Patents

Literature

1483 results about "Glass container" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Container glass is a type of glass for the production of glass containers, such as bottles, jars, drinkware, and bowls. Container glass stands in contrast to flat glass (used for windows, glass doors, transparent walls, windshields) and glass fiber (used for thermal insulation, in fiberglass composites, and optical communication).

Strengthened glass containers resistant to delamination and damage

ActiveUS20140151370A1Pharmaceutical containersLarge containersUltimate tensile strengthMaterials science

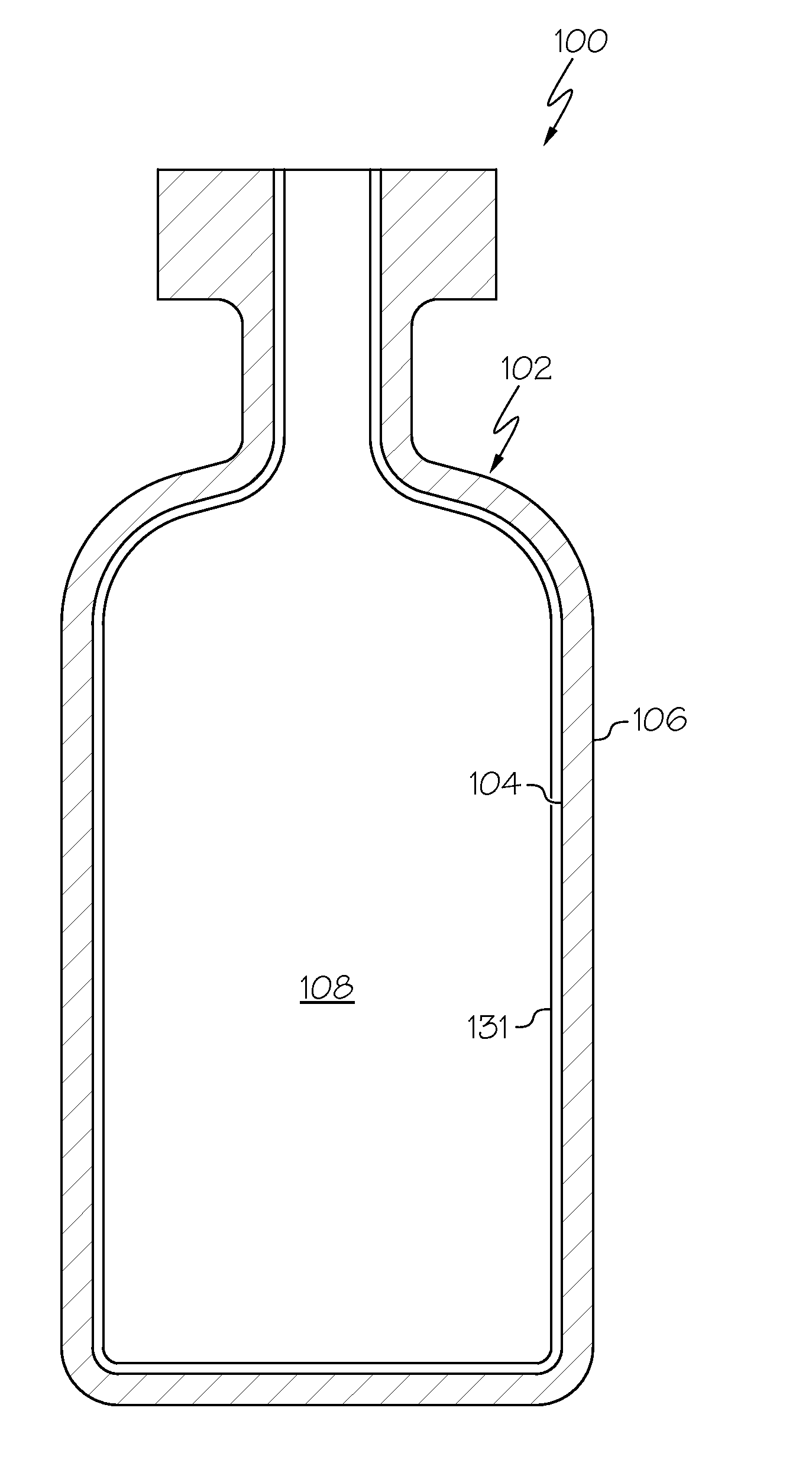

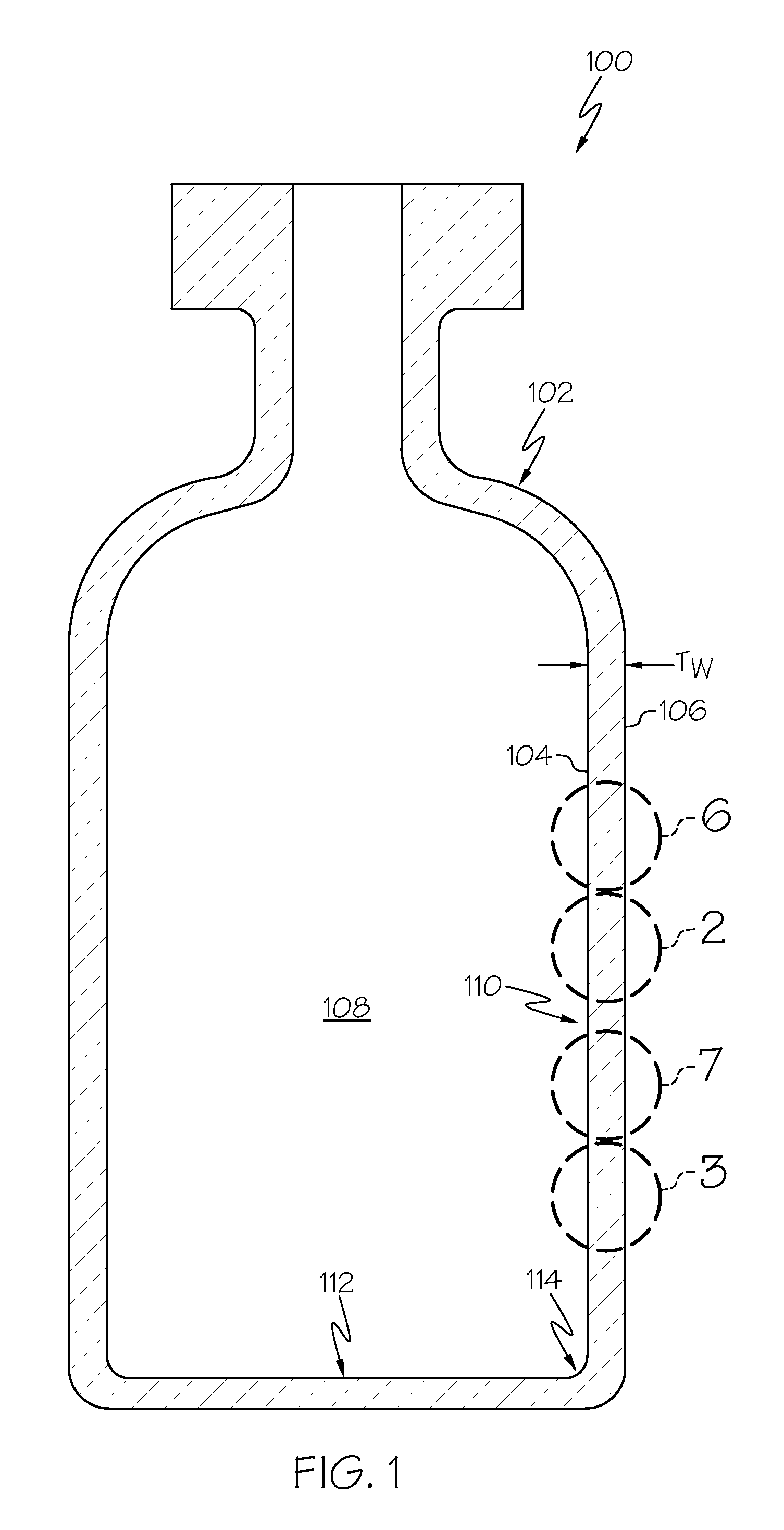

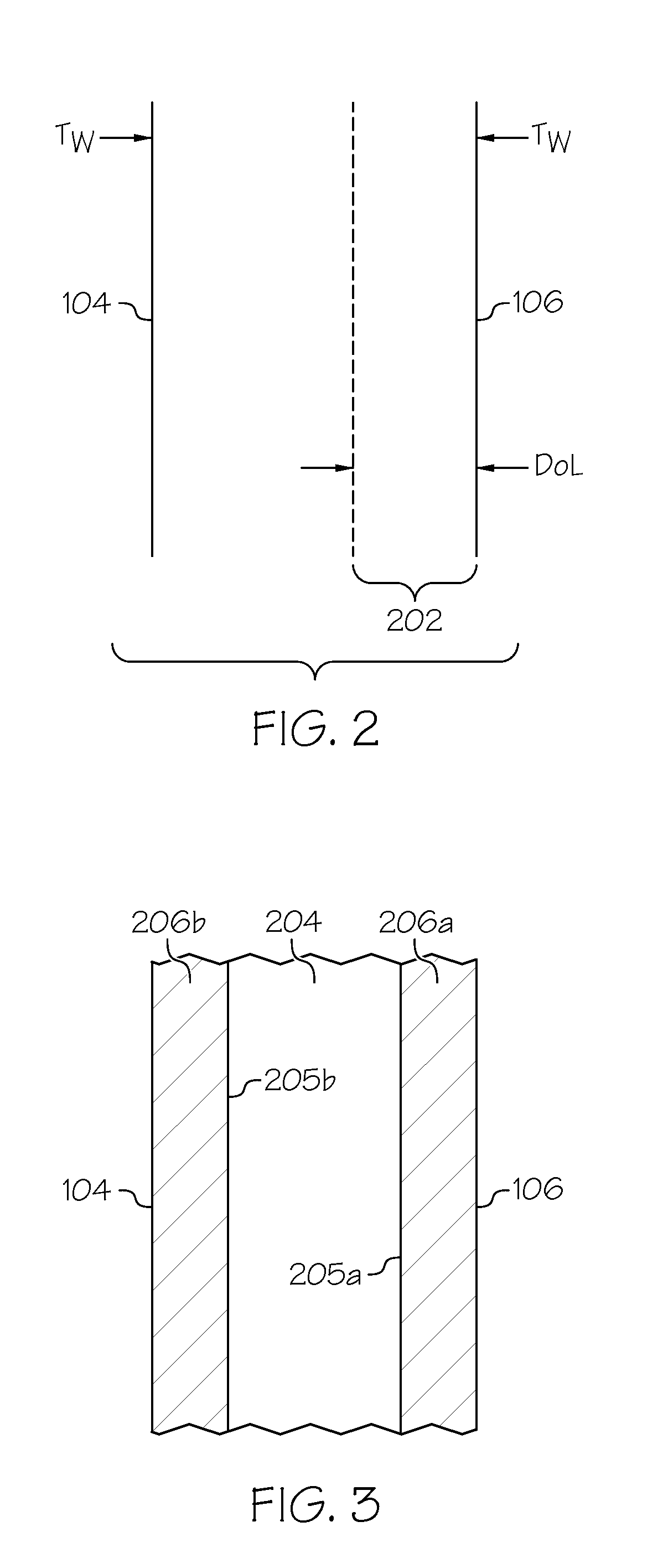

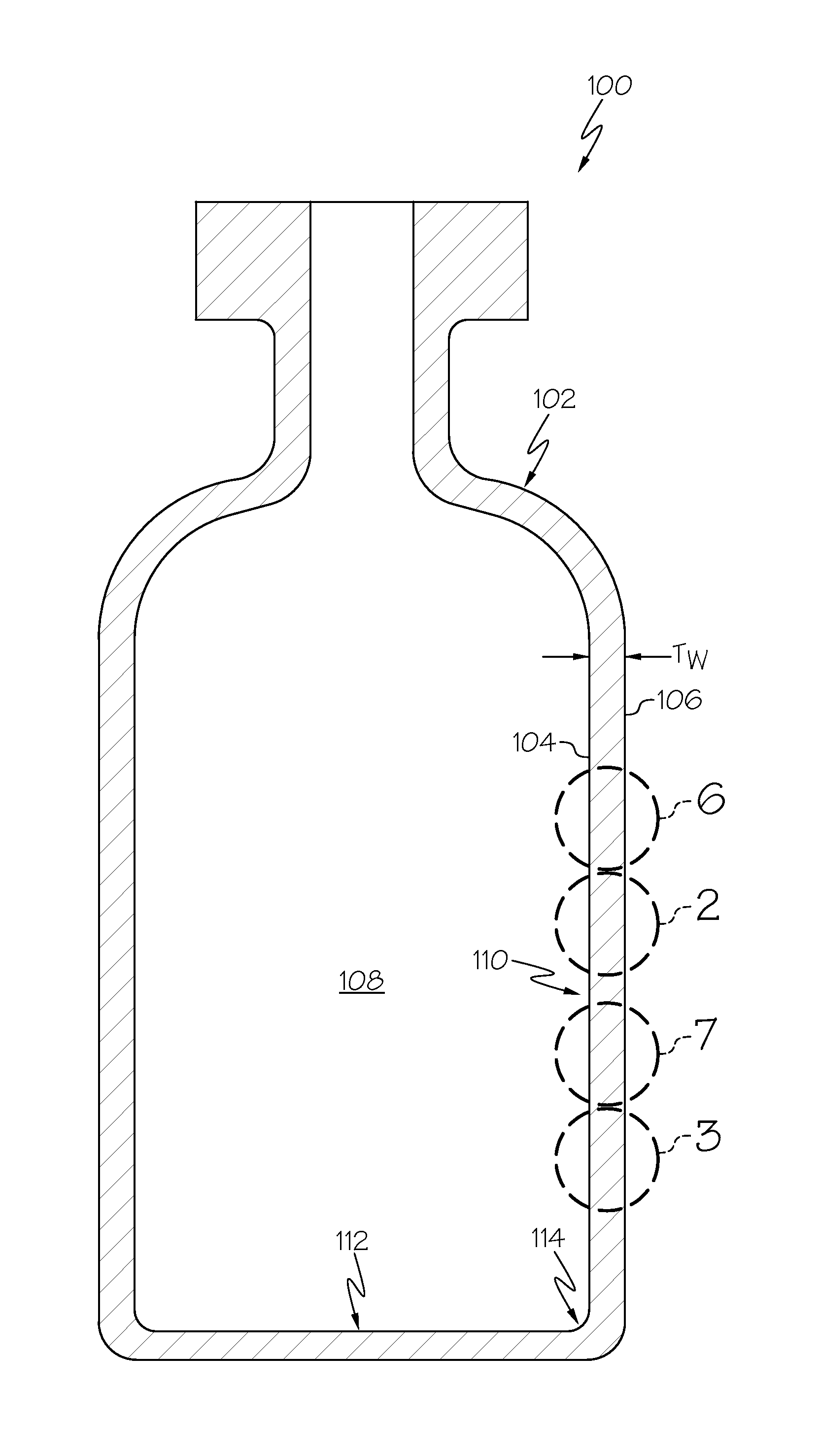

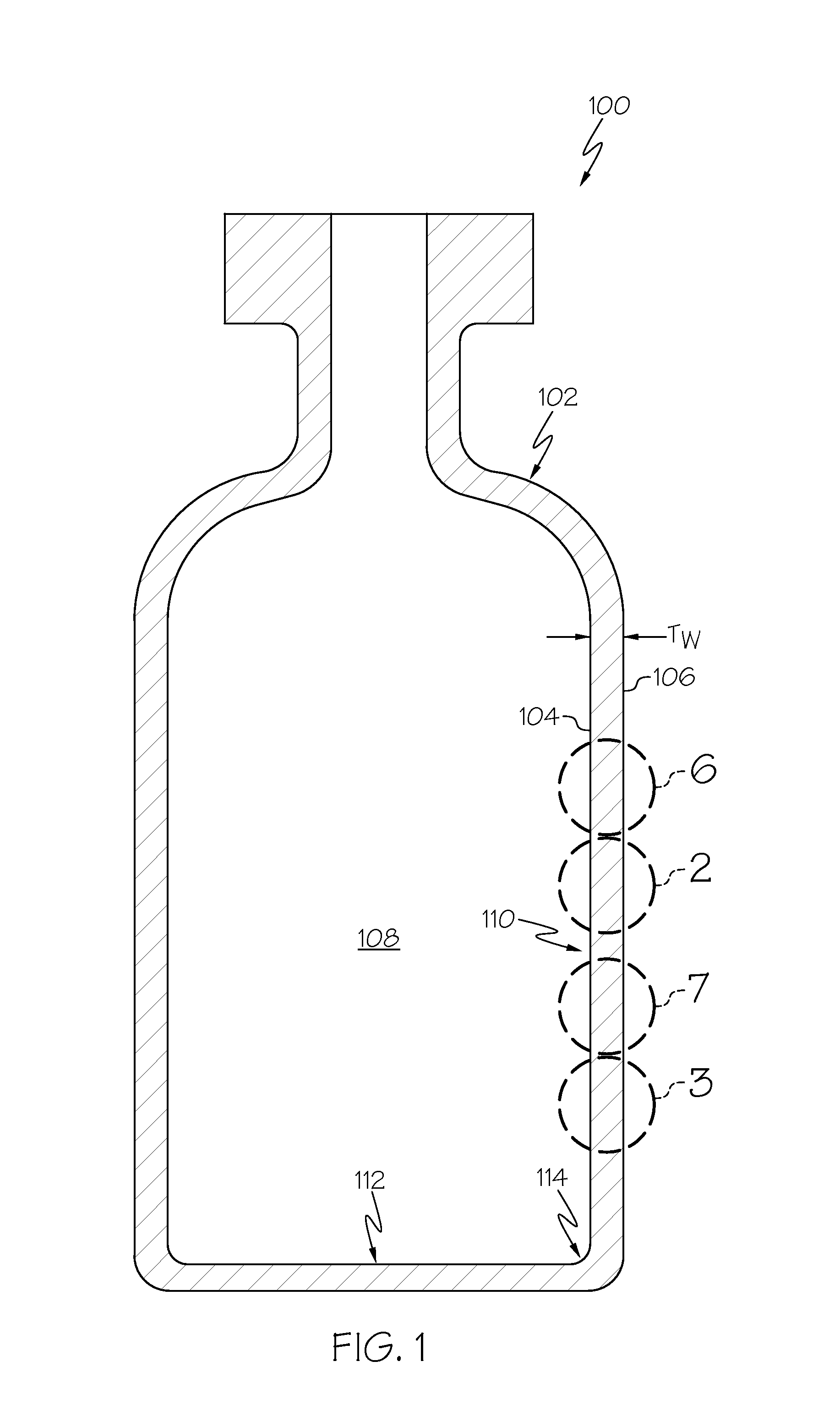

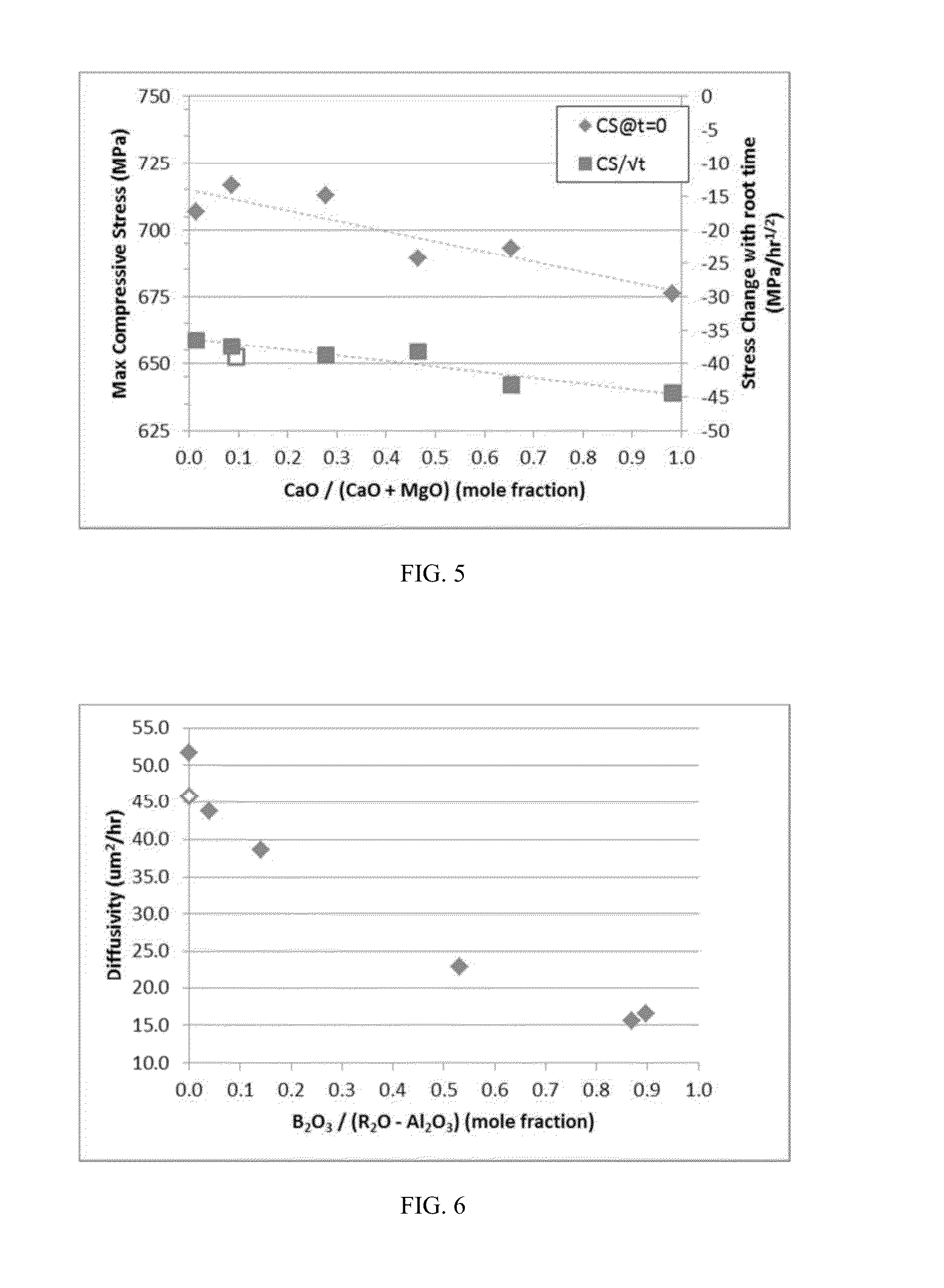

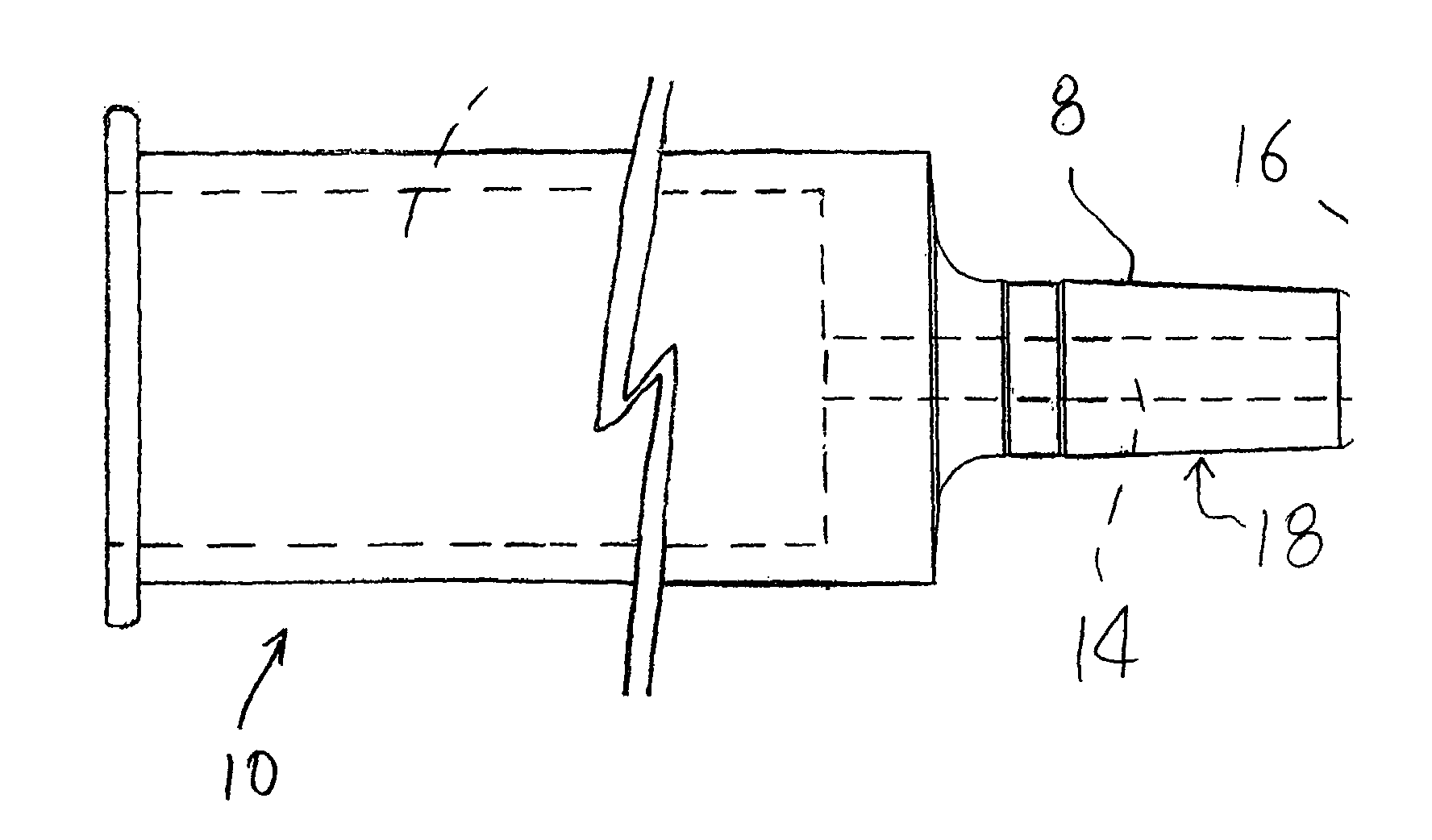

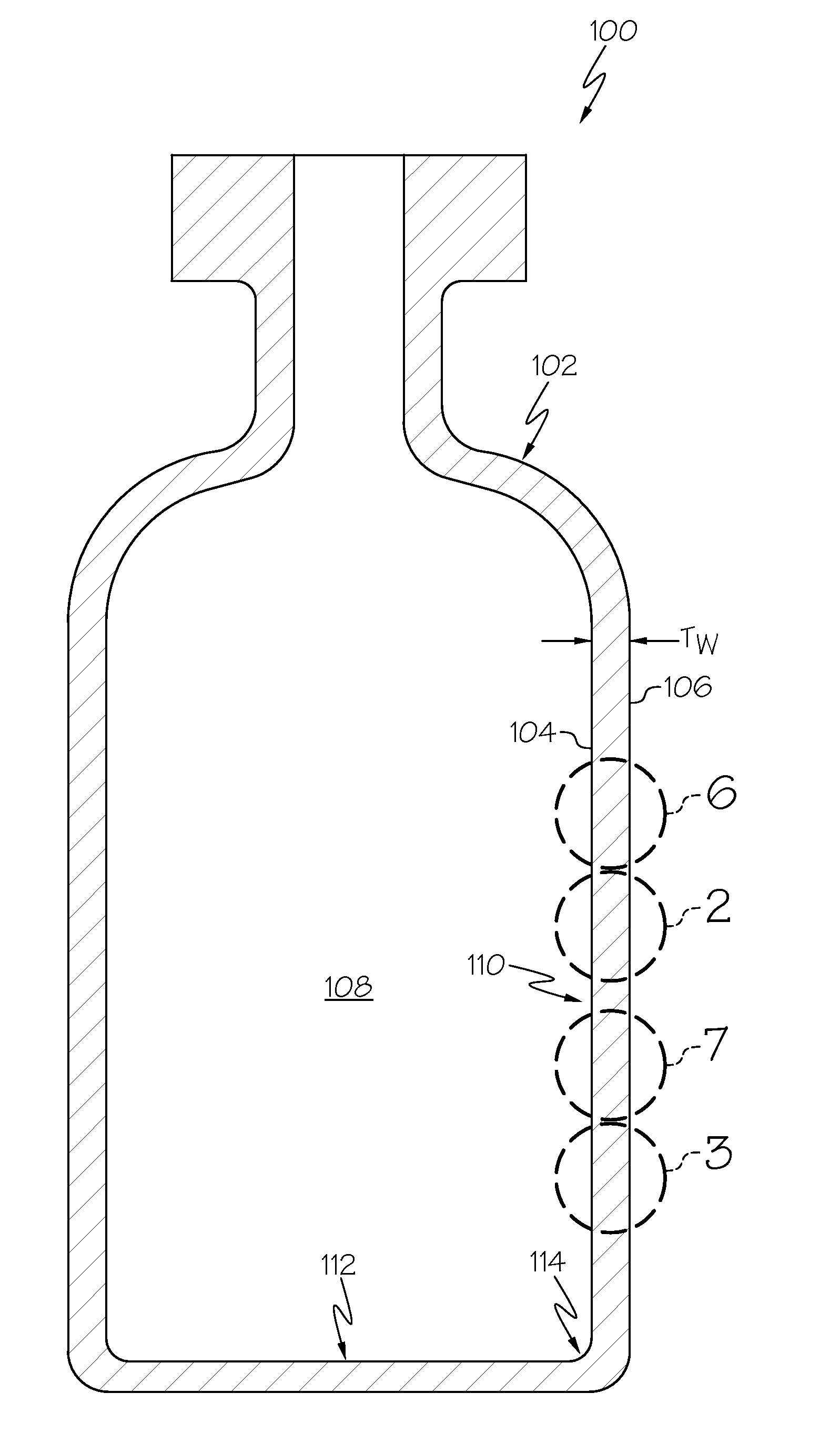

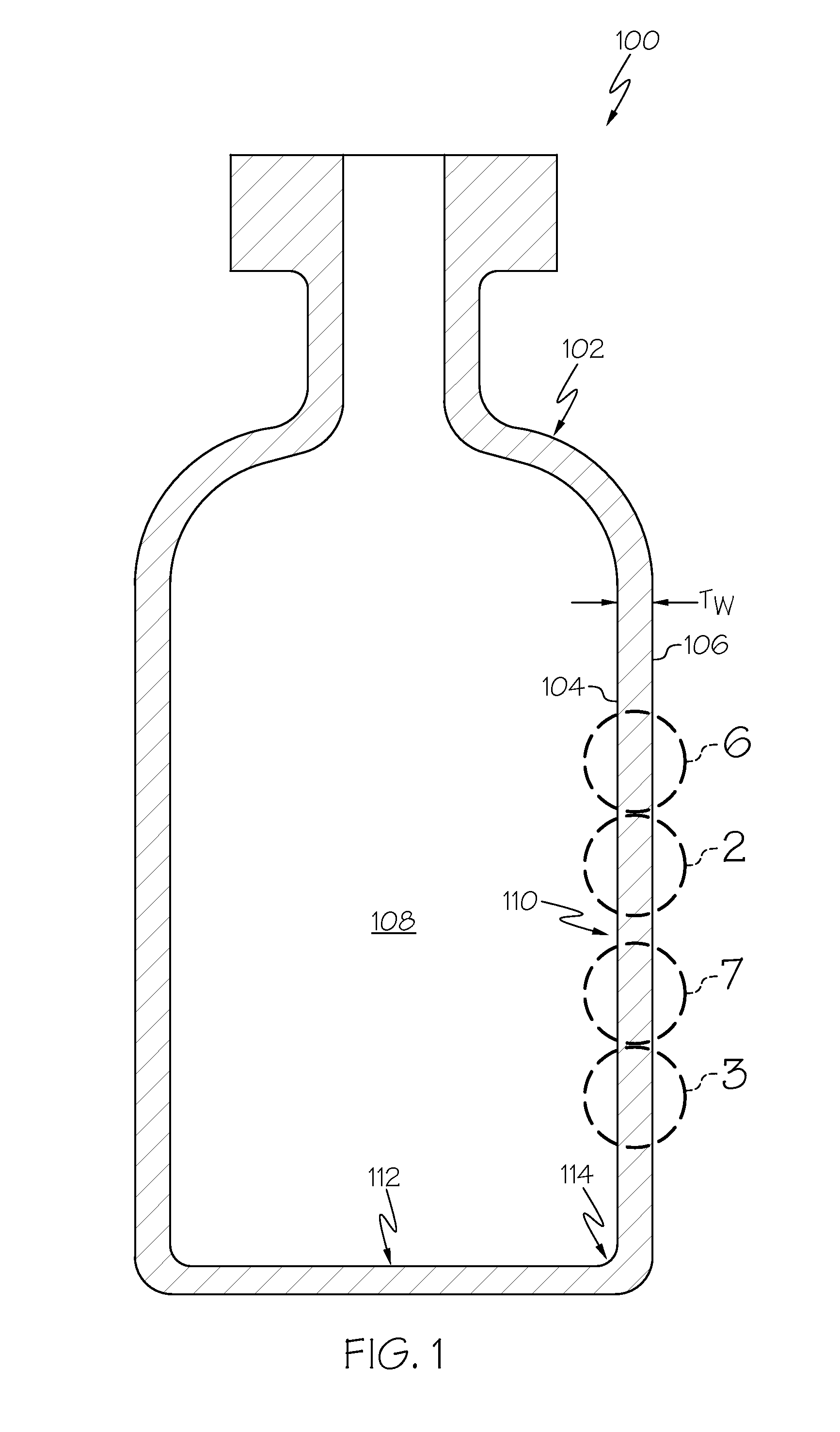

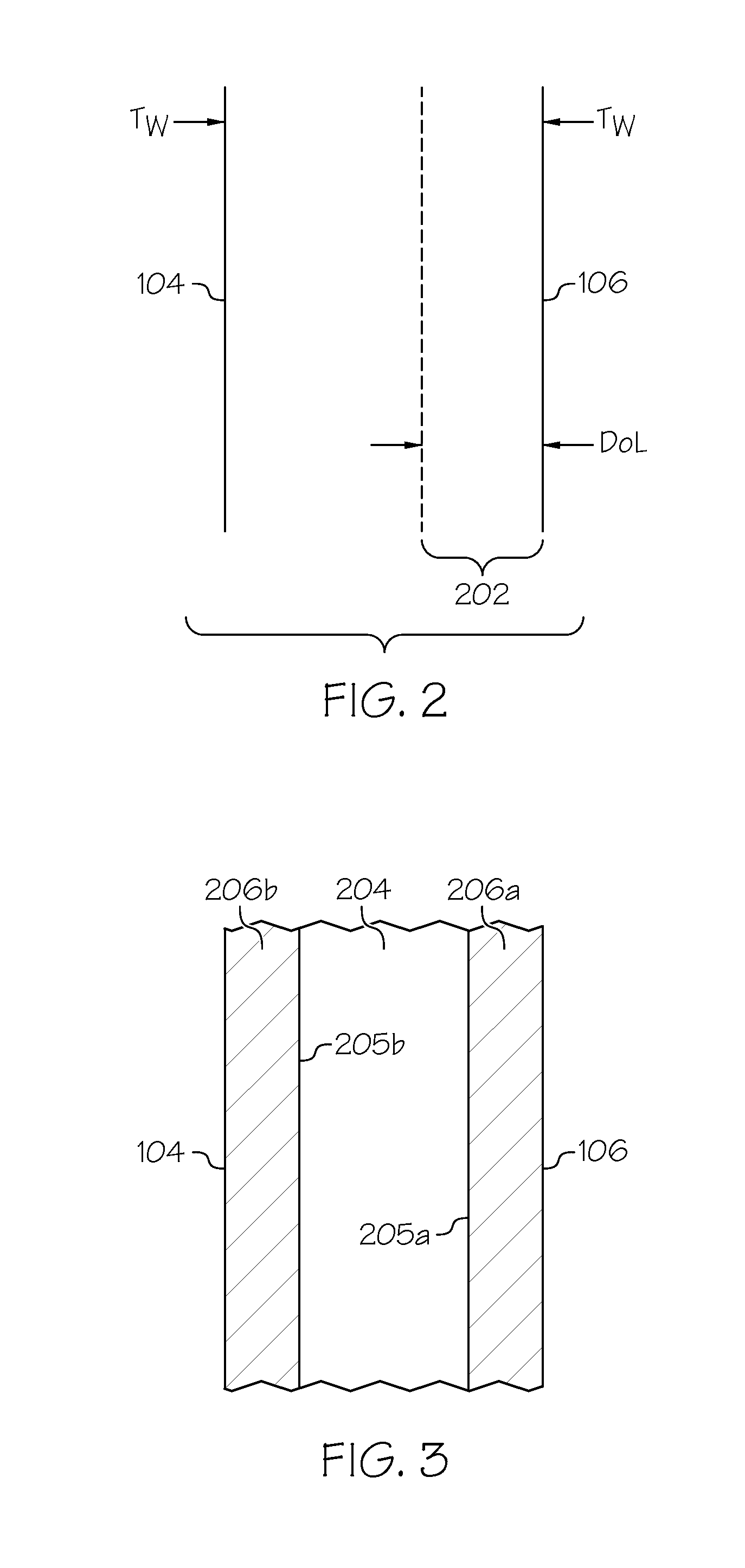

The glass containers described herein are resistant to delamination, have improved strength, and increased damage resistance. In one embodiment, a glass container may include a body having an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. At least the inner surface of the body may have a delamination factor less than or equal to 10. The body may also have a compressively stressed layer extending from the outer surface of the body into the wall thickness. The compressively stressed layer may have a surface