Patents

Literature

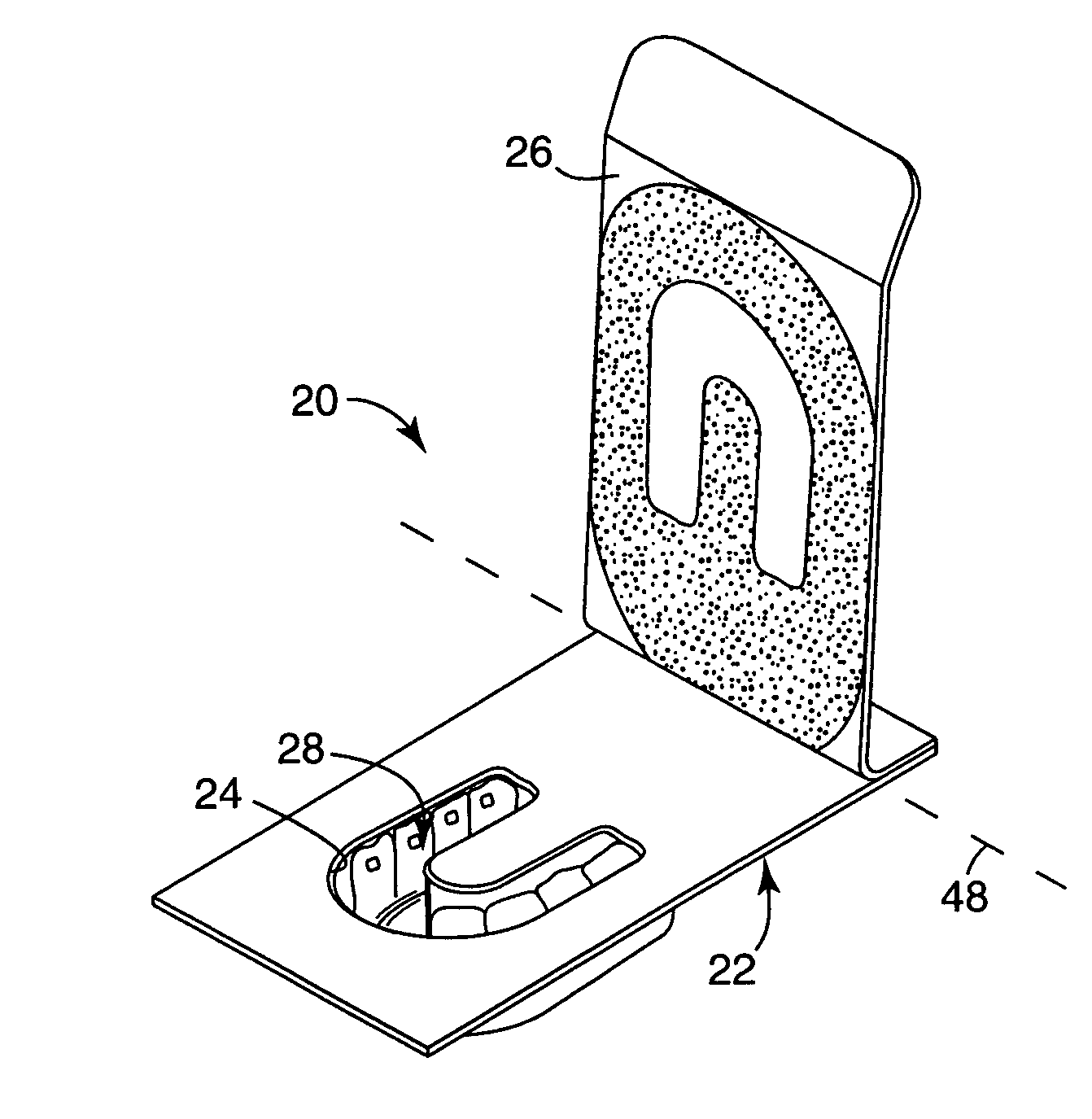

454 results about "Anodic bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anodic bonding is a wafer bonding process to seal glass to either silicon or metal without introducing an intermediate layer; it is commonly used to seal glass to silicon wafers in electronics and microfluidics. This bonding technique, also known as field assisted bonding or electrostatic sealing, is mostly used for connecting silicon/glass and metal/glass through electric fields. The requirements for anodic bonding are clean and even wafer surfaces and atomic contact between the bonding substrates through a sufficiently powerful electrostatic field. Also necessary is the use of borosilicate glass containing a high concentration of alkali ions. The coefficient of thermal expansion (CTE) of the processed glass needs to be similar to those of the bonding partner.

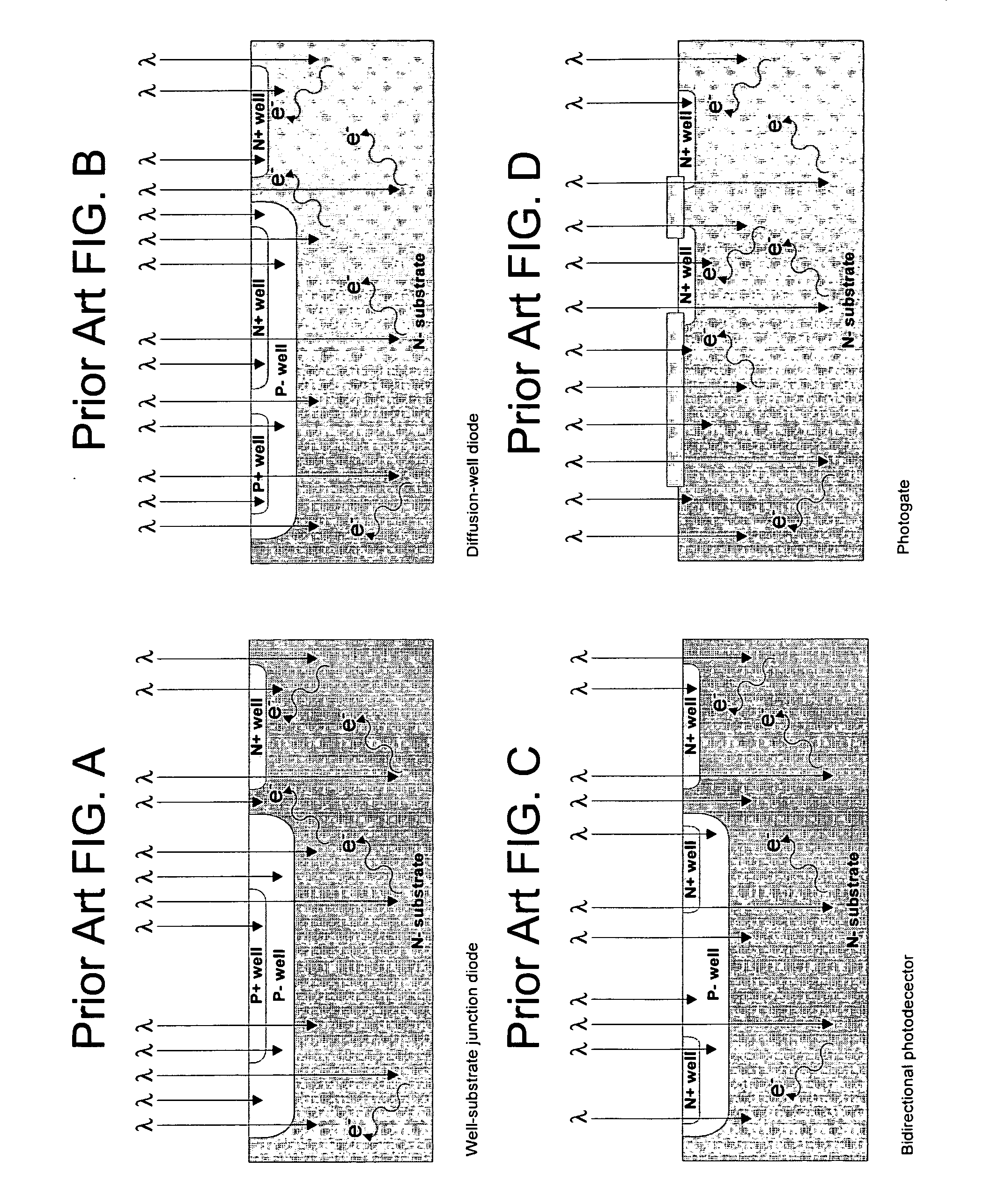

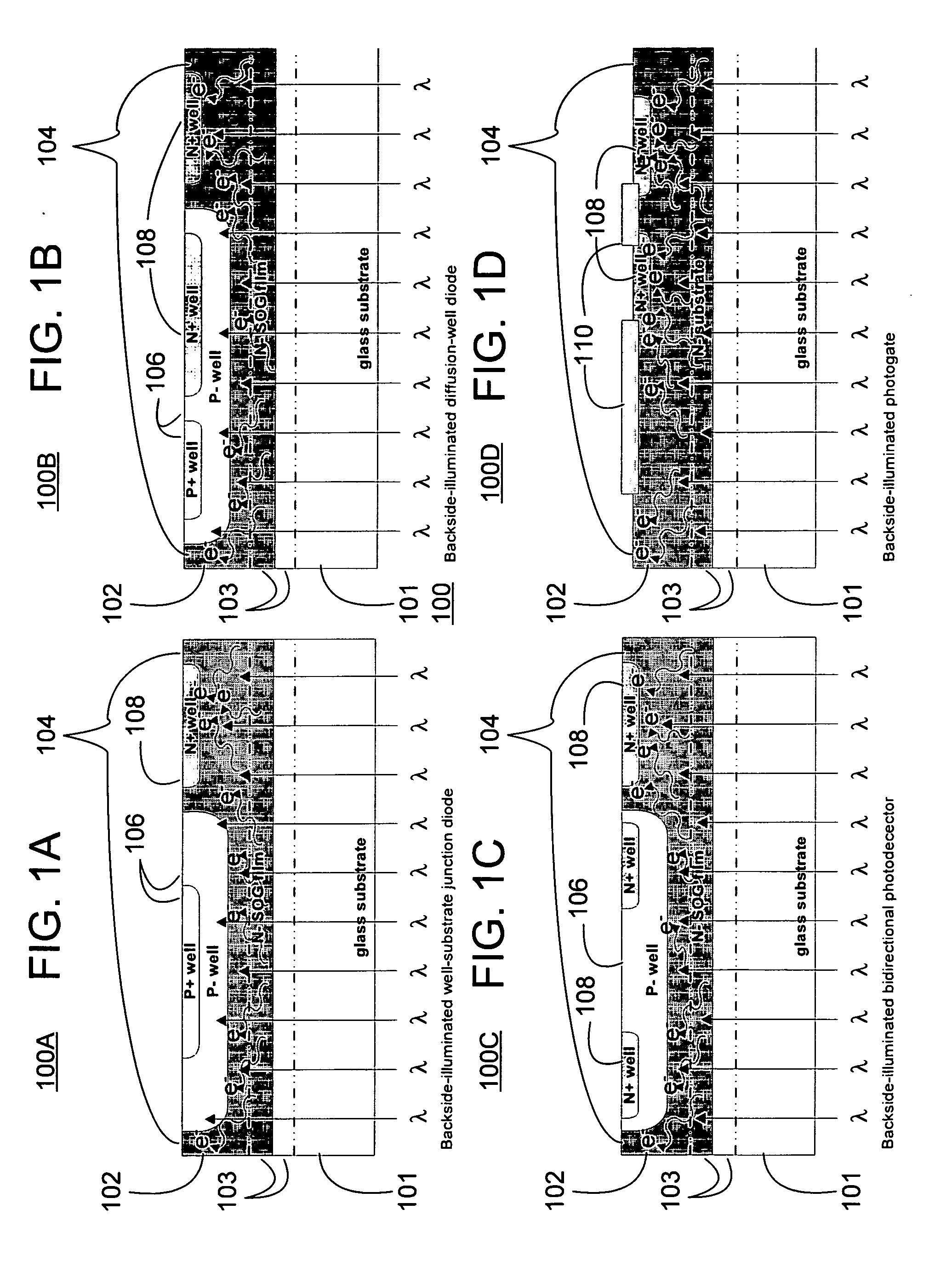

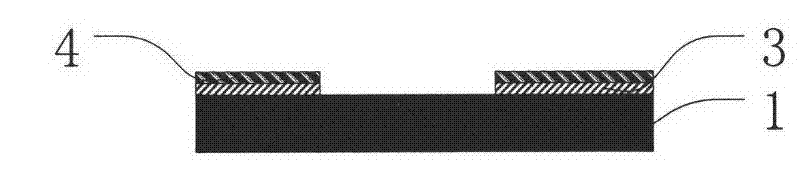

Image sensor using thin-film SOI

InactiveUS20080070340A1Faster throughputImage degradationSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalThin film soi

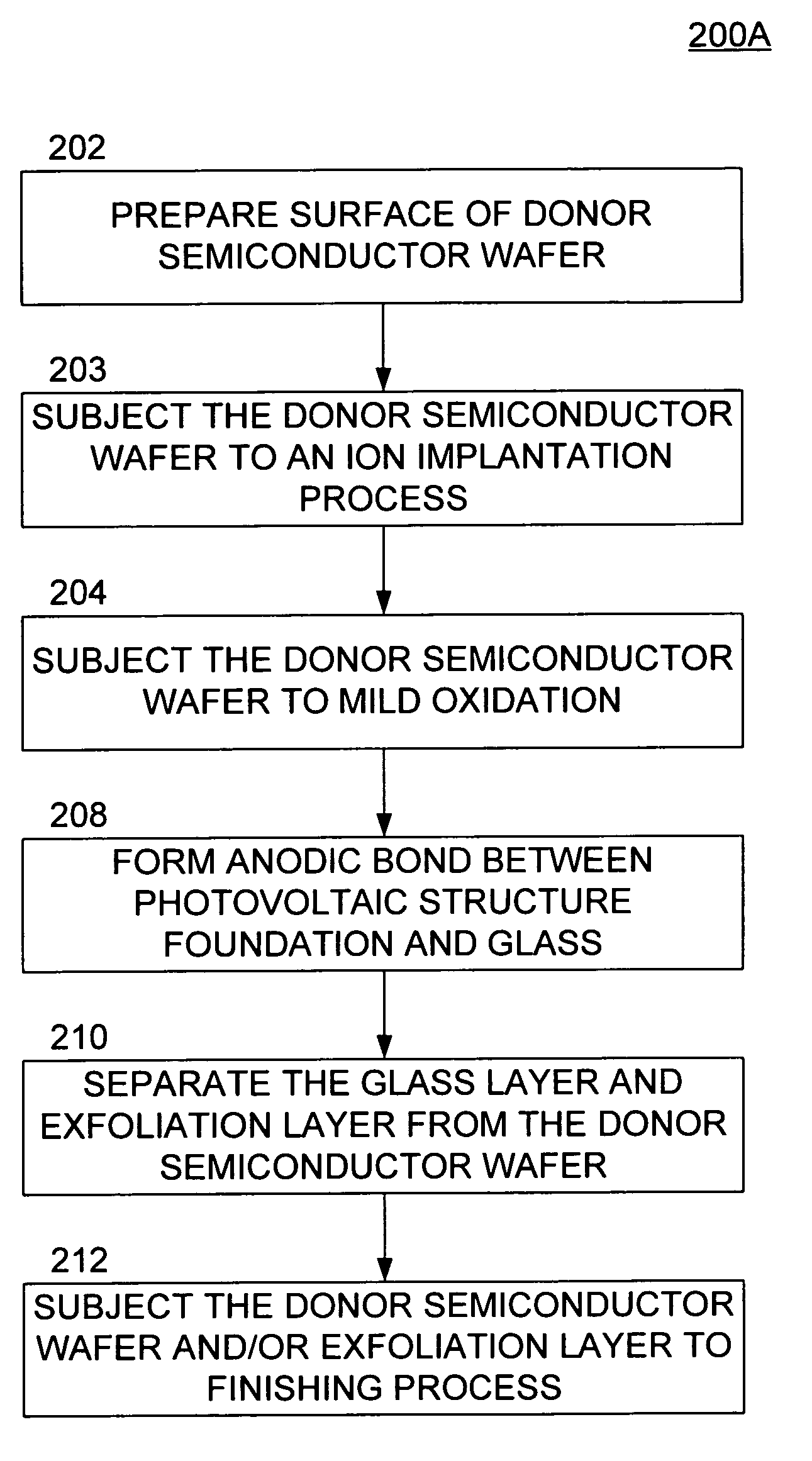

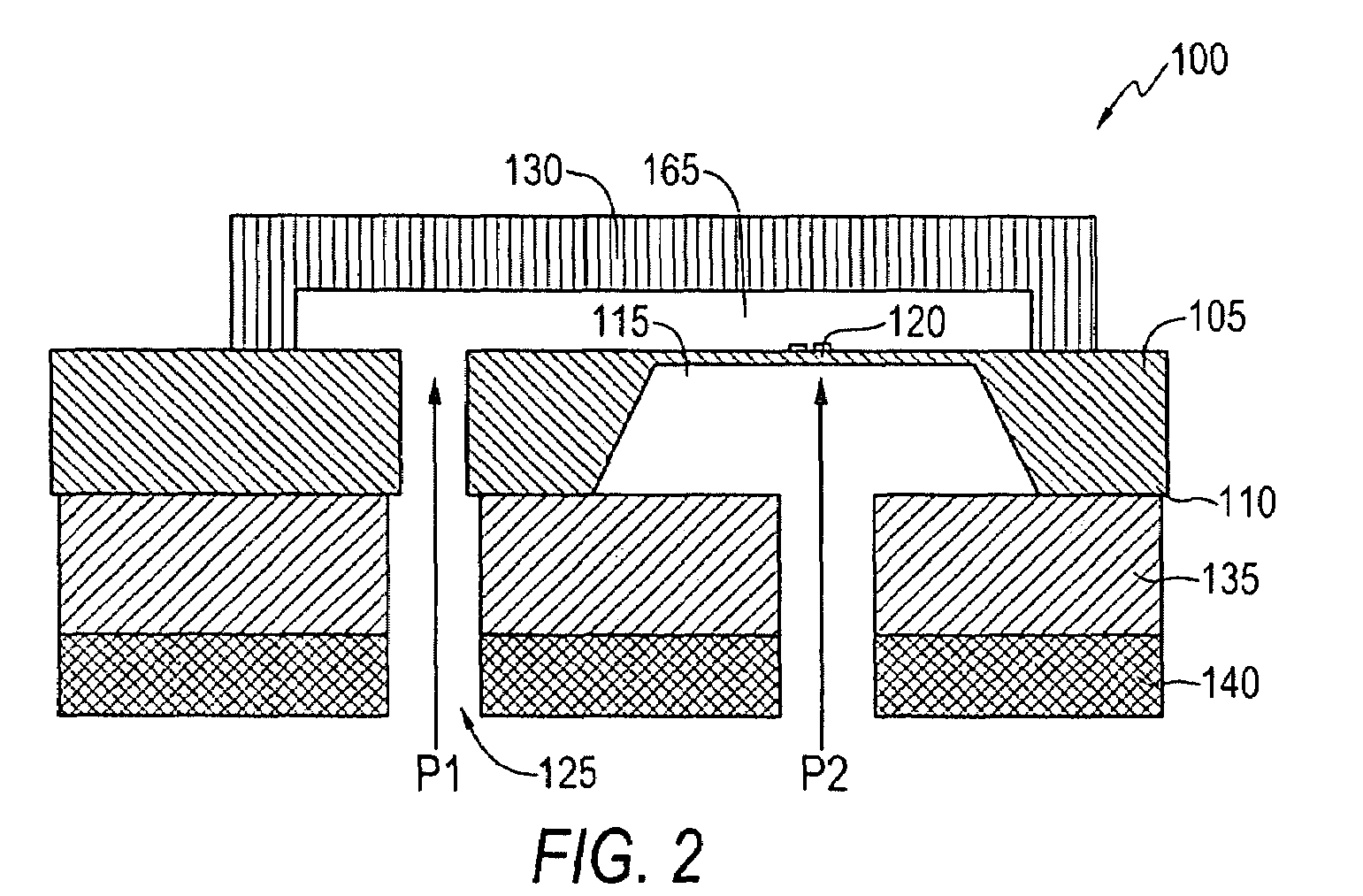

Systems and methods related to an image sensor of one or more embodiments include subjecting a donor semiconductor wafer to an ion implantation process to create an exfoliation layer of semiconductor film on the donor semiconductor wafer, forming an anodic bond between the exfoliation layer and an insulator substrate by means of electrolysis; separating the exfoliation layer from the donor semiconductor wafer to transfer the exfoliation layer to the insulator substrate; and creating a plurality of image sensor features proximate to the exfoliation layer. Forming the anodic bonding by electrolysis may include the application of heat, pressure and voltage to the insulator structure and the exfoliation layer attached to the donor semiconductor wafer. Image sensor devices include an insulator structure, a semiconductor film, an anodic bond between them, and a plurality of image sensor features. The semiconductor film preferably comprises an exfoliation layer of a substantially single-crystal donor semiconductor wafer.

