaxial layer grown on a single-crystal film bonded to a composite wherein at least one layer is polycrystalline, the method includes the step of bonding a single-crystal film at least one of the epitaxial layers on the single-crystal film wherein thermal coefficients of expansion for the substrate and the epitaxial layer are closely matched.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

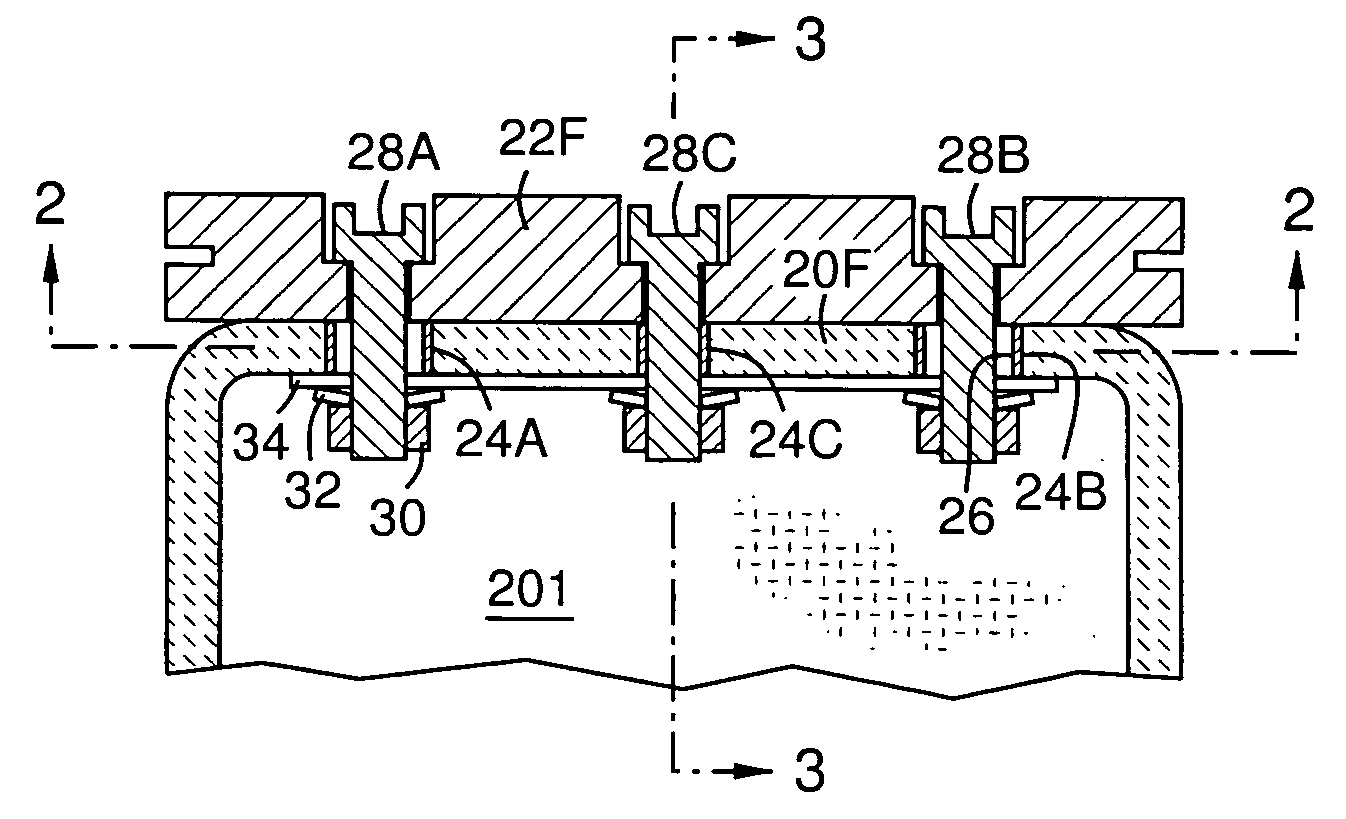

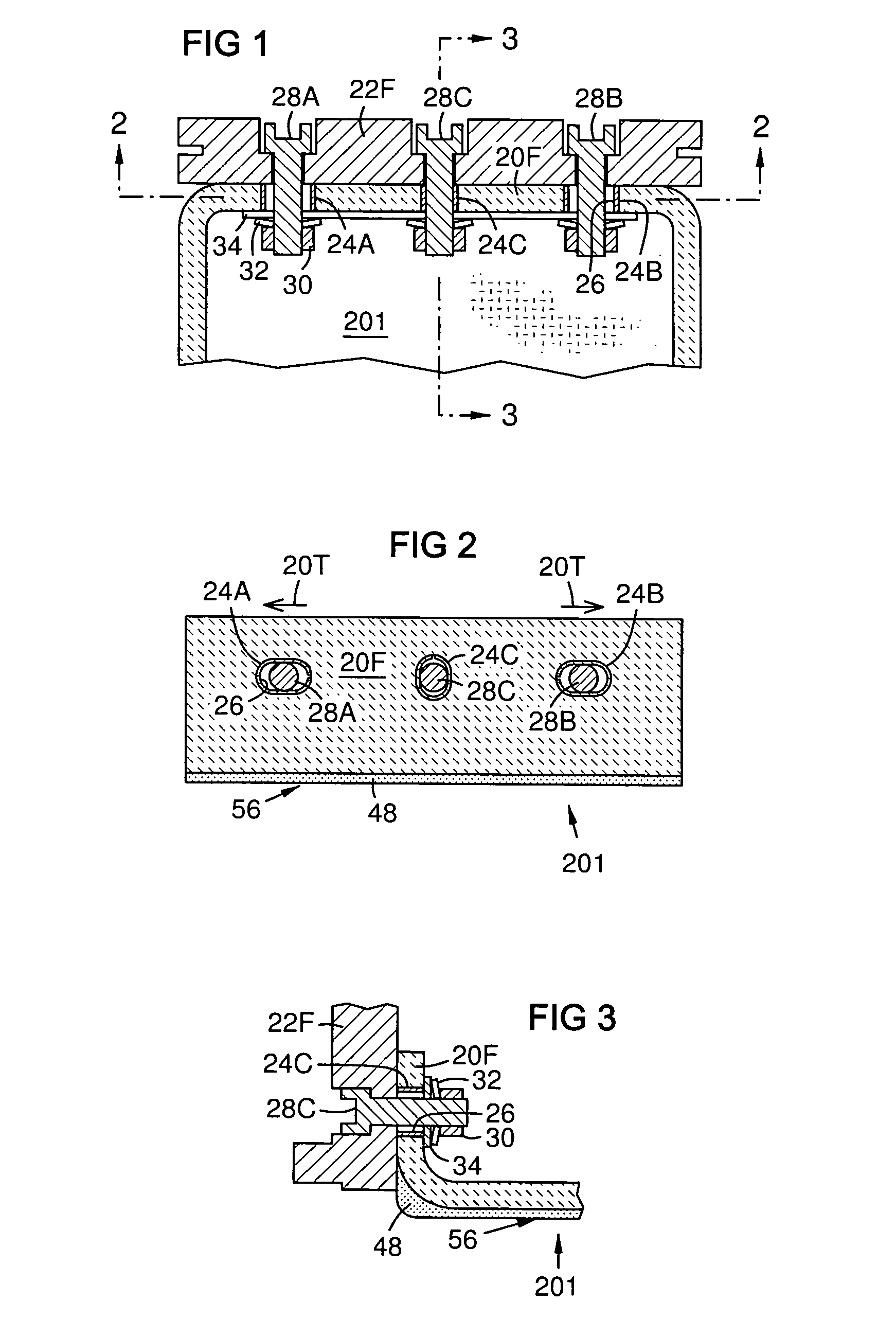

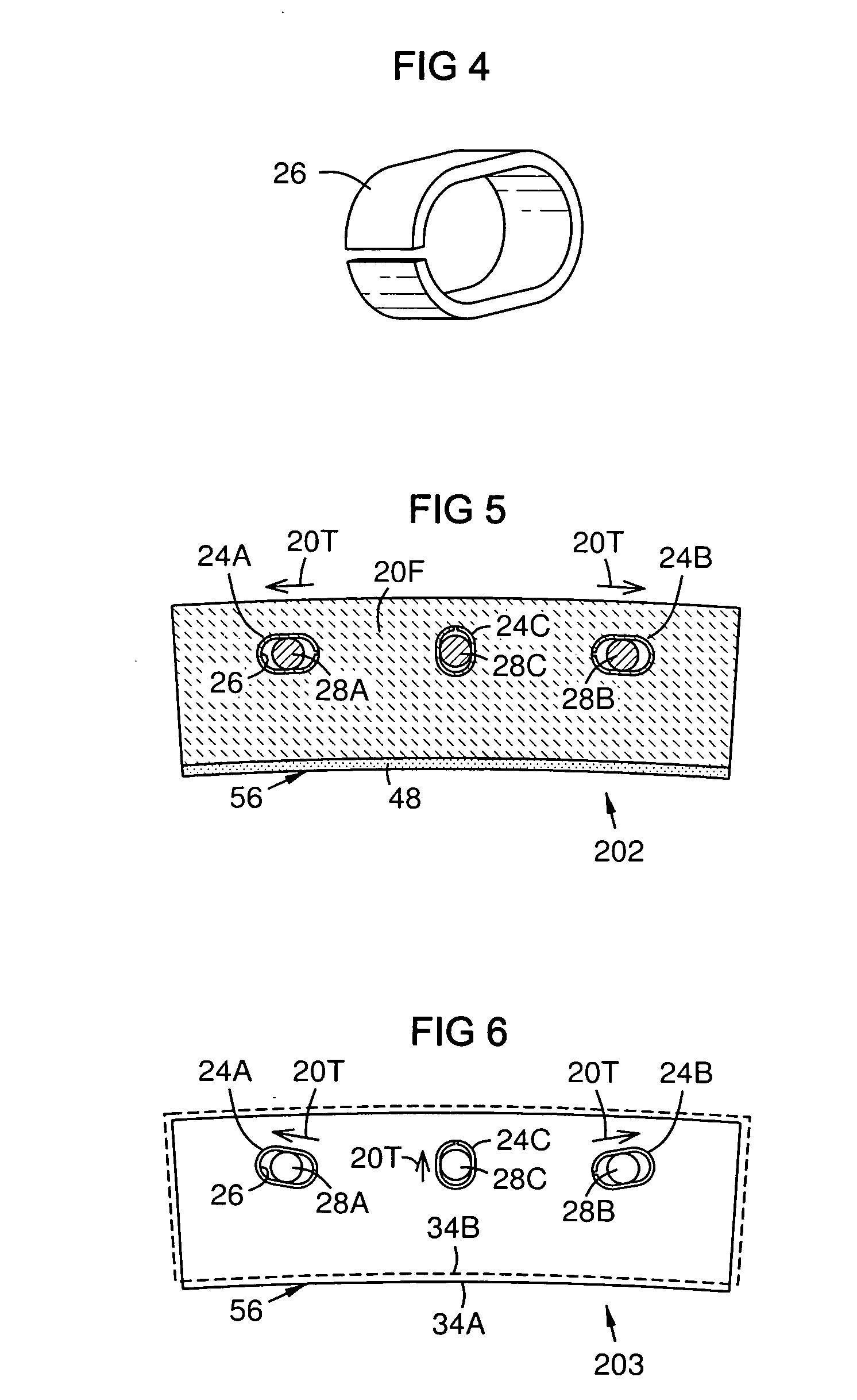

CMC to metal attachment mechanism

A CMC wall (20F) may be attached to a metal wall (22F) by a plurality of bolts (28A, 28B, 28C) passing through respective holes (24A, 24B, 24C) in the CMC wall (20F) and holes in the metal wall (22F), clamping the walls (20F, 22F) together with a force that allows sliding thermal expansion but does not allow vibrational shifting. Distal ones of the holes (24A, 24B) in the CMC wall (20F) or in the metal wall (22F) are elongated toward a central one of the bolts (24C) or at alternate angles to guide differential thermal expansion (20T) of the CMC wall (20F) versus the metal wall (22F) between desired cold and hot geometries. A second CMC wall (20R) may be mounted similarly to a second metal wall (22R) by pins (39A, 39B, 39C) that allow expansion of the CMC component (201) in a direction normal to the walls (20F, 20R).

Owner:SIEMENS ENERGY INC

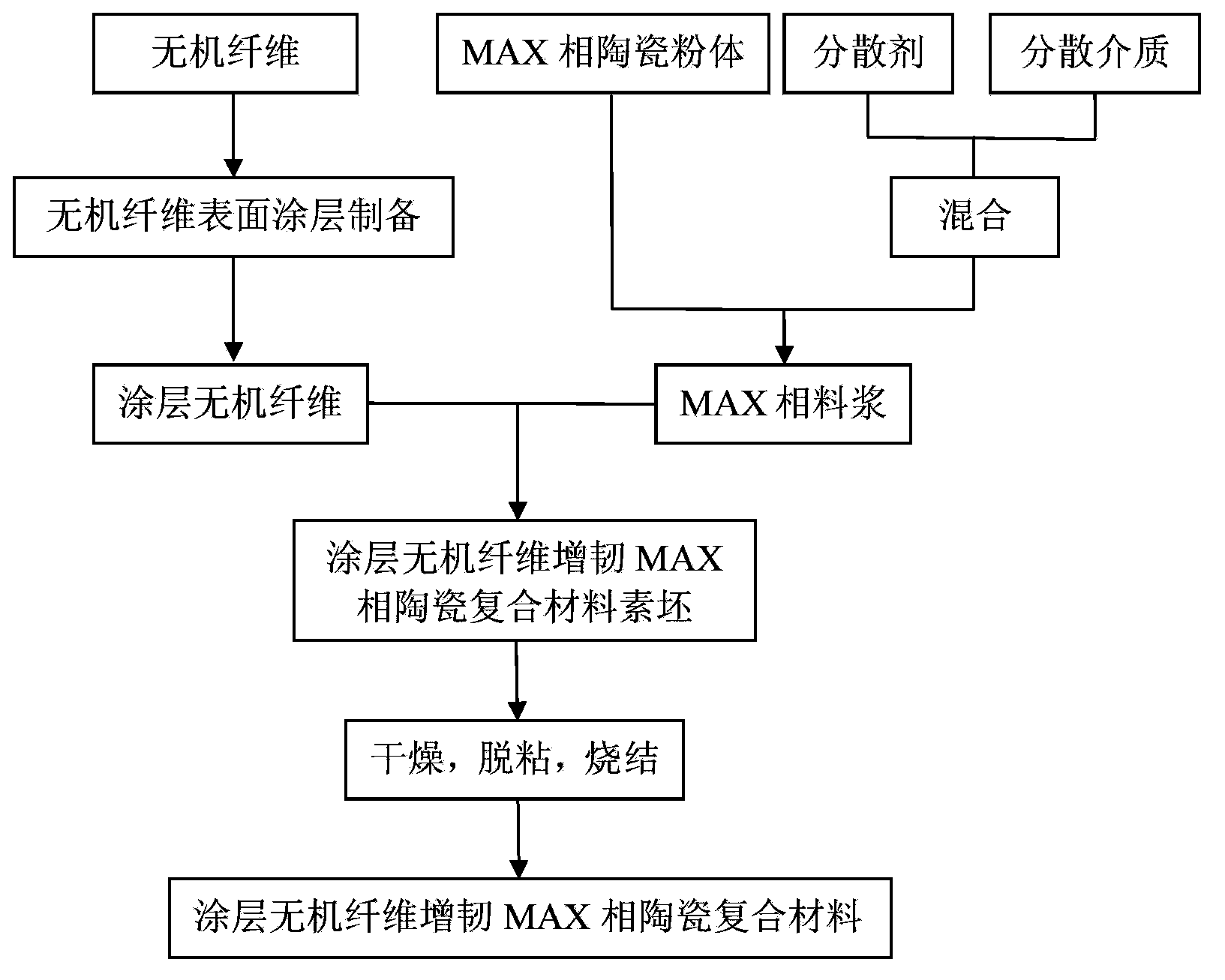

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Semiconductor flip-chip package and method for the fabrication thereof

InactiveUS20020031868A1Simple chip placementLow cost methodSemiconductor/solid-state device detailsSolid-state devicesElastic modulusSemiconductor

A flip-chip device and process for fabricating the device employs a multilayer encapsulant that includes a first portion encapsulant having a coefficient of thermal expansion of at most 30 ppm / .degree. C. and an elastic modulus of 2-20 GPa and a second portion comprising a polymer flux having a coefficient of thermal expansion that may exceed 30 ppm / .degree. C.