compressive stress greater than or equal to 150 MPa. A lubricous coating may be positioned around at least a portion of the outer surface of the body, such that the outer surface of the body with the lubricous coating has a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

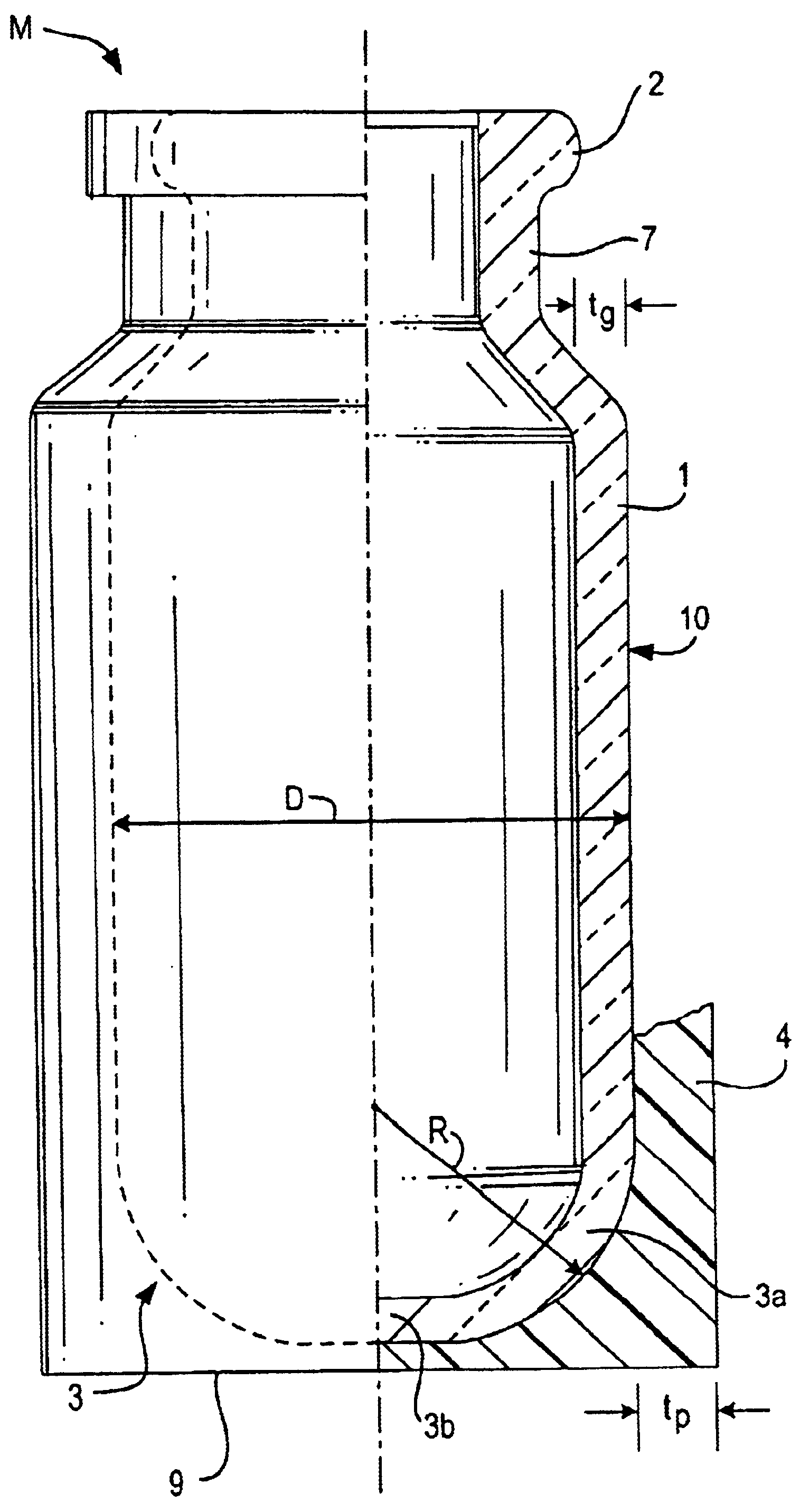

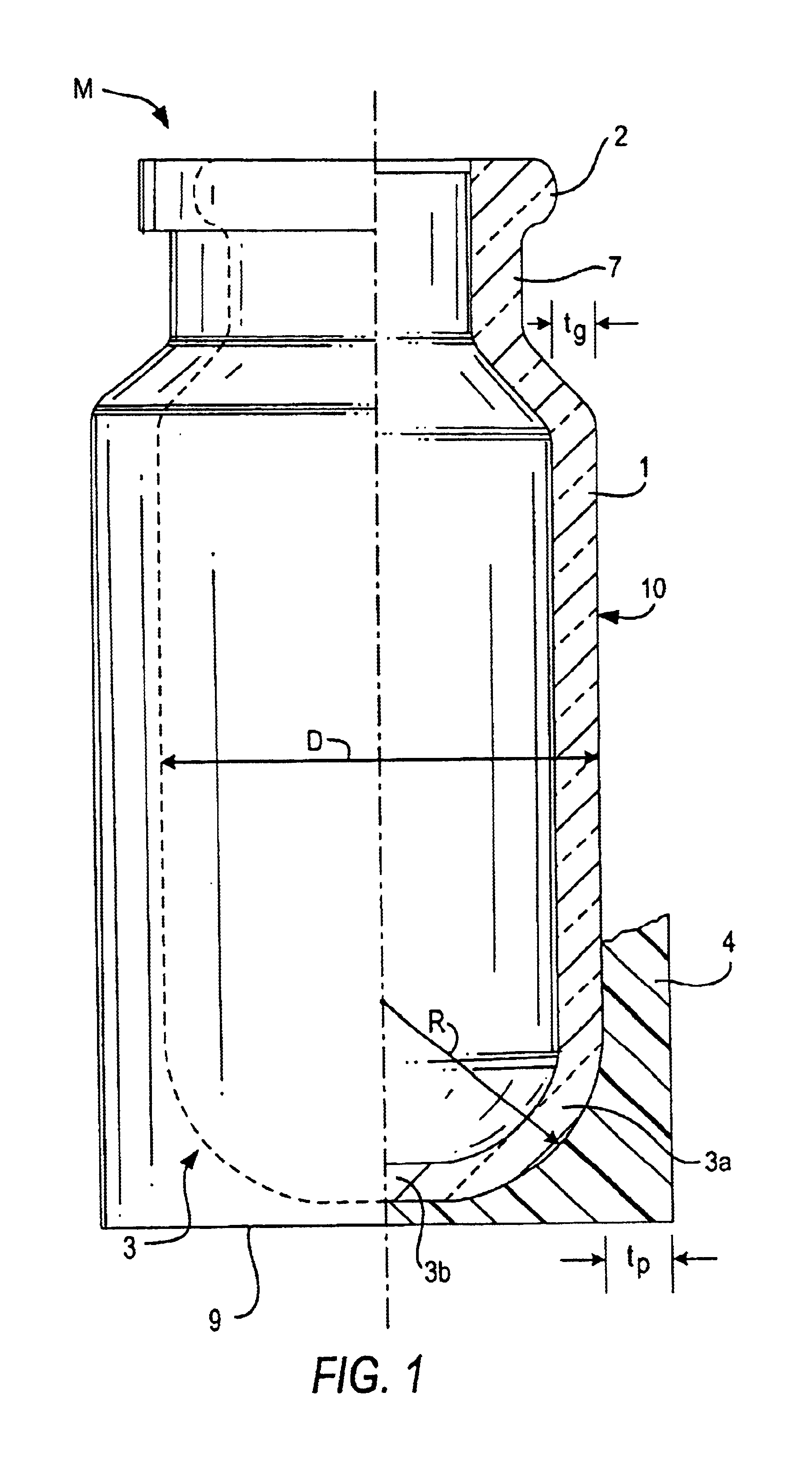

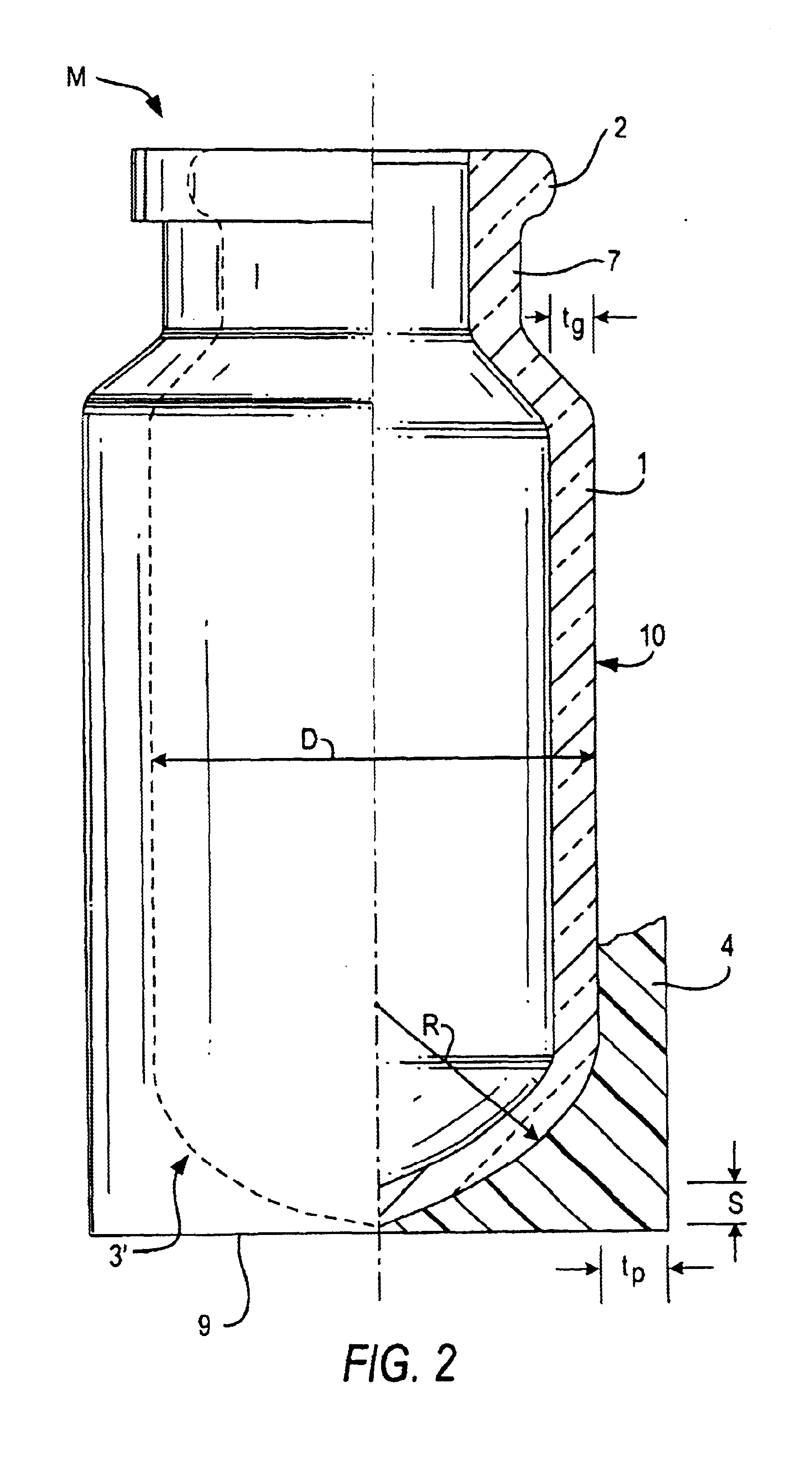

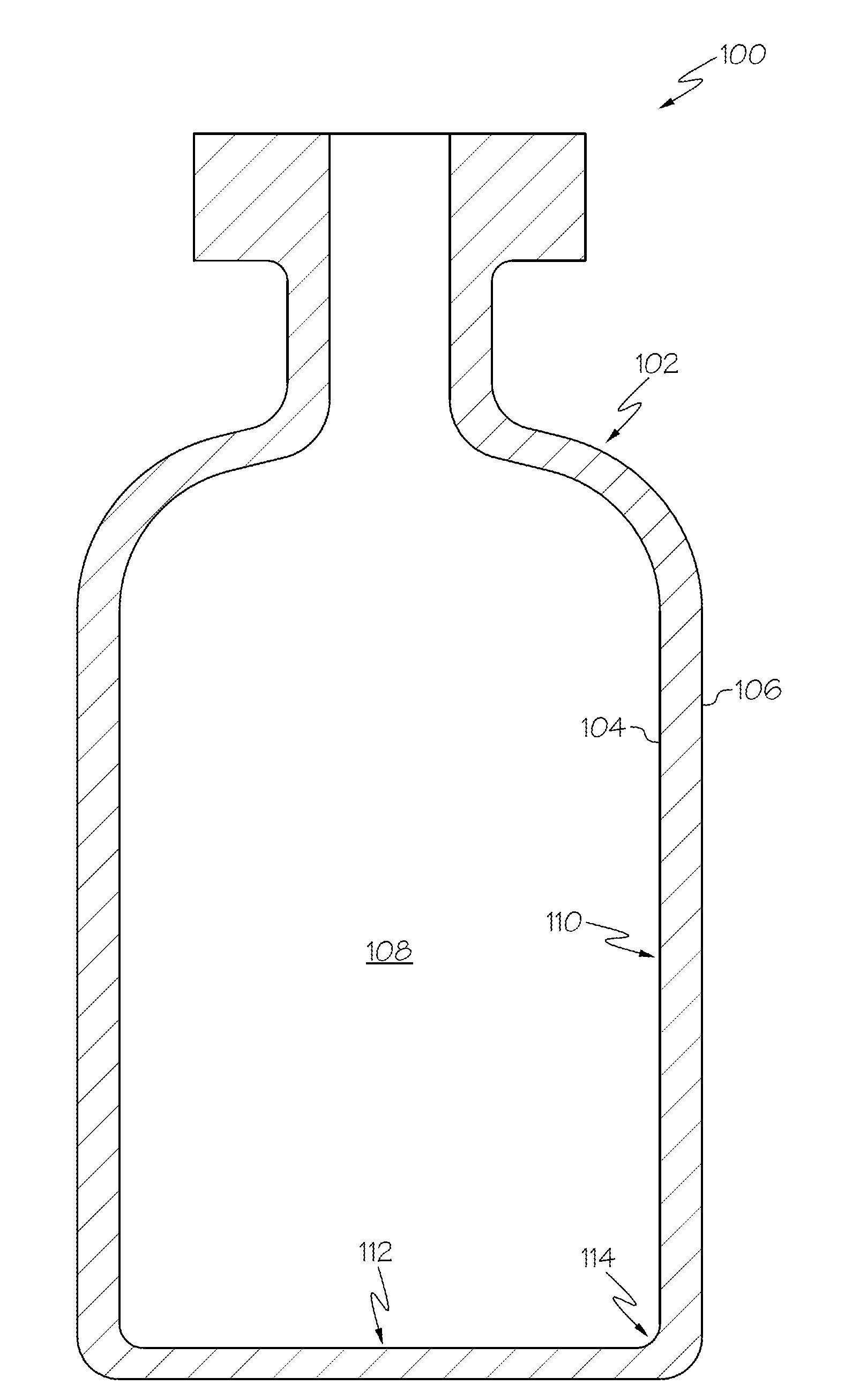

Closeable glass container comprising a plastic coating applied by injection molding and method for the production thereof

InactiveUS6866158B1Reduce wasteProduce some attenuationBottlesNon-pressured vesselsEngineeringBottle

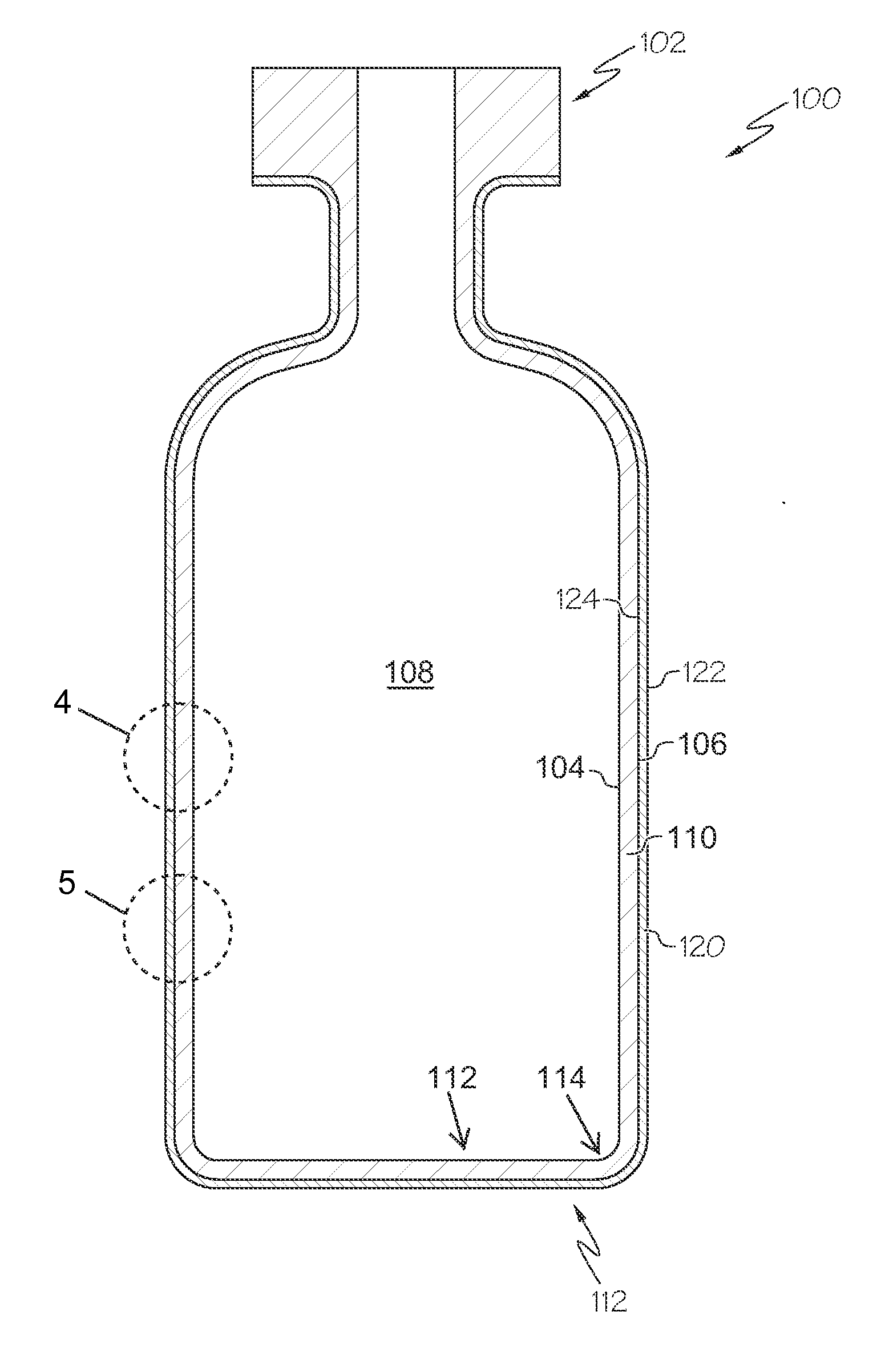

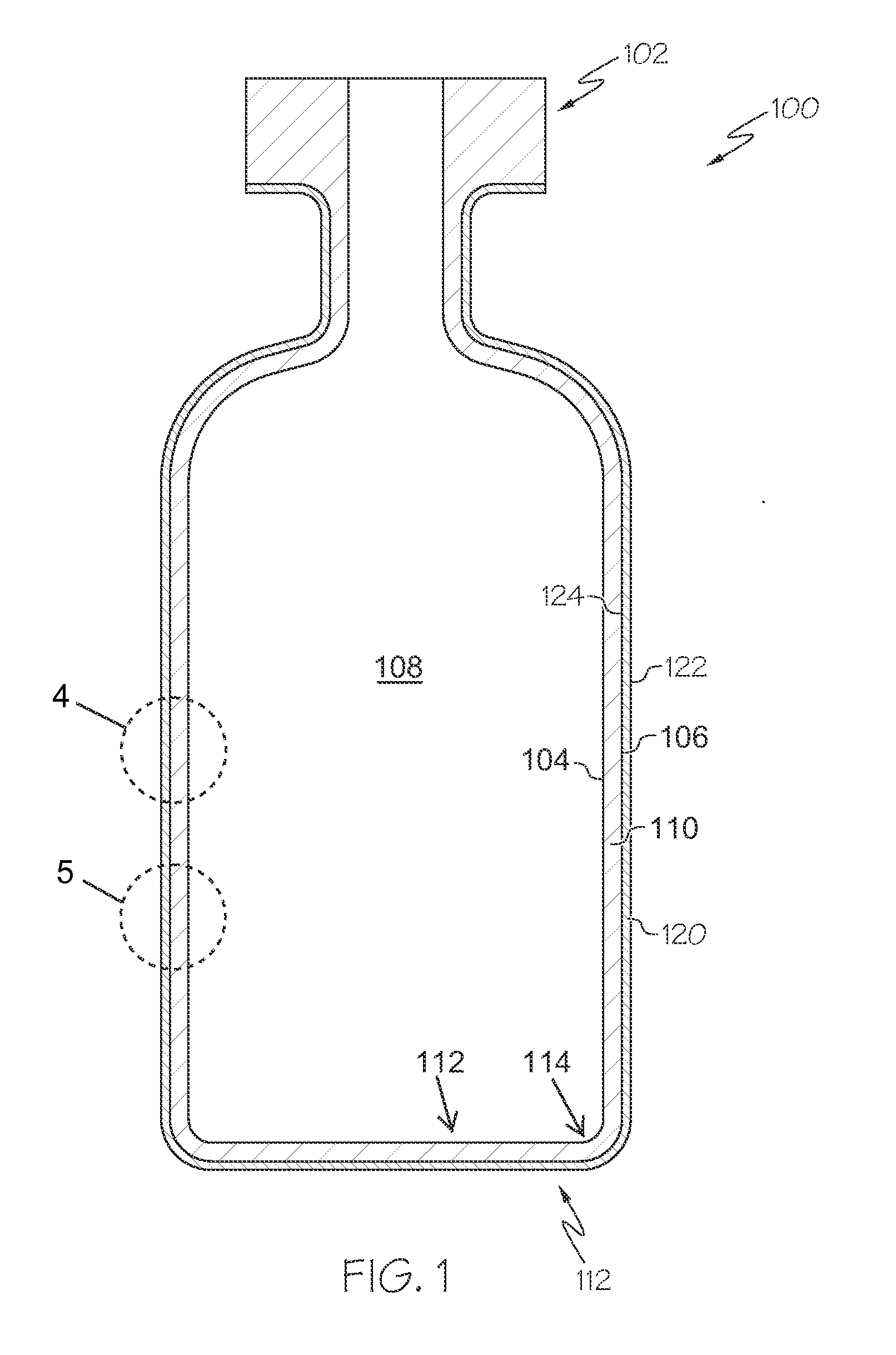

The container is a glass bottle (10) encased with a plastic coating (4) from its base section (3) to a sealing rim (2) around its mouth (M) in order to protect against shattering or explosive failure. The glass bottle, preferably a glass inlet, is fillable under pressure with a sprayable medically active substance and a propellant and provided with a delivery element attached to the sealing rim. To facilitate lower injection molding temperatures and pressures and to permit autoclaving at high temperatures the glass bottle with the plastic coating (4) is made by a method which includes injecting at least one reactively cross-linkable plastic capable of being heat-softened into a mold surrounding the glass bottle and forming the plastic coating (4) by a reaction injection molding (RIM) method.

