Patents

Literature

2064results about How to "Improve polishing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

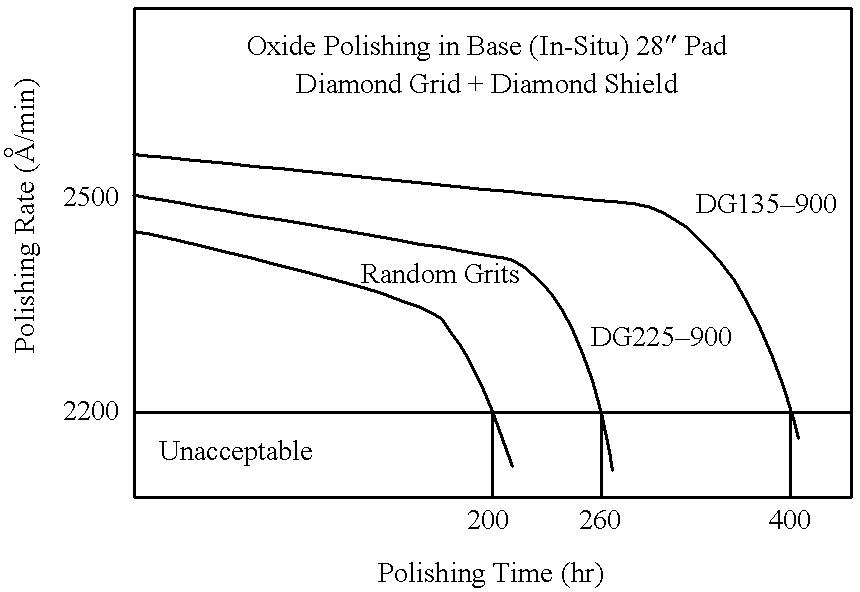

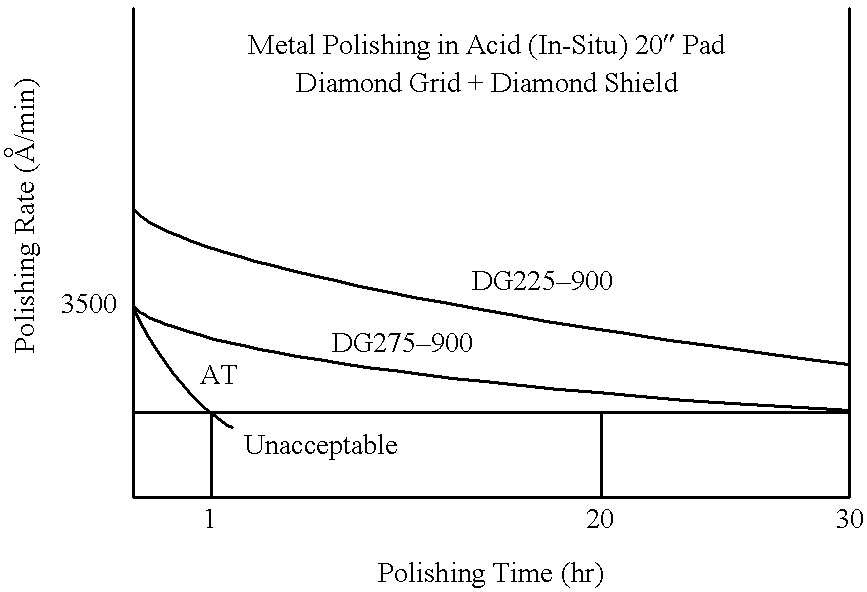

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

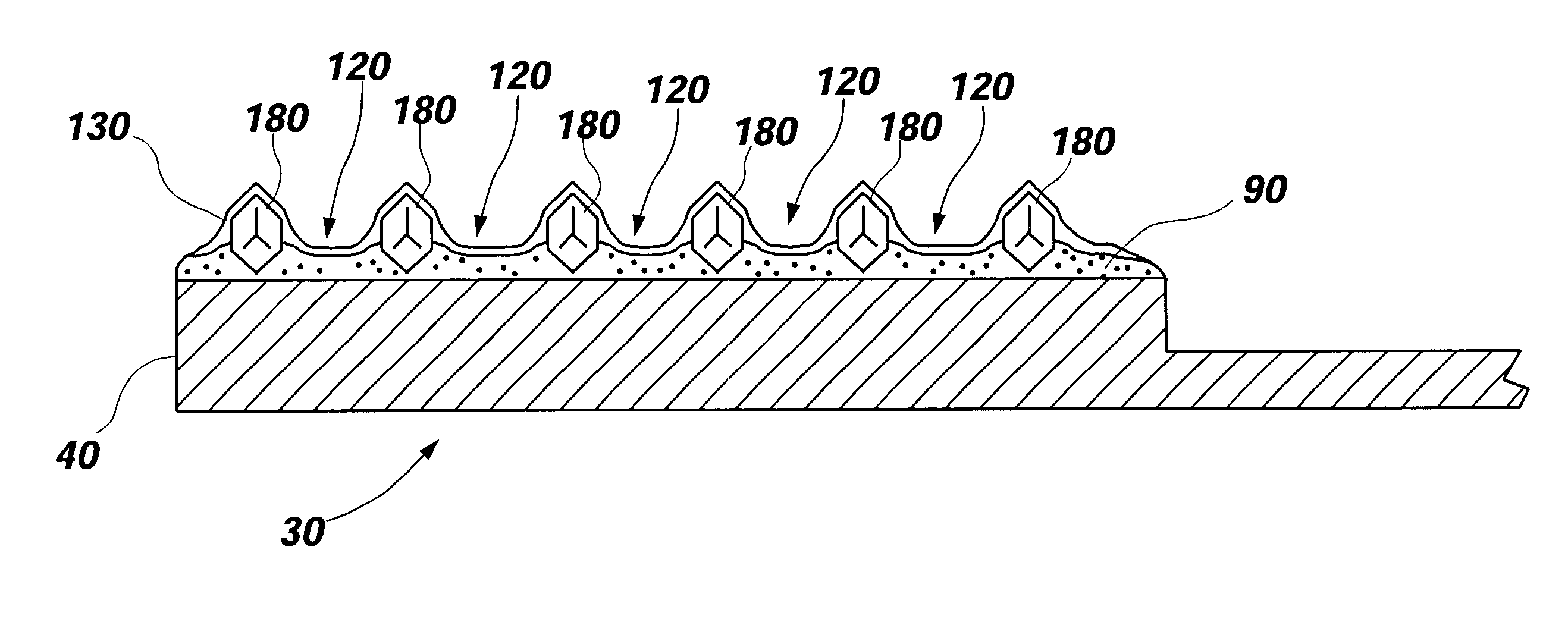

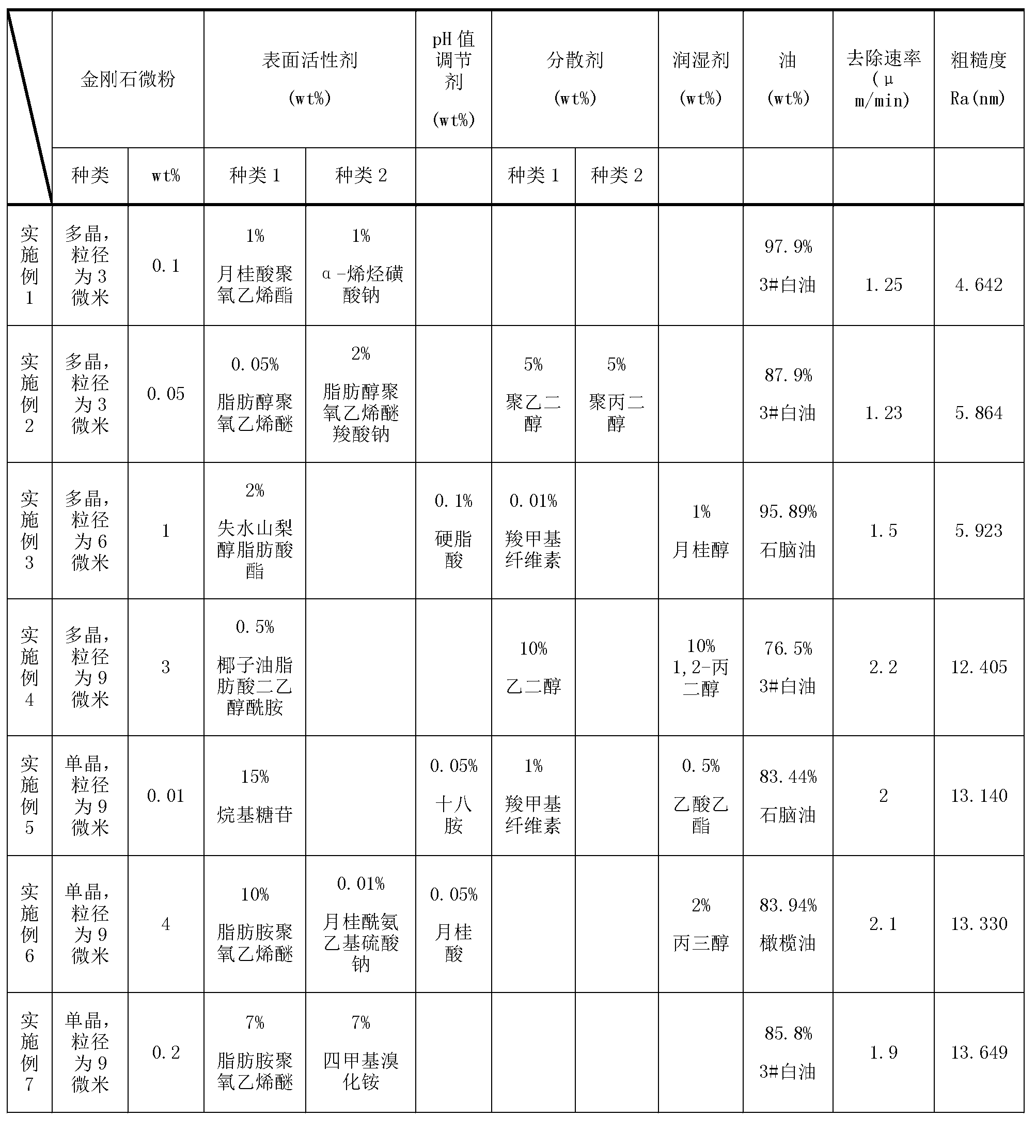

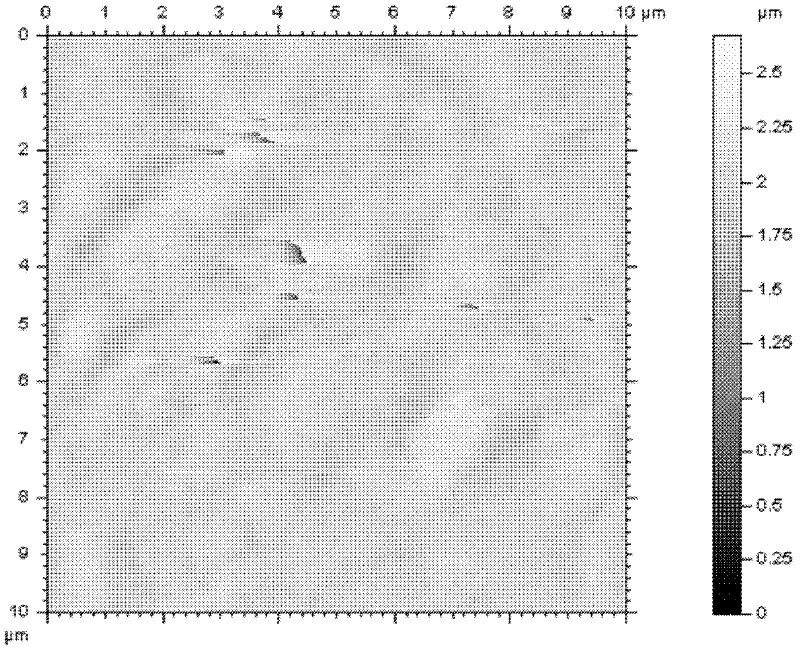

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

Water diamond lapping liquid and its preparation method and use

InactiveCN101186804AEnvironmentally friendlyAccelerated corrosionPolishing machinesOther chemical processesAlloySuspending Agents

The invention provides aqueous diamond polishing liquid, process for preparation and purpose. The main components are diadust, dispersion stabilizer, suspending agent, pH modifying agent, antiseptic agent, organic solvent and deionized water. The preparing technique of the invention is that organic solvent, diadust, prior prepared suspending agent, deionized water and dispersion stabilizer are mixed, then the mixture is stirred or supersonically dispersed uniformly, finally pH modifying agent and antiseptic agent are added, and the preparation is accomplished after shaking up. The lapping liquid can be widely used in grinding and polishing in various departments and areas of optical instruments, glasses, ceramics, rigid alloy, diamonds, artificial lens, optical fiber, LED display, integrated circuit, semiconductor, hard disk and the like. The lapping liquid can be kept in uniform and stable state, generates no precipitation, delamination or invalidation.

Owner:BEIJING GRISH HITECH

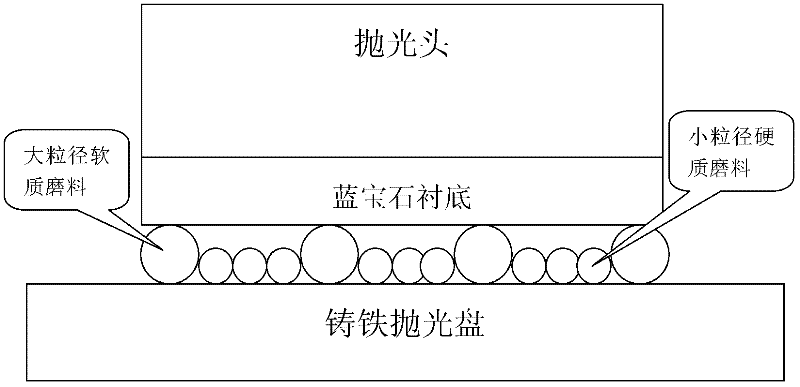

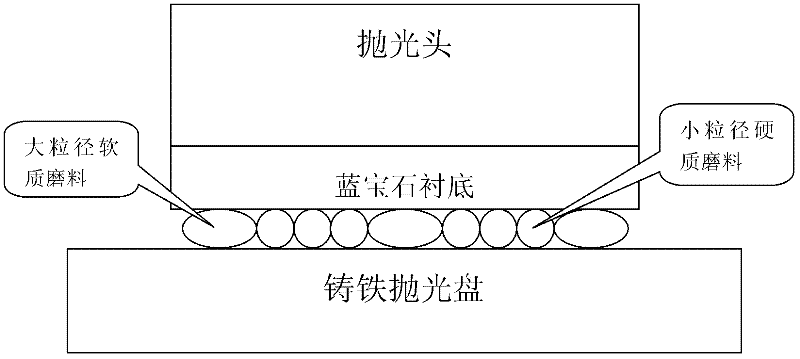

Thermochemistry mechanical polishing method of sapphire substrate material and polishing solution

InactiveCN102343547AImprove polishing rateGuaranteed uniformityLapping machinesPolishing compositions with abrasivesIonSurface-active agents

The invention relates to a thermochemistry mechanical polishing method of a sapphire substrate material; a polishing disk is heated in the polishing process; the temperature of the polishing disk is 30 DEG C-100 DEG C; a polishing solution adopted in the polishing method comprises a compound abrasive material, a pH compound conditioning agent, a surface active agent, a dispersing agent and deionized water, wherein the compound abrasive material is formed by mixing particles of a hard abrasive material and a soft abrasive material; the pH compound conditioning agent comprises organic strong base and organic weak base; and the pH value of the polishing solution is 8-13. The thermochemistry mechanical polishing method has the advantages: in the polishing process, the cast ion polishing disk is heated to promote a reaction rate between the polishing solution and the sapphire substrate material, thereby improving the polishing efficiency; problems such as surface scratch, subsurface cracks and the like can be avoided by using the compound abrasive material in the polishing solution so as to obtain surface characteristics of high quality and high evenness; meanwhile, the polishing efficiency is considered; and the polishing solution also has the advantages that the stability is high, equipment is not corroded, washing is easy and the like.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

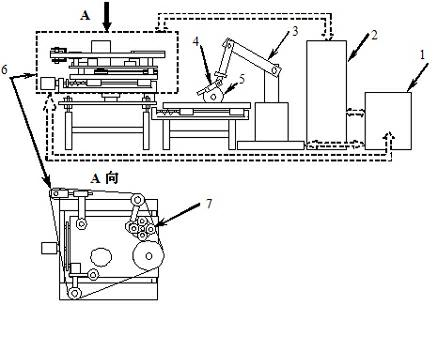

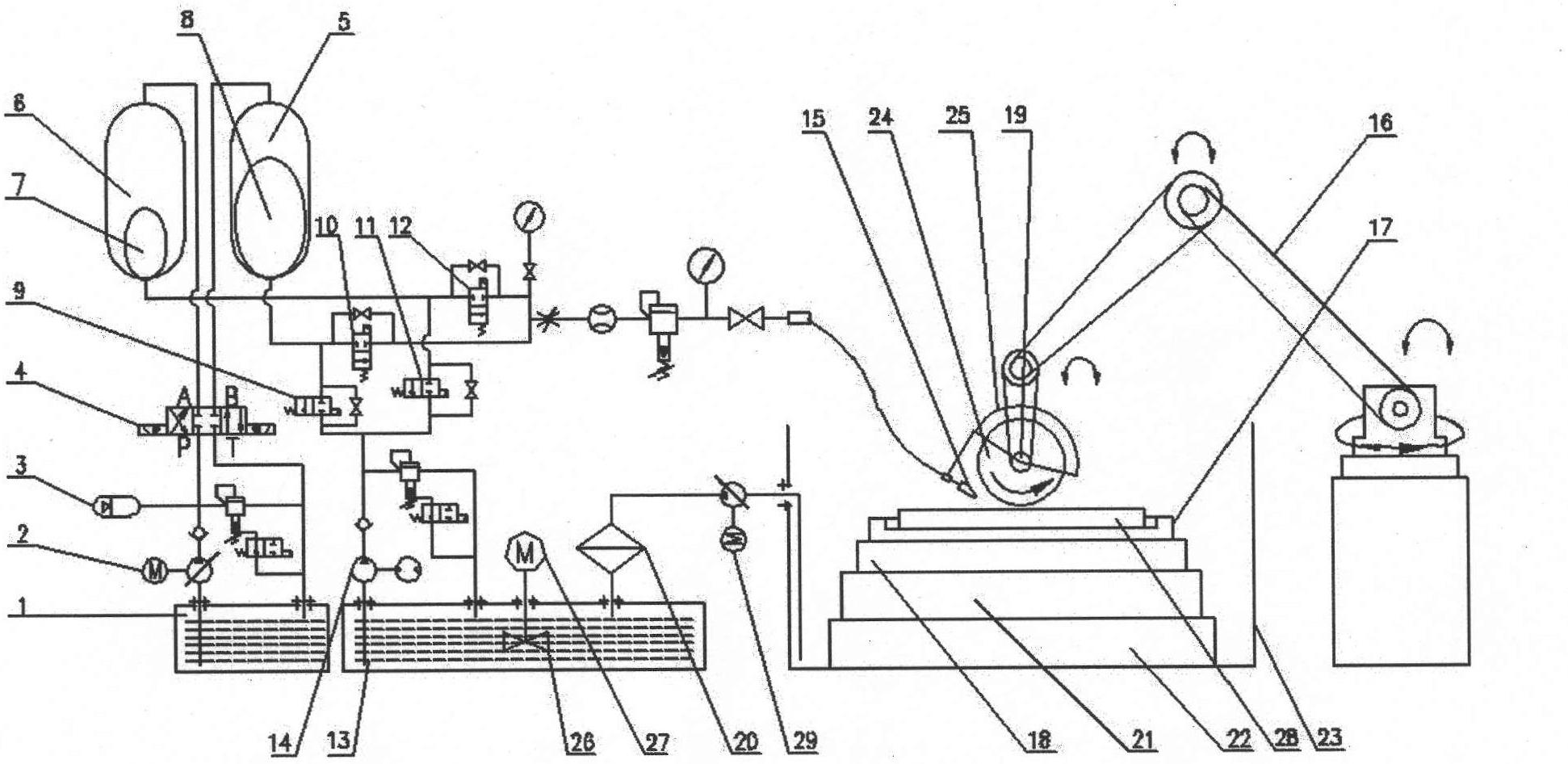

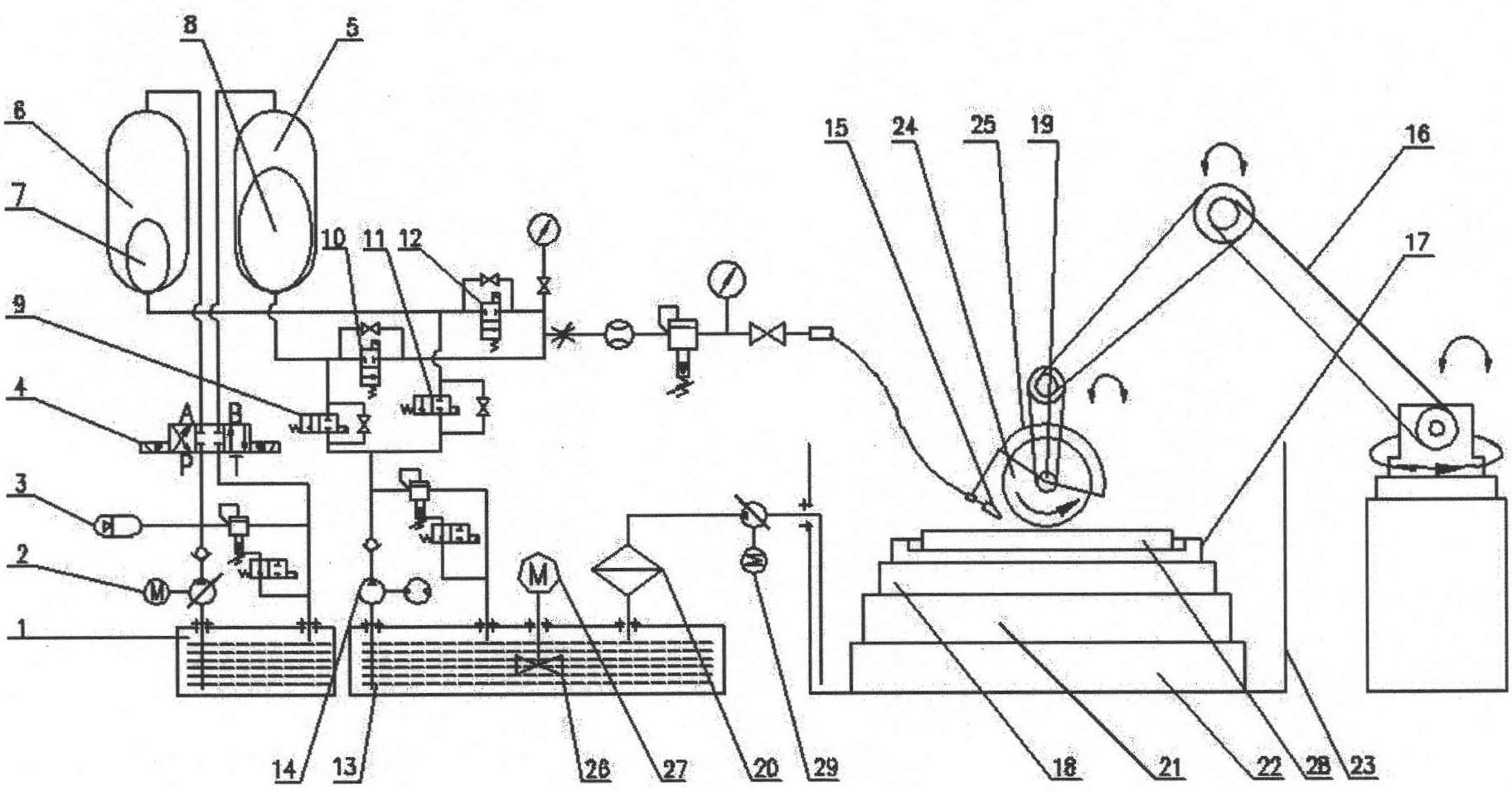

Automatic sanding and polishing device for industrial robot

InactiveCN102107384AGuaranteed positioning accuracyConsistent removalBelt grinding machinesContact forceAutomatic testing

The invention relates to an automatic sanding and polishing device for an industrial robot, wherein the industrial robot is served as the core of the device; the device comprises the industrial robot, an automatic shifting fixture, a polishing machine, and a force control program; and the device can be used for sanding and polishing the parts having complex exteriors, and is especially suitable for processing faucet, ironware, blade, and the like. A method for automatically sanding and polishing by using the device comprises the following steps: the automatic shifting fixture arranged on the tail end of the industrial robot is used for holding the parts; adjusting the position and posture of the industrial robot according to different areas for sanding or polishing of the parts; contacting the areas for sanding or polishing with a sanding belt of the polishing machine and keeping a certain contact force; controlling the size of the contact force by a force control mechanism; after finishing programming the whole surface of parts, using the industrial robot to perform the reprogramming operation; and sanding or polishing the parts having same exteriors in batch.

