Patents

Literature

205 results about "Chemical attack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

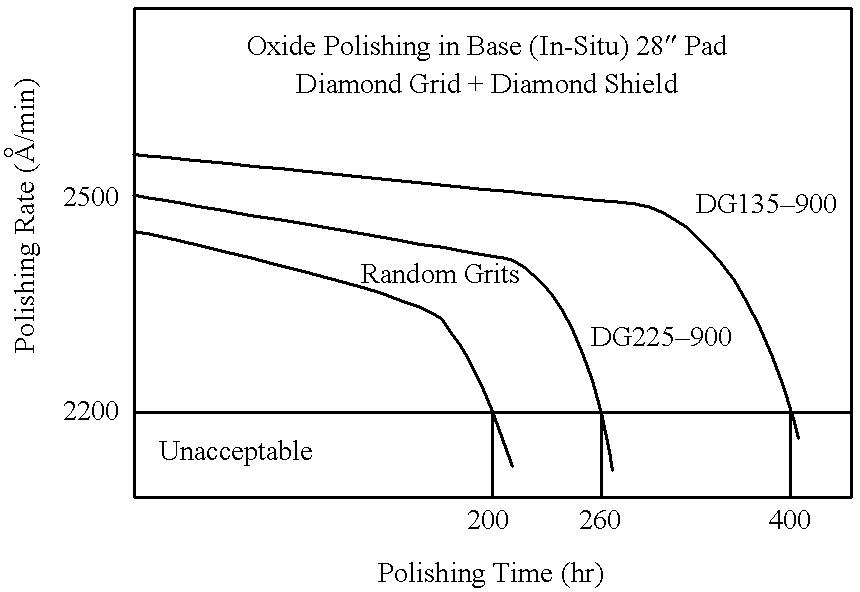

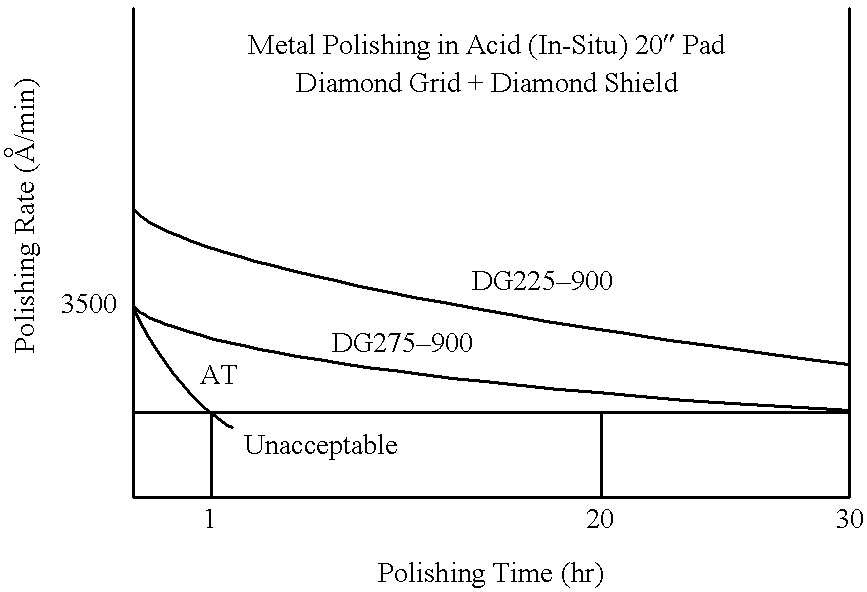

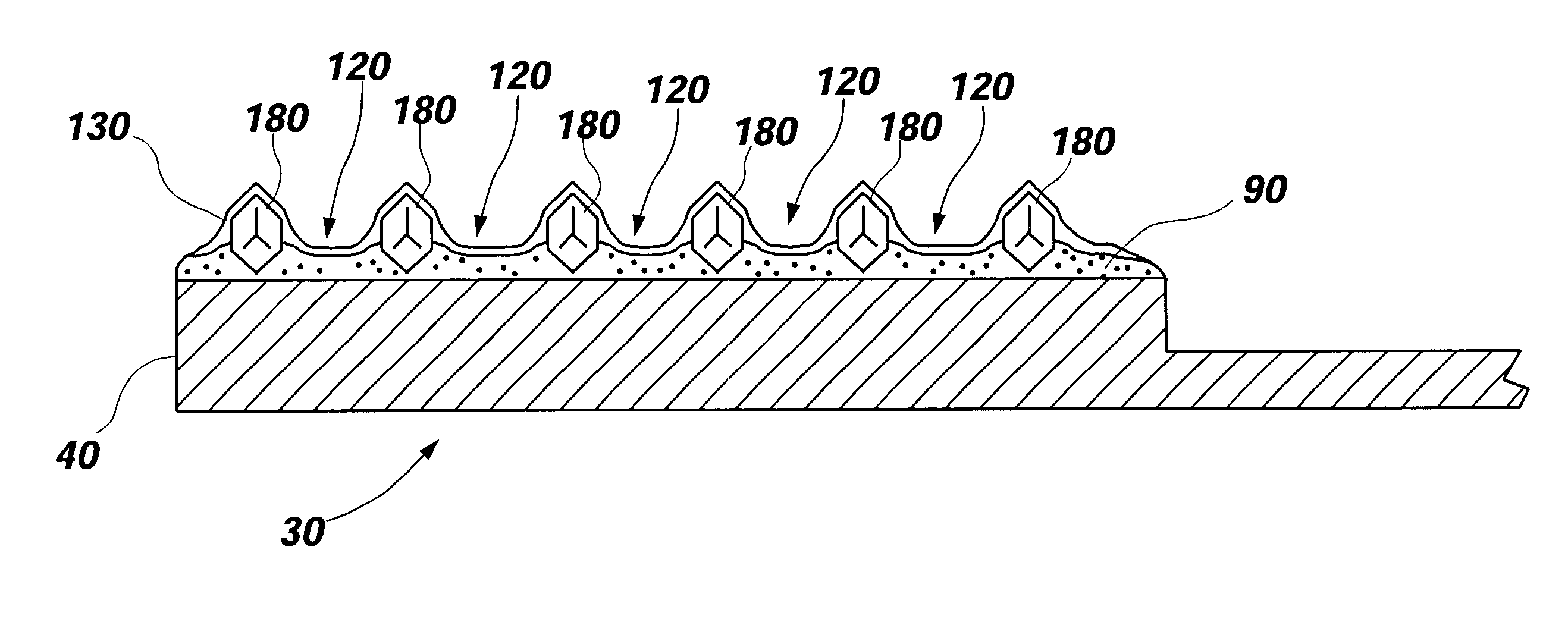

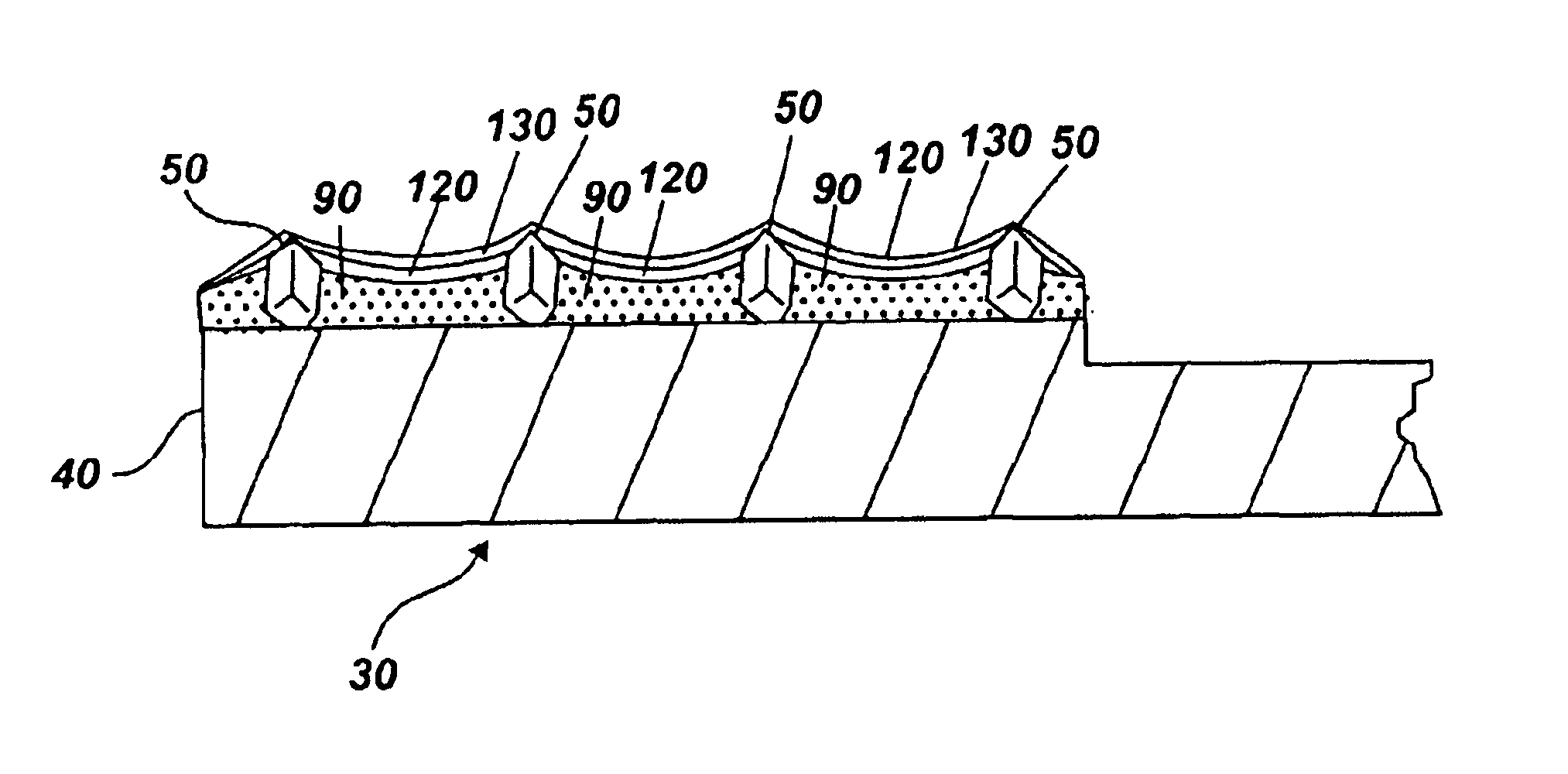

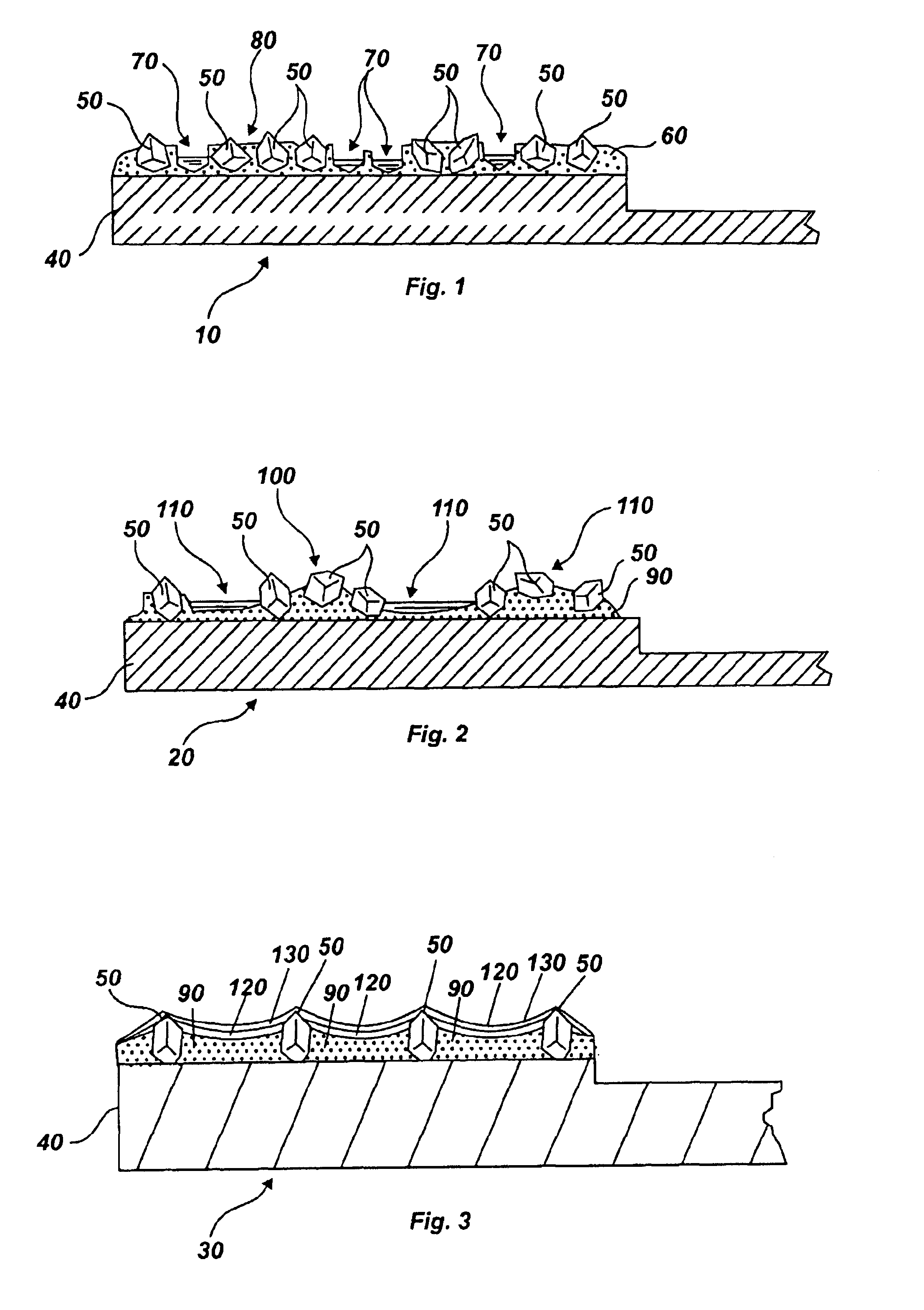

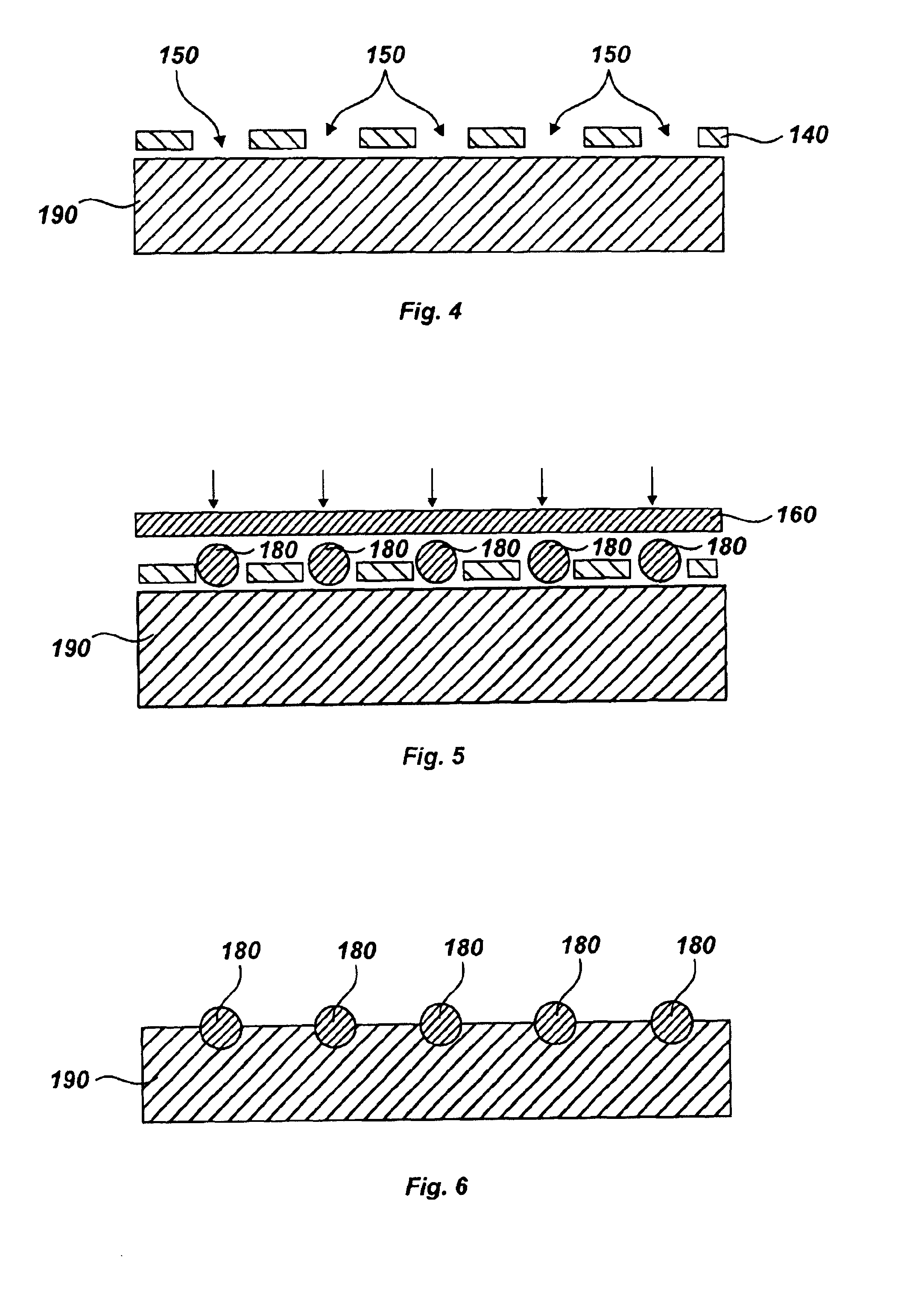

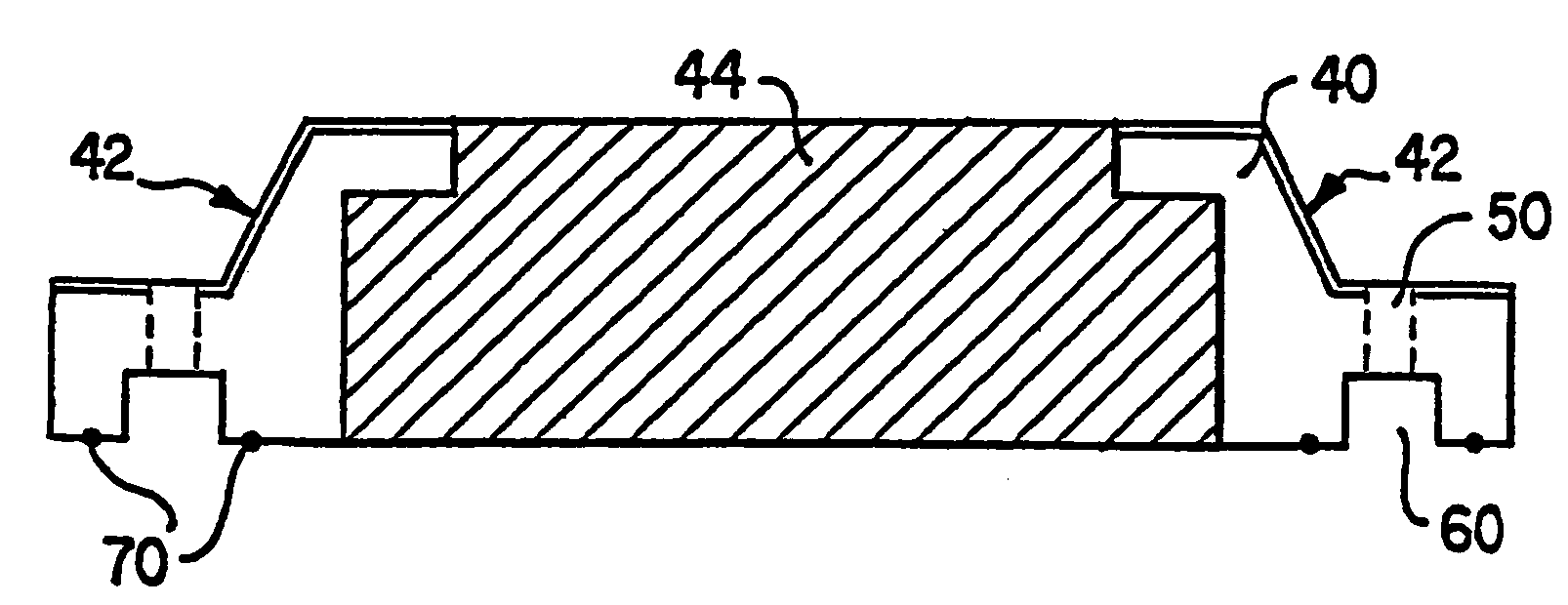

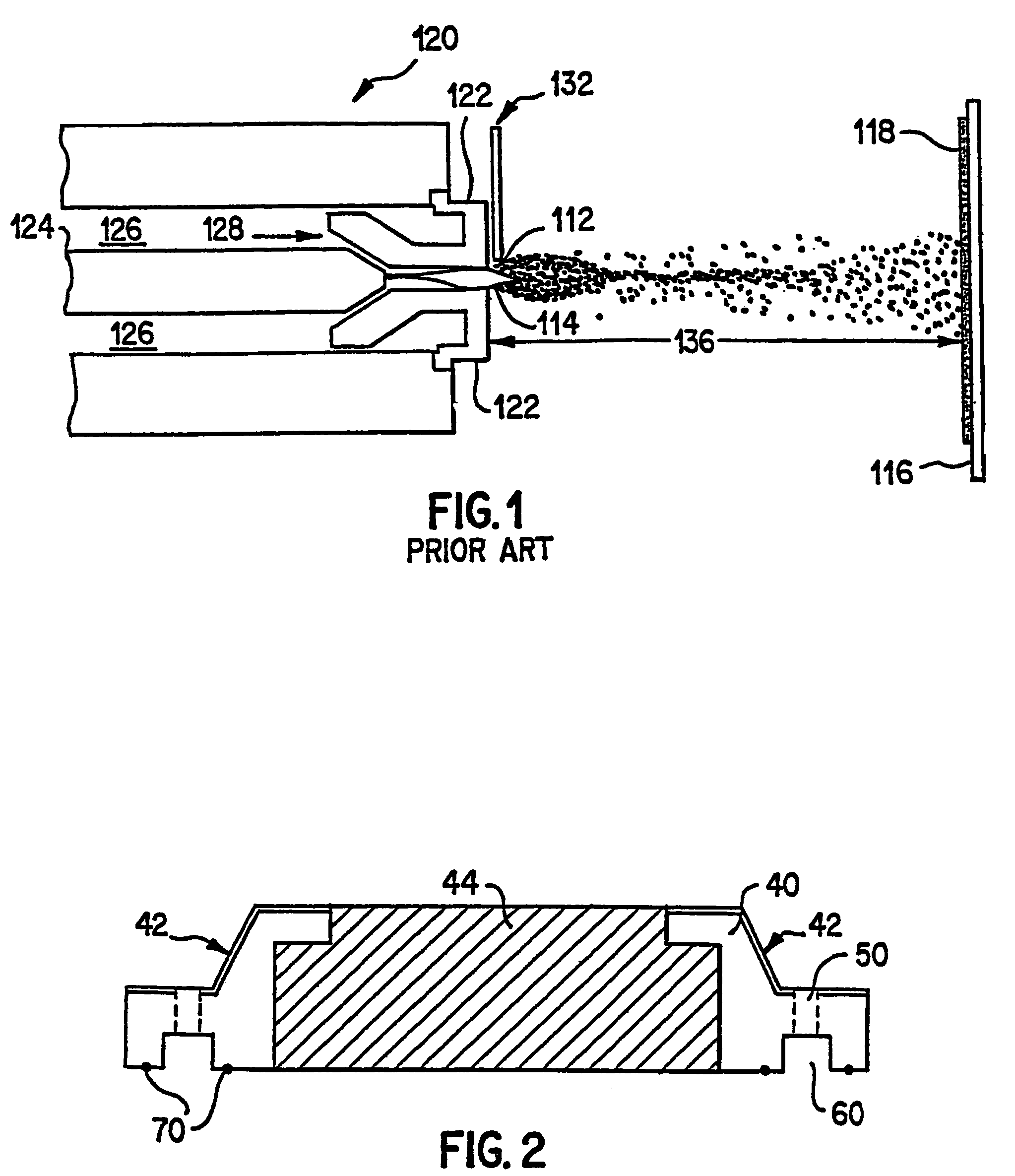

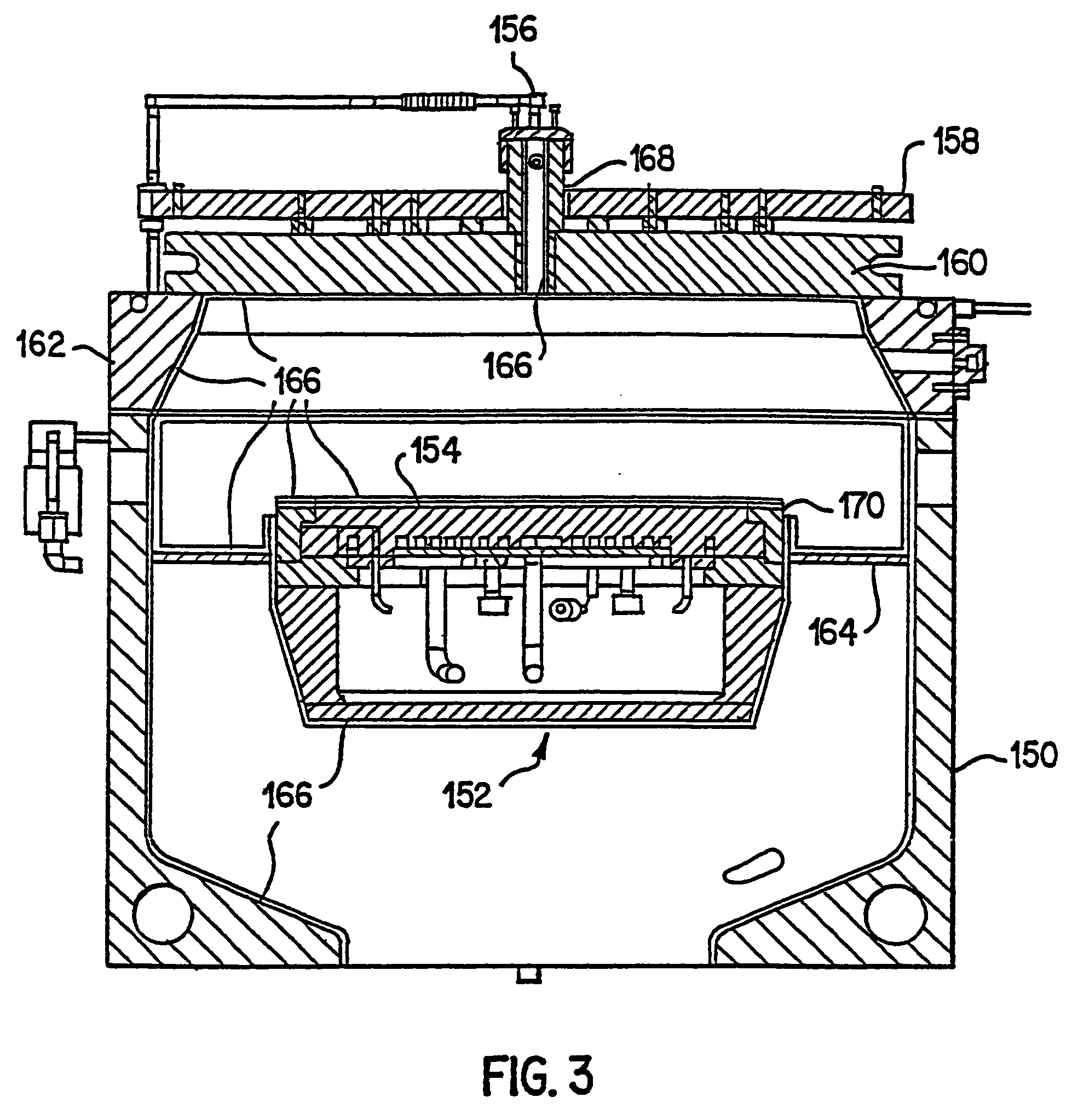

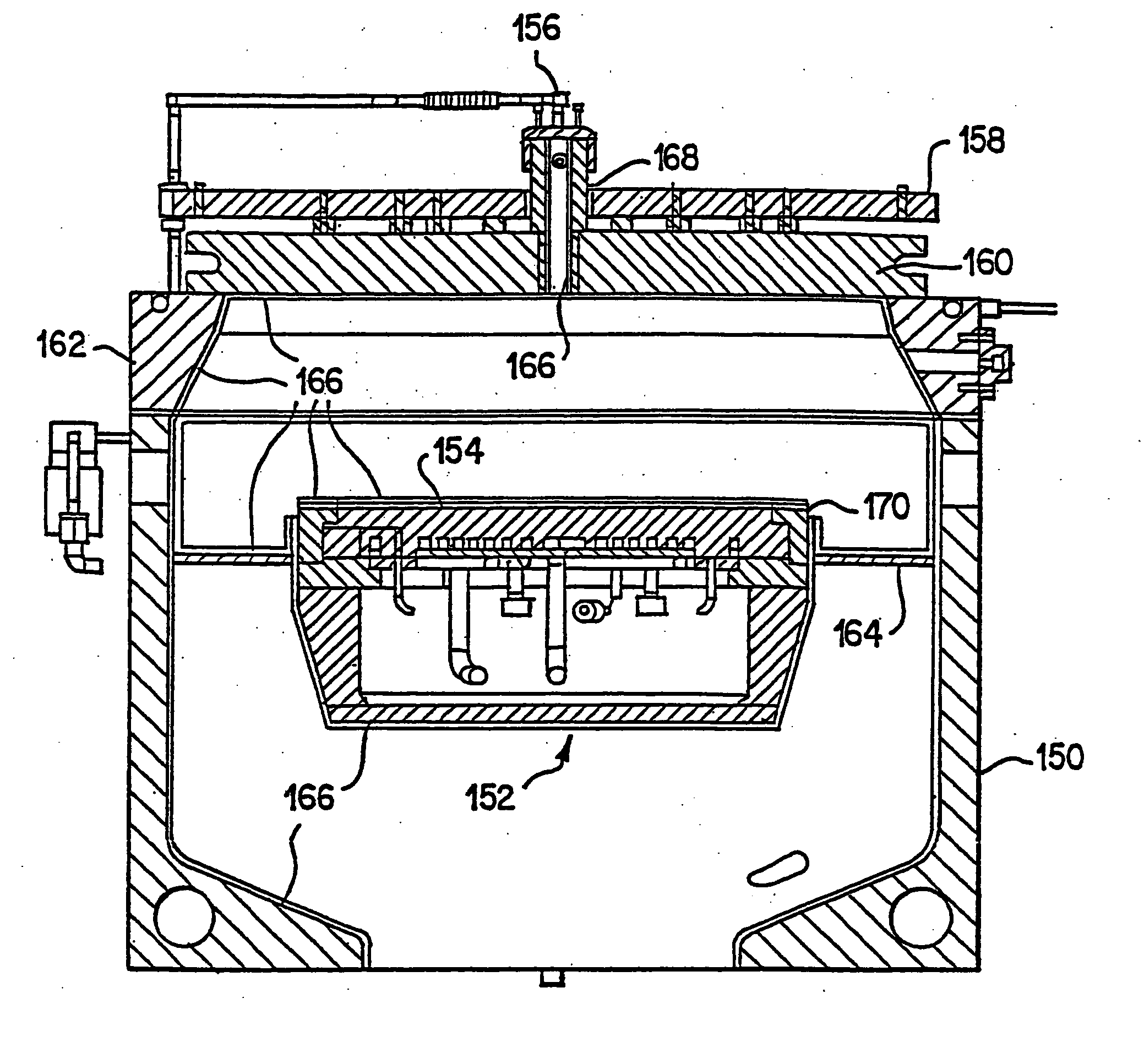

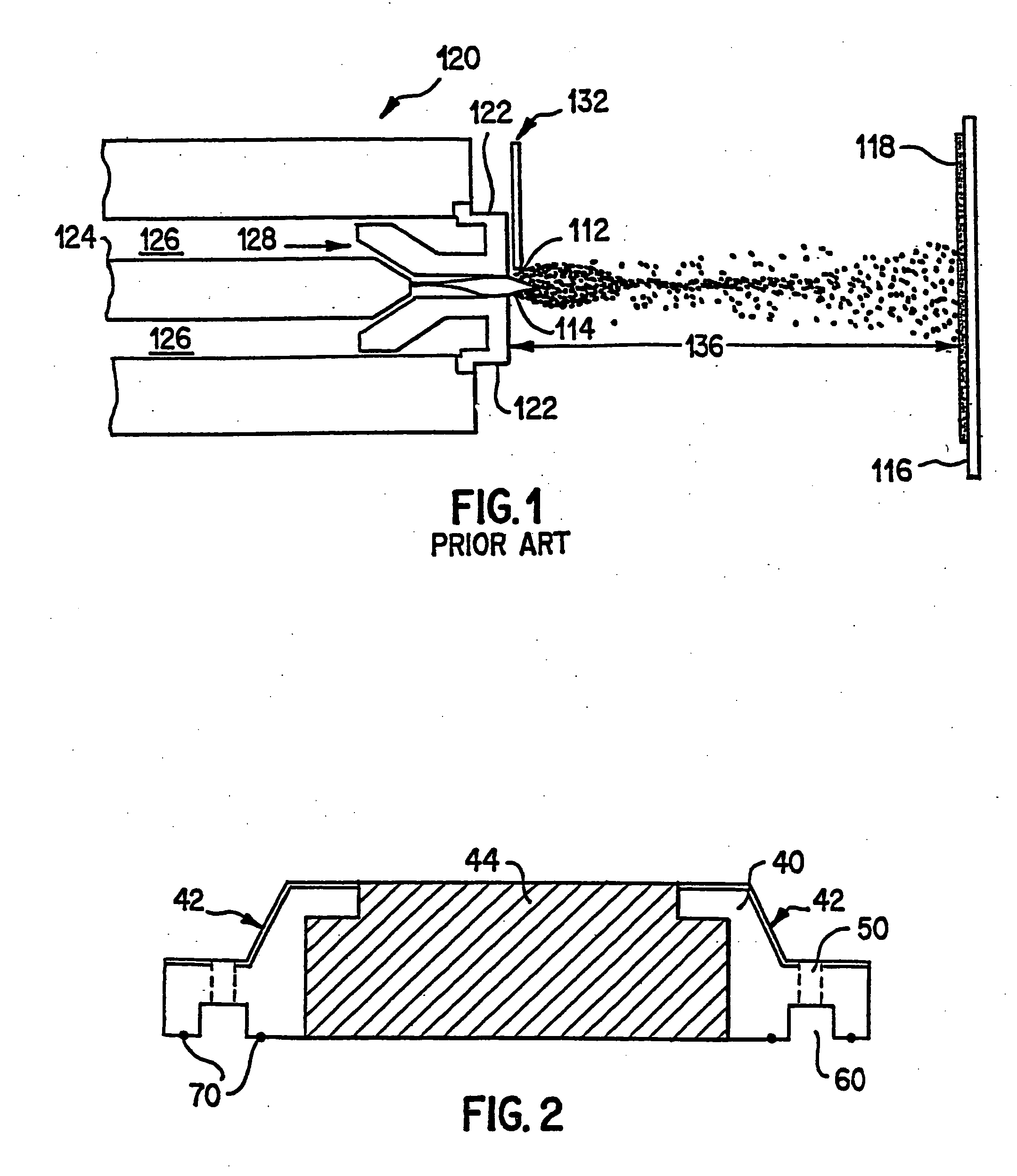

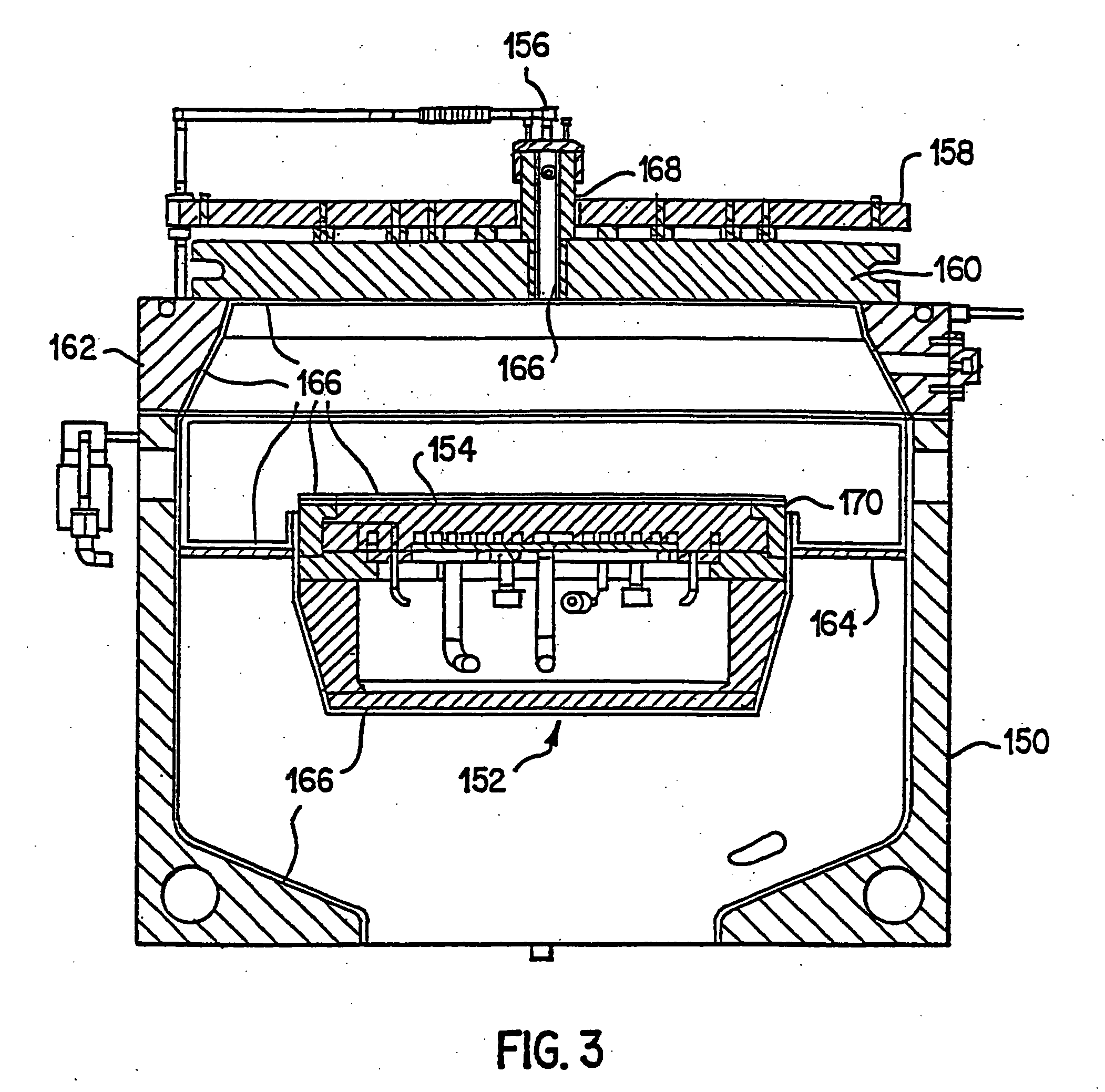

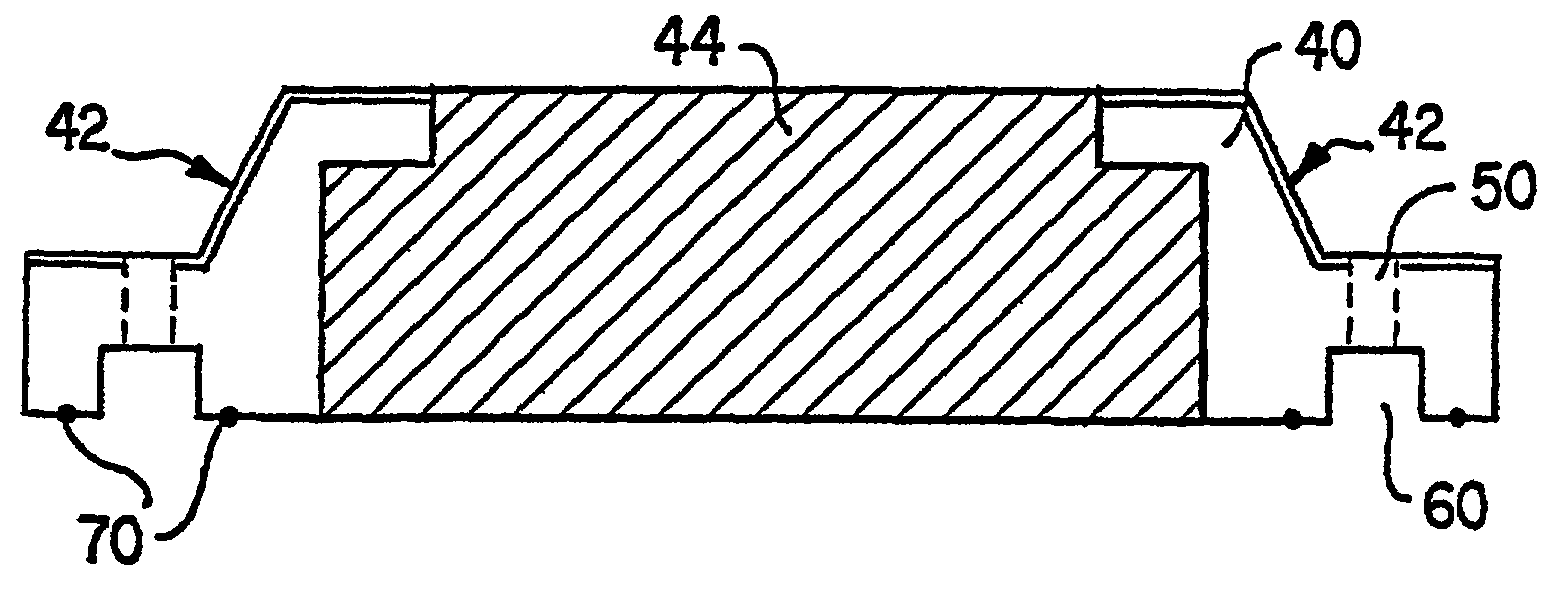

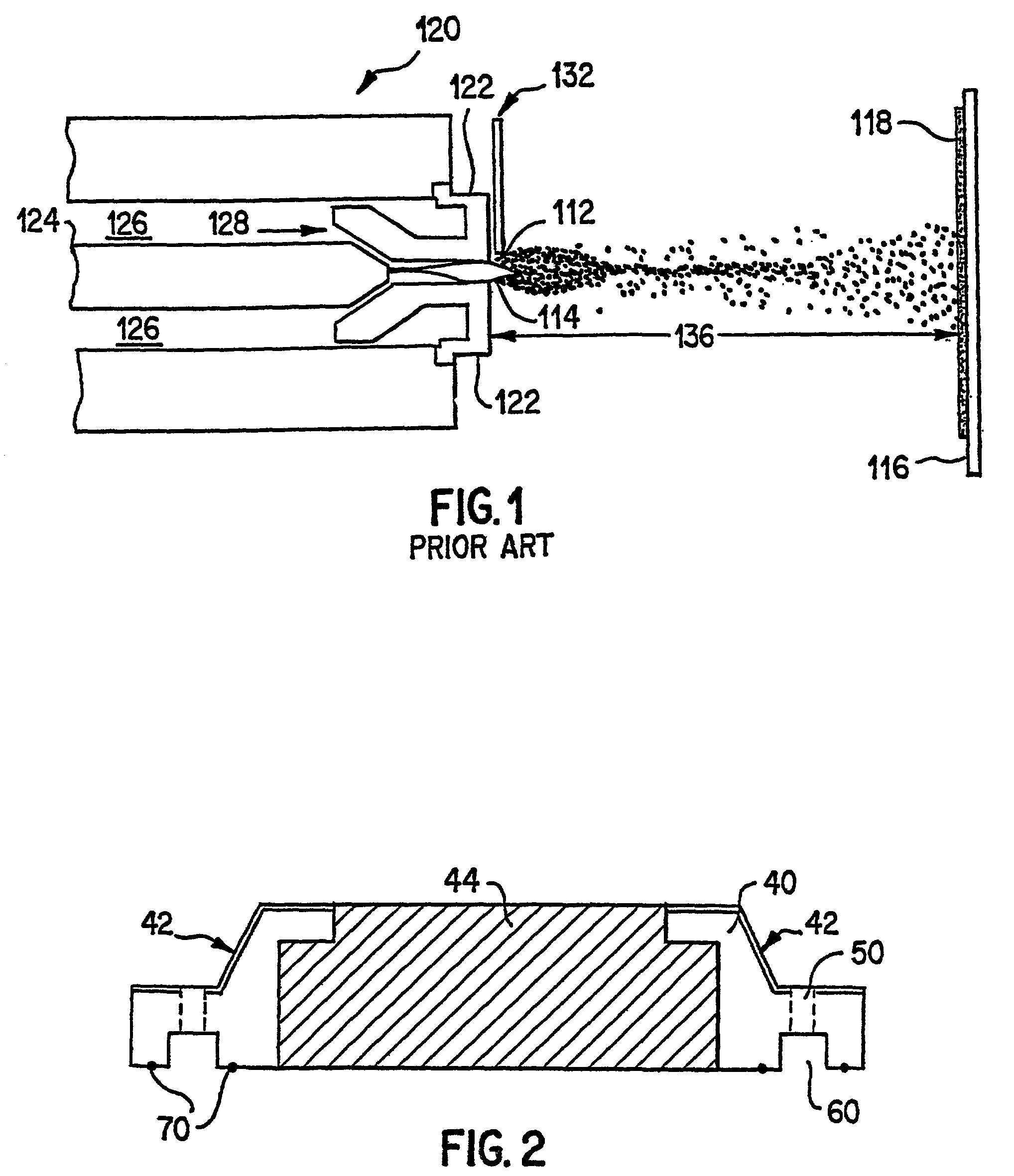

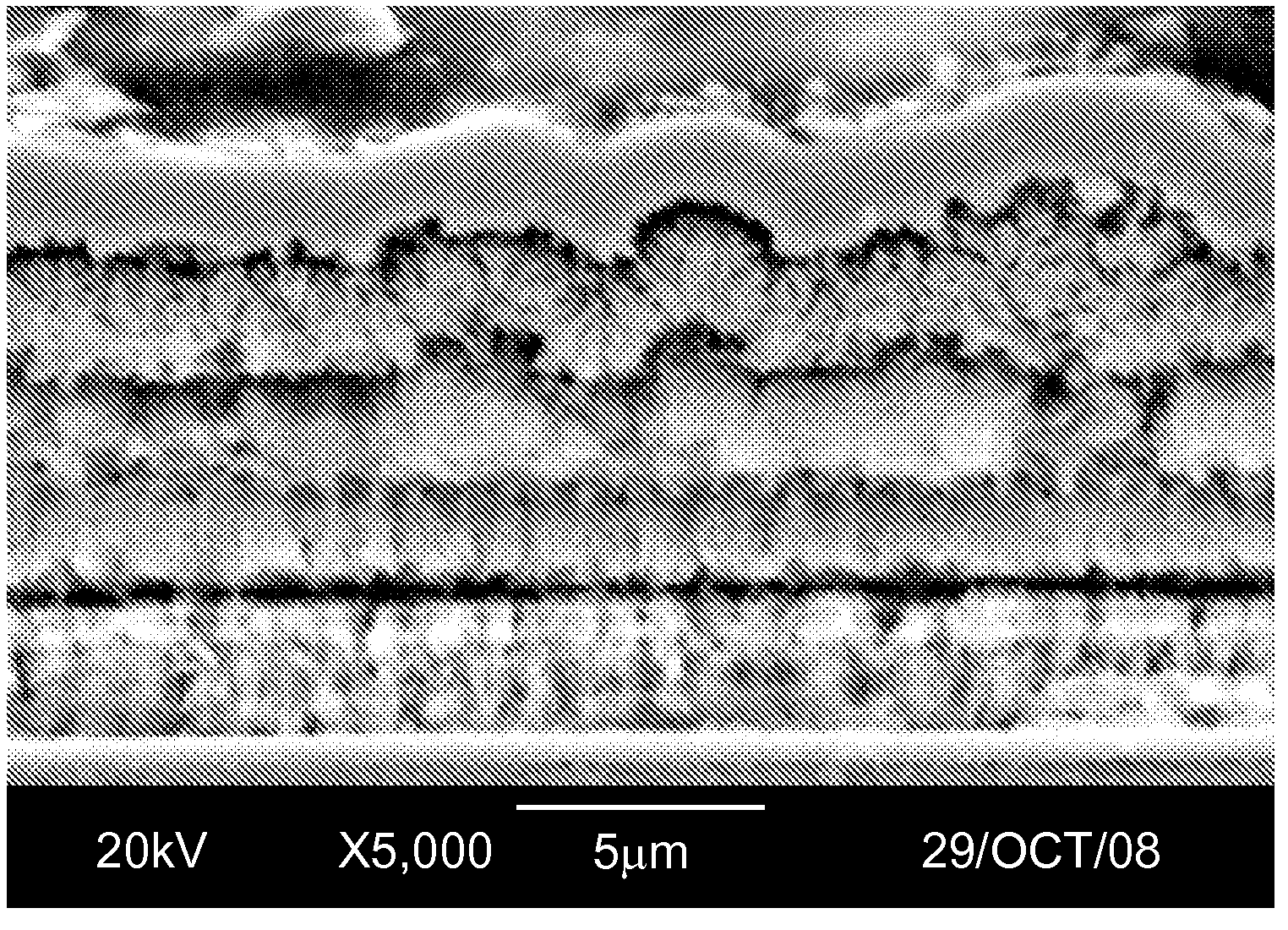

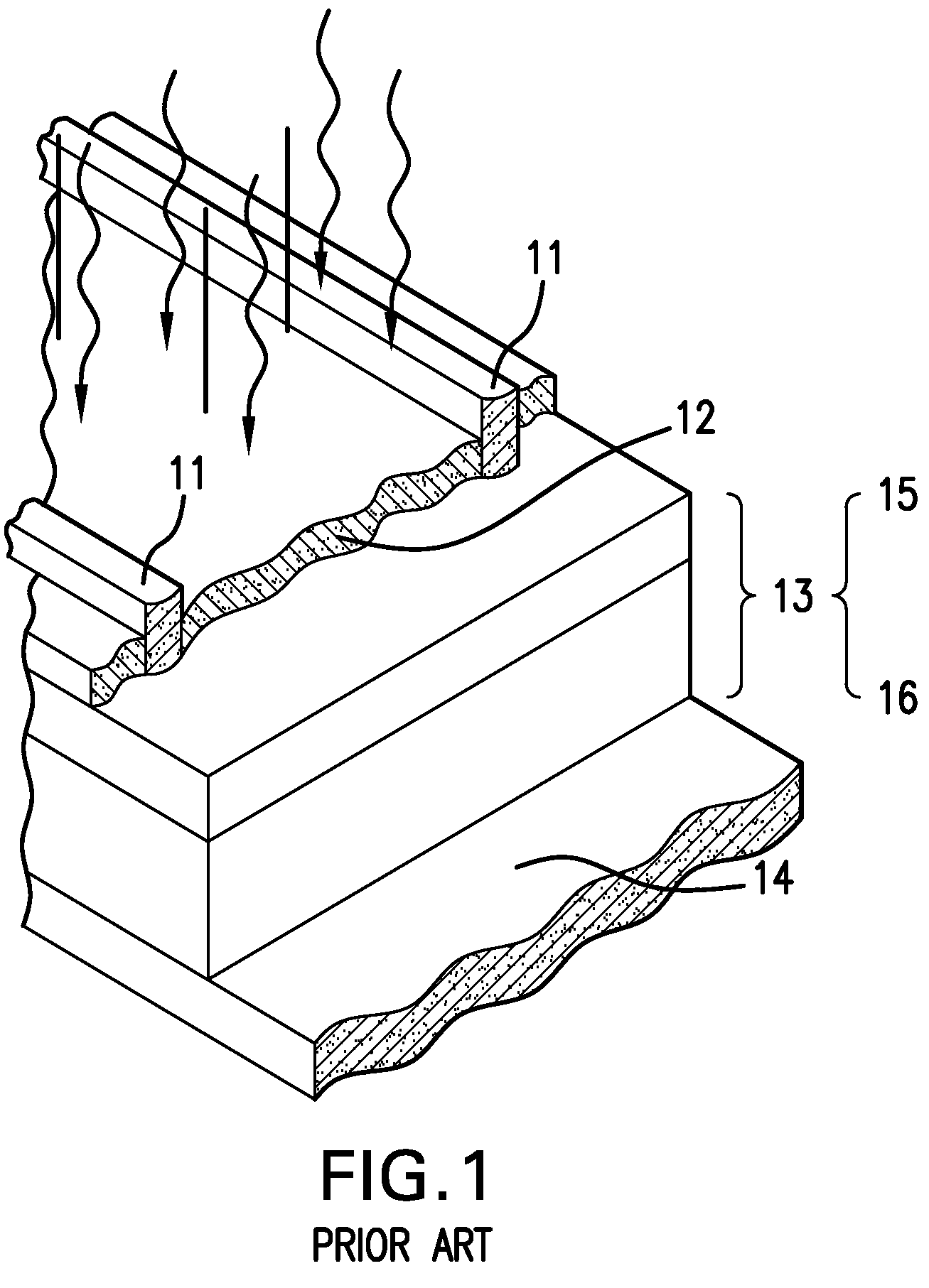

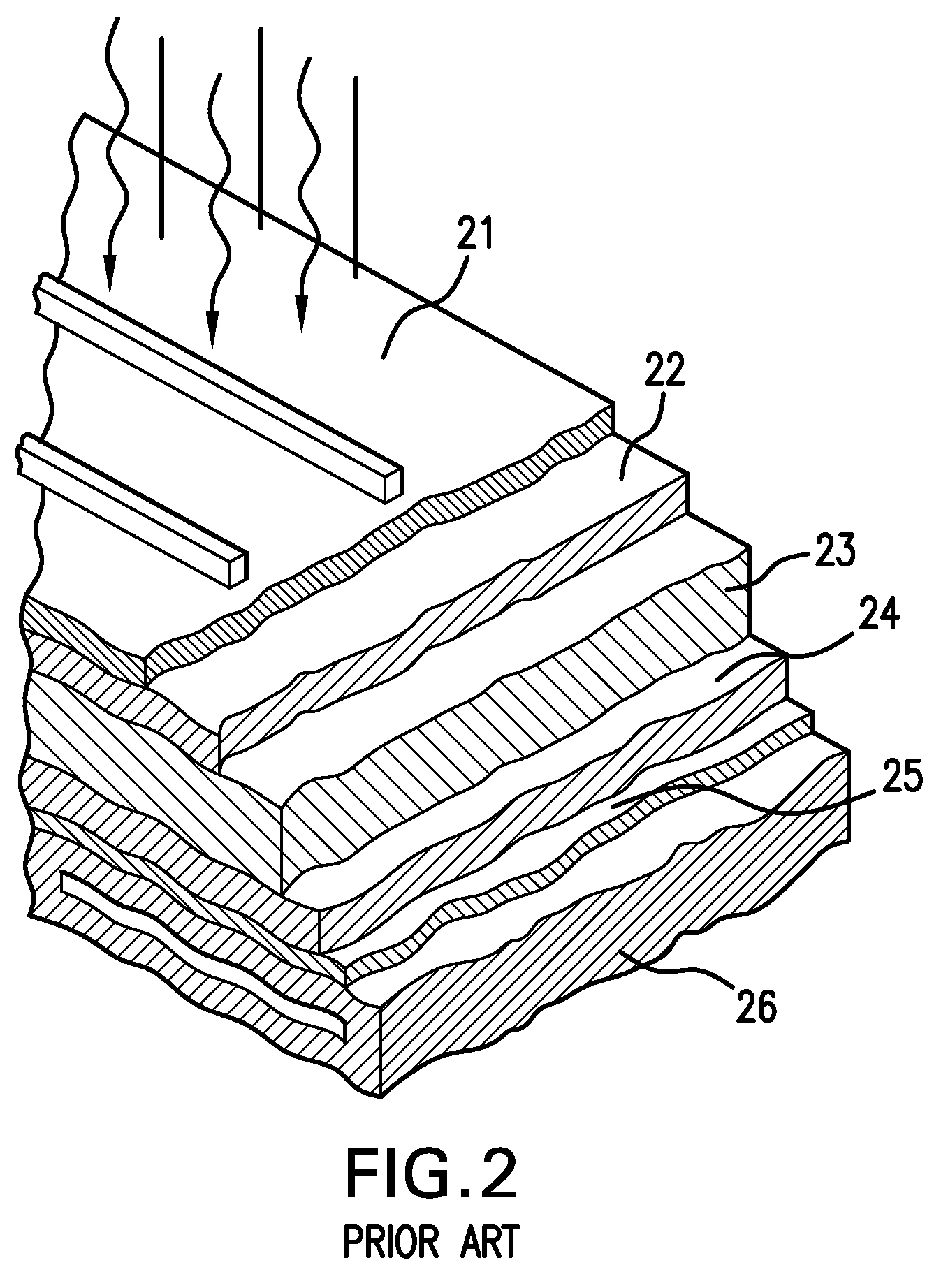

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

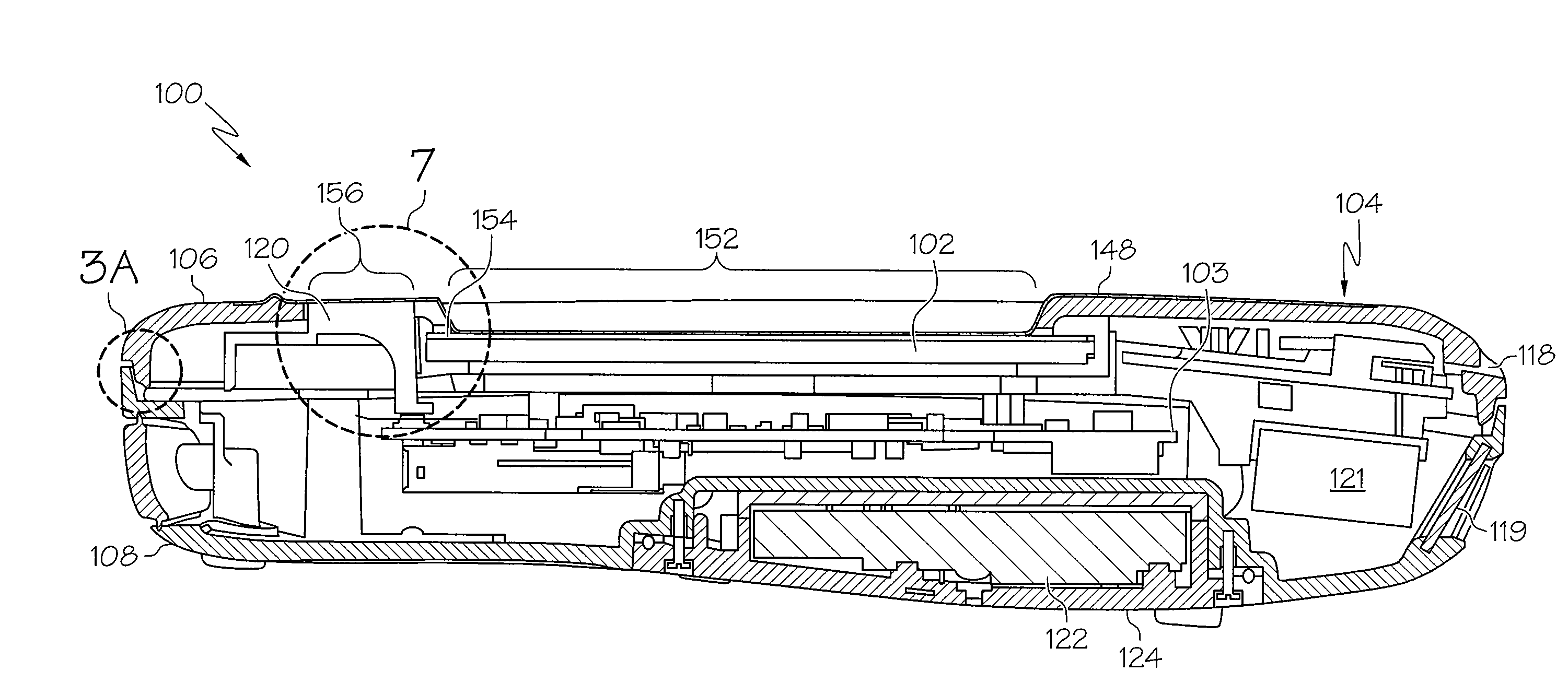

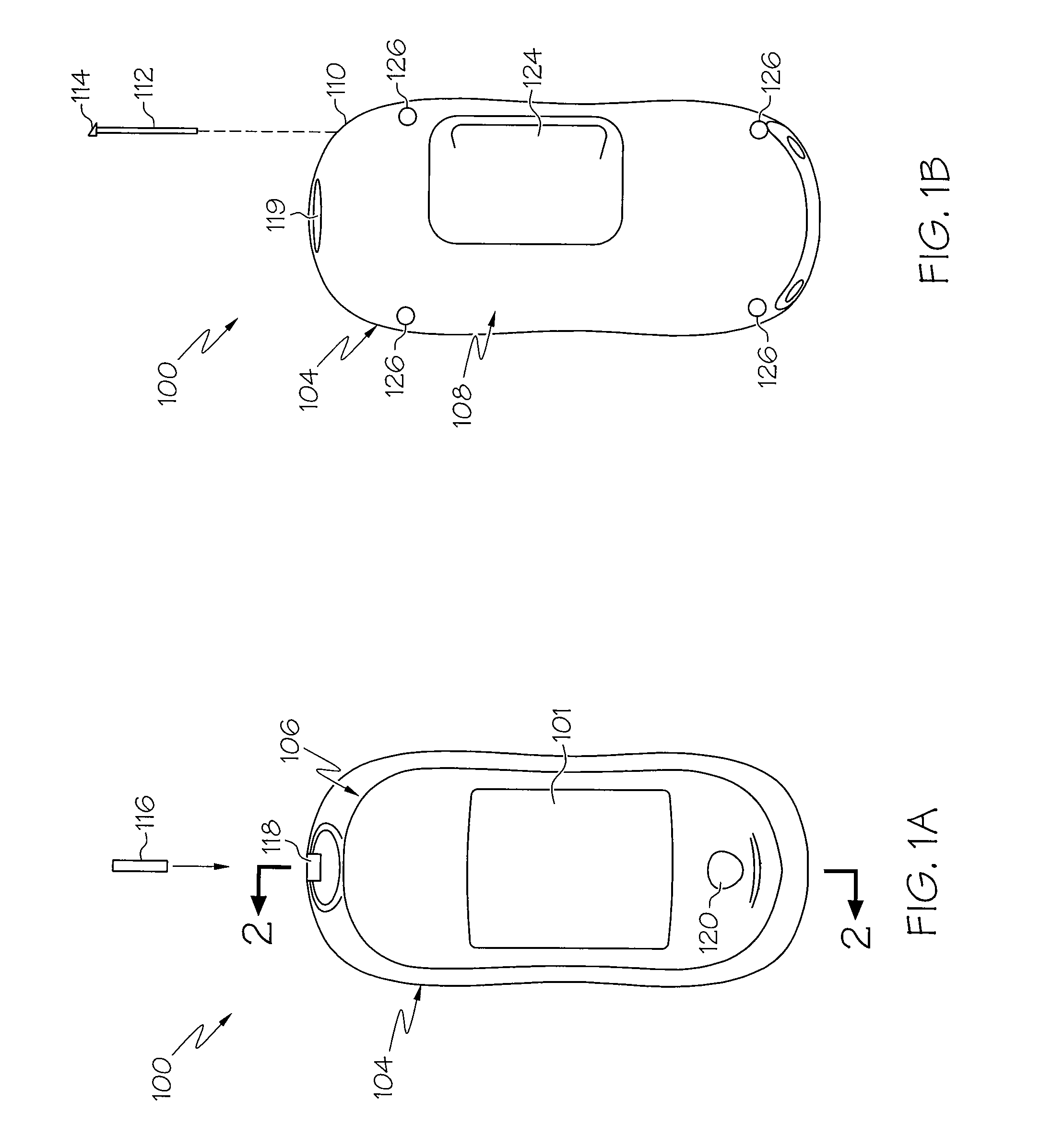

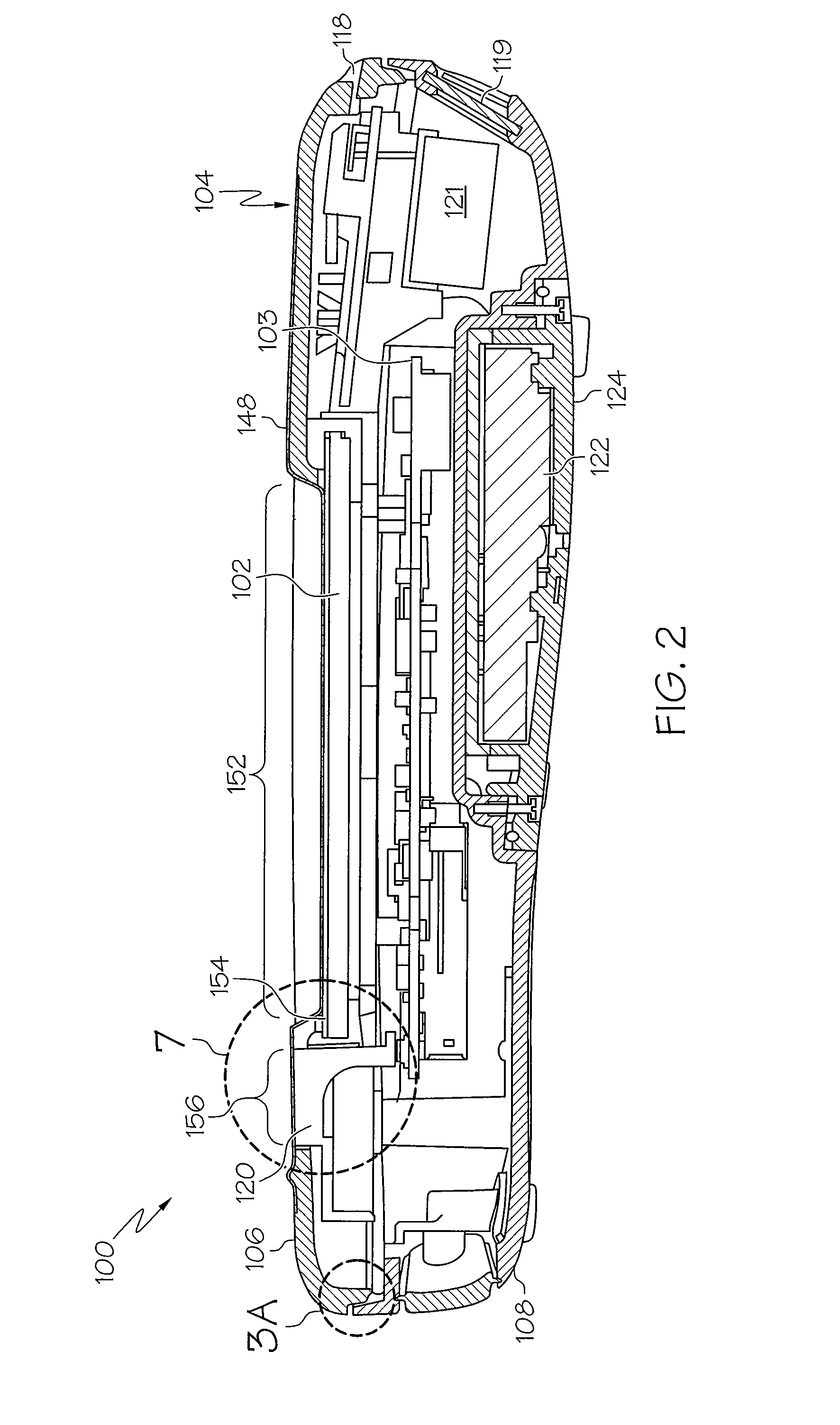

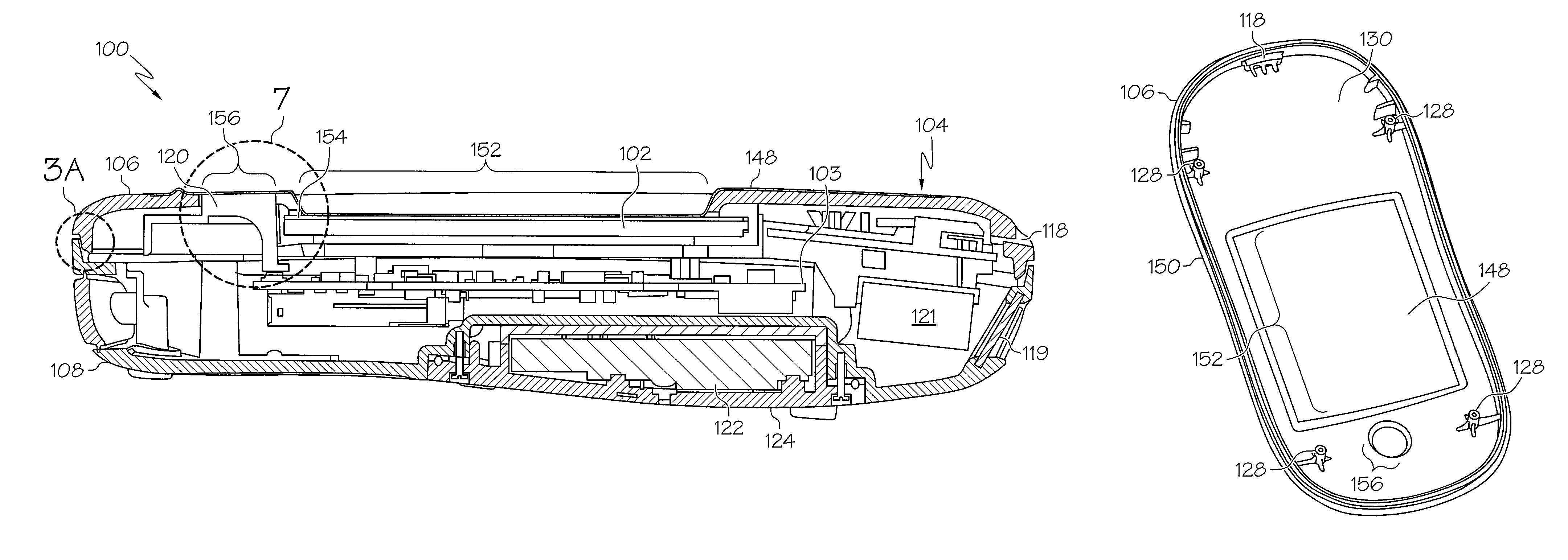

Enclosure to prevent fluid ingress of a device having a touch screen interface

InactiveUS20080055258A1Liquid tight sealOther accessoriesContainer/bottle contructionDisplay deviceEngineering

