Five-axis two-dimensional ultrasonic polishing machine tool for optical curved face machining and using method thereof

A curved surface processing and optical technology, applied in the field of polishing machinery, to achieve the effect of improving utilization rate, eliminating surface damage of workpiece, and improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings.

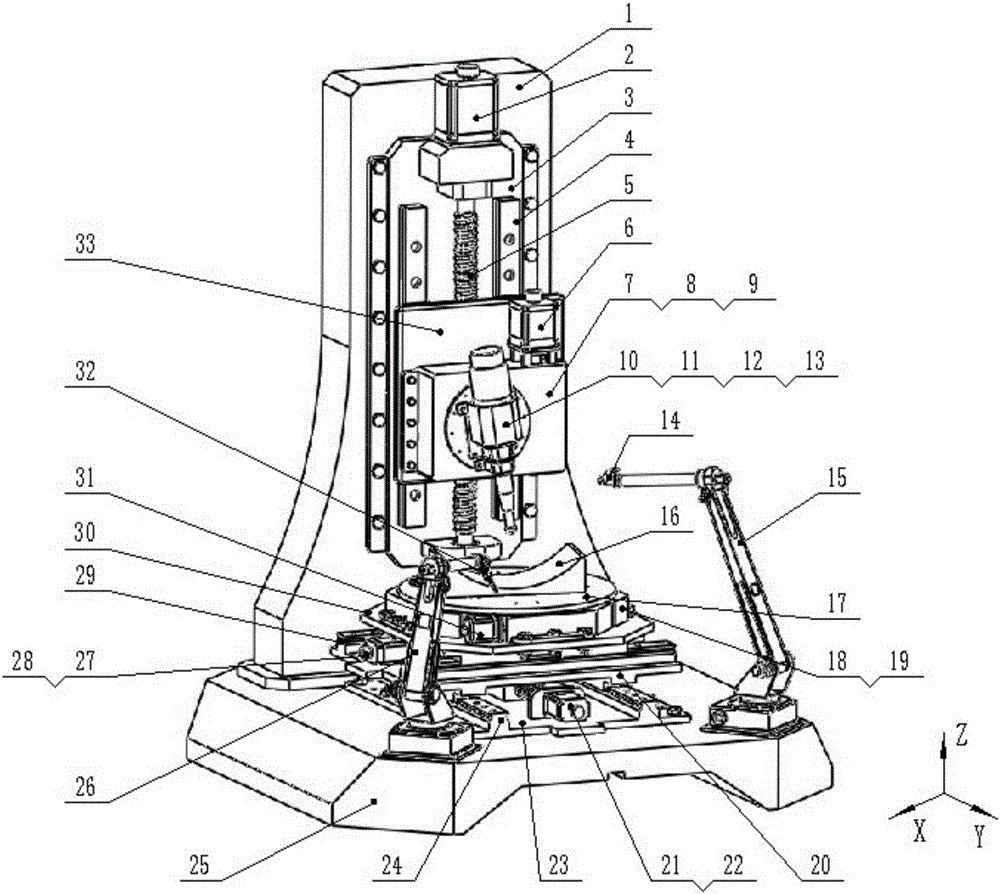

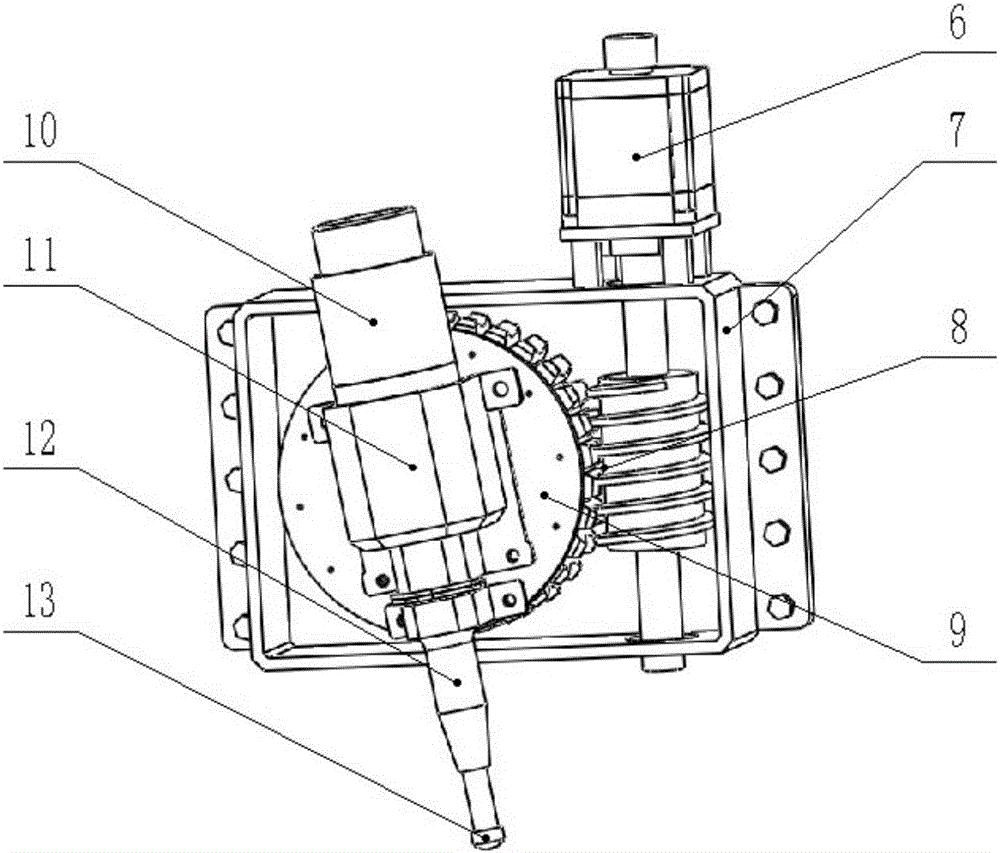

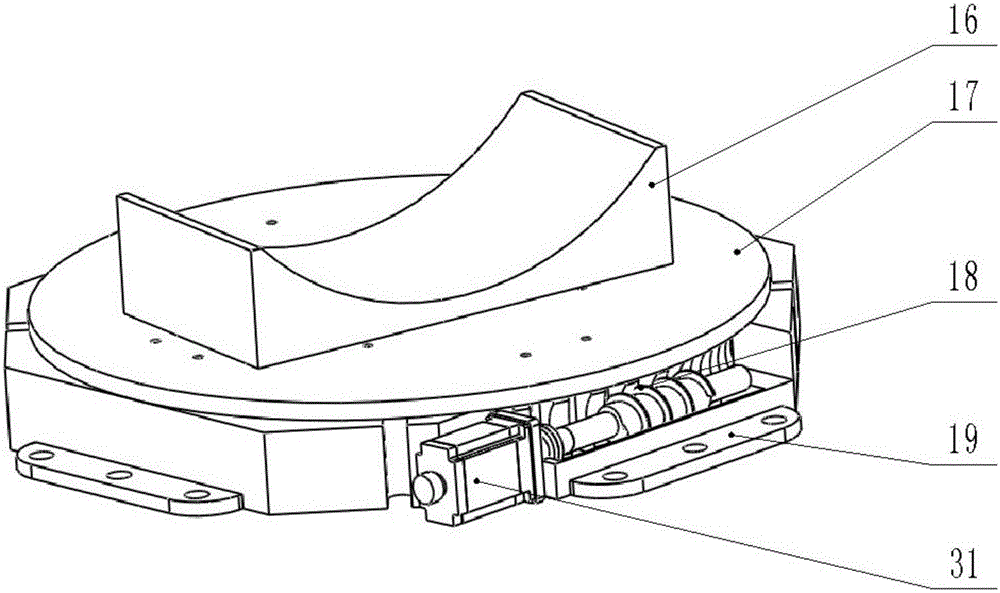

[0059] Such as figure 1 As shown, the five-axis two-dimensional ultrasonic polishing machine tool for optical curved surface processing of the present invention includes a frame, a three-dimensional (X, Y, Z) moving device, a rotary ultrasonic vibration polishing device, a rotary table, and an ultrasonic atomization liquid application of a polishing liquid Device and workpiece online detection device.

[0060] The frame is composed of a machine base 25 and a bed 1 vertically fixed on the machine base.

[0061] The three-dimensional moving device is composed of an X-direction moving mechanism, a Y-direction moving mechanism and a Z-direction moving mechanism, wherein the Z-direction movement mechanism is installed on the bed, and the X-direction movement mechanism and the Y-direction movement mechanism correspond to the Z-direction movement mechanism Installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com