Owner:厦门煜雄智能机器人有限公司

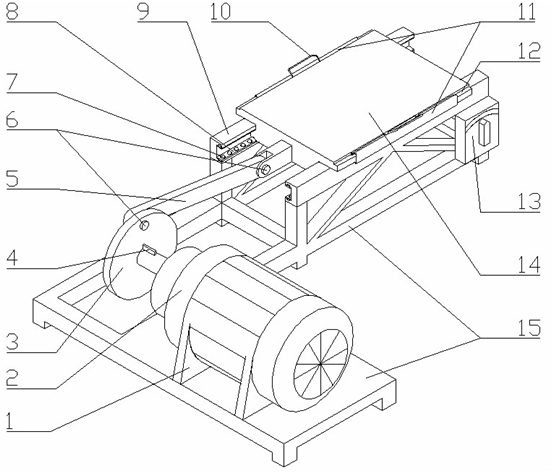

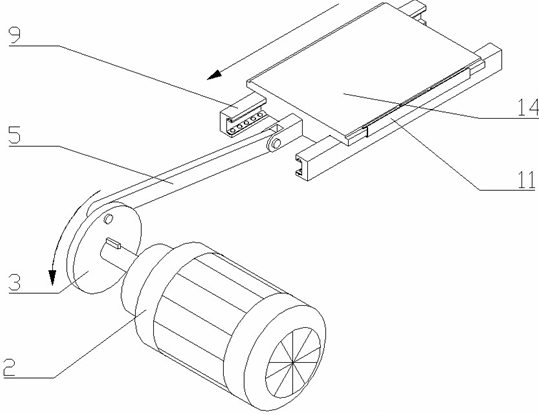

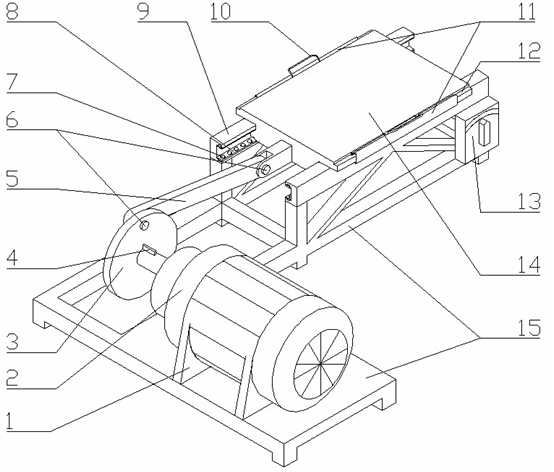

Linear reciprocating type pre-milling machine

InactiveCN102528612AMeet the polishing requirementsHigh polishing precisionPreparing sample for investigationGrinding machinesReciprocating motionSand-paper

The invention relates to a device for pre-milling before a metallic phase of metal is observed and a stress test sample is polished, in particular to a linear reciprocating type pre-milling machine which comprises a milling platform, a reciprocating link mechanism, a motor and a supporting base, wherein the milling platform comprises a linear guide rail, a plane milling plate and a sand paper fixing clamp; the reciprocating link mechanism comprises a cam and a connecting rod; a small-size alternated current motor with a speed-regulating device is served as the motor; a frame type simple supporting base is served as the supporting base; and a speed-regulating switch is placed on one side of the supporting base. The linear reciprocating type pre-milling machine can be used for keeping straight and homonymous scratches of a metal test piece all the time during a milling process and increasing the milling precision; the milling reciprocating speed can be adjusted according to the requirement during the milling process, so that the polishing and milling efficiency is increased. The linear reciprocating type pre-milling machine has the advantages of convenience in operation, simple and compact structure, space-saving property, cost-lowering property, wide application scope and capability of meeting the polishing and milling demands of various test pieces.

Owner:JIANGSU UNIV

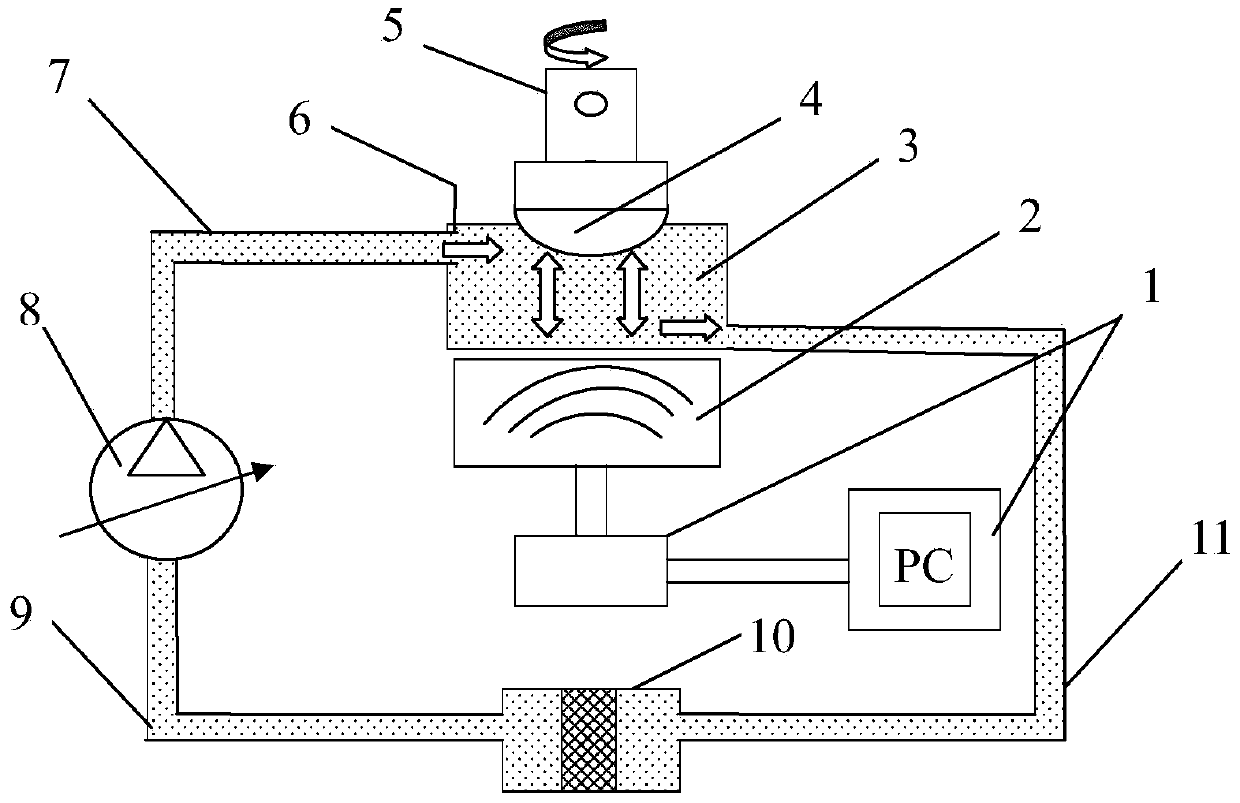

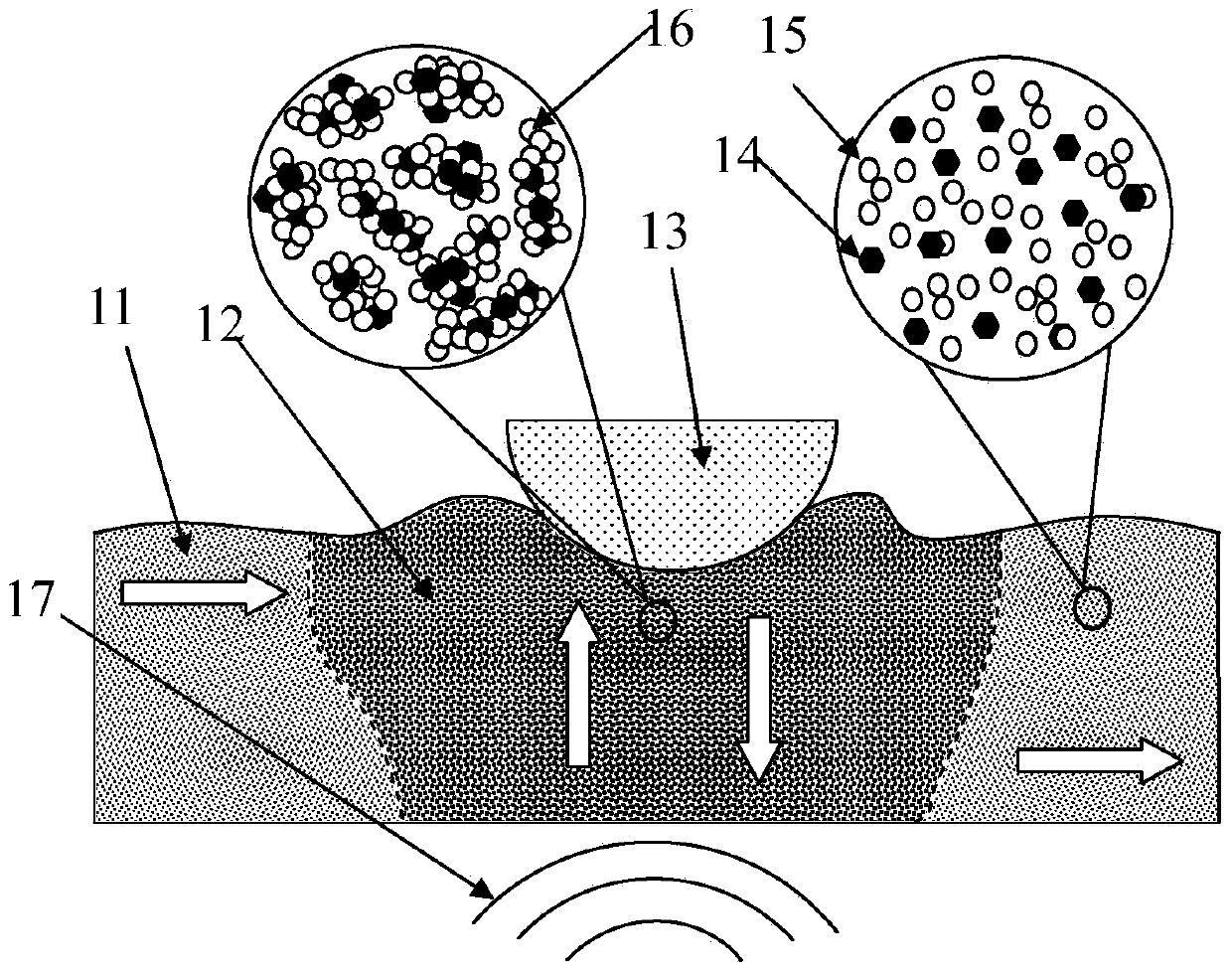

Ultrasonic control shear thickening and polishing method and device

An ultrasonic control shear thickening and polishing method comprises the following steps of 1 adding a non-Newtonian fluid polishing solution mixed with abrasive particles and having the shear thickening effect into a polishing pond and fixing a workpiece on a clamp, wherein the clamp is located above the polishing pond; 2 starting a polishing solution circulating system to enable the non-Newtonian fluid polishing solution to be circularly pumped out of the bottom of the polishing solution and fed into the upper portion of the polishing pond; 3 starting an ultrasonic wave generating device, and meanwhile setting the vibration frequency and vibration amplitude to enable the non-Newtonian fluid polishing solution in the polishing pond to rapidly vibrate and produce a strong shear thickening phenomenon; 4 adjusting the clamp to enable the workpiece to perform relative motion, wherein the abrasive particles having the polishing effect produce the micro-cutting effect or chemical mechanical effect on the workpiece to remove materials on the workpiece surface, and accordingly the workpiece surface polishing is achieved. The invention further provides an ultrasonic control shear thickening and polishing device. The ultrasonic control shear thickening and polishing method and device is high in polishing efficiency and low in cost.

Owner:ZHEJIANG UNIV OF TECH

Sealed type dust removal polishing machine

InactiveCN103921202AInhibited DiffusionKeep healthyPolishing machinesGrinding/polishing safety devicesEngineeringNoise reduction

The invention provides a sealed type dust removal polishing machine, and belongs to the technical field of polishing machines and environment-friendly facilities. The sealed type dust removal polishing machine comprises a rotary polishing table, a set of cover die drive mechanism and a polishing machine body, wherein the upper portion of the cover die drive mechanism is provided with cover dies. The sealed type dust removal polishing machine is characterized in that a noise reduction dust removal room is further included, the noise reduction dust removal room is composed of a polishing dust collection chamber and a waxing work chamber, the polishing dust collection chamber is connected with one end of a dust discharge pipe in a matched mode, the other end of the dust discharge pipe is connected with a dust removal device, the waxing work chamber is arranged in the center of the polishing dust collection chamber in a spaced mode, the wall of the waxing work chamber is provided with a waxing window, an automatic waxing mechanism is arranged at the bottom of the waxing work chamber, the cover dies and the polishing machine body are located in the polishing dust collection chamber, the noise reduction dust removal room further comprises an operation room, the polishing dust collection chamber is provided with a cover die outlet and a cover die inlet, and the outer wall of the polishing dust collection chamber is provided with an inlet opening and closing mechanism. The sealed type dust removal polishing machine can meet the requirement of continuous polishing, is high in polishing efficiency, lowers noise, prevents dust from spreading and lightens labor intensity.

Owner:SUZHOU VOCATIONAL UNIV

Capsule processing device

The invention discloses a capsule processing device. The capsule processing device comprises a feeding mechanism, a dust removal mechanism and a polishing split charging mechanism, wherein the feeding mechanism comprises a machine body, a supporting rod, a feeding box, a mesh screen, a discharging plate and a discharging disc, the dust removal mechanism is connected with the feeding box through a first air pipe, a medium-efficiency filter is installed in the dust removal mechanism, a dust removal fan is installed on the medium-efficiency filter, the discharging disc is provided with a sealing cover, a plurality of ultraviolet lamp tubes are installed in the sealing cover, the polishing split charging mechanism comprises a shell, a screen barrel, a control chamber, a separating device, a loading bottle, a slide plate, a fixed seat, a hydraulic system and a supporting frame. By adopting the capsule processing device, capsules can be directly bottled in a split charging manner after being polished, the counting accuracy is high, the production efficiency of the capsules is greatly improved, dust on the surfaces of the capsules can be cleaned, and the quality of the capsules can be improved.

Owner:ZHEJIANG YUEXI CAPSULE

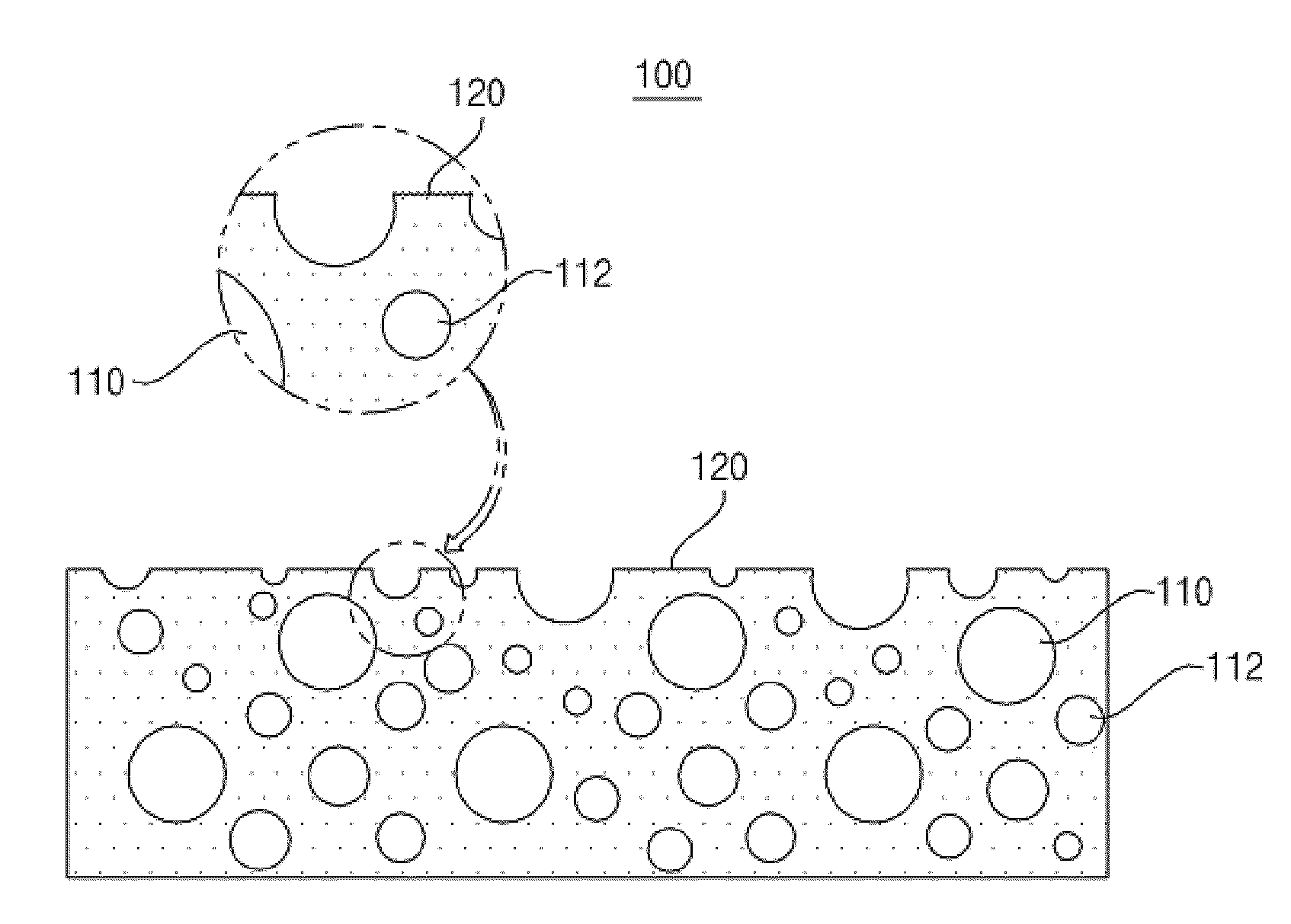

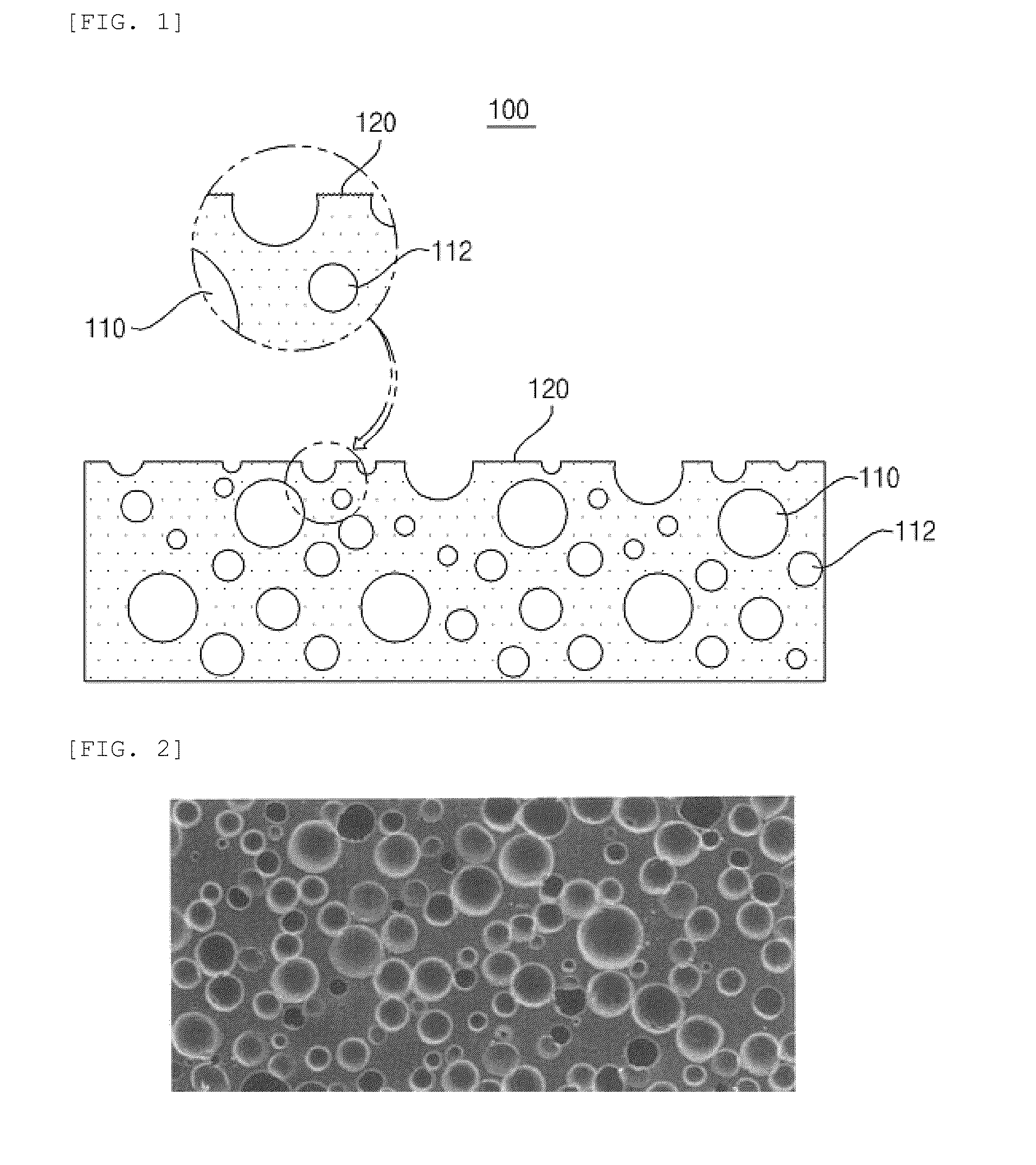

Polyurethane porous product and manufacturing method thereof and polishing pad having polyurethane porous product

InactiveUS20100247868A1Improve stabilityImprove uniformitySynthetic resin layered productsAbrasion apparatusIn planeHardness

The present invention relates to a method for manufacturing a polyurethane porous product, a polyurethane porous product according to the manufacturing method, and a polishing pad having the polyurethane porous product. According to the present invention, it is possible to manufacture a polishing pad that has excellent polishing efficiency and has a minimal difference in the polishing characteristic during a polishing process and improves uniformity in plane of material that will be polished because the polyurethane porous product of the present invention has small density difference, small hardness difference, and the stabilized quality of material.

