Patents

Literature

67 results about "Tribasic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tribasic acid is an acid that has three hydrogen ions to donate to a base in an acid-base reaction. Therefore, a tribasic molecule has three replaceable hydrogen atoms. Phosphoric acid and citric acid are examples of tribasic acids.

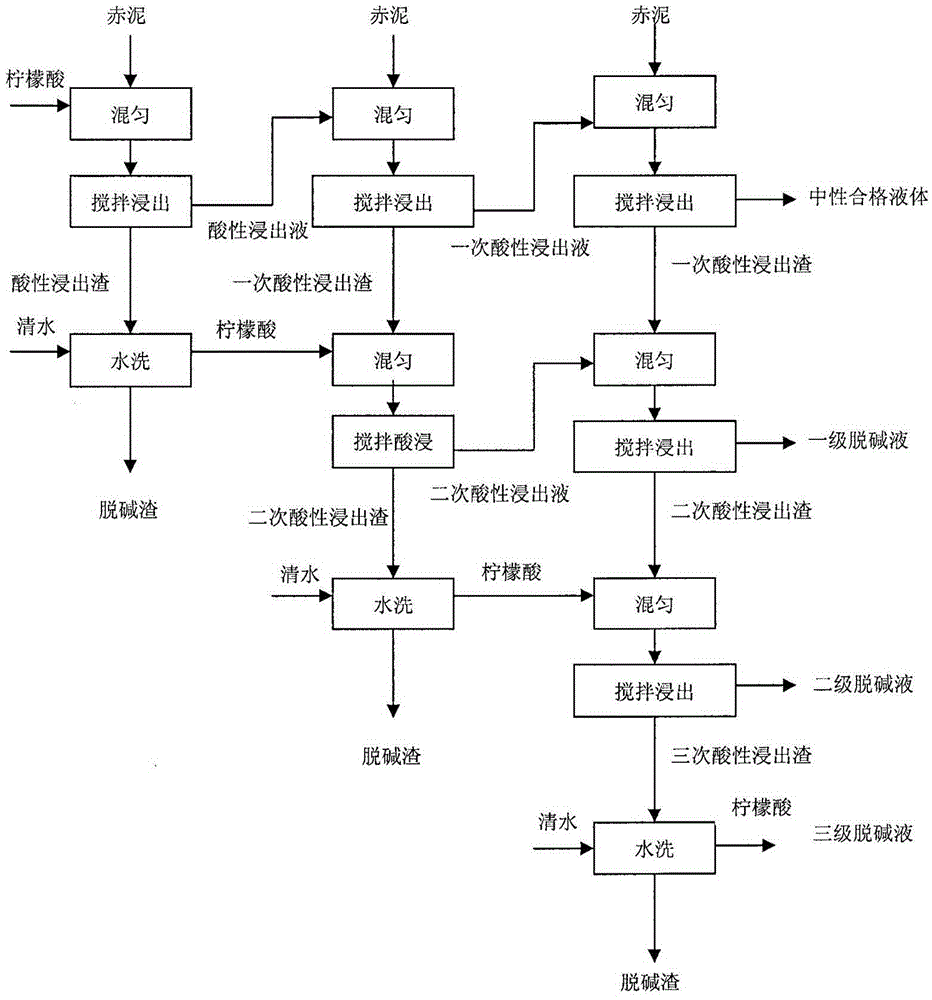

Red-mud citric acid dealkalizing technique

The invention discloses a red-mud citric acid dealkalizing technique. According to the technique, citric-acid three-level cross-flow dealkalizing operation is carried out on red mud, and Bayer-process red mud is dealkalized through citric acid. Due to the fact that the citric acid is organic tribasic acid, sodium and potassium in the red mud can be effectively removed under the condition of the lower citric acid using amount and the low temperature, the pH value of the dealkalized sludge ranges from 6.5 to 7.5, and the dealkalized sludge can be dammed and piled. Residual citric acid in the dealkalized sludge of the red mud can be degraded biologically, has a repairing function on alkaline soil and can serve as a modifying agent for the alkaline soil. The citric acid can generate calcium citrate sediment with other elements like calcium, so that calcium can be solidly stored in the dealkalized sludge of the red mud to be used as raw materials for manufacturing building materials. Elements like titanium, scandium and rare earth are difficult to dissolve out, the taste of the elements in the dealkalized sludge of the red mud is improved, and the dealkalized sludge can be used as raw materials to extract valuable rare metal. According to the red-mud citric acid dealkalizing technique, the citric acid can be recycled, and the consumption of chemical agents is reduced. In addition, the pH value of obtained dealkalized liquid ranges from 6.5 to 7.5, the dealkalized liquid does not contain heavy metal ions, and the dealkalized liquid can be drained and utilized.

Owner:HENAN POLYTECHNIC UNIV

Biodegradable branched co-polyester and preparation method thereof

The invention discloses biodegradable branched co-polyester and a preparation method thereof, and belongs to the polymeric chemical field. The preparation of branched co-polyester adopts a mature esterification and fasculation process route, butane diacid and butanediol which are used as main copolymerization units performs a copolymerization action with one or more than one of lateral group-containing aliphatic dibasic acid, C3, C5 to C8 alkane diacid, terephthalic acid or tribasic acid, or performs a copolymerization action with one or more than one of lateral group-containing dibasic alcohol, C2, C3, C5 to C10 alkane diol or aliphatic trivalent alcohol, so as to obtain random branched co-polyester finally. The intrinsic viscosity of prepared co-polyester ranges from 0.6 to 2.2dl / g, the melting point ranges from 70 to 115, the degree of crystallinity ranges from 20 to 70 percent, and the weight average molecular weight ranges from 5 to 300000. The co-polyester preparation method adopts efficient a blended catalyst, so that the polymerization time is reduced greatly, and the molecular weight and the performance of the products are increased. New performances are given to polyester through quoting third components containing lateral groupsor multi-functional groups, thereby extending the application range of polyester.

Owner:TSINGHUA UNIV

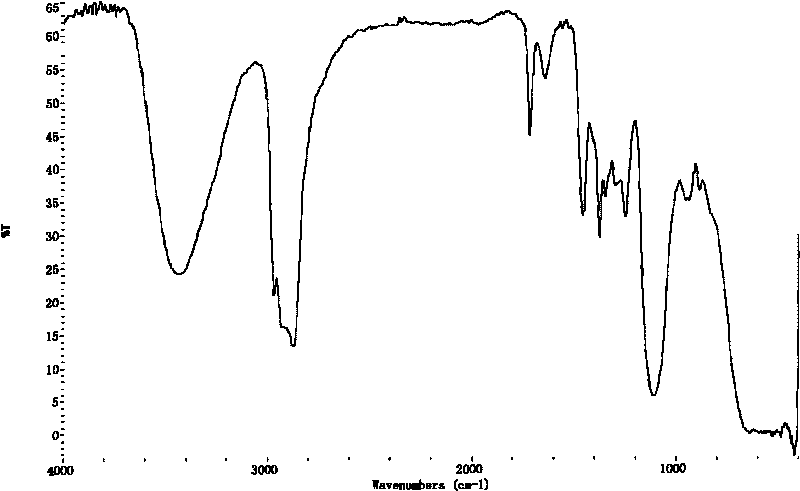

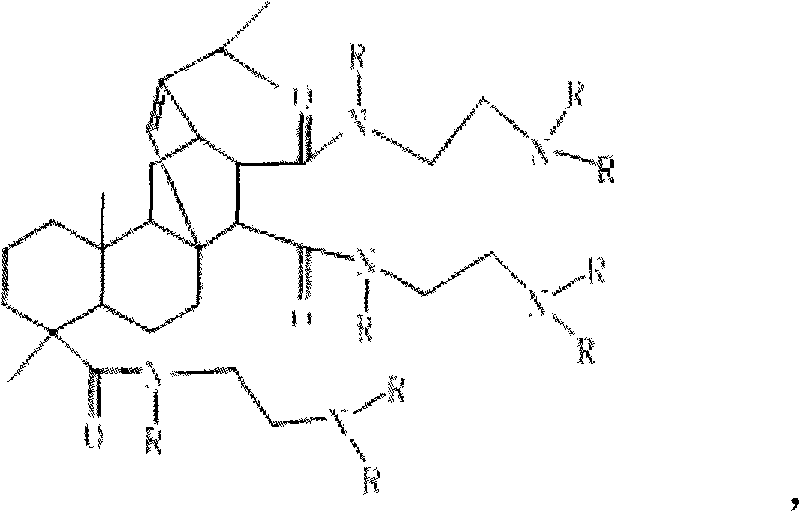

Rosin polyether glycol used for flame-retardant hard polyurethane foaming plastic and preparation method thereof

ActiveCN101693762AImprove thermal stabilityImprove flame retardant performanceNatural resin chemical modificationAlkanePolymer science

The invention discloses a rosin polyether glycol used for flame-retardant hard polyurethane foaming plastic, with the structural formula that: R is n which equals to 1 to 10. A preparation method of the rosin polyether glycol comprises the following steps: adding rosin dibasic acid or tribasic acid, alkane diamine and acid catalyst in a pressure-resistant reaction kettle, mixing and stirring with temperature raised, reacting for 3 to 8 hours, reducing the temperature to 100 to 120 DEG C, adding base catalyst, keeping the temperature at 130 to 150 DEG C under the vacuumization and anaerobic condition, dividing oxirane and epoxypropane into a plurality of times, conducting alternate circular reaction according to the sequence of firstly introducing the oxirane and then introducing the epoxypropane, and conducting reduced pressure distillation after that to obtain a flame-retardant rosin polyether glycol. As the rosin polyether glycol contains rosin phenanthrene ring rigid structure, and contains a certain amount of flame-retardant nitrogen elements, when being used in hard polyurethane foaming plastic, the rosin polyether glycol has higher thermal stability and flame retardance, and good compression strength, with 28 to 30 percent the oxygen index, thus being used in building, heat insulation and a plurality of special fields.

Owner:江苏真的旺节能科技有限公司

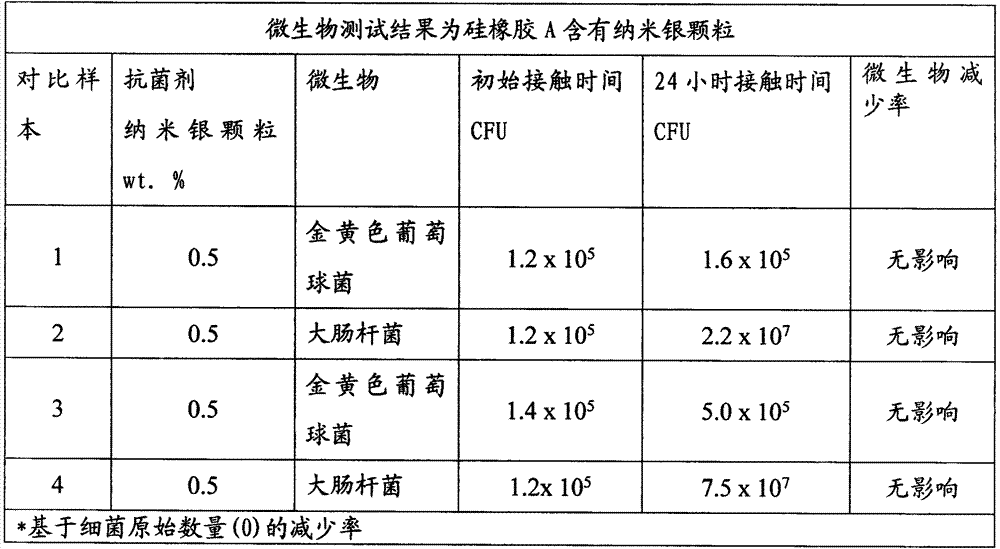

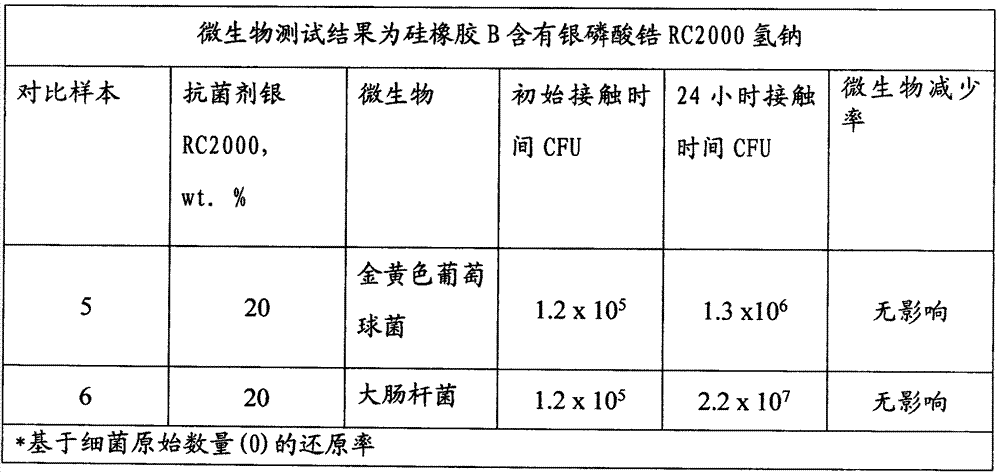

Antibacterial silicone rubber and preparation method thereof

The invention relates to silicone rubber and a preparation method thereof, in particular to antibacterial silicone rubber and a preparation method thereof. The antibacterial silicone rubber comprises, by weight percentage, 96.5-98% of silicone rubber, 0.1-10% of antibacterial additive containing silver ions and 0.1-5% of carboxylic acid, wherein the antibacterial additive containing silver ions comprises one or more of silver-loaded zirconium phosphate, silver carboxylates, silver-impregnated zeolite, glass particles with silver-loaded surface coatings, colloidal silver particles or nano silver particles; the carboxylic acid comprises one or more of single acid, double acid, tribasic acid, fatty acid, alicyclic acid, alicyclic acid aromatic carboxylic acid or the anhydride of the carboxylic acid. The silicone rubber is efficient in antibacterial activity and applicable to various application requiring antibacterial performance.

