Patents

Literature

607 results about "Triethylene glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

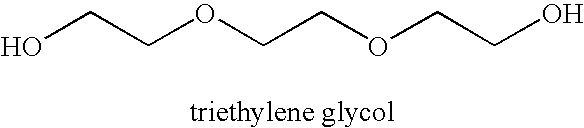

Triethylene glycol, TEG, or triglycol is a colorless odorless viscous liquid with molecular formula HOCH₂CH₂OCH₂CH₂OCH₂CH₂OH. It is used as a plasticizer for vinyl polymers. It is also used in air sanitizer products, such as "Oust" or "Clean and Pure". When aerosolized it acts as a disinfectant. Glycols are also used as liquid desiccants for natural gas and in air conditioning systems. It is an additive for hydraulic fluids and brake fluids and is used as a base for "smoke machine" fluid in the entertainment industry.

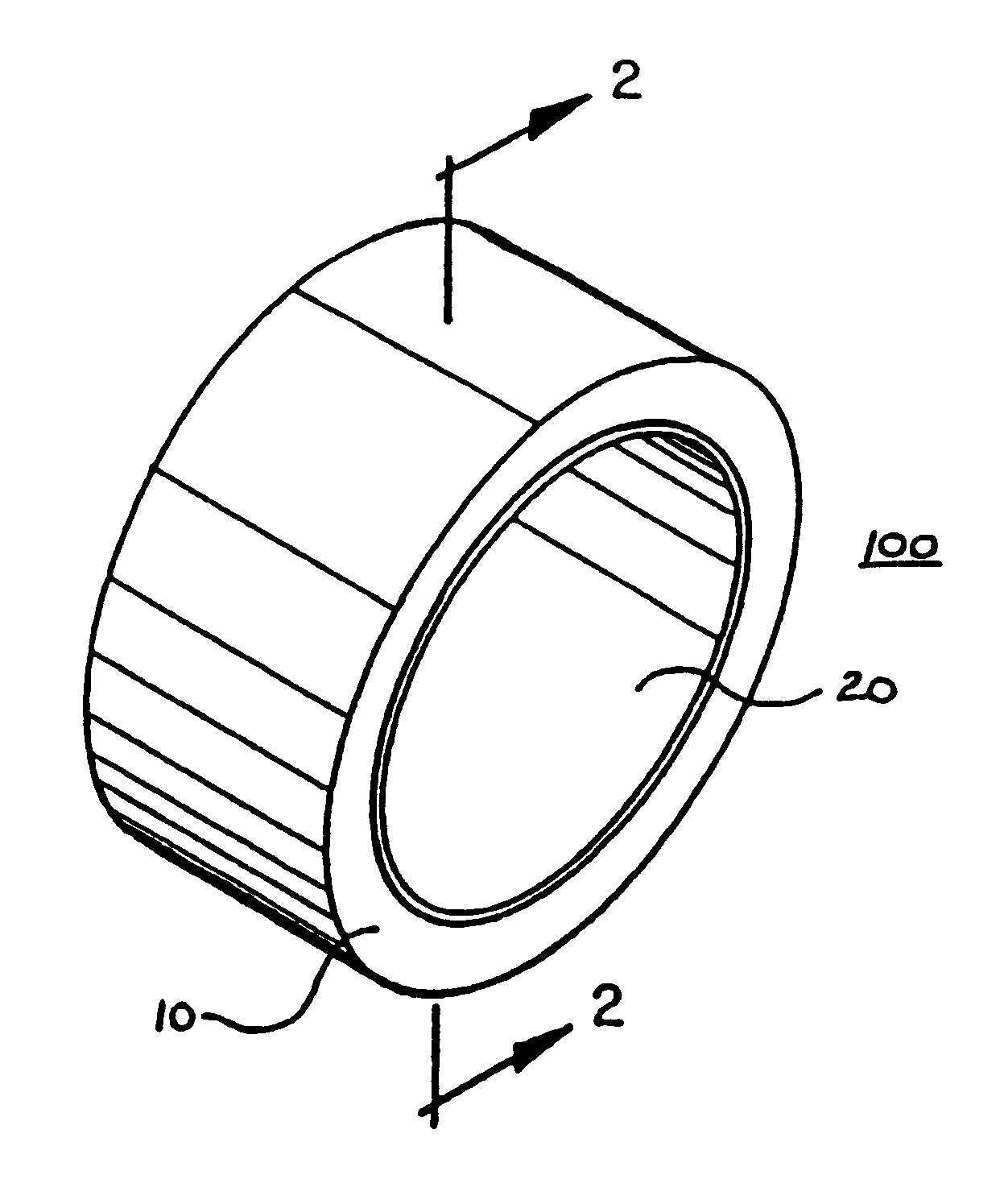

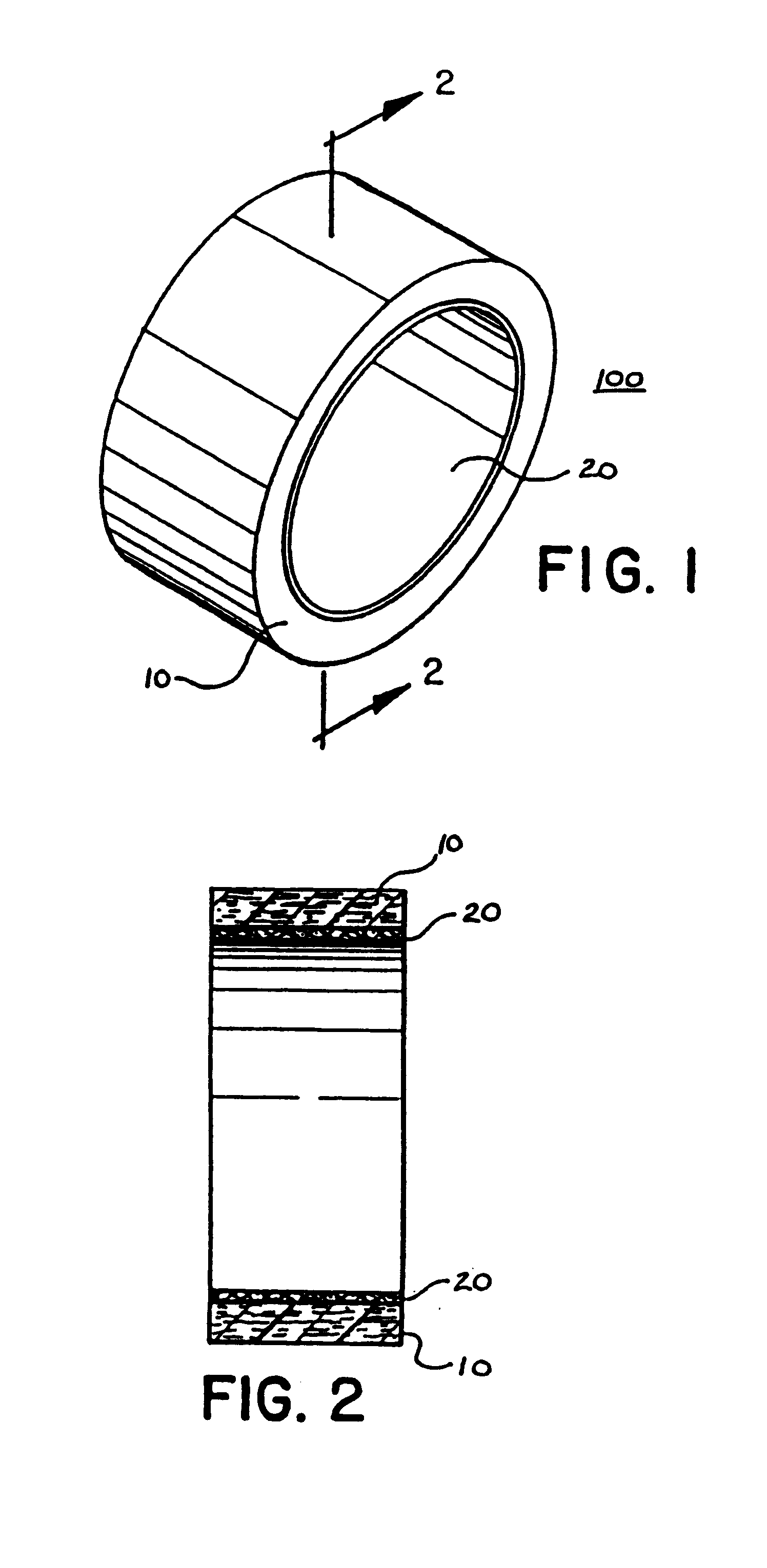

Self-lubricating bearing and coating

InactiveUS6180574B1Improve wear resistanceEasy bearing maintenanceNon-macromolecular adhesive additivesPretreated surfacesPentaerythritolAramides

A self-lubricating coating is provided which includes a mixture of a curable acrylate composition including a dipentaerythritol pentaacylate and a solid lubricant, such as polytetraflourethylenr. The curable acrylate composition may also include triethylene glycol dimethacrylate. An aramid pulp may also be added to the coating mixture. Also disclosed is a method of manufacturing the coating, and a self-lubricating bearing having the coating disposed on its surface.

Owner:REXNORD CORP

Ester slump retaining type polycarboxylate water reducer and preparation method thereof

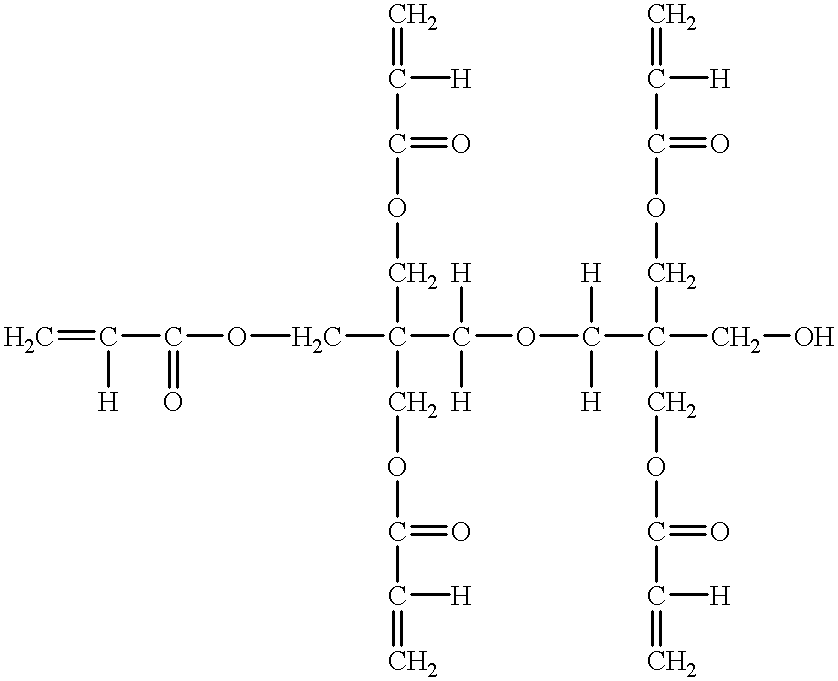

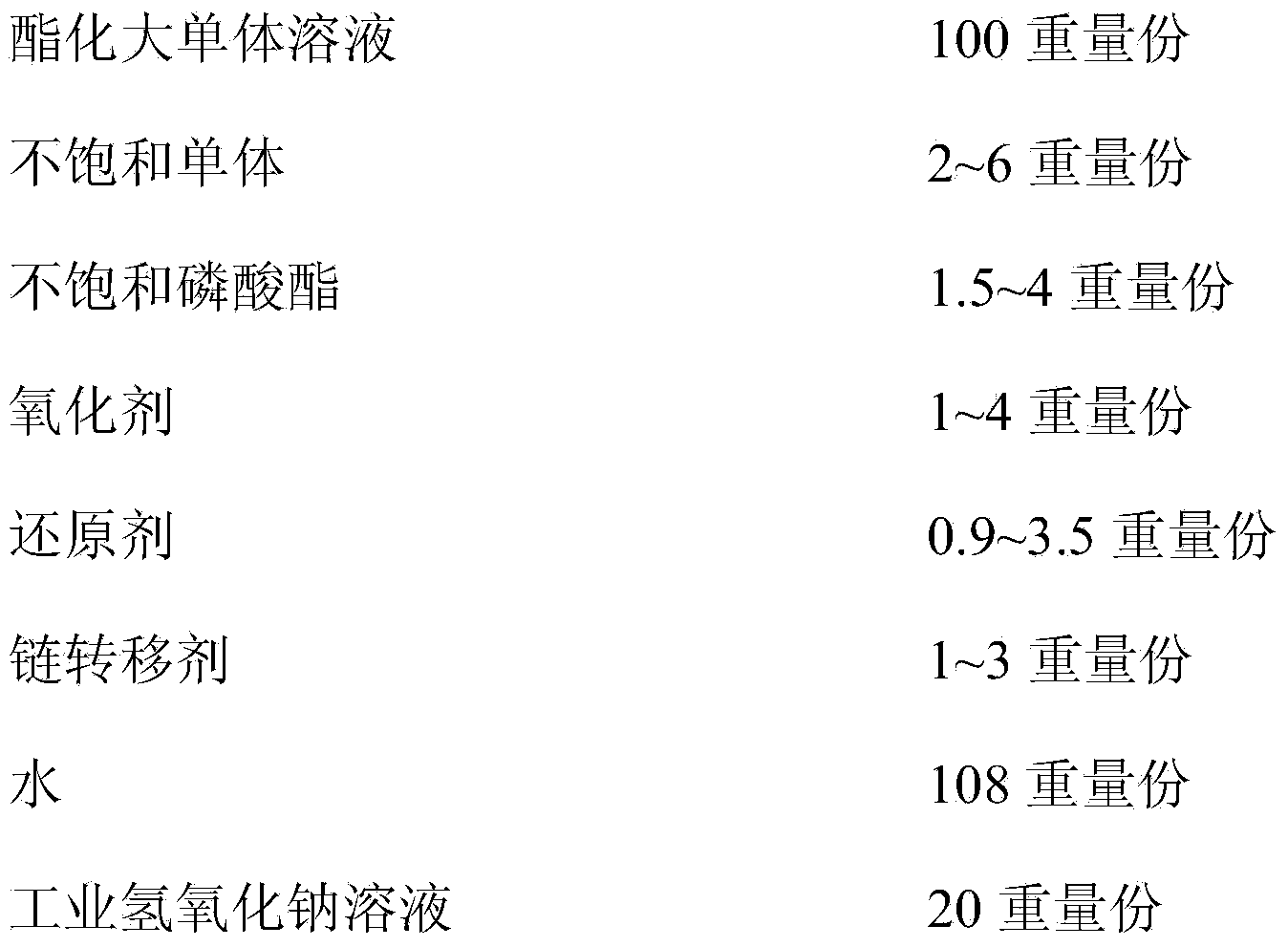

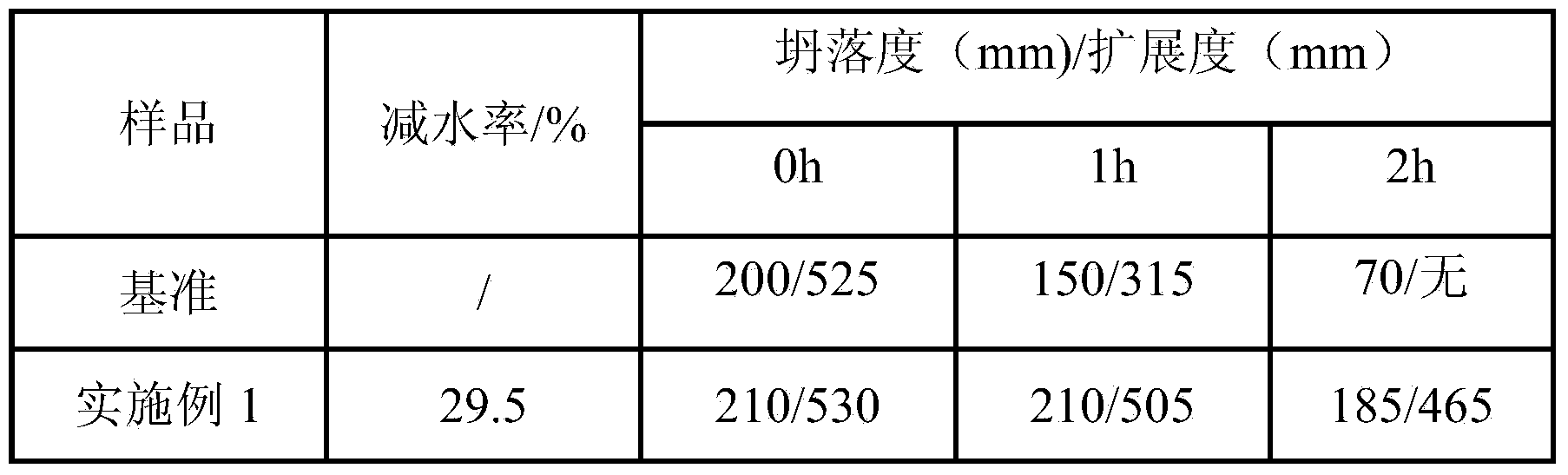

The invention discloses an ester slump retaining type polycarboxylate water reducer and a preparation method thereof. The ester slump retaining type polycarboxylate water reducer is made from raw materials comprising the following components in parts by weight: 100 parts of esterified macromer solution by weight, 2-6 parts of unsaturated monomer by weight, 1.5-4 parts of unsaturated phosphate by weight, 1-4 parts of an oxidizing agent by weight, 0.9-3.5 parts of a reducing agent by weight, 1-3 parts of a chain transfer agent by weight, 108 parts of water by weight, and 20 parts of industrial sodium hydroxide solution by weight, wherein the concentration of the esterified macromer solution is 75-85%, and a solute thereof is the mixture of methoxy polyethylene glycol methacrylate, crosslinking monomers triethylene glycol dmethylacrglate and methyl methacrylate; the unsaturated monomer is methacrylic acid, acrylic acid, hydroxyethyl methylacrylate, hydroxyethyl acrylate, hydroxypropyl methacrylate or hydroxypropyl acrylate. The ester slump retaining type polycarboxylate water reducer provided by the invention has good slump retaining performance, good dispersibility, good adaptability and low cost.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Hot melt adhesives for roll-applied labels