Owner:INVENSAS CORP

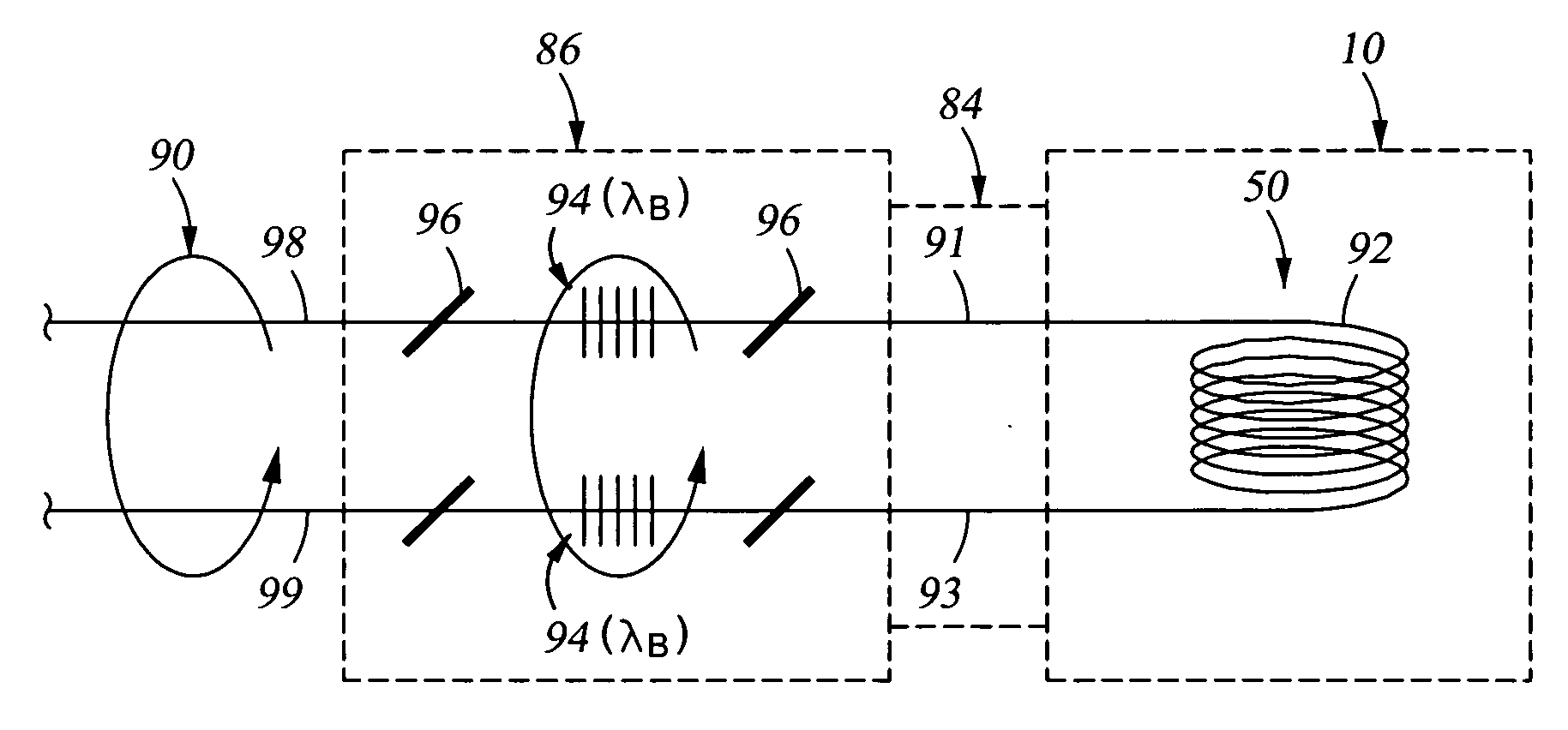

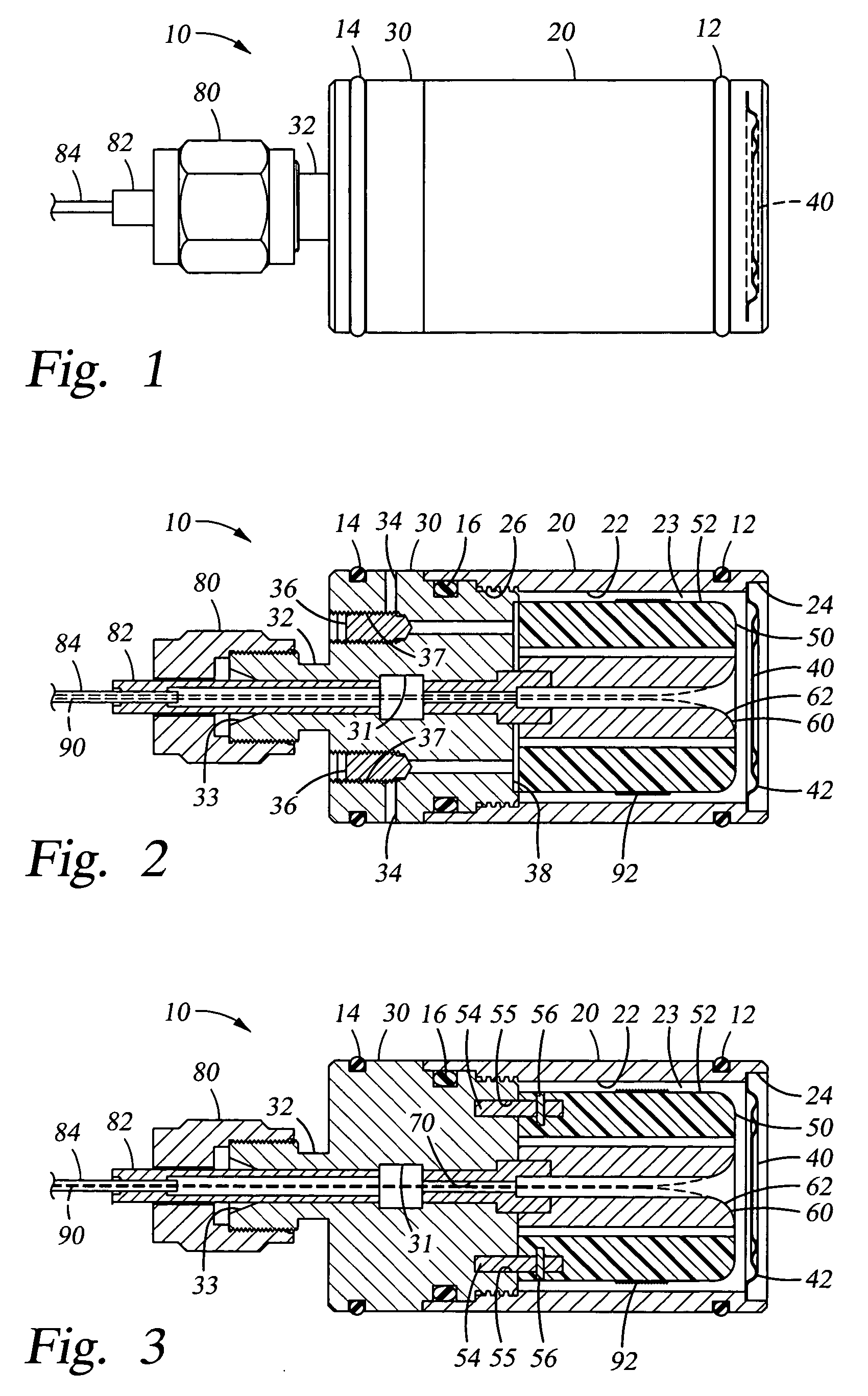

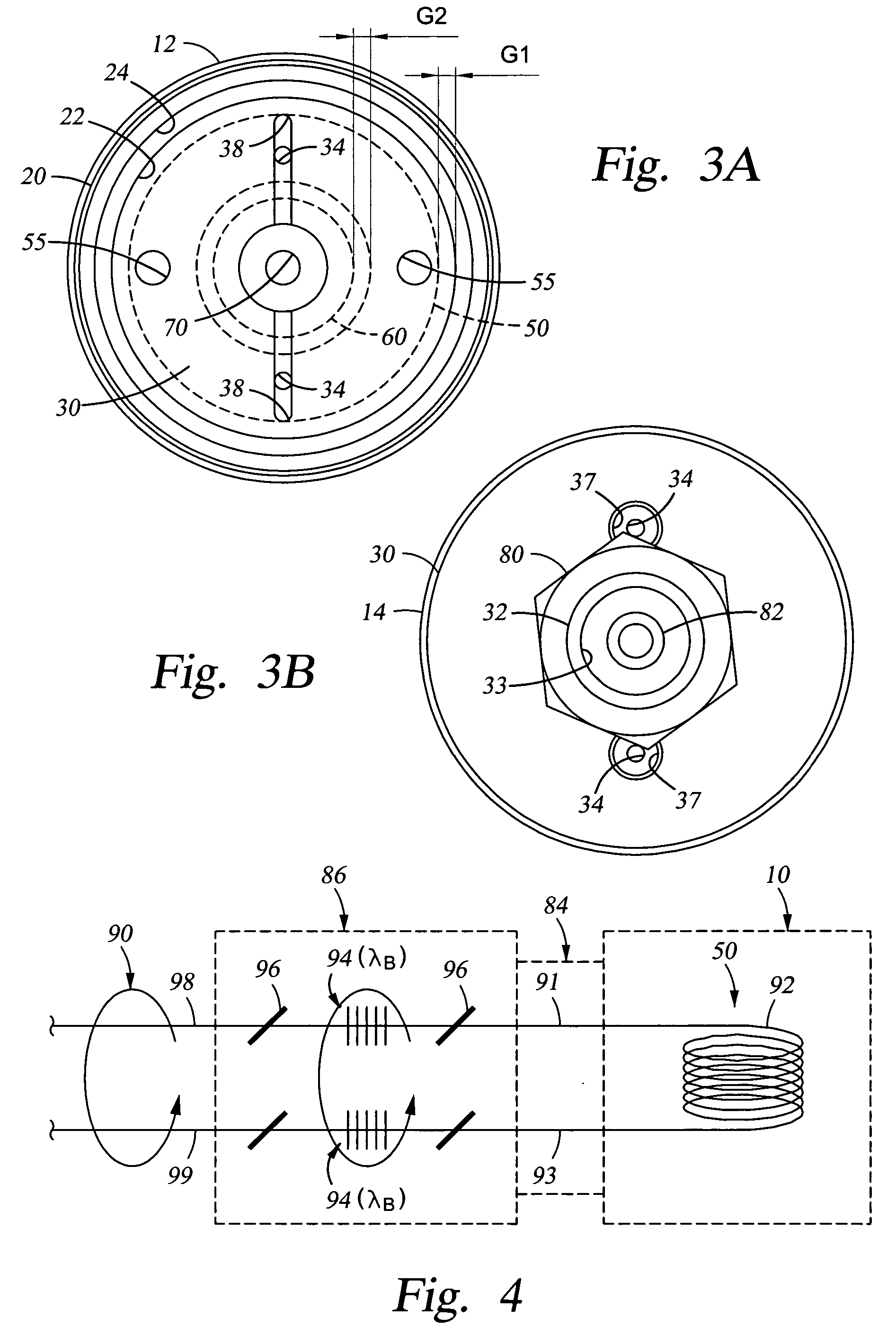

High pressure and high temperature acoustic sensor

An acoustic sensor, such as a hydrophone, is deployable in a fluidic media having high temperature, high pressure, and / or potentially caustic chemicals. The hydrophone includes a housing filled with an internal fluid and containing a sensing mandrel. The sensing mandrel senses the acoustic pressure transmitted to the internal fluid through a diaphragm. The sensing mandrel preferably includes a polymer tubular mandrel having a coil of optical fiber wound and bonded to its outer surface. The sensing mandrel can be suspended within the housing instead of being rigidly attached thereto. To relieve pressure created by thermal expansion of the internal fluid, the flexible diaphragm, a filler member, a pressure compensator, or combinations thereof can be used. The filler member is mounted in the hydrophone and reduces the amount of internal fluid required in the housing. The compensator may be a bellows or a buffer tube.

Owner:WEATHERFORD TECH HLDG LLC

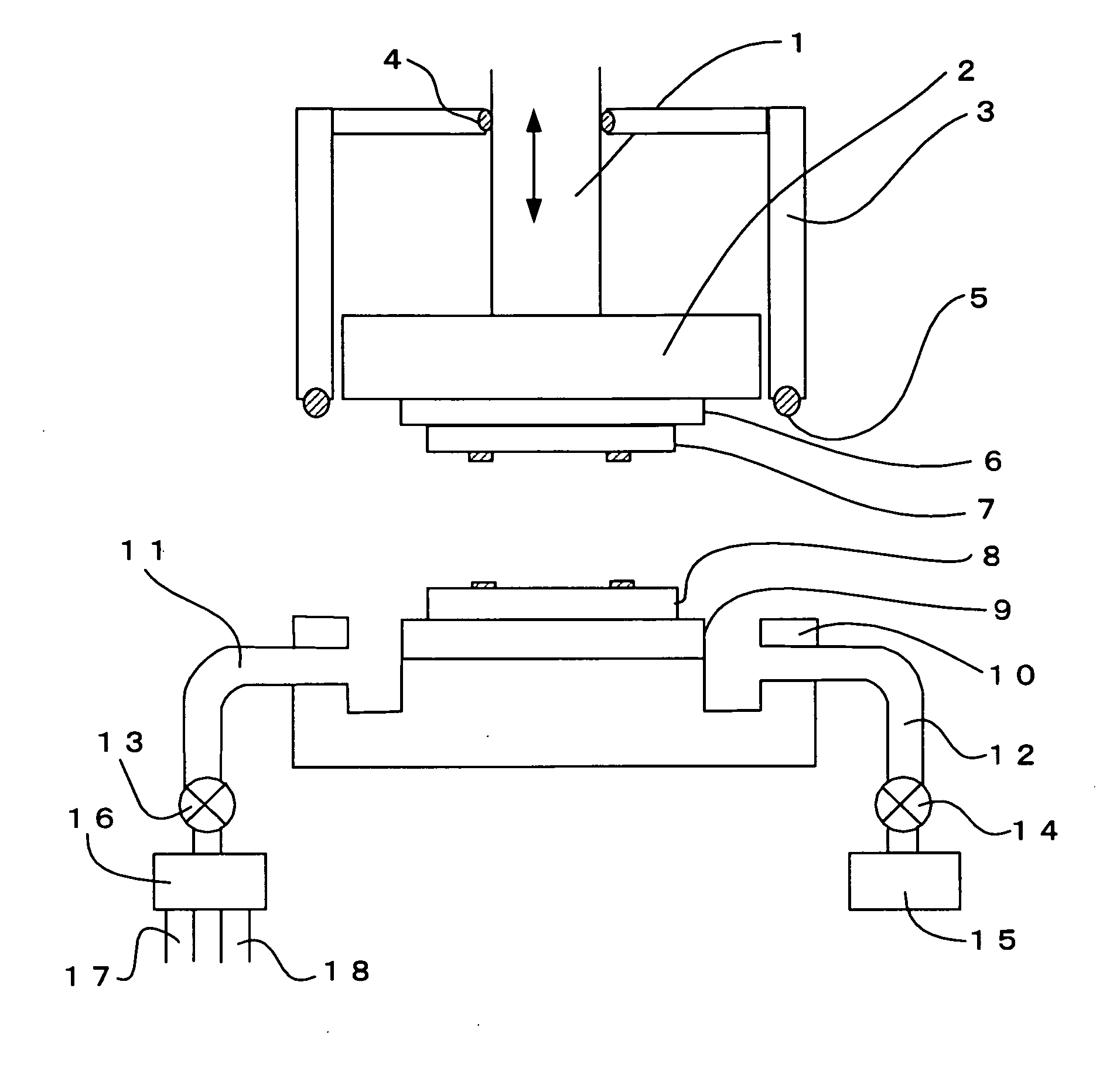

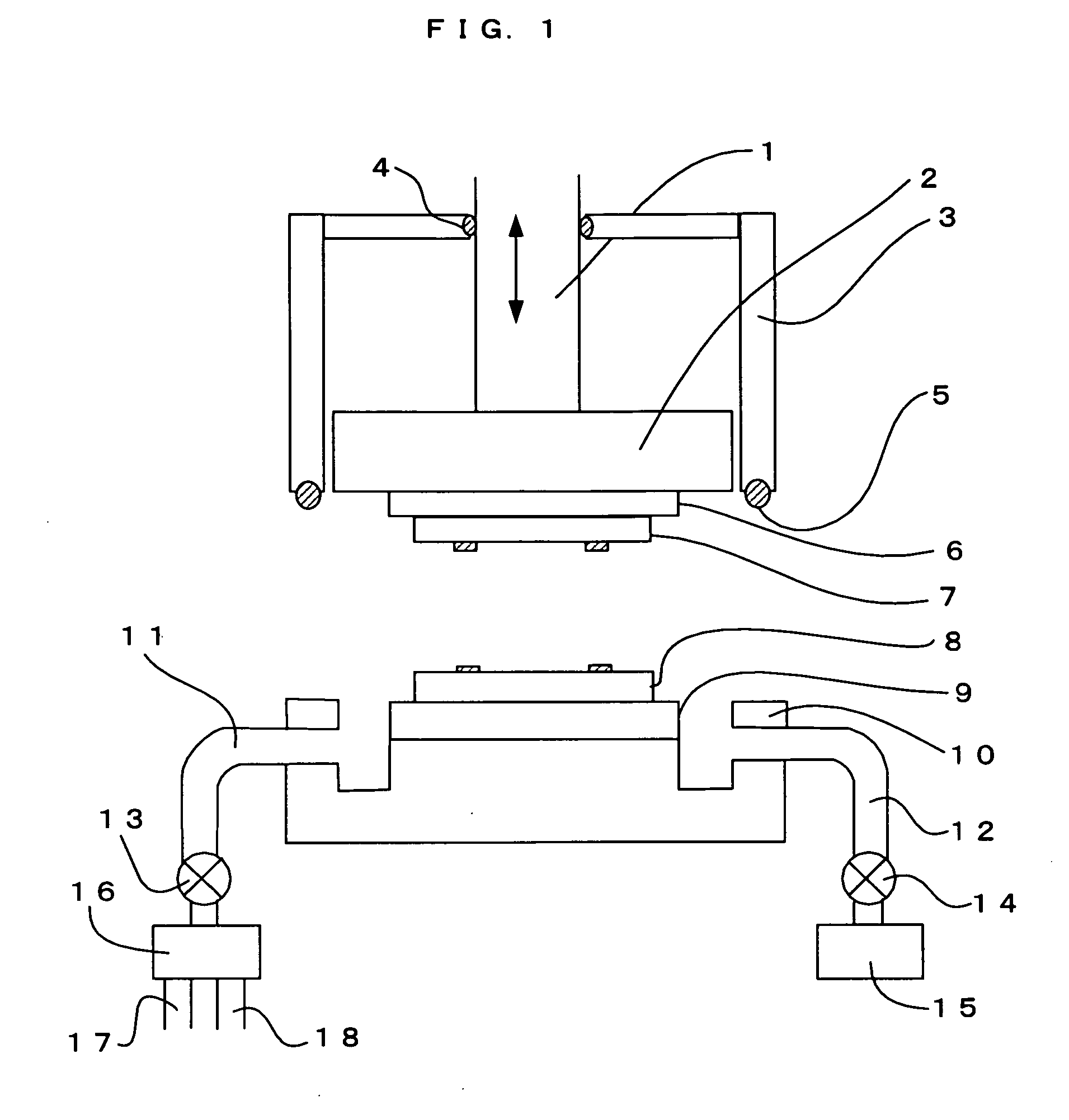

Bonding method, device produced by this method, and bonding device

ActiveUS20070111471A1High bonding strengthIncrease productivitySemiconductor/solid-state device manufacturingMicrostructural device assemblyThermal expansionEngineering

Conventional heat bonding and anodic bonding require heating at high temperature and for a long time, leading to poor production efficiency and occurrence of a warp due to a difference in thermal expansion, resulting in a defective device. Such a problem is solved. An upper wafer 7 made of glass and a lower wafer 8 made of Si are surface-activated using an energy wave before performing anodic bonding, thereby performing bonding at low temperature and increasing a bonding strength. In addition, preliminary bonding due to surface activation is performed before main bonding due to anodic bonding is performed in a separate step or device, thereby increasing production efficiency, and enabling bonding of a three-layer structure without occurrence of a warp.

