Patents

Literature

84results about How to "Good lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water soluble full-alloy metal grinding fluid

ActiveCN104017636ALubricity achievedImprove stabilityLubricant compositionOrganic EsterNonferrous metal

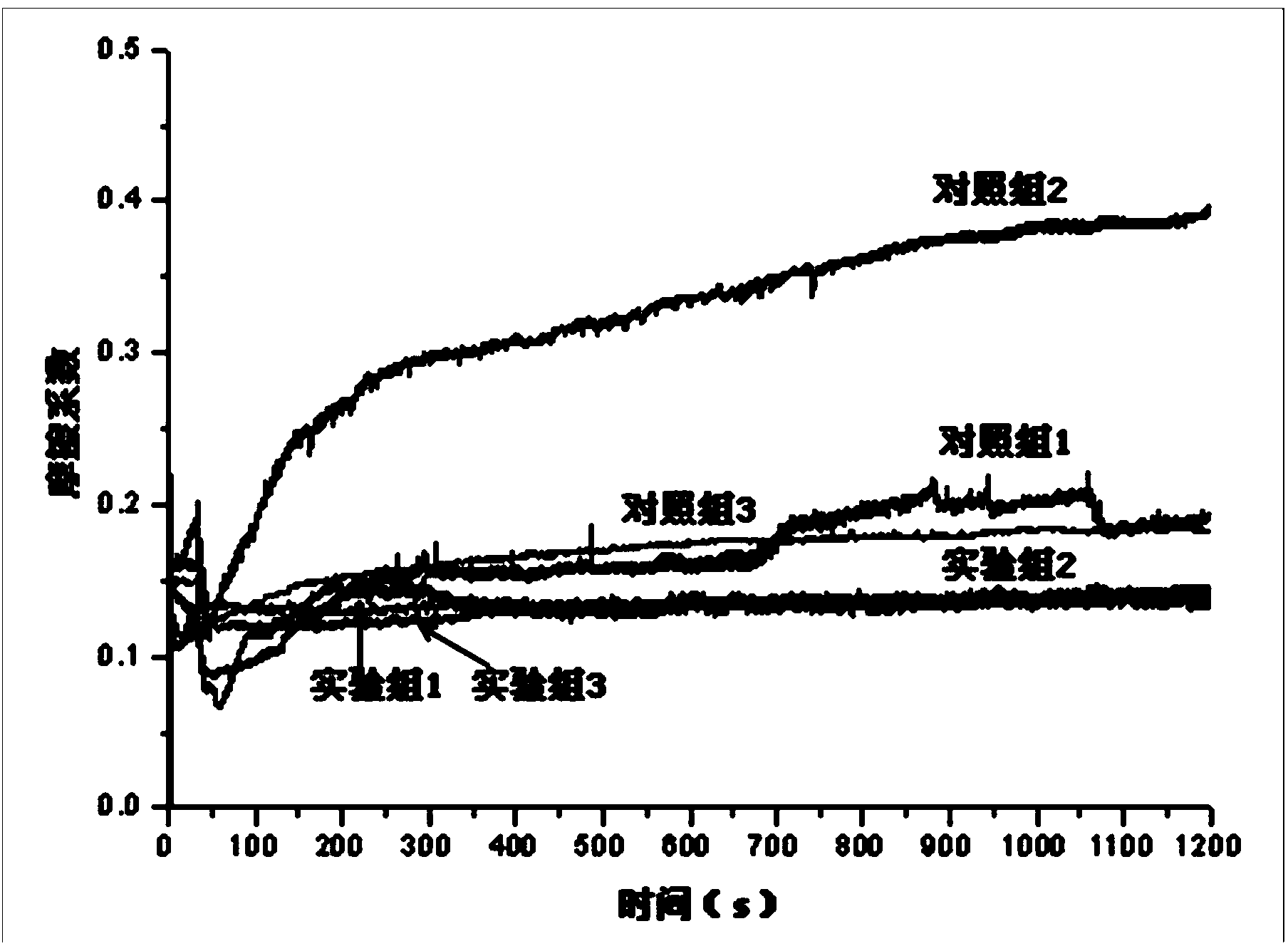

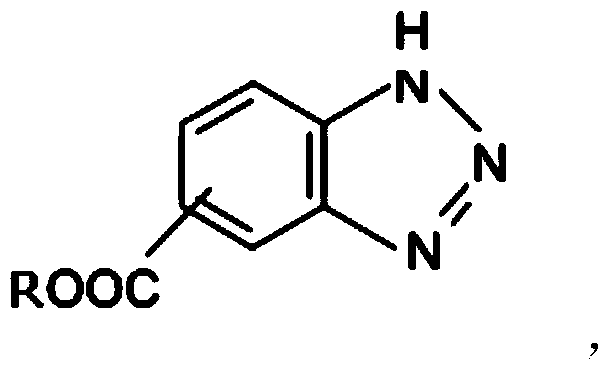

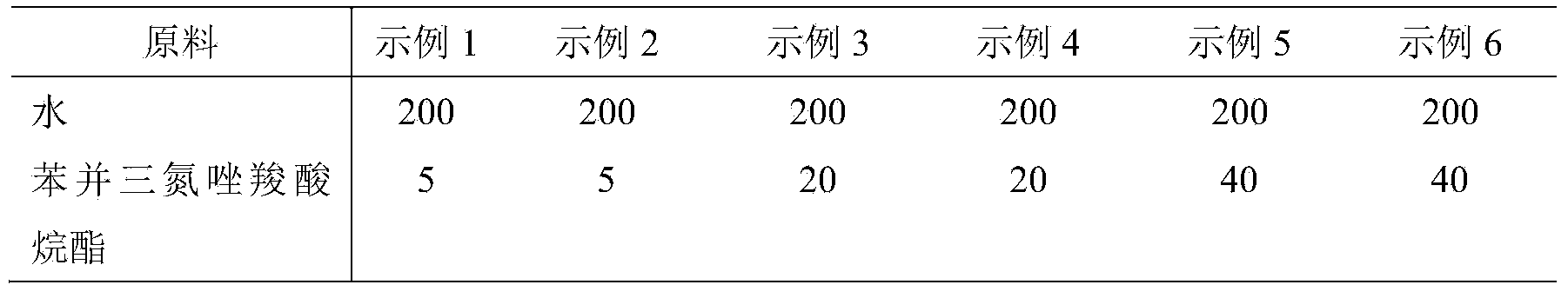

The invention discloses a water soluble full-alloy metal grinding fluid which belongs to the technical field of metal grinding fluids. The metal grinding fluid is prepared from the following components in percentage by weight: 5-40wt% of an antirust agent, 1-20wt% of a cleaning agent, 0.1-10wt% of a lubricating corrosion inhibitor, 1-20wt% of a penetrant, 1-20wt% of a solubilizer, 10-40wt% of a PH adjustor, 0.5-5wt% of a defoamer and the balance of water. Based on the total weight of the water soluble full-alloy metal grinding fluid, the pH value of the water soluble full-alloy metal grinding fluid is 7-11. The lubricating corrosion inhibitor is long chain nitrogen heterocyclic ring organic ester. The water soluble full-alloy metal grinding fluid has excellent lubricating, rust-preventing, cleaning and cooling performances and can be widely applied to grinding of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

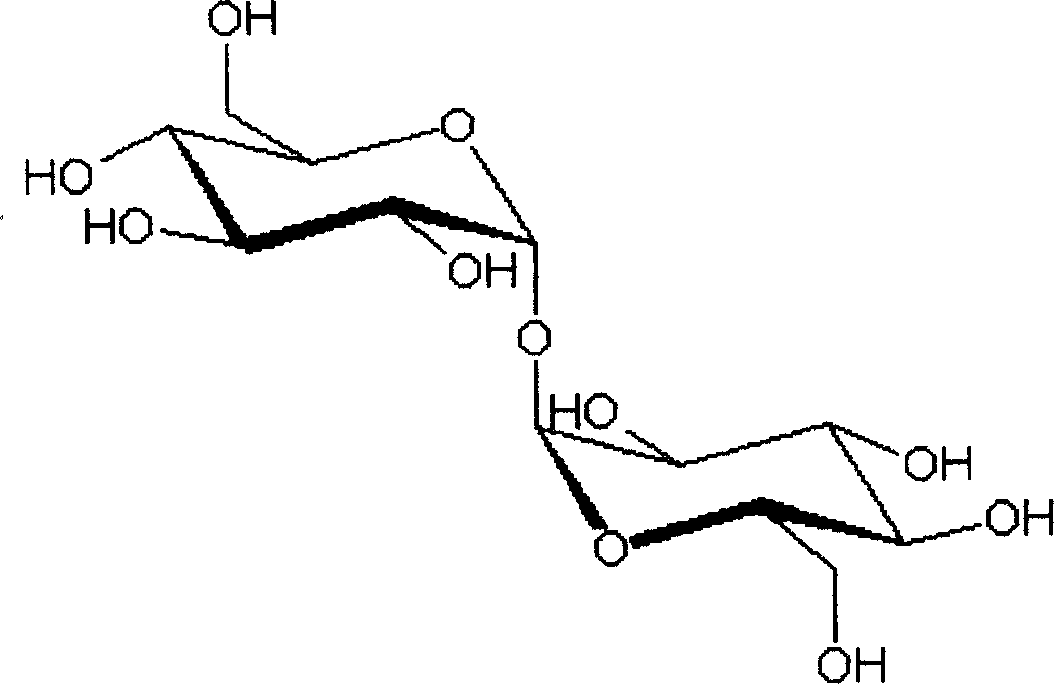

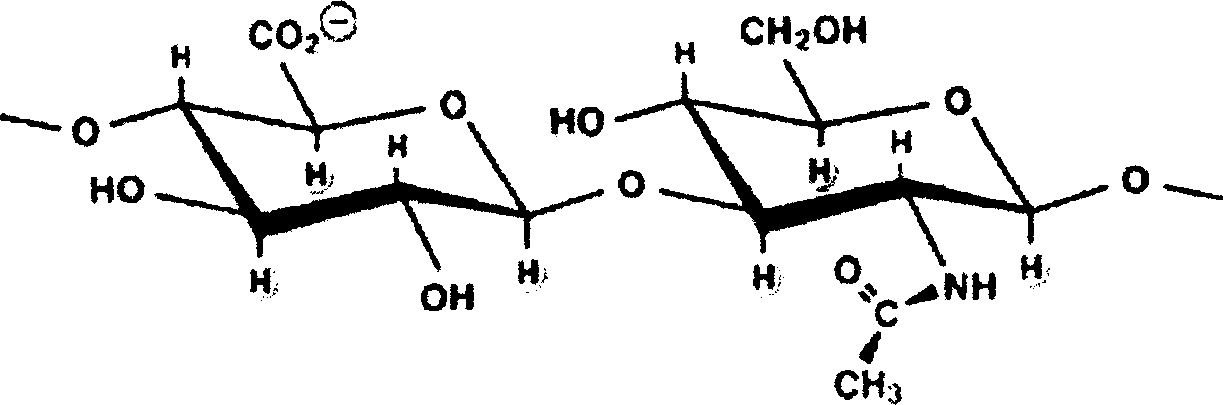

Composition containing trehalose and transparent acid for cosmetics and preparation thereof

A composition for cosmetics to clean, nurse and beautify the skin, hair and nails is prepared from trehalase, hyaluronic acid and other raw materials for cosmetics.

Owner:凌沛学

Mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect

The invention relates to a mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect. The mold powder comprises the following elements by weight percent: 38.02 to 40.1 percent of Cao, 28.8 to 30.02 percent of SiO2, 9.9 to 10.5 percent of CaF2, 9.06 to 9.5 percent of Na2O, 1.55 to 1.93 percent of MgO, 1.5 to 1.93 percent of AL203, 0.01 to 0.037 percent of Li2O and 0.035 to 0.053 percent of MnO. The mold powder has good lubricating property and spreadability. Because of the high melting speed, the invention can complement the quick consumption of liquid slag in time; because of the high alkalinity, the invention has strong absorbing and mixing capability; and because of the proper viscosity and the reasonable crystallization temperature, the invention plays an important role in uniformity. When the mold powder is applied to the casting of peritectic steel thick slab, the slag entrapment defect caused by crystallizer liquid level fluctuation is reduced greatly, the heat transmission uniformity is improved greatly and the surface quality of casting blank is good.

