Patents

Literature

34 results about "Dodecanedioate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

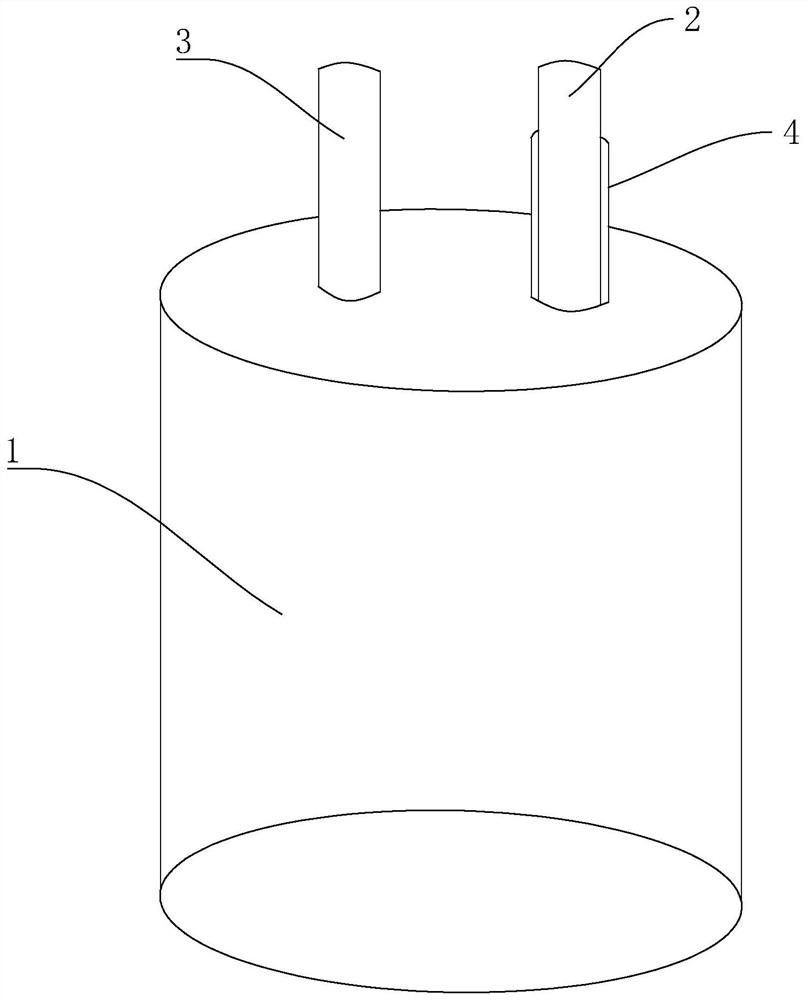

Electrolytic capacitor

InactiveCN109326447AInhibition of dissolutionLower impedanceLiquid electrolytic capacitorsCapacitanceAluminum anode

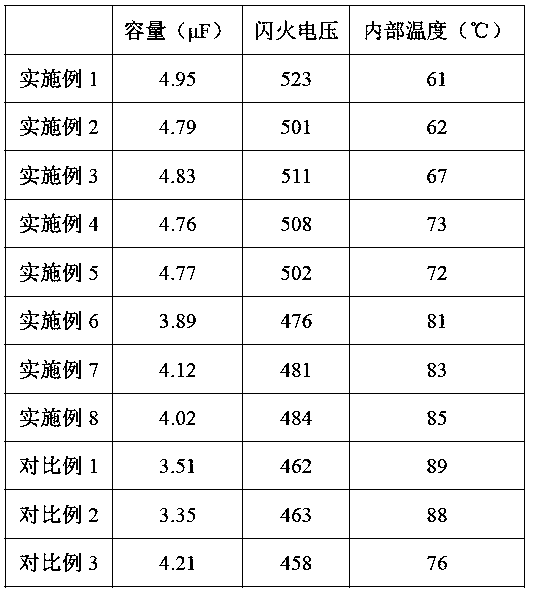

The invention relates to the field of capacitors, and provides an electrolytic capacitor for prolonging service life of capacitors. The electrolytic capacitor comprises an aluminum foil anode, an aluminum foil cathode, a partition and electrolyte; surfaces of the aluminum foil anode and the aluminum foil cathode are covered with alumina membrane; the partition is arranged in the electrolyte between the anode and the cathode; the electrolyte comprises, by mass, 65-70 parts of ethanediol, 1-6 parts of modifiers, 8-10 parts of ammonium sebacate, 1-2 parts of ammonium dodecanedioate, 5-8 parts ofpolyethylene glycol, and 2-4 parts of additives. The anode or cathode made of the aluminum foil can suppress dissolving of aluminium effectively, reduce impedance of the capacitor, and prolong servicelife of the capacitor; combination of the aluminum anode and aluminium cathode and the electrolyte can prolong the service life of the capacitor further.

Owner:广州金立电子有限公司

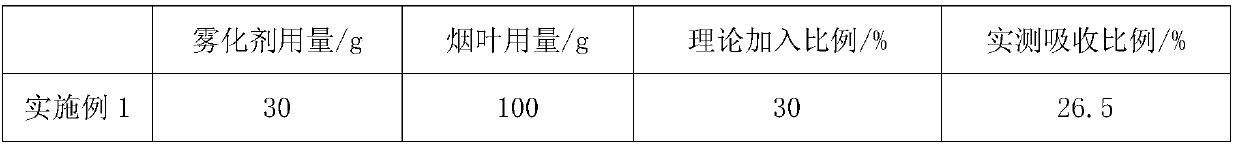

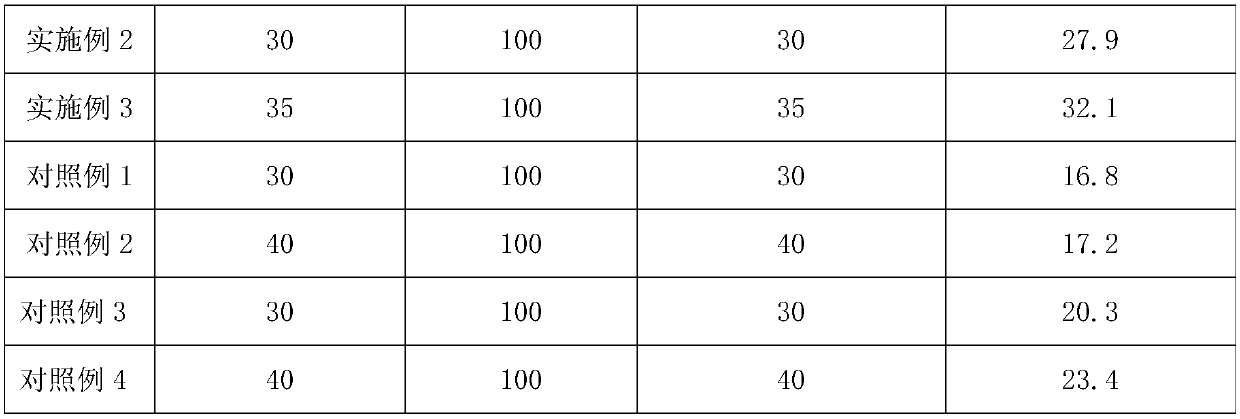

Atomizing agent for cigarettes and method for increasing atomizing agent absorbing amount of conventional tobacco leaves

InactiveCN109602074ALow viscosityPromote absorptionTobacco treatmentTriethylene glycol diacetateSteam pressure

The invention provides an atomizing agent for cigarettes and a method for increasing the atomizing agent absorbing amount of conventional tobacco leaves. The atomizing agent for the cigarettes is prepared by mixing sorbitol, glycerin, propanetriol, triethylene glycol diacetate, methyl stearate and dimethyl dodecanedioate according to a mass ratio of 1:(10-20):(10-20):(5-10):(2-6):(0.6-1.0). The method comprises the following steps: uniformly mixing formulated tobacco leaves, then performing steam explosion treatment under the conditions that the temperature is 30-50 DEG C, the steam explosiontime is shorter than 0.01 second, the steam pressure is 0.4-0.8 Mpa and the pressure retention time is 10-60 seconds, quickly spreading the prepared atomizing agent into the tobacco leaves after completion of the treatment, then sending to a leaf storage cabinet, balancing the moisture, thoroughly absorbing, and then taking out for shred preparation. By adopting the method, the atomizing agent adding amount of the conventional tobacco leaves can be greatly increased, and the atomizing agent can be applied to the cigarettes which are nonflammable after being heated.

Owner:HUBEI CHINA TOBACCO IND

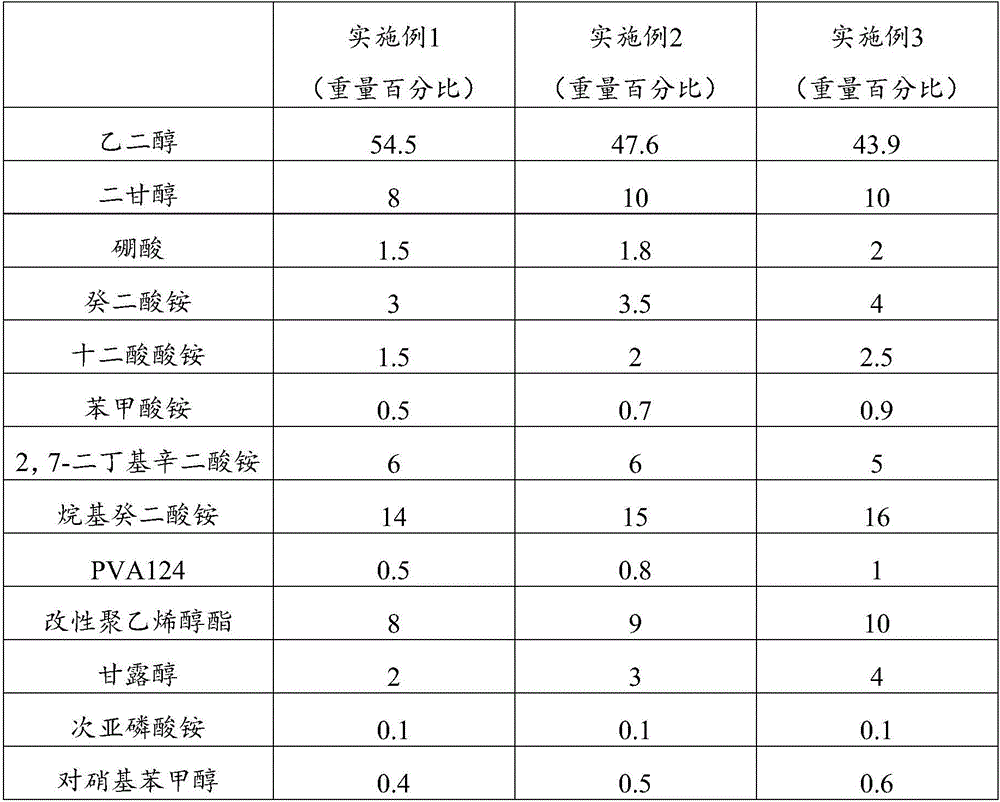

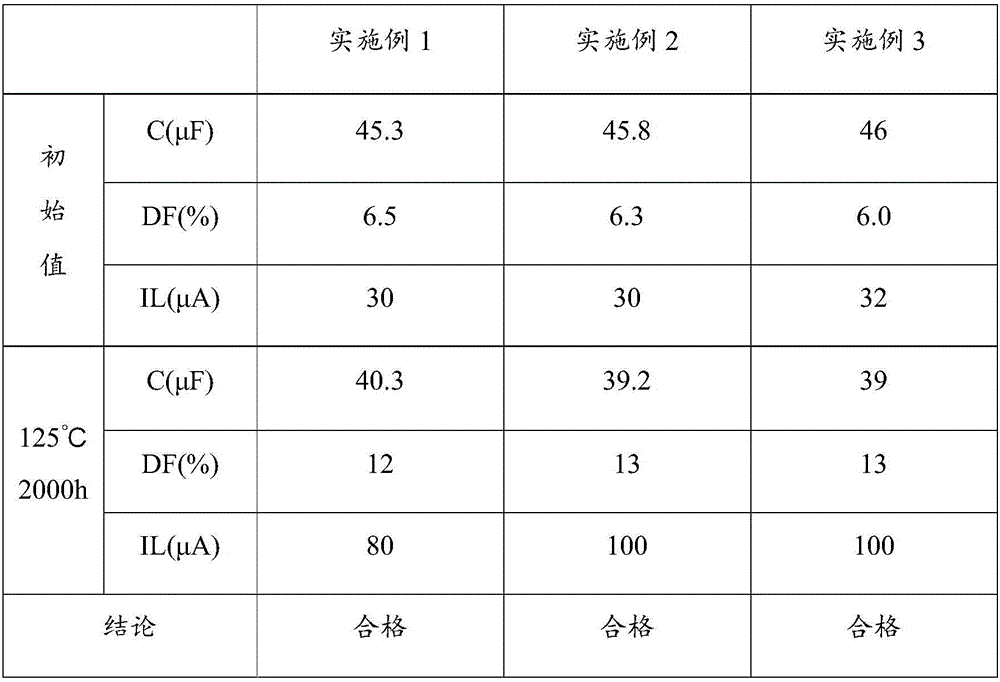

Electrolyte, electrolyte preparation method and aluminum electrolytic capacitor

ActiveCN106098379AImprove temperature resistanceImprove stabilityLiquid electrolytic capacitorsSolventTemperature resistance

The invention discloses an electrolyte, an electrolyte preparation method and an aluminum electrolytic capacitor. The electrolyte comprises, by weight percentage, 50-65w% of solvent, 23-33w% of solute, and 8-19w% of additive. The solute includes boric acid, ammonium benzoate, at least one material selected from ammonium dodecanedioate and 2,7-dibutyl octanedioic acid ammonium, and at least one material selected from ammonium sebate and alkyl ammonium sebate. Through the technical scheme, the temperature resistance performance and stability of the aluminum electrolytic capacitor are improved.