Owner:BONDTECH

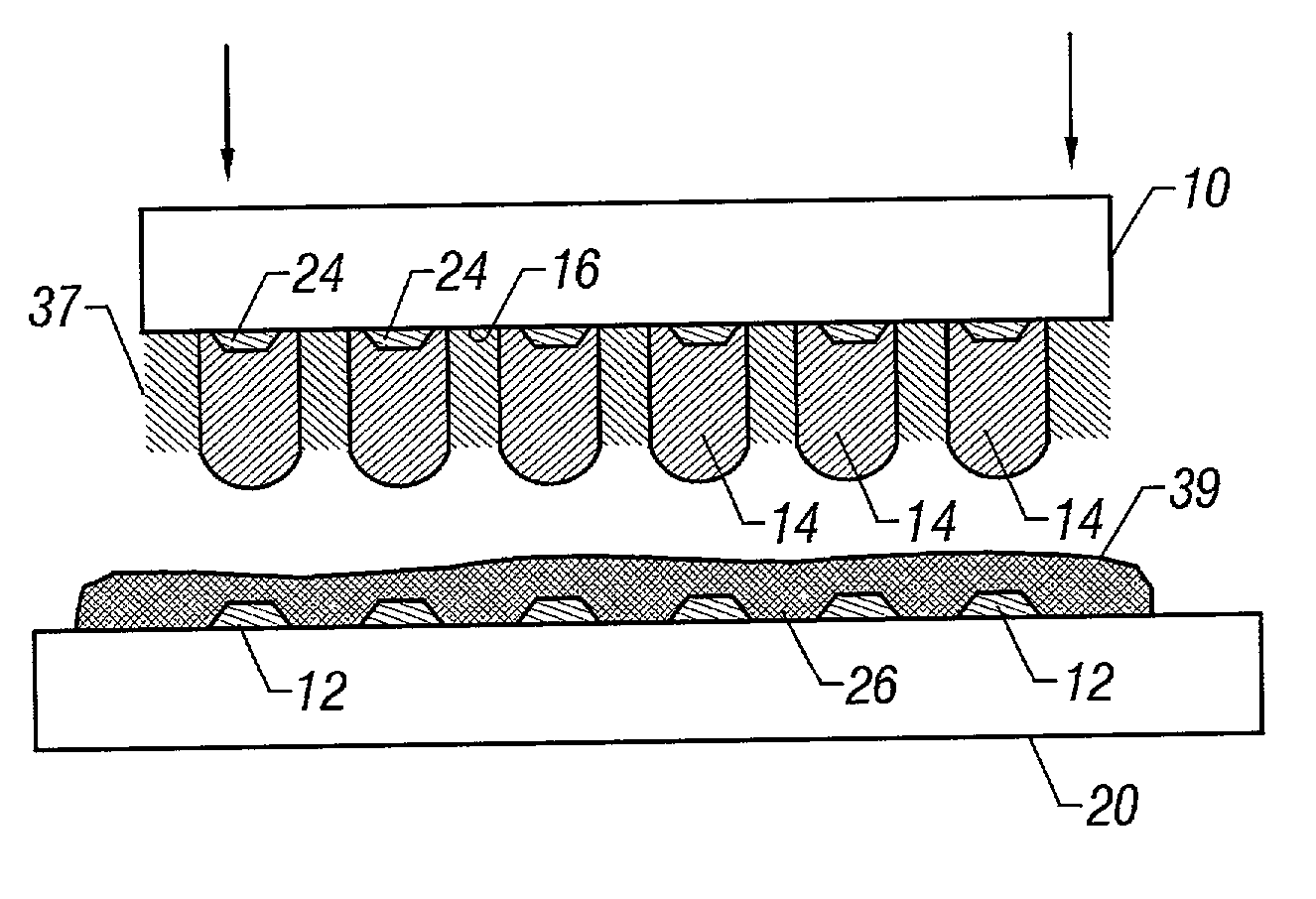

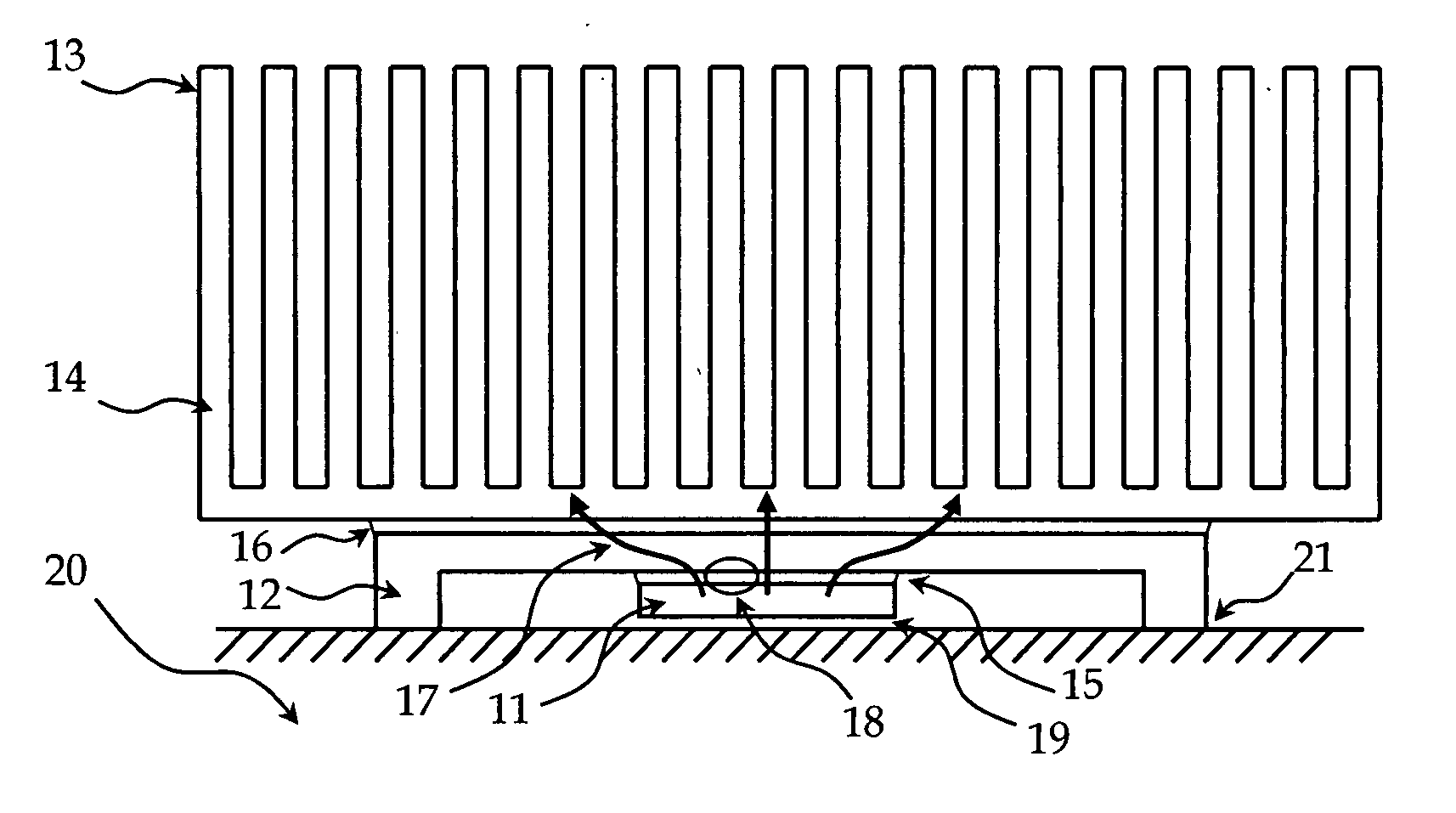

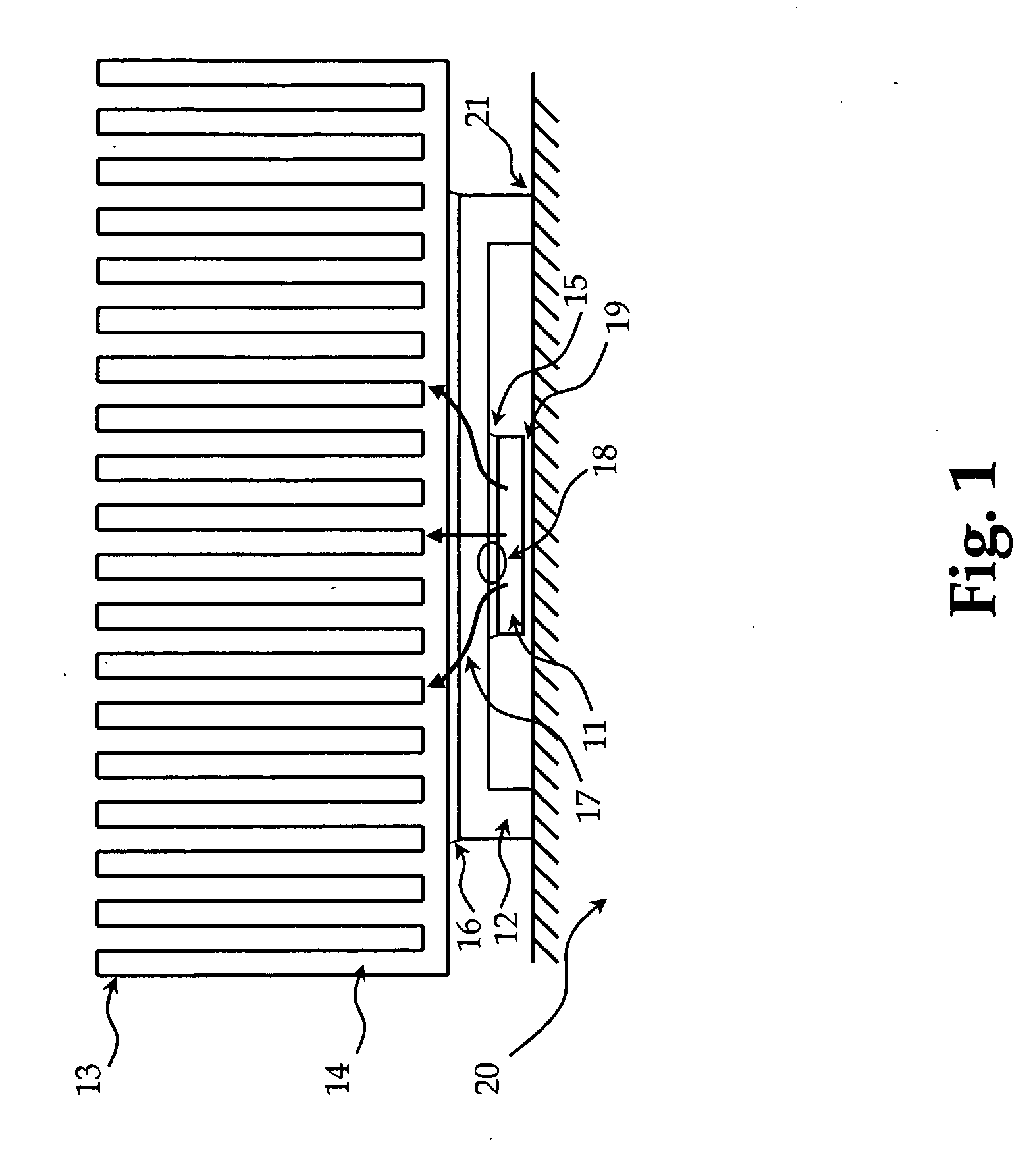

Aligned nanostructure thermal interface material

InactiveUS20050255304A1Wide gapMaterial nanotechnologySemiconductor/solid-state device detailsCarbon nanotubeThermal expansion

The invention relates to a thermal interface material comprising aligned nanostructures to increase the thermal conductivity of an electronic assembly. Aligned carbon nanotubes are a particularly suitable nanostructure possessing very high thermal conductivity. The novel use of nanostructures in the invention is particularly applicable to solving the issues of thermal expansion of the electronic assembly over time.

Owner:BRINK DAMON

Heat curable, thermally expandable composition with high degree of expansion

Compositions containing at least one liquid epoxy resin, at least one solid epoxy resin, at least one propellant, at least one curing agent and at least one mica-containing filler produce expandable, thermally curable binder systems which may be used without the addition of hollow glass beads for the production of stiffening and reinforcing laminates and for the production of stiffening and reinforcing mouldings. Said laminates according to the invention are suitable for the stiffening and reinforcing of components, in particular in the automotive industry, such as car body frames, doors, boot lids, engine bonnets and / or roof parts. In addition, the mouldings that may be produced from said binders are suitable for the stiffening and reinforcing of hollow metal structures, in particular of hollow car body parts such as body frames, body supports and posts or doors in the automotive industry.

Owner:HENKEL KGAA

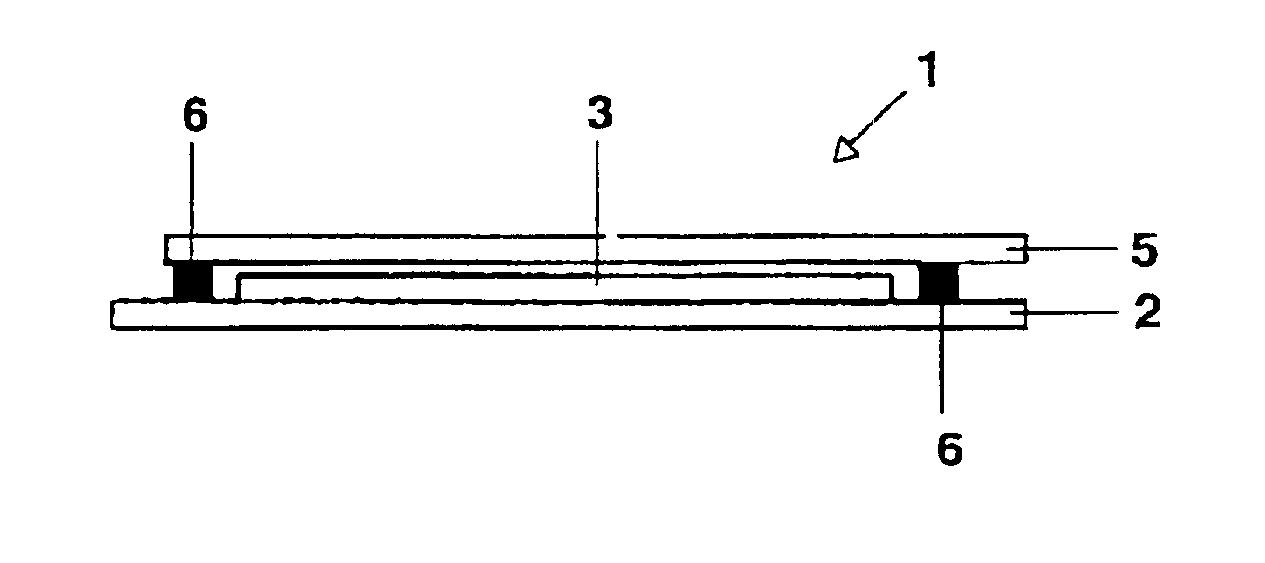

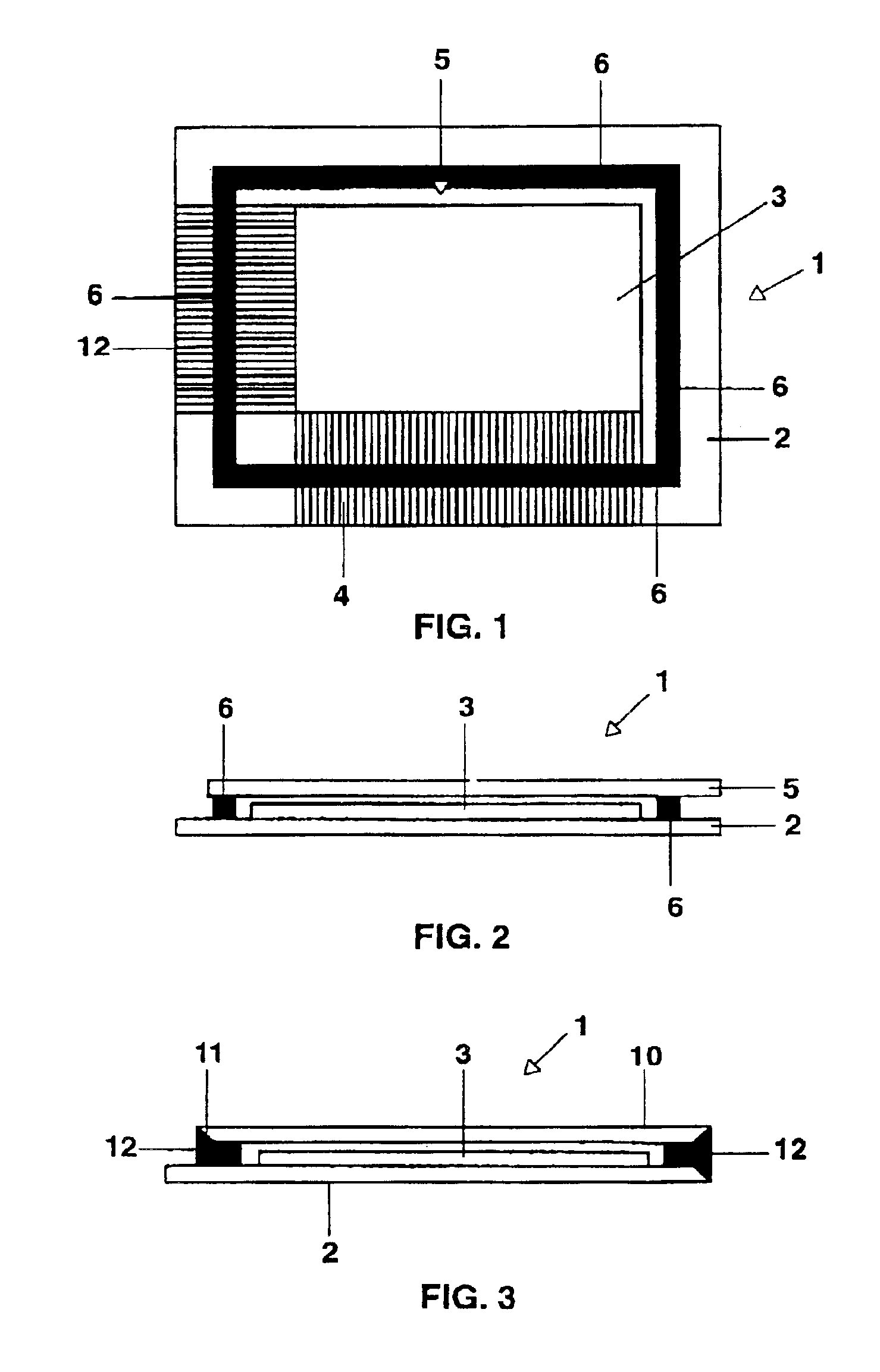

Process for encapsulating a component made of organic semiconductors

InactiveUS6936963B2Improve sealingLong life-timeDischarge tube luminescnet screensElectroluminescent light sourcesElectrical connectionThermal expansion

A process for encapsulating a component made of organic semiconductors is provided which includes steps of: a) providing a housing including a substrate with electrical connections and a cover; b) mixing a soldering glass with at least one of a binder and a solvent; c) applying the soldering glass at least to the cover, in the form of an encircling bank; d) expelling the binder or solvent; e) sintering-on of the solder; f) covering the substrate with layers which represent the semiconductor component together with electrodes; g) placing the cover onto the substrate; and h) locally heating the soldering glass by means of a light source with a predetermined peak wavelength, wherein the housing parts and soldering glass are matched to one another such that their coefficients of thermal expansion differ from one another by less than 1.0×10−6K−1.

Owner:PATENT TREUHAND GES GMBH

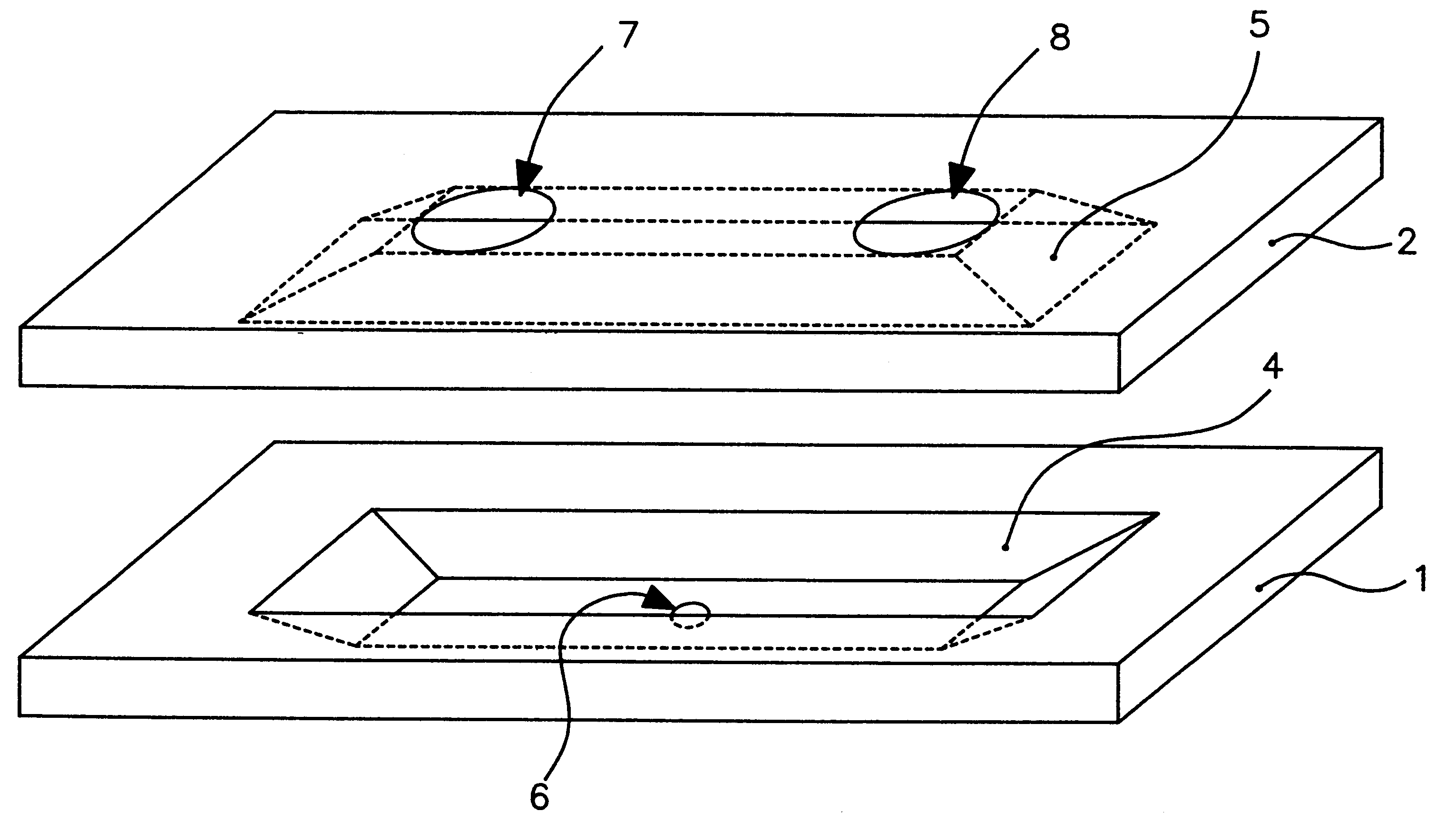

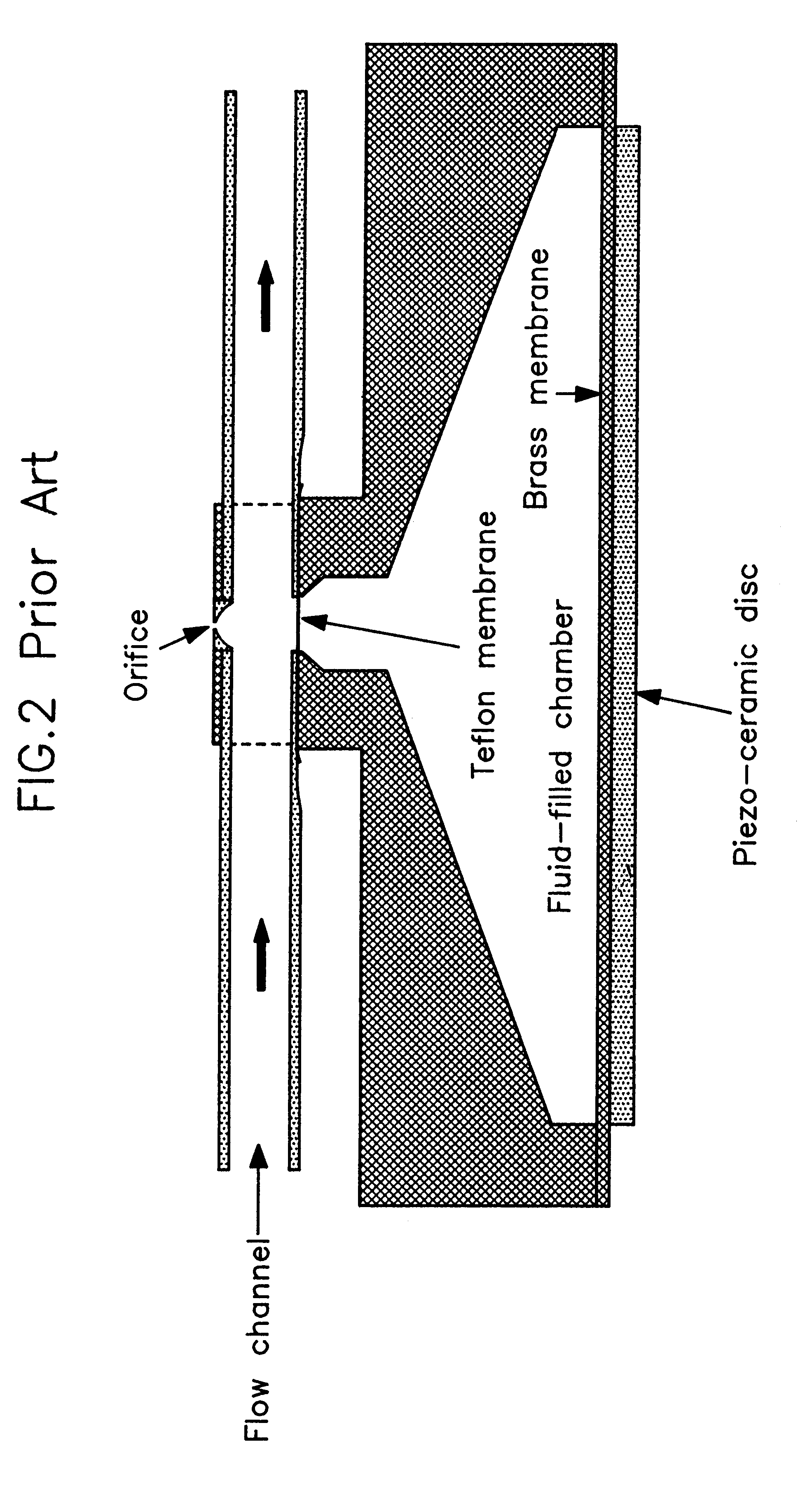

Flow-through sampling cell and use thereof

InactiveUS6192768B1Complicate and expensiveDestroy characteristicComponent separationTransportation and packagingElectricityEngineering

