Patents

Literature

1536 results about "Borosilicate glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion (≈3 × 10⁻⁶ K⁻¹ at 20 °C), making them more resistant to thermal shock than any other common glass. Such glass is subjected to less thermal stress and can withstand temperature differentials without fracturing of about 165 °C (329 °F). It is commonly used for the construction of reagent bottles. Borosilicate glass is sold under various trade names, including Borcam, Borosil, DURAN, Pyrex, Supertek, Suprax, Simax, BSA 60, BSC 51 (by NIPRO), Heatex, Endural, Schott, Refmex, Kimble, and MG (India).

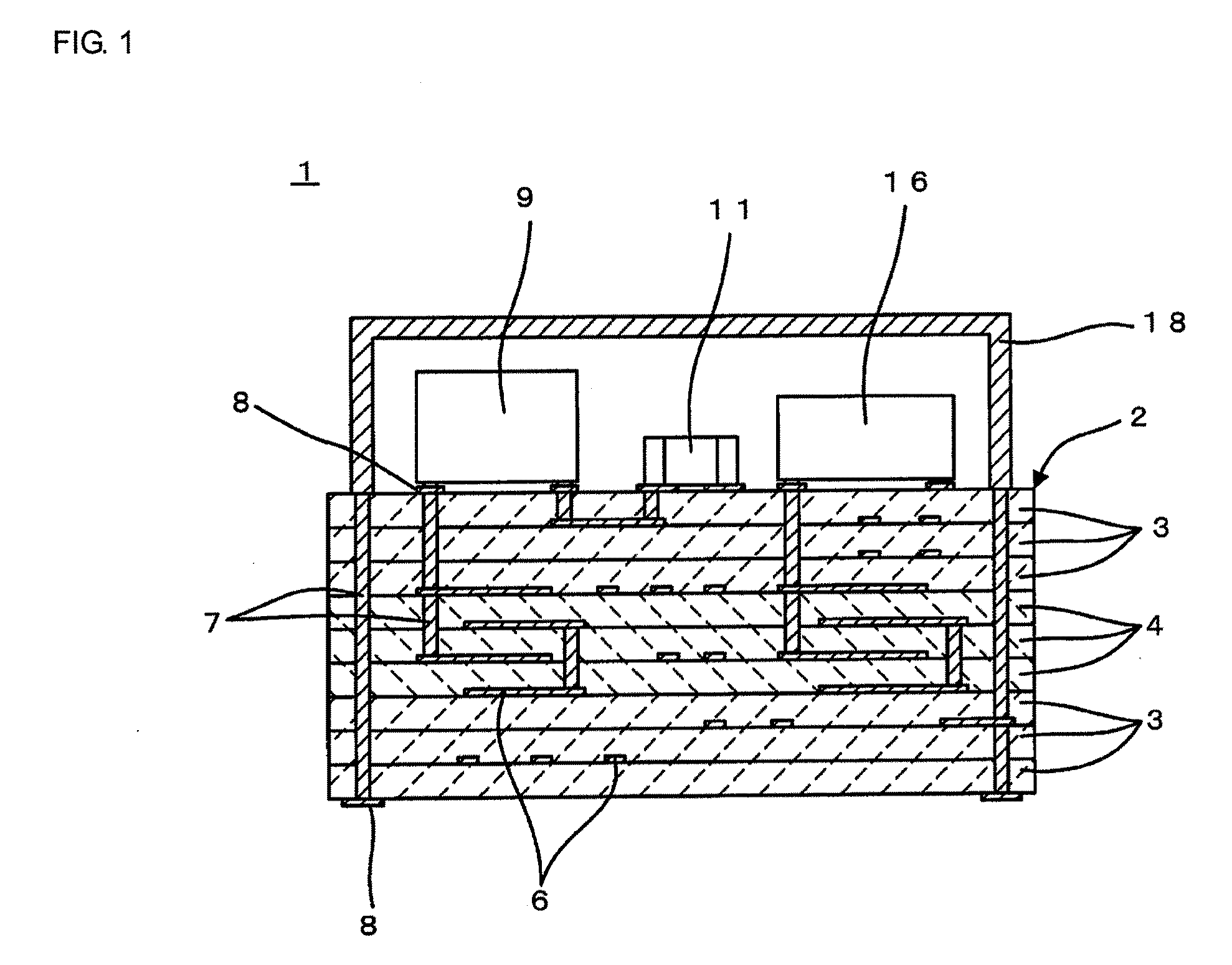

Optical switch and method for assembling the same

An optical switch includes a substrate having therein optical waveguides made of silicon and a silicon layer deposited on its top surface. A space is formed in the crossing portion of the optical waveguides which is covered with a lid, preferably made of low alkali borosilicate glass, and which is bonded to the silicon layer by anodic bonding. Preferably, a groove is formed in a surface of the optical waveguide substrate or a bonding surface of the lid. The groove, after the lid has been bonded, makes a passage which communicates between the space and an outside. The passage is a pouring slit for pouring an index-matching liquid and is connected to the space which acts as a driving slit in which the index-matching liquid moves. In one embodiment, the width of the pouring slit is smaller than that of the driving slit. The optical switch can be manufactured by providing an optical waveguide substrate and a lid substrate, one of which is formed with a groove in its surface on which the two substrates are bonded. The optical waveguide substrate and the lid substrate are bonded together by anodic bonding to make a passage which communicates between the space formed in a crossing portion of the optical waveguides and an outside. The regulation of the volume of the index-matching liquid is time-, temperature-, or pressure-based regulation.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

High chemical resistance borosilicate glass and purpose thereof

InactiveCN101717189AComply with packaging requirementsReduce manufacturing costPharmaceutical containersMedical packagingWorking temperaturePack material

The invention discloses high chemical resistance borosilicate glass, comprising the following components based on oxides in percentage by weight: 71-75 SiO2, 3-6 Al2O3, 8-10 B2O3, 4-10 Na2O and 0-2.5 K2O, 0-1.2 CaO, 0-1 MgO, 1-3 BaO and 0-0.3 CeO2, wherein Na2O+K2O ranges from 7 to 10, and CaO+MgO ranges from 0 to 1.2. The invention has the following advantages: 1. As2O3, Sb2O3, BaSO4 and other harmful substances are not used in constituents, and the borosilicate glass can be used as a material for packing medicines; and 2. tested by experiments, the high chemical resistance borosilicate glass prepared from the constituents by the traditional production equipment has the coefficient of heat expansion ranging from 5.0*10<-6> K<-1> to 6.0*10<-6> K<-1>, the inversion temperature Tg ranging from 520 DEGC to 572 DEGC, the softening point ranging from 765 DEGC to 782 DEGC, the working temperature ranging from 920 DEGC to 1200 DEGC and the density ranging from, 2.32 g / cm<3> to 2.5g / cm<3>, which meet the requirement on medicinal packing and reduces the production cost.

Owner:SHANDONG LINUO NEW MATERIAL

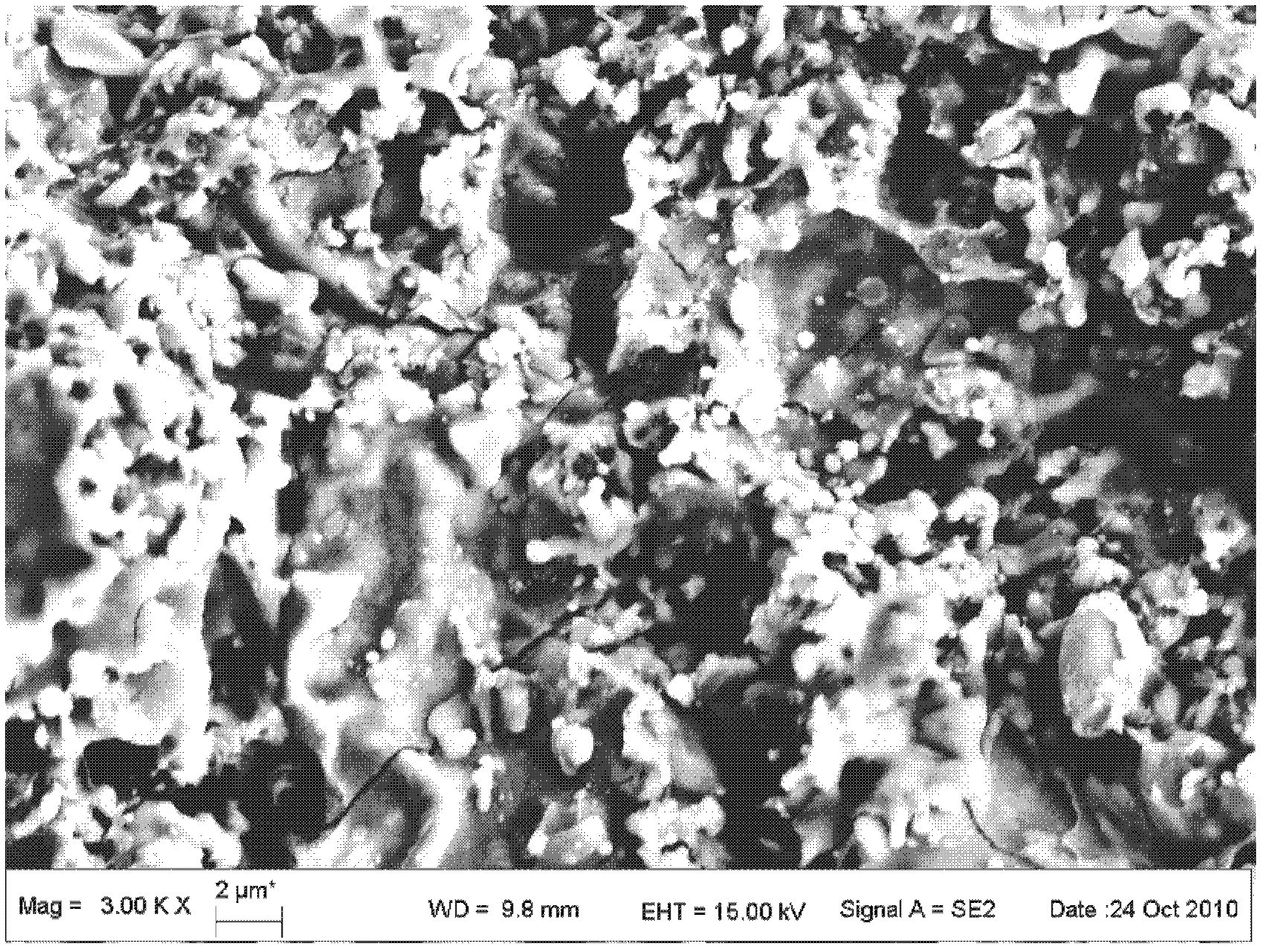

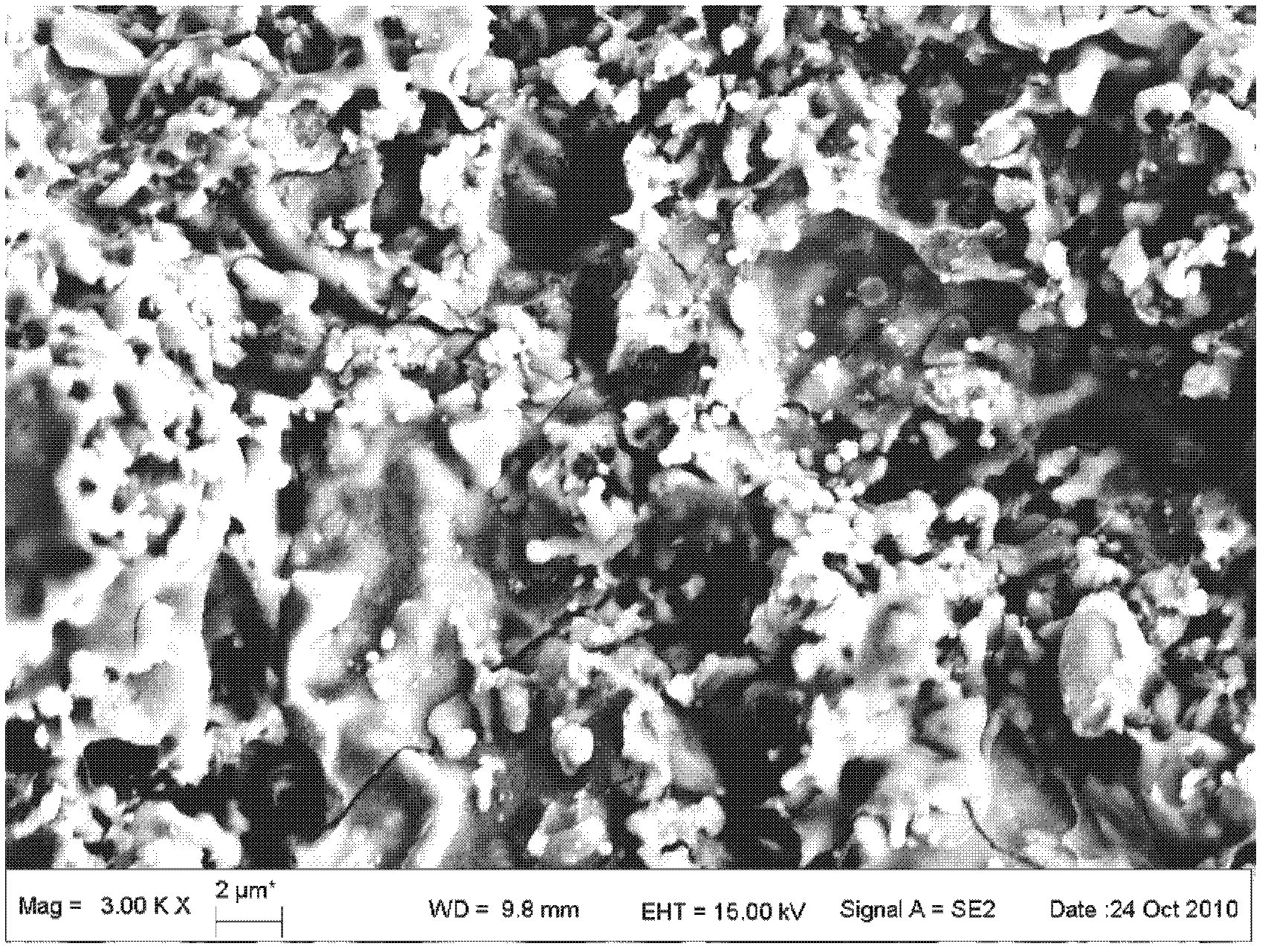

Superhydrophilic and Superhydrophobic Powder Coated Fabric

InactiveUS20090042469A1Fibre treatmentSynthetic resin layered productsSuperhydrophobeSelf-assembled monolayer

Superhydrophilic and superhydrophobic fabrics are taught having a superhydrophilic or superhydrophobic powder disposed on the fabric. The superhydrophilic powder has at least one material of sodium borosilicate glass and porous diatomaceous earth. The powder material has a contiguous interpenetrating structure with a plurality of spaced apart nanostructured surface features. The superhydrophilic powder is switched to superhydrophobic by adding at least one superhydrophobic material of perfluorinated organics, fluorinated organics, and self-assembled monolayers.

Owner:UT BATTELLE LLC

Crystallization-free glass frit compositions and frits made therefrom for microreactor devices

InactiveUS20070123410A1Low pour pointHigh acid resistanceLaboratory glasswaresChemical/physical/physico-chemical processesMicroreactorFrit

The invention is directed to a glass composition that can be used to make glass frits suitable for use in the manufacturing of microreactors. The glass compositions, after final sintering to produce a finished microreactor, have a surface crystalline layer of 30 μm or less, or are completely amorphous throughout. Generally, the borosilicate glasses of the invention have a composition of B2O3=12-22 mol %; SiO2=68-80 mol % and additional components selected from the group consisting of either (a) Al2O3=3-8 mol % and Li2O=1-8 mol %, or (b) K2O=0-2 mol % and Na2O=0-2 mol %, except that both K2O and Na2O cannot both equal zero at the same time. One borosilicate glass has a composition, in mole percent (mol %) of B2O3=18-22 mol %, SiO2=75-80 mol %, K2O=0-2 mol %, and Na2O=0-2 mol %, except that both K2O and Na2O cannot both equal zero at the same time.

