Patents

Literature

634results about How to "Minimizes problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

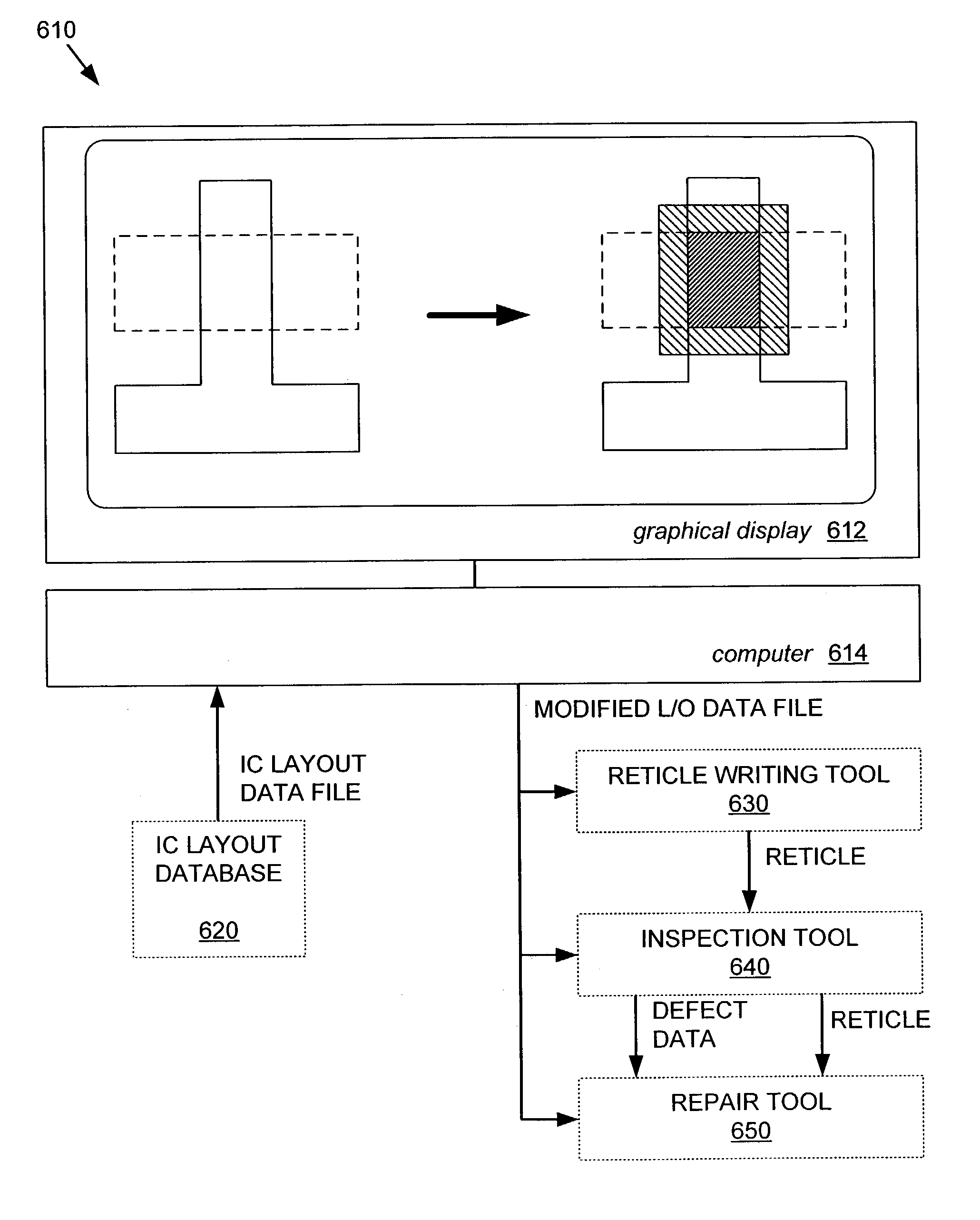

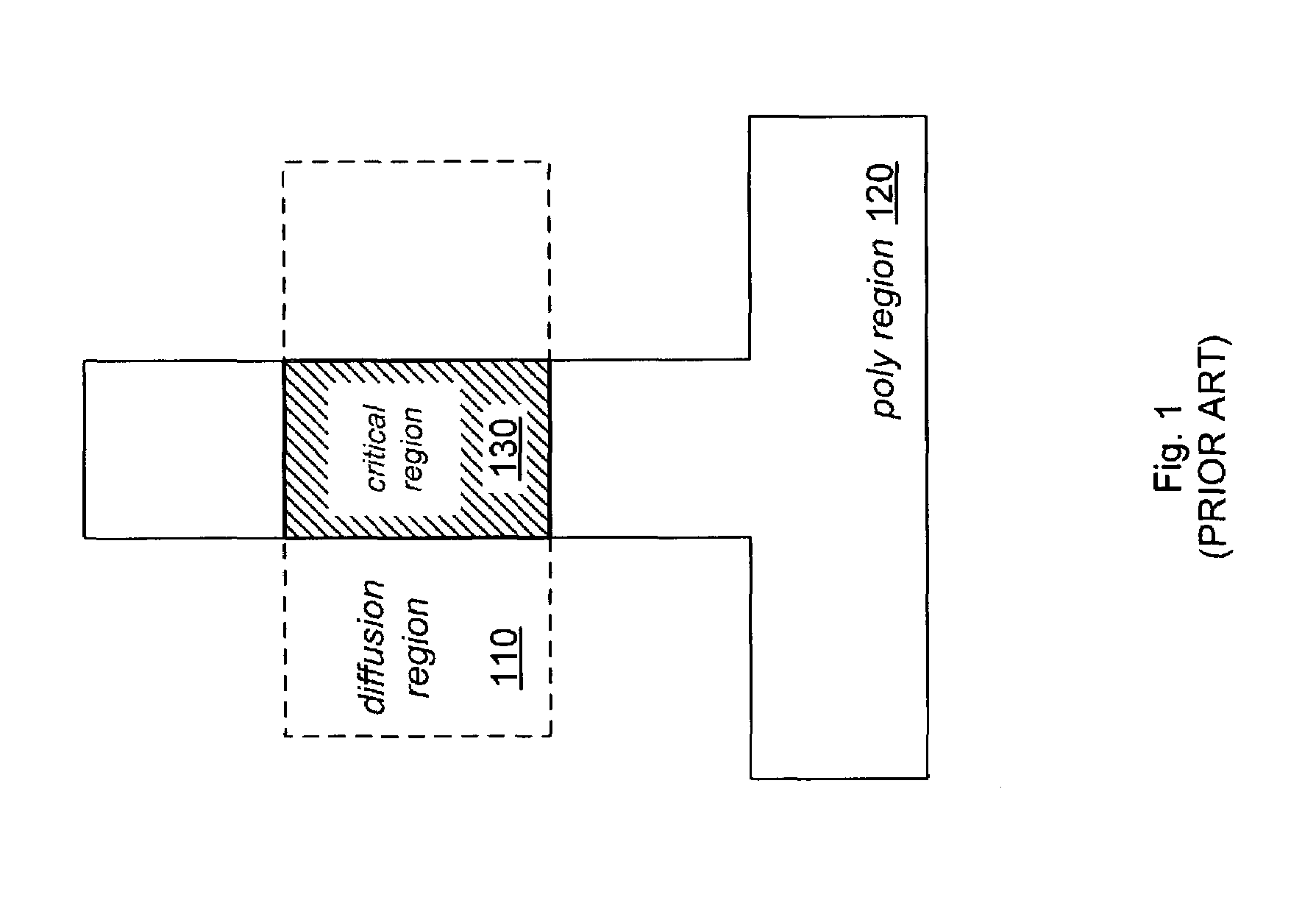

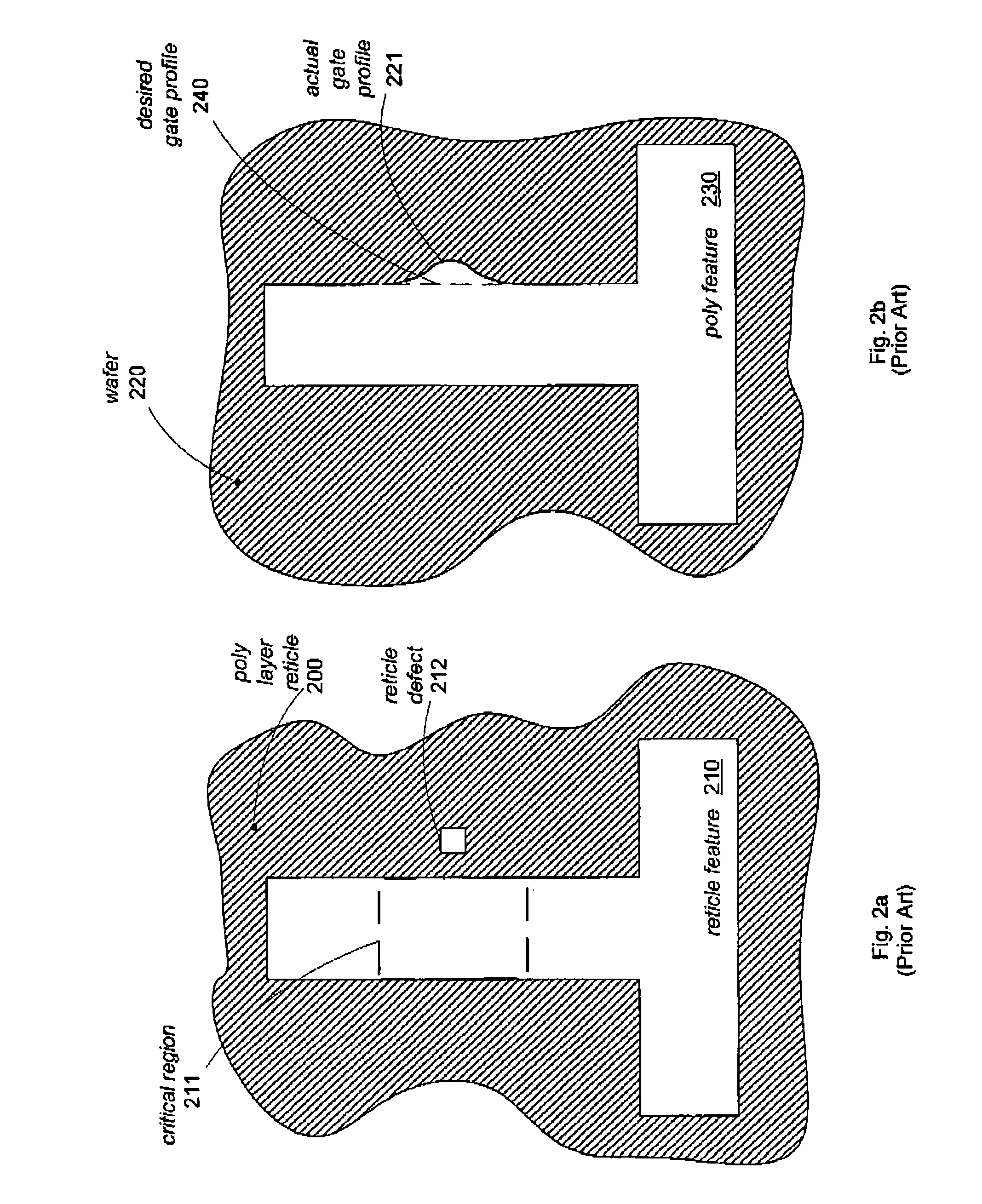

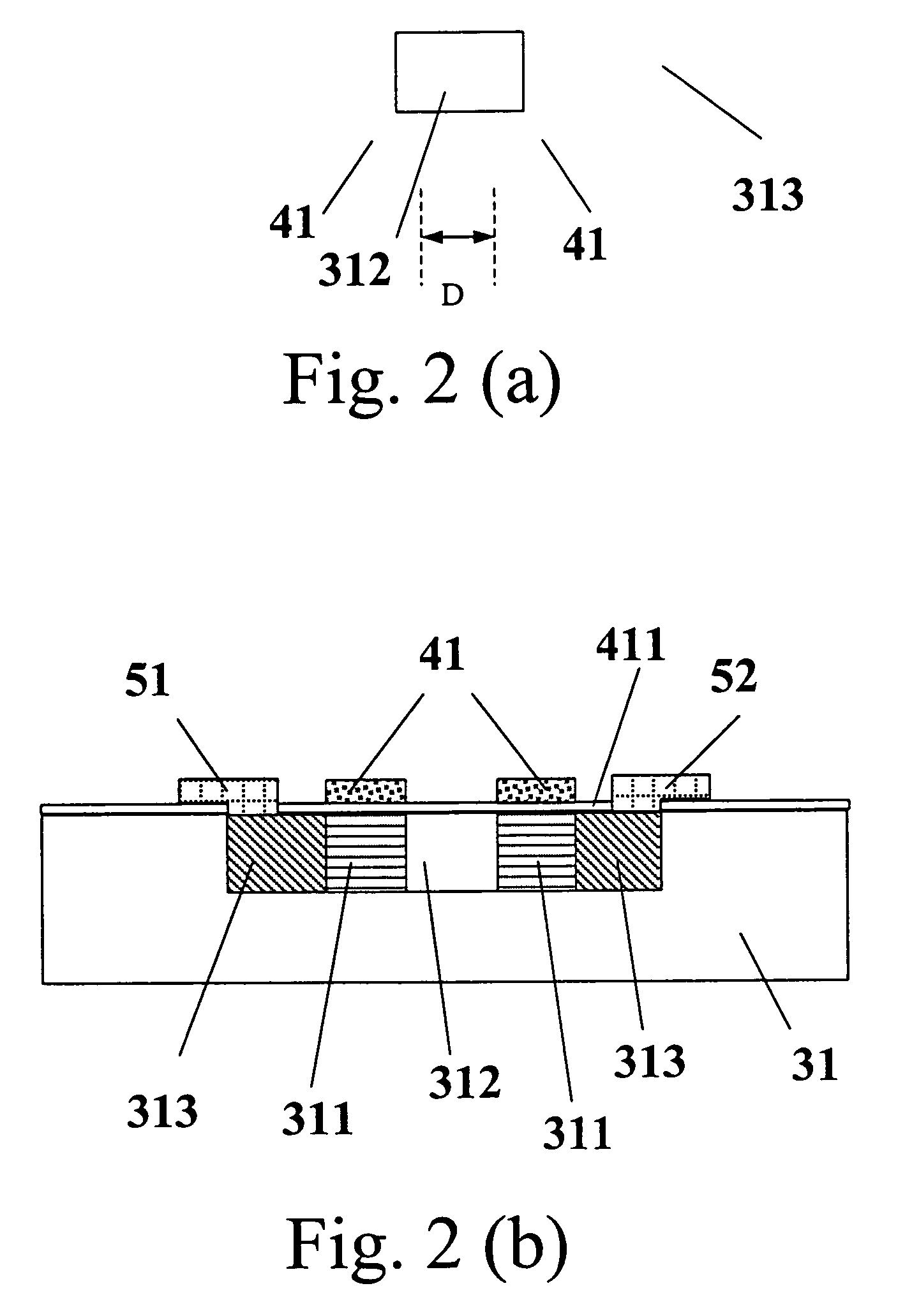

High yield reticle with proximity effect halos

InactiveUS6968527B2High degreeLow costElectric discharge tubesSemiconductor/solid-state device manufacturingGraphical displayData file

Owner:SYNOPSYS INC

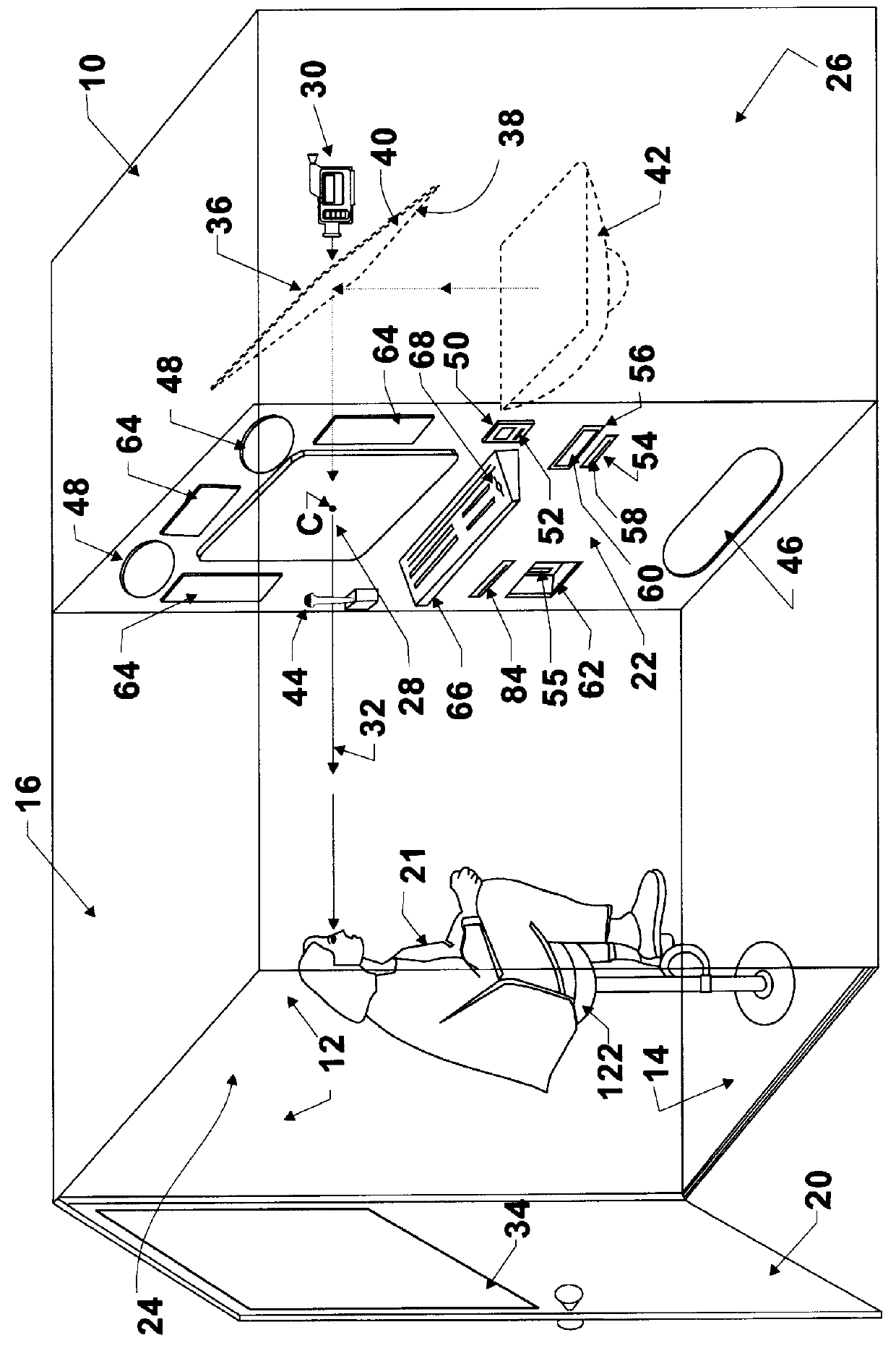

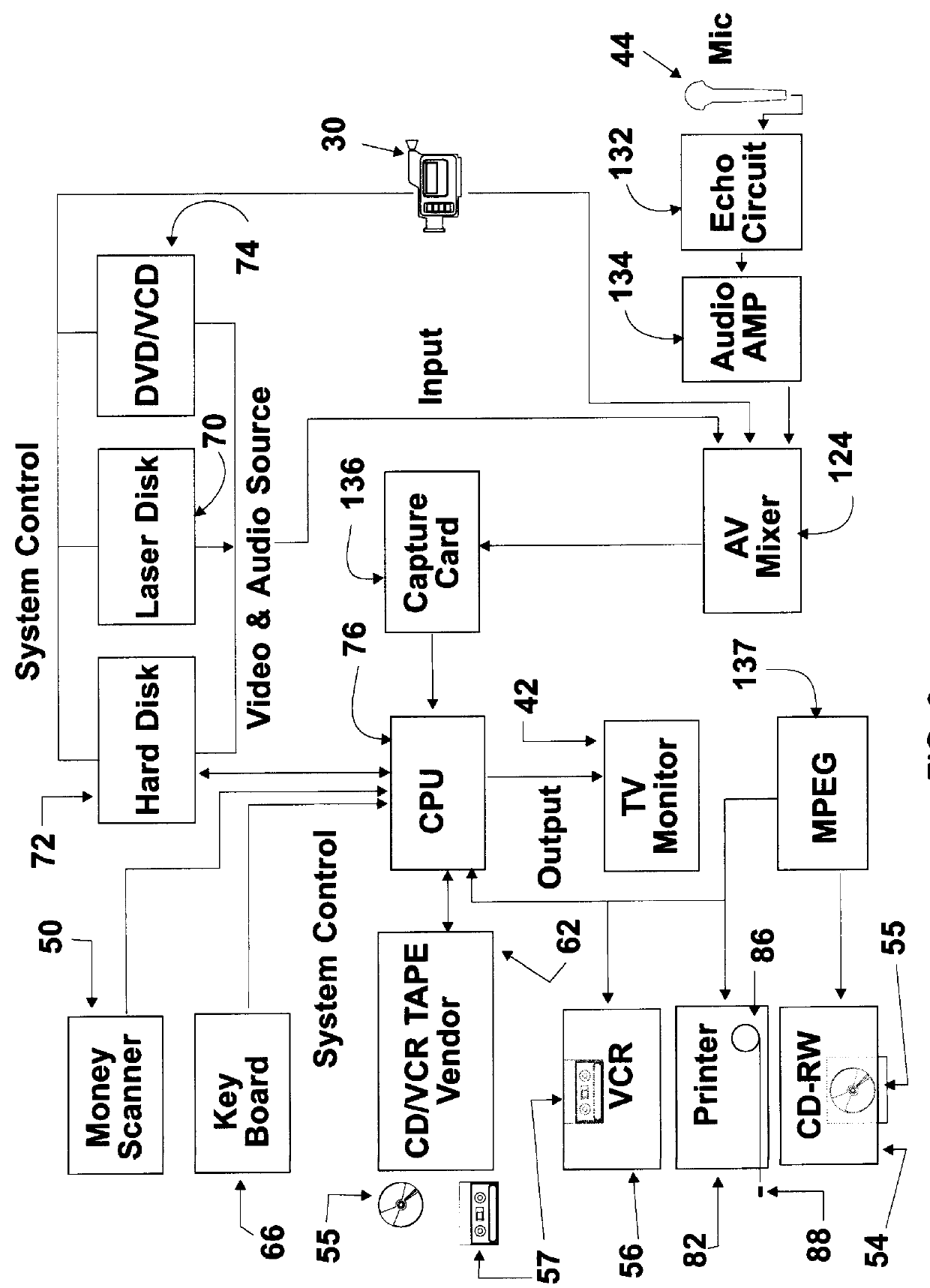

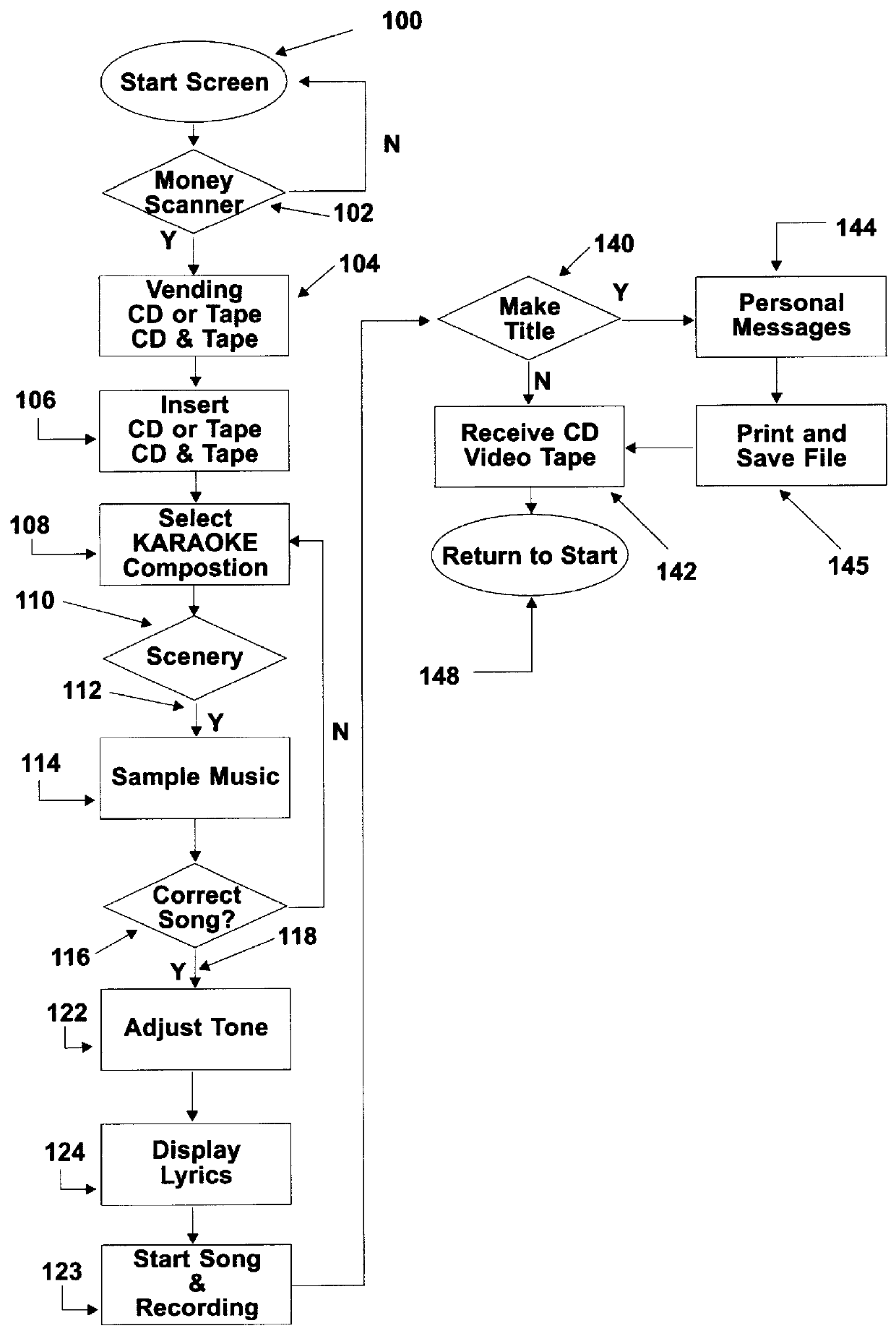

Personalized karaoke recording studio

InactiveUS6086380AMinimizes problemEasy to adaptGearworksMusical toysPersonalizationComputer graphics (images)

In a self-operated karaoke recording booth a user is provided with a selection of background scenes from which to choose and also with the option of having the lyrics of the karaoke selection displayed or suppressed. A video camera positioned at the user's eye level is located on the nonreflective side of a one-way mirror and is directed at a specified performer location through the one-way mirror, which is inclined at a forty-five degree angle relative thereto. Messages and video displays are provided to the user by a video display monitor connected to a computer that faces the reflective side of the one-way mirror and is also located at a forty-five degree angle relative thereto. The system is designed to maintain the visual focus of the performer directly into the lens of the video camera throughout the performance and to combine the video camera images with the background scene in such a way as to avoid a double exposure or phantom image of the performer against the background. The performer can choose to have the lyrics of the selected karaoke composition displayed or suppressed. If the election is for a display, the lyrics are displayed at the center of the viewing screen, directly in line with the video camera.