ActiveUS20100112250A1Plastic/resin/waxes insulatorsSynthetic resin layered productsPolyesterTriethylene glycol

Disclosed are hot-melt adhesives prepared from polyesters containing 1,4-cyclohexane-dicarboxylic acid as a diacid component and a diol component containing at least two diols chosen from 1,4-cyclohexanedimethanol, triethylene glycol, and diethylene glycol. These adhesives set up rapidly within a well-defined temperature window. The hot-melt adhesives can be used in a variety of applications, but are especially suited as seaming adhesives for roll-applied labels. These adhesives have melting temperatures and crystallization properties that allow their application at temperatures cool enough to prevent curling and premature shrinkage of the shrink label during seaming, and yet produce strong label seams that can withstand the elevated temperatures of a shrink tunnel without sacrificing line speed. Also disclosed are labeled containers and a process for applying a roll-on, shrink label to a container using the hot-melt adhesives of the invention.

Owner:EASTMAN CHEM CO

Biaxial orienting drawing formed polyvinyl alcohol membrane and production method thereof

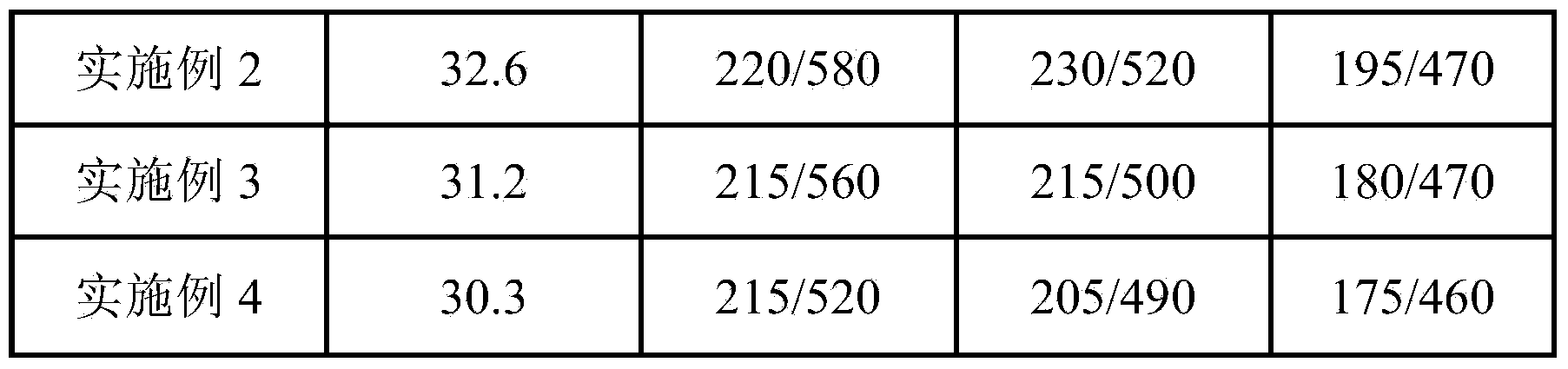

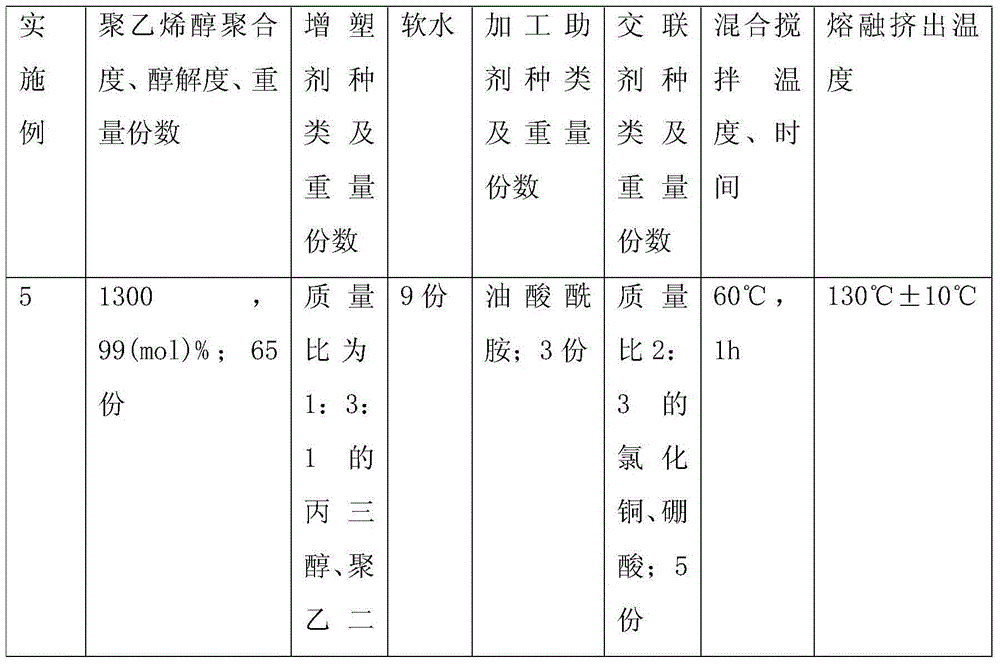

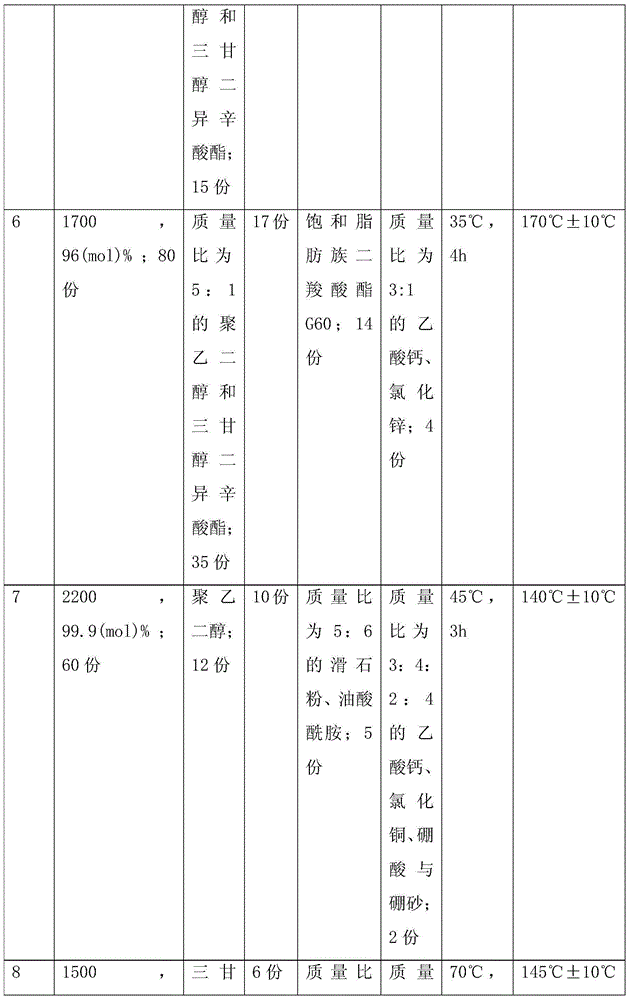

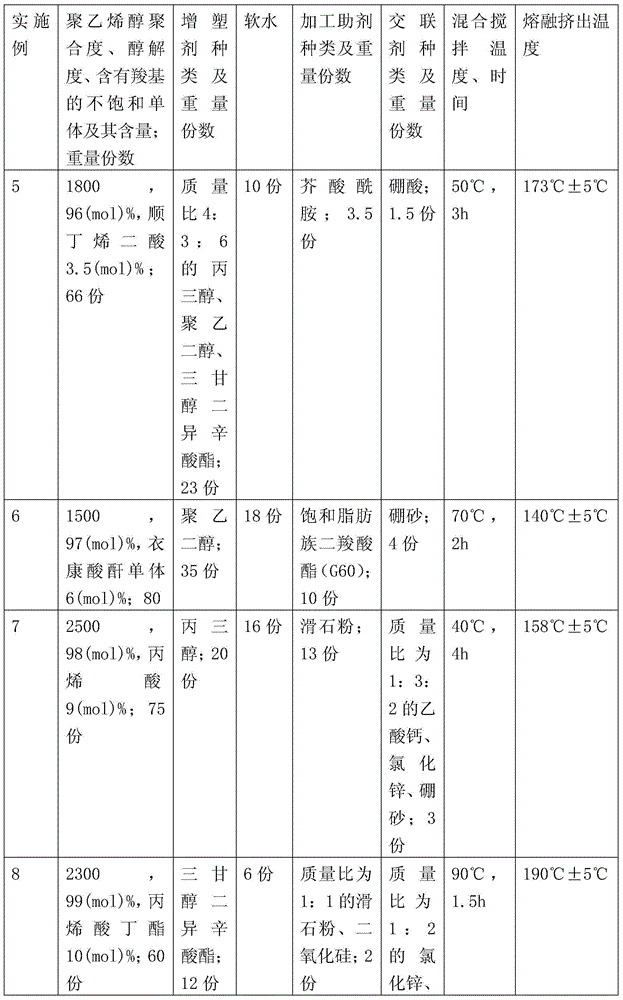

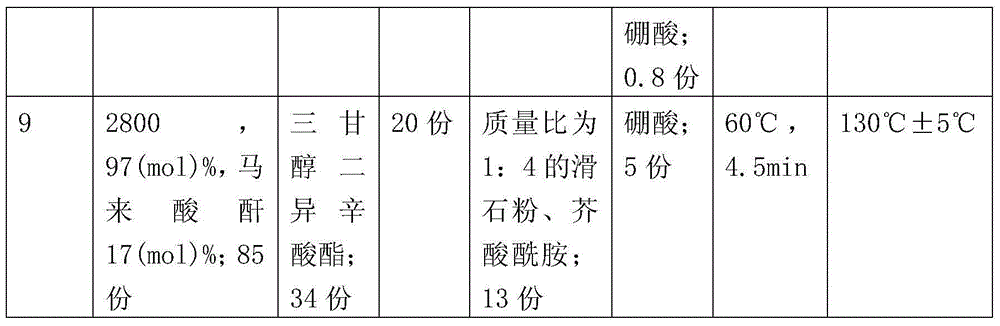

The invention provides a polyvinyl alcohol membrane. The polyvinyl alcohol membrane is produced through melt extrusion-biaxial orientating drawing formation of melt-processible polyvinyl alcohol resin, the tensile strength of the polyvinyl alcohol membrane is not lower than 40 MPa, the polyvinyl alcohol resin comprises effective amounts of polyvinyl alcohol, a plasticizer, soft water and a processing assistant, the degree of polymerization (DP) of the polyvinyl alcohol is 1000-3500, the degree of hydrolysis (DH) of the polyvinyl alcohol is greater than 95 (mol)% and is smaller than 99.9 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate, and the processing assistant is at least one of talcum powder, silica, oleamide and saturated aliphatic dicarboxylate. The polyvinyl alcohol membrane has the advantages of simple technology, less device investment and less occupied area. The polyvinyl alcohol membrane can be used in the field of high-end packaging, such as packaging of high-end clothes and packaging of foods and oil products, and can prolong the shelf life of the foods.

Owner:CHINA PETROCHEMICAL CORP +2

Preparation and application of magnetic ferroferric oxide nanoparticle modified carbon nanotube composite material

InactiveCN107803181AGood dispersionImprove adsorption capacityMaterial nanotechnologyComponent separationWater bathsModified carbon

The invention relates to preparation and application of a magnetic ferroferric oxide nanoparticle modified carbon nanotube composite material. The preparation method includes: mixing a divalent iron salt and a trivalent iron salt, adding NH3.H2O, conducting water bath and centrifugal separation, washing the precipitate, and carrying out drying and grinding to obtain magnetic Fe3O4 nanoparticles; adding concentrated nitric acid and concentrated sulfuric acid into pretreated carbon nanotubes, conducting heating refluxing, carrying out filtering, deionized water washing and vacuum drying, thus obtaining purified multiwalled carbon nanotubes; adding the purified multiwalled carbon nanotubes into a triethylene glycol solution, conducting ultrasonic treatment, adding magnetic Fe3O4 nanoparticles, performing stirring and heating, conducting heat preservation and cooling, separating the product, and conducting vacuum drying, thus obtaining the magnetic Fe3O4 nanoparticle modified carbon nanotube composite material. The composite material is used for detecting the residue amount of organophosphorus pesticides in food. The preparation method utilizes magnetic Fe3O4 nanoparticles to modify carbon nanotubes, and greatly improves the dispersibility and adsorption properties of carbon nanotubes in water. The prepared magnetic Fe3O4 nanoparticle modified carbon nanotube composite material hasgood stability, and the maximum recovery rate can reach 89.6%.

Owner:甘肃省商业科技研究所有限公司

Liquid glycol benzoate compositions and polymer compositions containing same

InactiveUS6184278B1Group 5/15 element organic compoundsPaper coatingDiethylene glycolOrganic polymer

The present invention relates to organic polymer compositions, containing liquid ester compositions as plastisizers, said compositions comprising mixtures of esters derived from (a) diethylene glycol and triethylene glycol and (b) benzoic or toluic acid, wherein the freezing point of the ester mixture is below the freezing points of the constituent esters when the relative concentrations of the constituent esters are within specified limits.