An electronic device enclosure having an integrated in-mold foil, which prevents fluid ingress around an included display of the electronic device, is disclosed. A portion of the in-mold foil is adapted to the specific contour and profile of the display, thereby allowing a user to use a touch screen interface of the display with no shortcomings. In addition, the in-mold foil protects the display from direct chemical attack, and may provide a liquid-tight seal between a button of the electronic device and the enclosure.

Owner:ROCHE OPERATIONS

Enclosure to prevent fluid ingress of a device having a touch screen interface

An electronic device enclosure having an integrated in-mold foil, which prevents fluid ingress around an included display of the electronic device, is disclosed. A portion of the in-mold foil is adapted to the specific contour and profile of the display, thereby allowing a user to use a touch screen interface of the display with no shortcomings. In addition, the in-mold foil protects the display from direct chemical attack, and may provide a liquid-tight seal between a button of the electronic device and the enclosure.

Owner:ROCHE OPERATIONS

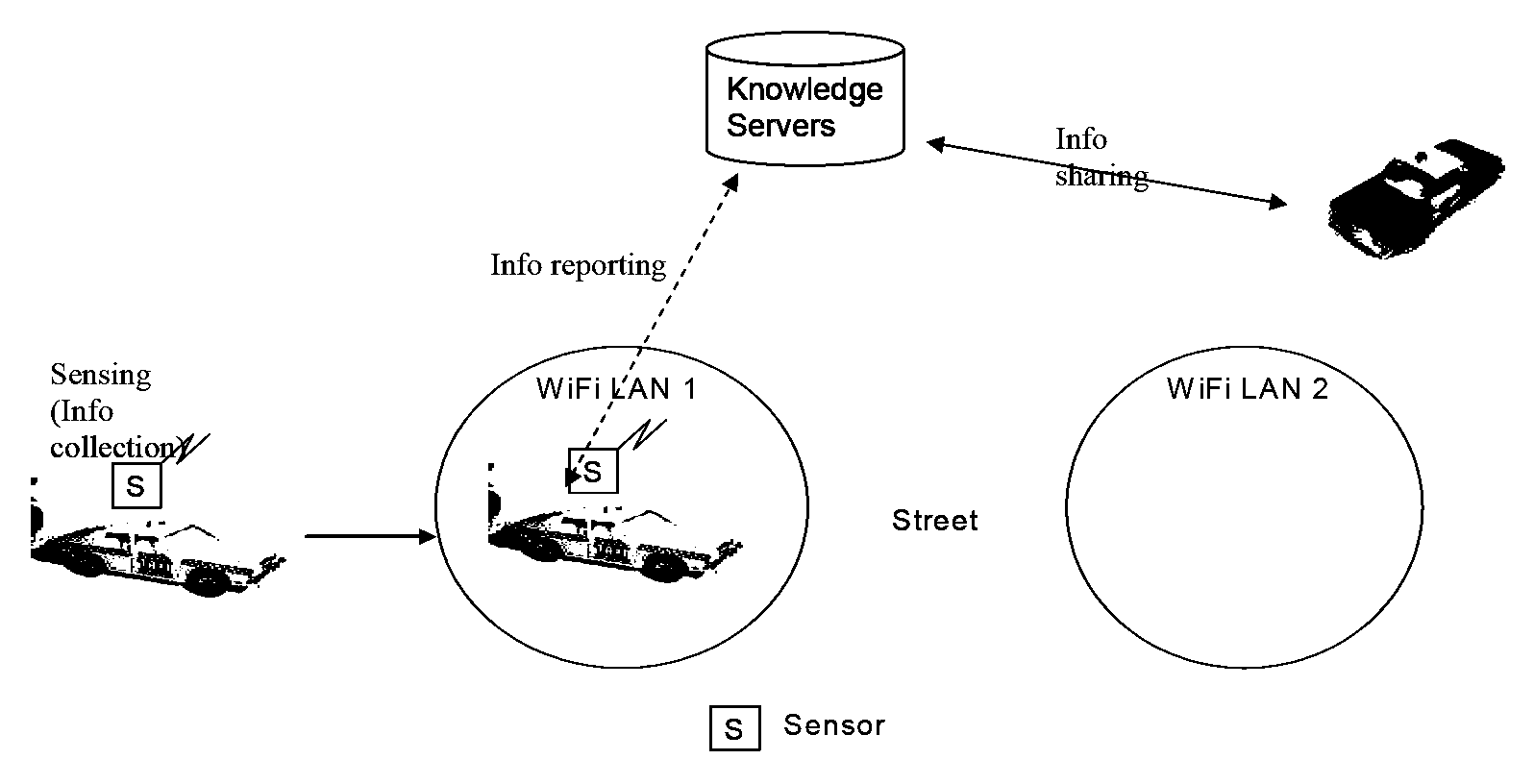

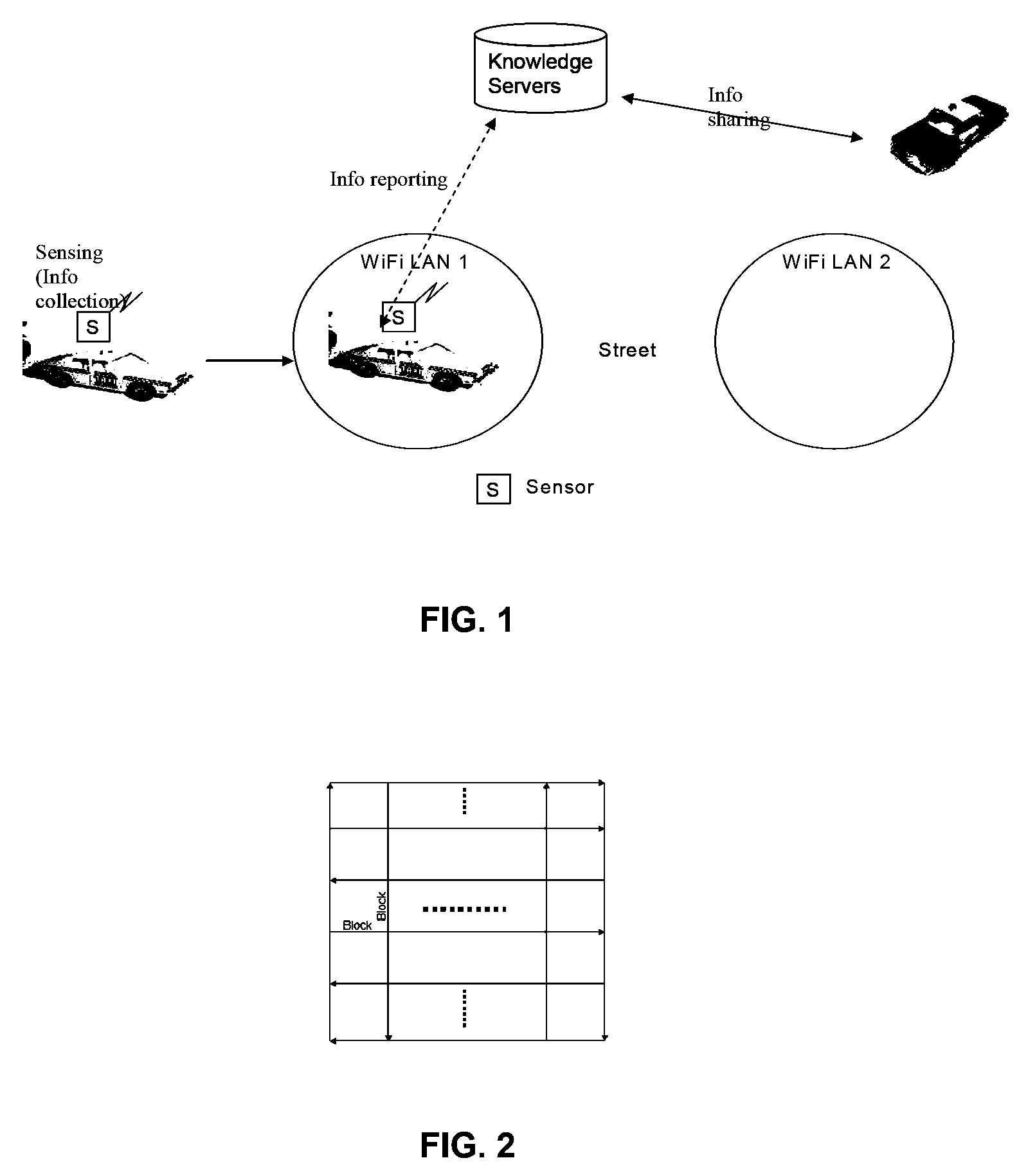

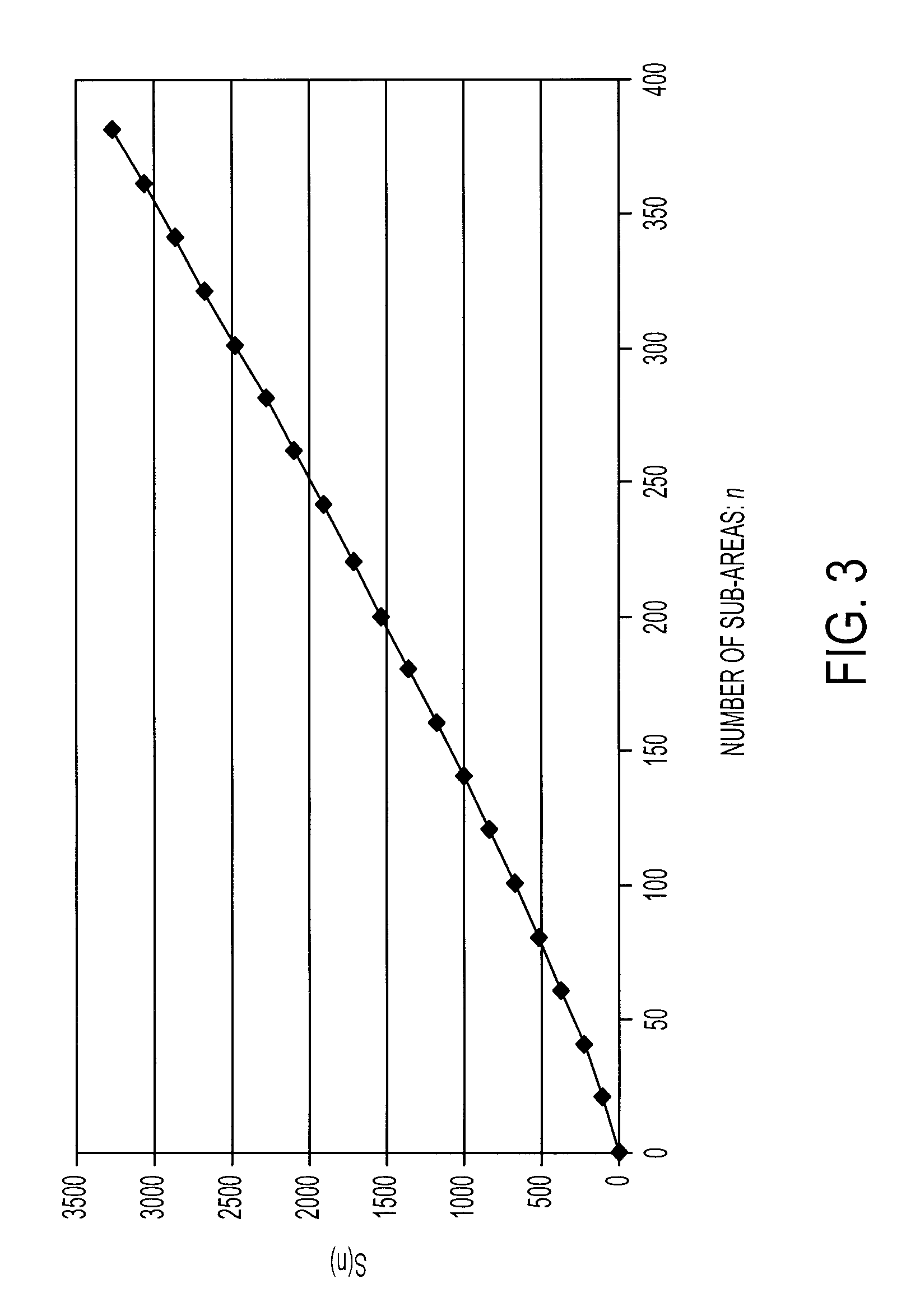

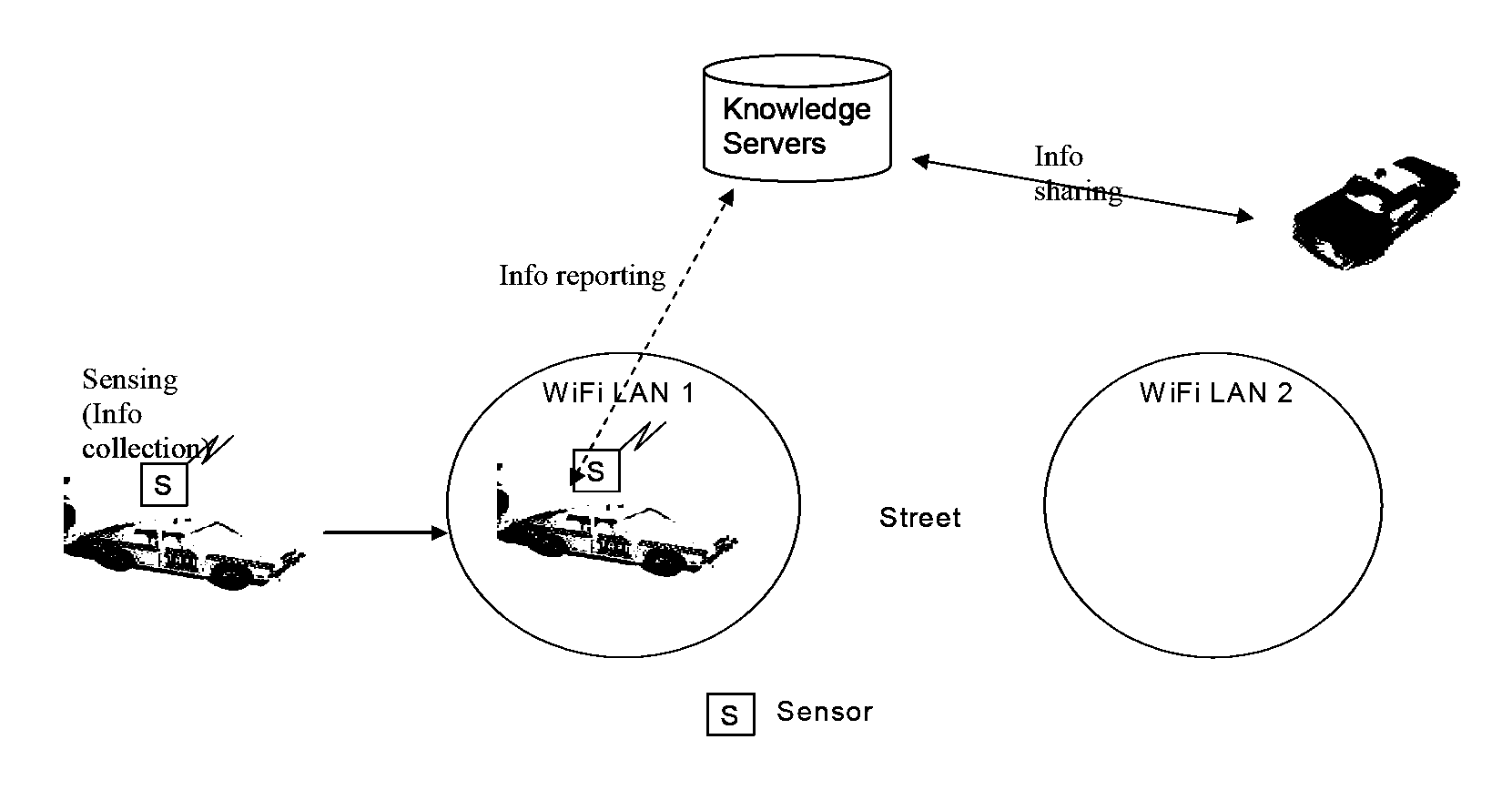

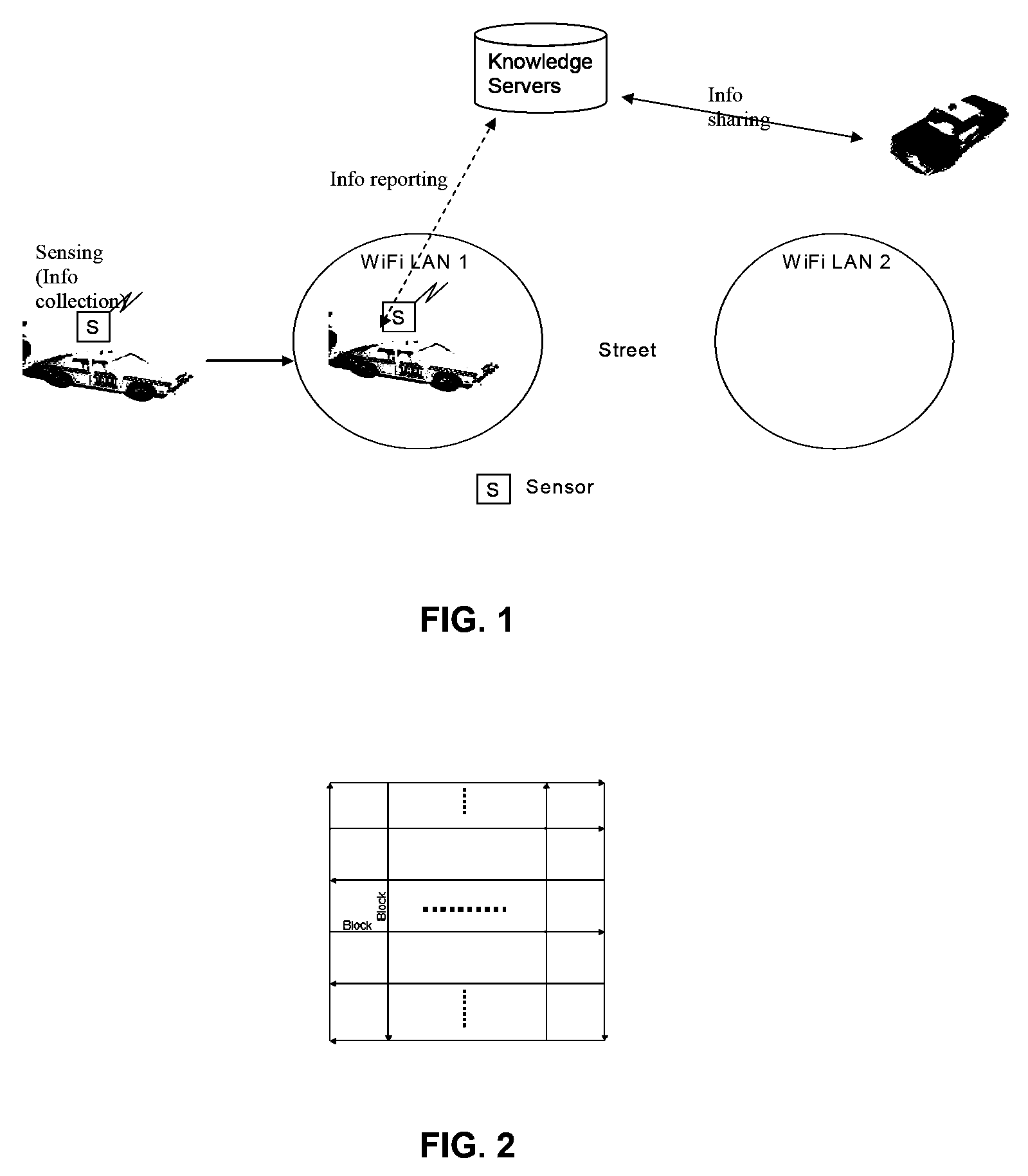

Environmental monitoring using mobile devices and network information server

ActiveUS7603138B2Reduce in quantityReduce complexityFrequency-division multiplex detailsTime-division multiplexGeolocationEngineering

Sensors mounted on vehicles (e.g., buses, taxis, police cars) and public personnel (e.g., policemen) are used to monitor various conditions and situations such as air quality, potential biological and chemical attacks, and road and traffic conditions. The invention improves upon the typical approach that deploys fixed sensors at every geographical position of interest. The total number of required sensors and the size and the complexity of the network infrastructure required to connect the sensors are reduced and simplified. A method for estimating the number of mobile sensors required to cover a region of interest also is disclosed. A relatively small number of mobile sensors may be sufficient to cover a large area at a lower cost and less complexity than a fixed sensor network.