Owner:CHU CHIA CHEN +3

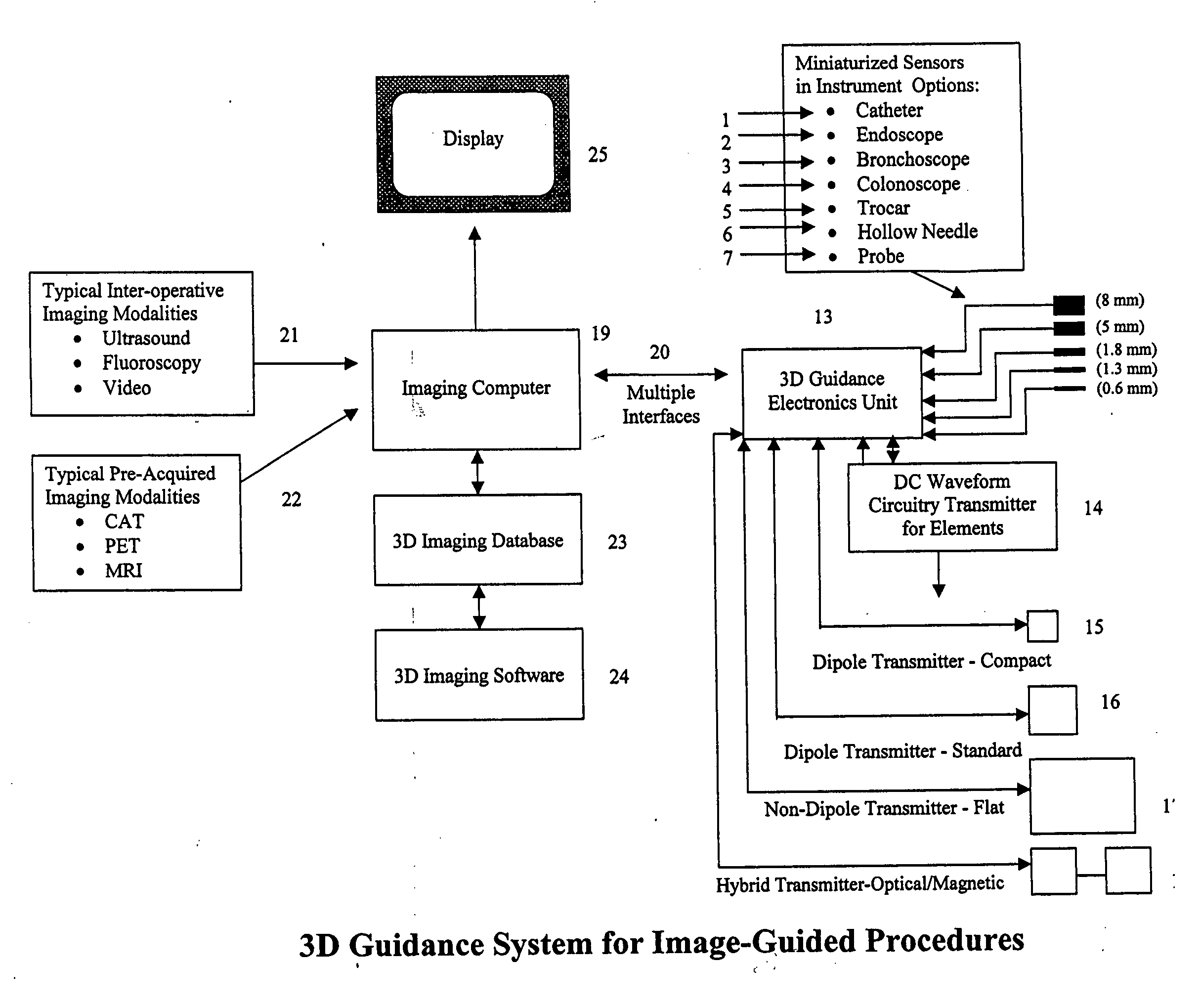

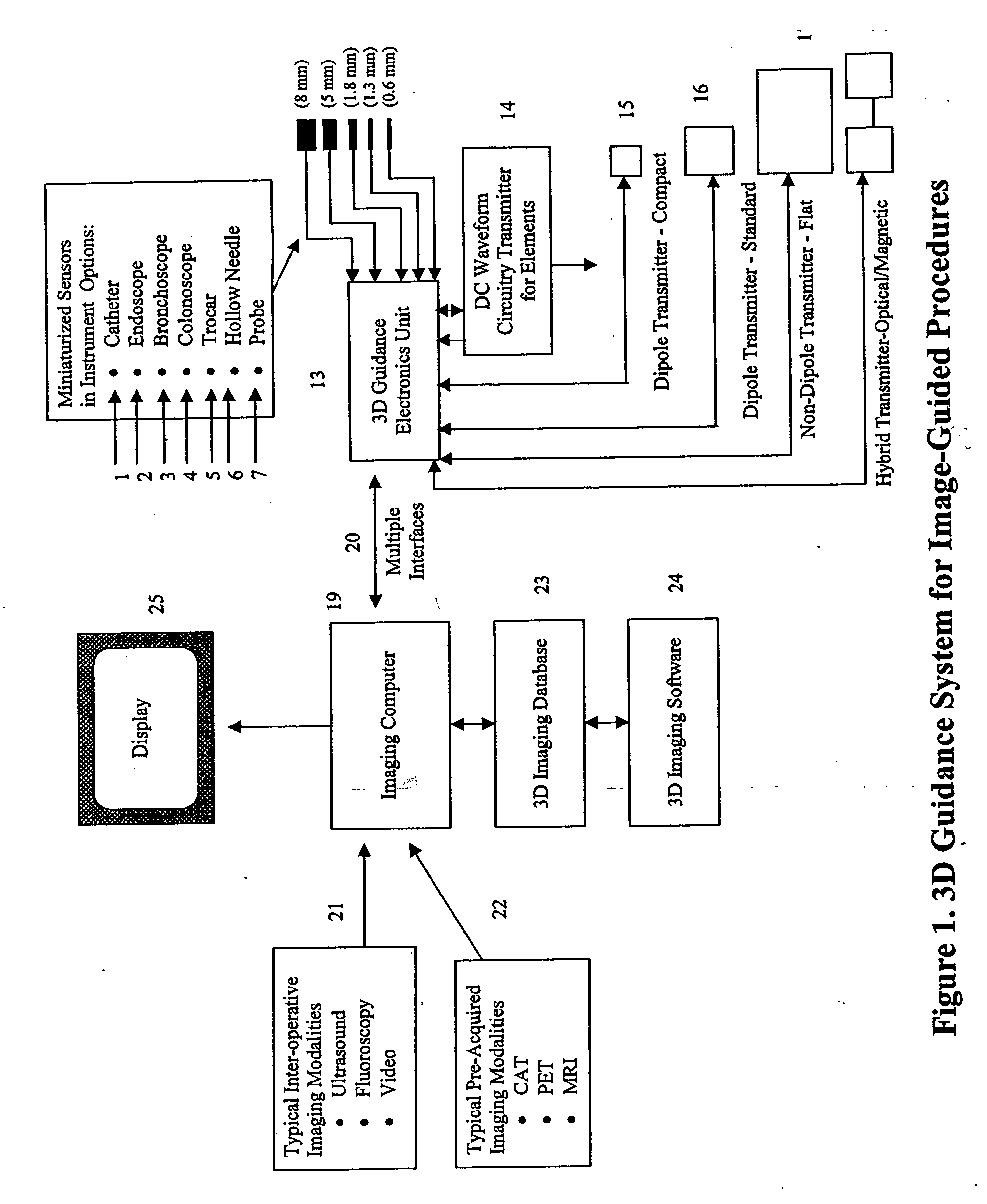

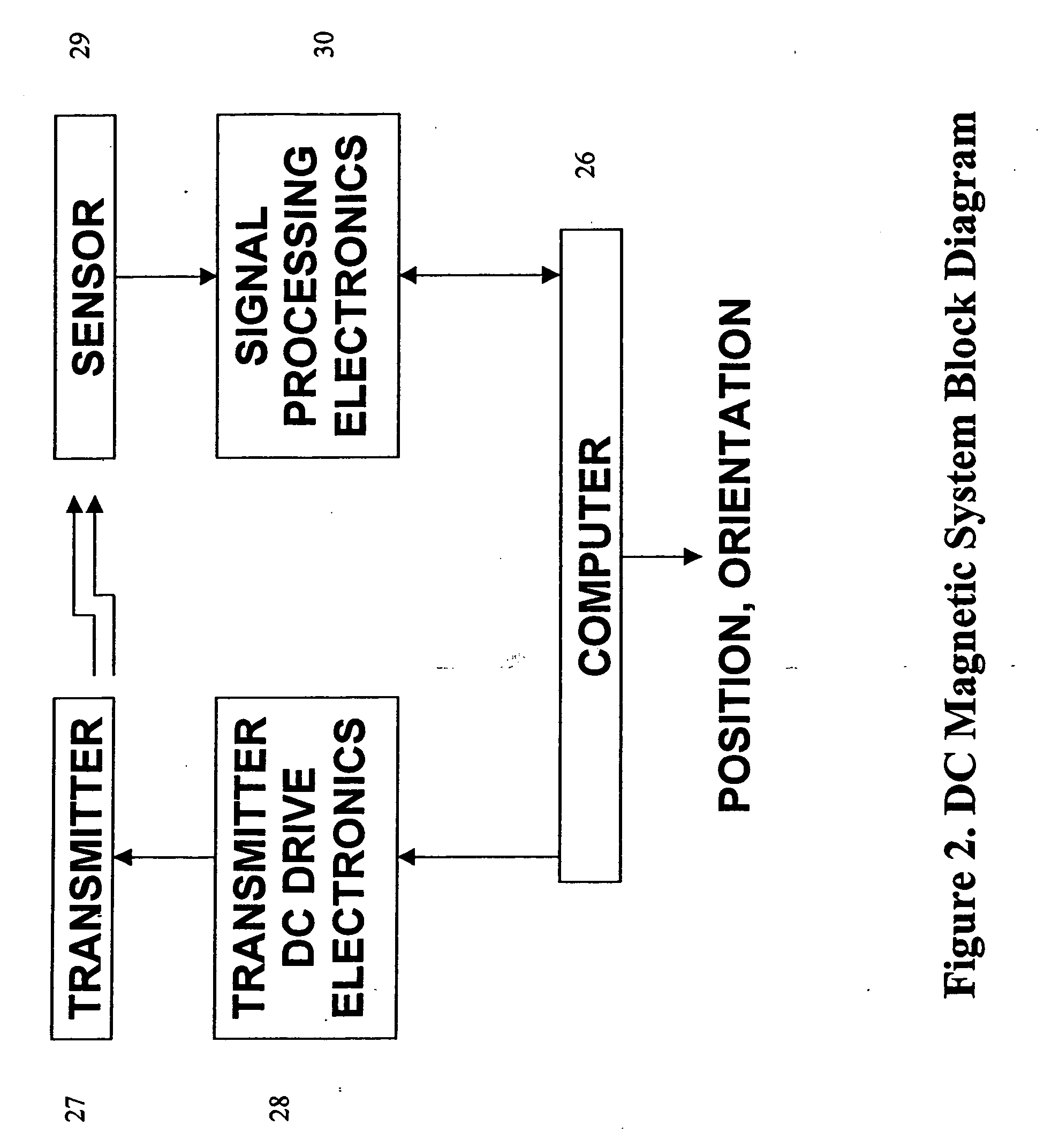

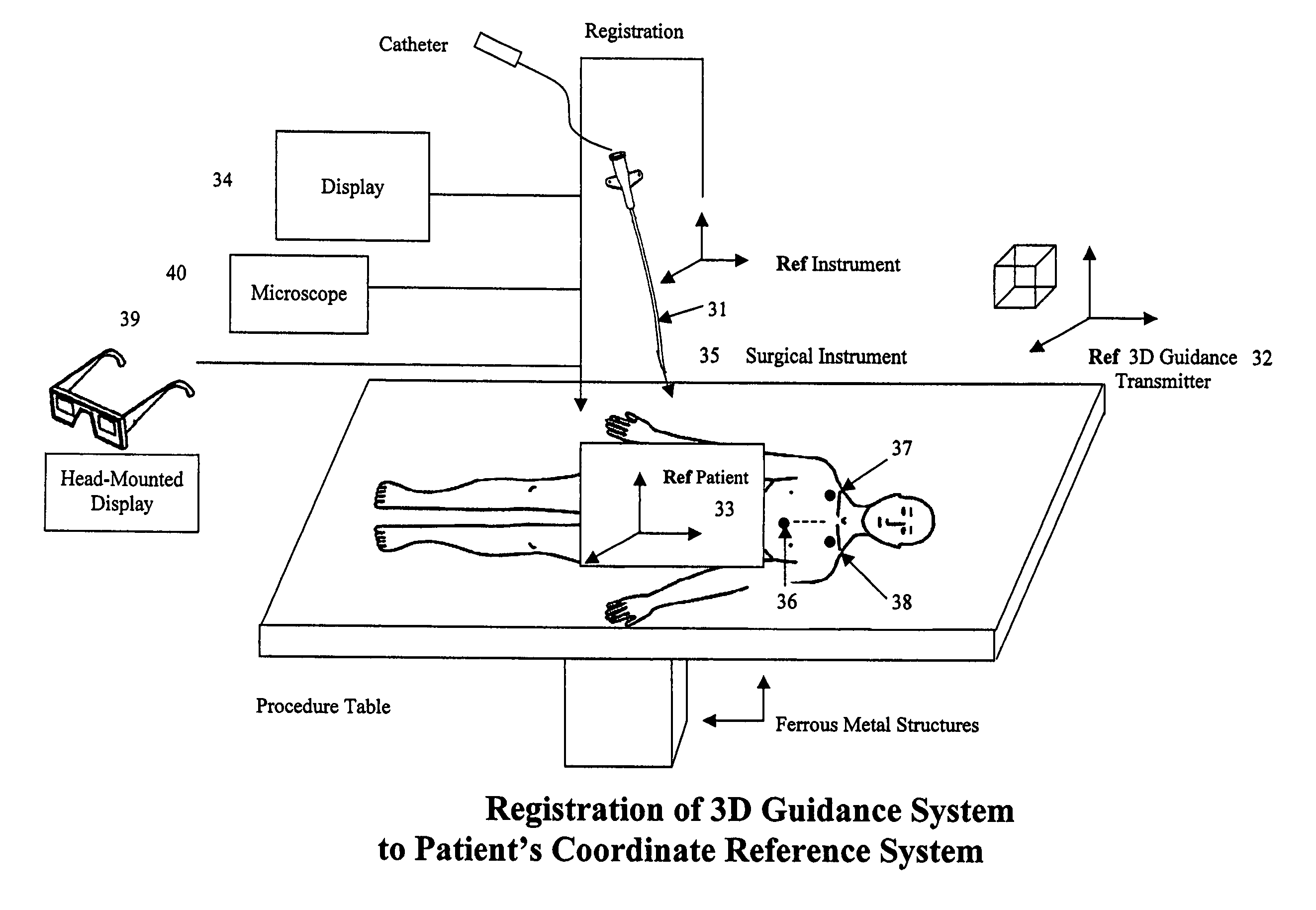

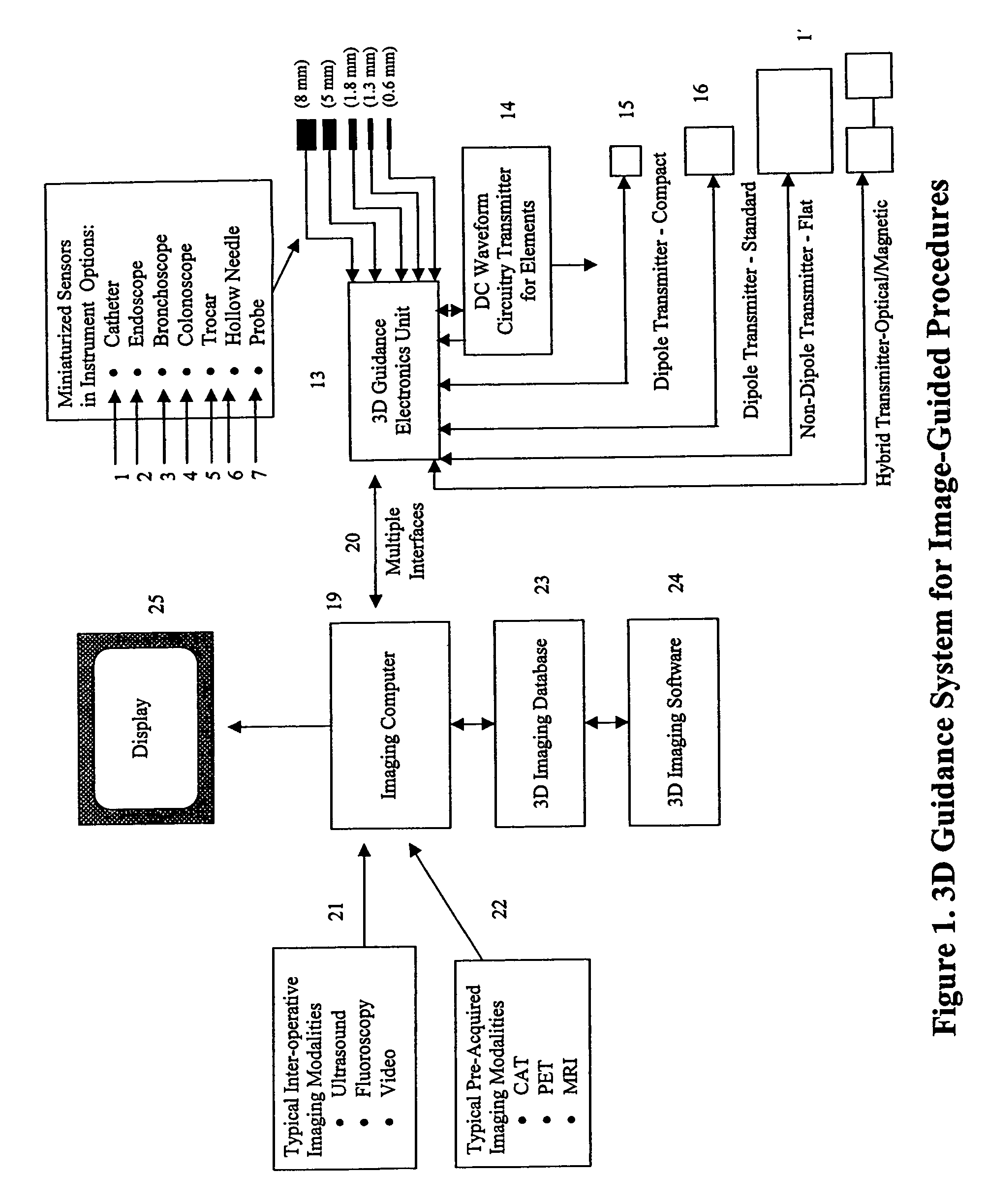

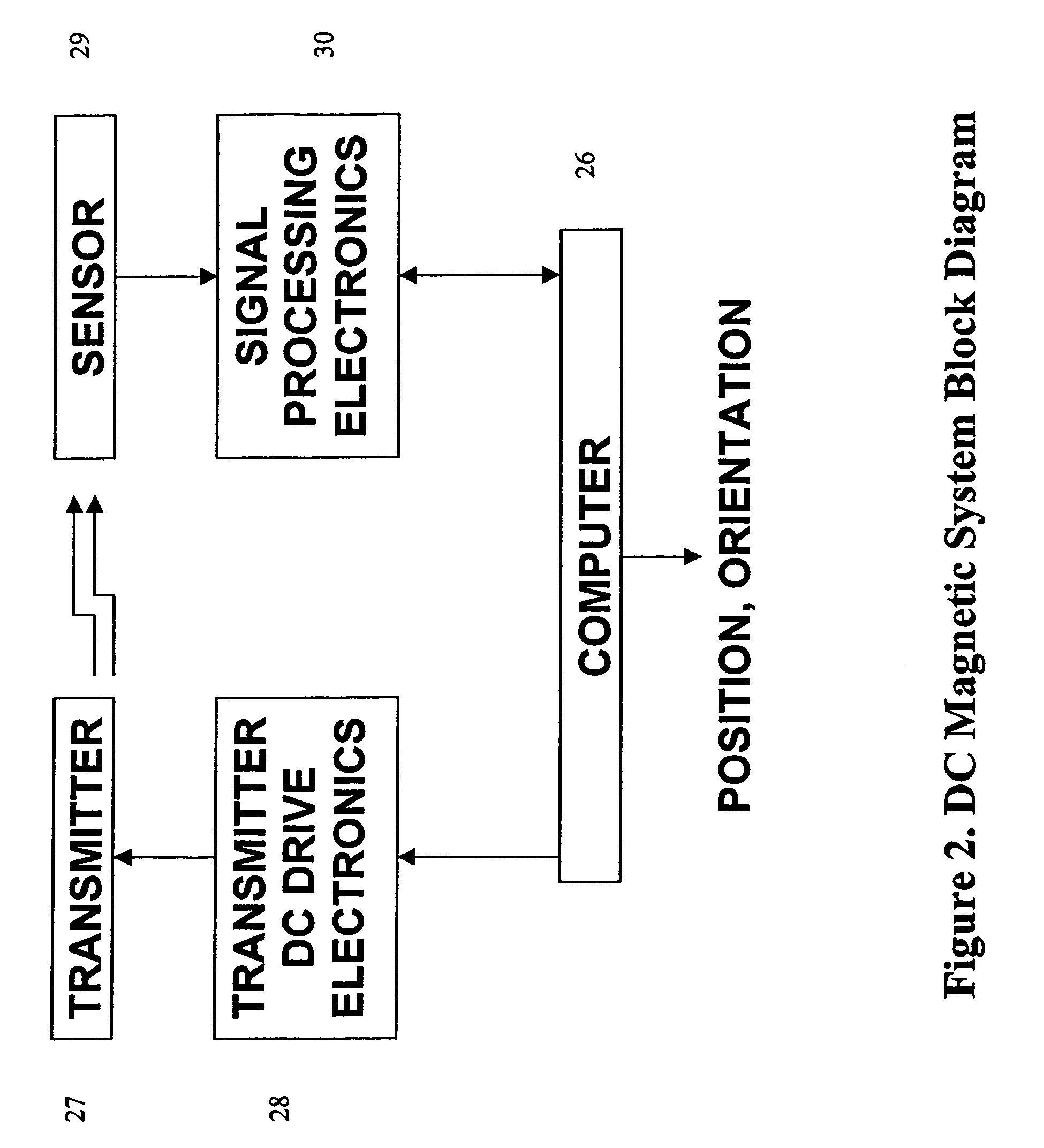

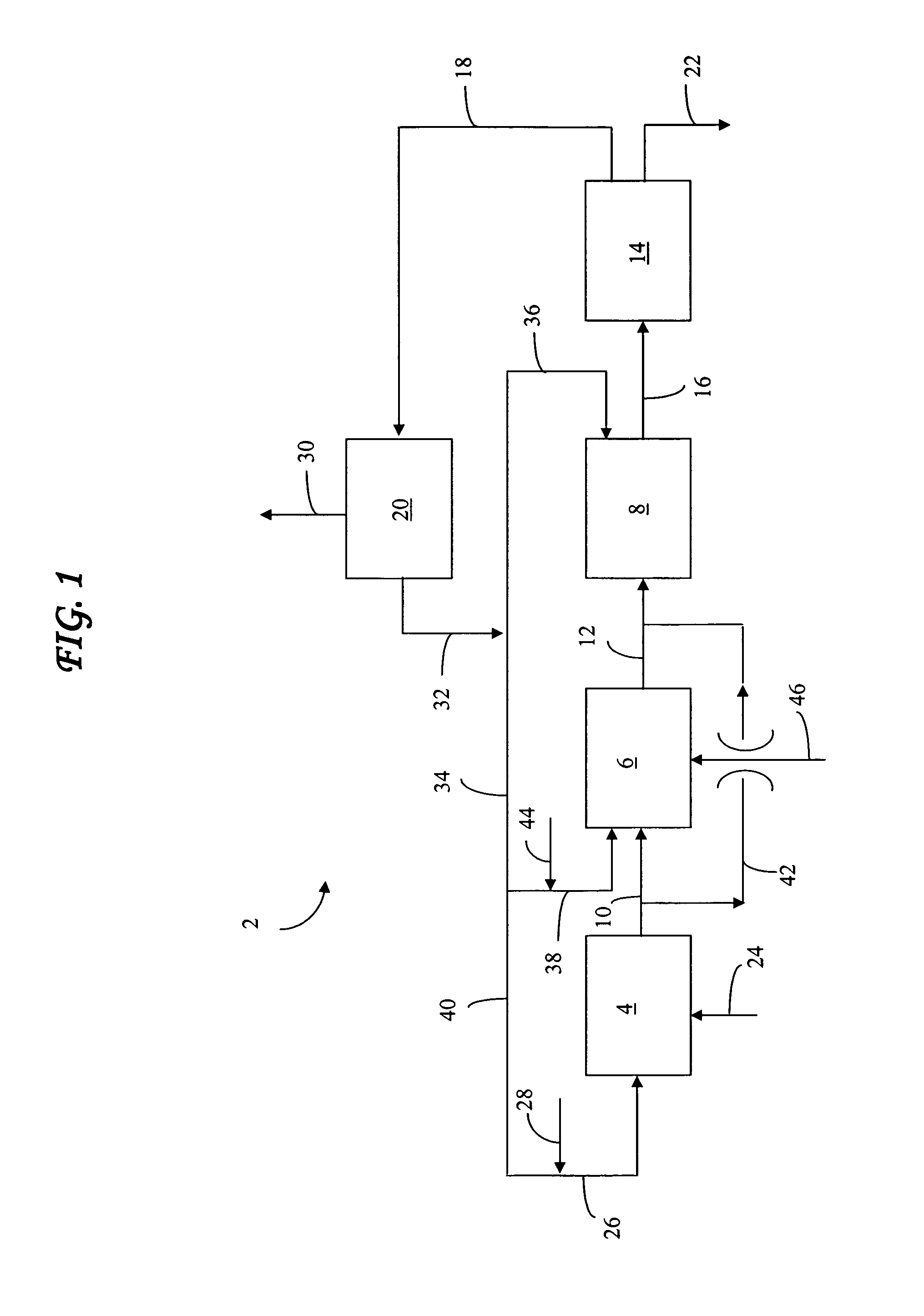

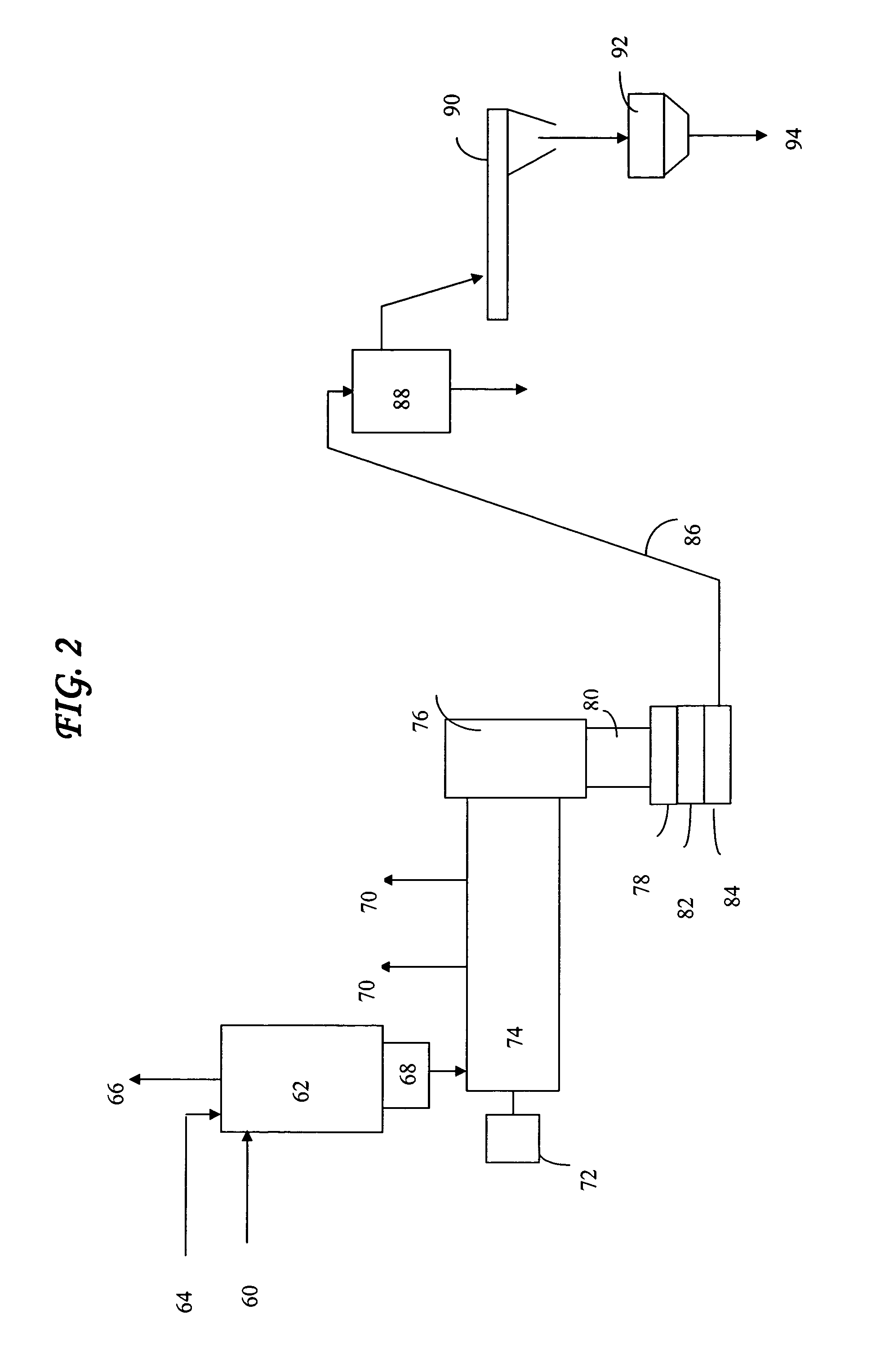

DC magnetic-based position and orientation monitoring system for tracking medical instruments

ActiveUS20070078334A1Overcome disposabilityOvercome cost issueDiagnostic recording/measuringSensors3d sensorEngineering

Miniaturized, five and six degrees-of-freedom magnetic sensors, responsive to pulsed DC magnetic fields waveforms generated by multiple transmitter options, provide an improved and cost-effective means of guiding medical instruments to targets inside the human body. The end result is achieved by integrating DC tracking, 3D reconstructions of pre-acquired patient scans and imaging software into a system enabling a physician to internally guide an instrument with real-time 3D vision for diagnostic and interventional purposes. The integration allows physicians to navigate within the human body by following 3D sensor tip locations superimposed on anatomical images reconstructed into 3D volumetric computer models. Sensor data can also be integrated with real-time imaging modalities, such as endoscopes, for intrabody navigation of instruments with instantaneous feedback through critical anatomy to locate and remove tissue. To meet stringent medical requirements, the system generates and senses pulsed DC magnetic fields embodied in an assemblage of miniaturized, disposable and reposable sensors functional with both dipole and co-planar transmitters.

Owner:NORTHERN DIGITAL

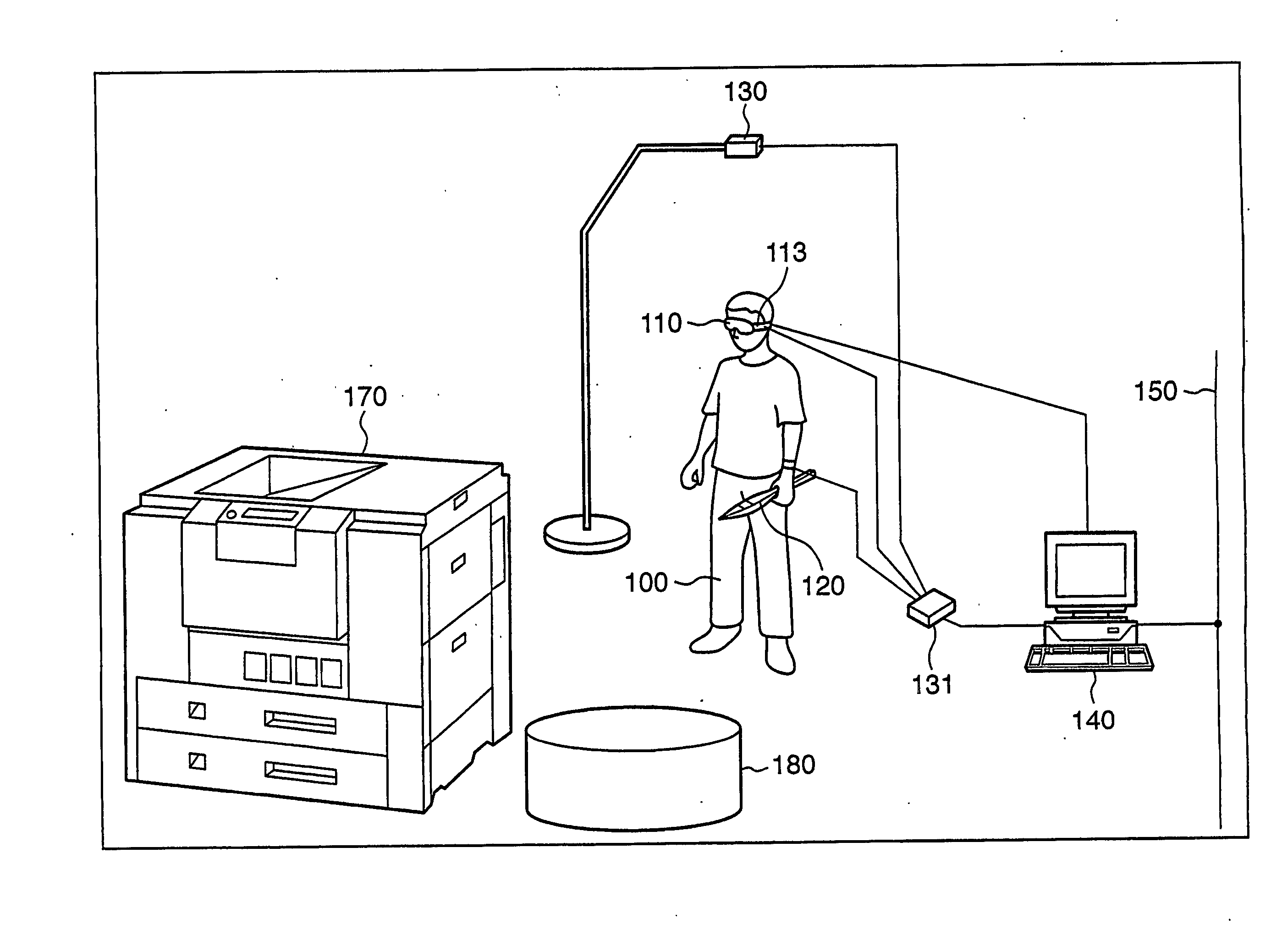

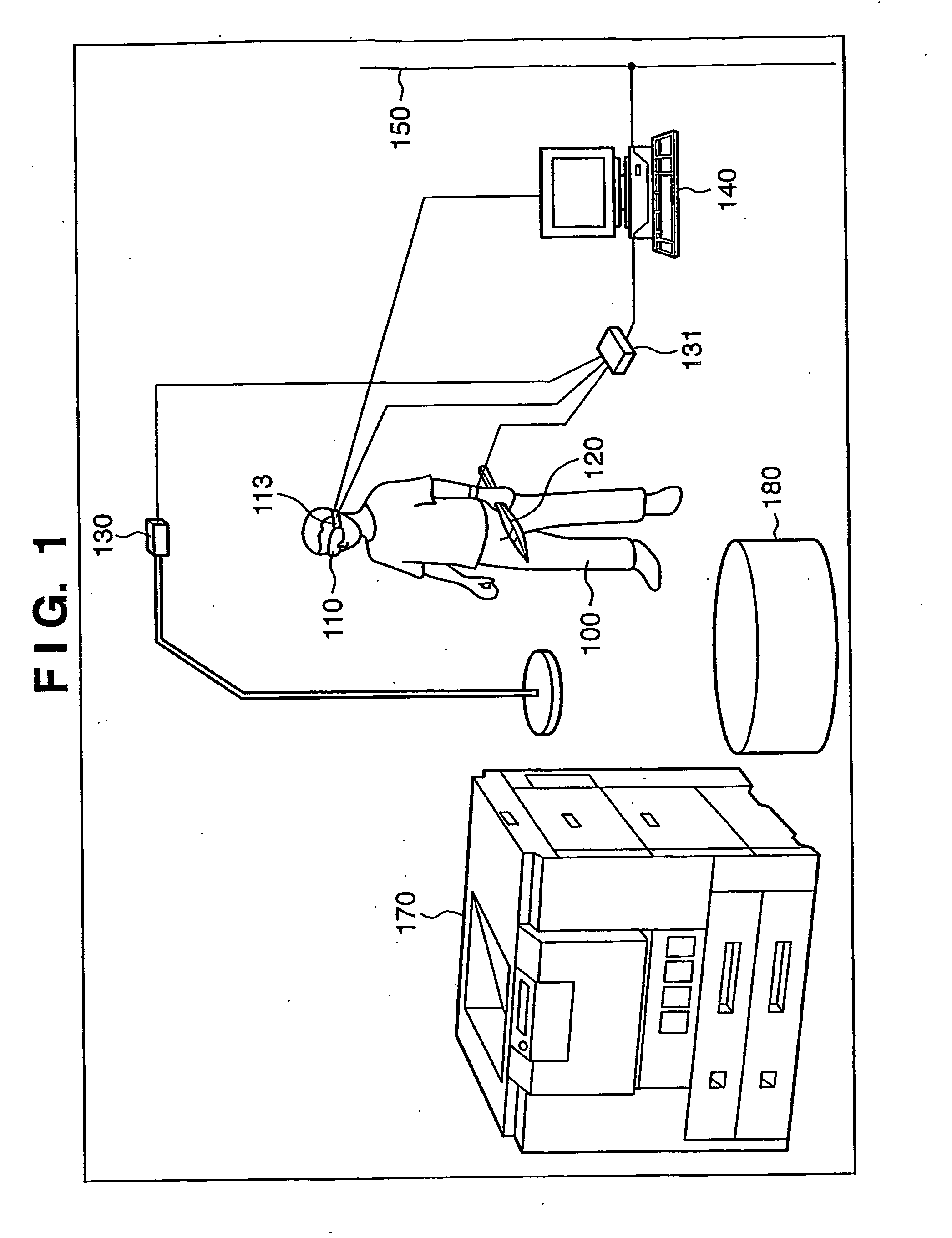

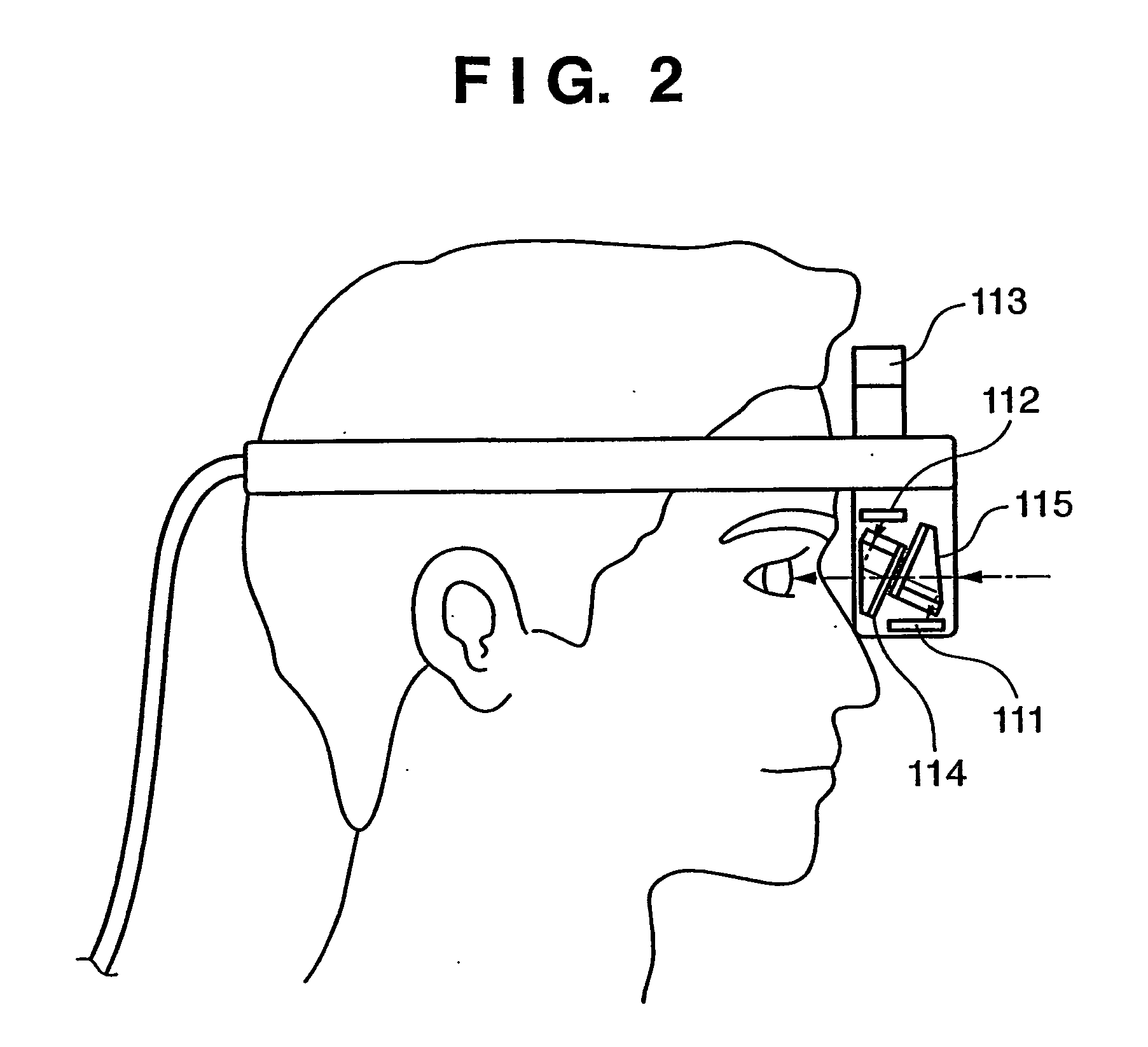

Information processing method, information processing apparatus, and image sensing apparatus

ActiveUS20070132662A1Minimizes problemInput/output for user-computer interactionCathode-ray tube indicatorsInformation processingViewpoints

The position and orientation of the viewpoint of an observer (100) are acquired. The position and orientation of a stylus (120) are acquired. A list image is laid out near the position of the stylus (120). An image of a virtual space after laying out the list image, which is seen in accordance with the position and orientation of the viewpoint, generated. The generated image is output to the display screen of an HMD (110).

Owner:CANON KK

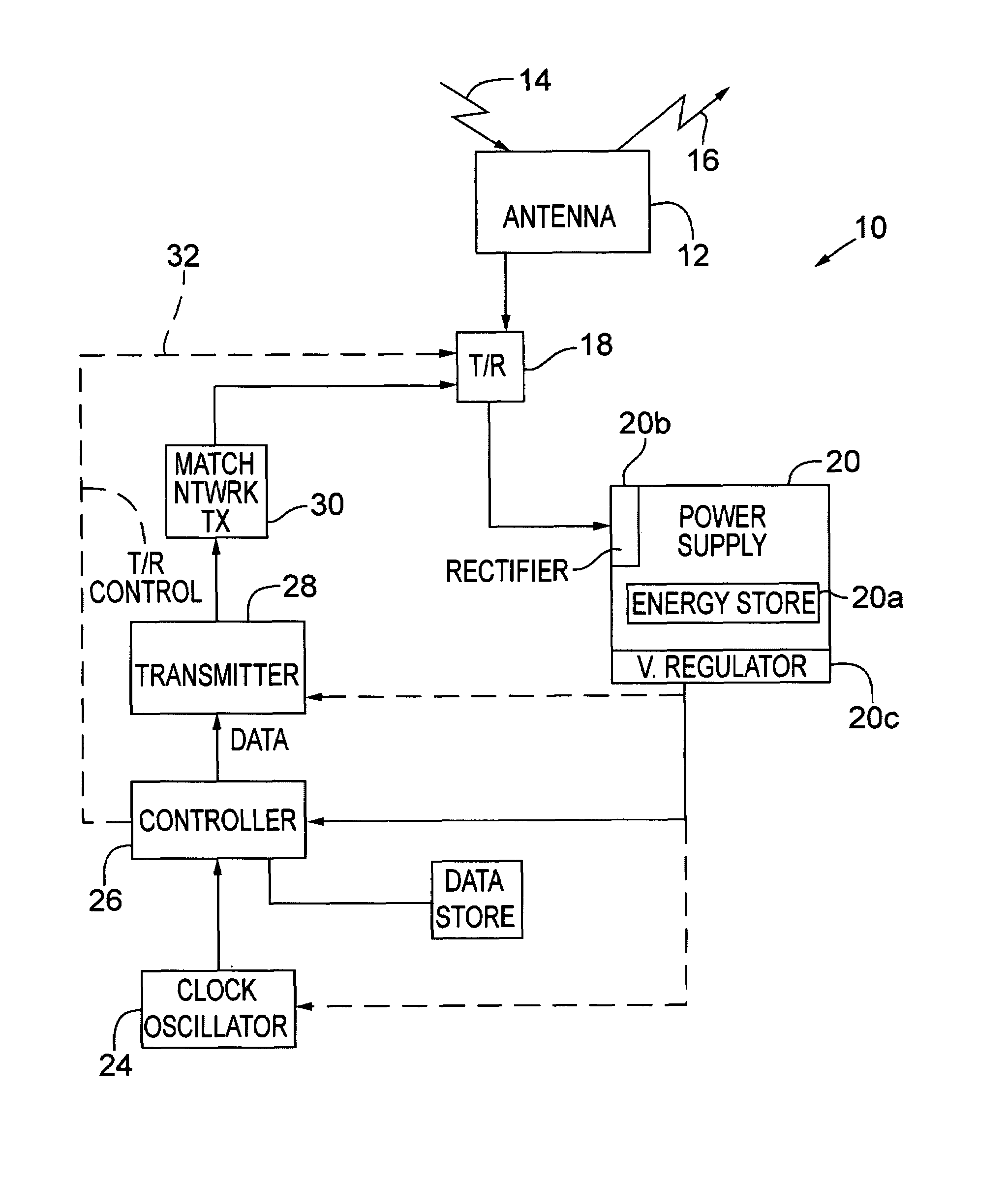

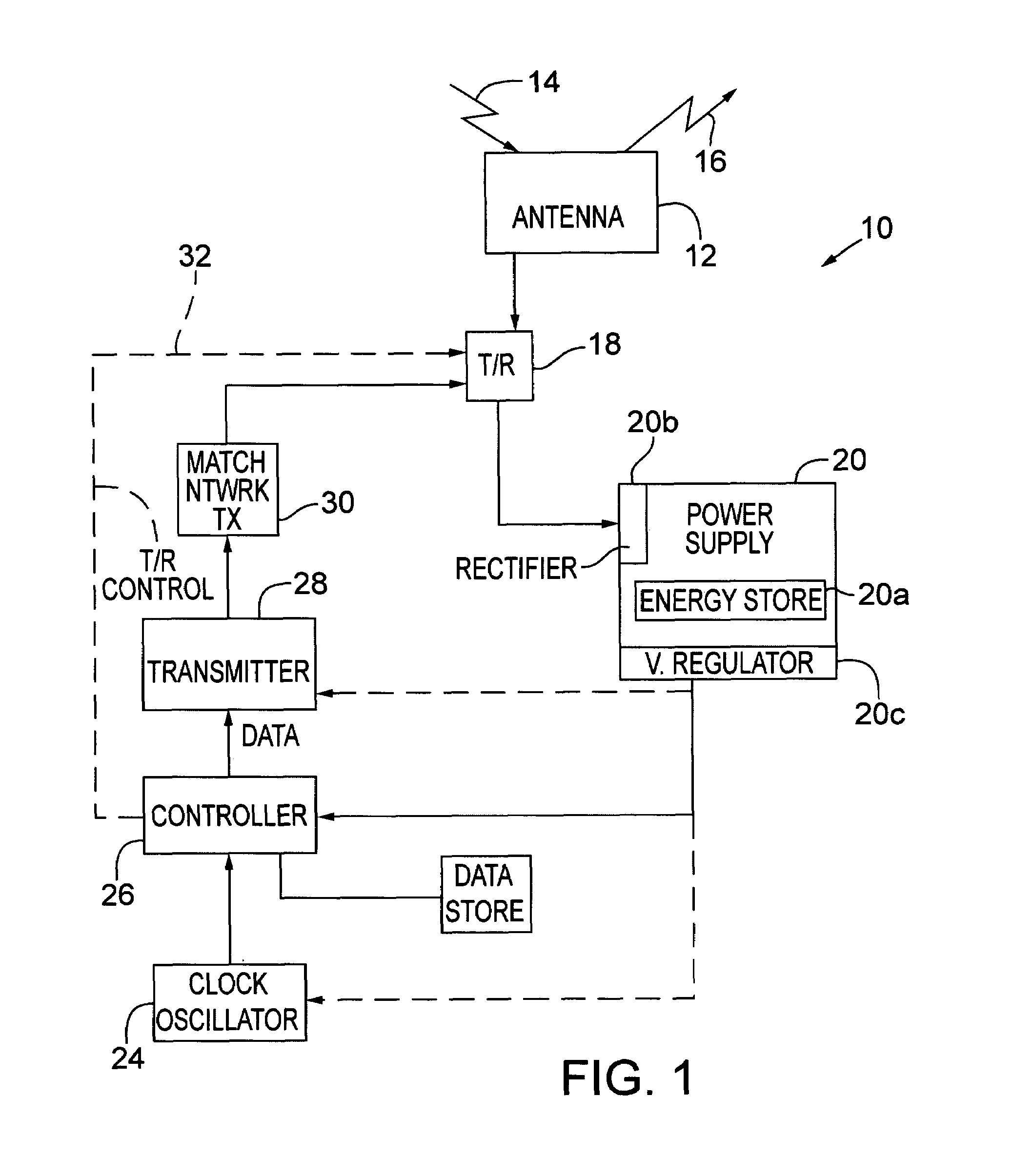

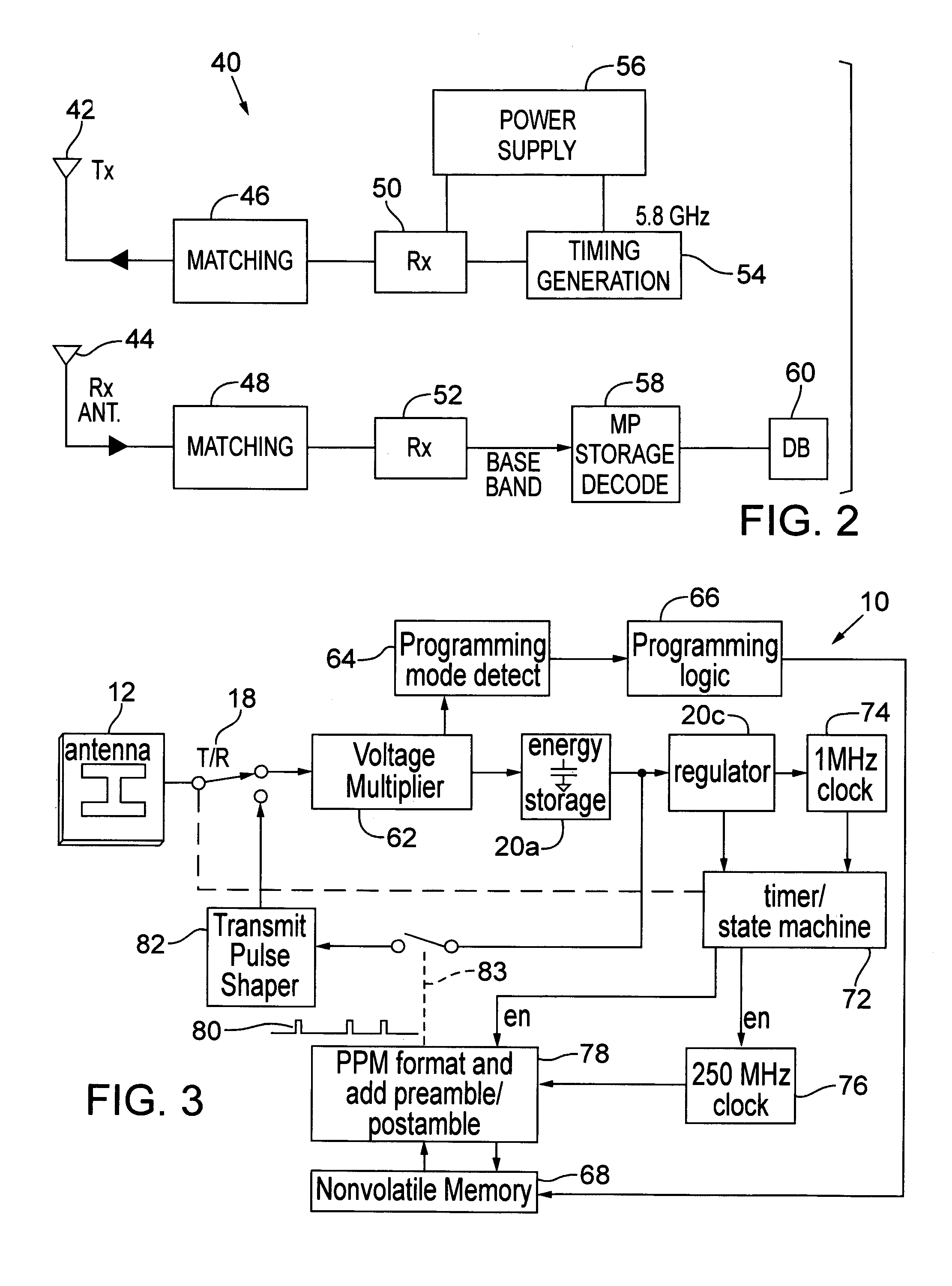

Product identification tag device and reader

InactiveUS7317378B2Improve efficiencyImprove performanceMemory record carrier reading problemsSubscribers indirect connectionStored energyElectronic identification

An electronic identification tag, usually in very small size, responds to a reader with an identification code unique to the object to which the tag is attached. The stand-alone device responds to a reader signal by storing energy received from the signal, then using the stored energy to generate another signal that is encoded with identification information. In operation, a reader generates RF energy which can reach a multiplicity of such tags over a distance of several meters. The system minimizes power requirements for the tag by minimizing intelligence in the IC. Use of a transmit frequency which is different from the reader's power frequency reduces interference between the power pulse and information pulse, eliminates the need for filters and enables the multiplied clock reference frequency as the transmit carrier frequency.