Owner:SCHOTT AG

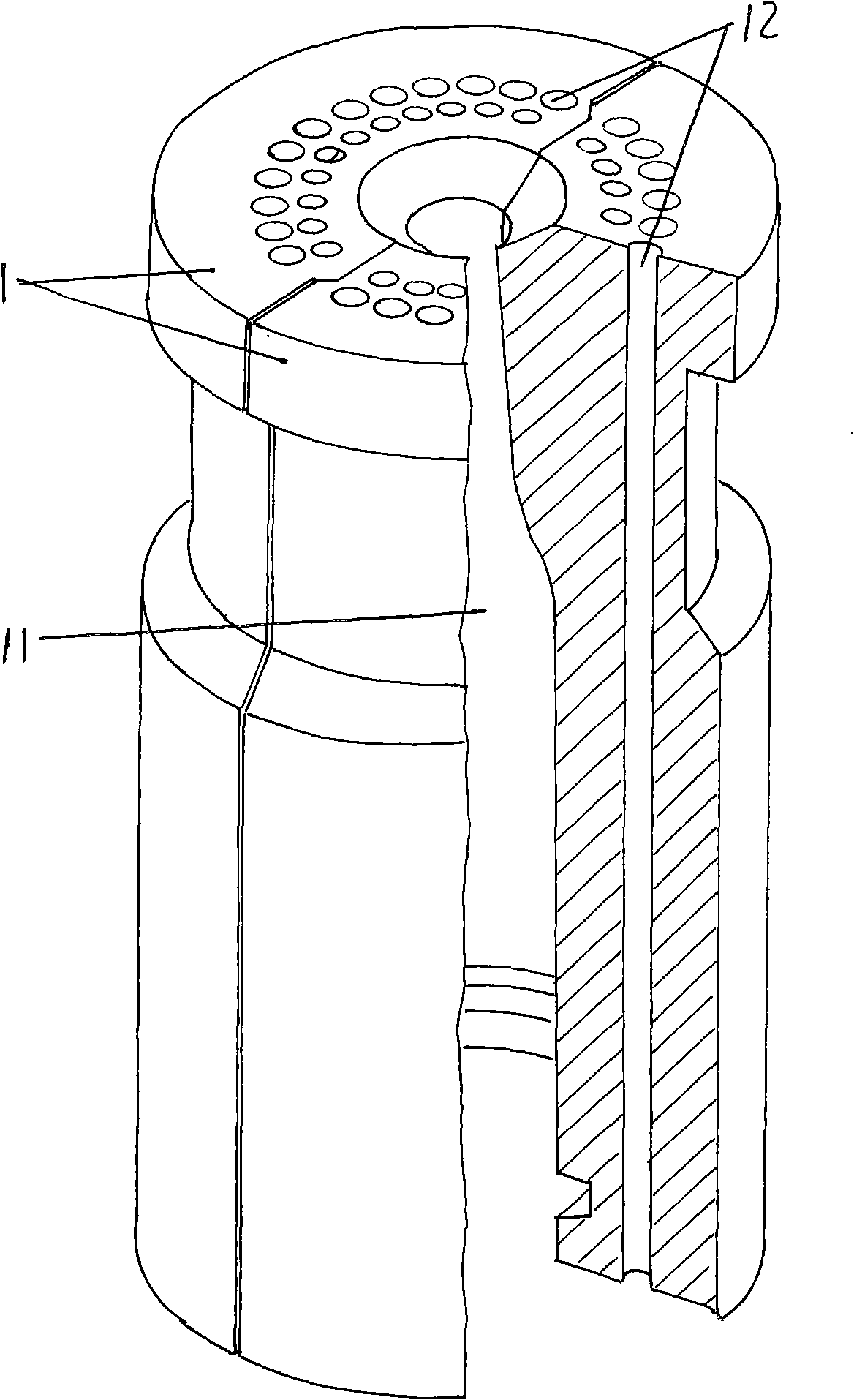

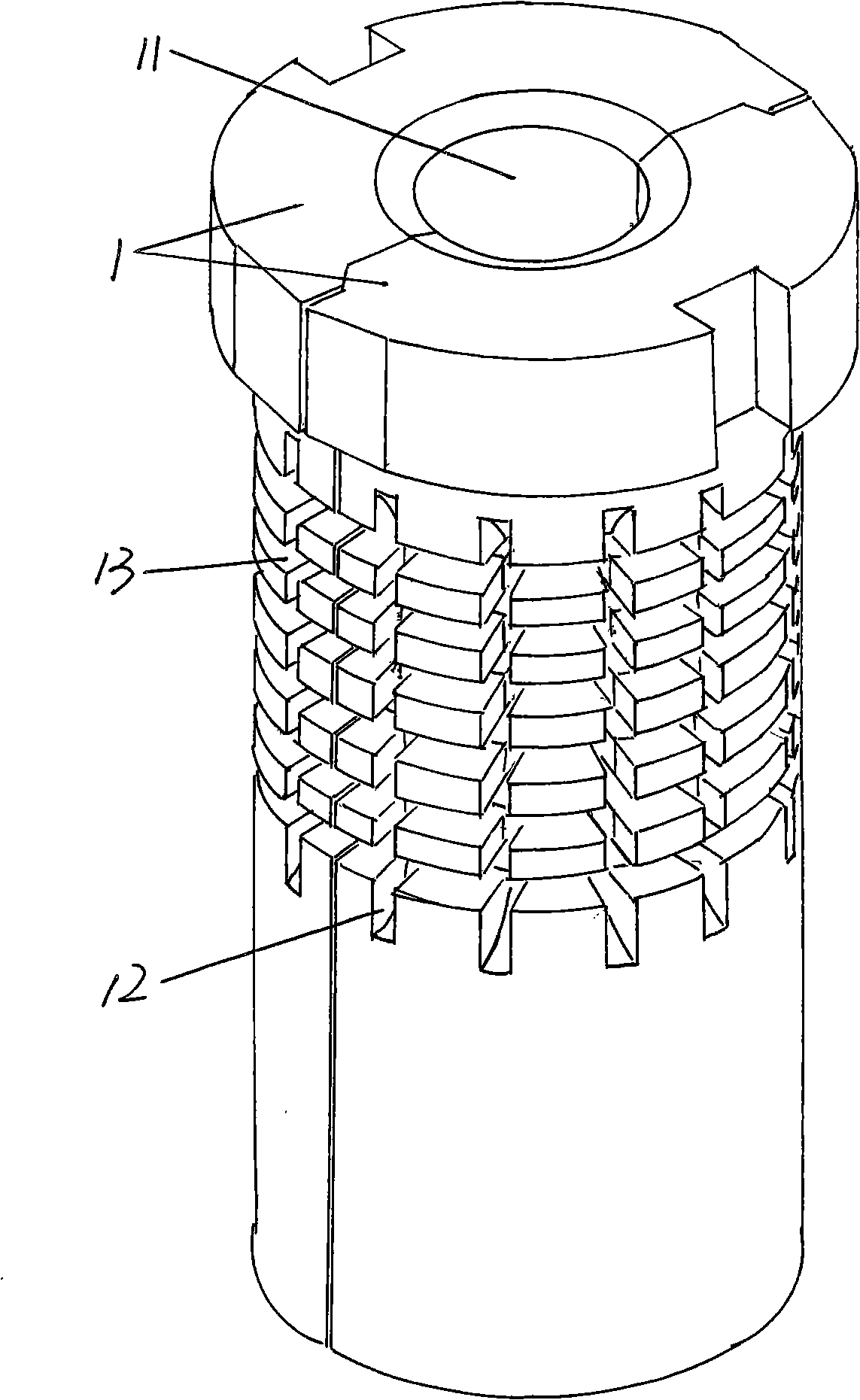

Mould for processing glass container

InactiveCN101298357AGuaranteed StrengthReduce the temperatureGlass shaping apparatusBottleMaterials science

The invention provides a mold for processing a glass container and belongs to the technical field of mold. The mold includes a pair of half molds that are opposite to each other and have the same shape, and a mold cavity is formed in each half mold. The mold is characterized in that vertical through ventilation holes which are communicated with each other are alternatively distributed around the mold cavity at the height direction of the half molds. The invention has the advantages that the bottle temperature can be cooled effectively due to the through ventilation holes around the mold cavity at the height direction, thus preventing the bottle from being deformed by high temperature and guaranteeing the strength of the half molds.

Owner:CHANGSHU WEIHENG MOLD MFG

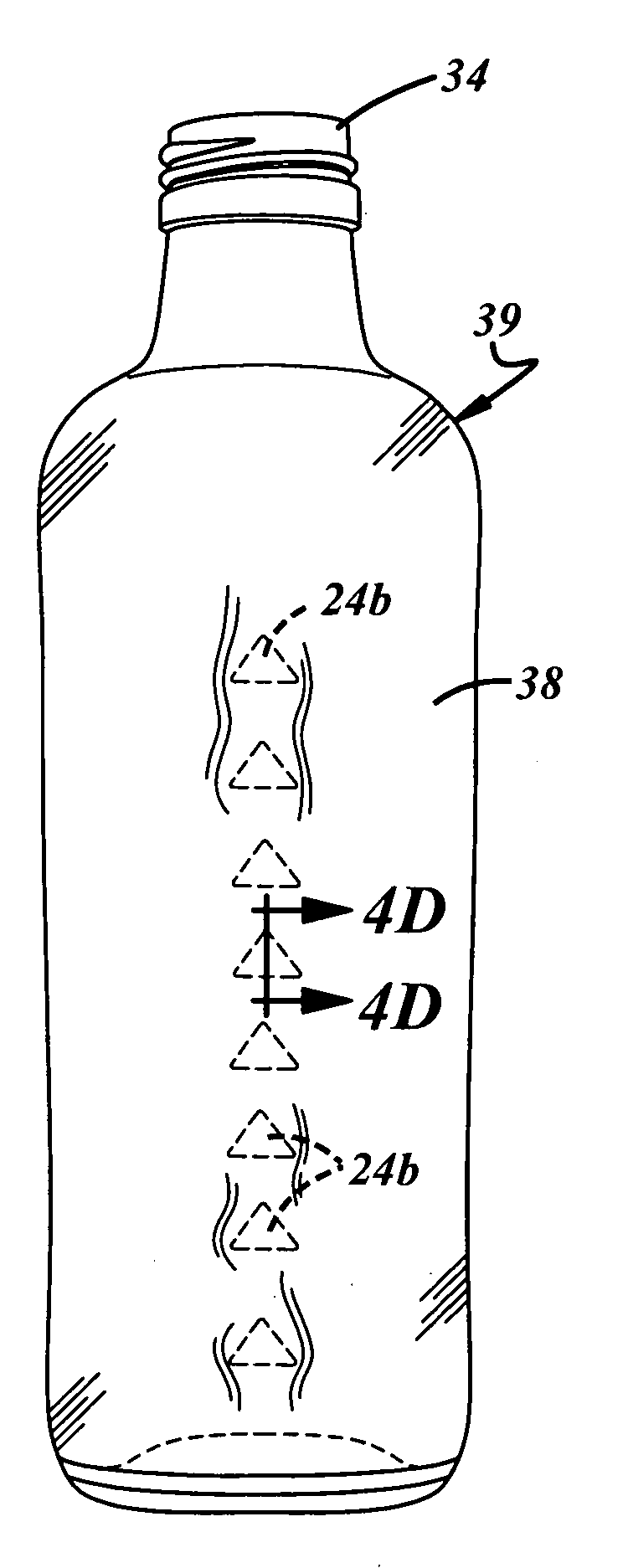

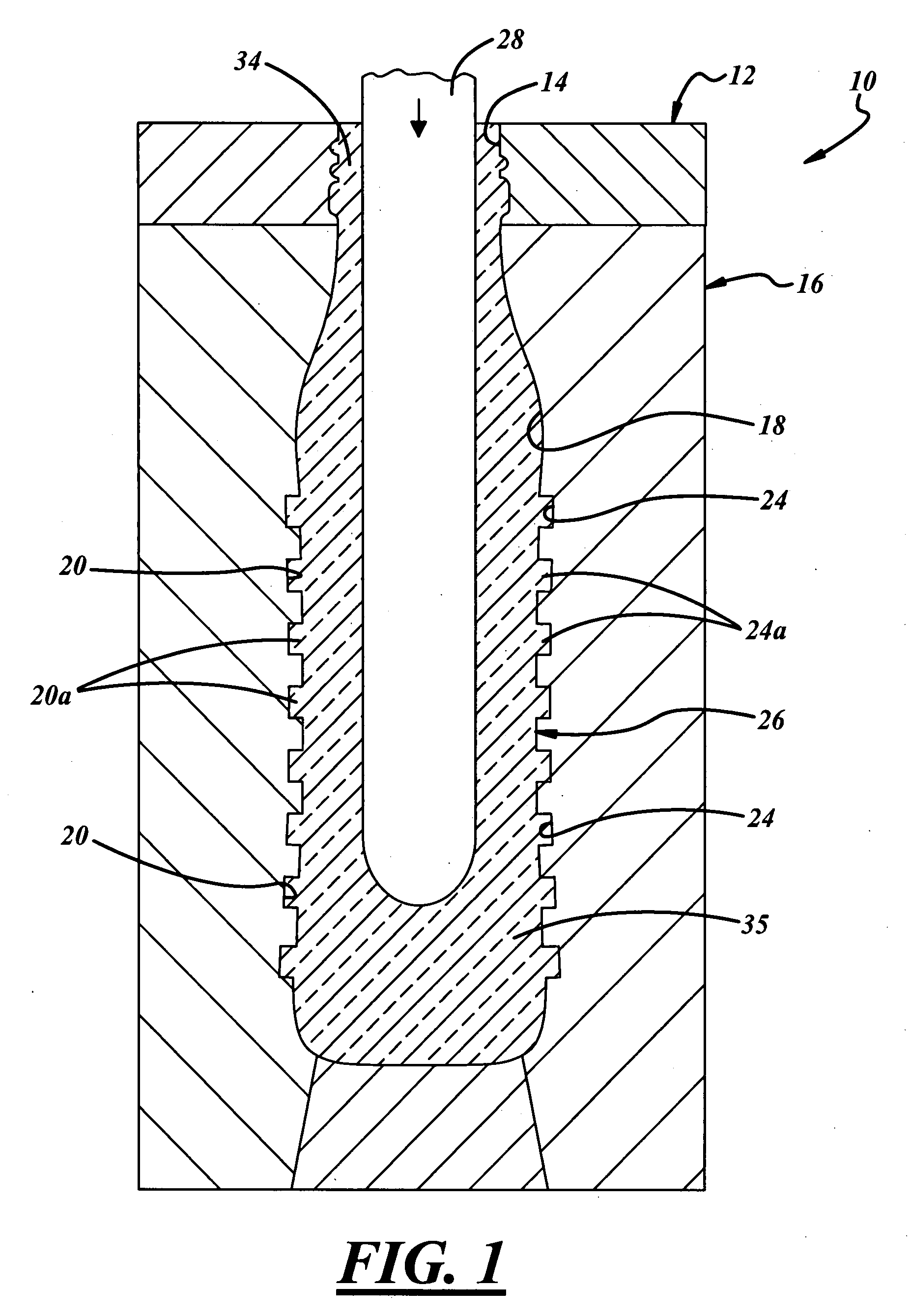

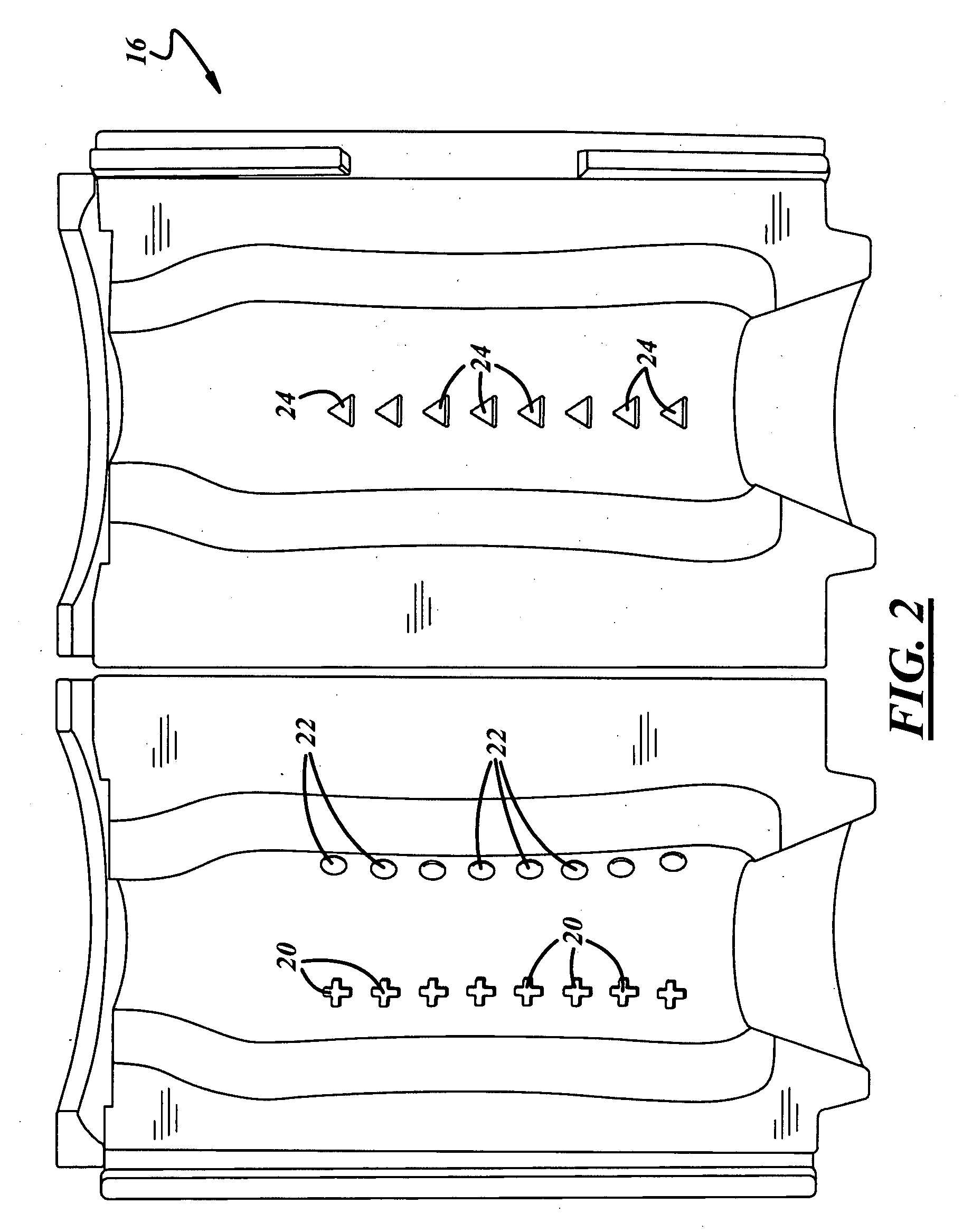

Narrow neck glass container with internal embossments and method of manufacture

InactiveUS20090084799A1Large containersPress and blow machinesMechanical engineeringGeometric pattern

A narrow neck glass container includes a container body and a container neck finish. The container neck finish has an external closure attachment diameter of not more than 36 mm, and the container body has at least one internal embossment of predetermined geometry. The at least one internal embossment preferably comprises a plurality of internal embossments in a geometric pattern.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

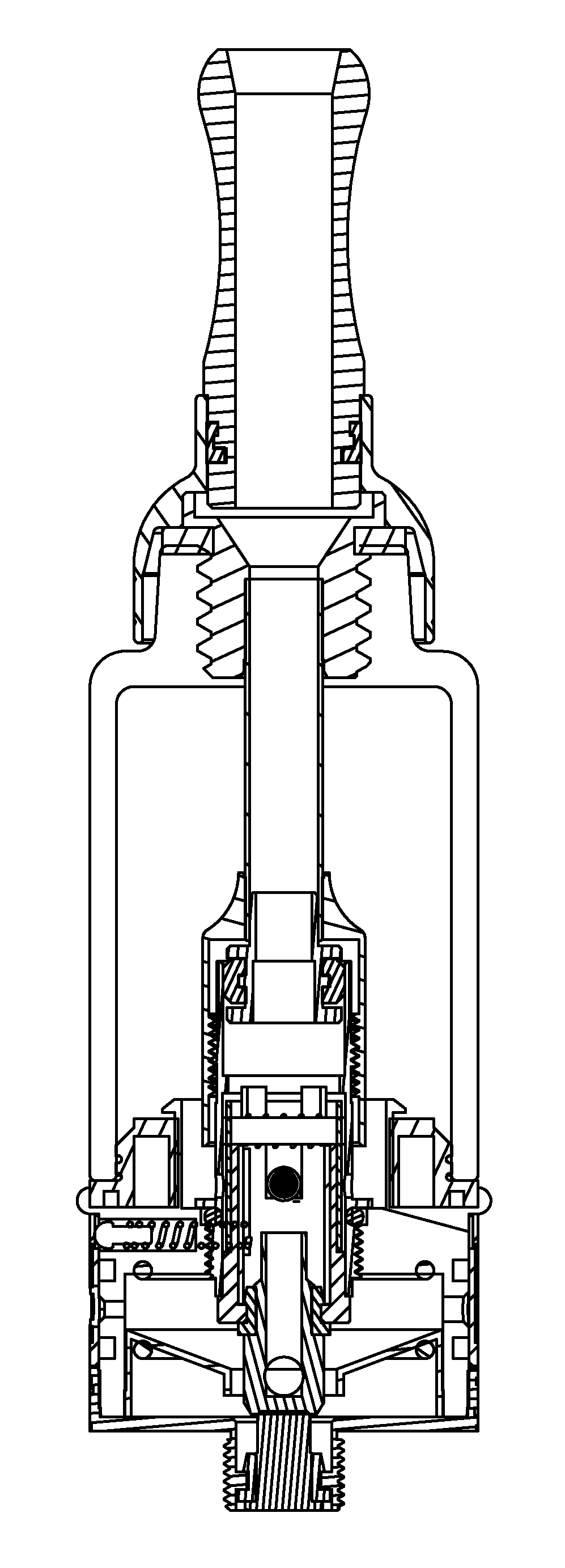

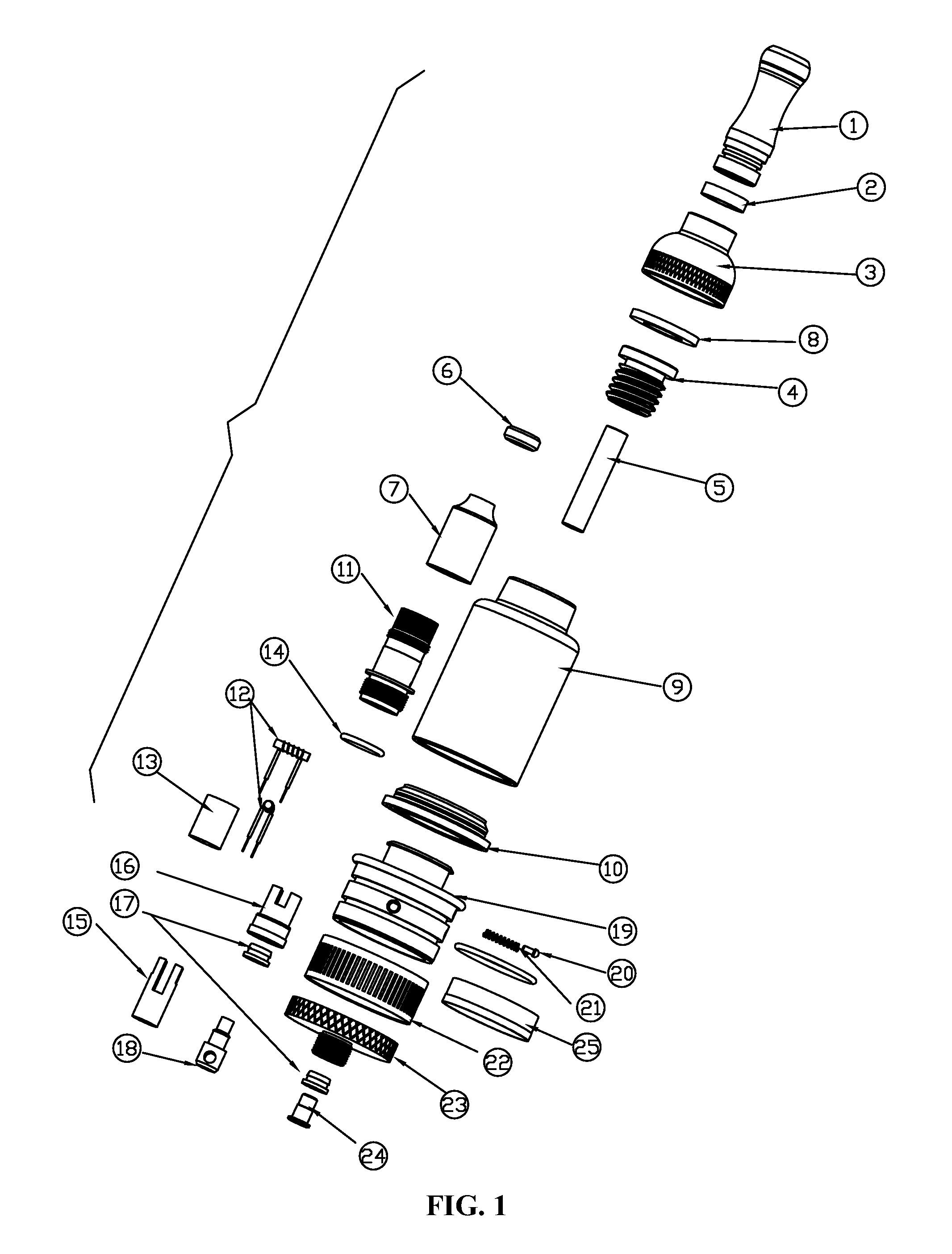

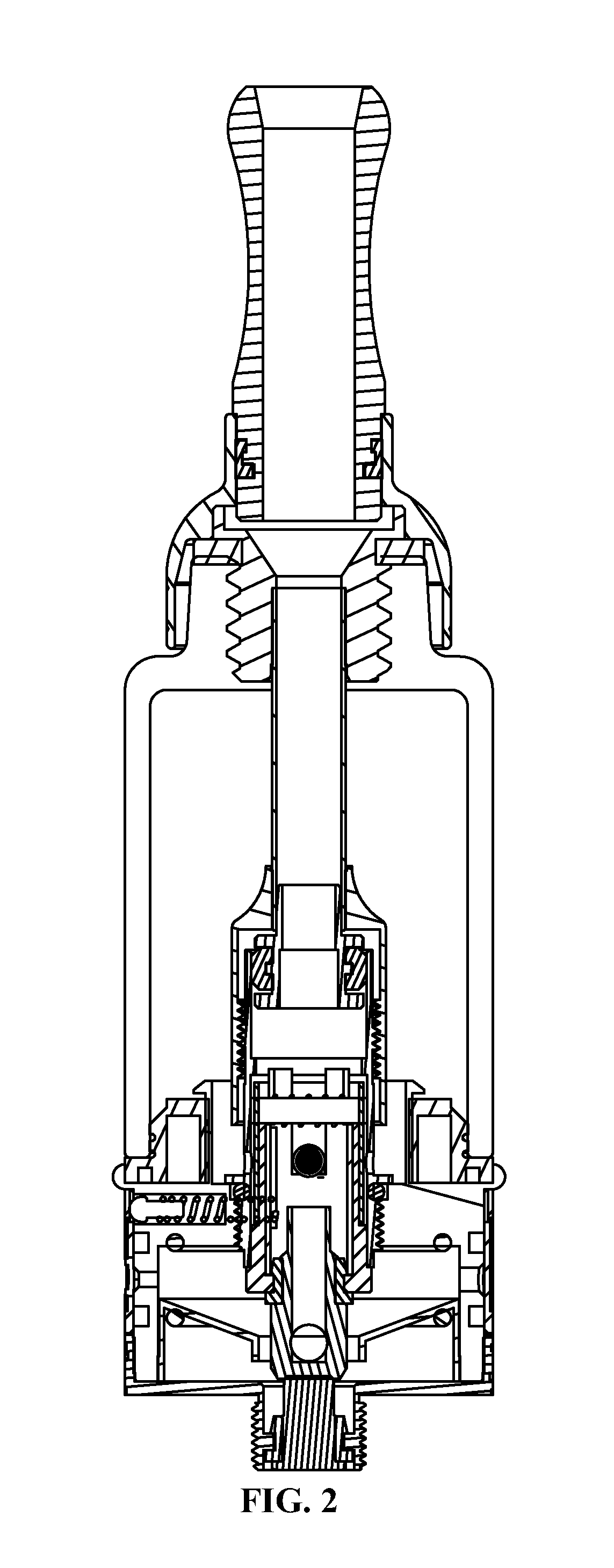

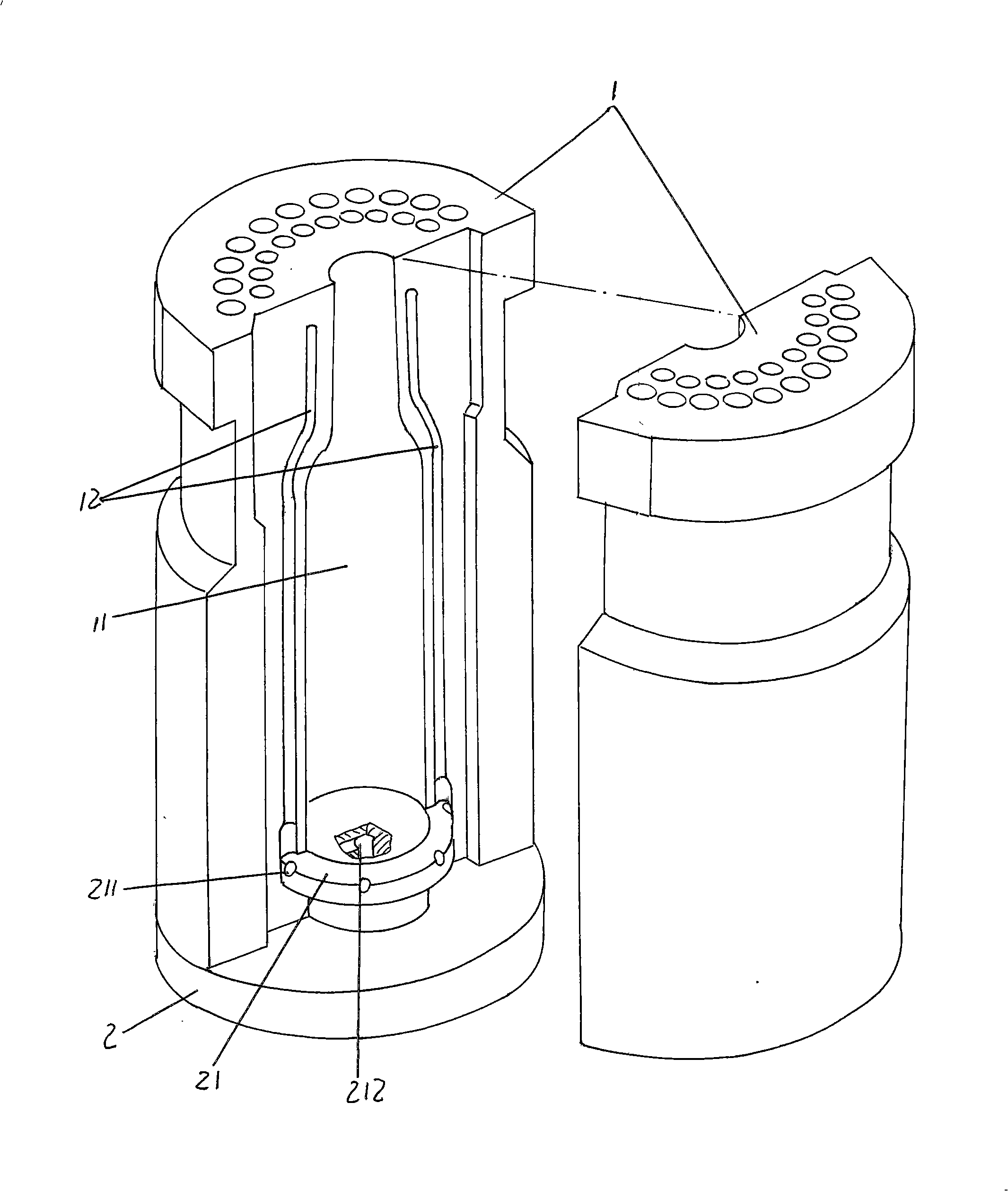

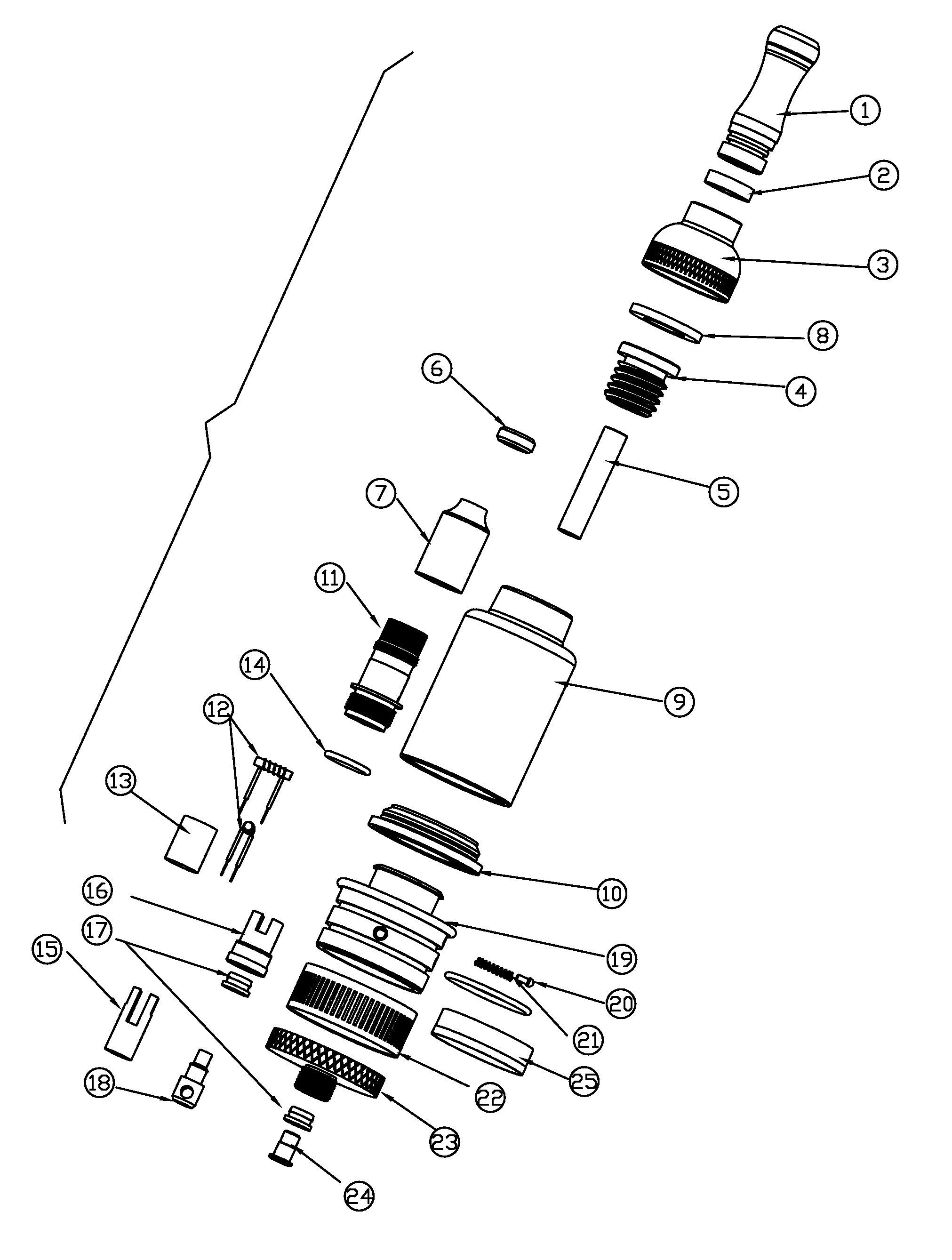

Electronic cigarette

ActiveUS20150136157A1Easy to useNot to polluteMedical devicesTobacco pipesEngineeringElectronic cigarette