Owner:HANGZHOU GEFANG NEW MATERIAL TECH CO LTD

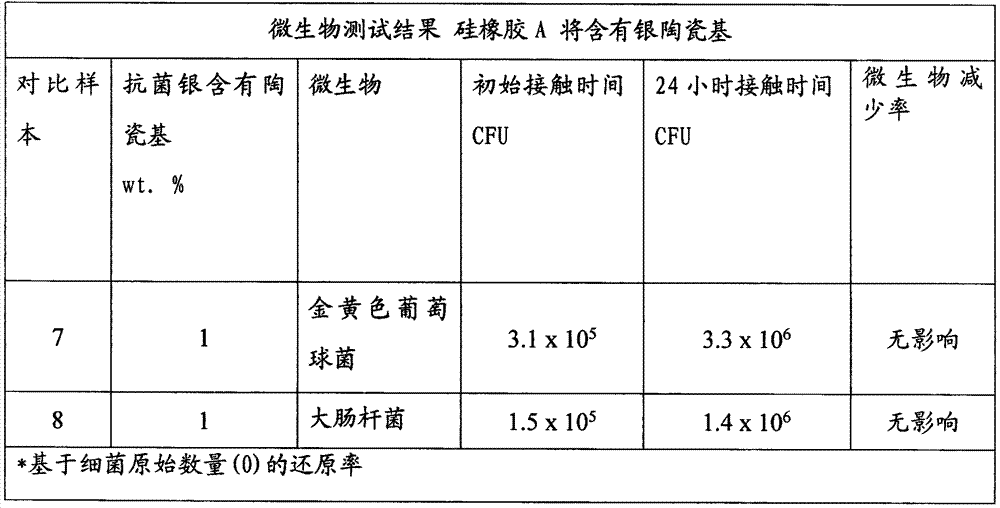

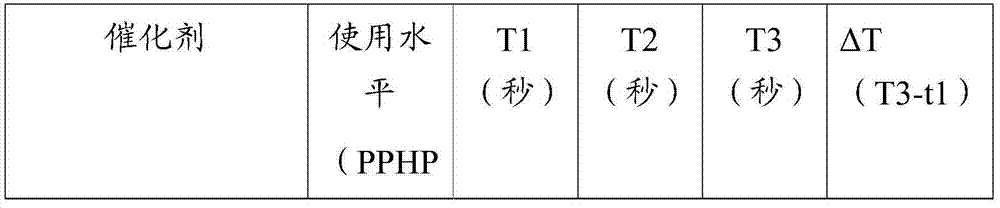

Delay action catalyst for improving the stability of polyurethane systems having halogen containing blowing agent

Catalyst compositions useful in the production of insulating polyurethane or polyisocyanurate foam are disclosed. The catalyst compositions impart increased stability of a mixture of the catalyst, a halogen-containing blowing agent, and a polyol. These catalyst compositions include amine / acid salts with a pH of < 7.0 which can be used in combined with tertiary amine catalysts and metal-based or ammonium-based trimerization catalyst and at least one metal-based gel catalyst and optionally one or more of an additional catalyst described in (1) or (2). These improved catalysts can be used with any halogenated blowing agent, and provide substantial stability benefits with the use of hydrofluoroolefins and hydrofluorochloroolefins. In an exemplary embodiment, a process includes providing a pre-mix comprising an organic carboxylic di-acid, tri-acid or poly-acid component and contacting a tetraalkylguanidine and / or a tertiary amine containing an isocyanate reactive group with the acid component in the pre-mix to form a mixture of tetraalkylguanidine salt or tertiary amine salt or their combination.

Owner:AIR PROD & CHEM INC

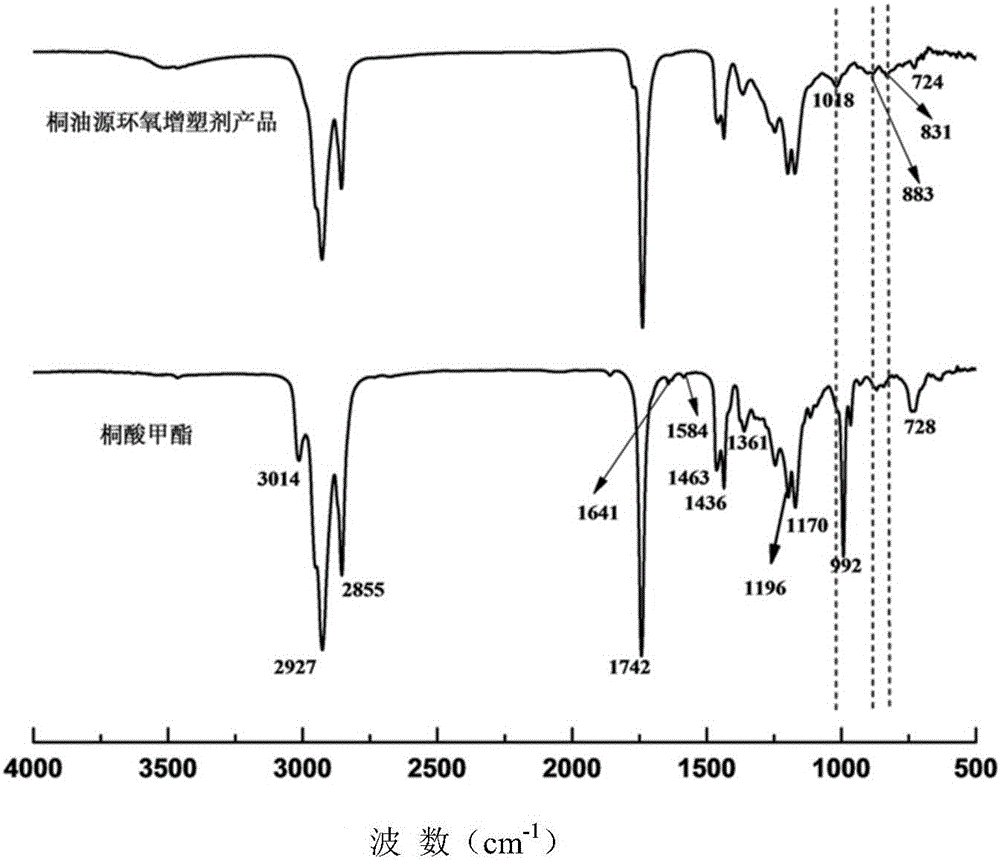

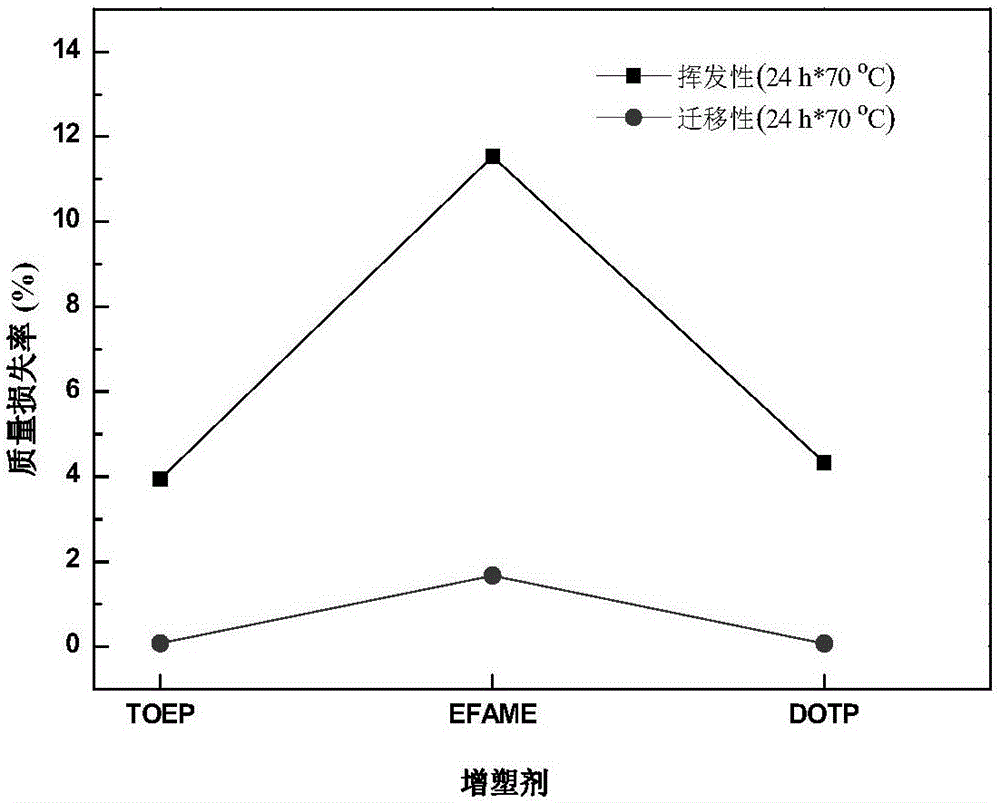

Tung oil source epoxy plasticizer product having function of heat stabilizer, preparation method thereof and application thereof

InactiveCN106397367AImprove migration resistanceImprove volatility resistanceOrganic chemistryEpoxyPhosphoric acid

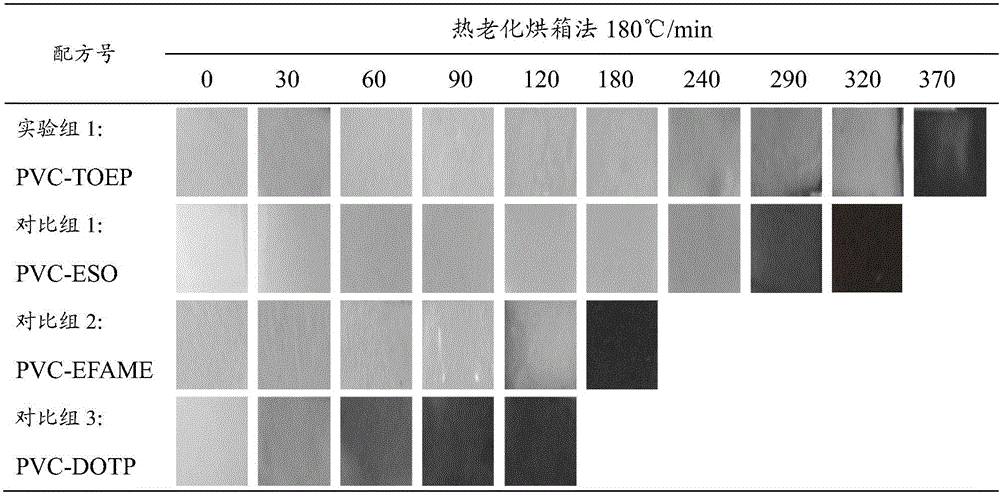

The invention provides a tung oil source epoxy plasticizer product having the function of a heat stabilizer, a preparation method thereof and an application thereof. According to the technical scheme of the invention, dienophile is uniformly mixed up and then methyl eleostearate is added. The dienophile and the methyl eleostearate are subjected to Diels-Alder addition reaction, and then fractions are collected in the vacuum condition so as to obtain tung oil source polybasic acid esters including tung oil source dibasic acid dimethyl ester, tung oil source ternary acid trimethyl ester and the like. With the existence of hydrogen peroxide, formic acid, phosphoric acid and the like, one part of unsaturated double bonds in the structures of the tung oil source polybasic acid esters is subjected to epoxidation, so that the tung oil source epoxy plasticizer product can be obtained. According to the technical scheme of the invention, methyl eleostearate is adopted as a raw material, and the obtained tung oil source epoxy plasticizer product is low in volatility, small in mobility and good in compatibility with polyvinyl chloride resin and the like. Meanwhile, polyvinyl chloride products are enabled to be good in plastification effect, and the heat stability of PVC products is effectively improved at the same time. The tung oil source epoxy plasticizer product can be used to replace or partially replace plasticizer products including dioctyl phthalate, dioctyl terephthalate, epoxidized fatty acid methyl ester and the like.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

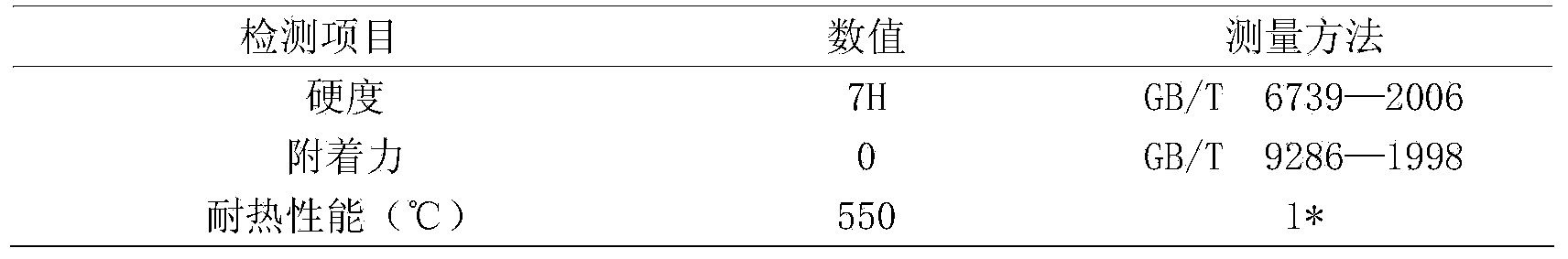

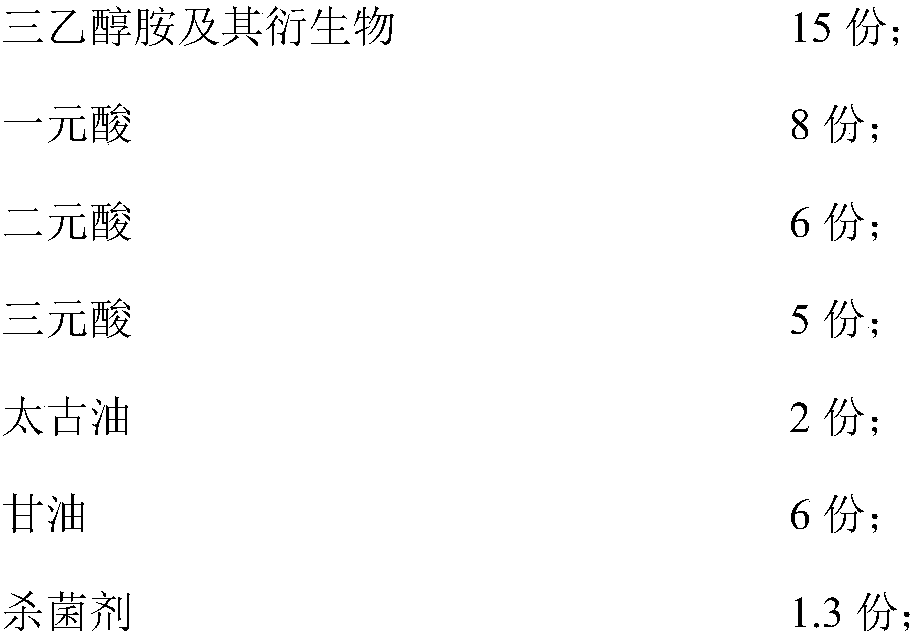

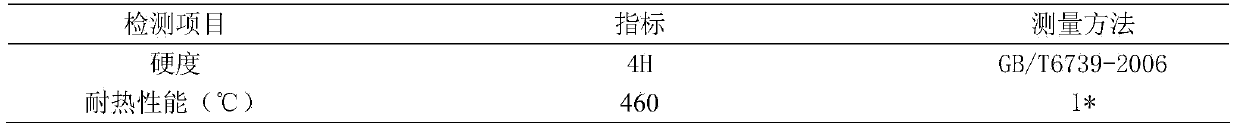

Preparation method of hyperbranched polyamide modified organic silicon resin and paint prepared from resin

The invention relates to a preparation method of a hyperbranched polyamide modified organic silicon resin, which comprises the following steps: uniformly mixing diamine, tribasic acid which is 1-2.0 times of diamine by mole, aminated superfine silicon dioxide which is 1-2 times of diamine by weight, a crosslinking catalyst which is 1-5% of diamine by weight, and dipropylene glycol monobutyl ether acetate which is 3-8 times of diamine by weight, and heating at 180-220 DEG C for 1-4 hours; cooling to 90 DEG C, adding epoxy-terminated organic silicon low polymer which is 1.5-2.0 times of diamine by weight, and heating at 120-140 DEG C for 2-3 hours; and finally, cooling to 90 DEG C, and adding an organic solvent until the solid content is 40-50 wt%. The resin prepared by the method can be used for preparing a high-temperature-resistant low-surface-energy paint. The aminated superfine silicon dioxide, diamine and tribasic acid react together to prepare the modified hyperbranched polyamide, thereby enhancing the heat resistance and hardness of the polyamide; and the modified hyperbranched polyamide and the epoxy-containing organic silicon low polymer are subjected to crosslinking reaction, thereby enhancing the heat resistance and hardness of the polyamide.

