Patents

Literature

405 results about "Butylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butylamine may refer to any of several related chemical compounds: n-Butylamine sec-Butylamine tert-Butylamine Isobutylamine

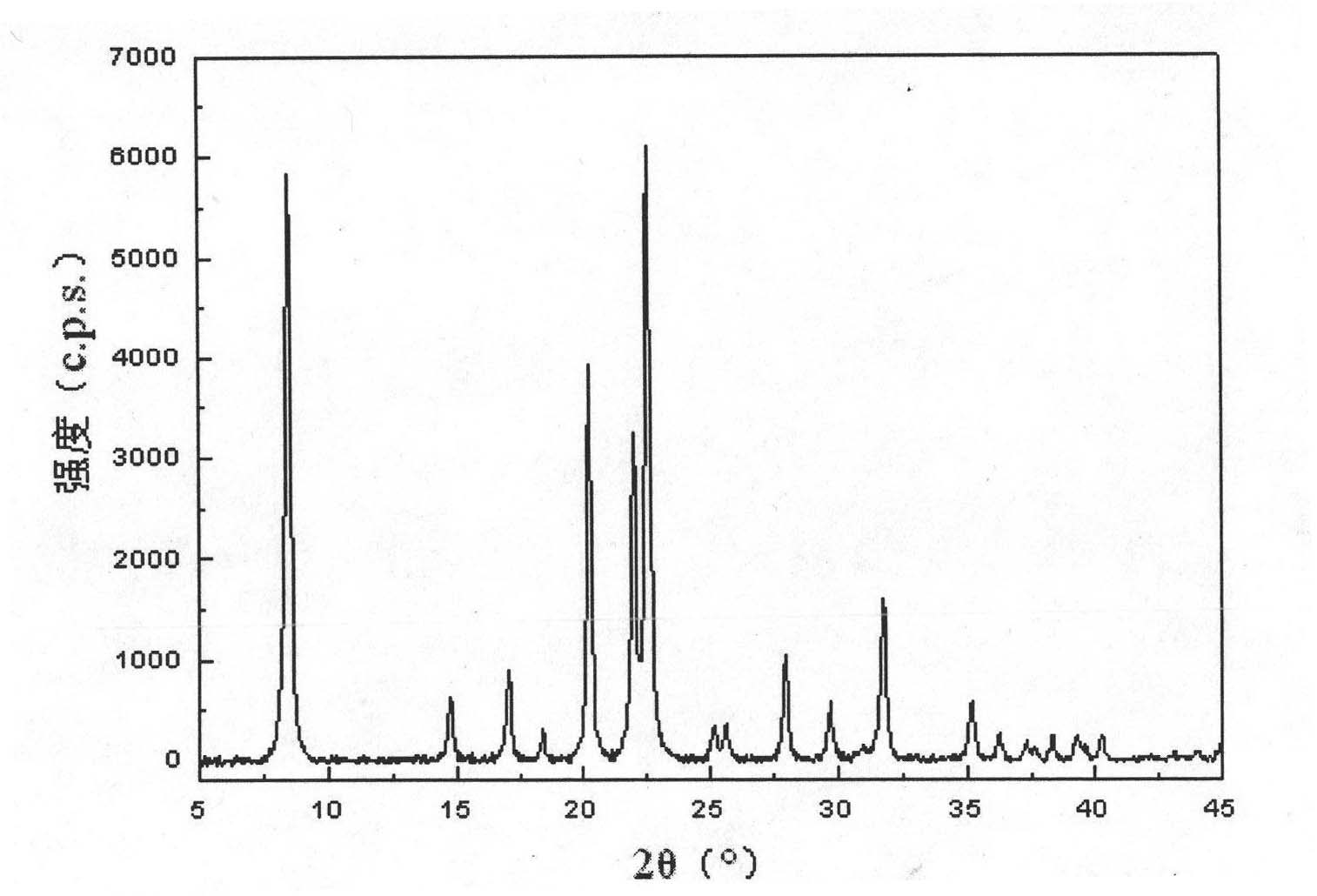

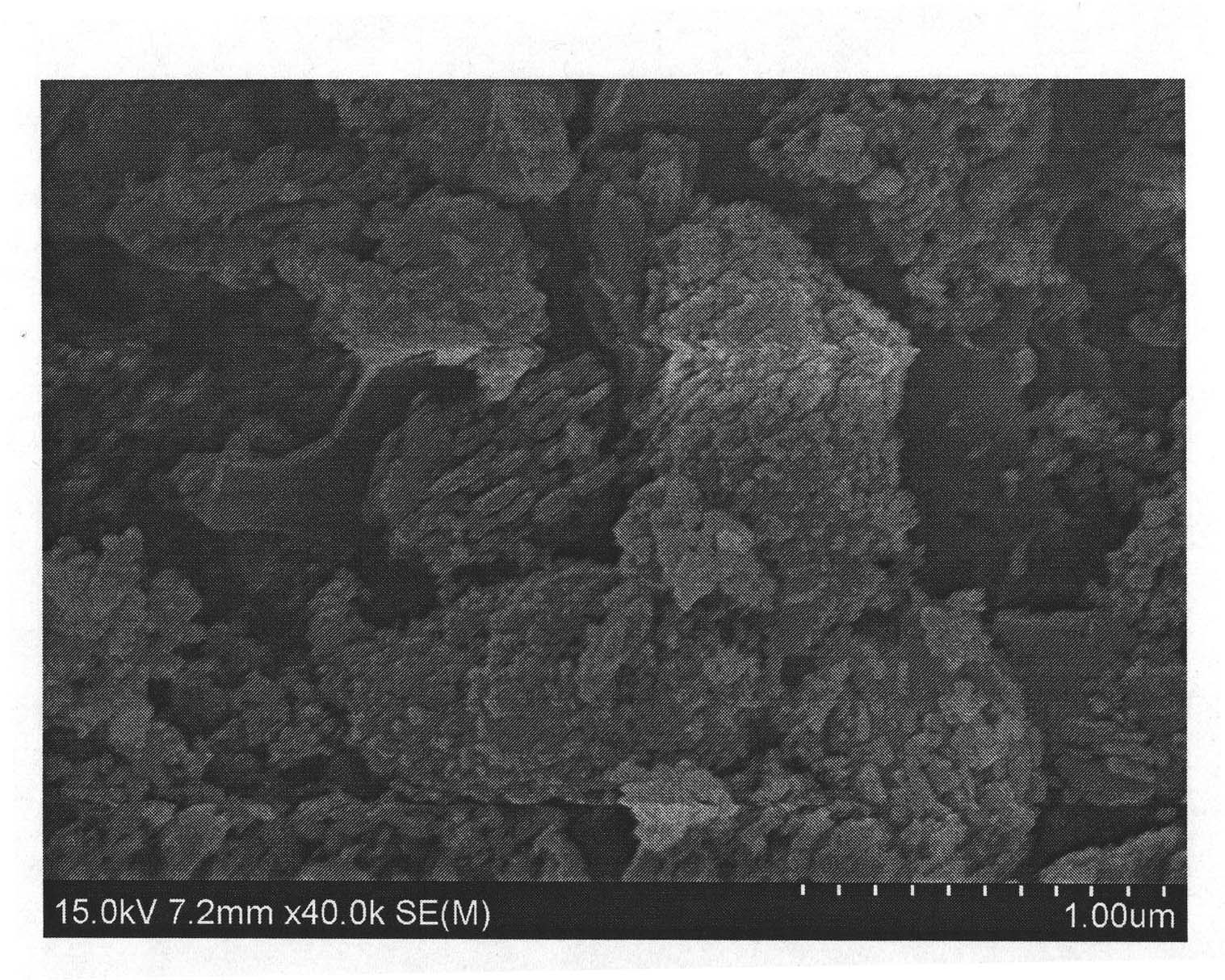

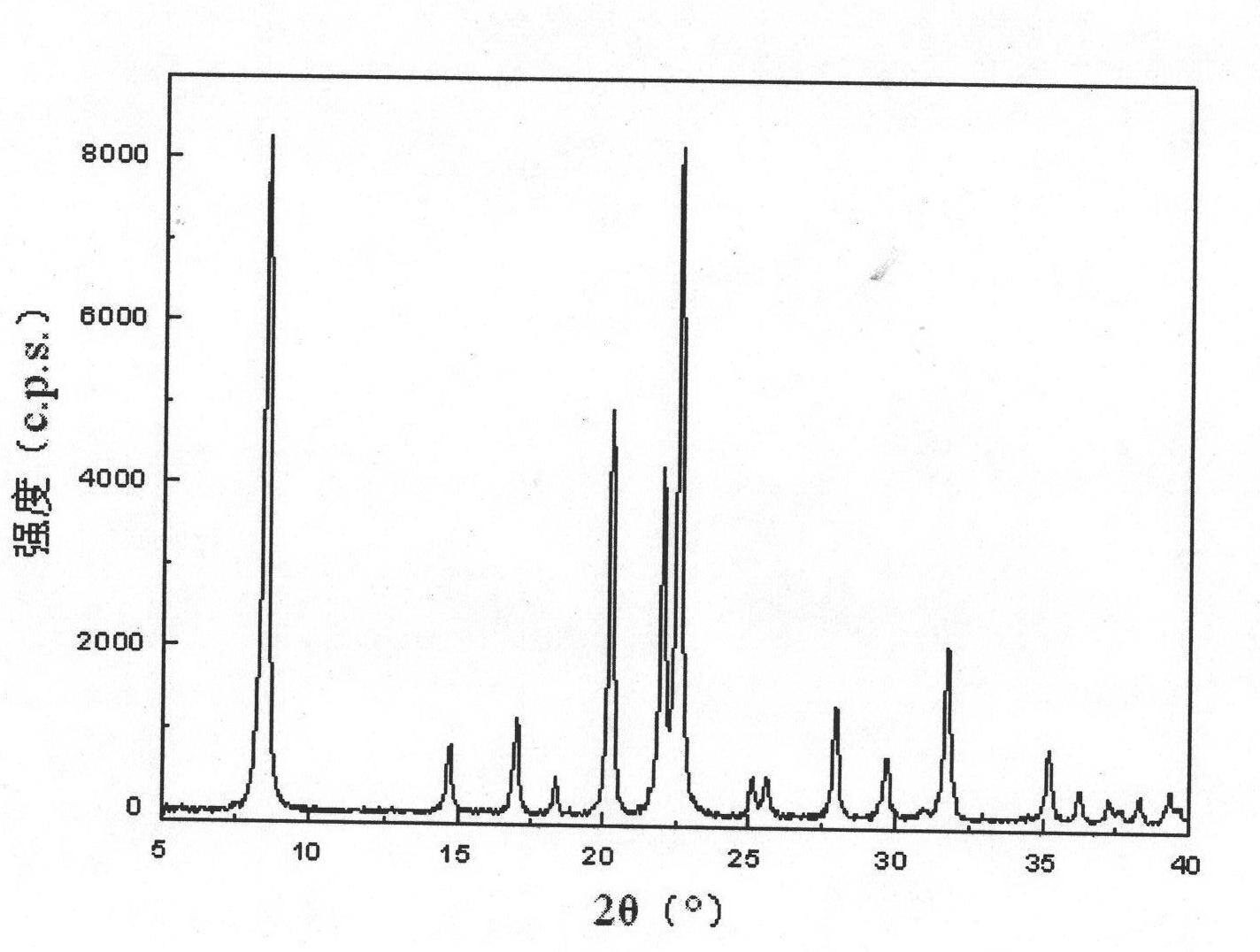

Synthetic method for MCM-22 molecular sieve

InactiveCN1789126AReduce dosageLower synthesis costMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveCyclohexylamine

A method for synthesizing MCM-22 molecular screen, which possesses MWW topological structure, employing silicon, aluminium, alkali, mould agent and deionized water as reacting raw material, blooming under the temperature of 135-185 Deg C for some time, hydrothermal synthesizing the needed molecular screen; the invention is characterized by using diamin liquid mixture (BA) as mould agent to prepare molecular screen, one (SDAI) is hexamethylene amine (HMI), another (SDA2) is any one of the followings: cyclohexylamine (CHA)or buta (BuA) or isopropyl amine (IPA).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

(S)-alpha-phenethylamine: pyruvate transaminase

Relating to an enzyme capable of efficiently converting a ketone compound to an optically active amino compound by transamination, and a process for preparing an optically active amino compound using the enzyme. An (S)-alpha-phenethylamine:pyruvate transaminase, which acts on (S)-alpha-phenethylamine and a ketone compound, thereby catalyzing transamination for forming acetophenone and an amino compound corresponding to the ketone compound; a process for preparing an optically active amino compound using the transaminase; and a method for culturing a microorganism for producing the above transaminase, comprising adding to a medium one or more compounds selected from the group consisting of propylamine, 1-butylamine, 2-butylamine, 2-pentylamine, isopropylamine and isobutylamine as an inducer for the enzyme when a microorganism for producing (S)-alpha-phenethylamine:pyruvate transaminase is cultured.

Owner:KANEKA CORP

Method for treating septic shock

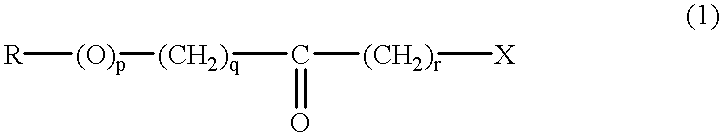

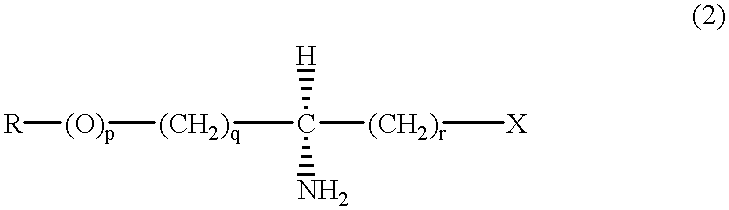

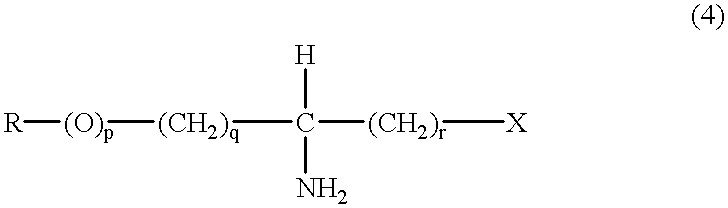

A method for the treating septic shock in a patient comprises administering to the patient a therapeutically-effective amount of a composition comprising a compound having the formula (I): wherein R1 is hydrogen, hydroxyl, carboxyl, amino or C1-C8alkyl; R2 is hydrogen, hydroxyl, amino or C1-C8 alkyl; and R3 is hydrogen, hydroxyl, carboxyl, amino, C1-C8 alkyl, substituted or unsubstituted phenyl, amide, C3-C8 aminoalkyl, or C1-C8 aminoalkylcarbonyl; or a therapeutically-effective salt, ester or solvate thereof. Particularly preferred compounds for use in the present invention include butylamine, propylamine, diaminopropane, diaminobutanone, tyrosine, threonine, asparagine, and aspartate.

Owner:SOO RAY WANG PH D M D

Heavy metal sewage treatment agent

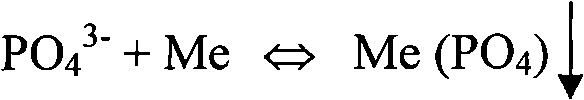

InactiveCN104118921ARemove reachEasy to remove by filtrationWater/sewage treatment by ion-exchangeWater/sewage treatment by flocculation/precipitationCelluloseCarbamate

The invention relates to a heavy metal sewage treatment agent which is prepared from dodecyl diethylene triamine, dimethyl diallyl ammonium chloride, acrylamide, dibenzoyl peroxide, powdered activated carbon, ethylene diamine tetraacetic acid, tert-butylamine, carbamate, dithiocar-bamate, thiocarbamic acid ester, starch, cellulose, water soluble starch xanthate ester, sodium silicate, potassium peroxodisulfate, sodium hydrosulfite, strong base and water. The heavy metal sewage treatment agent disclosed by the invention is formed by being modified with a high-molecular compound; the mixture contains a plurality of active groups which can be complexed, chelated, absorbed and exchanged with heavy metal, so that heavy metal ions in the aqueous solution can be removed; the heavy metal sewage treatment agent has good removal effect on heavy metal ions, the removal rate is above 97%, and furthermore, the heavy metal sewage treatment agent has stronger Ca2+ and Mg2+ resistant capability; the removal rate of cadmium-containing sewage is 99.8%, which meets the national emission standard; and the removal rate of chromium-containing sewage is above 99.6%.

Owner:江西省恩皓环保有限公司

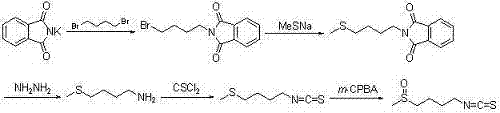

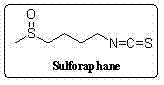

Synthetic method for sulforaphane

ActiveCN102249968AAvoid hydrazinolysisSimple and fast operationOrganic chemistryBulk chemical productionSulforaphaneSodium methanethiolate

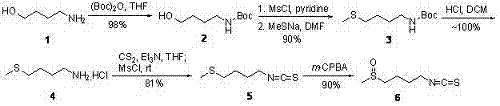

The invention provides a synthetic method for sulforaphane and belongs to the field of drug synthesis. The method comprises the following steps that: after amino in 4-amino-1-butanol is protected by Boc groups, hydroxy in 4-amino-1-butanol is changed into methanesulfonyl ester by methanesulfonyl chloride, and then the resultant reacts with sodium methyl mercaptide to produce 4-methylthio butyl-1-tert-butoxycarbonylamide; Boc protective groups are removed under acidic condition to obtain 4-methylthio-1-butylamine; 4-methylthio-1-butylamine reacts with carbon disulfide for one hour in the presence of triethylamine and p-toluenesulfonyl chloride is added for treatment for half an hour to produce 4-methylthio butyl-1-isothiocyanate; and at last 4-methylthio butyl-1-isothiocyanate is oxidized by m-CPBA to produce sulforaphane. According to the invention, complex hydrazinolysis of phthalimide in aftertreatment is avoided and toxic thiophosgene is not needed in the preparation of isothiocyanate; overall yield of sulforaphane is 64%, substantially higher than the overall yield of 8% reported in literature; the whole preparation process is simple and time-saving and is suitable for large scale production.