Owner:TAGENT

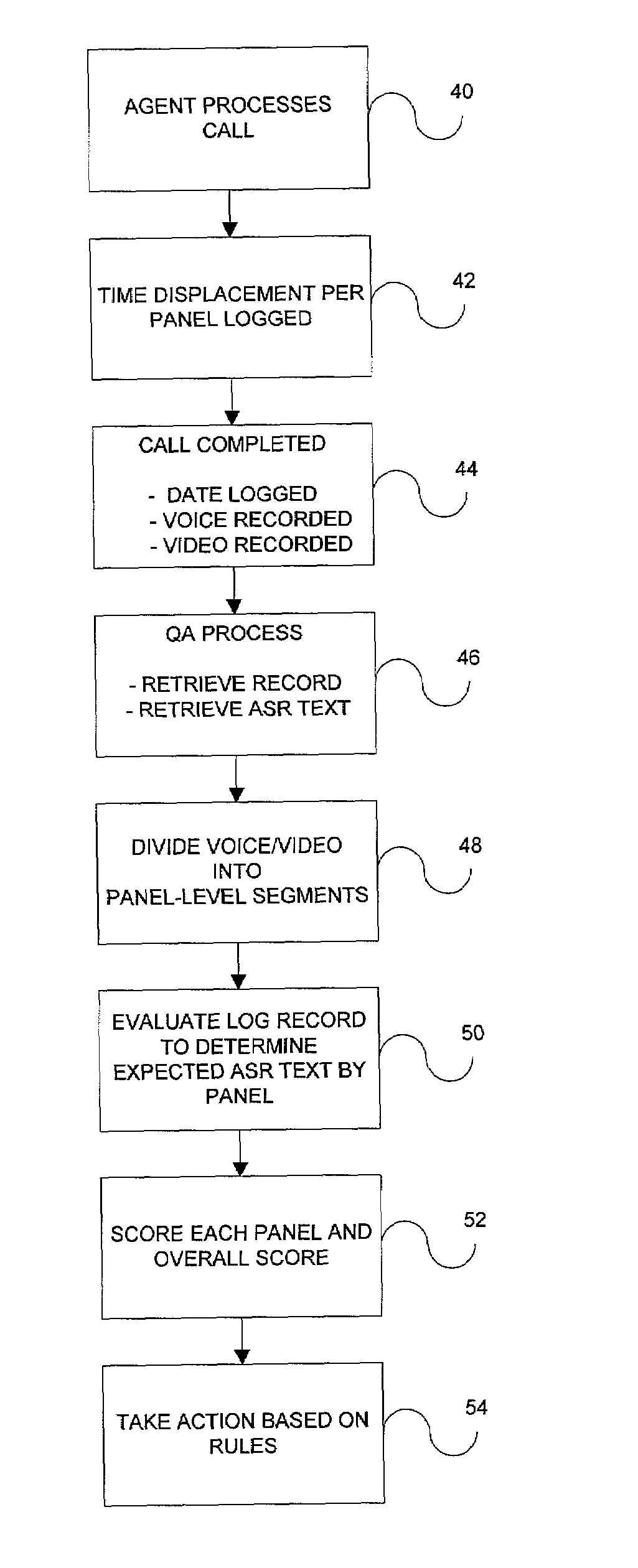

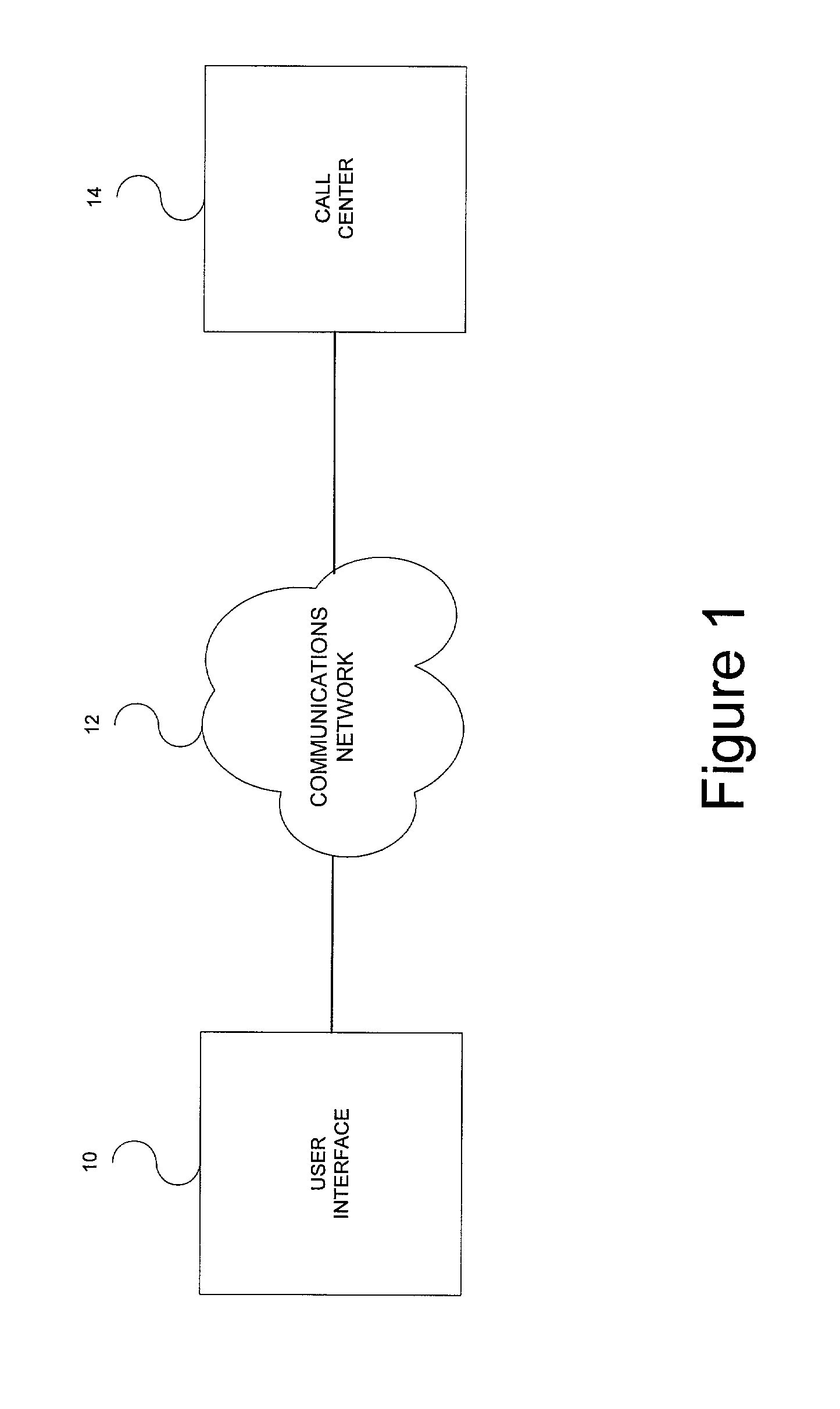

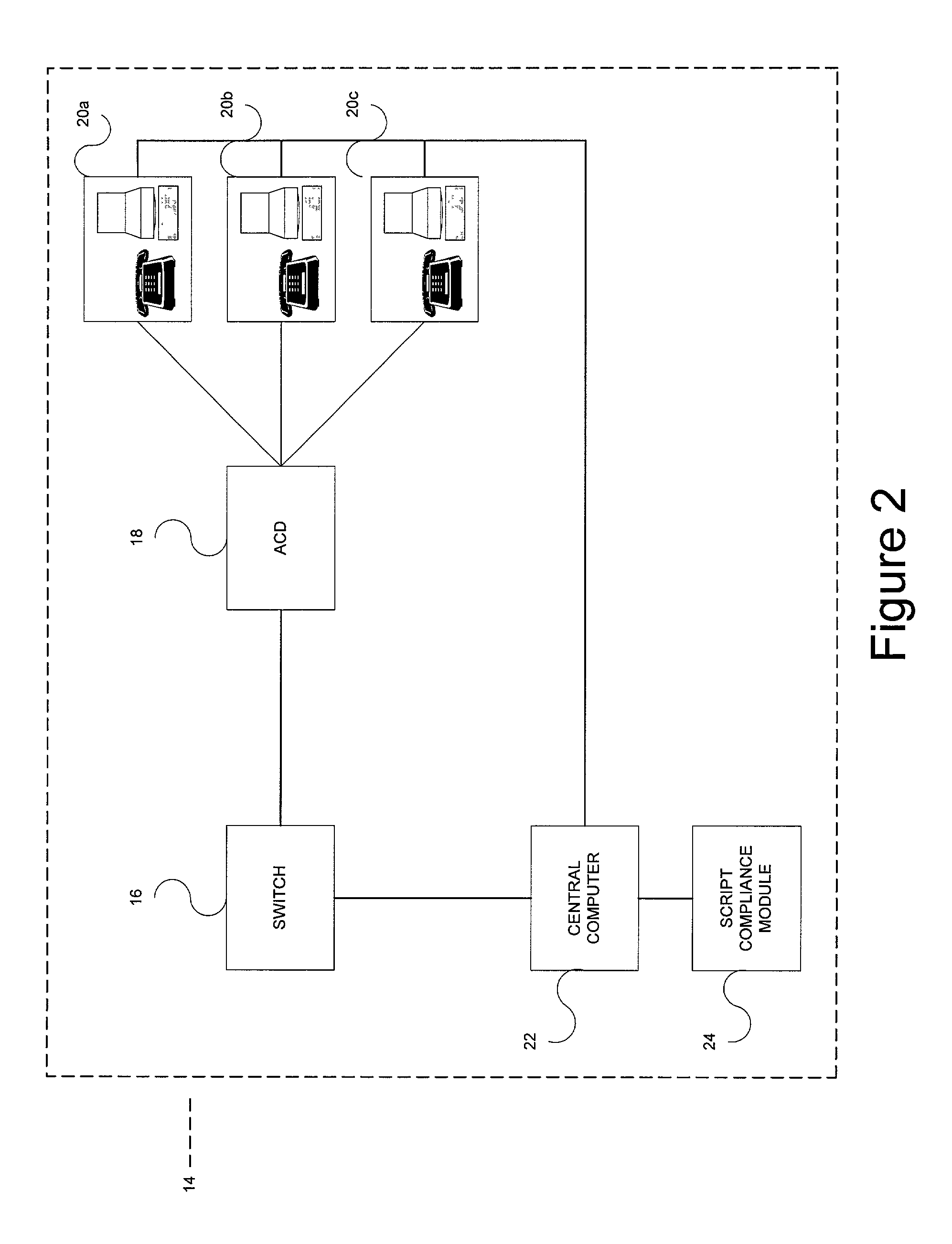

Script compliance using speech recognition

InactiveUS7191133B1Improved script compliance verificationIncrease flexibilityHardware monitoringManual exchangesSpeech identificationSpeech sound

Apparatus and methods are provided for using automatic speech recognition to analyze a voice interaction and verify compliance of an agent reading a script to a client during the voice interaction. In one aspect of the invention, a communications system includes a user interface, a communications network, and a call center having an automatic speech recognition component. In a second aspect of the invention, a script compliance method includes the steps of conducting a voice interaction between an agent and a client and evaluating the voice interaction with an automatic speech recognition component adapted to analyze the voice interaction and determine whether the agent has adequately followed the script.

Owner:ALORICA

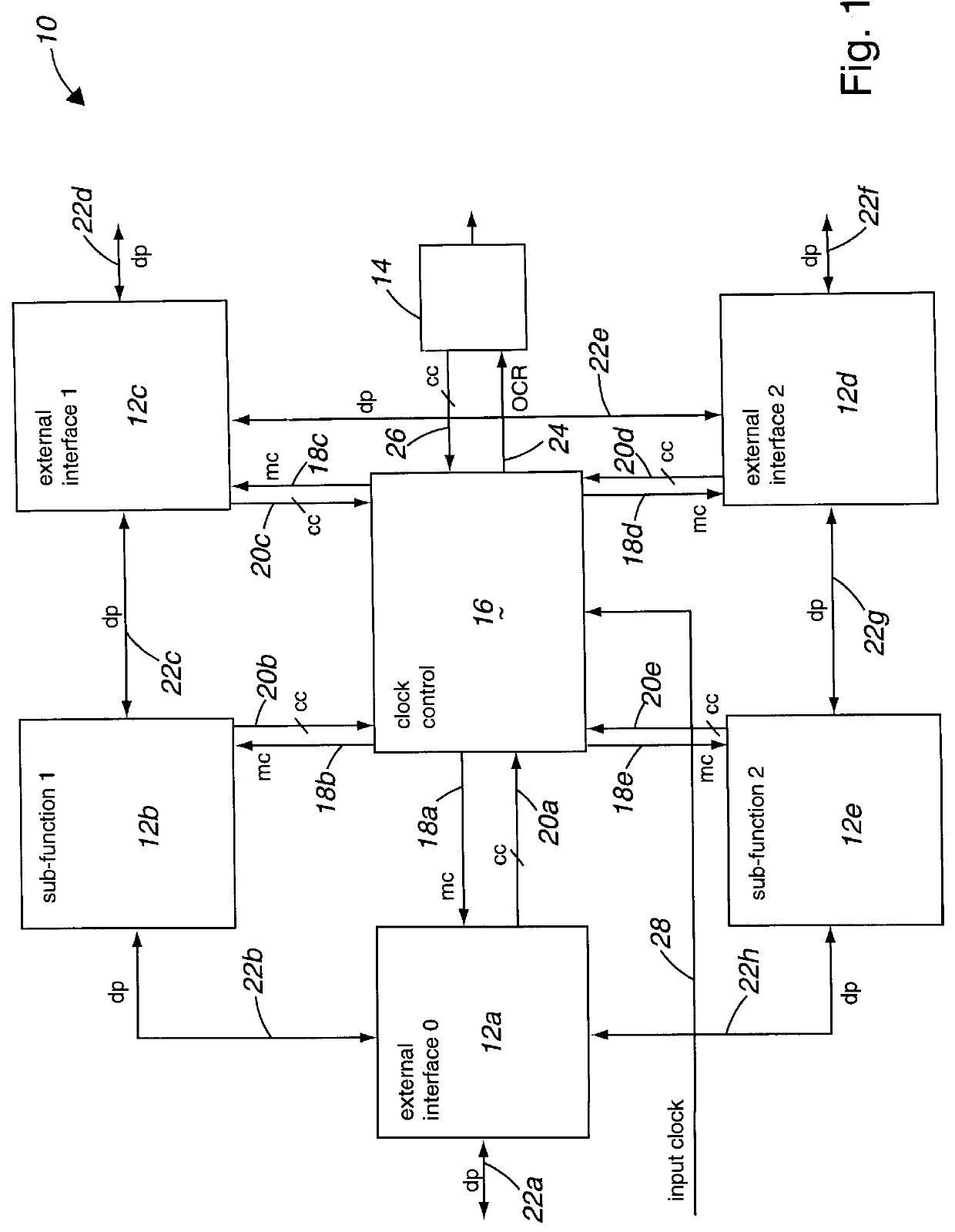

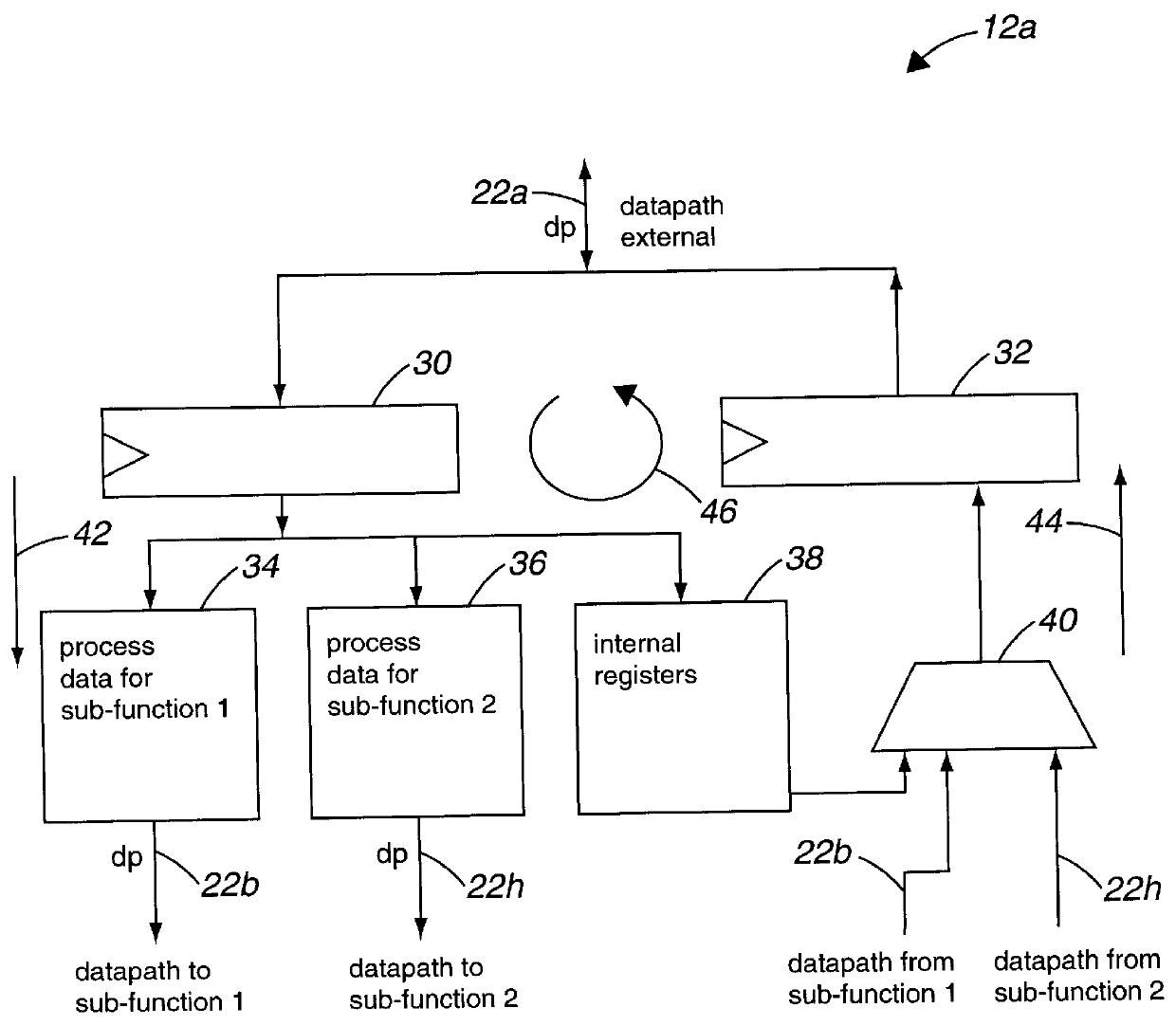

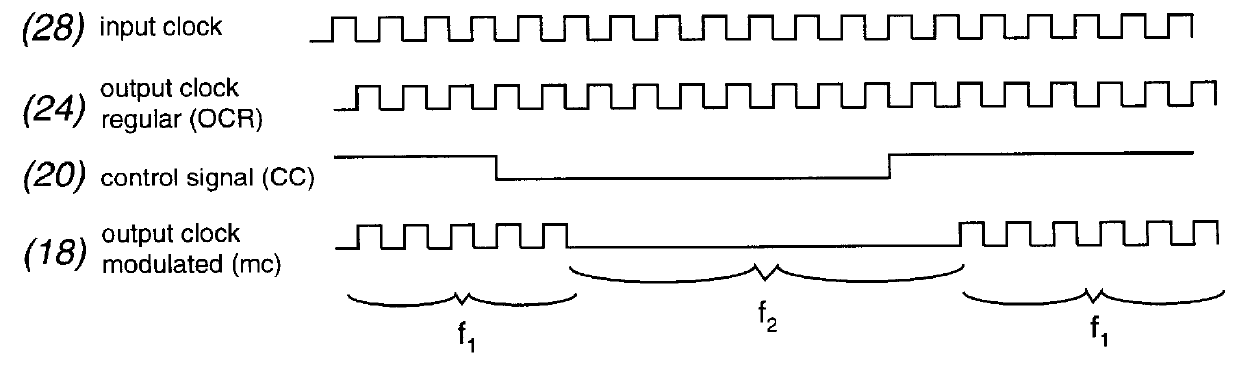

Method and apparatus for reducing power consumption in digital electronic circuits

InactiveUSRE36839E1Reduce power consumptionMinimize powerEnergy efficient ICTSolid-state devicesPower controllerData stream

An integrated circuit with power conservation includes a number of functional blocks, each of which includes a digital circuitry and at least one output control line, and a power controller coupled to the control lines. The output control lines develop clock control signals based upon a functional block's knowledge of the direction of data flow. The power controller the reduces power by deactivating functional blocks that are not needed as indicated by the clock control signals. More specifically, a system with power conservation includes a number of functional blocks capable of processing data, each of the functional blocks including a modulated clock input and N+1 clock control lines which reflect the direction of data flow, where N is a number of neighbors of a particular functional block, and a clock controller having an input clock, the clock controller being coupled to the modulated clock inputs and the clock control lines of the functional blocks. The clock controller is operative to modulate the input clock in accordance with the signals on the clock control lines to provide modulated clocks to each of the plurality of functional blocks. A method for reducing power consumption includes the steps of: a) receiving control signals from a number of functional blocks; b) selectively deactivating a particular functional block upon a request from that functional block or from another functional block; and c) activating the particular functional block upon a request from another functional block.

Owner:CONVERSANT INTPROP MANAGEMENT INC

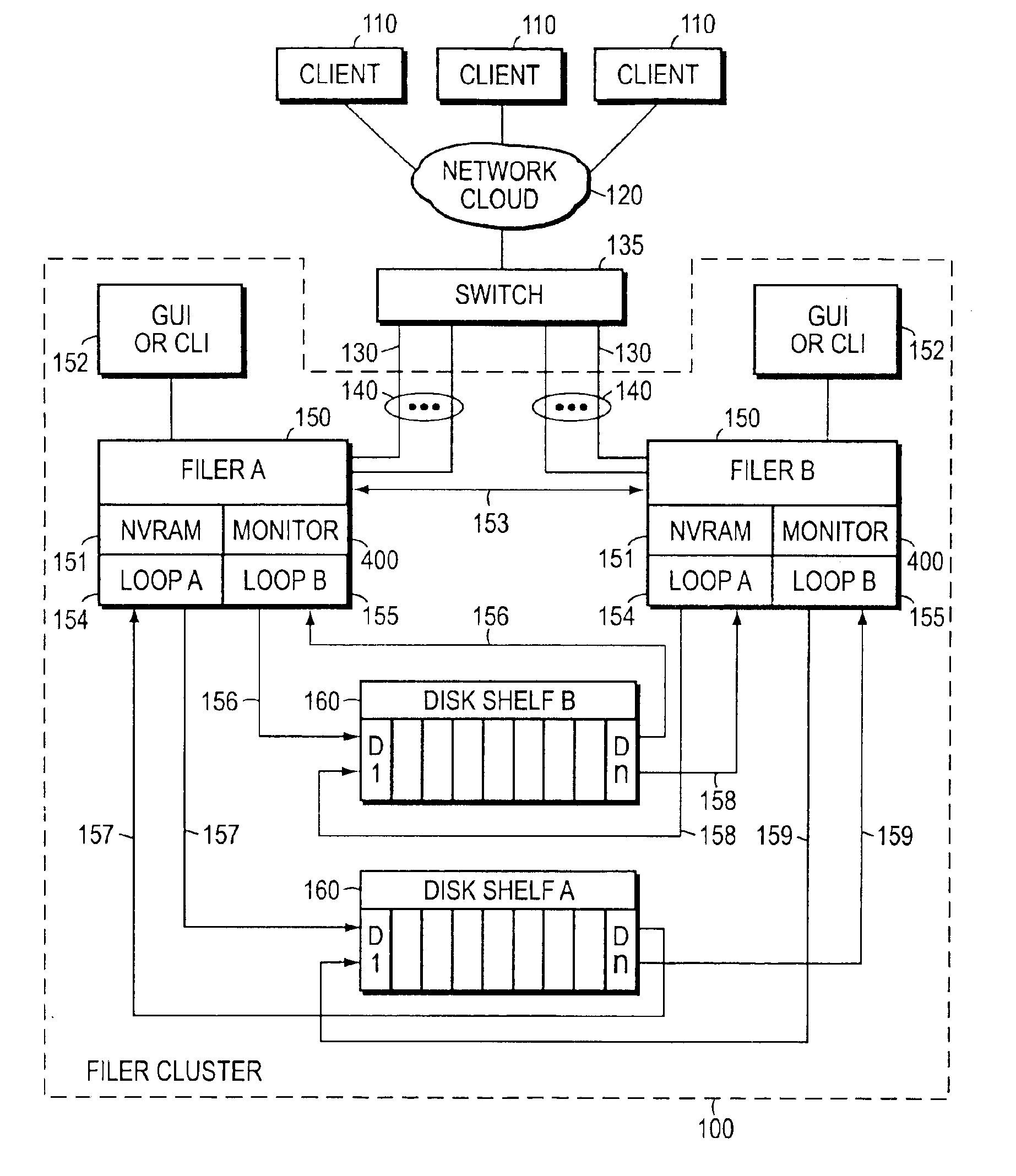

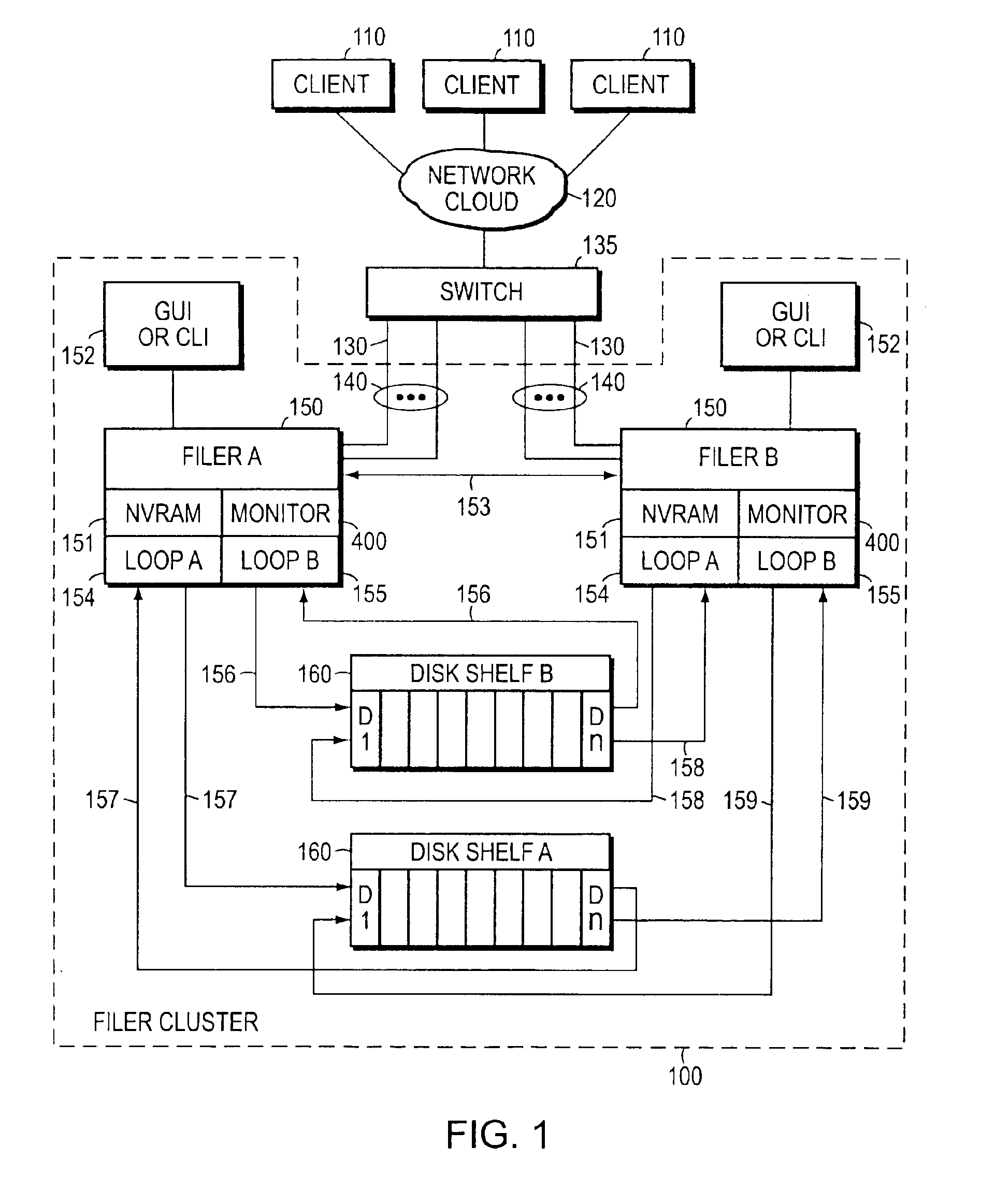

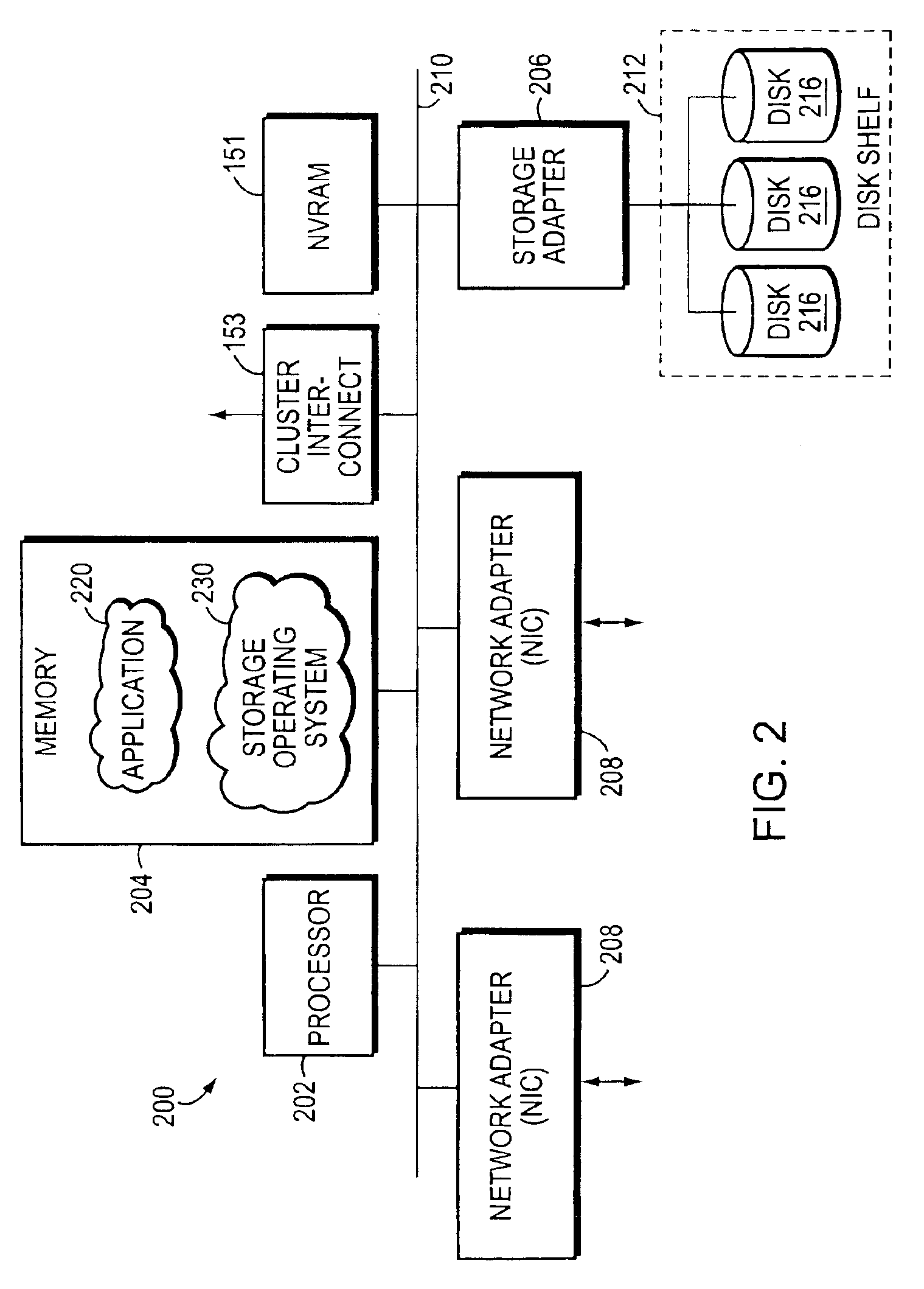

Negotiated graceful takeover in a node cluster

InactiveUS6920580B1Minimizes problemRedundant hardware error correctionNode clusteringNetwork addressing

The invention is a method for operating a file server system in a cluster mode that provides for relatively rapid and reliable takeover of a failed file server in the cluster by a partner file server when the failed file server has detected a fault that will cause it to shut down. This is done by the failed file server requesting the one file server to take over its file services after detecting the fault in its operations, the one file server letting the failed file server complete existing file service requests from clients, refusing further file service requests addressed to the failed file server, and the one file server taking over by transferring file service requests to the one file server. As part of this takeover the one file server takes on the identity of the failed filer and activates network interfaces and network addresses that replicate the failed server's network addresses.

Owner:NETWORK APPLIANCE INC

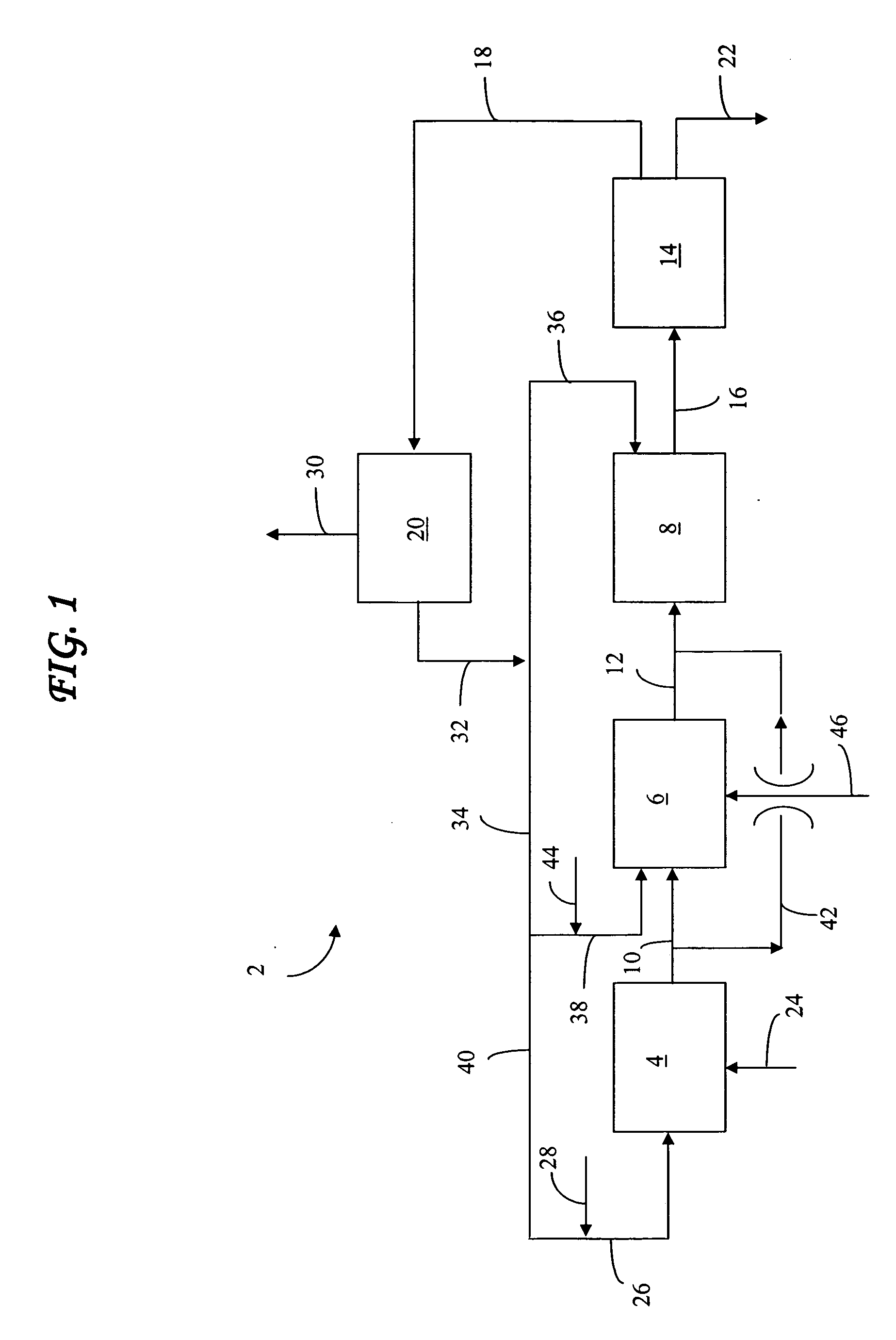

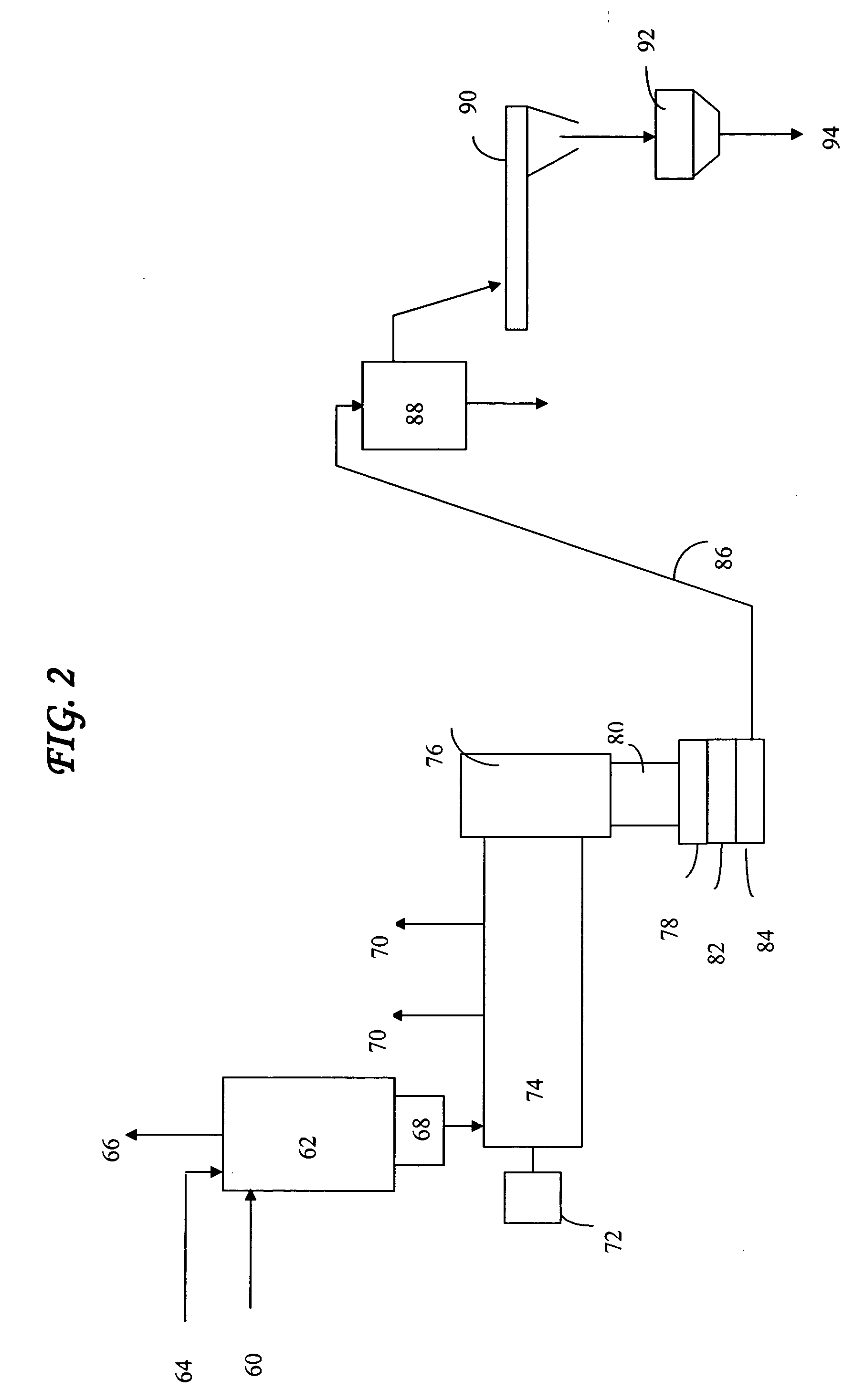

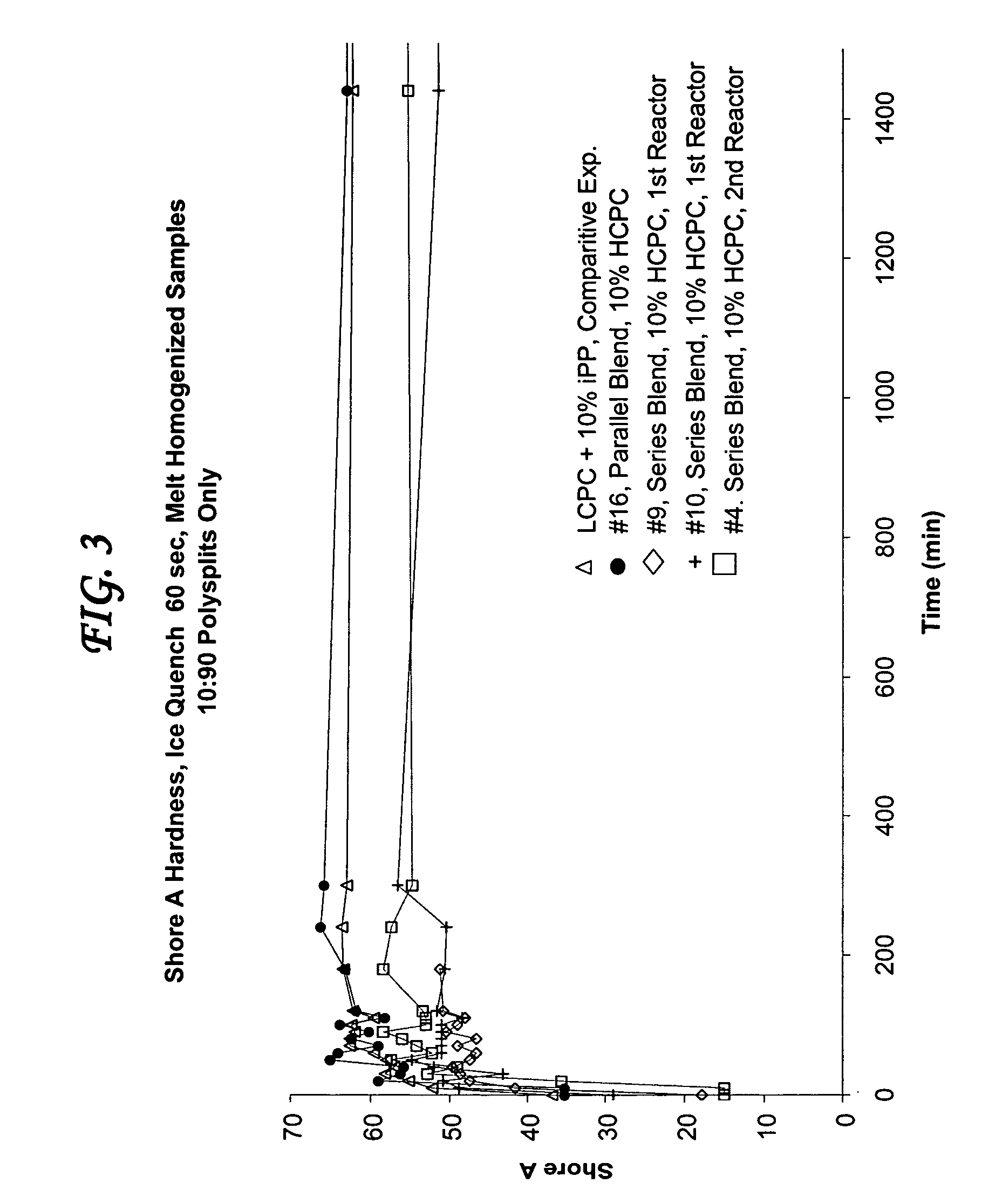

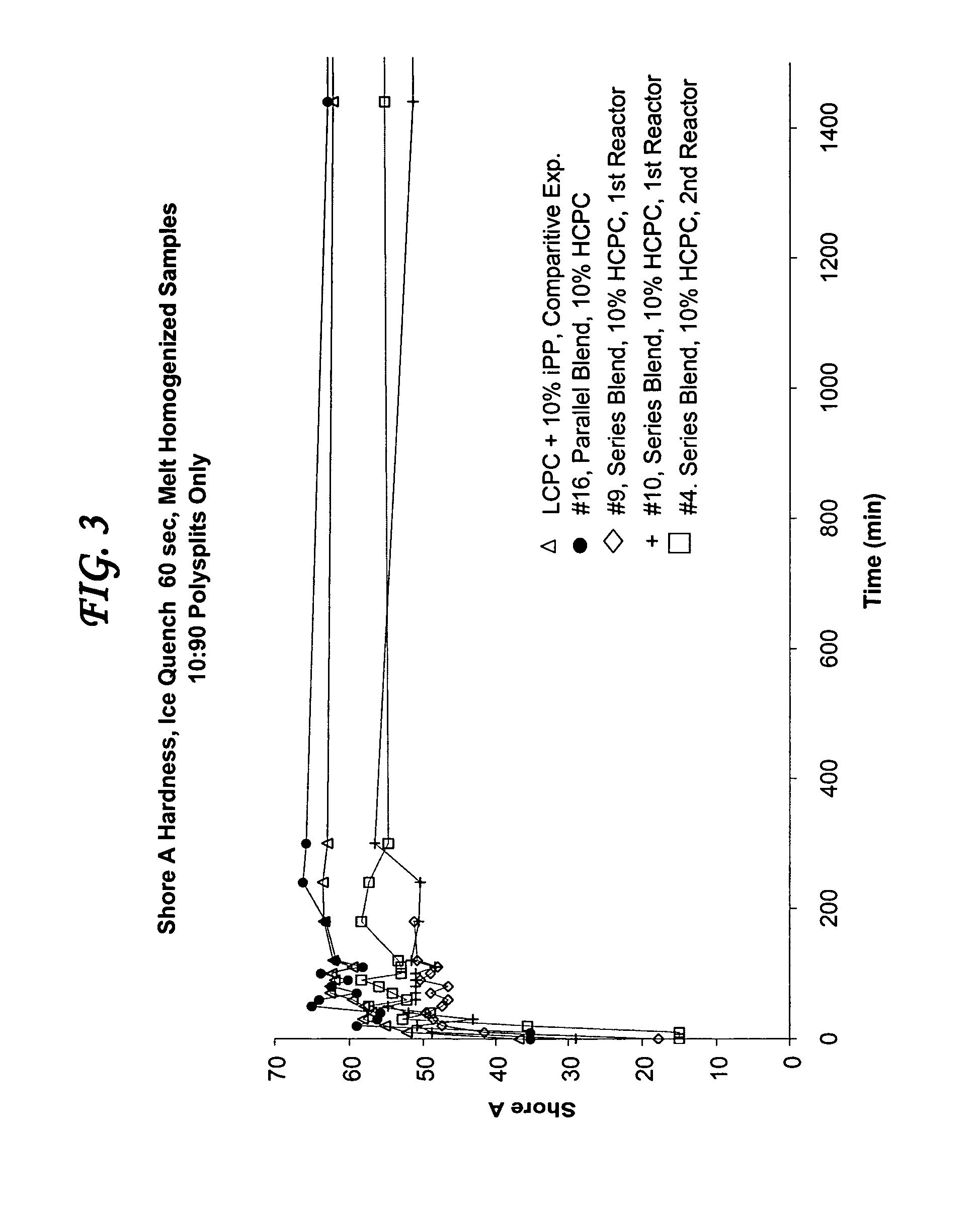

Polymer blends and pellets and methods of producing same

Blends of at least two polymers incorporating propylene-derived units and processes for producing such blends are provided. The first polymer of the blend is a low crystallinity polymer including propylene-derived units. The second polymer is a high crystallinity polymer including propylene-derived units. The polymer blends exhibit the beneficial performance characteristics of low crystallinity propylene polymers while minimizing certain processing and handling problems associated with low crystallinity propylene polymers. Low crystallinity propylene polymer pellets often exhibit a tendency to agglomerate because of the softness of such particles. Agglomeration of the pellets creates problems in handling and processing the particles. The polymer blends disclosed reduce the tendency of polymer pellets to agglomerate while maintaining the desirable physical properties, such as elastomeric properties, exhibited by low crystallinity propylene polymers. Various processes for producing the polymer blends are also provided.