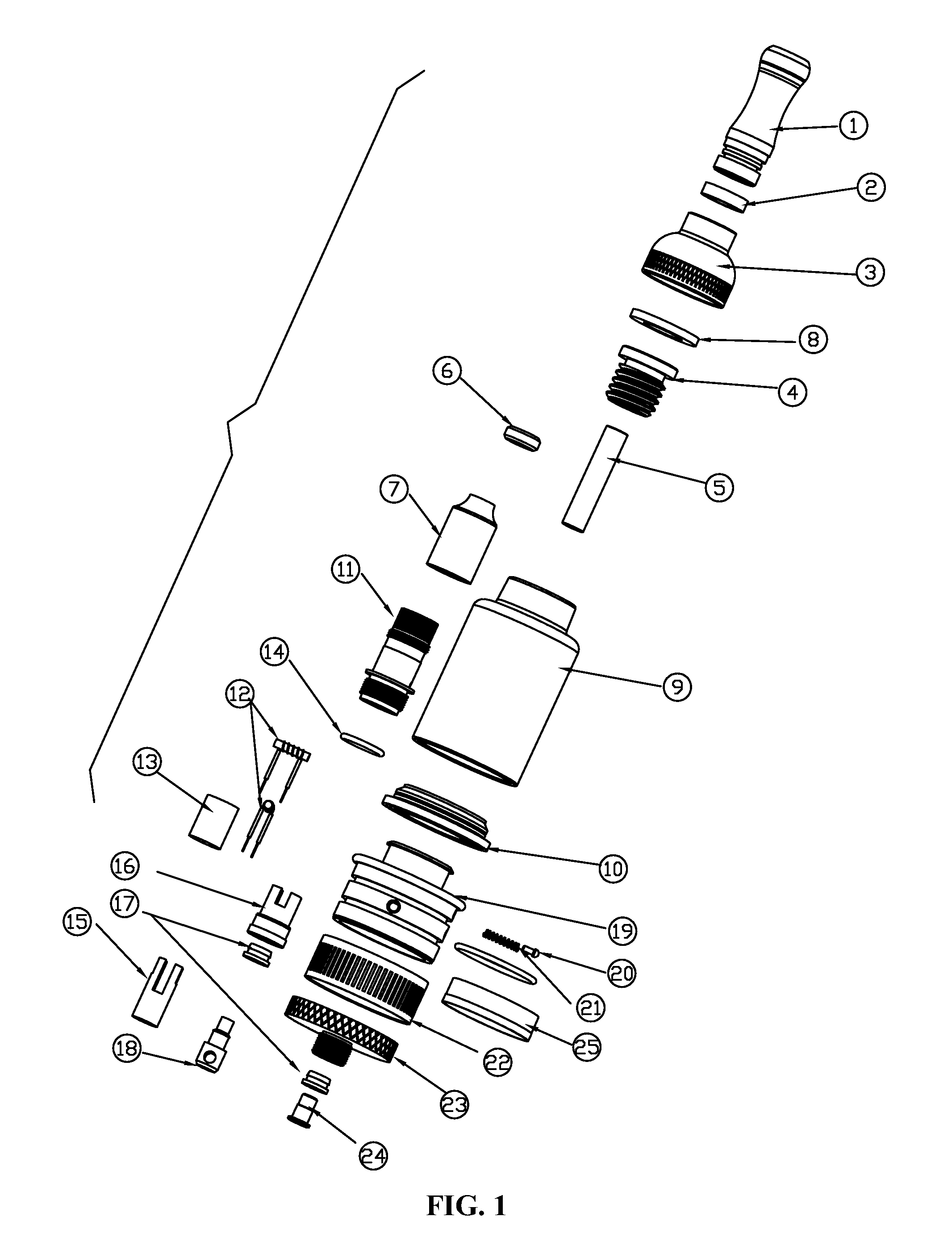

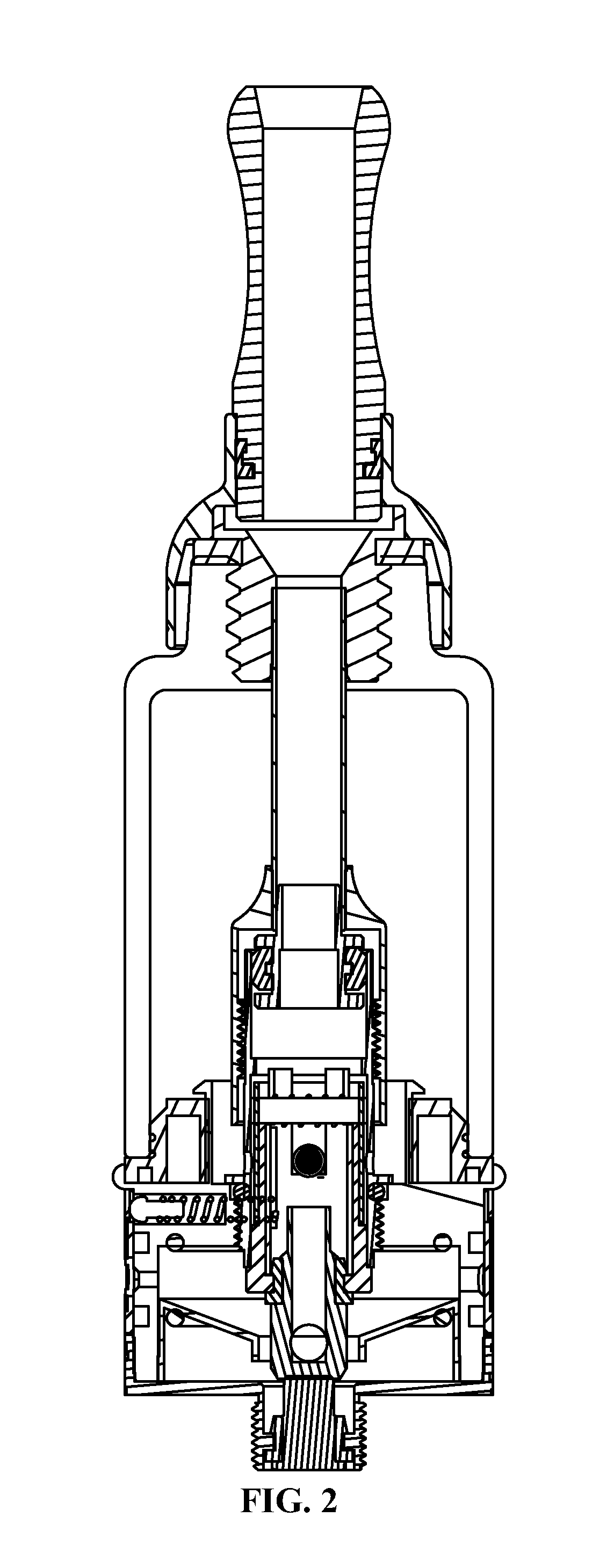

An electronic cigarette, including a cigarette holder assembly, an atomization assembly, a glass container for accommodating smoke oil, and a gas flow regulator. The cigarette holder assembly includes a mouthpiece, a first sealing ring, a seat for supporting the mouthpiece, a fixed screw, and a pole. The atomization assembly includes a pair of heating wires, a glass casing, a second sealing ring, a third sealing ring, oil-guiding cotton, a limit cover, an insulating ring, and a fixed ring. The glass container includes a first sealing gasket and a second sealing gasket which are respectively disposed at both ends of the glass container. The gas flow regulator includes a control ring, a steel ball, a spring, and a rotary button. The first sealing ring of the cigarette holder assembly is sleeved on the mouthpiece, and the mouthpiece is fixed on the seat via the fixed screw.

Owner:LIU TUANFANG

Mould for making glass container

ActiveCN101298355AIncrease temperatureEvenly distributedVacuum and blow machinesGlass containerMaterials science

The invention provides a mold for producing a glass container and belongs to the technical field of mold. The mold includes a pair of half bottle molds that are opposite to each other, a bottle die cavity is composed of a bottle body cavity and a bottleneck cavity and is formed on the inner wall of each of the half bottle molds. The mold is characterized in that heat-insulating holes are regularly distributed around the bottleneck cavity at the upper part of the half bottle mold, so the temperature around the bottleneck cavity can be improved, which is helpful to lead the materials to distribute evenly during the two blowing processes and can guarantee that the wall thickness of the bottleneck is uniform.

Owner:CHANGSHU WEIHENG MOLD MFG

Mould for making glass container

ActiveCN101298356AIncrease temperatureEvenly distributedVacuum and blow machinesBottleMaterials science

The invention provides a mold for producing a glass container and belongs to the technical field of mold. The mold includes a pair of half bottle molds that are opposite to each other, and a bottle die cavity is formed in the inner wall of each half bottle mold and is composed of a bottle body cavity and a bottleneck cavity. The mold is characterized in that a first heat-insulating hole and a second heat-insulating hole are alternatively distributed around the bottleneck cavity at the upper part of the half bottle mold, wherein, the depth of the two heat-insulating holes is different. The mold has the advantages that the temperature around the bottleneck cavity can be improved as the first heat-insulating hole and the second heat-insulating hole are arranged at the upper part of the half bottle mold and are corresponding to the surrounding of the bottleneck cavity, which is helpful to lead the materials to distribute evenly during the two blowing process and can guarantee that the wall thickness of the bottleneck is uniform.

Owner:CHANGSHU WEIHENG MOLD MFG

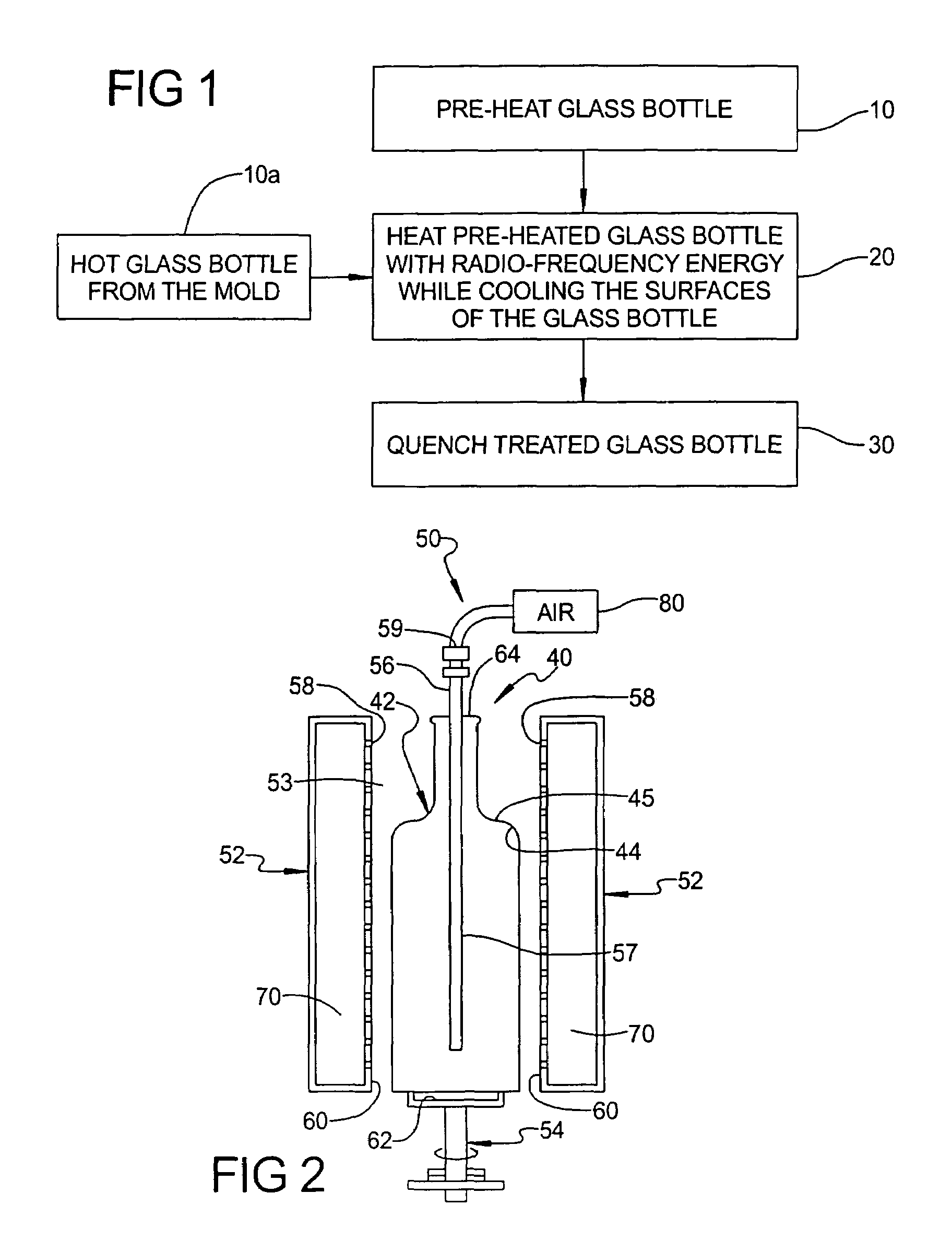

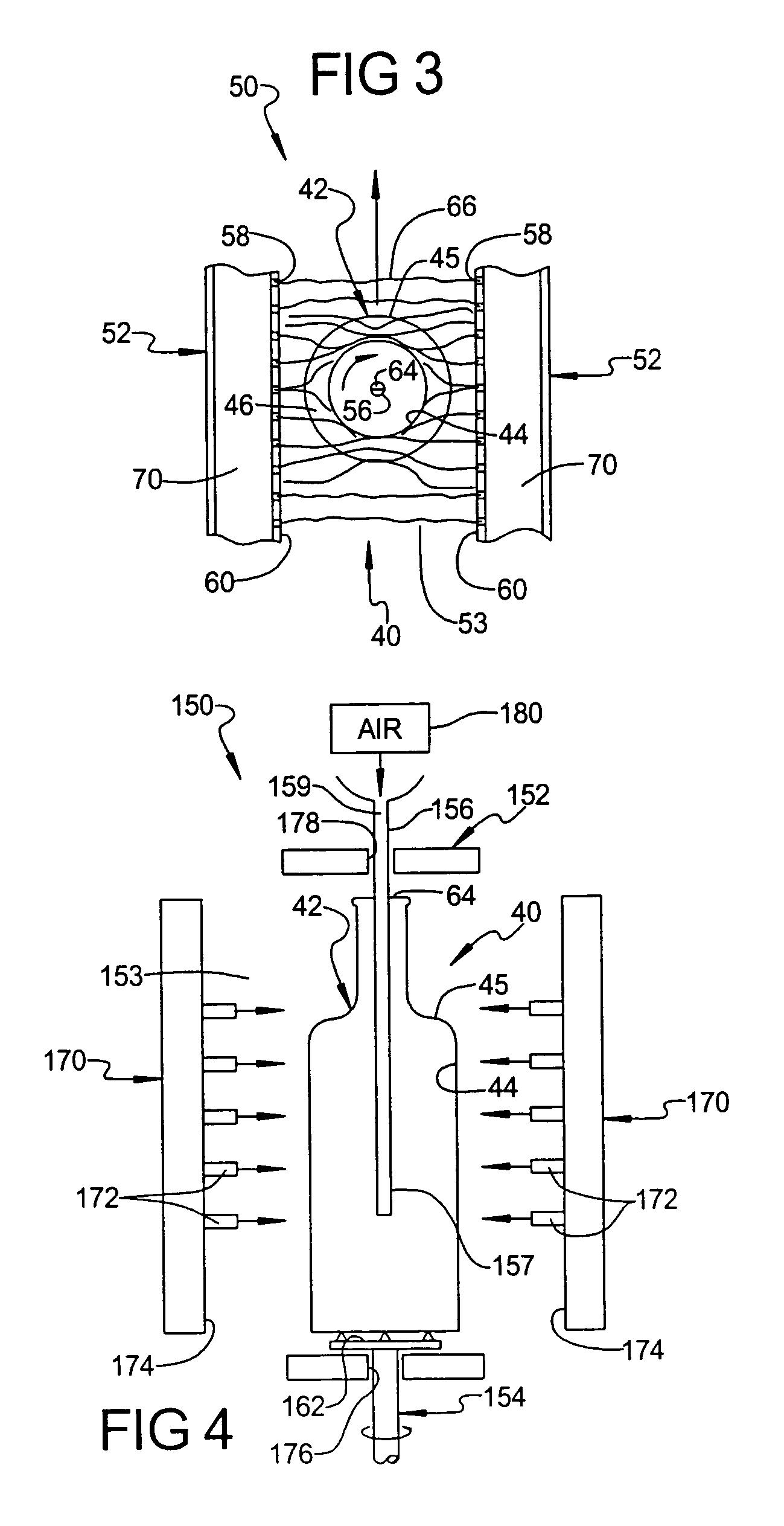

System and method for tempering glass containers

InactiveUS7694532B1Save energySave raw materialsInduction heatingFurnace typesRadio frequency energyEngineering

A system and method is provided for tempering a glass container. The method includes the steps of pre-heating the glass container to a first predetermined temperature. The method also includes the steps of applying radio-frequency energy to the pre-heated glass container to heat the glass container to a second predetermined temperature and, after a predetermined amount of time, simultaneously cooling at least one surface of the heated glass container to a third predetermined temperature to treat the glass container. The method further includes the steps of, after a predetermined amount of time, quenching the treated glass container to a fourth predetermined temperature to produce a tempered glass container.

