Patents

Literature

73results about How to "Good anti-rust function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous rust-conversion rust-inhibiting primer

The invention relates to a water-based rust conversion antirust primer which is characterized in that: the primer comprises the following components with the corresponding percentage by weight : main conversion agent 5-35, auxiliary conversion agents 2-15, film forming material 40-55, penetrant 0.2-1.0, humectant 1-10, anti-forming agent 0.1-0.5, corrosion inhibitor 0.2-0.5 and solvent 0.5-8; the process is as follows: adding deionized water to a charging basket and heating the water to 60-80 DEG C with aliphatic alcohol polyethenoxy ether added, adding propylene glycol and starting a high-speed dispersion machine for agitation, later on adding tributyl phosphate, potassium sorbate, tannic acid and one of the auxiliary conversion agents and cooling down to 20-33 DEG C after agitating for 30-55 minutes, and adding vinyl chloride-modified acrylic resin latex and discharging material after agitating for 10-20 minutes. The invention has the advantages of direct application to steel surfaces with rust, thorough conversion of rust, excellent adhesive force of a conversion film, good flexibility, adaptation to various forms, and good compatibility with various top coatings.

Owner:安泰能(上海)高分子材料有限公司

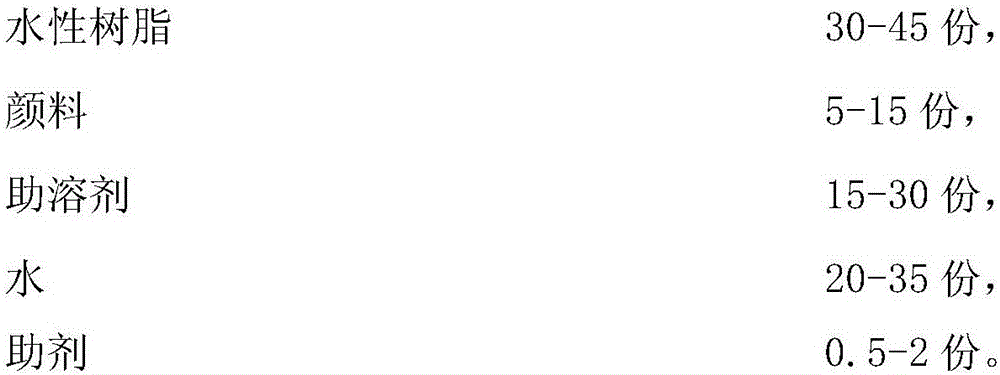

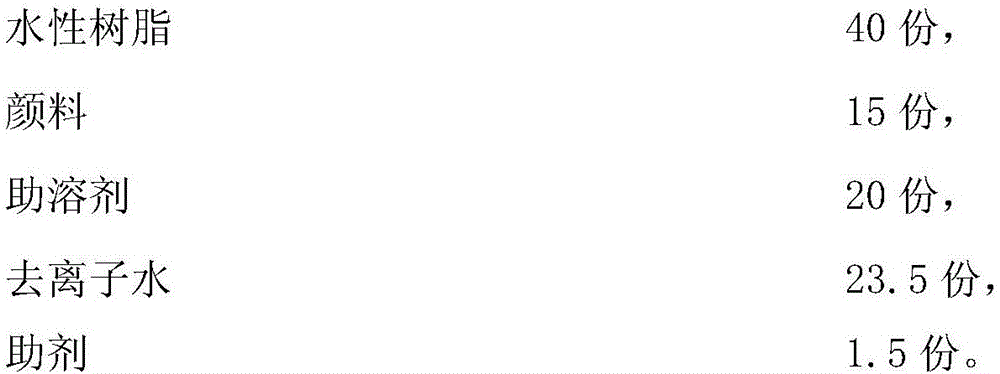

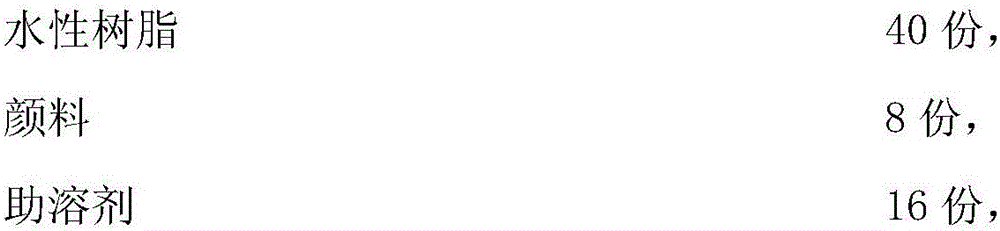

Environmentally-friendly aqueous spray paint and preparation method thereof

InactiveCN105907201AImprove atomization effectHigh ejection ratePolyurea/polyurethane coatingsEnvironmental resistanceHardness

The invention provides an environmentally-friendly aqueous spray paint liquid, a propellent, an aerosol coated environmentally-friendly aqueous spray paint and a preparation method of the paint. The liquid comprises, by weight, 30-45 parts of aqueous resin, 5-15 parts of a pigment, 15-30 parts of a cosolvent, 20-35 parts of water and 0.5-2 parts of an assistant. The environmentally-friendly aqueous spray paint liquid adopts an aqueous resin system, so a whole paint film has a good hydrophobic and oleophobic effect, and improvement of the quality of spray paint products is facilitated; water is used to substitute parts of a solvent, so the VOC is reduced, and environmental protection is realized; and the produced environmentally-friendly aqueous spray paint has good sprayability and a high spray rate, and a film formed by the paint has high fullness, excellent hardness, adhesion, glossiness, flexibility and impact resistance, and has abundant and gorgeous colors, excellent decorative effect, good ageing resistance, and extremely good antirust and protection functions.

Owner:中山市润宜汽车用品有限公司

Metal surface rust protection solution

InactiveCN102994995AGood anti-rust functionImprove bindingMetallic material coating processesLiquid wasteSodium phosphates

Owner:杨恒春

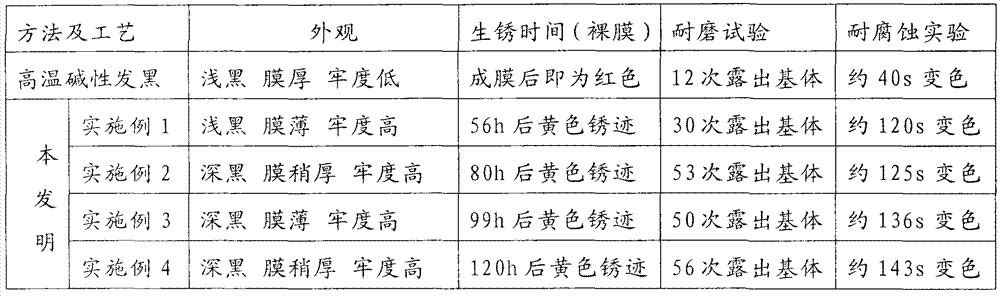

Room temperature blackening agent suitable for iron casting and method for preparing room temperature blackening agent suitable for iron casting

InactiveCN103046038AImprove applicabilityGood anti-rust functionMetallic material coating processesPolyethylene glycolStrong acids

The invention provides a room temperature blackening agent suitable for an iron casting and a method for preparing the room temperature blackening agent suitable for the iron casting. Each liter of the blackening agent is prepared from the following raw materials: 1-3 grams of sodium molybdate, 2-6 grams of copper sulfate, 1-3 grams of nickel sulfate, 1-3 grams of complexing agent, 4-8 grams of coalescing agent, 0.3-1.5 grams of additive, 0.5-3 grams of polyethylene glycol, 0.5-3 grams of oleate and the balance of water, wherein the pH is between 2.0 and 3.0. The room temperature blackening agent suitable for the iron casting provided by the invention is the room temperature blackening agent which is environment-friendly, is toxicity-free, has strong adaptability and an excellent rust-proof function and does not contain harmful substances such as strong acid, strong alkali, phosphorus, selenium, nitrite and the like; and the room temperature blackening agent can form a layer of black film which is black, bright and uniform and has high firmness and strong corrosion resistance on workpiece surfaces.

Owner:ANHUI WEILAI SURFACE TECH

Spray cleaning agent for metal assembly

The invention discloses a spray cleaning agent for a metal assembly. The cleaning agent is prepared from polyether carboxylate, carboxylate, block polyether, an alcohol ether surfactant, sodium gluconate, diethylenetriam inepentaacetate, ethylene diamine tetraacetic acid disodium salt, sodium metasilicate, sodium benzoate, triazole, triethanolamine, alcohols, glycol ether and deionized water. The cleaning agent is applicable to the oil-removing and rust-preventing cleaning of black metals, non-ferrous metals and assemblies formed by the black metals and the non-ferrous metals, has extremely high cleaning performance and a relatively long corrosion inhibition period, cannot cause the change of the color, is environment-friendly and low-foam, does not contain substances such as phosphorus and sodium nitrite, cannot pollute the environment, is particularly applicable to the spray cleaning at normal temperature, and is low in energy consumption in the cleaning process, the residue is avoided, corrosion spots are not generated, and waste liquor of the cleaning agent is can be easily disposed. The corrosion inhibition period of a copper-aluminum assembly exceeds 10 days; the corrosion inhibition period of a brass-cast iron assembly exceeds 7 days; the corrosion inhibition period of an aluminum-cast iron assembly exceeds 7 days; and the corrosion inhibition period of a copper tin-aluminum-low-carbon steel assembly exceeds 10 days.

Owner:AMER TECH CO LTD

Preparation method of water-base efficient metal surface cleaning agent

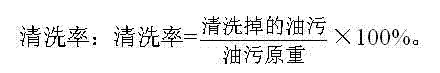

The invention relates to a preparation method of a water-base efficient metal surface cleaning agent. At present, the commonly used metal cleaning agent is a solvent type or a phosphorus-containing water-base cleaning agent so that the generated pollution becomes the concerned problem and the environmentally-friendly water-base efficient metal surface cleaning agent which has good functions of decontamination, rust removal and rust prevention is urgently needed to be developed. The preparation method provided by the invention comprises the following steps of: carrying out an esterification reaction of polyoxyethylene polyoxypropylene amine ether and oleic acid to obtain polyoxyethylene polyoxypropylene amine ether oleate; and then compounding the polyoxyethylene polyoxypropylene amine ether oleate with 6053, penetrant JFC, dodecyl sulfonic acid, urea, sodium silicate, sodium citrate, flake caustic soda, isopropanol, polyether L61 and water to obtain the water-base efficient metal surface cleaning agent. The water-base efficient metal surface cleaning agent, provided by the invention, has the excellent functions of dust removal, surface oil contamination removal and rust prevention, and can be widely applied to treatments including surface cleaning, rust removal, contamination removal and the like of various metal materials and work pieces before and after the various metal materials and the work pieces are processed; and meanwhile, the water-base efficient metal surface cleaning agent also has the characteristics of small pollution, no phosphorus, low corrosion on equipments and the like.