Owner:CORNING INC

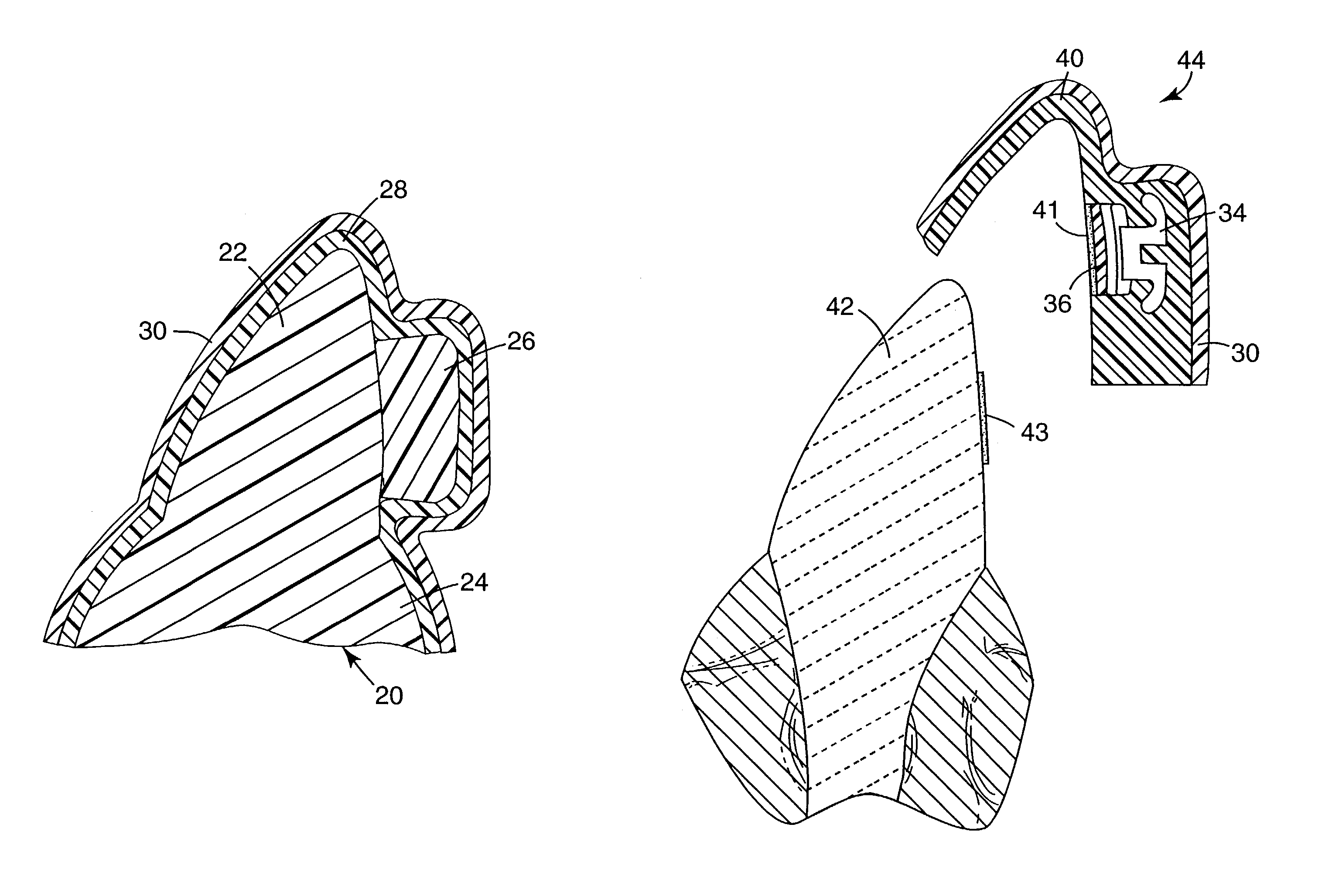

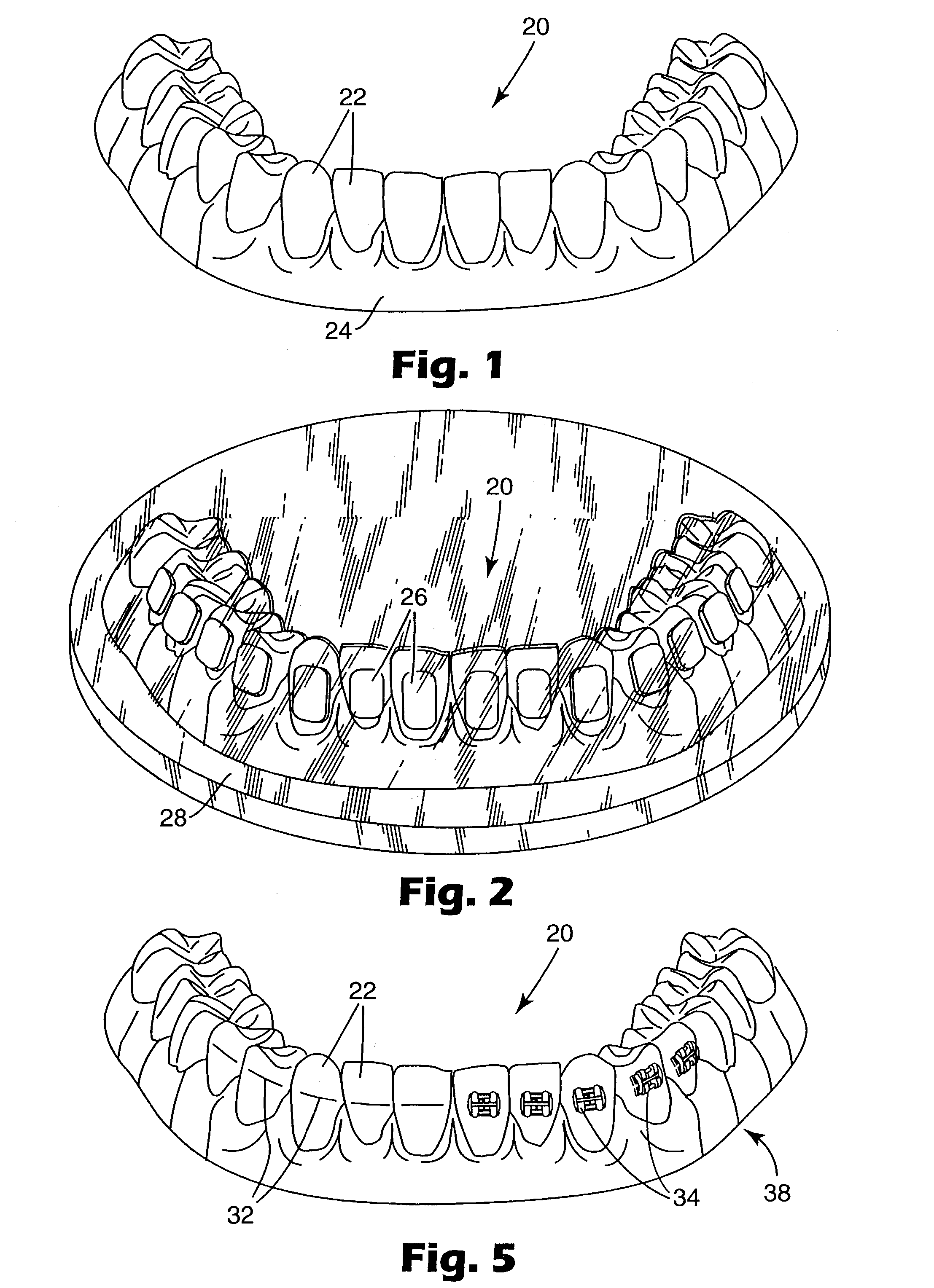

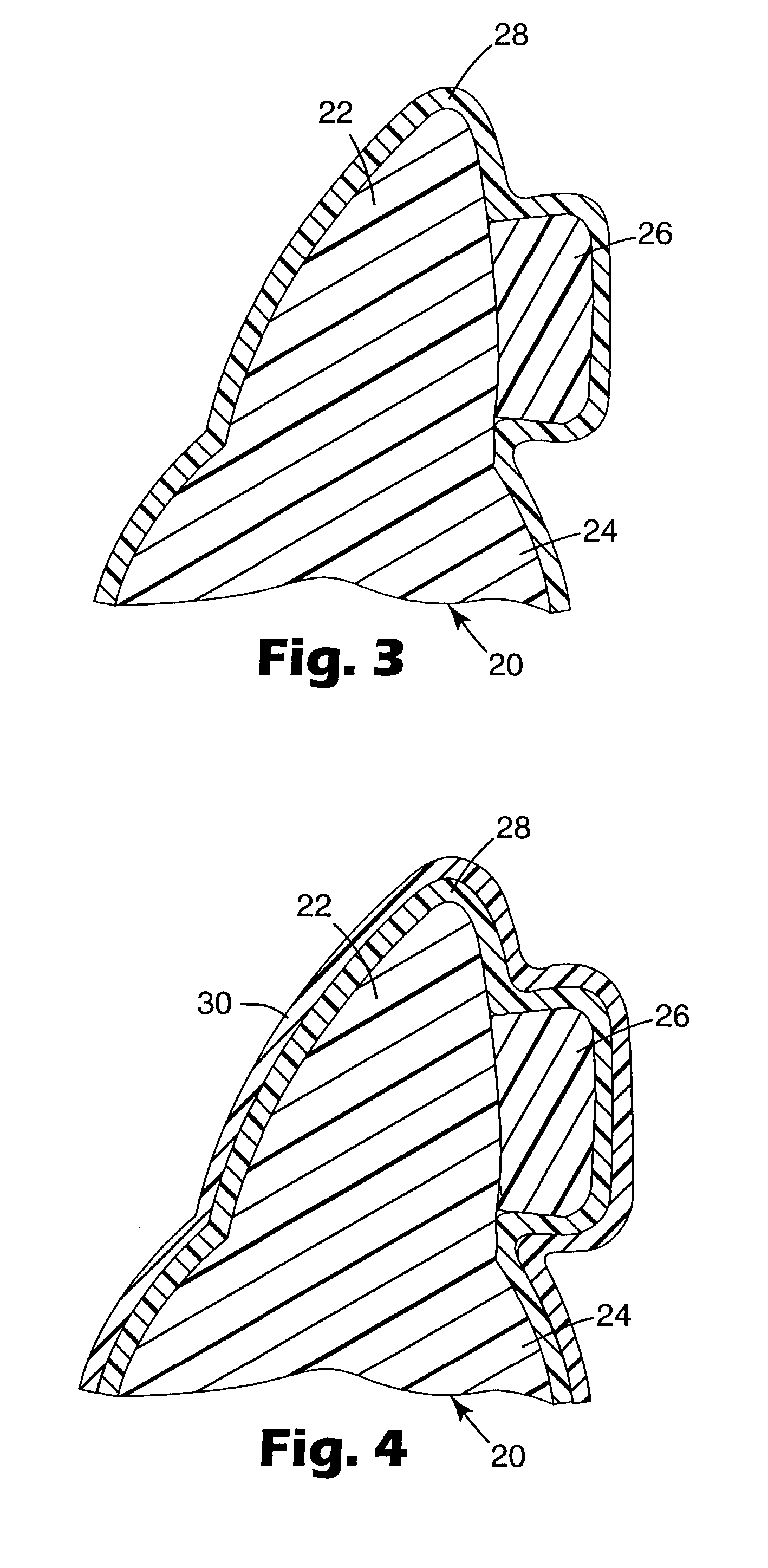

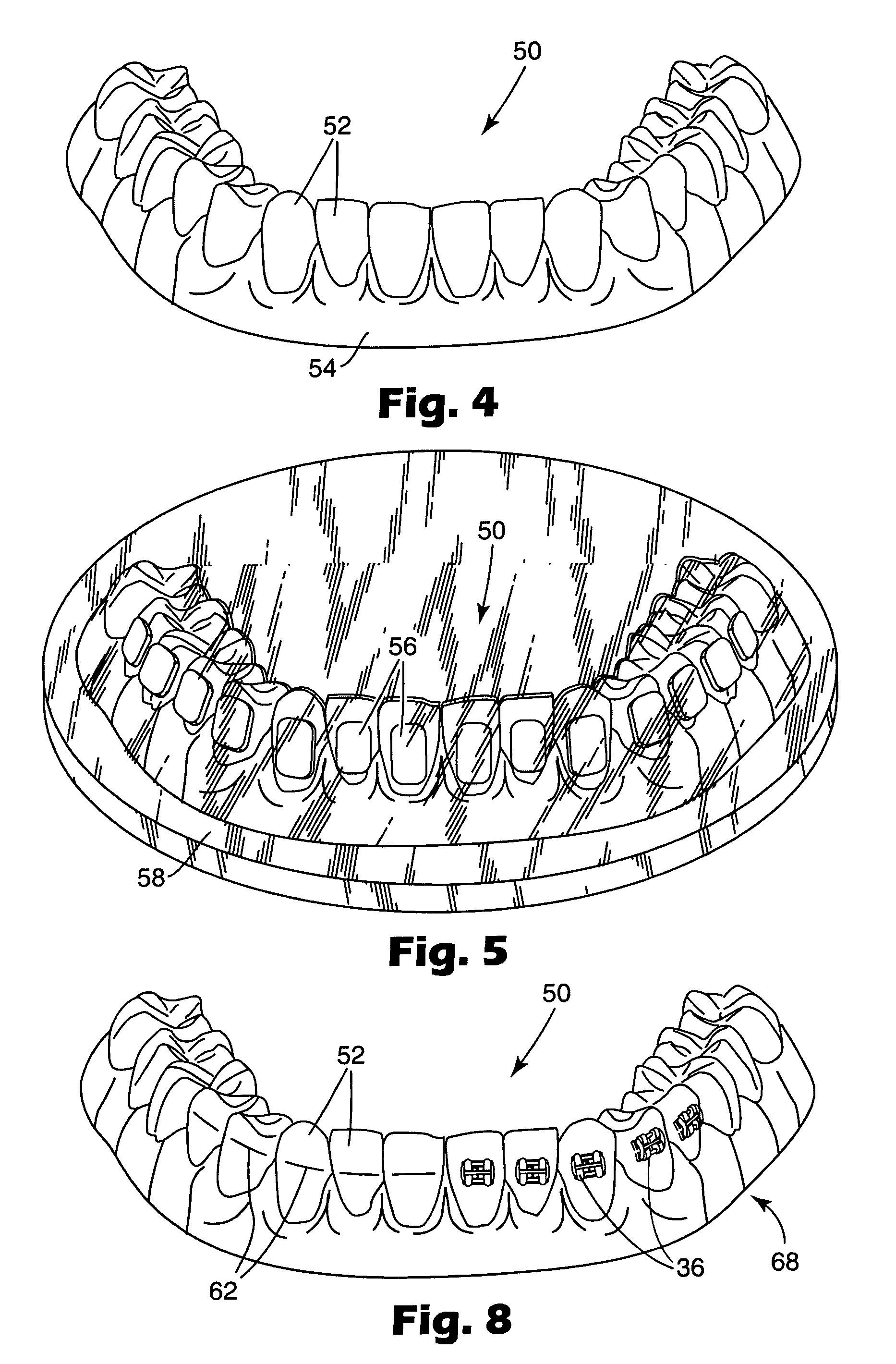

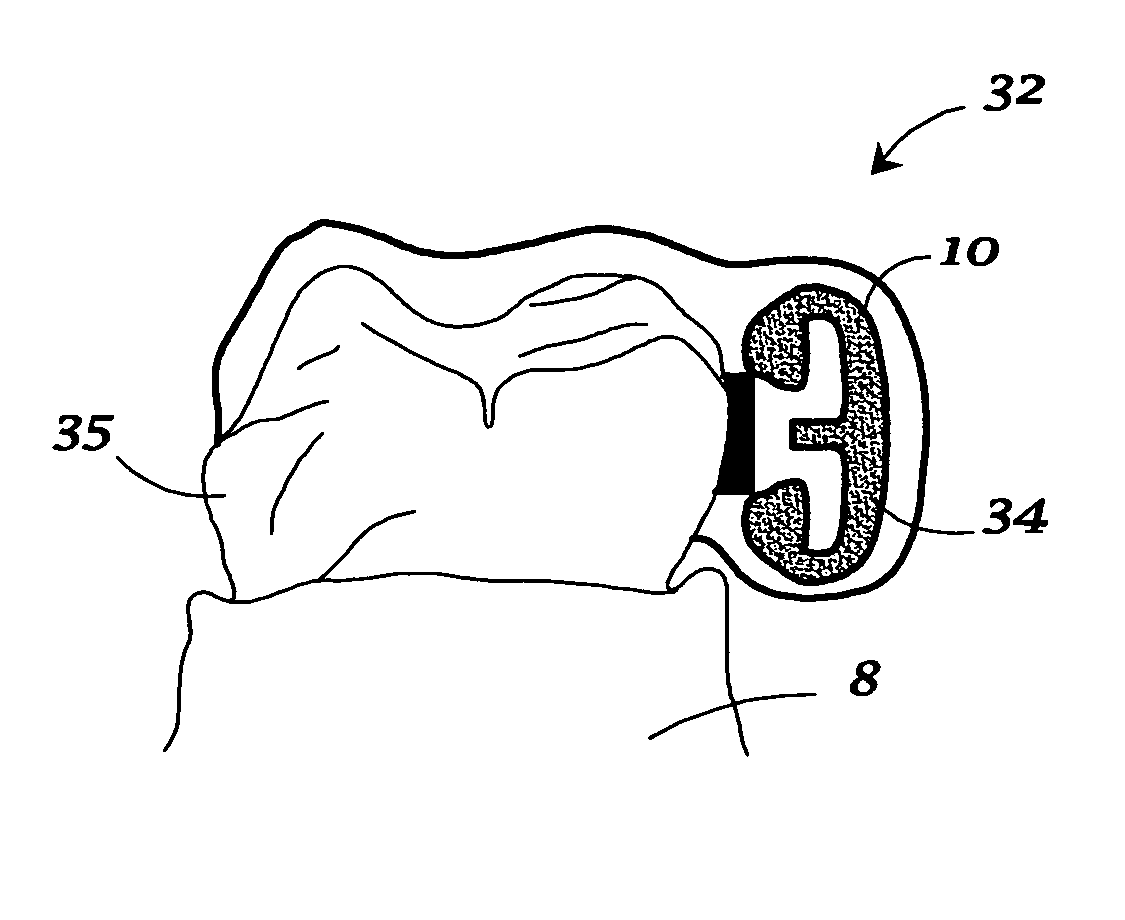

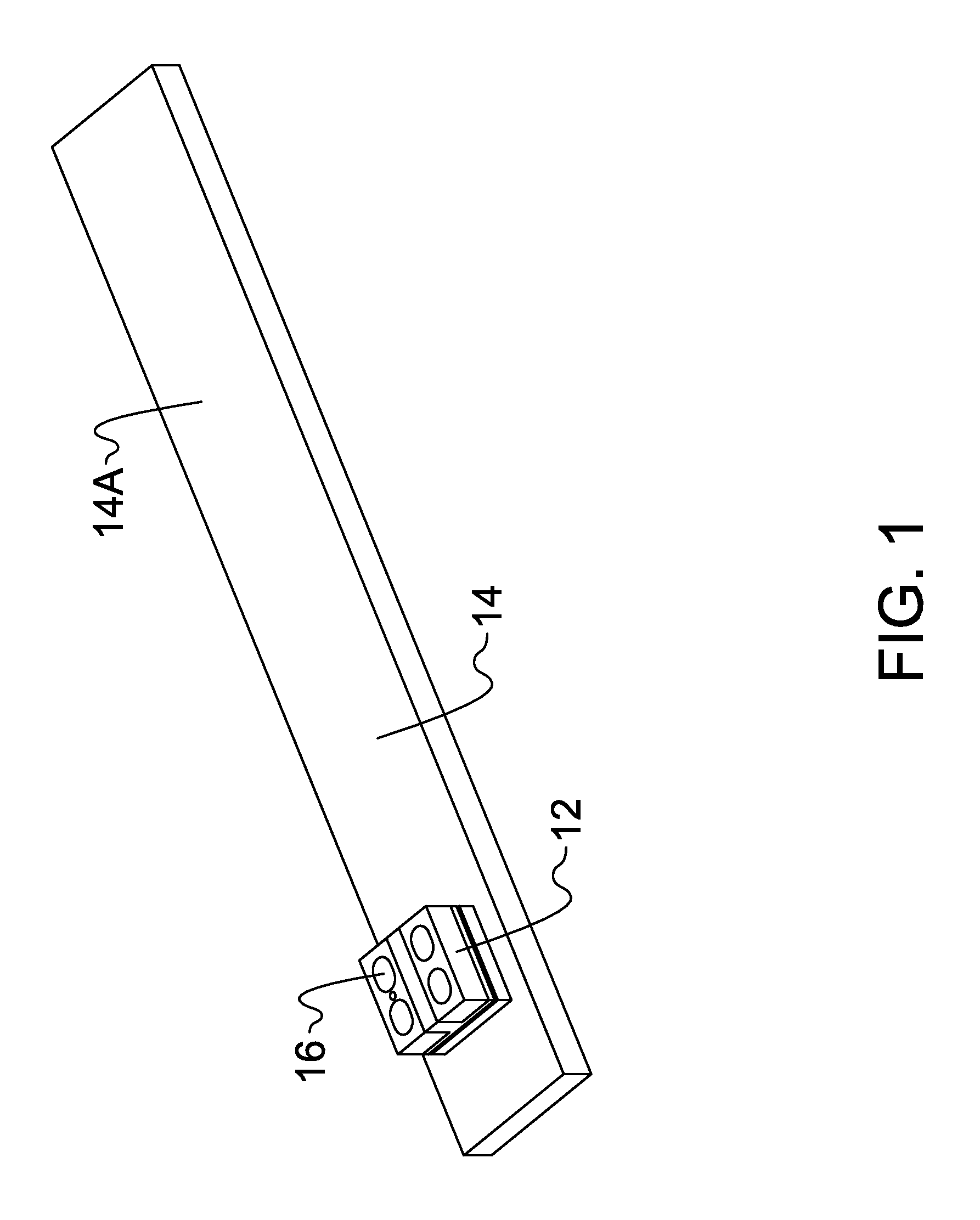

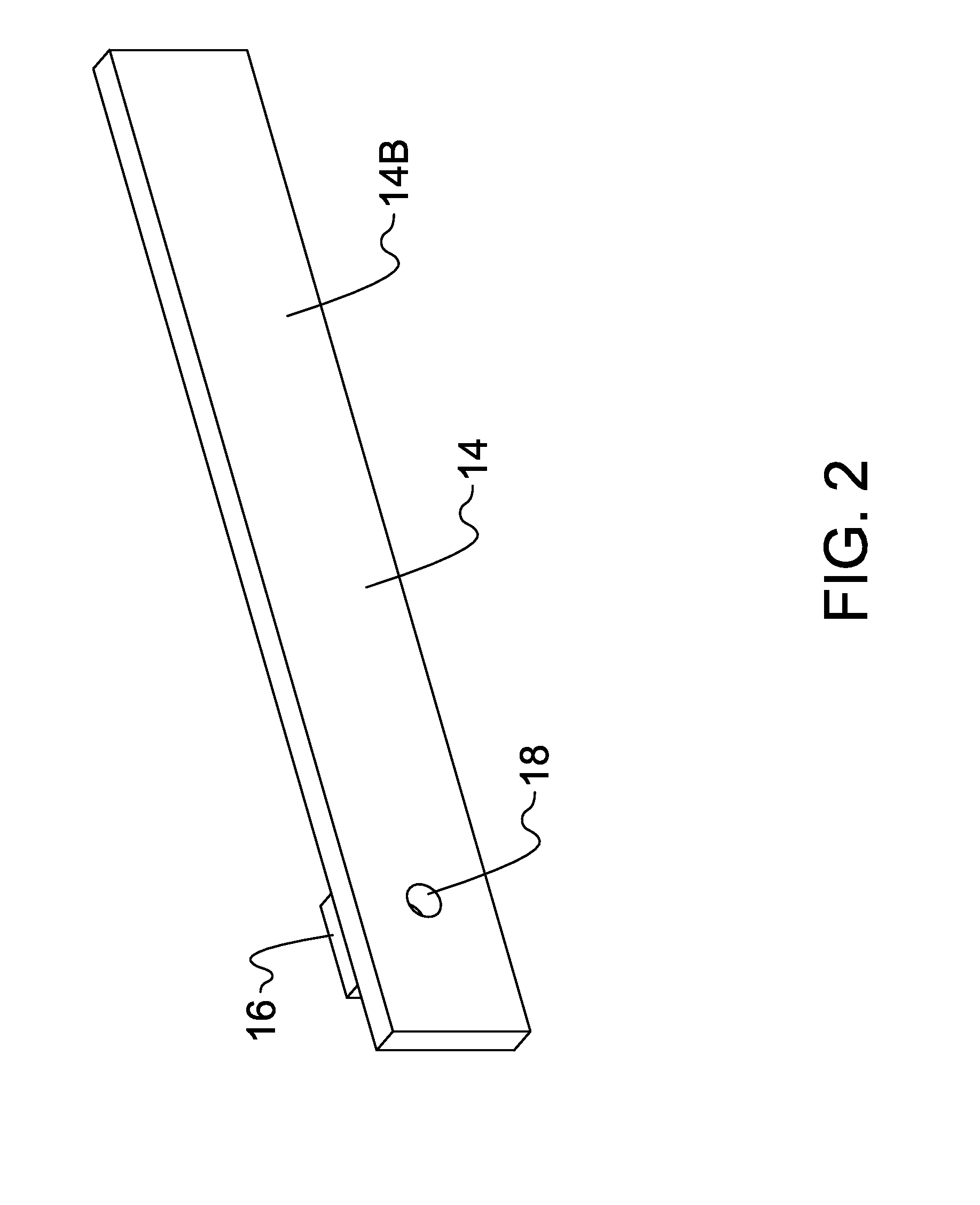

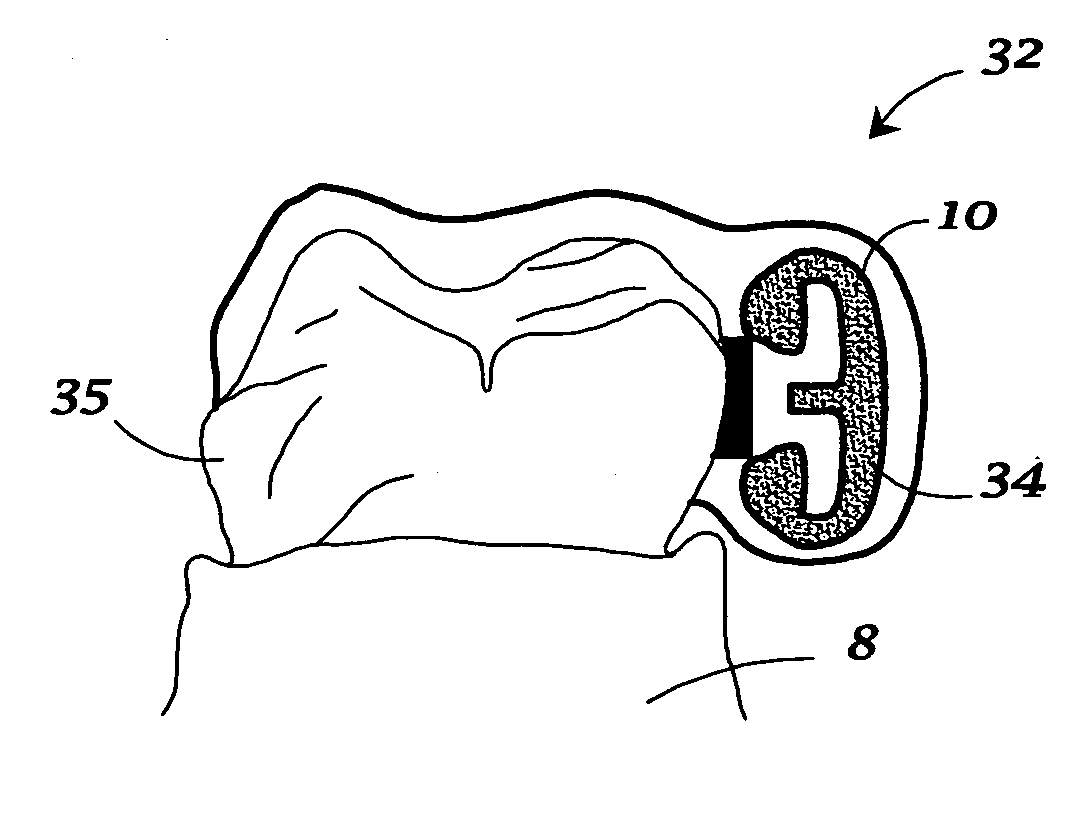

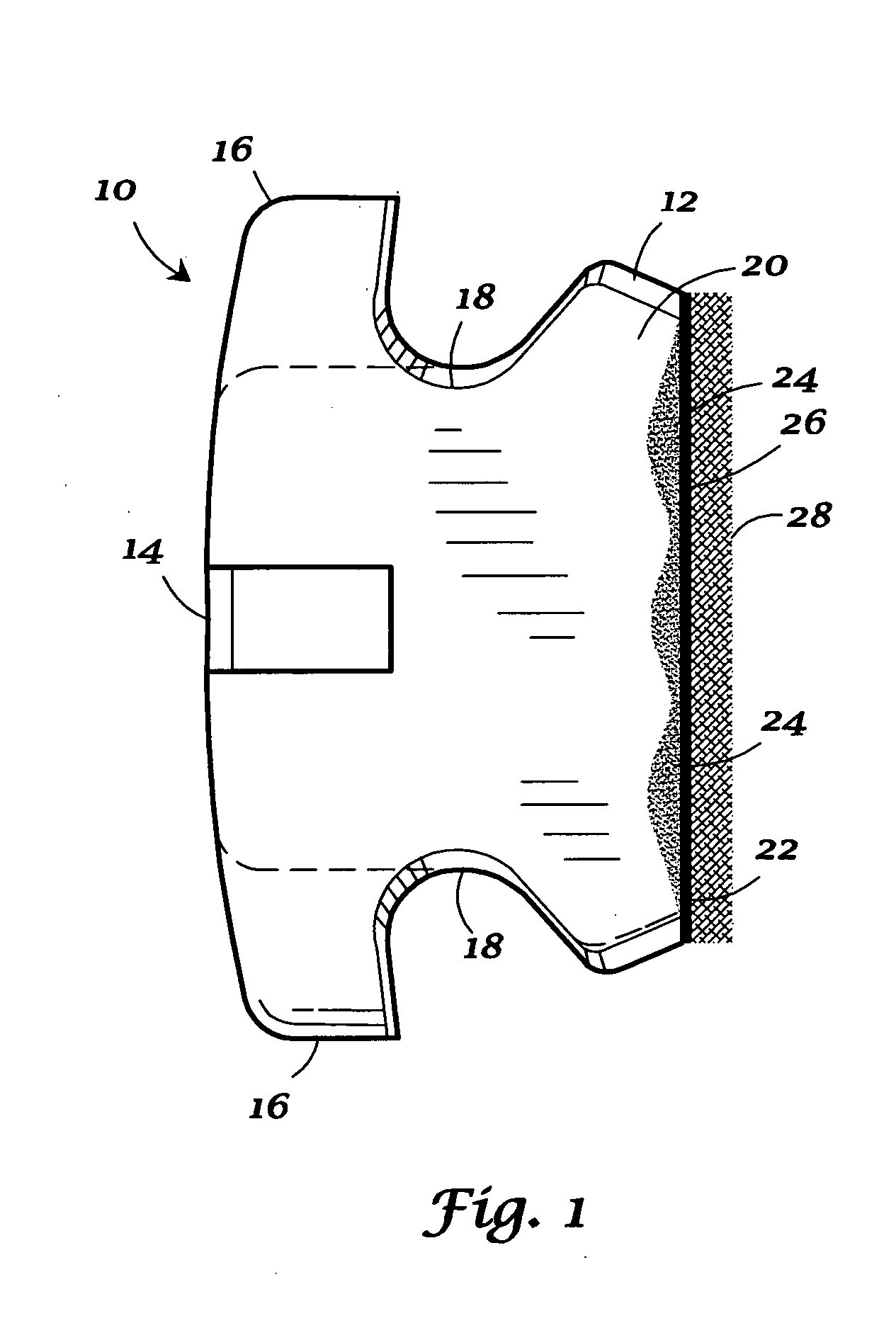

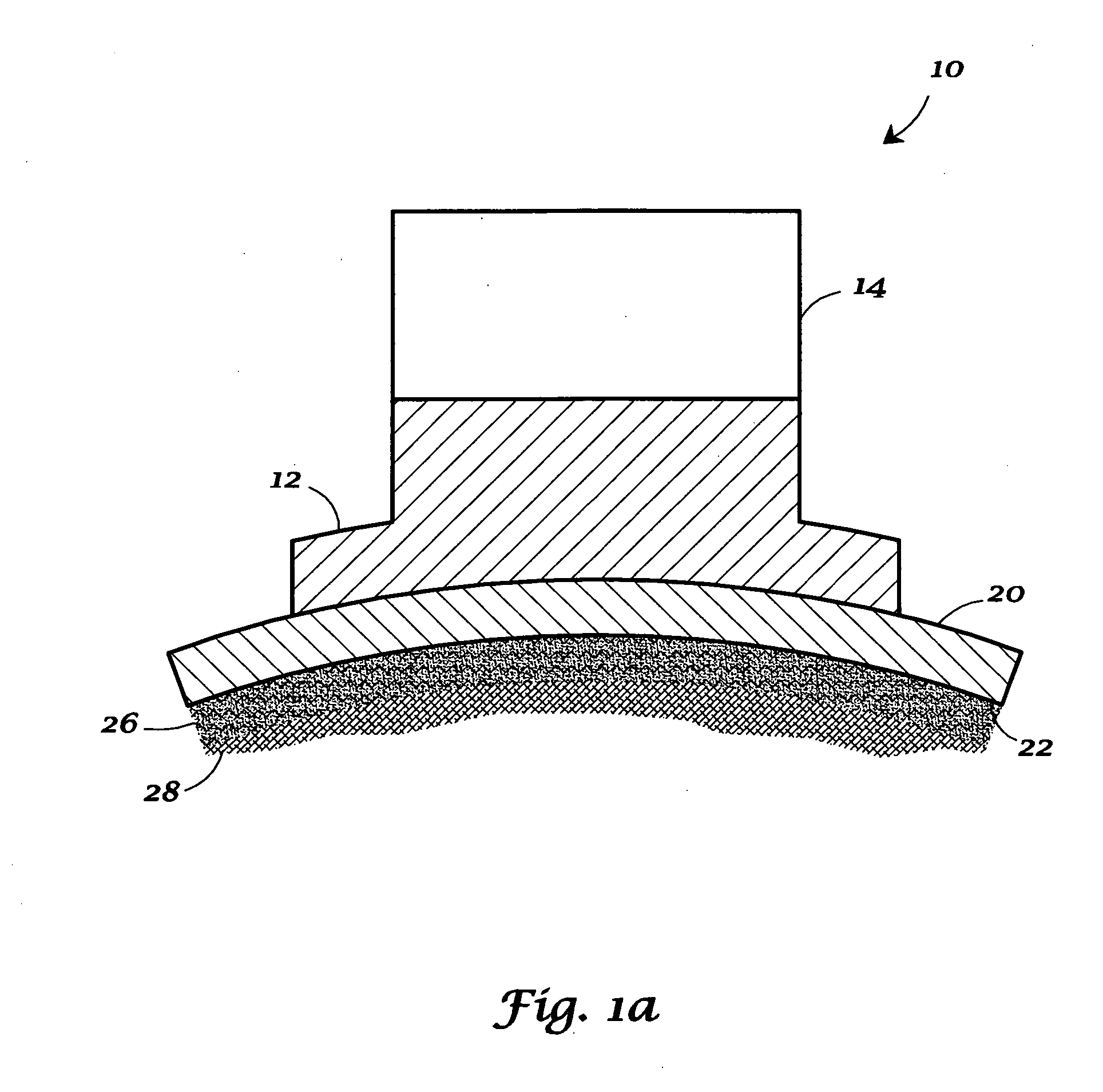

Method and apparatus for indirect bonding of orthodontic appliances

ActiveUS7020963B2Broaden applicationEasy to disengageBracketsAdditive manufacturing apparatusEngineeringAnodic bonding

Owner:3M INNOVATIVE PROPERTIES CO

Apparatus for indirect bonding of orthodontic appliances and method of making the same

InactiveUS7137812B2Prepare the base of each appliance for bonding is eliminatedHigh bonding strengthImpression capsDispensing apparatusAnodic bondingDental structure

Owner:3M INNOVATIVE PROPERTIES CO

Micromachined alkali-atom vapor cells and method of fabrication

A method of fabricating compact alkali vapor filled cells that have volumes of 1 cm3 or less that are useful in atomic frequency reference devices such as atomic clocks. According to one embodiment the alkali vapor filled cells are formed by sealing the ends of small hollow glass fibers. According to another embodiment the alkali vapor filled cells are formed by anodic bonding of glass plates to silicon wafers to seal the openings of holes formed in the silicon wafers. The anodic bonding method of fabricating the alkali vapor filled cells enables the production of semi-monolithic integrated physics packages of various designs.

Owner:THE NAT INST OF STANDARDS & TECH UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC

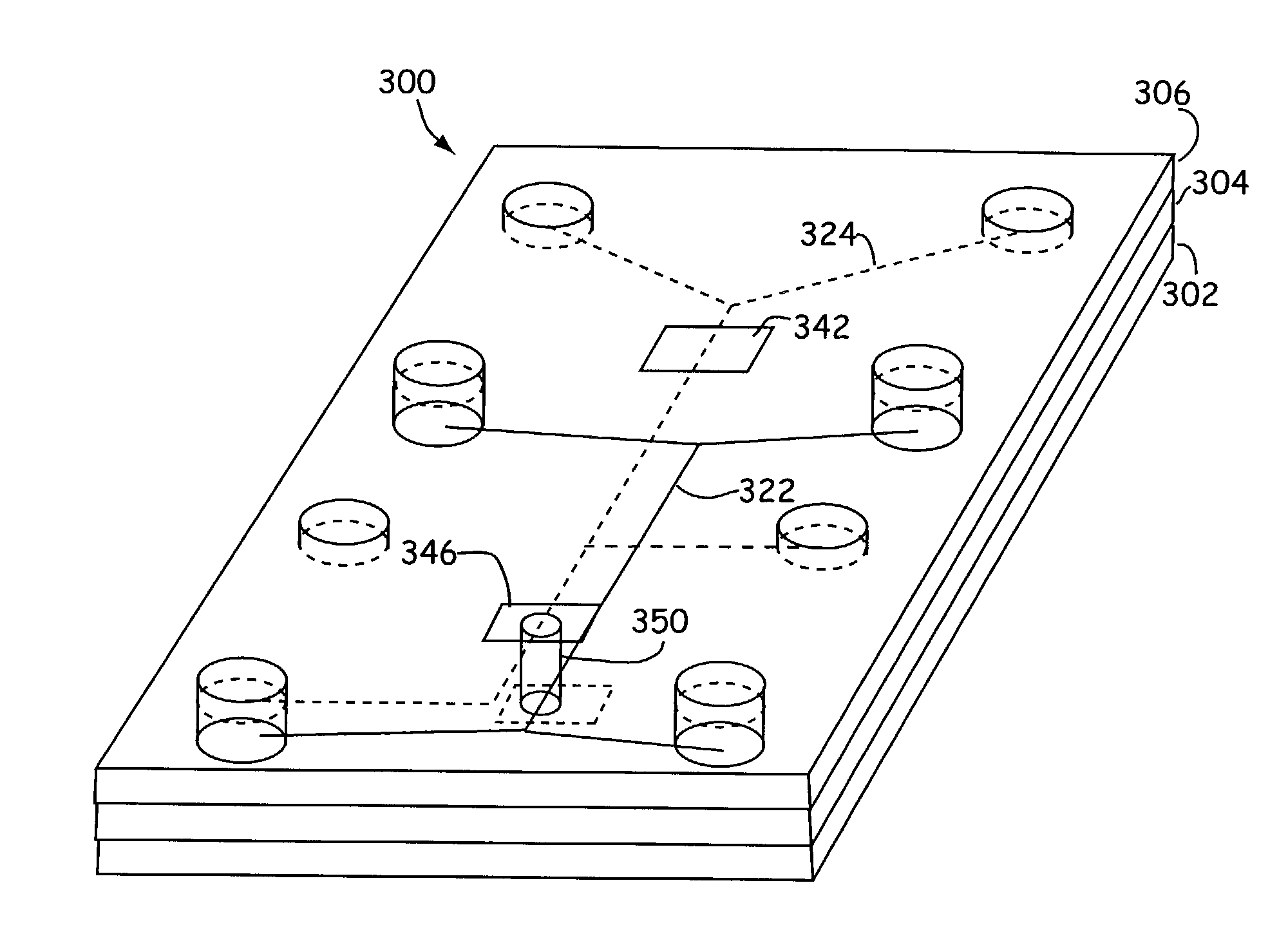

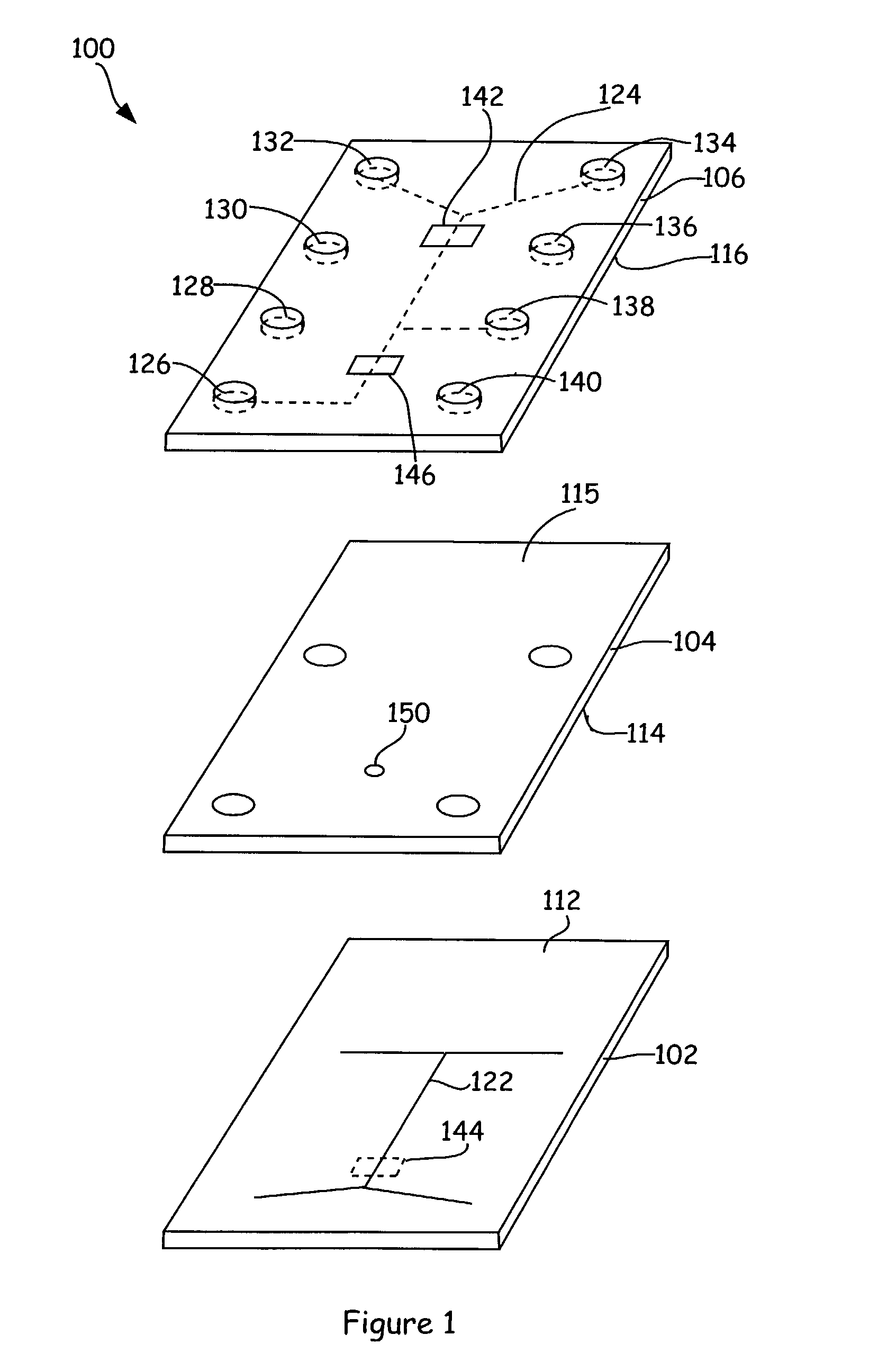

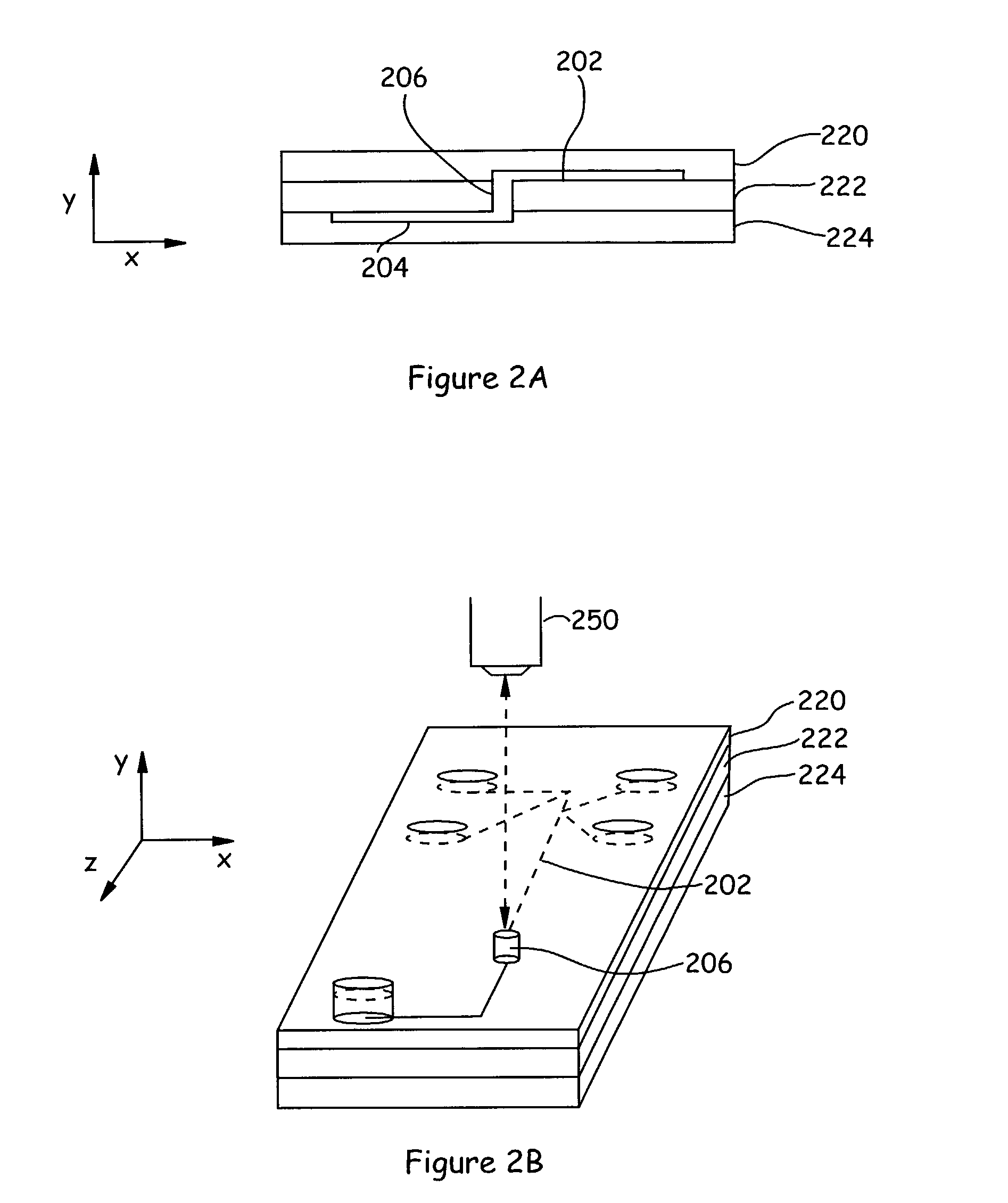

Microfluidic devices and methods of their manufacture

ActiveUS7069952B1Operating means/releasing devices for valvesCircuit elementsInterface layerAnodic bonding

The present invention provides multi-layered microfluidic devices comprising an interface layer between every two substrate layers. The interface layer simplifies the manufacturing process of the multi-layered devices because the interface may comprise a material suitable for etching whereby manufacturing of these devices is simplified to a great extent.The invention also provides methods of manufacturing the multi-layered devices wherein the devices may comprise substrates composed of non-similar materials that are bonded together by anodic bonding.

Owner:CAPLIPER LIFE SCI INC

Optical switch and method for assembling the same

An optical switch includes a substrate having therein optical waveguides made of silicon and a silicon layer deposited on its top surface. A space is formed in the crossing portion of the optical waveguides which is covered with a lid, preferably made of low alkali borosilicate glass, and which is bonded to the silicon layer by anodic bonding. Preferably, a groove is formed in a surface of the optical waveguide substrate or a bonding surface of the lid. The groove, after the lid has been bonded, makes a passage which communicates between the space and an outside. The passage is a pouring slit for pouring an index-matching liquid and is connected to the space which acts as a driving slit in which the index-matching liquid moves. In one embodiment, the width of the pouring slit is smaller than that of the driving slit. The optical switch can be manufactured by providing an optical waveguide substrate and a lid substrate, one of which is formed with a groove in its surface on which the two substrates are bonded. The optical waveguide substrate and the lid substrate are bonded together by anodic bonding to make a passage which communicates between the space formed in a crossing portion of the optical waveguides and an outside. The regulation of the volume of the index-matching liquid is time-, temperature-, or pressure-based regulation.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

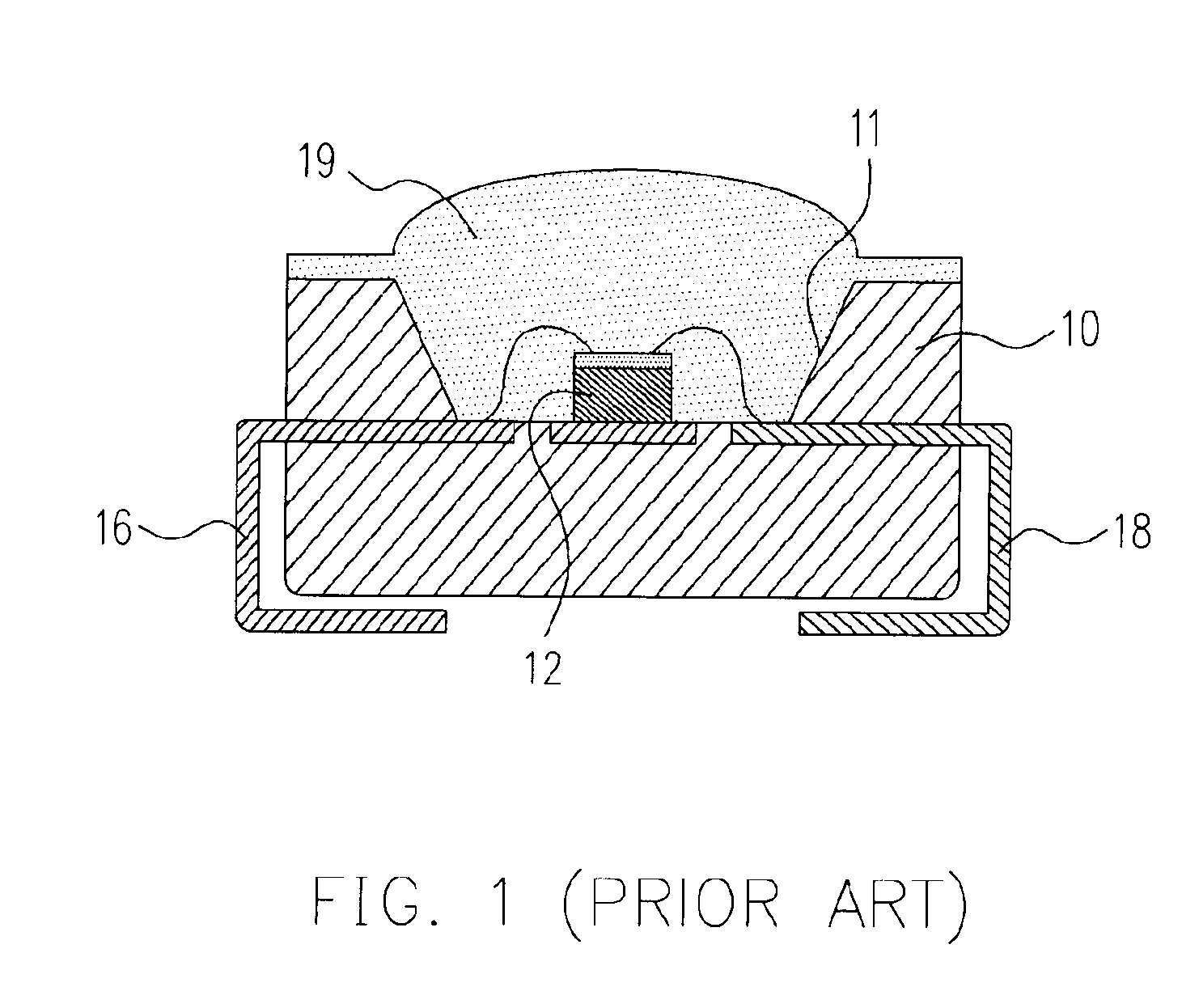

Package structure of light emitting diode

The present invention relates to a package structure for a light emitting diode (LED). The LED package structure of this invention includes a package housing having at least a trench and at least two leads. The package structure includes at least a die or an LED chip disposed on the bottom surface of the trench, while two electrodes of the die are respectively electrically connected to the ends of two leads on the bottom surface of the trench. A transparent plate of glass or crystal materials is mounted and connected to the housing by anodic bonding or glue bonding, to seal the trench, while the other ends of leads are exposed on the surface of the housing without being covered by the transparent plate.

Owner:NYTELL SOFTWARE LLC

Method of making resonant tunneling diodes and CMOS backend-process-compatible three dimensional (3-D) integration

InactiveUS7002175B1Improve performanceEase of fabricationSemiconductor/solid-state device detailsNanoinformaticsLow noiseElectrical connection

A double barrier resonant tunneling diode (RTD) is formed and integrated with a level of CMOS / BJT / SiGe devices and circuits through processes such as metal-to-metal thermocompressional bonding, anodic bonding, eutectic bonding, plasma bonding, silicon-to-silicon bonding, silicon dioxide bonding, silicon nitride bonding and polymer bonding or plasma bonding. The electrical connections are made using conducting interconnects aligned during the bonding process. The resulting circuitry has a three-dimensional architecture. The tunneling barrier layers of the RTD are formed of high-K dielectric materials such as SiO2, Si3N4, Al2O3, Y2O3, Ta2O5, TiO2, HfO2, Pr2O3, ZrO2, or their alloys and laminates, having higher band-gaps than the material forming the quantum well, which includes Si, Ge or SiGe. The inherently fast operational speed of the RTD, combined with the 3-D integrated architecture that reduces interconnect delays, will produce ultra-fast circuits with low noise characteristics.

Owner:AGENCY FOR SCI TECH & RES

Bonding method, device produced by this method, and bonding device

ActiveUS20070111471A1High bonding strengthIncrease productivitySemiconductor/solid-state device manufacturingMicrostructural device assemblyThermal expansionEngineering

Conventional heat bonding and anodic bonding require heating at high temperature and for a long time, leading to poor production efficiency and occurrence of a warp due to a difference in thermal expansion, resulting in a defective device. Such a problem is solved. An upper wafer 7 made of glass and a lower wafer 8 made of Si are surface-activated using an energy wave before performing anodic bonding, thereby performing bonding at low temperature and increasing a bonding strength. In addition, preliminary bonding due to surface activation is performed before main bonding due to anodic bonding is performed in a separate step or device, thereby increasing production efficiency, and enabling bonding of a three-layer structure without occurrence of a warp.