Owner:惠州市智胜新电子技术有限公司

Electrolyte of high-voltage aluminum electrolytic capacitor and preparation method of electrolyte

The invention discloses electrolyte of a high-voltage aluminum electrolytic capacitor. The electrolyte is characterized by comprising a main solvent, an auxiliary solvent, a solute and a spark voltage increasing agent, wherein the main solvent comprises one or more of ethylene glycol, gamma-butyrolactone, DMF and diglycol monobutylether; the auxiliary solvent comprises two or more of polyethylene glycol 200, polyethylene glycol 400, a nanosilicon dioxide solution, glycerol, propylene carbonate and ethylene carbonate; the solute comprises two or more of ammonium sebacate, ammonium adipate, adipic acid, boracic acid, ammonium pentaborate, ammonium azelate, ammonium dodecanedioate, ammonium formate, ammonium benzoate, mannitol, sorbitol, citric acid and quadrol. The electrolyte can be applied to 600V ultrahigh voltage, is stable in performance, low in viscosity, high in conductivity and beneficial to volume production, and can reduce the production cost.

Owner:HUNAN AIHUA GRP

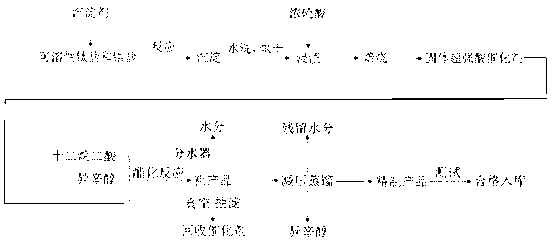

Method for catalytically synthesizing diisooctyl dodecanedioate base oil by solid superacid

InactiveCN103274938AHigh activityEasy to separatePhysical/chemical process catalystsOrganic compound preparationIsooctyl alcoholPtru catalyst

The invention discloses a method for obtaining high-purity diisooctyl dodecanedioate base oil by synthesizing solid superacid SO4<2-> / ZrO2-TiO2 catalyst with a precipitation-impregnation method, catalytically synthesizing diisooctyl dodecanedioate by dodecanedioic acid and isooctanol, and subjecting to separation and purification. The synthesized catalyst has the advantages of high activity, easiness in separation, capacity of recycling, good stability, high product yield and the like. The synthesized ester base oil has the advantages of high viscosity index and open cup flash point, low pour point and toxicity, good low temperature fluidity, wider operating temperature range, and excellent lubrication, environmental protection and biodegradation properties.

Owner:NANTONG ZHONGCHENG BIOTECH

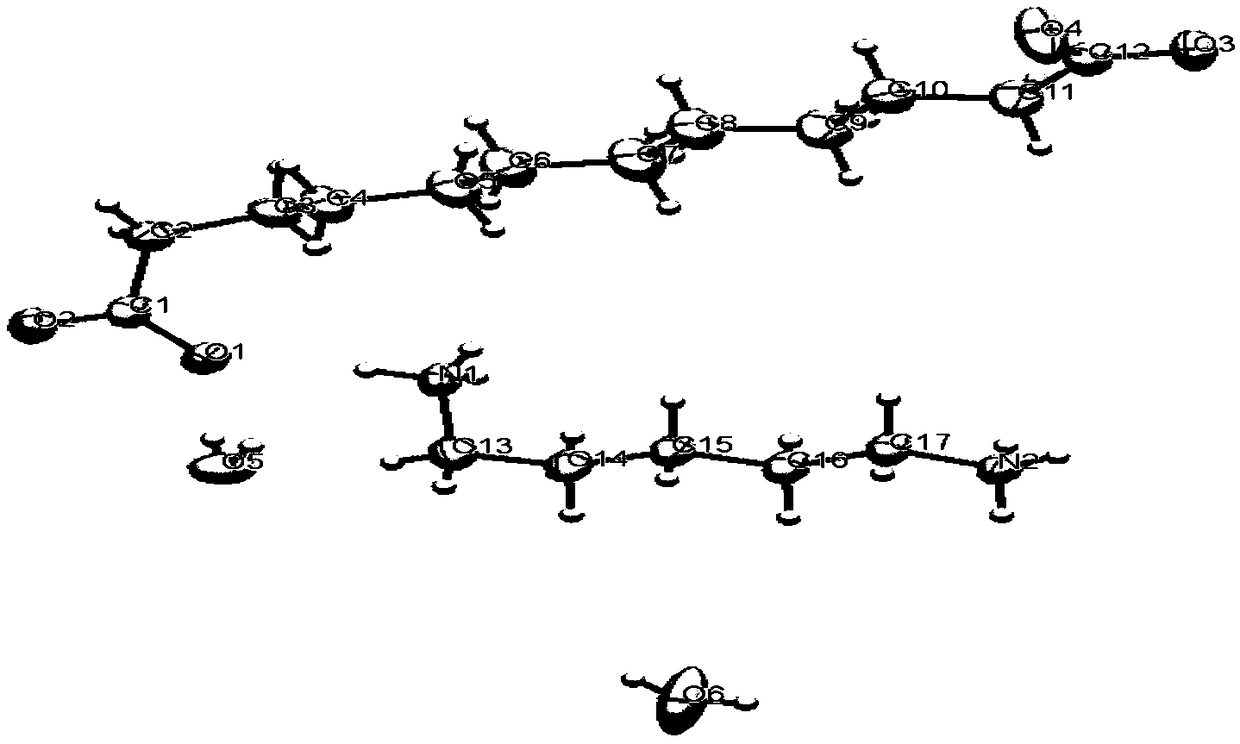

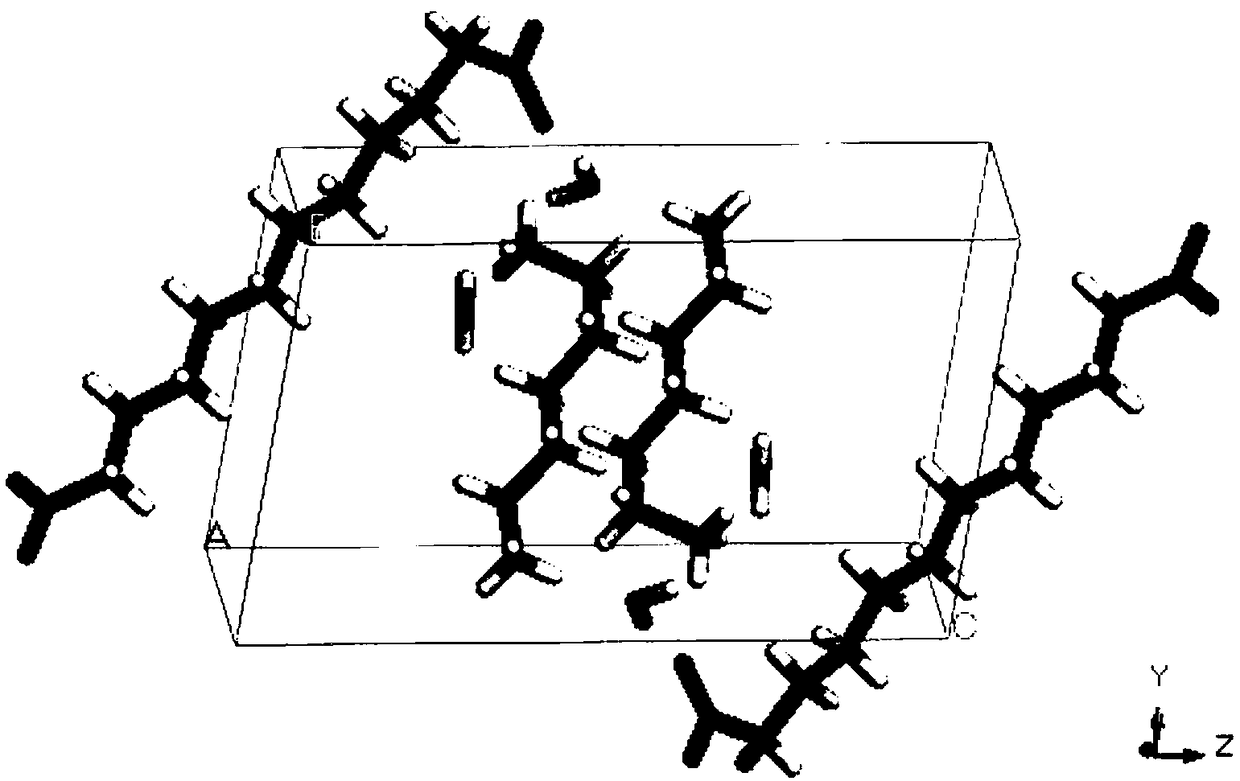

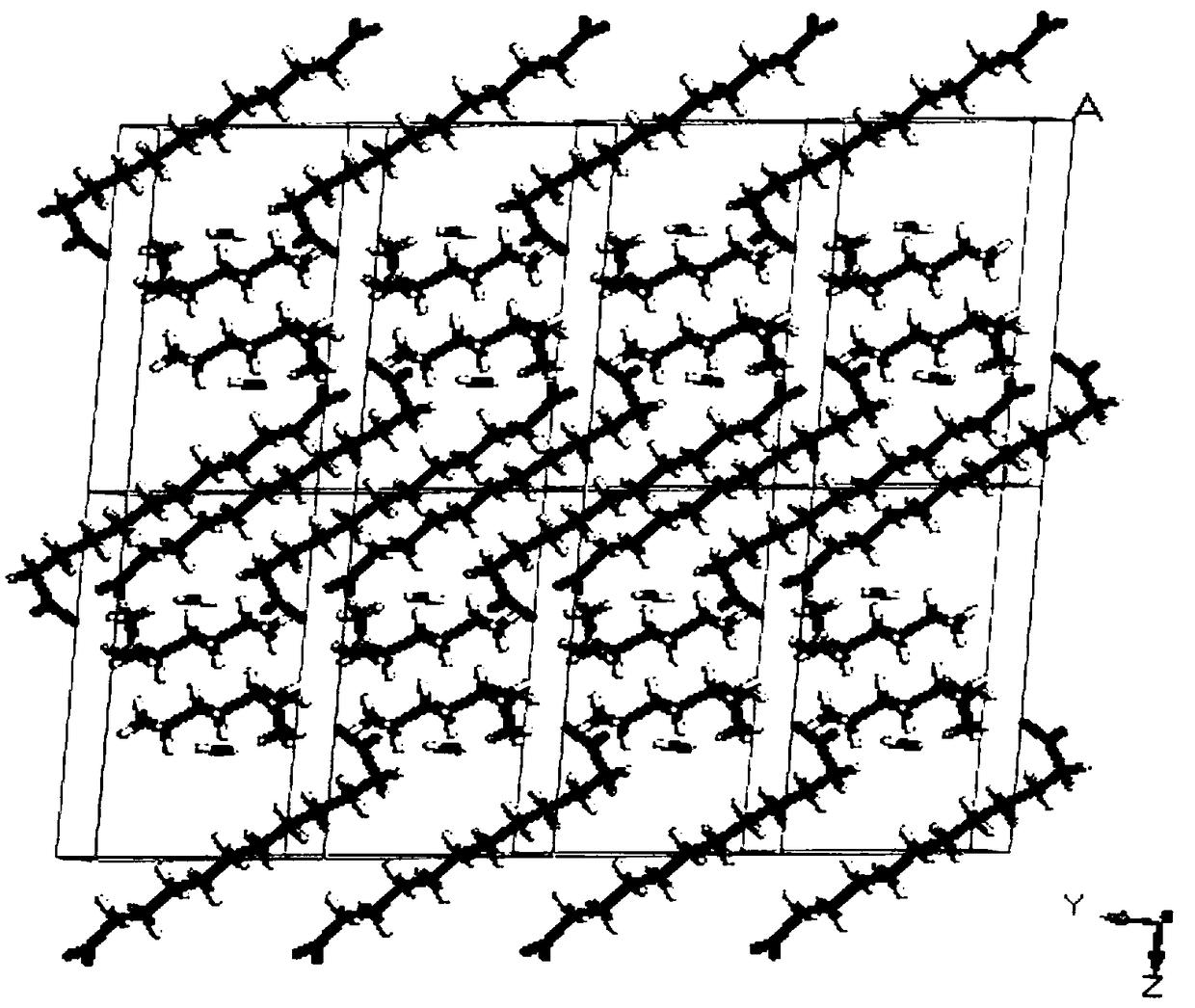

Pentanediamine dodecanedioate and crystal thereof

ActiveCN109265353AChange shapeImprove working environmentOrganic compound preparationOrganic chemistry methodsSpace groupRoom temperature

