Patents

Literature

21193results about "Bearing components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

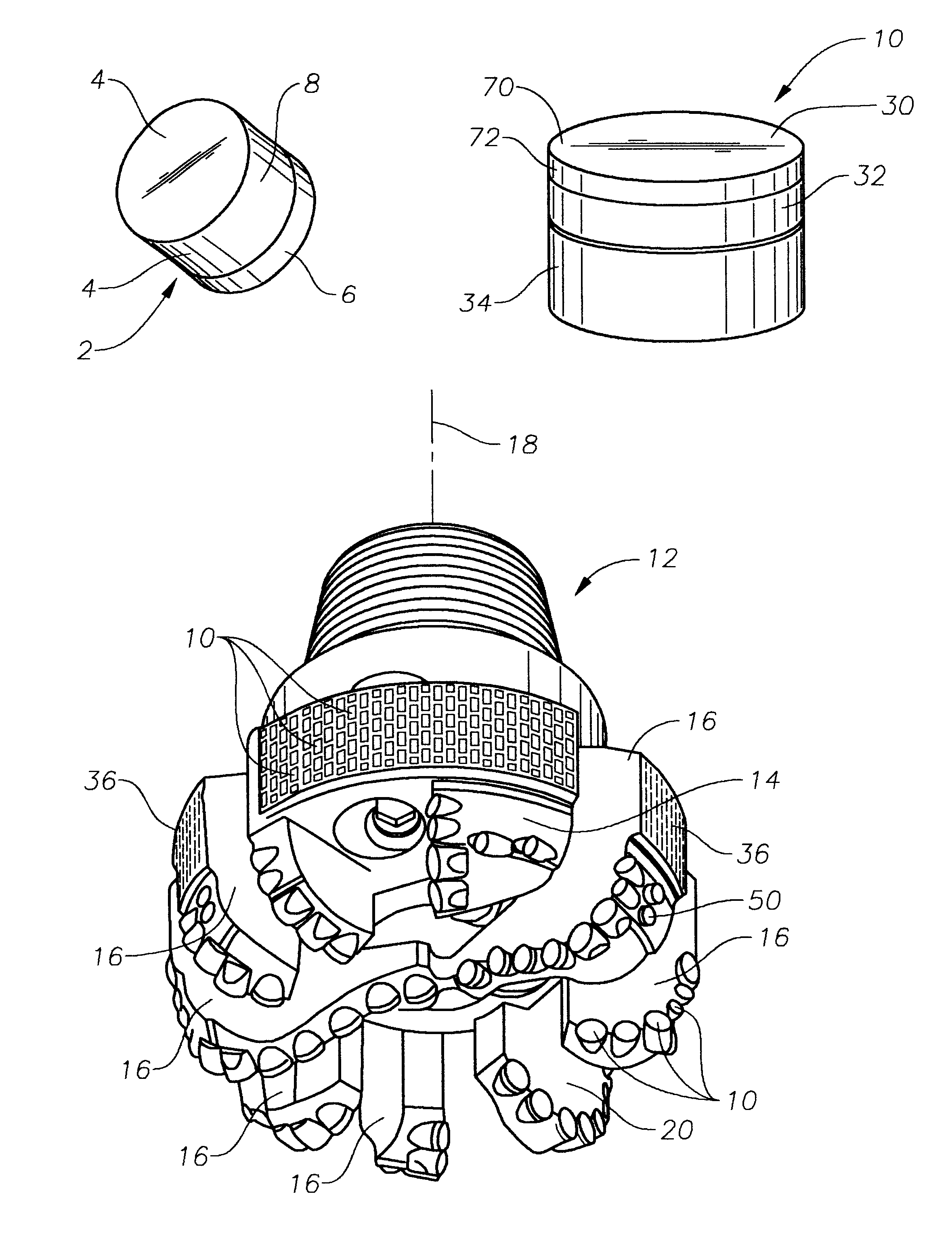

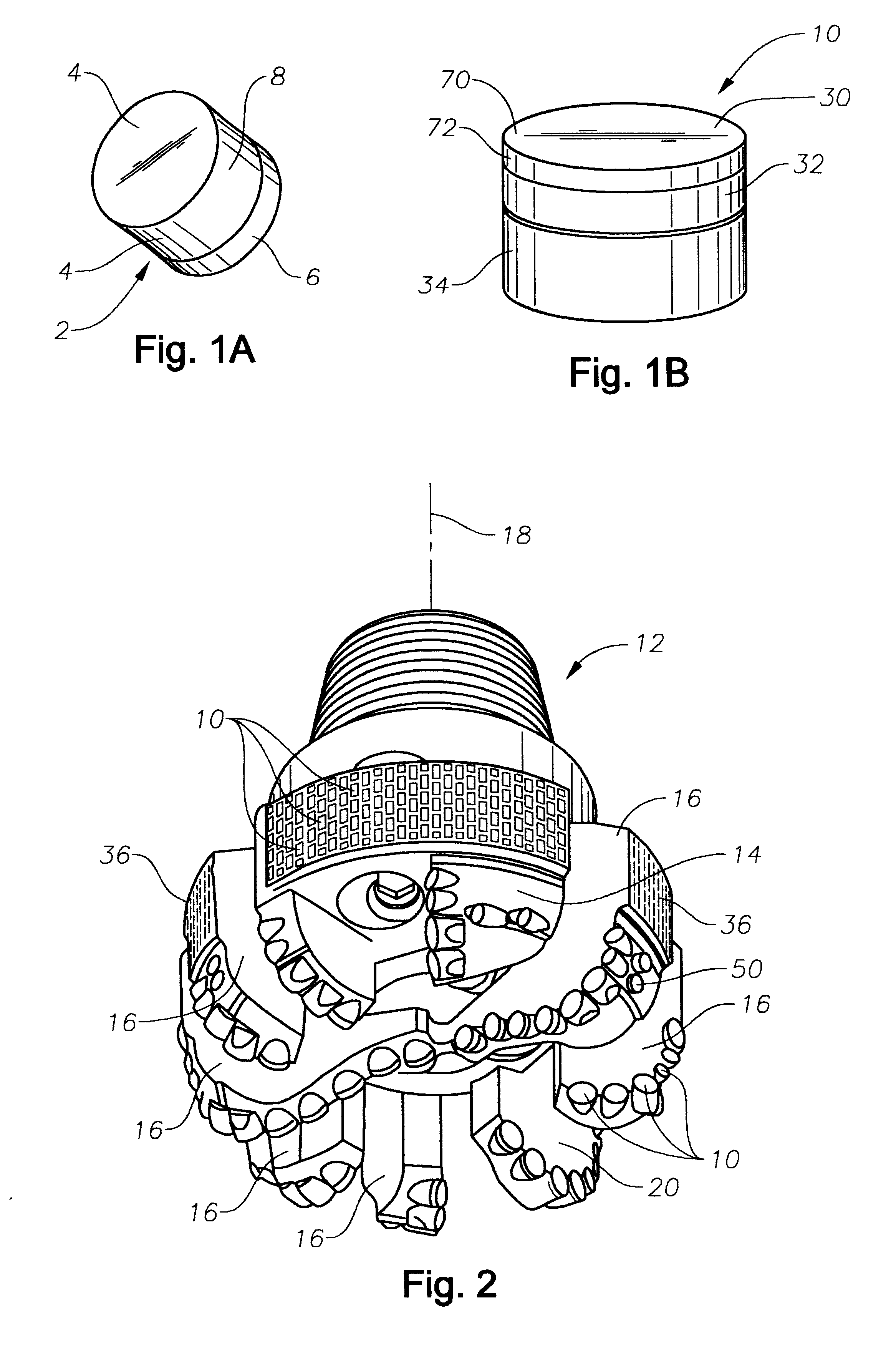

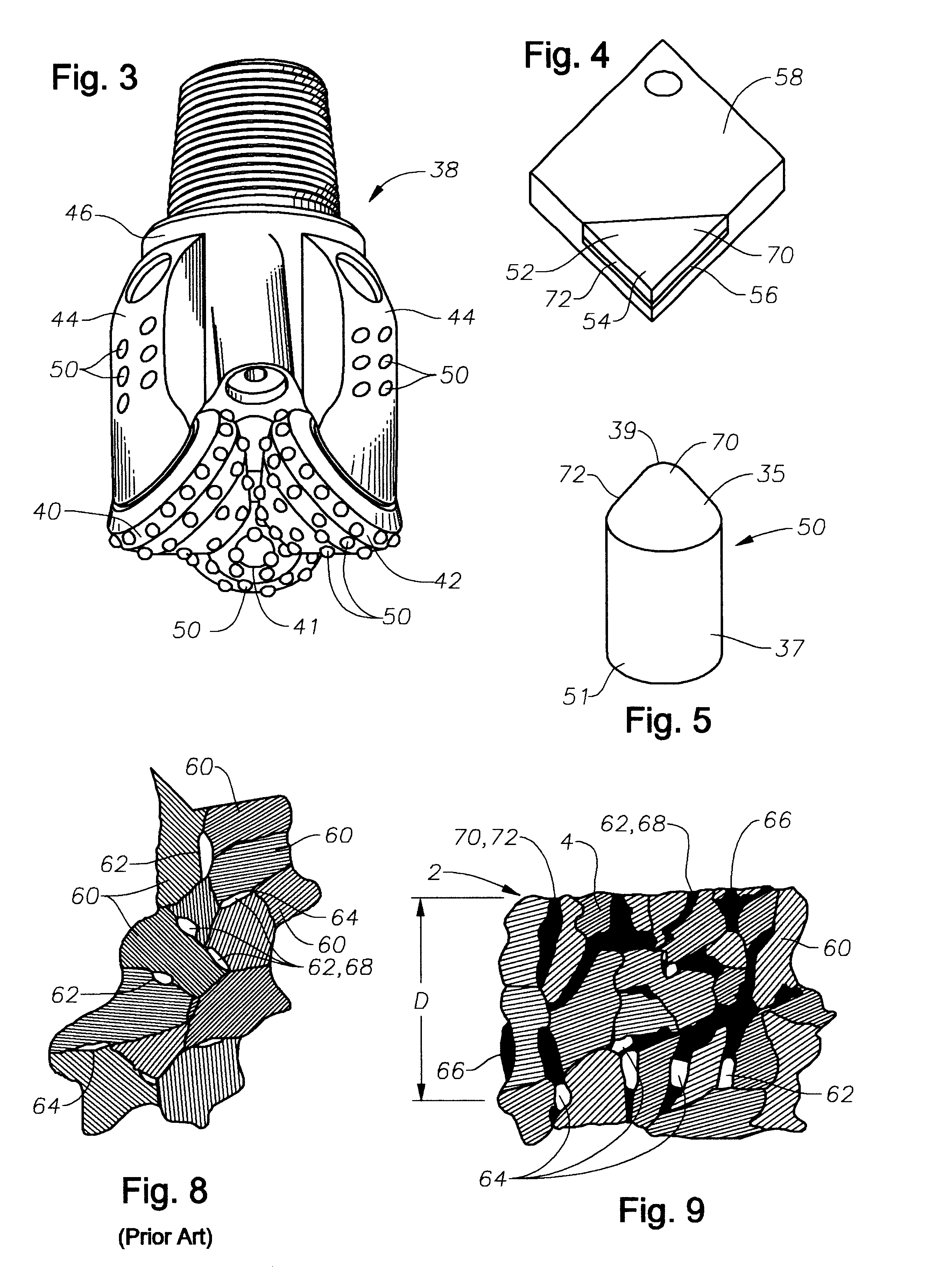

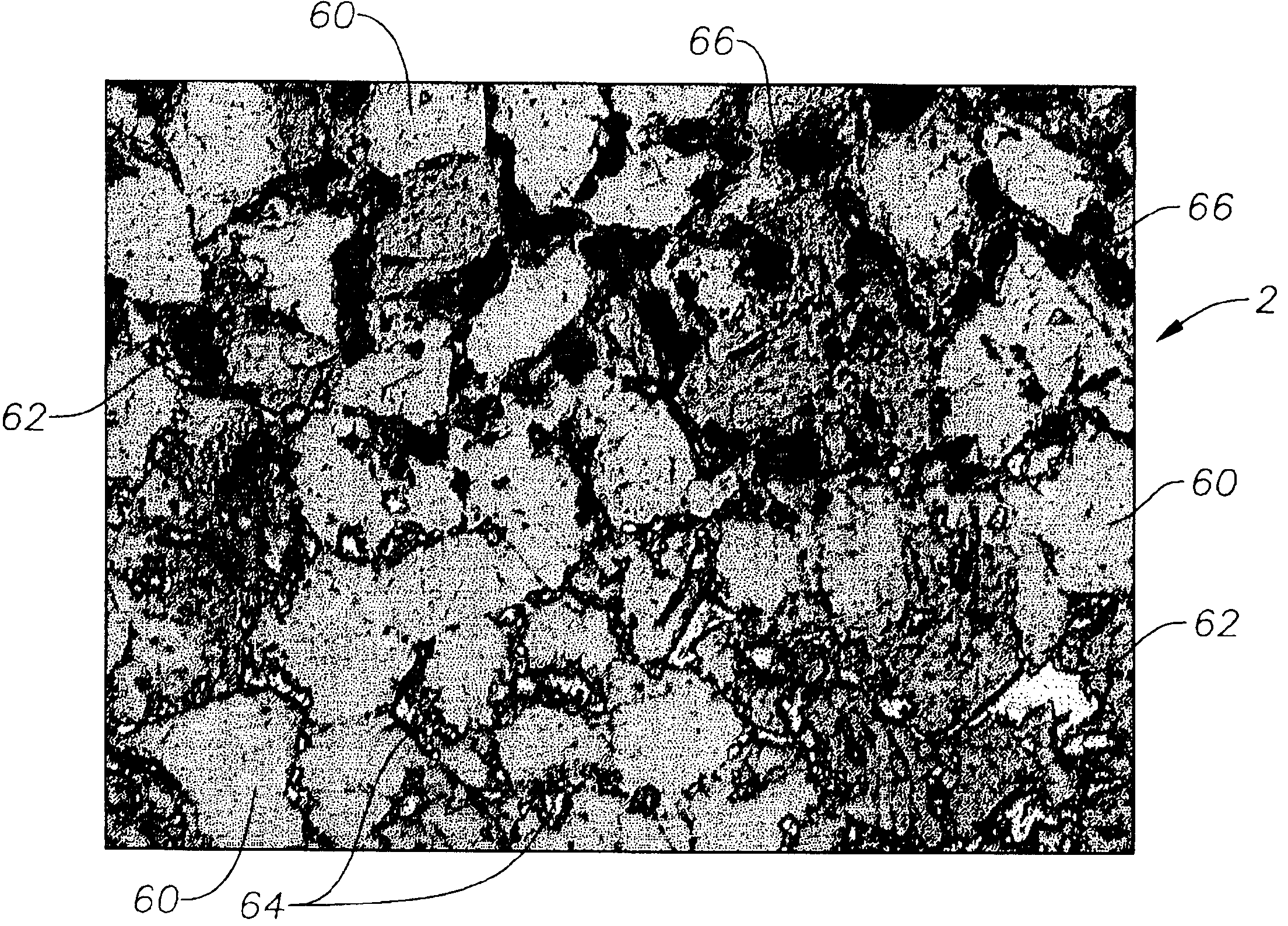

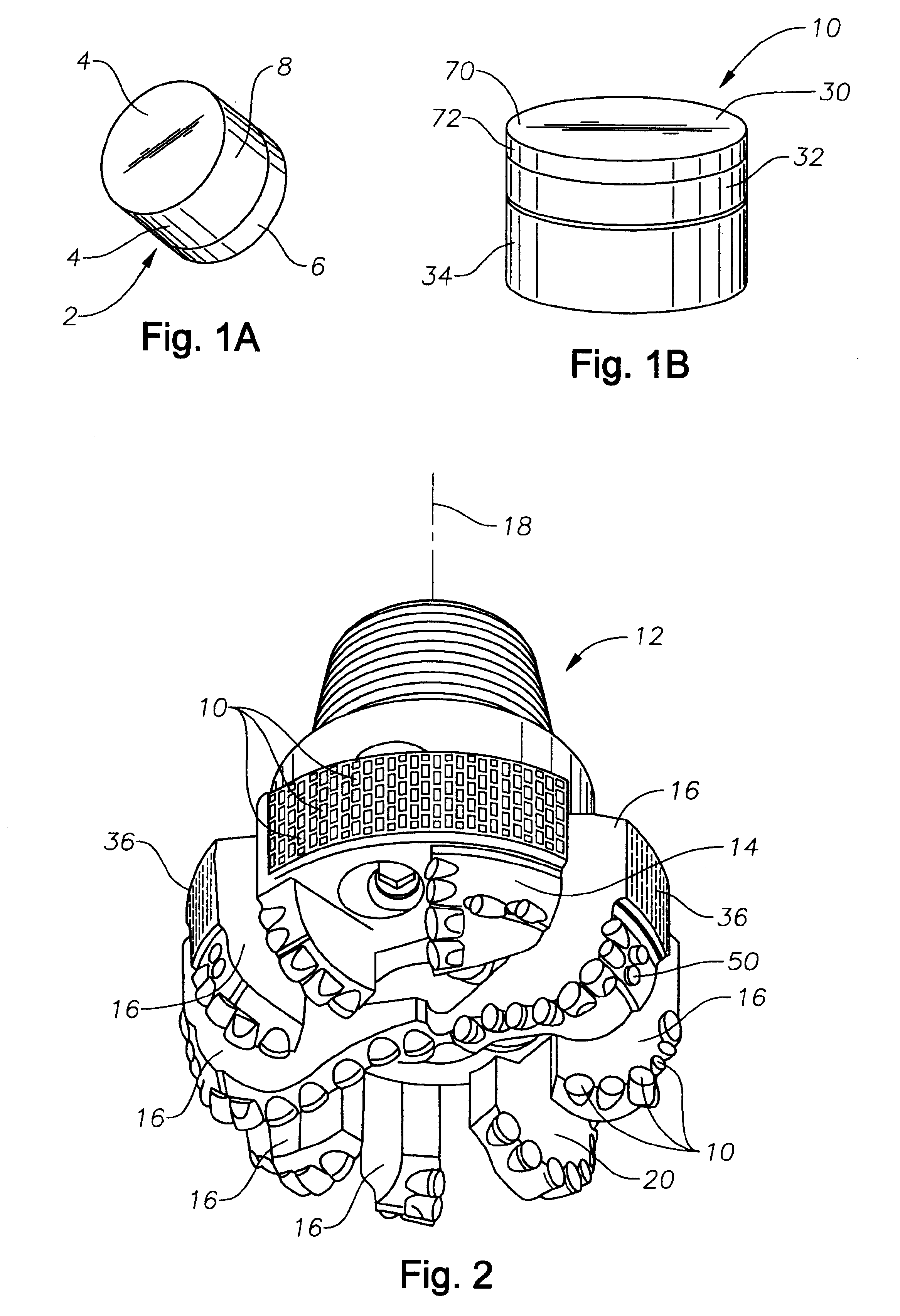

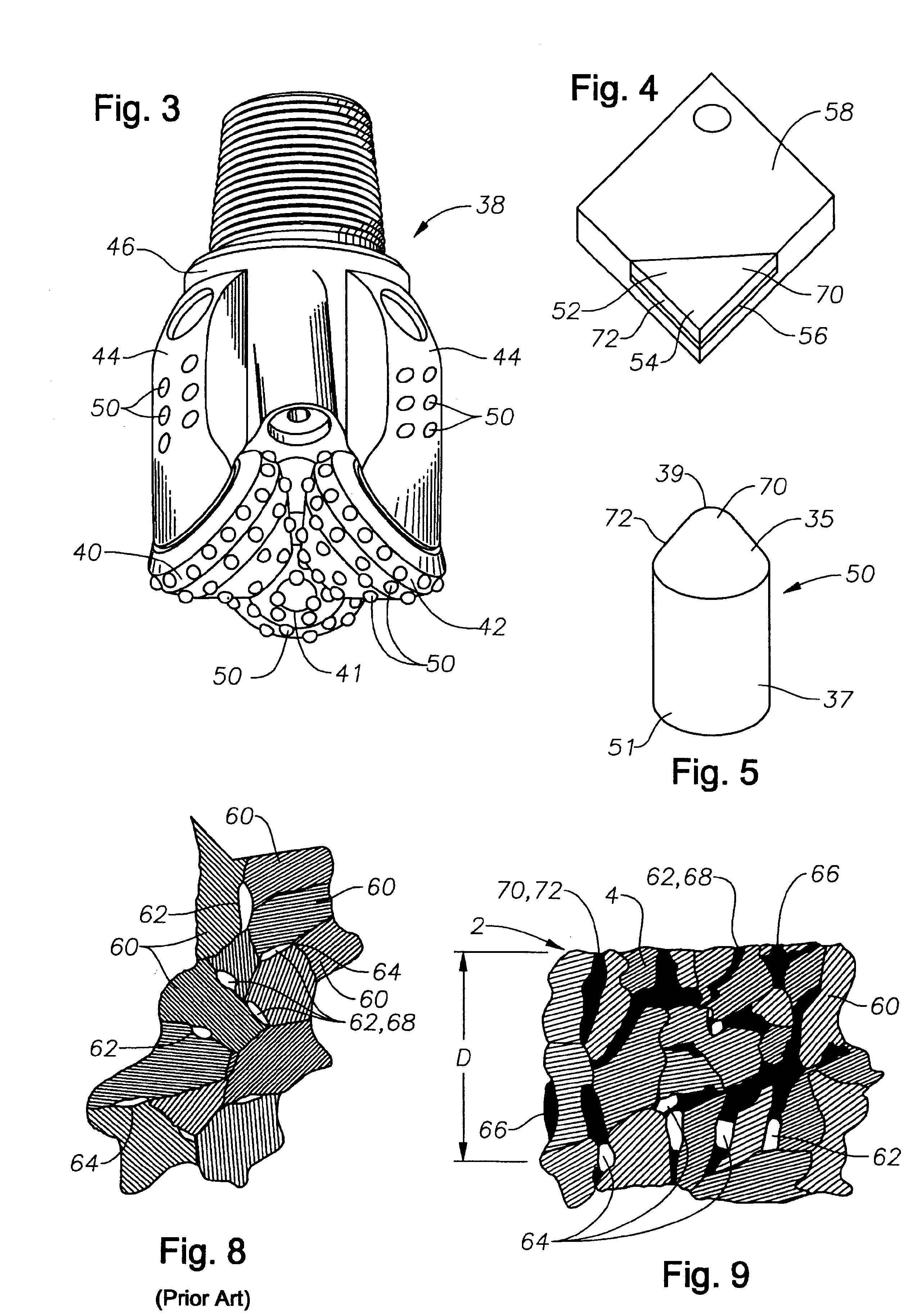

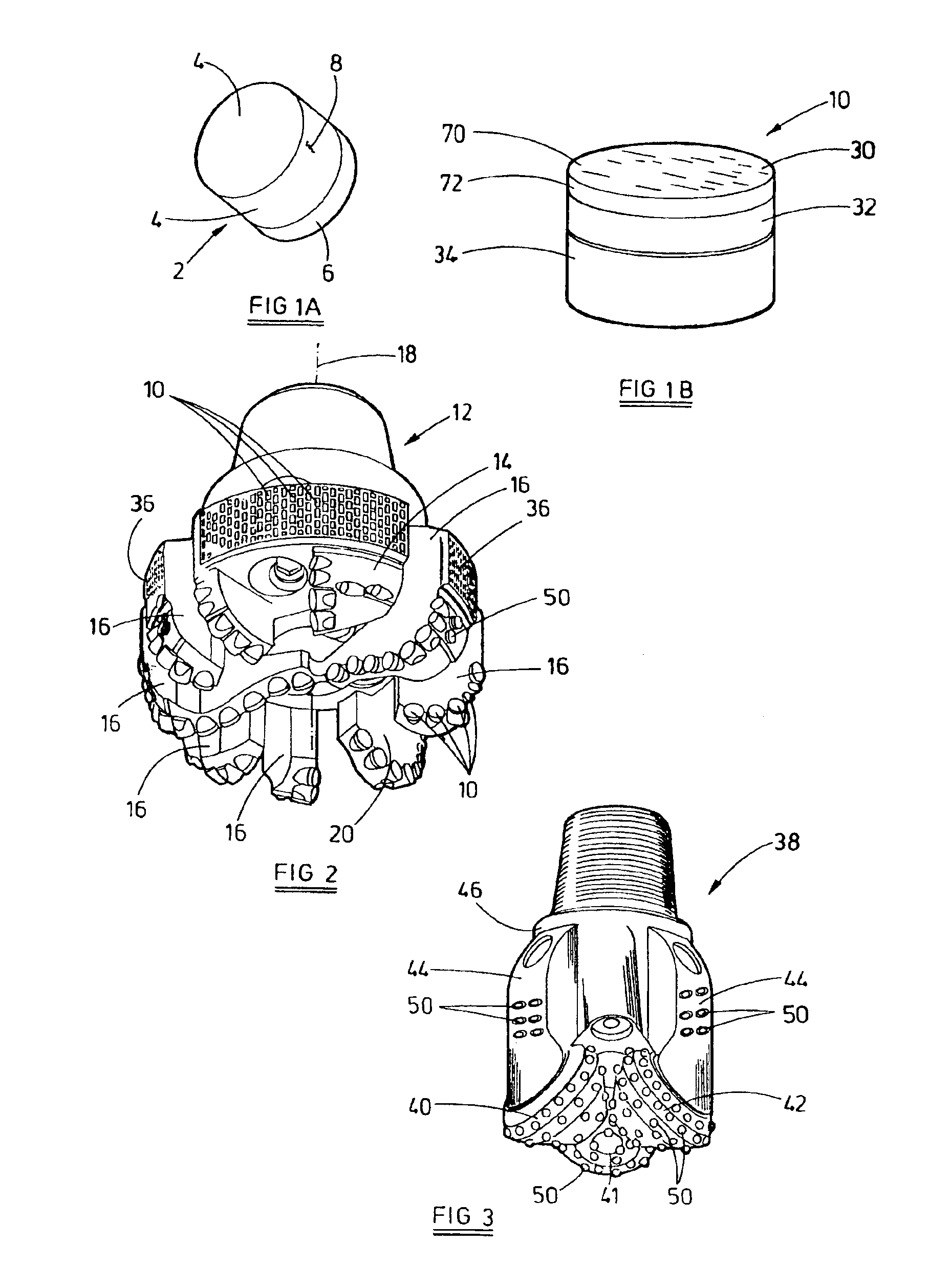

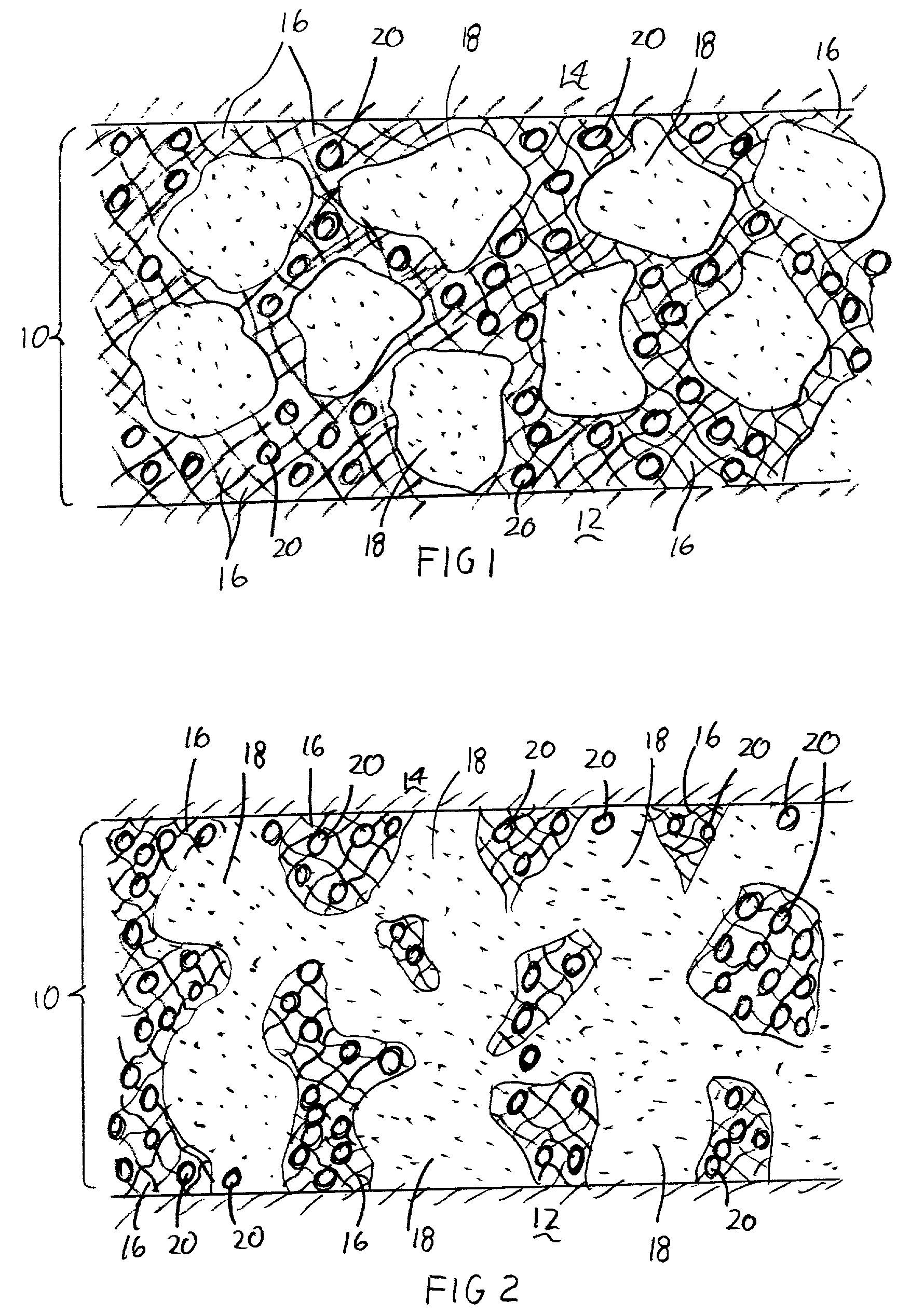

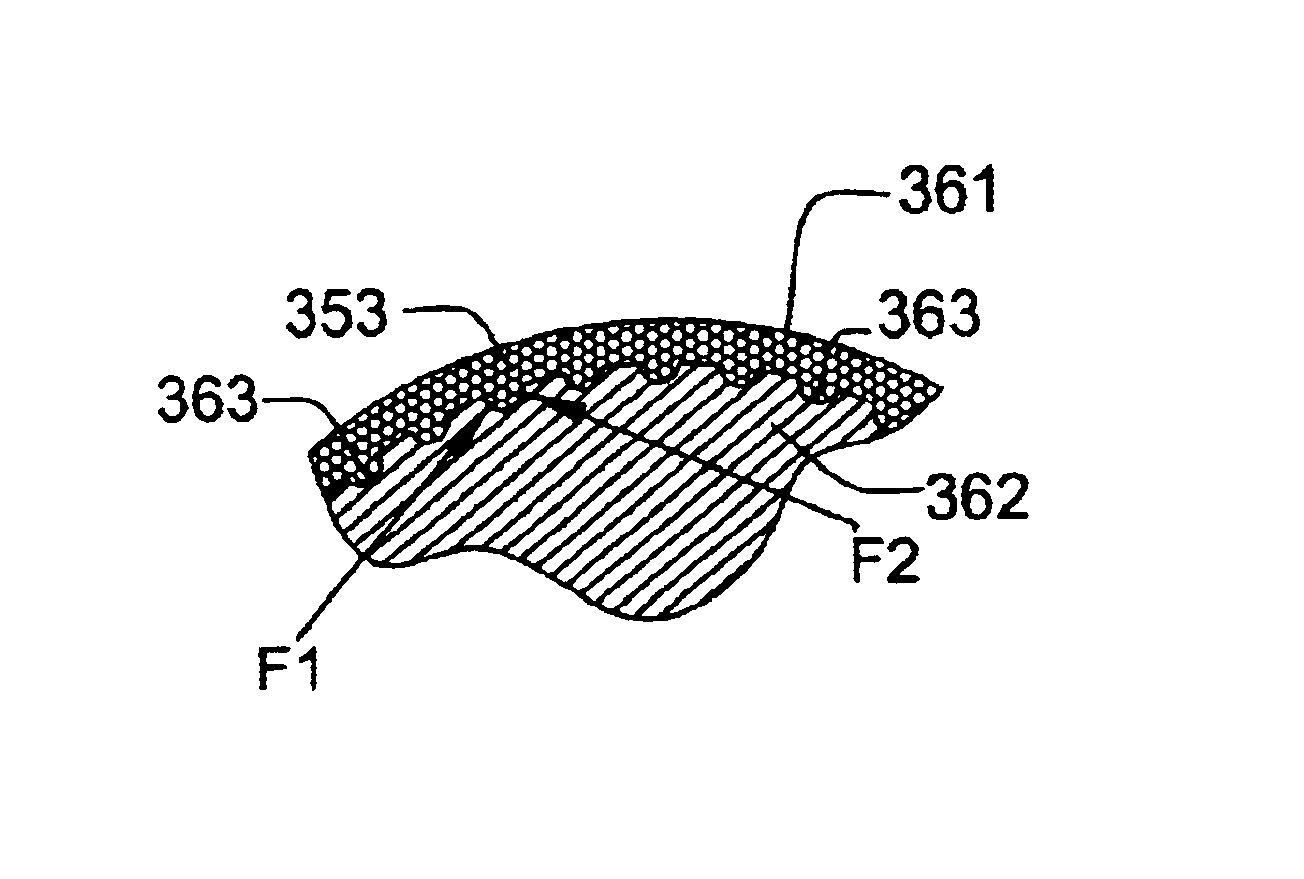

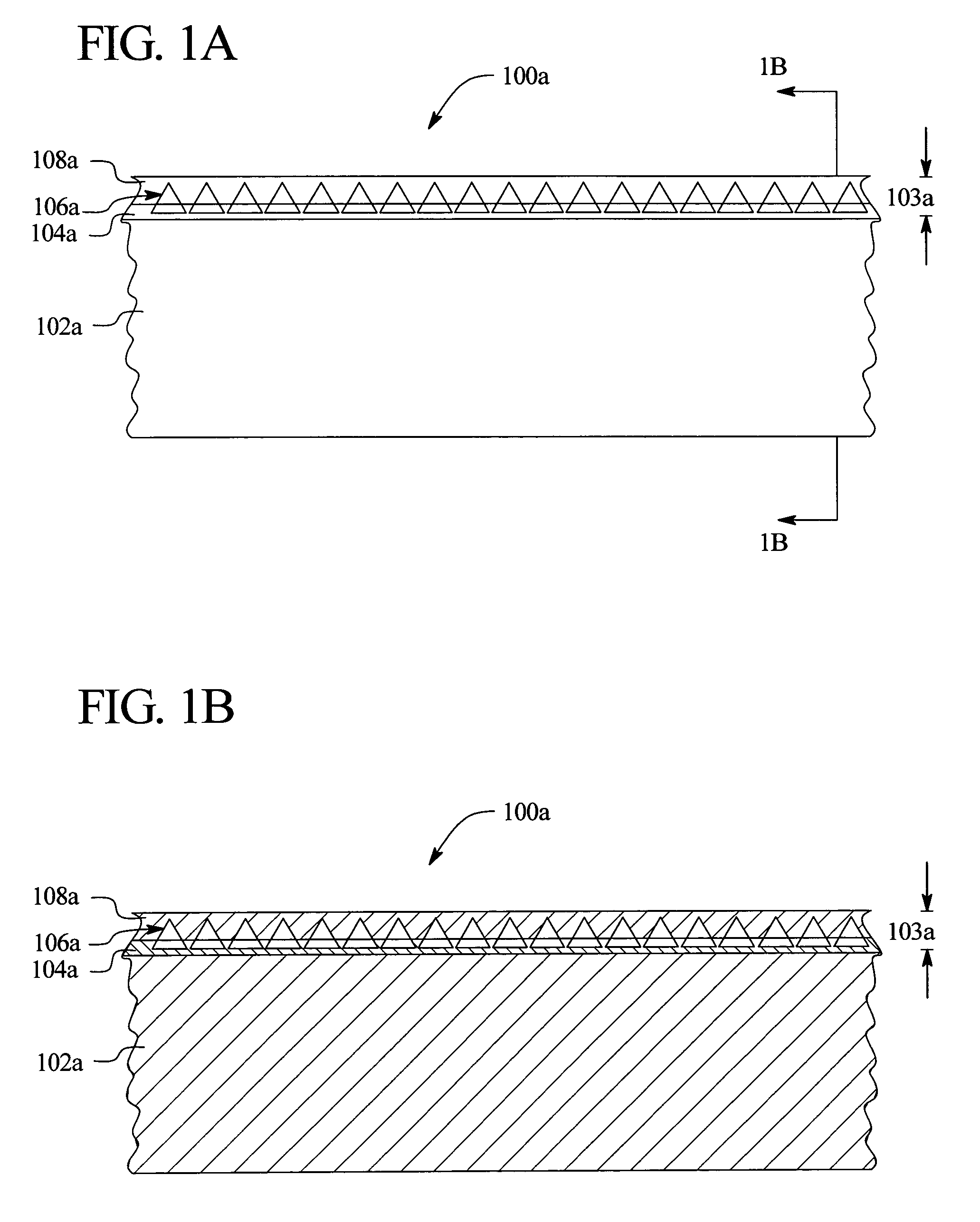

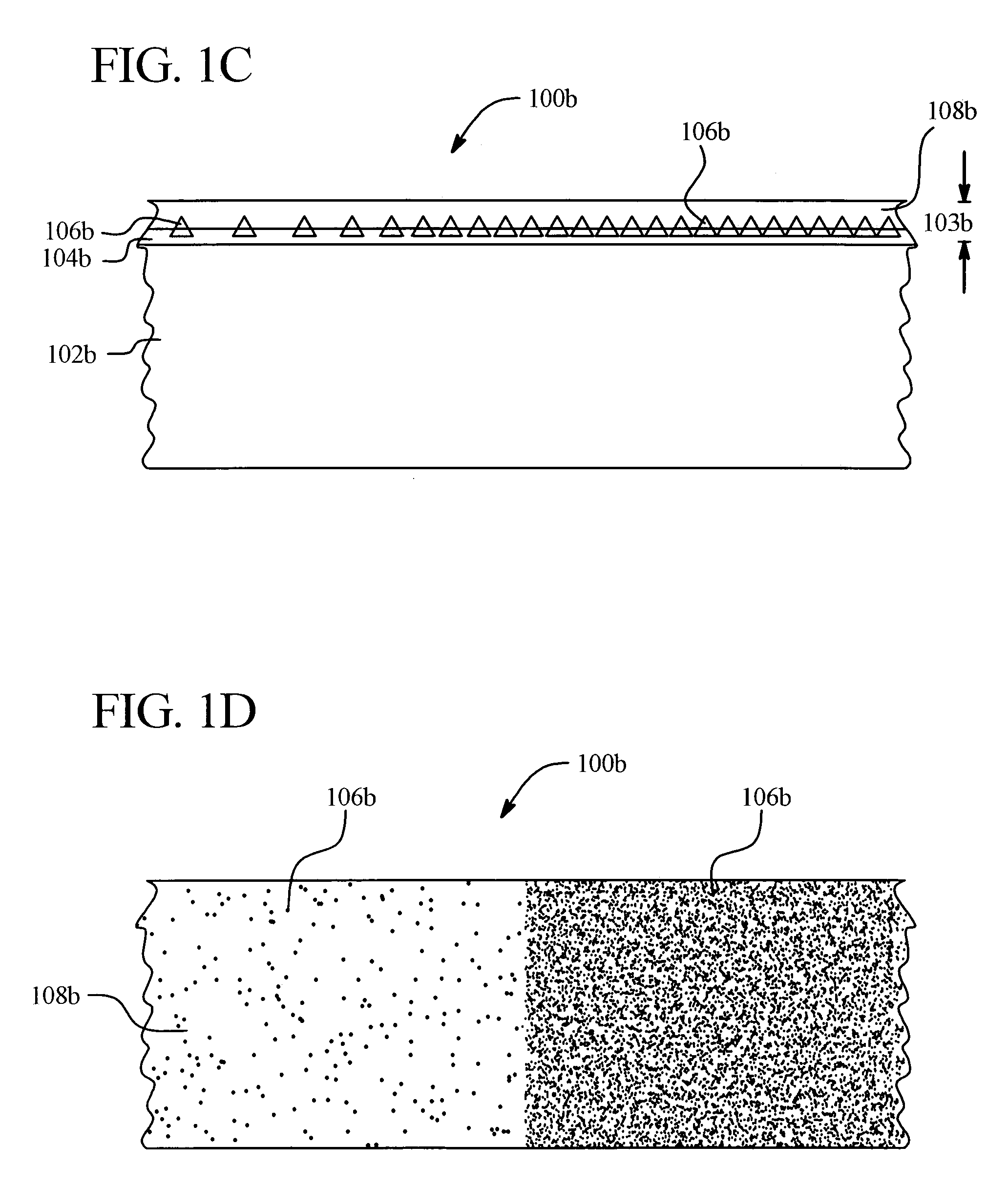

Polycrystalline diamond cutters with working surfaces having varied wear resistance while maintaining impact strength