Owner:江苏宁录科技股份有限公司

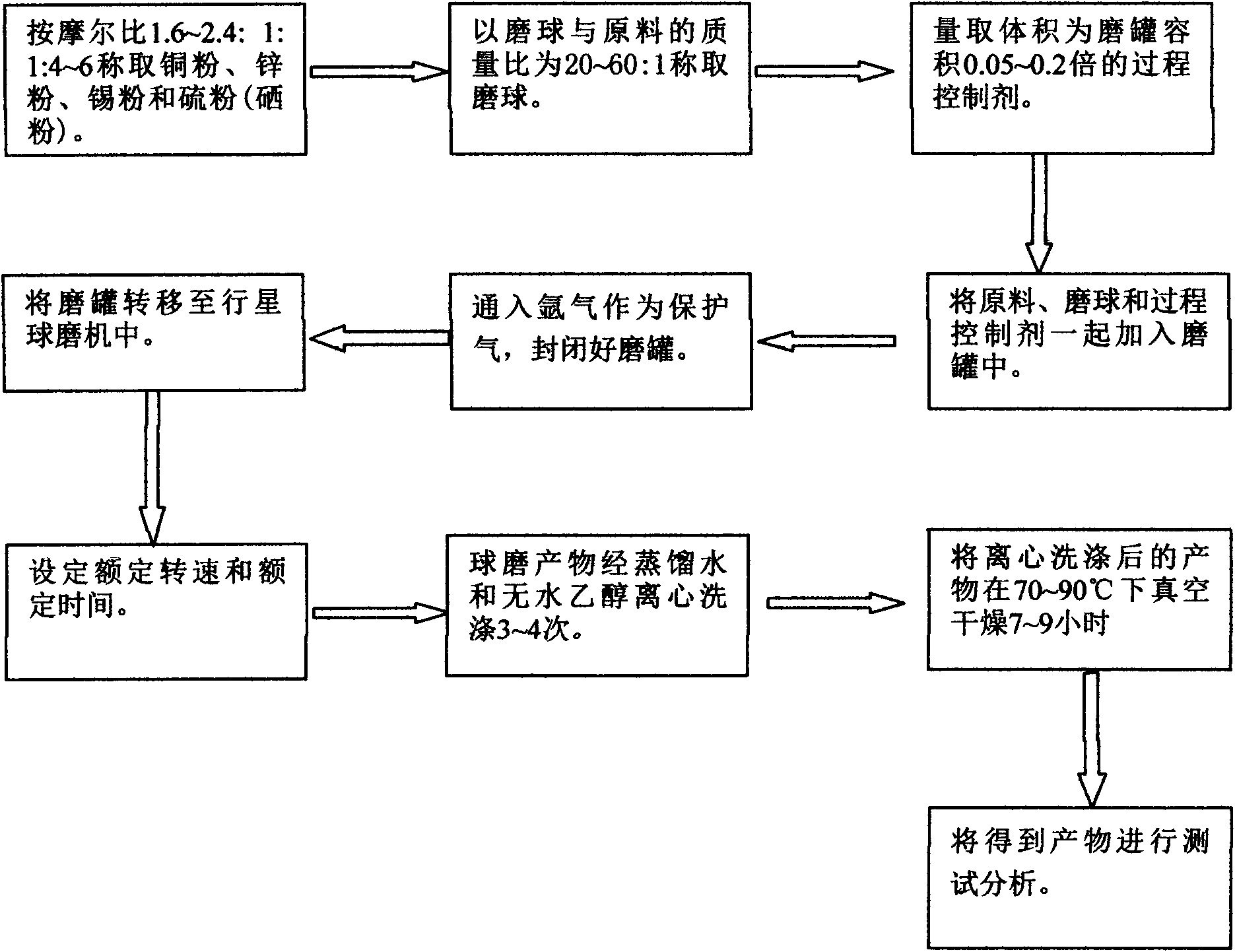

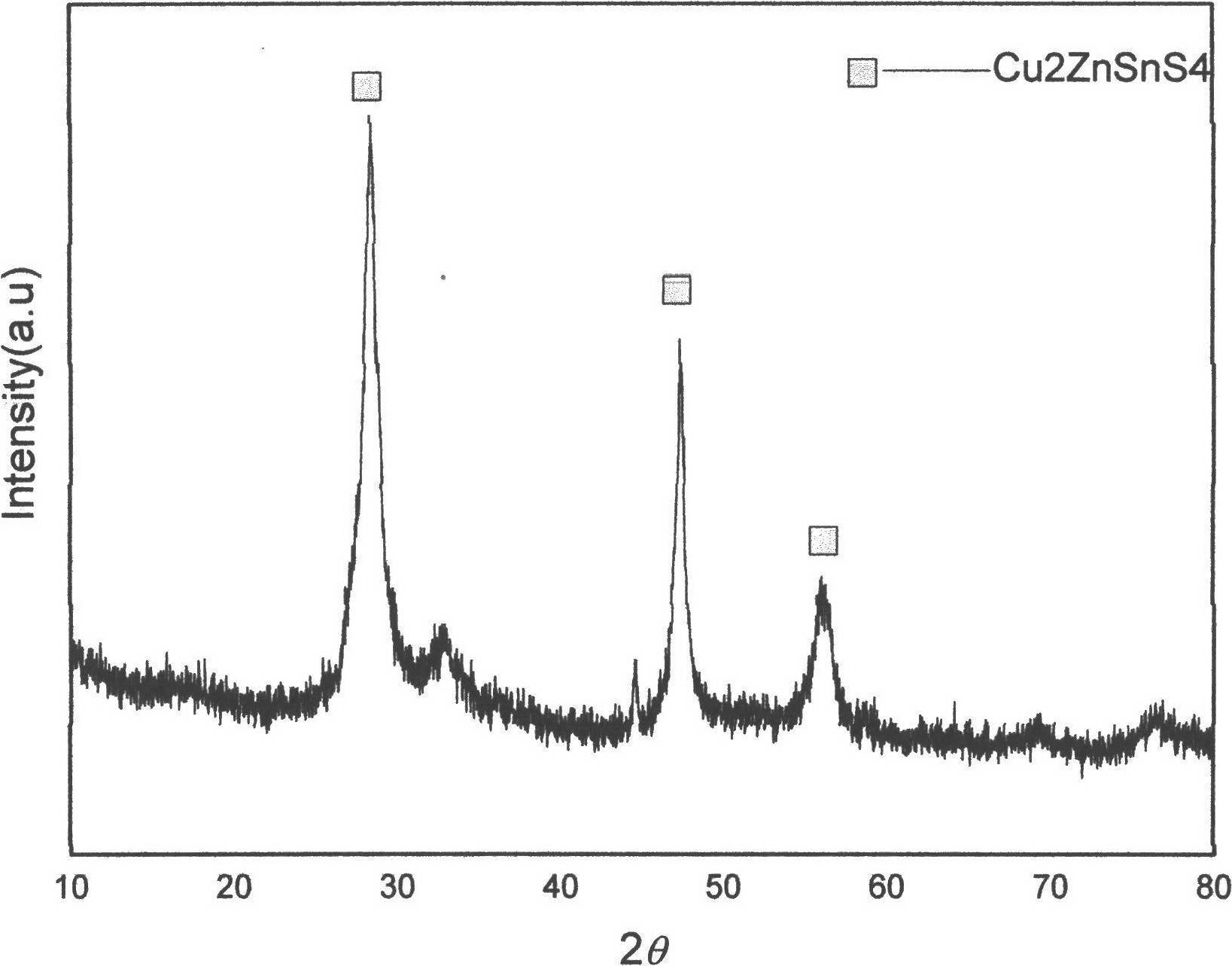

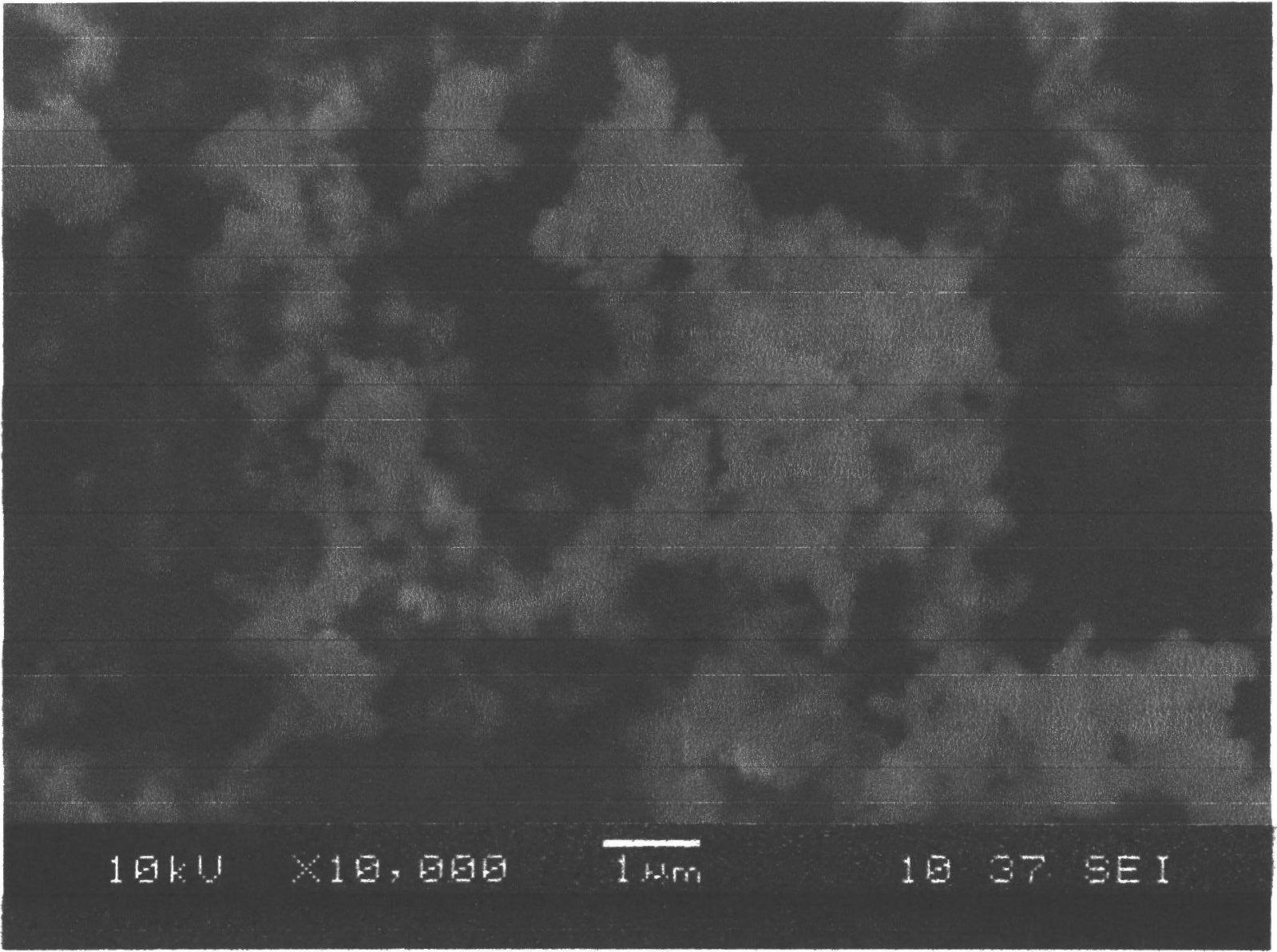

Method for preparing CZTS (Copper Zinc Tin Sulfide) (Se) series nanometer powder by low-temperature mechanical alloying

InactiveCN102642818AAvoid introducingReaction raw materials are readily availableTin compoundsSelenium/tellurium compundsIsobutanolHexamethylenediamine

The invention discloses a method for preparing CZTS (Copper Zinc Tin Sulfide) (Se) series nanometer powder by low-temperature mechanical alloying. Elementary substances Cu powder, Zn powder, Sn powder and S (Se) powder are added into a ball-milling tank according to a certain mole ratio, an alcohol and amine mixed liquor is used as a process control agent, ball milling is carried out according to a rated ratio of grinding media to material, a set rotational speed and ball milling time, and a ball-milled product is centrifugally washed and dried to obtain a target product. In the raw materials, elementary substances sulfur powder and selenium powder can be exchanged in any mole ratio; and the process control agent is the mixed liquor of alcohol and amine with the volume ratio of 1-20:1, the alcohol is one of ethanol, ethylene glycol, normal butanol, isobutanol, isoamylol, tertiary amyl alcohol and glycerol, and the amine is one of ethanediamine, iso-butylamine, diisopropylamine, hexamethylenediamine and triethylamine. The method disclosed by the invention has the advantages of easy obtainment of raw materials, pure products, low energy consumption, easy control in product shape and appearance, simple process and the like, and is suitable for industrial production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

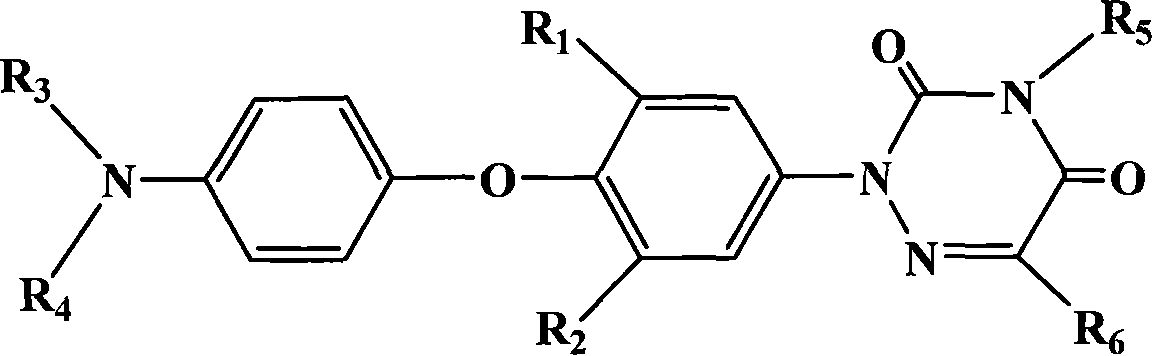

Compound in triazine class for anti activity of coccidian, preparation method and application

This invention discloses novel triazine compounds with anti-coccidial activity, their preparation method and application. The general structural formula of the compounds is shown in formula 1, wherein, R1 and R2 are the same or not, and are selected from H, halogen, alkyl, alkoxy, nitro and trifluoromethyl; R3 is COR7, cycloalkyl, or heterocycle; R4 is H or alkyl. The acids for forming pharmaceutically acceptable salts of the compounds include HCl, H2SO4, HBr, H3PO4, H2CO3, formic acid, acetic acid, citric acid, lactic acid, fumaric acid, tartaric acid, and gluconic acid. The alkalis for forming pharmaceutically acceptable salts of the compounds include NaOH, KOH, triethylamine, and t-butylamine. The compounds have good inhibitive effects on animal coccidiosis.

Owner:SHANGHAI VETERINARY RES INST CHINESE ACAD OF AGRI SCI

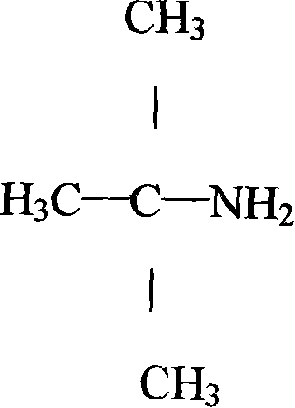

Environment-friendly preparation method of tert-butylamine

InactiveCN102633647AExtended service lifeLow reaction temperatureMolecular sieve catalystsAmino compound preparation by condensation/addition reactionsPtru catalystArgon atmosphere

The invention discloses an environment-friendly preparation method of tert-butylamine. Isobutylene and liquid ammonia are directly subjected to amination under the action of a catalyst to prepare the tert-butylamine. The catalyst uses a Y-type zeolite molecular sieve as the matrix, and the active component elements and modifying elements account for 10-30%. The Y-type zeolite molecular sieve is modified by the following steps: exchanging the Y-type zeolite molecular sieves with an NH4Cl aqueous solution, washing, drying in a nitrogen or argon atmosphere, and carrying out heat treatment by roasting to obtain an H-type zeolite molecular sieve; and carrying out dipping treatment on the H-type molecular sieve with metal salt, drying in a nitrogen or argon atmosphere, roasting to obtain the modified Y-type zeolite molecular sieve. The modified Y-type zeolite molecular sieve catalyst must be activated before use. The invention has the advantages of mild reaction conditions, high selectivity, high yield, environment friendliness and low catalyst modifying cost, and is suitable for industrial production.

