Patents

Literature

4130results about How to "Improve rust resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

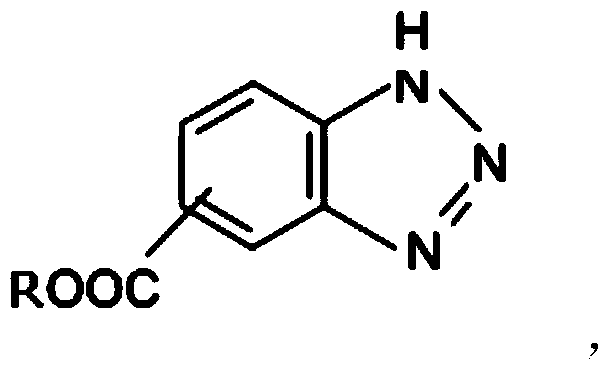

Water soluble full-alloy metal grinding fluid

ActiveCN104017636ALubricity achievedImprove stabilityLubricant compositionOrganic EsterNonferrous metal

The invention discloses a water soluble full-alloy metal grinding fluid which belongs to the technical field of metal grinding fluids. The metal grinding fluid is prepared from the following components in percentage by weight: 5-40wt% of an antirust agent, 1-20wt% of a cleaning agent, 0.1-10wt% of a lubricating corrosion inhibitor, 1-20wt% of a penetrant, 1-20wt% of a solubilizer, 10-40wt% of a PH adjustor, 0.5-5wt% of a defoamer and the balance of water. Based on the total weight of the water soluble full-alloy metal grinding fluid, the pH value of the water soluble full-alloy metal grinding fluid is 7-11. The lubricating corrosion inhibitor is long chain nitrogen heterocyclic ring organic ester. The water soluble full-alloy metal grinding fluid has excellent lubricating, rust-preventing, cleaning and cooling performances and can be widely applied to grinding of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