Owner:SOUTHERN MEDICAL UNIVERSITY

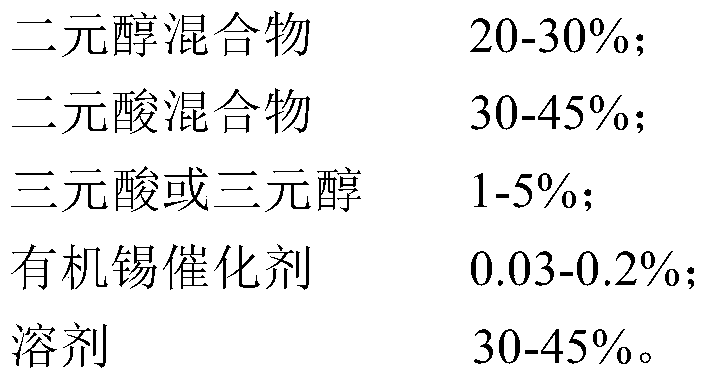

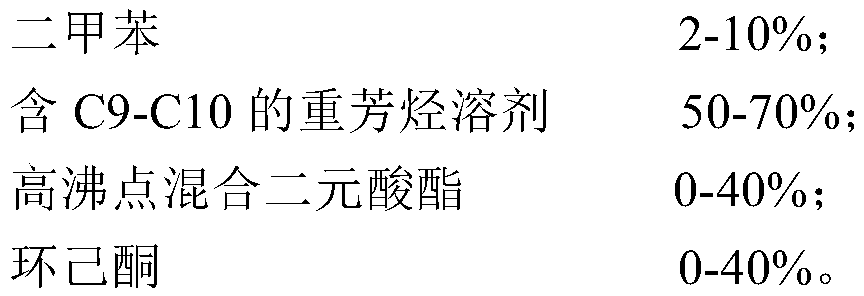

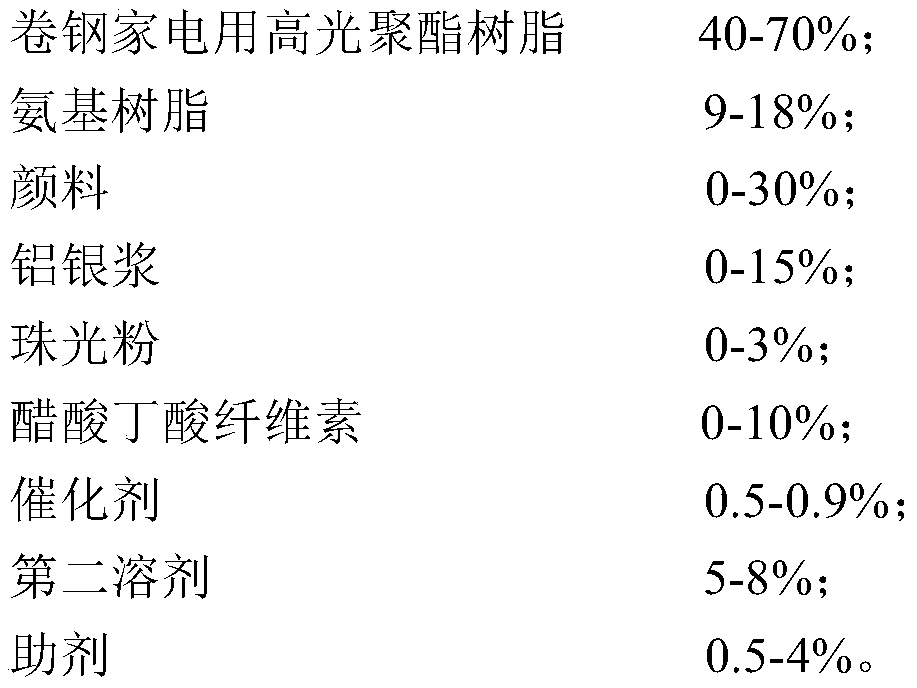

Highlight polyester resin for coil steel household appliance finish paint as well as preparation method and application thereof

InactiveCN111004375AImprove machinabilityGood resistance to MEKAntifouling/underwater paintsPaints with biocidesPolymer sciencePtru catalyst

The invention discloses a highlight polyester resin for coiled steel household appliances. The polyester resin is prepared by the following steps: carrying out polymerization reaction among a dibasicalcohol mixture, a dibasic acid mixture and tribasic acid or tribasic alcohol under the action of an organic tin catalyst, and diluting the reaction product by a solvent. The acid value of the polyester resin is 0-5 mg KOH / g, the hydroxyl value of the polyester resin is 60-80 mg KOH / g, the solid content of the polyester resin is 55-65 wt%, and the Gardner viscosity of the polyester resin at 25 DEGC is Z-Z4. The polyester resin effectively improves the MEK resistance of a coating containing the polyester resin and the particle / particle beam problem of a coated plate. The invention also discloses a preparation method and application of the polyester resin.

Owner:NIPPON PAINT GUANGZHOU

Powder binder for glass fiber chopped strand mat and preparation method thereof

The invention discloses a powder binder for a glass fiber chopped strand mat and a preparation method thereof. The powder binder is prepared from acid and alcohol according to a molar ratio of 1:0.95 to 1:1.05. The acid consists of fumaric acid, saturated dicarboxylic acid or acid anhydride of the saturated dicarboxylic acid and saturated tribasic acid or acid anhydride of the saturated tribasic acid according to the molar percentage of (40 percent to 94 percent):(5 percent to 50 percent):(1 percent to 10 percent); the saturated dicarboxylic acid or the acid anhydride of the saturated dicarboxylic acid is isophthalic acid or phthalic anhydride; the saturated tribasic acid or the acid anhydride of the saturated tribasic acid is trimesic acid or trimellitic anhydride; the dihydric alcohol consists of one of bisphenol A polyoxypropylene ether, hydrogenated bisphenol A and neopentyl glycol and bisphenol A polyoxyethylene ether according to the molar percentage of (5 percent to 50 percent):(50 percent to 95 percent); and the average addition molar number of the bisphenol A polyoxyethylene ether is 3. The powder binder disclosed by the invention not only can be fast dissolved inti vinyl benzene but also is good in transparency after being dissolved.