Owner:EXXONMOBIL CHEM PAT INC

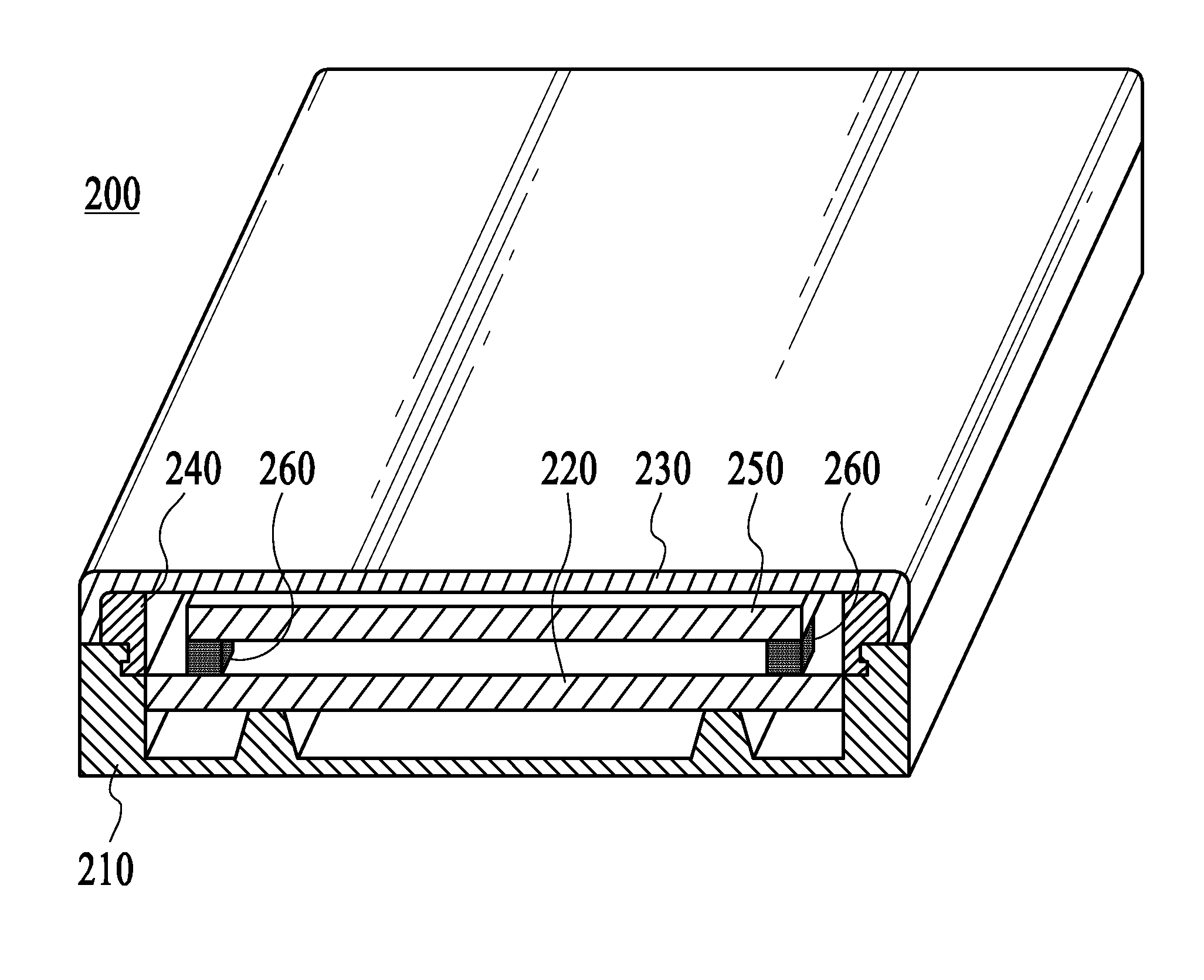

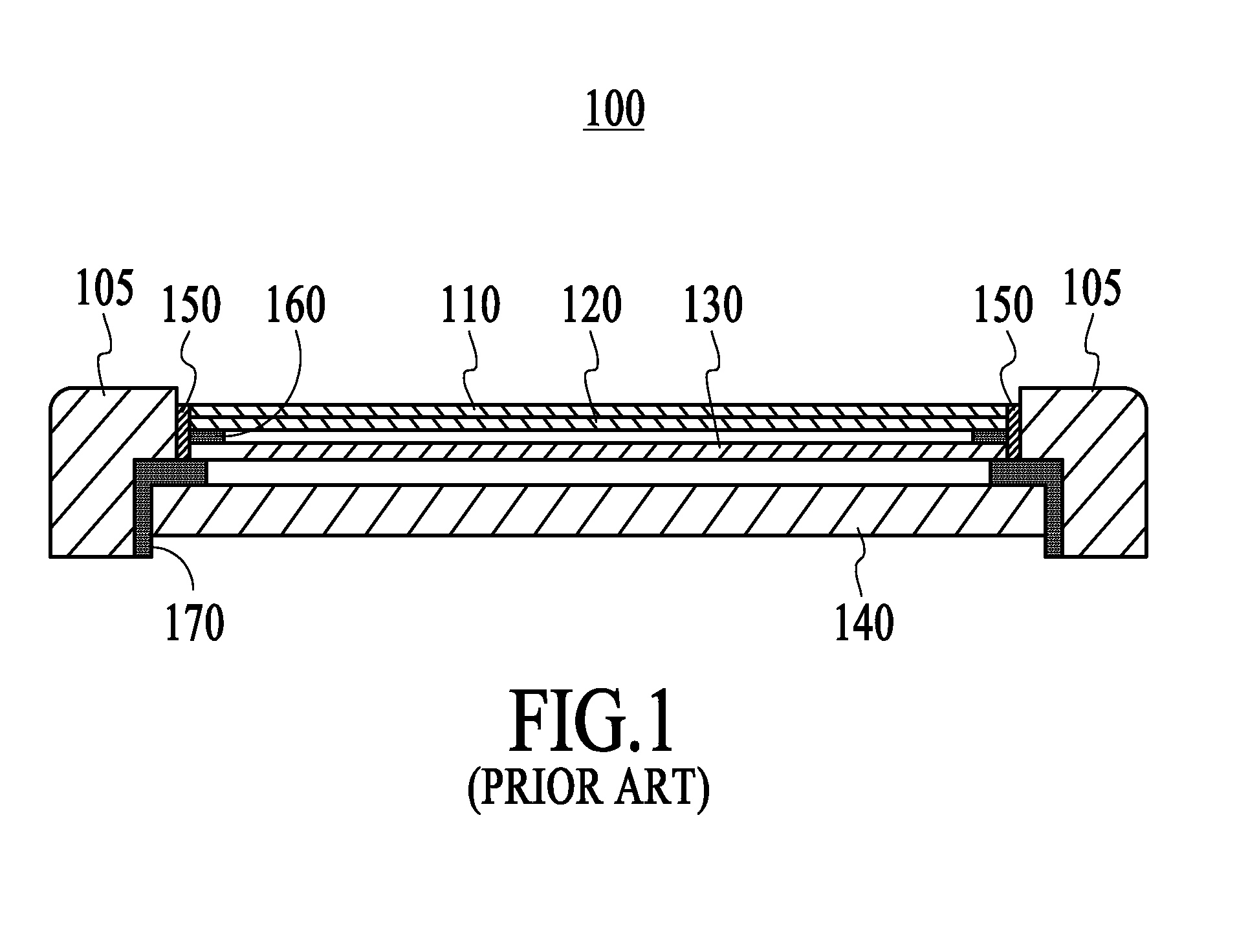

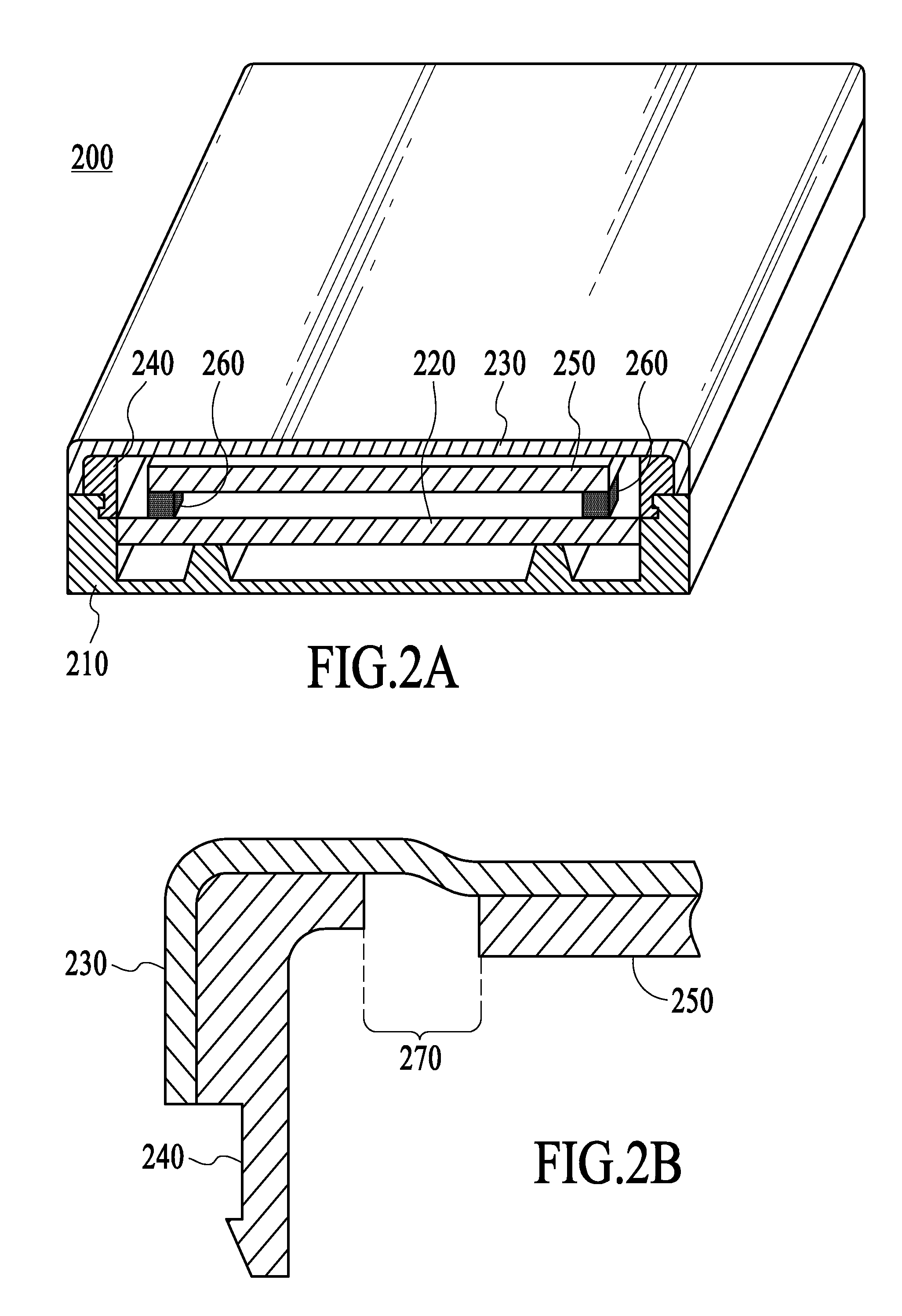

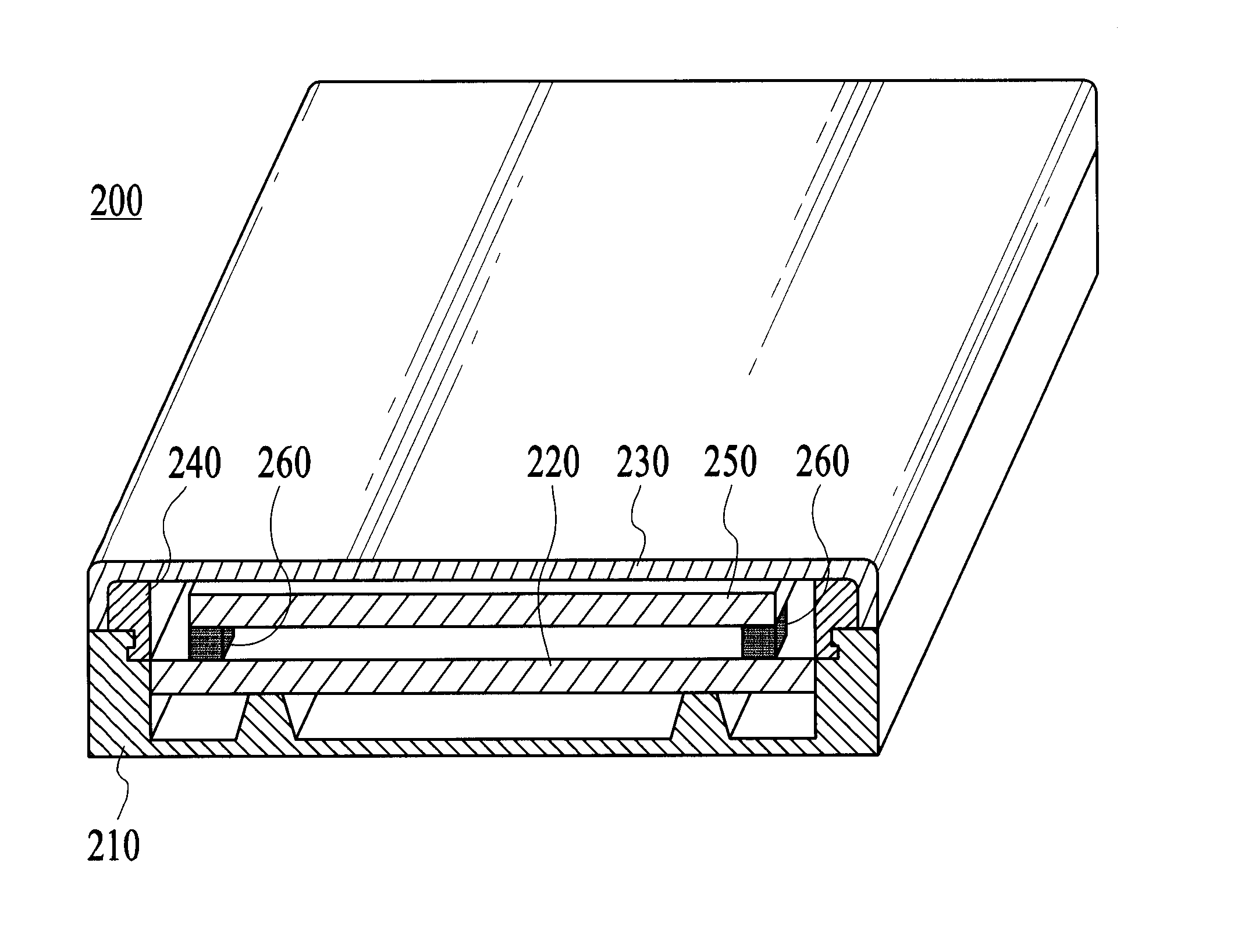

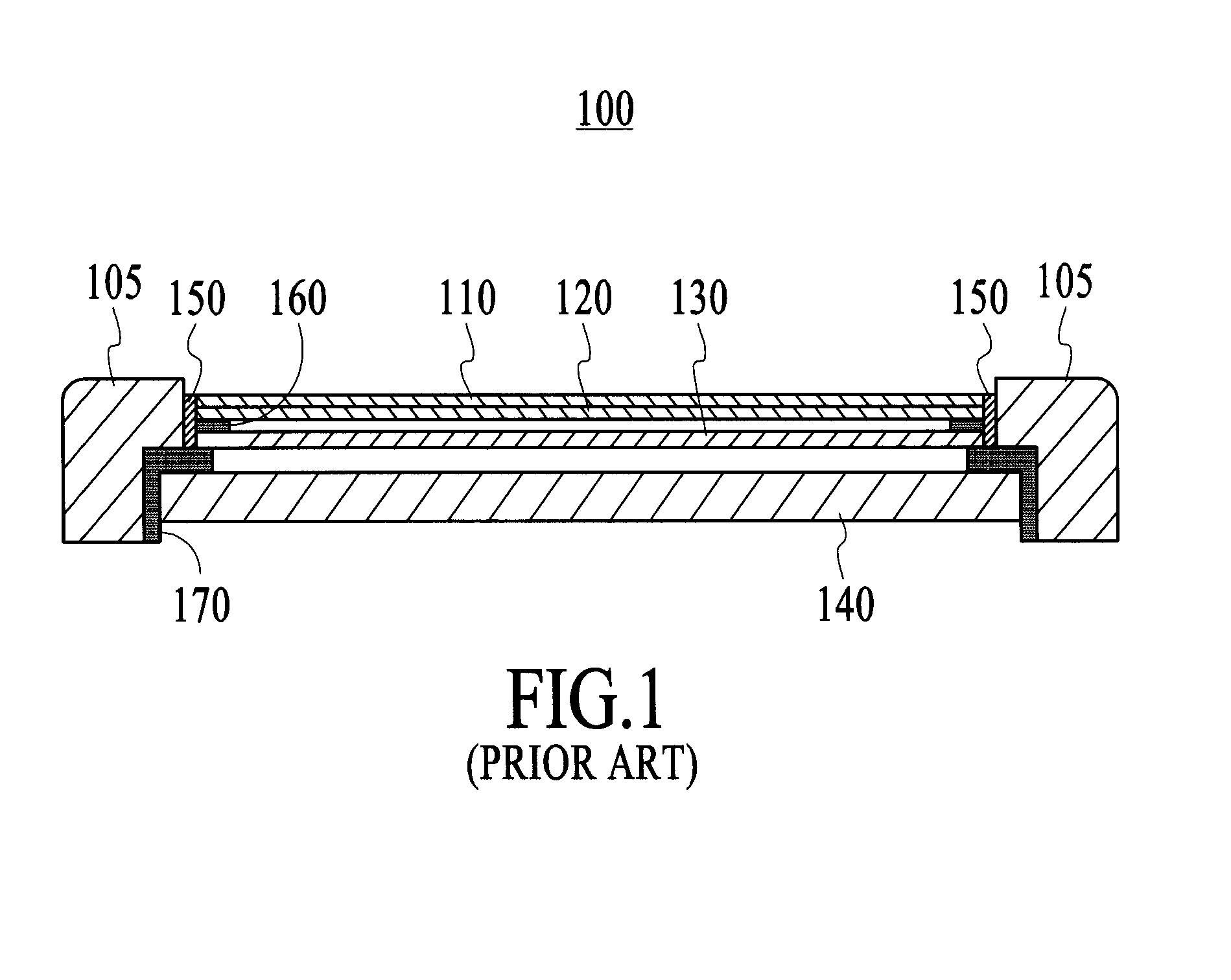

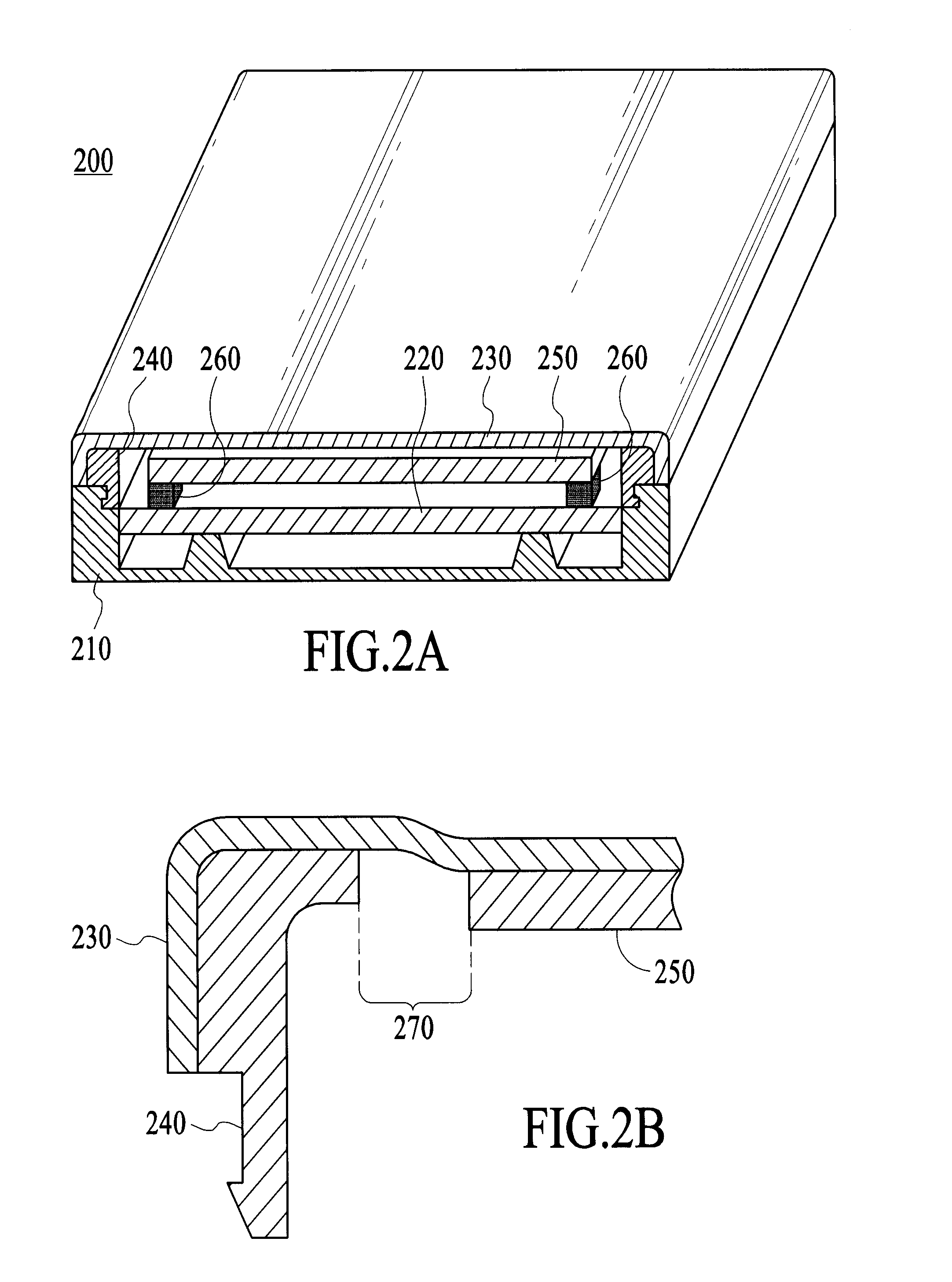

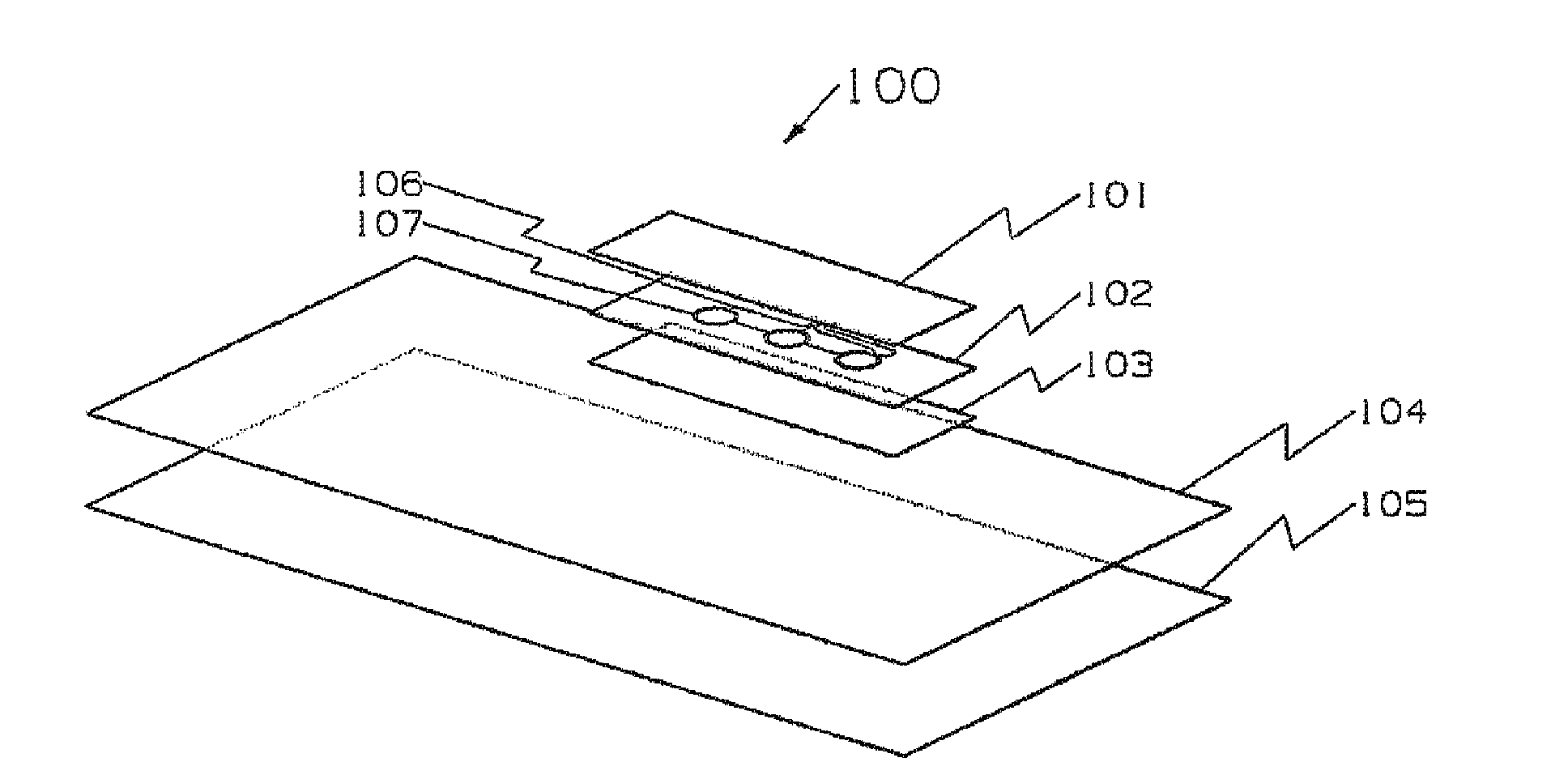

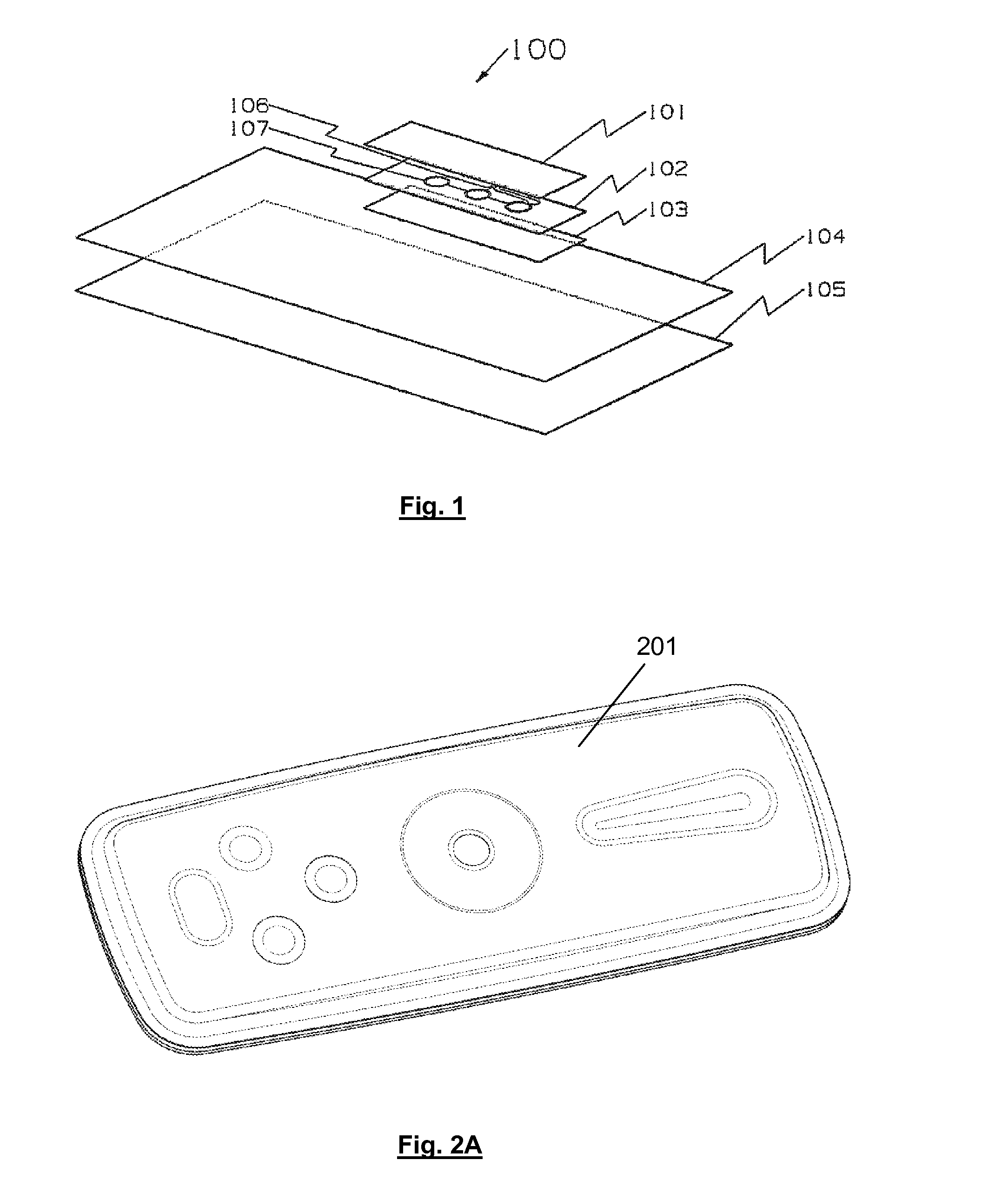

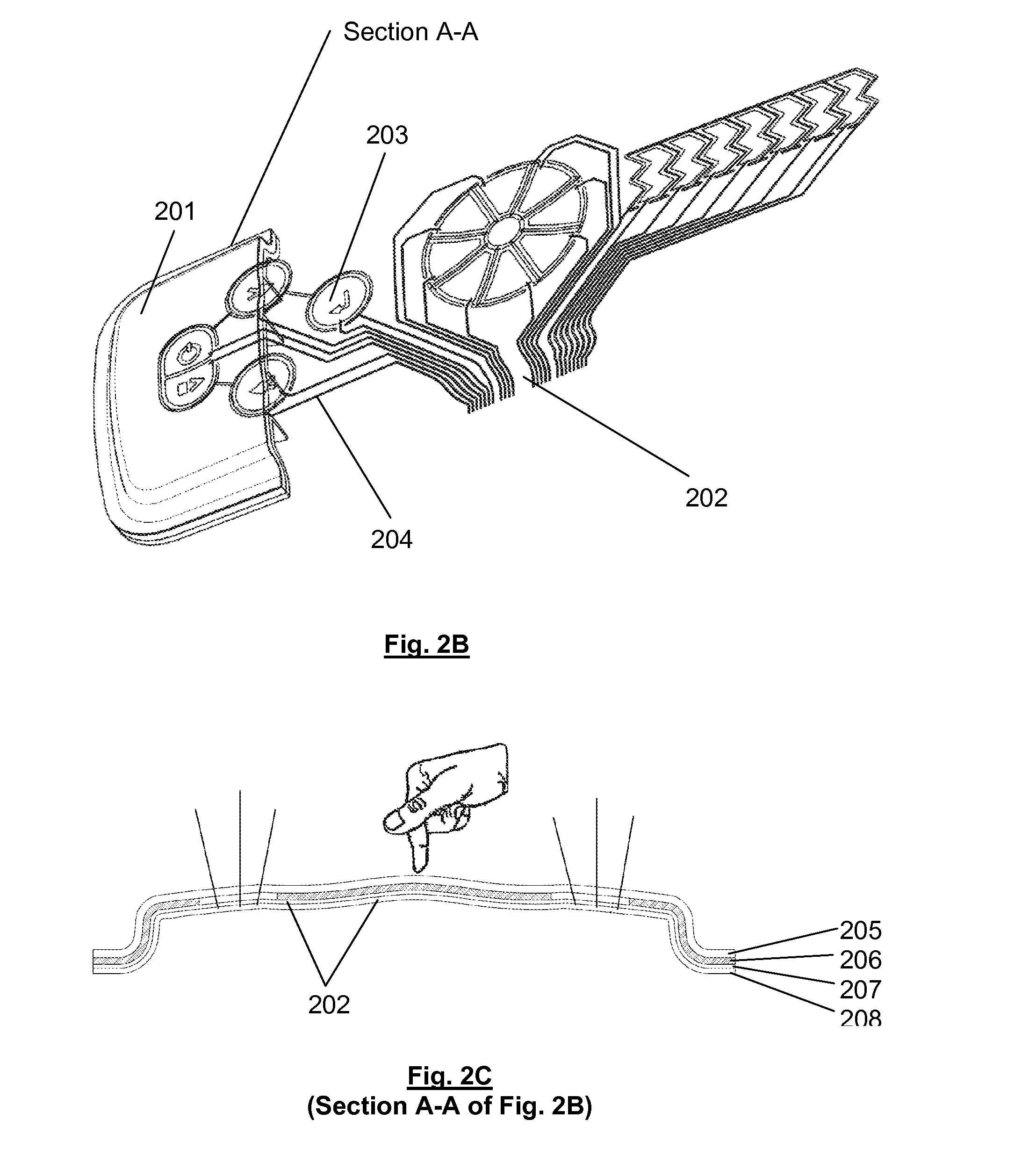

Single piece top surface display layer and integrated front cover for an electronic device

InactiveUS20070229475A1Reduce the possibility of damageReduces parallax effectNon-enclosed substationsInput/output for user-computer interactionSurface displayDisplay device

A single-piece top surface display and integrated front cover for an electronic device. In one embodiment, the cover comprises a thin, flexible, transparent layer coupled with a supporting structure. The flexible layer is supported above a display screen which is coupled with pressure activated sensors located under the display screen. The cover is dust-free, waterproof, and has a flat outer surface that is free of any steps or indentations. Users input data by applying pressure on the cover which causes the display screen to deflect and activate the sensors. The pressure exerted on the sensors is triangulated to register the position of the user input. In another embodiment, the cover is transparent, rigid, and directly contacts the pressure activated sensors which are located in front of the display screen or in the housing behind it. When pressure is applied to the cover, the cover deflects and activates the sensors. In both embodiments, an accelerometer identifies valid input events.

Owner:QUALCOMM INC

DC magnetic-based position and orientation monitoring system for tracking medical instruments

ActiveUS7835785B2Low costEasy to integrateDiagnostic recording/measuringSensors3d sensorDiagnostic Radiology Modality

Miniaturized, five and six degrees-of-freedom magnetic sensors, responsive to pulsed DC magnetic fields waveforms generated by multiple transmitter options, provide an improved and cost-effective means of guiding medical instruments to targets inside the human body. The end result is achieved by integrating DC tracking, 3D reconstructions of pre-acquired patient scans and imaging software into a system enabling a physician to internally guide an instrument with real-time 3D vision for diagnostic and interventional purposes. The integration allows physicians to navigate within the human body by following 3D sensor tip locations superimposed on anatomical images reconstructed into 3D volumetric computer models. Sensor data can also be integrated with real-time imaging modalities, such as endoscopes, for intrabody navigation of instruments with instantaneous feedback through critical anatomy to locate and remove tissue. To meet stringent medical requirements, the system generates and senses pulsed DC magnetic fields embodied in an assemblage of miniaturized, disposable and reposable sensors functional with both dipole and co-planar transmitters.