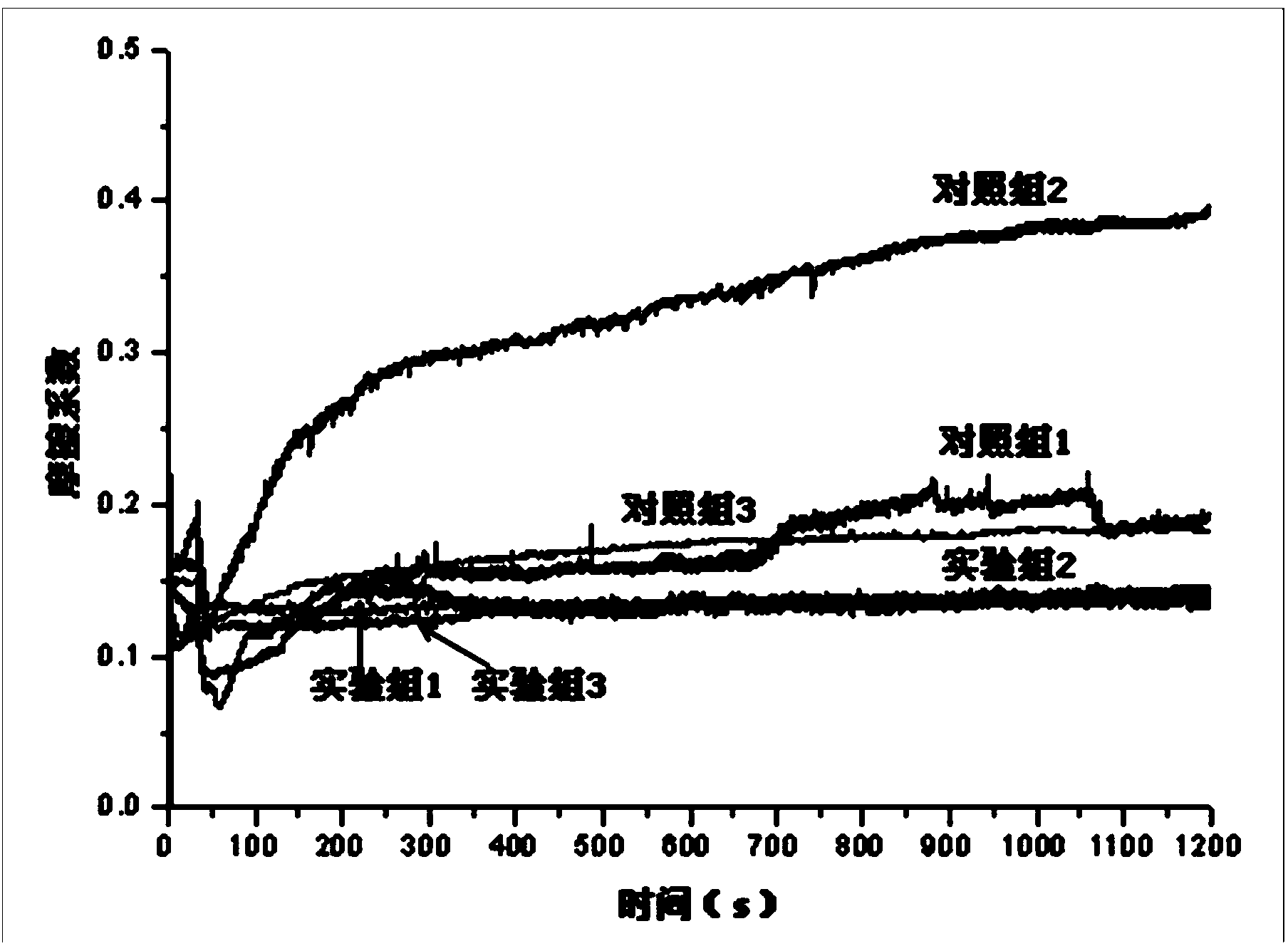

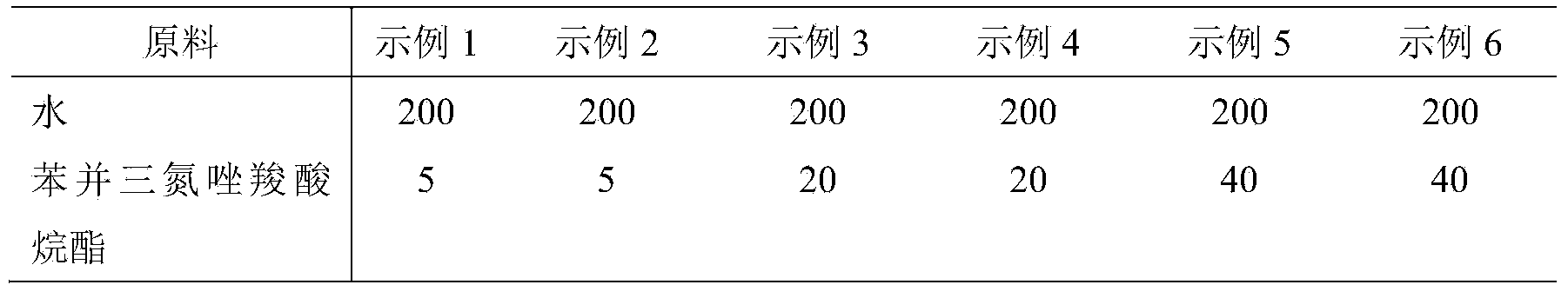

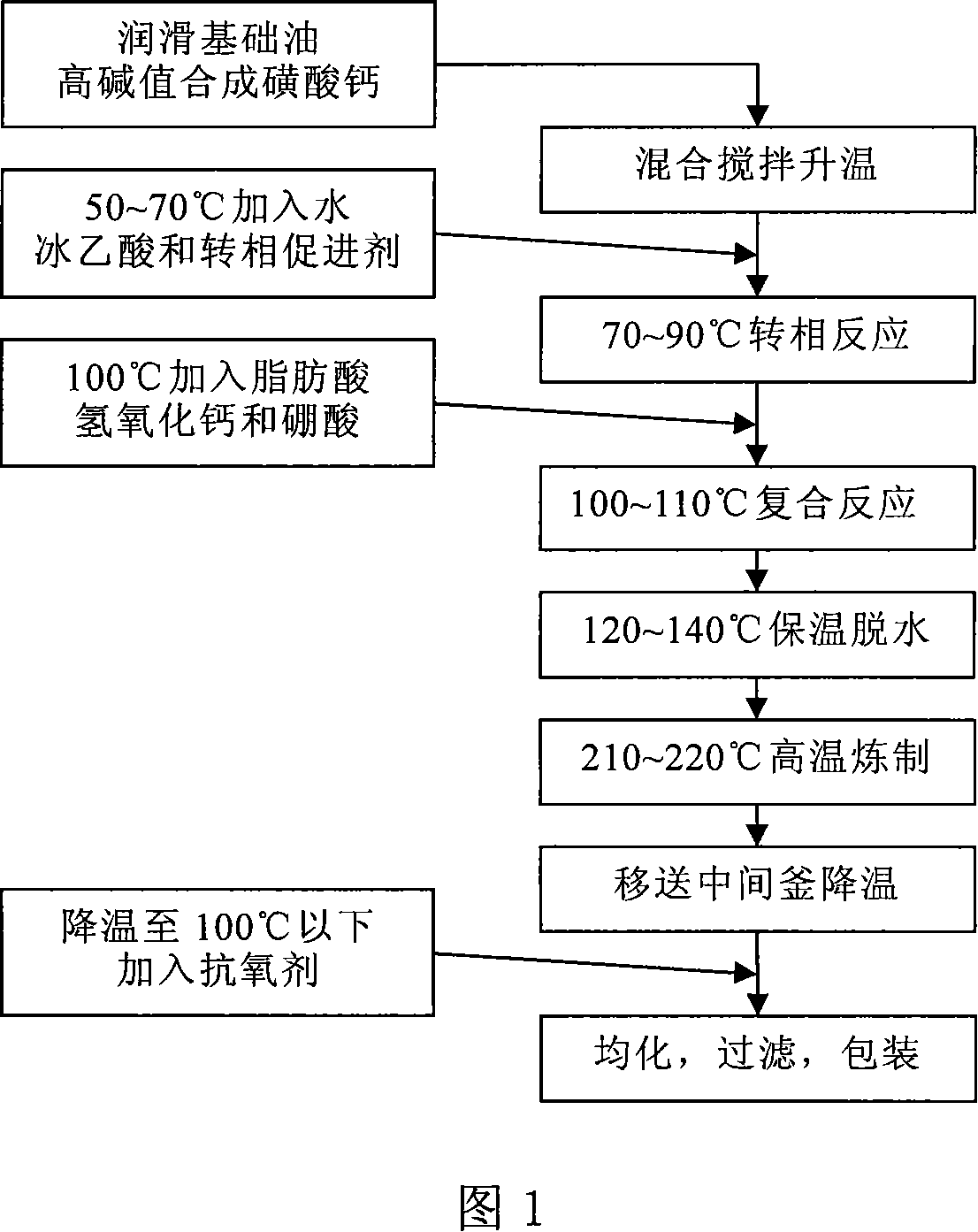

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

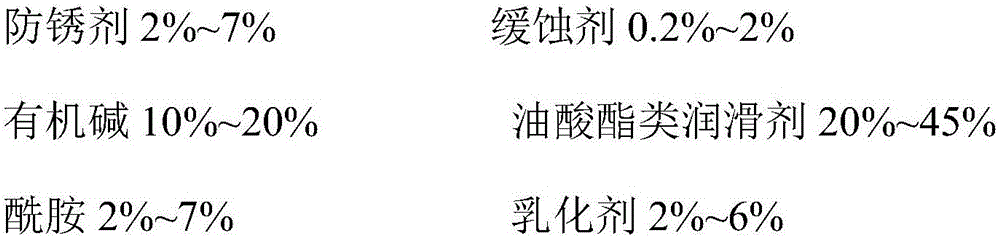

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

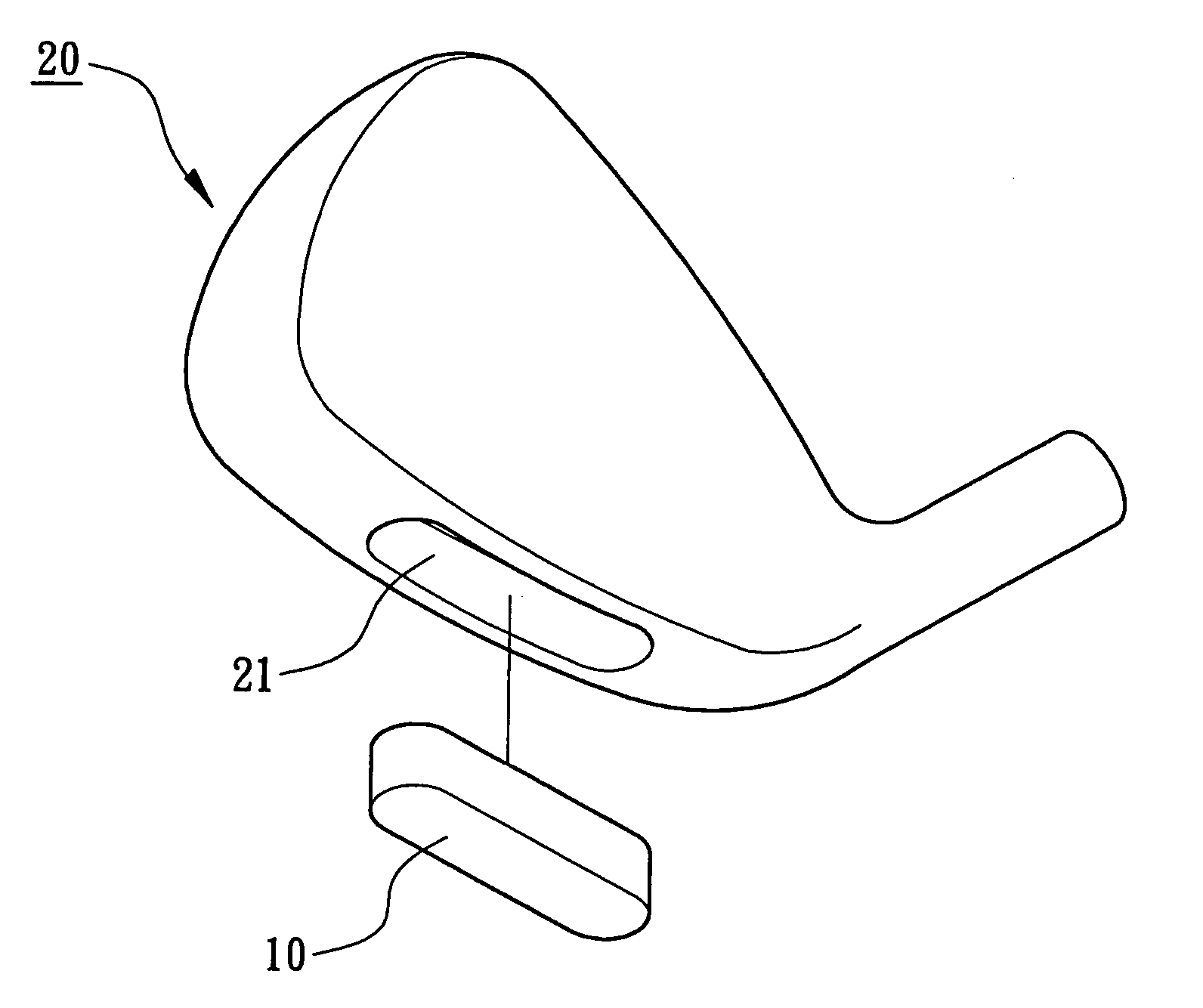

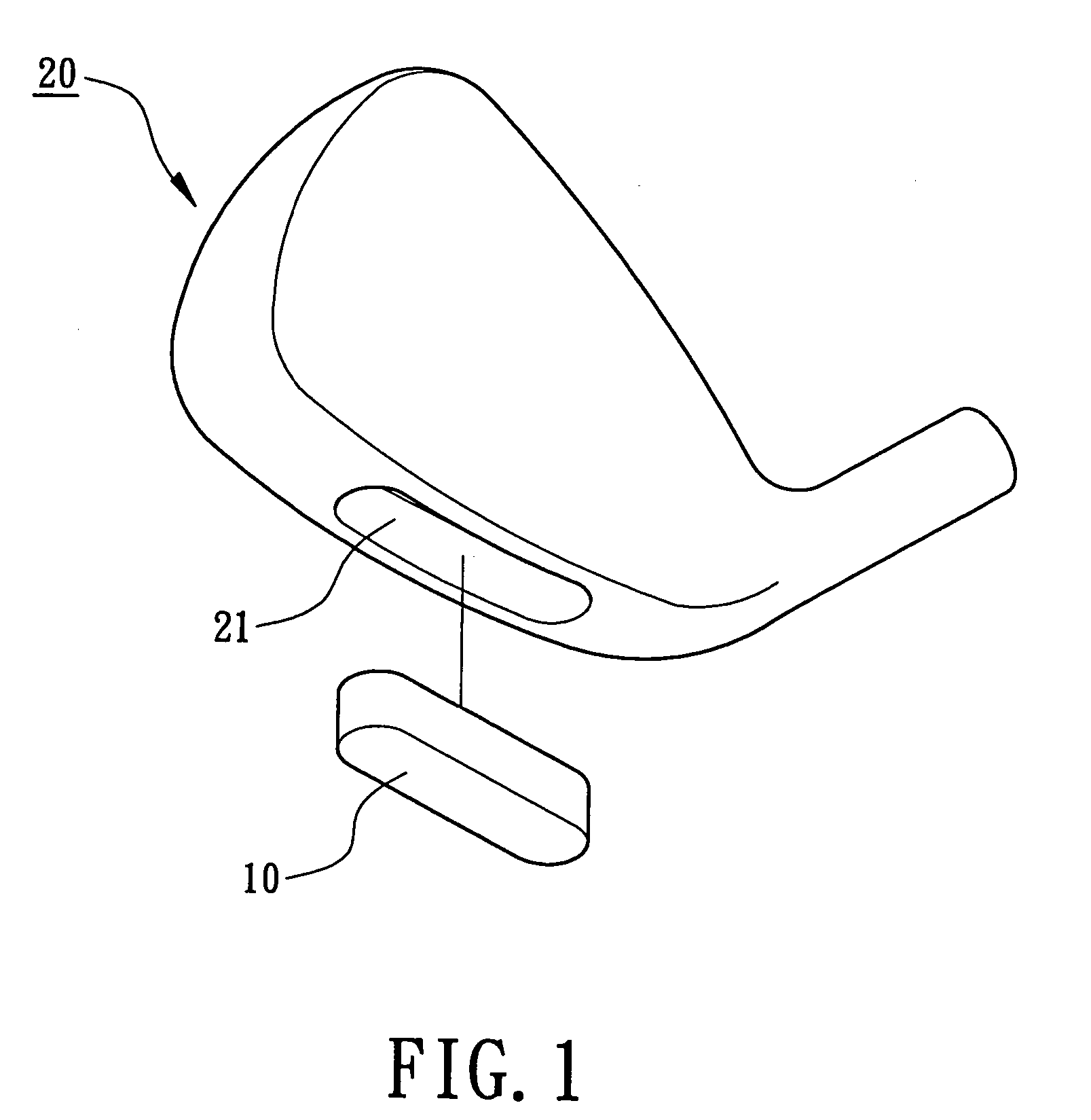

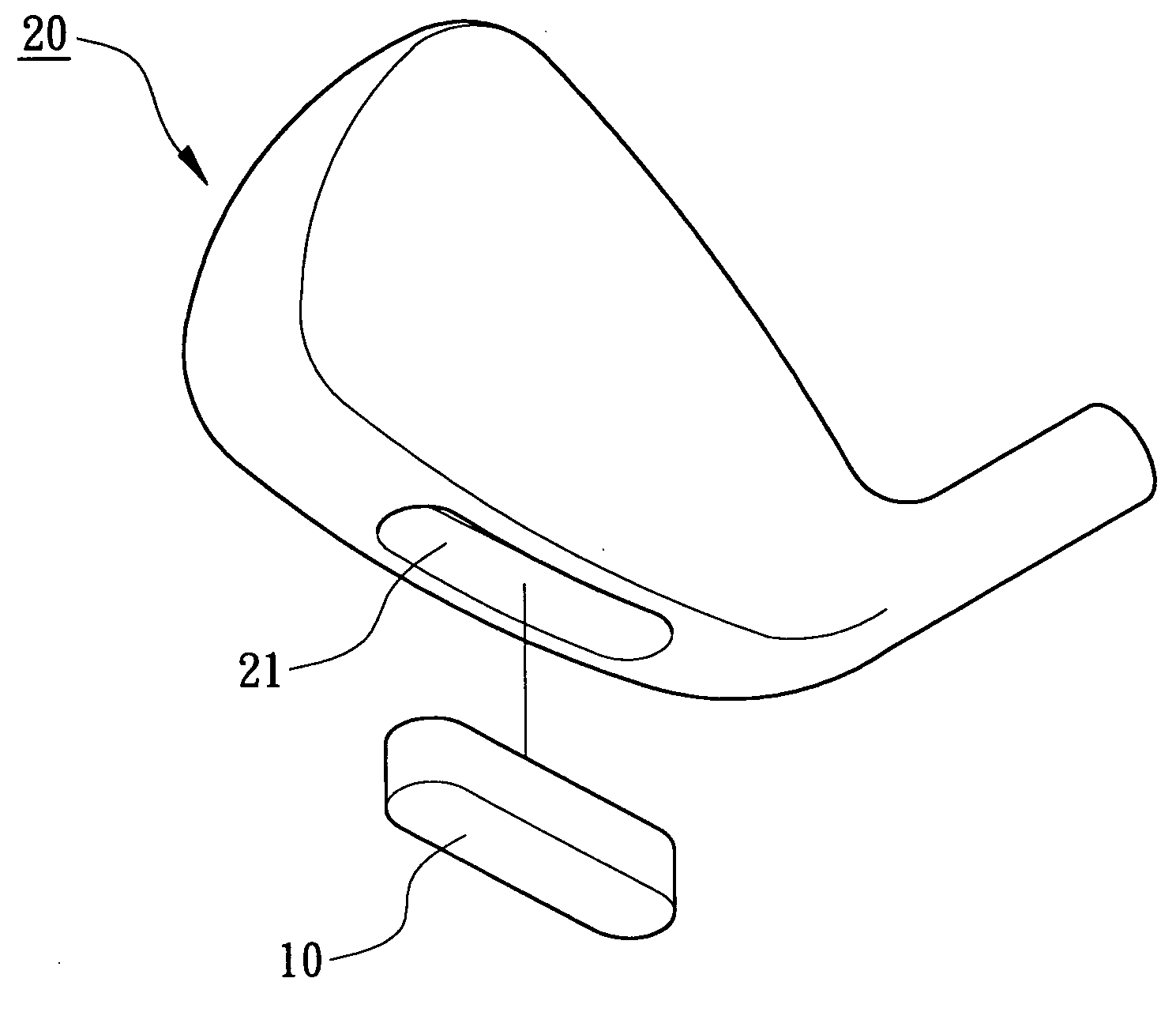

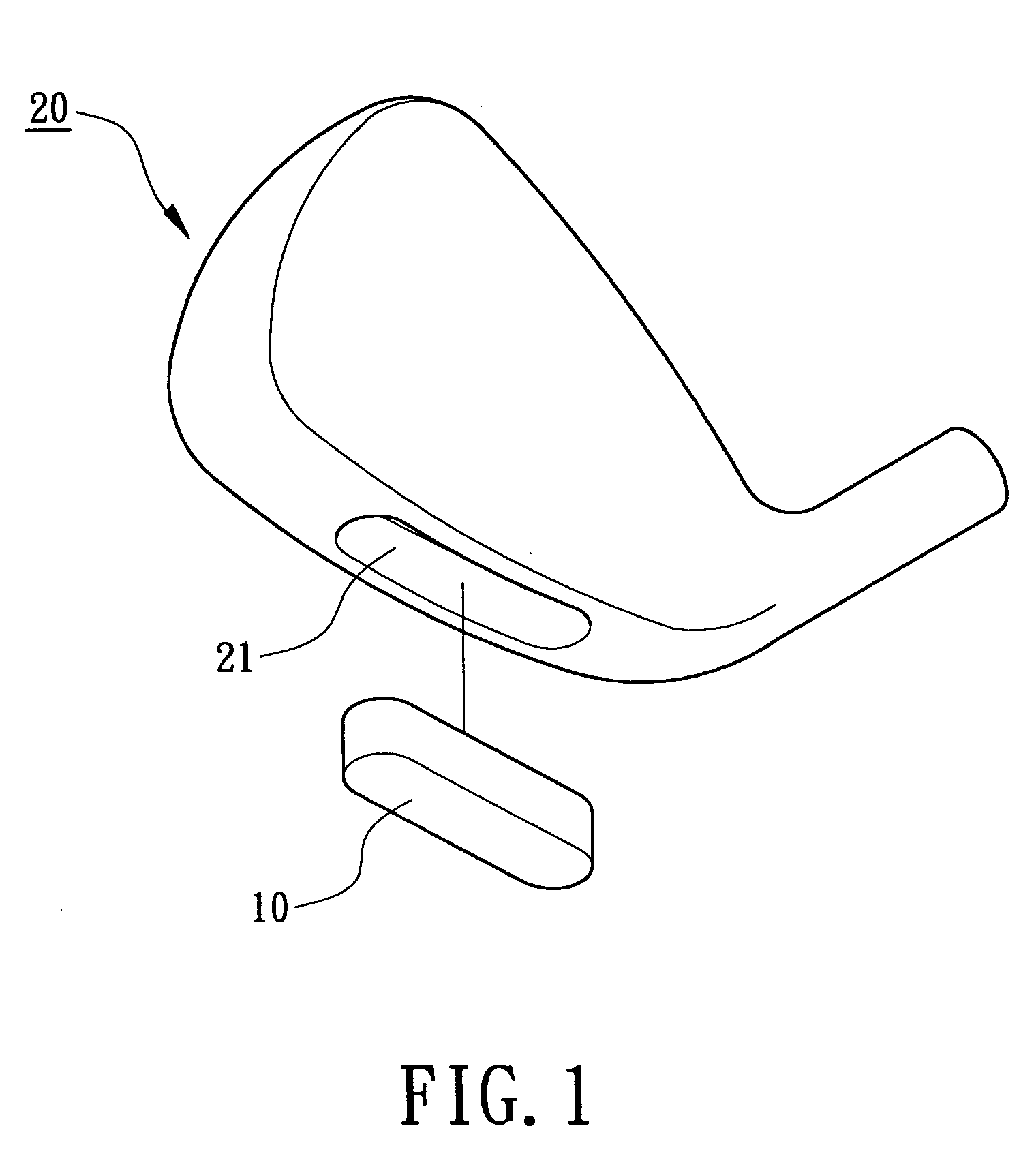

Weight member for a golf club head

InactiveUS20050227781A1High densityImprove rust resistanceGolf clubsRacket sportsSpecific gravityPowder metallurgy

A weight member for a golf club head is made of a WMoNi alloy by powder metallurgy or a precision casting process. The WMoNi alloy includes tungsten 1-35 wt %, molybdenum 4-55 wt %, and nickel 25-95 wt %, and has a specific gravity ranging between 8.6 and 13.3. Molybdenum increases the density of the weight member and improves the rust-resisting property of the weight member. The tungsten, molybdenum, and nickel provide a uniform metallographic phase. Uniformity of polishing of the weight member is thus improved.

Owner:FUSHENG IND CO LTD

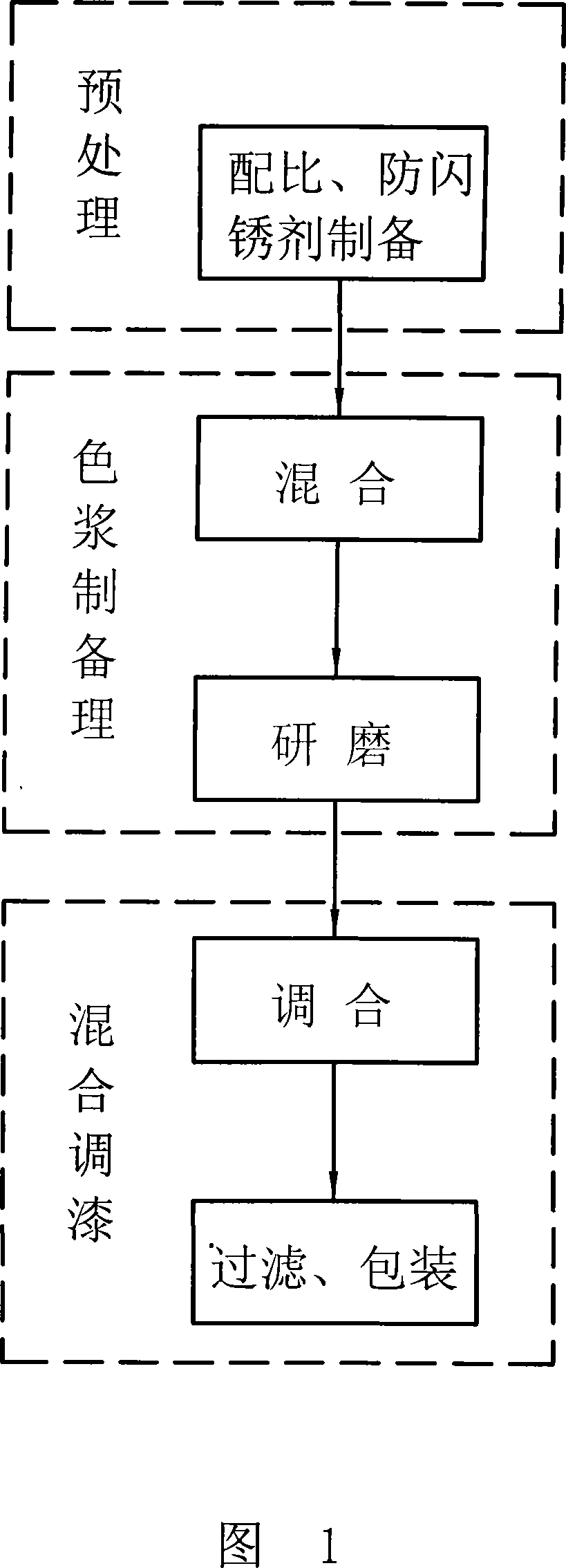

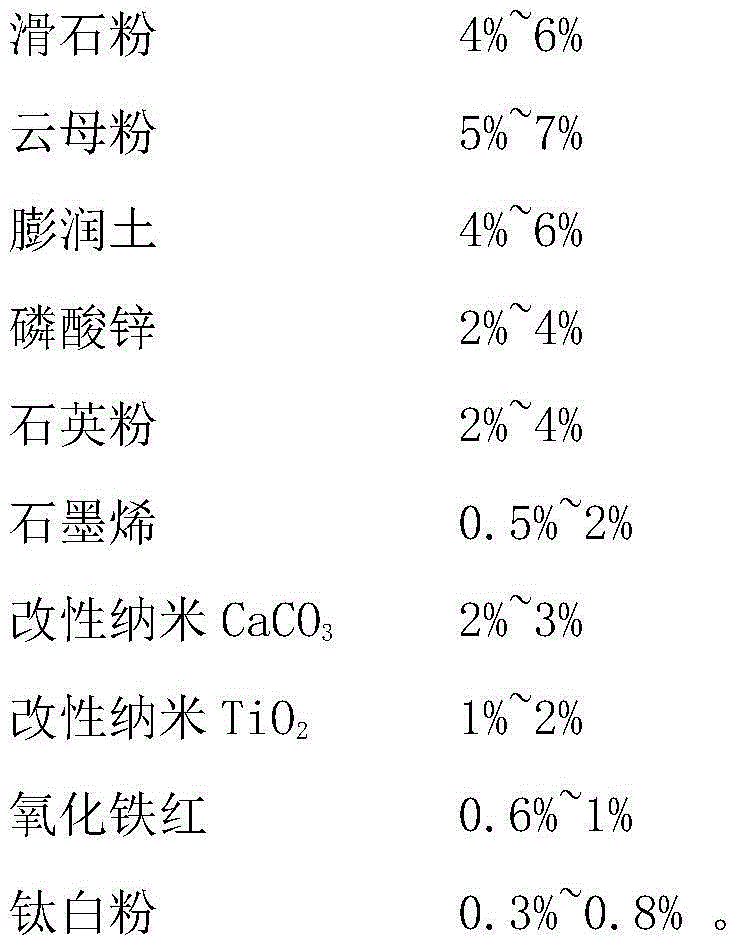

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

Water-based primer-topcoat braking paint and preparation method thereof

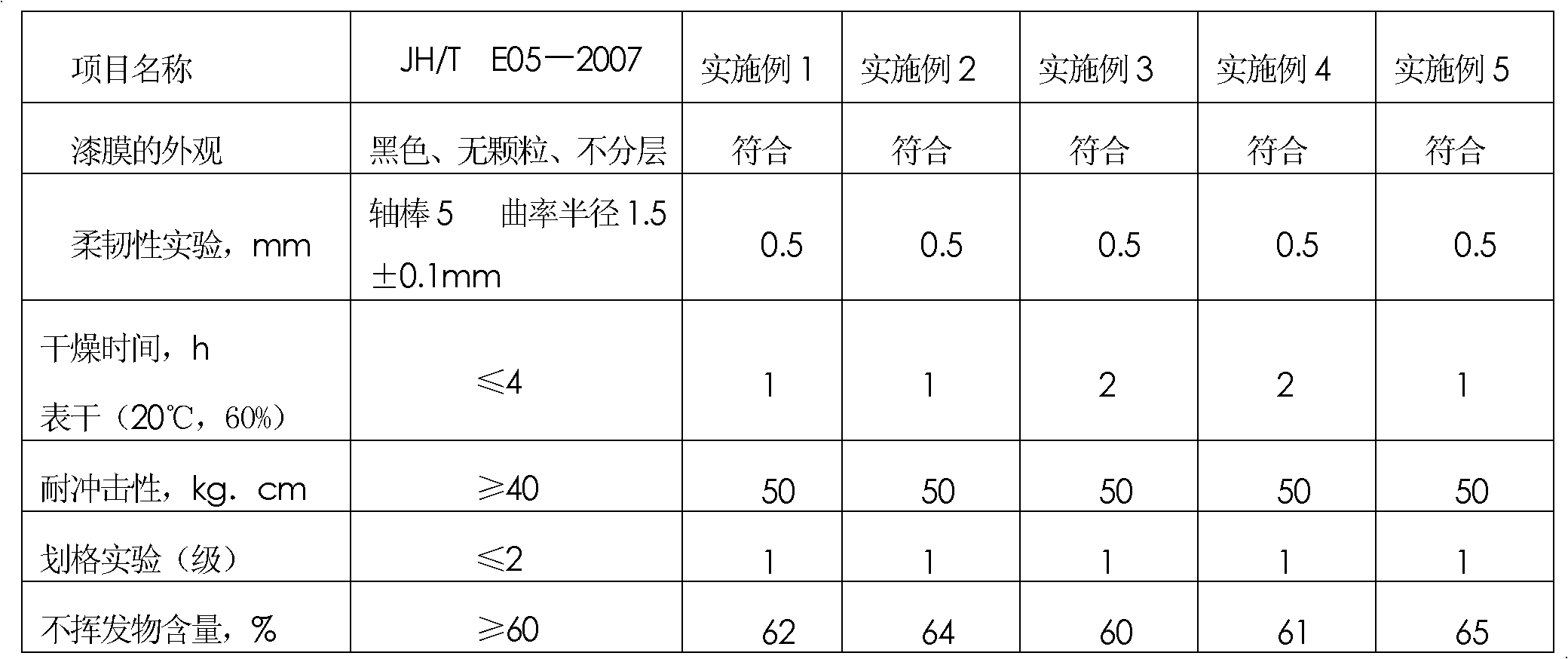

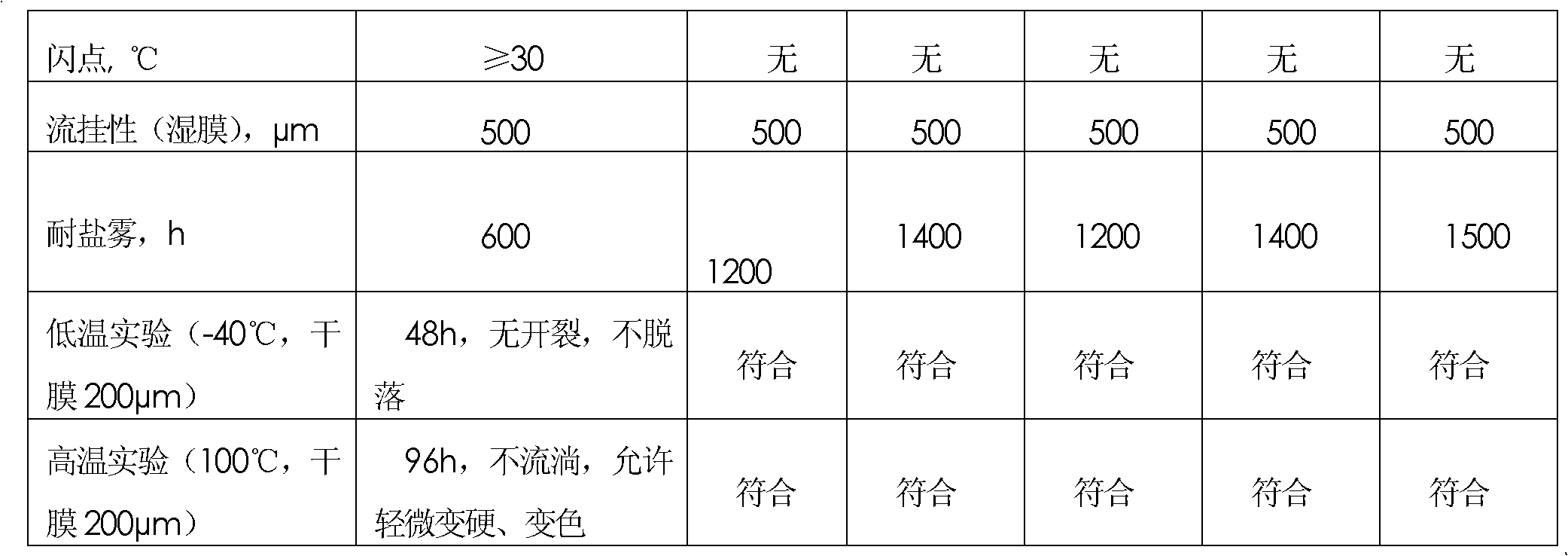

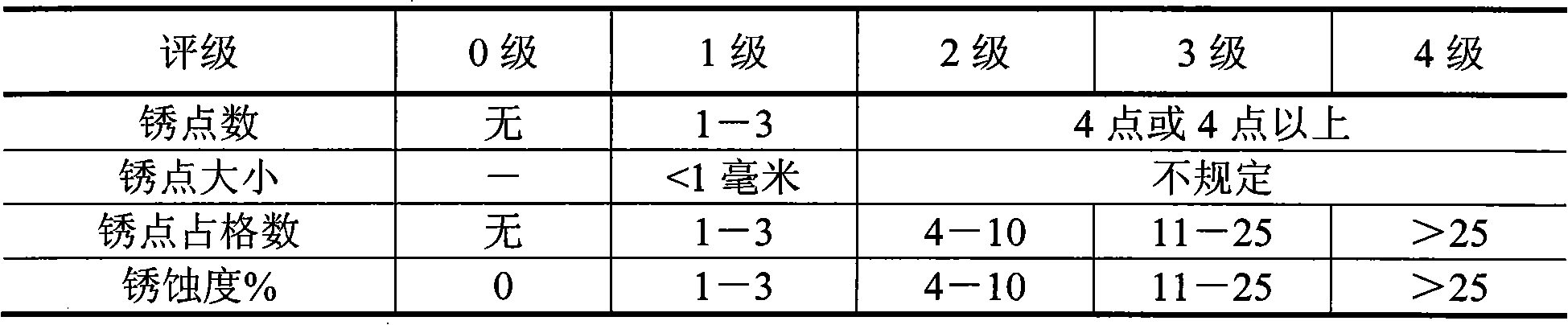

The invention relates to a water-based primer-topcoat braking paint and a preparation method thereof. The braking paint comprises the following materials by weight percentage: 30-40 of water-based acrylic resin, 2-10 of amino resin, 1-3 of neutralizing agent, 2-5 of compound rustproofing pigment, 1-3 of tinting pigment, 10-20 of filling agent, 0.1-0.5 of defoaming agent, 0.1-0.5 of flatting agent and 25-40 of deionized water, wherein the water-based acrylic resin is a free radical polymerization resultant which comprises the following materials by weight percentage: 10-30 of monomer containing hydroxy acrylic acid, 5-20 of monomer containing carboxyl acrylic acid, 2-8 of internal crosslinking monomer, 20-40 of other acrylic acid monomer, 15-30 of phenyl ethylene monomer, 1-5 of evocating agent and 40-50 of alcohol ether latent solvent. When the paint is prepared, the dispersion and the abrading condition of the pigments and the filling agents are reasonably controlled to ensure that each component of the paint fully plays the respective function. The paint ensures the corrosion prevention effect and the decoration of a coating and realizes the combination of a primer and a topcoat.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

Weight member for a golf club head

A weight member for a golf club head is made of a WMoNi alloy by powder metallurgy or a precision casting process. The WMoNi alloy includes tungsten 1-70 wt %, molybdenum 4-55 wt %, and nickel 25-95 wt %. Molybdenum increases the density of the weight member and improves the rust-resisting property of the weight member. The tungsten, molybdenum, and nickel provide a uniform metallographic phase. Uniformity of shining finishing of the weight member is thus improved.