Owner:CHANGZHOU TIANMA GROUP CO LTD

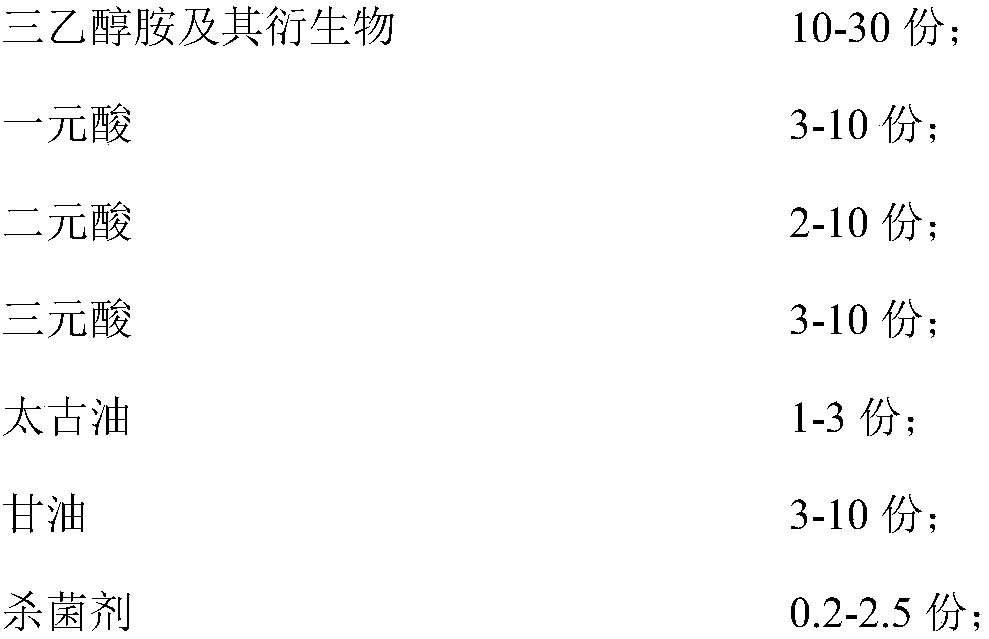

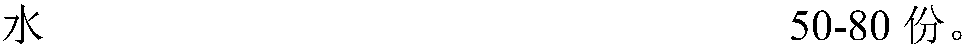

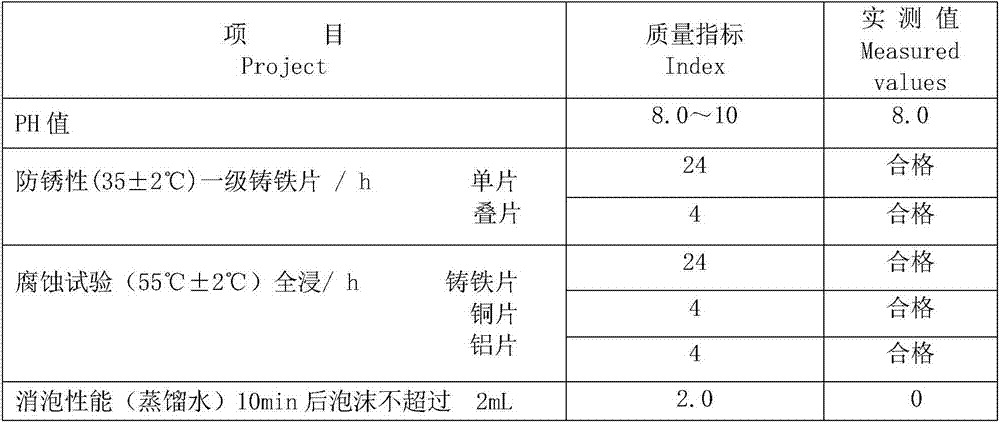

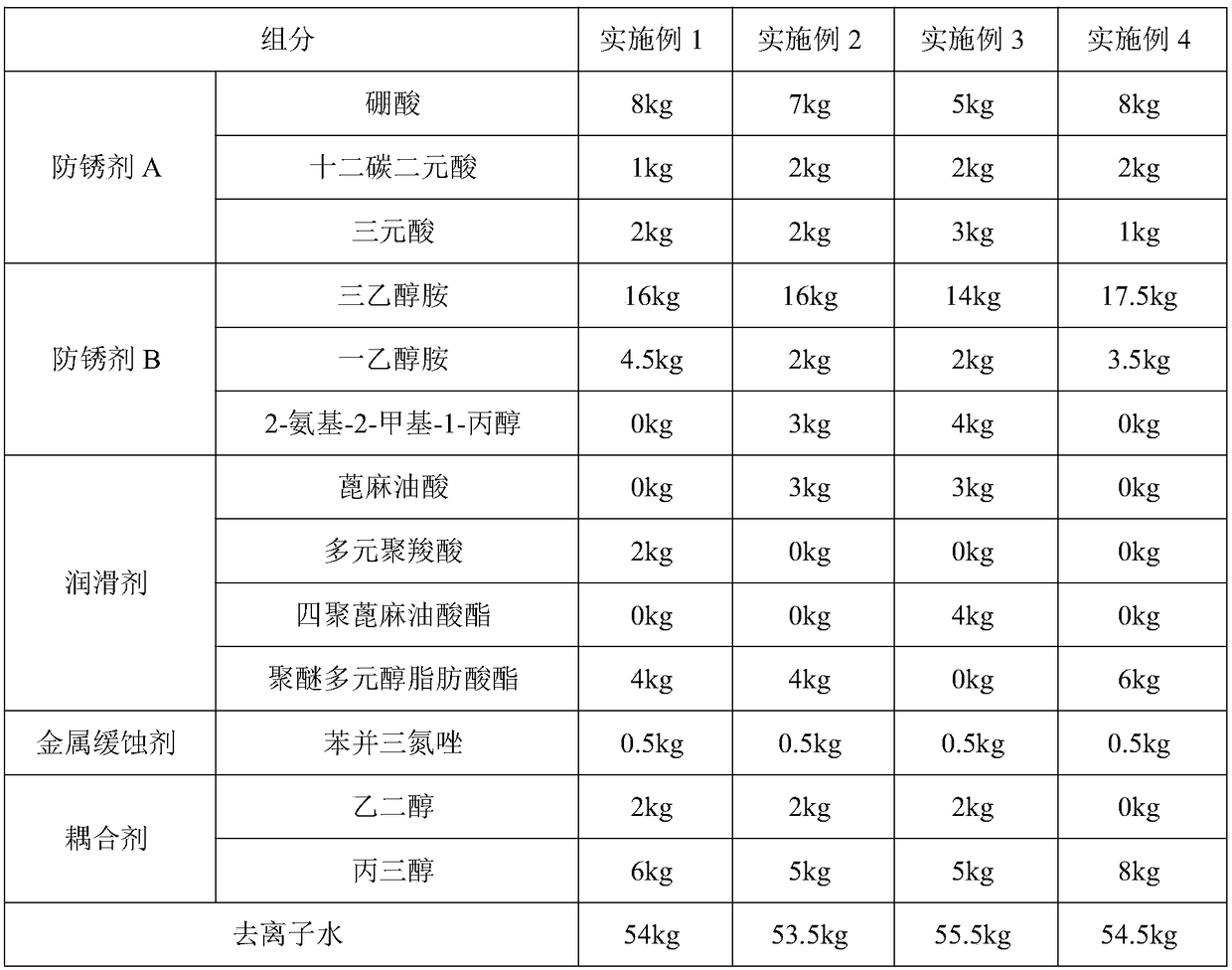

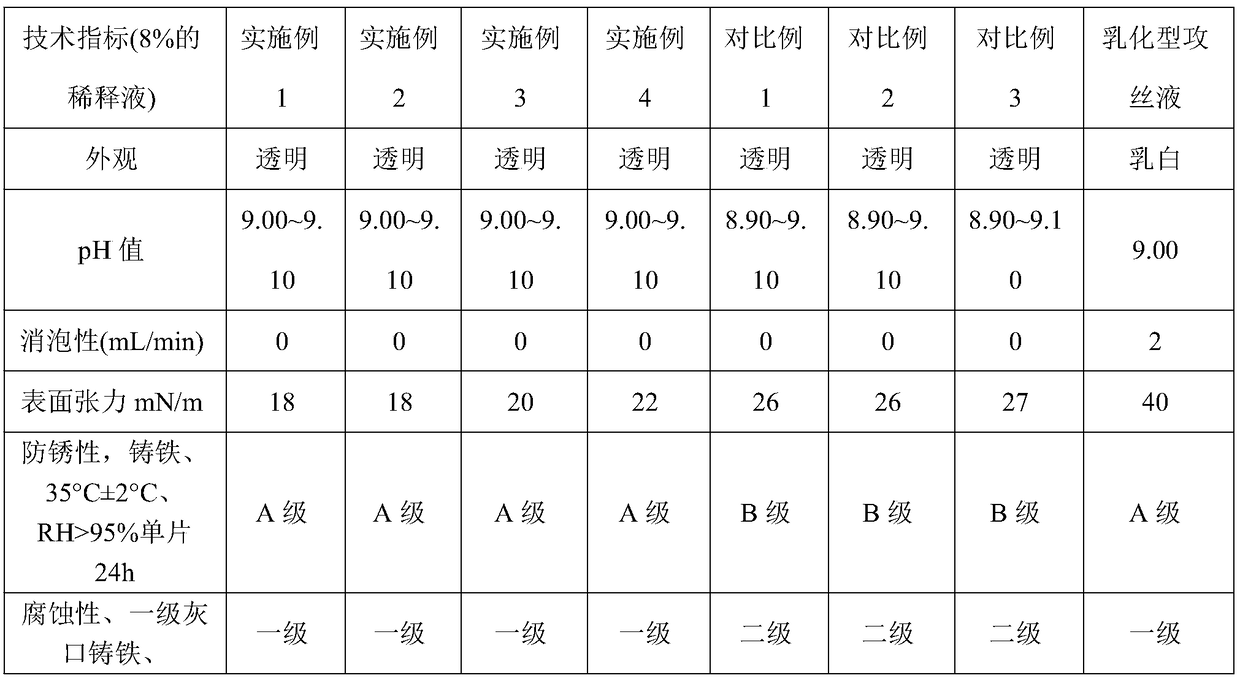

Preparation process of total synthesis cutting liquid with high lubricating property and high temperature resistance

ActiveCN108559608AImprove the lubrication effectImprove high temperature resistanceLubricant compositionGlycerolRoom temperature

The invention provides a preparation process of total synthesis cutting liquid with a high lubricating property and high temperature resistance. The preparation process includes the steps: S01 addingtriethanolamine and a derivative thereof serving as raw materials into water, starting stirring and heating, uniformly stirring the raw materials and heating the raw materials; S02 sequentially addingmonobasic acid and dicarboxylic acid serving as raw materials and stirring the raw materials until complete dissolution; S03 sequentially adding Turkey red oil and tribasic acid serving as raw materials and stirring the raw materials until complete dissolution; S04 adding glycerol and sterilizing agents serving as raw materials and stirring the raw materials to be uniform and transparent; S05 properly cooling the raw materials to room temperature and allowing discharging.

Owner:宇龙精机科技(浙江)有限公司

Coolant composition

InactiveUS20050274925A1Weak anticorrosion property against aluminumOther chemical processesMachines/enginesAlcoholCarboxylic acid

A coolant composition having anticorrosion properties against both aluminum and magnesium is provided. A coolant composition comprises a melting point depression agent selected from glycols and alcohols as the main component, and it contains a corrosion inhibitor selected from fluorides and a tribasic acid of an organic carboxylic acid or an alkali metal salt thereof.

Owner:TOYOTA JIDOSHA KK +1

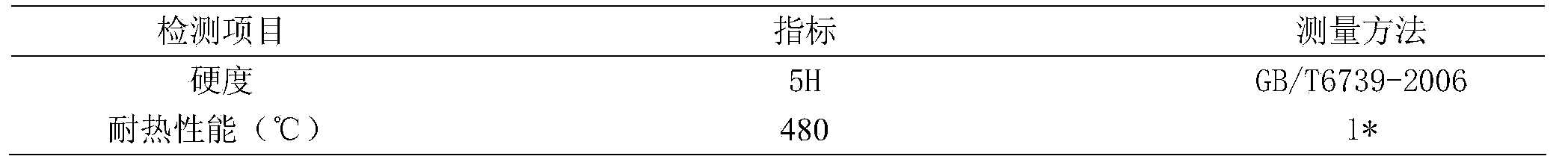

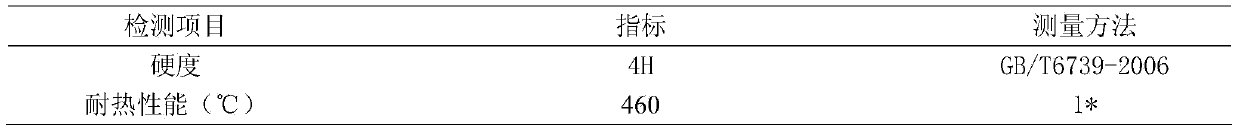

Preparation method of high-hardness polyamide modified organic silicon resin and coatings containing high-hardness polyamide modified organic silicon resin

The invention relates to a preparation method of high-hardness polyamide modified organic silicon resin. The method comprises the following steps that diamine, tribasic acid, aminated ultrafine alumina, a crosslinking catalyst and xylene are mixed evenly and heated at 180 DEG C-220 DEG C for 1 h-4 h, wherein the mole number of the tribasic acid is 1-2.0 times that of the diamine, the weight of the aminated ultrafine alumina is 1-2 times that of the diamine, the weight of the crosslinking catalyst is 1 percent-5 percent that of the diamine, and the weight of the xylene is 3-8 times that of the diamine; afterwards, the temperature is reduced to 90 DEG C, end-epoxy group organosilicone oligomer is added, and the mixture is heated at 120 DEG C-140 DEG C for 2 h-3 h, wherein the weight of the end-epoxy group organosilicone oligomer is 1.5-2.0 times that of the diamine; finally, the temperature is reduced to 90 DEG C, and an organic solvent is added, so that the solid content is 40 percent-50 percent by weight. The resin prepared through the method can be used for manufacturing high-temperature-resistant low-surface-energy coatings. According to the method, the aminated ultrafine alumina, the diamine and the tribasic acid react together to prepare modified hyperbranched polyamide, and the heat resistance and the hardness of polyamide are enhanced; as the modified hyperbranched polyamide and the epoxy-group-containing organosilicone oligomer are in a cross-linking reaction, the heat resistance and the hardness of the polyamide are further enhanced.

Owner:SOUTHERN MEDICAL UNIVERSITY

Preparation of efficient polybasic acid iron salt flocculant

The invention relates to a method for preparing a novel high-efficiency polybasic acid molysite flocculant. Industrial waste or a low-value byproduct is used as a main material. The flocculant can be widely used for multiple kinds of wastewater; the use amount of the flocculant is reduced by 1 to 3 times than that of other polymeric molysite; and the removing rate of TDS in the wastewater by the flocculant can reach between 45 and 80 percent and is higher than that of other polymeric molysite flocculant by 20 to 40 percent. The preparation method comprises that: firstly, iron slag with iron content of between 7 and 20 percent and other ferric scrap are heated by steam of waste sulphuric acid and react for 30 minutes to prepare a liquid ferrous sulfate coarse product; at a temperature of 60 DEG C, the coarse product is added with proper amount of sodium phosphate, is introduced with chlorine and is oxidized for 30 minutes; industrial waste alkali is used for regulating the basification degree for polymerization; and 2 percent calcium chloride as a stabilizing agent is added to the coarse product and is added with active carbon for adsorption and impurity removal to prepare a liquid product of a ferric sulfate chloride (phosphide)(abbreviated as tribasic acid molysite) flocculant in a polymeric state.

Owner:SHANGHAI AI QI ECOLOGICAL TECH

A method for the preparation of diazoalkanes

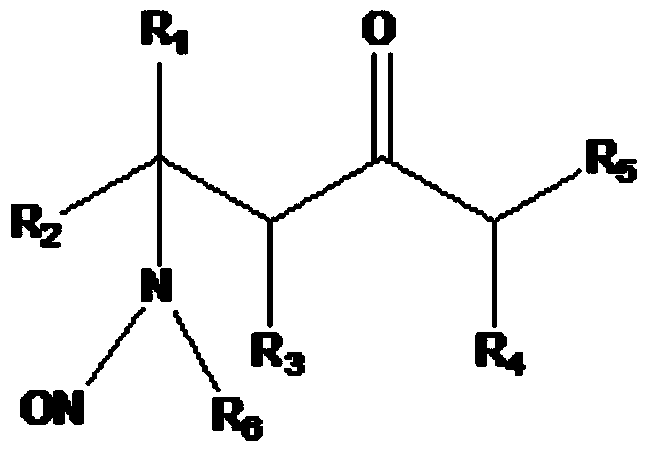

The present invention relates to a method of forming diazoalkanes. One aspect of the present invention provides a method for the production of a N-alkyl-N-nitroso compound from a starting material, comprising the use of a tribasic acid to acidify an amine. A second aspect of the present invention provides a method for the production of a diazoalkane, comprising reacting a N-alkyl-N-nitroso compound with a base and a phase transfer catalyst, wherein no organic solvent is used,