The invention discloses pentanediamine dodecanedioate, a crystal thereof, crystalline powder thereof and a preparation method thereof. The pentanediamine dodecanedioate is a salt which is formed in the manner of combining the divalent cation of pentanediamine with the divalent anion of dodecanedioic acid in a mole ratio of 1 to 1 and presents a solid state at normal temperature. The crystal structure of the pentanediamine dodecanedioate is C17H36N2O4.nH2O, belongs to a triclinic system and has a space group P-1; a is equal to 8.4747(7) angstroms; b is equal to 8.5175(7) angstroms; c is equal to 15.3901(14) angstroms; alpha is equal to 82.473(2) degrees; beta is equal to 78.06(10) degrees; gamma is equal to 86.313(2) degrees; the volume V of a crystal cell is equal to 1076.71(16) angstroms;and a minimal asymmetric unit number Z in the crystal cell is equal to 2. According to the pentanediamine dodecanedioate, the existing form of the pentanediamine is changed; the stability of a product is improved; and an original foul odor is greatly decreased.

Owner:NANJING UNIV OF TECH

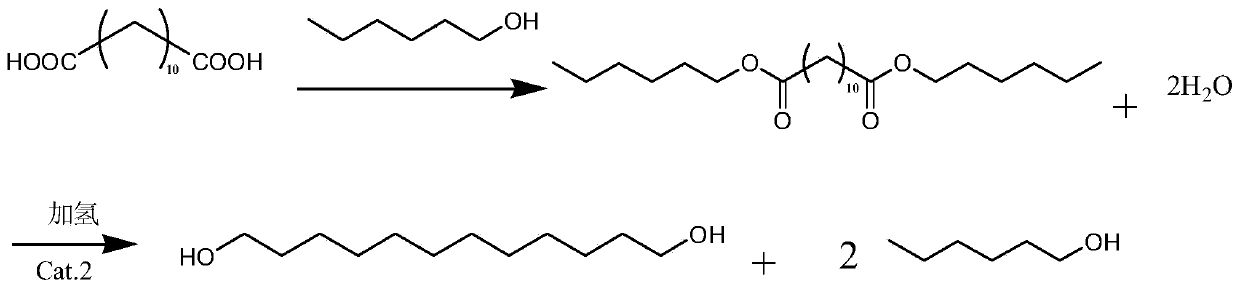

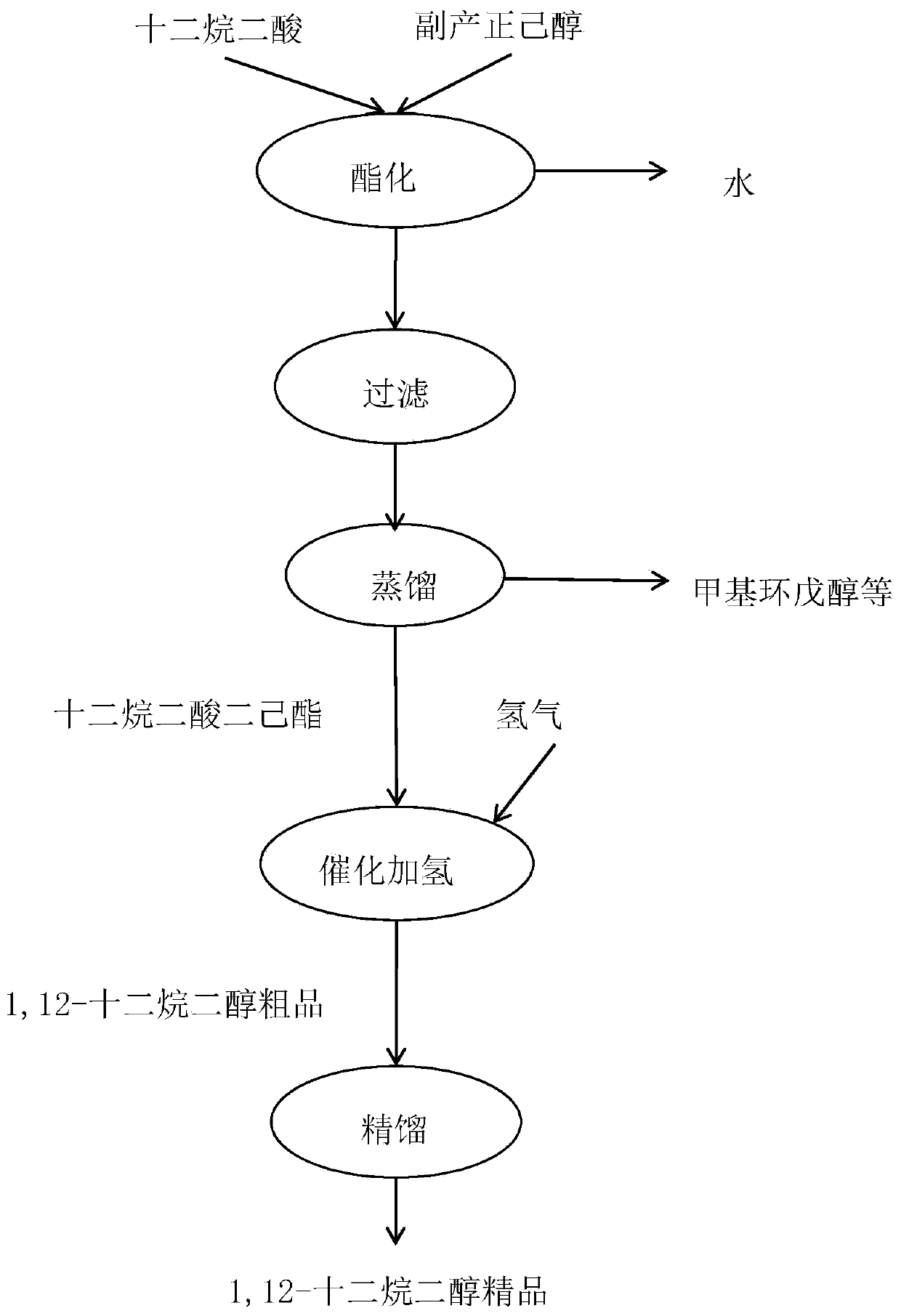

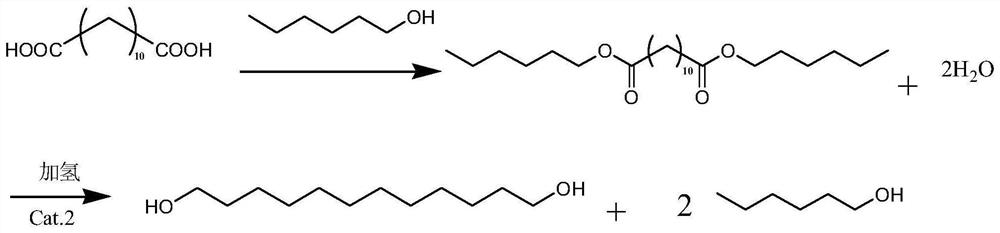

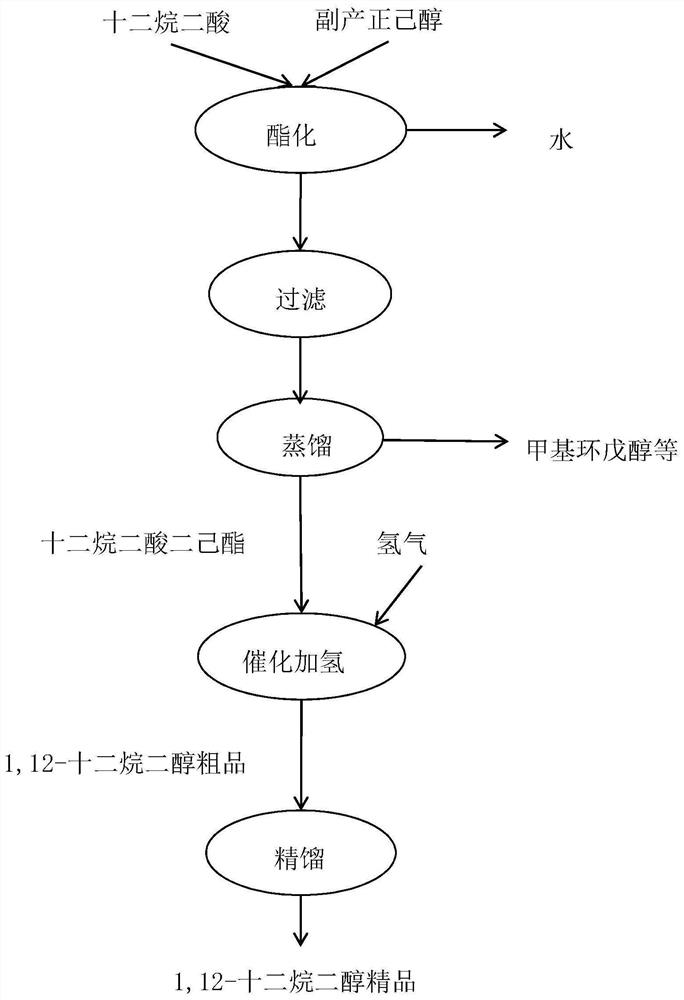

Preparation method of 1,12-dihydroxydodecane

ActiveCN110563553AFewer separation stepsReduce production stepsOrganic compound preparationHydroxy compound preparationChemical industryEsterification reaction

The invention relates to the technical field of pharmaceutical and chemical industry, in particular to a preparation method of 1,12-dihydroxydodecane. The preparation method of 1,12-dihydroxydodecanecomprises the steps that dodecanedioic acid is adopted to be subjected to an esterification reaction with n-hexanol, dihexyl dodecanedioate is obtained, and the target product 1,12-dihydroxydodecane is prepared through hydrogenation reduction. The method can be implemented without a catalyst, the separation step of the catalyst is reduced, so that esterification can be realized, the production steps are reduced, and the production cost is reduced.