Owner:BOAZ PREMAKARAN T

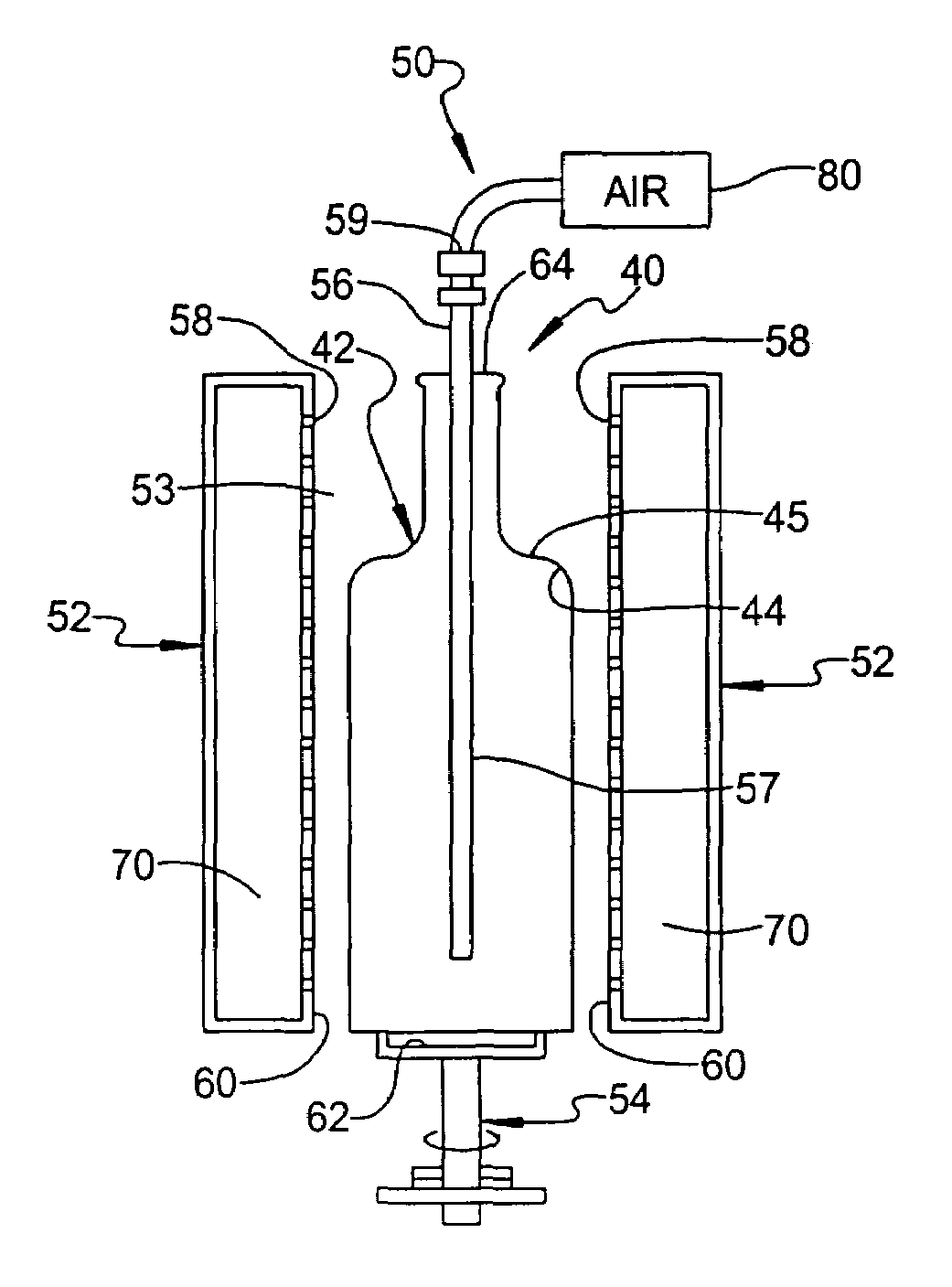

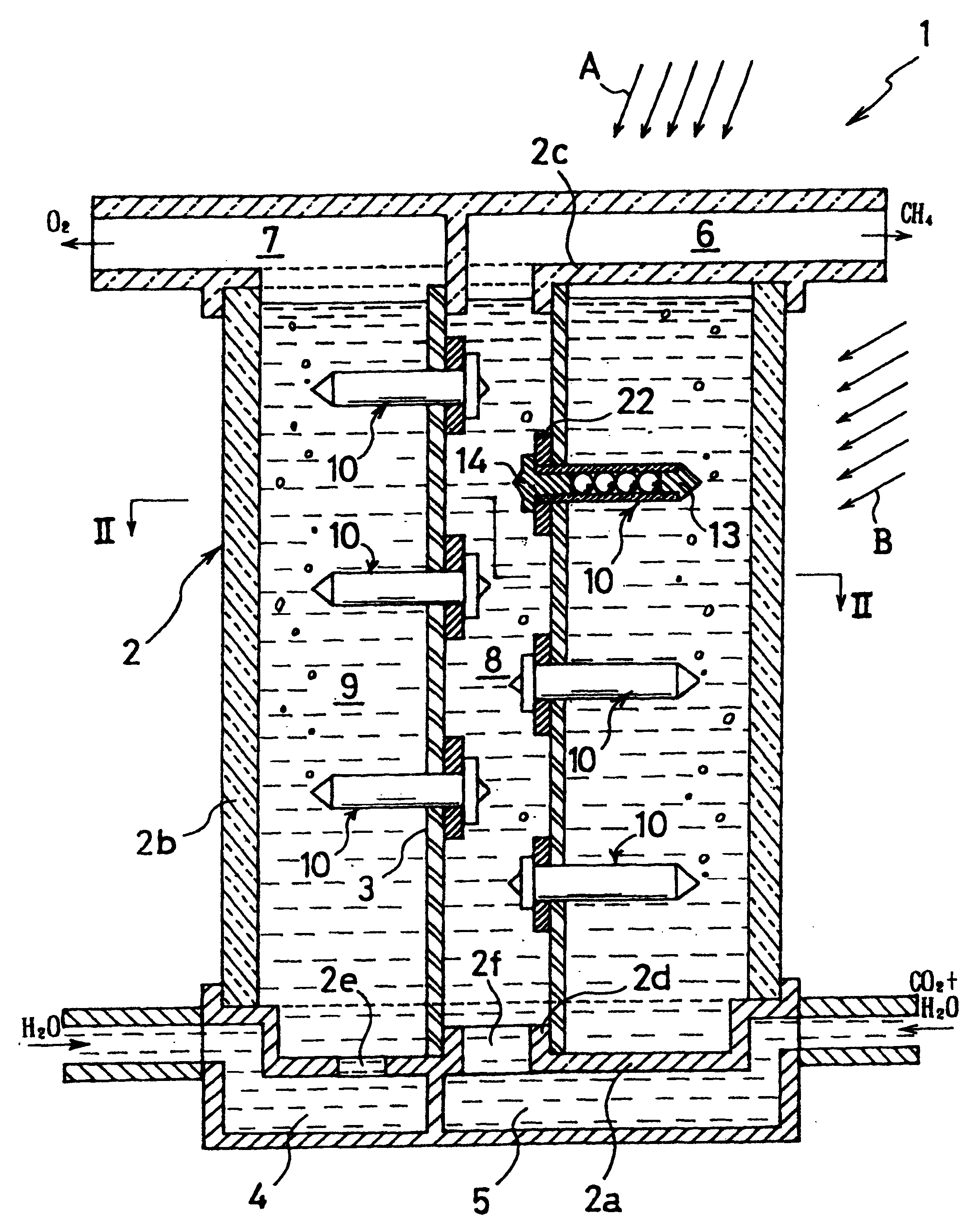

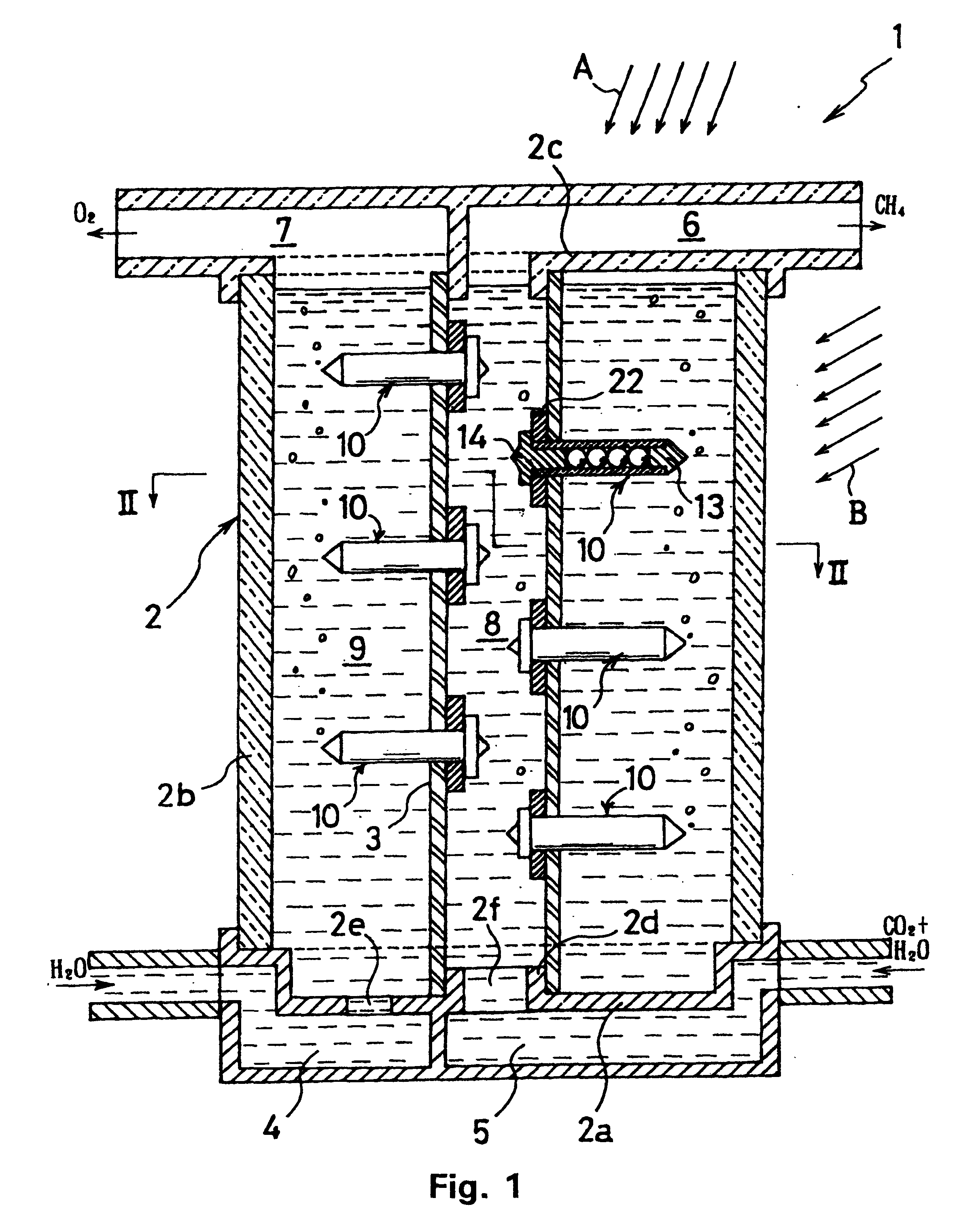

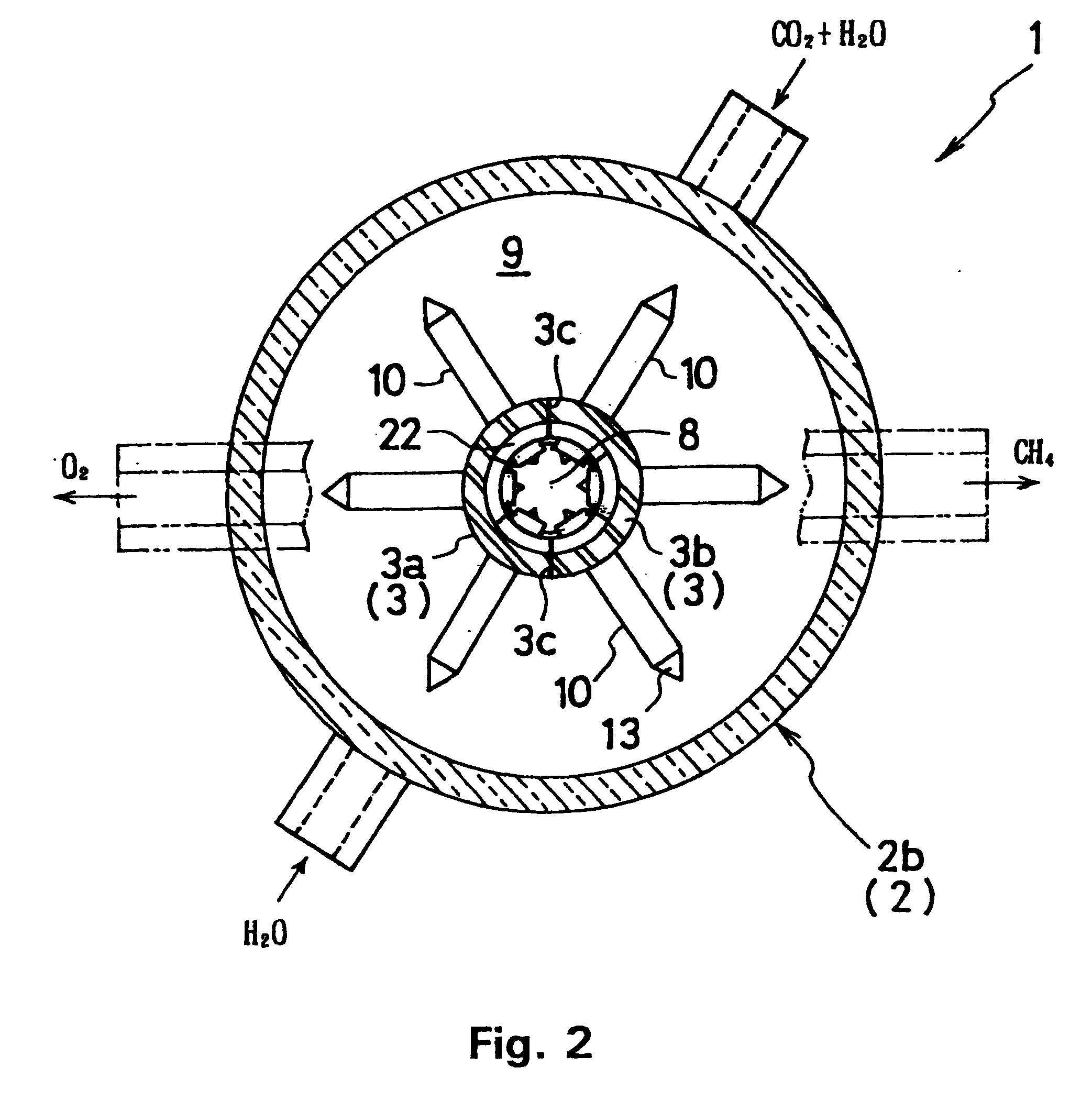

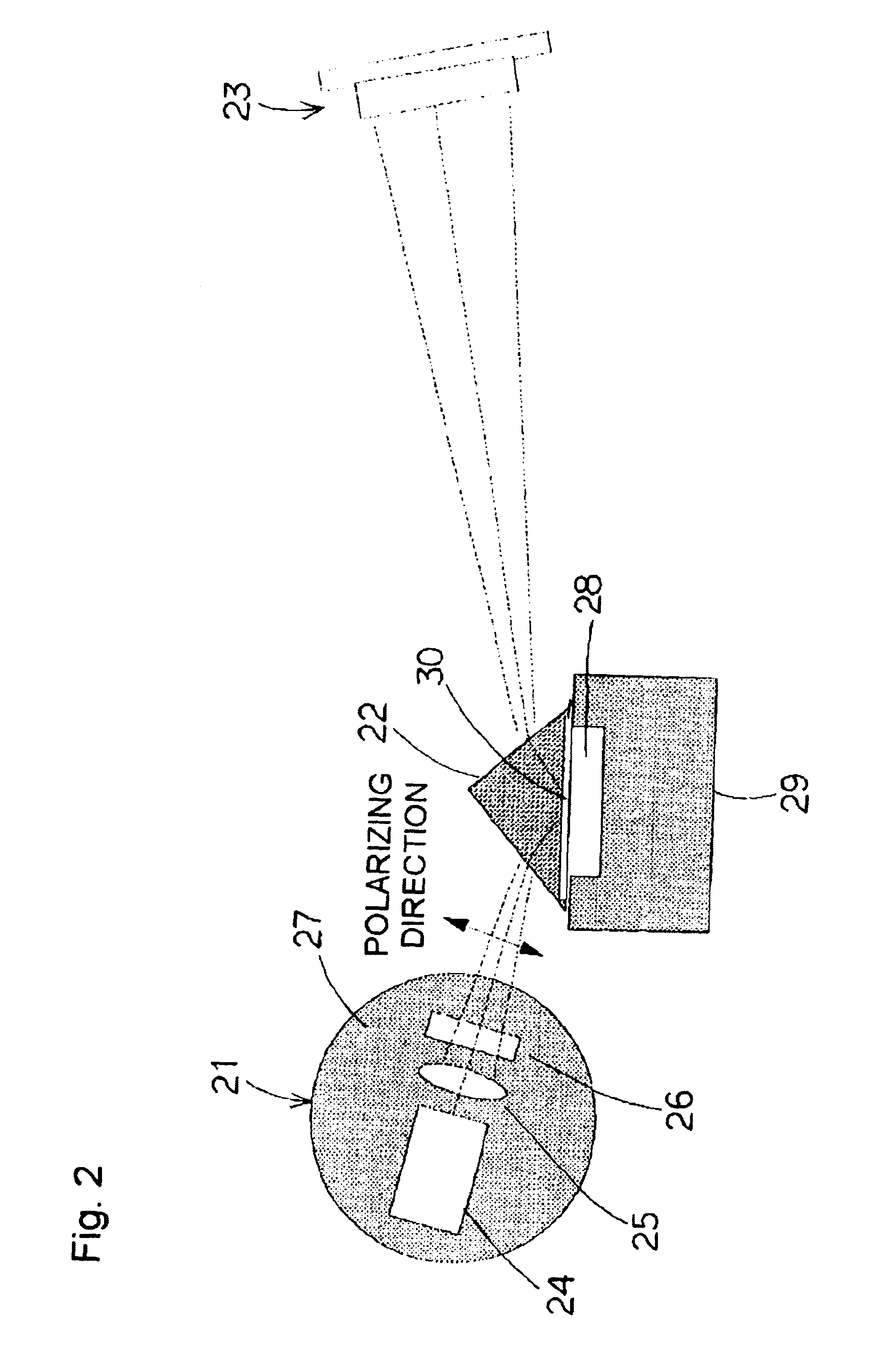

Solar battery module for optical electrolysis device and optical electrolysis device

InactiveUS6198037B1Avoid Overvoltage ProblemsEasy to separateCellsElectrolysisElectrolysisElectrical battery

Partition member 34 is provided, which partitions the interior of glass container 31 into reduction reaction chamber 32 and oxidation reaction chamber 33 and which is made of a polymer electrolyte that conducts hydrogen ions; solar battery modules 35 are mounted on this partition member 34, for example in a matrix arrangement of five rows and three columns; a solar battery module 35 has a photocell array (photoelectromotive force: 2.0-2.4 V) consisting of four spherical solar battery elements (photoelectromotive force: 0.5-0.6 V) connected in series, anode 46, and cathode 48; solar battery modules 35 are mounted on partition member 34 so that anode 46 is in contact with the electrolyte of oxidation reaction chamber 33 and cathode 48 is in contact with the electrolyte of reduction reaction chamber 32; sunlight is shined on solar battery modules 35, and the photoelectromotive force electrolyzes the water and produces hydrogen gas from cathode 48 and oxygen gas from anode 46.

Owner:SPHELAR POWER

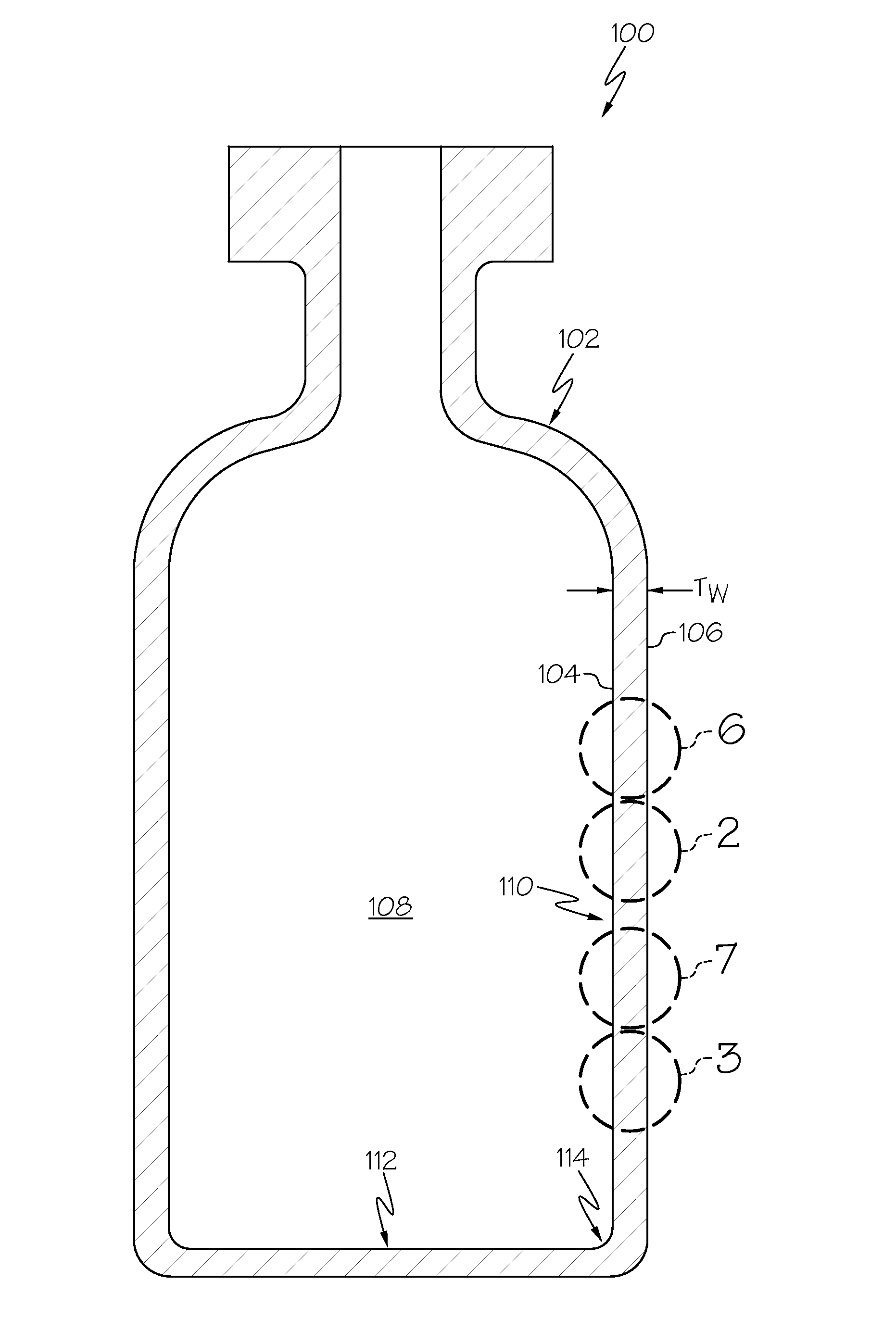

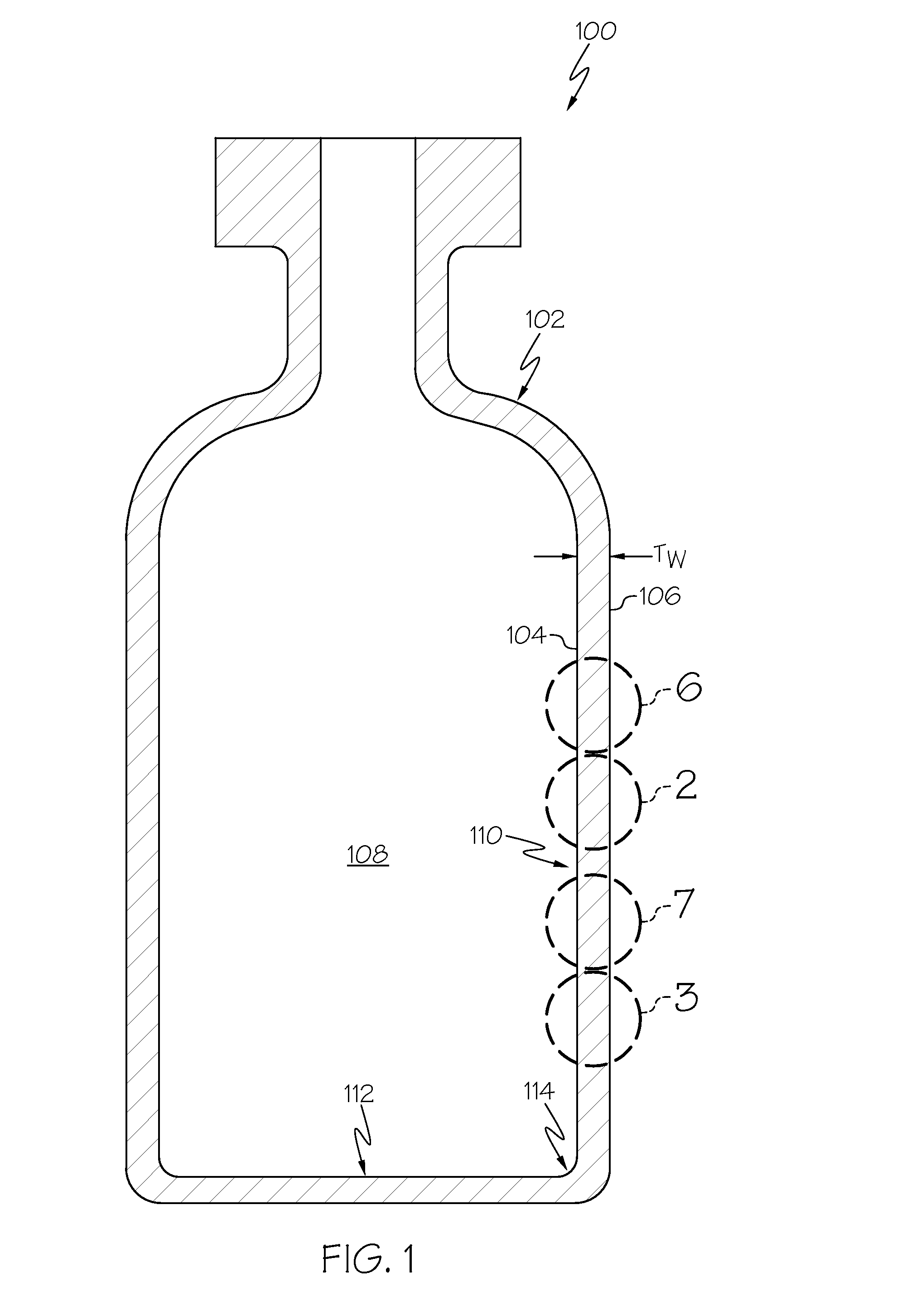

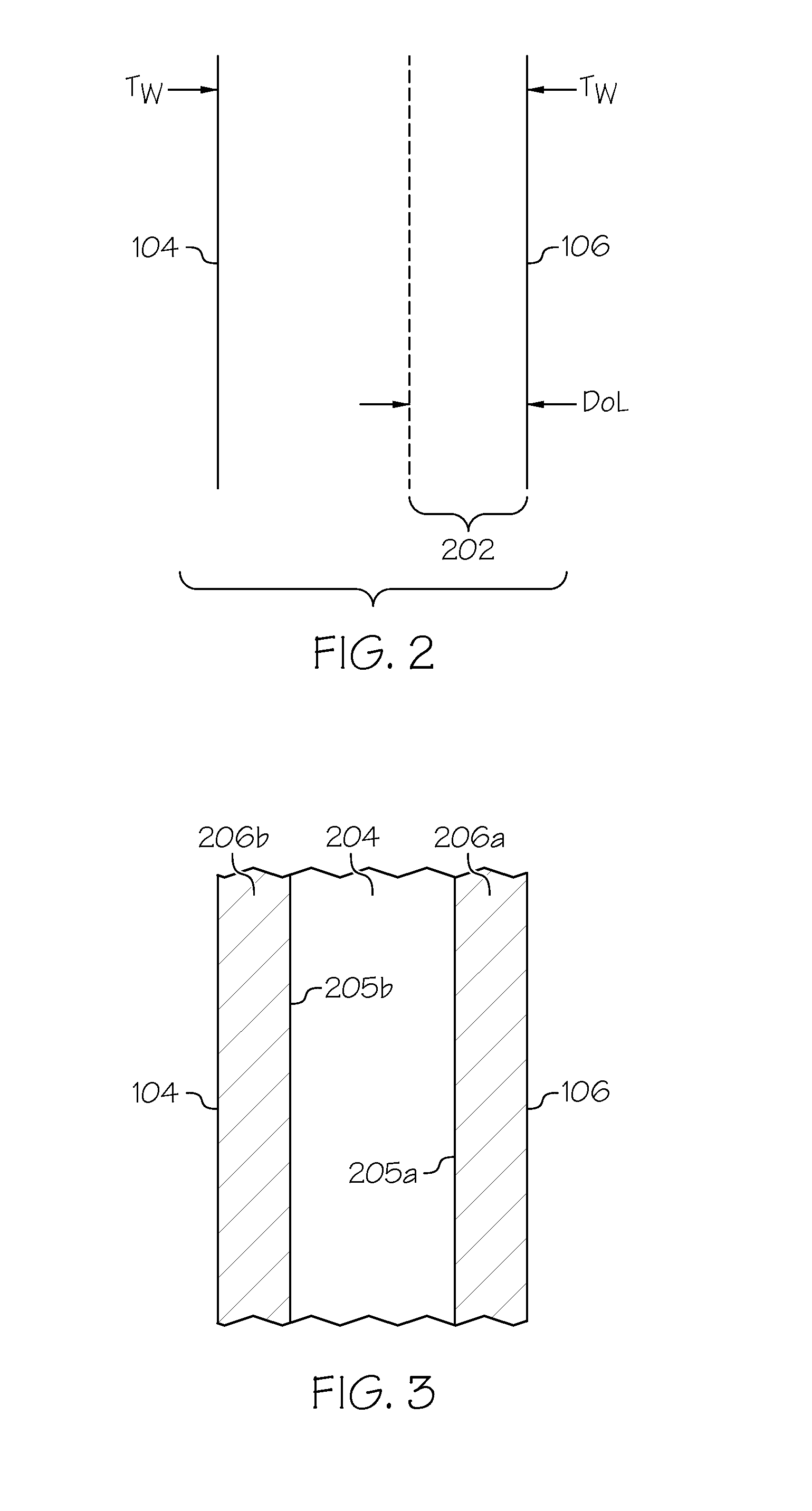

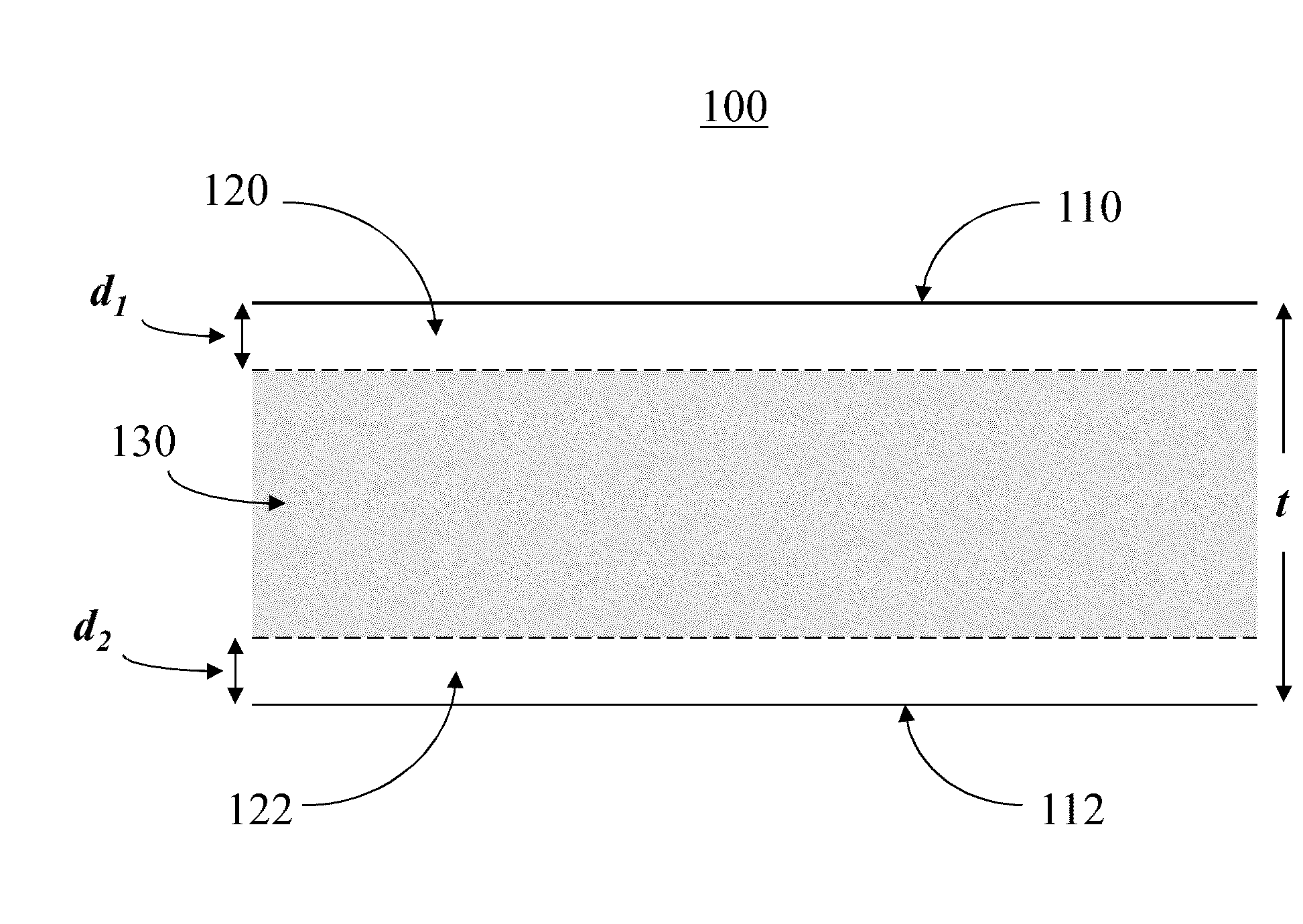

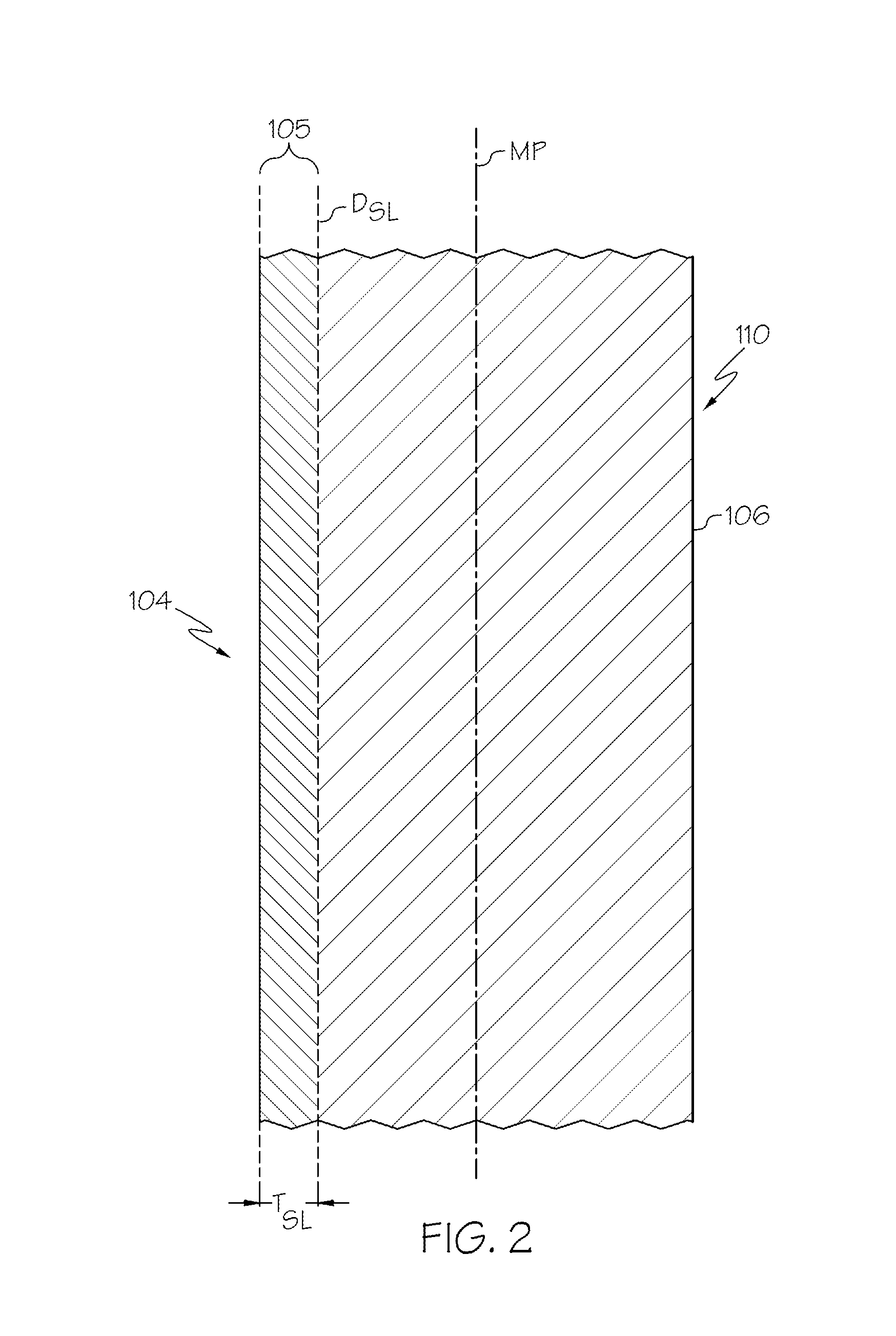

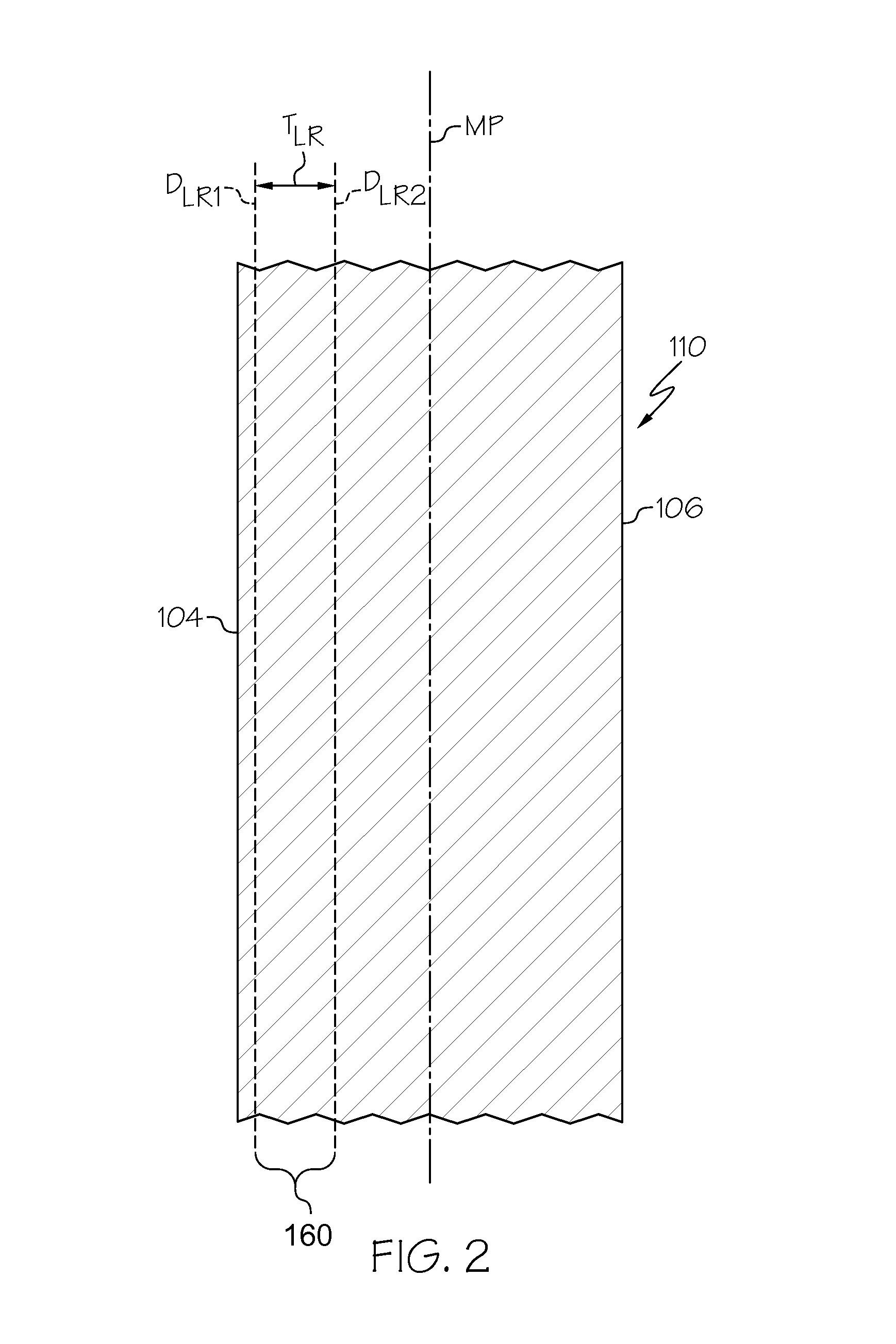

Glass containers with delamination resistance and improved damage tolerance

The glass containers described herein have at least two performance attributes selected from resistance to delamination, improved strength, and increased damage resistance. In one embodiment, a glass container may include a body having an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. At least the inner surface of the body may have a delamination factor less than or equal to 10. A tenacious inorganic coating may be positioned around at least a portion of the outer surface of the body. The outer surface of the body with the tenacious inorganic coating may have a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

Strengthened borosilicate glass containers with improved damage tolerance

According to one embodiment, a glass container may include a body formed from a Type I, Class B glass composition according to ASTM Standard E438-92. The body may have an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. The body may also include a compressively stressed layer extending into the wall thickness from at least one of the outer surface and the inner surface. A lubricous coating may be positioned on at least a portion of the outer surface of the body, wherein the outer surface of the body with the lubricous coating has a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

Mould for processing glass container

ActiveCN101298360AAvoid deformationFit closelyGlass shaping apparatusMaterials scienceGlass container

The invention provides a mold for processing a glass container and belongs to the technical field of mold. The mold includes a pair of half molds that are opposite to each other and a pair of bottom molds at the bottom of the half molds, a mold cavity is respectively opened along the height direction at the middle of each side of the opposing sides of the two half molds. The mold is characterized in that a vacuum groove is respectively opened at each side along the height direction of the mold cavity, and ventholes which are equal in number with the vacuum grooves and are communicated with the vacuum grooves are opened at the side edge of the bottom mold core, also a central hole for connecting with the vacuum pipeline is opened at the center of the bottom mold core and the central hole is communicated with the venthole. The mold has the advantages that the pair of half molds can have ideal closing effect due to the vacuum grooves at each side of the mold cavity, which restricts the deformation of the half molds, and guarantees that the glass container is smooth and has good quality.