Owner:BAKHU

Water-soluble cutting fluid

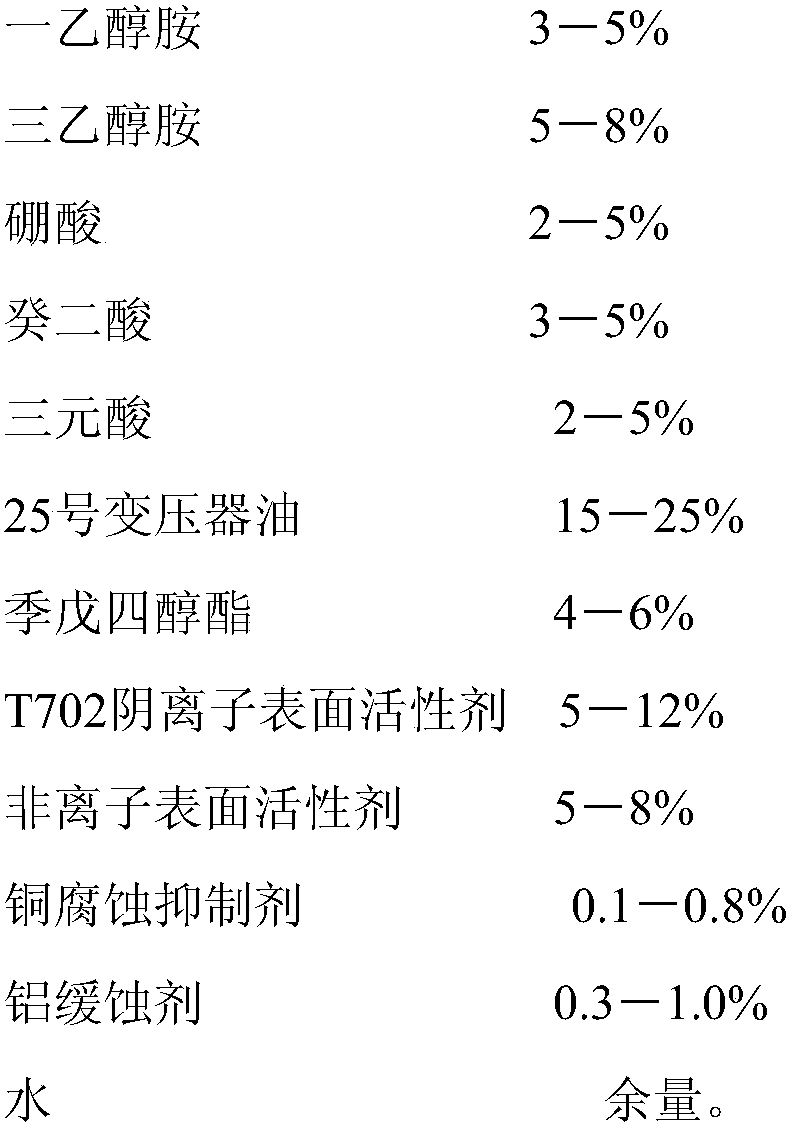

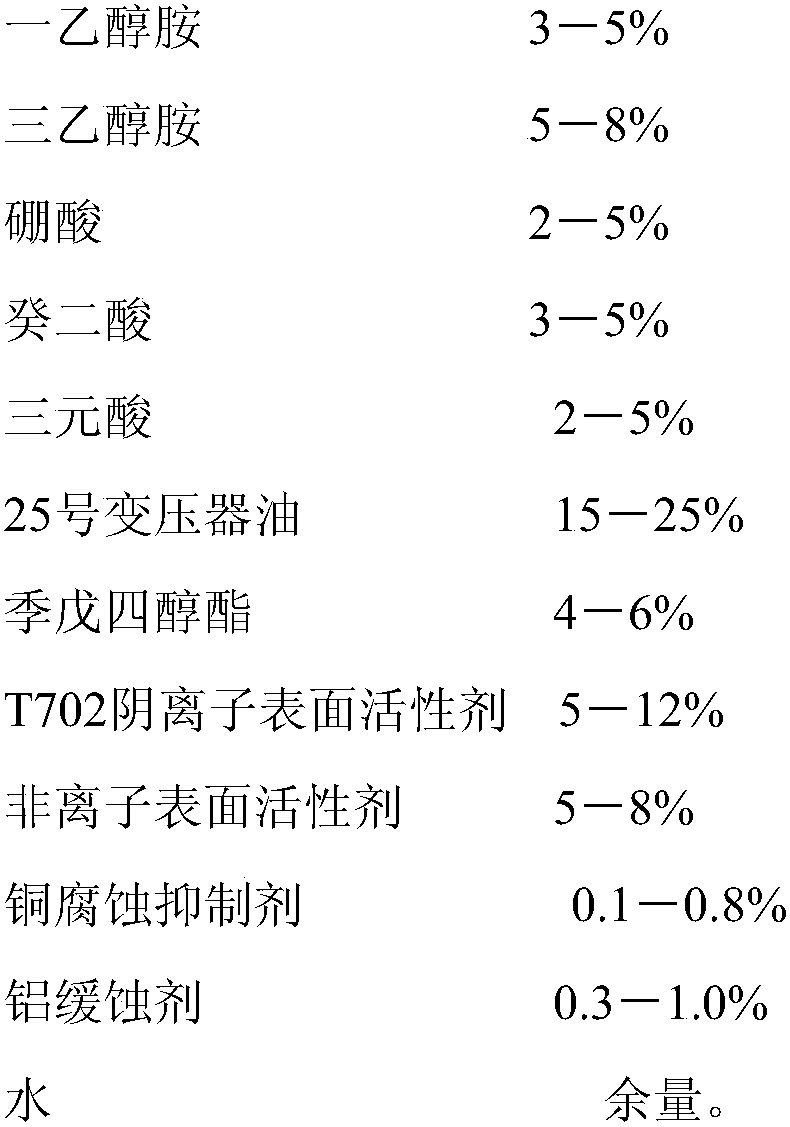

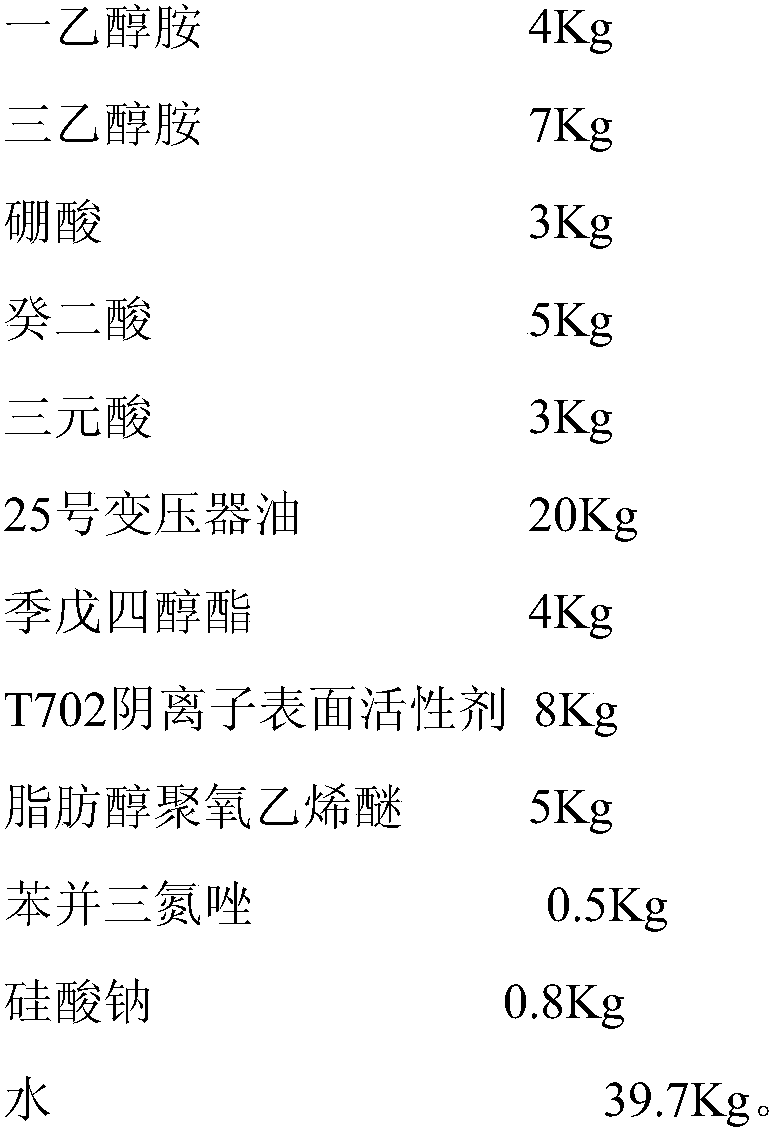

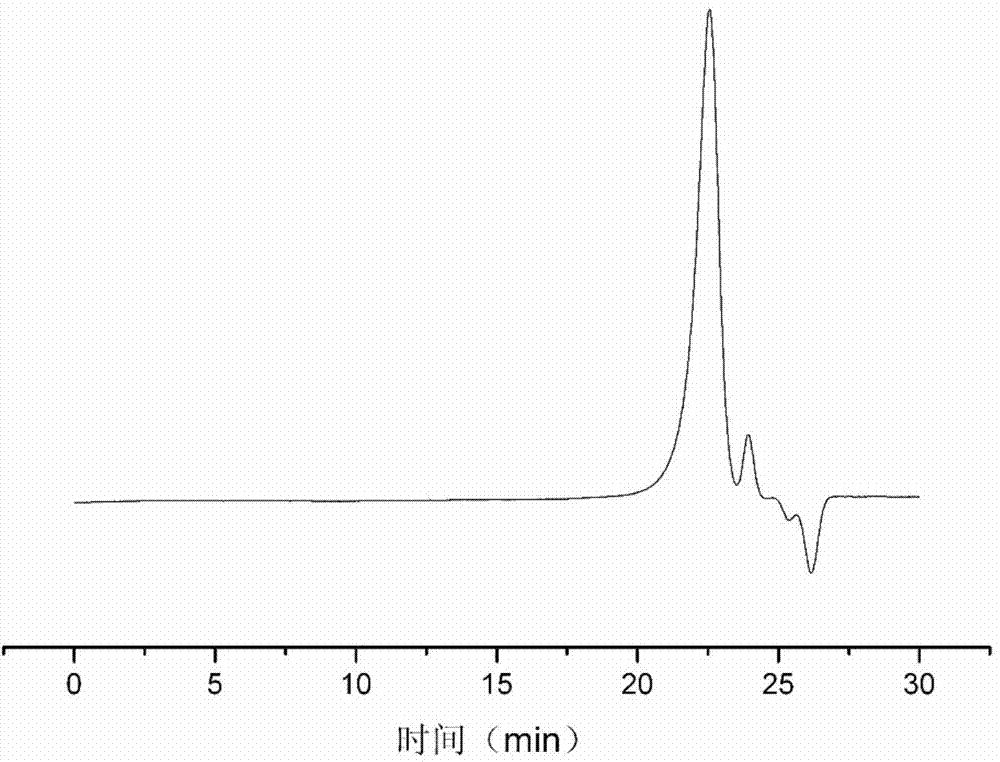

The invention relates to a water-soluble cutting fluid, which comprises the following raw material components by weight: 3-5% of monoethanolamine, 5-8% of triethanolamine, 2-5% of boric acid, 3-5% ofsebacic acid, 2-5% of tribasic acid, 15-25% of 25# transformer oil, 4-6% of pentaerythritol ester, 5-12% of a T702 anionic surfactant, 5-8% of a nonionic surfactant, 0.1-0.8% of a copper corrosion inhibitor, 0.3-1.0% of an aluminum corrosion inhibitor, and the balance of water. According to the present invention, the water-soluble cutting fluid is the universal water-soluble anti-hard water cutting fluid; the processing range of the water-soluble cutting fluid is wide, wherein the water-soluble cutting fluid can process cast iron, steel, stainless steel, copper alloys, aluminum alloys and a variety of metal materials; the water-soluble cutting fluid is generally suitable for soft water and hard water, can be used in all parts of the country, and has excellent hard-water resistance, whereinthe water-soluble cutting fluid can resist the hard water in Shandong area (the hard water rang is 500-1300); and with the independently researched and developed anticorrosion system, the product does not produce deterioration and odor changing within the service life of 1 year, and is environment-friendly .

Owner:天津市澳路浦润滑科技股份有限公司

Preparation method of poly (carbonate ester-ether) trihydric alcohol

The invention discloses a preparation method of poly (carbonate ester-ether) trihydric alcohol. According to the preparation method of the poly (carbonic ester-ether) trihydric alcohol, carbon dioxide, an epoxy compound and tribasic acid have a polymerization reaction under the action of a catalyst to obtain the poly (carbonic ester-ether) trihydric alcohol; the catalyst is rare earth doped Zn3[Co(CN)6]2 based bimetallic cyanide; the tribasic acid is one or more than one of oxalosuccinate, tricarballylic acid, 1,3,5- trimesic acid, 1,2,4-benzenetricarboxylic acid and phosphoric acid; and the time of polymerization reaction is 3-9 hours. The preparation method of the poly (carbonic ester-ether) trihydric alcohol has short reaction induction period and short reaction time and has high carbonic ester unit content and low byproduct cyclic carbonic ester content.

Owner:JUYUAN CHEM IND CO LTD

Modifier for polyester enamelled wire insulating paint, and preparation method and application thereof

The invention discloses a modifier for improving heat resistance and metal adhesion of common polyester enamelled wire paint and a preparation method and application thereof. The modifier is a dibasic acid-tribasic acid-dibasic alcohol condensation polymer. After dibasic acid, tribasic acid, dibasic alcohol and catalyst are esterified and condensed, cresol and xylene are added to obtain a productof which the solid content is 30-35%. After the modifier and polyester enamelled wire paint are mixed and subjected to curing reaction by an enamelling machine, the temperature index for evaluating temperature classification can be increased from 130 DEG C to higher than 155 DEG C; and after the polyester enamelled wire is subjected to stripping and twisting by more than 115 revolutions instead of 104 revolutions, the paint film still can not loose the adhesiveness. Thus, the modifier obviously enhances the heat resistance and adhesion property of the enamelled wire.

Owner:TIANHENGDA ELECTRICAL ENG SCI & TECH CO LTD +1

Aerolite cutting fluid with low PH value, its preparation and application

ActiveCN107151578AImprove protectionImprove the finishLubricant compositionPhosphateBenzisothiazolone

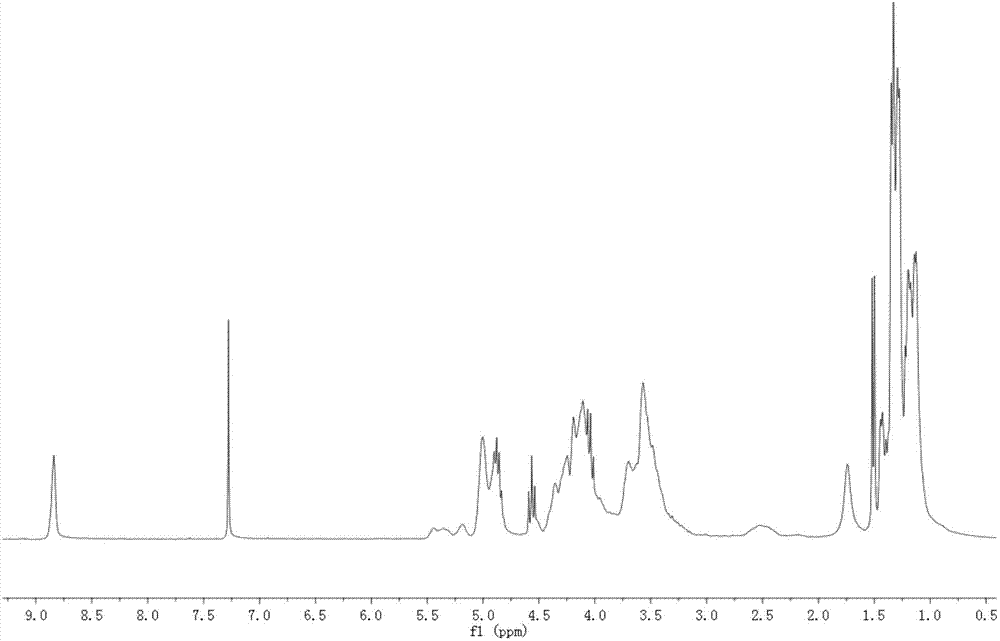

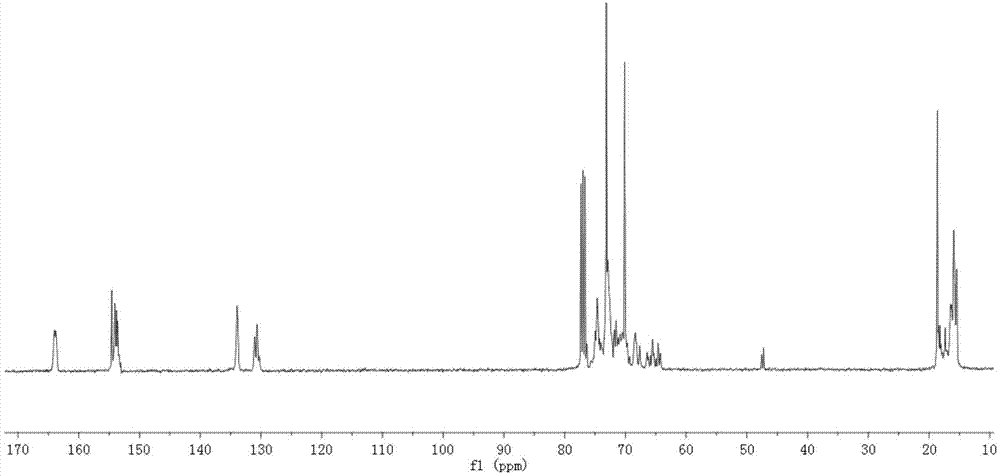

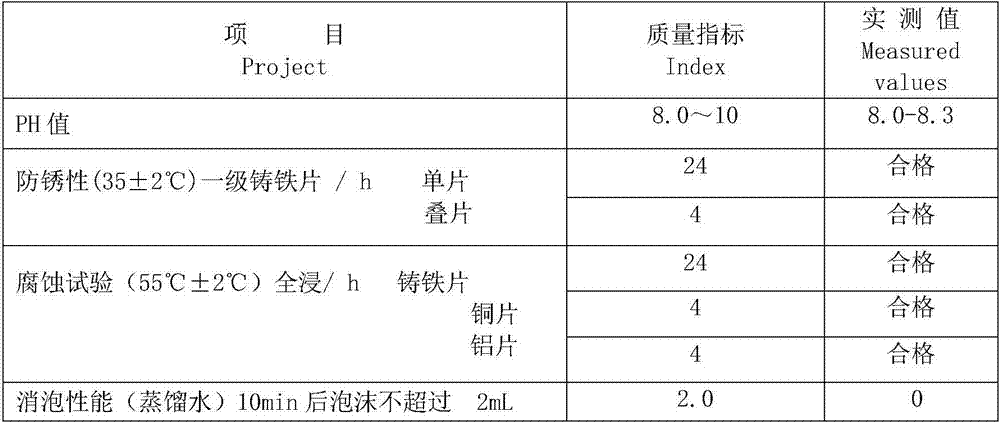

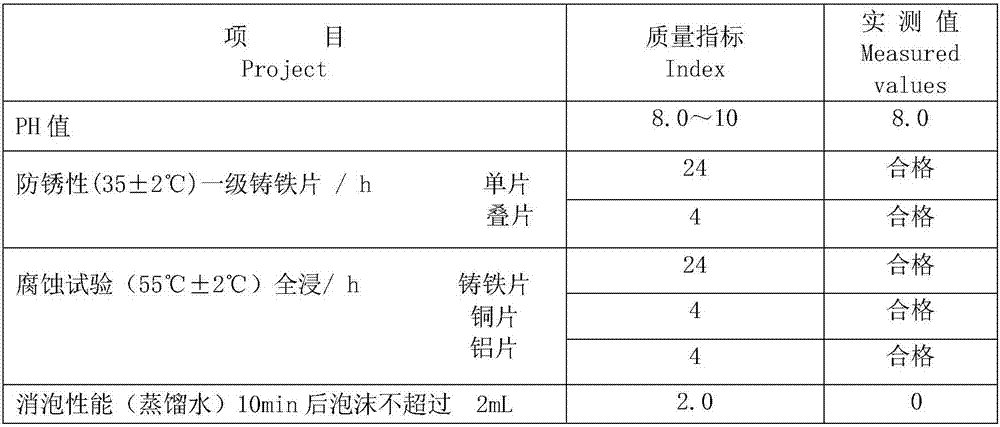

The invention discloses an aerolite cutting fluid with low PH value and its preparation method, and belongs to the domain of the cutting fluid. The cutting fluid is prepared from, by weight ratio, trimethylolpropane trioleate, tall oil, triethanolamine, neodecanoic acid, phosphate, benzisothiazolone, hard water resisting agent, tribasic acid, benzotriazole, castor oil polyoxyethylene ether, trihydroxy hexahydro-s-triazine, and 2, 6-bismethylmorpholine; the allowance is water. The aerolite is extremely sensitive to alkalinity; the cutting solution has low PH value due to its special preparation method and composition, and the PH value is ranged from 8.0 to 8.3; the cutting fluid is free from corrosion to the aerolite and magnalium zinc alloy which are extremely easy to corrode; moreover, the class 2 and class 7 aluminum alloys in the aerolite are big in hardness and not easy to process. The cutting solution has excellent lubricating performance and can be used for cutting during the process conveniently; the surface smoothness is high.