Owner:ZHEJIANG BOJU NEW MATERIALS CO LTD

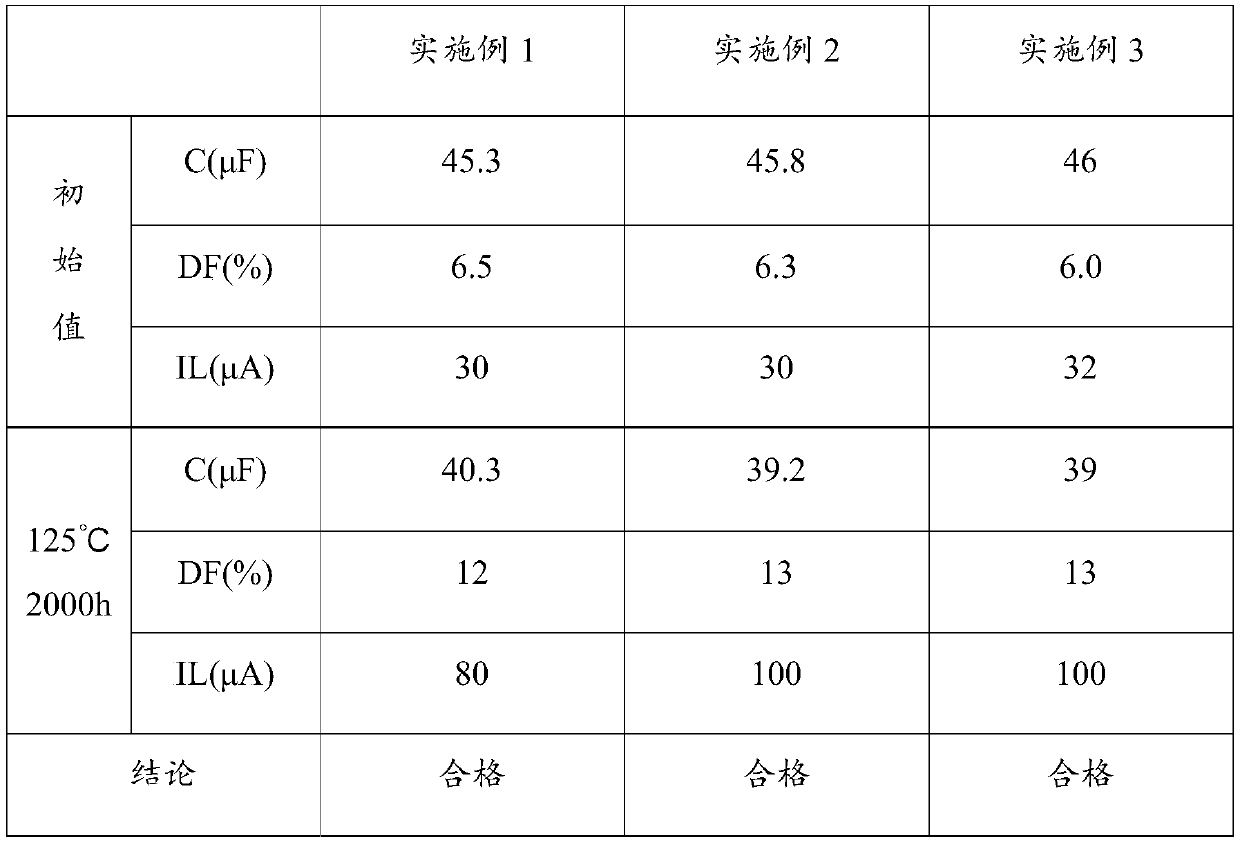

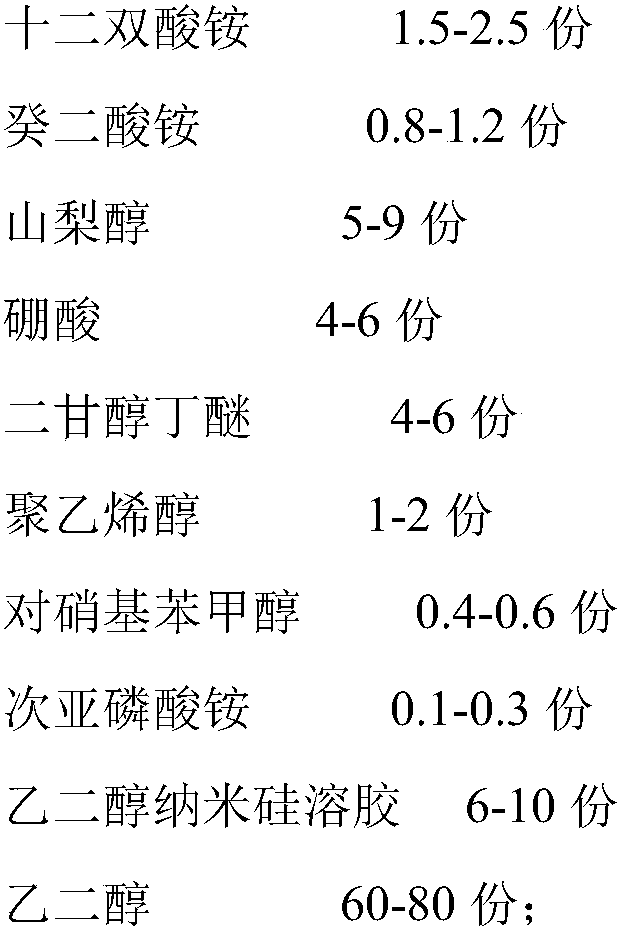

High-sparking and anti-lightning electrolyte for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469992ASimple processEasy to operate and controlElectrolytic capacitorsDiethylene glycol monobutyl etherElectrolysis

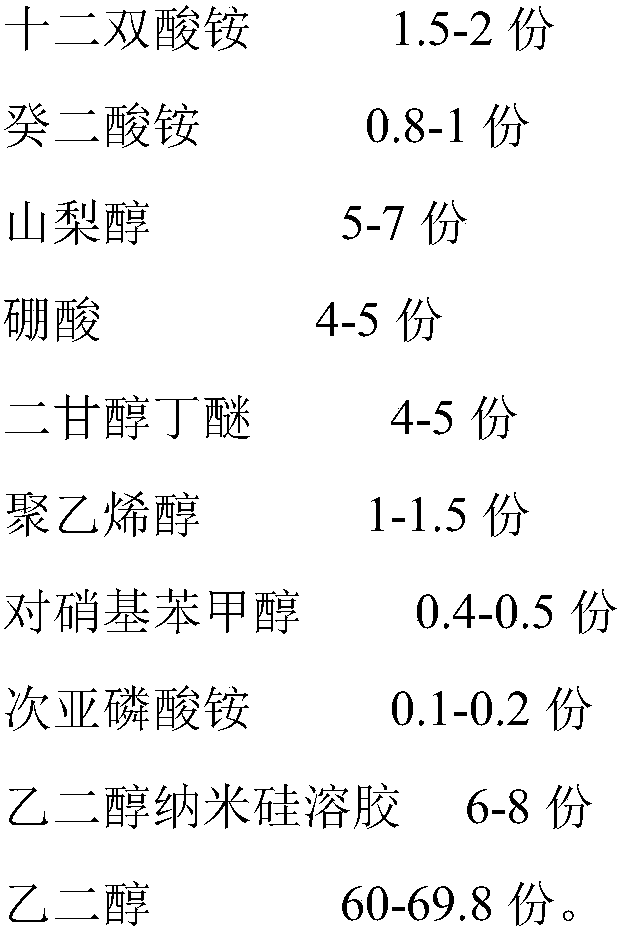

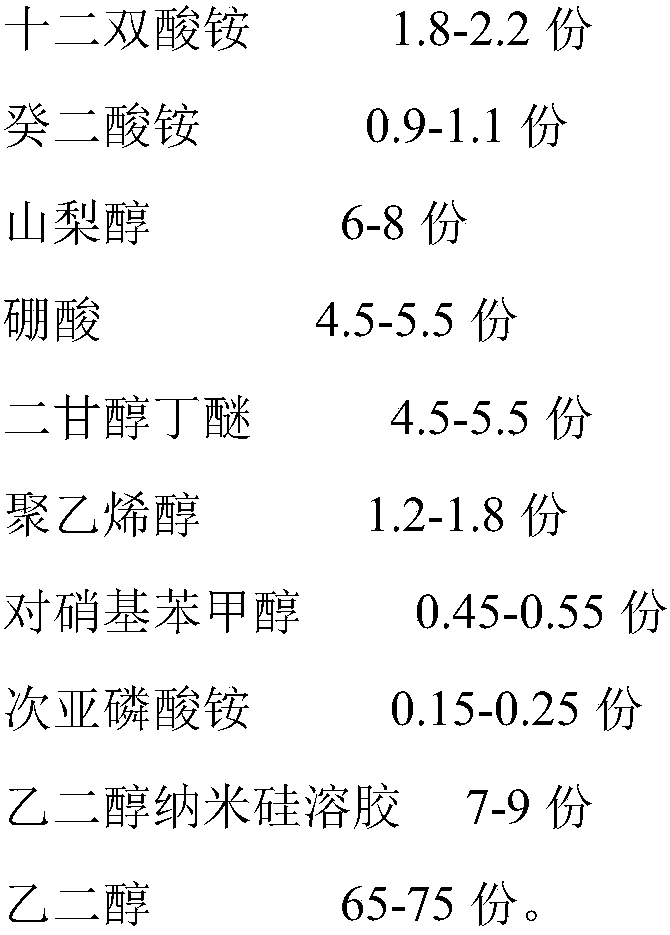

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and anti-lightning electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 1.5-2.5 parts of ammonium dodecanedioate, 0.8-1.2 parts of ammonium sebacate, 5-9 parts of sorbitol, 4-6 parts of boracic acid, 4-6 parts of diethylene glycol monobutyl ether, 1-2 parts of polyvinyl alcohol, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of ammonium hypophosphite, 6-10 parts of ethylene glycol nano silica sol and 60-80 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials and by strictly controlling a weight proportion of the raw materials; the sparking voltage of the prepared electrolyte can reach 590 V and the conductivity rate of the prepared electrolyte can reach 0.5 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage, lightning resistance and the like, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Aluminium electrolytic capacitor electrolyte and preparation method

InactiveCN104882284AHigh economic valueImprove high temperature resistanceElectrolytic capacitorsElectrolysisSebacic acid

The invention discloses an aluminium electrolytic capacitor electrolyte and a preparation method; the aluminium electrolytic capacitor electrolyte is mixed by glycol, diglycol, ammonium boron, sebacic acid ammonium, high temperature stabilizing agent, nitrophenol acetophenone, 17 sebacic acid ammonium and ammonium dodecanedioate according to mass ratio 155~165:6~10:14~18:11~15:4~6:1~3:75~85:5~7. A special polymer is used to serve as the high temperature stabilizing agent, thus improving stability of work electrolyte under high temperature environment. The electrolyte parameters are listed as below: conductivity (30degree)=3.5+ / -0.3ms / cm, PH value 6.8+ / -1, and scintillation voltage >510V. The aluminium electrolytic capacitor electrolyte is excellent in high temperature resistance and high scintillation voltage performance, can be widely applied to energy saving lamp and wind generating set fields, thus having very high economic values.

Owner:NANTONG HUAYU ELECTRONICS

High-sparking and long-service-life electrolyte for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469991AGood electrochemical propertiesIncrease the flash voltageLiquid electrolytic capacitorsCapacitor manufactureElectrolysisPhosphate

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and long-service-life electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 3-5 parts of ammonium sebate, 1-2 parts of ammonium pentaborate, 1-2 parts of sorbitol, 1.5-2.5 parts of ammonium dodecanedioate, 8-12 parts of a sparking boosting agent, 4-6 parts of branch-chain organic acid, 0.05-0.15 part of organic phosphate, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of p-nitrophenol, 5-7 parts of ethylene glycol nano silica sol, 4-6 parts of Y-butyrolactone and 55-75 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials; the sparking voltage of the prepared electrolyte can reach 535 V and the conductivity rate of the prepared electrolyte can reach 1.8 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage and long service life, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Preparation method of extra-high voltage anode foil forming solution

InactiveCN102568857AImprove performanceShort boost timeElectrolytic capacitorsCapacitor manufactureUltra high voltagePhysical chemistry

The invention relates to a preparation method of an extra-high voltage anode foil forming solution. The method comprises is characterized in that a formating efficiency promoting agent and a spark voltage promoting agent are added into a forming solution, wherein the main solute of the forming solution is boric acid, the content of ammonium dodecanedioate in the formating efficiency promoting agent is 0.001-0.050 wt% and the content of a silane coupling agent in the spark voltage promoting agent is 0.001-0.005v%. The preparation method provided by the invention is adopted to form a 700-1000v etched formed foil the product performance is stable, the voltage rising time is less than 160s, and the leakage current of the product is less than 25 mu A / cm <2>.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

Aluminum electrolytic capacitor electrolyte solute for industrial frequency converter

InactiveCN103440987AStrong ability to formIncrease the flash voltageElectrolytic capacitorsHigh pressureDodecanedioate

Aluminum electrolytic capacitor electrolyte solute for an industrial frequency converter is characterized in that a system with 1.6-ammonium dodecanedioate used as main solute and ammonium sebate used as auxiliary solute is adopted in a working electrolyte. Due to the fact that the system with the 1.6-ammonium dodecanedioate used as the main solute and the ammonium sebate used as the auxiliary solute is adopted in the working electrolyte, the aluminum electrolytic capacitor electrolyte solute for the industrial frequency converter has the advantages of being high in flash fire voltage and conductivity, has good forming ability for the anodic oxidation films and is extremely suitable for high-voltage large-capacity aluminum electrolytic capacitors.