Owner:ZHEJIANG HUANGMA TECH

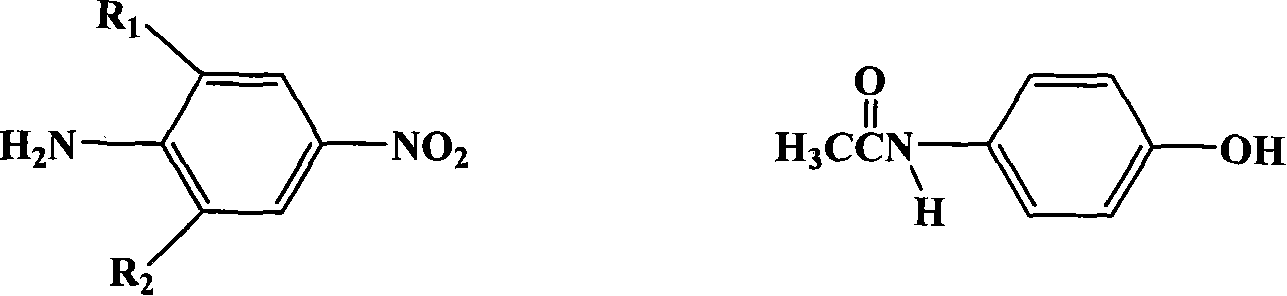

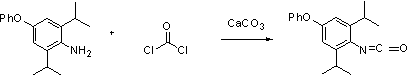

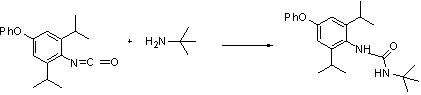

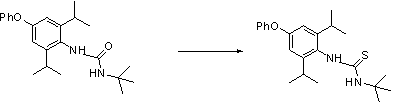

Synthesis process for diafenthiuron as thiourea insecticide and acaricide

InactiveCN102993075AMild reaction conditionsEasy to operateOrganic chemistryThioureaSynthesis methods

The invention discloses a synthesis research method for diafenthiuron as a novel thiourea insecticide and acaricide. The synthesis method comprises the following steps of: firstly, synthesizing an N-2,6-diisopropyl-4-phenoxylphenyl)isocyanate intermediate by taking 2,6-diisopropyl-4-aminobiphenyl ether and triphosgene as raw materials; then, subjecting the generated N-2,6-diisopropyl-4-phenoxylphenyl)isocyanate intermediate and tert-butylamine to a reaction to generate 3-(2,6-diisopropyl-4-phenoxylphenyl)-1-tert-butyl urea; and then, subjecting the 3-(2,6-diisopropyl-4-phenoxylphenyl)-1-tert-butyl urea and phosphorus pentasulfide to a reaction under the action of potassium carbonate to finally generate diafenthiuron. The synthesis process is a more effective method for synthesizing the diafenthiuron, which has the advantages of mild reaction conditions, simplicity in operation, cheaper raw materials, lower toxicity and the like.

Owner:JIANGSU CHANGQING AGROCHEMICAL CO LTD

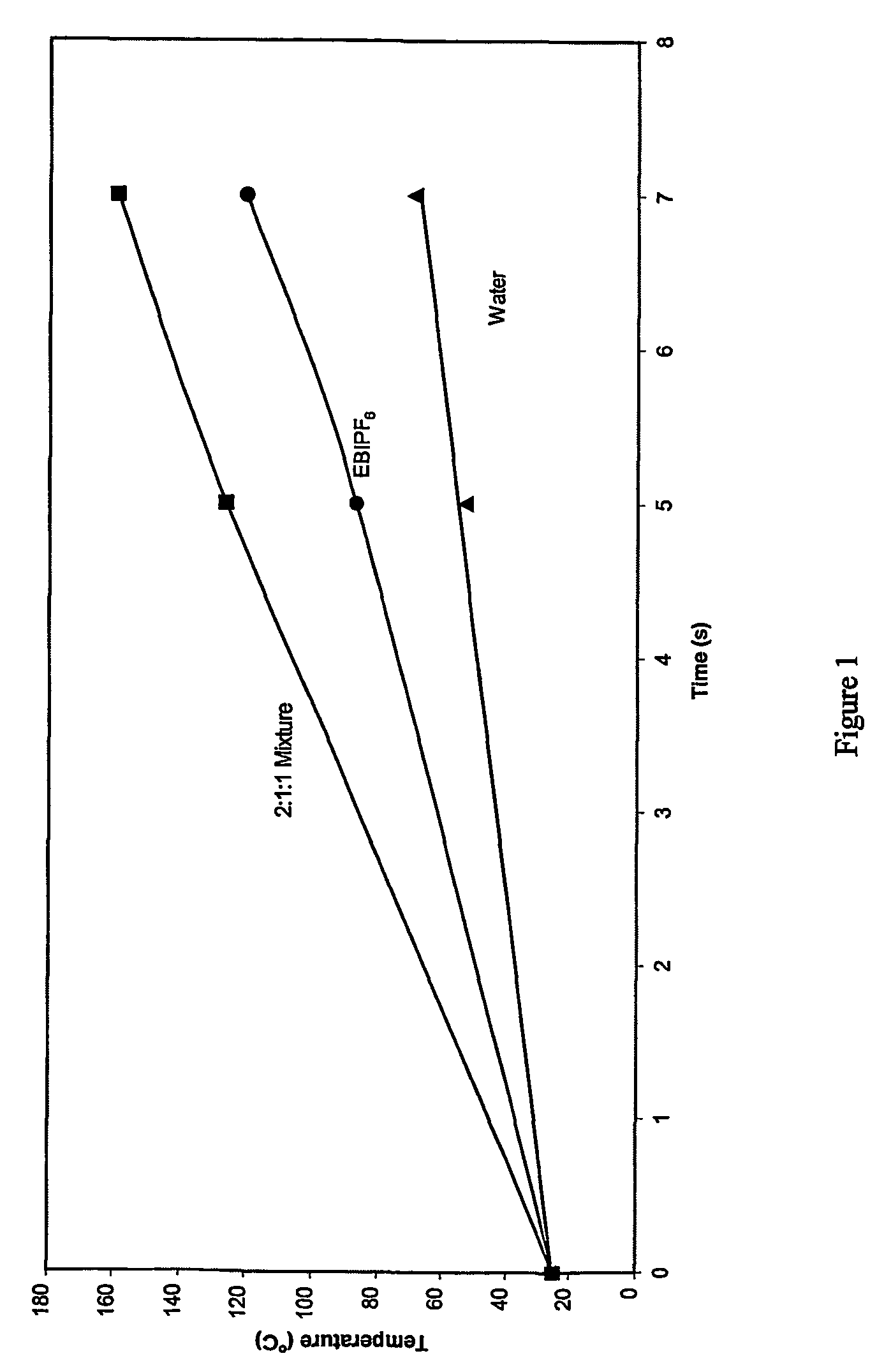

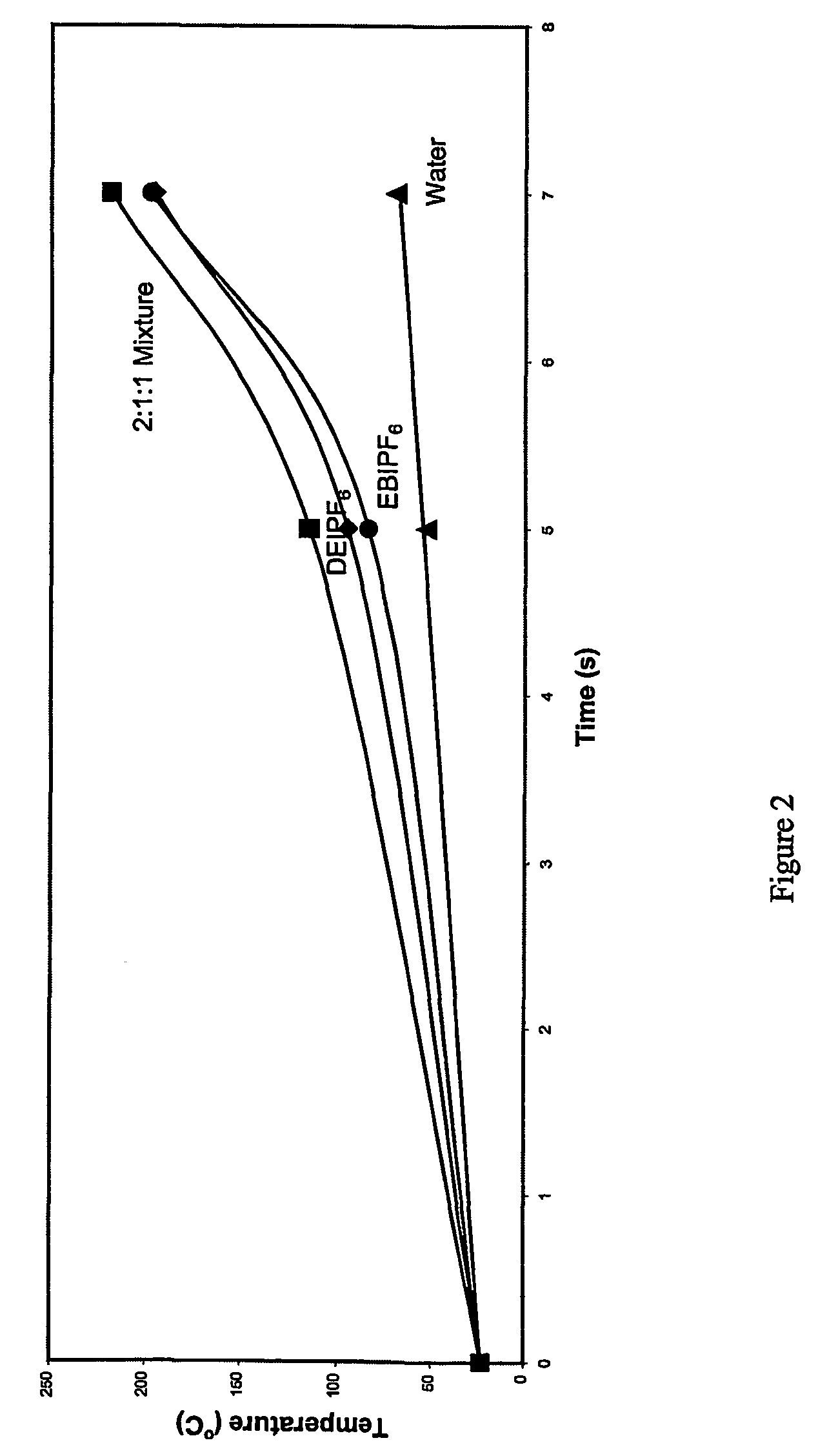

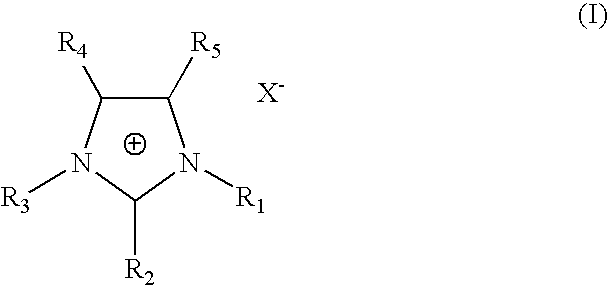

One-step process for the preparation of halide-free hydrophobic salts

InactiveUS7253289B2Conveniently separatedImprove ionic conductivityGroup 5/15 element organic compoundsPropylamineSolvent

This invention describes a one pot, single-step process for the preparation of halide-free hydrophobic salts comprising polyalkylated imidazolium cations and various anions in accordance with the following structure, where R1 and R3 represent the either the same or different alkyl groups, and R2, R4, and R5 represent either hydrogen atoms, or the same or different alkyl group substituents; X represents a polyatomic anion that is the conjugate base of an acid. By simply mixing aqueous formaldehyde with an alkyl amine such as methylanune, ethylamine, n-propyl oriso-propylamine, or n-butyl-, iso-butyl, or t-butylamine, or by mixing aqueous formaldehyde with two alkyl amines (preferably one being methylamine, ethylamine, n-propyl- or iso-propylamine, or n-butyl-, isobutyl, or t-butylamine) and another being n-propyl- or isopropylaine, or n-butyl-, isbutyl, or t-butylamine), an acid (such as hexafluorophosphoric acid, trifluoroacetic acid, pentafluoropropionic, heptafluorobutyric acid, or the free acid of a bis(perfluoroalkylsulfonyprnide or tris(perfluoroalkylsulfonyl)methide as the source of the anion) and aqueous glyoxal solution, the hydrophobic ionic salts or mixtures thereof thus formed may be conveniently separated directly from the aqueous byproduct layer. Like the single cation hydrophobic salts, these mixed hydrophobic ionic liquids are non-flammable and manifest no detectable vapor pressure up to their decomposition temperature of greater than 300° C. We have also discovered that, surprisingly, ternary mixtures of dialkylated ionic liquids manifest higher ionic conductivities than a single ionic liquid of the mixture alone. This property benefits electrochemical power source applications such as batteries and capacitors. Furthermore, we have discovered that ternary mixtures of dialkylated ionic liquids absorb microwave radiation more efficiently than a single ionic liquid of the mixture alone. This property benefits microwave-induced synthetic reactions. Such physical and chemical properties make it possible to employ inexpensive mixtures of polyalkylated imidazolium cations in an advantageous manner as thermal transfer fluids, high temperature lubricants, and plasticizers, and as solvents in the areas of electrochemistry, synthetic chemistry, catalysis, and separations chemistry.

Owner:COVALENT ASSOCS

Method for synthesizing SAPO-31 molecular sieves through microwave heating

ActiveCN101786640AAcidity is highly adjustableShorten crystallization timeMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesPhosphorous acidPhosphoric acid

The invention provides a method for synthesizing an SAPO-31 molecular sieve through microwave heating, which relates to a preparation method of an SAPO-31 molecular sieve. The invention solves the problems that the crystallization time of the existing preparation method of the SAPO-31 molecular sieve is long, stray crystals exist in products, and the price of template agents is high. The method of the invention comprises the following steps: firstly, preparing phosphorous acid, water, di-n-butylamine, aluminium isopropoxide and silicon aerosol into gel; then, placing the gel into a reaction kettle to be heated by microwaves; carrying out crystallization at 130 DEG C to 190 DEG C; and then, obtaining the SAPO-31 molecular sieve through centrifugal filtration, washing, drying and roasting. The invention has the advantages of short crystallization time, no stray crystal and low price of the template agents. The SAPO-31 molecular sieve of the invention is applied to the fields of petrochemical industry and fine chemistry industry as a catalyst.

Owner:HEILONGJIANG UNIV

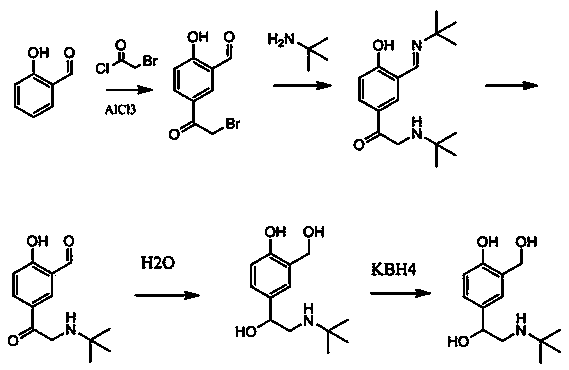

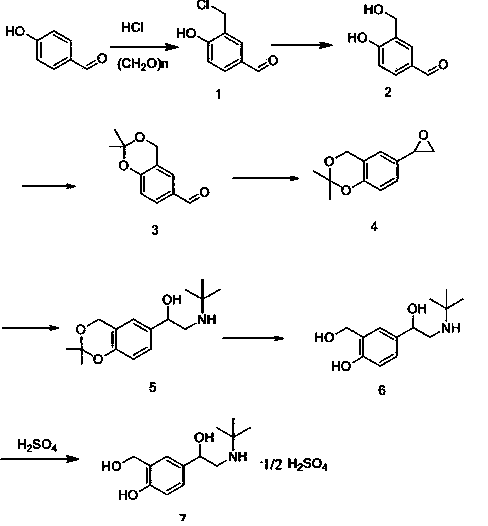

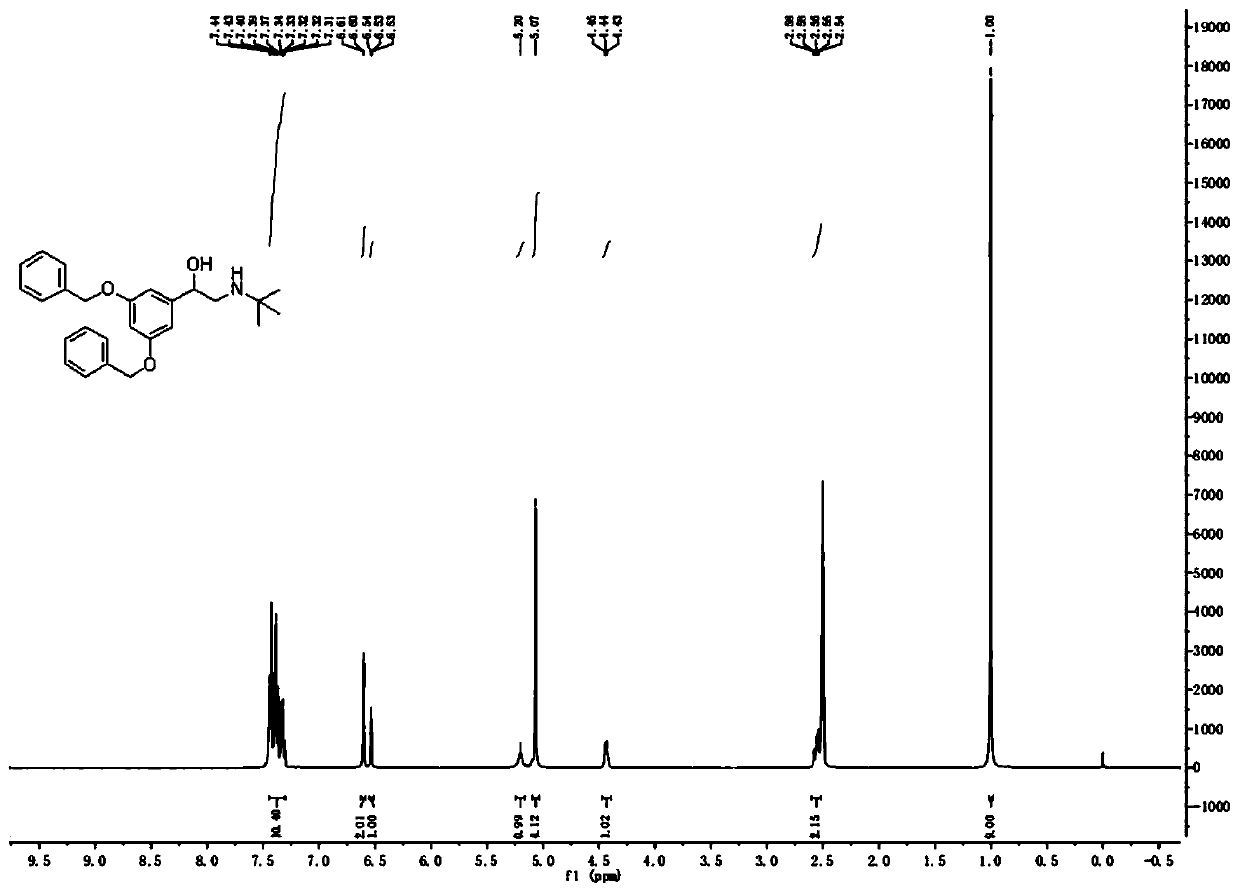

New process for synthesizing salbutamol and sulfate of salbutamol

ActiveCN103951568AMild reaction conditionsEasy to purifyOrganic compound preparationAmino-hyroxy compound preparationBenzaldehydeAminolysis

The invention discloses a new process for synthesizing salbutamol. The process comprises the steps that (1) chloromethylation reaction: reactants namely p-hydroxy benzaldehyde and paraformaldehyde react under an acidic condition to generate a compound 1; (2) hydrolysis reaction: the compound 1 is subjected to hydrolysis reaction under a weakly alkaline condition to generate a compound 2; (3) propylidene protective reaction: dihydroxy of a reactant 2 is subjected to propylidene protection under catalysis of concentrated sulfuric acid; (4) epoxidation reaction: a reactant 3 reacts to obtain a compound 4 by using the effect of strong base under the effects of a ylide reagent and a phase transfer catalyst; (5) aminolysis ring-opening reaction: the compound 4 is heated and refluxed in tert-butylamine, and is subjected to aminolysis ring-opening reaction to obtain a compound 5; (6) hydrolysis de-protective reaction: the compound 5 is subjected to hydrolysis reaction under the acidic condition to obtain salbutamol. The new process disclosed by the invention is mild in reaction condition, easy in purification, and simple and easily-available in raw materials; the total molar yield of the process reaches up to 45%, and the product quality reaches up to more than 99.5%.