Owner:辽宁泰克诺美科技有限公司

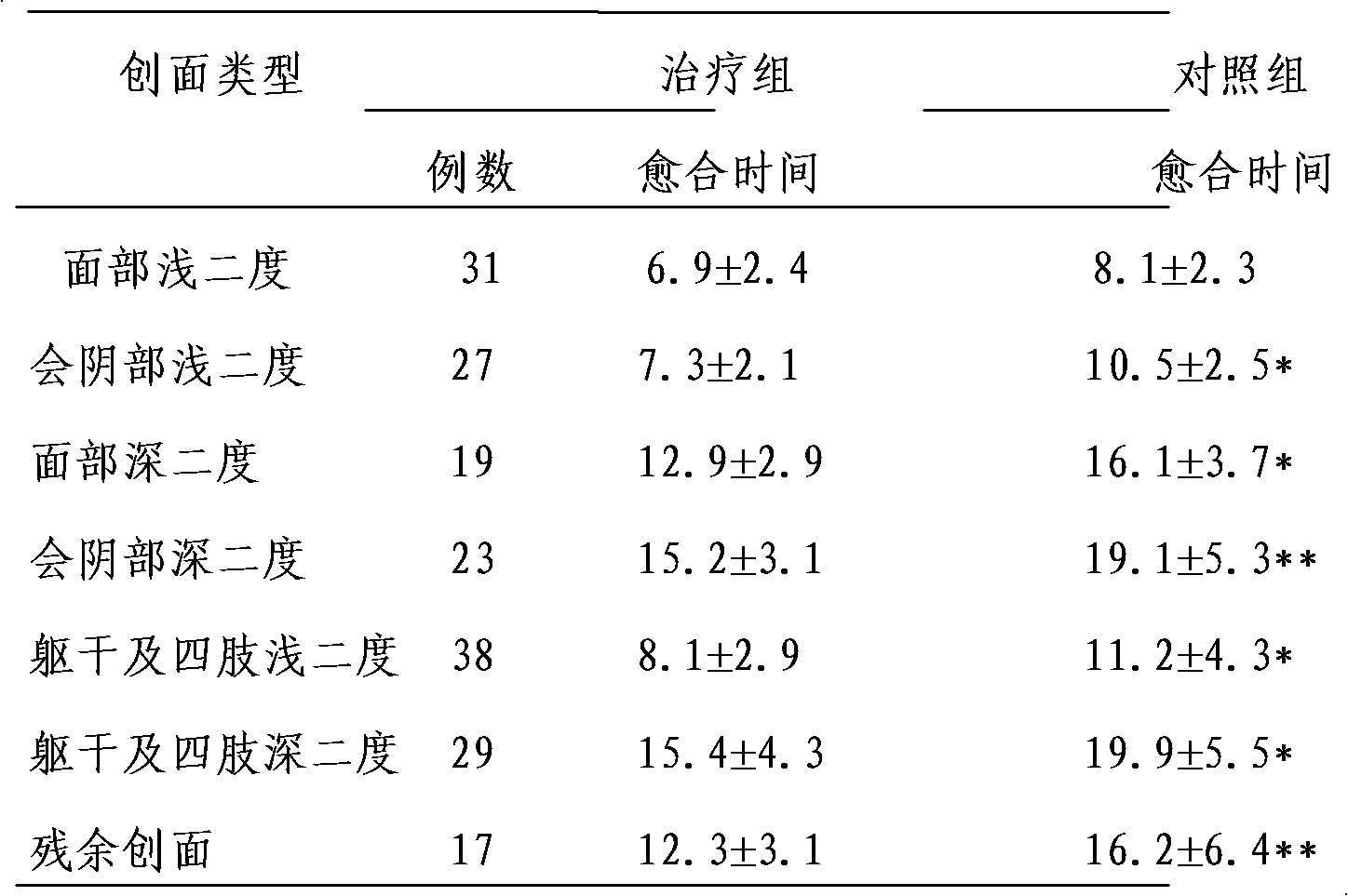

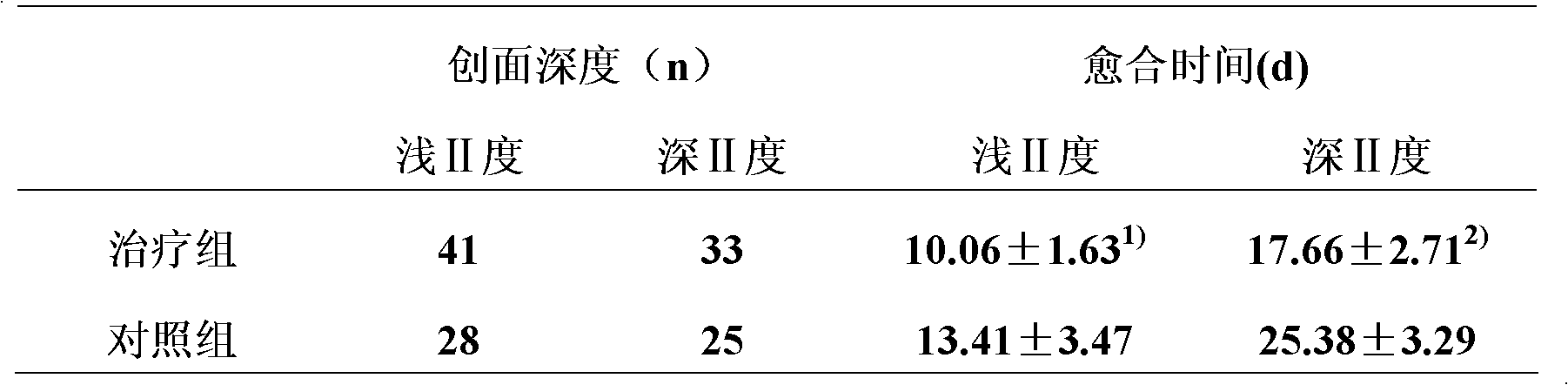

Biological colloid dispersant used for wound-protection and its preparation method

InactiveCN102218079ANo side effectsThe product has no peculiar smellAntibacterial agentsInorganic active ingredientsSide effectPhosphoric acid

The invention relates to a biological colloid dispersant used for wound-protection and its preparation method, which belongs to the technical field of medical surgical drugs. The invention is characterized in that every 1000g weight of a finished product dispersant comprises: 0.12 to 4g of ultrafine silver ion powder, 0.06 to 0.44g of sodium alginate, 0.5 to 1g of tribasic acid, 14.5 to 16g of osmotic agent, 0.4 to 0.8g of tartrate and the balance of pure water, wherein: the tribasic acid is any one type of phosphoric acid or citric acid, the osmotic agent is hydrogen peroxide. The invention has the advantages of security, stability and environmental protection performance; the invention has the ideal penetration effect, which is used for shortening the healing time of wound as well as the treatment period; the biological colloid dispersant used for wound-protection has the advantages of no side effect on patients, no abnormal odor and no sensitization; the preparation method has the merits of less process step and no harsh condition, which can adopt a mass production requirement.

Owner:苏州汇涵医用科技发展有限公司

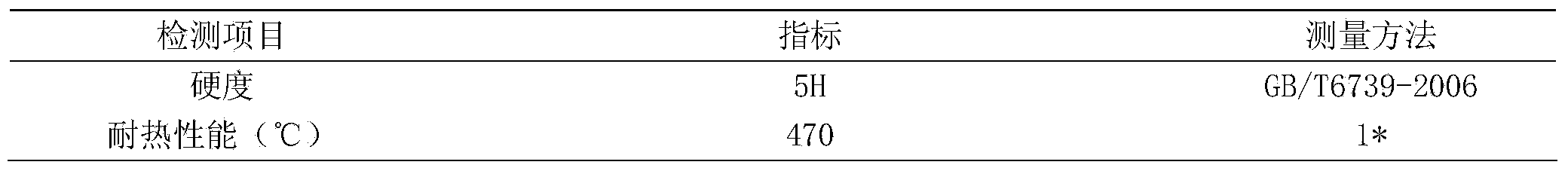

Method for preparing polyamide modified organic silicon resin and paint prepared from resin

The invention relates to a method for preparing polyamide modified organic silicon resin. The method includes the following steps that diamine, tribasic acid with the mole number 1 to 2.0 times that of the diamine, aminated superfine zinc oxide with the weight 1 to 2 times that of the diamine, cross-linking catalyst with the weight 1 percent to 5 percent that of the diamine and 2-(2-butoxyethoxy)ethyl acetate with the weight 3 to 8 times that of the diamine are evenly mixed and then heated at 180 DEG C to 220 DEG C for 1 h to 4 h; then, the mixture is cooled to 90 DEG C, organosilicone oligomer with end epoxy groups with the weight 1.5 to 2.0 times that of the diamine is added, and the mixture is heated at 120 DEG C to 140 DEGC for 2 h to 3 h; finally, the mixture is cooled to 90 DEG C, and organic solvent is added to make the solid content range from 40wt% to 50wt%. The resin prepared with the method can be used for preparing high-temperature-resistant paint with low surface energy. According to the method, the aminated superfine zinc oxide, the diamine and the tribasic acid react together to prepare modified hyperbranched polyamide, and thus the heat resistance and the hardness of the polyamide are improved; the modified hyperbranched polyamide and the organosilicone oligomer with end epoxy groups undergo cross-linking reaction, and thus the heat resistance and the hardness of the polyamide are improved.

Owner:SOUTHERN MEDICAL UNIVERSITY

Preparation method of environment-friendly type tapping liquid for cover plate of filter of automobile air conditioner and environment-friendly type tapping liquid

ActiveCN108949332AModerate pHSuitable for coolingLubricant compositionAutomobile air conditioningBoric acid

The invention discloses a preparation method of environment-friendly type tapping liquid for a cover plate of a filter of an automobile air conditioner. The preparation method comprises the followingsteps: (S10) providing the following raw materials: rustproof agent A, rustproof agent B, metal corrosion inhibitor, lubricant, coupling agent and deionized water; (S20) adding the rustproof agent A and the metal corrosion inhibitor into the deionized water, stirring, rising the temperature to 45-55 DEG C, and then carrying out heat insulation to prepare a first mixture; (S30) adding the rustproofagent B into the first mixture, stirring, rising the temperature to 75-85 DEG C and then carrying out heat insulation to prepare a second mixture; (S40) adding the lubricant and the coupling agent into the second mixture to prepare the environment-friendly type tapping liquid, wherein the rustproof agent A is one or mixture of at least two of boric acid, decyl dibasic acid, undecylenic dibasic acid, dodecenoic dibasic acid and tribasic acid; the rustproof agent B is one or mixture of at least two of monoethanolamine, triethanolamine, 2-amino-2-methyl-1-propanol. The environment-friendly typetapping liquid prepared by adopting the preparation method has the advantages of more stable pH value and better comprehensive use performance.

Owner:广州市方川润滑科技有限公司

Cross-linking agent for bio-based adhesive and preparation method of cross-linking agent

ActiveCN110790717AGood hot water resistance and adhesionLower heat curing temperatureOrganic chemistryNon-macromolecular adhesive additivesPolymer scienceCross linker

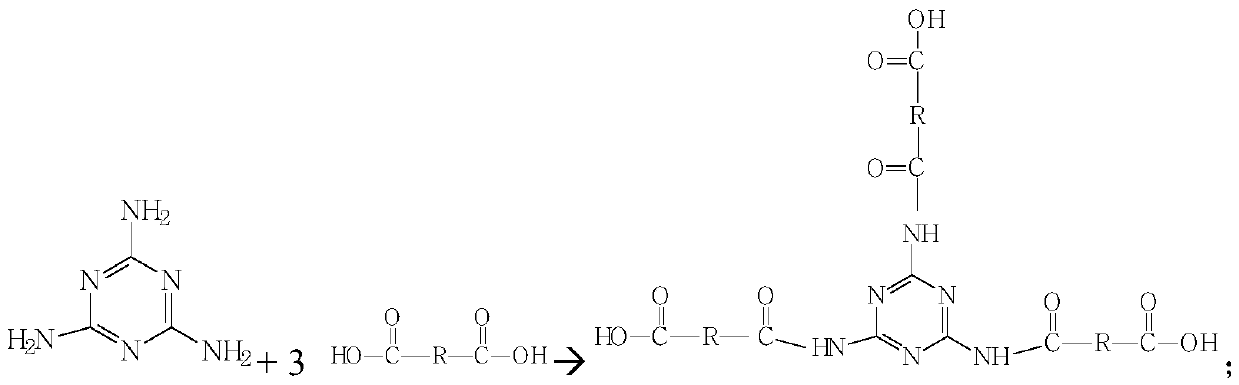

The invention discloses a cross-linking agent for a bio-based adhesive and a preparation method of the cross-linking agent. The method comprises the following steps: firstly, carrying out acid amine dehydration condensation reaction on melamine and a binary acid under the condition of 170-190 DEG C to obtain a polycondensed triacid; carrying out dehydration condensation reaction on the polycondensed triacid and a polyethylene polyamine at 160-180 DEG C to obtain an acid amine polycondensation intermediate; dissolving the acid amine polycondensation intermediate in water, regulating the pH value to 7-10, and dropwisely adding epoxy chloropropane at 50-70 DEG C to react, thereby obtaining the cross-linking agent for the bio-based adhesive. When the cross-linking agent is added into the formaldehyde-free albumen glue, the heat curing temperature of protein can be reduced from 130 DEG C or above to 85 DEG C, and meanwhile, the albumen glue is provided with relatively good hot water resistance and adhesion performance.