Owner:JIANGSU SHENYANG ELEVATOR PARTS

Water-based anti-rusting liquid and preparation method thereof

InactiveCN106191841AWill not polluteAnti-rustMetallic material coating processesWater basedDistillation

The invention discloses water-based anti-rusting liquid. The water-based anti-rusting liquid comprises raw materials of, by weight, 15-25 parts of isopropanolamine, 3.1-5.2 parts of boric acid, 25-30 parts of dimethyl dodecanedioate, 2-5 parts of a rare earth corrosion inhibitor, 1-2 parts of sodium molybdate, 4-6 parts of tartaric acid, 0.1-0.3 part of a defoaming agent, 0.1-0.2 part of a surfactant, 0.1-0.3 part of a sterilizing agent and 42-52 parts of water. The invention further discloses a preparation method of the water-based anti-rusting liquid. The preparation method includes the following steps that the raw materials are weighed according to the weight parts, the boric acid, the isopropanolamine and xylene are evenly mixed, and backflow, reduced pressure distillation and vacuum drying are conducted to obtain a material A; the material A and the dimethyl dodecanedioate are evenly mixed, heated and stirred, and then vacuum drying is conducted to obtain a material B; and the material B, the rare earth corrosion inhibitor, the sodium molybdate, the tartaric acid, the defoaming agent, the surfactant and the sterilizing agent are evenly mixed and then stirred after water is added, so that the water-based anti-rusting liquid is obtained. The water-based anti-rusting liquid is good in anti-rusting performance and free of environment pollution.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

High-voltage high-conductivity electrolytic solution for aluminum electrolytic capacitor

ActiveCN109903994AExtended service lifeSmall loss changeElectrolytic capacitorsPolyvinyl alcoholSolvent

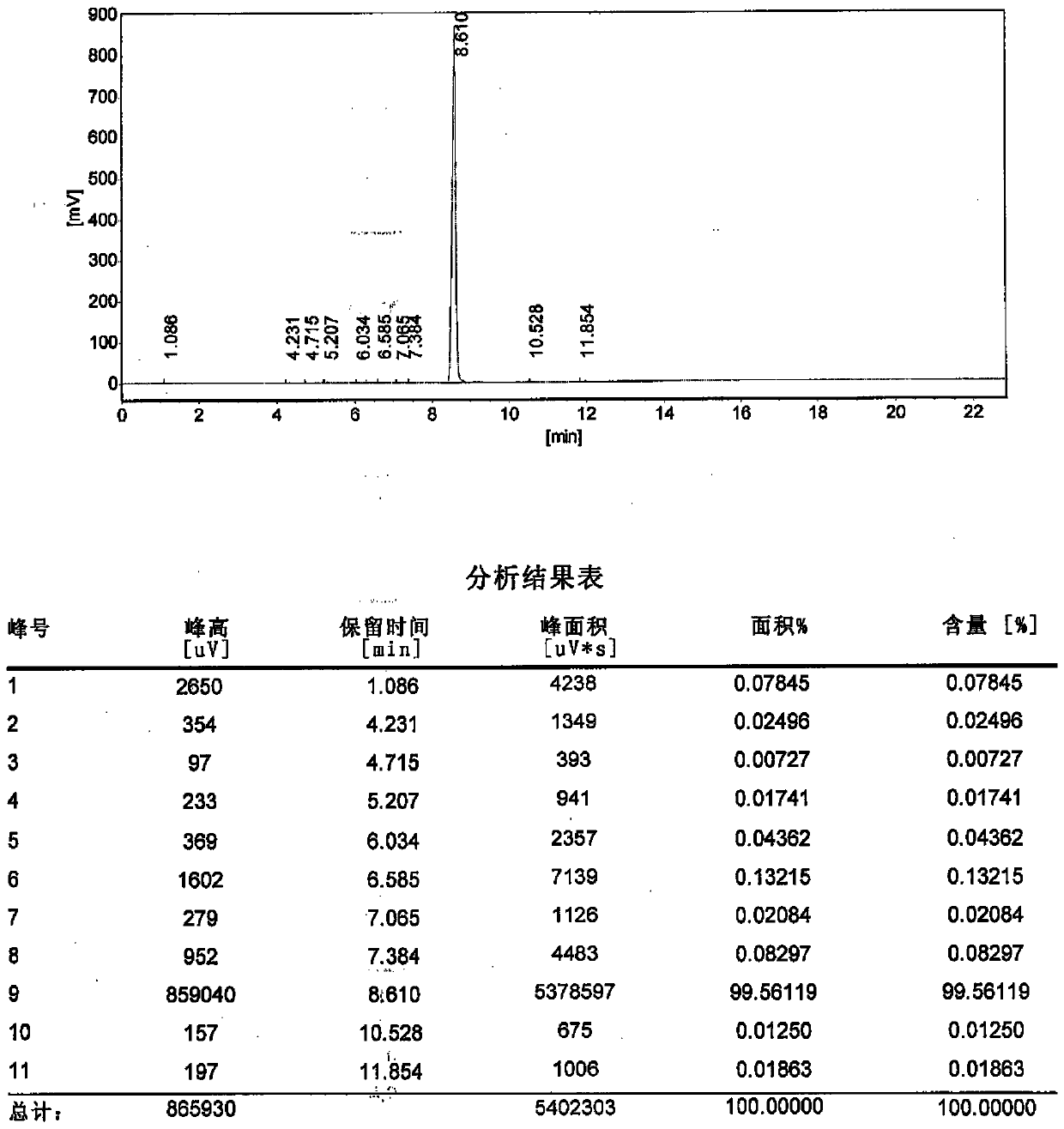

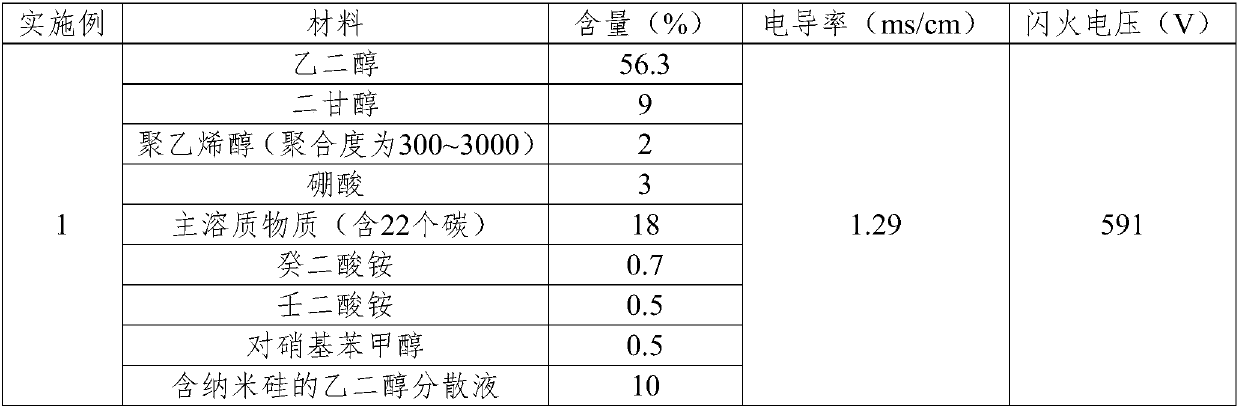

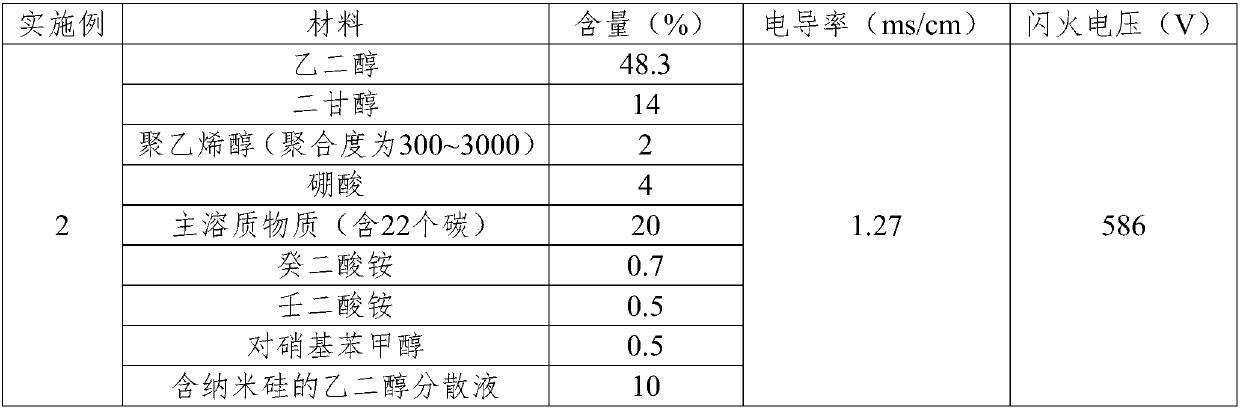

In order to overcome the problem that sparking voltage and conductivity are not high enough in the prior art, the invention provides a high-voltage high-conductivity electrolytic solution for an aluminum electrolytic capacitor. The electrolytic solution comprises 40%-60% of a main solvent, 15%-30% of a main solute, 9%-15% of an auxiliary solvent, 4%-7% of an auxiliary solute, 5%-10% of a sparkingimprover and 0.2%-0.5% of a hydrogen elimination agent, wherein the main solute is long-chain dicarboxylic acid containing 22-24 carbon atoms with branched chains or ammonium dicarboxylate; the auxiliary solute is selected from azelaic acid or azelate, sebacic acid or sebacate, dodecanedioic acid or dodecanedioate, dicarboxylic acid containing 16-18 carbon atoms with branched chains or dicarboxylate and inorganic acid or inorganic acid salt; and the sparking improver is selected from a glycol dispersion liquid containing nano-silicon and also contains polyvinyl alcohol borate, polyvinyl alcohol with the polymerization degree of 300-3,000, polyglycerol with the polymerization degree of 300-3,500, polypropylene glycol with the polymerization degree of 500-2,500, a silane coupling agent, polypropylene oxide ether and polyfatty acid or ammonium salt thereof. The high-voltage high-conductivity electrolytic solution for the aluminum electrolytic capacitor is high in sparking voltage which can reach 580V or above, and the conductivity is improved by 20%-40% compared with an existing electrolytic solution.

Owner:SHENZHEN CAPCHEM TECH CO LTD

Electrolyte and preparation method thereof

ActiveCN104934225AImprove pressure resistanceExtended service lifeElectrolytic capacitorsHydrogenPolyethylene glycol

The invention discloses an electrolyte, and a preparation method and application thereof. The electrolyte comprises the following parts by weight: 60-70 parts of glycol, 10-25 parts of butyl octanedioic acid ammonium, 1-2 parts of mannitol, 5-8 parts of polyethylene glycol 2000, 3-5 parts of boric acid, 3-5 parts of ammonium dodecanedioate, 2-5 parts of ammonium Hydrogen azelate, 0.5-1 part of ammonium hypophosphite, 2 parts of ammonium adipate and 0.5-2 parts of hydrogen elimination agent. According to the invention, the calorific value of a capacitor product can be reduced when a switching power supply works for a long time, and product performance is guaranteed; meanwhile the voltage endurance capability of the electrolyte is improved, thereby greatly prolonging the service life of the capacitor product, and guaranteeing that the switch power supply can be used for a long time.

Owner:淮安市华宙电子电器有限公司

Middle-high voltage aluminum electrolytic capacitor electrolyte

InactiveCN104112597AStrong oxidation forming abilityGood high pressureElectrolytic capacitorsTemperature resistanceHigh pressure

The invention relates to the technical field of capacitor electrolyte, and discloses a middle-high voltage aluminum electrolytic capacitor electrolyte. The middle-high voltage aluminum electrolytic capacitor electrolyte comprises the raw materials in percentages by weight as follows: 10-20% by weight of main electrolyte, 5-10% by weight of auxiliary electrolyte, 3-6% by weight of multi-polar-radical high polymer, 26-38% by weight of sorbitol, 27-38% by weight of diethylene glycol, 3-6% by weight of a hydrogen elimination agent, and 3-5% by weight of an additive agent, wherein the main electrolyte is ammonium dodecanedioate; the auxiliary electrolyte is sulphamic acid. According to the invention, the ammonium dodecanedioate serves as the main electrolyte, the sulphamic acid serves as the auxiliary electrolyte, and the multi-polar-radical high polymer is added at the same time, so that the middle-high voltage aluminum electrolytic capacitor electrolyte can work stably at 105 DEG C and 500-800 V for 1000 hours without any current leakage phenomenon, meets with the basic demands of a flash fire voltage and achieves a small specific resistance. The middle-high voltage aluminum electrolytic capacitor electrolyte disclosed by the invention is strong in oxidization forming capability, high-voltage resistant, good in high-temperature resistance, low in loss and long in service life.

Owner:宁国市裕华电器有限公司

Electrolyte suitable for high-voltage aluminum electrolytic capacitor and preparation method thereof

ActiveCN110010354AImprove heat resistanceExtended service lifeElectrolytic capacitor manufactureBenzoic acidO-Nitroanisole

The invention discloses an electrolyte suitable for a high-voltage aluminum electrolytic capacitor and a preparation method thereof and belongs to the technical field of high-voltage aluminum electrolytic capacitors. The electrolyte solution suitable for the high-voltage aluminum electrolytic capacitor comprises the following raw materials including, by weight, 40 to 60 parts of 4-hydroxybutyrolactone, 60 to 80 parts of polyethylene glycol, 50 to 70 parts of ethylene glycol, 30 to 50 parts of ethylene carbonate, 40 to 60 parts of propylene carbonate, 30 to 40 parts of diethyl carbonate, 20 to30 parts of dimethyl carbonate, 10 to 20 parts of ethyl methyl carbonate, 20 to 40 parts of ammonium azelate, 30 to 50 parts of ammonium dodecanedioate, 10 to 30 parts of benzoic acid, 40 to 60 partsof ammonium formate, 40 to 50 parts of diammonium hydrogen phosphate, 30 to 40 parts of phthalic acid, 10 to 20 parts of boric acid, 10 to 20 parts of p-nitrophenol, 5 to 10 parts of sodium hypophosphite, 10 to 20 parts of o-nitroanisole, and 20 to 30 parts of monobutyl phosphate. The preparation method of the invention has a simple preparation method and has a broad application prospect.