Owner:BONDTECH

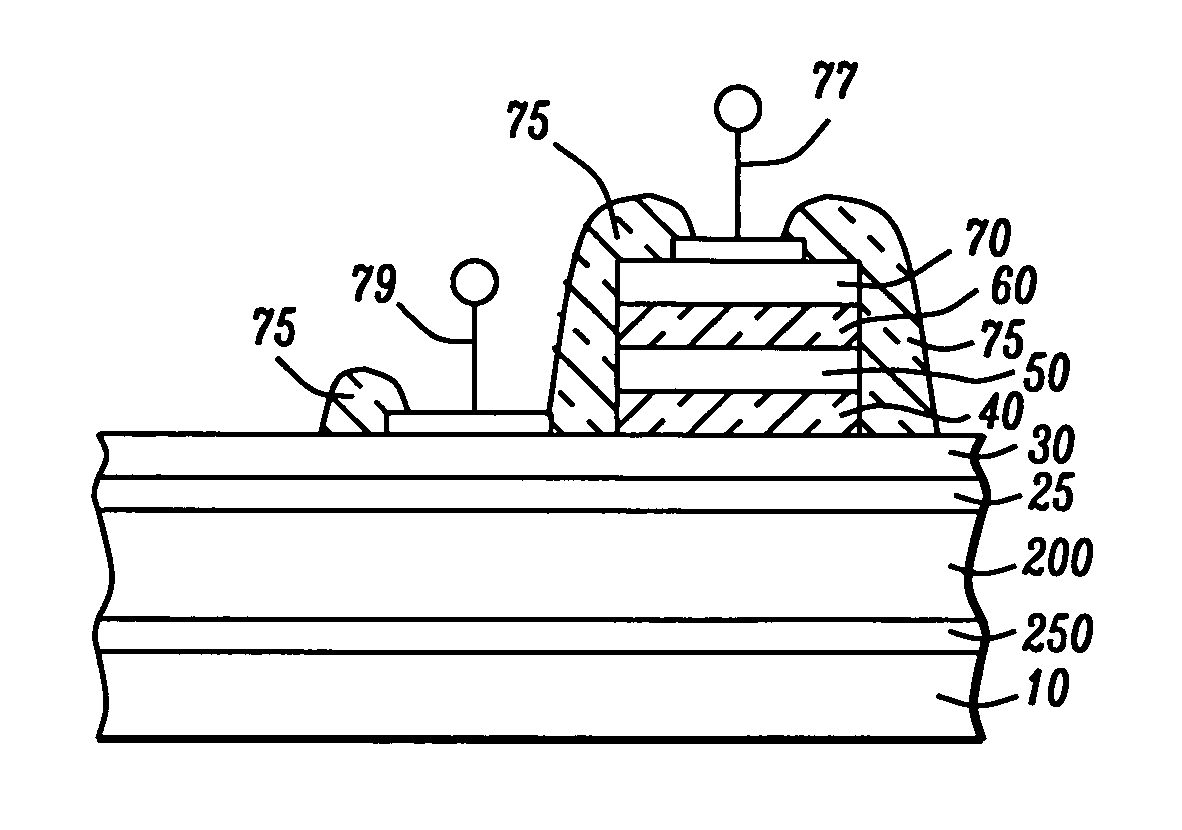

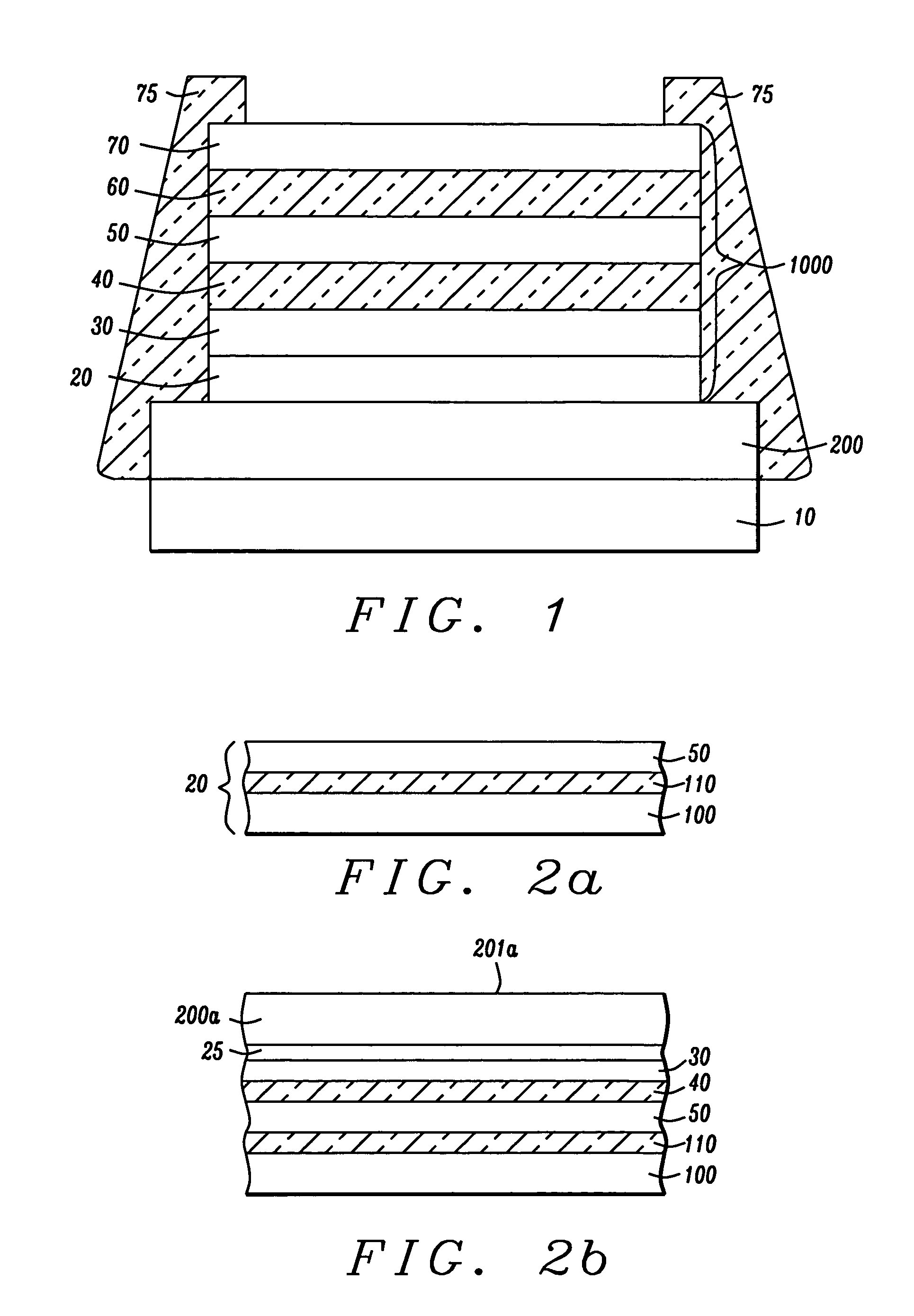

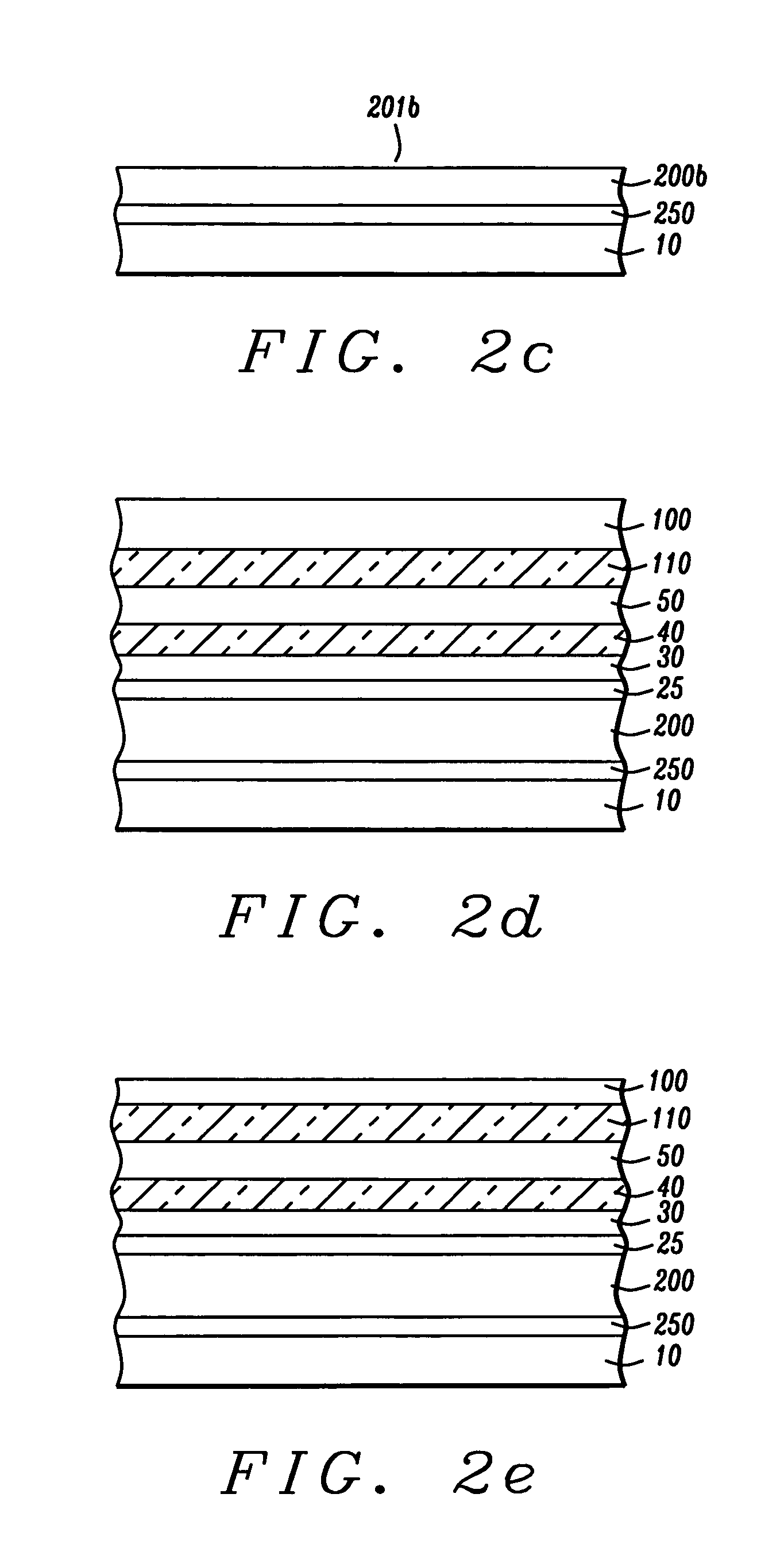

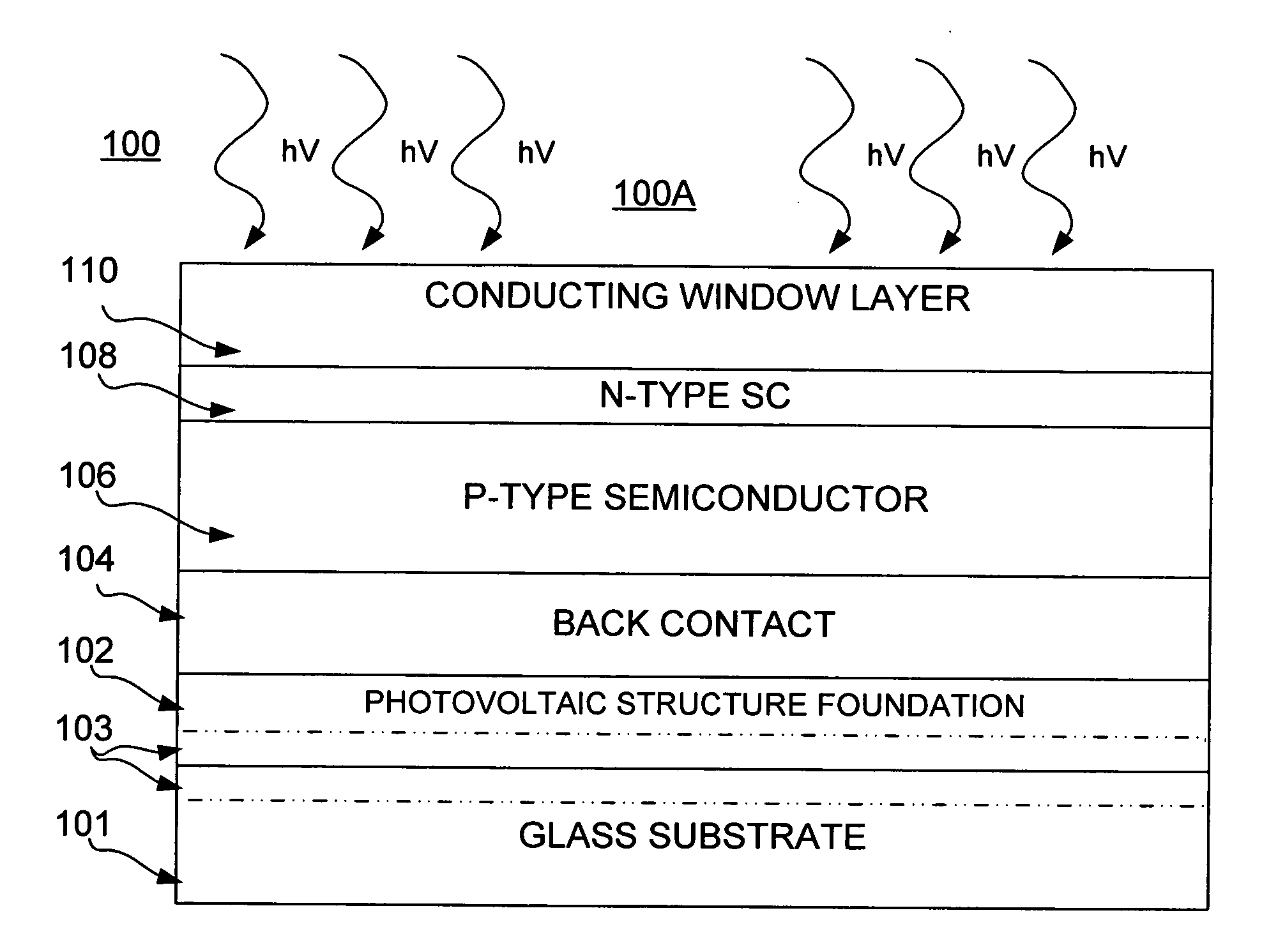

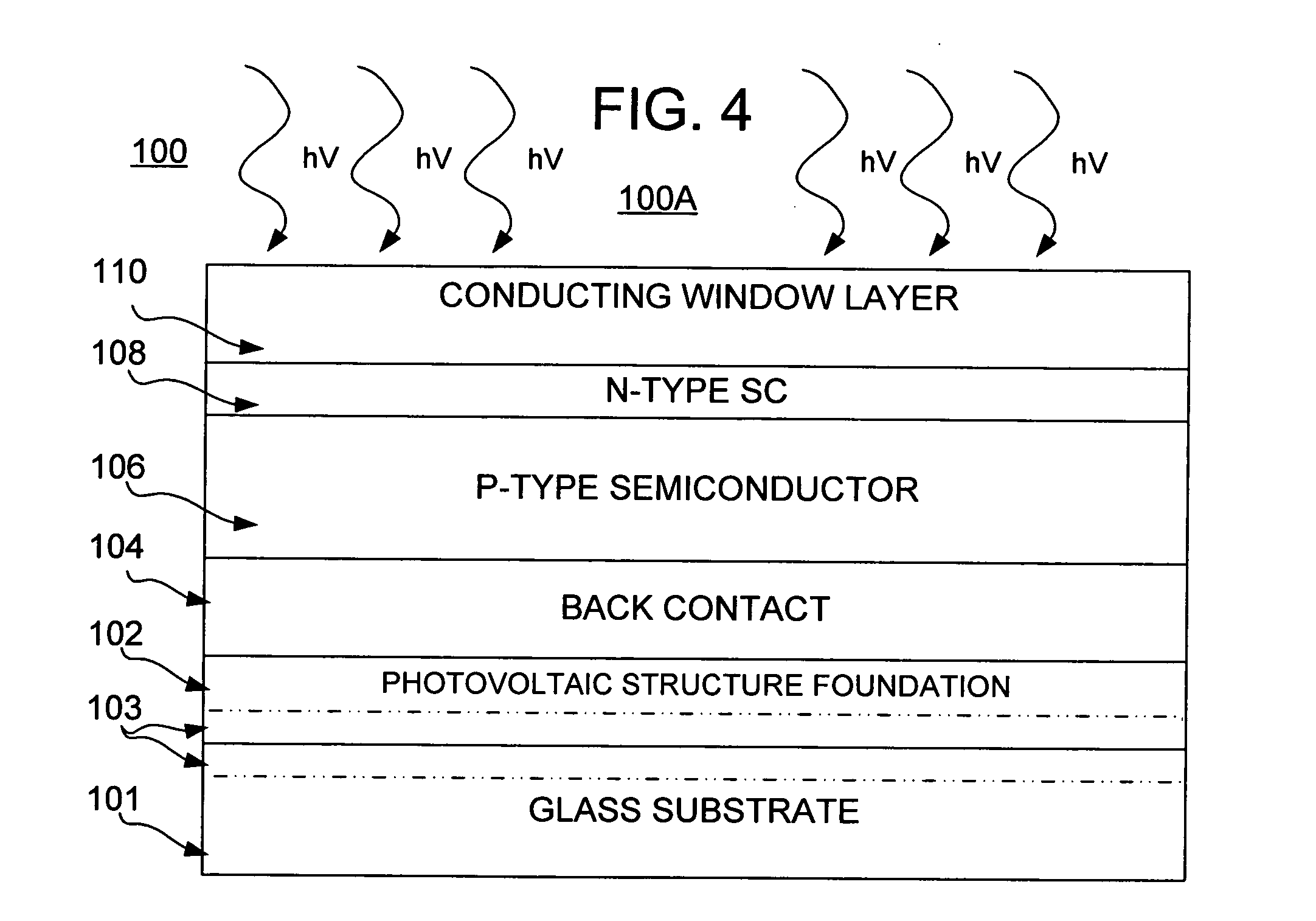

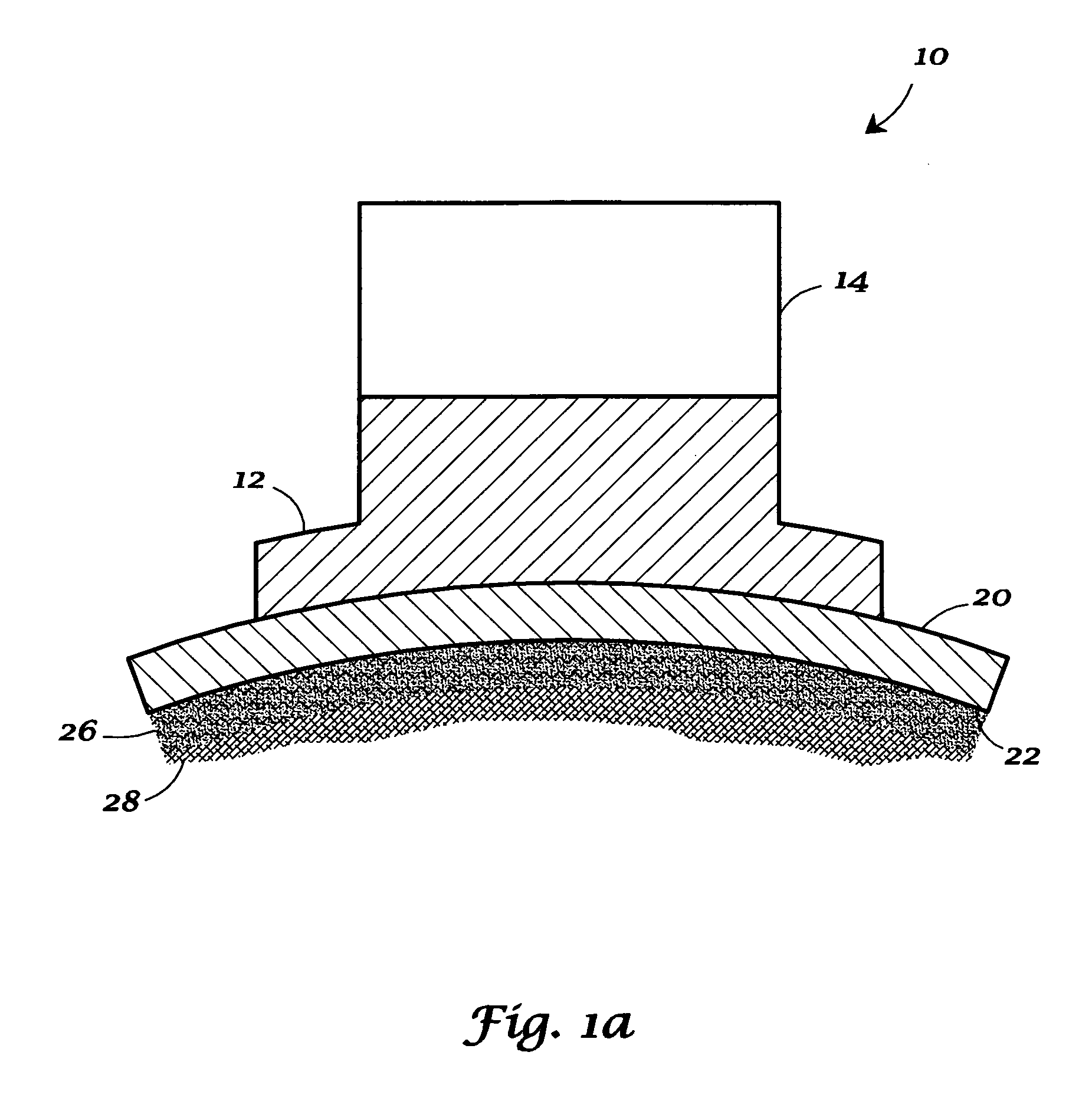

Thin film photovoltaic structure

InactiveUS20070277875A1Improve conversion efficiencyWide range of designsPhotovoltaic energy generationSemiconductor devicesSingle crystalEngineering

Photovoltaic devices include an insulator structure bonded to an exfoliation layer, preferably of a substantially single-crystal donor semiconductor wafer, and at least one photovoltaic device layer, such as a conductive layer. In a preferred embodiment, a device may include a conductive layer adjacent to the insulator substrate and integral to the exfoliation layer, near the side that faces the insulator substrate, such as between the insulator substrate and the exfoliation layer. In a further preferred embodiment, a device may include a plurality of photovoltaic device layers distal to the insulator substrate and in or on the exfoliation layer, preferably having been epitaxially grown on the exfoliation layer after the exfoliation layer has been anodically bonded to the insulator substrate by means of electrolysis.

Owner:CORNING INC

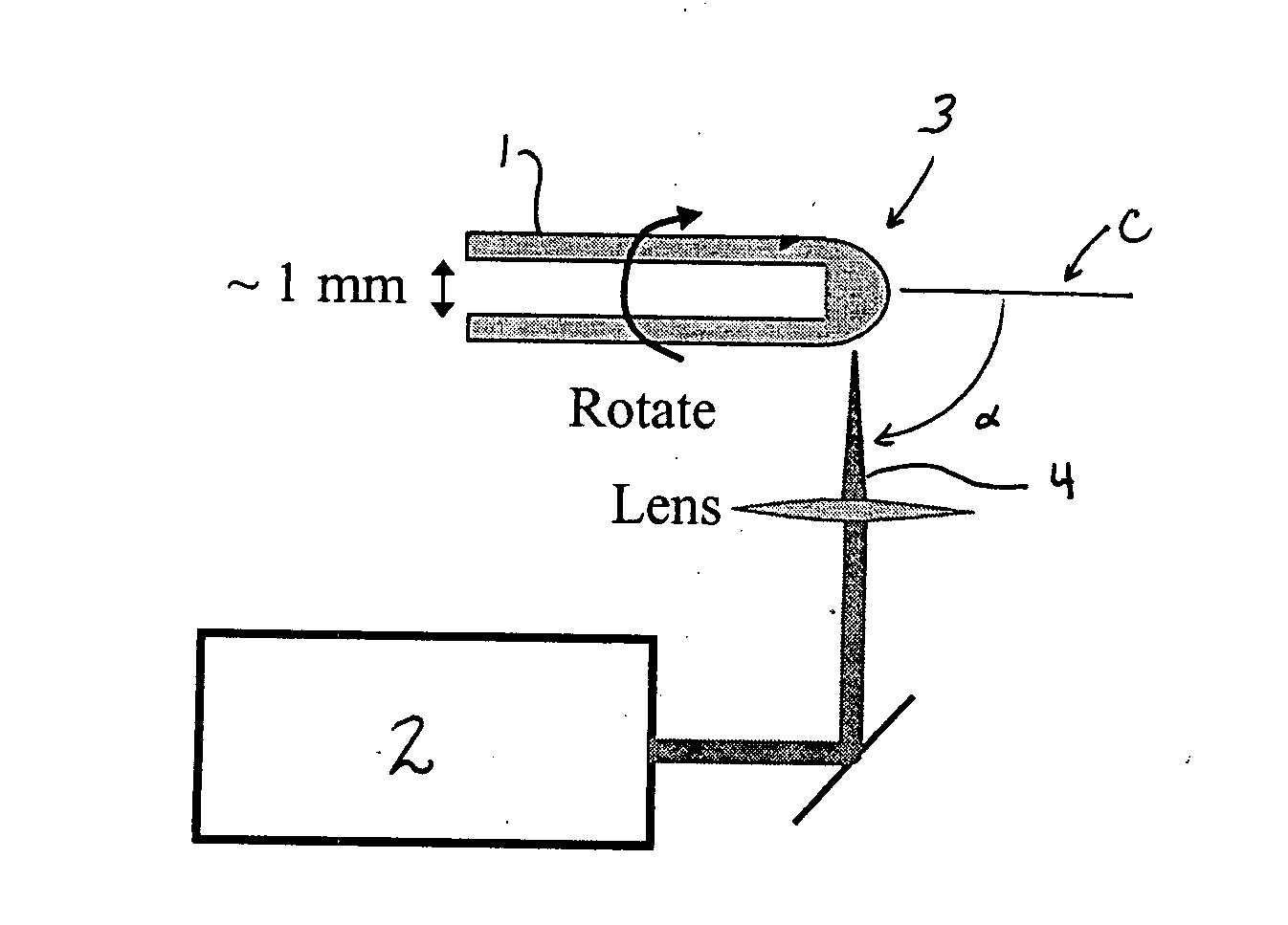

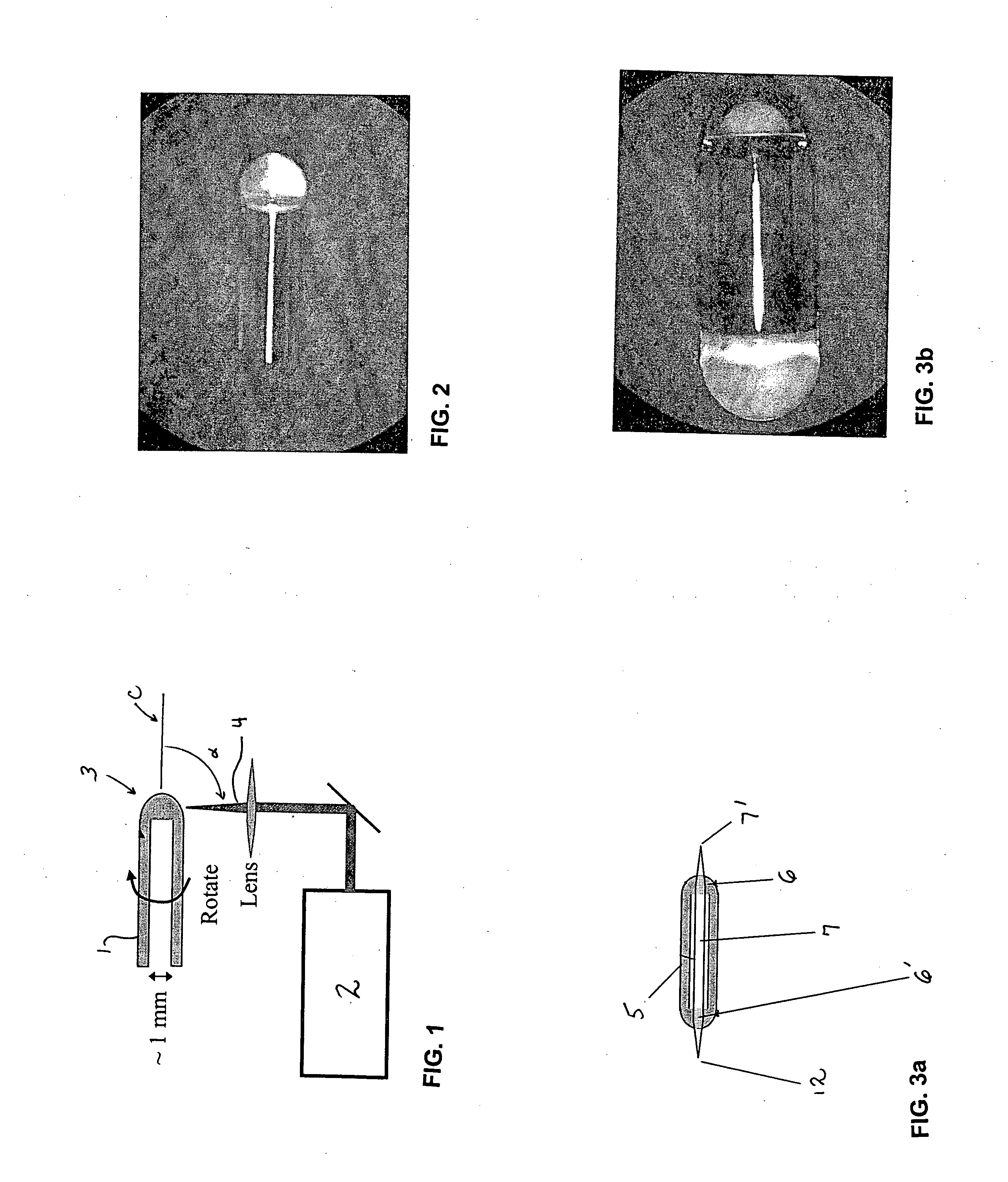

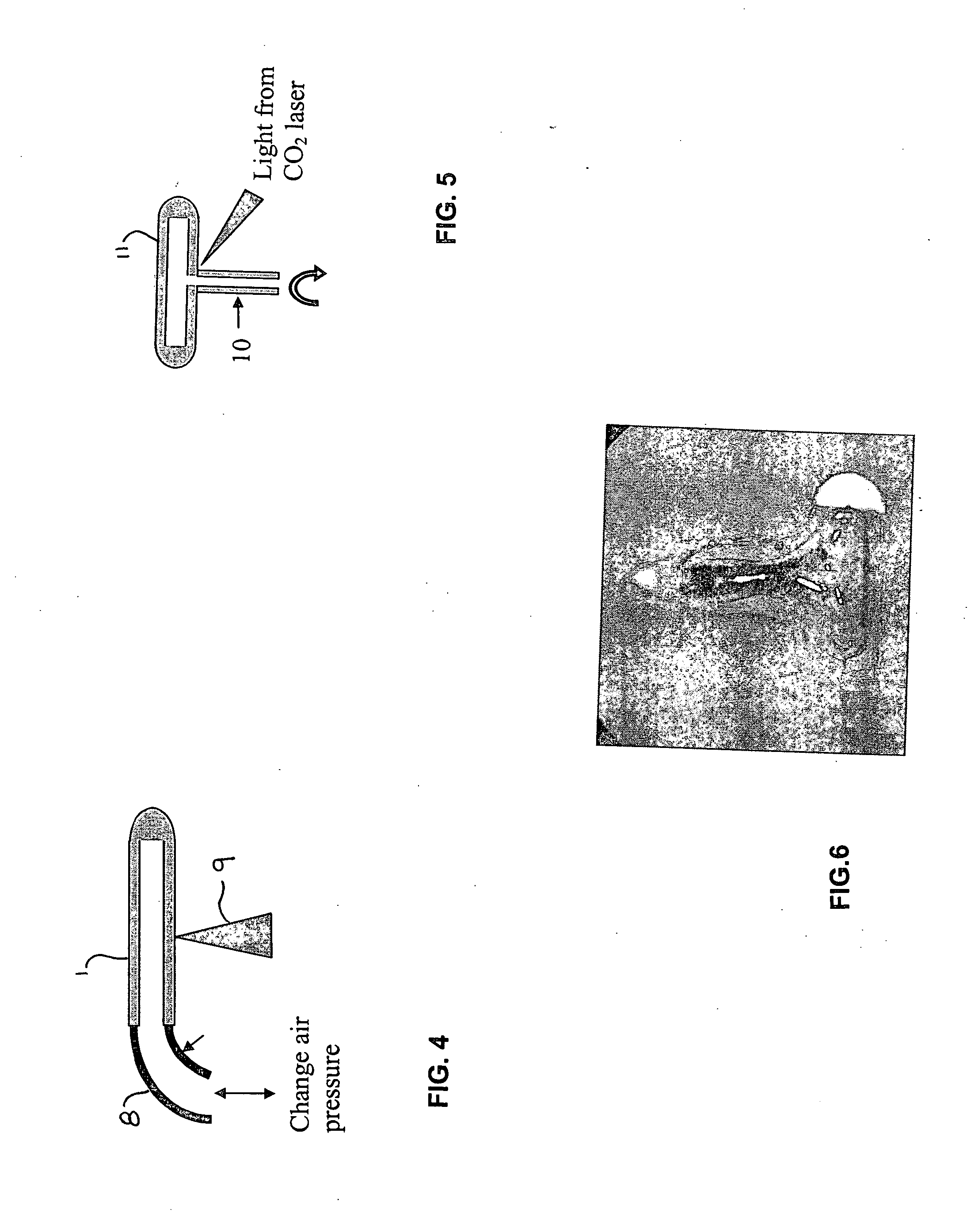

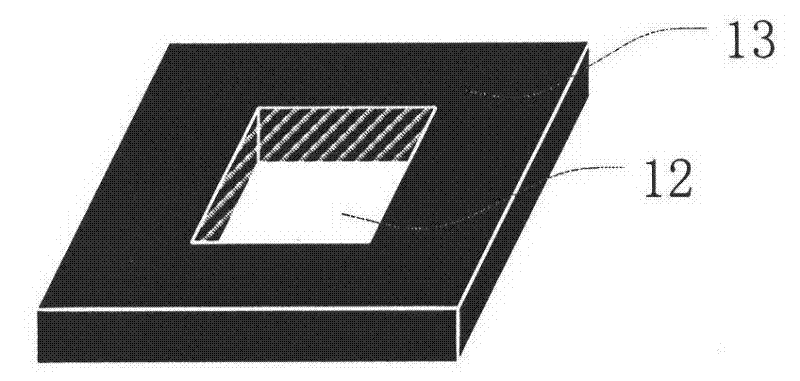

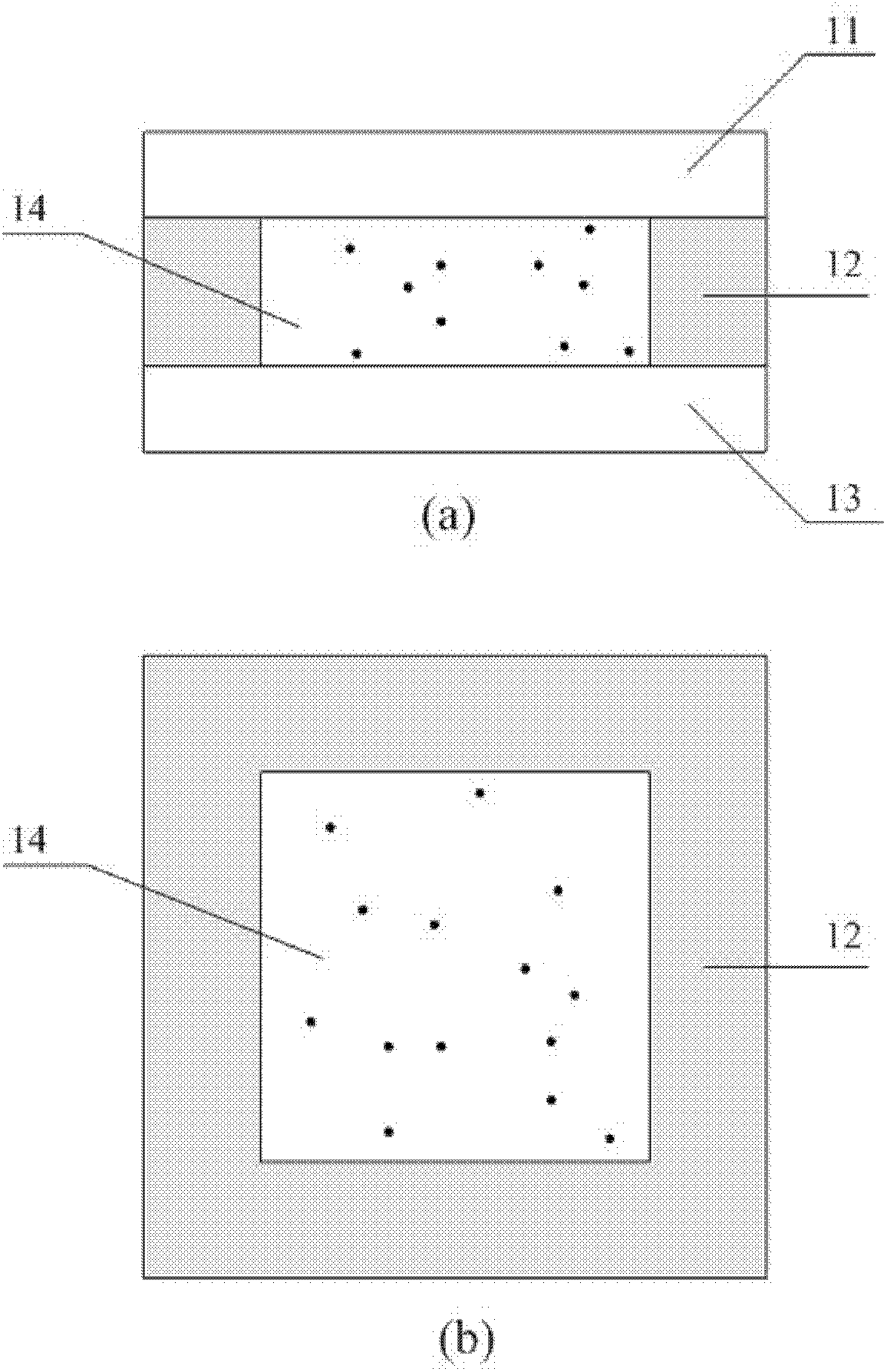

A kind of preparation method of mems atomic vapor chamber and atomic vapor chamber

ActiveCN102259825AEasy to makeIncrease contrastPrecision positioning equipmentDecorative surface effectsWater vaporRubidium

The invention relates to a preparation method for a micro-electro-mechanical system (MEMS) atomic vapor chamber and the atomic vapor chamber. The chamber is prepared by bonding a Pyrex glass sheet, a silicon wafer and a Pyrex glass sheet by an anodic bonding technology; the Pyrex glass sheet is taken as a window of the chamber; a chamber space is formed by etching or corroding the silicon wafer; paraffin packaged alkali metal such as rubidium (Rb) or cesium (Cs) is put into the chamber, and buffer gas with appropriate pressure is introduced simultaneously; paraffin is taken as a packaging material of the alkali metal, so that active alkali metal is isolated from oxidants such as oxygen, water vapor and the like in an environment; the paraffin is also used as a plating material of the chamber, so that collision between Rb or Cs atoms and a chamber wall is slowed down; and a CO2 laser is used for melting the paraffin to release the alkali metal, so that a uniform paraffin plating is formed on the chamber wall. The problem of long-term drift caused by reaction residues generated by a field preparation mode is solved, the collision between the Rb or Cs atoms and the chamber wall is slowed down, and the contrast of atomic resonance line width of the alkali metal is improved.