InactiveUS6601662B2Improve wear resistanceMaintain strengthDrill bitsConstructionsDiamond crystalPolycrystalline diamond

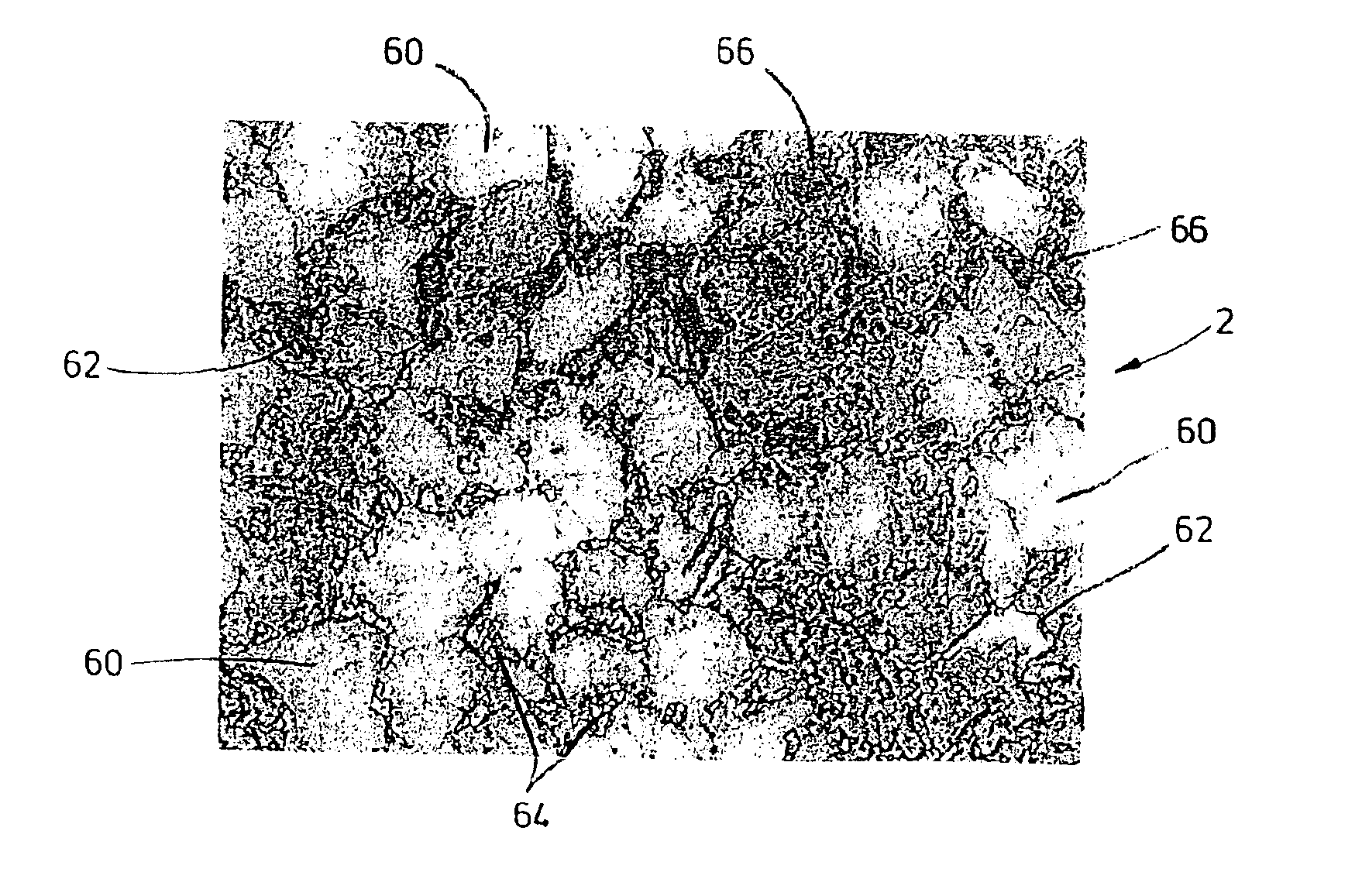

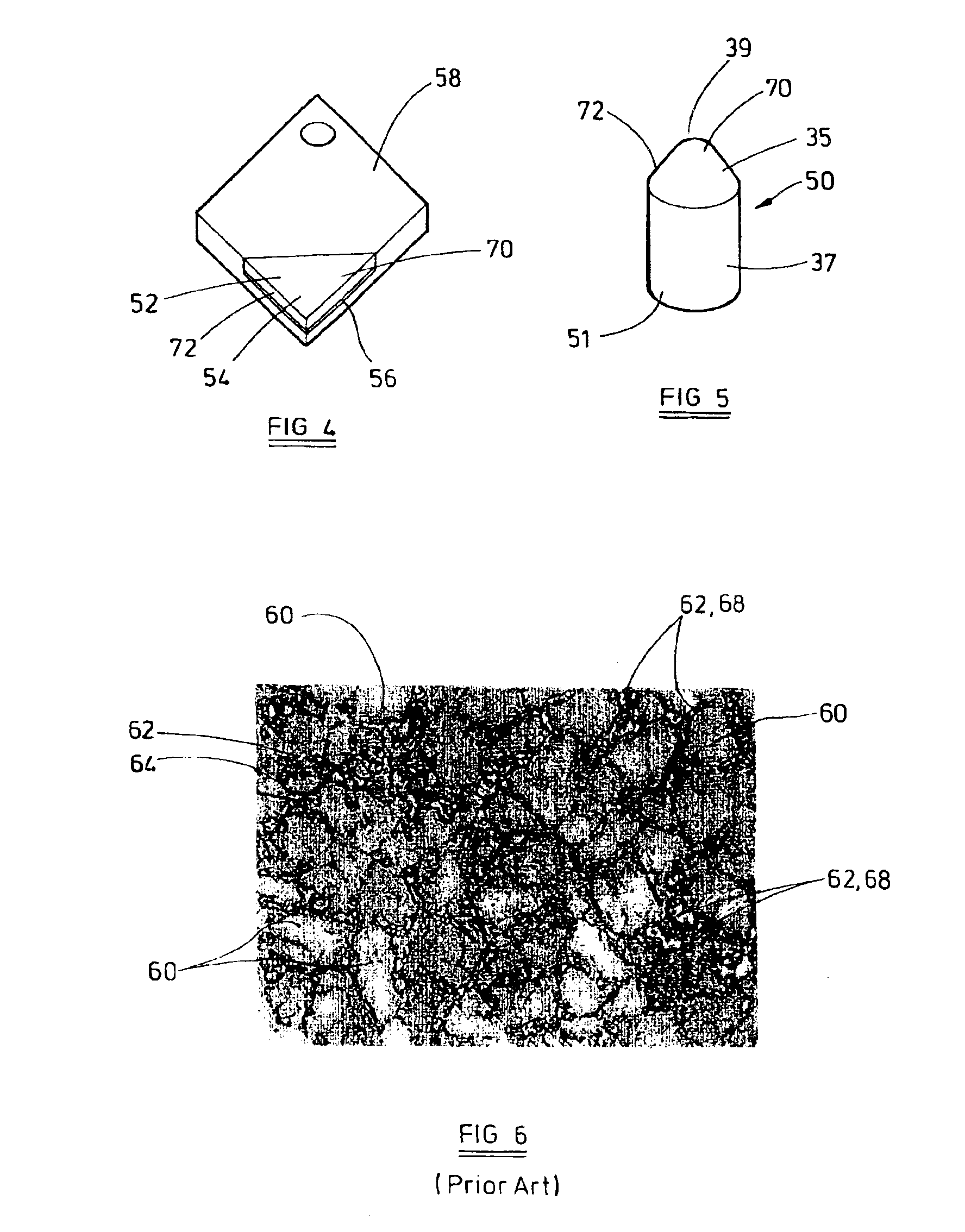

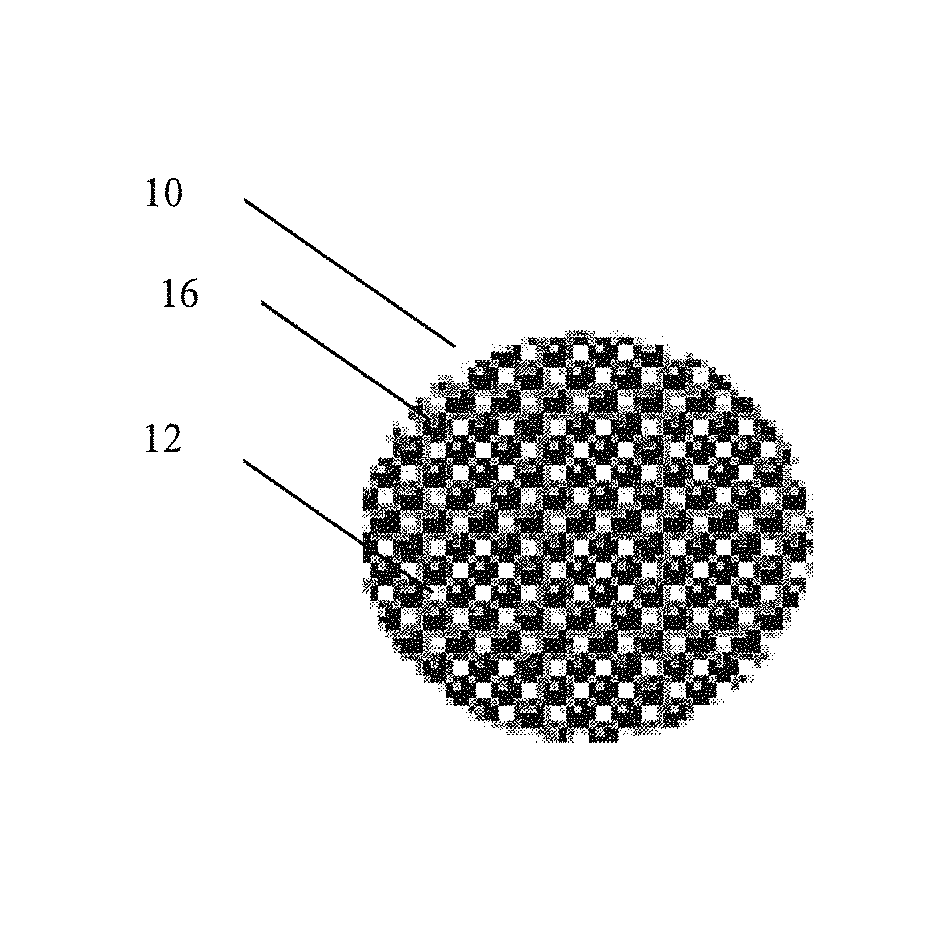

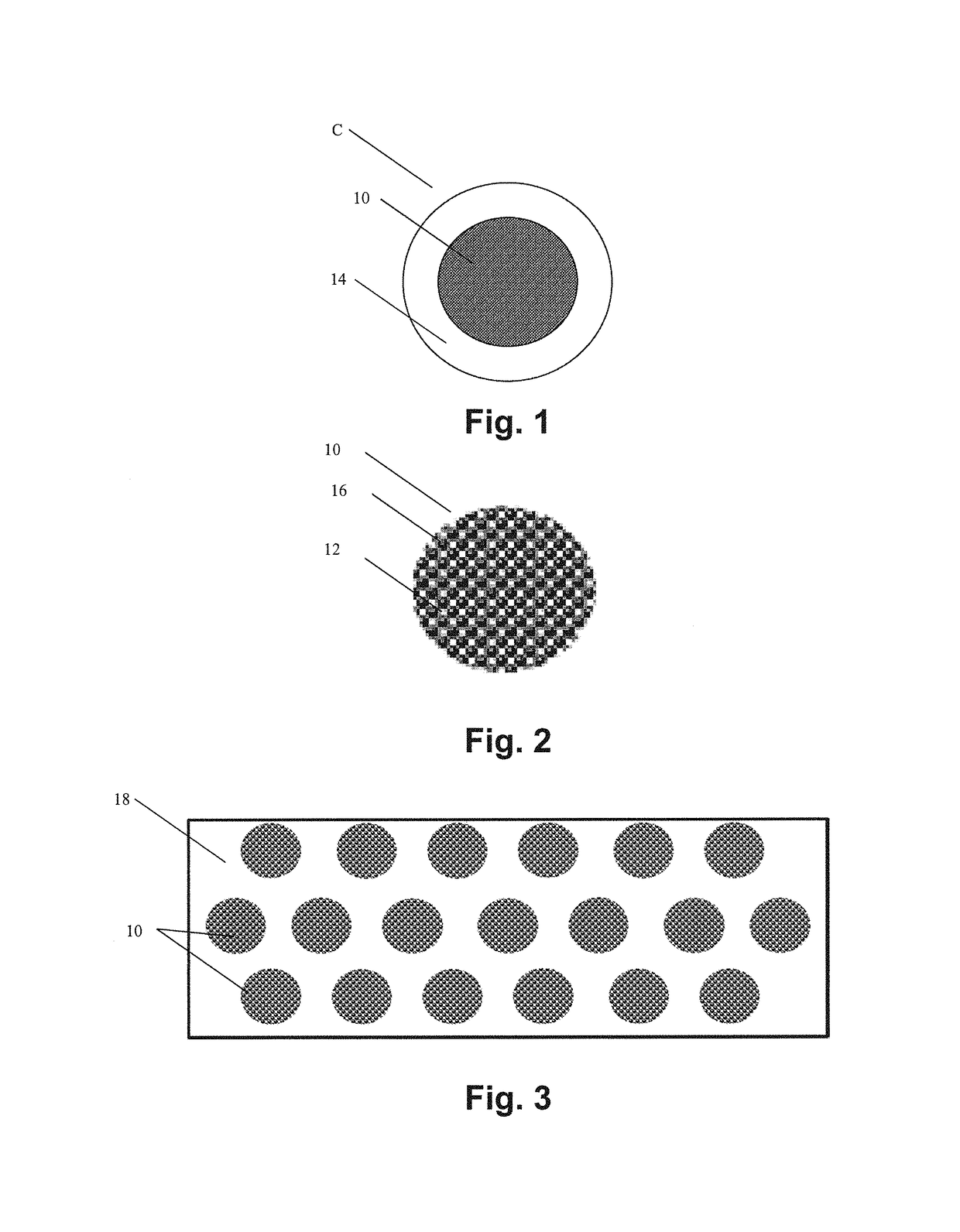

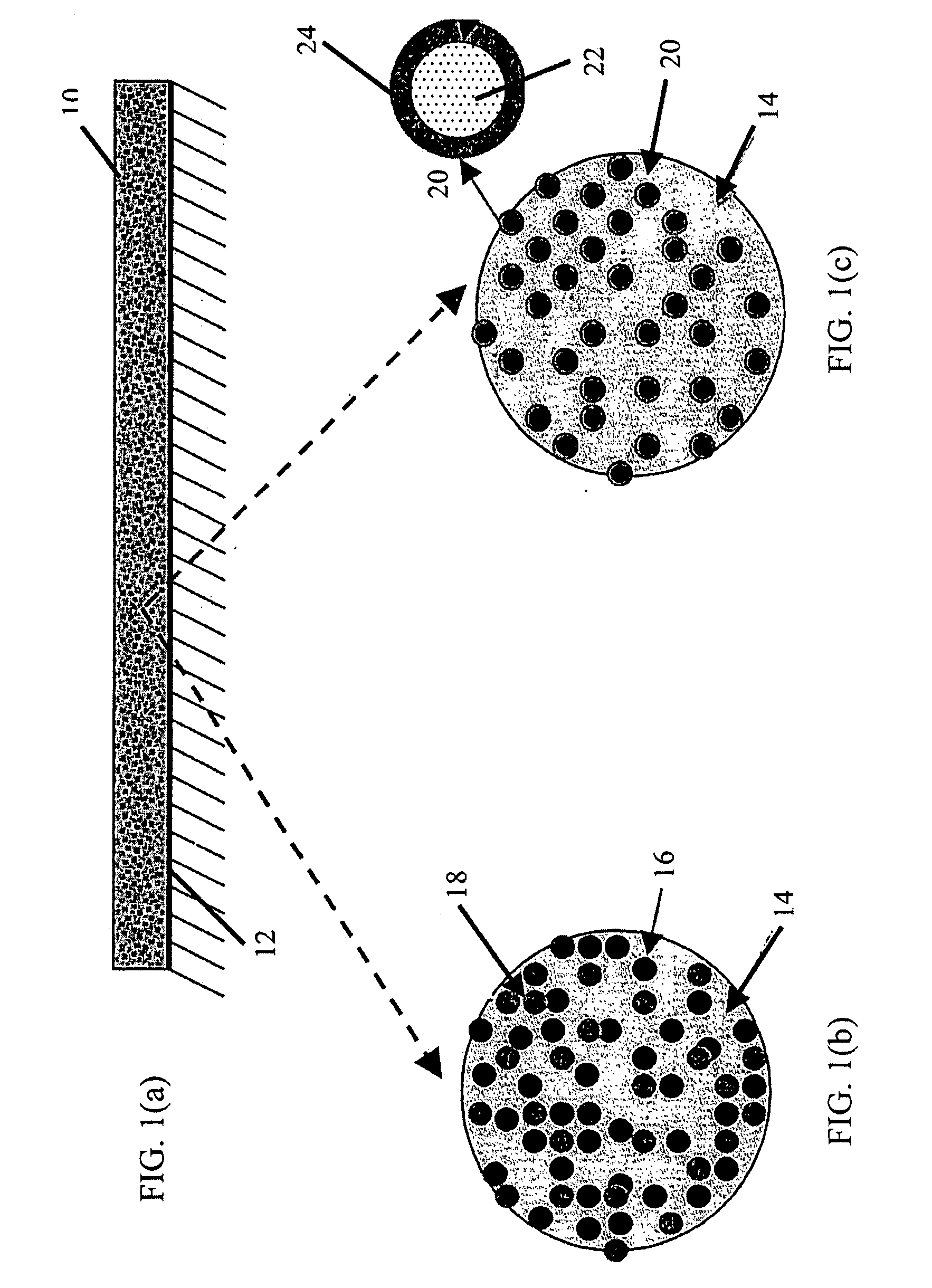

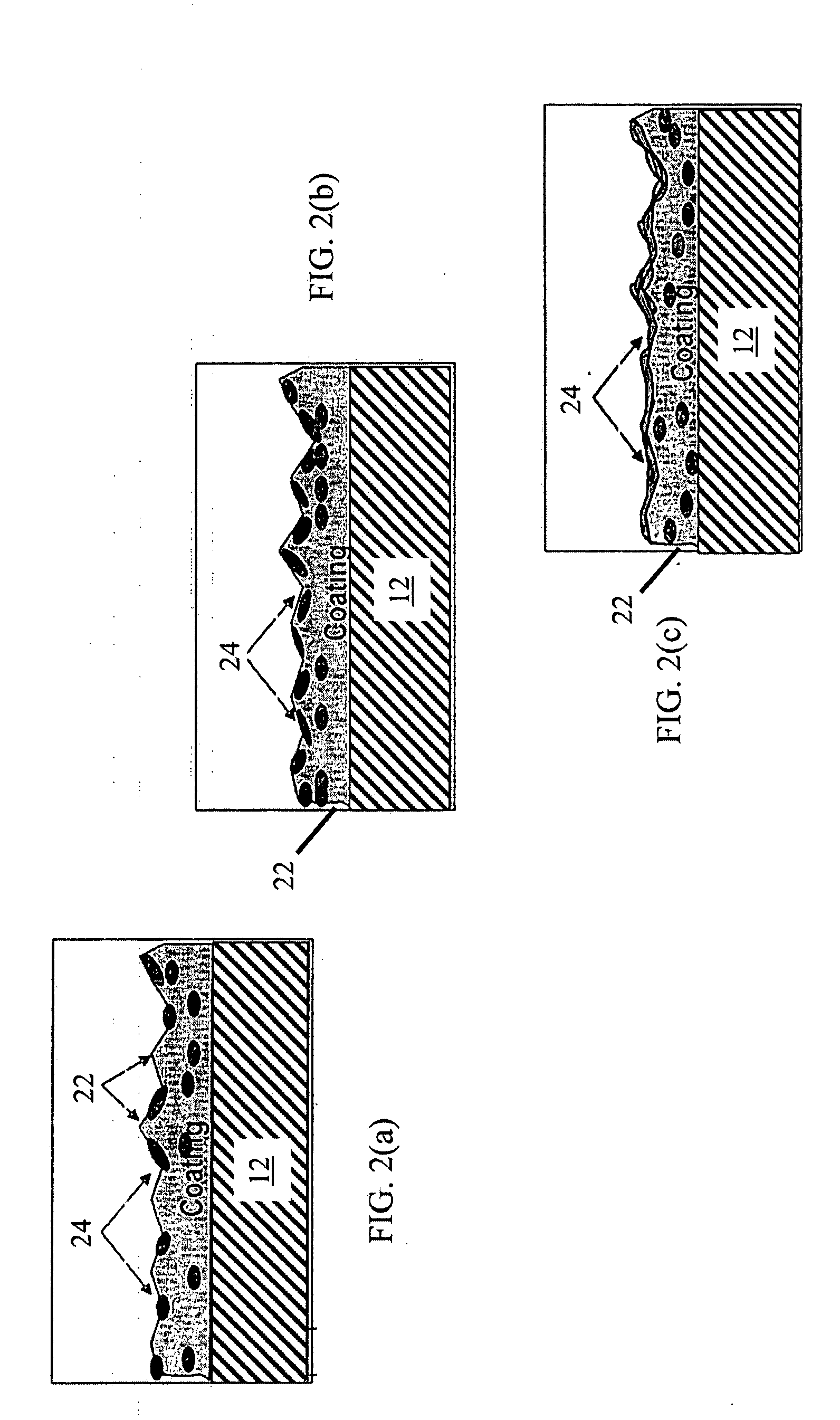

Disclosed is a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a first portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and a second portion of the interstitial matrix in the body adjacent to the working surface contains the catalyzing material. The first portion of the interstitial matrix and the second portion of the interstitial matrix have substantially the same impact strength.

Owner:REEDHYCALOG UK

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

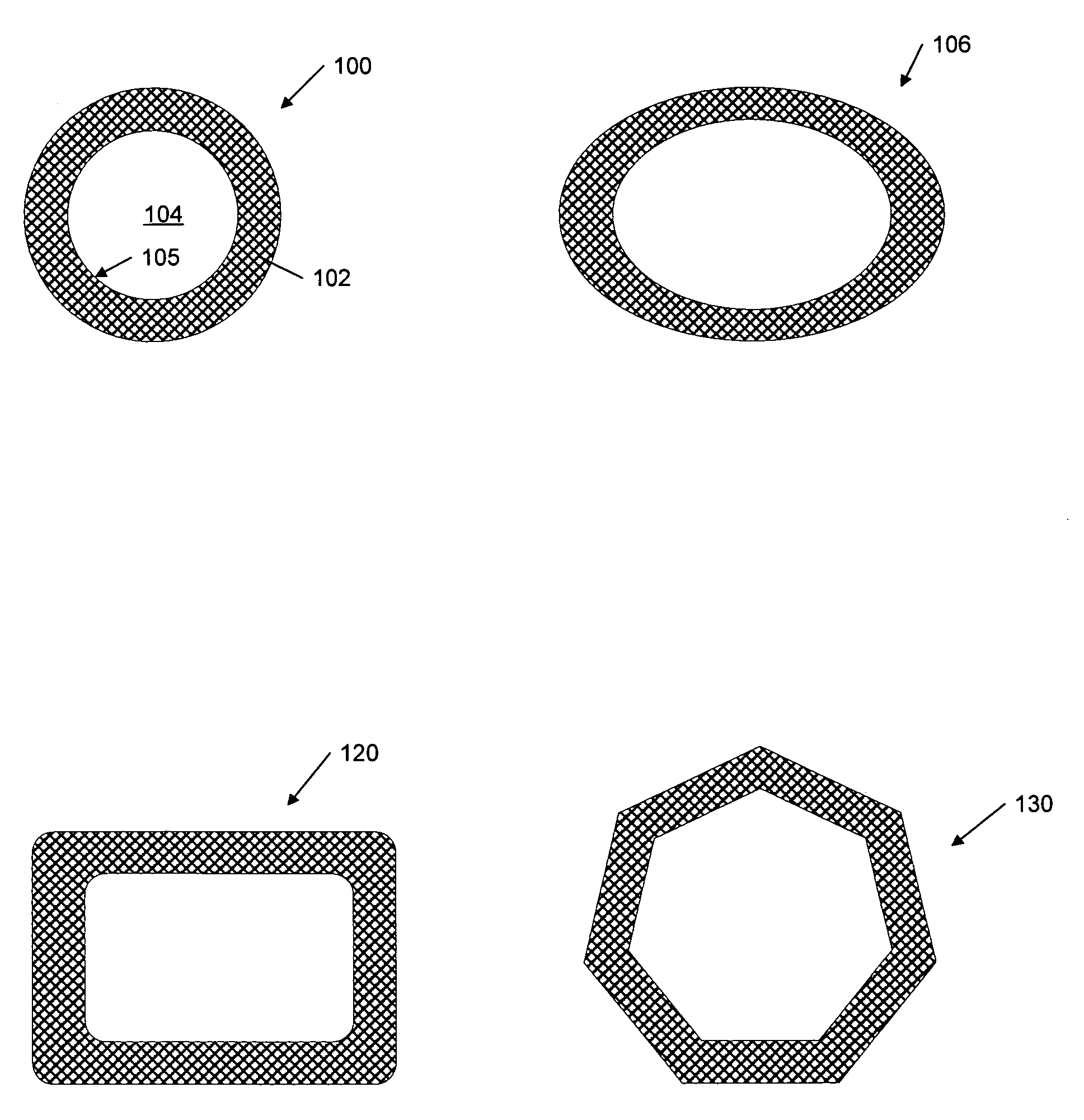

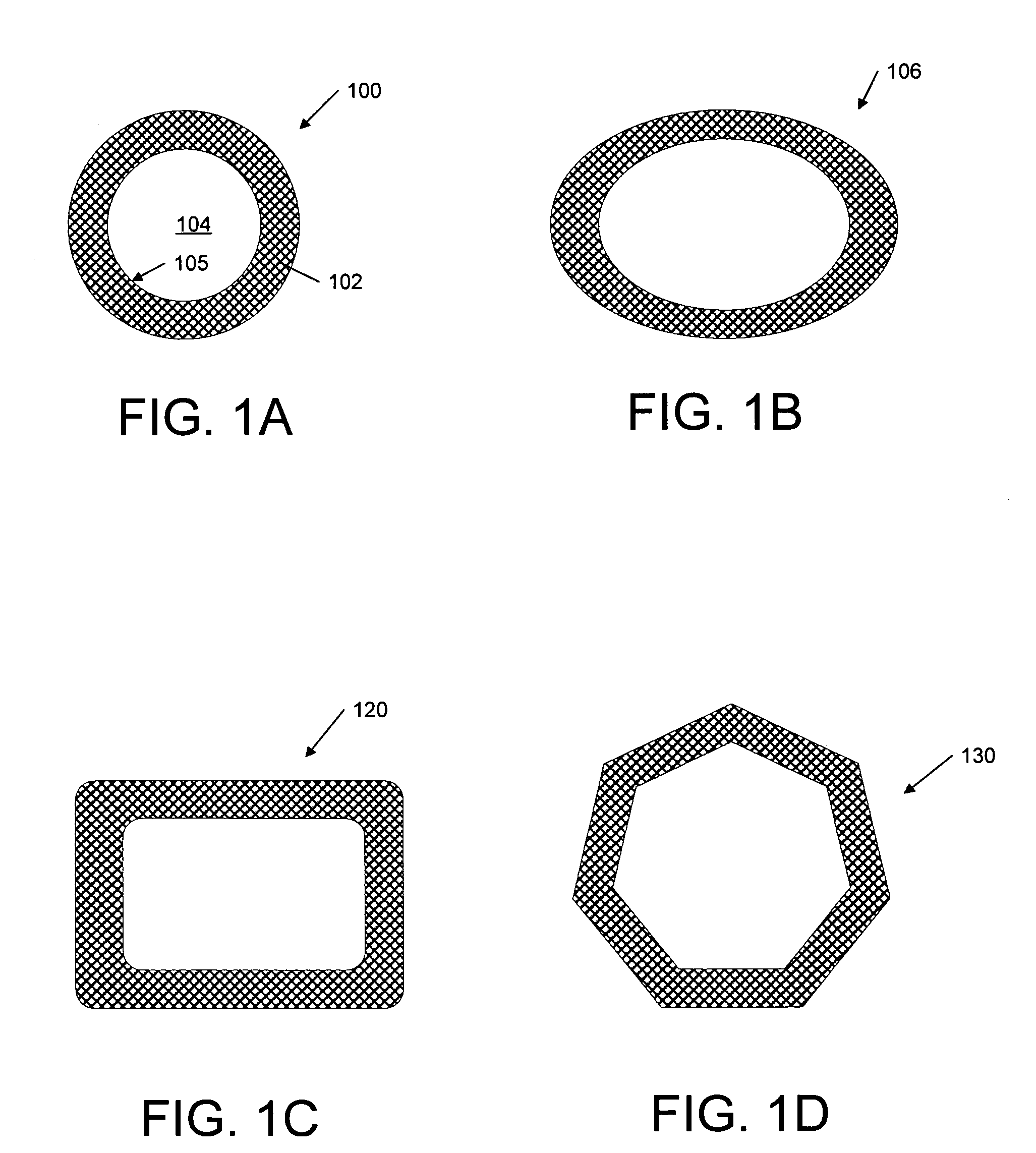

Diamond capsules and methods of manufacture

InactiveUS20100297391A1Reduce temperature differenceImprove conductivityLayered productsShaftsNanocrystalAccess port

Capsules and similar objects are made from materials having diamond (sp3) lattice structures, including diamond materials in synthetic crystalline, polycrystalline (ordered or disordered), nanocrystalline and amorphous forms. The capsules generally include a hollow shell made of a diamond material that defines an interior region that may be empty or that may contain a fluid or solid material. Some of the capsules include access ports that can be used to fill the capsule with a fluid. Capsules and similar structures can be manufactured by growing diamond on suitably shaped substrates. In some of these methods, diamond shell sections are grown on substrates, then joined together. In other methods, a nearly complete diamond shell is grown around a form substrate, and the substrate can be removed through a relatively small opening in the shell.

Owner:SUNSHELL

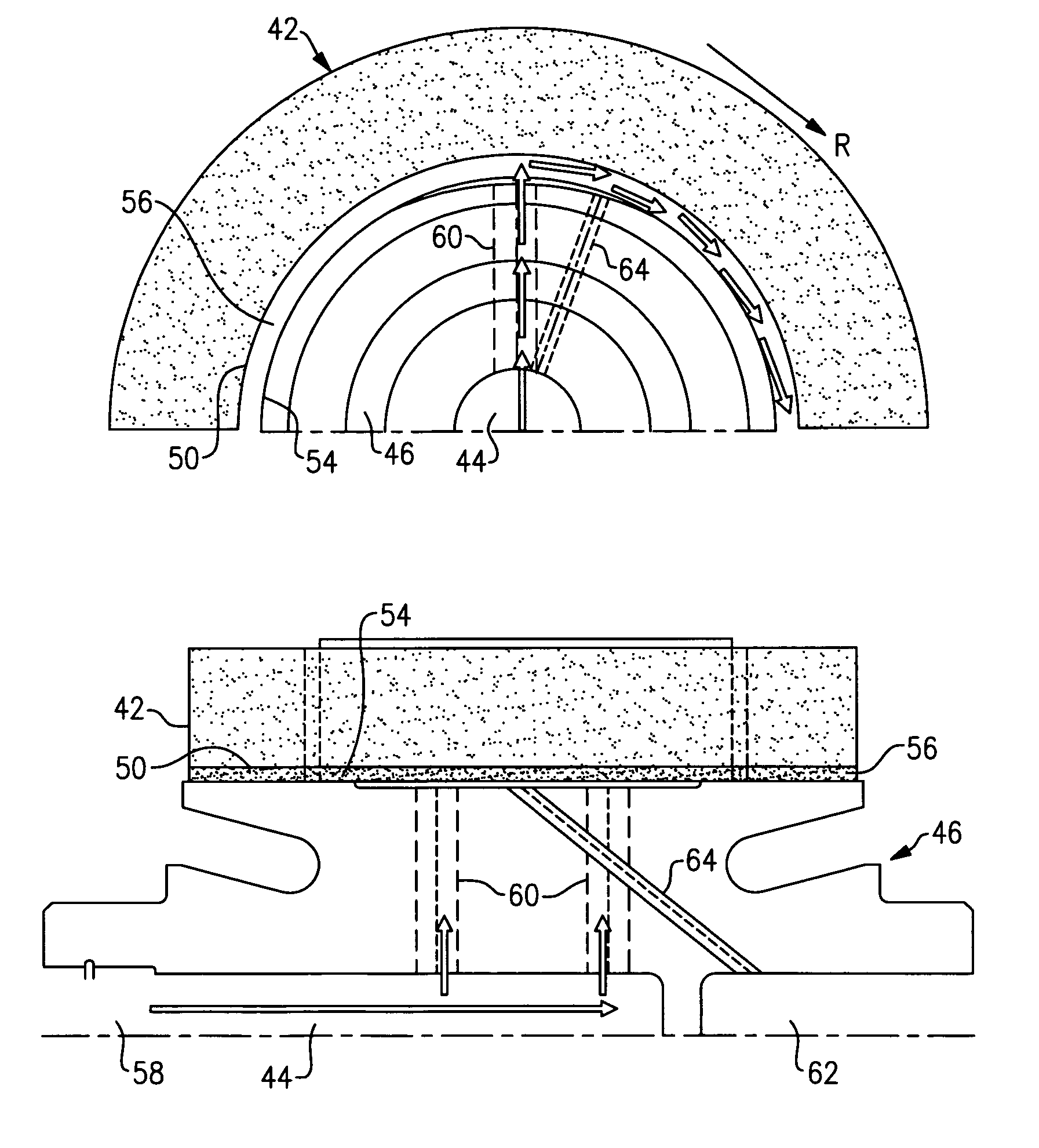

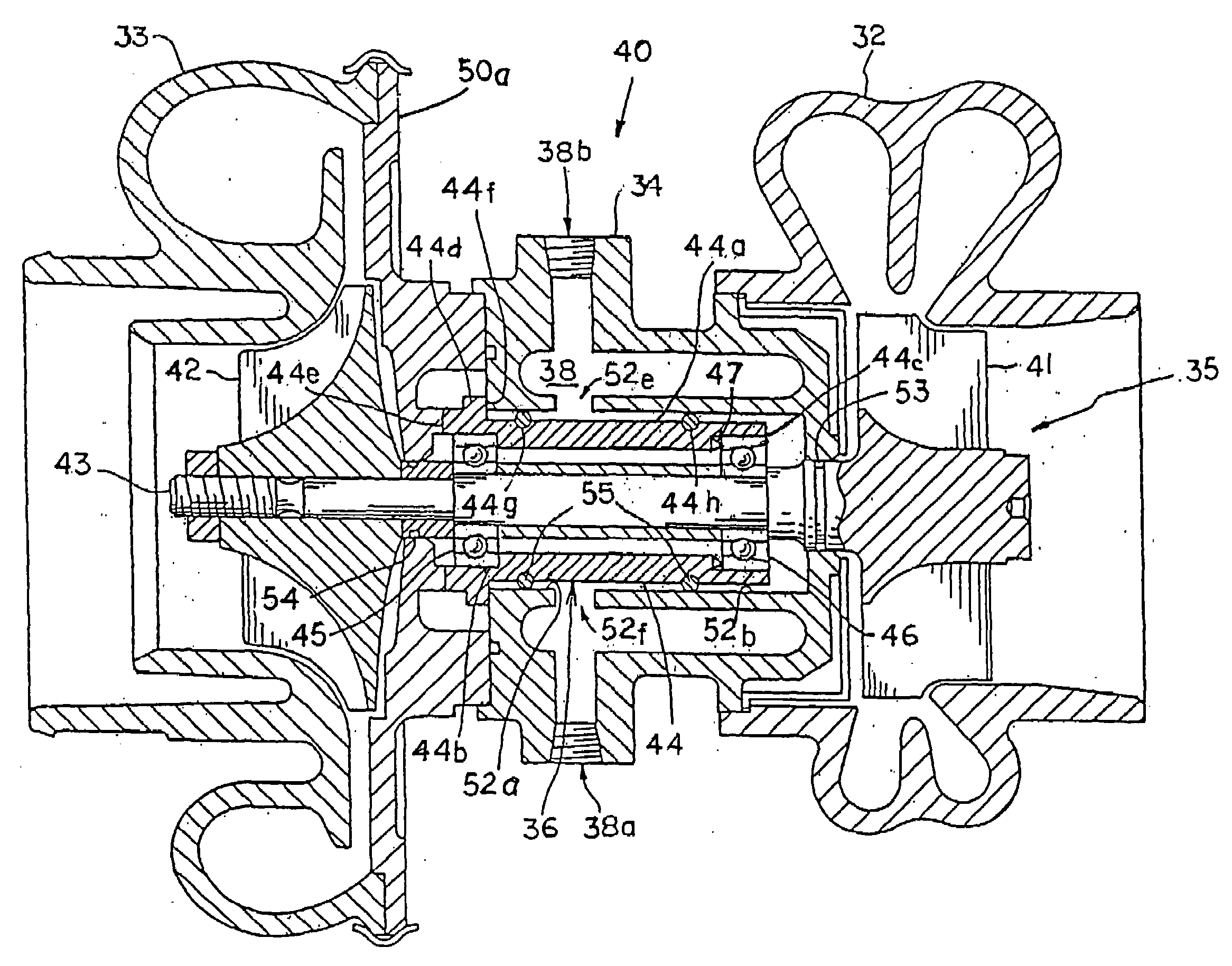

Lubrication of windmilling journal bearings

A support shaft provides lubrication to a journal bearing during windmilling operation of a gear set. A primary oil pump provides oil from an oil supply during driven operation of the fan, and a secondary oil pump provides oil from an internal sump during windmilling operation of the fan. During driven operation of the fan, oil is pumped with the primary oil pump through a primary oil flow path to an outer surface of the support shaft. During windmilling fan operation, oil is pumped from an internal sump with a secondary oil pump through the secondary oil flow path. The secondary oil flow path has a smaller flow capacity, and the secondary oil pump is a smaller capacity pump.