Owner:CHANGSHU WEIHENG MOLD MFG

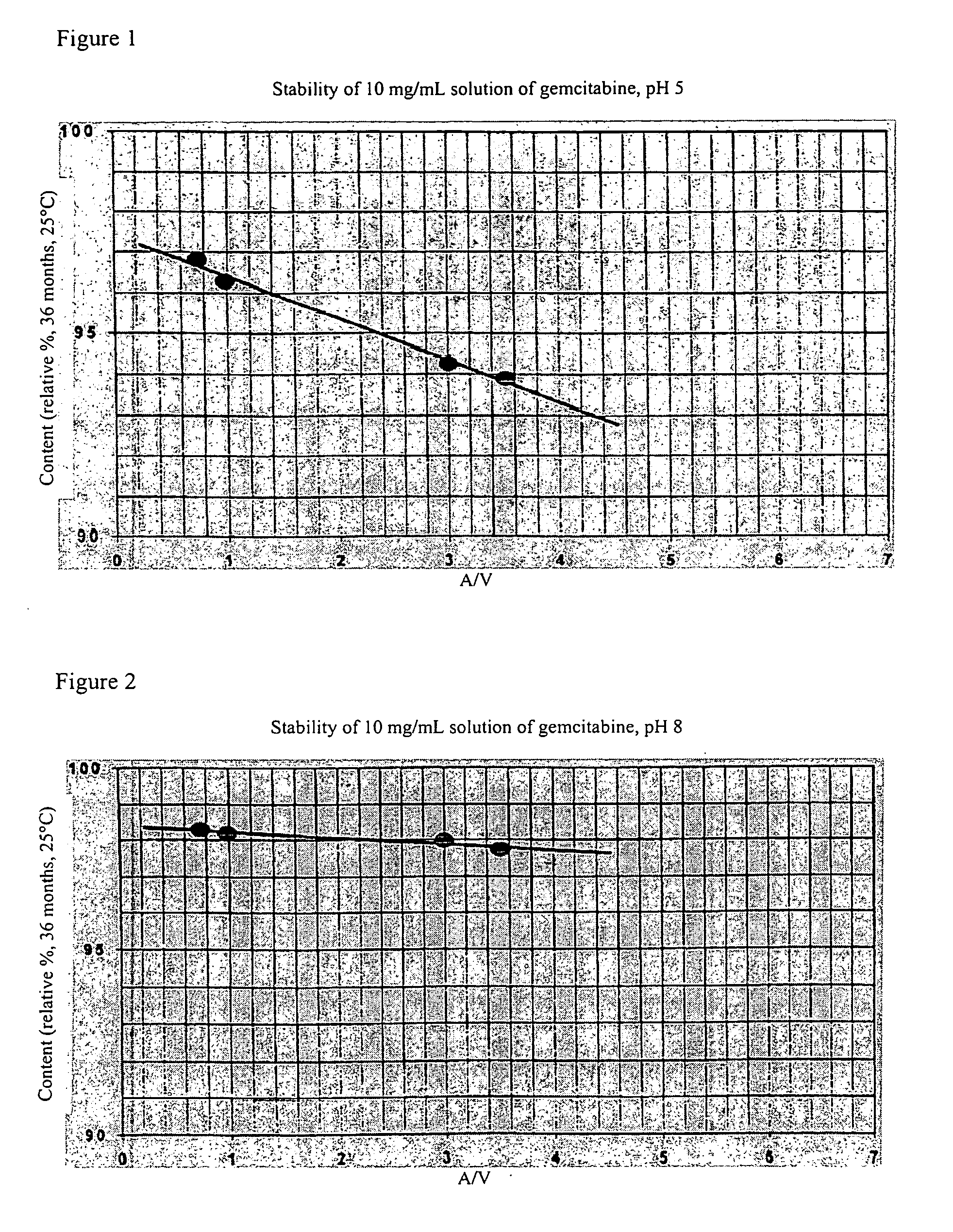

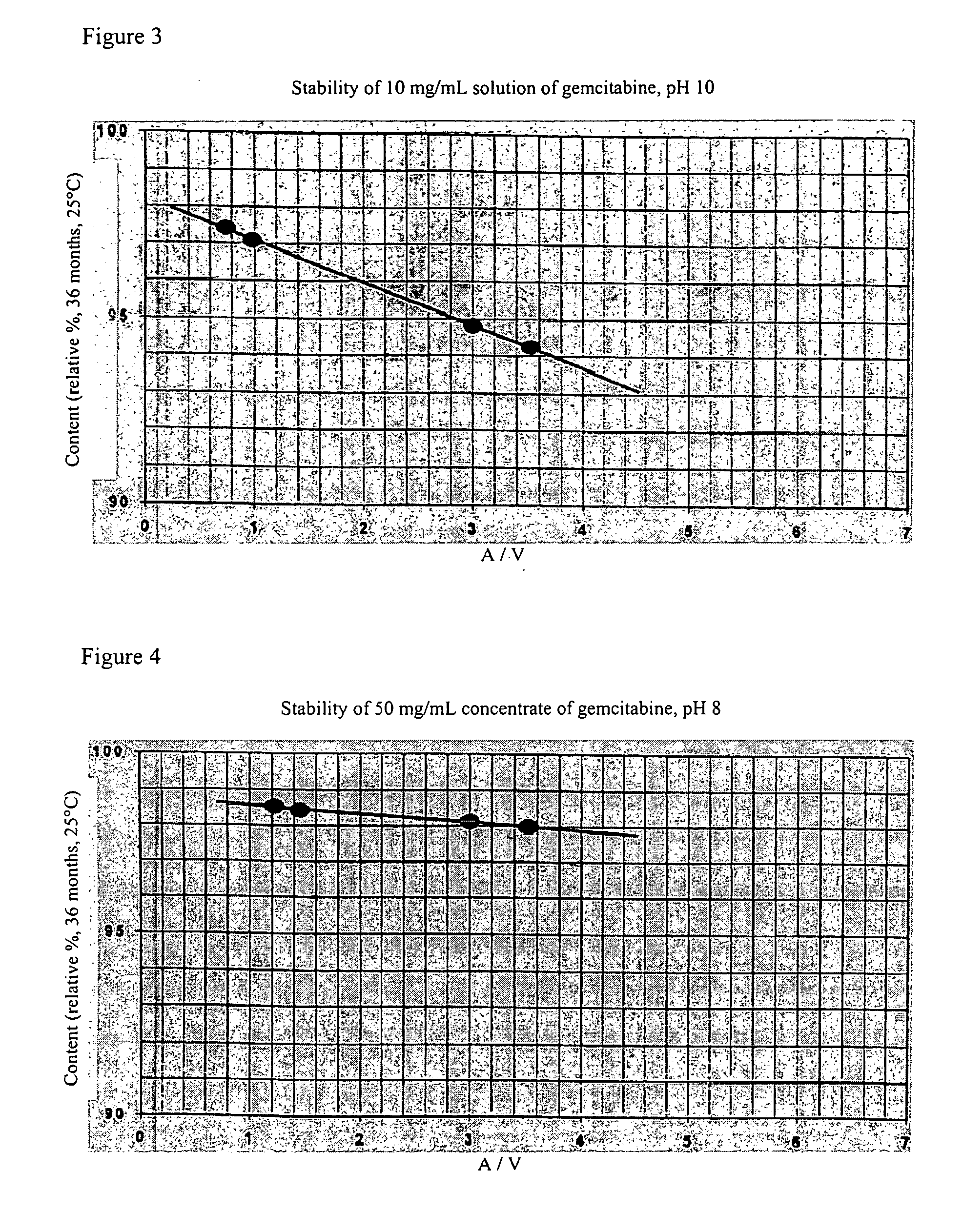

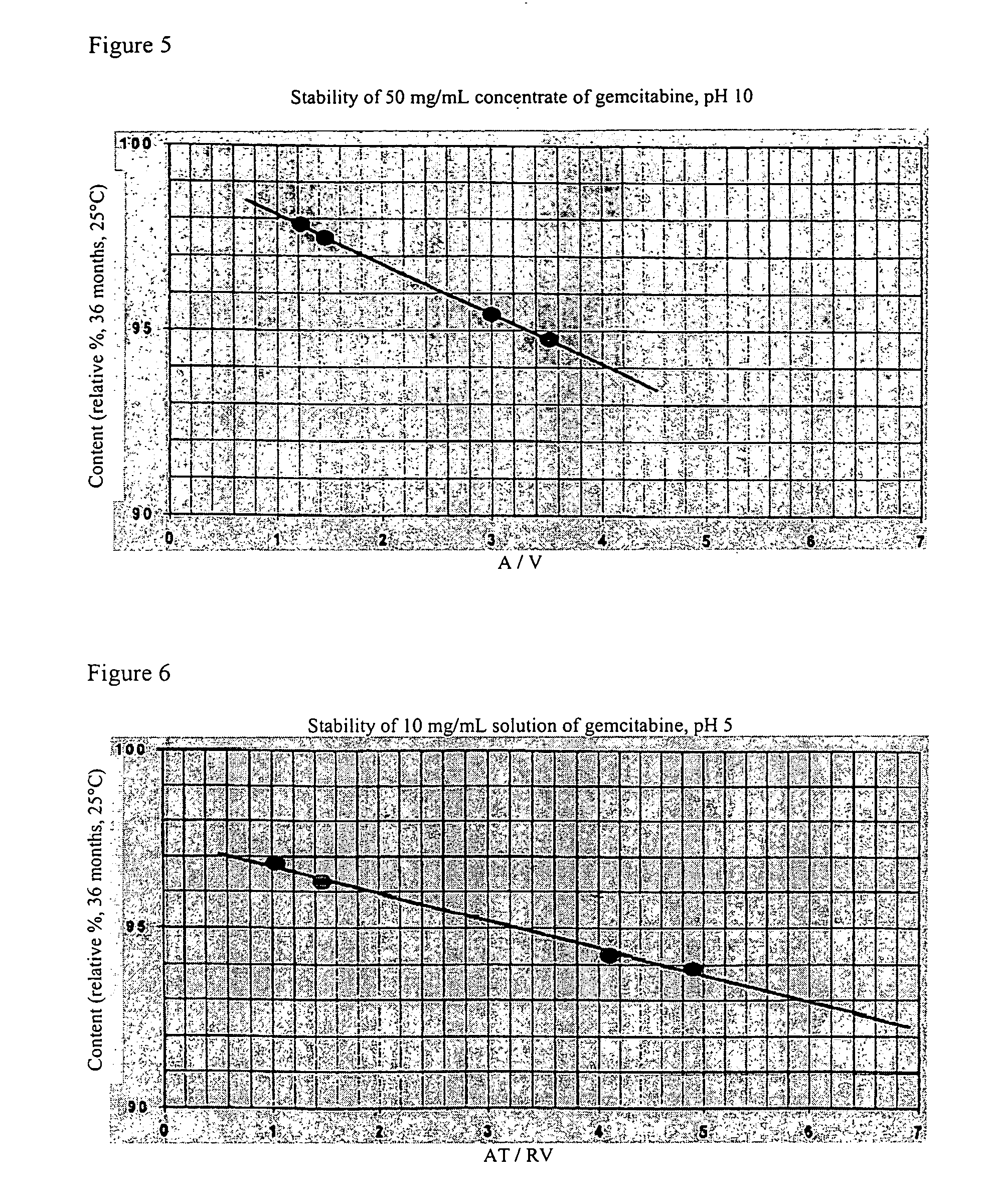

Ready-to-use gemcitabine solutions and gemcitabin concentrates

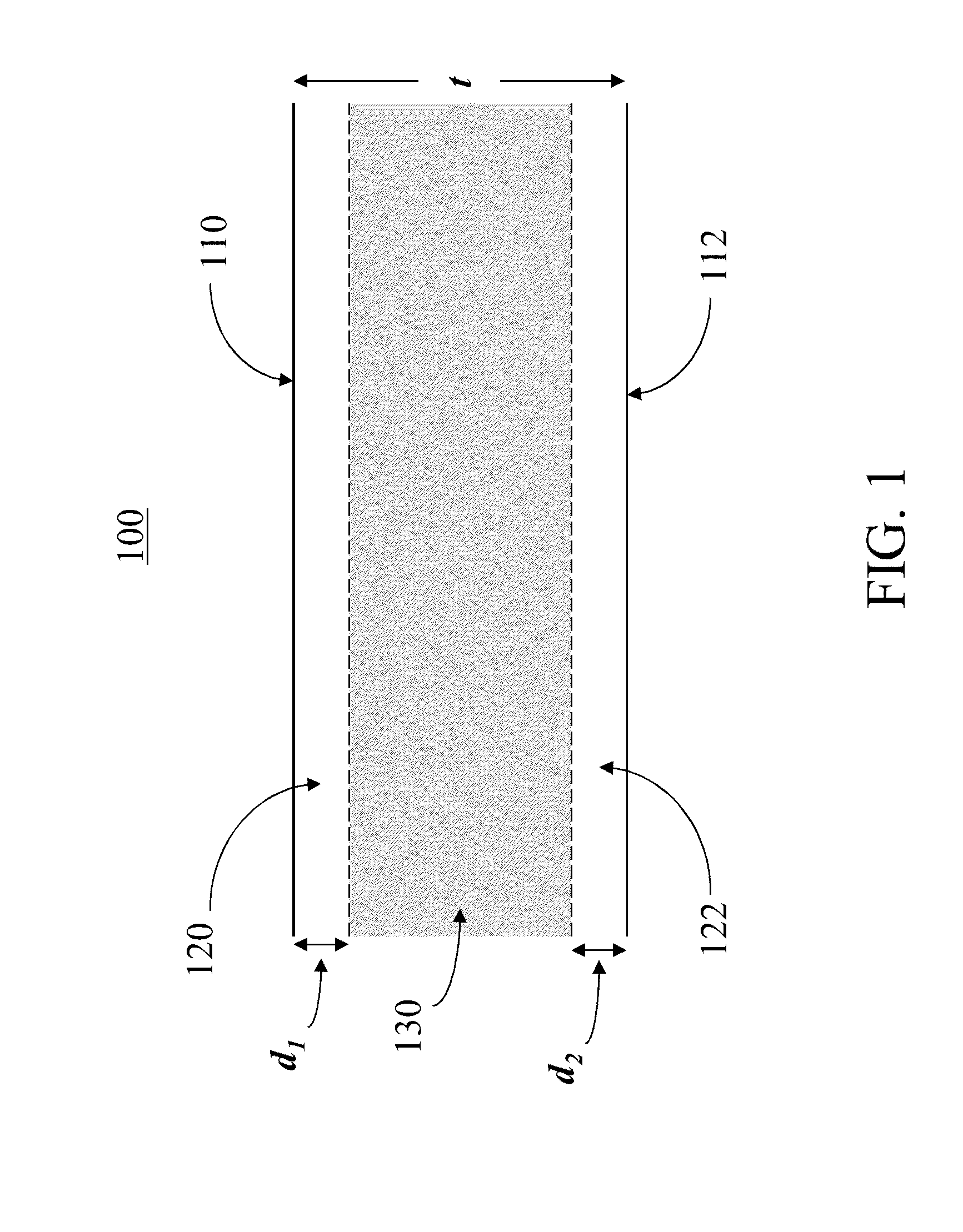

Pharmaceutical compositions in the form of ready-to-use preparations of gemcitabine in aqueous solutions in a glass containers having specified dimensional relationships demonstrate long shelf life over a wide range of solution pH values. The ratio of the surface area of the container wetted by the solution to the volume of the solution, expressed in cm2 to cm3, is less than 3.4.

Owner:STADA ARZNEIMITTEL AG

Electronic cigarette

An electronic cigarette, including a cigarette holder assembly, an atomization assembly, a glass container for accommodating smoke oil, and a gas flow regulator. The cigarette holder assembly includes a mouthpiece, a first sealing ring, a seat for supporting the mouthpiece, a fixed screw, and a pole. The atomization assembly includes a pair of heating wires, a glass casing, a second sealing ring, a third sealing ring, oil-guiding cotton, a limit cover, an insulating ring, and a fixed ring. The glass container includes a first sealing gasket and a second sealing gasket which are respectively disposed at both ends of the glass container. The gas flow regulator includes a control ring, a steel ball, a spring, and a rotary button. The first sealing ring of the cigarette holder assembly is sleeved on the mouthpiece, and the mouthpiece is fixed on the seat via the fixed screw.

Owner:LIU TUANFANG

Delamination resistant pharmaceutical glass containers containing active pharmaceutical ingredients

ActiveUS20130196094A1Organic active ingredientsPeptide/protein ingredientsParticulatesBULK ACTIVE INGREDIENT

The present invention is based, at least in part, on the identification of a pharmaceutical container formed, at least in part, of a glass composition which exhibits a reduced propensity to delaminate, i.e., a reduced propensity to shed glass particulates. As a result, the presently claimed containers are particularly suited for storage of pharmaceutical compositions and, specifically, a pharmaceutical solution comprising a pharmaceutically active ingredient, for example, NEUPOGEN (filgrastim), NEULASTA (pegfilgrastim), EPOGEN (epoetin alfa) or ENBREL (etanercept).

Owner:CORNING INC

Method For Reducing Or Eliminating Residue In A Glass Container And A Glass Container Made In Accordance Therewith

A method of preparing a glass medical container is provided including the steps of providing a glass blank and forming a channel through a part of the glass blank, the channel being substantially free of tungsten or derivatives thereof. In a further aspect of the subject invention, a glass medical container is provided including a glass body having a channel extending through a part of the glass body, the channel being substantially free of tungsten or derivatives thereof. With the subject invention, tungsten or derivatives thereof can be generally or altogether completely avoided in glass medical containers.

Owner:BECTON DICKINSON & CO

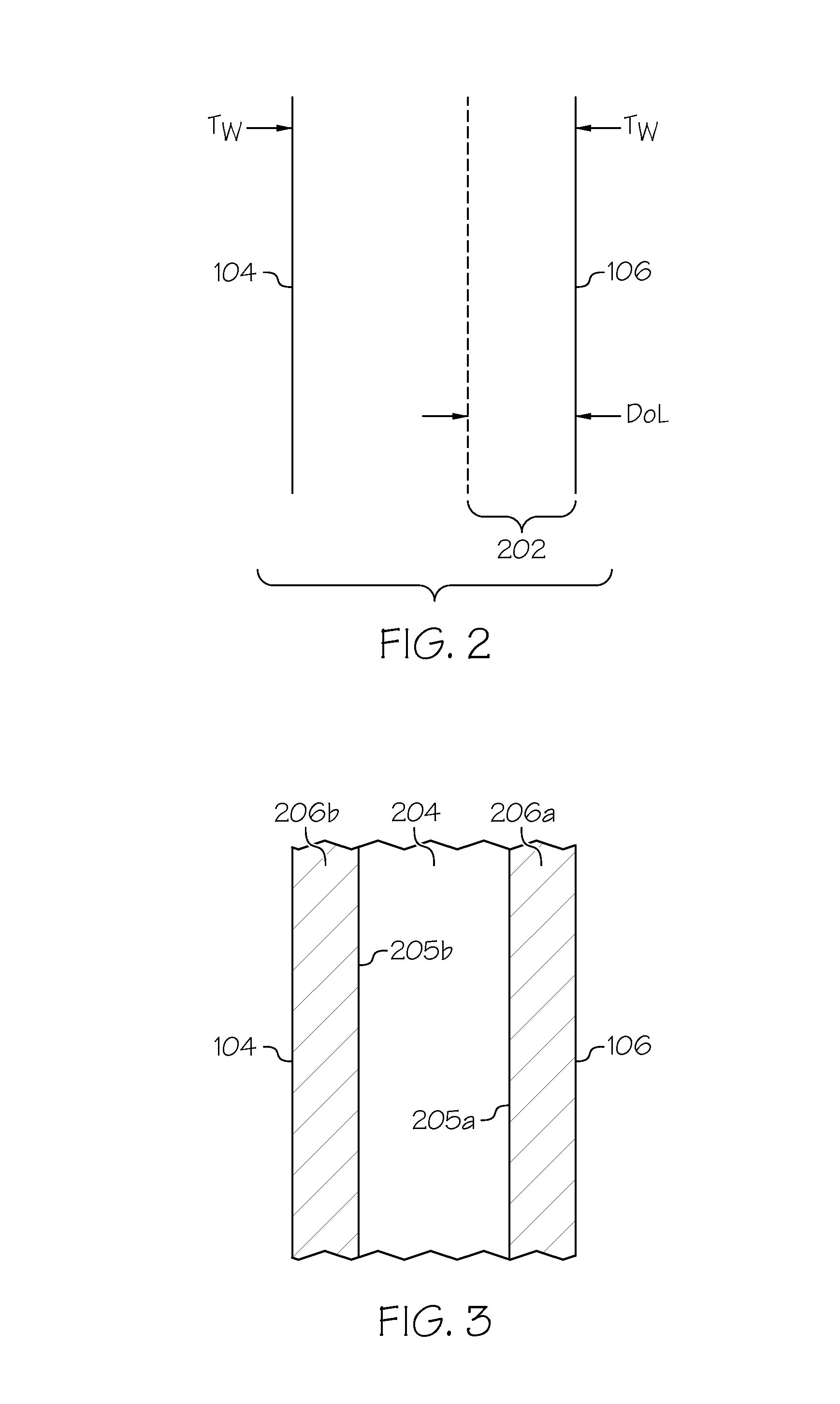

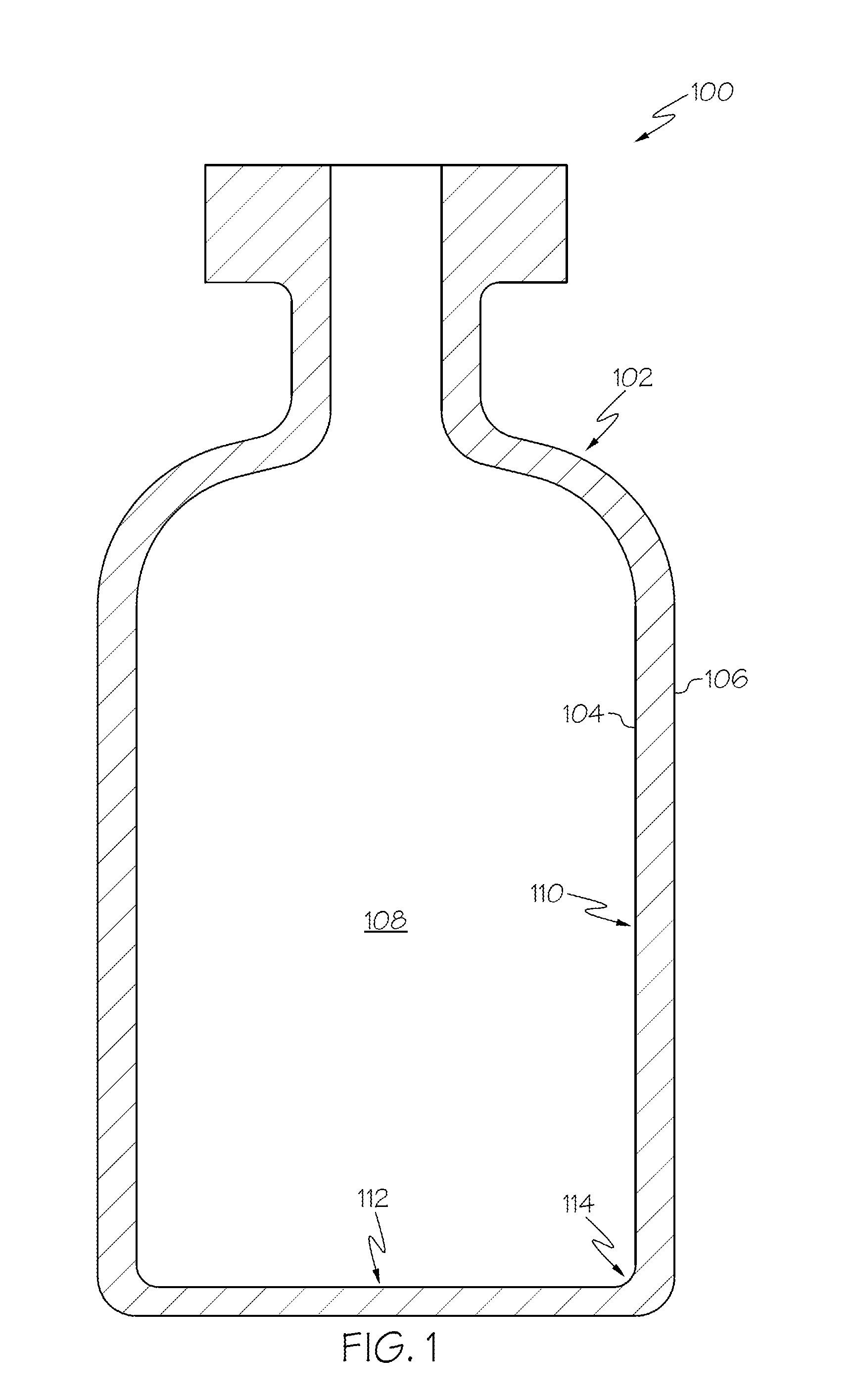

Glass packaging ensuring container integrity

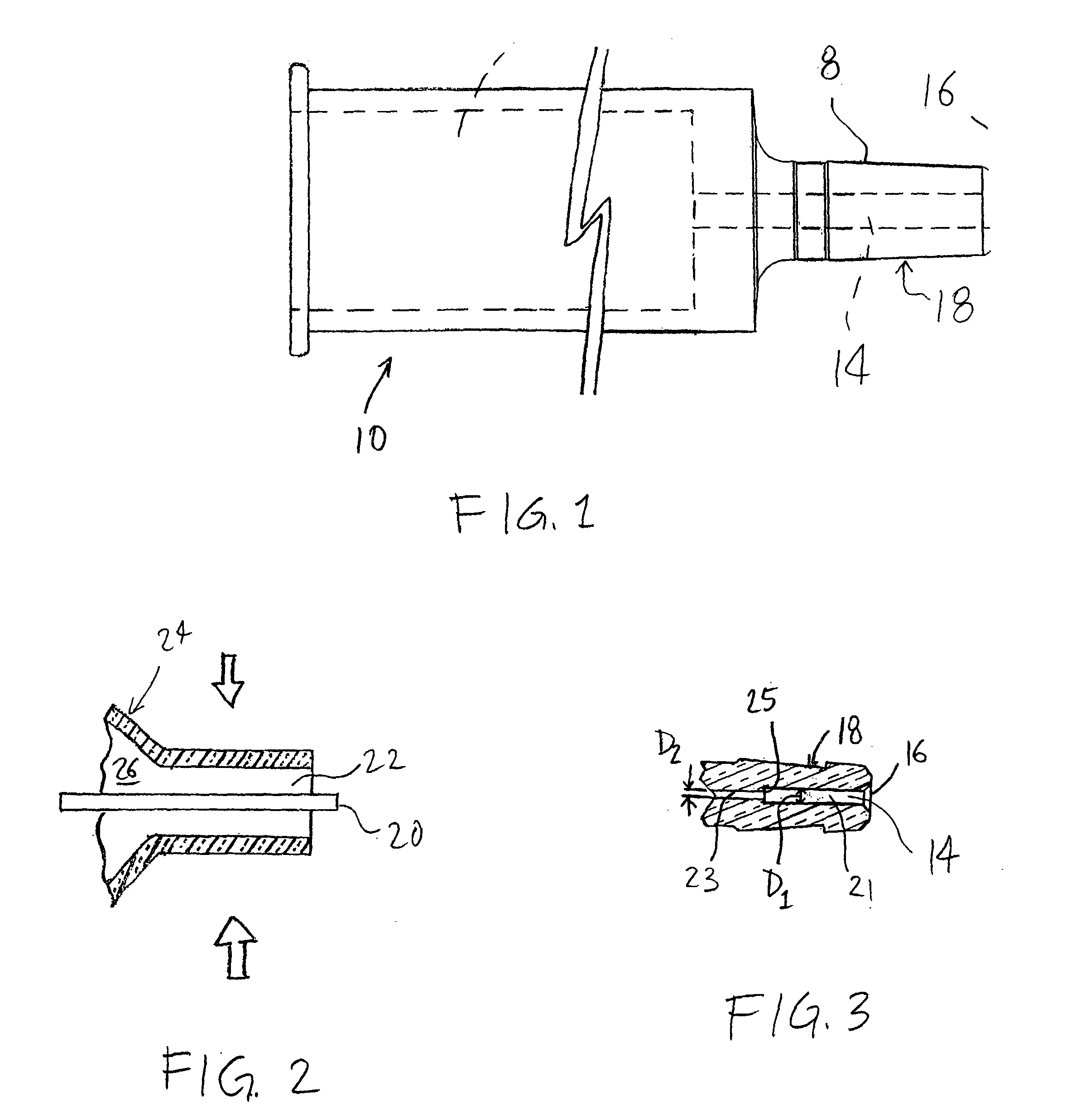

ActiveUS20140120279A1Reducing and eliminating potentialCatastrophic failure is enhancedGlass blowing apparatusGlass/slag layered productsEngineeringCatastrophic failure

A strengthened glass container or vessel such as, but not limited to, vials for holding pharmaceutical products or vaccines in a hermetic and / or sterile state. The strengthened glass container undergoes a strengthening process that produces compression at the surface and tension within the container wall. The strengthening process is designed such that the tension within the wall is great enough to ensure catastrophic failure of the container, thus rendering the product unusable, should sterility be compromised by a through-wall crack. The tension is greater than a threshold central tension, above which catastrophic failure of the container is guaranteed, thus eliminating any potential for violation of pharmaceutical integrity.

Owner:CORNING INC

Methods for producing strengthened and durable glass containers

A method of forming a glass container including forming a glass container having a sidewall at least partially enclosing an interior volume, at least a portion of an interior surface of the sidewall having an interior surface layer; and contacting the glass container with a substantially fluoride-free aqueous treating medium to remove a thin layer of the interior surface layer having a thickness of from about 100 nm to about 1.0 μm from the interior surface of the sidewall. The interior surface is resistant to delamination. Before contacting the glass container with the substantially fluoride-free aqueous treating medium, the exterior surface of the sidewall comprises strength-limiting surface flaws having a first shape, and after the contacting the exterior surface of the sidewall with the substantially fluoride-free aqueous treating medium, the strength-limiting surface flaws have a second shape.