Owner:江苏智能微系统工业技术股份有限公司

Methods for indirect bonding of orthodontic appliances

ActiveUS8308478B2High strengthIncrease elasticityBracketsTeeth fillingDental patientsDental restorative materials

Improved methods for indirect bonding of orthodontic appliances, such as brackets, to the tooth surfaces of dental patients are provided. The methods use a transfer tray to accurately position the brackets on the tooth surfaces. Preferably, the tray is made of an ethylene vinyl acetate copolymer (EVA) / siloxane material. The brackets are coated with a protective coating to prevent them from becoming embedded in the tray. Preferably, a translucent, blue-tinted coating is used to cover the brackets. Dental restorative materials are used to bond the brackets to the teeth. The transfer tray is then removed from the mouth, while the appliances remain firmly bonded to the tooth surfaces.

Owner:DENTSPLY SIRONA INC

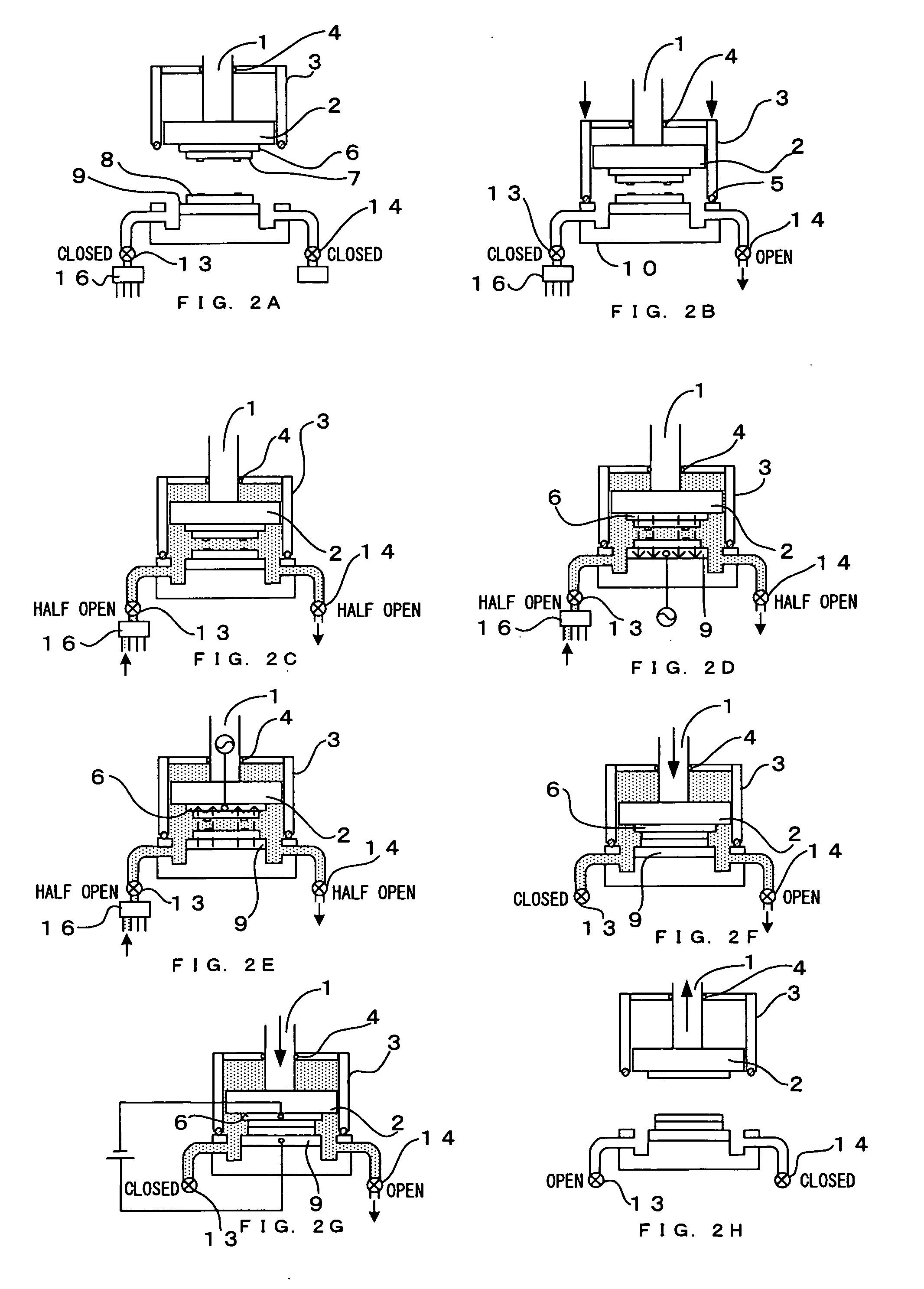

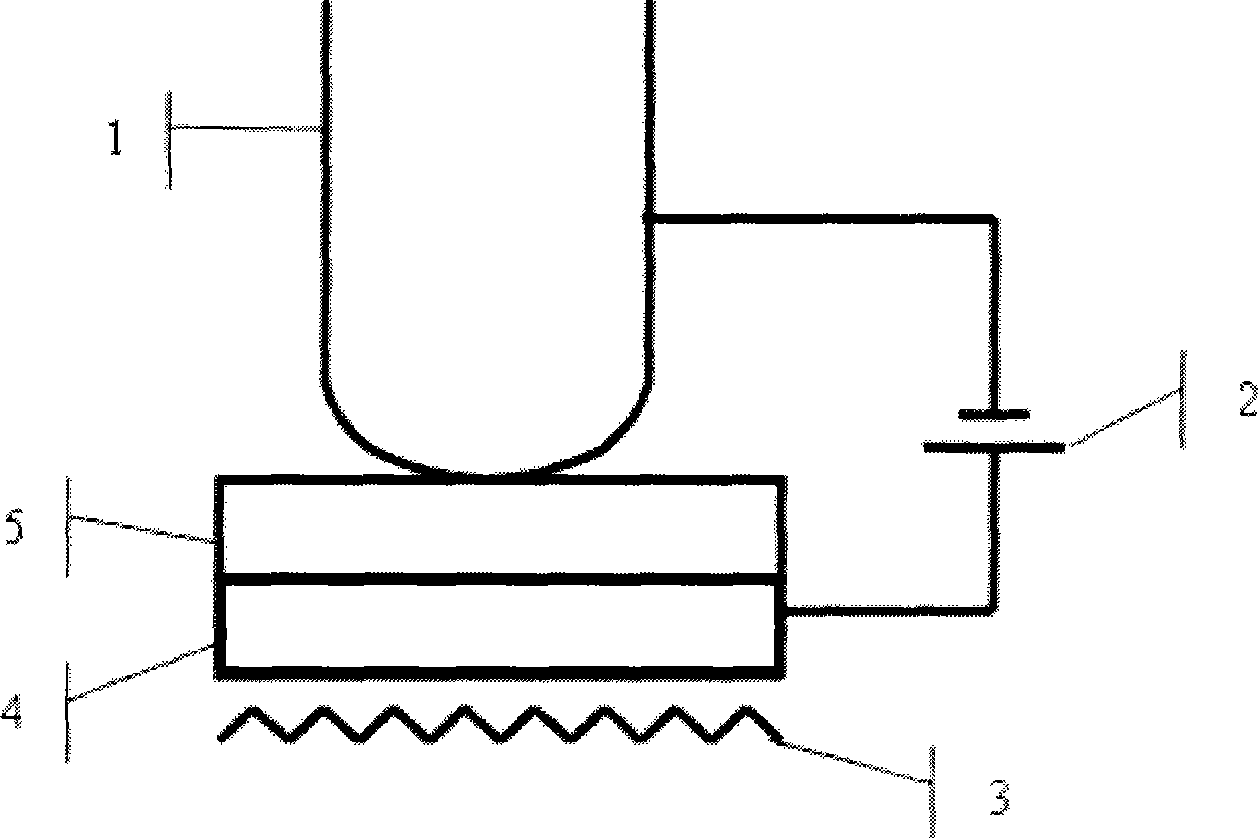

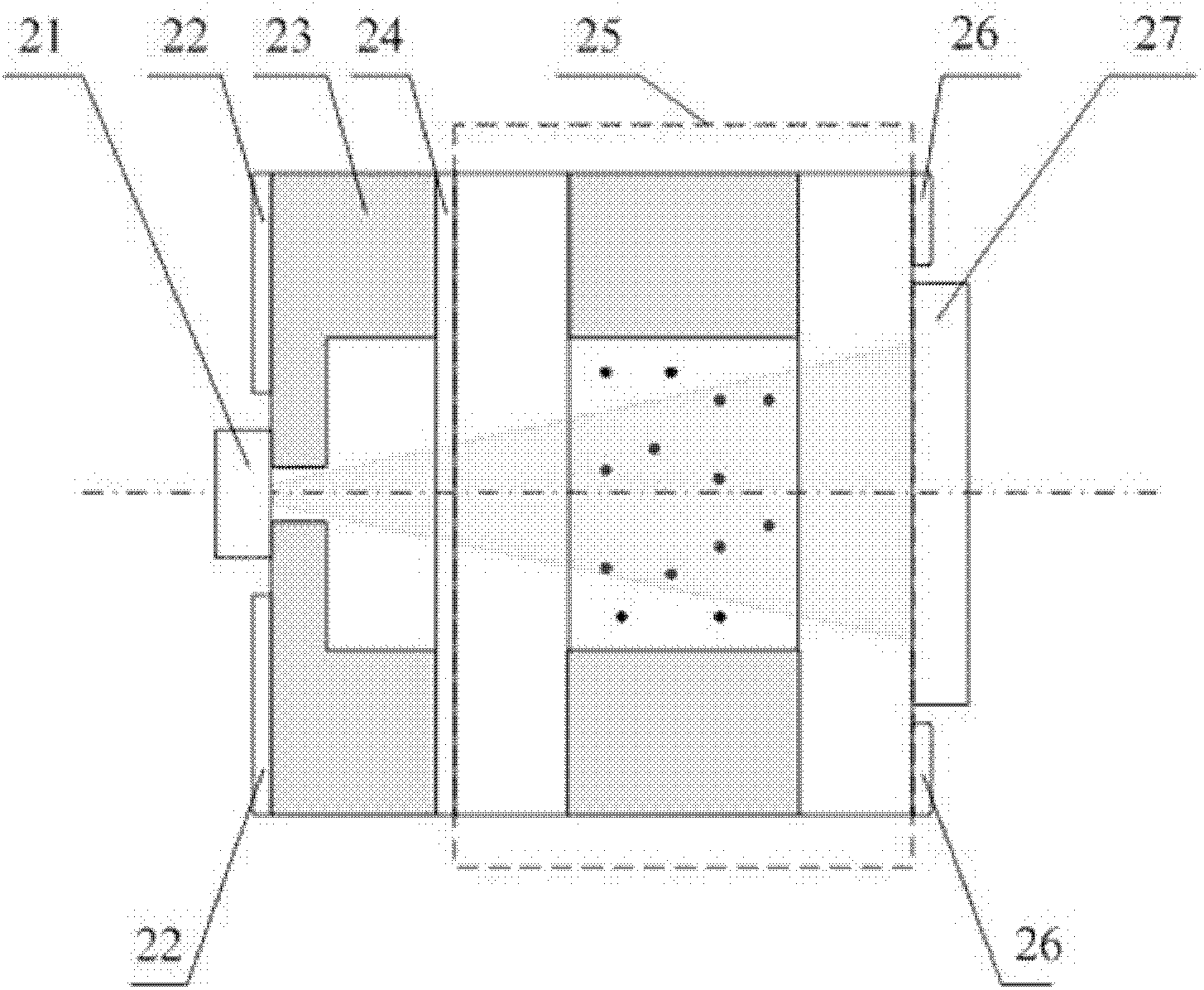

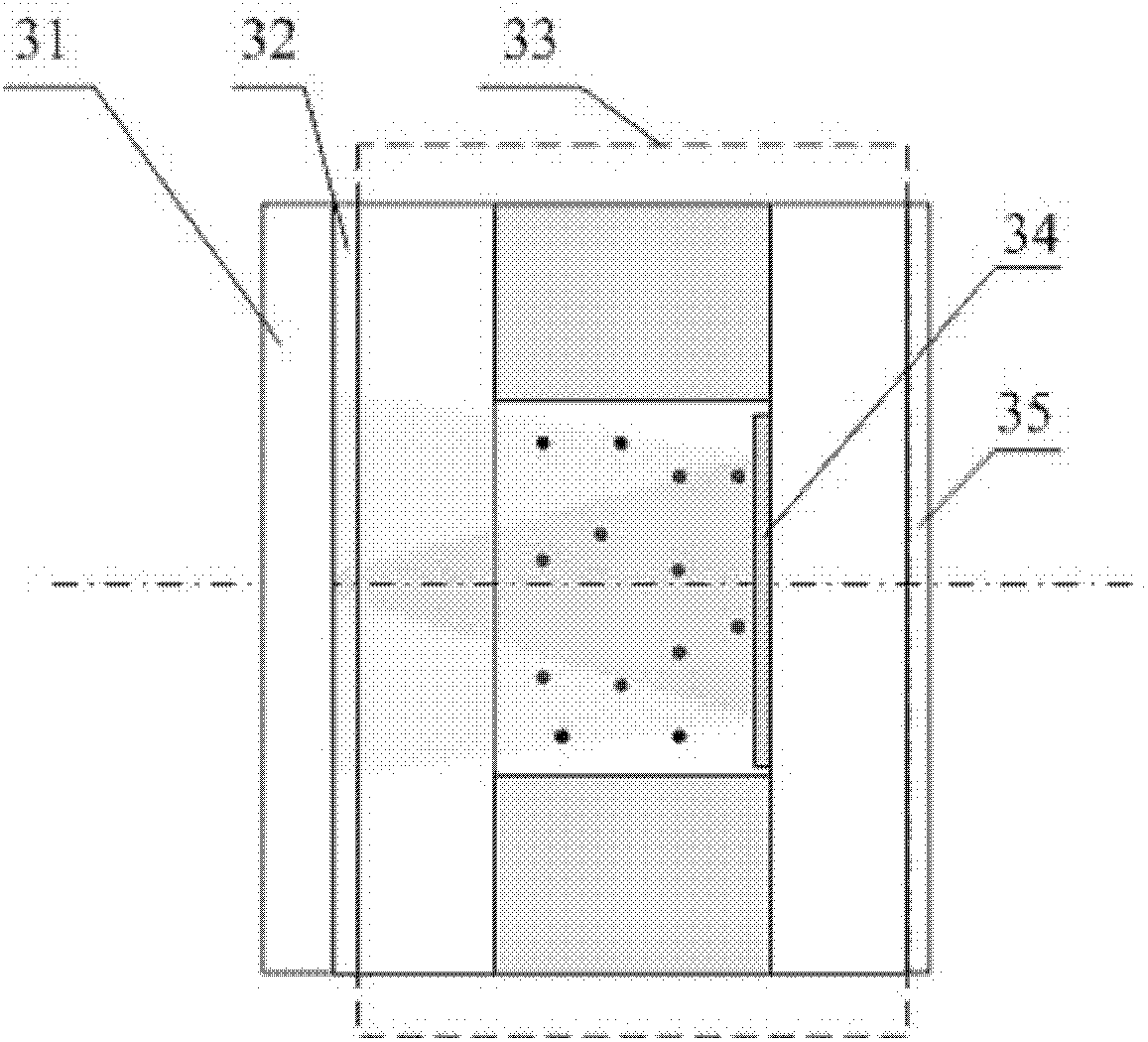

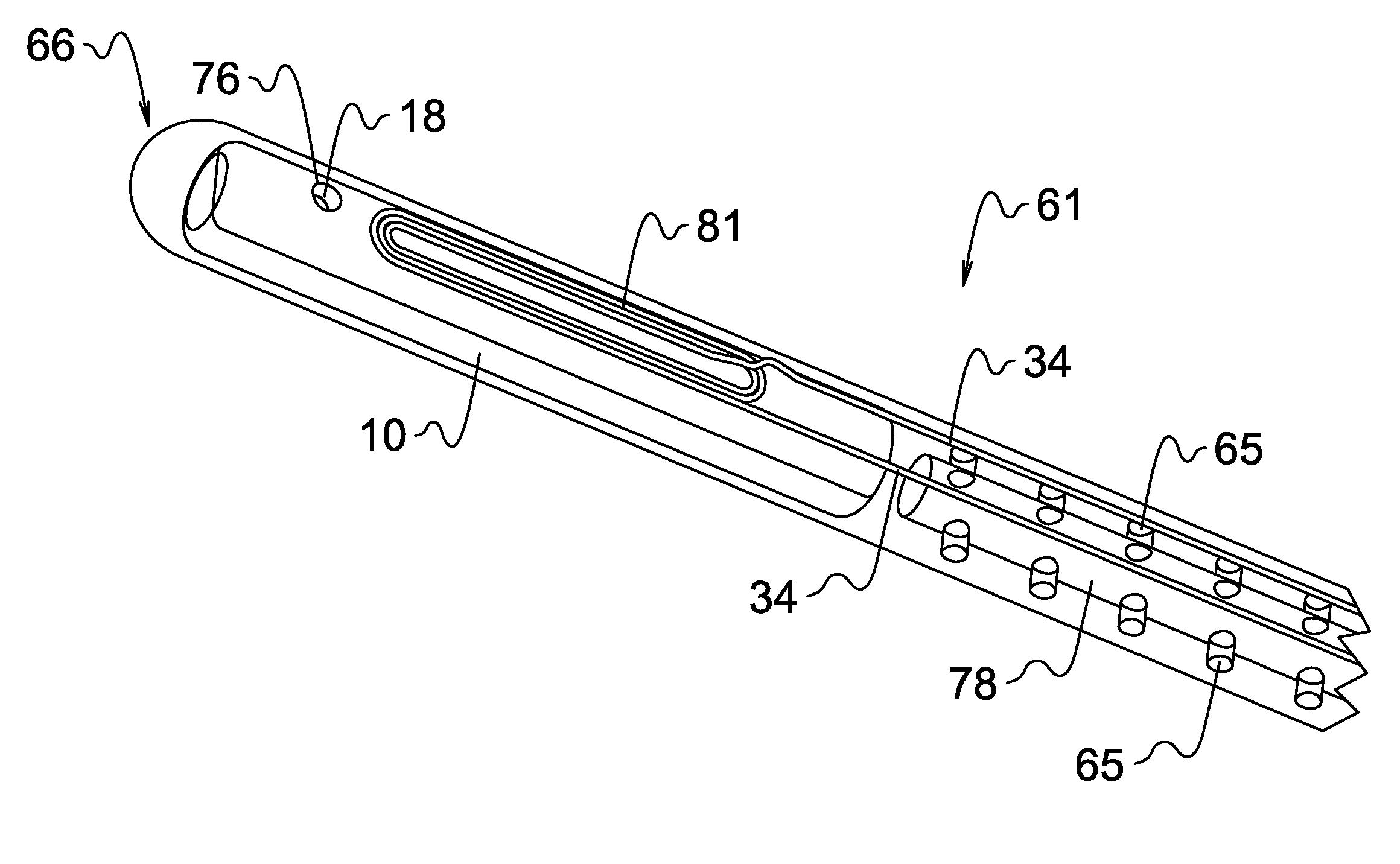

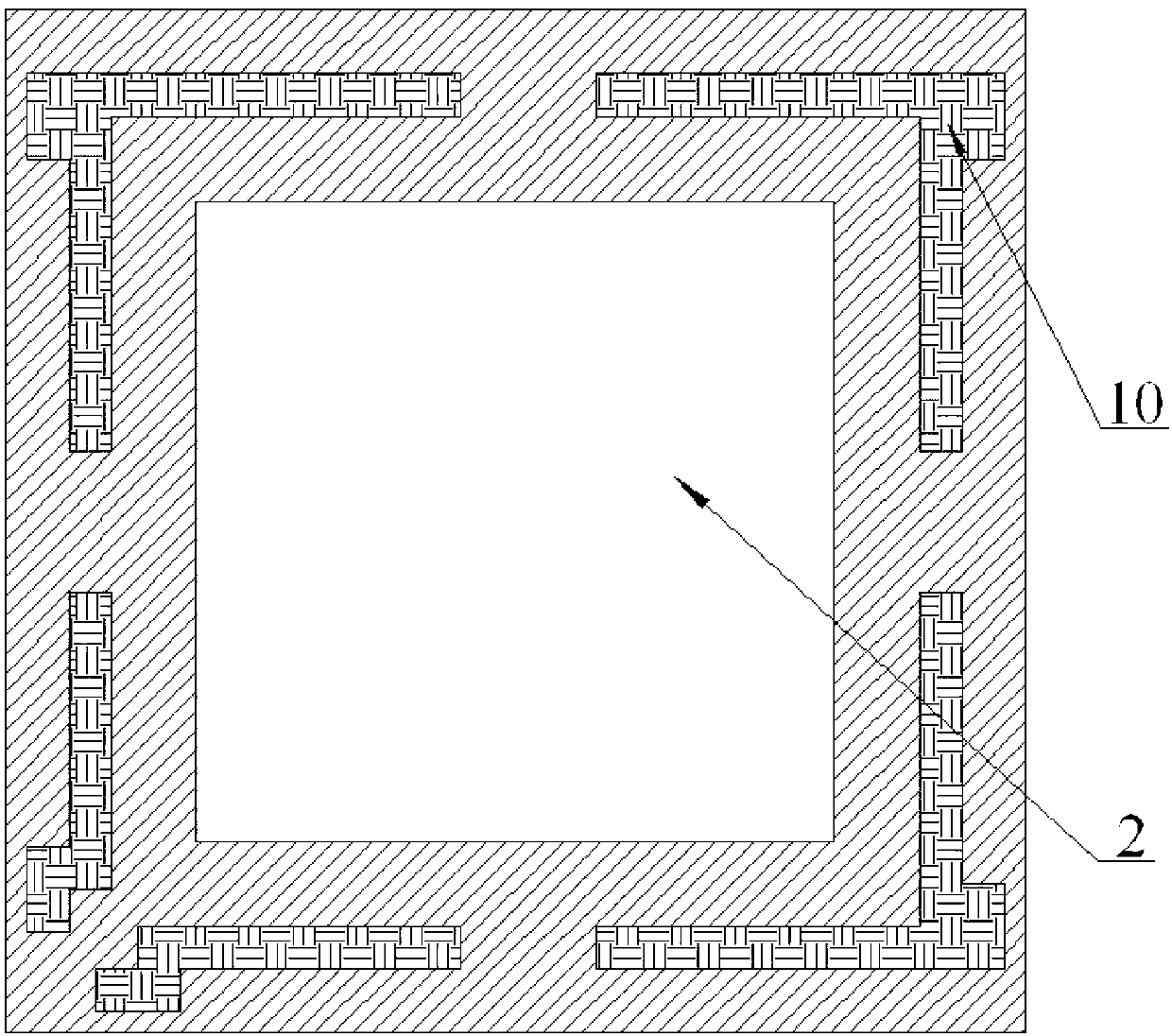

Miniature atomic air chamber encapsulation apparatus and technology method

InactiveCN101439843AImplement encapsulationAchieve bondingPrecision positioning equipmentSoldering apparatusChemical reactionRubidium

The invention discloses packaging equipment for a micro atomic gas chamber and a process technology method thereof. The equipment comprises a sample chamber, a pressure bar, a sample wafer, a sample stage, a heating wire, a temperature measurement probe, a vacuum pump connector, an inflation inlet, a direct-current high-voltage power supply, a voltmeter, a resistor, and other measurement and control devices. The method comprises: step 1, the selection of materials; step 2, the processing of the materials; step 3, the washing of the sample wafer; step 4, the bonding of a first surface; step 5, the bonding of a second surface; and step 6, the detection of a sample, and is a method which closes metal rubidium generated by adopting an in-situ chemical reaction method in a micro gas chamber. The method has the advantages that the special equipment is a common high vacuum system which is based on an anode bonding technology principle and adopts a relatively cheap mechanical pump, namely molecular pump air-bleed set; at the same time, inert gas is used to take measures such as the repeated inflation to the vacuum system to clean, the high temperature baking to the local sample wafer to remove gas and so on, to lighten the influence of residual gas and adsorbed gas as far as possible, particularly lighten the oxidation of rubidium.

Owner:PEKING UNIV

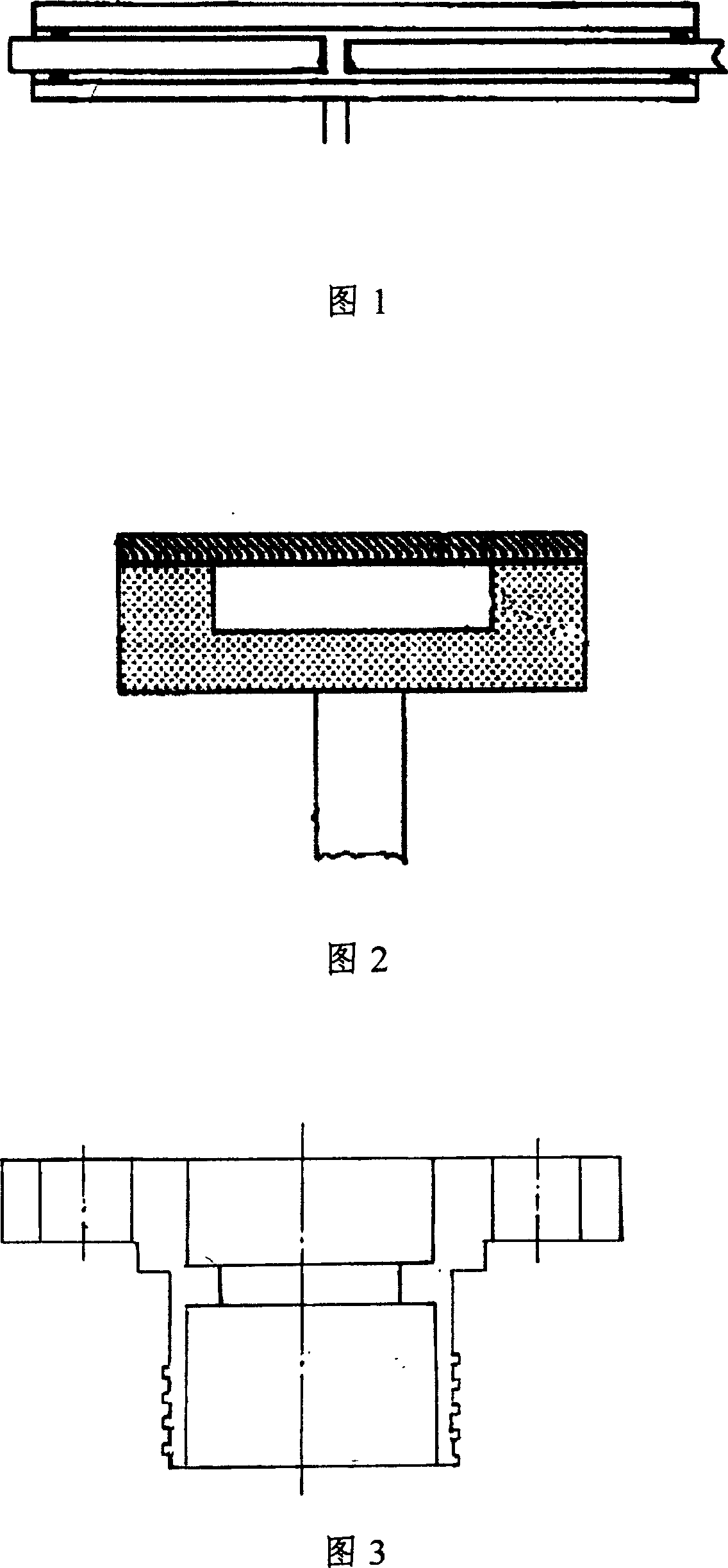

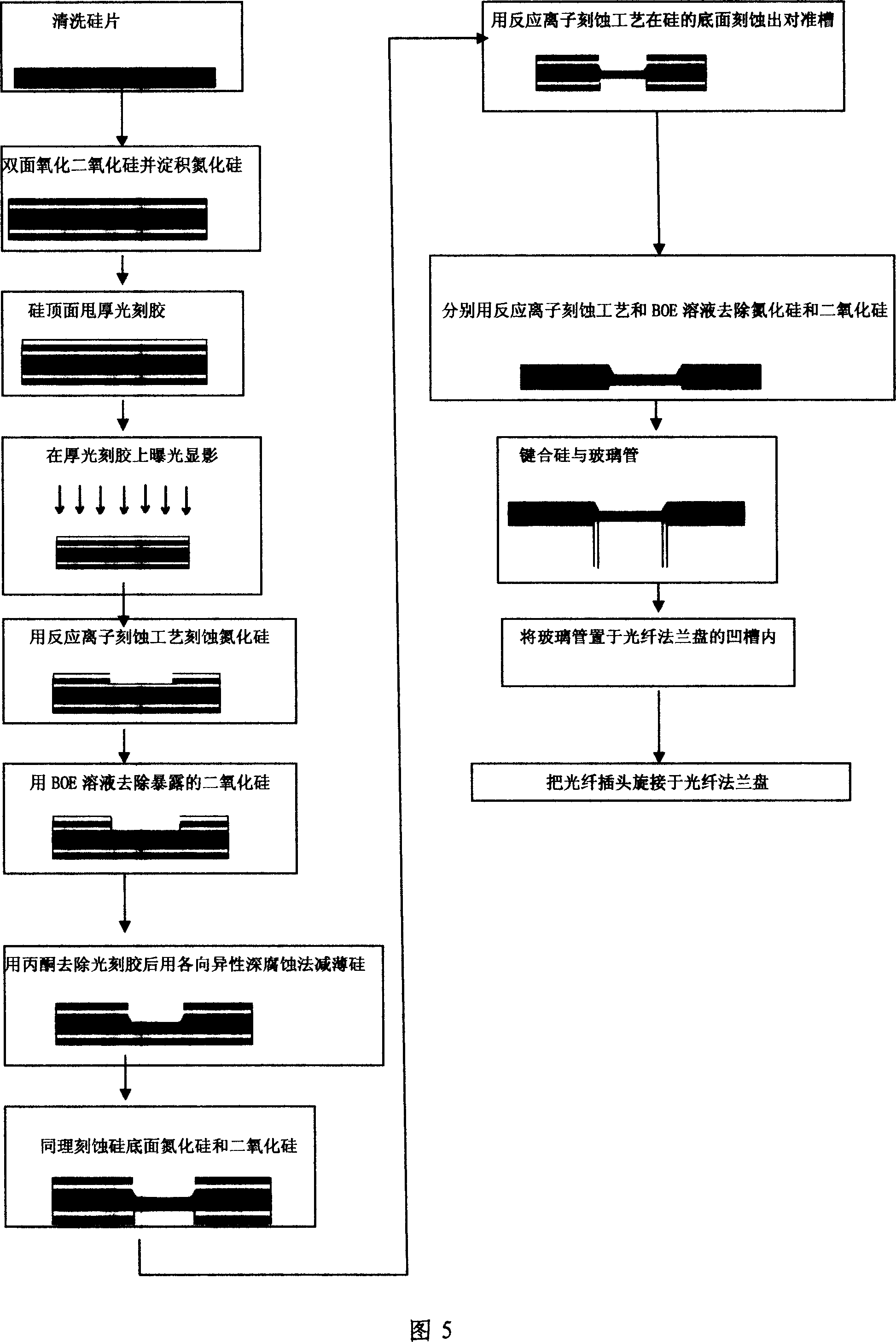

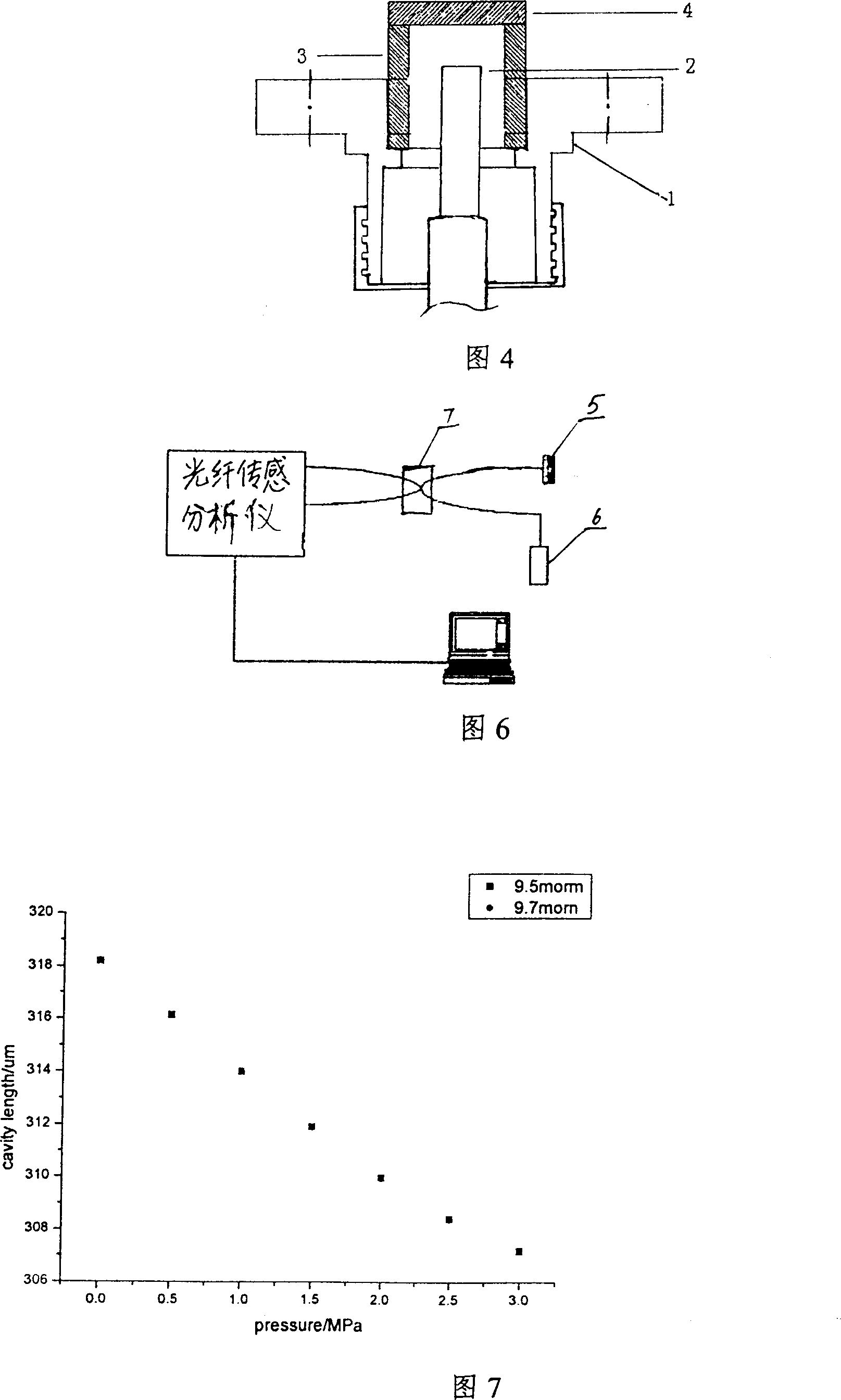

Fabry-Perotw fiber-optic pressure sensor and manufacture method therefor

InactiveCN101017116AAvoid influenceEasy to manufactureForce measurement by measuring optical property variationCoupling light guidesFiberCutting glass

This invention discloses one Fabry-Perot fiber pressure sensor, which comprises single silicon slice, glass round tube, fiber flange disc and fiber plug and is characterized by the following: the single silicon slice and glass round tube one end are connected through anode keys; other end of round tube is added to fiber flange disc tank; the fiber plug is connected to flange disc with ceramics needle and silicon slice form the chamber. This invention also discloses one method for it, which comprises the following steps: putting the cut glass tube and silicon slice onto key furnace; the glass tube outer wall is coasted with epoxy resin to flange concave tank; connecting the fiber plug into fiber flange disc to form the chamber.