Owner:FUSHENG IND CO LTD

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

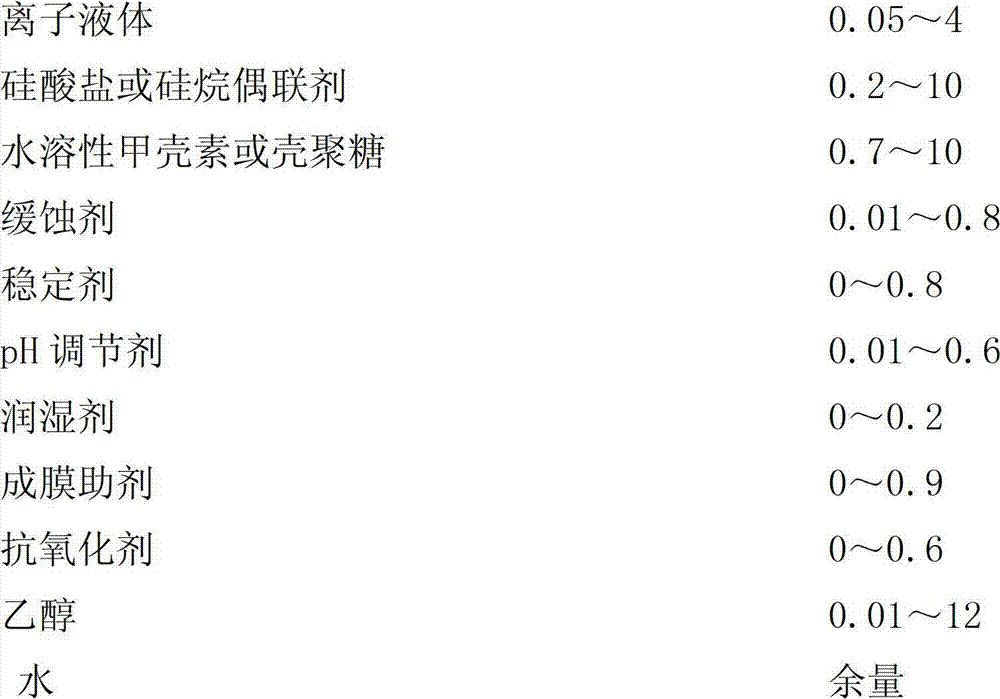

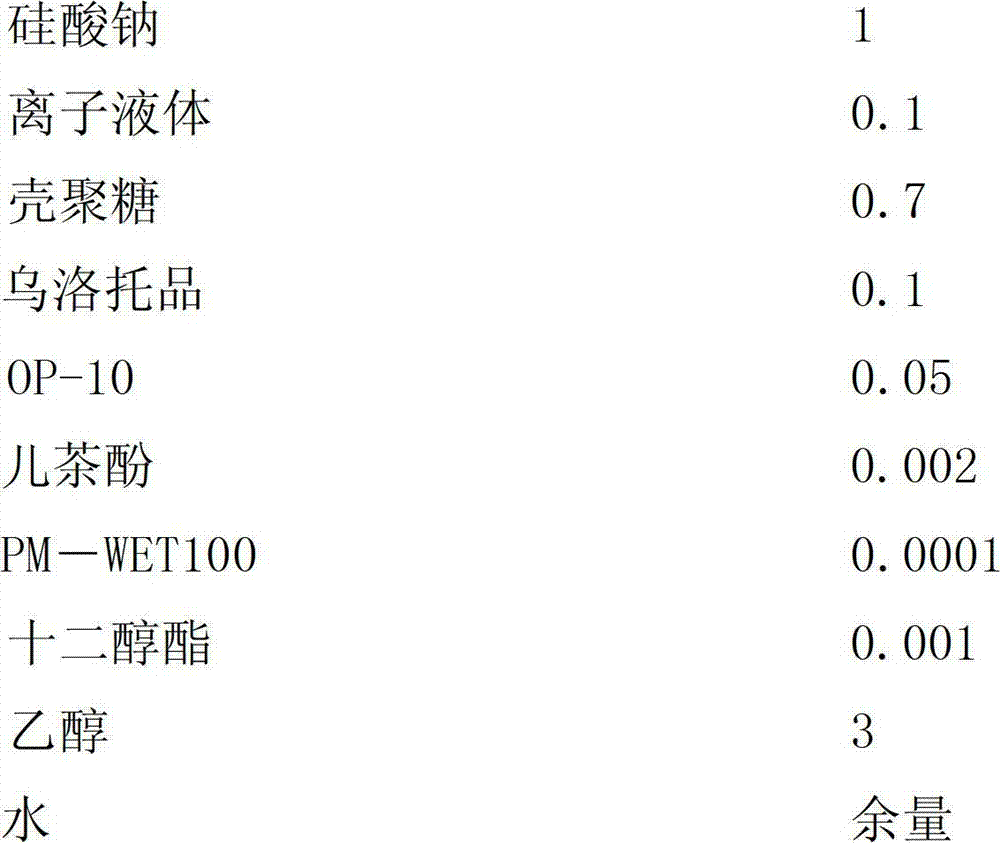

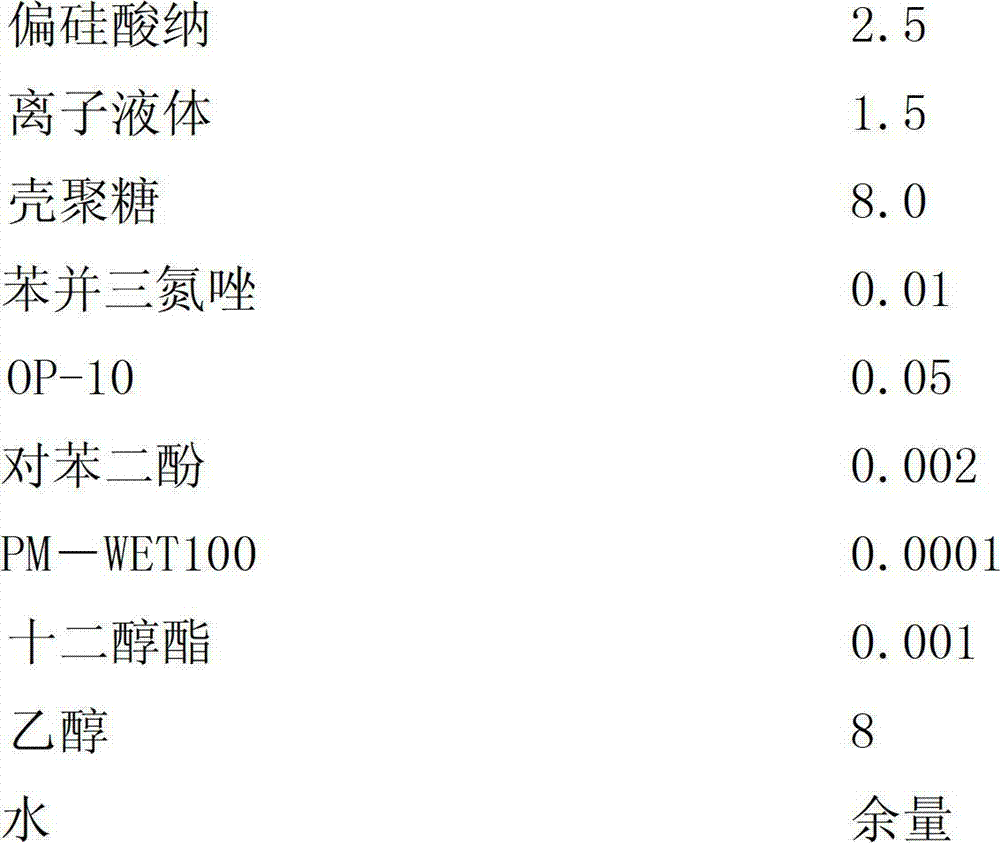

Metal surface treatment agent

InactiveCN102787310AReduce corrosion rateReduce surface tensionMetallic material coating processesNitrogenous heterocyclic compoundIonic liquid

The invention provides a metal surface treatment agent composed of aqueous solution or aqueous emulsion containing ionic liquid. The metal surface treatment agent comprises the ionic liquid, silicate or silane coupling agent, water-soluble chitin or chitosan, corrosion inhibitor, stabilizer, pH modifier, wetter, coalescing agent, antioxidant, ethanol and water, the ionic liquid is room-temperature ionic liquid consisting of nitrogenous heterocyclic compound cations and inorganic or organic anions, one or more of nanoscale titanium dioxide, zirconium oxide or zirconium fluoride is uniformly mixed into the silicate or silane coupling agent by the weight equivalently accounting for 3%-25% of that of the silicate or silane coupling agent. A chemical conversion coating is formed on a metal surface by the metal surface treatment agent, can inhibit corrosion of the metal surface, and has a fine coating performance. The metal surface treatment agent is used for treating cold-rolled plates, galvanized plates and aluminum plates, and the metal surface treated by the metal surface treatment agent has the coating adhesion force equivalent to that of a metal surface treated by a phosphorus-containing metal surface treatment agent.

Owner:DALIAN POLYTECHNIC UNIVERSITY

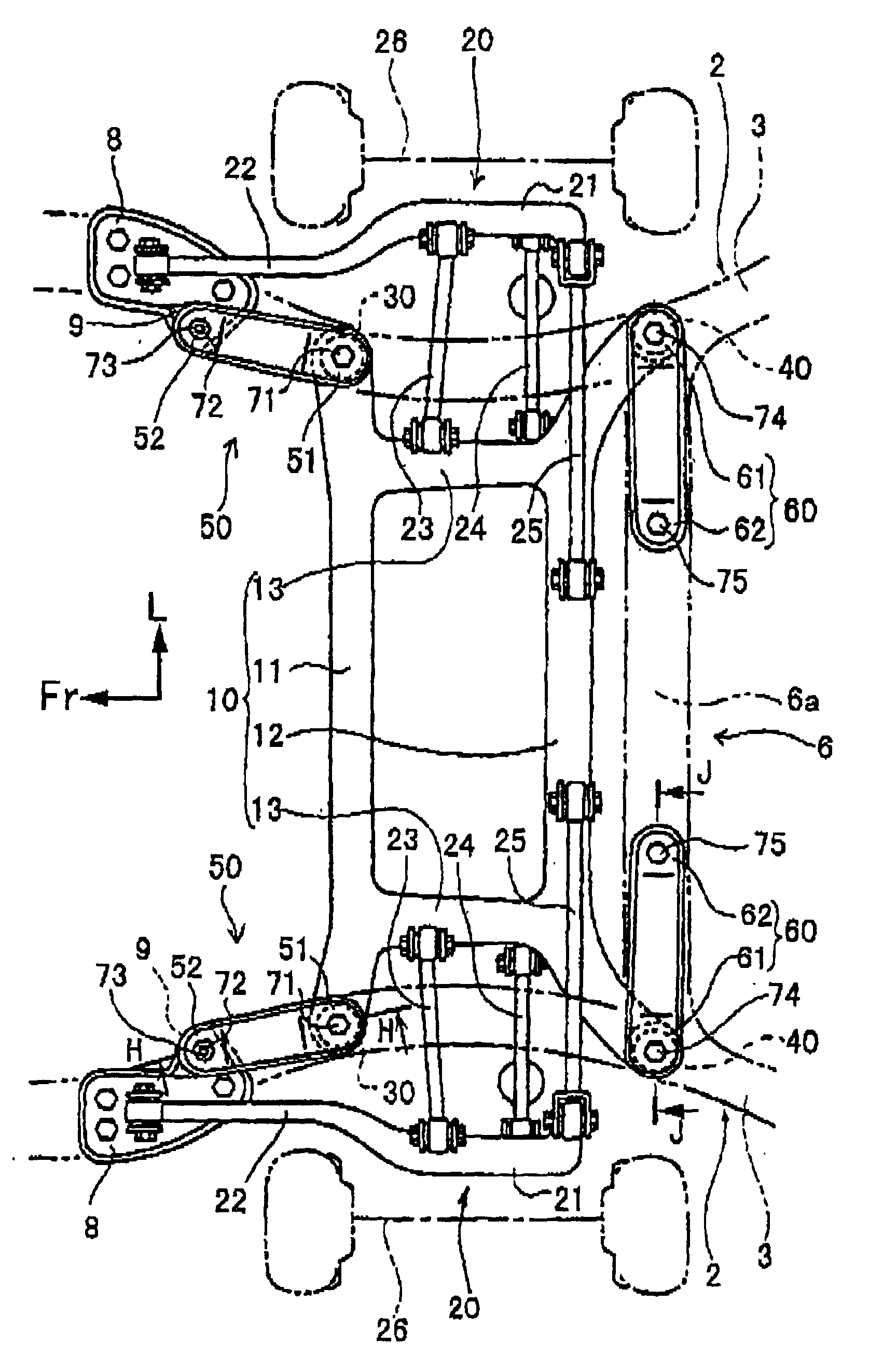

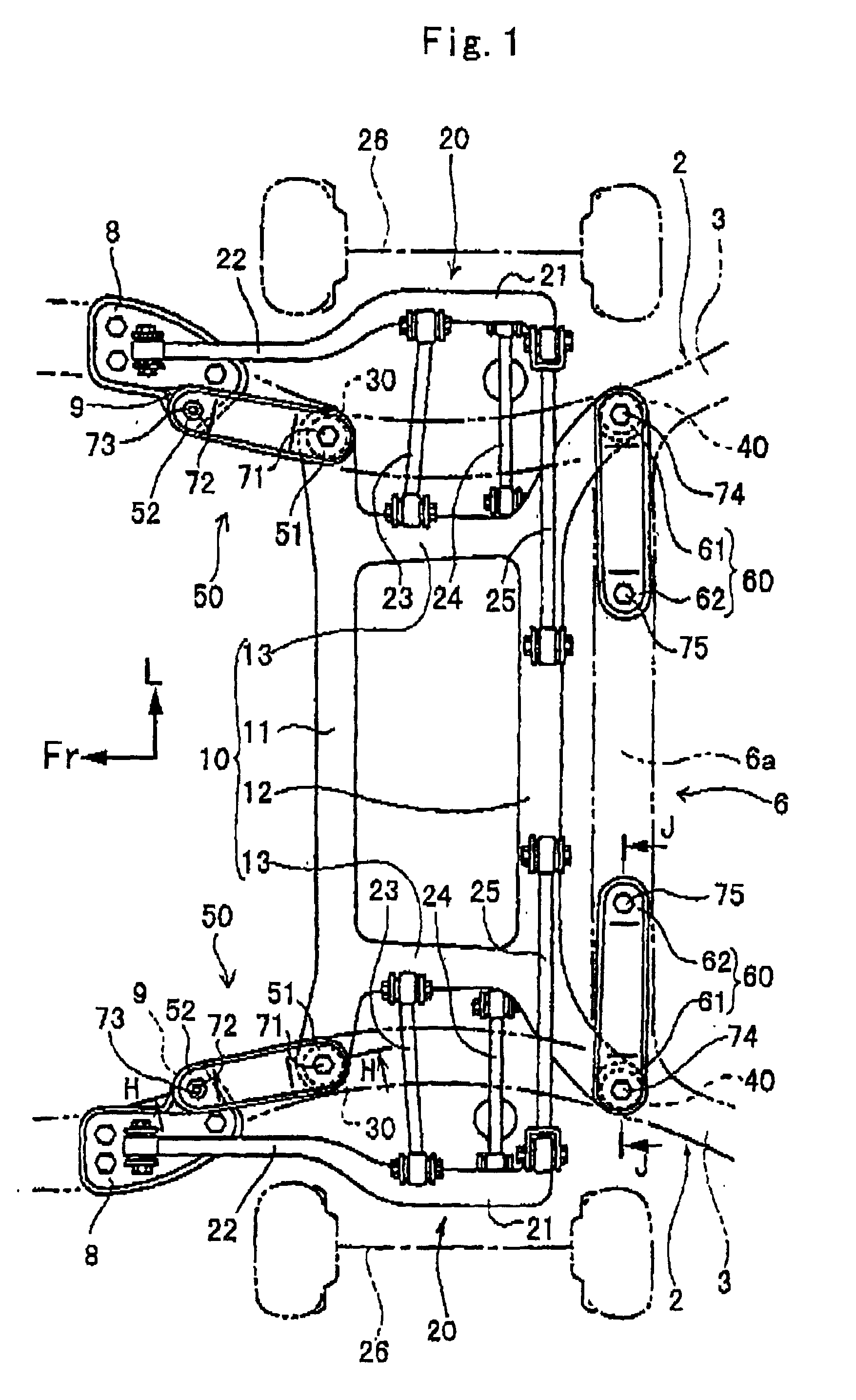

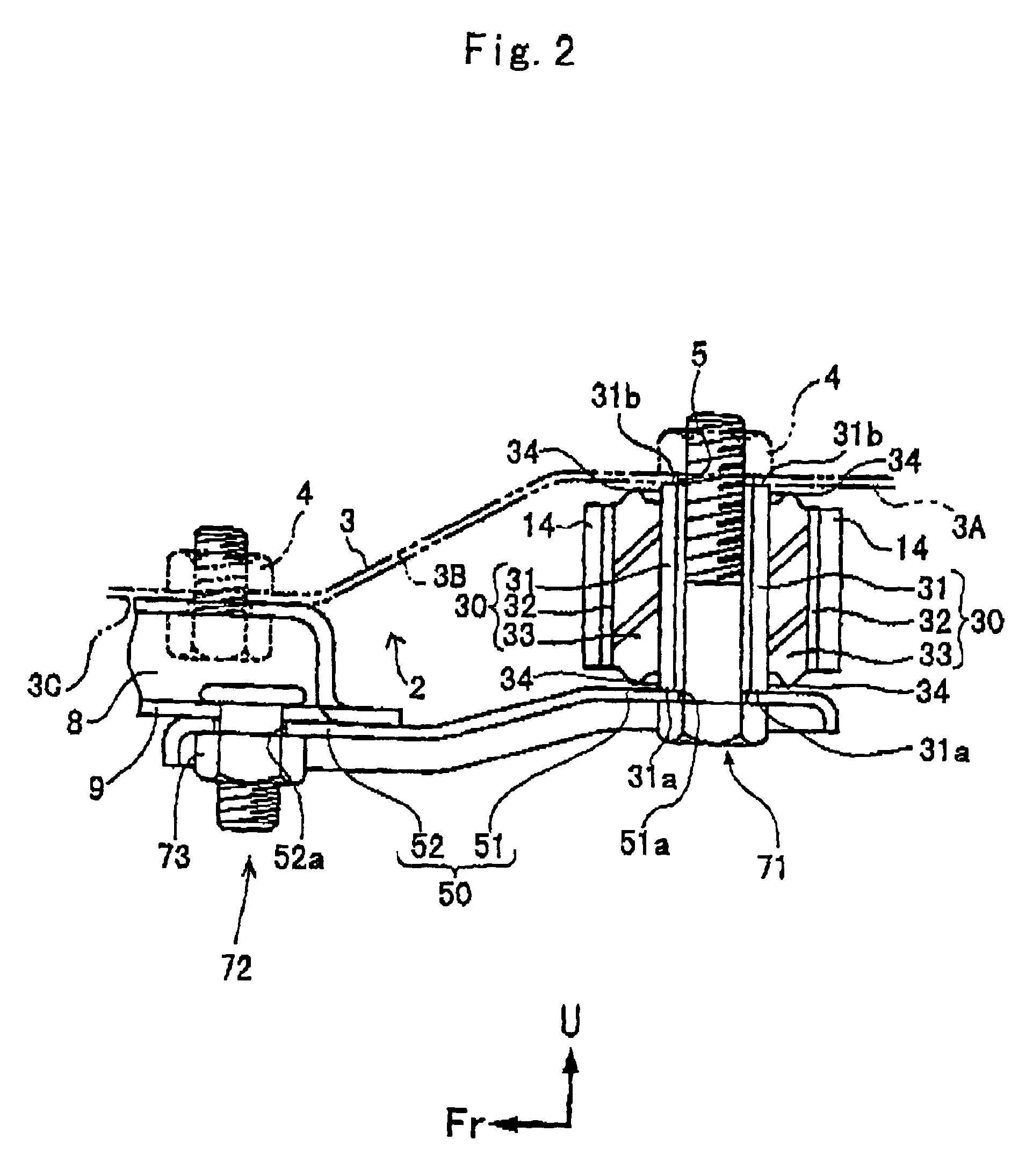

Supporting structure of sub-frame in suspension system for vehicle

InactiveUS6869090B2Improve productivityImprove rust resistanceVehicle body-frame connectionsSteering linkagesFistVehicle frame

A supporting structure of a sub-frame for a suspension system contains a body frame, a sub-frame, elastic bushings, each having an inner cylinder having a lower edge. And an outer cylinder and an elastic member are interposed between the inner and outer cylinders. The sub-frame is supported on the body frame via the elastic bushings, at least one of first stay extends along the body frame, and at least one second stay extends along the body frame in a different direction from the first stay. Both ends of each of the fist and second stays respectively are supported on the lower edge of the inner cylinder and the body frame.