Owner:SHOUGANG CORPORATION

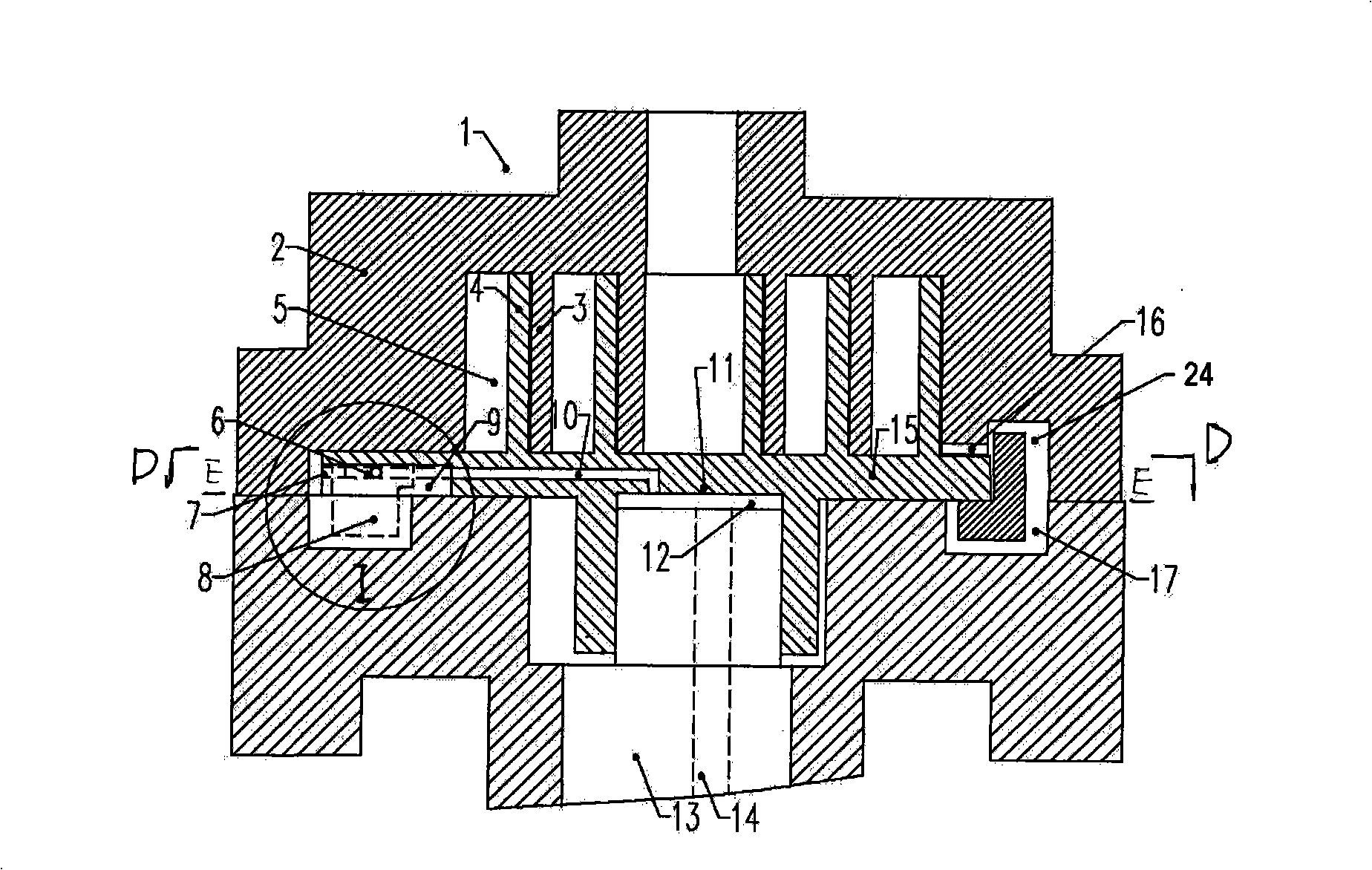

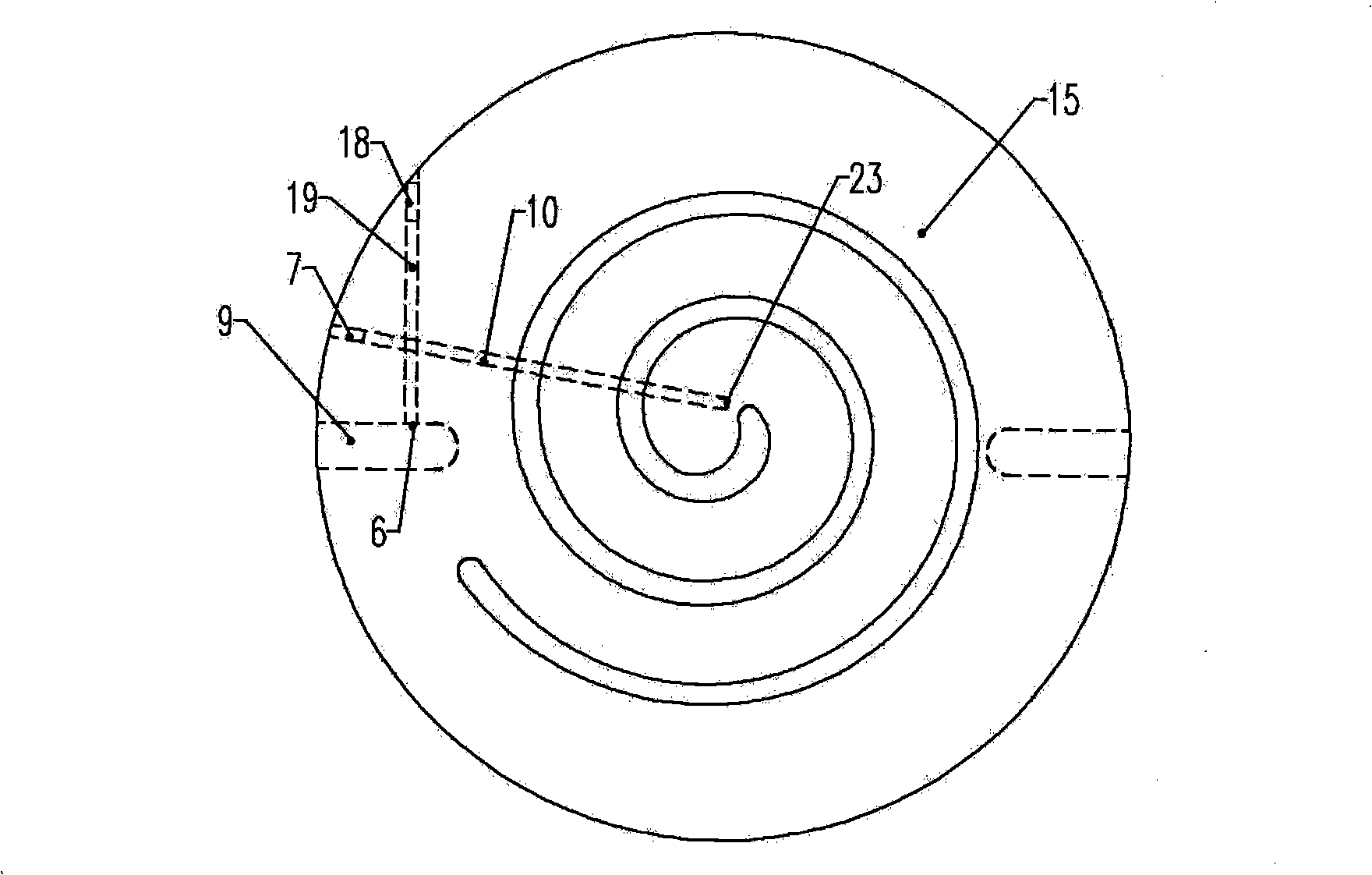

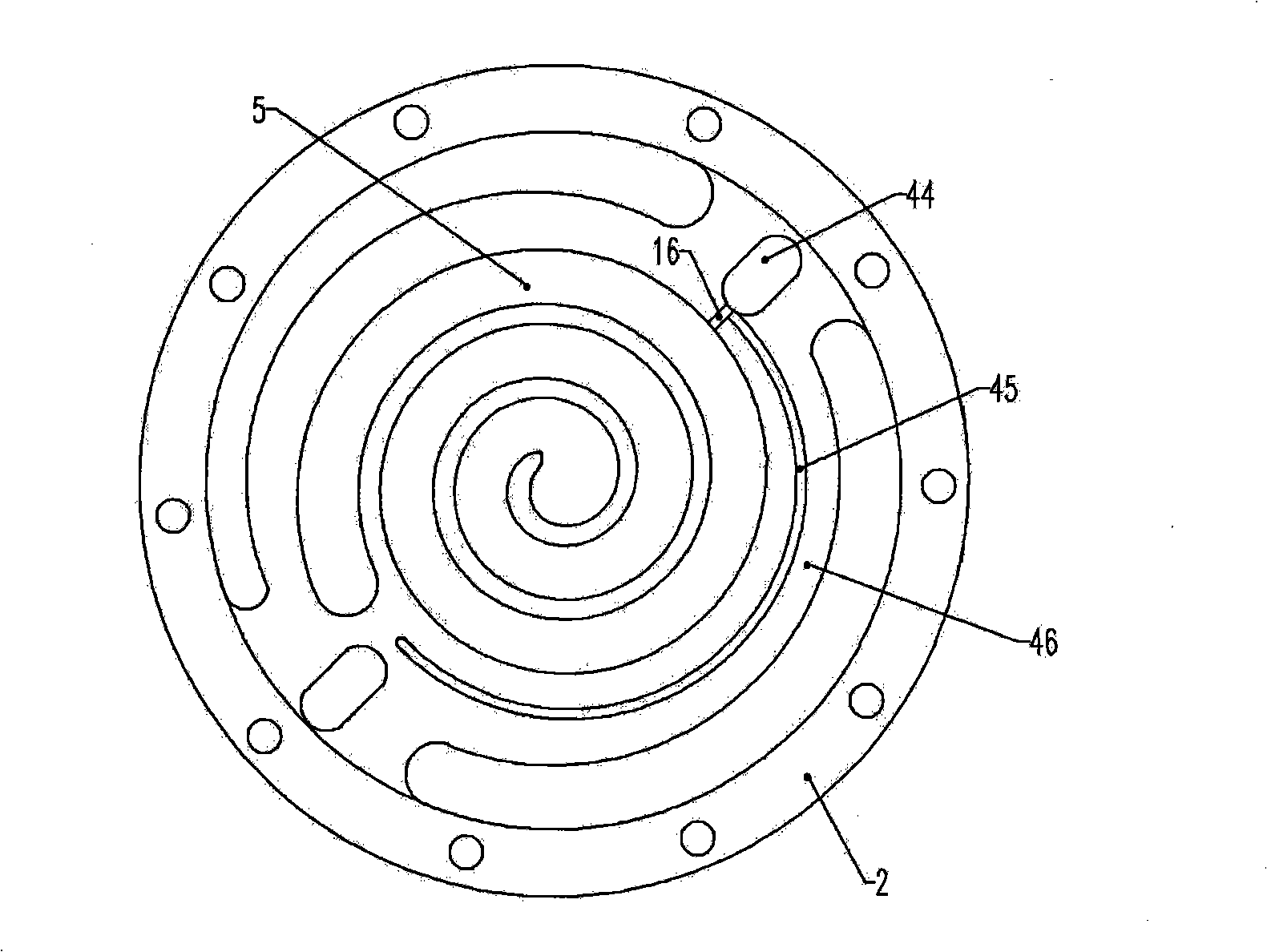

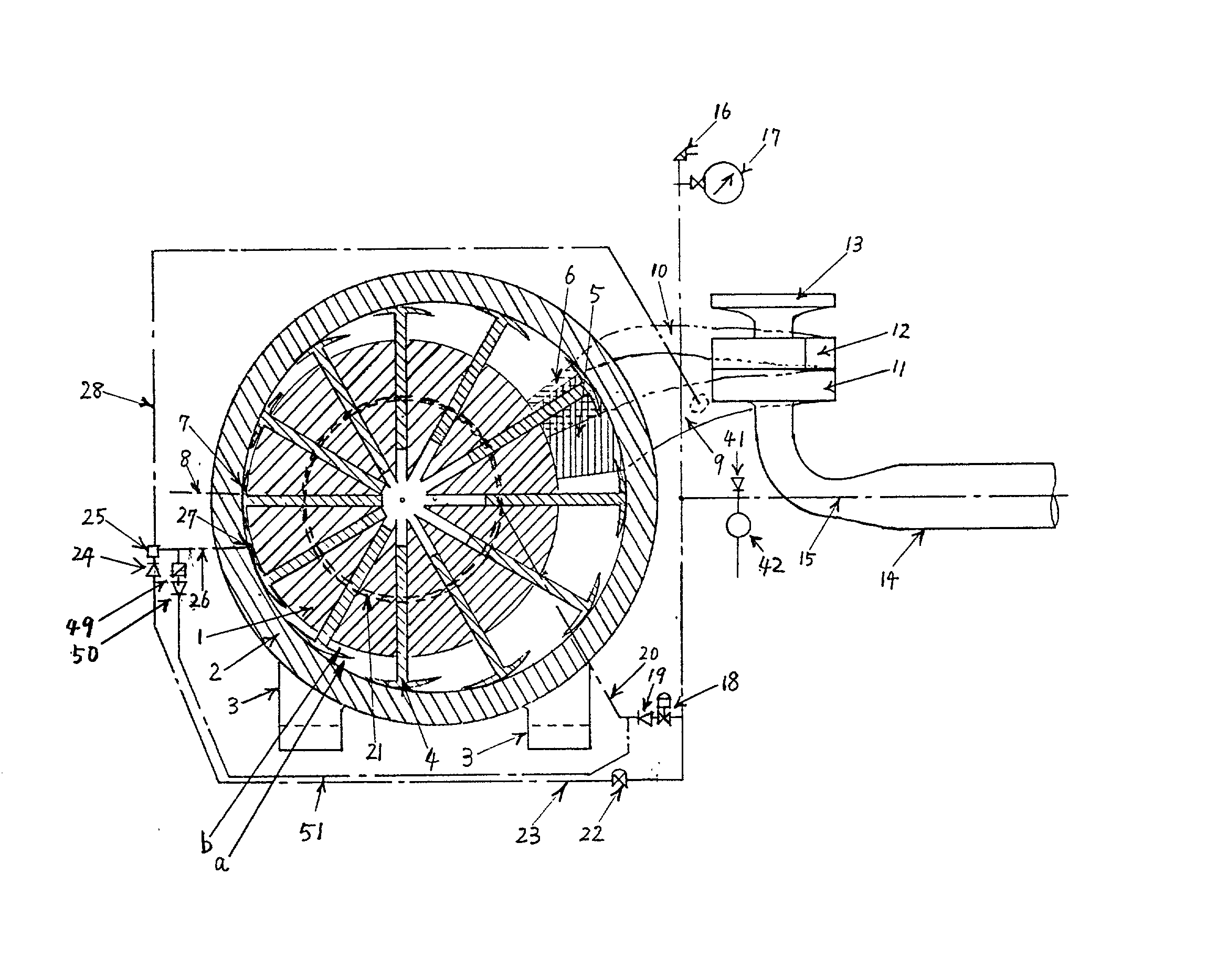

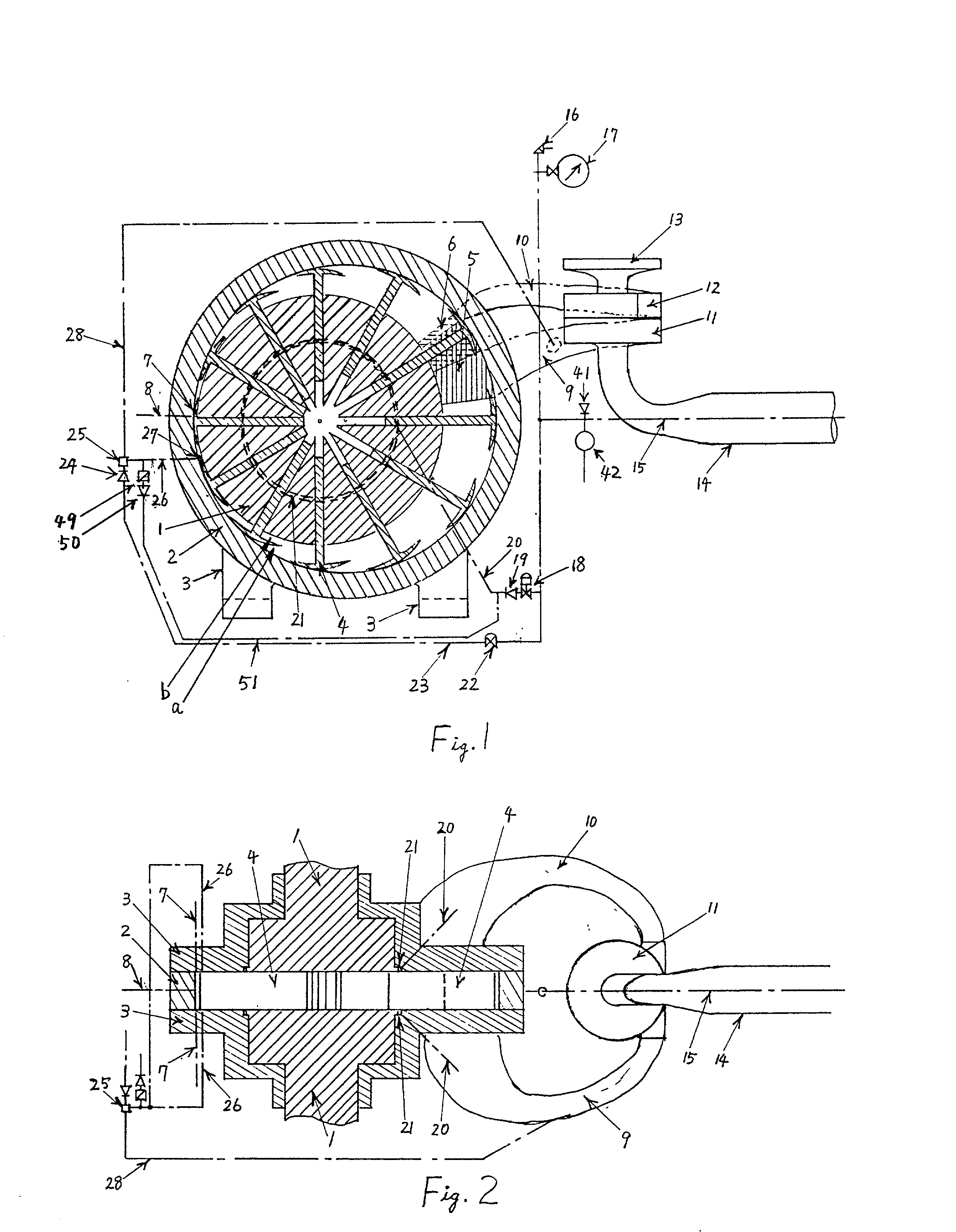

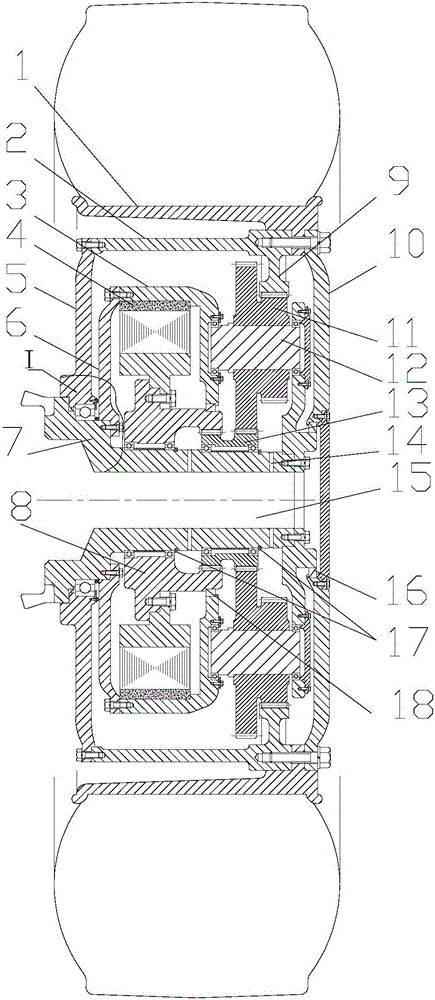

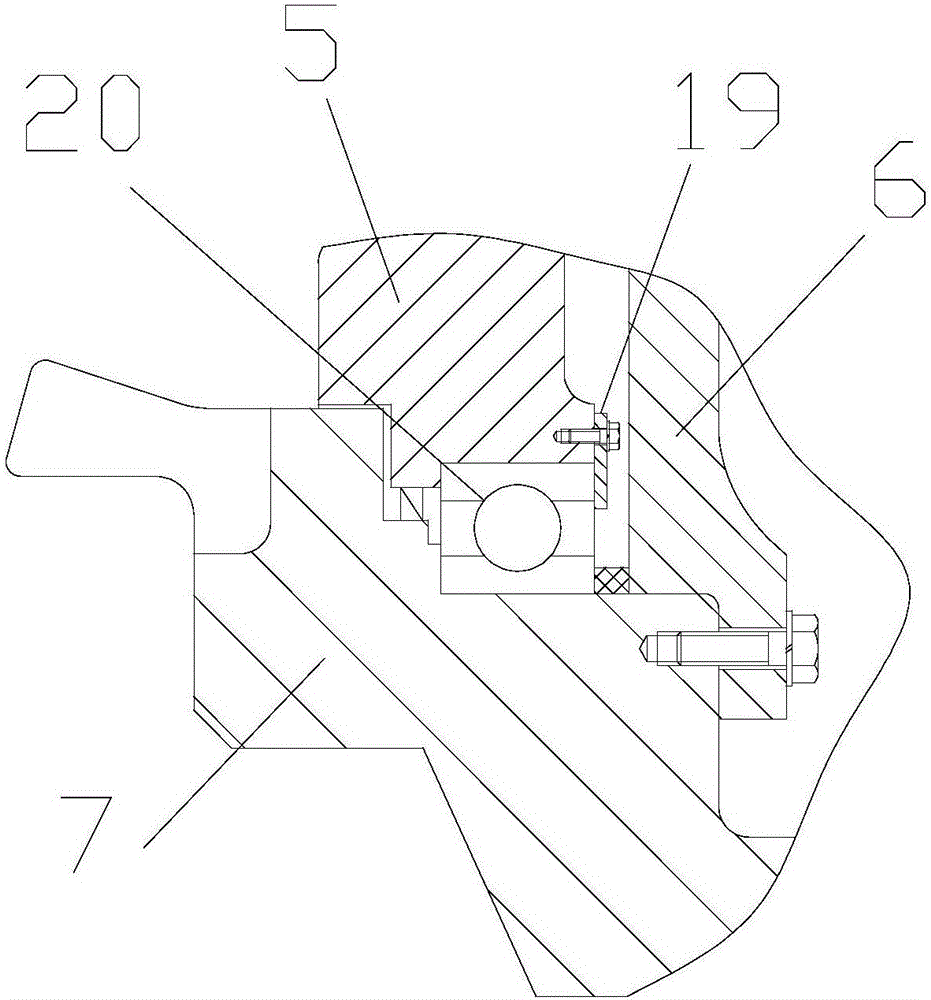

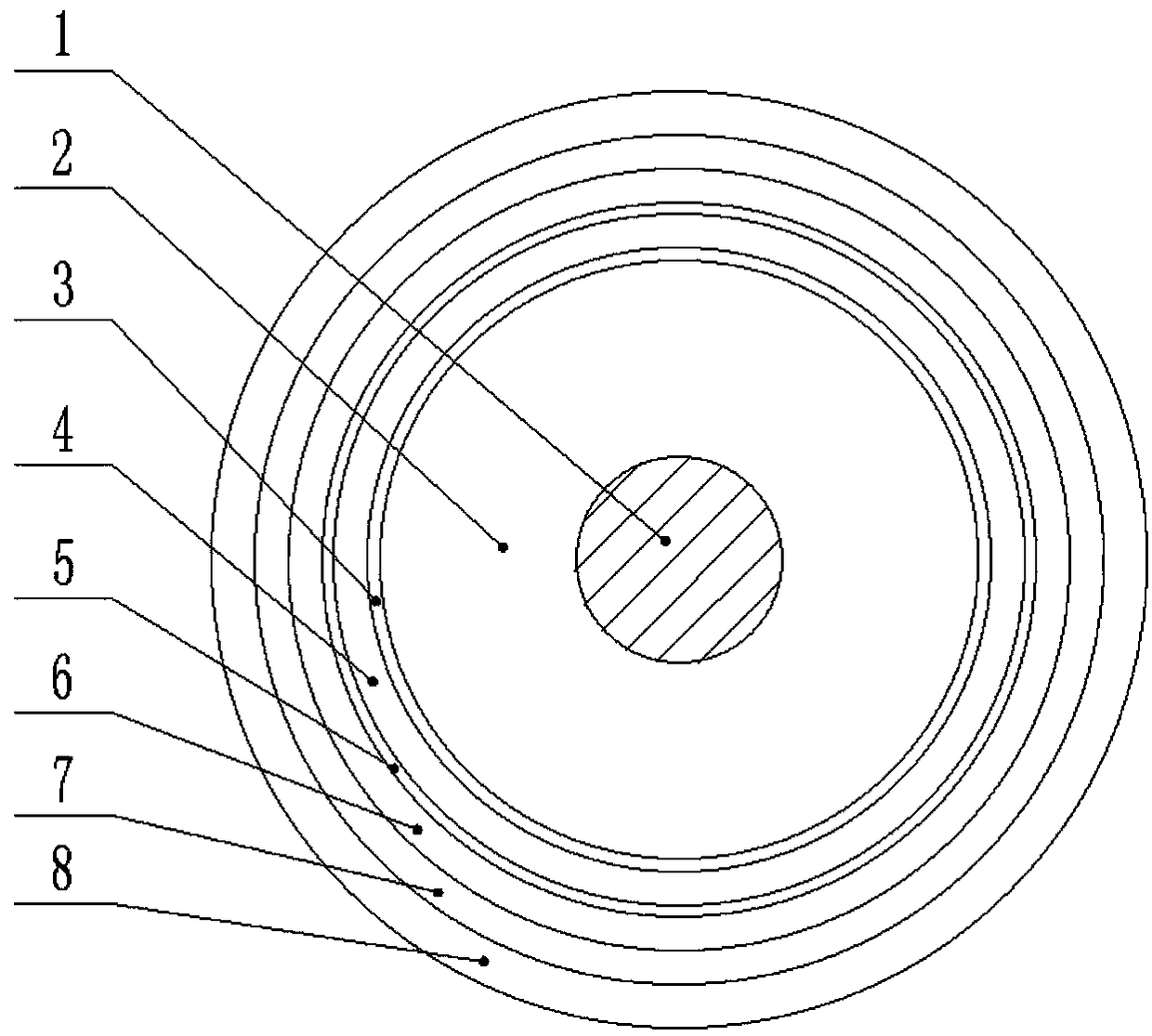

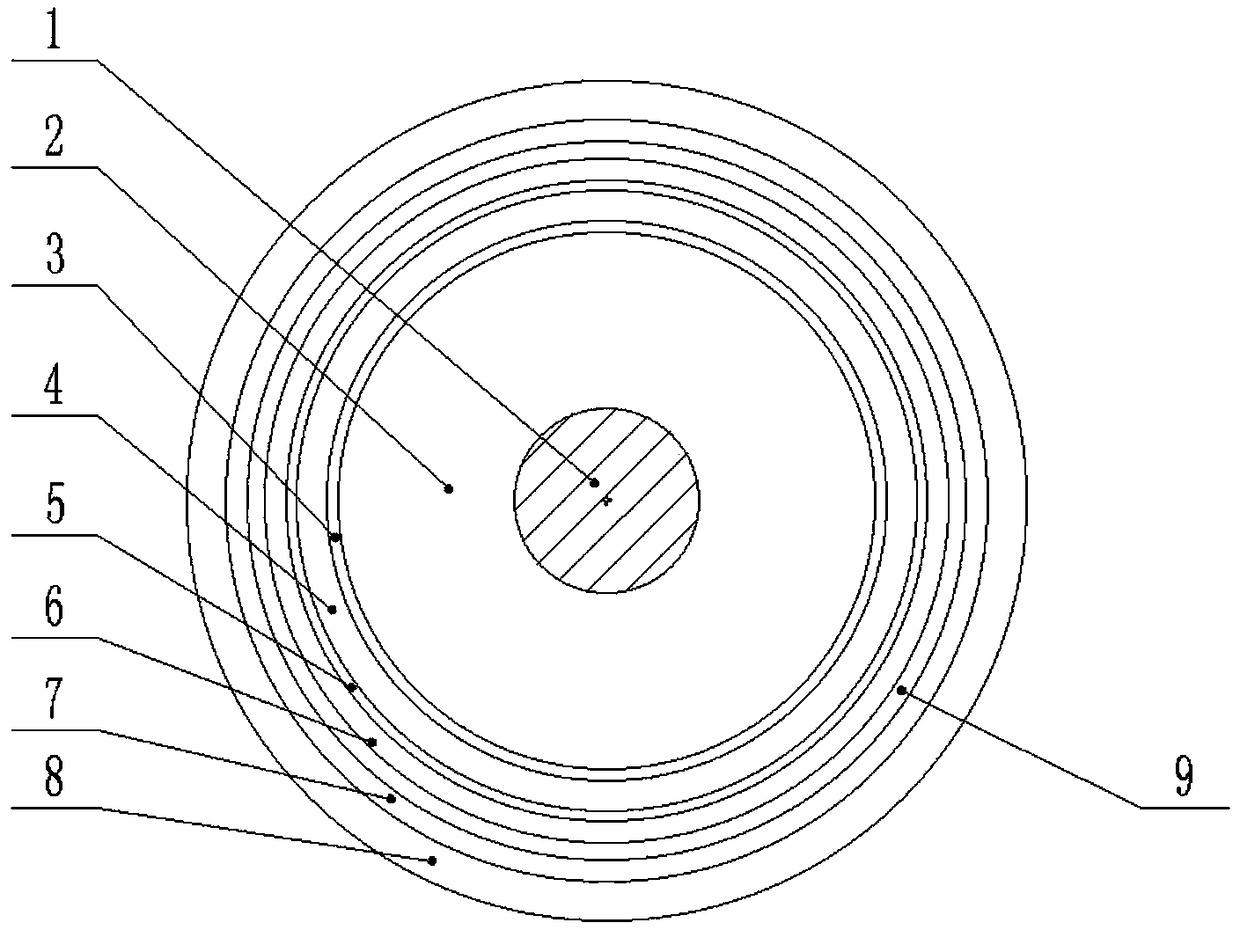

Cyclone compressor possessing lubricating system

ActiveCN101338754AGood lubricationImprove compression efficiencyRotary piston pumpsRotary piston liquid enginesLinear compressorMoving parts

The present invention relates to a compressor, in particular to a scroll compressor with a lubricating system, an oil channel is arranged on a movable swirl part, and the end oil hole of the oil channel is communicated with a socket to feed lubricant to a cross ring-shaped moving part in the socket. The present invention improves the lubricating system of the scroll compressor, so that the lubricant can be fed into a chamber formed by a fixed swirl part and the movable swirl part via a specific channel, and the oil hole can be periodically opened in order to accurately control the flow of the lubricant into the chamber, so that the chamber can be better lubricated. Thereby, the scroll compressor can be better lubricated in the process of operation, and meanwhile, the quantity of the lubricant fed into the chamber can be accurately controlled in order to ensure the stability of operation and obtain higher compressing efficiency.