Owner:TELCORDIA TECHNOLOGIES INC +1

Diamond grid CMP pad dresser

InactiveUS6884155B2Easy to monitorUniform sizePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

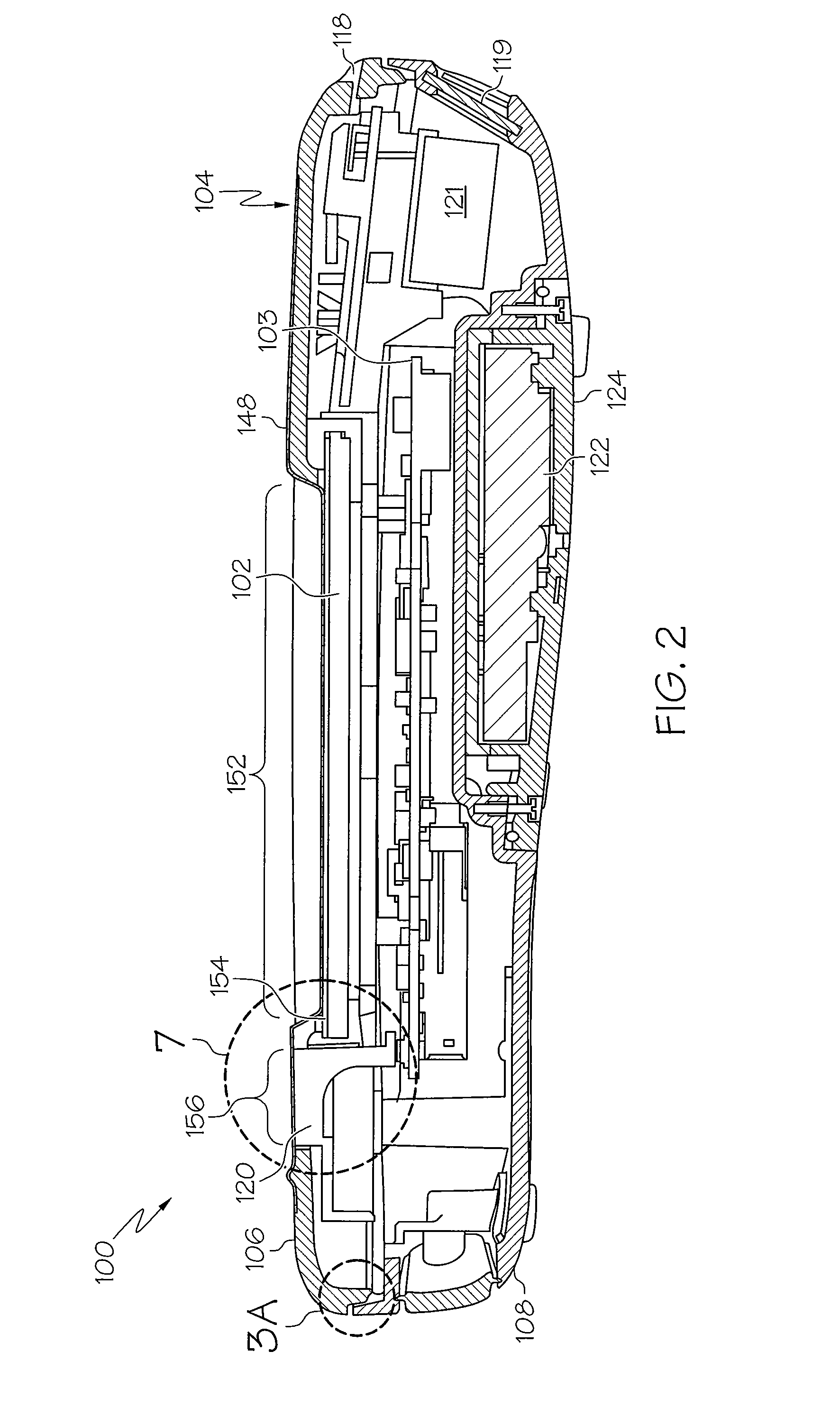

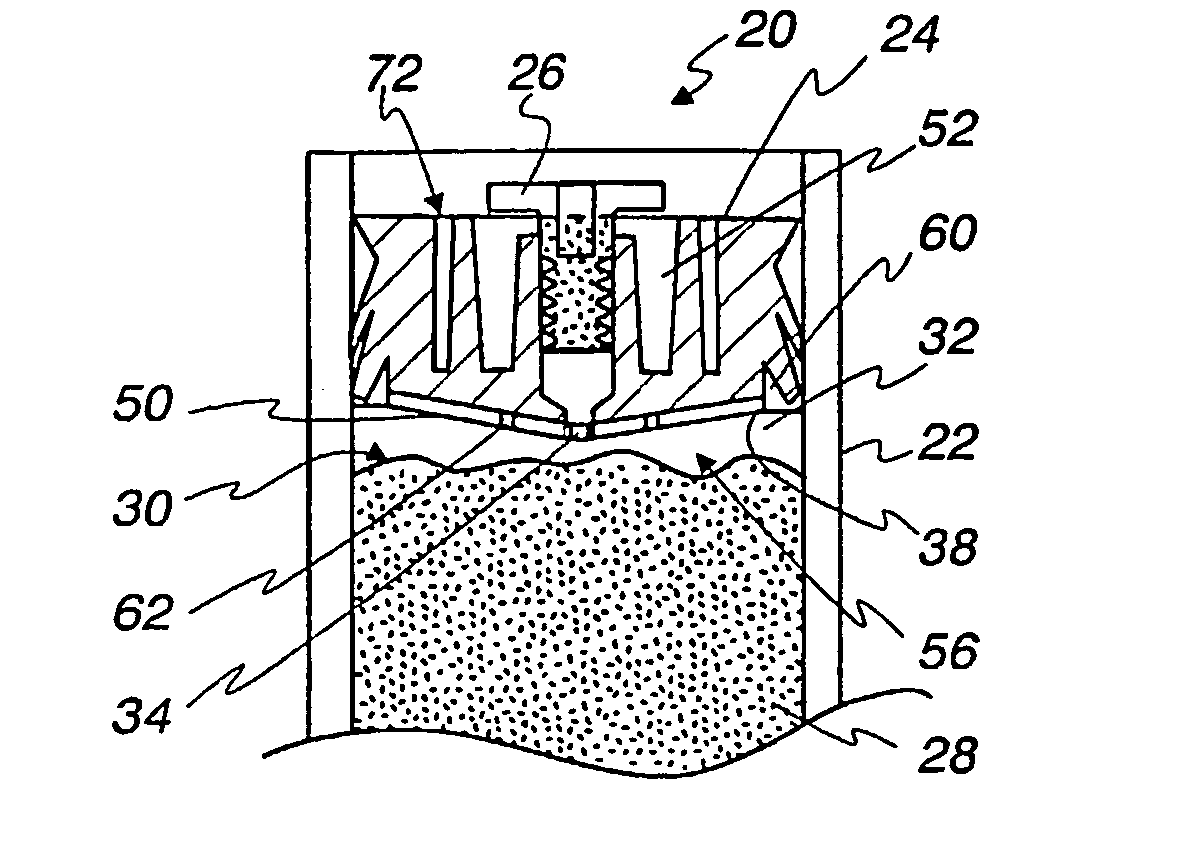

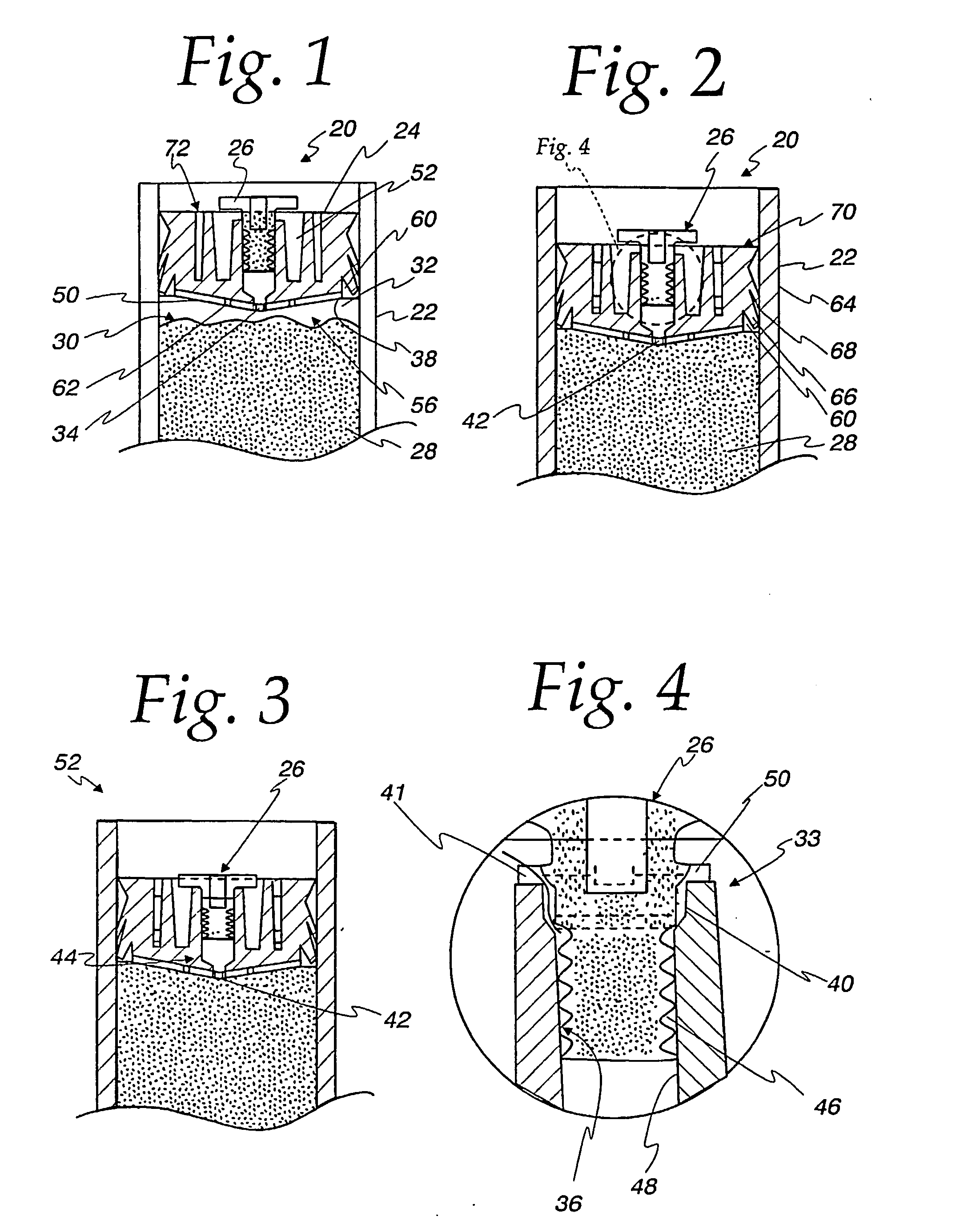

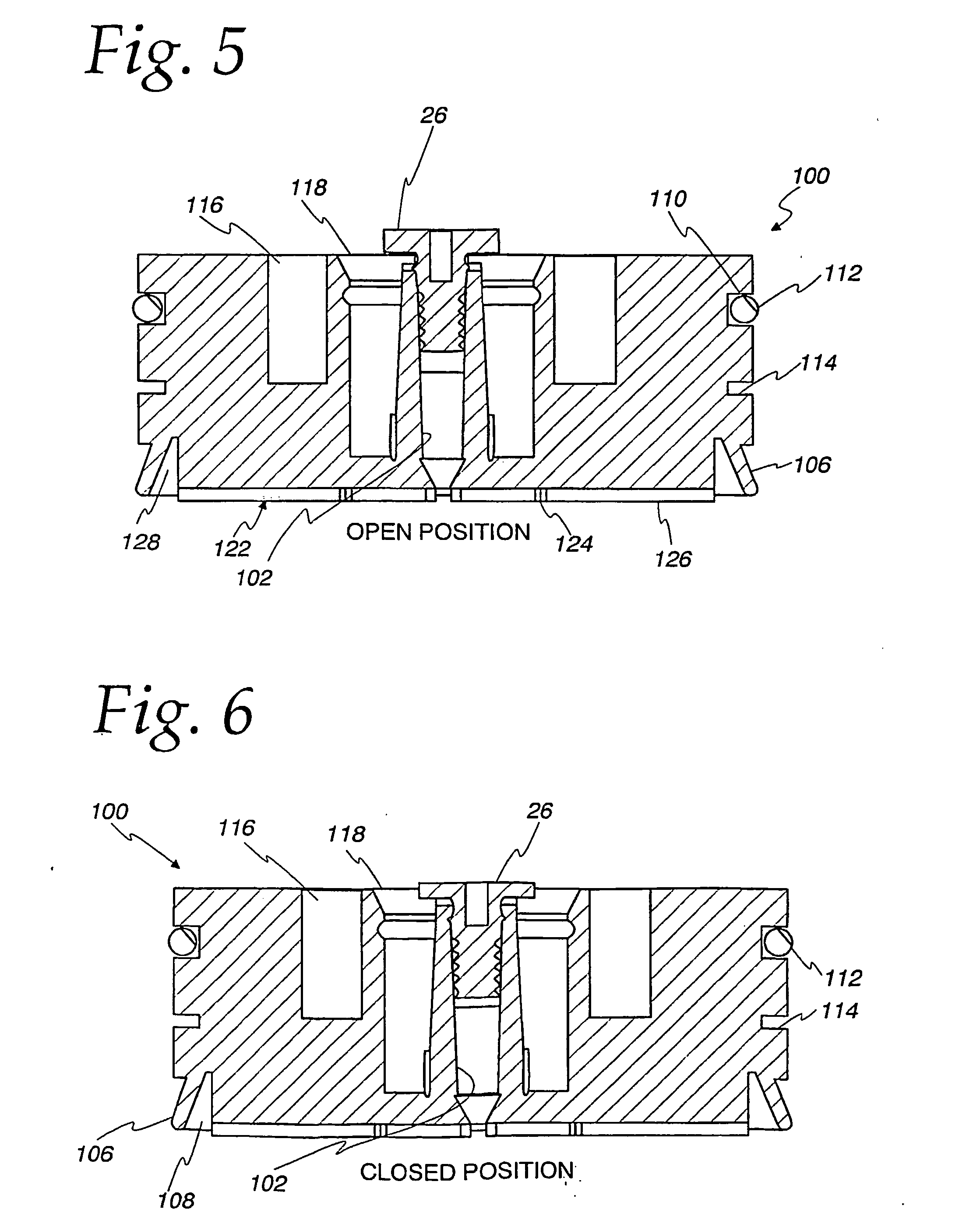

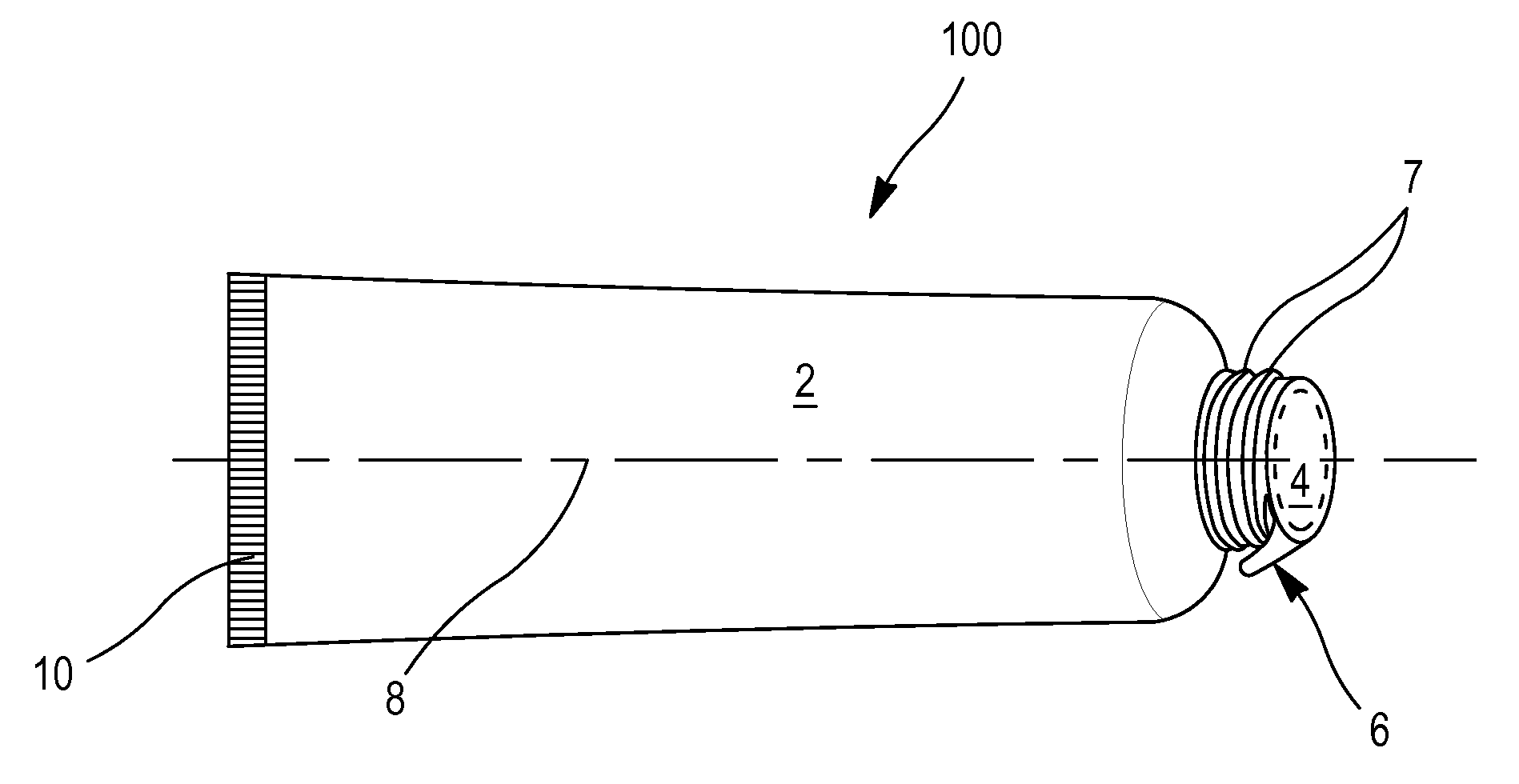

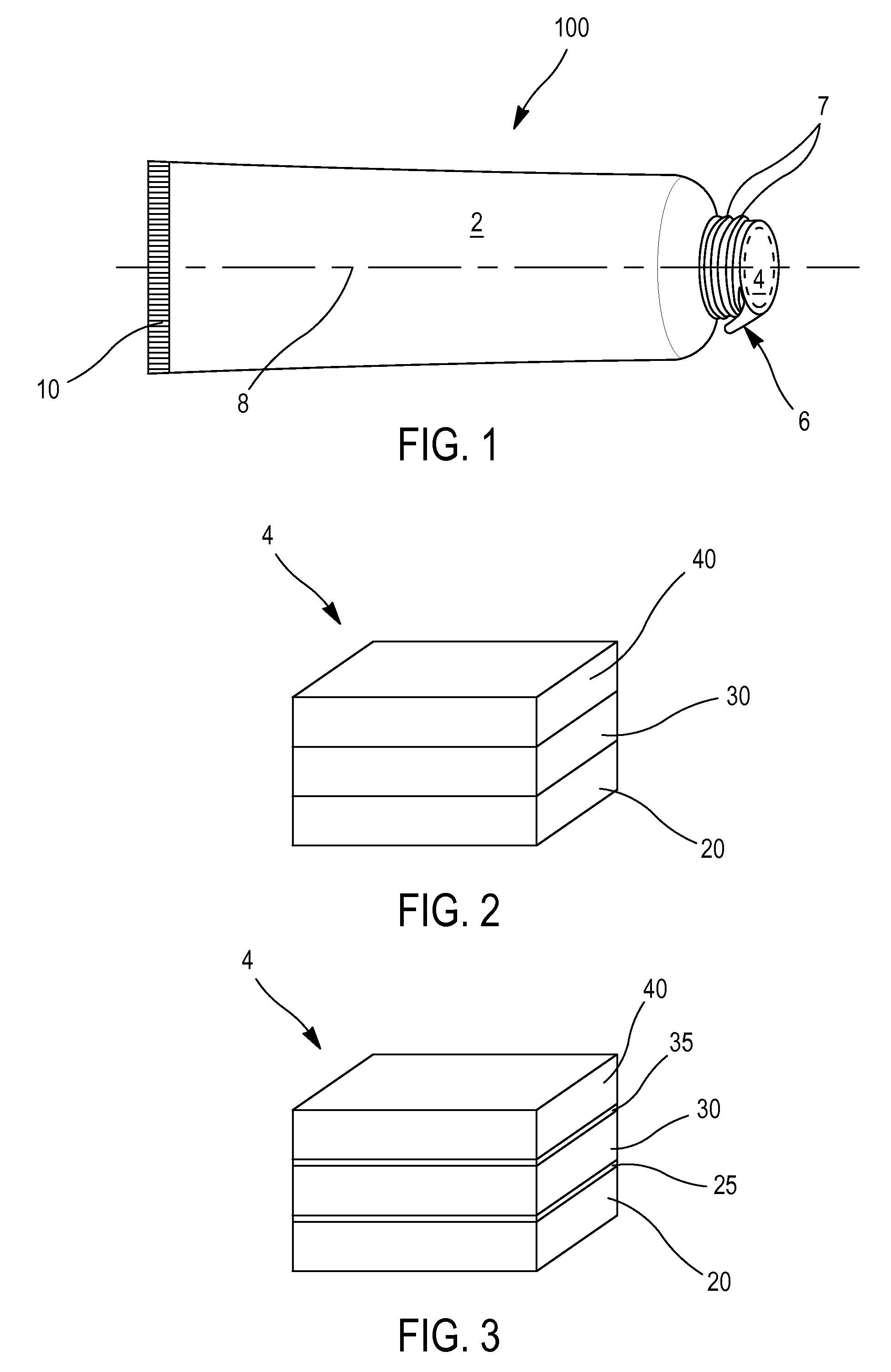

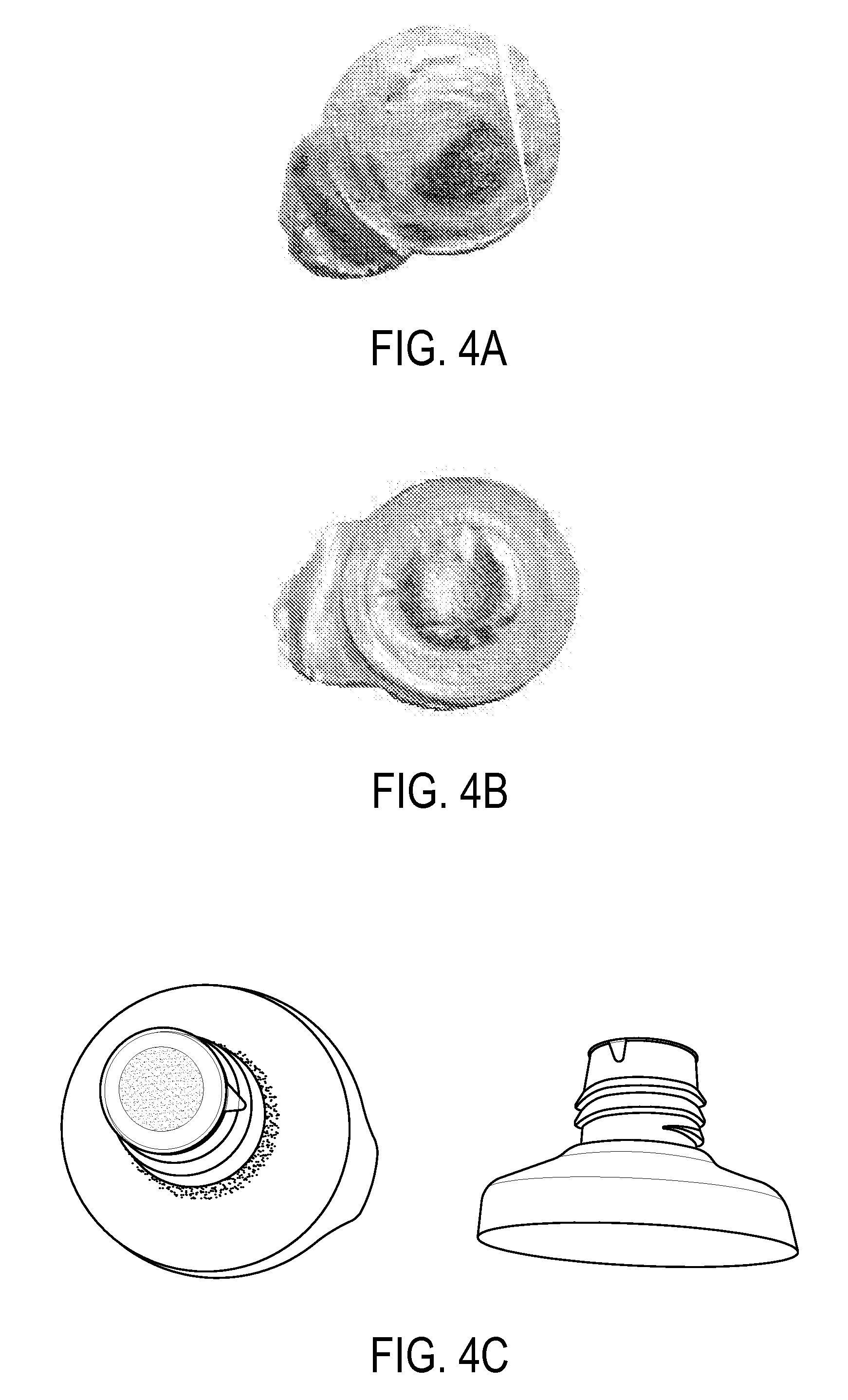

Dispensing cartridge with tortuous vent path

InactiveUS20050029306A1Wide viscosity rangeSimple configurationLiquid surface applicatorsContracting/expanding measuring chambersCombined useEngineering

A dispensing cartridge for a relatively precise dispensing of various fluids having a relatively wide range of viscosities is disclosed. The dispensing cartridge in accordance with the present invention is relatively simpler in configuration than known dispensing cartridges while minimizing leakage of the fluid and eliminating problems associated with chemical attack of the O-ring by the fluid in the dispensing cylinder. In particular, the dispensing cartridge in accordance with the present invention includes a cylinder; a piston with a central bore and a bleed plug. In order to simplify the design, the air vent is configured as a tortuous path, for example, a spiral path, defined by a spiral bleed plug, which in a pre-staged position, allows air to freely escape along the spiral path along the circumference of the plug. As the piston contacts the fluid, the forward motion of piston is resisted by the high back pressure created by the small effective diameter and relatively long length of the spiral path. Once the piston contacts the fluid, the spiral plug is pushed into the piston closing the spiral path. By controlling the fluid flow by way of a tortuous path, the amount of fluid backflow through the piston is minimized if not eliminated, thus eliminating the need for an annular overflow chamber, thereby simplifying the design of the piston. In order to minimize problems related to the sealing of the piston within the dispensing cartridge, the piston may be provided with one or more radially extending sealing lips. These sealing lips are used in lieu of or in conjunction with an O-ring. The sealing lips further simplify the design by eliminating the O-ring as well as the need for an annular chamber adjacent thereto as well as problems relating to chemical attack of the O-ring by the fluid within the dispensing cylinder. In an alternative embodiment for use that is particularly adapted with non-aggressive fluids, the piston is provided with a single sealing lip and an O-ring.

Owner:NORDSON CORP

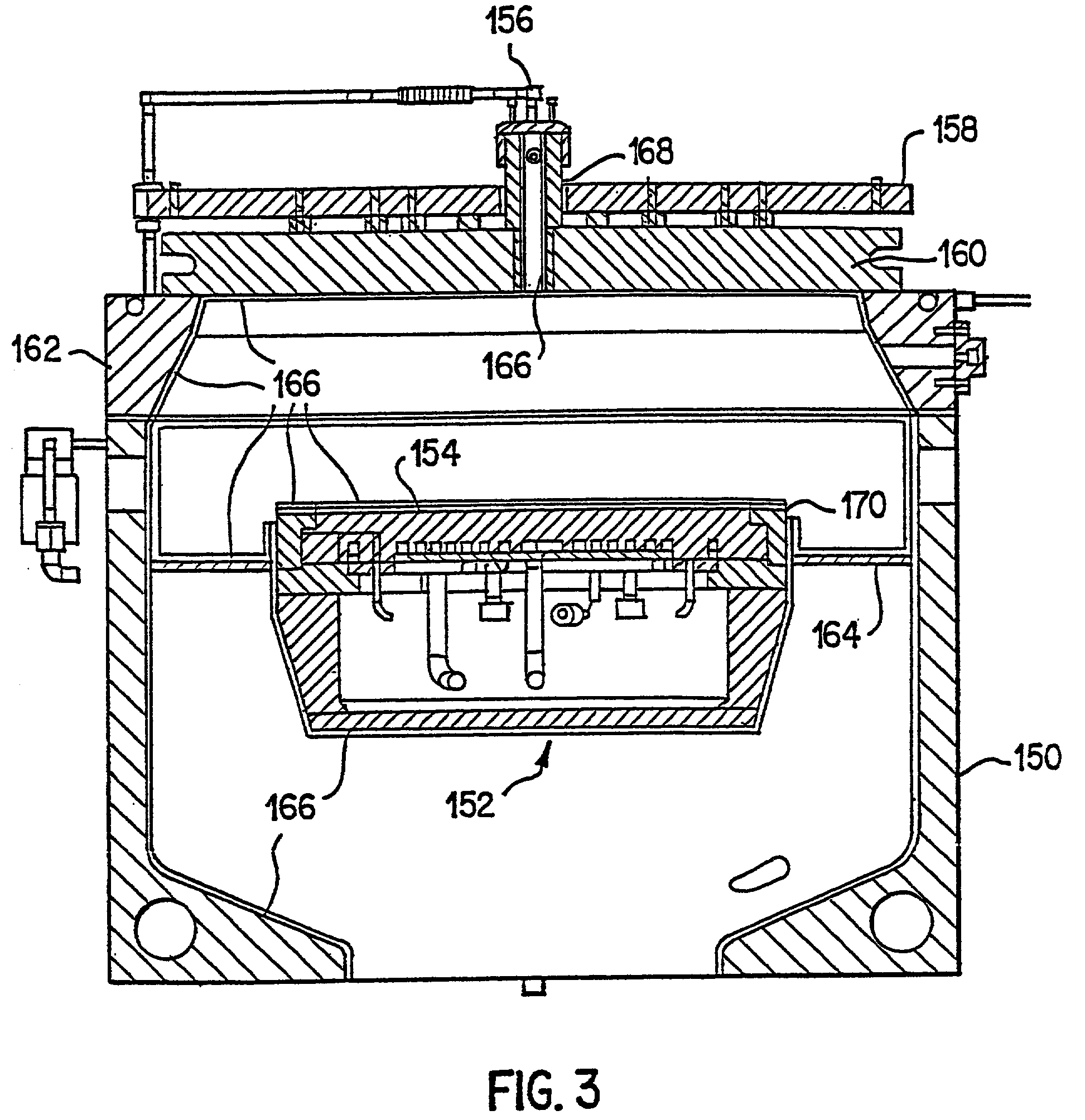

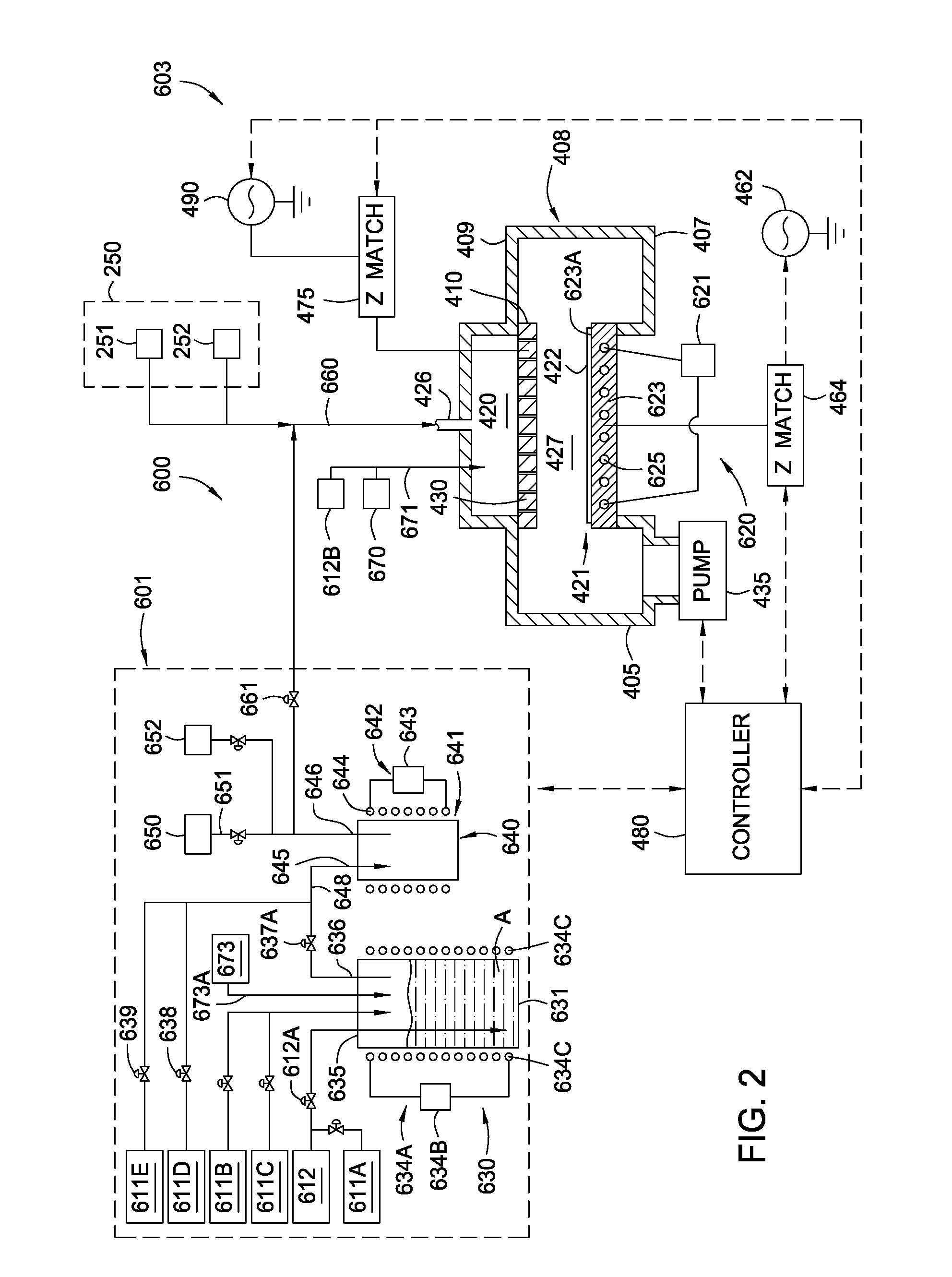

Productivity enhancing thermal sprayed yttria-containing coating for plasma reactor

InactiveUS7300537B2Improve wear resistanceLow level of contaminationCellsElectric discharge tubesProduction ratePlasma reactor

Components of semiconductor processing apparatus comprise thermal sprayed yttria-containing coatings that provide erosion, corrosion and / or corrosion-erosion resistance in plasma atmospheres. The coatings can protect substrates from physical and / or chemical attack.