Owner:RTX CORP

Polycrystalline diamond partially depleted of catalyzing material

Owner:REEDHYCALOG UK

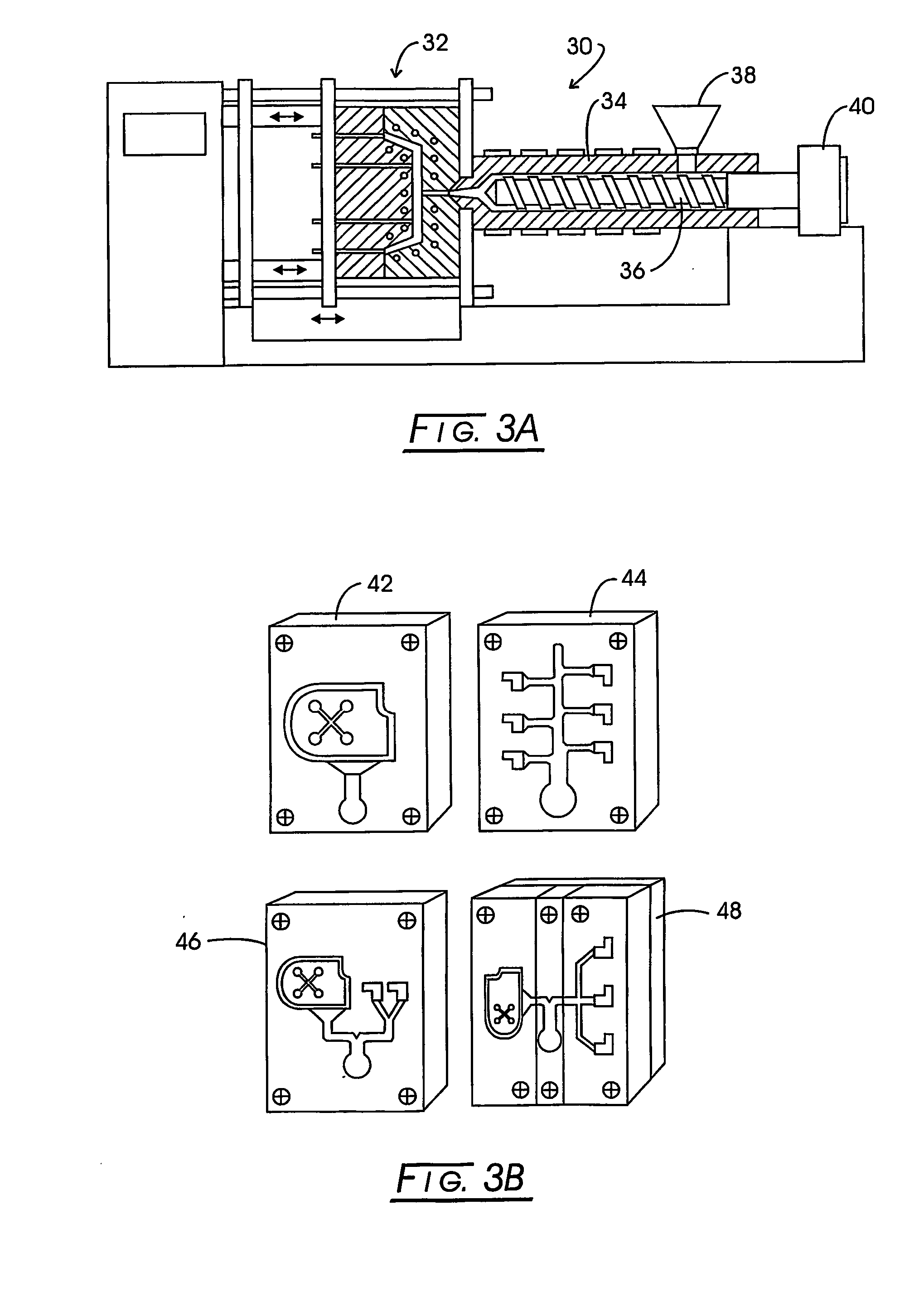

Heterogeneous composite bodies with isolated cermet regions formed by high temperature, rapid consolidation

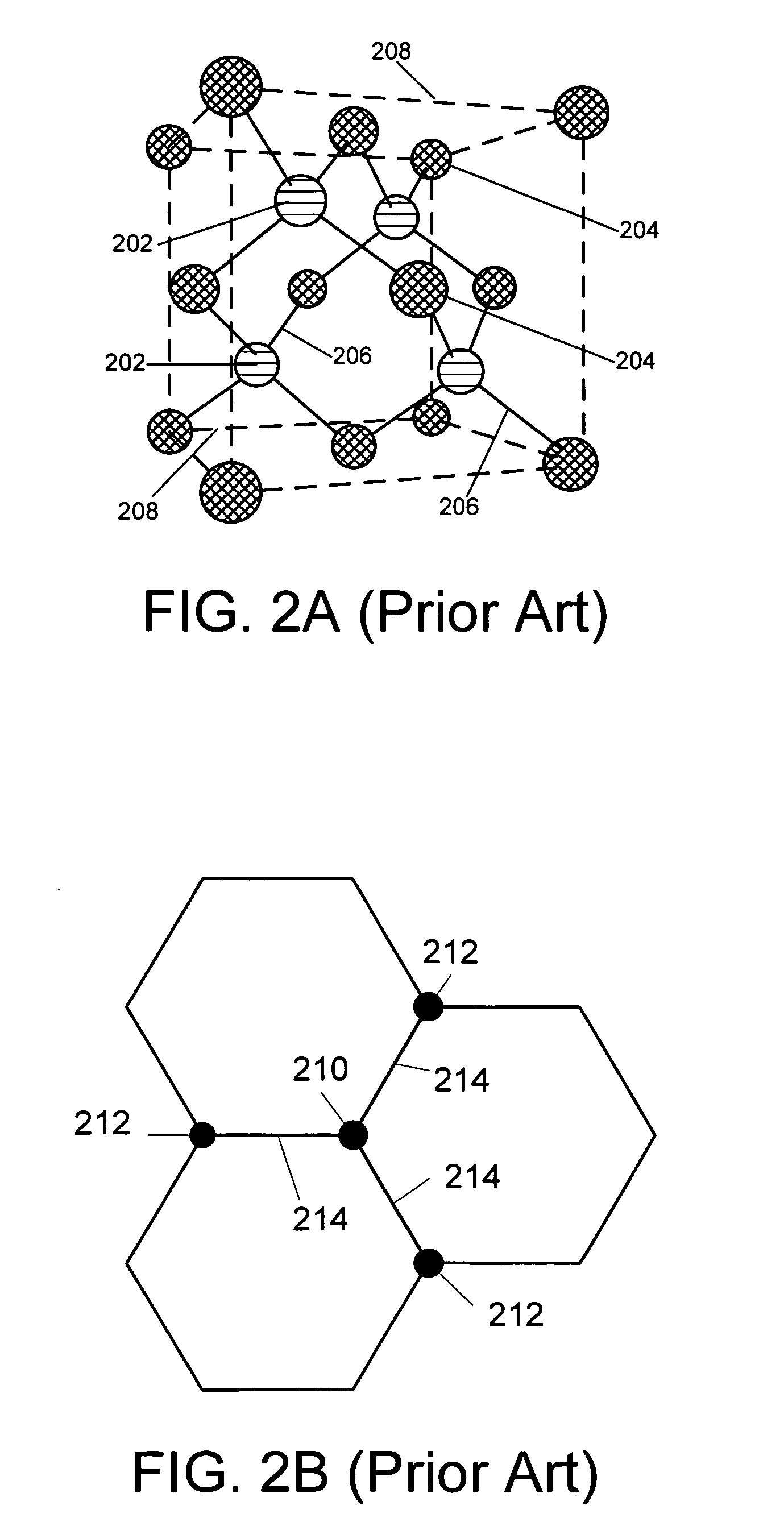

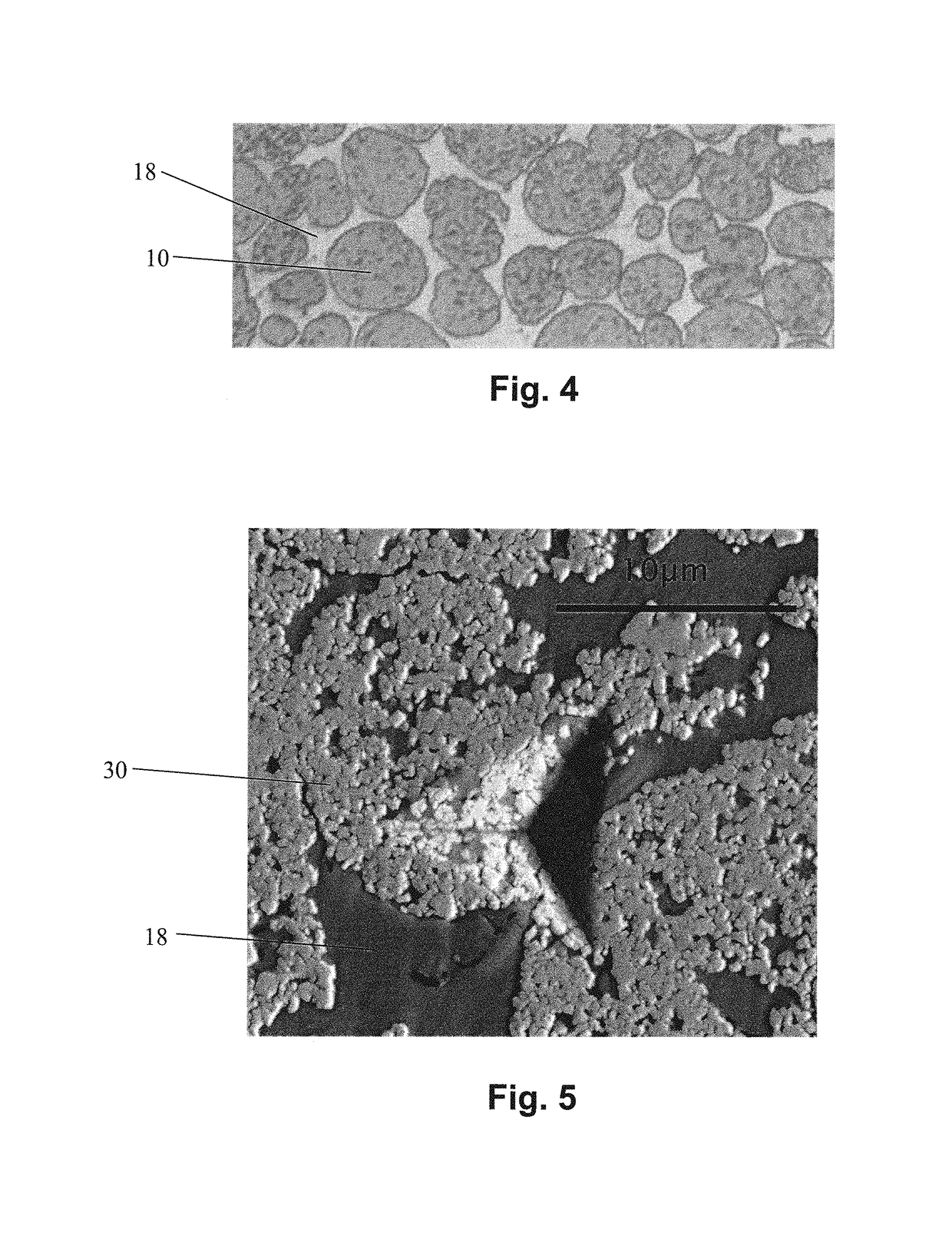

ActiveUS9943918B2Increase spacingUniform compositionRolling contact bearingsTransportation and packagingNanoparticleNanometre

A heterogeneous composite consisting of near-nano ceramic clusters dispersed within a ductile matrix. The composite is formed through the high temperature compaction of a starting powder consisting of a core of ceramic nanoparticles held together with metallic binder. This core is clad with a ductile metal such that when the final powder is consolidated, the ductile metal forms a tough, near-zero contiguity matrix. The material is consolidated using any means that will maintain its heterogeneous structure.

Owner:POWDERMET

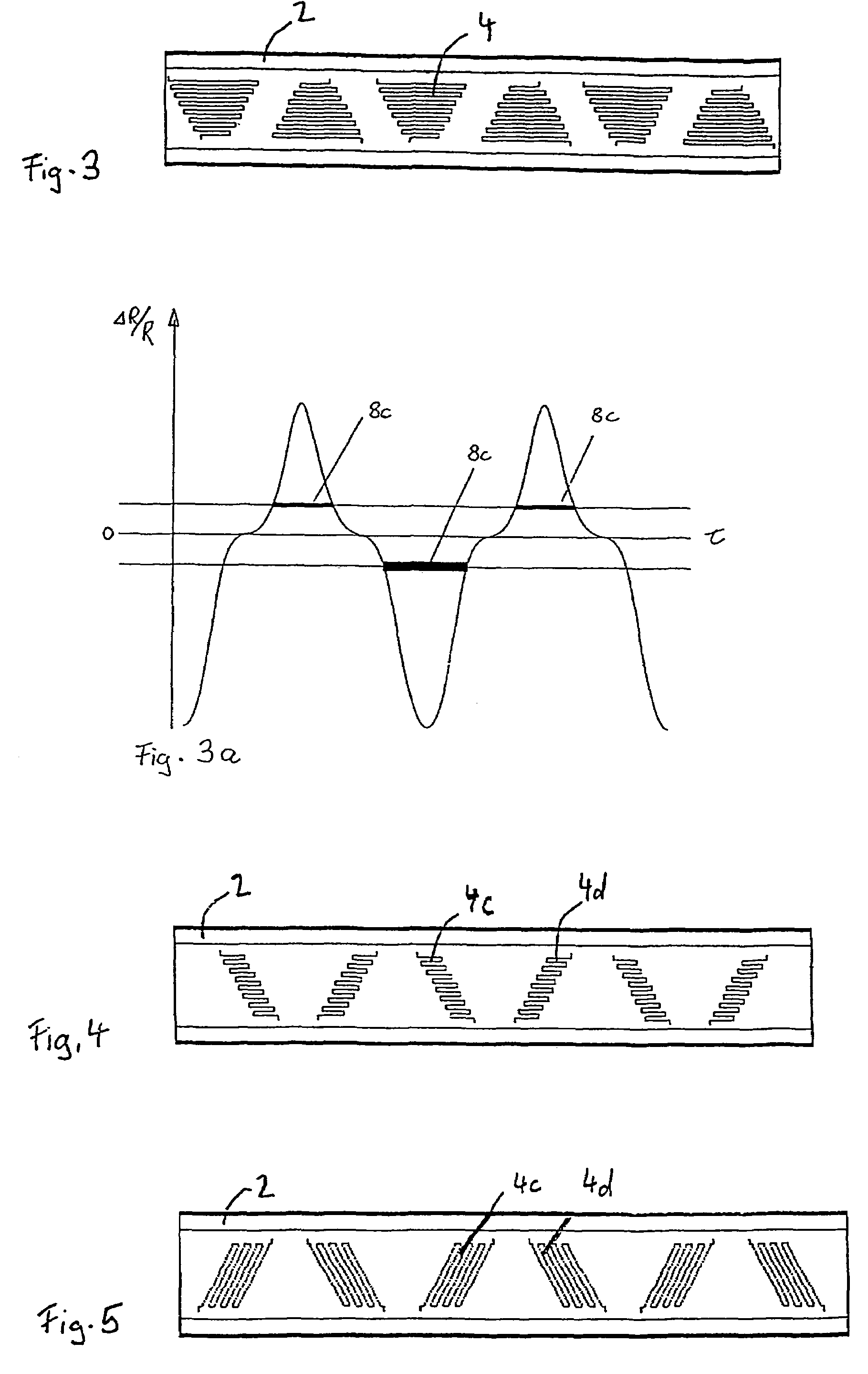

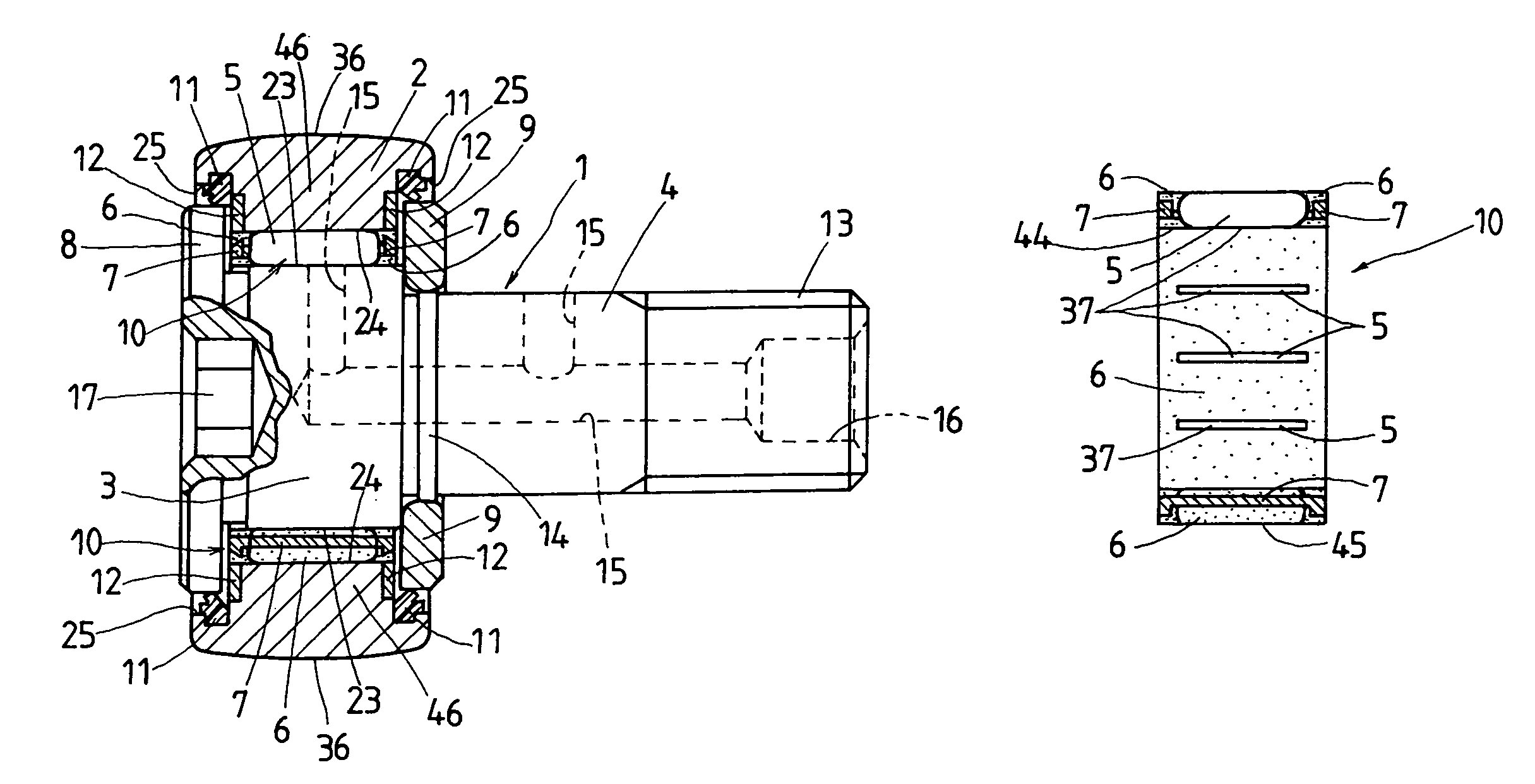

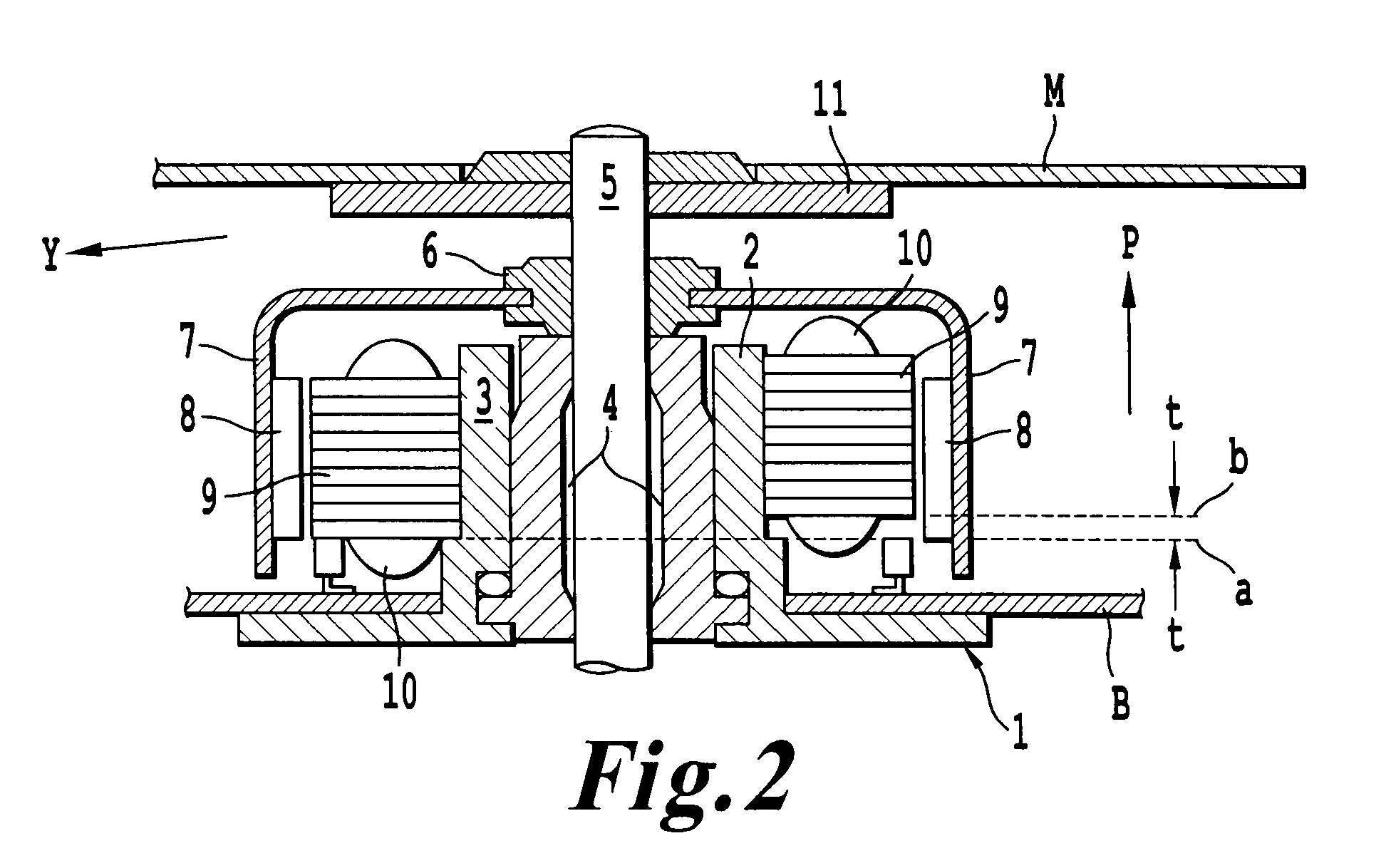

Force-sensing bearing

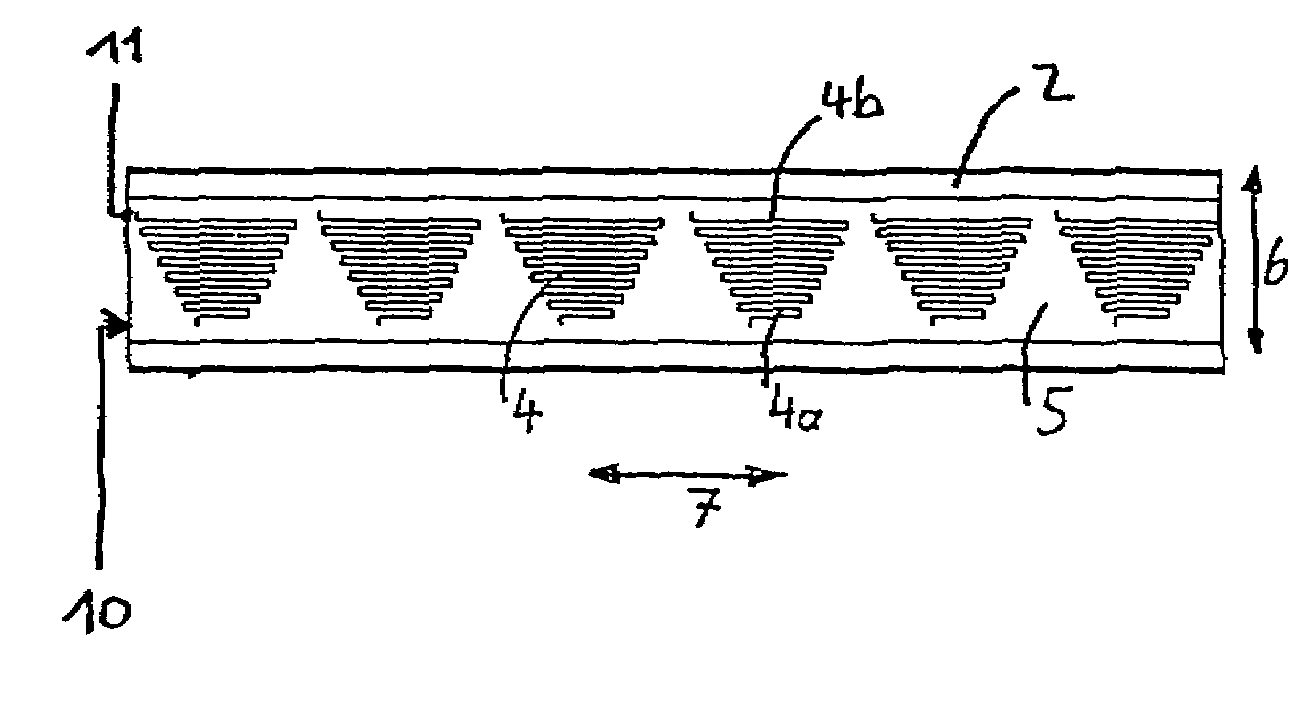

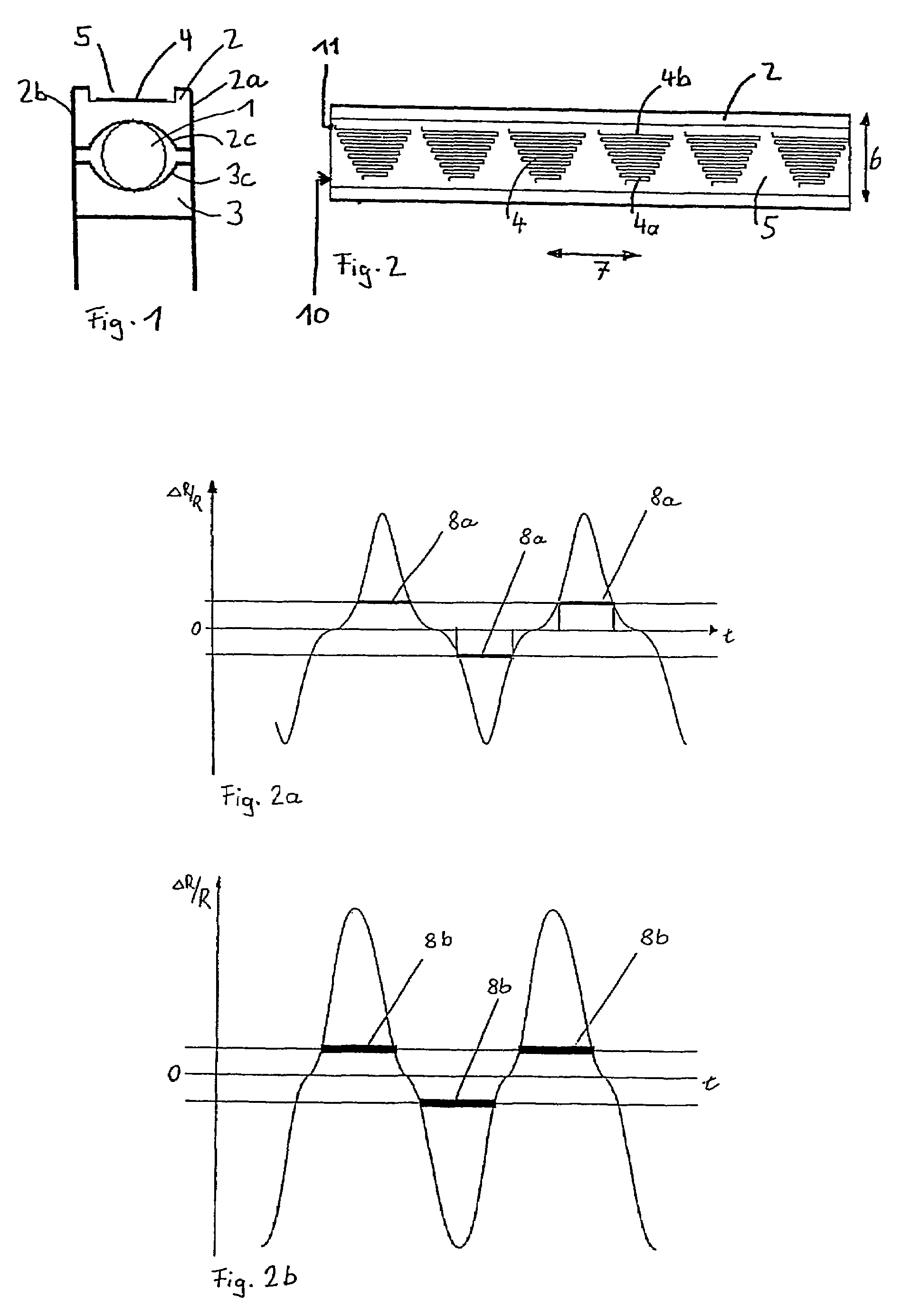

InactiveUS7316168B2Rolling contact bearingsMachine bearings testingElectrical conductorPulp and paper industry

The invention relates to a roller bearing comprising curved running paths, in addition to roller bodies and strain gauge sensors which are arranged between said running paths, said sensors being located in a groove on the outer diameter of the outer ring and / or on the inner diameter of the inner ring. The length of two adjacent strip conductor sections of the strain gauge sensor varies in such a way as to measure the angular position of the roller bodies between the strip conductors.