Owner:SUZHOU HOMESUN PHARMA

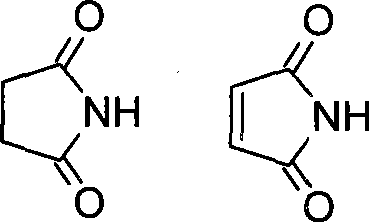

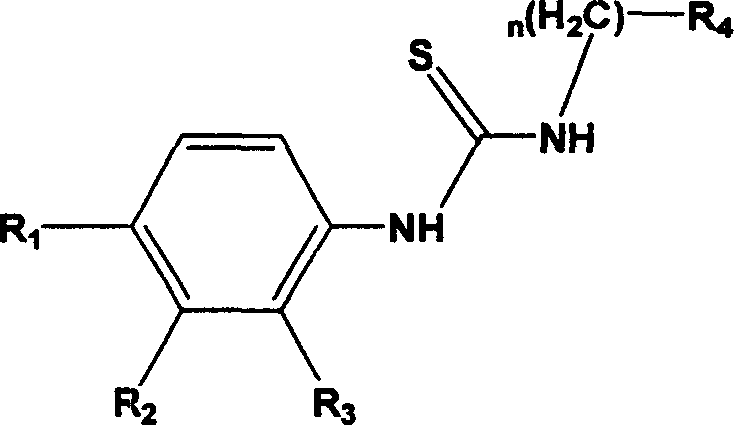

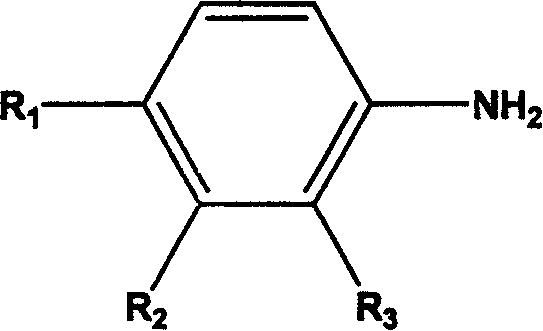

Thiourea kind compund with inhibiting virus capsid protain activity and its preparation process and application thereof

The invention relates to a compound that is made up by chemical compounding method. R1, R2, and R3 represent one or several radical of hydrogen, alkyl, halogen and alkoxy and they could be same or different; R4 represents ({5-[(dimethylin)-methyl]-2-furan}-methyl-slfur, 4-(2-lignocaine-6-alkyl-5-nitryl-pyridine)-amidogen, 4-(2-lignocaine-6-alkyl- pyridine)-amidogen; n represents 1, 2, 3, 4, 5, 6. The pharmacy could accept acid or alkali to form addition salt. The acid includes hydrochloric acid, vitriol, hydrobromic acid, phosphoric acid, carbonic acid, formic acid, acetic acid, citric acid, lactic acid, fumaric acid, tartaric acid and gluconic acid. The alkali includes sodium hydroxide, potassium hydroxide, spasmolytol and ert-butylamine. The compound has good inhibitory effect to HIV virus.

Owner:PEKING UNIV

Flying ash processing method

The invention relates to a flying ash processing method. The method comprises the following steps: A, weighting a certain amount of flying ash; sequentially adding sodium phosphate, aluminum sulfate, chitosan and butyl amine aerofloat to the flying ash; adding water to the flying ash in a ratio of 1:1; stirring; and then drying in an oven to form a flying ash chelate; B, for improving the reaction effect, calcining kaolin at a temperature of 800 DEG C for 6 hours to prepare metakaolin; dissolving sodium hydroxide in soluble glass to prepare an alkali activator; doping the metakaolin in the flying ash chelate in a ratio range of 3:5 to 3:2; adding the alkali activator to the mixture in a ratio of 0.7:1; C, guiding the mixed pulp into a die; compacting and demolding; and D, culturing for 4 weeks at a room temperature for a toxic test. The invention adopts the chemical medicaments to burn the flying ash and fully mixes with the flying ash, thereby fully trapping heavy metals in the flying ash and achieving the aim of stabilizing the heavy metals in the flying ash for a long time.

Owner:SHANGHAI ENVIRONMENTAL ENG DESIGN & RES INST CO LTD +1

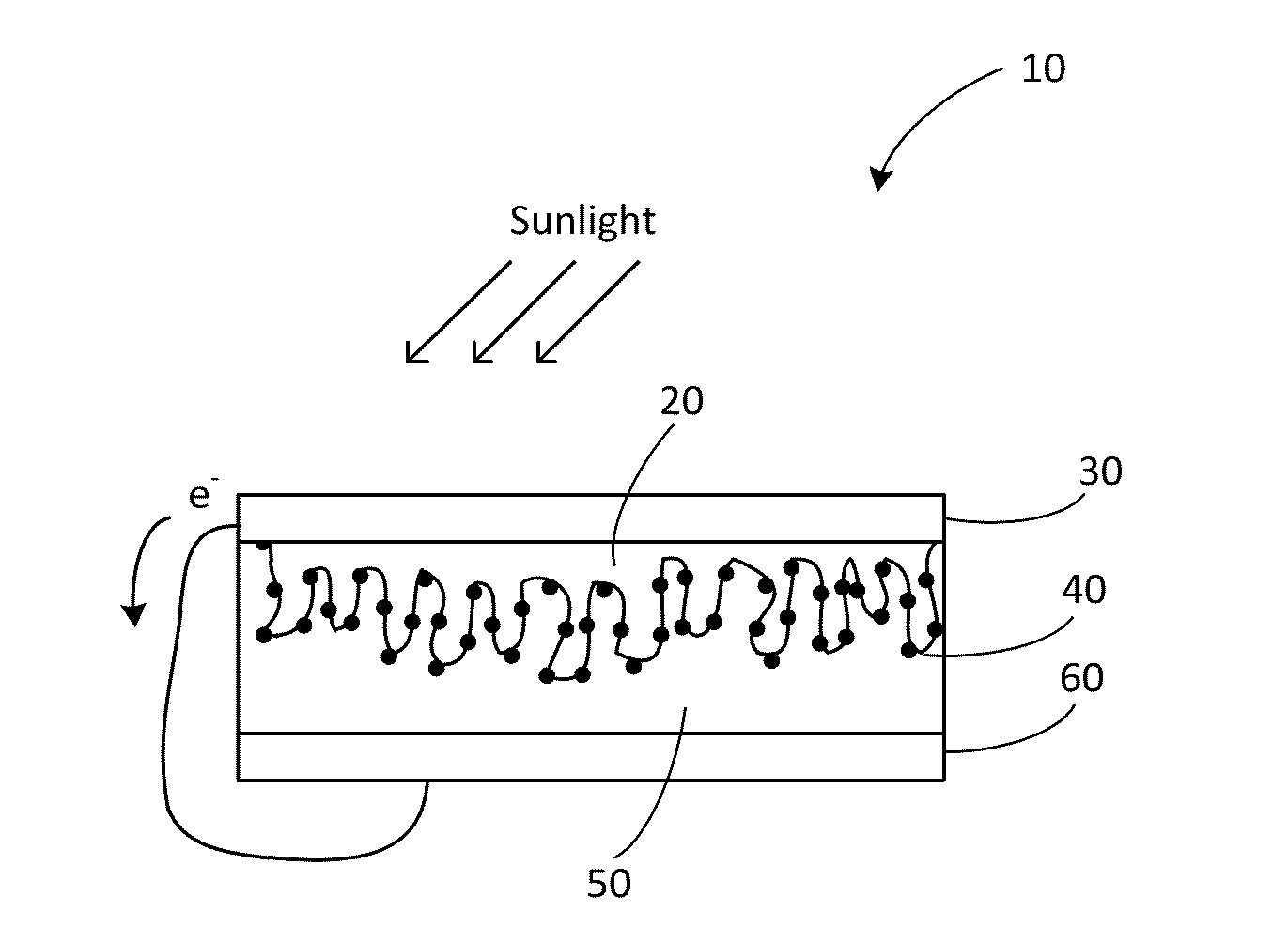

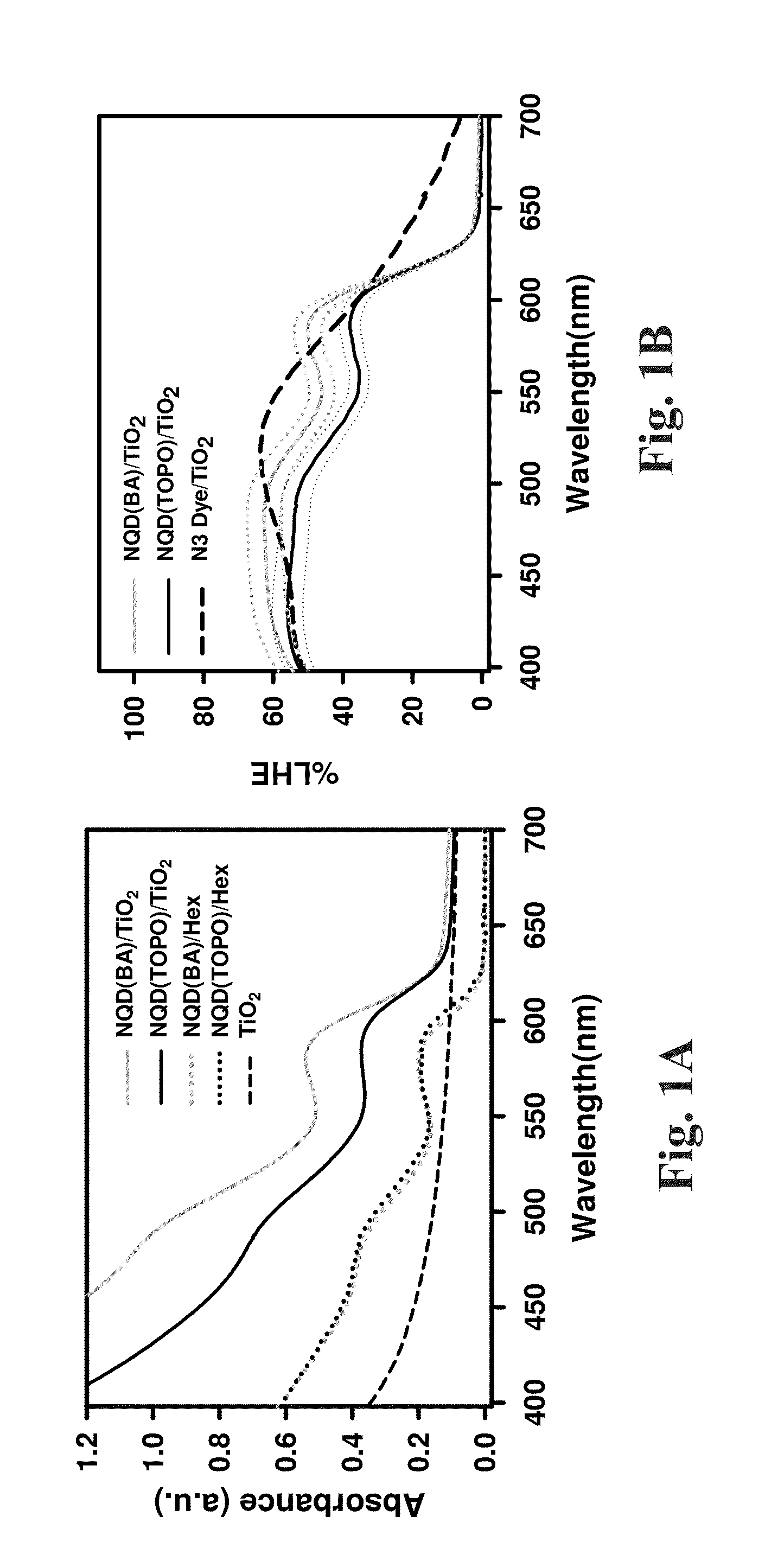

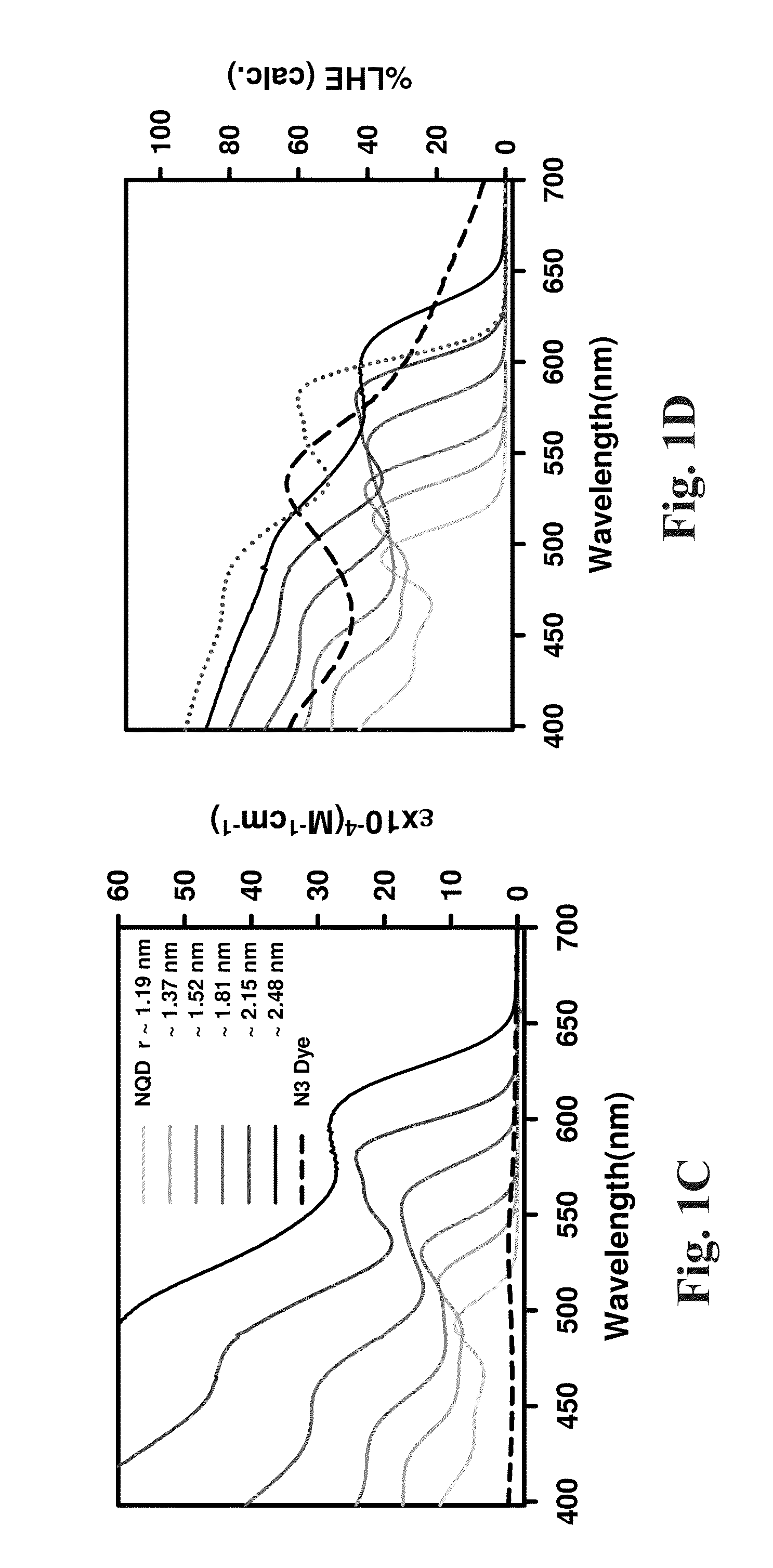

Quantum dot sensitized solar cell

InactiveUS20130206215A1Material nanotechnologyLight-sensitive devicesElectron injectionAqueous electrolyte

Photoelectrochemical solar cells (PECs) have been constructed and studied, the cells comprising a photoanode prepared by direct deposition of independently synthesized nanocrystal quantum dots (NQDs) onto a nanocrystalline metal oxide film, aqueous electrolyte and a counter electrode. It has been shown that the light harvesting efficiency (LHE) of the NQD / metal oxide photoanode is significantly enhanced when the NQD surface passivation is changed to a smaller ligand (e.g. butylamine (BA)). In the PEC the use of NQDs with a shorter passivating ligand leads to a significant enhancement in both the electron injection efficiency at the NQD / metal oxide interface and charge collection efficiency at the NQD / electrolyte interface.