Owner:SUBARU CORP

Marine anticorrosive coating

InactiveCN104087126AImprove anti-corrosion performanceGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsHigh resistanceEpoxy

The invention discloses a marine anticorrosive coating. The marine anticorrosive coating consists of the following components in percentage by mass: 30-40 percent of film forming matter, 21.5-33.8 percent of pigment filler, 6.2-15.4 percent of aids and 30-42.3 percent of solvent, wherein the film forming matter consists of 16-23 mass percent of water-based phenolic epoxy resin and 14-16 mass percent of waterborne polyurethane; the pigment filler comprises graphene; the solvent is deionized water. The marine anticorrosive coating has high corrosion resistance, high flexibility, high wear resistance, high oil and aging resistance and good antirust performance. The film forming matter integrates high adhesion force, high strength, low shrinkage rate and high corrosion resistance of the water-based phenolic epoxy resin as well as high flexibility, wear resistance, oil and aging resistance and good film-forming performance of the waterborne polyurethane.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

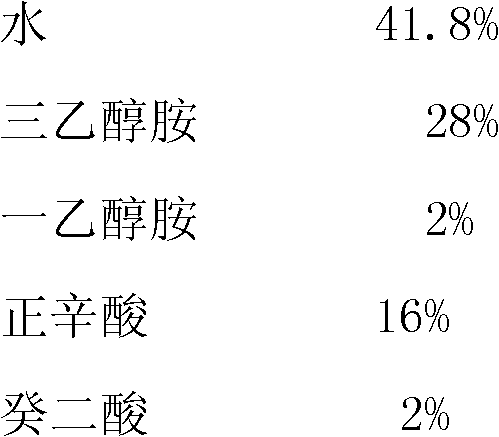

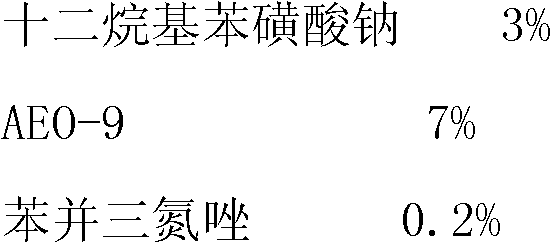

Environment-friendly water-based cleaning agent

The invention discloses an environment-friendly water-based cleaning agent which is characterized by comprising the following components in percentage by weight: 15-60% of antirust agent, 5-20% of surfactant, 0.1-0.5% of nonferrous metal corrosion inhibitor, 0-0.5% of bactericide and the balance of water. The environment-friendly water-based cleaning agent disclosed by the invention has the beneficial effects of no toxicity or phosphorus, excellent antirust performance, favorable inter-process antirust effect, wide application range, suitability for cleaning various metals including black metal, aluminum alloy and copper alloy, no corrosion to nonferrous metal, excellent cleaning capability for oil stain with higher viscosity, long service cycle and effective range, simplicity and practicability in use and maintenance, multiple functions for efficiently removing oil, preventing rusting and the like, no harm to body health and no adverse effect on the environment.

Owner:LOCKS LUBE SHANGHAI

Anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid

InactiveCN104498164AImprove the lubrication effectImprove rust resistanceLubricant compositionWater basedCombustion

The invention discloses anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid. The anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is prepared from the following components in percentage by mass: 5 to 10 parts of base oil, 5 to 15 parts of an oiliness agent, 10 to 25 parts of organic amine, 5 to 15 parts of a synthetic rust inhibitor, 15 to 25 parts of a functional polyether surfactant, 0.2 to 3 parts of an extreme pressure additive, 3 to 8 parts of a solubilizer, 0.1 to 2 parts of a metal corrosion inhibitor, 0.1 to 2 parts of a magnesium alloy anti-fading agent, 0.1 to 2 parts of a bactericide, 0.1 to 1 part of an antifoaming agent, 0.1 to 10 parts of a pH regulator and 15 to 30 parts of water. The nticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is outstanding in ticorrosive and lubricating and has water resisting performances, and is high in cleaning and cooling effects, and effectively reduces the major technical problems such as corrosion, oxidative combustion, fading of magnesium alloy, demulsification and layering of the cutting fluid in the magnesium alloy processing process; the pH ranges from 9 to 11, and therefore, the demand of magnesium alloy cutting process can be met well.

Owner:苏州禾川化学技术服务有限公司

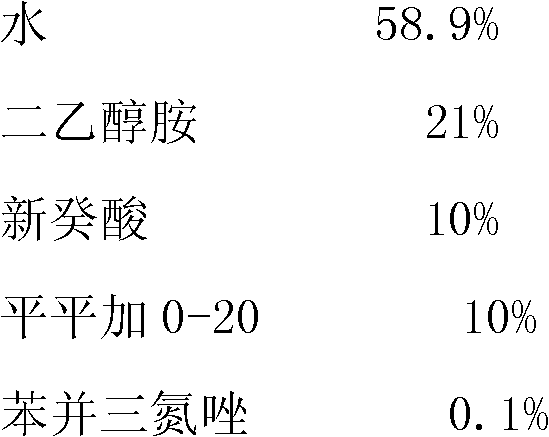

Electrostatic painting anticorrosive oil and production method thereof

ActiveCN101486945ADoes not affect post-processing effectsPost-processing effect is reducedAdditivesAntioxidantBase oil

The invention relates to electrostatic spraying anti-rust oil and a production method thereof, which essentially solves the problems of the prior art that the lubricating property of the anti-rust oil is poor; and interlayer sliding is caused due to larger tension during the reeling process of the steel plate, resulting in steel plate scratch and having impact on the surface quality of the steel plate. The electrostatic spraying anti-rust oil commendably solves the problems by using the technical proposal comprising components of weight percentages as follows: a) 5 to 30 percent of anti-rust agent, b) 0.1 to 5 percent of surface activator, c) 0.1 to 15 percent of anti-friction composition, d) 0.1 to 5.0 percent of antioxidant and e) 50 to 90 percent of base oil, and can be used for the electrostatic spraying rust resistance of the cold-rolled carbon steel plate, galvanized plate and aluminized zinc silicon plate of the steel enterprises.

Owner:CHINA PETROLEUM & CHEM CORP

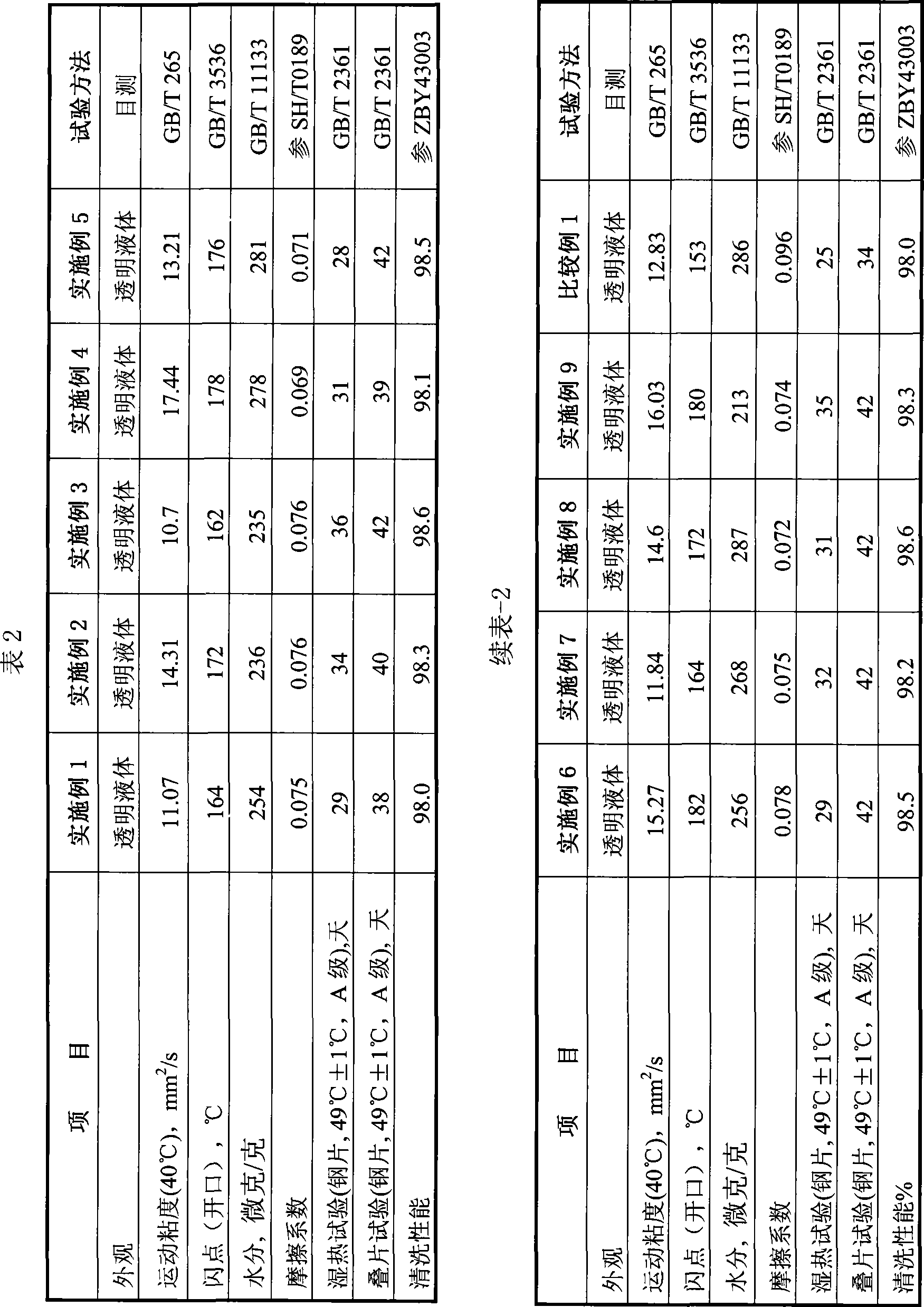

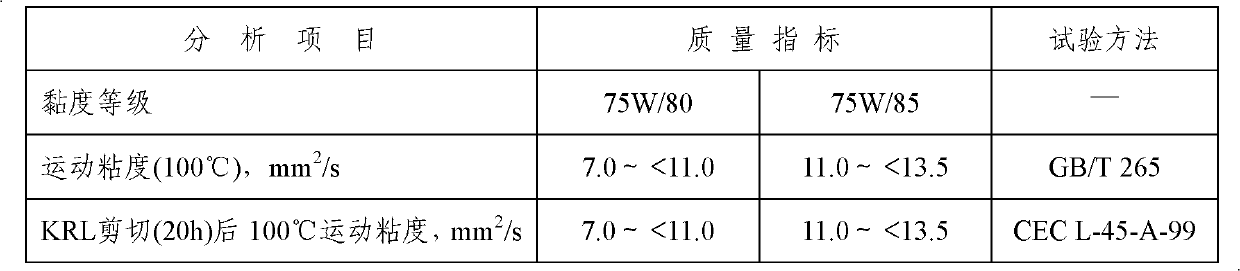

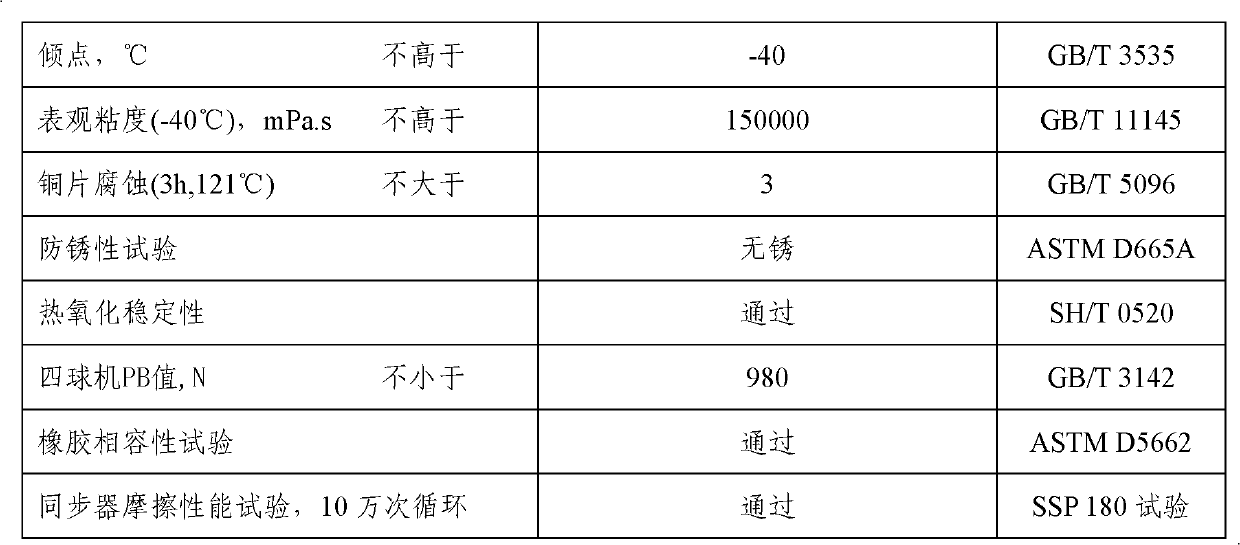

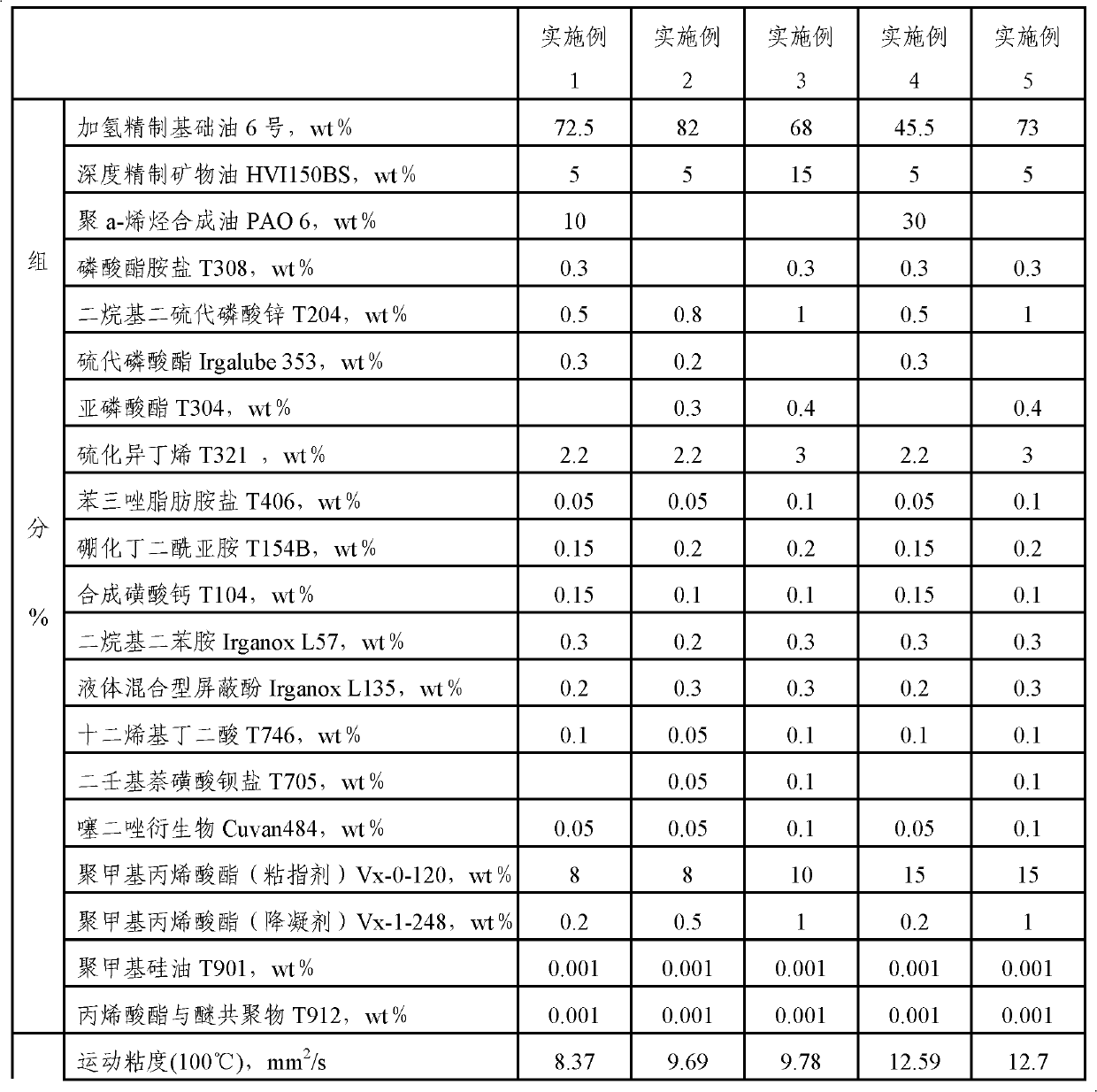

Manual transmission lubricating oil composition

ActiveCN103374452AGood high and low temperature performanceGood thermo-oxidative stabilityLubricant compositionManual transmissionViscosity index

The invention provides a manual transmission lubricating oil composition. The manual transmission lubricating oil composition comprises (a) at least one mineral oil and / or synthetic oil with high viscosity index, (b) at least one viscosity index improving agent, (c) at least one pour point depressant, (d) at least one phosphorus-containing antiwear agent, (e) at least one sulfur-containing extreme pressure agent, (f) at least one friction improving agent, (g) at least one clean dispersion agent, (h) at least one antioxidant, (i) at least one antirust agent, (j) at least one metal deactivator and (k) at least one anti-foaming agent. The manual transmission lubricating oil composition provided by the invention meets the vehicle gear oil viscosity level of 75W / 80 or 75W / 85, has excellent high-low temperature performances, anticorrosion performance, antirust performance and shearing-resistance performance, especially has excellent synchronizer friction performance, can be used for a manual transmission with a synchronizer, and can be completely suitable for the improvement of oil product performance requirement brought about by technique improvement of the manual transmission at present.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly type galvanizing metal surface treating agent

InactiveCN101033363AExcellent long-term inhibition of white rustImprove rust resistanceLiquid surface applicatorsAnti-corrosive paintsSilica gelSolvent

The invention provides a kind of metal surface disposal which formes an environment friendly waterbase film to inhibit corrosion of the metal surface, and the disposal particularly brings excellent anti-corrosion properties with the galvanized metal products. The metal surface disposal basically contains following components which take alcohol and water as the solvent: A. silicates, polymerization silicates, fluoride silicates, B. silica (aqueous dispersion of nano) and / or SinOmXR1R2R3, C. phenolic resin and modified phenolic resin, D. stabilizer, E. pH regulator, F. thickener, G. leveling agent, H. film builder, I. wetting agent, J. antioxidant.