Owner:CHA YOON JONG +1

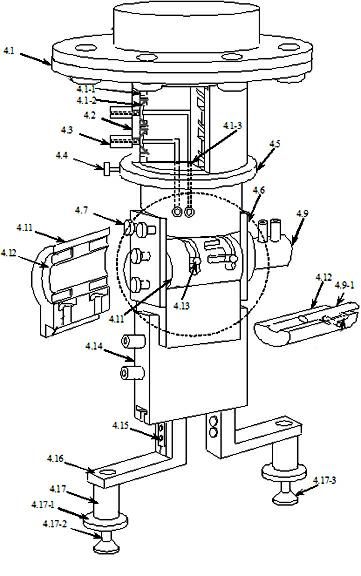

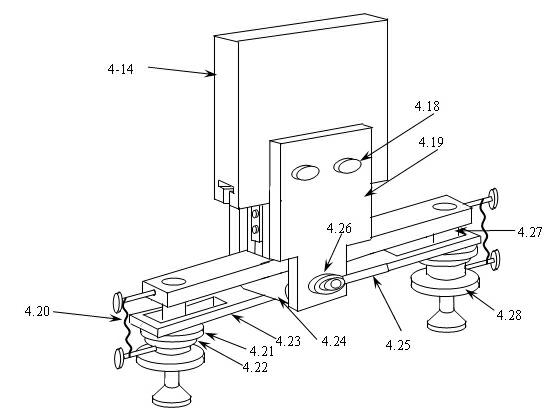

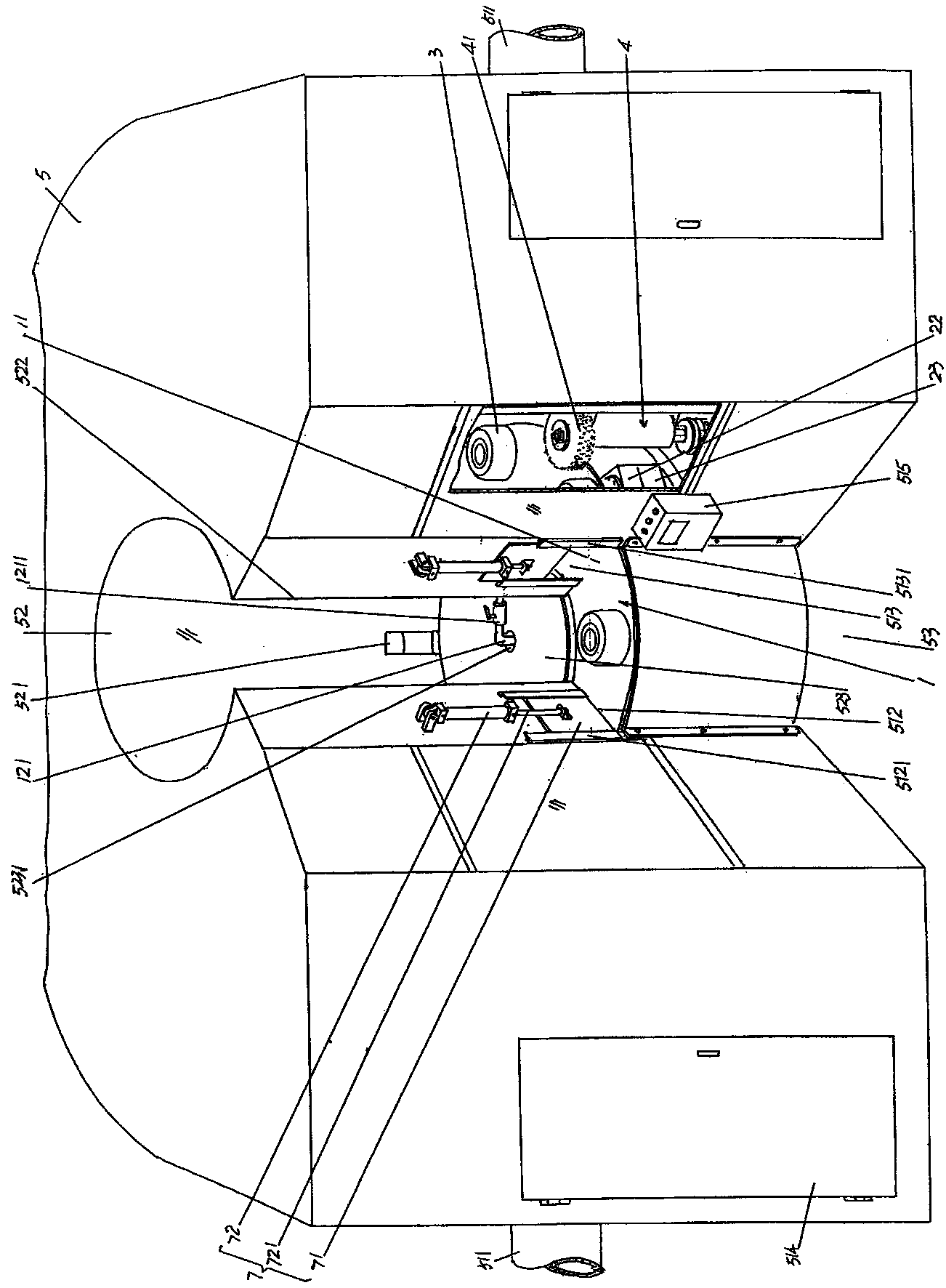

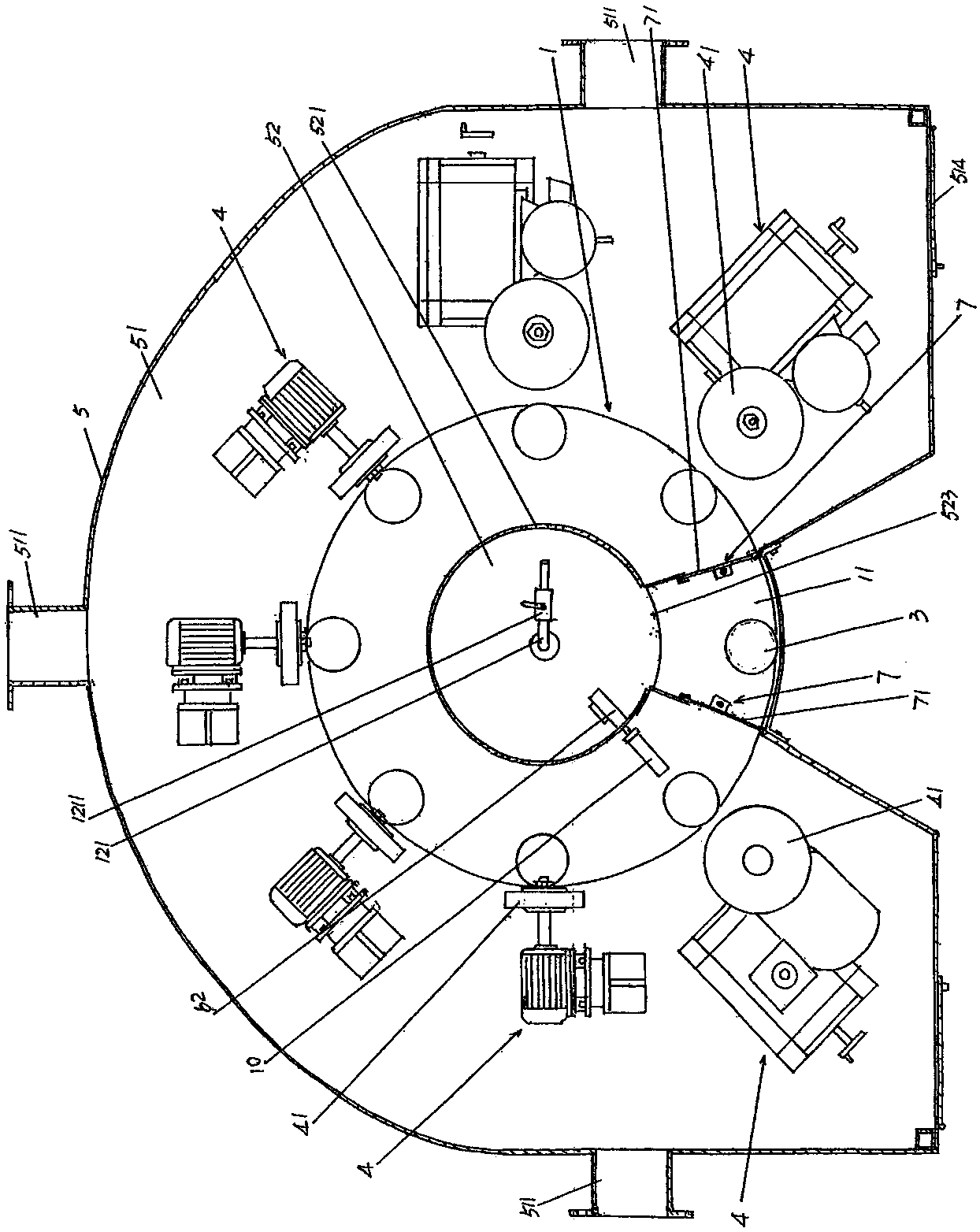

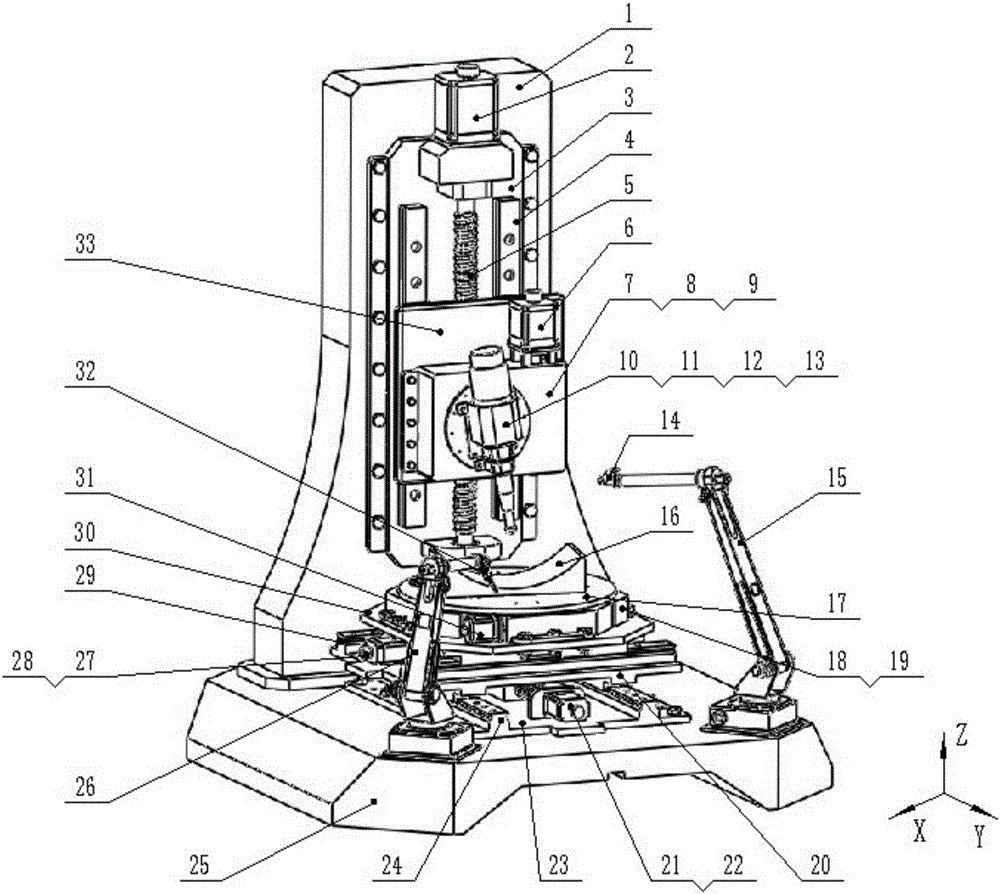

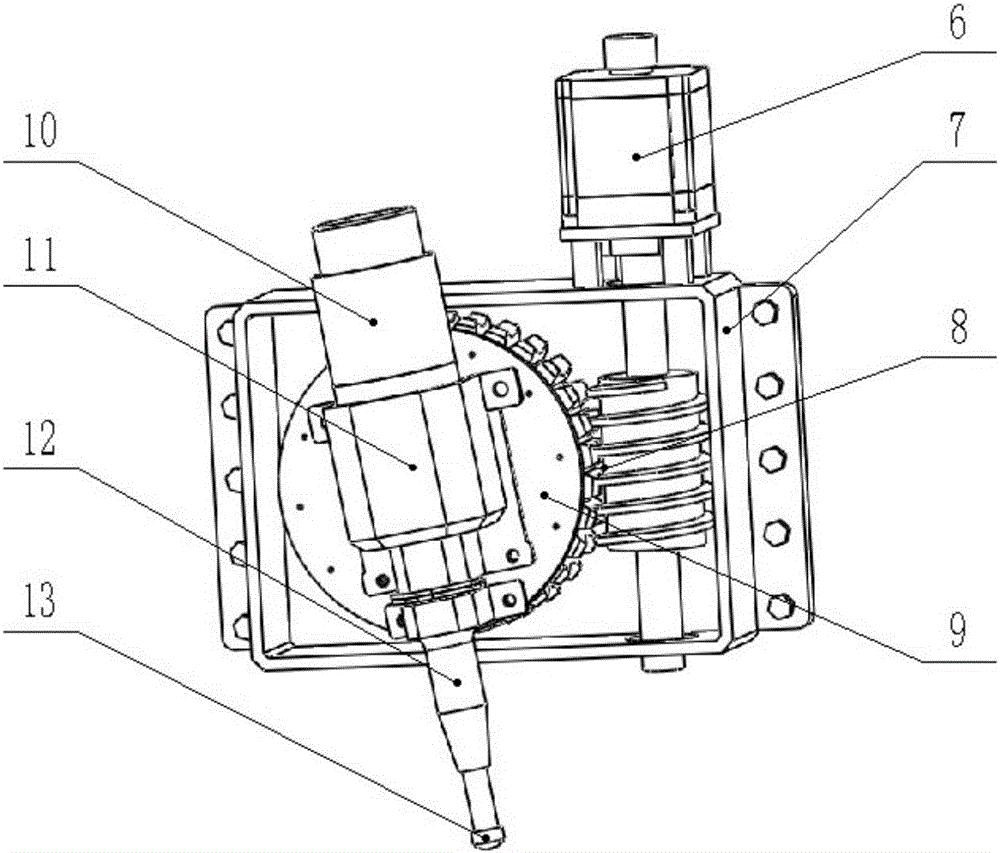

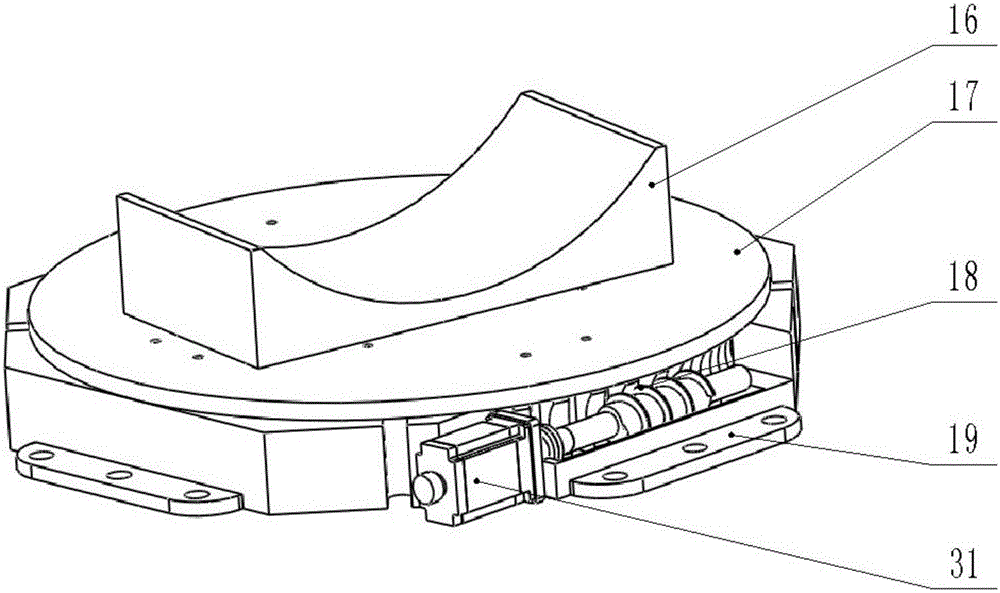

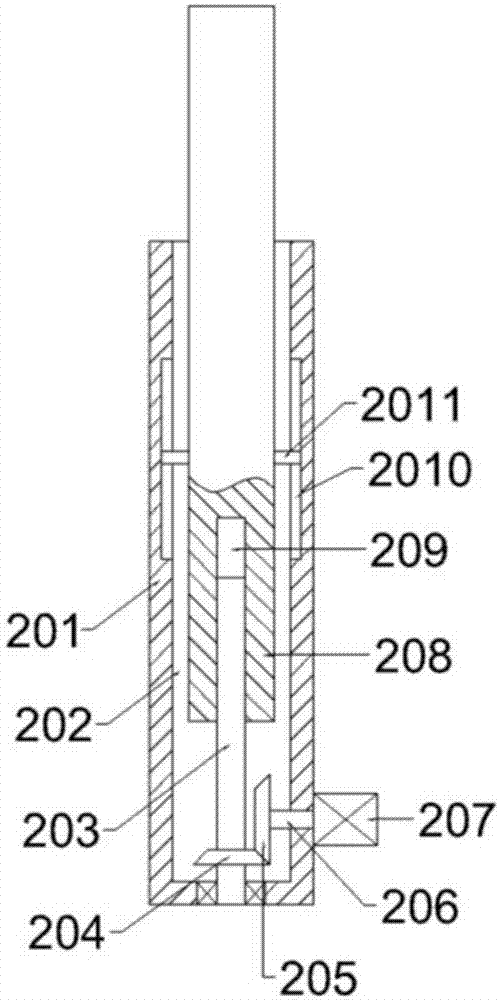

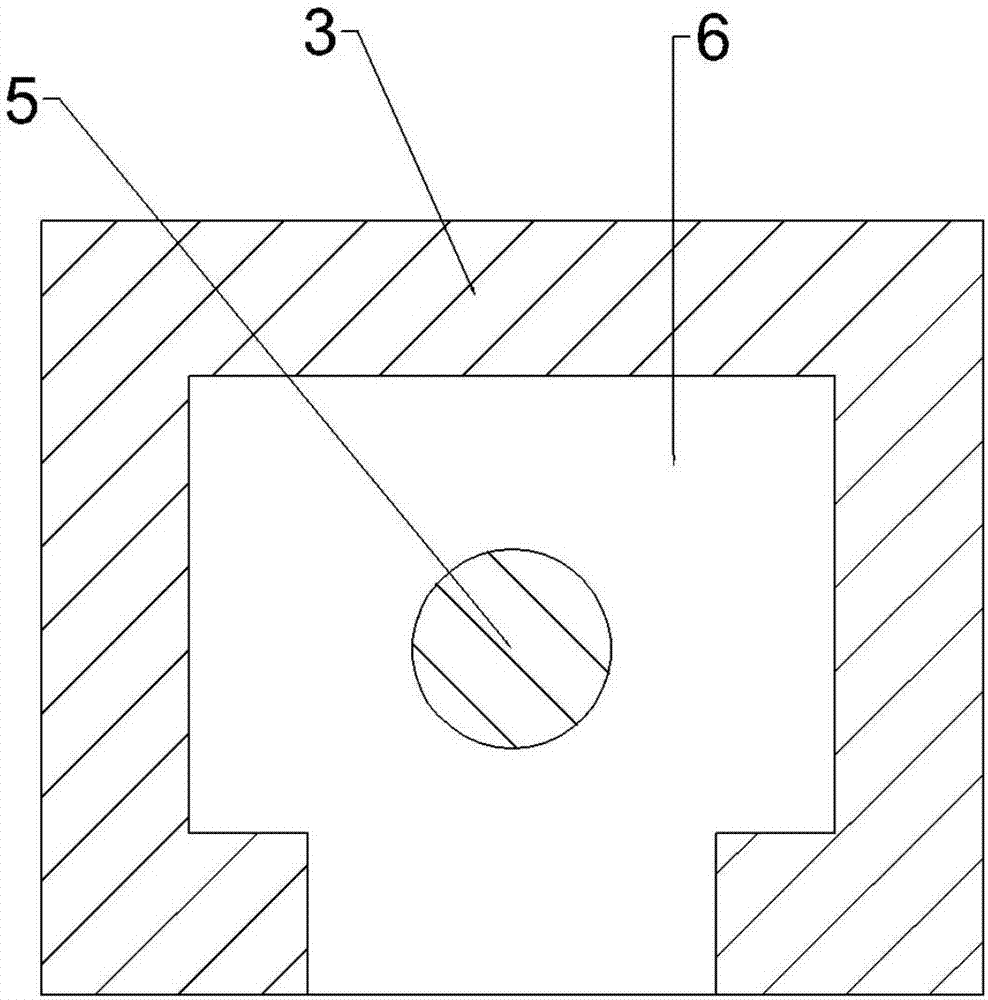

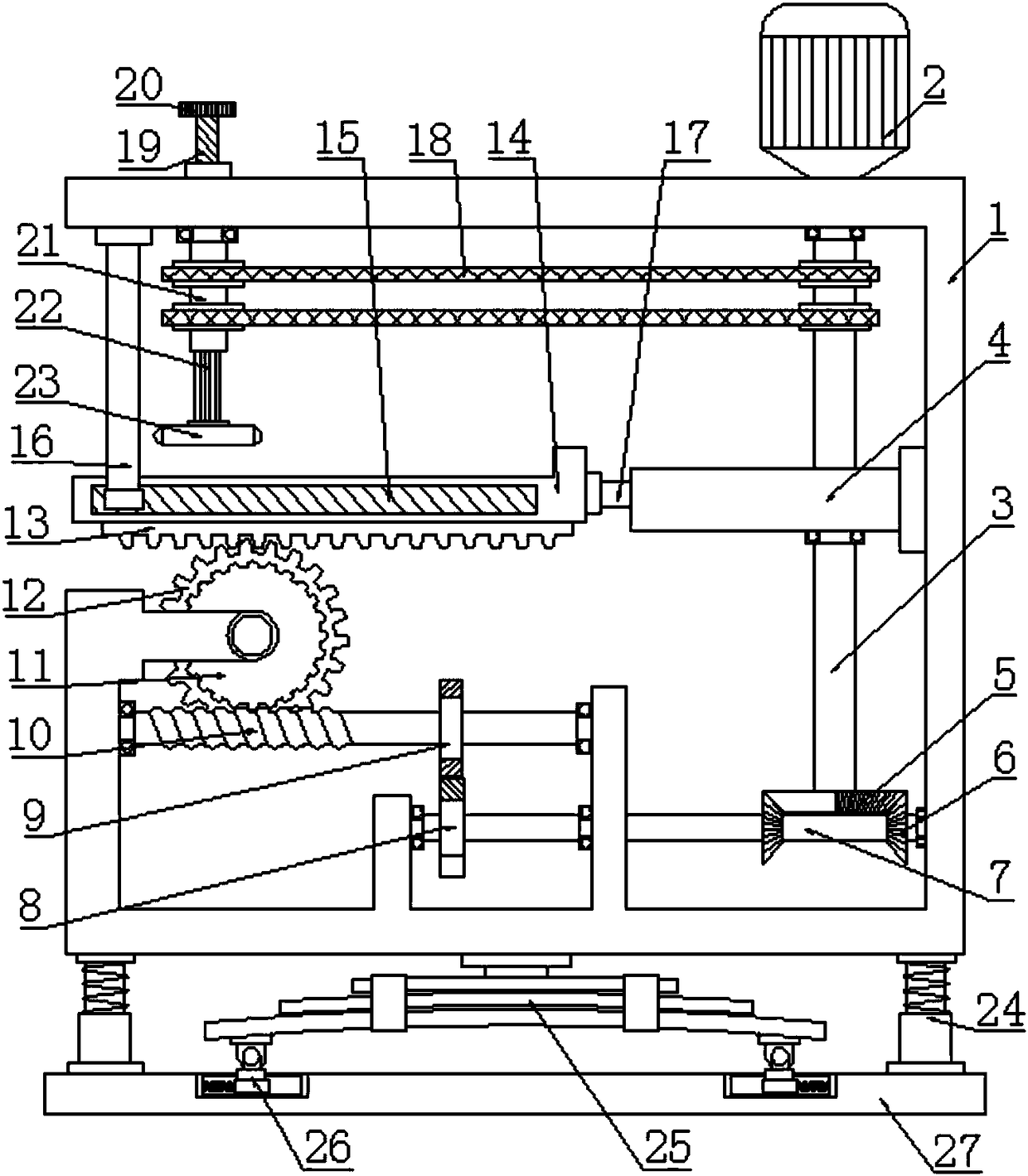

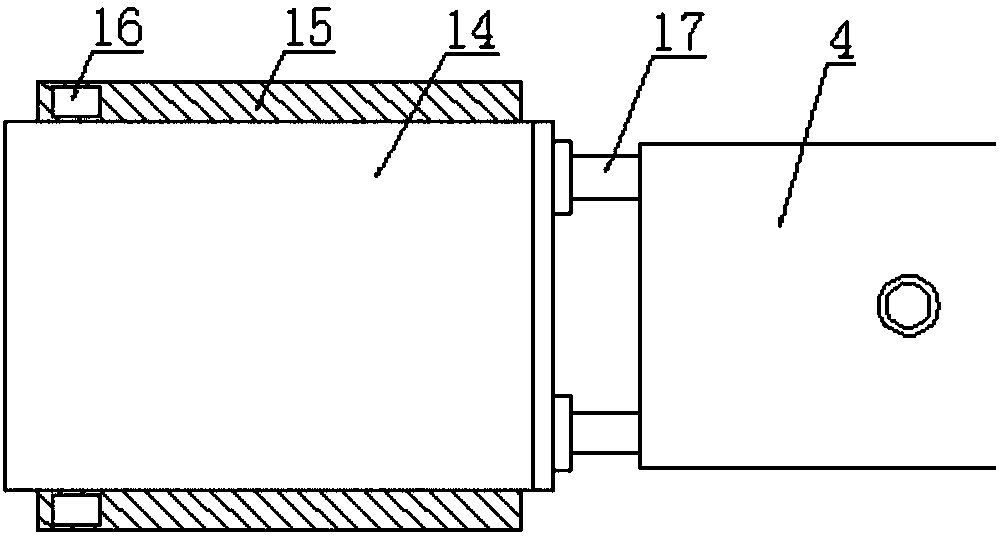

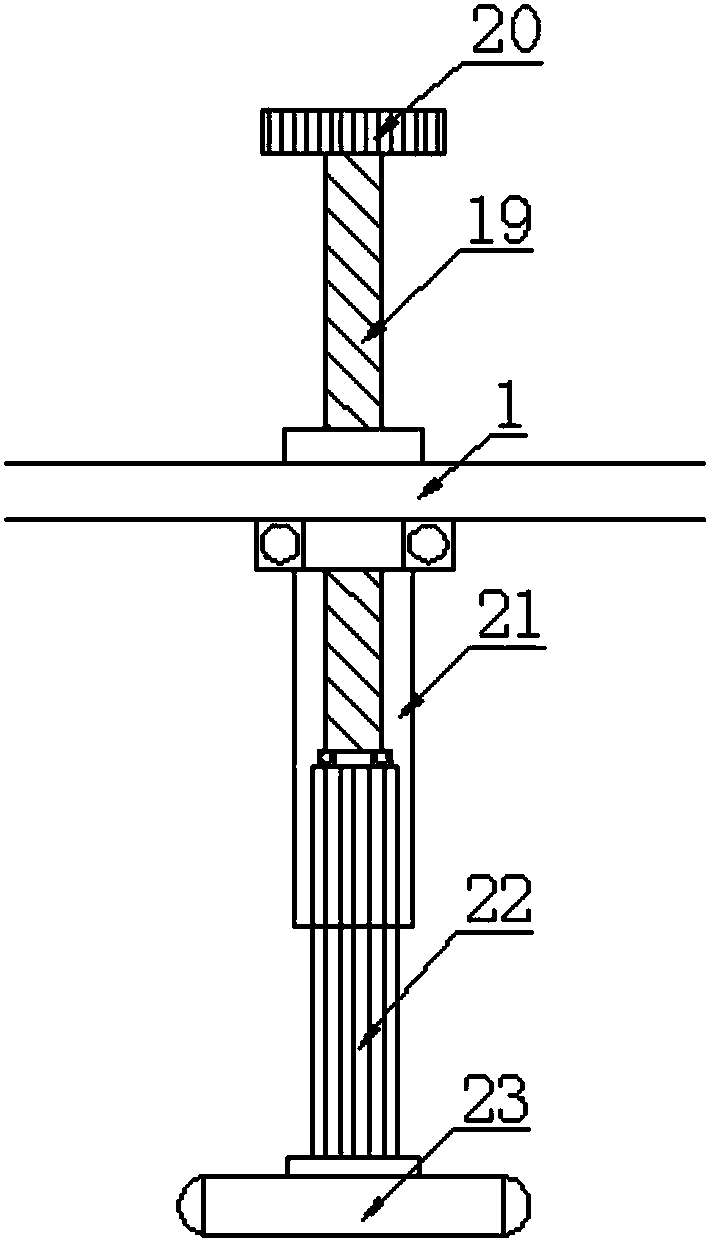

Five-axis two-dimensional ultrasonic polishing machine tool for optical curved face machining and using method thereof

ActiveCN106475868AUniform contact stressHigh polishing precisionGrinding carriagesOptical surface grinding machinesUltrasonic vibrationEngineering

The invention discloses a five-axis two-dimensional ultrasonic polishing machine tool for optical curved face machining. The machine tool is composed of a rack, a three-dimensional moving device, a rotary ultrasonic vibration polishing device, a rotary workbench, a polishing liquid ultrasonic atomizing and applying device and an on-line workpiece detection device. When the machine tool is used, the amplitude of the ultrasonic vibration polishing device is obtained according to the calculation formula (please see the formula in the description); five-axis linkage is achieved through a program control system, and the axis of a polishing head is made to always coincide with the normal line of a workpiece polishing point; a 45-degree included angle is kept between the jetting direction of polishing liquid and the normal line of the polishing point. The polishing machine tool has the advantages that ultrasonic energy transmission is concentrated, the contact stress between the surface of the polishing head and the surface of a workpiece is uniform, the polishing precision is high, the removal rate in the polishing process is high, the utilization rate of the polishing liquid is high, and the polishing precision of the workpiece can be detected on line.

Owner:NORTHEASTERN UNIV

Polishing solution used for amorphous alloy and polishing method of amorphous alloy

The invention provides a polishing solution used for an amorphous alloy and a polishing method of an amorphous alloy. The polishing solution comprises: a sodium salt, an ammonium salt and a brightener, i.e. ceric sulfate. The polishing method includes plasma polishing to an amorphous alloy. And the plasma polishing method consists of: connecting the amorphous alloy to a positive electrode, and immersing the amorphous alloy into an electrolytic cell containing the polishing solution, and taking the electrolytic cell body as a negative electrode for plasma polishing. The amorphous alloy prepared with the polishing solution provided in the invention and by the plasma polishing method of the invention has a smooth surface and high surface reflectivity.