A sampling cell of flow-through type and use of such a sampling cell. The sampling cell is preferably manufactured by etching of silicon wafers. It is especially useful for continuous picovolume sampling in an analytical flow. The pressure pulse generator (9) generates pulses directly into a flow channel (3). The flow channel (3) is preferably formed by a first basin (4) in a first structure (1) and a second basin (5) in a second structure (2). In a first embodiment the pressure pulse generator (9) comprises at least one piezo-ceramic disc and / or devices acting by way of magnetostrictive, electrostatical or electromechanical forces and / or devices acting by way of thermal expansion. Method of directing samples from a flow-through sampling cell by establishing a difference in electrical potential between the liquid in the flow-through sampling cell and the object to which the samples are to be directed. Use of a flow-through sampling cell for coating of surfaces, especially for achieving biospecific surfaces, for extracting samples from a continuous liquid flow, for extracting a precise sample amount by collecting a defined number of samples or for injecting samples for electrophoresis, especially capillary electrophoresis, and for electrochromatography.

Owner:GYROS

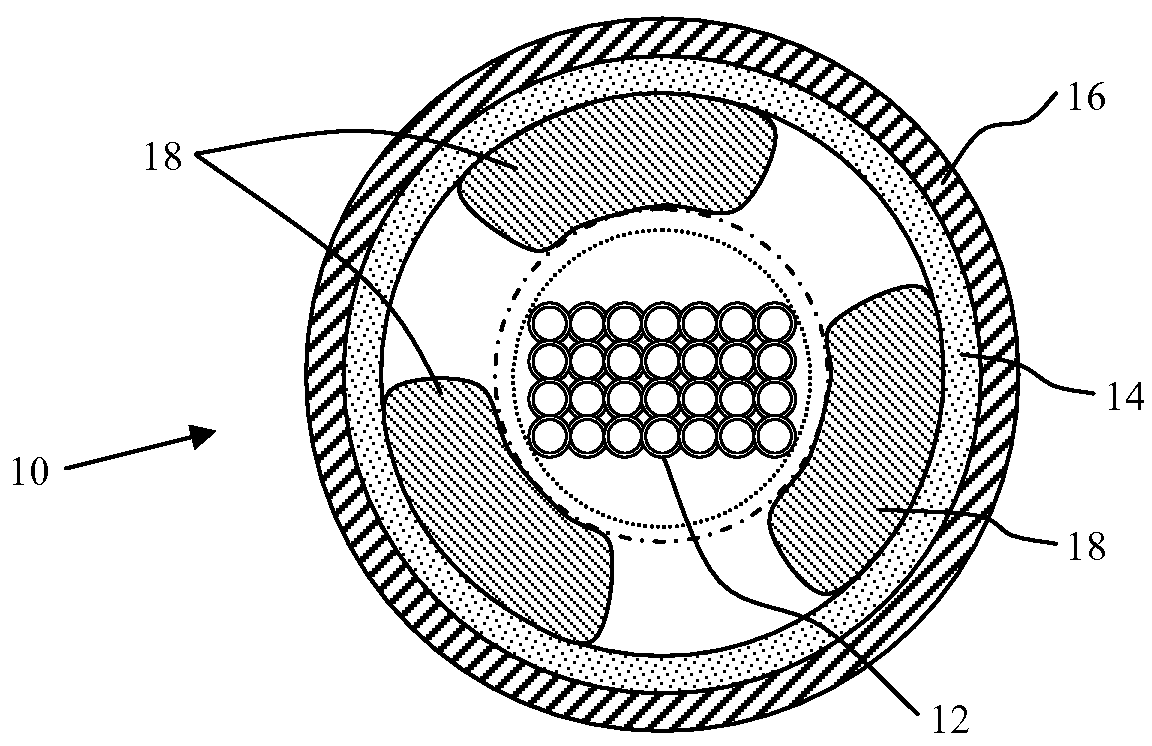

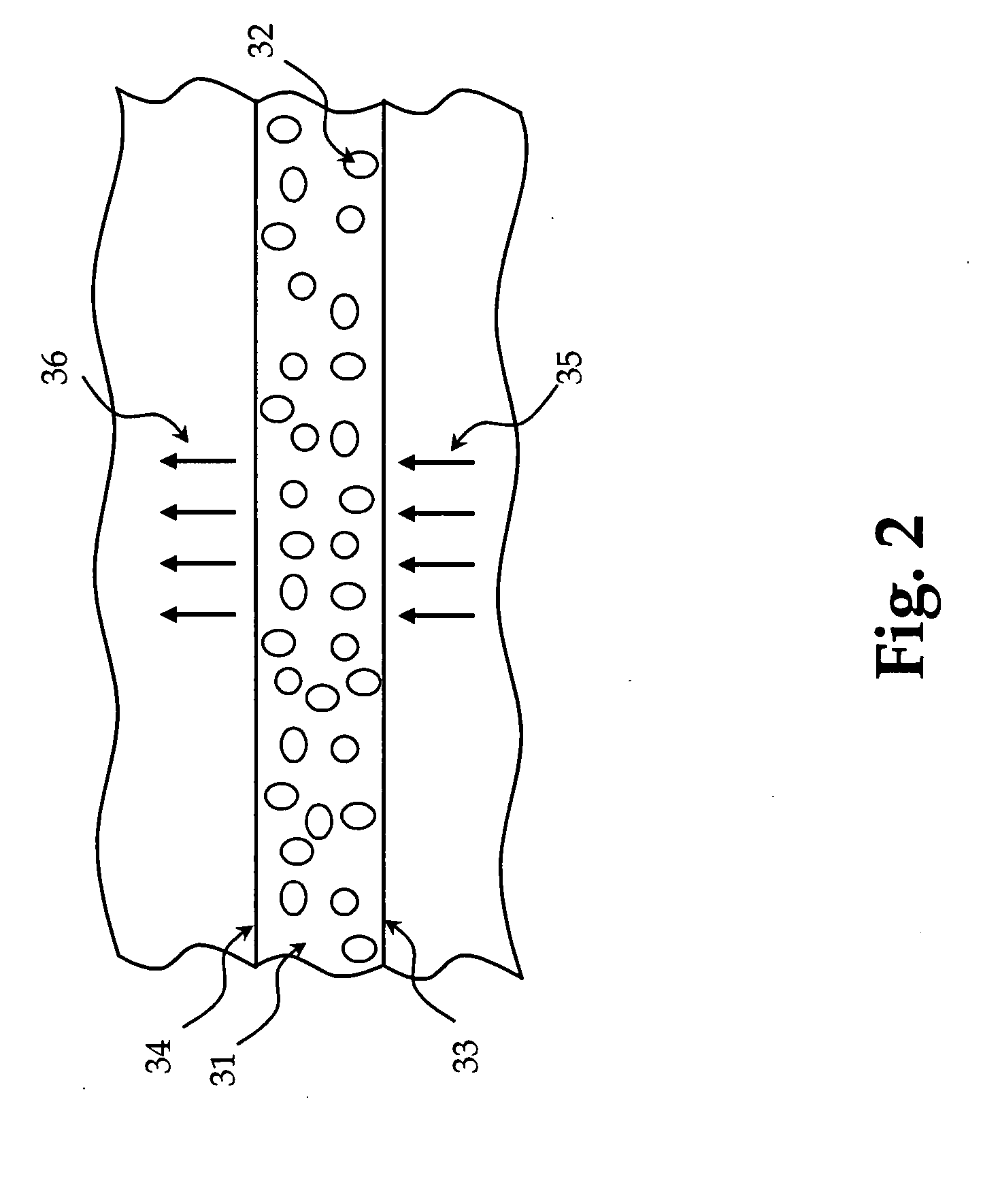

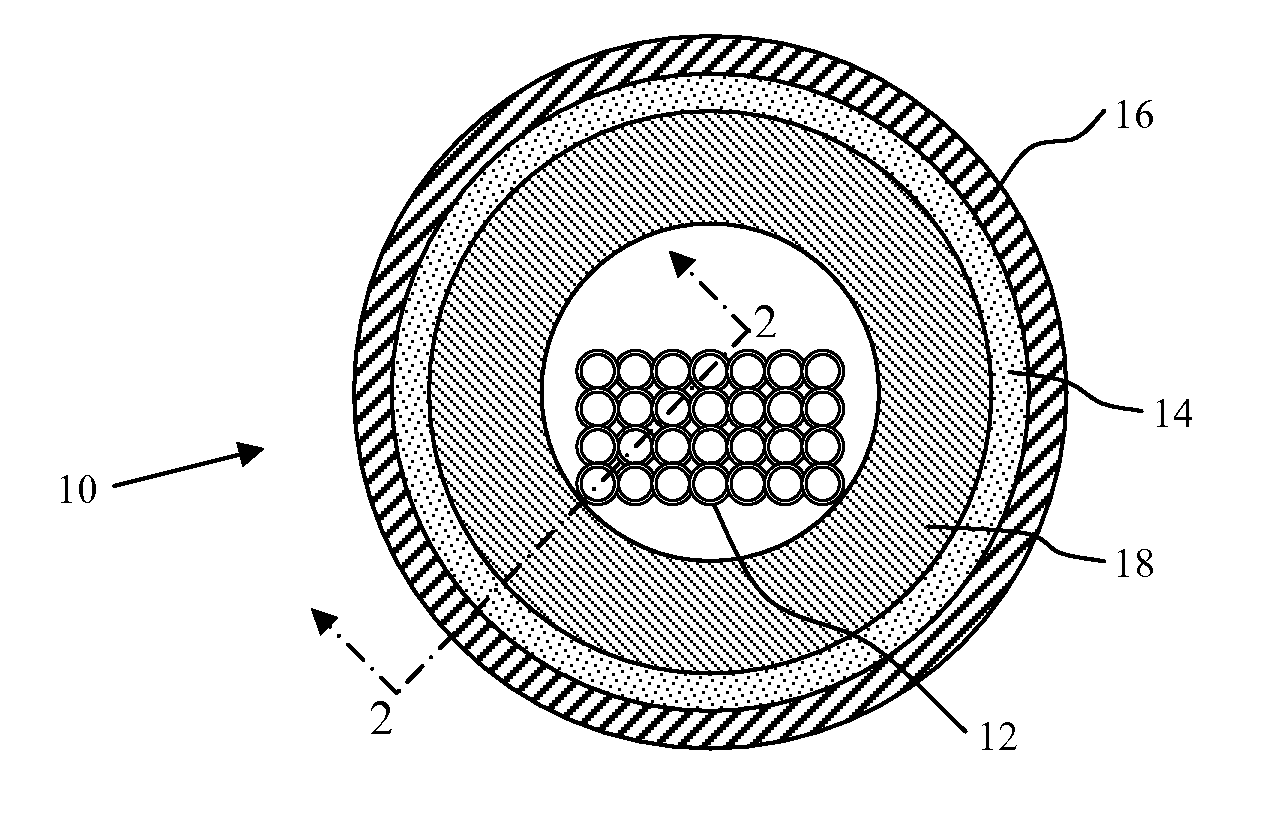

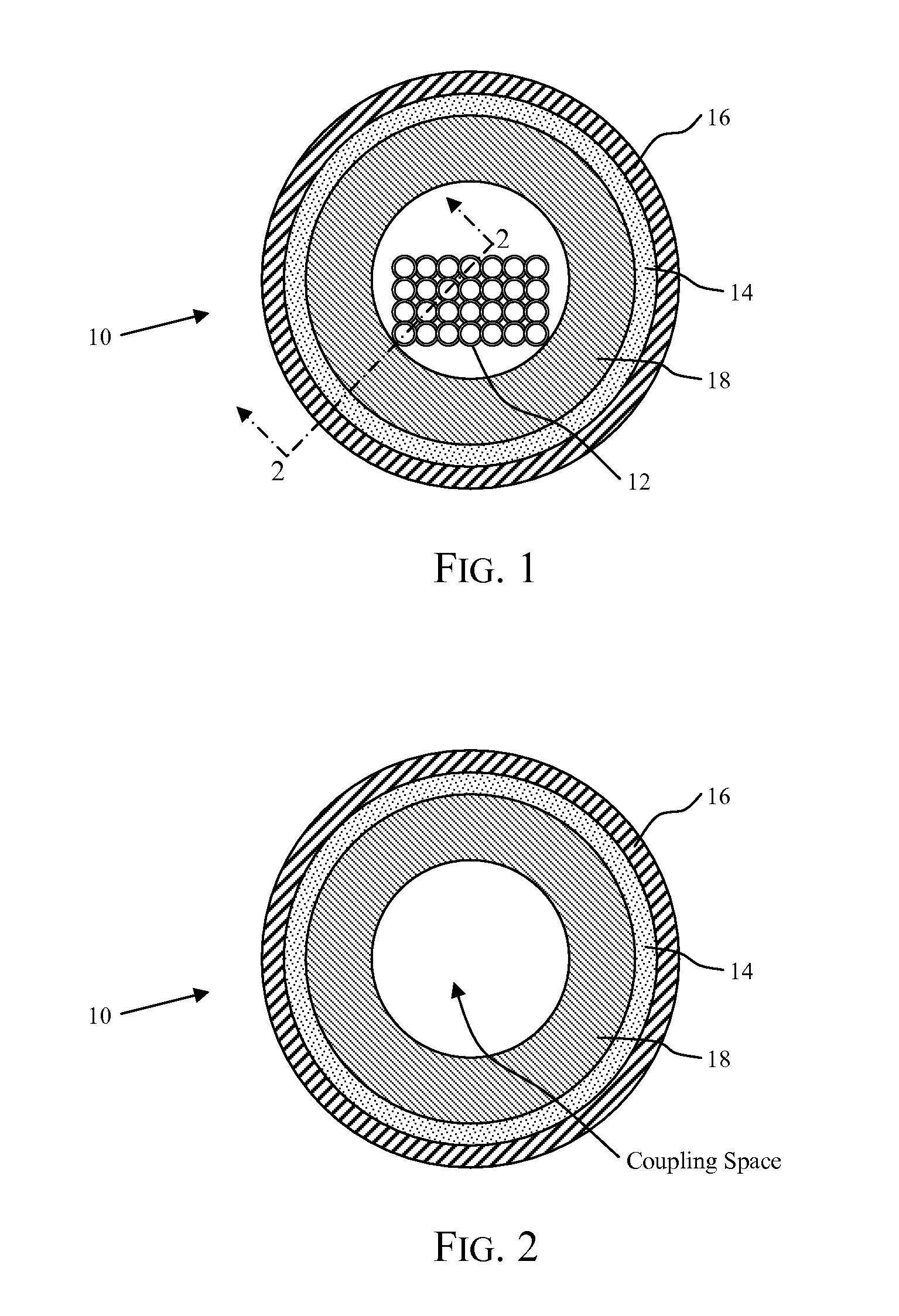

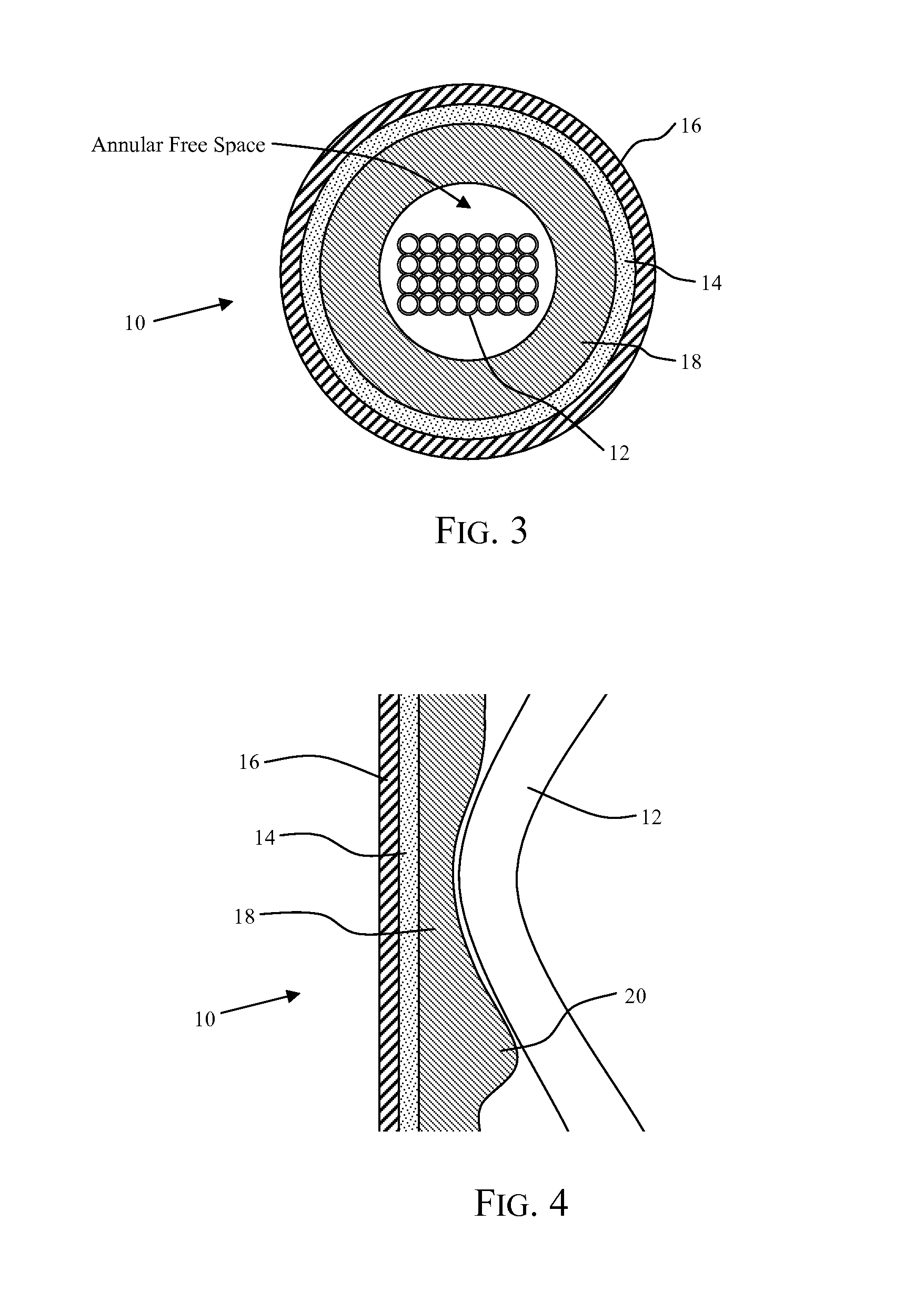

Optical Fiber Cable Having A Deformable Coupling Element

InactiveUS20090003781A1Reduce collectionInhibitionGlass making apparatusFibre mechanical structuresThermal dilatationEngineering

Disclosed is an optical fiber cable that includes optical fibers and a deformable coupling element enclosed within a buffer tube. The coupling element is formed from a deformable yet substantially incompressible material that is capable of releasably and intermittently coupling the optical fibers to the buffer tube in various orientations. The design of the coupling element layer permits coupling of the optical fibers to the buffer tube without the use of a compressive cushioning layer and yet permits localized movement the optical fibers relative to the buffer tube to account for disparate thermal expansion and to accommodate optical fiber placement.