Owner:SHARP KK +1

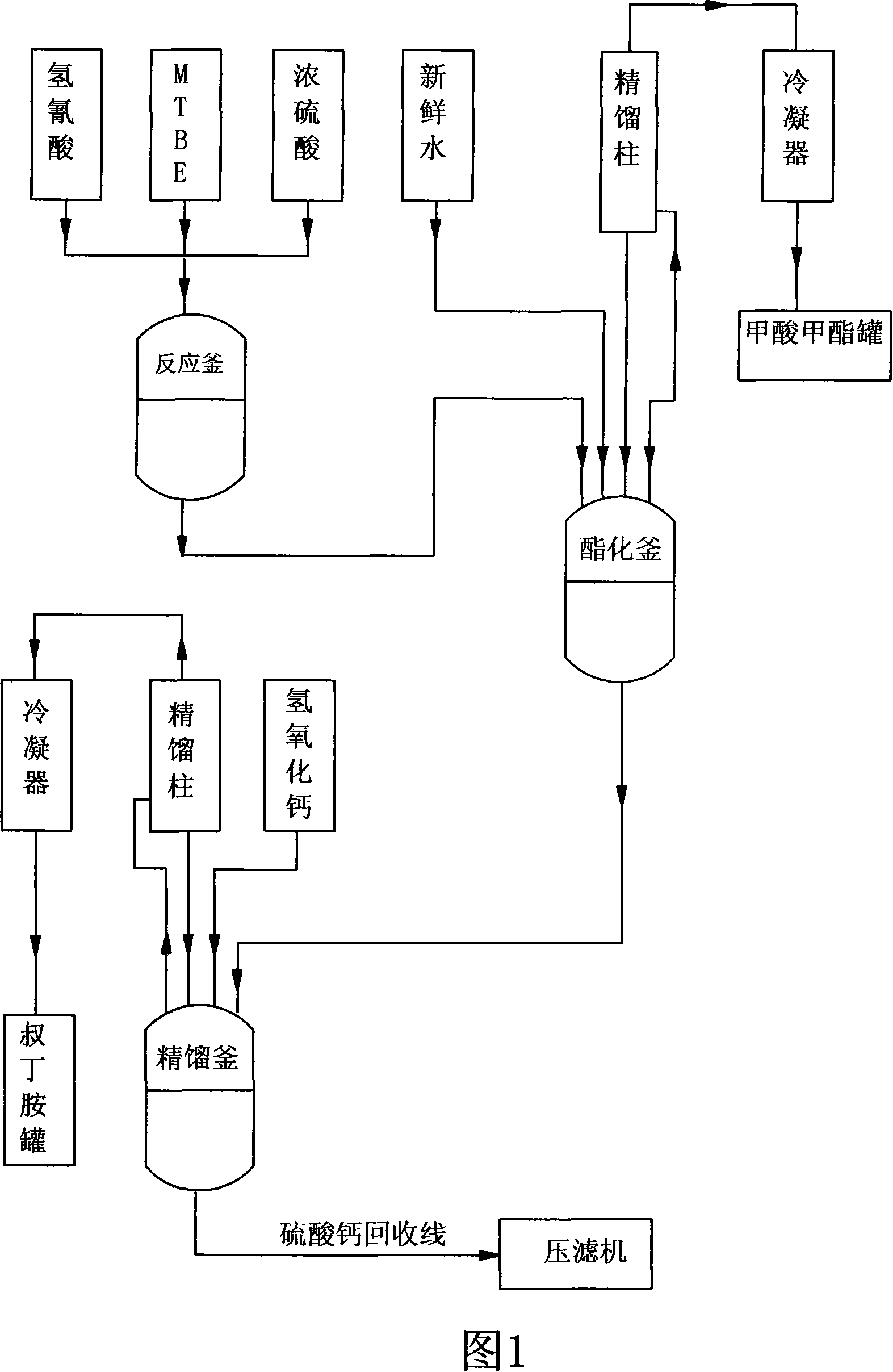

Technique for synthesizing tert-butylamine

ActiveCN101108806APromote hydrolysisPromote esterification reactionOrganic compound preparationAmino compound preparationTert-ButylamineCALCIUM HYDROXIDE SOLUTION

The invention belongs to the fine chemical field, which is mainly used for the synthesis of rubber accelerator NS and the intermediate raw material of the rifampicin-tert-butylamine. The invention is characterized in that: the methyl tert-butyl ether-hydrocyanic acid method is adopted to produce tert-butylamine; under normal pressure, the methyl tert-butyl ether is added with hydrocyanic acid and is added with concentrated sulphuric acid to carry out fully catalytic reaction; the methanol produced in the catalytic reaction is fully adopted and is added with water to perform hydrolysis, deep hydrolysis and esterification, and methyl formate and methanol without react completely are distilled; sulphates in calcium hydroxide solution and the butylamine to replace the butylamine to gain the butylamine through rectification and produce the byproduct calcium sulfate. The invention adopts the water instead of the methanol to carry out the hydrolysis and esterification and neutralizes the raw materials and adopts the calcium hydroxide to produce butylamine, which has the advantages of simple process, short production period, high yield, stable product quality, low production cost and small environment pollution.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

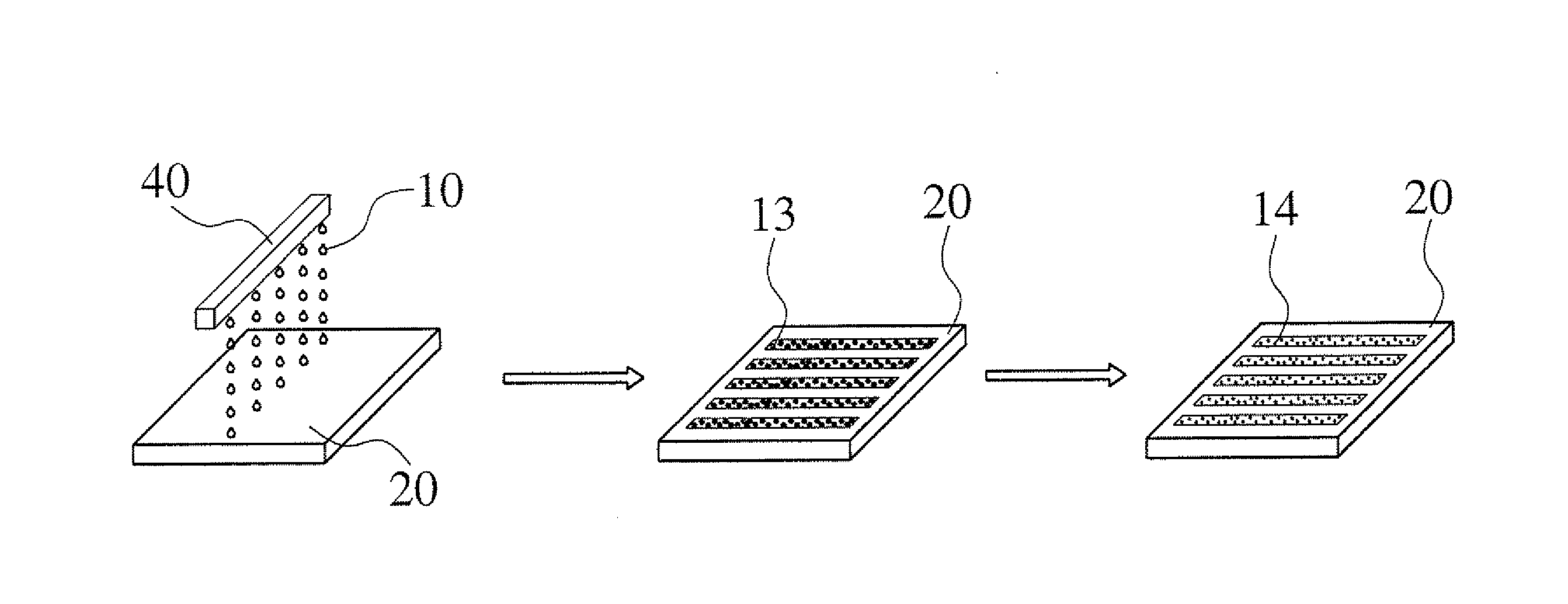

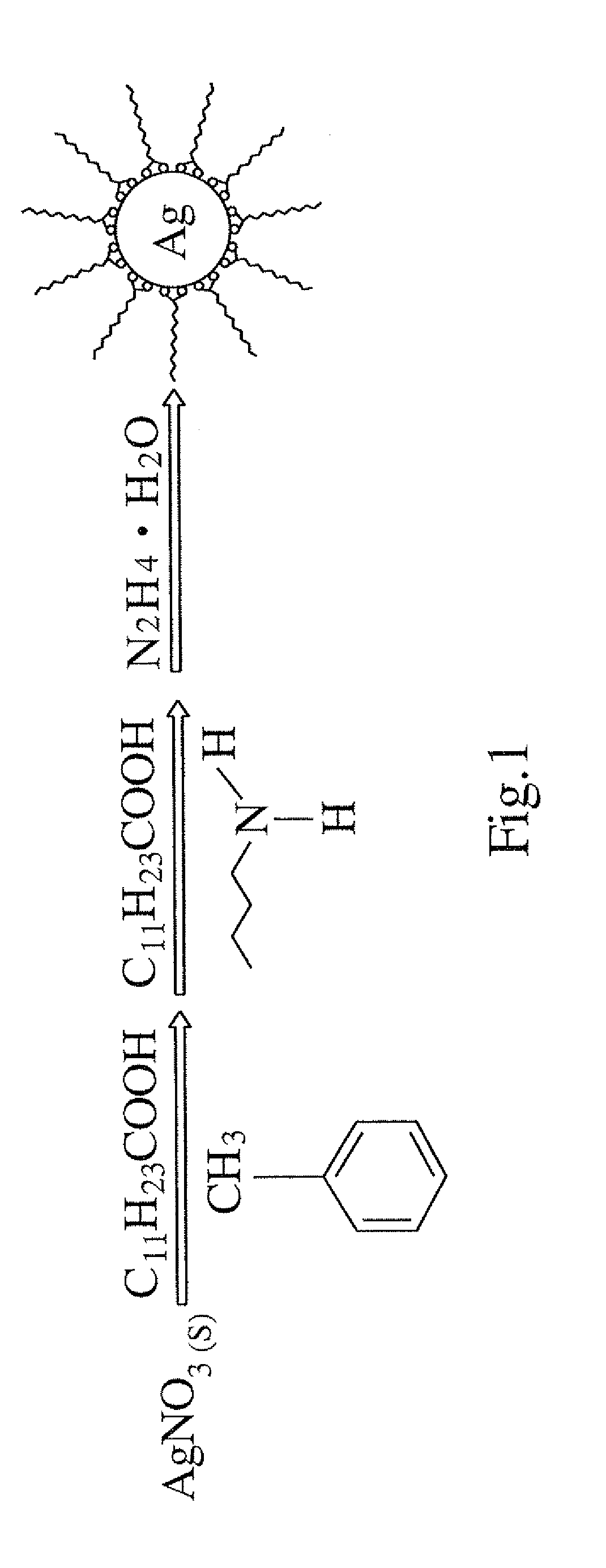

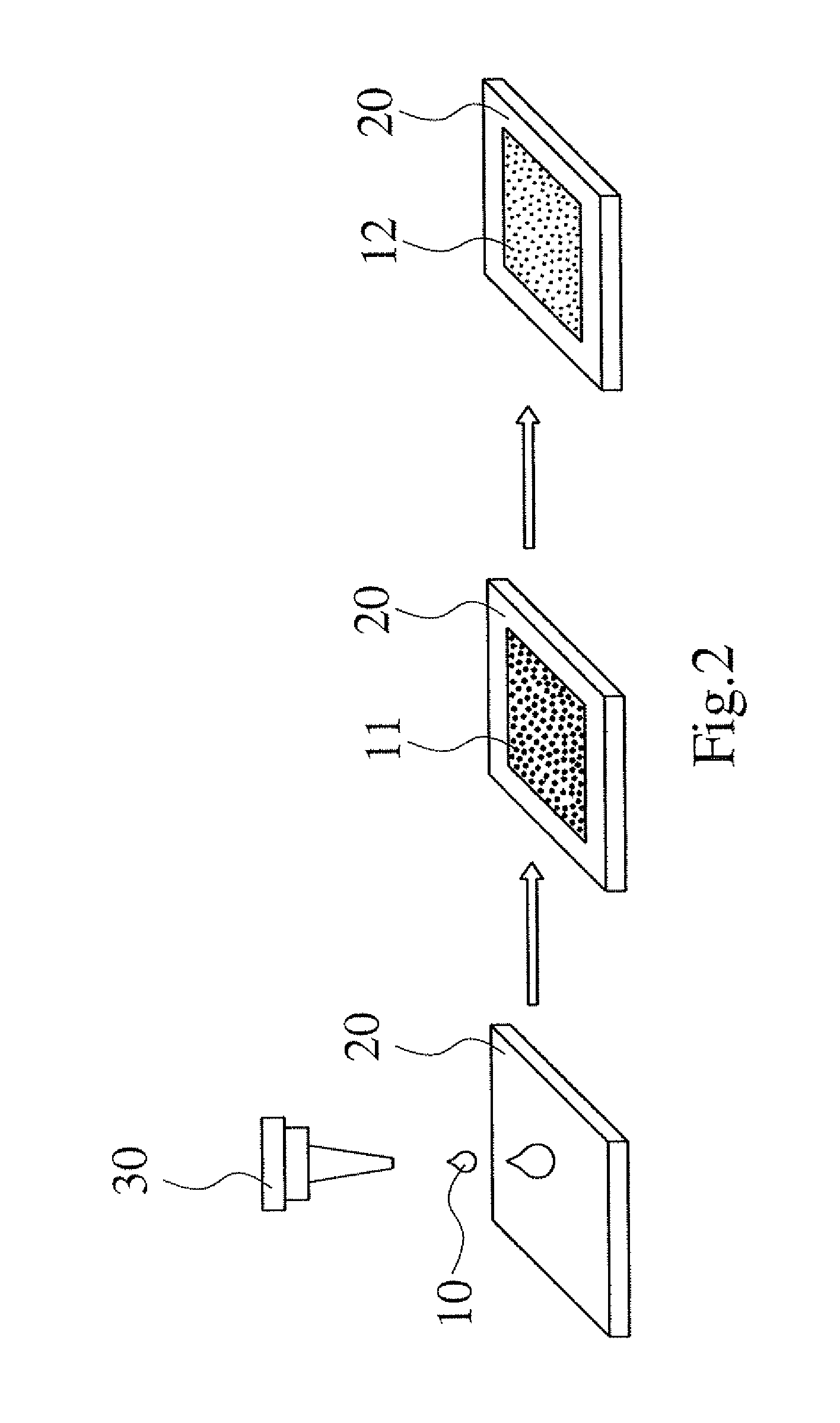

Method for forming conductive film at room temperature

InactiveUS20140161972A1Conveniently and rapidly printHigh application potentialSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingSolventN-Butylamine

A method for forming a conductive film at room temperature is provided and includes steps of: adding AgNO3 into a first solution of dodecanoic acid; dropping n-butylamine and a diluted aqueous solution of a reducing agent into the first solution in turn, so as to initially obtain the dodecanoate-protected silver nanoparticles as a capping ligand; then using cyclohexane as a solvent to apply the silver nanoparticles onto a surface of a substrate to form a patterned film of silver nanoparticles; and finally immersing the substrate into a high concentrated aqueous solution of a reducing agent to chemically reduce the patterned film of silver nanoparticles into a conductive silver film. Thus, a patterned film or circuit can be conveniently and rapidly formed, and the silver nanoparticles can be applied to flexible substrates with low material cost and temperature sensitivity.