Owner:CORNING INC

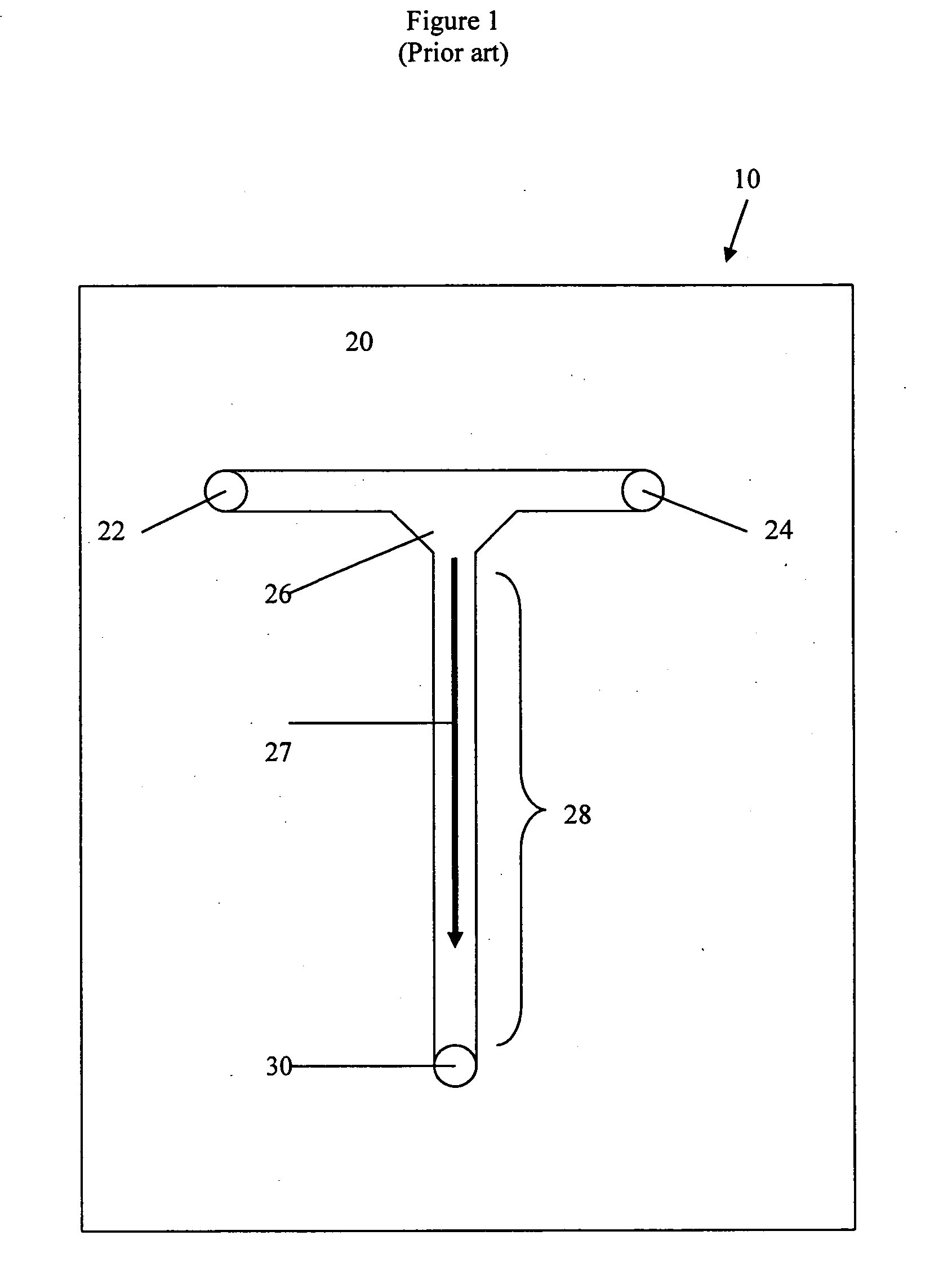

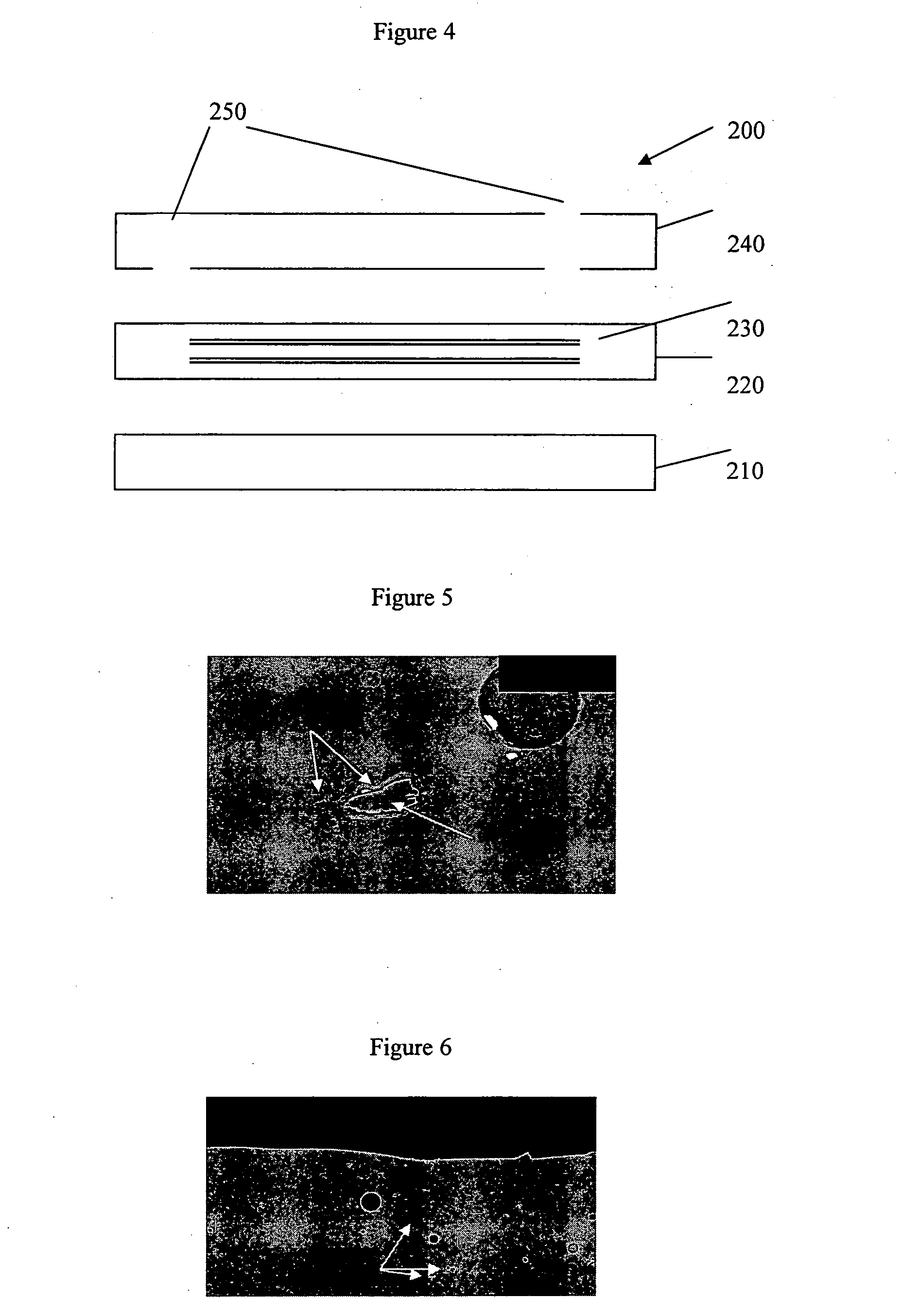

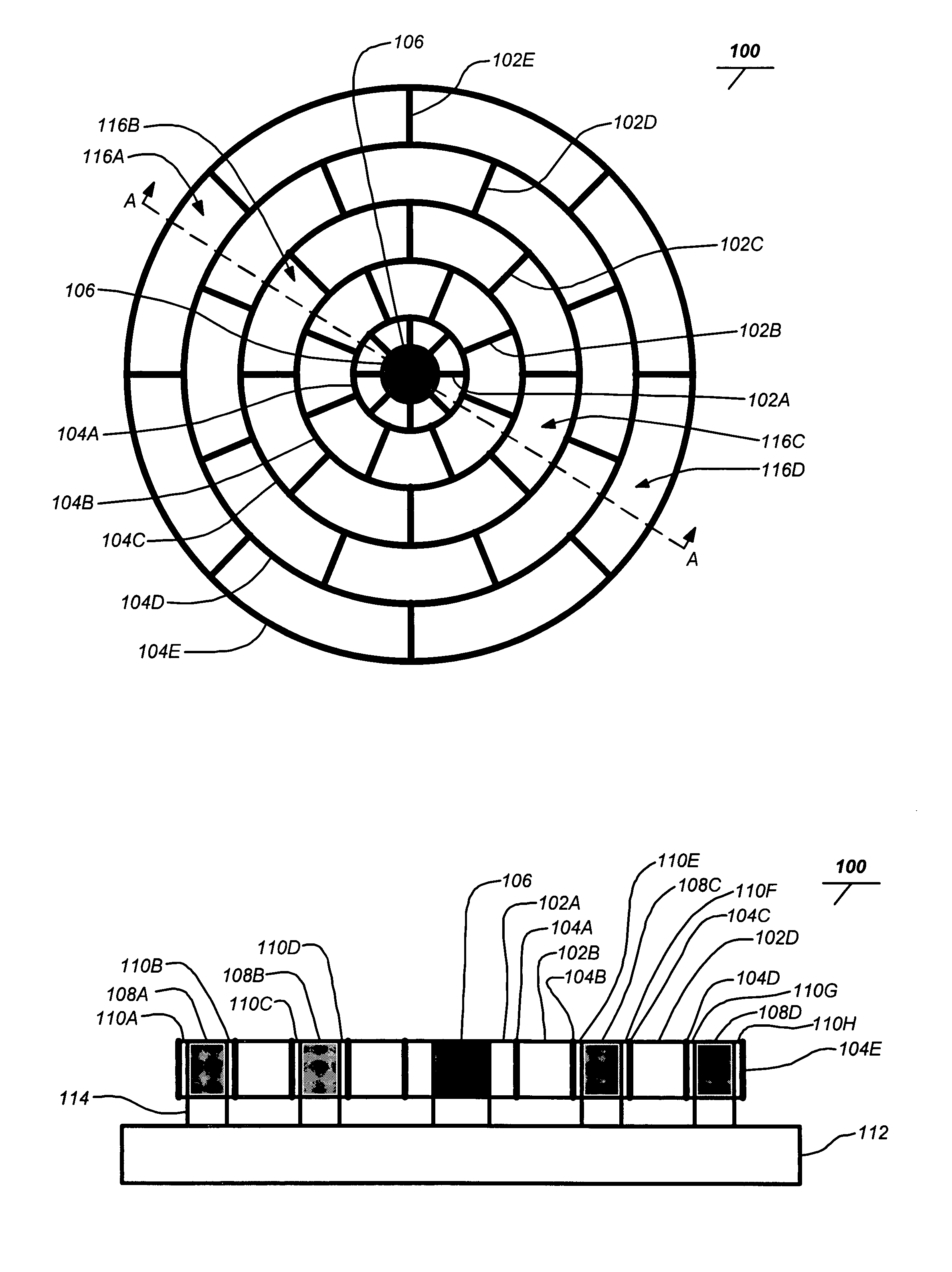

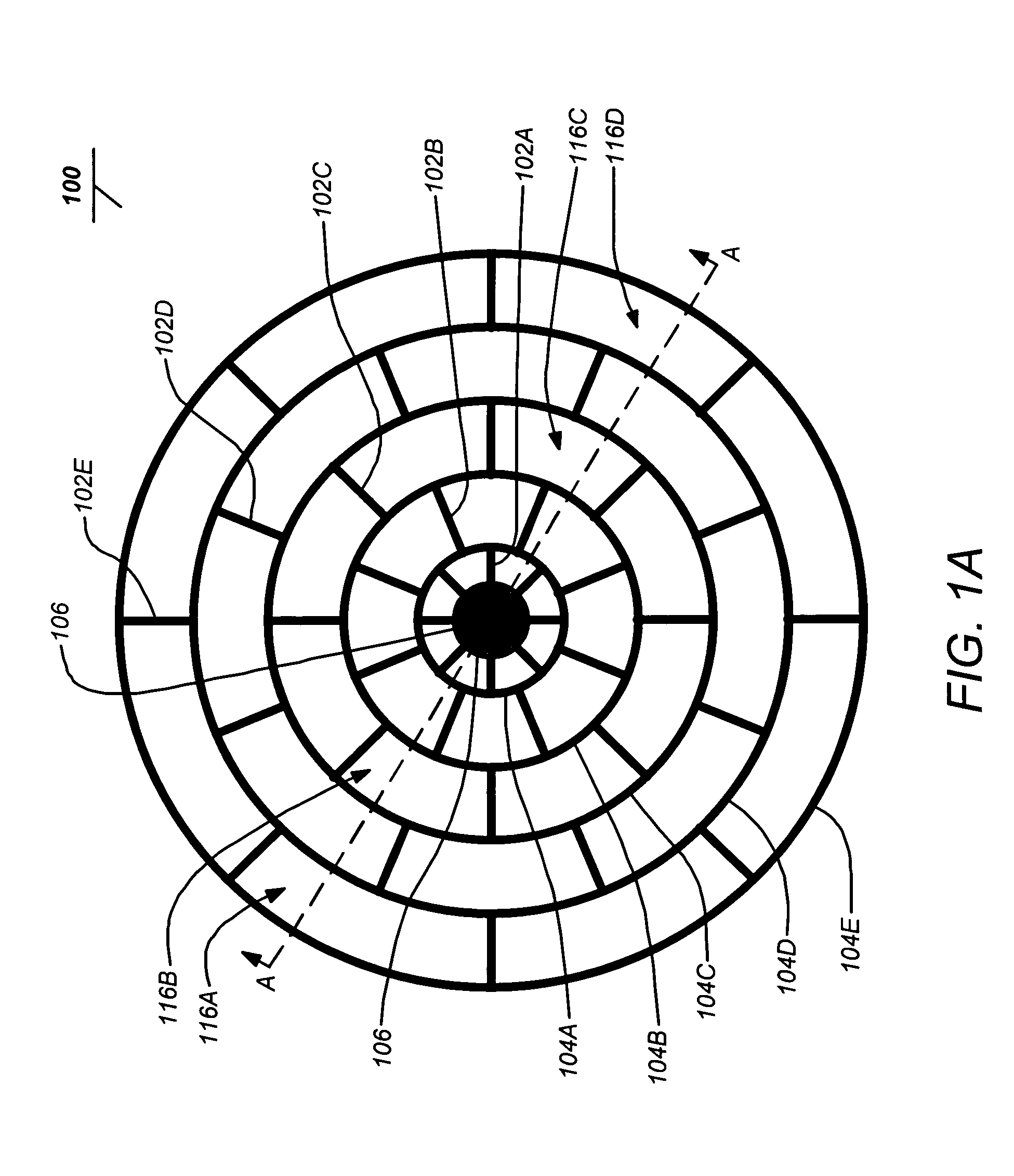

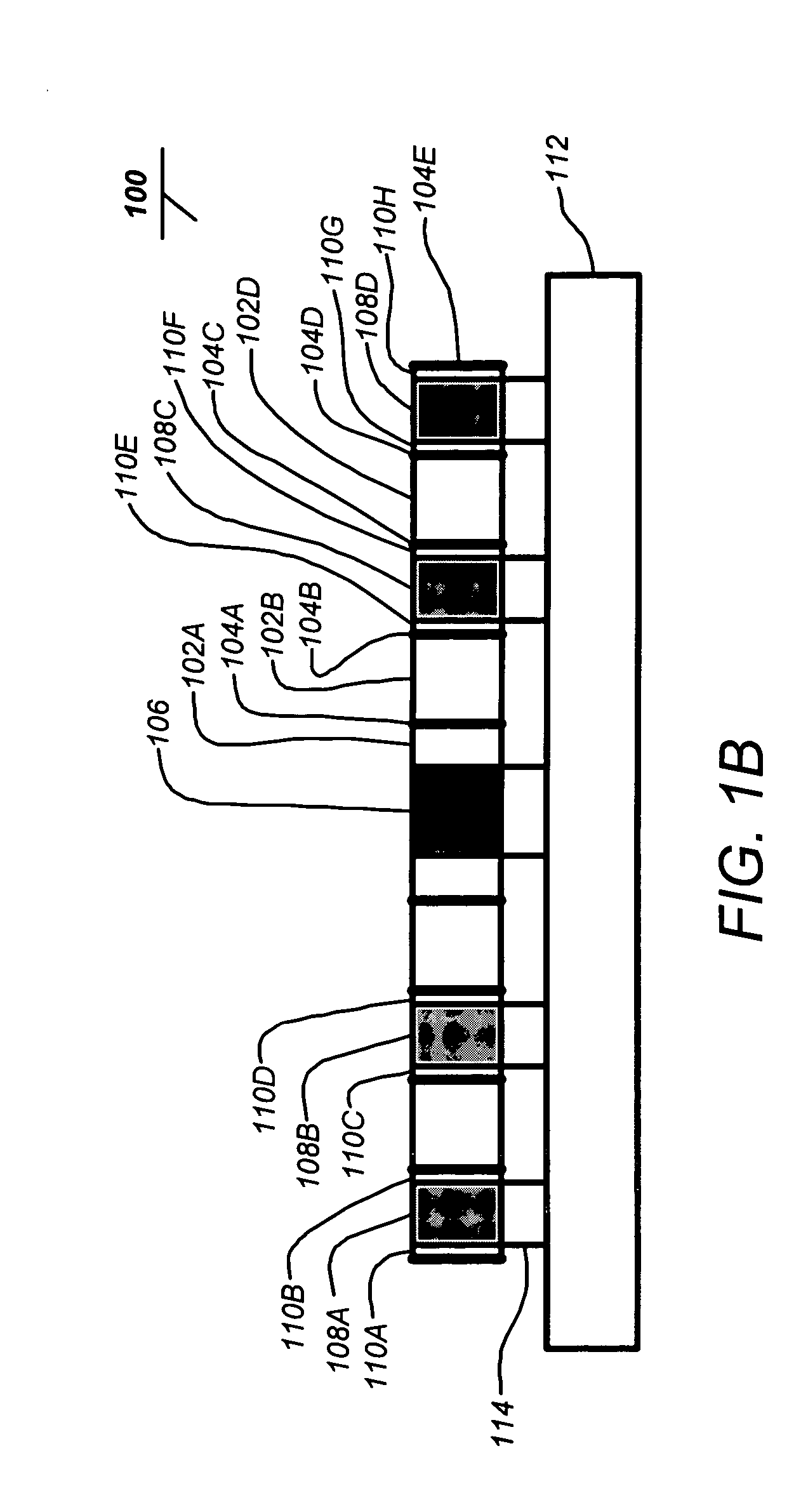

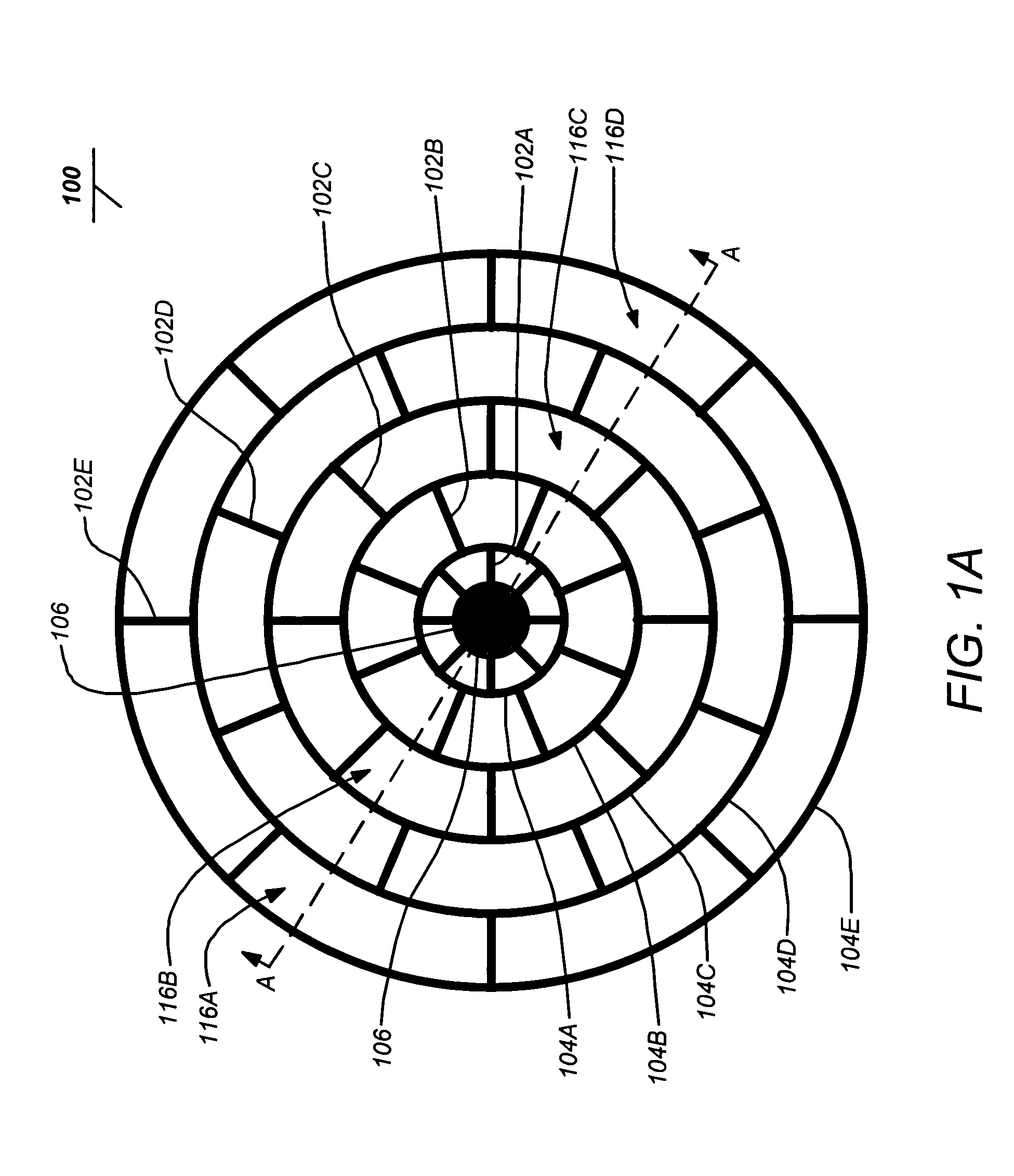

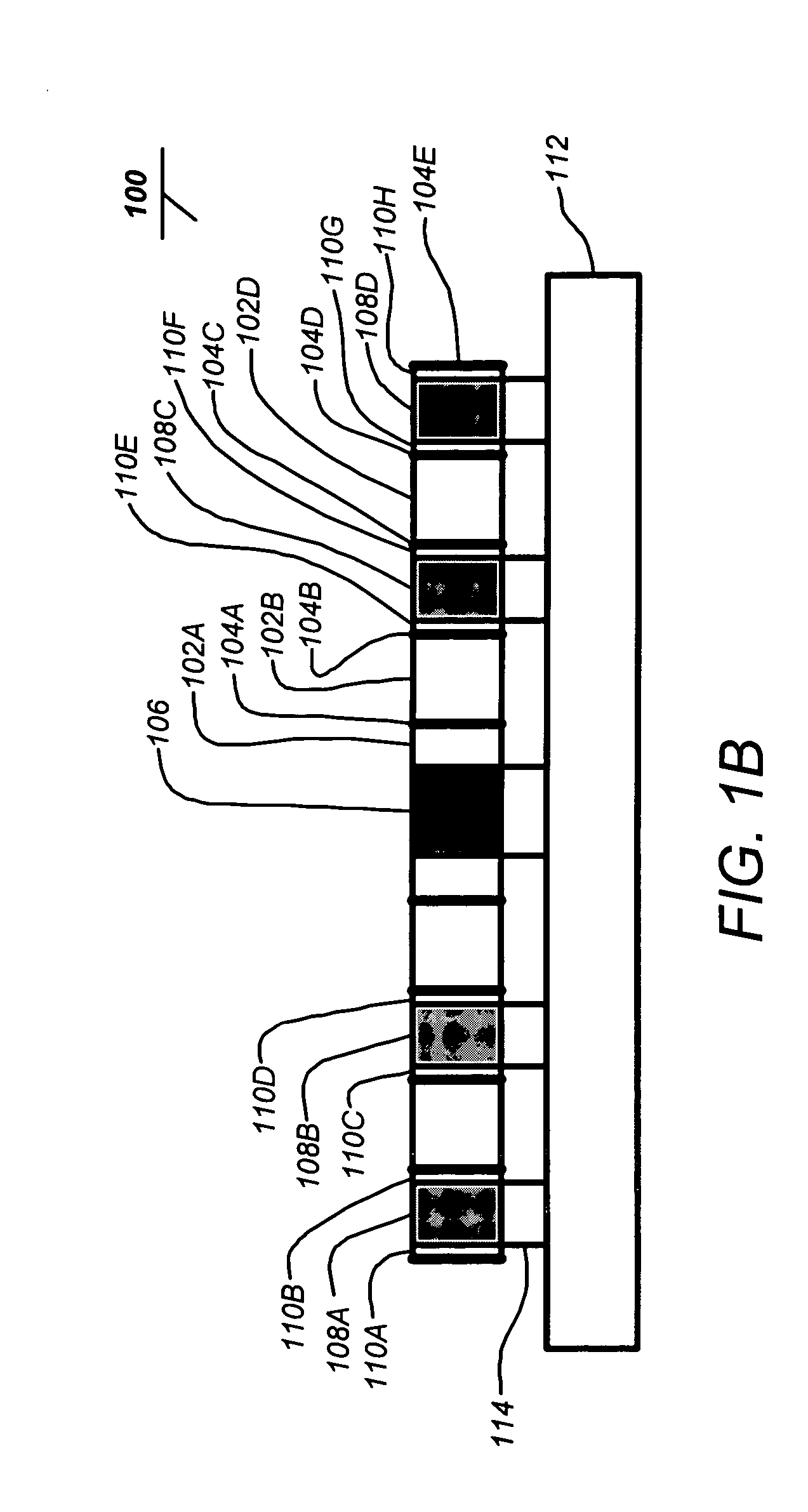

Isolated planar mesogyroscope

InactiveUS7168318B2Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsIn planeThermal expansion

Owner:CALIFORNIA INST OF TECH +1

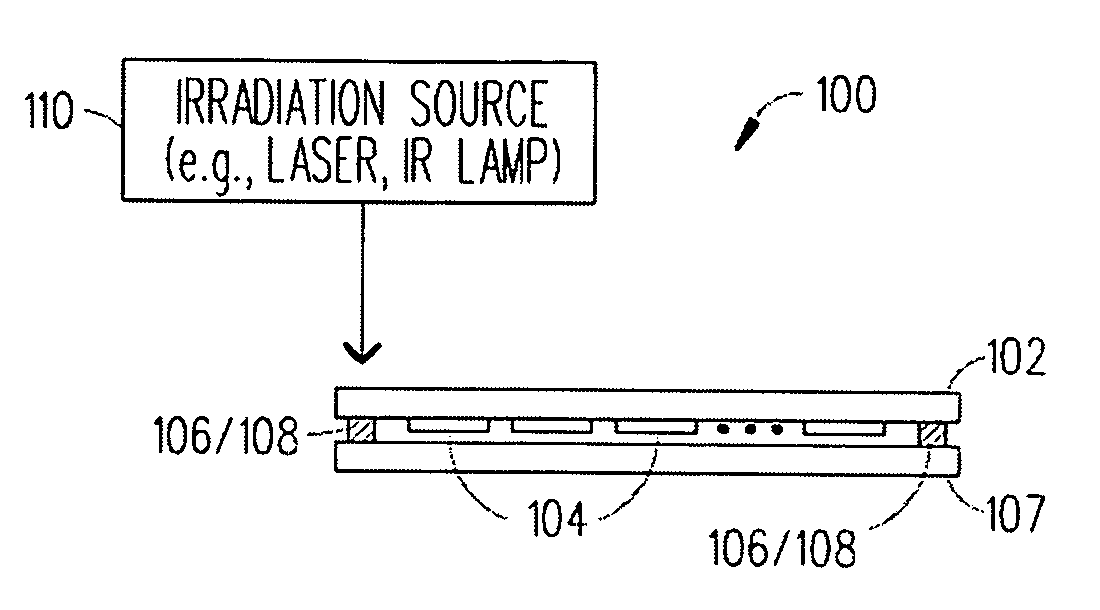

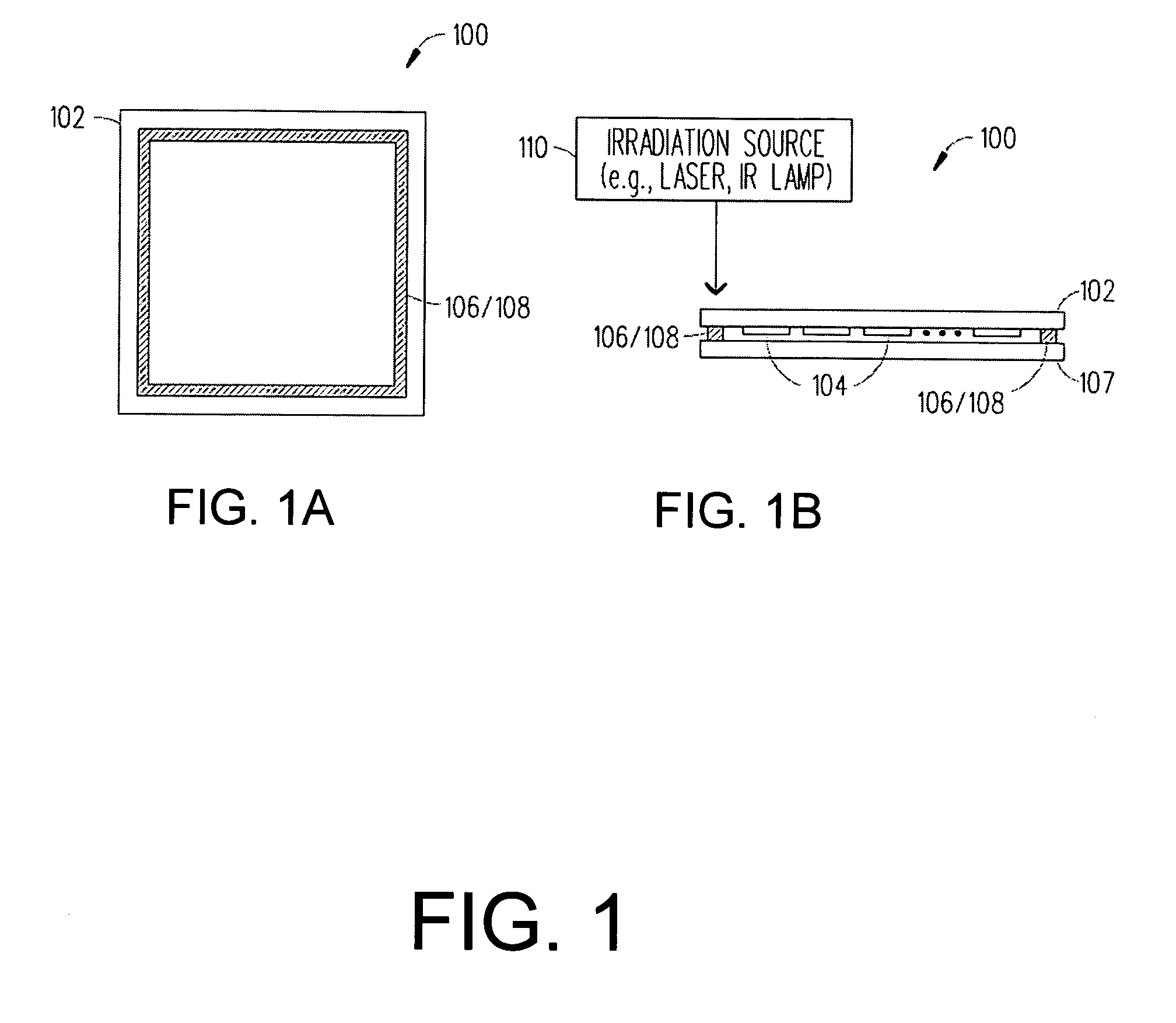

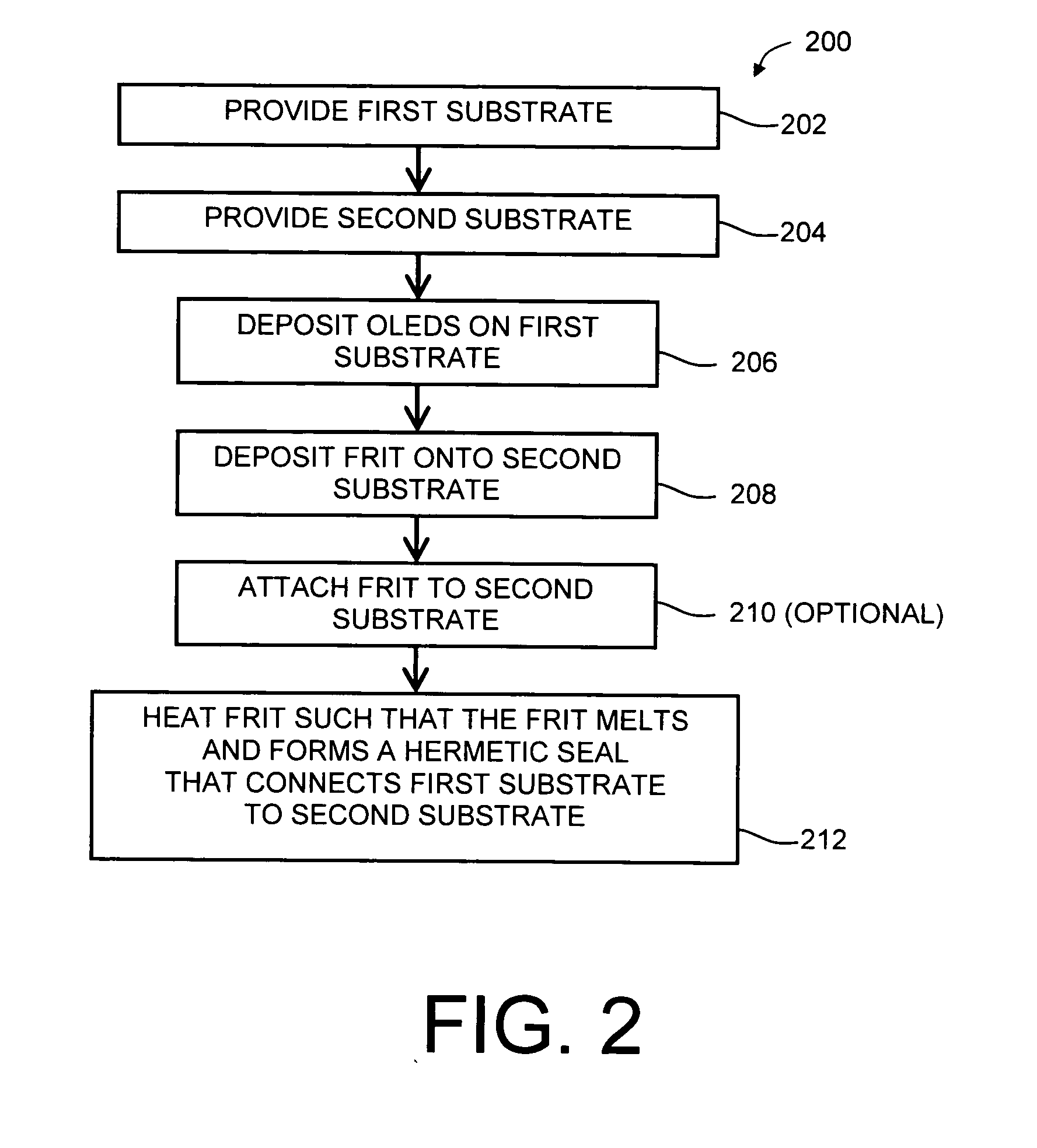

Boro-silicate glass frits for hermetic sealing of light emitting device displays

InactiveUS20080124558A1Problem be addressLamination ancillary operationsSolid-state devicesFritSilicate glass

A frit composition useful for sealing a light emitting device is disclosed. The frit composition comprises a glass portion comprising a base component and at least one absorbing component. The glass portion of the frit comprises silica, boron oxide, optionally alumina, and (a) cupric oxide and / or a (b) combination of ferric oxide, vanadium pentoxide, and optionally titanium dioxide. Also disclosed is an article comprising a substrate and a frit, and a glass package comprising two substrates and a frit positioned between the substrates. A method for manufacturing a hermetically sealed glass package comprising the deposition of a glass frit and heating of the glass frit to form a hermetic seal is also disclosed.