Owner:INA SCHAEFFLER KG

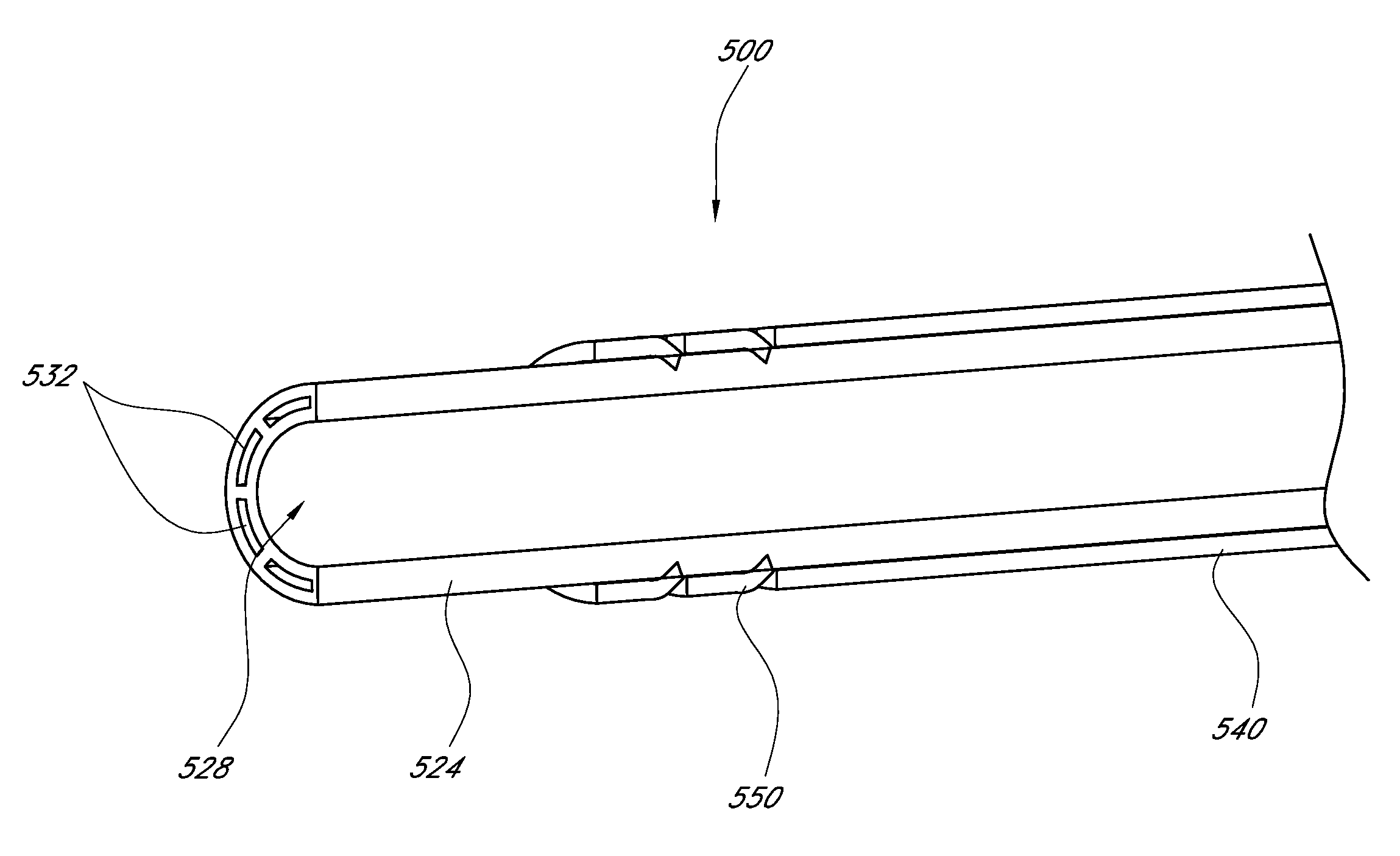

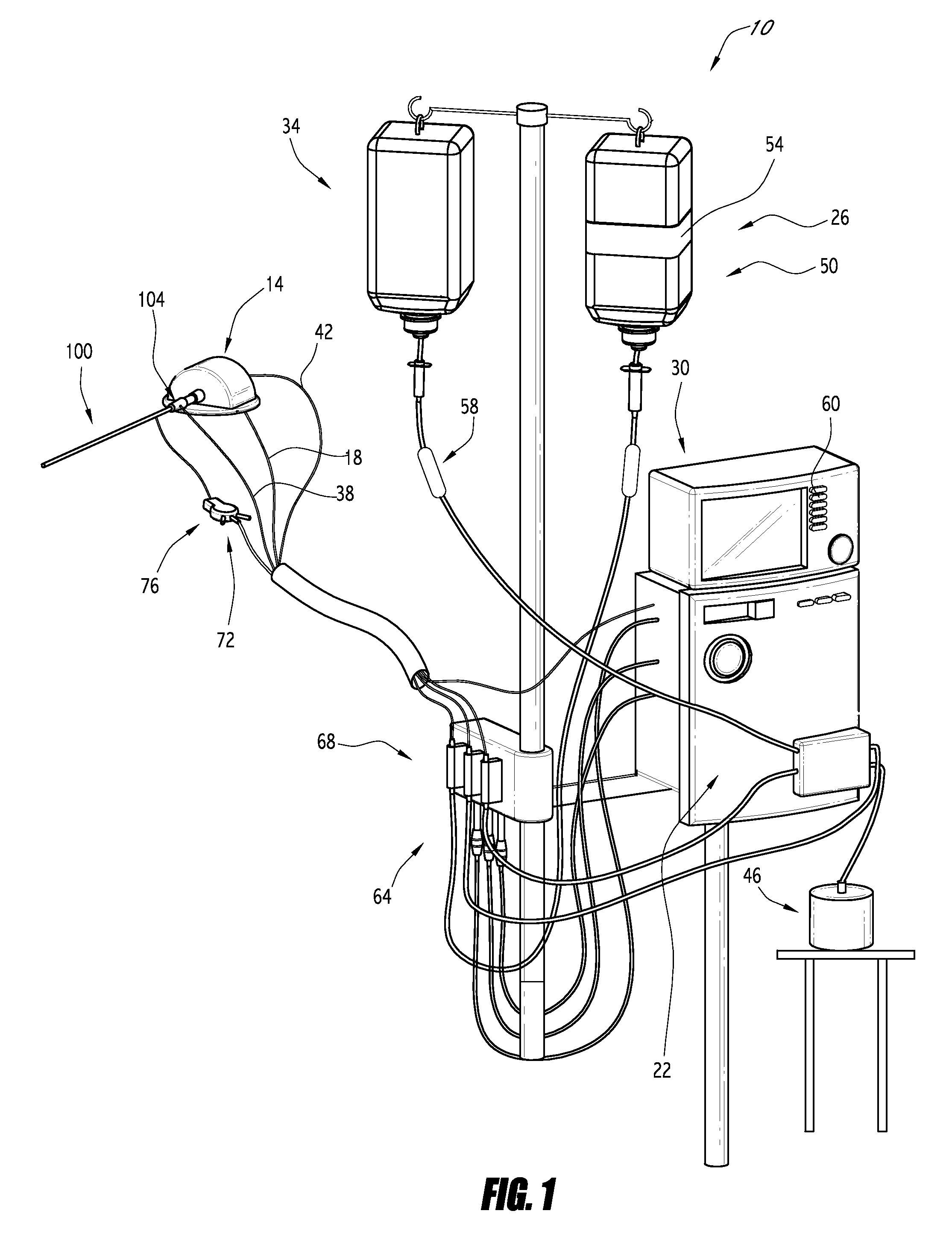

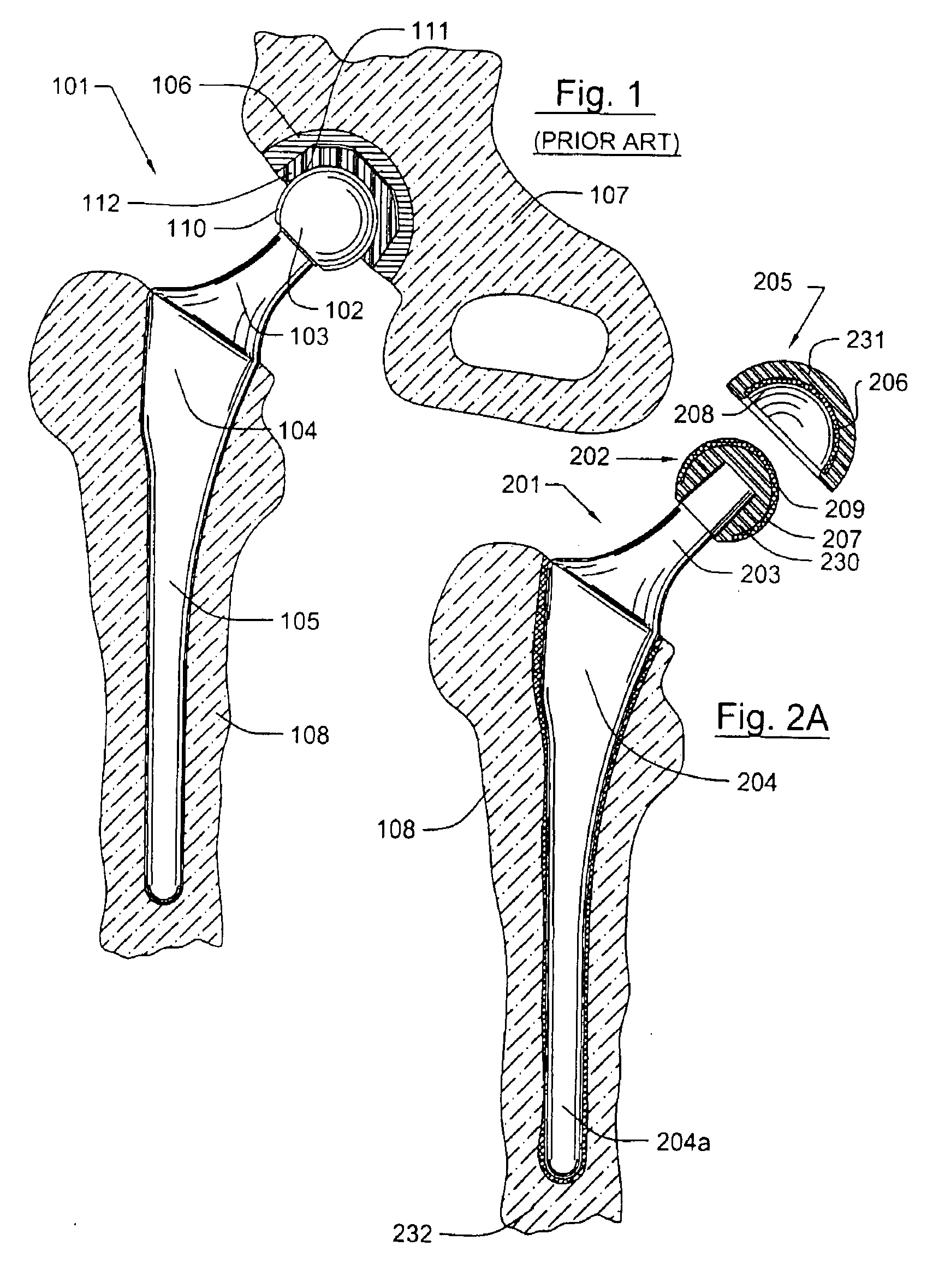

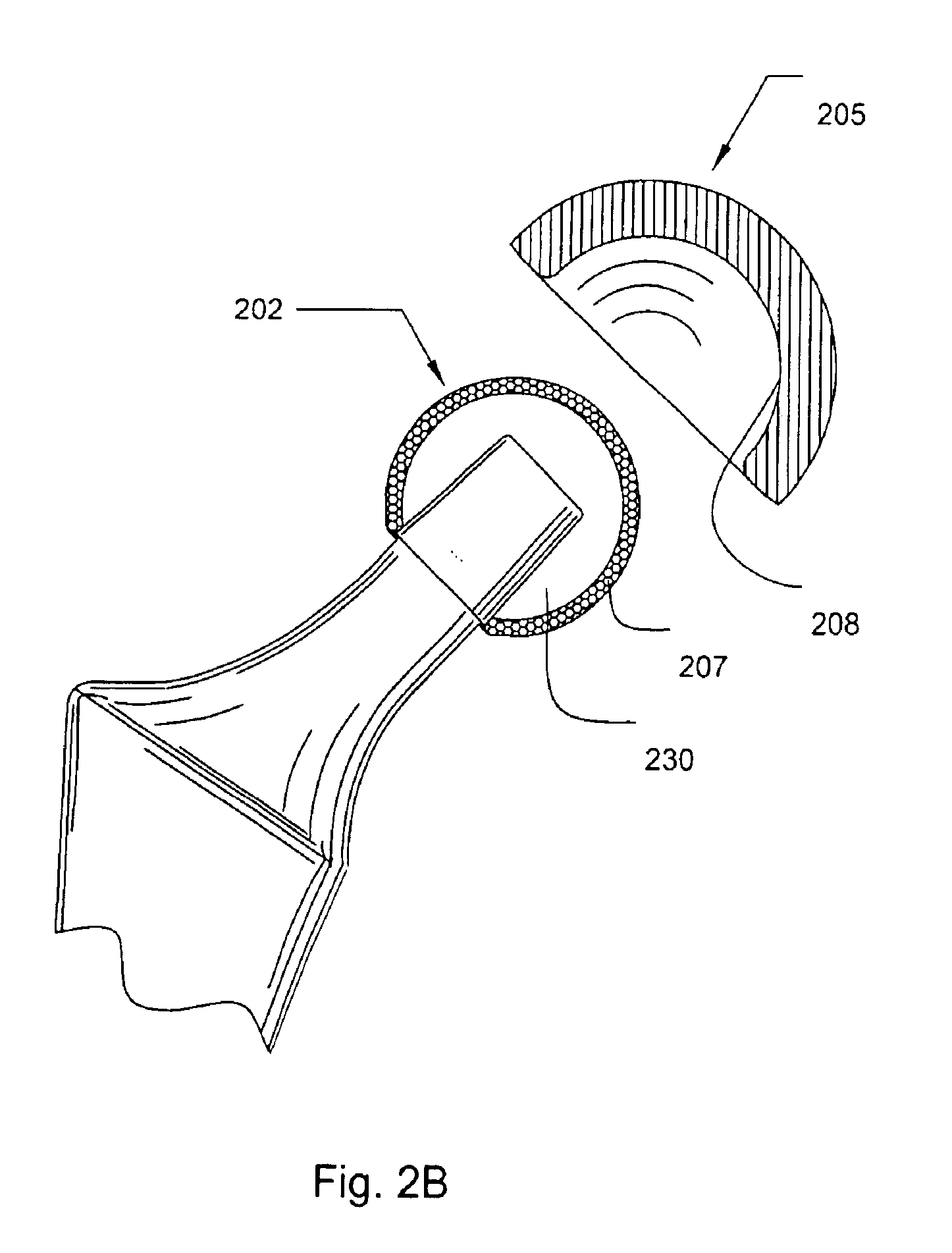

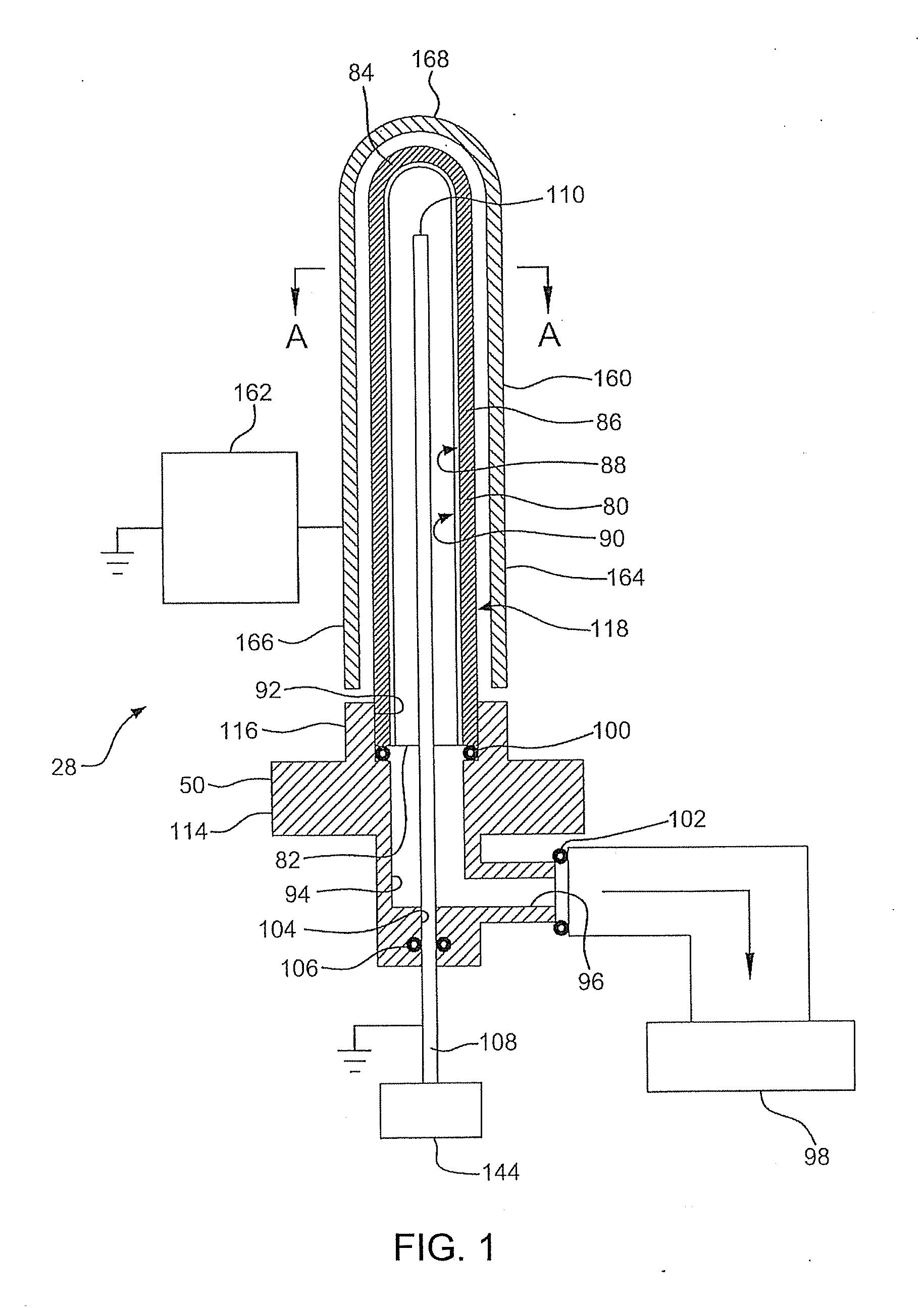

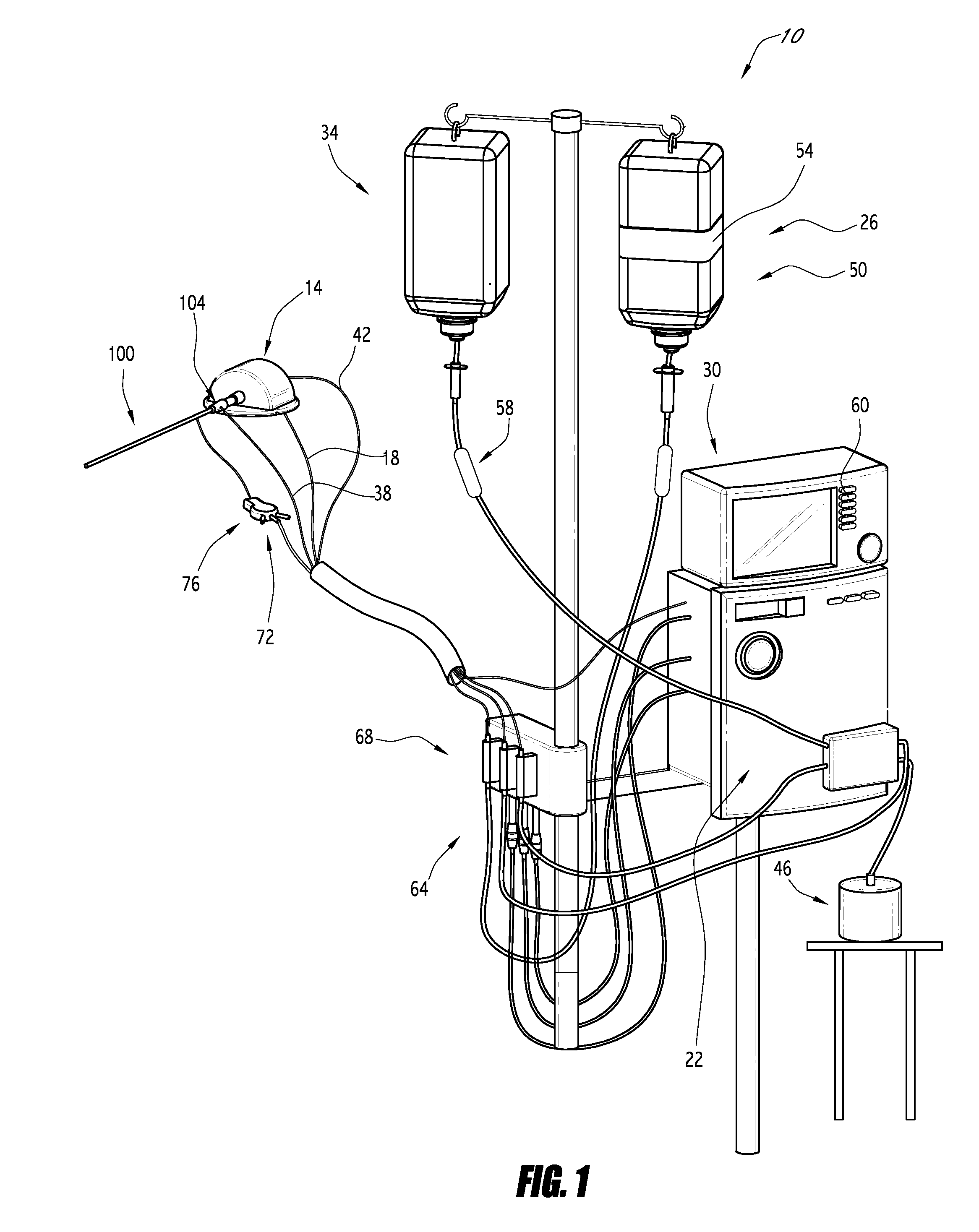

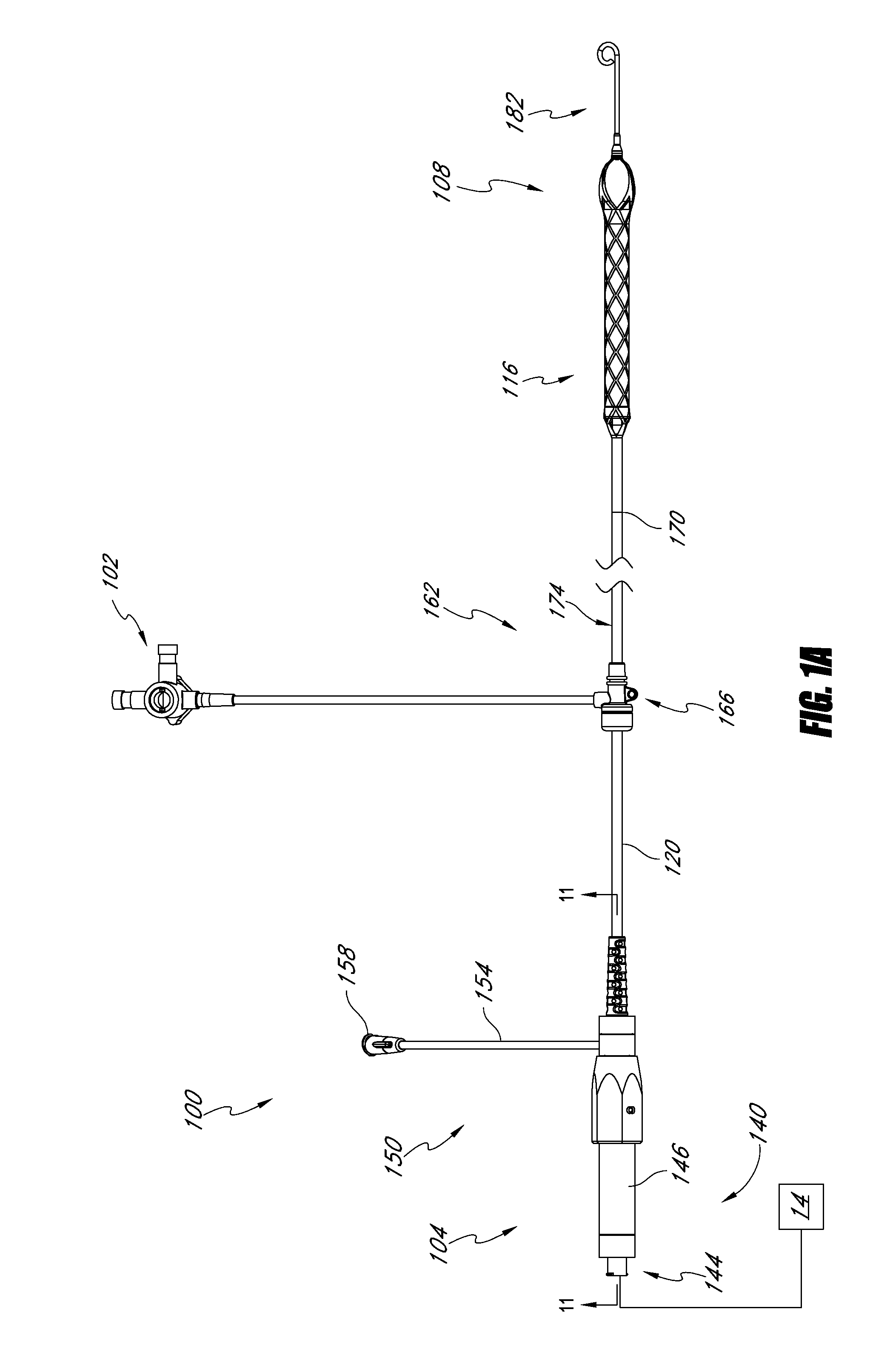

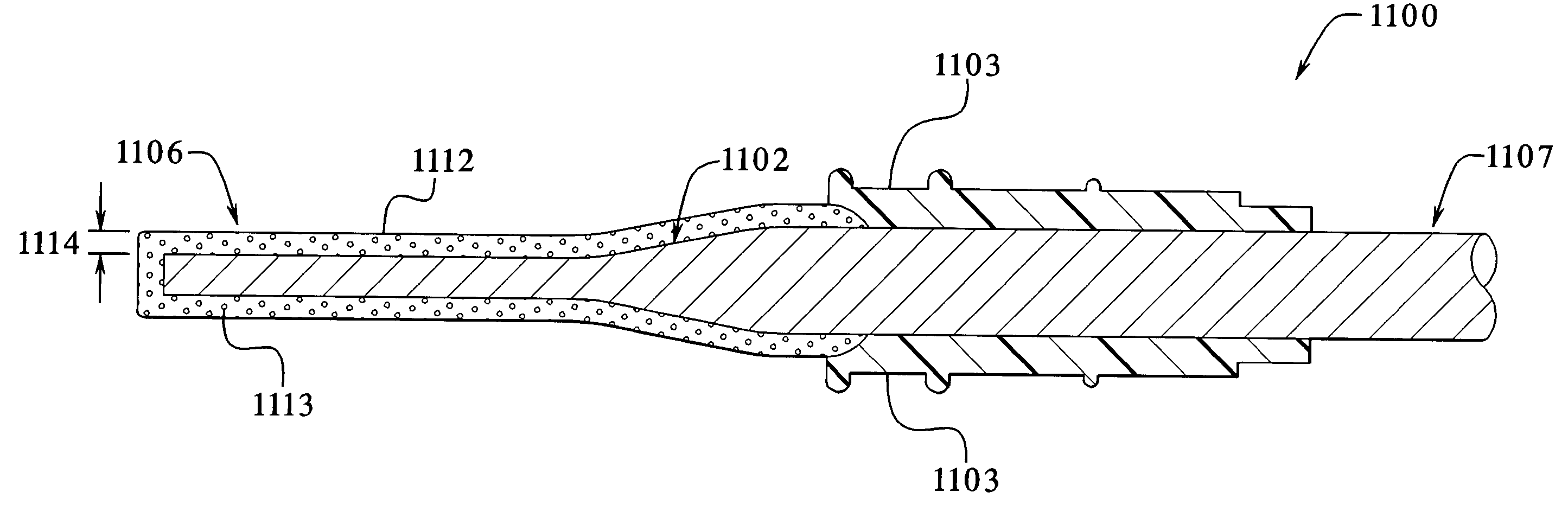

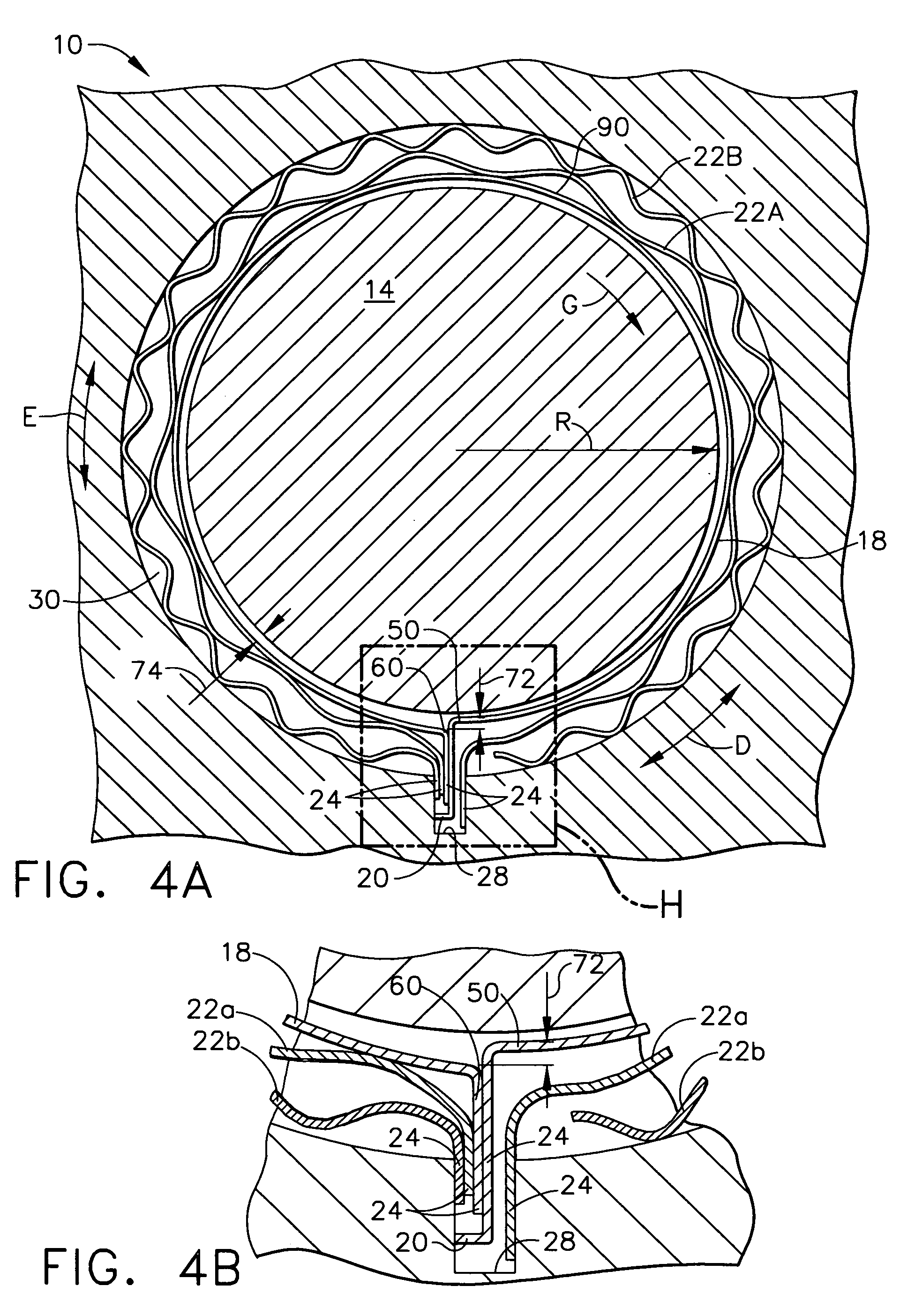

Catheter pump

A heart pump and a catheter assembly therefor are provided that include a flexible catheter body having a proximal end and a distal end, the catheter body having a plurality of lumens therethrough. The catheter body can be sufficiently flexible to extend from a peripheral access to a patient's heart. The catheter assembly can also include an impeller assembly having an impeller and a housing. The impeller assembly can be coupled with the flexible catheter body such that a tensile force applied to opposite ends of the catheter assembly enhances the security of the connection between the catheter body and the impeller assembly.

Owner:PENN STATE RES FOUND +1

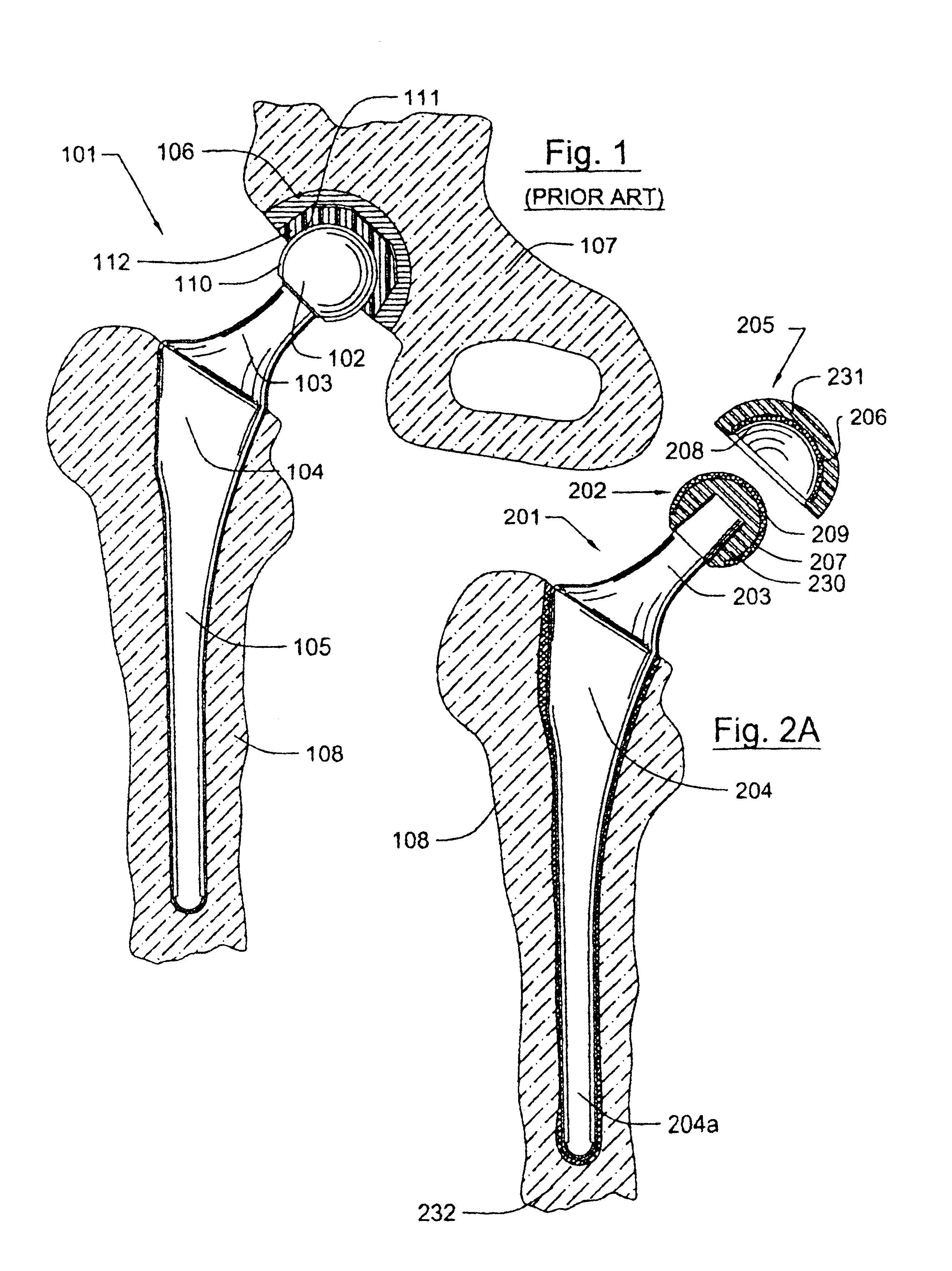

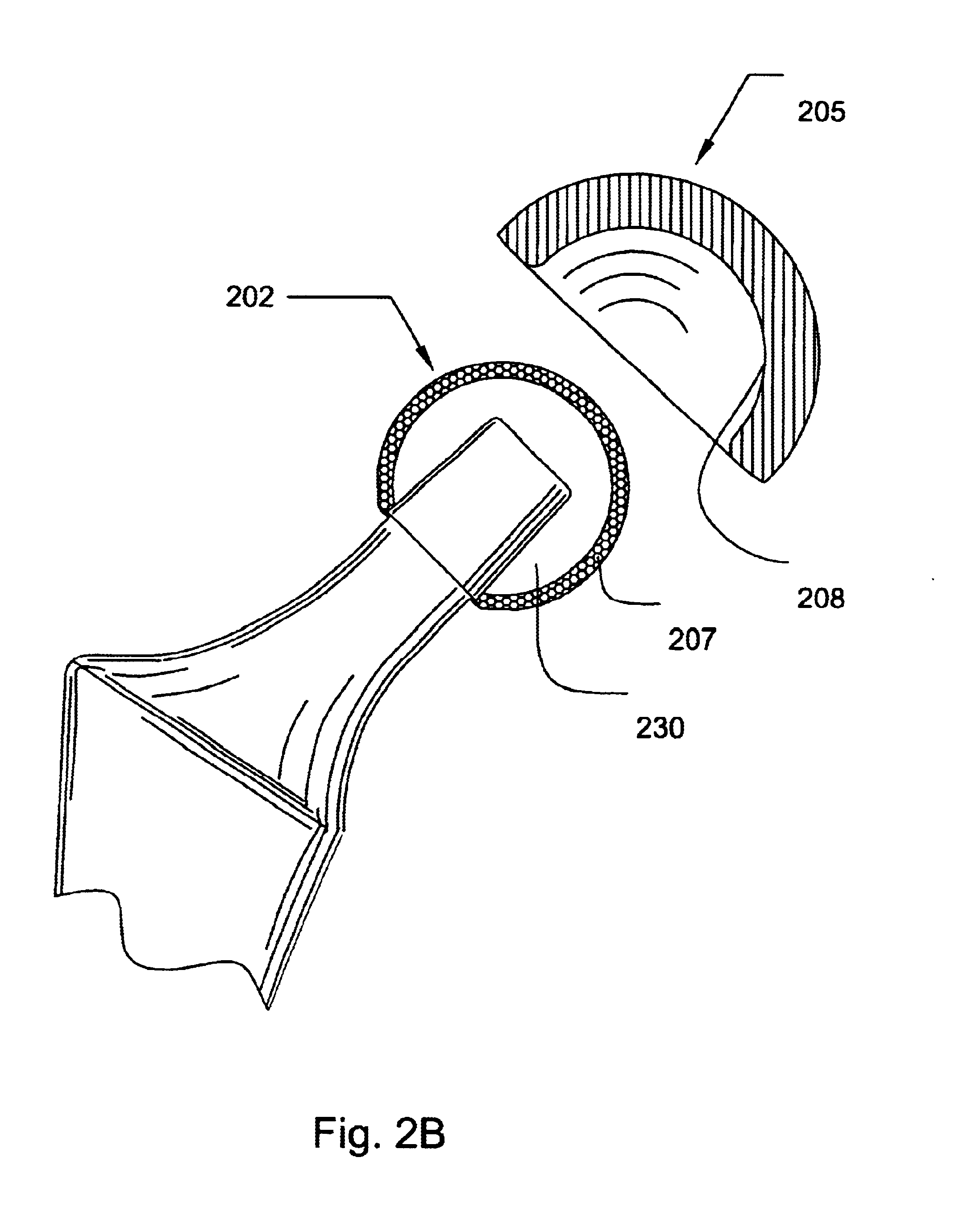

Prosthetic knee joint having at least one diamond articulation surface

InactiveUS7077867B1Improve wear resistanceReduce coefficient of frictionFinger jointsWrist jointsArticular surfacesKnee Joint

