Advanced locomotive brake fluid composition

A technology for motor vehicles and brake fluids, which is applied in lubricating compositions, petroleum industry, additives, etc. It can solve the problems of compatibility, oxidation resistance, corrosion resistance, high temperature resistance and low temperature performance, and achieve easy raw materials. Obtain, solve the effect of poor fluidity and good anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the triethylene glycol monomethyl ether borate is as follows: metering triethylene glycol monomethyl ether into a closed reaction kettle with heating and decompression functions, stirring, and when the temperature is raised to 60 ° C, the boric acid Add it into the reaction kettle, stir, raise the temperature, reduce the pressure (the pressure is -0.09--1.0Mpa), control the temperature at 90-150°C, and react for 4h. After the reaction, take a sample from the kettle to detect the water content. When the water content is ≤0.1%, a qualified esterification liquid is obtained, that is, the esterification is completed, and the weight ratio of triethylene glycol monomethyl ether and boric acid is 10:1;

[0022] Production process: put triethylene glycol monomethyl ether borate, diethylene glycol dibutyl ether, polyol rubber expansion inhibitor, antioxidant, preservative and pH regulator into the reaction kettle according to the above percentages, at ro...

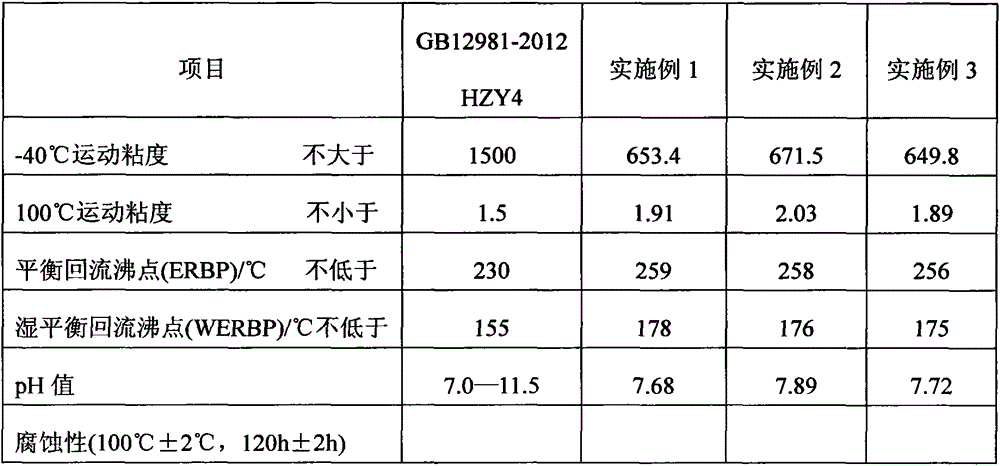

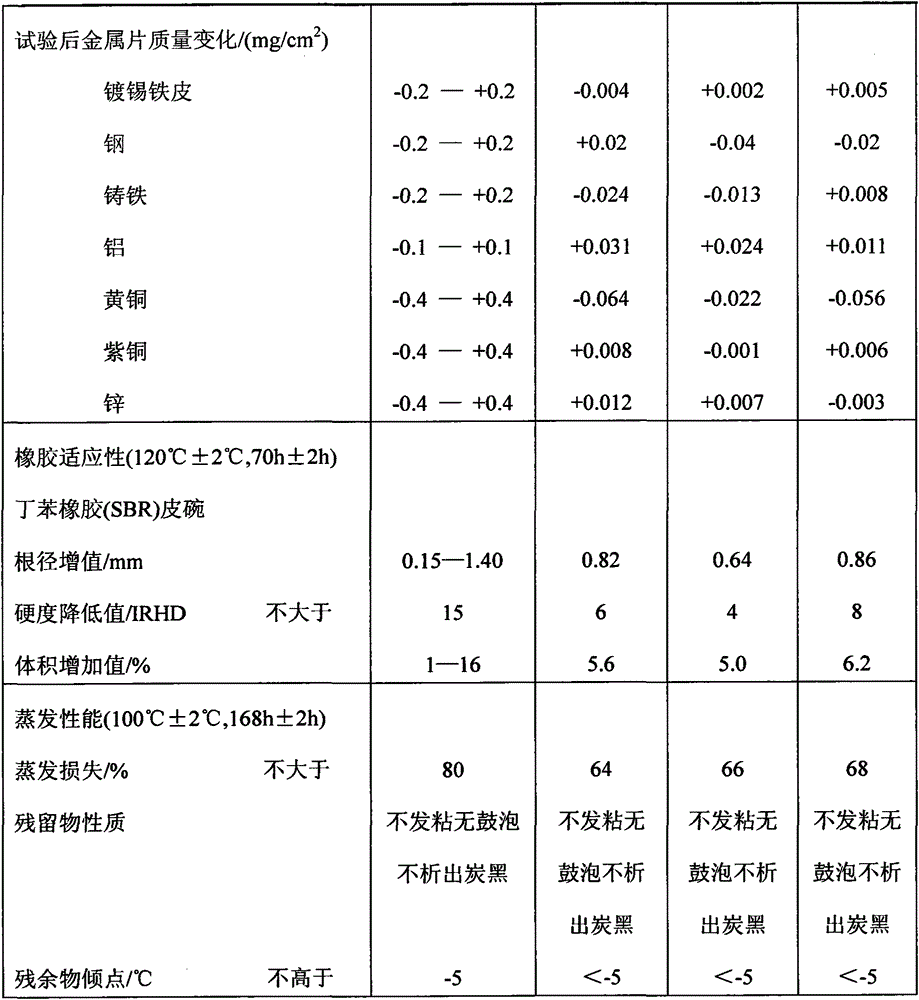

Embodiment 1

[0029] Take 61% of triethylene glycol monomethyl ether borate, 17.8% of diethylene glycol dibutyl ether, 20% of triethylene glycol, 0.2% of antioxidant 501, 0.2% of benzotriazole, Di-n-butylamine ether 0.8%, add the above raw materials into the reaction kettle in turn, stir at normal temperature and pressure for 60 minutes, after the various raw materials are fully mixed and dissolved, take samples from the kettle for testing, after passing the test, filter, and import it into the finished product tank for standby.

Embodiment 2

[0031] Take triethylene glycol monomethyl ether borate 73%, thinner diethylene glycol dibutyl ether 10.72%, diethylene glycol 15%, antioxidant 300 0.18%, methyl benzotriazole 0.5% by mass percentage %, 0.6% of 3-methylamine ether, add the above raw materials into the reaction kettle one by one, stir at room temperature and pressure for 60 minutes, after the various raw materials are fully mixed and dissolved, take samples from the kettle for inspection, after the inspection is qualified, filter and import into the finished product tank in spare.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com