Owner:CORNING INC

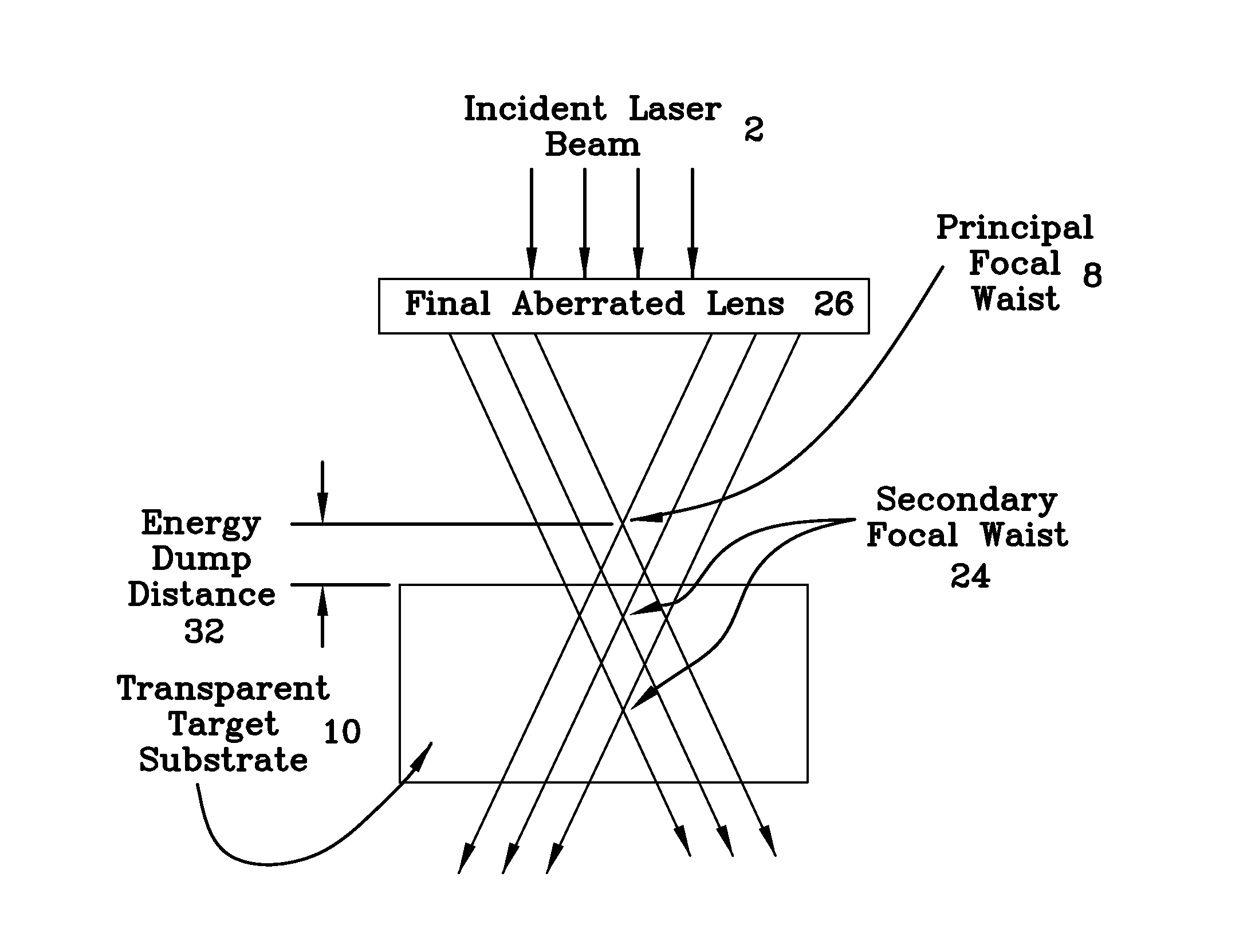

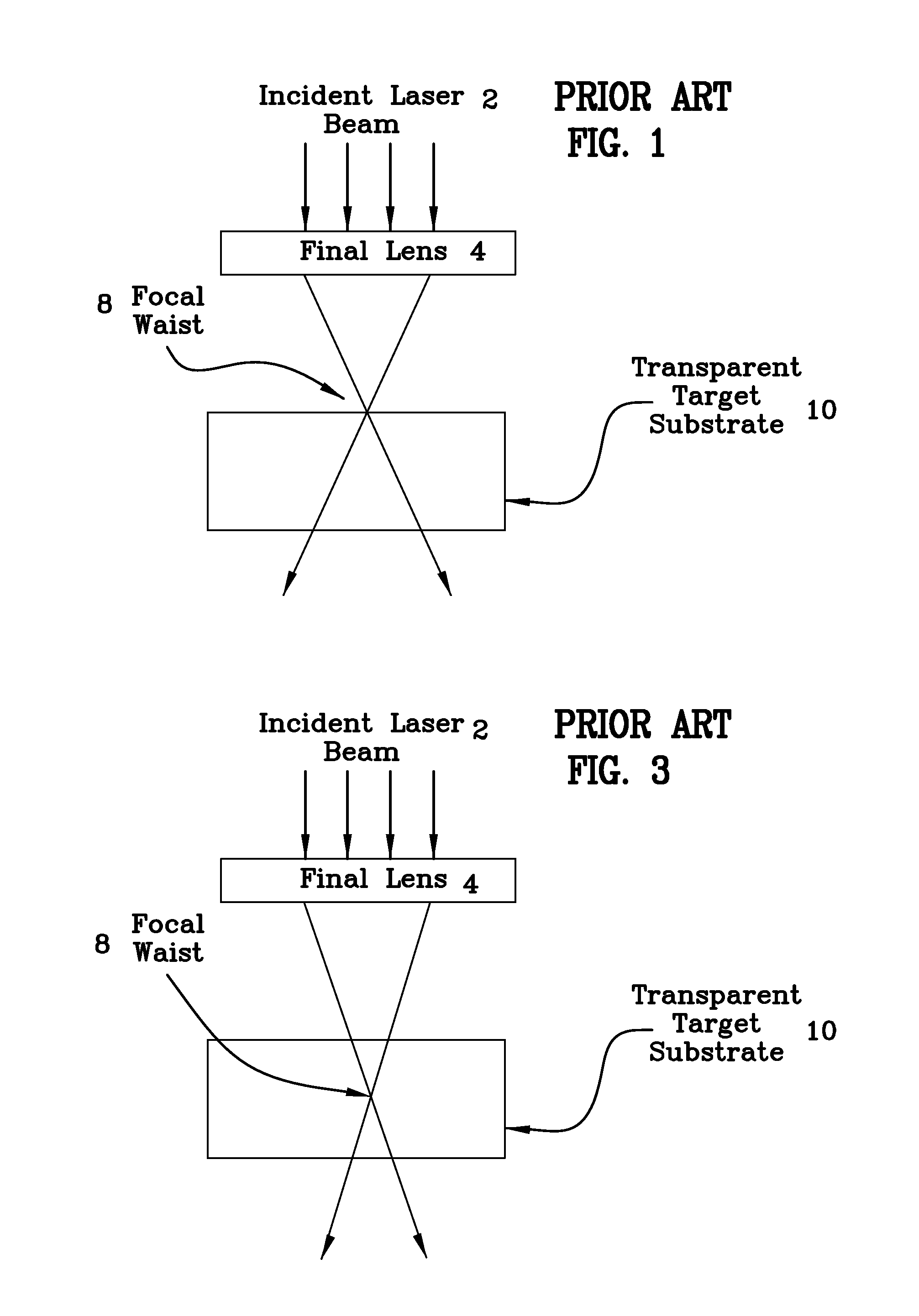

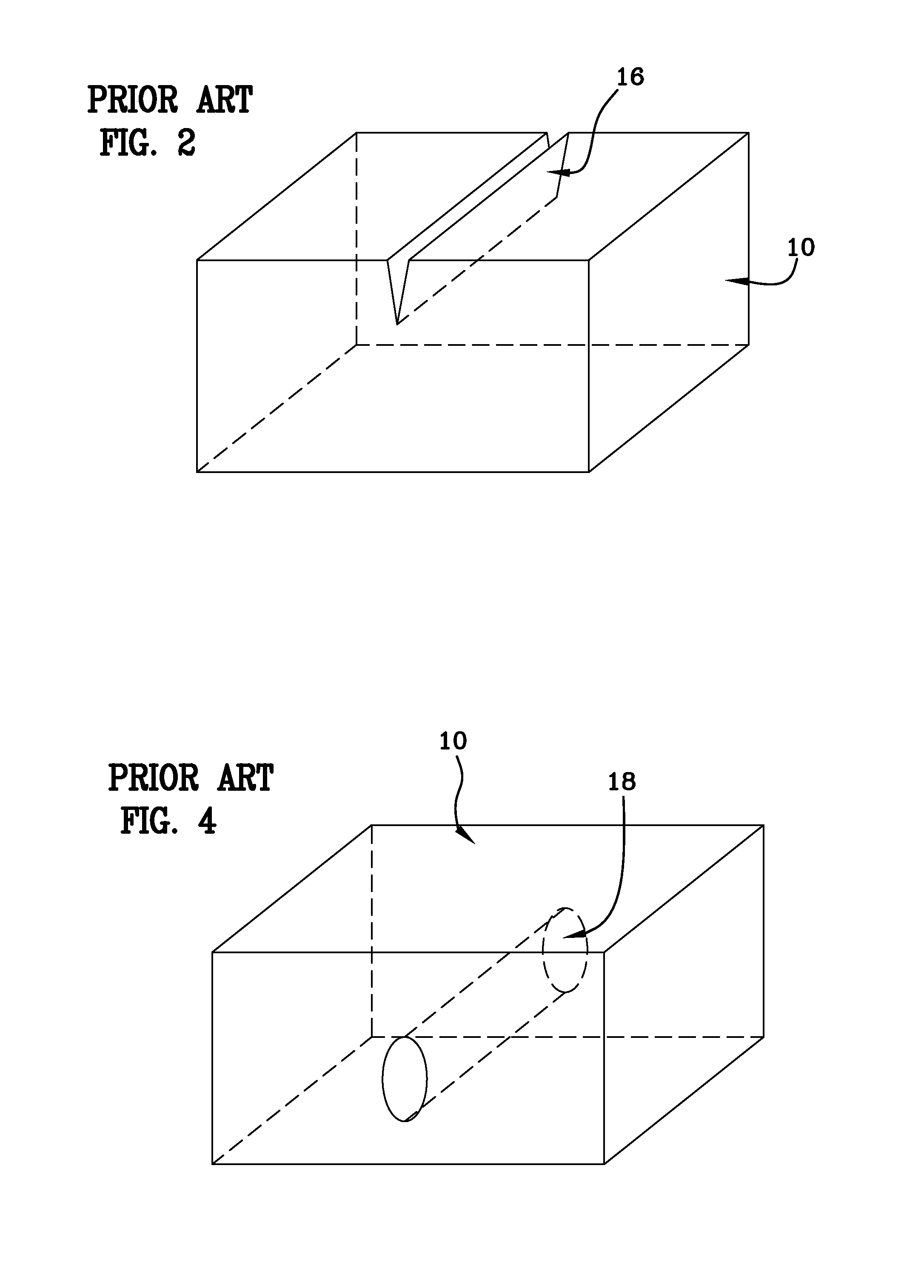

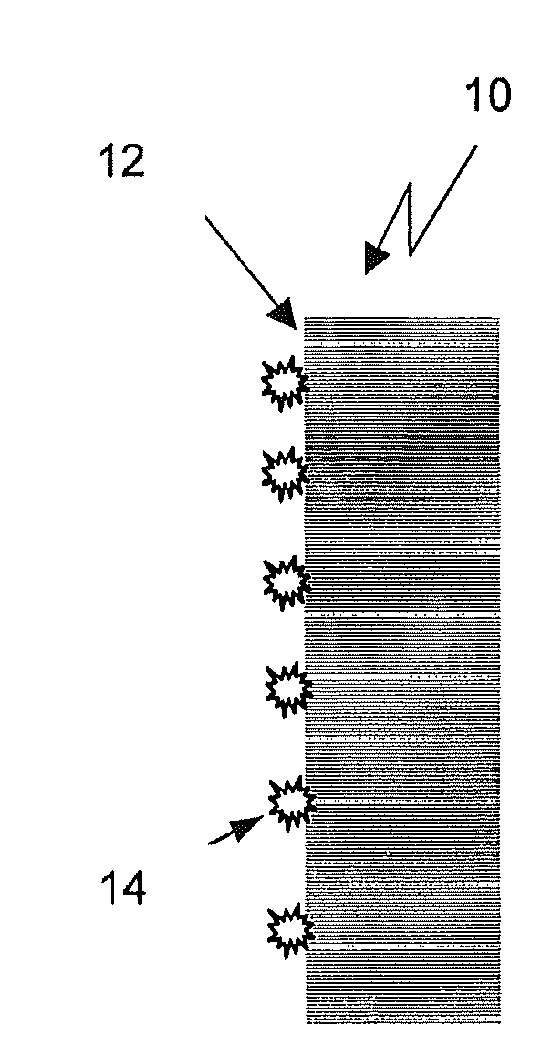

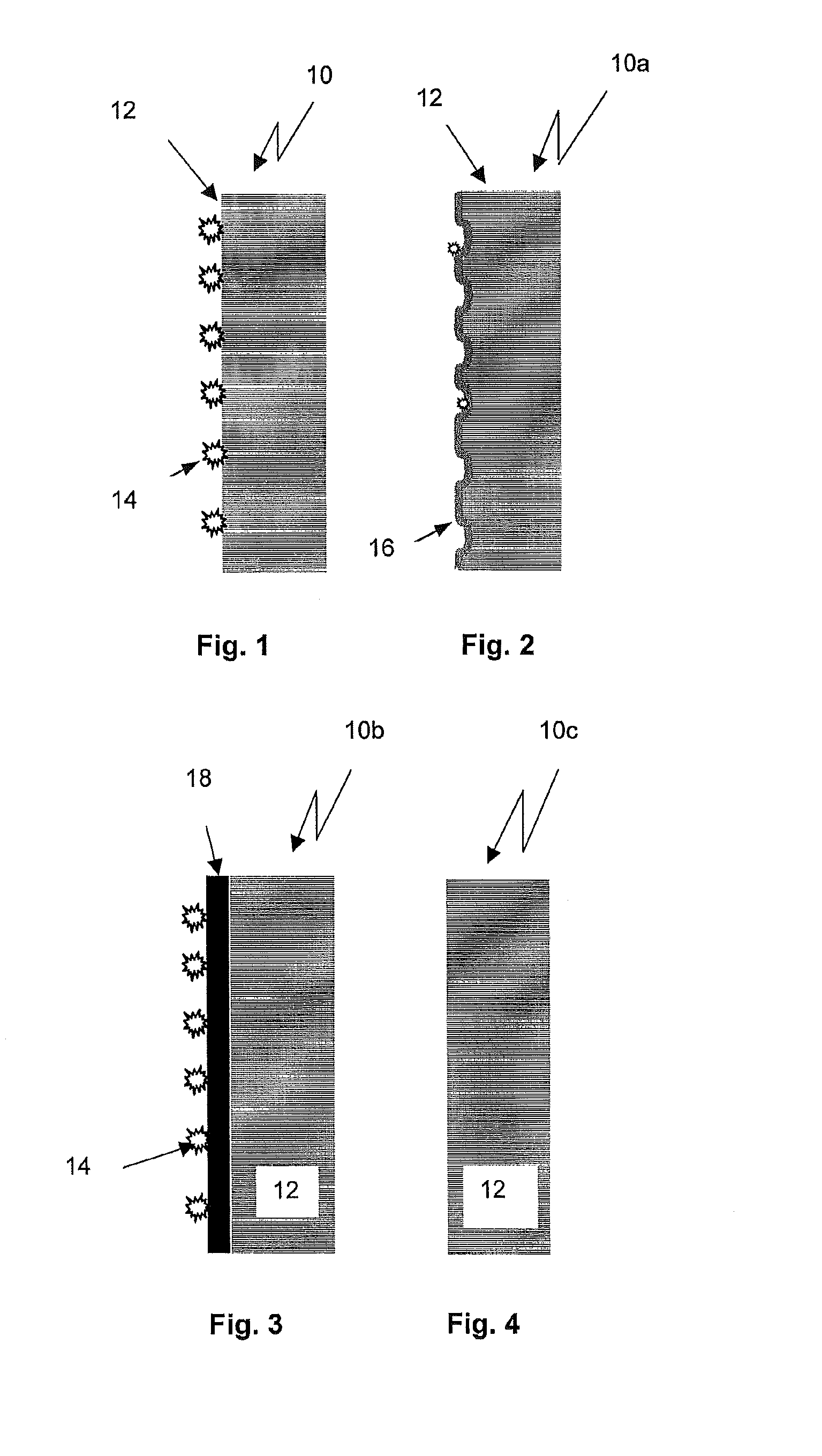

Method and apparatus for non-abaltive, photoaccoustic compression machining in transparent materials using filamentation by burst ultrafast laser pulses

ActiveUS20150034612A1Minimize distortionReduced collateral damageWelding/soldering/cutting articlesThin material handlingFilamentationLight beam

An apparatus, system and method for the processing of orifices in materials by laser filamentation that utilizes an optical configuration that focuses the incident laser light beam in a distributed manner along the longitudinal beam axis. This distributed focusing method enables the formation of filaments over distances, and the laser and focusing parameters are adjusted to determine the filament propagation and termination points so as to develop a single / double end stopped orifice, or a through orifice. Selected transparent substrates from a stacked or nested configuration may have orifices formed therein / therethrough without affecting the adjacent substrate. These distributed focusing methods support the formation filaments with lengths well beyond ten millimeters in borosilicate glass and similar brittle materials and semiconductors.