Owner:DALIAN SANYO COMPRESSOR

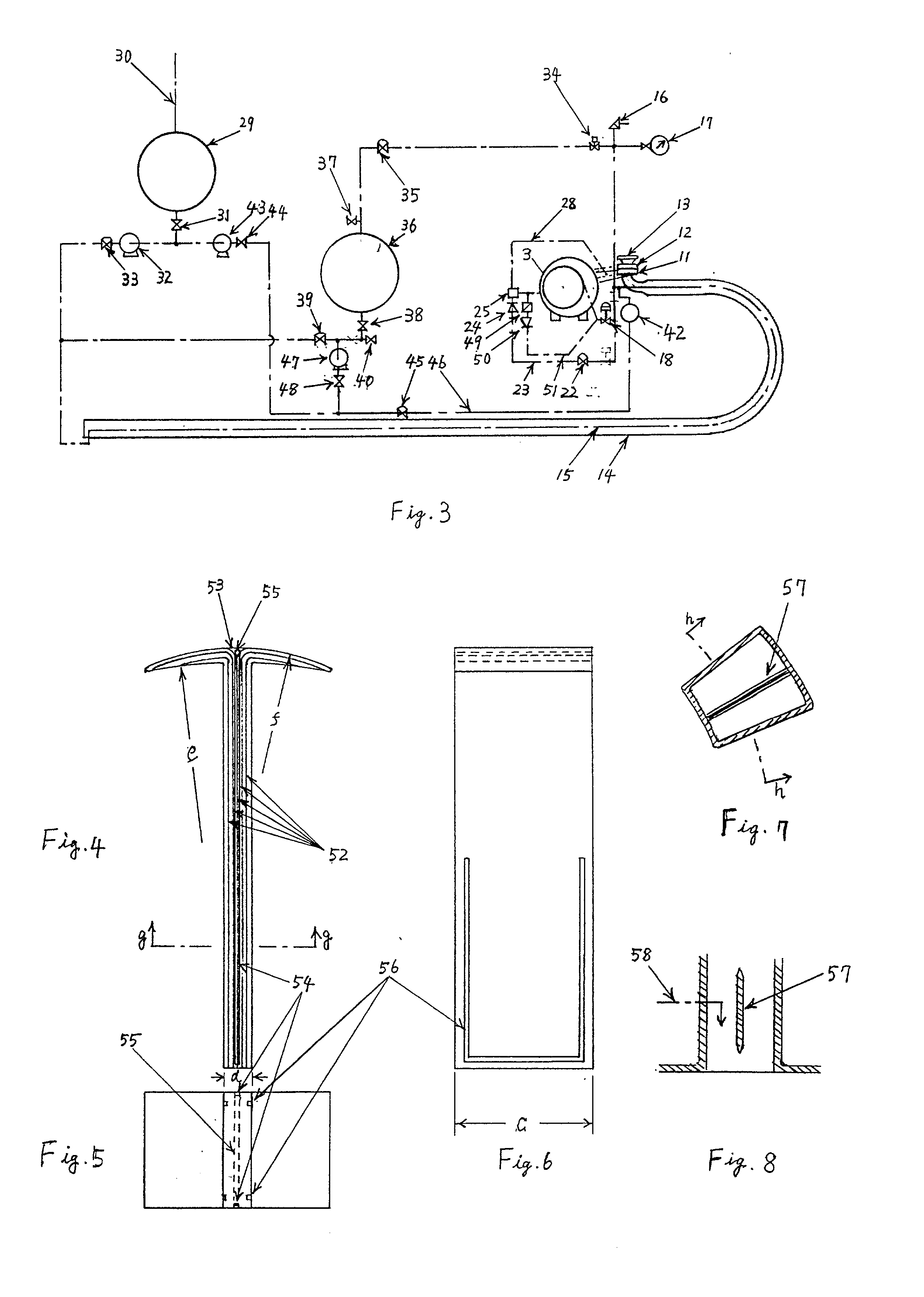

Reciprocating vane type rotary internal combustion engine (vane engine)

InactiveUS20030121494A1Coefficient of friction be smallGood lubricationInternal combustion piston enginesEngine componentsLubricationChamber pressure

On the reciprocating bane of a reciprocating vane type rotary internal combustion engine (vane engine), big centrifugal force is generated by a high-speed rotation and is opposed to combustion pressure, and force equal to or more than seal action force to be necessary for vanes tip is added to the case inside, and friction loss becomes big. For get the force to support centrifugal force and to make this friction loss small, a vane tip cross-section vertical to a rotating axis is formed in a pick-shaped so as to generate gas bearing action force greatly. In addition, in order to raise a hydrostatic pressure in neighborhood of tangent line of both the outside curved surface of vanes tip and the case inside, and to get the multiplication effect that raise a hydrodynamic pressure in the vanes tip, gas supply hole is established parallel to the rotating axis in the midsection of the vanes tip. Therein, porous matrix or great many minute holes connect between the gas supply hole and outside curved surface of the vanes tip. High pressure air, combustion pressure gas or steam is provided to gas supply hole, then, it is spouting out from outside curved surface of it, and get a high hydrostatic pressure and raise a hydrodynamic pressure. Furthermore, because there is not the first steam for lubrication searing in a start, steam reservoir and pressurization pump is established. Therein, compress the air in the steam reservoir by press-fitting water in steam reservoir, then it is used to lubrication searing. After an engine began to move in start or activation, till pressure of revitalization vapor by exhaust becomes proper, as method to get the high pressure gas for lubrication searing, part of the combustion gas which is pulled out from the second steam supply-cum-combustion gas pulling out port, which established a little to the bottom dead point from the center point of the front side vane toward rotating, this vane which combustion chamber pressure of this engine, in which continued fuel injection and combustion (make the best use of characteristic of this engine), become maximum, is connected with the first steam supply pipe for lubrication searing through a filter and a check valve. Fuel injection in neighborhood of the top dead point is difficult to avoid the surface of a wall adhesion, because combustion chamber is so flat. As substitute for it, I devised a method to do vaporization of fuel or injection on the part which close late of air supply port near the bottom dead point, so as to vaporized or injected fuel mix with supply air without loss and so as not to join the air to pass without dropping in.

Owner:YOSIKANE IKITAKE

Polyethylene glycol monooleate fully-synthetic cutting fluid and preparation method thereof

ActiveCN102776060AComprehensive lubricationExtend the life cycleLubricant compositionPolyethylene glycolMaterials science

The invention relates to a cutting fluid for metal processing, and particularly relates to a polyethylene glycol monooleate fully-synthetic cutting fluid and a preparation method thereof. Polyethylene glycol monooleate is used as a lubricating agent, and borate generated by boric acid and monoethanolamine and triazine amino-acid ester are combined to form an anti-rust component which has better anti-rust property, thus solving the defects of poor lubricating property, easy deterioration and smelliness and short service life of polyethylene glycol lubricating agents, polyether lubricating agents, oleic acid soap lubricating agents and sulfonated caster oil lubricating agents, and further achieving a corrosion inhibition and synergy function by adding a proper amount of benzotriazole copper corrosion inhibitor and other anti-rust agents. The fully-synthetic cutting fluid prepared from the raw materials is complete in property, has excellent hard water resistance, can be used under a high hard water environment, is high in pH buffer capacity, is stable in quality, has excellent lubricating, anti-rust and anti-corrosion functions, belongs to an environment-friendly product, can be biodegraded, is suitable for various kinds of machining, and is especially suitable for various machining processes of a grinder.

Owner:温州宝罗润滑材料有限公司

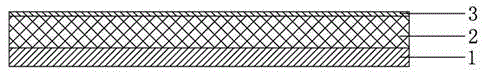

Elastic TPU (Thermoplastic Polyurethane) polishing composite membrane

InactiveCN105313033AImprove surface qualityIncrease elasticityPolyureas/polyurethane adhesivesAbrasion apparatusAntistatic agentAdhesive

The invention discloses an elastic TPU (Thermoplastic Polyurethane) polishing composite membrane. The elastic TPU polishing composite membrane comprises a TPU adhesive membrane layer and a grinding material layer, wherein the lower surface of the grinding material layer is stuck on the upper surface of the TPU adhesive membrane layer through a modified adhesive; a lubricating antistatic coating is uniformly coated on the upper surface of the grinding material layer; the modified adhesive is prepared from three materials including polyurethane resin, a curing agent and a flatting agent at the weight ratio of 100 : (10 to 20) : (0.5 to 1.5); the lubricating antistatic coating is prepared from three materials including a lubricating solution paraffin, a film forming agent and an antistatic agent at the weight ratio of 100 : (8 to 12) : (5 to 8). The grinding material layer composed of a polishing and grinding material is compounded on the TPU adhesive membrane layer so that the properties of the grinding material layer and the TPU adhesive membrane layer are effectively combined; the lubricating antistatic coating has good anti-blocking and lubricating functions so that the service life can be prolonged, the surface quality of polishing is improved and scratches are reduced. Therefore, the elastic TPU polishing composite membrane has the advantages of novel design, stable and reliable structure and wide applicable range.

Owner:DONGGUAN GOLDEN SUN ABRASIVES

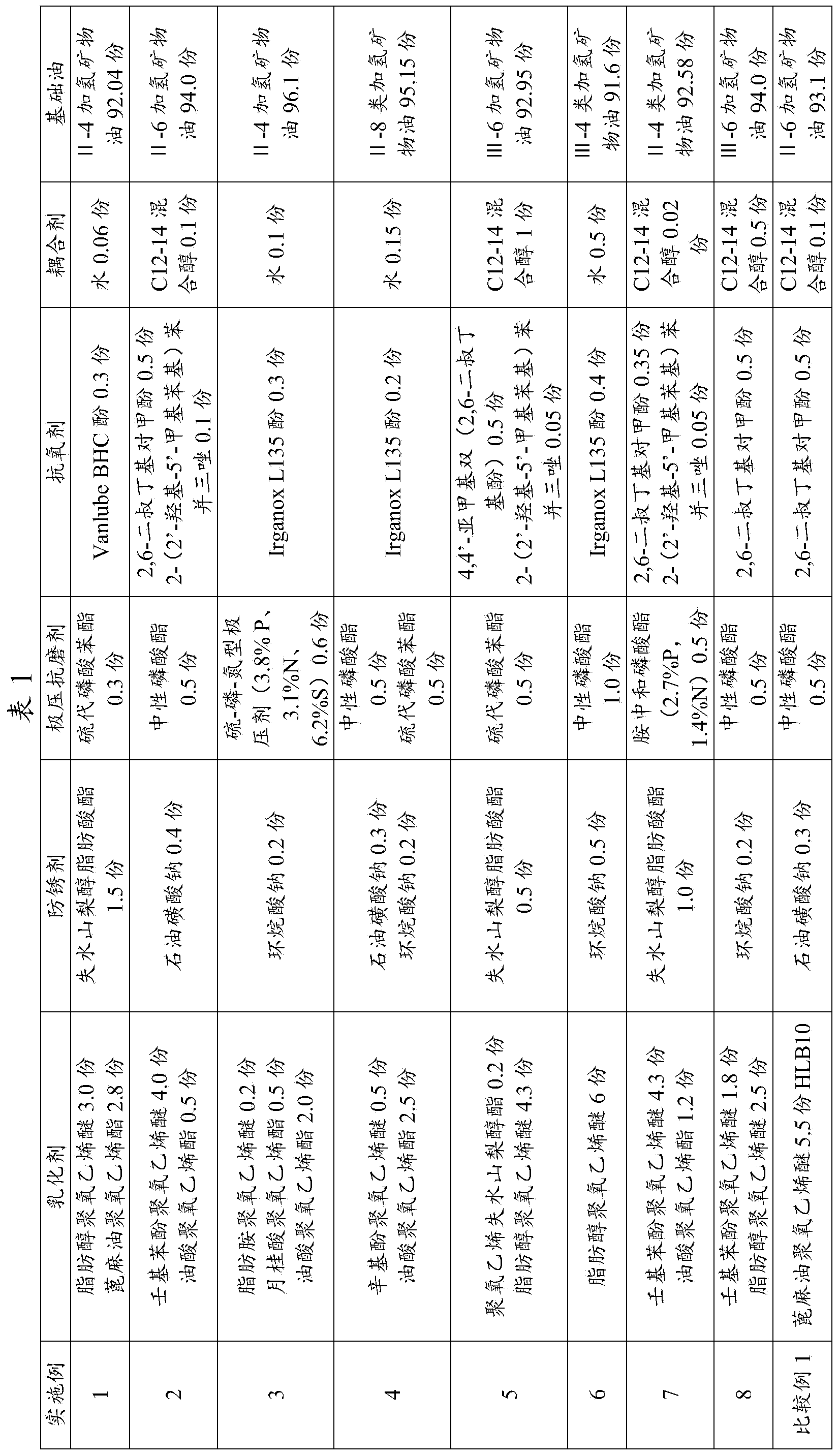

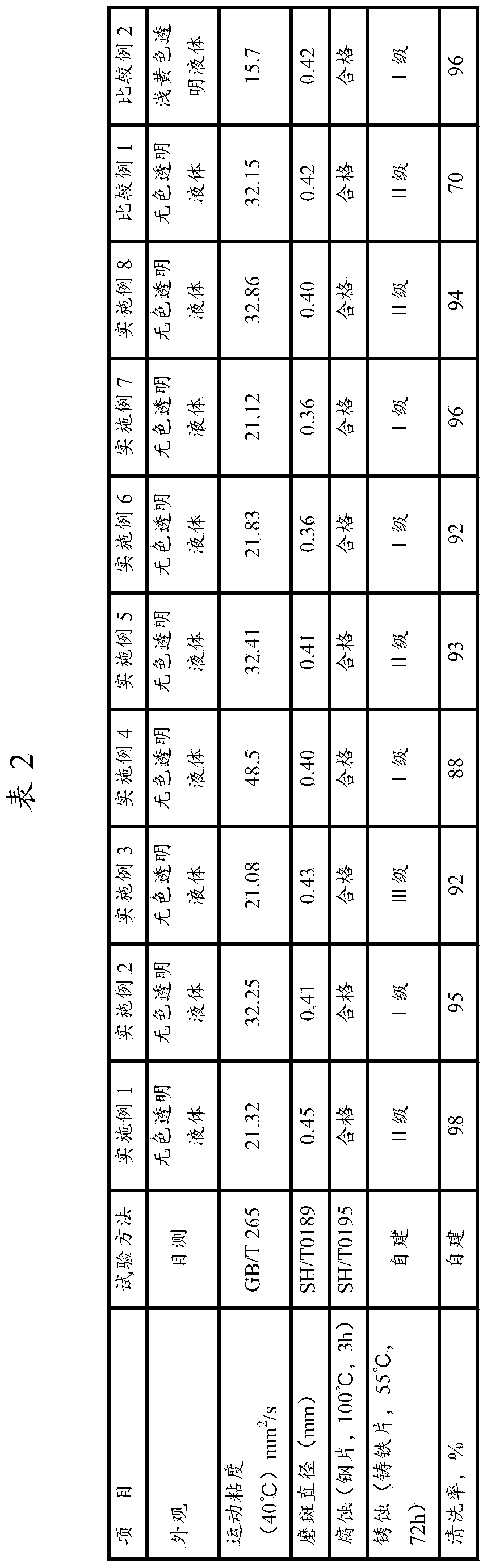

Easy-to-clean antirust knitting machine oil composition and use thereof

The invention relates to an easy-to-clean antirust knitting machine oil composition and use thereof, and mainly solves the problems in the prior art that the knitting machine oil composition cannot simultaneously have cleanability, excellent anti-rust property and colorless and transparent appearance. The easy-to-clean antirust knitting machine oil composition comprises the following components in parts by mass: a) 2-6 parts of an emulsifier, b) 0.1-2 parts of an antirust agent; c) 0.1-1 part of an extreme-pressure anti-wear agent, d) 0.01-0.5 part of an antioxidant, e) 0.1-1.0 part of a coupling agent; and f) 90-97 parts of base oil. According to the technical scheme, the problems are well solved, and the easy-to-clean antirust knitting machine oil composition is used for lubricating a circular knitting machine.

Owner:CHINA PETROLEUM & CHEM CORP

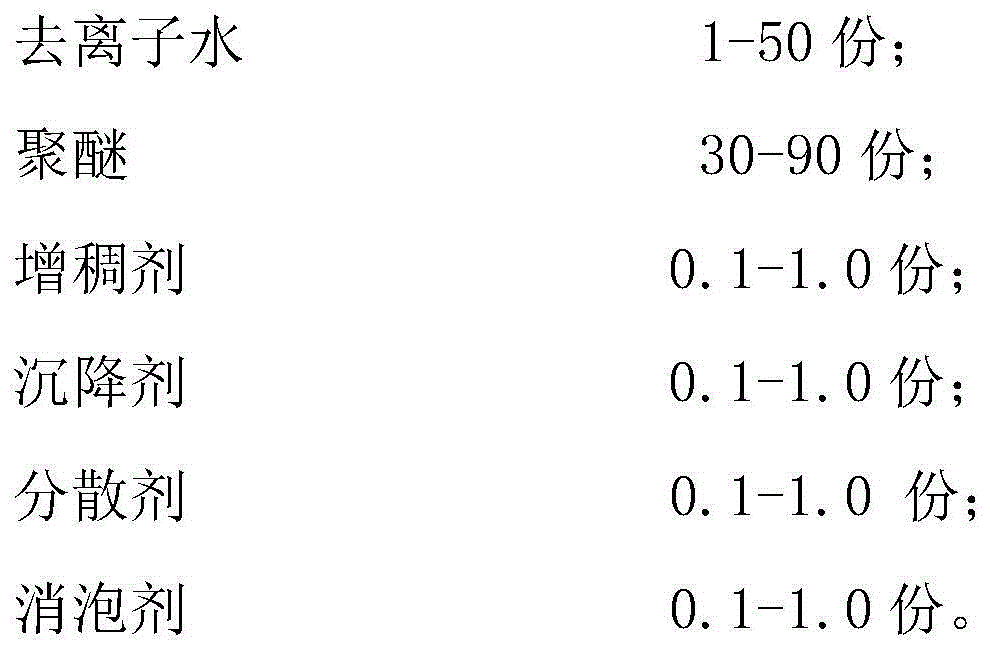

Novel diamond abrasive wire cutting fluid

InactiveCN105985852AInhibition of hydrogen productionGood lubricationLubricant compositionWire cuttingLubrication

The invention discloses a novel diamond abrasive wire cutting fluid. The novel diamond abrasive wire cutting fluid comprises, by mass, 1 to 50 parts of deionized water, 30 to 90 parts of polyether, 0.1 to 1.0 part of a thickening agent, 0.1 to 1.0 part of a settling agent, 0.1 to 1.0 part of a dispersing agent and 0.1 to 1.0 part of an antifoaming agent. The diamond abrasive wire cutting fluid provided by the invention can inhibit generation of hydrogen, has obvious lubrication effect, is easy to clean, low in cost, stable in performance and friendly to environment, has low COD value and can be directly discharged.

Owner:CHANGZHOU JUNHE TECH

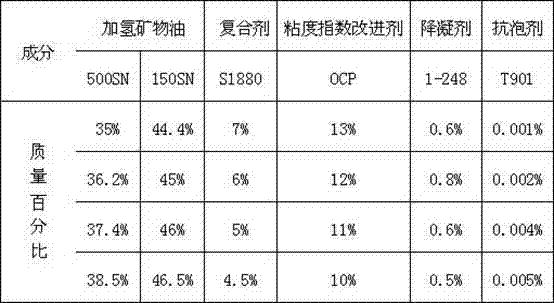

Formula as well as production technology of special lubricating oil for dual-fuel engine

InactiveCN104119992AGood antioxidant capacityGood lubricationLubricant compositionLubricationChemistry

The invention relates to a formula and a production technology of special lubricating oil for a dual-fuel engine. The lubricating oil is characterized by comprising base oil and an additive, wherein imported hydrogenated mineral base oil 500SN and 150SN are adopted as the base oil, the additive consists of a complexing agent S1880, a viscosity index improver OCP, a pour point depressant 1-248 and an anti-foaming agent T901, and the base oil and the additive are mixed according to a certain proportion. The lubricating oil is prepared by refining and blending hydrogenated base oil and special complex additives for imported dual fuels, and has better anti-oxidization capability and nitration resisting stability at higher temperature; the lubricating oil has protection and more excellent lubrication effects on parts difficult to lubricate, and can reduce the emission of harmful gas and generation of waste engine oil to purify the environment; the lubricating oil has excellent cleanliness and dispersion properties, and the generation of oil sludge and carbon deposit can be effectively inhibited, so that the engine can be cleaner, the oil is not easily aged, and the service life of the engine can be prolonged.