Owner:NANJING UNIV OF SCI & TECH

1,3,5-benzene tricarboxylic acid coolant composition

Owner:TOYOTA JIDOSHA KK +1

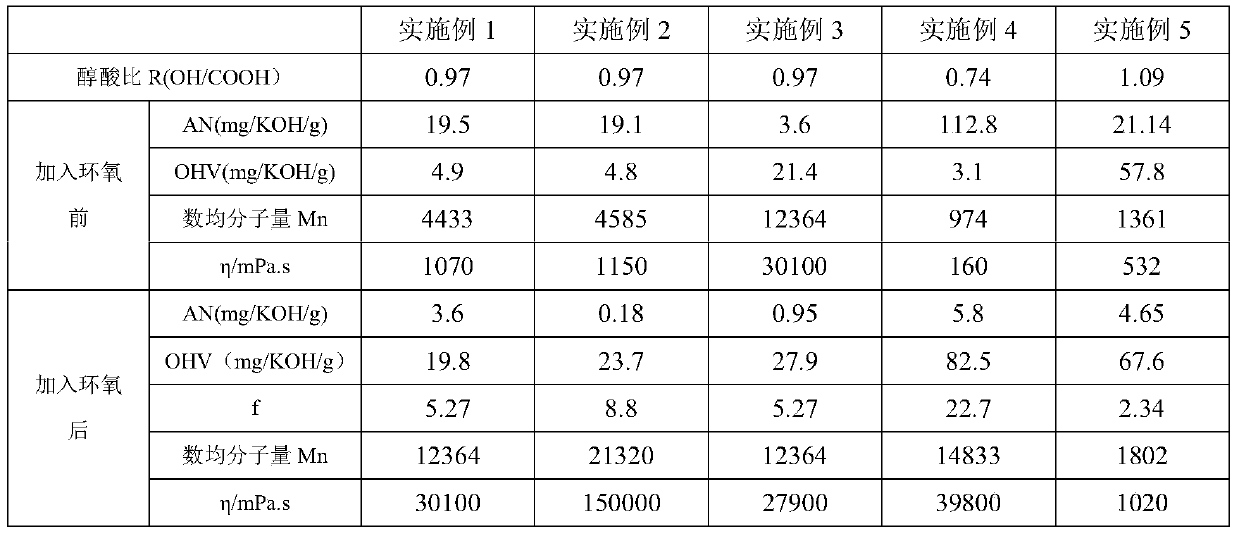

Method for synthesizing linear and multifunctional polyester polyol by using double epoxy compound

PendingCN111072941AHigh functionalityHigh molecular weightPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention relates to the technical field of polyester polyol preparation, in particular to a method for synthesizing linear and multifunctional polyester polyol by using a double epoxy compound. Specifically, the method is characterized by adjusting the feeding ratio of dihydric alcohol to binary acid, when the reaction is carried out to a certain degree (acid value), a diepoxy compound is added, the functionality of the linear polyester polyol can be greater than any value (such as 2-10) of 2, and the product does not have a gel phenomenon in the synthesis process, which cannot be realized by synthesizing the polyfunctional polyester polyol by using trihydric alcohol or tribasic acid small molecules as an initiator. Particularly, only when the OH / COOH ratio (1.0 (i.e., COOH / OH is greater than 1), high-hydroxyl-value polyester polyol with the functionality of more than 4 can be synthesized, and linear polyol which cannot be gelled can be obtained. The product is widely applied to adhesives, synthetic leather, rubber and composite material products, and has practical application value.

Owner:无锡博锦高分子研究发展有限公司

Black metal water-based antirust agent

InactiveCN108998782AImprove rust resistancePlay a protective effectMetallic material coating processesWater basedDefoaming Agents

The invention discloses a black metal water-based antirust agent. The black metal water-based antirust agent comprises the following raw materials in parts by weight: 7 to 12 parts of ethanol amine, 1to 1.5 parts of dodecyl tribasic acid, 0.5 to 1.5 parts of boric acid, 2 to 3 parts of a settling agent, 0.3 to 0.7 part of a hard water resistant agent, 1 to 2 parts of a corrosion inhibitor, 0.5 to1 part of a defoaming agent, 1 to 1.5 parts of trisodium phosphate, 1 to 3 parts of sodium tripolyphosphate, 2 to 4 parts of sodium hydroxide, 0.3 to 0.9 part of sodium molybdate, 2 to 5 parts of benzotriazole, 0.5 to 1.5 parts of a complexing agent, 2 to 3 parts of zinc oxide, 1 to 3 parts of sodium benzoate and 0.2 to 1 part of dibutyl phthalate. The black metal water-based antirust agent has agood antirust function, also has a certain cleaning effect and is suitable for popularizing.

Owner:广州市融宽科技有限公司

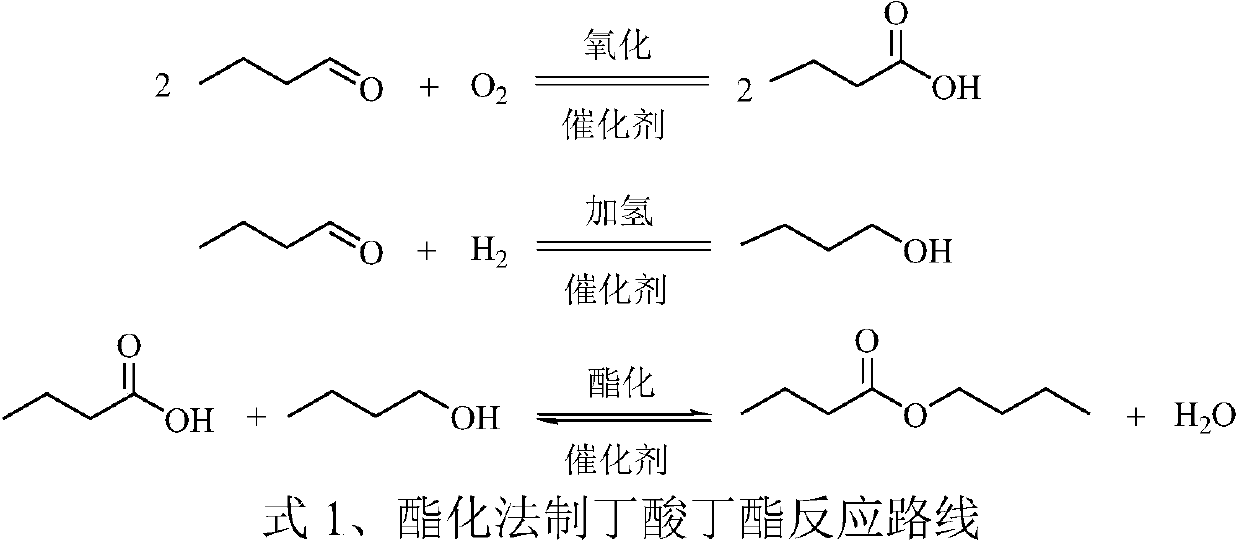

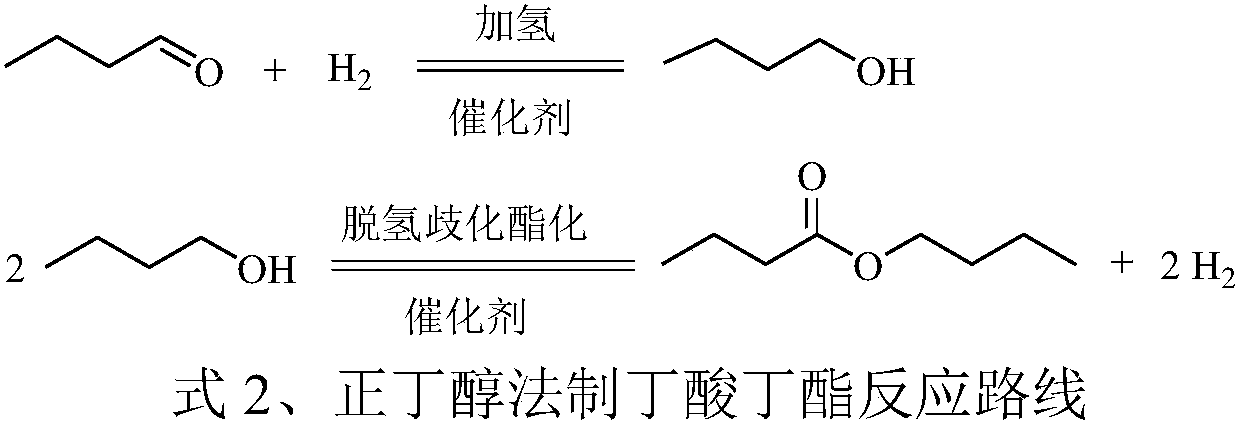

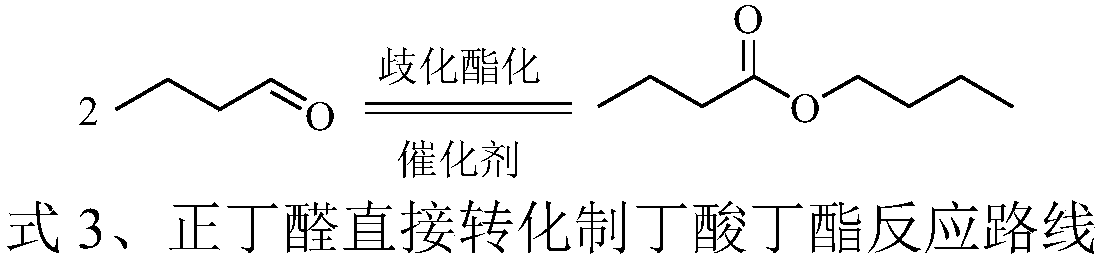

Method for preparing butyl butyrate through direct catalytic conversion of n-butyraldehyde

ActiveCN111217704AHigh selectivityShort routePreparation by aldehyde oxidation-reductionChemical recyclingPtru catalystReaction temperature

The invention relates to a method for preparing butyl butyrate by directly converting n-butyraldehyde. According to the method, n-butyraldehyde is used as a raw material, one or more than two of organic dibasic acid aluminum or organic tribasic acid aluminum such as aluminum oxalate, aluminum citrate, aluminum tartrate, aluminum malate, aluminum adipate, aluminum heptanedioate, aluminum dodecanedioate and the like are used as catalysts, the use amount of the catalyst is 0.2-1.0% of the mass of the n-butyraldehyde, the reaction temperature is 0-20 DEG C, the reaction time is 0.5-2 hours, and the n-butyraldehyde conversion rate and the butyl butyrate selectivity can reach more than 99%. The method has the advantages of short route, good atom economy, mild reaction conditions, catalyst recyclability, high raw material conversion rate, high product selectivity and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Water-based unsaturated polyester as well as preparation method and application thereof

PendingCN113717357ARelieve consumption pressureReduce manufacturing costAnti-corrosive paintsPolyester coatingsPolymer sciencePolyol

The invention discloses water-based unsaturated polyester as well as a preparation method and application thereof. The water-based unsaturated polyester contains a structural unit I derived from unsaturated dibasic acid, a structural unit II derived from hydroxyl-containing aliphatic dibasic acid and / or hydroxyl-containing aliphatic tribasic acid and a structural unit III derived from polyhydric alcohol. The water-based unsaturated polyester disclosed by the invention has excellent water stability, high adhesive force and high flexibility, is simple in preparation process, does not contain an organic solvent, is green and environment-friendly, can be used as a water-based environment-friendly UV coating, and has a wide market prospect.

Owner:GUANGZHOU UNIVERSITY

Polyester thermal fuse with low melting point and good elasticity

InactiveCN110284211ALow melting pointImprove mechanical propertiesMonocomponent copolyesters artificial filamentFiberMechanical property

The invention discloses a polyester thermal fuse with a low melting point and good elasticity, and relates to the technical field of new materials. Organic dibasic acid, organic tribasic acid and alpha-propylene glycol of a certain molar ratio are adopted as modifiers, a modified high polymer is prepared by using the modifiers, terephthalic acid and ethylene glycol as raw materials through esterification reaction and polycondensation reaction, and then the polyester thermal fuse fiber is made by spinning. The polyester thermal fuse has the low melting point, excellent mechanical properties and good elasticity; when the polyester thermal fuse is elongated by 6.14%-7.05%, the polyester thermal fuse can be almost completely recovered; the wrinkle resistance of the polyester thermal fuse exceeds that of other fibers; the melting point range of the polyester thermal fuse is 118-138 DEG C.