Owner:NORTHERN DIGITAL

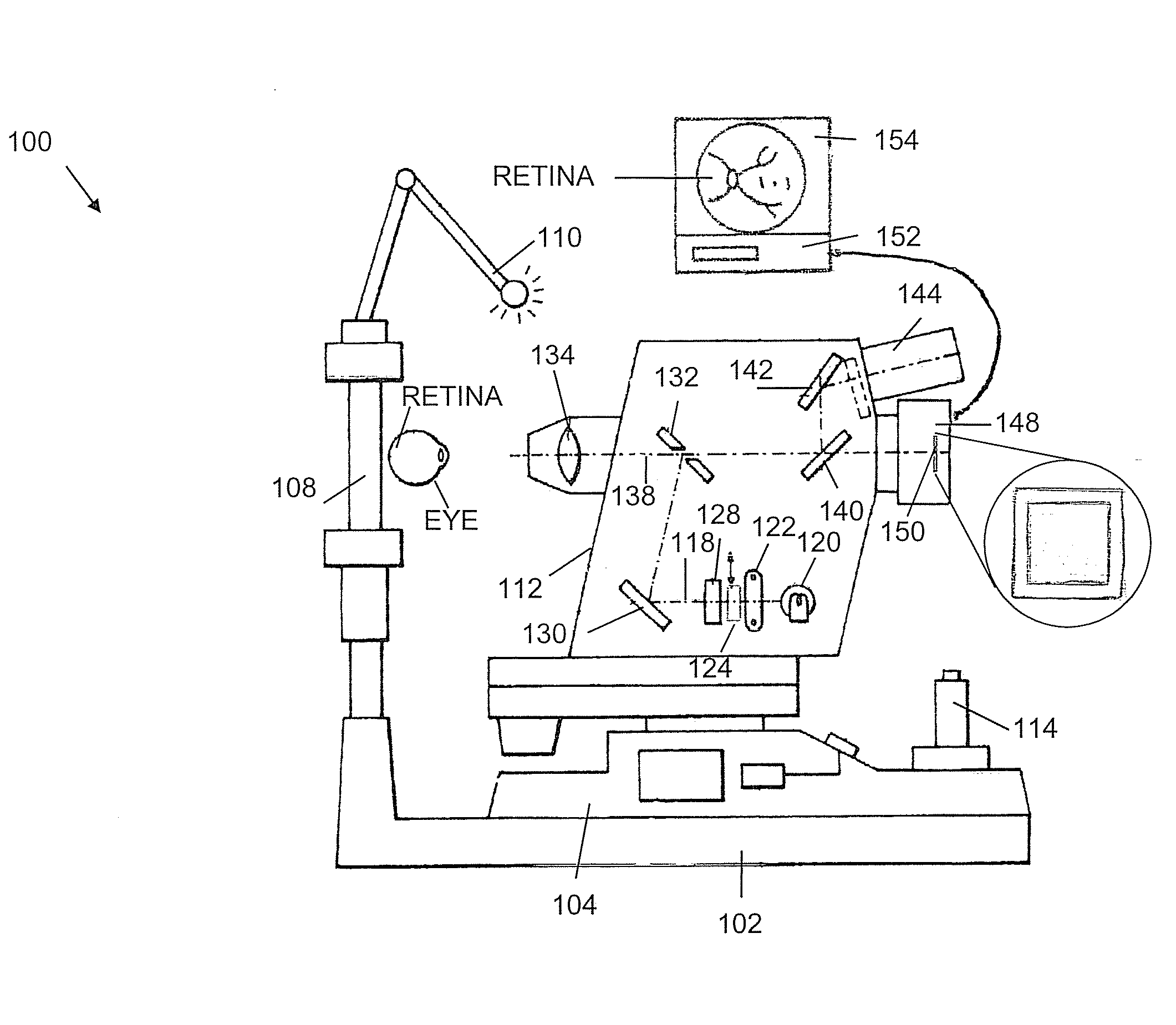

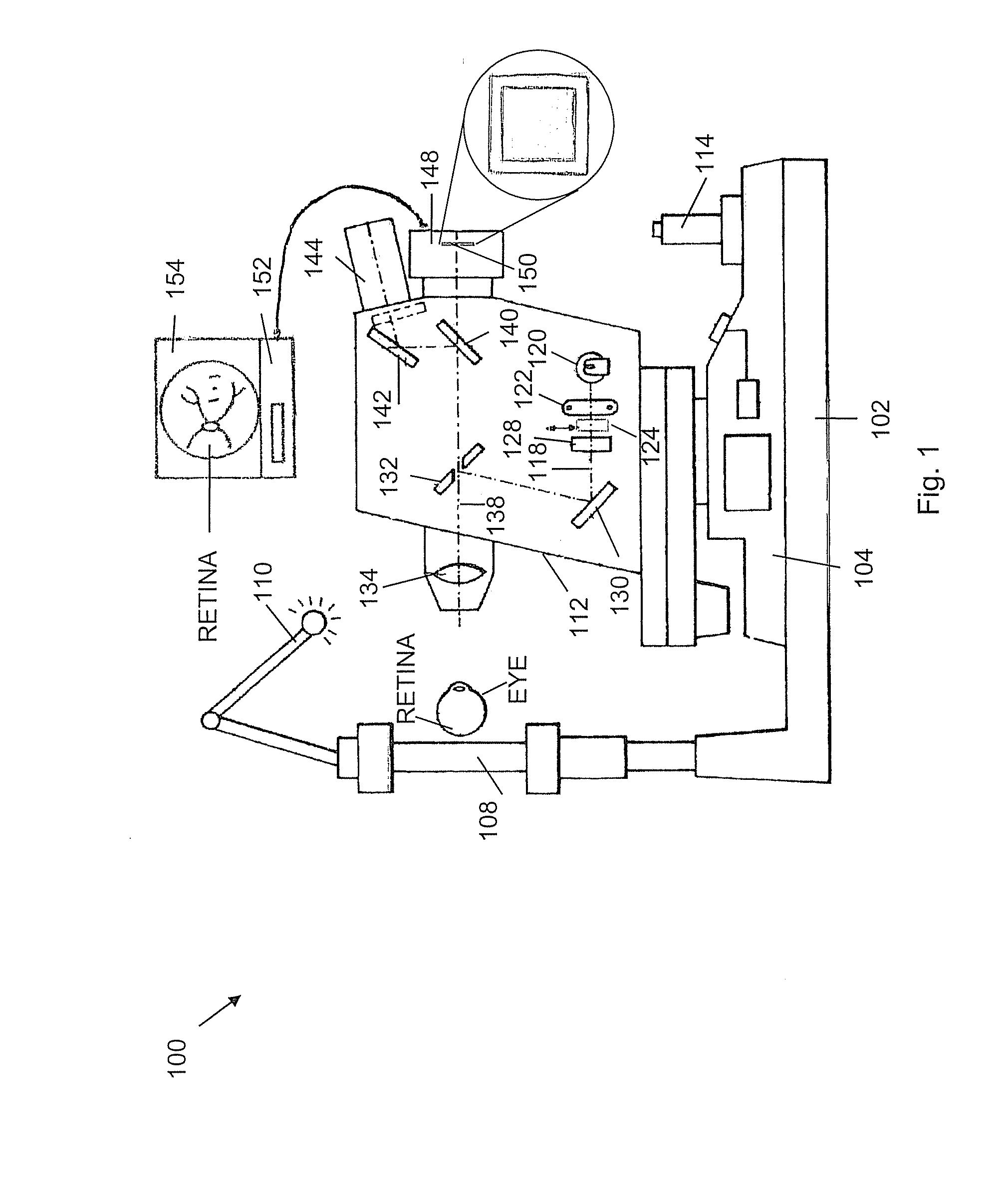

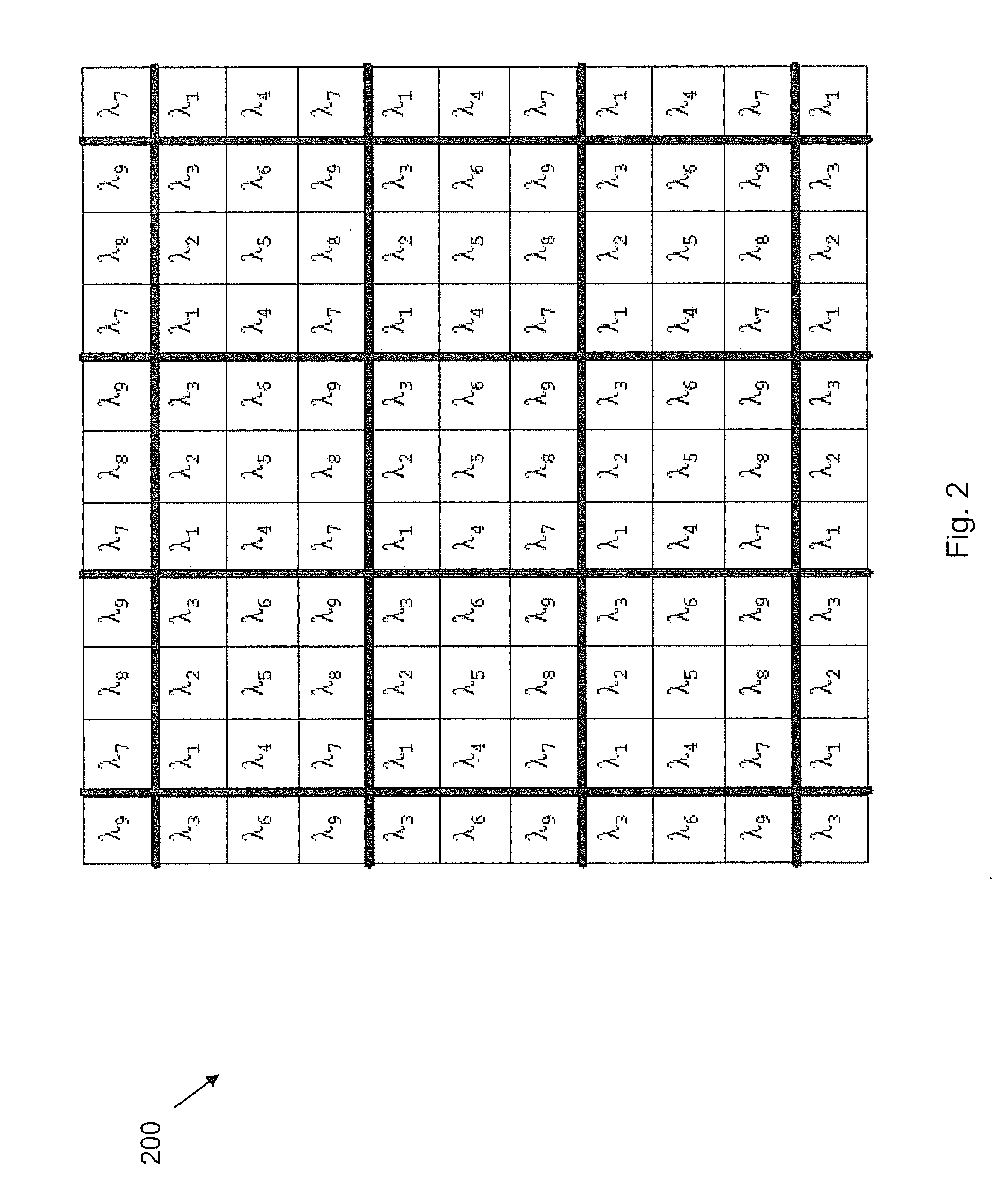

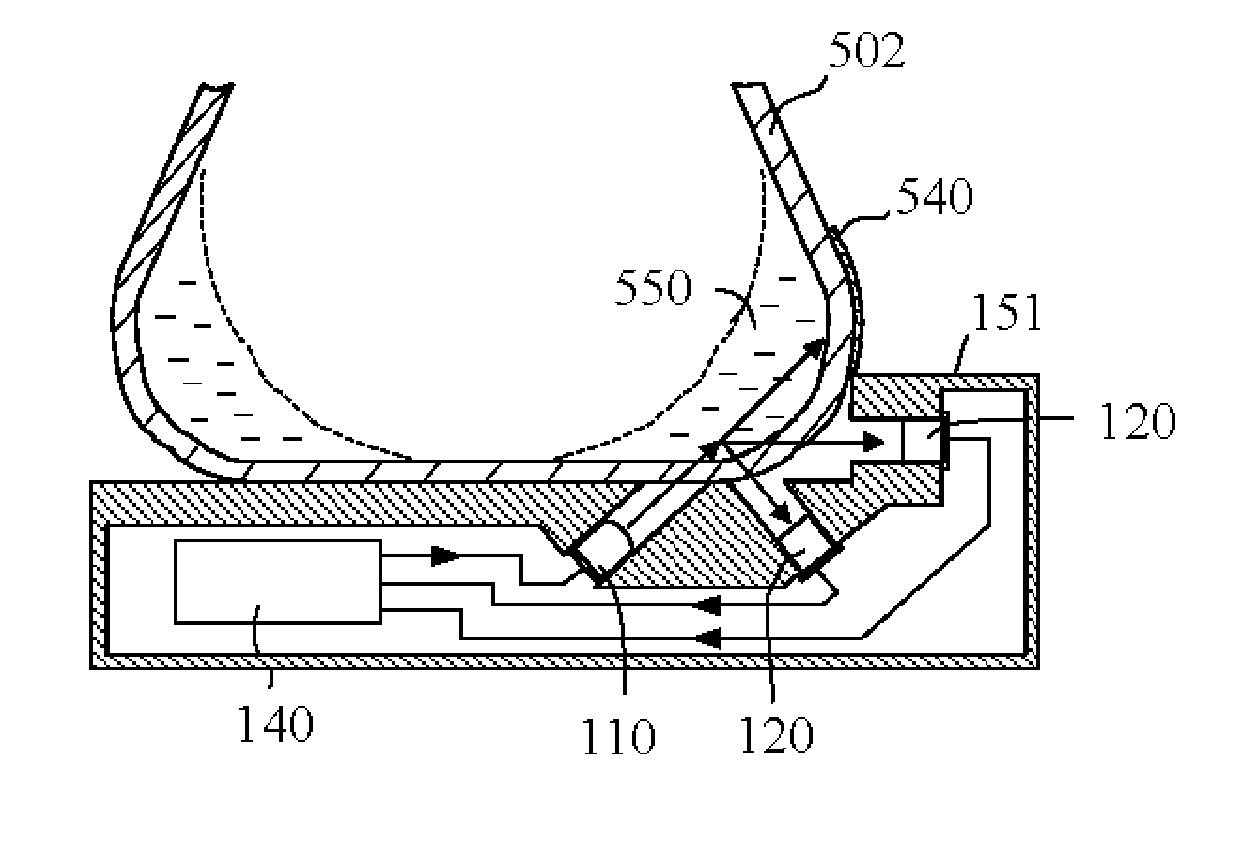

Snapshot Spectral Imaging of the Eye

ActiveUS20090225277A1Minimizes problemStrong robustnessSpectrum investigationDiagnostic recording/measuringFundus cameraPupil

Obtaining spectral images of an eye includes taking an optical system that images eye tissue onto a digital sensor array and optically fitting a multi-spectral filter array and the digital sensor array, wherein the multi-spectral filter array is disposed between the digital sensor array and an optics portion of the optical system. The resulting system facilitates acquisition of a snap-shot image of the eye tissue with the digital sensor array. The snap shot images support estimation of blood oxygen saturation in a retinal tissue. The resulting system can be based on a non-mydriatic fundus camera designed to obtain the retinal images without administration of pupil dilation drops.

Owner:MERGE HEALTHCARE

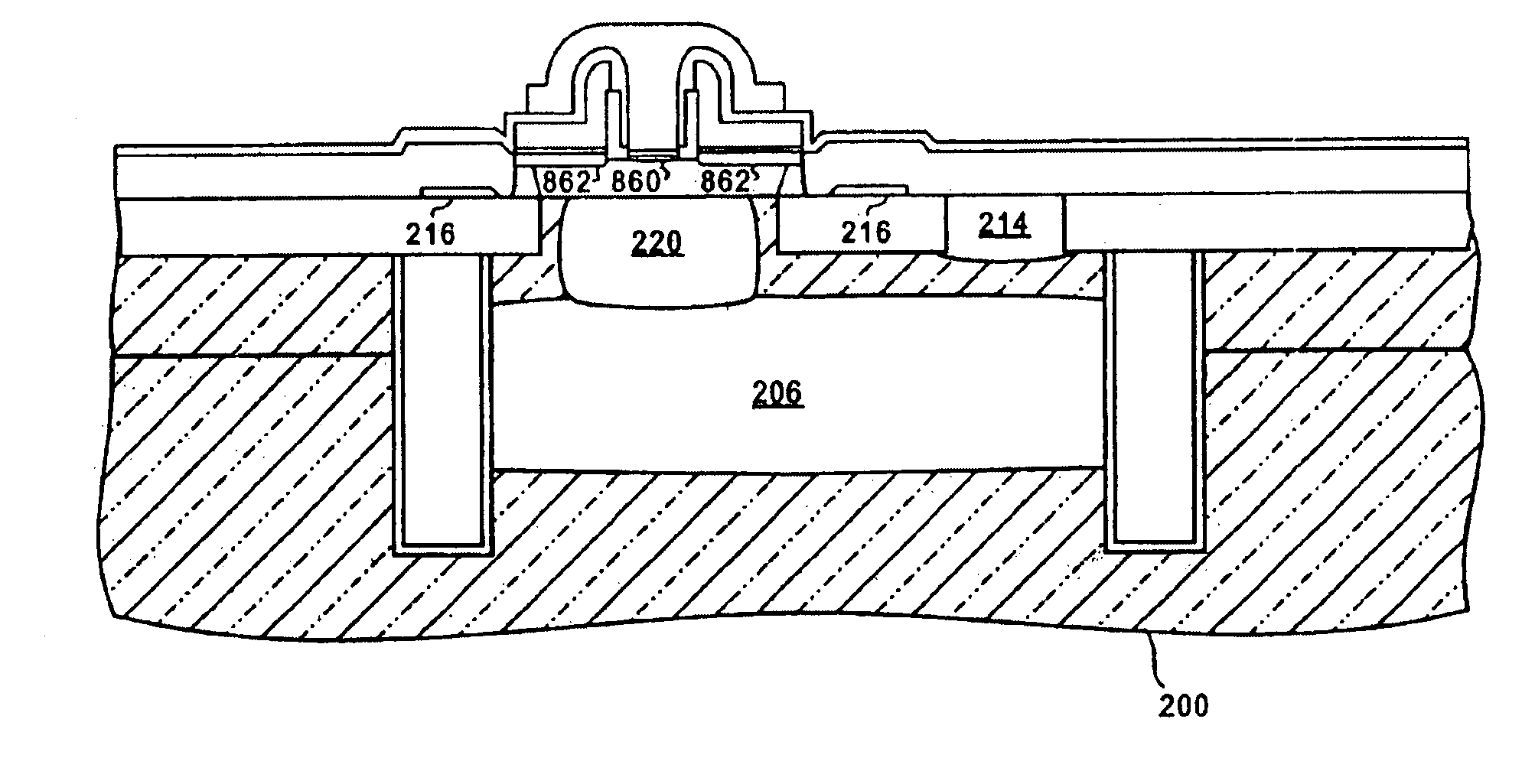

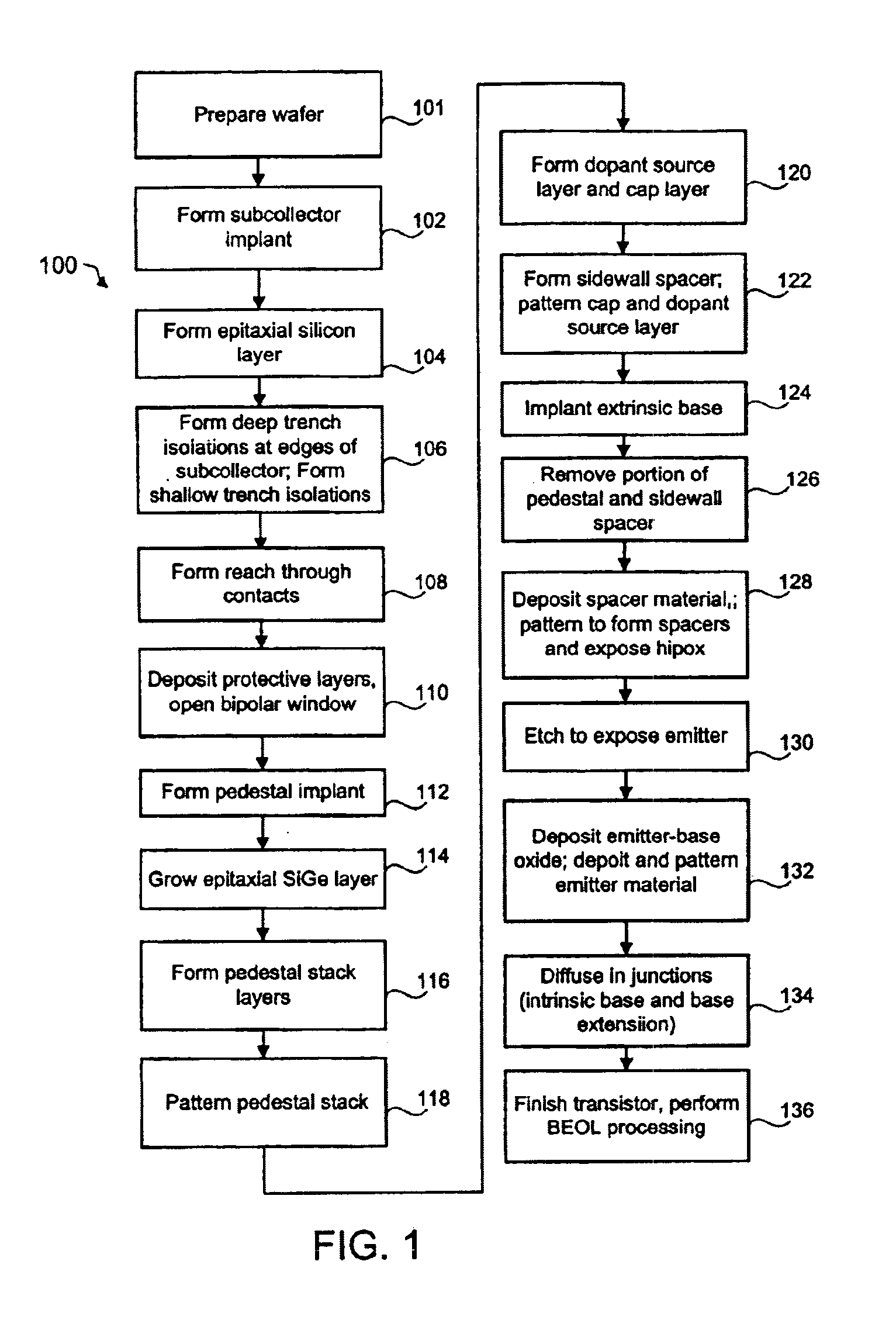

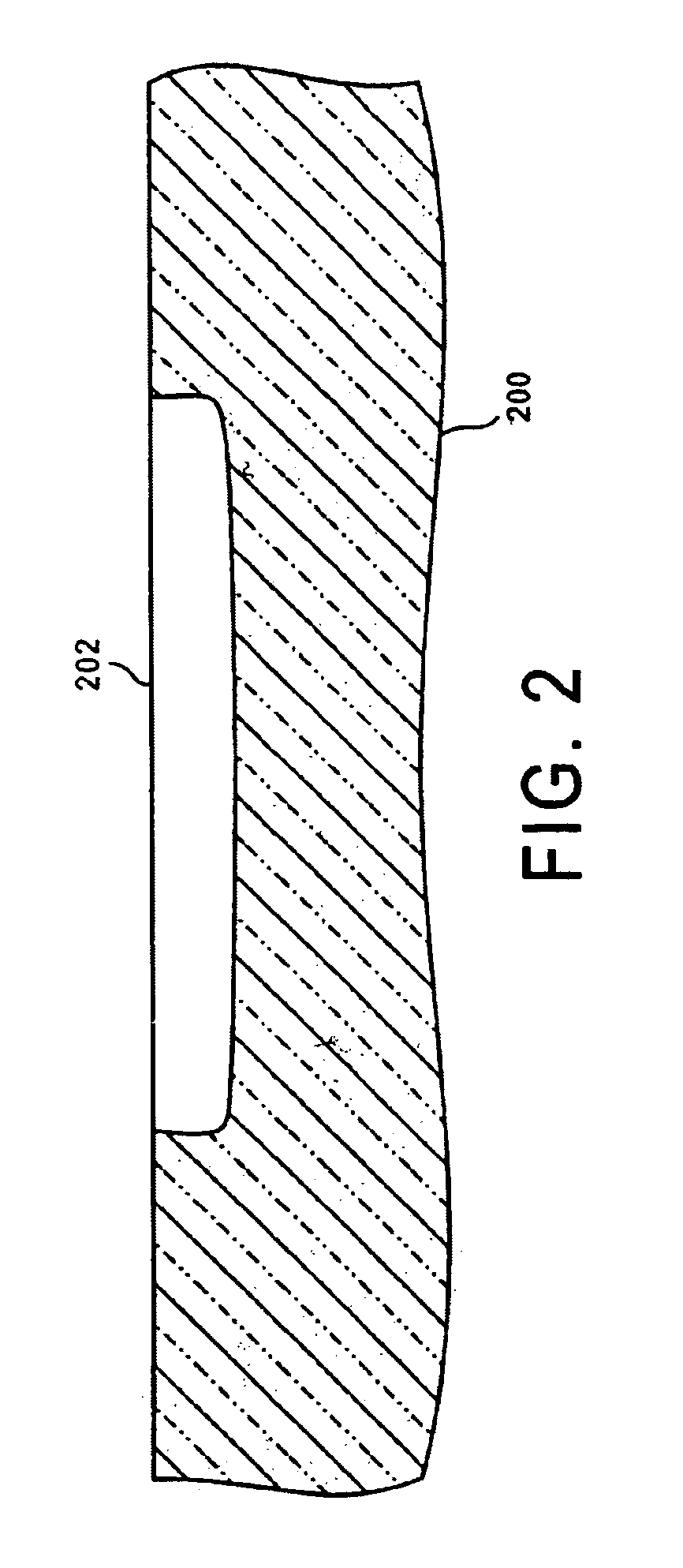

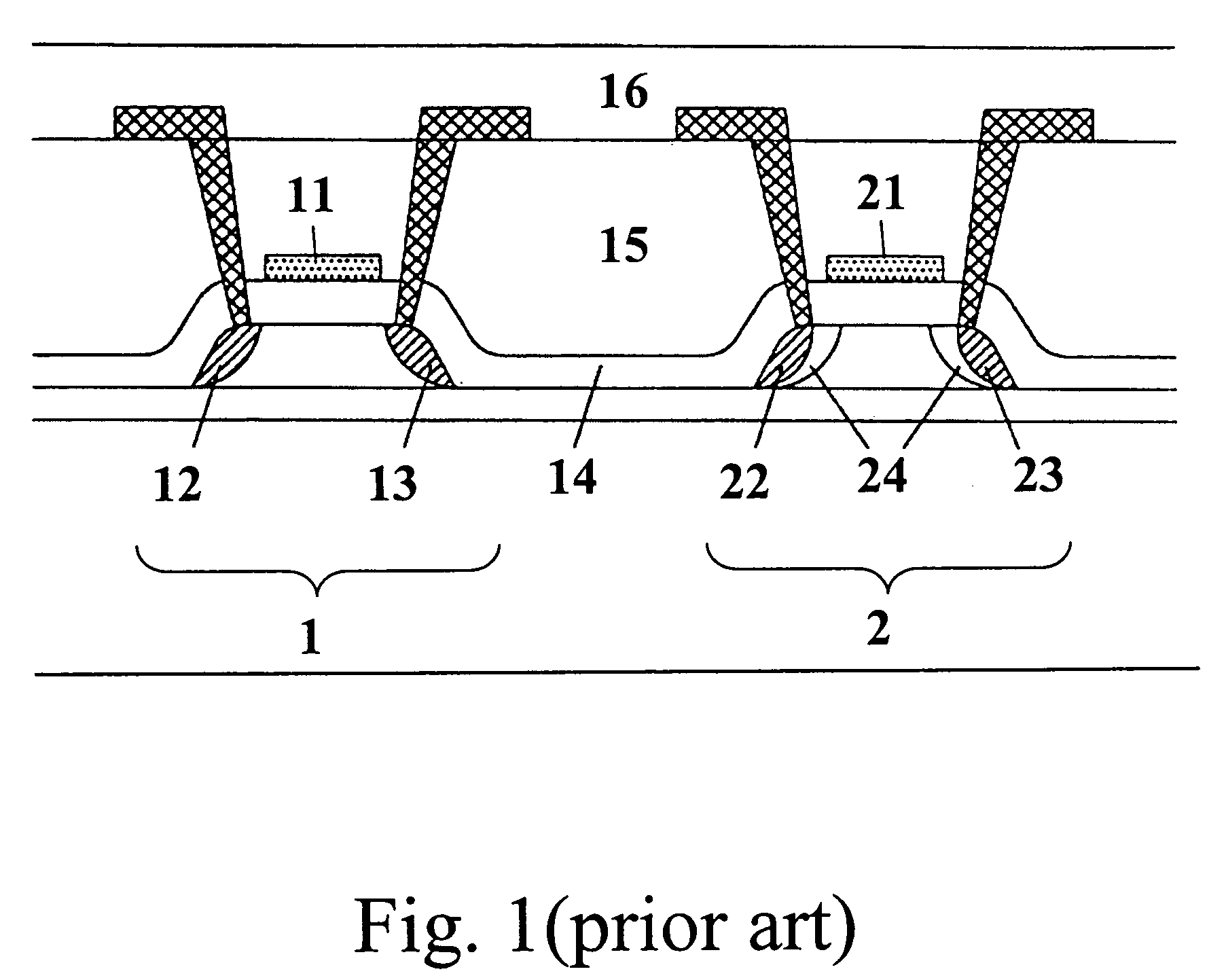

Diffused extrinsic base and method for fabrication

InactiveUS6900519B2Improve performanceImprove the immunityTransistorSolid-state devicesDopantEngineering

The present invention provides a unique device structure and method that provides increased transistor performance in integrated bipolar circuit devices. The preferred embodiment of the present invention provides improved high speed performance by providing reduced base resistence. The preferred design forms the extrinsic base by diffusing dopants from a dopant source layer and into the extrinsic base region. This diffusion of dopants forms at least a portion of the extrinsic base. In particular, the portion adjacent to the intrinsic base region is formed by diffusion. This solution avoids the problems caused by traditional solutions that implanted the extrinsic base. Specifically, by forming at least a portion of the extrinsic base by diffusion, the problem of damage to base region is minimized. This reduced damage enhances dopant diffusion into the intrinsic base. Additionally, the formed extrinsic base can have improved resistence, resulting in an improved maximum frequency for the bipolar device. Additionally, the extrinsic base can be formed with a self-aligned manufacturing process that reduces fabrication complexity.

Owner:GLOBALFOUNDRIES US INC

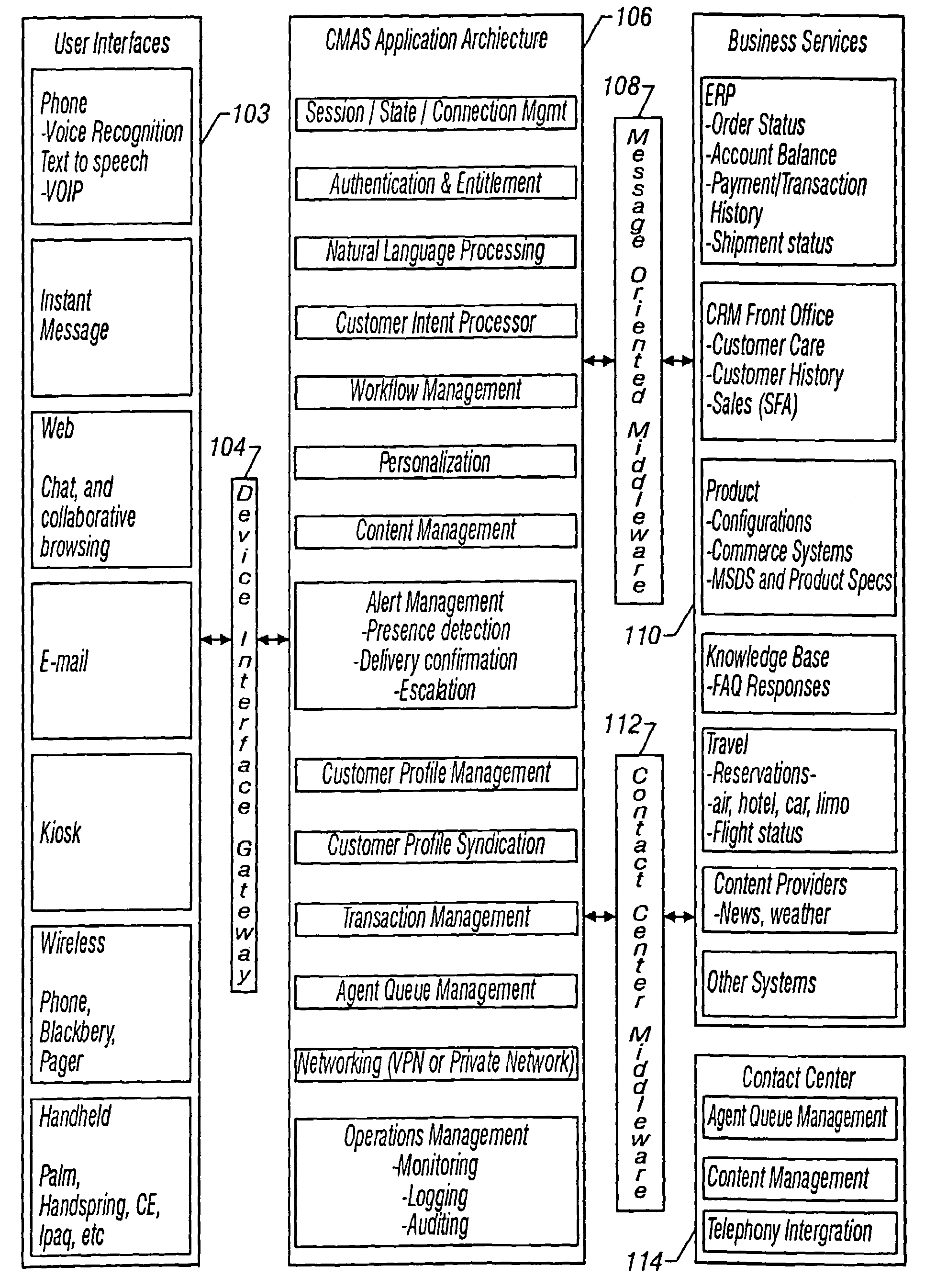

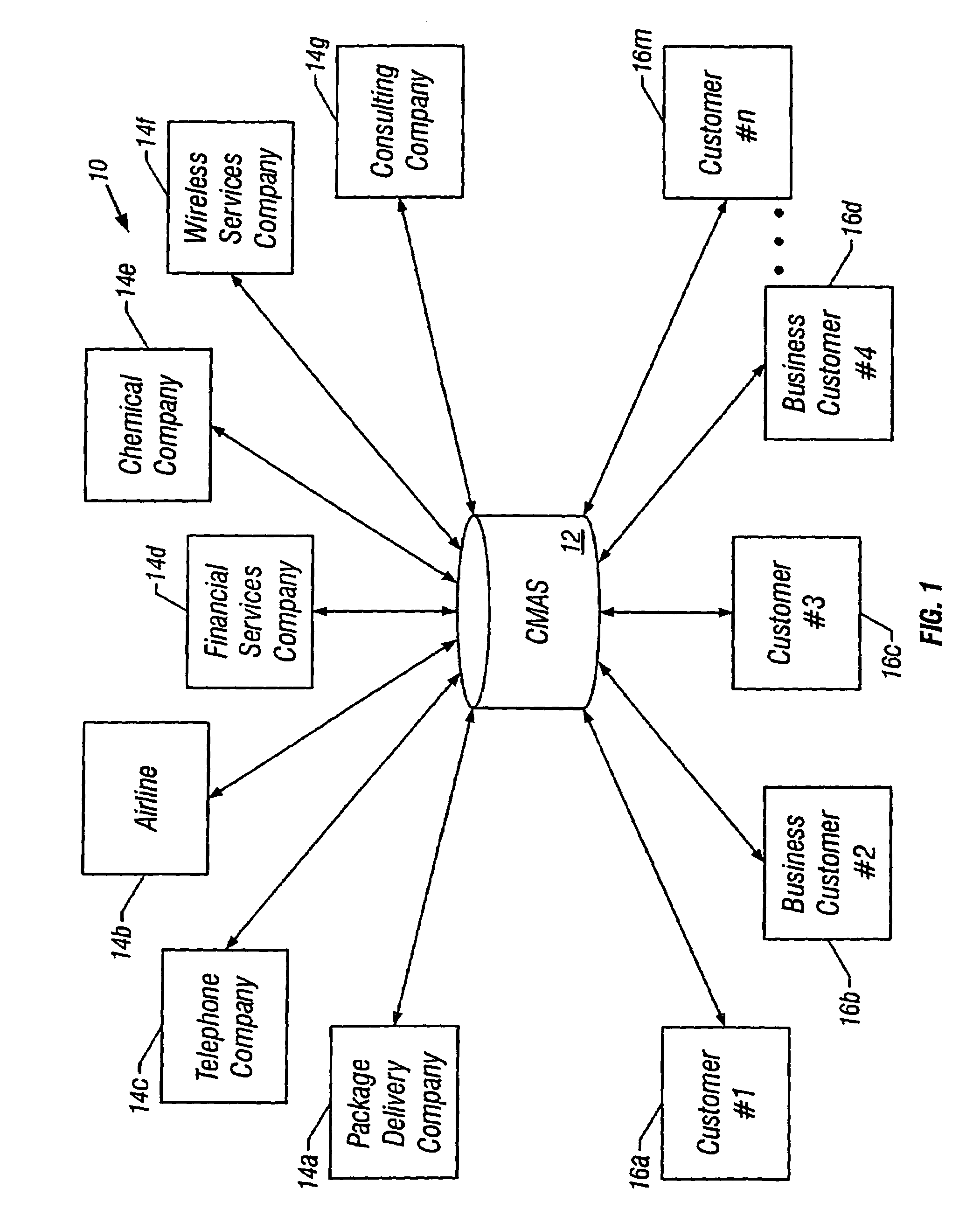

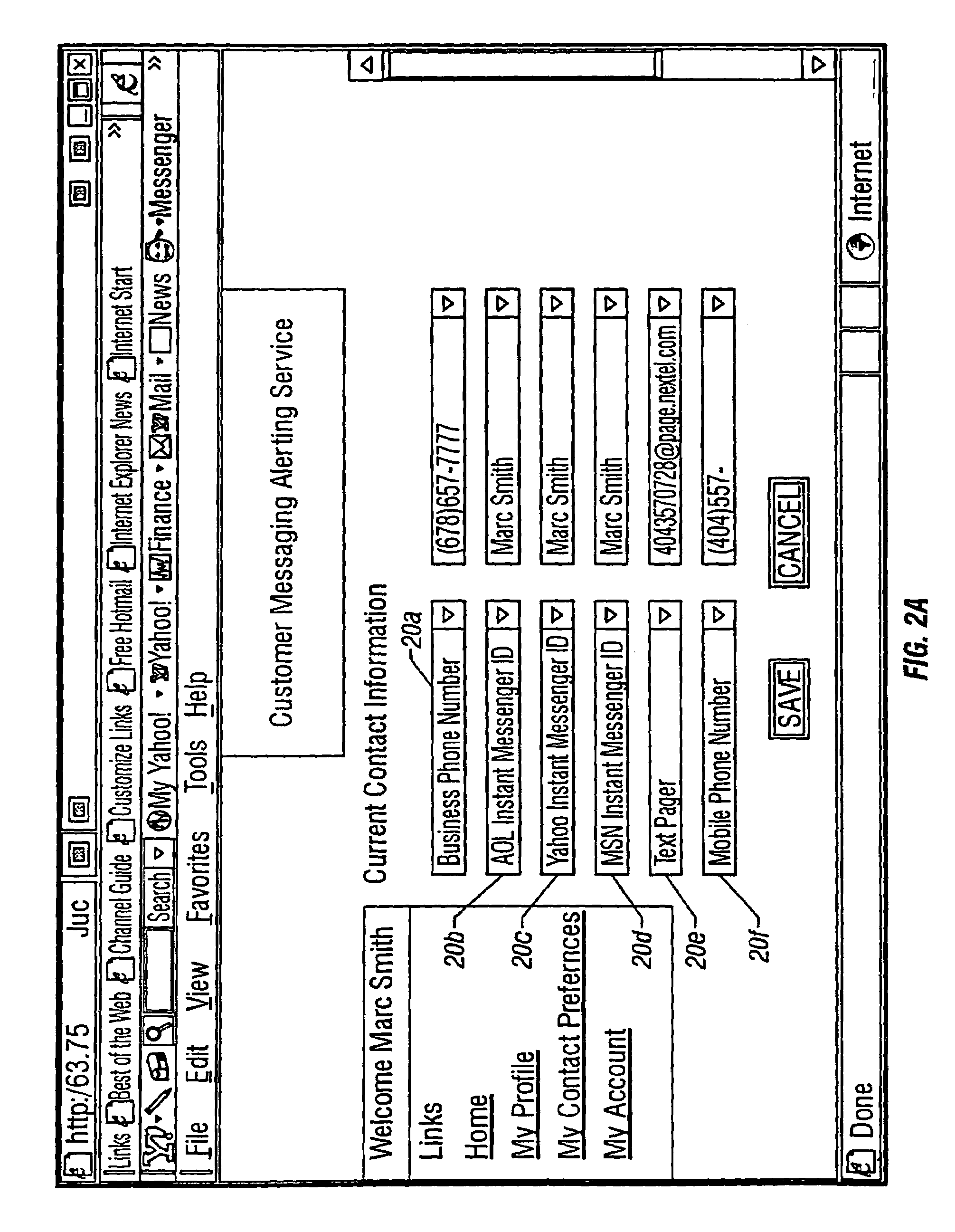

Customer messaging service

ActiveUS7653573B2Easy to operateEfficient communicationSubstation equipmentOffice automationMessage passingDatabase

Owner:ACCENTURE GLOBAL SERVICES LTD

Polymer blends and pellets and methods of producing same

Blends of at least two polymers incorporating propylene-derived units and processes for producing such blends are provided. The first polymer of the blend is a low crystallinity polymer including propylene-derived units. The second polymer is a high crystallinity polymer including propylene-derived units. The polymer blends exhibit the beneficial performance characteristics of low crystallinity propylene polymers while minimizing certain processing and handling problems associated with low crystallinity propylene polymers. Low crystallinity propylene polymer pellets often exhibit a tendency to agglomerate because of the softness of such particles. Agglomeration of the pellets creates problems in handling and processing the particles. The polymer blends disclosed reduce the tendency of polymer pellets to agglomerate while maintaining the desirable physical properties, such as elastomeric properties, exhibited by low crystallinity propylene polymers. Various processes for producing the polymer blends are also provided.

Owner:EXXONMOBIL CHEM PAT INC

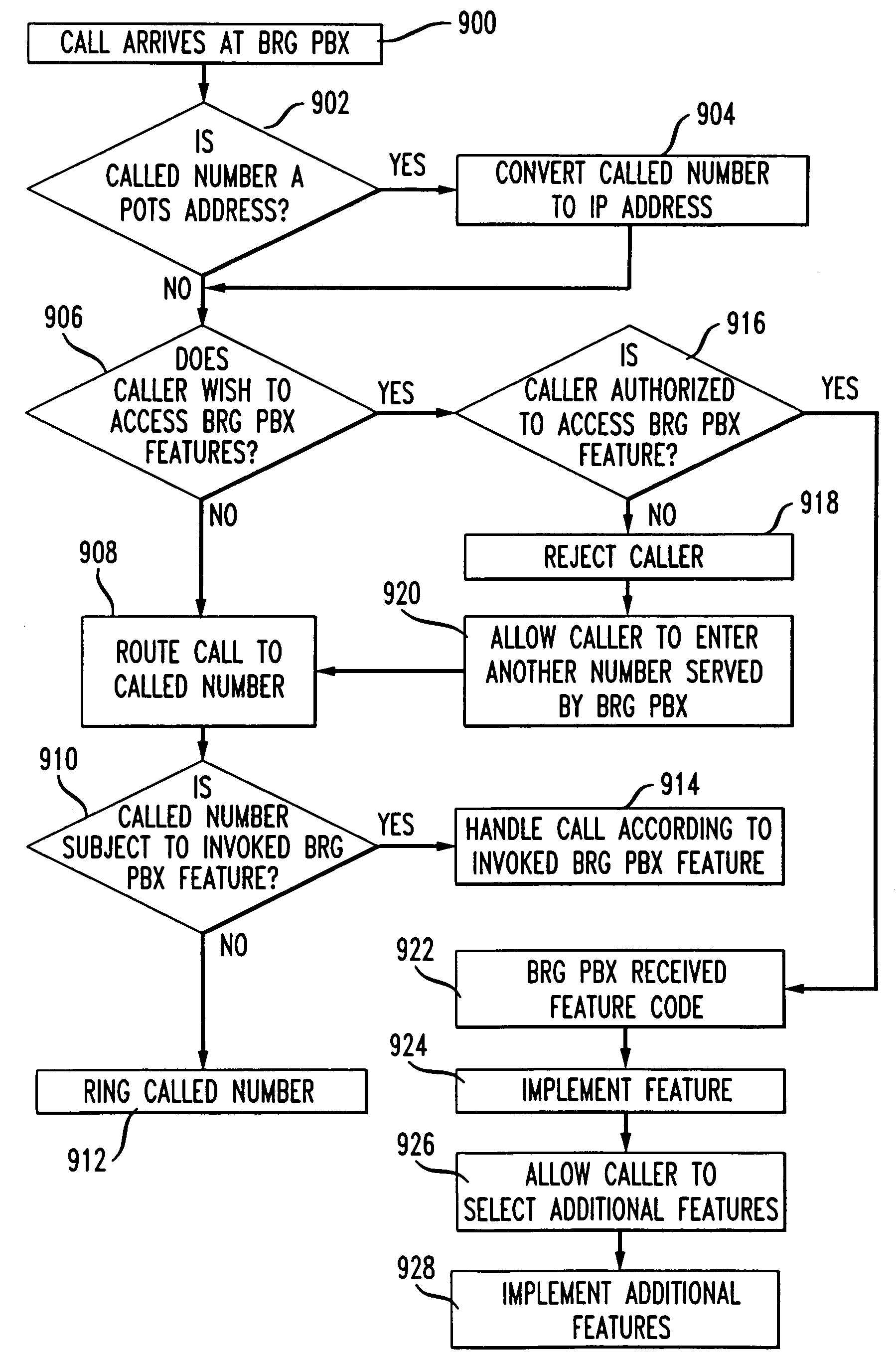

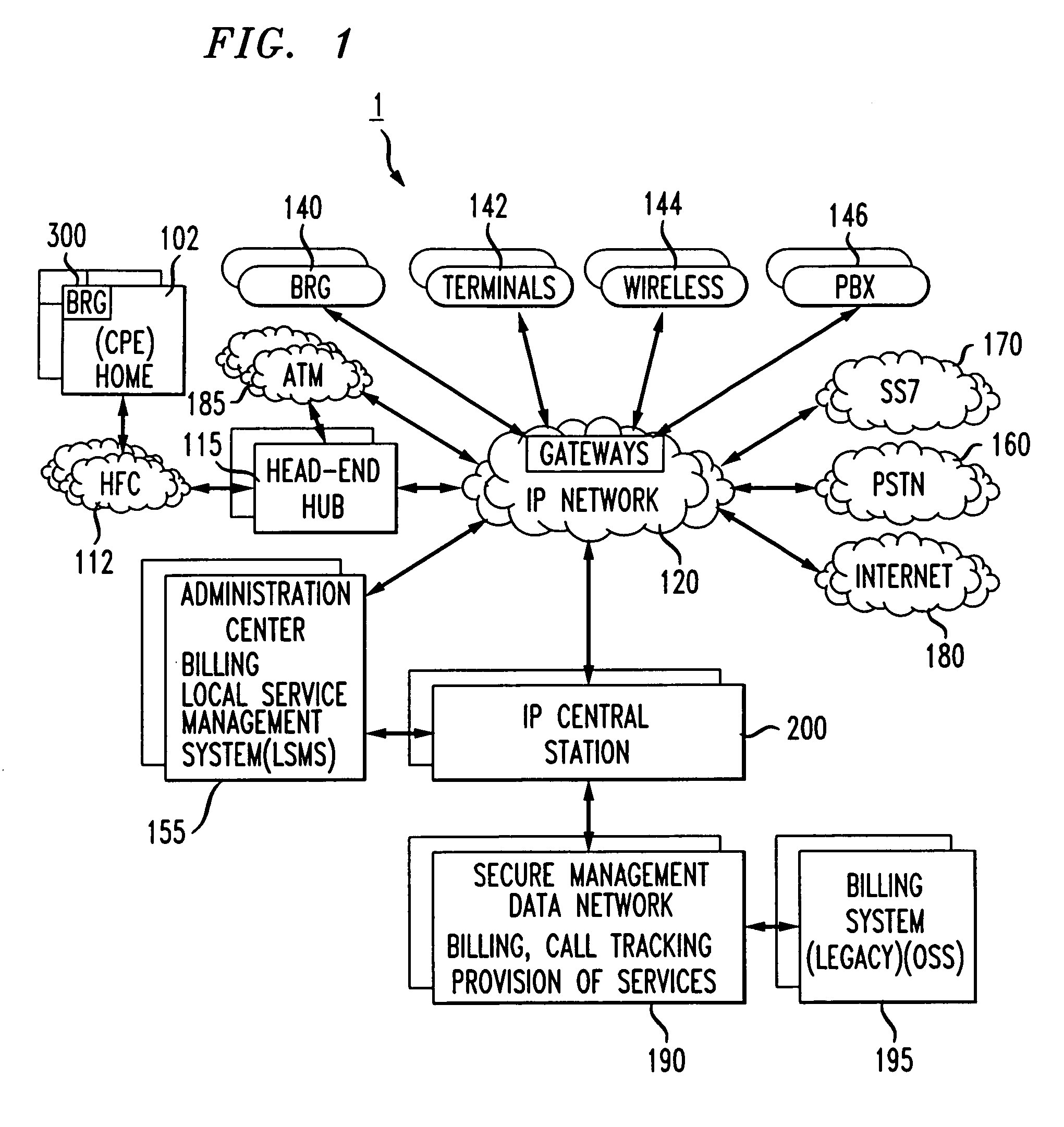

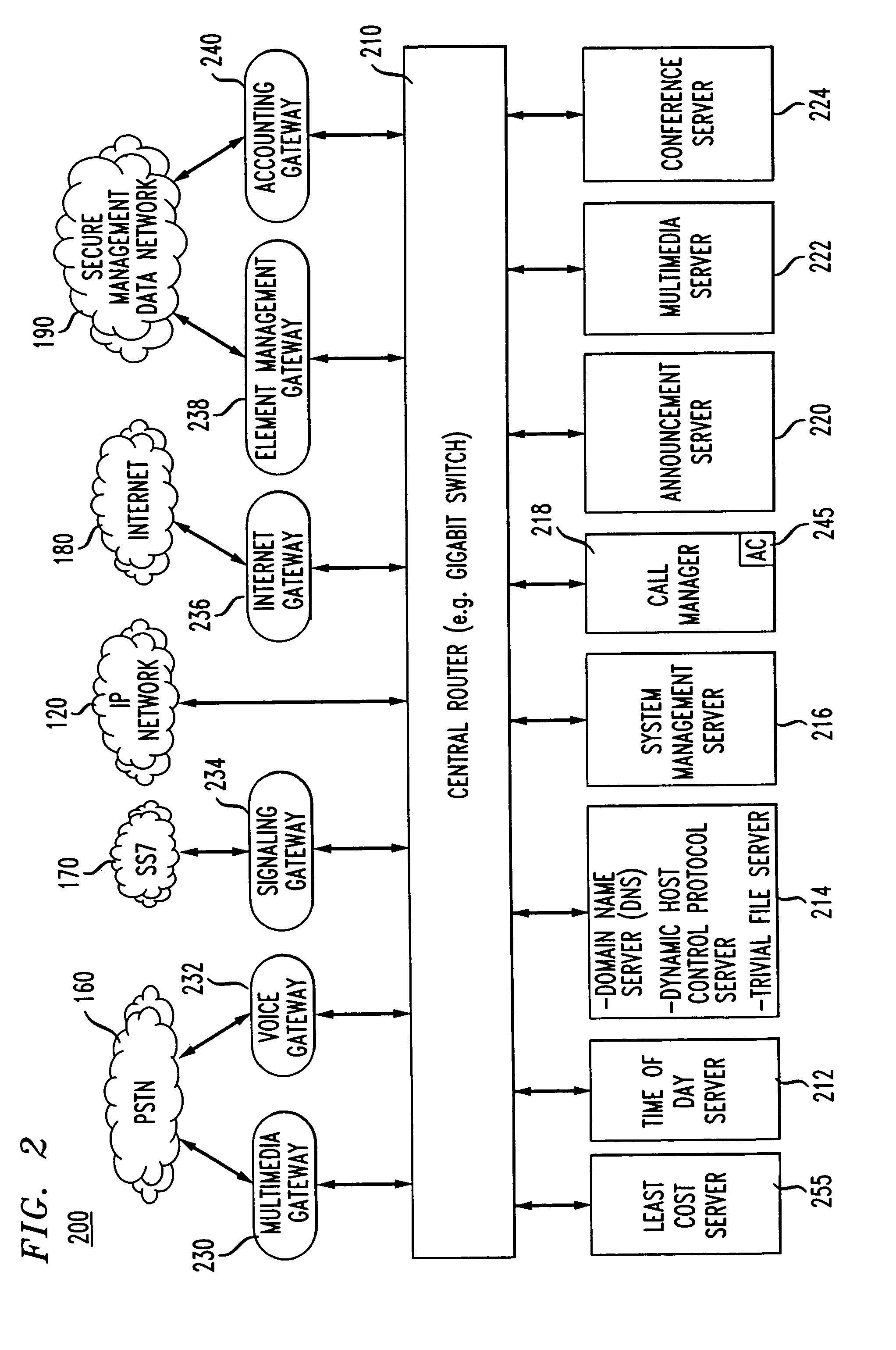

BRG with PBX capabilities

InactiveUS7075918B1Minimizing problems during installationMinimizes problemInterconnection arrangementsSpecial service for subscribersGeographic regionsResidence

A residential private branch exchange (PBX) allowing IP telephones, analog telephones and computers to connect to an IP communication network. A broadband residential gateway (BRG) PBX provides residences with multiple phone lines capability and the implementation of complex calling features traditionally associated with complex and expensive business PBX systems. The BRG PBX provides an open architecture interface minimizing problems during installation and operation, minimizes interoperability problems across multi-vendor equipment platforms and may provide customers with an option to bypass the local telephone company's high cost infrastructure. The BRG PBX may also provide a range of services from basic calling with few features to highly sophisticated calling features servicing multiple phone lines to the residence. The BRG PBX may be configured to connect multiple BRG PBX systems together in a Local Area Network (LAN) or Wide Area Network (WAN) configuration. These network configurations may be implemented to connect neighborhoods or families across multiple geographic regions. In addition to having the capability of connecting to each other, the BRG PBXs may be connected to IP Central Stations forming an IP communication network.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

Single-piece top surface display layer and integrated front cover for an electronic device

InactiveUS7348964B1Flat bezel-freeReduce the possibility of damageTransmission systemsDigital data processing detailsSurface displayAccelerometer

A single-piece top surface display and integrated front cover for an electronic device. In one embodiment, the cover comprises a thin, flexible, transparent layer coupled with a supporting structure. The flexible layer is supported above a display screen which is coupled with pressure activated sensors located under the display screen. The cover is dust-free, waterproof, and has a flat outer surface that is free of any steps or indentations. Users input data by applying pressure on the cover which causes the display screen to deflect and activate the sensors. The pressure exerted on the sensors is triangulated to register the position of the user input. In another embodiment, the cover is transparent, rigid, and directly contacts the pressure activated sensors which are located in front of the display screen or in the housing behind it. When pressure is applied to the cover, the cover deflects and activates the sensors. In both embodiments, an accelerometer identifies valid input events.