Owner:LAM RES CORP

Productivity enhancing thermal sprayed yttria-containing coating for plasma reactor

InactiveUS20050150866A1Improve wear resistanceLow level of contaminationElectric discharge tubesDecorative surface effectsProduction rateThermal spraying

Components of semiconductor processing apparatus comprise thermal sprayed yttria-containing coatings that provide erosion, corrosion and / or corrosion-erosion resistance in plasma atmospheres. The coatings can protect substrates from physical and / or chemical attack.

Owner:LAM RES CORP

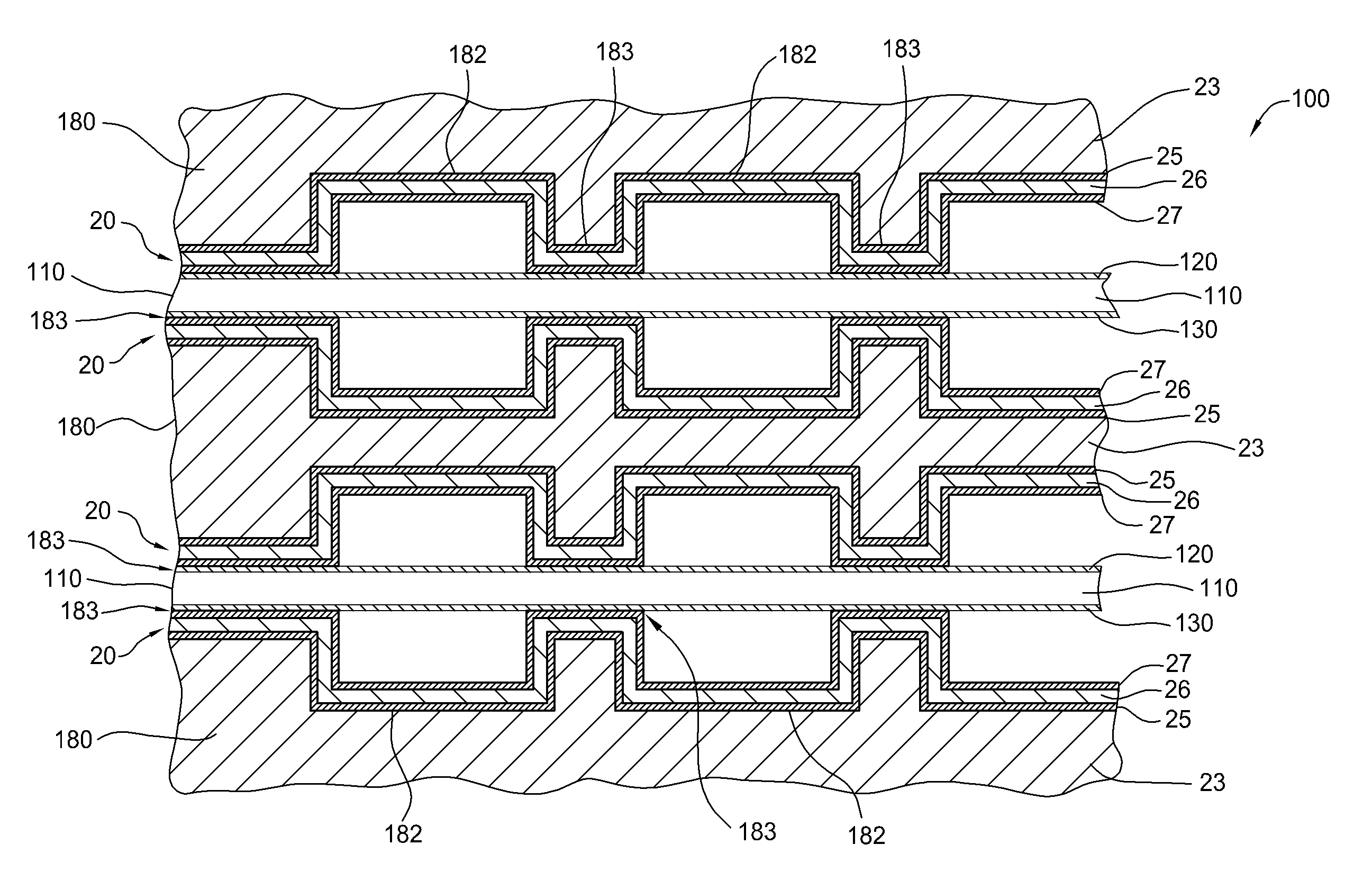

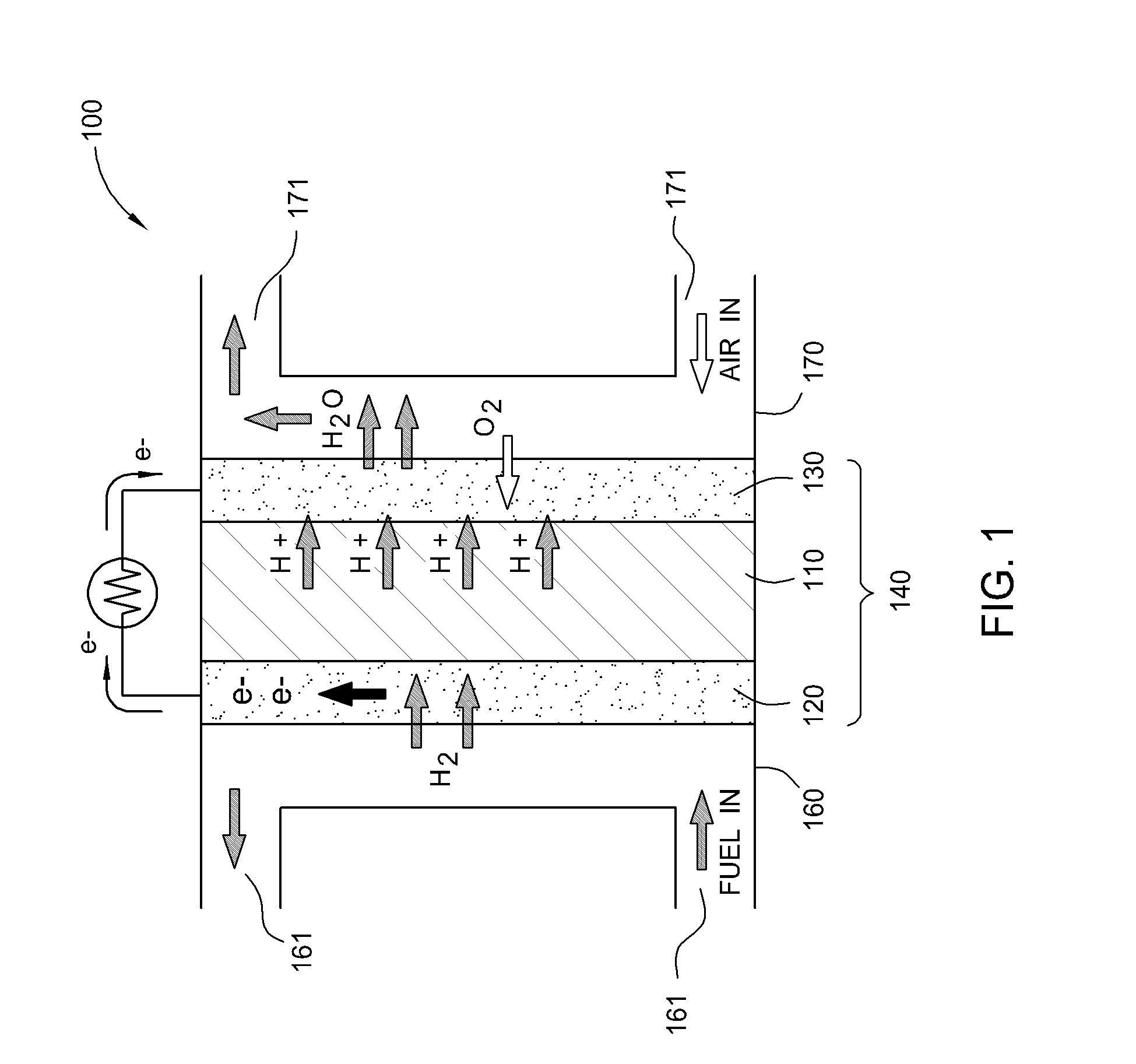

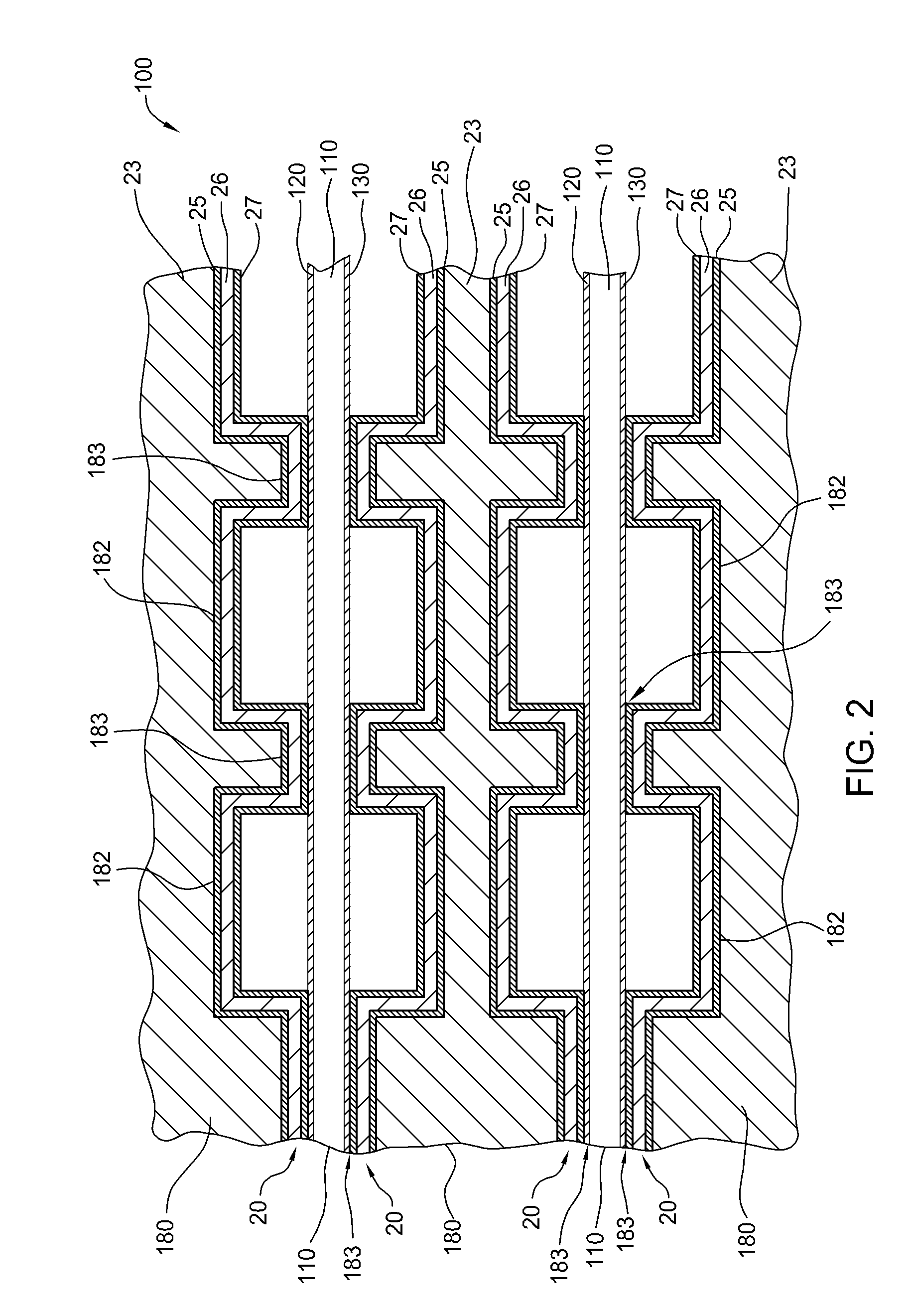

Reliable fuel cell electrode design

InactiveUS20070243452A1Avoid Surface CorrosionAvoid corrosionFinal product manufactureFuel cell auxillariesFuel cellsEngineering

The present invention generally relates to the creation of fuel cell components and the method of forming the various fuel cell components that have an improved lifetime, lower production cost and improved process performance. The invention generally includes treating or conditioning a substrate surface by depositing a material layer, or layers, having good adhesion to the substrate, low electrical resistivity (high conductivity) and has good resistance to chemical attack during the operation of fuel cell. The substrate may be, for example, a fuel cell part, a conductive plate, a separator plate, a bipolar plate or an end plate, among others. In one embodiment, the substrate surface is treated or conditioned by exposing at least a portion of it to a gas or liquid comprising ruthenium tetroxide.

Owner:APPLIED MATERIALS INC

Productivity enhancing thermal sprayed yttria-containing coating for plasma reactor

InactiveUS7311797B2Improve wear resistanceLow level of contaminationCellsElectric discharge tubesProduction ratePlasma reactor

Components of semiconductor processing apparatus comprise thermal sprayed yttria-containing coatings that provide erosion, corrosion and / or corrosion-erosion resistance in plasma atmospheres. The coatings can protect substrates from physical and / or chemical attack.

Owner:LAM RES CORP

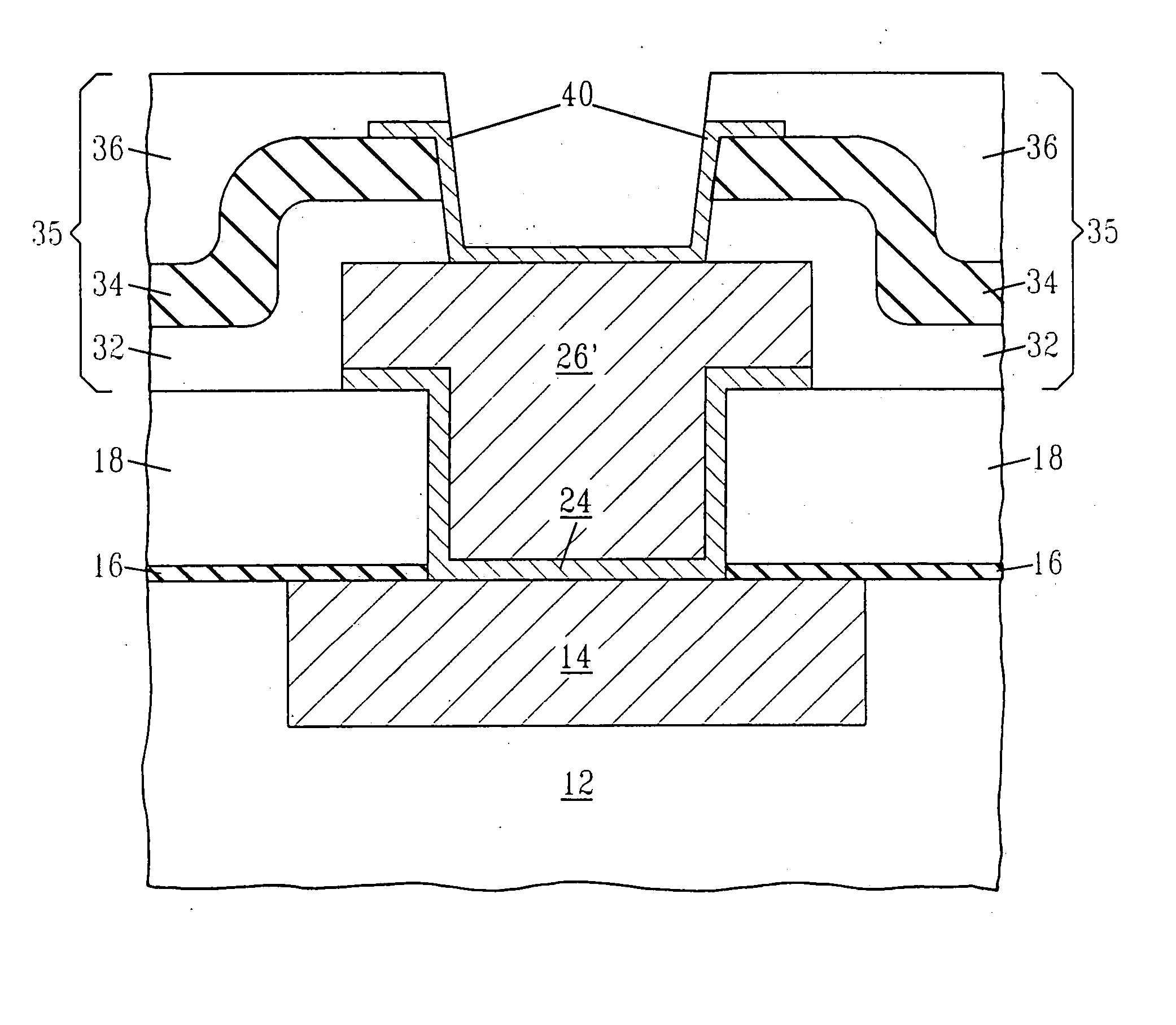

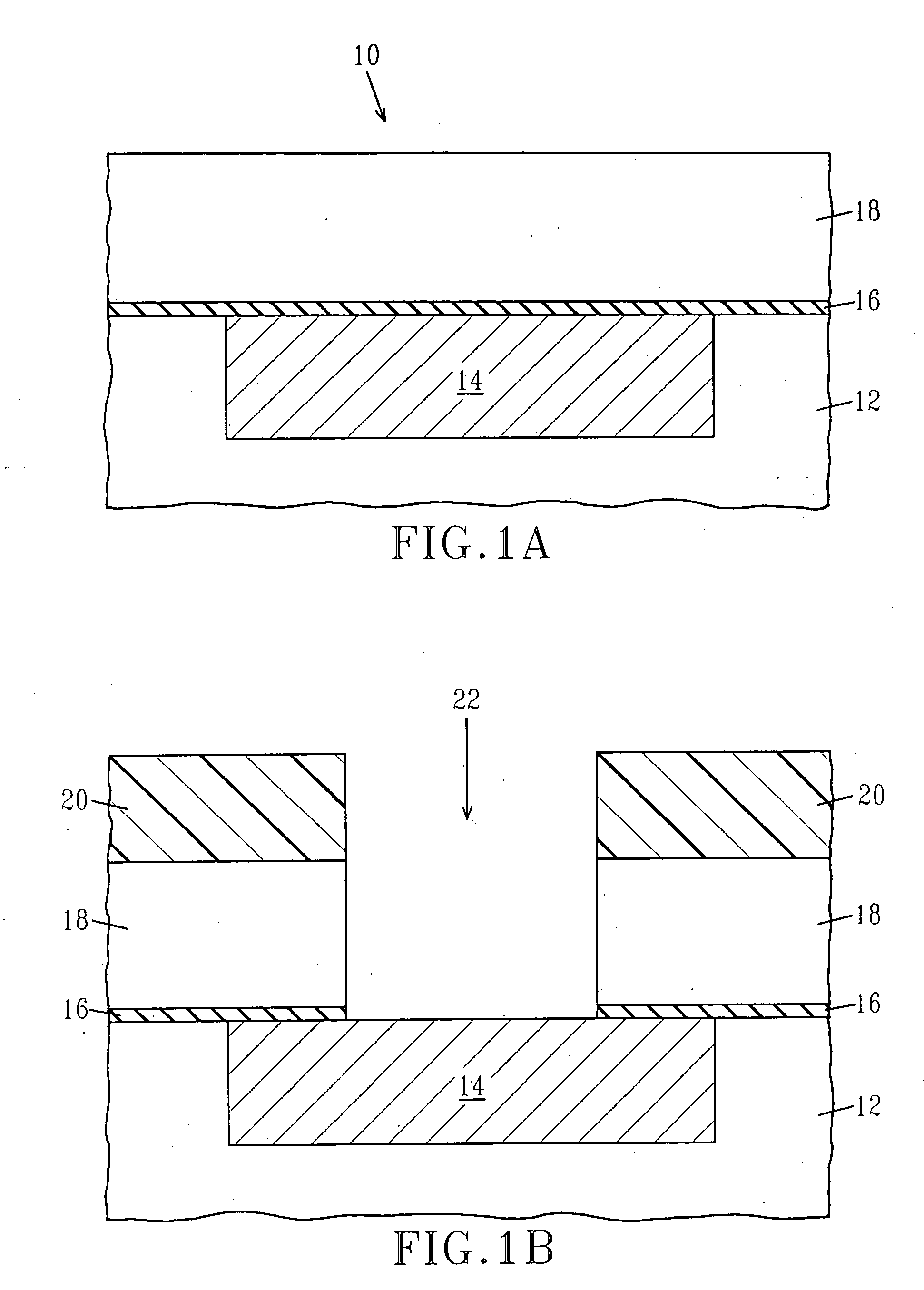

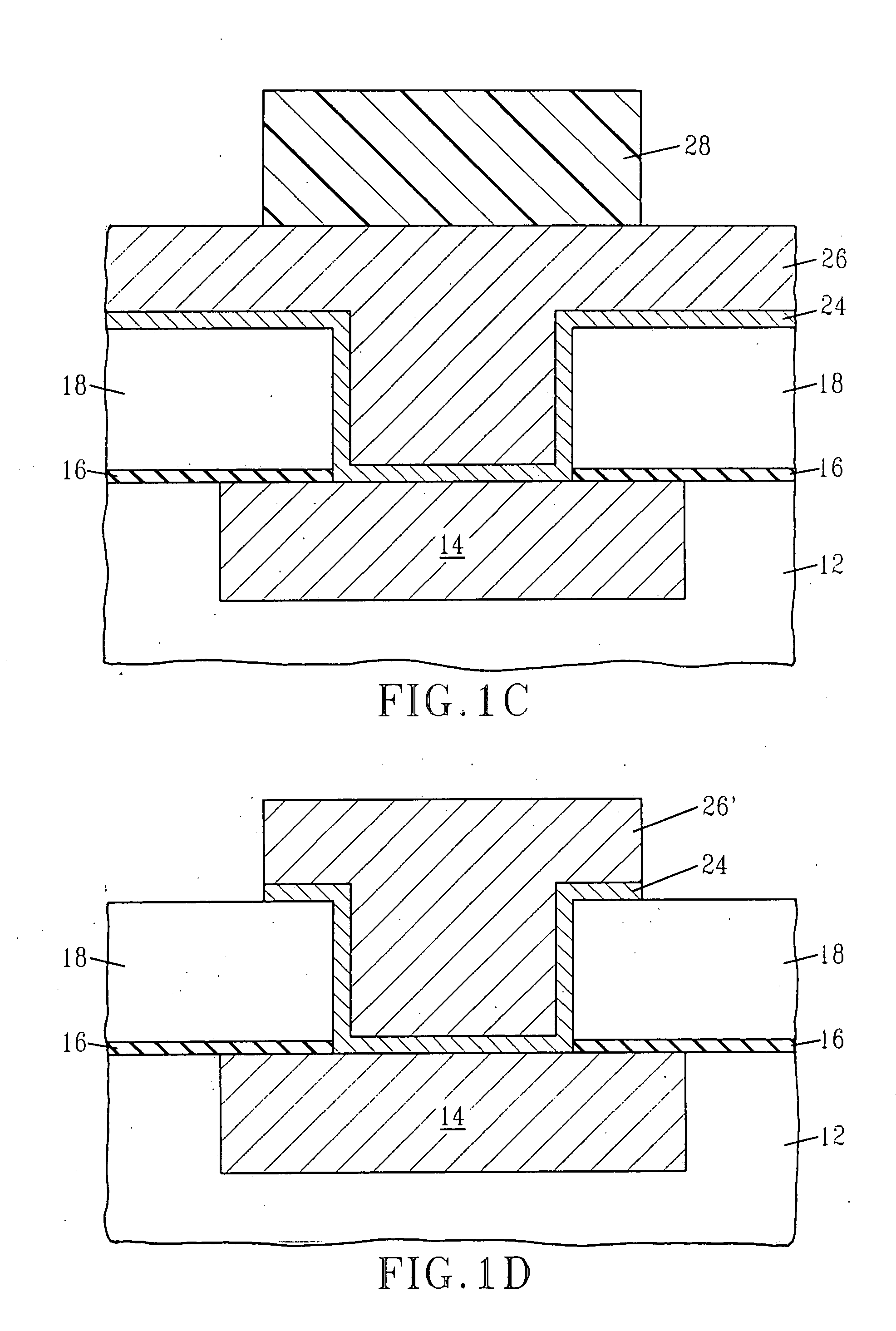

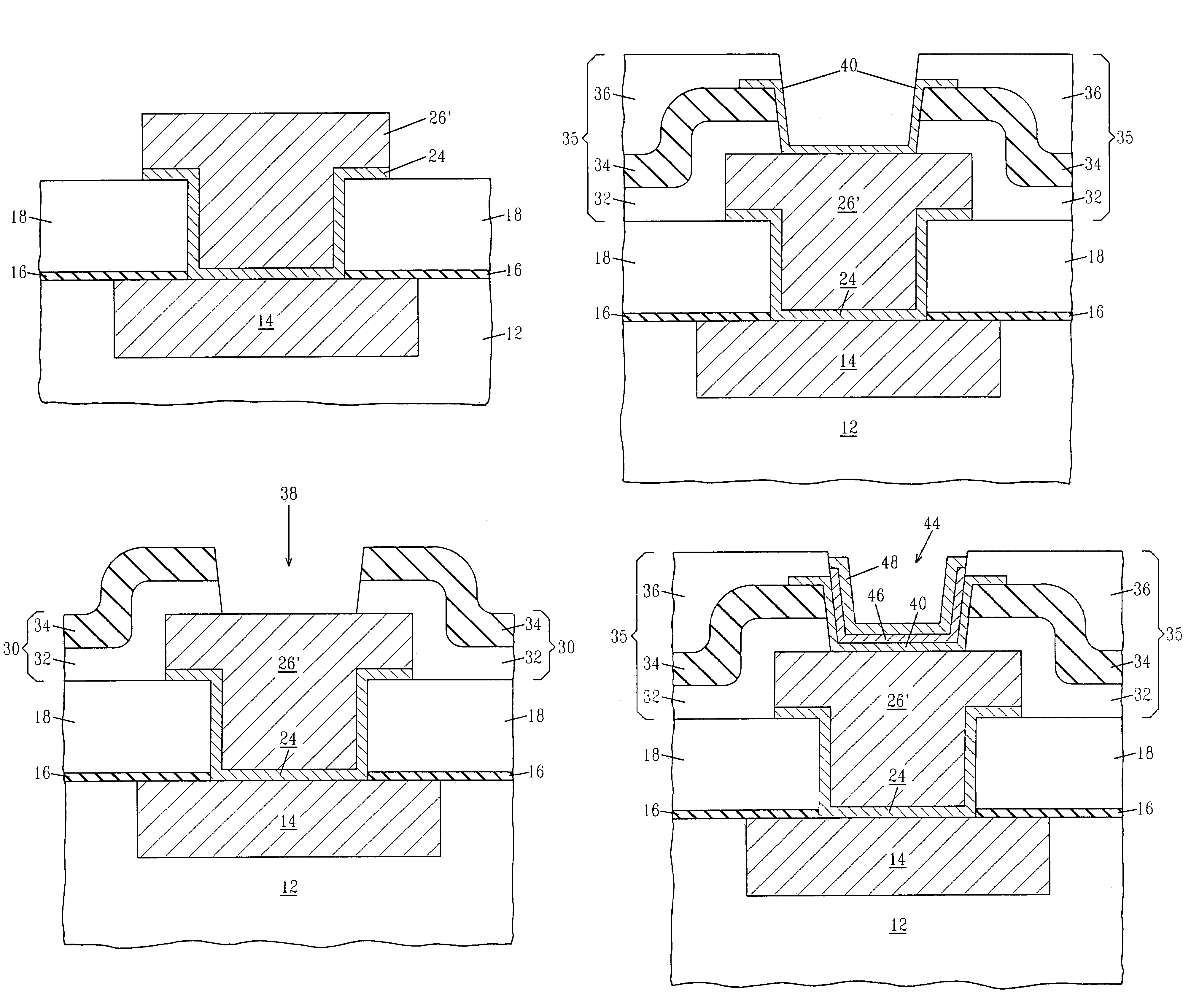

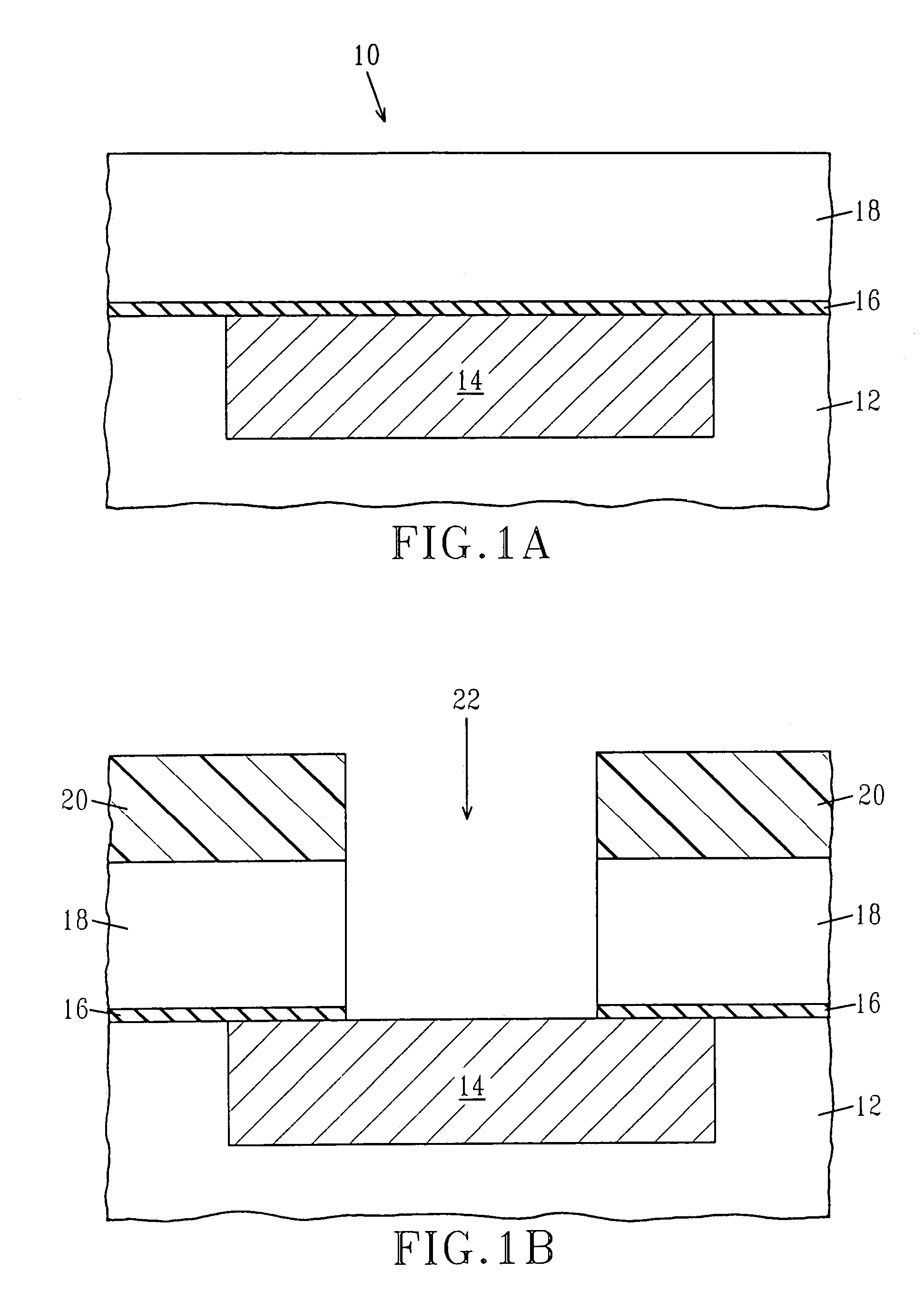

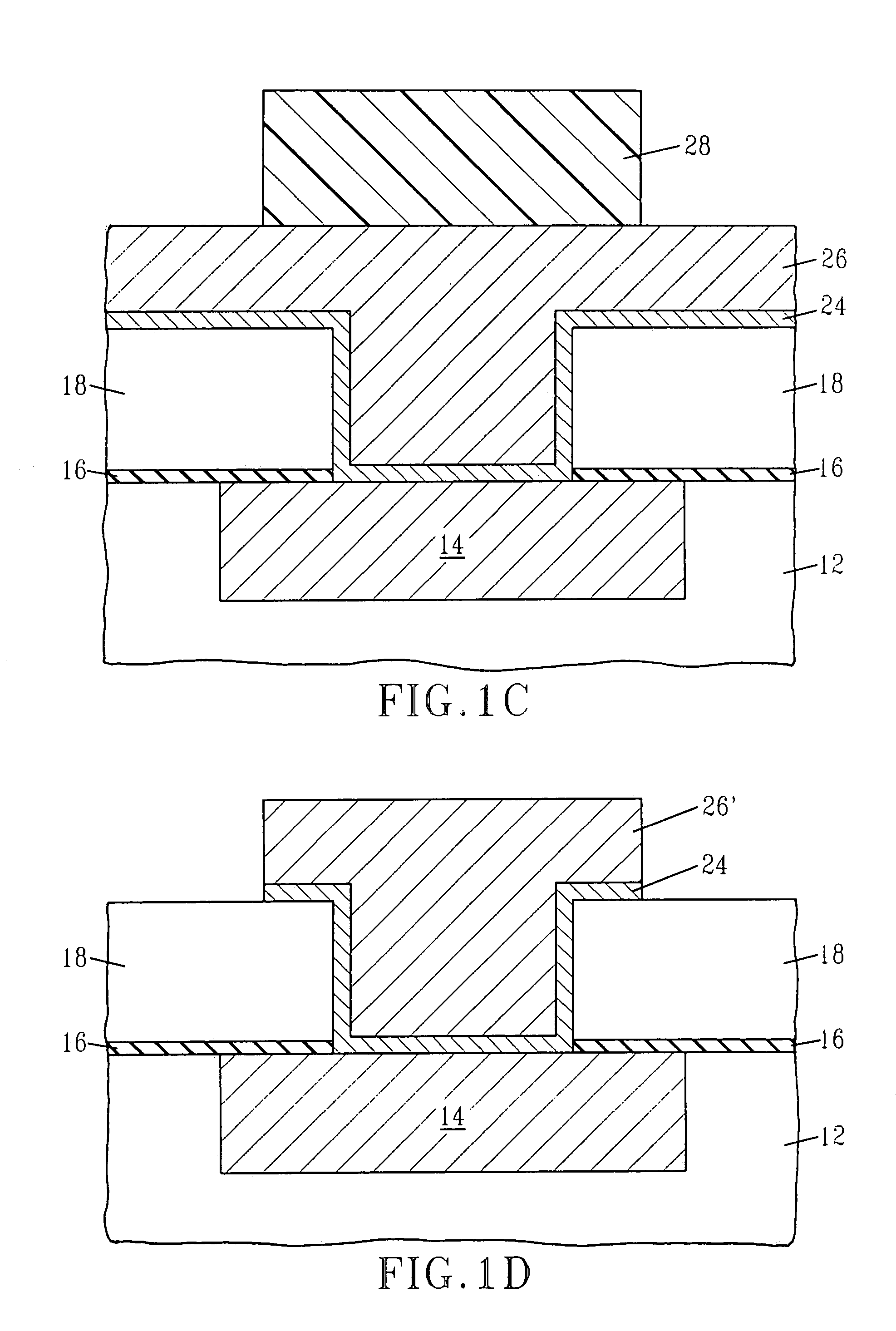

Novel integration of wire bond pad with Ni/Au metallization

InactiveUS20050074959A1Semiconductor/solid-state device detailsSolid-state devicesElectroless depositionMaterials science