Owner:DRAKA COMTEQ BV

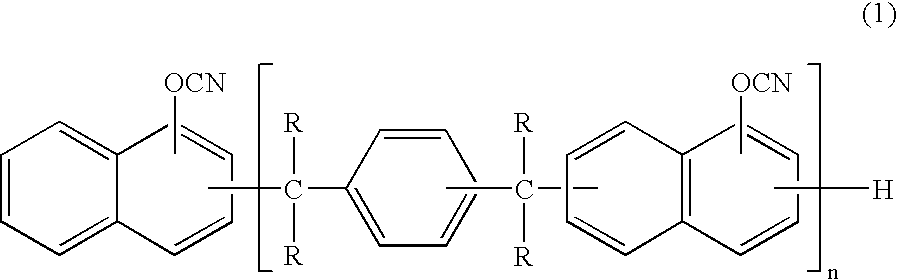

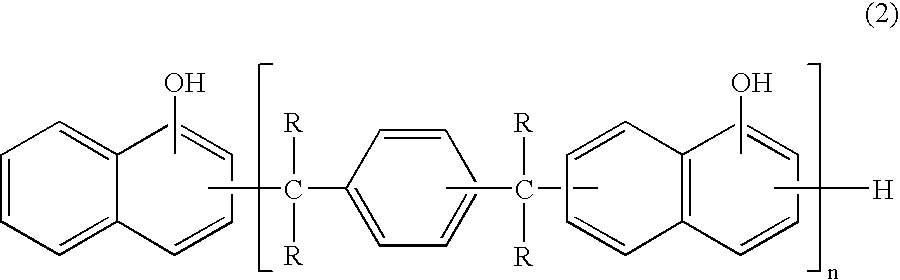

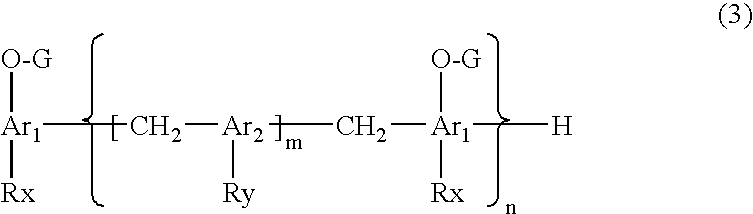

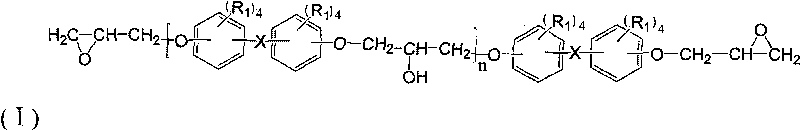

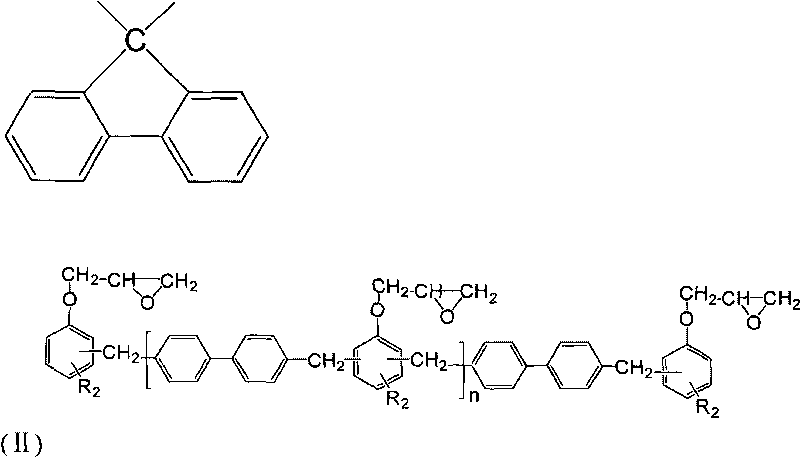

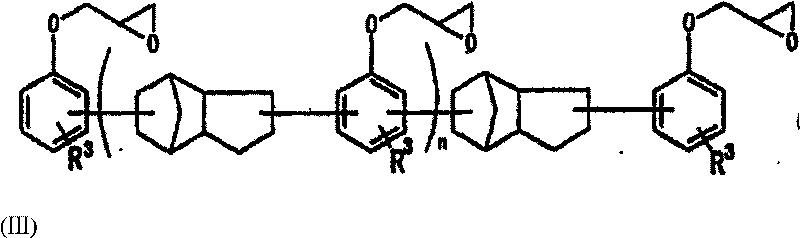

Prepreg and laminate

ActiveUS20090017316A1Improve flame retardant performanceImprove heat resistanceSpecial tyresElectrical equipmentThermal dilatationPolymer science

A prepreg for a printed wiring board, comprising a cyanate ester resin having a specific structure, a non-halogen epoxy resin, a silicone rubber powder as a rubber elasticity powder, an inorganic filler and a base material, which prepreg retains heat resistance owing to a stiff resin skeleton structure, has high-degree flame retardancy without the use of a halogen compound or a phosphorus compound as a flame retardant, and has a small thermal expansion coefficient in plane direction without using a large amount of inorganic filler, and a laminate comprising the above prepreg.

Owner:MITSUBISHI GAS CHEM CO INC

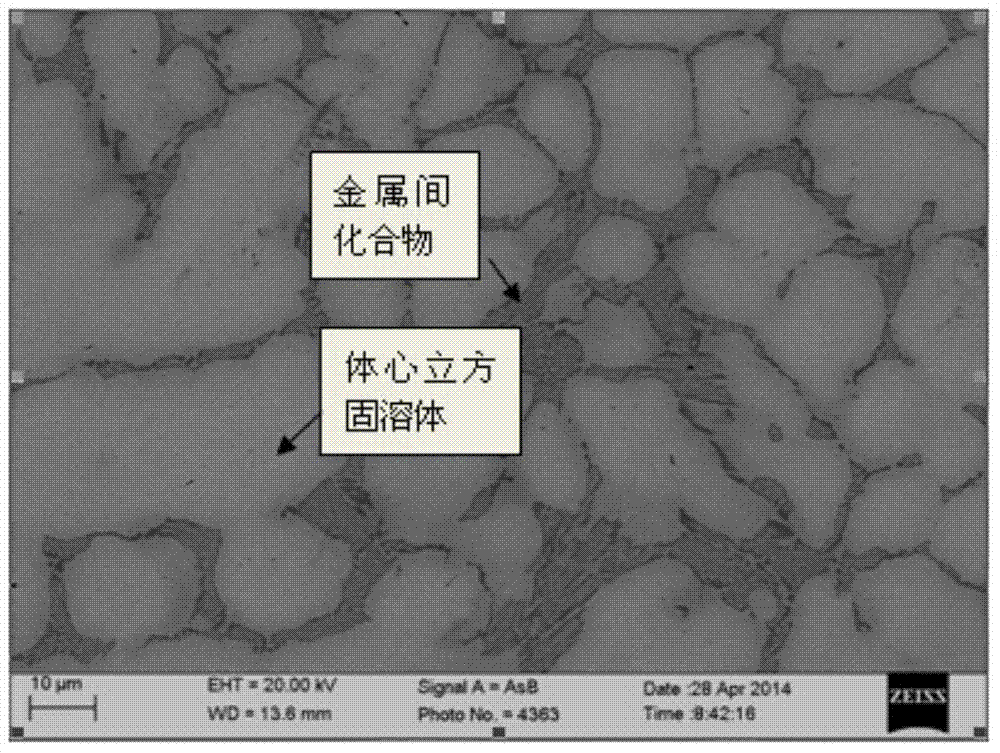

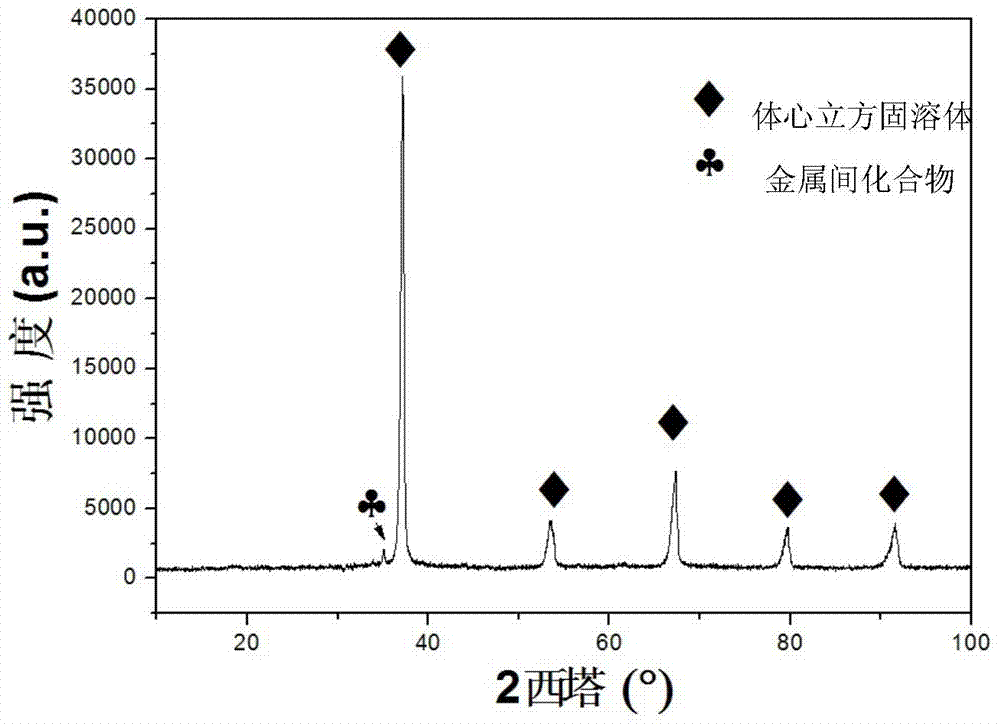

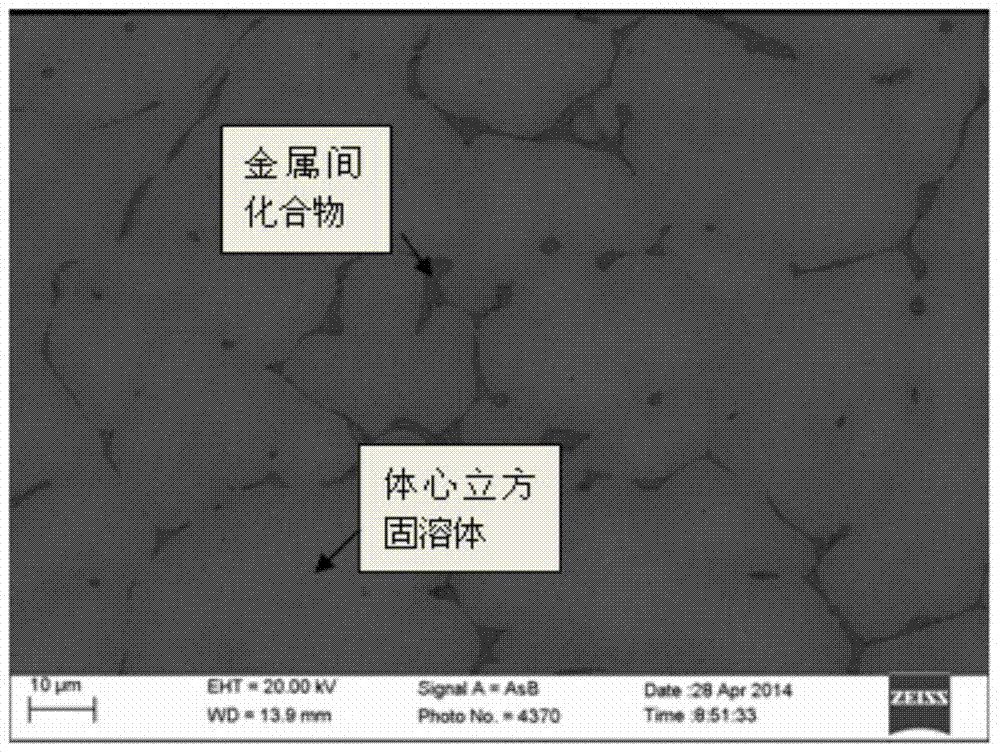

Low thermal expansion coefficient NaMxAlySiz high entropy alloy and preparation method thereof

The invention relates to a low thermal expansion coefficient NaMxAlySiz high entropy alloy and a preparation method thereof, the chemical components of the alloy are as follows: 75 <= a <= 100%, 0 <= x <= 10%, 0<= y<= 10%, 0<= z<= 5%, N is arbitrary three or more than three of Ta, Nb, Hf, Zr, Ti, Mo and W, and M is any one or more than one of V, Mn, Fe, Co, Ni and Cr. The alloy phase structure is as follows: a body centered cubic solid solution and an intermetallic compound. The alloy is prepared by arc melting method in three stages. The NaMxAlySiz high entropy alloy has a low thermal expansion coefficient at the temperature in the range of room temperature to 1000 DEG C, the change rate is less than 20%, and the alloy has a broad application prospect in the high temperature industrial field.