Owner:HUNAN AIHUA GRP +1

Electrolyte solution for electrolytic condenser

The invention discloses an electrolyte solution for an electrolytic condenser. The electrolyte solution for the electrolytic condenser comprises 86-87 parts of ethylene glycol, 3.2-3.5 parts of sebacic acid, 0.5-0.6 part of ammonium dodecanedioate, 0.1-0.13 part of p-nitrobenzoic acid, 0.15-0.17 part of hypophosphorous acid, 1-1.2 parts of trinitrophenol, 1-1.5 parts of polyethylene glycol and 2-2.4 parts of boric acid. According to the electrolyte solution for the electrolytic condenser, the sparking voltage is 420-440V, the conductivity at 40 DEG C is (2.4-2.7)*10-3S / cm, high temperature resistance and long service life can be achieved, more than 2500 hours can last in a 125 DEG C life test, the capacitance change rate is smaller than 0.3%, and the leakage current is 5-6 muA.

Owner:宁国市裕华电器有限公司

Multifunctional boric acid-free electrolyte and preparation method thereof

PendingCN114360913AImprove solubilityIncrease the flash voltageElectrolytic capacitorsElectrolytic agentCarboxylic acid

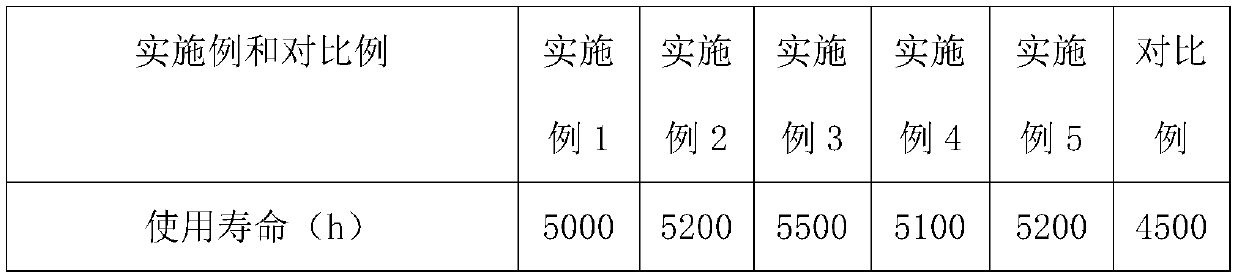

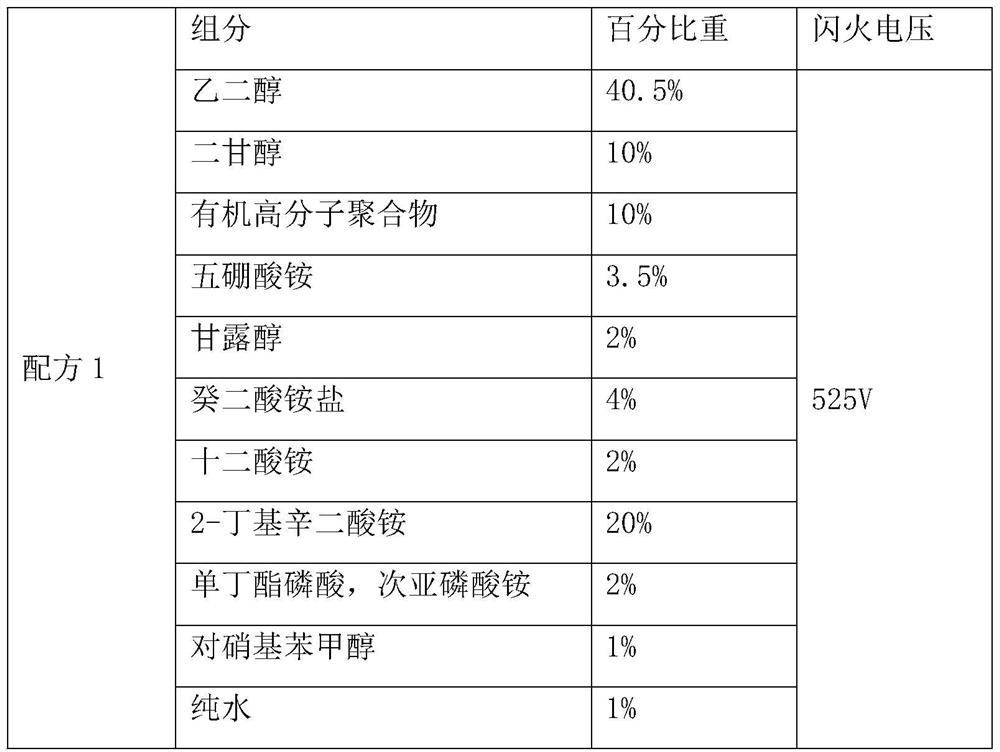

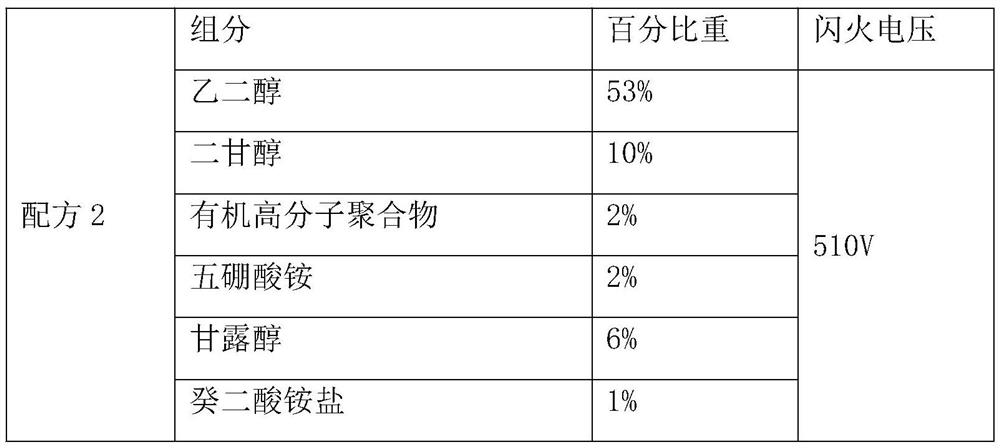

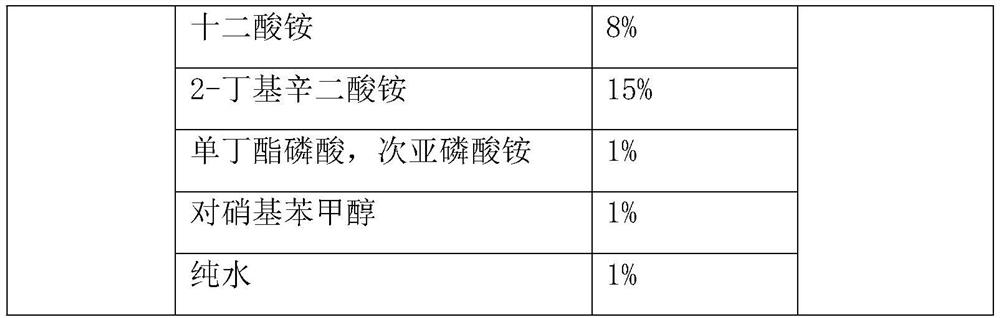

The invention belongs to the technical field of electrolytes, and particularly relates to a multifunctional boric-acid-free electrolyte and a preparation method thereof. The multifunctional boric-acid-free electrolyte is characterized by comprising the following components: ethylene glycol, diethylene glycol, an organic high-molecular polymer, ammonium pentaborate, mannitol, ammonium sebacate, ammonium dodecanedioate, organic long-carbon-chain ammonium carboxylate with a branched chain, an oxygen inhibitor, a hydrogen elimination agent and pure water. The preparation method comprises the following steps: S1, heating the ethylene glycol and the diethylene glycol to 135 DEG C, and then adding the organic high-molecular polymer to completely dissolve the ethylene glycol and the diethylene glycol; s2, after the organic high-molecular polymer is completely dissolved, cooling to 130 DEG C, then adding ammonium pentaborate, mannitol, ammonium sebacate, ammonium dodecanedioate and organic long-carbon-chain ammonium carboxylate with a branched chain, and keeping the temperature for 1 hour at 120 DEG C; s3, preserving heat for 1 hour, cooling to 85 DEG C, adding an oxygen inhibitor, a hydrogen eliminating agent and pure water, and uniformly stirring; and S4, uniformly stirring, and cooling to normal temperature.