Owner:EASTMAN SPECIALITIES HLDG CORP

Blow molded polyvinyl alcohol membrane and production method thereof

The invention provides a polyvinyl alcohol membrane. The polyvinyl alcohol membrane is produced through blow molding of melt-processible polyvinyl alcohol resin, the tensile strength of the polyvinyl alcohol membrane is not lower than 20 MPa, the melt-processible polyvinyl alcohol resin comprises effective amounts of polyvinyl alcohol, a plasticizer, soft water and a processing assistant, the degree of polymerization (DP) of the polyvinyl alcohol is 1000-3500, the degree of hydrolysis (DH) of the polyvinyl alcohol is greater than 72 (mol)% and is smaller than 99.9 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate, and the processing assistant is at least one of talcum powder, silica, oleamide and saturated aliphatic dicarboxylate. The method has the advantages of simple process, less device investment, small occupied area, and realization of blow molding of normal-temperature, medium-temperature and high-temperature water soluble membranes. The method is mainly used for producing double-layer membranes, and the membranes can be directly processed to produce various water-soluble bags, and the water-soluble bags are used in the field of medium and low end packaging application, and can be used as a pesticide and chemical engineering product inner packaging liner bag, a hospital washing packaging bag and a refuse bag.

Owner:CHINA PETROCHEMICAL CORP +2

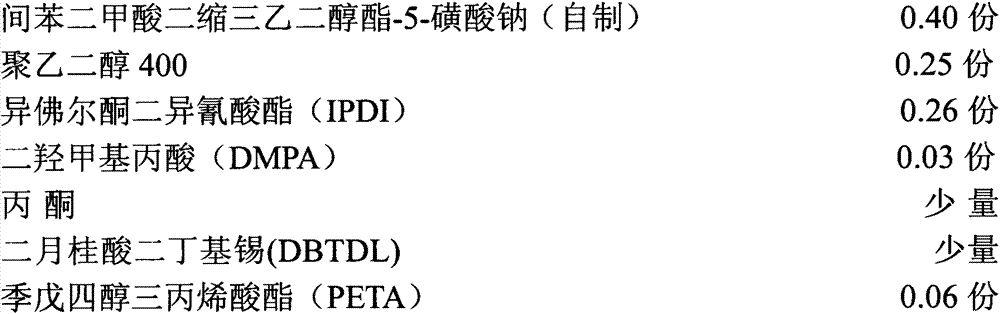

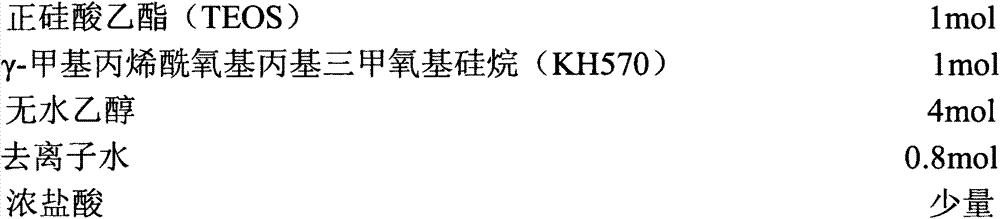

Preparation method for antifogging thin film coating with high light transmission

ActiveCN103709927APolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsSolventDibutyltin dilaurate

Provided is a preparation method for an antifogging thin film coating with high light transmission. M-phthalic acid triethylene glycol ester-5-sodium sulfonate (self made), polyethylene glycol 400, isophorone diisocyanate and pentaerythritol triacrylate are employed as main raw materials, dibutyltin dilaurate is employed as a catalyst, dimethylolpropionic acid is employed as a chain extender, acetone is employed as a solvent, and hydrophilic UV prepolymers are prepared; ethyl orthosilicate is employed as a precursor, gamma-methacryloxy propyl trimethoxysilane is employed as a modifier, a sol-gel method is employed, and uniform and stable modified SiO2 sol is prepared; the hydrophilic UV prepolymers and the modified SiO2 sol are subjected to hybridization through a UV curing way, and a thin film coating is obtained. The prepared thin film coating has good hardness and adhesive force, water resistance and high light transmission and good antifogging effects, and can be used for antifog of surfaces of glass and eyeglass. The preparation technology of the thin film coating accords with green environmental protection concepts, curing and film forming are fast, and comprehensive performances are good. The antifogging thin film coating has good market prospect and is suitable for popularization and application.

Owner:JIANGNAN UNIV

Melt extrusion-casting/calendering molded polyvinyl alcohol membrane and production method thereof

InactiveCN106189008ALower melt processing temperatureReduce processing temperatureFlat articlesProcedure AgentsPolyethylene glycol

The invention provides a polyvinyl alcohol membrane. The polyvinyl alcohol membrane is produced through casting or calendering molding of melt-processible polyvinyl alcohol resin, the tensile strength of the polyvinyl alcohol membrane is not lower than 25 MPa, the melt-processible polyvinyl alcohol resin comprises effective amounts of polyvinyl alcohol, a plasticizer, soft water and a processing assistant, the degree of polymerization (DP) of the polyvinyl alcohol is 1000-3500, the degree of hydrolysis (DH) of the polyvinyl alcohol is greater than 72 (mol)% and is smaller than 95 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate, and the processing assistant is at least one of talcum powder, silica, oleamide and saturated aliphatic dicarboxylate. A production method of the polyvinyl alcohol membrane has the advantages of simple process, less device investment, small occupied area, and formation of normal-temperature and medium-temperature water-soluble membranes through melt extrusion casting / calendering. The method is mainly used for producing single-layer membranes which are applied to the fields of hydrographics transfer printing base membranes, printing paper hot melt adhesive membranes, agricultural membranes and other medium-and-high end products.

Owner:CHINA PETROCHEMICAL CORP +2

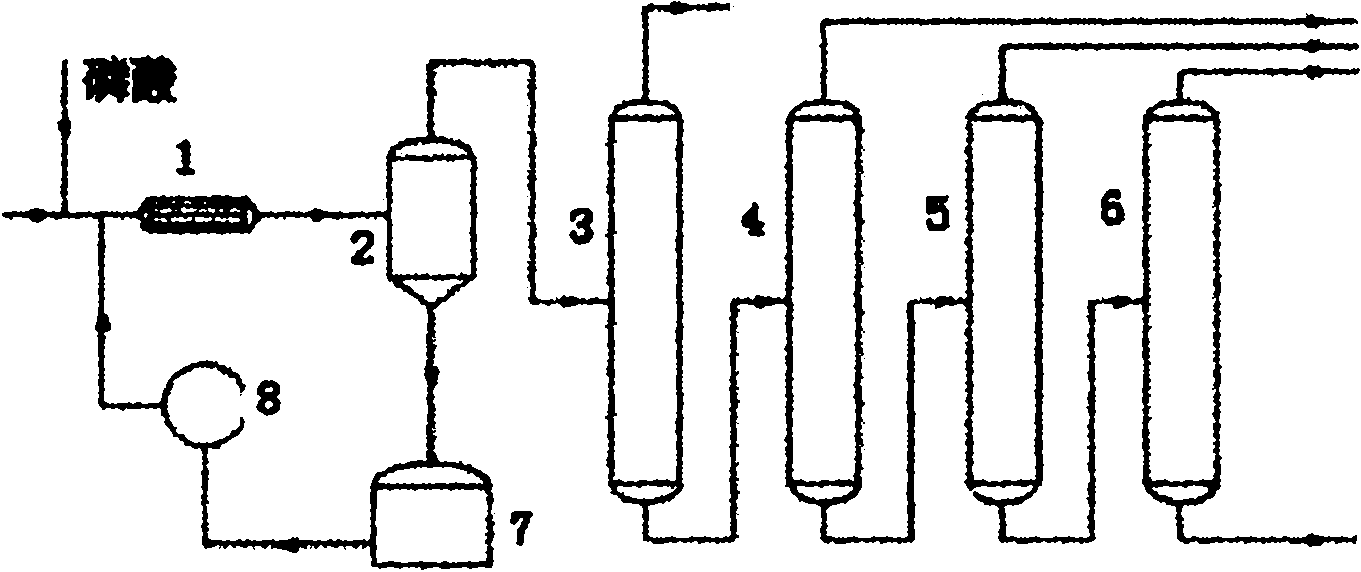

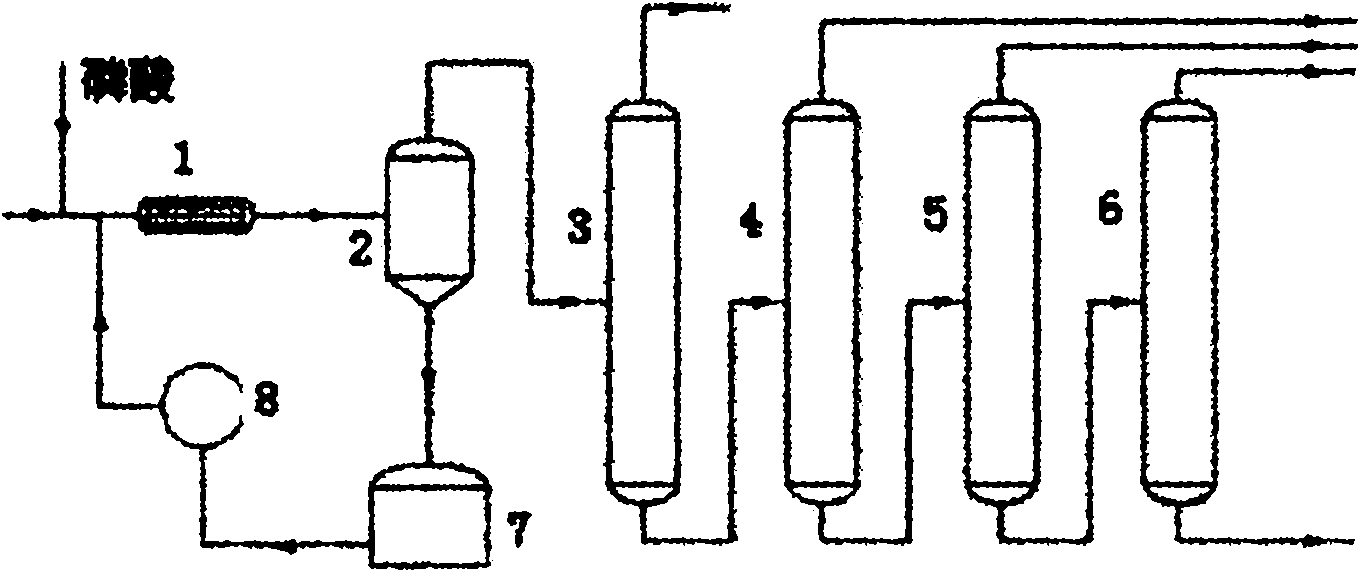

Method and device for recovering polyethylene glycol raffinate byproduct from ethylene glycol process

InactiveCN102010294AImprove film formationReduce corrosionEther separation/purificationMultistage water/sewage treatmentAlcoholPolyethylene glycol

The invention relates to a method and a device for recovering a polyethylene glycol raffinate byproduct form an ethylene glycol process. The method comprises the following steps of: (1) adding phosphoric acid into the polyethylene glycol raffinate, controlling the pH value to be between 7 and 9, conveying the mixture to a preheater (1), and preheating; (2) allowing a preheated material to enter a scraper falling-film evaporator (2), discharging a material at the bottom of the evaporator into an intermediate tank (3), and allowing the material to enter the preheater (1) through a centrifugal separator (8); (3) conveying the mixture of water and alcohol on the top of the falling-film evaporator to a dehydration rectifying tower (3); (4) conveying a mixed alcohol material at the bottom of the tower to an ethylene glycol separating tower (4); (5) conveying the material at the bottom of the tower to a diethylene glycol separating tower (5); and (6) conveying the material at the bottom to a triethylene glycol separating tower (6), and collecting products on the top and bottom of the tower respectively. The method is simple, efficient and low in energy consumption, and is suitable for industrial application; and by the method, the utilization rate of the raffinate produced by ethylene glycol is improved.

Owner:NINGBO POLYTECHNIC +1

Gold plating liquid and gold plating method

InactiveUS20090038957A1Improve stabilitySimply and easily formedPhotography auxillary processesCoatingsPolyolDiethylene glycol

In a stable gold plating liquid having a low toxicity besides properties comparable to those of a cyan-type gold plating liquid, iodine and / or iodide ions, gold ions, and a polyalcohol having at least 4 carbon atoms are contained. The polyalcohol having at least 4 carbon atoms may be diethylene glycol or triethylene glycol. The content of the polyalcohol having at least 4 carbon atoms in the gold plating liquid is generally 10 to 90 percent by weight. The gold plating liquid may contain water.