Owner:SHAANXI UNIV OF SCI & TECH

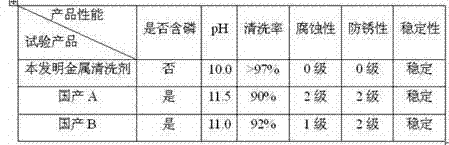

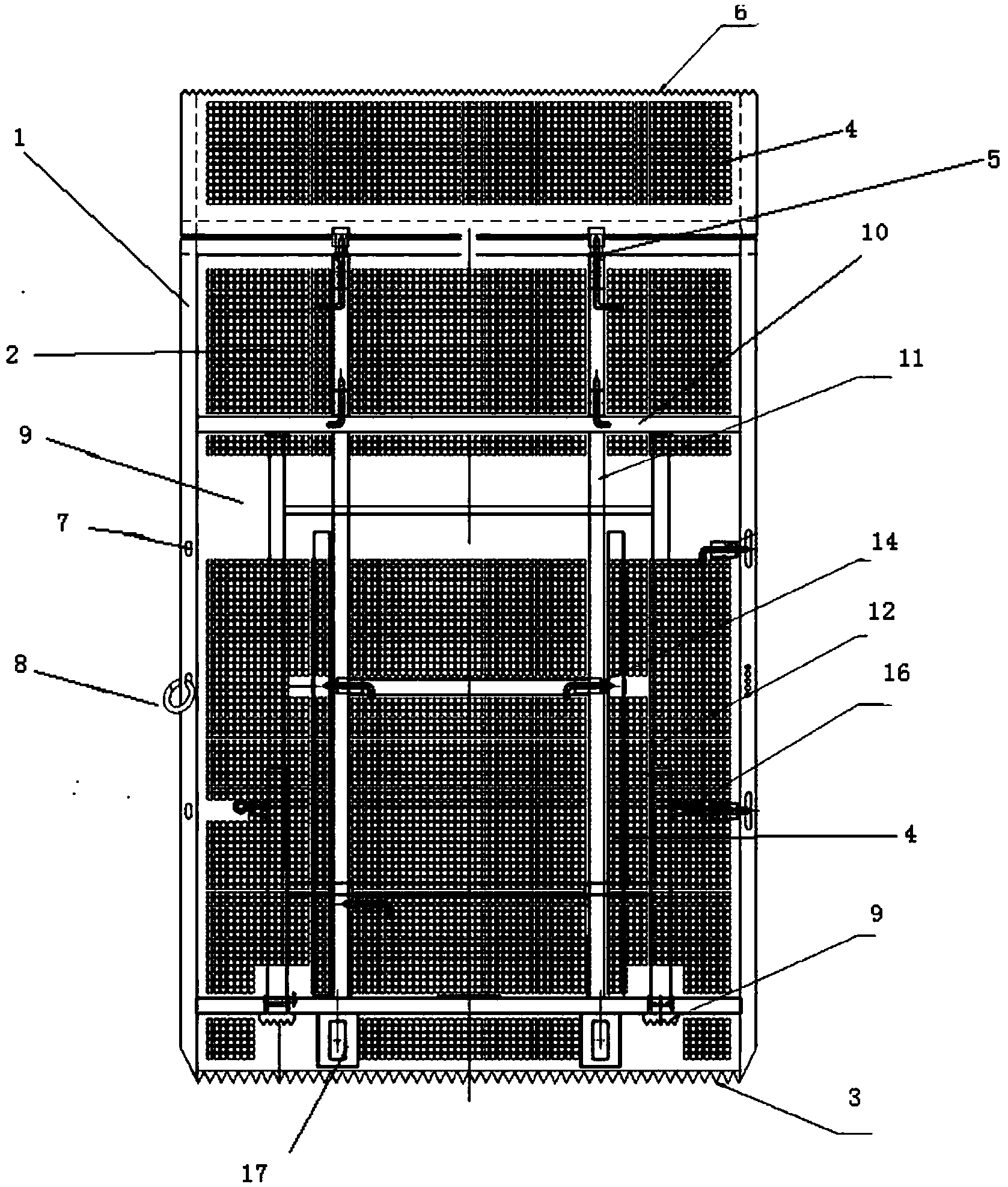

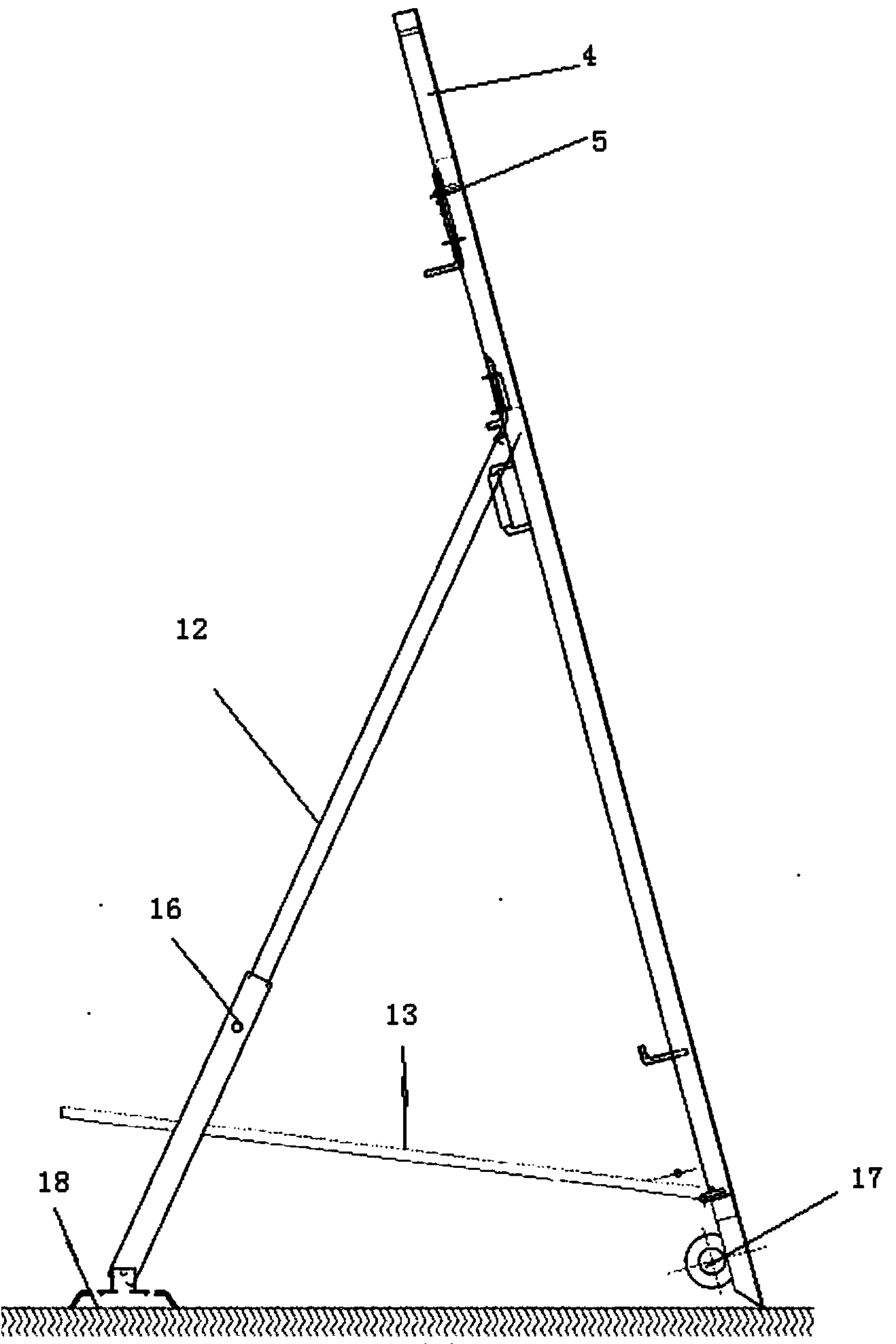

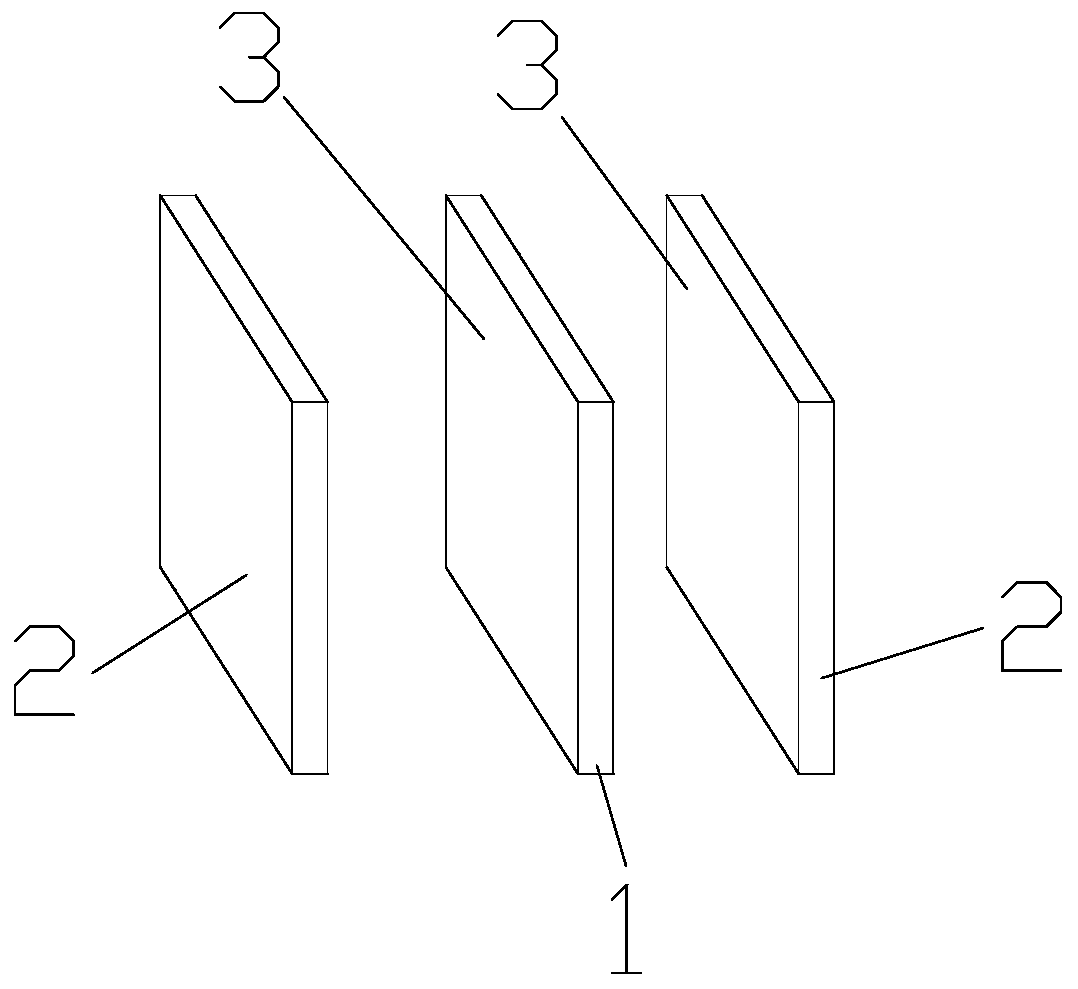

Isolating net piece and carrier vehicle for loading isolating net pieces

ActiveCN103470097ANot easy to dumpPrevent reaching outFencingItem transportation vehiclesStructural engineeringMechanical engineering

Owner:北京安龙特种车辆有限公司

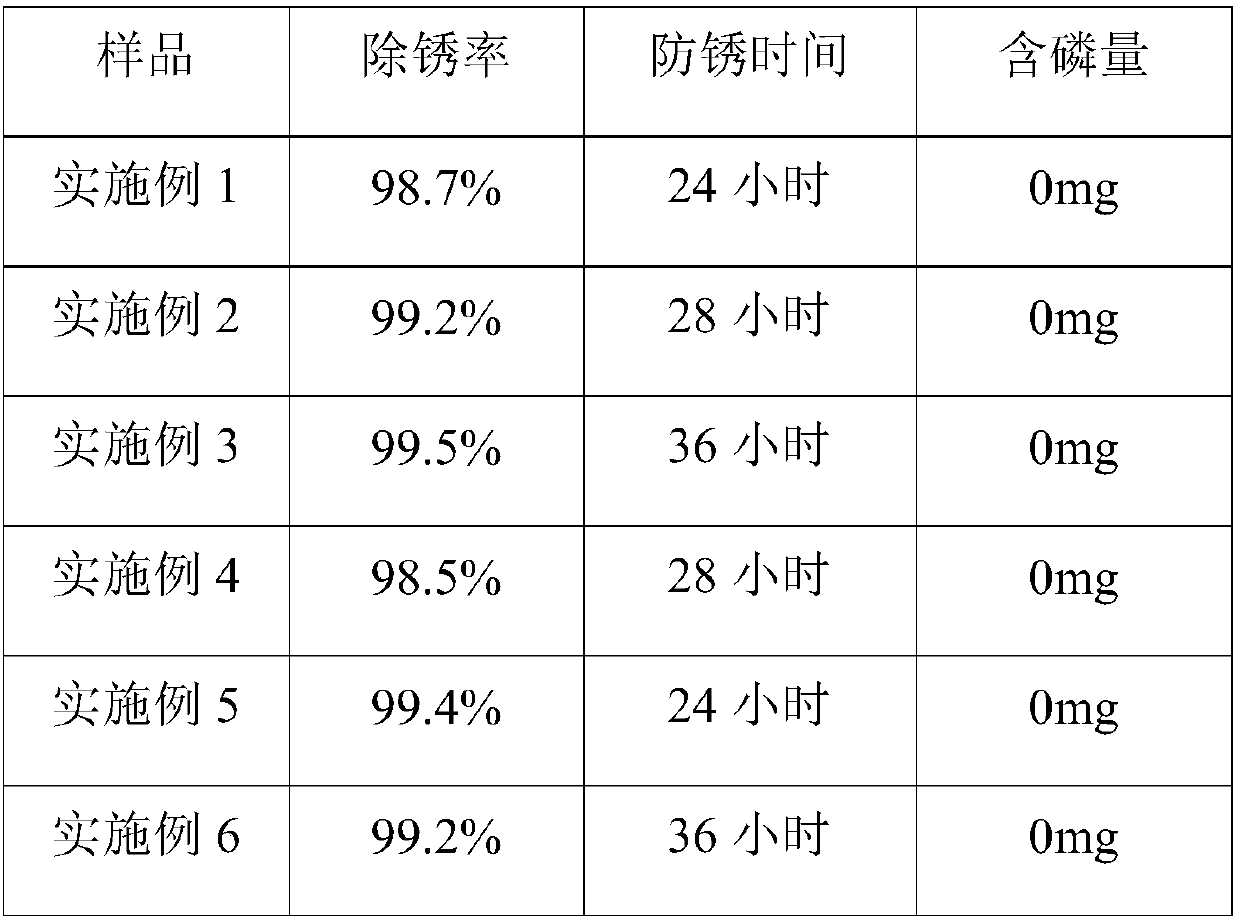

Neutral environment-friendly rust remover and preparation method thereof

The invention discloses a neutral environment-friendly rust remover and a preparation method thereof. The neutral environment-friendly rust remover is prepared from the following raw materials in percentage by mass according to a standard that the total mass of the rust remover is 100 percent: 10 to 15 percent of organic acid, 3 to 6 percent of a chelating agent, 2 to 4 percent of a corrosion inhibitor, 0.5 to 1 percent of a penetrating agent, 5 to 20 percent of a pH adjuster and the balance of water. According to the neutral environment-friendly rust remover disclosed by the invention, by adoption of combination of the organic acid, the chelating agent, the corrosion inhibitor, the penetrating agent and the like, the obtained rust remover is neutral and does not contain phosphorus and heavy metals, and no acid mist escapes; the neutral environment-friendly rust remover cannot cause a hydrogen embrittlement phenomenon or an over etching phenomenon for equipment and workpieces; furthermore, the rust remover disclosed by the invention cannot pollute the environment and a water source, and a rust removing method is simple; the neutral environment-friendly rust remover can be used forremoving rusts and has a good anti-rust function.

Owner:广州旭淼新材料科技有限公司

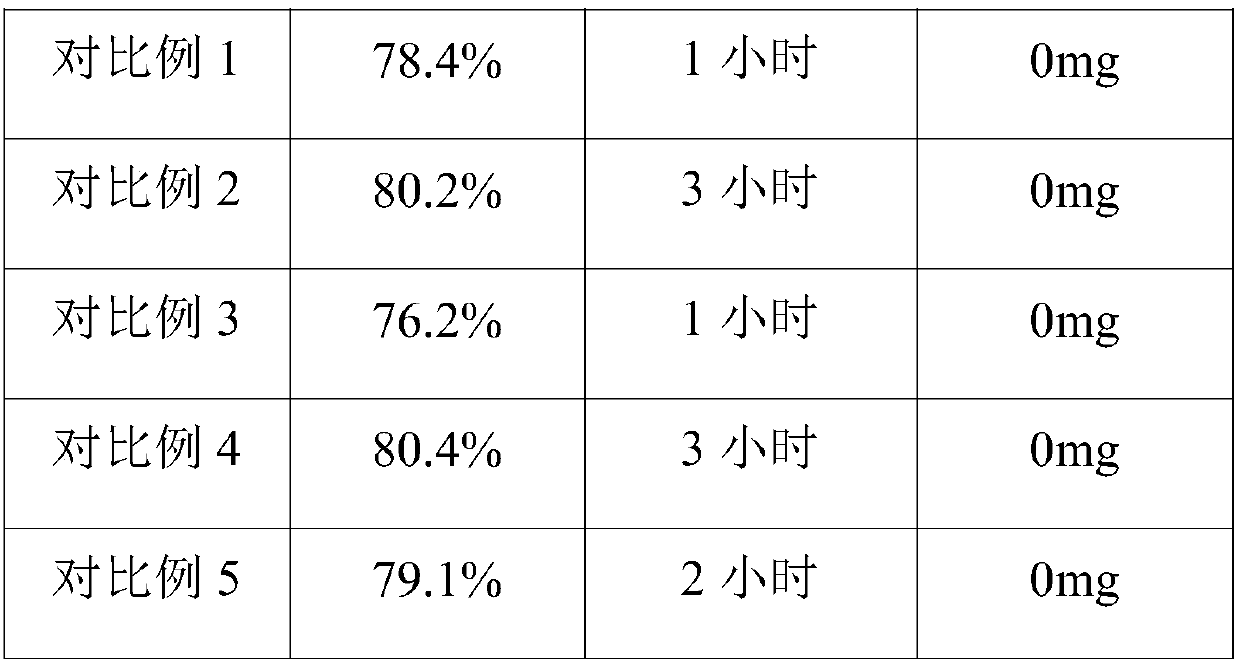

Defrosting heater of refrigerator

InactiveCN1584459ASimple structureReduce manufacturing costLighting and heating apparatusDefrostingElectric heatingCeramic coating

A defrosting heater for electric refrigerator consists of electric heating-wires, insulating casings with outer casings and ceramic coatings. The outer casings are made of high strength thermal conductive metals. The ceramic coatings are of far-infrared materials, so that they work in high efficiency, when the heater works, with simple structure, low cost and good corrosion-proof performance.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