Owner:CORNING INC

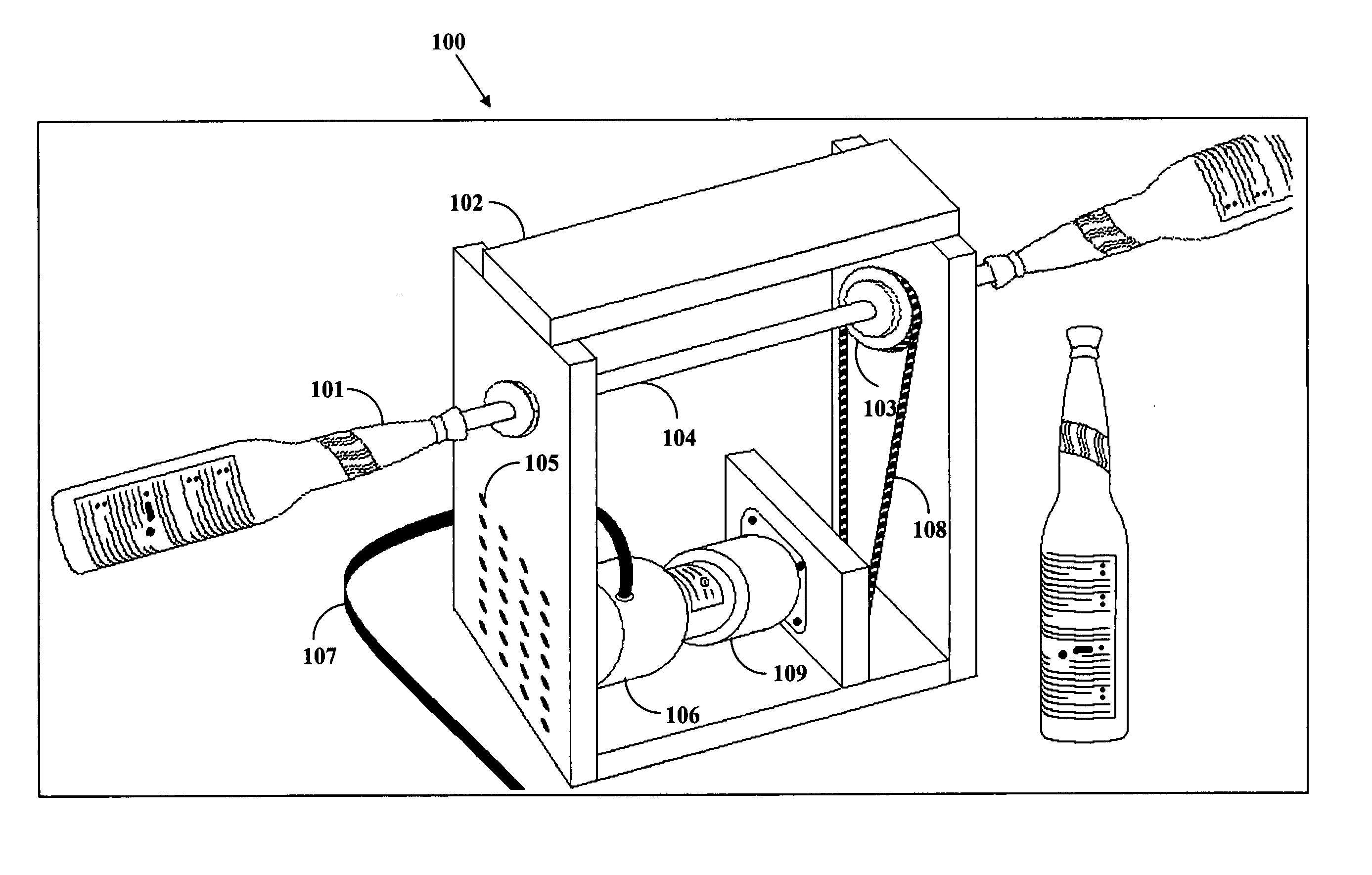

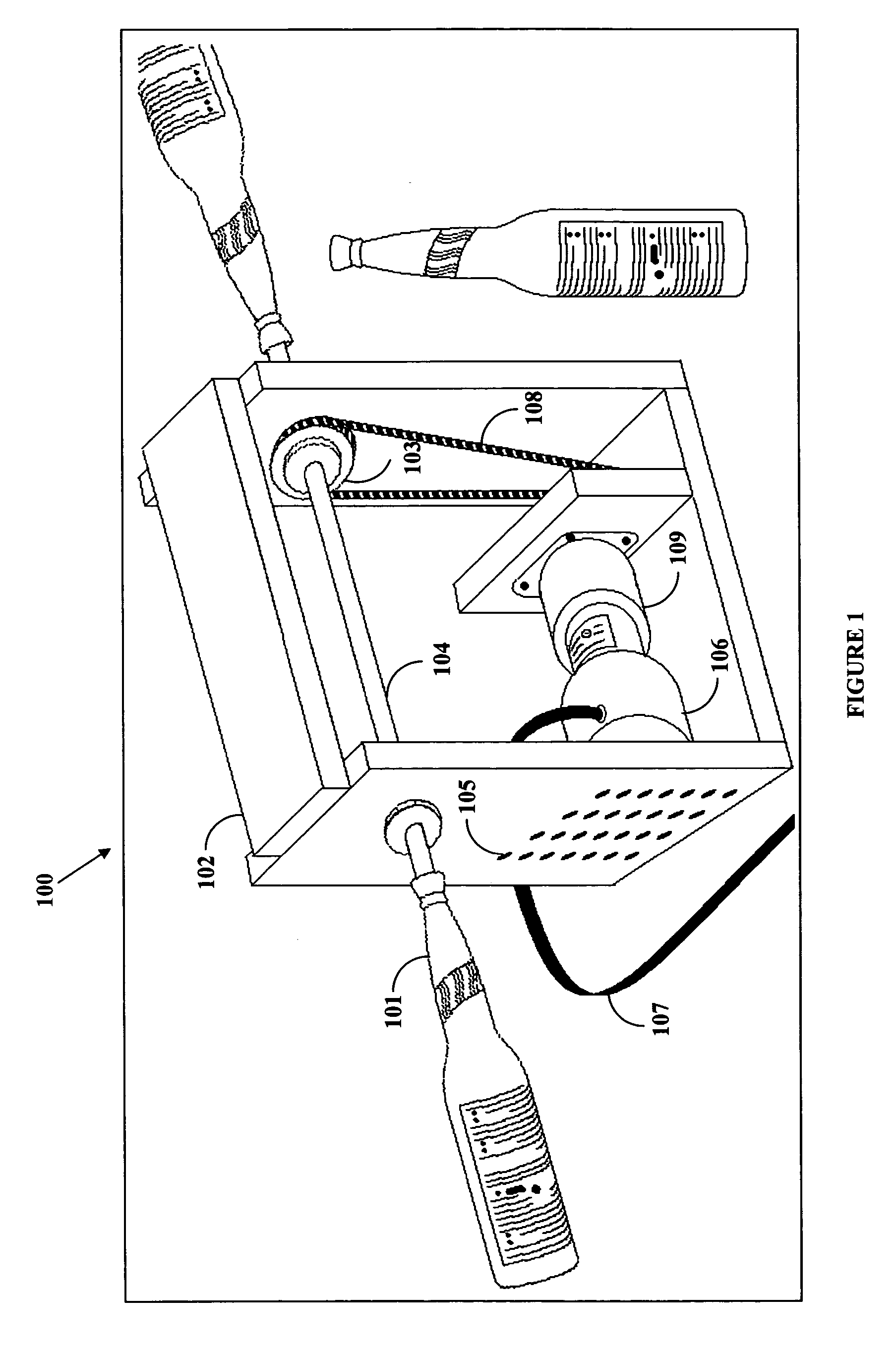

Coating glass containers and labels

A method is disclosed herein for uniformly coating the exterior surface of a glass bottle and the label affixed thereon to enhance the aesthetic appeal of the bottle and the label affixed thereon, to waterproof the label, and to allow the reuse of the label when the bottle is recycled without the need to remove or peel the label and reapply a new label. The method comprises preparing the clear coating to be applied on the surface of the bottle, rotating the bottle in a horizontal position about its center-line, applying the clear coating on the surface of the rotating bottle, adjusting the rotational speed of the bottle to allow the clear coating to spread uniformly over the surface of the bottle and the label affixed thereon, and allowing the applied coating to cure with or without the application of heat.

Owner:LEE VINCENT

Mould for processing glass container

InactiveCN101298359AImprove cooling effectIntensity effectGlass shaping apparatusGlass productionBottleMaterials science

The invention provides a mold for processing a glass container and belongs to the technical field of mold. The mold includes a pair of half molds that are opposite to each other and have the same shape and a bottle mold cavity, a first heat-radiating groove and a second heat-radiating groove are alternatively opened on the outer wall of the two half molds. The mold has the advantages that the first and the second heat-radiating grooves on the outer wall of the two half molds are helpful for heat radiation of the half molds, which leads the temperature of the mold cavity to drop under the softening point rapidly and is favorable for improving the formation speed of the bottle in the mold cavity and the production speed of the bottle; the opening of the first heat-radiating groove and the second heat-radiating groove does not affect the strength of the half molds, thus being capable of ensuring the service life of the mold.

Owner:CHANGSHU WEIHENG MOLD MFG

Compositions and methods for storing aqueous chlorine dioxide solutions

InactiveUS6284152B1Little and no diffusional lossLoss and degradationCosmetic preparationsBiocideDiffusionChlorine dioxide

The present invention is directed to both physical and chemical means for maintaining continuous high levels of chlorine dioxide in aqueous solutions for extended periods, with minimum loss through degradation in the solution and dissipation through the walls of the containing vessel within which the solution is stored. The ClO2 may be maintained even in the absence of very high levels of chlorite, from which supplemental, offsetting levels of ClO2 may be generated. The present invention relates to the discovery that certain types of plastic and glass containers have the ability to maintain relatively constant levels of ClO2 in their contained solutions over extended periods, particularly in aqueous compositions comprising chlorite / ClO2 ratios sufficient for a stabilizing complex of the two, presumably Cl204-, to suppress the ClO2 loss. Of particular value is certain high-density polyethylene terephthalate (PETE) plastic bottling and plastic containers which have been initially exposed to a fluorinating environment. Specifically, in the latter regard, it has been discovered that certain plastic containers which ordinarily are incapable of maintaining aqueous ClO2 levels can be treated with fluorine gas to transform their surfaces so as to effectively suppress ClO2 diffusion therethrough.

Owner:PROFRESH PROPERTIES

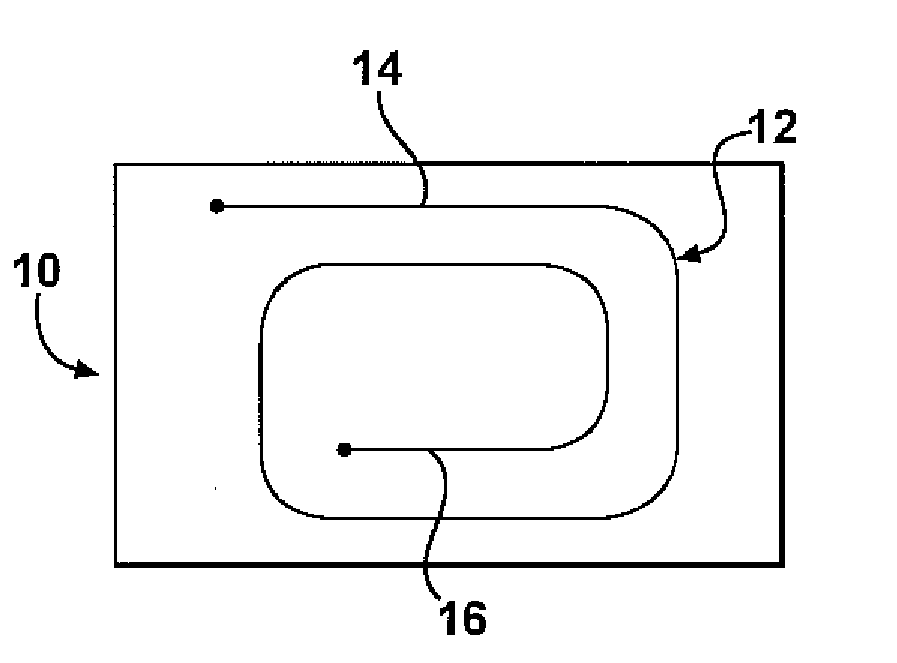

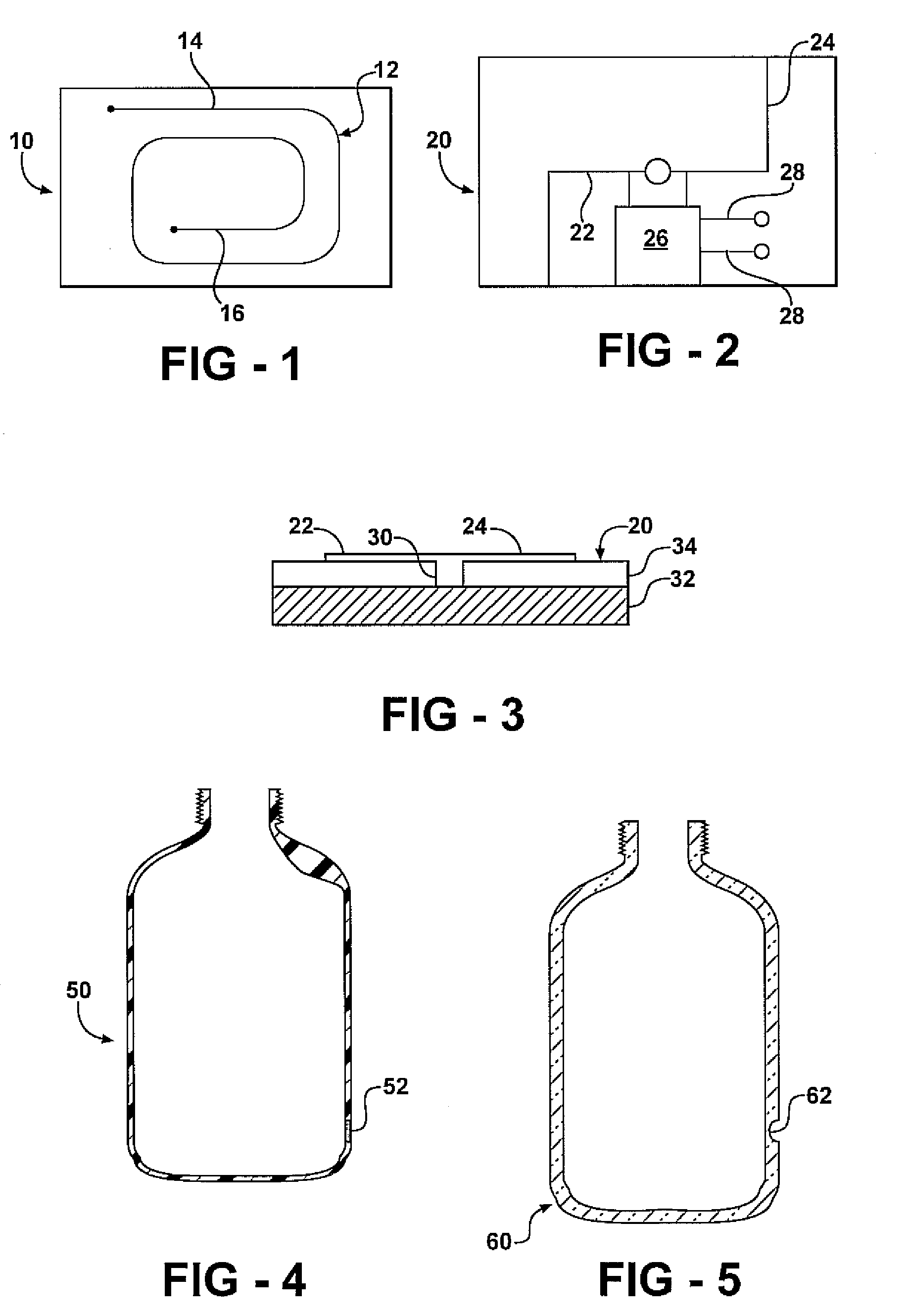

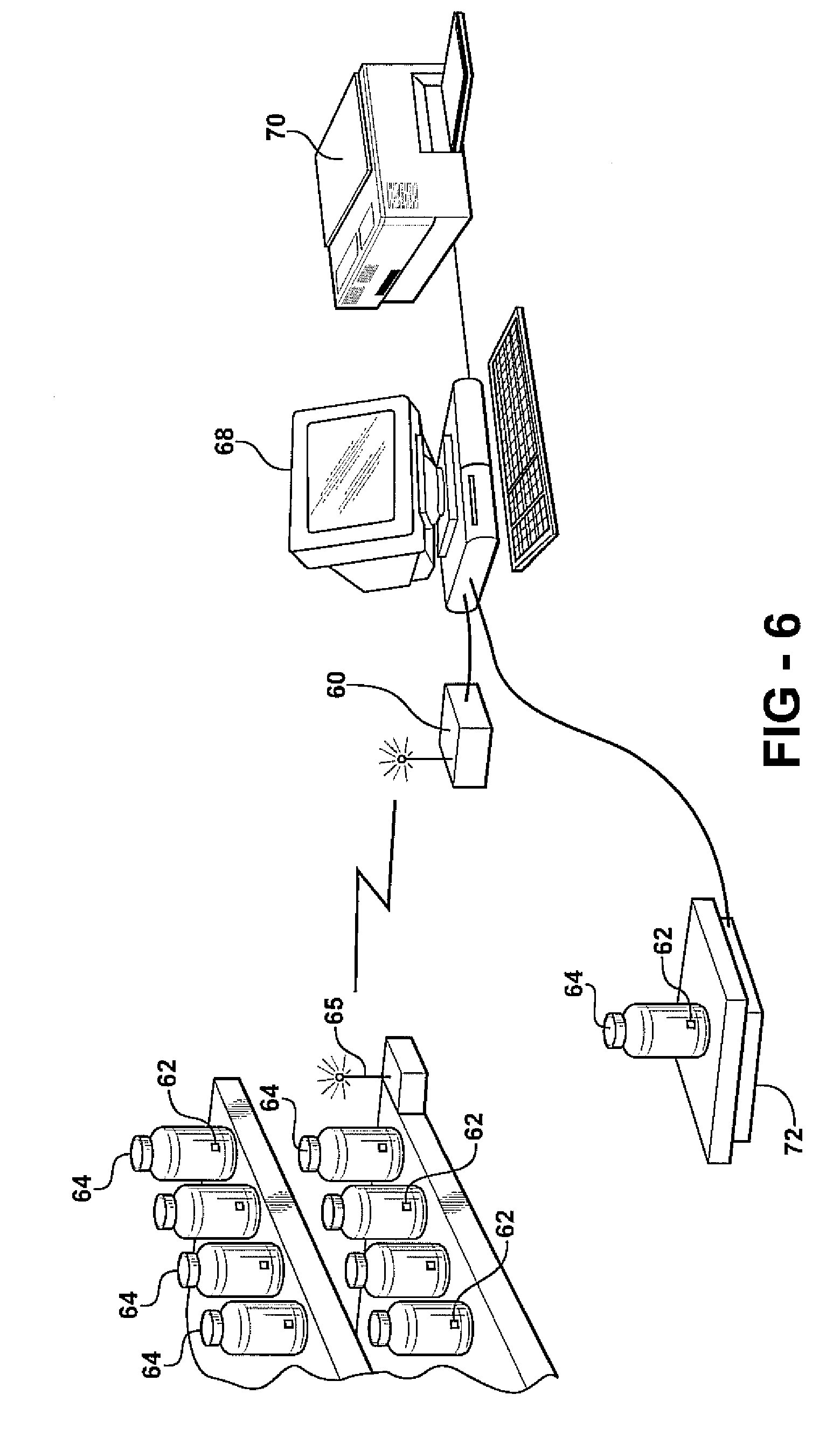

Container with embedded RFID tag

A container for pharmaceuticals such as pills and tablets has an RFID chip embedded within its wall. The chip preferably transmits and receives at a frequency of approximately 24 GHz. When the container is formed of a thermoplastic, the chip is preferably injected into the soft sidewall of the thermoplastic while it is at an elevated temperature and still in a moldable state. For a glass container, a recess is molded in the wall of the container of an appropriate size to accommodate the chip and after molding the chip is secured within the recess with an adhesive and may be covered to prevent tampering. The memory of the chip stores the nature and quantity of elements stored in the container. By weighing the container after a portion of the contents have been removed, the stored quantity in the chip may be modified.

Owner:RUBINSTEIN WALTER M

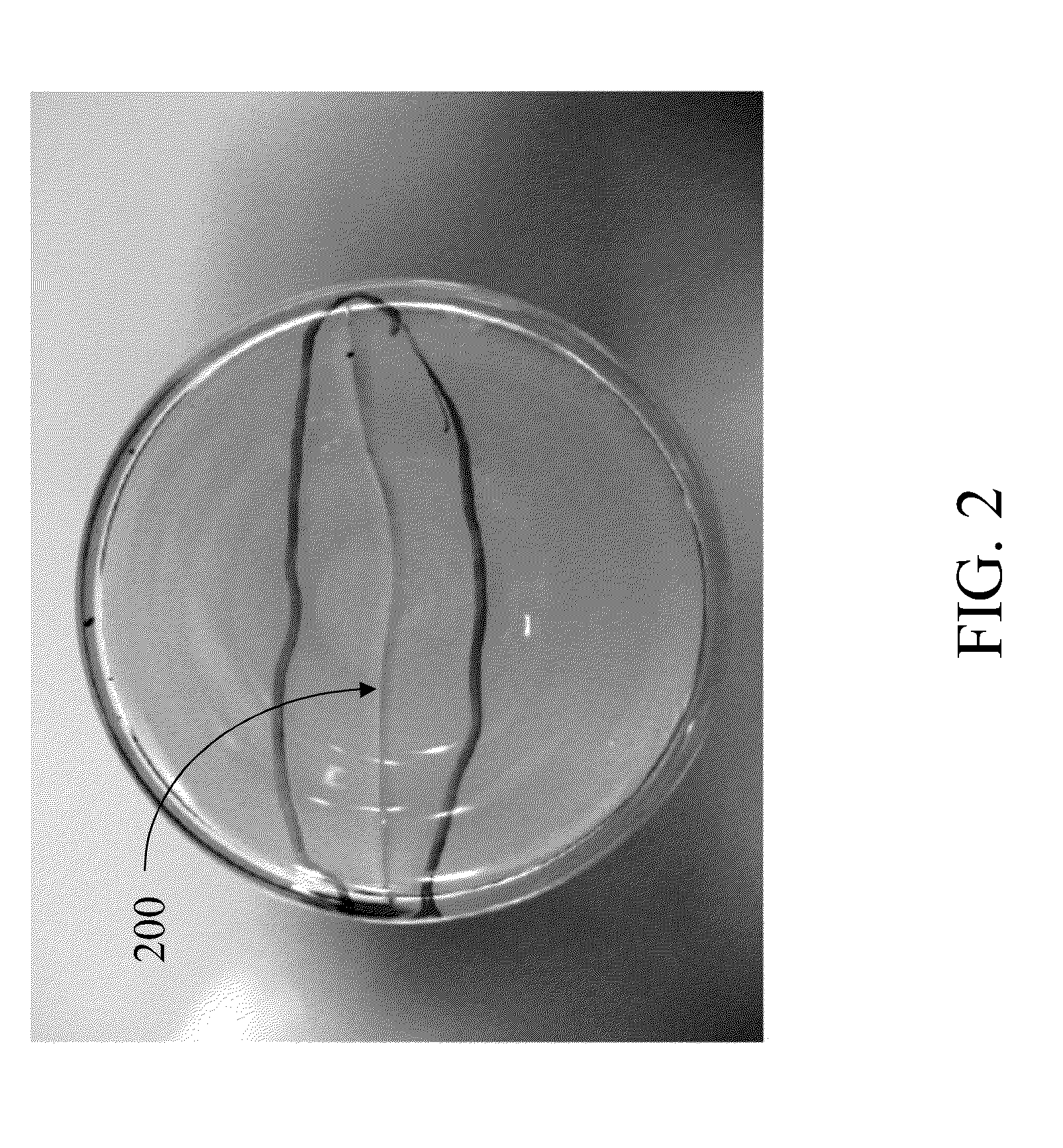

Method for culturing cordyceps militaris by living silkworm chrysalises

InactiveCN101720627AChange the current situation that the cultivated Cordyceps militaris has grass but no insectsChange the status quo of grass without insectsHorticultureFertilizer mixturesCordycepsBiotechnology

The invention belongs to the field of edible fungus culture and discloses a method for culturing cordyceps militaris by living silkworm chrysalises. The method comprises the following steps of: the preparation of stains, the selection of the silkworm chrysalises and disinfection treatment. The method is characterized by specifically comprising the following steps of: inoculating cordyceps militaris stains into silkworm chrysalis bodies through an injection method, wherein the stain dosage of each silkworm chrysalis body is 0.1-0.5ml; putting the inoculated silkworm chrysalises in sterile glass containers to culture the silkworm chrysalises in a culture room for 10-15 days at 18-25 DEG C, wherein 10-20 silkworm chrysalises are put in each container generally; increasing illumination from the twelfth day to promote sprouts to form; when little grass grows to 1cm, puncturing holes on sealing films so as to increase oxygen supply; meanwhile, watering the ground of the culture room to supplement the humidity; and after 20-30 days, when the height of stromata is 5-8 cm and the tops grow into wooden club shapes, collecting and drying. The method directly adopts the live silkworm chrysalises as culture carriers, can harvest the cordyceps militaris with the silkworm chrysalis bodies and changes the current situation that the cordyceps militaris cultured by rice culture media has no silkworm chrysalises.

Owner:江苏江南生物科技有限公司

Scratch masking coating for glass containers

InactiveUS20090208657A1Flexible handlingMinimizes problemPretreated surfacesCoatingsBottleScratch marks

The present invention provides a scratch masking coating system for glass containers such as bottles that is adaptable to a variety of bottle surface and application conditions. The scratch masking coating is applied as an oil in water emulsion which provides flexibility in handling and application techniques while minimizing handling problems. In the present invention, the oil in water emulsion is treated with an emulsion breaker or destabilizer so that the emulsion is destabilized or broken after application to the surface to be treated. The destabilization or breaking is instigated by the addition of an emulsion breaker or heat to the emulsion in sufficient quantity to provide the desired break time.