Owner:MITSUBISHI CHEM CORP +1

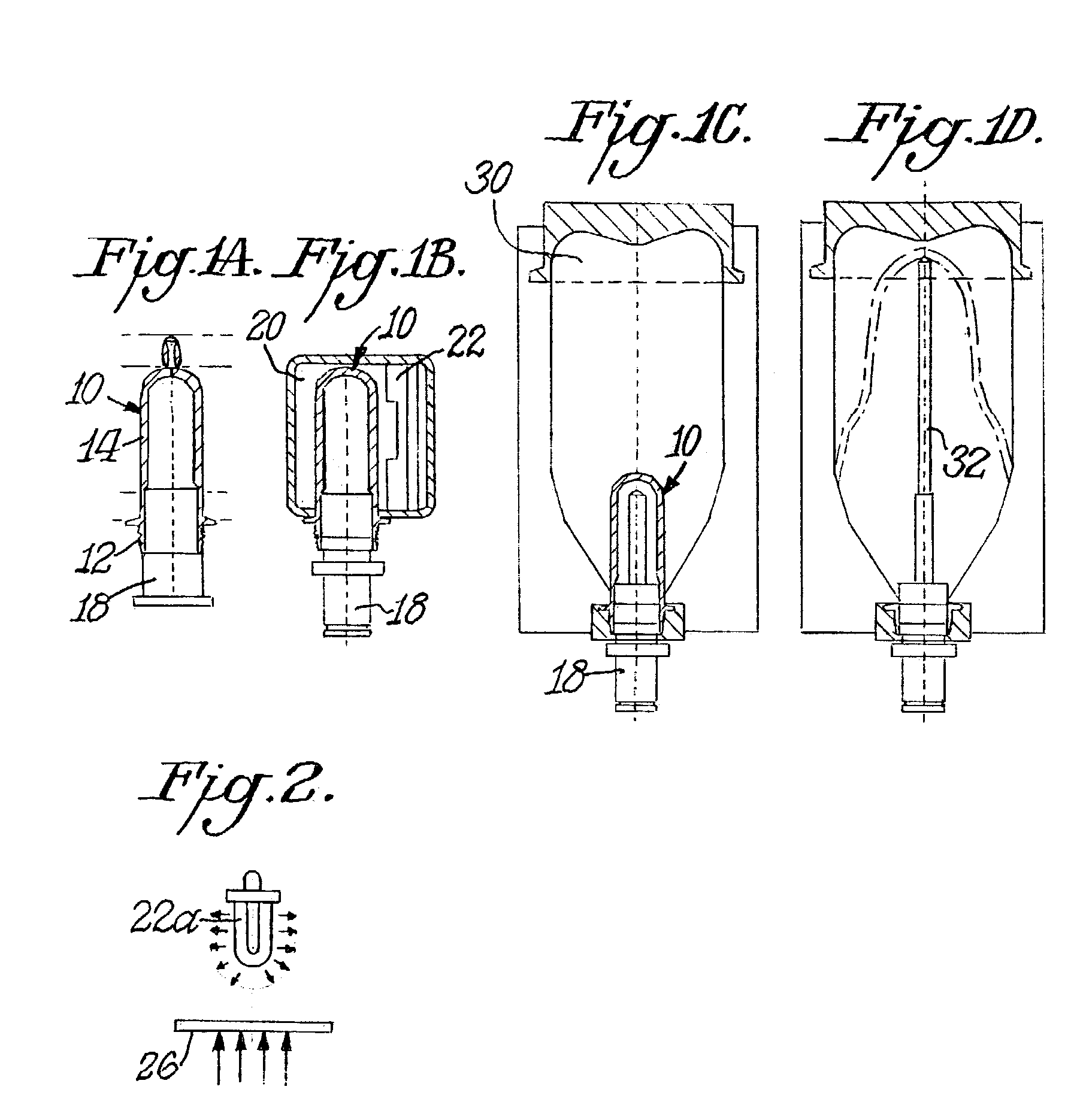

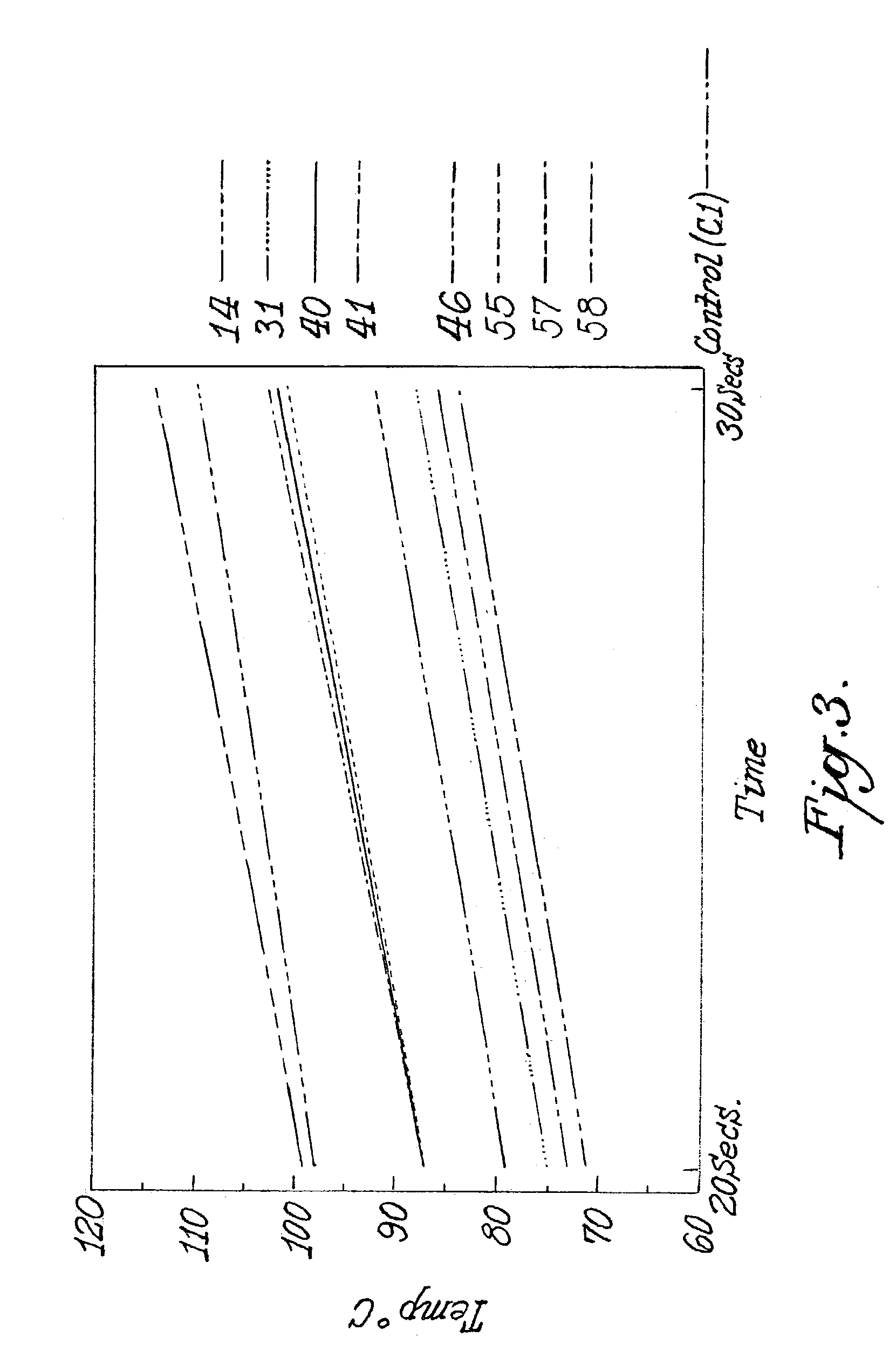

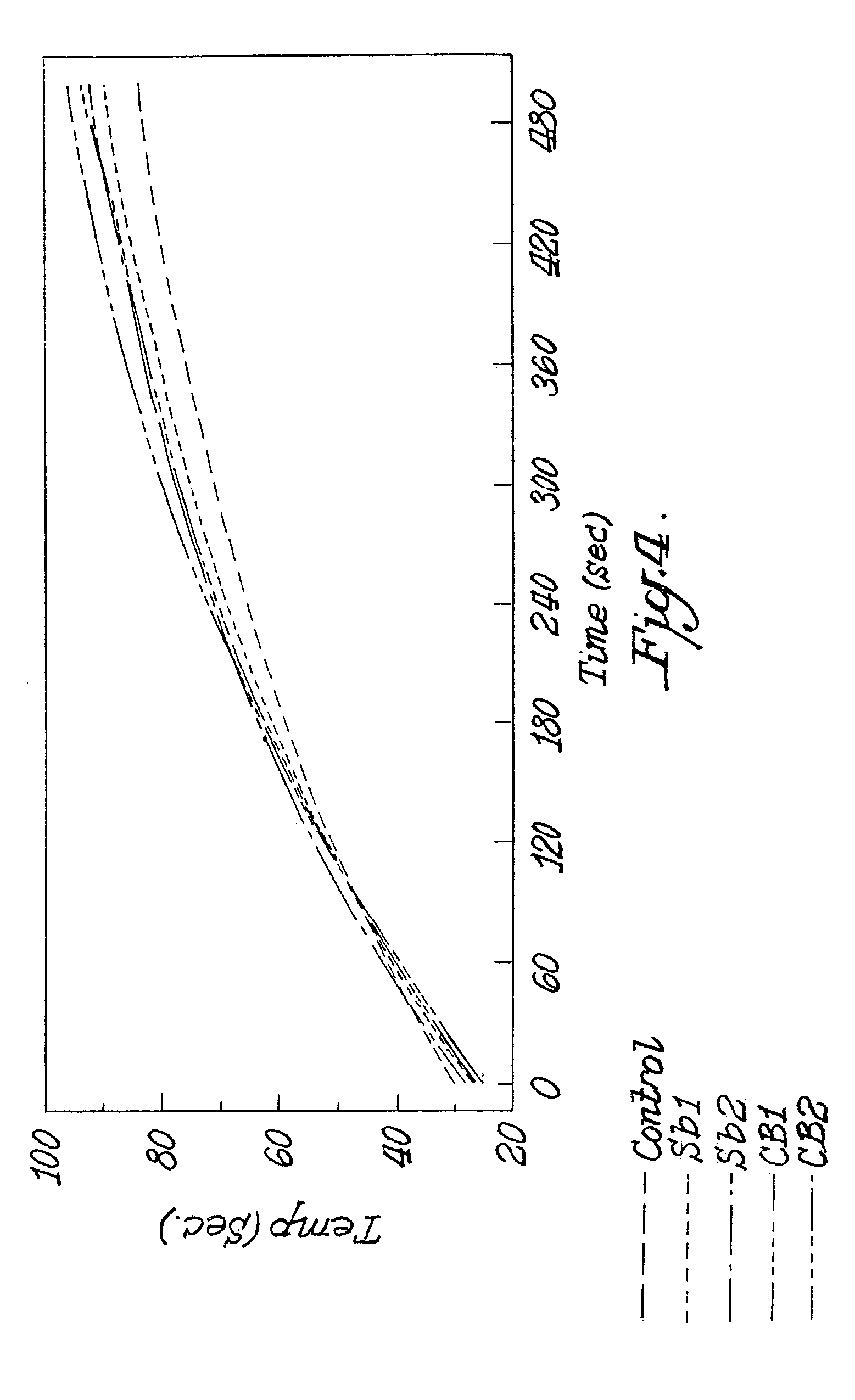

Molding of polypropylene with enhanced reheat characteristics

InactiveUS7303795B2Synthetic resin layered productsDomestic articlesHigh concentrationIn situ chemical reduction

Bottles, containers and other articles are formed from polypropylene compositions that include a reheating agent, such as antimony, carbon black, graphite, titanium, copper, manganese, iron, tungsten, graphite, infra-red absorbing dyes or other infra-red absorbing material. The reheating time for the polypropylene composition is shortened for injection stretch blow molding or thermoforming, and the polypropylene granule composition with reheating agent has an L* value of at least 80% of the L* value for a polypropylene granule control without added reheating agents as measured by the Gardner color test. The reheating agent may be incorporated into the polypropylene composition by in situ chemical reduction of a metal compound, such as antimony triglycolate, with a reducing agent, such as hypophosphorous acid. In addition, the polypropylene composition with reheating agent may be derived from a polypropylene masterbatch with high concentrations of reheating agent.

Owner:INVISTA NORTH AMERICA R L

Oil and low-temperature resistant low-smoke and halogen-free flame retardant cable material for boats, and its preparation method

ActiveCN102977609AImprove flame retardant performanceExcellent non-flammabilityInsulated cablesInsulated conductorsMeth-Carbamate

The invention provides an oil and low-temperature resistant low-smoke and halogen-free flame retardant cable material for boats. The cable material is prepared from the following raw materials, by weight, 20-30 parts of polyurethane, 60-80 parts of methyl vinyl silicone rubber, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of magnesium hydroxide, 0.5-1.0 part of butyl stearate, 1-3 parts of barium stearate, 8-12 parts of triglycol dioctate, 4-6 parts of copper oxide, 0.5-1.0 parts of molybdenum trioxide, 30-50 parts of fumed silica, 10-13 parts of modified argil, 0.5-1.0 part of an antioxidant H, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter NOBS, 0.2-0.5 parts of a vulcanizing agent DCBP, 8-10 parts of triphenyl phosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance.

Owner:广东蓝宇塑料制品有限公司

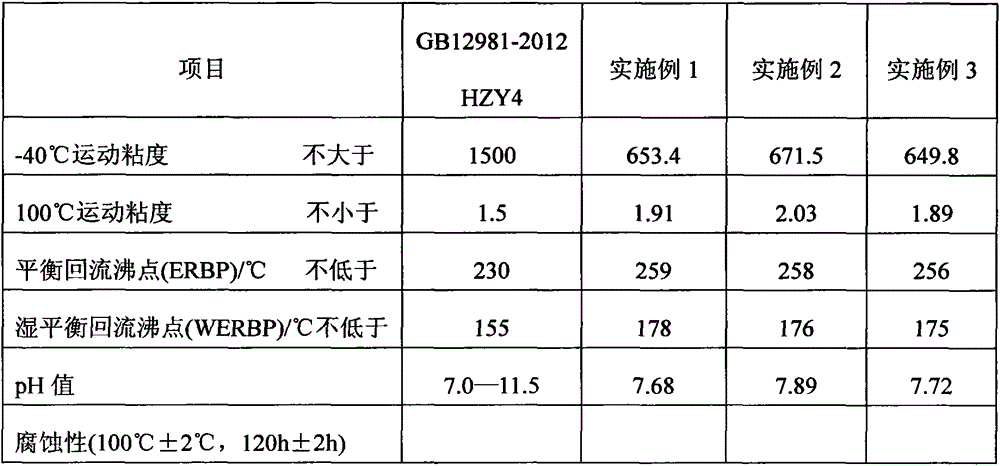

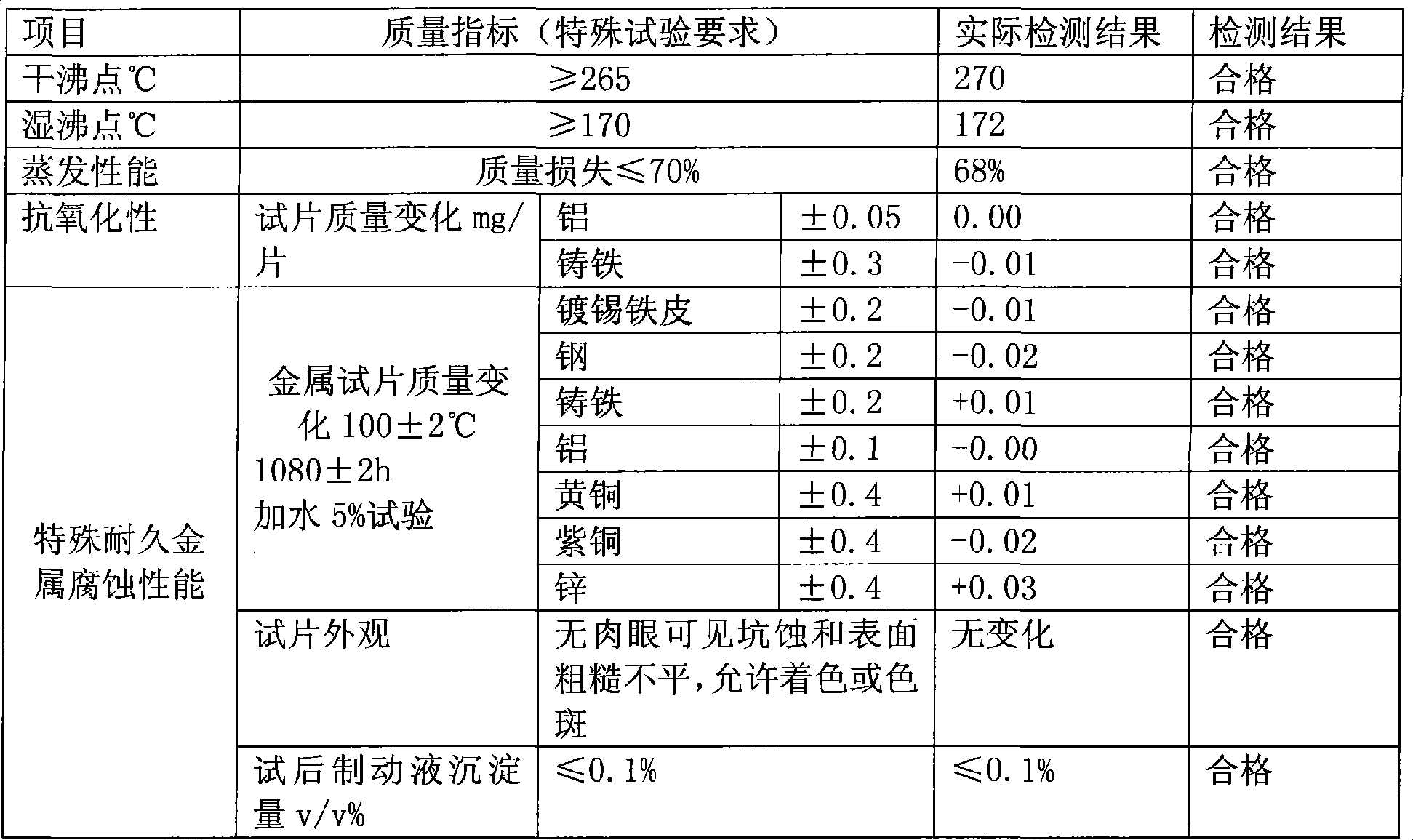

Advanced locomotive brake fluid composition

The invention discloses an advanced locomotive brake fluid composition, and relates to a car brake fluid composition, and the advanced locomotive brake fluid composition is invented fro solving the problems of poor compatibility, poor corrosion resistance and poor low-temperature performance of an existing car brake fluid. The advanced locomotive brake fluid composition is prepared from the following raw materials in percentage by weight: 60-74% of triethylene glycol monomethyl ether borate, 10-21% of di-ethylene glycol di-butyl ether, 14-20% of a polyalcohol rubber expansion restraint, 0.1-1.0% of an antioxidant, 0.1-1.0% of a preservative and 0.5-1.0% of a pH regulator. A preparation method for advanced locomotive brake fluid composition comprises the following steps: preparing triethylene glycol monomethyl ether borate from triethylene glycol monomethyl ether and borate at a weight ratio of 10 to 1; then, adding raw materials into a reaction kettle, stirring for 60 minutes at a normal temperature under normal pressure, and keeping the stirring speed at 50r / min; and after sufficiently mixing and dissolving various raw materials, sampling, detecting, filtering and guiding the raw materials into a finished product tank. The advanced locomotive brake fluid composition has the advantages of good compatibility, good corrosion resistance and good low-temperature performance.