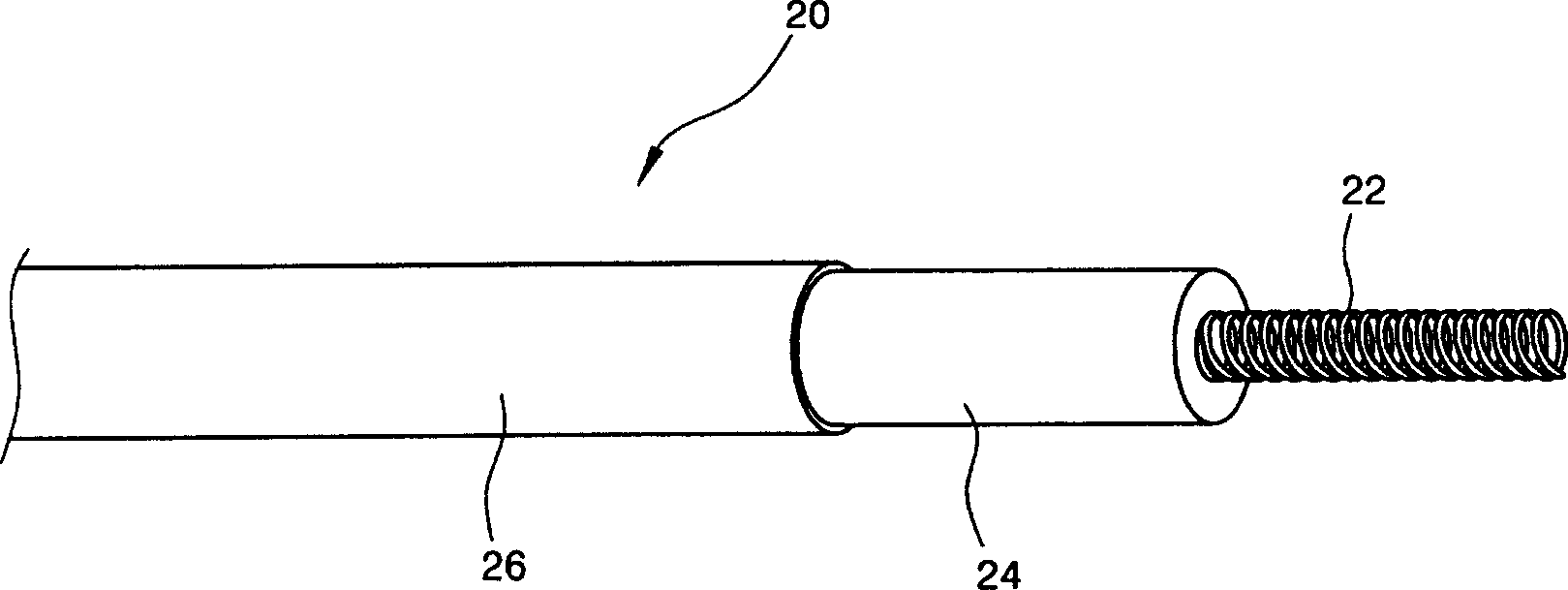

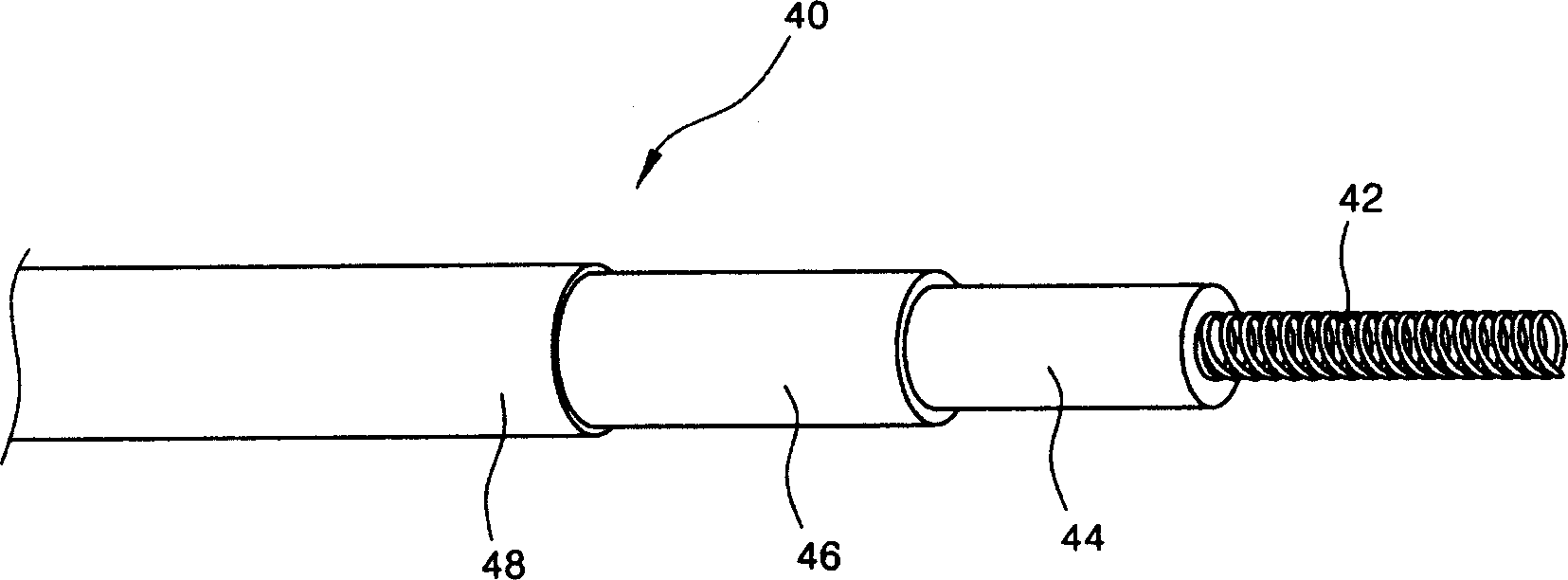

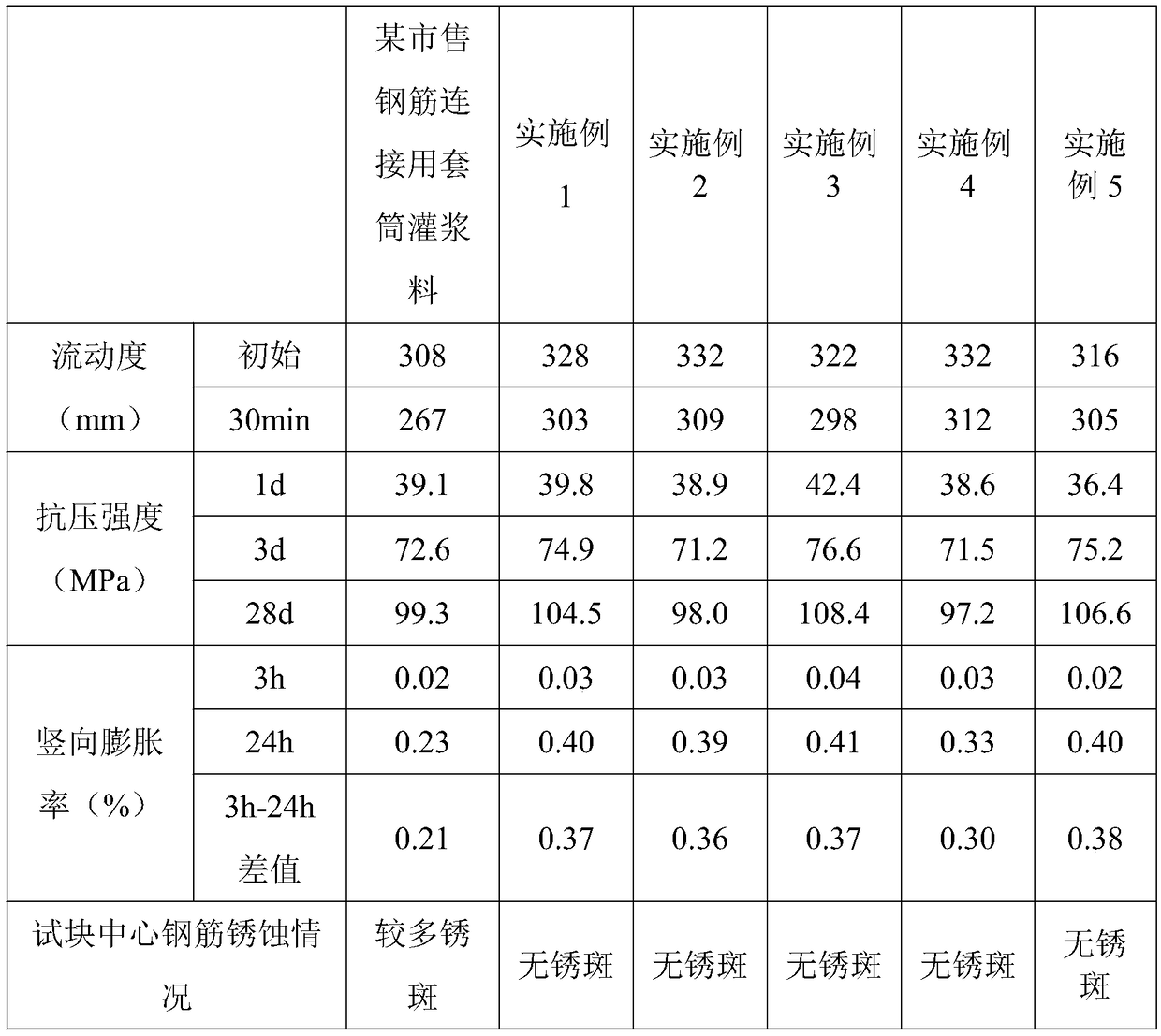

Corrosion-inhibiting sleeve grout material for rebar splicing and manufacturing method thereof

The invention belongs to the field of building materials and discloses a corrosion-inhibiting sleeve grout material for rebar splicing. The grout material includes, by weight, 390-410 parts of cement,90-110 parts of an admixture, 460-500 parts of sand, 1.4-1.6 parts of a defoamer, 15-20 parts of a corrosion inhibitor, 6-8 parts of a composite water reducing agent, 40-50 parts of a composite retarder, 35-40 parts of a composite expanding agent, 7-10 parts of a composite early strength agent and 135-145 parts of water. A manufacturing method of the grout material includes weighing the componentmaterials according to the ratio and fully stirring the materials according to a certain stirring manner. The composition of the grout material is optimized according to a high amount of experiment data. The prepared grout material has good fluidity, compressive strength, vertical expansivity and corrosion inhibiting performance. The corrosion inhibiting performance of the grout material is obviously better than that of common commercially available sleeve grout materials for rebar splicing.

Owner:成都宏基建材股份有限公司

Antibacterial and antitoxic compound enzyme cleaning agent for medical instruments

InactiveCN111394197AGood anti-rust functionQuick washInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPropanoic acidMedical equipment

The invention relates to an antibacterial and antitoxic compound enzyme cleaning agent for medical instruments. The antibacterial and antitoxic compound enzyme cleaning agent comprises a surfactant, acompound enzyme, a stabilizer, an antiviral and antibacterial agent, an antirust agent, a preservative, an assistant and the like. The surface active agent is a non-ionic surface active agent. The content of the components in the formula is respectively 1%-10% of fatty alcohol-polyoxyethylene ether sulfate, 1%-5% of alkyl glycoside, 1%-5% of compound enzyme, 5%-15% of enzyme stabilizer, 0.5%-1% of allicin, 0.5%-2% of ginger extract, 1%-2% of triethanolamine, 1%-3% of calcium propionate, 0.1%-2% of pH regulator, 2%-5% of ethanol, 0.1% of essence, 0.1% of pigment and the balance of deionized water. The compound enzyme cleaning agent can quickly and effectively decompose and remove residues attached to the inside and the outside of medical equipment and has the effects of efficiently killingviruses and protecting the metal surface.

Owner:宿迁盾嘉生物科技有限公司

Method for preventing copper from discolouring

The invention belongs to the technical field of metal antioxidation and discloses a method for preventing copper from discolouring and aims at providing a method for preventing copper from discolouring with good anti-corrosion property, no corrosion in long time and no fading in colour. The method for preventing copper from discolouring sequentially comprises the following steps: 1) uniformly mixing 1 part by weight of copper discolouration preventing agent with 6-10 parts by weight of water, so that a mixed discolouration preventing solution is obtained; 2) soaking a copper part requiring discolouration prevention into the mixed discolouration preventing solution obtained in the step 1) for 5-10 minutes; 3) cleaning the copper part soaked in the step 2) with clear water; 4) washing with hot water, drying, and carrying out operation of the next step, wherein each litre of the copper discoloration preventing agent in the step 1) is composed of the following components: 50-100g of hydroxyl ethidene diphosphonate, 50-100g of ethyl alcohol, 80-150g of hydrogen peroxide, 20-40g of corrosion inhibitor, 10-20g of isothiocyanate, 8-15g of alkyl sulfate, 10-20g of sodium molybdate, 8-12g of sodium tripolyphosphate and balance of water.