Owner:NANJING NORMAL UNIVERSITY

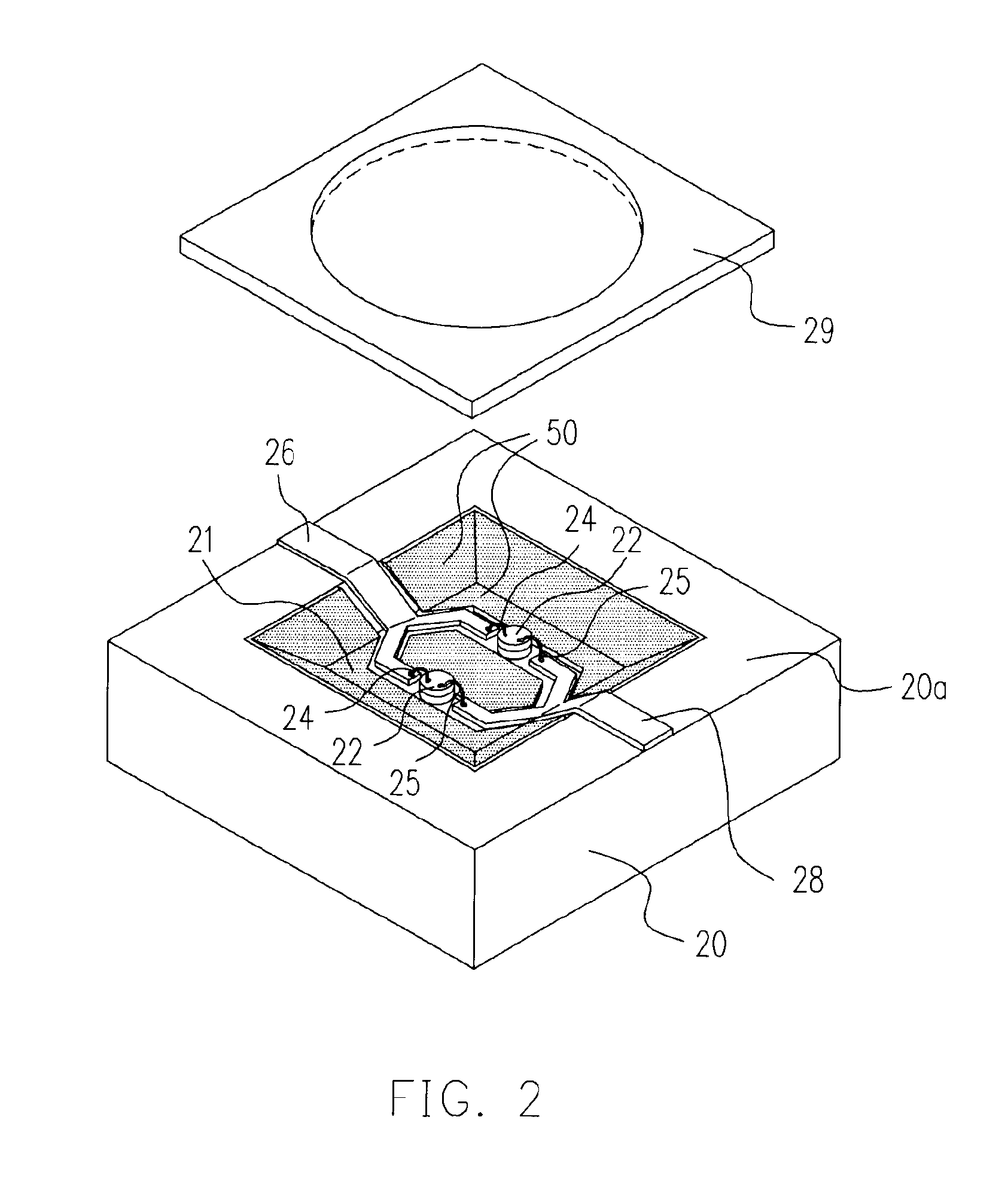

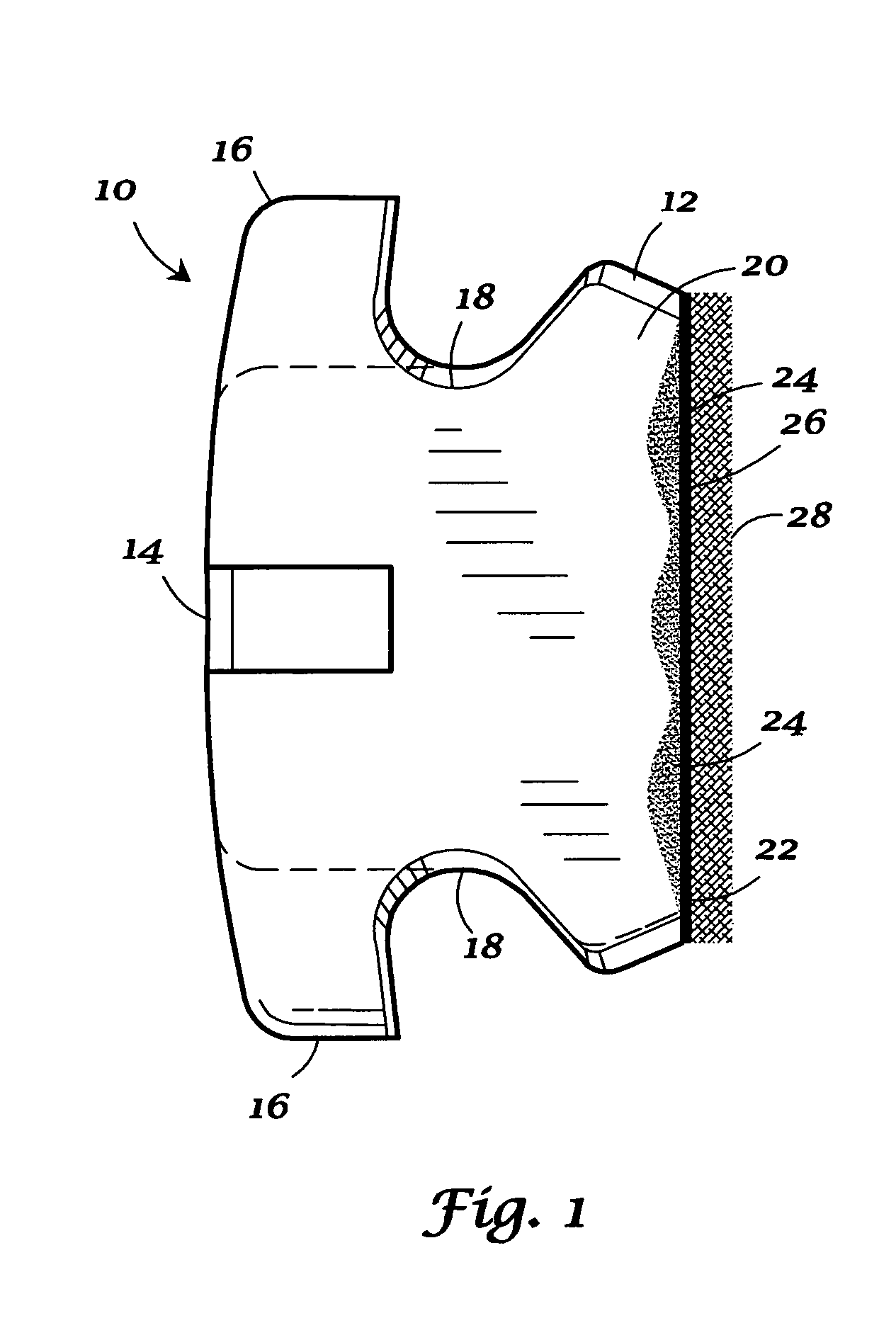

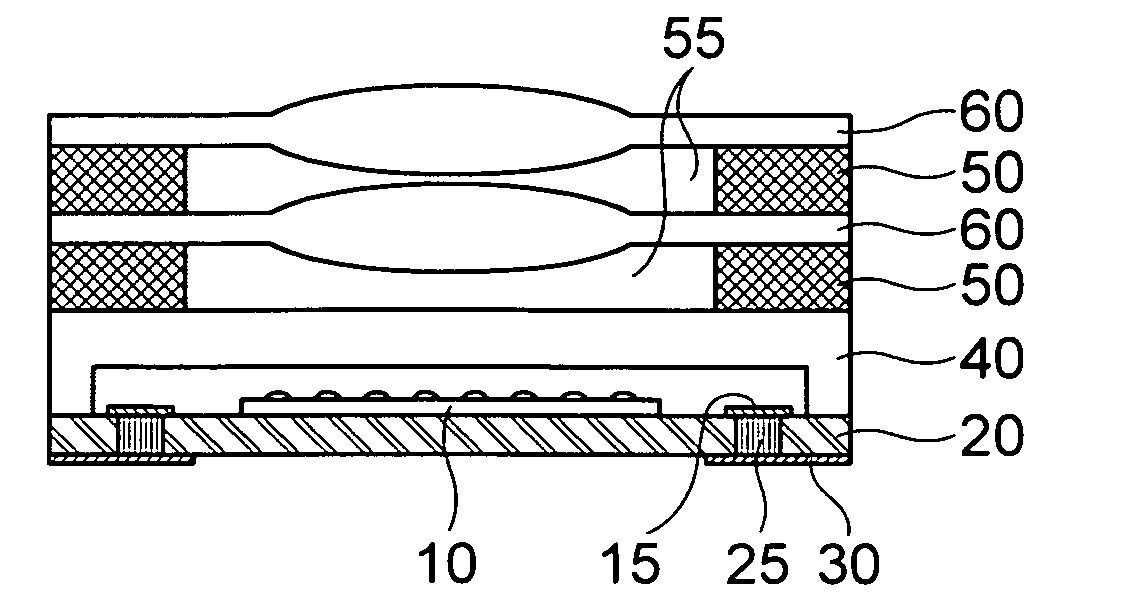

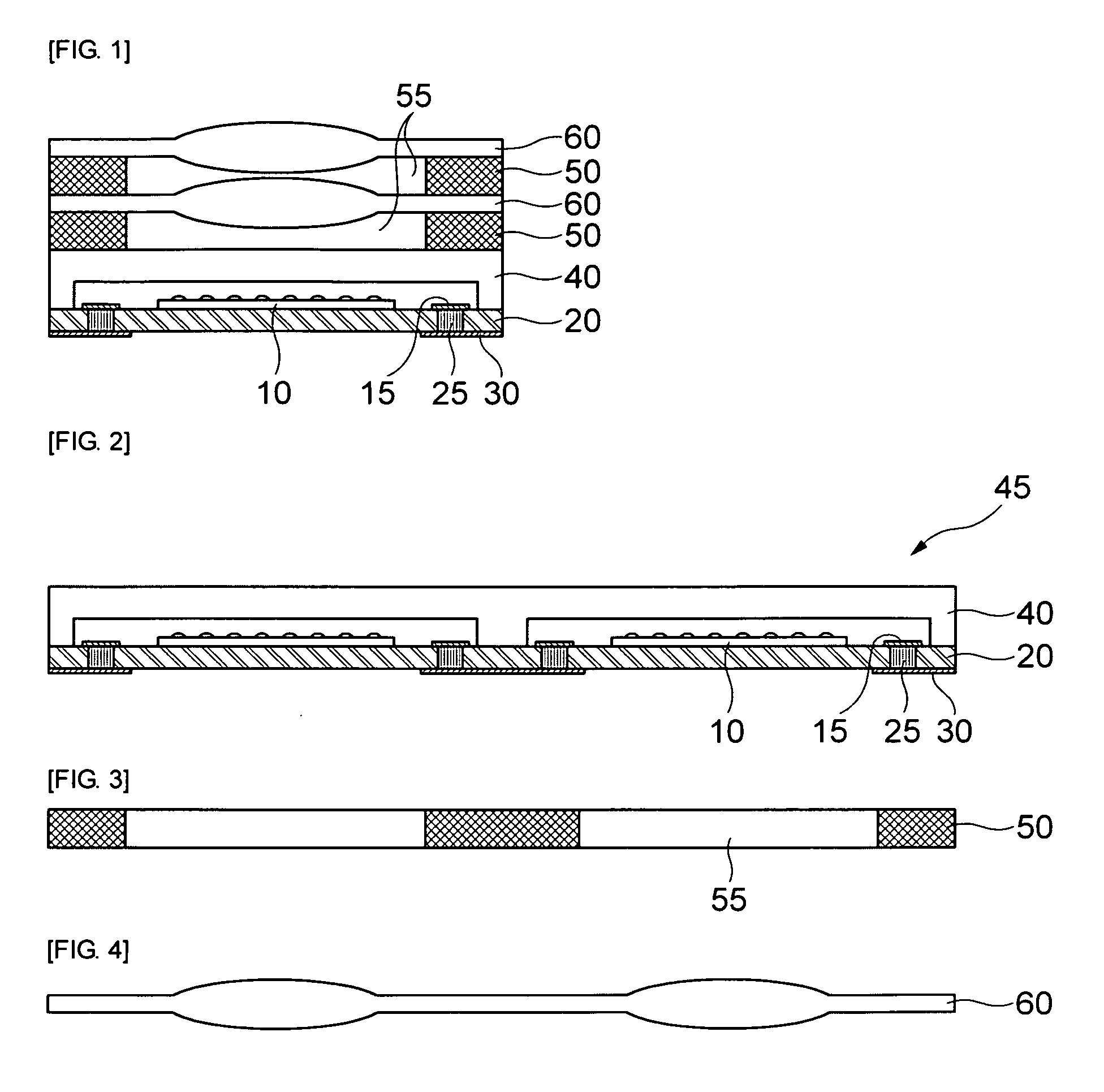

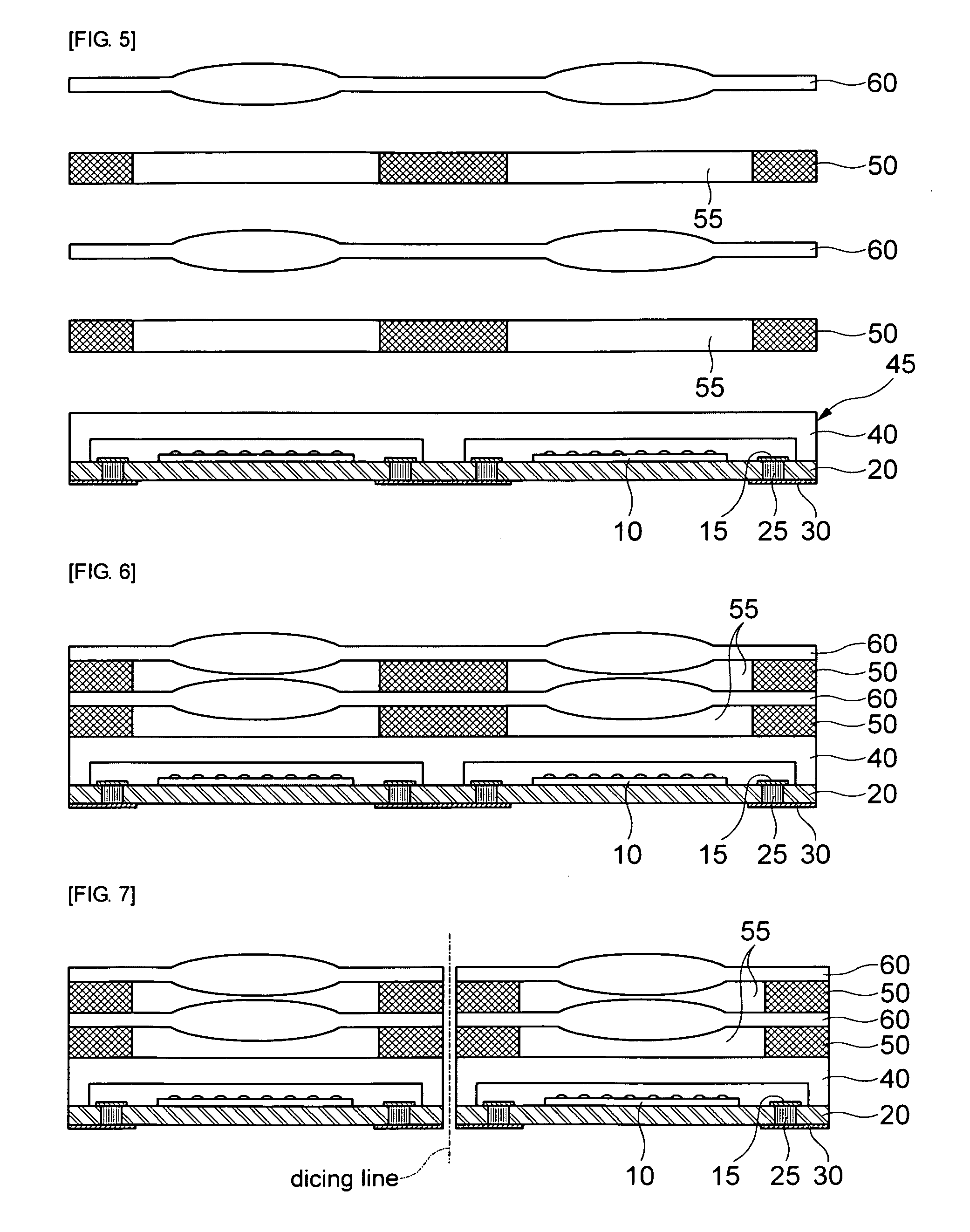

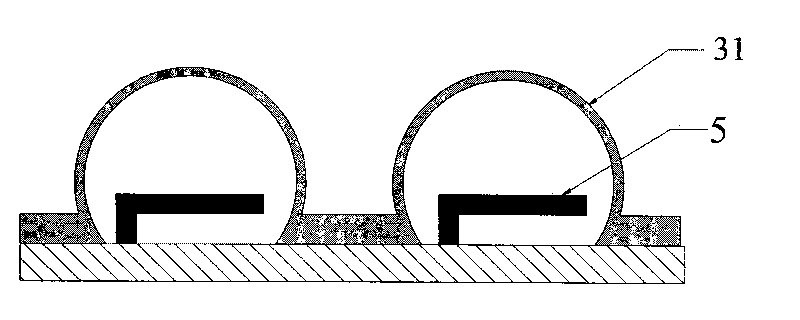

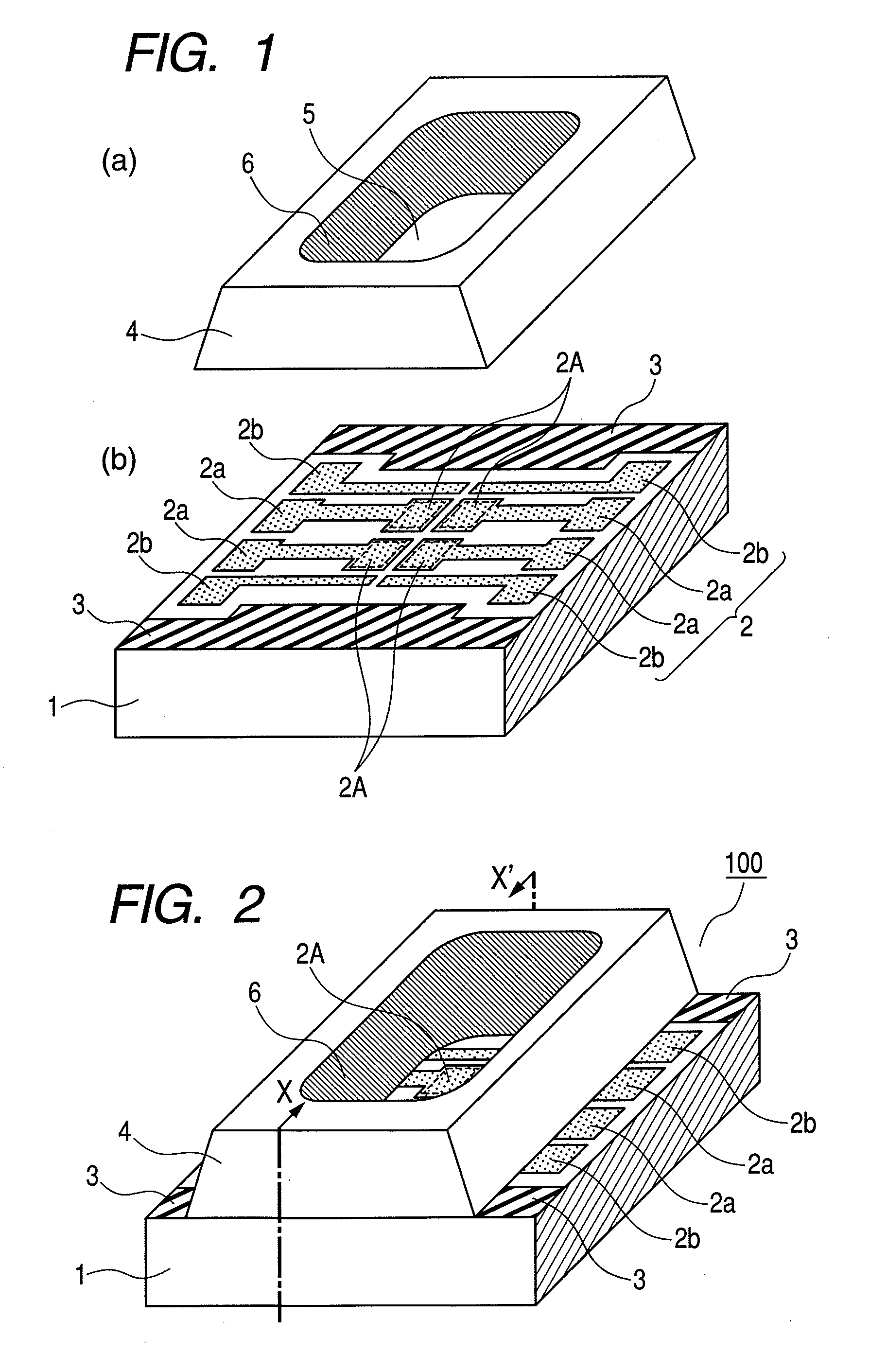

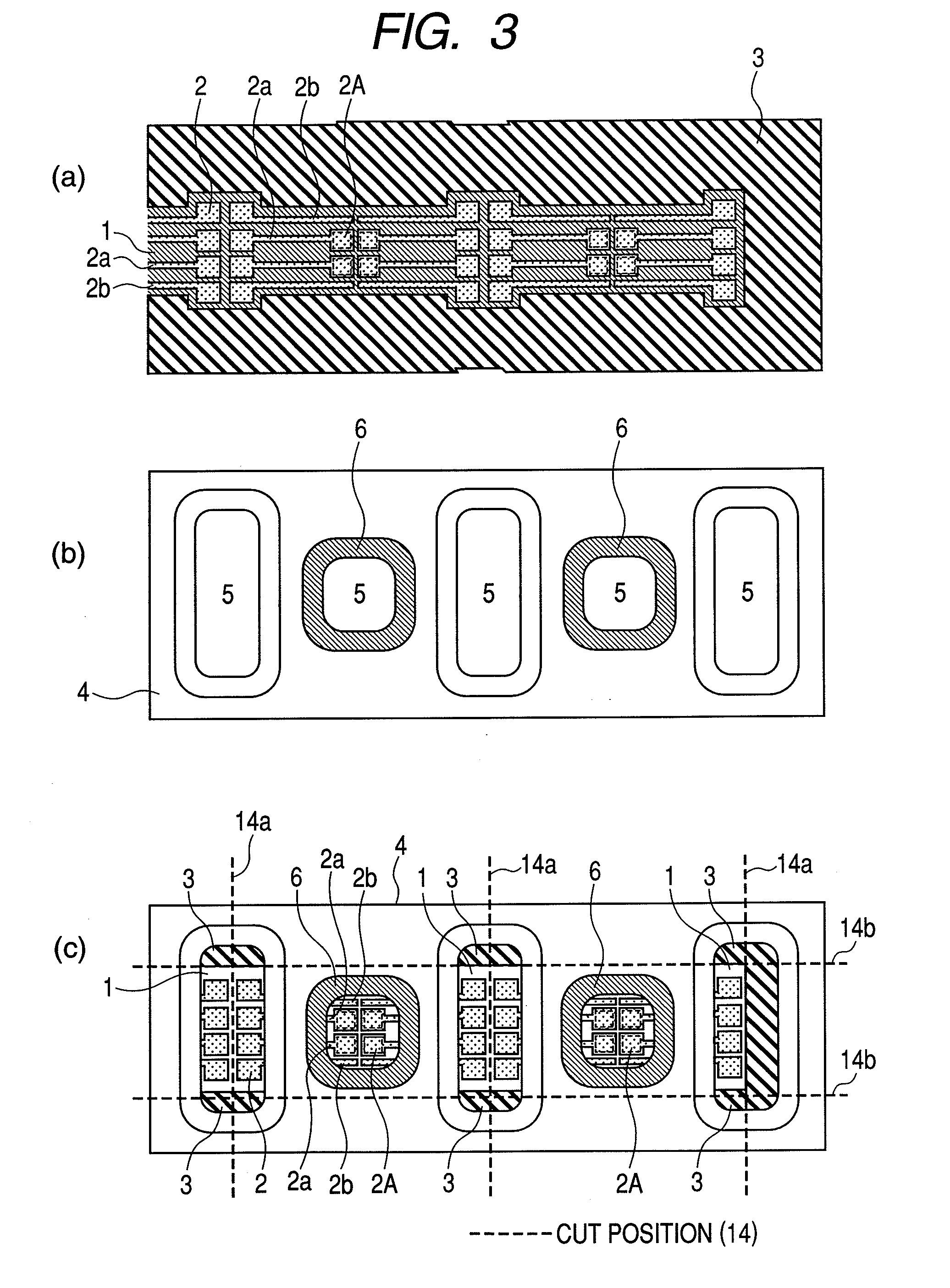

Wafer level camera module and method of manufacturing the same

InactiveUS20090309177A1Ease of mass productionReduce materialSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringCamera module

The present invention relates to a wafer level camera module and a method of manufacturing the same and provides a wafer level camera module including a wafer provided with an image sensor on a top surface; a transparent member bonded to the wafer through anodic bonding to seal the image sensor; a spacer bonded to the transparent member through the anodic bonding by including a window to expose the image sensor; and a wafer lens bonded to the spacer through the anodic bonding to cover the window of the spacer and further a method of manufacturing the same.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Manufacturing method of wafer level glass microcavity used for packaging MEMS

ActiveCN101734612AHigh forming heightLow costPrecision positioning equipmentSoldering apparatusMicrofabricationPositive pressure

The invention provides a manufacturing method of a wafer level glass microcavity used for packaging an MEMS, which comprises the following steps of: (1) etching a shallow slot on an Si wafer by an Si microfabrication process; (2) placing a right amount of high-temperature gas release agent in the shallow slot; (3) carrying out anodic bonding on the Si wafer and a Pyrex7740 glass wafer in air or vacuum and enabling the shallow slot on the Pyrex7740 glass to form a sealed cavity body; and (4) heating the bonded wafer in the air to the temperature of 810-890 DEG C, keeping the temperature for 3-5min, enabling molten glass corresponding to the sealed cavity body to be in a spherical shape by the high-temperature gas release agent because of positive pressure generated by gas generated by heating, cooling to the normal temperature, annealing and removing a silicon wafer to obtain a wafer level spherical glass microcavity array. The invention adopts the release of the high-temperature gas release agent to provide a gas source, is used for forming the glass microcavity and has the characteristics of low cost, simple method, high forming height and good degree of sphericity.

Owner:SOUTHEAST UNIV

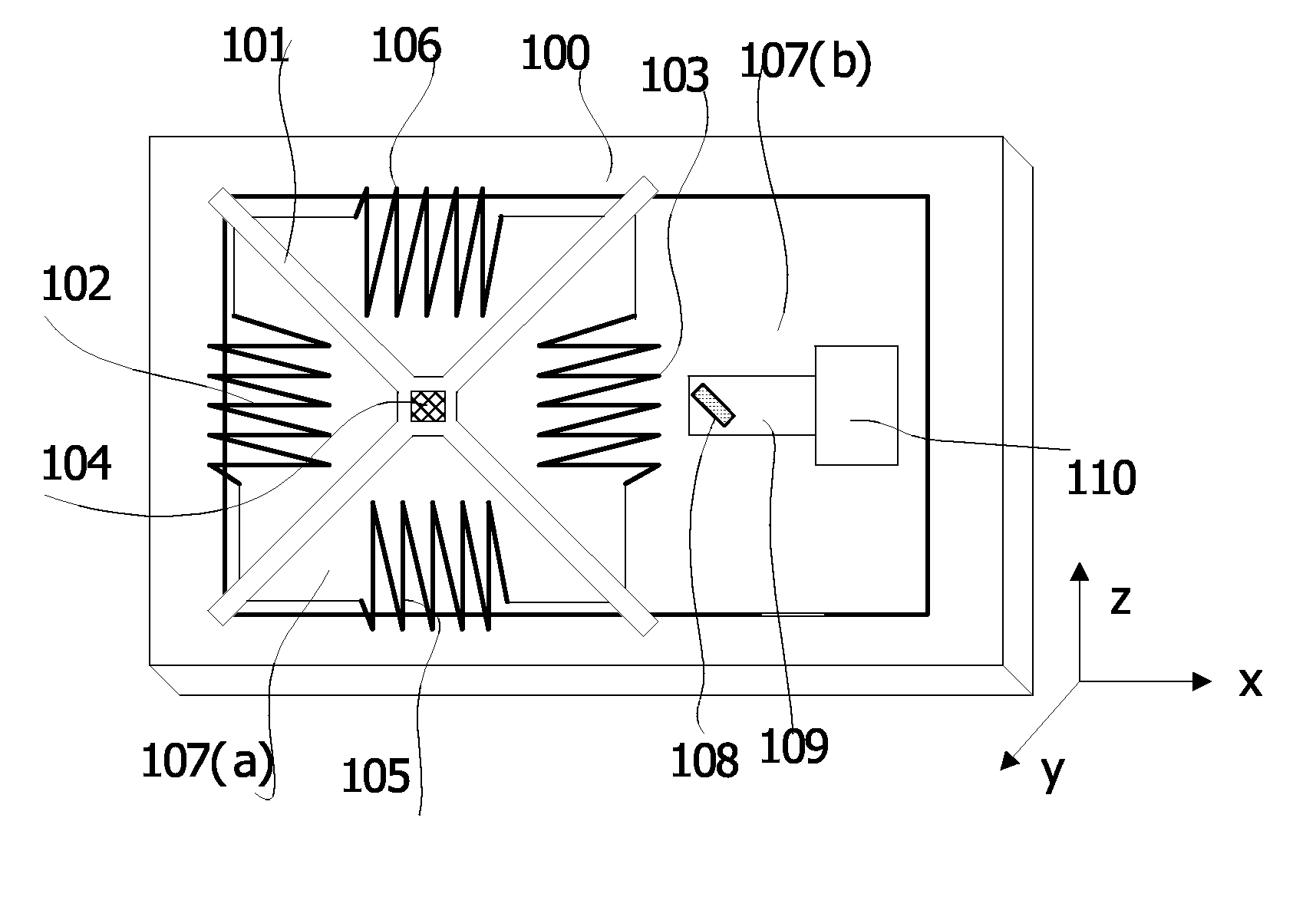

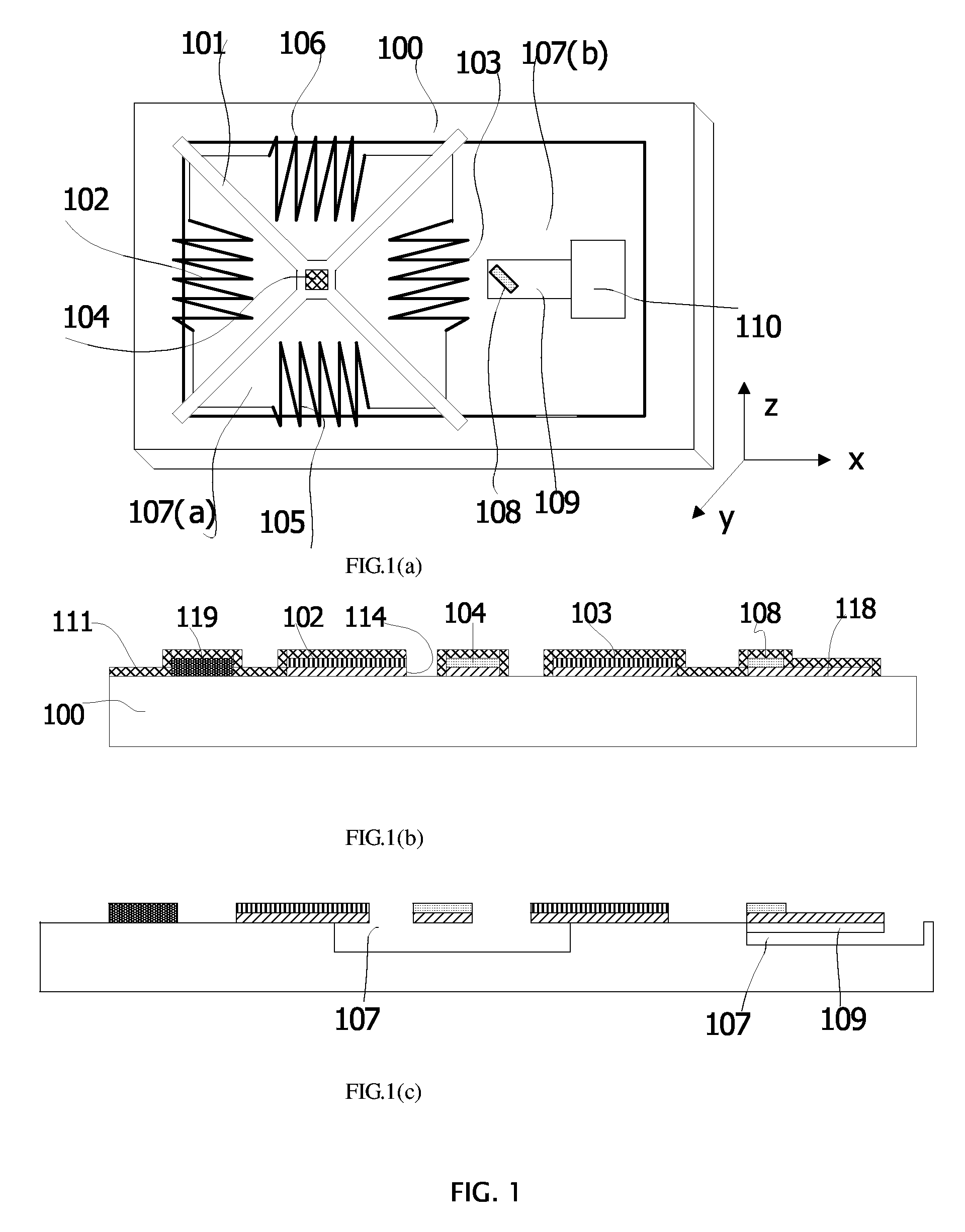

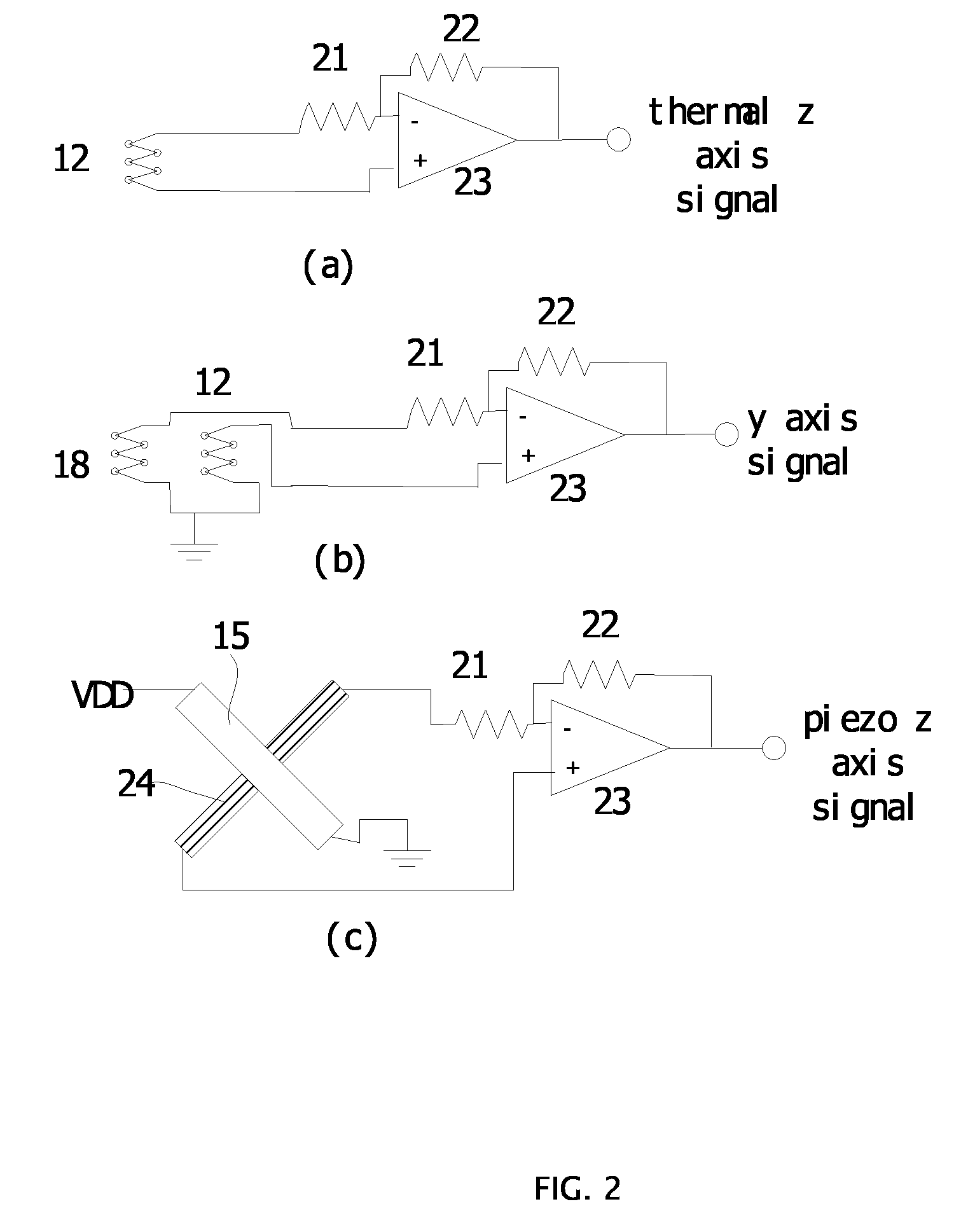

Ultra-small Profile, Low Cost Chip Scale Accelerometers of Two and Three Axes Based on Wafer Level Packaging

Several micro-machined, ultra-profile two-axis and three-axis accelerometers are fabricated by CMOS-compatible process, which makes them suitable for volume production. The x, y axis signal is based on natural thermal convection, and z-axis signal may be based on thermal convention or piezoresistive in nature. The bulk MEMS (Micro-Electro-Mechanical-Systems) process is based on Deep Reactive Ion Etching (DRIE). After the front-end fabrication process, the accelerometers are packaged at wafer level by glass frit and / or anodic bonding, which lowers the device cost.