Owner:LIAONING RUNDI AUTOMOTVE ENVIRONMENTAL PROTECTIONTECH

Solutions and Catalysts Comprising Group VI Metal, Group VIII Metal, Phosphorus and An Additive

ActiveUS20120145600A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyethylene glycolMonoethylene Glycol

This invention provides a process for forming a solution composition, which process comprises forming a primary solution by bringing together, in an aqueous medium, i) at least one phosphorus compound, ii) at least one Group VI metal compound, iii) at least one Group VIII metal compound, and iv) an additive which is a) tetraethylene glycol, b) polyethylene glycol having an average molecular weight in the range of about 200 to about 400, c) a mixture of tetraethylene glycol and polyethylene glycol having an average molecular weight in the range of about 200 to about 400, or d) a mixture of (1) tetraethylene glycol and / or polyethylene glycol having an average molecular weight in the range of about 200 to about 400 and (2) one or more of monoethylene glycol, diethylene glycol, and triethylene glycol. The molar ratio of additive to the total moles of Group VI metal and Group VIII metal is above 0.30:1, and the atomic ratio of phosphorus to Group VI metal is at least about 0.33:1. Optionally, the primary solution is heated at a temperature above about 40° C. to form a heated solution. The heated solution is optionally cooled to form a cooled solution. Also provided are compositions formed by such processes, processes for forming catalyst compositions from these compositions, and catalyst compositions formed by these processes.