Owner:UNIV OF SCI & TECH BEIJING

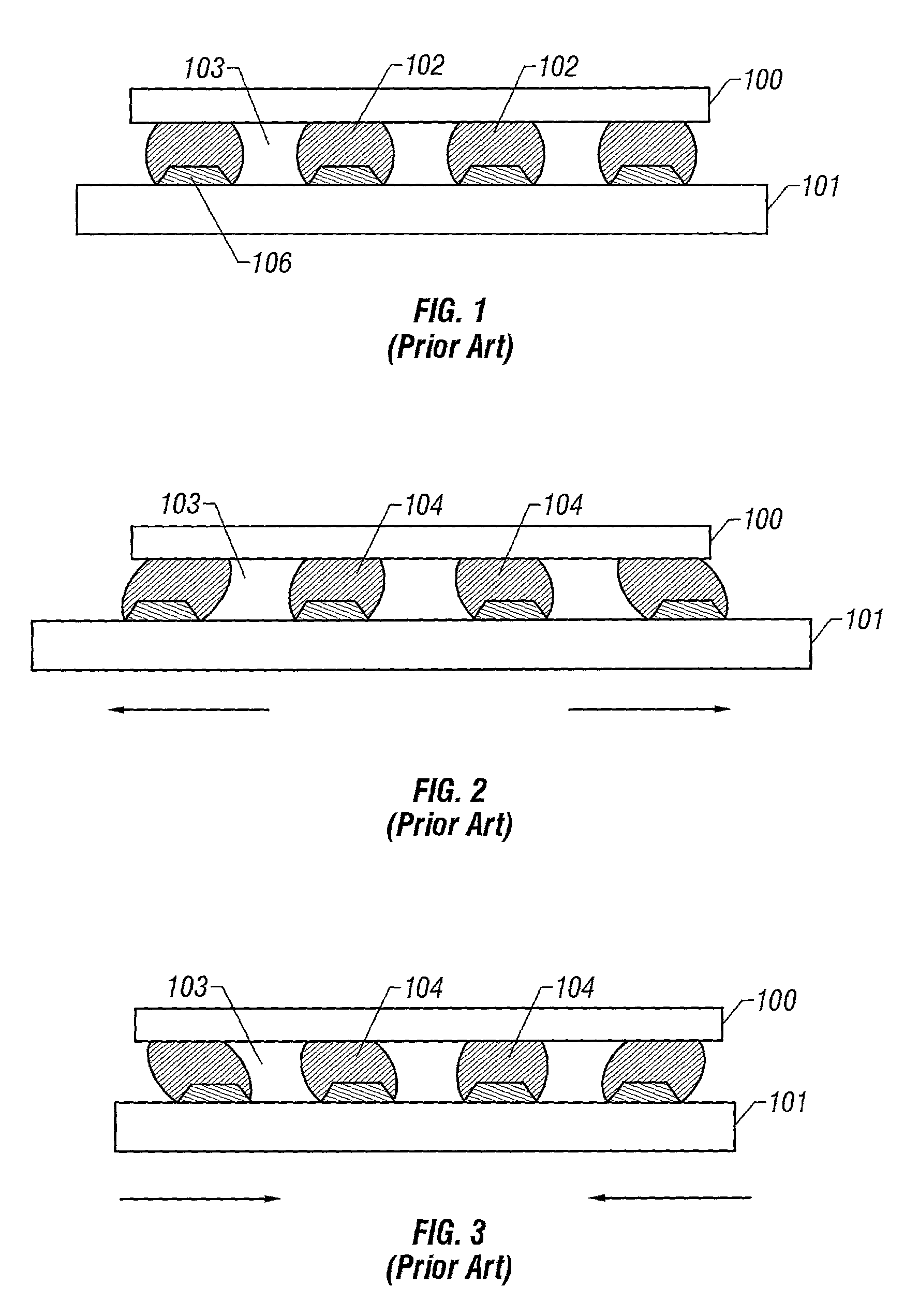

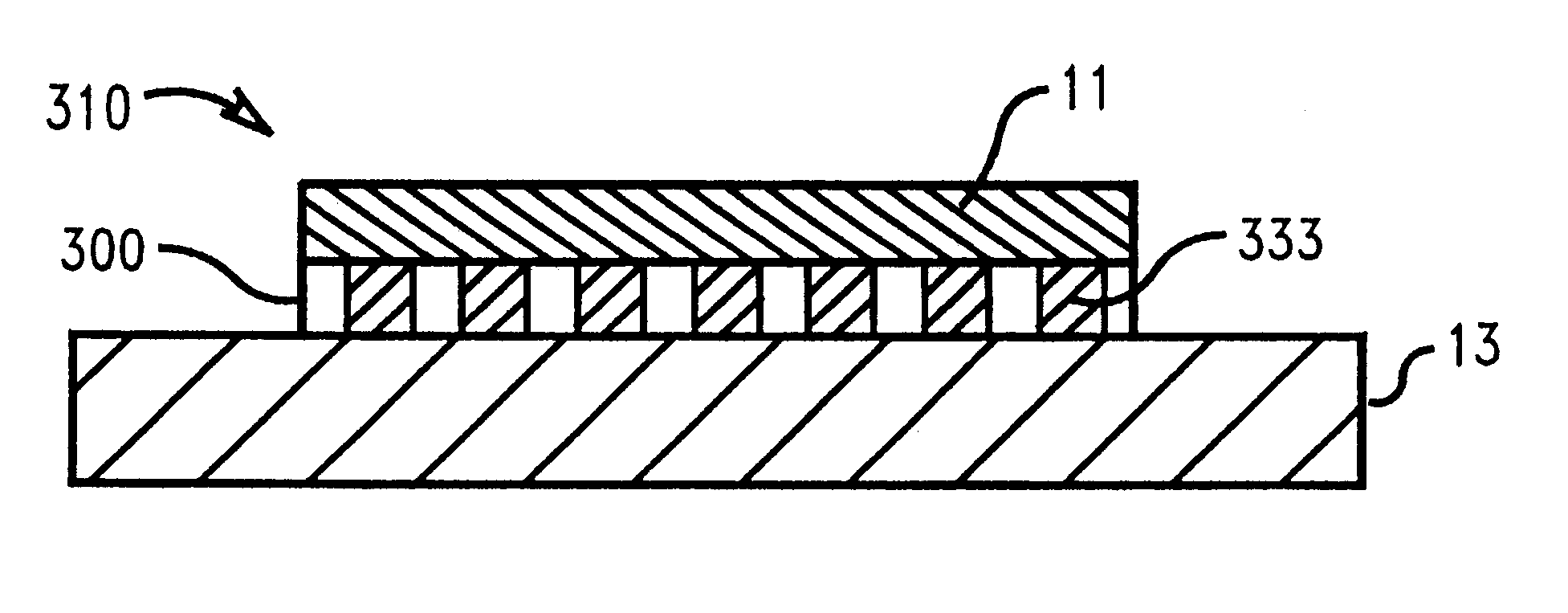

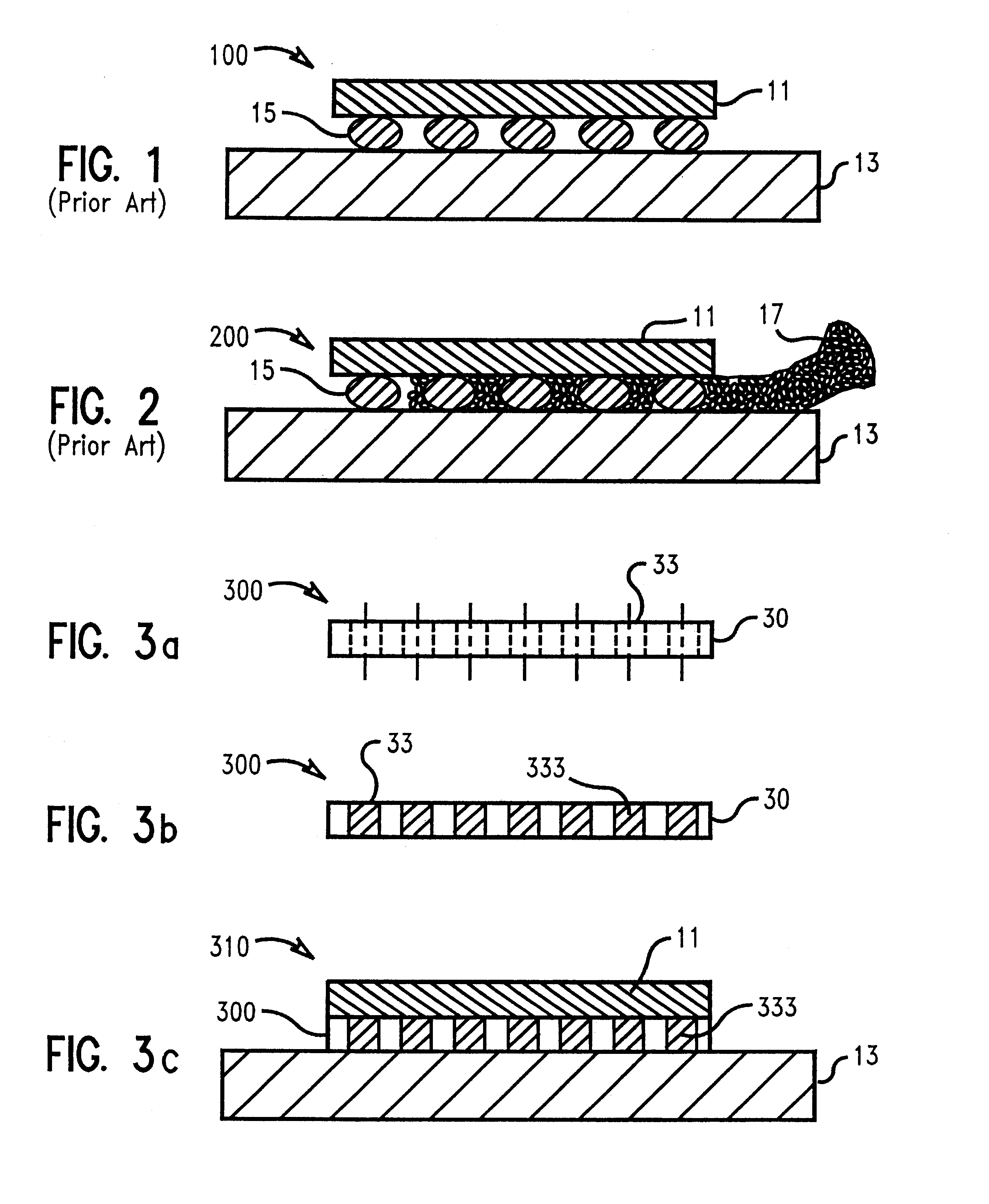

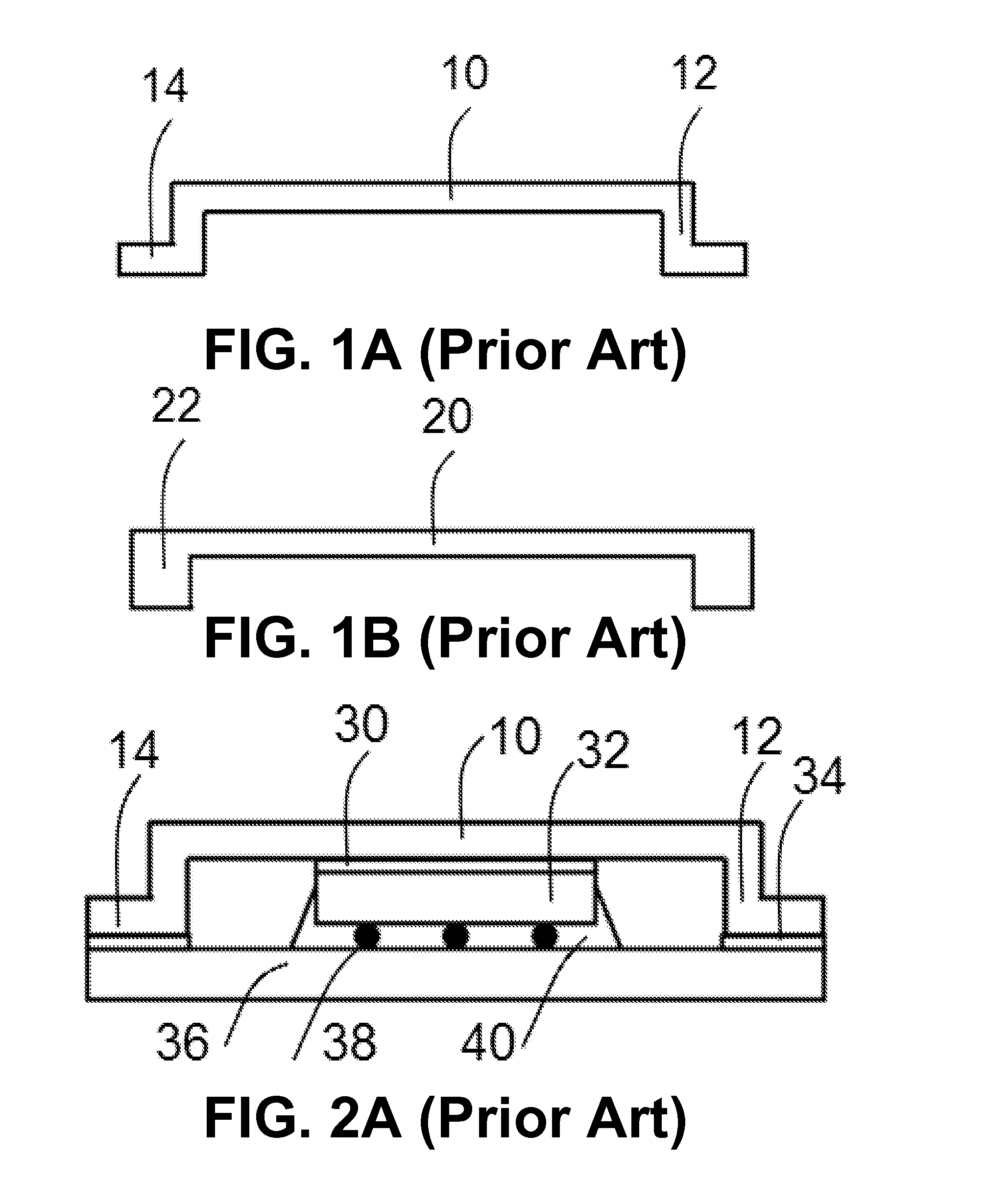

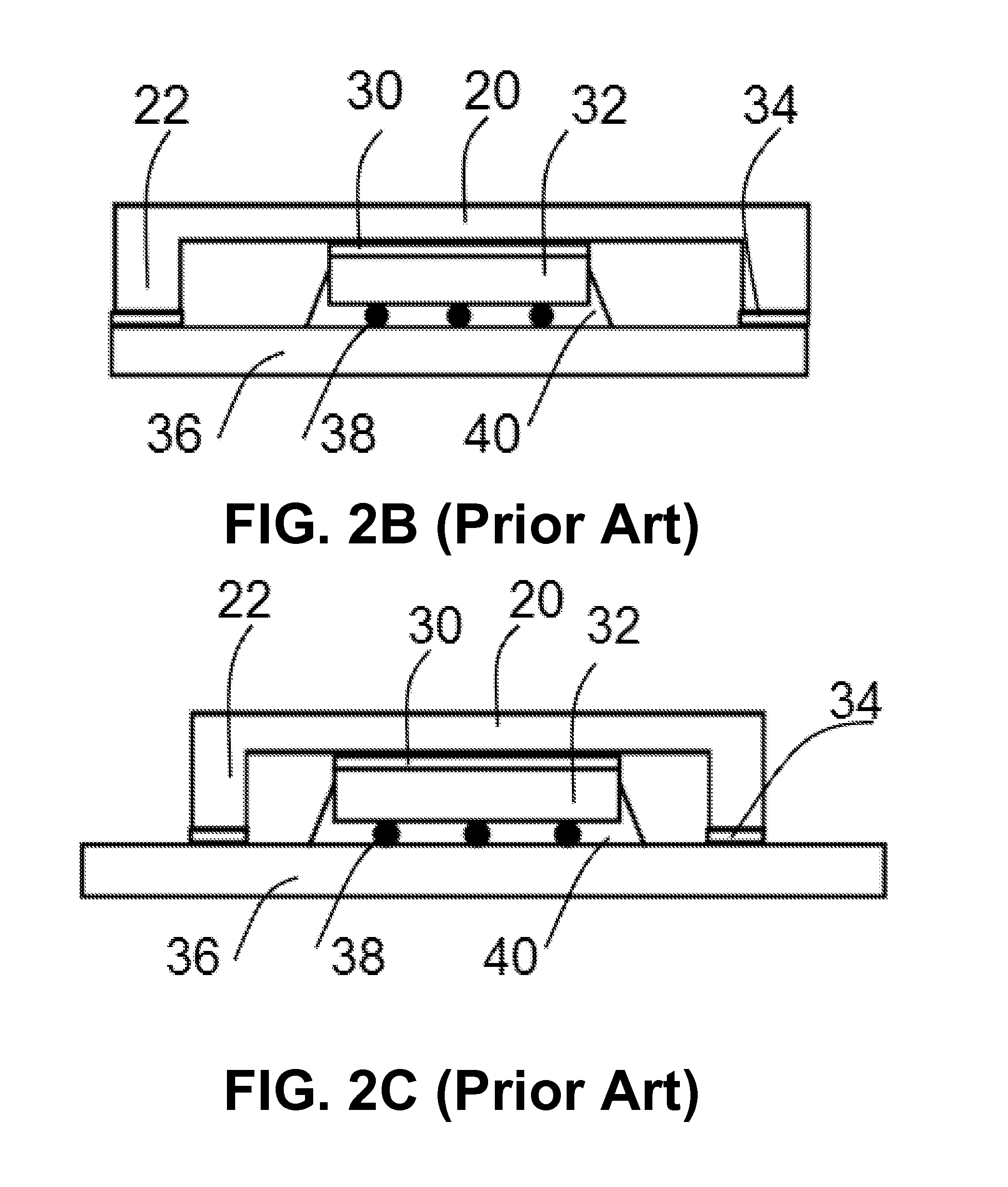

Underfill preform interposer for joining chip to substrate

An apparatus for and method of minimizing the thermo-mechanical fatigue of flip-chip packages. The interposer of the present invention, preferably comprising an organic polymer such as polyimide, contains apertures having conductive plugs inserted therein for joining a chip to a substrate in an electronic module utilizing flip-chip packaging. The interposer is selected to provide optimum spacing between the chip and substrate having a coefficient of thermal expansion adapted to the thermal cycling temperature extremes of the module components. The interposer may comprise an inner core with two adhesive outer layers which may comprise different materials to promote adhesion at their respective interfaces within a module. Conductive plugs are disposed within the apertures of the interposer comprising of a first and second solder or comprising a conductive plug having top and bottom surfaces coated with a conductive adhesive. Preferably, the first solder is disposed within an interior of the apertures and the second solder is disposed within an exterior of the apertures such that the first solder is between a first portion and a second portion of the second solder. Upon reflow, the second solder is reflowed while the first solder remains solid.

Owner:IBM CORP

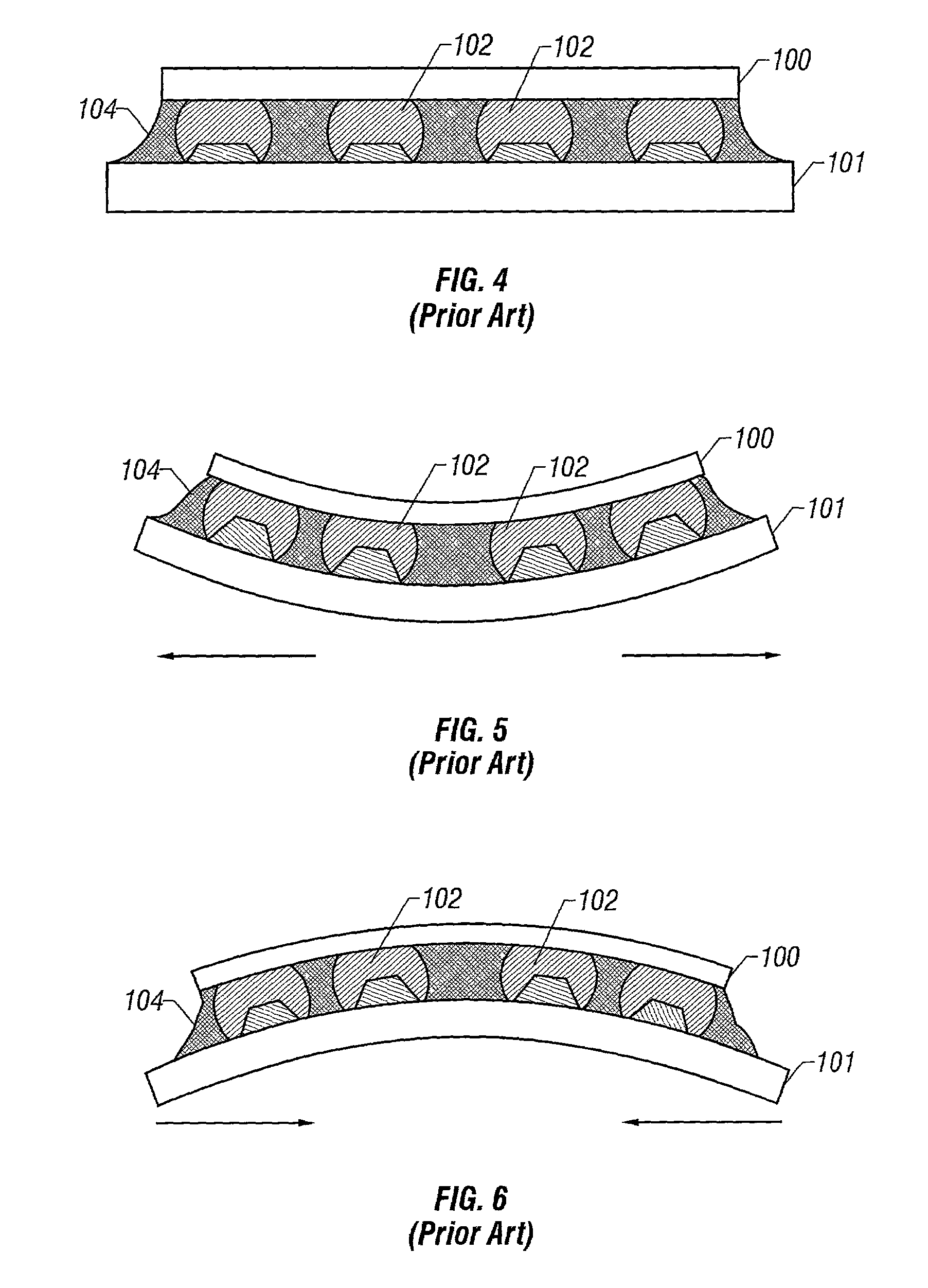

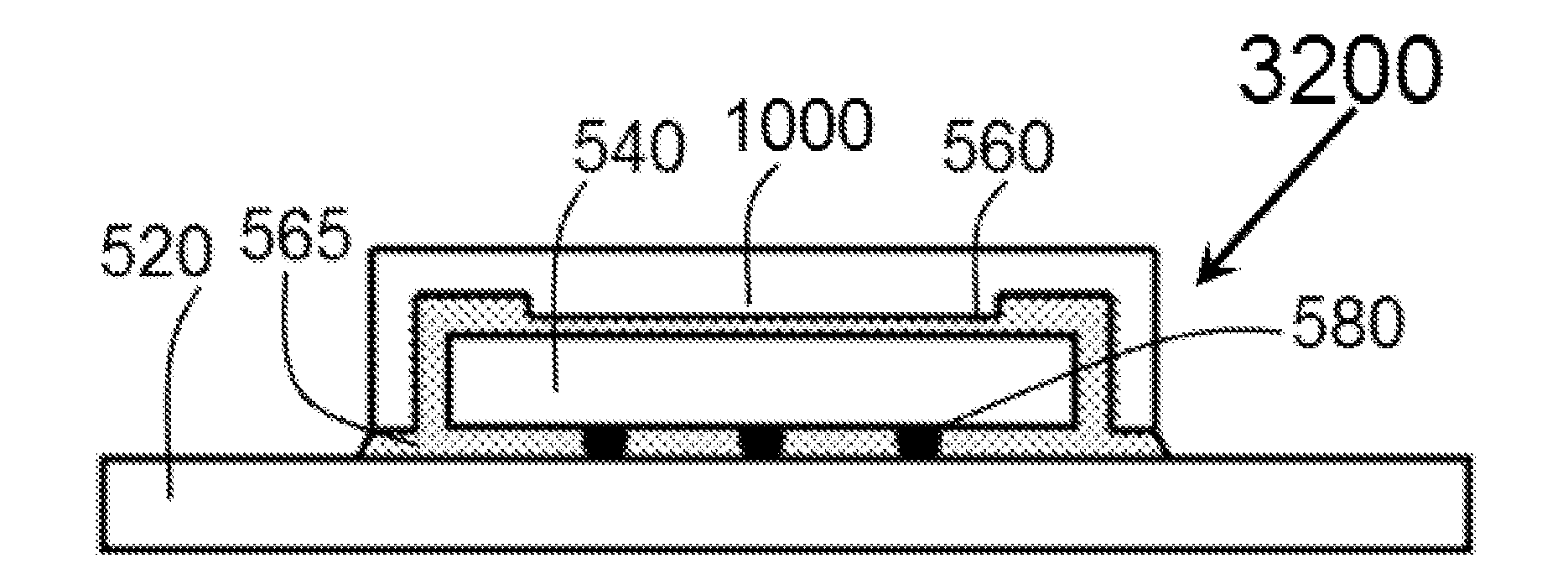

Die cap for use with flip chip package

InactiveUS20140091461A1Reduce riskImprove thermal efficiencySemiconductor/solid-state device detailsSolid-state devicesThermal dilatationThermal deformation

A die cap for use with flip chip packages, flip chip packages using a die cap, and a method for manufacturing flip chip packages with a die cap are provided in the invention. A die cap encases the die of flip chip packages about its top and sides for constraining the thermal deformation of the die during temperature change. The CTE (coefficient of thermal expansion) mismatch between the die and substrate of flip chip packages is the root cause for warpage and reliability issues. The current inventive concept is to reduce the CTE mismatch by using a die cap to constrain the thermal deformation of the die. When a die cap with high CTE and high modulus is used, the die with the die cap has a relatively high overall CTE, reducing the CTE mismatch. As a result, the warpage and reliability of flip chip packages are improved.

Owner:SHEN YUCI

Erosion-resistant components for plasma process chambers

An erosion-resistant article for use as a component in plasma process chamber. The erosion-resistant article comprises a support and an oxide coating comprising yttrium, which is disposed over the support. The support and the oxide coating preferably have material compositions that differ from one another in coefficient of thermal expansion by no more than 5x10<-6> / K. Preferred oxide coating compositions include yttria and yttrium aluminum garnet. Preferred supports include alumina supports and aluminum-silicon carbide supports.