Owner:山东力牌石油化学有限公司

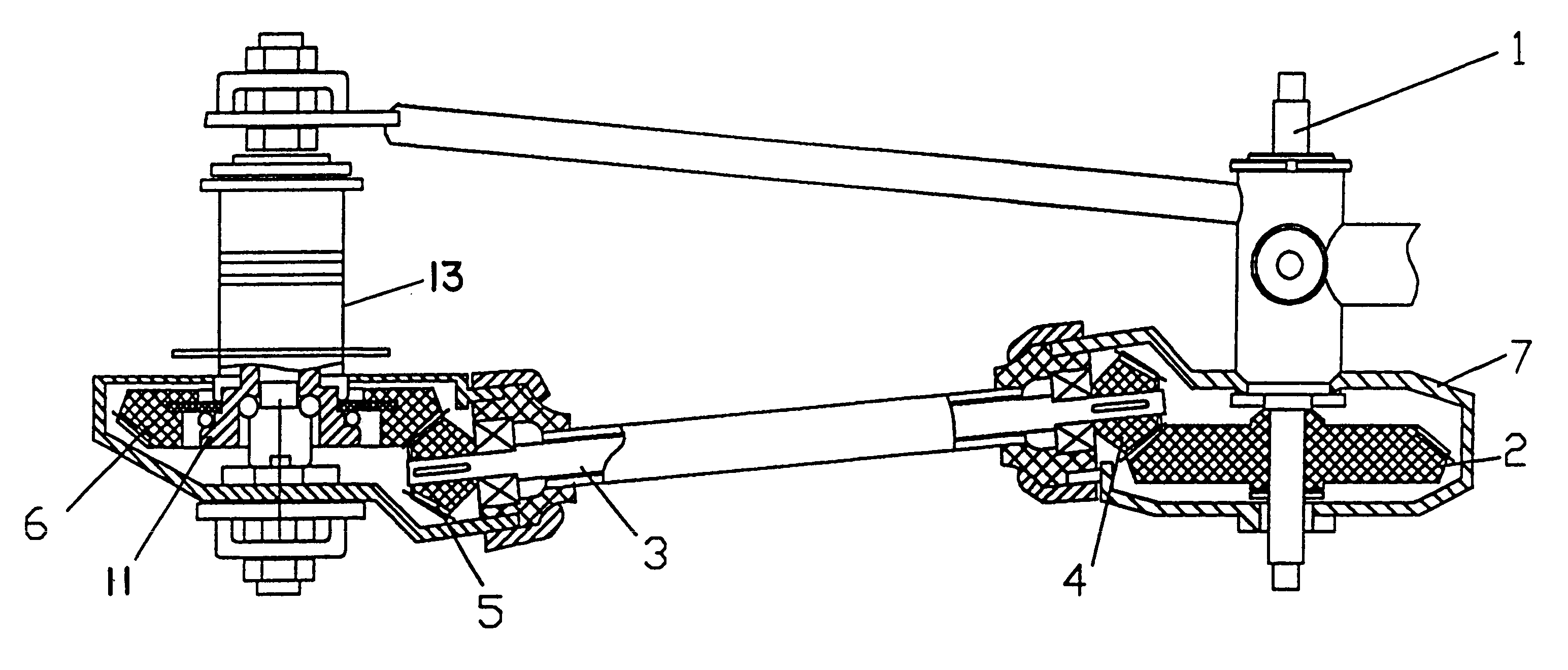

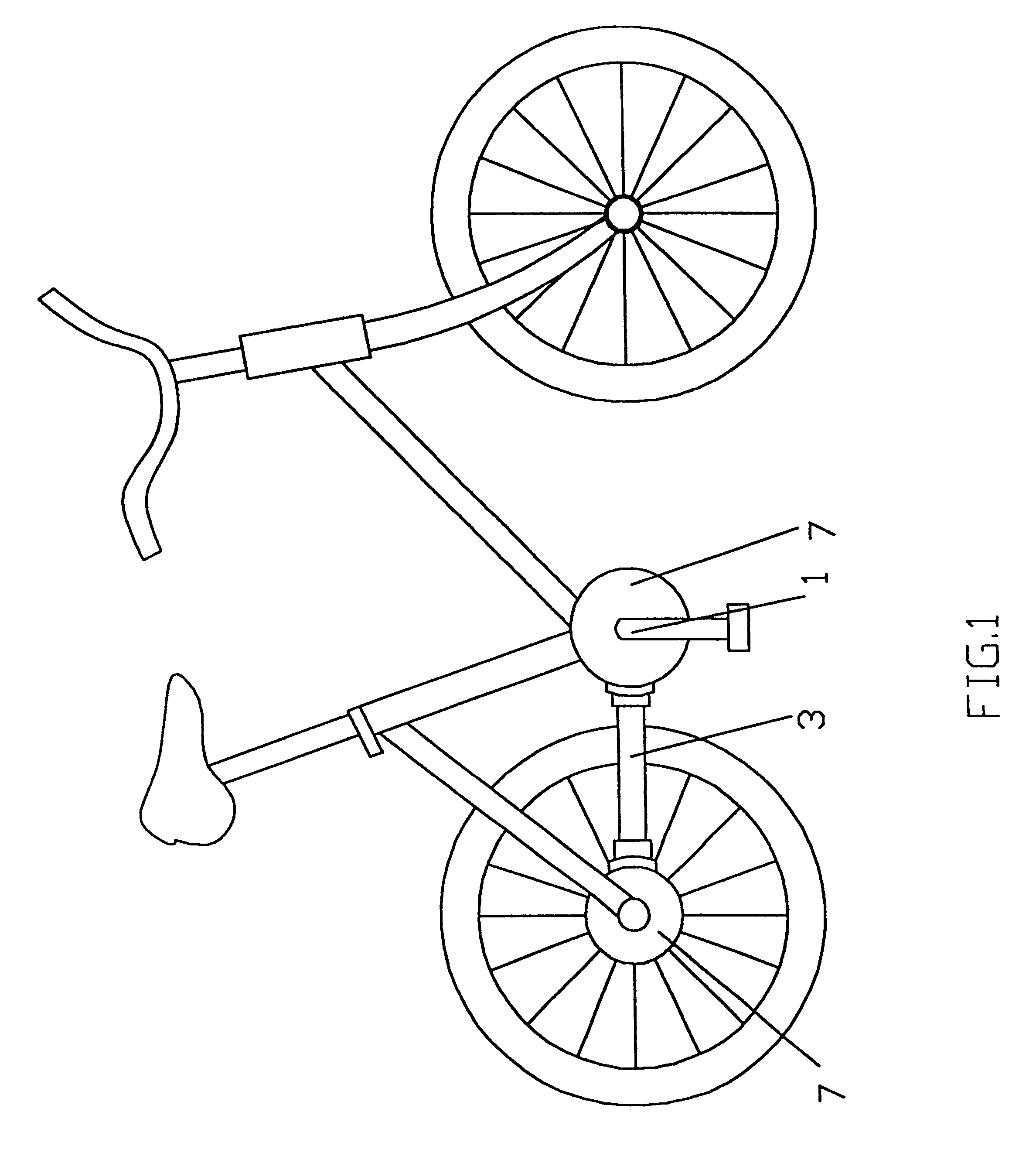

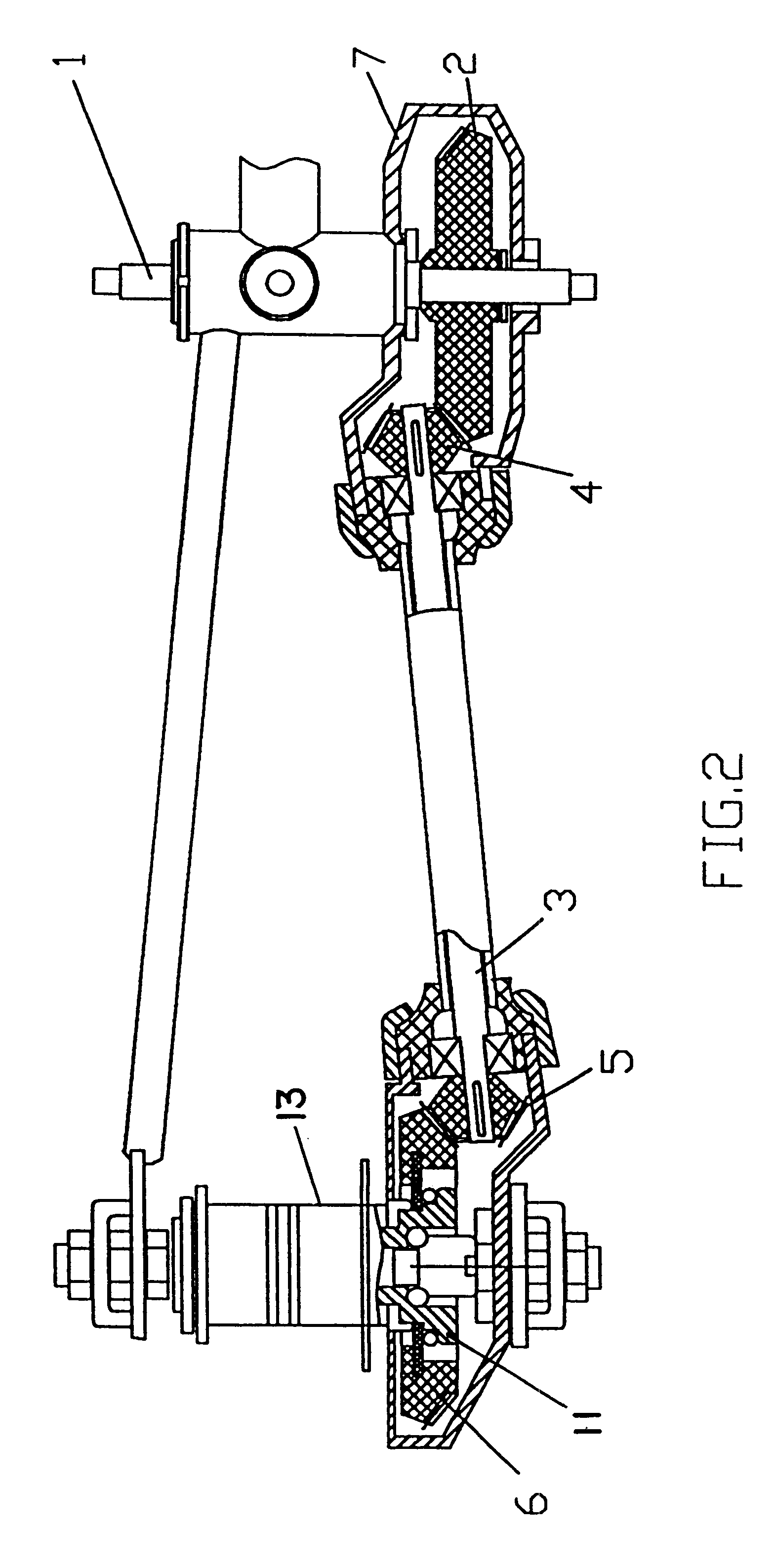

Bicycle with bevel gear drive for children

InactiveUS6446995B1Clean and safe for useEasy maintenanceWheel based transmissionChildren cyclesGear wheelEngineering

A children's bicycle with a bevel gear driving device that includes a pedal intermediate axle, characterized in that the pedal intermediate axle is connected with a drive bevel gear, which drives a connecting rod having bevel gears on both ends thereof, that the bevel gear on the other end of the connecting rod drives the rear wheel bevel gear, and that protecting hoods are provided over the driving bevel gear, the connecting rod with bevel gears, and the rear wheel bevel gear. The driving device avoids the problem of chain falling-off and allows safer use.

Owner:BAOLIN BICYCLE SHANGHAI

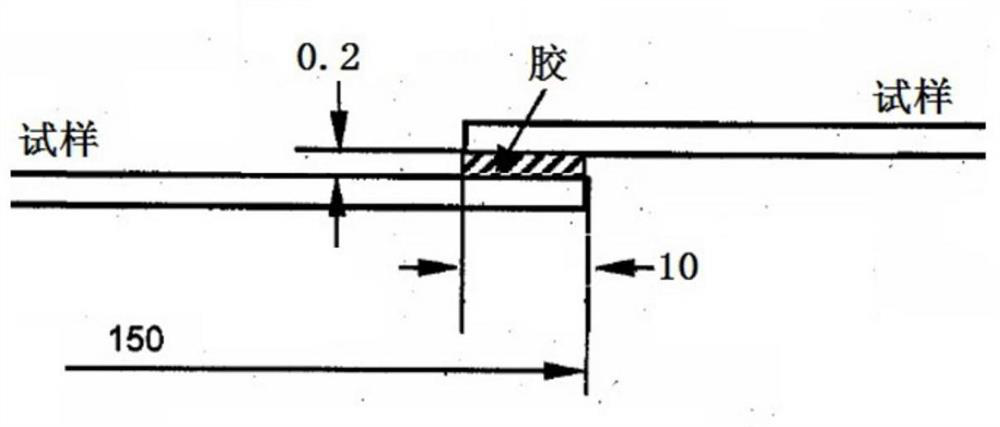

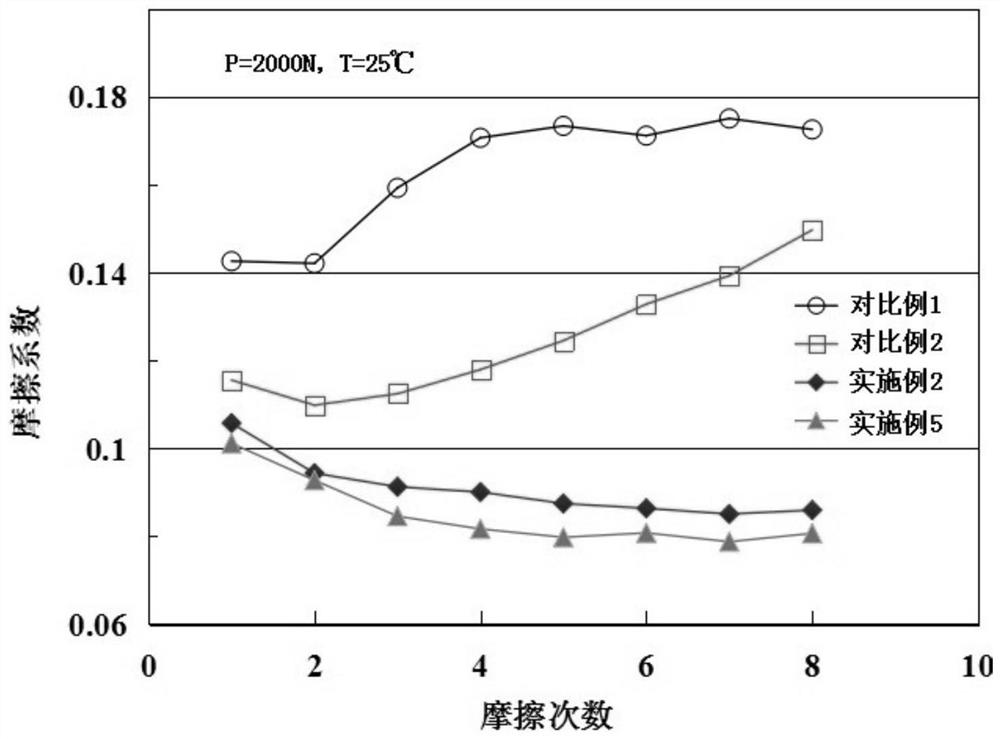

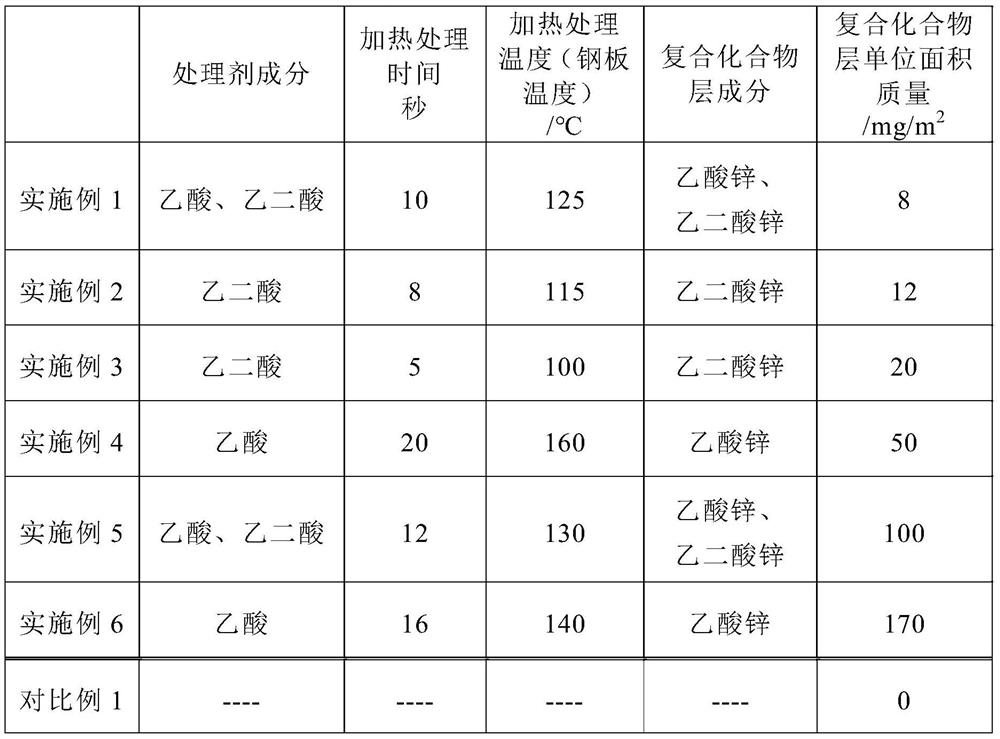

Lubricated hot-dip galvanized steel sheet with excellent viscidity and manufacturing method thereof

ActiveCN111748758AImprove liquidityImprove stamping formabilityHot-dipping/immersion processesLiquid surface applicatorsAdhesiveMachining

The invention discloses a lubricated hot-dip galvanized steel sheet with excellent viscidity and a manufacturing method thereof. The hot-dip galvanized steel sheet comprises a cold rolled steel sheet,and a hot-dip galvanized coating, a compound composite layer and an anti-rust oil film which are arranged on the surface of the cold roller steel sheet in sequence from bottom to top, wherein the hot-dip galvanized coating is prepared from the following components in percentage by mass: 0.1 to 0.4 percent of Al and the balance of Zn and unavoidable impurities. The hot-dip galvanized coating has the roughness value of 0.6 to 1.5 mu m. The compound composite layer mainly comprises one or two salts of zinc acetate and zinc oxadiate; the mass per unit area of the compound composite layer is 8 to170mg / m<2>; the weight of the anti-rust oil film is 0.1 to 3 g / m<2>. The cold rolled steel sheet is IF steel for stamping. According to the lubricated hot-dip galvanized steel sheet with excellent viscidity and the manufacturing method thereof, the hot-dip galvanized steel sheet has original performance of the steel sheet used for an automobile body, and also has good machining formability (good surface lubricity and stamping stability), and moreover, has excellent viscidity to the adhesive used for an automobile.