Owner:ALBEMARLE EURO

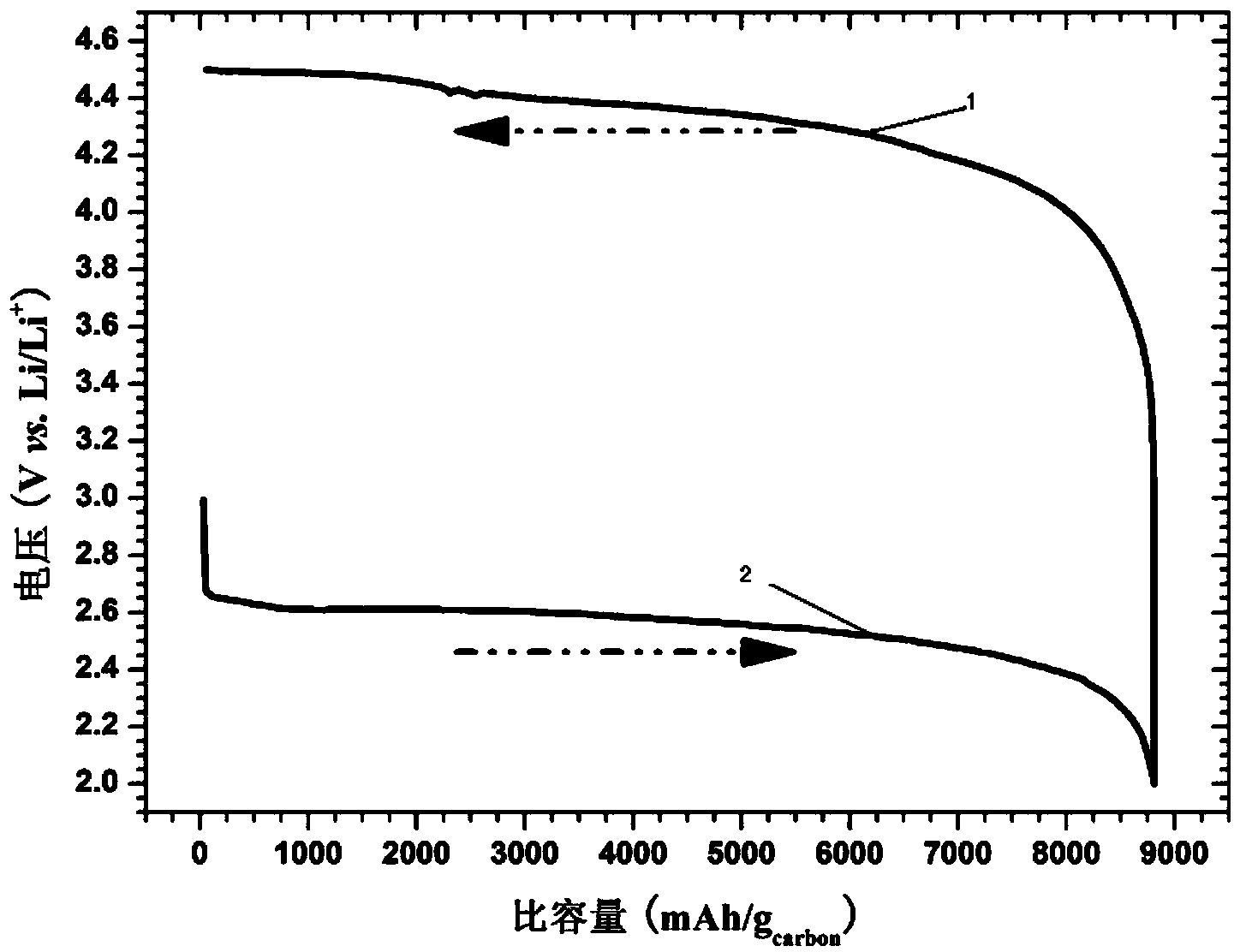

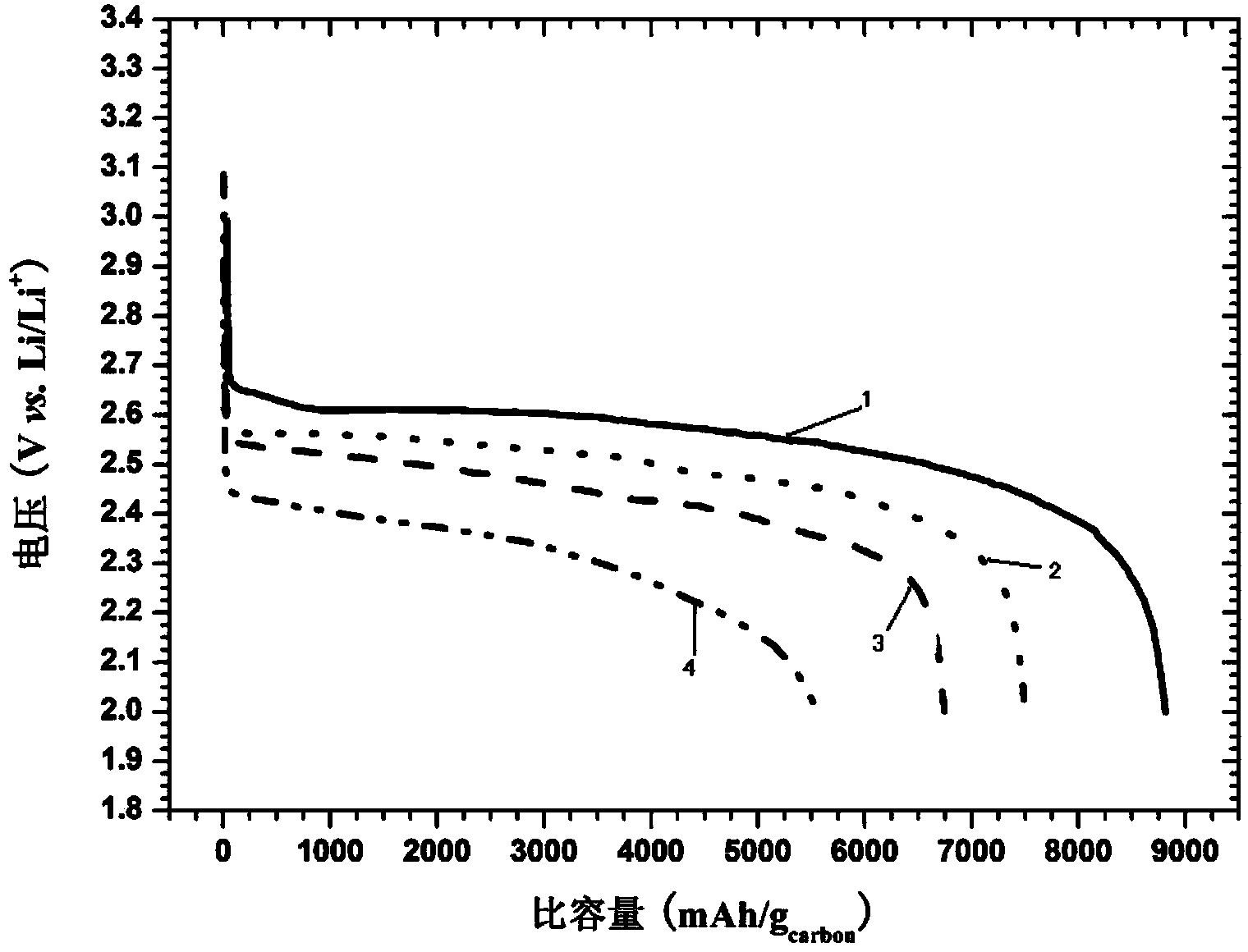

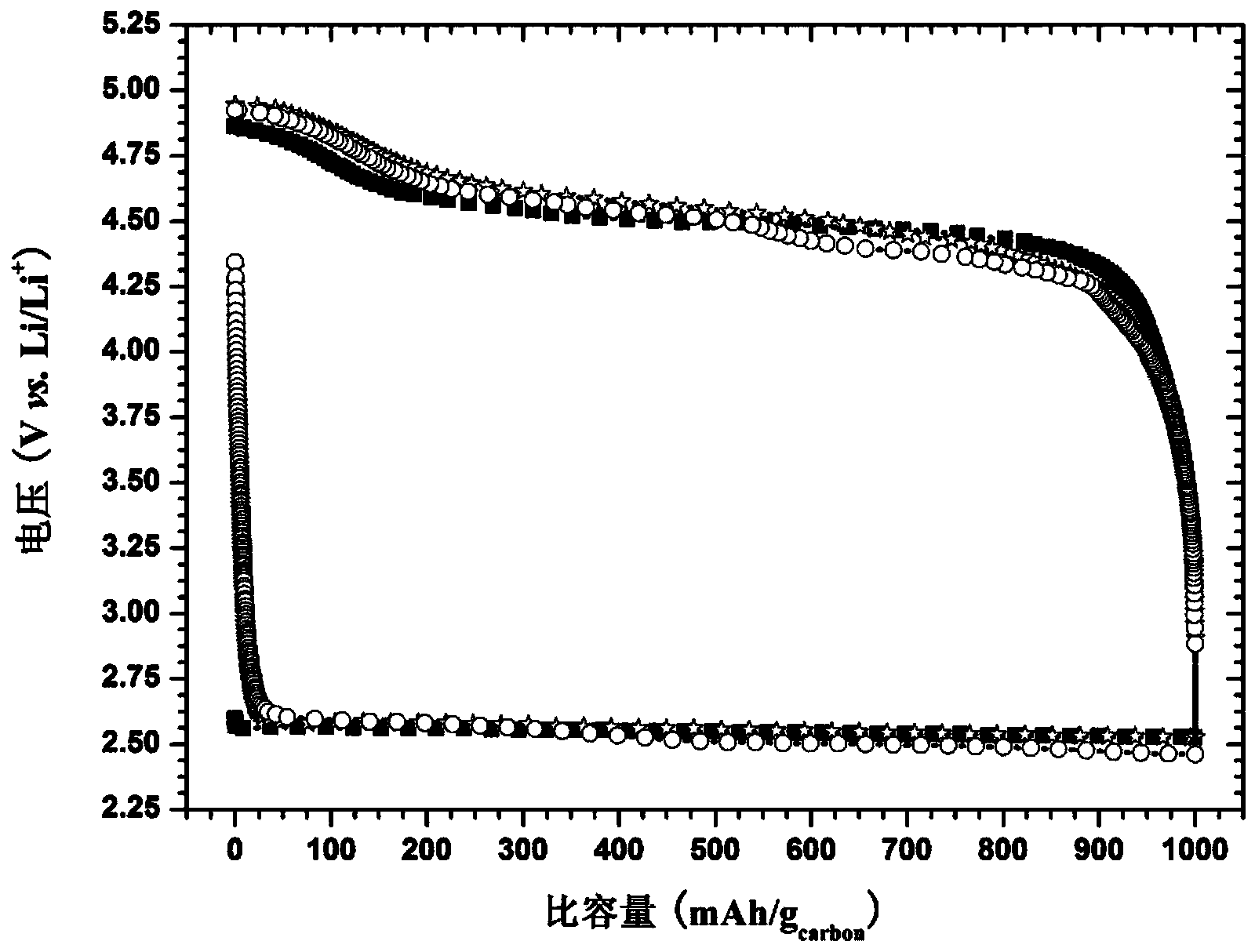

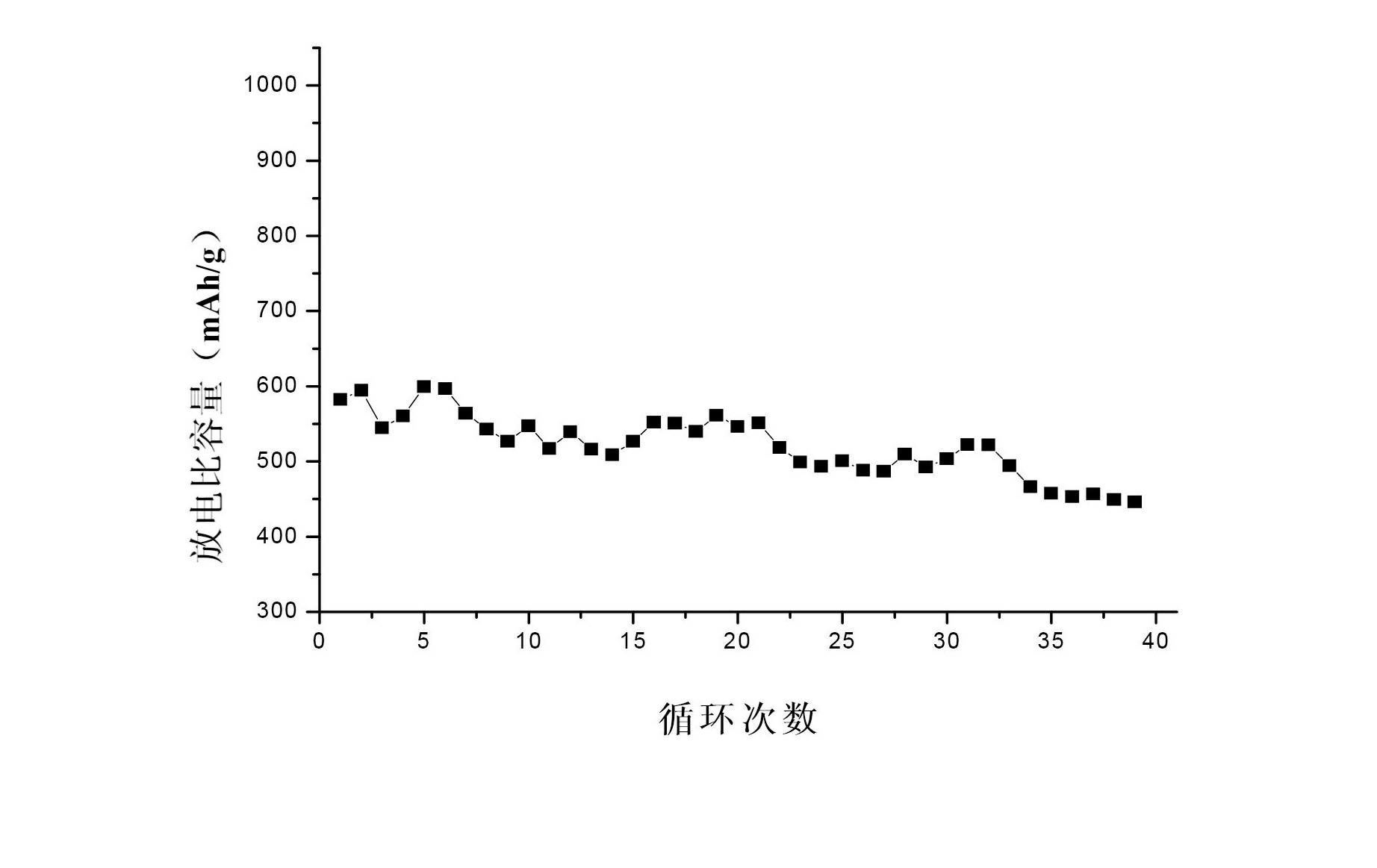

Ether electrolyte and lithium air battery

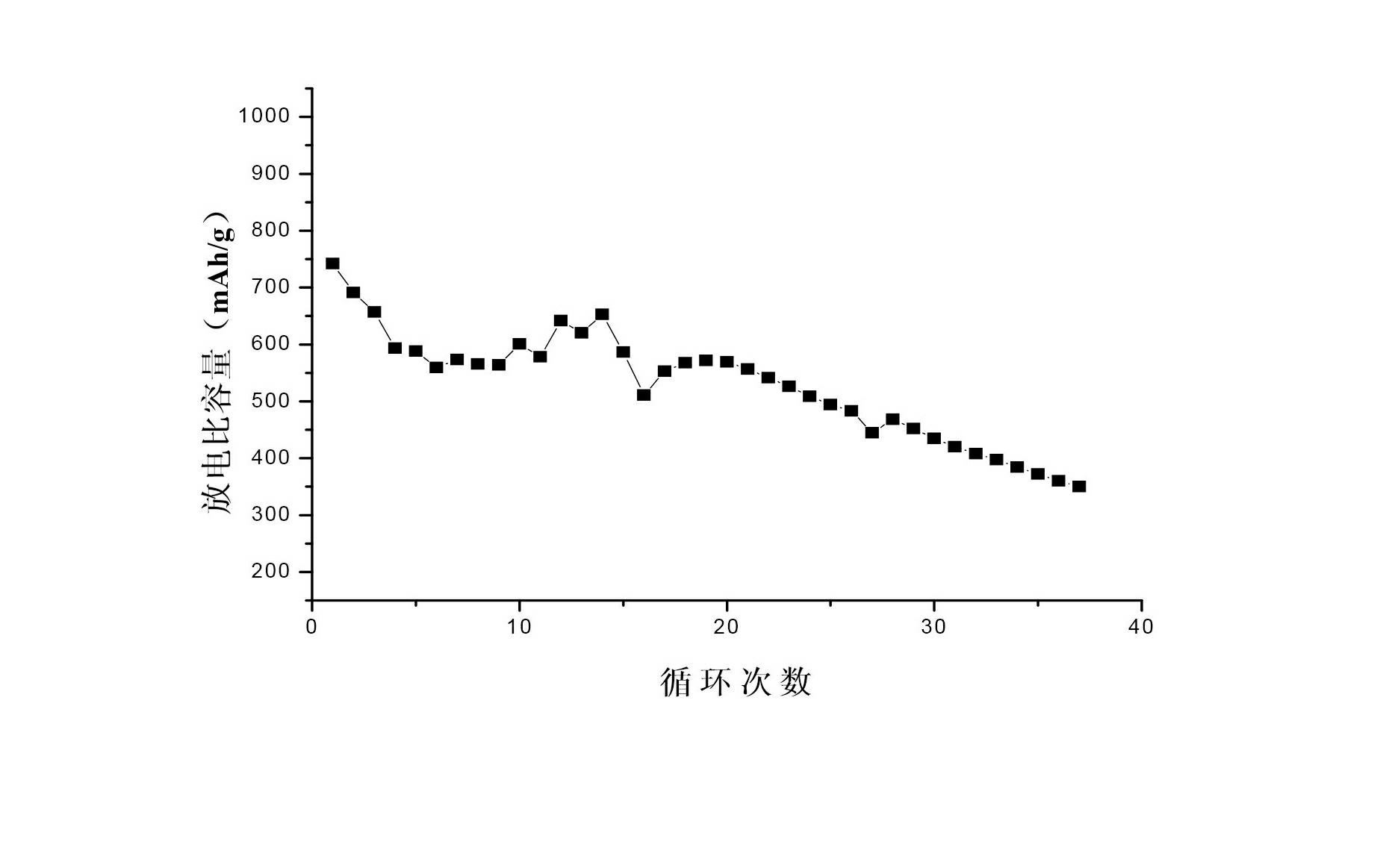

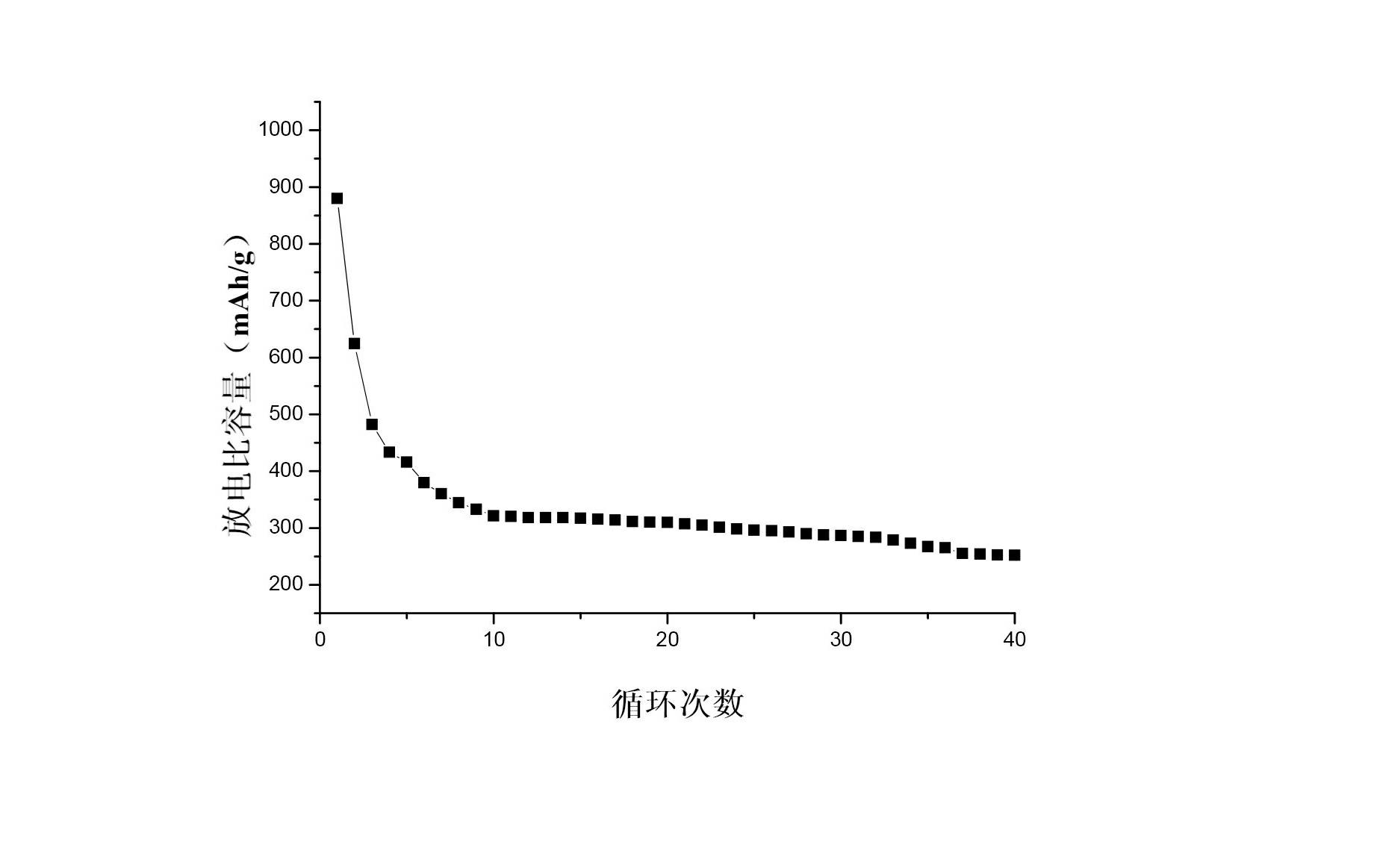

InactiveCN103996892ANot volatileImprove oxygen solubilityFuel and primary cellsFuel and secondary cellsCharge dischargeOxygen

The invention provides ether electrolyte. The ether electrolyte comprises lithium salt and an organic solvent, wherein the organic solvent comprises one or more of 1,2-dimethoxyethane, diethylene glycol dimethyl ether, triethylene glycol dimethyl ether and tetraethylene glycol dimethyl ether. The ether electrolyte has advantages that the ether electrolyte is unlikely to volatize, the oxygen dissolving degree is high, the electrochemical stable window is wide, and the like, and has excellent chemical stability for a discharging intermediate product O2<-1> or LiO2 and a discharging final product Li2O2. The lithium air battery prepared by utilizing the ethers electrolyte is excellent in long cycling stability. The experimental result shows that a charging-discharging curve is not obviously changed after the lithium air battery assembled by utilizing the ether electrolyte is circularly charged and discharged for 30 times at a limit capacity of 1,000mAh / g under the current density of 100mA / g.

Owner:常州盈华高科储能材料科技有限公司 +1

Aqueous coating material, method for the production thereof, and use thereof

ActiveCN101331196AEasy to manufactureLess spray cakingPolyurea/polyurethane coatingsSulfolane1-Pentanol

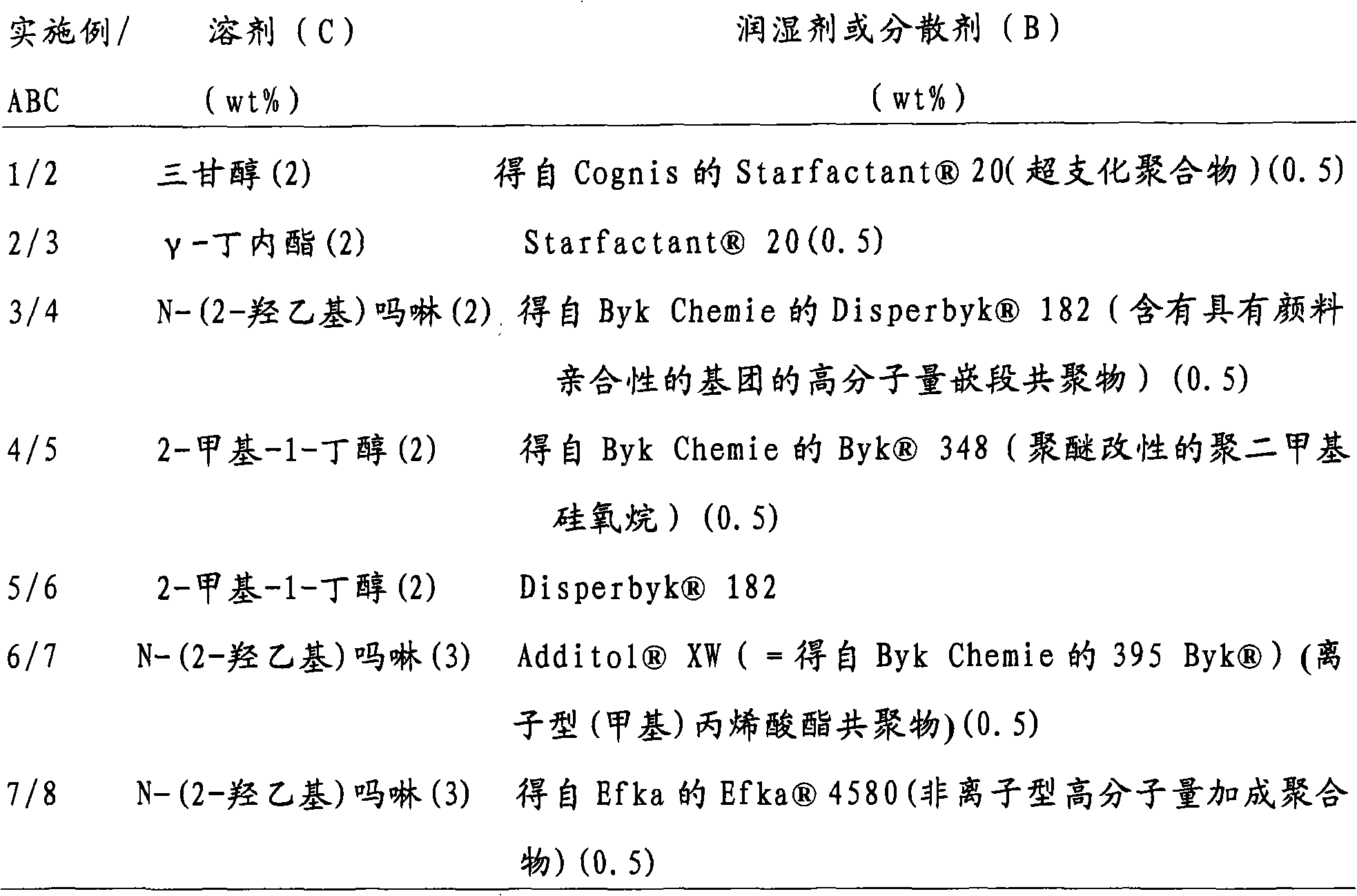

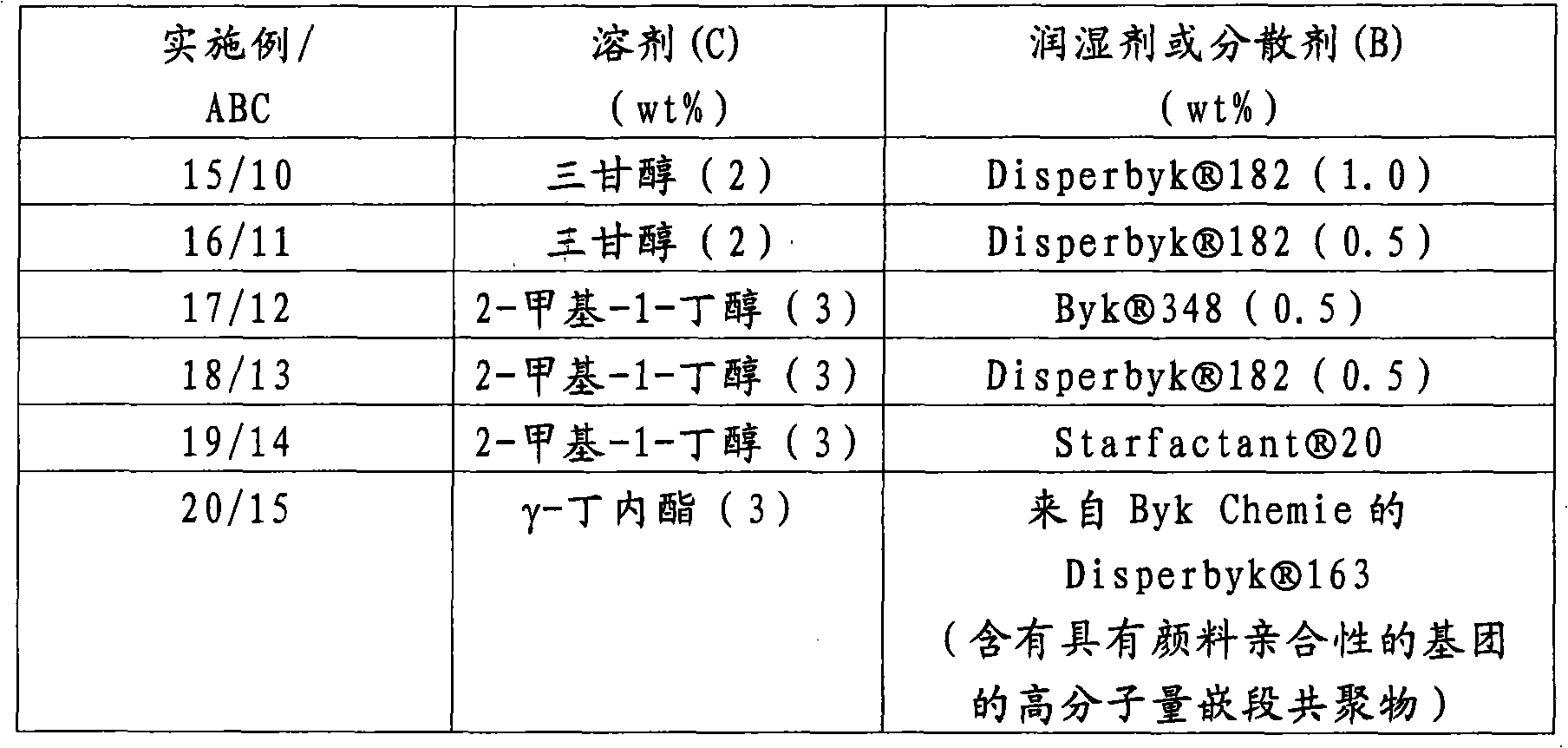

Disclosed is an aqueous coating material containing (A) at least one saturated and / or unsaturated polyurethane and / or an ionically and / or non-ionically stabilized polyurethane grafted with olefinically unsaturated compounds, (B) at least one wetting agent or dispersing agent, and (C) at least one organic solvent selected among the group comprising dimethylsulfoxide, sulfolane, 2-methyl-1-butanol, 3-methyl-1-butanol, 2-methyl-1-pentanol, hexylglycol, 1,6-hexanediol, diethylene glycol, triethylene glycol, glycerin, trimethylolpropane solutions, pentaerythrite solutions, sorbit solutions, reactive polyether polyols having a number-average molecular weight of 110 to 6,000 Dalton and a hydroxyl number of 25 to 1,000 mg KOH / g, propylene glycol monobutyl ether, dipropylene glycol dimethyl ether, glycerin ethoxylate, ethyl-3-ethoxypropionate, gamma-butyrolactone, N-(2-hydroxyethyl); -piperidine, N-methylmorpholine, N-(2-hydroxyethyl)-morpholine, N-acetylmorpholine, N-cyclohexyl pyrrolidone, and N-octyl-2-pyrrolidone. Also disclosed are a method for producing said aqueous coating material and the use thereof.