Owner:NAT SUN YAT SEN UNIV

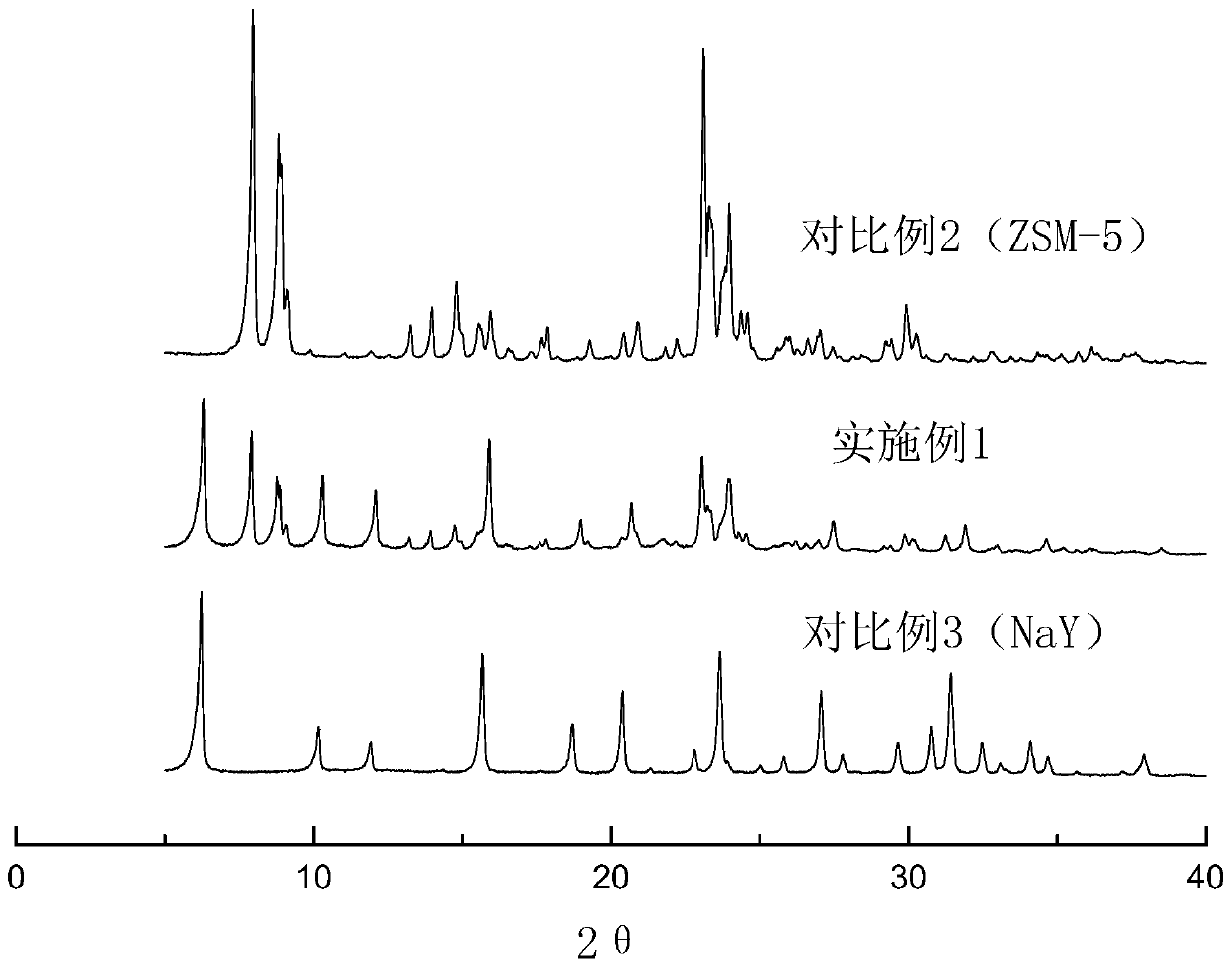

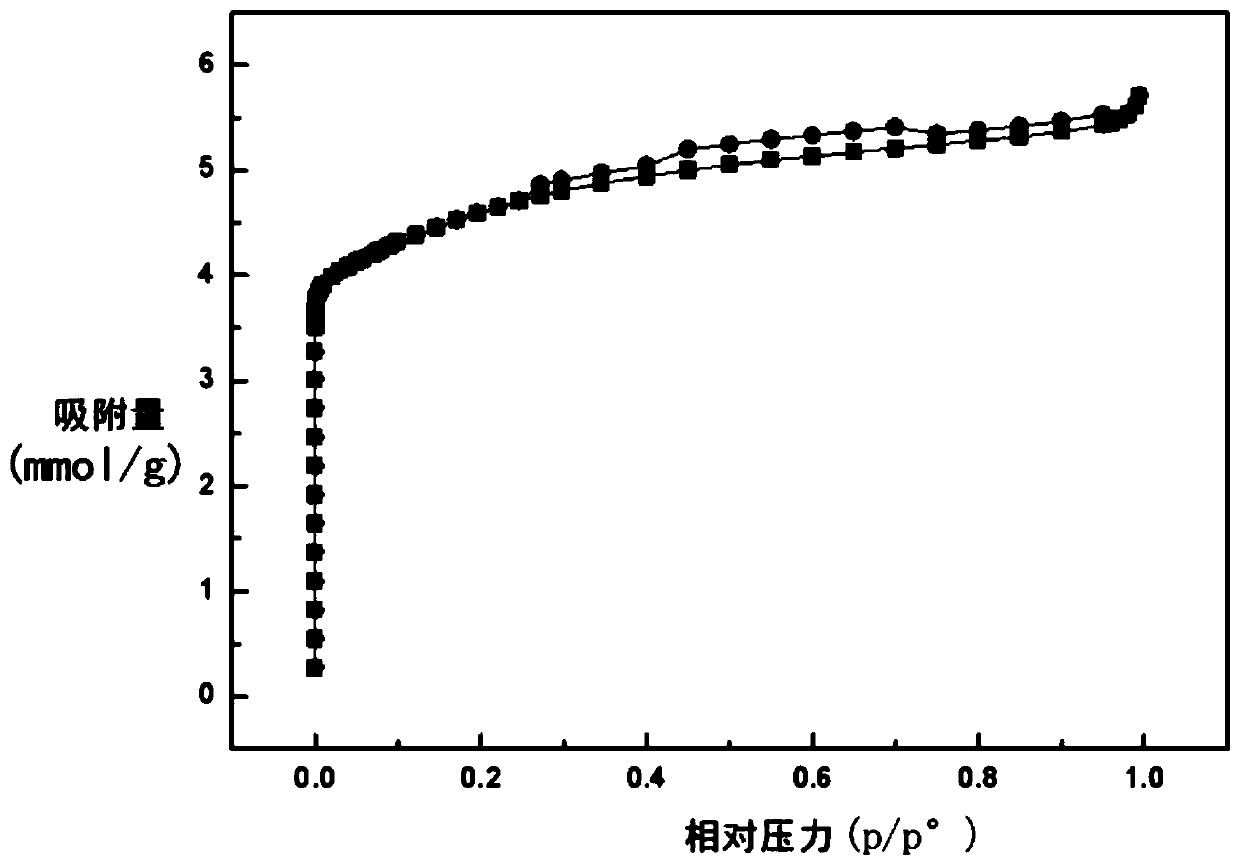

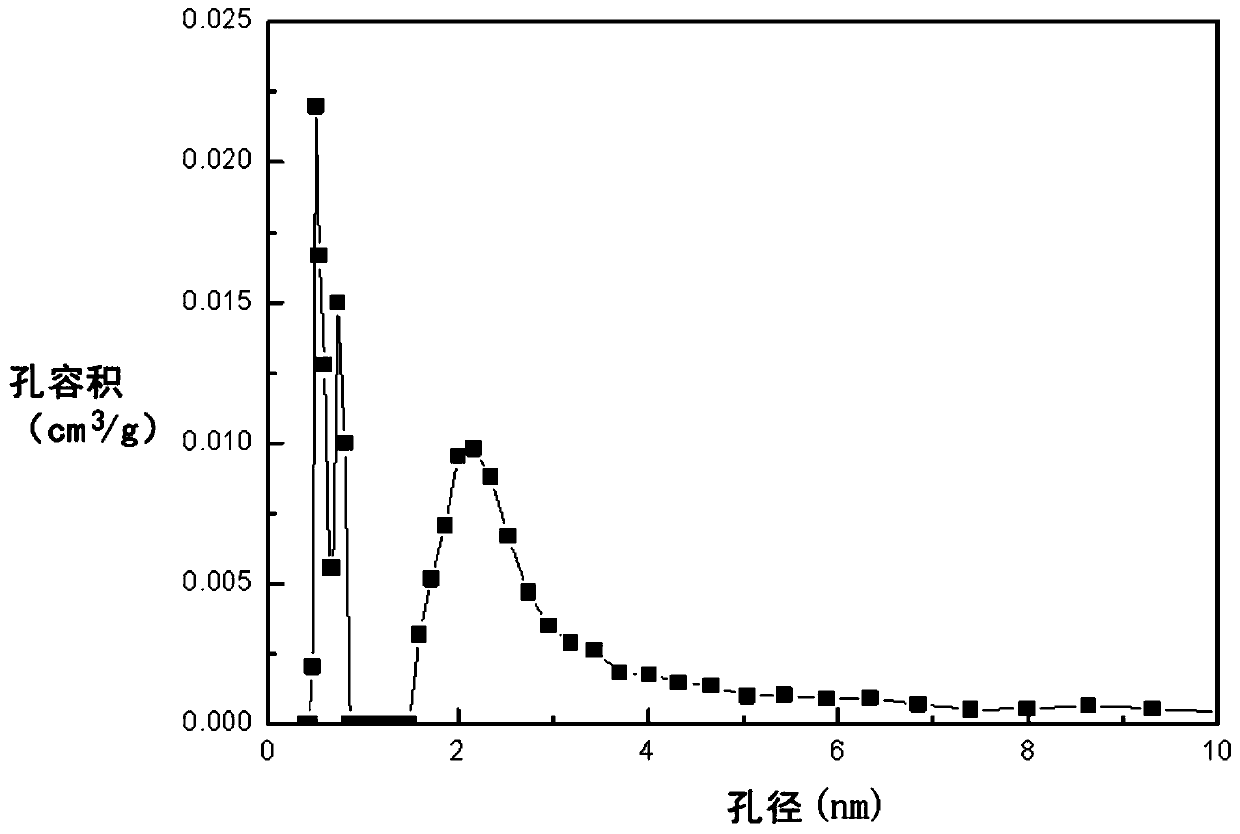

High-silicon composite molecular sieve adsorbent for removing VOCs and preparation method of high-silicon composite molecular sieve adsorbent

ActiveCN111408342AGood for desorption stabilityImprove adsorption capacityGas treatmentOther chemical processesMolecular sieveGlass fiber

The embodiment of the invention discloses a high-silicon composite molecular sieve adsorbent for removing VOCs and a preparation method thereof. The preparation method comprises the following steps: mixing an aluminum source I, an alkali source I and H2O, adding the mixture into a silicon source I, and carrying out ultrasonic aging treatment to obtain a Y-type molecular sieve guiding agent; mixingH2O, an alkali source II and an aluminum source II, adding n-butylamine and a silicon source II, carrying out a crystallization reaction under the microwave condition to obtain ZSM-5 crystallizationturbid liquid; adding a Y-type molecular sieve guiding agent, an aluminum source III and H2O into the ZSM-5 crystallization turbid liquid, adjusting the pH value to 12-12.5, performing hydrothermal crystallization treatment under a microwave condition, performing filtration and water washing after crystallization is completed to obtain a filter cake, and performing pulping treatment on the filtercake to obtain an emulsion; carrying out acid pickling on the emulsion, and then sequentially carrying out filtering, washing, drying and hydrothermal roasting treatment to obtain high-silicon composite molecular sieve powder; stirring the prepared powder with glass fibers, silica sol and H2O at a high speed to obtain mixed slurry, performing vacuum degassing, and performing spray molding to obtain the high-silicon composite molecular sieve adsorbent.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

Method for preparing methylchlorosilane with high boiling organosilicon

InactiveCN101314606AHigh selectivitySimple processGroup 4/14 element organic compoundsDimethylaniline N-oxideMethyltrichlorosilane

The invention relates to a method for preparing methyl chlorosilane from organosilicon high-boiling products. The method comprises the steps as follows: the whole composition of the high-boiling products which are the byproduct in the production process of dimethyl dichlorosilane as the organosilicon monomer is adopted as the raw material and reacts with hydrogen chloride in the presence of N,N-dimethylanlilne and tri-n-butylamine as a catalyst in a cracking kettle with a fractionating tower to obtain a mixed monomer mainly containing dimethyl dichlorosilane, trimethylchlorosilane, methyldichlorosilane and methyltrichlorosilane; and the mixed monomer is collected via the overhead condenser of the fractionating tower. The method can improve the conversion of the high-boiling products. The conversion is higher than 90%, the dimethyl dichlorosilane allows a selectivity of higher than 50%, and the selectivety of trimethylchlorosilane reaches 10%. The organosilicon monomer can be prepared at low cost.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

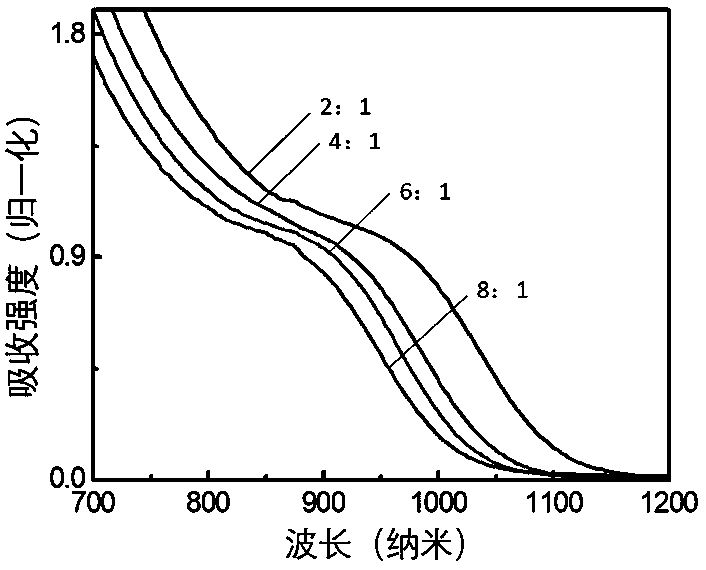

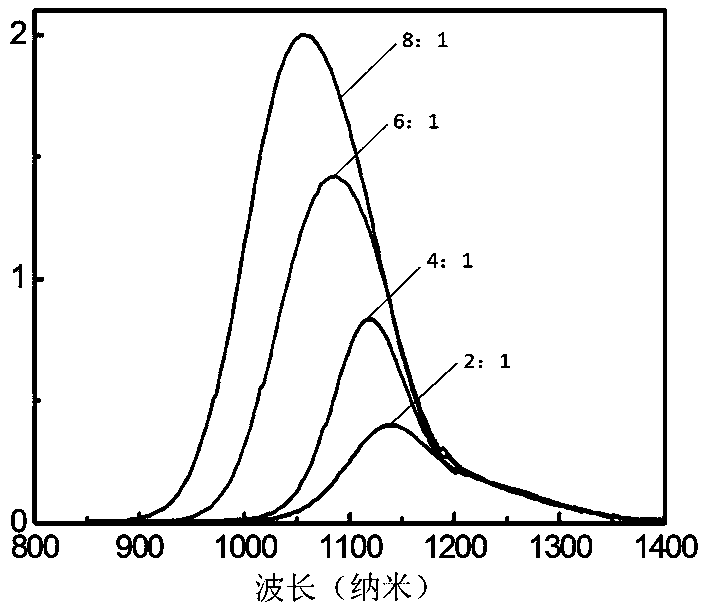

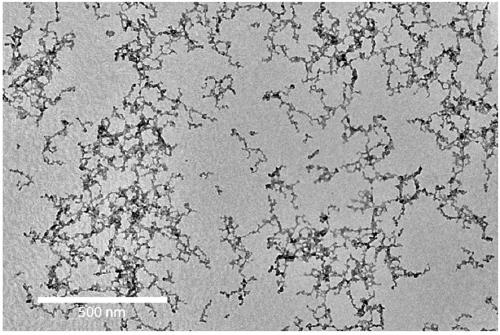

Preparation method of iodide ionic ligand PbS nanocrystal, iodide ionic ligand PbS nanocrystal ink and solar battery

InactiveCN110040769ALow costQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingIodideIodine

The invention discloses a preparation method of an iodide ionic ligand PbS nanocrystal, iodide ionic ligand PbS nanocrystal ink and a solar battery. According to the preparation method, a Pbs nanocrystal passivated by a iodide ionic ligand is synthesized directly at one step under the action of butyl amine by taking lead iodide and N,N-thiocarbanilide as precursors and taking N,N-dimethyl formamide as a solvent, so that the preparation process flow is simplified, and the synthetic preparation cost and device preparation cost of the nanocrystal are lowered. The iodide ionic ligand Pbs nanocrystal provided by the invention can be dissolved in N,N-dimethyl formamide and other solvents to obtain iodide ionic ligand PbS nanocrystal ink of which the nanocrystal absorption peak is adjustable within a range of 850 to 1100 nanometers. Meanwhile, when a N,N-dimethyl formamide solution of the PbS nanocrystal passivated by the iodide ionic ligand is used for preparing a solar battery, the device performance which is comparable to solution phase ligand exchange can be achieved.