Owner:BYD CO LTD

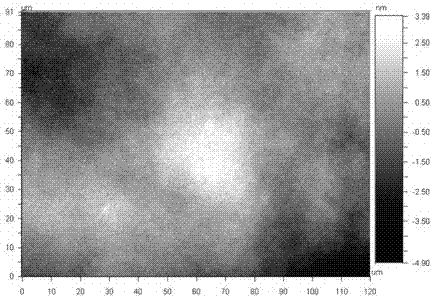

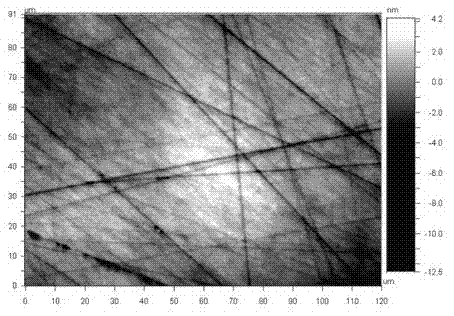

Preparation and use of cerium oxide / silicon oxide compound abrasive

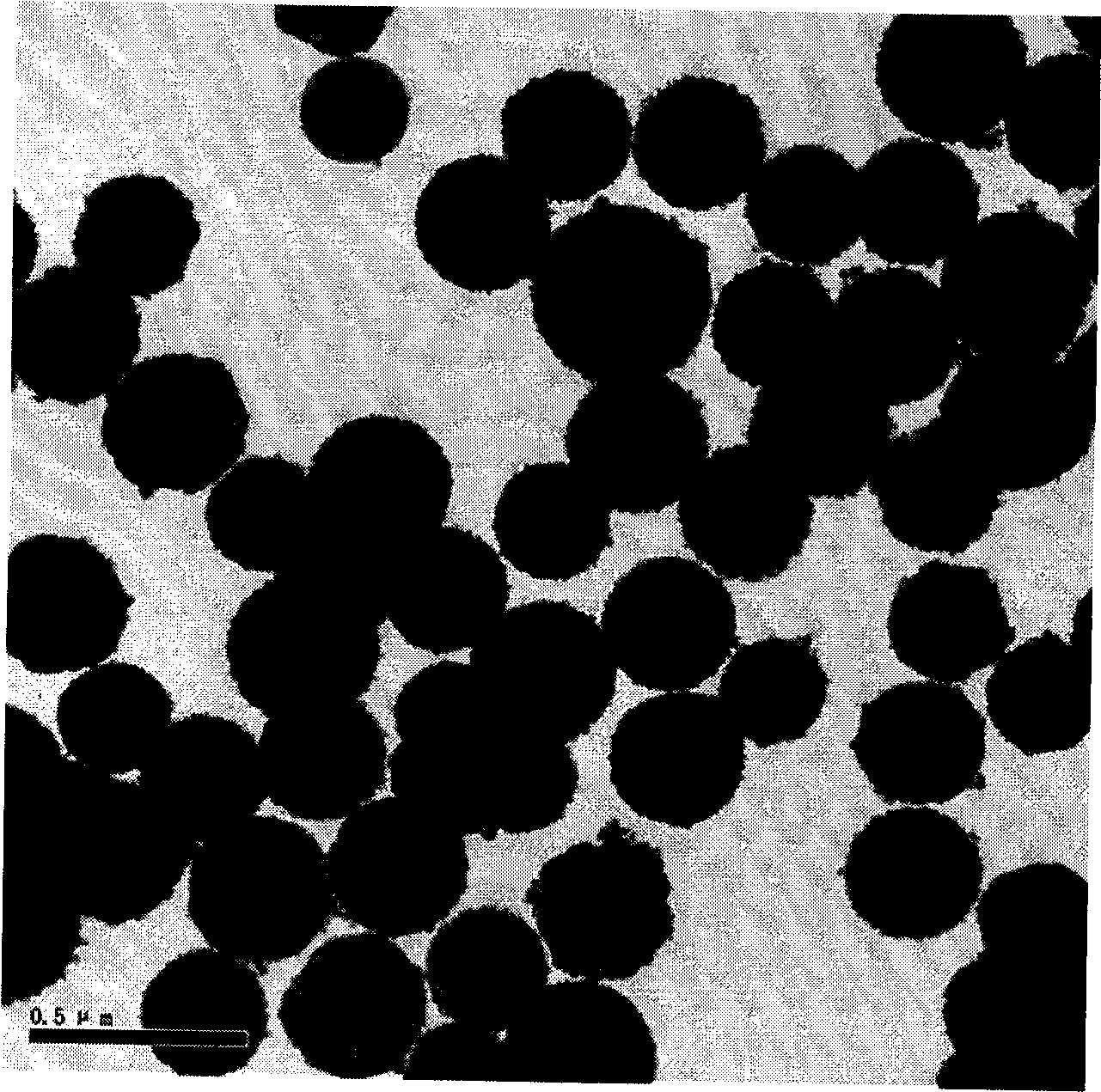

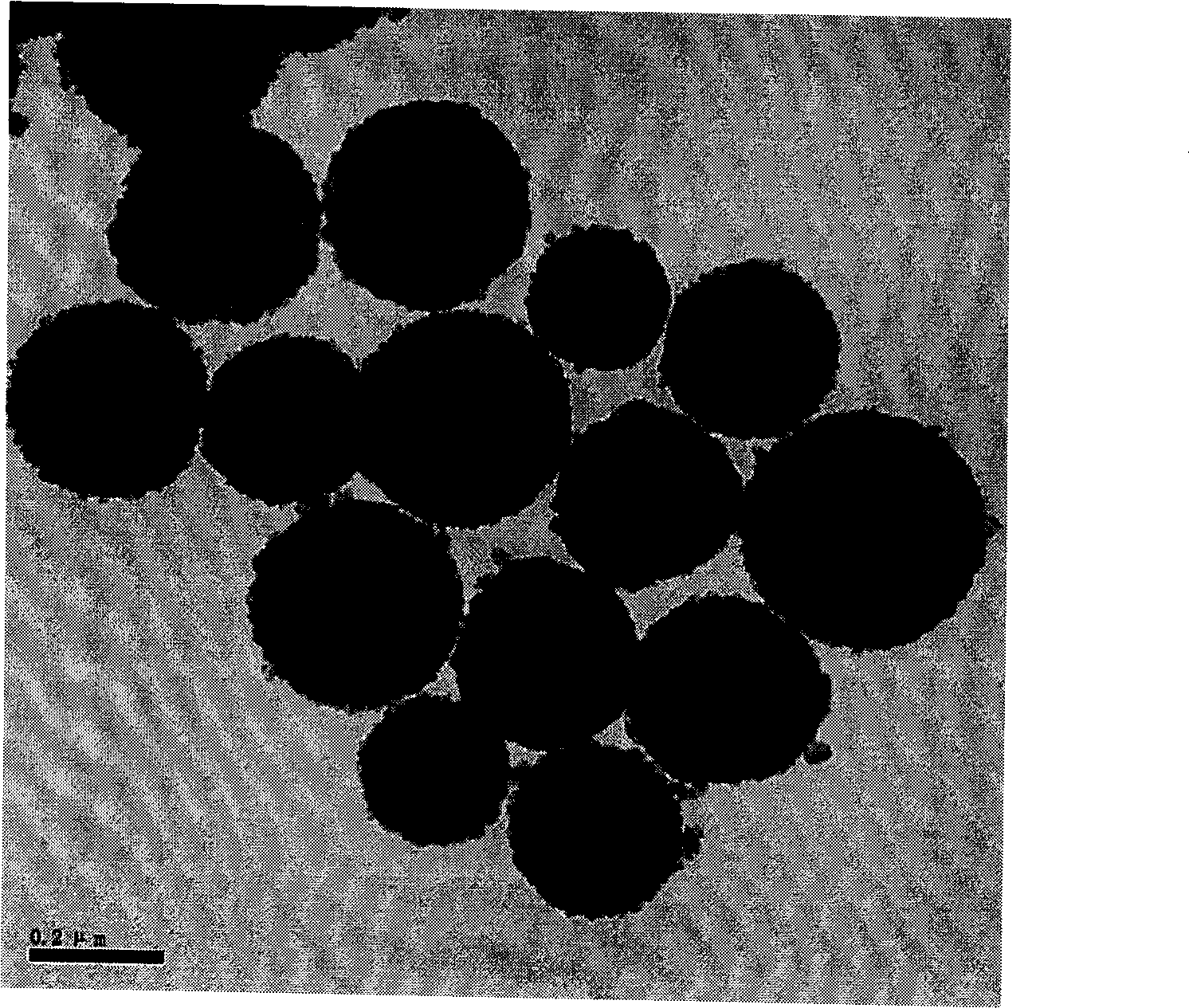

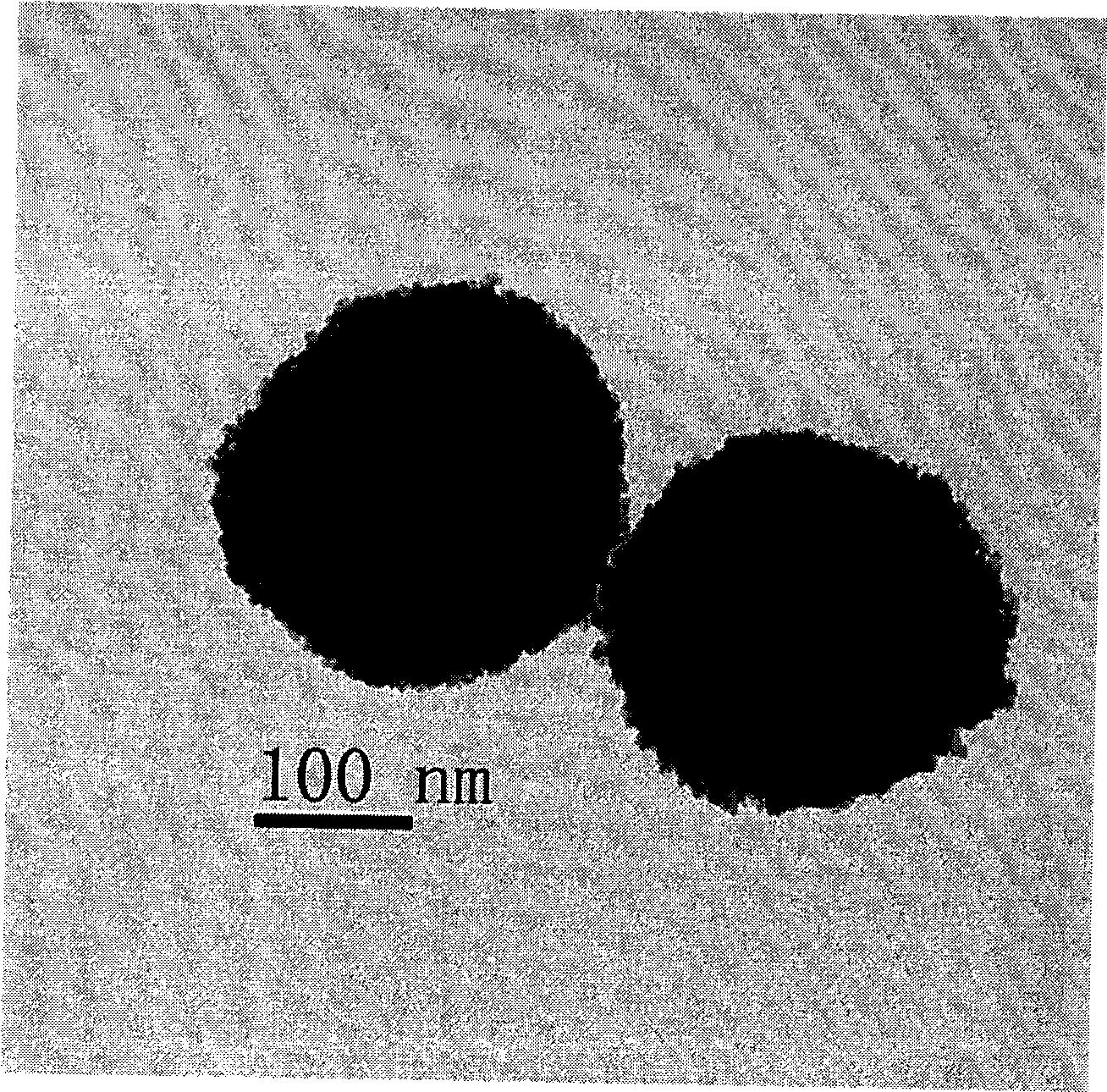

ActiveCN101475791ACoated evenlyGood monodispersityOther chemical processesHexamethylenetetramineCerium

The invention relates to a method for preparing a ceria / monox compounded abrasive, and application of the compounded abrasive. The method uses monodisperse spherical monox as a kernel of a coating type compounded abrasive, hexamethylenetetramine (HMT) as a precipitator and cerium salt as a raw material, and adopts an even precipitation method process to synthesize the ceria / monox compounded abrasive. Through the optimization of process parameters, such as the use amount ratio of monox master particles to the cerium salt, the molar ratio of the HMT to the cerium salt, and reaction and calcination temperature, the method controls the covering amount, the shape and the distribution state of ceria particles on the surface of the monox, thereby preparing the ceria / monox compounded abrasive of which the nanometer-level ceria particles evenly cover on the surface of the monox and which has good monodispersity; the method does not need complex equipment; and the needed chemical materials have less varieties, cheap prices and good experiment repeatability. The ceria / monox compounded abrasive is prepared into polishing slurry for chemical mechanical polishing of a gallium arsenide chip so as to obtain the polishing surface with the roughness in sub-nanometer magnitude and further improve polishing speed, reduce polishing pass and improve efficiency.

Owner:溧阳常大技术转移中心有限公司

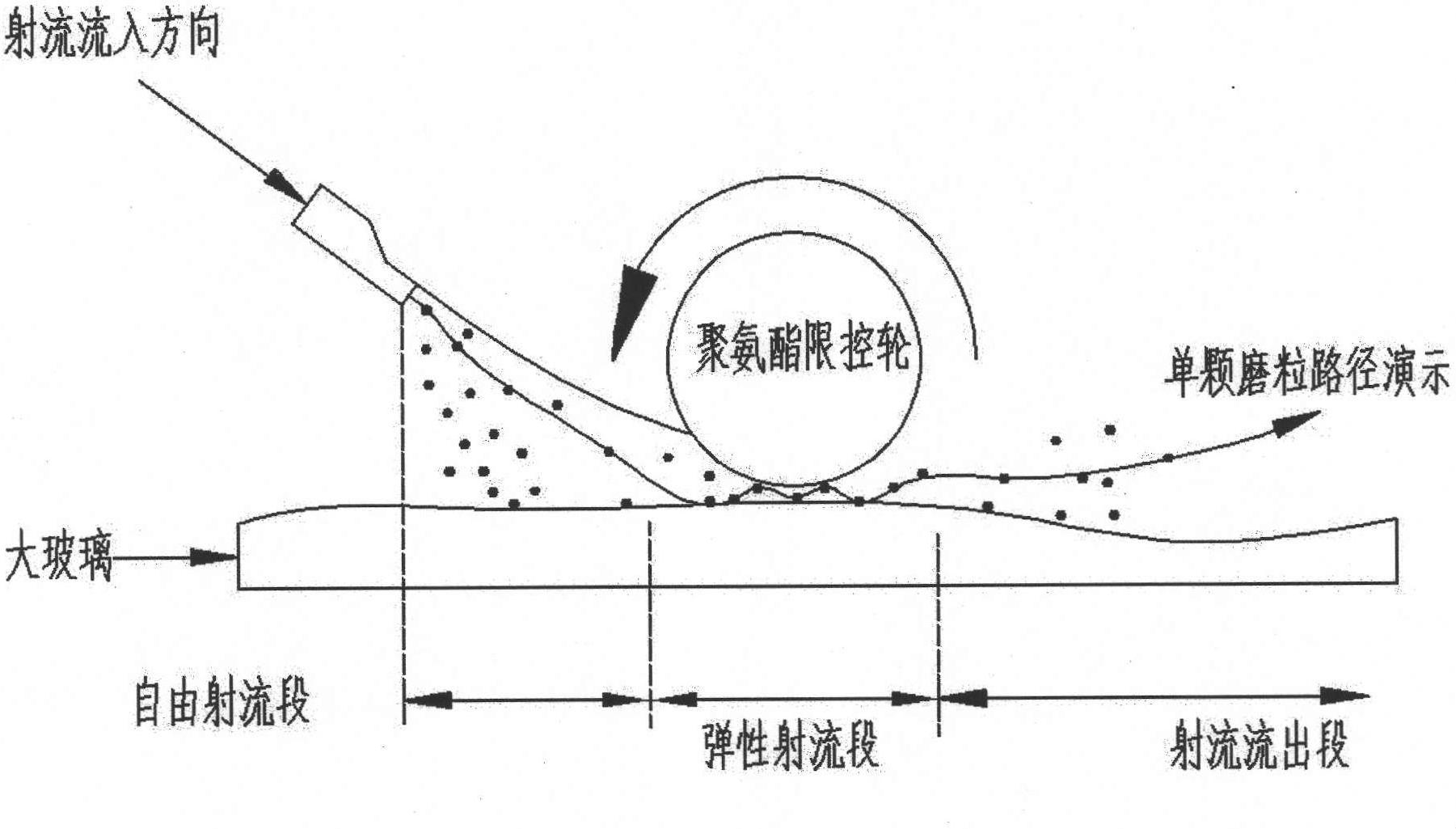

Controllable mix abrasive jet polishing equipment for large-scale ultra-precision optical glass

InactiveCN102689246AIncrease roughnessImprove polishing efficiencyPlane surface grinding machinesEngineeringOptical glass

The invention provides controllable mix abrasive jet polishing equipment for large-scale ultra-precision optical glass. The controllable mix abrasive jet polishing equipment is characterized by comprising a jet generating and transmission system and a robot controllable abrasive fluid polishing system. The equipment provided by the invention increases the machining precision and the machining efficiency, remarkably improves the shape precision and the roughness of large glass, eliminates subsurface damage and realizes machining of free surfaces.