Owner:BASF COATINGS GMBH

Electronic mouth cavity atomized liquid using multi-element ethanediol series lower alcohols as base solution

The invention discloses electronic mouth cavity atomized liquid using multi-element ethanediol series lower alcohols as a base solution. The electronic mouth cavity atomized liquid is composed of 3%w / v to 5%w / v of tobacco leaf extracts, 30%w / v to 80%w / v of the lower alcohols, 5%w / v to 10%w / v of pure water, 3%w / v to 5%w / v of tobacco essence, 0%w / v to 3%w / v of nicotine, 0.2%w / v to 1.0%w / v of stabilizers, 3%w / v to 8%w / v of thickeners and 15%w / v to 20%w / v of taste modifiers, wherein the lower alcohols are the mixtures of triethylene glycol and / or tetraethylene glycol and / or pentaethylene glycol and / or hexaethylene glycol and / or heptaethylene glycol and / or octaethylene glycol and / or nonaethylene glycol. The electronic mouth cavity atomized liquid has the advantages that remaining taste is clear, fragrance lasts for a long time, and safety is realized after the electronic mouth cavity atomized liquid is used.

Owner:FEELLIFE BIOSCI INT

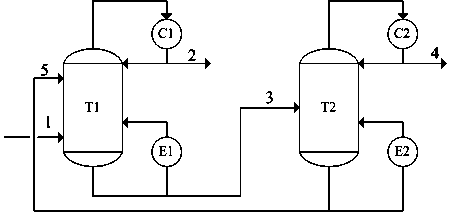

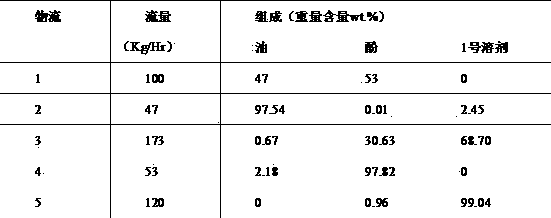

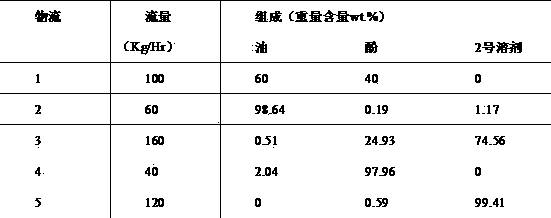

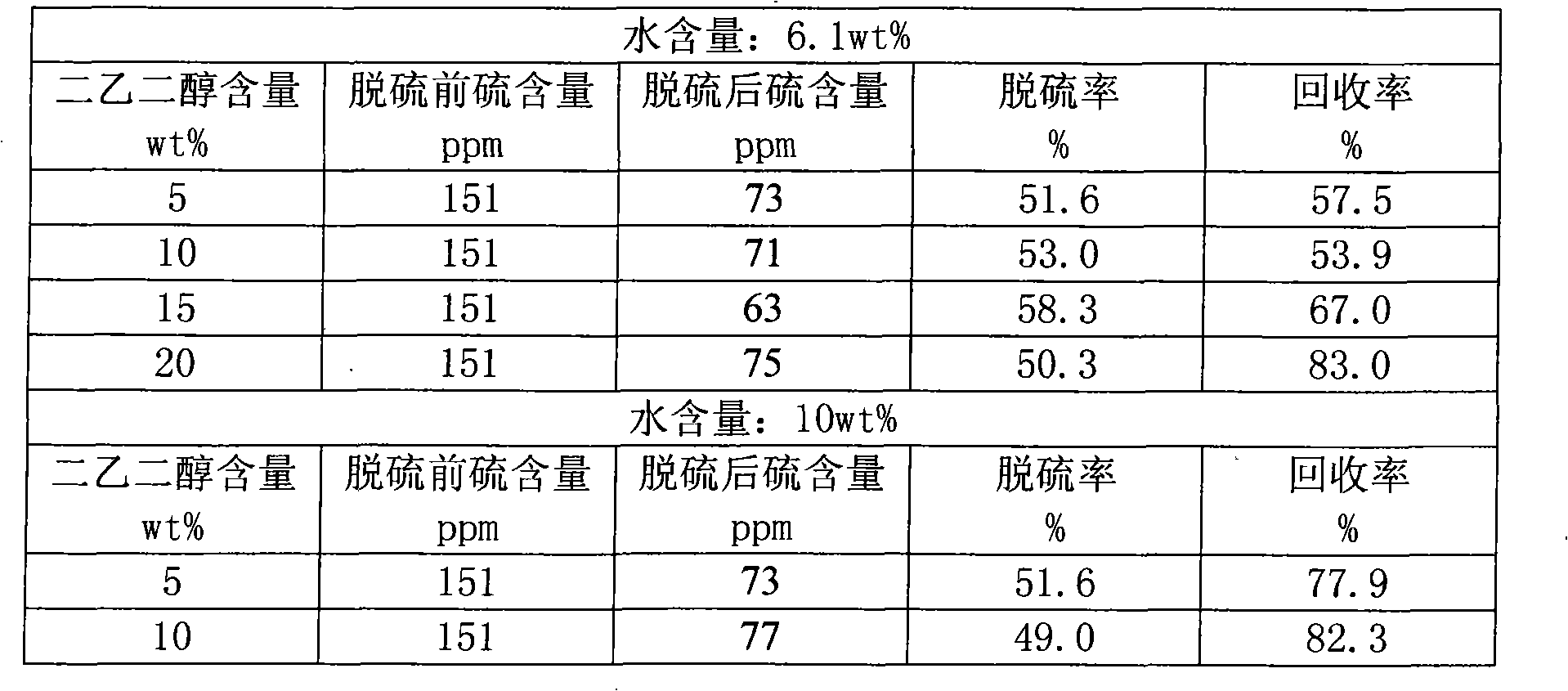

Method for extracting phenol compounds from direct coal liquefied oil through extractive distillation

ActiveCN103896739AHigh recovery rateIncrease relative volatilityOrganic chemistryOrganic compound preparationSulfolaneExtractive distillation

The invention relates to a method for extracting phenol compounds from direct coal liquefied oil through extractive distillation. An extractive distillation solvent (hereinafter referred to as solvent) adopted in the method is glyceryl triacetate and / or sulfolane, or a mixed solvent formed by mixing glyceryl triacetate and / or sulfolane and one or more selected from glycerol, triethanolamine, triethylene glycol, tetraethylene glycol, dimethyl sulfoxide and diethanol amine according to any proportion. The method is used for extracting phenol compounds from direct coal liquefied oil in an extraction distillation tower by using the solvent, then, a solvent flow rich in the phenol compounds enters a recovery tower and is separated, the phenol compounds discharged from the top of the recovery tower are recovered after being cooled to obtain phenol products, and the solvent is recycled after being discharged from the bottom of the recovery tower. The method has the characteristics of high product purity, low system energy consumption, no wastewater generation, no acid and alkaline waste and no corrosion to equipment.

Owner:TAIYUAN UNIV OF TECH

Dental filling composite resin using silicon dioxide nano-fiber as filler and preparation method thereof

InactiveCN104083289AGood physical and mechanical propertiesImprove wear resistanceImpression capsDentistry preparationsGlycidyl methacrylateTriethyleneglycol dimethacrylate

The invention discloses a dental filling composite resin using a silicon dioxide nano-fiber as a filler. The resin is prepared from the following raw materials in percentage by mass: 18-22 percent of bisphenol A-glycidyl methacrylate, 4-16 percent of triethylene glycol dimethacrylate, 0.5-1 percent of camphorquinone, 0.5-1 percent of ethyl 4-N,N-dimethylaminobenzoate and 60-75 percent of silicon dioxide nano-fiber. The preparation process is simple and easy to operate, the raw materials are easily available at relatively low price, and the prepared composite resin has excellent physical mechanical performance, good abrasion resistance and long service life, has the characteristics of light color, low polymerization shrinkage and the like, and is expected to be used in clinical application.

Owner:JIANGSU UNIV OF SCI & TECH

Extractive agent for depriving sulphide in C9 fuel oil and depriving method

The present invention relates to extractant used to remove sulfide in C9 fuel oil and a removing method. The extractant comprises N, N-dimethylformamide, dimethyl sulfoxide, N-methyl pyrrolidine, triethylene glycol, diethylene glycol, acetonitrile, methanol, ethanol or aqueous single-component solvent or double-component mixed solvent or three-component mixed solvent: the mass percentage composition of each component of the extractant is as follows: a first component: 70 percent to 100 percent; a second component: 0 percent to 30 percent; and a third component: 0 percent to 20 percent. According to a mass portion ratio which is 2 : 1 to 1 : 2, the C9 fuel oil and the extractant are blended, the extraction temperature is between 20 DEG C and 70 DEG C, the extraction time lasts 10 minutes to 60 minutes, the constant-temperature quiescence time lasts 20 minutes to 40 minutes, and after extraction, the C9 fuel oil phase is washed by water in order to wash out the solvent, so that desulfurized fuel oil is produced. The used extractant can take account of both the yield and desulfurization rate of the C9 fuel oil, the desulfurization rate can reach 58 percent, and the yield can reduce the pressure of the subsequent recovery of the solvent.

Owner:TIANJIN UNIV

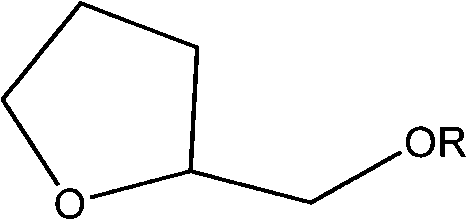

Vinyl content method for controlling polybutadiene in elastomer

A method of controlling the vinyl content in polybutadiene of elastomers relates to the polymer synthesis field. Symmetric Lewis base has the following problem in the application that the relatively high content of regulator will reduce the rate of polymerization and impact further polymerization as well as the coupling process after the polymerization. The invention introduces an asymmetric ethers-polar compound in a regulator system to form a composite regulation system with symmetrical ethers or amines compound, wherein, the asymmetric ethers compound is alkylte trahydrofurruryl ethers, and the other polar reagent can be symmetrical ethers or amines compound, such as N,n,n',n',n-Pentamethyldiethylenetriamine (hereinafter referred to as PMEDTA), diethylene glycol dimethyl ether (hereinafter referred to as 2G), triethylene glycol dimethyl ether (hereinafter referred to as 3G). The method of the invention can increase the content of vinyl, without reducing the rate of polymerization; the coupling efficiency of the coupling reaction can reach 90%.

Owner:BEIJING UNIV OF CHEM TECH

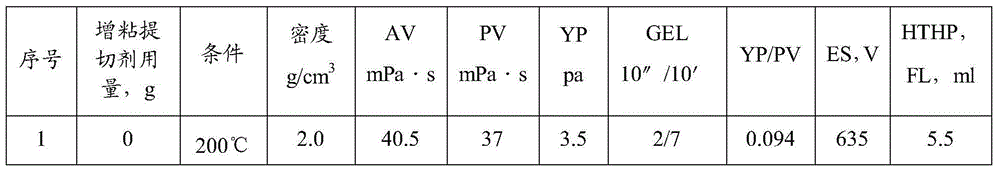

Tackifying and shear strength improving agent as well as preparation method and application of tackifying and shear strength improving agent

The invention relates to a tackifying and shear strength improving agent and a preparation method thereof. The tackifying and shear strength improving agent disclosed by the invention is prepared through the steps of reacting dimeric fatty acid and polyethylene polyamine according to the molar ratio, namely 1: (0.4-1.6) of carboxyl to amino in the existence of triethylene glycol monobuthyl ether, wherein the reaction temperature is 140-160 DEG C; keeping the temperature until no water comes off, and then, further reacting for 10-20 minutes to finish the reaction; and removing water generated by the reaction while reacting. A soilless oil-based drilling fluid system with the tackifying and shear strength improving agent is good in suspension property, enhanced in solid-phase and stratum water pollution resistance, little in reservoir damage, increased in system permeability recovery value, stable in performance, strong in inhibiting property, good in lubricating property, low in plastic viscosity and high in temperature resistance up to 260 DEG C.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Gold plating liquid and gold plating method

Disclosed is a gold plating liquid and a method for gold plating, wherein the gold plating liquid containing iodine and / or iodide ions, gold ions and a polyhydric alcohol having 4 or more carbon atoms. This gold plating liquid is stable and low in toxicity, while achieving performance comparable to cyan-type gold plating liquids. The polyhydric alcohol having 4 or more carbon atoms may be diethylene glycol or triethylene glycol. The amount of the polyhydric alcohol having 4 or more carbon atoms contained in the gold plating liquid is usually 10-90% by weight. The gold plating liquid may contain water.

Owner:MITSUBISHI CHEM CORP +1

Thermoplastic modified polyvinyl alcohol resin and preparation method thereof

ActiveCN105440521ALower melting temperatureSmooth realization of thermoplastic processingThermoplasticDecomposition

The invention discloses thermoplastic modified polyvinyl alcohol resin. The thermoplastic modified polyvinyl alcohol resin comprises an effective amount of carboxyl-modified polyvinyl alcohol, a plasticizer, soft water and a processing auxiliary agent. The carboxyl-modified polyvinyl alcohol is obtained by copolymerization of a vinyl acetate monomer and an unsaturated monomer containing carboxyl and then alcoholysis and has an alcoholysis degree of 95-99.9(mol)%, a polymerization degree of 1000-3500 and carboxyl content of 0.1-20mol%. The plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate. The processing auxiliary agent is at least one of talcum powder, silica, erucyl amide and saturated aliphatic dicarboxylic acid ester. The thermoplastic carboxyl-modified high temperature water soluble polyvinyl alcohol resin has a melting temperature of 120-200 DEG C and a decomposition temperature of 300 DEG C or more, can be dissolved in water at a temperature of 80-90 DEG C, is colorless and transparent, does not produce yellowing and has excellent quality.