Owner:WUZHOU HENGSHENG ELECTRONICS

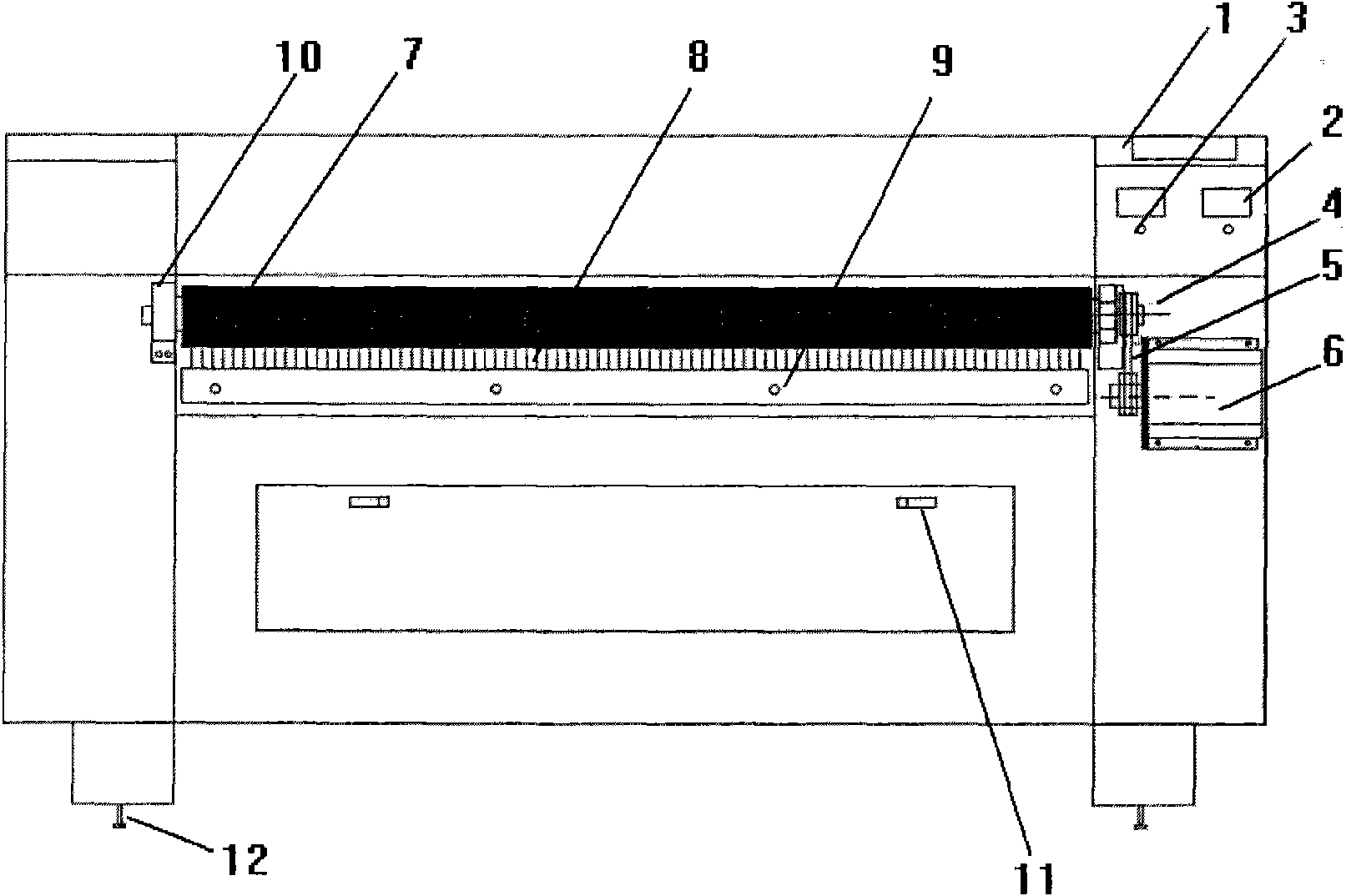

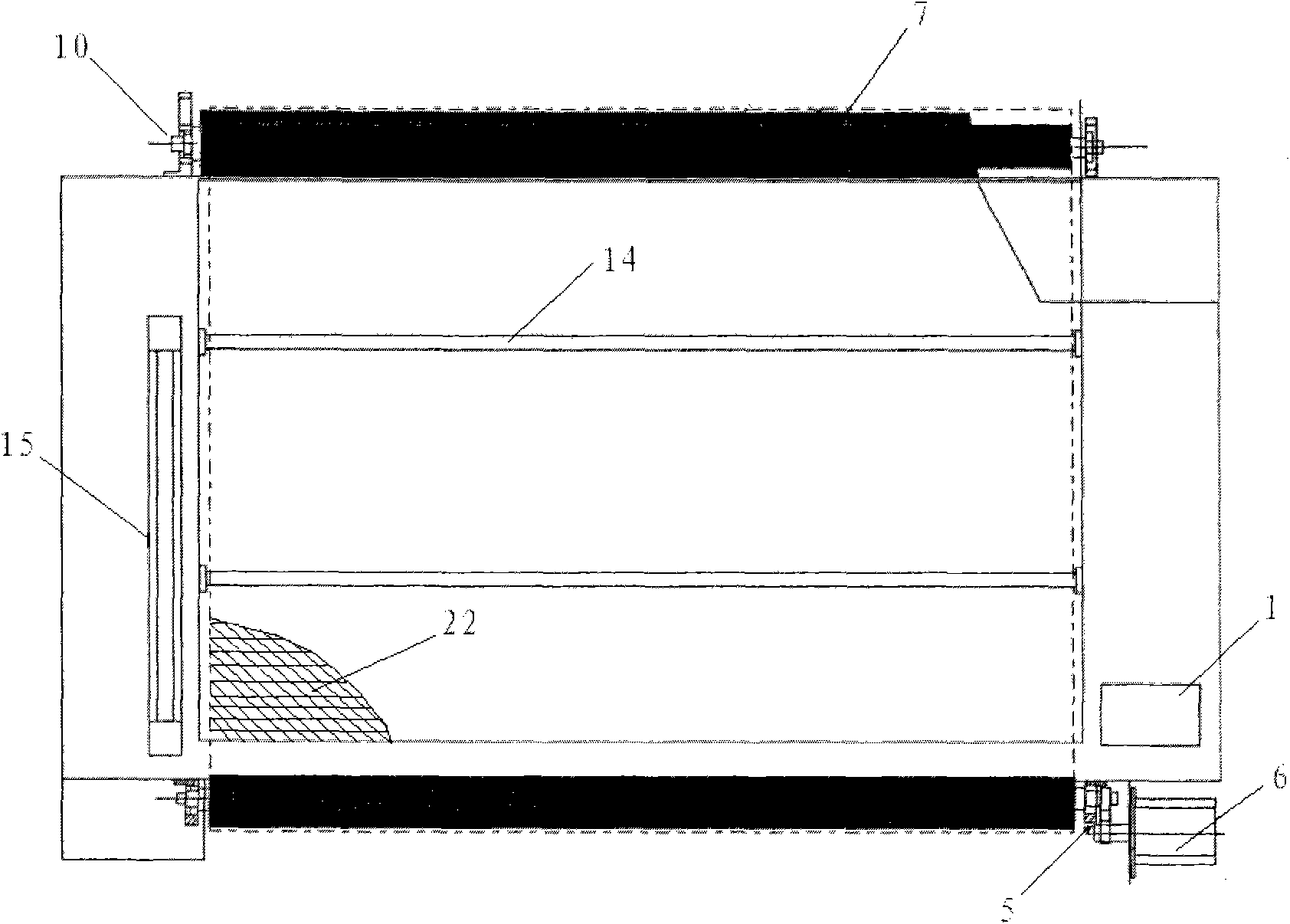

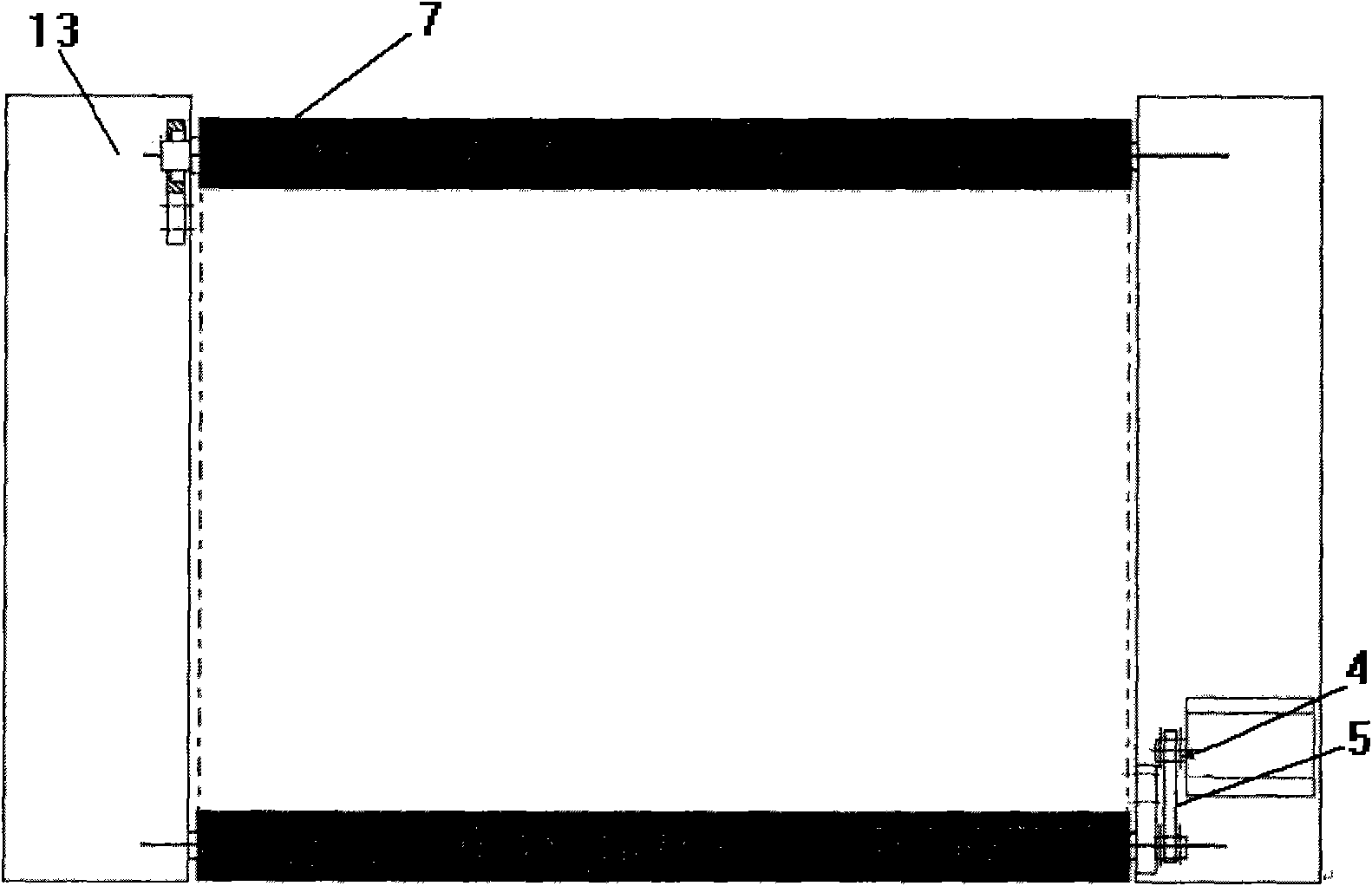

Novel laser automatic cutting bed machine frame structure

InactiveCN101775739AReduce distortionGuaranteed to be accurateHauling chainsHoisting chainsCurrent meterChain structure

The invention relates to a novel laser automatic cutting bed machine frame structure, which belongs to the technical field of cloth machinery. The novel laser automatic cutting bed machine frame structure comprises a work table part (a rubber roller, a rubber roller support frame, a net belt support frame, a fixed screw, a hair brush and a work surface net belt), a guide driving device (a step motor, a belt tensioning mechanism, a dragging chain structure and a guide rail), a laser support frame, a control panel (a panel, a current meter and a positioning device), a machine frame case, a lock and a support frame. The invention is characterized in that the surface treatment process of the work surface net belt adopts phosphate treatment after acid washing stain removal, the dragging chain structure is a front-back dragging and top-bottom lifting type dragging chain, a moving position mechanism adopts the groove design, the regulation range (0 to 20 mm) of the belt tensioning mechanism of a motive power transmission belt is large, the regulation is convenient and easy, the tightness of the belt can be freely regulated through loosening or tightening the screws and screwing a top screw, the structure is firm, the intensity is high, the step motor is completely arranged outside the machine frame, and an externally installed motor protective cover opening is additionally provided with heat radiation fans.

Owner:彭绍益

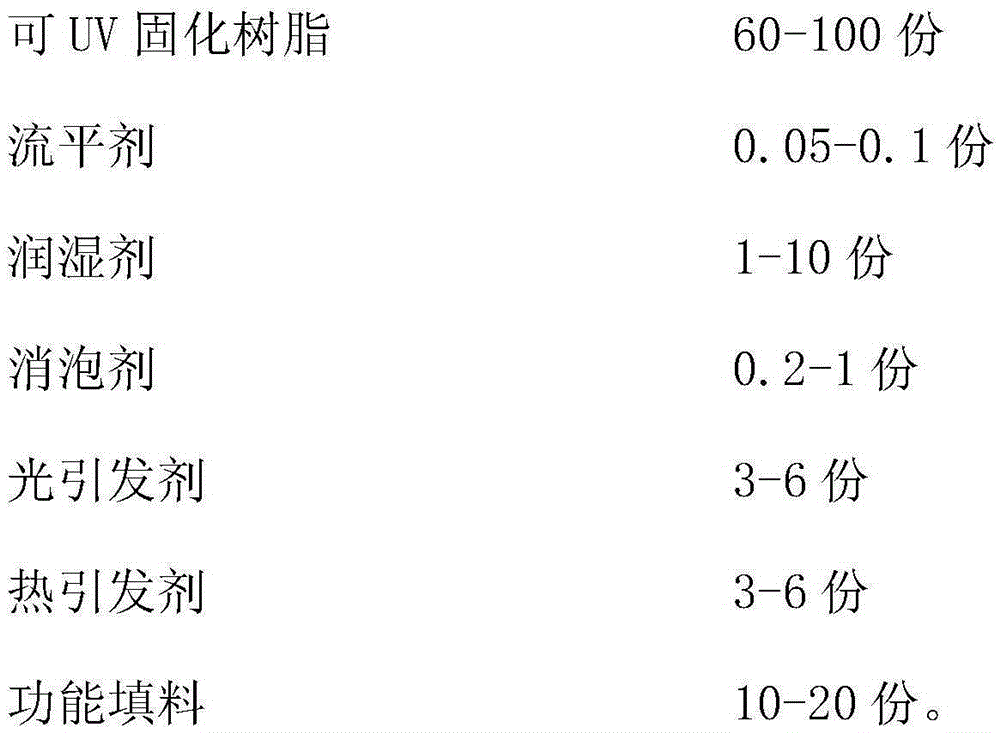

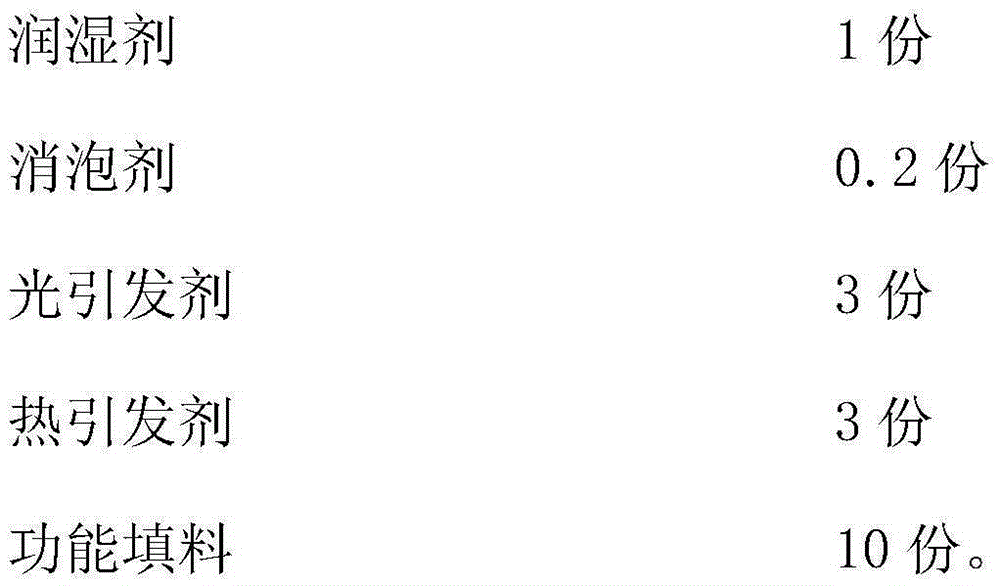

Dual UV curable peelable coating and preparation method thereof

InactiveCN105400386AShorten drying timeMature technologyPolyurea/polyurethane coatingsEpoxy resin coatingsFiltrationDrying time

The present invention belongs to the technical field of polymer materials, and in particular to a dual UV curable peelable coating. The coating comprises the following raw materials by weight: 60-100 parts of a UV-curable resin, 0.05-0.1 part of a leveling agent, 1-10 parts of a wetting agent, 0.2-1 part of a defoamer, 3-6 parts of a photoinitiator, 3-6 parts of a thermal initiator, and 10-20 parts of a functional filler. The preparation method comprises the following steps: according to the formula, adding part of the wetting agent, defoamer and functional filler in a high speed disperser, dispersing by 1600-2800 r / min for 30-50min, reducing the rotational speed to 300r / min, adding the UV curable resin and the remaining defoamer, wetting agent, leveling agents, photoinitiator and thermal initiator, stirring well, continuing the dispersion for 5-10min, mixing evenly, and removing the residue by filtration to obtain the coating. the dual UV curable peelable coating obtained by the present invention has short dry time and good rust resistance of cured material; and the preparation method is simple for process, and easy to control, so the technology has the characteristics of maturation, fastness, and high efficiency.