Owner:DONGHUA UNIV

Chemical mechanical polishing solution for processing surface of sapphire or carborundum wafer for LED (Light Emitting Diode) substrate slice and preparation method thereof

InactiveCN102888193AAvoid damageNo subsurface damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesActive agentSilicon oxide

The invention discloses a chemical mechanical polishing solution for processing a surface of a sapphire or carborundum wafer for an LED (Light Emitting Diode) substrate slice. The chemical mechanical polishing solution comprises the following raw materials by weight: 2 to 30% of grinding material, 0.01 to 5% of chelating agent, 0.01 to 10% of surface active agent, 0.01 to 10% of dispersing agent, 0.1 to 20% of oxidant and the balance of deionized water. The preparation method comprises the steps as follows: preparing a grinding material-silica sol; then, sequentially adding the chelating agent, surface active agent, dispersing agent, oxidant and deionized water to the obtained silica sol along with agitating; and continuously uniformly agitating to obtain the chemical mechanical polishing solution for processing the surface of the sapphire or carborundum wafer for the LED substrate slice. The chemical mechanical polishing solution disclosed by the invention can not bring damage, scratching and corrosive pits to the surface of the LED substrate and has no pollution to the environment; the raw materials are cheap, and the cost is low; and the chemical mechanical polishing solution is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

Chemical polishing liquid used for metal and polishing technology

The invention belongs to the technical field of metal surface treatment and discloses chemical polishing liquid used for metal and a polishing technology. The polishing liquid includes 60 g / L-90 g / L of nitrate, 60 g / L-90 g / L of hydrochloric acid, 120 ml / L-180 ml / L of medium-strong acid, 20 g / L-50 g / L of a viscosity modifier, 1 g / L-10 g / L of a corrosion inhibitor, 2 g / L-6 g / L of a brightening agent and water. The polishing technology includes the steps that a metal workpiece is subjected to degreasing and activating pretreatment, the obtained metal workpiece is placed in the polishing liquid to be soaked for 2.5 min-4 min at the temperature ranging from 60 DEG C to 100 DEG C for being polished, after polishing is completed, the metal workpiece is subjected to neutralization aftertreatment, and therefore a flat and smooth metal surface can be obtained. The chemical polishing liquid is safe, environment-friendly, high in polishing efficiency, low in cost and suitable for industrial application.

Owner:SOUTH CHINA UNIV OF TECH

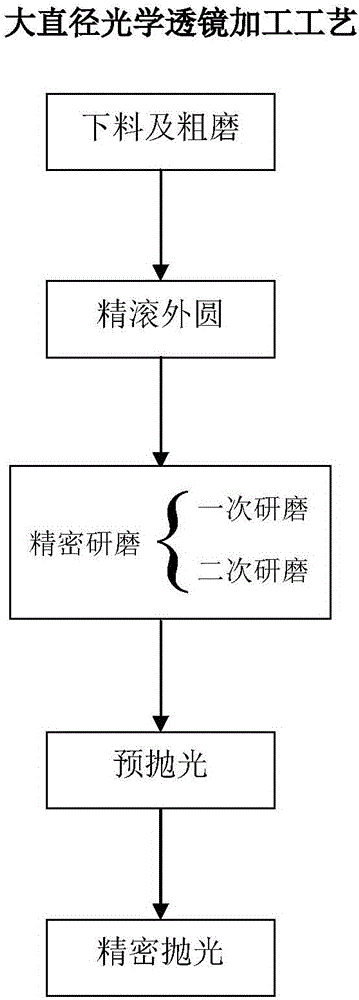

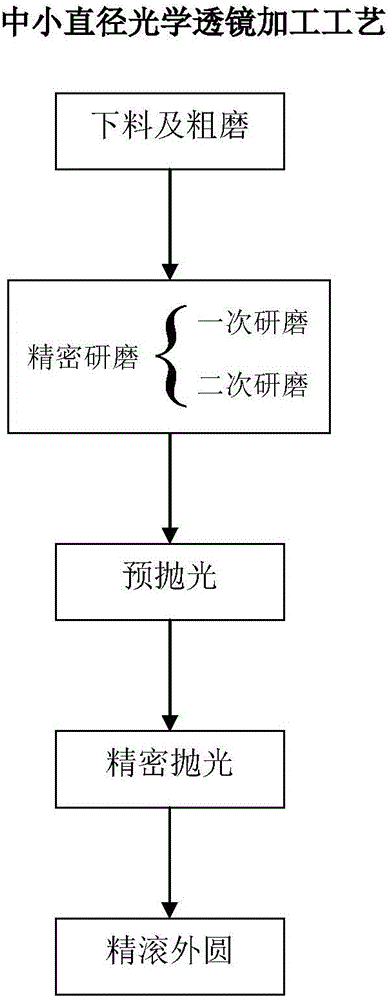

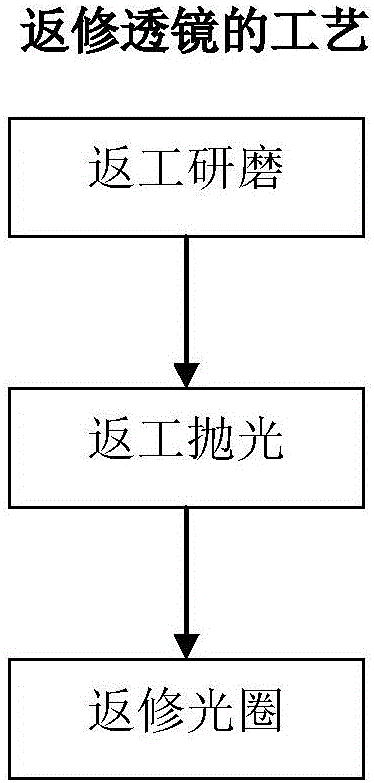

Cold-machining technology for high-precision optical lenses

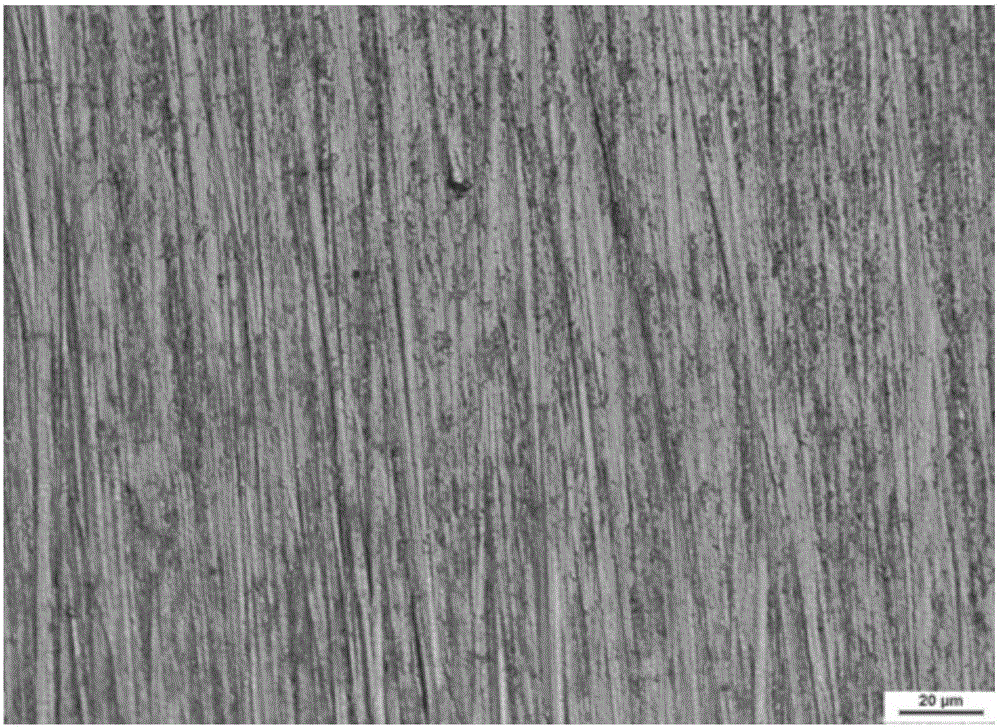

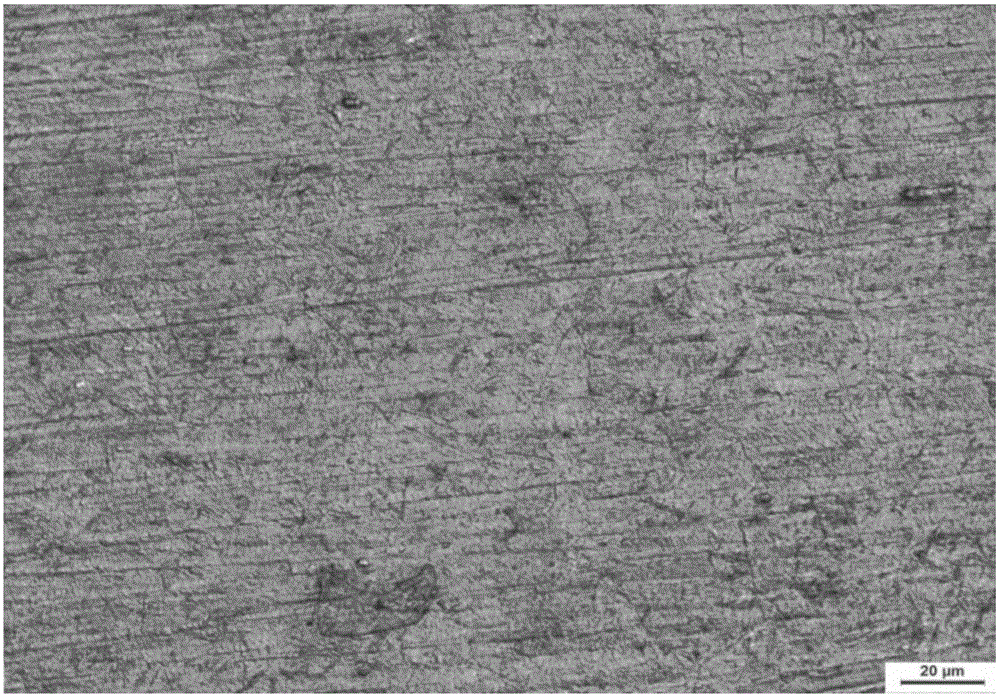

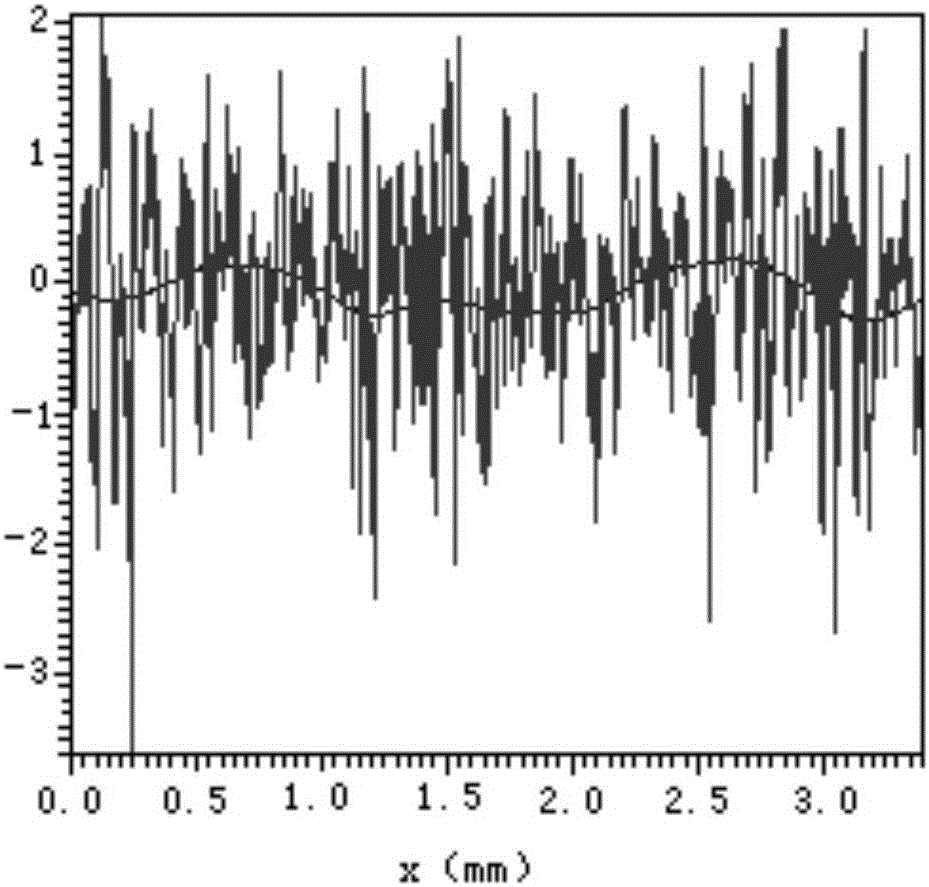

InactiveCN105834859AGuarantee processing qualityIncrease productivityOptical surface grinding machinesHobbingLow speed

The invention discloses a cold-machining technology for high-precision optical lenses. The cold-machining technology for high-precision optical lenses includes the following steps that S1, blanking and rough grinding are conducted, specifically, a material is cut into a square, the thickness is modified, and the outer ring is subjected to rough grinding; S2, the outer ring is subjected to precise hobbing, specifically, the outer ring is subjected to precise hobbing till meeting the requirement of a drawing, the radius portion is subjected to milling and grinding, and the face form and center thickness are controlled; S3, precise grinding is conducted, specifically, the lens material is placed in a grinding clamp and is grinded on a high-speed horizontally-swinging fine grinder through a diamond pellet; S4, pre-polishing is conducted, specifically, the lens is subjected to pre-polishing on a high-speed horizontally-swinging polishing machine through a polyurethane chip; and S5, precise polishing is conducted, specifically, the workpiece is subjected to precise polishing, aperture modification and detection on a low-speed polishing machine so that the lens can meet the requirements for the center thickness, surface form and degree of roughness finally. The process of the cold-machining technology for high-precision optical lenses is designed for high-precision optical lenses, and the high-speed fine grinder, the high-speed polishing machine and the low-speed polishing machine are combined for machining. The optical lens obtained through machining has the characteristics of being few in surface defect, high in degree of finish, good in surface form and low in degree of surface roughness.

Owner:THE OPTICAL ELEMENT FACTORY OF THE INST OF OPTICS & ELECTRONICS THE CHINESE ACADEMY OF SCI

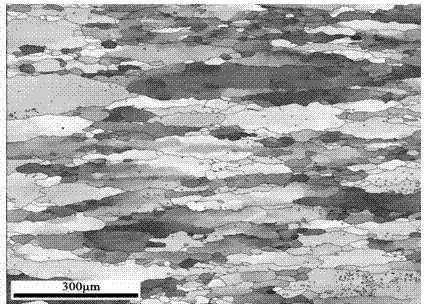

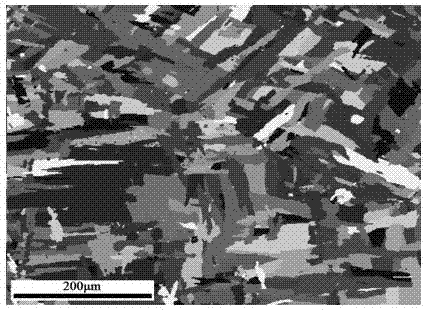

Electrolytic polishing solution for titanium and titanium alloys and electrolytic polishing process

InactiveCN102899711AEasy to get materialsLow costPreparing sample for investigationAcetic acidProcess equipment

The invention discloses electrolytic polishing solution for titanium and titanium alloys and an electrolytic polishing process, wherein the polishing solution is prepared by perchloric acid with volume fraction of 8-15% and acetic acid with volume fraction of 85-92%. The polishing solution is convenient in material selection, easy in preparation and storage, simple in polishing process equipment, easy in operation, smooth in surface, free of obvious scratches and oxide films and high in EBSD (Electron Back-Scattered Diffraction) pattern recognition rate, and has the effects of greatly reducing the superficial stress of the samples and greatly improving the detection precision.

Owner:CHONGQING UNIV

Alkaline computer hard disk polishing liquid and producing method thereof

InactiveCN101016438AImprove polishing efficiencyPolishing machinesPolishing compositions with abrasivesAbrasive agentChemical preparation

The invention discloses a preparing method of alkality computer hard disk polishing liquid in chemical preparation domain, which comprises the following steps: setting pH value of polishing liquid at 7-10; making the mass percent of oxidant, organic complexing agent and grinding agent at 0.1%-5%, 0.1%-5% and 0.5%-20% separately; composing ingredient A with diamond pyramid hardness bigger than 7 and ingredient B with diamond pyramid hardness bigger than 5; getting grinding agent; forming oxidant, organic metal chelating agent, high hardness and low hardness rubbing agent in neutral and alkality agent; adopting soft and hard merging multiple polished rubbing particle method; decreasing grievous fish tail caused by big particle boule aluminum oxide; increasing graduation efficiency; This invention adopts alkality polishing agent, which decreases the polishing loss of hard disk edge.