Owner:重庆川维科技有限公司 +1

Electrolyte used for Li-S battery, Li-S battery and method for preparing electrolyte membrane contained in same

The invention discloses an electrolyte used for a Li-S battery, comprising an electrolyte membrane and electrolyte, wherein the electrolyte membrane takes PVDF (polyvinylidene fluoride) or PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene) as a main chain, the side chain of the main chain comprises one or more than one of lithium sulphonate group, lithium carboxylate group and lithium amide group; and the electrolyte is mixed solution containing at least one of 1,3-dioxolame, dimethoxyethane, diethylene glycol dimethyl ether, triethylene glycol dimethyl ether and sulfolane. The electrolyte, an anode and a cathode form the Li-S battery in the invention. The method for preparing the electrolyte membrane contained in the electrolyte comprises the following steps: firstly dissolving PVDF or PVDF-HFP, heating and stirring, and casting to obtain a membrane; treating the membrane with KOH / ethyl alcohol solution, then transferring the membrane into mixed solution of graft monomer / tetrahydrofuran, and adding formylamine peroxide for grafting; and cleaning the grafted membrane and soaking to obtain the electrolyte membrane. The electrolyte membrane in the invention is simple to prepare,the cost is low, the loss of active substance can be reduced, and the cycle life of the battery can be prolonged.

Owner:NAT UNIV OF DEFENSE TECH

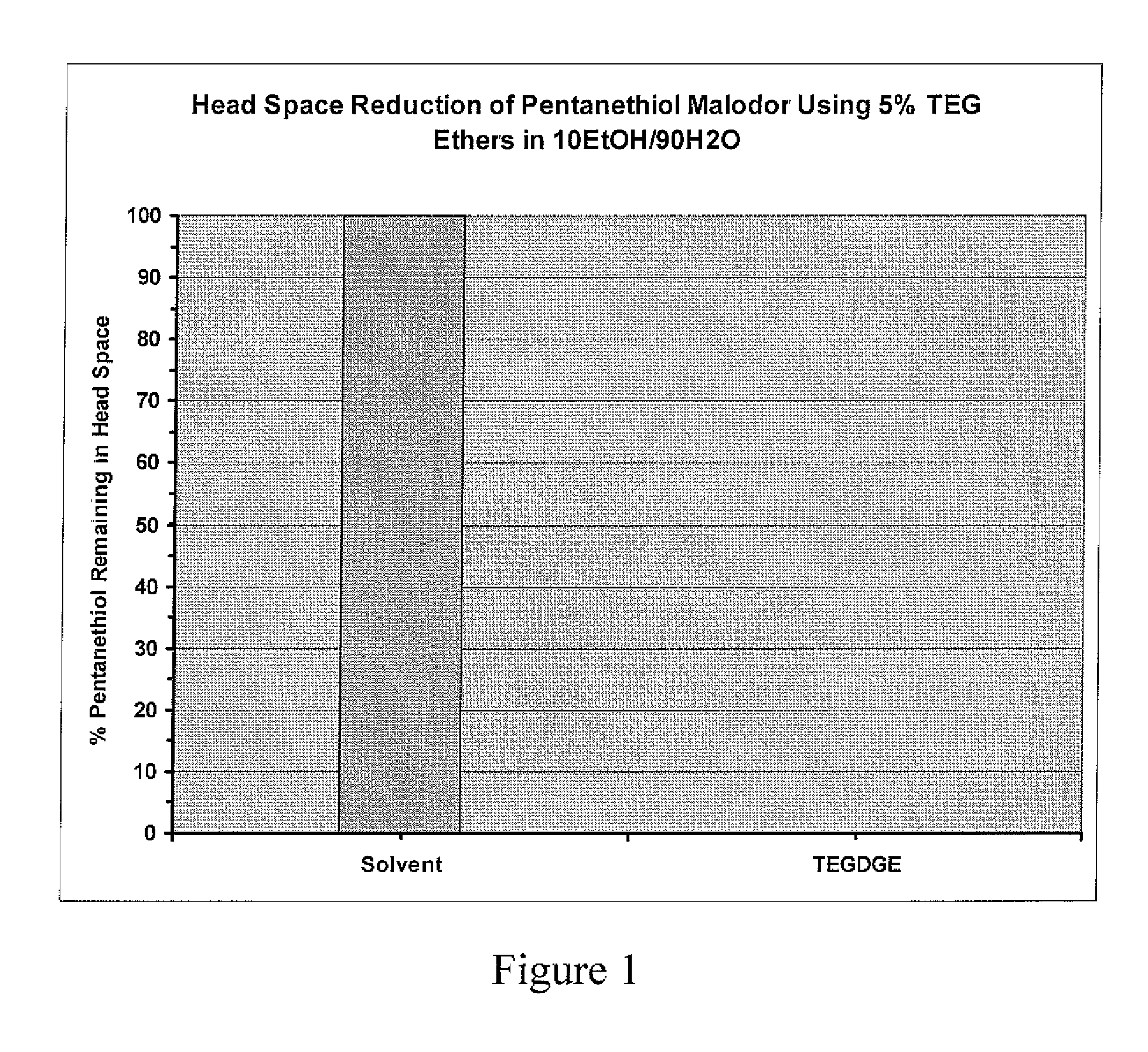

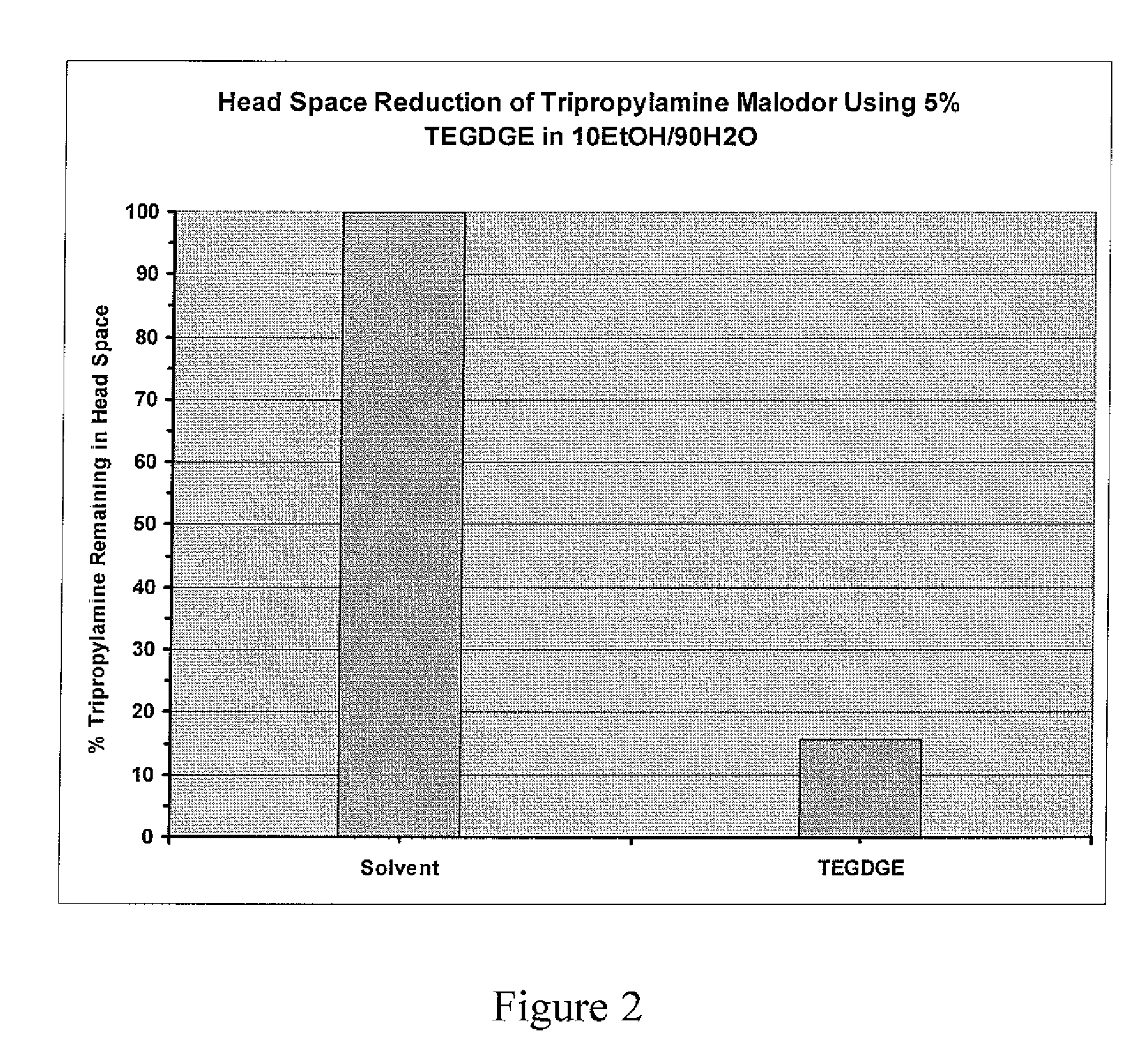

Odor elimination and air sanitizing composition

A deodorizing composition for eliminating airborne and surface malodors is disclosed. The composition comprises triethylene glycol di- and / or mono-glycidyl ether as the malodor counteractant(s). Optionally, the composition may further include triethylene glycol and / or other malodor counteractants. The deodorizing composition eliminates malodors at least by modification reactions between odor-causing molecules and triethylene glycol di- and / or mono-glycidyl ether thereby rendering the odor-causing molecules innocuous.

Owner:SC JOHNSON & SON INC

DOT4 boric acid ester type brake fluid

ActiveCN101418249ASolve the problem of long-term storage hydrolytic stabilityAdditivesBase-materialsMorpholinePhenol

The invention discloses a DOT4 boric acid ester type brake fluid, which comprises the following components in weight percentage: 4.3 to 4.7 percent of triethylene glycol methyl ether, 15 to 17 percent of tetraethylene glycol methyl ether, 1.9 to 2.1 percent of diethylene glycol, 74 to 76 percent of alcohol ether borate, 0.19 to 0.21 percent of benzotriazole, 0.33 to 0.37 percent of N-phenyl morpholine, 0.76 to 0.84 percent of tri-n-butylamine, 0.57 to 0.63 percent of 2, 2-di (4-hydroxyl phenyl) propane (bisphenol A), 0.057 to 0.063 percent of thiodipropionic acid didodecyl alcohol ester, 0.19 to 0.21 percent of 2.6-di-tert-butyl-4-methyl phenol, 0.095 to 0.105 percent of mercapto styrene-acrylic thiazole, and 0.38 to 0.42 percent of dodecatylene butane diacid (T746). The DOT4 boric acid ester type brake fluid has the advantages that the DOT4 boric acid ester type brake fluid can thoroughly solve the problem of hydrolytic stability of boric acid ester for long term storage by using a formulation technology of combining organic substances and additives.

Owner:张家港迪克汽车化学品有限公司

Textile dye as well as preparation method and waterless dyeing method of textile dye

ActiveCN107541966AReduce the impactAvoid hydrolysisDyeing processSodium bicarbonateNuclear chemistry

The invention belongs to the technical field of textile waterless dyeing and specifically discloses a textile dye as well as a preparation method and a waterless dyeing method of the textile dye. Thetextile dye is mainly prepared from the following components in parts by weight: 1-10 parts of toner, 3-30 parts of organic solvent, 3-5 parts of triethylene glycol, 2-4 parts of glycerin, 0.5-5 partsof sodium lignin sulfonate, 2-5 parts of sodium metanitrobenzene sulfonate, 1-10 parts of ammonium polyacryloyldimethyl taurate, 1-10 parts of triethanolamine alginate, 0.01-0.5 part of sodium bicarbonate, 1-2 parts of hexadecylpyridinium chloride, 0.5-1 part of coco-dimethylammonium diethyl sulfate and 50-90 parts of deionized water. According to the dye prepared by the invention and the waterless dyeing method, the dyeing effect is good; moreover, washing is not needed, thus any wastewater is not generated, environmental protection is facilitated, and the production cost is lowered.

Owner:KUNSHAN KAIZHOU ENVIRONMENTAL PROTECTION MACHINERY CO LTD

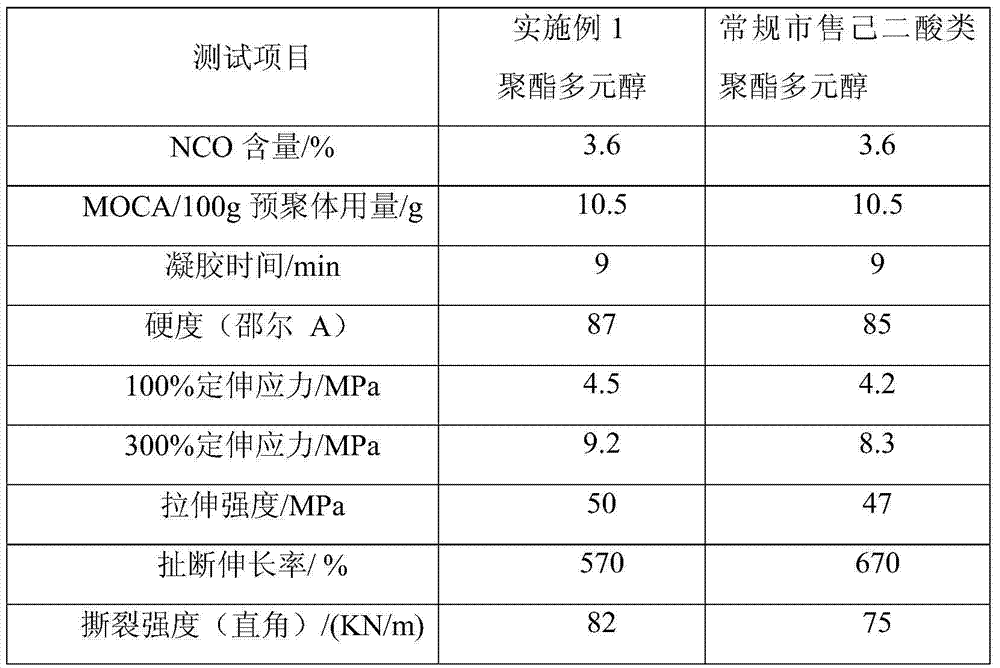

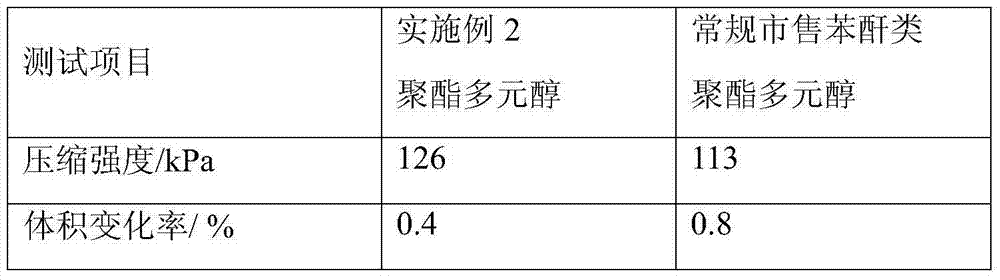

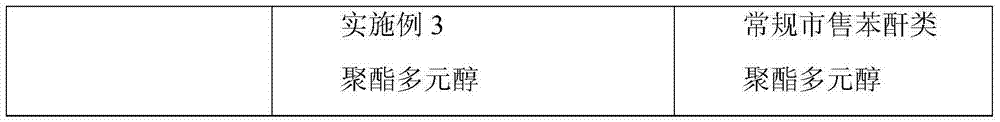

Mixed acid type polyester polyol and preparation method thereof

The invention relates to a polyester polyol, and particularly relates to a mixed acid type polyester polyol and a preparation method thereof. The mixed acid type polyester polyol is prepared from mixed acids and mixed alcohols through polymerization reaction under the action of a catalyst; the mixed acids are two or more of adipic acid, terephthalic acid, phthalic acid, isophthalic acid or phthalic anhydride; and the mixed alcohols are two or more of ethylene glycol, propylene glycol, 1,4-butanediol, pentanediol, glycerol, diethylene glycol, triethylene glycol, dipropylene glycol, polyethylene glycol, trimethylolpropane, pentaerythritol or sorbitol. According to the mixed acid type polyester polyol disclosed by the invention, the rigidity of an elastomer product is increased; the color of a composition is not deepened when the mixed acid type polyester polyol is applied to rigid polyurethane foam; the intersolubility stability with the composition is increased; the compressive strength and the dimensional stability of the polyurethane foam are improved; and the preparation method disclosed by the invention is simple in posttreatment and suitable for industrialized production.

Owner:SHANDONG INOV POLYURETHANE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com