Owner:DIAMICRON

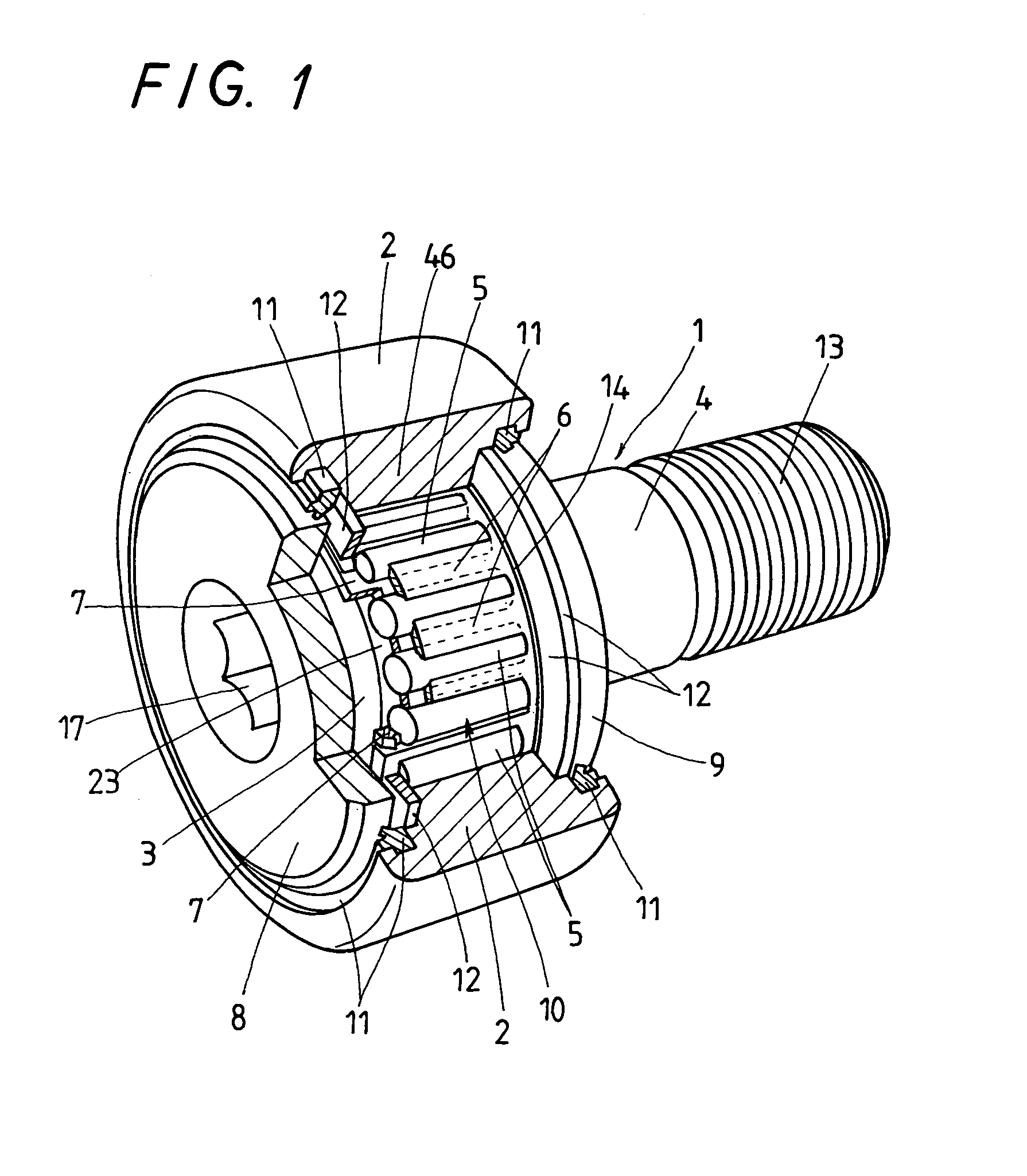

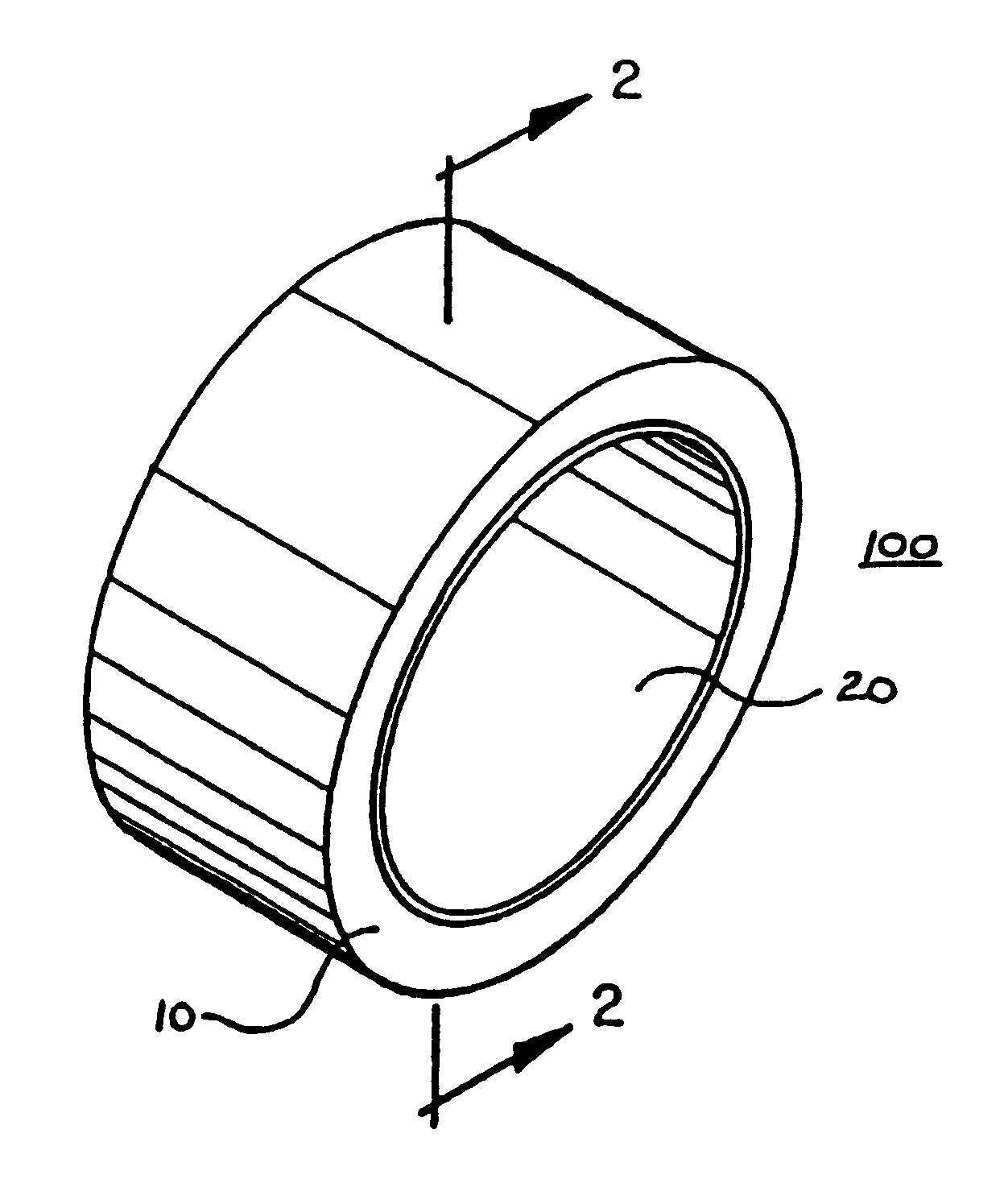

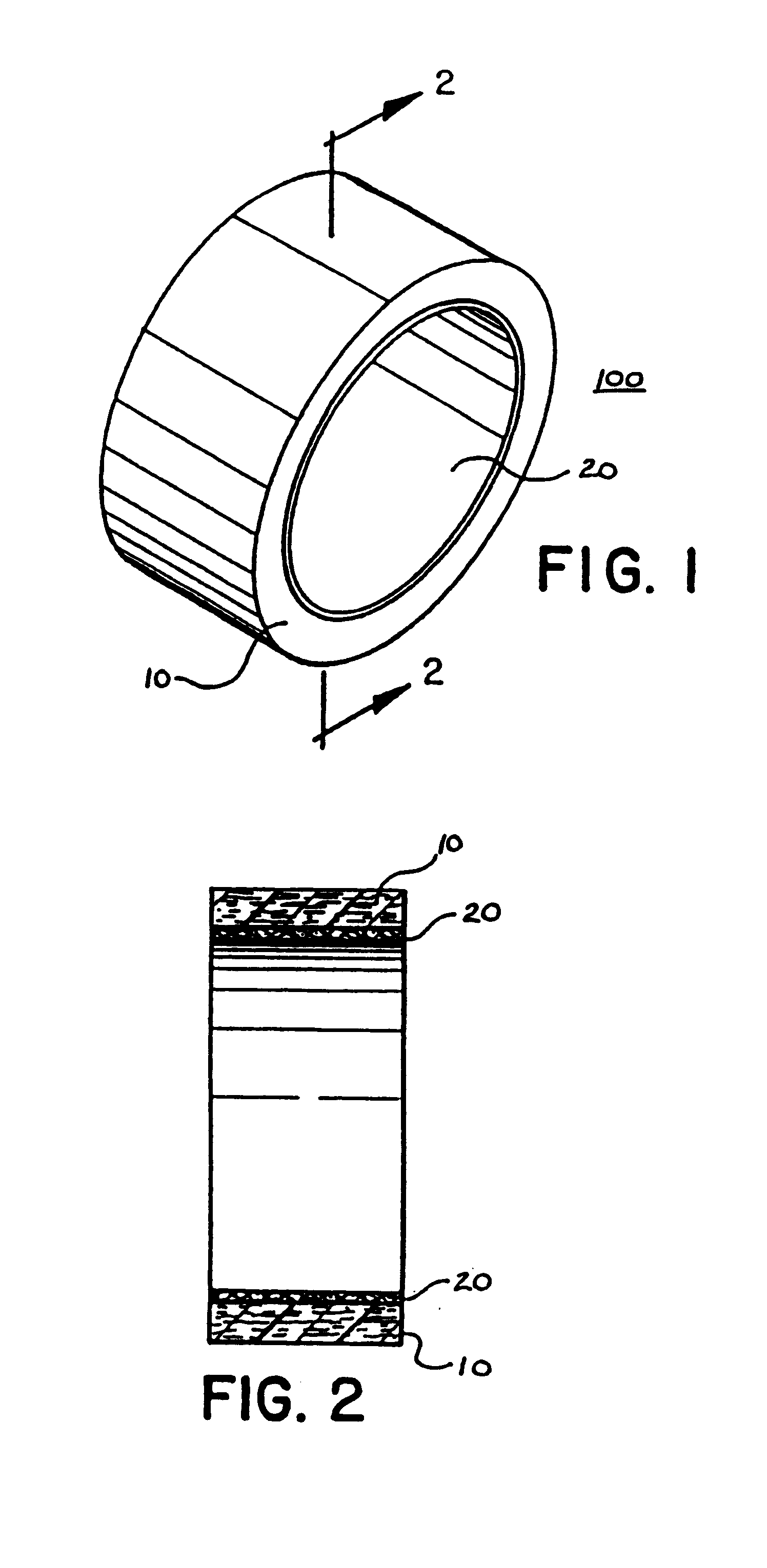

Rolling-contact bearing containing solid lubricant therein

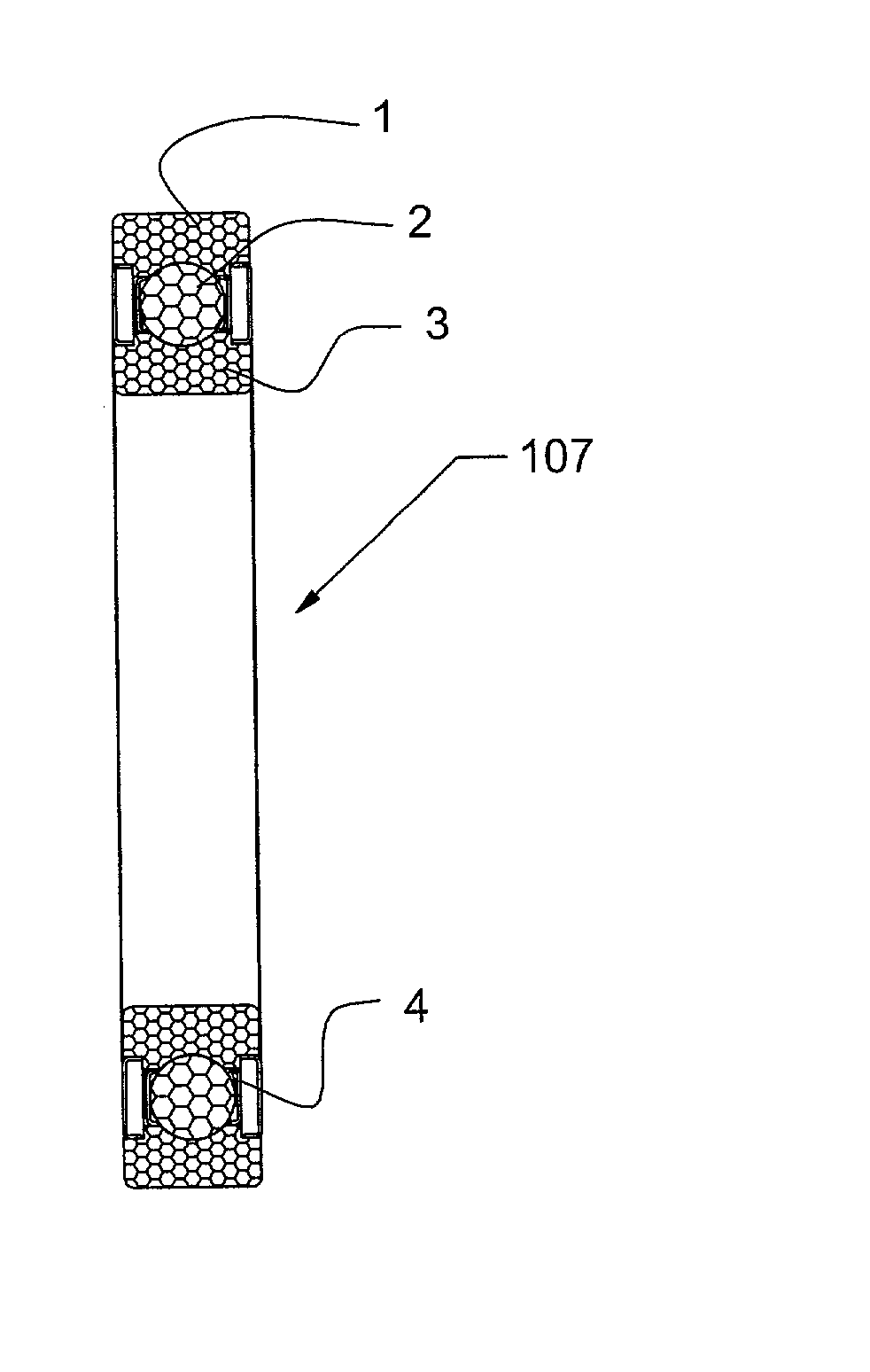

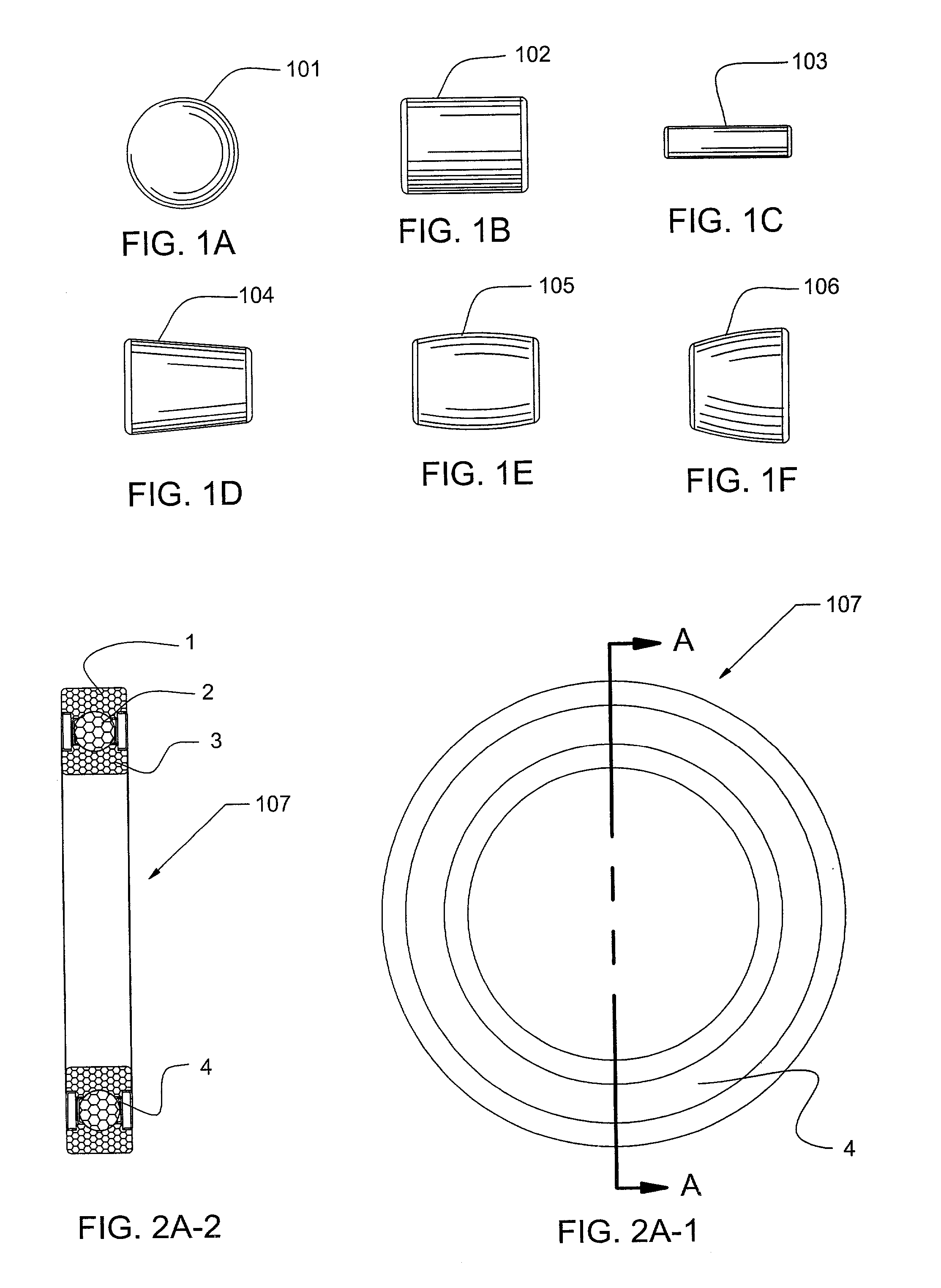

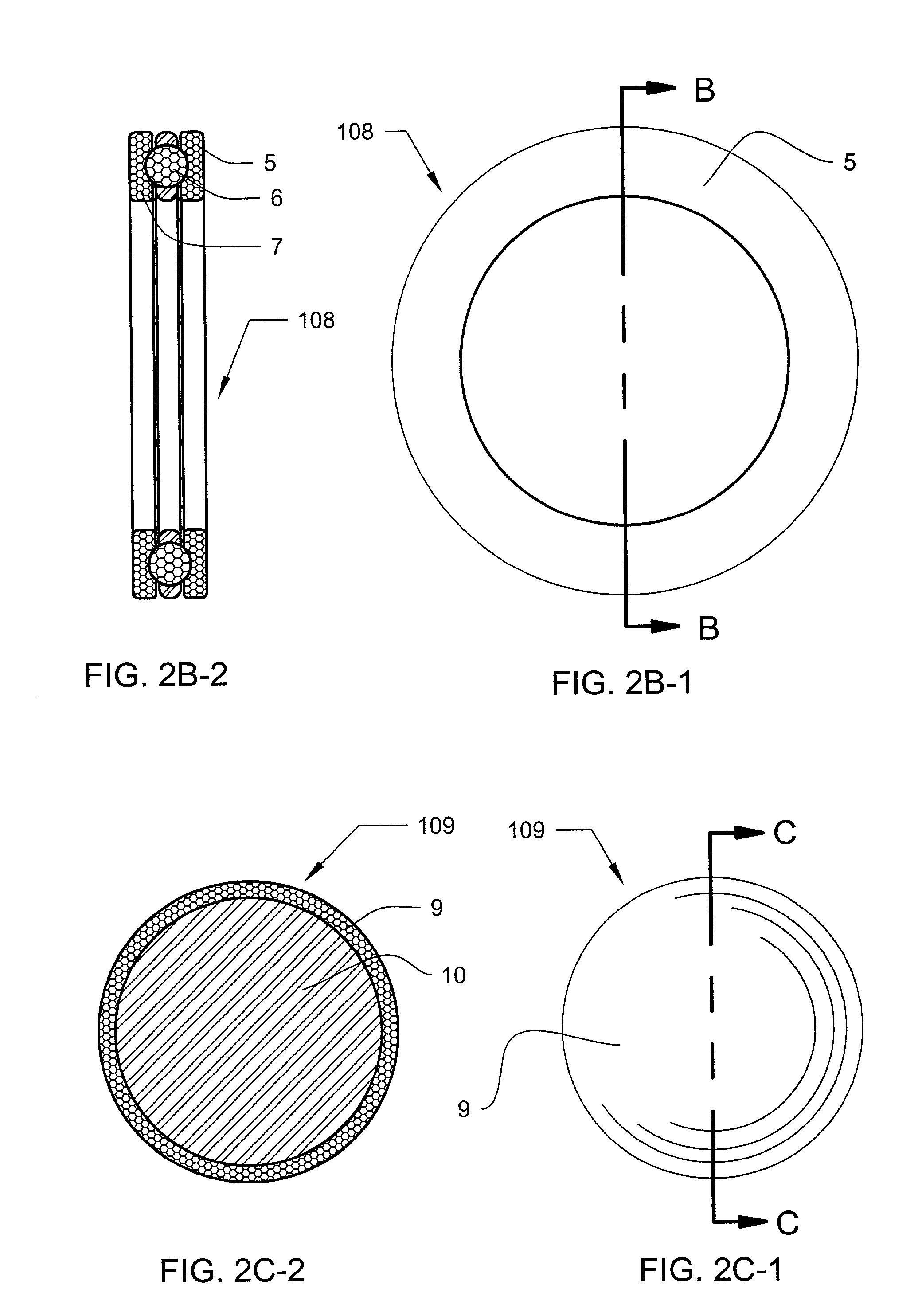

ActiveUS7234873B2Improve air tightnessSmooth movementBearing componentsNeedle bearingsRolling-element bearingEngineering

A cage, rollers and solid lubricant are all formed integrally into a complete unitary molding with using difference in thermal expansion in a mold. Assembling the complete unitary molding into the race in the rolling-contact bearing is made easier. The complete unitary molding is made such that the rollers remain exposed partially at their rolling surfaces above the inside circular surface of the complete unitary molding while the solid lubricant on the outside circular surface of the complete unitary molding is squeezed out from between the rolling surfaces of the rollers and the inside circular surface of the outside mold upon molding operation, thereby getting the rolling surfaces of the rollers exposed partially. The mold is composed of an outside mold, an inside mold and an intermediate mold, which is made of a substance larger in thermal expansion than other substance for the outside and inside molds.

Owner:NIPPON THOMPSON

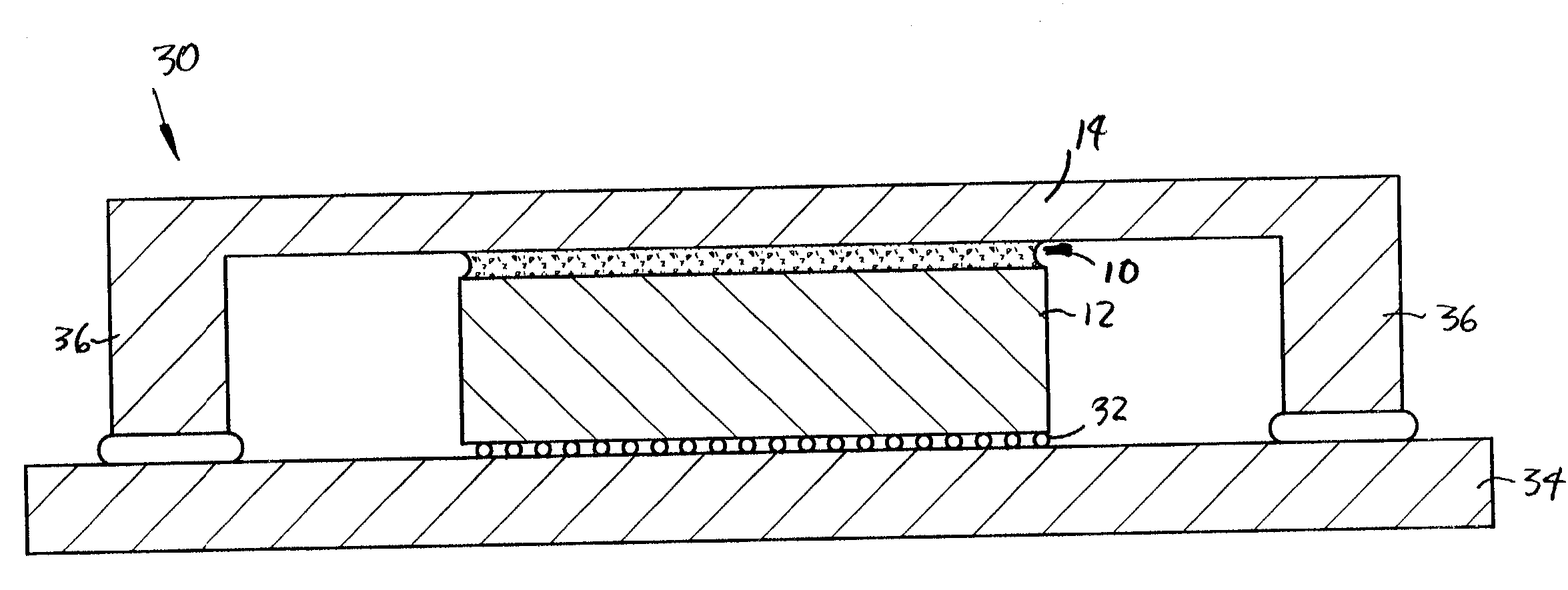

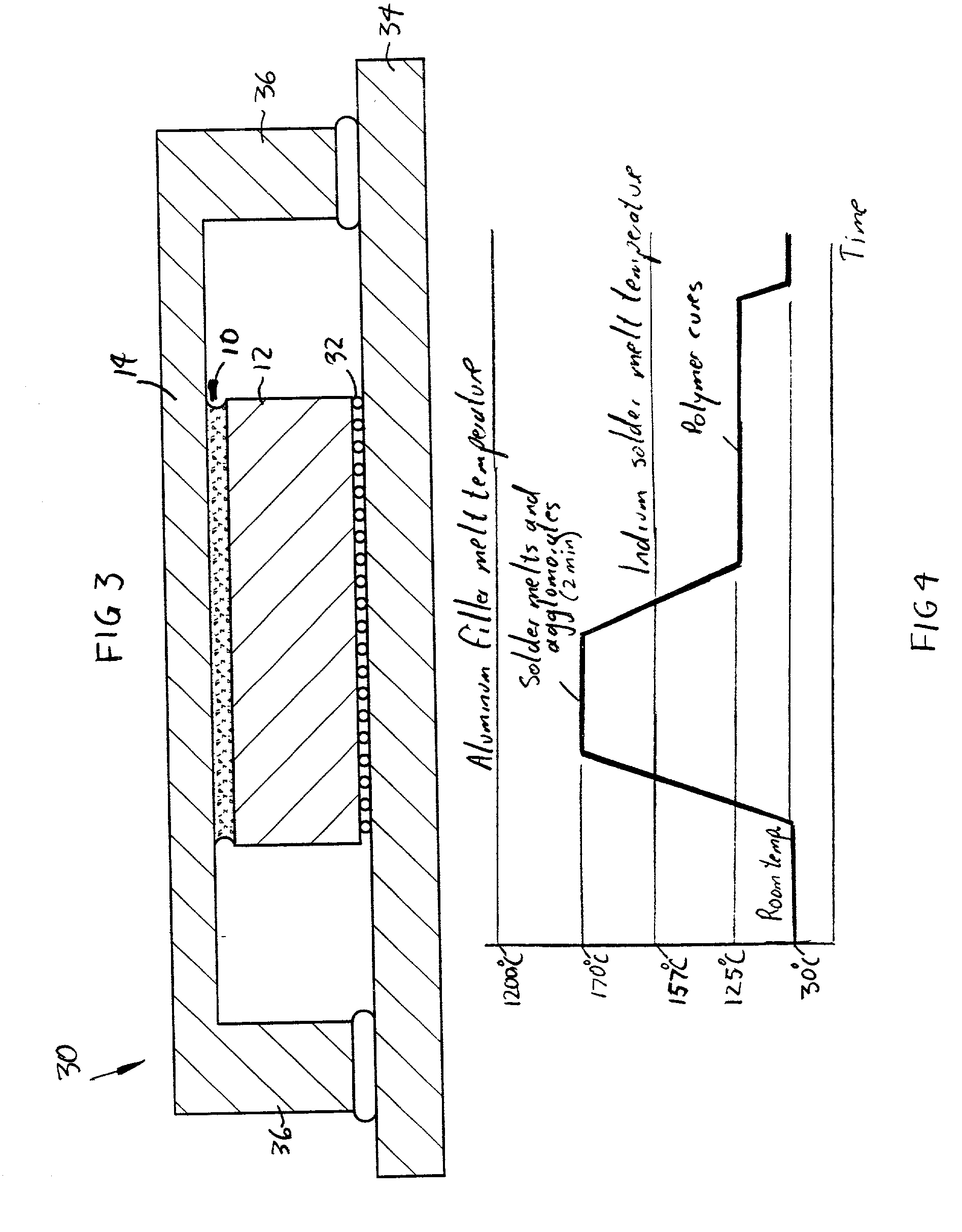

Thermal interface material and electronic assembly having such a thermal interface material

InactiveUS20030077478A1Artificial flowers and garlandsSemiconductor/solid-state device detailsStress conditionsIndium

A thermal interface material is described for thermal coupling of an electronic component to a thermally conductive member. The thermal interface material includes a viscoelastic polymer matrix material, fusible solder particles in the matrix material, and filler particles in the matrix material. The solder particles have a melting temperature below a selected temperature (e.g. 157° C. for indium) and the filler particles have a melting temperature substantially above the selected temperature (e.g. 961° C. for silver). The filler particles keep the thermal interface material intact under adverse thermal and stress conditions.

Owner:INTEL CORP

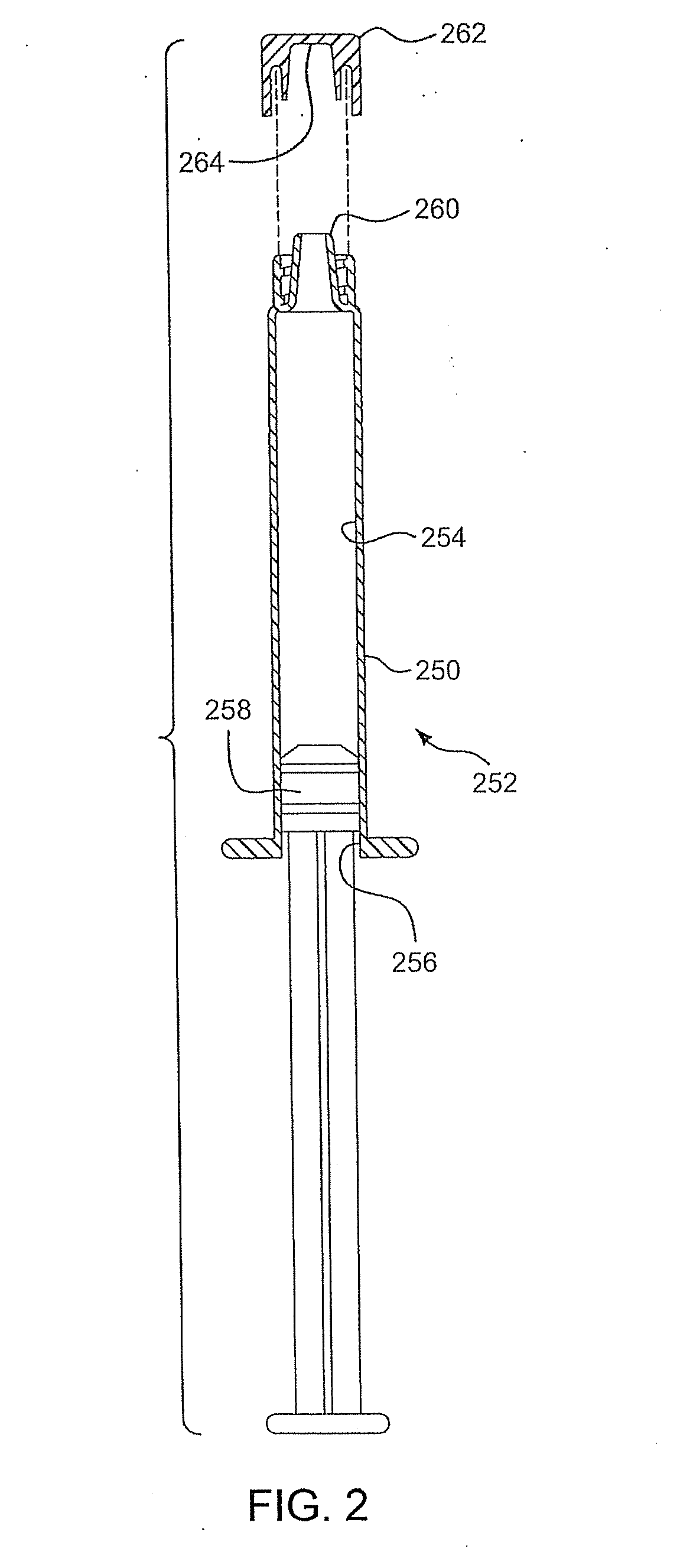

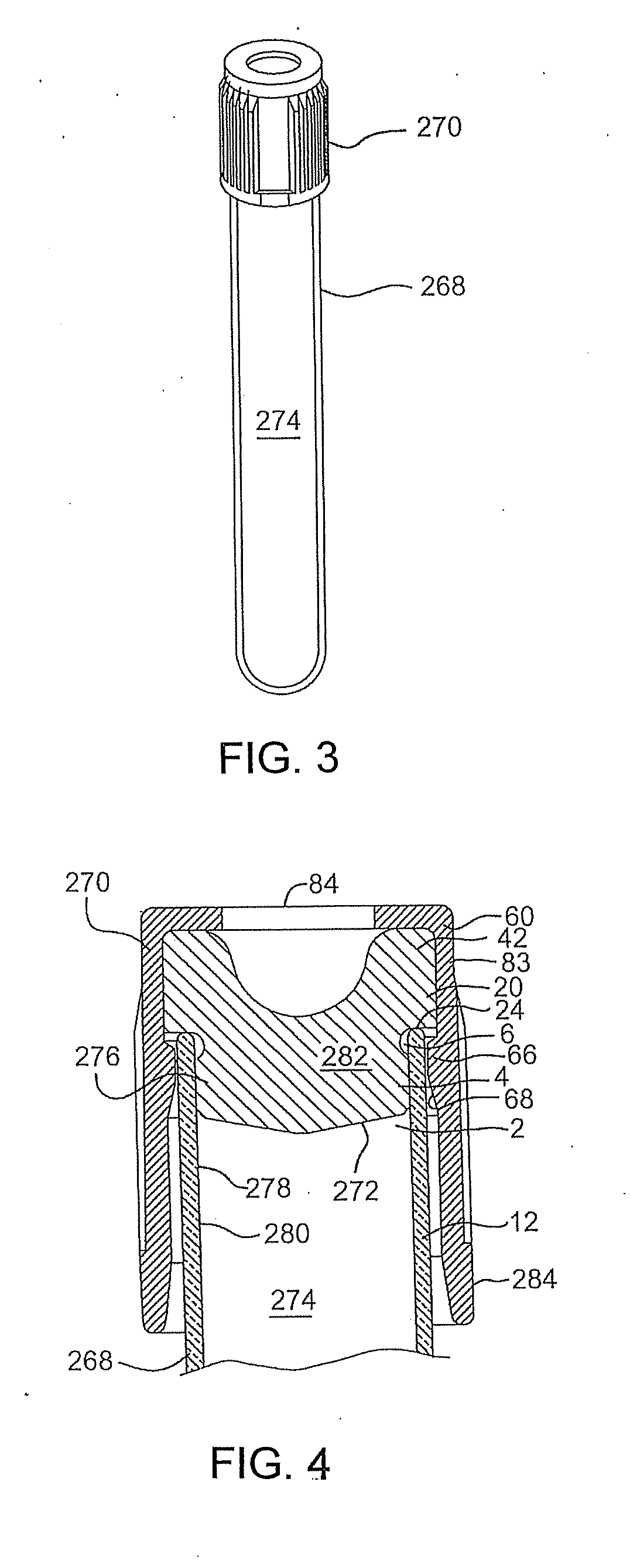

Vessels, contact surfaces, and coating and inspection apparatus and methods

ActiveUS20120252709A1Reduce transmission of fluidReduce transmissionInfusion syringesBearing componentsProduct gasSurface barrier

Methods for processing a contact surface, for example to provide a gas barrier or lubricity or to modify the wetting properties on a medical device, are disclosed. First and second PECVD or other contact surface processing stations or devices and a contact surface holder comprising a contact surface port are provided. An opening of the contact surface can be seated on the contact surface port. The interior contact surface of the seated contact surface can be processed via the contact surface port by the first and second processing stations or devices. contact surface barrier, lubricity and hydrophobic coatings and coated contact surfaces, for example syringes and medical sample collection tubes are disclosed. A contact surface processing system and contact surface inspection apparatus and methods are also disclosed.

Owner:SI02 MEDICAL PRODS

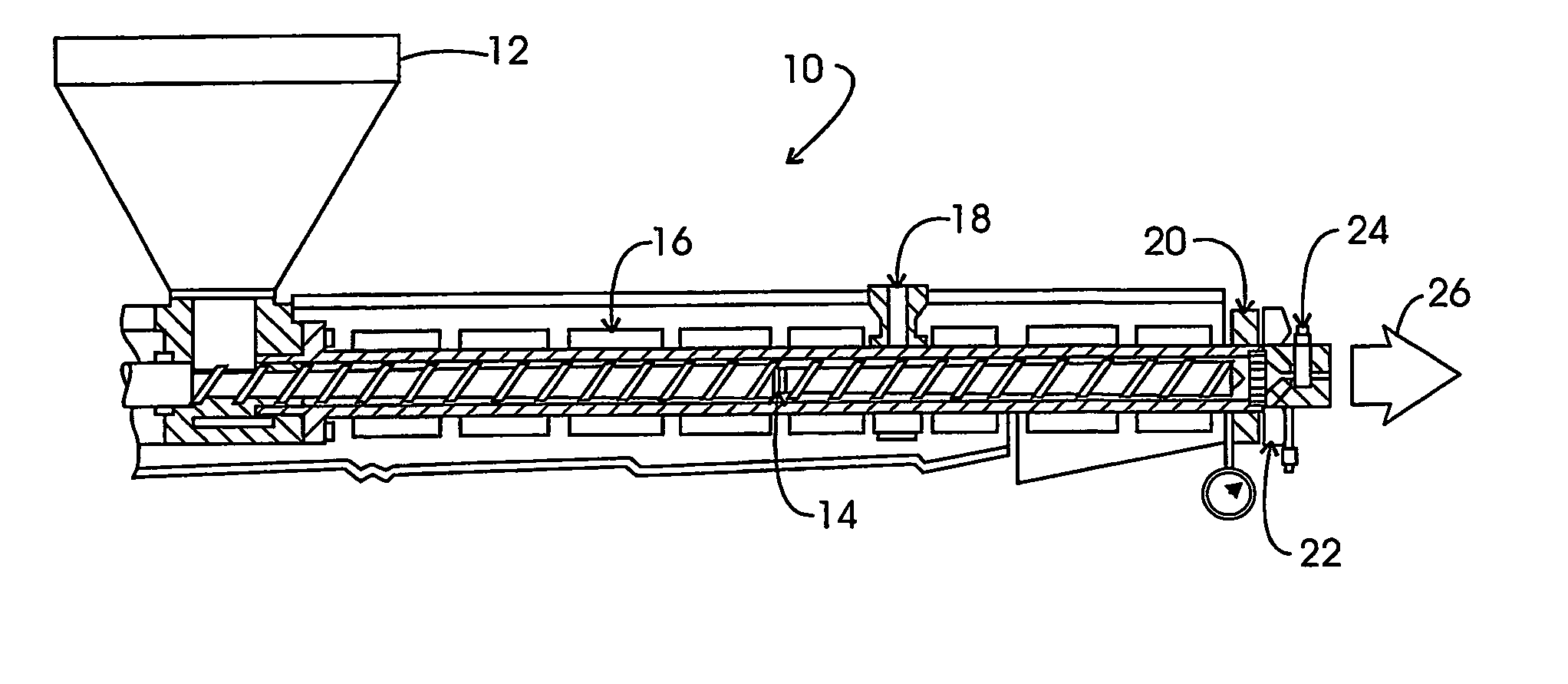

Methods for making bearings, races and components thereof having diamond and other superhard surfaces

InactiveUS20030019106A1Easy to polishReduce coefficient of frictionShaftsMetal-working apparatusPolycrystalline diamondHigh pressure

Method for making diamond bearings and diamond bearing components. Some methods include sintering diamond feedstock and a substrate under high pressure and high temperature to create a sintered polycrystalline diamond compact with a non-planar bearing and articulation surface. Various machining, grinding and polishing methods for finishing the compact are provided.