Owner:QUALCOMM INC

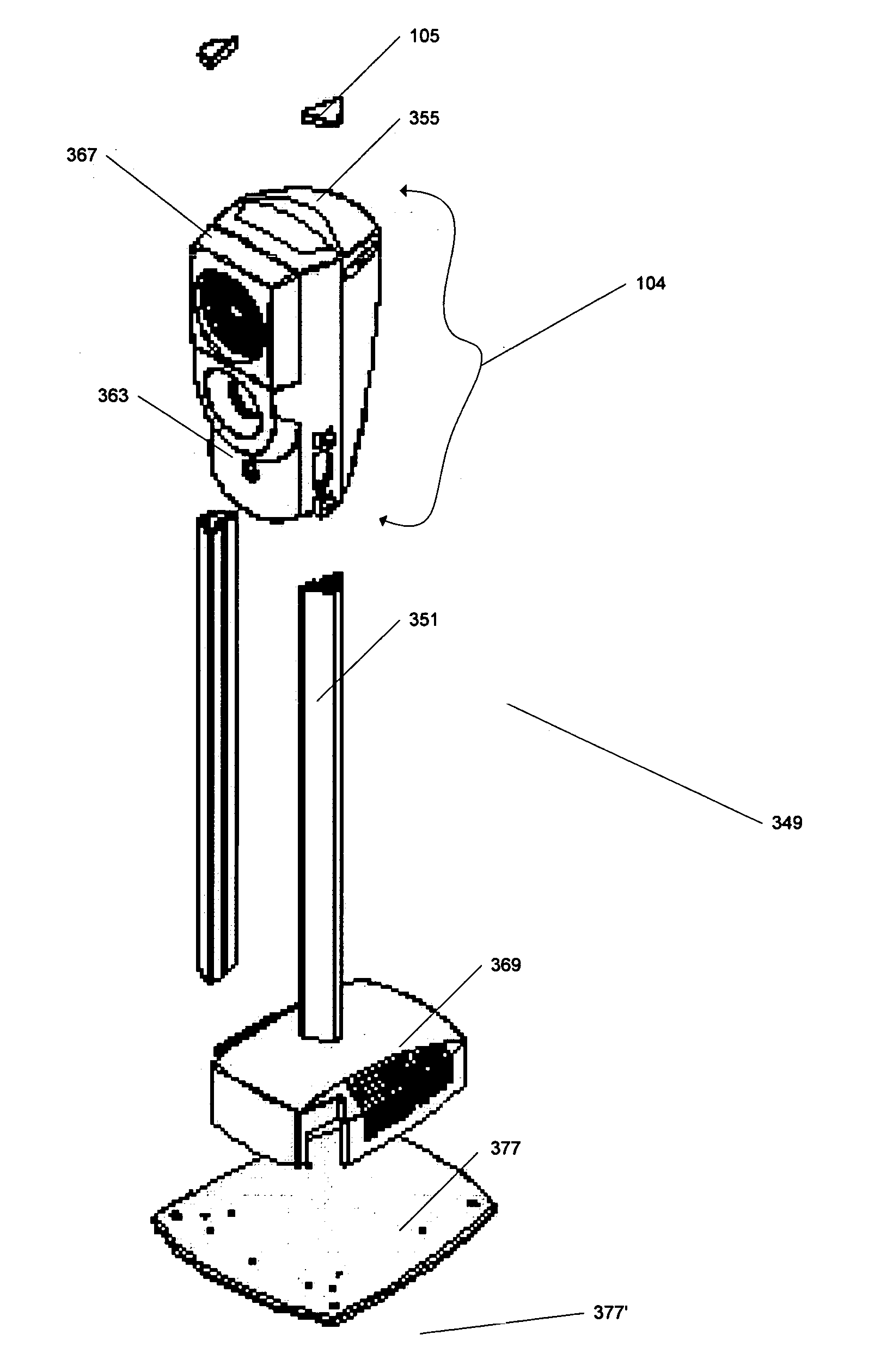

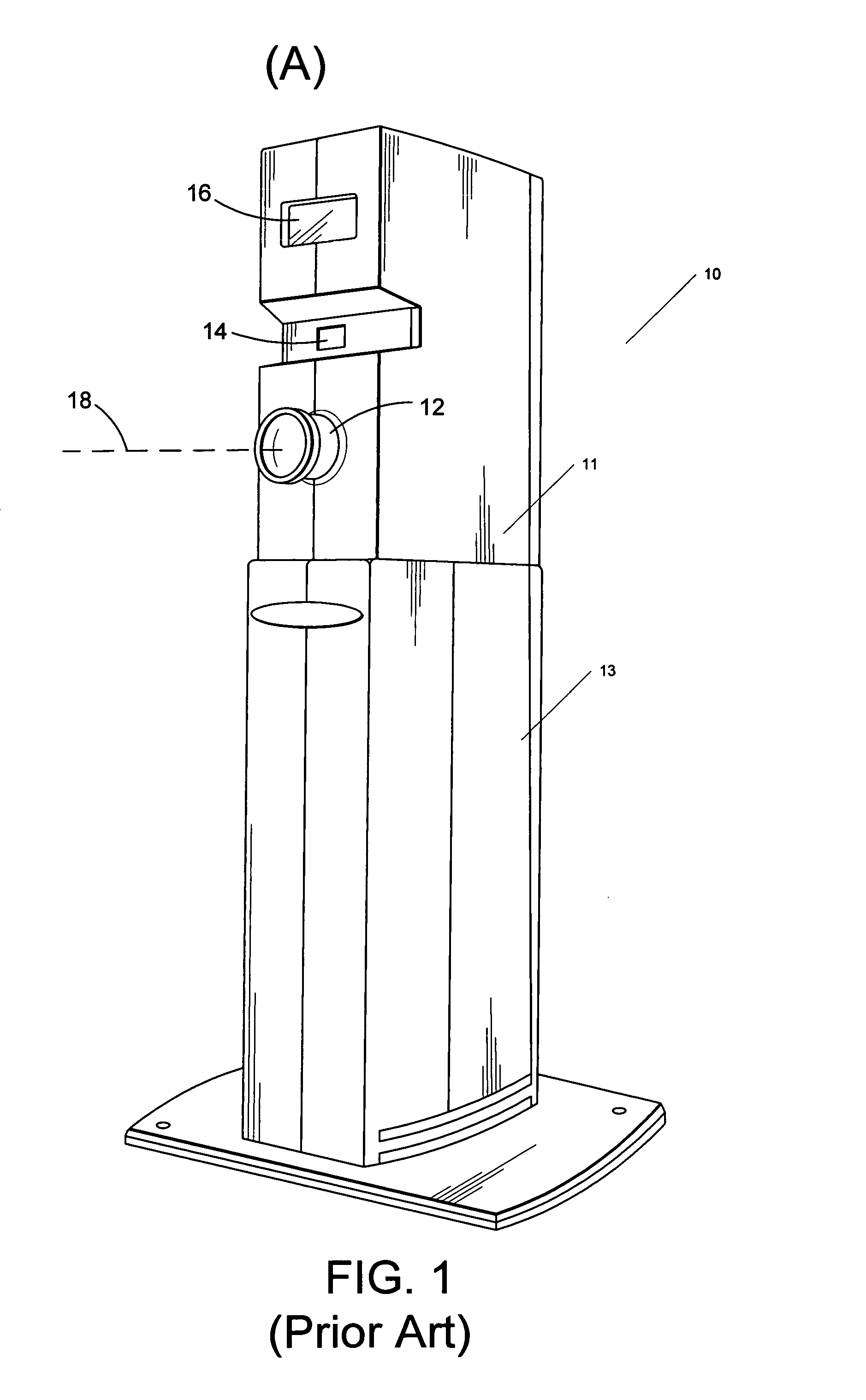

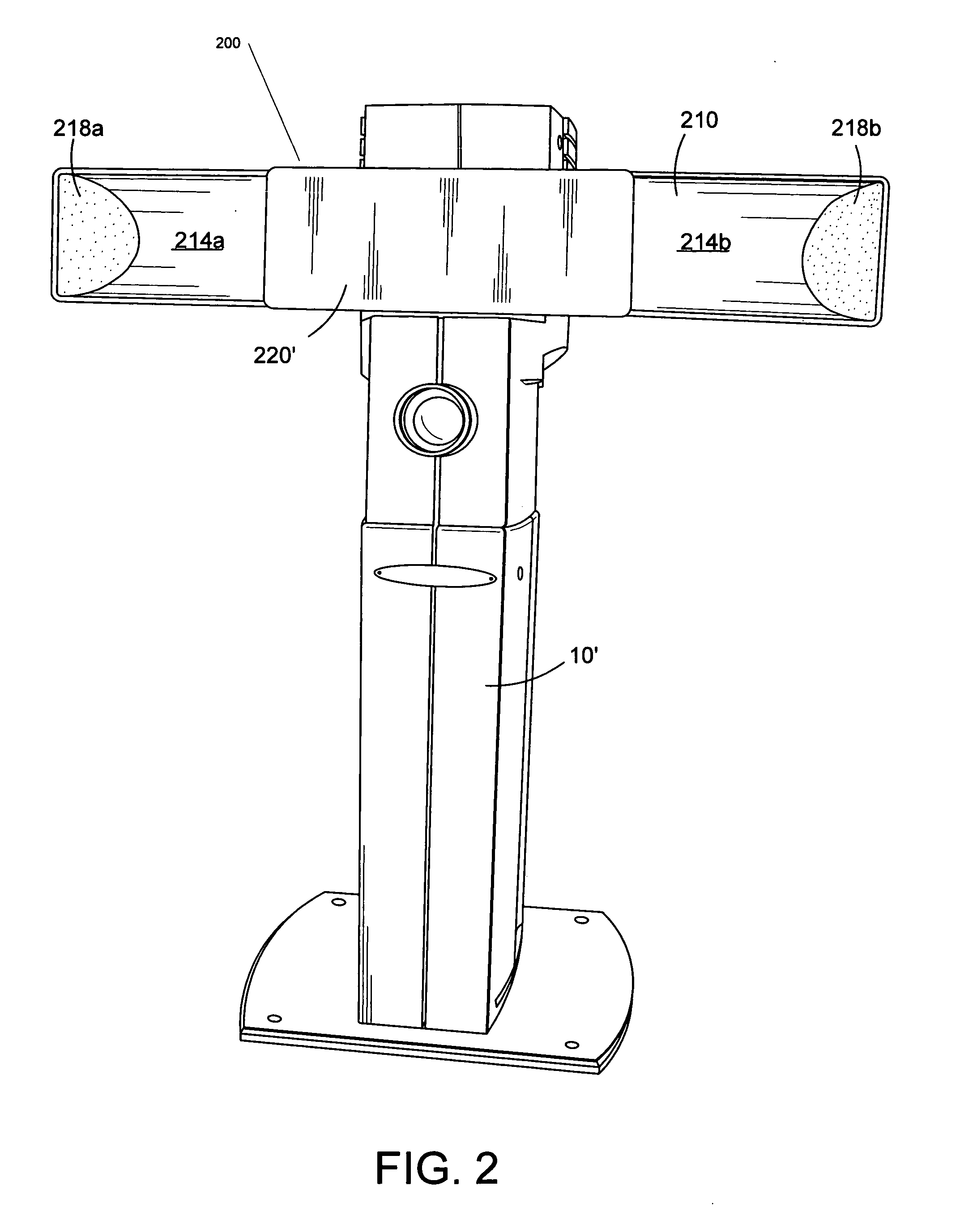

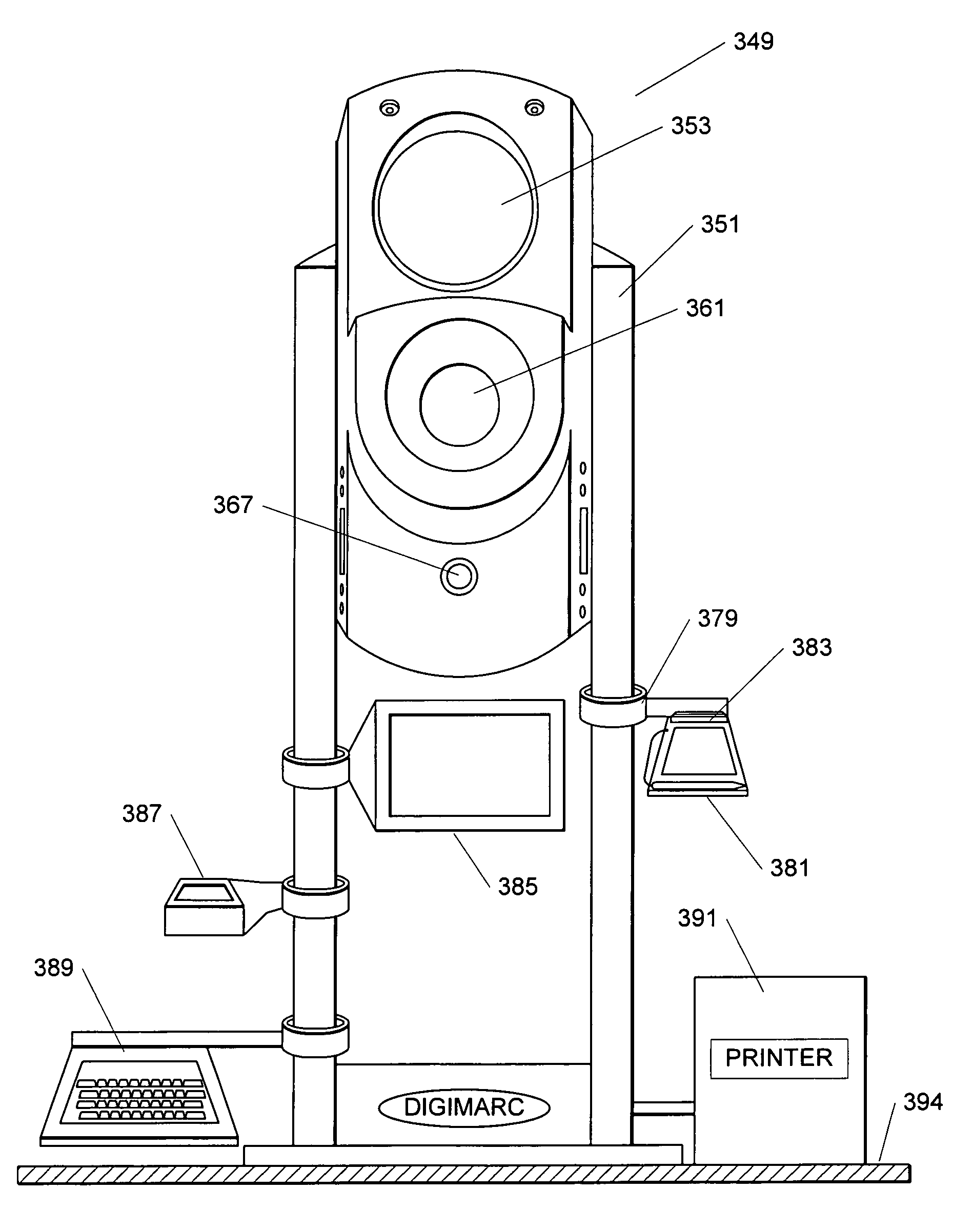

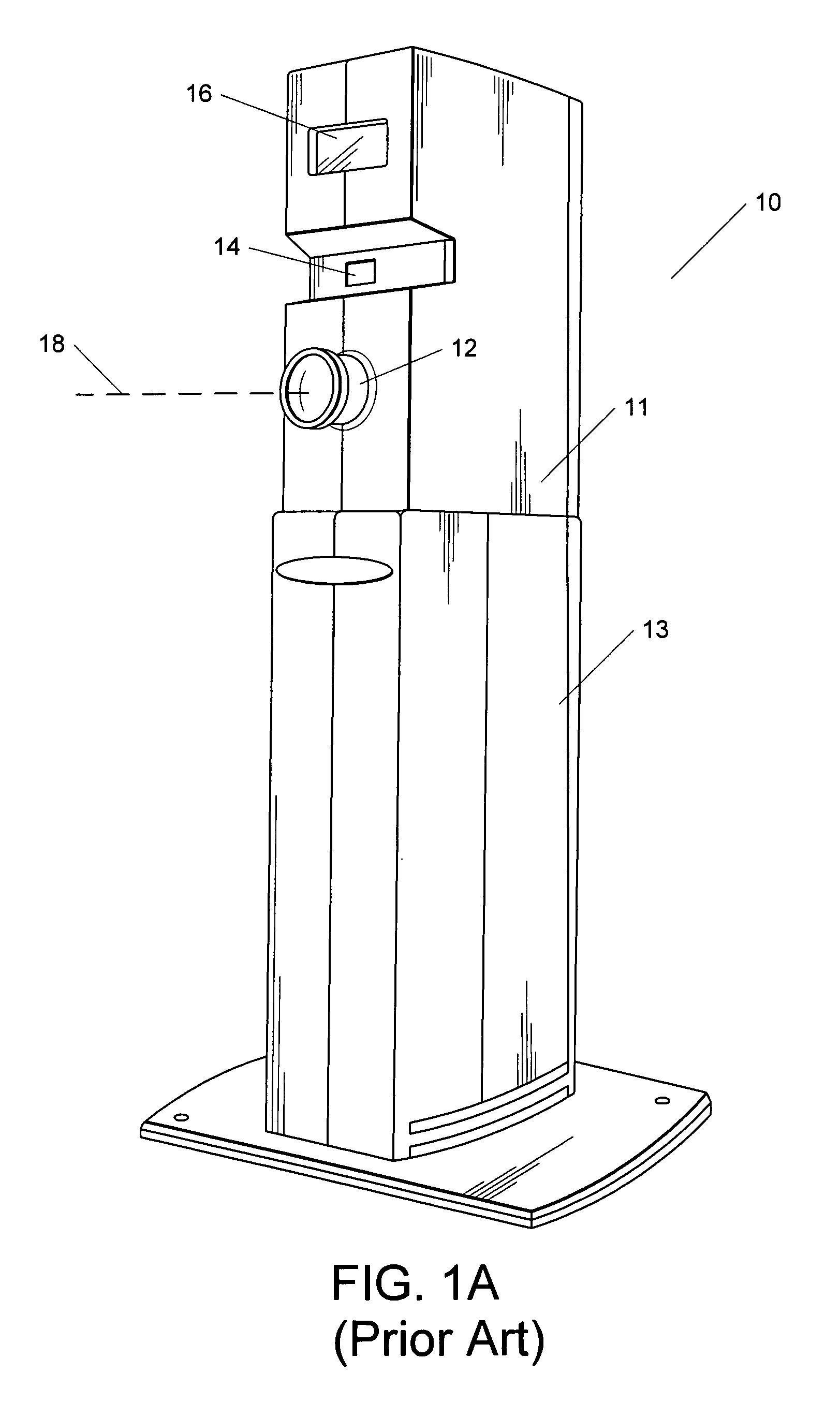

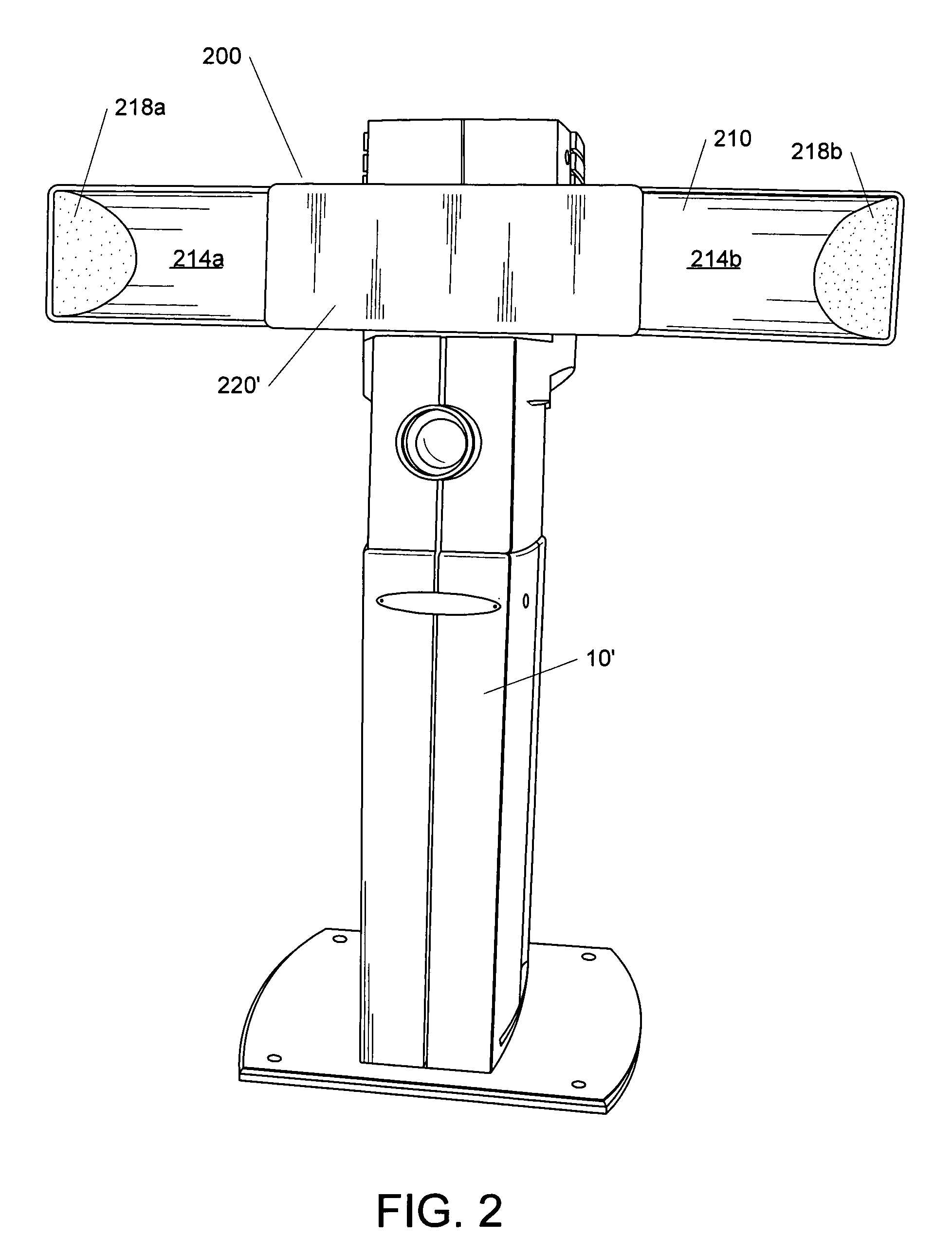

Multifunction all in one capture station for creating identification documents

ActiveUS20050243199A1Reduce shadowsEnhanced Shadow Reduction SystemTelevision system detailsCharacter and pattern recognitionNetwork connectionRemote computer

A capture station for creating identification documents comprises a housing including a camera and lighting device, a base, and at least one leg extending from the base. The housing is mounted to the leg to enable height adjustment of the camera. One configuration of the capture station has two substantially rigid and parallel legs with the housing mounted between the legs. Configurations of the capture station can include a processor, such a CPU or embedded controller, enabling ID document data capture functions to be executed within the capture station, and to be controlled via a remote computer via a network connection. In one embodiment, the processor is housed in the base and communicates with the camera via wiring routed through the leg. Peripherals used in capture functions, such as a fingerprint reader, signature pad, display, etc., may be mounted to the leg via clamps, or a plug in receptacle with power and communication wiring provided in the leg.