Owner:KINESTRAL TECH

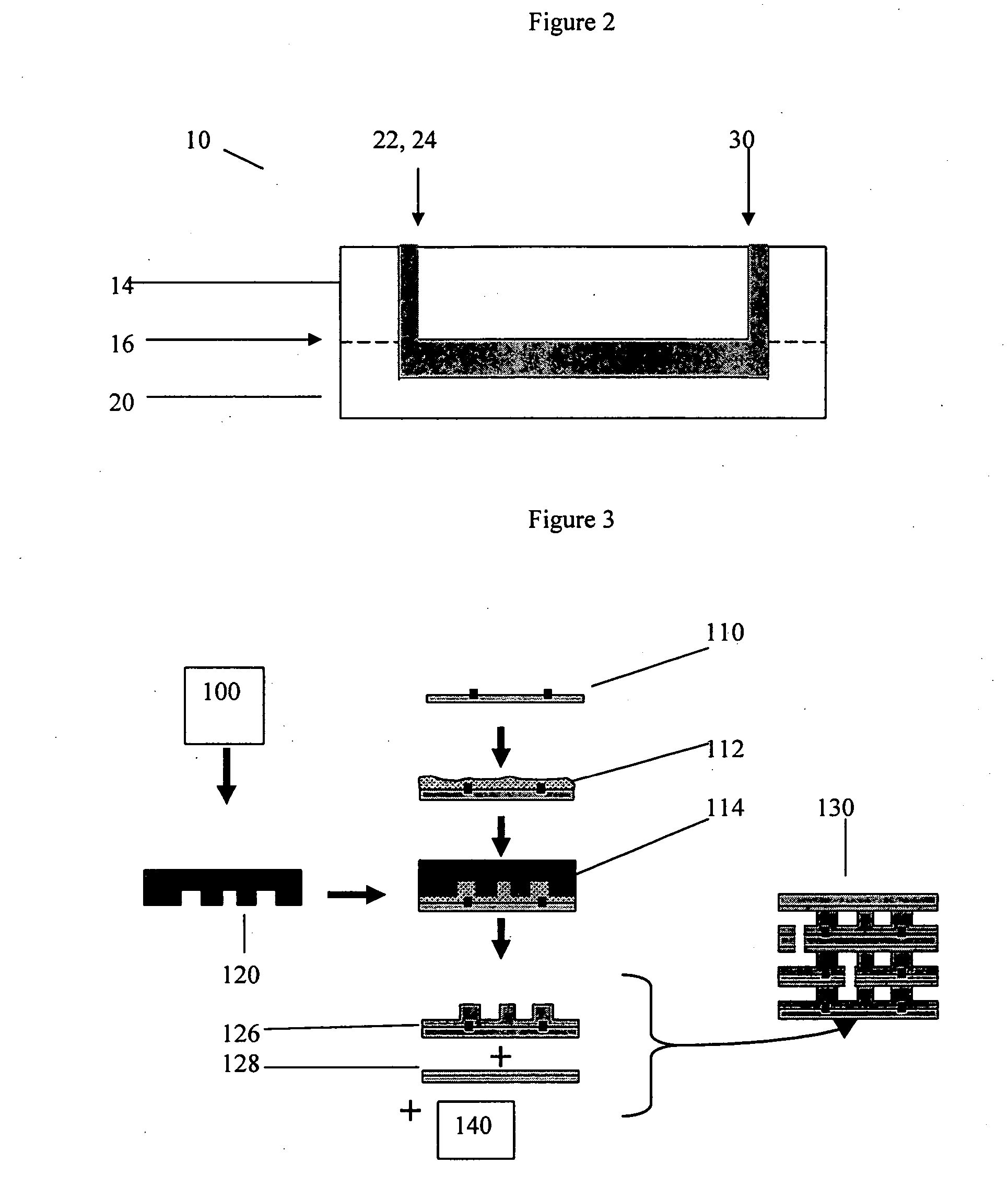

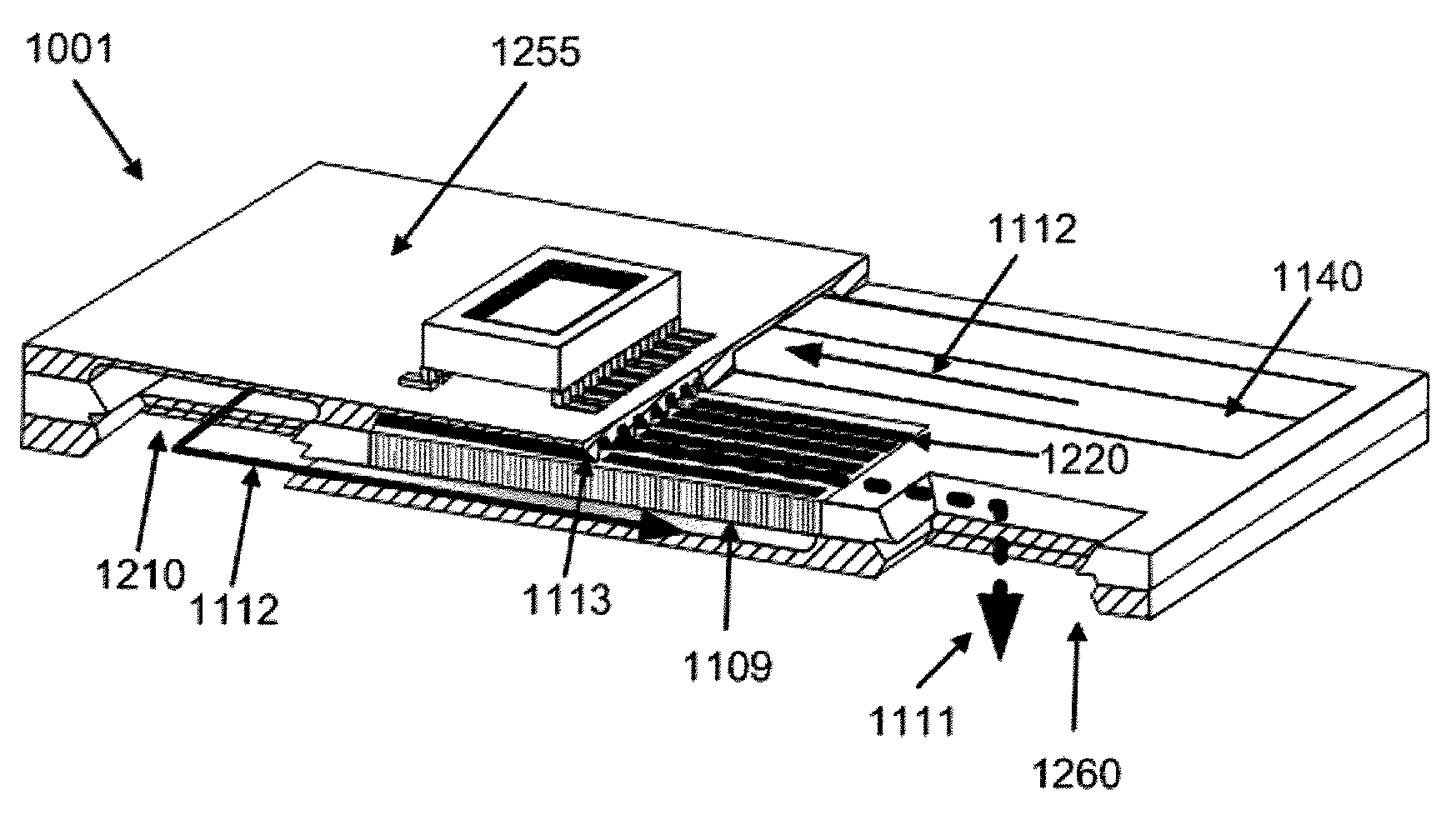

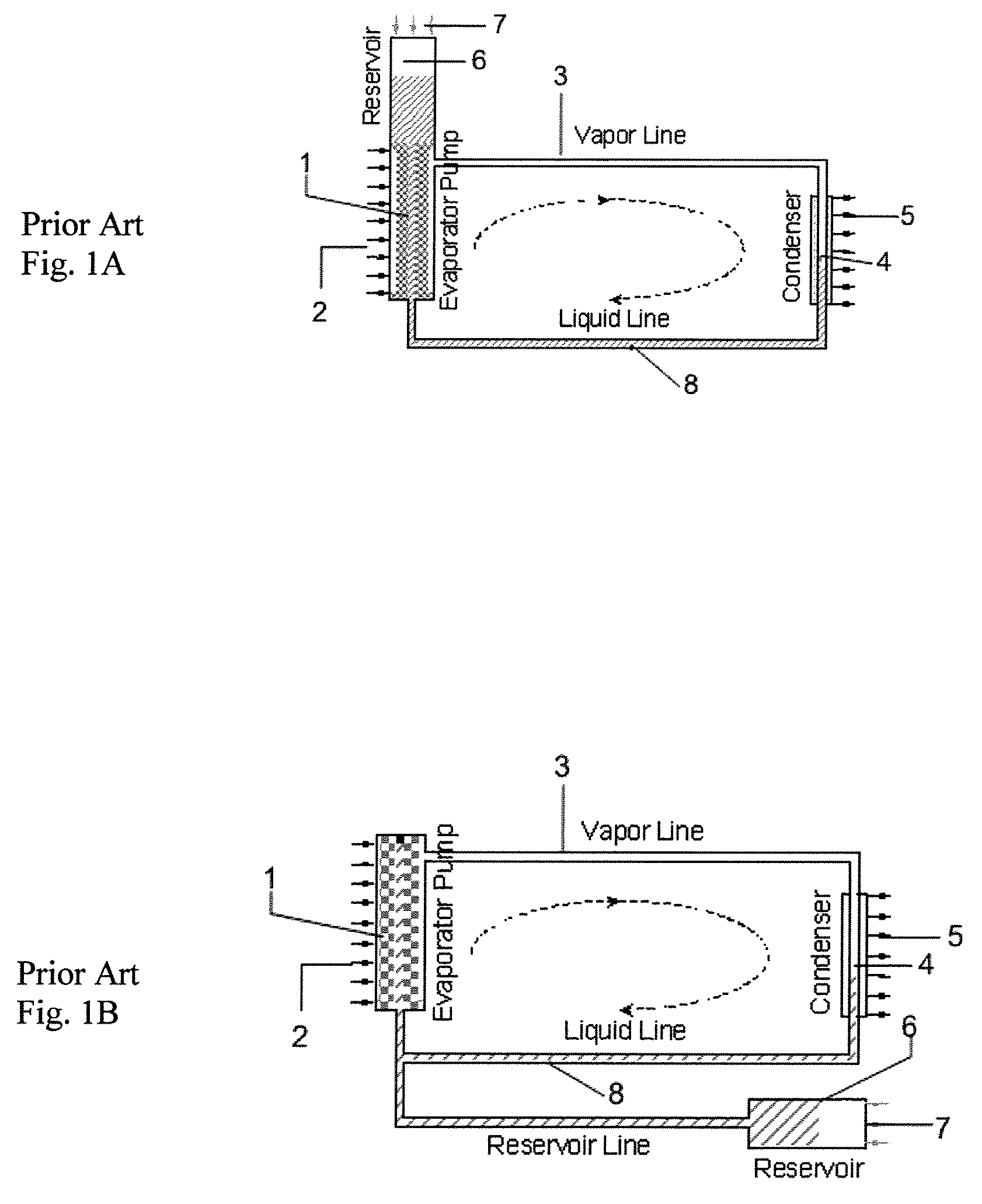

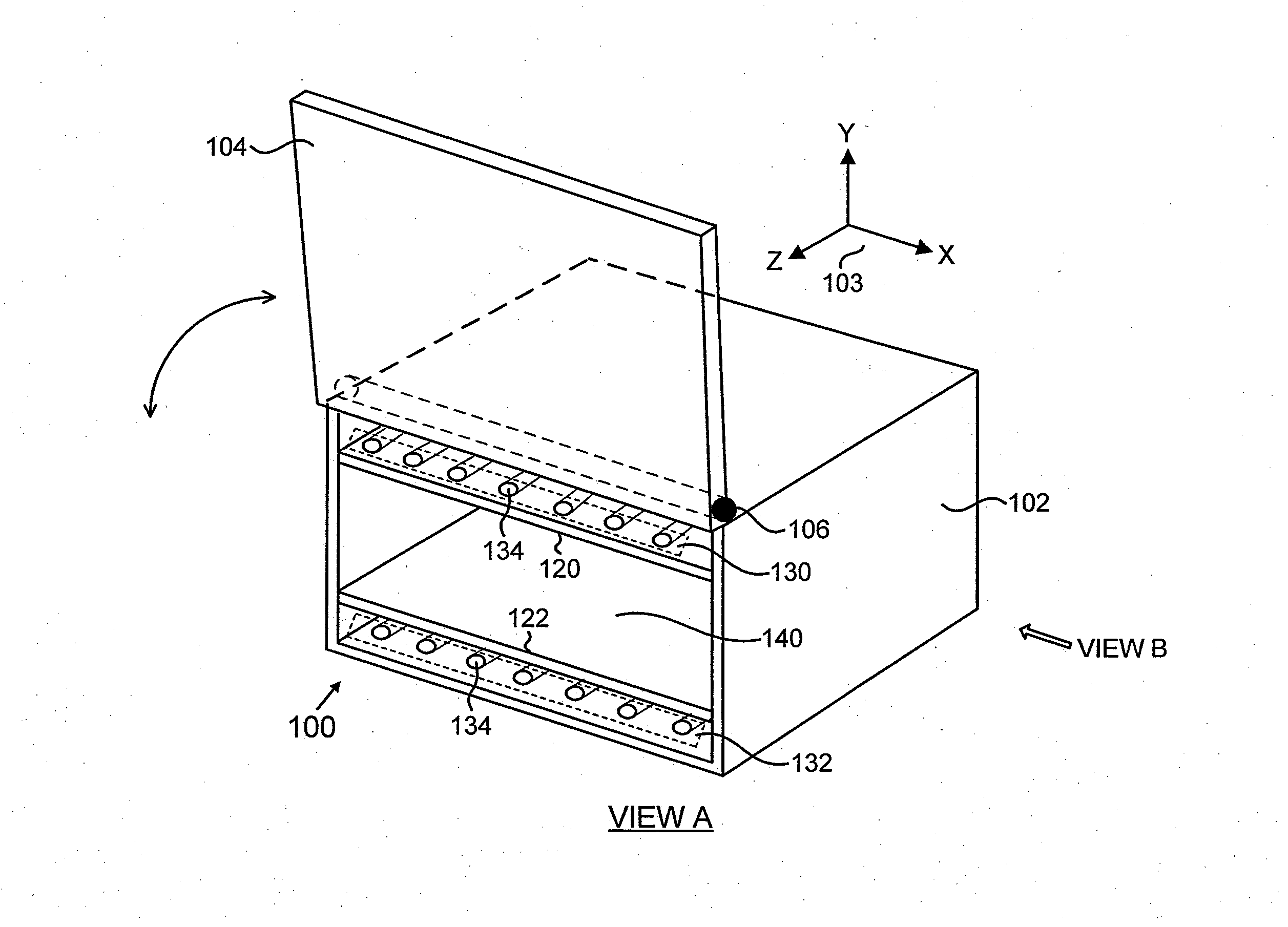

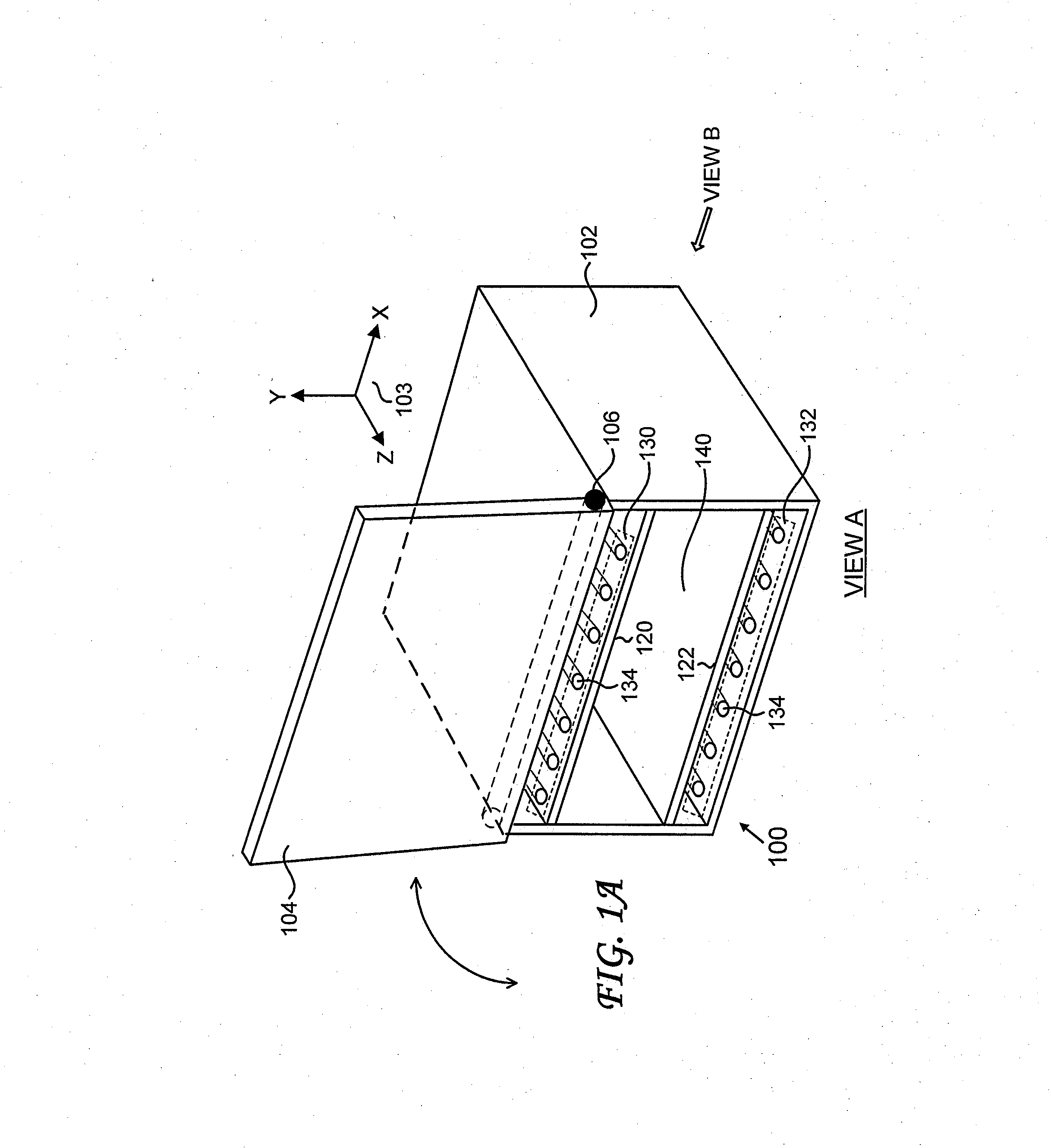

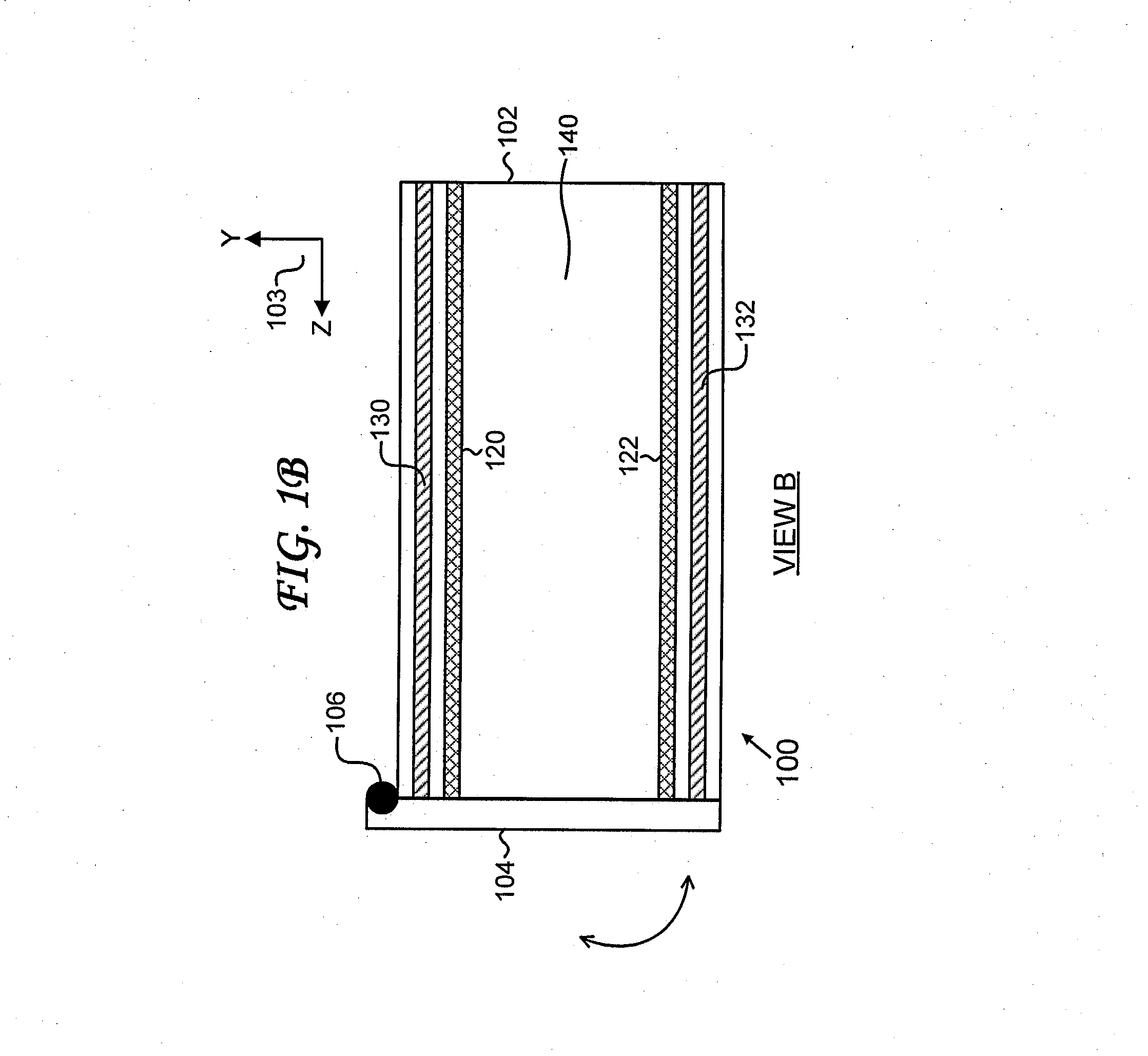

Silicon MEMS based two-phase heat transfer device

InactiveUS20070095507A1Semiconductor/solid-state device detailsSolid-state devicesMicron scaleVolumetric Mass Density

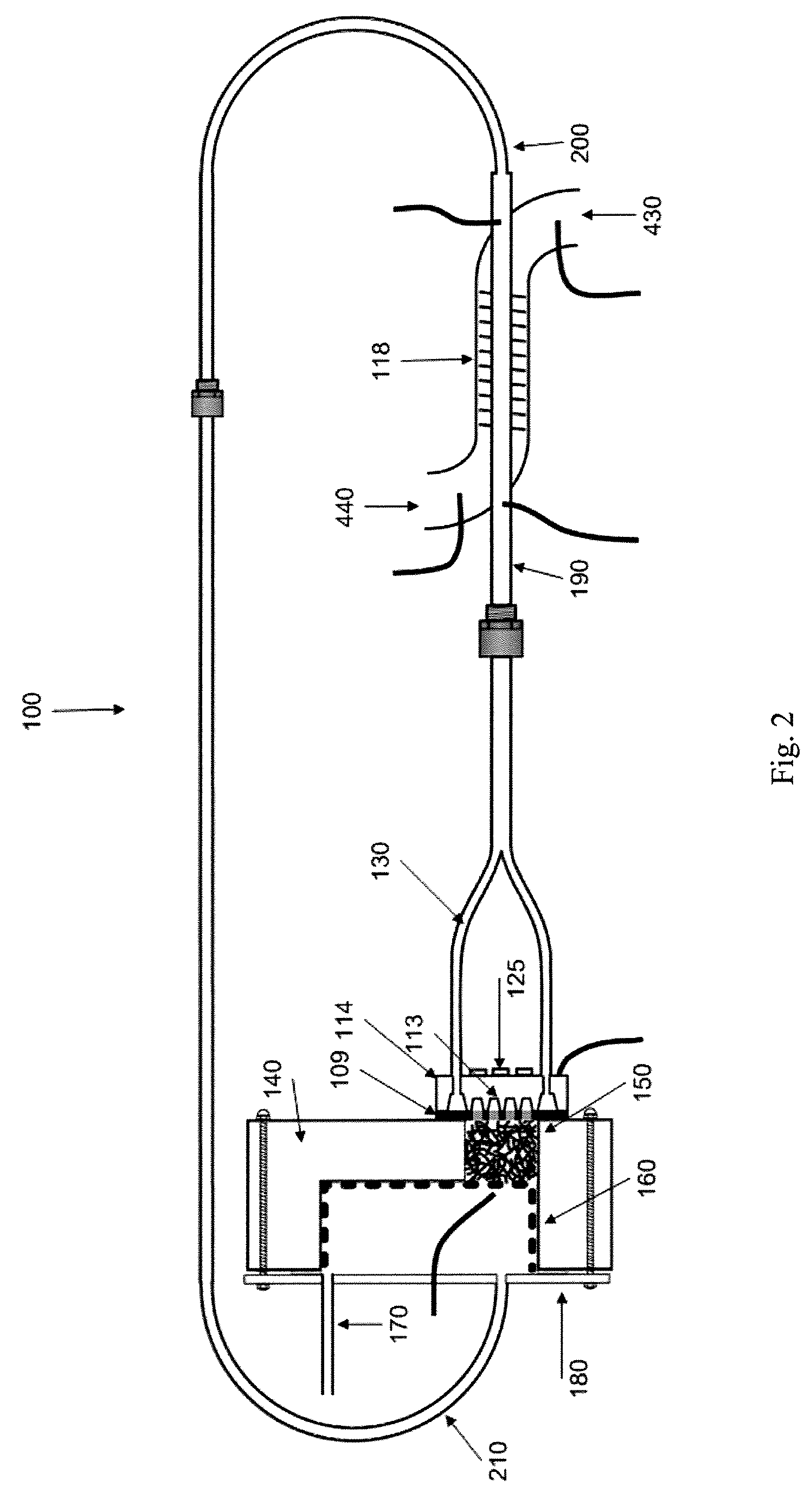

The present invention is a MEMS-based two-phase LHP (loop heat pipe) and CPL (capillary pumped loop) using semiconductor grade silicon and microlithographic / anisotrophic etching techniques to achieve a planar configuration. The principal working material is silicon (and compatible borosilicate glass where necessary), particularly compatible with the cooling needs for electronic and computer chips and package cooling. The microloop heat pipes (μLHP™) utilize cutting edge microfabrication techniques. The device has no pump or moving parts, and is capable of moving heat at high power densities, using revolutionary coherent porous silicon (CPS) wicks. The CPS wicks minimize packaging thermal mismatch stress and improves strength-to-weight ratio. Also burst-through pressures can be controlled as the diameter of the coherent pores can be controlled on a sub-micron scale. The two phase planar operation provides extremely low specific thermal resistance (20-60W / cm2). The operation is dependent upon a unique micropatterened CPS wick which contains up to millions per square centimeter of stacked uniform micro-through-capillaries in semiconductor-grade silicon, which serve as the capillary “engine,” as opposed to the stochastic distribution of pores in the typical heat pipe wick. As with all heat pipes, cooling occurs by virtue of the extraction of heat by the latent heat of phase change of the operating fluid into vapor. In the cooling of a laptop computer processor the device could be attached to the processor during laptop assembly. Consistent with efforts to miniaturize electronics components, the current invention can be directly integrated with a unpackaged chip. For applications requiring larger cooling surface areas, the planar evaporators can be spread out in a matrix and integrally connected through properly sized manifold systems.

Owner:UNIVERSITY OF CINCINNATI

Water based environmental barrier coatings for high temperature ceramic components

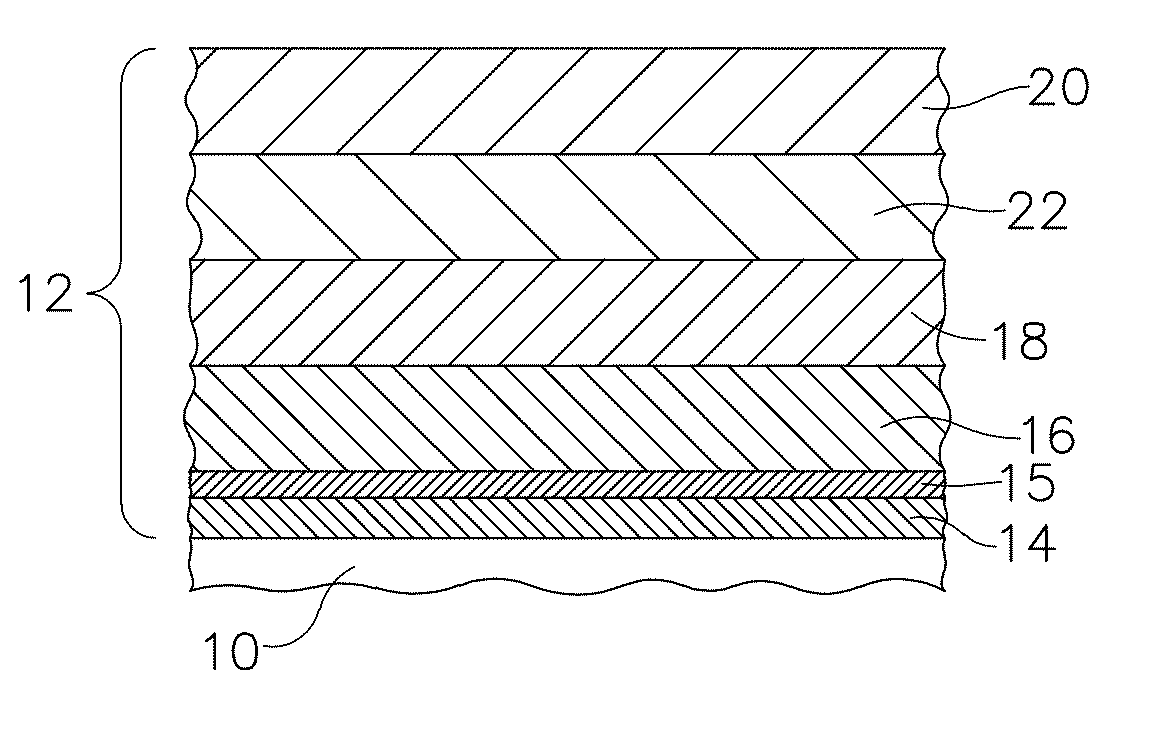

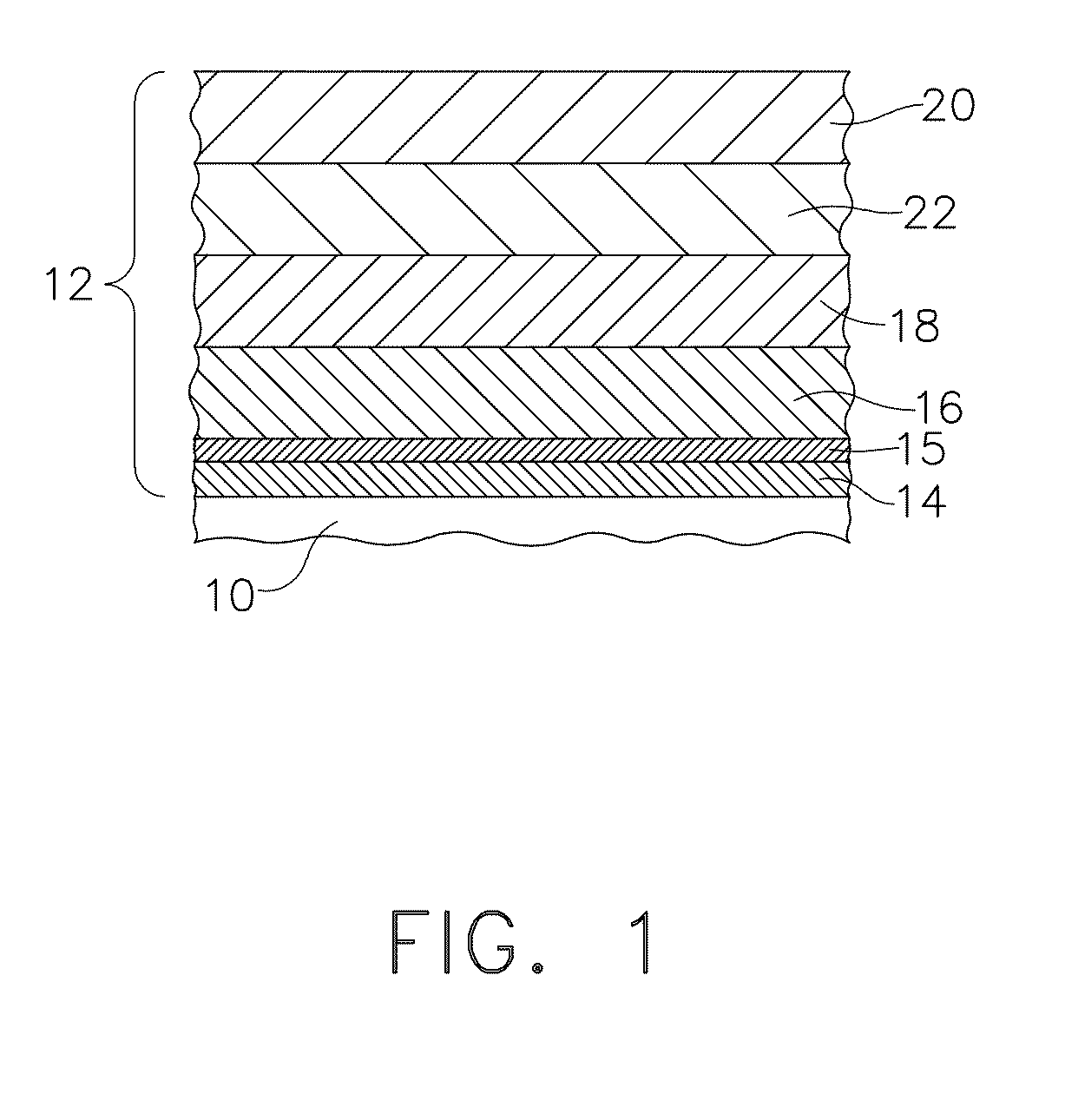

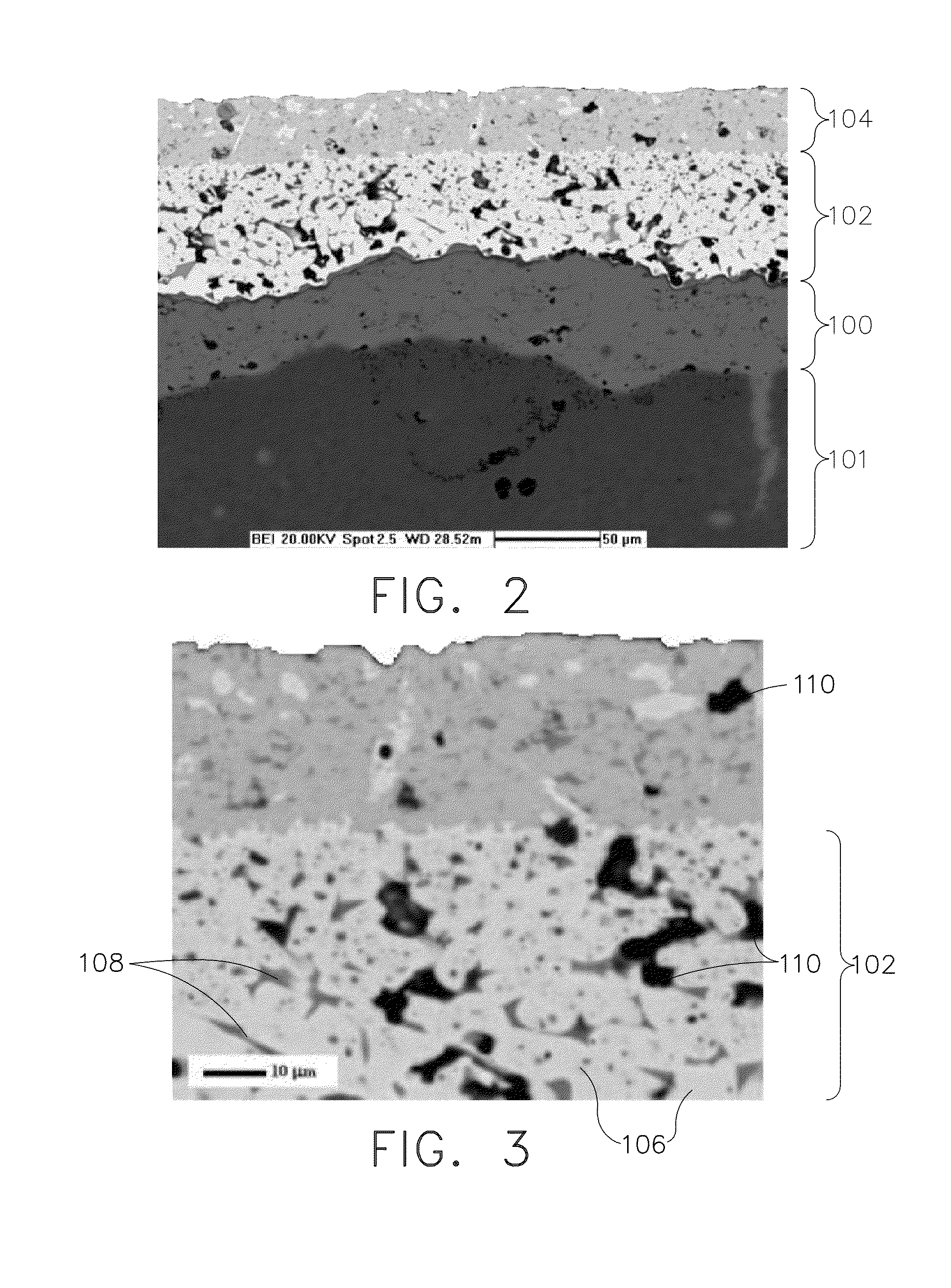

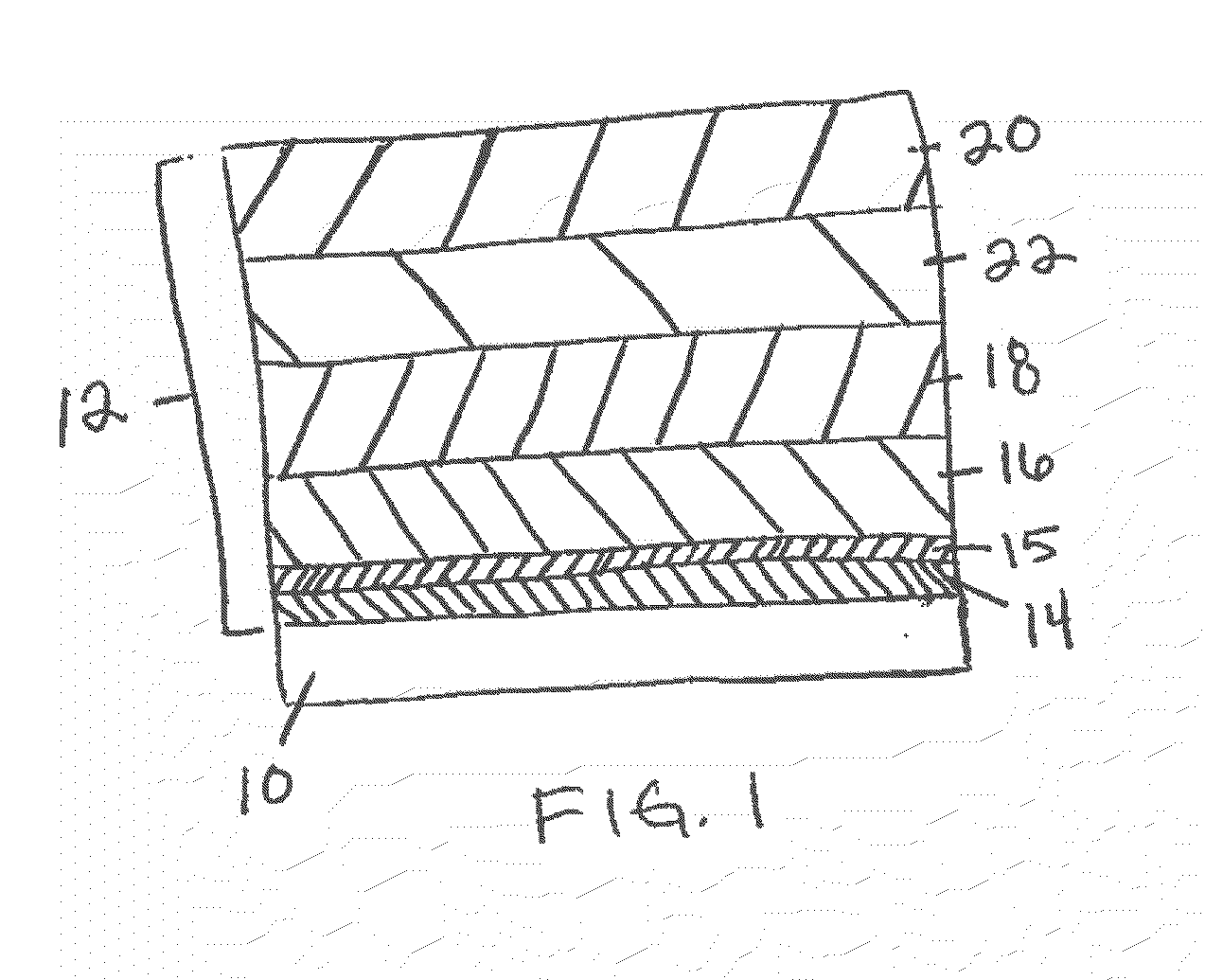

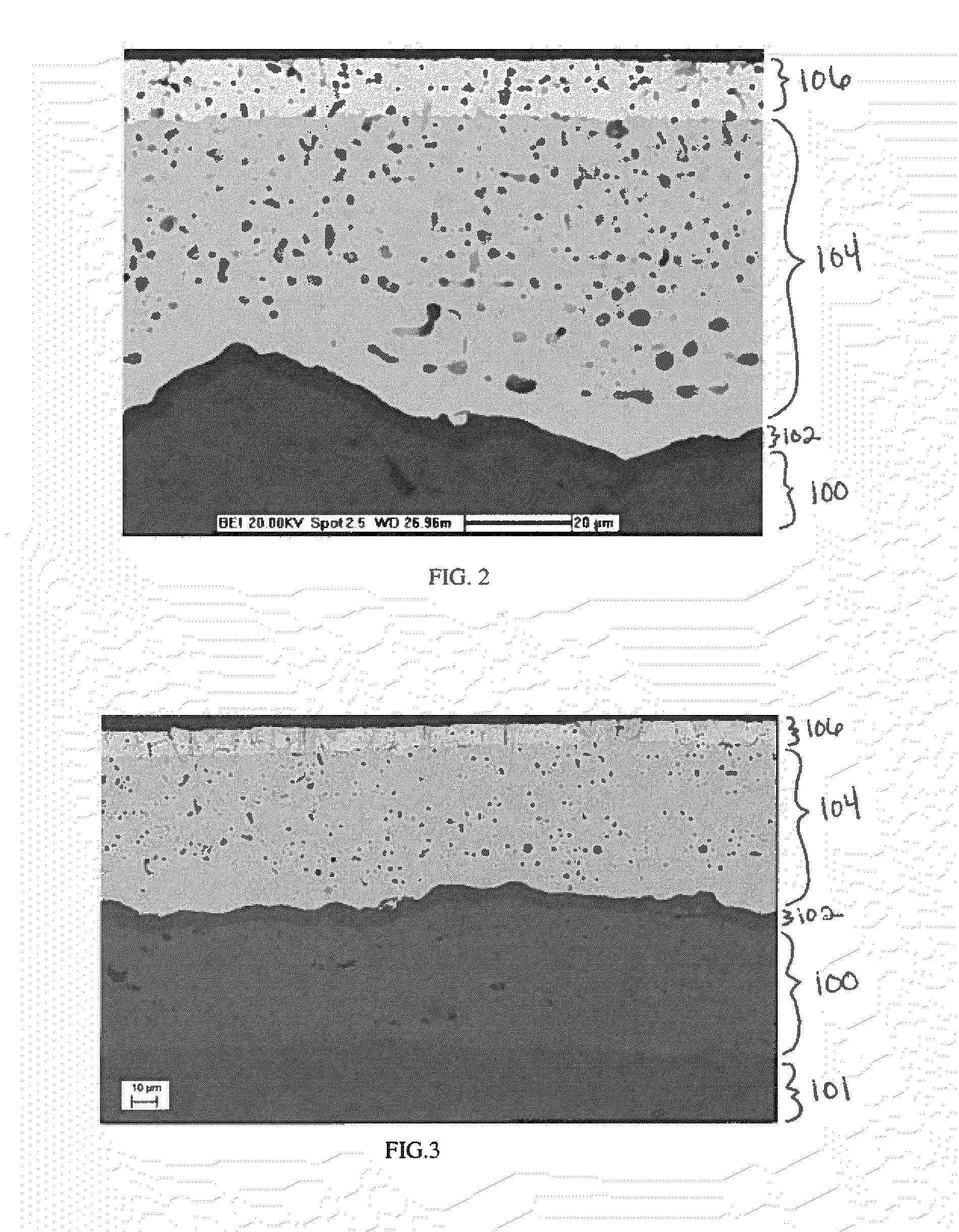

Environmental barrier coatings for high temperature ceramic components including: a bond coat layer; an optional silica layer; and at least one transition layer including: from about 85% to about 100% by volume of the transition layer of a primary transition material selected from a rare earth disilicate, or a doped rare earth disilicate; and from 0% to about 15% by volume of the transition layer of a secondary material selected from Fe2O3, iron silicates, rare earth iron oxides, Al2O3, mullite, rare earth aluminates, rare earth aluminosilicates, TiO2, rare earth titanates, Ga2O3, rare earth gallates, NiO, nickel silicates, rare earth nickel oxides, Lnb metals, Lnb2O3, Lnb2Si2O7, Lnb2SiO5, borosilicate glass, alkaline earth silicates, alkaline earth rare earth oxides, alkaline earth rare earth silicates, and mixtures thereof; where the transition layer is applied to the component as a slurry including at least water, the primary transition material and at least one slurry sintering aid, and where a reaction between the slurry sintering aid and the primary transition material results in the transition layer having a porosity of from 0% to about 15% by volume of the transition layer.