Owner:DIAMICRON

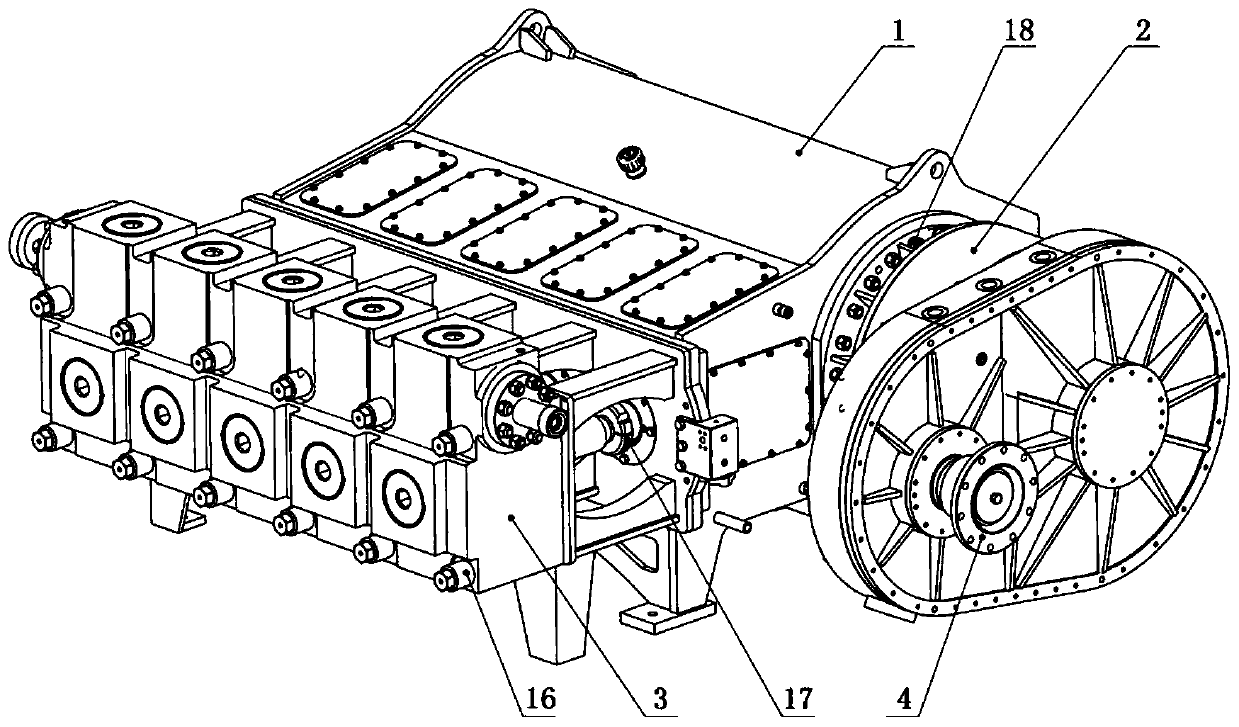

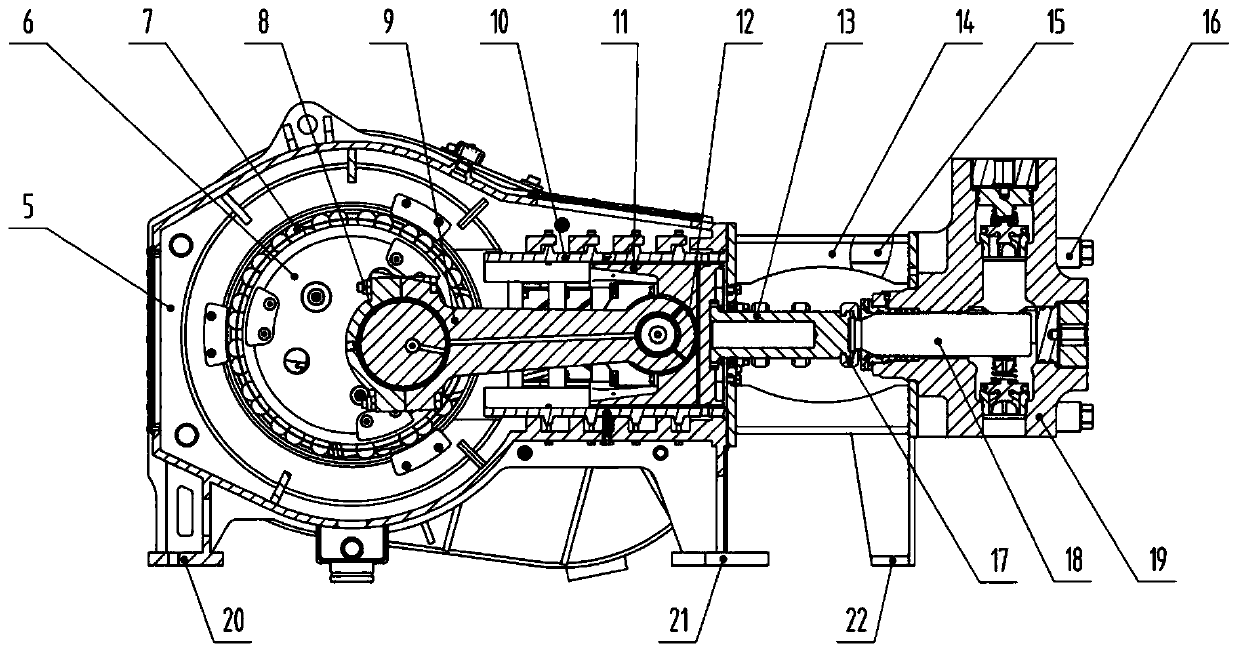

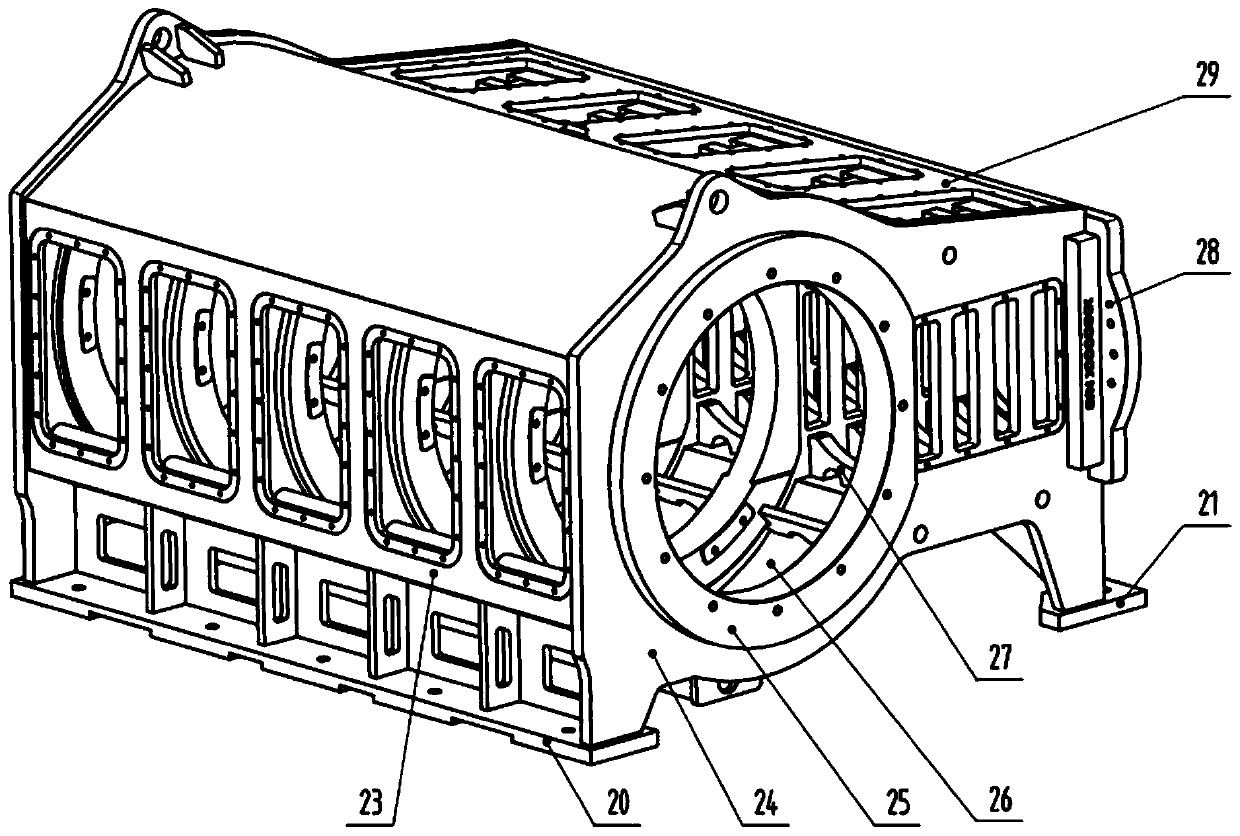

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

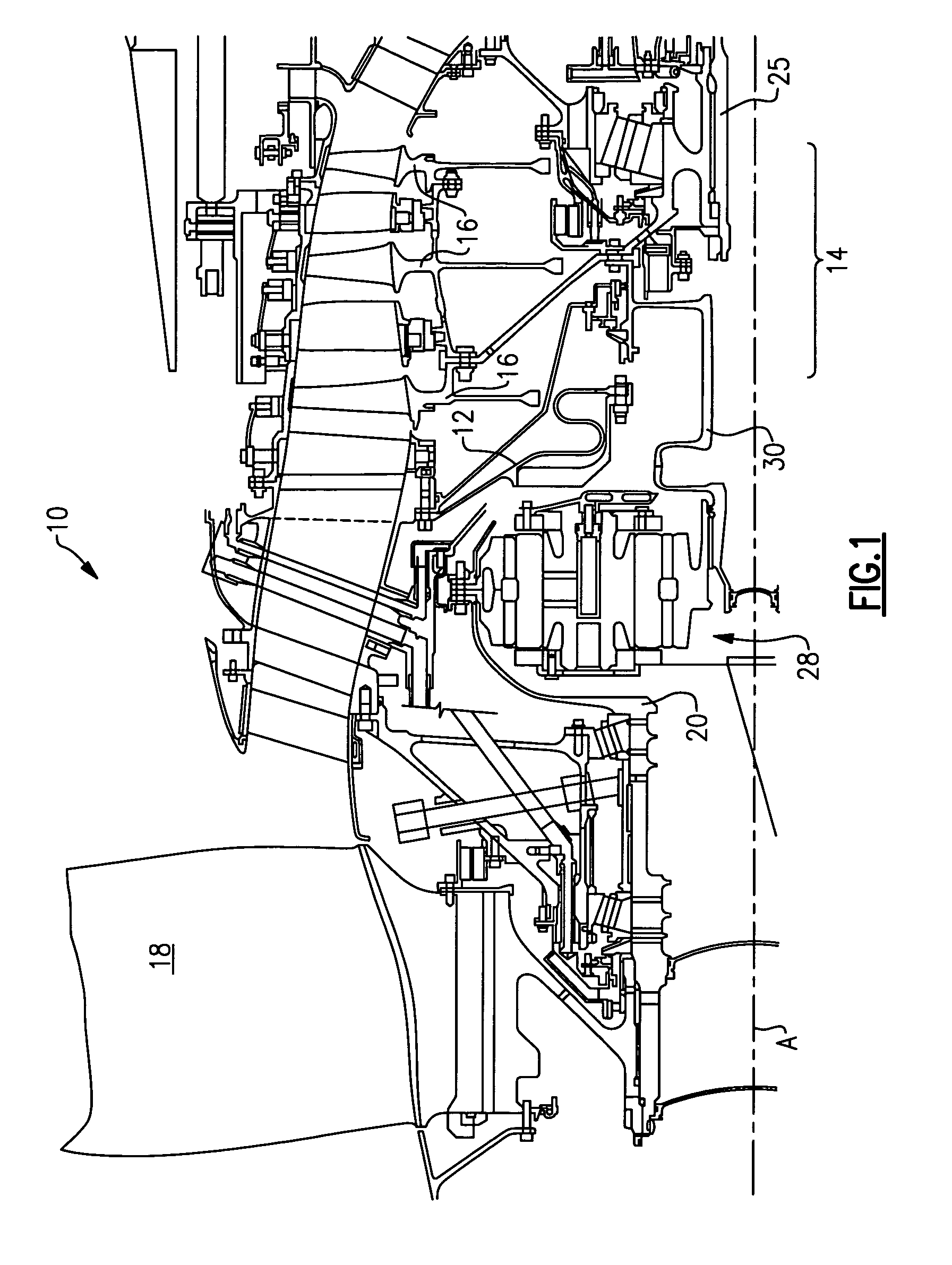

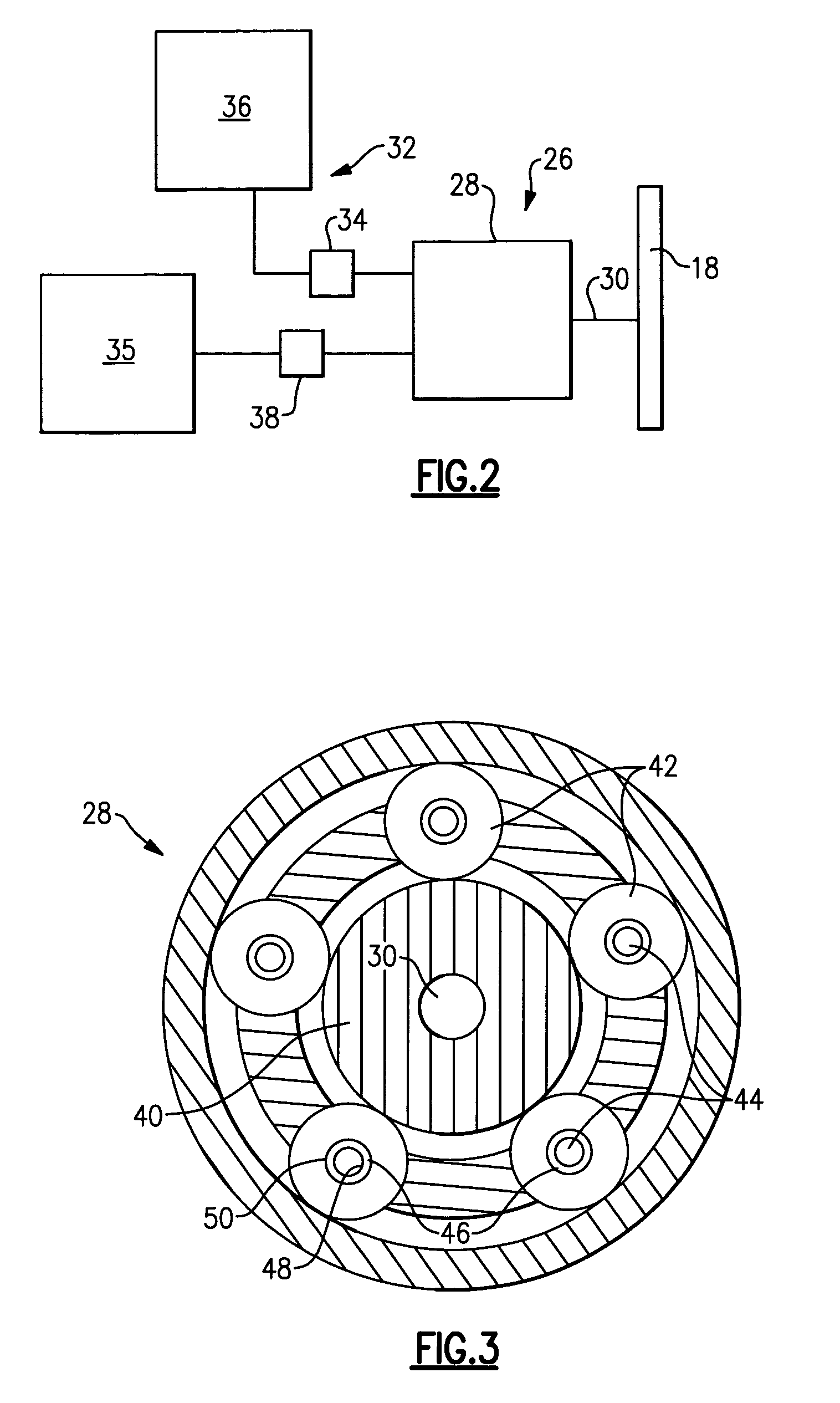

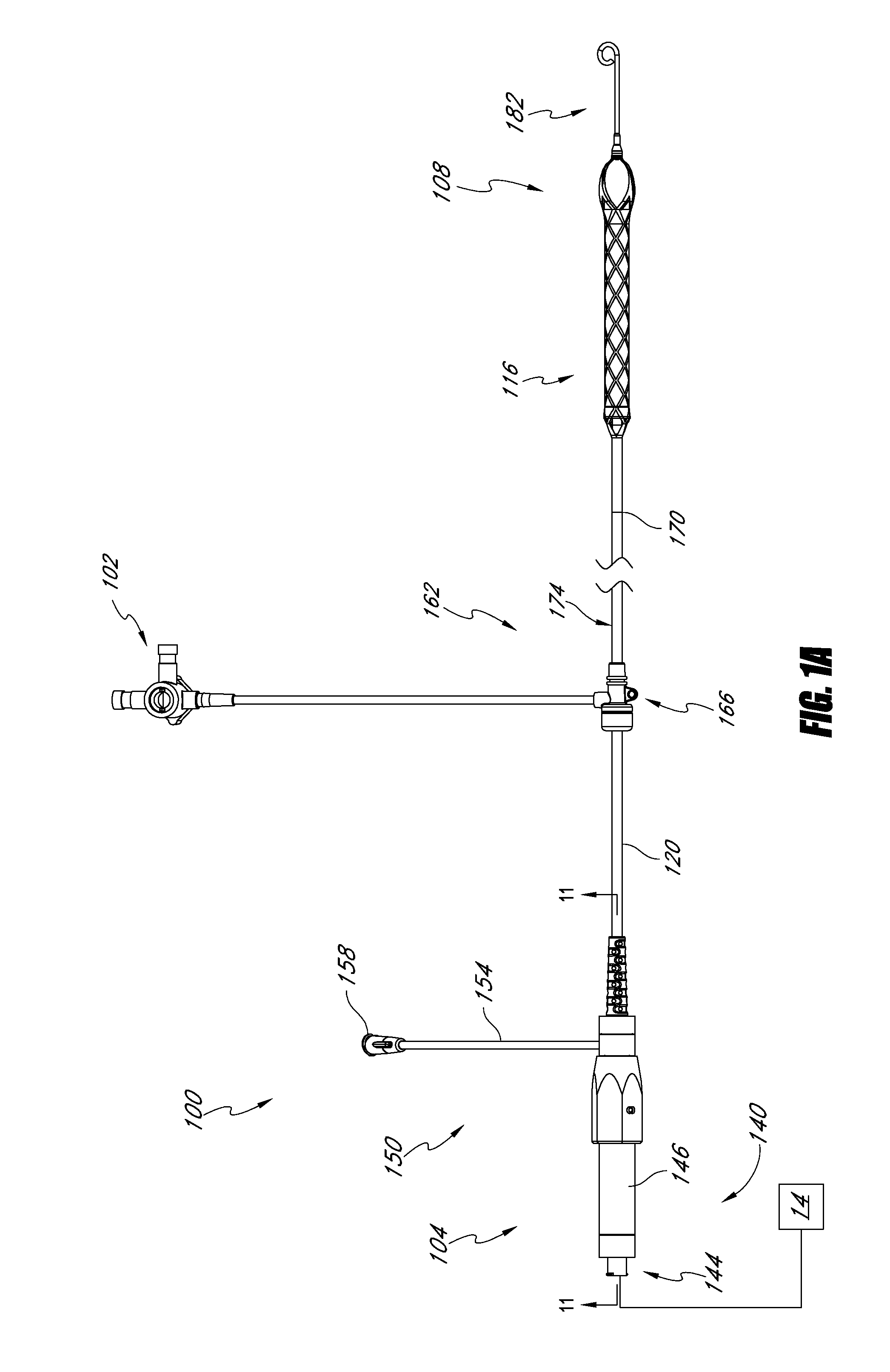

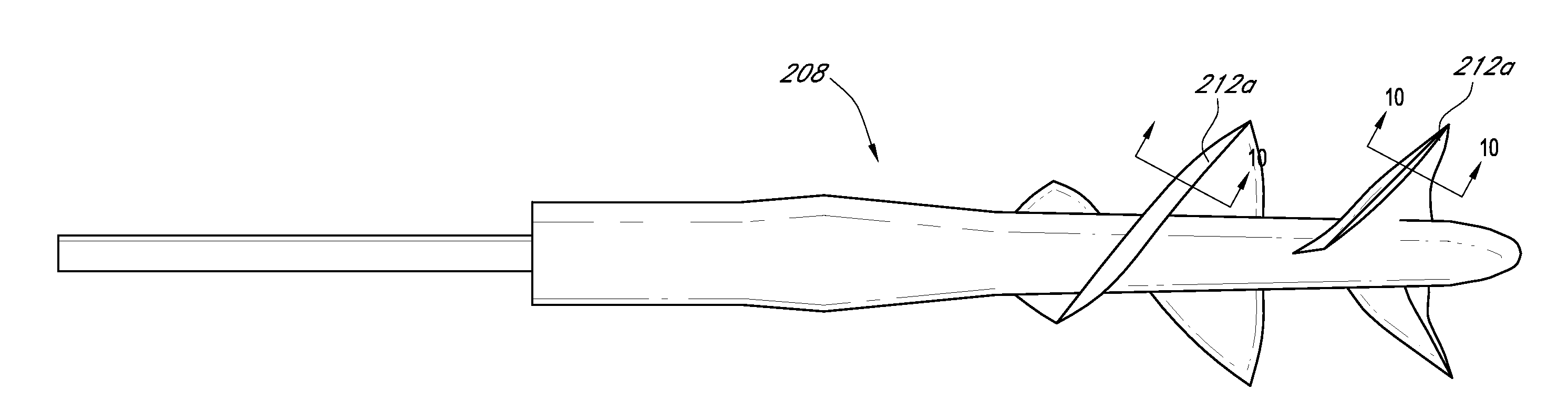

Percutaneous heart pump

ActiveUS20120172656A1Good biocompatibilityImprove connection securityShaftsBlood pumpsImpellerPull force

A heart pump and a catheter assembly therefor are provided that include a flexible catheter body having a proximal end and a distal end, the catheter body having a plurality of lumens therethrough. The catheter body can be sufficiently flexible to extend from a peripheral access to a patient's heart. The catheter assembly can also include an impeller assembly having an impeller and a housing. The impeller assembly can be coupled with the flexible catheter body such that a tensile force applied to opposite ends of the catheter assembly enhances the security of the connection between the catheter body and the impeller assembly.

Owner:PENN STATE RES FOUND +1

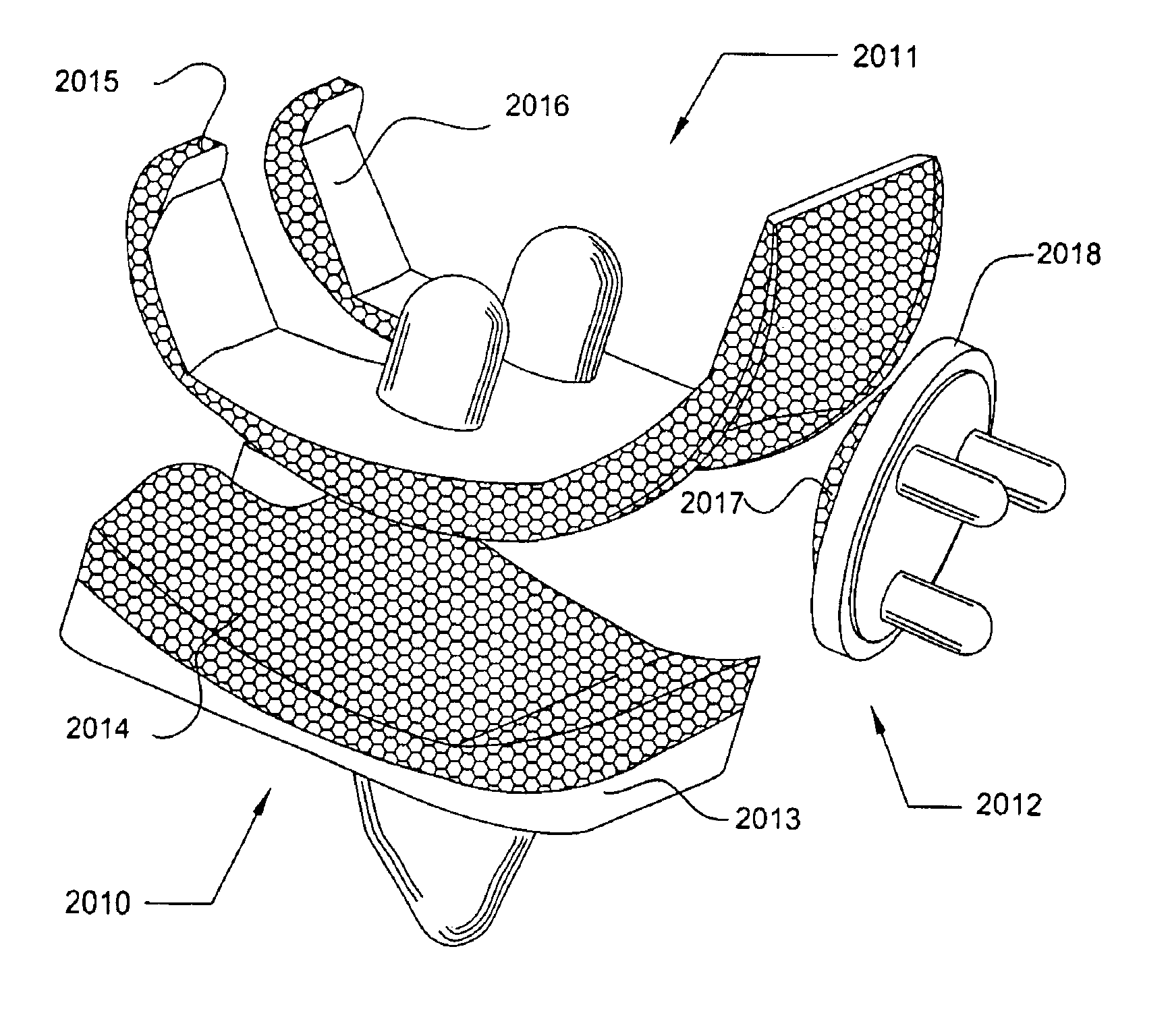

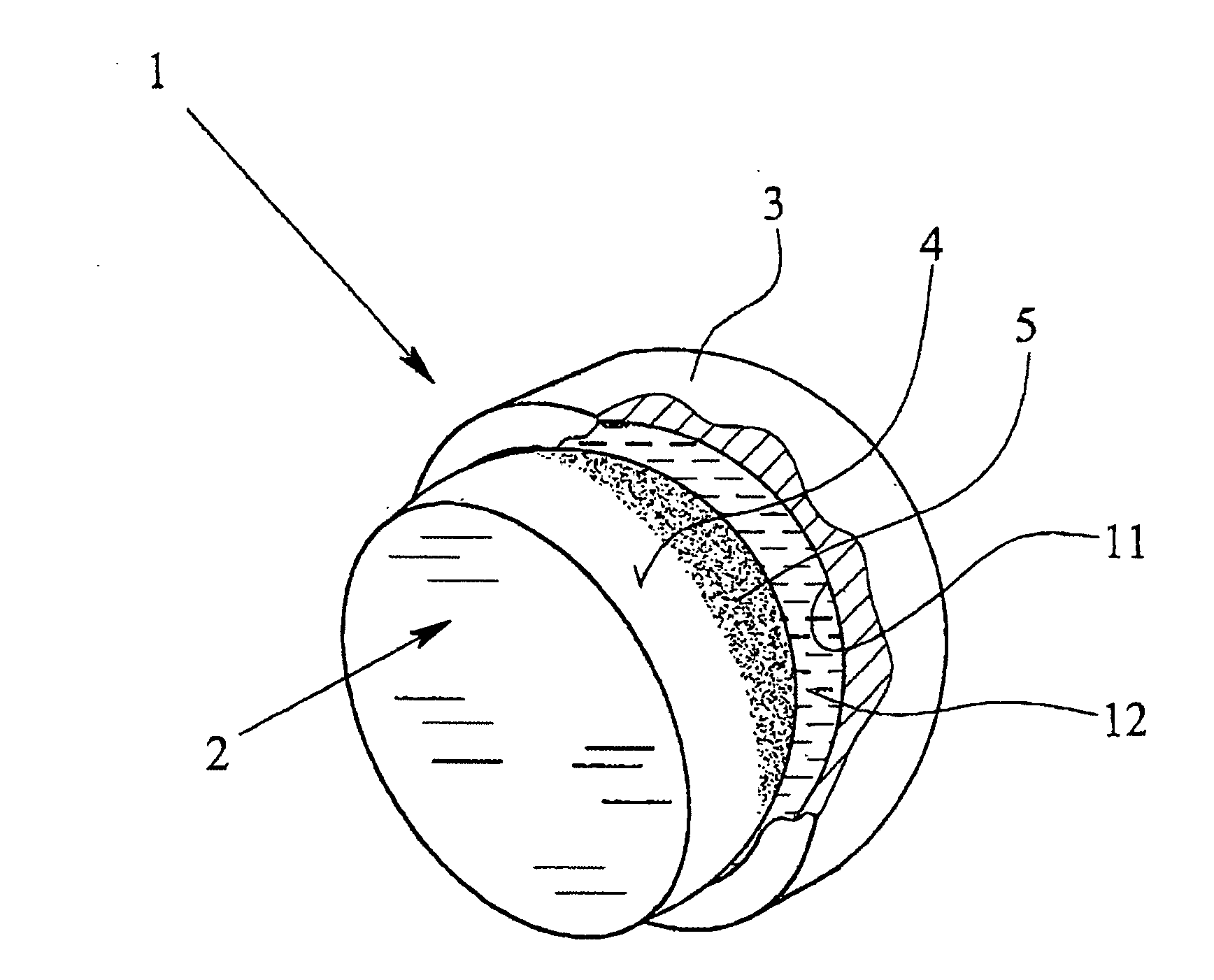

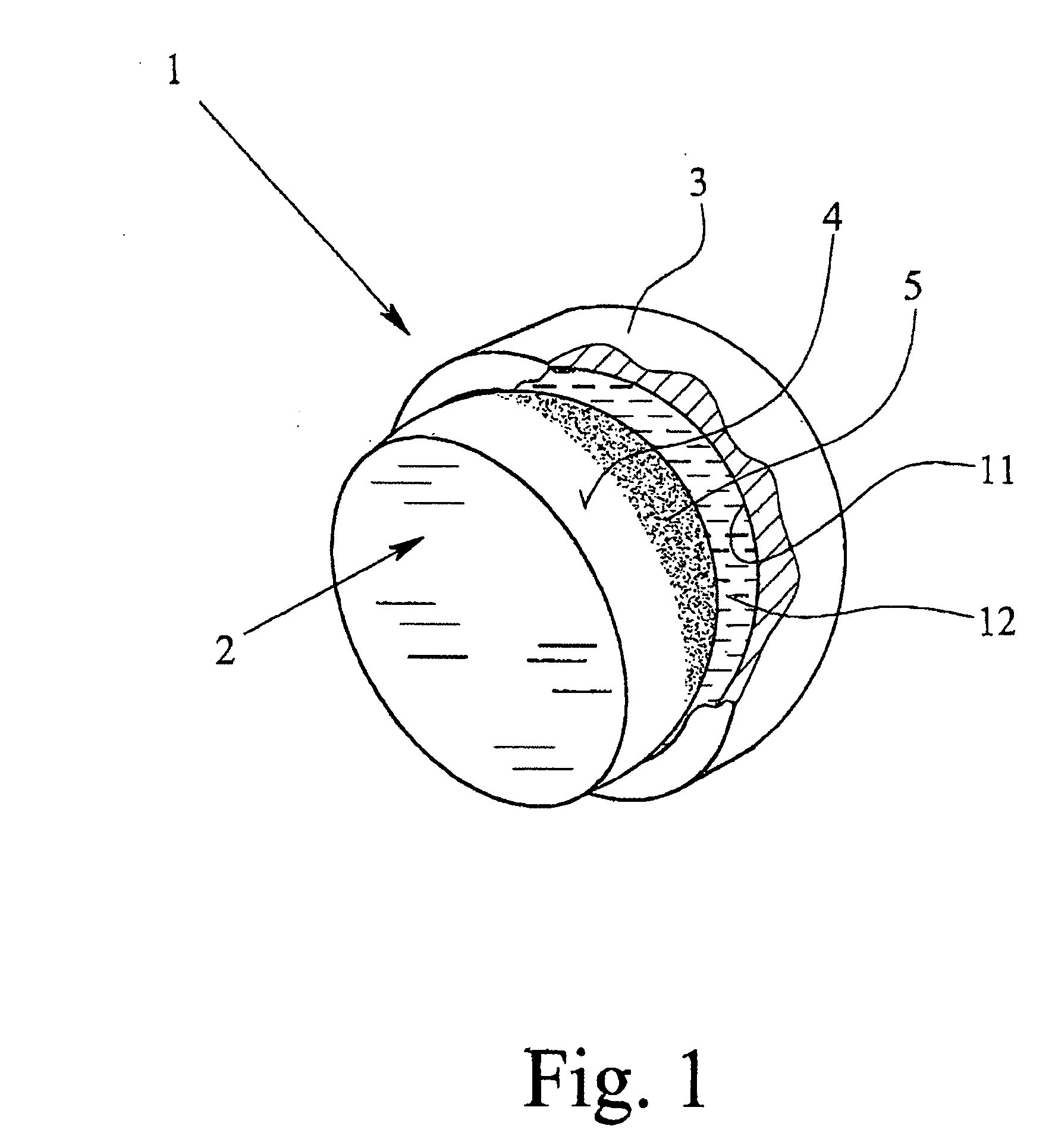

Prosthetic joint component having at least one sintered polycrystalline diamond compact articulation surface and substrate surface topographical features in said polycrystalline diamond compact

InactiveUS6676704B1Less disruptiveImprove overall utilizationFinger jointsWrist jointsArticular surfacesPolycrystalline diamond

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a prosthetic joint component having at least one sintered polycrystalline diamond compact articulation surface and substrate surface topographical features in said polycrystalline diamond compact.

Owner:DIAMICRON

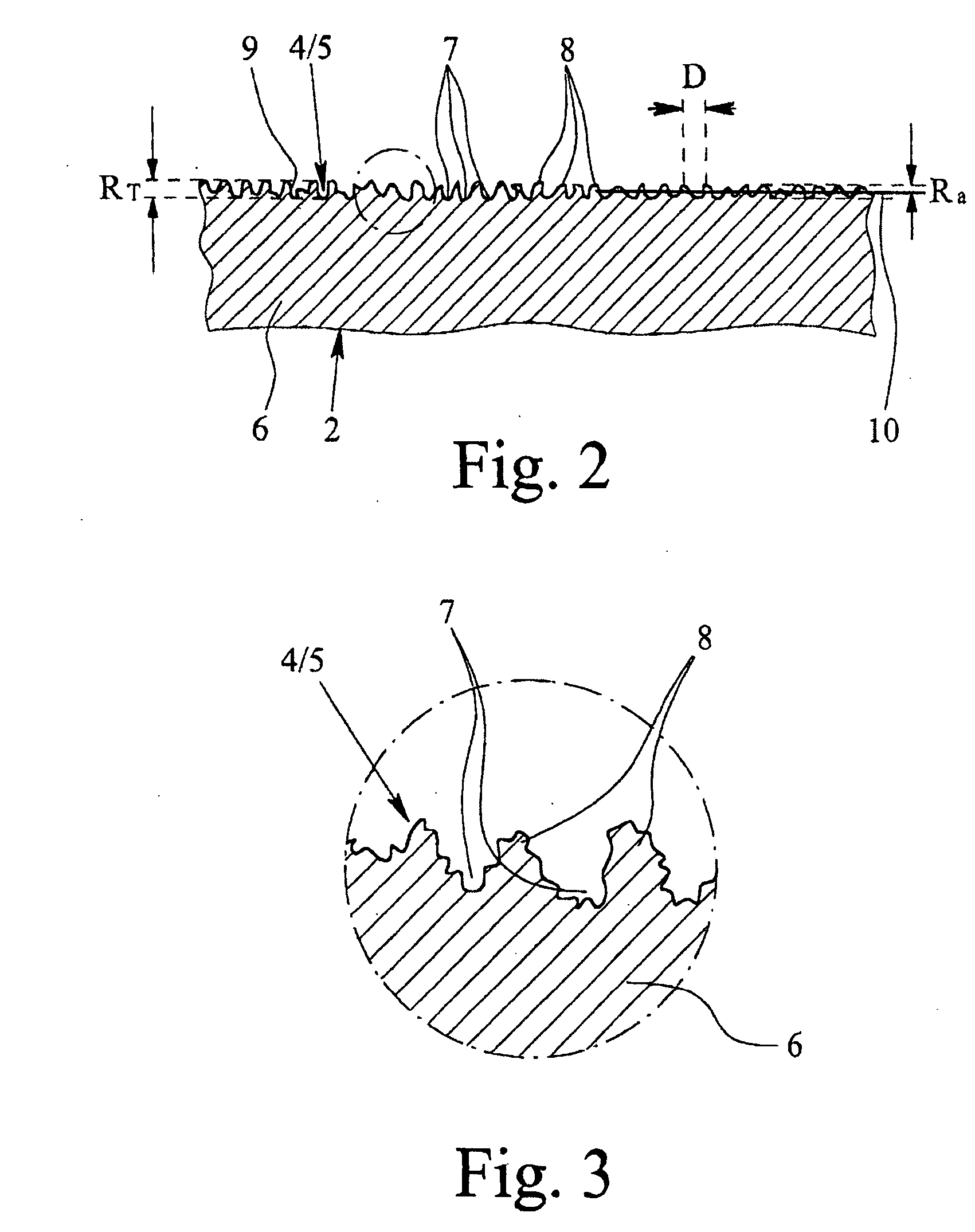

Bearing and composite structure

InactiveUS20050049716A1Minimize abrasionMinimize wearPharmaceutical delivery mechanismJoint implantsBearing surfaceMaterials science

A bearing, a composite structure, an implant and a method for producing a bearing with a micro-rough bearing surface are proposed. An improvement in the bearing properties—minimization of particle formation and reduction of friction—and a universally usable composite structure are achieved by the surface of the bearing or of the composite structure being roughened by etching and possibly provided with a coating, preferably consisting of plastic.

Owner:UNIV DUISBURG ESSEN

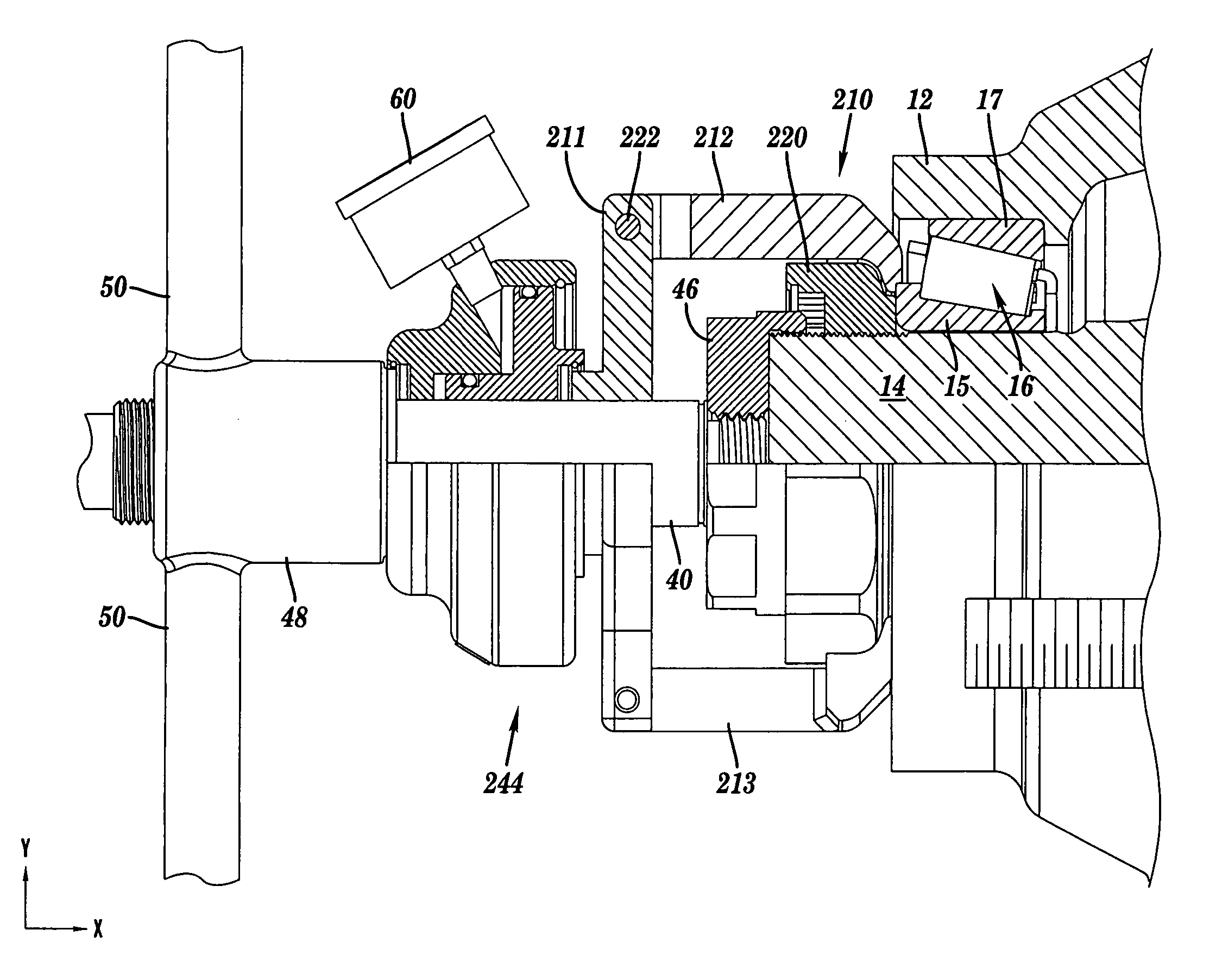

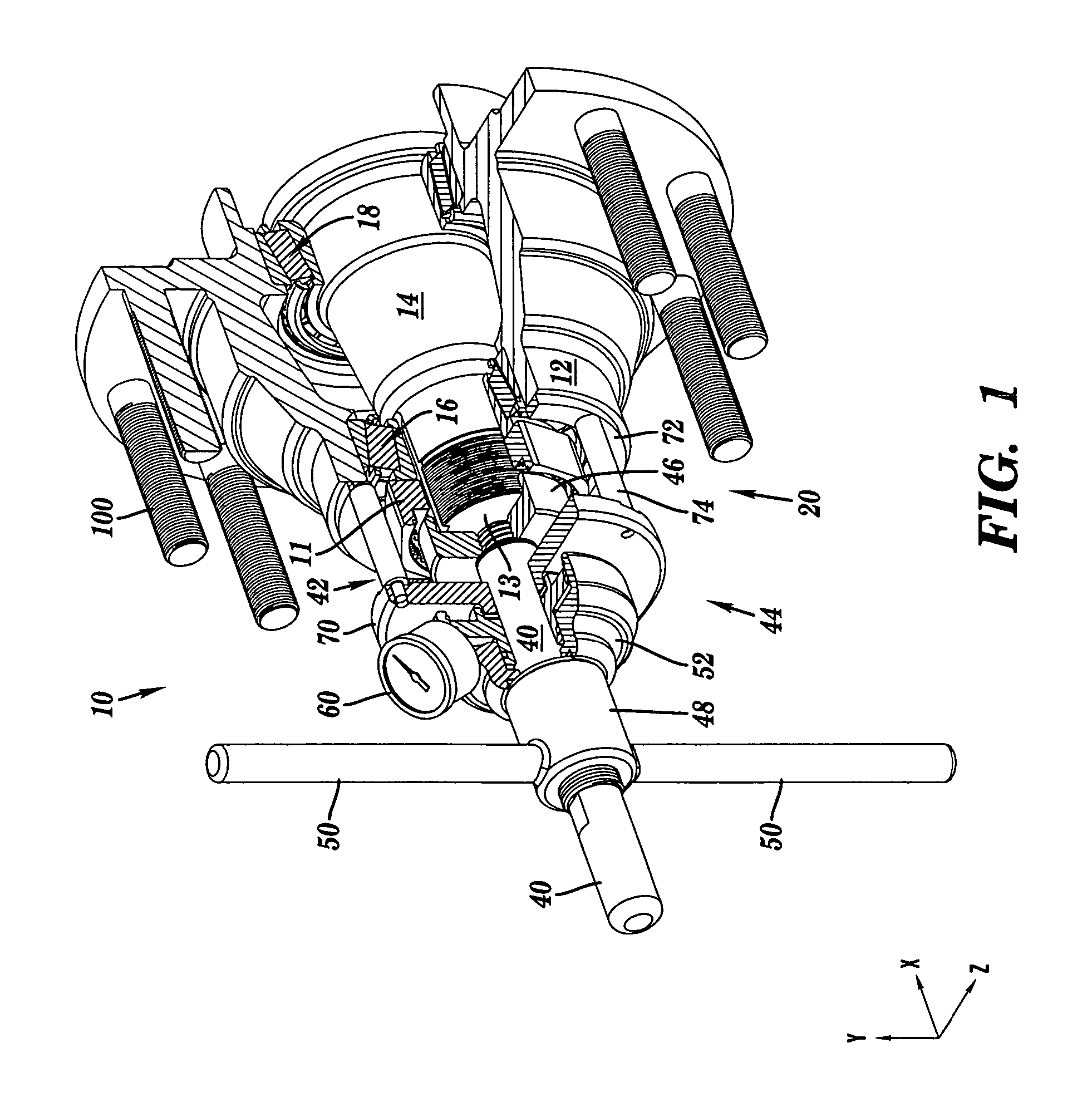

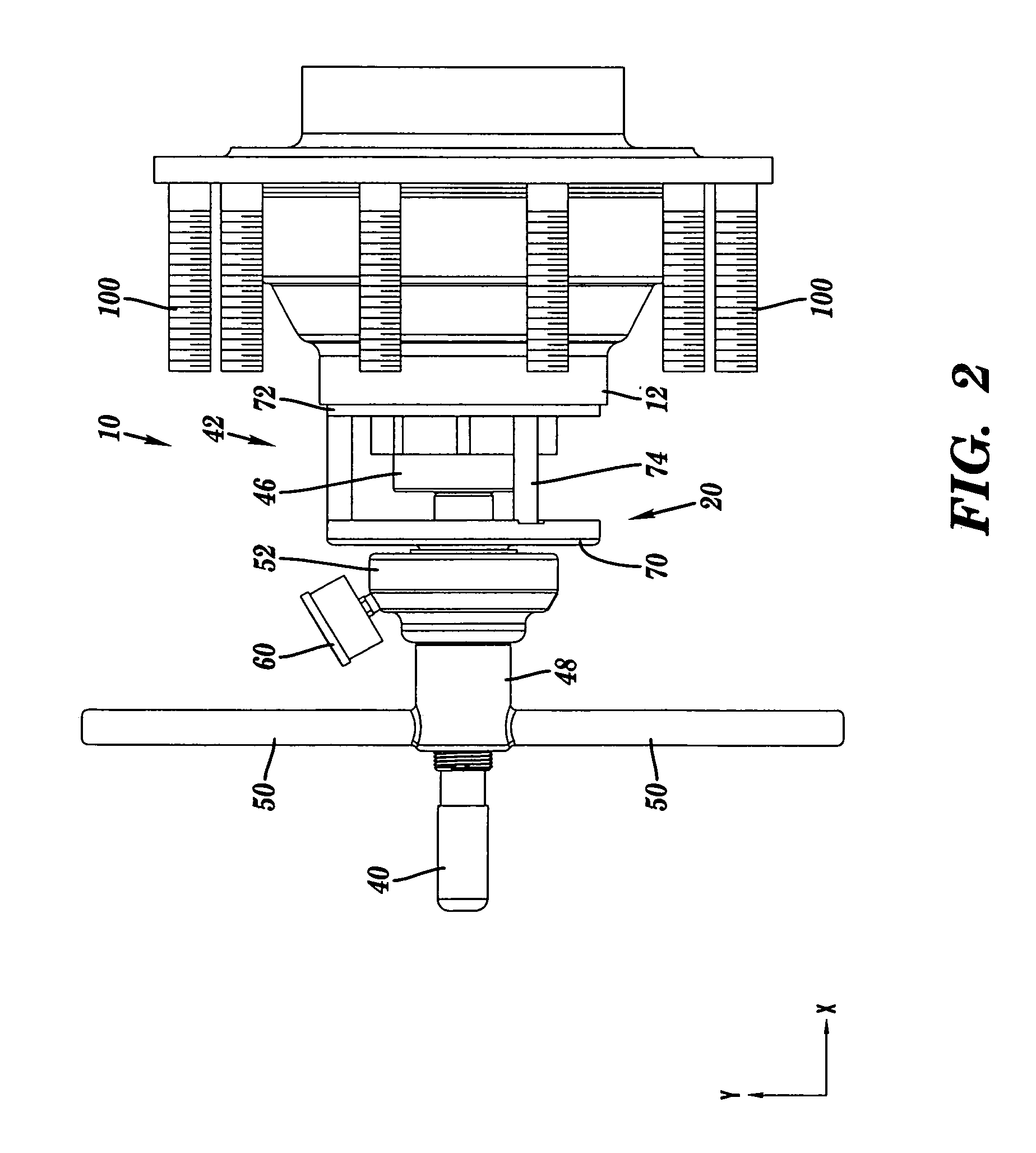

Apparatus for providing a load on a bearing, the bearing having an inner race mounted to a shaft and the bearing retained by a nut

Owner:TEMPER +1

Self-lubricating bearing and coating

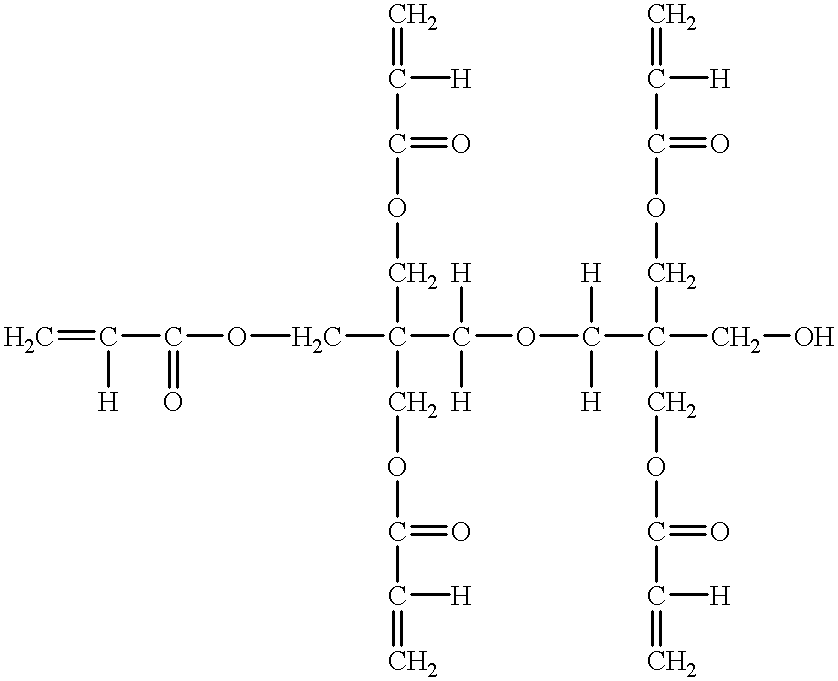

InactiveUS6180574B1Improve wear resistanceEasy bearing maintenanceNon-macromolecular adhesive additivesPretreated surfacesPentaerythritolAramides

A self-lubricating coating is provided which includes a mixture of a curable acrylate composition including a dipentaerythritol pentaacylate and a solid lubricant, such as polytetraflourethylenr. The curable acrylate composition may also include triethylene glycol dimethacrylate. An aramid pulp may also be added to the coating mixture. Also disclosed is a method of manufacturing the coating, and a self-lubricating bearing having the coating disposed on its surface.

Owner:REXNORD CORP

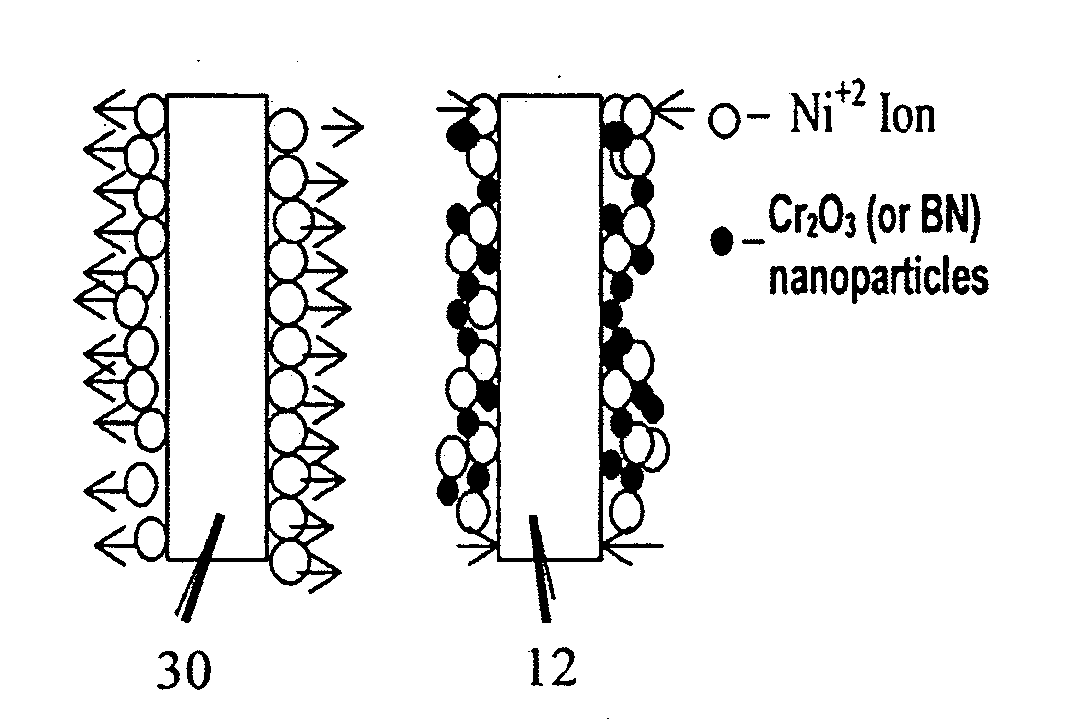

Process equipment wear surfaces of extended resistance and methods for their manufacture

A method for producing process equipment having a wear surface having extended resistance to one or more of abrasion, erosion, or corrosion, associated with fillers or solids processed by said process equipment includes applying to said process equipment wear surface a metal matrix coating filled with superabrasive particles. Diamond and cubic boron nitride superabrasive particles can fill the metal matrix, which can be a nickel coating.