Owner:BAOSHAN IRON & STEEL CO LTD

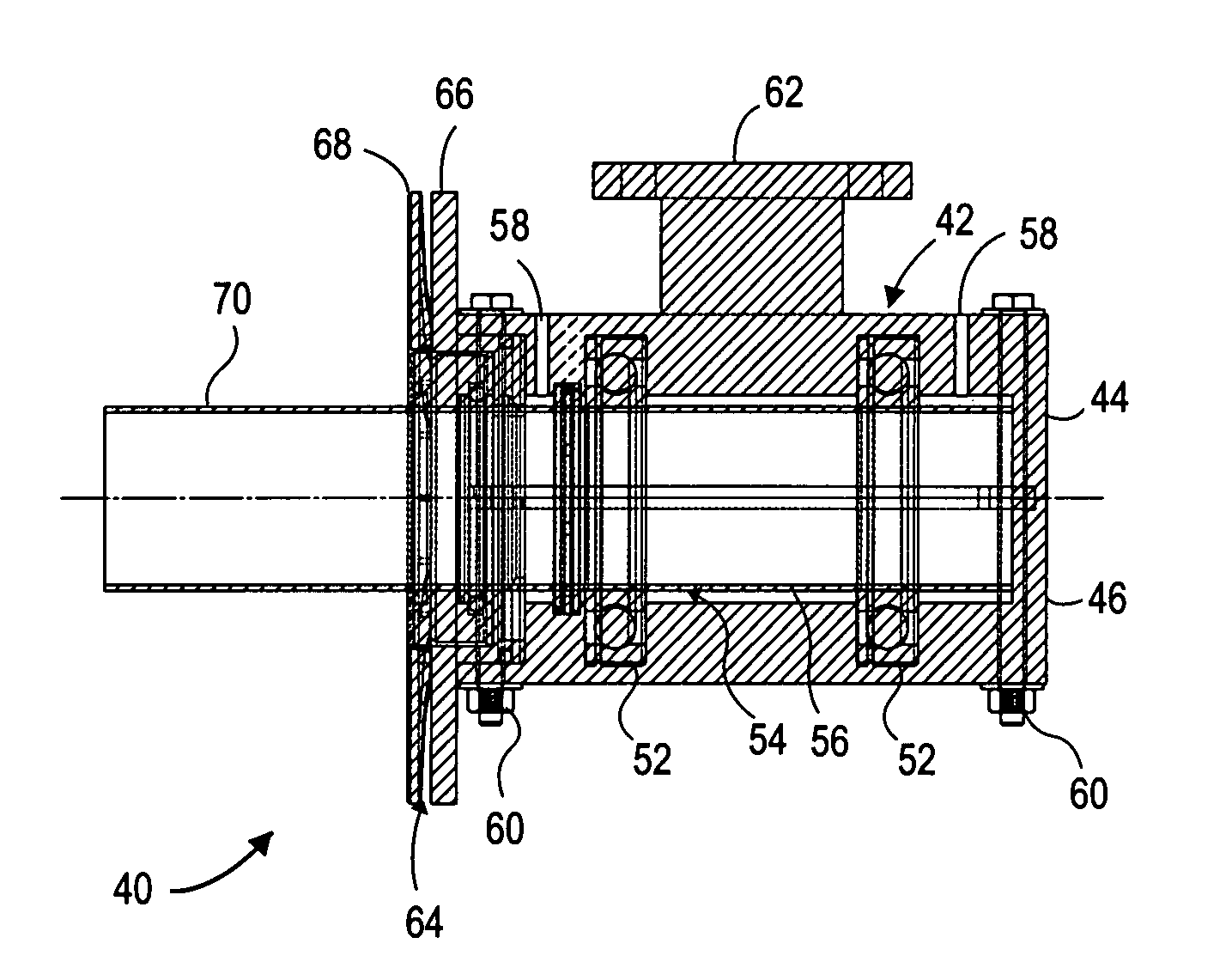

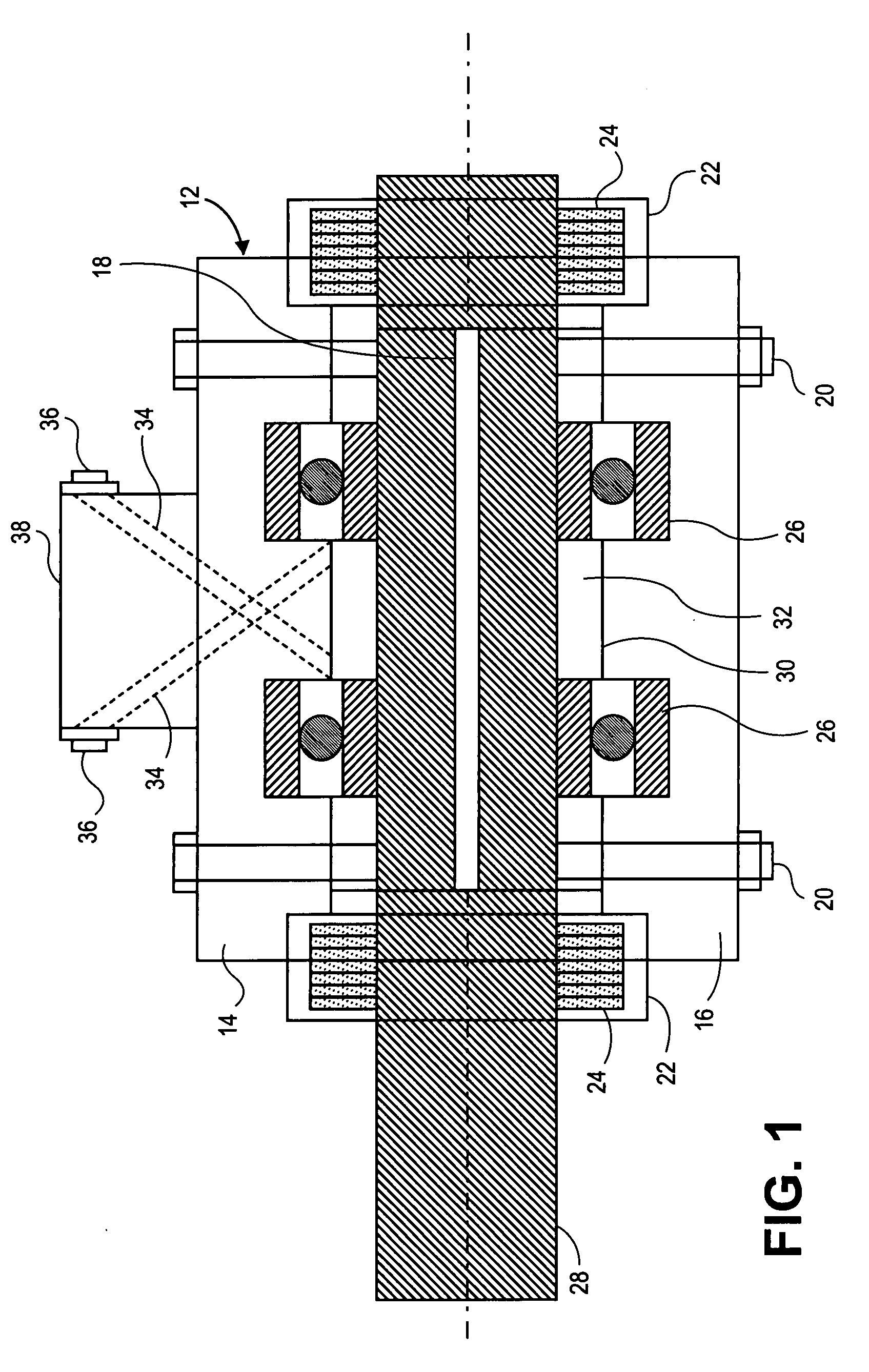

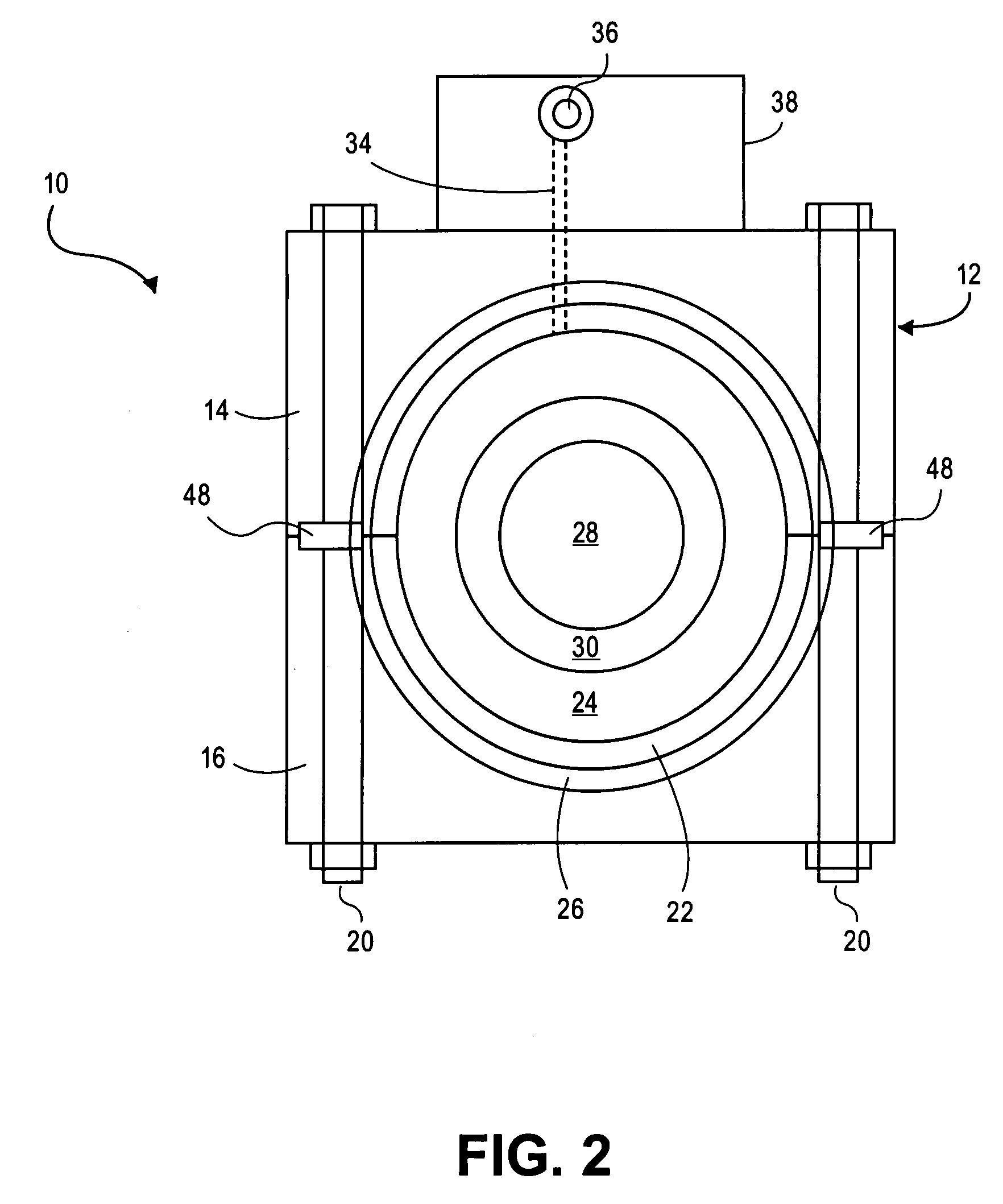

Pressurized bearing assembly

InactiveUS20080085071A1Good lubricationPrevent wearEngine sealsBearing componentsCorrosion resistantLubrication

A pressurized bearing assembly includes a pressurized housing having a bearing seal that protects bearings that are provided within the housing. The bearing seal may include a stator, a rotor, and a pressure bleed. The rotor may be provided with one or more fins. The housing may be pressurized with air and / or a lubricant. The housing may also include two or more portions separated by a housing seal. The housing may include a chamber for maintaining the air or lubricant. The lubricant may circulate through the housing via a closed-loop lubrication system. The housing may also be provided with an anti-wetting compound. The housing, stator, and rotor may be made from temperature and corrosion resistant material.

Owner:GARNCARZ JOHN HENRY

Electric wheel hub with wheel edge reduction gear

ActiveCN106828076ASimple structureImprove support stiffnessMotor depositionControl devicesReduction ratioPinion

The invention discloses an electric wheel hub with a wheel edge reduction gear. The electric wheel hub comprises a wheel hub main shaft, a wheel hub, a wheel hub motor and the wheel edge reduction gear, wherein the wheel hub is in running fit with the wheel hub main shaft; the wheel hub motor and the wheel edge reduction gear are arranged in the wheel hub; the wheel edge reduction gear comprises a center gear in running fit with the wheel hub main shaft, an inner gear ring and a plurality of duplicate gears; the inner gear ring is coaxially fixed to the wheel hub; the plurality of duplicate gears are distributed around the wheel hub main shaft; the center gear is used for distributing power output by the wheel hub motor to rack wheels of each duplicate gear; and a pinion of each duplicate gear is meshed with the inner gear ring. The fixed-shaft electric wheel hub is simple in structure, compact in component assembly, high in support stiffness, large in reduction ratio, high in power and relatively long in service life, and has a good lubricating function.

Owner:CHONGQING UNIV

Cutting fluid for cutting high-precision dies and preparation method thereof

A cutting fluid for cutting high-precision dies is prepared from the following raw materials in parts by weight: 20-24 parts of kerosene, 2-3 parts of span-80, 1-2 parts of benzotriazol, 10-12 parts of soybean oil, 1-2 parts of melamine, 1-2 parts of sodium sulfate, 1-2 parts of 1,3,5-tris(2-hydroxyethyl)cyanuric acid, 4-6 parts of urea, 6-8 parts of an auxiliary agent and 200 parts of water. The cutting fluid provided by the invention not only has excellent performances such as lubricity, cooling performance, wear resistance, rust resistance, sterilization performance and cleaning performance, but also has the performance of forming a film on the surface of a workpiece, and is applicable to processing of high-precision workpieces, the yield is high and the cutting speed is fast. By utilizing the cutting fluid to process a long-diameter Fresnel lens die, the surface quality of the die is uniform, the precision is high, the cost is low and no pollution exists.

Owner:MAANSHAN HENGYI MACHINERY MFG

A preparation method of a coaxial cable and a microwave absorbing inner sheath of a TTC radar for an aircraft

PendingCN109192387AImprove shielding effectImprove structural performanceCable conductor constructionCable insulation constructionCoaxial cableMicrowave

The invention discloses a preparation method of a coaxial cable and a microwave absorbing inner sheath of a TTC radar for an aircraft, comprising a conductor, an insulating layer, an aluminum-plasticcomposite tape shielding layer, an inner braided shielding layer, a braided lubricating layer, an outer braided shielding layer, an inner sheath and an outer sheath arranged in sequence from the inside to the outside; Multi-layer composite is adopted to refine the structure of the cable, and the shielding layer is divided into an inner braided shielding layer, a braided lubricating layer and an outer braided shielding layer according to the prior art, so that the structural performance and the shielding performance of the cable are greatly improved.

Owner:湖南华菱线缆股份有限公司

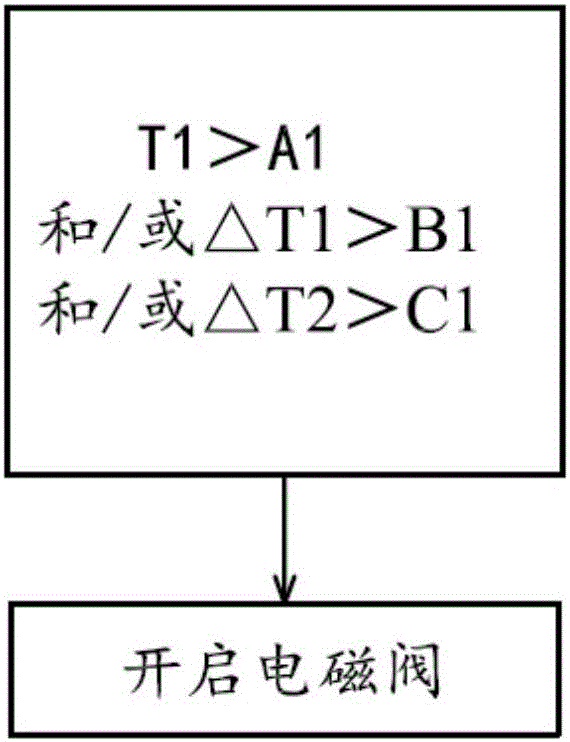

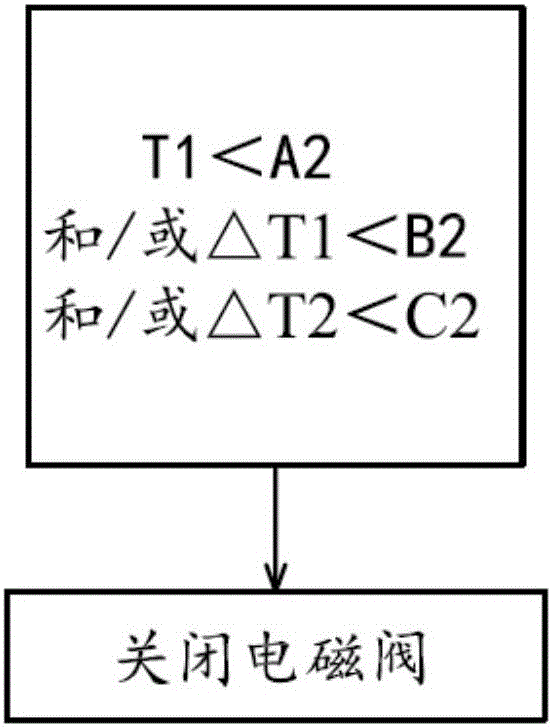

Control method and system of electromagnetic valve for air conditioner liquid injecting cooling and air conditioner

ActiveCN105928277AGood lubricationImprove reliability and service lifeRefrigeration safety arrangementRefrigerantLubrication

The invention provides a control method of an electromagnetic valve for air conditioner liquid injecting cooling. An air conditioner comprises a control unit and the electromagnetic valve used for controlling liquid refrigerants of a compressor of the air conditioner to be bypassed to the low-pressure side of the compressor. The control unit is used for controlling the electromagnetic valve to be opened and closed. The control unit controls the electromagnetic valve to be opened and closed according to the magnitude relation of the exhaust temperature T1 of the compressor and the exhaust temperature preset value and / or the magnitude relation of the exhaust superheat degree of the compressor of the control unit and the preset temperature value. The electromagnetic valve is controlled to be opened and closed by increasing the magnitude relation of the exhaust superheat degree and the preset temperature value. Thus, compressor oil has a good lubrication effect, the service life of the compressor is prolonged, and the reliability of the compressor is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