Owner:贵州云睿电子科技有限公司

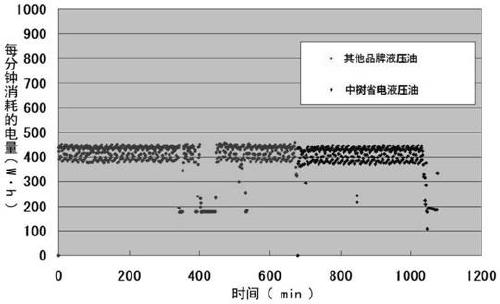

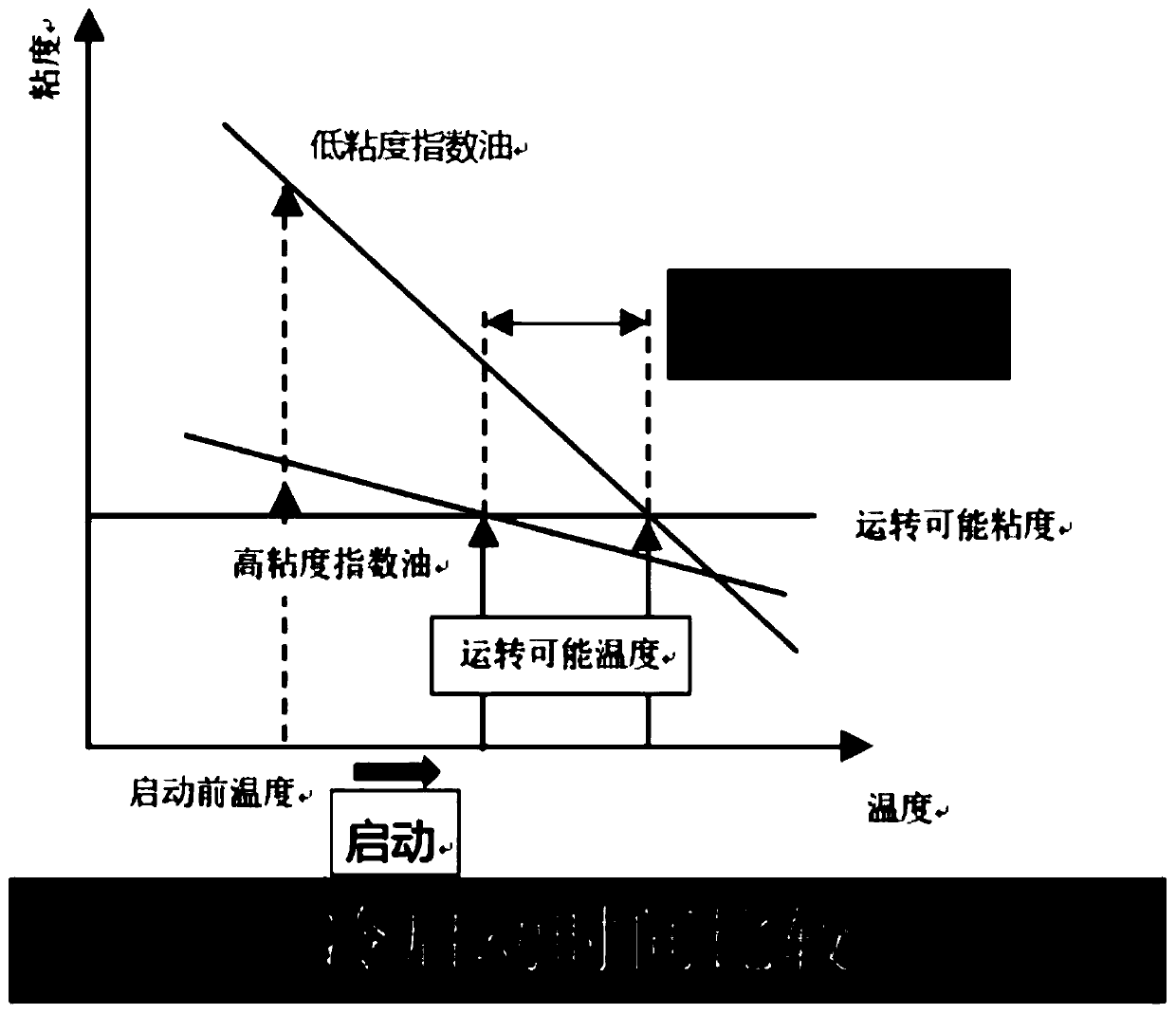

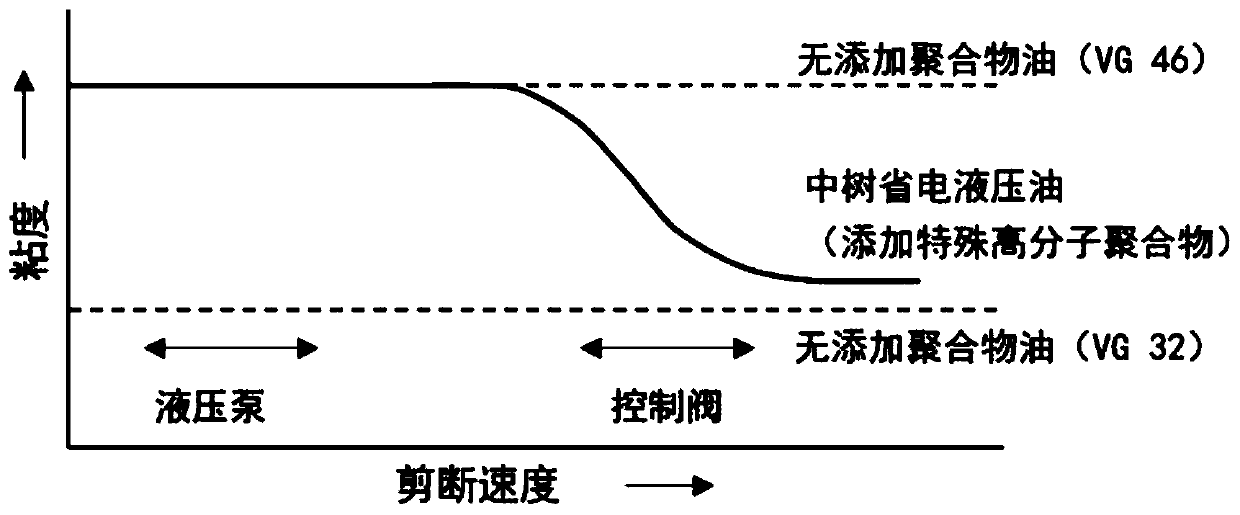

Power-saving hydraulic oil formula

PendingCN111411013AImprove efficiencyReduce operating costsLubricant compositionEngineeringMechanical equipment

The invention discloses a power-saving hydraulic oil formula. The composition comprises, in the form of a mixture, at least 80% of a synthetic base oil and 0.01-5% (mass) of an amine antioxidant (A),0.01-5% (by mass) of a phenolic antioxidant (B), 0.01-5% (by mass) of a phosphate (C), and 0.01-5% (by mass) of a fatty acid amide and dimethyl dodecanedioate, and 0.01-5% of an ethylene-propylene polymer. According to the invention, environmental protection components such as a medium-tree special high-molecular polymer, an antioxidant, an extreme pressure agent and an antifriction agent are added into the secondary hydrogenation high-performance base oil of the power-saving hydraulic oil system for blending to form the power-saving hydraulic oil, so that the better use performance can be achieved, the maximum use efficiency and the lowest operation cost of the hydraulic system can be achieved, and therefore electricity and energy are saved, the productivity is improved, high-quality baseoil and unique additives are added to synthesize new hydraulic oil, mechanical equipment can be better protected, energy consumption can be directly reduced, energy is saved, and the environment is protected.

Owner:上海中树润滑油有限公司

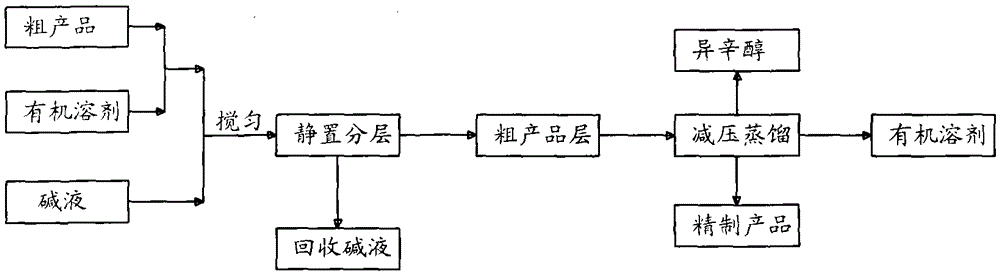

A kind of refining method of di-isooctyl dodecanedioate

ActiveCN103755563BLow densityEase emulsificationOrganic compound preparationCarboxylic acid esters separation/purificationPurification methodsAcid value

The invention discloses a refining method for diisooctyl dodecanedioate. According to the refining method, an organic solvent is used for diluting a diisooctyl dodecanedioate crude product, and the mixture of the organic solvent and the diisooctyl dodecanedioate crude product is uniformly mixed with relatively mild alkali liquor, so that the phenomenon of emulsification of esters and the alkali liquor is relieved, the standing demixing time and the loss of the crude product are reduced, the acid value of a product is effectively reduced, and the purity and yield of the product are improved; a process and equipment are simple, the method is high in yield and suitable for industrial production, and the inorganic solvent can be recycled.

Owner:江苏兰博士新材料有限公司

Soldering lug type aluminum electrolytic capacitor electrolyte and preparation method thereof

PendingCN114724856APrevent intrusionImprove waterproof performanceLiquid electrolytic capacitorsElectrolytic capacitor manufactureElectrolytic agentPhosphorous acid

The invention relates to a soldering lug type aluminum electrolytic capacitor electrolyte, and relates to the technical field of electrolytes, and the soldering lug type aluminum electrolytic capacitor electrolyte comprises the following raw materials by weight: 55-65 parts of ethylene glycol; 15 to 25 parts of diglycerol; 2 to 6 parts of ammonium dodecanedioate; 5 to 15 parts of ammonium sebacate; 2-3 parts of a waterproof mixture; 1-2 parts of a hydrogen eliminating agent; 0.5 to 1.5 parts of a flash fire improver; the waterproof mixture is mixed ester prepared from polymethylacrylic acid, 3-methyl-1, 5-pentanediol and hypophosphorous acid. The electrolyte has the effect of improving the waterproof performance of the electrolyte.

Owner:富之庆电子(深圳)有限公司

Preparation method of solid acid catalyst for preparing dimethyl dodecanedioate

PendingCN114308007AHigh catalytic activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationDodecanedioateDodecandioic acid

The invention discloses a preparation method of a solid acid catalyst for preparing dimethyl dodecanedioate, and belongs to the field of catalysts. The preparation method of the catalyst comprises the following steps: weighing 20-40% by mass of charcoal particles, 10-30% by mass of SnCl4. 5H2O and 30-70% by mass of diatomite, adding the charcoal particles, the SnCl4. 5H2O and the diatomite into a certain amount of deionized water, neutralizing, stirring and extruding to obtain a precursor; and soaking the precursor in a 1-5 mol / L H2SO4 solution, drying, and calcining at 400-650 DEG C under the protection of N2 to obtain the solid acid catalyst. The catalyst has high conversion rate and selectivity when applied to preparation of dimethyl dodecanedioate, and can be reused.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD +1

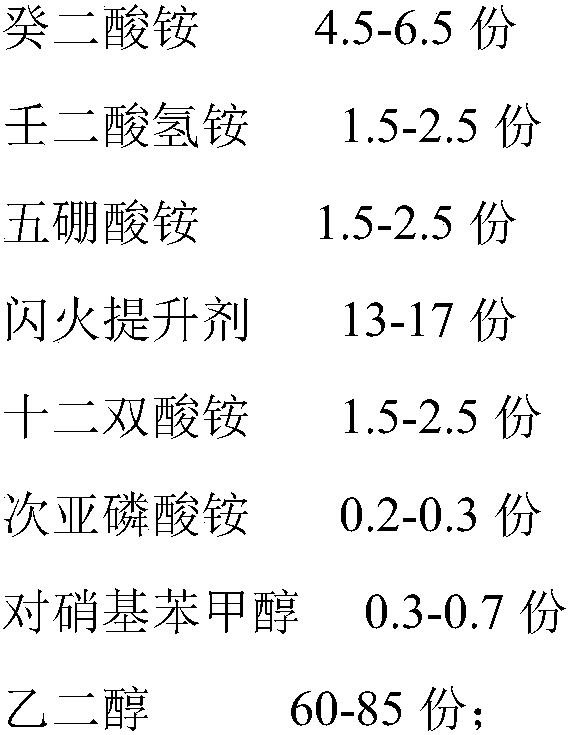

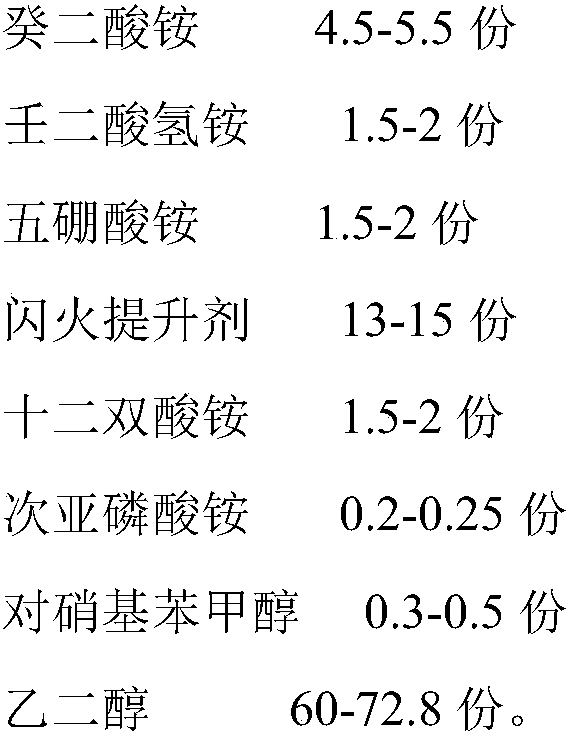

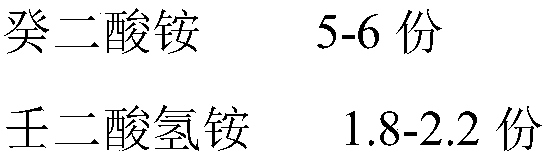

A kind of electrolytic solution for aluminum electrolytic capacitor with high conductance and high flash fire and preparation method thereof

ActiveCN105469988BReliable continuous workThere is no cracking or burningElectrolytic capacitor manufactureElectrochemistryDodecanedioate