Owner:GENERAL ELECTRIC CO

Aluminum-free borosilicate glass and applications thereof

InactiveUS20070004580A1Maintain good propertiesGood chemical resistanceSolid cathode detailsGas discharge lamp detailsThermal expansionTitanium alloy

Owner:SCHOTT AG

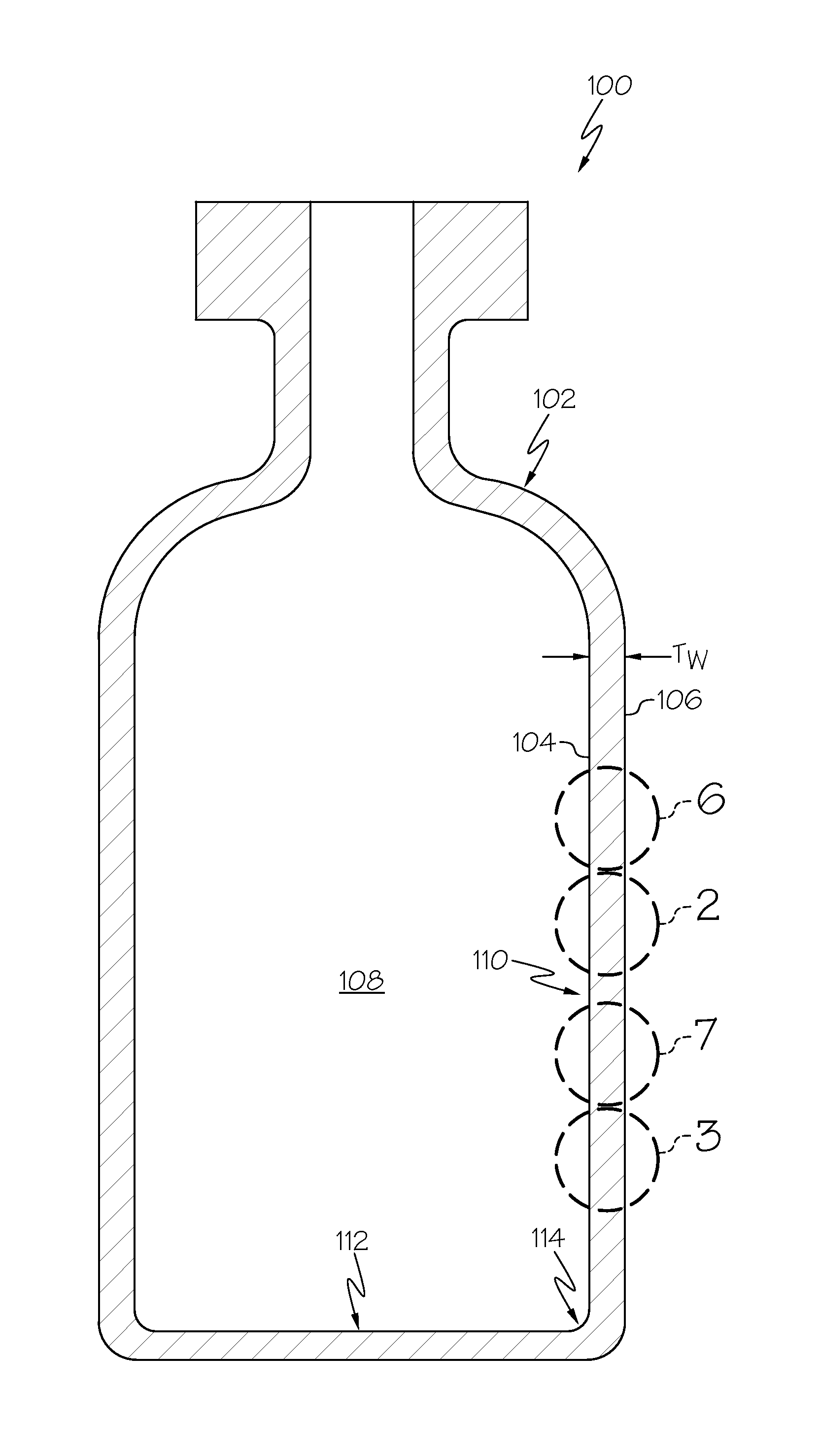

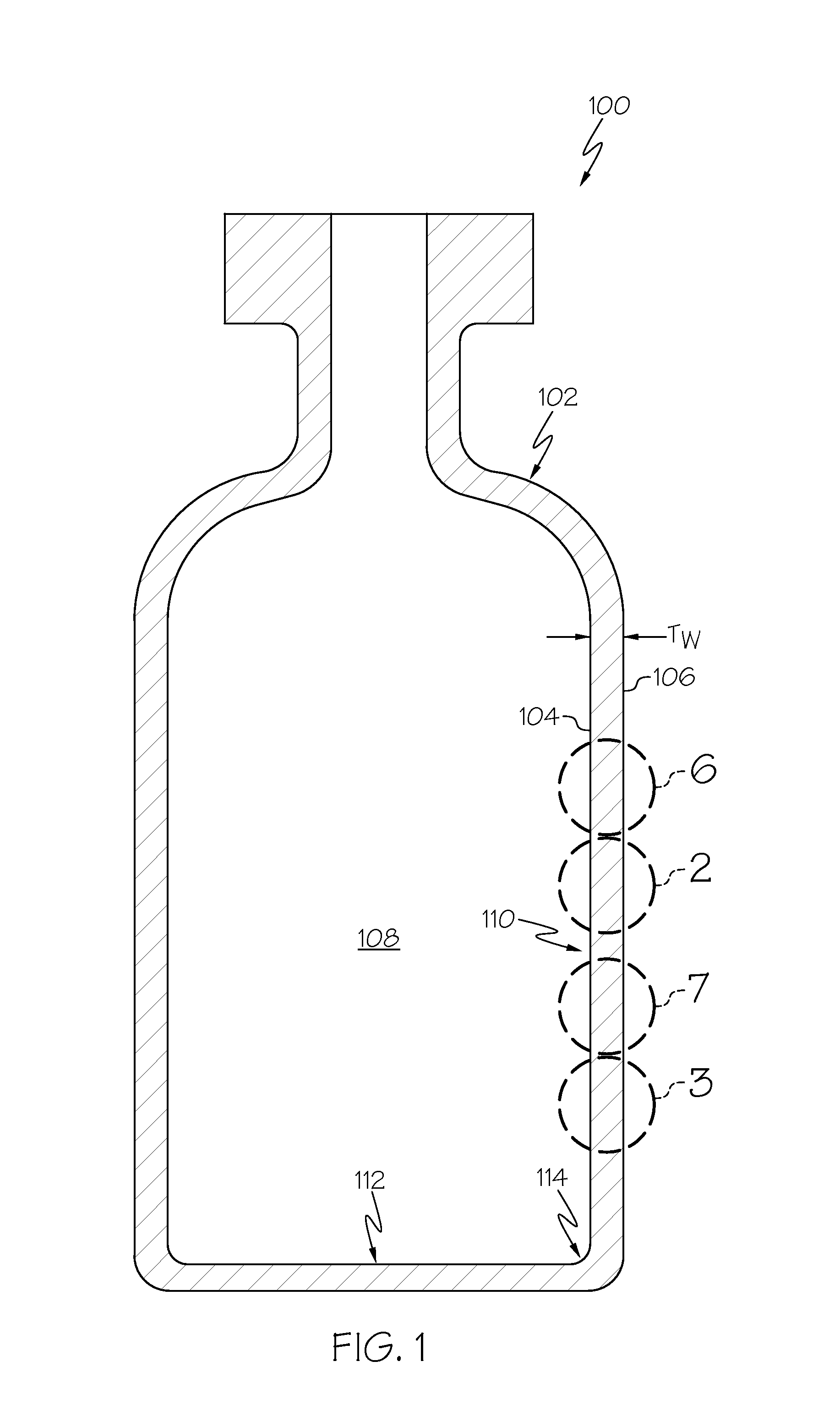

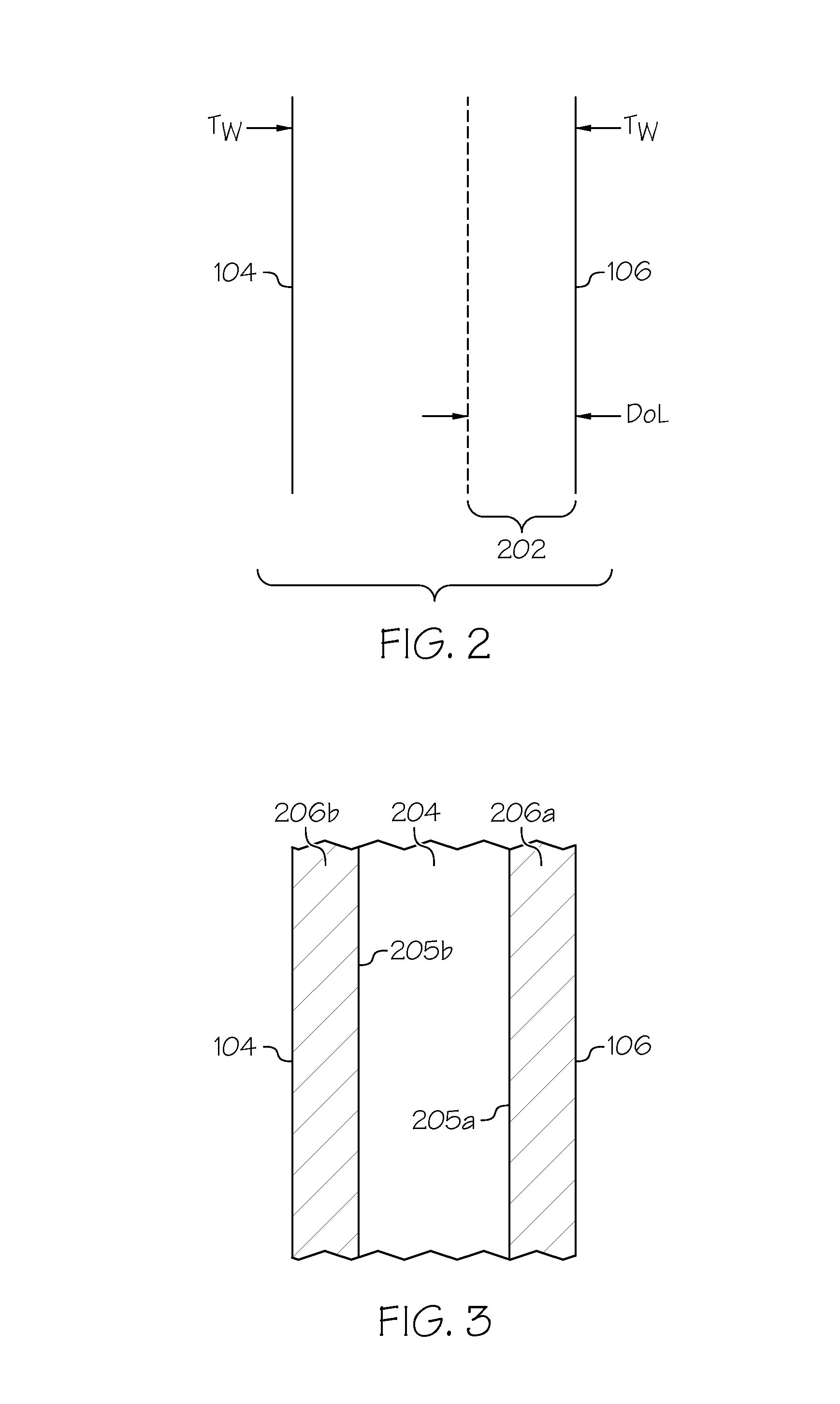

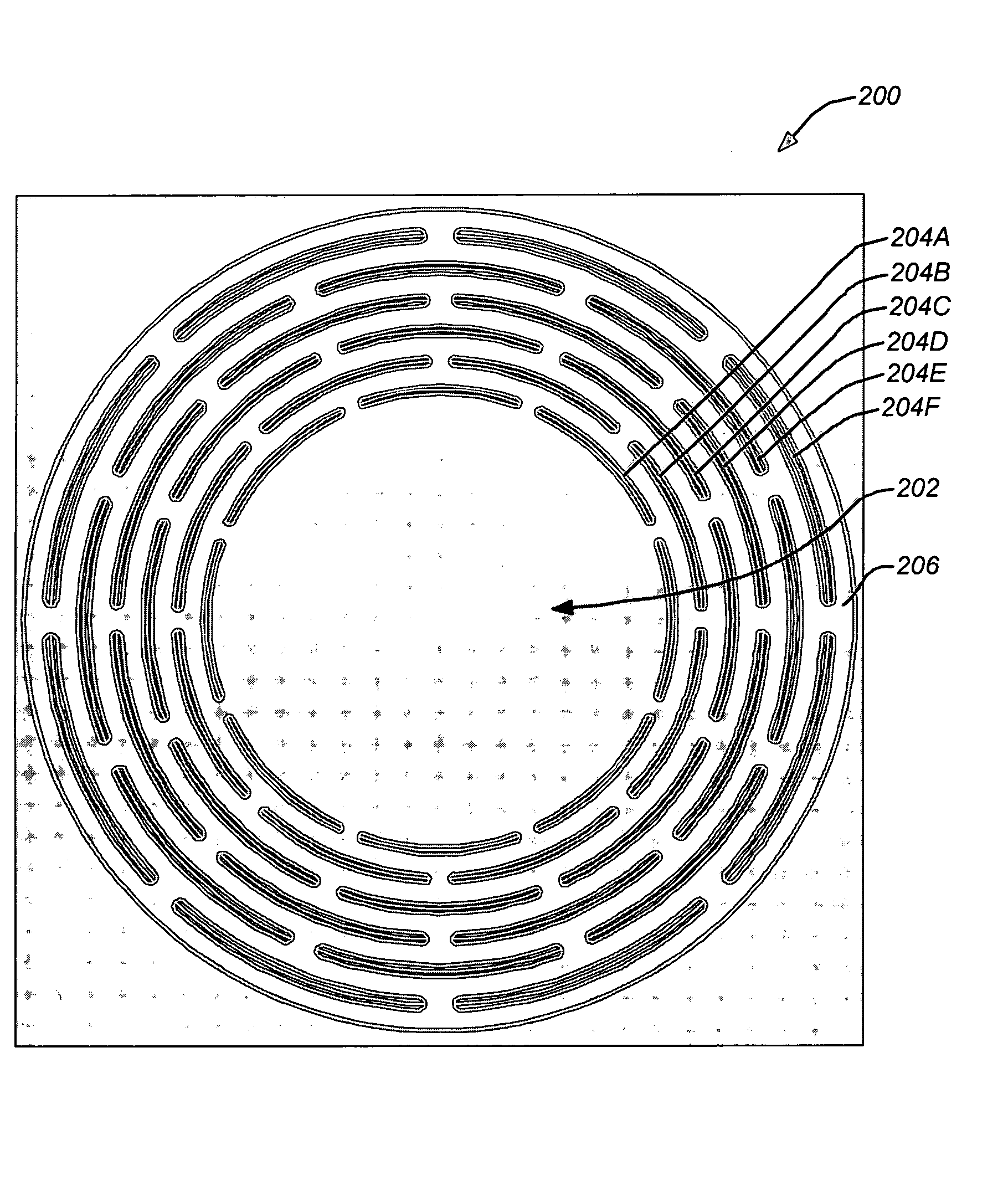

Strengthened borosilicate glass containers with improved damage tolerance

According to one embodiment, a glass container may include a body formed from a Type I, Class B glass composition according to ASTM Standard E438-92. The body may have an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. The body may also include a compressively stressed layer extending into the wall thickness from at least one of the outer surface and the inner surface. A lubricous coating may be positioned on at least a portion of the outer surface of the body, wherein the outer surface of the body with the lubricous coating has a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

Isolated planar mesogyroscope

ActiveUS20050172714A1Reduce frequencyEffect of errorAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsIn planeThermal expansion

An inertial sensor includes a mesoscaled disc resonator comprised of micro-machined substantially thermally non-conductive wafer with low coefficient of thermal expansion for sensing substantially in-plane vibration, a rigid support coupled to the resonator at a central mounting point of the resonator, at least one excitation electrode within an interior of the resonator to excite internal in-plane vibration of the resonator, and at least one sensing electrode within the interior of the resonator for sensing the internal in-plane vibration of the resonator. The inertial sensor is fabricated by etching a baseplate, bonding the substantially thermally non-conductive wafer to the etched baseplate, through-etching the wafer using deep reactive ion etching to form the resonator, depositing a thin conductive film on the through-etched wafer. The substantially thermally non-conductive wafer may comprise a silicon dioxide glass wafer, which is a silica glass wafer or a borosilicate glass wafer, or a silicon-germanium wafer.

Owner:CALIFORNIA INST OF TECH +1

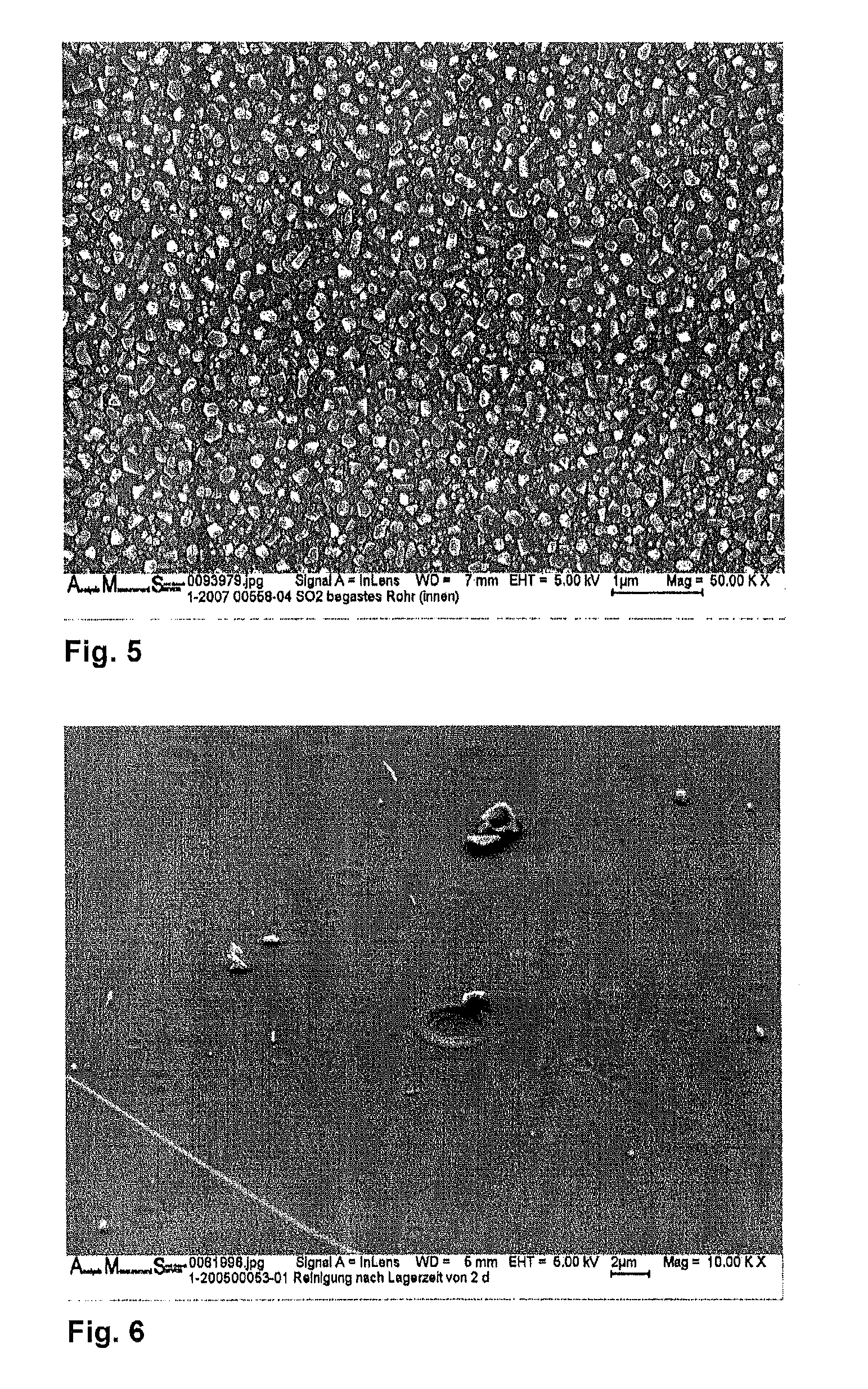

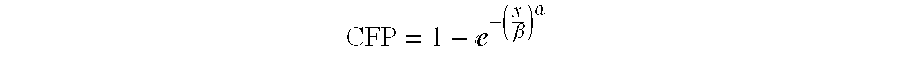

Method for the production of pharmaceutical packaging

InactiveUS20100089097A1Increased susceptibilityDeterioration of surface qualityGlass drawing apparatusGlass reforming apparatusRoom temperatureMedical product

The invention discloses a method for the production of packaging made from borosilicate glass for pharmaceutical products and medical products comprising the steps of: providing a glass tube made from a borosilicate base glass, generating a temporary interface layer on an inner surface of the glass tube, hot-forming the glass tube at a temperature above Tg, and cooling down the glass tube to room temperature.

Owner:SCHOTT AG

Flat panel liquid-crystal display such as for a laptop computer

InactiveUS6867158B2Improve heat resistanceFavorable processing rangeSemiconductor devicesHigh resistanceAlkali free

Flat panel liquid-crystal displays, such as for laptop computers. The displays include twisted nematic displays, supertwisted nematic displays, active matrix liquid-crystal displays, thin film transistor displays, and plasma addressed liquid-crystal displays. The displays are furnished with glass substrates. The glass substrates exhibit high resistance to thermal shock, a high transparency over a broad spectral range in the visible and ultra violet ranges and the glass being configured to be free of bubbles, knots, inclusions, streaks, and surface undulations, which glass substrates are made from alkali-free aluminoborosilicate glasses. There are also provided analogous thin-film photovoltaics.

Owner:SCHOTT AG

Method of making amber glass composition having low thermal expansion

InactiveUS20050061033A1Low thermal expansionAdequate ultraviolet filtrationGlass furnace apparatusSilicate glassThermal expansion

A method of making an amber borosilicate glass having a thermal expansion coefficient which ranges from 29×10−7 cm / cm / ° C. to 48×10−7 cm / cm / °C. having the steps of: forming a substantially homogeneous melt comprising, in weight %, 70.0-80.0% SiO2; 10.0-15.0% B2O3; 1.0-5.0% Al2O3; 0.0-7.0% Na2O; 0.0-8.0% K2O; 0.1-2.0% Fe2O3; 0.1-5.0% TiO2; 0.0-4.0% CaO; 0.0-4.0% MgO; 0.0-4.0% BaO and SrO combined; 0.0-1.0% ZnO; 0.0-1.0% Cl2; 0.0-1.0% F2; and 0.0-1.0% ZrO2; refining the melt to remove substantially all gas bubbles from the melt; and cooling the melt to form amber glass. The amber glass formed according to the method of the present invention meets both the hydrolytic resistance requirements and light protection requirements for Type I glass in accordance with USP containers.

Owner:ALCAN PACKAGING PHARMA & PERSONAL CARE

Alkali-free aluminoborosilicate glasses for lighting means with external or internal contacting

InactiveUS20090129061A1Improve machinabilityGlass transformationDischarge tube luminescnet screensLamp detailsAlkali freeSilicate glass

Owner:SCHOTT AG

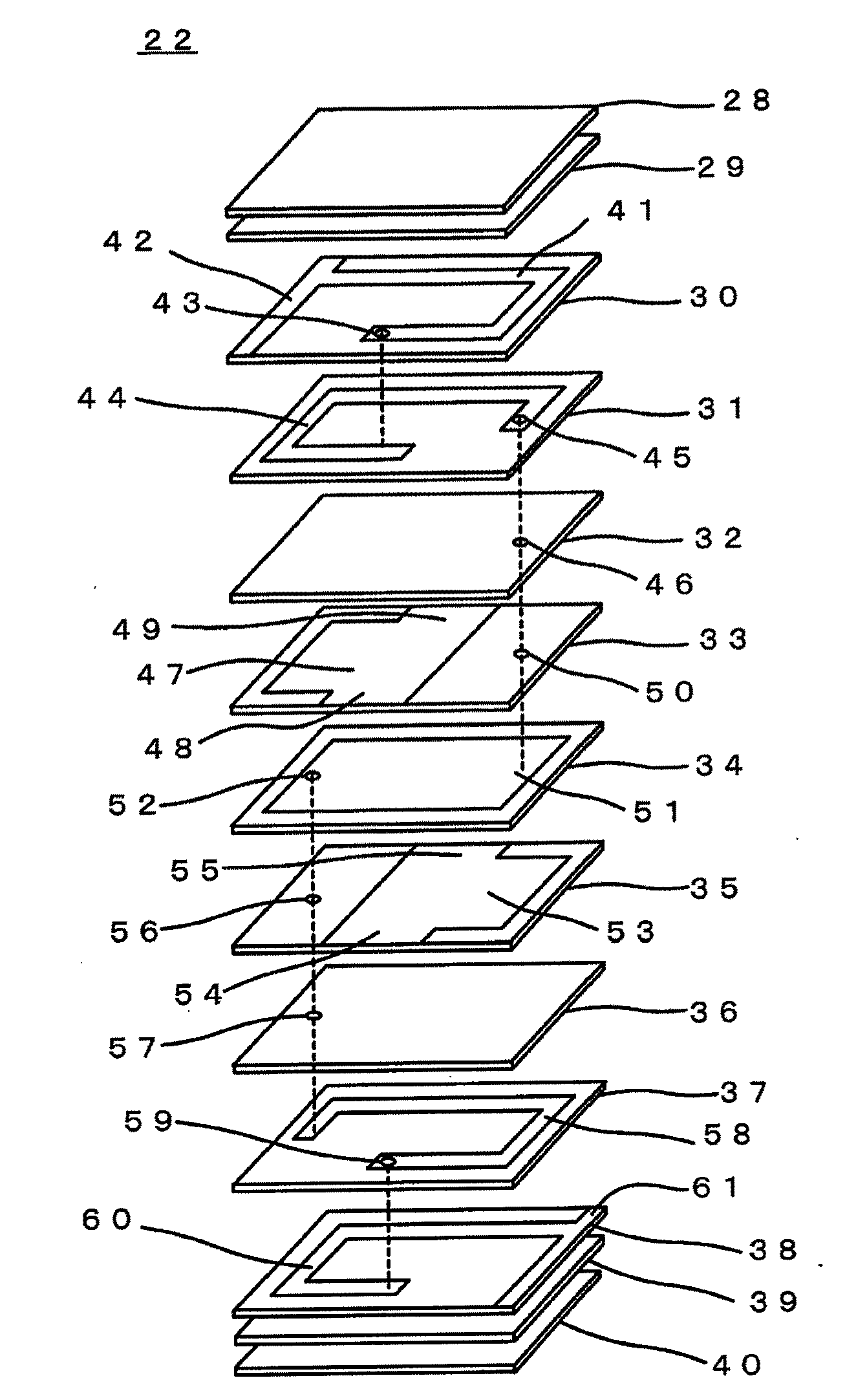

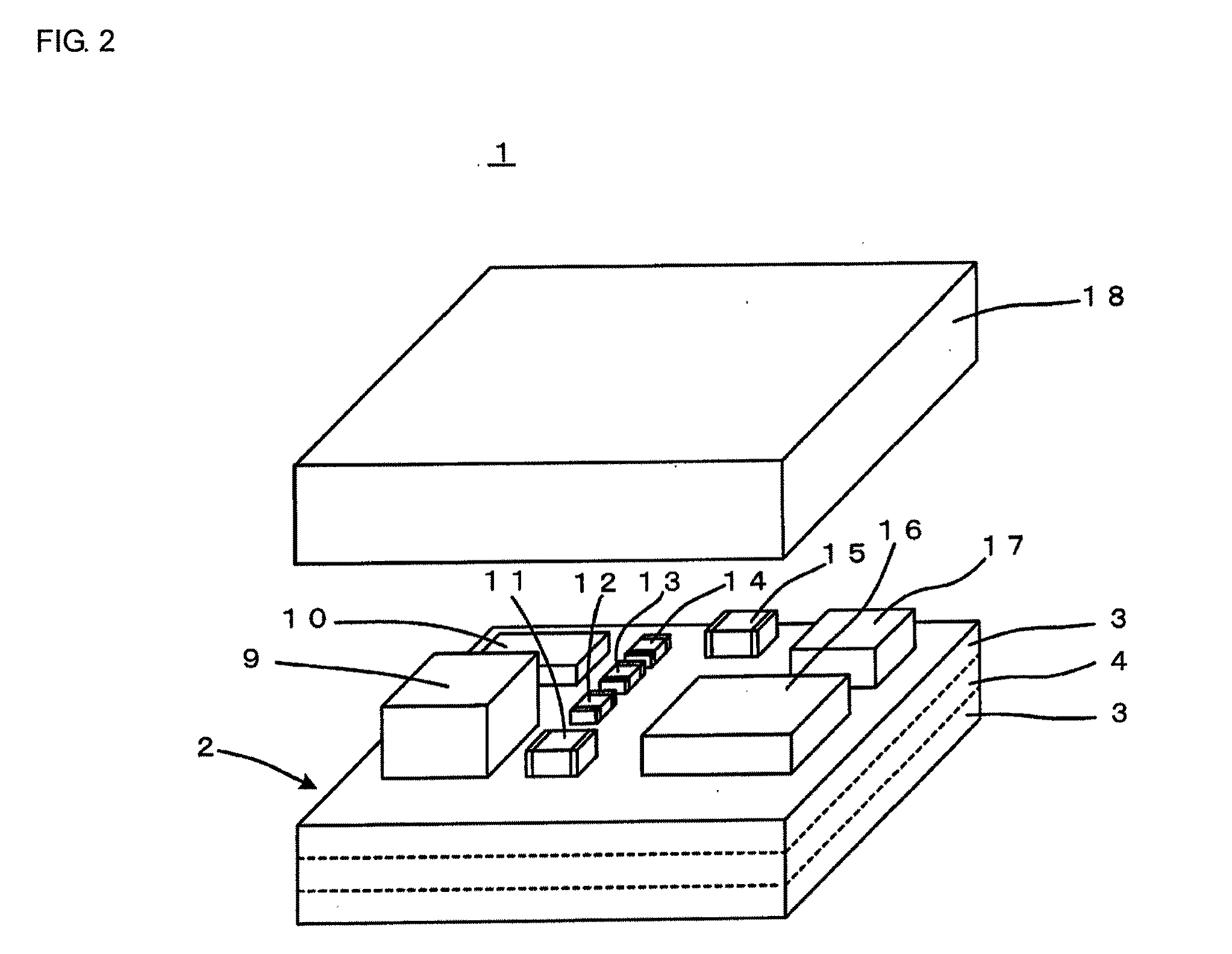

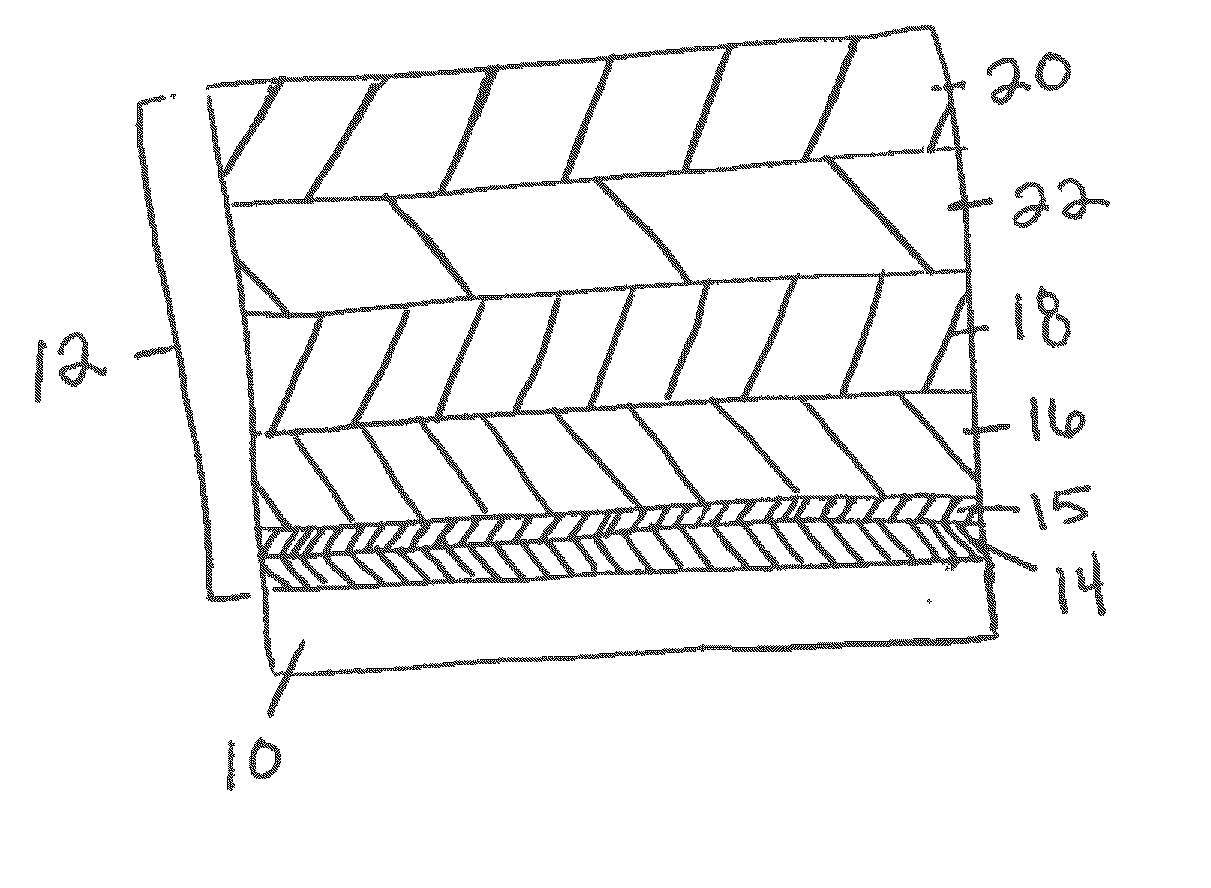

Glass ceramic composition, glass ceramic sintered body, and multilayer ceramic electronic device