Owner:WUHAN FINEMEMS

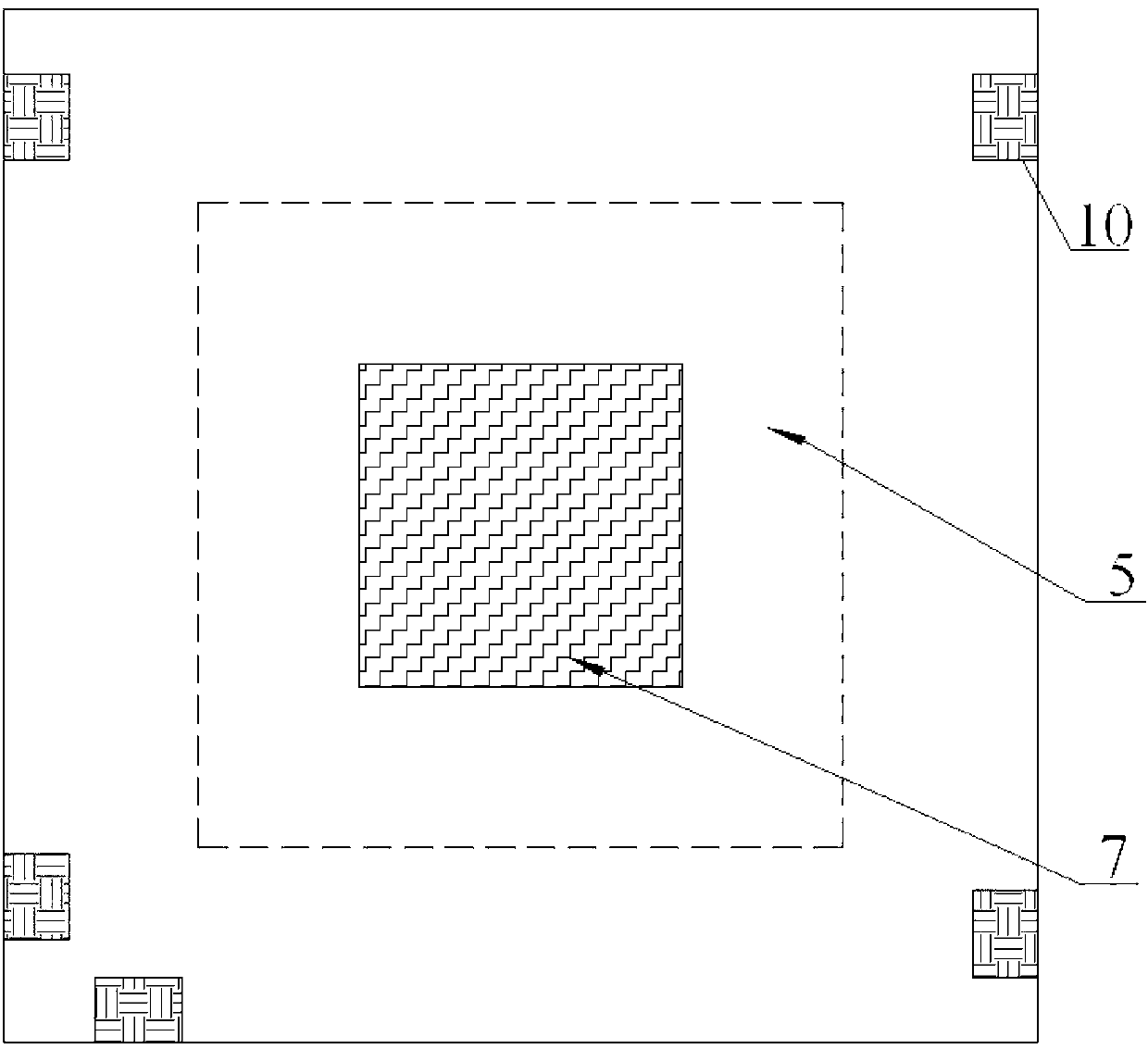

Groove type atomic gas cavity and atomic clock physical system formed by same

ActiveCN102323738ALower working temperatureUnlimited thicknessApparatus using atomic clocksCrystal planeParticle physics

The invention relates to a groove type atomic gas cavity produced by applying MEMS technology and an atomic clock physical system formed by the same. The cavity is characterized in that the cavity is formed in such a manner that a silicon wafer with a groove and Pyrex glass sheets define a cavity structure through bonding; the cavity structure is used for alkali metal atom vapor and buffer gases to fill in; the cross section of the groove is in a shape of inverted trapezoid; and the groove comprises a bottom surface and side walls forming included angles with the bottom surface. The cavity is manufactured based on MEMS (micro-electro-mechanical system) technology. The silicon groove is formed through anisotropic etching of the (100) monocrystalline wafer. The groove type cavity is manufactured through silicon-glass anode bonding. The side walls of the cavity are {111} crystal planes of the silicon wafer. The cavity and the system have the following beneficial effects: by utilizing the cavity, the distance between two reflectors in the cavity is easy to enlarge through atomic cavity dimension design, thus increasing the length of the interaction space between laser and atomic gas, enhancing the signal to noise ratio of the CPT (coherent population trapping) signal and being beneficial to improvement of the frequency stability of the micro CPT atomic clock.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

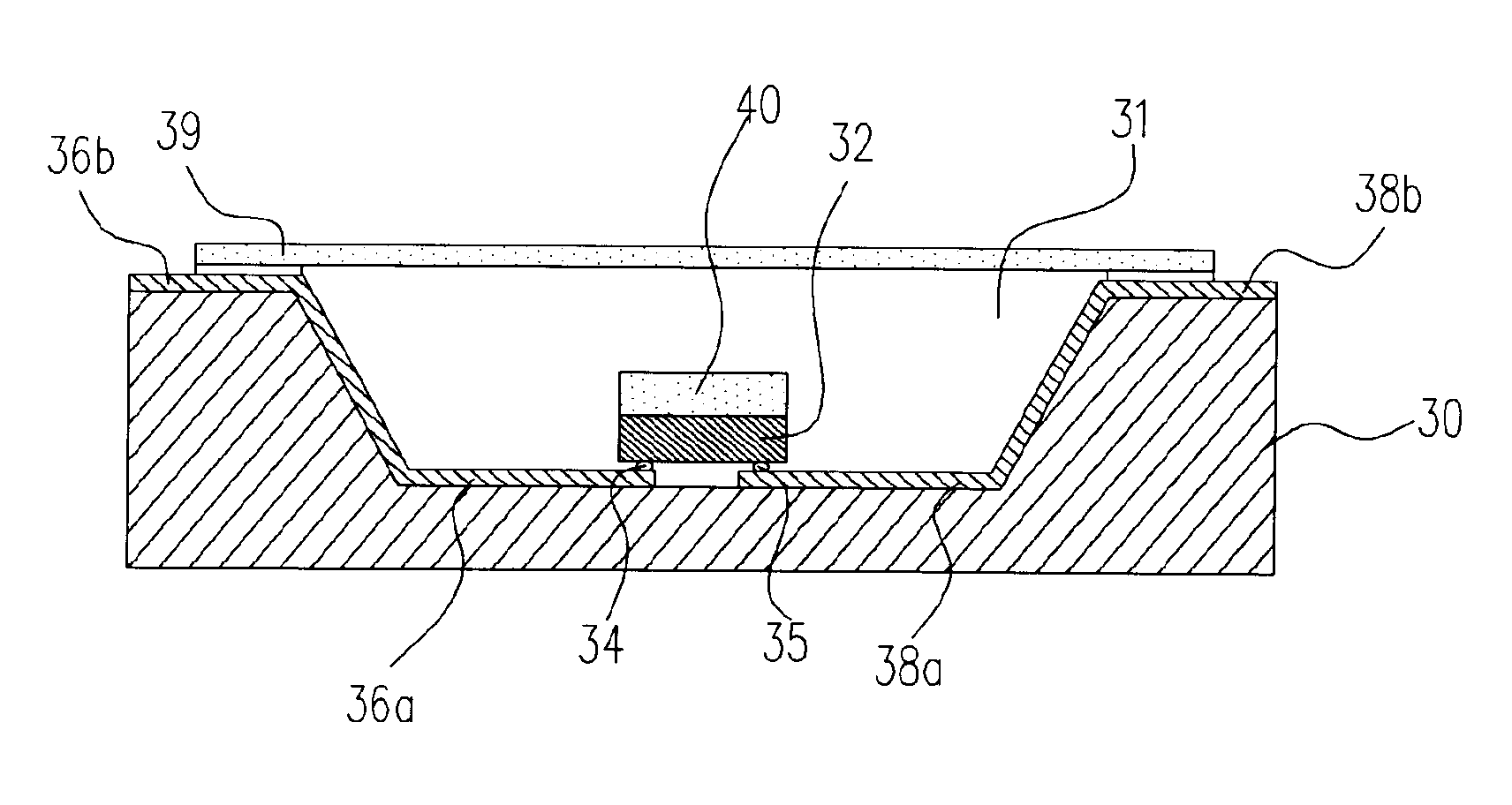

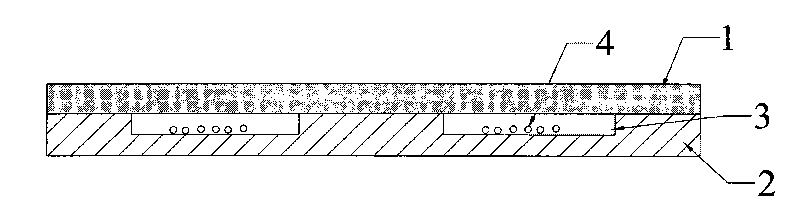

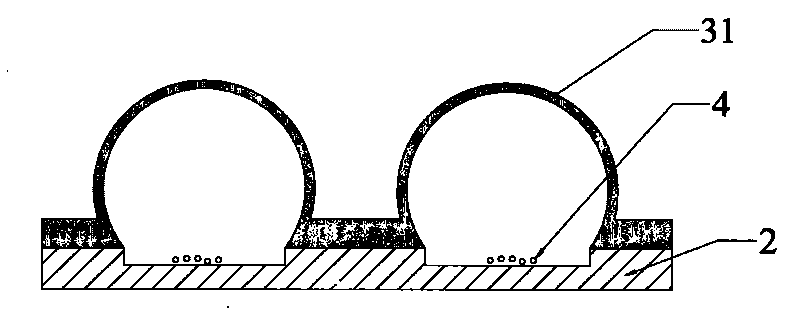

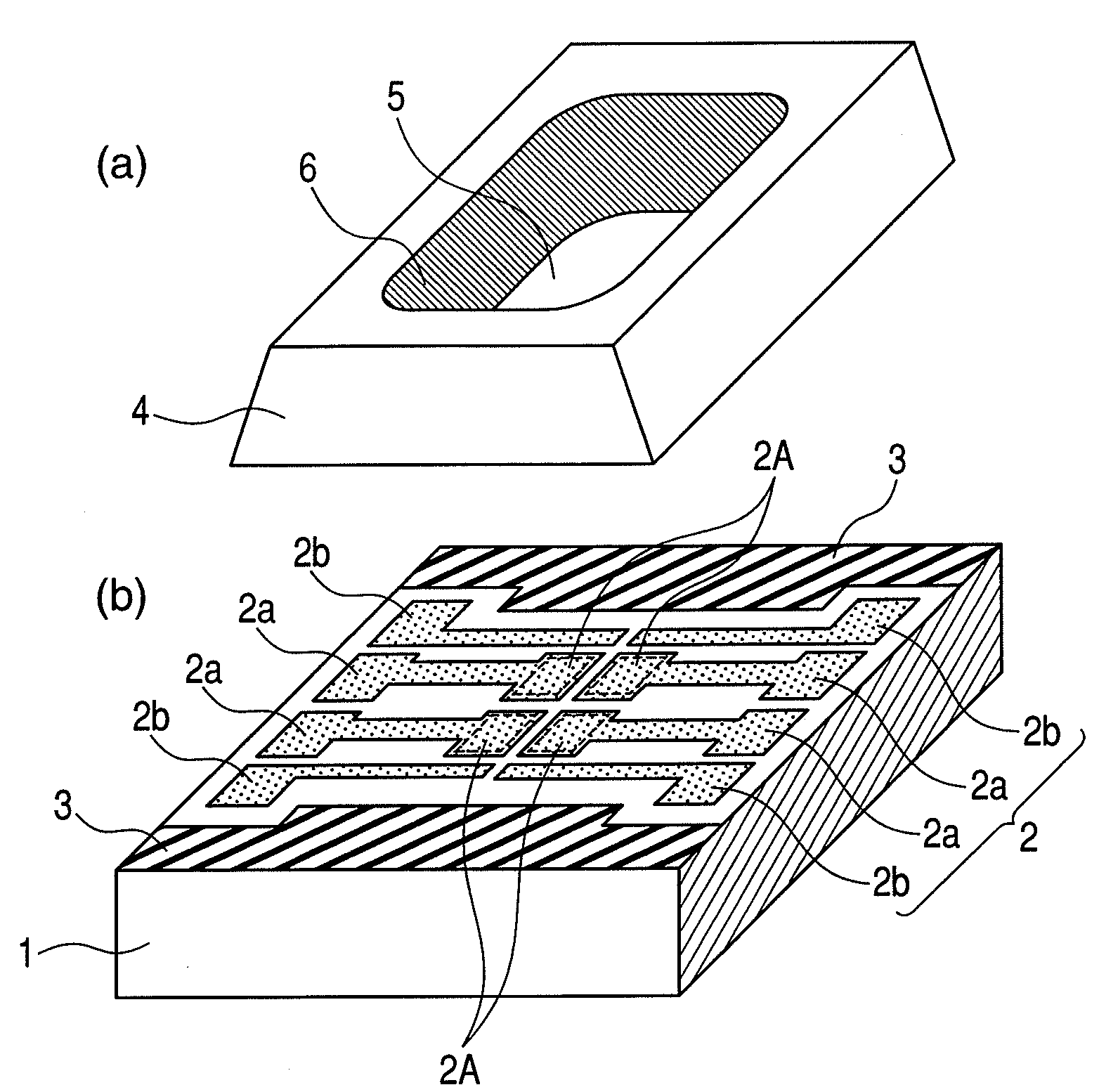

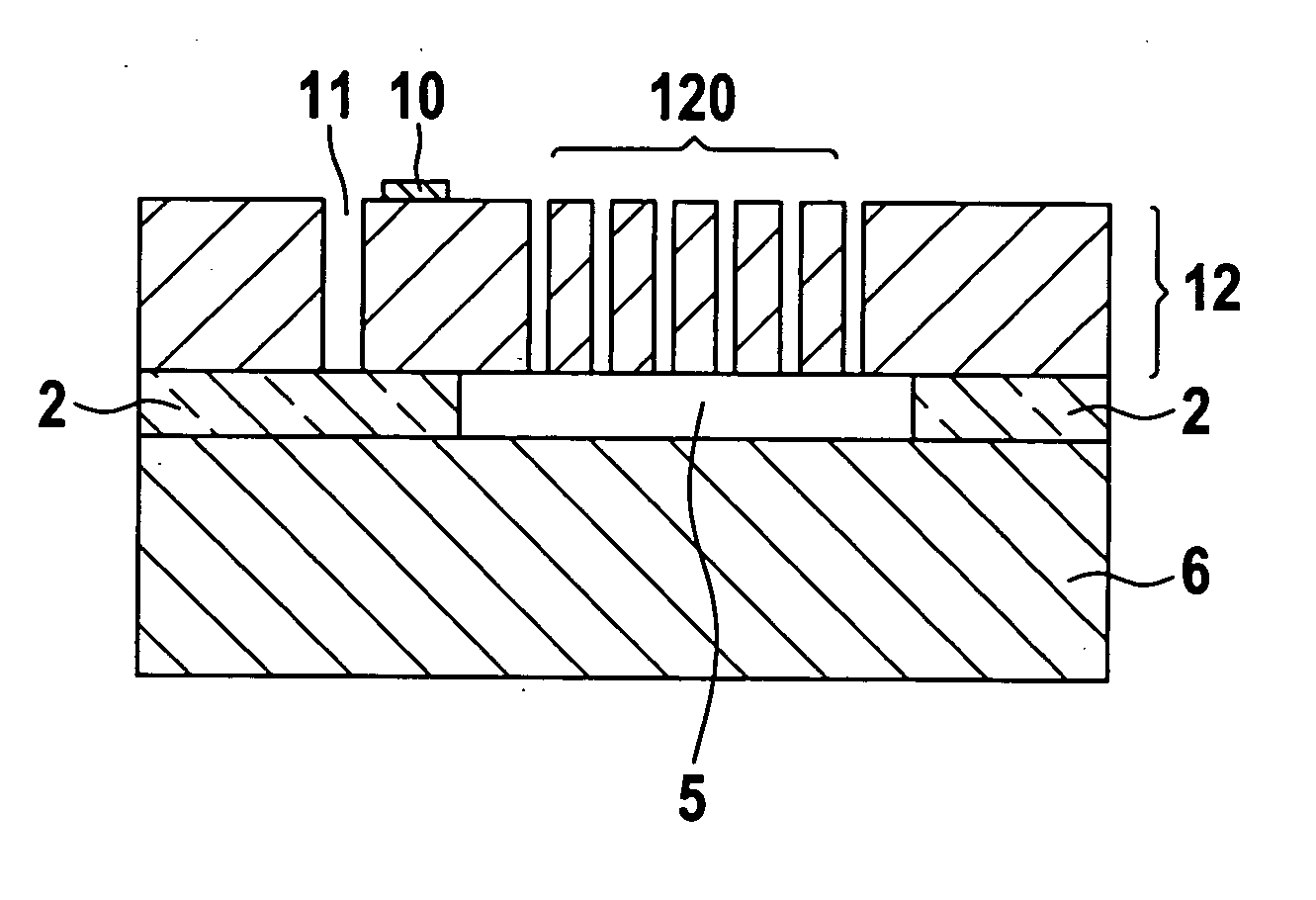

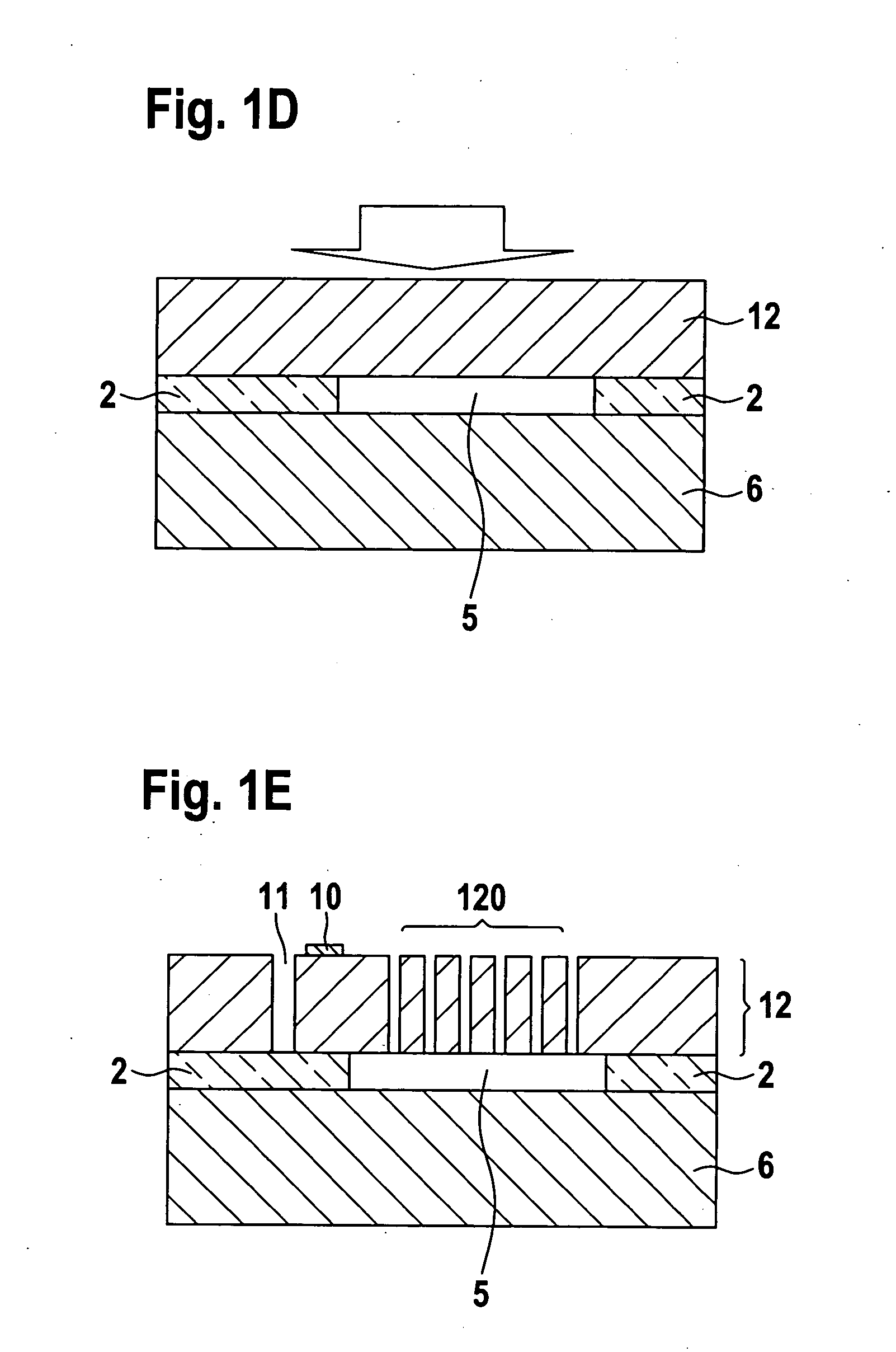

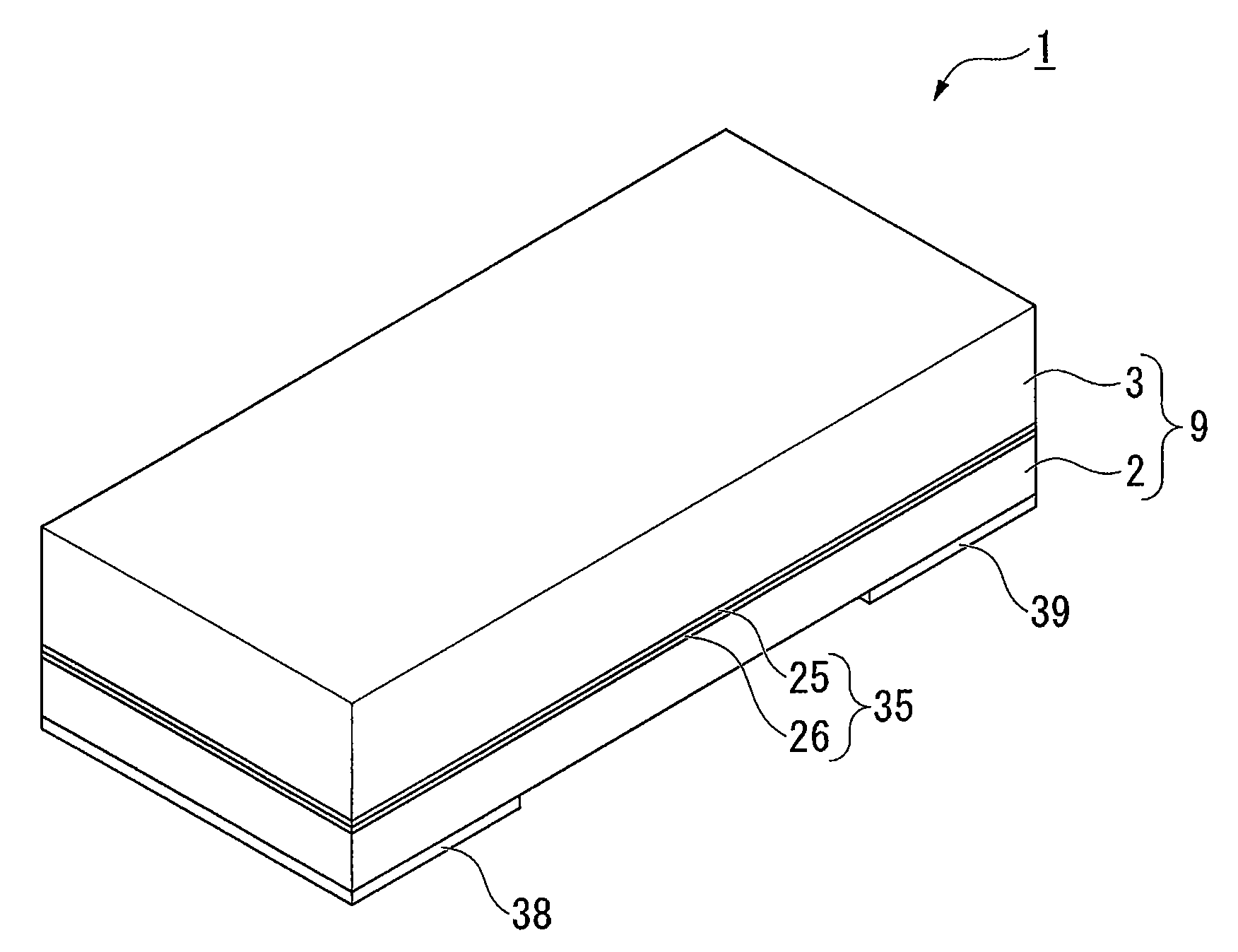

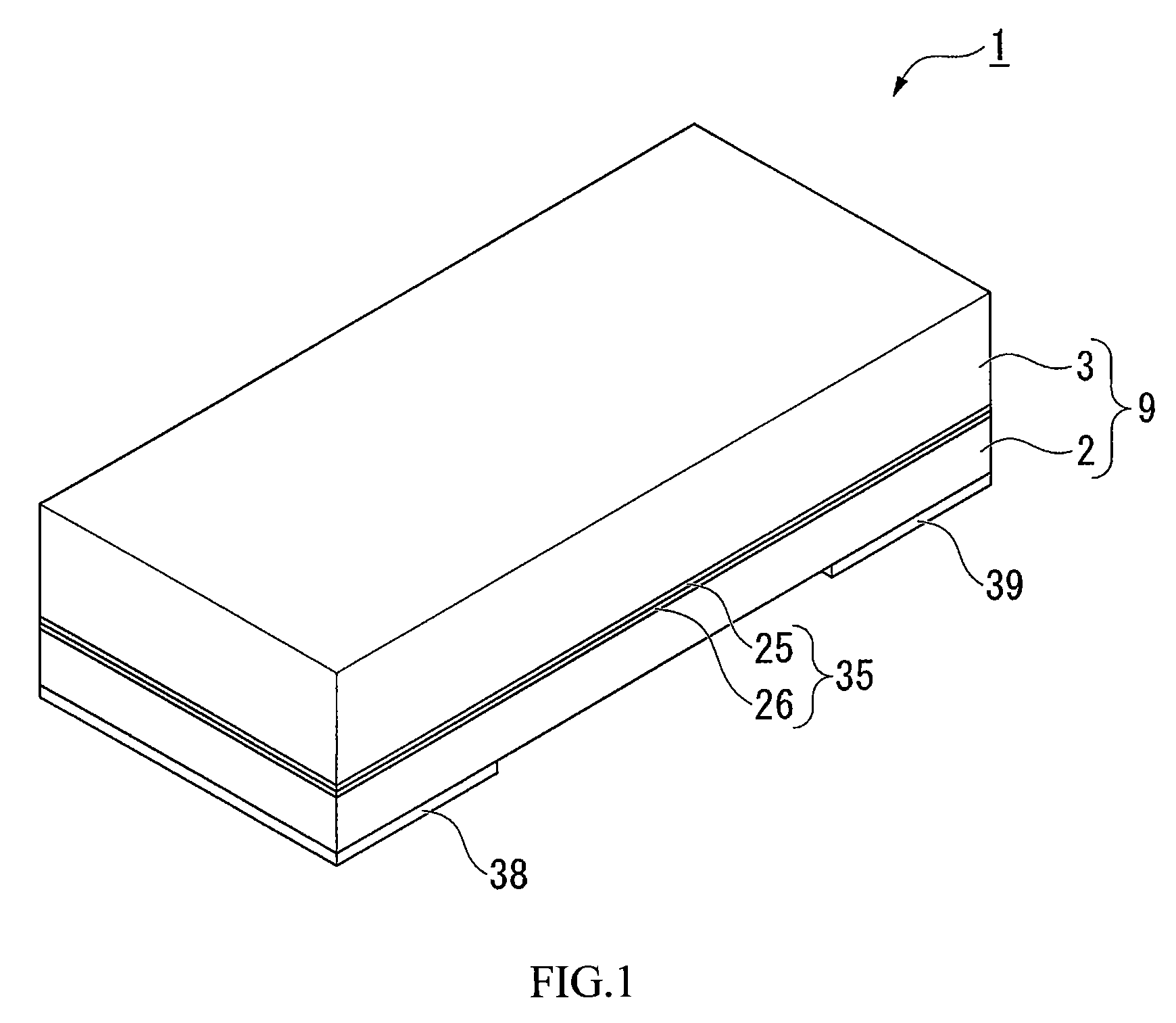

Submount and its manufacturing method

ActiveUS20090219728A1Efficiently focusHigh densityLamination ancillary operationsLighting support devicesEngineeringAnodic bonding

Submounts for mounting optical devices which have an excellent heat radiating property and can be formed in a wafer state in batch are provided.A metallized electrode including optical device mounting parts and wiring parts is formed on a surface of a first substrate containing an insulating material as a main component, a through hole is formed in a glass substrate serving as a second substrate, the optical device mounting parts of the first substrate are aligned to be located inside the through hole of the second substrate, and the first substrate and the second substrate are joined together by use of a method such as anodic bonding.

Owner:HITACHI KYOWA ENG

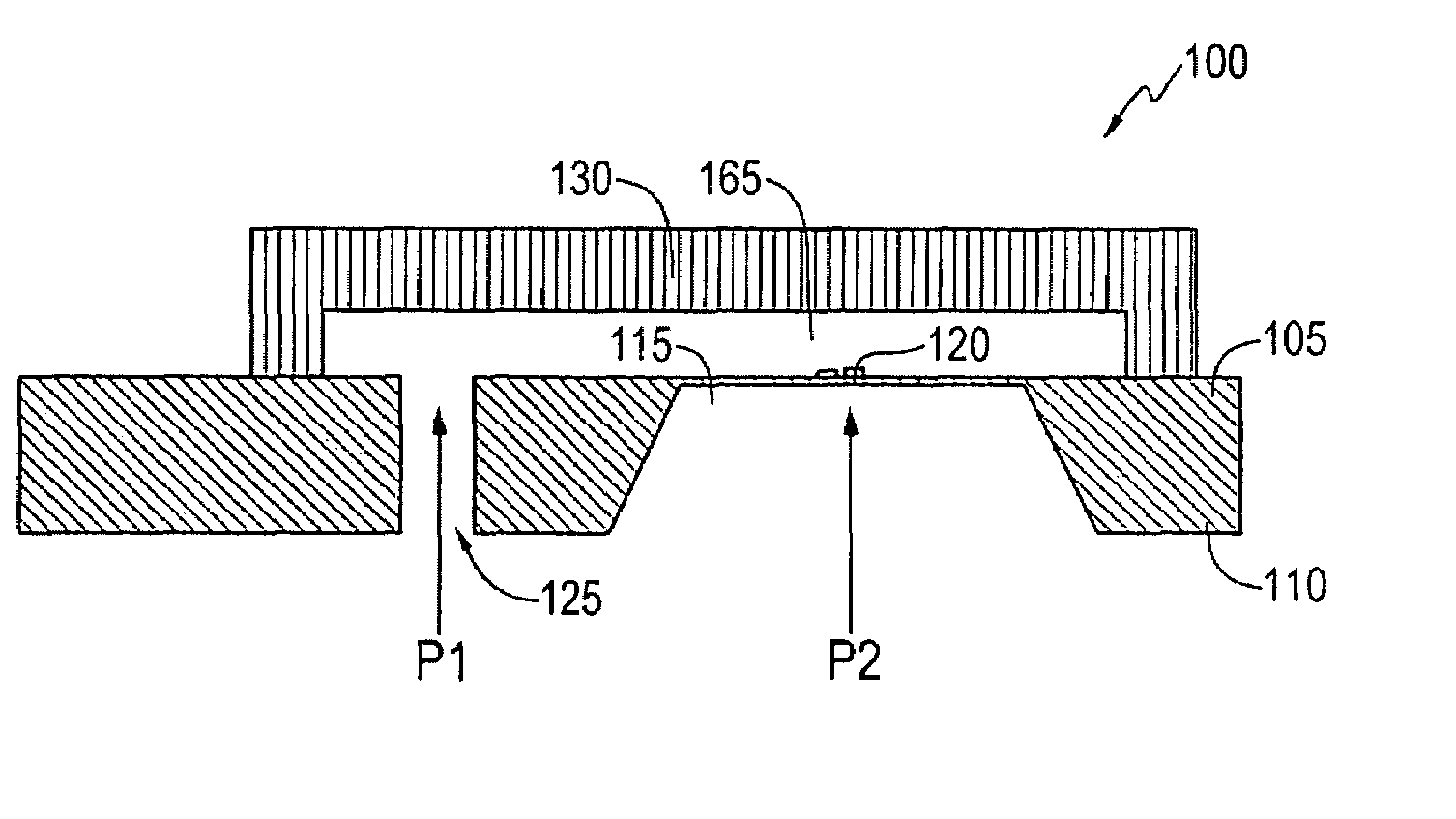

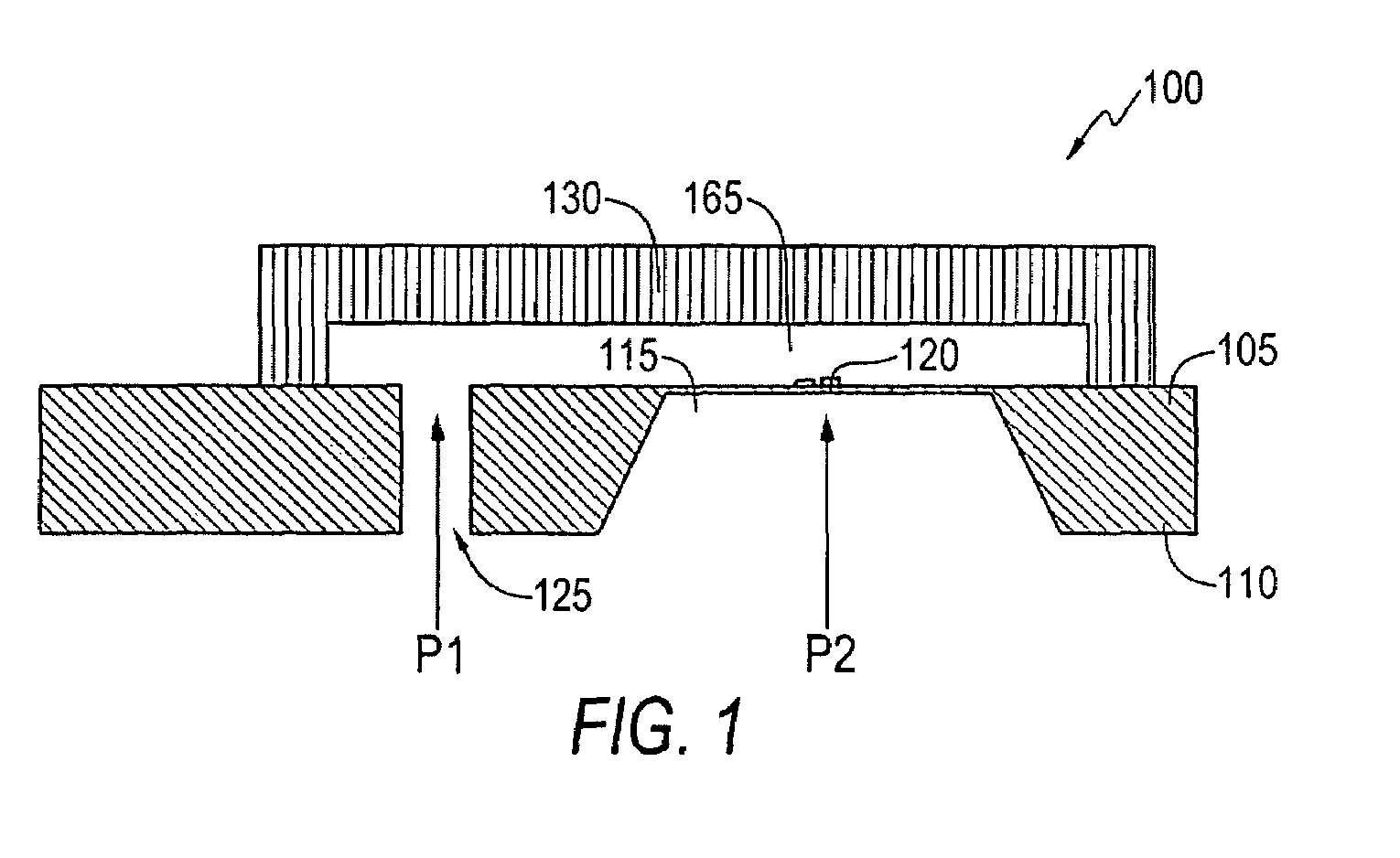

Differential pressure sense die based on silicon piezoresistive technology

ActiveUS7644625B2Improve performanceSemiconductor/solid-state device manufacturingFluid pressure measurement by mechanical elementsDifferential pressureFrit

A method and apparatus for designing a differential pressure sense die based on a unique silicon piezoresistive technology for sensing low differential pressure in harsh duty applications is disclosed. The pressure sense die comprises of an etched pressure diaphragm and a hole that is drilled through the sense die wherein the pressure sense die possess a backside and a front side and are associated with varying pressures. A top cap can be attached to the front side and an optional constraint for stress relief can be attached to the backside of the differential pressure sense die. The top cap and the constraint comprise of glass and / or silicon and can be attached with an anodic bonding process or glass frit process.

Owner:HONEYWELL INT INC

Implantable shunt system and associated pressure sensors

ActiveUS20140243703A1Reduce overpressureElectrotherapyCircuit arrangementsDual stageThermal coefficient

A hermetically sealed biocompatible pressure sensor module configured for implant at a desired site at which a pressure is to be measured. Anodic bonding of the pressure module package components which have similar thermal coefficients of expansion provides low stress bonding and maintains long term reliability, dependability and accuracy. The pressure sensor module includes a pressure sensitive membrane which is in direct contact with the environment at which a pressure is to be measured. The pressure sensor module forms a part of a pressure measuring system which uses a telemetry link between the pressure sensor module and an external controller for data transmission and transfer. Operating power for the pressure sensor module is provided by the external controller and an internal rechargeable energy storage component. Accordingly, the pressure measuring system provides a dual stage power and data transfer capability for use with an implantable system. An exemplary use of the pressure sensor module is in a three pressure sensor system including a flow control valve in a shunt to treat hydrocephalus. The use of integrated circuit chips and an internal coil with an optional ferrite core in the pressure sensor module provides for low power consumption and reliable signal processing. An embodiment of the invention includes a pressure sensor and associated electromagnetic coils embedded in the tip portion of the shunt for measuring the pressure of fluid externally of the shunt at the tip portion.