Owner:SHANGHAI INST OF TECH

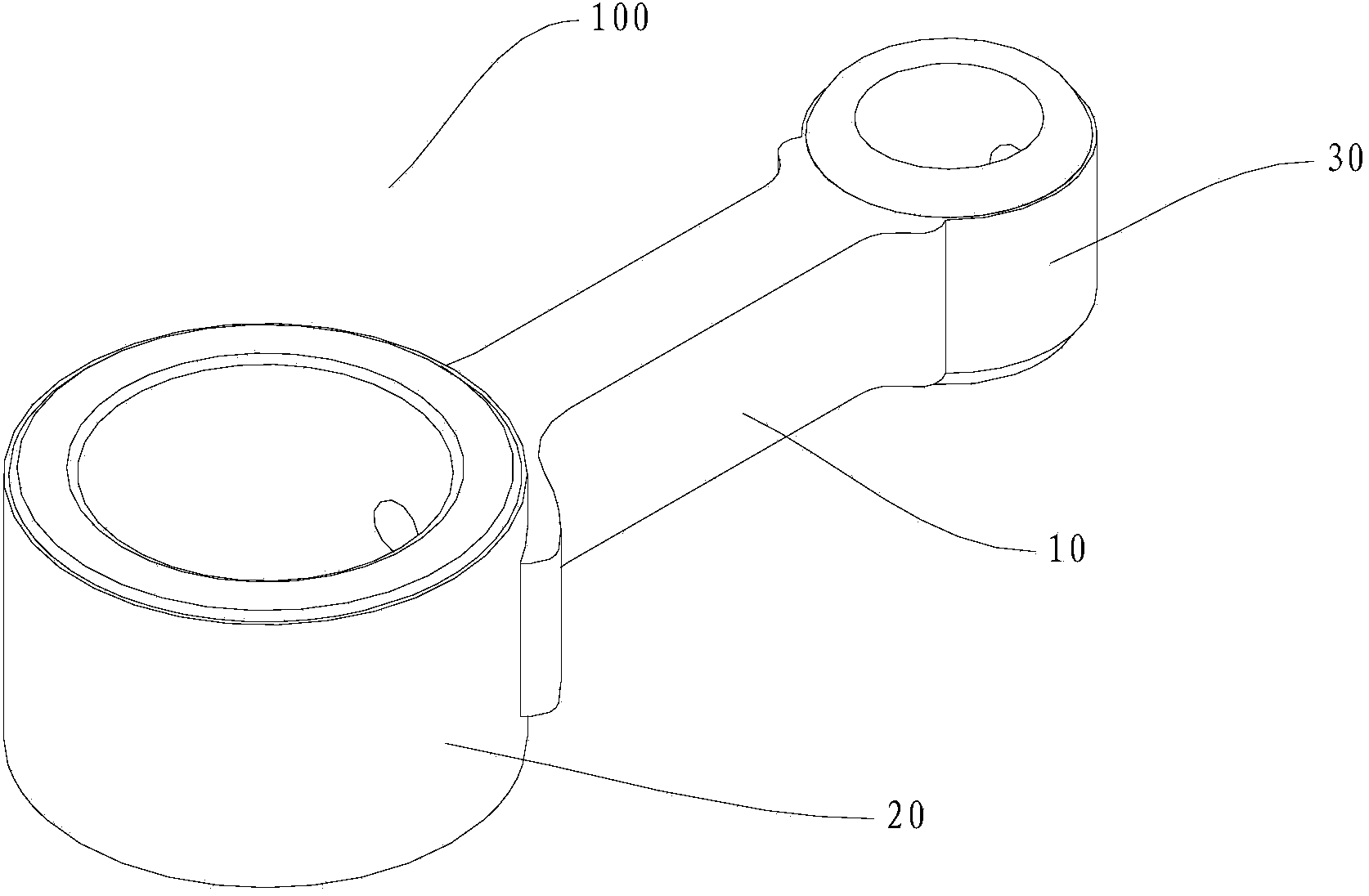

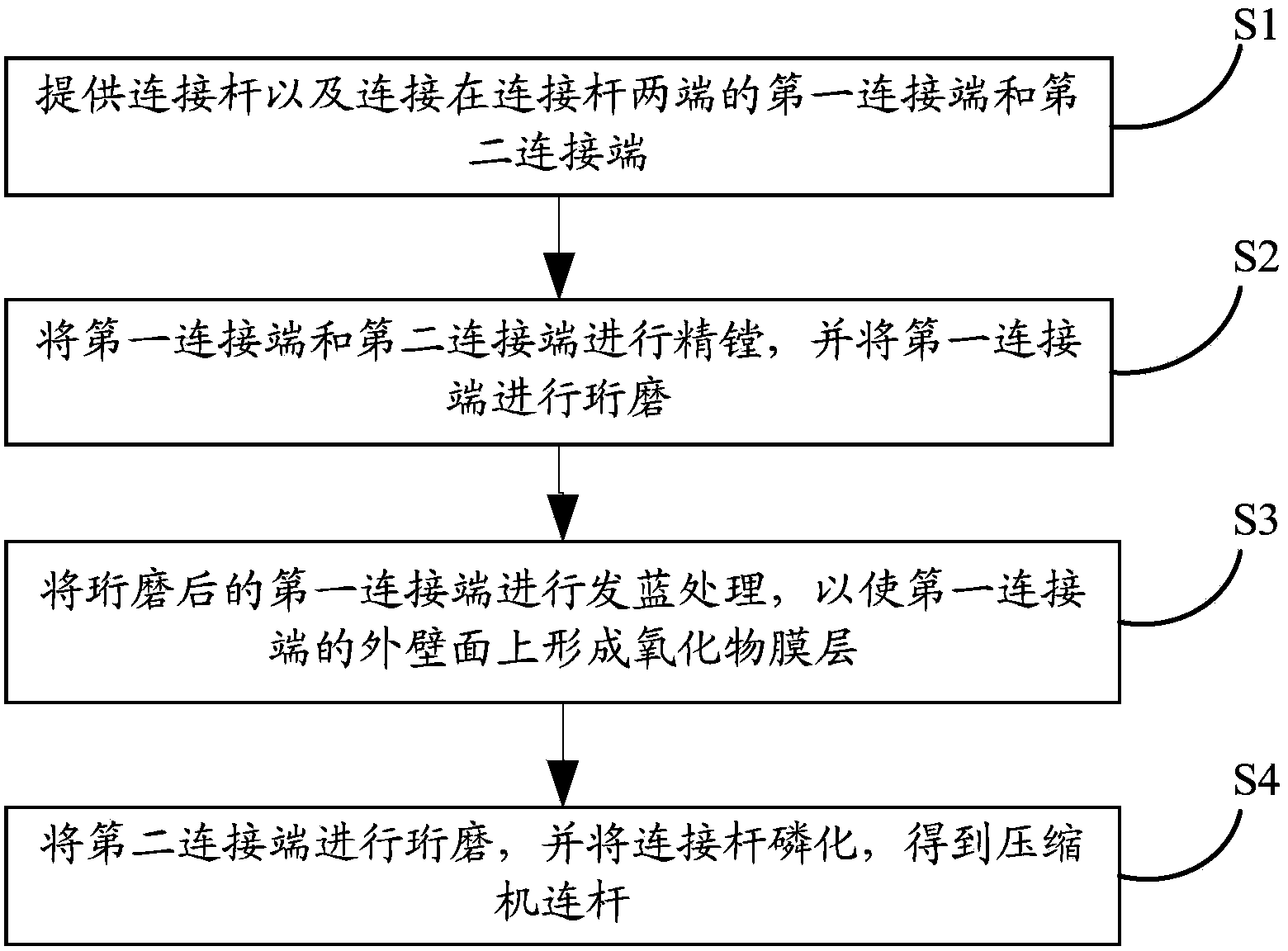

Compressor connecting rod and production method thereof

InactiveCN104141600AHigh hardnessImprove wear resistanceConnecting rodsPositive displacement pump componentsEngineeringHardness

The invention discloses a compressor connecting rod and a production method thereof. The compressor connecting rod comprises a connecting rod, a first connecting end and a second connecting end, wherein the first connecting end and the second connecting end are respectively arranged at the two ends of the connecting rod, the radial dimension of the first connecting end is larger than the radial dimension of the second connecting end, and the outer wall surface of the first connecting end is covered with an oxide film layer. According to the compressor connecting rod of the embodiment of the invention, by covering the first connecting end with larger radial direction with the oxide film layer, the oxide film layer covers the basal body surface of the first connecting end and is densely and firmly attached, vapor and corrosive medium in the environment are difficult to enter the internal part of the first connecting end, not only a good antirust function is achieved, but also a certain anticorrosive effect is obtained, the voids in parts can be closed, and the hardness and the wear resistance of the parts are improved.

Owner:ANHUI MEIZHI COMPRESSOR

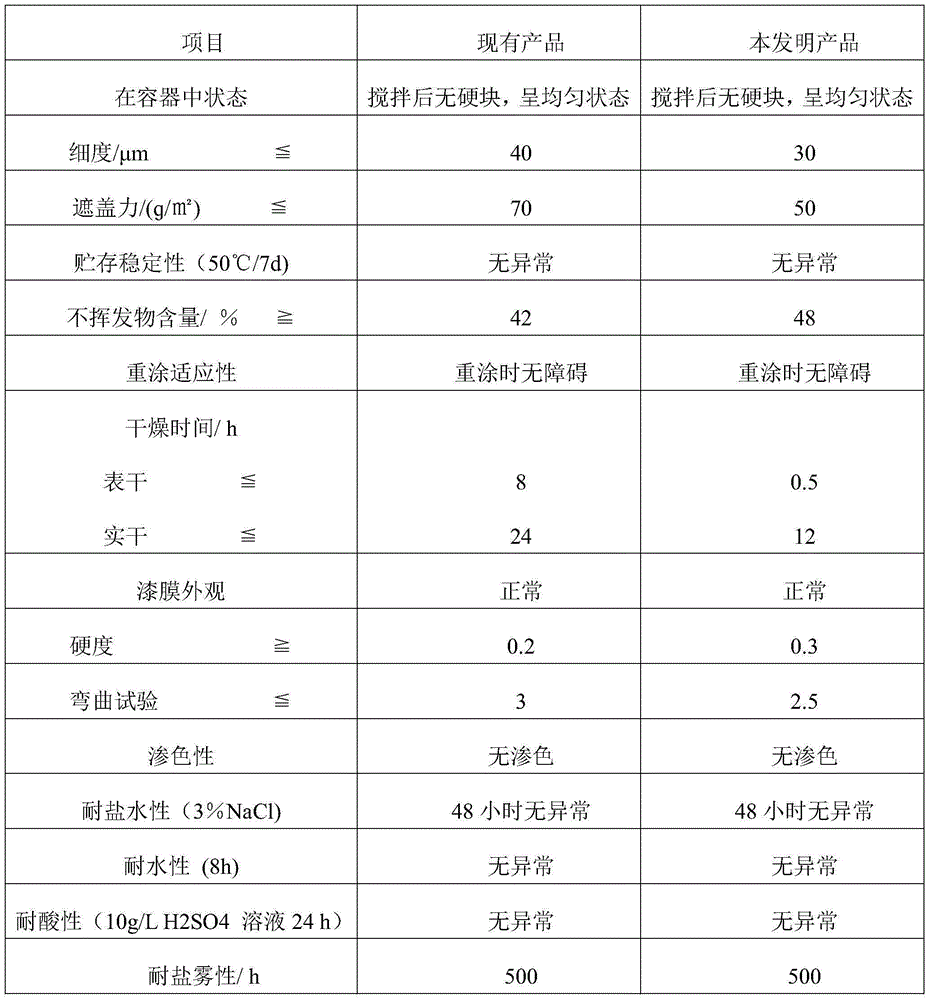

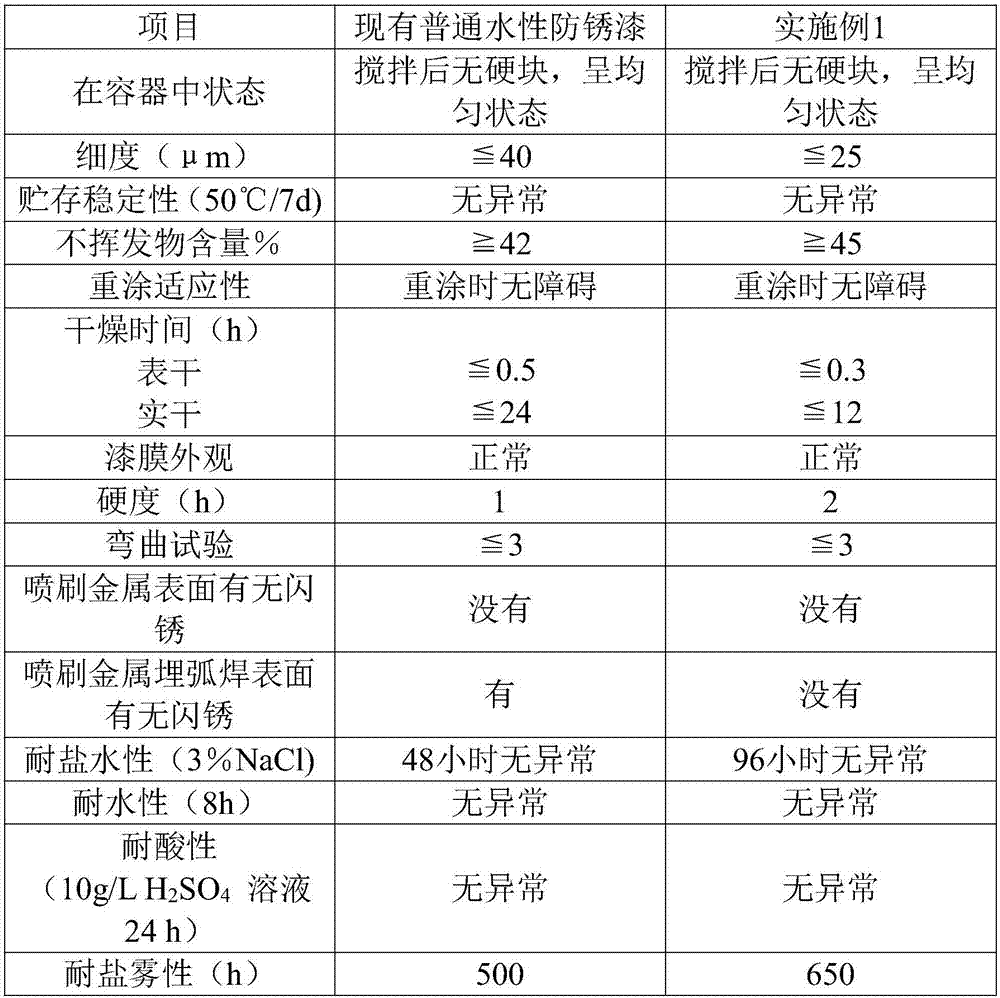

Aqueous anti-rusting paint and preparation method therefor

ActiveCN105219239AUnparalleled environmental friendlinessGood resistance to salt sprayAnti-corrosive paintsPolyester coatingsSolubilityLacquer

An aqueous anti-rusting paint and a preparation method therefor. The paint is characterized in that: the raw materials in a formula in parts by mass are as follow: 600-700 parts of an acrylate modified alkyd resin emulsion, 100-120 parts of deionized water, 90-110 parts of pigments and fillers, 5-10 parts of a rheological agent, 5-10 parts of a dispersant, 1-5 parts of a defoamer, 1-3 parts of a bactericide, 70-90 parts of film forming auxiliaries, 15-25 parts of a co-solvent, 3-8 parts of a flash-rust agent, 5-10 parts of a multi-functional agent and 4-10 parts of a thickener solution. The process steps comprises: dispersing, milling, paint mixing, thickening, filtering and packaging. According to the present invention, water is used as a dispersion medium, multiple anti-rusting mechanism of physical, chemical and the like are used to prepare and produce the anti-rusting industrial paint. The paint combines an undercoat and a finishing coat and is constructed at one-time, so that the mode that the undercoat and the finishing coat of the conventional paint are constructed separately is broken. The paint is unequalled in environmental protection performance, good in salt-spray resistance and weather resistance and strong in anti-rusting function, and is an excellent product of a new generation that can replace the traditional anti-rusting paint. The paint has water solubility and non-flammable property, and is safe in use, and the paint is good in water resistance and good in thermal stability, and has a good anti-rusting function even in a high-temperature state.

Owner:LIAOYANG YIBANG NEW BUILDING MATERIALS GRP CO LTD

Finishing liquid for hot-galvanized plate and preparation method for finishing liquid

ActiveCN104194908AGood anti-rust functionImprove rust resistanceLubricant compositionSodium metasilicateTricarboxylic acid

The invention relates to finishing liquid for a hot-galvanized plate and a preparation method for the finishing liquid. The finishing liquid comprises a component I and a component II, wherein the component I comprises following ingredients in parts by weight: 23-33 parts of water, 5-8 parts of dibasic acid, 8-12 parts of tricarboxylic acid and 54-57 parts of triethanolamine; the component II comprises following ingredients in parts by weight: 47-68 parts of water, 4-8 parts of sodium carbonate, 3-5 parts of potassium hydroxide, 2-4 parts of disodium ethylenediamine tetraacetate, 6-10 parts of sodium metasilicate pentahydrate, 8-12 parts of reverse block polyether, 6-8 parts of neodecanoic acid and 3-6 parts of sodium benzoate. The finishing liquid has relatively good rust-proof and lubricating effects, has excellent wetting and cleaning properties and relatively high cleaning ability, and can lubricate and repair the surface of a roll; the finished galvanized plate is smooth in surface, and defects of finishing spots and coating moire can be effectively eliminated or reduced; the finishing liquid has good foam-inhibiting and defoaming functions, so that liquid can be avoided from remaining on the surfaces of the roll and a steel plate and the foam can be avoided from overflowing around to affect the working environment.