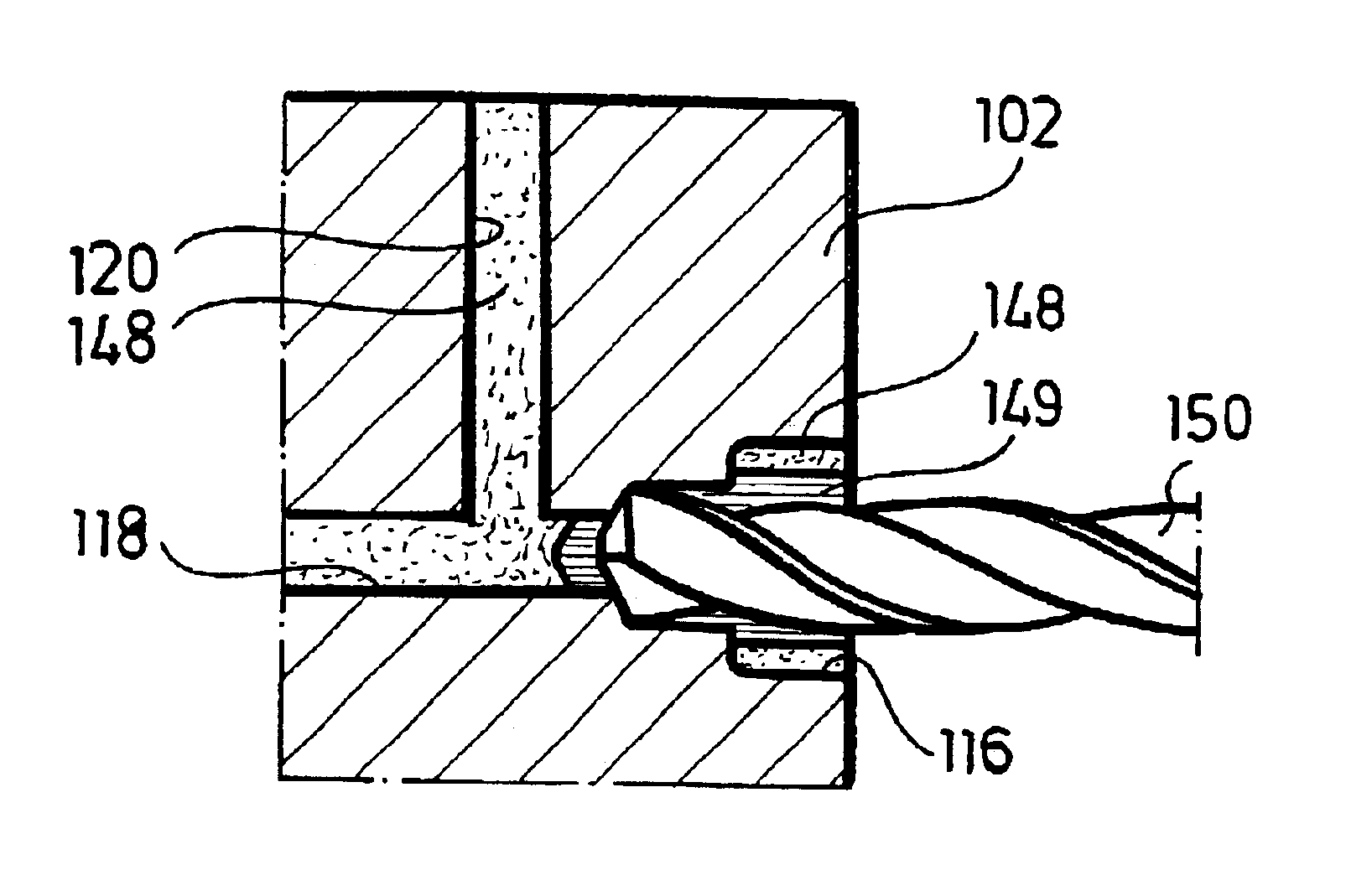

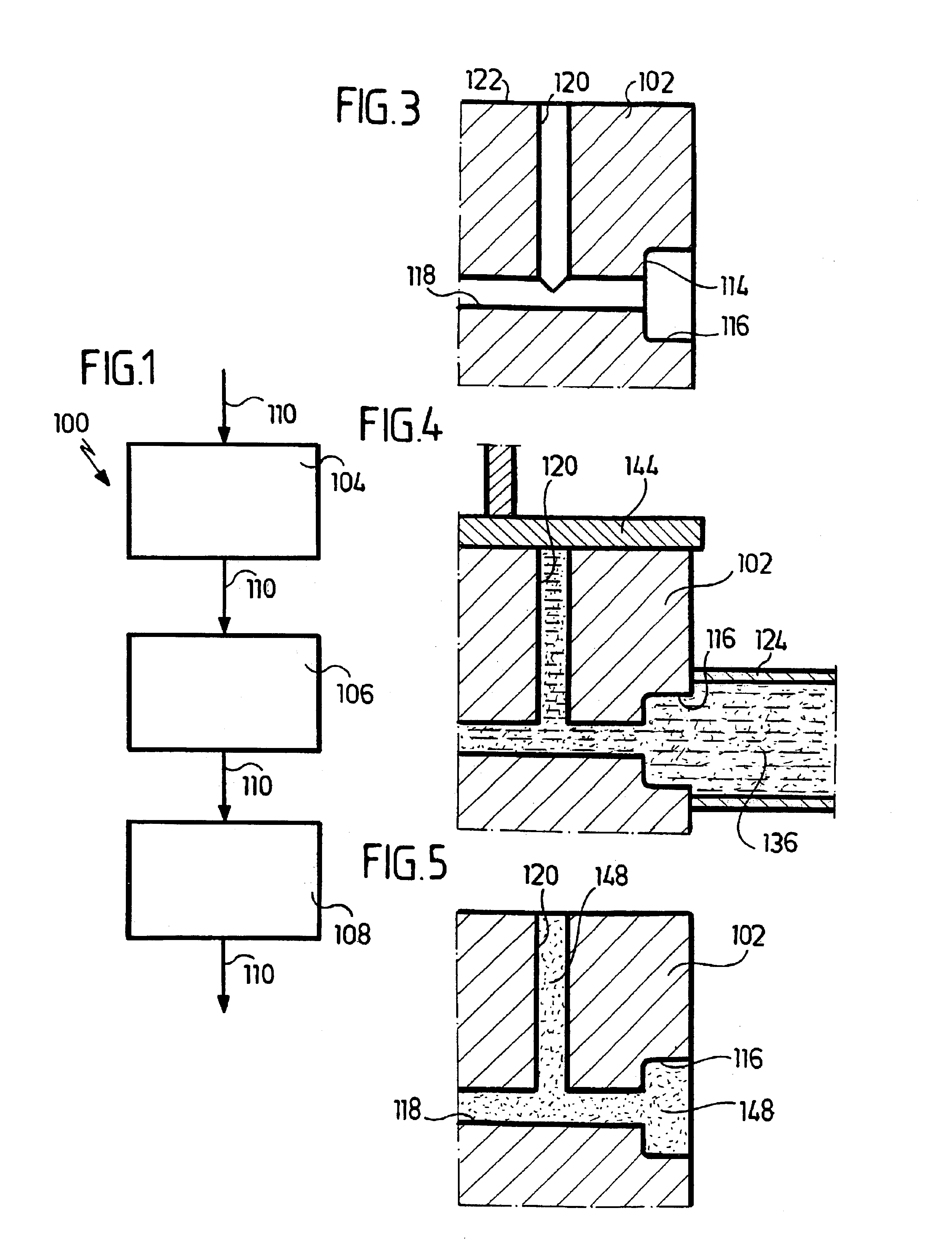

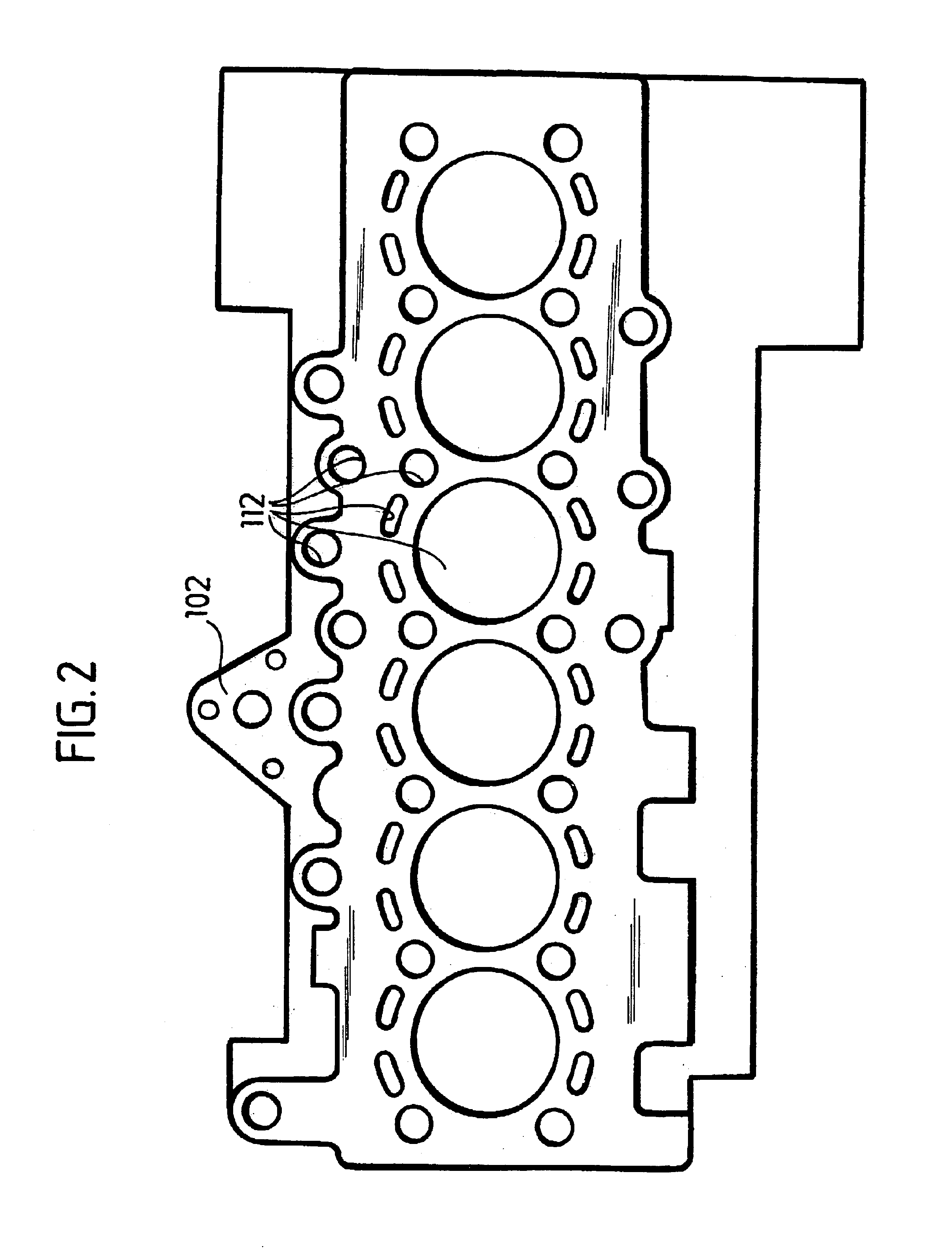

Method and apparatus for machining a workpiece, whereby chips are removed from the workpiece

InactiveUS6890131B2Good lubricationImprove the lubrication effectThread cutting feeding devicesTransportation and packagingLubricationSwarf

To provide a method for machining a workpiece, whereby chips are removed from the workpiece, wherein sufficient lubrication of the machining tool and sufficient cooling of the machining tool and the workpiece being machined are ensured, and chips resulting from the machining are simultaneously prevented from remaining inside recesses in the workpiece, a method comprising the following method steps is proposed:introducing a lubricant in a flowable state into at least one recess of the workpiece;solidifying the lubricant in the recess;machining the workpiece, whereby chips are removed from the workpiece, with at least one machining tool coming into direct contact with the lubricant and being lubricated by the lubricant;transforming the lubricant remaining in the recess of the workpiece into the flowable state and removing the lubricant from the workpiece.

Owner:DUERR ECOCLEAN GMBH

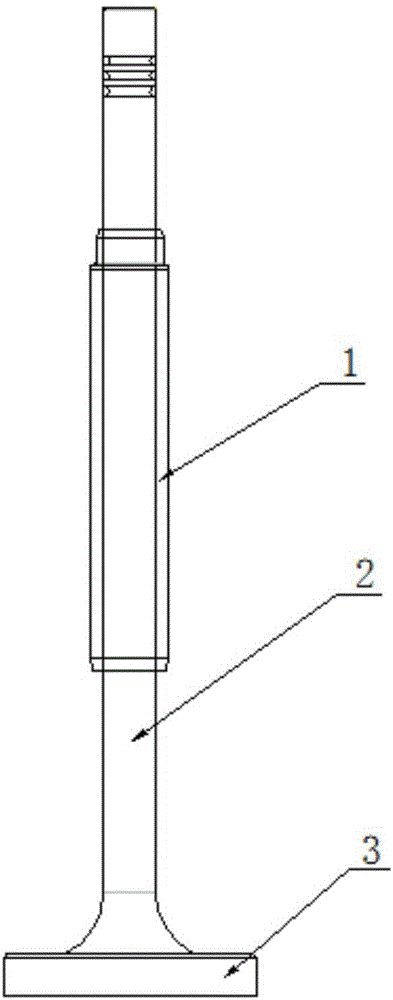

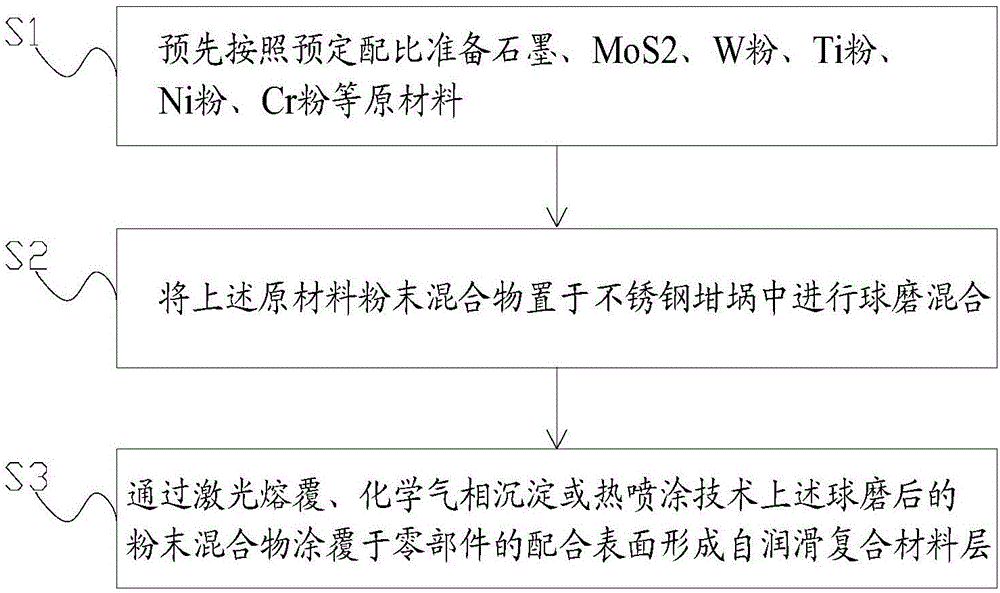

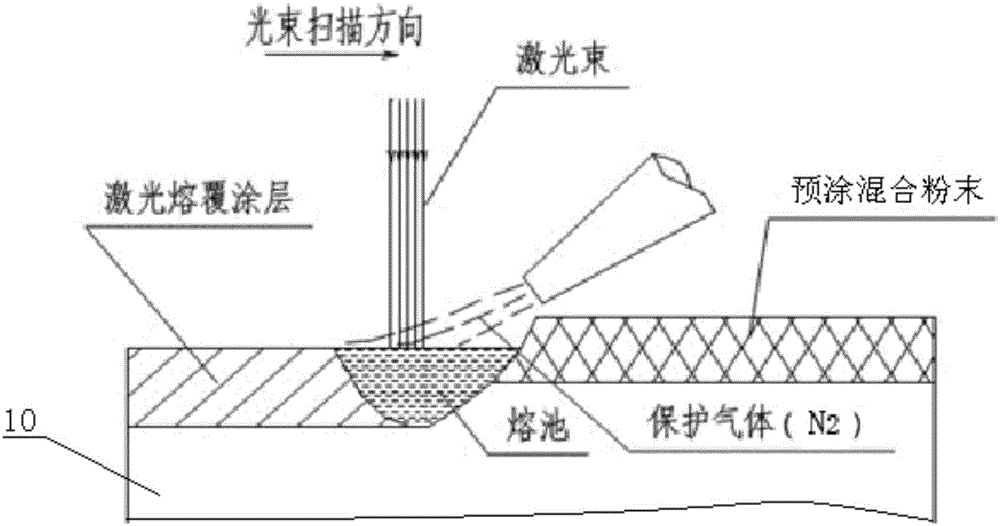

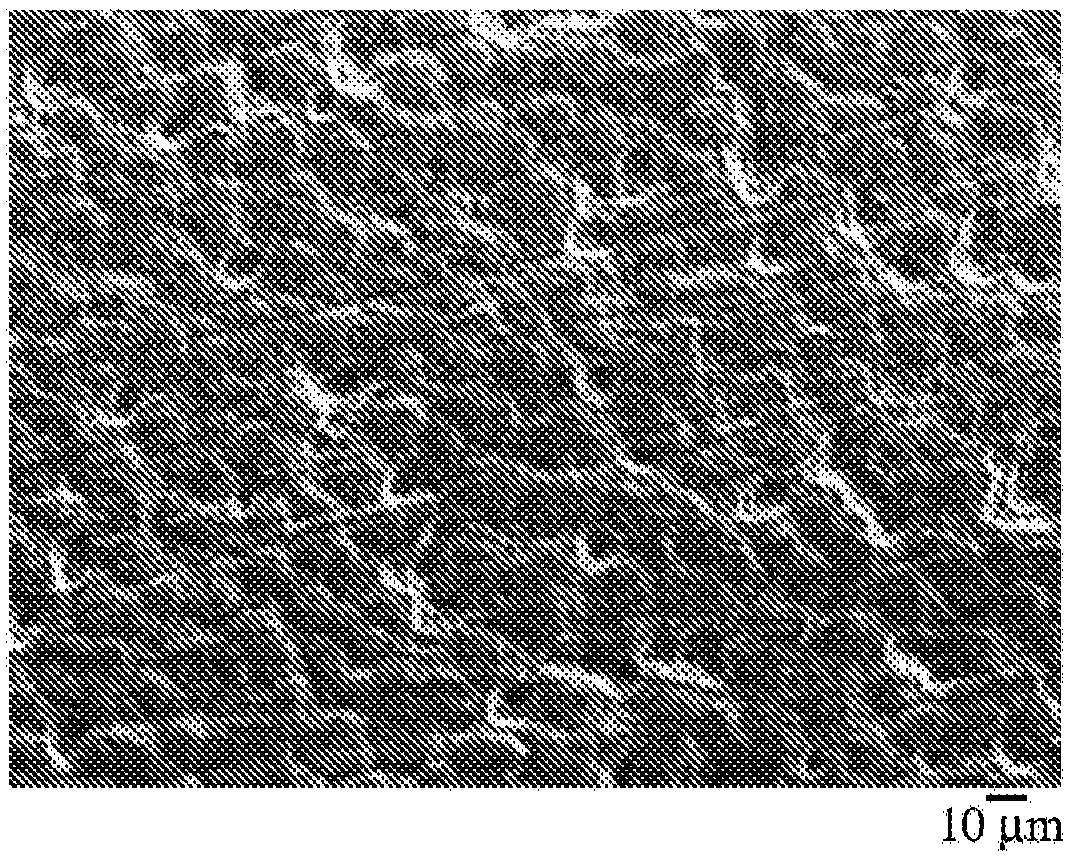

Self-lubricating composite material layer, preparation method and component with self-lubricating function

ActiveCN106191619AImprove wear resistanceImprove antioxidant capacityMolten spray coatingMachines/enginesMo elementInlet valve

The invention discloses a self-lubricating composite material layer, a preparation method and a component with a self-lubricating function. The self-lubricating composite material layer is prepared from, by mass, 5-20% of graphite powder, 5%-20% of MoS2, 3%-10% of W powder, 1%-5% of Ti powder, 40%-60% of Ni powder and 10%-15% of Cr powder. In the laser cladding process of the particle mixture, on the one hand, part of graphite reacts with W, Cr and Ti so that new phase carbide can be formed, and besides, through solution strengthening of the Mo element, the strength of a coating is improved; on the other hand, MoS2 and chrome generate sulfide of a high-temperature solid lubricating agent, and excellent lubricating performance is achieved at high temperature; and in addition, the residual simple substance graphite not involved in the reaction serves as an excellent room temperature solid lubricating agent. Thus, an intake valve has excellent abrasion resistance and oxidation resistance and further has excellent lubricating function at both high temperature and low temperature, and the lubricating condition of the intake valve is greatly improved.

Owner:WEICHAI POWER CO LTD

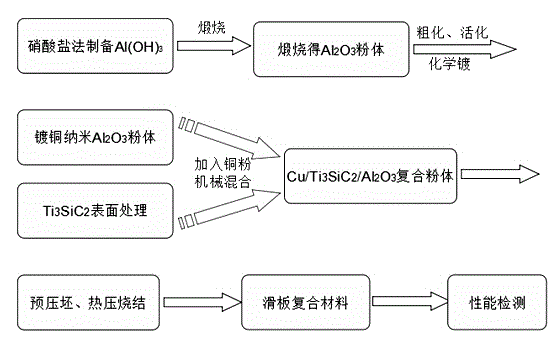

Ti3SiC2/Al2O3 hybrid reinforcing copper-based composite sliding plate material and preparation method thereof

ActiveCN104388741AGood lubricationExtend your lifeTransportation and packagingMetal-working apparatusPower gridPantograph

The invention discloses a Ti3SiC2 / Al2O3 hybrid reinforcing copper-based composite sliding plate material and a preparation method thereof. The copper-based composite sliding plate material is characterized by consisting of the following components in percentage by mass: 1-5% of nano Al2O3 powder, 20-40% of Ti3SiC2 powder and the balance of copper powder. By adopting the copper-based composite sliding plate material and the preparation method thereof, disclosed by the invention, the problems of formation of defects and pits and poor running reliability of a pantograph sliding plate and a contact power network which are prepared from a conventional pantograph sliding plate material and are short in service life and poor in impact resistance are solved; moreover, the problems of poor performance indexes of working stability, wear resistance and the like of the conventional pantograph sliding plate prepared from a copper-titanium silicon carbide composite material are solved.

Owner:安徽科益工业设计服务有限公司

Potato fully utilized noodles and preparation method thereof

The present invention discloses a preparation method of potato fully utilized noodles. The preparation method comprises the steps of peeling, beating, dough kneading, curing, tableting, noodle cutting, drying and cutting. The beating step is as follows: peeled potatoes are cut into small slices, the small slices are rapidly put into a beater to enable the small slices to be submerged in an aqueous phase or a slurry liquid, and the submerged small slices are beat under a heating condition to obtain a slurry at a temperature of 80-85 DEG C; the dough kneading is conducted by pouring the slurry, flour, and refine konjac flour proportionally into a dough kneading machine; and the time of the curing is 10-15 min more than the common curing time. The present invention also discloses the potato fully utilized noodles prepared by the method. The method can effectively prevent the potatoes from browning, increase the noodle ductility, reduce the noodle breaking rate, and better overcome the defects that potato full flour is poor in cohesiveness and the quality of the noodles is not easy to control. The prepared noodles are low in noodle breaking rate, low in costs, and high in nutritional value.

Owner:HUBEI UNIV OF TECH

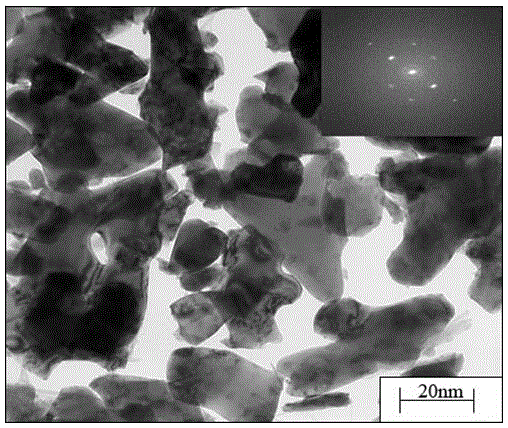

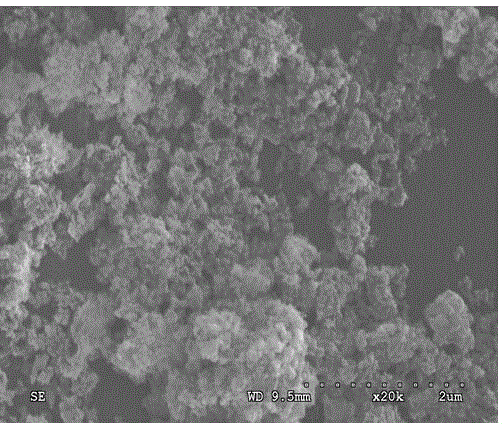

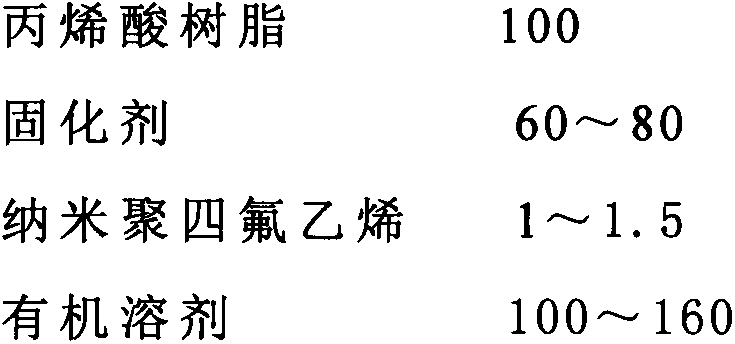

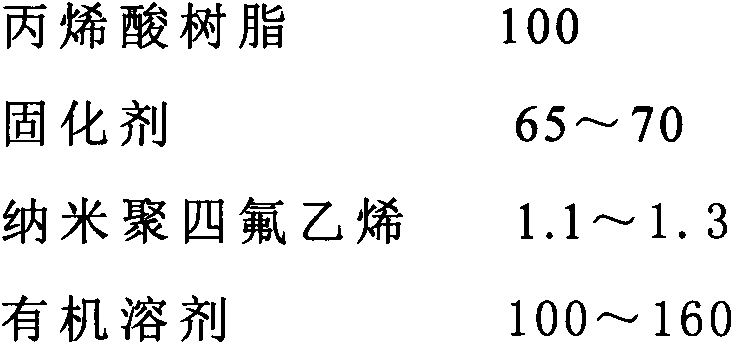

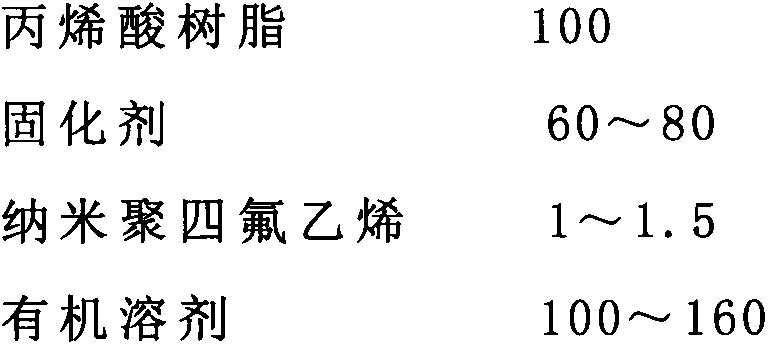

Acrylic resin paint composition

The invention discloses an acrylic resin composition which has excellent scratch resistance and friction resistance. Particularly, the scheme adds polytetrafluoroethylene, which has chemical resistance, heat resistance and applicability to occasions with high frictional property requirements, into the traditional acrylic resin paint in the form of nano dimensions, and obtains the acrylic resin paint, which has improved properties and is suitable for industrialization, without changing the original paint processing technique.