Owner:ALFRED E MANN FOUND FOR SCI RES

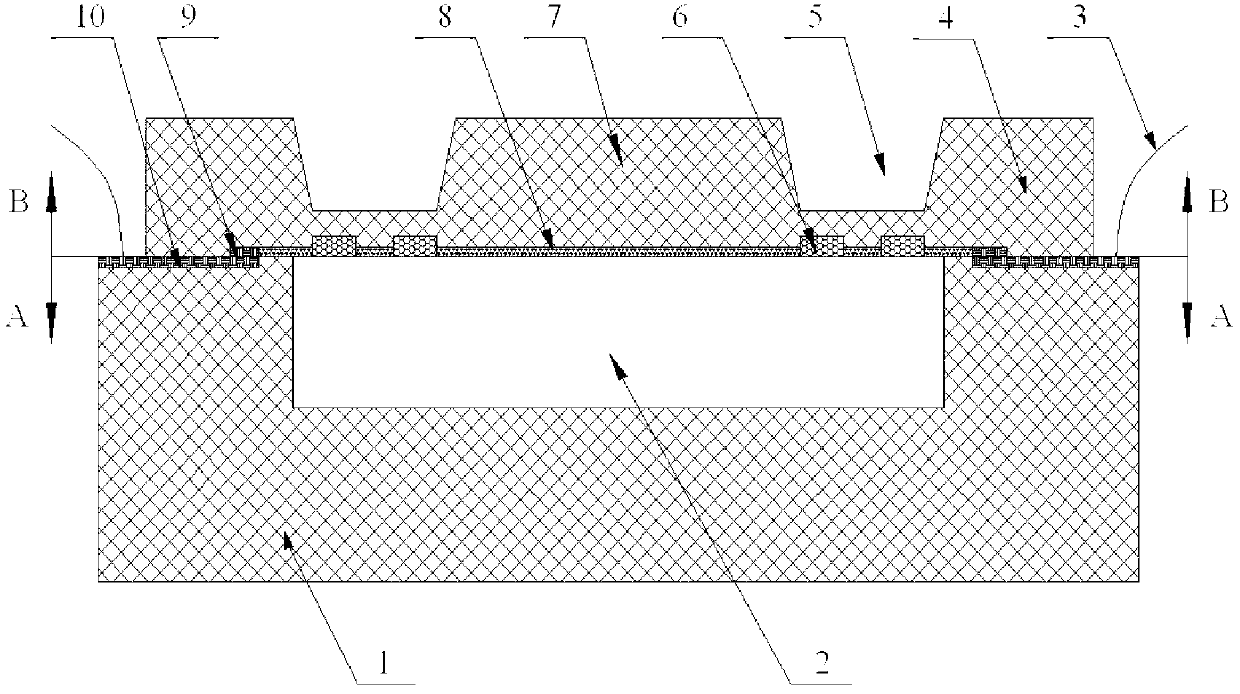

Silicon-glass micro pressure sensor chip of island membrane self-packaging structure and manufacturing method

ActiveCN103278270AImprove reliabilityGuaranteed isolationPiezoelectric/electrostrictive device manufacture/assemblyForce measurementPressure senseEngineering

The invention provides a silicon-glass micro pressure sensor chip of an island membrane self-packaging structure and a manufacturing method, and relates to a micro pressure sensor. The silicon-glass micro pressure sensor chip of the island membrane self-packaging structure and the manufacturing method are not only high in reliability but also suitable for severe environments of moist, acid-base, static electricity and the like. The silicon-glass micro pressure sensor chip of the island membrane self-packaging structure is provided with a pressure sensing membrane and a base provided with a cavity; the pressure sensing membrane is of an obverse side island membrane composite structure, four voltage dependent resistors are arranged in a concentration area with the maximum stress of the island membrane composite structure, the four voltage dependent resistors form a Wheatstone bridge through metal electrodes, a silicon-glass anodic bonding process is adopted to enable the Wheatstone bridge to be sealed in a sealed absolute pressure cavity, and the Wheatstone bridge enables an interface preset electrode to be connected with external testing equipment through metal leads to form a complete pressure sensitive and measuring system. The manufacturing method comprises the steps of technological manufacturing of an SOI wafer; manufacturing of a substrate part; bonding and follow-up processes.

Owner:厦门纵能电子科技有限公司

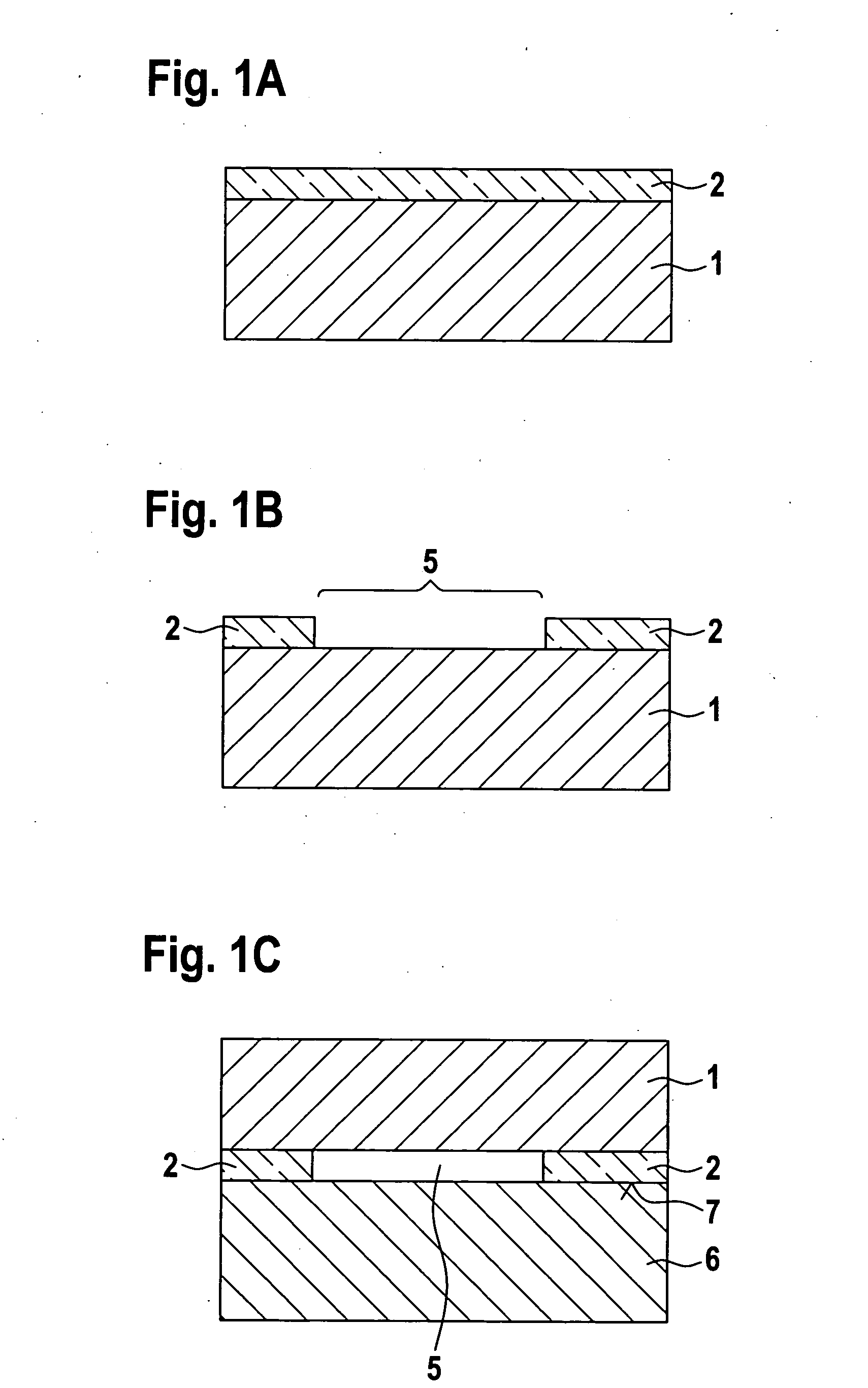

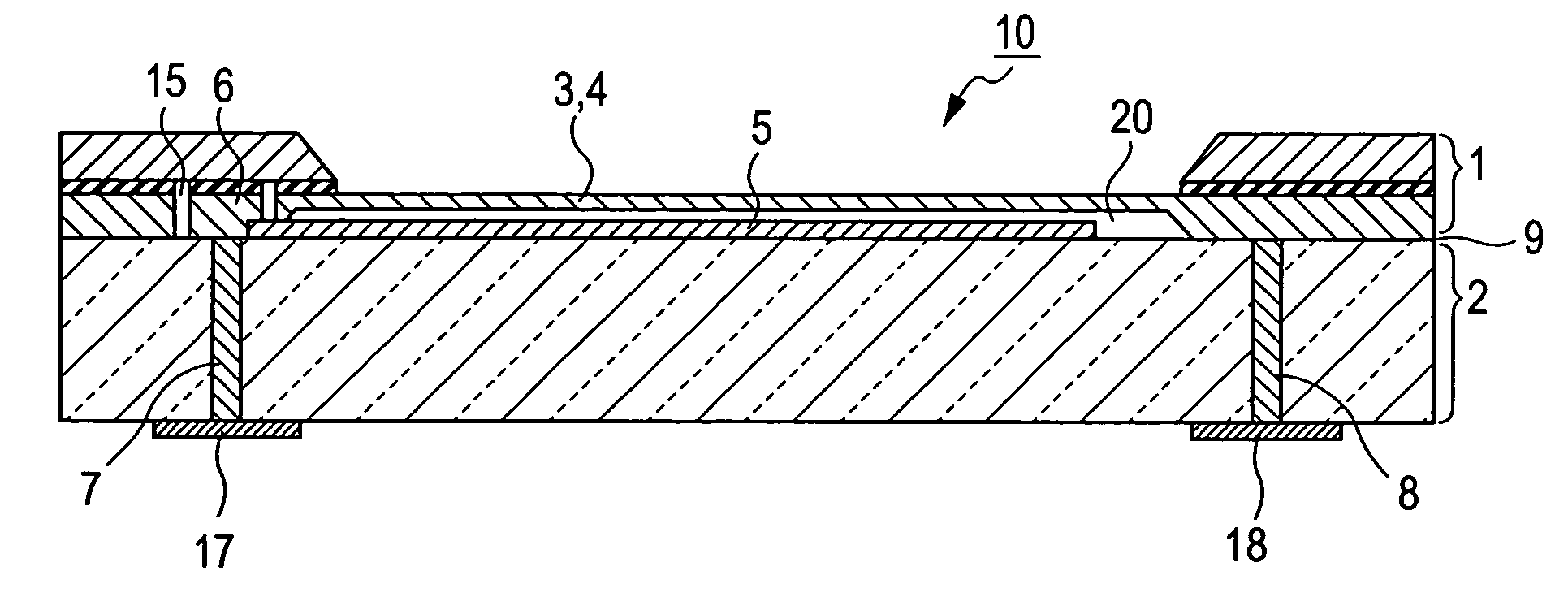

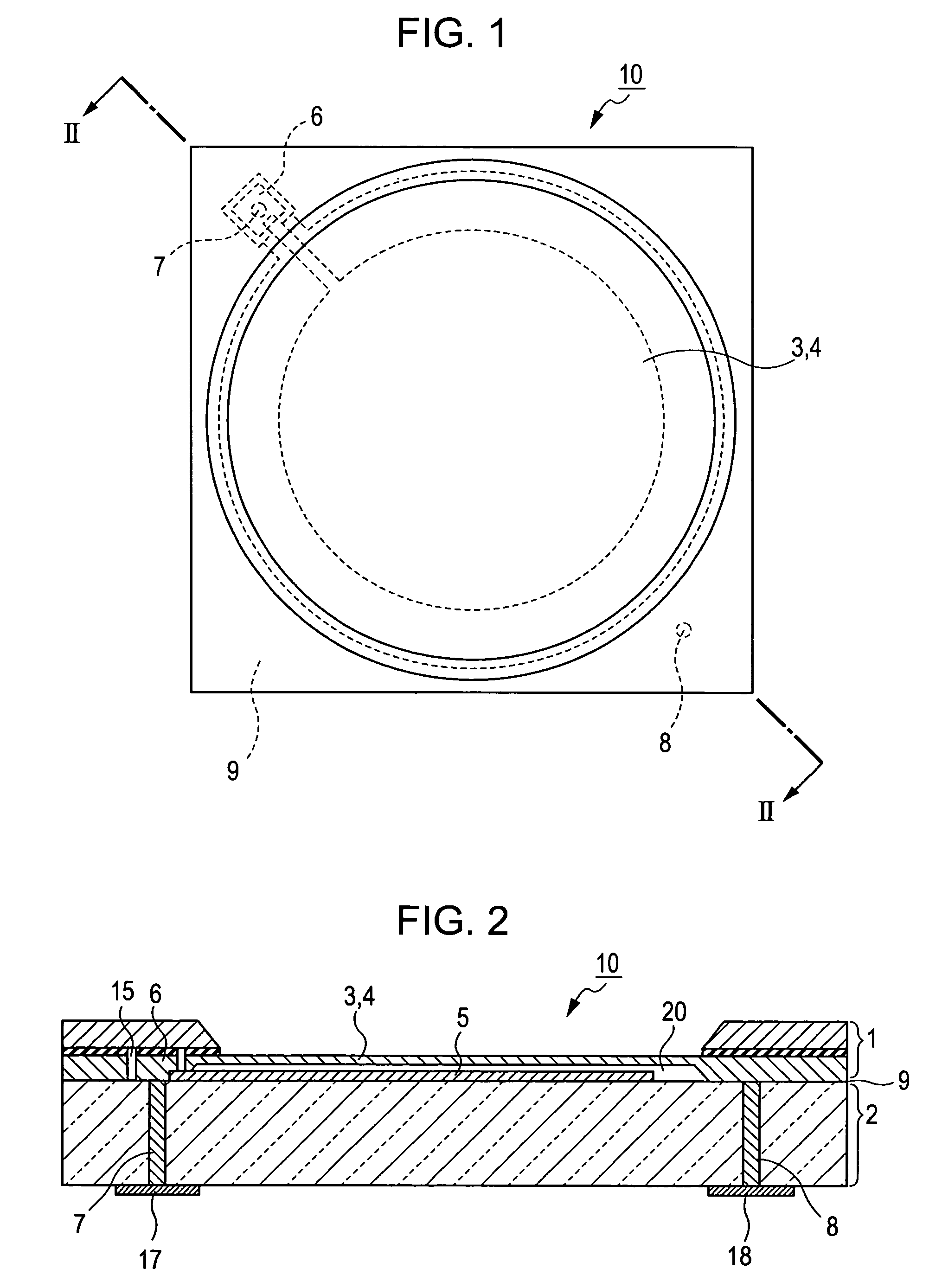

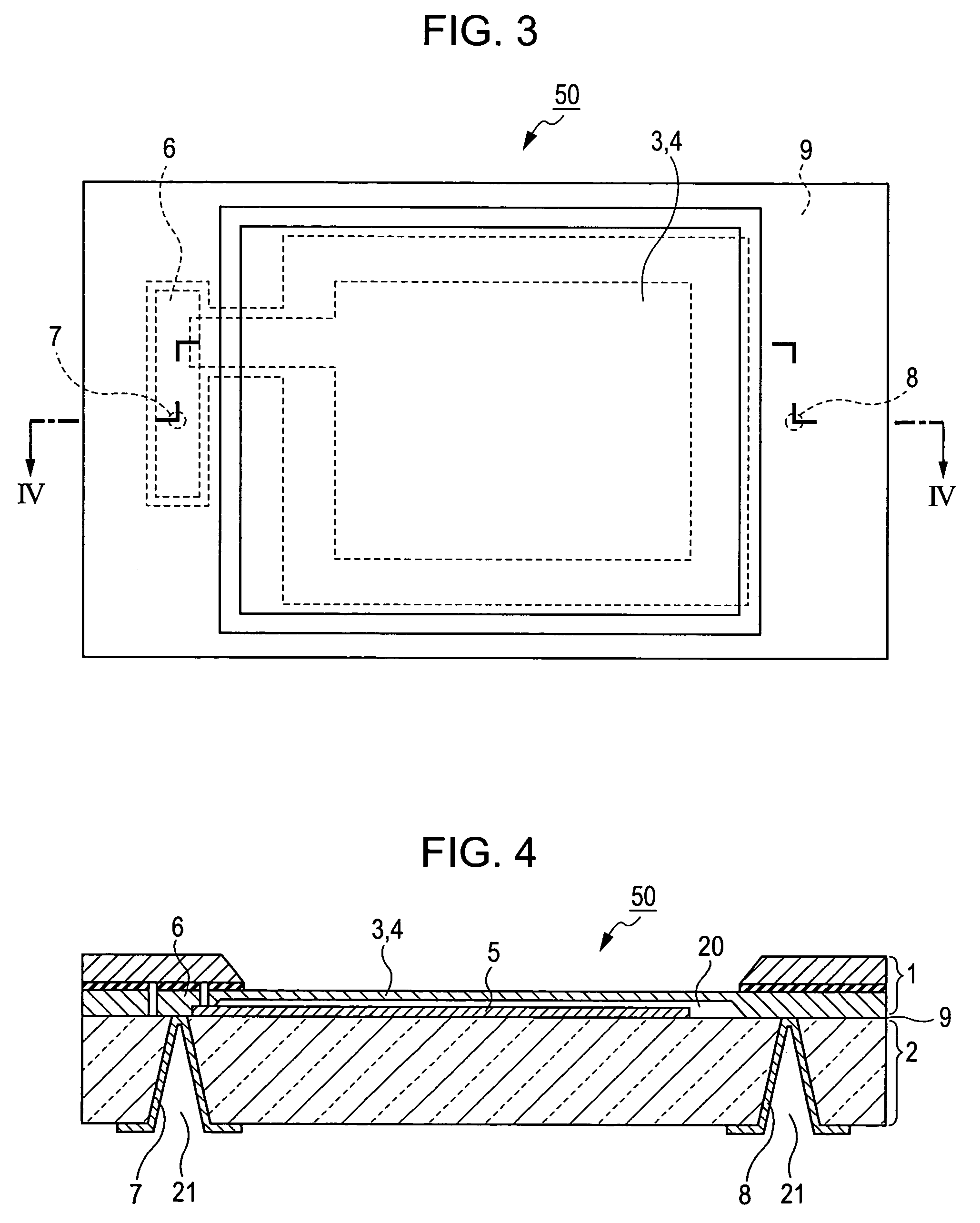

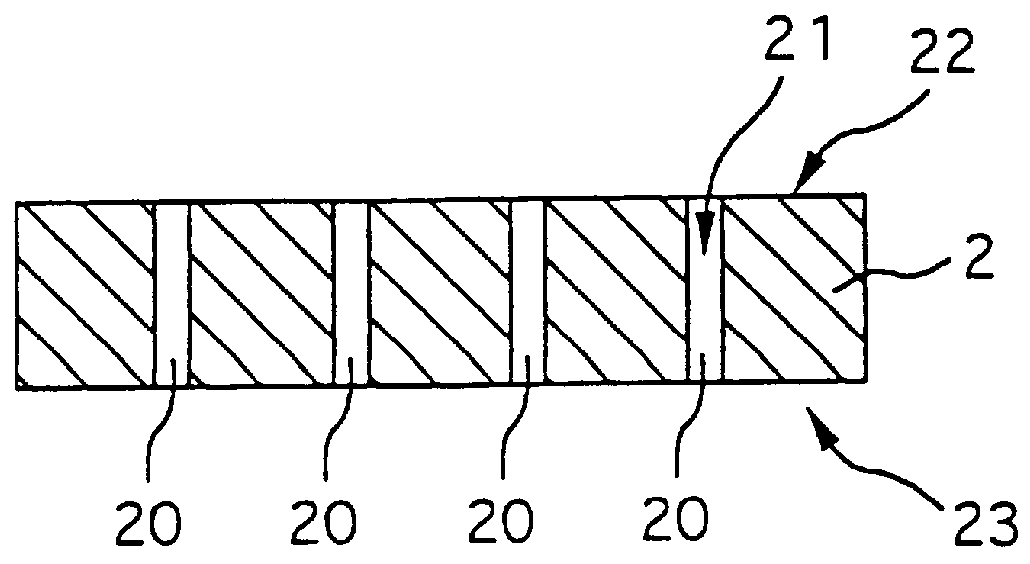

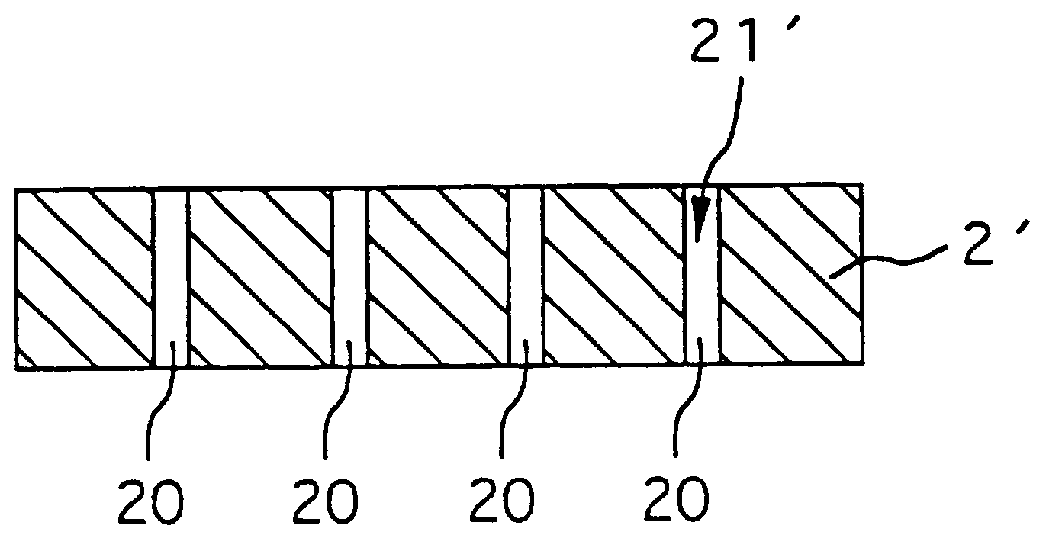

Method for anodic bonding of wafers and device

InactiveUS20050112843A1Avoid Bonding DefectsCost-effectiveSolid-state devicesSemiconductor/solid-state device manufacturingInter layerEngineering

A method for anodic bonding of wafers and a device essentially composed of such bonded wafers. An intermediate layer is placed between two wafers, after which the two wafers are anodically bonded. The method and the device have the advantage of being implementable and manufacturable, respectively, in a particularly cost-effective manner. The anodically bonded intermediate layer plastically encloses any possible particles present or evens out differences in height of the wafer surfaces to be bonded and thus prevents any extensive bond defects from occurring.

Owner:ROBERT BOSCH GMBH

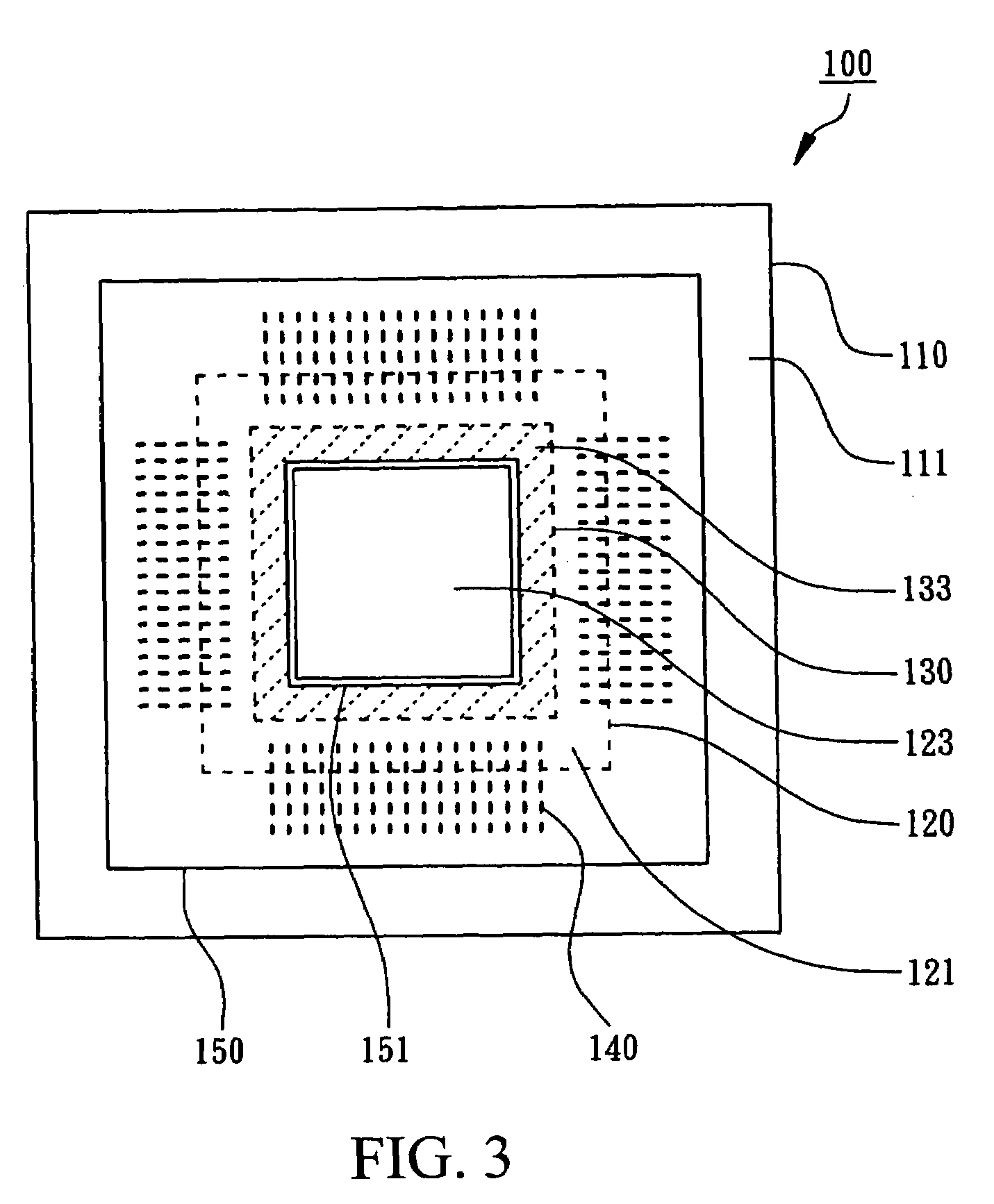

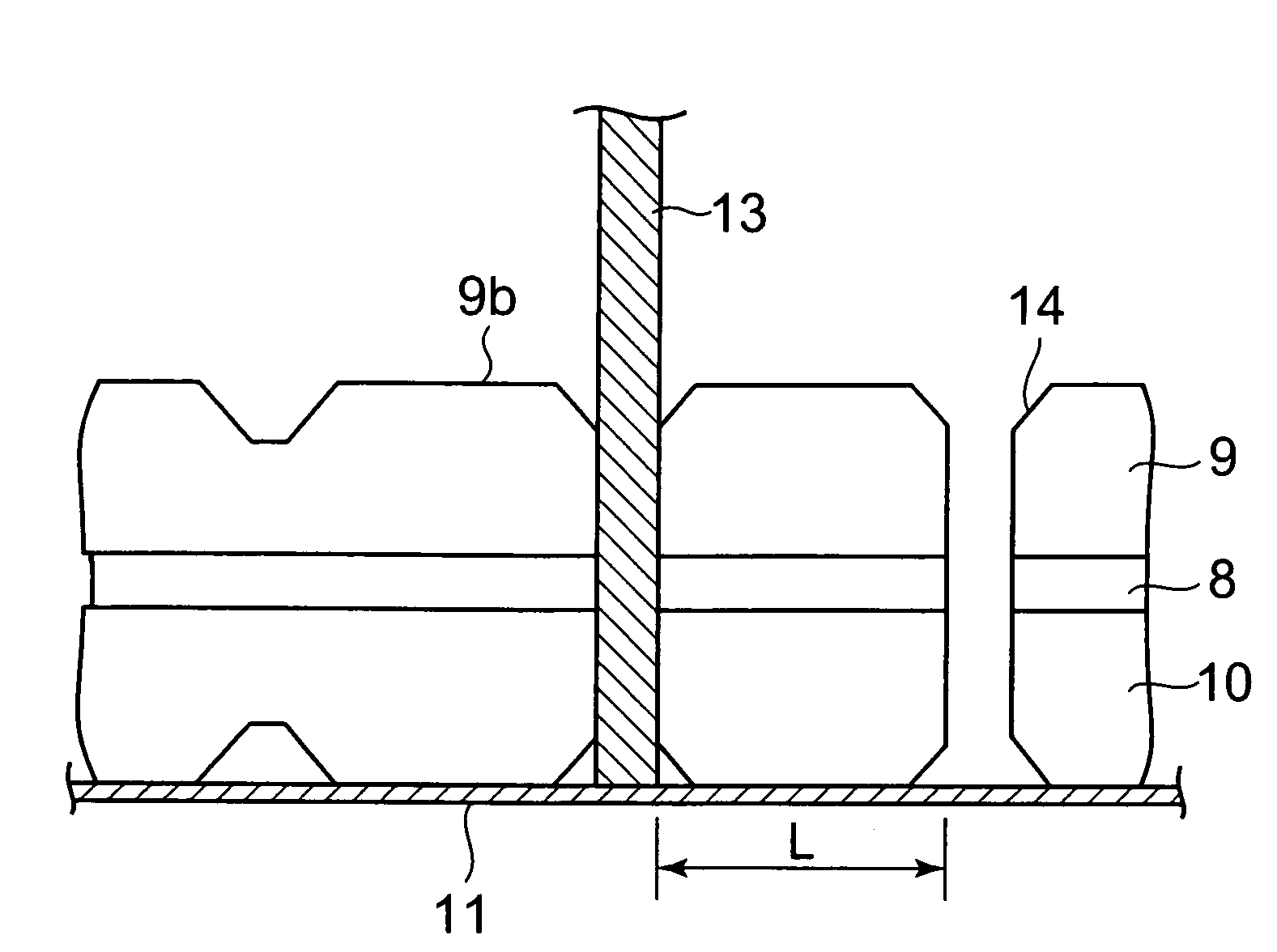

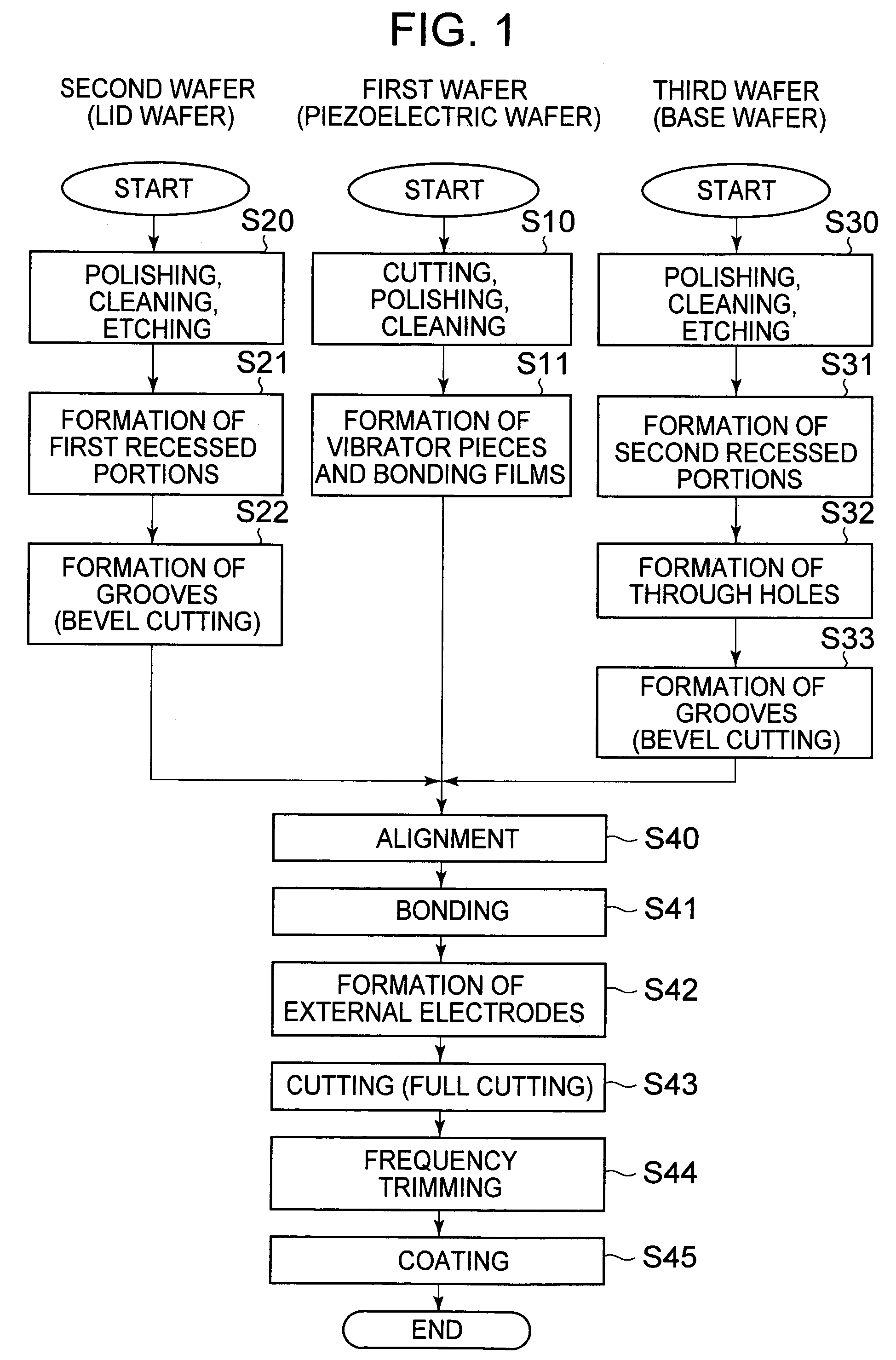

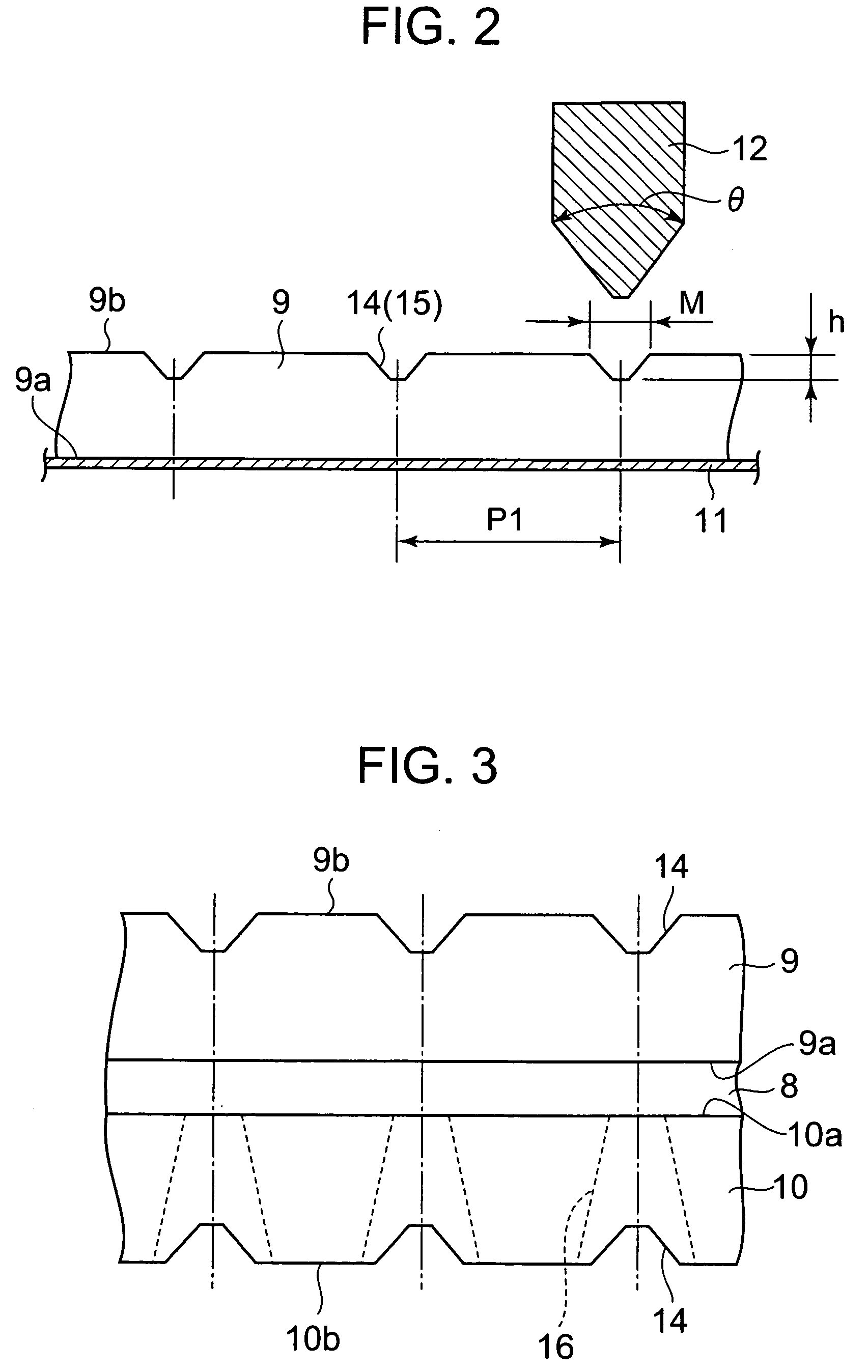

Glass substrate bonding method, glass assembly, package manufacturing method, package, piezoelectric vibrator, oscillator, electronic device, and radio-controlled timepiece

InactiveUS20110227661A1Improve energy efficiencyImprove production efficiencyPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksOptoelectronicsAnodic bonding

Provided are a glass substrate bonding method capable of securely anodically bonding a bonding material and a glass substrate even when Si having a large resistance value is used as a material for the bonding material, a glass assembly obtained by the glass substrate bonding method, a package manufacturing method, a package, a piezoelectric vibrator, and an oscillator, an electronic device, and a radio-controlled timepiece having the piezoelectric vibrator. A glass substrate bonding method includes an anodic bonding step of anodically bonding a bonding material fixed to an inner surface of a lid substrate wafer to a base substrate wafer. The bonding material is formed of an ITO film and a Si film which are sequentially formed on the inner surface of the lid substrate wafer.