Owner:SUZHOU UNIV

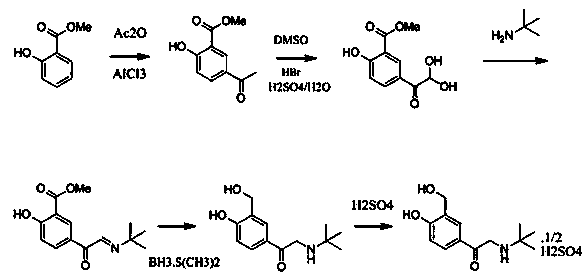

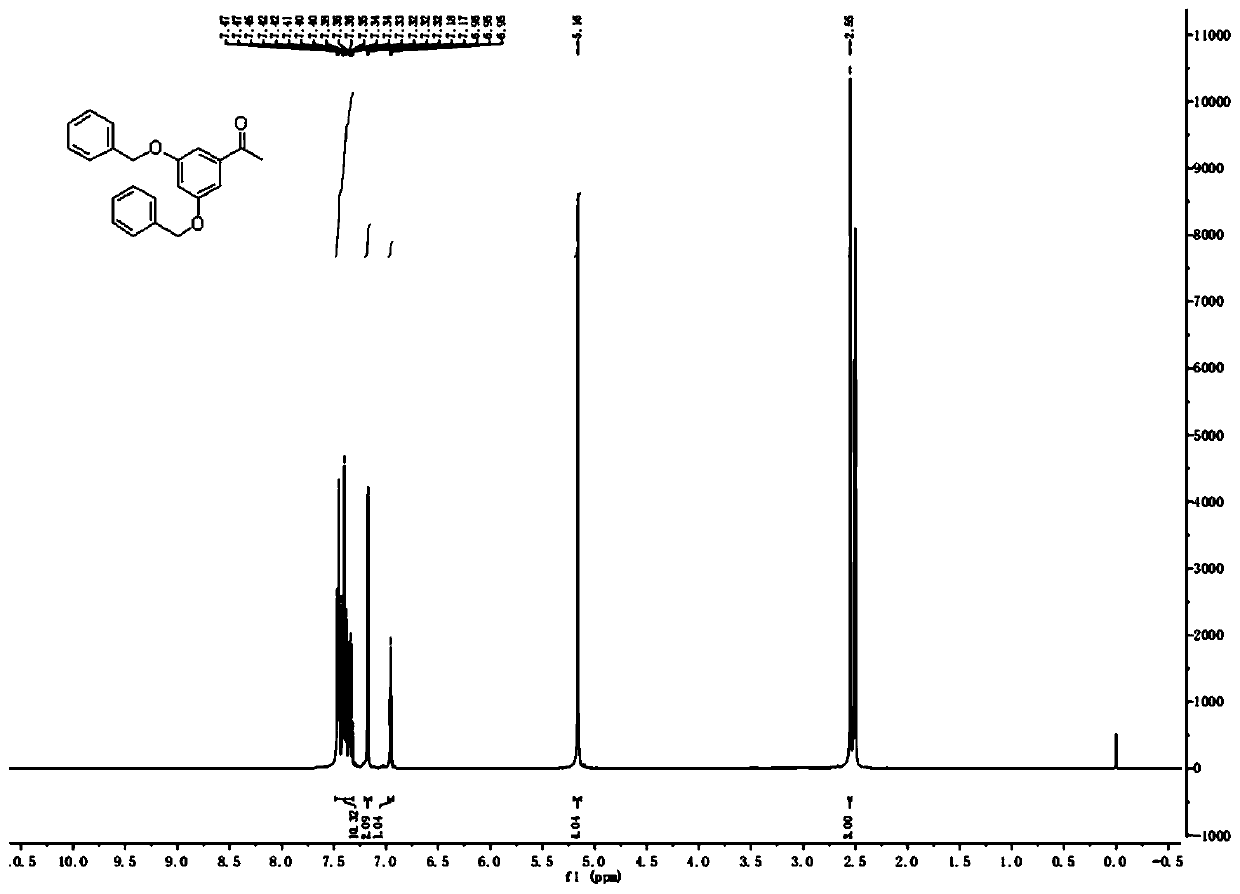

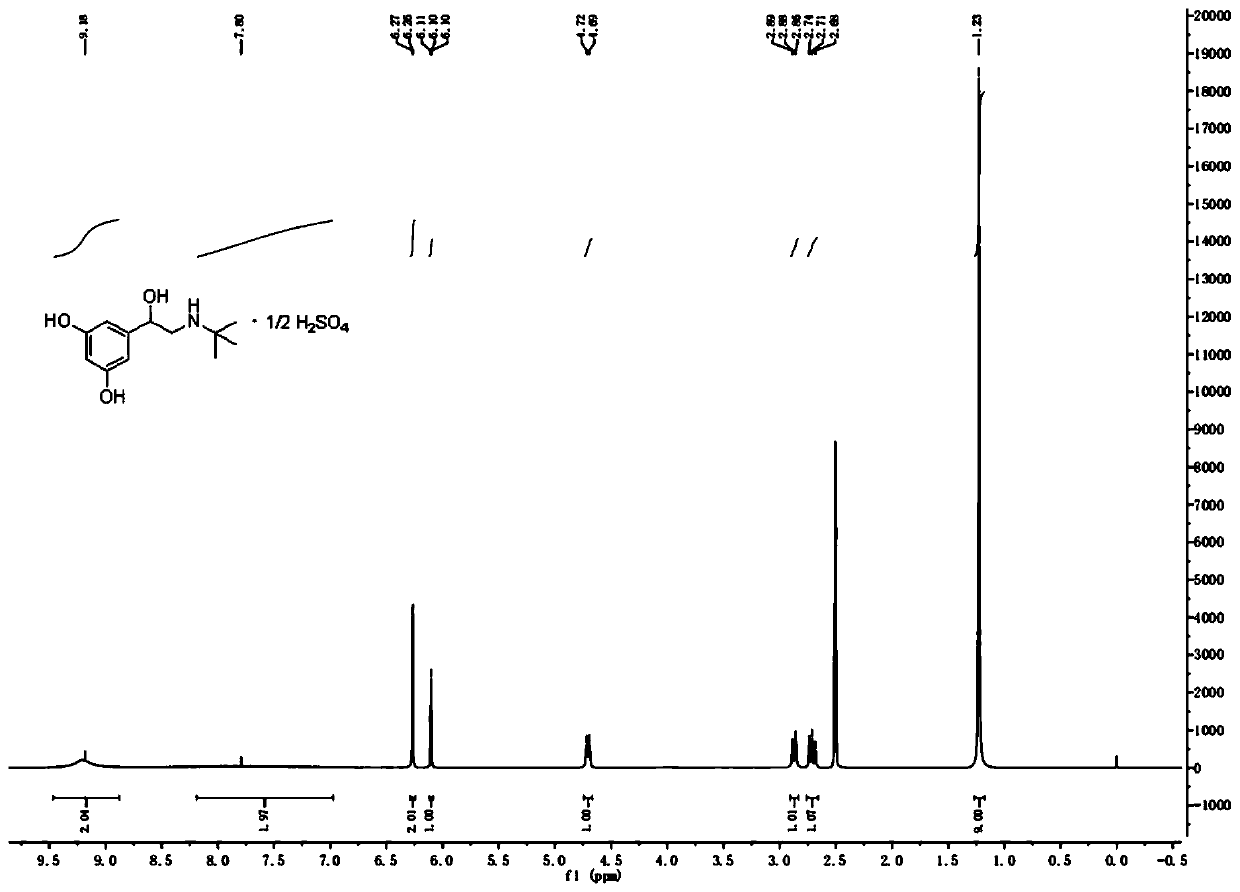

Preparation method of terbutaline sulfate

ActiveCN110950765AReduce usageAvoid high temperature and high pressure reactionsOrganic compound preparationCarbonyl compound preparationAcetophenonePhenyl group

The invention discloses a preparation method of terbutaline sulfate. The method comprises the steps: taking 3,5-dihydroxyacetophenone as an initial raw material, firstly, carrying out benzyl protection to obtain 3,4-dibenzyloxyacetophenone, carrying out copper bromide bromination and DMSO oxidation on 3,5-dibenzyloxyacetophenone to obtain 3,5-dibenzyloxyacetophenone aldehyde, carrying out reductive amination on 3,5-dibenzyloxyacetophenone aldehyde and tert-butylamine to generate 1-[3,5-di(benzyloxy)phenyl]-2-(tert-butylamino)ethanol, and finally carrying out hydrogenation debenzylation and sulfuric acid salification, to obtain terbutaline sulfate. Compared with the prior art, the method has the advantages that the used raw materials and auxiliary materials are cheap and easily available, the use of high-risk and highly-toxic reagents is avoided, high-temperature and high-pressure reaction is avoided, the operation is simple and convenient, the reaction conditions are mild, and the defects of long steps, low yield, potential safety hazards and the like in the prior art are overcome.

Owner:ZHEJIANG PHARMA COLLEGE

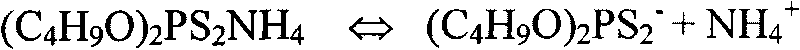

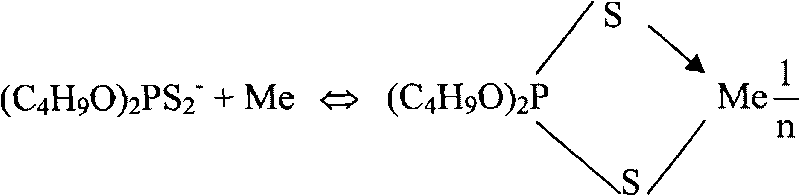

Collecting agent for separating gold from high-arsenic type gold ores and preparation method for collecting agent

ActiveCN103657868AStrong harvesting abilityEnhanced harvesting capacityFlotationSulfite saltXanthate

A collecting agent for separating gold from high-arsenic type gold ores is prepared by the following raw materials in part by weight: 2-3 parts of sodium sulfite, 1-2 parts of calcium oxide, 22-24 parts of alkyl xanthate acrylic nitrile ester, 2-3 parts of sodium carbonate, 3-4 parts of sodium pyrosulfite, 1-2 parts of sodium sulphide, 34-38 parts of xanthate, 2-3 parts of glycerin polyethenoxy ether propylene ether fatty acid ester, 14-16 parts of butylamine aerofloat, 12-14 parts of terpenic oil, 3-4 parts of ammonium citrate and 10-12 parts of activating agent. The collecting agent has a restraining effect on arsenic in the high-arsenic type gold ores, and is high in gold collecting ability; secondary environmental pollution is avoided; complex pre-treatment work procedures are not required; the process is simple; and the recycling cost is low. Moreover, by using the activating agent, the surface hydrophobicity of the gold ores is changed, the internal structure is activated, and the gold collecting performance of the collecting agent is improved.

Owner:ANHUI CHAOSHAN NEW MATERIAL

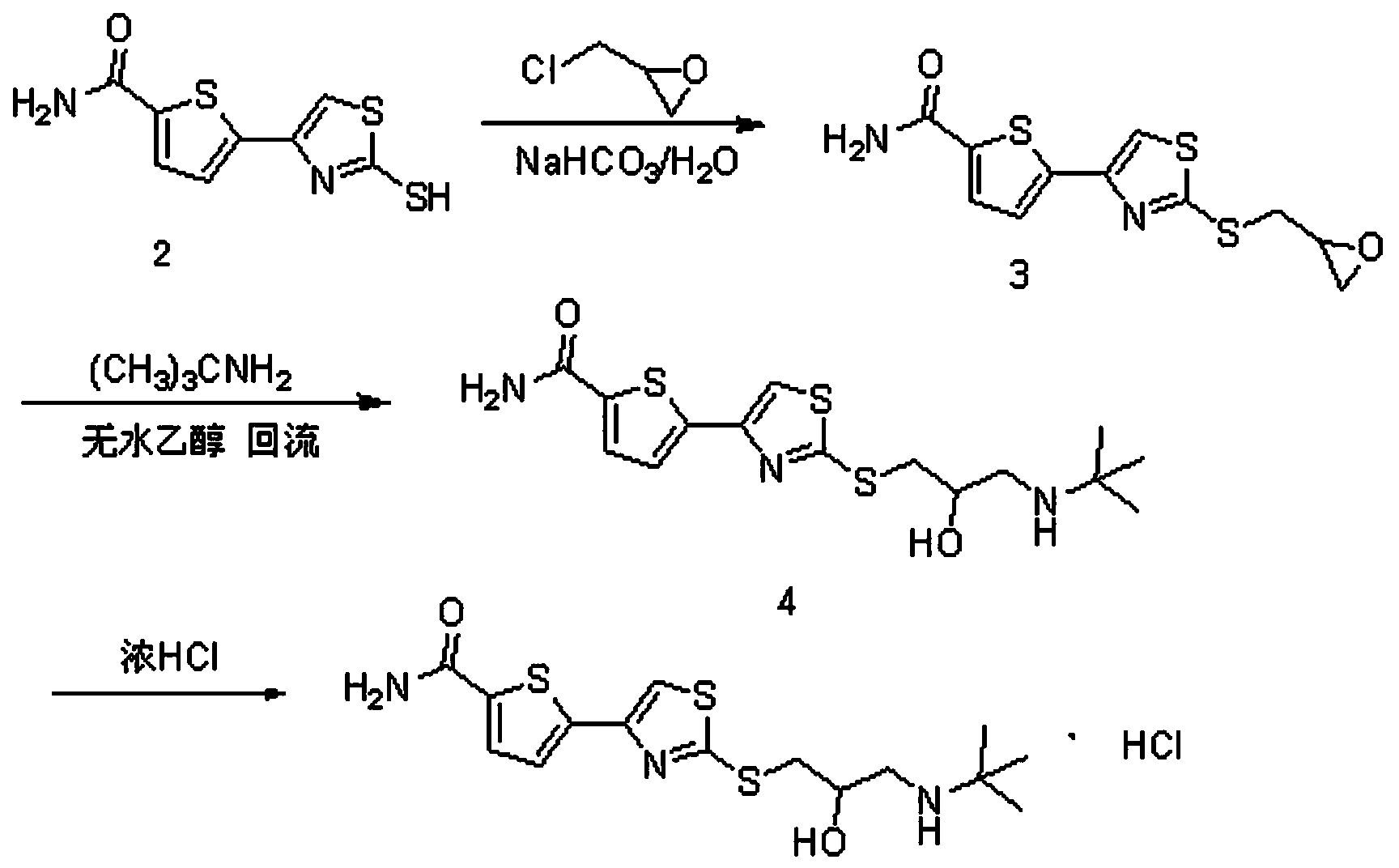

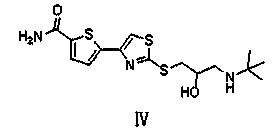

Preparation method of arotinolol hydrochloride

The invention relates to a preparation method of arotinolol hydrochloride. The preparation method comprises the following steps: (1) preparing 2-[2,3-glycidyl-4-(5-carbamyl-2-thienyl)] thiazole; (2) dissolving 2-[2,3-glycidyl-4-(5-carbamyl-2-thienyl)] thiazole in absolute ethyl alcohol, adding tert-butylamine and performing a reflux reaction to obtain arotinolol; and (3) dissolving arotinolol in dimethyl sulfoxide and then adding concentrated hydrochloric acid to generate the arotinolol hydrochloride. The preparation method disclosed by the invention is short in production period, simple in process, high in yield, safe and reliable, and the arotinolol hydrochloride prepared by the method disclosed by the invention is high in purity.

Owner:SHIJIAZHUANG GERUI PHARMA CO LTD

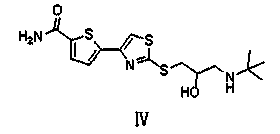

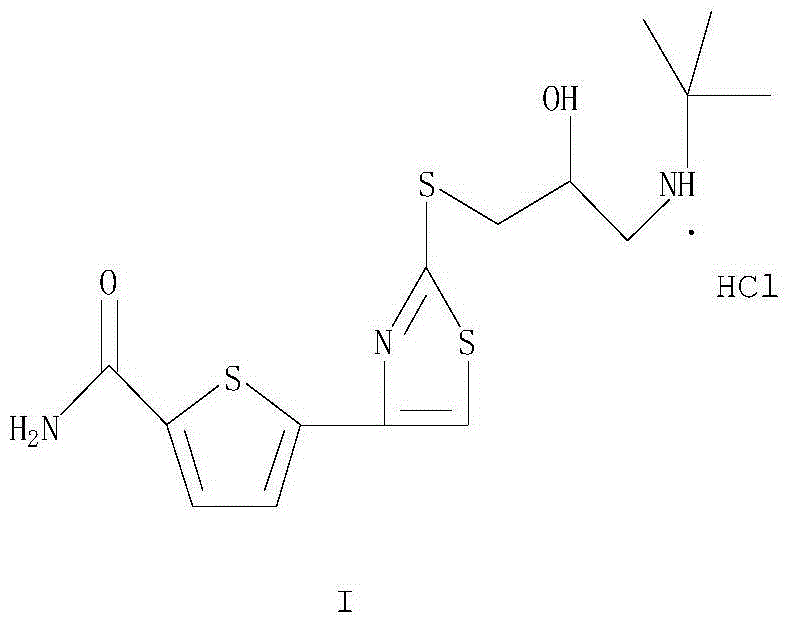

Novel process method for preparing arotinolol hydrochloride

The invention belongs to the technical field of medicines and particularly relates to a simple and efficient method for preparing selective beta 1 adrenoceptor antagonists 5-[2-[[[3-(1,1-dimethylethyl)amino]-2-hydroxypropyl]thio]-4-thiazolyl]-2-thiophene carboxamide hydrochloride. The method comprises the following steps: firstly, reacting 5-(2-mercapto-4-thiazolyl)-2-thiophenecarboxamide and epoxy chloropropane in the presence of Lewis acid as a catalyst in an organic solvent, after the reaction is completed by the monitoring of TLC, filtering and carrying out pressure reduced concentration to dryness to obtain an intermediate; and secondly, reacting the intermediate and t-butylamine in an organic solvent, cooling to room temperature, adding hydrochloric acid to adjust the pH, carrying out reflux reaction, naturally cooling and crystallizing to obtain arotinolol hydrochloride.

Owner:JIANGXI BAISHEN PHARMA

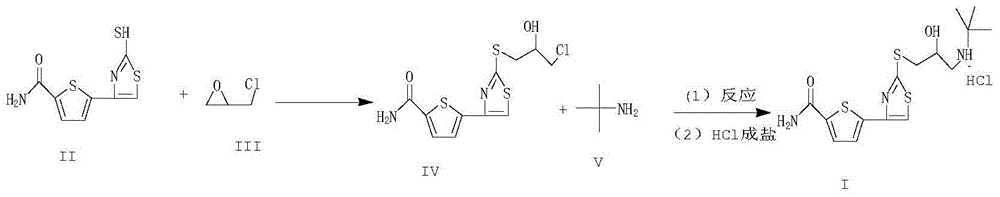

Recycling method for phosgene in tail gas generated in calorescence reaction for synthesizing normal-butyl isocyanate

ActiveCN103638688ATake advantage ofMaximize utilizationDispersed particle separationVapor condensationCalorescenceN-butylisocyanide

The invention relates to a recycling method for phosgene in tail gas generated in calorescence reaction for synthesizing normal-butyl isocyanate. The recycling method comprises the steps of continuously cooling and absorbing the tail gas generated in the calorescence reaction for synthesizing the normal-butyl isocyanate through a low temperature solvent, and condensing the tail gas through a condenser, wherein the non-condensing gas directly enters a tail gas processing system; preparing normal-butyl acyl chloride from the solvent containing the phosgene with certain quality concentration through cold light reaction, metering the phosgene-containing solvent, shifting the solvent into a cold light kettle, dropwise adding n-butylamine at -8 DEG C to -2 DEG C, after the dropwise adding, keeping the temperature for 1 hour so as to obtain the n-butylamine acyl chloride; and resolving the n-butylamine acyl chloride in a calorescence reaction kettle to obtain the normal-butyl isocyanate. The method provided by the invention has the advantages that the phosgene is utilized to the greatest extent, the load of the tail gas generated in the normal-butyl isocyanate calorescence reaction in a tail gas processing system and the alkali charge during tail gas processing are reduced, the production cost of the product is reduced, and the purpose of saving and recycling resources is achieved.