Owner:DIAMOND INNOVATIONS INC

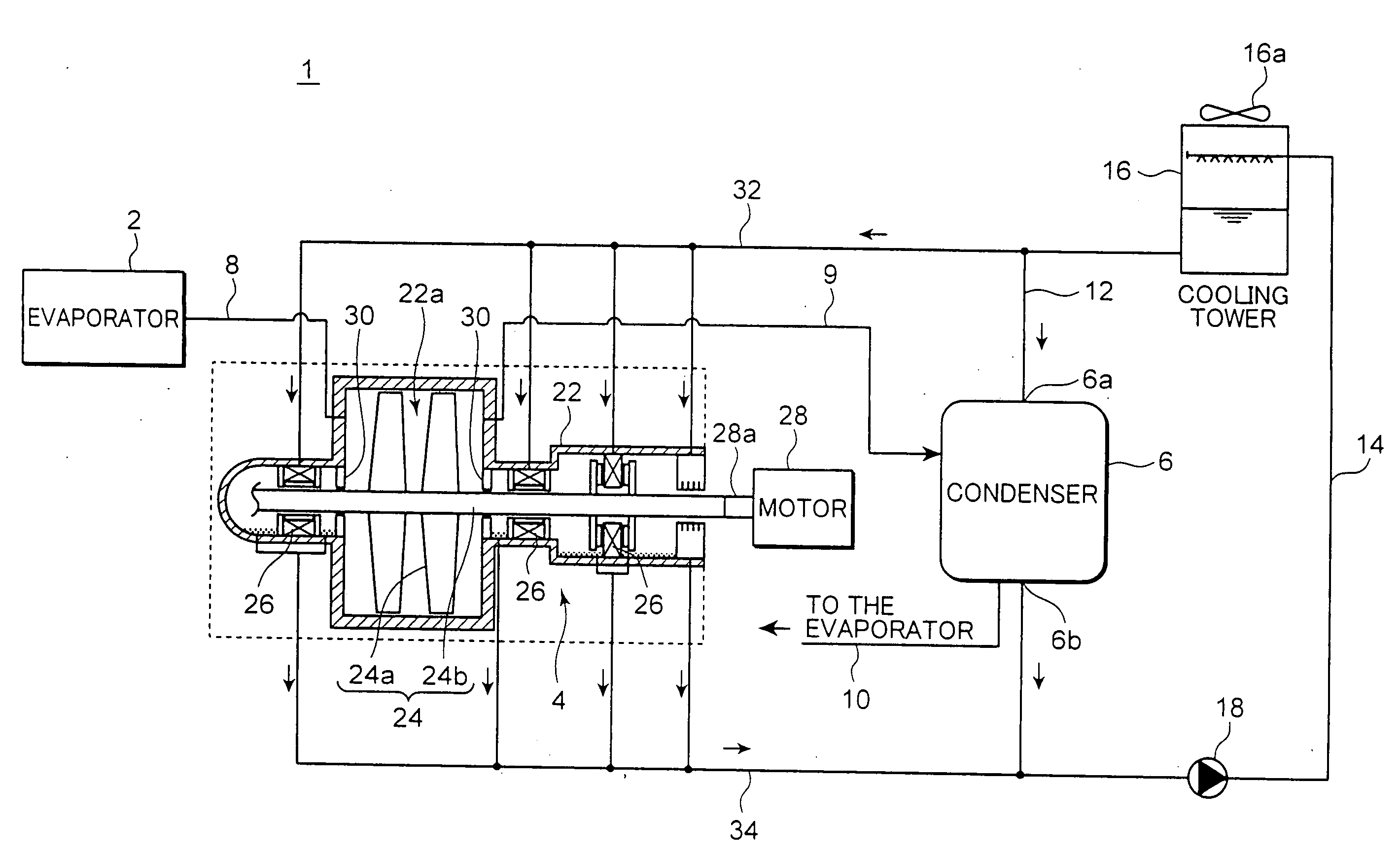

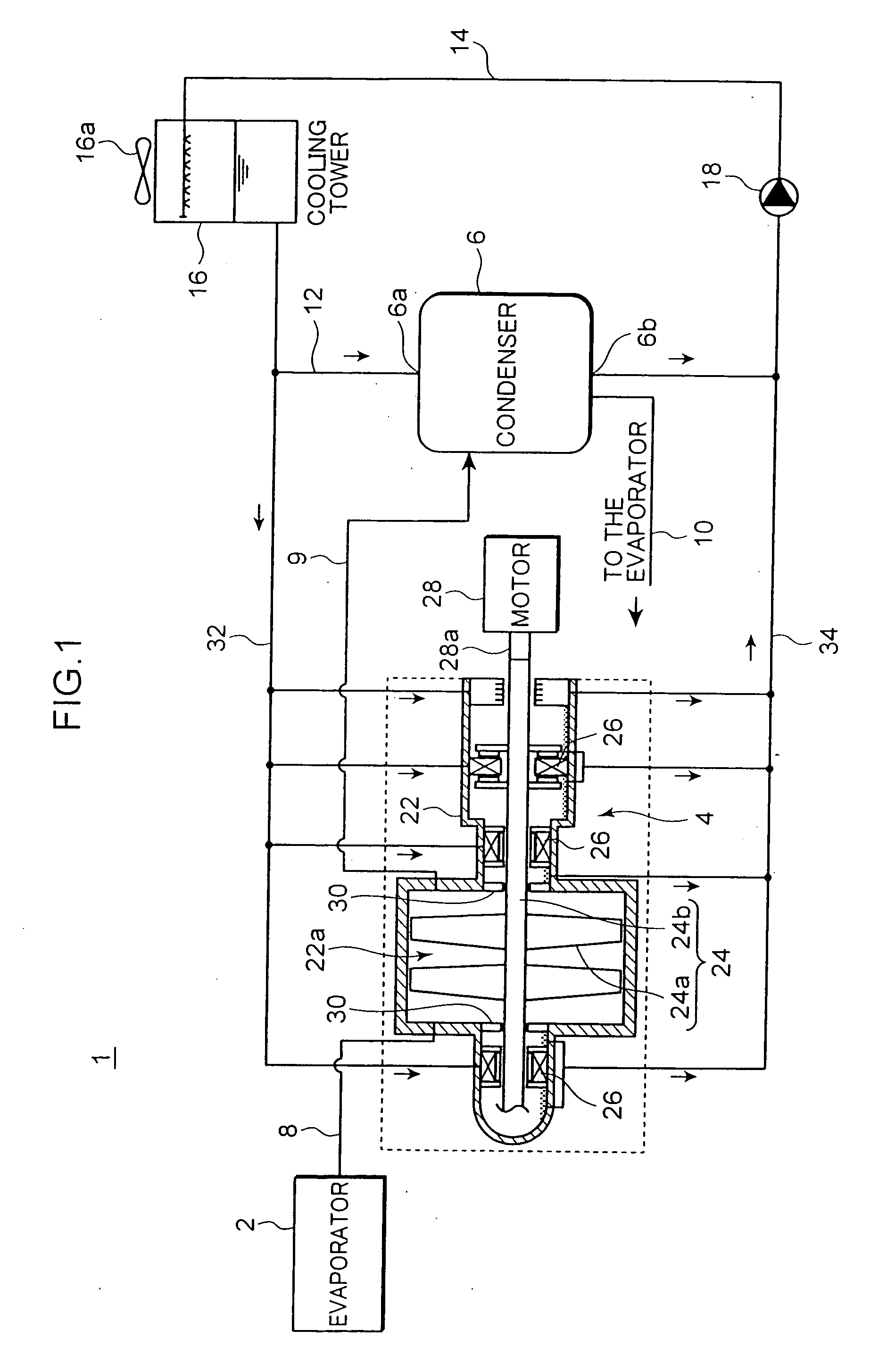

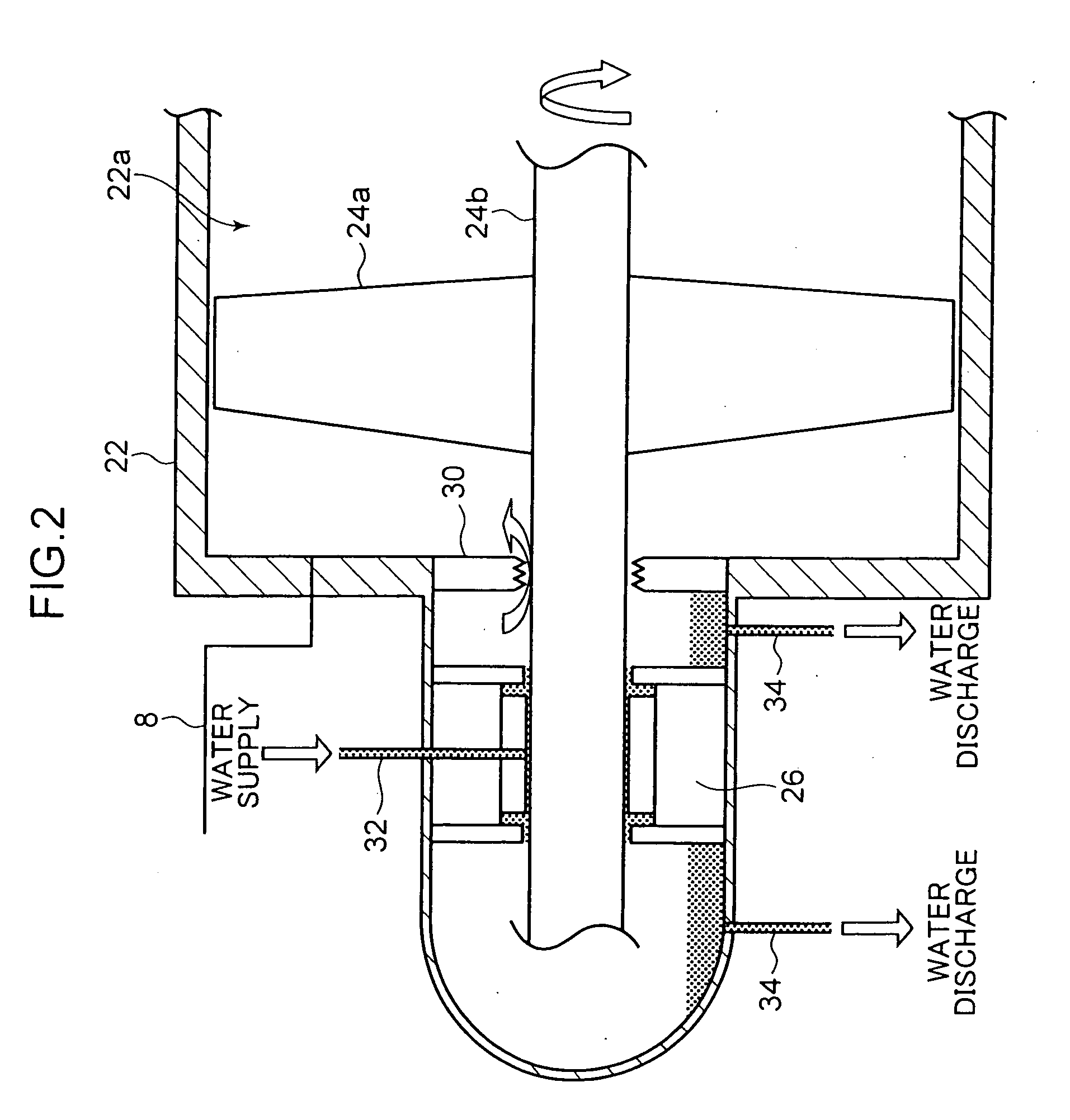

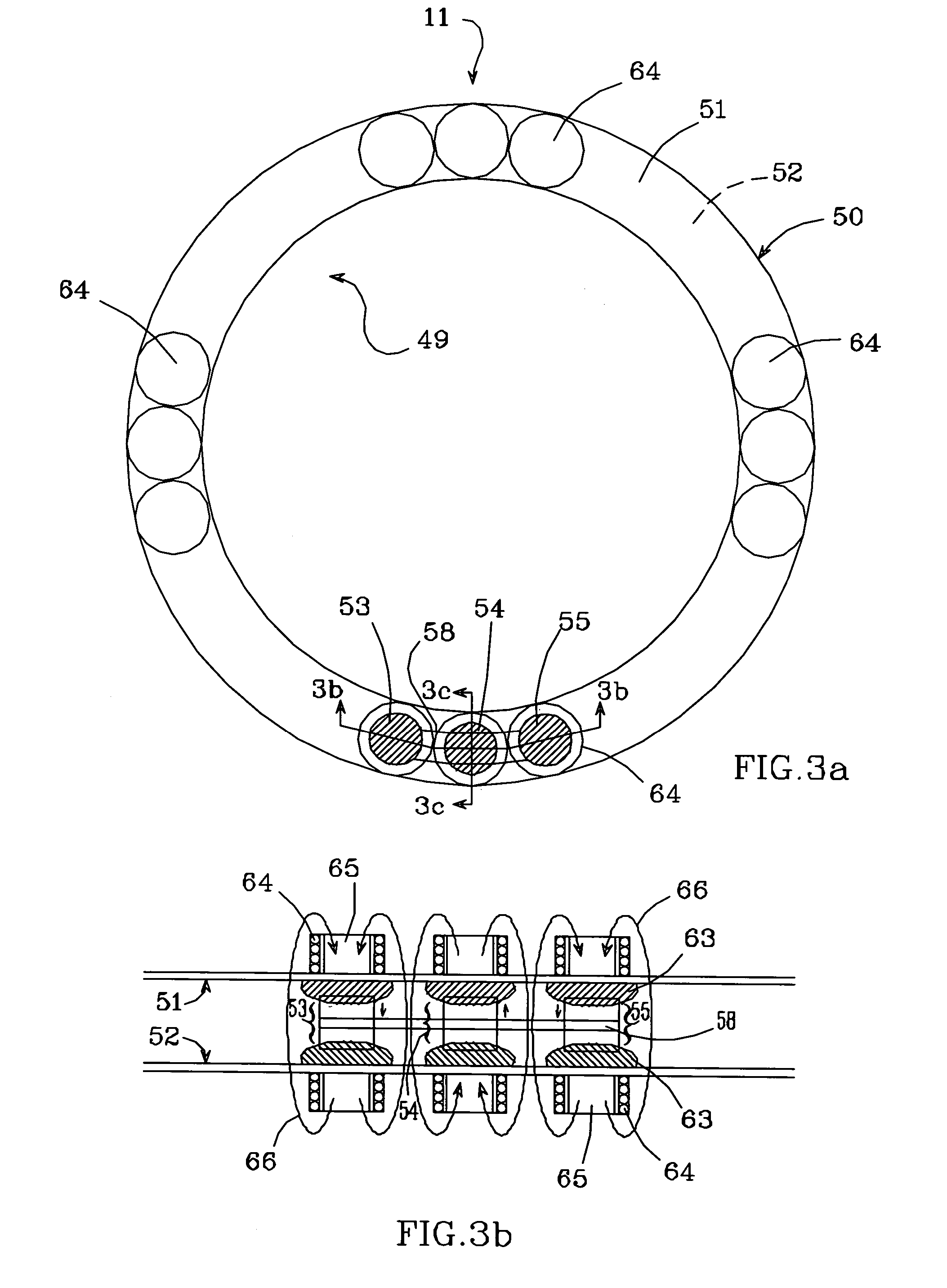

Compressor and refrigerating machine

ActiveUS20110174009A1Easy disposalSimple configurationCompressorPump componentsRotational axisWater vapor

A compressor and a refrigerating machine which enable an easy disposal of a lubricant, are friendly to the natural environment, and have simple configurations, are provided.The compressor which is used in a refrigerating machine including an evaporator and a condenser and adapted for compressing refrigerant gas evaporated in the evaporator to convey the compressed refrigerant gas to the condenser, includes: a motor; a housing having a compression chamber inside; a rotary member which has a rotating shaft and is rotated by a driving force of the motor so as to compress water vapor serving as the refrigerant gas in the compression chamber; a bearing for supporting the rotating shaft of the rotary member in the housing; and a lubricant supplier for supplying water serving as a lubricant to the bearing.

Owner:THE TOKYO ELECTRIC POWER CO INC +3

Lubricant-hard-ductile nanocomposite coatings and methods of making

InactiveUS20090155479A1Liquid surface applicatorsMolten spray coatingNanocomposite coatingWear resistance

Lubricant-hard-ductile composite coating compositions and methods of making the same are provided. In embodiment, a composite coating composition comprises: a lubricant phase for providing lubrication to a surface; a hard ceramic phase for providing structural integrity and wear resistance to the surface; and a ductile metal phase for providing ductility to the surface.

Owner:INFRAMAT CORPORATION

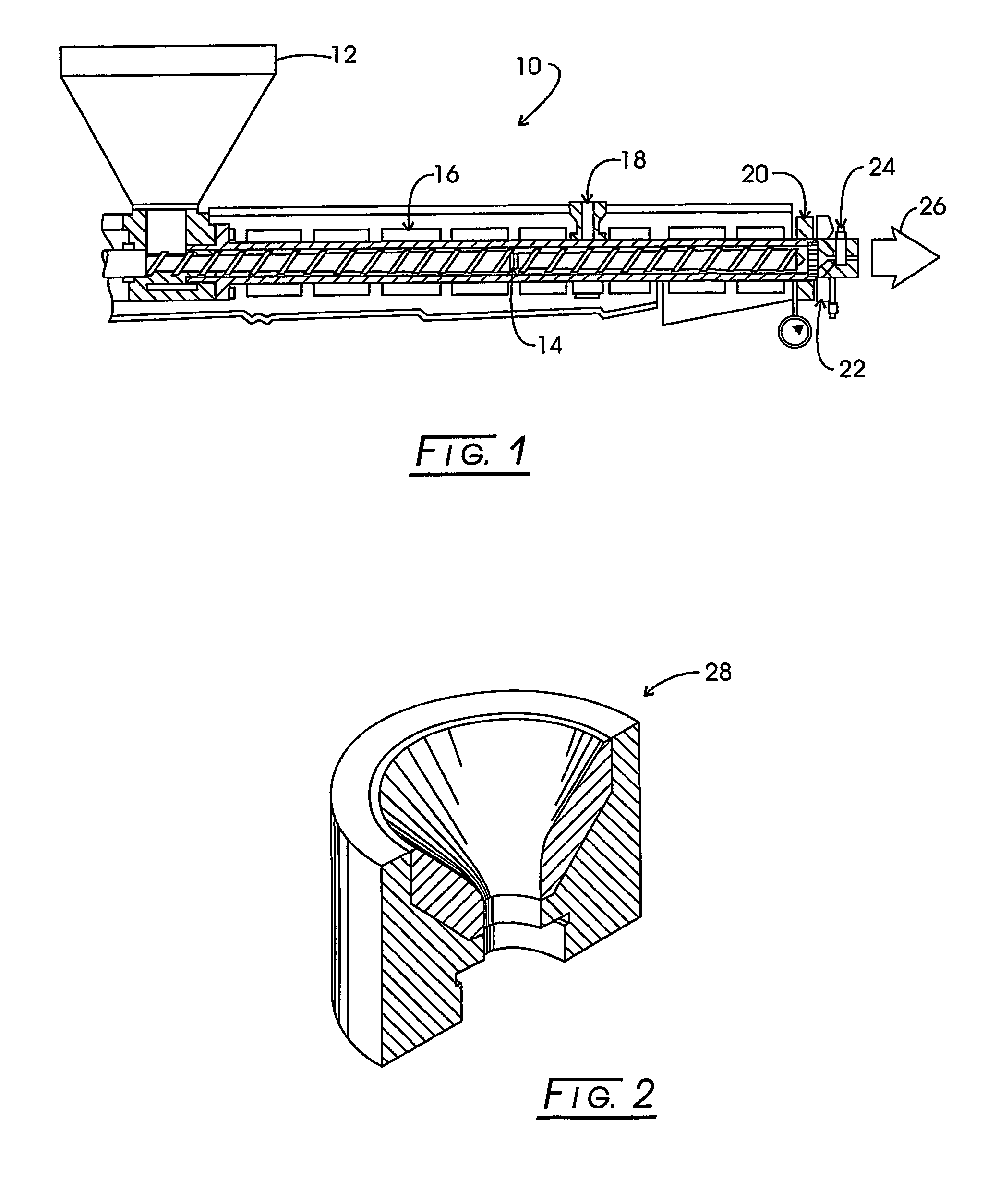

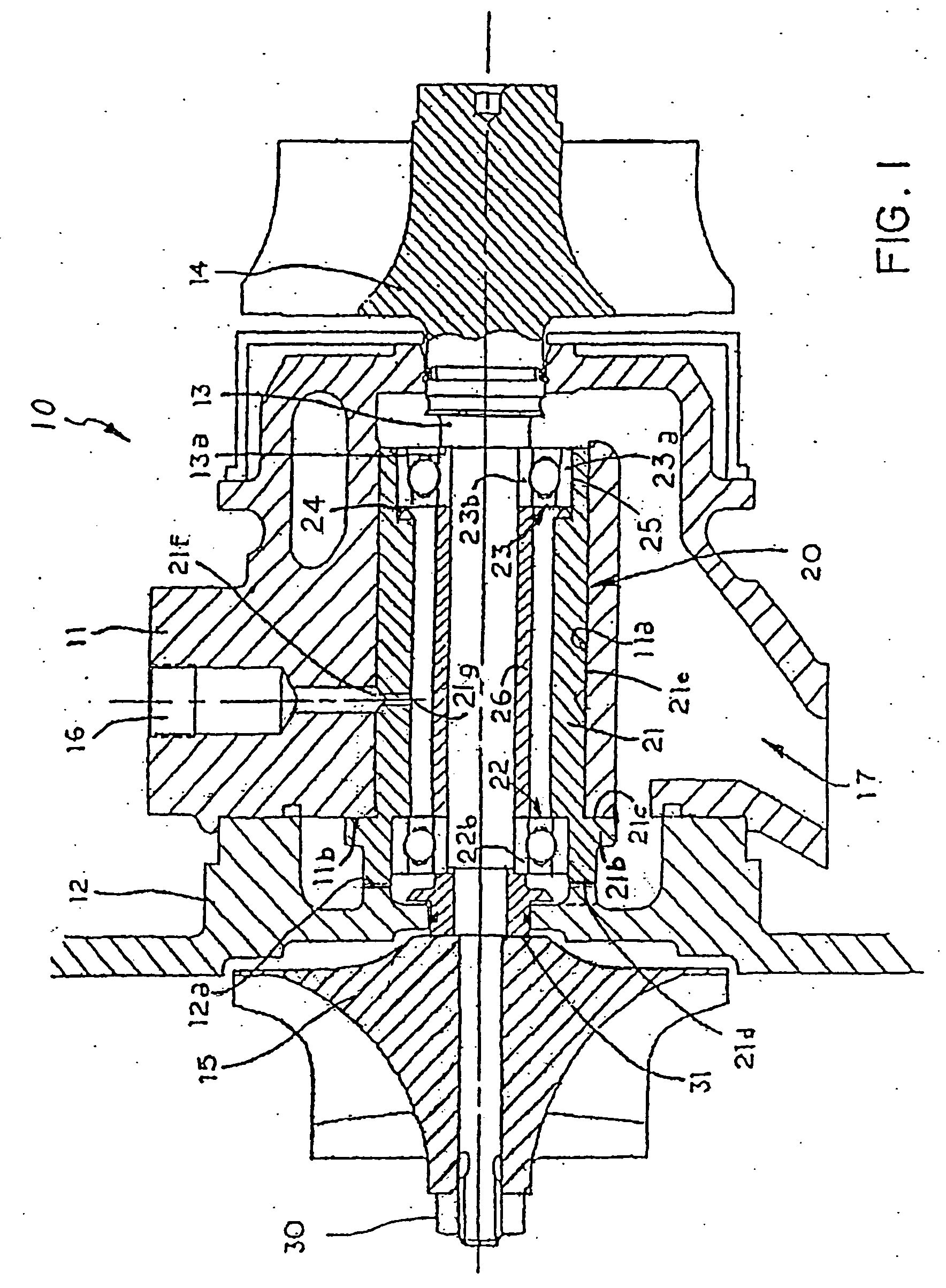

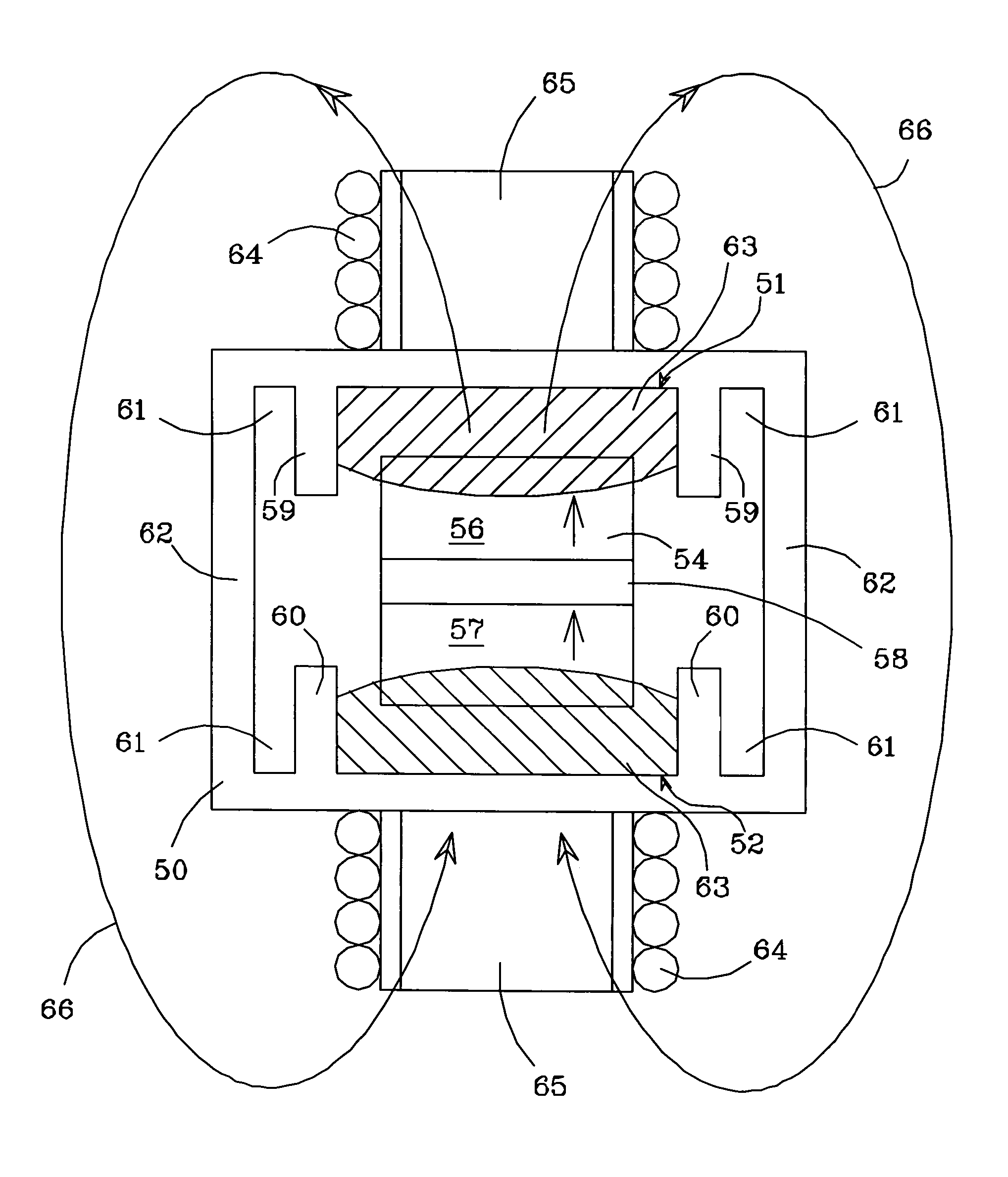

Bearing systems for high-speed rotating machinery

InactiveUS20080087018A1Improve performanceMaintain integrityRolling contact bearingsShaftsBall bearingTurbocharger

Bearing systems for high speed rotating shafts, such as turbocharger shafts, include a first ball bearing in one end of an elongated cylinder capable of carrying axial thrust in both directions and a second ball bearing in the opposite end of the elongated cylinder with its outer race slideably mounted in the cylinder against the biasing force of a preload spring. The second ball bearing is free to move axial with the shaft upon axially expansion of the shaft when exposed to high temperature. The inner races of the ball bearings are clamped to and rotate with the shaft as part of the rotating assembly.