Owner:DALIAN POLYTECHNIC UNIVERSITY

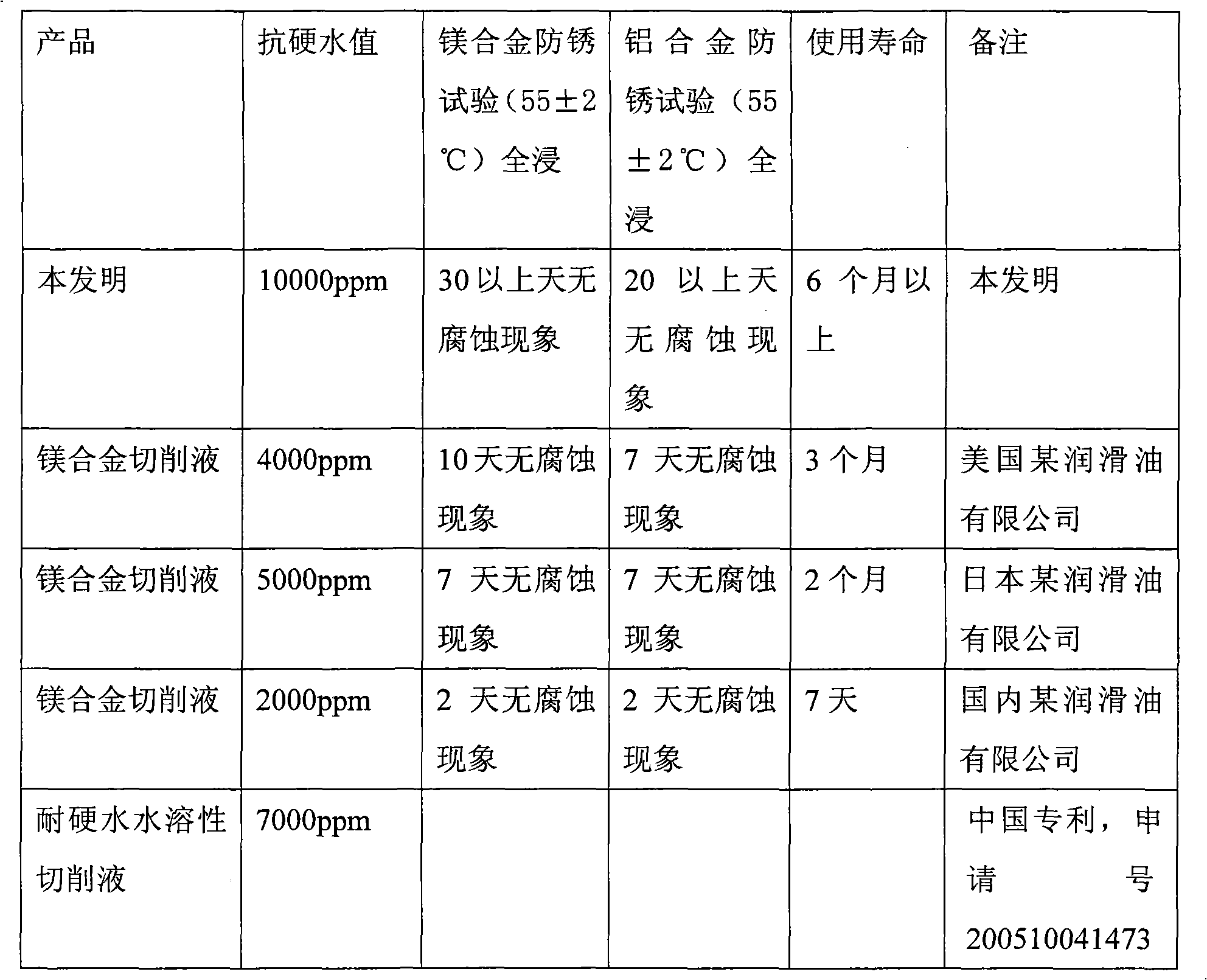

Magnesium alloy cutting liquid

ActiveCN101870909AImprove rust resistanceInhibition of hydrogen evolutionAdditivesColor changesCast iron

The invention relates to metal cutting liquid, in particular to magnesium alloy cutting liquid, which comprises basic oil, nonionic surfactants, anionic surfactants, antirust agents, lubricating agents, coupling agents, corrosion inhibitors and bactericide raw materials. The unique recipe in the invention has the advantages that magnesium alloy can no generate color change corrosion phenomena after being continuously soaked for more than 30 days at 55 DEG C in 5 percent diluent, the hydrogen release phenomenon of the magnesium alloy in water can be effectively inhabited, in addition, the hardwater resistance of the product is as high as 10000 ppm, and in addition, the work liquid can be used for more than half a year. At the same time, the invention has excellent performance such as rust prevention, lubrication, cooling and the like. In addition, the cutting liquid can be used for processing the magnesium alloy, and can also be used for processing metals such as aluminium alloy, cast iron, stainless steel and the like.

Owner:东莞太平洋博高润滑油有限公司

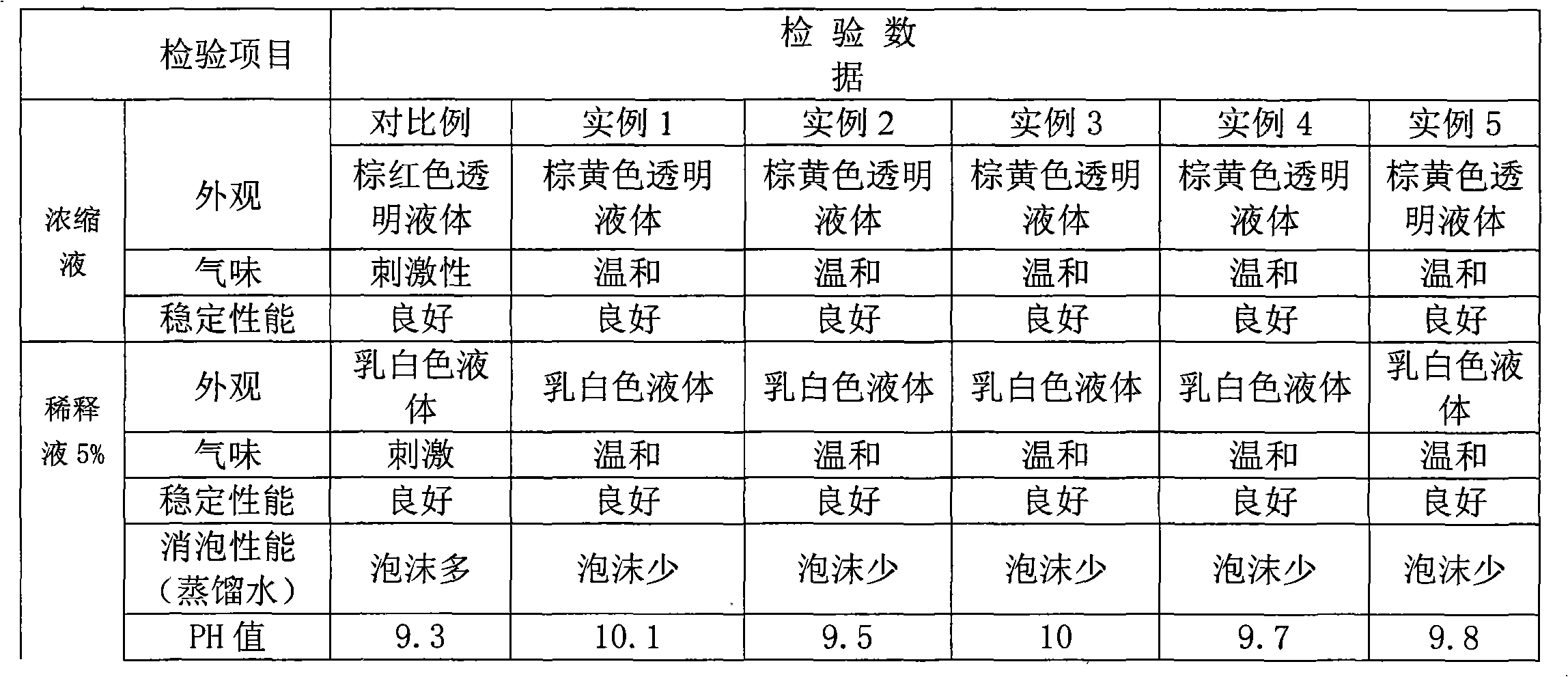

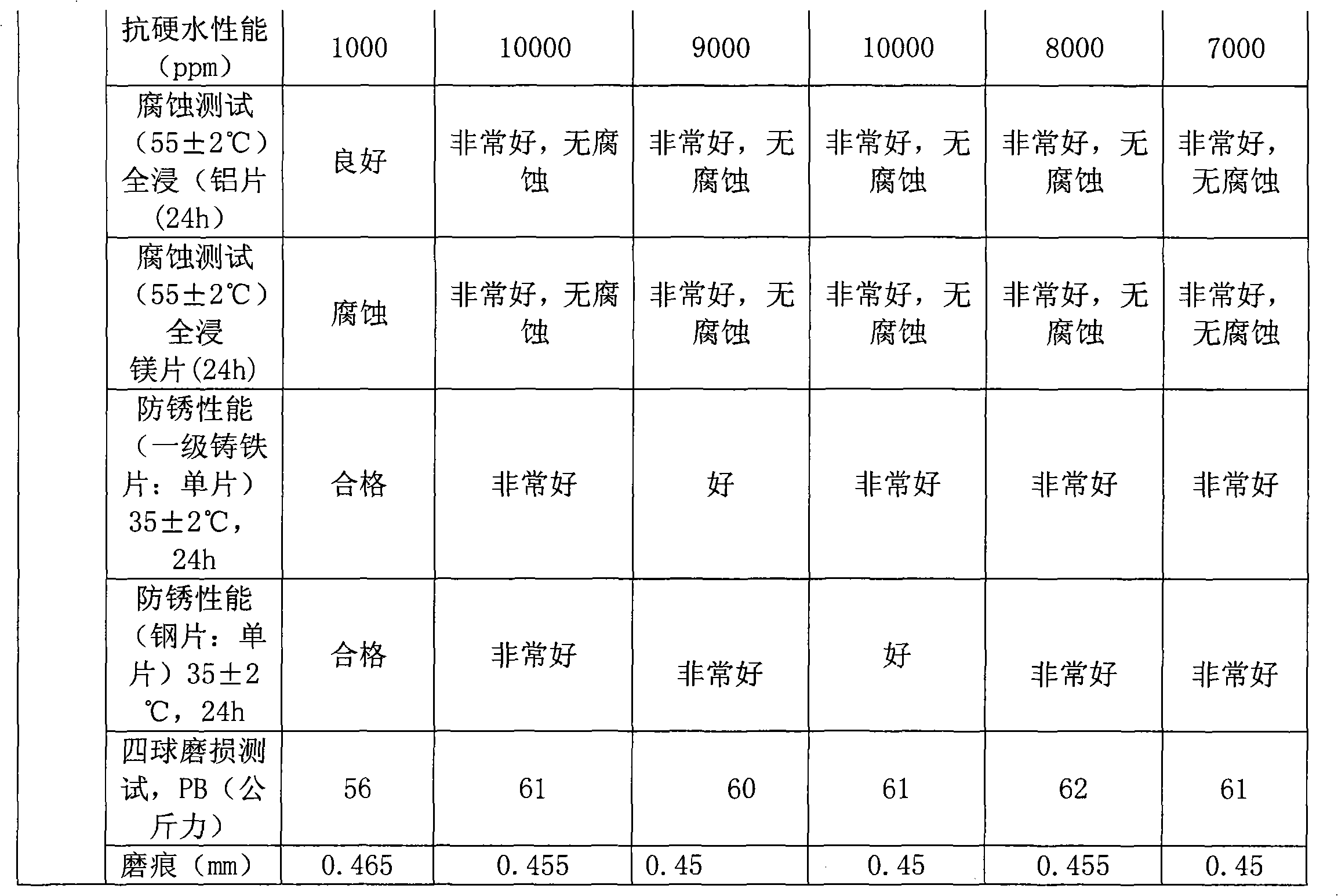

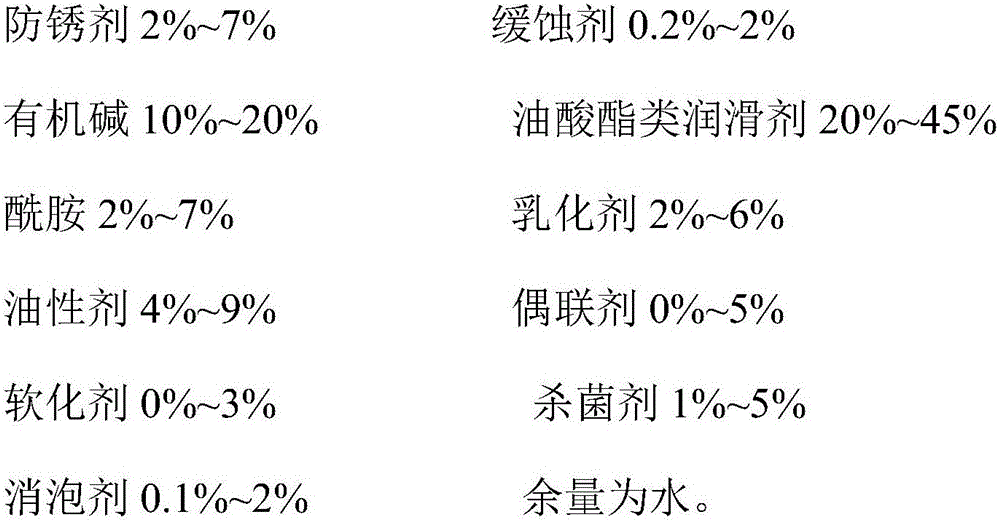

Water-based metal cutting liquid

InactiveCN106479654AGood compatibilityStrong synergistic functionLubricant compositionWater basedSulfur

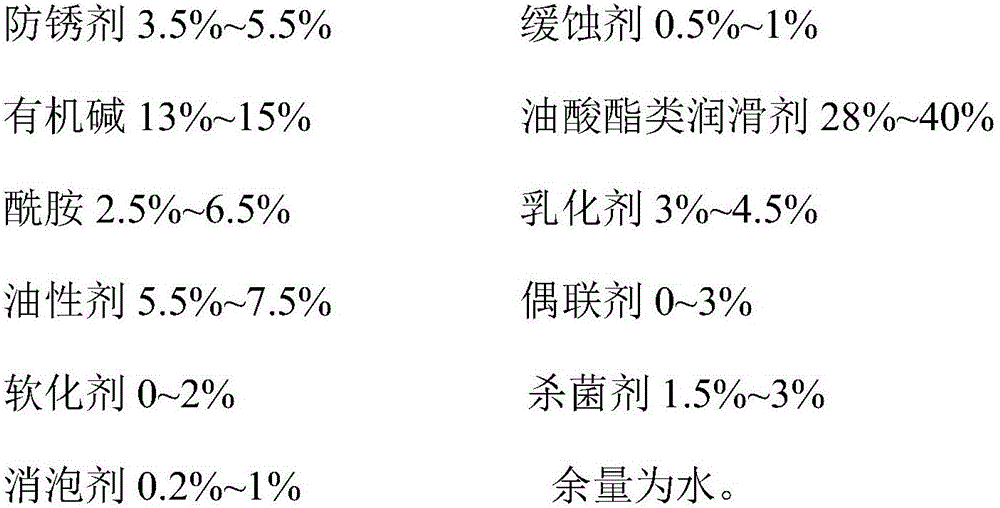

The invention discloses a water-based metal cutting liquid. The water-based metal cutting liquid is prepared from raw materials in percentage by mass as follows: 2%-7% of an antirust agent, 0.2%-2% of a corrosion inhibitor, 10%-20% of organic alkali, 20%-45% of an oleate lubricant, 2%-7% of amide, 2%-6% of an emulsifier, 4%-9% of an oiliness agent, 0%-5% of a coupling agent, 0%-3% of a softener, 1%-5% of a sterilizing agent, 0.1%-2% of a defoaming agent and the balance of water. The water-based metal cutting liquid provided by the invention contains no sulfur, phosphorus, chlorine or boric acid and is efficient, environment-friendly and recyclable.