Owner:孙韬

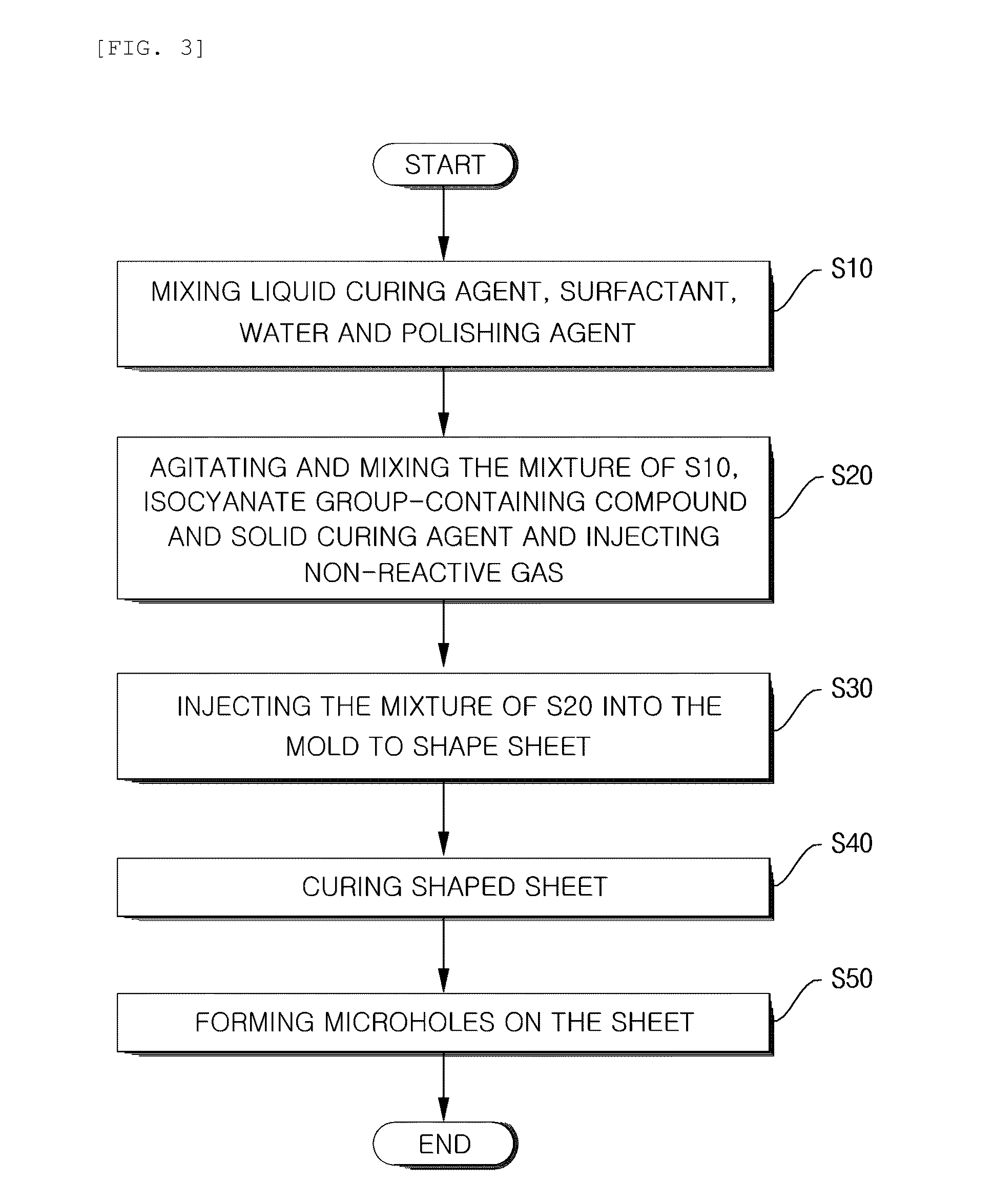

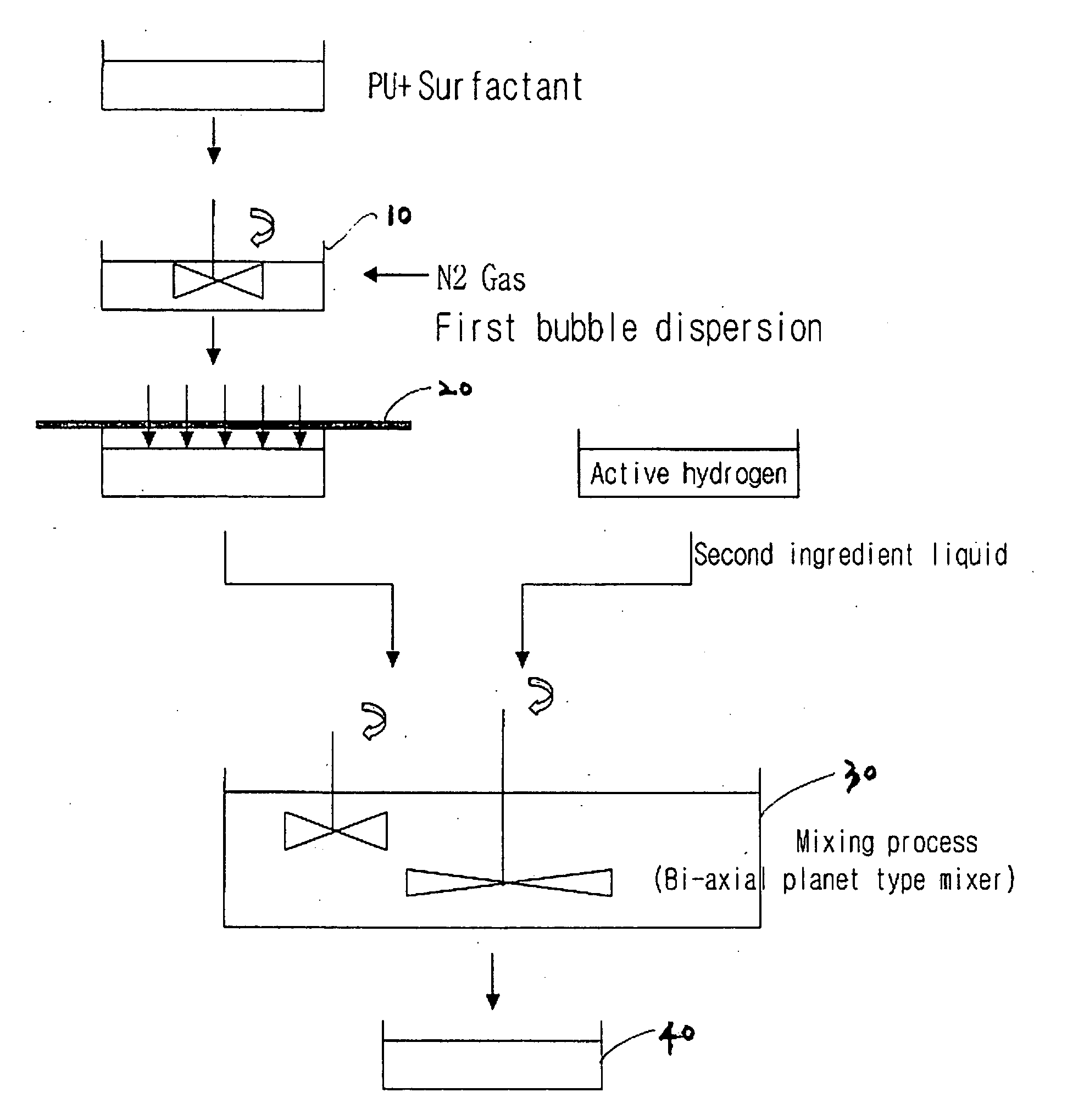

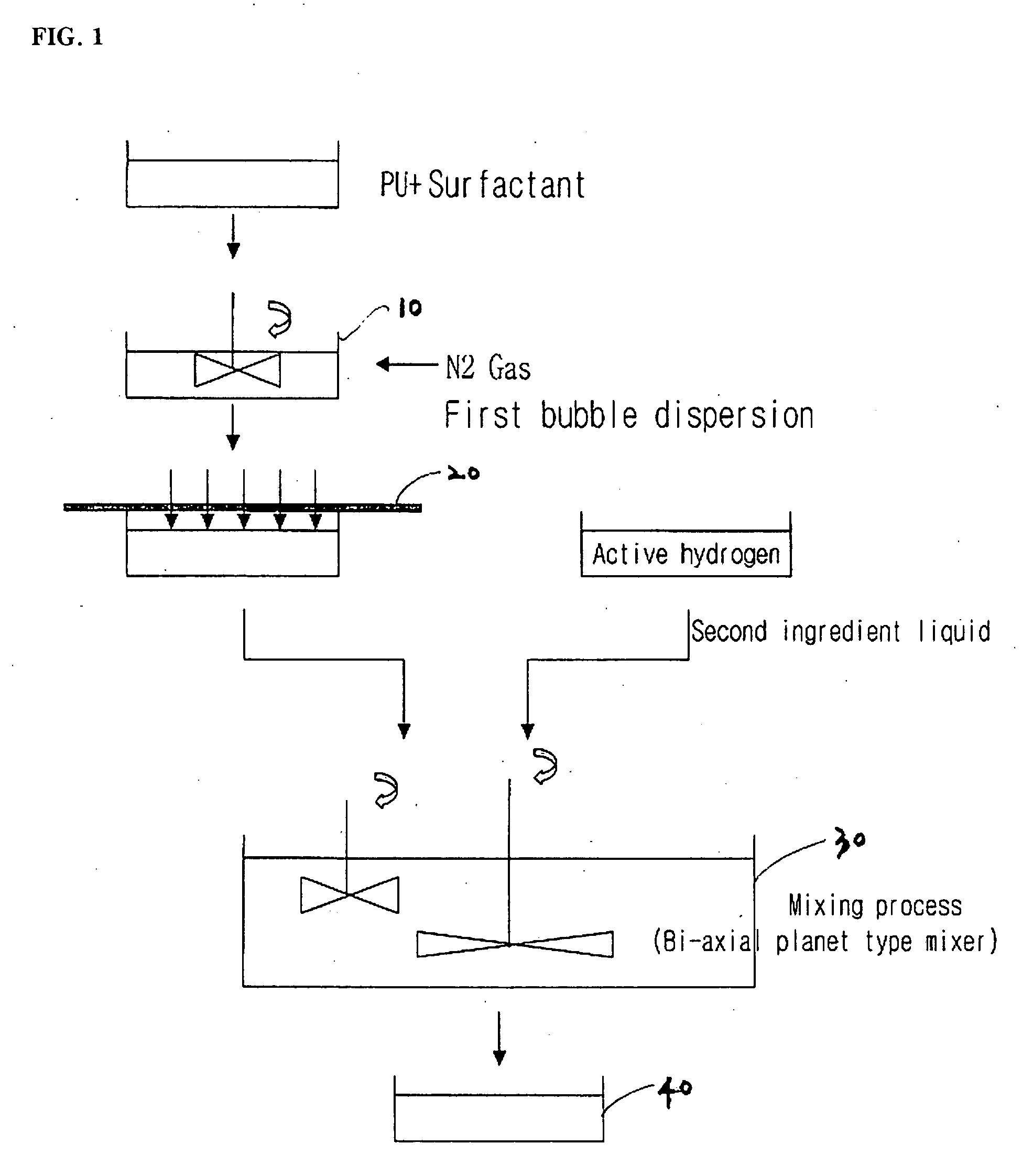

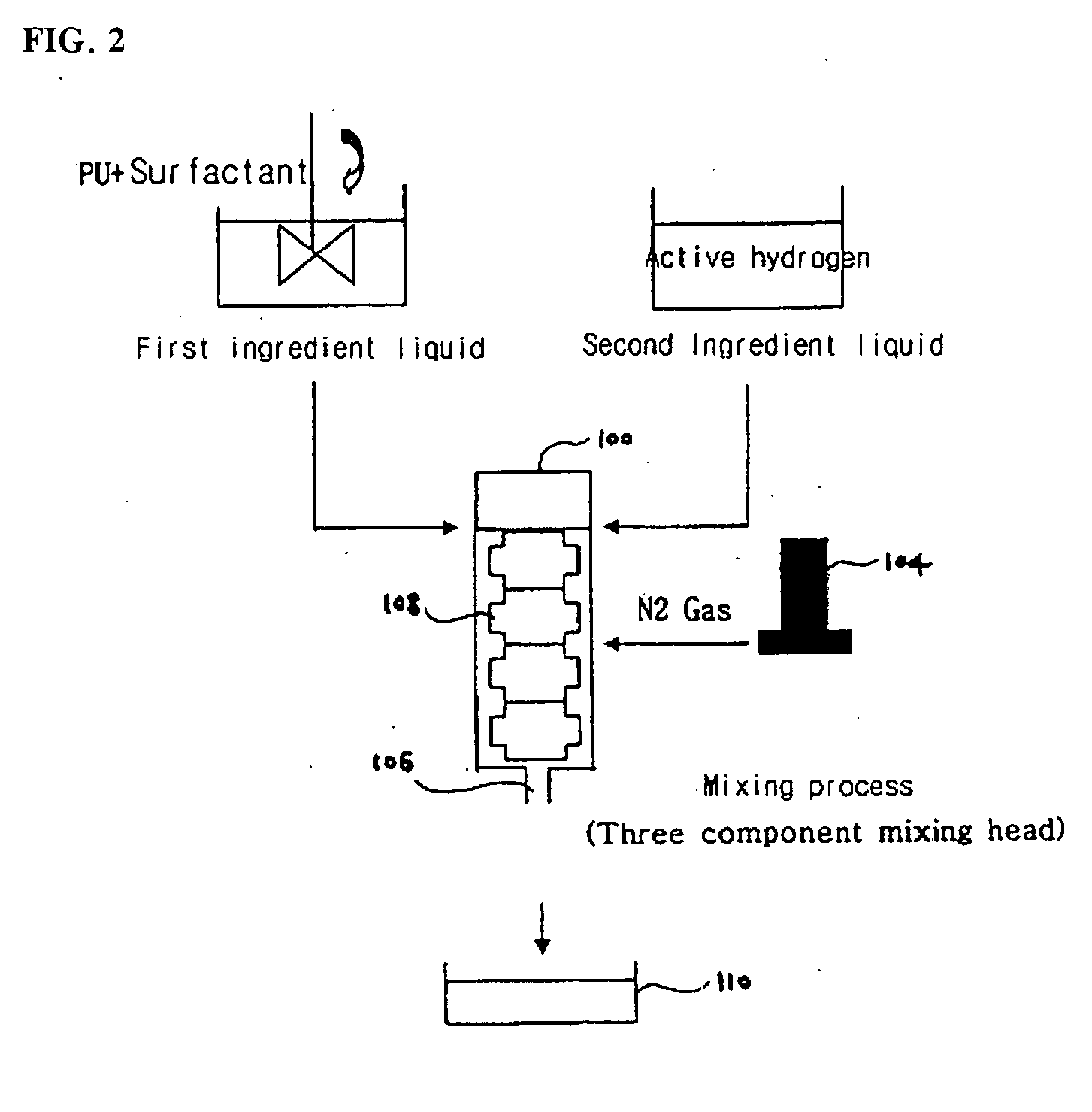

Method of fabricating polyurethane foam with micro pores and polishing pad therefrom

InactiveUS20060022368A1Good flexibilitySimplify the manufacturing processSemiconductor/solid-state device manufacturingFlexible-parts wheelsHydrogenAdditive ingredient

To provide a method of fabricating a polyurethane foam with micro pores, and a polishing pad therefrom, the method including steps of (a) adding a nonionic surfactant into at least one of a first ingredient including an isocyanate group-containing compound and a second ingredient including an active hydrogen group-containing compound, (b) agitating and mixing the mixture of the first ingredient and the second ingredient while adding a non-reactive gas thereto, (c) discharging the mixture out of a container at a predetermined rate, and (d) injecting the discharged mixture into a mold so as to form a mold body into a predetermined shape.

Owner:DONG SUNG A & T

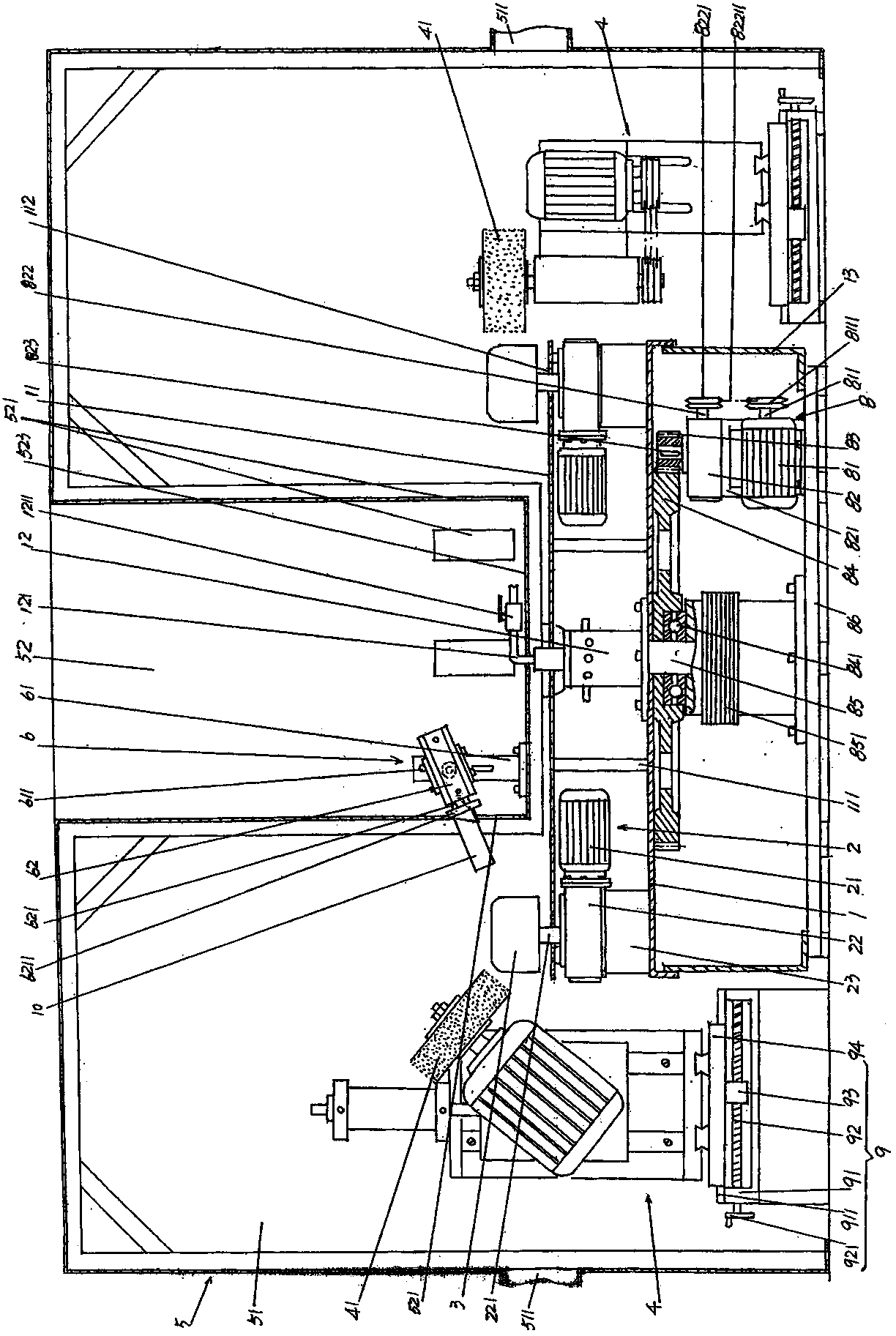

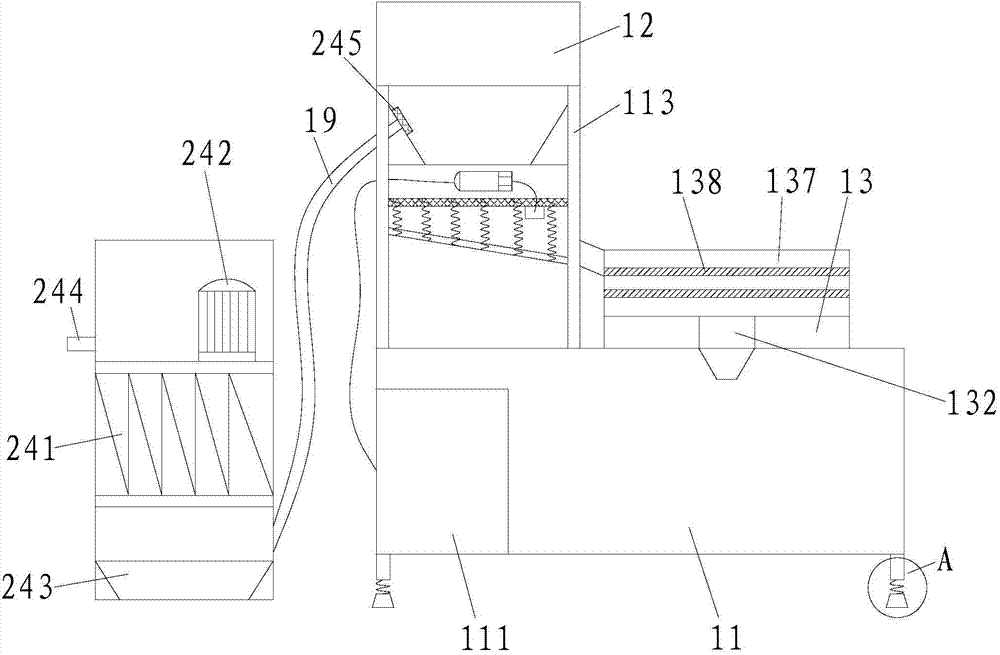

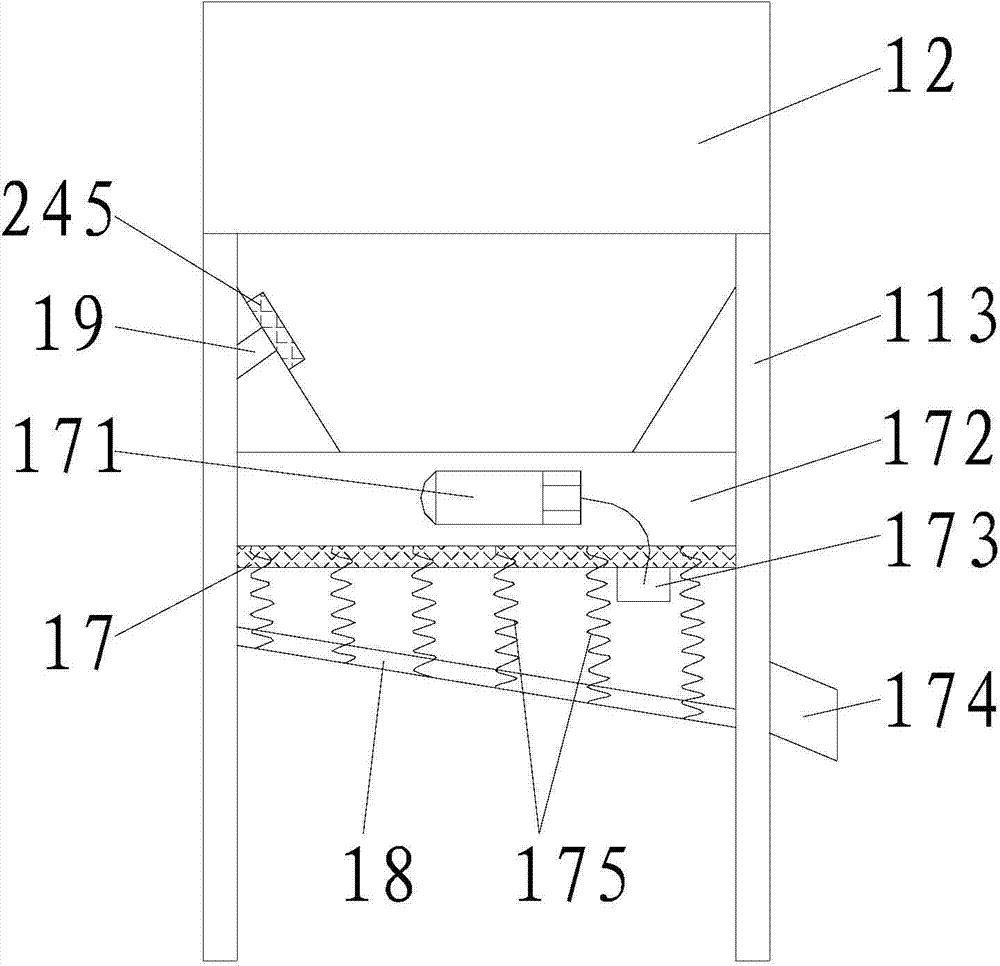

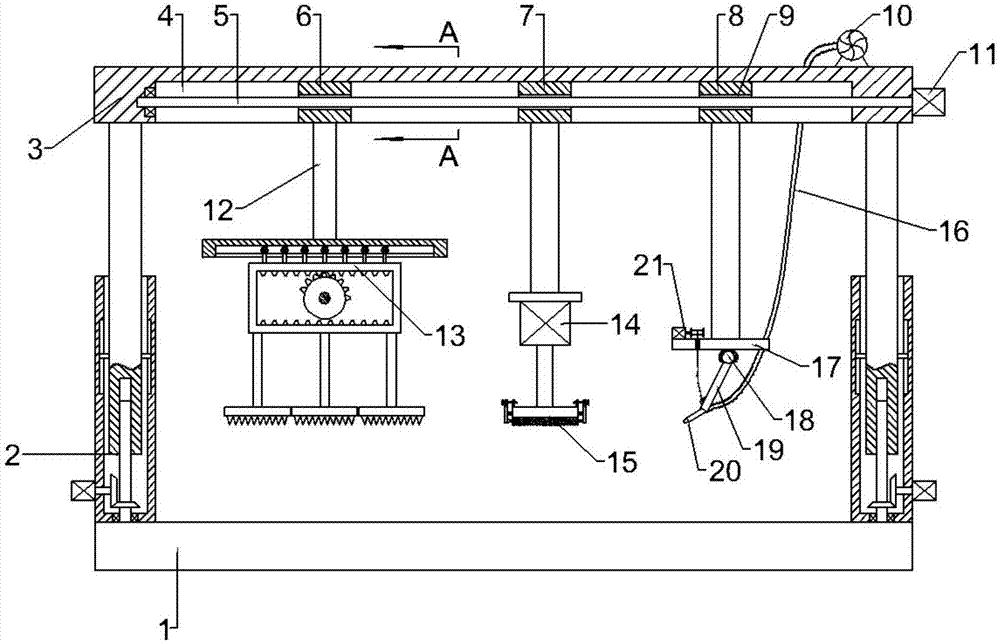

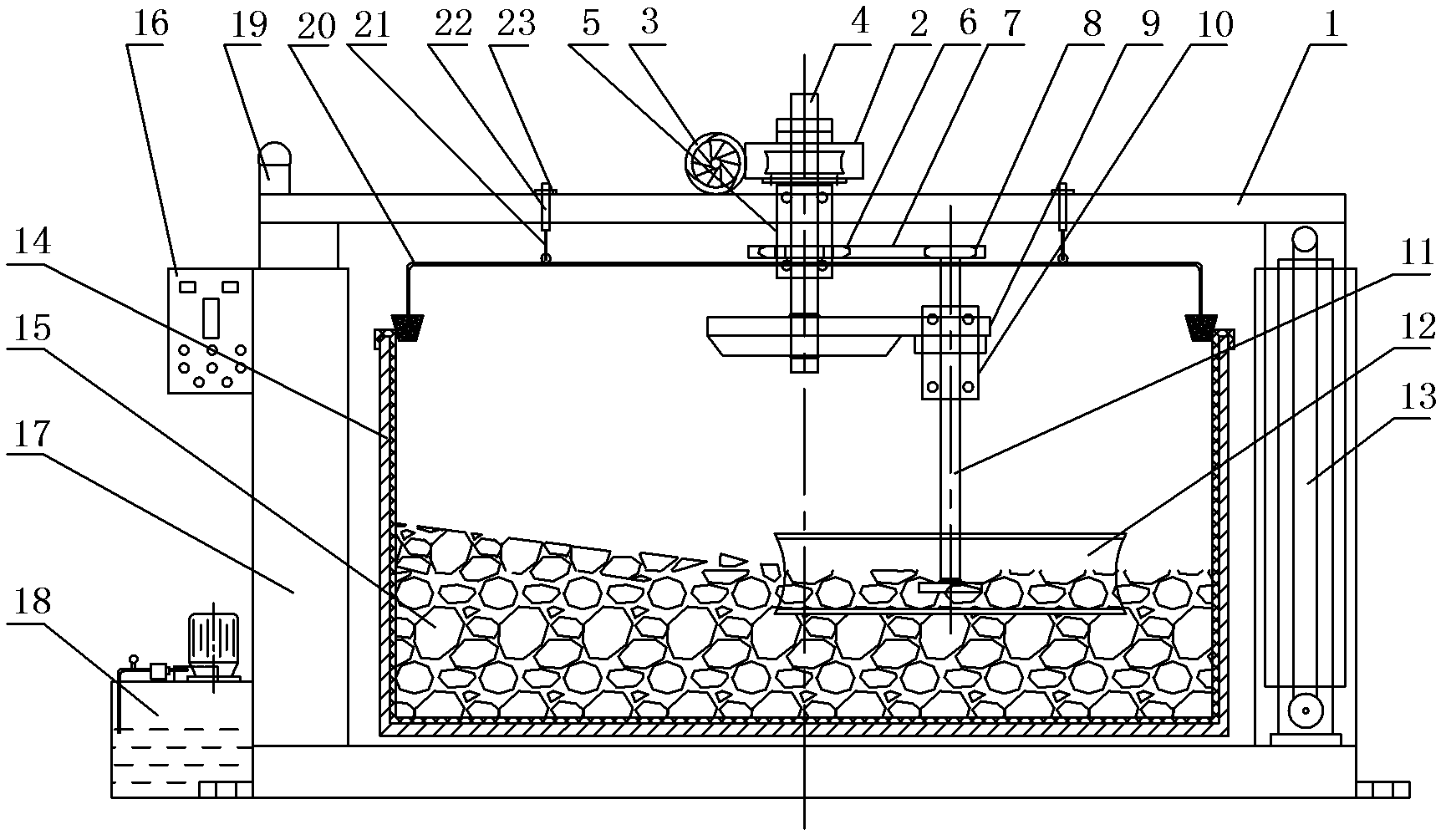

Building artificial stone block integrated machining equipment with reciprocating grinding function

InactiveCN107414625AImprove sanding effectImprove grinding efficiencyGrinding wheel securing apparatusGrinding carriagesProcess efficiencyEngineering

The present invention provides an integrated building artificial stone processing equipment with a reciprocating grinding function, which includes a base, a height adjustment device is fixedly connected to both ends of the base, and a support plate is fixedly connected to the top ends of the two height adjustment devices. The support plate is provided with a moving groove with the opening facing downwards, and the first moving block, the second moving block and the third moving block are arranged in the moving groove from left to right, and the first moving block, the second moving block and the The third moving block is provided with threaded through holes, and the three threaded through holes are jointly threaded with horizontal threaded rods, and the two ends of the horizontal threaded rods are erected at the two ends of the support plate. The invention has the following beneficial effects: it realizes the integrated treatment of grinding, polishing and cleaning, effectively improves the processing efficiency of stone materials, has a high degree of integration, effectively reduces labor input, keeps the operator away from the processing site, and reduces The incidence of occupational diseases among workers has been reduced.