Owner:L 1 SECURE CREDENTIALING

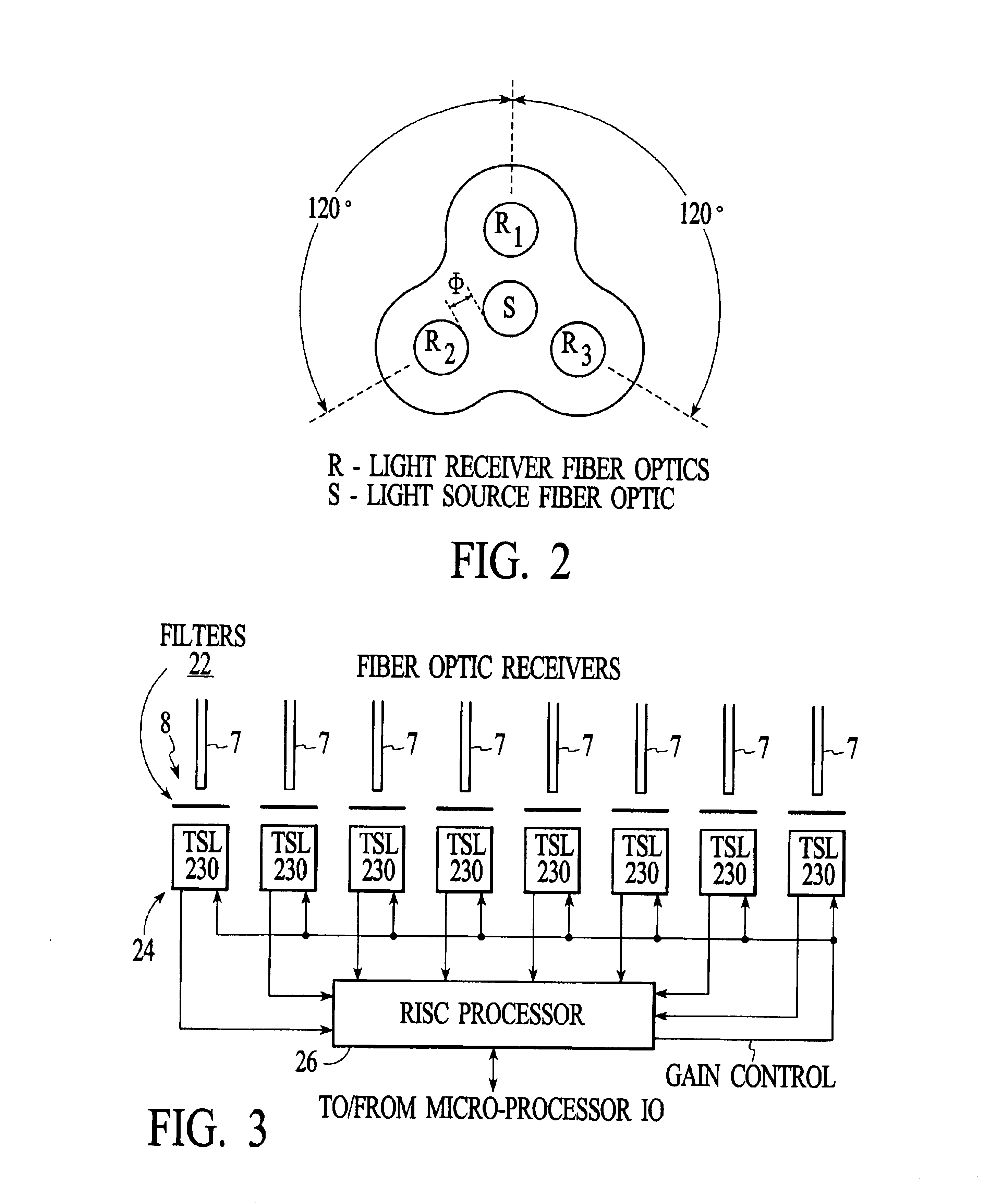

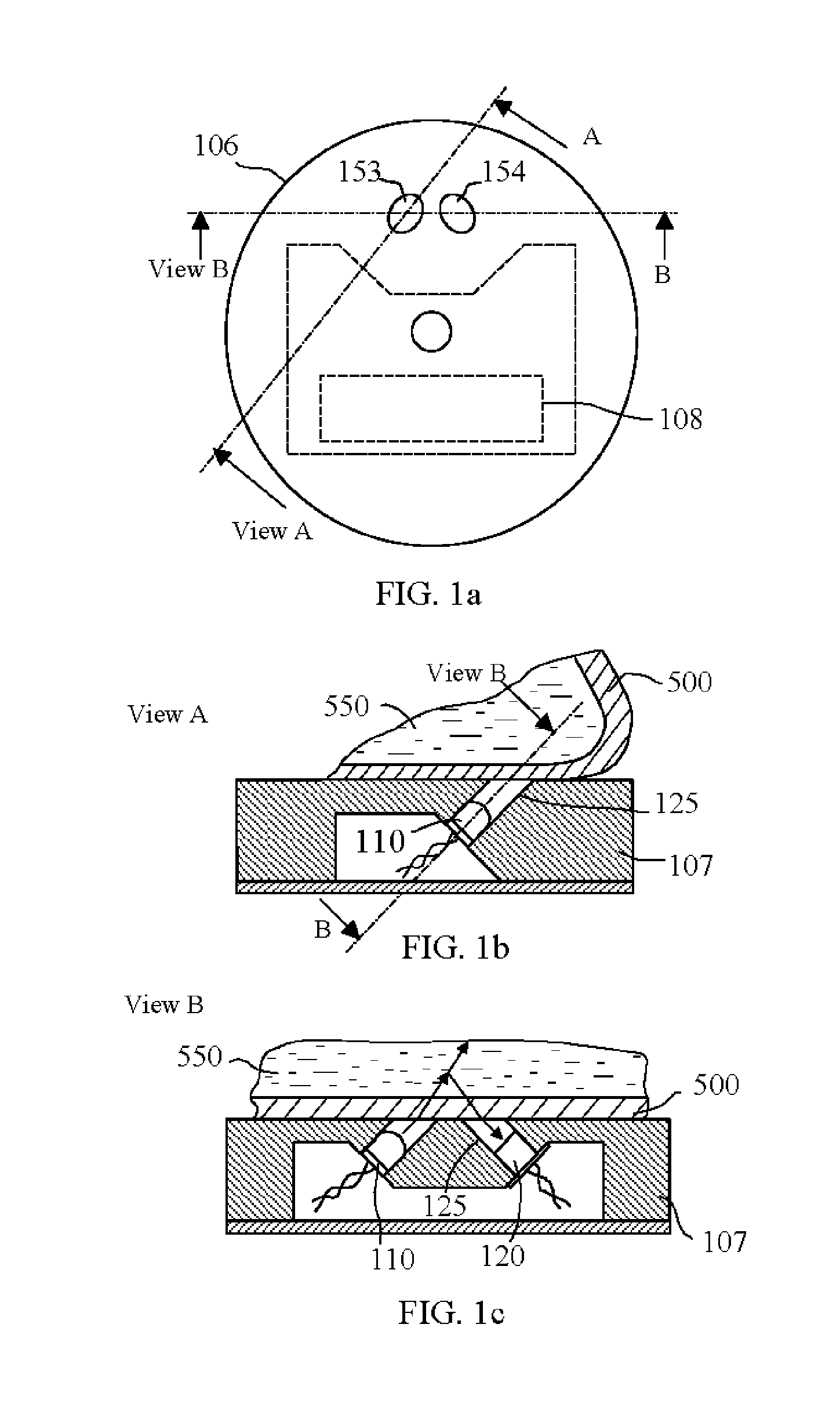

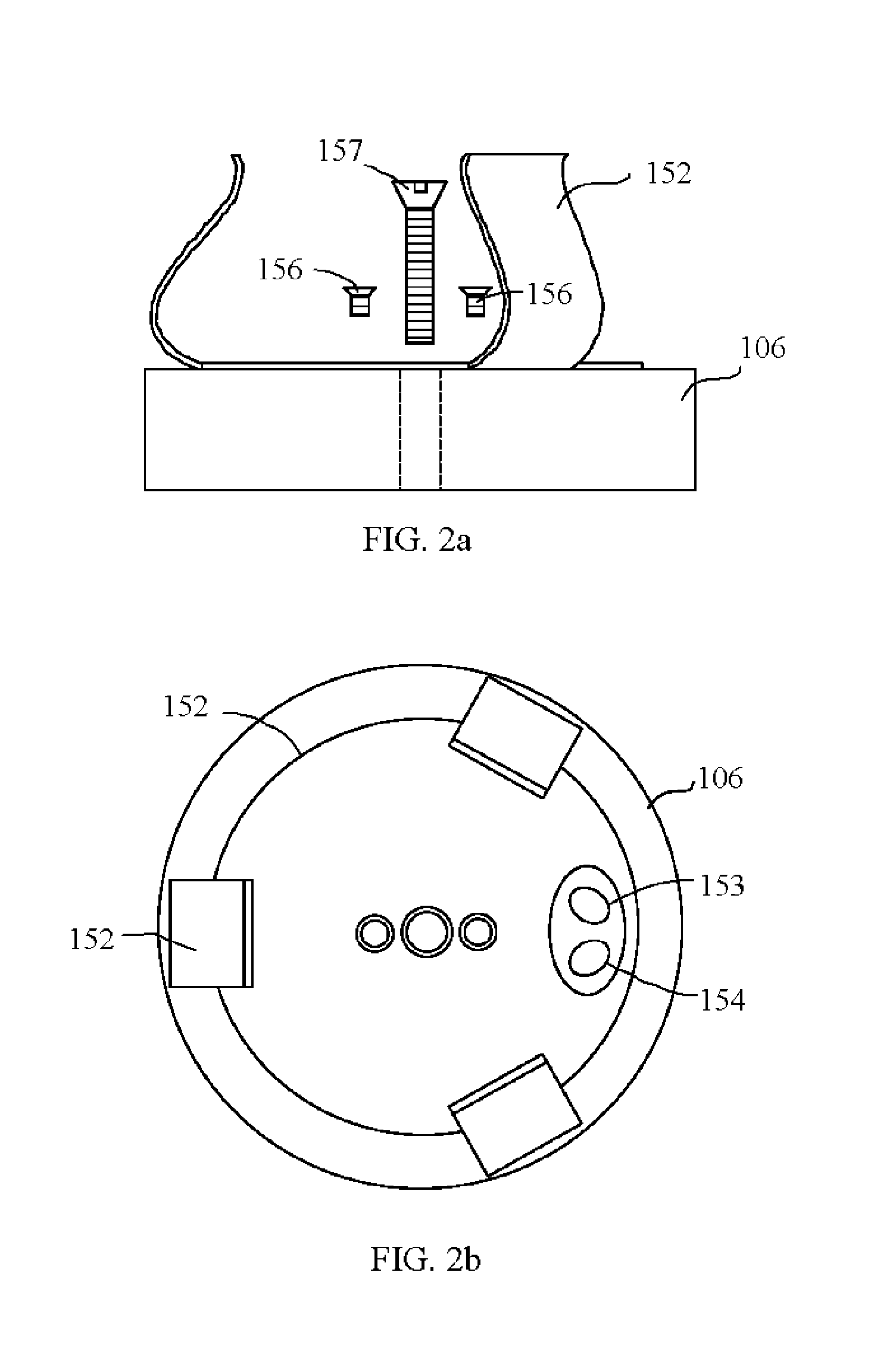

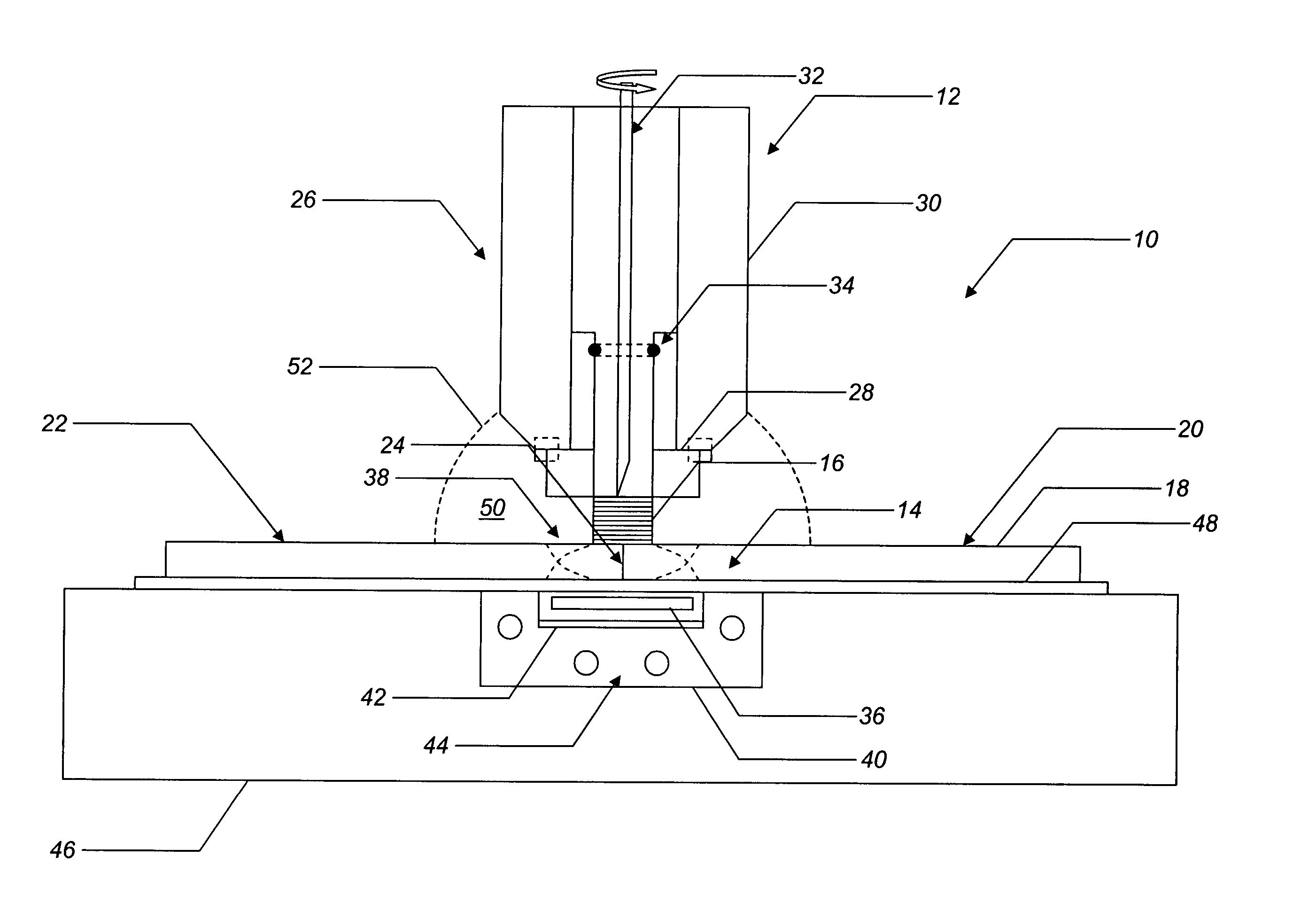

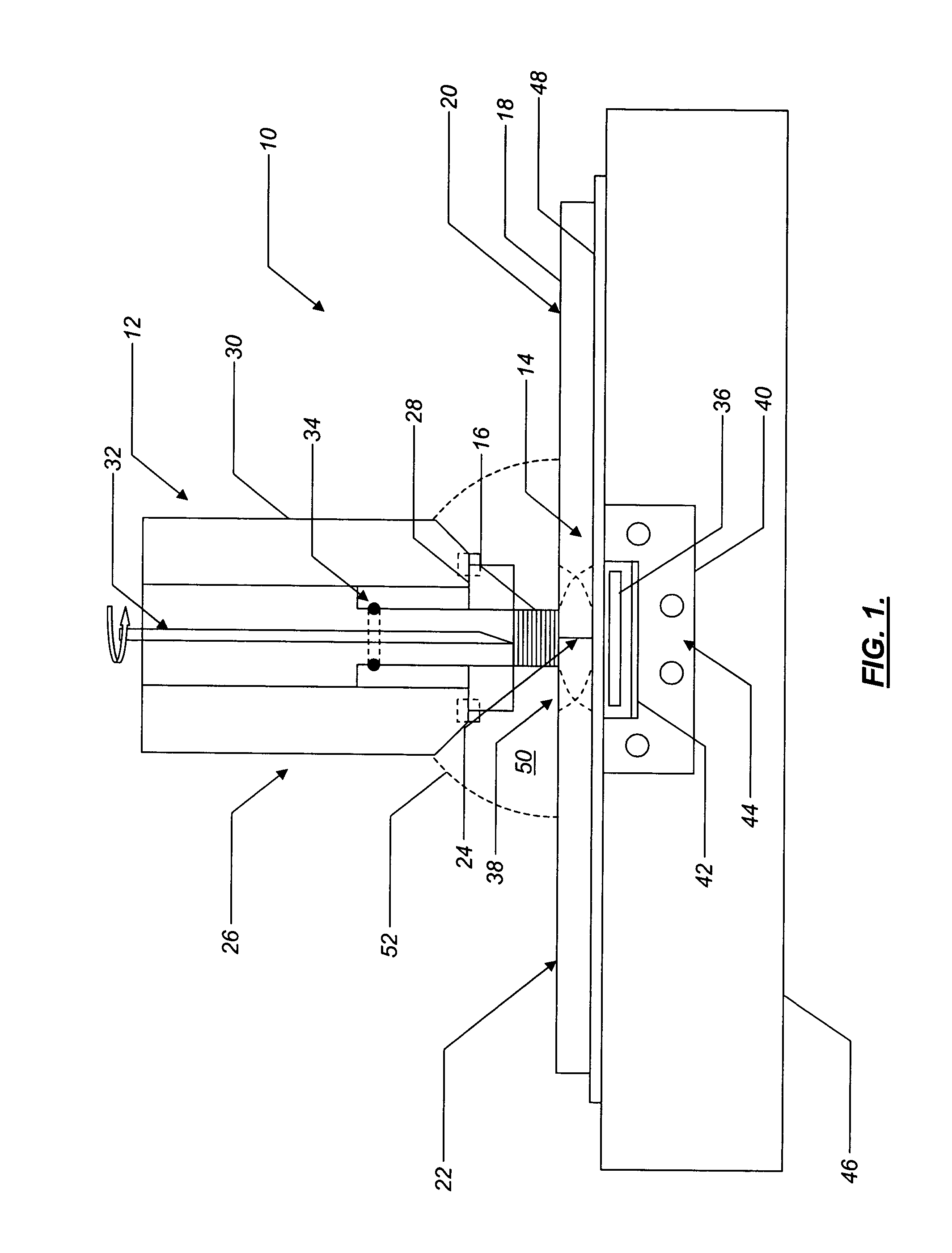

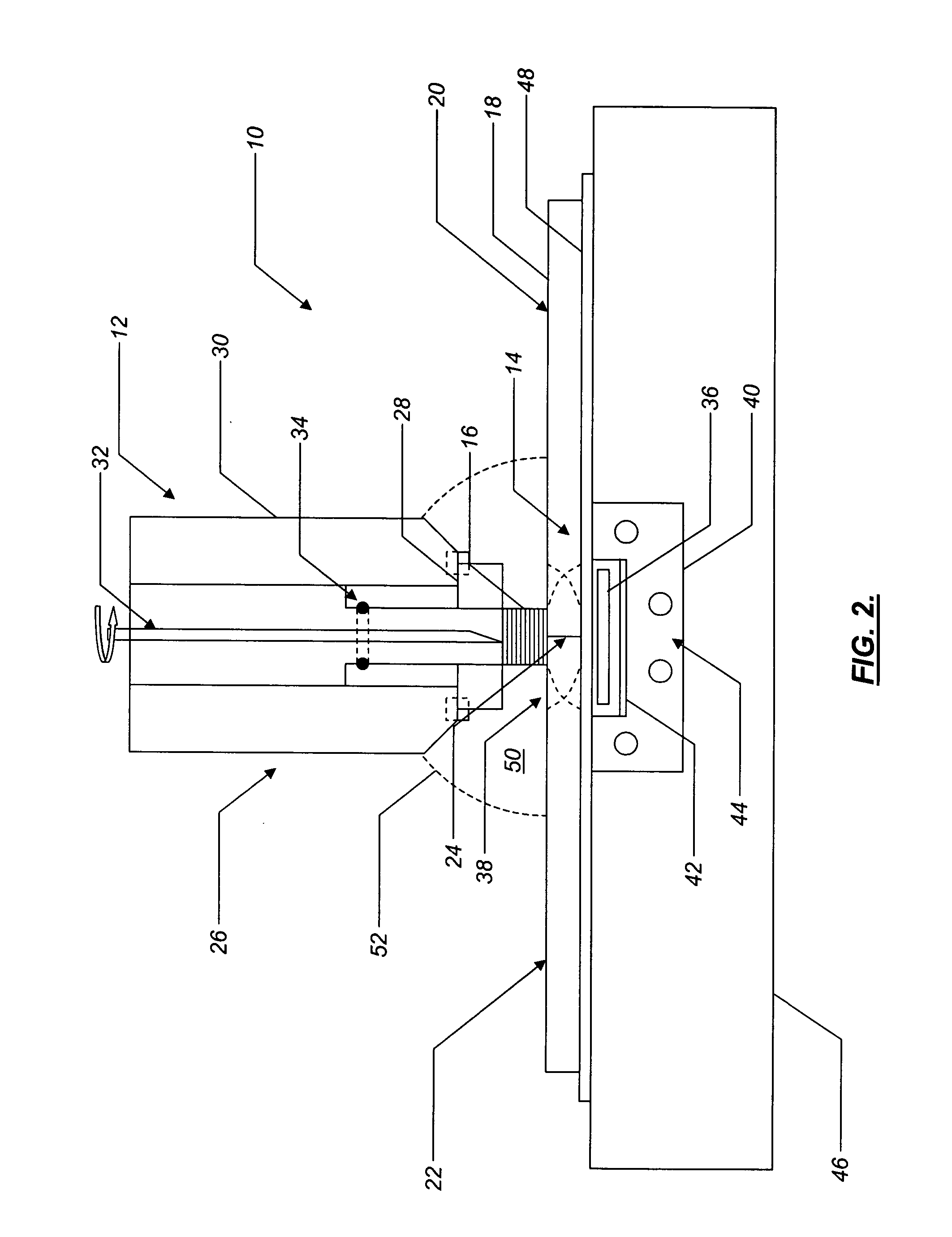

Spectrometer apparatus for determining an optical characteristic of an object or material having one or more sensors for determining a physical position or non-color property

InactiveUS6870616B2Low costSmall sizeRadiation pyrometrySpectrum investigationOptical propertyGray level

A spectrometer apparatus for determining an optical characteristic of an object or material is disclosed. A probe is positionable to be in proximity to the object or material. First and second receivers are provided on the probe. Light from one or more first receivers is coupled to one or more first optical sensors via a spectral separation implement. Light from one or more second receivers is coupled to one or more second sensors without spectral separation of the light. A light source provides light to the object or material via the probe. A processor coupled to receive one or more signals from the first and second sensors determines the optical characteristic of the object or material and determines a physical position property of the probe with respect to the object or material or a non-color optical property of the object or material. The physical position property may be a distance or angular position of the probe with respect to a surface of the object or material. The non-color optical property may be translucence, gloss, gray level and / or surface texture.

Owner:RPX CORP +1

Multifunction all in one capture station for creating identification documents

ActiveUS7646425B2Reduce shadowsEnhanced Shadow Reduction SystemTelevision system detailsCharacter and pattern recognitionNetwork connectionRemote computer

A capture station for creating identification documents comprises a housing including a camera and lighting device, a base, and at least one leg extending from the base. The housing is mounted to the leg to enable height adjustment of the camera. One configuration of the capture station has two substantially rigid and parallel legs with the housing mounted between the legs. Configurations of the capture station can include a processor, such a CPU or embedded controller, enabling ID document data capture functions to be executed within the capture station, and to be controlled via a remote computer via a network connection. In one embodiment, the processor is housed in the base and communicates with the camera via wiring routed through the leg. Peripherals used in capture functions, such as a fingerprint reader, signature pad, display, etc., may be mounted to the leg via clamps, or a plug in receptacle with power and communication wiring provided in the leg.

Owner:L 1 SECURE CREDENTIALING

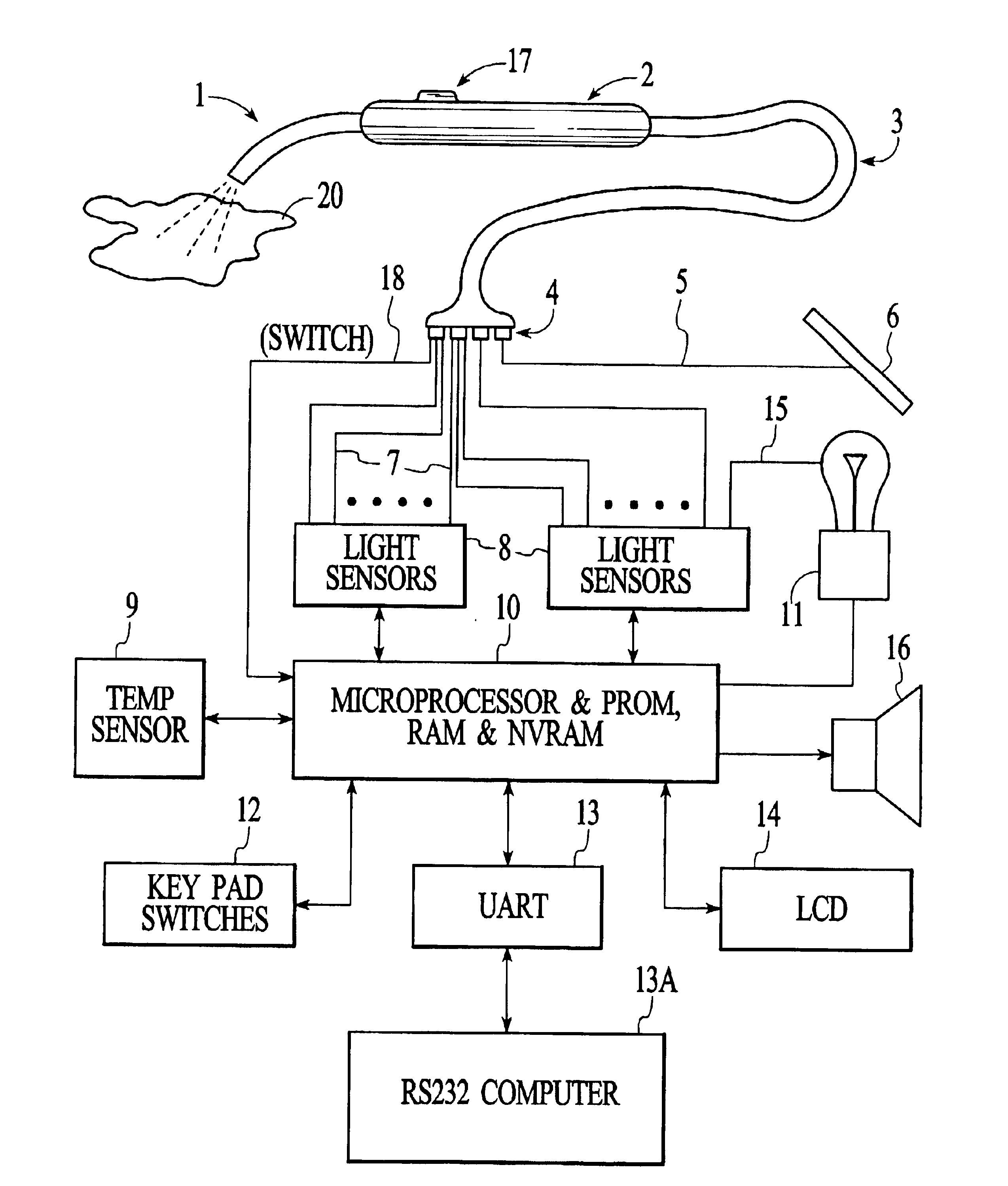

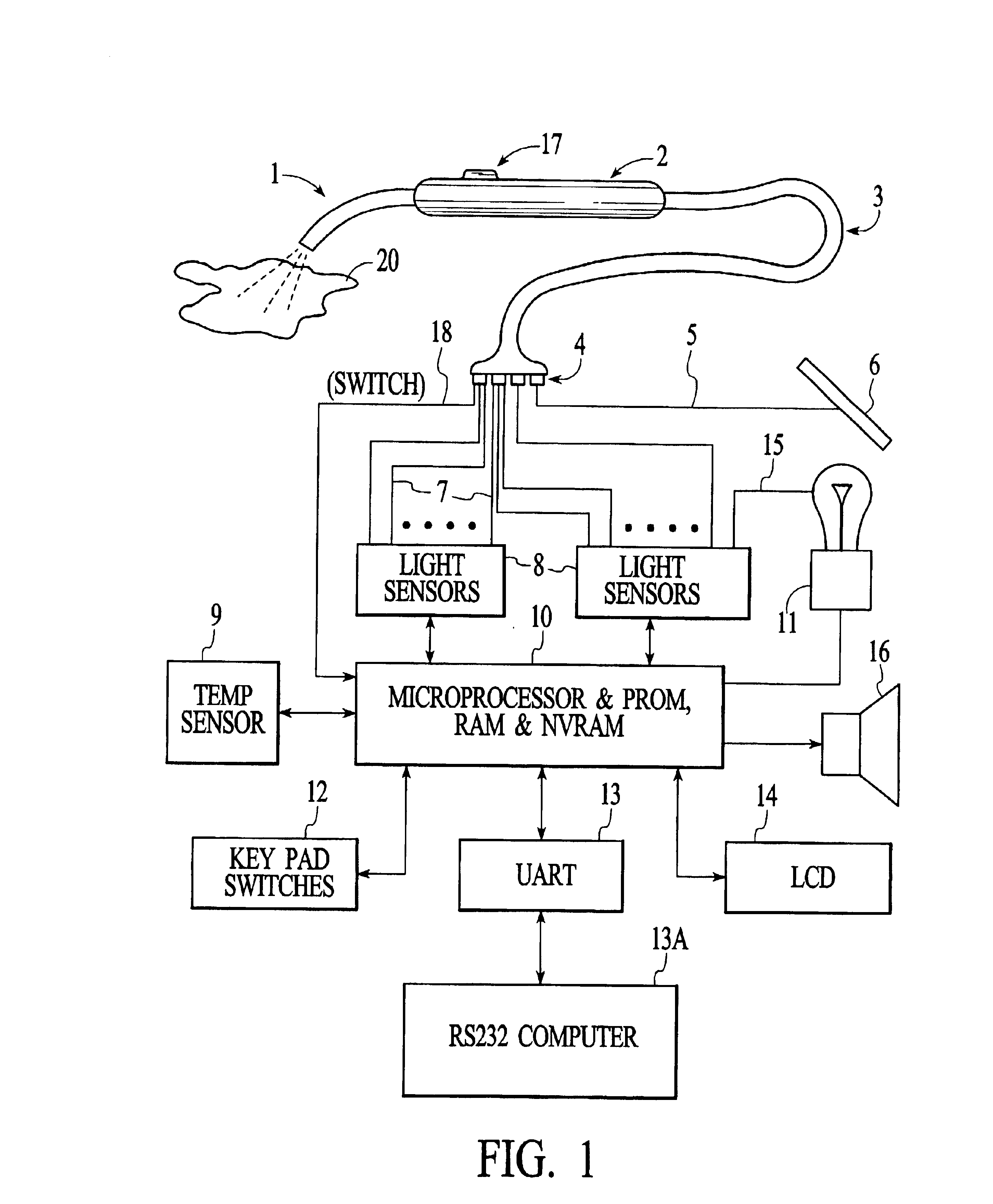

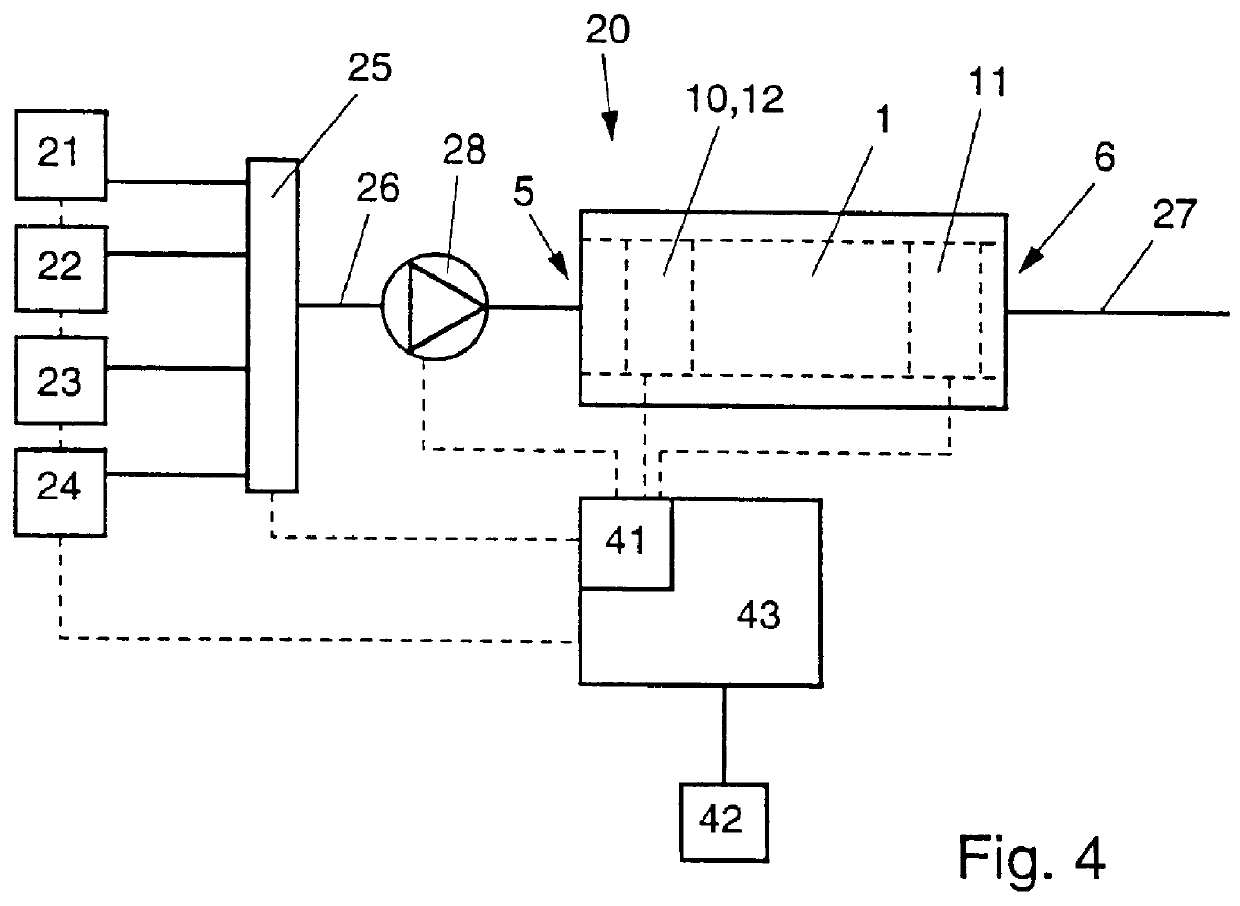

Apparatus and method for monitoring biological cell culture

ActiveUS20050254055A1Fluctuation problemMinimizes problemBioreactor/fermenter combinationsBiological substance pretreatmentsPhysicsGrowth cell

An apparatus and method for real-time and on-line monitoring the cell growth and concentration in a dynamic cell culture environment, with techniques that suppressing noise from ambient light, non-uniform scattering distribution, bubble and interface reflection effects in the dynamic environment.

Owner:PENG HONG

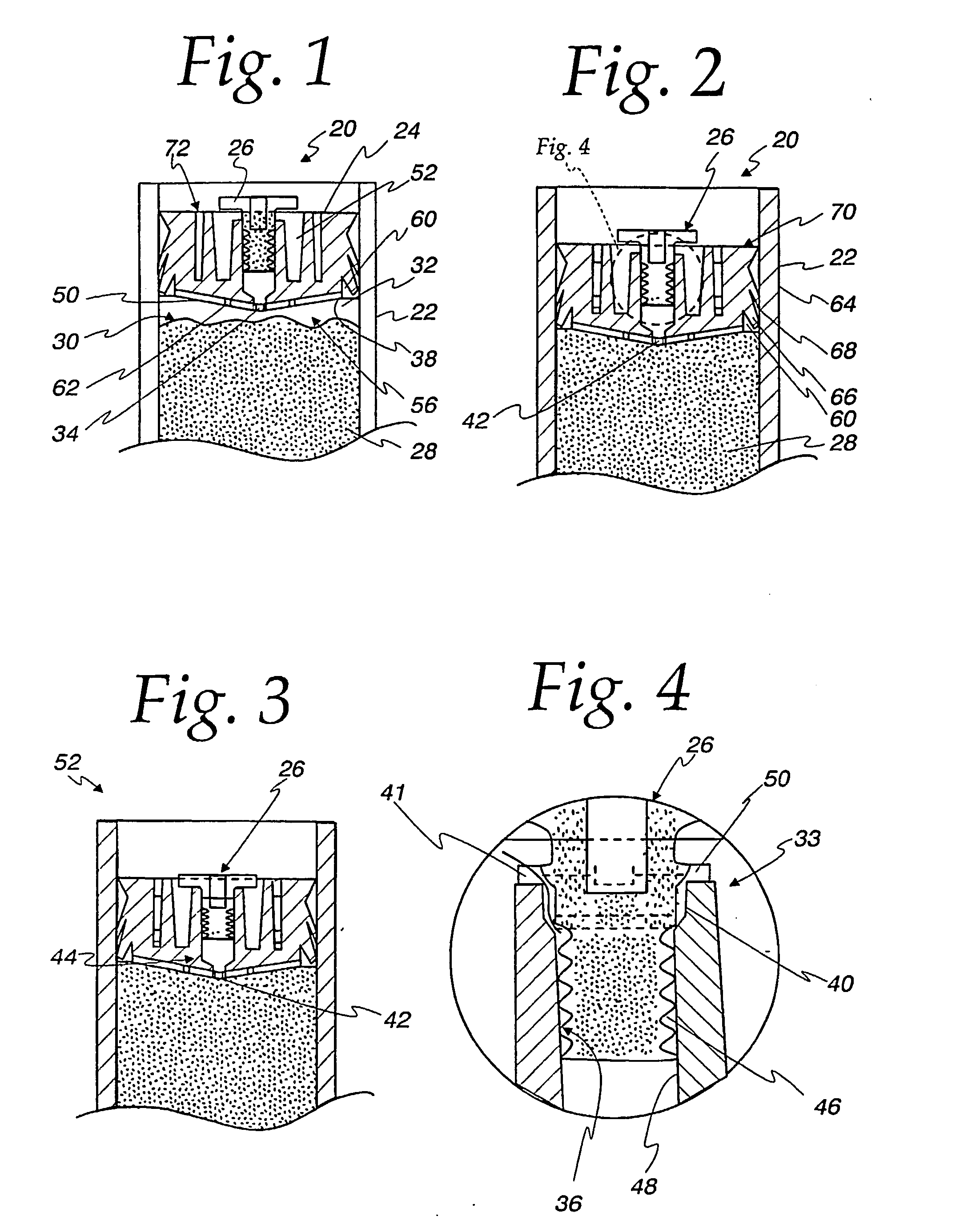

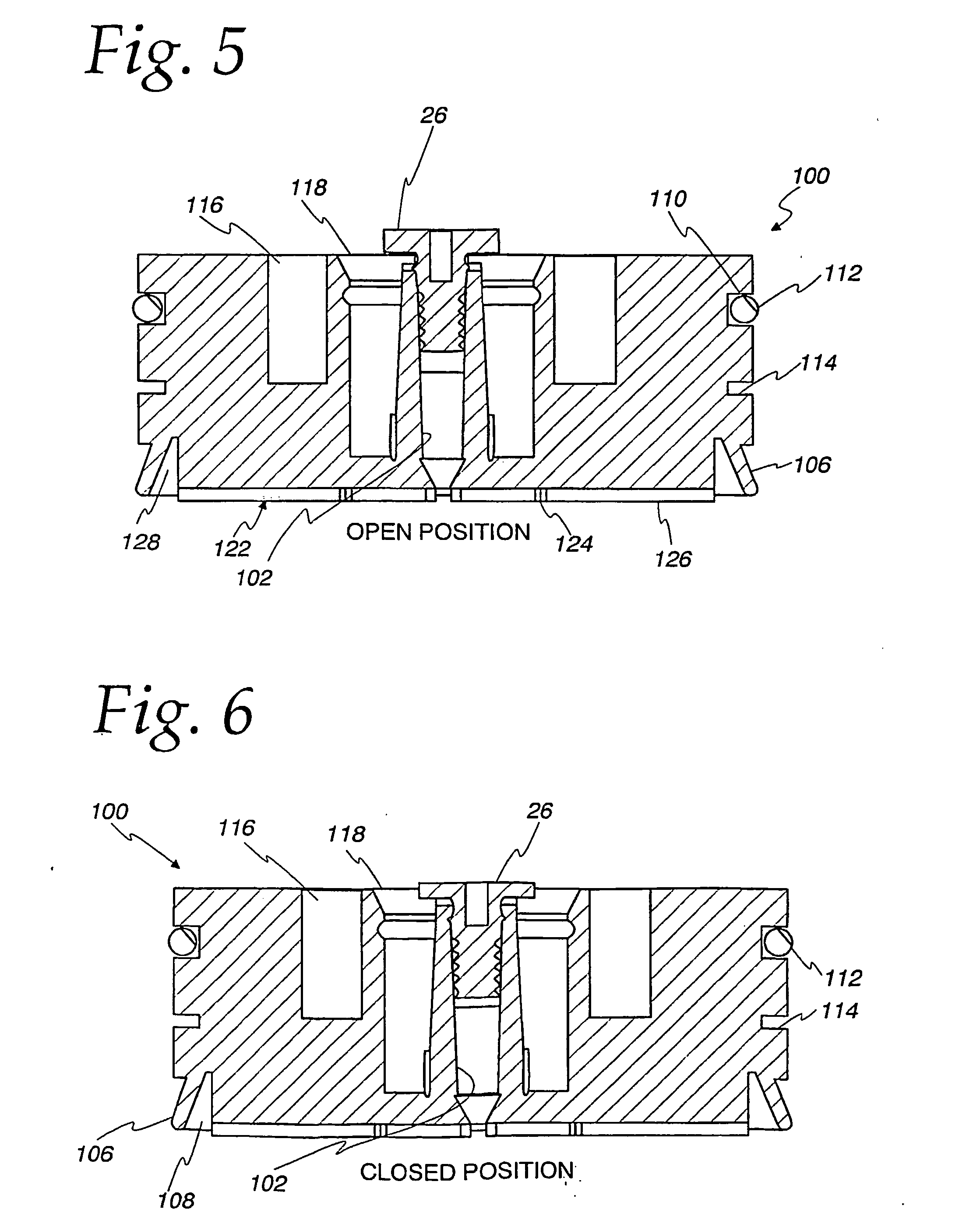

Dispensing cartridge with tortuous vent path

InactiveUS20050029306A1Wide viscosity rangeSimple configurationLiquid surface applicatorsContracting/expanding measuring chambersCombined useEngineering

A dispensing cartridge for a relatively precise dispensing of various fluids having a relatively wide range of viscosities is disclosed. The dispensing cartridge in accordance with the present invention is relatively simpler in configuration than known dispensing cartridges while minimizing leakage of the fluid and eliminating problems associated with chemical attack of the O-ring by the fluid in the dispensing cylinder. In particular, the dispensing cartridge in accordance with the present invention includes a cylinder; a piston with a central bore and a bleed plug. In order to simplify the design, the air vent is configured as a tortuous path, for example, a spiral path, defined by a spiral bleed plug, which in a pre-staged position, allows air to freely escape along the spiral path along the circumference of the plug. As the piston contacts the fluid, the forward motion of piston is resisted by the high back pressure created by the small effective diameter and relatively long length of the spiral path. Once the piston contacts the fluid, the spiral plug is pushed into the piston closing the spiral path. By controlling the fluid flow by way of a tortuous path, the amount of fluid backflow through the piston is minimized if not eliminated, thus eliminating the need for an annular overflow chamber, thereby simplifying the design of the piston. In order to minimize problems related to the sealing of the piston within the dispensing cartridge, the piston may be provided with one or more radially extending sealing lips. These sealing lips are used in lieu of or in conjunction with an O-ring. The sealing lips further simplify the design by eliminating the O-ring as well as the need for an annular chamber adjacent thereto as well as problems relating to chemical attack of the O-ring by the fluid within the dispensing cylinder. In an alternative embodiment for use that is particularly adapted with non-aggressive fluids, the piston is provided with a single sealing lip and an O-ring.

Owner:NORDSON CORP

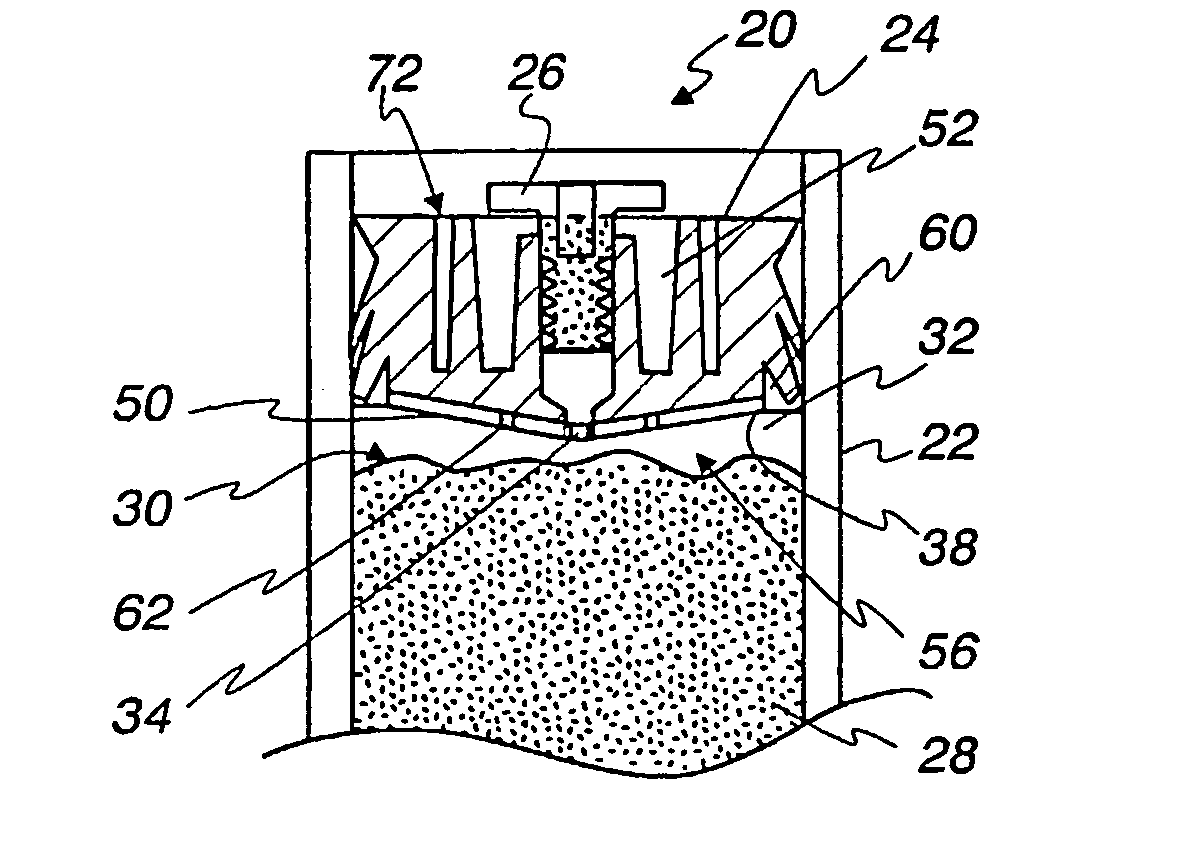

Detection of analytes using electrochemistry

InactiveUS6100045ALow costReduce lossesImmobilised enzymesBioreactor/fermenter combinationsElectrochemical responseMatrix solution

The present invention relates to diagnostic assays whereby the detection means is based on electrochemical reactions. This means that the label to be detected provides an electric signal. Preferred labels are enzymes giving such a signal. Provided is a flow cell whereby a solid phase is provided in a flow stream of the sample, in close proximity to a working electrode to detect any electrical signal. In a typical embodiment, a sample is mixed with molecule having specific binding affinity for an analyte of which the presence in the sample is to be detected, whereby said specific binding molecule is provided with a label. The conjugate of labelled specific binding molecule and analyte is then immobilized on the solid phase in the vicinity of the working electrode, the flow cell is rinsed with a solution and afterwards a substrate solution for the label (an enzyme) is provided upon which an electrical signal is generated and can be detected by the working electrode. The methods and devices of the present invention are particular useful for liquids which comprise many substances that may disturb measurement in conventional assays. The design of the flow cell allows for removal of said interfering substances before measurement. In a preferred embodiment at least part of the solid phase is provided in the form of magnetic beads. In this embodiment the solid phase can be mixed with the sample thereby creating a longer reaction time, a better sensitivity and a higher speed of the assay.

Owner:DSM NV

Friction stir welding apparatus and associated thermal management systems and methods

ActiveUS20050045694A1Good mechanical integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThermal management system

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

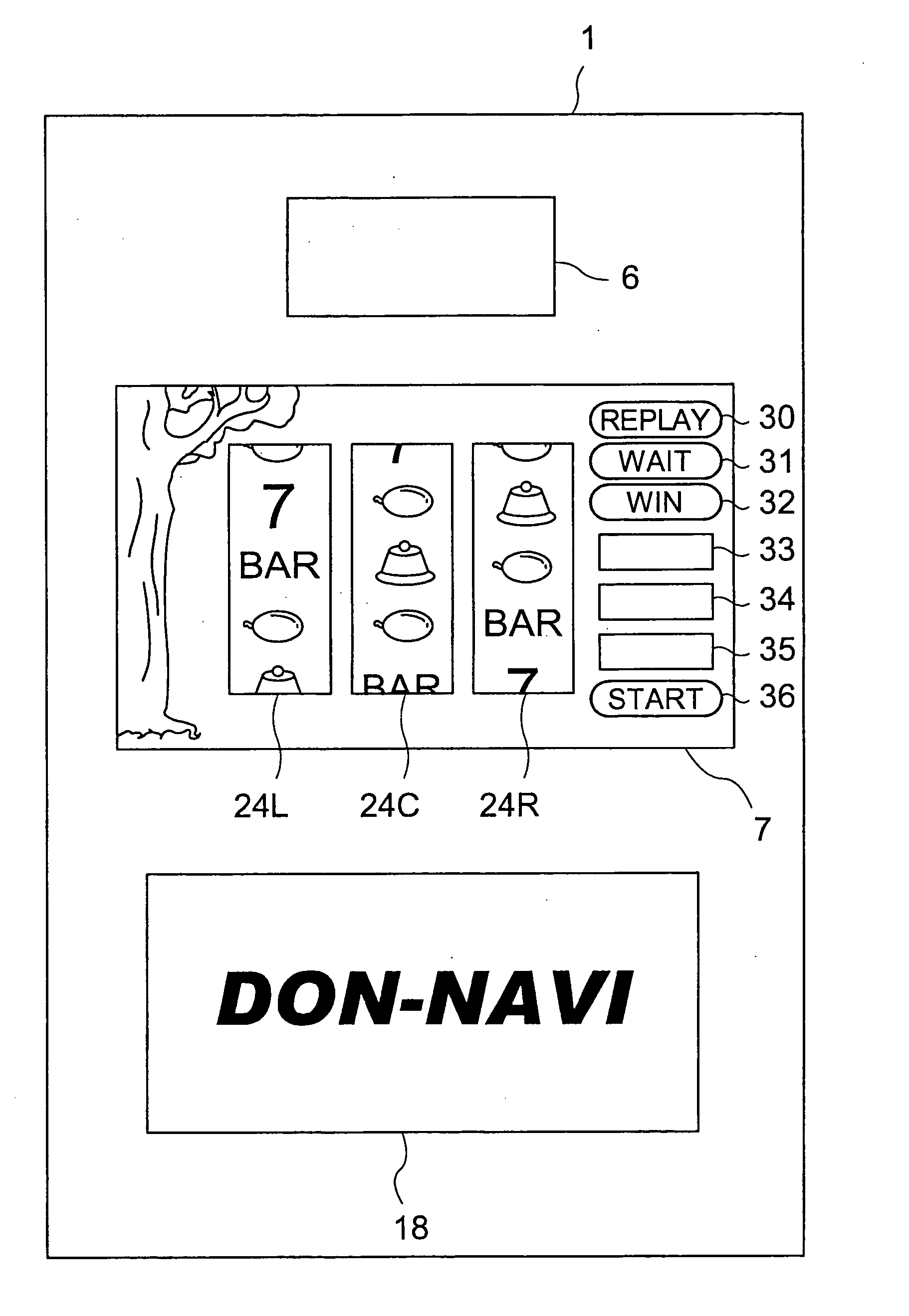

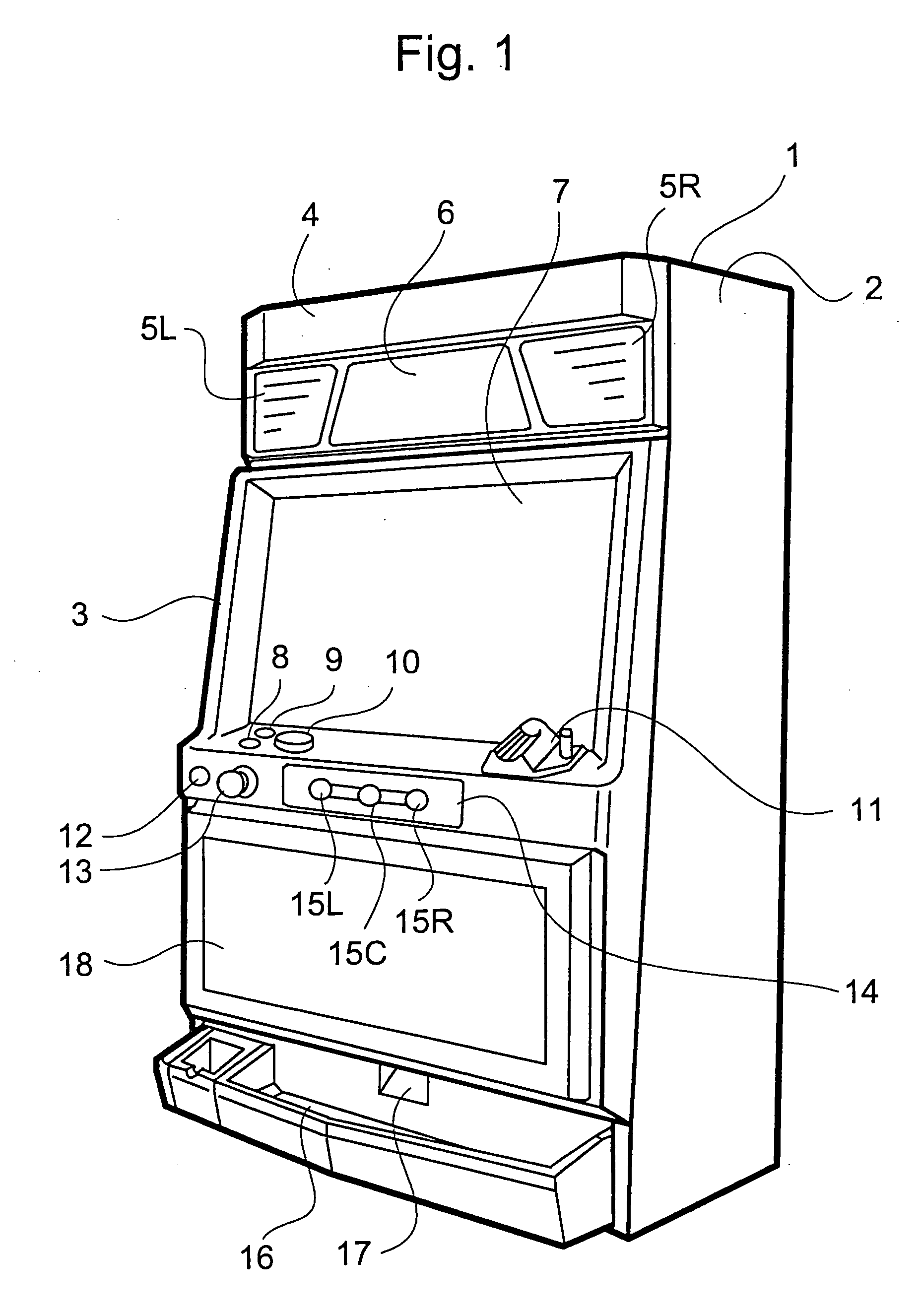

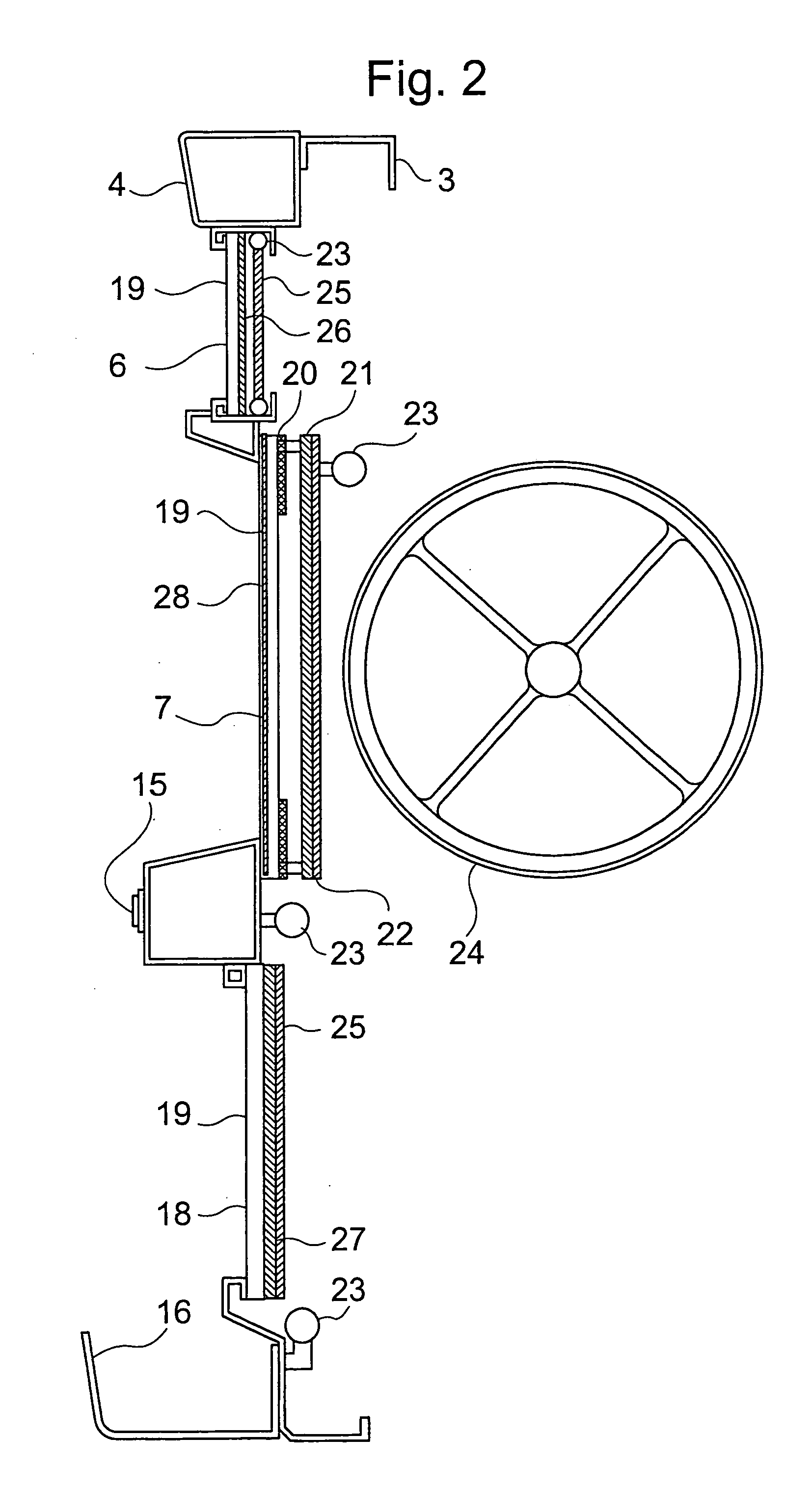

Gaming machine

InactiveUS20040152502A1Minimizes problemIncrease the number of componentsRoulette gamesApparatus for meter-controlled dispensingLiquid-crystal displayCold cathode

A gaming machine is provided with an upper display panel formed by an electric display device so that display contents can be changed. A display panel is comprised of a transparent acrylic plate that is a protective cover, a liquid crystal display device that serves as an electric display device, and a cold-cathode tube that serves as a back light. The amount of media to be paid out that is displayed thereon can be changed with a touch panel provided on a reel display part, and an arbitrary payout table can be selected from among a plurality of payout tables. It is possible to lessen labor required to produce the panel that displays a model name, etc., for each model.