ActiveUS20100046137A1Good chemical stabilityLow dielectric constantFixed capacitor electrodesFixed capacitor dielectricCapacitanceFlexural strength

A glass ceramic composition is provided which can be fired at a temperature of 1,000° C. or less to form a sintered body having a low relative dielectric constant, a small temperature coefficient of resonant frequency, a small change in capacitance before and after a loading test, a high Qf value, high electrical insulating reliability, and a high flexural strength. A glass ceramic composition forming glass ceramic layers laminated to each other in a multilayer ceramic substrate is also provided. The glass ceramic composition includes a first ceramic powder containing forsterite as a primary component; a second ceramic powder containing SrTiO3 and / or TiO2 as a primary component; a third ceramic powder containing BaZrO3 as a primary component; a fourth ceramic powder containing SrZrO3 as a primary component; and a borosilicate glass which contains Li2O, MgO, B2O3, SiO2, and ZnO, and also which contains at least one of CaO, BaO, and SrO.

Owner:MURATA MFG CO LTD

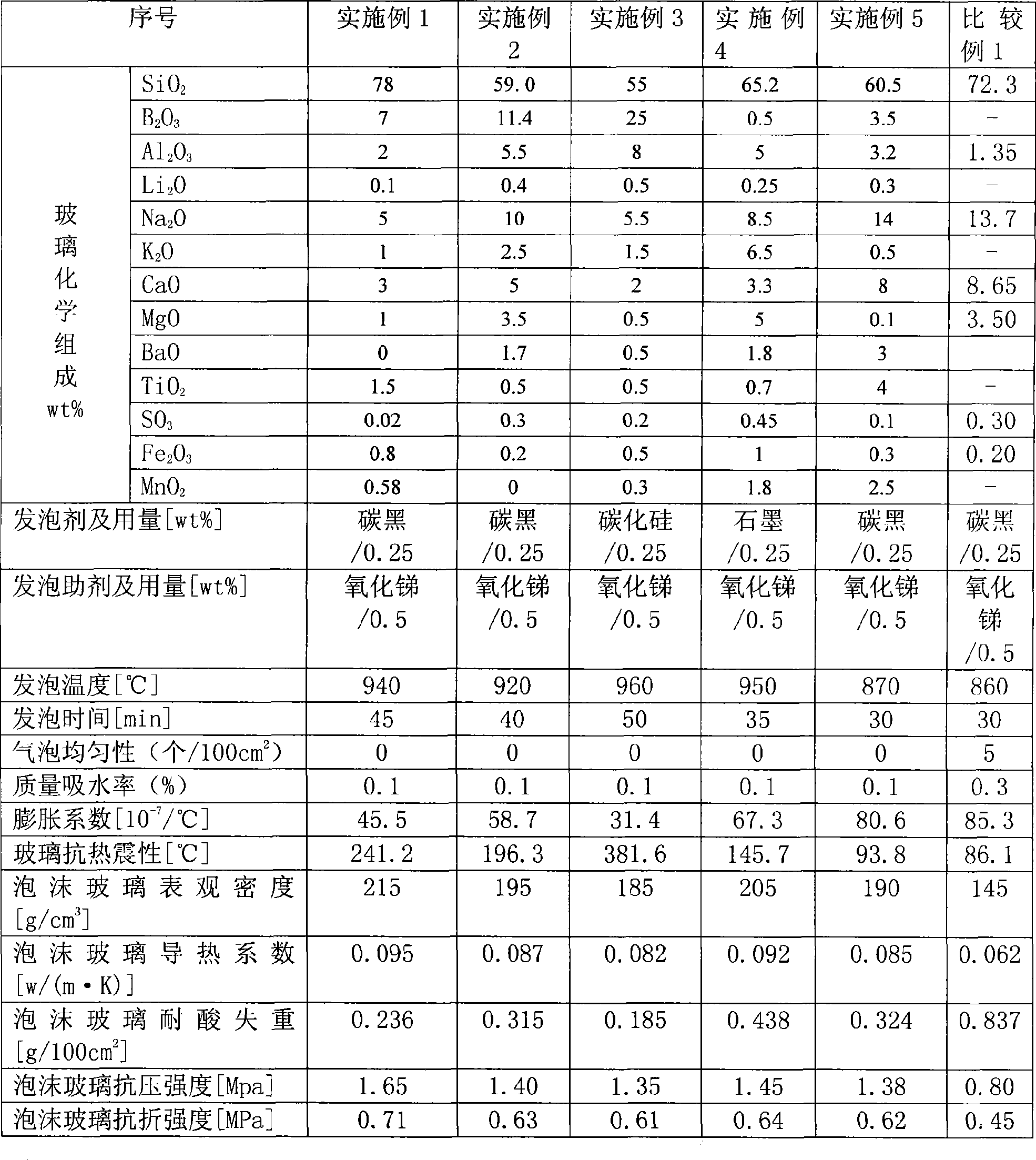

Method for preparing borosilicate foam glass

The invention relates to a method for preparing borosilicate foam glass, comprising the following steps: glass raw materials, foaming agent and blowing promoter are finely ground and evenly mixed to form batch mixture; the batch mixture is placed in a heat resistant mould; the batch mixture is prepared into multiaperture glass materials after the processes of preheating, sintering, frothing, annealing and the like; the method is characterized in that the chemical composition(wt%) of the glass materials is: SiO2: 55-78, B2O3: 0.5-25, Al2O3: 2-8, Li2O: 0.1-0.5, Na2O: 5-14, K2O: 0.5-6.5, MgO: 1-5, CaO: 3-8, BaO: 0-3, TiO2: 0.5-4, SO3: 0.02-0.45, Fe2O3: 0.2-1.0, MnO2: 0-2.5. the glass material belongs to the system of borosilicate glass and can be prepared into foam glass product featuring good acid fastness, good thermal shock stability, high mechanical strength, good scour resistance, low heat conducting coefficient and even aerated structure by adopting carbon blowing agents(carbon black, graphite, carborundum) and blowing promoter material.

Owner:BEIJING UNIV OF TECH

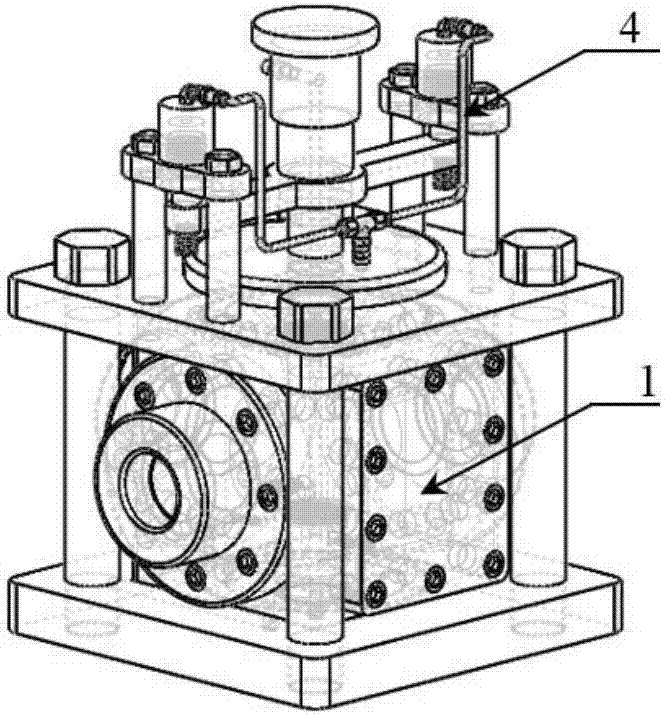

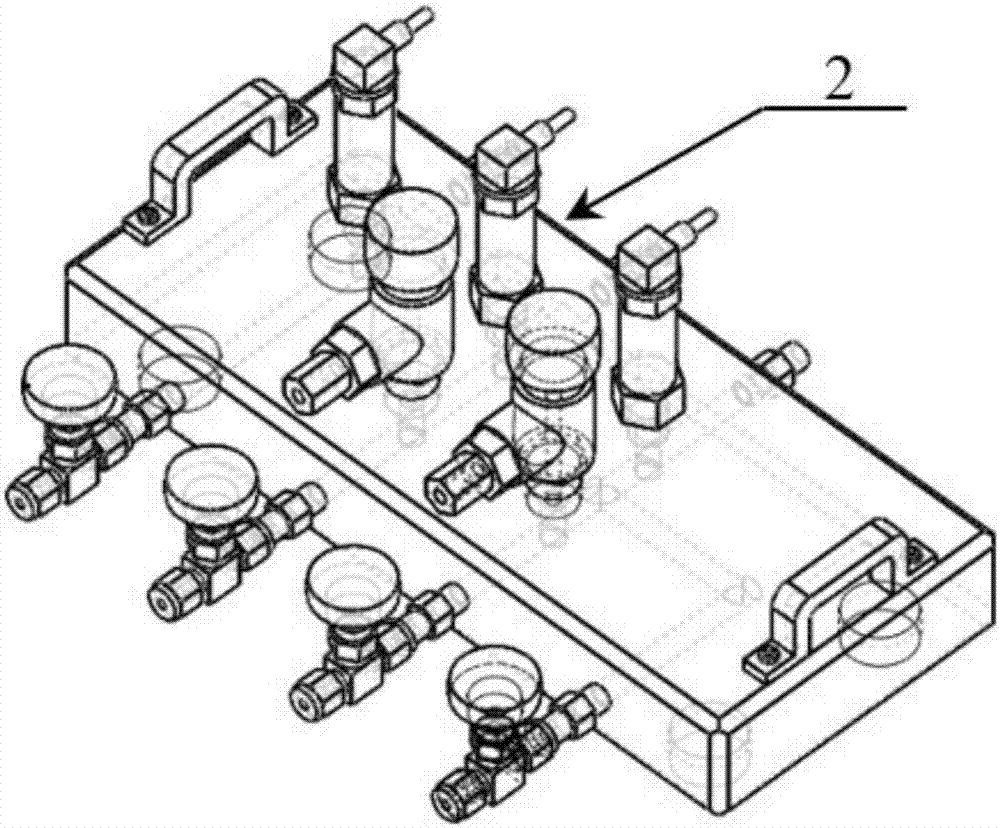

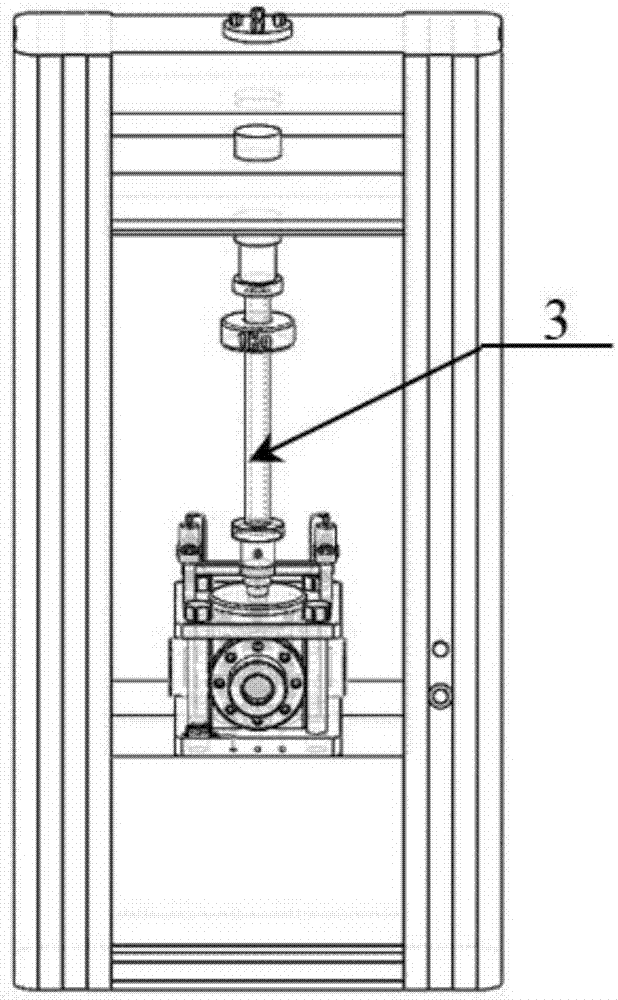

Dynamic and static combined loading rock test machine and test method used for multiphase coupling

ActiveCN106918531AModule division of labor is clearWith a clear purposeMaterial strength using tensile/compressive forcesEngineeringCoal

The invention discloses a dynamic and static combined loading rock test machine and test method used for multiphase coupling. The machine comprises a visual confining pressure loading chamber module, air pressure control modules, a dynamic loading module and constant volume modules; and the loading chamber of the visual confining pressure loading chamber module is a steel cylinder structure with a square outside and a circular inside, three surfaces of the loading chamber has windows, high borosilicate glass is embedded in every window to realize the visualization of the test process, an opening in one surface of the loading chamber is provided with a rear door which is convenient to replace and take a test piece, and various monitoring devices are arranged in the loading chamber and are led out through sensor lead wires of a baseboard to realize real-time monitoring of all physical-mechanical parameters of the test piece in the test process. The machine has the advantages of small size, simple structure, convenience in dismounting, and realization of accurate, quantitative and visual monitoring of the adsorption-desorption characteristic of a coal rock standard test piece in different load forms and coupling form and the permeability and the damage dilatancy process of gas-containing coal body in different loading stages.

Owner:SHANDONG UNIV

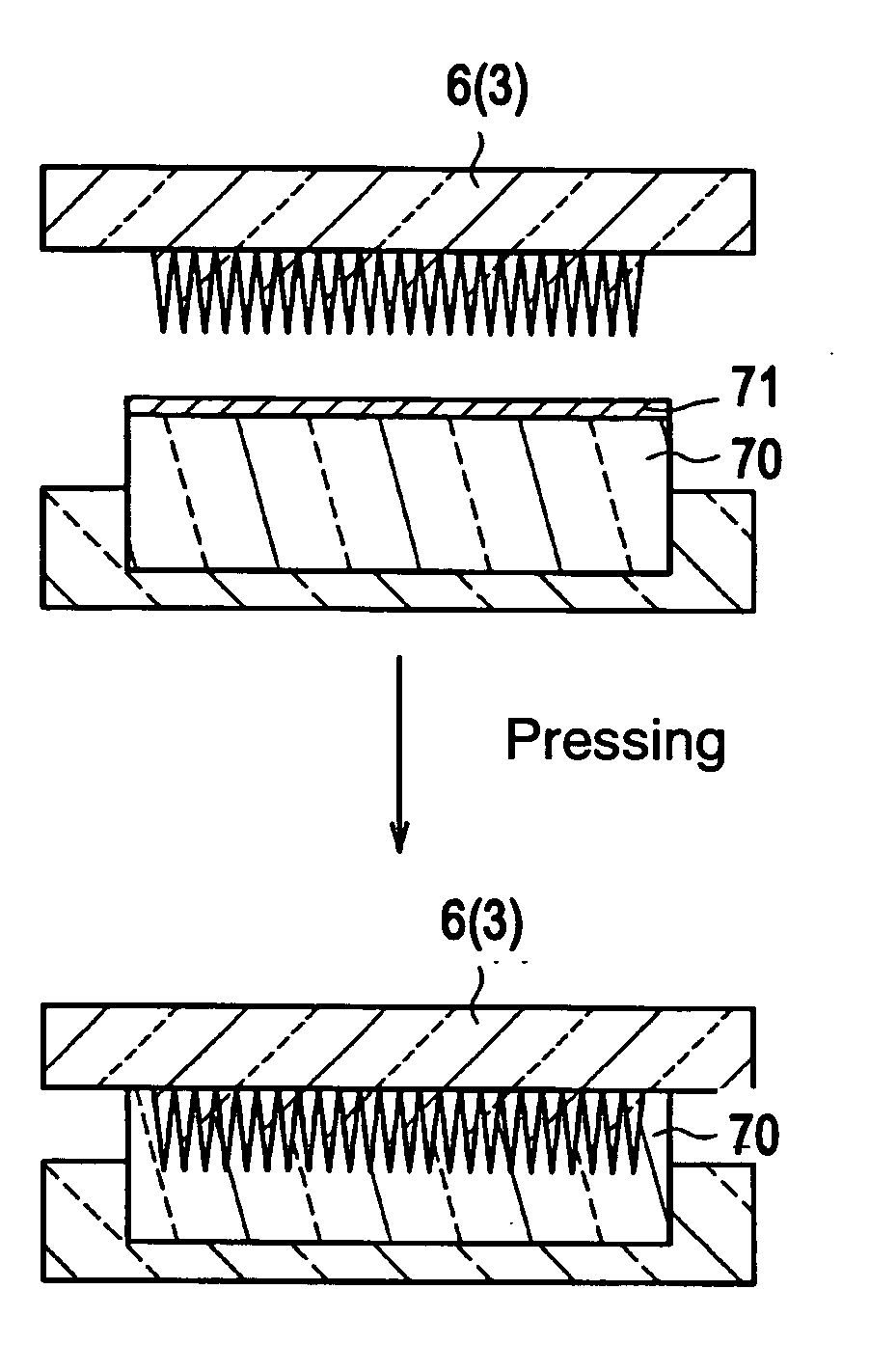

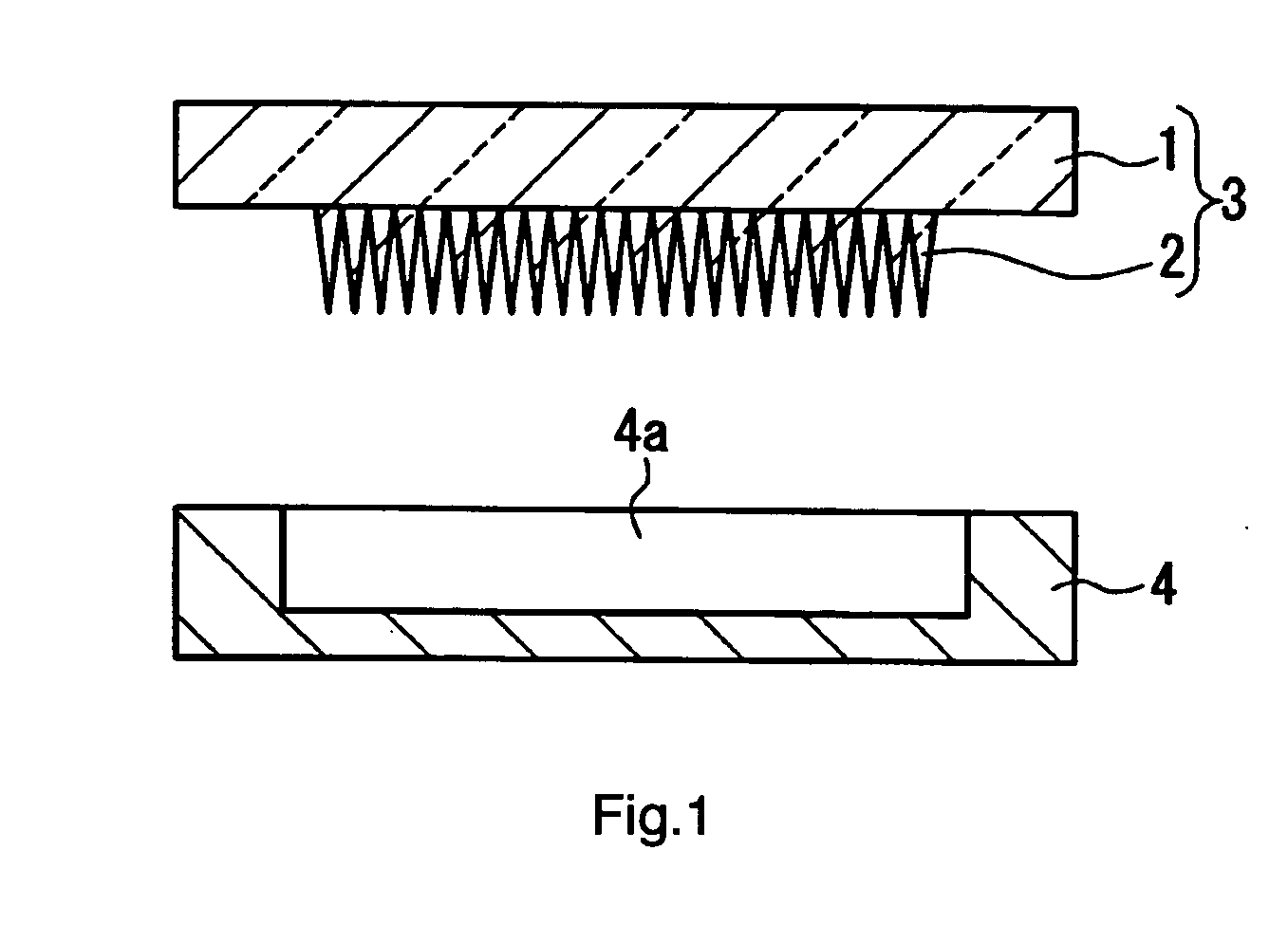

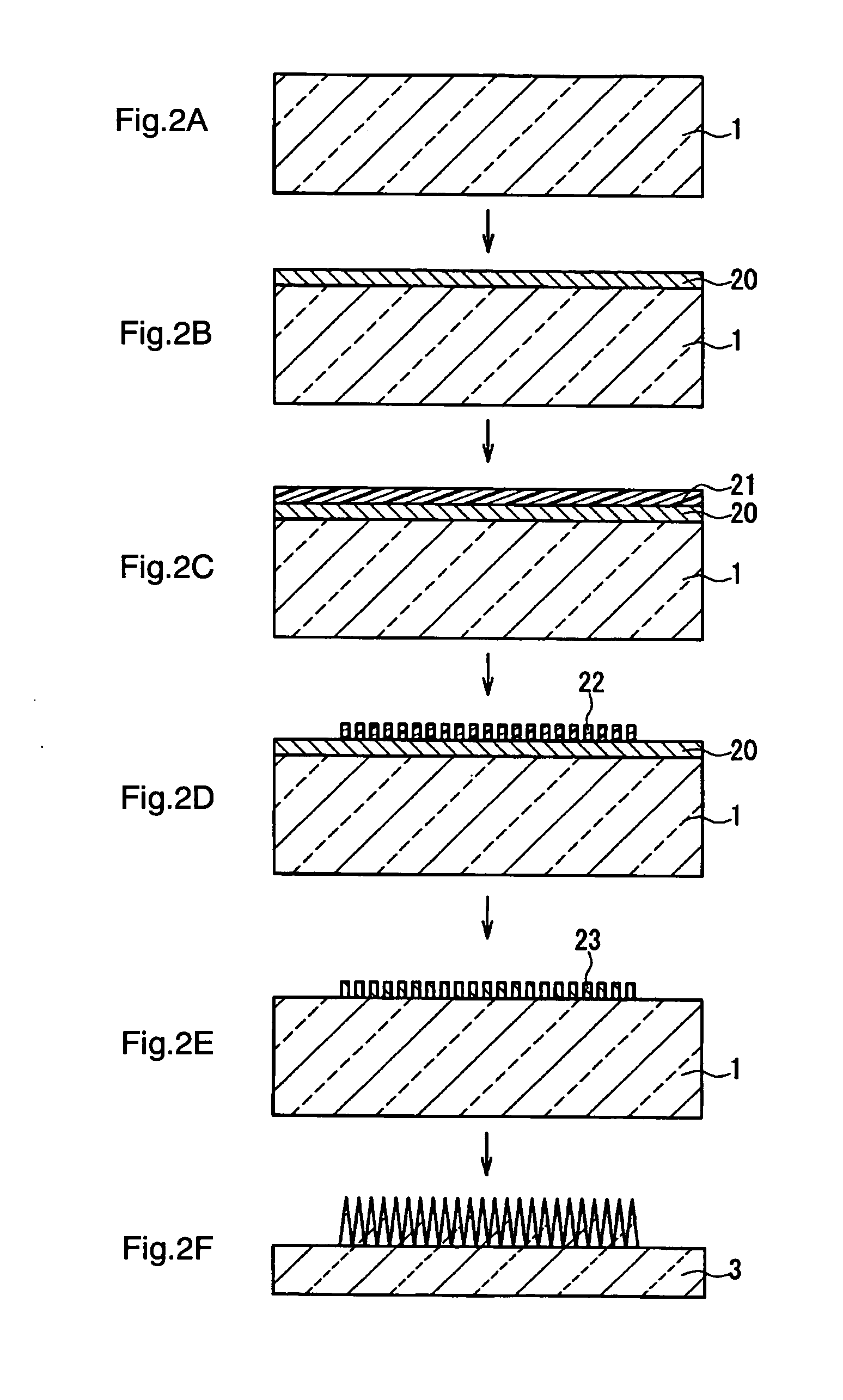

Method for producing optical element having antireflection structure, and optical element having antireflection structure produced by the method

InactiveUS20050093210A1Easy to disassembleGlass pressing apparatusHollow wall articlesAlloyDry etching

A cylinder-shaped Cr mask having a diameter of 0.15 μm is formed at a pitch of 0.15 μm on a quartz glass substrate. The quartz glass substrate on which the cylinder-shaped Cr mask is formed is placed in a RF dry-etching apparatus and the surface of the quartz glass substrate is etched with CHF3+O2 gas. Thus, a cone-shaped antireflection structure with a pitch of 0.15 μm and a height of 0.15 μm is formed on the surface of the quartz glass substrate. An Ir—Rh alloy film having a thickness of 0.05 μm for protecting the surface is formed on the surface (pressing surface) of the quartz glass substrate provided with the cone-shaped antireflection structure to form a mold having an antireflection structure. An optical material 11 (crown based borosilicate glass) to which a releasing agent containing carbon (C) particulates for mold release is applied is press-molded with the mold having an antireflection structure, and the press-molded optical material is released from the mold having an antireflection structure without cooling. After the press-molded optical material is cooled, the releasing agent is removed.