A method for sealing an exposed surface of a wire bond pad with a material that is capable of preventing a possible chemical attack during electroless deposition of Ni / Au pad metallurgy is provided. Specifically, the present invention provides a method whereby a TiN / Ti or TiN / Al cap is used as a protective coating covering exposed surfaces of a wire bond pad. The TiN / Ti or TiN / Al cap is not affected by alkaline chemistries used in forming the Ni / Au metallization, yet it provides a sufficient electrical pathway connecting-the bond pads to the Ni / Au pad metallization.

Owner:GOOGLE LLC

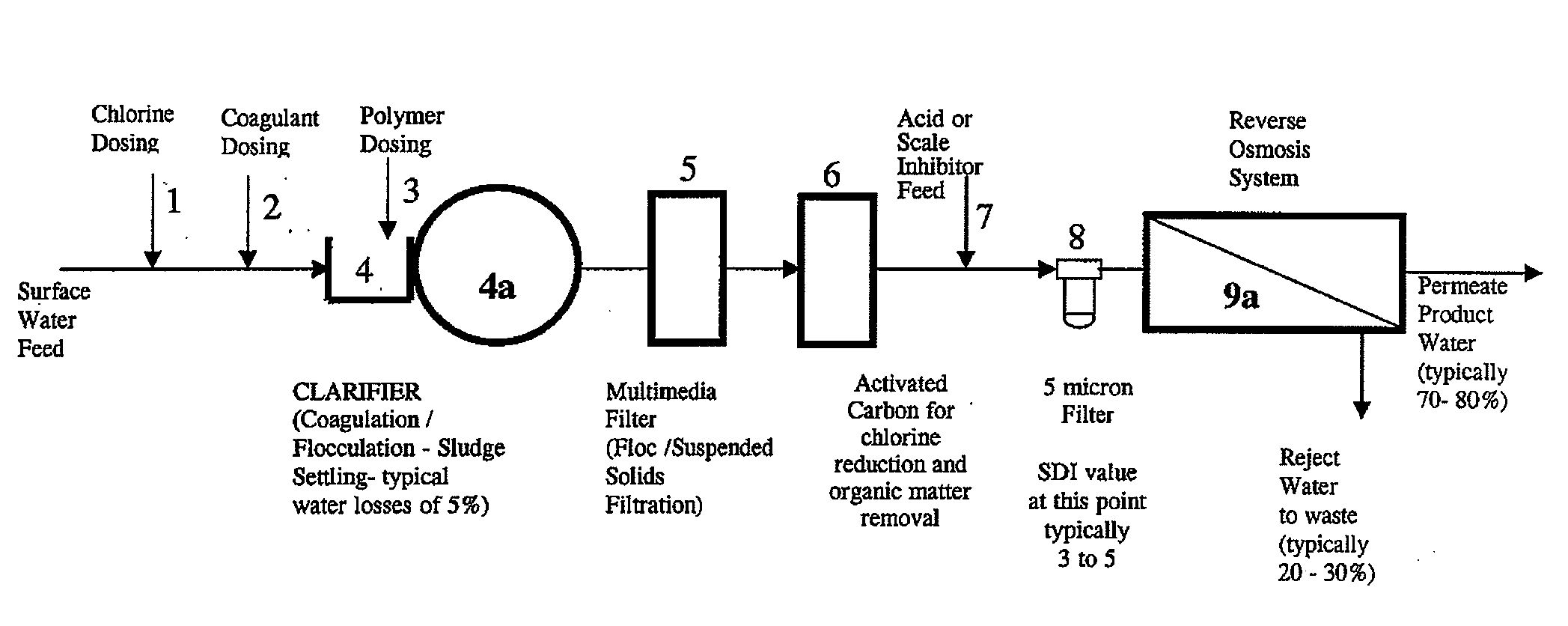

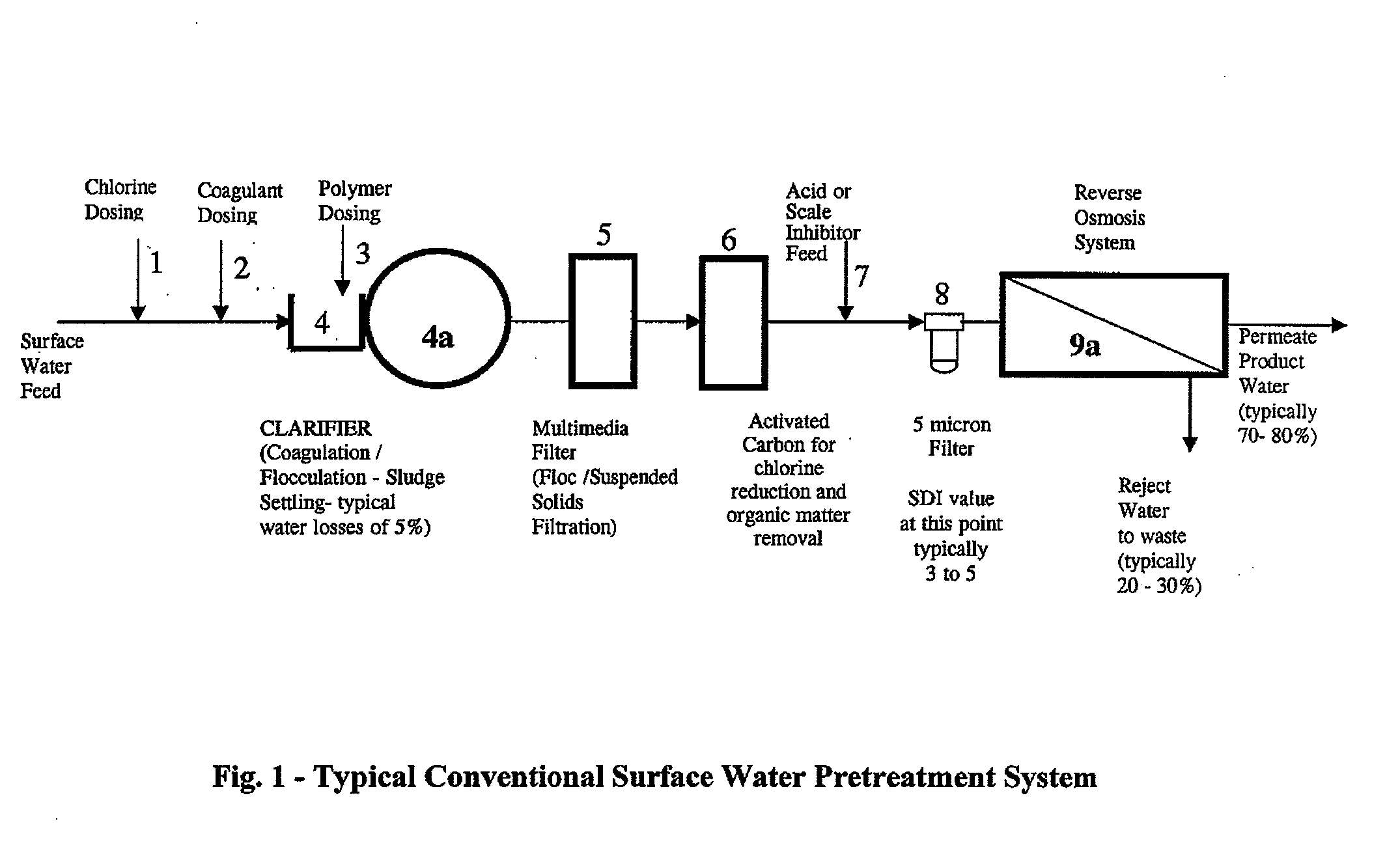

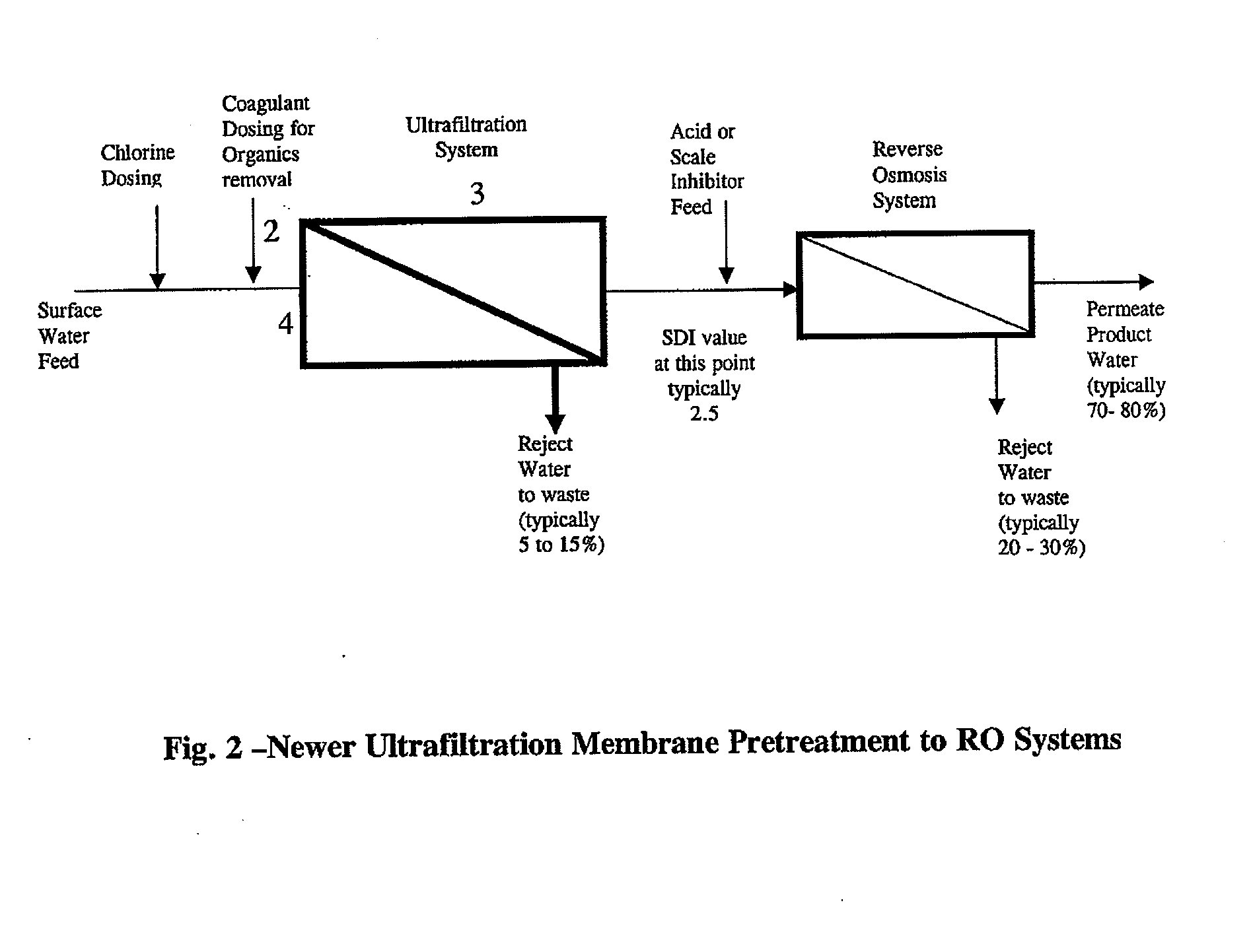

Reduced fouling of reverse osmosis membranes

ActiveUS20080173583A1Number of neededSmall sizeSpecific water treatment objectivesWater contaminantsPurification methodsReverse osmosis

The present invention provides a new water purification method and system using reverse osmosis. In particular, the present invention provides methods and water purification systems using an ion exchange resin and absorbent media for pretreatment of water being fed to a reverse osmosis treatment system, where the pretreatment reduces fouling of, or deposits or chemical attack on the membrane surfaces and passageways. Particularly, a macroporous resin having an average pore diameter in the range of 1,000 to 500,000 Angstroms and a crush strength or Chatillon value of at least 24 g / bead (710 μm bead diameter) is used.

Owner:PUROLITE CORP

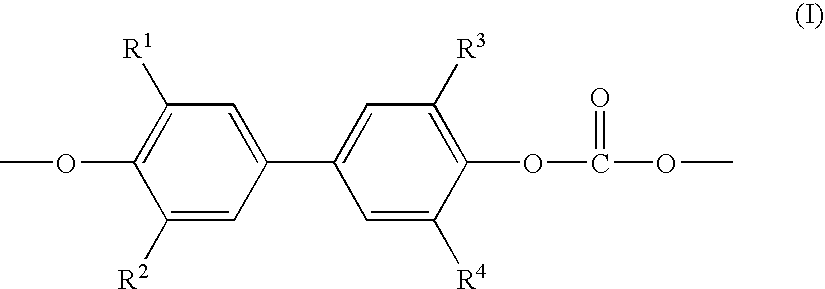

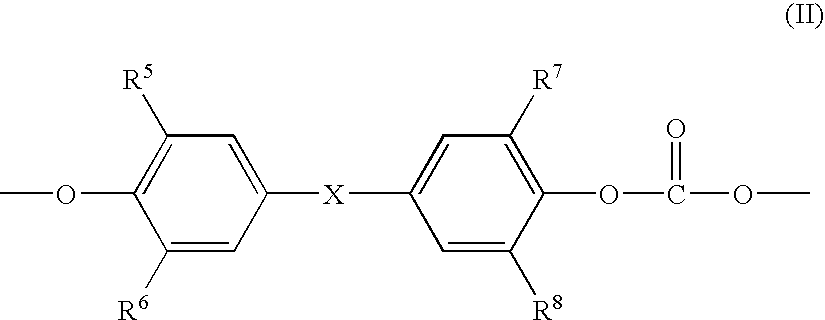

Multi-layer product containing polycarbonate

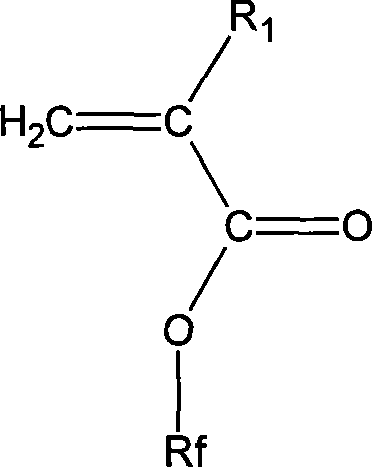

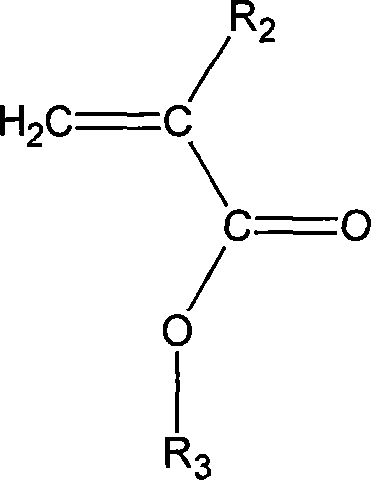

InactiveUS20040013882A1Simple and inexpensive to produceImprove impact resistanceSynthetic resin layered productsThin material handlingPolycarbonateChemical resistance

A multi-layer product comprising a coex layer and a base layer is disclosed. The coex layer contains a copolycarbonate derived from repeat units having the formula (I) where R<1 >to R<4 >are defined and repeat units having the formula (II) where R<5 >to R<8 >and X are defined. The base layer contains a polycarbonate characterized in that its chemical resistance is lesser than that of said copolycarbonate. The product is characterized by its improved resistance to chemical attack. Also disclosed are a uses of, and a method for producing the product.

Owner:BAYER AG

Method of metallizing solar cell conductors by electroplating with minimal attack on underlying materials of construction

InactiveUS20090120497A1Improve conductivity and efficiencyImprove conductivityAnodisationMirrorsIndiumElectrical conductor

The invention relates to a metallized solar cell and the method of making thereof that includes depositing a metal or metals such as silver, nickel, copper, tin, indium, gallium, or selenium or their alloys on solar cells in a manner to form more substantial and robust electrical contacts that can carry current more efficiently and effectively or to provide the active layers required to convert sunlight into electricity. These deposits also protect the underlying metallic materials from corrosion, oxidation or other environmental changes that would deleteriously affect the electrical performance of the cell. The invention also relates to the use of specialized electroplating chemistries that minimize residual stress and / or are free of organic sulfonic acids to minimize chemical attack on solar cell substrates or prior metallizations that include organic and / or inorganic binders or related materials for depositing the initial metallic portions of the cell.

Owner:TECHNIC INC

Microfiller-reinforced polymer film

A thin polymer film having improved properties of reduced coefficient of thermal expansion (CTE), reduced shrinkage, increased modulus, and greater resistance to chemical attack is produced by a method wherein a plastic material is filled with a microfiller. Optimally, the present invention provides a micro-filled polyimide film.

Owner:HANKET GREGORY M

Environmental monitoring using mobile devices and network information server

ActiveUS20070109119A1Reduce in quantityReduce complexityFrequency-division multiplex detailsTime-division multiplexEngineeringMobile device

Sensors mounted on vehicles (e.g., buses, taxis, police cars) and public personnel (e.g., policemen) are used to monitor various conditions and situations such as air quality, potential biological and chemical attacks, and road and traffic conditions. The invention improves upon the typical approach that deploys fixed sensors at every geographical position of interest. The total number of required sensors and the size and the complexity of the network infrastructure required to connect the sensors are reduced and simplified. A method for estimating the number of mobile sensors required to cover a region of interest also is disclosed. A relatively small number of mobile sensors may be sufficient to cover a large area at a lower cost and less complexity than a fixed sensor network.

Owner:TELCORDIA TECHNOLOGIES INC +1

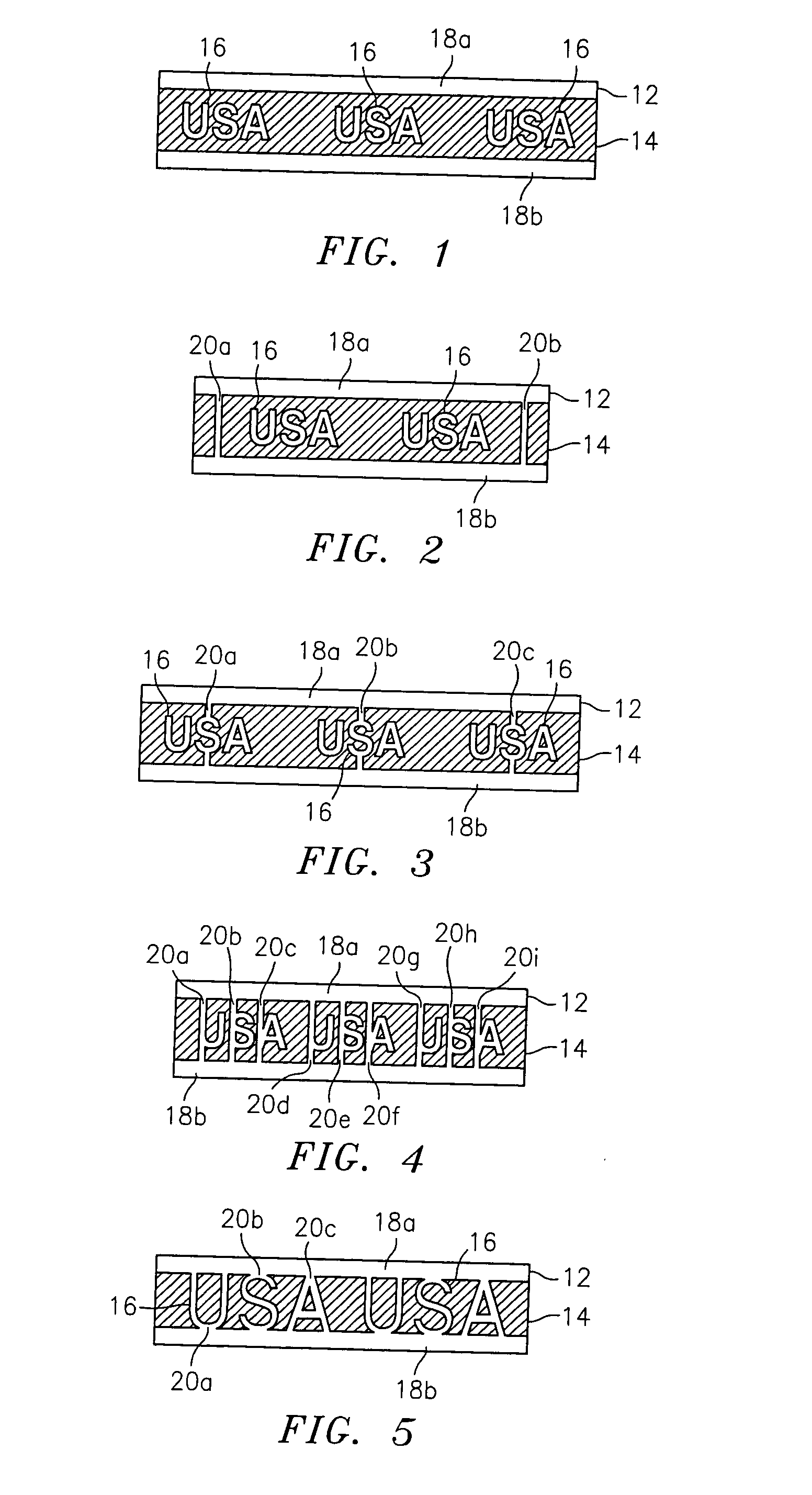

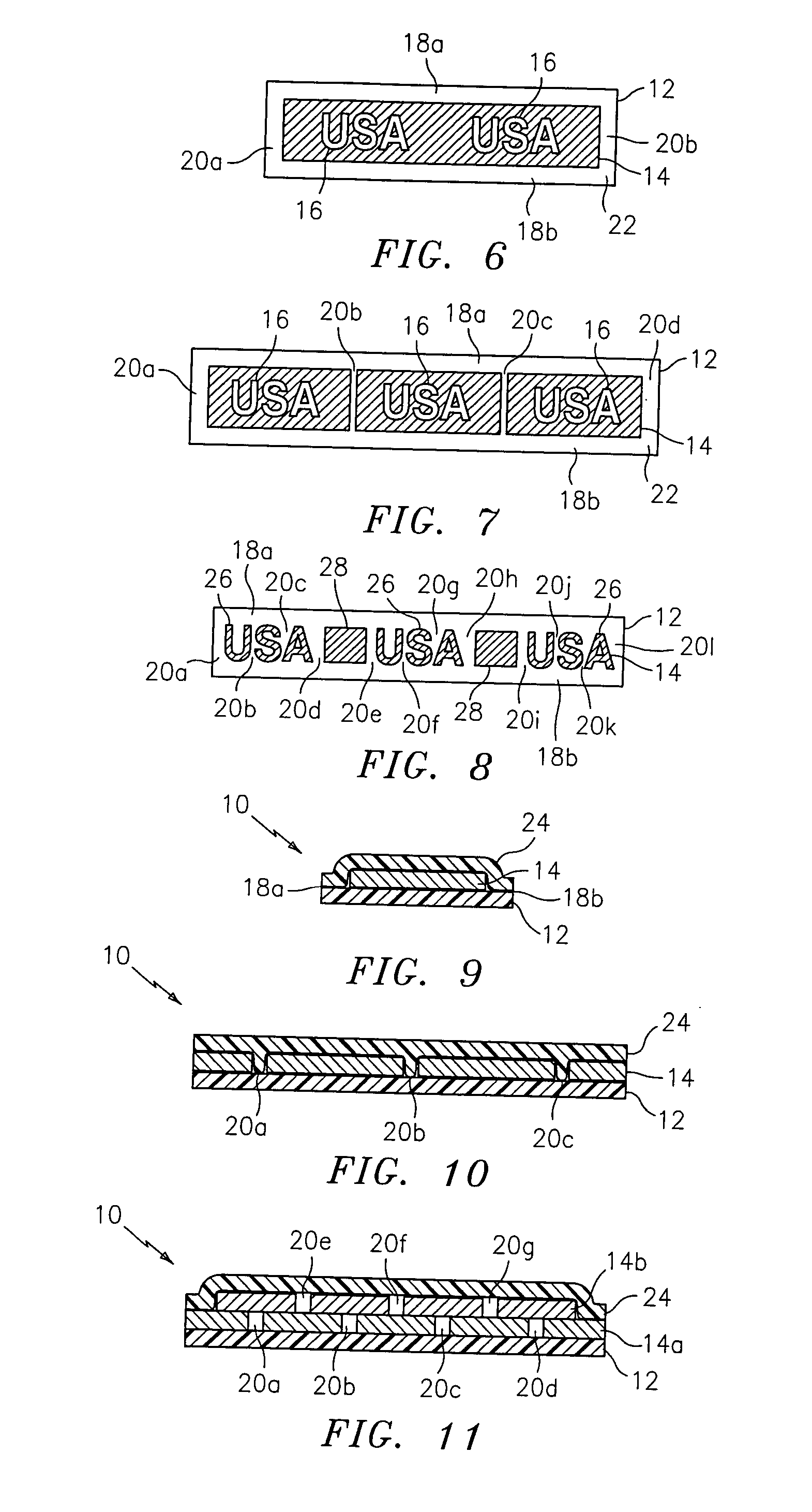

Durable security devices and security articles employing such devices

InactiveUS20050040641A1Other printing matterCellulosic plastic layered productsEngineeringSafety Equipment

Durable security devices that are resistant to chemical attack and mechanical degradation and security articles employing such devices, are provided. By way of the durable security device of the present invention, opposing longitudinal borders adjacent an information-bearing layer are sealed, thereby preventing corrosive and / or degrading materials from reaching this layer through these sealed borders. In a preferred embodiment, at least a portion of the information-bearing layer is fully encapsulated, thereby rendering this portion or layer and the information conveyed thereby, impervious to chemical attack.