Owner:刘丽

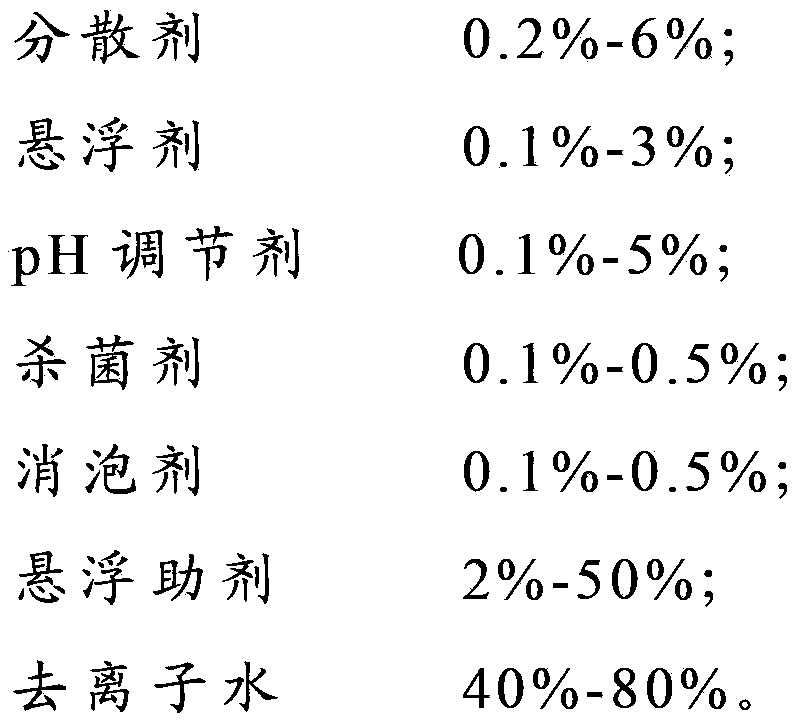

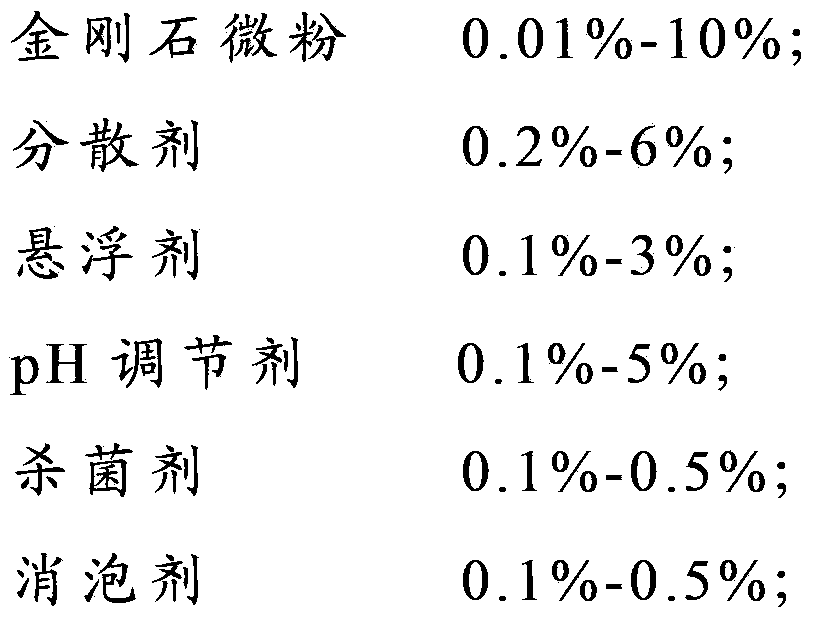

Water-based diamond polishing solution and preparation method thereof

InactiveCN104293205AGood stabilityImprove polishing efficiencyPolishing compositions with abrasivesIonMaterials science

The invention provides a water-based diamond polishing solution. The water-based diamond polishing solution consists of the following components in percentage by weight: 0.01-10 percent of diamond micro-powder, 0.2-6 percent of a dispersing agent, 0.1-3 percent of a suspending agent, 0.1-5 percent of a pH adjusting agent, 0.1-0.5 percent of a sterilizing agent, 0.1-0.5 percent of a deforming agent, 2-50 percent of a suspension aid and 40-80 percent of deionized water. The invention further provides a preparation method of the water-based diamond polishing solution.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Chemical mechanical polishing solution for large-sized silicon wafers and preparation method thereof

ActiveCN101870852AImprove consistencyReduce hardnessPolishing compositions with abrasivesCompound (substance)Cleansing Agents

The invention relates to a chemical mechanical polishing solution for large-sized silicon wafers and a preparation method thereof, and the chemical mechanical polishing solution is mainly applied to the ultraprecision machining of large-sized semiconductor silicon substrate slices, and can obtain a nanometer-level ultrasmooth surface. The polishing solution consists of the following components inpercentage by weight: 5 to 50 percent of silicon dioxide abrasive, 1 to 10 percent of pH value regulator, 0.01 to 5 percent of surfactant, 0.01 to 0.05 percent of cleaning auxiliary, 0.01 to 2 percent of chelator and the balance of deionized water; and the silicon dioxide is added in the state of silicasol. Under proper polishing technological conditions, the polishing solution prepared with the components according to the contents can obtain a high-quality polished surface and meet the requirement of the semiconductor industry on the surface quality and removal rate of silicon substrate slices, and moreover, the invention has the advantages of low cost, easy cleaning, low corrosiveness and the like, and has a good application prospect.

Owner:BEIJING GRISH HITECH

Universal dust-free polishing equipment for hubs

InactiveCN105479317AAchieve recyclingReduce riskGrinding carriagesPolishing machinesWorking environmentZero emission

The invention discloses novel universal dust-free polishing equipment for hubs. The novel universal dust-free polishing equipment for hubs comprises a base, noise-reducing and dust-removing equipment and a universal mechanism arranged in the noise-reducing and dust-removing equipment. A universal dust-free hub polishing platform for polishing the hubs is designed through a mechanical structure and a unique dust-removing structure, a dust-free, safe and zero-emission production system is established, the problems of poor working environments of polishing workers, severe environmental pollution and potential safety hazards are solved fundamentally, meanwhile, the polishing quality cannot be reduced, and the polishing yield is improved.

Owner:江苏密斯特工业机器人有限公司

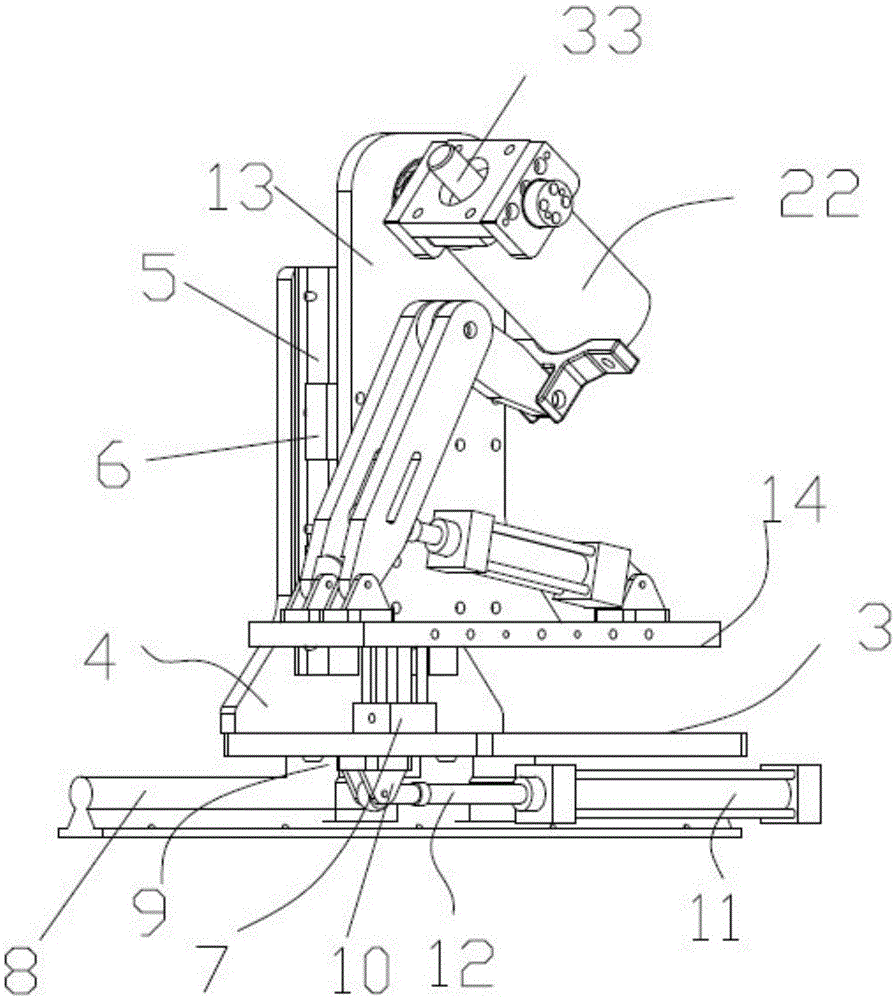

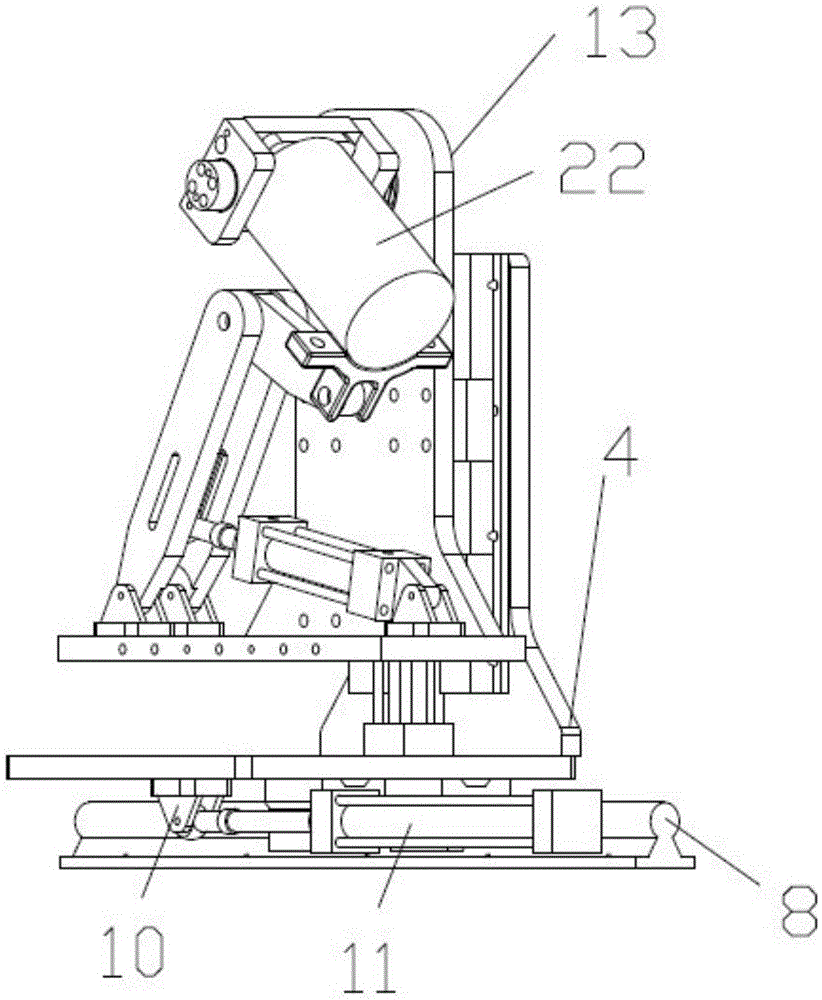

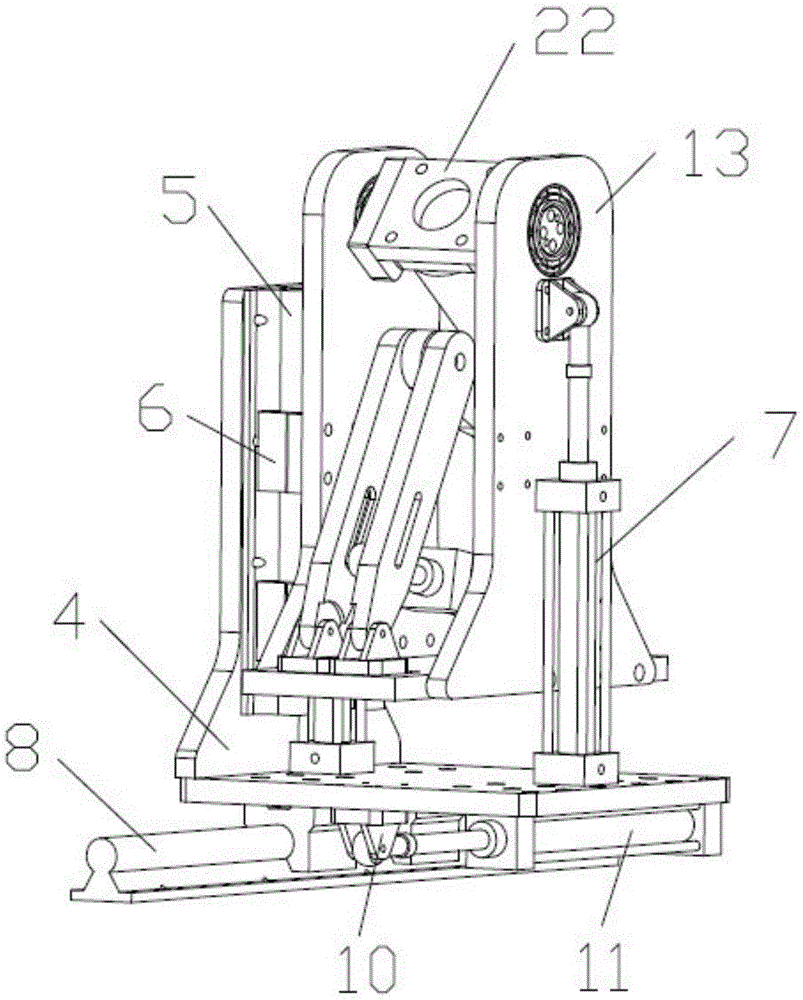

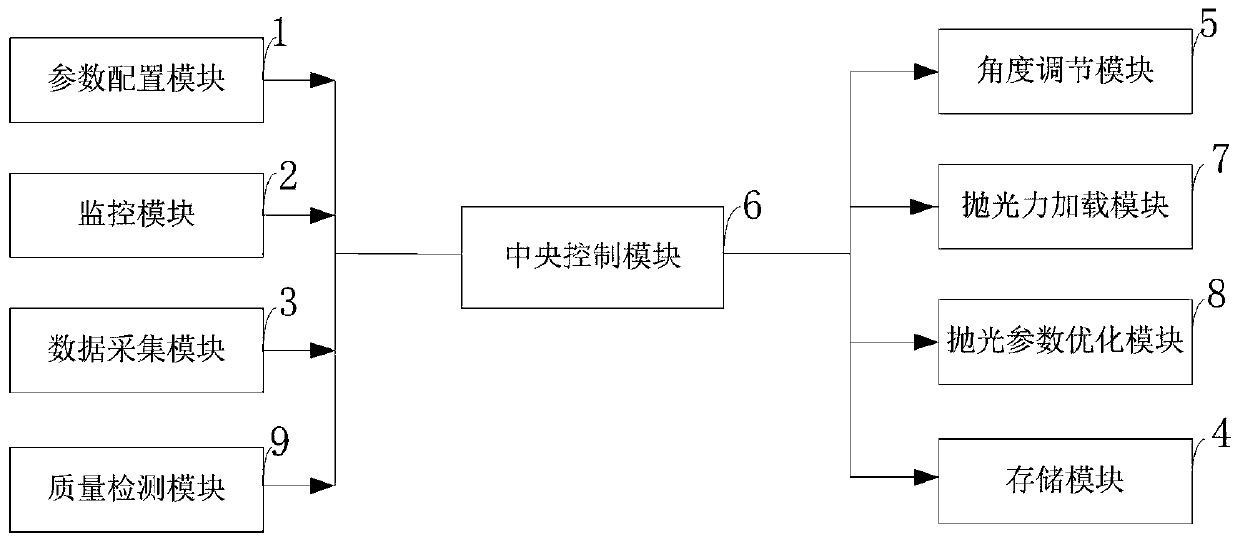

Five-axis linkage numerical control manipulator polishing control system and method

InactiveCN111468989AOptimizing Process ParametersAccurate and fast variable polishing force controlPolishing machinesAutomatic grinding controlNumerical controlControl system