Owner:DELGADO LAUREN N

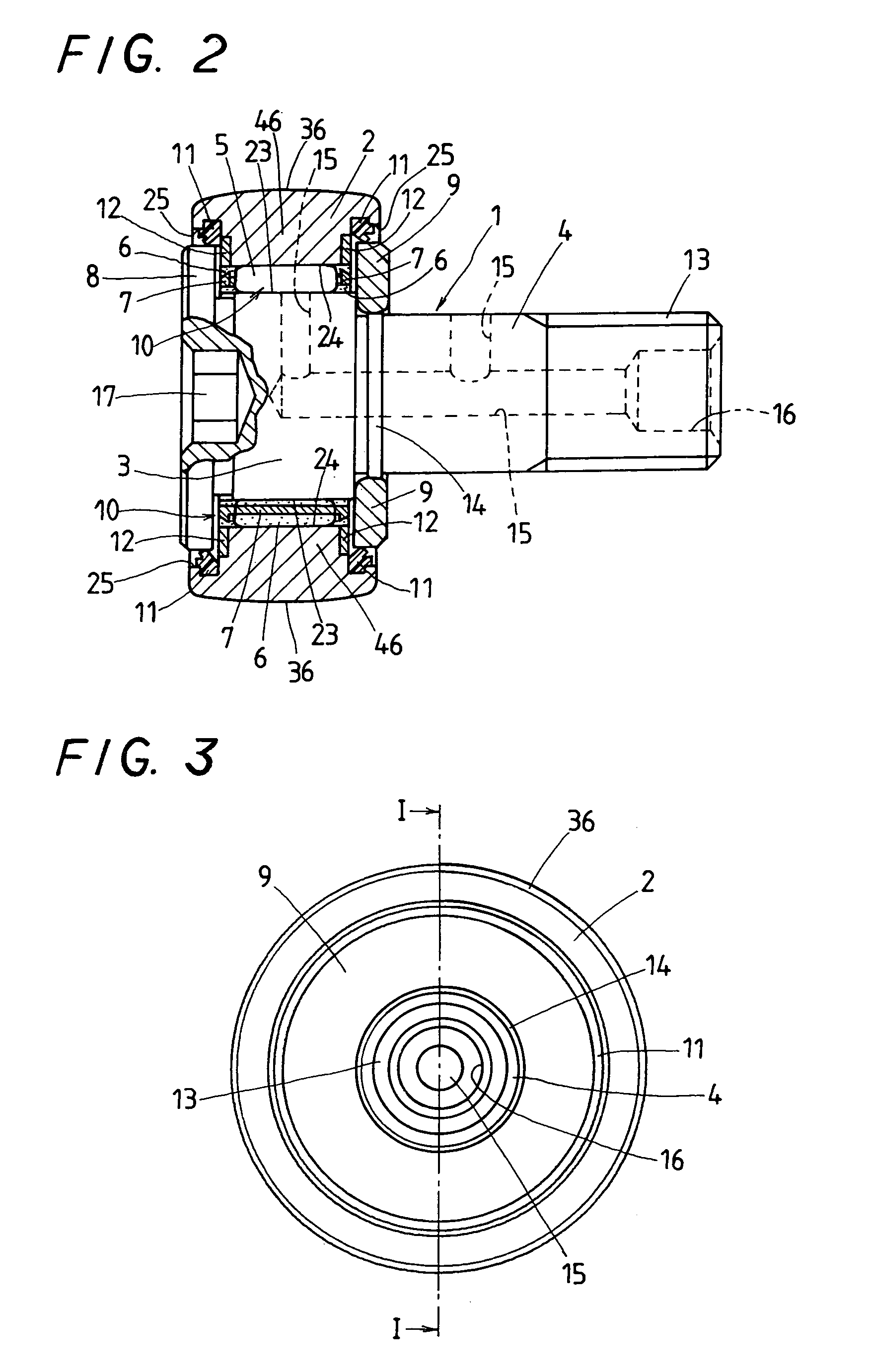

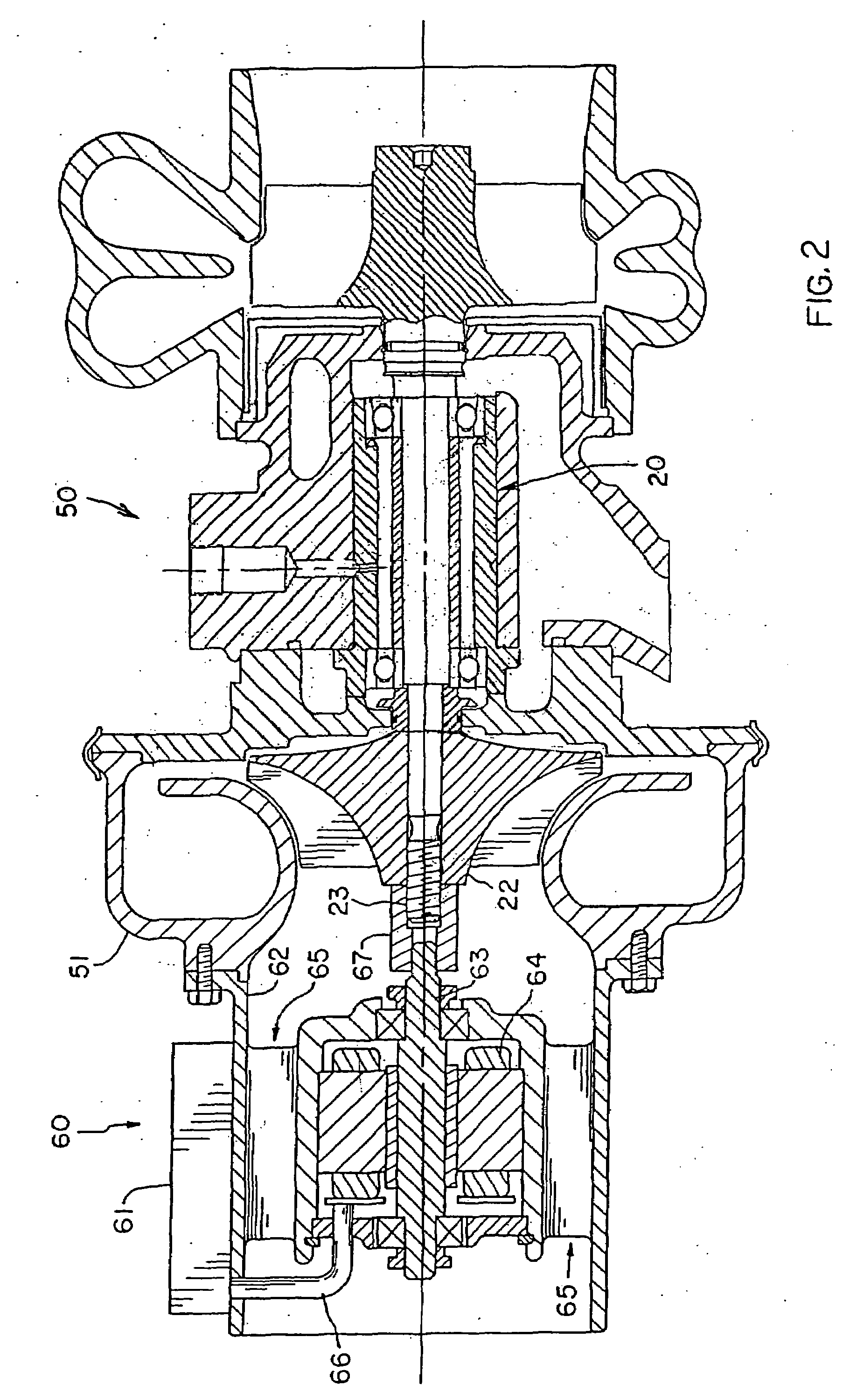

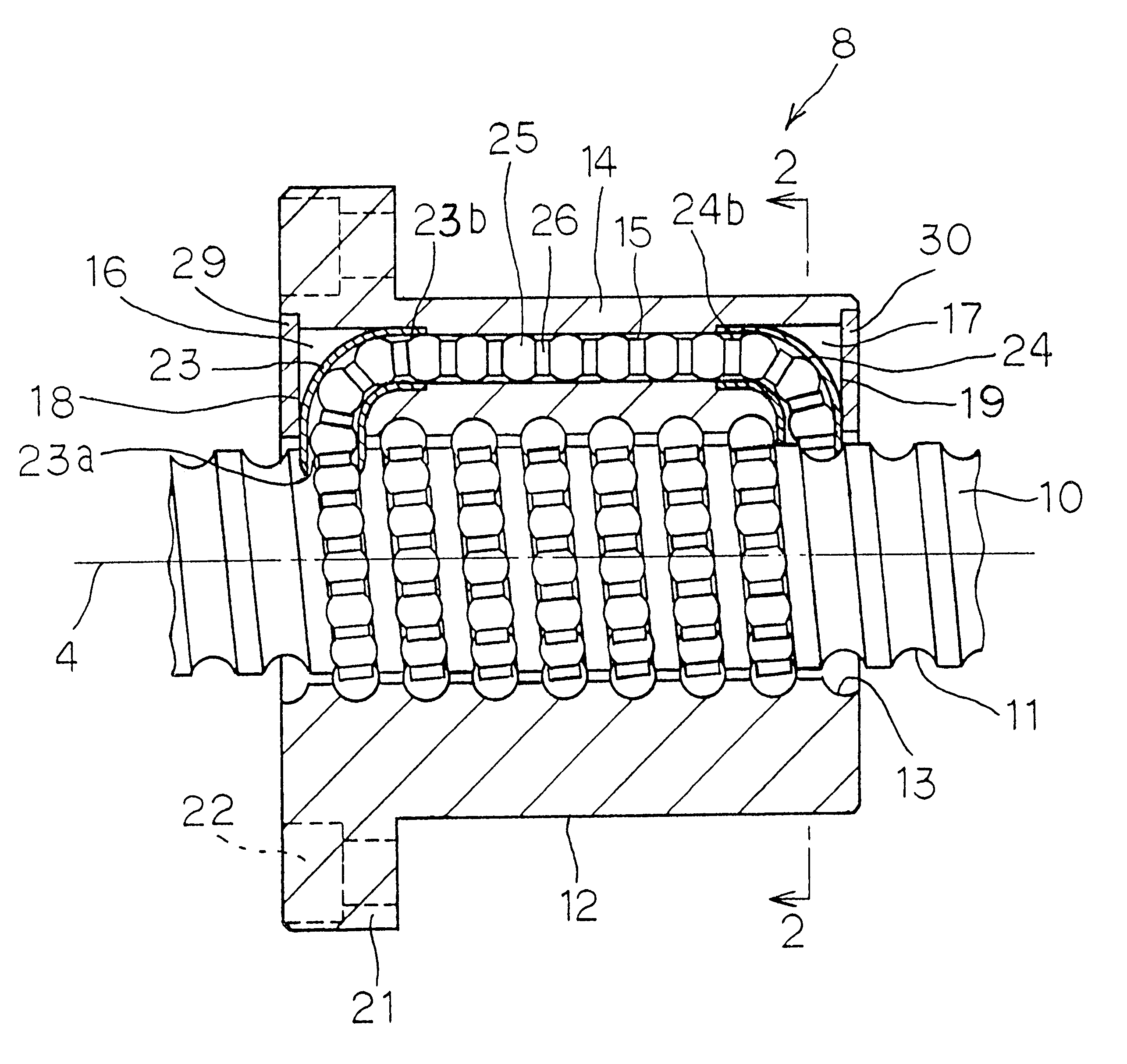

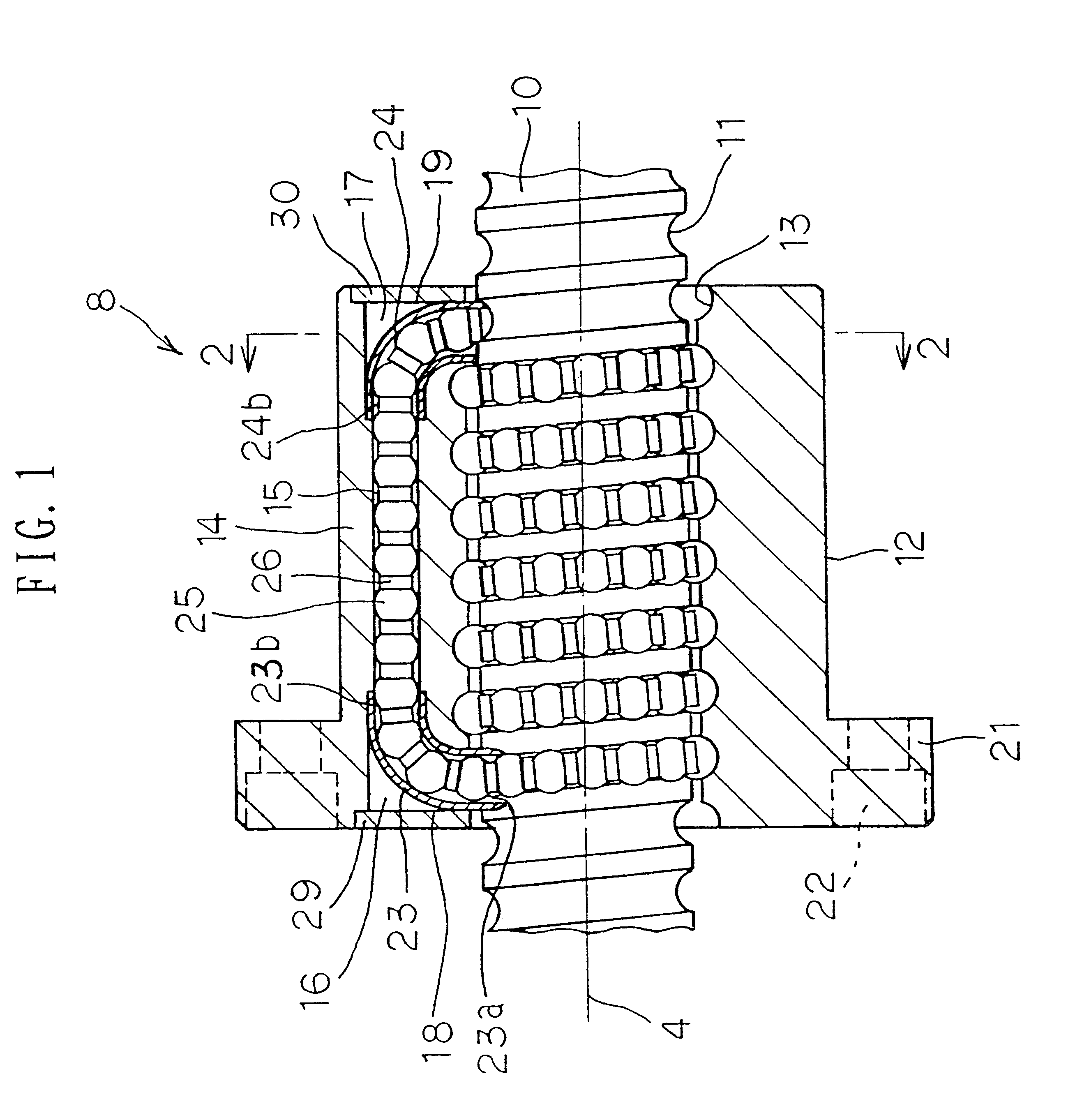

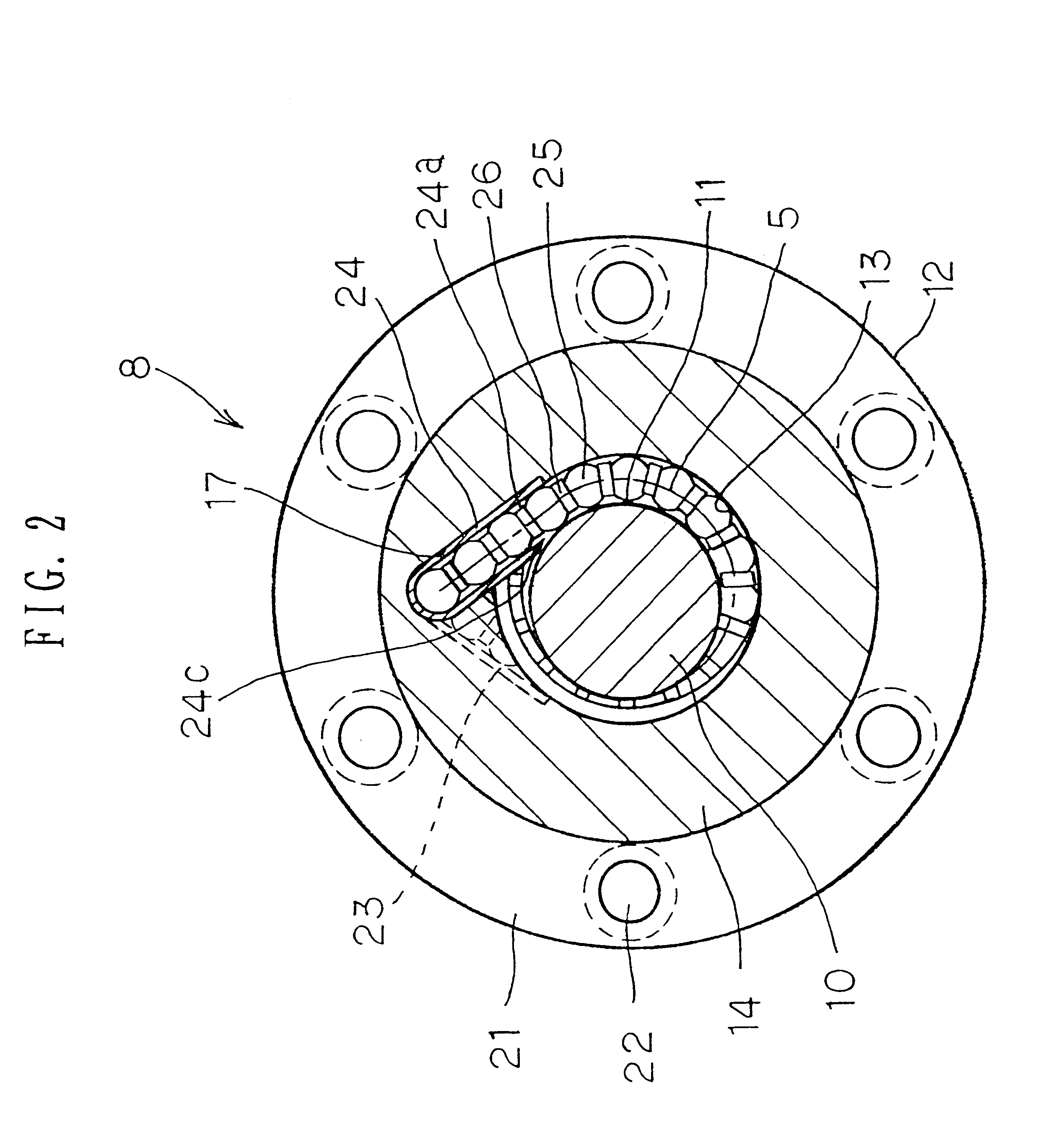

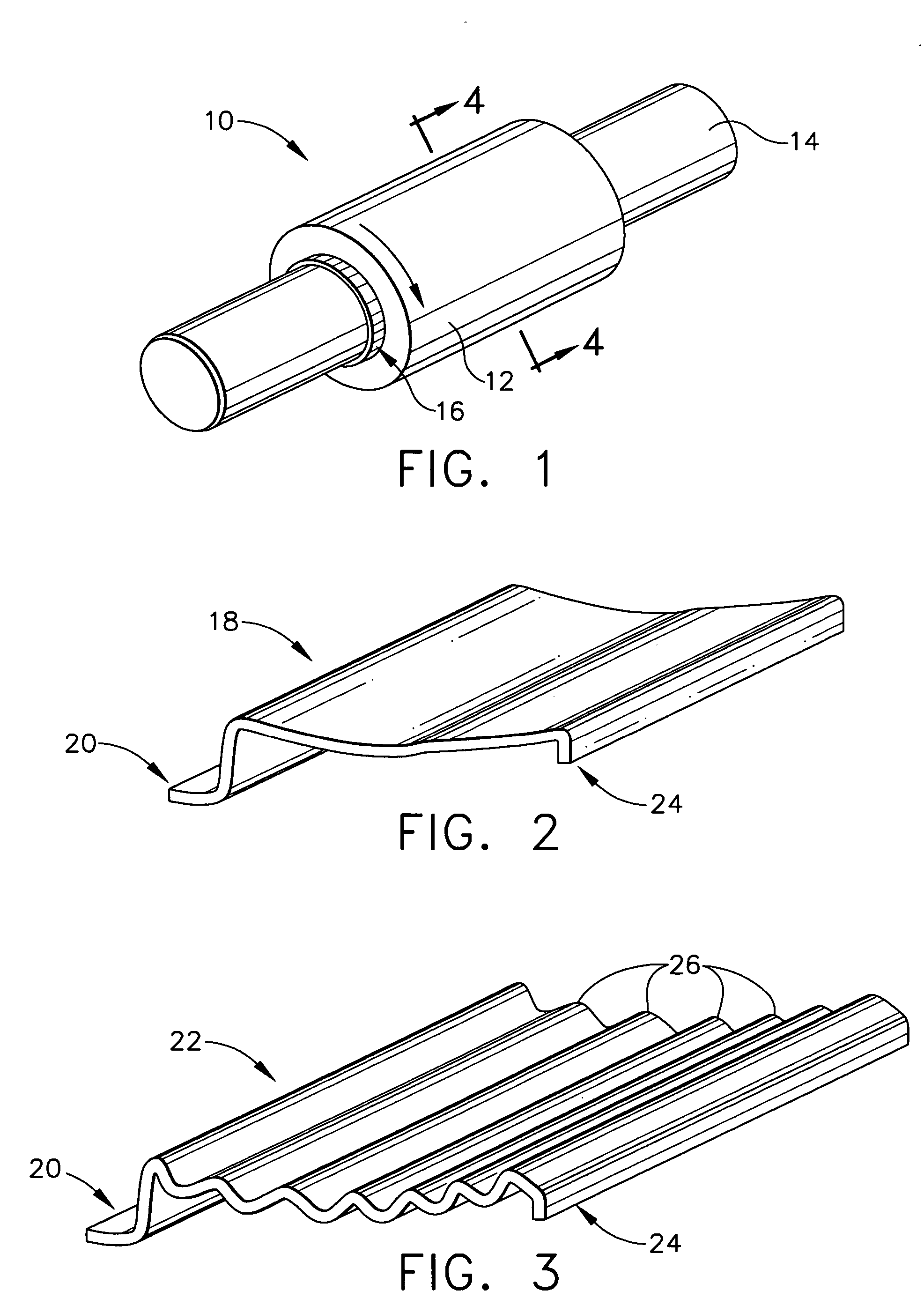

Ball screw having spacers

InactiveUS6176149B1Improve carrying capacityIncrease stiffnessControlling membersLinear bearingsCarrying capacityReciprocating motion

Spacers 26 each of which has a concave surface 27 complementary to the spherical surface of a ball 25 at each end thereof are disposed at areas between the adjacent balls 25, 25. A ball circulation mechanism comprises; a through hole 15 which extends in parallel to an axial line 4 of the ball nut 12 inside a thick wall part 14 of the ball nut 12; and adapters 23, 24 having open ends 23a, 24a provided with tongue portions 23c, 24c for scooping up or returning balls 25 between a ball screw groove 11 of a ball shaft 10 and a ball screw groove 13 of the ball nut 12, and the other open ends 23b, 24b being connected to be in communication with the through hole 15, and each adapter being fitted into recesses 16, 17 provided on both axial ends in the thick wall part 14 of the ball nut 12. Therefore, there is no need of upsizing a ball screw, and thus a compact ball screw which has a high load-carrying capacity and is suitable for a reciprocating movement can be provided.

Owner:TSUBAKI NAKASHIMA

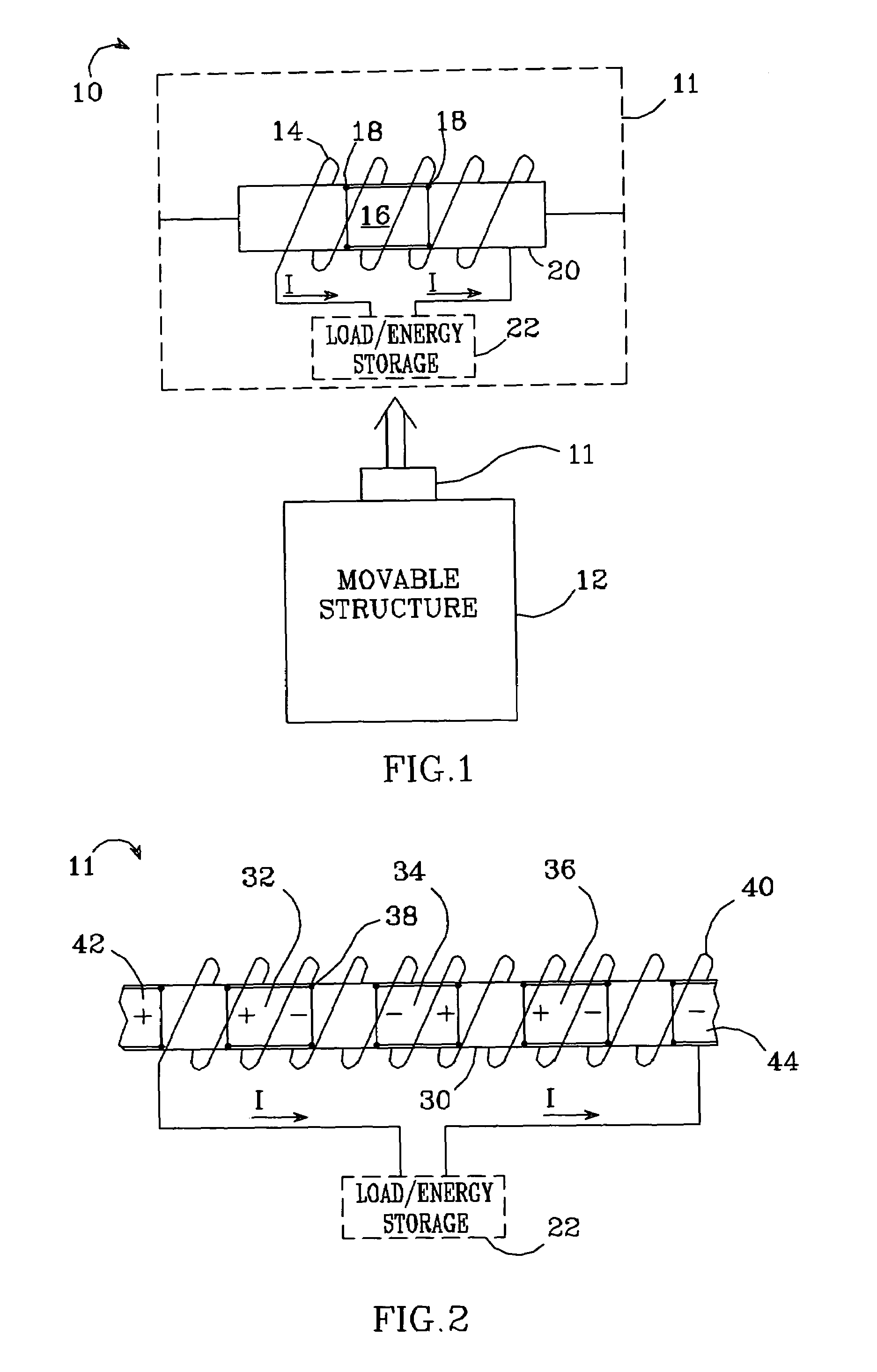

Autonomous power source

InactiveUS7009310B2Reduce frictionHigh sensitivityBearing componentsMachines/enginesElectrical batteryEngineering

Owner:TELEDYNE SCI & IMAGING

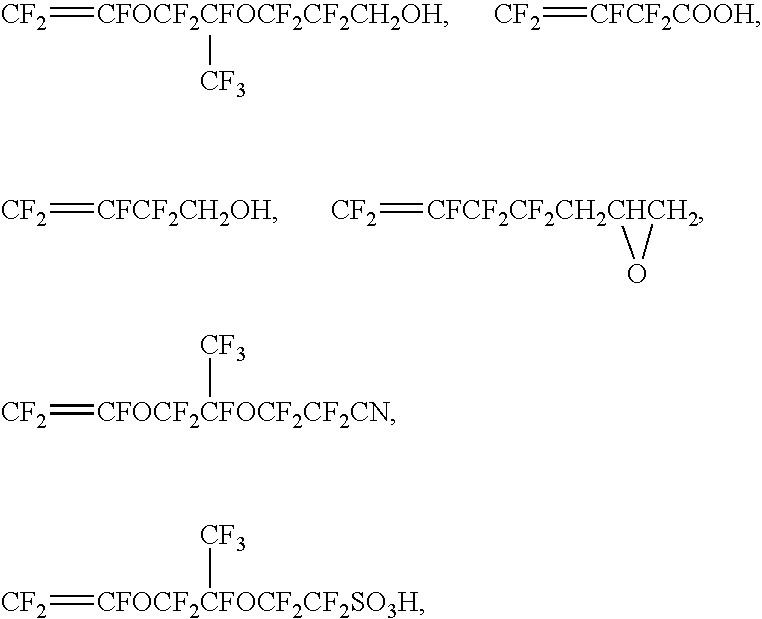

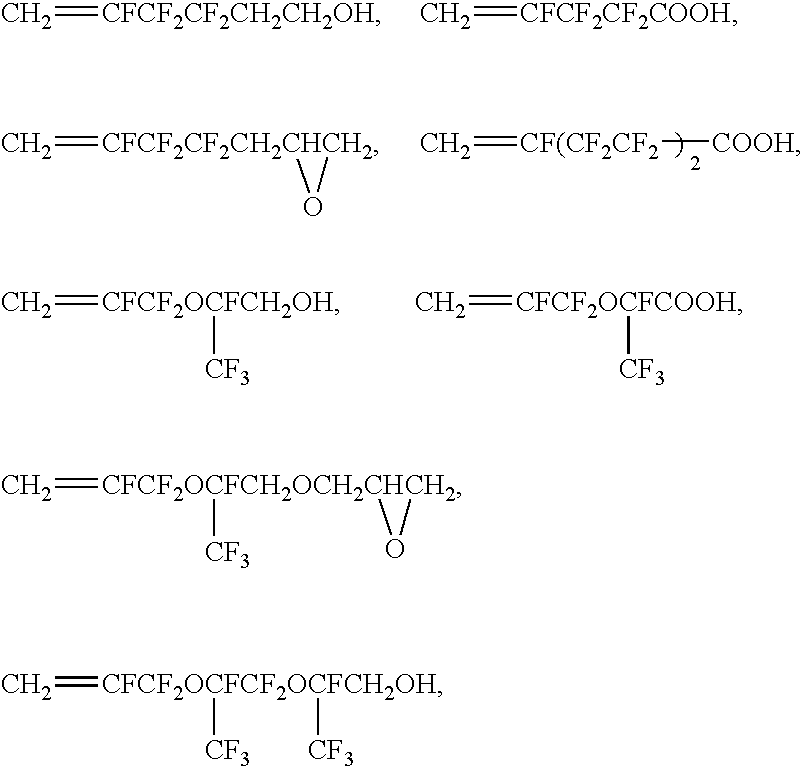

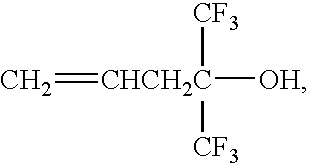

Structural member of fluorine-containing polymer having adhesive property at high temperature and sliding material produced by using same

InactiveUS6726994B1Easy to useImprove friction performanceSynthetic resin layered productsBearing componentsUltimate tensile strengthAdhesive materials

The structural member of the present invention comprises (A) a layer which comprises a fluorine-containing polymer and does not contain an adhesive material other than the fluorine-containing polymer substantially and (B) a substrate, in which the layer (A) is adhered directly to the substrate (B) without interposing a binder therebetween and a longitudinal shear strength between the layer (A) comprising a fluorine-containing polymer and the substrate (B) is not less than 0.98 N / mm<2 >at 150° C. The structural member comprising a fluorine-containing polymer and a substrate adhered to each other, particularly the structural member having improved adhesive strength at high temperature and the sliding material produced by using the structural member are provided.

Owner:DAIKIN IND LTD

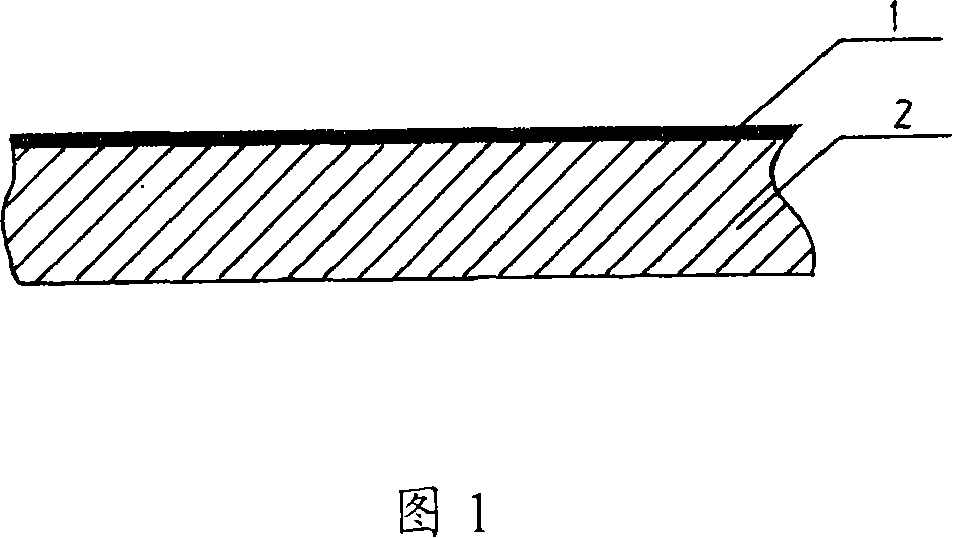

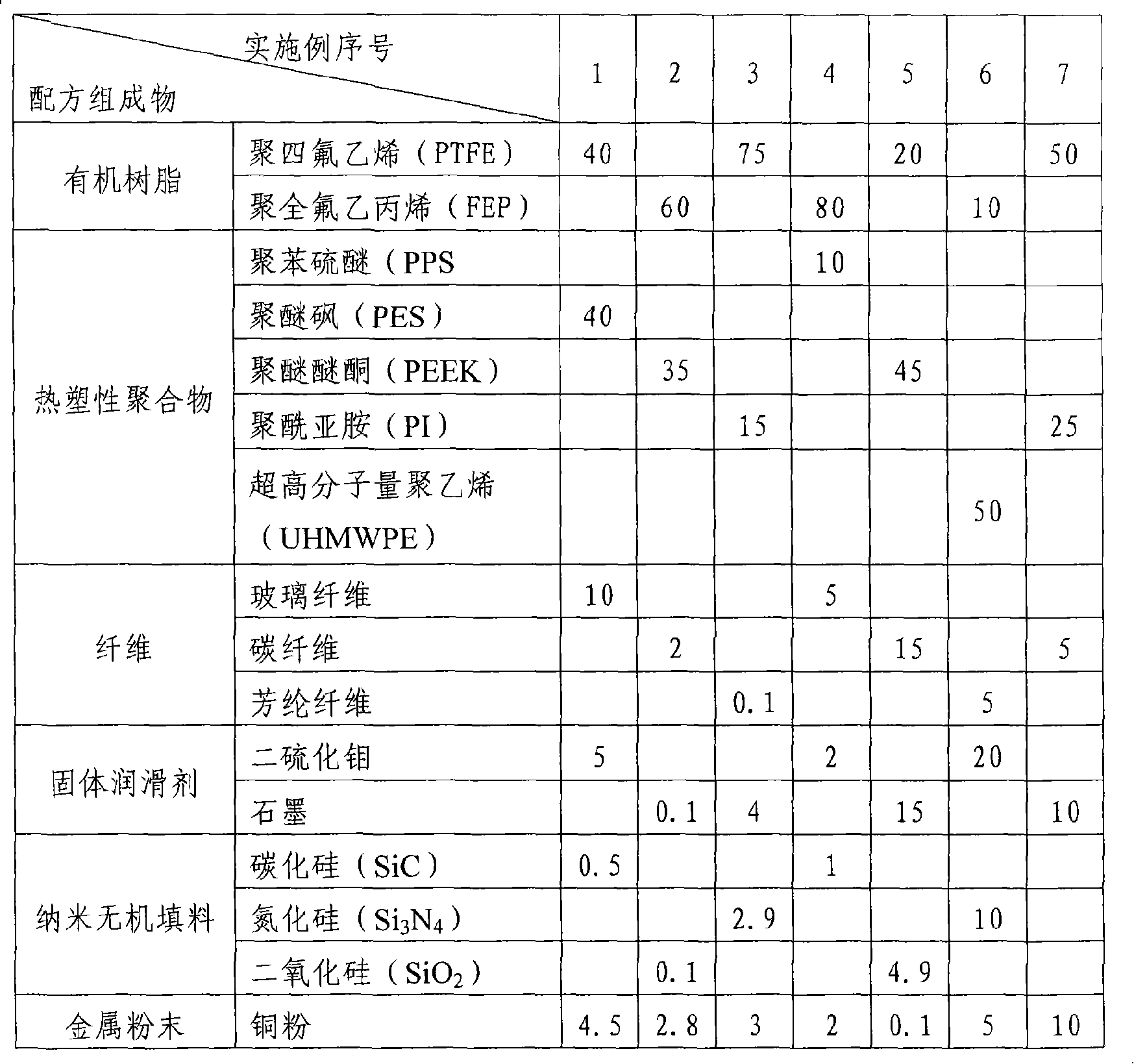

Self-lubricating sliding bearing material and its preparation method

ActiveCN101126417AImprove carrying capacityReduce frictionBearing componentsCarrying capacityMetal sheet

The invention discloses a self-lubrication sliding bearing material and the preparation method, the self-lubrication sliding bearing material includes a self-lubrication sliding layer made of composite material which adopts the organic resin as the basis and a metal substrate, the sliding layer and the metal substrate are directly adhered together. During the preparation, the composite material for the self-lubrication sliding layer is blended proportionally and is laid on the metal sheet after being mixed mechanically, the surface of the metal sheet is treated, and then the metal sheet is sintered in a sintering furnace, then rolled immediately after the sintering process so that the surface coat is adhered on the metal substrate. The sliding bearing made of the material provided by the invention has the characteristics of higher carrying capacity and low friction and good wearing resistance, the metal substrate and the self-lubrication sliding layer can be stably adhered with each other, and is suitable for the dry friction and boundary or fluid friction conditions.

Owner:COB PRECISION PARTS

Anti-microbial electrosurgical electrode and method of manufacturing the same

InactiveUS7160297B2Improve featuresExcellent characteristicsConveyorsLayered productsELECTROSURGICAL DEVICEMaterials science

An electrosurgical device including a reinforcing underlayment having a non-stick, anti-microbial coating. In one embodiment, the coating includes a non-stick material having anti-microbial particles interspersed in the non-stick material. This coating is applied to the surfaces of the electrode to minimize the build-up of charred tissue on the surfaces of the electrode. Also, the coating tends to kill harmful organisms residing on the surfaces of the electrode. In another embodiment, a primer coating is initially applied to the surfaces of the electrode. A plurality of anti-microbial particles are then applied to the primer coating layer and engage and are embedded in the primer coating layer. A top coat including a non-stick material is applied to the anti-microbial particle layer. In either embodiment, the coating layers applied to the surfaces of the electrode are cured to harden and adhere the layers to the electrode.

Owner:INNOVATECH

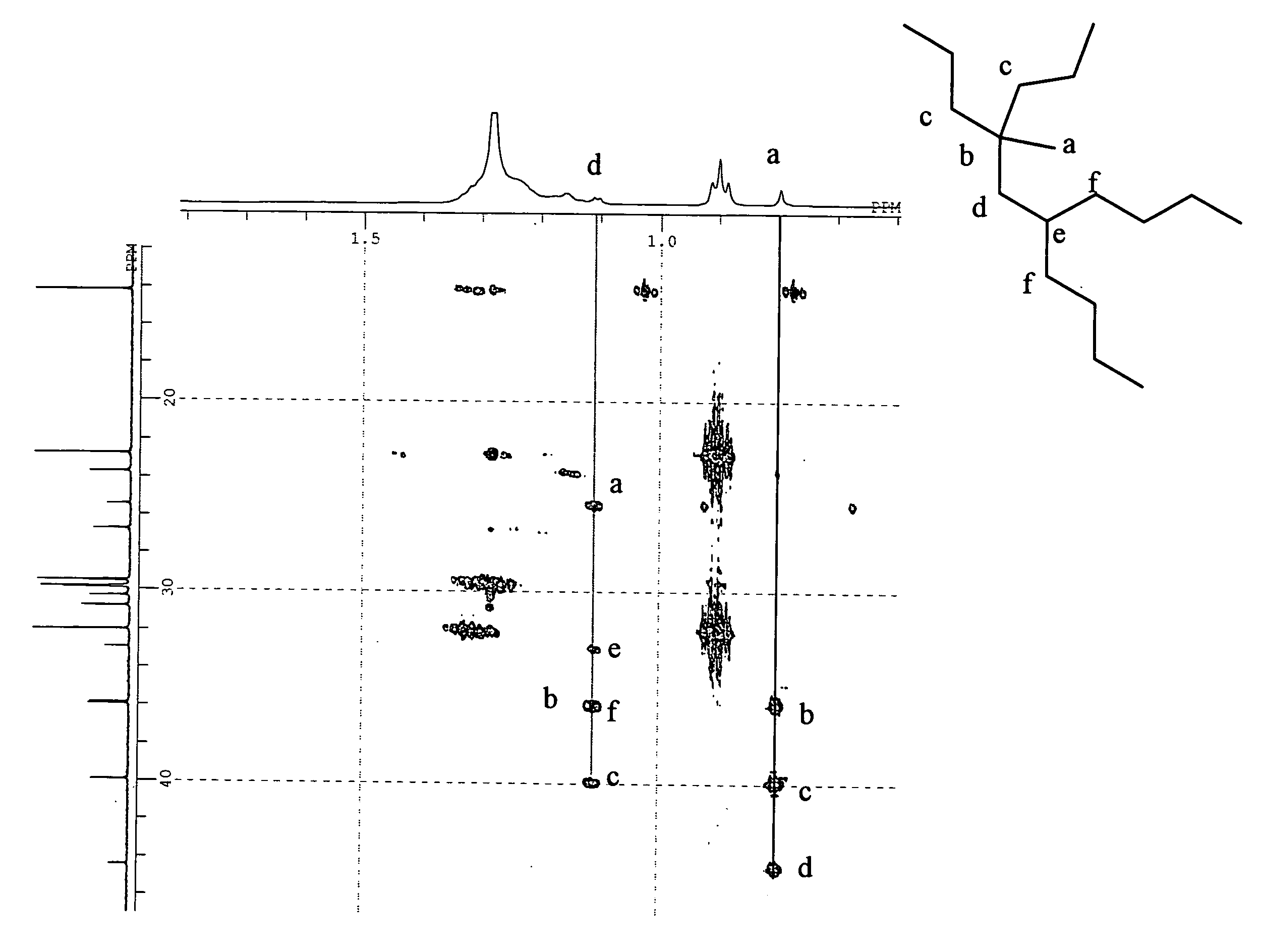

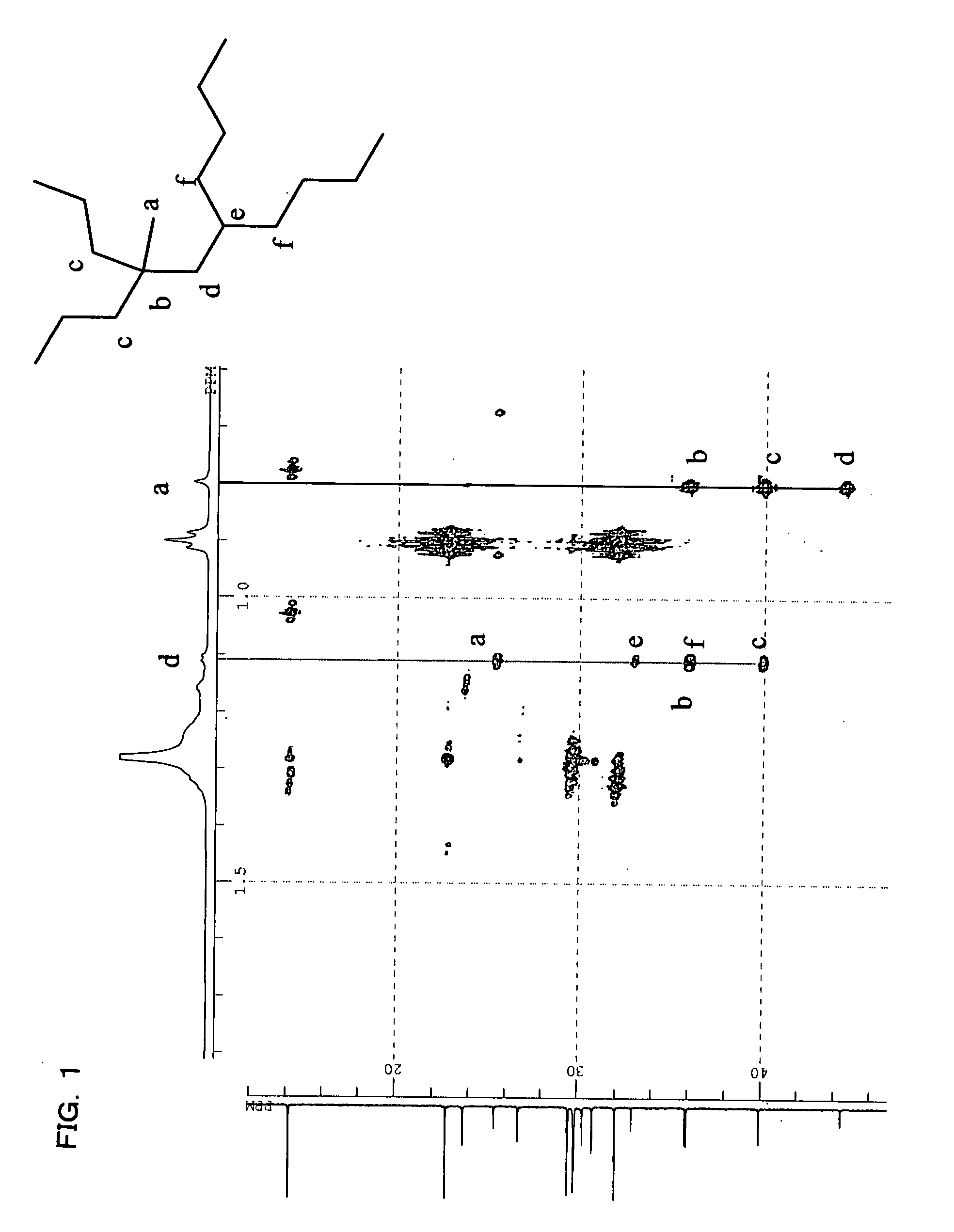

Process for producing saturated aliphatic hydrocarbon compound, and lubricant composition

InactiveUS20080146469A1Low-temperature fluidityImprove Oxidation StabilityHydrocarbon by hydrogenationCatalystsAlpha-olefinCoordination complex

The present invention provides a process for producing a saturated aliphatic hydrocarbon prepared using an α-olefin as a raw material and represented by the general formula (1), including the steps of: (I) producing a vinylidene olefin by dimerizing the α-olefin in the presence of a metallocene complex catalyst; (II) further dimerizing the vinylidene olefin in the presence of an acid catalyst; and (III) hydrogenating the obtained dimer. Further, there are provided a lubricant composition containing the saturated aliphatic hydrocarbon compound produced by the above process, a bearing oil consisting of the lubricant composition, and making use of the same, a bearing and gyral equipment. The saturated aliphatic hydrocarbon compounds produced by the process of the present invention have low-temperature fluidity, exhibiting low evaporativity, and excellent in thermal stability and oxidation stability. Thus, the saturated aliphatic hydrocarbon compounds are suitable for use as, for example, a base oil of lubricant composition for hydraulic pressure, turbine, working machine, bearing, gear, metal-working, etc.

Owner:IDEMITSU KOSAN CO LTD

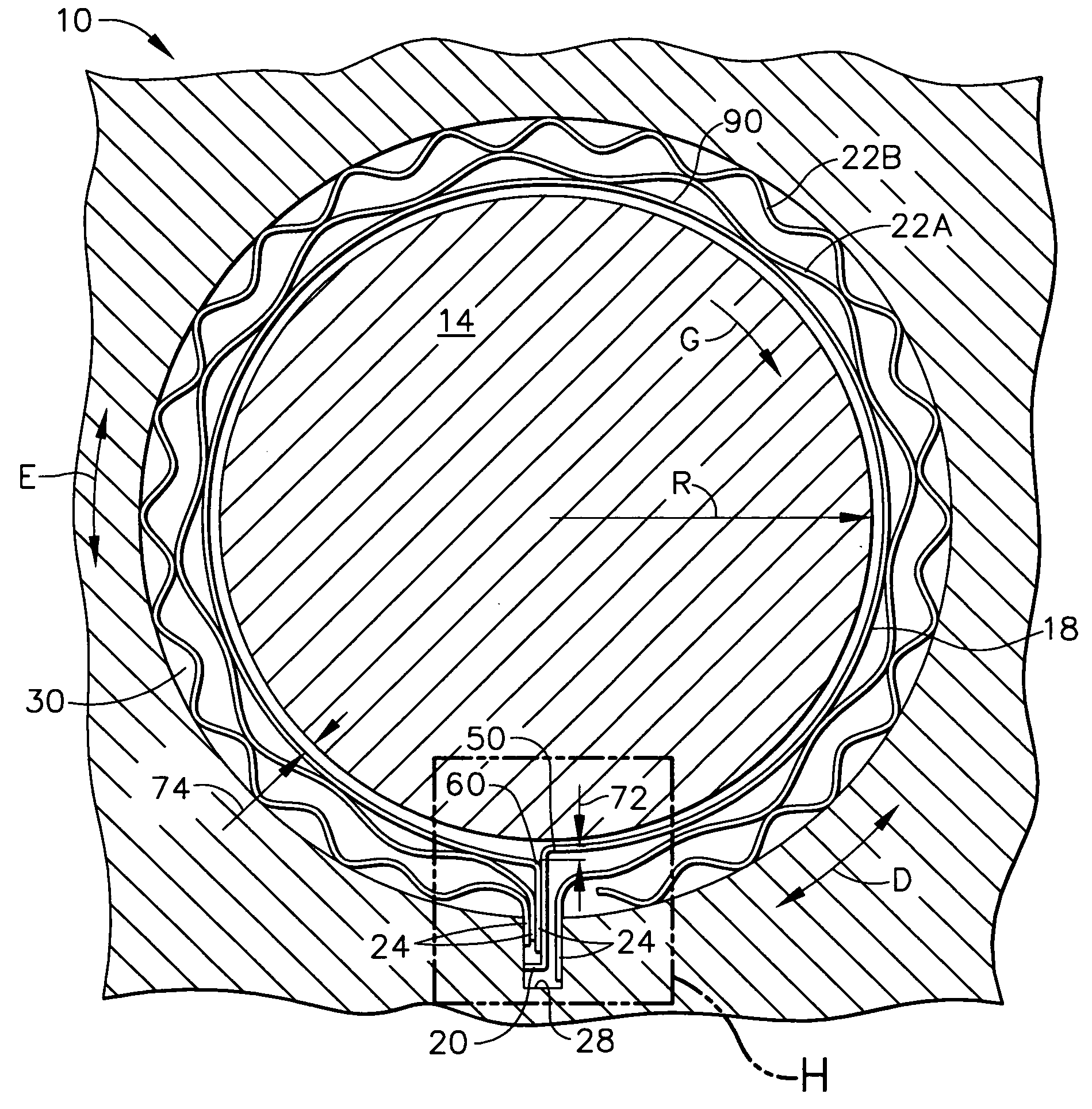

Hydrodynamic journal foil bearing system

A high load capacity hydrodynamic journal foil bearing system is disclosed, which comprises a top foil and a plurality of undersprings. Preload forces are transferred from the undersprings to internal circumferential compressive forces within a top foil, resulting in low preload forces against the shaft, allowing the shaft to expand at high speeds without increasing the preload forces or overloading the fluid film. One underspring may have a different spring rate than another underspring. The top foil may be normalized to shaft shape and dimensions. These features may be accomplished with using less mechanical parts than other journal foil bearing system designs.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com