Owner:江苏苏北能源科技有限公司

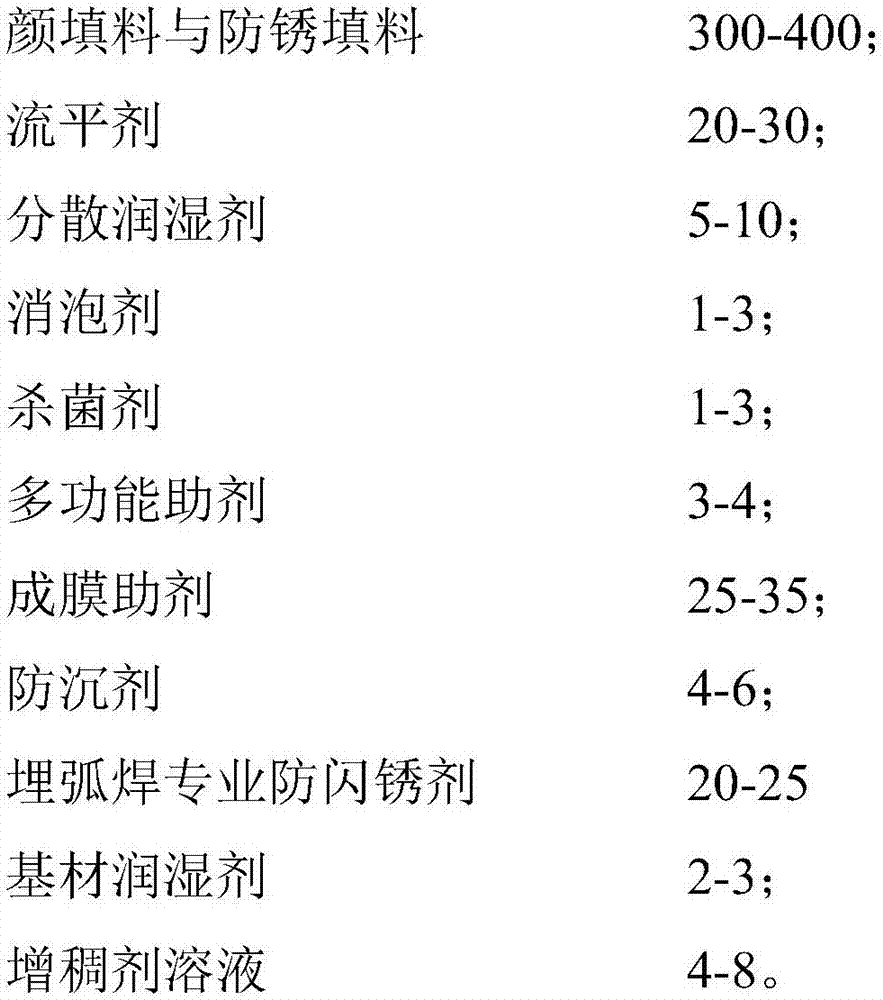

Special water-based anti-rust paint for submerged arc welding and preparation process thereof

InactiveCN106854406ALong-term flash rust problem solvingImprove rust resistanceAntifouling/underwater paintsPaints with biocidesWater basedWater dispersible

The invention discloses special water-based anti-rust paint for submerged arc welding. The water-based anti-rust paint comprises the following components in parts by weight: 400-500 parts of a film-forming material, 80-100 parts of deionized water, 300-400 parts of a pigment filler and an anti-rust filler, 20-30 parts of a levelling agent, 5-10 parts of a dispersing and wetting agent, 1-3 parts of a defoaming agent, 1-3 parts of a bactericide, 3-4 parts of a multifunctional auxiliary agent, 25-35 parts of a film-forming auxiliary agent, 4-6 parts of an anti-settling agent, 12-16 parts of a professional submerged arc welding flash rust preventer, 8-10 parts of a metal environment-friendly flash rust preventer, 2-3 parts of a substrate wetting agent and 4-8 parts of a thickening agent solution, wherein the film-forming material is an environment-friendly water-dispersible acrylic modified emulsion. The water-based anti-rust paint has the advantages of water-based environmental friendliness and good water resistance, salt fog resistance and weather resistance, has strong rust resistance, has good thermal stability, and is mainly applicable to rust prevention at a metal submerged arc welding position.

Owner:LIAOYANG YIBANG NEW BUILDING MATERIALS GRP CO LTD

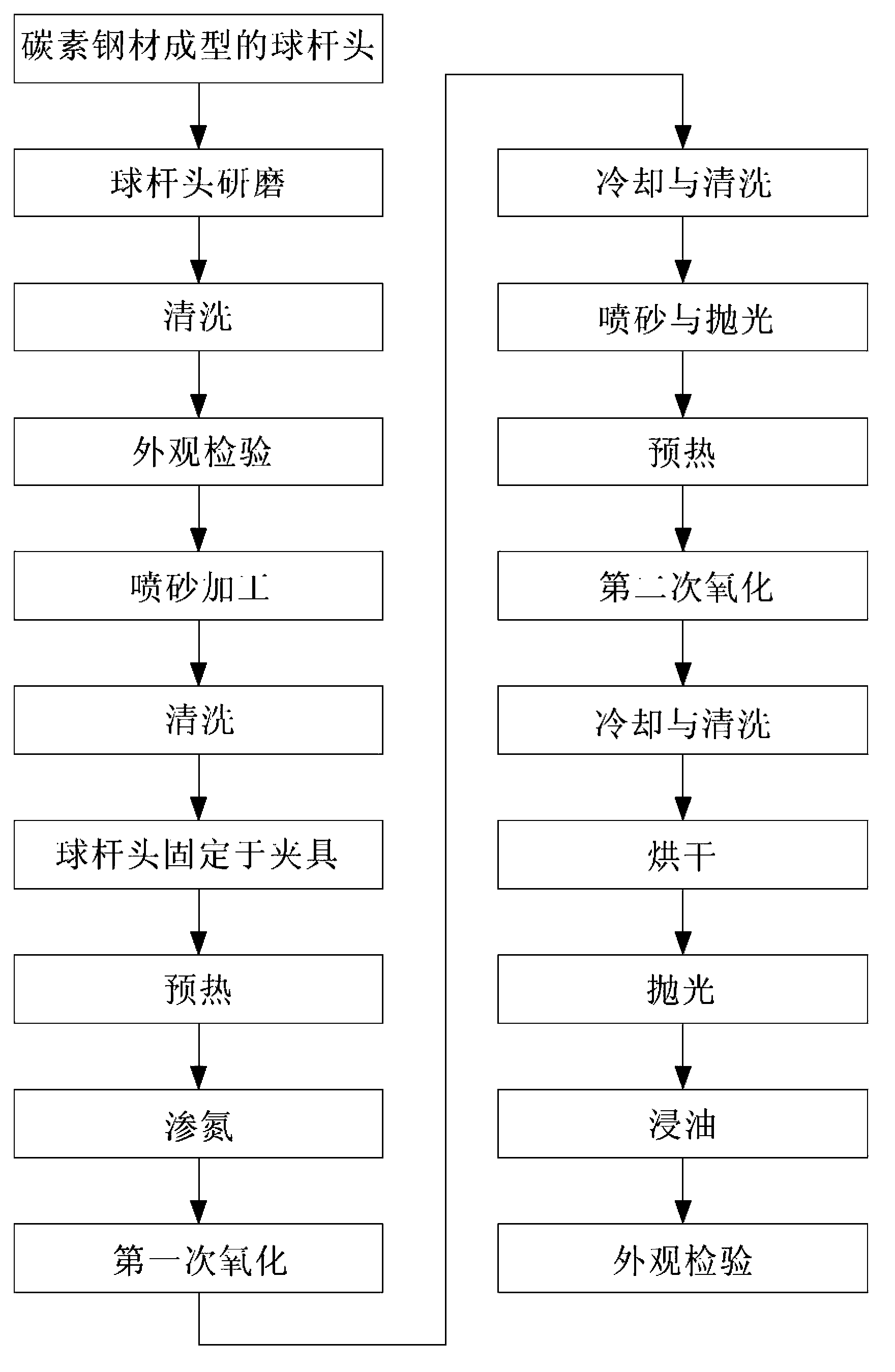

Golf club head surface processing method

The invention relates to a golf club head surface processing method which mainly includes conducting nitridation and two-stage oxidation on a club head formed by a carbon steel material, matching surface processing and washing steps such as grinding and sand blasting, and then conducting polishing, oil immersing and the like to enable the club head to have the even black surface appearance and achieve good corrosion resistance and abrasion resistance. The surface of the club head cannot be stripped and the like. The club head surface processing method achieves the effects of low pollution, low cost and the like and solves the problems of high pollution, high cost, coating film stripping and the like of the existing carbon steel club head adopting rust prevention technologies like a galvanized or plasma coating film.

Owner:苏 基宏

Metal antirust agent

The invention discloses a metal antirust agent. The metal antirust agent comprises, by weight, 50-80 parts of styrene-acrylic emulsion, 9-16 parts of lithium silicate, 3-9 parts of sodium phytate, 3-9parts of sodium gluconate,1-5 parts of amino acid, 1-3 parts of benzotriazole, 8-15 parts of hydroxyquinoline, 1-4 parts of modified thiadiazole, 3-9 parts of ricinoleic acid, 5-9 parts of oleamide,2-5 parts of triethanolamine borate, 0.5-2 parts of barium petroleum sulfonate, 0.3-1.1 parts of 2-aminoethyl heptadecene imidazolidine, 2-5 parts of zinc dihydrogen phosphate, 0.01-0.1 part of hexamethylene tetramine, 0.1-0.8 part of graphene oxide, 0.2-1 part of diethanolamine, 3-8 parts of ethylene glycol, 0.3-1 part of silane coupling agents, 0.01-0.1 part of potassium hydroxide and 100 partsof water. The metal antirust agent has the advantages of safety, environmental protection, good antirust effect and long antirust period.