Owner:TECHN GRAPHICS

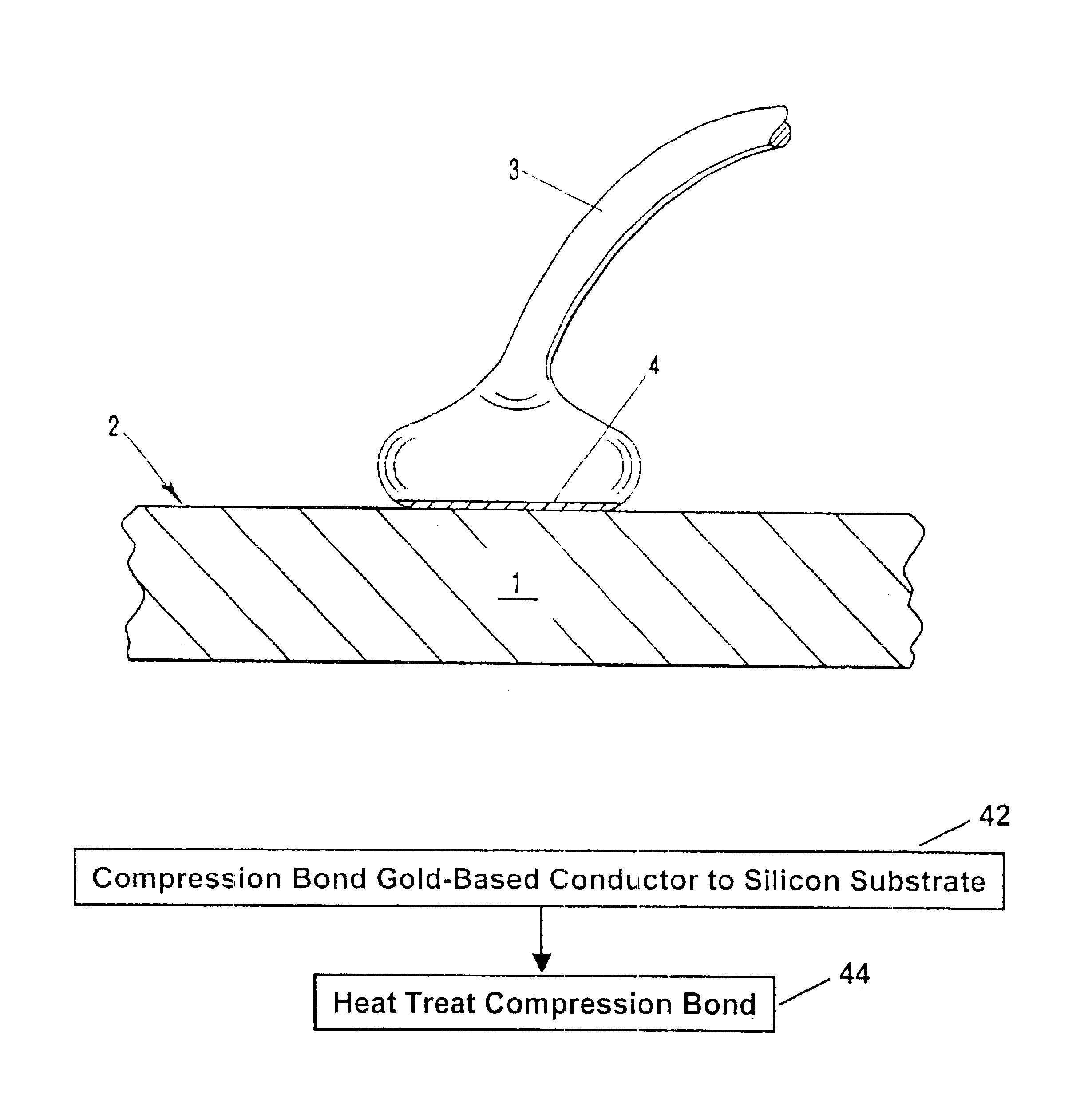

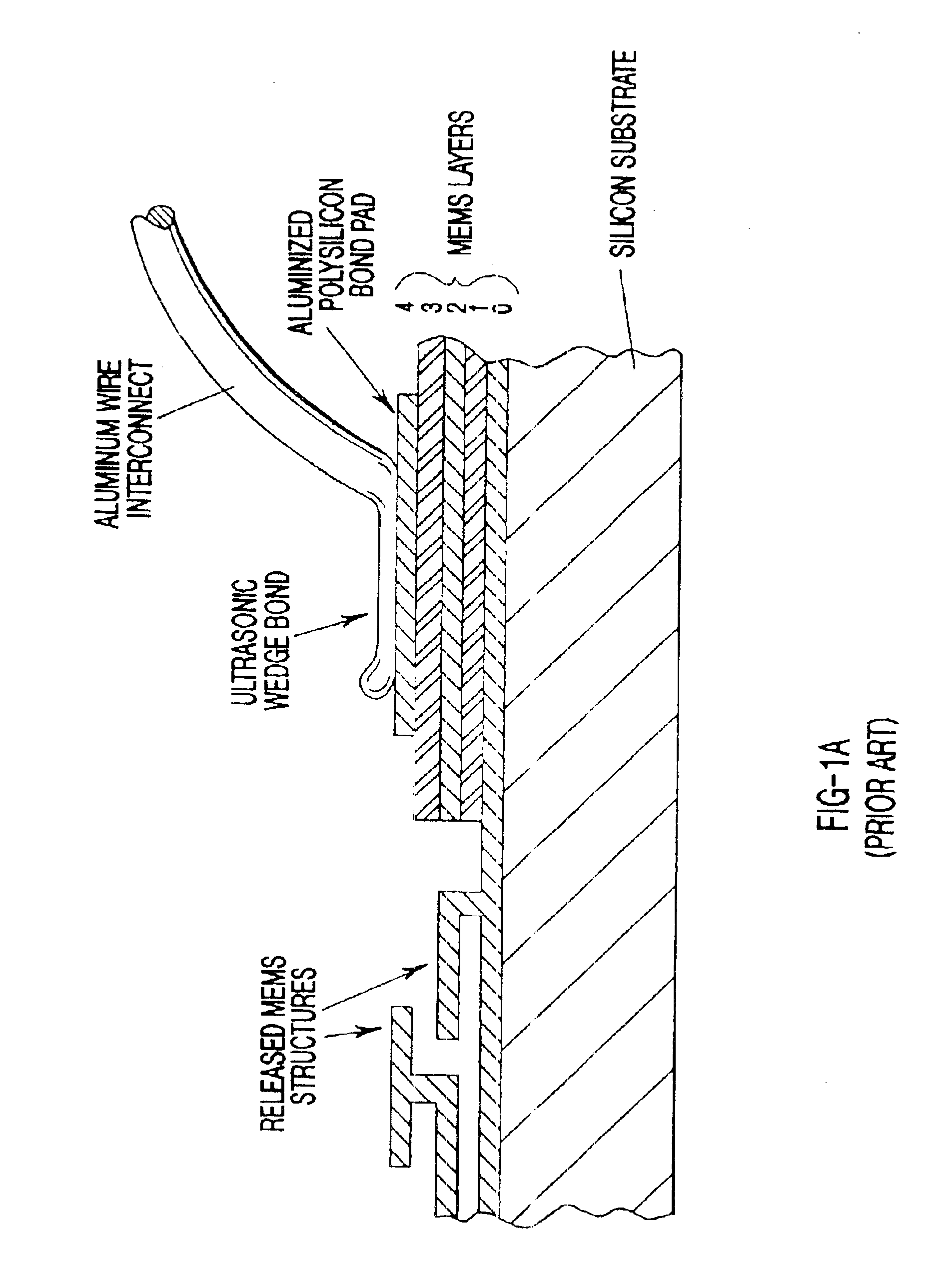

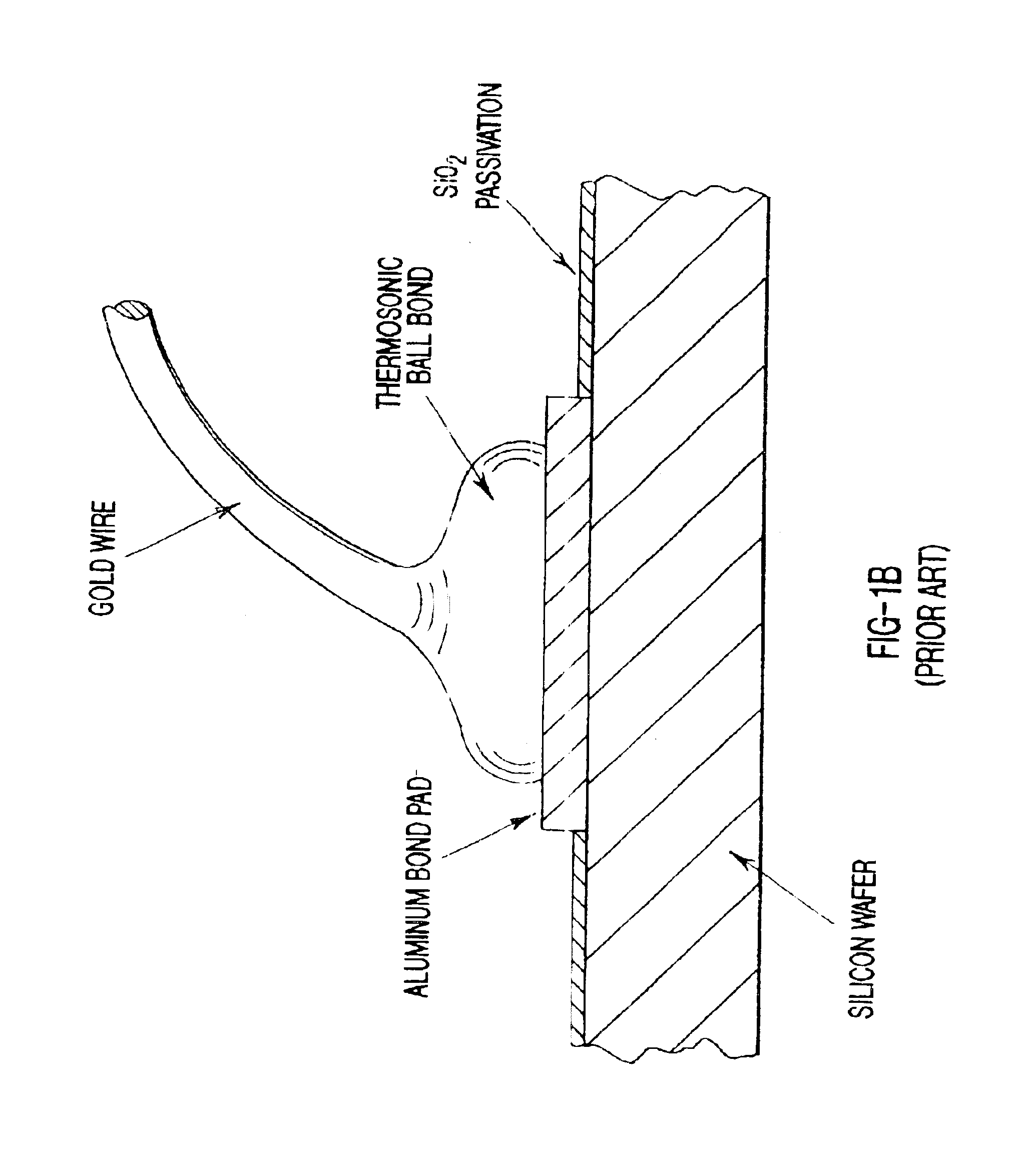

Release resistant electrical interconnections for MEMS devices

InactiveUS6858943B1High bonding strengthImprove bindingMaterial nanotechnologySemiconductor/solid-state device detailsElectrical conductorEngineering

A release resistant electrical interconnection comprising a gold-based electrical conductor compression bonded directly to a highly-doped polysilicon bonding pad in a MEMS, IMEMS, or MOEMS device, without using any intermediate layers of aluminum, titanium, solder, or conductive adhesive disposed in-between the conductor and polysilicon pad. After the initial compression bond has been formed, subsequent heat treatment of the joint above 363 C creates a liquid eutectic phase at the bondline comprising gold plus approximately 3 wt % silicon, which, upon re-solidification, significantly improves the bond strength by reforming and enhancing the initial bond. This type of electrical interconnection is resistant to chemical attack from acids used for releasing MEMS elements (HF, HCL), thereby enabling the use of a “package-first, release-second” sequence for fabricating MEMS devices. Likewise, the bond strength of an Au—Ge compression bond may be increased by forming a transient liquid eutectic phase comprising Au-12 wt % Ge.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Special adhesive for underwater construction and preparation method thereof

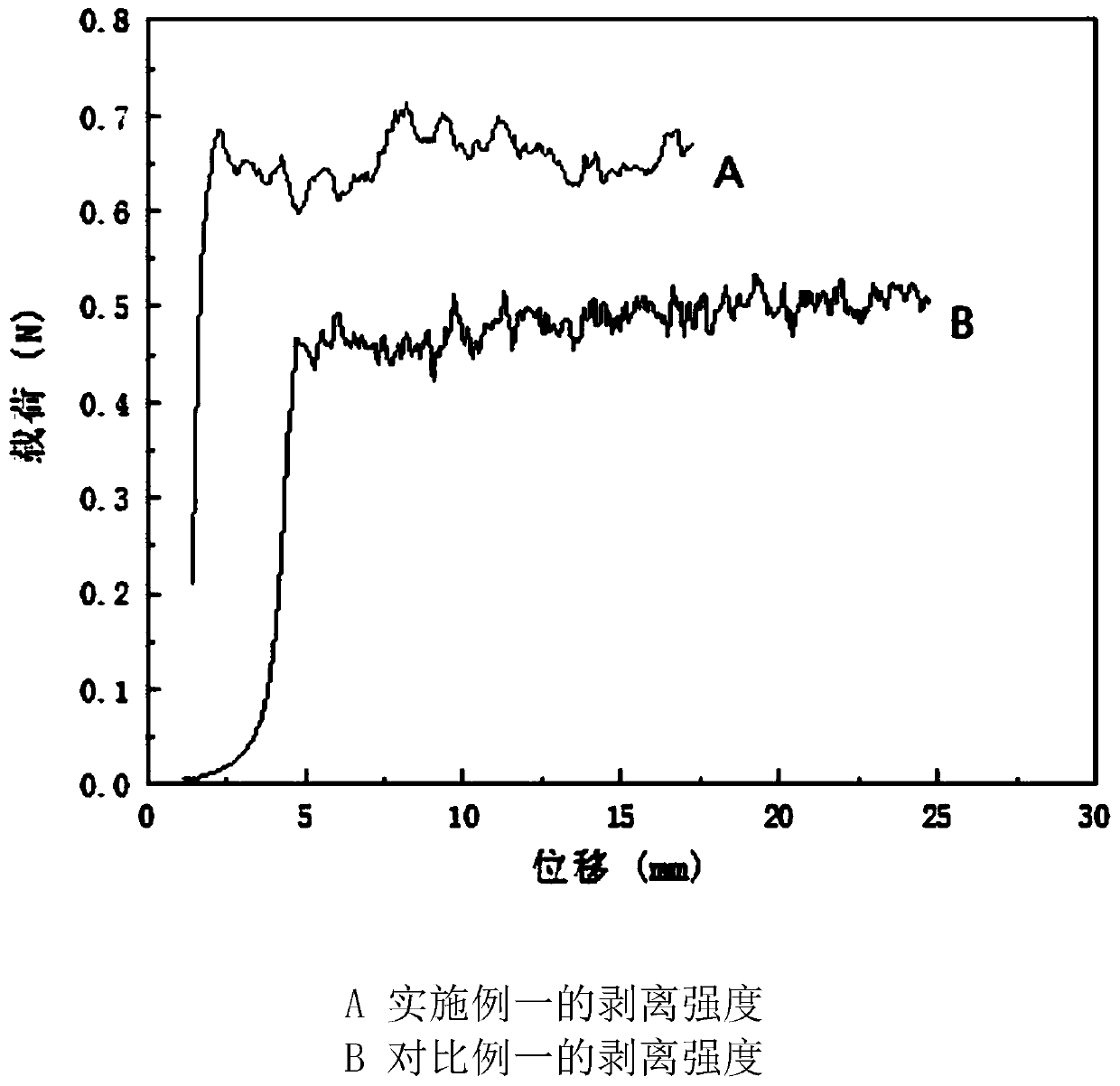

InactiveCN103555243AIncrease elasticityGood resistance to cold and heat shockNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesiveActive agent

The invention discloses a special adhesive for underwater construction, and the special adhesive comprises an A component and a B component at a weight ratio of 100:(20-100):25, wherein the A component is prepared from the following raw materials in parts by weight: 30-60 parts of modified epoxy resin, 5-30 parts of tackifier, 2-10 parts of accelerant, 5-15 parts of reactive diluent, 0.1-0.3 parts of surfactant, and 10-35 parts of filler powder; the B component is prepared from the following raw materials in parts by weight: 0-60 parts of ketimine, 0-60 parts of phenalkamine, 30-65 parts of modified polyamide, 1-6 parts of curing accelerator, and 2-15 parts of moisture repellent. The special adhesive for underwater construction has the advantages of being good in bonding strength in water, good in toughness, water-resistant, capable of resisting chemical attack, strong in initial viscous force and convenient to construct, and great improvement is brought for the underwater construction field.

Owner:YANTAI DARBOND TECH

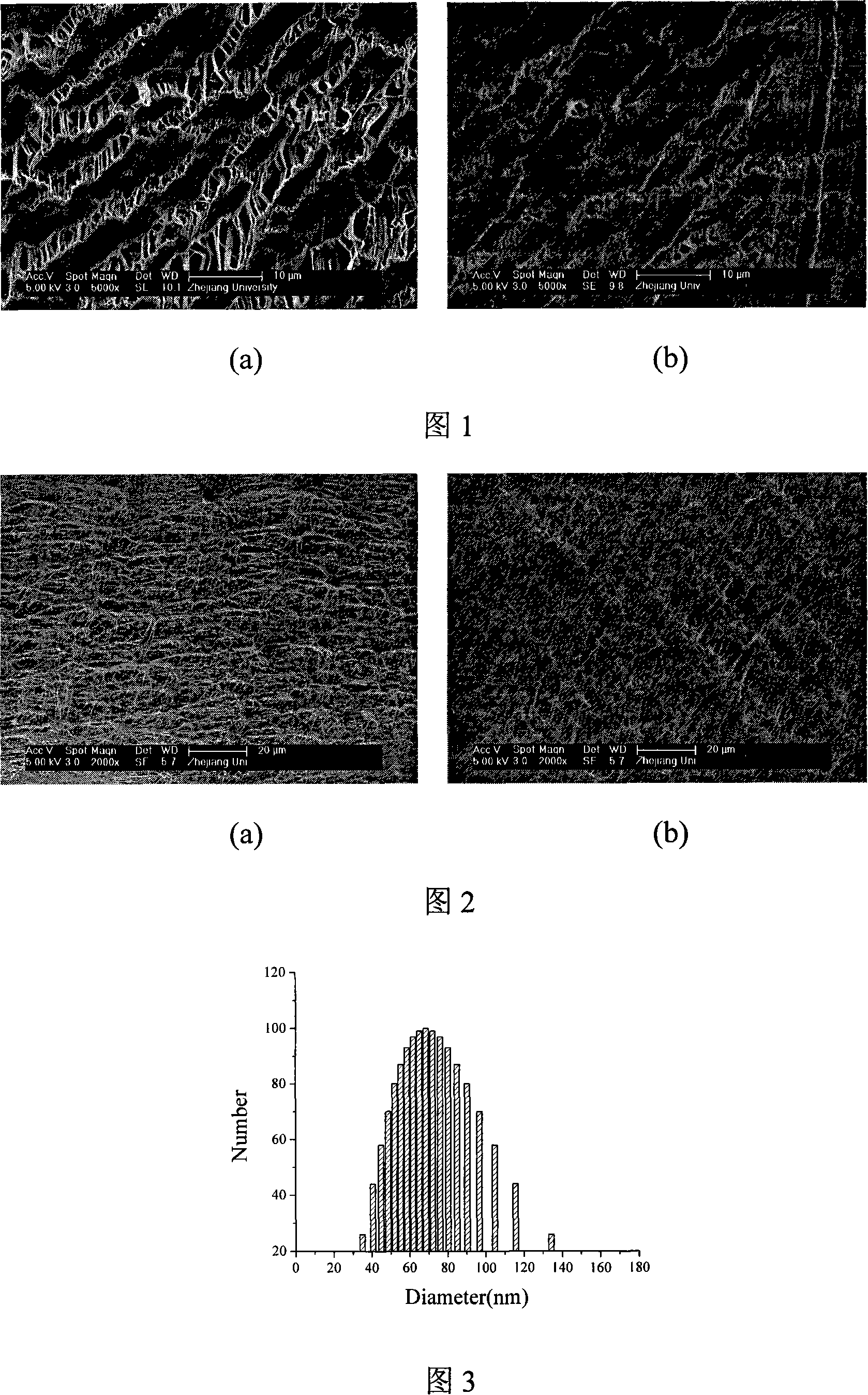

Method of amphipathic nature fluorine-contained copolymer modifying surface of polytetrafluoroethylene porous membrane

InactiveCN101108313AImprove anti-pollution performanceImprove hydrophilic abilitySemi-permeable membranesFiberTetrafluoroethylene

Owner:ZHEJIANG UNIV

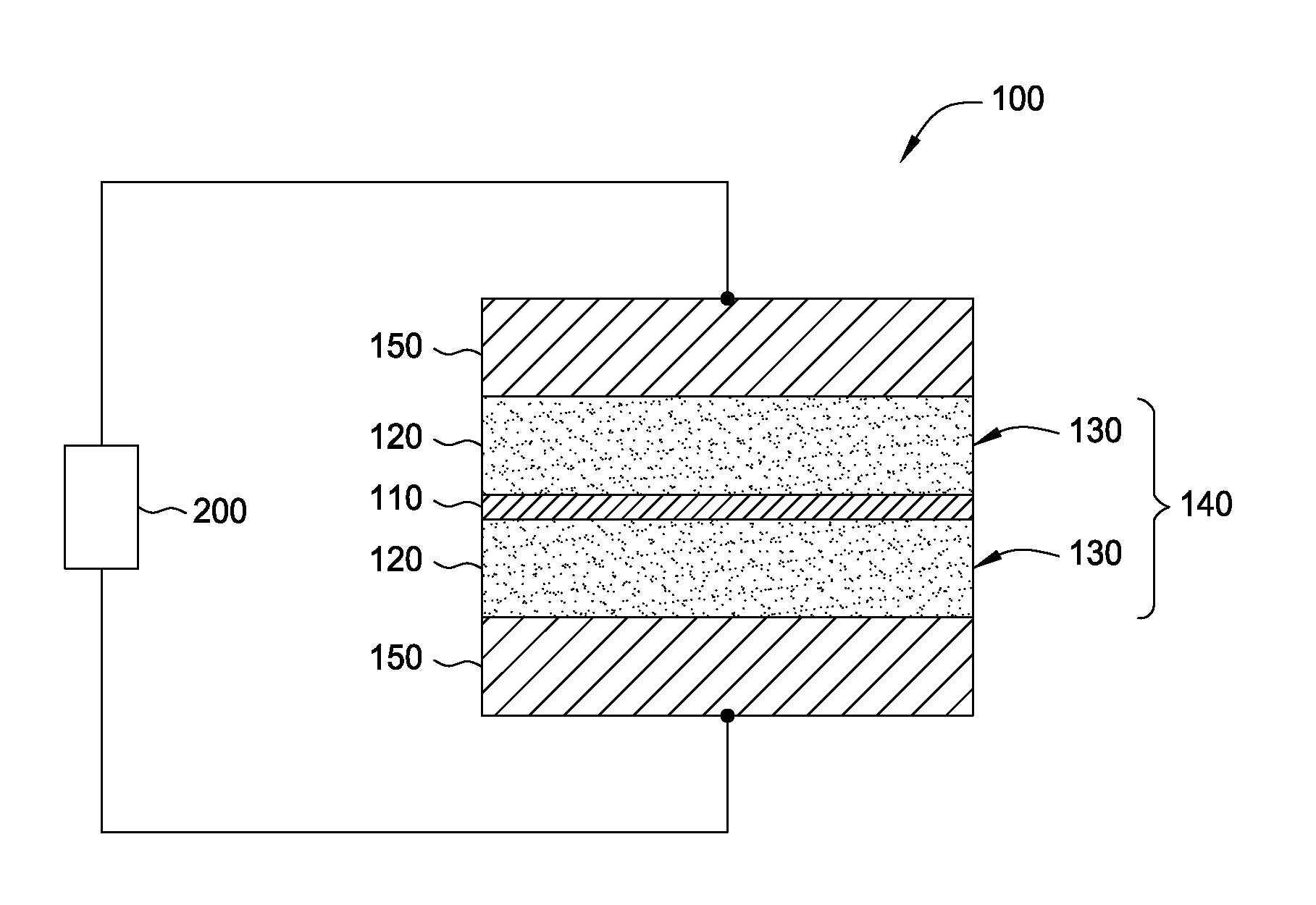

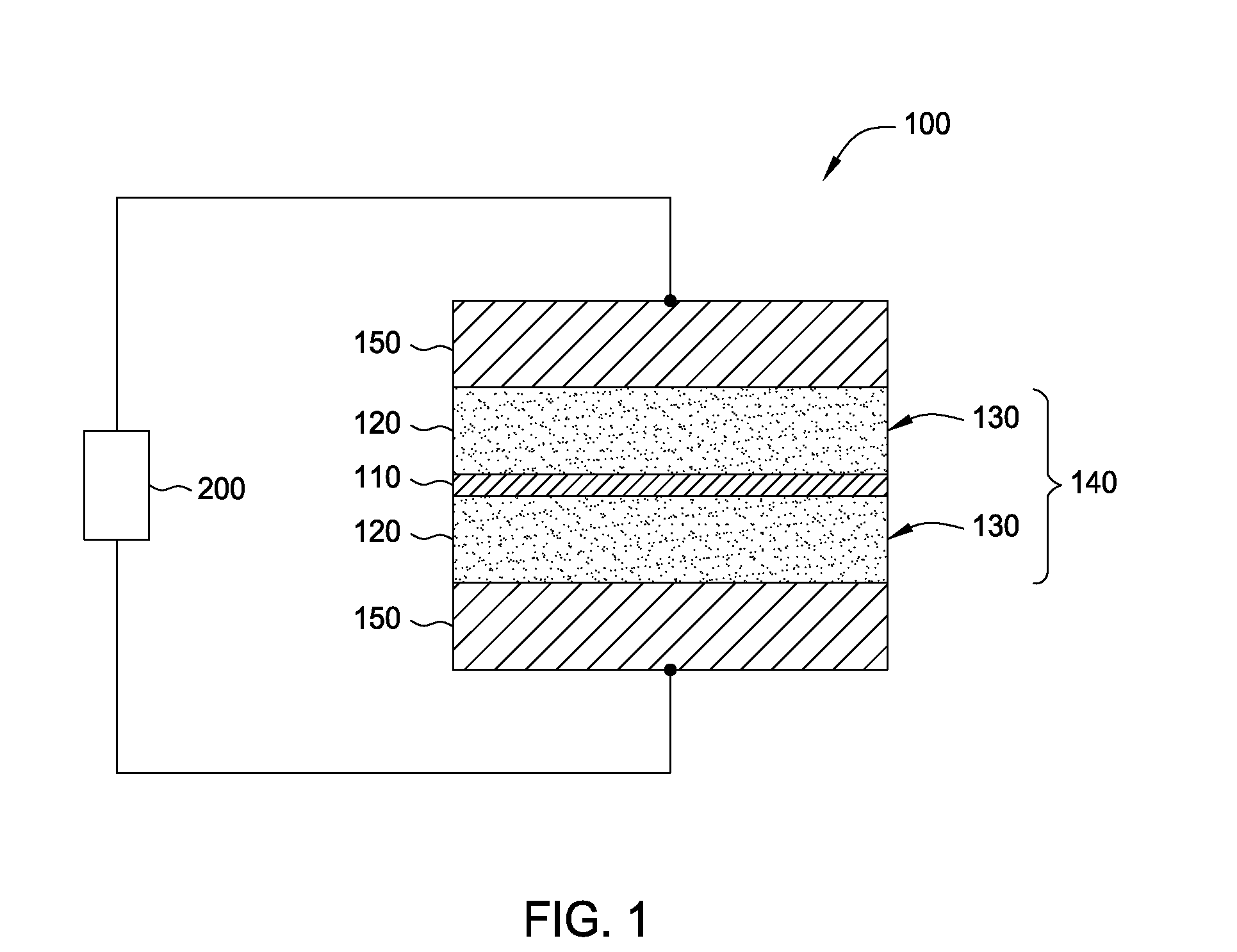

Method of forming a reliable electrochemical capacitor

The present invention generally relates to the method of creating a reliable and cost efficient electrochemical capacitor electrode that has an improved lifetime, lower production cost and improved process performance. The invention generally includes treating or conditioning an electrode surface by depositing a ruthenium containing layer, or layers, having good adhesion to the substrate, low electrical resistivity (high conductivity) and has good resistance to chemical attack during the operation of electrochemical capacitor. One aspect of the invention discussed herein is a method of forming an electrode by depositing a ruthenium containing layer at relatively low temperatures, such as <180° C.