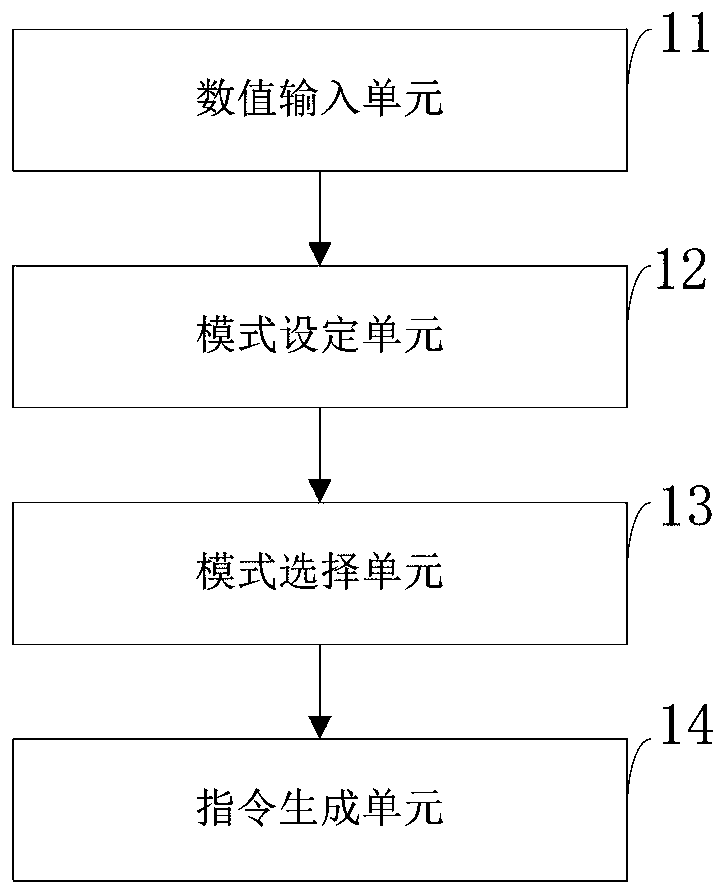

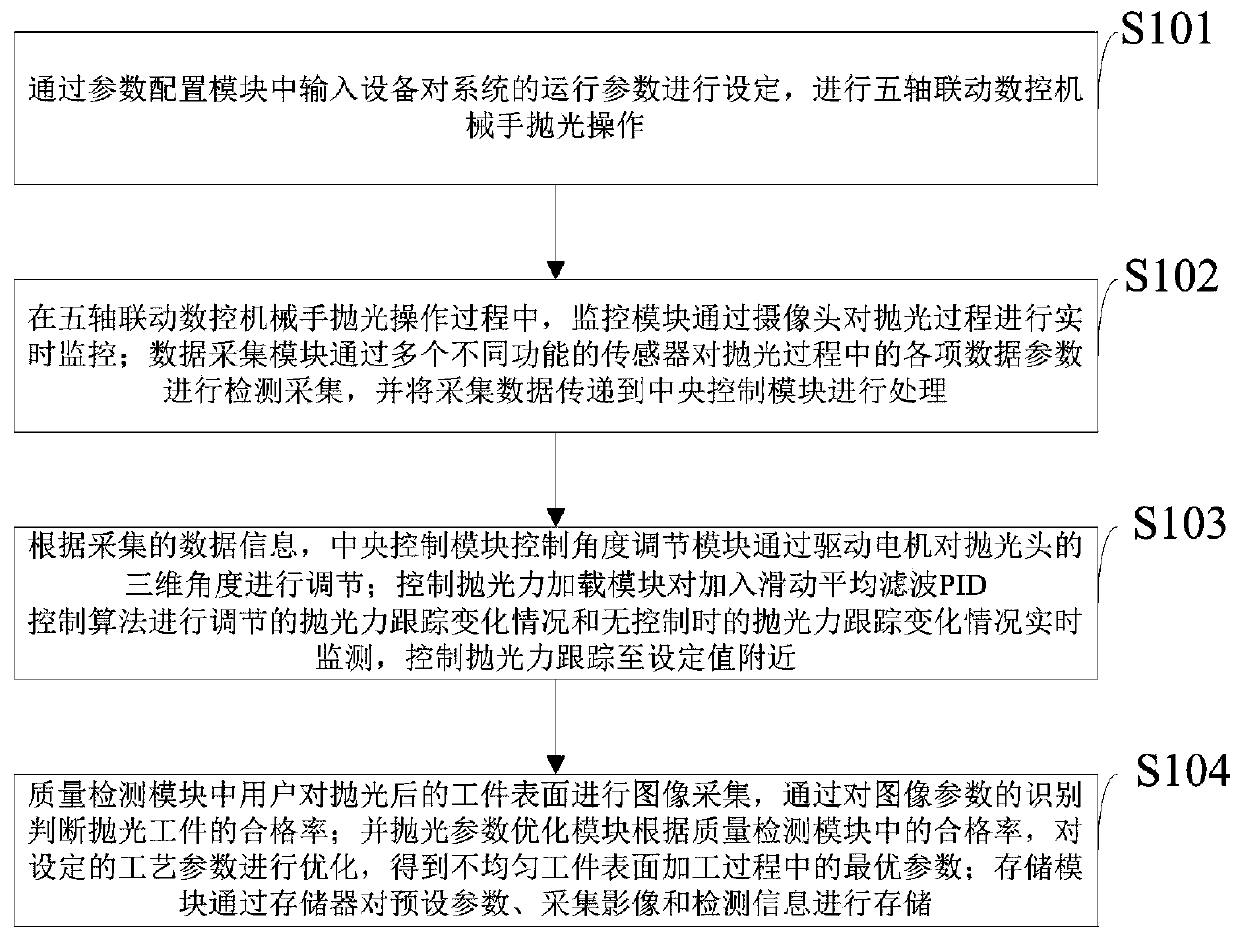

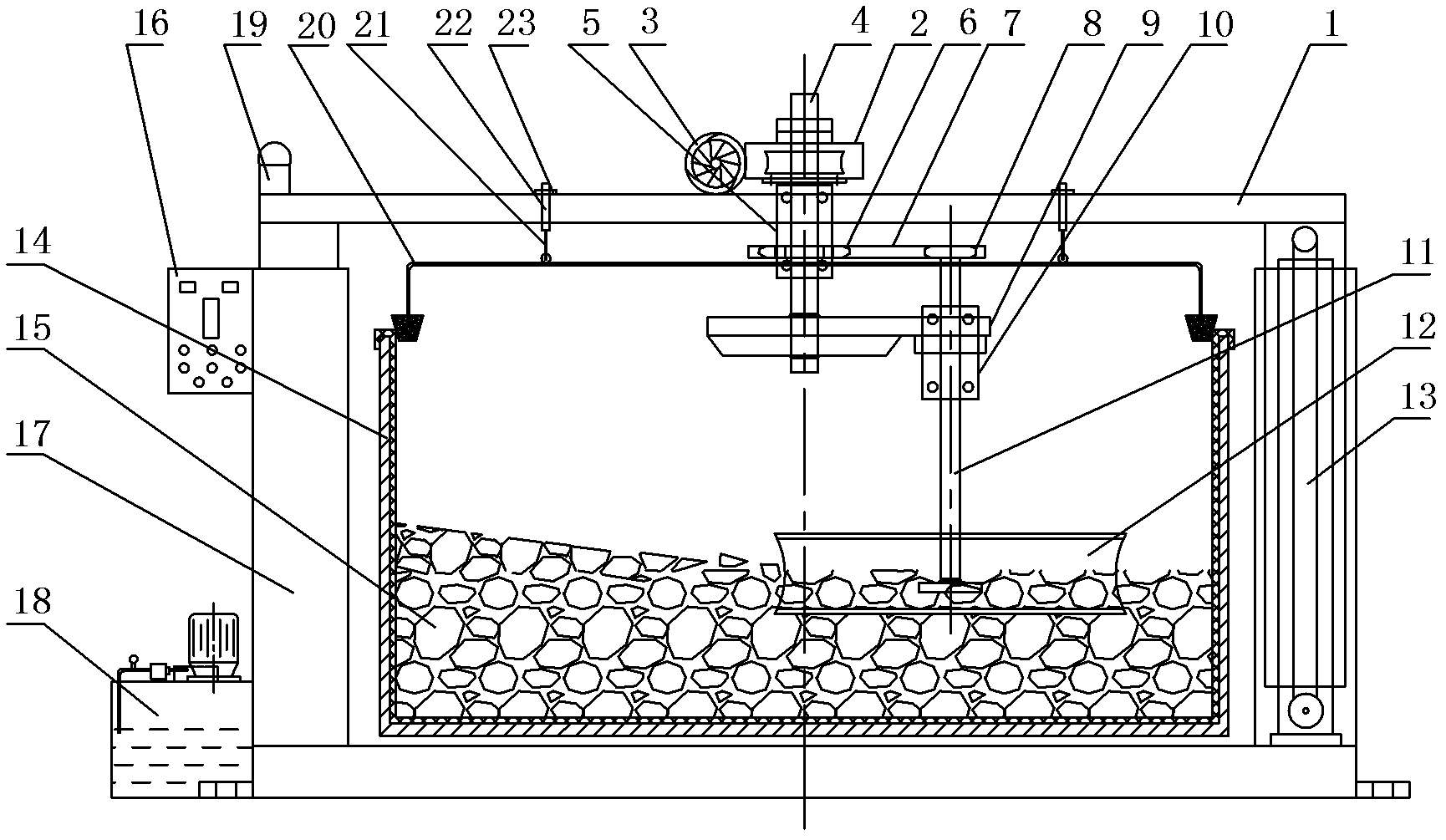

The invention belongs to the technical field of machining, and discloses a five-axis linkage numerical control manipulator polishing control system and method. The five-axis linkage numerical controlmanipulator polishing control system comprises a parameter configuration module, a monitoring module, a data acquisition module, a storage module, an angle adjustment module, a central control module,a polishing force pneumatic loading module, a polishing parameter optimization module and a quality detection module. The parameter configuration module comprises a numerical value input unit, a modesetting unit, a mode selection unit and an instruction generation unit. The monitoring module monitors the polishing process in real time through a camera. The data acquisition module detects and acquires various data and parameters in the polishing process through a plurality of sensors with different functions. According to the five-axis linkage numerical control manipulator polishing control system and method, accurate and rapid tracking variable polishing force control can be achieved in the polishing process, the corresponding polishing force is controlled in real time, and the force control requirement of polishing machining can be effectively met; and on the premise that the polishing quality is guaranteed, the working efficiency is improved.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

Smokeless polishing treatment solution for high-gloss aluminum profile and method of use

The invention provides a smoke-free polishing treatment solution for a high-gloss aluminum sectional material and a use method thereof. The smoke-free polishing treatment solution is characterized by comprising 85% H3PO4, 98% H2SO4, 30% hydrogen peroxide or potassium permanganate or perchloric acid or sodium molybdate or ammonium persulfate or sodium vanadate, cerium nitrate or sodium silicate, imidazoline or benzotriazole or phytic acid or thiourea, sodium dodecyl benzene sulfonate or sodium benzene sulfonate or sodium toluene sulfonate or sodium xylene sulfonate, and nickel chloride or nickel sulfate or lead acetate. Compared with the prior art, the smoke-free polishing treatment solution provided by the invention has advantage of no generation of high-pollution NOx yellow smoke, and enables the surface of the aluminum sectional material to have excellent gloss and no pitting microscopic defects.

Owner:GUANGDONG XINGFA ALUMINUM

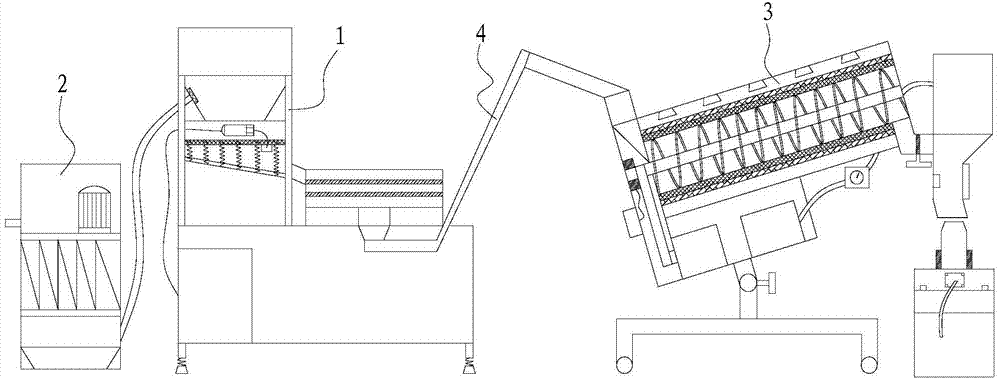

Method for polishing automobile hubs and device

ActiveCN102554752ASmooth rotationStable and safe rotationEdge grinding machinesPolishing machinesHydraulic cylinderAdhesive

The invention discloses a method for polishing automobile hubs and a device. The method for polishing automobile hubs sequentially includes steps of 1, driving an automobile hub to rotate by a rotating device, placing the automobile hub into a polishing device and then leading the automobile hub to realize revolution around the rotating device; 2, roughly polishing the automobile hub which rotates and realizes revolution around the rotating device and rough polishing abrasive materials for the first time; 3, finely polishing the automobile hub which rotates and realizes revolution around the rotating device and fine polishing abrasive materials for the second time; and brilliantly polishing the automobile hub which rotates and realizes revolution around the rotating device and brilliant polishing abrasive materials for the third time. The polishing device comprises a polishing cylinder with a lining made of PU (polyurethane) adhesive, a hydraulic cylinder is disposed on one side of the polishing cylinder, a portal frame is disposed on the upper portion of the hydraulic cylinder, the rotating device used for driving the automobile hub to rotate is arranged on the portal frame, an adjusting screw stem provided with an adjusting nut is disposed on the portal frame, and a suspension cover which is placed above the polishing cylinder is connected onto the adjusting screw stem by an iron chain. By the aid of the method for polishing automobile hubs and the device, polishing efficiency can be improved, labor cost is lowered, a polishing effect is guaranteed, and the device is simple in structure and low in manufacturing cost.

Owner:湖州中云机械制造股份有限公司

Polishing solution for hard disk magnetic head and preparation method thereof

ActiveCN102174294AImprove suspension stabilityImprove dispersion uniformityOther chemical processesPolishing compositions with abrasivesHydrocarbon solventsMachined surface

The invention discloses polishing solution for a hard disk magnetic head and a preparation method thereof. The polishing solution is mainly prepared from diamond abrasive particles, a dispersing agent, a corrosion inhibitor, a phase transfer solvent, an oil phase medium regulator and a hydrocarbon solvent, wherein the average particle size of the diamond abrasive particles is 30 to 150nm, the particle size distribution of the particles is 20 to 300nm, and the length-diameter ratio of the particles is 1.0 to 2.0. The preparation method comprises the following steps of: mixing diamond powder and a surface modifier, grinding, removing impurities, and grading to obtain suspension slurry; adding the phase transfer solvent into the suspension slurry, and stirring and dispersing the system; removing fine particles and coarse particles in the phase transfer solvent system by grading to ensure that the particle size distribution and concentration of the diamond abrasive particles meet the requirements; and transferring to the hydrocarbon solvent, adding the oil phase medium regulator, the dispersing agent and the corrosion inhibitor, and uniformly stirring to obtain the polishing solution for the hard disk magnetic head. The polishing solution prepared by the method has high suspension stability and dispersion uniformity, and high polishing efficiency during polishing, and a machined surface has high quality.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Building steel plate intermittent polishing device

The invention discloses a building steel plate intermittent polishing device. The middle of a guide rail is rotatably connected with the middle of a driving shaft, the guide rail is fixedly connectedwith the right wall of a device body, the lower end of the driving shaft is fixedly connected with a semi-circular bevel gear, the toothed part of the semi-circular bevel gear is engaged with bevel gears, the bevel gears are fixedly connected with a driven shaft, the left end of the driven shaft is fixedly connected with a semi-circular gear, and the toothed part of the semi-circular gear is engaged with a first gear; and the first gear is fixedly connected with a worm, the upper end of the worm is engaged with a worm wheel, the rear portion of the worm wheel is fixedly connected with a secondgear, and the second gear and the worm wheel are both rotatably connected with the device body. According to the building steel plate intermittent polishing device, the bevel gears at the left end and the right end are driven to rotate through the semi-circular bevel gear, further the driven shaft is driven to conduct reciprocating forward and reverse rotation, the toothed part of the semi-circular gear intermittently drives the first gear to conduct forward and reverse rotation so that the worm can be driven to conduct intermittent forward and reverse rotation, and thus reciprocating left-right intermittent moving of a working table can be achieved; and the structural design of the building steel plate intermittent polishing device is reasonable and applicable, the polishing efficiency of a building steel plate is greatly improved, machining of all the parts of the steel plate is even, and the polishing effect is excellent.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

Device for polishing outer peripheral edge of semiconductor wafer

InactiveUS6921455B1High precisionImprove uniformityEdge grinding machinesPolishing machinesEngineeringSemiconductor

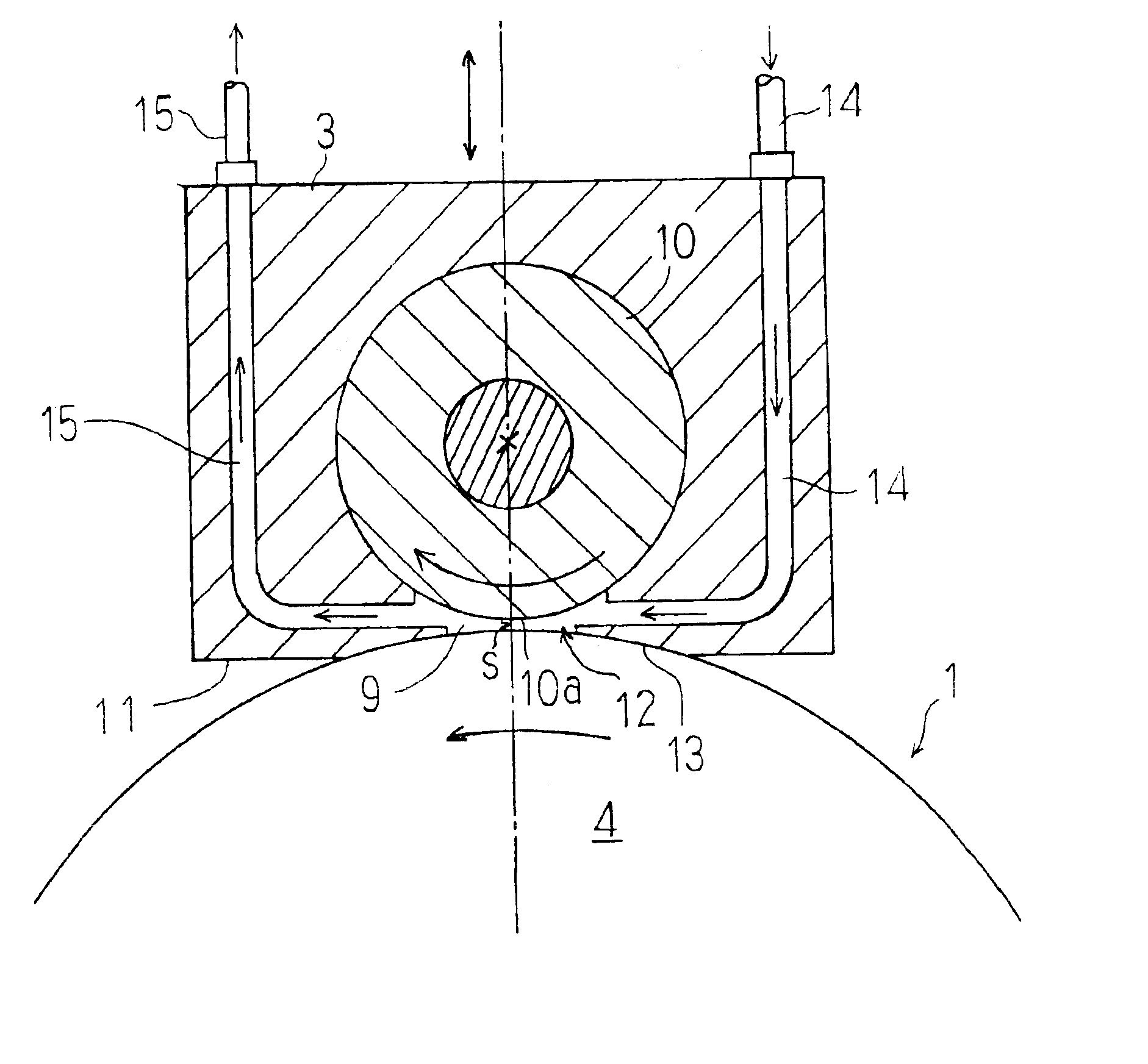

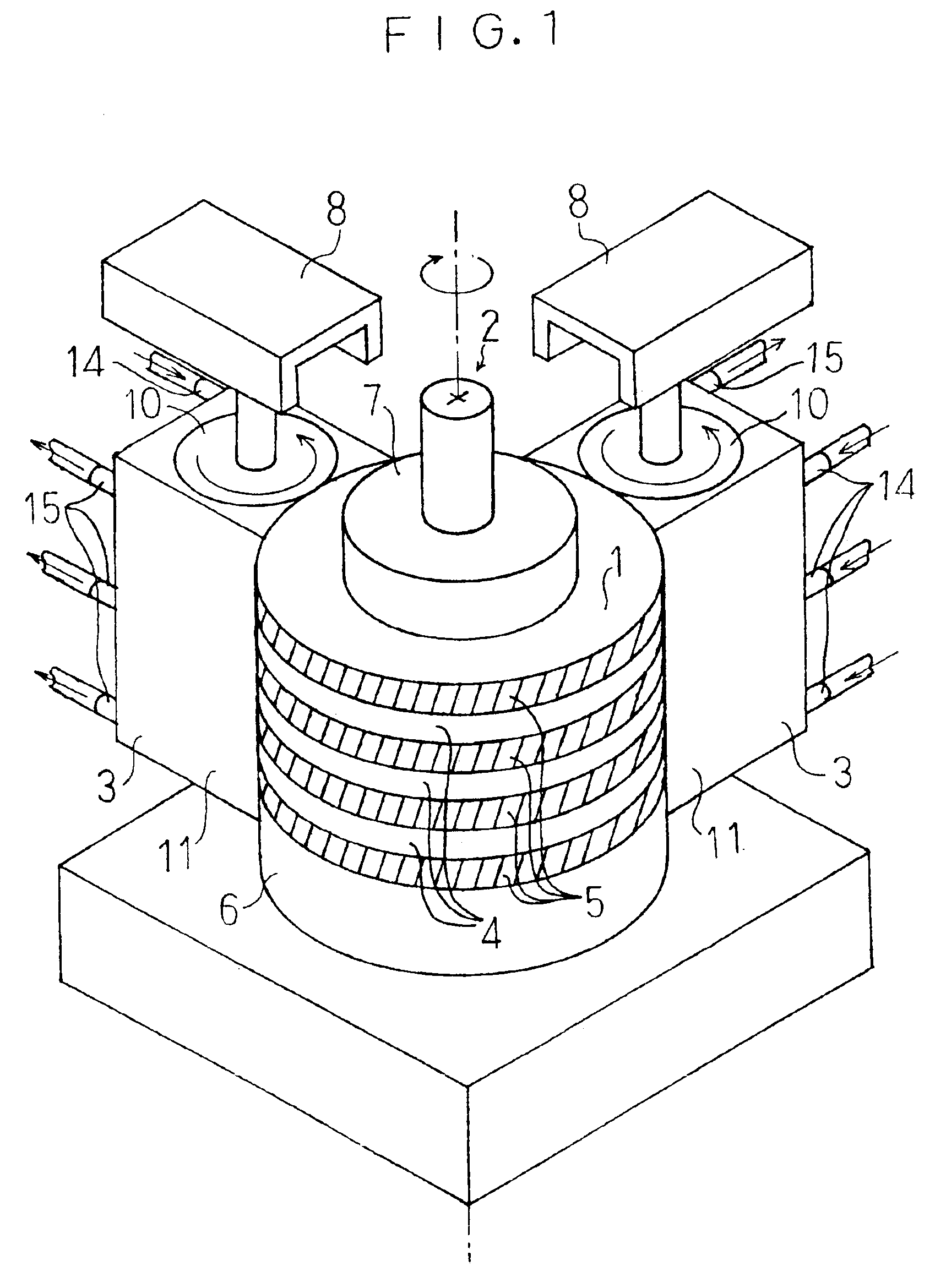

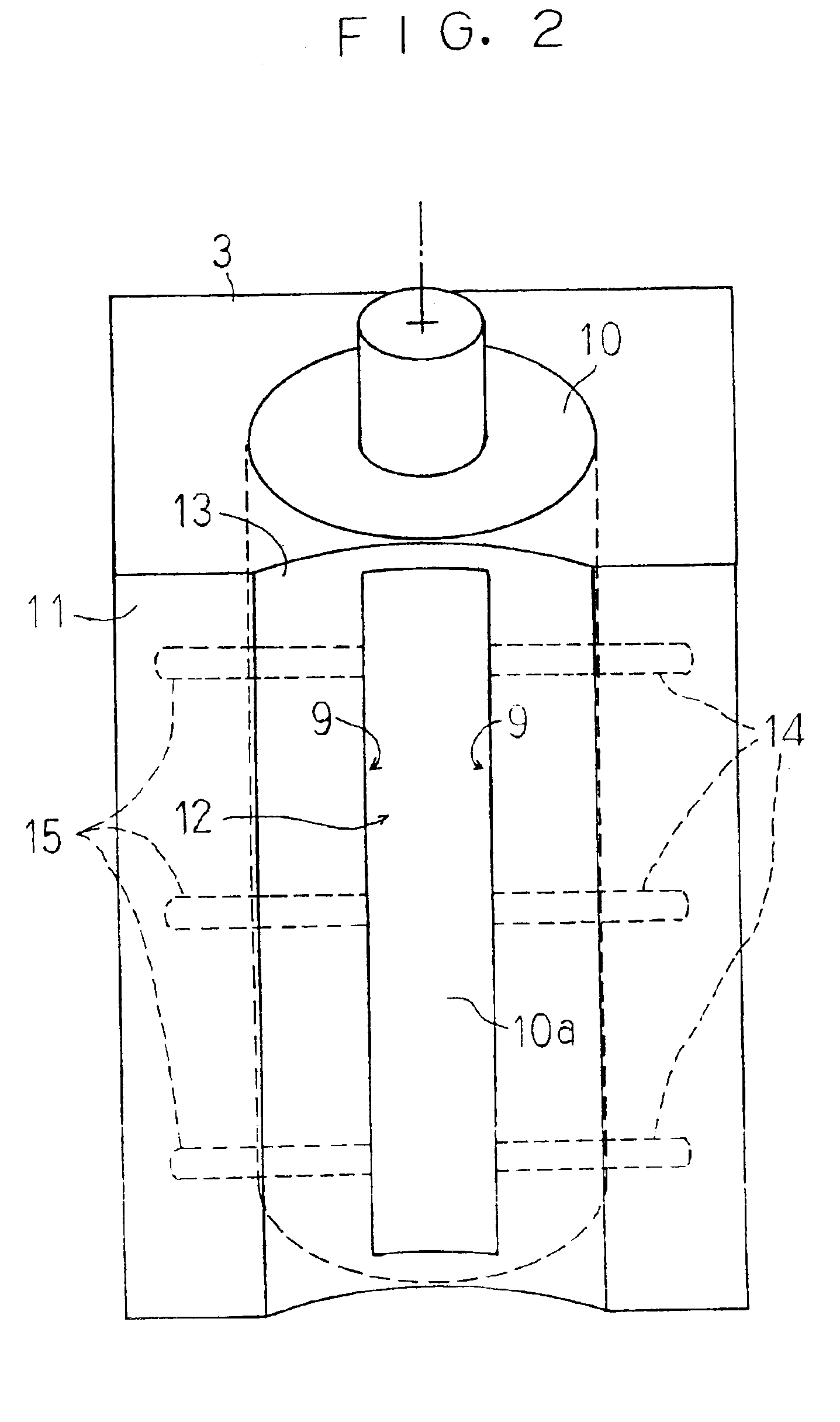

A polishing machine for a peripheral edge of a semiconductor wafer comprises a rotary mechanism 2 which rotates a stack 1 of semiconductor wafers 4 mounted thereon, and a polishing mechanism 3 which is arranged to be movable in the radial direction of the rotary mechanism 2 and polishes the peripheral edges of the rotating semiconductor wafers 4 by means of contactless polishing. Minute gaps s are formed between the rotary column 10 of the polishing mechanism 3 and the stack 1 of semiconductor wafers 4, and polishing solution is drawn into these minute gaps s. The peripheral edges of the semiconductor wafers 4 are polished by means of contactless polishing, using polishing abrasive particles included in polishing solution.

Owner:ISHII HYOKI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com