Owner:HEFEI LYUJIE ENVIRONMENTAL PROTECTION TECH

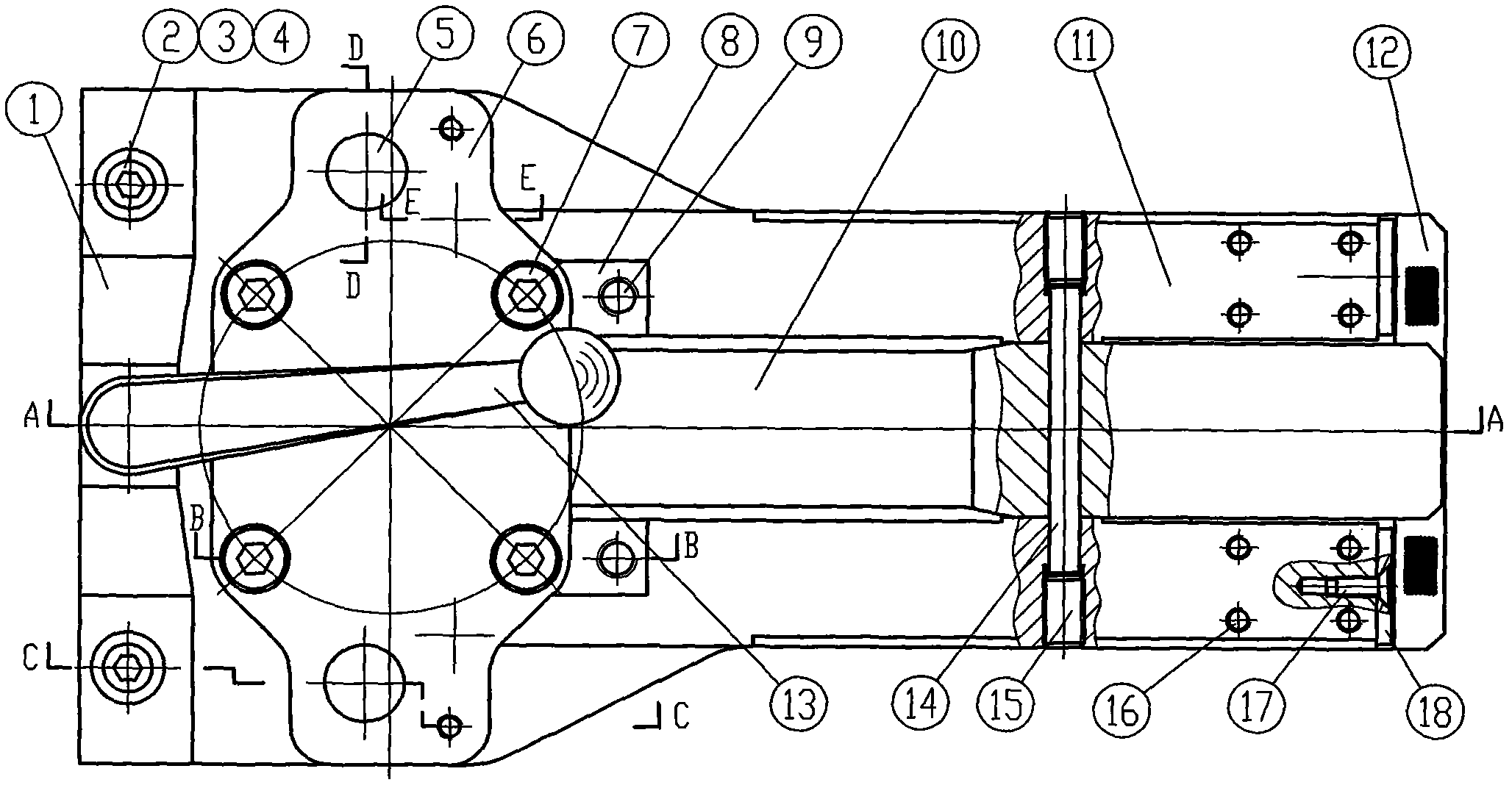

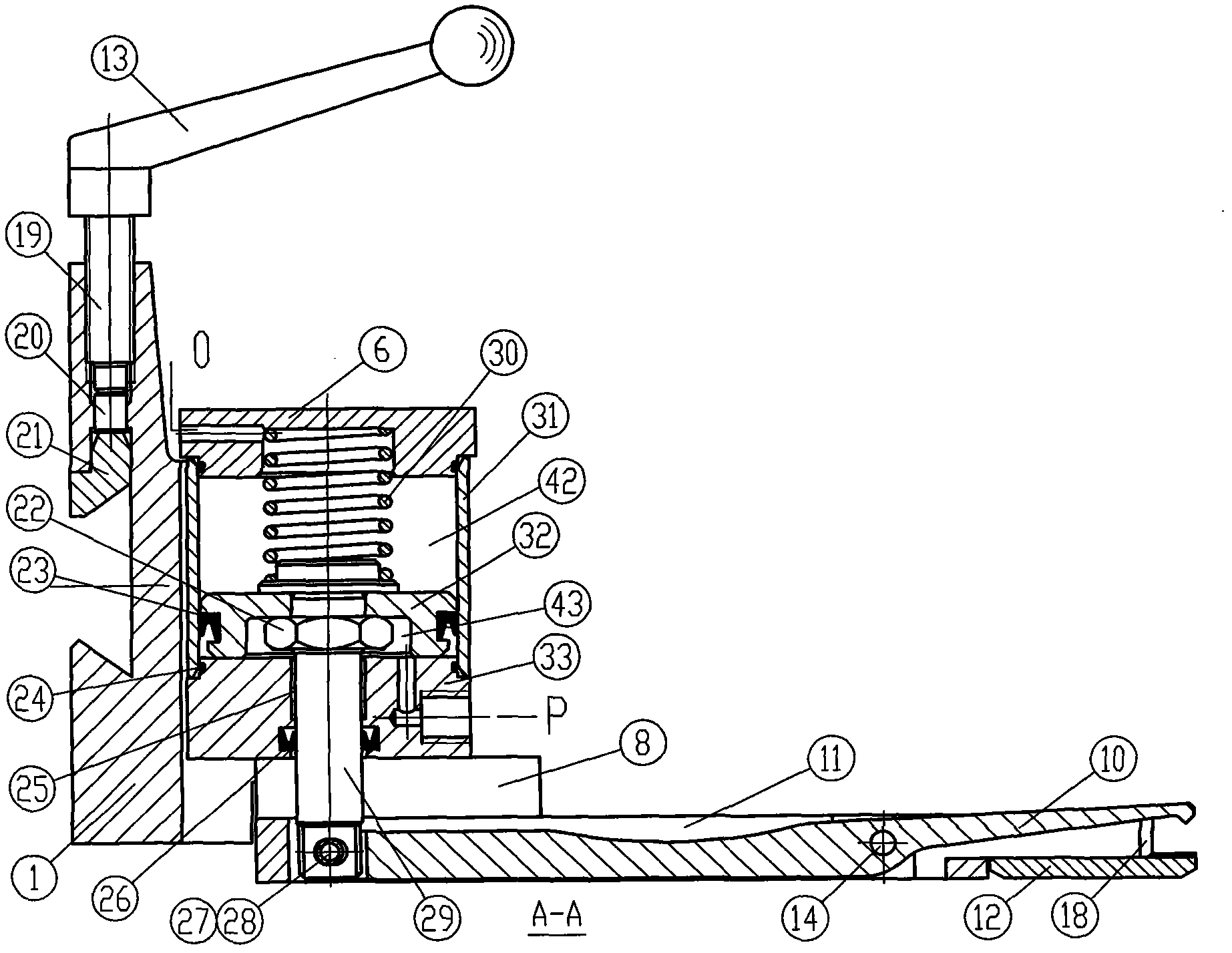

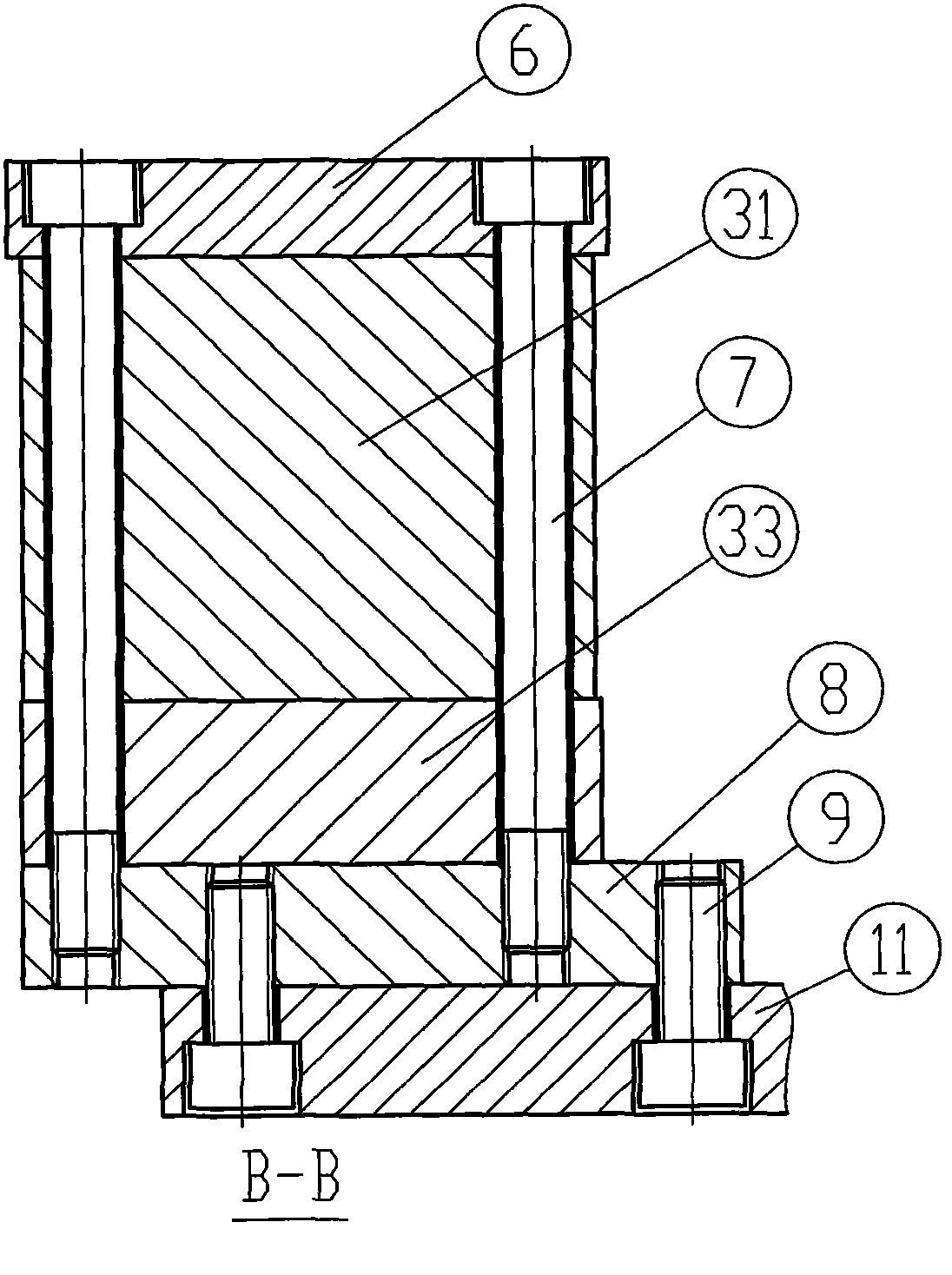

Pneumatic tongs

ActiveCN102069402AReduce wasteSimple structurePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a pair of pneumatic tongs, which belongs to the technical field of machine tool clamps. The pair of pneumatic tongs comprises a base, an air cylinder, an upper tong body and a lower tong body, wherein the middle part of the upper tong body is hinged with the lower tong body through a pin shaft; and the rear end of the upper tong body is connected with the tail end of a piston rod of the air cylinder through a pin shaft. The pair of pneumatic tongs is characterized in that: an air cylinder cover, an air cylinder drum and an air cylinder base are fastened on the lower tong body through two contour pads by a bolt; two slide columns are strung on the air cylinder cover, the lower tong body and the base; a linear bearing is arranged in a base hole through which the slide columns pass; the tail end of the piston rod is a flat tail; a round waist hole is formed on the flat tail; a roller sleeve is arranged in the round waist hole; and the pin shaft connecting the rearend of the upper tong body and the tail end of the piston rod is sleeved in the roller sleeve. The pair of pneumatic tongs has a reasonable and simple structure, low material waste, low machining cost, good anti-rust function, high sealing effect and long service life and is easy to manufacture. The air cylinder is connected with the lower tong body at a plurality of points; the connection area is large; and the connection strength is high. The pair of pneumatic tongs is strong in overall rigidity; the deformation displacement of a tong tooth part during working is small; and the service lifeis long.

Owner:扬州兴浦机械设备有限公司

Micro emulsion type metal anti-rusting liquid and preparation method thereof

The invention discloses a micro emulsion type metal anti-rusting liquid and a preparation method thereof. The micro emulsion type metal anti-rusting liquid comprises base oil, an anti-rusting agent, a surfactant, silica sodium, thiourea, sodium metabisulfite, nitrogenous trimethylene phosphoric acid, benzotriazole, myo-inositol hexakis dihydrogen phosphate, vinyl acetate, trimethyl ammonium chloride, methacrylic acid dimethylamino ethyl ester, agar and deionized water. The preparation method comprises the following steps: firstly, mixing the base oil, the anti-rusting agent, silica sodium and thiourea, stirring, heating, subsequently adding myo-inositol hexakis dihydrogen phosphate, stirring so as to obtain a mixture I, further adding the surfactant, sodium metabisulfite, nitrogenous trimethylene phosphoric acid and benzotriazole into the deionized water, heating, adding vinyl acetate, and stirring so as to obtain a mixture II, mixing the mixture I and the mixture II, further adding the rest components, heating, and uniformly stirring, thereby obtaining the anti-rusting liquid. By adopting the anti-rusting liquid disclosed by the invention, the anti-rusting time is prolonged, and the anti-rusting effect is improved.

Owner:江苏悠谷未来科技有限公司

Rust-proof lubricating oil

InactiveCN104031728AGood lubricationGood anti-rust functionLubricant compositionNano zinc oxideLubrication

The invention discloses rust-proof lubricating oil, belonging to the technical field of lubricating oil. The lubricating oil is prepared from the following raw materials in parts by weight: 10-15 parts of trimethylolpropane, 1-5 parts of sorbitan monooleate, 3-8 parts of monobutanimide, 0.5-0.8 part of nano zinc oxide, 2-4 parts of glycidyl acrylate, 0.5-0.8 part of alkenyl dibutyrate and 0.01-0.02 part of salicylate. The rust-proof lubricating oil provided by the invention has good lubrication and rust prevention effects.

Owner:柳州市汉森机械制造有限公司

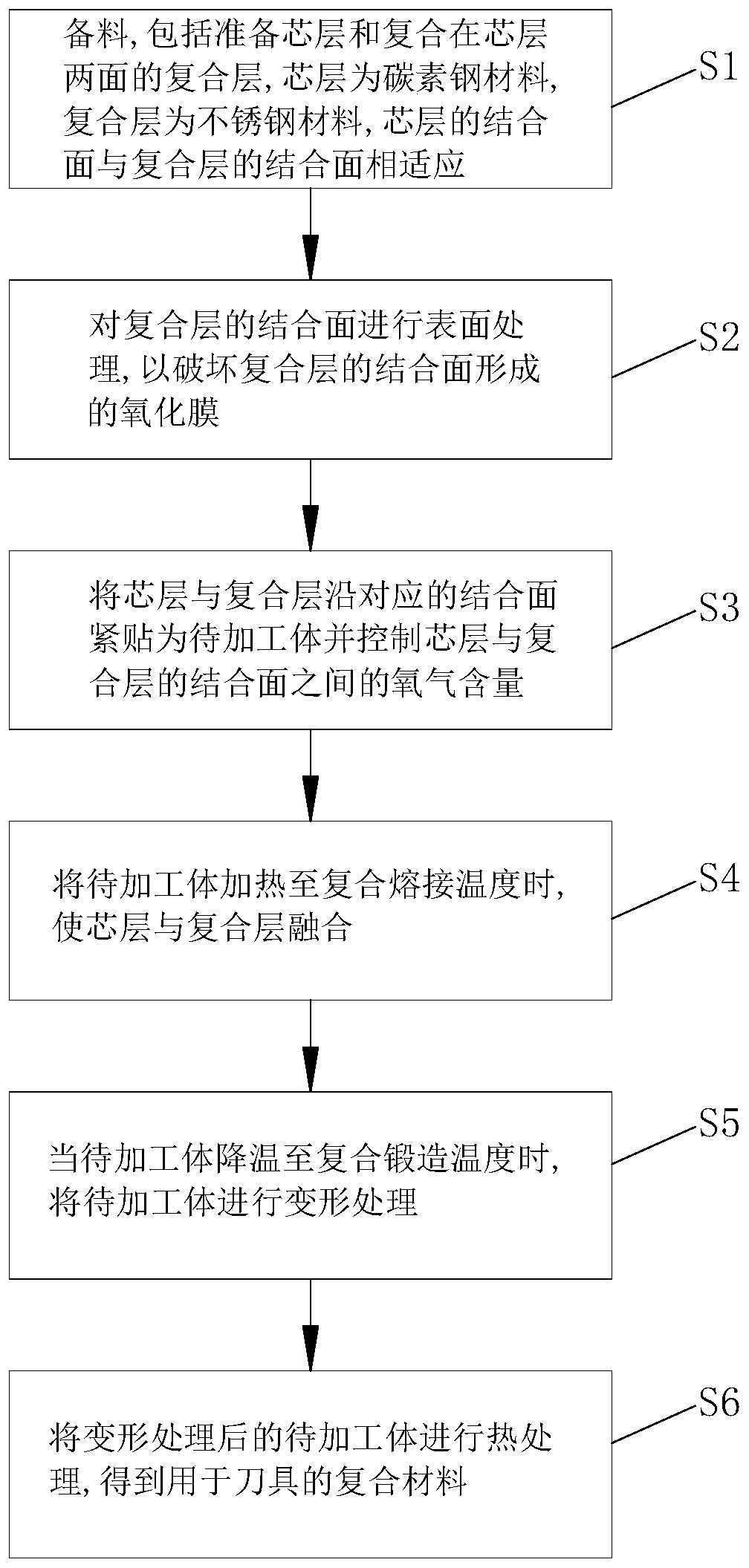

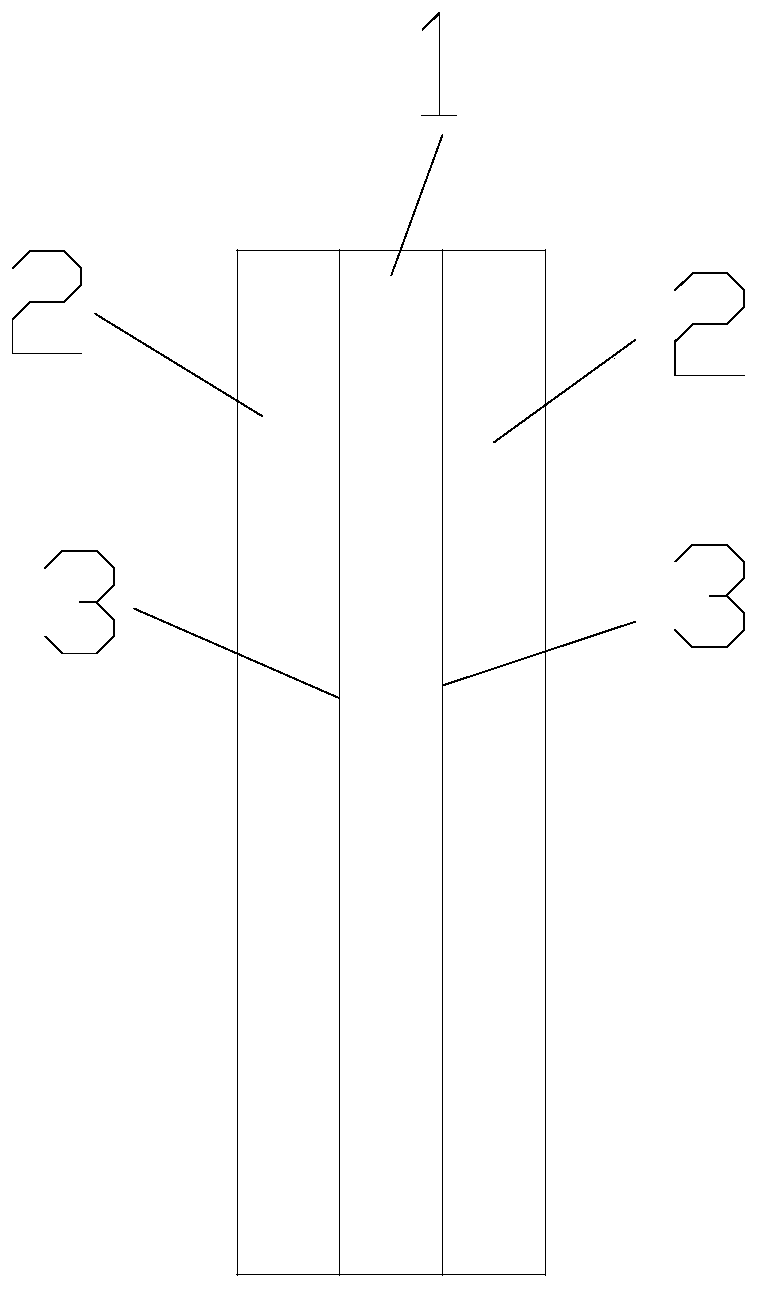

Cutter, composite material thereof and preparation method of composite material

InactiveCN110170605AGood anti-rust functionHigh hardnessMetal rolling arrangementsCutleryMaterials preparationHardness

The invention discloses a cutter, a composite material thereof and a preparation method of the composite material. The preparation method of the composite material includes the steps of material preparation; performing surface treatment on the joint face of a composite layer; tightly closing a core layer to the composite layer and forming a to-be-machined body in a sealing manner; when the to-be-machined body is heated to a composite fusion welding temperature, the surface of the composite layer of the to-be-machined body is slightly knocked; at a composite forging temperature, the to-be-machined body is subjected to deformation treatment; and the to-be-machined body after deformation treatment is subjected to heat treatment. The composite material of the cutter is made according to the preparation method, and the cutter is made according to the composite material. The preparation method solves the problem that combination of stainless steel and plain carbon steel is difficult, the composite material obtained through the preparation method of the composite material has good rust preventing function, large hardness and toughness is achieved, and the cutter made from the composite material has good rust preventing function; and meanwhile, a cutting edge is large in hardness, a cutter body is good in toughness, the cutting edge is not likely to generate a notch and cutting edge curving, re-grinding performance is good, and use by a user is convenient.