Owner:ARKEMA INC

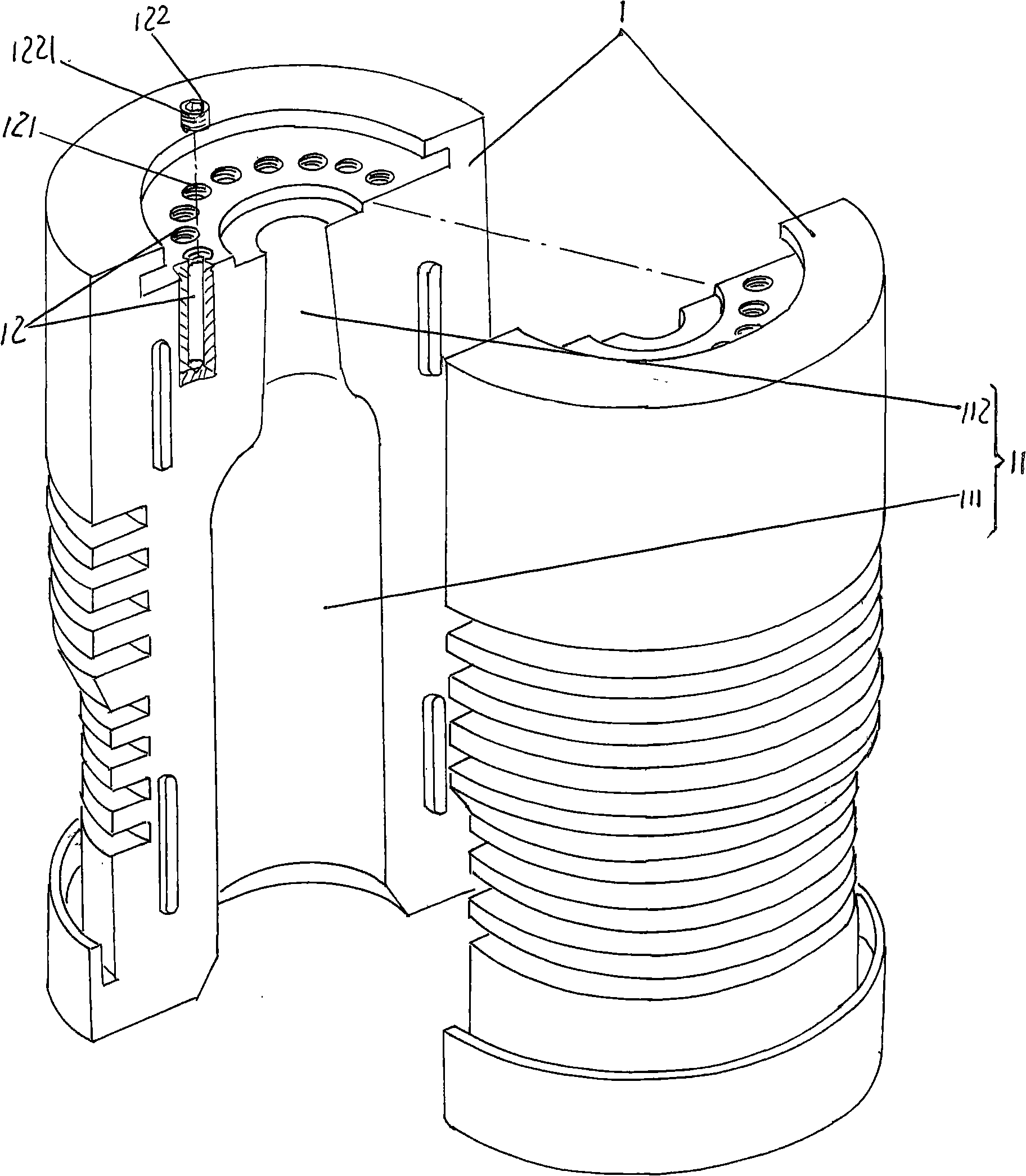

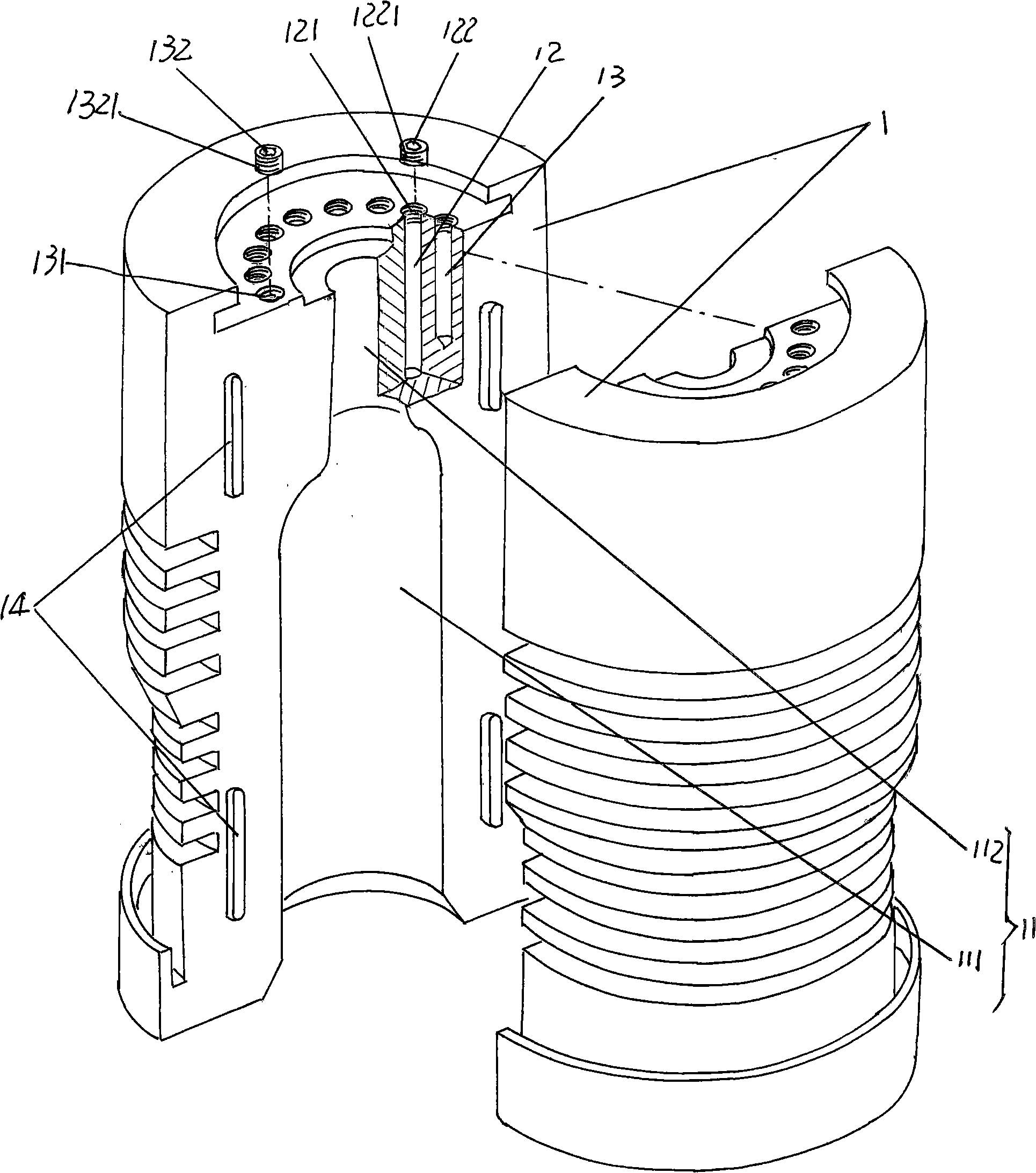

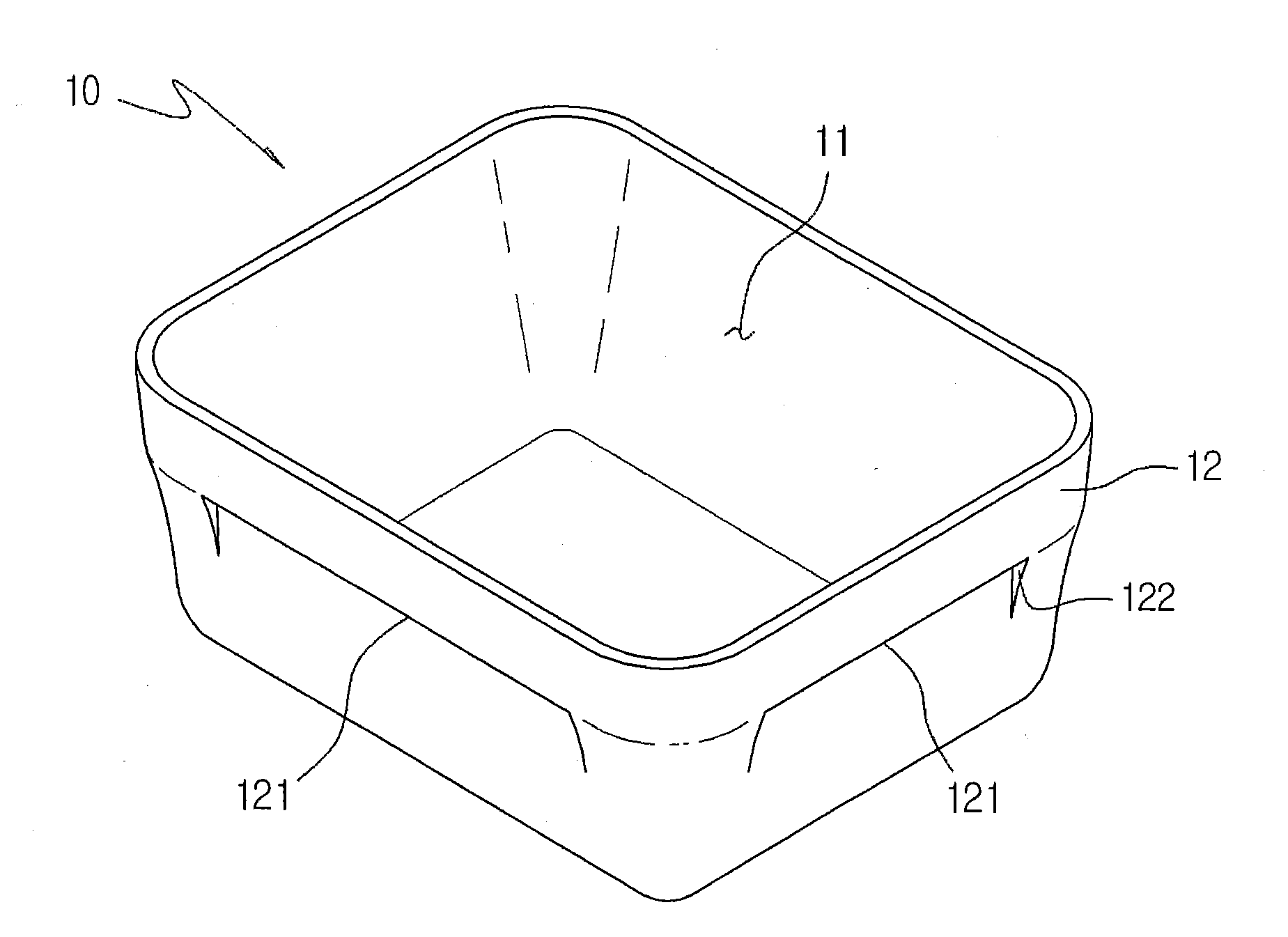

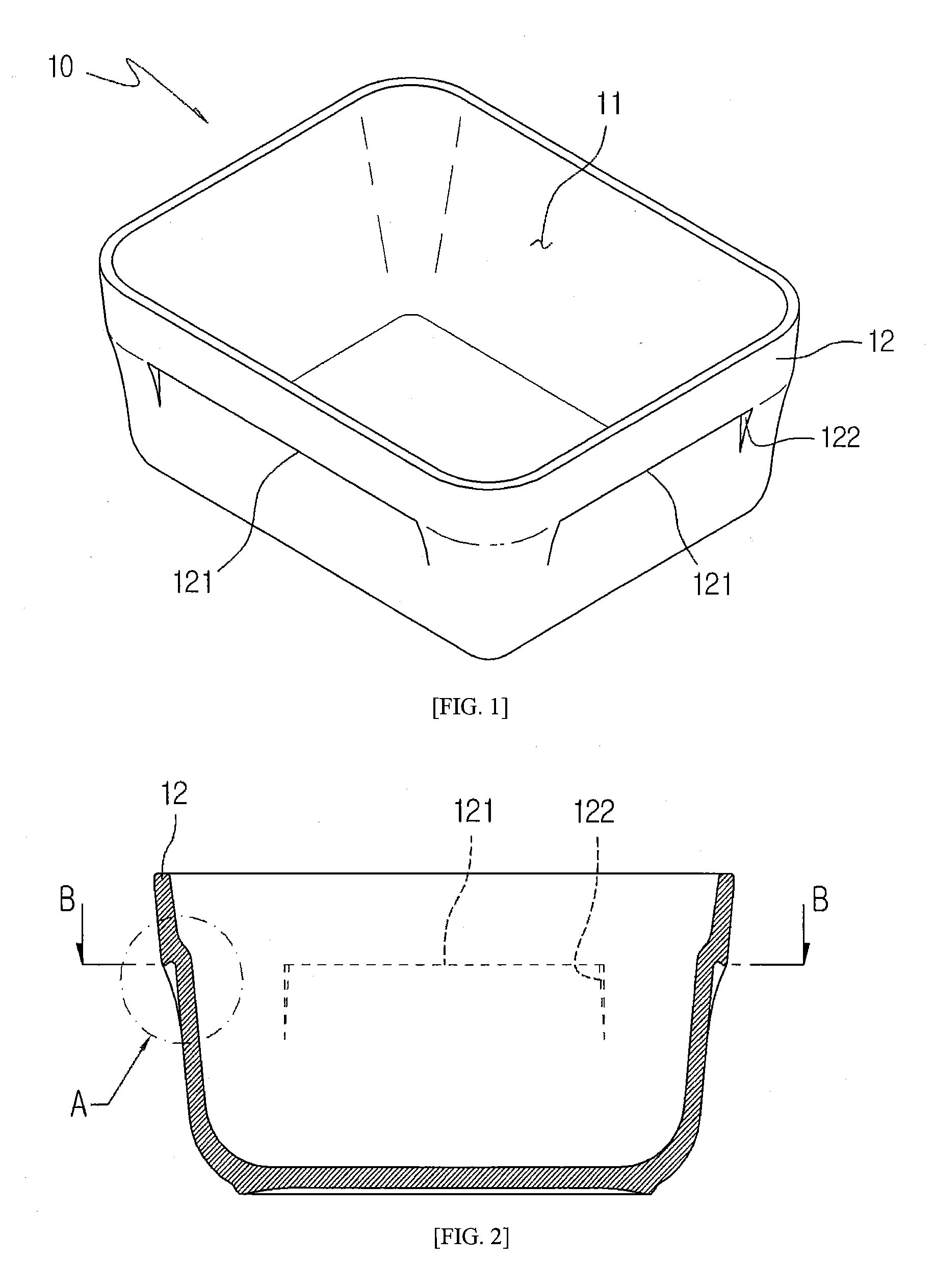

Airtight container for keeping food

InactiveUS20140069925A1Lower unit production costIncreased durabilityBoxesClamping mechanismPreserved FoodsEngineering

The present invention relates to an airtight container for preserving food, and more particularly, in order to make the molding of the container easy, reduce the manufacturing cost of the container while minimizing the fraction defective, and manufacture a tempered glass container which is not broken by collision among containers during production or distribution by making the thickness of the entire container uniform, the present invention provides an airtight container for preserving food comprising a container body wherein a lid with a locking member is detachably coupled on the upper portion on the peripheral surface and a space for food accommodation is provided therein, wherein a stumbling sill 121 with a lateral groove toward the inner direction is formed on the outer surface of the wall 12 of the container body, a side wall of groove 122, which is extended downwardly from the width of the stumbling sill to the outer surface of the wall, is formed on both ends of the stumbling sill, and protruded surface 124 corresponding to the groove depth of the stumbling sill is formed internally in the inner surface of the wall, thereby forming the wall with a uniform thickness.

Owner:SAMKWANG GLASS

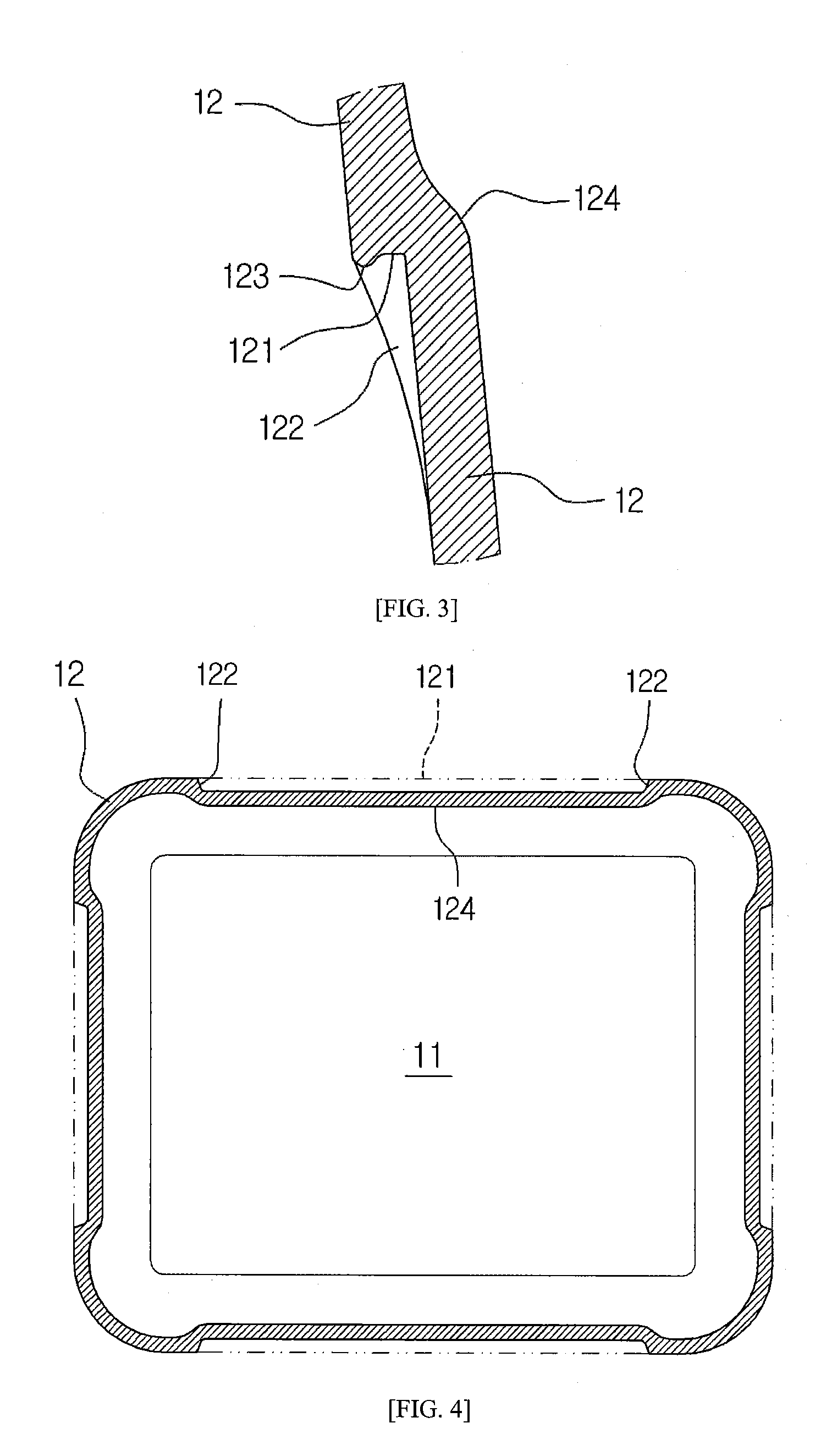

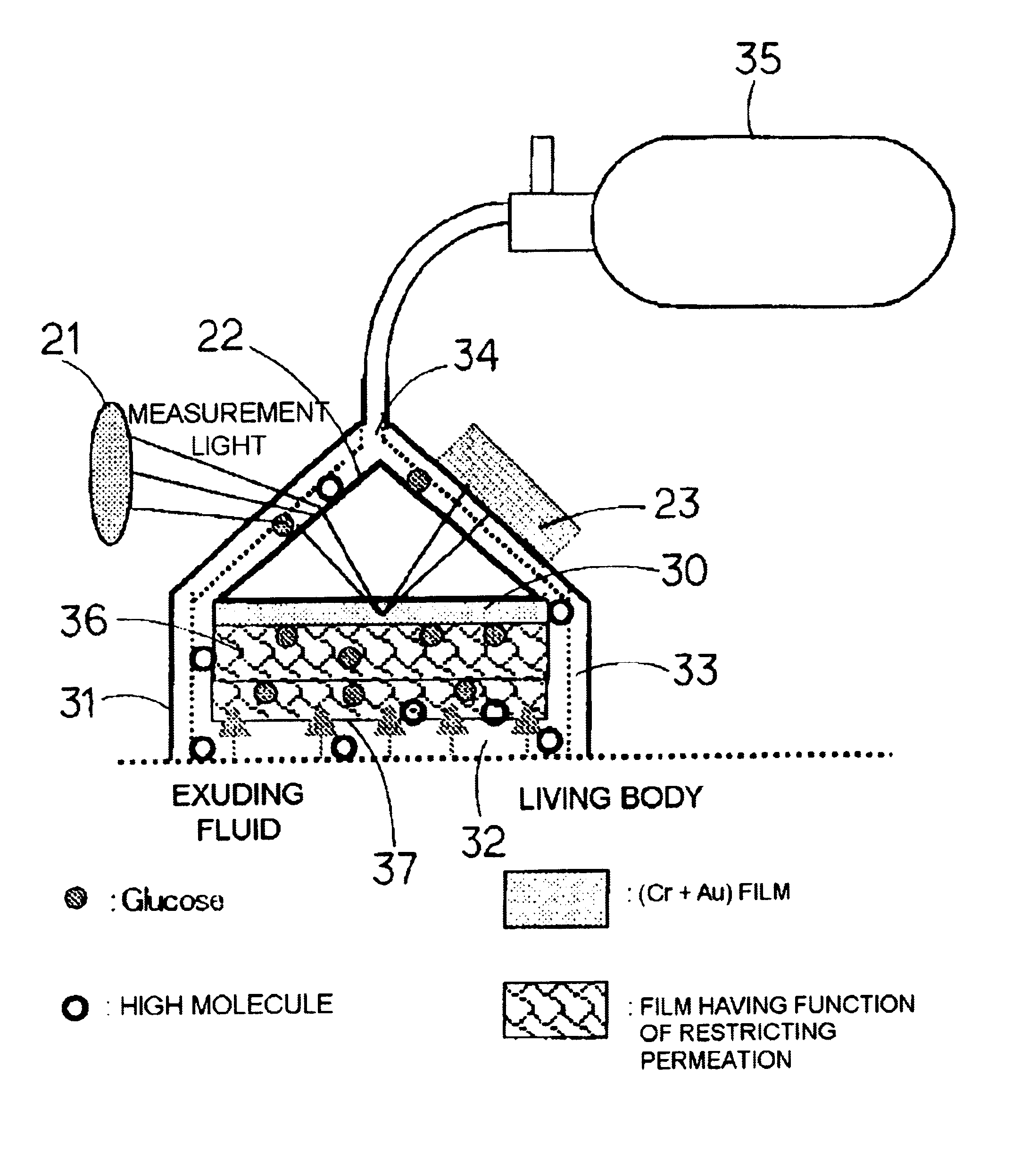

Method for measuring concentration of component contained in bodily fluid and apparatus for measuring concentration of component contained in bodily fluid

InactiveUS7016021B2Easy to measureAlleviated physicalWithdrawing sample devicesPreparing sample for investigationContinuous measurementPrism

A measuring unit is placed at the surface of a living body. The pressure inside of a glass container is reduced by a pressure reducing tank, so that a subcutaneous exuding fluid is taken out at the surface of the living body from under a skin. The subcutaneous exuding fluid is allowed as a sample to be measured to reach a metallic film through porous molecular weight selective films. A light beam emitted from a light source passes through a prism, and then, is reflected on the metallic film, and finally, is received on a linear array sensor. A minimum intensity position on the linear array sensor, generated by surface plasmon resonance is obtained, and then, a resonant angle is detected. The concentration of substance to be measured contained in the sample to be measured is calculated based on the resonant angle and position. Thus, the concentration of a component contained in a bodily fluid can be readily measured for a long time of period in a continuous manner without any special treatment by taking a very small quantity of exuding fluid without any pain.

Owner:OMRON HEALTHCARE CO LTD

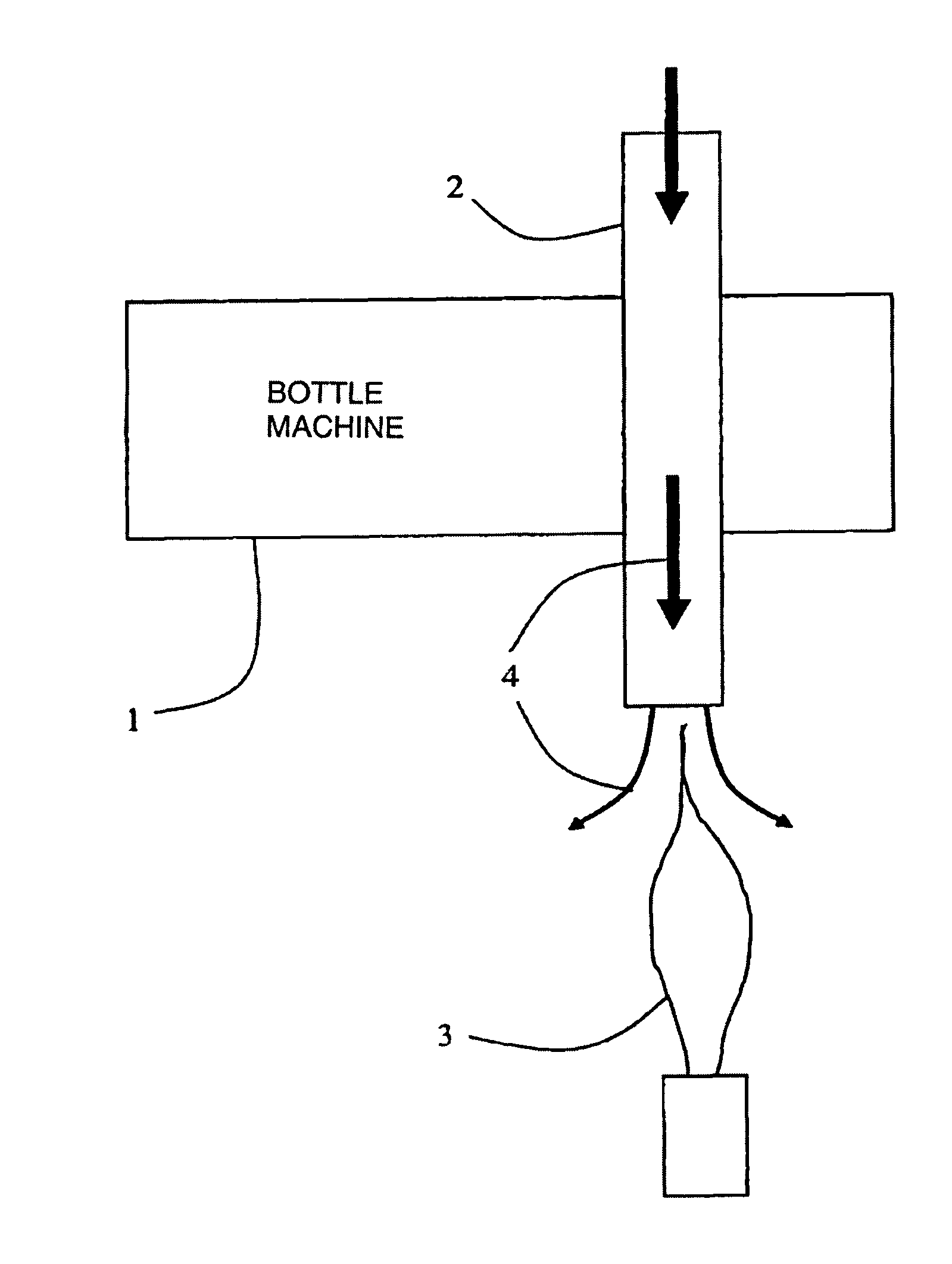

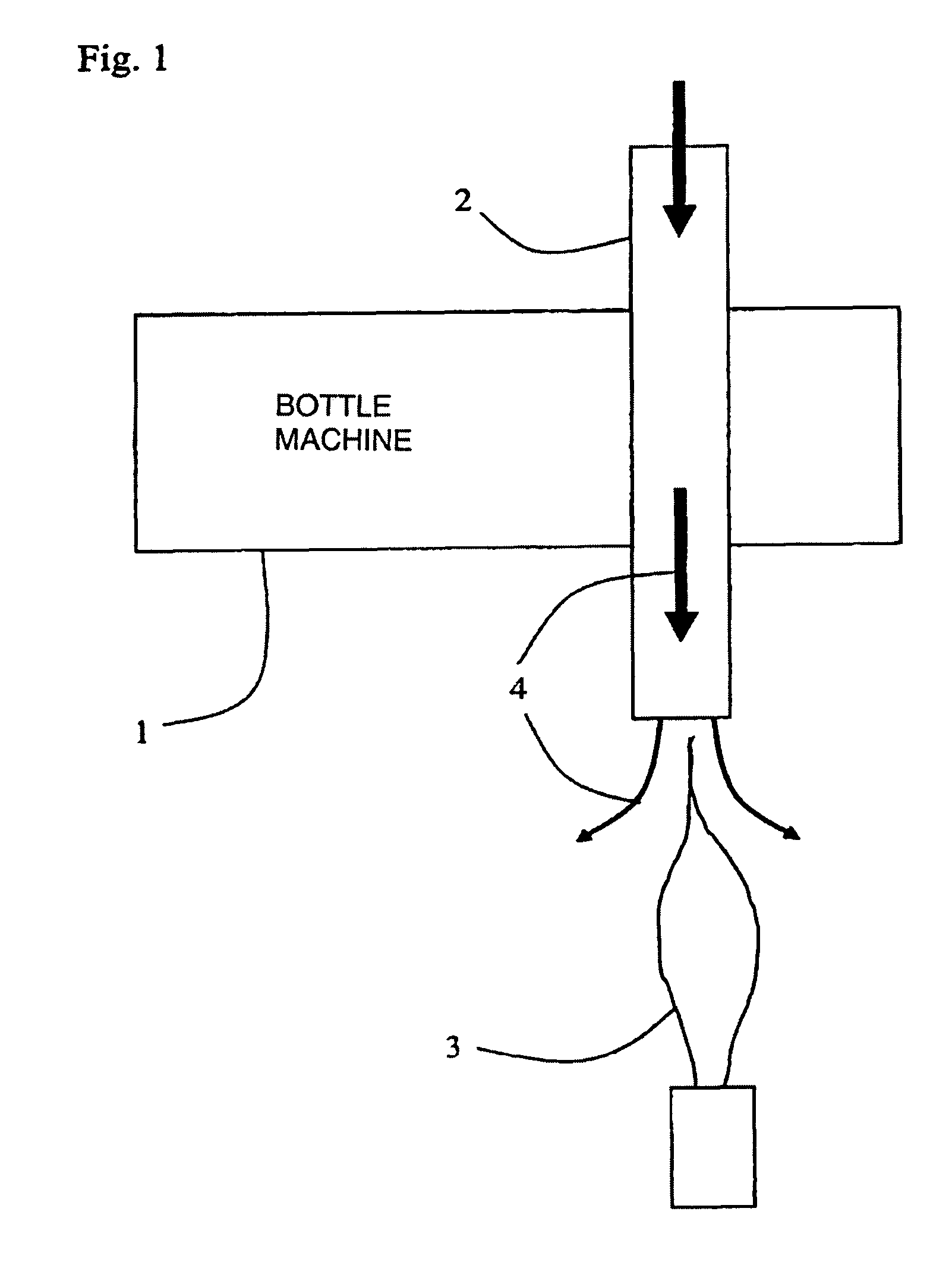

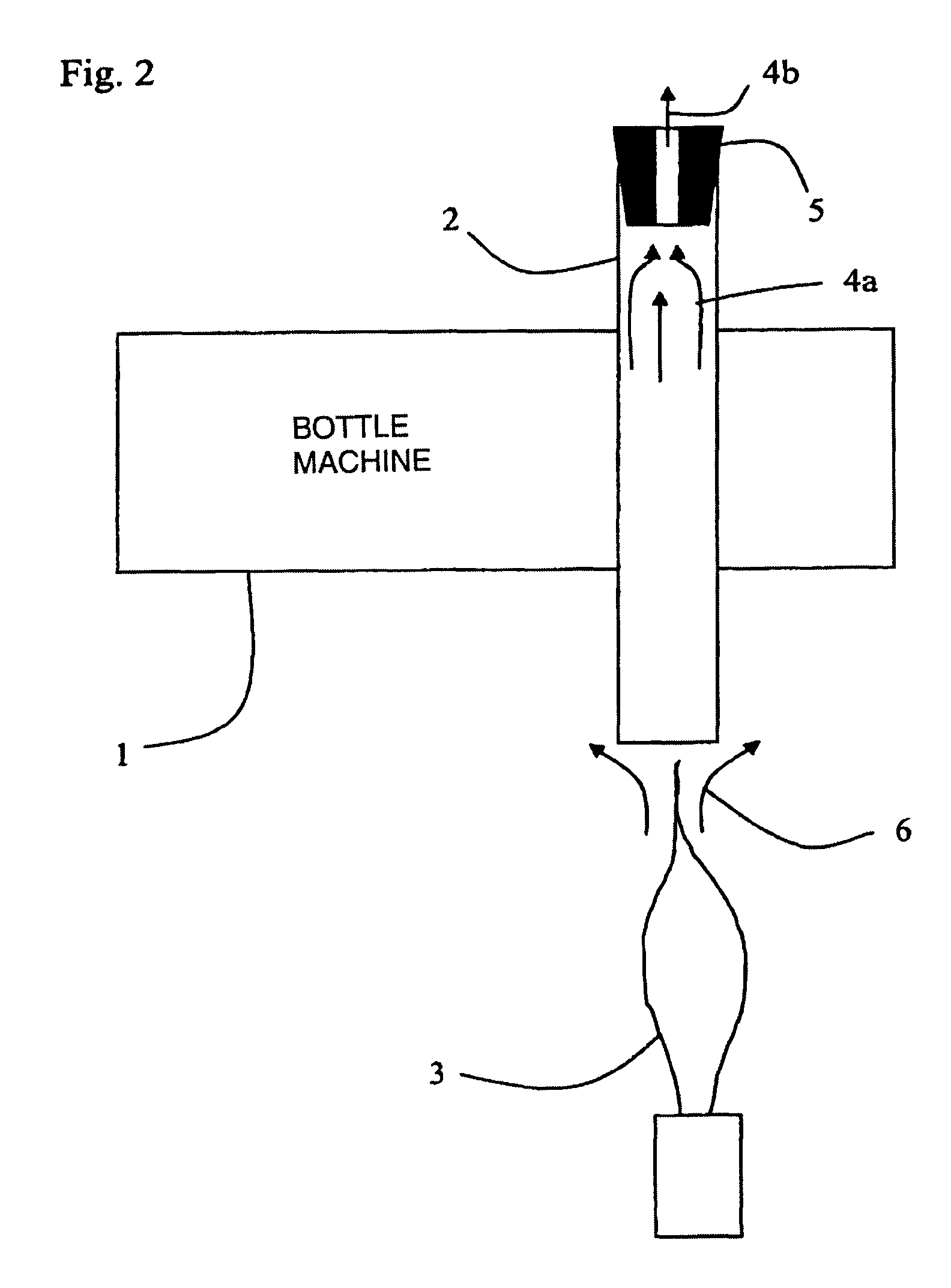

Method for preventing contamination of an inner surface of a hollow glass body by alkali compounds and glass container, especially for medicinal purposes

InactiveUS7980096B2Preventing and avoiding contaminationBlock compoundPharmaceutical containersGlass drawing apparatusVitreous BodiesContamination

In order to avoid deposition of evaporating alkali compounds on an inner surface of a hollow glass body during thermal processing to form a glass container from the hollow glass body, an overpressure is provided in the hollow glass body during the thermal processing. Either rinsing the hollow glass body with a gas, such as air, or at least partially closing the glass body at one end so that sufficiently rapid pressure equilibration is avoided, can provide this overpressure. The glass containers made by these methods are especially suited for food or pharmaceuticals because they have a reduced alkali release from their inner surfaces, for example at most about 2.0 mg / l sodium oxide.

Owner:SCHOTT AG

Glass containers with delamination resistance and improved strength

The glass containers described herein have at least two performance attributes selected from resistance to delamination, improved strength, and increased damage resistance. In one embodiment, a glass container with resistance to delamination and improved strength may include a body having an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. At least the inner surface of the body may have a delamination factor less than or equal to 10. The glass container may further include a compressively stressed layer extending from the outer surface of the body into the wall thickness. The compressively stressed layer may have a surface compressive stress greater than or equal to 150 MPa.

Owner:CORNING INC

Corrosive capable of displaying ultra low carbon steel solidification arborescent structure and preparation method thereof

ActiveCN102023112ASimplify the manufacturing processReduced finish requirementsPreparing sample for investigationTin(II) chlorideMaterials science

The invention discloses a corrosive capable of displaying an ultra low carbon solidification arborescent structure and a preparation method thereof. The corrosive is prepared from the following components: picric acid, stannous chloride, copper chloride, hydrochloric acid, surfactant, absolute ethyl alcohol and distilled water. The preparation method is as follows: taking a specified amount of the distilled water, and equally dividing the distilled water into two parts; mixing and putting solid medicament into a glass container according to fixed quantity, and adding one part of the distilledwater into the solid mixed medicament to dissolve the medicament; adding a specified amount of the absolute ethyl alcohol into another part of spare distilled water; adding a hydrochloric acid solution into the absolute ethyl alcohol solution; mixing the ethyl alcohol and the hydrochloric acid solution which are poured into an aqueous solution containing the solid medicament; fully stirring; and finally adding the surfactant to finish preparing. By utilizing the reagent provided by the invention, the solidified arborescent structure forms of ultra low C, S, P continuous casting steel billets can be displayed clearly, a finish requirement on sample surface is lowered, the sample preparation working procedure is simplified and the larbour intensity of operators is lowered.

Owner:ANGANG STEEL CO LTD

Delamination resistant glass containers with heat-tolerant coatings

Delamination resistant glass containers with heat-tolerant coatings are disclosed. In one embodiment, a glass container may include a glass body having an interior surface, an exterior surface and a wall thickness extending from the exterior surface to the interior surface. At least the interior surface of the glass body is delamination resistant. The glass container may further include a heat-tolerant coating positioned on at least a portion of the exterior surface of the glass body. The heat-tolerant coating may be thermally stable at temperatures greater than or equal to 260° C. for 30 minutes.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com