Owner:HUNAN GOFAR FINE CHEM IND TECH CO LDT

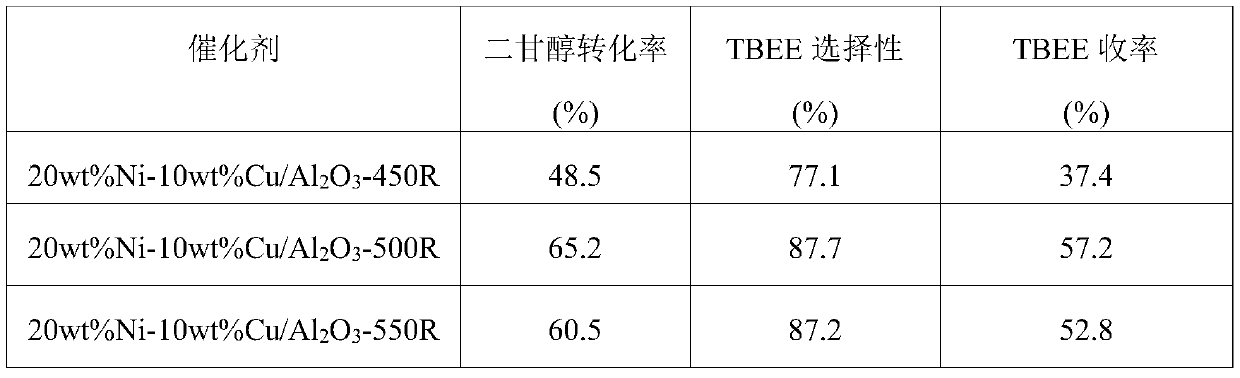

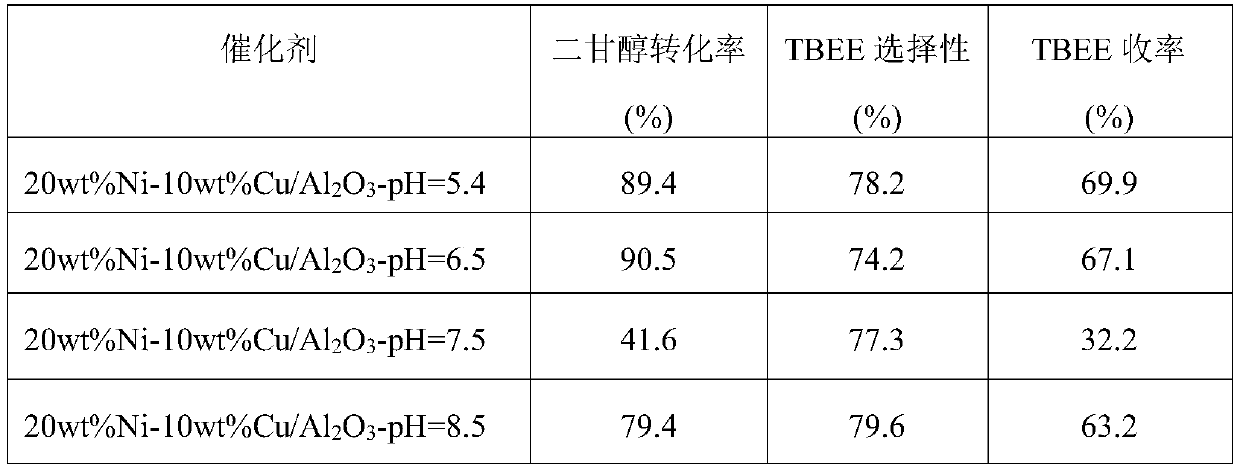

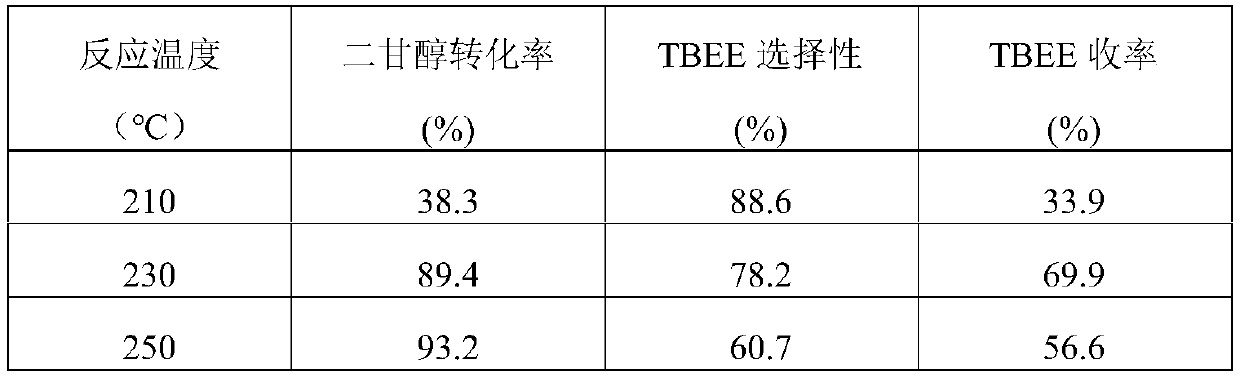

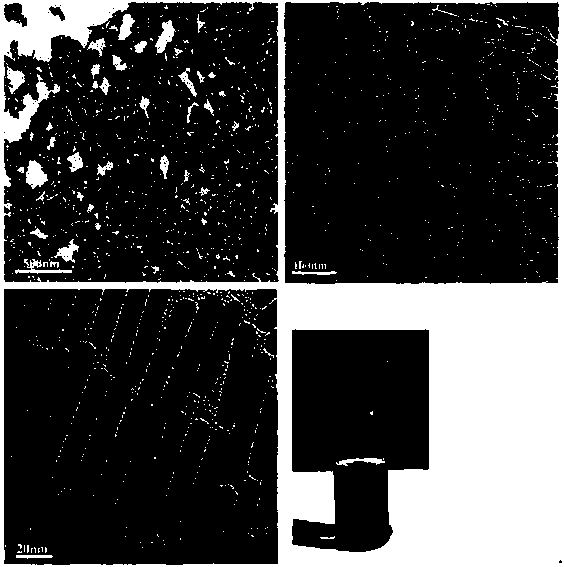

Ni-Cu/Al2O3 bimetal catalyst and preparation method thereof, and application of Ni-Cu/Al2O3 bimetal catalyst in preparation of (tert-butylaminoethoxy)ethanol (TBEE)

InactiveCN110508287ALow costHigh yieldOrganic compound preparationCatalyst activation/preparationTert-ButylamineEthylene oxide

The invention provides a Ni-Cu / Al2O3 bimetal catalyst and a preparation method thereof, and application of the Ni-Cu / Al2O3 bimetal catalyst to catalysis of an amination reaction of diethylene glycol (DEG) with tert-butylamine (TBA) for preparation of the desulphurization solvent TBEE with severe steric-hinerance effect, belonging to the field of heterogeneous catalysis. The catalyst is composed ofa Ni-Cu bimetal active component and an Al2O3 carrier, wherein the loading amount of Ni accounts for 5 wt%-30 wt% of the mass of the carrier, and the loading amount of Cu accounts for 5 wt%-20 wt% ofthe mass of the carrier. The Ni-Cu / Al2O3 bimetal catalyst described in the invention has high reactivity and product yield in the synthesis of TBEE through the amination reaction of DEG with TBA; thepreparation cost of the catalyst is low; the catalyst can be produced on a large scale; in addition, the by-product DEG produced during the production of ethanol from ethylene oxide can be effectively used as a reaction raw material; meanwhile, the preparation method is of great significance to solving of environmental pollution caused by H2S emissions.

Owner:JILIN UNIV

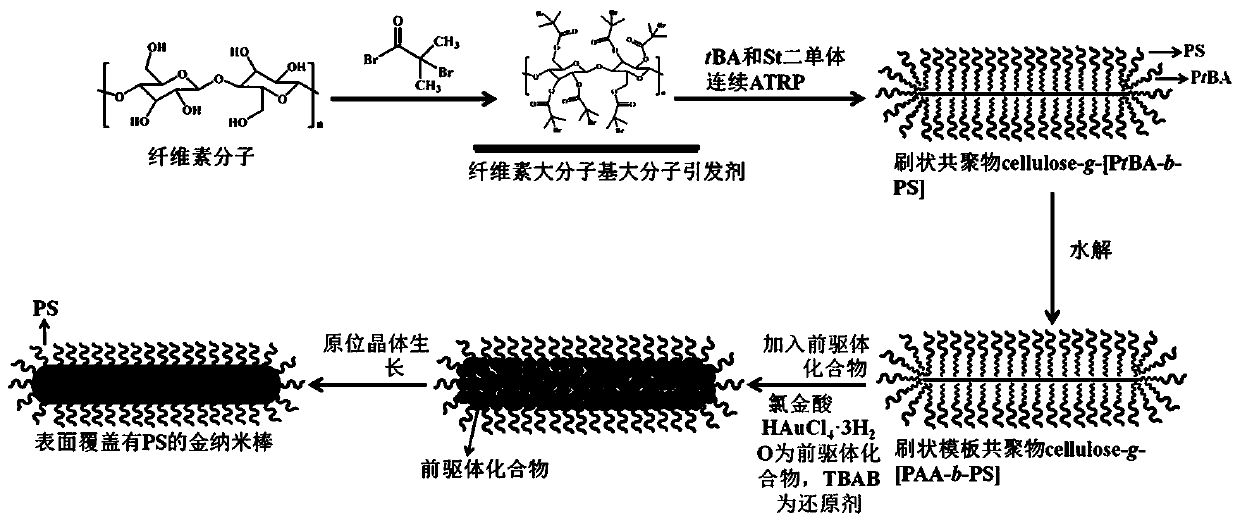

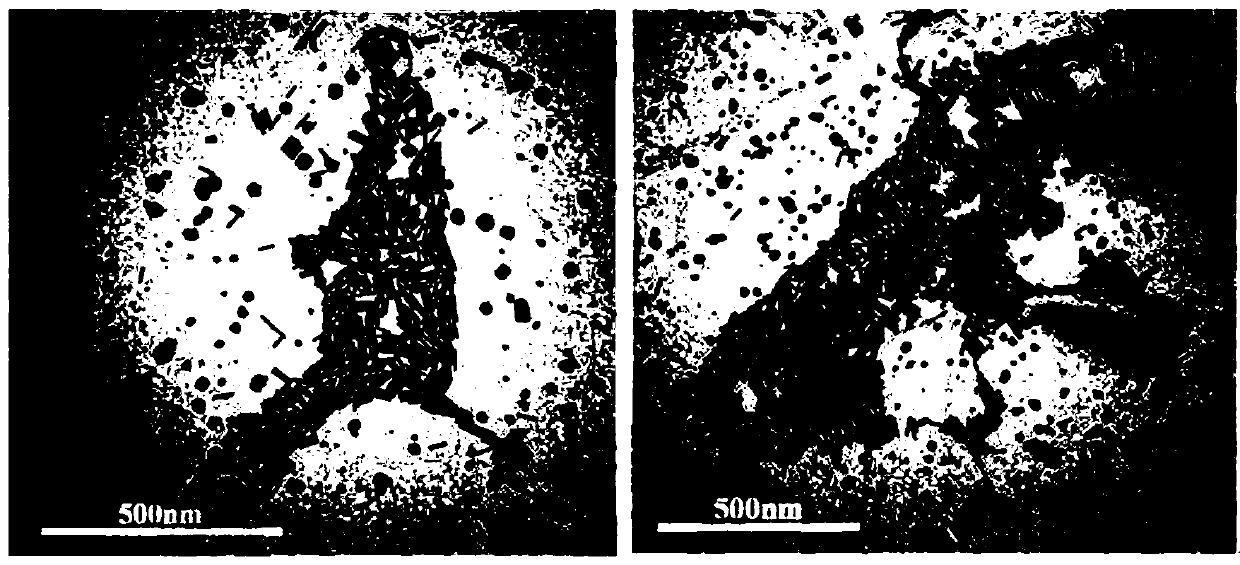

Preparation method of gold nanorods with large-scale preparation and controllable sizes and dispersibility

ActiveCN107552807AHigh graft densityClear structureNanotechnologyBulk chemical productionCelluloseWater dispersible

The invention discloses a preparation method of gold nanorods with large-scale preparation and controllable sizes and dispersibility, and belongs to the multidisciplinary field of polymeric activity polymerization methods, functional polymer molecular design, inorganic crystal growth, etc. The method comprises the steps: (1) taking ionic liquid AMIMCl as solvents, and anhydrous dimethylformamide and N-Methyl pyrrolidone (NMP) as diluents and acid absorbents separately, applying 2-bromoisobutyryl bromide to hydroxyls on a cellulose chain, and converting the hydroxyls into macroinitiators whichcan be used for atom transfer radical polymerization (ATRP); (2) preparing a series of brushy two-block polymers: cellulose-g-[PAA-b-PS] and cellulose-g-[PAA-b-PEG] with a continuous ATRP technology,a technology of combination of ATRP and Click Chemistry and other technologies by taking cellulose-Br as the macroinitiators; and (3) preparing the gold nanorods with oil dispersibility and water dispersibility based on a solution phase synthesis method by taking a certain amount of the brushy two-block polymers as monomolecular templates, chloroauric acid (HAuCl4.3H2O) as precursor compounds andtert-butylamine boron (TBAB) as reducing agents.

Owner:郑州科斗科技有限公司

Novel gold flotation catching agent

The invention discloses a novel gold flotation catching agent. The catching agent is composed of sodium n-butylxanthate, sodium isoamylxanthate and butylamine aerofloat. The weight ratio of the sodium n-butylxanthate to the sodium isoamylxanthate to the butylamine aerofloat is 4 to 8:1 to 5:0.5 to 2. Preferably, the weight ratio of the sodium n-butylxanthate to the sodium isoamylxanthate to the butylamine aerofloat is 6:3:1. The mode that in the traditional gold floatation process, the sodium n-butylxanthate with the single carbon chain is adopted is broken through, different catching properties and selectivity of different carbon chains are adopted, the catching properties of the sodium n-butylxanthate and the selectivity of the sodium isoamylxanthate are complemented, the selectivity of the butylamine aerofloat is added, the three agents are fully mixed, contradiction of the catching capability and the selectivity is resolved, and therefore the catching properties and the selectivity are developed to the great extent. Compared with a traditional agent, the recycling rate of the novel gold flotation catching agent is improved by 0.5 percent, the use number of the agents is reduced by 12 g / t, and the concentrate grade is improved by 0.74 g / t.

Owner:HABAHE JINBA MINING

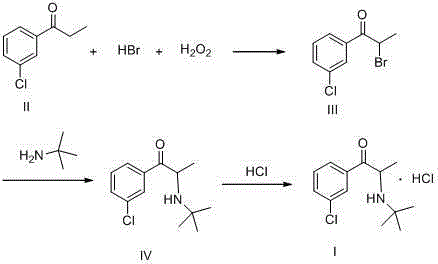

Method for preparing bupropion hydrochloride

InactiveCN105968023AAvoid damageReduce pollutionOrganic chemistryOrganic compound preparationTert-ButylamineAlcohol

The invention discloses a novel method for preparing bupropion hydrochloride. According to the invention, m-chlorophenylacetone is taken as an initiator, then is brominated in a hydrobromic acid-hydrogen peroxide system, 3'-chlorine-alpha-bromophenyl ethyl ketone is synthesized; then through replacement by tert-butylamine and acidification by HCl-absolute ethyl alcohol, bupropion hydrochloride is obtained. The preparation method of bupropion hydrochloride replaces traditional bromine bromination, pollution can be effectively reduced, damage due to bromine volatilization on the operators can be greatly mitigated, and the method has the advantages of simple operation, low cost, high yield, and less side reaction, and is very suitable for industrial production.

Owner:WEIHAI DISU PHARMA CO LTD

Antirust coating, antirust method and application of antirust coating

InactiveCN102690544AAccelerated corrosionImprove rust resistancePretreated surfacesAnti-corrosive paintsNitriteWater dispersible

The invention relates to an antirust coating, an antirust method and application of the antirust coating. The antirust coating comprises the following components: a compound with sulfo-carbonyl, water-dispersible silicon dioxide, nitrite, tri-n-butylamine and nitrilo-triethanolamine. The antirust method comprises the following steps of: applying the antirust coating on an object to be coated, and then heating the coated object by hot air to be dried; or heating the object to be coated, applying the antirust coating on the heated object, and drying the object by heat retained in the object. The antirust coating is suitable for being applied on zinc-plated steel or aluminum-plated steel or non-plated steel so as to perform antirust treatment on the zinc-plated steel or the aluminum-plated steel or the non-plated steel. The non-chrome antirust coating provided by the invention has the advantages of excellent storage stability, relatively low environmental toxicity and high antirust performance.

Owner:TIANCHANG JULONG TRAVEL PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com