Owner:UNIVERSAL ENTERTAINMENT CORP

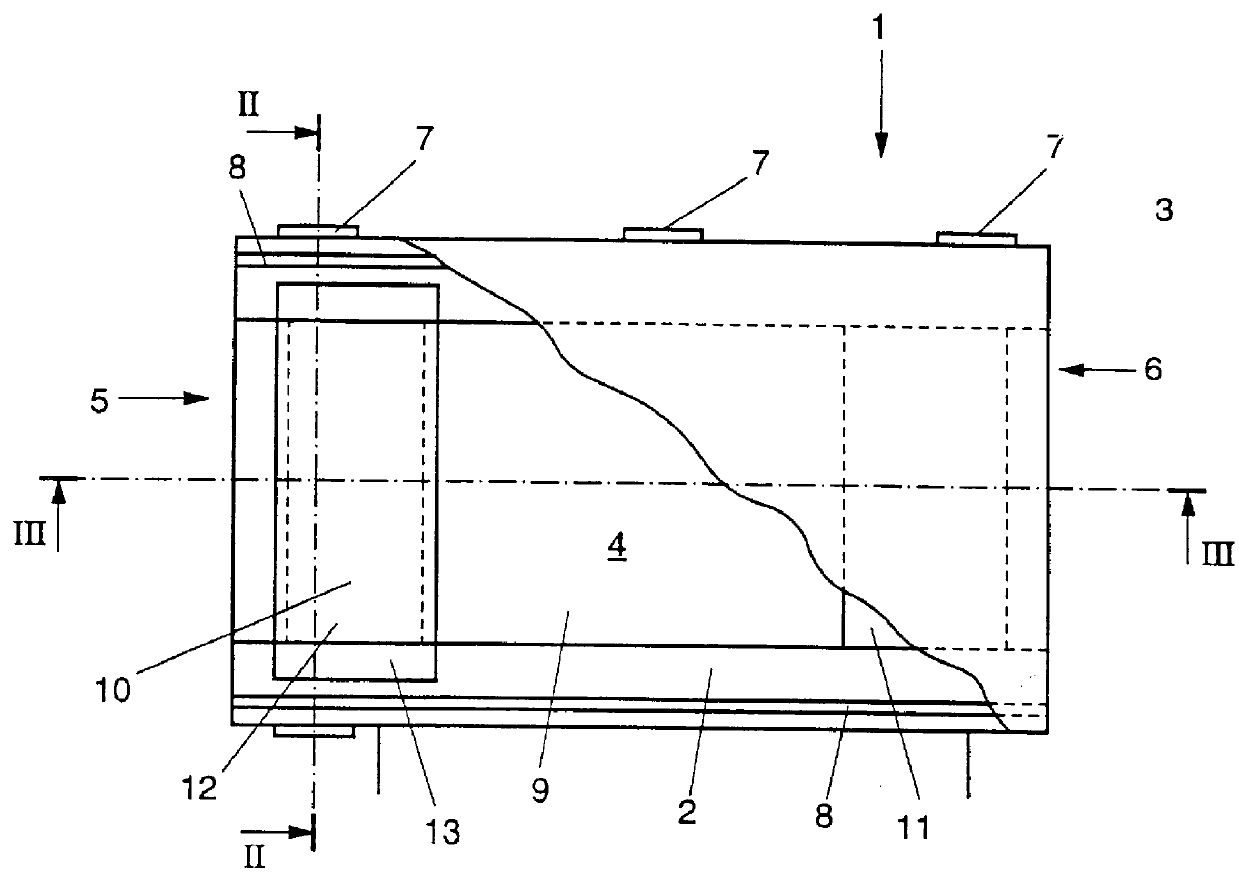

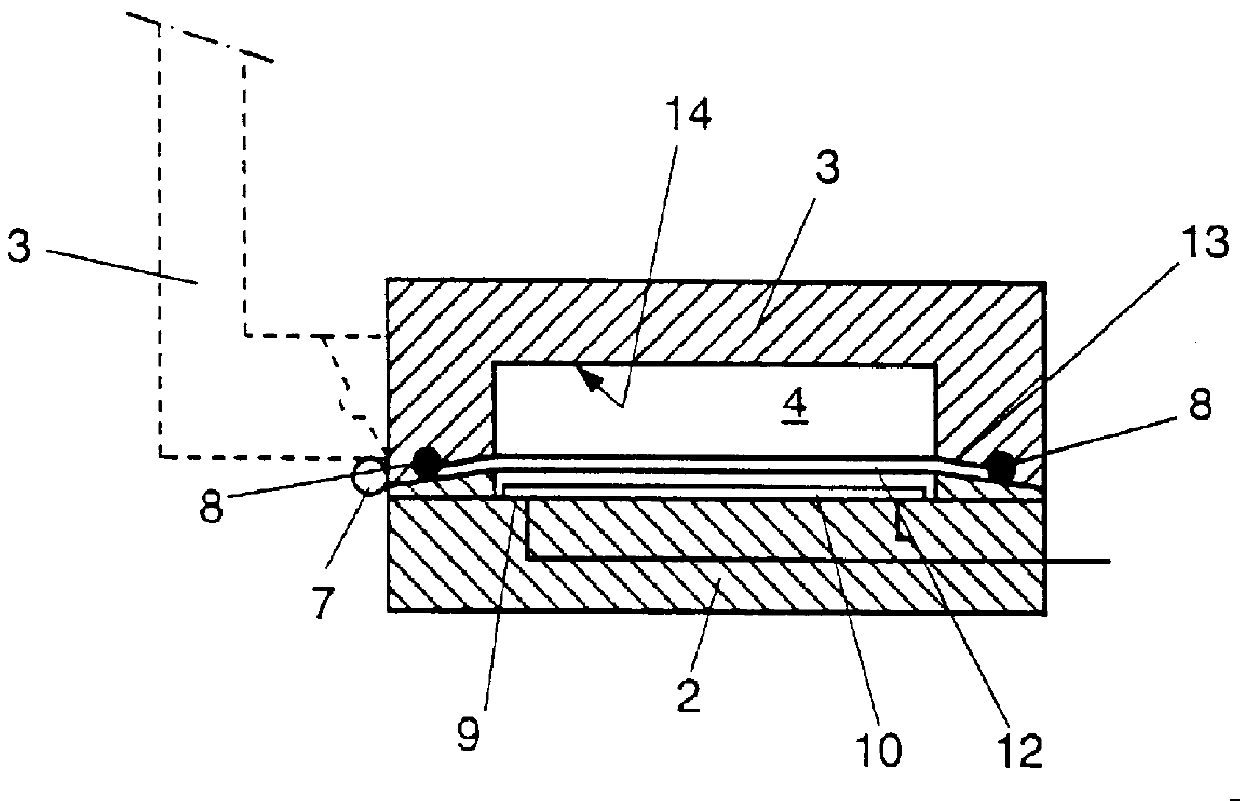

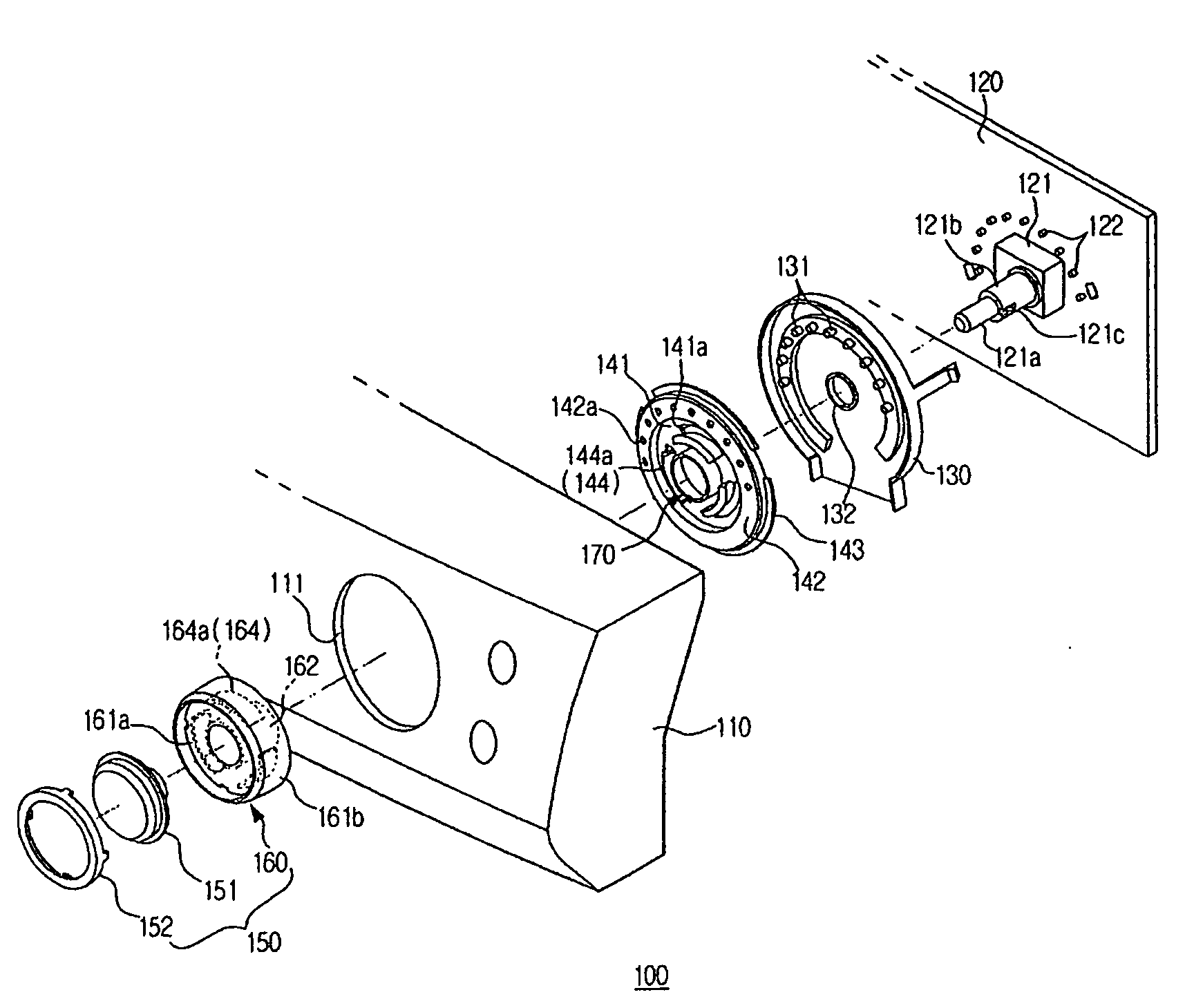

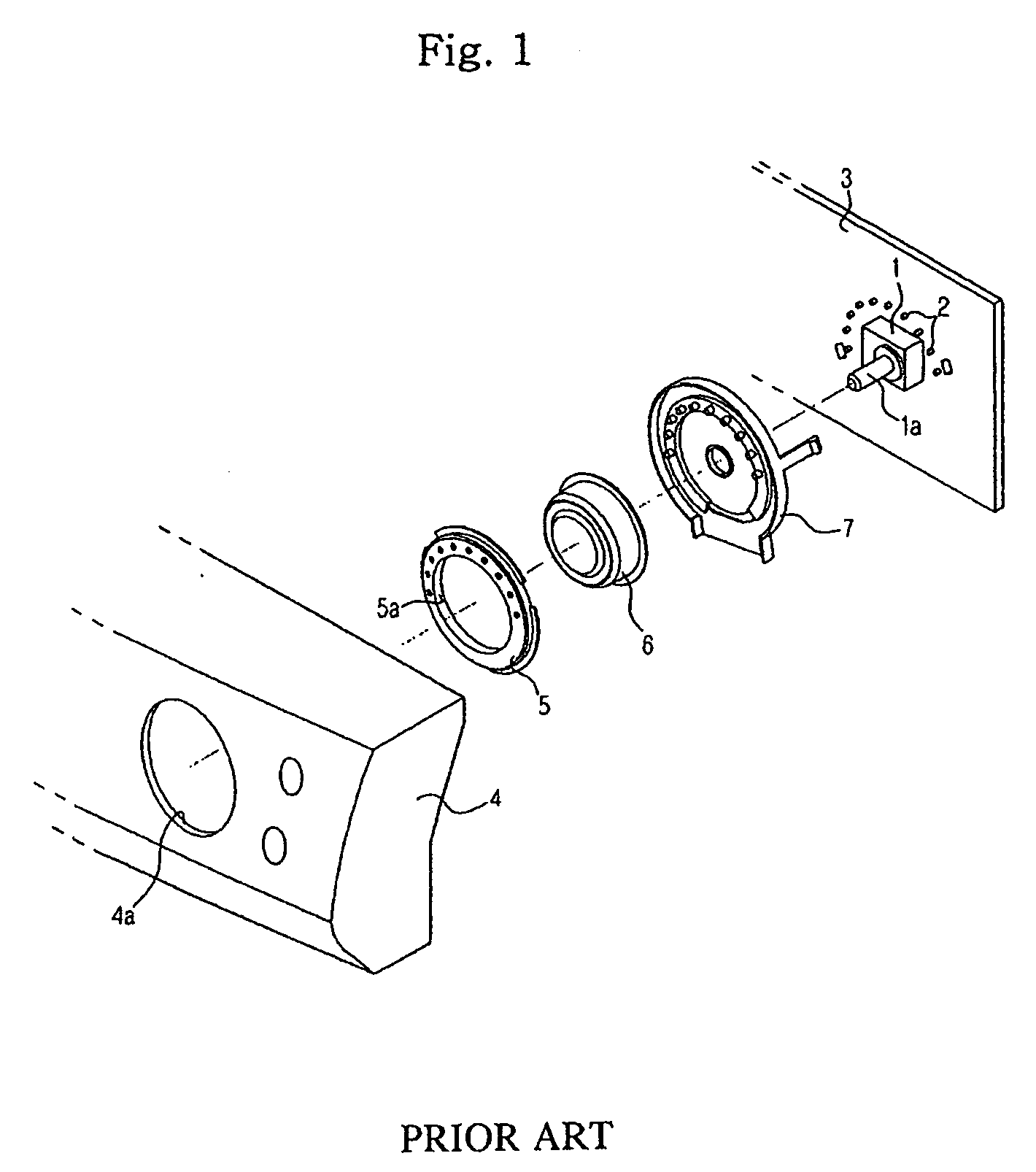

Washing machine and control panel assembly thereof

ActiveUS20080289940A1Vibration minimizationMinimizes problemEmergency actuatorsLegendsMechanical engineeringEngineering

Disclosed is a washing machine, a control panel assembly of which has an improved structure to minimize problems caused by a shaking of a rotary knob and the interference of the rotary knob with other surrounding parts. The control panel assembly of the washing machine includes a control panel; a knob guide installed on the control panel; and a rotary knob rotatably mounted on the knob guide and including a boss passing through the knob guide. The knob guide includes a boss insertion part restricting the boss to prevent the rotary knob from shaking. The boss insertion part includes an extension extended from the bottom surface of the knob guide and forming a boss insertion hole, into which the boss is inserted, therein.

Owner:SAMSUNG ELECTRONICS CO LTD

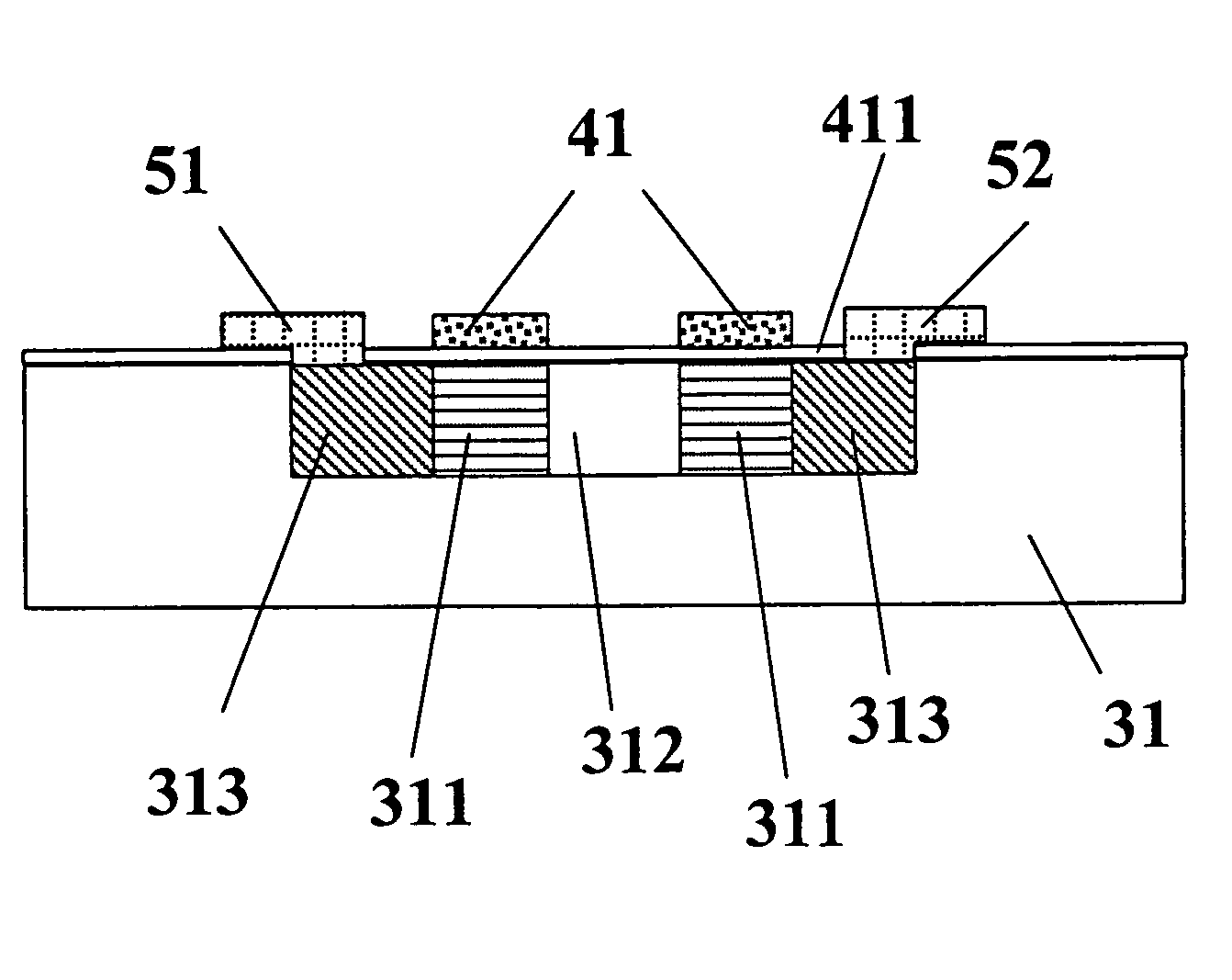

Thin film transistor with self-aligned intra-gate electrode

InactiveUS7009204B2Minimizes problemGood imaging propertiesTransistorSolid-state devicesActive-matrix liquid-crystal displayLiquid-crystal display

A thin film transistor for use in an active matrix liquid crystal display includes a substrate, a source and a drain regions, and at least a gate electrode. The substrate includes therein a plurality of intrinsic regions, at least one first doped region and two second doped regions. The first doped region is disposed between the plurality of intrinsic regions. The plurality of intrinsic regions are linked together to form a connection structure via the first doped region, and the two second doped regions are disposed at both ends of the connection structure, respectively. The source and the drain regions are coupled to the two second doped regions disposed at both ends of the connection structure, respectively. The gate electrode is disposed over the plurality of intrinsic regions, such that the periphery of each of the plurality of intrinsic regions and the periphery of a corresponding gate electrode are substantially aligned with each other.

Owner:INNOLUX CORP

Method of moulding

InactiveUS20140036428A1Cost-effective manufacturingMinimize cracksCircuit arrangements on support structuresLaminationEngineeringPatterned substrate

A method comprising: patterning one or more electrical layers on a substrate; shaping the patterned substrate into a 3-dimensional contour, wherein the contour including a significant change in gradient in or adjacent to one or more sensing areas of the electrical layer, and over-moulding the shaped substrate, wherein degradation of a trace in the electrical layer at or adjacent to the one or more sensing areas during shaping and / or over-moulding is substantially minimised based on the width of the trace, the thickness or number of layers of the trace, the bending radius of the trace, the material of the trace, and / or a primer over layer on the trace.

Owner:FISCHER TECH

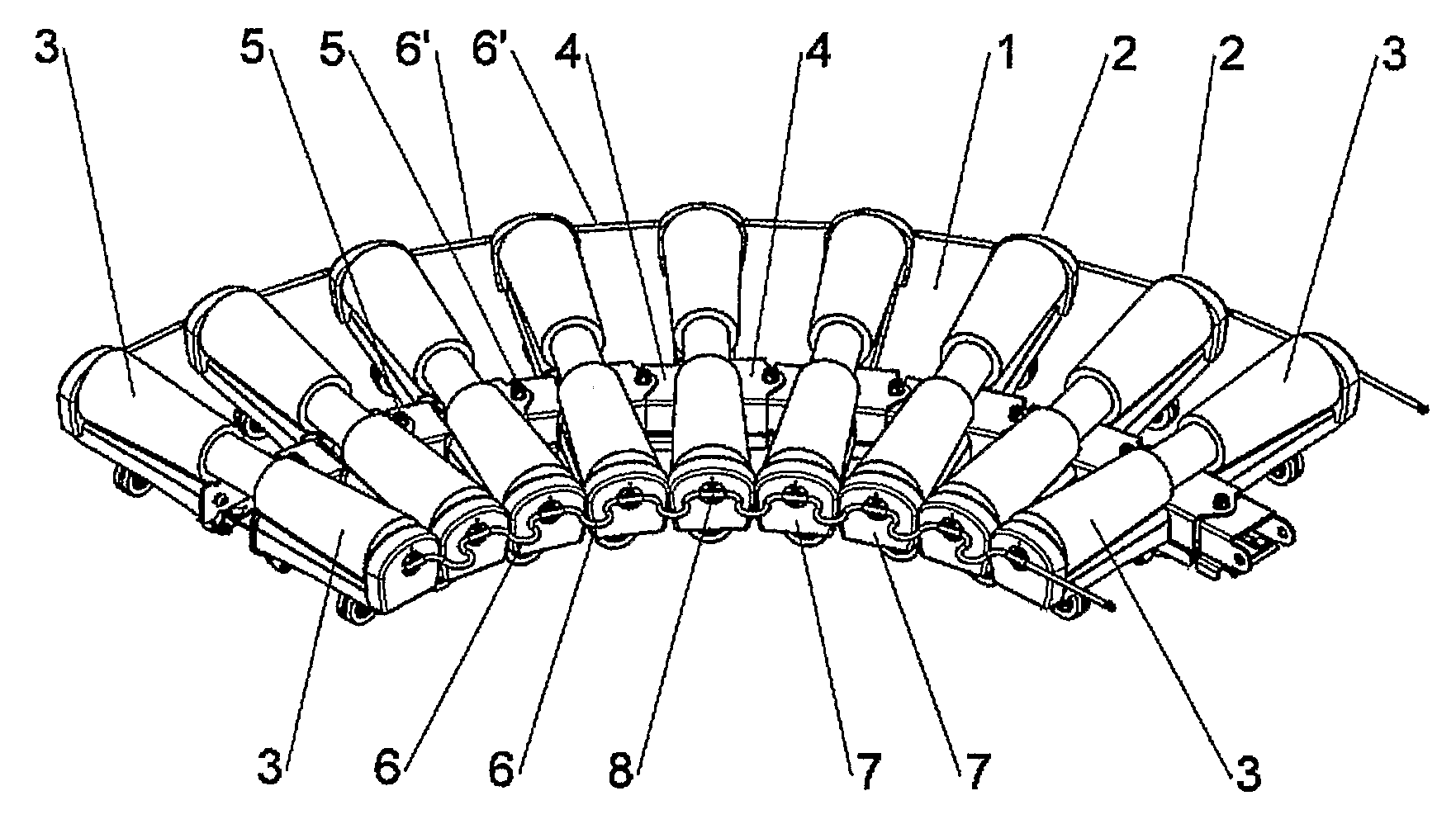

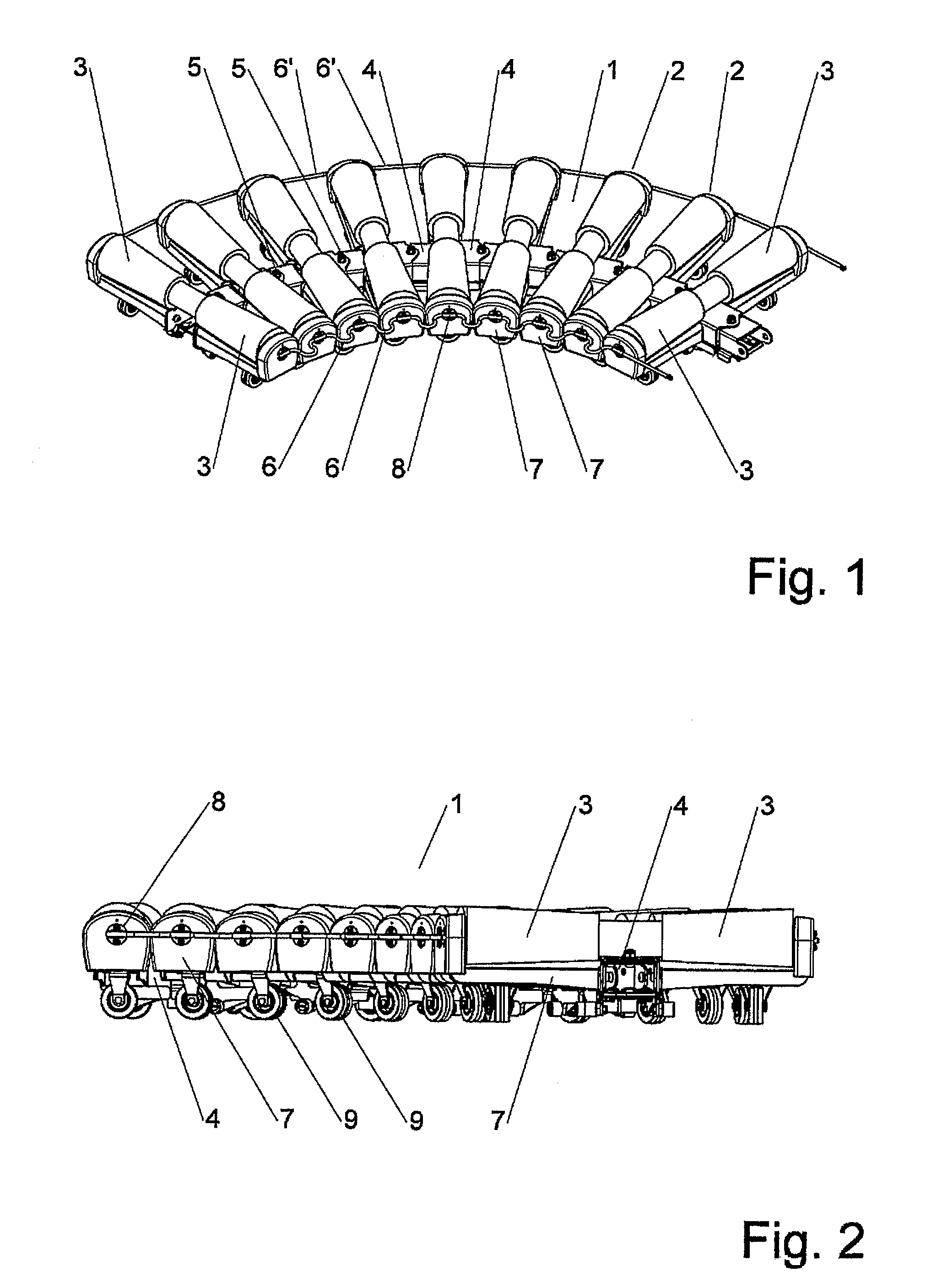

Conveyor guard

ActiveUS7530452B2Improve usability and reliabilityImprove rigidityConveyorsSupporting framesEngineeringMechanical engineering

Owner:VESTERGAARD MARTIN

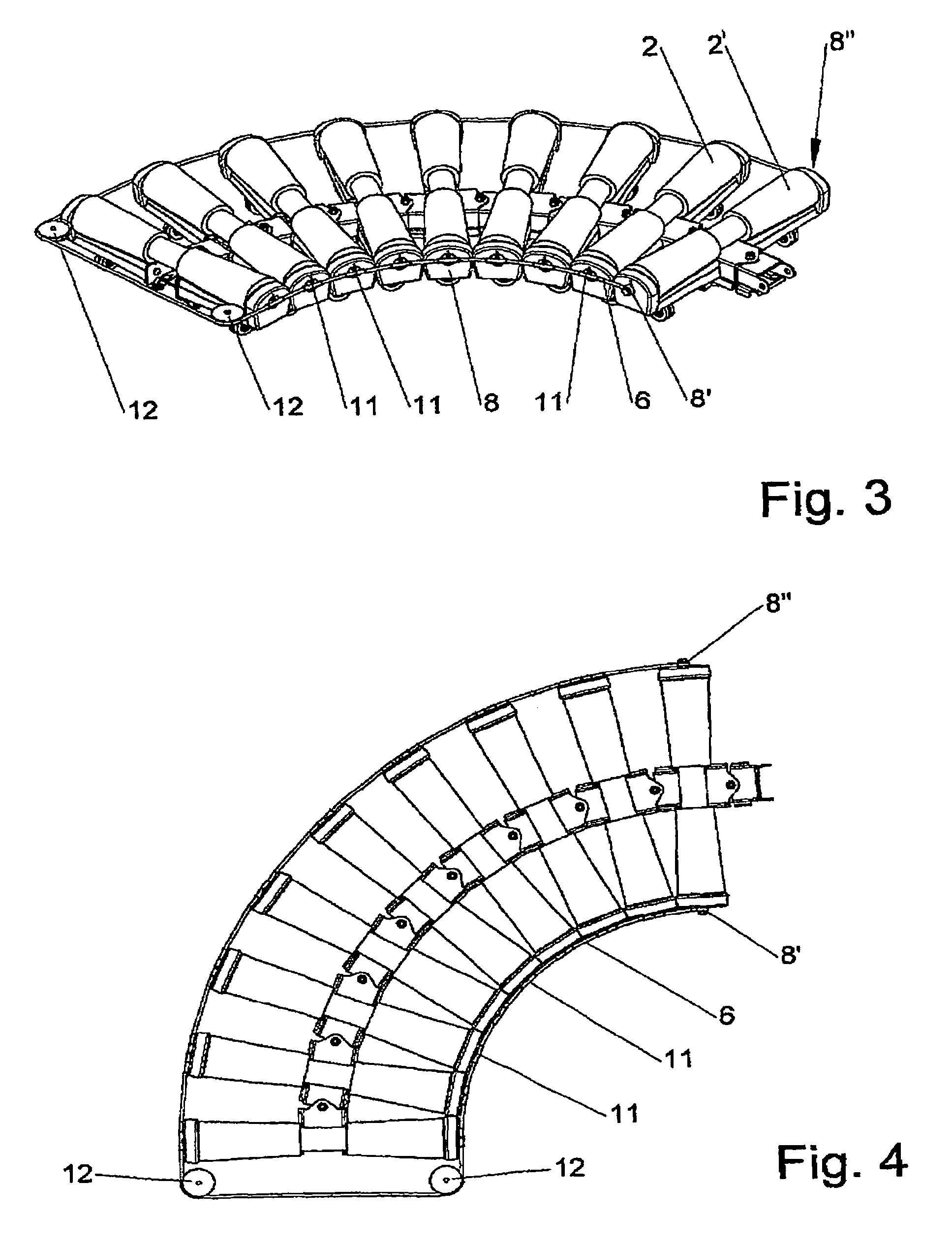

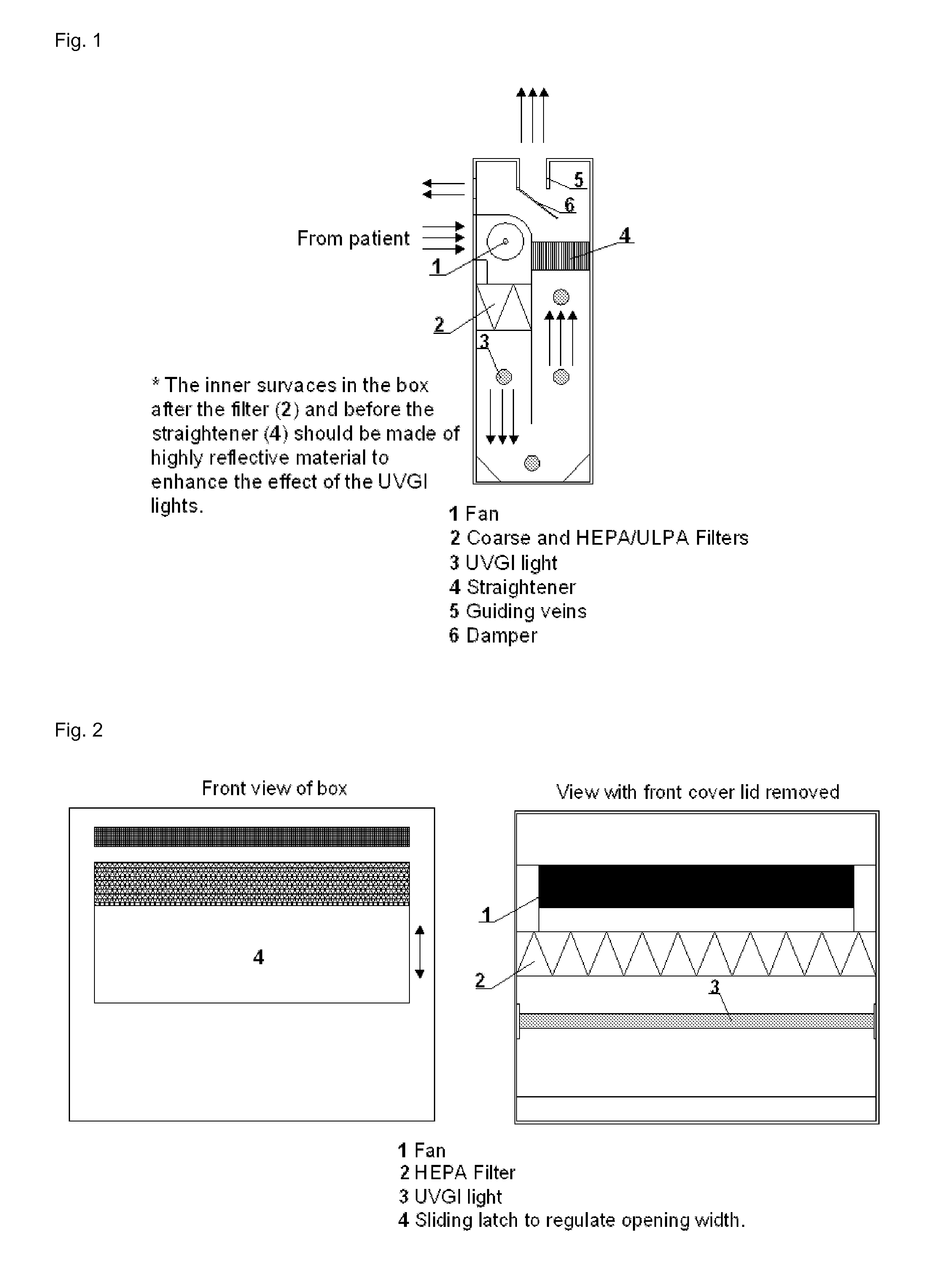

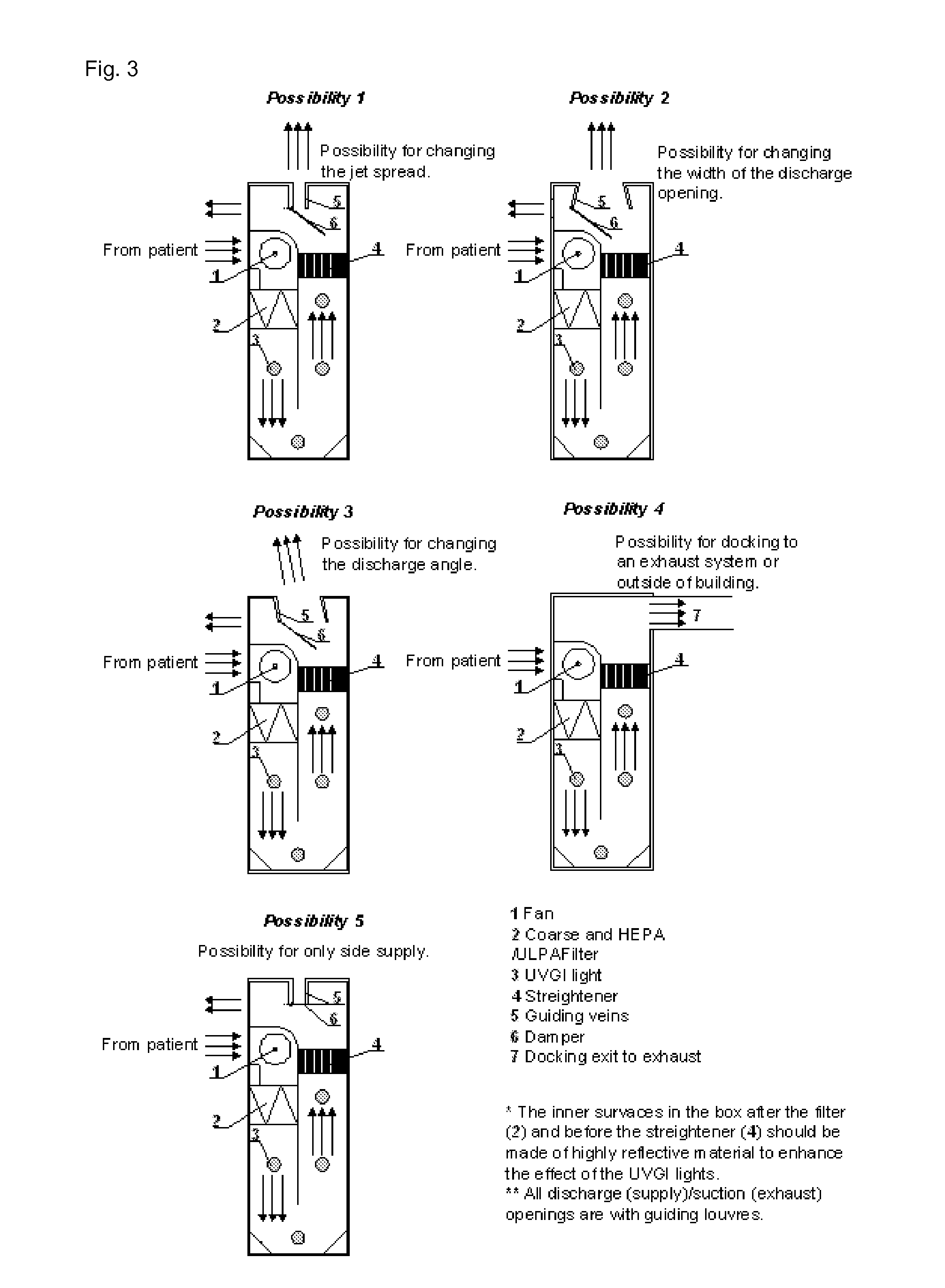

Device and method for reducing spread of microorganisms and airborne health hazardous matter and/or for protection from microorganisms and airborne health hazardous matter

InactiveUS20120199003A1Risk minimizationMinimizes problemCombination devicesMechanical apparatusDistribution controlFiltration

Disclosed is an air distribution control unit or a filtration / ventilation unit which is portable and / or can be mounted on or integrated in furniture e.g. as a cabinet of at the head region of a bed. The filtration / ventilation unit cleanses air from a person / patient by aspirating the person's / patient's exhalation air into the filtration / ventilation unit. To construct an at least partly isolated area around the patient, filtered air can be directed e.g. vertically out of the filtration / ventilation unit to perform an air curtain. Use of the filtration / ventilation unit reduces the risk of dissipation of air-borne diseases and health hazardous matter, and reduces the amount of air to ventilate a room with patients.

Owner:DANMARKS TEKNISKE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com