Owner:SEIKO INSTR INC

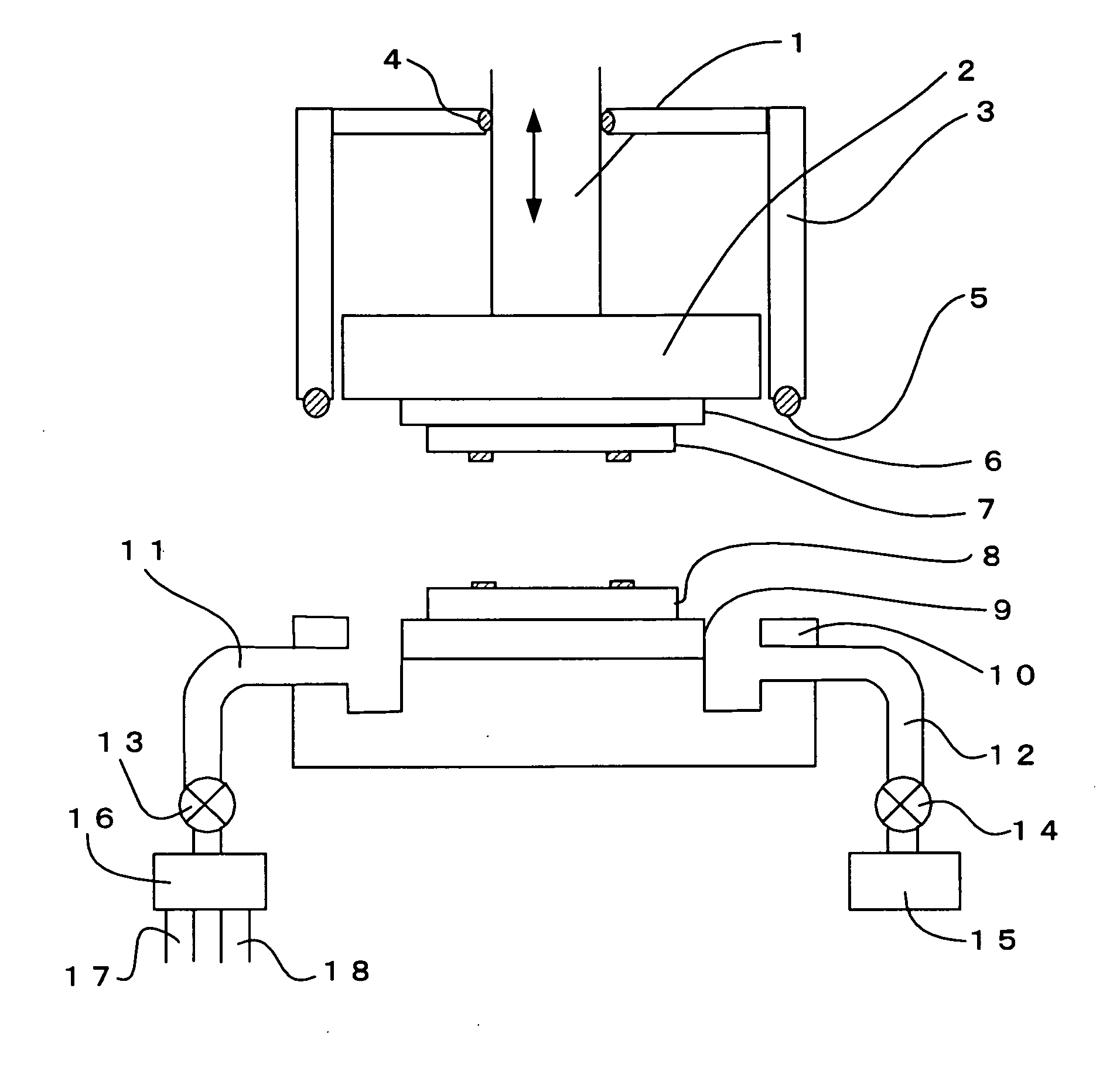

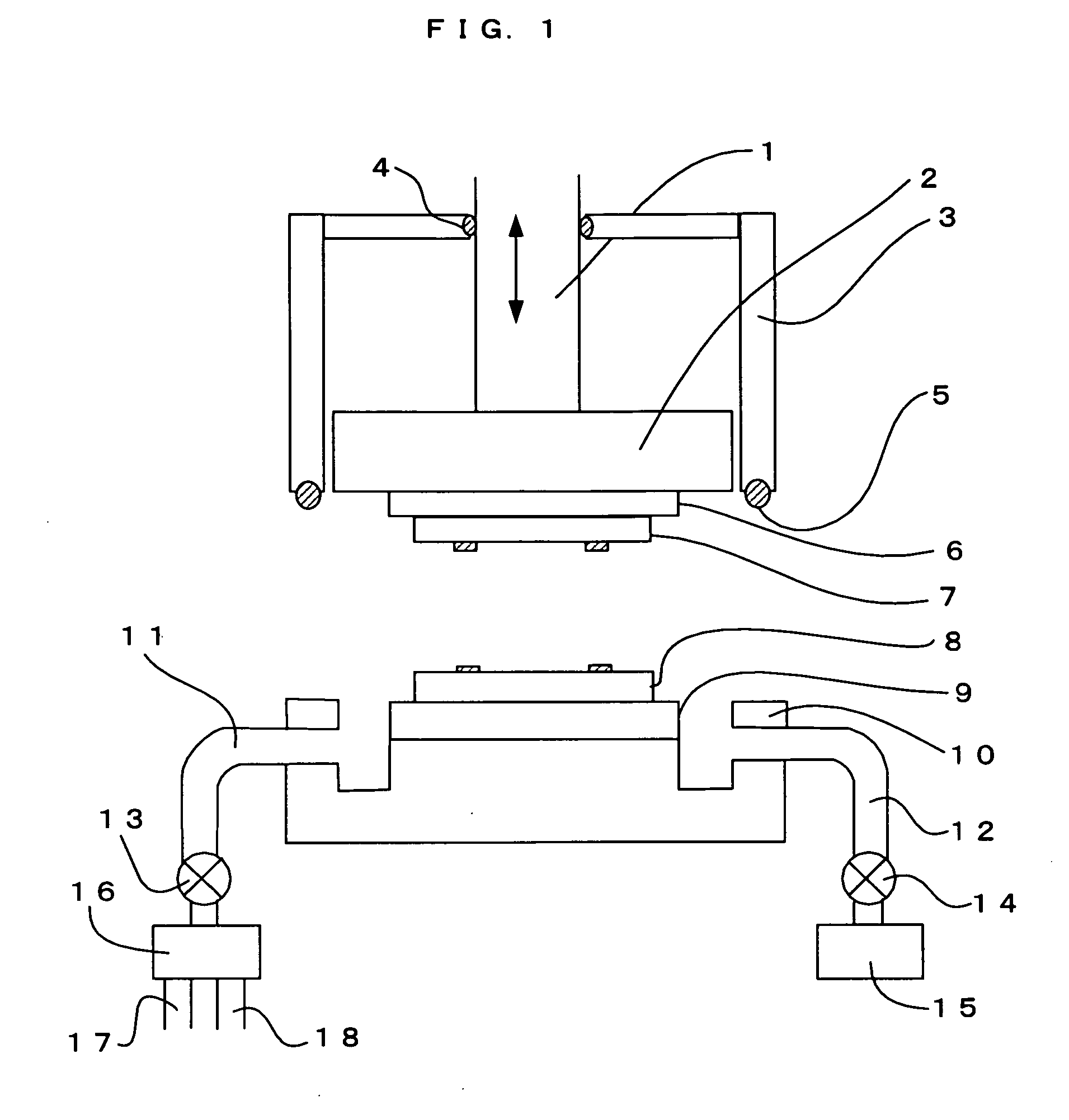

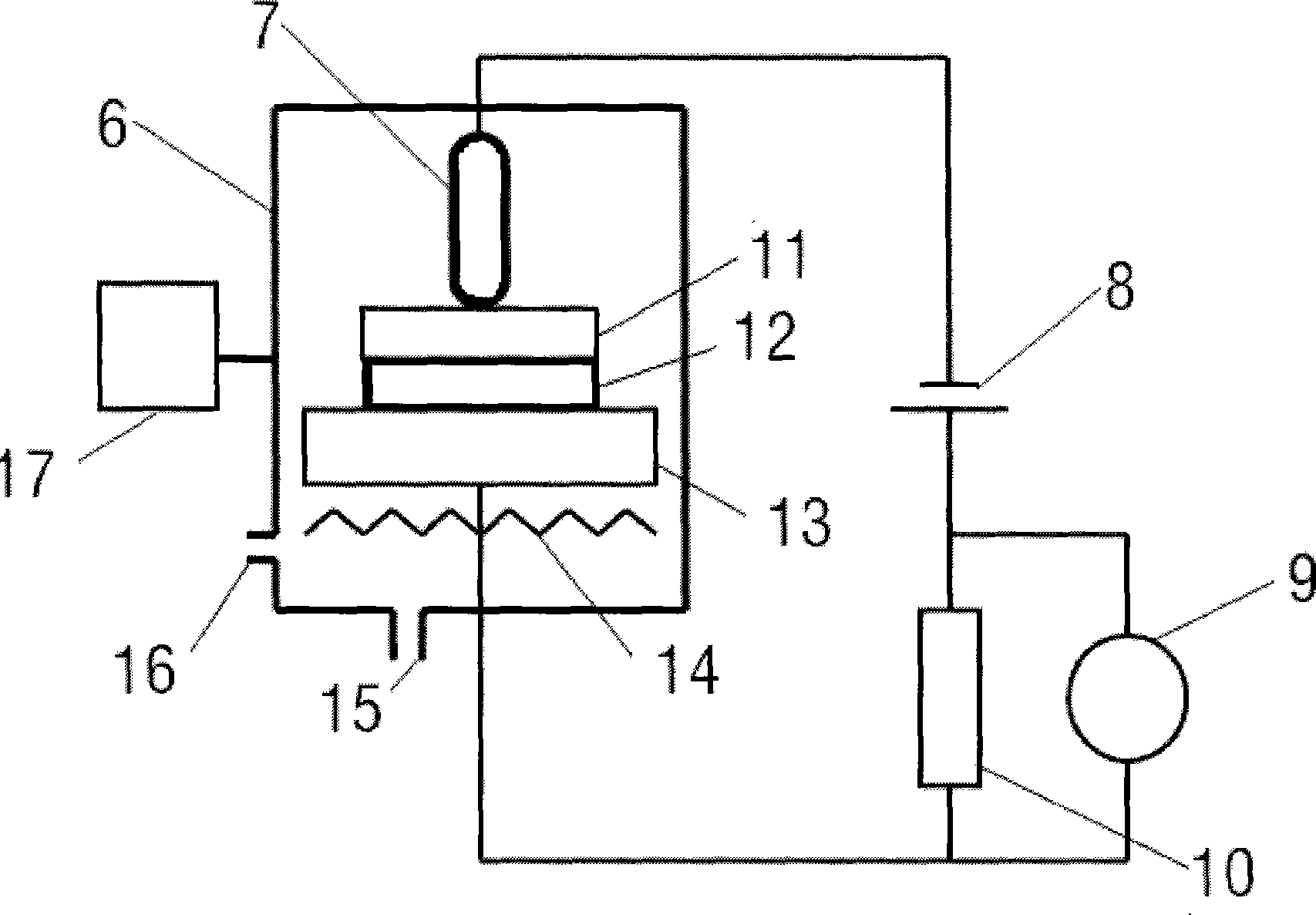

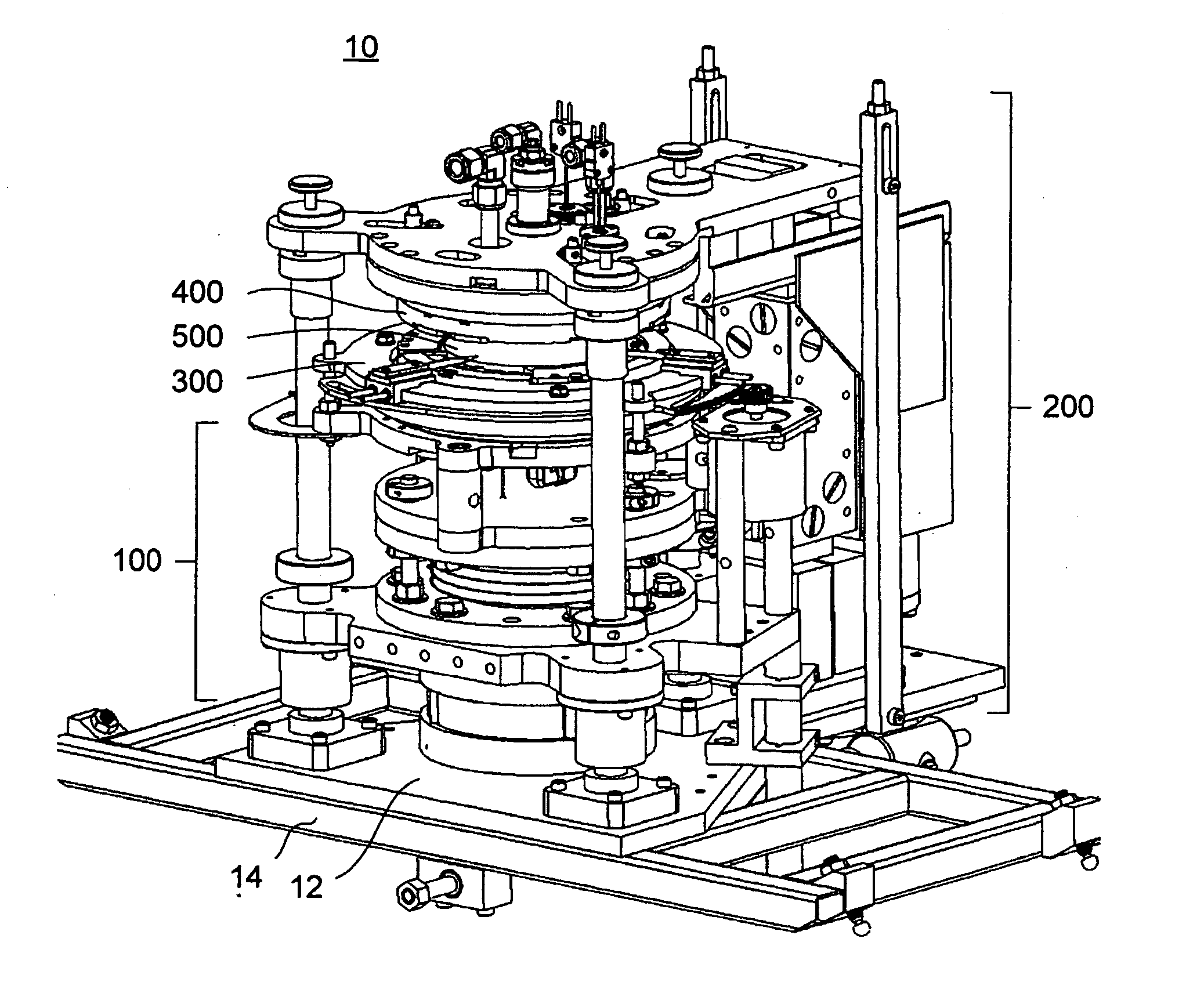

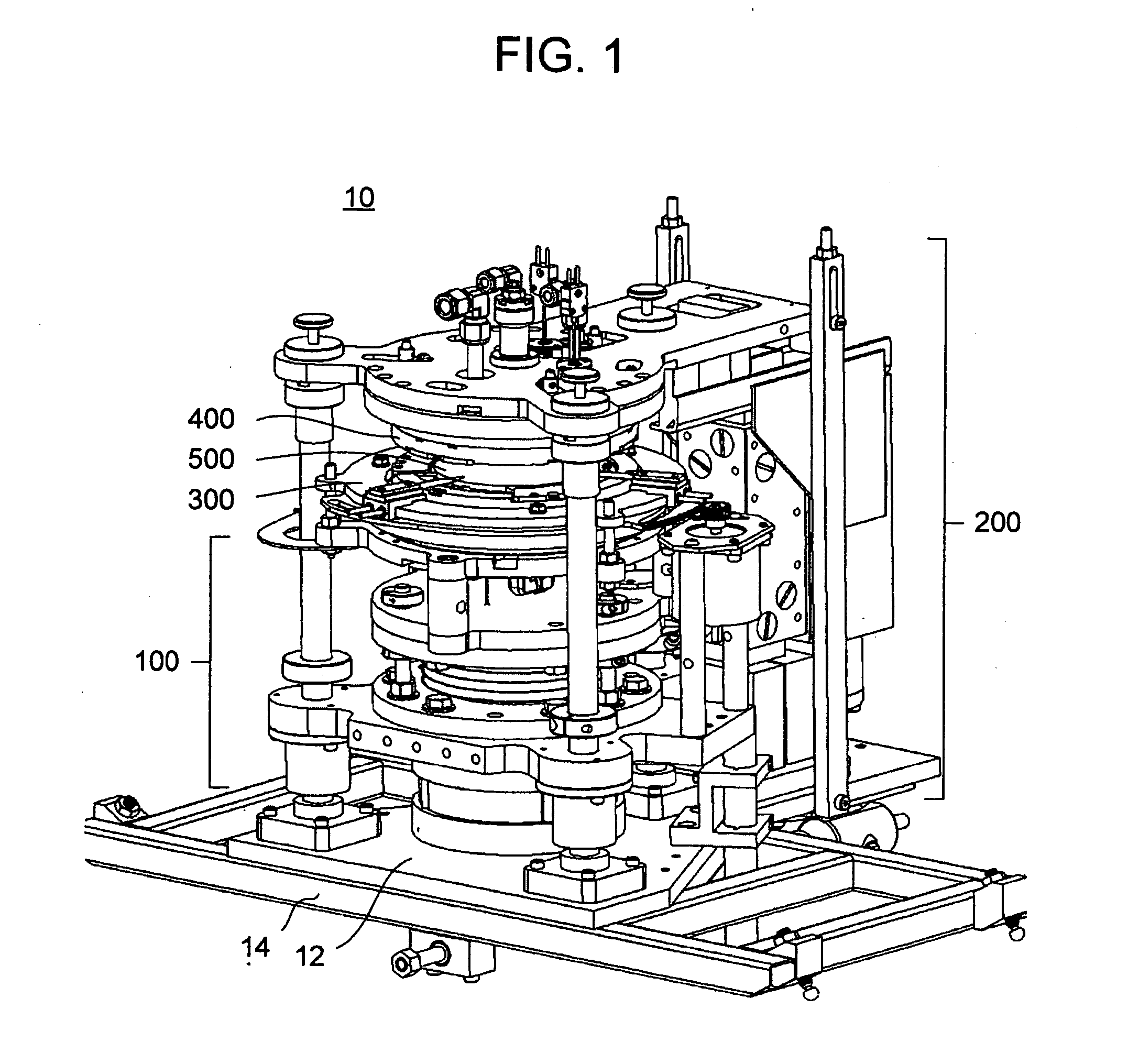

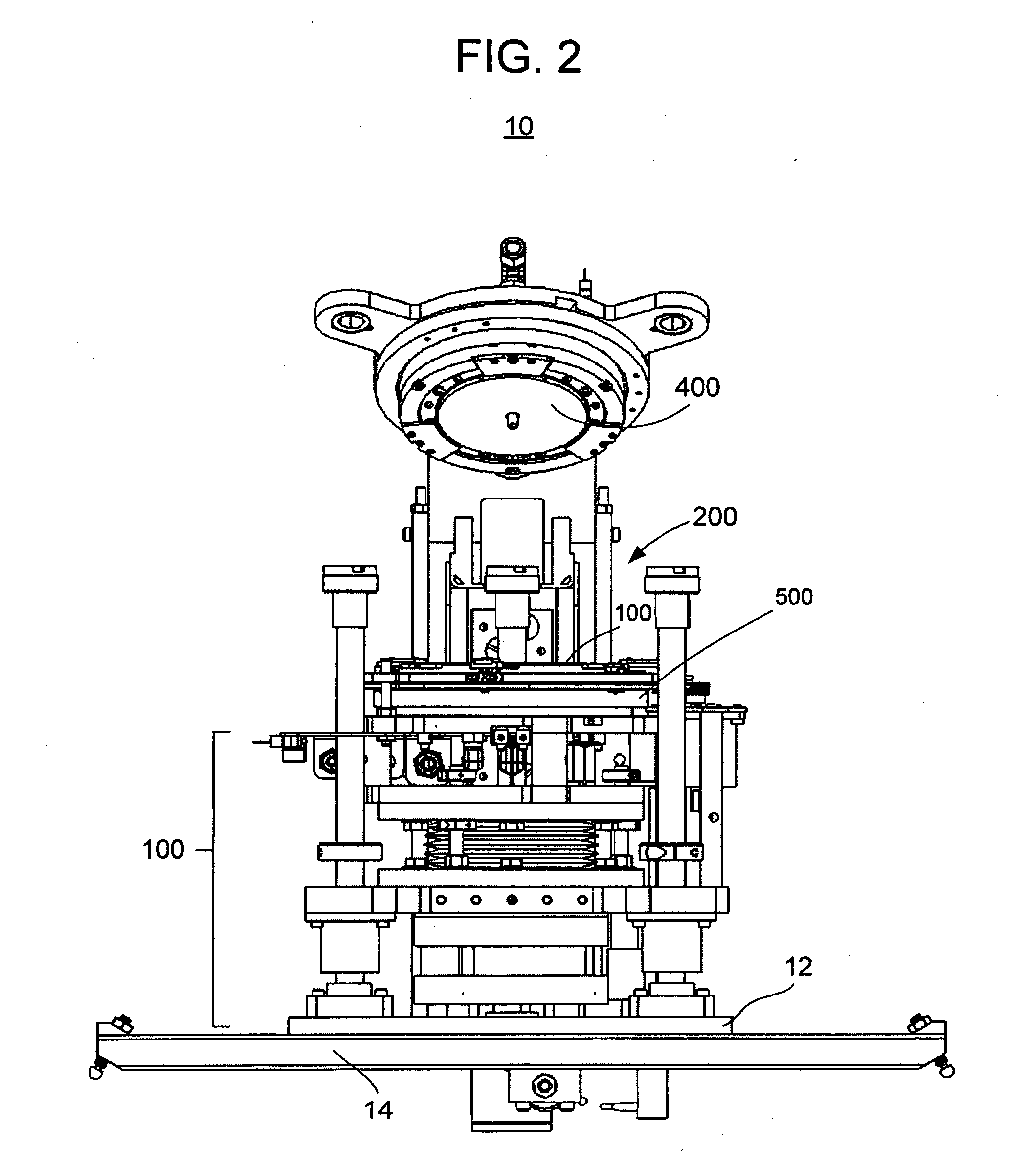

High temperature anodic bonding apparatus

InactiveUS20070246450A1Solid-state devicesSemiconductor/solid-state device manufacturingControl signalEngineering

An anodic bonding apparatus includes: a first bonding plate mechanism operable to engage a first material sheet, and to provide at least one of controlled heating, voltage, and cooling thereto; a second bonding plate mechanism operable to engage a second material sheet, and to provide at least one of controlled heating, voltage, and cooling thereto; a pressure mechanism operatively coupled to the first and second bonding plate mechanisms and operable to urge the first and second bonding plate mechanisms toward one another to achieve controlled pressure of the first and second material sheets against one another along respective surfaces thereof; a control unit operable to produce control signals to the first and second bonding plate mechanisms and the pressure mechanism to provide heating, voltage, and pressure profiles sufficient to achieve anodic bonding between the first and second material sheets.

Owner:CORNING INC

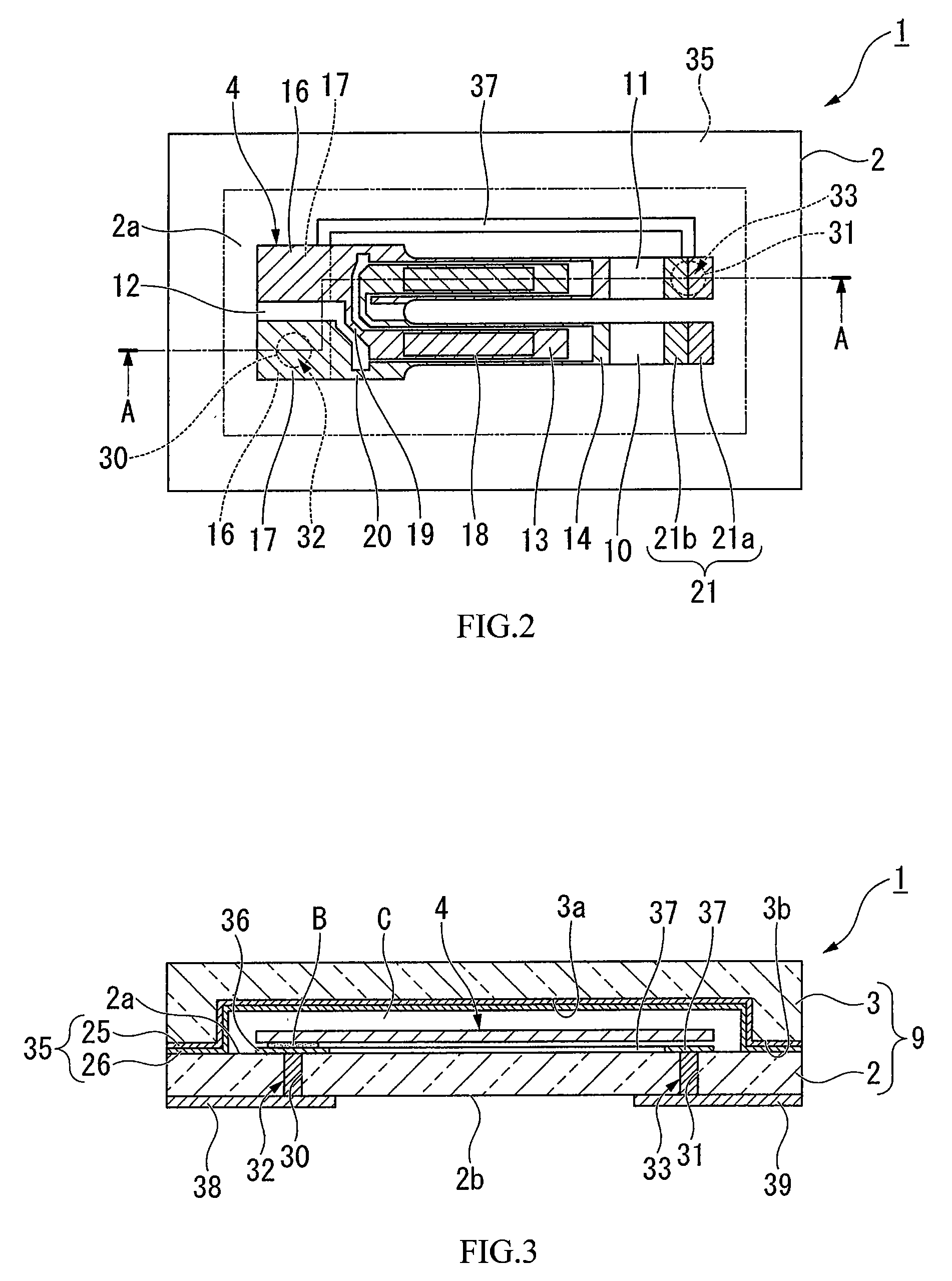

Pressure sensor

InactiveUS7135749B2Precise thickness controlLittle changeTransducer detailsSolid-state devicesSoi substrateConductive materials

A pressure sensor includes a silicon-on-insulator (SOI) substrate, a glass substrate bonded to the SOI substrate by anode bonding, a silicon island formed on a part of a silicon layer of the SOI substrate and surrounded by a groove extending to an insulating layer of the SOI substrate, a through hole formed in the glass substrate, and an output electrode that is made of a conductive material, is disposed inside the through hole, and is electrically connected to an electrode formed on the glass substrate via the silicon island.

Owner:ALPS ALPINE CO LTD

Method of producing an anodic bonded semiconductor sensor element

InactiveUS6077721AFluid pressure measurement using ohmic-resistance variationSemiconductor/solid-state device manufacturingProduction rateHydrofluoric acid

A semiconductor sensor mount is formed as follows: through holes are formed that penetrate a glass plate; and then the glass plate having the through holes is dipped into hydrofluoric acid etchant to smooth the inner peripheral surfaces of the respective through holes. By etching the inner peripheral surfaces of the respective through holes after the through hole formation, minute roughness and cracks formed on the inner peripheral surfaces are removed, and thereby the areas for adsorbing gas are substantially reduced. That is, vacuums within the through holes can be maintained at a high degree during the anodic bonding, whereby undesirable electric discharge phenomena are prevented even if a relatively high voltage is applied during the anodic bonding. Accordingly, the yield of products can be improved while improving productivity.

Owner:DENSO CORP +1

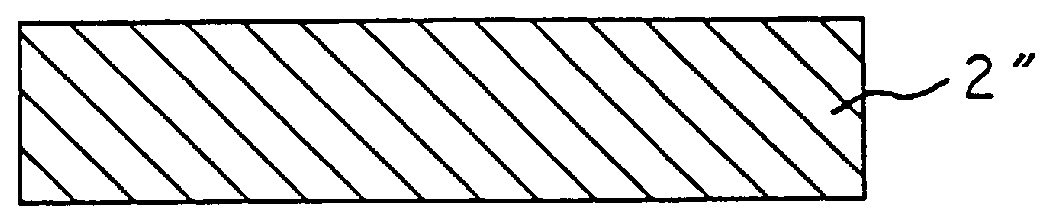

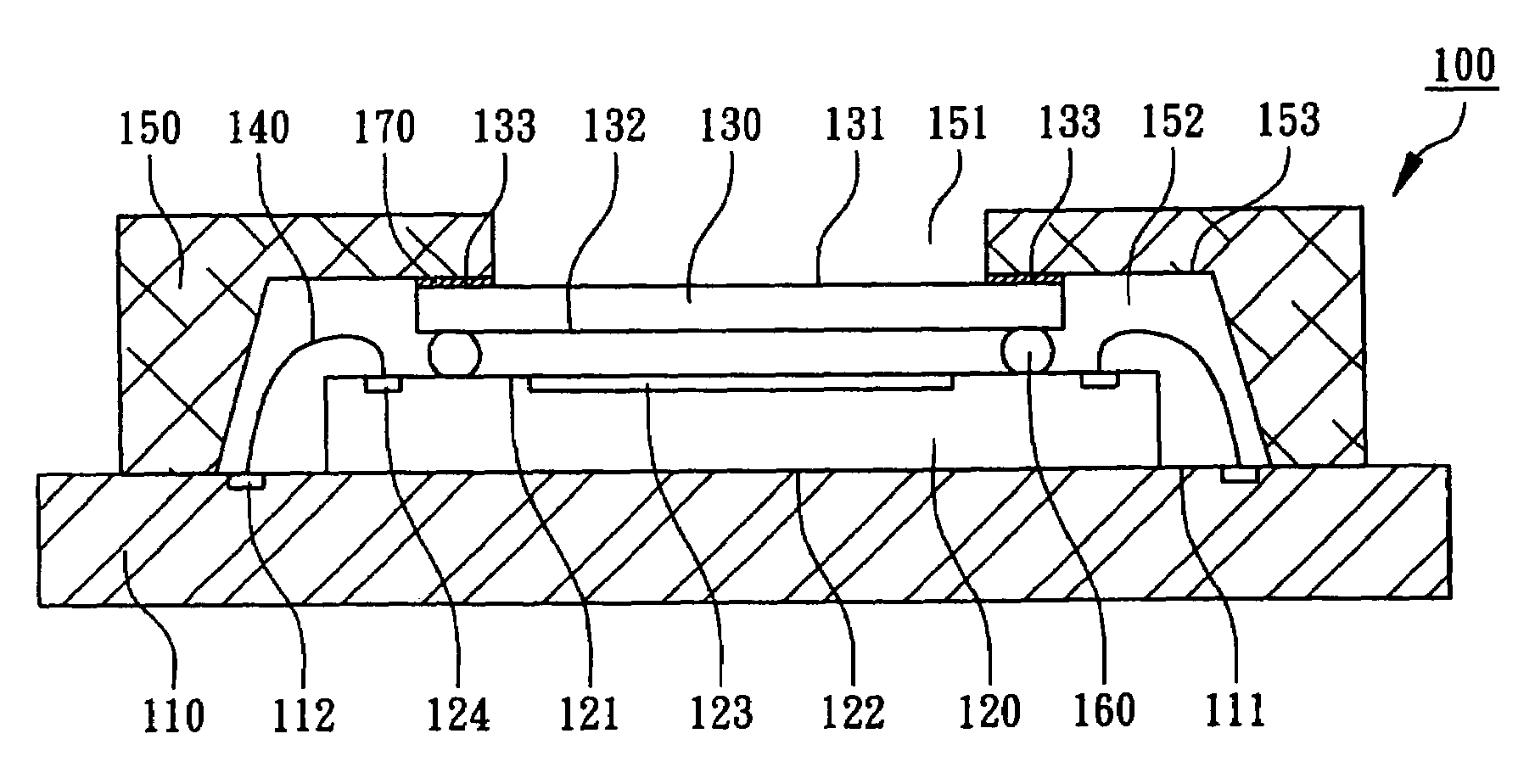

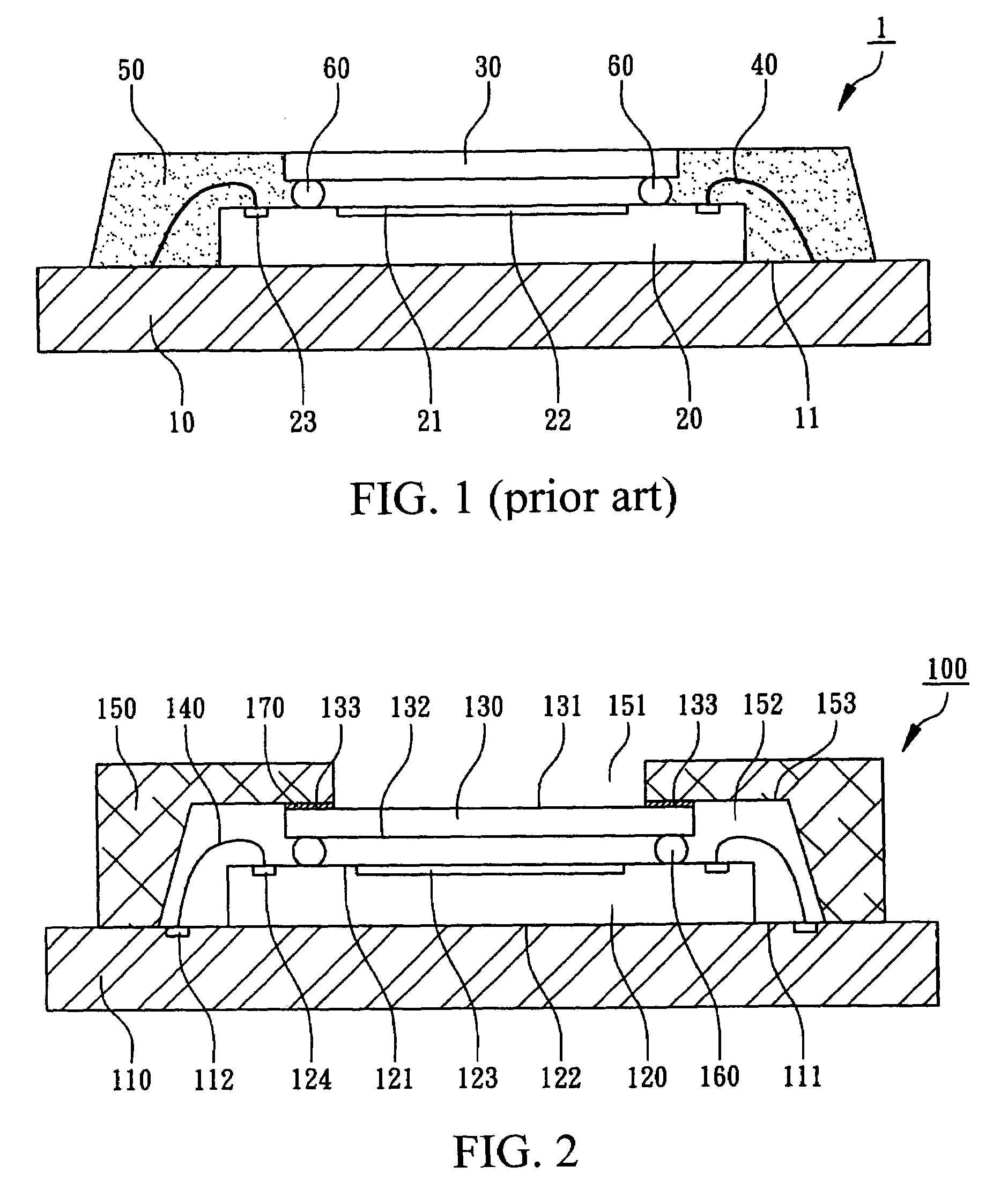

Optoelectronic package with wire-protection lid

ActiveUS7154053B2Quality improvementAvoid problemsSemiconductor/solid-state device detailsSolid-state devicesEngineeringAnodic bonding

An optoelectronic package with a wire-protection lid is provided. An active surface of a silicon die includes a light working area. The silicon die is disposed on a substrate and electrically connected to the substrate through a plurality of bonding wires. A glass is disposed on the active surface of the silicon die. A silicon base lid with an opening is located above the substrate and connected to the glass by anodic bonding to mask the bonding wires. In addition, the opening of the silicon base lid is aligned with the light working area of the silicon die.

Owner:ADVANCED SEMICON ENG INC

Piezoelectric vibrator, manufacturing method thereof, oscillator, electronic equipment, radio clock

InactiveUS7294951B2Minimize fluctuationReduce manufacturing costPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRadio clockAnodic bonding

Owner:SII CRYSTAL TECH

Methods for indirect bonding of orthodontic appliances

ActiveUS20090220920A1Improve visibilityIncrease elasticityBracketsTeeth fillingDental patientsDental restorative materials

Improved methods for indirect bonding of orthodontic appliances, such as brackets, to the tooth surfaces of dental patients are provided. The methods use a transfer tray to accurately position the brackets on the tooth surfaces. Preferably, the tray is made of an ethylene vinyl acetate copolymer (EVA) / siloxane material. The brackets are coated with a protective coating to prevent them from becoming embedded in the tray. Preferably, a translucent, blue-tinted coating is used to cover the brackets. Dental restorative materials are used to bond the brackets to the teeth. The transfer tray is then removed from the mouth, while the appliances remain firmly bonded to the tooth surfaces.

Owner:DENTSPLY SIRONA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com