Owner:佛山市徐城记厨具有限公司

Black metal water-based antirust agent

InactiveCN108998782AImprove rust resistancePlay a protective effectMetallic material coating processesWater basedDefoaming Agents

The invention discloses a black metal water-based antirust agent. The black metal water-based antirust agent comprises the following raw materials in parts by weight: 7 to 12 parts of ethanol amine, 1to 1.5 parts of dodecyl tribasic acid, 0.5 to 1.5 parts of boric acid, 2 to 3 parts of a settling agent, 0.3 to 0.7 part of a hard water resistant agent, 1 to 2 parts of a corrosion inhibitor, 0.5 to1 part of a defoaming agent, 1 to 1.5 parts of trisodium phosphate, 1 to 3 parts of sodium tripolyphosphate, 2 to 4 parts of sodium hydroxide, 0.3 to 0.9 part of sodium molybdate, 2 to 5 parts of benzotriazole, 0.5 to 1.5 parts of a complexing agent, 2 to 3 parts of zinc oxide, 1 to 3 parts of sodium benzoate and 0.2 to 1 part of dibutyl phthalate. The black metal water-based antirust agent has agood antirust function, also has a certain cleaning effect and is suitable for popularizing.

Owner:广州市融宽科技有限公司

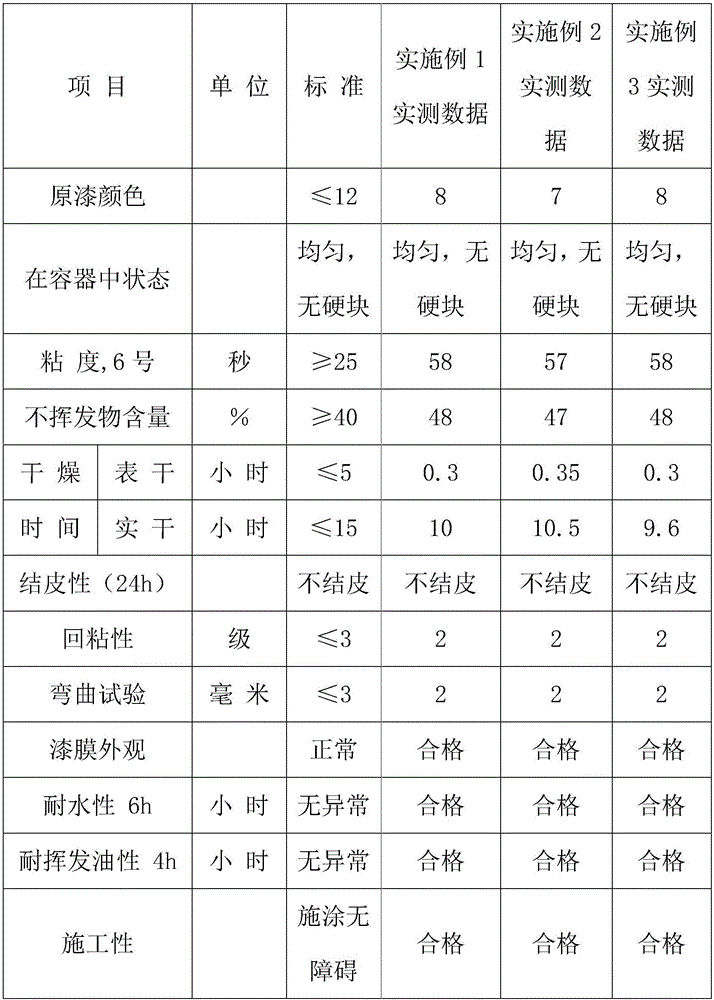

Quick-drying alkyd resin and preparation method thereof as well as quick-drying varnish

ActiveCN105153406AGood anti-rust functionFast dryingAnti-corrosive paintsPolyester coatingsXylylenePolymer science

The invention provides quick-drying alkyd resin and a preparation method thereof as well as quick-drying varnish, and relates to the technical field of industrial coating. The quick-drying varnish comprises the following components in weight proportion: 75-85% of quick-drying alkyd resin, 0.4-0.6% of a drier, 0-0.2% of an anti-skinning agent and the balance of xylene. The surface drying time of the quick-drying alkyd provided by the invention is about 15 minutes in a normal temperature state, and the hard drying time of the quick-drying alkyd is about 8 hours, the drying speed of the quick-drying alkyd resin is increased greatly in comparison with that of conventional alkyd resin at the normal temperature and the drying speed is extremely high. All technical indexes of the quick-drying varnish provided by the invention reach state specified standards, in addition, the salt spray resistance test can reach about 72 h and the quick-drying varnish has a better antirust function.

Owner:湖南开磷雁峰塔涂料有限公司

Polishing solution

InactiveCN104194650AExcellent decontaminationBright surfaceAqueous dispersionsSodium molybdateSulfate zinc

The invention discloses a polishing solution which is prepared from the following raw materials in parts by weight: 9-15 parts of sodium salicylate, 3-7 parts of methylsilicone oil, 2.5-6 parts of monopotassium phosphate, 6-10 parts of orthophosphate, 1.3-3.8 parts of polyvinyl alcohol, 0.6-1.4 parts of sodium molybdate, 3-8 parts of ethylenediamine tetramethylenephosphonic acid, 3.5-9 parts of zinc sulfate, 2.5-5.8 parts of methylsilicone oil and 2.4-5.4 parts of a dispersing agent. The surface of a part can be well decontaminated by the polishing solution disclosed by the invention, so that the surface of the part is bright and glossy and has a good antirust function.

Owner:QINGDAO QIYUAN ZHENDONG ELECTRIC

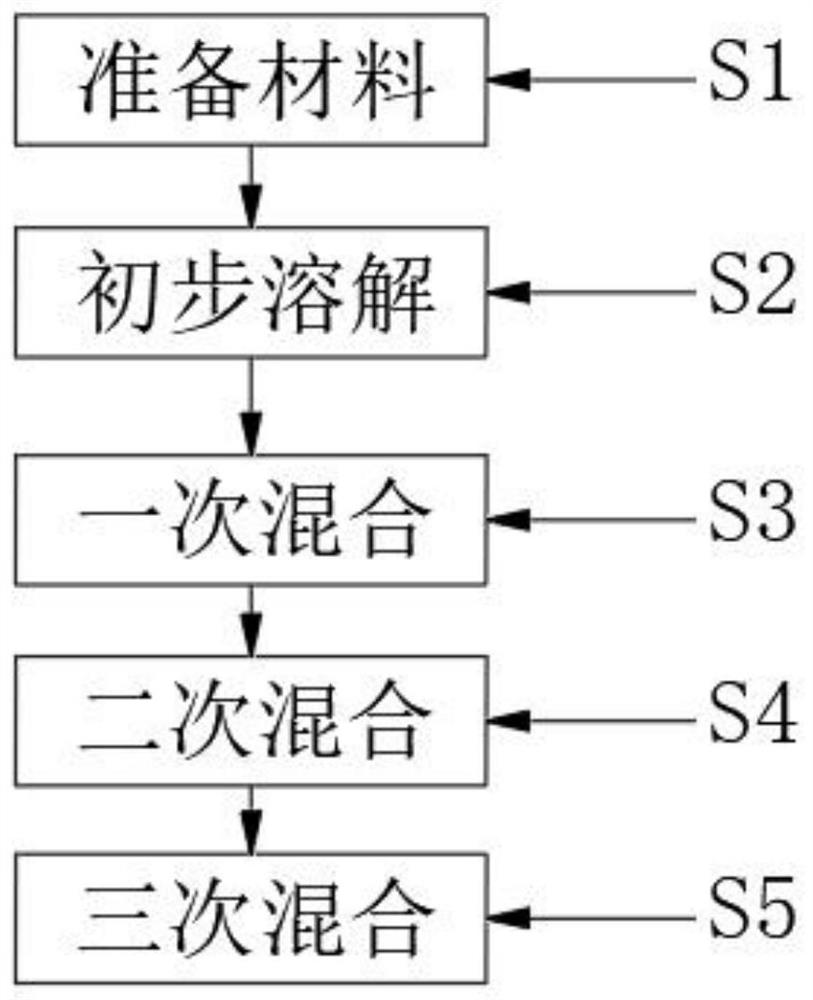

High-strength steel fiber adhesive and preparation method thereof

PendingCN111978889AStrong toughnessGood passivation and anti-rust functionNon-macromolecular adhesive additivesUnsaturated alcohol polymer adhesivesIndustrial constructionPolymer science

The invention relates to the technical field of industrial buildings and discloses a high-strength steel fiber adhesive and a preparation method thereof. The high-strength steel fiber adhesive comprises the following components in parts by weight: 60-80 parts of a vinyl acetate-ethylene copolymer, 6-8 parts of polyvinyl alcohol, 15-20 parts of phosphorylated polyvinyl alcohol resin, 0.1-1.0 part of an amine cross-linking agent, 2-5 parts of an emulsifier and 5-10 parts of deionized water. The preparation method of the high-strength steel fiber adhesive comprises the following steps of: S1, material preparation; S2, preliminary dissolution; S3, primary mixing; S4, secondary mixing; and S5, tertiary mixing. The high-strength steel fiber adhesive is high in toughness, high in bonding strength, high in water dissolving speed and higher in anti-rust function, the amount of an adhesive for producing tandem steel fiber is small, and the cost of a product is reduced.

Owner:天津恒沣栩翔金属新材料股份有限公司 +1

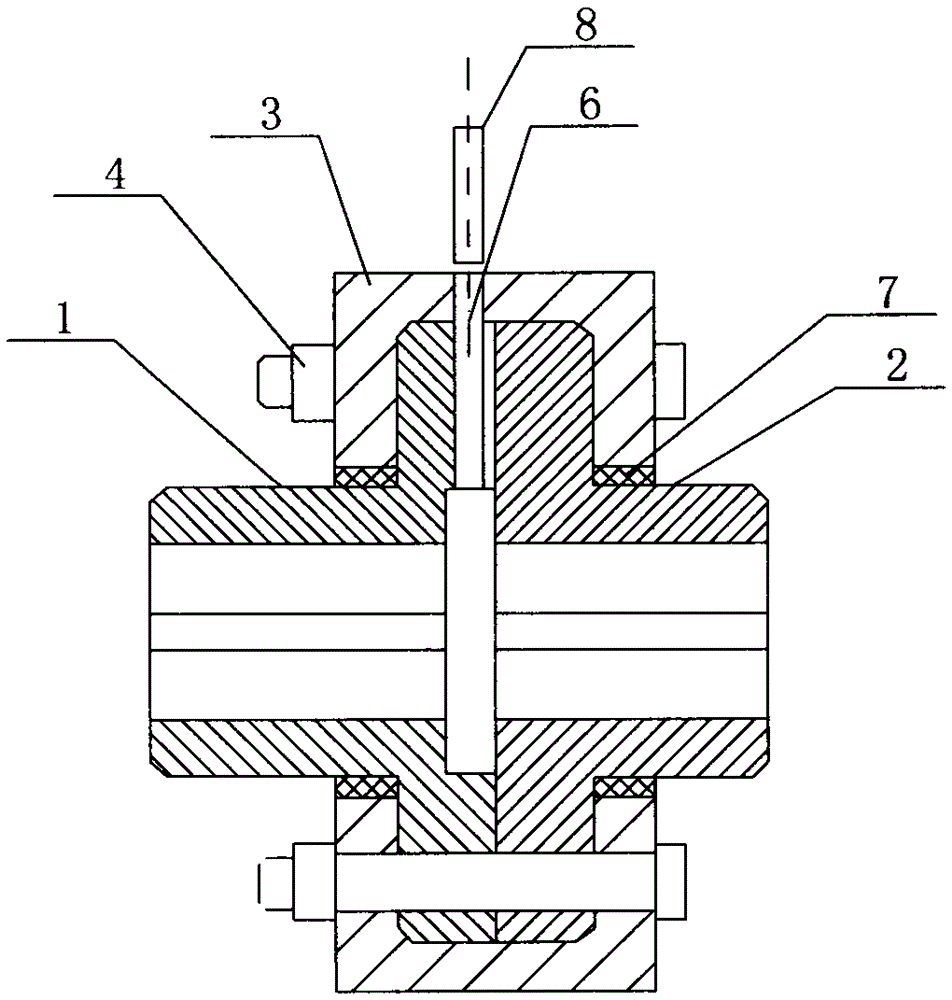

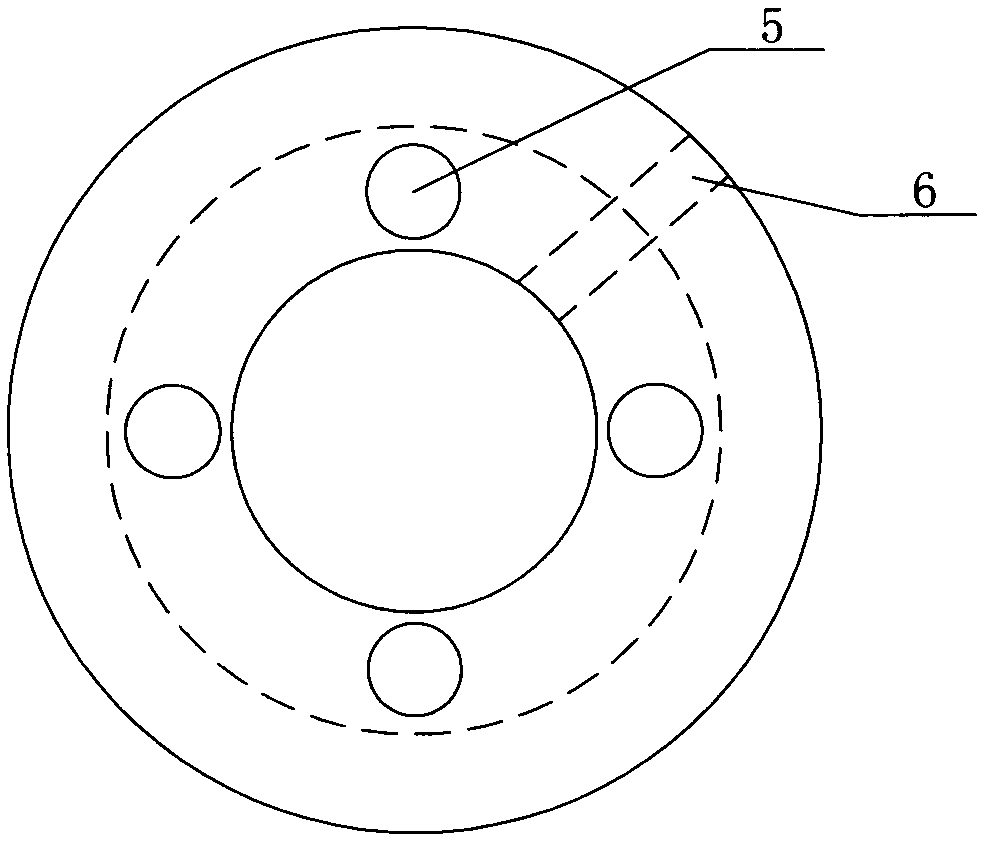

Oiling rust-proof coupling

The invention relates to the technical field of couplings, in particular to an oiling rust-proof coupling. The oiling rust-proof coupling comprises a left half coupling body and a right half coupling body. The right half coupling body is arranged on one side of the left half coupling body. The oiling rust-proof coupling further comprises a sealing end cover, and fixed through holes are formed in the sealing end cover, the left half coupling body and the right half coupling body; the sealing end cover is fixedly connected with the left half coupling body and the right half coupling body through fixed bolts; and oiling holes are formed in the sealing end cover. The oiling rust-proof coupling has a good rust-proof function, the problems that due to the fact that the oiling rust-proof coupling is not used for a long time, rusty spots are generated, and dismounting is not easy are solved, and the service life of the coupling is effectively prolonged.

Owner:镇江市润州联轴器厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com