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

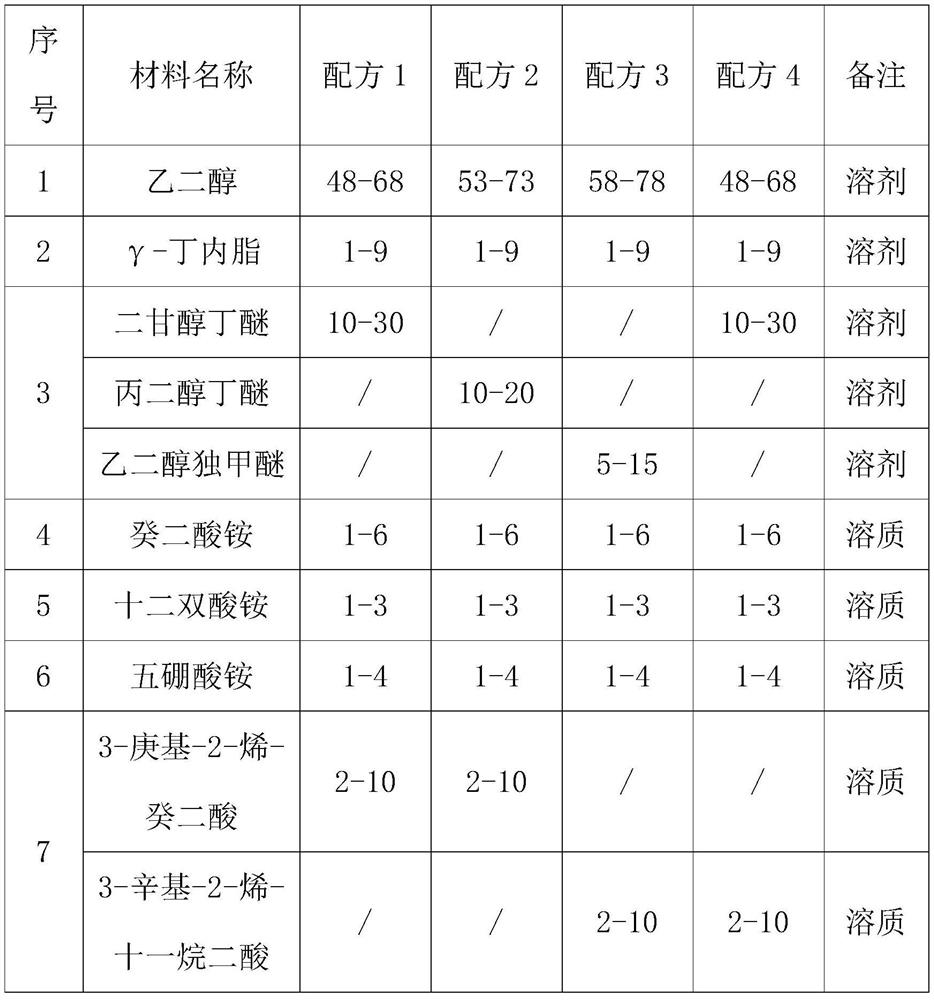

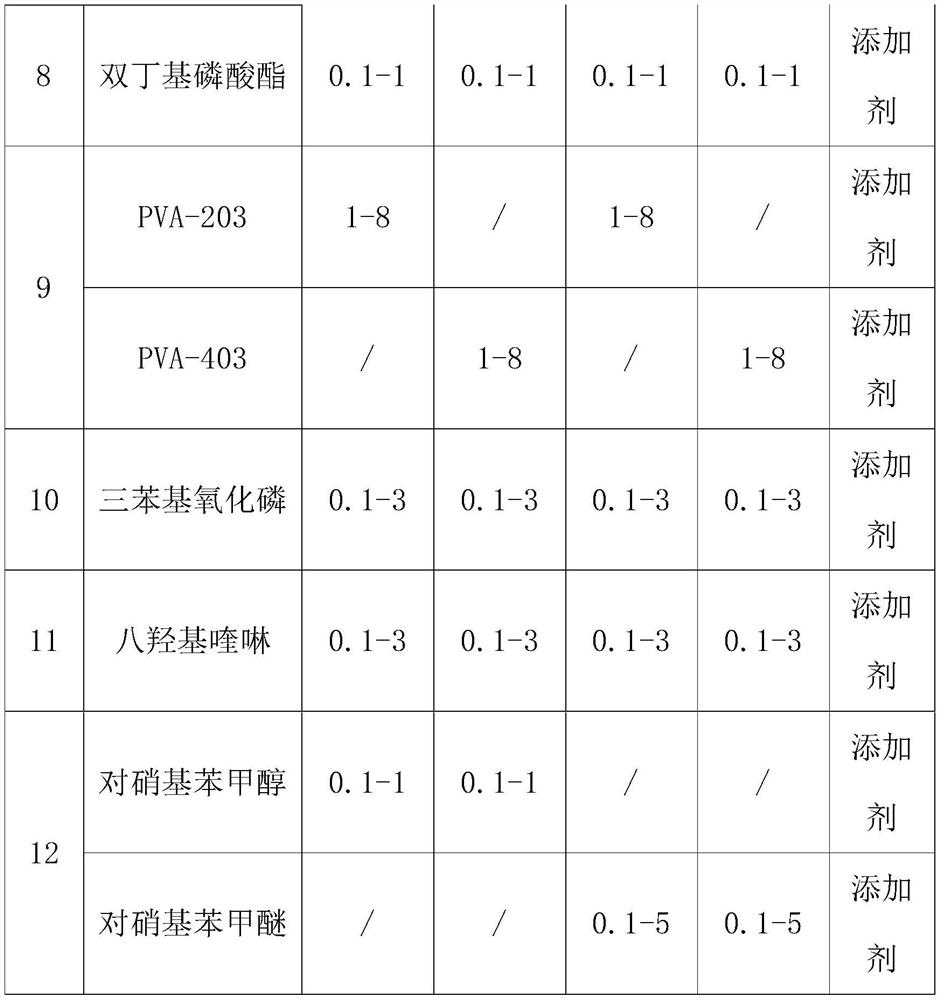

Electrolyte for high-voltage soldering lug type aluminum electrolytic capacitor and preparation method thereof

PendingCN114709079ASmall loss angleSmall capacity attenuationLiquid electrolytic capacitorsPhosphoric Acid EstersElectrolytic agent

The invention provides an electrolyte for a high-voltage soldering lug type aluminum electrolytic capacitor and a preparation method thereof, and the electrolyte comprises solvent ethylene glycol and gamma-butyrolactone. The cleaning agent further comprises any one of solvent diethylene glycol butyl ether, propylene glycol butyl ether and ethylene glycol monomethyl ether; the invention relates to a high-temperature-resistant and corrosion-resistant coating, which comprises a solute, and further comprises solute ammonium sebacate, ammonium dodecanedioate, ammonium pentaborate, 3-heptyl-2-ene-sebacic acid or 3-octyl-2-ene-undecanedioic acid. And additives such as dibutyl phosphate and the like are also included. The conductivity of the prepared electrolyte is 2.0 + / -0.2 ms / cm, meanwhile, the loss angle can be reduced by 0.02 on the original basis, meanwhile, the ripple current resistance is effectively improved, the capacity attenuation at the temperature of minus 40 DEG C can be reduced, the internal aging breakdown rate can be effectively reduced, and the production qualification rate can be increased.

Owner:ZHUHAI GREE XINYUAN ELECTRONICS +1

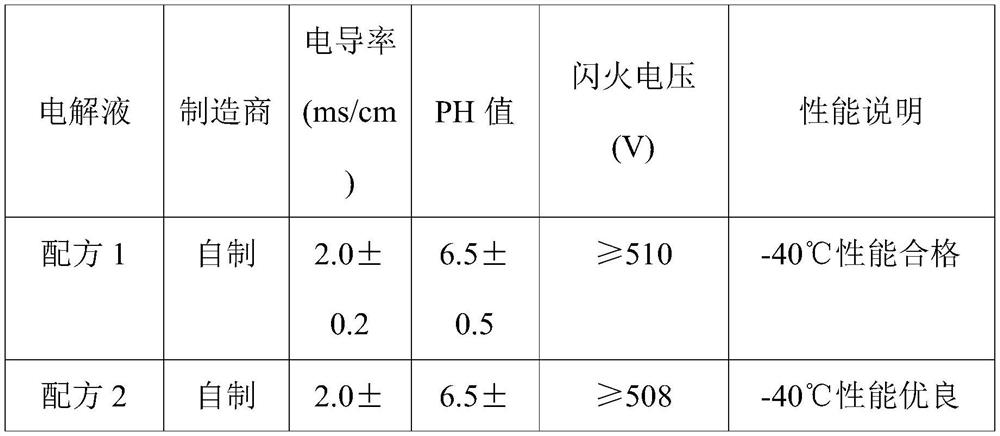

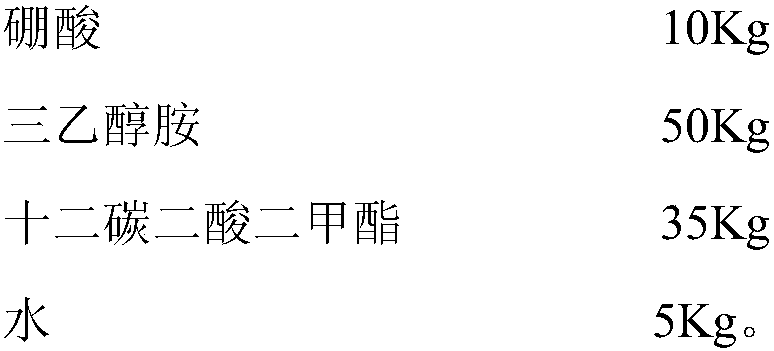

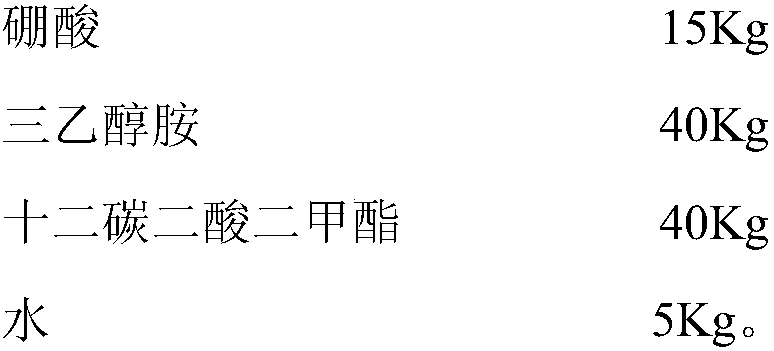

Water-based metal rust inhibitor

The present invention relates to a water-based metal rust inhibitor, which comprises the following raw material components by weight: 10-15% of boric acid, 40-50% of triethanolamine, 35-40% of dimethyl dodecanedioate, and the balance of water. According to the present invention, the used raw materials are environment-friendly and pollution-free; the product has the high concentration, and is usedafter mixing with water, such that the product is economical and durable; during the use, when the water-based metal rust inhibitor concentration is 1%, the damp heat box single sheet anti-rust time is more than 72 h, and the stacked sheet anti-rust time is more than 24 h; and the water-based metal rust inhibitor can be widely used for rush resistance of ferrous metals, and can be used as the anti-rust agent so as to be added to metal cleaning agents and cutting fluids.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

Capacitor working electrolyte used for 8000V lightning stroke resistance, and preparation method thereof

InactiveCN110415980AIncrease the electric field strengthImprove electrochemical performanceElectrolytic capacitorsCapacitancePolyvinyl alcohol

The invention relates to a capacitor working electrolyte used for 8000V lightning stroke resistance, and a preparation method thereof. The capacitor working electrolyte comprises the following ingredients in parts by weight: 65-75 parts of ethylene glycol, 15-23 parts of iso-ammonium sebate, 2-2.5 parts of ammonium pentaborate, 2-2.5 parts of 1-6DDA (1-6 Ammonium dodecanedioate), 0.5-1 part of m-dinitrobenzene, 0.3-0.6 part of PVA(polyvinyl alcohol)-1179 and 0.1-0.2 part of tributyl hypophosphite. The preparation method comprises the following steps that: (1) firstly, mixing the ethylene glycol, the ammonium pentaborate, the iso-ammonium sebate and the 1-DDA, heating to 135DEG C, keeping the temperature for 25 minutes, and continuously stirring; (2) then, adding the tributyl hypophosphite,heating to 145DEG C, keeping the temperature for 10min, cooling to 70DEG C, and keeping for 210 minutes; and (3) finally, adding the PVA-1179 and the m-dinitrobenzene, heating to 85DEG C, and naturally cooling. The capacitor working electrolyte has the advantages of good electrochemical performance and high lightning stroke resistance.

Owner:WUXI TAIWEI ELECTRONICS CO LTD

Electrolyte, preparation method of electrolyte and aluminum electrolytic capacitor

ActiveCN106098379BImprove temperature resistanceImprove stabilityLiquid electrolytic capacitorsSolventTemperature resistance

The invention discloses an electrolyte, an electrolyte preparation method and an aluminum electrolytic capacitor. The electrolyte comprises, by weight percentage, 50-65w% of solvent, 23-33w% of solute, and 8-19w% of additive. The solute includes boric acid, ammonium benzoate, at least one material selected from ammonium dodecanedioate and 2,7-dibutyl octanedioic acid ammonium, and at least one material selected from ammonium sebate and alkyl ammonium sebate. Through the technical scheme, the temperature resistance performance and stability of the aluminum electrolytic capacitor are improved.

Owner:惠州市智胜新电子技术有限公司

A kind of electrolytic solution for high flash fire anti-lightning stroke aluminum electrolytic capacitor and preparation method thereof

ActiveCN105469992BReliable continuous workThere is no cracking or burningElectrolytic capacitorsDiethylene glycol monobutyl etherElectrolysis

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and anti-lightning electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 1.5-2.5 parts of ammonium dodecanedioate, 0.8-1.2 parts of ammonium sebacate, 5-9 parts of sorbitol, 4-6 parts of boracic acid, 4-6 parts of diethylene glycol monobutyl ether, 1-2 parts of polyvinyl alcohol, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of ammonium hypophosphite, 6-10 parts of ethylene glycol nano silica sol and 60-80 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials and by strictly controlling a weight proportion of the raw materials; the sparking voltage of the prepared electrolyte can reach 590 V and the conductivity rate of the prepared electrolyte can reach 0.5 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage, lightning resistance and the like, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

A kind of preparation method of 1,12-dodecanediol

ActiveCN110563553BFewer separation stepsReduce production stepsOrganic compound preparationHydroxy compound preparationChemical industryDodecane

Owner:ZHEJIANG BOJU NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com