Owner:APPLIED MATERIALS INC

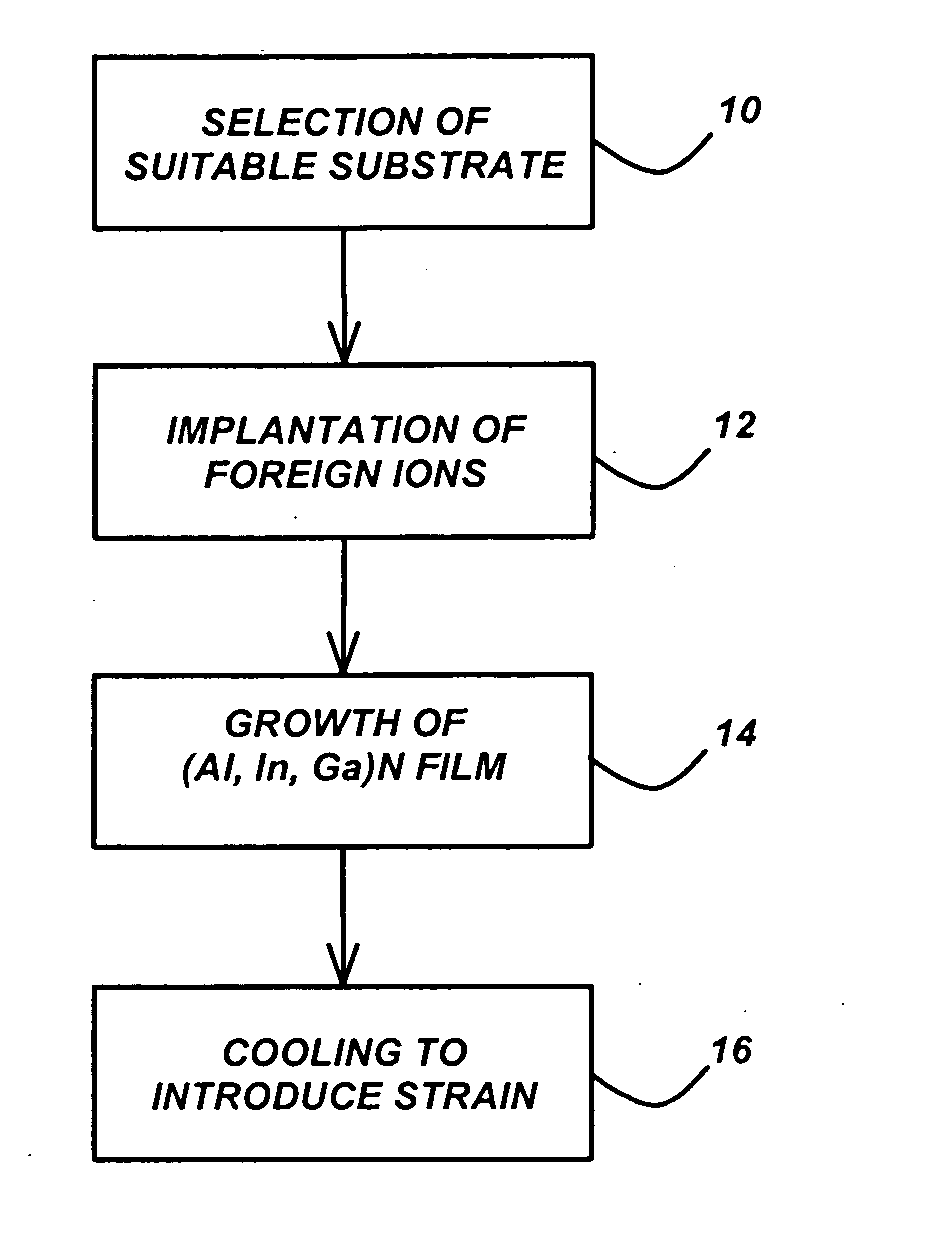

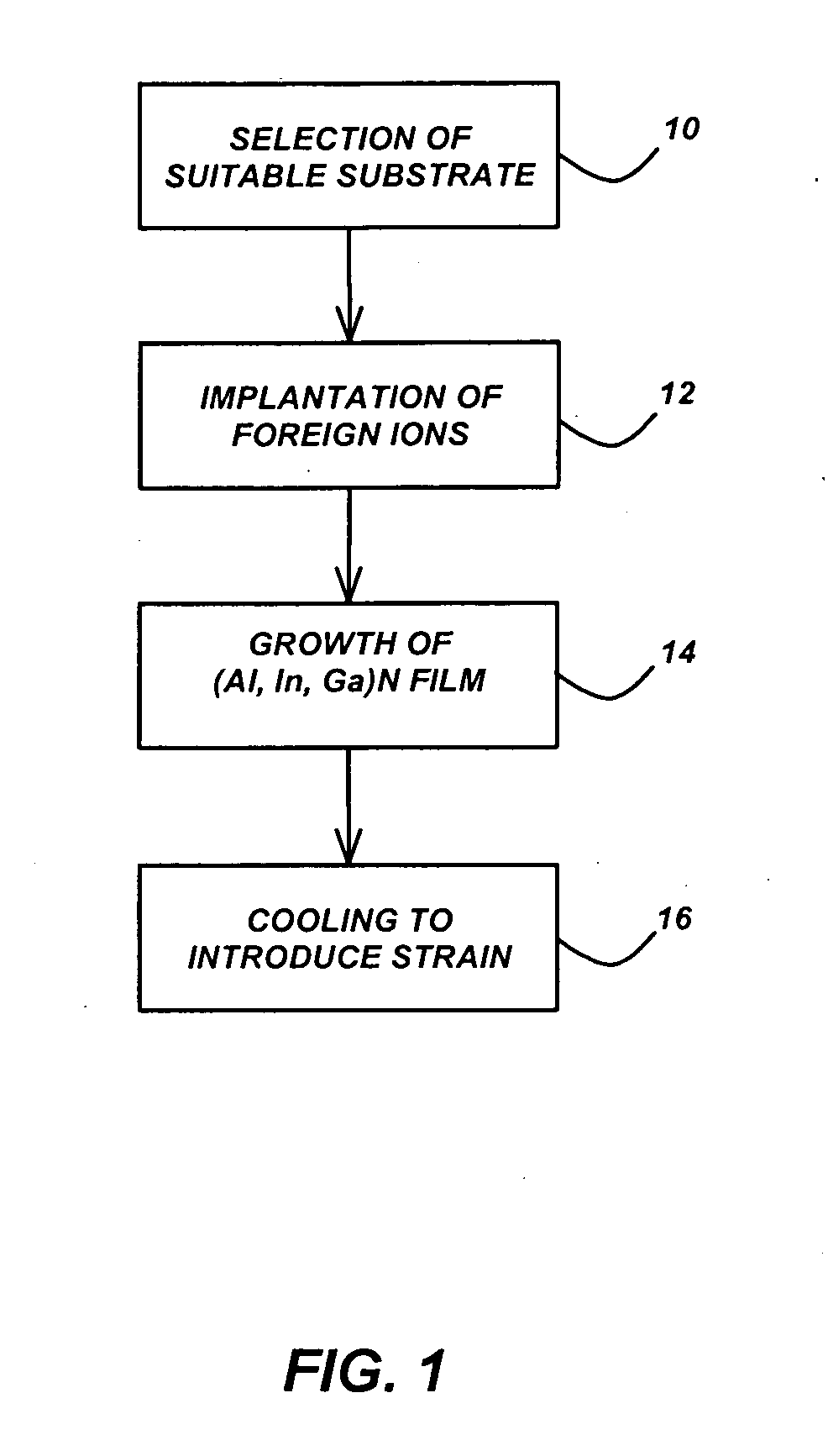

Wafer separation technique for the fabrication of free-standing (Al,In,Ga)N wafers

InactiveUS20060234486A1Minimize deleterious effect of stressEliminates undesirable crackingPolycrystalline material growthAfter-treatment detailsWaferingThermal expansion

A method of fabricating free-standing (Al, In, Ga)N substrates, by in situ separation of thick epitaxially grown nitride films from their foreign substrates. A suitable substrate for (Al, In, Ga)N film growth is selected, and foreign ions are implanted in the substrate to form a comparatively sharp concentration profile. An (Al, In Ga)N film is deposited on the substrate, and the deposited film is cooled to introduce thermal expansion mismatch-related strain, so that the film spontaneously separates from the substrate.

Owner:JAPAN SCI & TECH CORP

High weather-proof thermosetting resin composite and prepreg and copper-clad laminate prepared thereby

InactiveCN101735456AImprove heat resistanceSmall coefficient of thermal expansionFibre treatmentPaper coatingEpoxyManufacturing technology

The invention relates to a high weather-proof thermosetting resin composite and prepreg and copper-clad laminate prepared thereby. The high weather-proof thermosetting resin composite comprises the following components in parts by weight: 10-40 parts of allyl compound, 8-80 parts of bismaleimide compound, 0-30 parts of epoxy resin and 0.05-5 parts of catalyst, wherein the molar ratio of allyl compound to bismaleimide compound is 1:2-4. The high weather-proof thermosetting resin composite provided by the invention has higher heat resistance, and the coefficient of thermal expansion (CTE) can be lowered to be below 2.0% to satisfy the requirements of manufacturing high multi-layer PCB. The prepreg prepared by the high weather-proof thermosetting resin composite has simple manufacture, better heat-resistant effect and high heat conductivity. The copper-clad laminate of the invention can be applied to heat-resisting and high multi-layer circuits and has simple manufacturing technology and low cost.

Owner:GUANGDONG SHENGYI SCI TECH

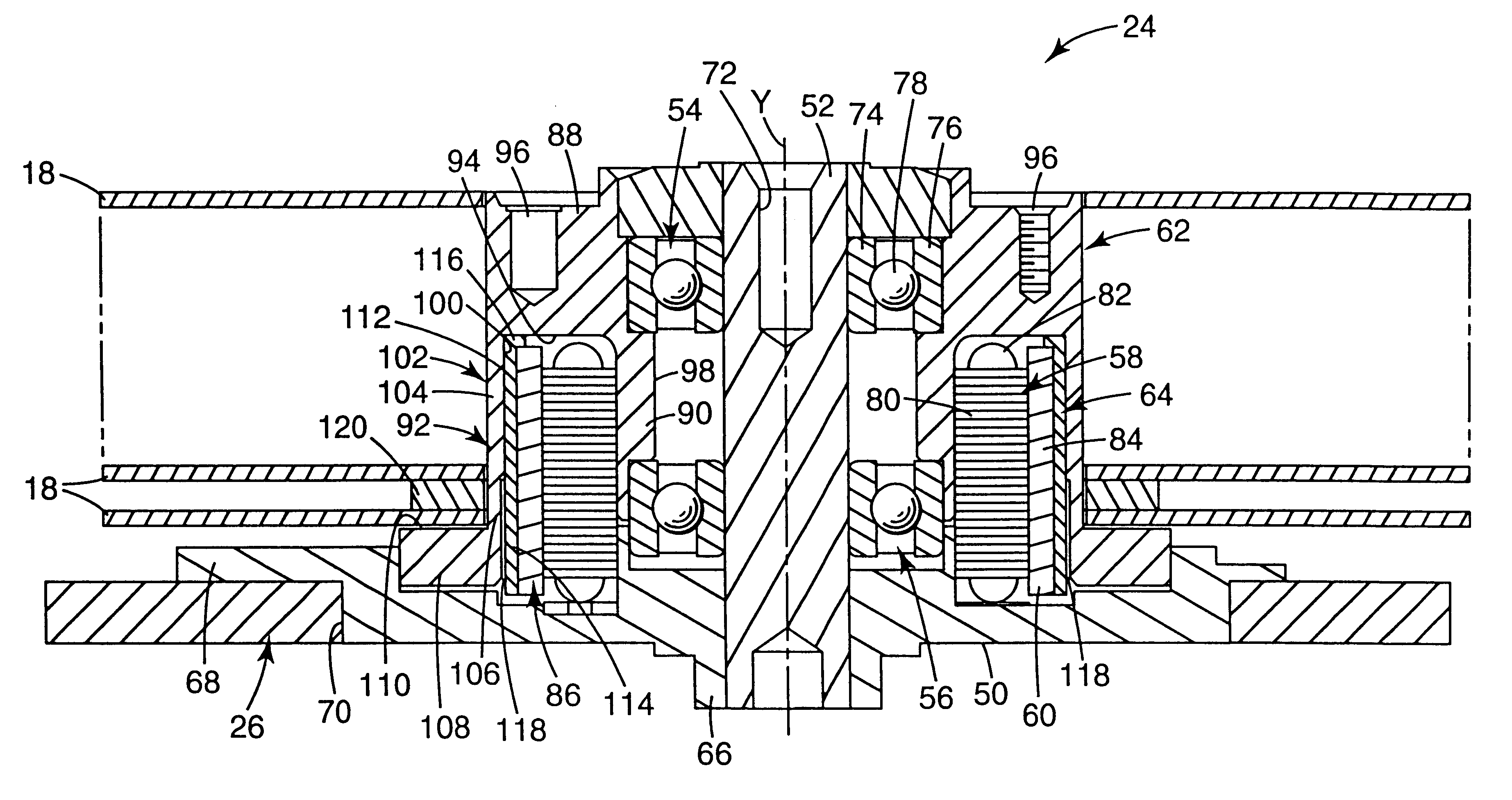

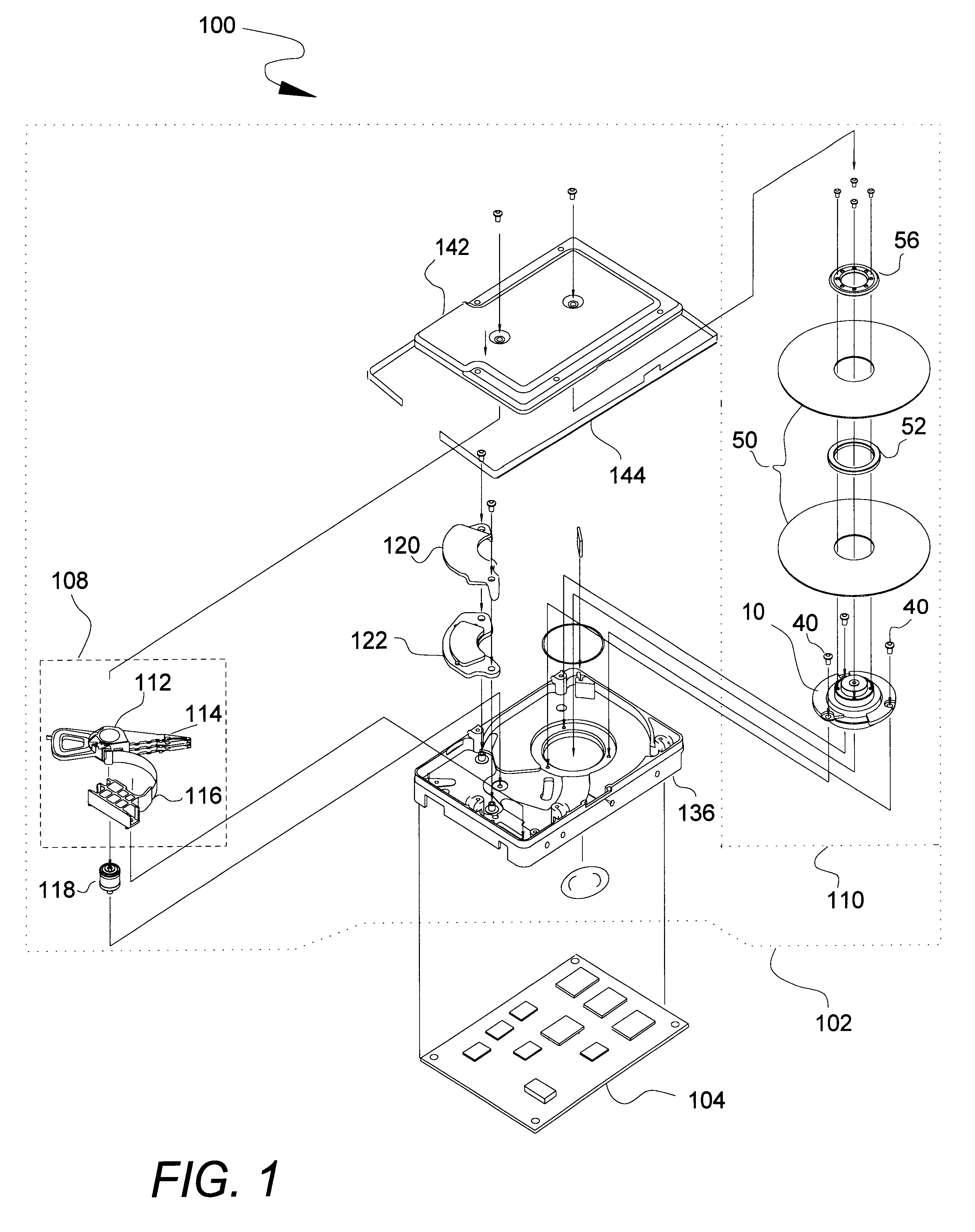

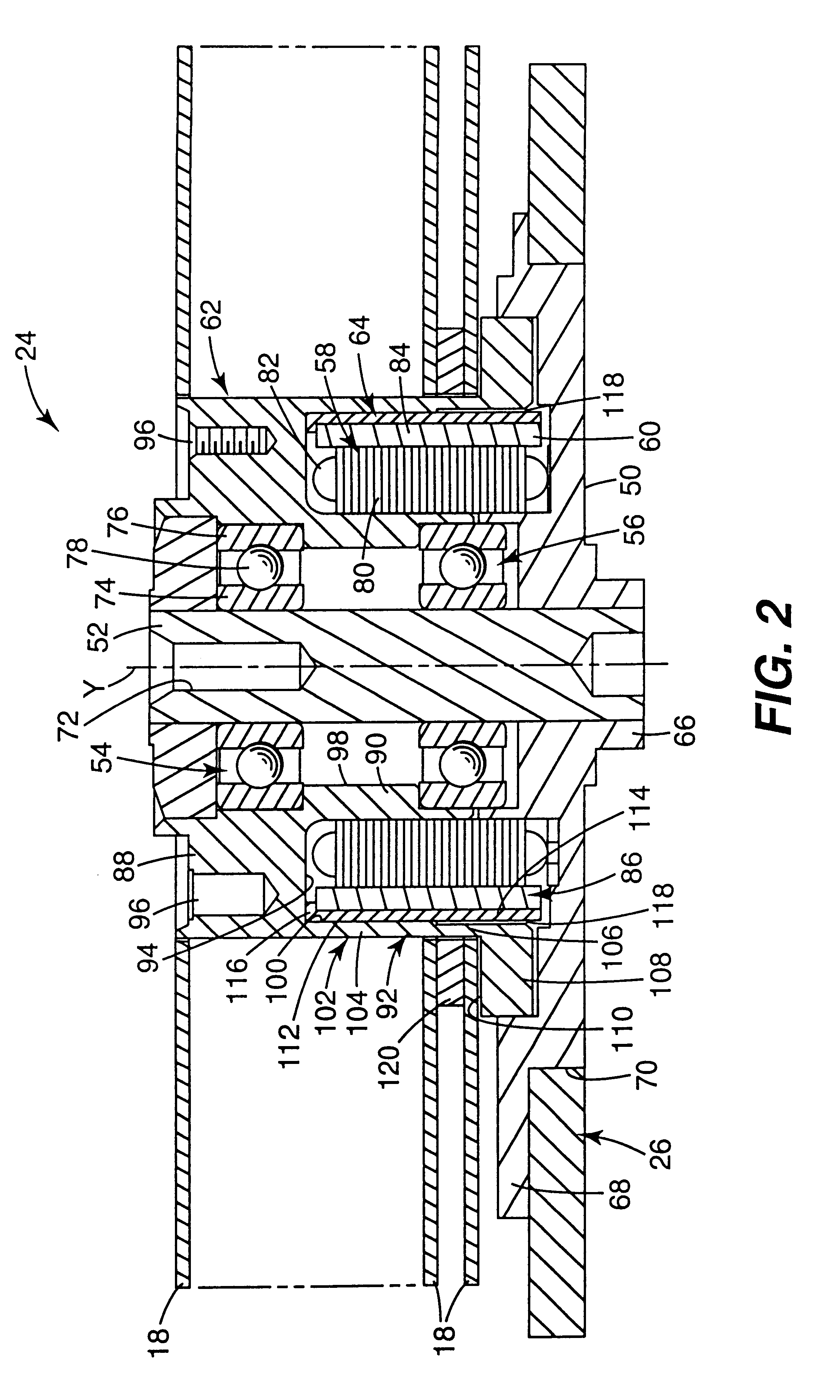

Disk drive with reduced thermal expansion induced disk slip

InactiveUS6185067B1Carrier constructional parts dispositionMagnetic circuit rotating partsThermal dilatationEngineering

A spindle motor for a disk drive includes a shaft, an aluminum hub, a bearing, a magnetic steel back iron, and a magnet. The hub includes an axial wall having an inner surface. The back iron has an upper portion and a lower portion. The hub is concentrically position about the shaft such that the inner surface extends along a direction of a longitudinal axis defined by the hub. The bearing is positioned between the hub and the shaft. The back iron is secured to the hub such that the upper portion abuts the inner surface, whereas the lower portion is spaced-apart radially from the inner surface, thereby forming a single gap between the back iron and the hub. Finally, the magnet is attached to the back iron such that an axial length of the magnet is substantially coextensive with an axial length of the back iron.