Owner:张先玉

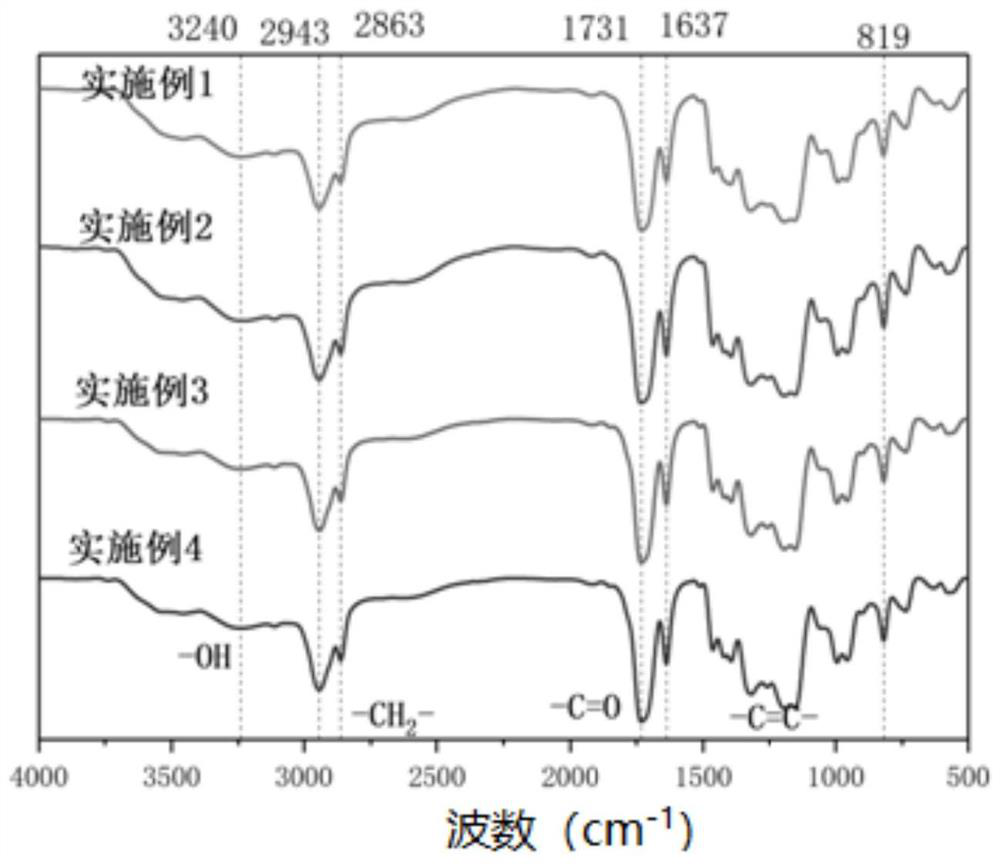

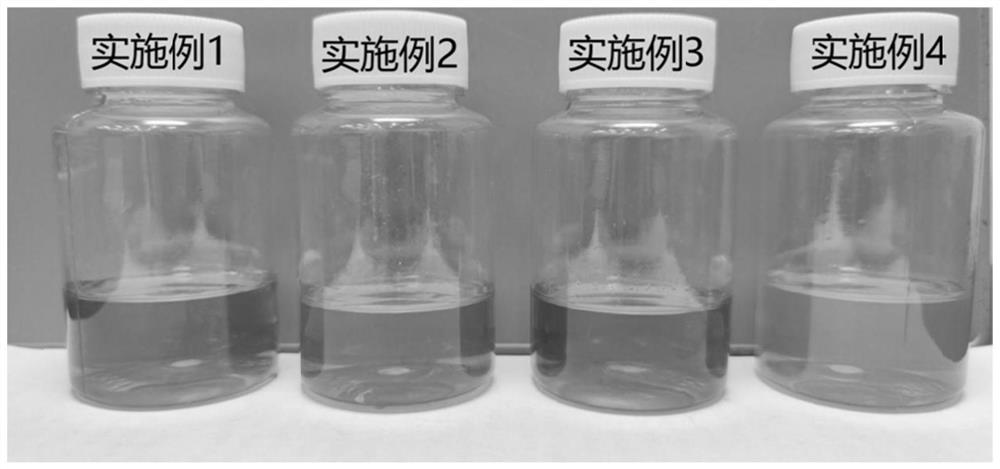

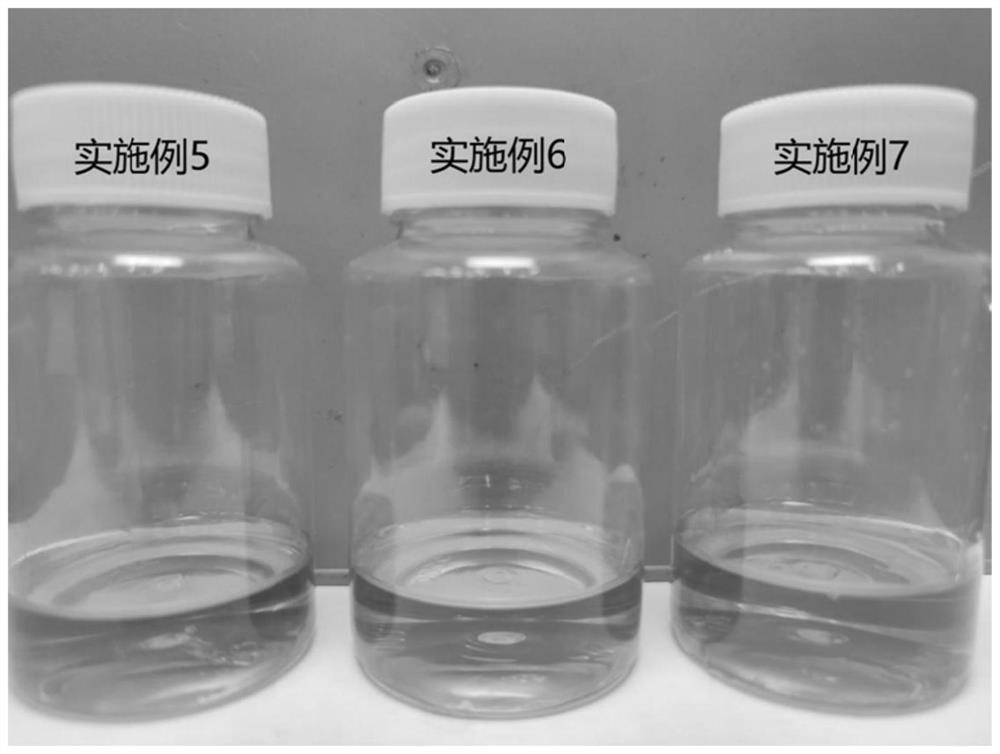

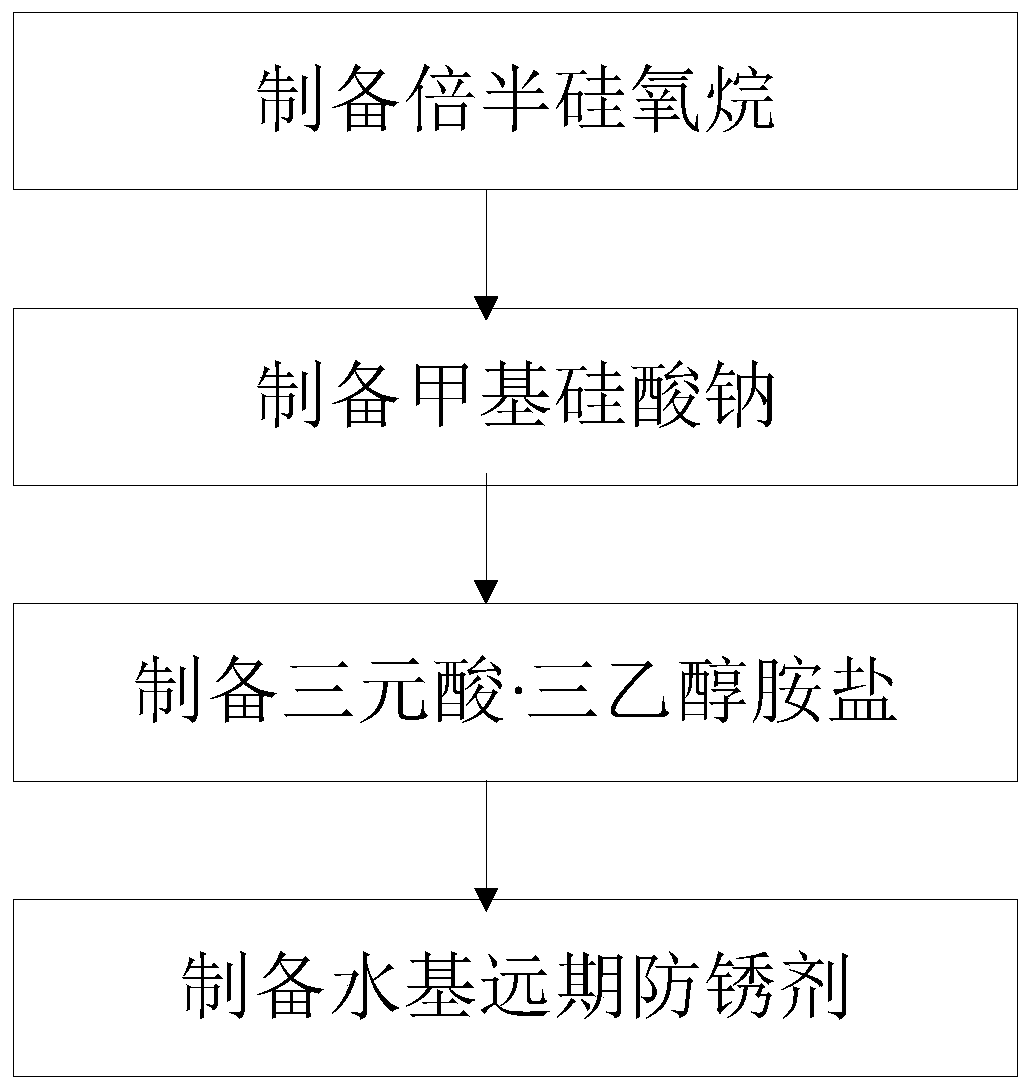

Water-based long-term antirust agent preparing method

ActiveCN110042396AA technological breakthrough to realize long-term anti-rust water-basedFill the gap in the marketWater basedSilsesquioxane

The invention discloses a water-based long-term antirust agent preparing method. The water-based long-term antirust agent preparing method comprises the following steps that silsesquioxane is prepared; sodium methyl silicate is prepared; tribasic acid.triethanolamine salt is prepared, triethanolamine is added in tribasic acid for standing for 10 min, slight heating and stirring are conducted tilldissolving, and the faint yellow and transparent tribasic acid.triethanolamine salt is obtained; a water-based long-term antirust agent is prepared, a sodium methyl silicate concentrated solution is diluted, then, TC-941, LS-150 and the tribasic acid.triethanolamine salt are added in the diluted sodium methyl silicate concentrated solution to be stirred, PH is adjusted to be 9-14, and the water-based long-term antirust agent is obtained after uniform stirring. By adoption of the above water-based long-term antirust agent preparing method, the metal long-term antirust water base technical breakthrough is achieved; and metal materials treated through the antirust agent can be directly subjected to coating treatment without complex treatment procedures such as rust removal, oil removal, phosphorization and passivation, and the market vacancy in the field is filled up.

Owner:LANGFANG NORMAL UNIV

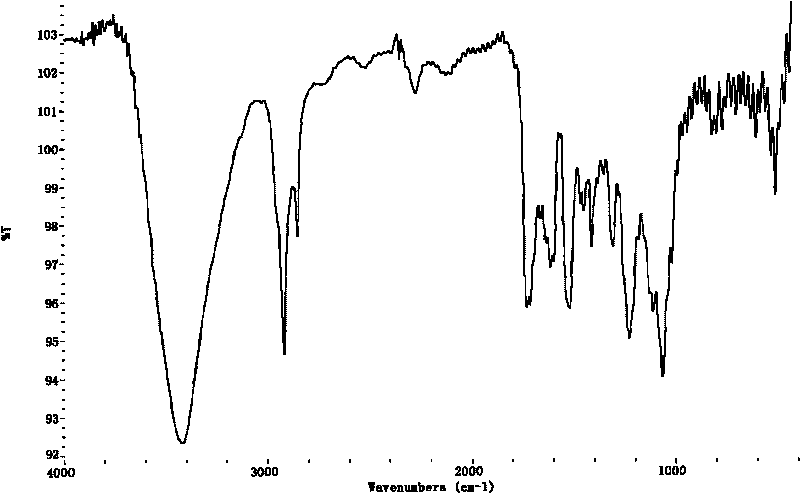

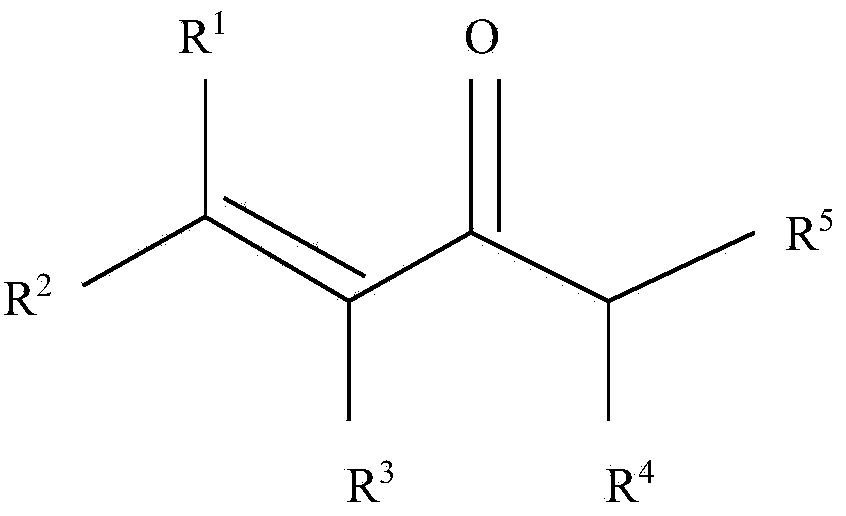

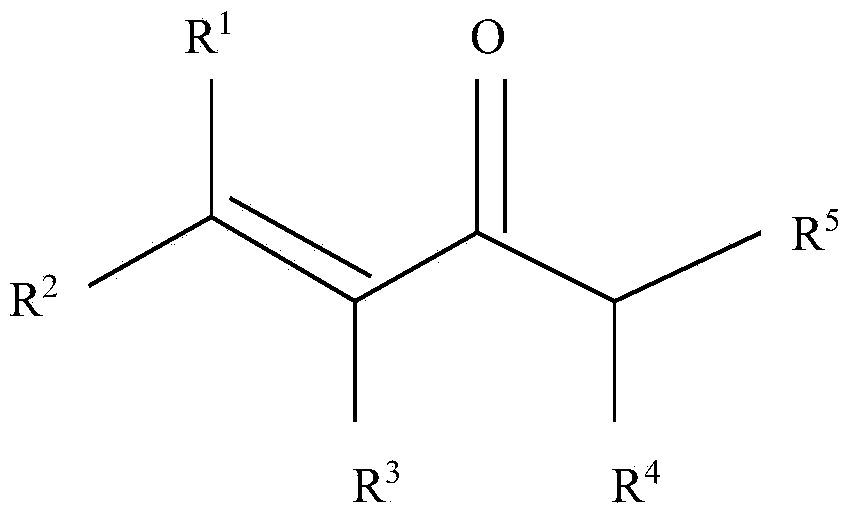

Light-cured resin based on organic polyatomic acid as well as preparation method and application of light-cured resin

ActiveCN111978444AHigh yieldSimple processOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses light-cured resin based on organic polybasic acid as well as a preparation method and application of the light-cured resin. The light-cured resin based on the organic polyatomic acid has a structure shown as a formula (I) and / or a formula (II) as shown in the description, wherein R comprises a substituted or unsubstituted aliphatic chain or aromatic ring, and a substituentgroup comprises one or more hydroxyl groups. The preparation method comprises the following steps: heating a uniformly mixed reaction system containing a dibasic acid and / or tribasic acid, glycidyl methacrylate and an epoxy ring-opening catalyst to perform a ring-opening reaction so as to obtain the light-cured resin with the structure shown in the formula (I) and / or the formula (II). The preparation process is simple, the operation method is simple and convenient, the controllability is good, implementation is easy, the method is suitable for large-scale industrial production, and a repairable and remodelable light-cured coating prepared from the light-cured resin and UV photoinitiators or visible light initiators has excellent thermal property, mechanical property and recoverability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com