Owner:APPLIED MATERIALS INC

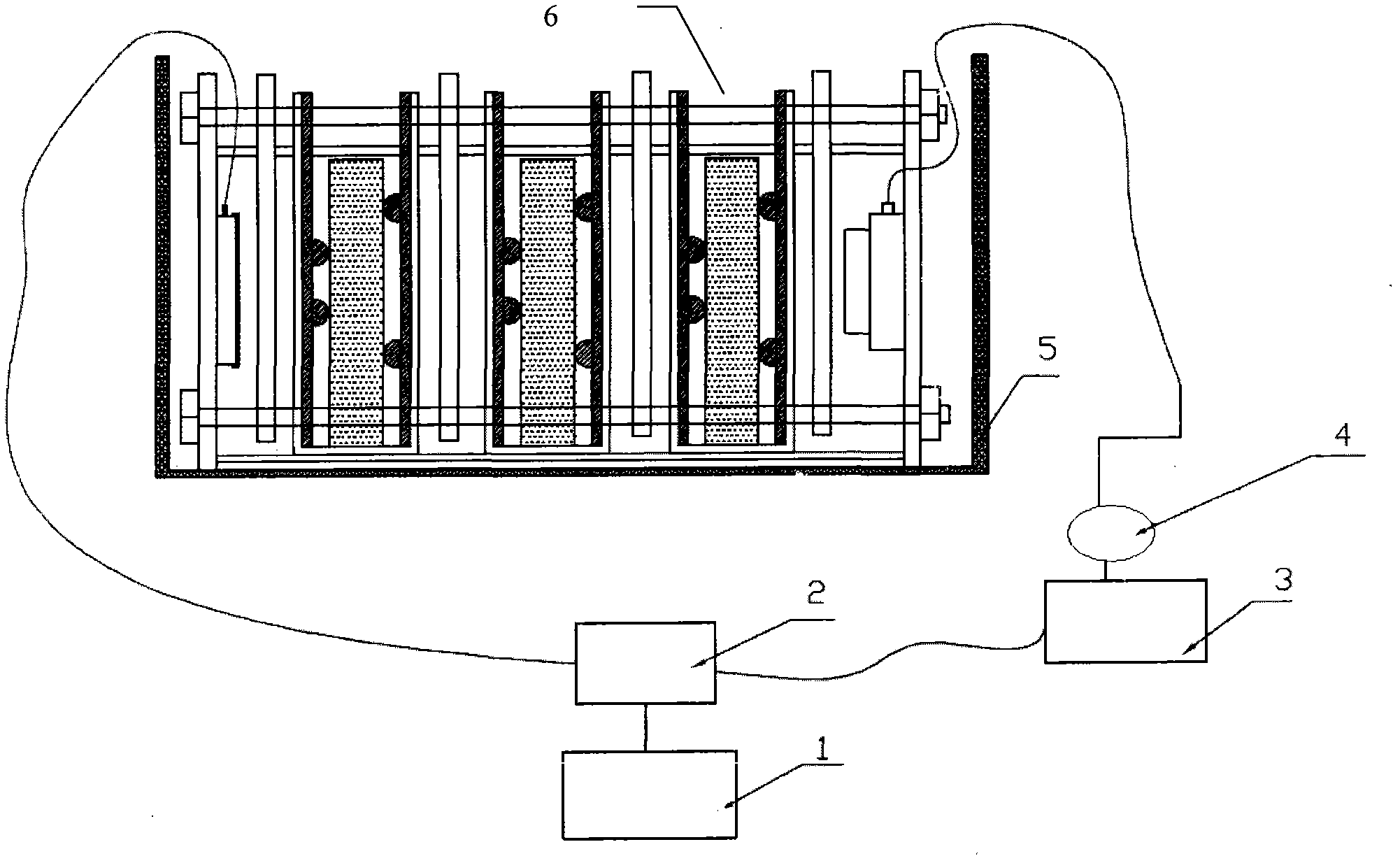

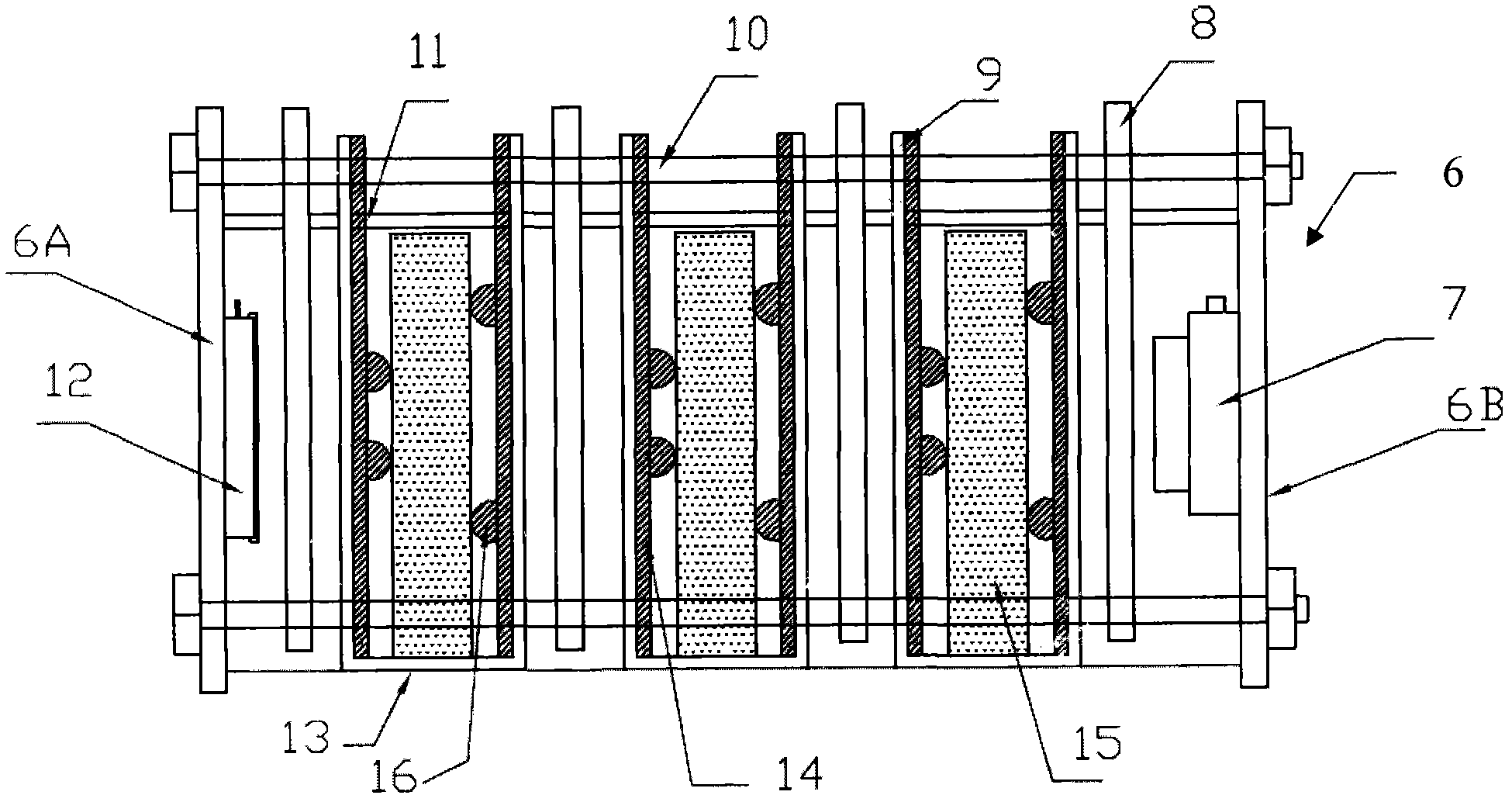

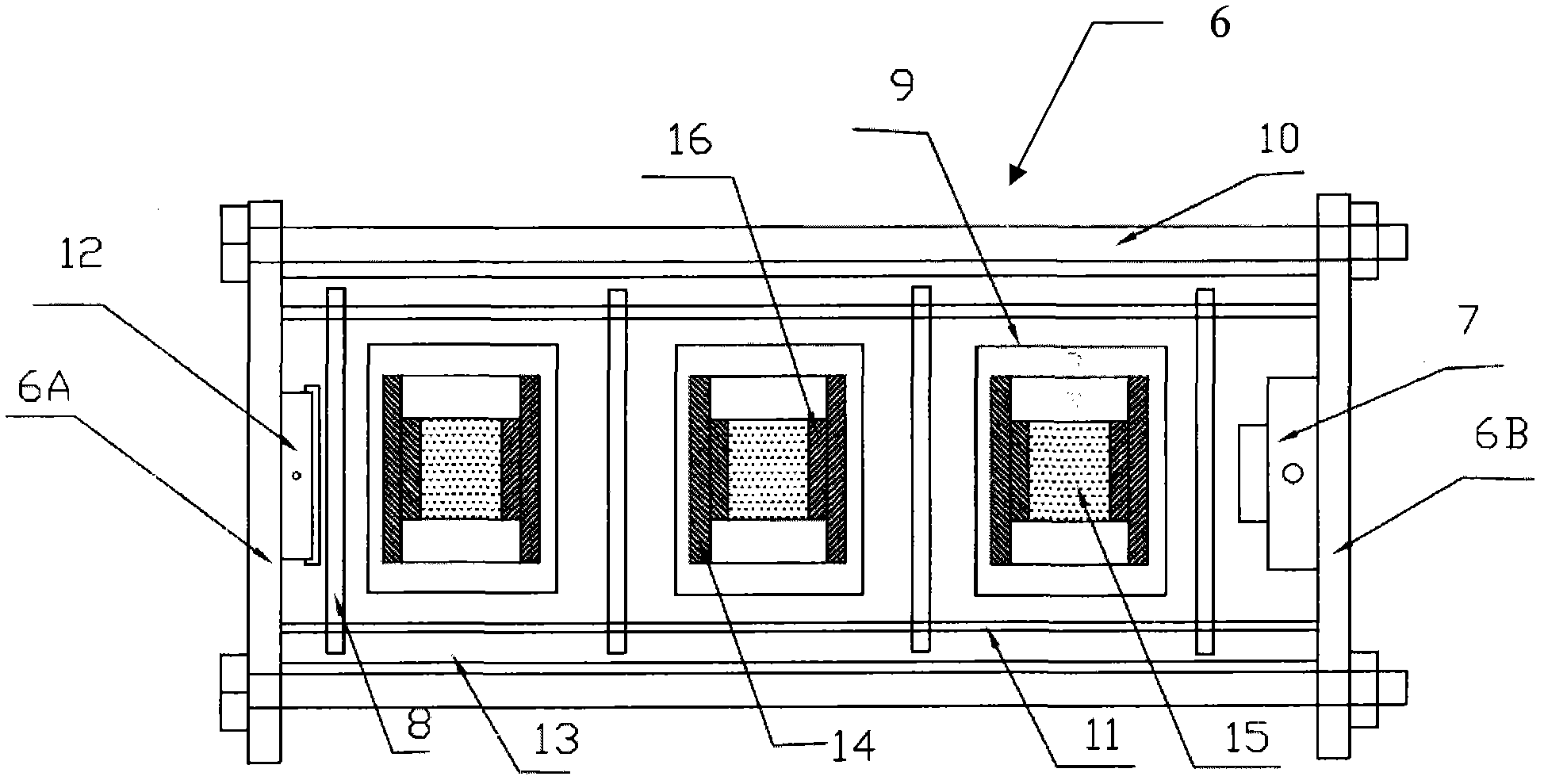

Constant loading device for testing durability of reinforced concrete

ActiveCN102466596AApply load accuratelyReflect durabilityWeather/light/corrosion resistanceMaterial strength using steady bending forcesFreeze thawingReinforced concrete

The invention discloses a device for constantly loading pressure for testing the durability of reinforced concrete, comprising a touch screen, a controller, an electric hydraulic pump, an energy storage tank, a loading assembly, and a rapid freeze-thaw cycle instrument box, wherein, the loading assembly comprises fixed left and right baffle plates, a hydraulic jack is fixed on the inner side of one baffle plate, and a pressure sensor is fixed on the inner side of the other baffle plate, a plurality of slidable slide plates and specimen boxes comprising four-point bending backing plates and rubber boxes are parallelly arranged between the pressure sensor and the hydraulic jack, specimens are arranged in the specimen boxes; the touch screen is connected with a controller data line, the pressure sensor is connected with the controller data line, the controller is connected with an electric hydraulic pump data line, and the hydraulic jack is communicated with the electric hydraulic pump and the energy storage tank through a three-way pipe. According to the invention, real working conditions of the interaction of stress, chemical attack, dry-wet cycle or freeze-thaw cycle on a concretemember in a practical project can be simulated, thus the data obtained by laboratory tests has great value for engineering reference.

Owner:CHINA BUILDING MATERIALS ACAD

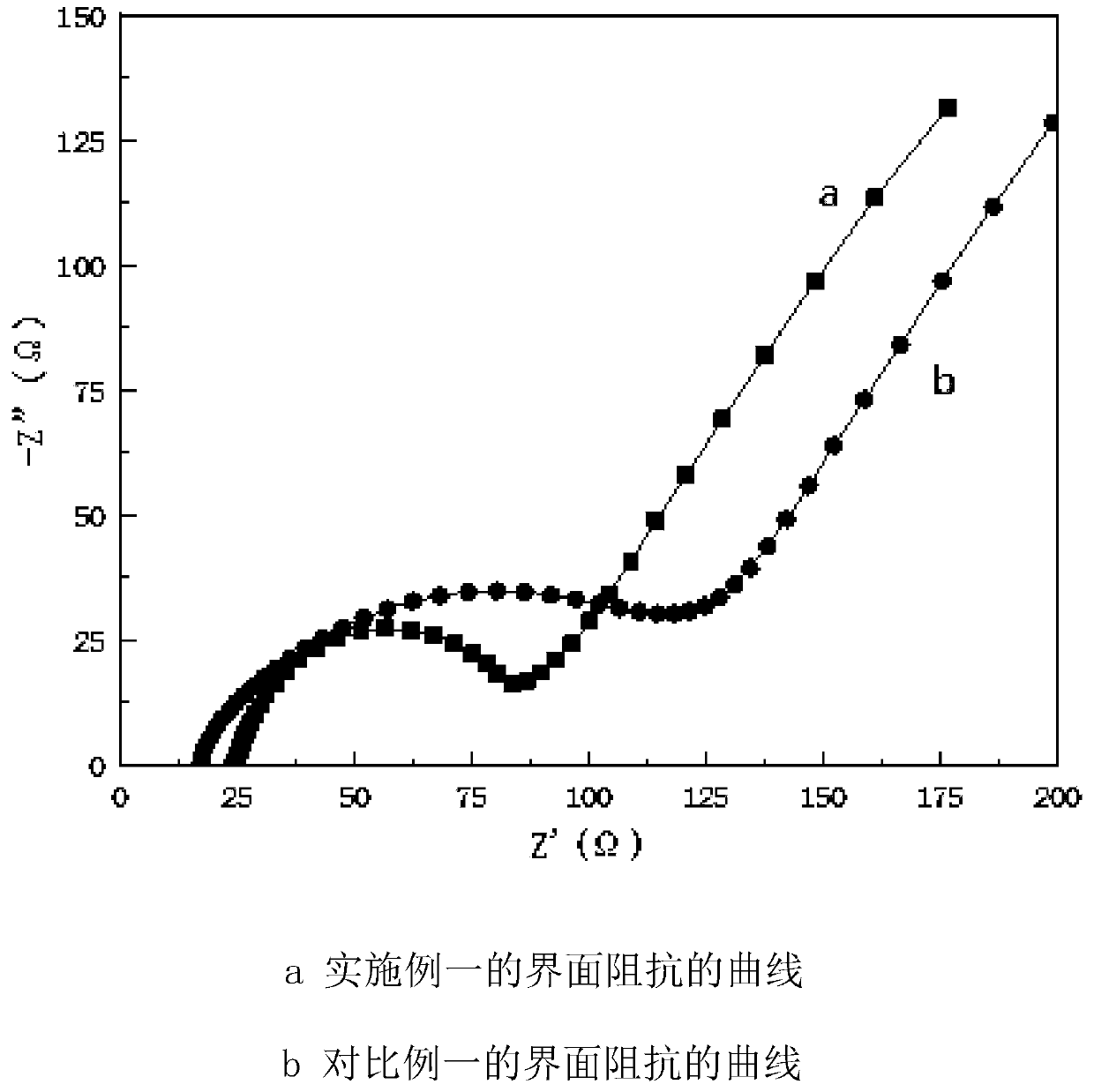

Preparation method of composite electrolyte layer and solid state battery

ActiveCN109860720AImprove protectionIncrease productivityFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteComposite electrolyte

The present invention discloses a preparation method of a composite electrolyte layer, and relates to the field of solid state batteries. The method comprises the following steps of: S1, uniformly mixing an inorganic solid electrolyte powder body and an organic polymer powder body according to a mass ratio to obtain a composite electrolyte powder body; S2, uniformly spraying the composite electrolyte powder body obtained in the S1 through an electrostatic powder spraying device to a positive plate and / or a negative plate; and S3: performing heat treatment of the positive plate and / or the negative plate after spraying, taking out the positive plate and / or the negative plate for natural cooling. According to the technical scheme, the use of an organic solvent is omitted to improve the effecton environmental protection, and the produced composite electrolyte powder is high in binding with an electrode plate, high in capacities of resistance to chemical attack and resistance to high temperature, and is suitable for large-scale production. Besides, the produced solid state battery is small in internal resistance.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

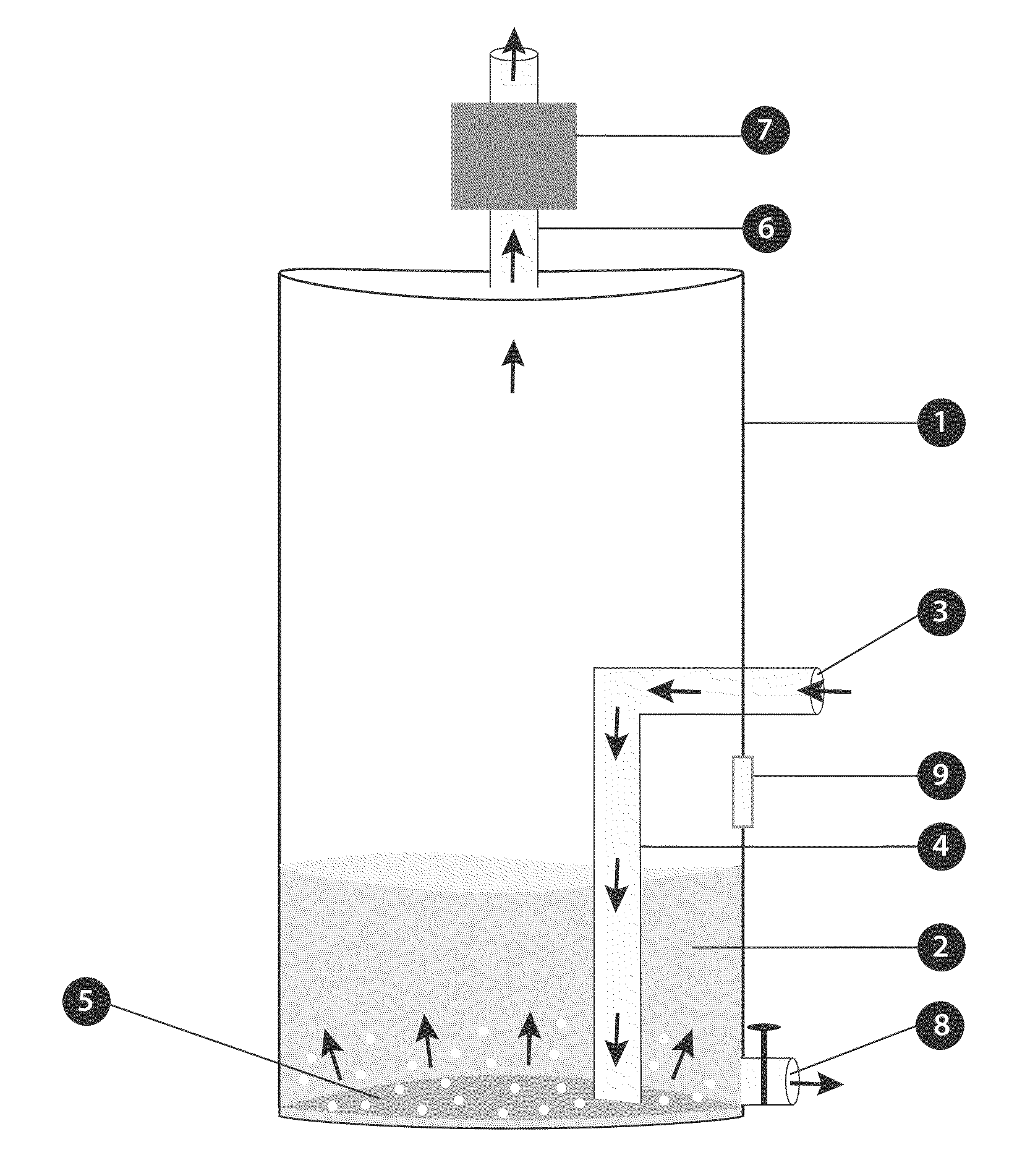

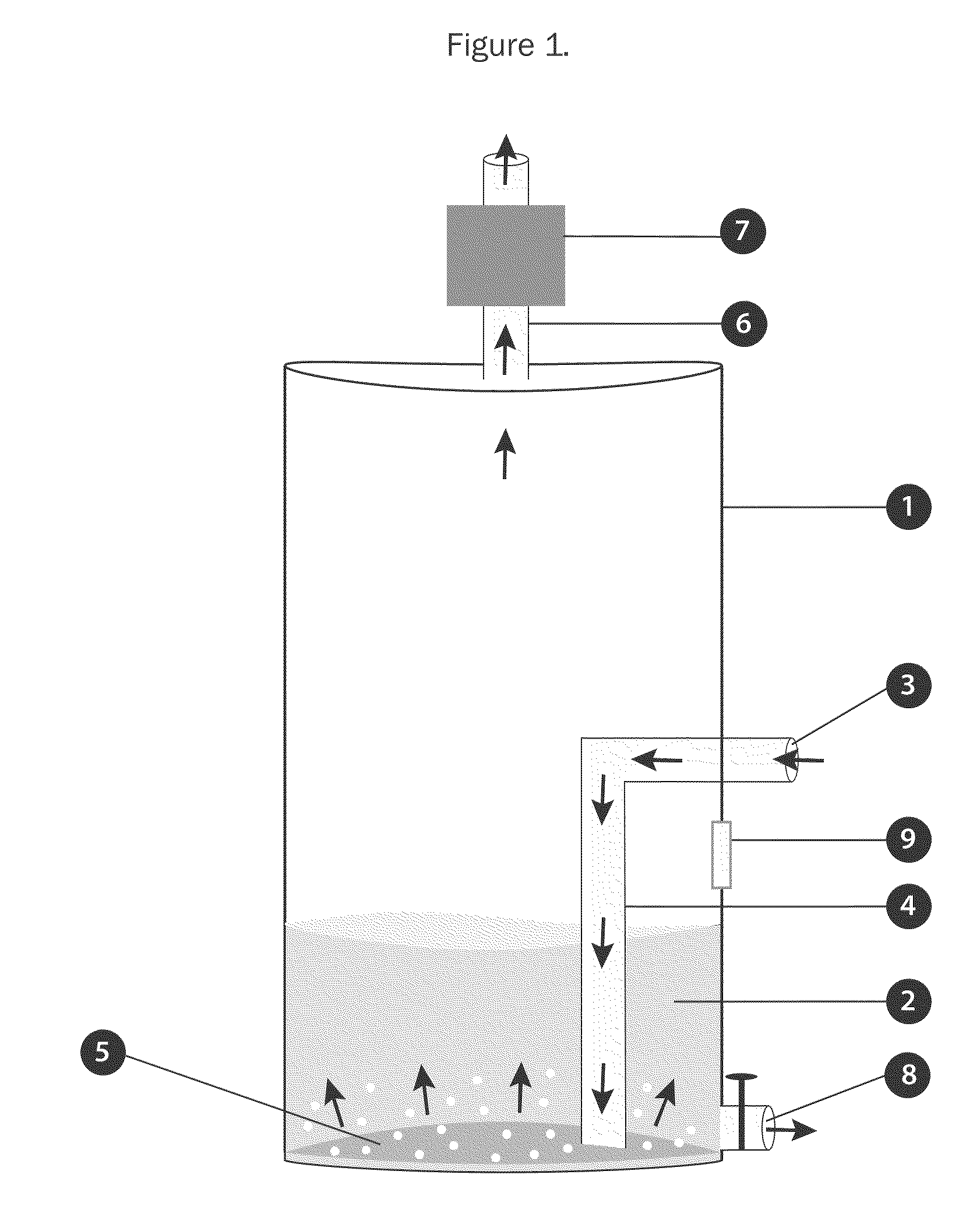

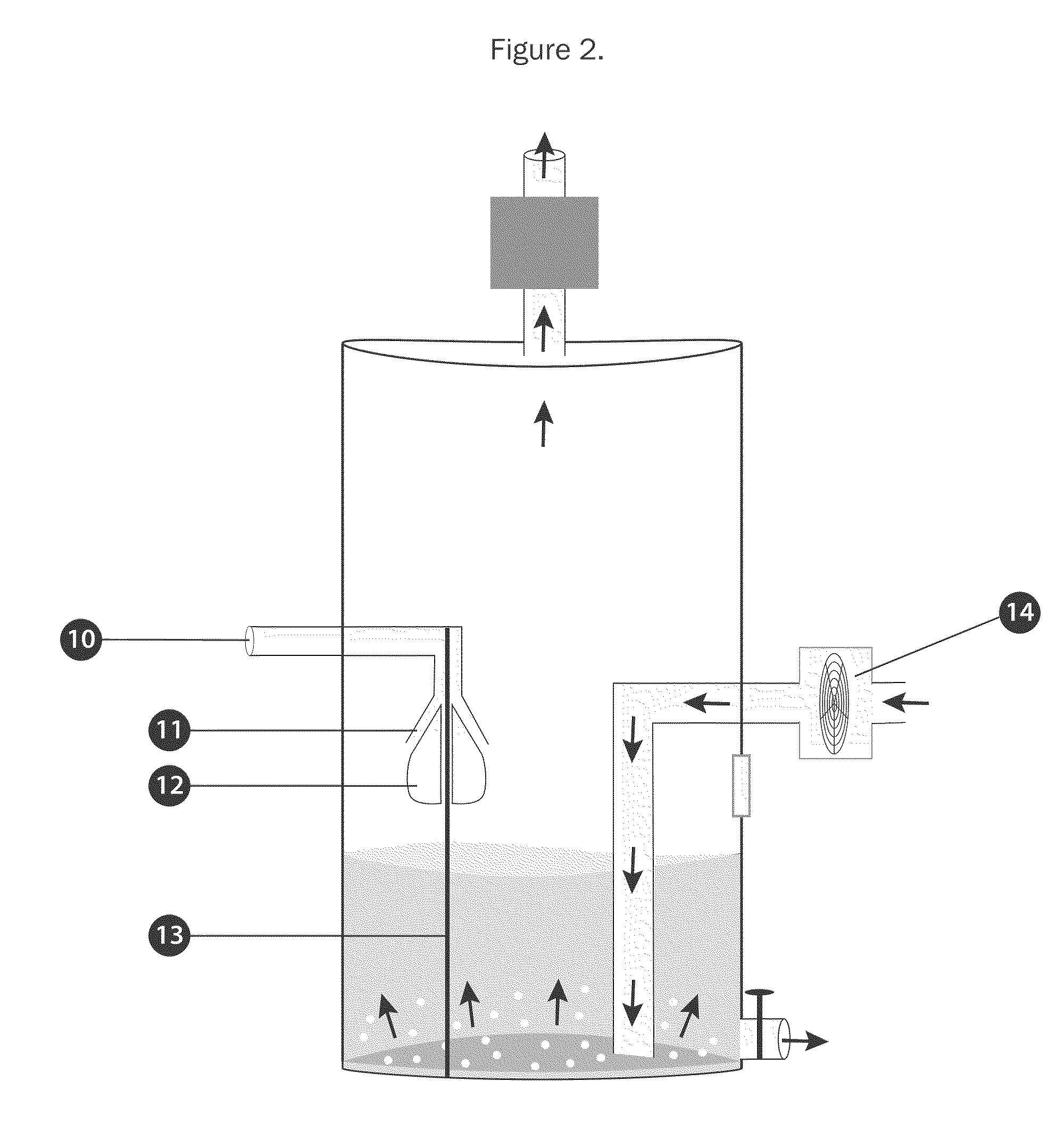

Air scrubbing system

InactiveUS20100316534A1Prevent accidental flowReduce stepsUsing liquid separation agentIsotope separationRespiratorAir pollutants

An air scrubber for eliminating an associated airborne contaminants and sterilizing air provided to protect against nocosomial infections, environmental allergens, weapons of biological and chemical attacks and operations requiring clean environment. The air scrubber includes a housing containing an alkali solution at pH 14 through which air passes and suspended liquid particles removed; provides are made for use in central air-conditioning systems, stand-alone applications and portable use along with respirators.

Owner:NIAZI SARFARAZ K +1

Impact resistant acrylic alloy

ActiveUS20120164364A1Reduced melt flow viscosityReduce melt viscositySynthetic resin layered productsWater/sewage treatment by flocculation/precipitationPolymer scienceHigh surface

The invention relates to an acrylic polymer, modified with one or more hard core core / shell impact modifier, which is blended with one or more low melt viscosity polymer. The alloy formed by the blend has good impact properties, good melt processability, high modulus, high surface hardness, and excellent resistance to chemical attack.

Owner:TRINSEO EURO GMBH

Container and Sealing Membrane for Packaging of Reactive Products

InactiveUS20110017772A1Improved performance characteristicsImprove sealingCapsDecorative coversHigh resistanceChemical reaction

Sealing (peel seal) membranes for packaging aggressive or chemically reactive products such as hair colorants over long periods without seal failure are described. Advantageously, the membranes and other packaging components have a high resistance to chemical attack and exhibit other advantageous characteristics, such as good barrier properties that minimize or eliminate interaction with the external environment, chemical inertness with respect to the product, and desirable heat sealing properties for prolonged adhesion without cracking and / or product leakage. The membranes comprise an inner bonding layer comprising a blend of polyethylene (PE) with an anti-cohesion additive, and a barrier layer.

Owner:ALCAN PACKAGING BEAUTY SERVICES

Ultrathin wide teflon turning film and manufacturing technology thereof

ActiveCN103144324AReduce thicknessOvercome the defect that the width cannot exceed 1 meterFlat articlesManufacturing technologyEngineering

The invention relates to an ultrathin wide teflon turning film and a manufacturing technology thereof. The technology comprises the steps of: (1) sieving raw materials, namely, screening Teflon suspension fine powder coarse waste by a 60-mesh vibrating sieve; (2) manufacturing blank, namely, manufacturing a cylindrical blank through a mould pressing manner and removing the inner stress of the blank; (3) sintering; (4) after preheating of the blank, turning the blank by a high-precision numerically-controlled lathe; and (5) rolling. The width of the turning film is 200-2000mm, and the thickness of the turning film is 0.02-0.50mm. According to the technology, the calendering step in the traditional technology is omitted, the technology steps and construction installation equipment are improved, the turning film is doubled in width compared with the traditional products, the film is uniform in thickness, is not easy to curl, has excellent performances such as impact resistance, wear resistance, chemical attack resistance and self-lubrication, can be used for a long time under an environment being +250 DEG C to -180 DEG C, and can basically meet the requirement of the market on the ultrathin wide teflon film.

Owner:JIANGSU TAIFULONG TECH

Method of fabricating a wire bond pad with Ni/Au metallization

InactiveUS7294565B2Semiconductor/solid-state device detailsSolid-state devicesElectroless depositionMaterials science

A method for sealing an exposed surface of a wire bond pad with a material that is capable of preventing a possible chemical attack during electroless deposition of Ni / Au pad metallurgy is provided. Specifically, the present invention provides a method whereby a TiN / Ti or TiN / Al cap is used as a protective coating covering exposed surfaces of a wire bond pad. The TiN / Ti or TiN / Al cap is not affected by alkaline chemistries used in forming the Ni / Au metallization, yet it provides a sufficient electrical pathway connecting the bond pads to the Ni / Au pad metallization.

Owner:GOOGLE LLC

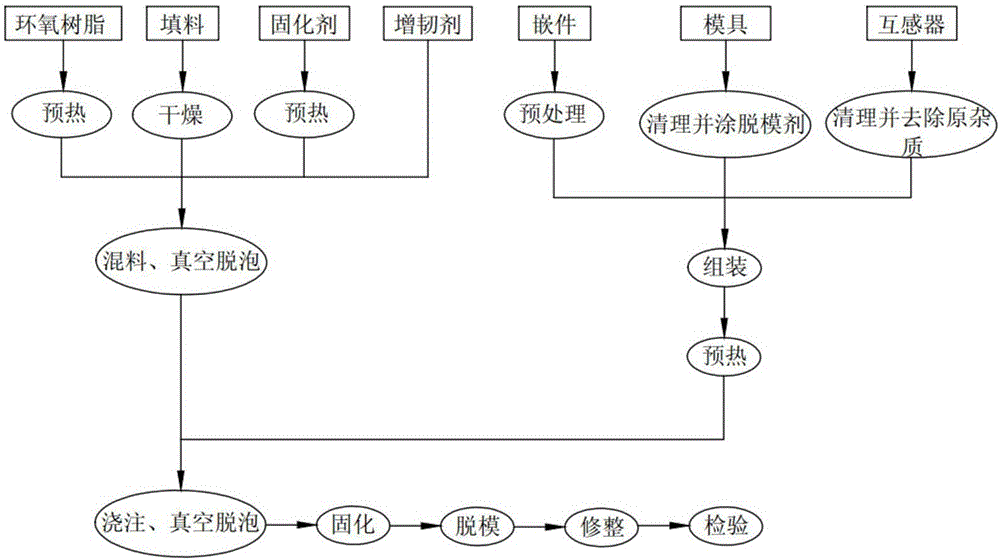

Pouring technology for all-fiber optical current transformer

The invention discloses a pouring technology for an all-fiber optical current transformer. Firstly, epoxy resin castables are obtained and then subjected to preheating and drying treatment; then the epoxy resin castables are placed in vacuum and subjected to mixing and defoaming treatment; a transformer semi-finished product is placed into a mould and preheated; finally, the defoamed epoxy resin castables are placed in vacuum and subjected to pouring defoaming treatment; and after pouring is completed, a mould is subjected to solidification demoulding treatment, and a transformer pouring body is obtained. The pouring technology for the all-fiber optical current transformer adopts a full-vacuum pouring technology and has a good applying effect on transformer type high voltage electric energy meter. Burdening, mixing and the whole process of pouring are all in a vacuum state so that bubbles in a pouring product can be reduced to a large extent, electric insulation strength and mechanical property of the product is improved, the yield of the product is improved, and the cost of the product and labor intensity are reduced. Epoxy resin has excellent electric insulation performance and high mechanical strength, heat resistance and chemical attack resistance are achieved, the cure shrinkage rate and the linear expansion coefficient are good, and dimensional stability and manufacturability are good.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +1

Base material of self-adhesive water-proof coiled material and self-adhesive water-proof coiled material manufactured by the same

InactiveCN1919958AReduce volatilityImprove migration resistanceOther chemical processesRoof covering using flexible materialsPolyesterThermal distortion

The invention discloses the base material and self-adhering water-proofing coiled material made with the base material. The base material is made by the modified PVC material, comprising PVC, polyester plasticity agent, modifier, filling agent, stabilizer, lubricating agent and antiaging agent. On the surface of base material add creep rubber bitumen self-adhering layer and non-stick coating to get self-adhering water-proofing coiled material. The self-adhering water-proofing coiled material has good physical-mechanical properties, thermal distortion property, elasticity, cold-resistant, flame-proof, abrasion-proof and resistance to chemical attack; it also has low volatility and long life.

Owner:GUANGDONG PSYLIC WATERPROOF MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com