Owner:SUZHOU TAIZHENG CHEM TECH CO LTD

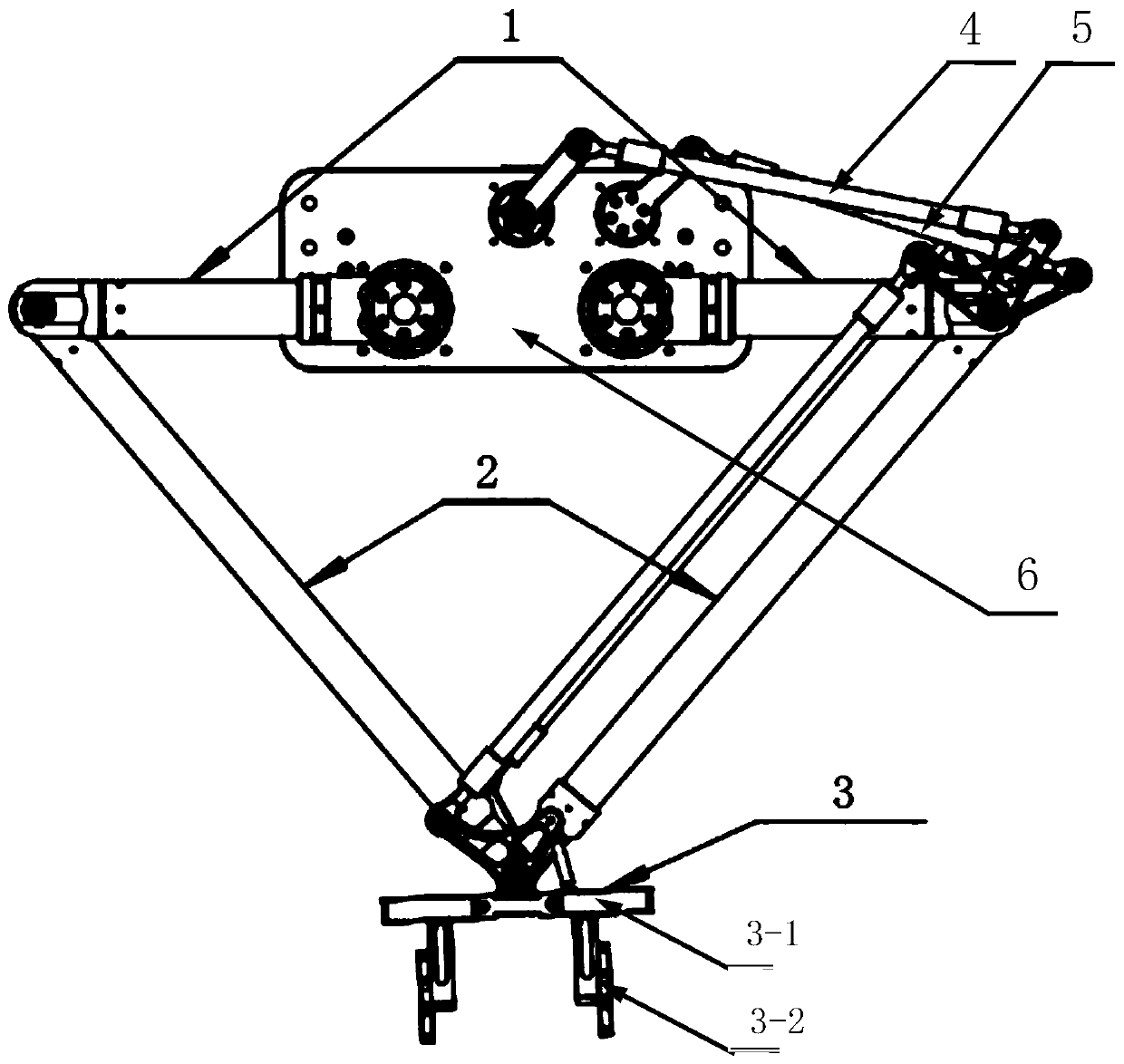

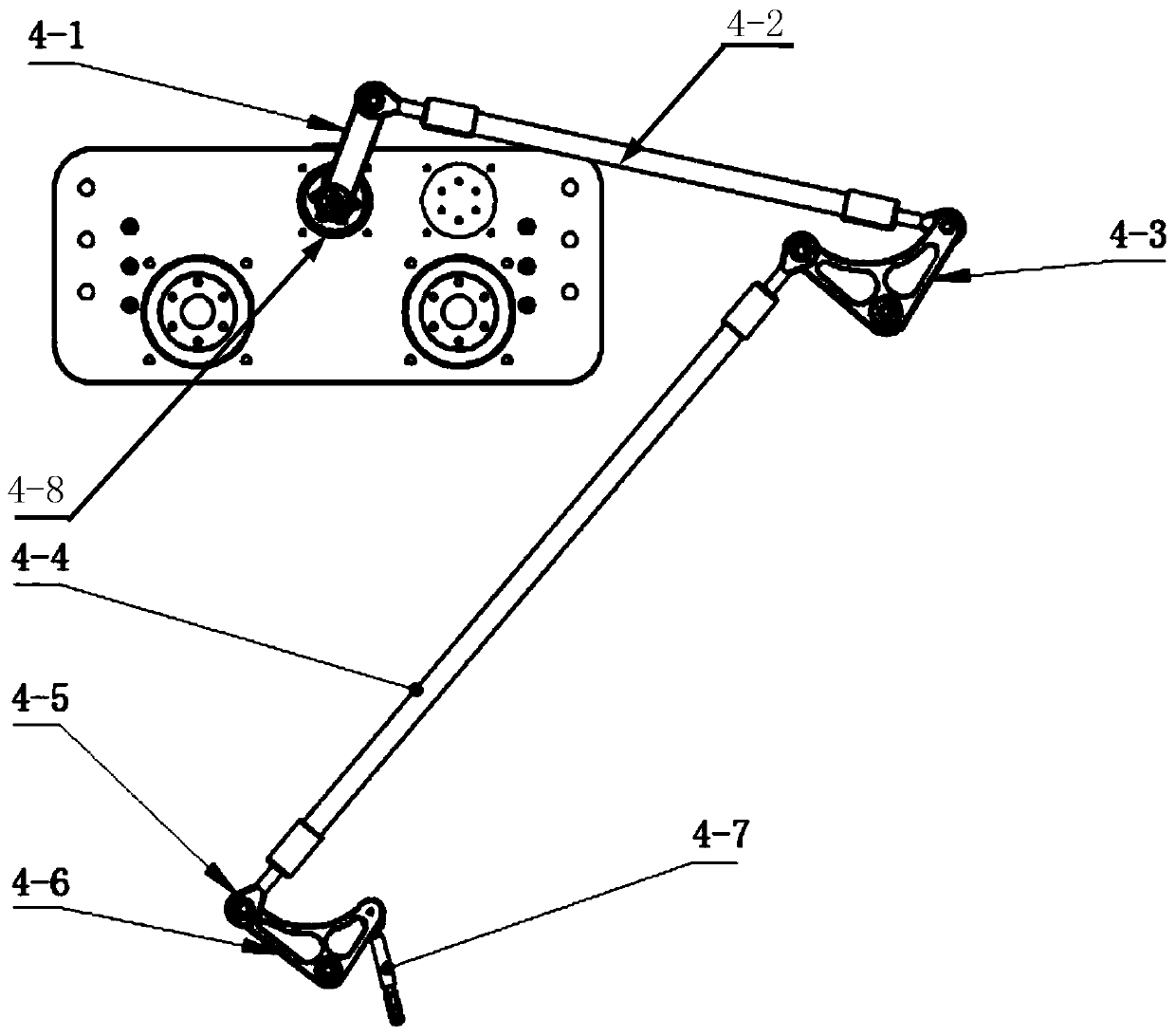

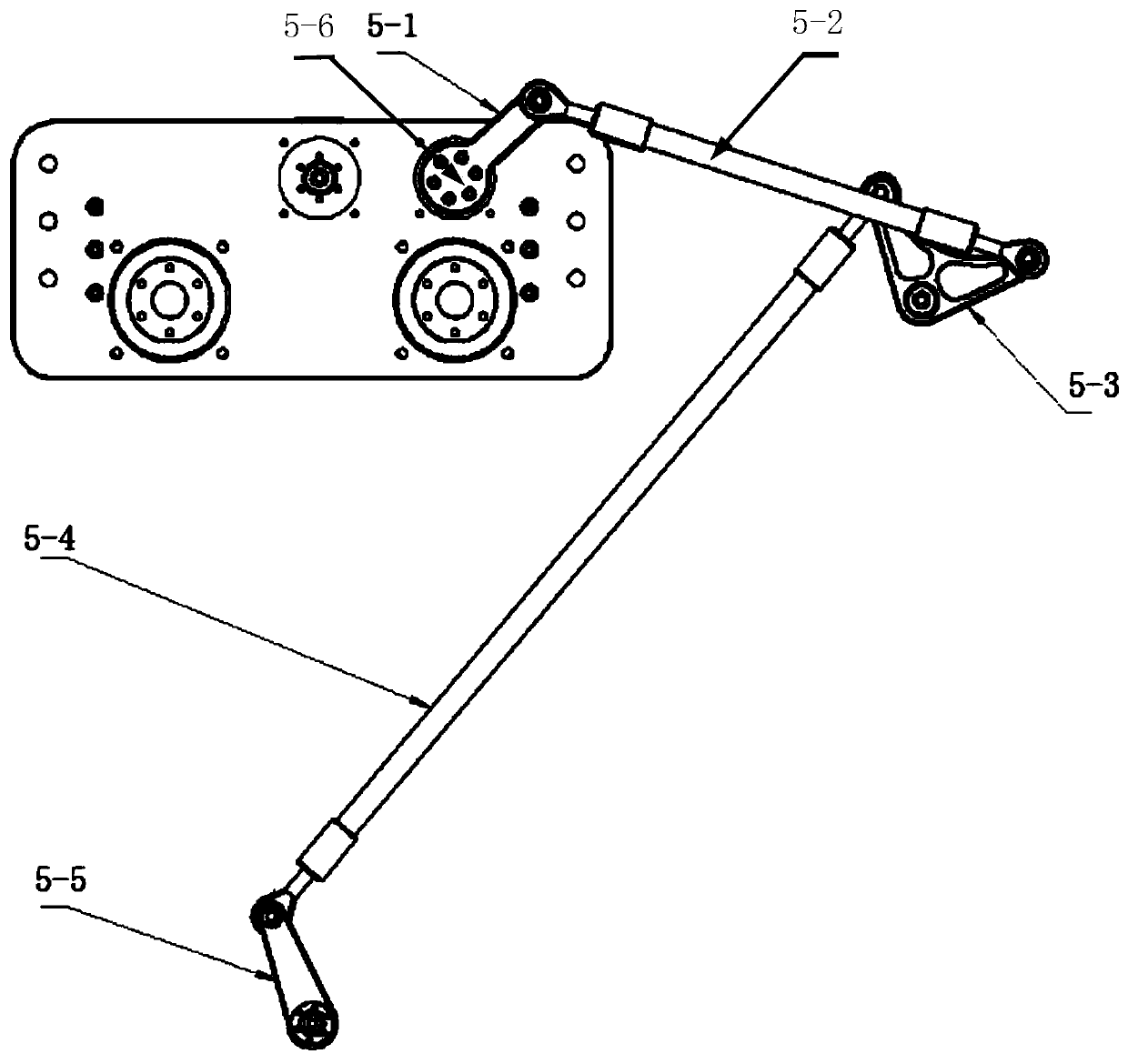

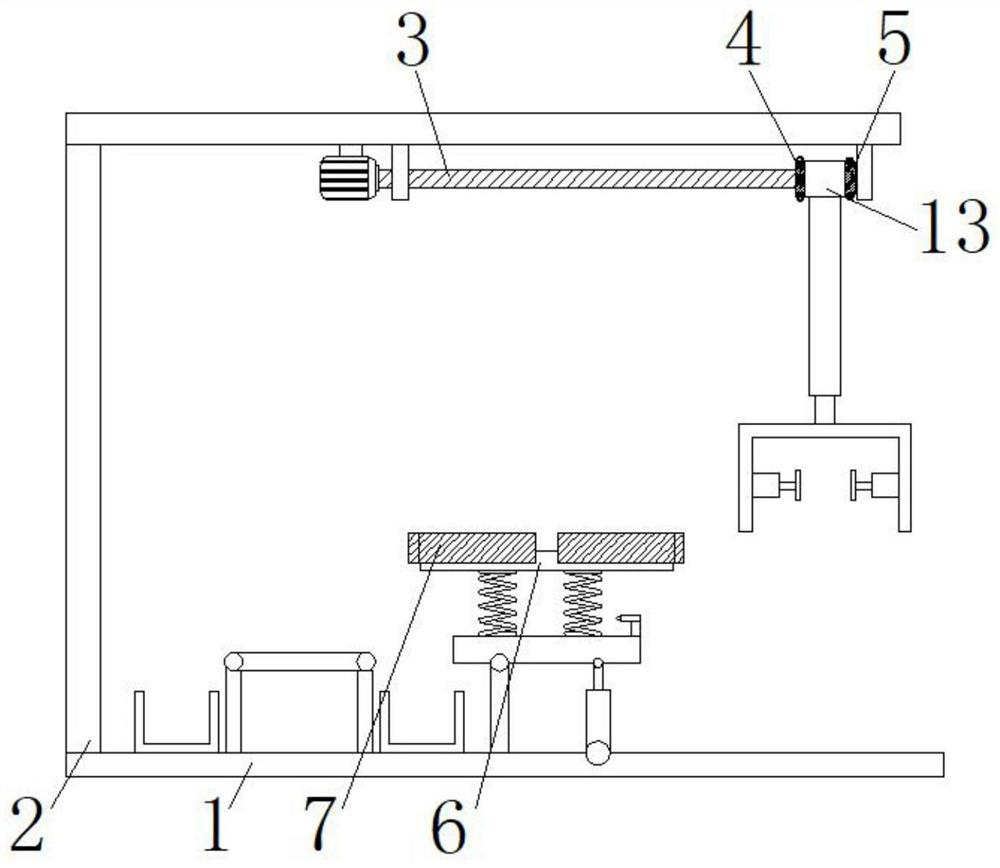

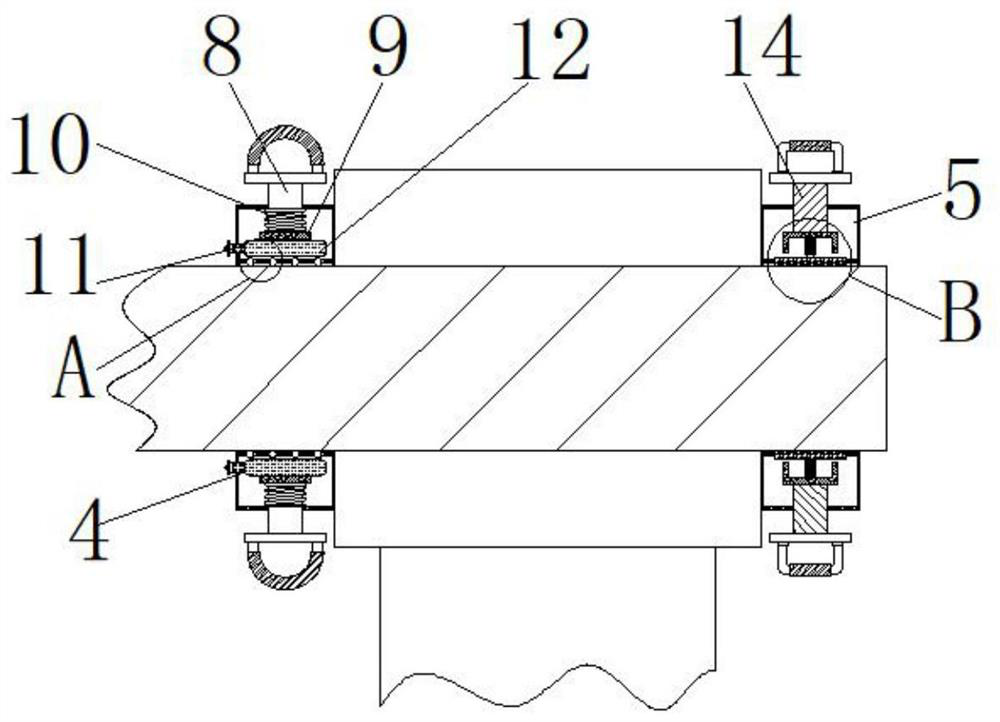

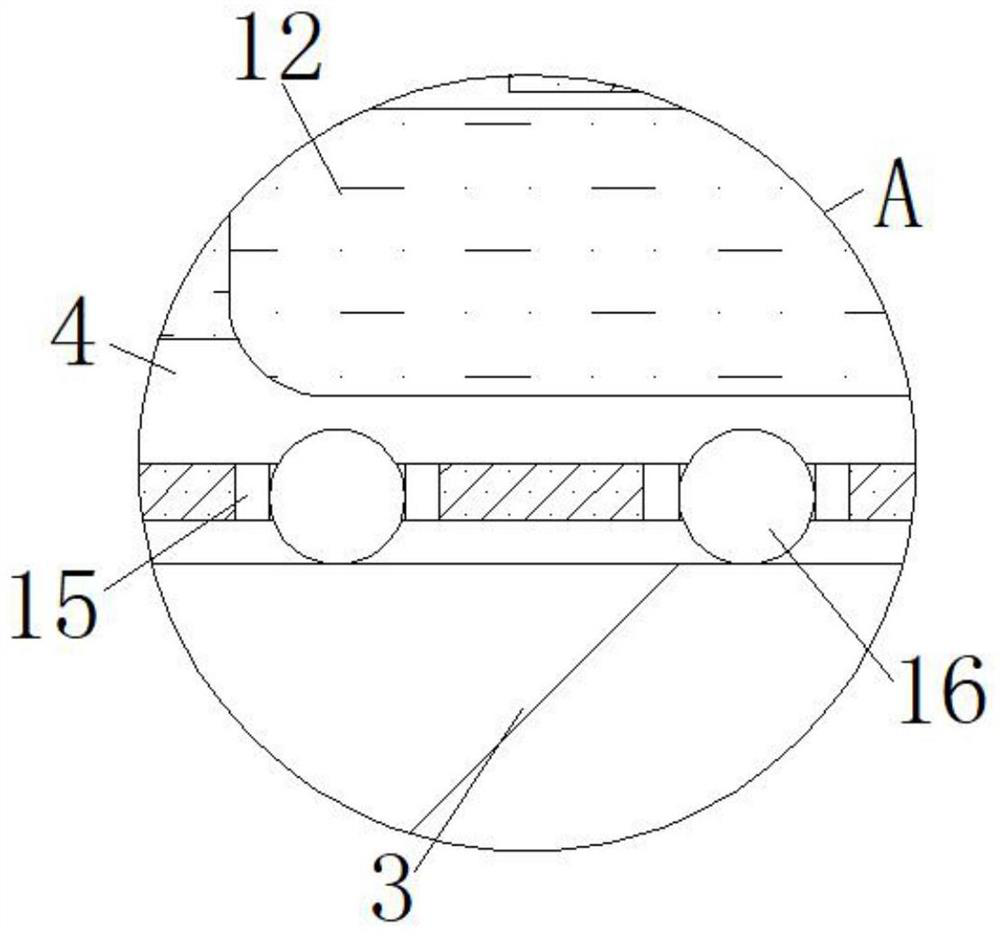

Two-shaft parallel turnover grabbing robot

PendingCN110524513AImprove carrying capacityGood lubricationProgramme-controlled manipulatorGripping headsDrive motorEngineering

The invention relates to a two-axis parallel turnover grabbing robot which comprises a supporting seat, driving arms, driven arms, an end effector and a driving motor, a pair of driving arms are installed on the supporting seat, and each driving arm is connected with one driven arm. The lower ends of the driven arms are jointly connected to the end effector, and the end effector comprises a movable platform and a clamping jaw. The robot is technically characterized by comprising a grabbing mechanism, wherein the grabbing mechanism comprises a grabbing motor, a grabbing connecting rod mechanismand a grabbing connecting rod, the grabbing motor is installed on the supporting base, and the grabbing motor drives the driving end of the grabbing connecting rod mechanism; the driven end of the grabbing connecting rod mechanism drives the grabbing connecting rod, and the grabbing connecting rod drives a clamping jaw of the end effector to grap or release. According to the invention, the problem that the robot moves in the third degree-of-freedom is fundamentally solved.