Owner:深圳市宏达威表面处理技术有限公司

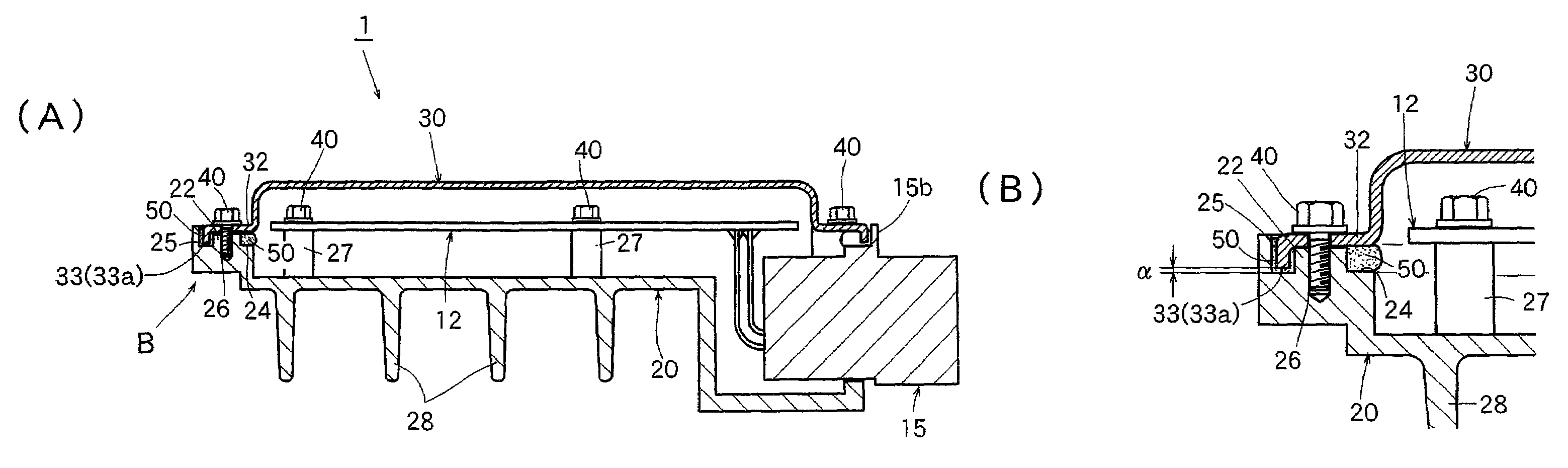

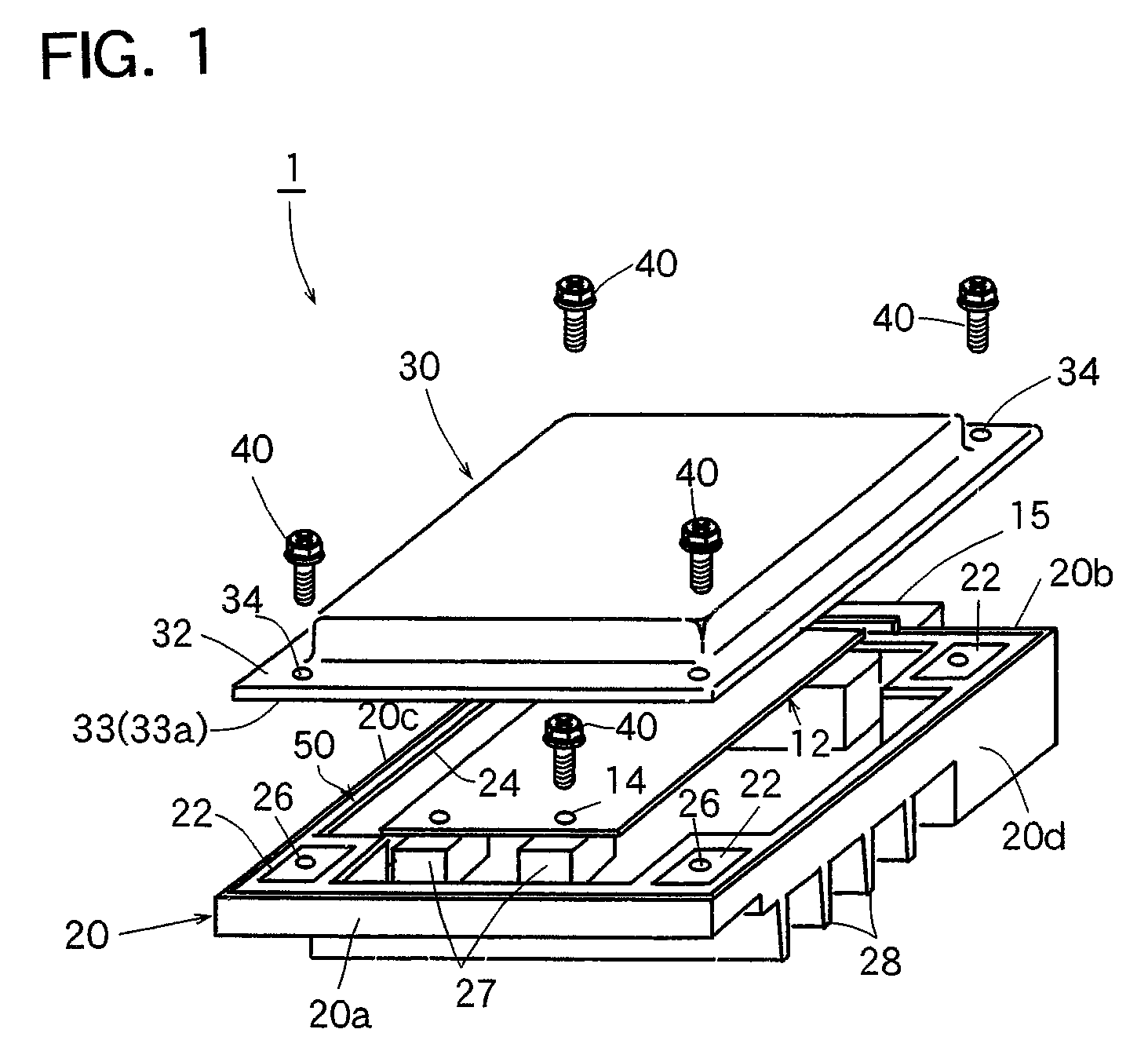

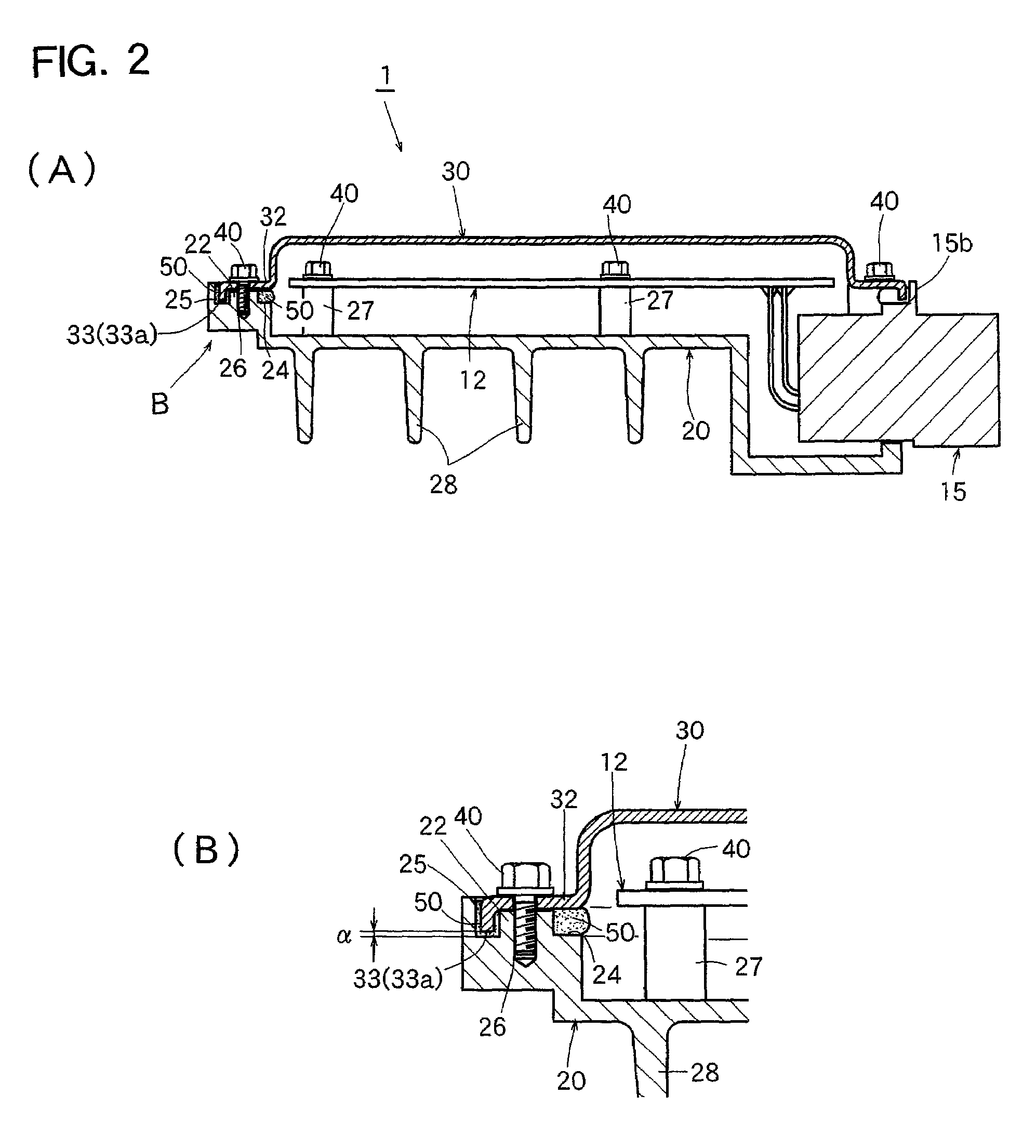

Engine controller

ActiveUS7561435B2Improve reliabilityAvoid contactCasings/cabinets/drawers detailsCouplings bases/casesAdhesiveDie casting

There is proposed an engine controller which is excellent in reliability in that the outer peripheral edge face (cut surface) of covering member can be prevented from being rusted while securing the water-proofness and dust-proofness. This engine controller comprises a circuit board (12) for controlling an engine; an aluminum die-cast main case body (20) having an open top; and a covering member (30) made of an iron-based metal plate which is preliminarily applied with surface treatment, the covering member (30) being fixedly clamped to the main case body (20) by means of a setscrew (40) so as to hermetically close the open top of the main case body (20); wherein the main case body (20) is provided thereon with a pedestal (24) or groove (25) on which a liquid or jellied water-proofing adhesive (50) is coated or filled (piled), thereby enabling entire outer peripheral edge face (33a) of the covering member (30) to be covered by the water-proofing adhesive (50).

Owner:HITACHI ASTEMO LTD

Weather-resistant rust-proof water paint and preparing method thereof

InactiveCN101012351AReduced photodecomposition functionWide choiceAnti-corrosive paintsEmulsion paintsAdjuvantUltraviolet

The invention discloses a weather resistant anti-rust aqueous paint and preparing method, which comprises the following steps: allocating raw material with 10-40% deionized water, 30-70% waterthinnable resin emulsion, 1-10% titanium oxide particle and fitful paint adjuvant; making the even grain size of titanium oxide particle less than 1um; packing inorganic silica on the surface; dispersing deionized water, waterthinnable resin emulsion, titanium oxide particle and fitful paint adjuvant evenly to obtain the product.

Owner:SOUTH CHINA UNIV OF TECH +2

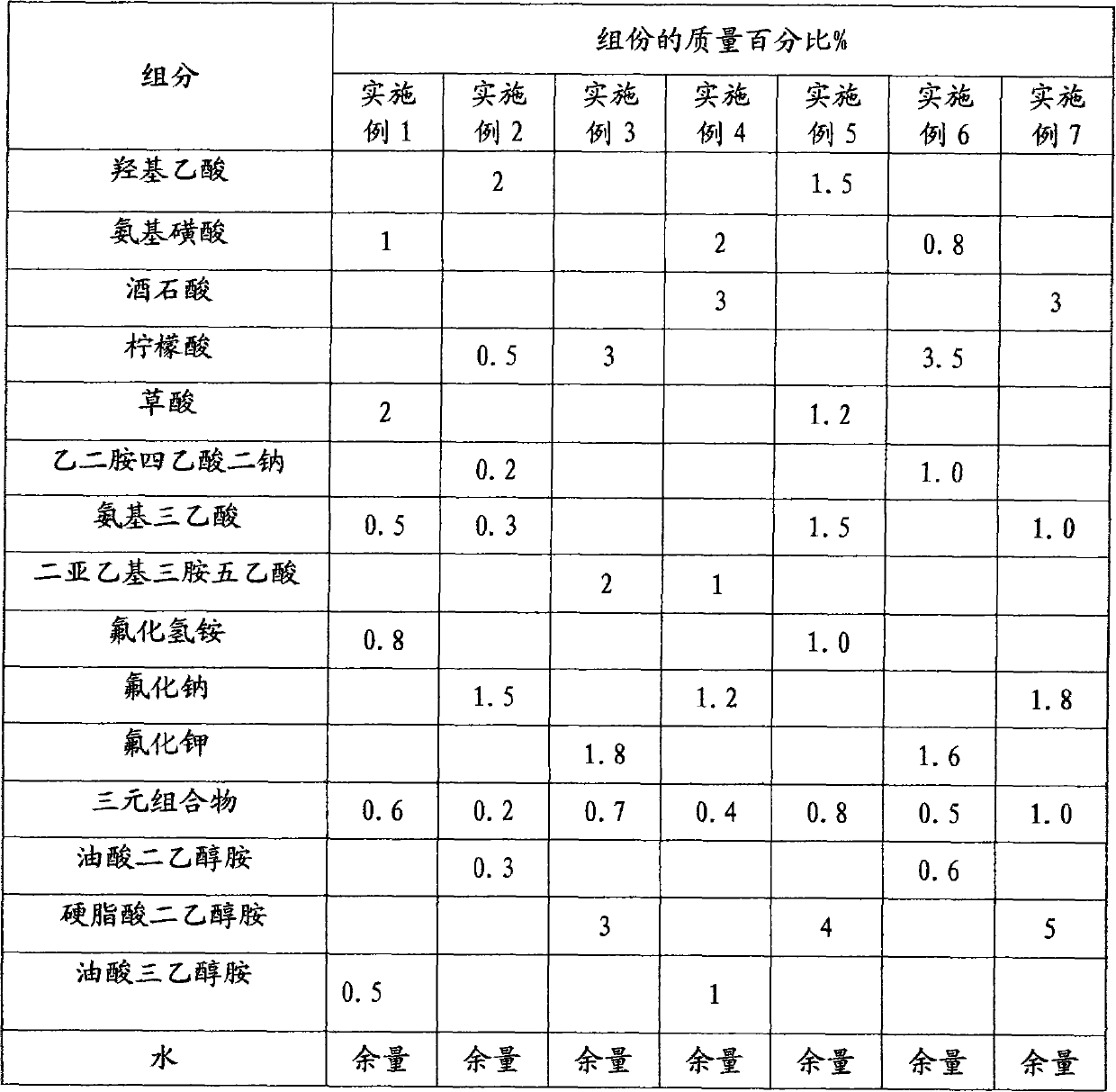

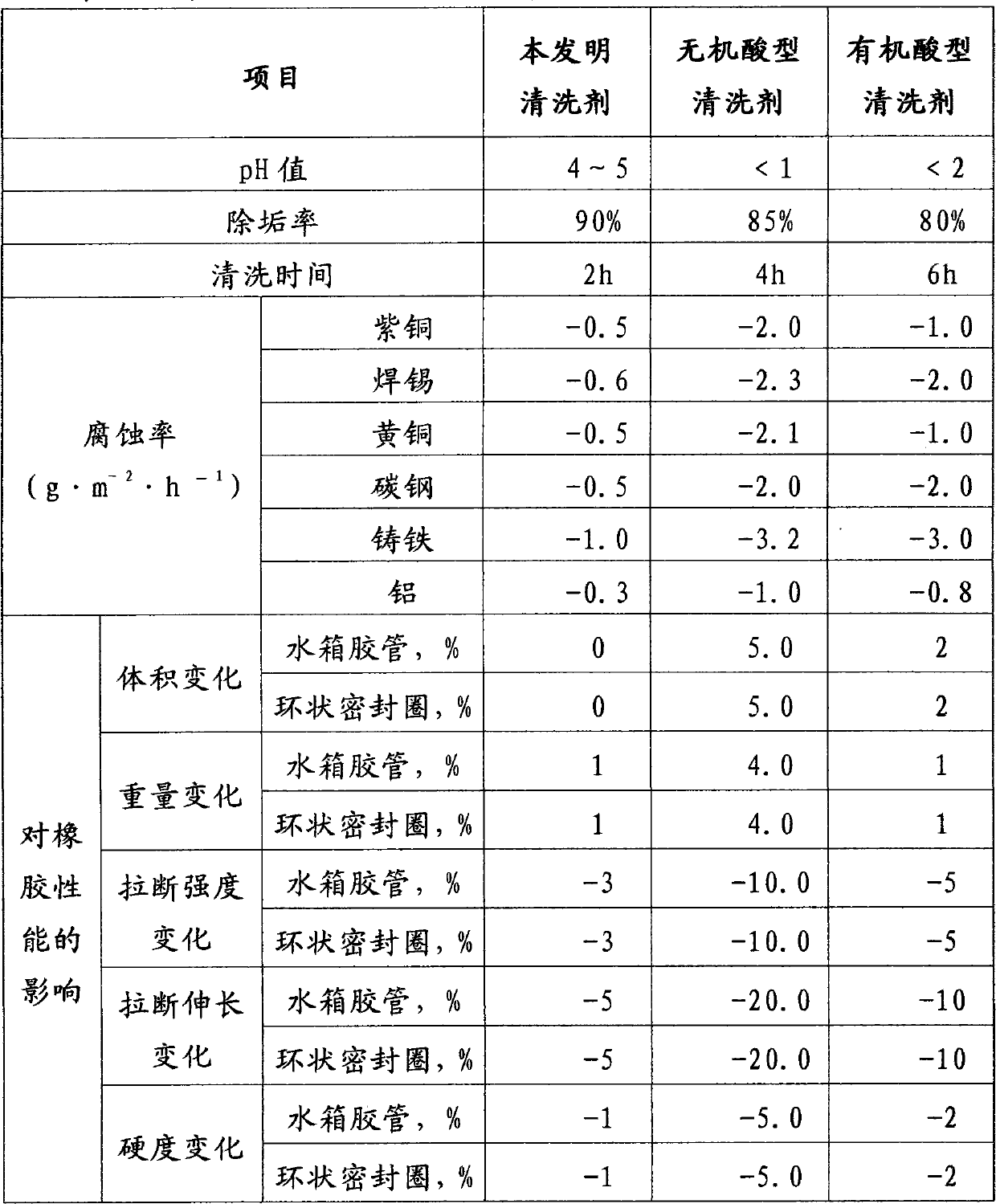

Broad-spectrum and efficient cleaning agent for cooling system

ActiveCN101768529AQuick clearAlso has the effect of metal corrosion inhibitionOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsOrganic acidCleansing Agents

The invention discloses a broad-spectrum and efficient cleaning agent for a cooling system, comprising the following components in percentage by weight: 1-5% of organic acid, 0.5-3% of metallic ion chelating agent, 0.5-2% of cleansing promotion agent, 0.1-1% of corrosion and scale inhibition dispersing agent, 0.3-5% of degreasing agent and the balance of water. The cleaning agent of the invention has safe use, the cleaning time is 1-2h, and the descaling rate is more than 90%, thereby greatly reducing corrosion and damage on the cooling system.

Owner:北京蓝星清洗有限公司

Water-based capillary crystalline concrete surface layer repairing and reinforcing material as well as preparation method and application thereof

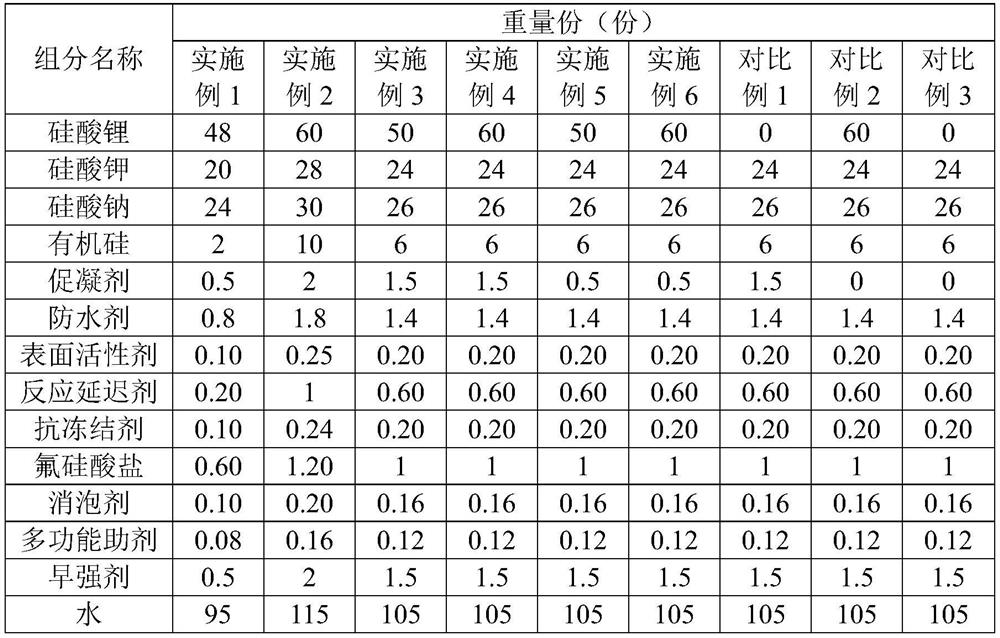

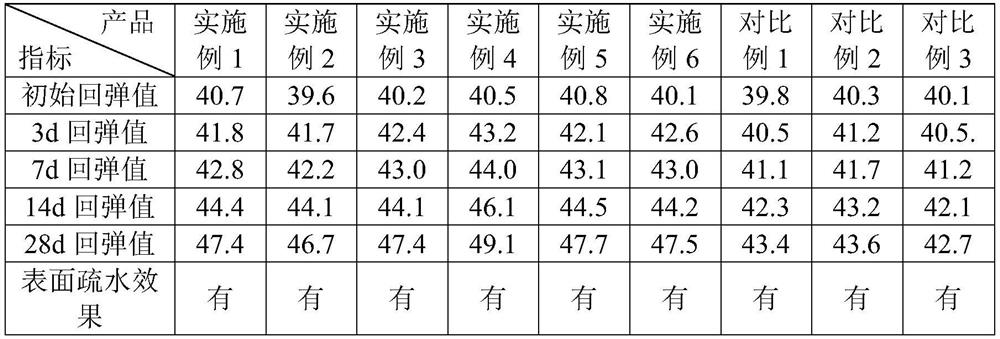

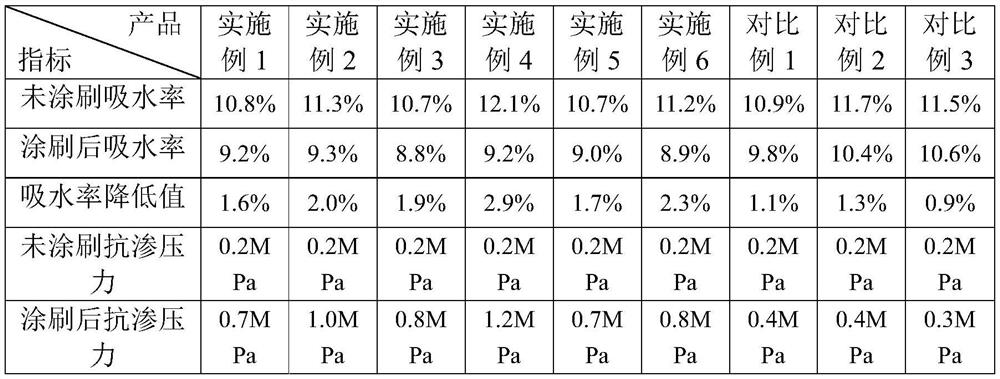

The invention discloses a water-based capillary crystalline type concrete surface layer repairing and reinforcing material as well as a preparation method and application thereof. The material comprises 48-60 parts of lithium silicate, 20-28 parts of potassium silicate, 24-30 parts of sodium silicate, 2-10 parts of organosilicon, 0.5-2 parts of a coagulant, 0.8-1.8 parts of a waterproof agent, 0.1-0.25 parts of a surfactant, 0.2-1 part of a reaction retarder, 0.1-0.24 parts of an anti-freezing agent, 0.6-1.2 parts of fluosilicate, 0.1-0.2 parts of an antifoaming agent, 0.08-0.16 parts of a multifunctional auxiliary agent, 0.5-2 parts of an early strength agent and 95-115 parts of water. The water-based capillary crystalline type concrete surface layer repairing and reinforcing material hasthe characteristic of quick strength improvement, has an obvious repairing effect on concrete and mortar, and can repair and heal cracks and fine cracks, so that the water permeability resistance ofthe concrete can be improved. The water-based capillary crystalline type concrete surface layer repairing and reinforcing material is good in durability, long in service life, simple and convenient toprepare and convenient to construct.