Owner:PANASONIC CORP

Formulation for medicinal neutral boron silicate glass

The present invention is one kind of neutral borosilicate glass for medicine production. The neutral borosilicate glass has recipe comprising quartz sand 168-178 Kg, feldspar powder 14.7-18.7 Kg, borax pentahydrate 49-51 Kg, sodium carbonate 8-12 Kg, barium carbonate 8.6-9.4 Kg, sodium nitrate 0.4-0.6 Kg, calcite 1-2 Kg, fluorite 0-4 Kg, potassium carbonate 8.5-9.5 Kg, salt 0.8-1.6 Kg, cerium oxide 0.5-0.9 Kg and cullet 120 Kg. It has high chemical stability, high hydrolysis stability, few alkali metal volatilizations, simple production process and low cost.

Owner:东营力诺玻璃制品有限责任公司

Solvent based environmental barrier coatings for high temperature ceramic components

InactiveUS20110027557A1Suitable for useEfficient propulsion technologiesGlass/slag layered productsPorosityAluminate

Environmental barrier coatings for high temperature ceramic components including a bond coat layer; an optional silica layer; and at least one transition layer including: from about 85% to about 100% by volume of the transition layer of a primary transition material including a rare earth disilicate, or a doped rare earth disilicate; and from 0% to about 15% by volume of the transition layer of a secondary material selected from Fe2O3, iron silicates, rare earth iron oxides, Al2O3, mullite, rare earth aluminates, rare earth aluminosilicates, TiO2, rare earth titanates, Ga2O3, rare earth gallates, NiO, nickel silicates, rare earth nickel oxides, Lnb metals, Lnb2O3, Lnb2Si2O7, Lnb2SiO5, borosilicate glass, alkaline earth silicates, alkaline earth rare earth oxides, alkaline earth rare earth silicates, and mixtures thereof; where the transition layer is applied to the component as a slurry including at least an organic solvent, the primary transition material and at least one slurry sintering aid, and where a reaction between the slurry sintering aid and the primary transition material results in the transition layer having a porosity of from 0% to about 15% by volume of the transition layer.

Owner:GENERAL ELECTRIC CO

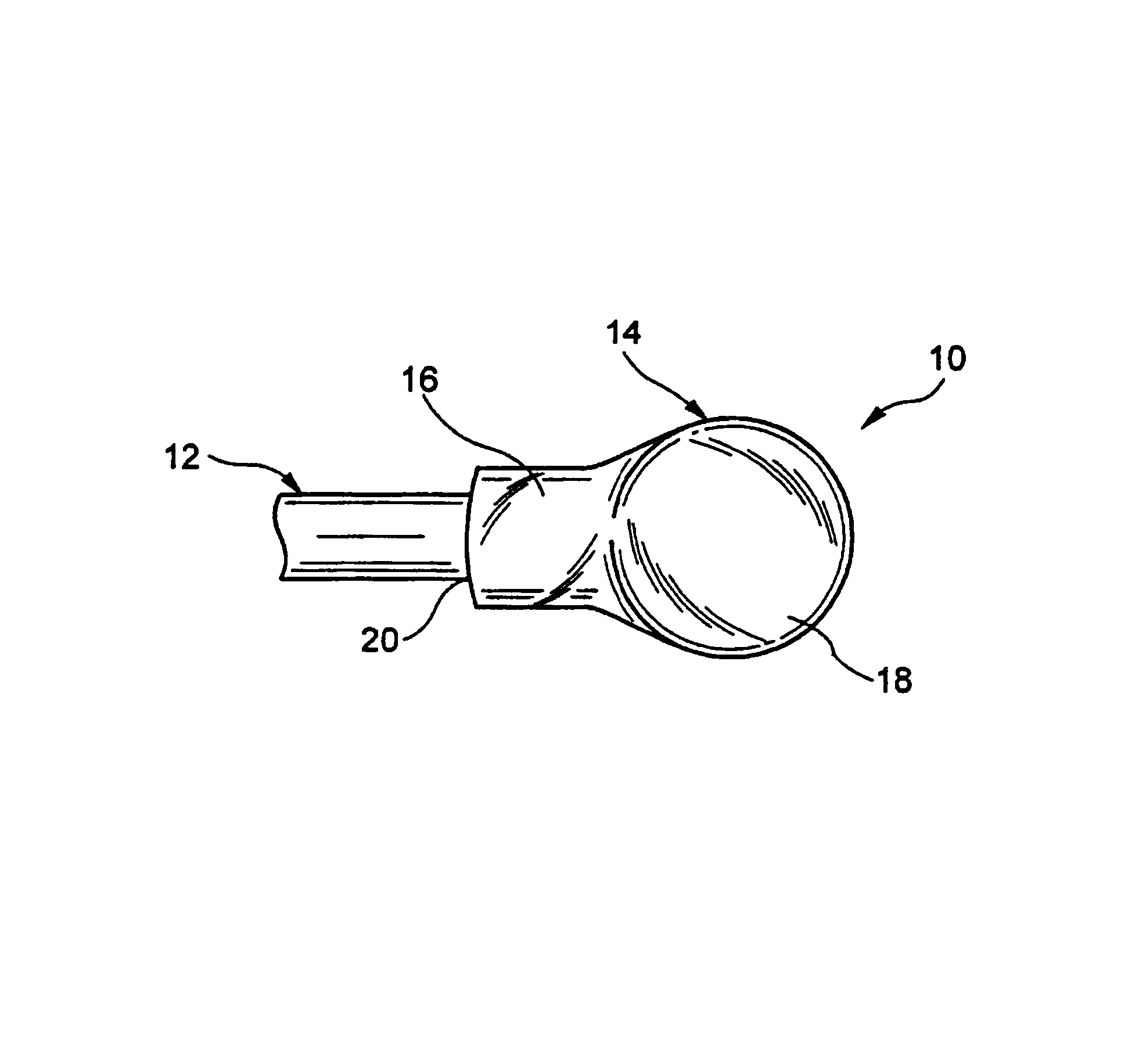

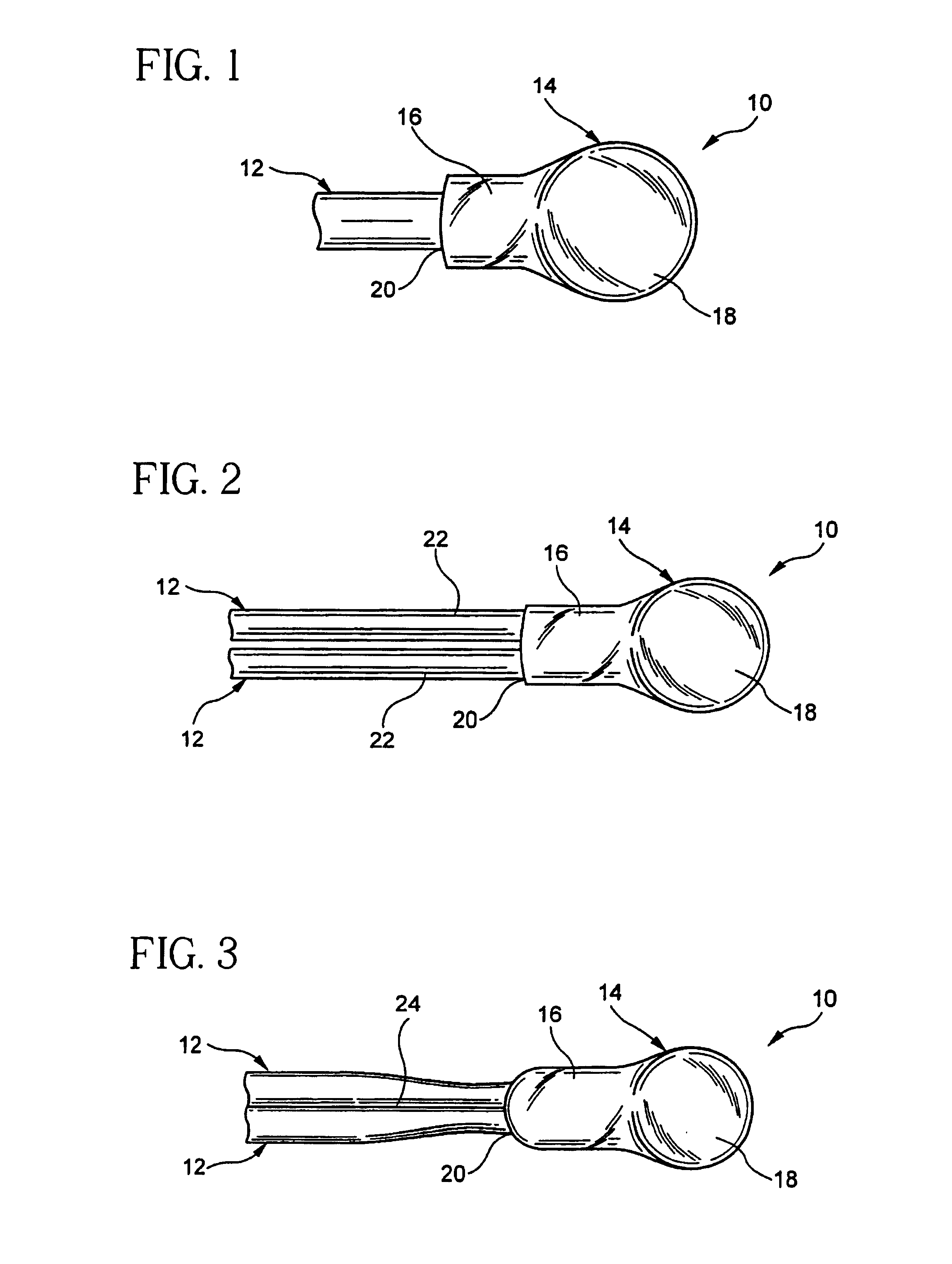

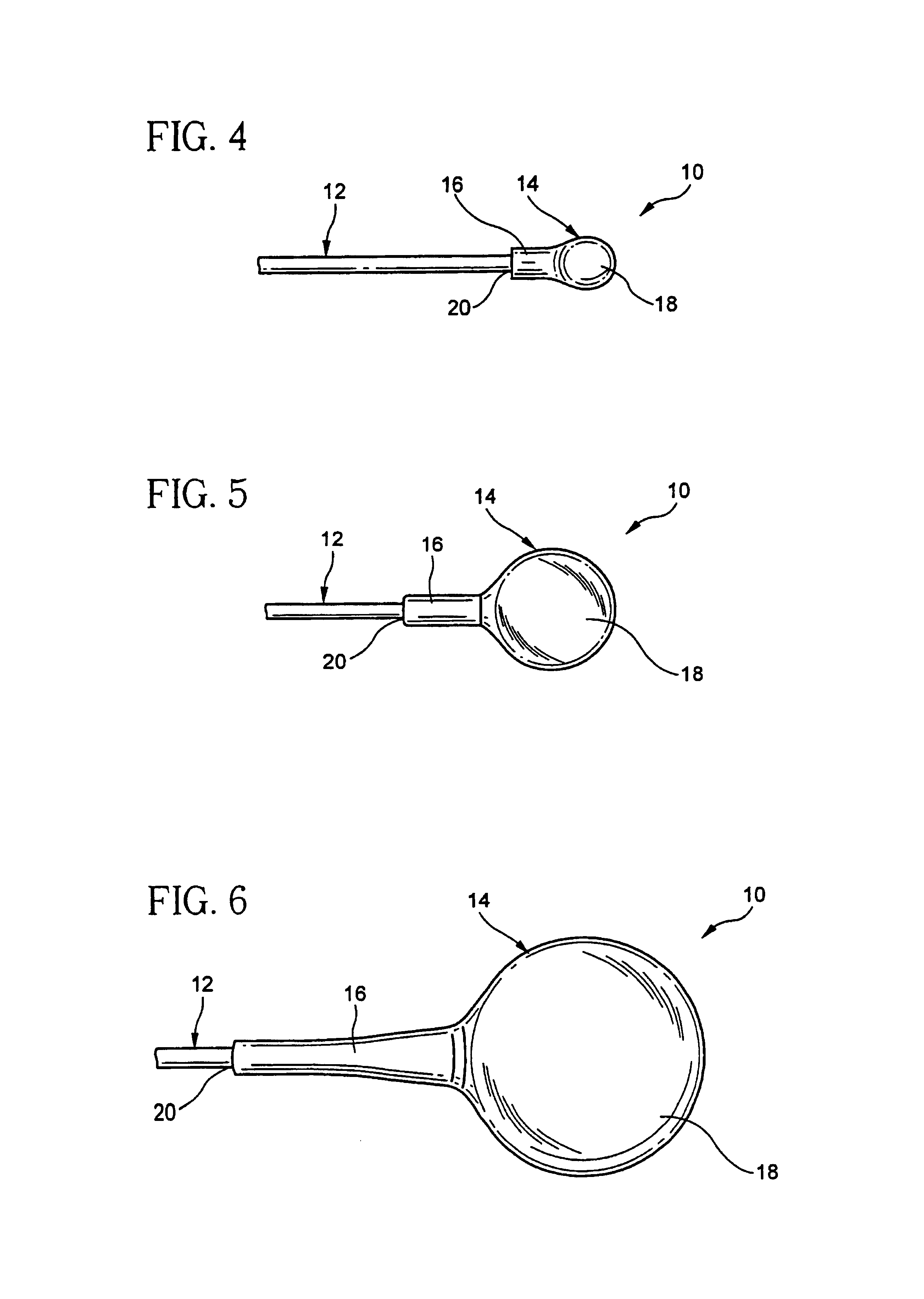

Optical waveguide lens and method of fabrication

A spherical lens formed by fusing a generally homogenous glass lens blank to the distal end of an optical fiber, heating and tensioning the lens blank to separate it in two segments with the segment attached to the optical fiber defining a tapered end, and heating the lens blank above its softening point so that the spherical lens forms. The lens blank is fabricated from a 4 weight percent borosilicate glass having a softening point less than that of the core of the optical fiber. The lens member defines a throat region adjacent the optical fiber whose cross-sectional dimension is substantially greater than the diameter of the optical fiber, but substantially less than the diameter of the spherical lens.

Owner:CORNING INC

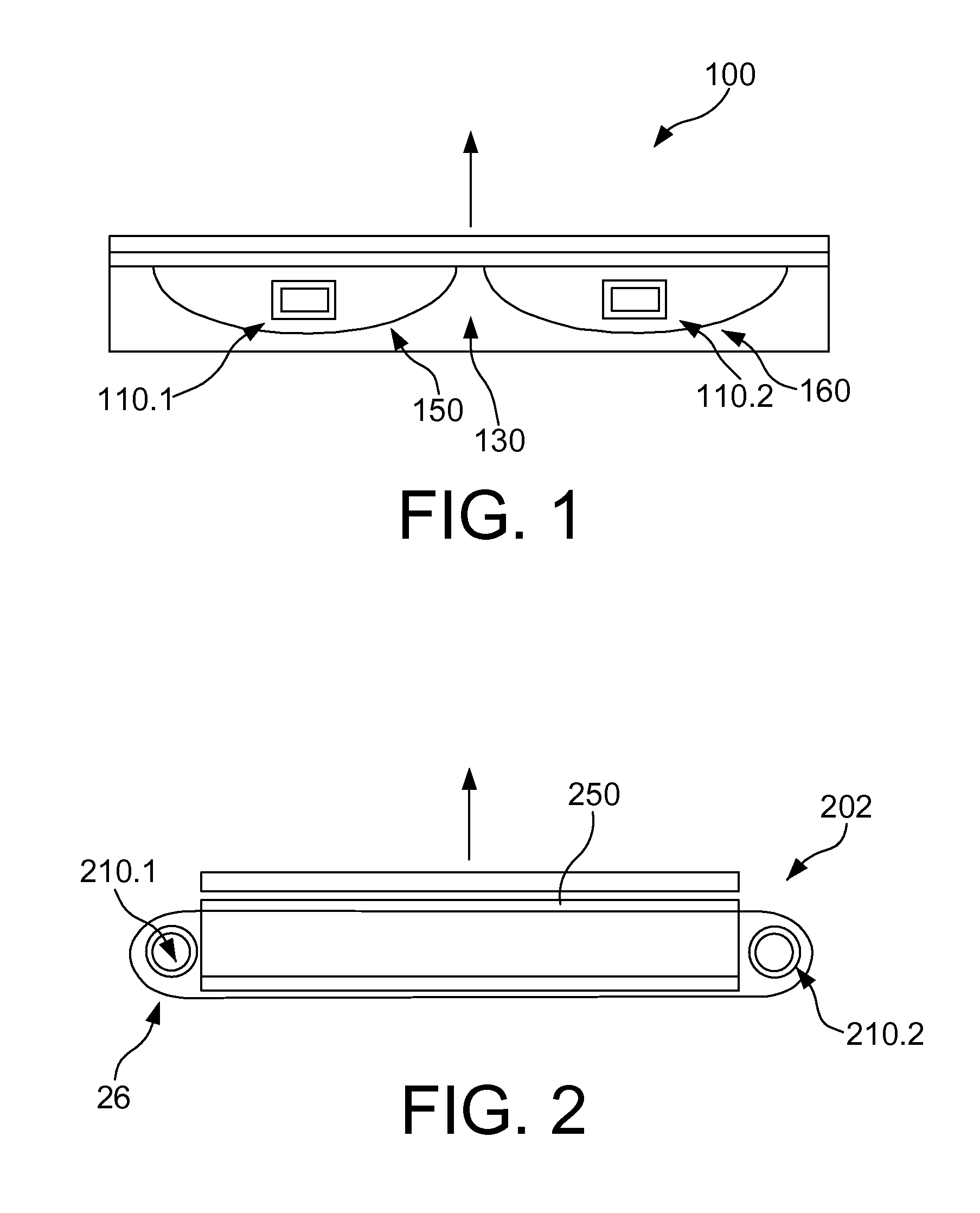

Method and Apparatus for Sterilization of Medical Instruments and Devices by Ultraviolet Sterilization

An object is sterilized with ultraviolet-C (UV-C) radiation having a wavelength from about 235 nm to about 295 nm. An advantageous wavelength for the UV-C radiation is about 253.7 nm. The object is inserted into a container, which is then sealed. At least a portion of the container is substantially transparent to UV-C radiation over the wavelengths of interest. The container and object are placed into a UV-C irradiation device and are irradiated for an exposure time with UV-C radiation having a predetermined intensity. The exposure time is determined such that a predetermined portion of user-specified pathogens disposed on the object is inactivated. Technical sterilization (99.9999% inactivation) can be attained with relatively short exposure times. The container can be a flexible pouch or a rigid kit. Suitable materials that are substantially transparent to UV-C radiation over the wavelengths of interest include quartz, borosilicate glass, cyclic olefin copolymer, and fluoropolymer.

Owner:GERMGARD LIGHTING

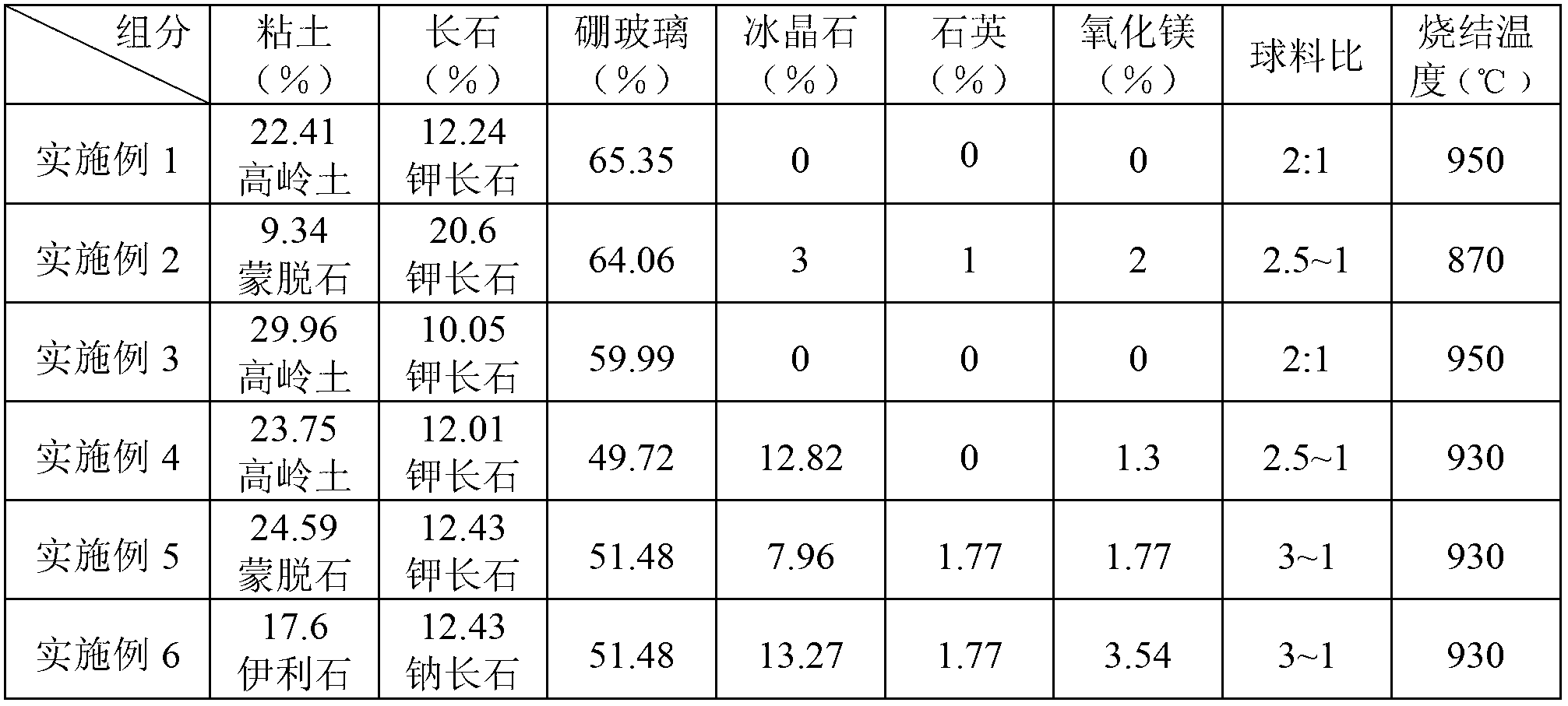

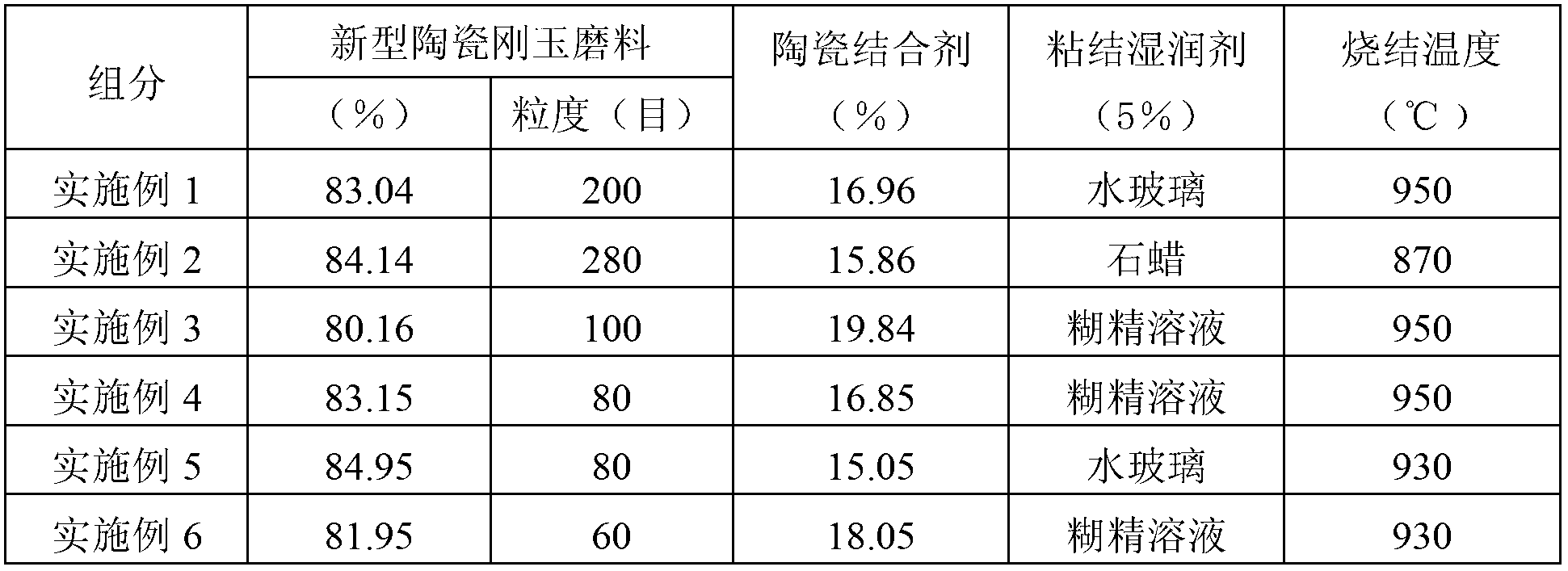

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

Process of photomorphogenically enhancing plants

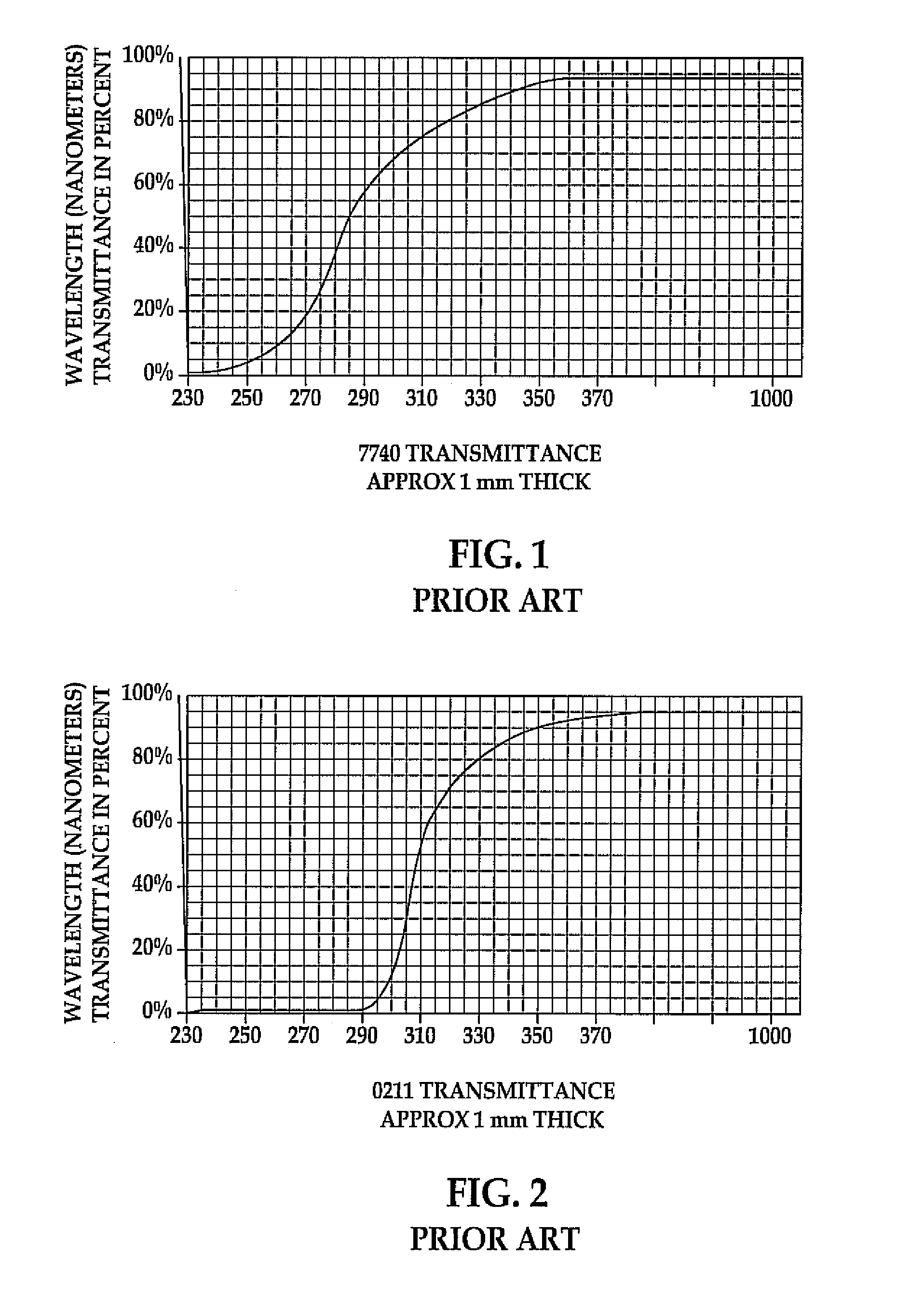

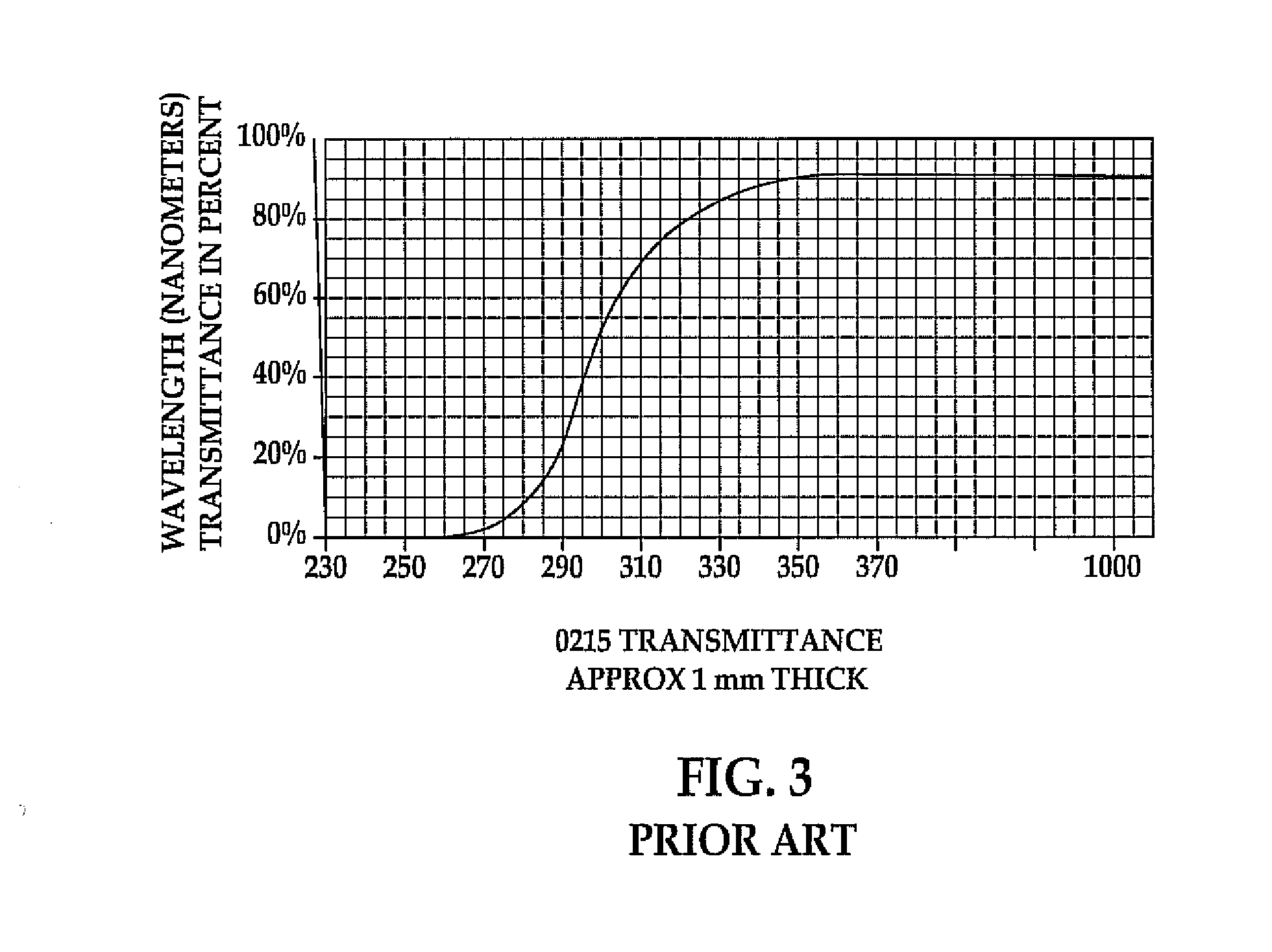

InactiveUS20080120736A1Improve the level ofFlavor can be alteredMutant preparationSaving energy measuresTransmittanceBorosilicate glass

A process for photomorphogenically enhancing plants is presented wherein a natural or artificial light source emits light through a transmittive material. The material is optionally borosilicate glass with a steep edge situation at or near 280 nm so as to selectively filter out light in the UVC or low UVB regions. The glass allows high transmissibility such that as much as 98% of all light at or above the edge situation passes thorough the material. The percent transmission and edge situation may be defined by glass thickness or by combining multiple types of glass. The light is then contacted with a plant whereby a photomorphogenic response is elicited.