Owner:勃肯特(镇江)机器人技术有限公司

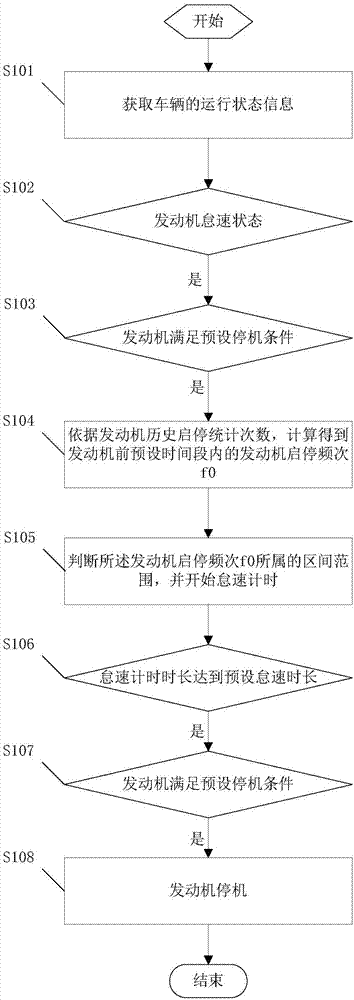

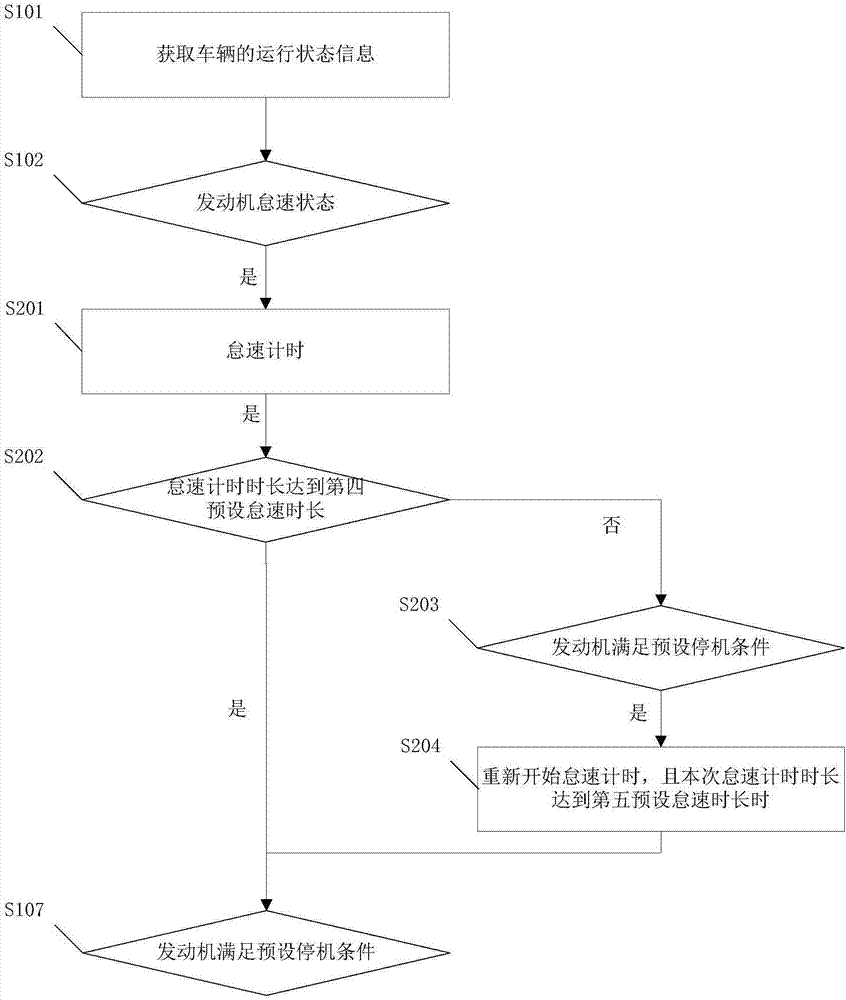

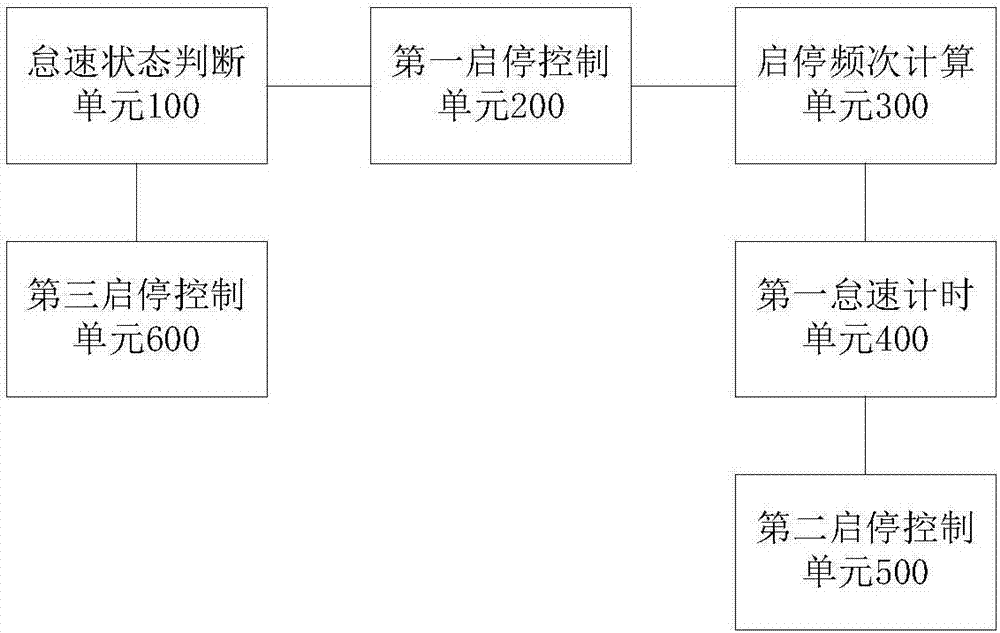

Engine idle speed control method and system

ActiveCN106907251AGood lubricationImprove the lubrication effectEngine controllersMachines/enginesLubricationTime duration

The invention provides an engine idle speed control method and system. The engine idle speed control method comprises the steps that when an engine is not in an idle speed state, whether the engine meets the shutdown condition or not is judged, and if the shutdown condition is met, the starting and stopping frequency f0 of the engine during the prior period delta T0 is calculated; the preset range of the starting and stopping frequency f0 of the engine is judged, and idle speed timing is started; and when the idle speed timing duration reaches the preset idle time corresponding to the preset frequency, whether the engine meets the shutdown condition or not is judged, and if the shutdown condition is met, the engine is stopped. Therefore, good lubrication of the engine and a supercharger is ensured, meanwhile, unrestrained frequent starting and stopping of the engine are limited, the service life of the engine is prolonged, and the problem that the economical efficiency of a vehicle is reduced due to frequent starting and stopping is solved.

Owner:WEICHAI POWER CO LTD

Preparation method for environmentally-friendly waterproof mercerized suede leather

ActiveCN109536649AGood light fastnessGood lubricationLeather impregnationChemistryEnvironmentally friendly

The invention discloses a preparation method for environmentally-friendly waterproof mercerized suede leather. The preparation method comprises the steps of sequentially carrying out the processes ofretanning, neutralizing, packed fat liquoring and the like. According to the preparation method, a novel environmentally-friendly material is adopted in the packed fat liquoring process and is subjected to step-by-step fat liquoring for preparation, the prepared environmentally-friendly mercerized waterproof suede leather has a good silk-like feeling and writing effect, the trimming rate of the finished leather is low, the utilization rate of the leather is high, a technical process adopts step-by-step fat liquoring, so that the material absorption is sufficient and complete, the waste discharge is reduced, and the environmental protection treatment difficulty is lowered.

Owner:FENGAN LEATHER

Hydroxyl magnesium silicate nanotube anti-wear material doped with organic silicon

InactiveCN109439388AImprove anti-wear and anti-friction performanceExtended service lifeAdditivesMicrometerMechanical equipment

The invention relates to the field of materials, in particular to a magnesium silicate nanotube anti-wear material doped with organic silicon. The material is prepared by doping an organic silicon material into a hydroxyl magnesium silicate nanotube according to the mass concentration of 1: 30-50 to form the hydroxyl magnesium silicate anti-wear nano material doped with the organic silicon, wherein the hydroxyl magnesium silicate nanotube is obtained by heating a magnesium compound containing magnesium element and a silicon compound containing silicon element in an alkali solution for reaction, and then centrifuging, washing and drying in sequence. The hydroxyl magnesium silicate nanotube anti-wear material doped with the organic silicon is in a nanotube shape, has a tube diameter of 15-55nanometers and a length of 100 nanometers to 5 micrometers, and has relatively regular products, uniform fineness and even dispersion. As an additive of lubricating oil, the anti-wear and anti-friction performance of lubricating oil can be greatly improved, the lubricating function is excellent, and the service life of mechanical equipment is prolonged.

Owner:科特龙环境科技江苏有限公司

Efficient sorting device based on logistics information scanning recognition

InactiveCN112013092AGood lubricationImprove work efficiencyGearingGear lubrication/coolingStructural engineeringManufacturing engineering

The invention discloses an efficient sorting device based on logistics information scanning recognition. The device comprises a bottom plate. A support is fixed to the top end of the bottom plate, a lead screw is rotationally arranged at the top end of the support, and a ball nut rotationally sleeves the outer wall of the lead screw in a connection mode. A fixing block fixedly sleeves the outer surface of the ball nut in a connection mode, and a lubricating sleeve and a cleaning sleeve are fixed to the surfaces of the two sides of the fixing block respectively. Two push rods symmetrically andmovably penetrate through the outer wall of the lubricating sleeve, the push rods extend into a cavity of the lubricating sleeve, and an extrusion plate is fixed to the tail end of each push rod. Extrusion springs are fixed at the joint of the extrusion plates and the cavity of the lubricating sleeve and surround the outer surfaces of the push rods. Due to the arranged lubricating sleeve, the surface of the lead screw can be conveniently, rapidly and efficiently lubricated; due to the arranged cleaning sleeve, the surface of the lead screw can be conveniently and rapidly cleaned; and due to arranged protective baffles, the protective baffles can be conveniently and rapidly installed and disassembled, and objects can be conveniently protected.

Owner:上海贵蓉国际物流有限公司

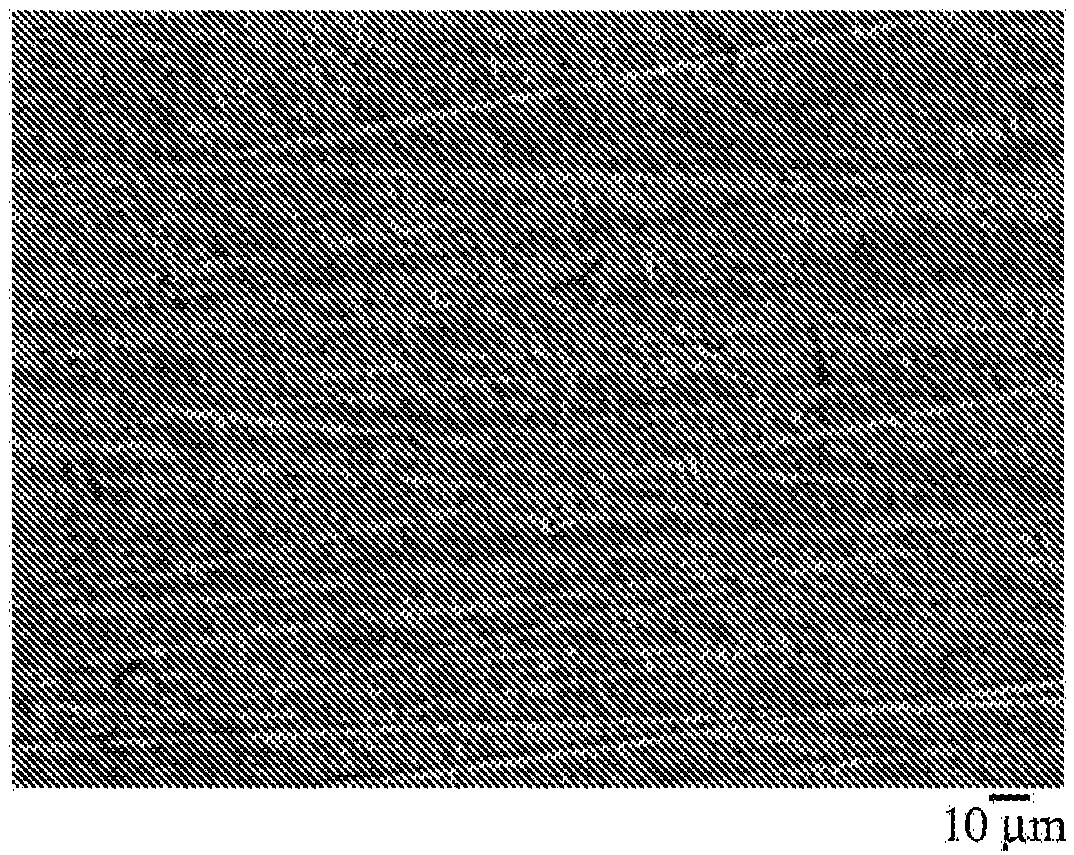

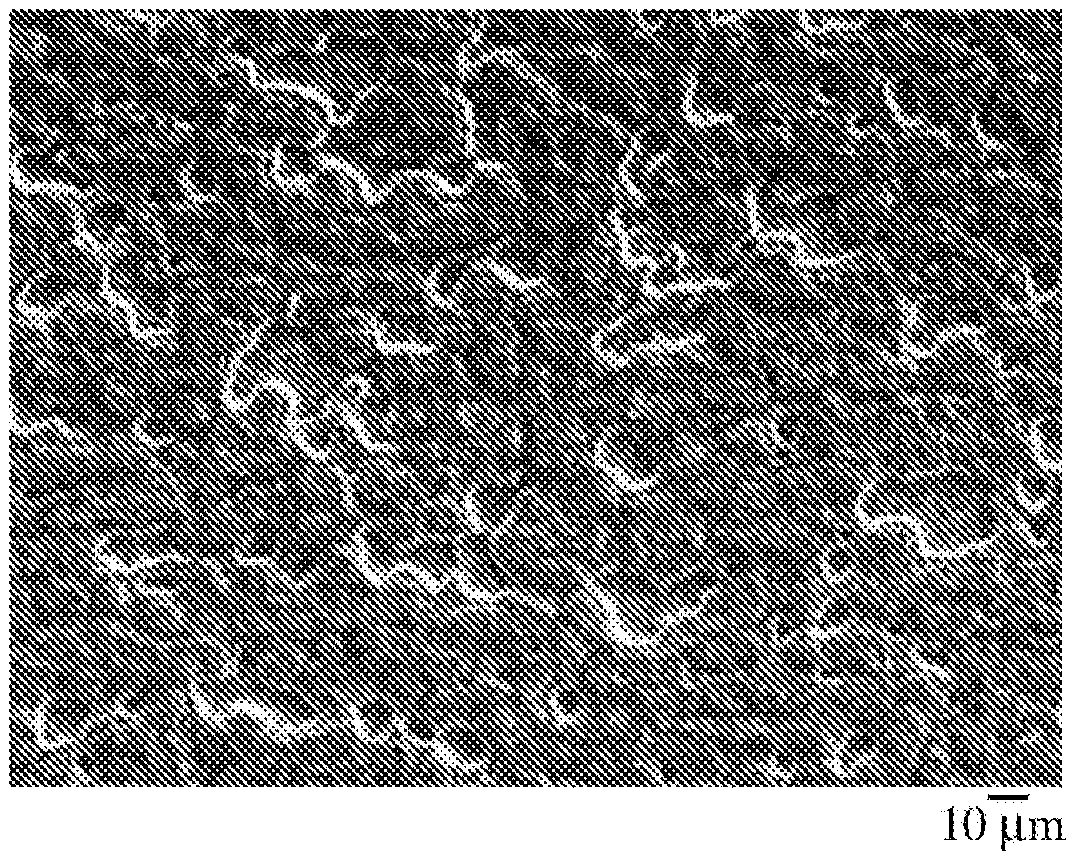

Piston ring and manufacturing method therefor

ActiveCN107636367AAvoid stickingImprove wear resistancePiston ringsCylinder headsPiston ringHigh pressure

The purpose of the present invention is to provide: a piston ring with which aluminum adhesion can be prevented over long periods even when used in a high temperature, high pressure environment and which exhibits excellent side surface abrasion resistance; and a manufacturing method therefor. By forming a nitride layer on the upper and / or lower side surface of the piston ring and then applying a phosphate chemical conversion treatment, the nitride layer is made to comprise granular and / or worm-shaped surface forms.

Owner:RIKEN CO LTD

Rust-proof lubricating oil

InactiveCN104031728AGood lubricationGood anti-rust functionLubricant compositionNano zinc oxideLubrication

The invention discloses rust-proof lubricating oil, belonging to the technical field of lubricating oil. The lubricating oil is prepared from the following raw materials in parts by weight: 10-15 parts of trimethylolpropane, 1-5 parts of sorbitan monooleate, 3-8 parts of monobutanimide, 0.5-0.8 part of nano zinc oxide, 2-4 parts of glycidyl acrylate, 0.5-0.8 part of alkenyl dibutyrate and 0.01-0.02 part of salicylate. The rust-proof lubricating oil provided by the invention has good lubrication and rust prevention effects.

Owner:柳州市汉森机械制造有限公司

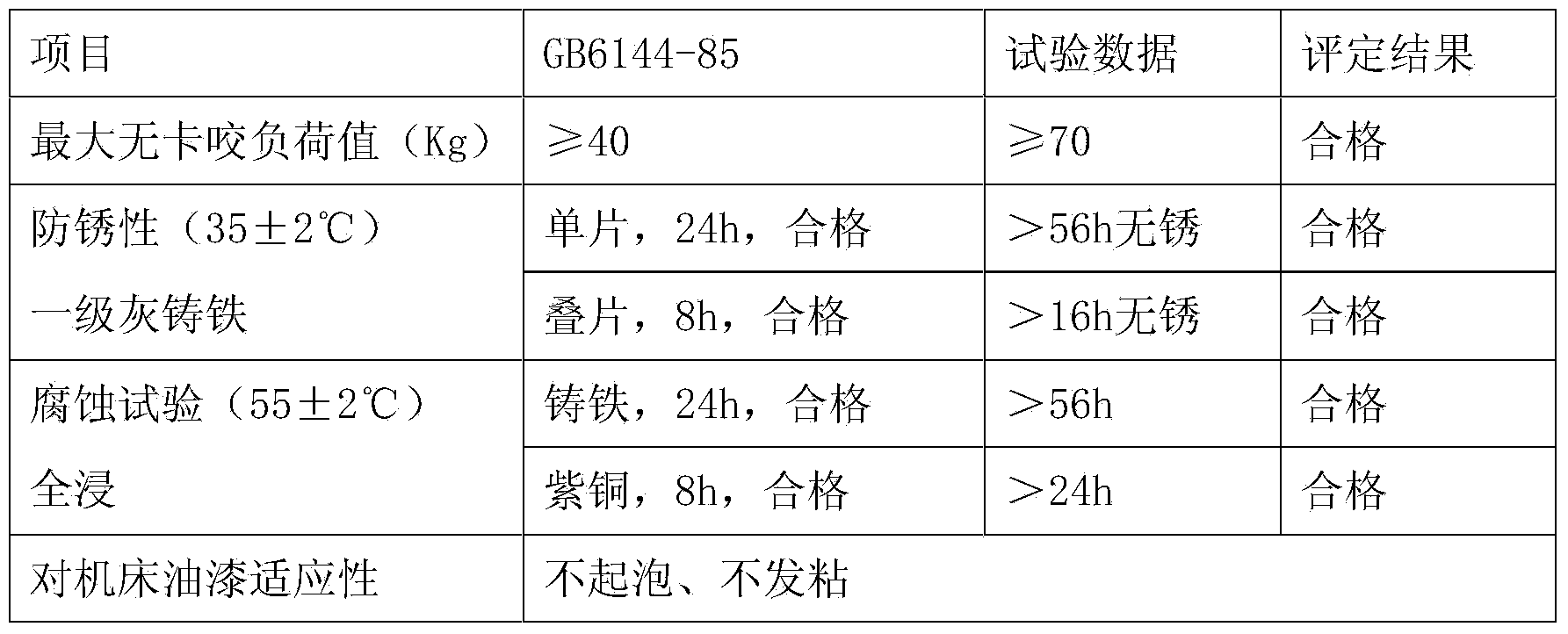

Lubrication cutting liquid

InactiveCN105985855AGood lubricationImprove lubrication and anti-rust performanceLubricant compositionLubricationPhenols

The invention discloses lubrication cutting liquid. The lubrication cutting liquid comprises, by mass, 33-35 parts of naphthenic base oil, 28-30 parts of tetramer castor-oil plant ester, 18-24 parts of sodium alkyl benzene sulfonate, 3-5 parts of alkyl phosphonic acid, 4-6 parts of tribasic carboxylic acid salt, 15-17 parts of oleamide, 7-9 parts of glycol, 23-25 parts of octaphenyl polyoxyethyiene, 6-8 parts of dicarboximide, 2-4 parts of polydimethylsiloxane and 60-68 parts of water. The invention further discloses a preparing method of the lubrication cutting liquid. According to the lubrication cutting liquid, a nontoxic and pungent-smell-free addition agent is adopted, the skin of the human body is not damaged, use is convenient, and operation is safe; the poor influence such as bubbling, cracking and falling of machine-tool oil paint can not be caused; the stability of product storage is good, and the service life is long.

Owner:全椒县兴盛化工厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com