Owner:苏州佳固士新材料科技有限公司

Non-barium metal rust preventive oil of compound containing rare earth cerium

The invention relates to a non-barium metal rust preventive oil of an oil-soluble rare earth compound. The metal rust preventive oil comprises the following components by weight percent: 1-10% of oil-soluble rare earth cerium compound, 1-5% of organic acid, 1-5% of sorbitan ester and 0.1-2% of benzotriazole. Compared with the rust preventive oil system using barium petroleum sulfonate additive, the rust preventive oil system of the oil-soluble rare earth compound has good rust resistance and outstanding damp and hot resistant property, does not contain organic barium compound and meets the environmental protection requirement that the rust preventive oil does not contain barium; and when the total dosage of the rust resistant additive is within 10%, the rust preventive oil blended in mineral oil can resist rust under a humid and hot environment for more than 60 days.

Owner:PETROCHINA CO LTD

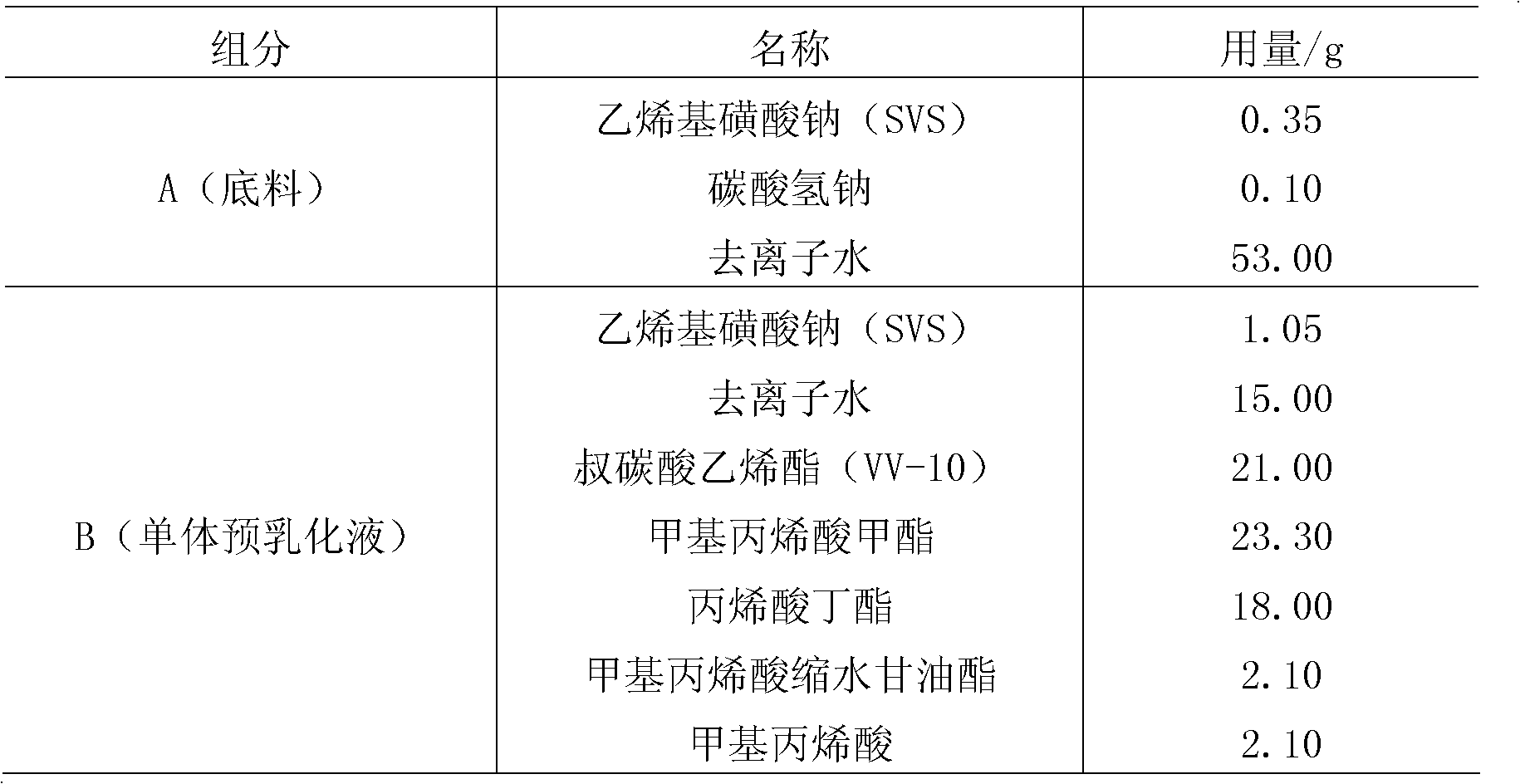

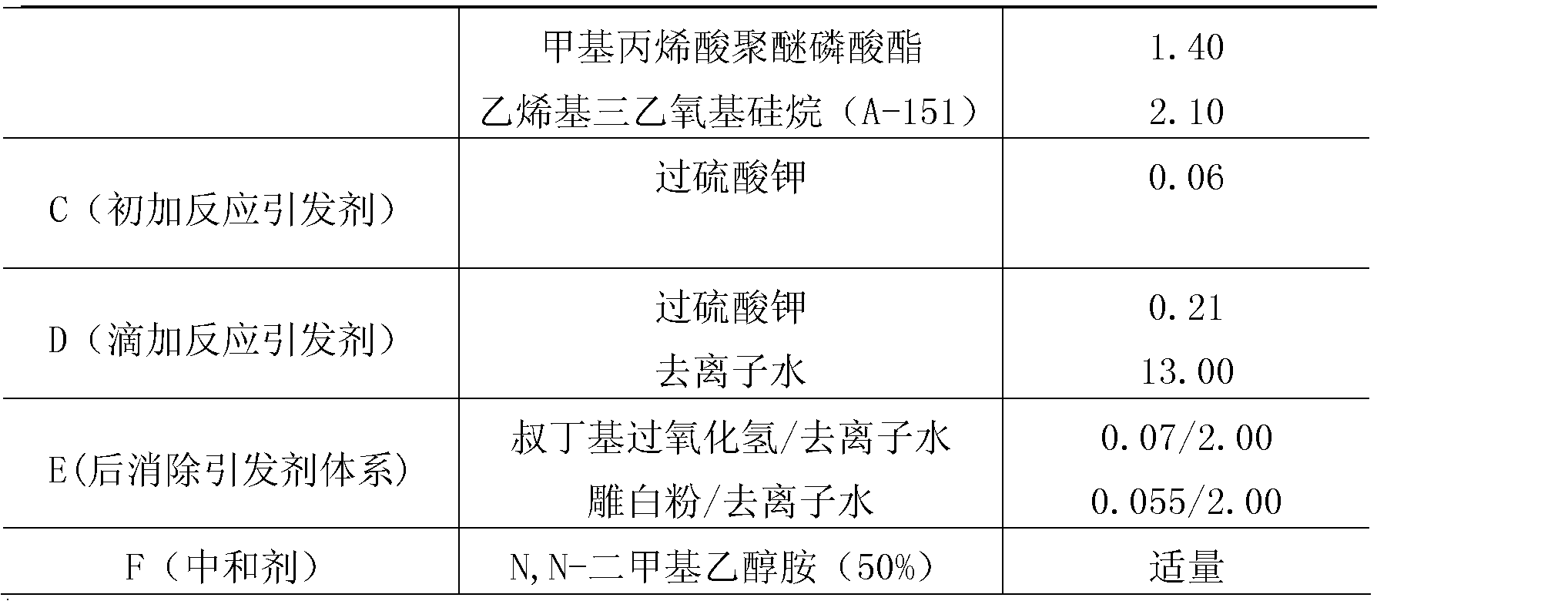

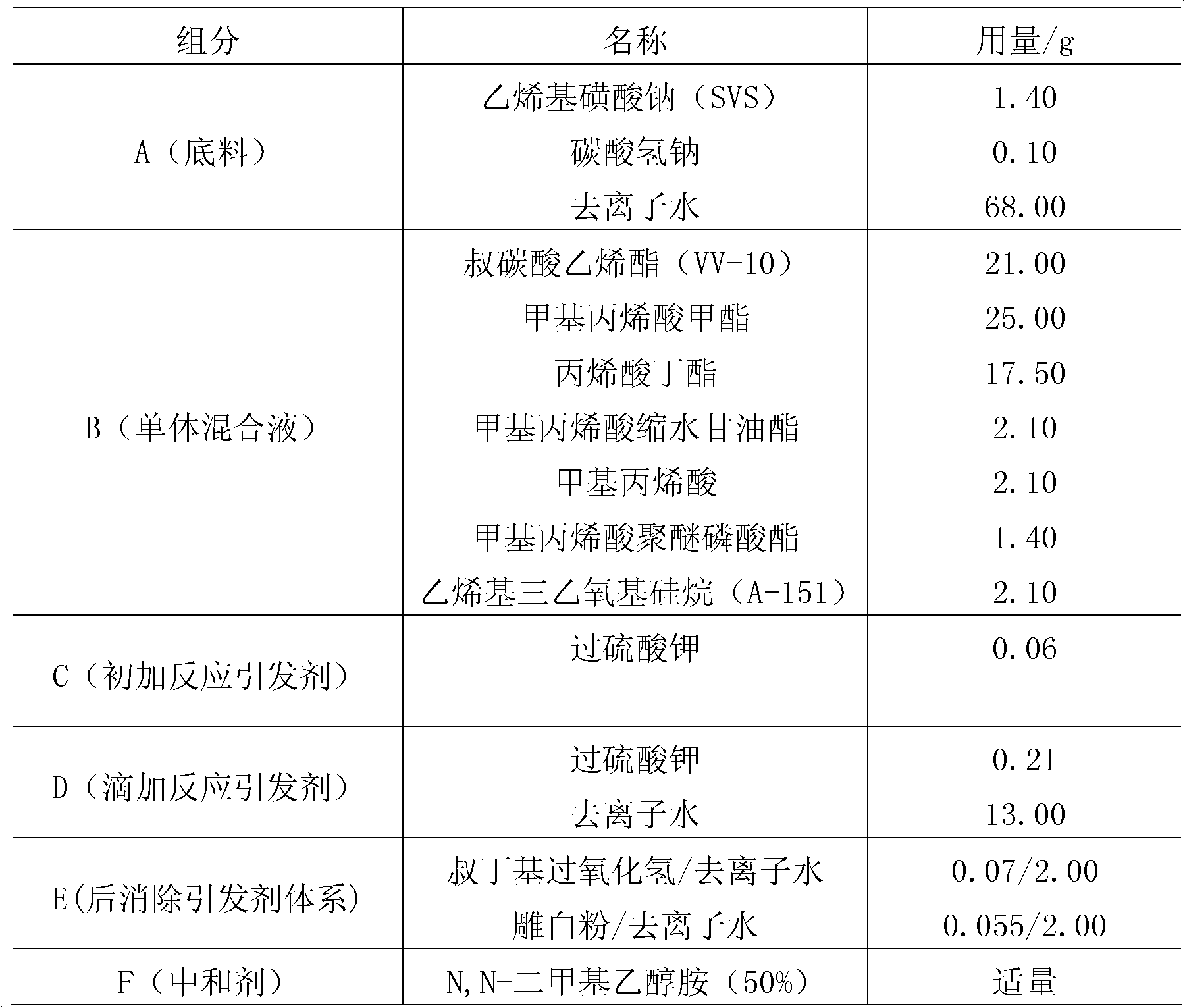

Preparation method for anti-rust soap-free acrylate emulsion

The invention relates to a preparation method for a base material of an anti-rust coating. The preparation method for an anti-rust soap-free acrylate emulsion is characterized in that a reactive emulsifier is selected, a polymeric monomer comprises (methyl) acrylic acid and an acrylic monomer thereof, a versatic acid vinyl monomer and a crosslinking monomer, a phosphate monomer is taken as a modified monomer, and the emulsion polymerization is carried out through semi-continue process under the action of an initiator, so that the soap-free anti-rust acrylate emulsion adopting water as dispersive medium is synthesized. The preparation method for the anti-rust soap-free acrylate emulsion can not only meet the requirement of environmental protection, but also enhance the rust resistance.

Owner:HUBEI EAST ST SPECIAL COATING TECH

Special-purpose protection dope for petroleum pipe/drill pipe and its preparation method and construction method

The invention relates to a protecting paint special for petroleum pipe / drill pipe, and a construction method and a preparation method thereof. The paint is composed of modified acrylic resin and modified alkyd resin as main film-forming substances, formaldehyde resin, chlorinated polyether resin and epoxy resin, etc. as modifiers, nontoxic tinting pigment, nanometer micro powder, environment-friendly solvent, nontoxic excluder pigment, additive, accessory ingredient, etc.; the paint is provided with the following advantages: low cost, good storage stability, not prone to deposit, good application property, strong anti-sagging property, coat flame retarding, good drying and fullness, strong adhesion, weathering resistance, rust prevention, non-toxicity and environment-friendly. The protecting paint special for petroleum pipe / drill pipe is specially designed for short-term antiseptic coat, such as sleeve of petroleum casing pipe, oil well pipe, oil well drill pipe, etc.

Owner:江阴市天邦涂料股份有限公司

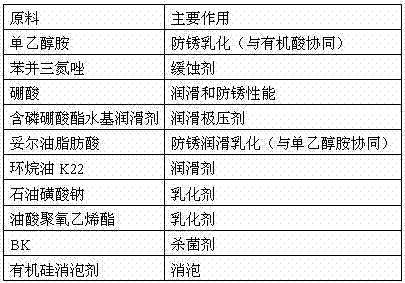

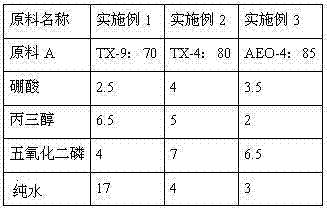

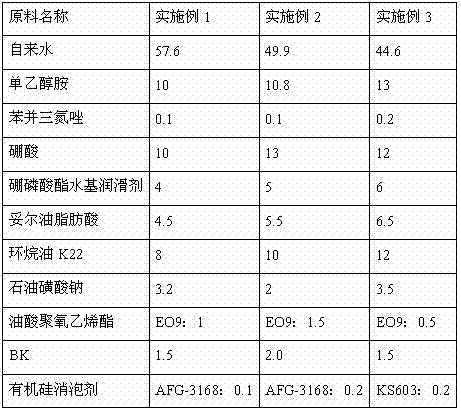

Multi-effect semi-synthetic cutting solution

ActiveCN102899152AReduce dosageHigh lubricating extreme pressure performanceLubricant compositionWater basedPhosphate

The invention discloses a multi-effect semi-synthetic cutting solution. The solution is prepared by uniformly mixing the following raw material components in percentage by total mass of 100%: 10 to 14% of monoethanolamine for industrial use, 0.1 to 0.2% of benzotriazole for industrial use, 10 to 13% of boric acid for industrial use, 4 to 6% of phosphate-borate-containing water-based lubricant, 4 to 7% of tall oil fatty acid for industrial use, 8 to 12% of naphthenic oil K22, 2 to 4% of petroleum sodium sulfonate No.55, 0.5 to 1.5% of oleic acid polyoxyethylene ester for industrial use, 1.5 to 2% of 1,3,5-tri(2-hydroxyethyl)-hexahydrotriazine for industrial use, 0.1 to 0.2% of organic silicon defoamer for industrial use and the balance of water. The solution has high lubrication extreme pressure performance and is biodegradable and environment-friendly.