Owner:WESTERN DIGITAL TECH INC

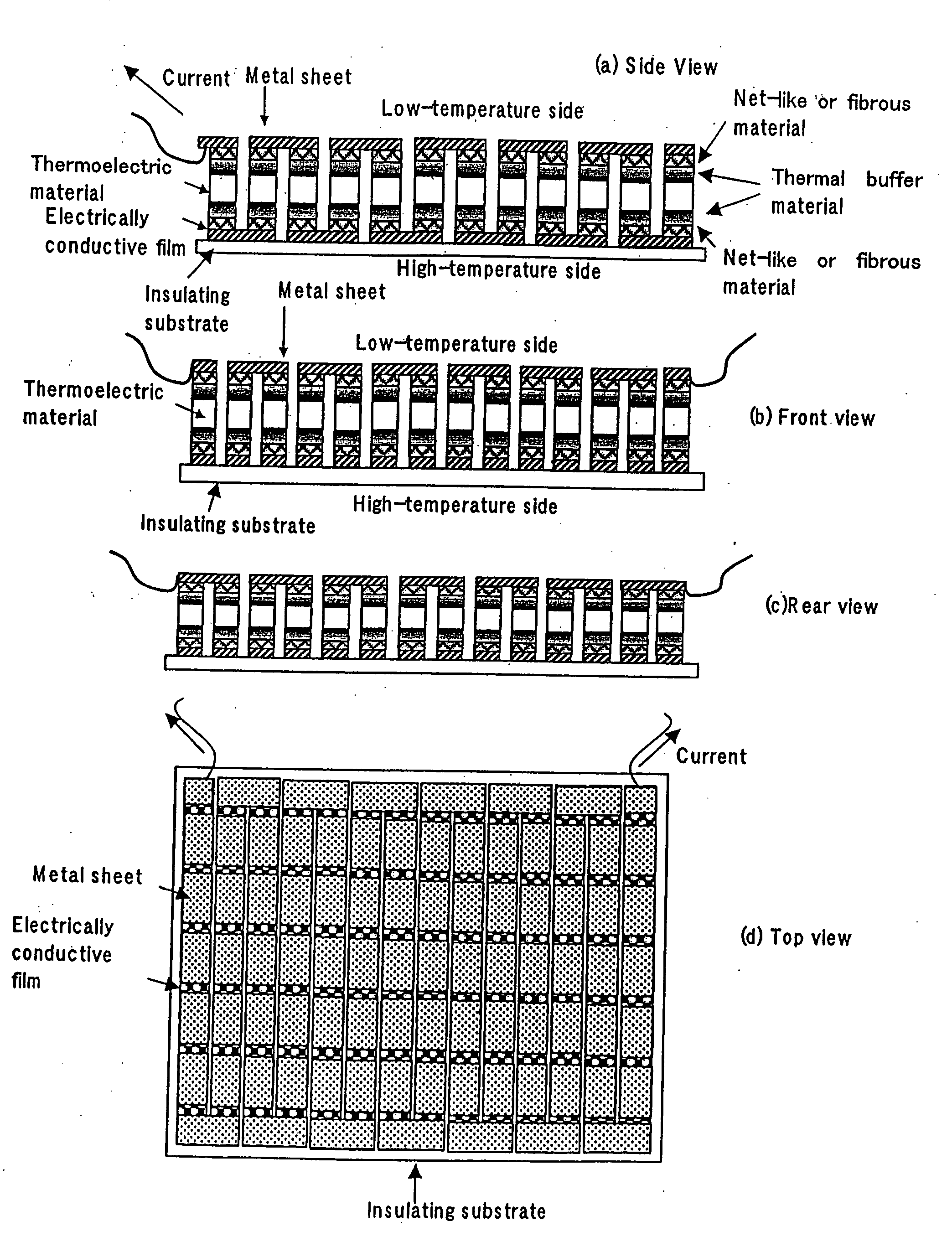

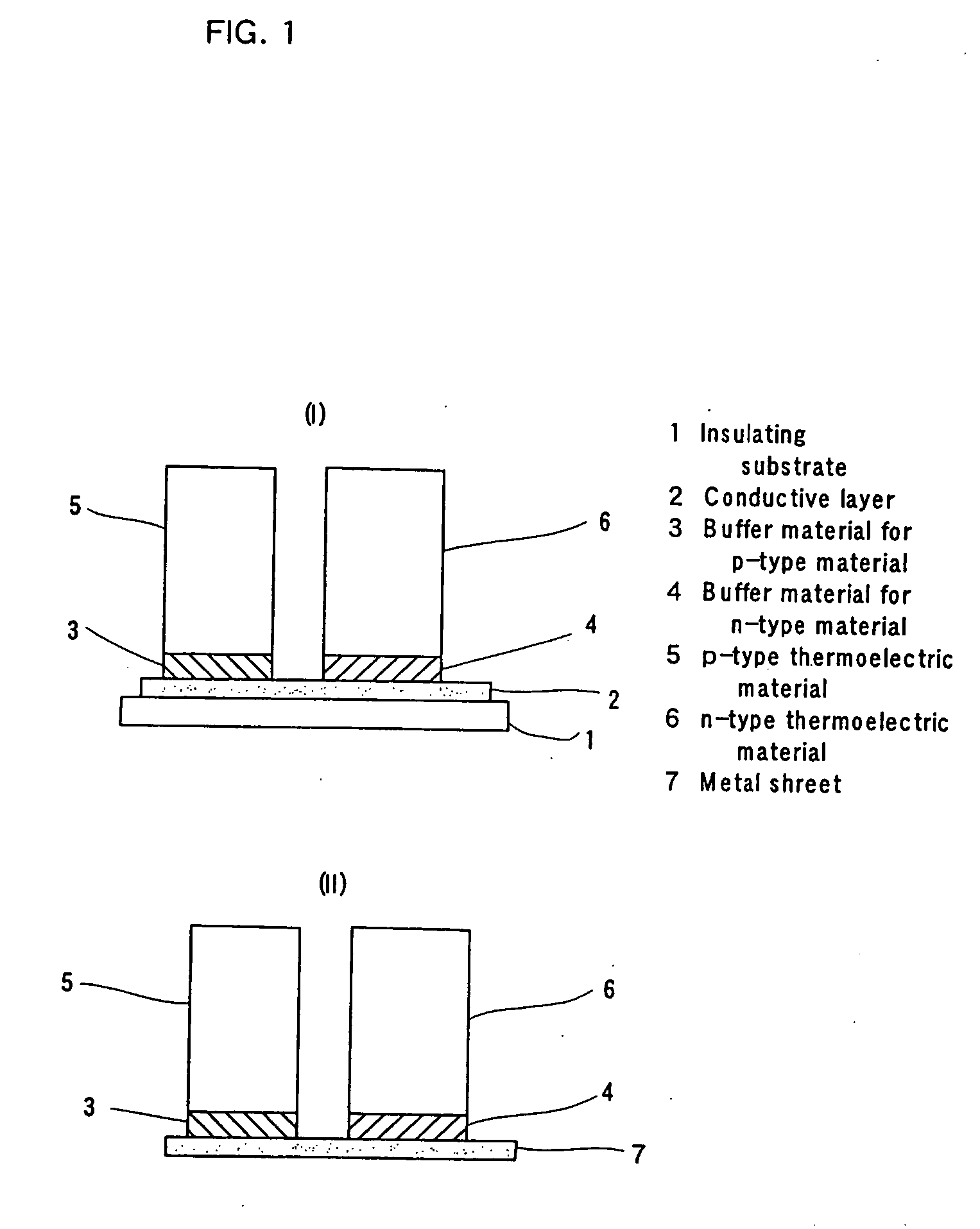

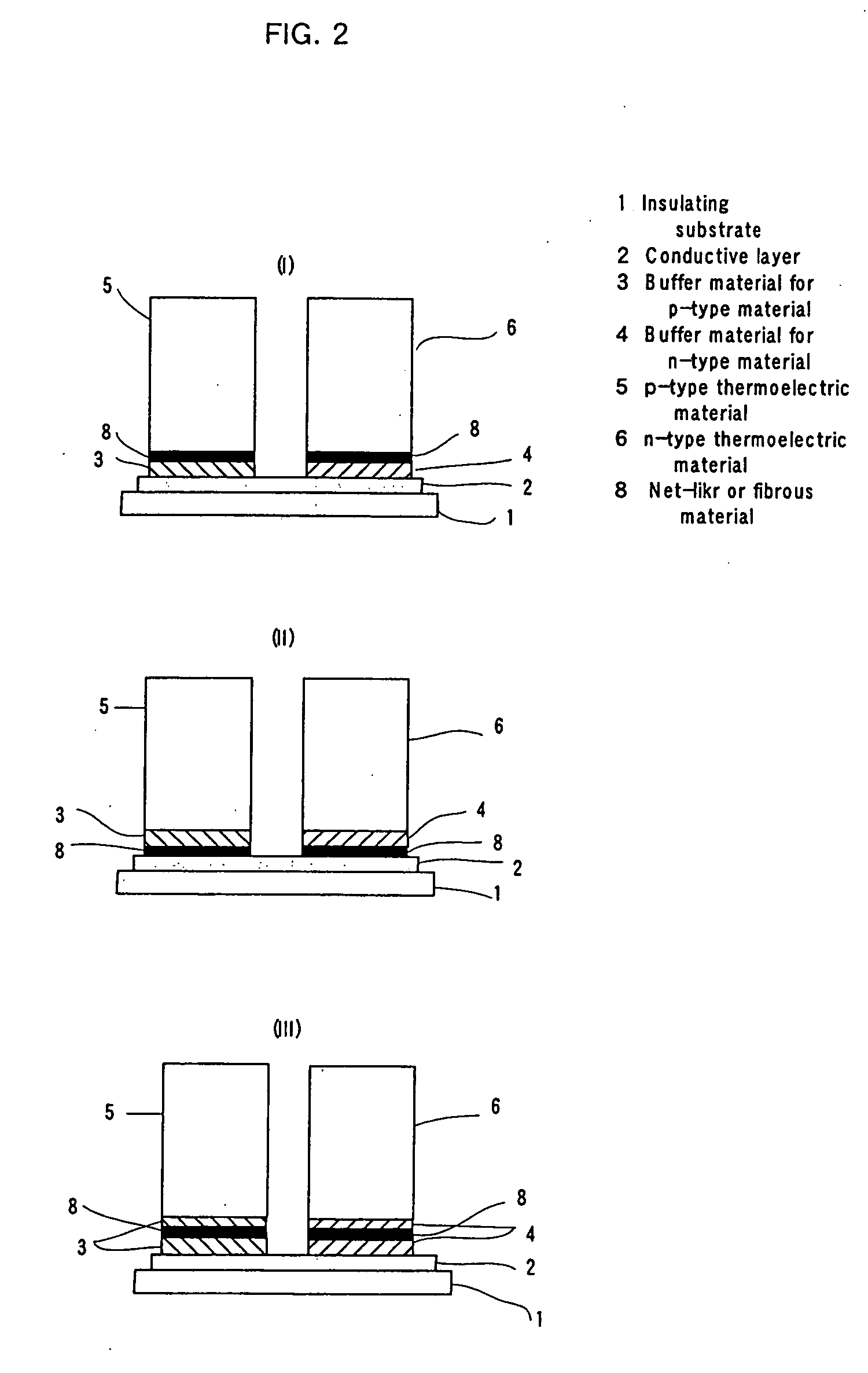

Thermoelectric element and thermoelectric module

InactiveUS20060118160A1Improve thermoelectric conversion efficiencyExcellent chemical durabilityThermoelectric device with peltier/seeback effectThermoelectric device detailsThermoelectric materialsThermal dilatation

The present invention provides a thermoelectric element comprising an electrically conductive substrate, a p-type thermoelectric material, and an n-type thermoelectric material; the p-type thermoelectric material being positioned on the substrate via an electrically conductive thermal buffer material, and the n-type thermoelectric material being positioned on the substrate via an electrically conductive thermal buffer material; wherein each thermoelectric material comprises a specific oxide and each electrically conductive thermal buffer material comprises an electrically conductive material having a thermal expansion coefficient between that of the thermoelectric material to which the thermal buffer material is bonded and that of the substrate. The invention also provides a thermoelectric module comprising a plurality of the thermoelectric elements. The thermoelectric element and the thermoelectric module have both a high thermoelectric conversion efficiency and excellent properties in terms of thermal stability, chemical durability, etc.

Owner:NAT INST OF ADVANCED IND SCI & TECH

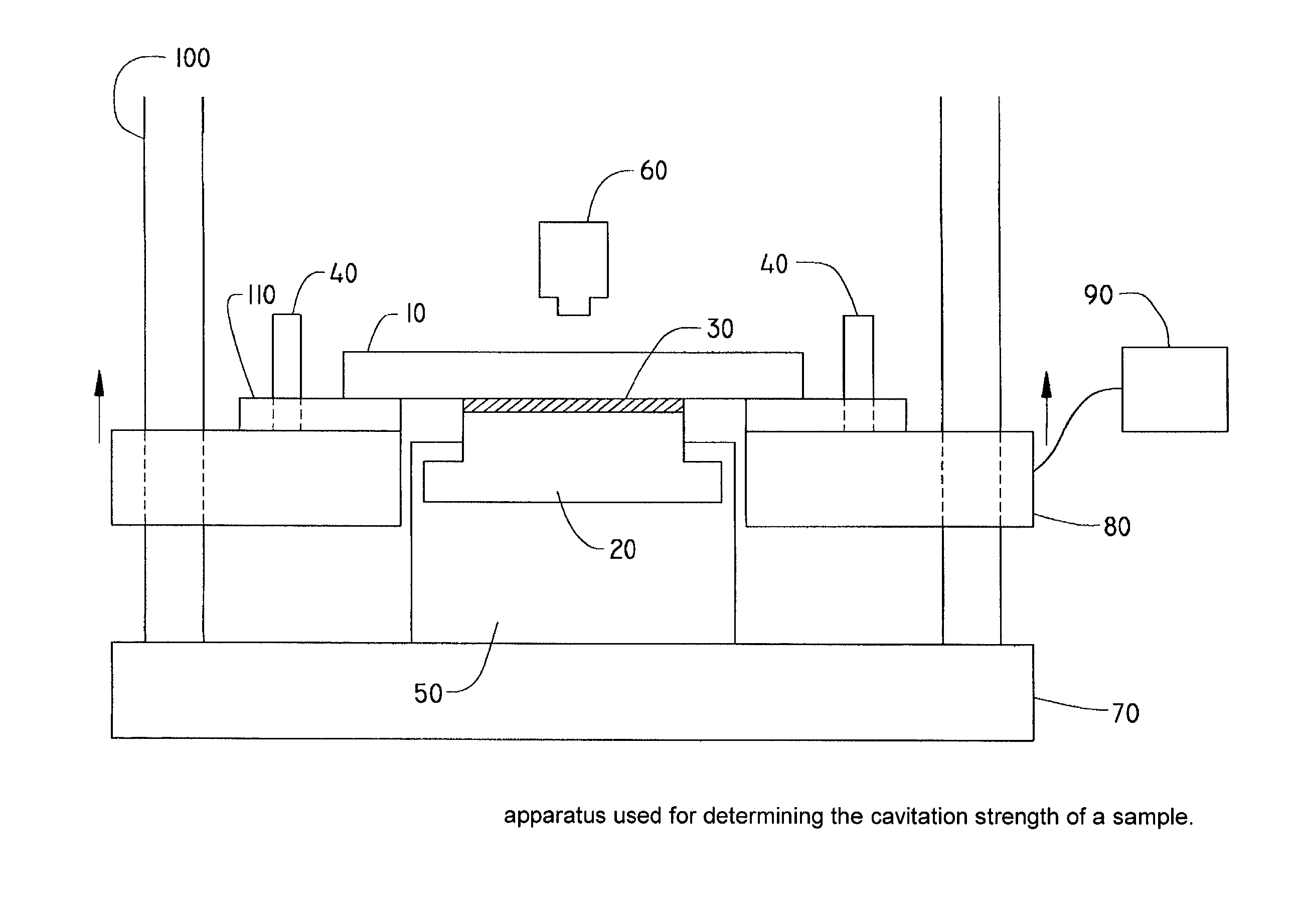

Coated optical fibers

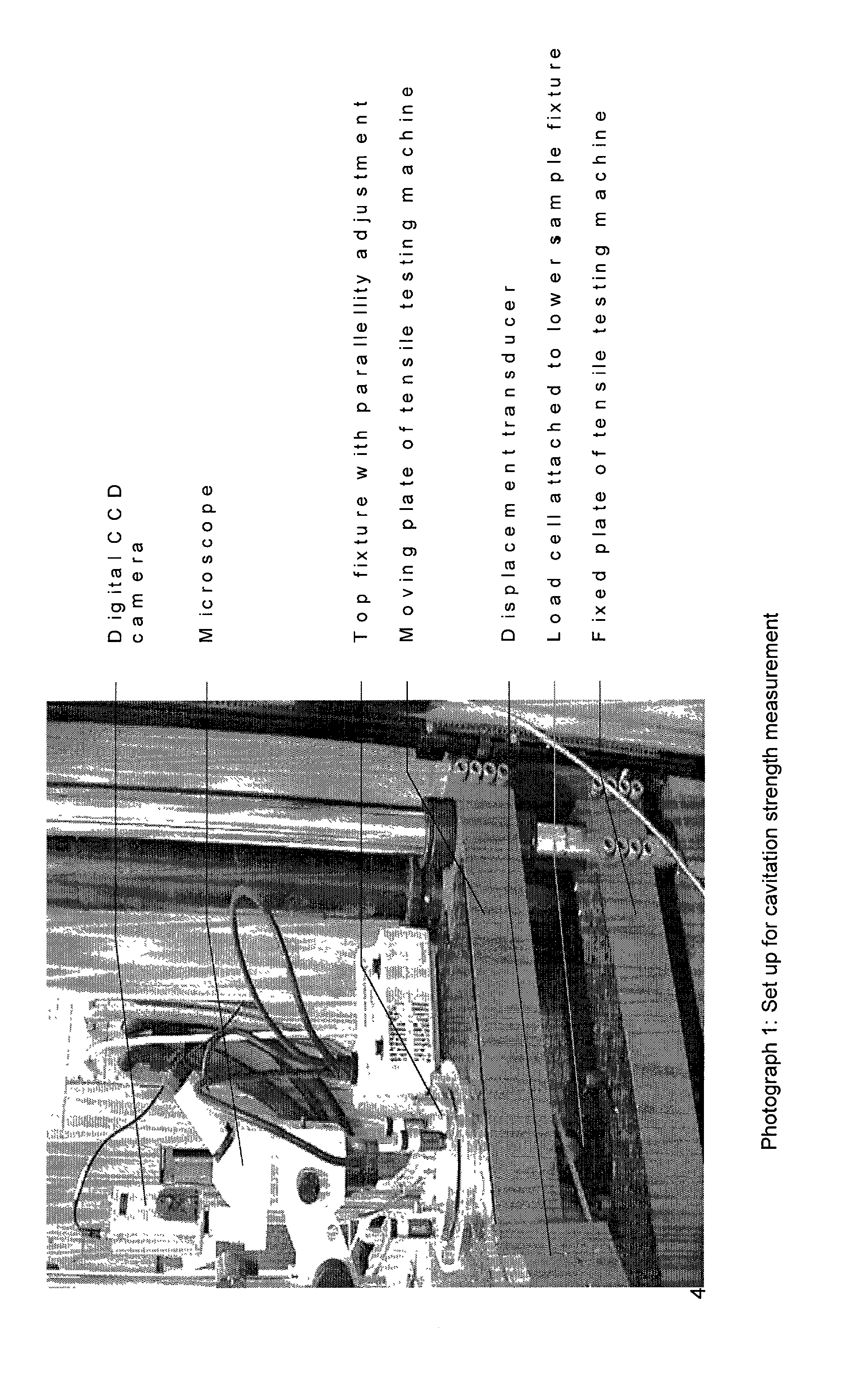

InactiveUS20020146225A1Sufficient high cavitation strengthLow modulusGlass optical fibreSynthetic resin layered productsHigh resistanceCavitation

The invention relates to coated optical fibers comprising soft primary coatings and to such primary coatings for protecting glass optical fibers having a sufficient high resistance against cavitation. In particular, the primary coatings have a cavitation strength at which a tenth cavitation appears (sigma10cav) of at least about 1.0 MPa as measured at a deformation rate of 0.20% min-1 and of at least about 1.4 times their storage modulus at 23° C. The coating preferably shows strain hardening in a relative Mooney plot, preferably has a strain energy release rate Go of about 20 J / m2 or more, and preferably has a low volumetric thermal expansion coefficient. The invention furthermore provides a method and apparatus for measuring the cavitation strength of a primary coating.

Owner:DSM IP ASSETS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com