Owner:HURST WILLIAM E

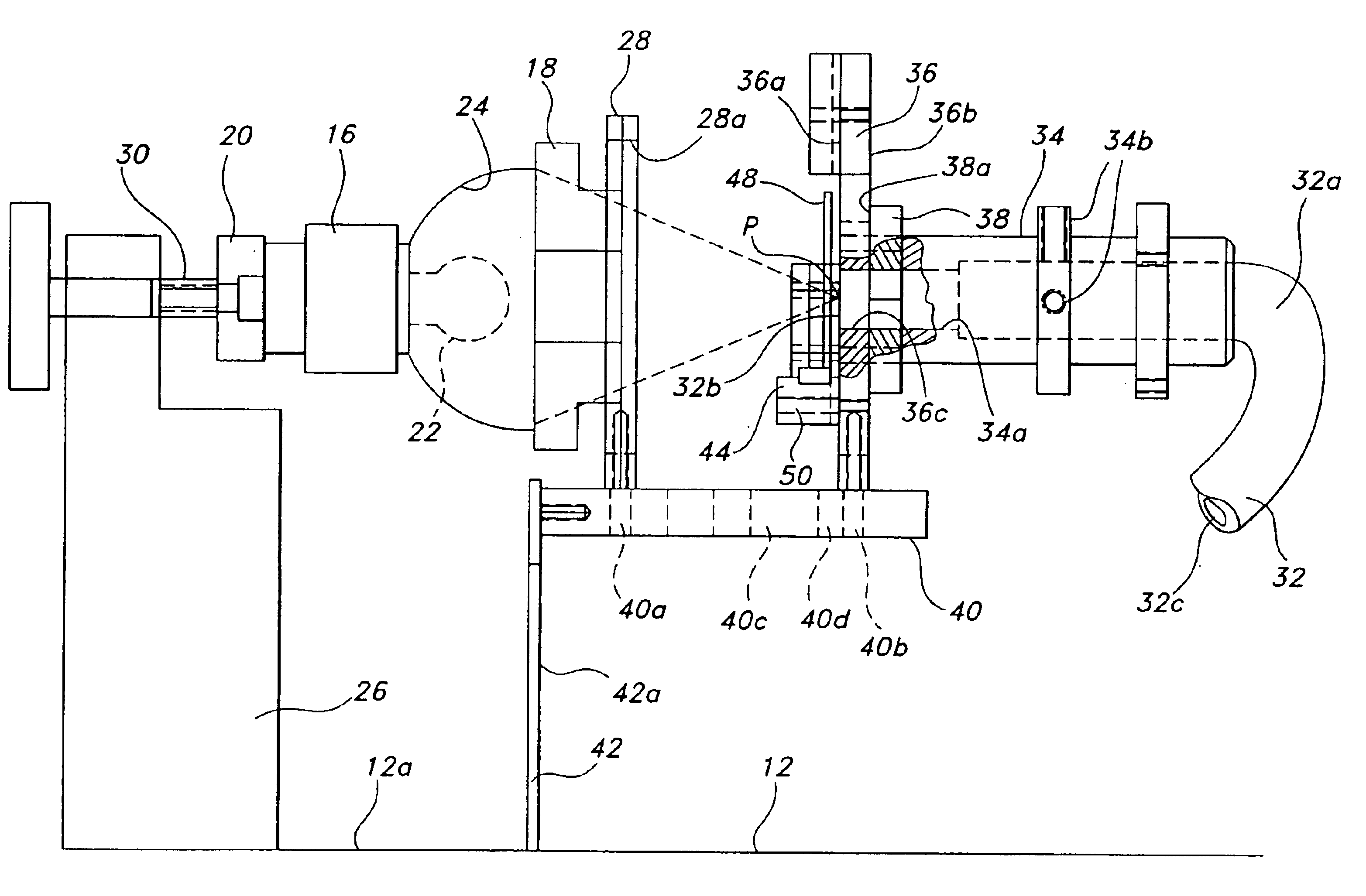

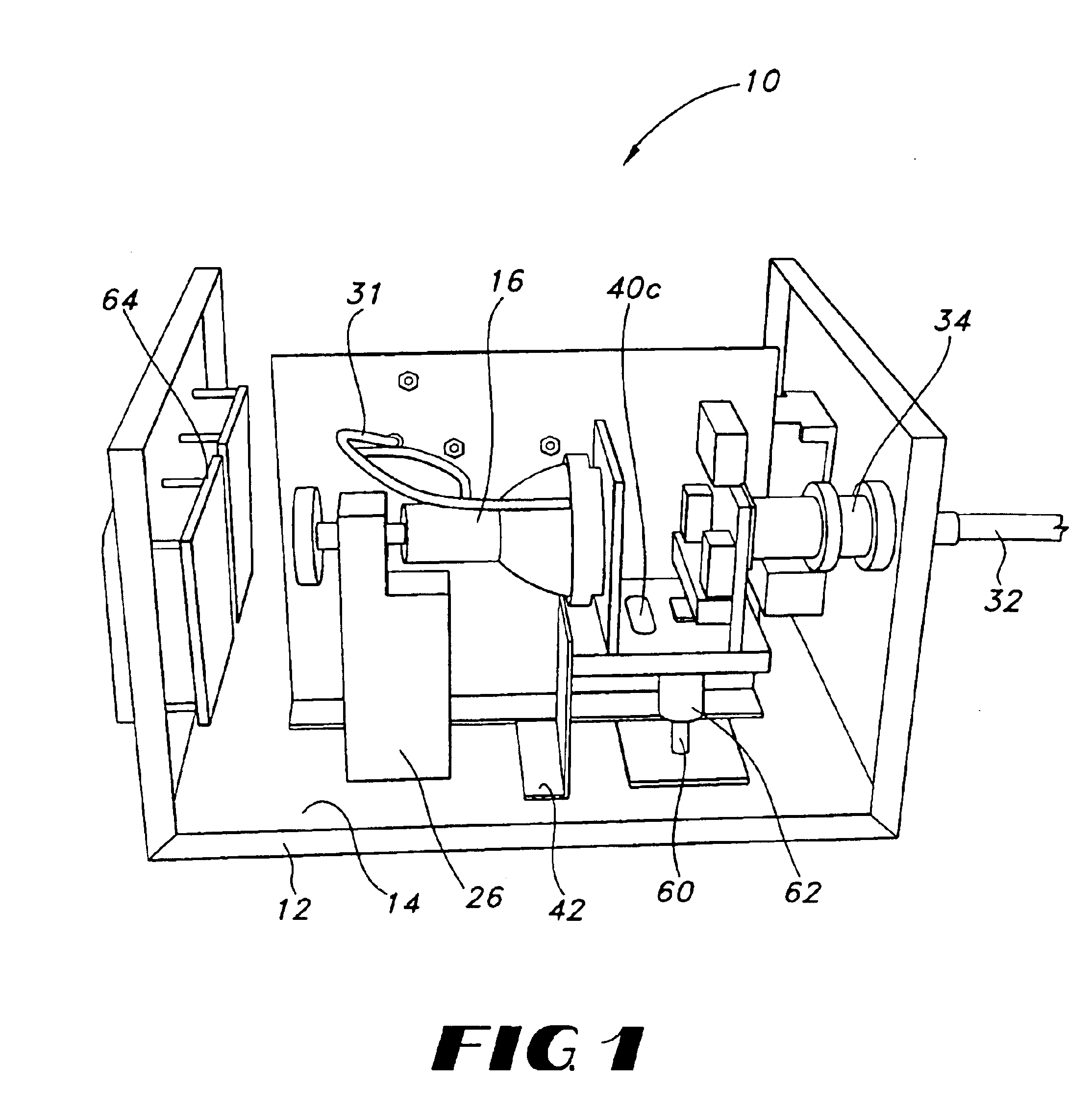

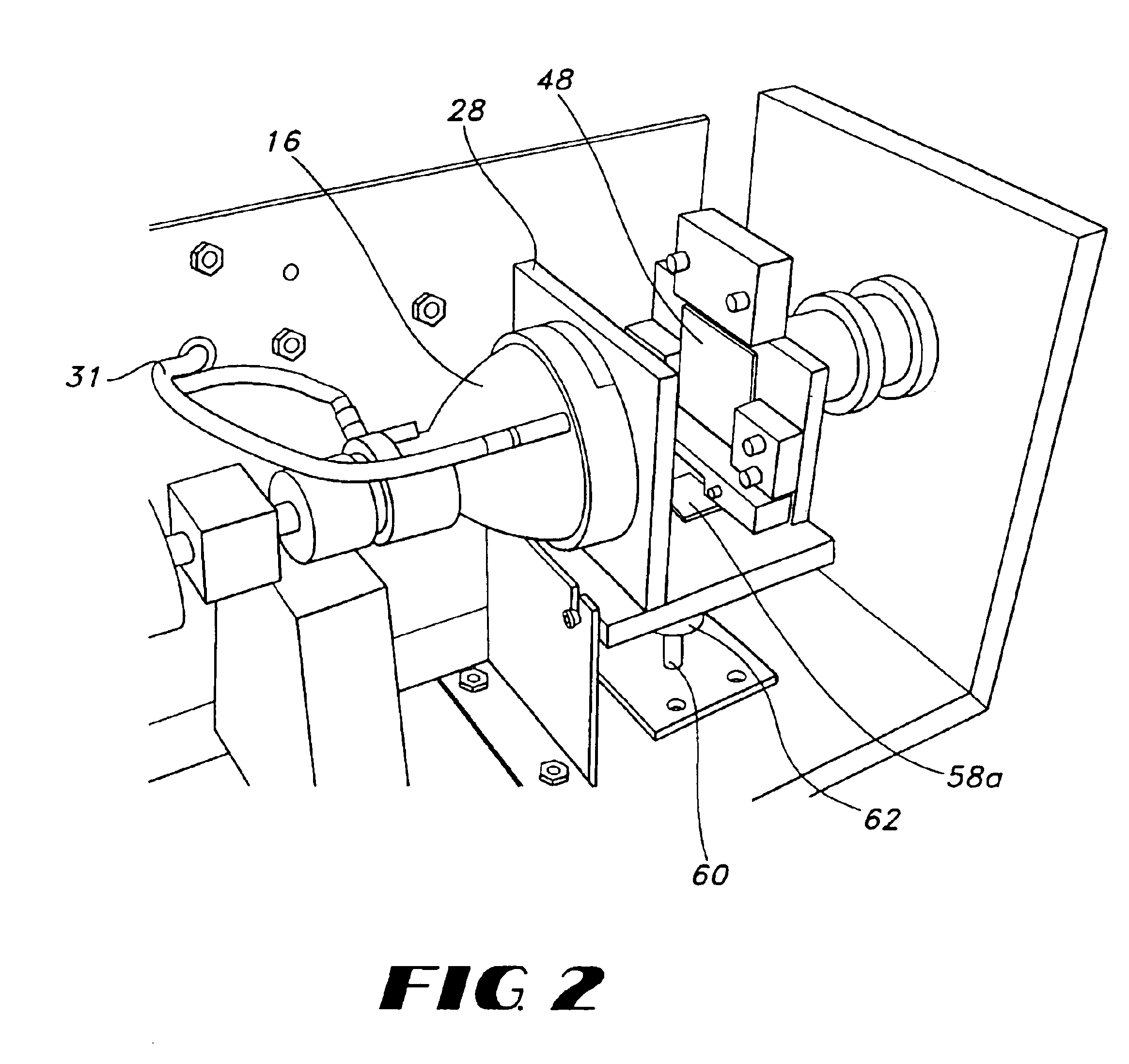

Integral filter support and shutter stop for UV curing system

A UV spot curing lamp assembly comprises an integral filter support and shutter stop mechanism. The assembly includes a UV lamp and a light guide spaced therefrom for receiving filtered light from the lamp and for directing light through the light guide to a selected target or work site for curing materials thereat. A filter plate in the form of a borosilicate glass, having a selected thickness for the particular application, is disposed in relatively close proximity to the entrance surface of the light guide. A movable shutter plate, having an opening therethrough, is disposed between the filter and the light guide entrance surface. The shutter is movable from a first position wherein the opening is in registry with the light guide entrance surface to receive light from the lamp to a second position wherein a solid portion of the shutter plate blocks light from being received by the light guide entrance surface. Effective cooling of the lamp assembly is provided by a fan by which forced air is drawn over the lamp and the integral filter support and shutter stop, and by an internal mounting system configured to direct the drawn air for effective convective heat dissipation.

Owner:HENKEL CORP

Carbon/carbon composite material ultrahigh temperature oxidation resistant coating and preparation method thereof

The invention discloses a carbon / carbon composite material ultrahigh temperature oxidation resistant coating. The coating comprises the following components, by volume, 40-60% of ZrB2, 15-25% of SiC, 15-20% of TaB2 and 10-15% of Sc2O3. In addition, the invention also provides a preparation method of the coating. According to the invention, TaB2 and Sc2O3 are added to make the melting point of an external layer oxidation product borosilicate glass be risen, the viscosity of the borosilicate glass be risen, the evaporation rate of the borosilicate glass be reduced, the oxygen dispersion coefficient of the borosilicate glass be reduced, an internal layer oxidation product ZrO2 phase be stable, the melting point of ZrO2 be risen, and the oxygen diffusion coefficient of ZrO2 be reduced, so thecoating can satisfy requirements of the ultrahigh temperature oxidation resistance of a carbon / carbon composite material, the coating can be sintered without applying a pressure through adding TaB2 and Sc2O3, the coating has the advantages of high combination strength, compactness, and good ultrahigh temperature mechanical property, and the preparation process has no damages to matrixes.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

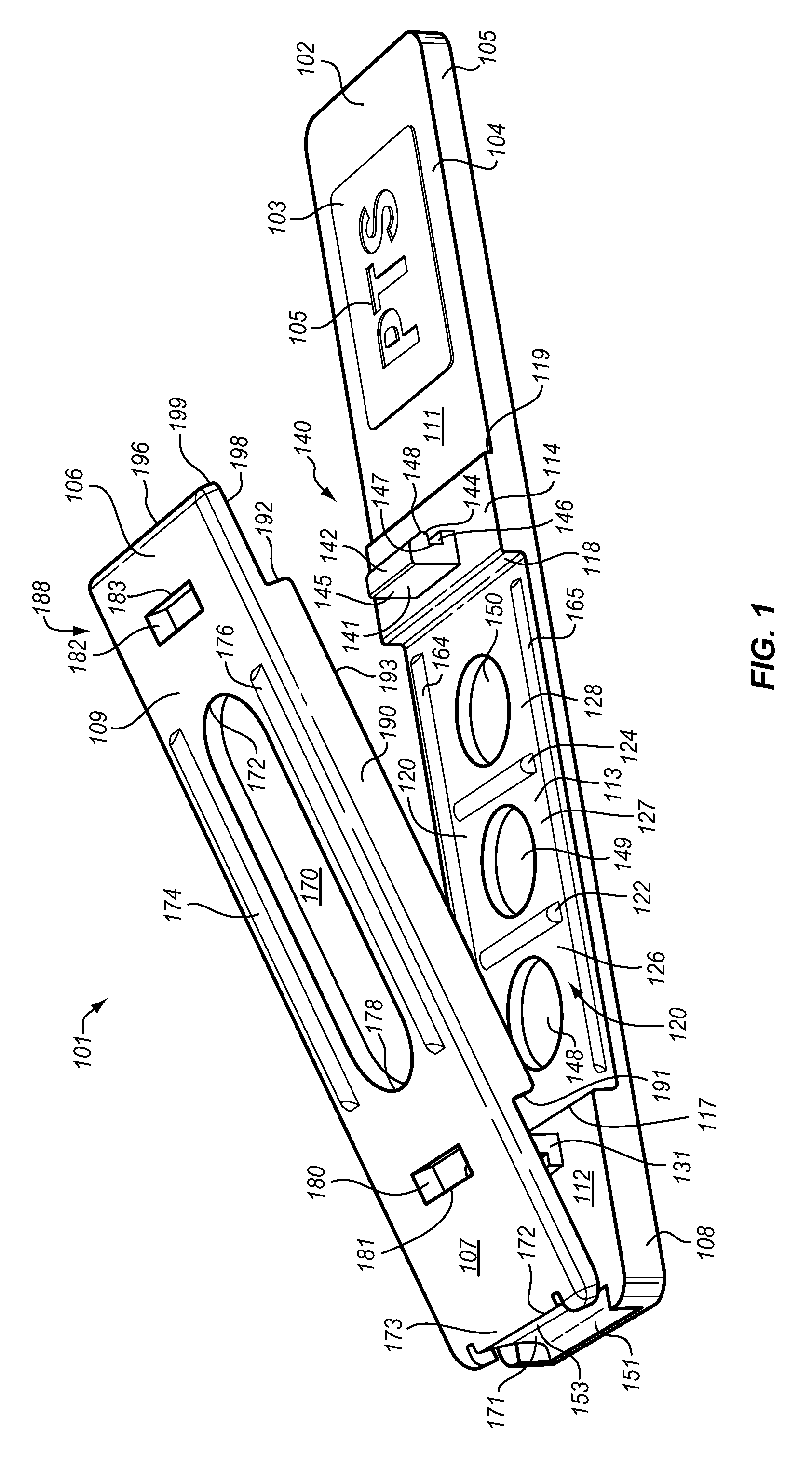

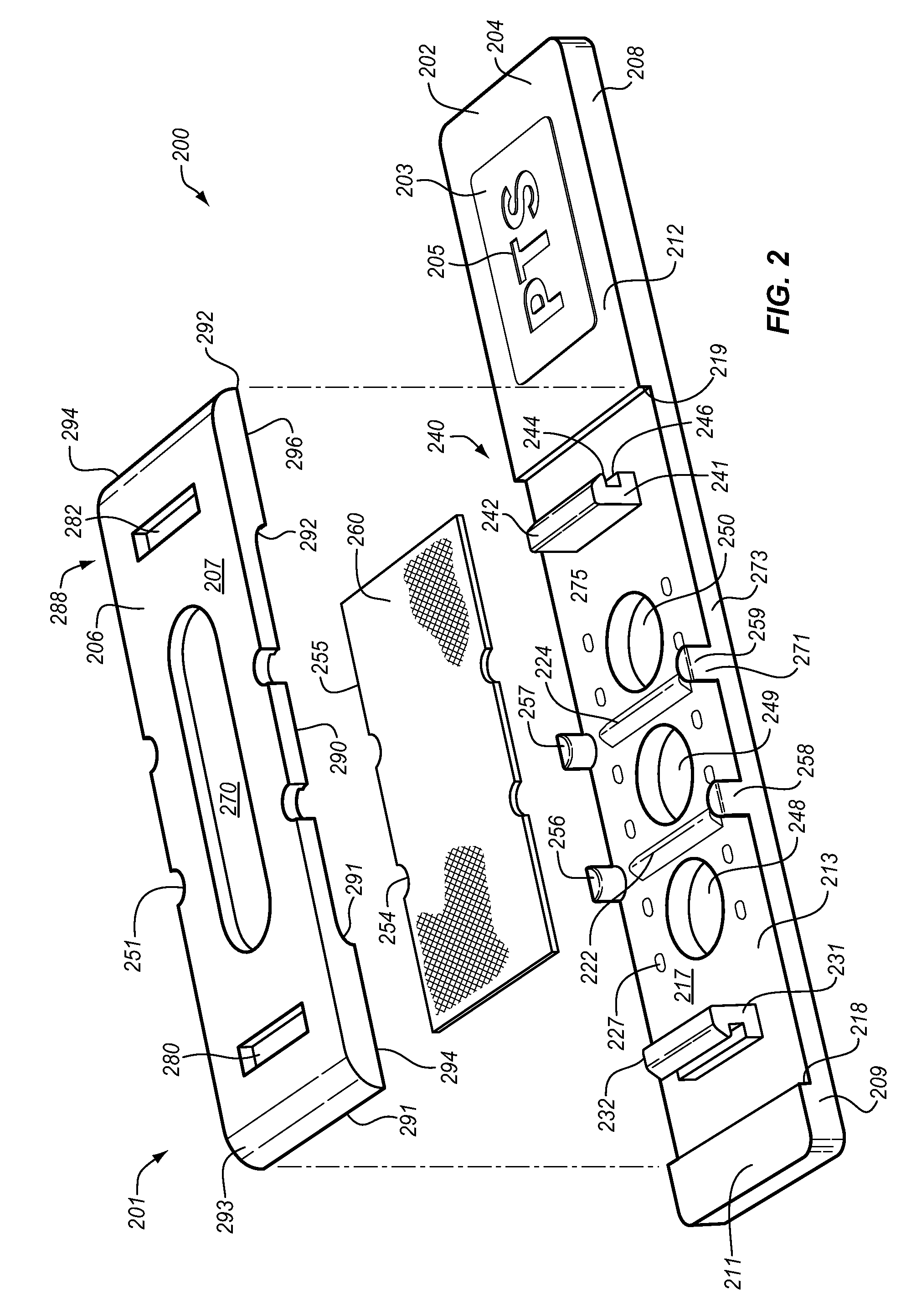

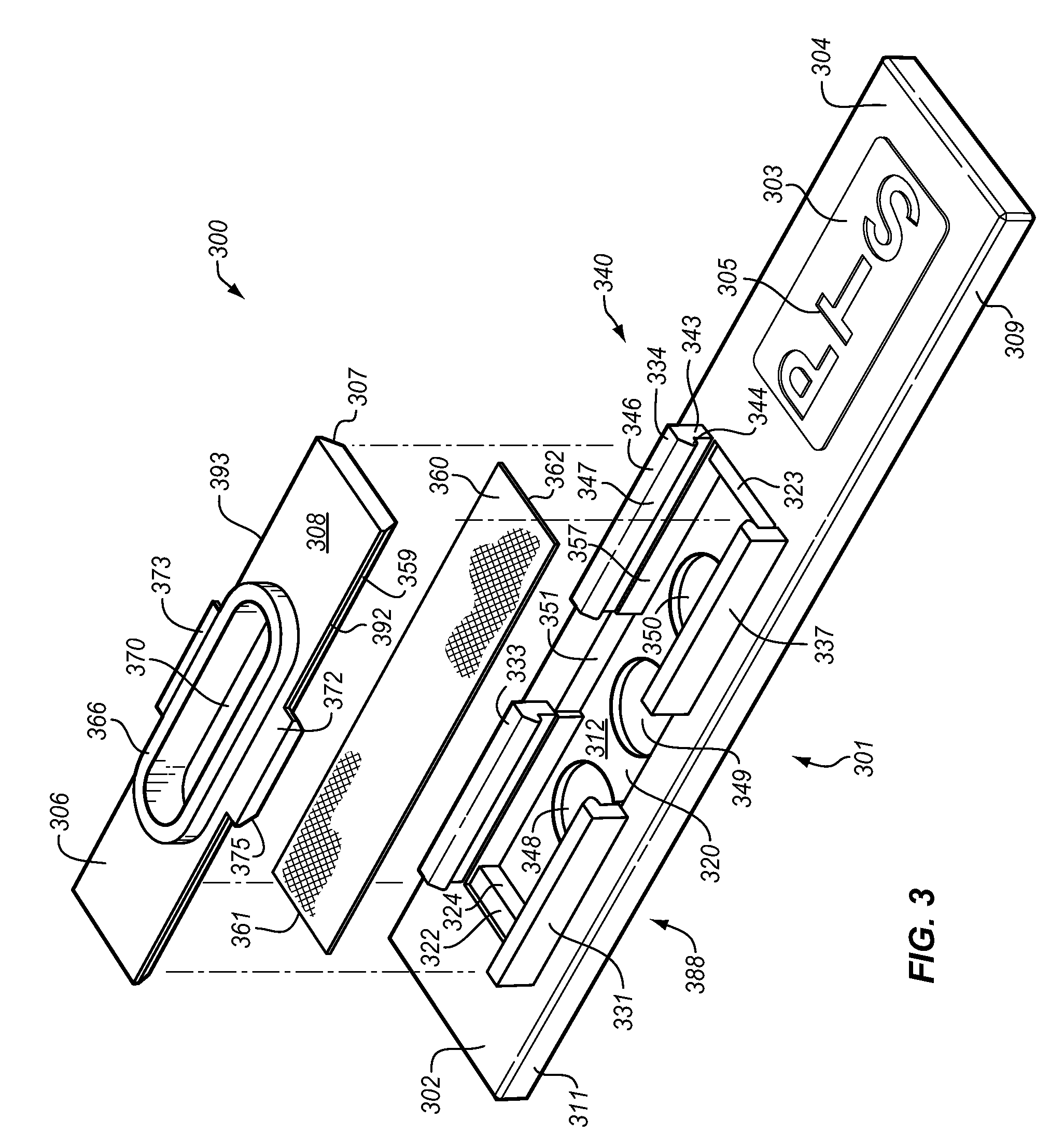

Blood separation system and method for a dry test strip

InactiveUS20120282634A1Less brittleImprove hydrophilicityBiological material analysisEnzymology/microbiology apparatusGlass fiberAnimal science

A dry test strip layer for filtering red blood cells includes a Borosilicate Glass Fiber layer and lectin, impregnated in the borosilicate layer, such that the dry test strip is configured to filter red blood cells from a blood sample.

Owner:POLYMER TECH SYST

Borosilicate glass-spherical alumina low temperature co-fired ceramic green tape and preparation method thereof

The invention discloses a borosilicate glass-spherical alumina low temperature co-fired ceramic (LTCC) green tape and its preparation method. The green tape is composed of a glass-ceramic composite material and a casting medium. Specifically, the glass-ceramic composite material consists of borosilicate glass and spherical alumina. The casting medium consists of a mixed solvent, a monomer binder, a plasticizer and a dispersing agent. The low temperature co-fired ceramic green tape prepared in the invention has a level and smooth surface, a solid content up to 88-92wt%, and a firing shrinkage rate of 9-11%. The difference between the sintering shrinkage rate of each direction is small. And the green tape can achieve wiring co-firing with Au, Ag and other low melting point metals at 850DEG C. The raw material tape sintered ceramic body provided in the invention has excellent dielectric properties. Under the condition of less than 10GHz, the dielectric constant (epsilon r) of 7-8, the dielectric loss (Tan delta) is less than 2*10<-3>, and effectively solves the anisotropy problem of traditional LTCC green tape sintering shrinkage.

Owner:凤阳凯盛硅材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com