Owner:无锡纳润特科技有限公司 +1

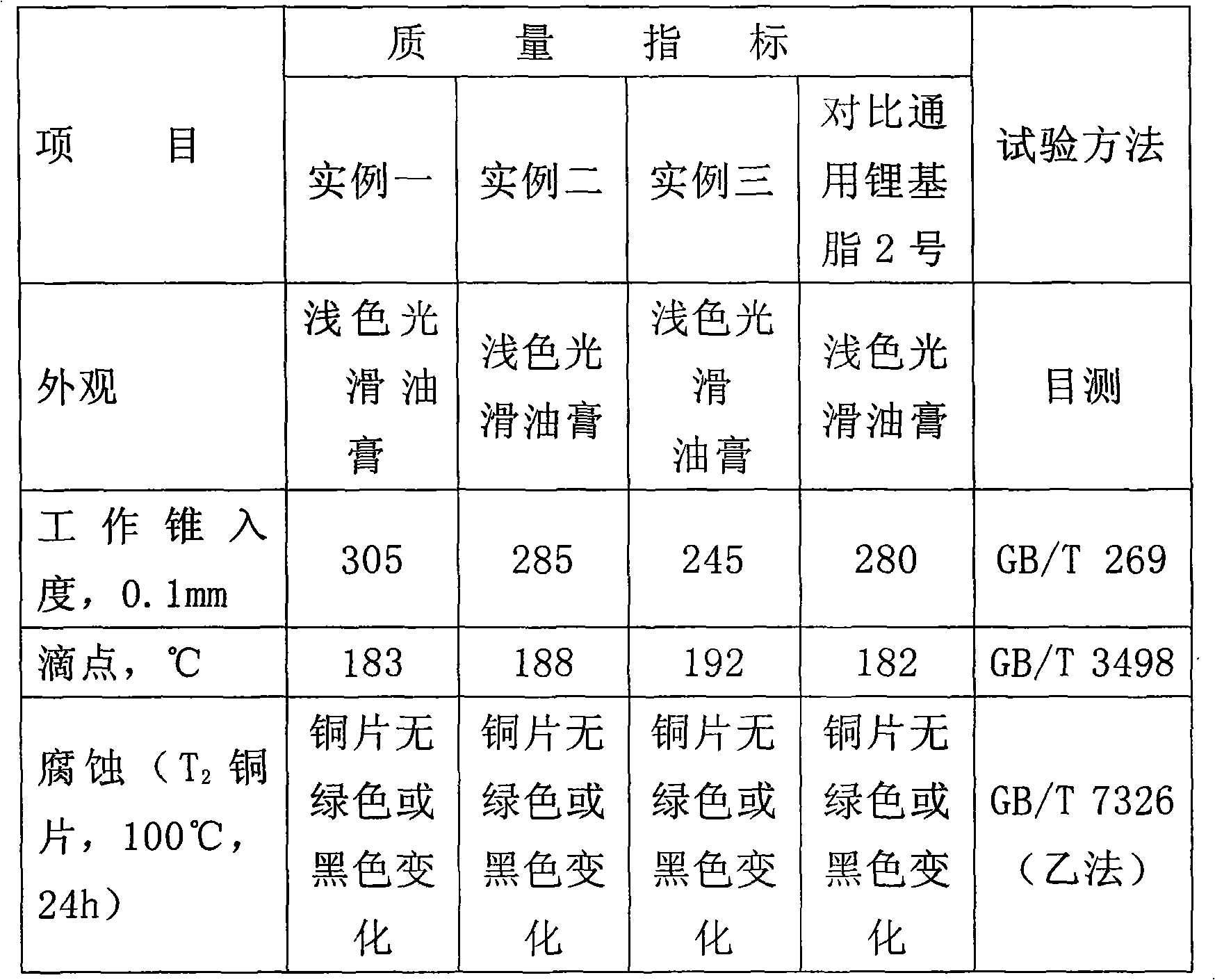

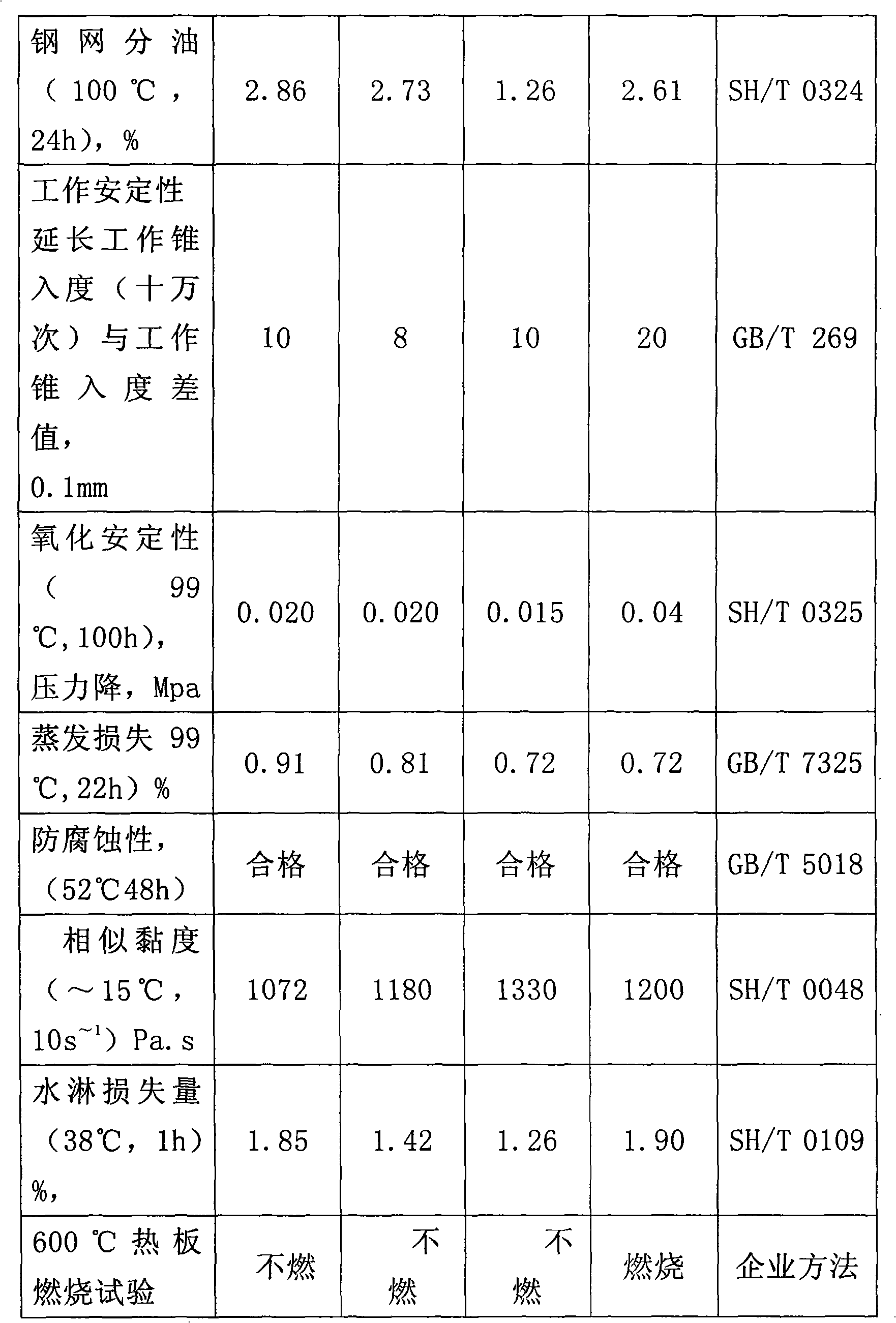

Flame-retarded lubricating grease and preparation method thereof

ActiveCN101619261AImprove performanceImprove flame retardant performanceThickenersAdditivesLithium soapAntioxidant

The invention relates to flame-retarded lubricating grease and a preparation method thereof. The preparation method comprises the following technical steps: firstly, putting base oil and an inorganic thickening agent in an open reaction kettle for stirring and mixing, adding a dispersant after heating and heating again to take the mixture out of the kettle for use; secondly, mixing fatty acid calcium soap with the base oil, adding fatty acid lithium soap after heating, keeping heat, dehydrating and refining; finally, removing the materials to a middle kettle, lowering the temperature by cooling, stirring the materials with lubricating grease prepared by the inorganic thickening agent, adding an antioxidant, a flame retardant and an anti-rusting agent for homogenization and filtering to obtain finished products. The lubricating grease not only keeps various excellent properties of original general lithium grease, but also specially enhances the incombustible flame retardance of a 600 DGE C hot plate. Assessment of the properties of the flame-retarded lubricating grease shows that the flame-retarded grease lubricant has excellent mechanical stability, water resistance, lubricating property, anti-rusting property and flame retardance, long service life and low cost, and can replace general lithium grease used in coal mine, subway, metallurgy and other industries at present.

Owner:无锡中石油润滑脂有限责任公司

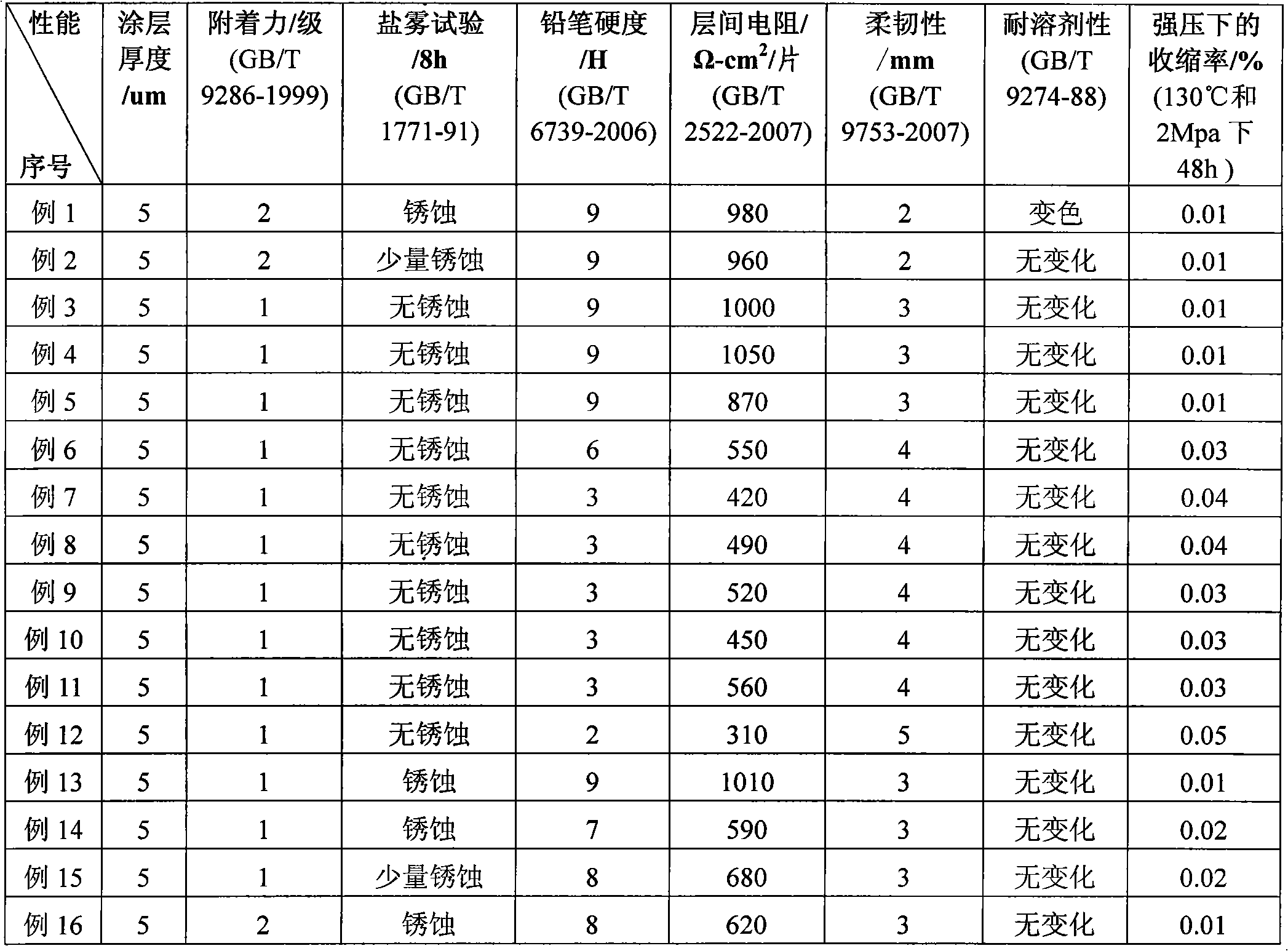

Strong-pressure resisting water-based insulting paint for electric steel and preparation method thereof

InactiveCN101792635AImprove surface resistivityGood corrosion resistanceEpoxy resin coatingsPolyester coatingsSurface resistivityMicrometer

The invention relates to a strong-pressure resisting water-based insulting paint for electric steel and a preparation method thereof. The strong-pressure resisting water-based insulting paint can be prepared by the following steps of: mixing 10-40 percent by weight of water-borne acrylic resin, 2-20 percent by weight of water-borne amine resin, 30-60 percent by weight of pigment, 0-10 percent by weight of addition agent, 0.1-5 percent by weight of catalyst, 0-5 percent by weight of corrosion inhibitor and 1-30 percent by weight of deionized water; and grinding the mixture in a sand mill until the fineness is below 15 micrometers and packaging. The components have no chromate and toxic and harmful ingredients, so that the strong-pressure resisting water-based insulting paint is environment-friendly; the prepared paint is coated on the surface of the electric steel and forms a protective layer with strong adhesion performance after being subjected to high-temperature braking and curing; and the protective layer has the advantages of very high surface resistivity, excellent corrosion resistance and very high strong pressure resistance and creep resistance.

Owner:WUHAN UNIV OF SCI & TECH

Aqueous asphalt imitation anticorrosion coating for container chassis and preparation method thereof

ActiveCN102533029ANo pollution in the processImprove rust resistanceAnti-corrosive paintsOrganic solventEmulsion

The invention discloses aqueous asphalt imitation anticorrosion coating for container chassis and a preparation method thereof. The aqueous asphalt imitation anticorrosion coating for container chassis comprises the following components in percentage by weight: 5 to 13 percent of running water, 46 to 62 percent of aqueous acrylic acid emulsion, 10 to 15 percent of rust resisting pigment, 15 to 22 percent of body filler, 0.6 to 1.0 percent of anti-settling agent, 0.05 to 0.2 percent of wetting dispersant reagent A, 0.2 to 1.0 percent of wetting dispersant reagent B, 4 to 6 percent of film-forming aid, 0.1 to 0.3 percent of defoaming agent, 0.2 to 0.4 percent of pH regulator, 0.4 to 0.8 percent of salt spray resistant aid, 0.1 to 0.2 percent of flash rust resistant agent and 0.1 to 0.7 percent of thickener. According to the invention, the flash rust resistant agent and the body filler are dispersed in the aqueous coating system together, so the coating has excellent anticorrosion performance; and the aqueous asphalt imitation anticorrosion coating does not contain harmful materials such as organic solvents and heavy metals, so the environment protection performance of the coating is high. And the coating makes construction simple, can be safely stored and has stable performance.

Owner:GUANGZHOU JOINTAS CHEM

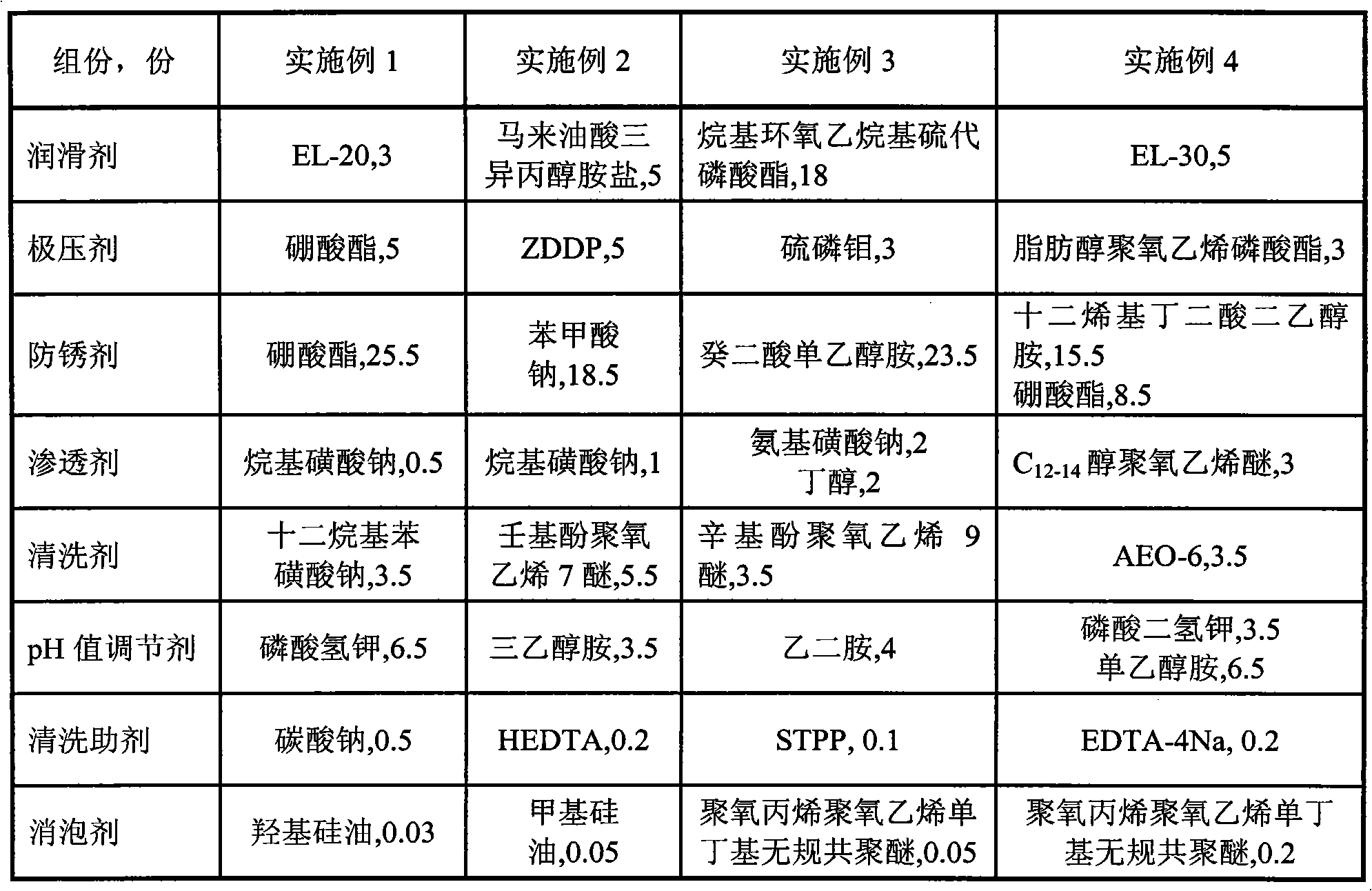

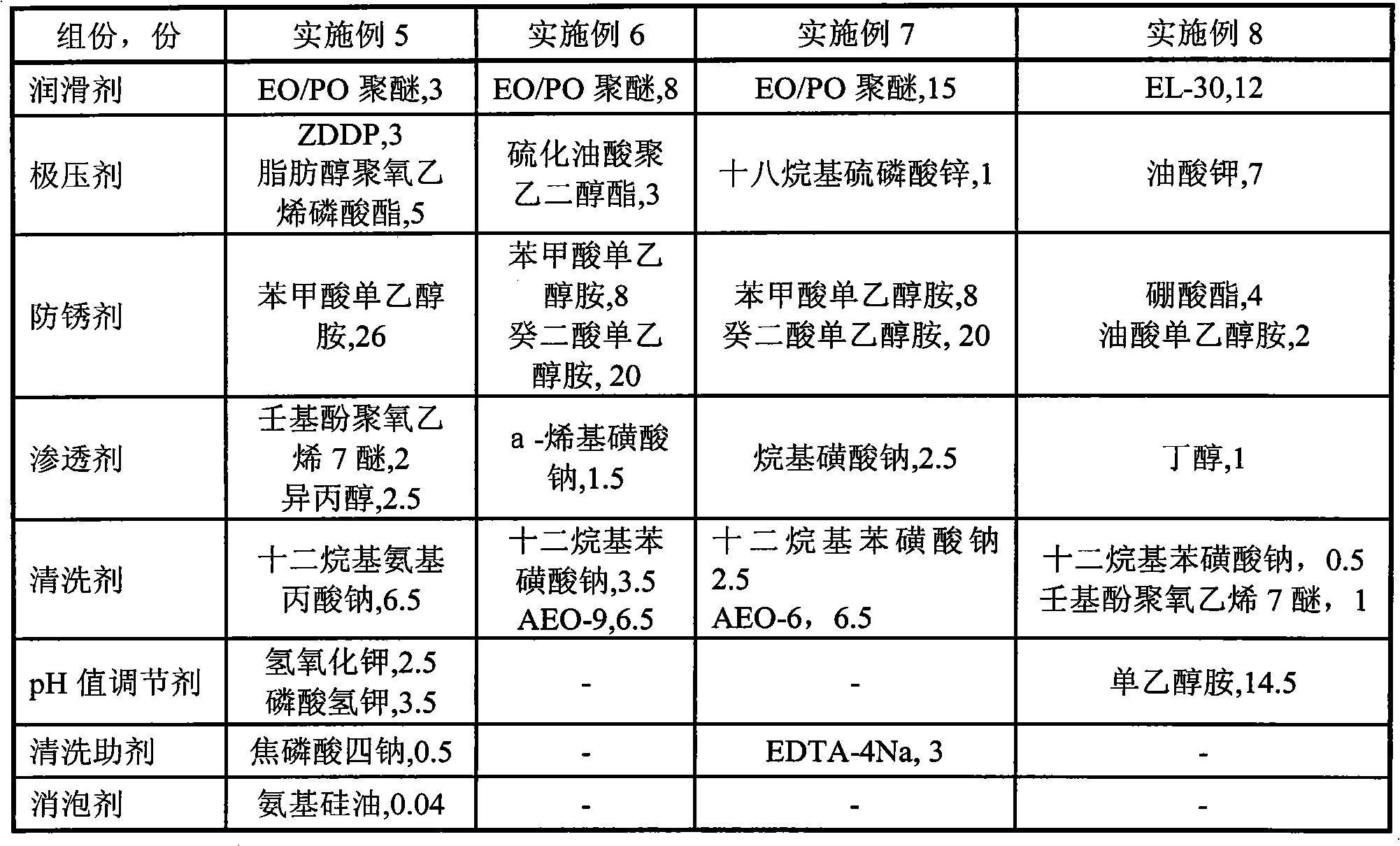

Water-soluble rolling liquid composition and application thereof

ActiveCN102757848AImprove the lubrication effectImprove rust resistanceLubricant compositionEmulsionMetallurgy

The invention relates to a water-soluble rolling liquid composition and application thereof. The water-soluble rolling liquid composition mainly solves the problems of low cooling performance of pure oil type rolling liquid and low emulsion stability and low detergency of emulsion type rolling liquid in the prior art. The water-soluble rolling liquid composition comprises the following components by weight: a) 3 to 30 parts of lubricating agent; b) 0.5 to 10 parts of extreme pressure additive; c) 5 to 30 parts of antirusting agent; d) 0.1 to 5 parts of penetrating agent; e) 0.1 to 10 parts of cleaning agent; and f) 15 to 92.3 parts of water. Through the adoption of the technical scheme, the problem is solved well and the water-soluble rolling liquid composition can be applied to the rolling and lubricating procedure of a cold-rolled steel plate.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com